Preparation method of biodegradable carbon dioxide-based polyester-polycarbonate terpolymer

A technology of polycarbonate terpolymer and carbon dioxide, which is applied in the field of preparation of biodegradable carbon dioxide-based polyester-polycarbonate terpolymer, can solve the problems that have not been reported and limit large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

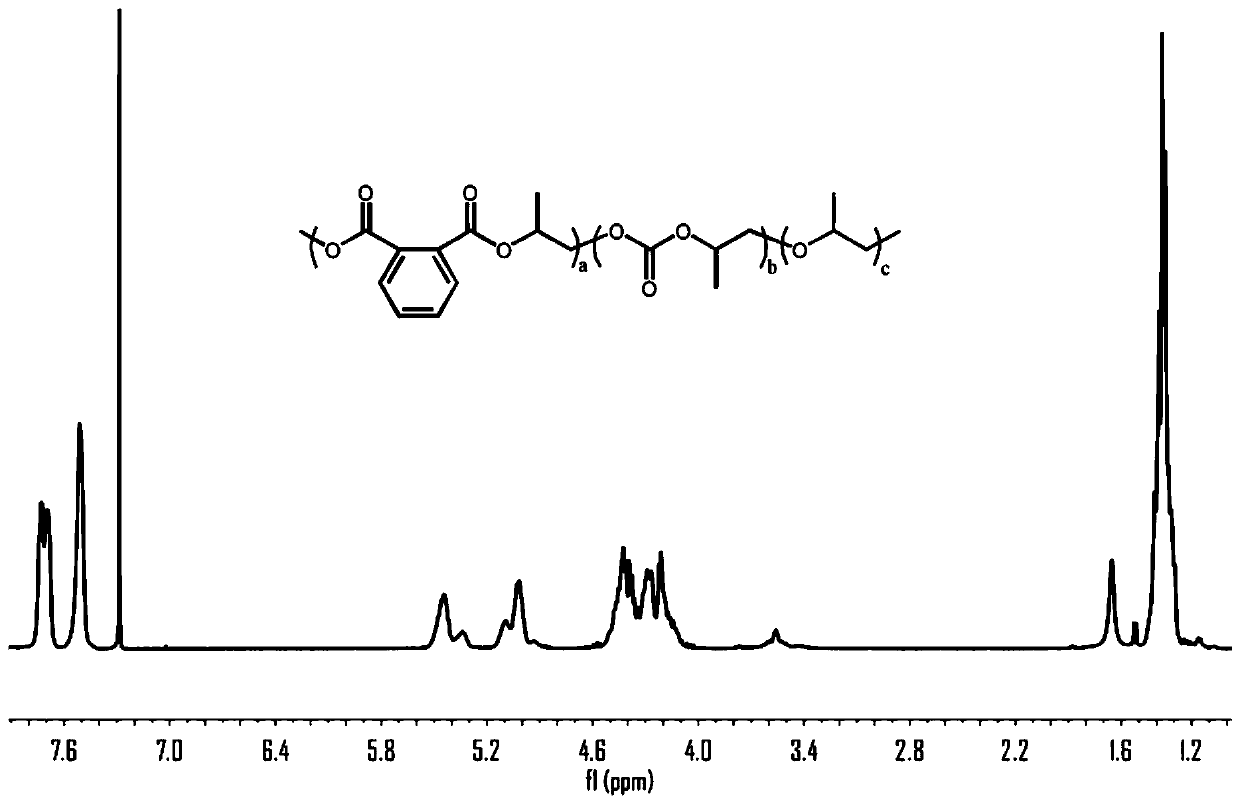

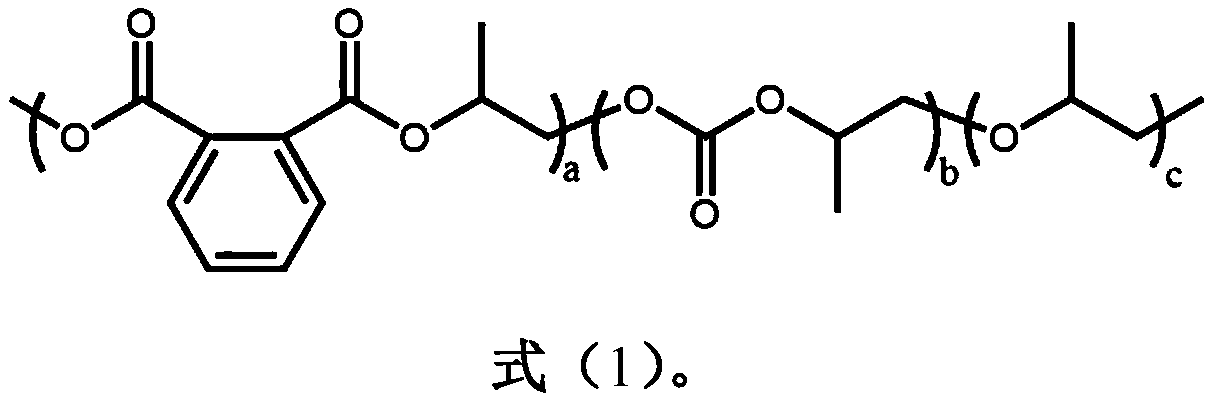

Embodiment 1

[0020] With a 50mL autoclave as the reaction vessel, in an anhydrous and oxygen-free environment, 1.0g of phthalic anhydride, 3.92g of propylene oxide, 7.5mg of tetra-n-butylammonium chloride, and 54μL of triethylboron solution were sequentially Put it into a high-pressure reactor, fill it with 1.0MPa carbon dioxide, react at 80°C for 12 hours, release the carbon dioxide pressure after the reaction, dissolve the product with dichloromethane, quench the reaction with dilute hydrochloric acid / methanol solution, and precipitate in ethanol to obtain a polymer , After the polymer is vacuum-dried, do molecular weight testing, nuclear magnetic analysis and thermal performance analysis. m n =52.7kDa, PDI=1.16, polyester content 14.8%, polycarbonate content=81.6%, polyether content=3.6%, T g = 40.5°C.

Embodiment 2

[0022] With a 50mL autoclave as the reaction vessel, in an anhydrous and oxygen-free environment, 2.5g of phthalic anhydride, 4.90g of propylene oxide, 9.4mg of tetra-n-butylammonium chloride, and 200μL of triethylboron solution were sequentially Put it into a high-pressure reactor, fill it with 1.0MPa carbon dioxide, react at 80°C for 12 hours, release the carbon dioxide pressure after the reaction, dissolve the product with dichloromethane, quench the reaction with dilute hydrochloric acid / methanol solution, and precipitate in ethanol to obtain a polymer , After the polymer is vacuum-dried, do molecular weight testing, nuclear magnetic analysis and thermal performance analysis. m n =102.8kDa, PDI=1.35, polyester content 39.9%, polycarbonate content=55.2%, polyether content=4.9%, T g =47.4°C

Embodiment 3

[0024] With a 50mL autoclave as the reaction vessel, in an anhydrous and oxygen-free environment, 1.0g of phthalic anhydride, 4.0g of propylene oxide, 7.5mg of tetra-n-butylammonium chloride, and 54μL of triethylboron solution were sequentially Put it into a high-pressure reactor, fill it with 3.0MPa carbon dioxide, react at 80°C for 12 hours, release the carbon dioxide pressure after the reaction, dissolve the product with dichloromethane, quench the reaction with dilute hydrochloric acid / methanol solution, and precipitate in ethanol to obtain a polymer , After the polymer is vacuum-dried, do molecular weight testing, nuclear magnetic analysis and thermal performance analysis. m n =61.2kDa, PDI=1.27, polyester content 33.4%, polycarbonate content=60.8%, polyether content=5.8%, T g = 45.6°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com