Equipment for preparing recycled building material from building waste and production method

A technology for recycling building materials and construction waste, which is applied in the field of construction waste to prepare recycled building materials, and can solve problems such as residues and insufficient screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

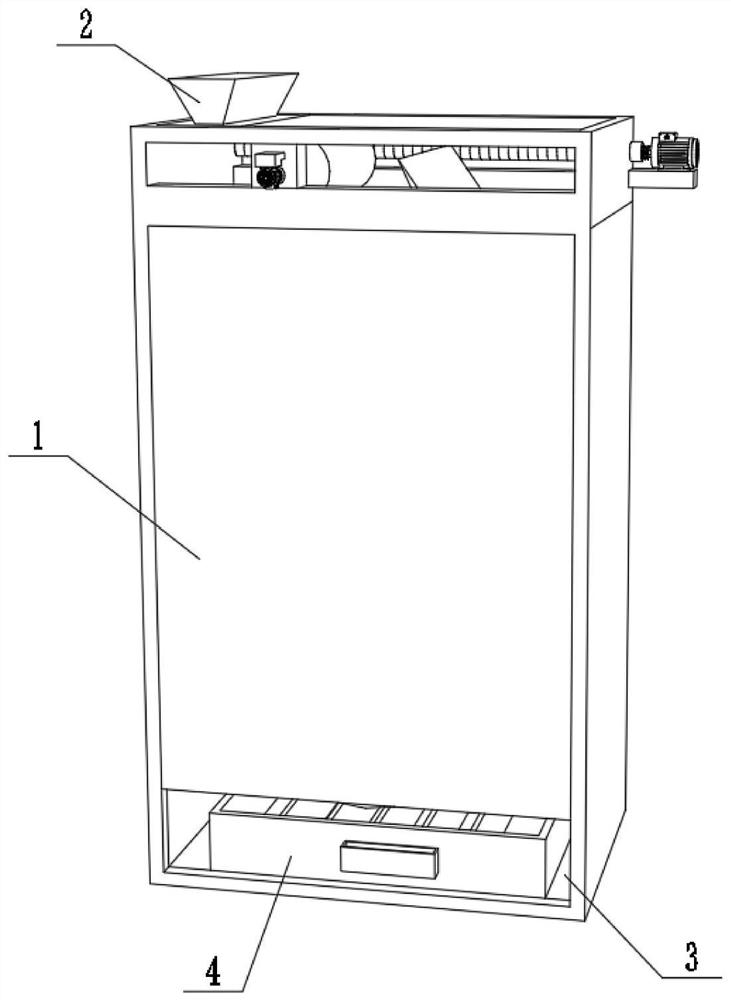

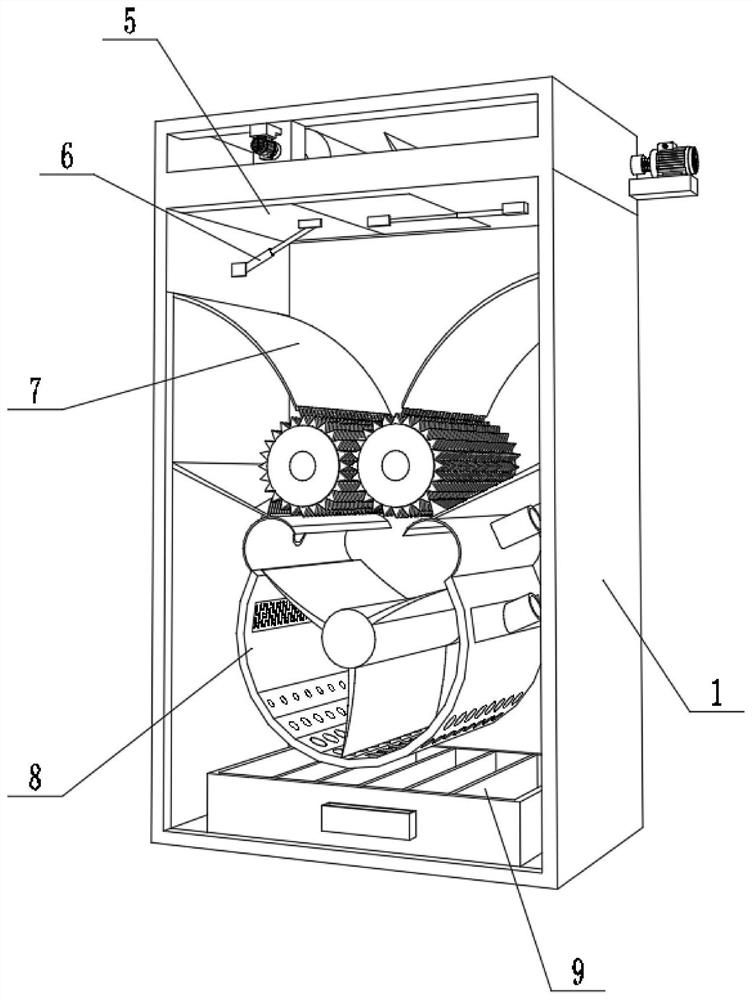

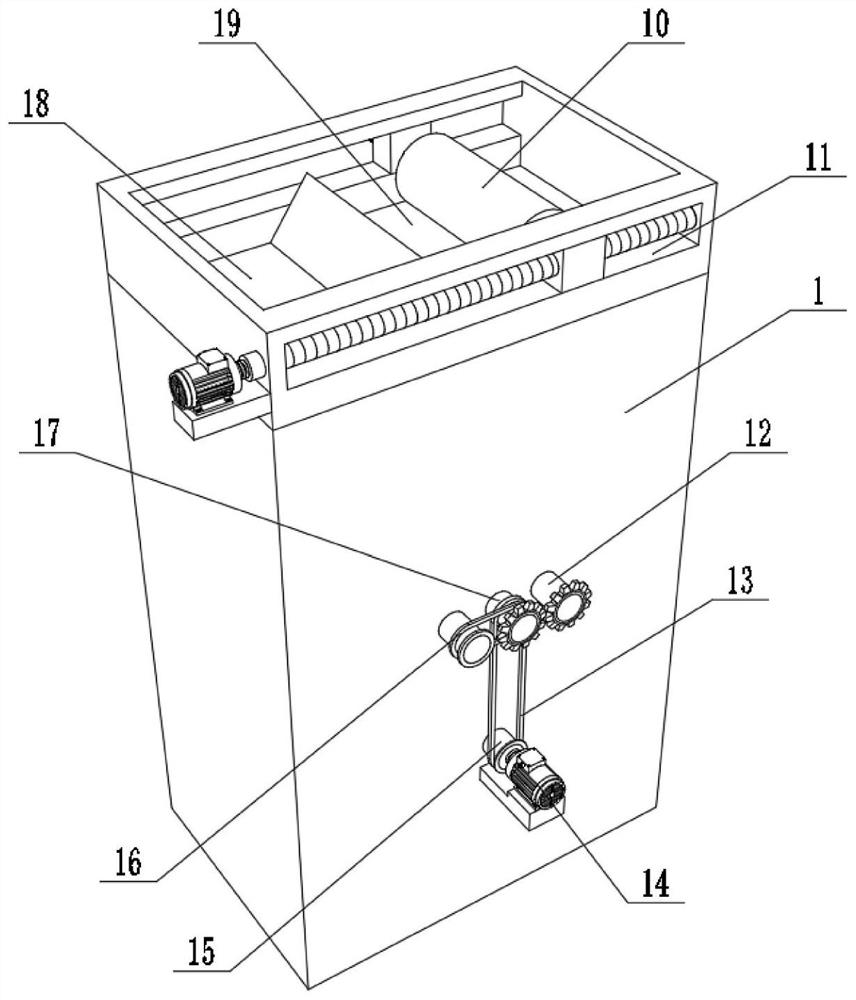

[0042] Equipment for building waste preparation regeneration building materials, such as figure 1 , 3 As shown in FIG. 4, including the treatment tank 1, the inner wall of the treatment box 1 is opened, and the inner wall welded by the groove bottom portion 25, the inner wall of the groove is opened, two sliding grooves two 11 An electromagnetic adsorption sleeve 10 is fixed by a moving mechanism, and the blade one 25 is inclined, and the blade one 25 is adjacent to the electromagnetic adsorption sleeve 10 side outer wall is provided with cleaning brush 24, and the highest end of the scraper one 25 The highest end of the electromagnetic adsorption sleeve 10, the groove is formed with a collection groove 2 18 and the cleaning tank 19 through the scraper one 25, and the outer wall of the cleaning tank 19 is provided with a feed funnel 2, and the electromagnetic adsorption sleeve 10 is located at the cleaning tank 19. Inside; by a processing box 1, the groove is formed with a collect...

Embodiment 2

[0048] Equipment for building waste preparation regeneration building materials, such as figure 1 , 2 As shown in 6, in order to sieve the material after the material is sieved, the inner wall welded is welded with the screening sleeve 8, and the outer wall of the top of the sieving sleeve 8 is opened, and the opening is located below the pulverizer, screening points The inner wall of the sleeve 8 is rotated and connected to the rotating rod 4 35. The power mechanism is connected to the rotating rod 4 35, and the rotor rod 4 35 circumferential outer wall welding has three scraper two 34, three scrapers two 34 are curved, three The blade two 34 is in contact with the inner wall of the sieve sleeve 8, and the outer wall of the sieving sleeve 8 has two sieved port 33 having two or more diameter sizes, and the inner wall of the treatment box 1 is opened with a sliding tank. 3, The inner wall sliding in the bottom of the sliding groove is slid with a collection groove 1 4, and the inne...

Embodiment 3

[0053] Method for the use of equipment for building waste to prepare regeneration building materials, including the following steps:

[0054] S1: Add construction waste through the feed funnel 2 to the cleaning tank 19, using the motor 2 20 and the motor three 23 to move and rotate;

[0055] S2: The electromagnetic adsorption sleeve 10 is adsorbed to metal waste, and during the process of rotation, there is a non-metallic garbage residue on the electromagnetic adsorptive sleeve 10 until the electromagnetic adsorption sleeve 10 is in contact with the scraper one 25, and the scraper one 25 The metal waste is scraped out into the collection tank 2 18, and the cleaning brush 24 is cleaned to the electromagnetic adsorption sleeve 10, preventing dust such as dust;

[0056] S3: Control the motor 2 20 is inversely rotating, so that the electromagnetic adsorption sleeve 10 is rehabilized in the cleaning tank 19 such that the metal material is sufficiently adsorbed, and the control motor 3 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com