Patents

Literature

1882 results about "Melt viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

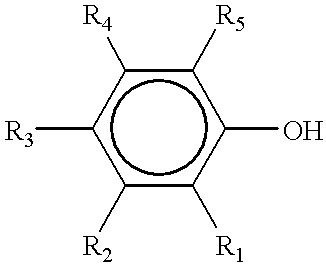

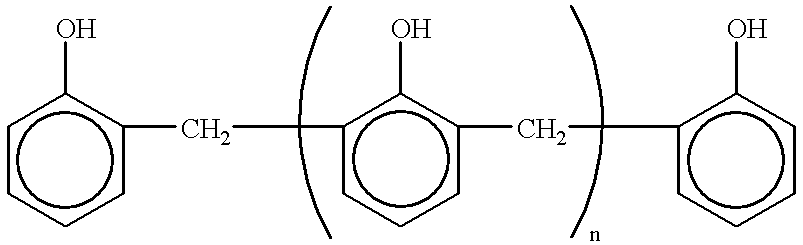

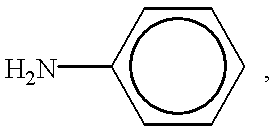

Ternary systems of benzoxazine, epoxy, and phenolic resins

Low viscosity ternary mixtures of benzoxazine, epoxy and phenolic resins have been developed. The blends render homogeneous and void free cured specimen with a wide range of properties. Melt viscosity values as low as 0.3 Pa.s at 100° C. can be achieved. The phenolic resin acts as a cure accelerator to the system, besides its typical function as a hardener of epoxy resin. Glass transition temperatures Tg as high as 170° C. can also be obtained.

Owner:EDISON POLYMER INNOVATION EPIC

Compatibilized blends of biodegradable polymers with improved rheology

This invention relates to a blend of biodegradable polymers comprising: (A) about 5% to about 95% by weight of at least one flexible biodegradable polymer (A) having a glass transition less than about 0° C., (B) about 5% to about 95% by weight of at least one rigid biodegradable polymer (B) having a glass transition greater than about 10° C., and (C) about 0.25 to about 10 weight % of at least one compatibilizer (C), said percentages being based on the total weight of the polymer blend; where the polymer blend has a higher zero shear melt viscosity than polymers (A) and (B) separately.

Owner:NOVAMONT SPA

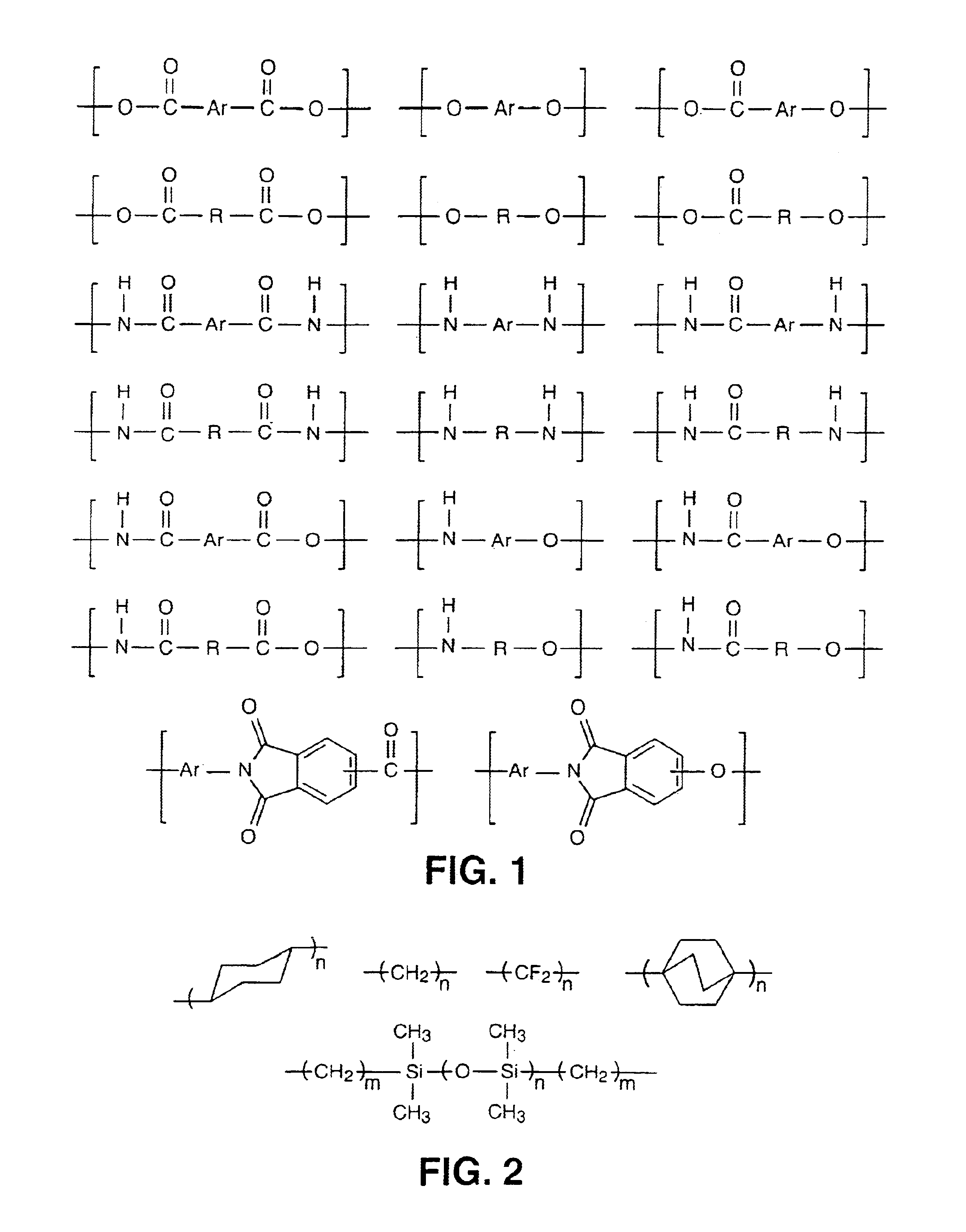

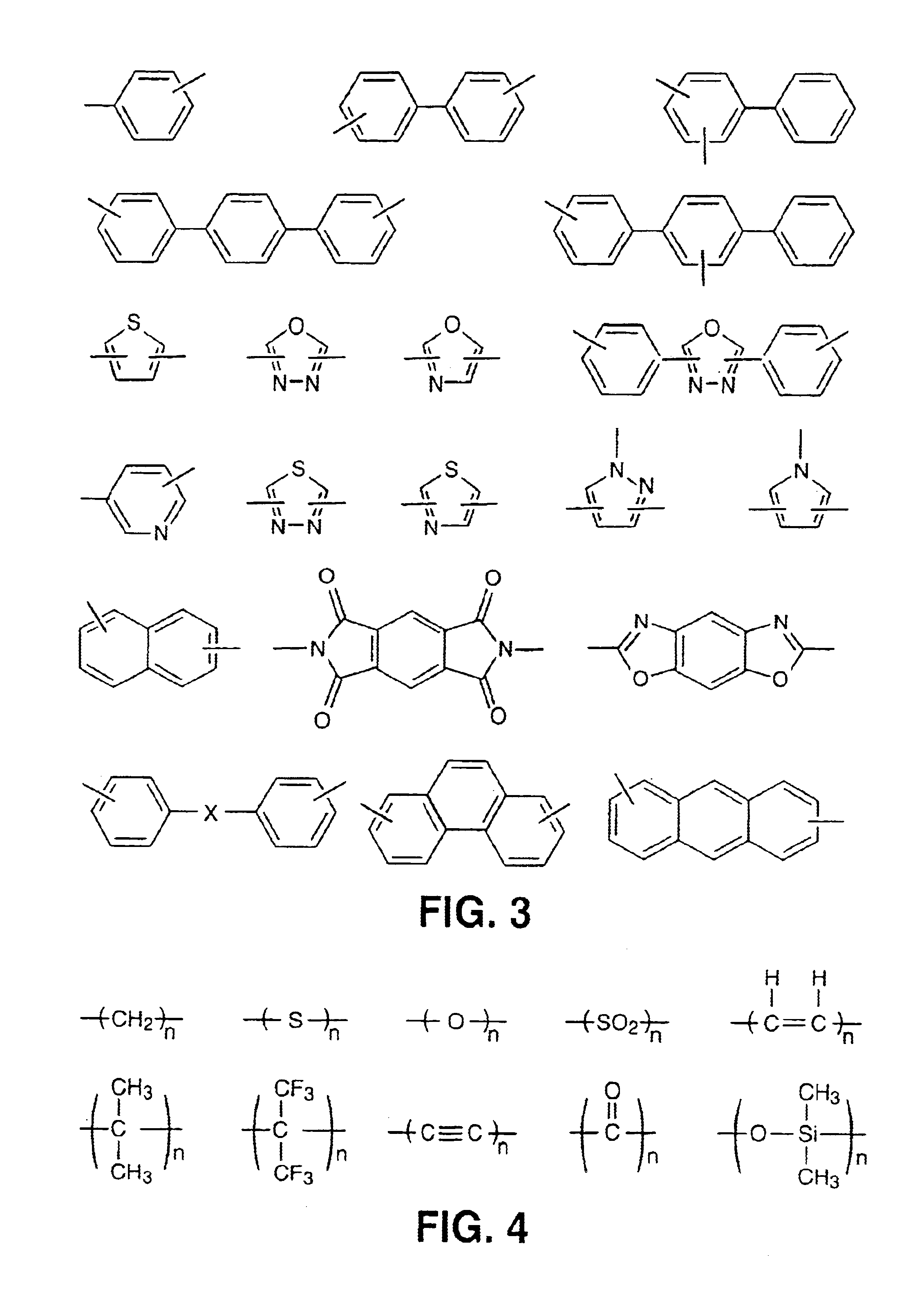

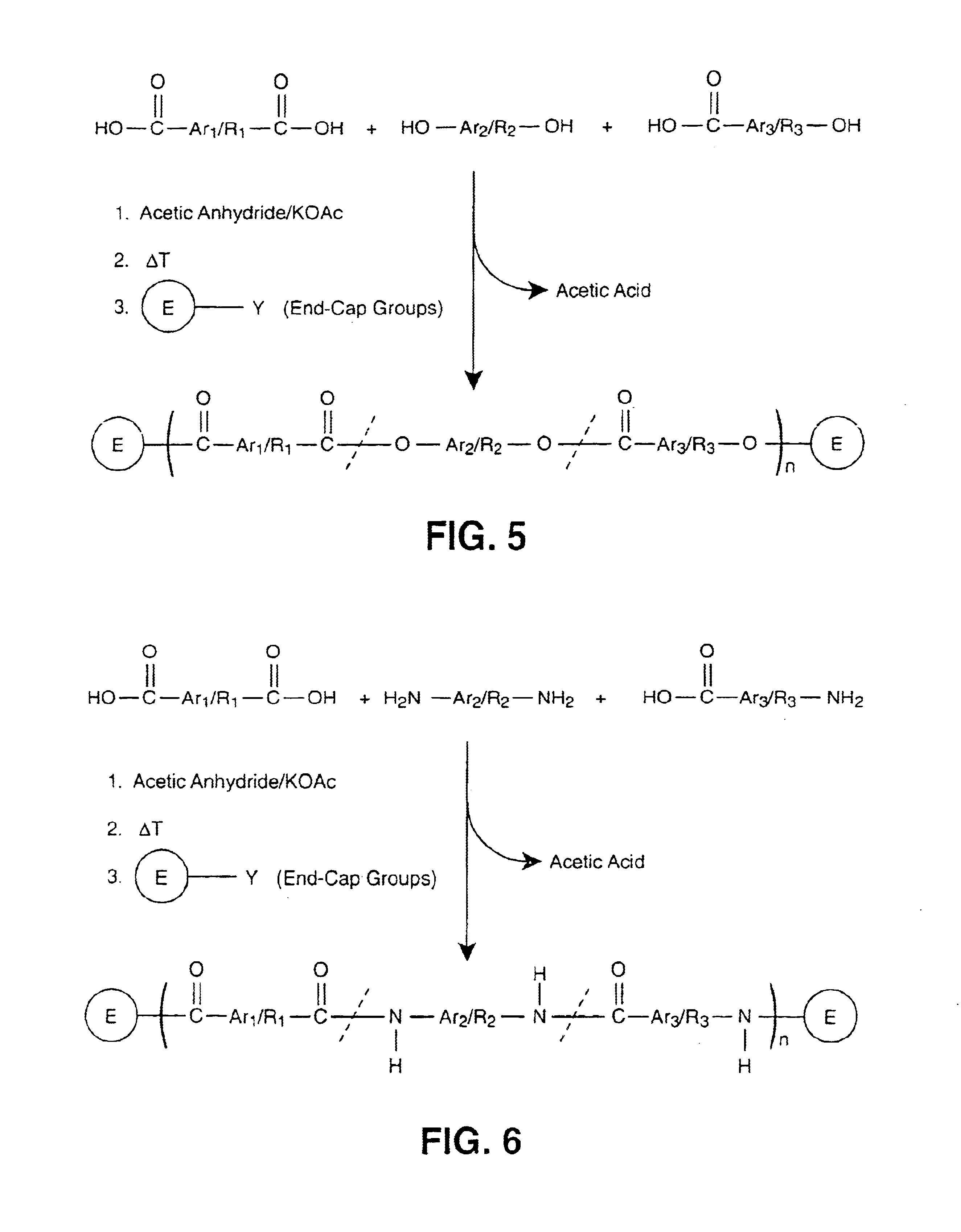

Liquid crystalline thermosets from ester, ester-imide, and ester-amide oligomers

InactiveUS6939940B2Low viscosityLow dielectric constantLiquid crystal compositionsLiquid crystallineEnd-group

Main chain thermotropic liquid crystal esters, ester-imides, and ester-amides were prepared from AA, BB, and AB type monomeric materials and were end-capped with phenylacetylene, phenylmaleimide, or nadimide reactive end-groups. The resulting reactive end-capped liquid crystal oligomers exhibit a variety of improved and preferred physical properties. The end-capped liquid crystal oligomers are thermotropic and have, preferably, molecular weights in the range of approximately 1000-15,000 grams per mole. The end-capped liquid crystal oligomers have broad liquid crystalline melting ranges and exhibit high melt stability and very low melt viscosities at accessible temperatures. The end-capped liquid crystal oligomers are stable for up to an hour in the melt phase. These properties make the end-capped liquid crystal oligomers highly processable by a variety of melt process shape forming and blending techniques including film extrusion, fiber spinning, reactive injection molding (RIM), resin transfer molding (RTM), resin film injection (RFI), powder molding, pultrusion, injection molding, blow molding, plasma spraying and thermo-forming. Once processed and shaped, the end-capped liquid crystal oligomers were heated to further polymerize and form liquid crystalline thermosets (LCT). The fully cured products are rubbers above their glass transition temperatures. The resulting thermosets display many properties that are superior to their non-end-capped high molecular weight analogs.

Owner:NASA

Void-containing polyester shrink film

InactiveUS20050119359A1Improve performanceHigh opacitySynthetic resin layered productsLabelsPolyesterVolumetric Mass Density

Disclosed are polyester shrink films comprising a voiding agent dispersed within a continuous polyester phase. The voiding agent comprises at least one first polymer and at least one second polymer, in which the polymer components have selected physical properties such as glass transition temperature, melting point, tensile modulus, surface tension, and melt viscosity. The resulting shrink films have high opacity, a low coefficient of friction, lower density, low shrink force, and good printability. The films are useful for sleeve label and other shrink film applications, and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations. Also disclosed is a process for separating a void-containing polyester from a mixture of polymers.

Owner:SHELBY MARCUS DAVID +2

Compatibilized blends of biodegradable polymers with improved rheology

Owner:NOVAMONT SPA

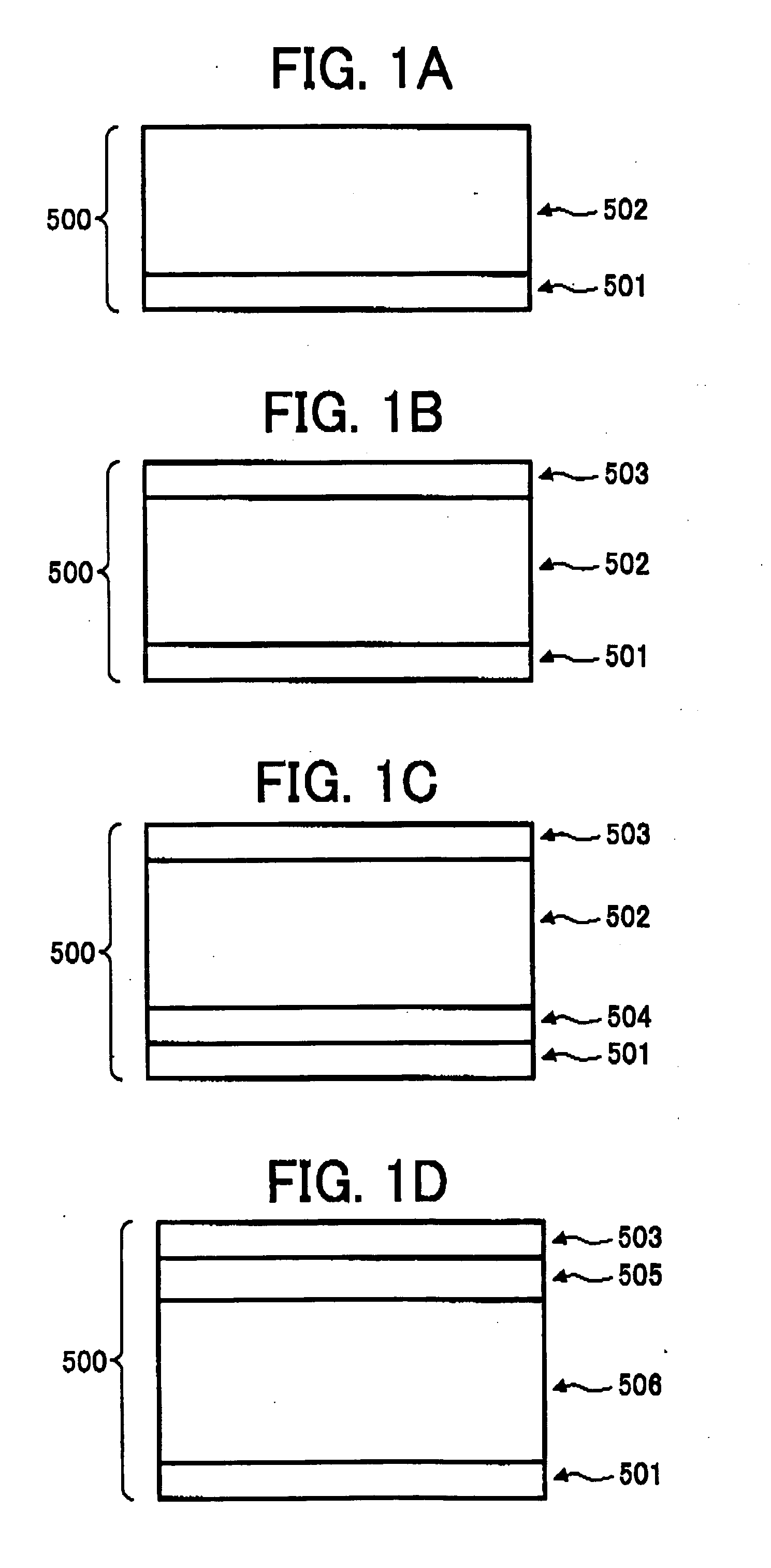

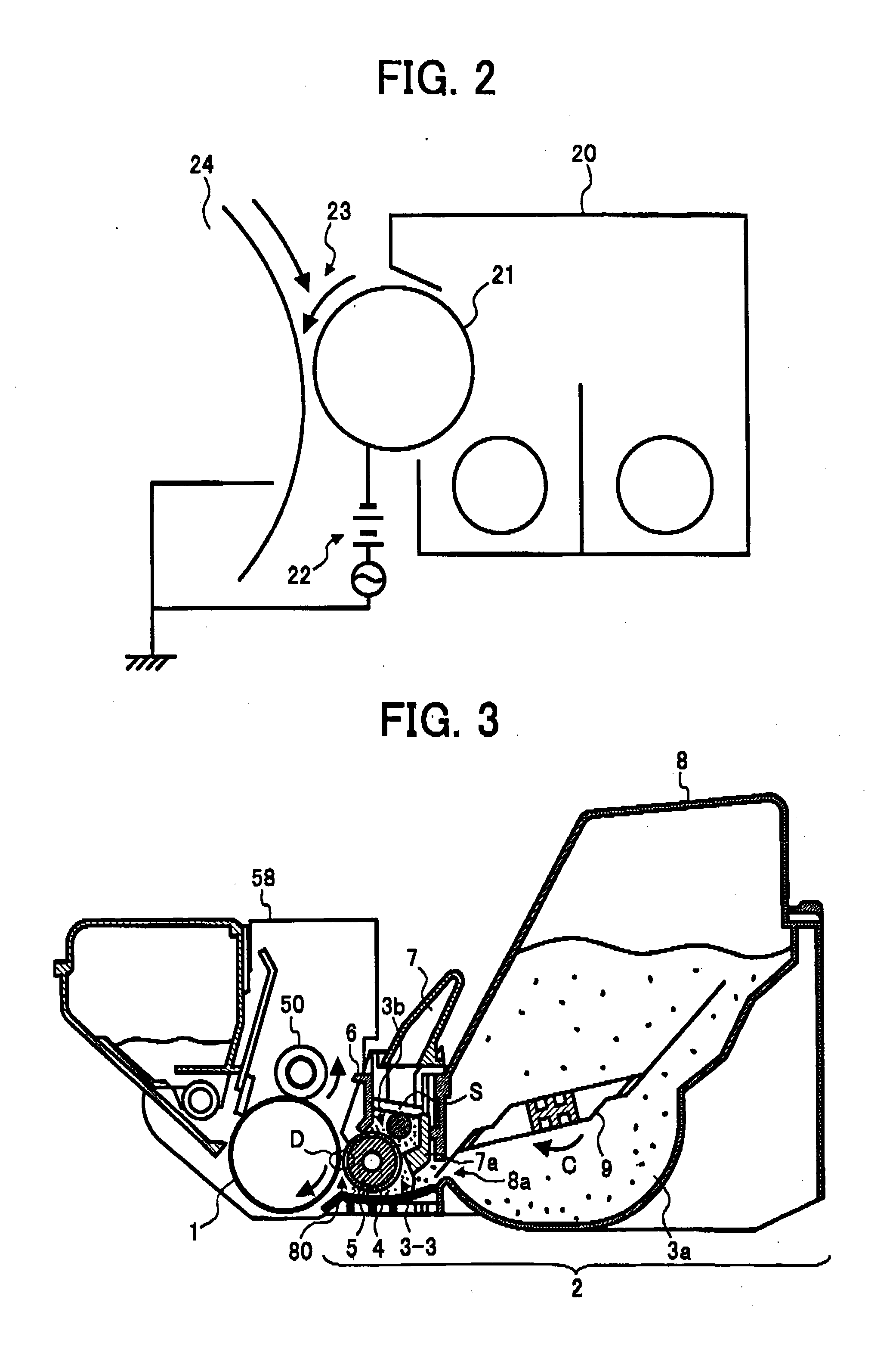

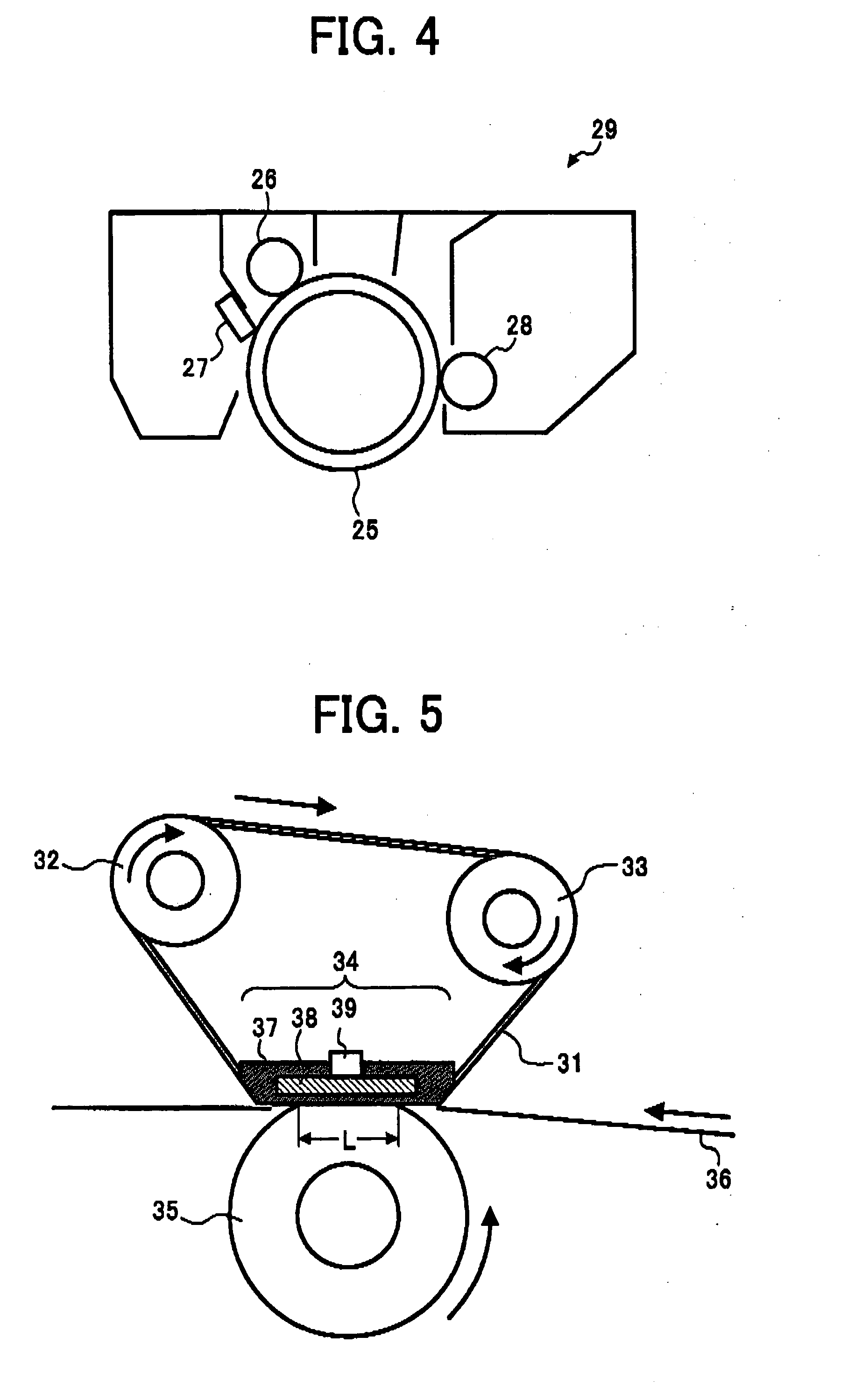

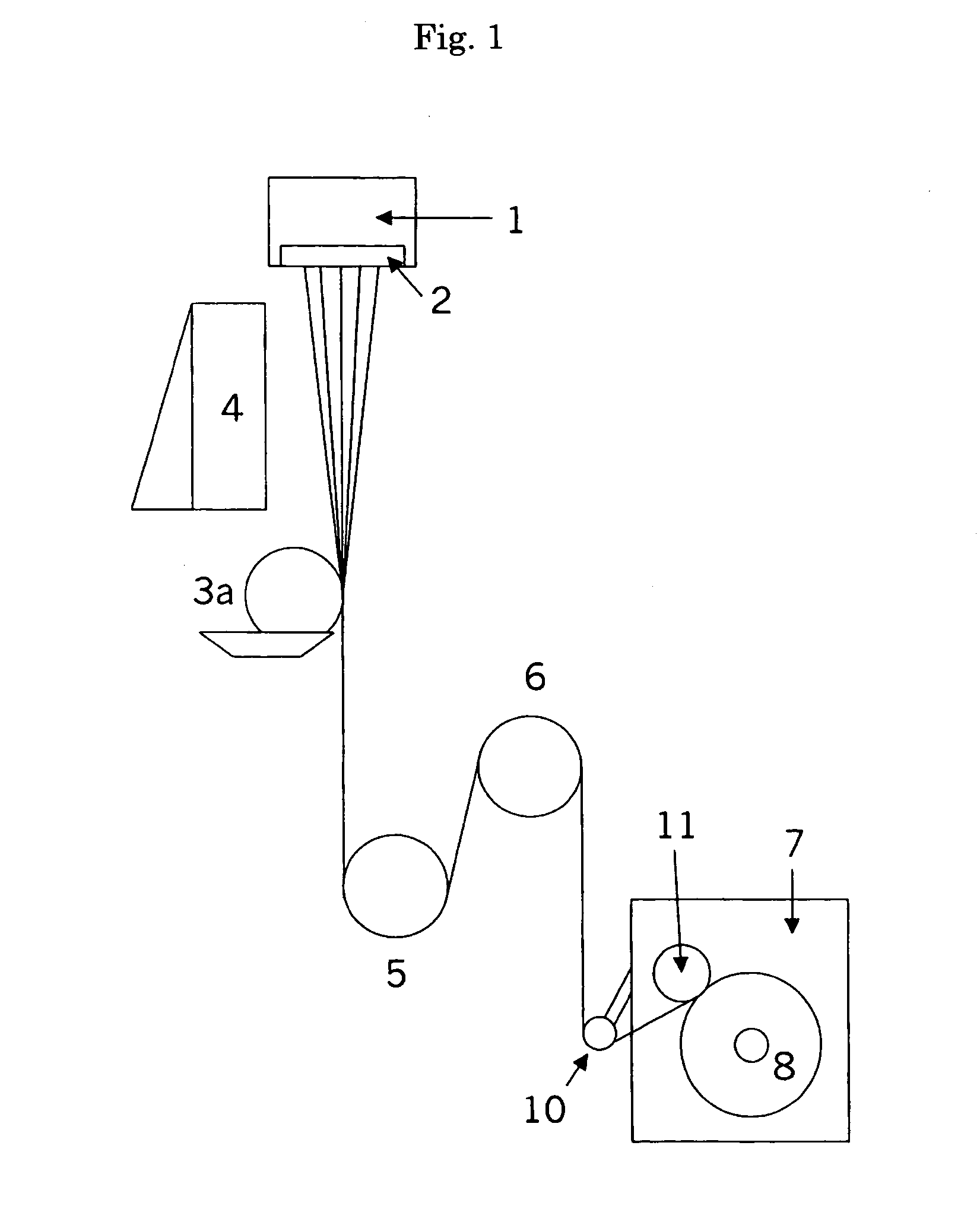

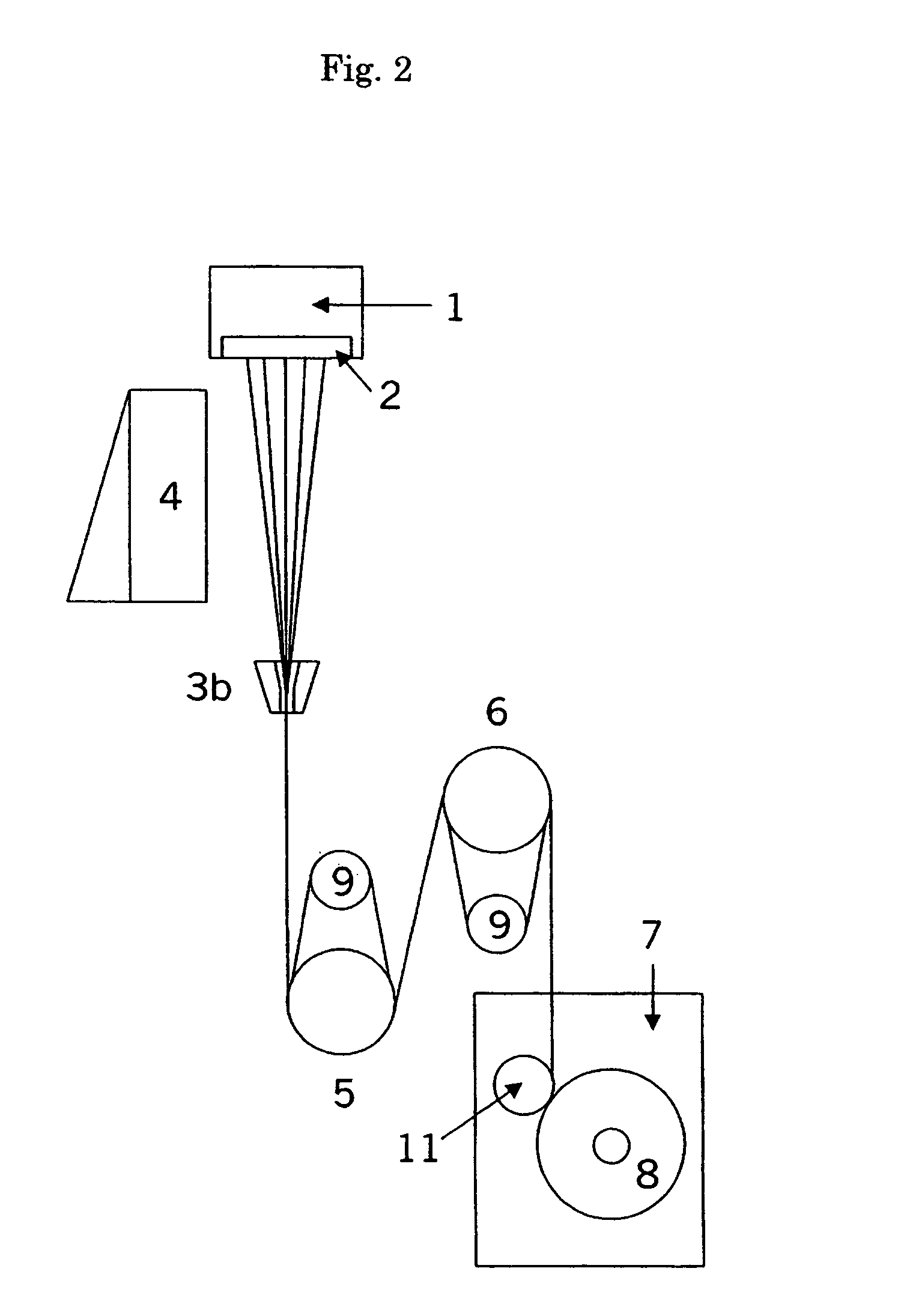

Toner and developer, and image forming method and apparatus using the developer

A toner is provided that contains a particulate toner material (mother toner) having an average circularity of from 0.93 to 0.99, and including a modified polyester resin and a colorant; and an external additive in an amount of from 0.3 to 5.0 parts by weight per 100 parts by weight of the mother toner, wherein the toner has a melting viscosity of from 70 to 140 Pa·s at 160° C., a weight-average particle diameter of from 3 to 7 μm, a ratio thereof to a number-average particle diameter of from 1.91 to 1.25, wherein particles satisfy at least one of (I) and (II): (I) particles having a diameter of 4 μm or less in an amount less than 10% by number; or (II) particles having a diameter of 8 μm or more in an amount less than 2% by volume, along with a one or two component developer containing the toner, a cartridge containing the toner, an image forming method using the toner and an image forming apparatus using the toner.

Owner:RICOH KK

Molding composition with good capability for blow molding

InactiveUS6677015B2Reduce concentrationIncrease stiffnessSynthetic resin layered productsThin material handlingBlow moldingPolymer science

A molding composition of at least 50% by weight of a polyamine-polyamide copolymer obtained from 0.05 to 2.5% by weight of a polyamine having at least 4 nitrogen atoms and having a viscosity of at least 5 000 Pa.s at 250° C. and at a shear rate of 0.1 l / s, and having a viscosity ratio of at least 7 at 250° C., when the melt viscosities at shear rates of 0.1 l / s and 100 l / s are compared with one another, has high melt stiffness and is easy to cut, and performs well in blow molding.

Owner:EVONIK DEGUSSA GMBH

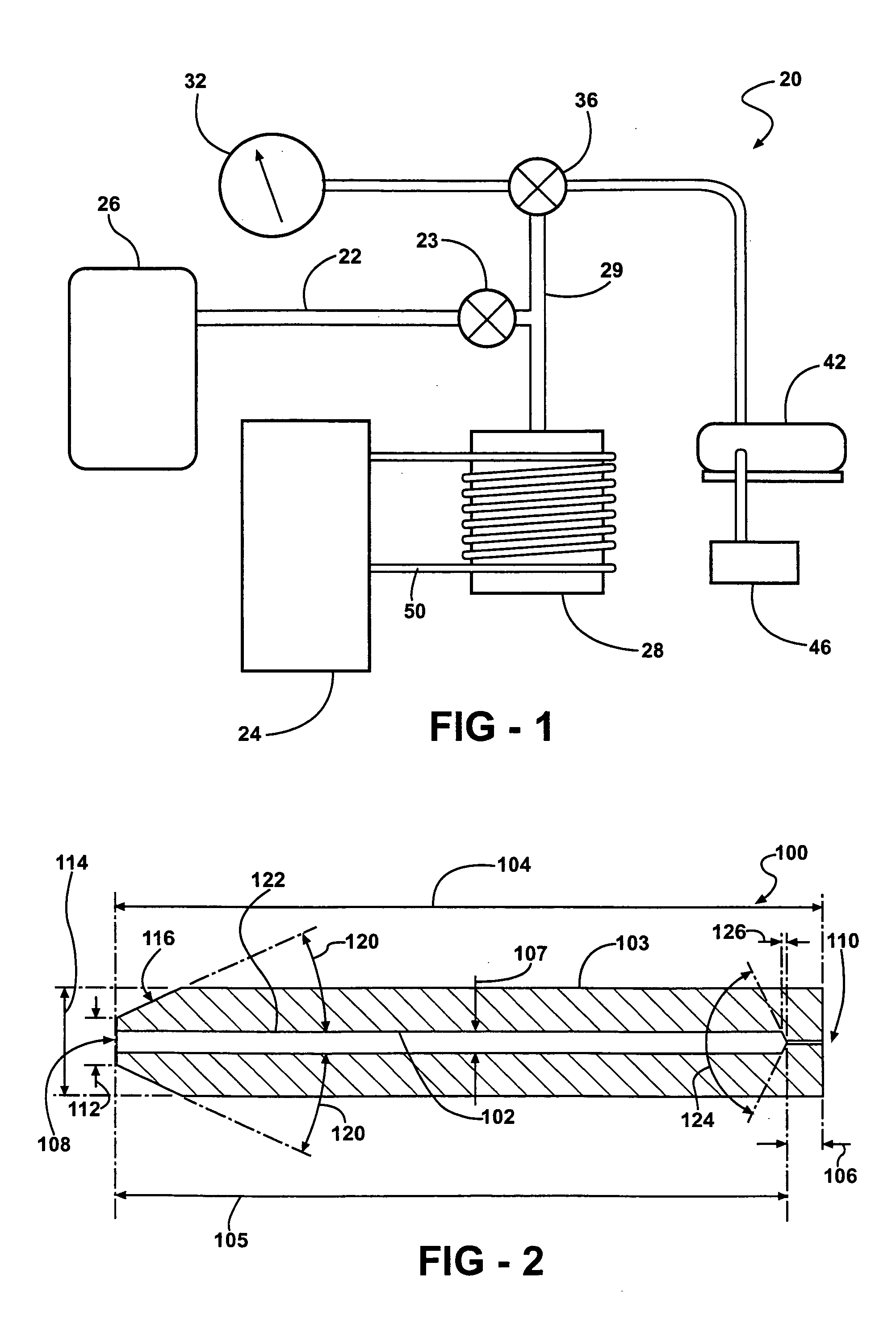

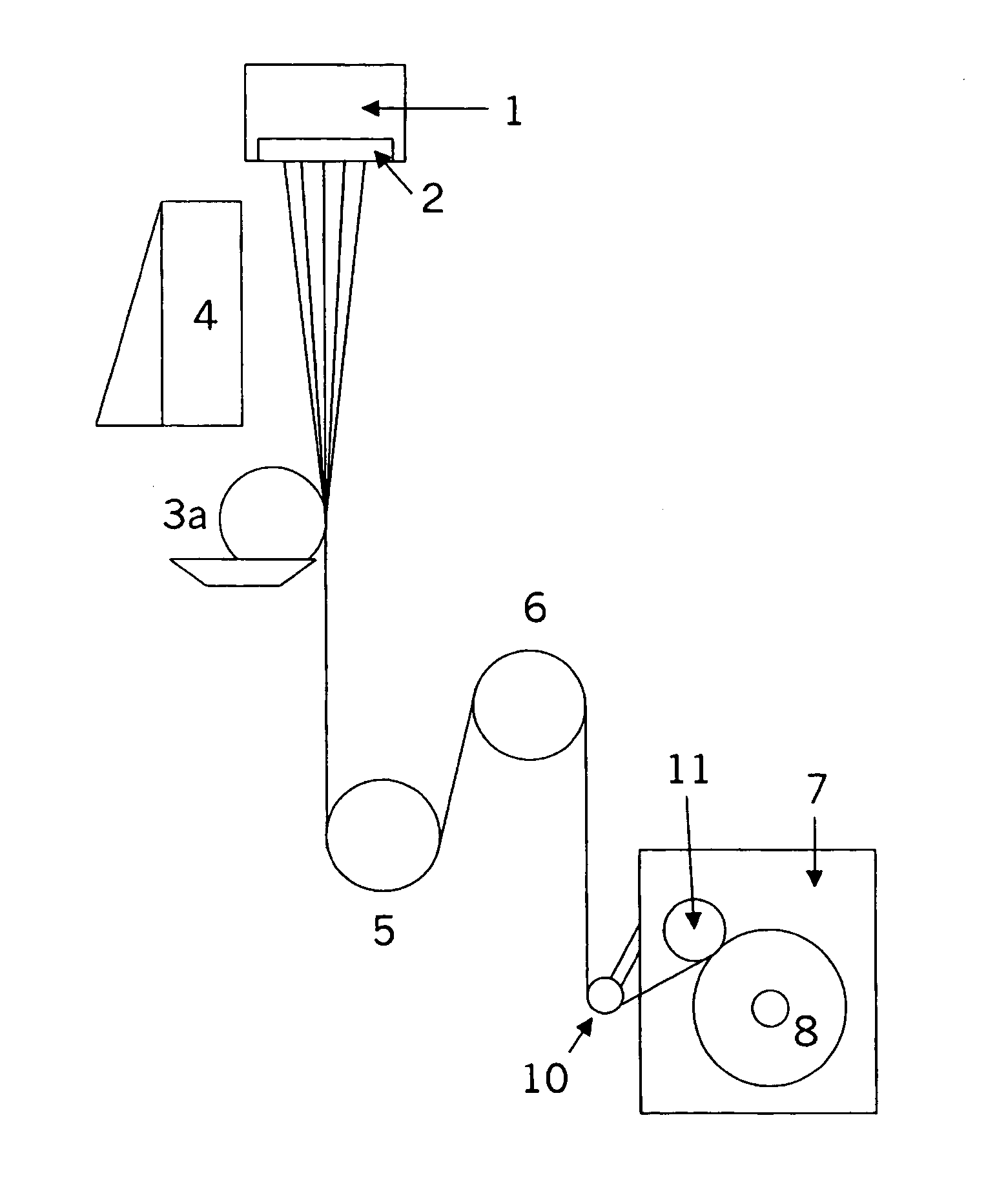

Process for forming polymeric micro and nanofibers

Polymers that have extremely high melt viscosities are very difficult to extrude and stretch making it difficult to synthesize fibers of such polymers via conventional methods. A process is provided for producing a polymer fiber which involves blowing a mixture of a polymer and a gas through a nozzle such that polymer micro- and / or nano-fibers are produced. The polymer fibers are characterized in that they have a diameter less than the diameter of the outlet aperture of the nozzle.

Owner:PENN STATE RES FOUND

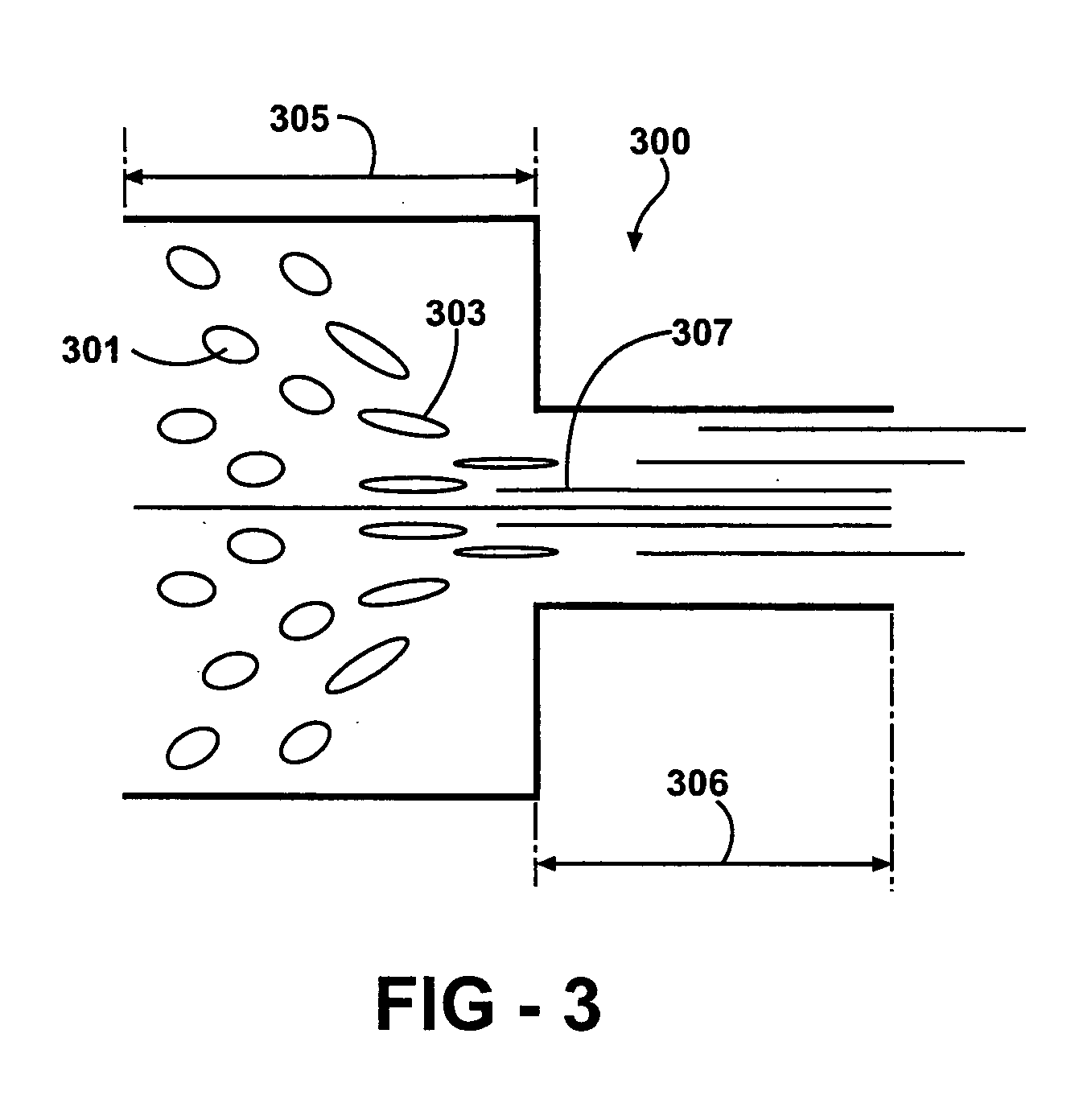

Water-dispersible and multicomponent fibers from sulfopolyesters

Disclosed are multicomponent fibers derived from a blend of a sulfopolyester with a water non-dispersible polymer wherein the as-spun denier is less than about 6 and wherein the water dispersible sulfopolyester exhibits a melt viscosity of less than 12,000 poise measured at 240° C. at a strain rate of 1 rad / sec, and wherein the sulfopolyester comprising less than about 25 mole % of residues of at least one sulfomonomer, based on the total moles of diacid or diol residues. The multicomponent fiber is capable of being drawn at a relatively high fiber speed, particularly at least about 2000 m / min, and may be used to produce microdenier fibers. Fibrous articles may be produced from the multicomponent fibers and microdenier fibers. Also disclosed is a process for multicomponent fibers, nonwoven fabrics, and microdenier webs.

Owner:EASTMAN CHEM CO

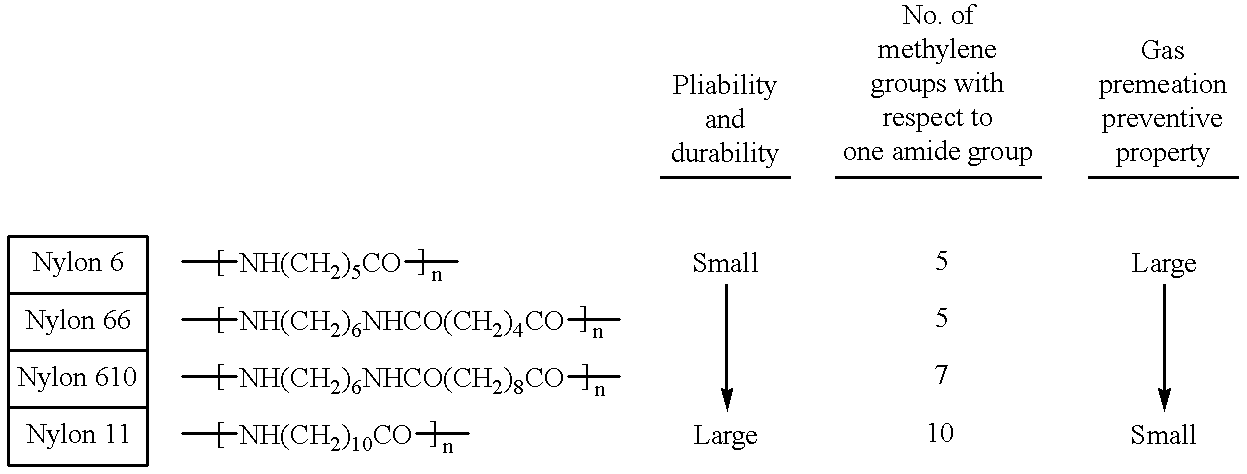

Thermoplastic elastomer composition, process for producing the same, and pneumatic tire and hose made with the same

InactiveUS6359071B1More flexibleLarge elongationSpecial tyresWheelsPolymer scienceThermoplastic elastomer

A thermoplastic elastomer composition dynamically vulcanized to a gelation rate of 50 to 95% which is superior in heat resistance and durability while maintaining flexibility and superior in air permeation preventive property which can be efficiently used as, for example, a pneumatic tire as an air permeation preventive layer. In particular, a thermoplastic elastomer composition having a reduced particle size of the domain rubber is produced by a material having a high rubber ratio by mixing a composition (C) mixed under conditions of a ratio of melt viscosities of the rubber composition (A) / resin (B) of 0.8 to 1.2 and the formula (phiA / phiB)x(etaB / etaA)<1.0 under conditions of a ratio of melt viscosities of the rubber composition (D) / composition (C) of 0.8 to 1.2 and the formula (phiD / phiC)x(etaC / etaD)<1.0, wherein phiA: volume fraction of rubber composition (A), phiB: volume fraction of resin (B), etaA: melt viscosity of rubber composition (A), etaB: melt viscosity of resin (B), phiC: volume fraction of composition (C), phiD: volume fraction of rubber composition (D), etaC: melt viscosity of composition (C), etaD: melt viscosity of rubber composition (D).

Owner:THE YOKOHAMA RUBBER CO LTD

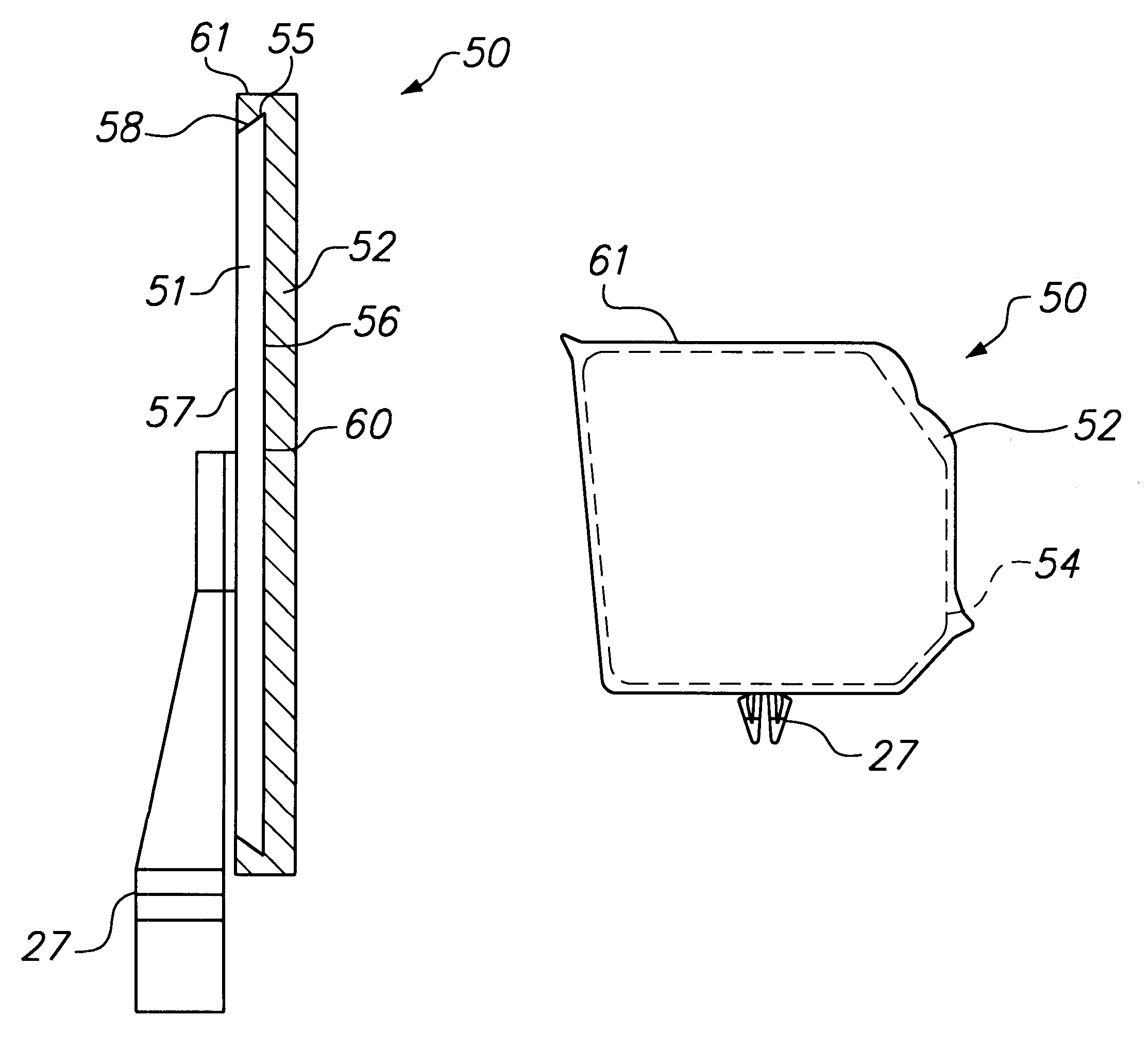

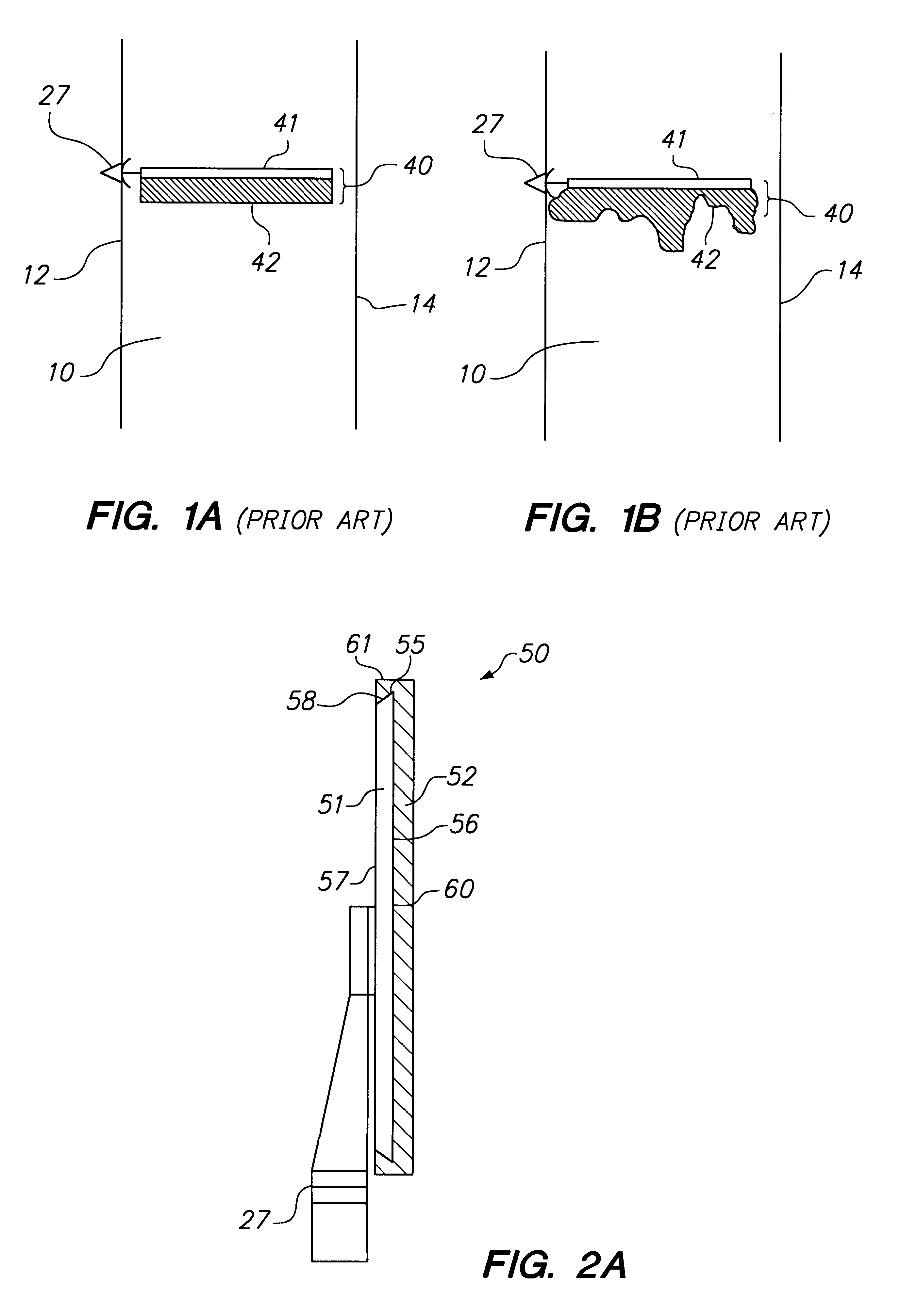

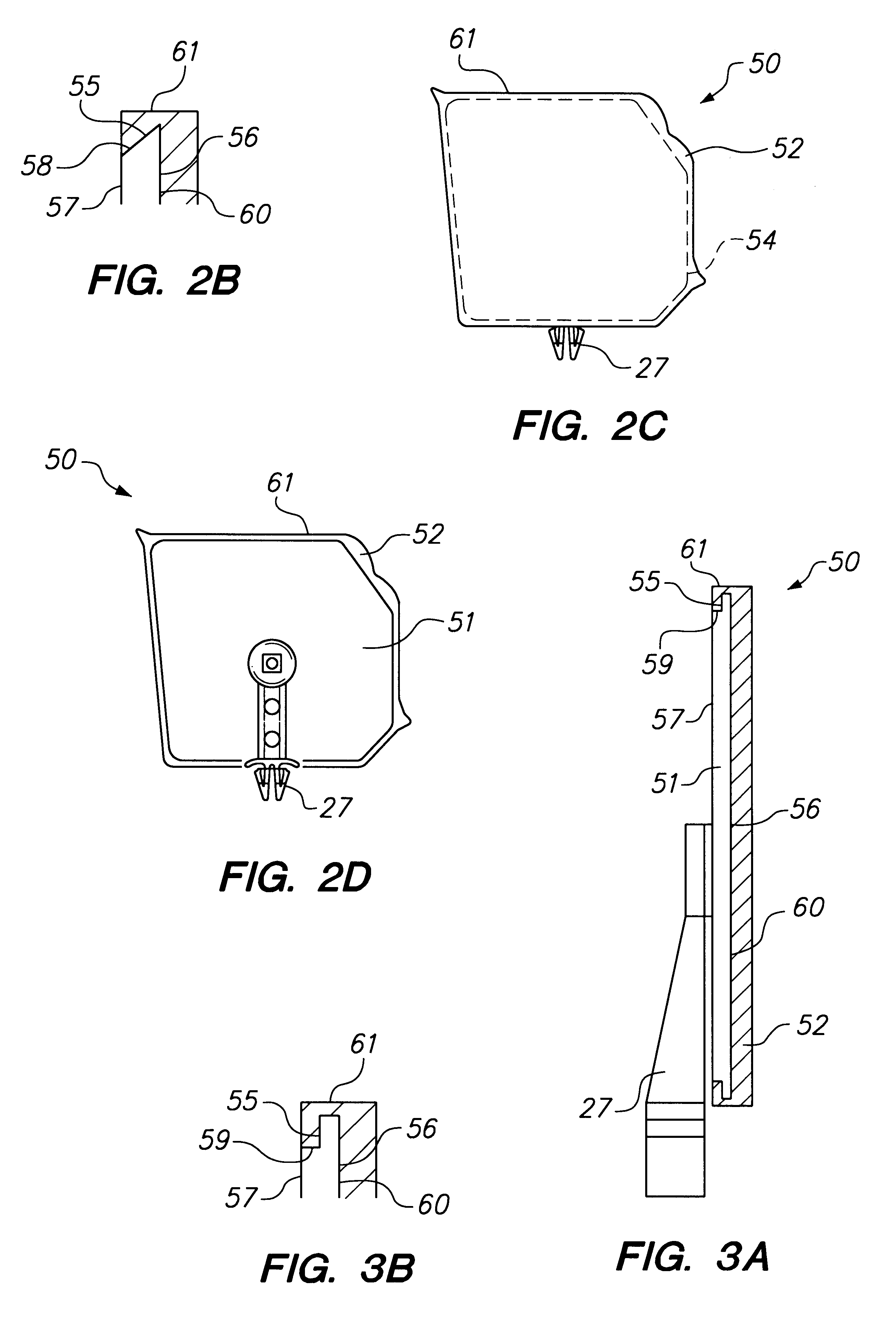

Cavity sealing article having improved sag resistance

Conventional foamable cavity sealing articles are susceptible to sagging when expanded in a vertical orientation with the foaming material facing downwards, because of gravitational drag on the molten material during expansion. The problem is particularly pronounced in foaming materials formulated to have high expansion ratios and low melt viscosities. A solution to the problem is presented in the form of a cavity sealing article having a planar holder and a foamable sealer, the foamable sealer circumscribing the edge of the support member. This construction creates a gripping effect which prevents sagging of the sealing member during expansion.

Owner:TYCO INT PA +2

Resin composition and jig for use in transportation

InactiveUS6344513B1Excellent static charge dissipating performanceLittle changeSemiconductor/solid-state device manufacturingSpecial tyresFiberCarbon fibers

Owner:TEIJIN LTD

Stretch blow molded container and production process thereof

InactiveUS6159416AImprove barrier propertiesHigh mechanical strengthBottlesRefuse receptaclesShear rateVolumetric Mass Density

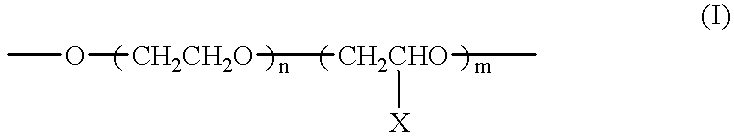

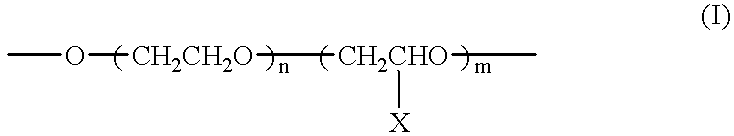

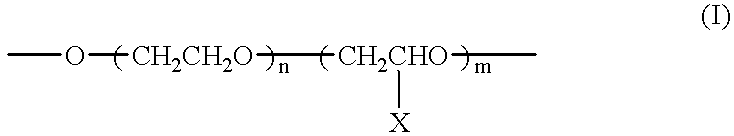

The invention provides a stretch blow molded container formed from a thermoplastic resin material which comprises polyglycolic acid having (a) a repeating unit represented by the following formula (1): (b) a melt viscosity, eta * [as measured at a temperature of (the melting point, Tm of the polymer+20 DEG C.) and a shear rate of 100 / sec] of 500-100,000 Pa.s; (c) a melting point, Tm of at least 180 DEG C.; (d) a melt enthalpy, DELTA Hm of at least 20 J / g; and (e) a density of at least 1.50 g / cm3 as measured in an unoriented, crystallized form, wherein the stretch blow molded container has tensile strength (in a circumferential direction) of at least 100 MPa and a carbon dioxide permeability (as measured at a temperature of 23 DEG C. and 80% relative humidity; in terms of the thickness of 50 mu m) of 300 cc / m2.day.atm or smaller at the body sidewall thereof, and a production process thereof.

Owner:KUREHA KAGAKU KOGYO KK

Water-dispersible and multicomponent fibers from sulfopolyesters

InactiveUS7687143B2Reduces blocking and fusionLayered productsConjugated synthetic polymer artificial filamentsPolymer scienceWater dispersible

Disclosed are multicomponent fibers derived from a blend of a sulfopolyester with a water non-dispersible polymer wherein the as-spun denier is less than about 6 and wherein the water dispersible sulfopolyester exhibits a melt viscosity of less than 12,000 poise measured at 240° C. at a strain rate of 1 rad / sec, wherein the sulfopolyester comprising less than about 25 mole % of residues of at least one sulfomonomer, based on the total moles of diacid or diol residues, and wherein said poly(ethylene) terephthalate has an inherent viscosity of less than 0.55 dL / g. The multicomponent fiber is capable of being drawn at a relatively high fiber speed, particularly at least about 2000 m / min, and may be used to produce microdenier fibers. Fibrous articles may be produced from the multicomponent fibers and microdenier fibers. Also disclosed is a process for multicomponent fibers, nonwoven fabrics, and microdenier webs.

Owner:EASTMAN CHEM CO

Thermoplastic cellulose derivative composition and fiber comprising the same

InactiveUS6984631B2Good fluidityIncrease resistanceOrganic active ingredientsBiocidePolyesterSide chain

A thermoplastic cellulose derivative composition of the present invention contains, as a main component, a cellulose ester having an aliphatic polyester side chain having a repeat unit having 2 to 5 carbon atoms, wherein a rate of heating loss at 200° C. is 5 wt % or less, a melt viscosity at 200° C. and 1000 sec−1 is 50 to 300 Pa·sec, and a melt tension at the time of take-up at 200° C. and 100 m / min is 0.1 to 40 mN. The present invention can provide excellent fiber products by melt spinning of the composition.

Owner:TORAY IND INC

Water-dispersible and multicomponent fibers from sulfopolyesters

InactiveUS20070259177A1Layered productsConjugated synthetic polymer artificial filamentsPolymer scienceWater dispersible

Disclosed are multicomponent fibers derived from a blend of a sulfopolyester with a water non-dispersible polymer wherein the as-spun denier is less than about 6 and wherein the water dispersible sulfopolyester exhibits a melt viscosity of less than 12,000 poise measured at 240° C. at a strain rate of 1 rad / sec, wherein the sulfopolyester comprising less than about 25 mole % of residues of at least one sulfomonomer, based on the total moles of diacid or diol residues, and wherein said poly(ethylene) terephthalate has an inherent viscosity of less than 0.55 dL / g. The multicomponent fiber is capable of being drawn at a relatively high fiber speed, particularly at least about 2000 m / min, and may be used to produce microdenier fibers. Fibrous articles may be produced from the multicomponent fibers and microdenier fibers. Also disclosed is a process for multicomponent fibers, nonwoven fabrics, and microdenier webs.

Owner:EASTMAN CHEM CO

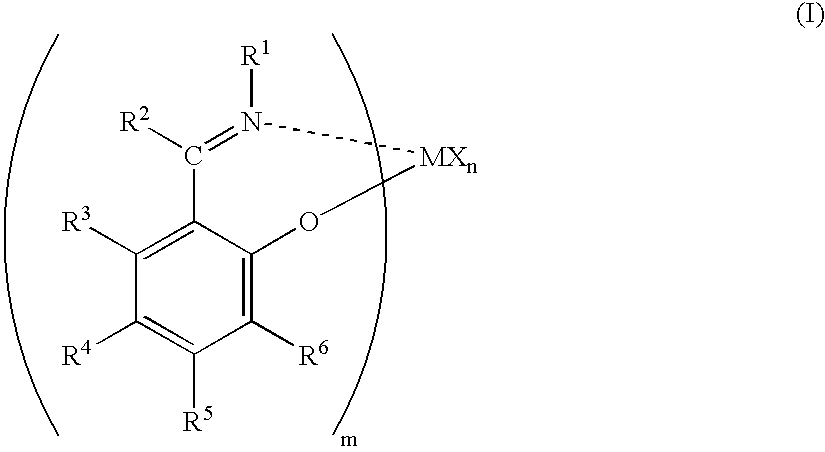

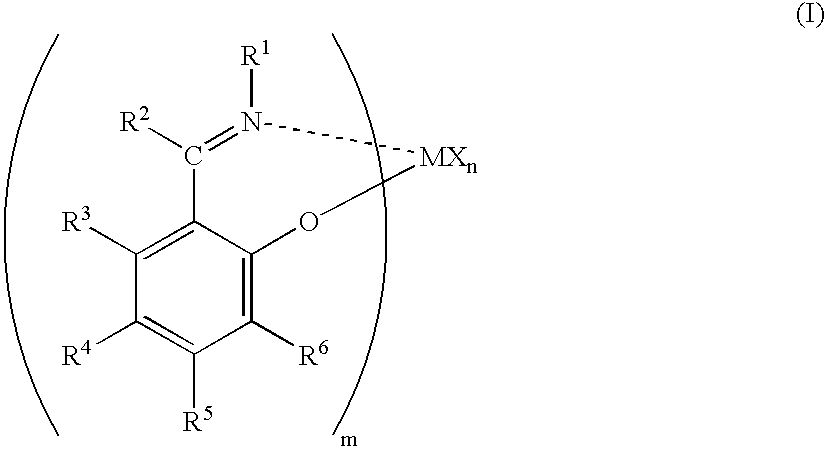

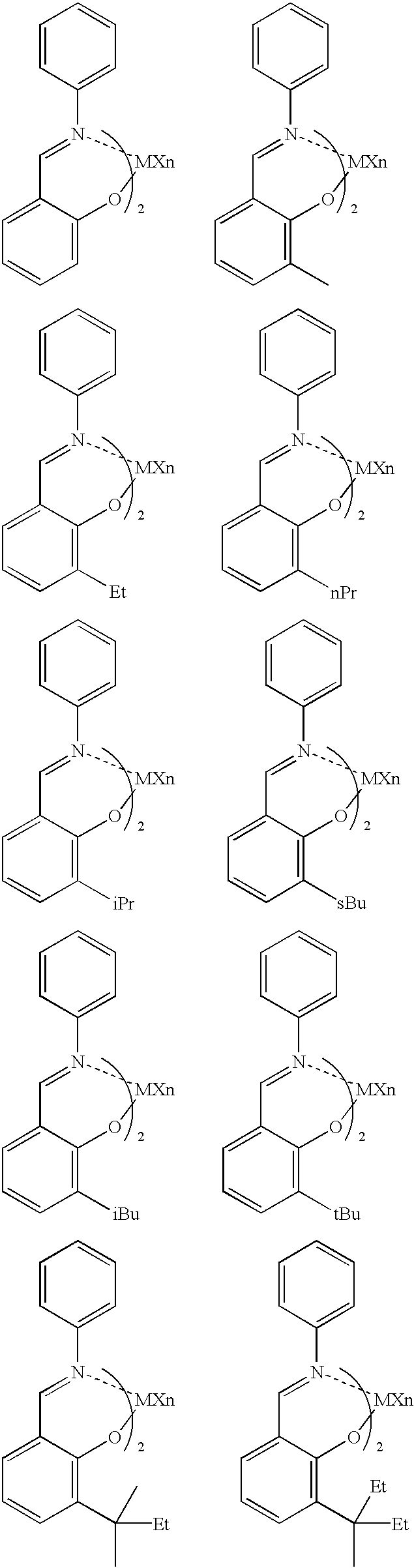

Ethylene copolymer and process for producing the same, resin composition containing the copolymer, and uses of these

InactiveUS6462136B1High tear strengthUniform processElectric/magnetic detectionAcoustic wave reradiationPolymer scienceActivation energy

The present invention is intended to provide an ethylene copolymer having excellent mechanical properties and moldability, a process for preparing the copolymer, a resin composition containing the copolymer and uses thereof. The ethylene copolymer has the following properties: the copolymer comprises 90 to 99% by mol of ethylene constituent units and 1 to 60% by mol of C3-20 alpha-olefin constituent units; the ratio (Mz / Mw) of a Z average molecular weight (Mz) to a weight-average molecular weight (Mw), each molecular weight being measured by GPC, is in the range of 10 to 30, and said ratio (Mz / Mw) and the ratio (Mw / Mn) of a weight-average molecular weight (Mw) to a number-average molecular weight (Mn), each molecular weight being measured by GPC, satisfy the relation (Mz / Mw)>(Mw / Mn); the intrinsic viscosity is in the range of 0.5 to 9 dl / g; the ratio (n*0.01 / n*8) of a melt viscosity (eta*0.01) at a shear rate of 0.01 rad / sec, as measured at 190° C., to a melt viscosity (eta*8) at a shear rate of 8 rad / sec, as measured at 190° C., and the intrinsic viscosity (eta) satisfy the relation (eta*0.01 / eta*8)>=0.893x(eta)+1.0; and the absolute value of an activation energy (Ea) of a shift factor of melt viscoelasticity is not more than 4x104 J / mol.K.

Owner:MITSUI CHEM INC

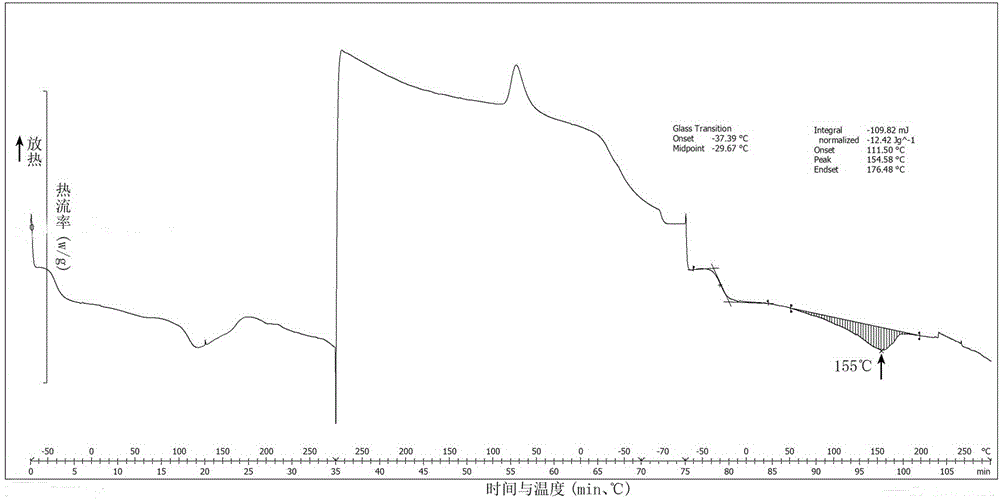

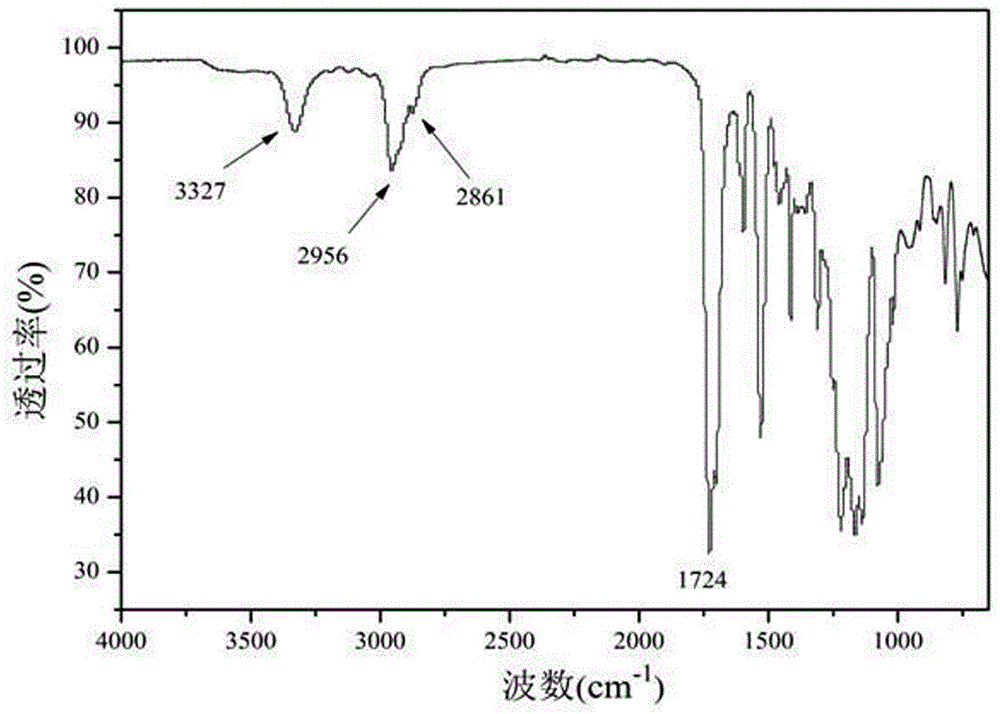

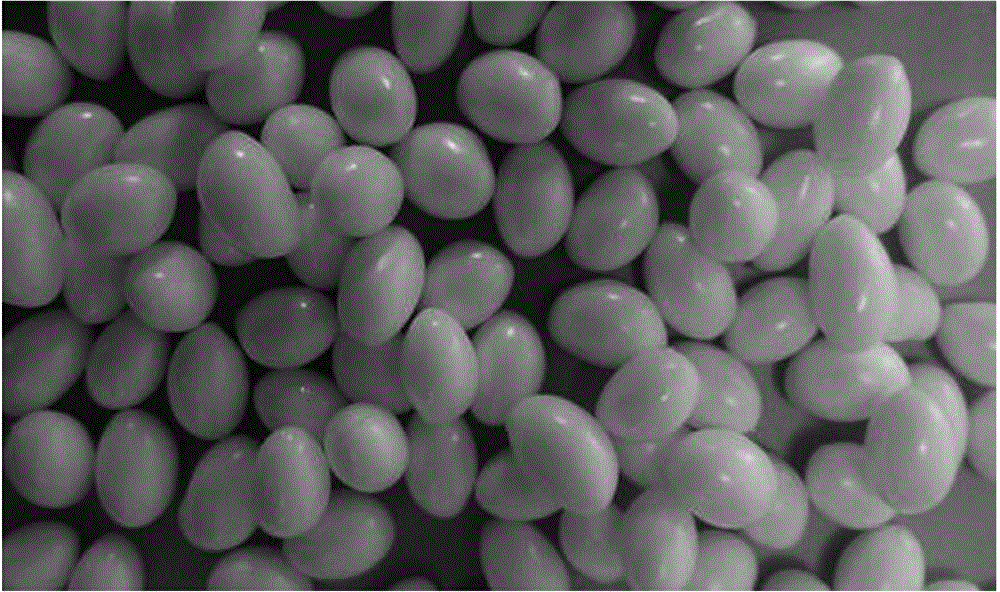

Preparation method of thermoplastic polyurethane beads and bead molding technology

The present invention discloses a preparation method of thermoplastic polyurethane beads and a bead molding technology. High foaming thermoplastic polyurethanes (TPU) beads are obtained through: melting and granulating TPU, melt viscosity modifiers, fillers and age resisters to prepare TPU co-blending granules; using clean, cheap, environmentally-friendly CO2 and / or N2 as foaming agents; and performing medium-temperature and high-pressure soakage, dissolution equilibrium, pressure relief and pre-foaming, saturated steam secondary foaming and other techniques. The obtained high foaming TPU beads are small in shrinkage ratio and smooth in surface. The invention further discloses the bead molding technology which uses a water vapor assisted mould pressing technology to prepare molded bodies of the TPU foaming beads, the prepared molded bodies of the TPU foaming beads are low in density, small in shrinkage ratio and uniform in surface texture, and also have an unique property of TPU resin. The TPU beads can be widely applied in the fields of vibration-absorptive materials, packaging materials, toys for children, sporting goods, aviation models, heat insulating materials, automotive interior materials, etc.

Owner:CHANGZHOU SHUNXIANG NEW MATERIAL TECH CO LTD

Compositions for the preparation of void-containing articles

ActiveUS7273894B2Efficiently formedEfficient voidingSynthetic resin layered productsFoundry mouldsPolyesterCellulose

Disclosed are novel compositions for the preparation of void-containing articles comprising a polymer matrix and a voiding agent The voiding agent comprises at least one first polymer and at least one second polymer, which are selected on the basis of physical properties such as glass transition temperature, tensile modulus, melting point, surface tension, and melt viscosity. Shaped articles such as sheet, film, bottles, tubes, labels, and sleeves may prepared from these compositions. Also disclosed are polyester shrink films prepared using a voiding agent comprising a novel blend of cellulosic and olefinic polymers. The resulting shrink films have better opacity, lower density, reduced shrink force, and improved printability as compared with most standard voiding agents. The films are useful for sleeve label and other shrink film applications and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations.

Owner:EASTMAN CHEM CO

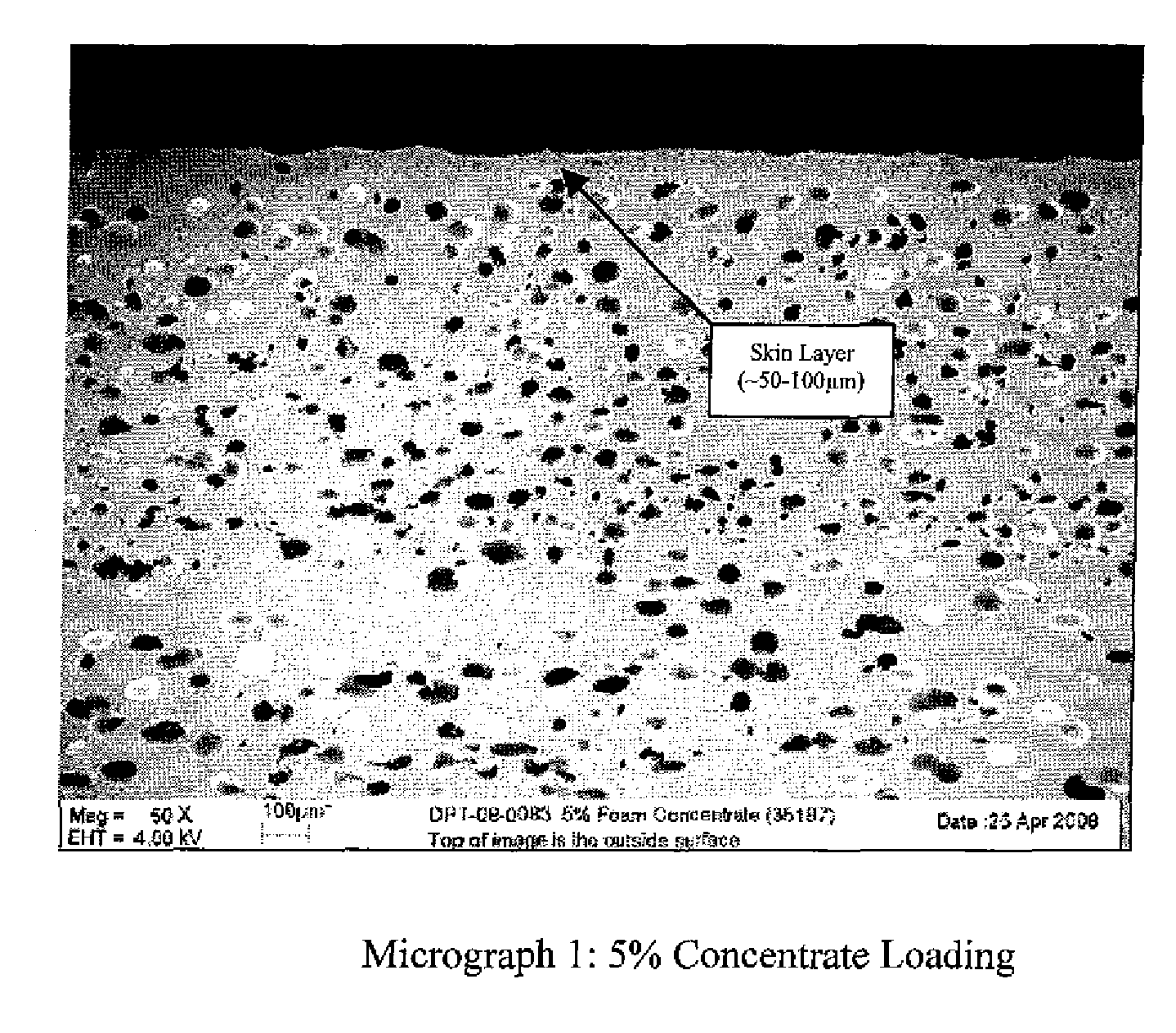

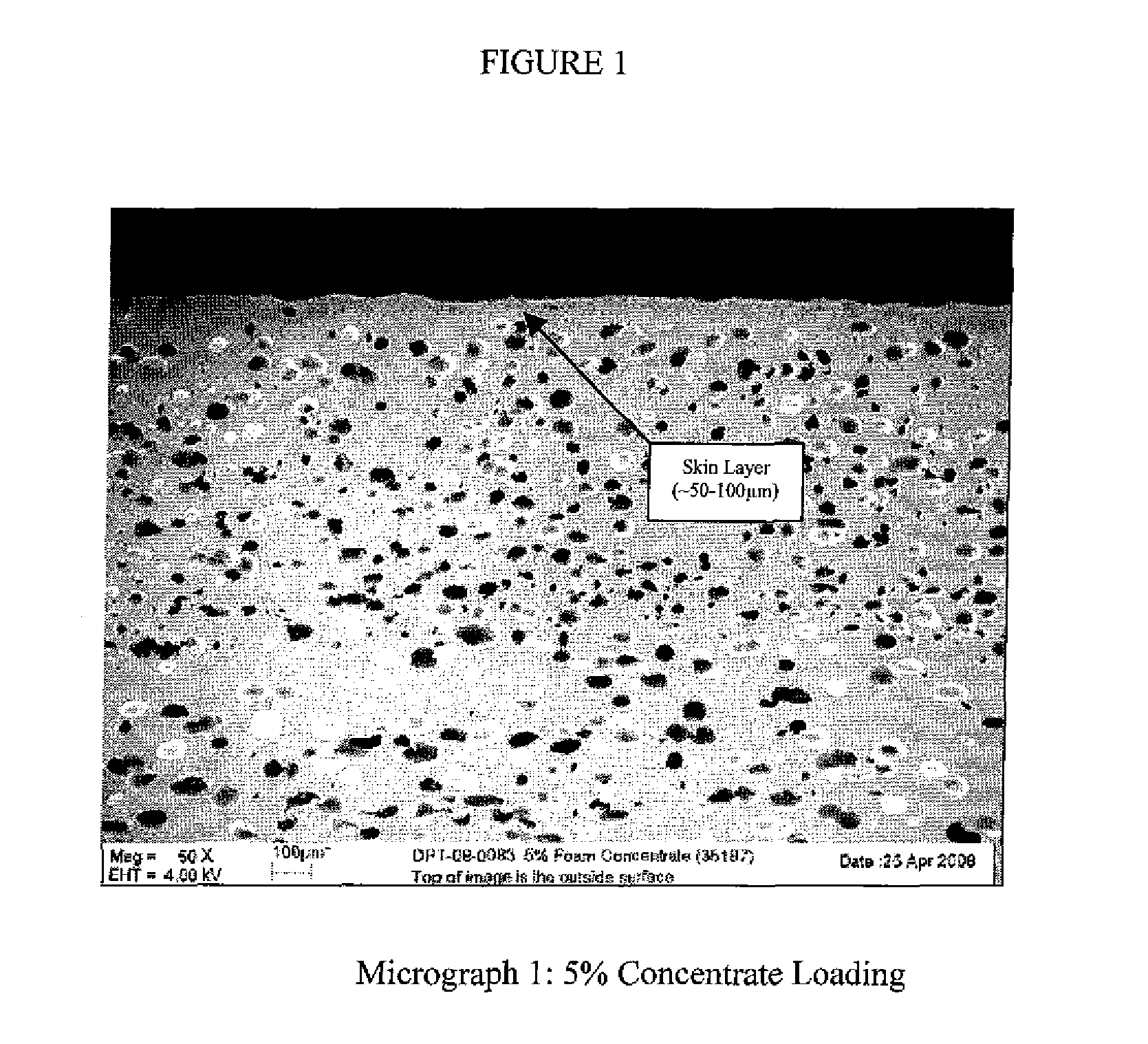

Foamed polyvinylidene fluoride structure

InactiveUS20120045603A1Improve impact resistanceImprove hysteresisLayered productsFlexible pipesHysteresisFoaming agent

The invention relates to a foamed fluoropolymer, preferably a polyvinylidene fluoride (PVDF) structure, such as from Kynar® resins. The foamed structure is continuous self-supporting, sized, and has a dense skin. The foamed structure is manufactured in a process using foaming agents and nucleating agents. The structure is sized into a specific shape during the manufacturing process—requiring a good melt viscosity of the PVDF foam. In one process, a master batch containing the nucleating agent is used. The foamed article could be a sheet, film, profile, tube, pipe, article, rod foam-core structure, or other self-supporting shape. Foamed tubes, pipes, rods, sheets and conduit are especially useful. The foamed structure of the invention provides added value by being lighter weight, more flexible, and more impact resistant than a comparable non-foamed PVDF structure. It also has increased hysteresis, increased insulation properties, reduced dielectric constant, and increased compressibility.

Owner:ARKEMA INC

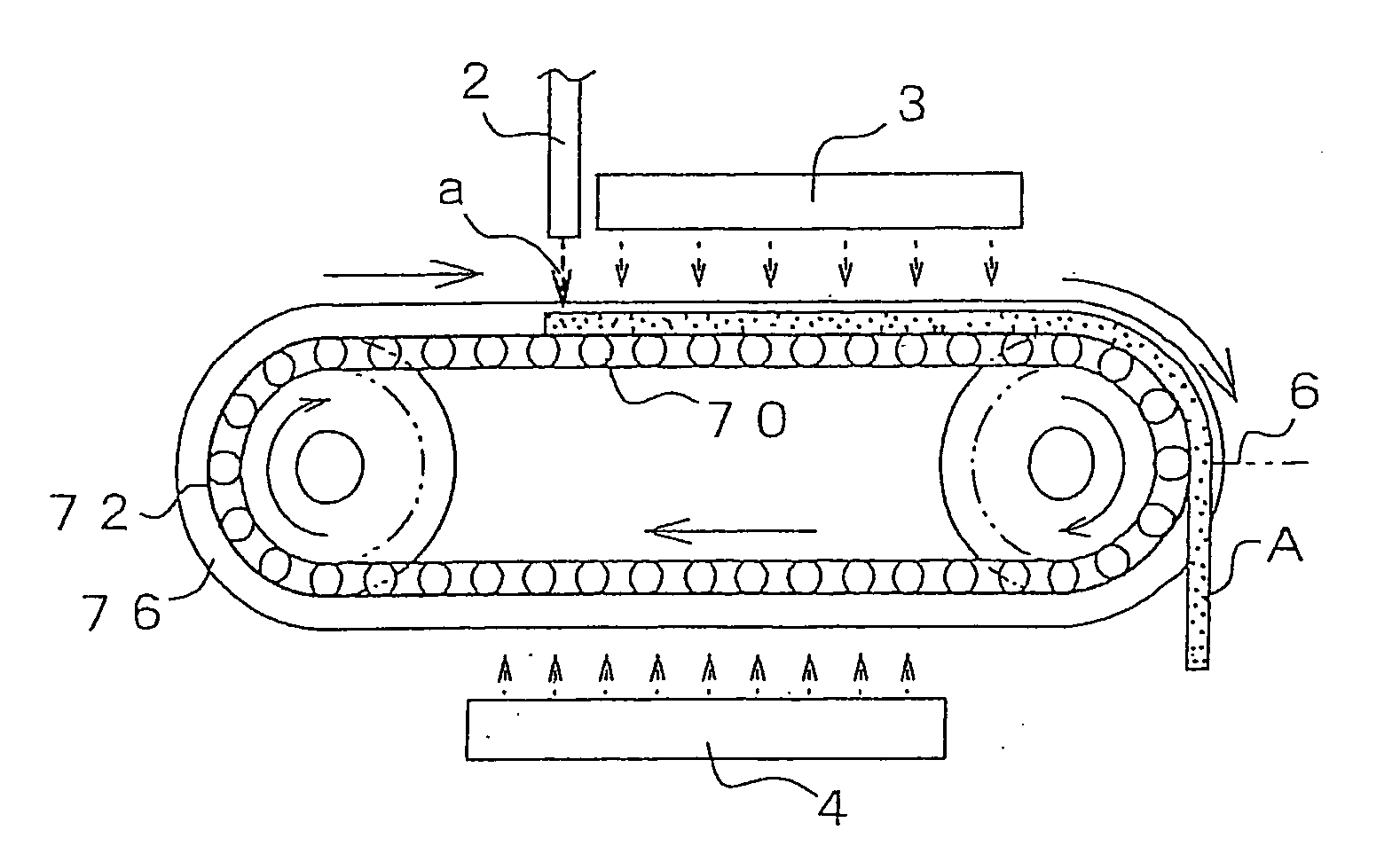

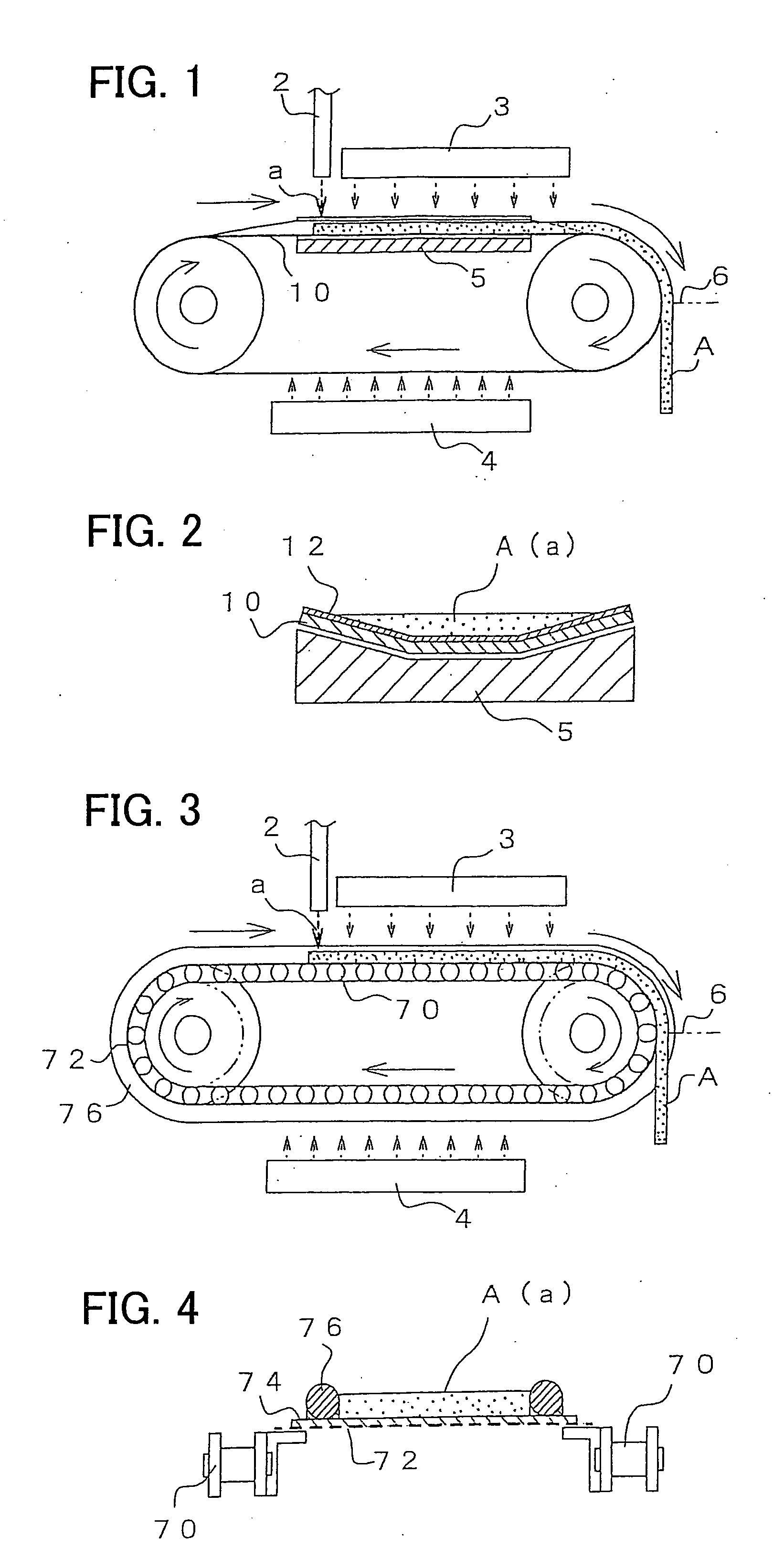

Production method of water-absorbent resin

ActiveUS20060167198A1Decrease productivityPromote aggregationChemical/physical/physico-chemical stationary reactorsProduction ratePolymer science

A production method of a water-absorbent resin includes the steps of: obtaining a hydrogel by supplying monomer liquid to a reaction device so that the monomer liquid is polymerized; and detaching the hydrogel from the reaction device, wherein the reaction device's surface in contact with the monomer liquid at a position where polymerization occurs is made of a fluororesin having a melt viscosity of less than 1×108 poise at 380° C. On this account, it is possible to obtain a water-absorbent resin having less amounts of an extractable content with high productivity and it is possible to carry out continuous production for an extended period of time.

Owner:NIPPON SHOKUBAI CO LTD

Compositions for the preparation of void-containing articles

InactiveUS20070004813A1Improve performanceEfficient voidingLayered productsFoundry mouldsPolyesterCellulose

Disclosed are novel compositions for the preparation of void-containing articles comprising a polymer matrix and a voiding agent The voiding agent comprises at least one first polymer and at least one second polymer, which are selected on the basis of physical properties such as glass transition temperature, tensile modulus, melting point, surface tension, and melt viscosity. Shaped articles such as sheet, film, bottles, tubes, labels, and sleeves may prepared from these compositions. Also disclosed are polyester shrink films prepared using a voiding agent comprising a novel blend of cellulosic and olefinic polymers. The resulting shrink films have better opacity, lower density, reduced shrink force, and improved printability as compared with most standard voiding agents. The films are useful for sleeve label and other shrink film applications and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations.

Owner:EASTMAN CHEM CO

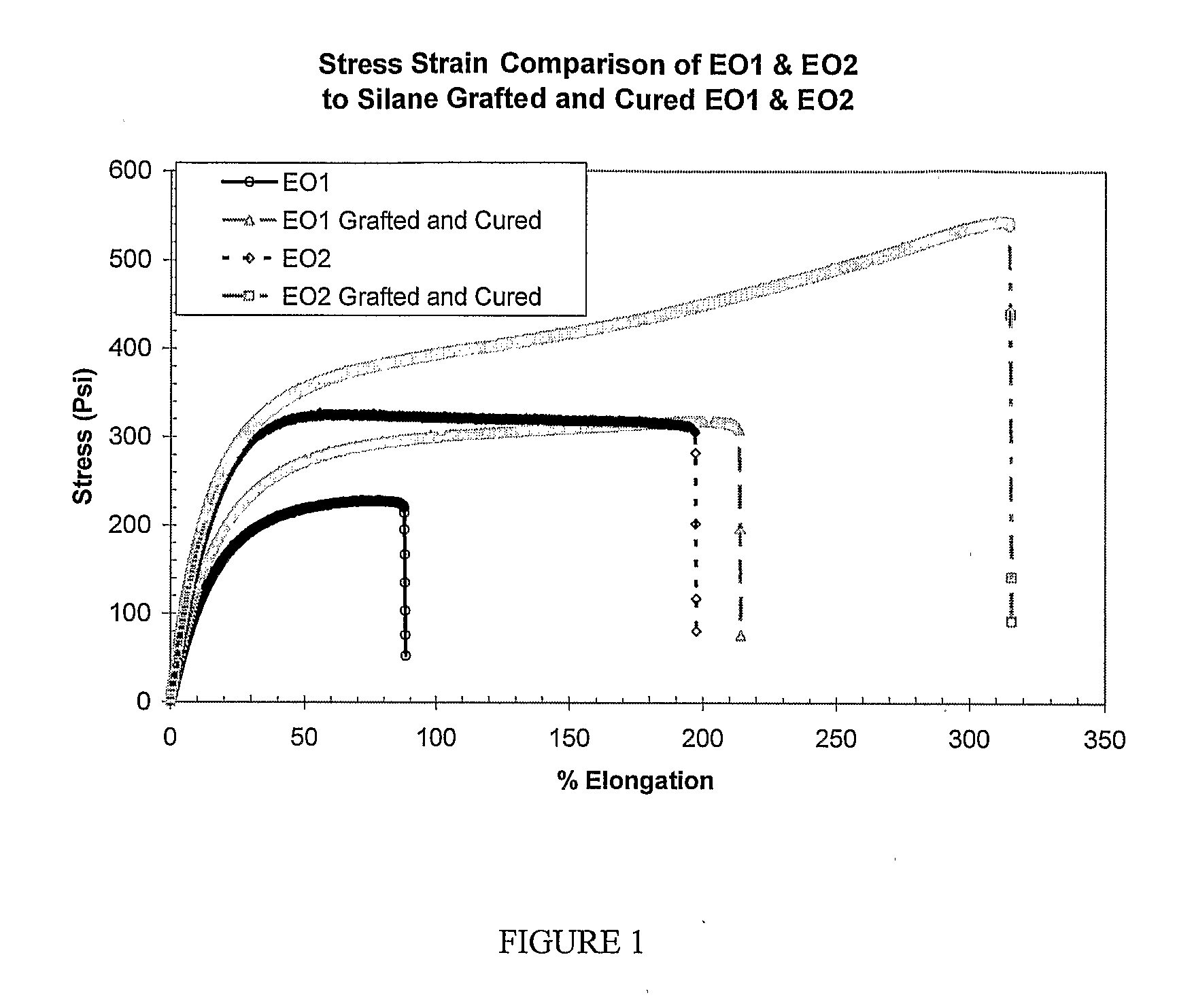

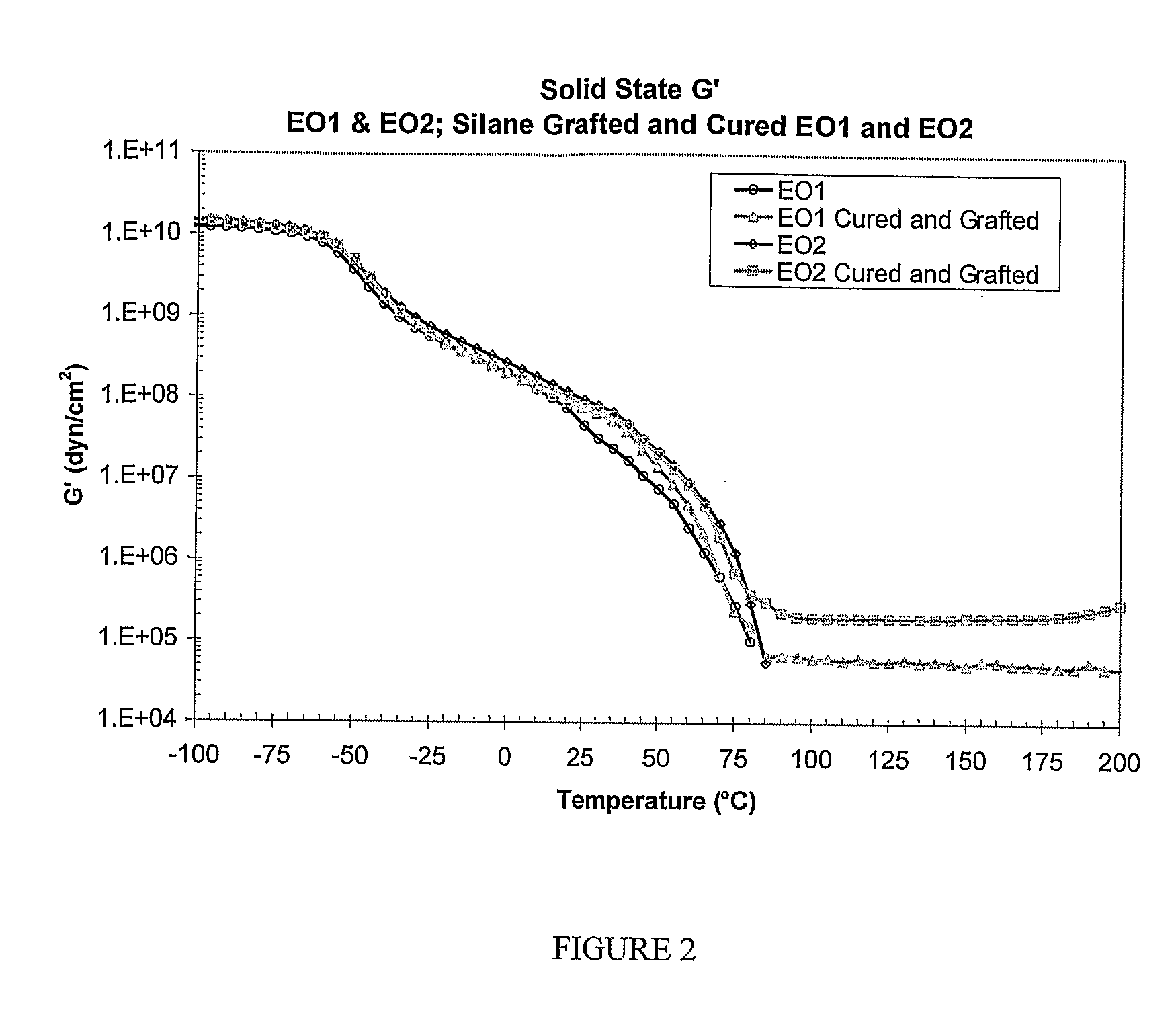

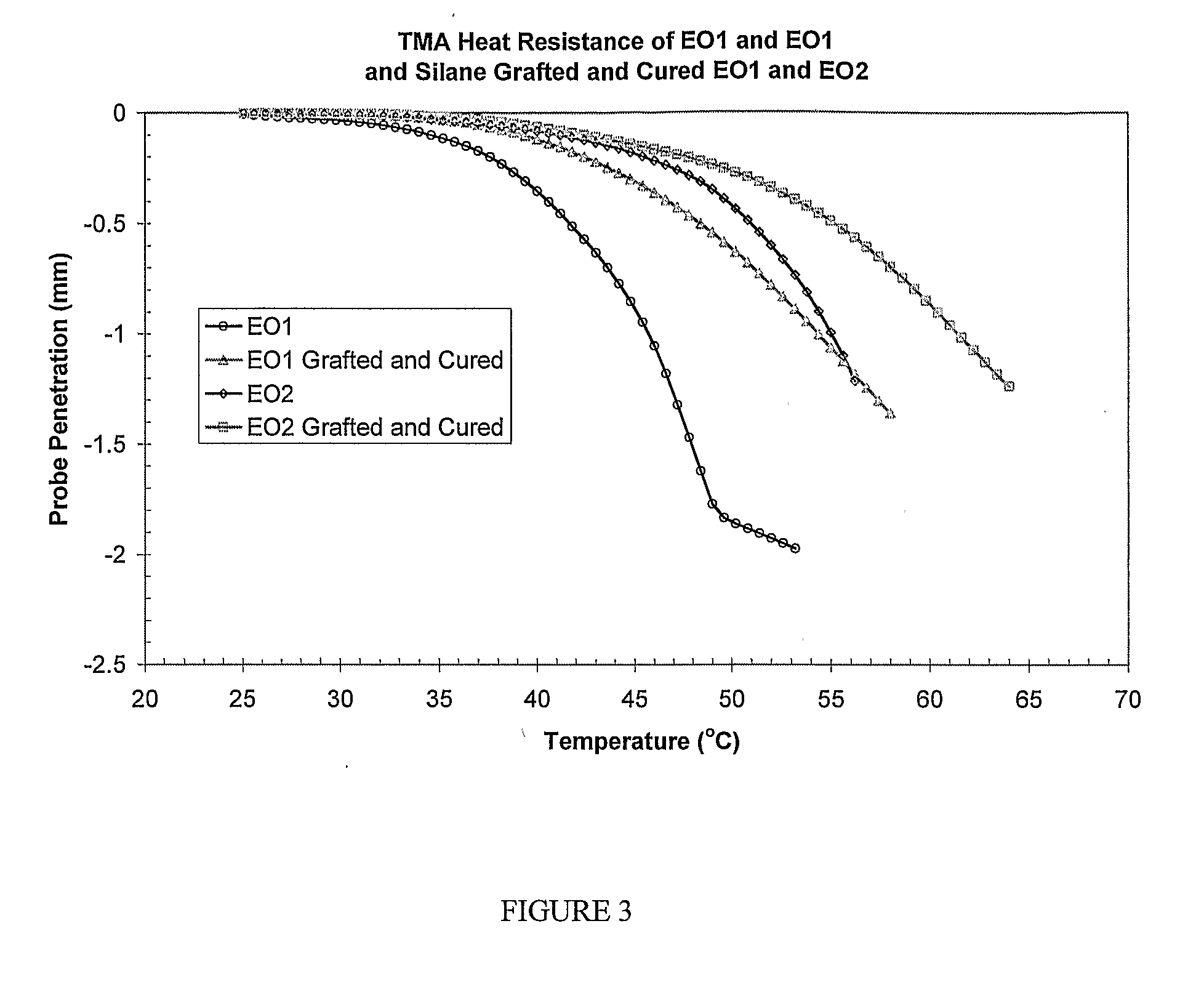

Silane-Grafted Olefin Polymers, Compositions and Articles Prepared Therefrom, and Methods For Making the Same

ActiveUS20080167421A1Improve adhesionReduce crystallinitySpecial tyresGraft polymer adhesivesSilane compoundsPolyolefin

The invention relates compositions containing at least one silane-grafted polyolefin, and in particular, to compositions containing at least one silane-grafted ethylene / α-olefin polymer, which has a melt viscosity less than 50,000 cP, and adhesives containing the same. In one embodiment, the at least one silane-grafted ethylene / α-olefin polymer is formed from an ethylene / α-olefin polymer that has a molecular weight distribution from 1 to 3.5. The invention also relates to the preparation of the silane-grafted polymers, by reacting, for example, an ethylene / α-olefin polymer with at least one silane compound and at least one initiator.

Owner:DOW GLOBAL TECH LLC

Production method of polyamide

ActiveUS7138482B2Rapid and simple estimationRapid and simple estimation of propertyPolymer sciencePolyamide

In the production method of polyamide of the present invention, the mole balance at a set point during melt polymerization is estimated from a pre-established equation for calculating the mole balance during melt polymerization from a melt viscosity. On the basis of the estimated mole balance, the subsequent conditions of melt polymerization of a batch and the polymerization conditions of the next and subsequent batches are determined. In addition, the mole balance, molecular weight and relative viscosity of melt-polymerized polyamide are estimated from pre-established equations each for respectively calculating the mole balance, molecular weight and relative viscosity at the end point of melt polymerization from the melt viscosity. The conditions for solid phase-polymerizing the melt-polymerized polyamide are determined on the basis of estimated values.

Owner:MITSUBISHI GAS CHEM CO INC

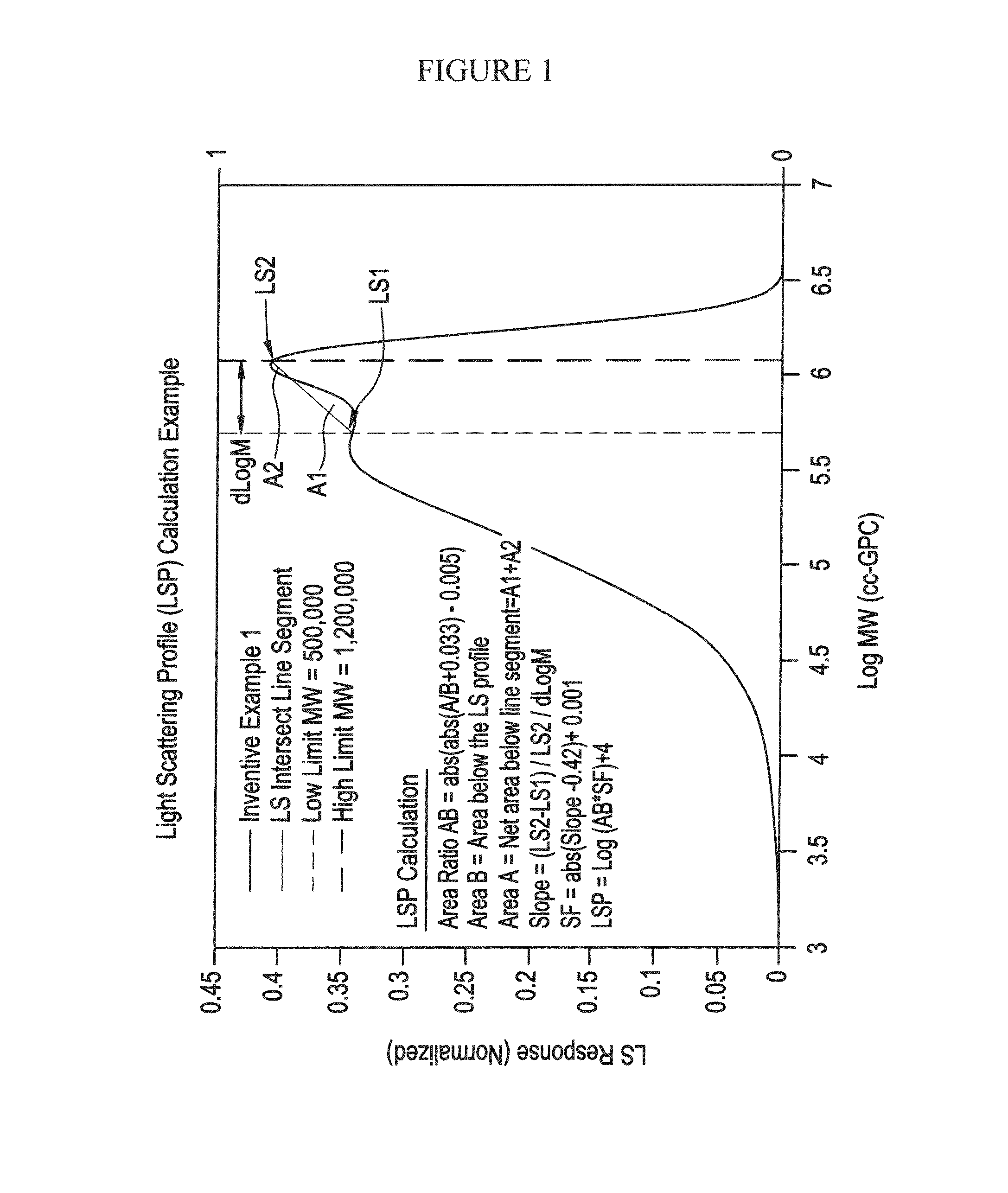

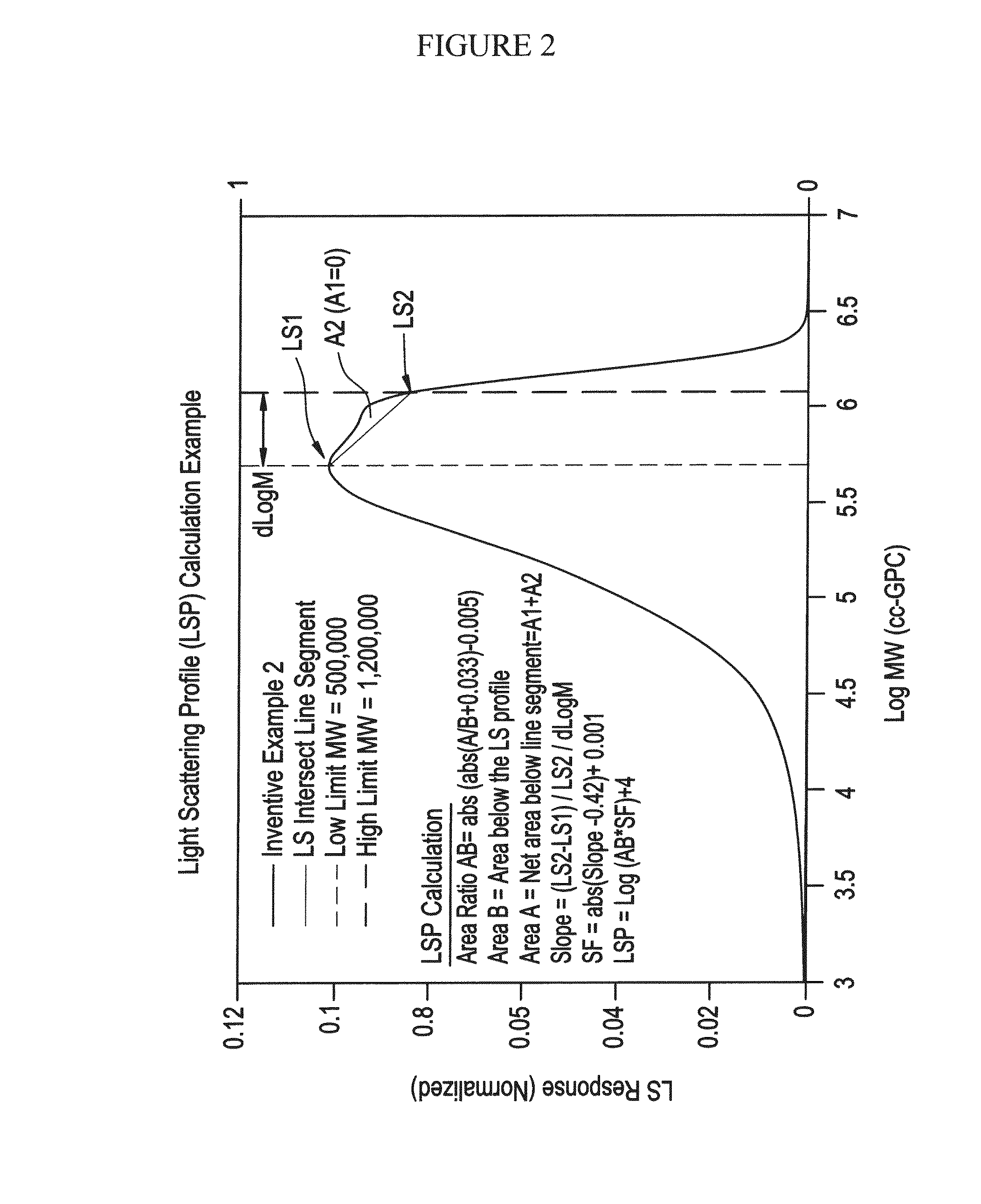

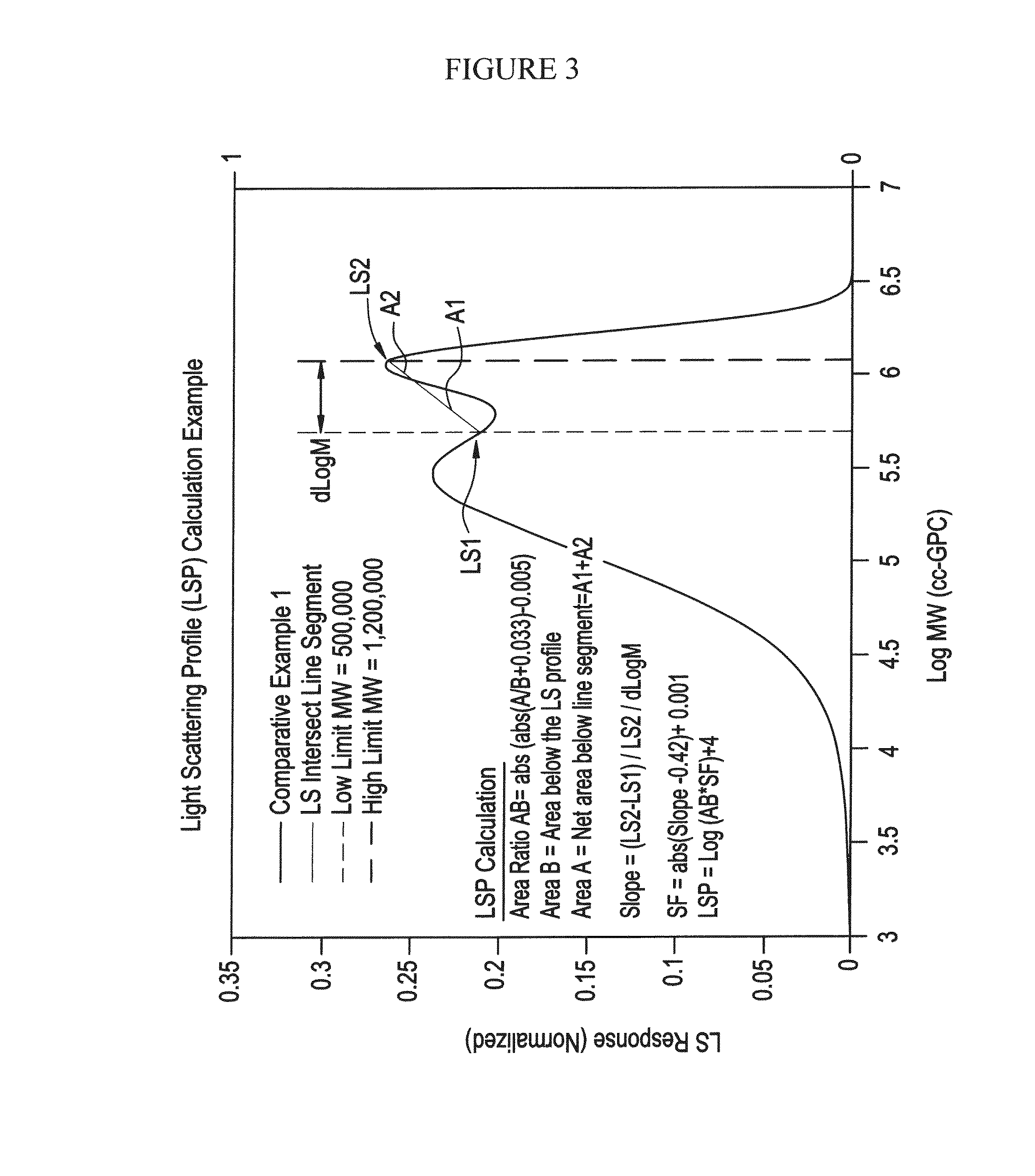

Ethylene-based polymers and processes to make the same

An ethylene-based polymer, which is a low density polyethylene (LDPE), obtained by free radical polymerization of ethylene, and wherein the LDPE has a GPC parameter “LSP” less than 1.60.An ethylene-based polymer that comprises the following features:a) at least 0.1 amyl groups per 1000 total carbon atoms;b) a melt index of 0.01 to 0.3;c) a z-average molecular weight of Mz (conv.) of greater than 350,000 g / mol and less than 425,000 g / mol;d) a gpcBR value from 1.50 to 2.05, ande) a MWD(conv) [Mw(conv) / Mn(conv)] from 6 to 9.An ethylene-based polymer that comprises the following features:a) at least 0.1 amyl groups per 1000 total carbon atoms;b) a melt viscosity ratio (V0.1 / V100), at 190° C., greater than, or equal to, 58;c) a melt viscosity at 0.1 rad / s, 190° C., greater than, or equal to, 40,000 Pa·s, andd) a gpcBR value from 1.50 to 2.25.

Owner:DOW GLOBAL TECH LLC

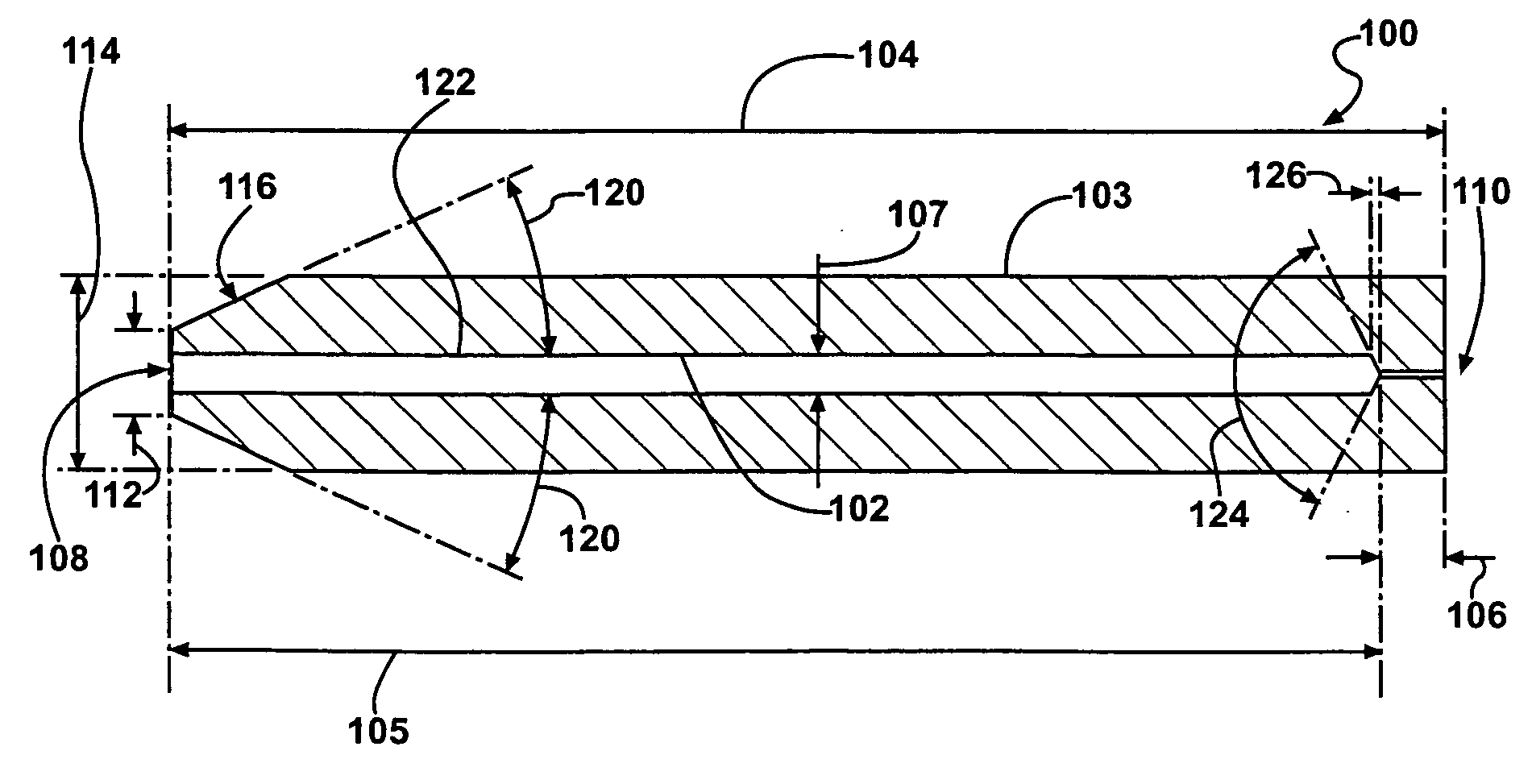

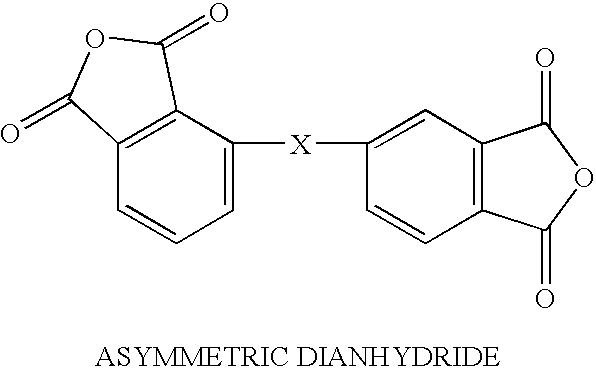

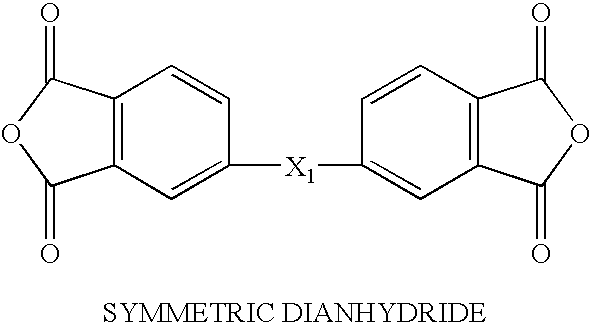

Solvent free low-melt viscosity imide oligomers and thermosetting polyimide composites

This invention relates to the composition and a solvent-free process for preparing novel imide oligomers and polymers specifically formulated with effective amounts of a dianhydride such as 2,3,3′,4-biphenyltetra carboxylic dianydride (a-BPDA), at least one aromatic diamine and an endcapped of 4-phenylethynylphthalic anhydride (PEPA) or nadic anhydride to produce imide oligomers that possess a low-melt viscosity of 1–60 poise at 260–280° C. When the imide oligomer melt is cured at about 371° C. in a press or autoclave under 100–500 psi, the melt resulted in a thermoset polyimide having a glass transition temperature (Tg) equal to and above 310° C. A novel feature of this process is that the monomers; namely the dianhydrides, diamines and the endcaps, are melt processable to form imide oligomers at temperatures ranging between 232–280° C. (450–535° F.) without any solvent. These low-melt imide oligomers can be easily processed by resin transfer molding (RTM), vacuum-assisted resin transfer molding (VARTM) or the resin infusion process with fiber preforms e.g. carbon, glass or quartz preforms to produce polyimide matrix composites with 288–343° C. (550–650° F.) high temperature performance capability.

Owner:NASA

Inorganic powder highly filled polyvinyl alcohol composite material and preparation method thereof

ActiveCN102643497AThermoplastic processabilityReduce hydrogen bondingPVA - Polyvinyl alcoholUltimate tensile strength

The invention discloses an inorganic powder highly filled polyvinyl alcohol composite material, which consists of the following components in parts by weight: 10-60 parts of polyvinyl alcohol, 30-80 parts of inorganic powder, 5-30 parts of plasticizing agent and 5-15 parts of flow modifying agent. Further, the composite material has the tensile strength of 17.0-75.0 MPa and the breaking elongation of 70-450%, and the melt viscosity is 1.0*10<2> to 5.0*10<3> Pa s at 180 DEG C when the shearing rate is 10<2>-10<3> s<-1>. The invention further discloses a preparation method of the inorganic powder highly filled polyvinyl alcohol composite material. By using the inorganic powder highly filled polyvinyl alcohol composite material and the preparation method, not only can inorganic powder highly filled polyvinyl alcohol be realized, the cost of the composite material be greatly reduced, but also the flowability of the composite material can be guaranteed; the favorable thermoplastic processing of the composite material is realized; the obtained composite material is excellent in combination property; products such as a fiber, a sheet and a thin film can be prepared through a routine thermoplastic processing method; and the inorganic powder highly filled polyvinyl alcohol composite material is used for the fields of writing paper, printing paper, instrument and meter packaging films, wallpaper, heat-insulating gaskets, toys and the like. The preparation method provided by the invention is simple in process and short in flow and industrial production is easy to realize.

Owner:SICHUAN UNIV

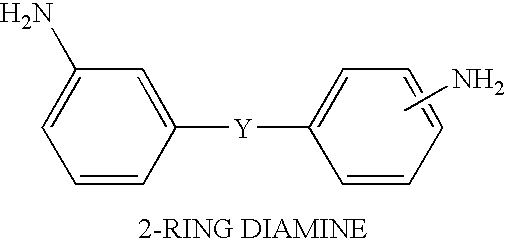

Method to prepare processable polyimides with reactive endogroups using 1,3-bis(3-aminophenoxy)benzene

InactiveUS6288209B1Improved solvent resistance and modulus and elevated use temperatureImproved melt processabilityNon-fibrous pulp additionSynthetic resin layered productsPolymer scienceBackbone chain

Polyimide copolymers were obtained containing 1,3-bis(3-aminophenoxy)benzene (APB) and other diamines and dianhydrides and terminating with the appropriate amount of reactive endcapper. The reactive endcappers studied include but should not be limited to 4-phenylethynyl phthalic anhydride (PEPA), 3-aminophenoxy-4'-phenylethynylbenzophenone (3-APEB), maleic anhydride (MA) and nadic anhydride (5-norbornene-2,3-dicarboxylic anhydride, NA). Homopolymers containing only other diamines and dianhydrides which are not processable under conditions described previously can be made processable by incorporating various amounts of APB, depending on the chemical structures of the diamines and dianhydrides used. By simply changing the ratio of APB to the other diamine in the polyimide backbone, a material with a unique combination of solubility, Tg, Tm, melt viscosity, toughness and elevated temperature mechanical properties can be prepared. The copolymers that result from using APB to enhance processability have a unique combination of properties that include low pressure processing (200 psi and below), long term melt stability (several hours at 300° C. for the phenylethynyl terminated polymers), high toughness, improved solvent resistance, improved adhesive properties, and improved composite mechanical properties. These copolyimides are eminently suitable as adhesives, composite matrices, moldings, films and coatings.

Owner:NASA

Method to prepare processable polyimides with reactive endgroups using 1,3-bis (3-aminophenoxy) benzene

InactiveUS6133401AImprove adhesionImprove composite effectSynthetic resin layered productsThin material handlingSolubilityAdhesive

Polyimide copolymers were obtained containing 1,3-bis(3-aminophenoxy)benzene (APB) and other diamines and dianhydrides and terminating with the appropriate amount of reactive endcapper. The reactive endcappers studied include but should not be limited to 4-phenylethynyl phthalic anhydride (PEPA), 3-aminophenoxy-4'-phenylethynylbenzophenone (3-APEB), maleic anhydride (MA) and nadic anhydride (5-norbornene-2,3-dicarboxylic anhydride, NA). Homopolymers containing only other diamines and dianhydrides which are not processable under conditions described previously can be made processable by incorporating various amounts of APB, depending on the chemical structures of the diamines and dianhydrides used. By simply changing the ratio of APB to the other diamine in the polyimide backbone, a material with a unique combination of solubility, Tg, Tm, melt viscosity, toughness and elevated temperature mechanical properties can be prepared. The copolymers that result from using APB to enhance processability have a unique combination of properties that include low pressure processing (200 psi and below), long term melt stability (several hours at 300 DEG C. for the phenylethynyl terminated polymers), high toughness, improved solvent resistance, improved adhesive properties, and improved composite mechanical properties. These copolyimides are eminently suitable as adhesives, composite matrices, moldings, films and coatings.

Owner:NAT AERONAUTICS & SPACE ADMINSTRATION NASA THE

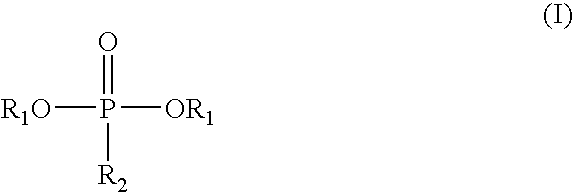

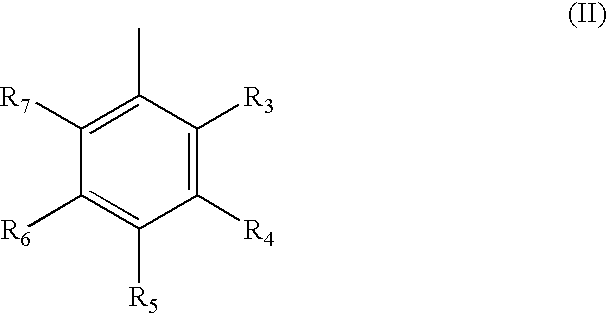

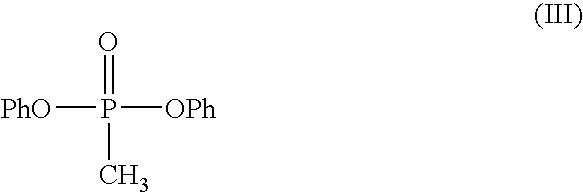

Method for the production of block copolycarbonate/phosphonates and compositions therefrom

Disclosed is a new method and compositions from the method consisting of block copolycarbonate / phosphonates that exhibit an excellent combination of flame resistance, hydrolytic stability, high Tg, low melt viscosity, low color and high toughness. Also disclosed are polymer mixtures or blends comprised of these block copolycarbonate / phosphonate compositions and commodity and engineering plastics and articles produced therefrom. Further disclosed are articles of manufacture produced from these materials, such as fibers, films, coated substrates, moldings, foams, adhesives and fiber-reinforced articles, or any combination thereof.

Owner:FRX POLYMERS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com