Patents

Literature

265results about How to "Clean up fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

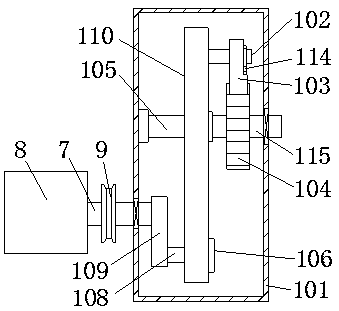

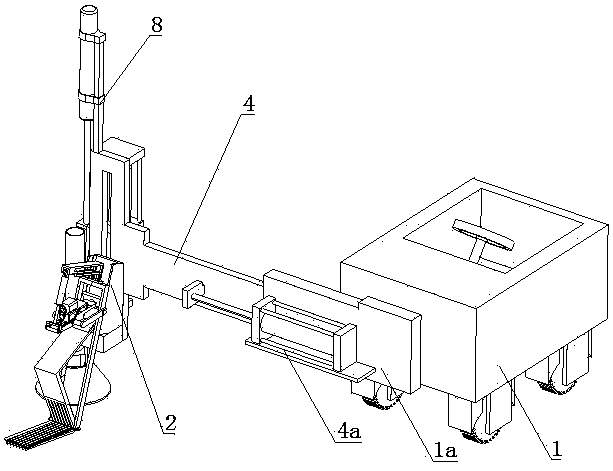

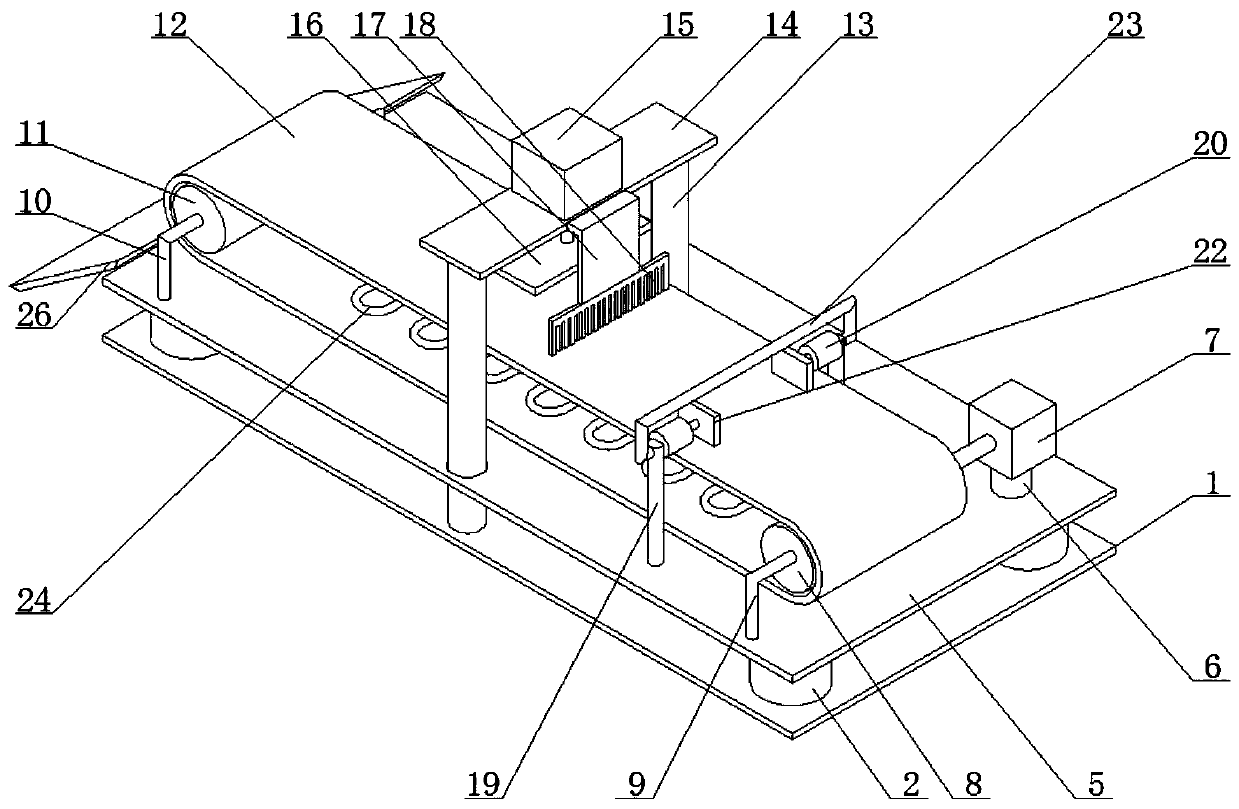

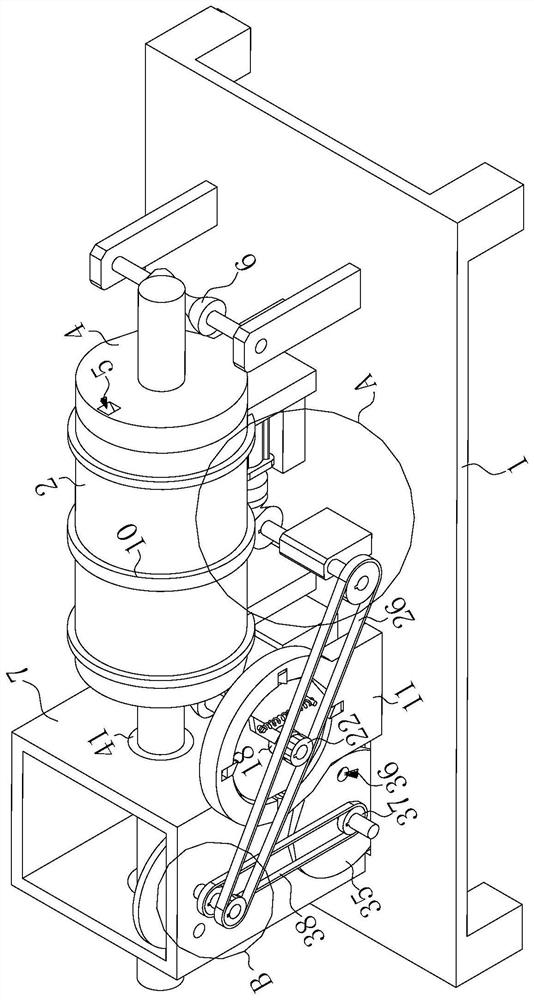

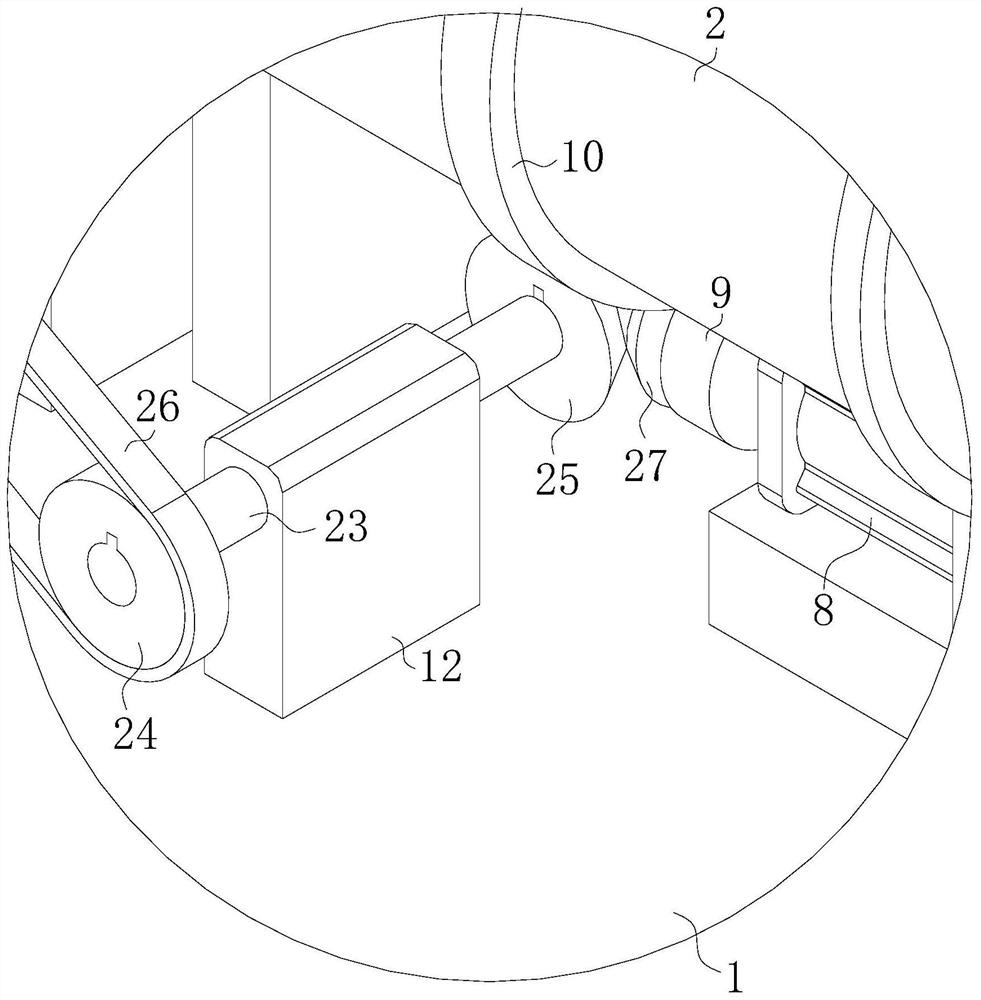

Fast cutting off device for hardware parts

ActiveCN107096962AControl altitudeFully truncatedMaintainance and safety accessoriesEngineeringKnife blades

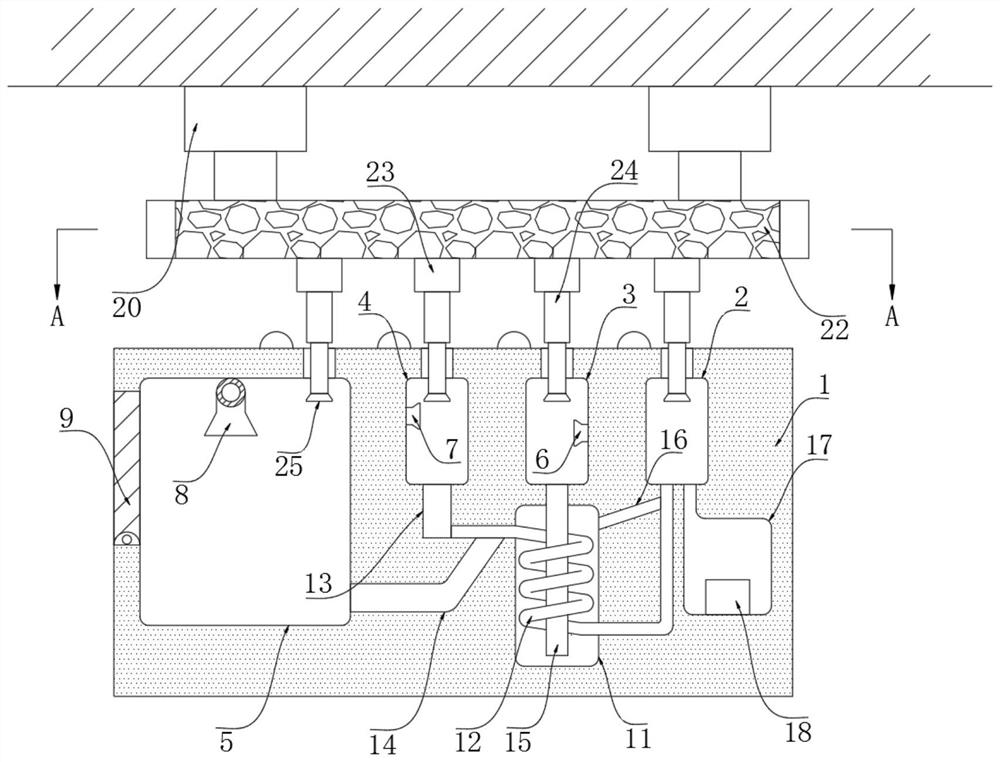

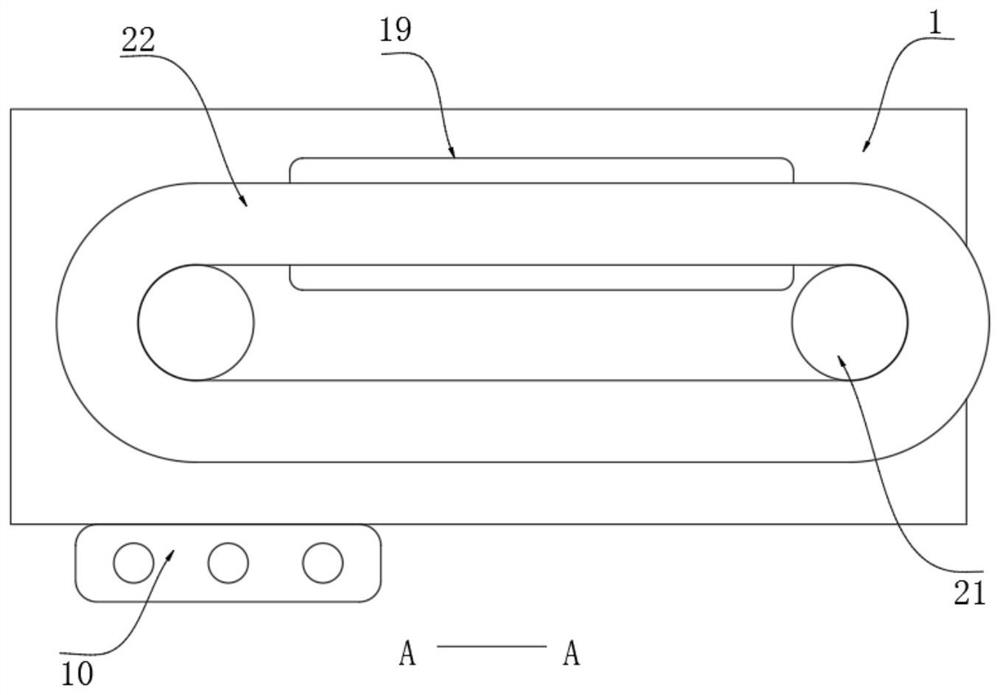

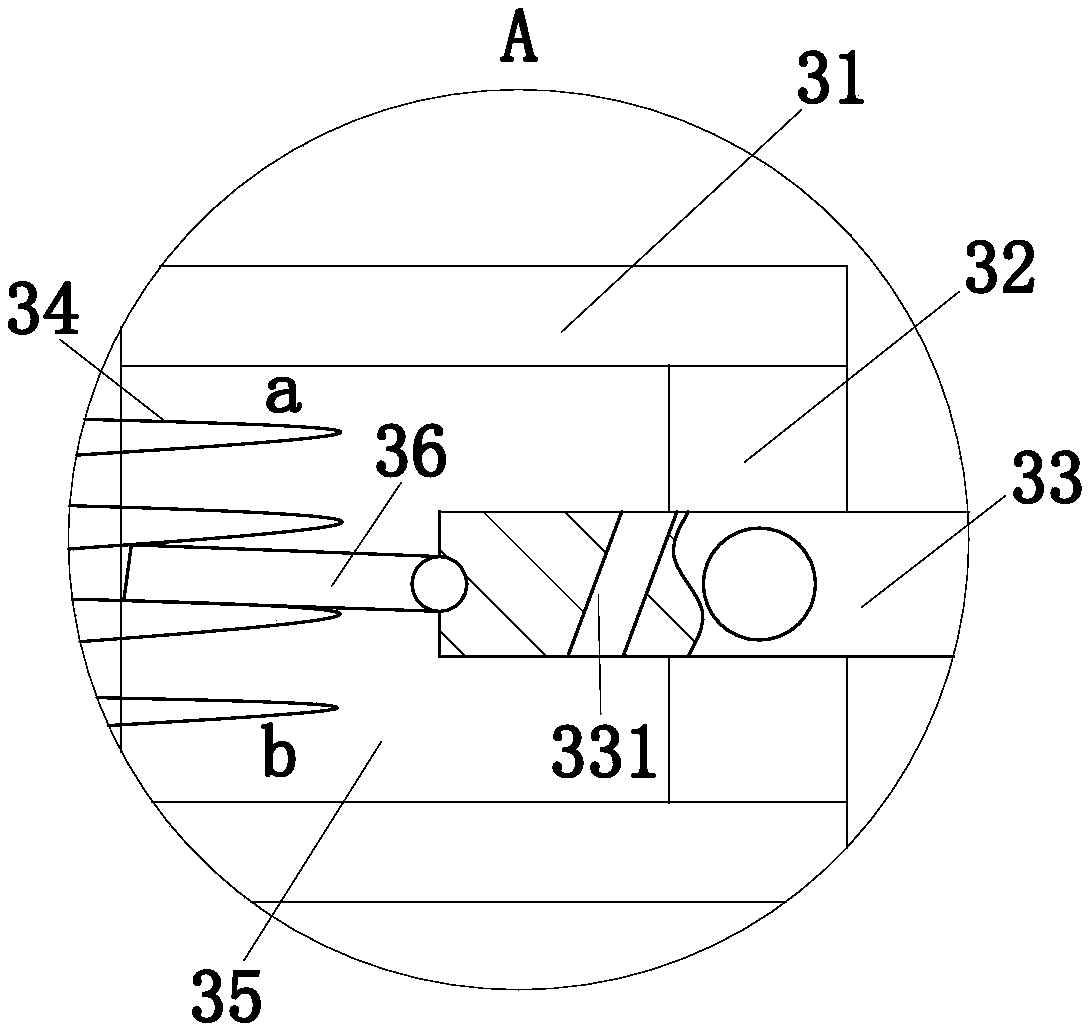

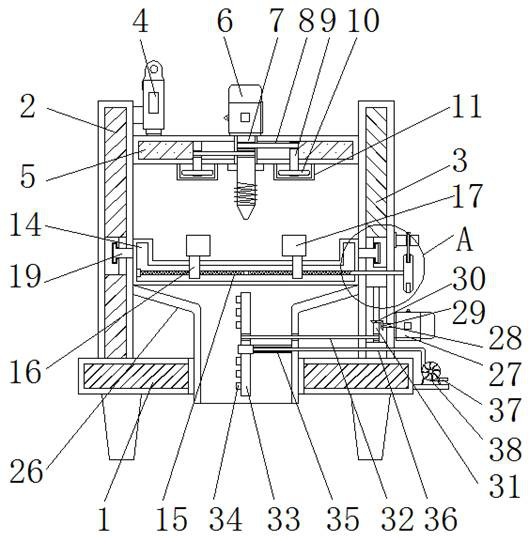

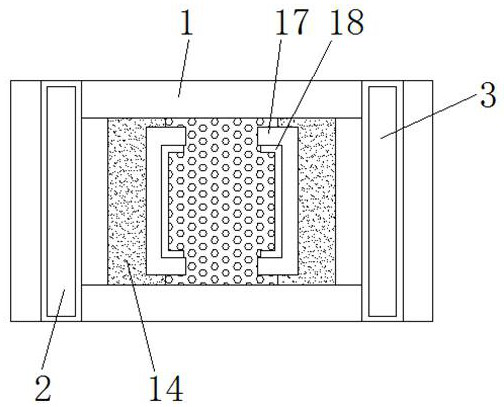

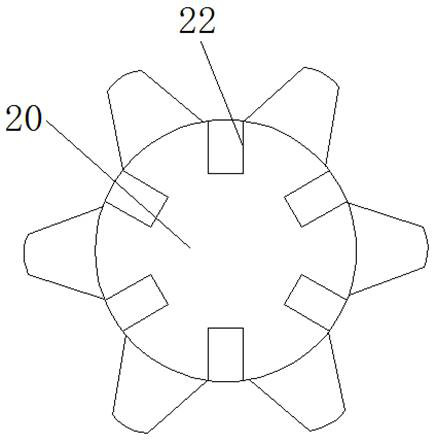

The invention relates to a cutting off device, in particular to a fast cutting off device for hardware parts. The invention solves the technical problem of providing a cutting device for a covering steel plate for production of a circuit board, which is light and handy, fast in cutting off and good in cutting off effect. In order to solve the technical problem above, the invention provides such a fast cutting off device for hardware parts, which comprises a bottom plate, first guide rods, first guide covers, a moving rod, a lifting device, a top plate, a moving device, a lifting rod, a mounting rod, a second motor, a blade, first supports, and the like; the first guide rods are symmetrically welded on the left side and the right side of the top of the bottom plate, the top plate is welded on the top ends of the two first guide rods, the middle of the bottom of the top plate is provided with the lifting device, and the bottom of the lifting device is connected to the lifting rod. By controlling the lifting device to move up and down, the blade is controlled in an optimal position, such that the cutting off effect is better, and by driving the blade to move left and right through the moving device, the cutting off is more thorough.

Owner:NANTONG KAIDI AUTOMATIC MACHINERY

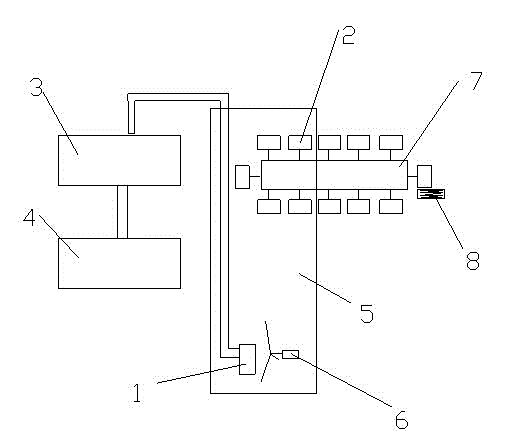

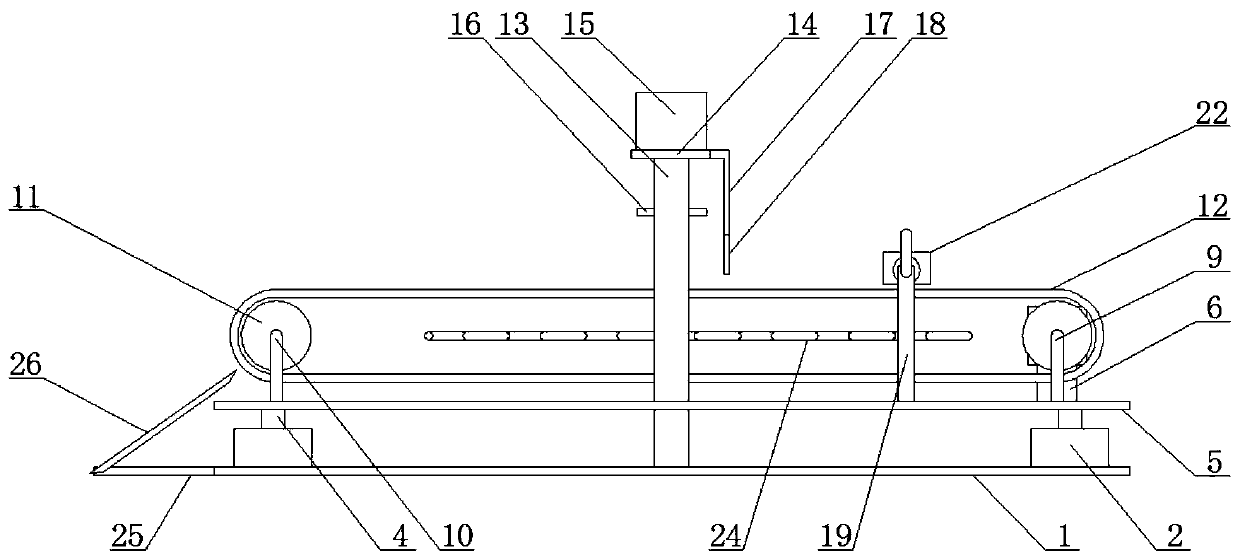

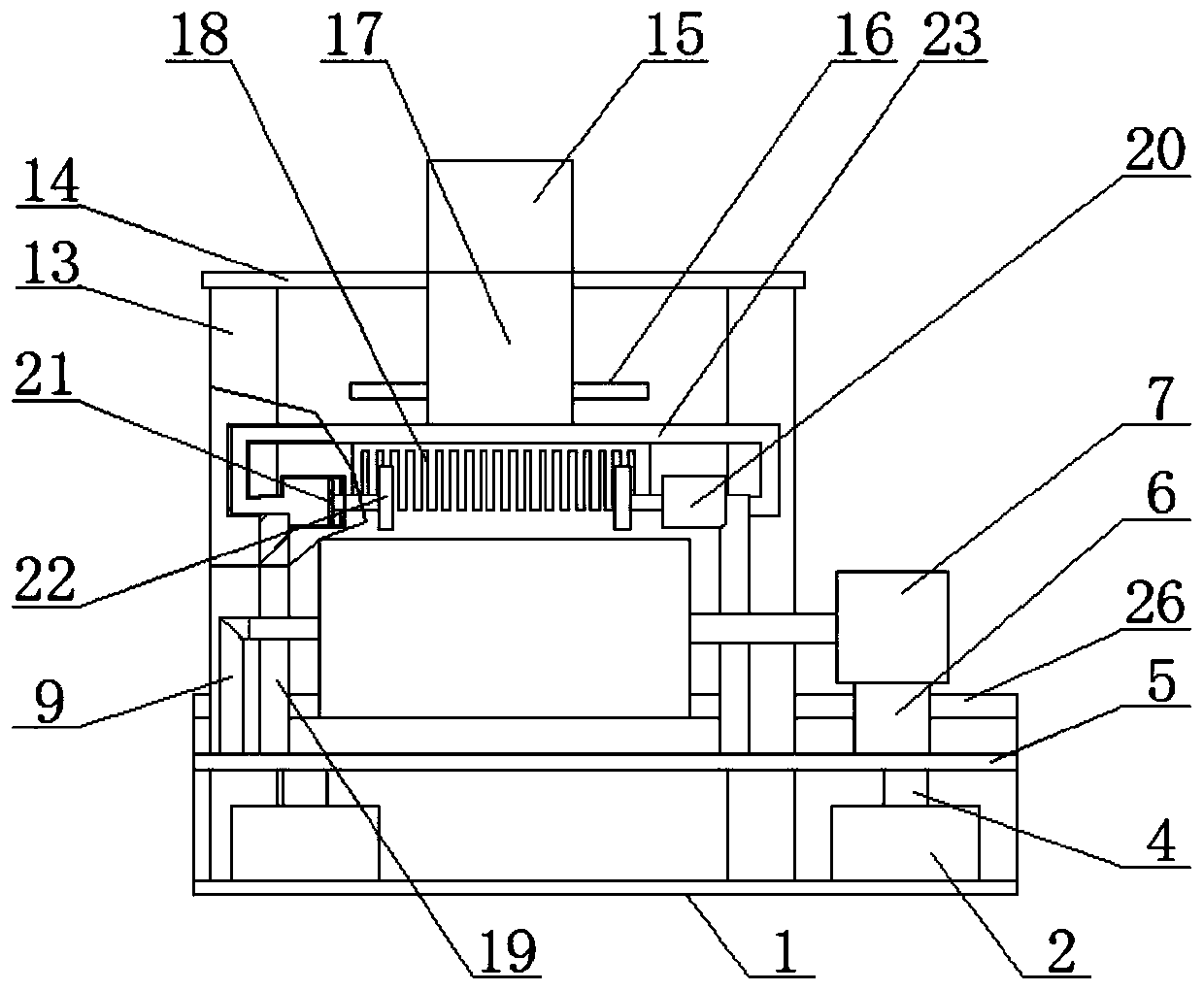

Efficient fish manure removal system applying pond circulating running water breeding

The invention discloses an efficient fish manure removal system applying pond circulating running water breeding. The system comprises a fish manure pond. Rails are arranged on the tops of the outer walls of the two sides of the fish manure pond. The rails are each of a C-shaped structure. Wheels are installed in the two rails in a sliding mode. The two wheels are connected through a connecting rod. The two ends of the connecting rod are rotationally connected with the two wheels respectively, the outer wall of the midpoint of the connecting rod is sleeved with a first gear, the two wheels are rotationally connected with a U-shaped support, an installing plate is connected to the top of the U-shaped support, a motor is installed on the outer wall of the bottom of the installing plate, an output shaft of the motor is sleeved with a second gear, and the second gear is engaged with the first gear. The installing plate and a mud pump slide on the guide rails, sludge and manure at all positions of the fish manure pond can be conveniently cleaned away, a brush can clean away the sludge and the manure on the inner wall of the bottom of the fish manure pond, suckers can suck the sludge and the manure in the fish manure pond, and the fish manure and the sludge in the fish manure pond can be fully cleaned away.

Owner:合肥万康渔业科技有限公司

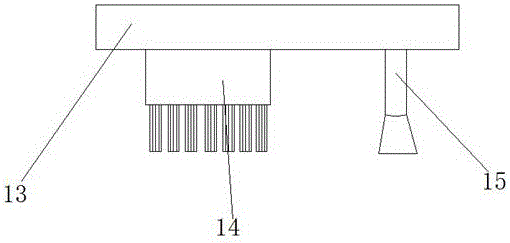

Carpet cleaning device

InactiveCN107088029AFully sterilizedEasy to collectCarpet cleanersFloor cleanersDrive shaftEngineering

The invention discloses a carpet cleaning device, which comprises a body, a handle is welded to the upper end of the side of the body, and a motor, a dust collecting box, a vacuum cleaner, a water pump, a water tank, a baffle, a drying Dryer and ultraviolet lamp, the lower end of the motor output shaft is welded with a transmission shaft outside the bottom of the main body, the lower end of the transmission shaft is connected with a brush through a fixing device, and the lower end of the second motor on one side of the water pump is provided with a roller. The drum is connected to the output shaft of the second motor through a belt, the bottom of the baffle is provided with a protruding head, and the protruding head is connected to the baffle through a spring, and the ultraviolet lamp is fixedly embedded on the outer wall of the bottom of the body . The invention has the advantages of simple structure, reasonable design, clean cleaning, thorough drying and obvious sterilization effect.

Owner:徐广文

Automatic high-efficiency cleaning device for workpiece machining

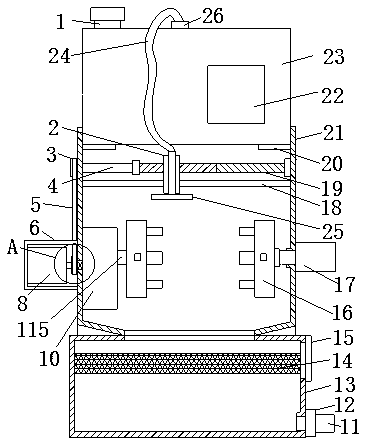

InactiveCN110216103AClean up fullyExpand the range of spray cleaningCleaning using liquidsDrive shaftMachining

The invention discloses an automatic high-efficiency cleaning device for workpiece machining. Aiming at the problems that the existing workpiece cleaning device is low in cleaning efficiency and troublesome in operation, the following scheme is provided. The automatic high-efficiency cleaning device for the workpiece machining comprises a device shell; two supporting plates are symmetrically and fixedly mounted on the inner wall of the device shell; the two supporting plates are both fixedly mounted at the lower end of a water tank; a motor is fixedly mounted at the left end of the device shell through a motor frame; a power output shaft of the motor is fixedly connected with a second transmission shaft; the right end of the second transmission shaft penetrates through the device shell; asecond transmission wheel is fixedly arranged at the position, between the motor and the device shell, of the second transmission shaft in a sleeving manner; a driving mechanism is fixedly mounted onthe left side wall in the device shell; the right end of the second transmission shaft is connected with the driving mechanism; an air cylinder is fixedly mounted at the right end of the device shell;and the power output rod of the air cylinder movably penetrates through the device shell. The automatic high-efficiency cleaning device for the workpiece machining is good in cleaning effect, high inefficiency, high in automation degree and good in environment friendliness, and is suitable to be popularized and used.

Owner:左吉吉

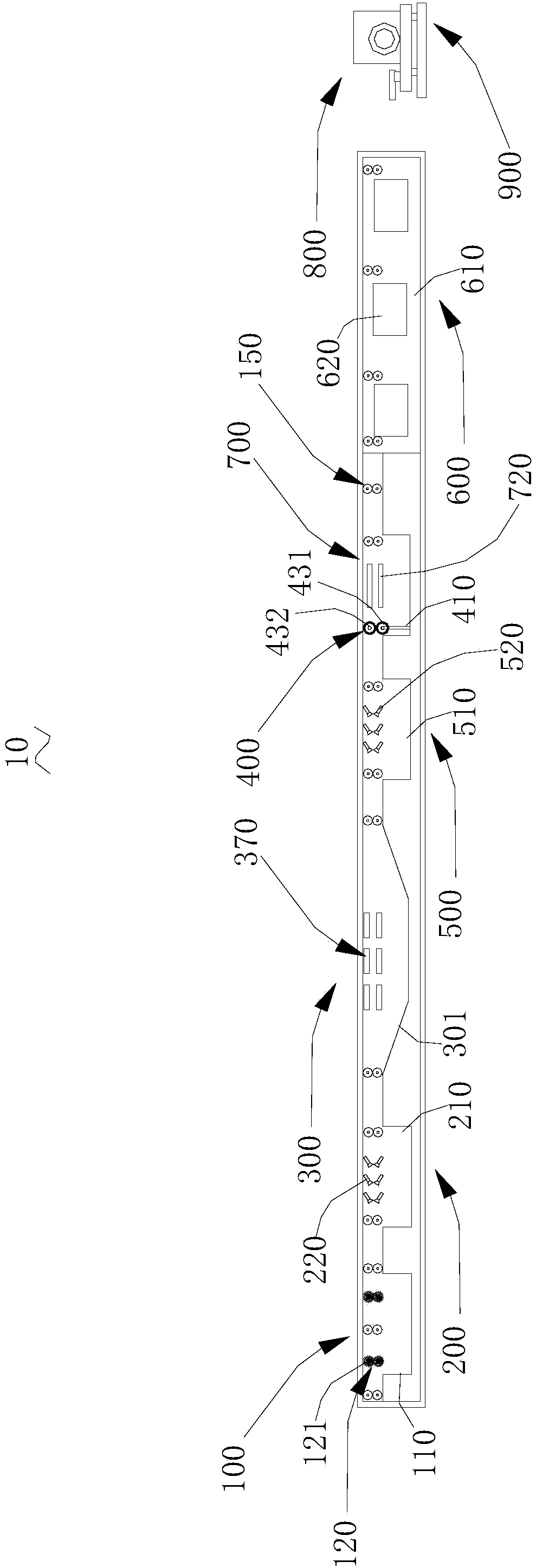

Steel sheet cleaning device

InactiveCN107597642AFully cleanedEasy to dryDrying gas arrangementsCleaning using toolsMegasonic cleaningEngineering

The invention relates to a steel sheet cleaning device comprising a scrubbing cleaning mechanism, a spraying cleaning mechanism, an ultrasonic cleaning mechanism, a sprinkling mechanism, a water scrapping mechanism and a drying mechanism, wherein the scrubbing cleaning mechanism, the spraying cleaning mechanism, the ultrasonic cleaning mechanism, the sprinkling mechanism, the water scrapping mechanism and the drying mechanism are sequentially arranged on one straight line. A steel sheet sequentially passes through the scrubbing cleaning mechanism, the spraying cleaning mechanism, the ultrasonic cleaning mechanism, the sprinkling mechanism, the water scrapping mechanism and the drying mechanism. Through scrubbing cleaning of scrubbing cleaning rollers, spraying cleaning of spraying heads and ultrasonic cleaning, surface oil stains and impurities of the steel sheet are fully removed, clean water is sprinkled to the surface of the steel sheet through the sprinkling mechanism, so that thesurface of the steel sheet is cleaner, then through a first squeezing wheel and a second squeezing wheel of the water scrapping mechanism, residual water on the surface of the steel sheet is scrappedoff, a trace amount of water remains on the surface of the steel sheet, and then the steel sheet can be rapidly dried after entering a drying box. By the adoption of the process, the steel sheet is more fully cleaned and is cleaner, the drying efficiency is effectively improved, and the overall cleaning efficiency of the steel sheet is effectively improved.

Owner:深圳市志虹供应链有限公司

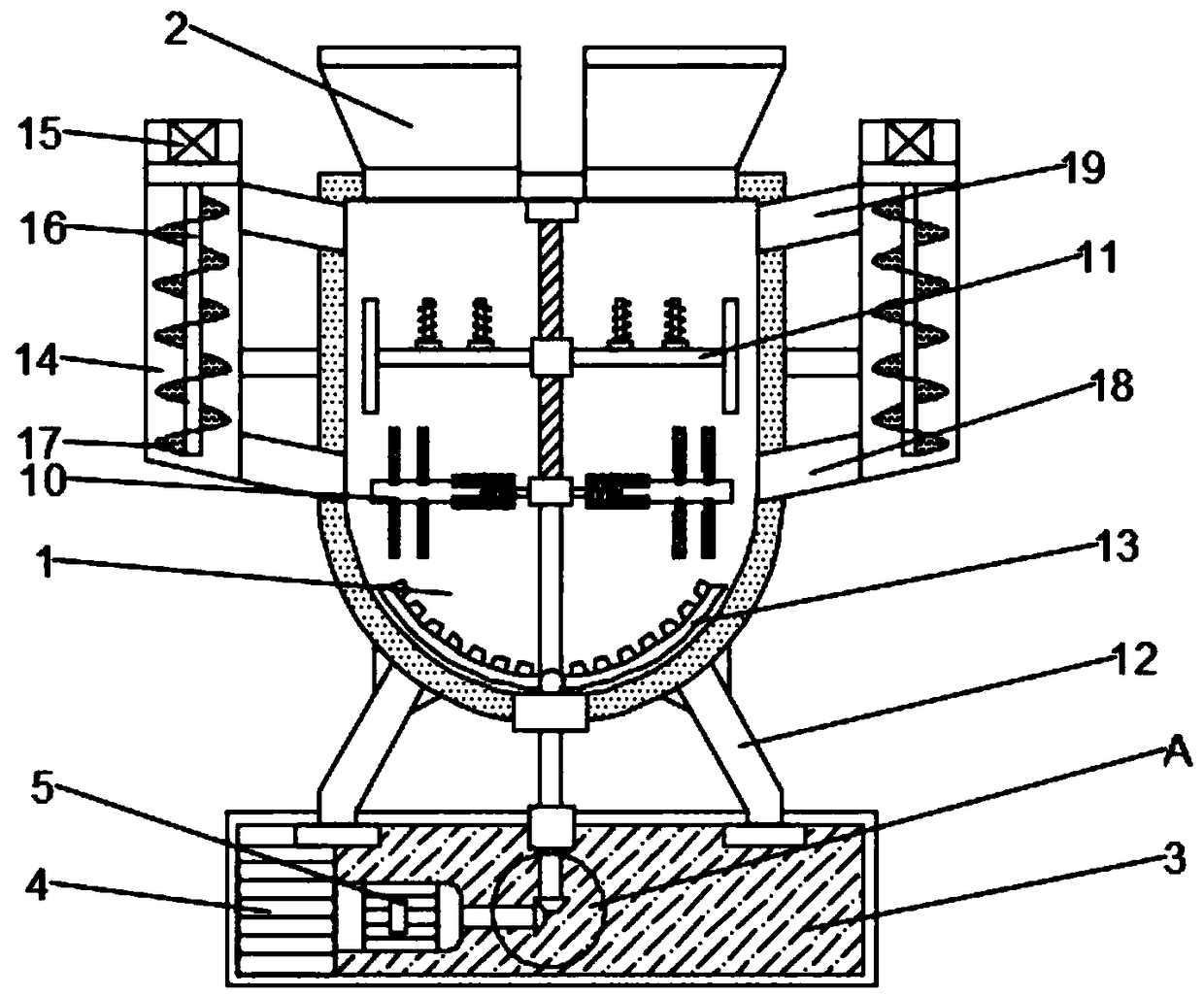

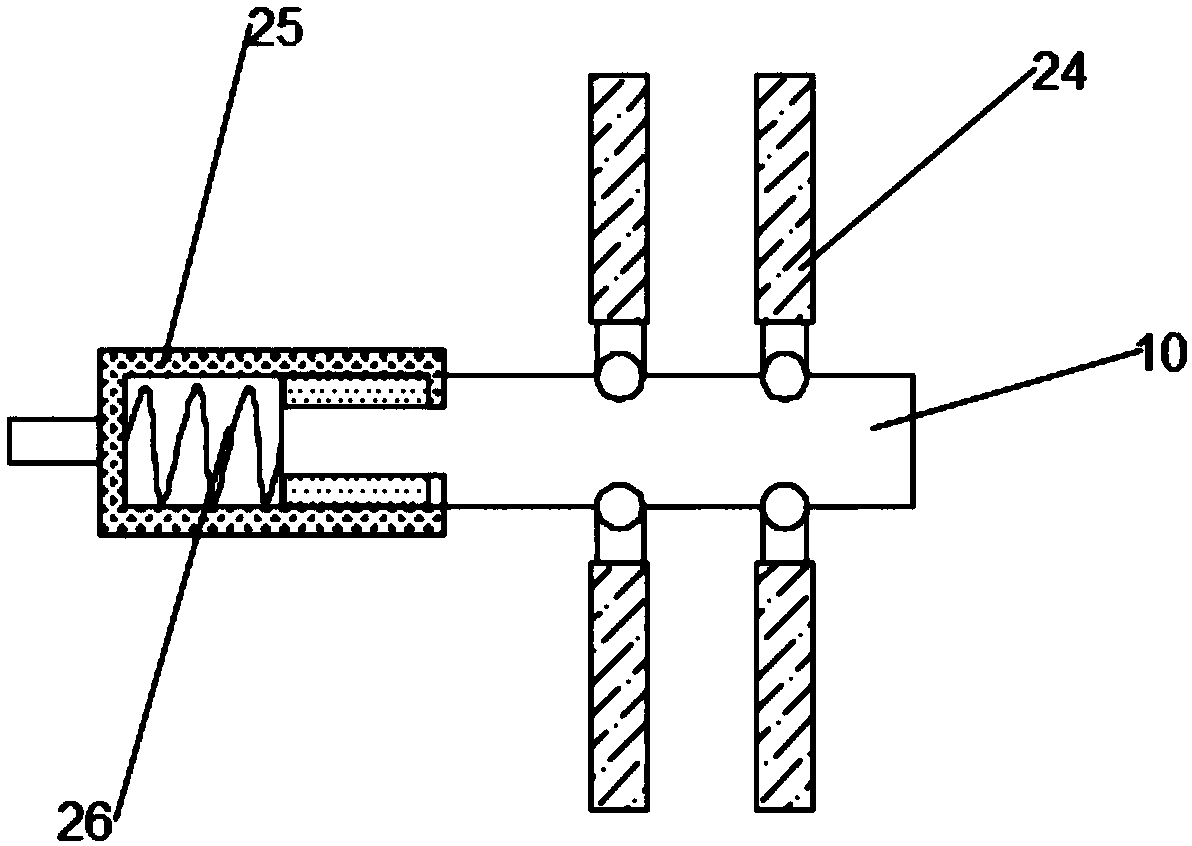

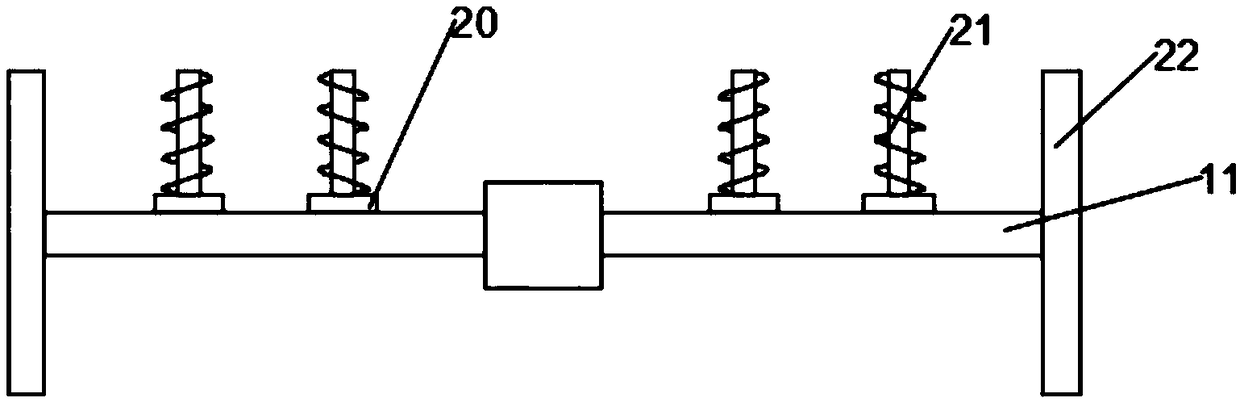

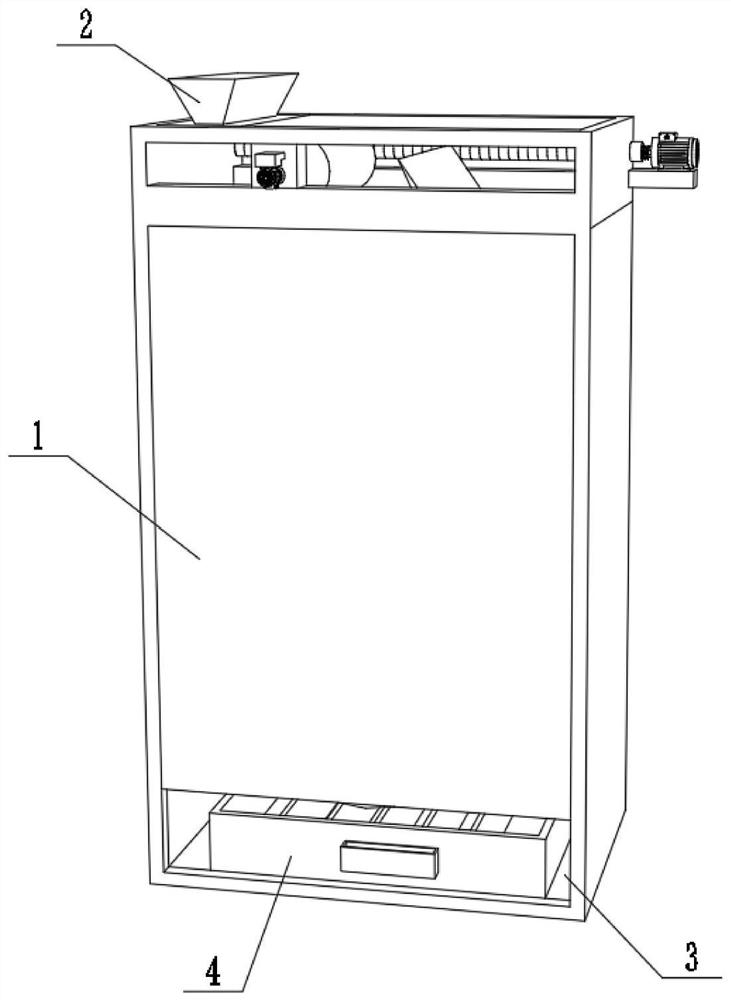

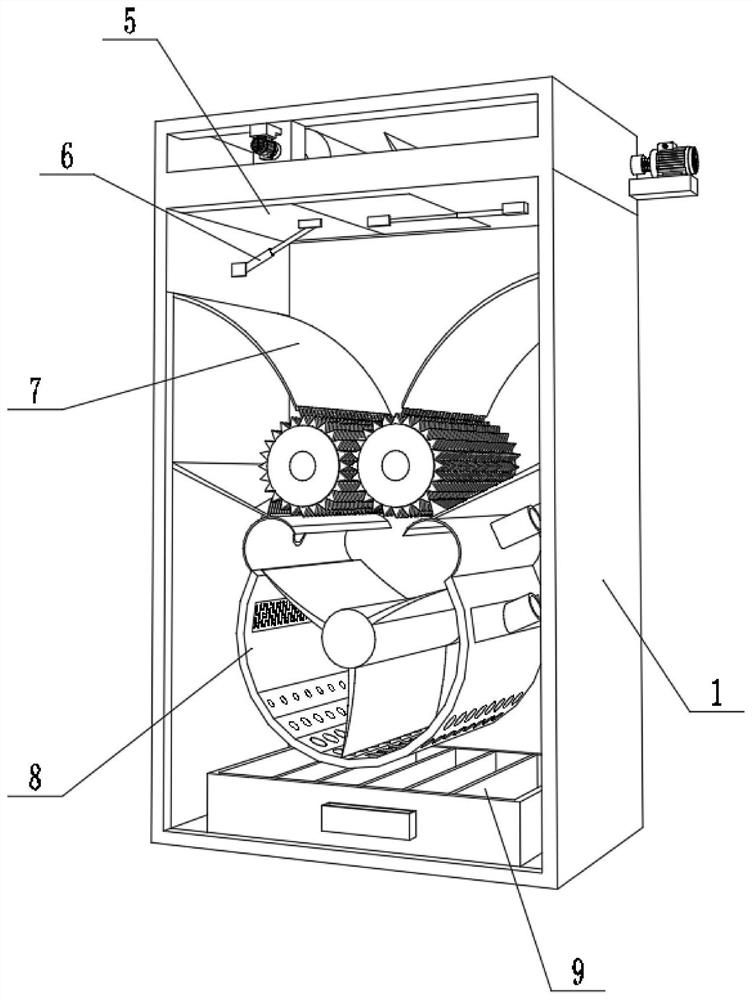

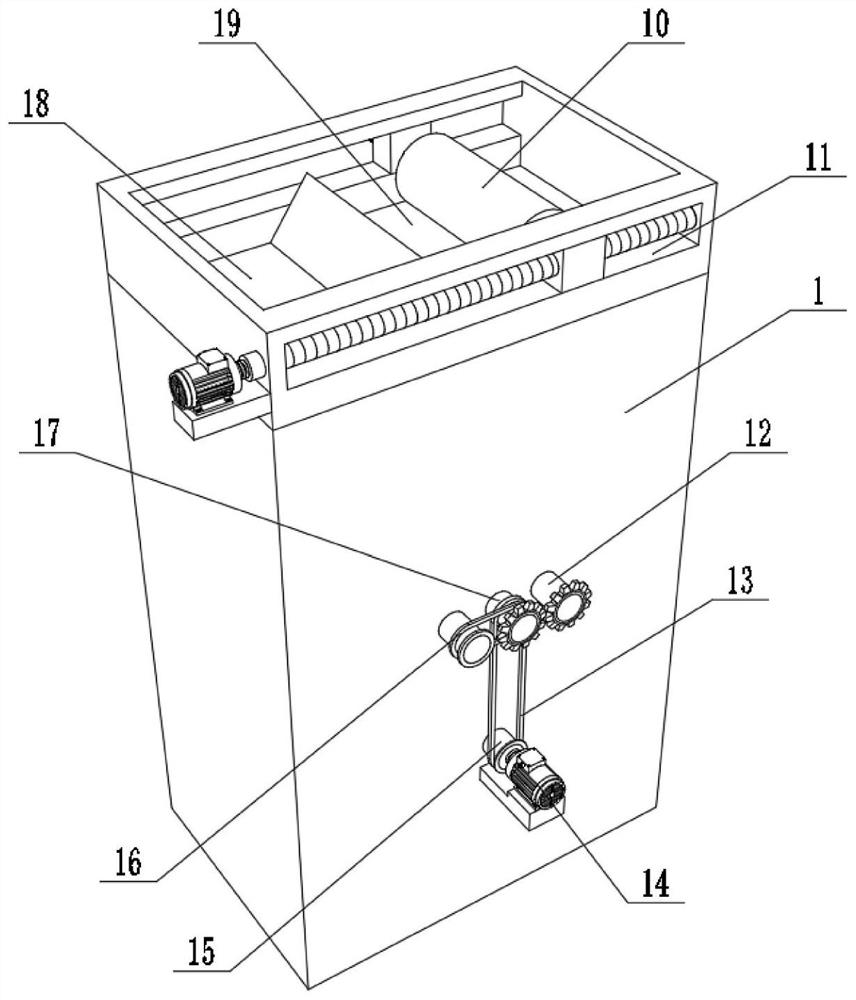

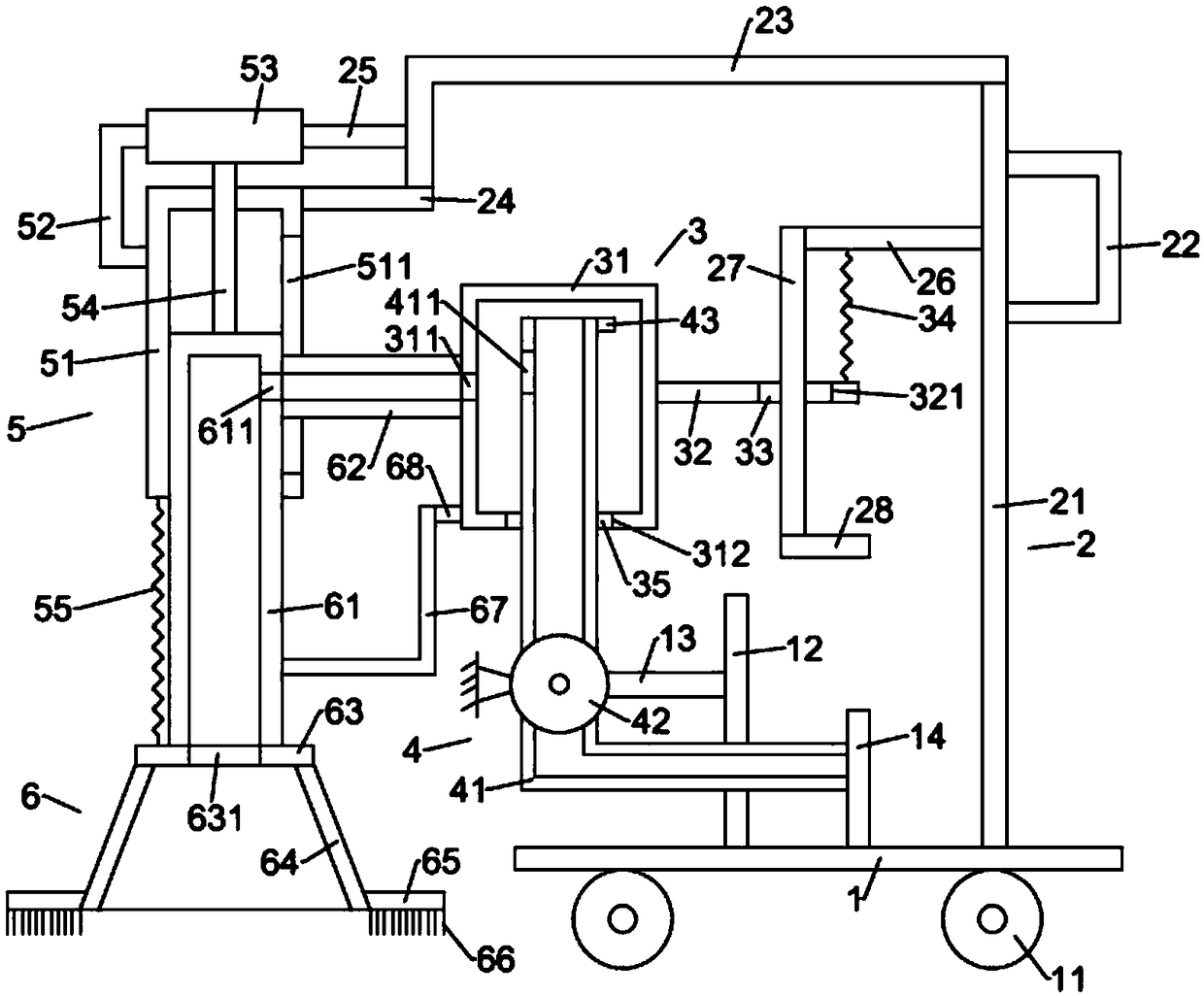

Peanut kernel processing machine for squeezing peanut oil

InactiveCN110564492AThe seed coat is crispSmall footprintSievingScreeningMechanical engineeringArachis hypogaea

The invention relates to a peanut kernel processing machine for squeezing peanut oil. The machine comprises a rack, a shell breaking device, a screening and drying channel, a stirring and peeling device, a separating channel and a feeding hopper; wherein the rack is divided into an upper rack and a lower rack; wherein a shell breaking cavity and a drying cavity are sequentially formed in the upperrack from top to bottom, the shell breaking device is installed in the shell breaking cavity, the feeding hopper is installed at the upper end of the shell breaking device, the screening and drying channel is formed in the drying cavity, a stirring cavity and a separating cavity are sequentially formed in the lower rack from left to right, the stirring and peeling device is installed in the stirring cavity, and the separating channel is formed in the separating cavity; shelling, peeling and crushing devices are combined together, the overall occupied area is reduced, the mode of peeling afterdrying is adopted, peanut seed coats are dry and crisp, and therefore the peanut seed coats can be easily separated from peanut kernels; oil can be pressed after the peanuts are processed in a smallworkshop, and the dried peanuts are crushed into peanut grains, so that subsequent oil pressing treatment is facilitated.

Owner:朱运霞

Welding method for welding steel pipe spirally

The invention discloses a welding method for welding a steel pipe spirally. The welding method comprises the steps of: uncoiling a plate coil, flattening, milling edges, forming, welding and tracking detection. The welding method is characterized in that firstly the plate coil is uncoiled and flattened into a steel belt, and edge-milled into an X-shaped groove, the steel belt is conveyed to a spiral welded steel pipe former continuously according to the spiral angle; the formed steel-belt spiral steel pipe adopts a process with combination of internal and external submerged-arc welding and double-wire serial electric-arc and submerged-arc automatic welding, and then pre-internal welding, refined internal welding and external welding are carried out; a tracking sensor is adopted to detect the lowest point of a V-shaped groove of the formed seam at a distance before internal welding of the groove welded of the steel pipe to be welded to realize automatic tracking of refined welding and internal welding. The welding method disclosed by the invention has the advantages that the process with combination of internal and external submerged-arc welding and double-wire serial electric-arc and submerged-arc automatic welding and the tracking detection system is adopted, the welding deviation phenomenon and the fluctuation of welding offset can be avoided, the workload for correction and adjustment is reduced, the welding process is stable and reliable and the quality of the welding seam is ensured.

Owner:方晓东

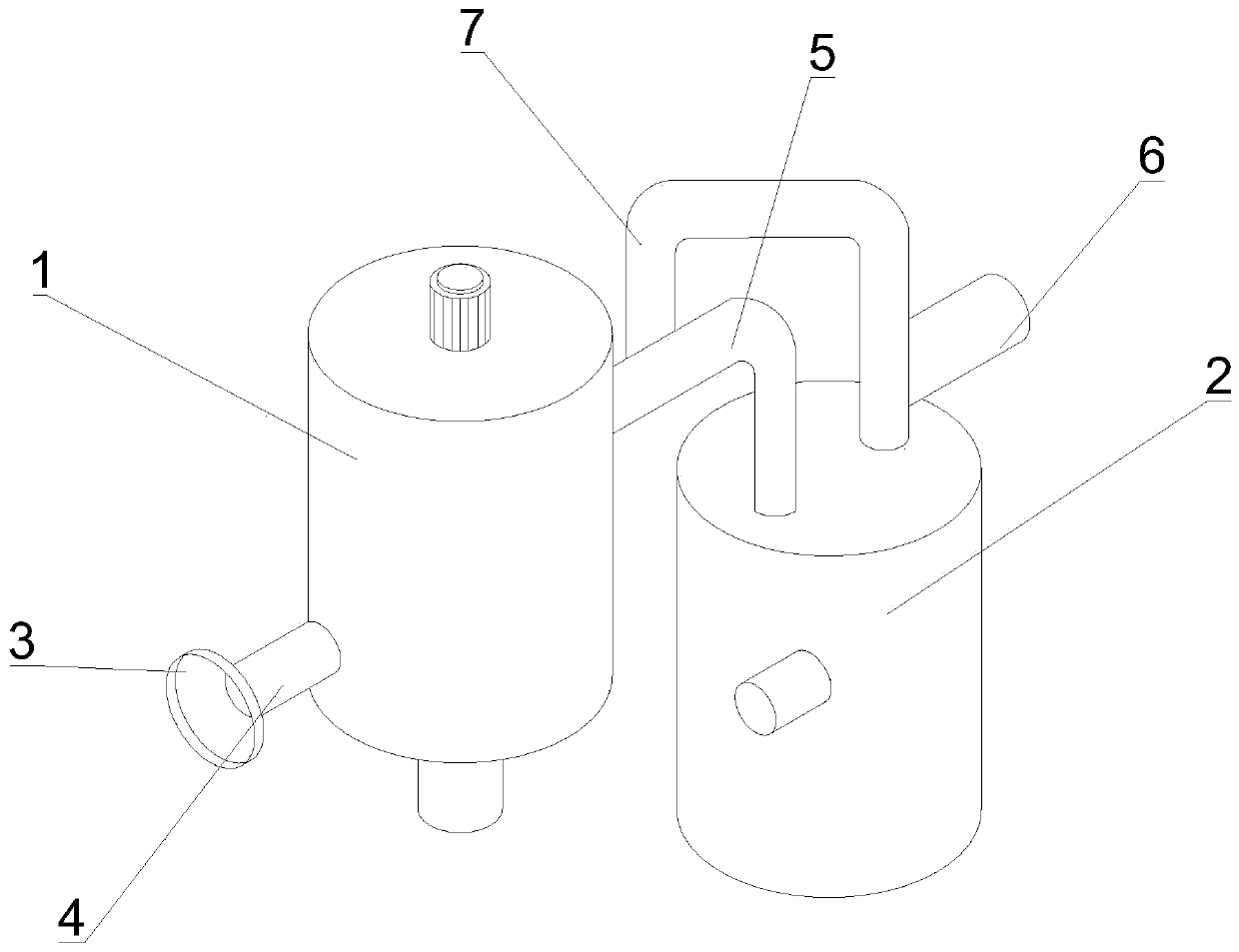

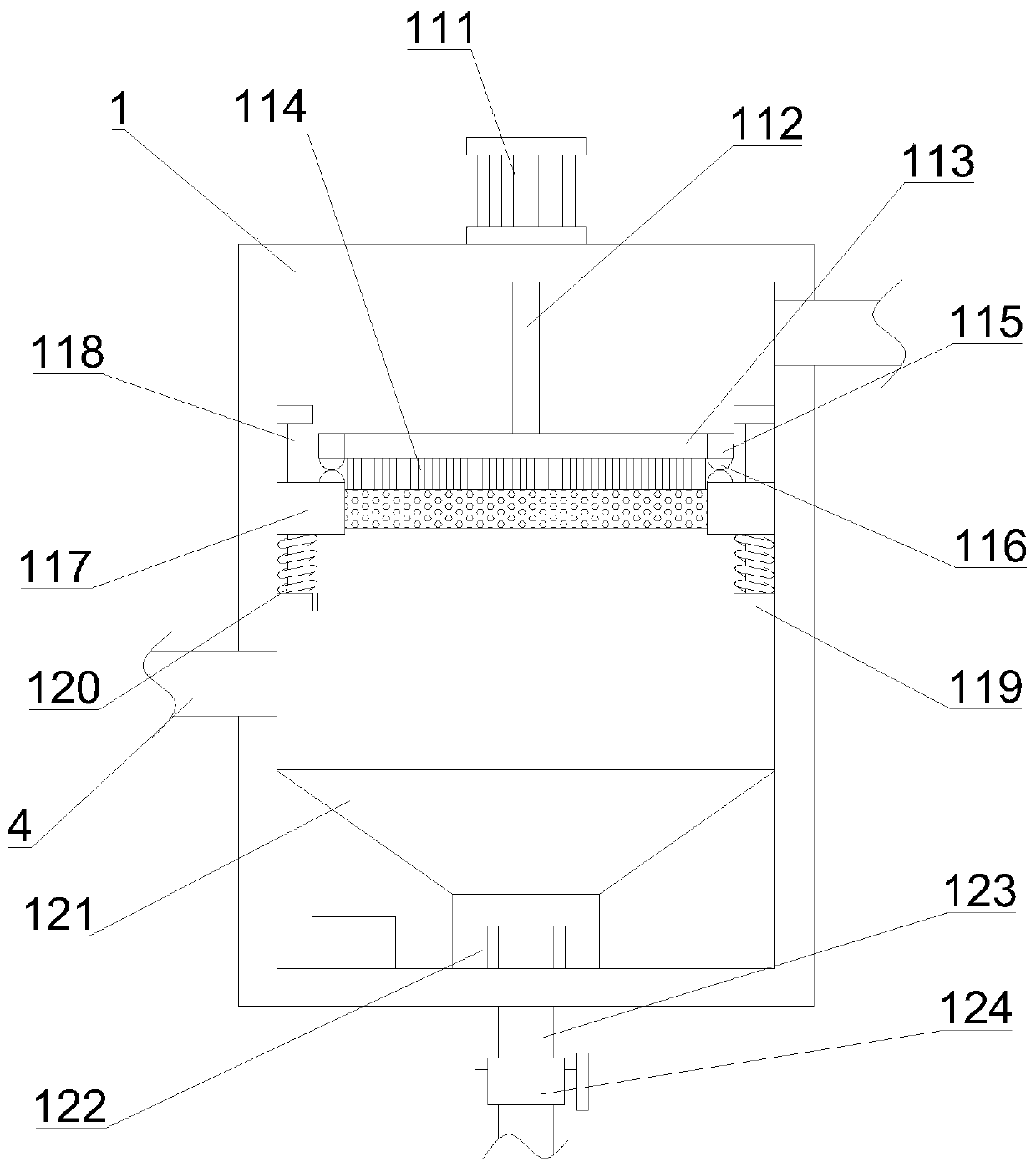

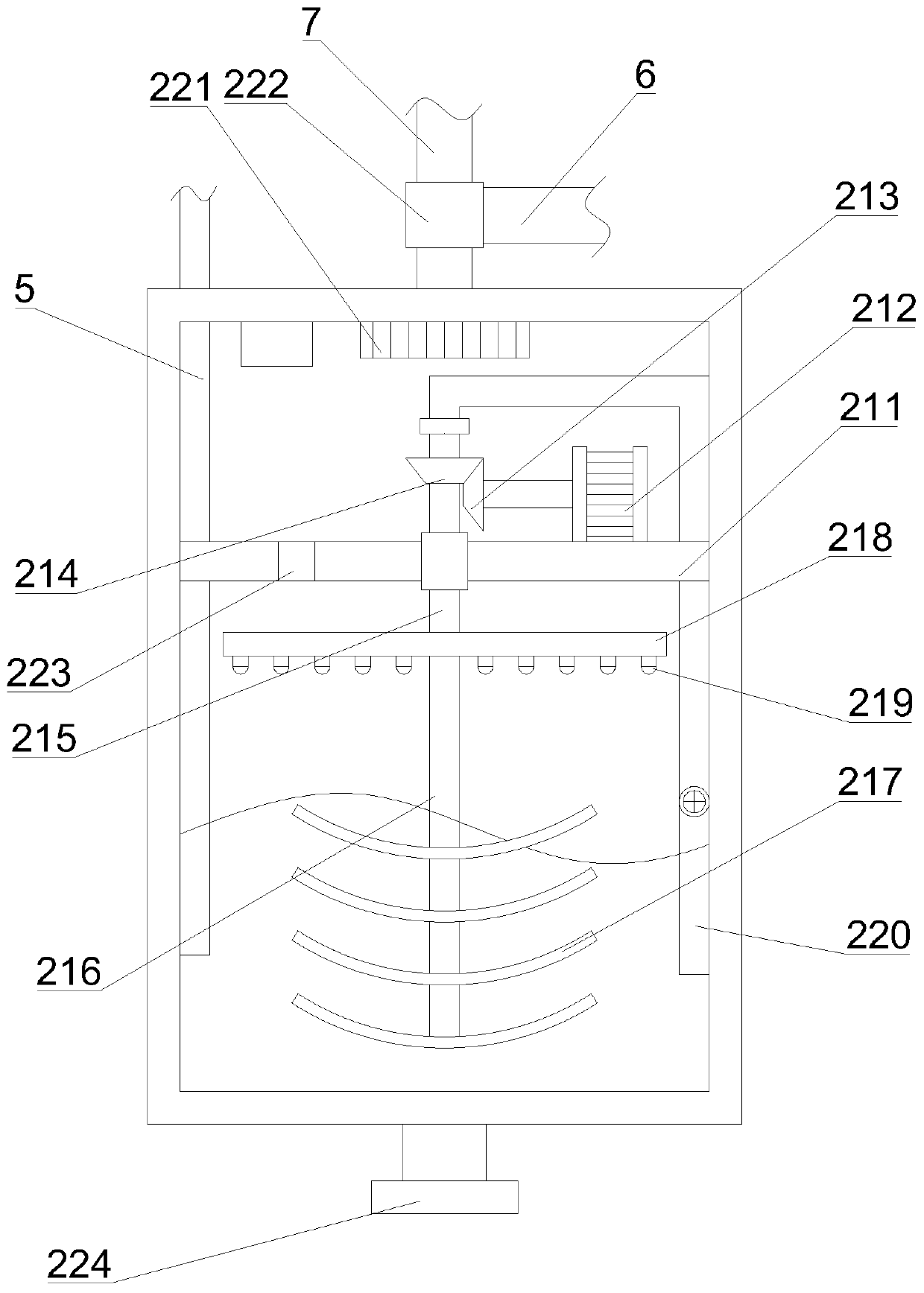

Tail gas treatment device for waste incineration

InactiveCN110613984AClean up fullyPurify thoroughlyDispersed particle filtrationTransportation and packagingEngineeringExhaust pipe

The invention discloses a tail gas treatment device for waste incineration. The device comprises a dust removal tank and a purification tank, wherein the gas outlet end of the top of the purificationtank communicates with an exhaust pipe and a circulating pipe through a three-way electromagnetic valve, while the other end of the circulating pipe is connected with a communicating pipe; a discharging pipe is arranged at the discharging end of the bottom of the purification tank, and a tail gas dust removal mechanism and a tail gas purification mechanism are arranged in the dust removal tank andthe purification tank respectively; the output end of the first motor is connected with the first rotating shaft; the bottom end of the first rotating shaft extends into the dust removal tank and isrotationally connected with the dust removal tank; the bottom end of the first rotating shaft is connected with the middle of a transverse plate, brush hairs are arranged on the bottom face of the transverse plate, connecting blocks are arranged on the two sides of the transverse plate respectively, first magnets are arranged on the bottom faces of the connecting blocks, the inner wall of the dustremoval tank is connected with a filtering piece through a limiting assembly, and a weight sensor is arranged at the bottom of the dust collection cover. The device has the advantages that dust removal and ash removal are facilitated, the tail gas purification efficiency is high, automatic operation is improved, and labor output is reduced.

Owner:ANHUI SHENGYUN ENVIRONMENT PROTECTION GRP CO LTD

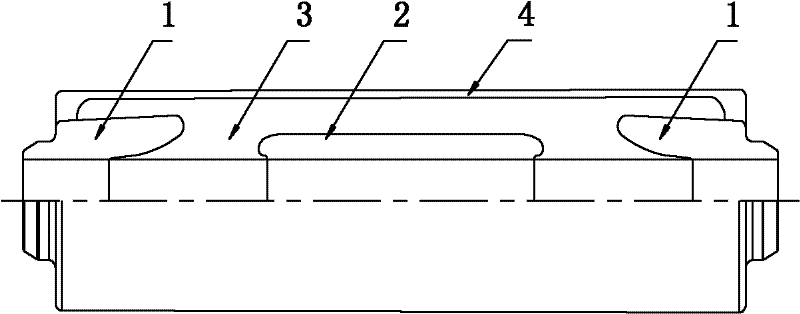

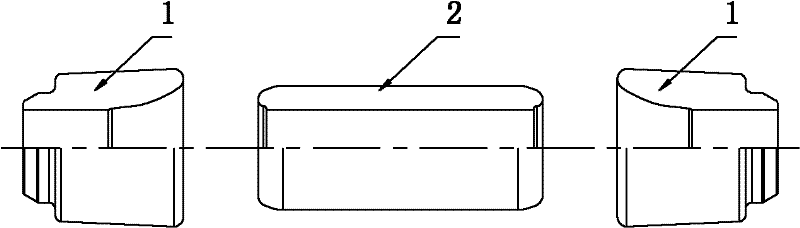

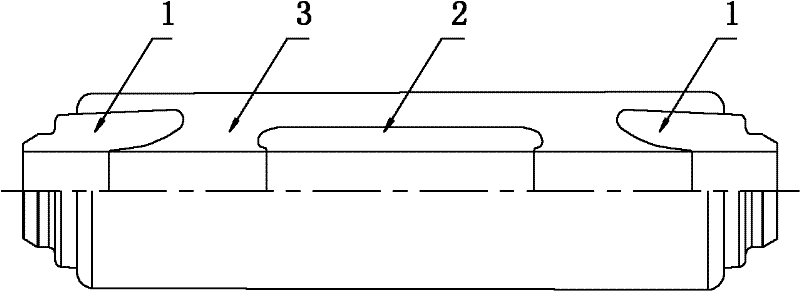

110KV intermediate head and production process thereof

ActiveCN102185274AImprove visibilityConvenient inspectionLine/current collector detailsCable junctionsEngineeringSilicon rubber

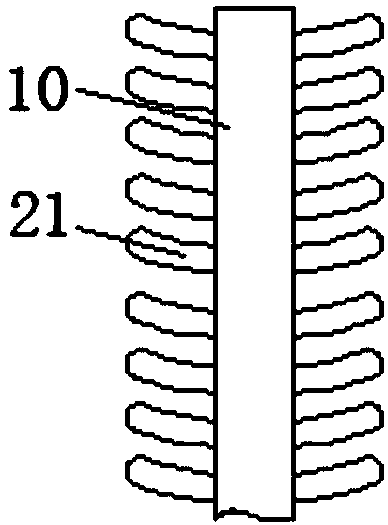

The invention provides an 110KV intermediate head and a production process thereof. The intermediate head comprises two stress cones (1), a screening tube (2), insulating layers (3) and outer screening layers (4), wherein the screening tube (2) is arranged between the two stress cones (1); the insulating layers (3) are filled between the screening tube (2) and the two stress cones (1); and the outer screening layers (4) are coated outside the insulating layers (3). The process of producing the 110KV intermediate head comprises three formations, that is, the first formation is the formation ofthe conductive stress cones and the screening tube; the second formation is the formation of the insulating layers: the formed stress cones and a formed stress tube are arranged in a mould during glue injection and then integrated after formation; and the third formation is the formation of outer conducting layers: all parts are integrated after formation to form the intermediate head. The formedinsulating layers of the intermediate head are made from transparent insulated rubbers, thus being high in visibility and being convenient to check.

Owner:江苏远航电缆附件有限公司

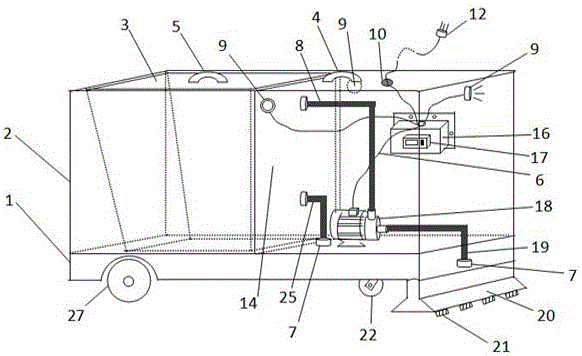

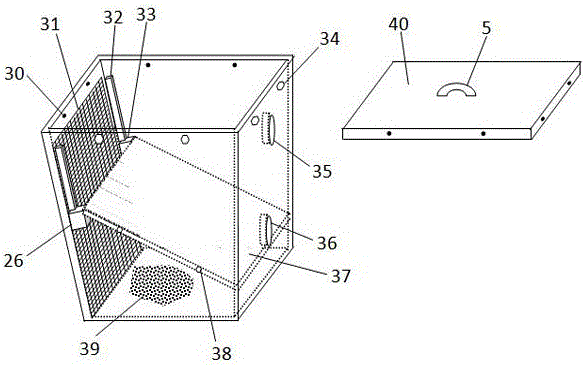

Automatic fishpond contamination suction machine and contamination clearing method

ActiveCN106035199AAvoid repeated decontaminationImprove cleaning efficiencyPisciculture and aquariaUltrasonic sensorSewage

The invention discloses an automatic fishpond contamination suction machine and a contamination clearing method. An MCU controller controls a submerged pump to work, sewage in a fishpond is ejected to the upper space of a filtering container, and the sewage impacts a filtering screen and then is filtered; the filtered sewage returns to the fishpond via a water outlet pipe of the filtering container, and excrement and residual bait falls into the lower space of the filtering container through a gap between the filtering screen and an intermediate baffle plate; and the MCU controller detects signals of three waterproof ultrasonic sensors, calculates out the distances between the front wall, the left wall and the right wall of a vehicle body and opposite walls of the fishpond, control the vehicle body to straightly move forward or turn left and turn right at the angle of 90 degrees, and allows the vehicle body to traverse the bottom of the fishpond along a continuous extension rectangular path in a reciprocation manner. The ultrasonic sensors and the MCU controller are combined to determine the position of the contamination suction machine in the bottom of the fishpond, the contamination clearing path covers the whole fishpond through the reciprocation movement manner, repeated contamination clearing jobs can be avoided, and the efficiency of contamination clearing can be improved.

Owner:扬中市广善科创服务有限公司

New material stirring mixing device capable of changing stirring scope

InactiveCN108889229AAvoid deposition adsorptionEasy to useRotary stirring mixersTransportation and packagingEngineeringNew materials

The invention discloses a new material stirring mixing device capable of changing a stirring scope. The new material stirring mixing device comprises a shell, feeding ports, a support base, a first stirring shaft, a second stirring shaft and material circulating chambers; the support base is arranged at the bottom of the shell; support legs are symmetrically welded on the two sides of the lower surface of the shell; the support legs are bias arranged; the lower ends of the support legs are fixed on the upper surface of the support base; a bottom stirring paddle, the first stirring shaft and the second stirring shaft are successively arranged in an inner chamber of the shell from bottom to top; two feeding ports are symmetrically formed in the upper surface of the shell; two material circulating chambers are symmetrically vertical arranged on two side walls of the shell; the new material stirring mixing device is characterized in that a storage battery is welded on a left side wall of the inner chamber of the support base; a servo motor is arranged on the right side of the storage battery. The new material stirring mixing device is convenient in use, is capable of continuously changing the stirring scope so as to optimize the mixing stirring effect of raw materials and is capable of realizing efficient mixing of the raw materials.

Owner:佛山博发智能科技有限公司

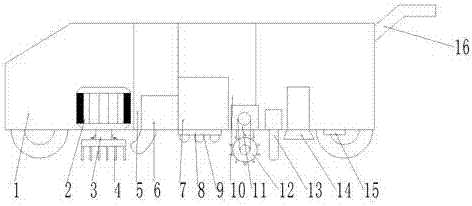

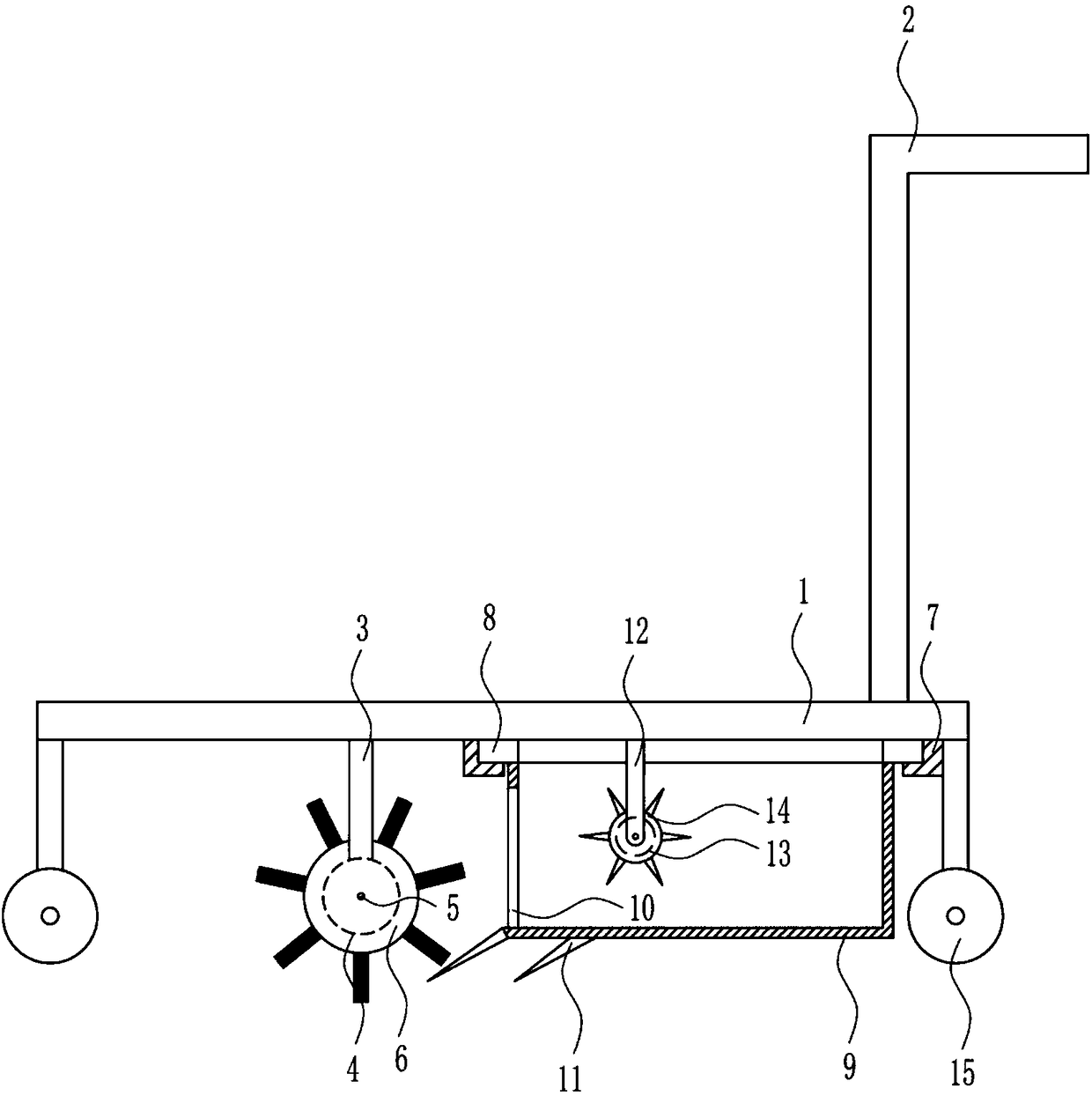

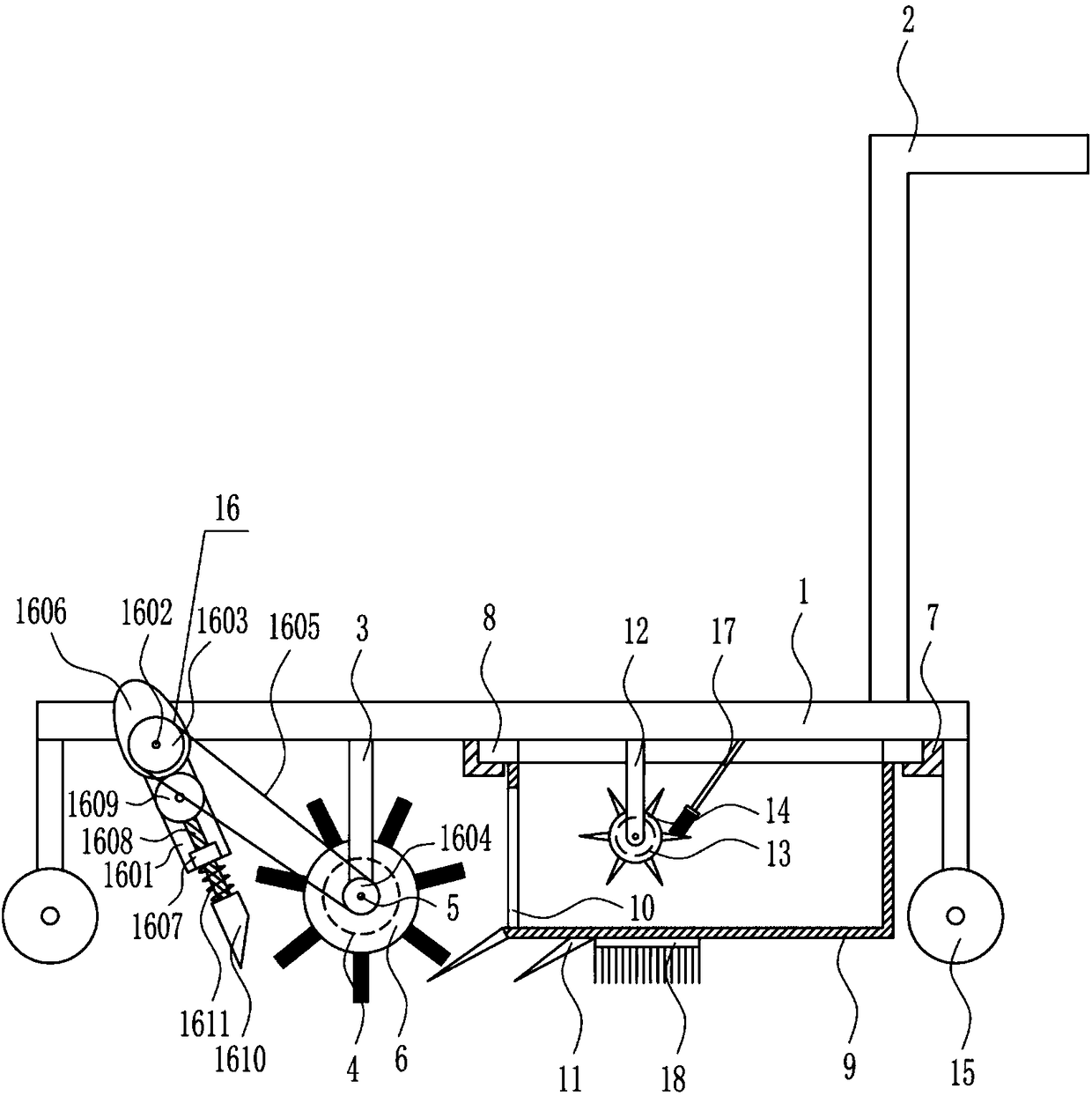

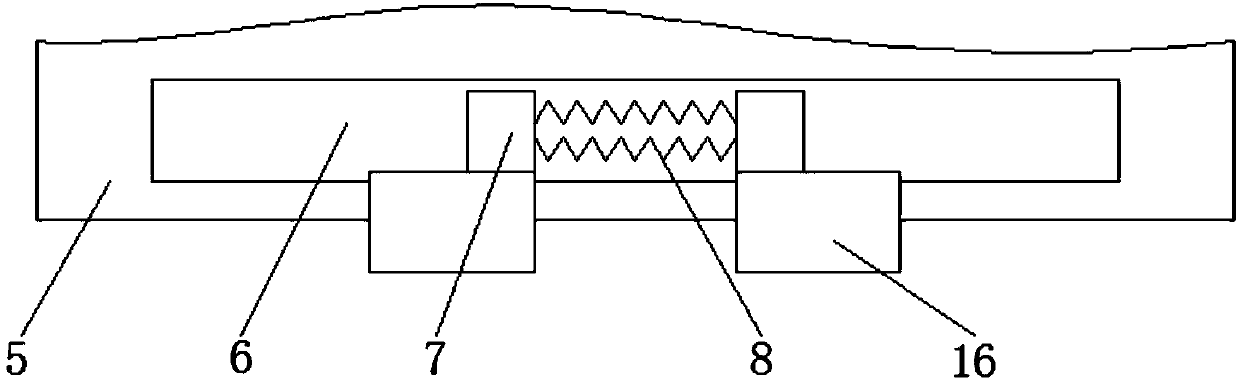

Excessive asphalt cleaning equipment for petroleum asphalt road joint filling

InactiveCN108532427AImprove collection effectImprove working conditionRoads maintainenceRoad surfaceUltimate tensile strength

The invention relates to cleaning equipment, in particular to excessive asphalt cleaning equipment for petroleum asphalt road joint filling. The excessive asphalt cleaning equipment can sufficiently clean petroleum asphalt on the surface of a road and is simple and reliable in structure and capable of reducing labor intensity of an operator. The excessive asphalt cleaning equipment comprises a bottom plate, a push hand, a first supporting rod, a first motor, a first rotating shaft, a roller brush, an L-shaped clamping plate, a first fixing plate and a collecting box, the push hand is arrangedon the right side of the top of the bottom plate, and traveling wheels are arranged at the bottom of the bottom plate. The roller brush is driven through the first motor to rotate to sweep surplus petroleum asphalt on the road into the collecting box, and a prodding wheel is utilized to compact the asphalt collected in the collecting box, so that collecting capacity of the collecting box is increased; by optimizing a knocking mechanism, the petroleum asphalt on the road can be cleaned sufficiently.

Owner:刘健红

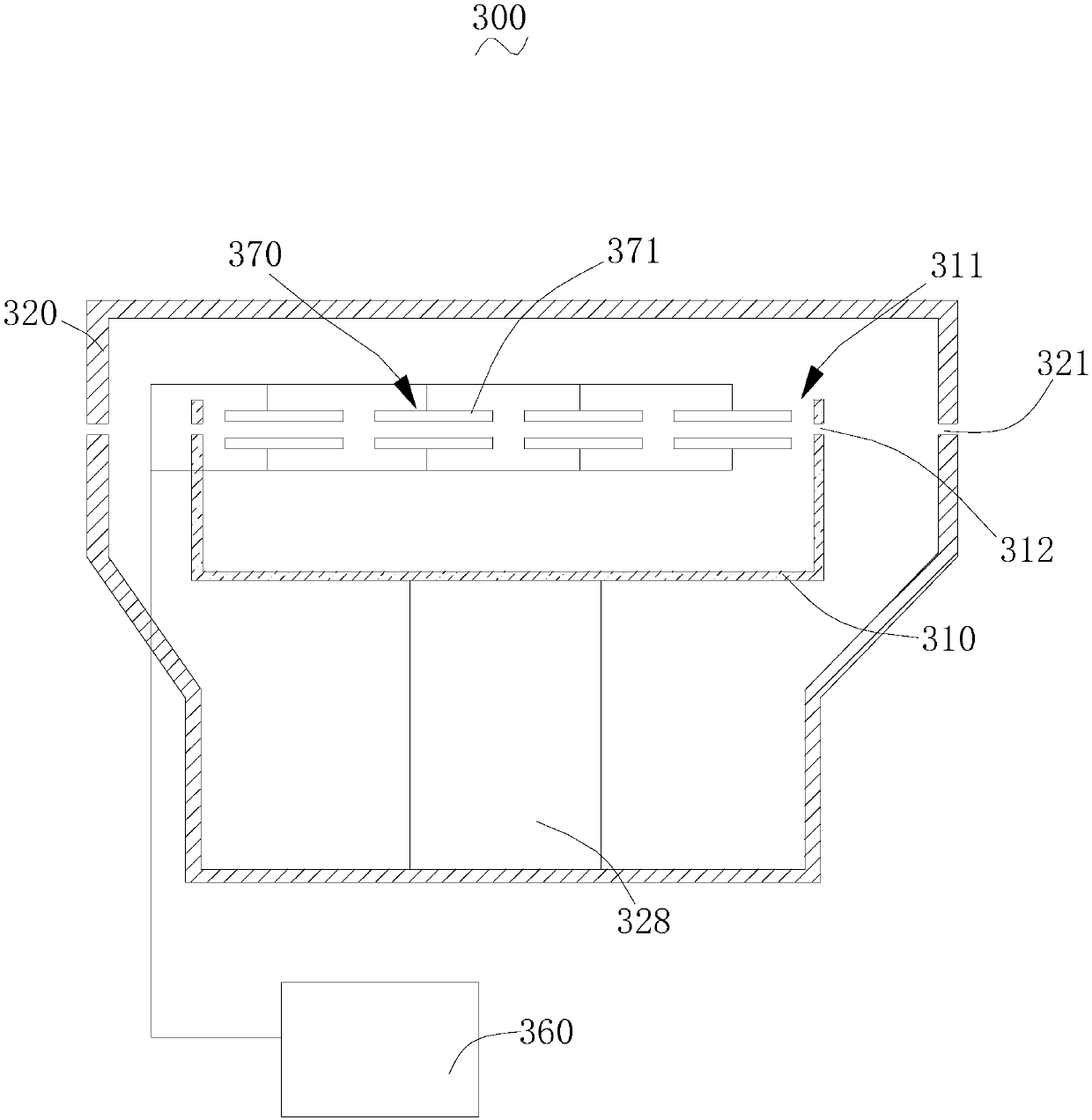

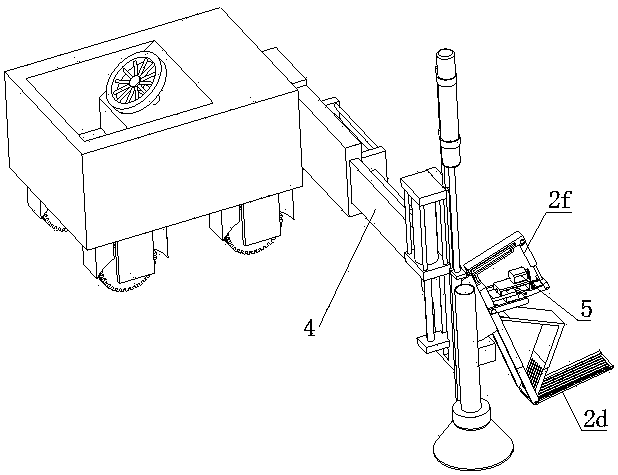

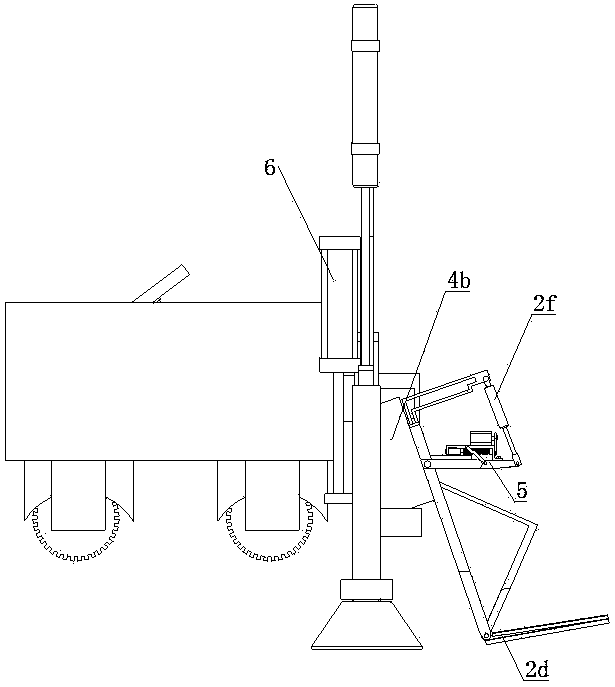

All-dimensional dead-corner-free self-cleaning environment-friendly air conditioner

ActiveCN105509205AAchieve cleanupImprove cleanlinessMechanical apparatusSpace heating and ventilation safety systemsIndoor air qualityPhysical health

The invention discloses an all-dimensional dead-corner-free self-cleaning environment-friendly air conditioner. The air conditioner comprises an enclosure, a pneumatic unit, a dedusting device, a cleaning device, a dust collection box and a control device. The dedusting device is arranged on a rear shell and side walls of the enclosure, the cleaning device is arranged on the inner side of a front shell of the enclosure, the dust collection box is arranged below the enclosure and closely connected with the enclosure, and the pneumatic unit, the dedusting device and the cleaning device are all connected with the control device. The all-dimensional dead-corner-free self-cleaning environment-friendly air conditioner has the advantages that by the dedusting device and the cleaning device in the enclosure, dust in the enclosure is removed by the dedusting device, and then thick dirt of an air outlet is thoroughly cleaned by the cleaning device, so that all-dimensional cleaning of the air conditioner is realized, cleanliness of the air conditioner is improved, influences of dust or dirt in the air conditioner on indoor air quality are avoided, and physical health is guaranteed.

Owner:苏州圣典企业管理咨询有限公司

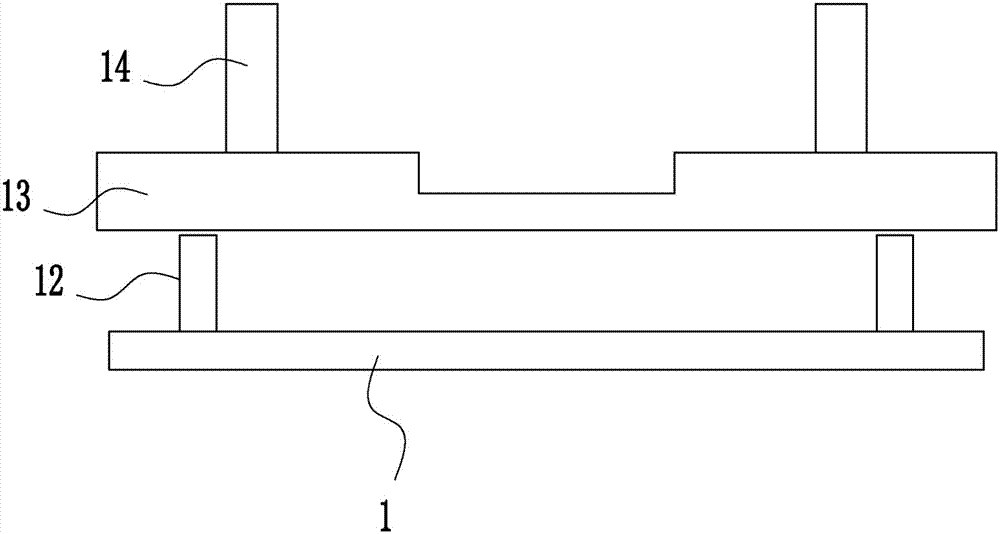

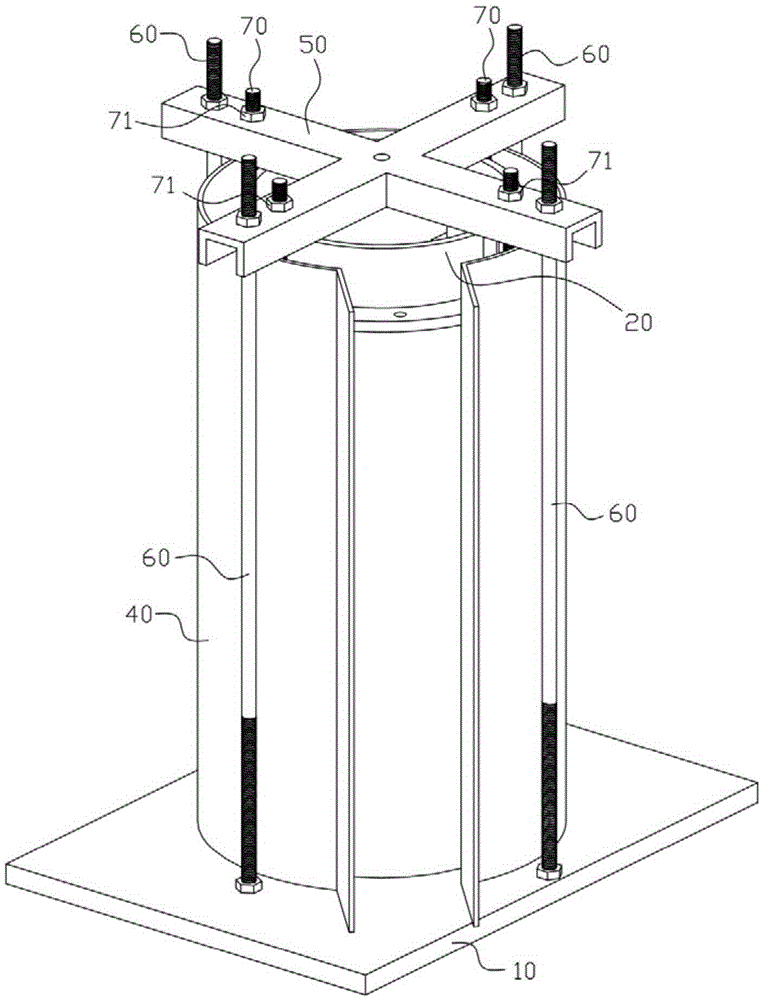

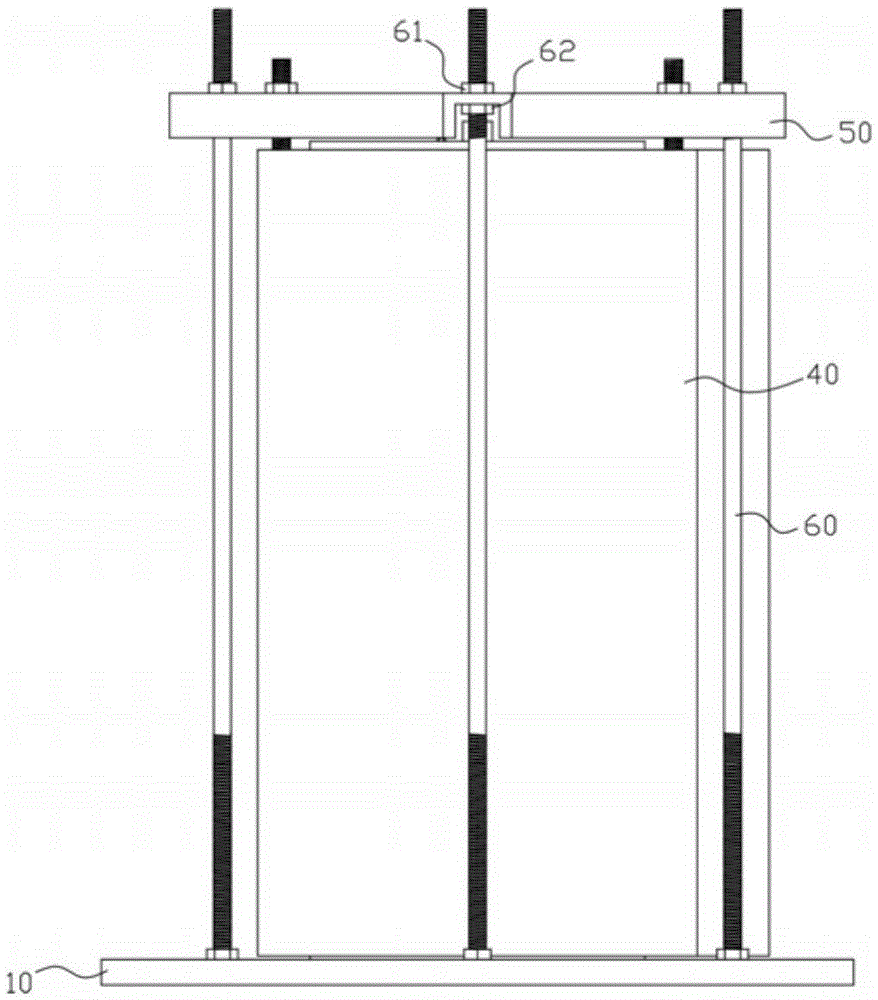

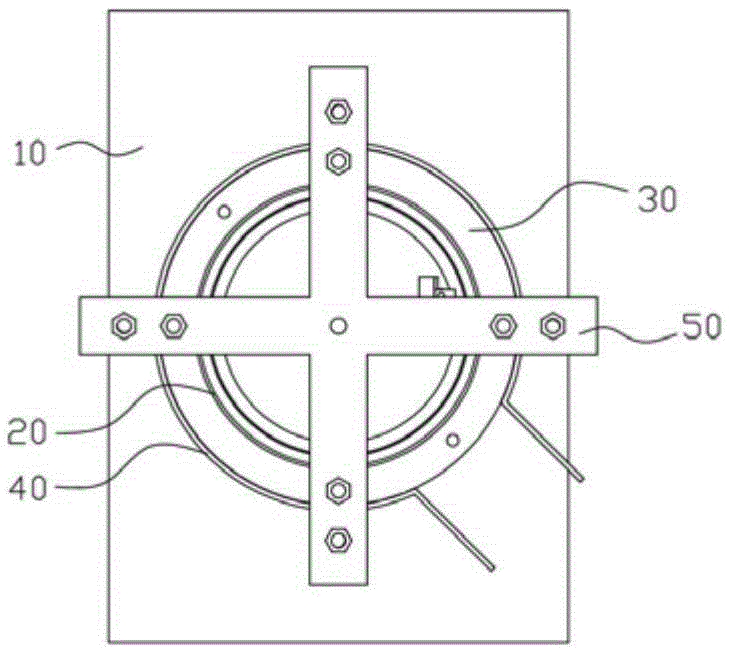

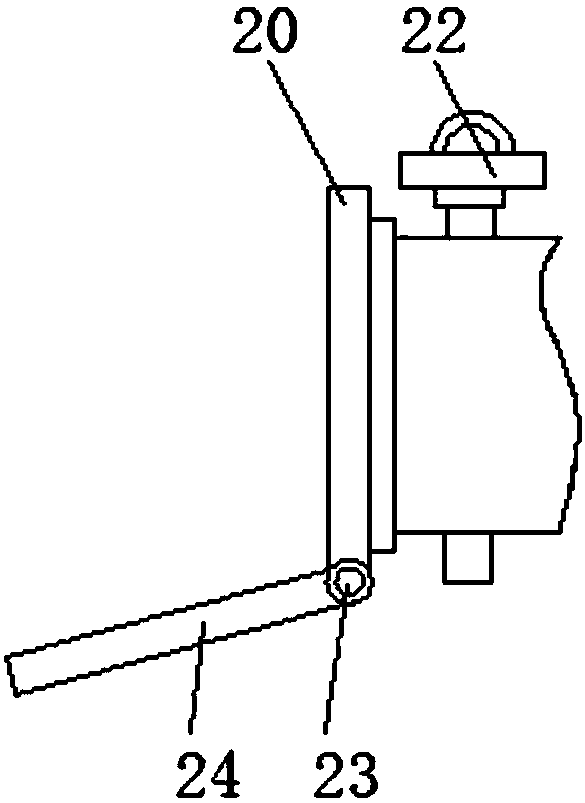

Epoxy casting mold with adjustable casting height and easy-to-disengage inner mold body

The invention discloses an epoxy casting mold with the adjustable casting height and an easy-to-disengage inner mold body. The epoxy casting mold comprises a bottom plate, the inner mold body, an outer mold body, an upper end cover and a pressing part. The inner mold body and the outer mold body are installed on the bottom plate, the upper end cover is located between the inner mold body and the outer mold body, and the pressing part is located above the outer mold body. The tops of long threaded rods installed on the bottom plate are inserted into first through holes of the pressing part, and upper nuts and lower nuts for clamping the pressing part are screwed to the long threaded rods. The tops of short threaded rods screwed to the upper end cover are inserted into second through holes of the pressing part, and upper nuts and lower nuts for clamping the pressing part are screwed to the short threaded rods. Lifting of the long threaded rods for the pressing part and the short threaded rods are matched to adjust the height of the upper end cover, the position of the upper end cover is adjusted at will within a certain range accordingly, and then the epoxy resin casting height of various transformers is met. The inner mold body is formed by coiling a board in a barrel shape, and a certain gap is formed between the two ends of the board. After casting is completed, a worker can conveniently dismount the short threaded rods so as to remove attachments on the short threaded rods, and the inner mold body and a finished product can be conveniently disengaged.

Owner:AQ ELECTRIC SUZHOU

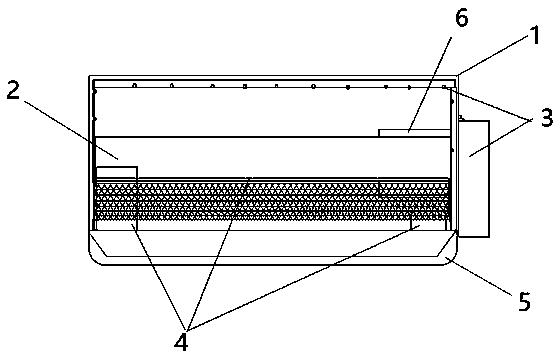

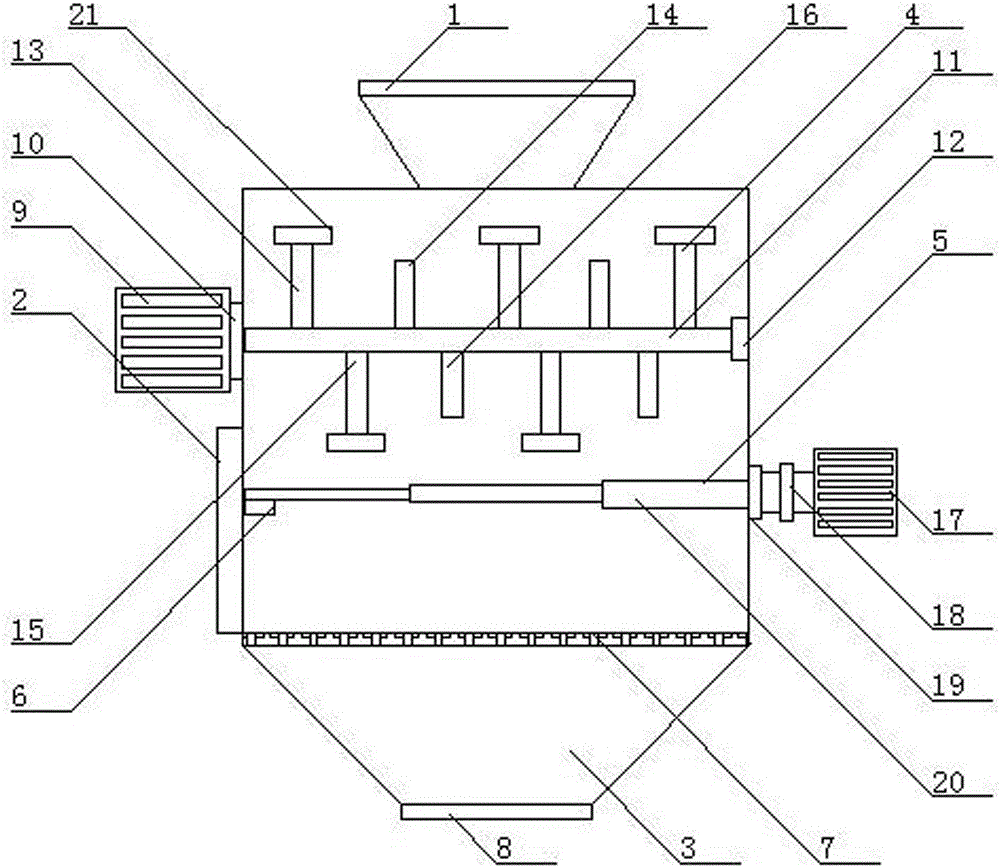

Magnetic separating device for rice processing

InactiveCN106513167AQuality assuranceImprove adsorption capacityMagnetic separationGrain millingMetal adsorptionMagnetic separator

The invention discloses a magnetic separating device for rice processing. The magnetic separating device comprises a machine body; a feeding funnel is arranged in the middle of the top end of the machine body; a clearing door is arranged at the lower end at the left side of the machine body; a tapered discharge hopper is arranged at the bottom end of the machine body; a stirring magnetic separator is arranged at the upper end inside the machine body; a telescopic baffle plate mechanism is arranged at the middle lower end inside the machine body; a fixed blocking part is arranged at the middle lower end at the left side inside the machine body; and a metal adsorption net is arranged at the lower end inside the machine body. The magnetic separating device for rice processing solves the problems that magnetic separating equipment in the prior art is generally not good in magnetic separating effect, is low in working efficiency and is inconvenient to use; a stirring magnetic-separating design is adopted to carry out magnetic separating processing while stirring; and the metal adsorption net is arranged, so that dual adsorption effects are achieved, rice can be quickly and comprehensively subjected to magnetic separating processing, the magnetic separating effect is better, and magnetic separating efficiency is extremely high.

Owner:HARBIN MIMI RICE IND TECH CO LTD

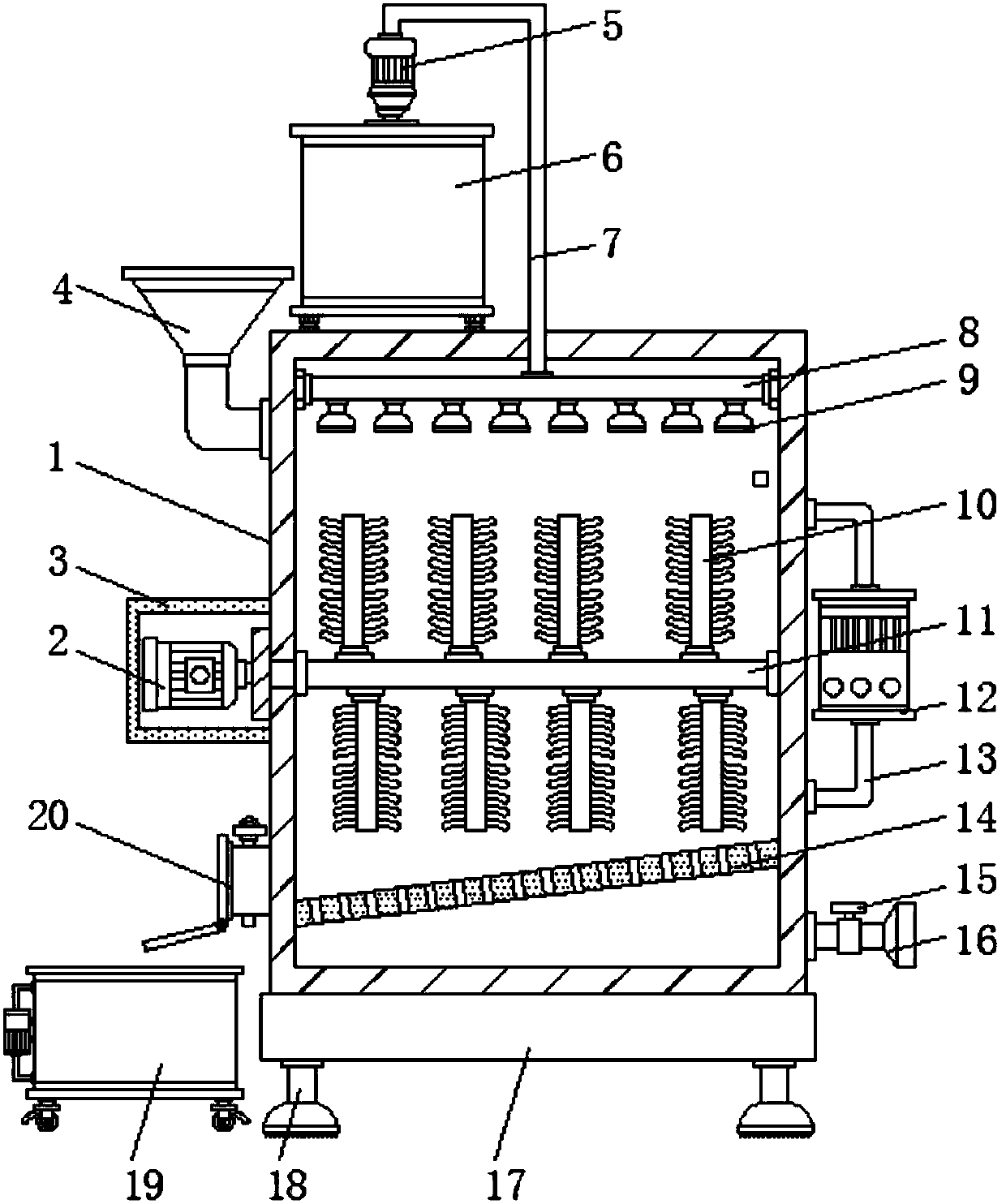

High-efficiency peanut cleaning device

The invention discloses a high-efficiency peanut cleaning device, which includes a cleaning box, a stirring motor is arranged on the side wall of the cleaning box, the output shaft of the stirring motor is connected to a stirring shaft through a reducer, and a stirring shaft is arranged on the stirring shaft Stirring rods distributed in a staggered manner, a water spray pipe is installed on the top wall of the inner cavity of the cleaning box, and an obliquely arranged filter plate is arranged inside the cleaning box, and the side wall of the cleaning box is close to the lower end of the filter plate A discharge pipe is arranged on the top, a base is fixed on the bottom of the cleaning box, and an ultrasonic generator is arranged inside the base. The present invention has simple structure and is easy to use. When cleaning, the stirring motor can continuously stir the peanuts, so that the spray tube can clean the peanuts more fully, and the cleaning efficiency is high, and the ultrasonic generator installed inside the base can use ultrasonic waves to clean the peanuts. Dirt adhering to the peanut shells is separated, resulting in faster and more thorough cleaning.

Owner:安徽省皖凯机械有限公司

Sewage treatment device

InactiveCN104445680AClean up fullyPlay a cleaning roleMultistage water/sewage treatmentFiltrationSewage

The invention discloses a sewage treatment device. The sewage treatment device comprises a sewage lifting pump, a debris filter mesh, a precipitation treatment tank and a sewage purification tank, wherein the sewage lifting pump is arranged in a tower type sewage tank, the debris filter mesh is movably arranged in the sewage tank in a circulating manner through a conveyor belt device, the precipitation treatment tank is connected with a water outlet of the sewage lifting pump, and the sewage purification tank is connected with the precipitation treatment tank. By arranging a crushing device, impurities in sewage can be fully crushed and refined, so that damages to the lifting pump device are reduced; by designing a turnover type filter hopper, the crushed impurities in the sewage can be well cleared and filtered; and by arranging a vibration device, the impurities adhered on the filter hopper can be vibrated to drop, so that the filtration working efficiency of the filter hopper is improved.

Owner:SHENZHEN KEEN ENVIRONMENTAL CO LTD

Polishing device for production of metal tools

PendingCN107855880AAchieve cleanupReduce workloadGrinding machine componentsGrinding machinesPolishingPhysics

The invention discloses a polishing device for production of metal tools. The polishing device for production of metal tools comprises a bottom plate, wherein the top of the bottom plate is fixedly connected with a box; the top of the box is fixedly connected with a working table; the top of the bottom plate is fixedly connected with supporting rods which are positioned on two sides of the box separately; the top ends of the supporting rods are fixedly connected with a cross plate; a sliding groove is formed in the top of the cross plate; two sides of the sliding groove are slidably connectedwith sliding blocks separately; a retractable spring is fixedly connected between the sides, which are opposite to each other, of the two sliding blocks; the top of each of the two sliding blocks is rotatably connected with a connecting rod; and the end, which is away from the corresponding sliding block, of each connecting rod is rotatably connected with a moving block. The invention relates to the technical field of metal tools. By the polishing device for production of metal tools, polishing scraps of the metal tools can be cleaned, thus, manual cleaning is not required, the workload of workers is relieved, furthermore, time is saved, and the polishing efficiency is improved.

Owner:WUXI FEITIAN GREASE

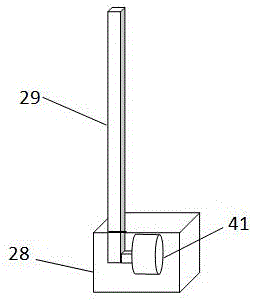

Through hole ash blowing device used in mechanical part machining

InactiveCN110560426AWon't shake and fallShorten the timeFouling preventionDispersed particle filtrationMachine partsEngineering

The invention discloses a through hole ash blowing device used in mechanical part machining. First supporting frames are welded to the positions of all corners of the top end of a supporting bottom plate, a first middle plate is welded to the top ends of the two first supporting frames located on one edge portion of the top end of the supporting bottom plate, and the outer sides of two sleeve rollers are sleeved and connected with a conveying belt. An air blower is installed at the bottom of the surface of the other side of a cavity in a communication manner, and clamping springs are installedat the top end of a clamping plate at equal intervals. The through hole ash blowing device is scientific, reasonable and safe and convenient to use; a clamping plate is used for clamping a part to the top end of the conveying belt, the part is pushed to move along with the conveying belt so that through hole ash blowing operation can still be conducted in the part moving process, and the part canbe rapidly placed and move; ash blowing and transportation are combined, the time consumed in the ash blowing process is greatly shortened, and the work efficiency is improved; and meanwhile, a rubber sleeve and a supporting plate are arranged, and therefore the part can be more stable in the moving process and cannot wobble and fall.

Owner:HUZHOU TEACHERS COLLEGE

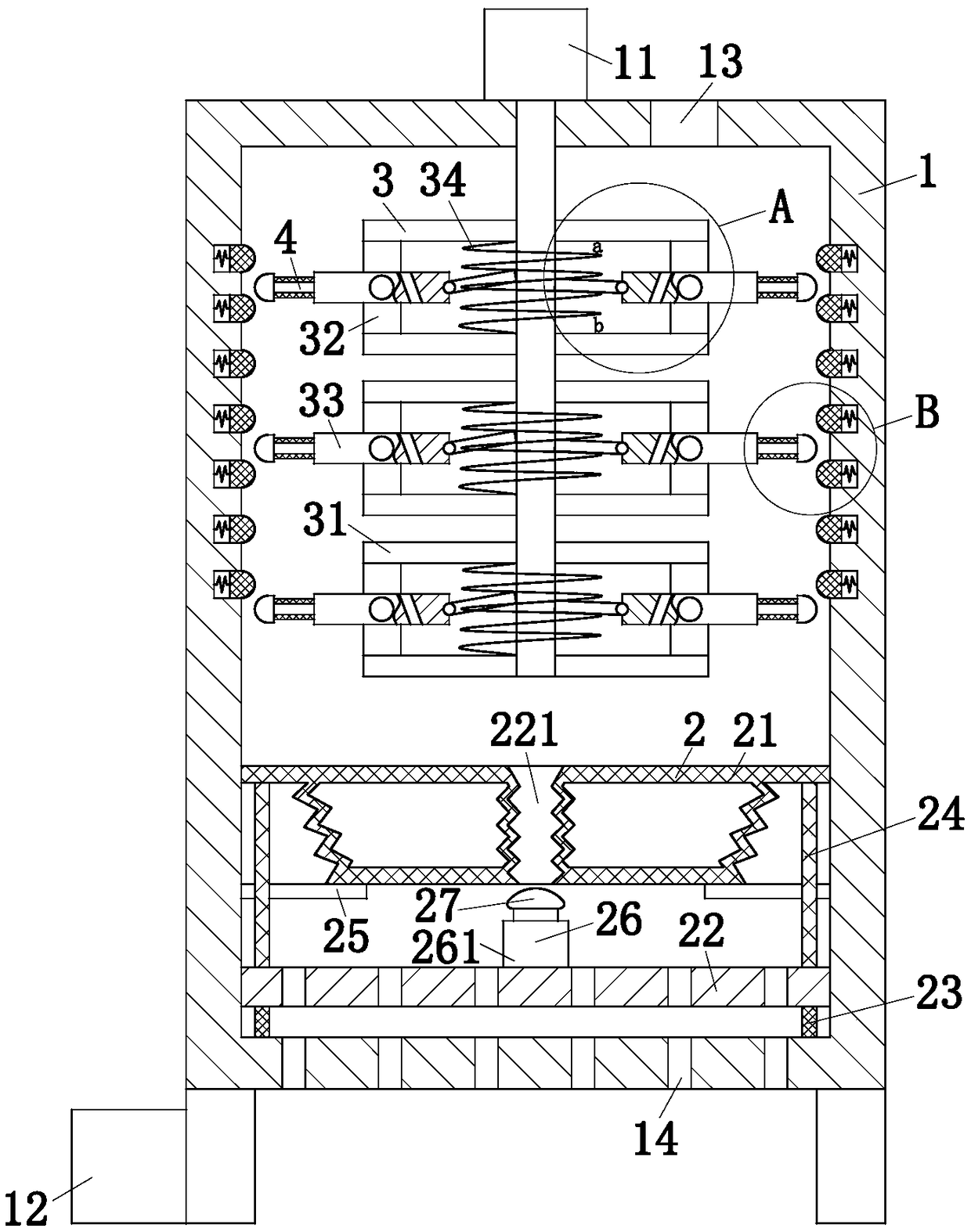

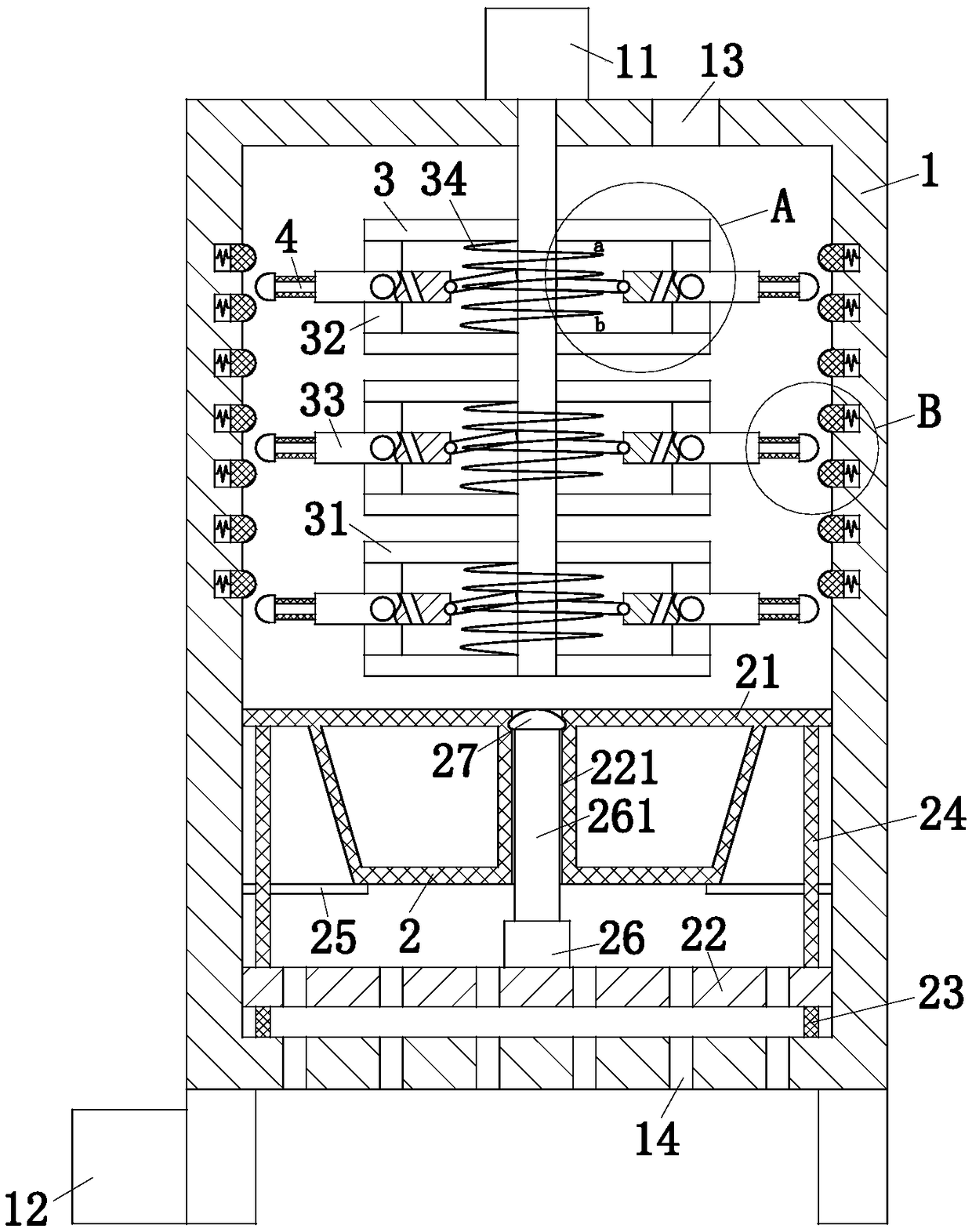

Equipment for preparing recycled building material from building waste and production method

InactiveCN113102020AAvoid residueClean up fullyMagnetic separationGrain treatmentsArchitectural engineeringMetallic materials

The invention discloses equipment for preparing a recycled building material from building waste and a production method, and relates to the technical field of building waste. The problem that metal garbage screening is insufficient is solved. The equipment comprises a treatment box, a groove is formed in the inner wall of the top of the treatment box, a first scraping plate is arranged on the inner wall of the bottom of the groove, second sliding grooves are formed in the inner walls of the two sides of the groove, electromagnetic adsorption sleeves are fixed to the inner walls of one sides of the two second sliding grooves through moving mechanisms, the first scraping plate is in an inclined state, and a cleaning brush is arranged on the outer wall of the side, close to the electromagnetic adsorption sleeves, of the first scraping plate. A use method of the equipment comprises the following steps of absorbing a metal material; crushing; screening; and screening and collecting. The building waste is added into a cleaning tank through a feeding hopper, then the electromagnetic adsorption sleeves are driven by the moving mechanism to move towards the first scraping plate, and the moving mechanisms drive the electromagnetic adsorption sleeves to rotate to adsorb metal waste.

Owner:武汉合创四联科技发展有限公司

Automatic dredging equipment of paddy field irrigation water canal

The invention relates to the field of canal dredging, in particular to automatic dredging equipment of a paddy field irrigation water canal. The equipment comprises a driving device, a main arm, a dredging device and a sludge clearing device, wherein the main arm is installed on the front side of the driving device and can rotate, the dredging device and the sludge clearing device are movably arranged at the free end of the main arm, the dredging device comprises a U-shaped frame, a grating frame and a lever assembly, wherein the grating frame is hinged to the opening of the U-shaped frame andused for removing waste in the water canal, and the lever assembly is used for driving the grating frame to rotate in a small amplitude mode; the free end of the main arm is movably provided with a sub-arm, the U-shaped frame can be vertically installed at the front end of the sub-arm far away from the main arm through a first oil cylinder in a movable mode, the bottom of the grating frame is provided with a tool set for enabling the grating frame to slowly travel in the water canal, and the sludge clearing device is installed on the outer side of the front end of the sub-arm. According to the equipment, the descending stroke is adjusted according to the actual situation in the first oil cylinder, so that a grid plate is enabled to adapt to the depth in the plurality of water canals, andthe sludge and the waste in the water canal can be thoroughly cleared.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

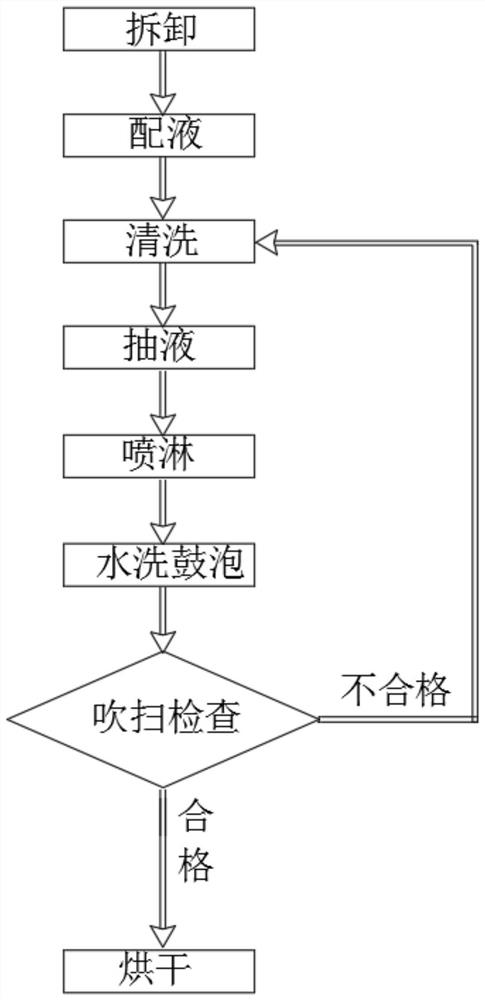

Method for improving graphite boat treatment effect

InactiveCN111962047AAvoid reuseEasy to cleanFinal product manufactureChemical vapor deposition coatingAqueous dropletPhysical chemistry

The invention relates to the technical field of treatment of graphite boats, and discloses a method for improving the graphite boat treatment effect. The method comprises the following steps of S1, disassembly, wherein a graphite boat which needs to be cleaned is prepared and disassembled, and the graphite boat and clamping pieces are cleaned respectively; S2, solution preparation, wherein a hydrofluoric acid solution with the concentration of 7-15% is prepared in a cleaning tank; S3, cleaning, wherein the whole graphite boat is placed into the prepared hydrofluoric acid solution and soaked for 5-7 hours, and bubbling is started while soaking; S4, pump-out of the solution, wherein after the whole graphite boat is soaked for 5-7 hours, the hydrofluoric acid solution in the previous step ispumped out. By means of the method, it can be ensured that each face can be effectively sprayed and cleaned, the cleaning effect is improved, and the situation can be prevented that there are water drops on the surface of the graphite boat during drying, due to the residues obtained after drying, normal use of the graphite boat is affected; due to the checking step, the graphite boat which is notwell cleaned can be prevented from being used again, and the cleaning effect is improved.

Owner:无锡鼎桥新能源科技有限公司

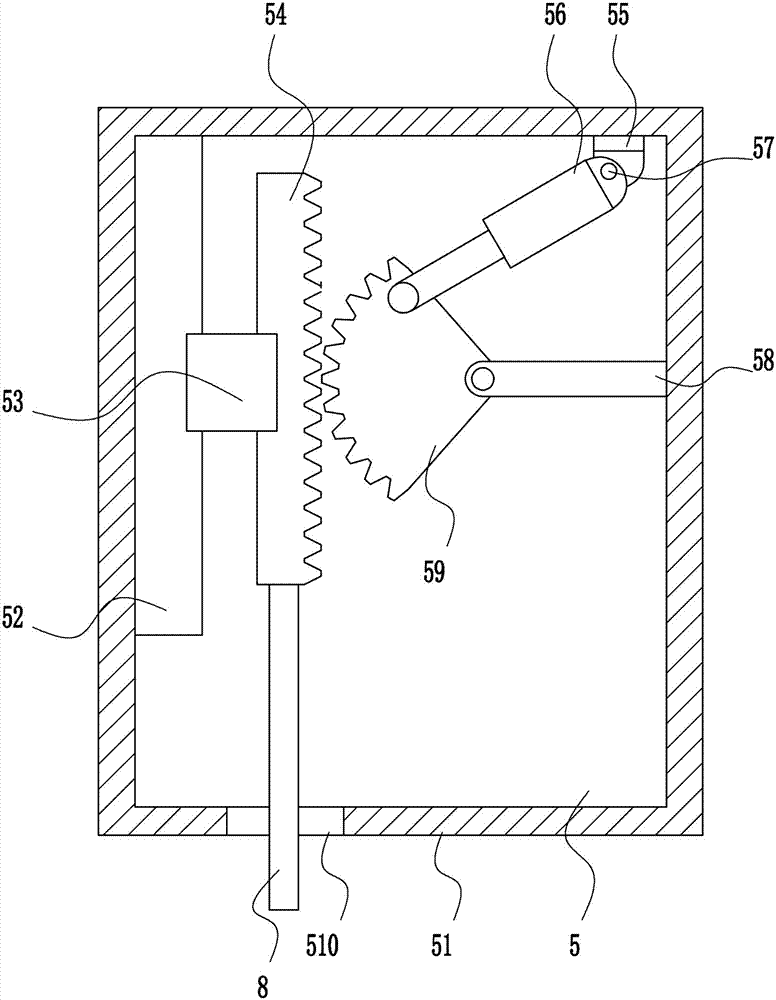

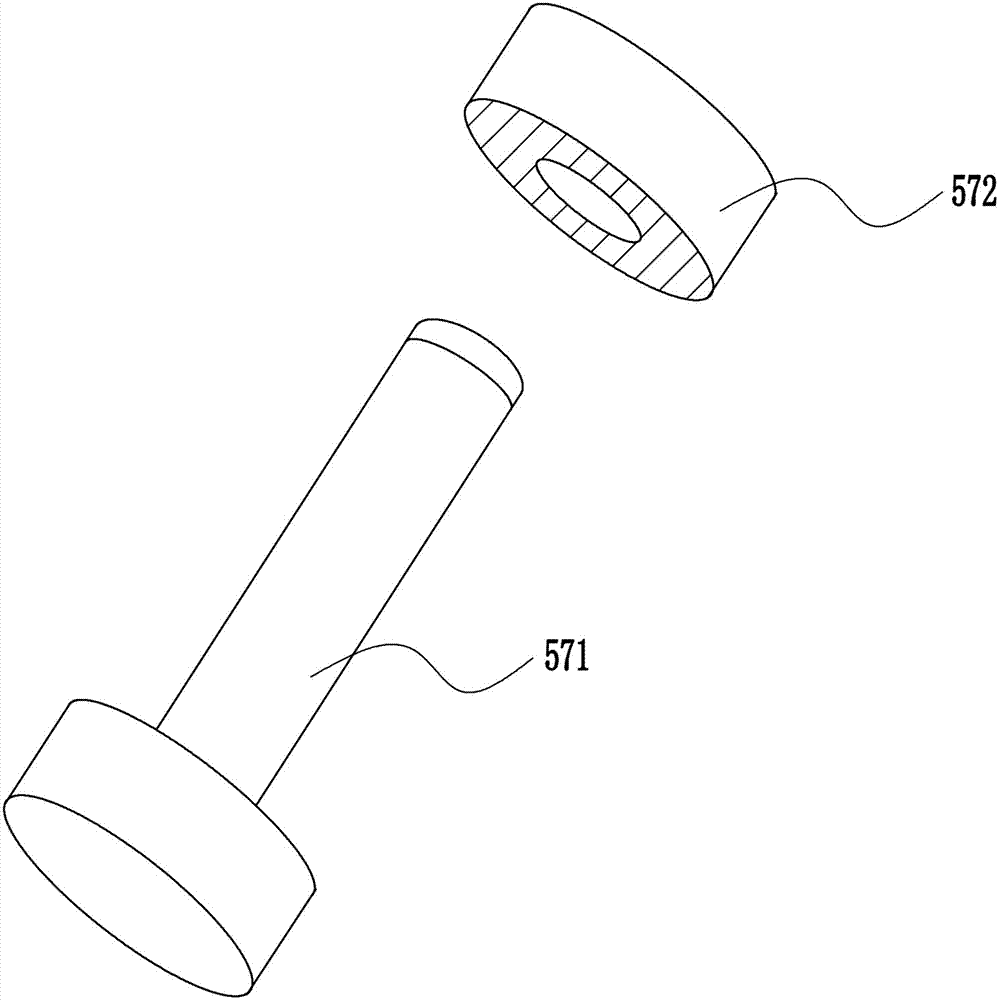

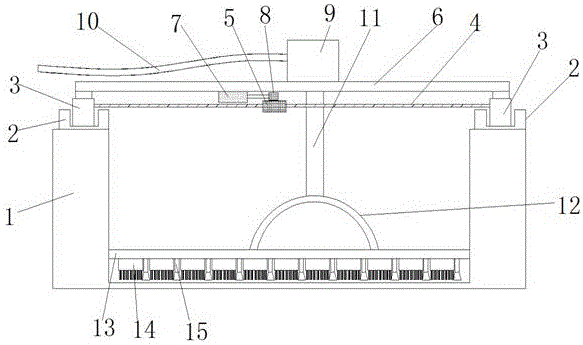

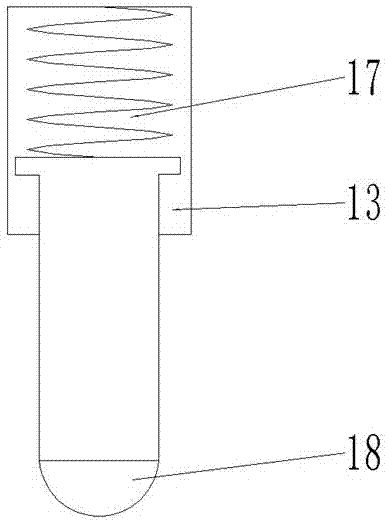

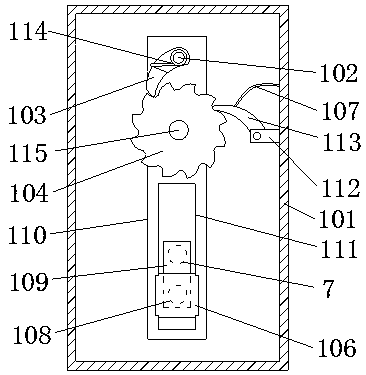

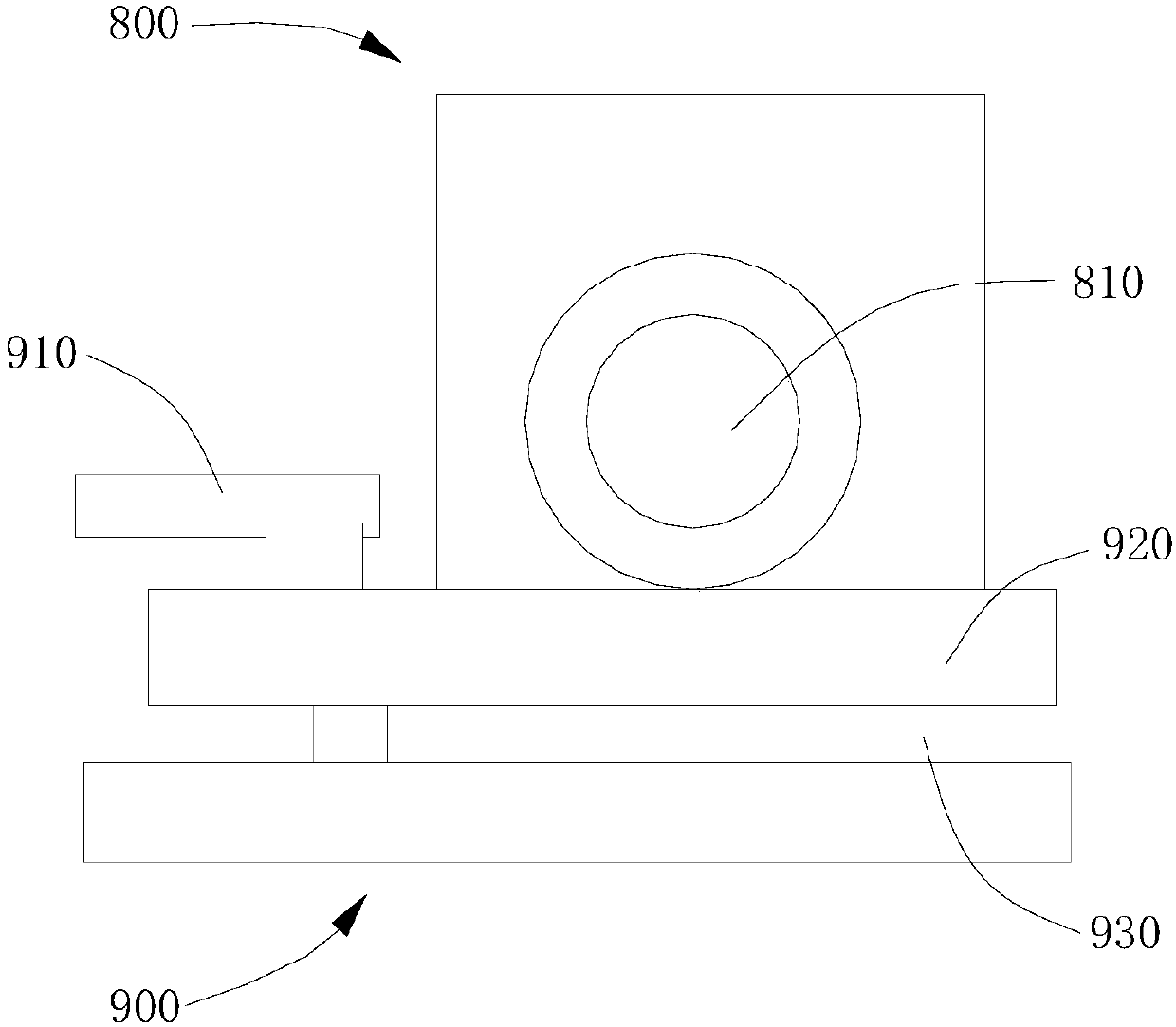

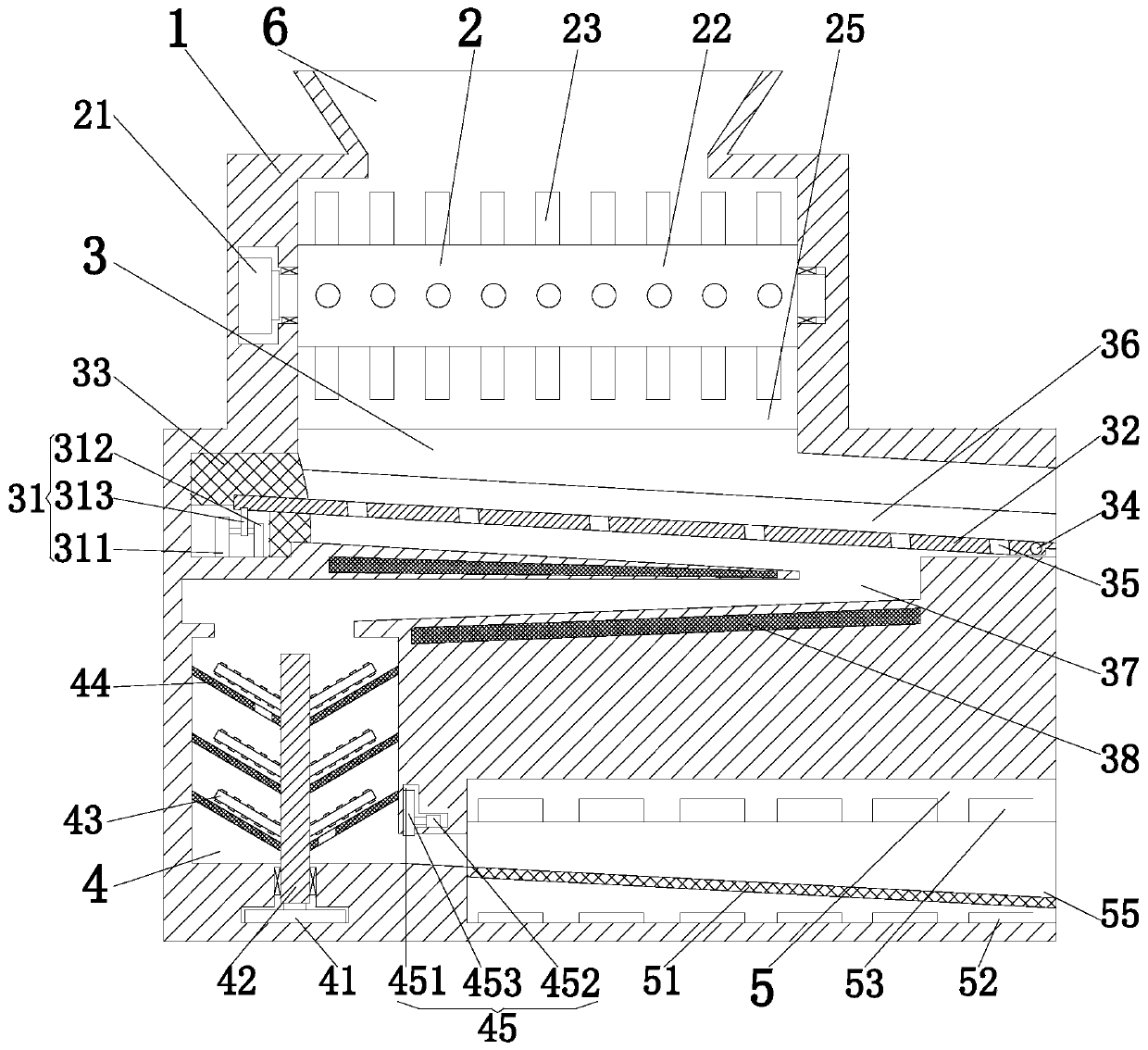

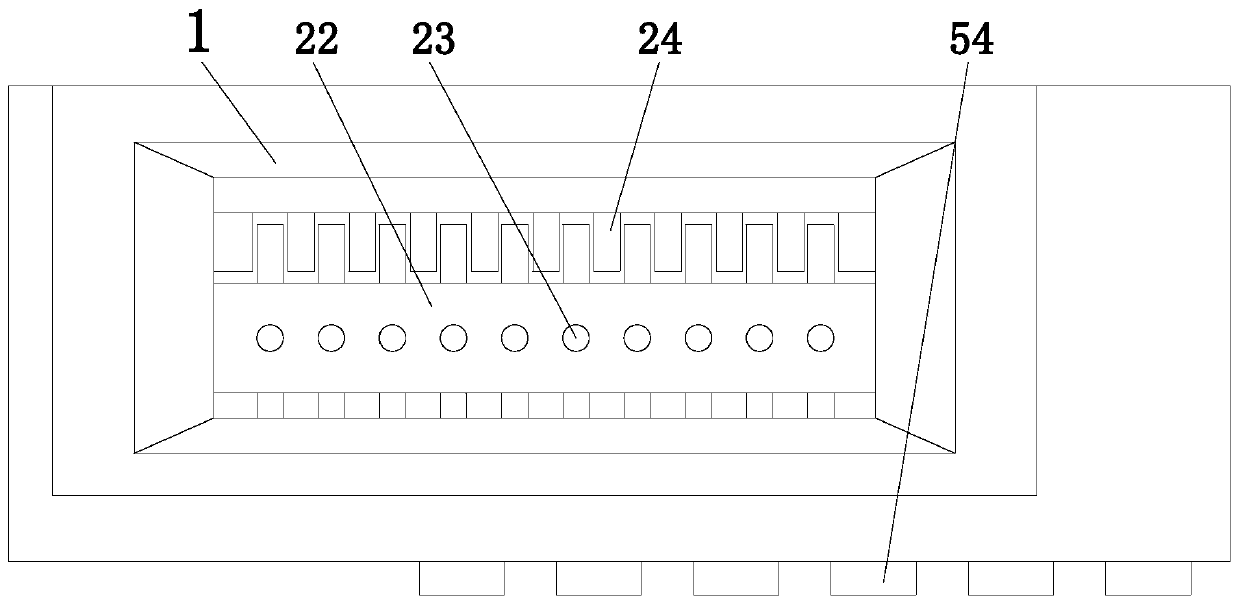

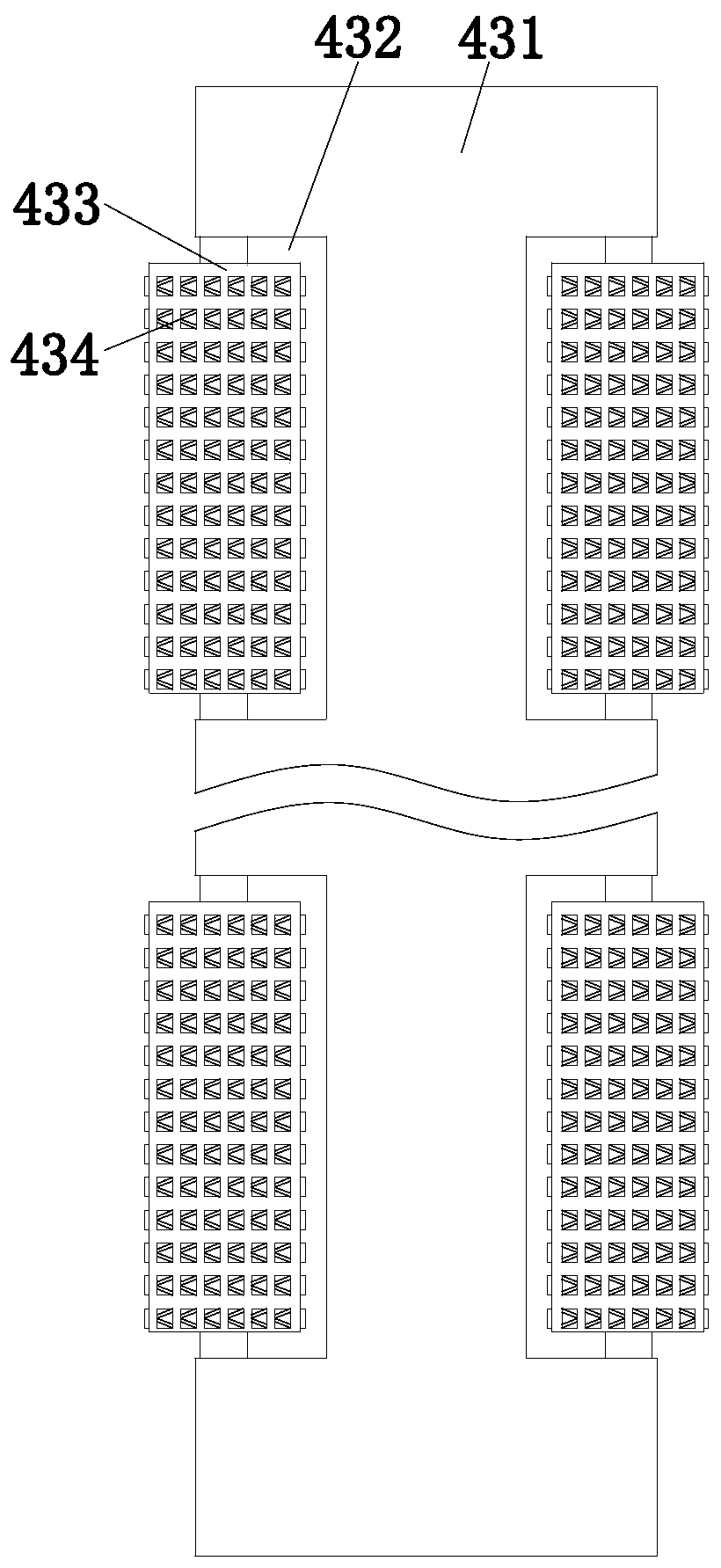

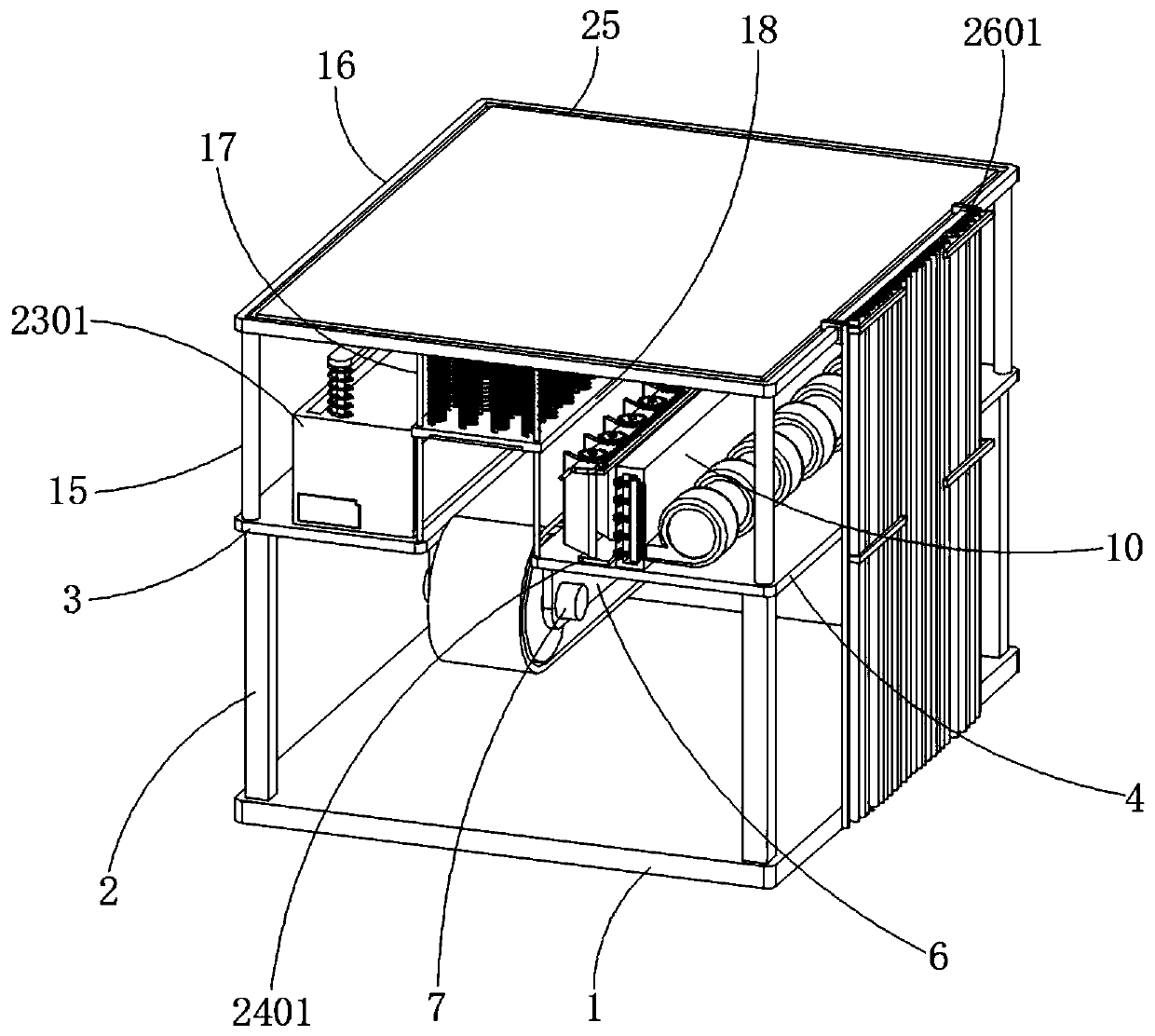

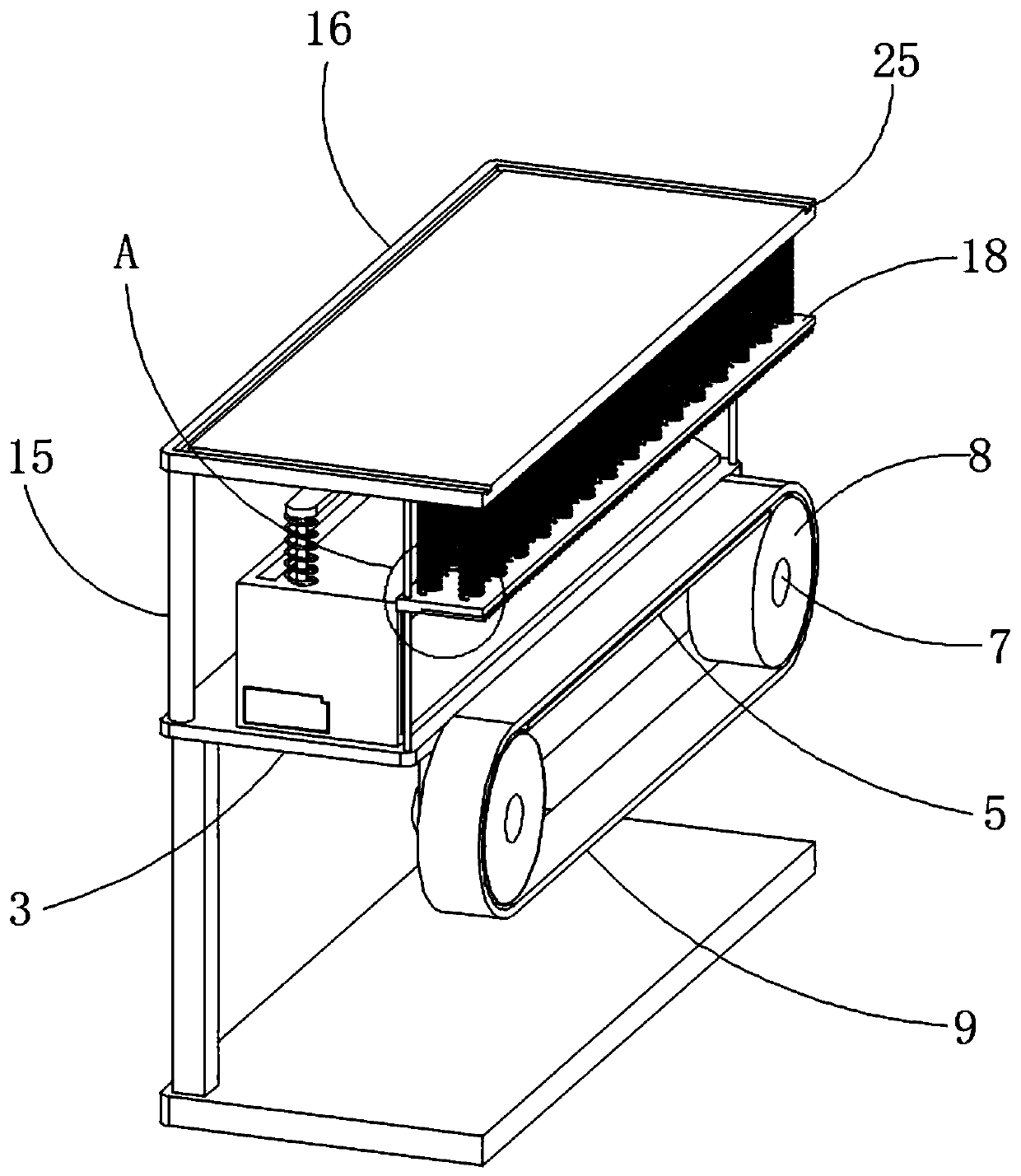

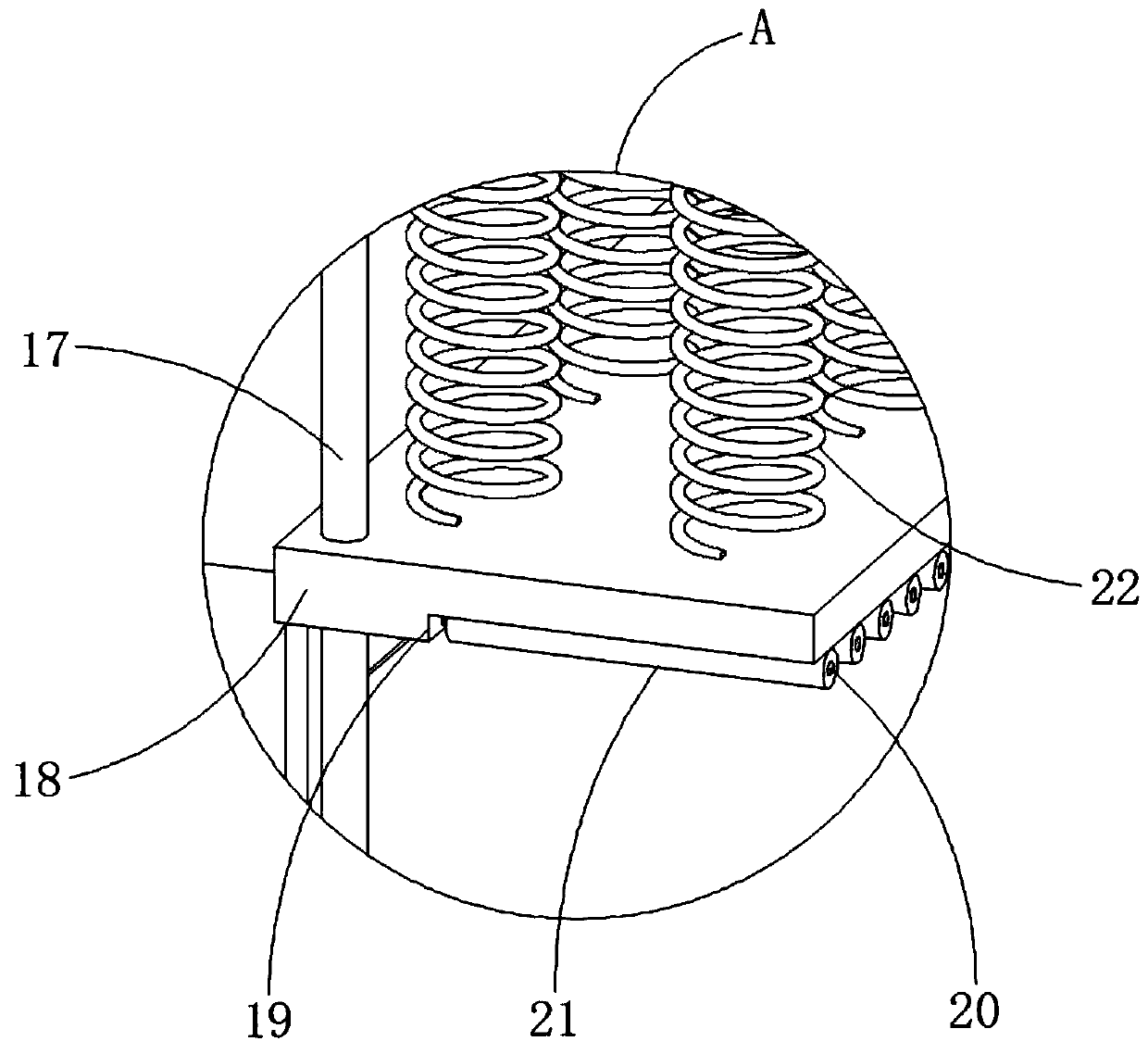

Laminating false sticking machine for flexible printed circuit board

ActiveCN110856366APlay a buffer roleClean up fullyConductive pattern polishing/cleaningNon-metallic protective coating applicationDrive wheelEngineering

The invention discloses a laminating false sticking machine for a flexible printed circuit board and relates to the technical field of circuit board processing. The machine comprises a first bottom plate, wherein first pistons are fixedly connected with four corners of the first bottom plate correspondingly, a telescopic spring is arranged in each first piston, a bottom end of each telescopic spring is fixedly connected with the first bottom plate, a top end of each telescopic spring is fixedly connected with a first piston rod, a second bottom plate is arranged above the first bottom plate, and a top end of each first piston rod is fixedly connected with the second bottom plate. The laminating false sticking machine is advantaged in that the first bottom plate, a first piston and the telescopic spring are arranged, the second bottom plate can play a role in buffering when being pressed downwards, the circuit board can move along with the conveying belt by arranging a driving wheel, adriven wheel and the conveying belt, and the circuit board can be automatically pressed downwards to complete film covering by arranging a stand column, a transverse plate, an electric telescopic rodand an electric heating plate.

Owner:GUANGDONG ZECHENG TECHNOLOGY CO., LTD

Dust cleaning device used for pavement of landscape garden

The invention relates to a dust cleaning device used for the pavement of a landscape garden, comprising a bottom plate, a support device arranged on the bottom plate, a moving frame device arranged above the bottom plate, a fan device arranged on the moving frame device, an electric cylinder device arranged on the support device, and a cleaning device arranged on the electric cylinder device. According to the invention, dust on the pavement of the landscape garden can be sufficiently cleaned, the cleaning effect is good, lifting of a brush can be realized, and due to adding of a filtering net,the device is environment-friendly and pollution-free in use, and the operation is simple.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

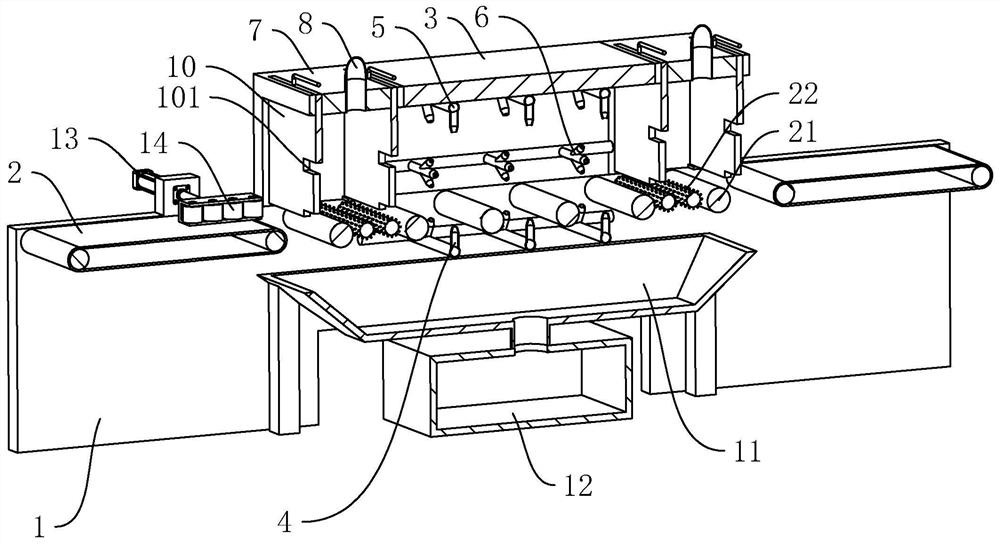

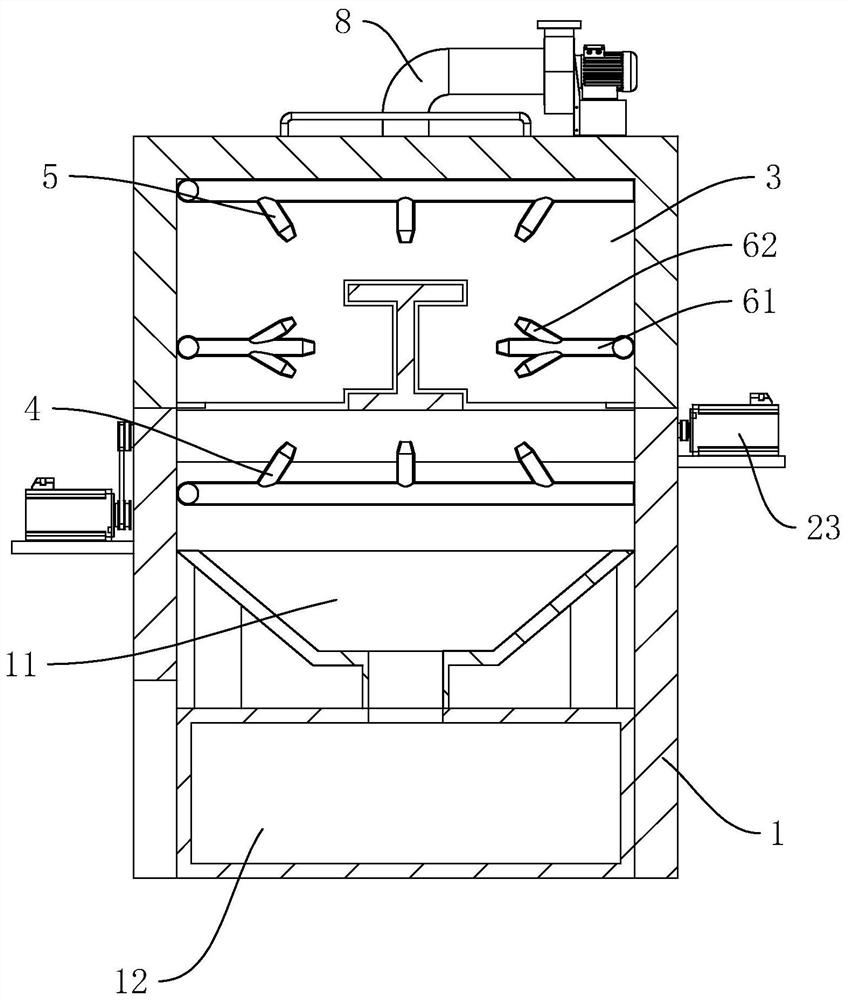

Sand-blasting derusting device for I-steel

ActiveCN111975644AFull rust removalClean up fullyAbrasive machine appurtenancesMetallurgySand blasting

The invention relates to a sand-blasting derusting device for I-steel. The sand-blasting derusting device for I-steel comprises a rack. A conveyor belt for conveying I-steel is arranged on the rack, and a cleaning chamber is further arranged above the conveyor belt on the rack; the conveyor belt comprises a plurality of transfer rollers, the transfer rollers are in contact with the lower surface of the I-steel, and a plurality of lower spray guns for cleaning the lower surface of the I-steel are further arranged between the transfer rollers on the rack; a plurality of upper spray guns for cleaning the upper surface of the I-steel are further arranged above the conveyor belt in the cleaning chamber, and a plurality of side spray guns for cleaning the side surface of the I-steel are furtherarranged on two sides of the width direction of the conveyor belt in the cleaning chamber. The s and-blasting derusting device for I-steel has an effect of derusting the surface of the I-steel fully.

Owner:杭州恒途钢结构有限公司

High-applicability pipe surface oxide skin removing device

InactiveCN112936049AClean up fullyReduce workloadEdge grinding machinesPolishing machinesSpiral bladePipe fitting

The invention discloses a high-applicability pipe surface oxide skin removing device, and belongs to the technical field of pipe surface treatment. The high-applicability pipe surface oxide skin removing device comprises a base, a sand box is rotationally arranged at the top of the base, a spiral blade is fixedly arranged in the sand box, a sealing cover is rotationally connected to the right side wall of the sand box, and a sand inlet is formed in the sealing cover; and feeding rollers fixedly connected to the top of the base are symmetrically arranged on the left side and the right side of the sand box, a pickling tank fixedly connected to the top of the base is arranged on the left side of the feeding roller on the left side, a driving mechanism used for driving the sand box to rotate is arranged at the top of the base, a linkage mechanism is further arranged at the top of the base, and the linkage mechanism realizes intermittent feeding under the linkage of the driving mechanism. According to the high-applicability pipe surface oxide skin removing device, oxide skin on the surface of the pipe can be fully cleaned, secondary cleaning can be avoided, and the workload of workers is reduced.

Owner:张朋朋

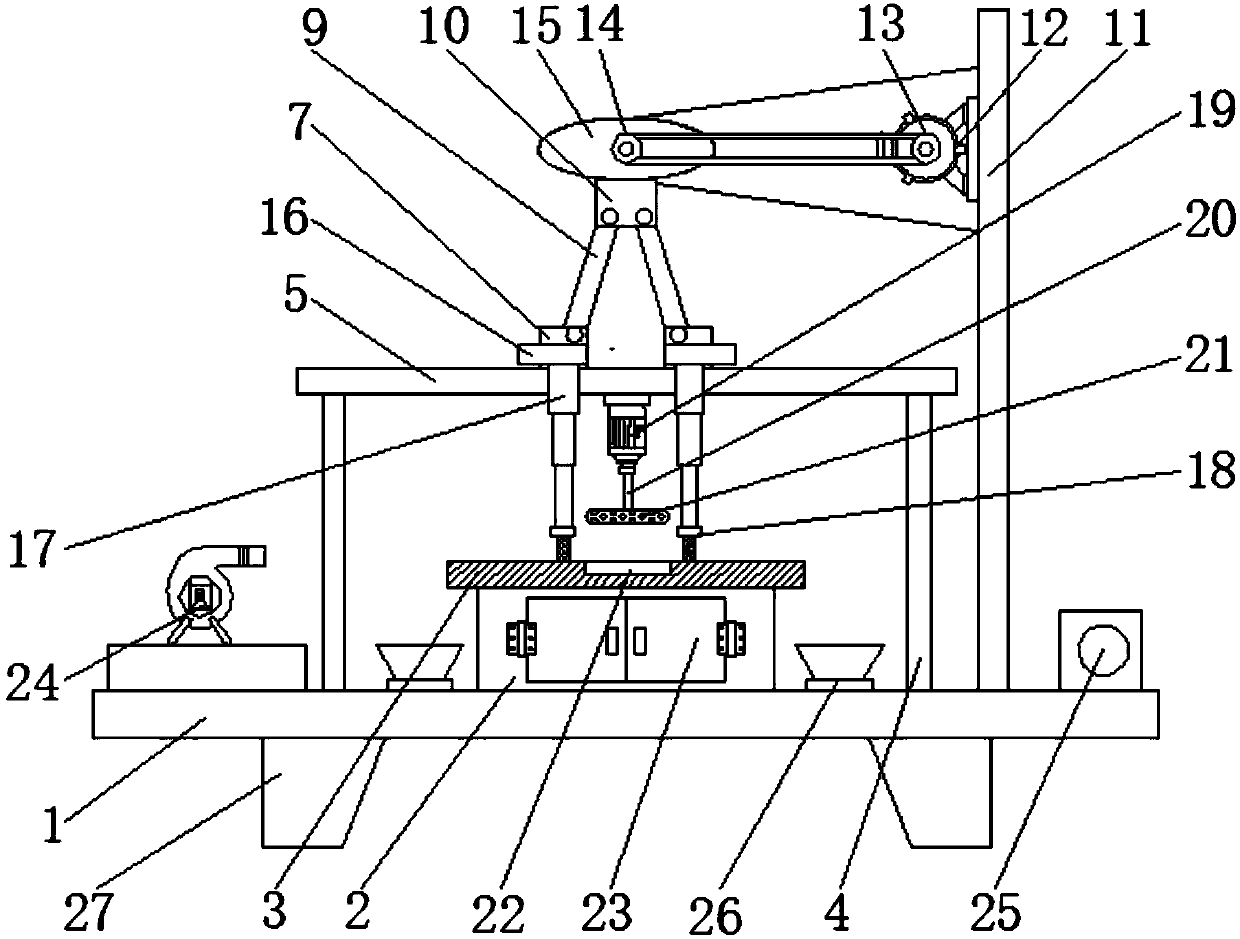

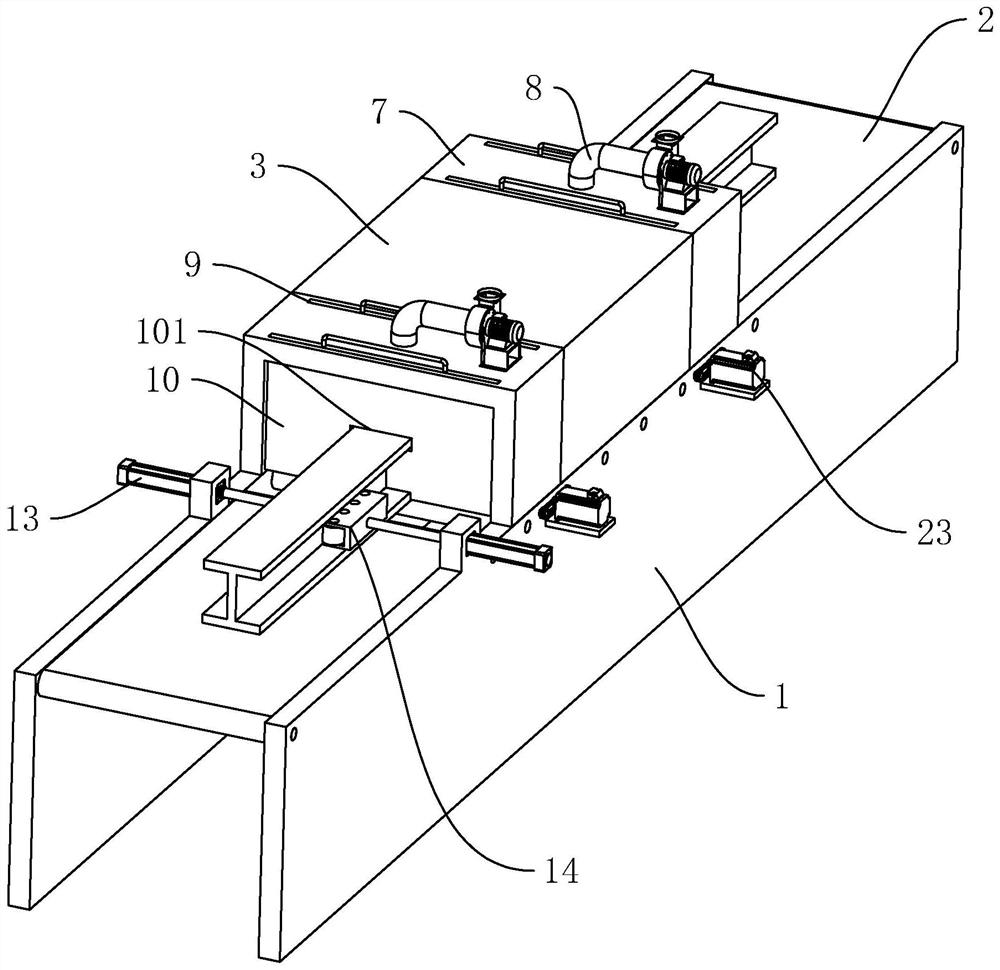

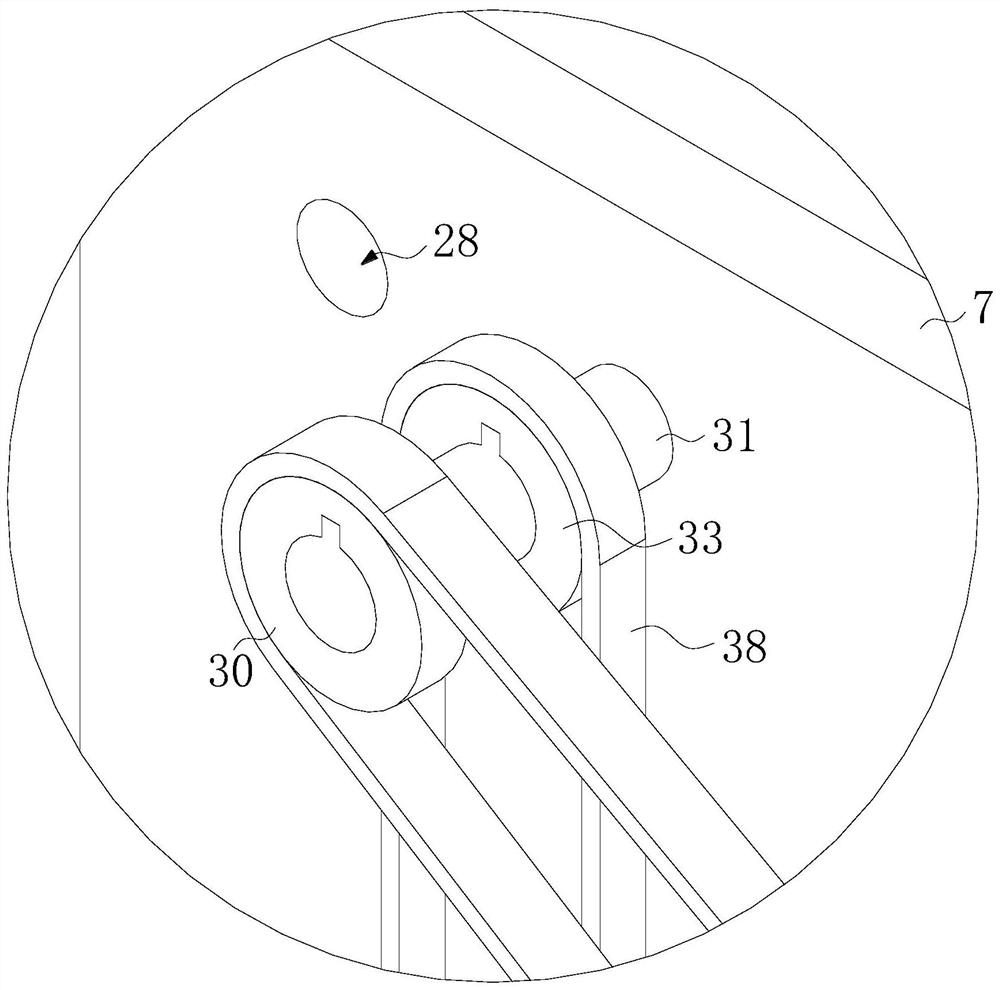

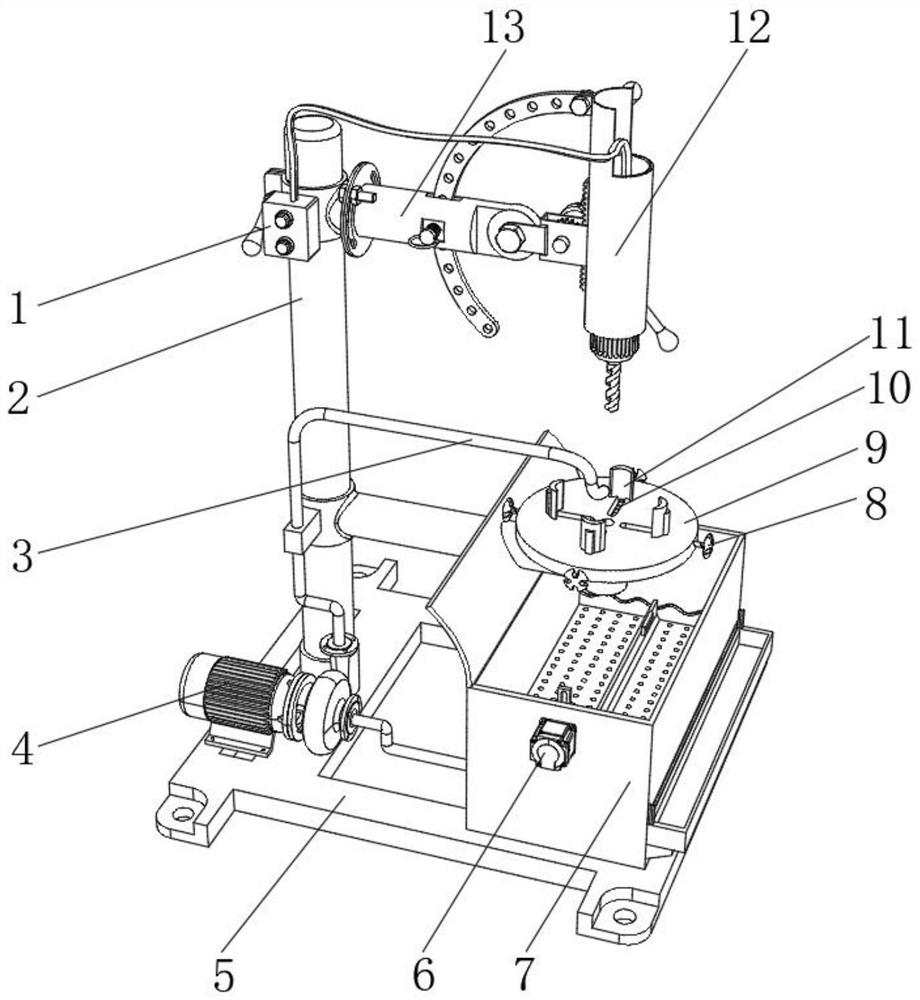

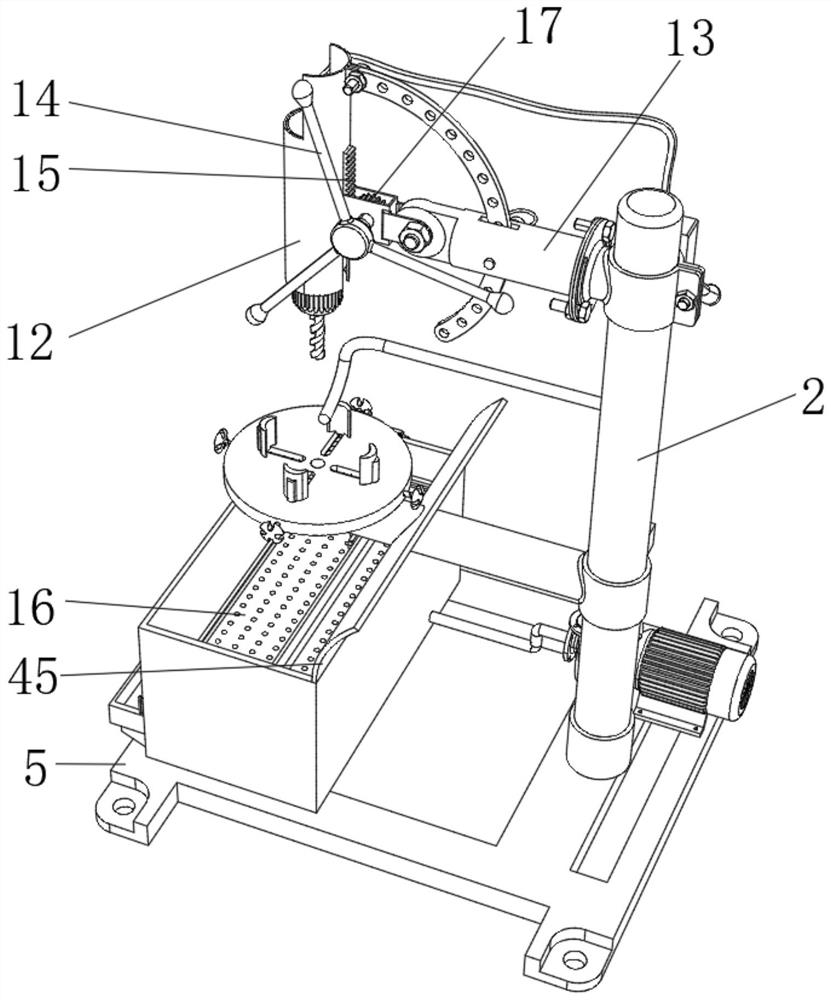

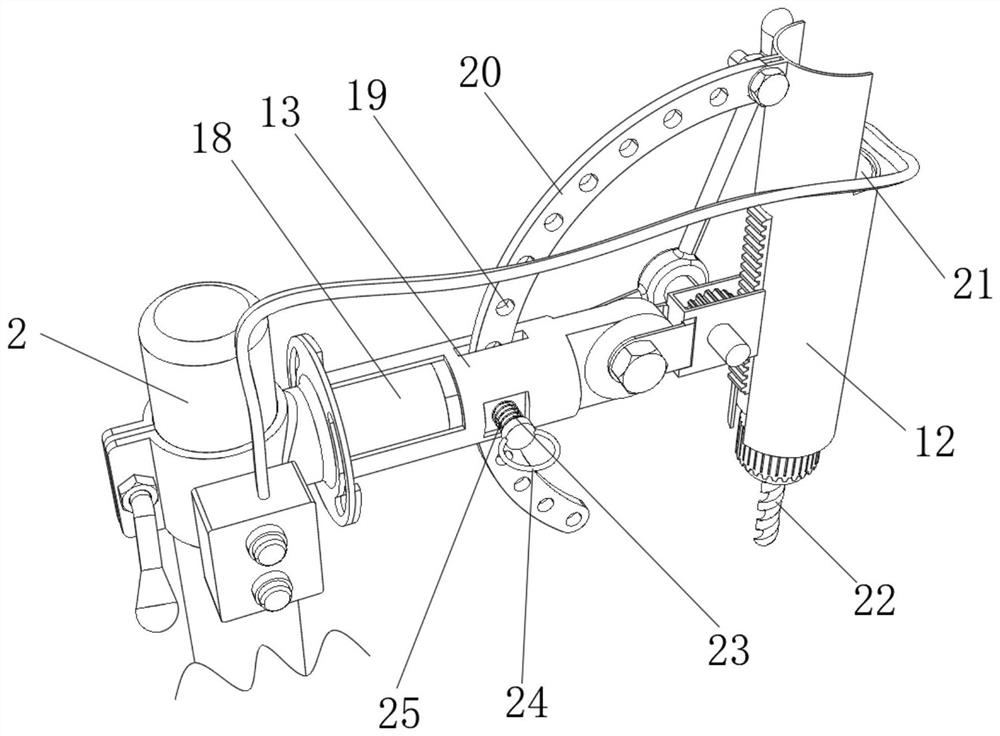

Cooling circulation mechanism for drilling machining of forged workpieces

PendingCN113579283AReduce filter effectImprove filtering effectLarge fixed membersPositioning apparatusElectric machineryEngineering

The invention relates to the technical field of forging machining, and discloses a cooling circulation mechanism for drilling machining of forged workpieces. The cooling circulation mechanism comprises a fixing seat, a collecting box and a moving frame, the upper surface of the fixing seat is fixedly connected with a water tank, the outer wall of one side of the water tank is fixedly connected with a first motor, one end of an output shaft of the first motor penetrates through the water tank and is fixedly connected with a connecting rod, a first sliding groove is formed in the moving frame, the connecting rod is glidingly connected with the first sliding groove, a positioning frame is fixedly connected to the inner wall of one side of the water tank, and the positioning frame is glidingly connected with the moving frame. Metal scraps on a filter screen plate can be fully cleaned through a scraping plate, so that the filtering effect of the filter screen plate is improved; meanwhile, through cooperative use of a top frame and a wedge-shaped block, the device can achieve automatic discharging, and the convenience of the device is improved; the workpieces can be stably clamped through a clamping seat, so that a drill bit can conveniently and stably machine the workpieces subsequently, and the using effect of the device is improved.

Owner:无锡市麒啸机械有限公司

Mold energy-saving cleaning equipment

InactiveCN112387676AClean up fullyEasy to cleanDrying gas arrangementsCleaning using liquidsWater storage tankSurface cleaning

The invention discloses mold energy-saving cleaning equipment which comprises a rack and a conveying mechanism arranged on the upper portion of the rack, a preheating tank, a cleaning tank, a drying tank and a cold storage tank are formed in the upper end of the rack, and a water spraying head, a hot air spraying head and a cold air spraying head are fixed in the cleaning tank, the drying tank andthe cold storage tank correspondingly; and a taking-out plate is rotationally connected to the side wall of the cold storage tank, a recycling cavity is formed in the rack, a waste heat utilization mechanism is not arranged in the recycling cavity, a water storage tank is formed in the bottom of the preheating tank, and a high-pressure pump connected with a water spraying head is arranged in thewater storage tank. The mold energy-saving cleaning equipment has the advantages that by arranging the preheating tank, the cleaning tank, the drying tank and the cold storage tank, pretreatment, surface cleaning, hot air drying and cooling storage of the mold are completed in the one-time stroke process, the mold is cleaned more sufficiently through step-by-step operation, and the overall cleaning effect is improved.

Owner:卢博

Building material powder mixing machine

ActiveCN109126578AWell mixedImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingPower equipmentDrive motor

The invention relates to the technical field of mixers, in particular to a building material powder mixer. The building material powder mixer comprises a box body and also comprises a driving motor, an ejection unit, a stirring unit, a gas storage box and a controller. By arranging the driving motor, the ejection unit, the stirring unit and the gas storage box, on the one hand, during stirring andmixing of building material powder, an ejection gas bag sucks gas and bounces the building material powder falling on the ejection gas bag, the stirring unit stirs and mixes the building material powder again, and through the mutual cooperation between the ejection gas bag and the stirring unit, the stirring unit fully stirs and mixes the building material powder, thus improving the mixing effectof the building material powder; and on the other hand, a power source generated in the stirring and mixing of the building material powder is utilized to reduce the addition of additional power equipment, thereby reducing the manufacturing cost of the building material powder mixing machine.

Owner:明光久智知识产权管理有限公司

Chip removal device capable of adjusting cleaning range for metal accessory trepanning

InactiveCN111745188AGuaranteed cleanlinessEasy to cleanLarge fixed membersPositioning apparatusHydraulic cylinderElectric machinery

The invention discloses a chip removal device capable of adjusting the cleaning range for metal accessory trepanning. The chip removal device comprises a base, a first motor, a handle, a collecting box, a second motor and a draught fan; a left stand column and a right stand column are welded to the left side and the right side of the upper portion of the base respectively, a hydraulic cylinder isconnected to the inner wall of the left stand column through bolts, and the output end of the hydraulic cylinder is connected with a transverse plate; a suction fan blade is installed at the bottom end of a first rotating shaft, and a baffle is arranged on the outer side of the suction fan blade. According to the chip removal device capable of adjusting the cleaning range for the metal accessory trepanning, limiting plates are arranged on the left side and the right side of a placement plate correspondingly, the limiting plates are in sliding connection with the left stand column and the rightstand column correspondingly, and the distance between two clamping plates on the placement plate can be adjusted, in this way, under the condition that fixing of metal parts is not affected, the placement plate can be moved front and back, and then trepanning operation can be carried out on different positions of the accessories, and the flexibility of the device during use is improved.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com