Patents

Literature

3381results about How to "High tear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

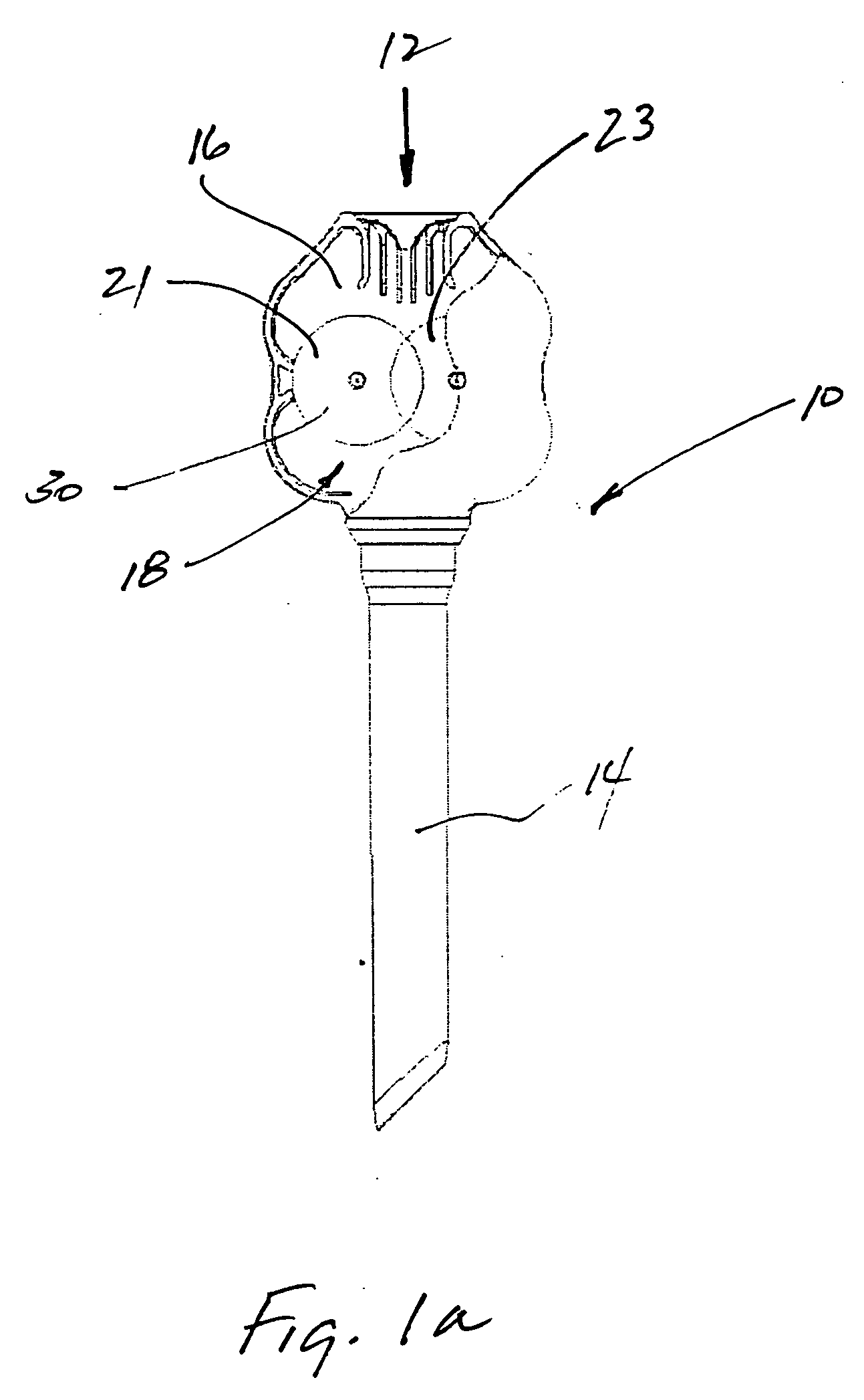

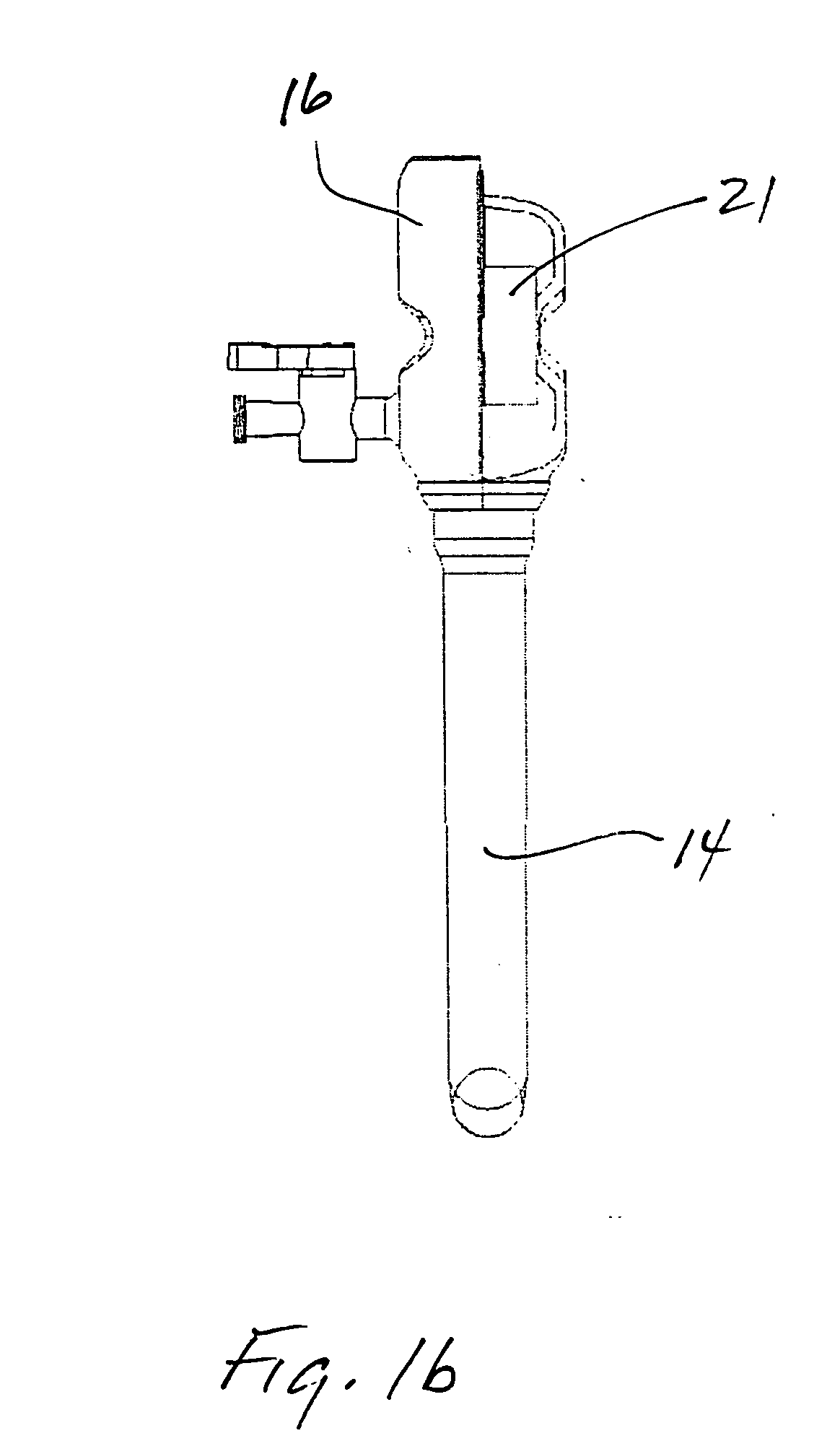

Surgical access system

InactiveUS20050020884A1High tear strengthLow durometerCannulasSurgical needlesSurgical departmentVALVE PORT

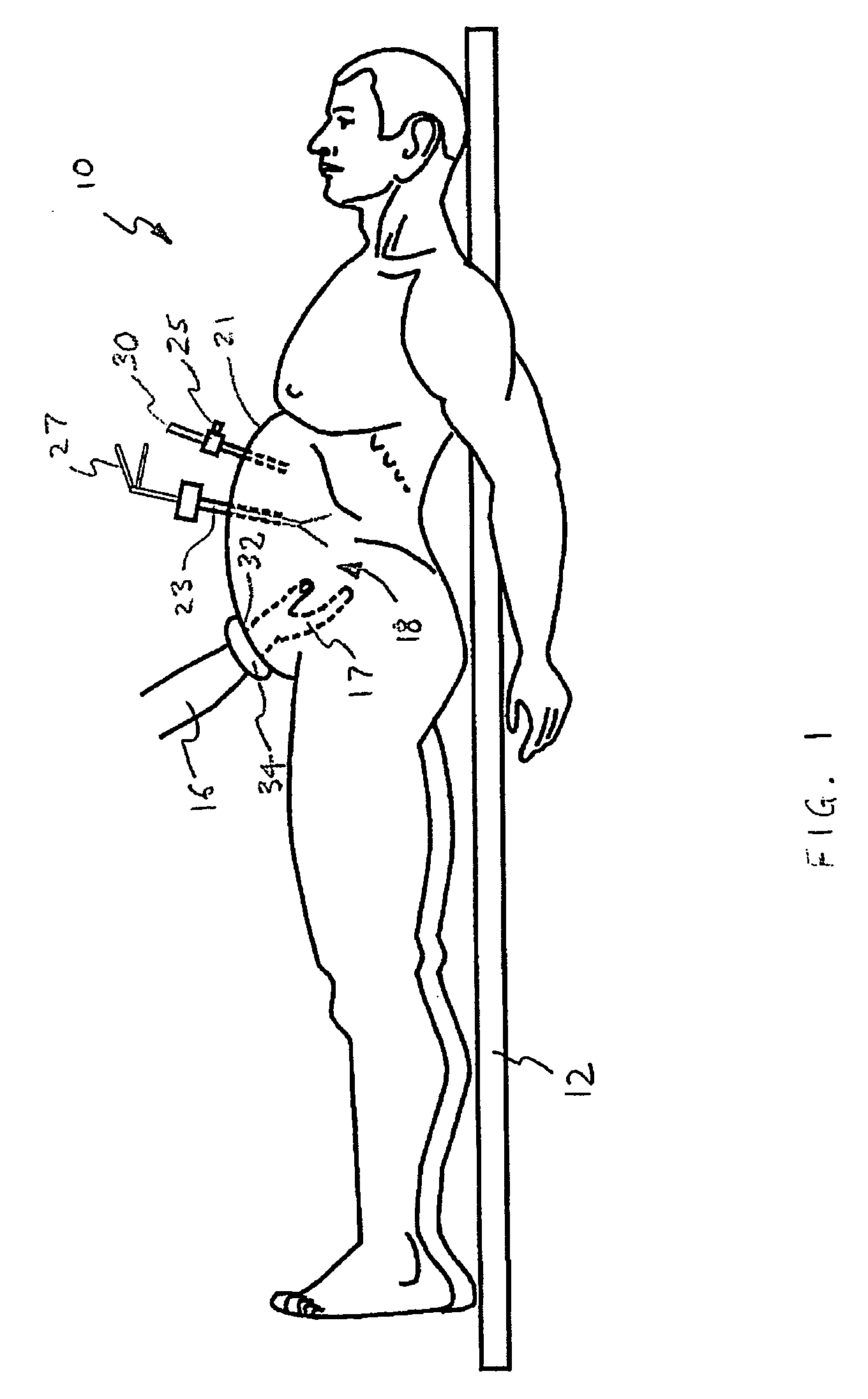

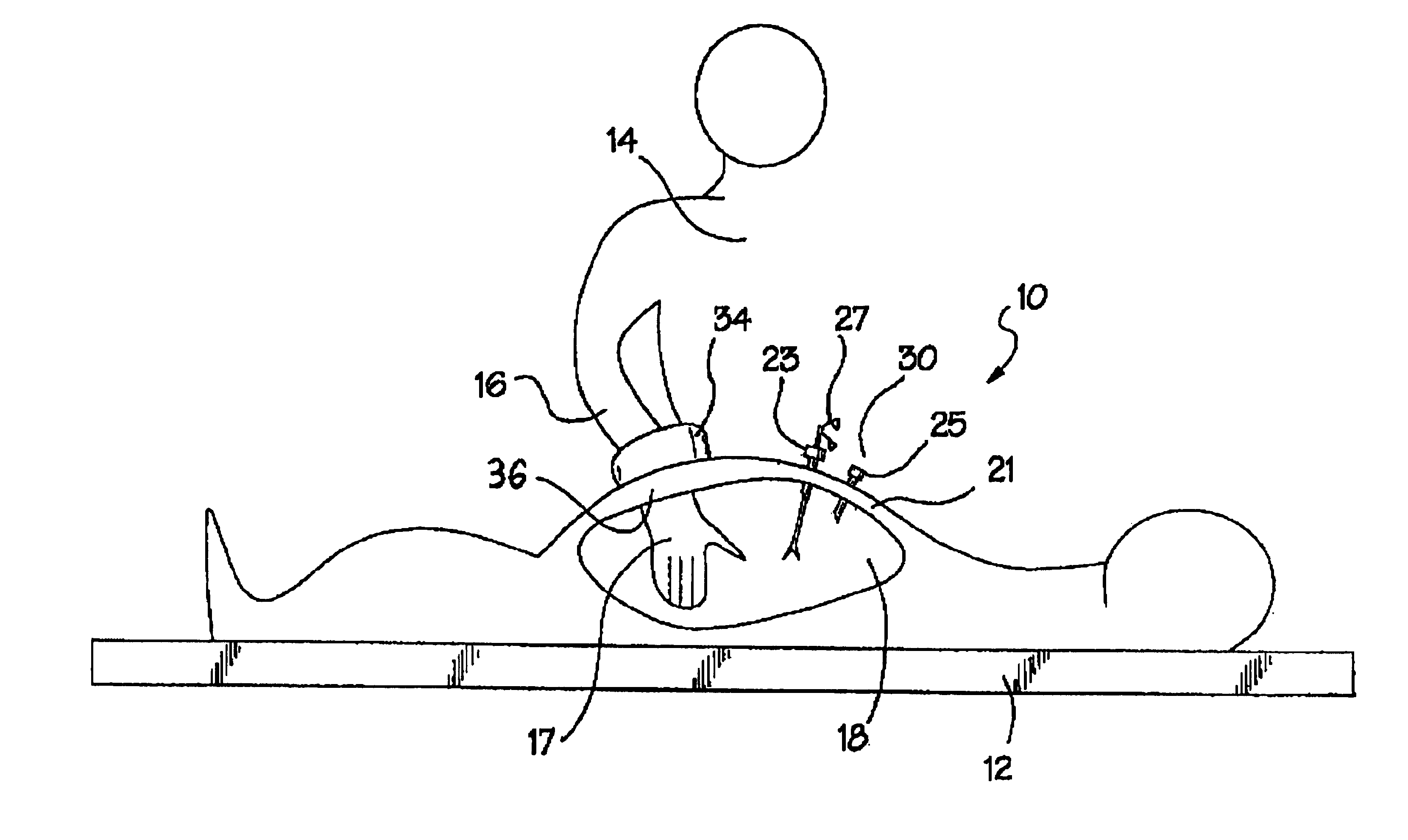

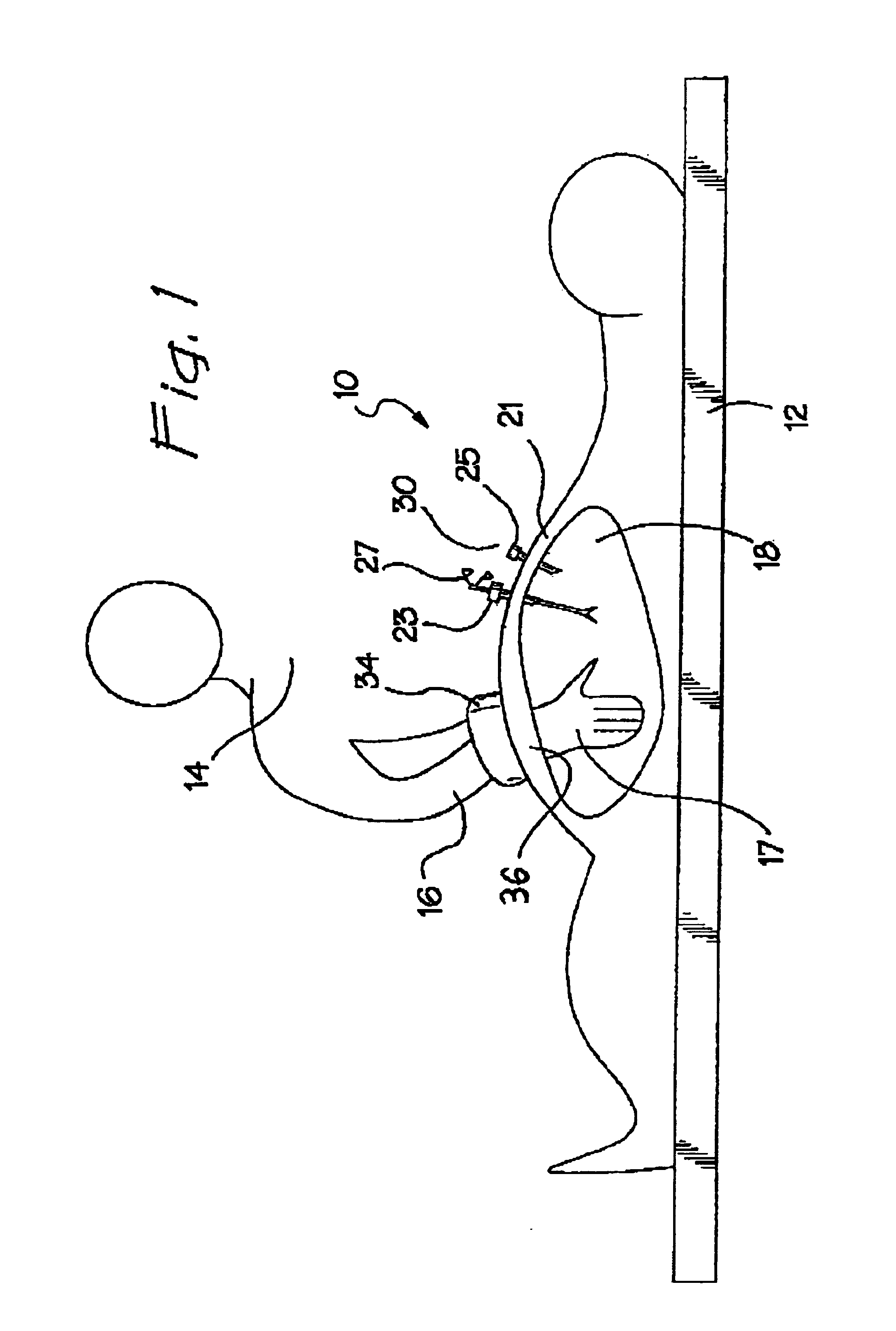

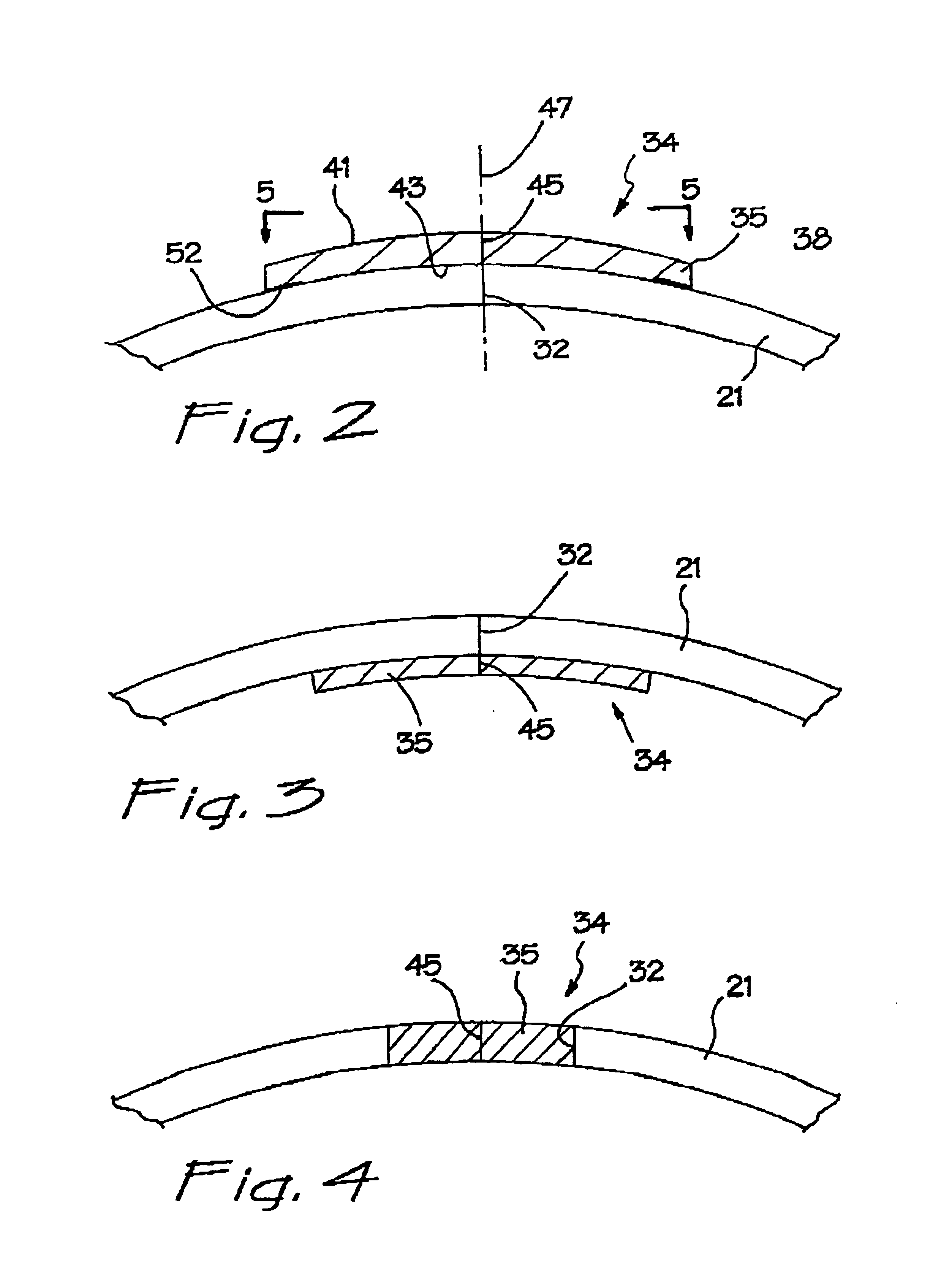

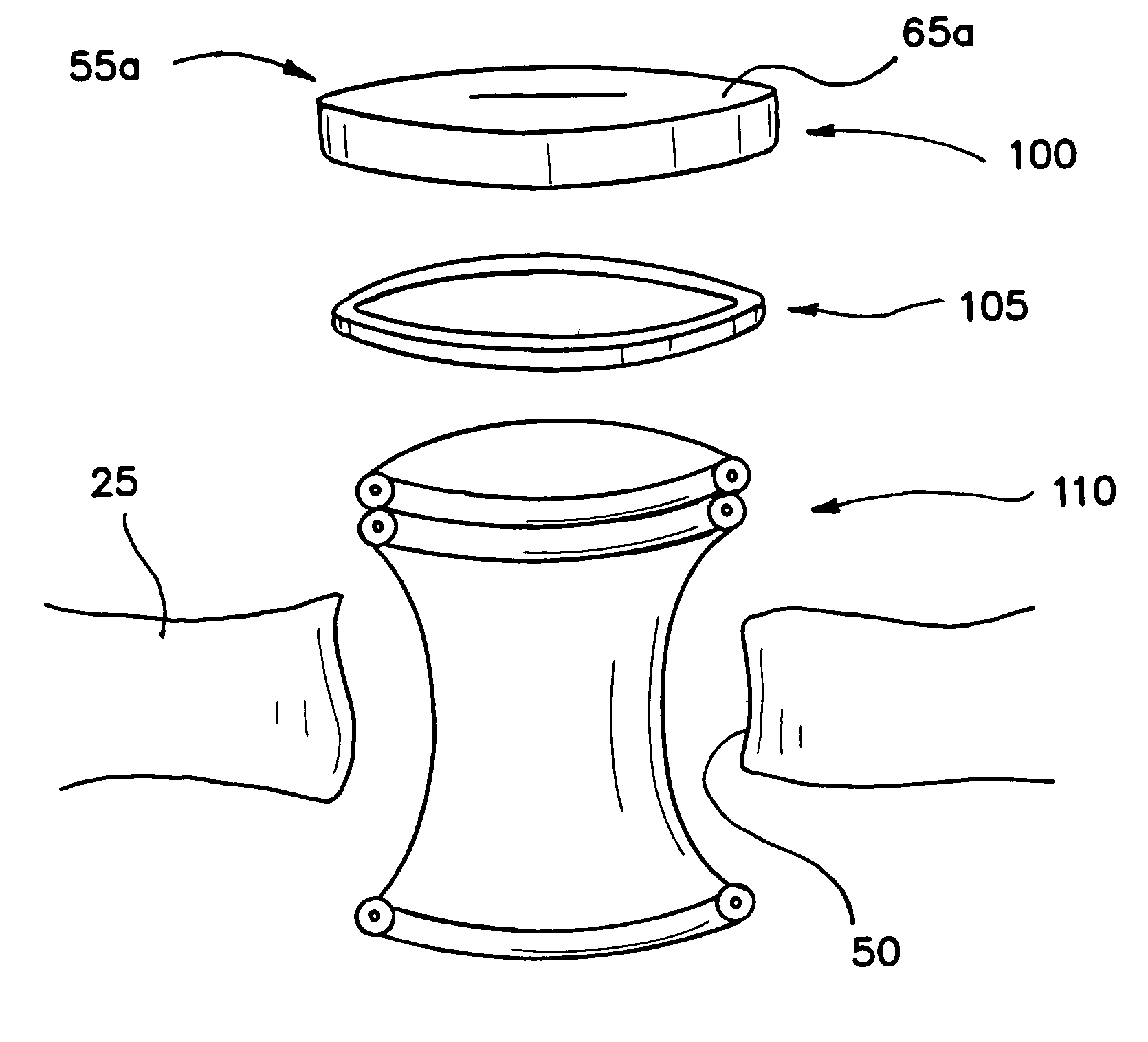

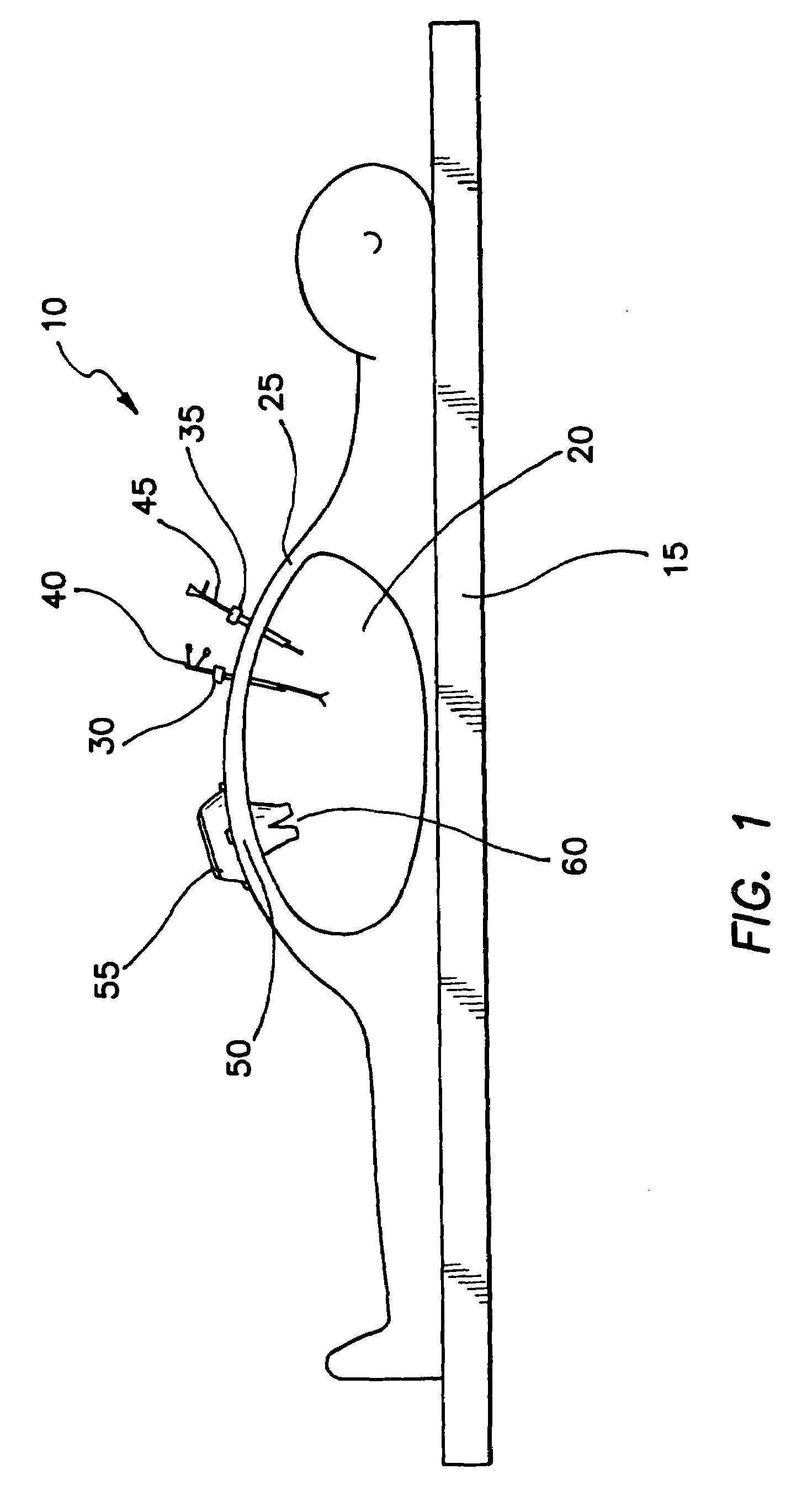

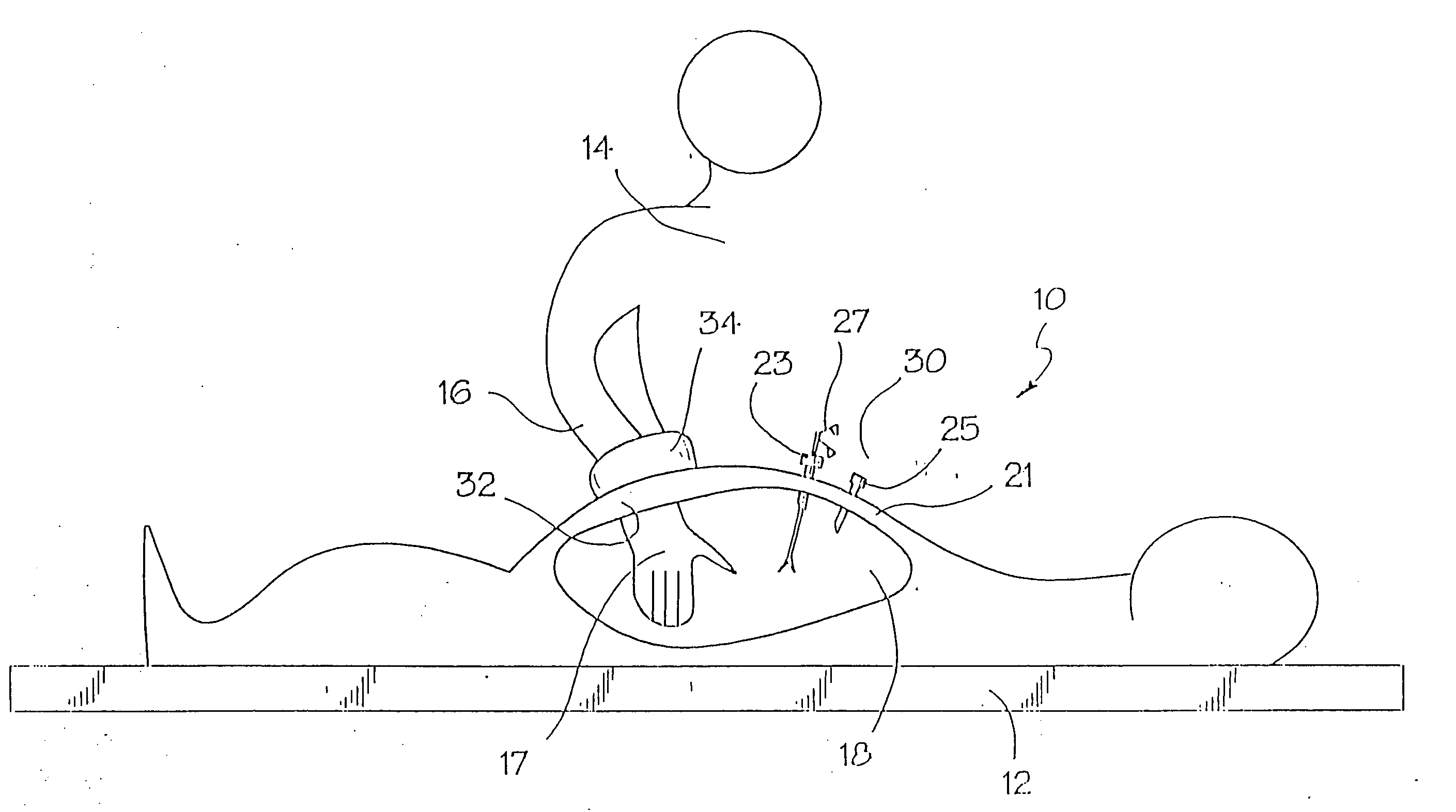

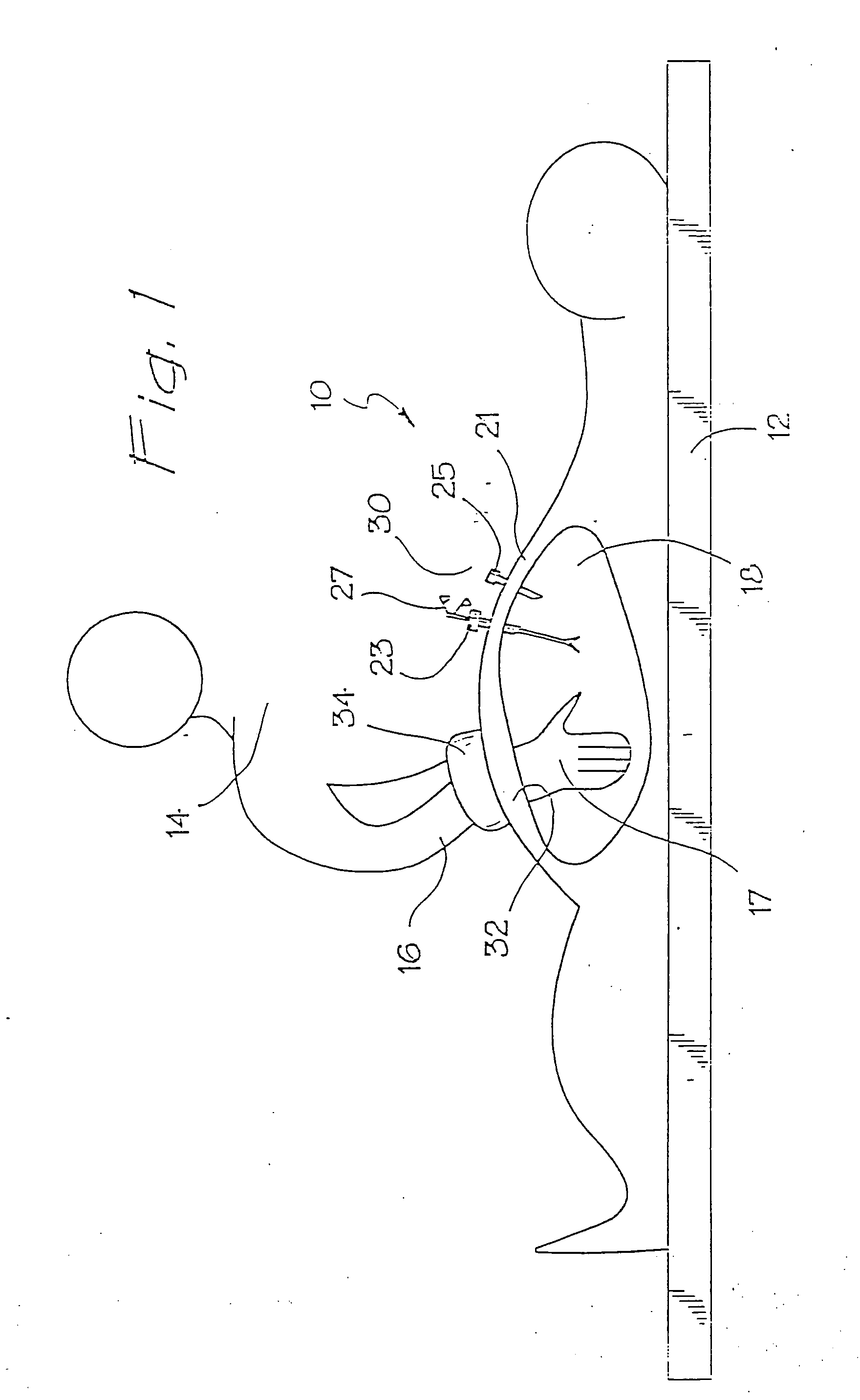

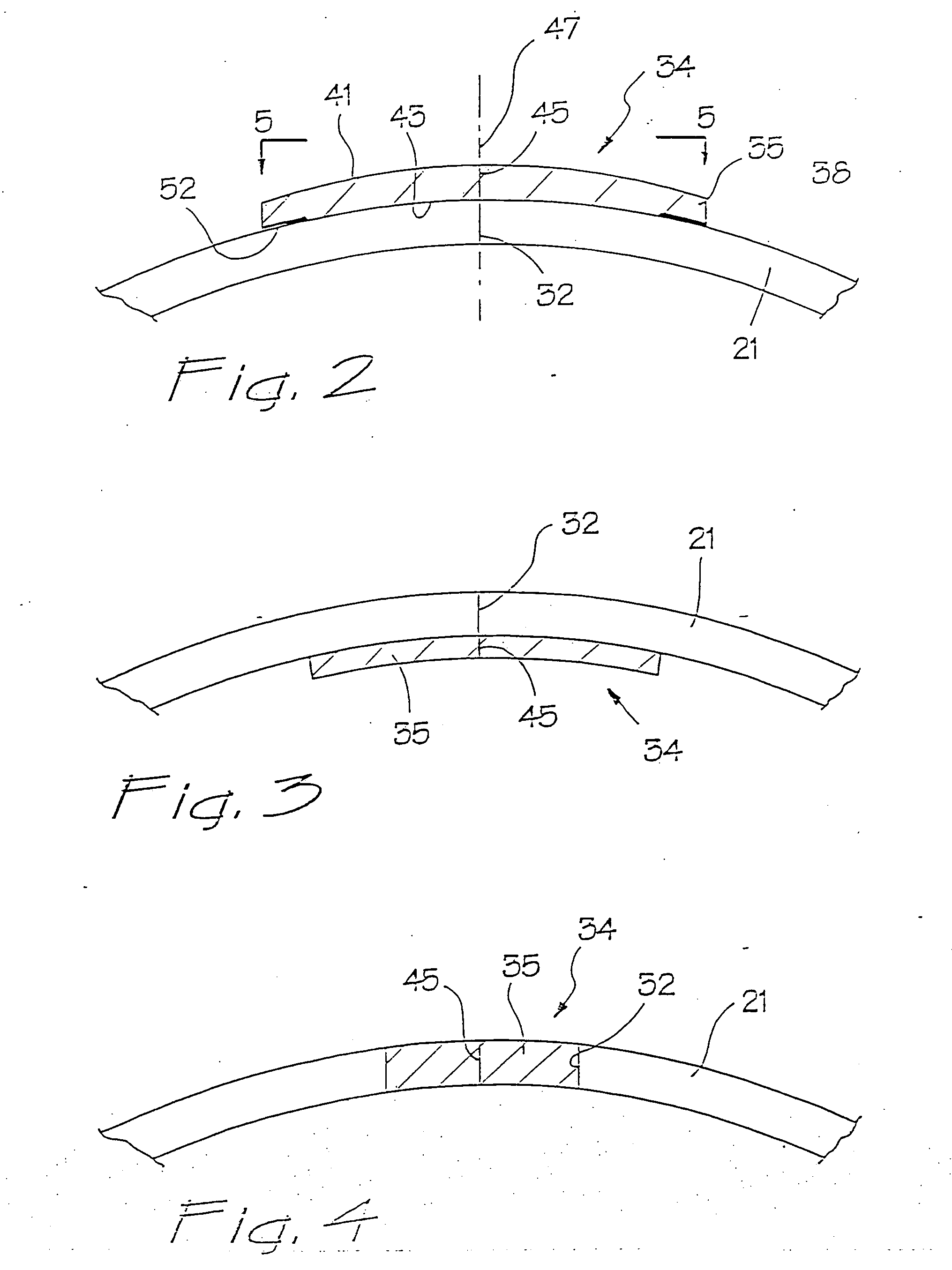

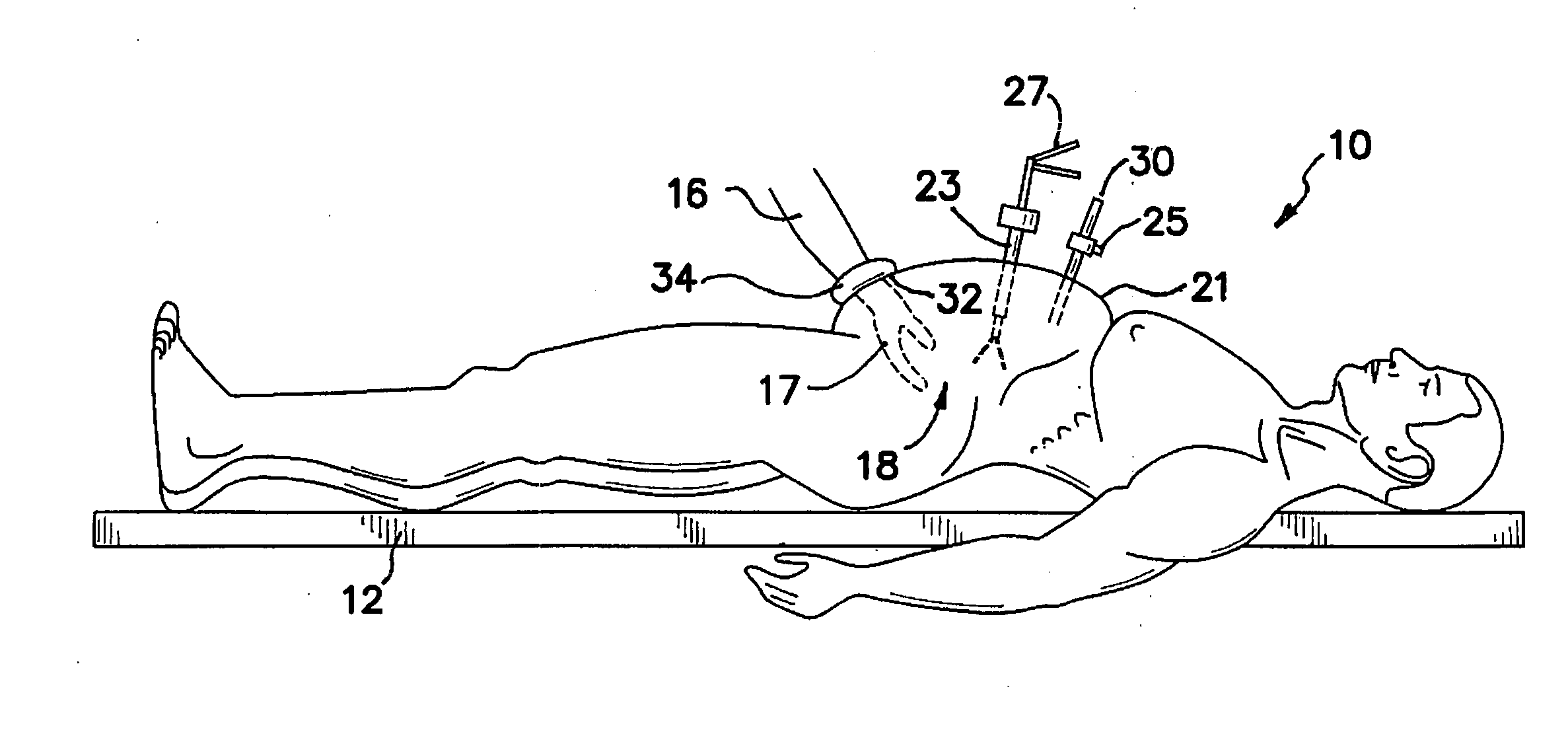

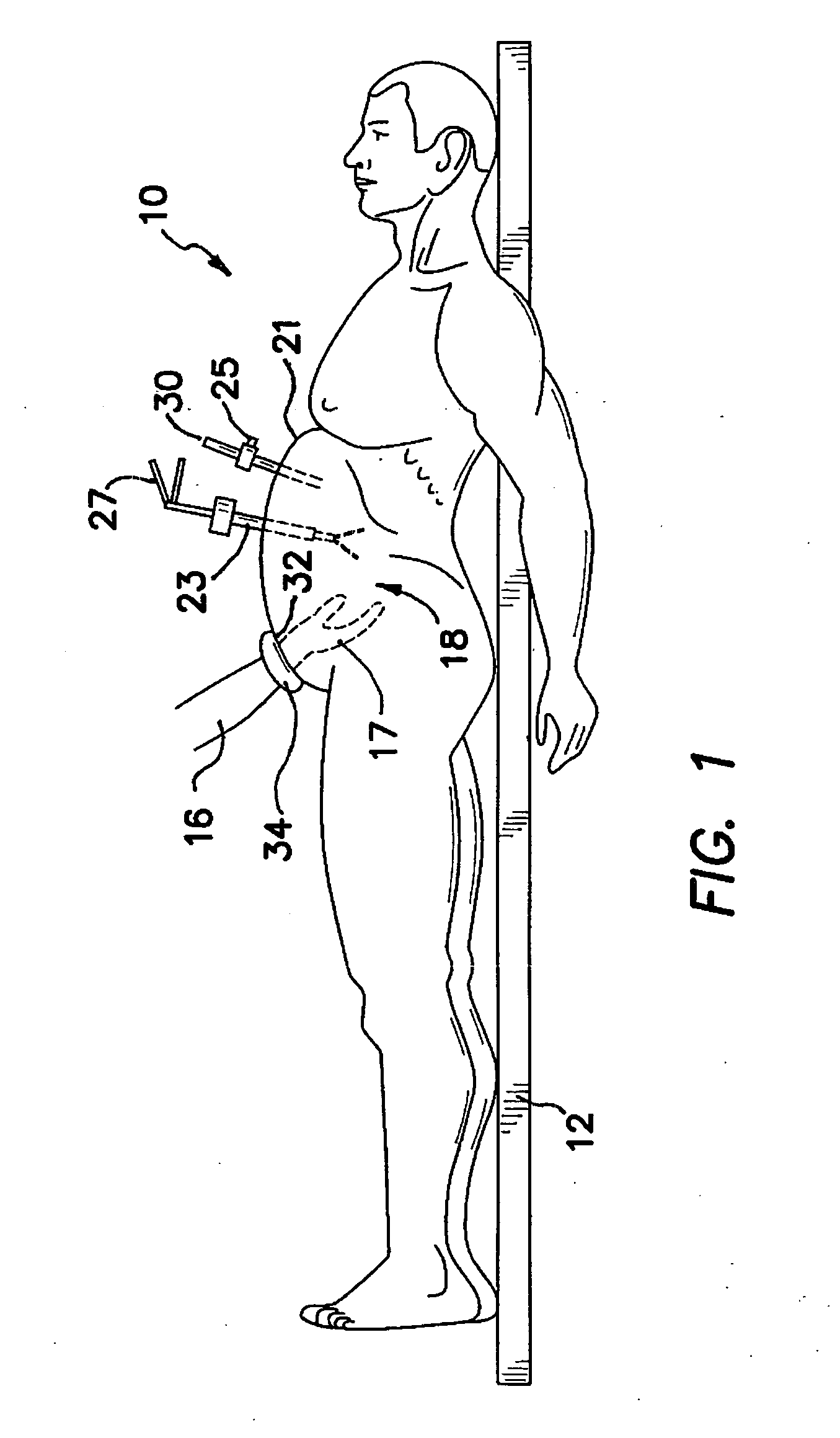

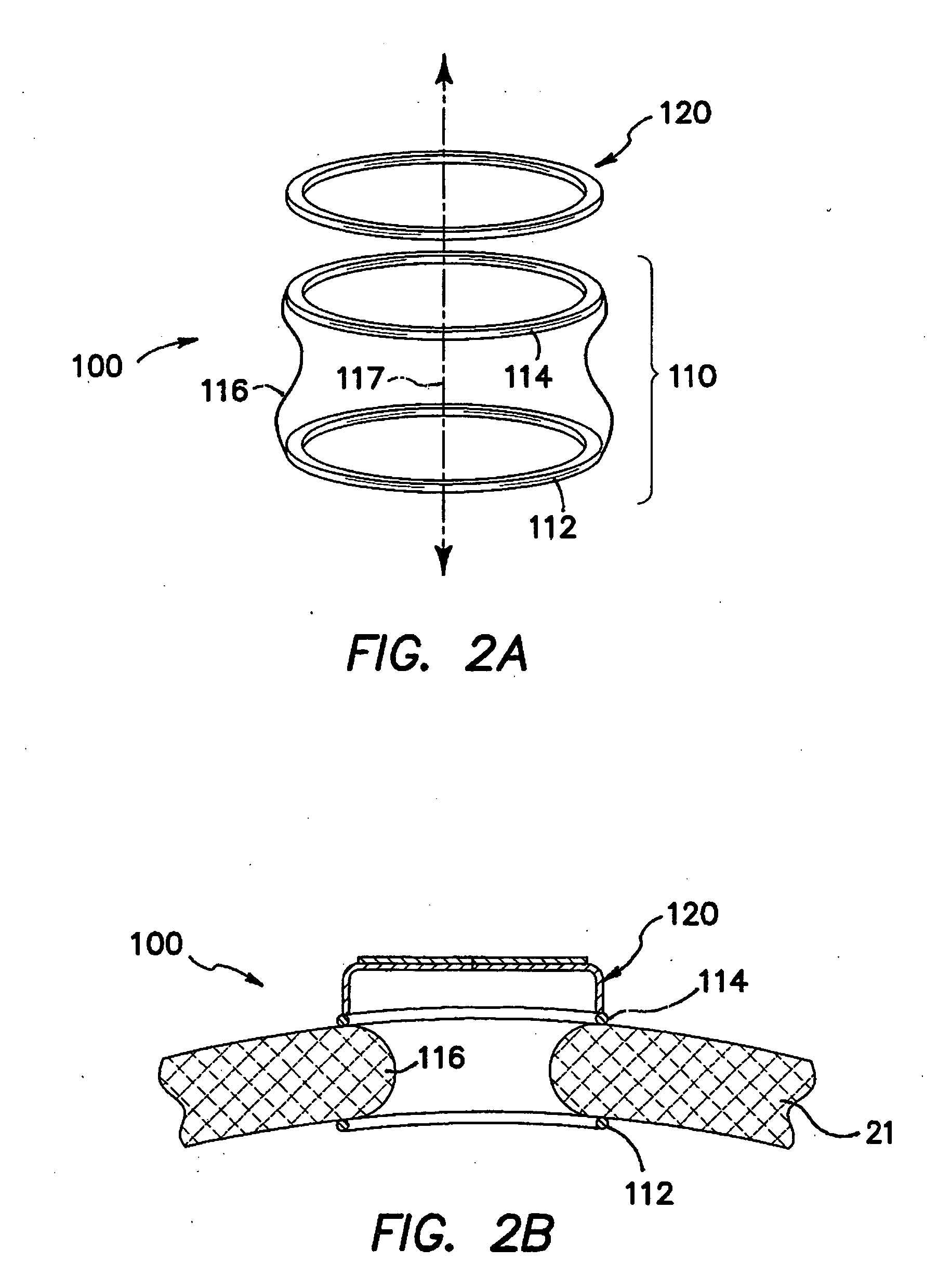

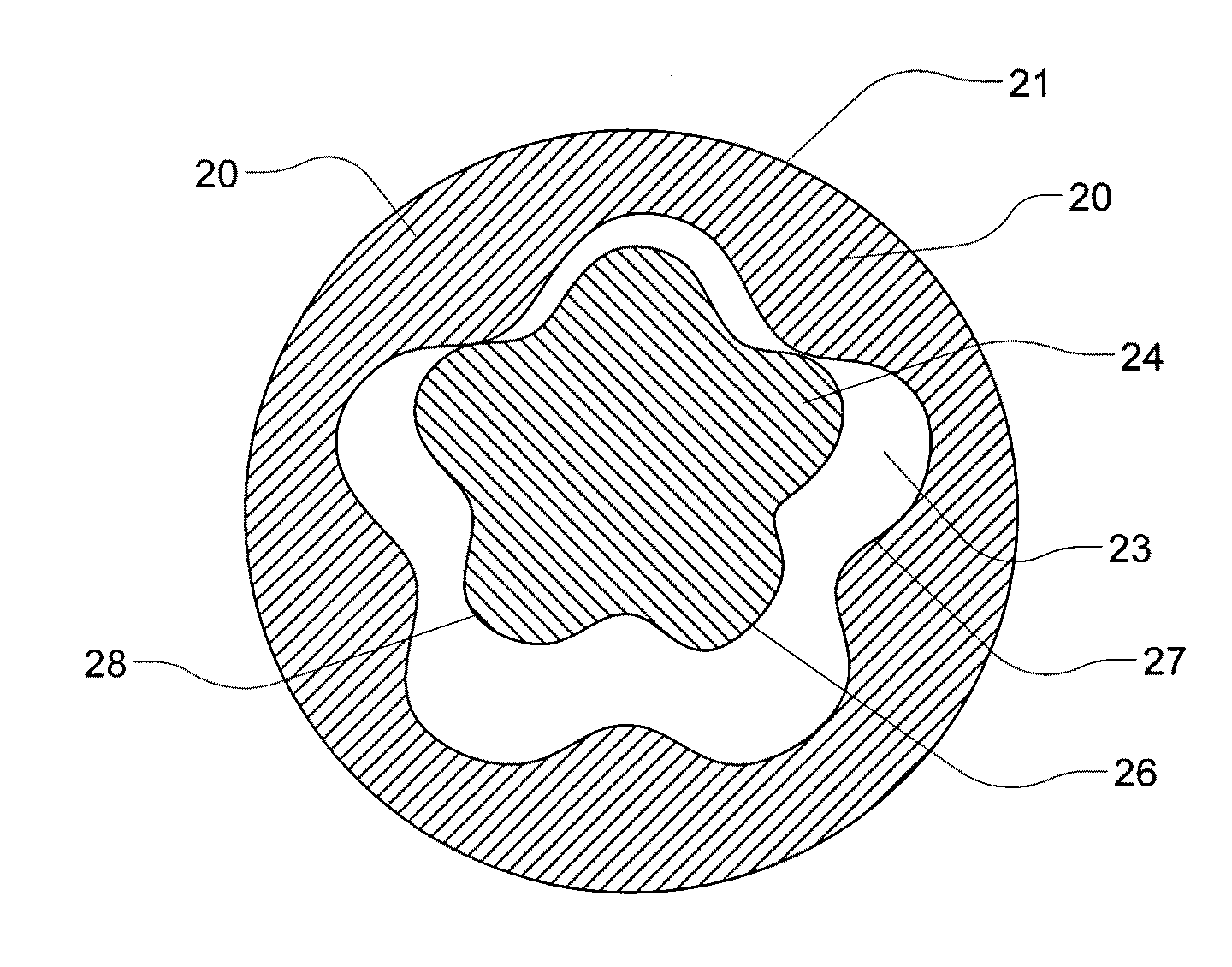

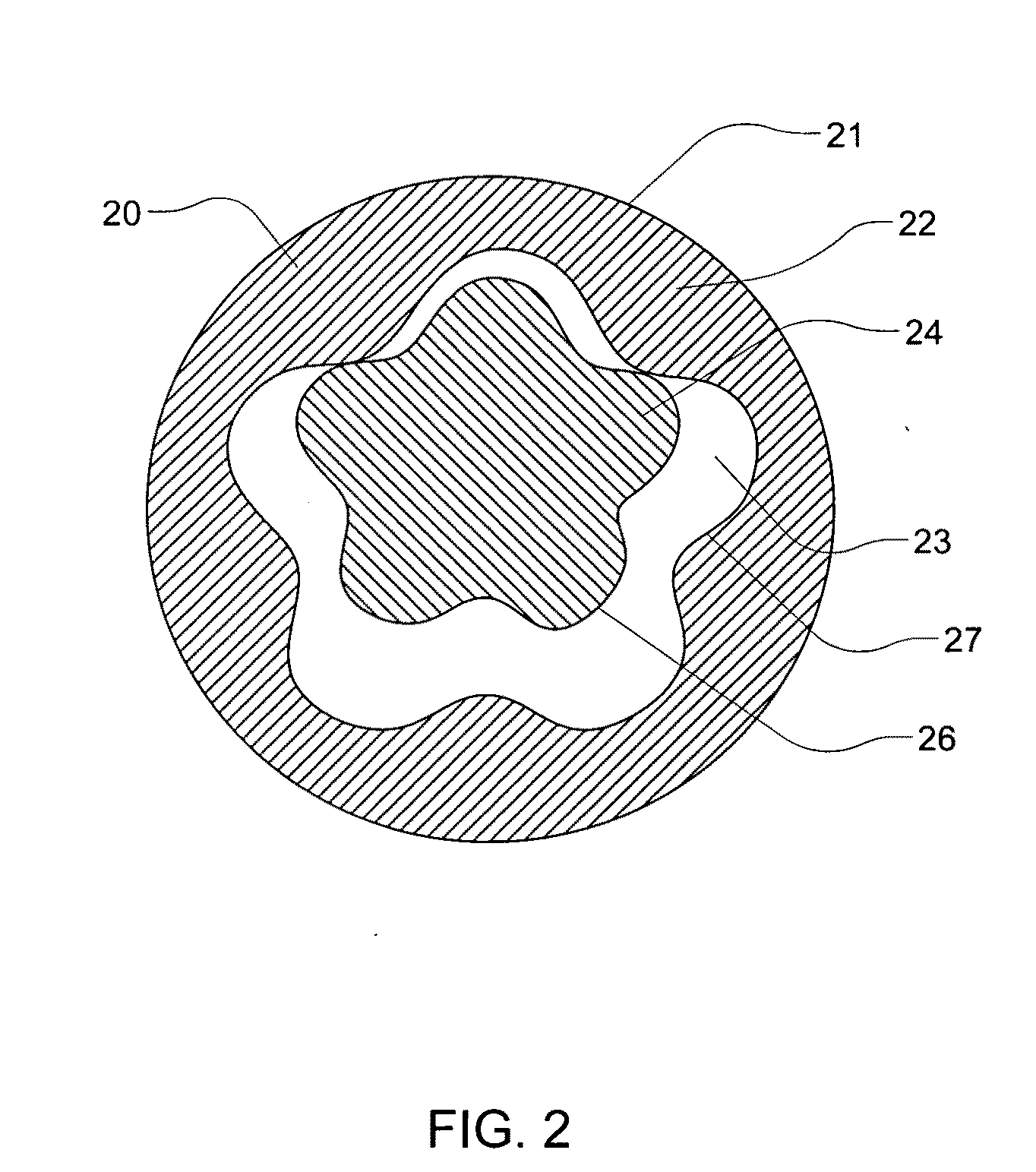

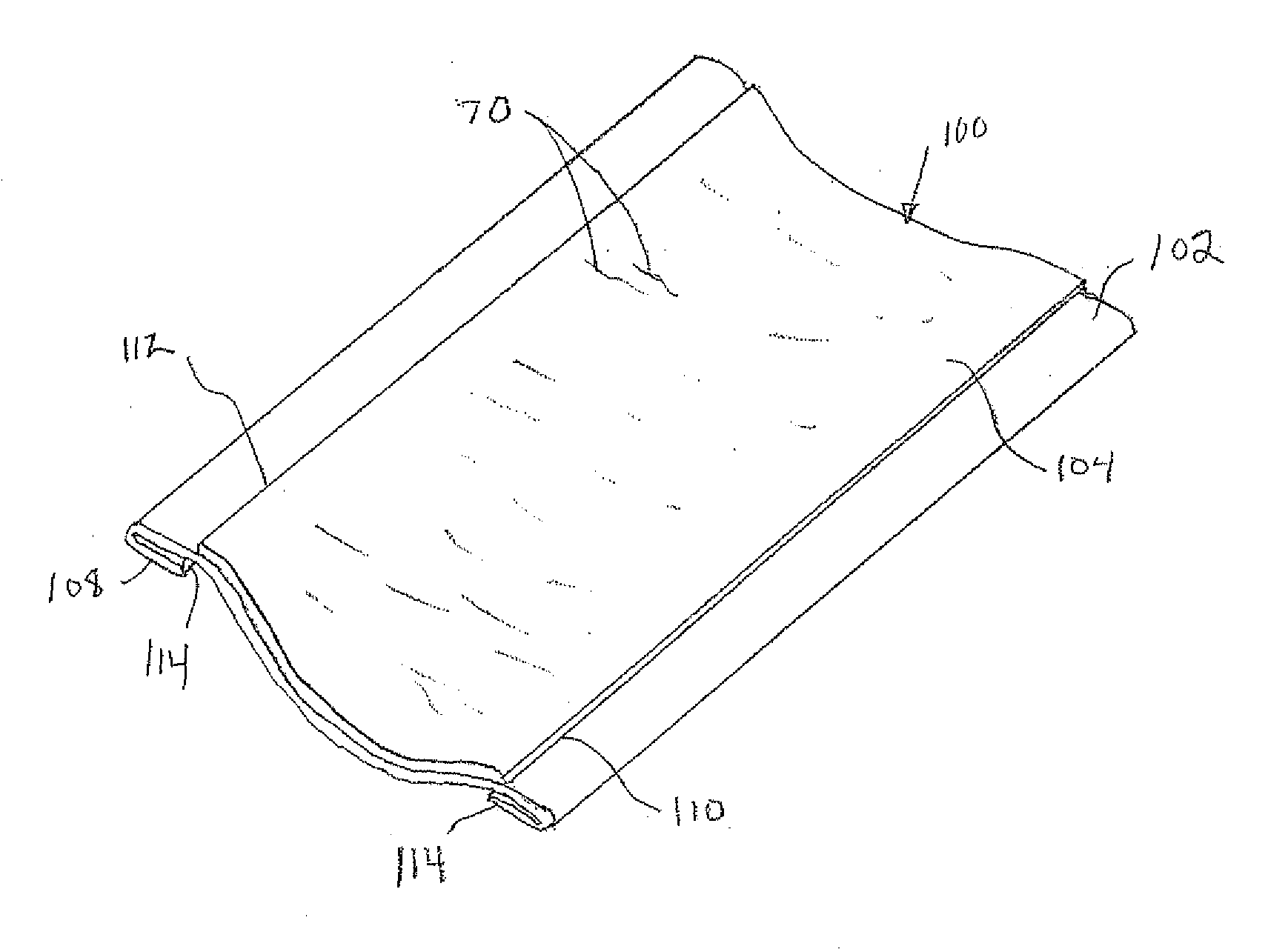

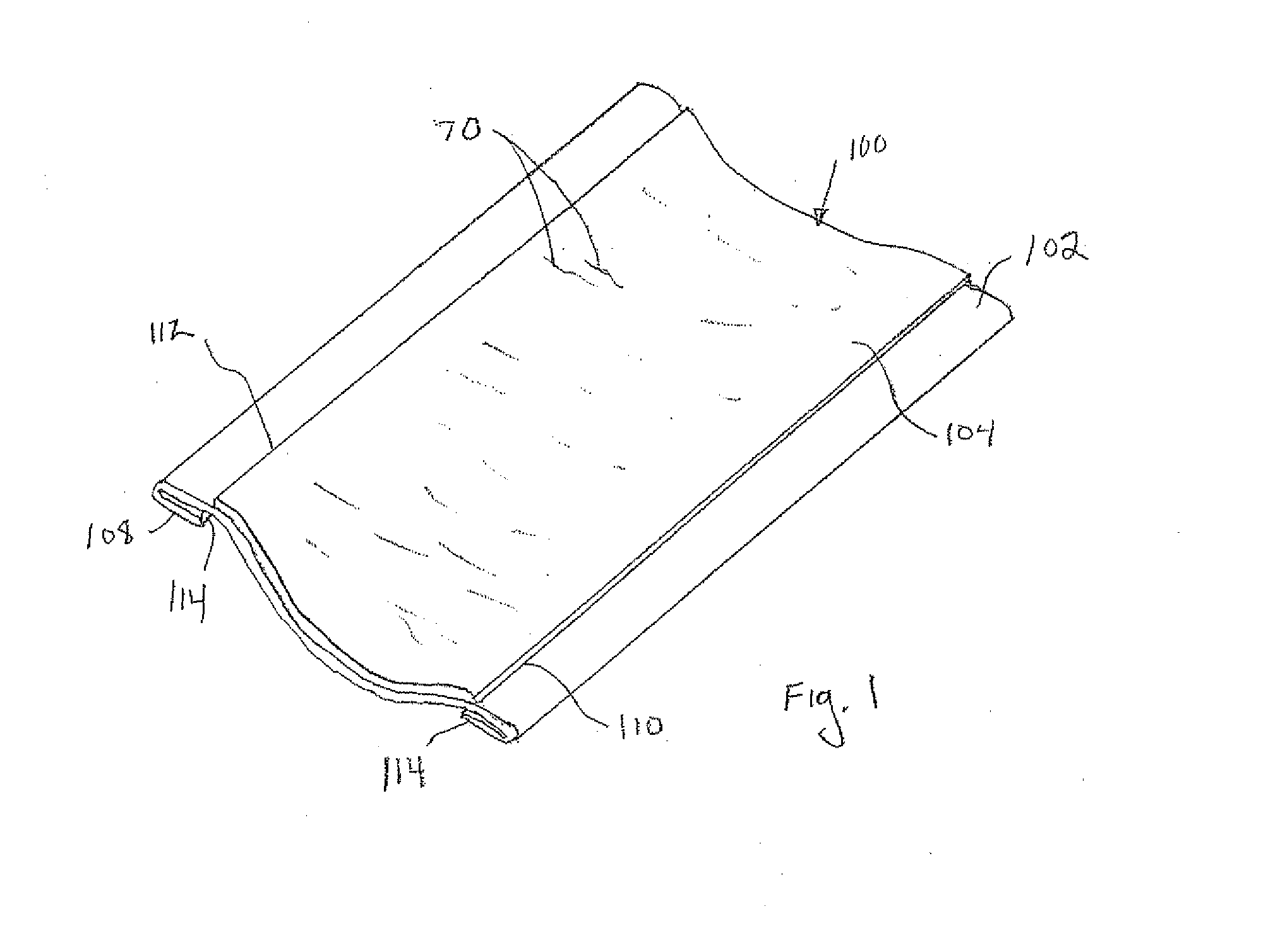

The invention is directed to a hand access system that provides hand access to a surgical area while maintaining pneumoperitoneum during laparoscopic surgery. The hand access system comprises a sheath retractor adapted to dilate a wound stretchable to a desired diameter, the sheath retractor includes a first ring being adapted for disposition interiorly of the wound, a second ring being adapted for disposition exteriorly of the wound, and a sheath being disposed in a generally cylindrical form between the first ring and the second ring and operable to exert a radial retraction force on the wound. The hand access system further comprises a detachable hand seal adapted to be removable from the second ring of the sheath retractor. The sheath retractor may be formed of an elastomeric material, and the hand seal may be formed of a gel material and includes a slit providing an instrument seal in the presence of an instrument or hand and a zero seal in the absence of the instrument or hand. In another aspect, there is disclosed a surgical access device adapted for disposition relative to an incision in a patient comprising a valve including a plurality of overlapping sheets defining an access channel, and a ring having an inner diameter for holding the valve by fixing each of the overlapping sheets along a portion of the perimeter, the access channel extends into communication with the incision in the patient. Each of the overlapping sheets includes a portion of the perimeter that is not fixed to the inner diameter of the ring, which provide open edges defining the access channel. The open edges slightly overlap at the center of the ring. The open edges may have different shapes including at least one of a straight edge, concave, convex and a cross-configuration. The hand access device may further comprise a septum seal formed at the proximal and distal ends of the ring.

Owner:APPL MEDICAL RESOURCES CORP

Laparoscopic illumination apparatus and method

InactiveUS6939296B2Improve rendering capabilitiesImprove tear resistanceCannulasRestraining devicesPERITONEOSCOPESurgical site

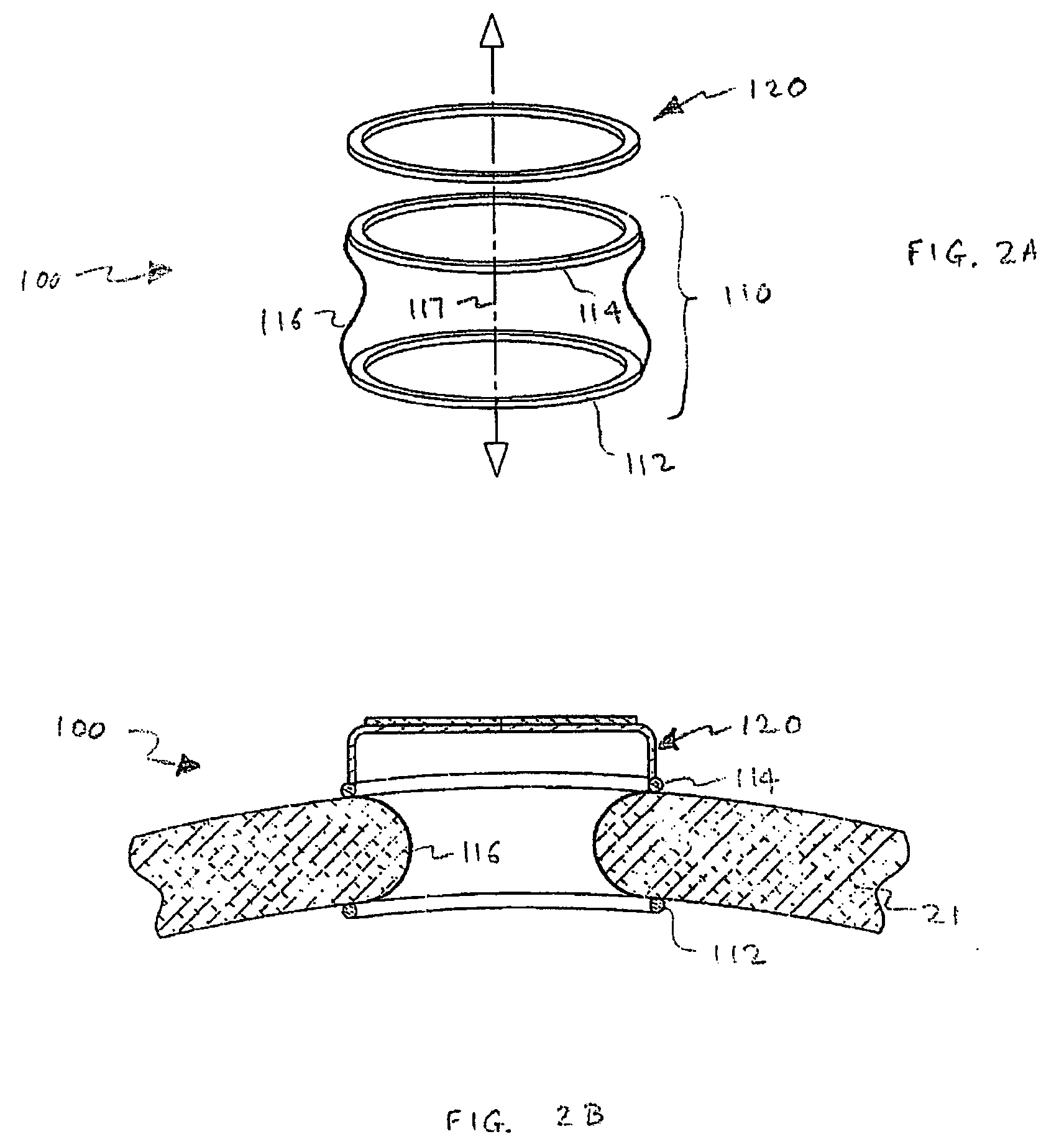

An access device particularly adapted for use in laparoscopic surgery facilitates access with instruments, such as the hand of the surgeon, across a body wall and into a body cavity. The device can be formed of a gel material having properties for forming a zero seal, or an instrument seal with a wide range of instrument diameters. The gel material can be translucent facilitating illumination and visualization of the surgical site through the access device.

Owner:APPL MEDICAL RESOURCES CORP

Surgical instrument access device

ActiveUS7163510B2High tear strengthHigh elongationCannulasInfusion syringesSurgical departmentVALVE PORT

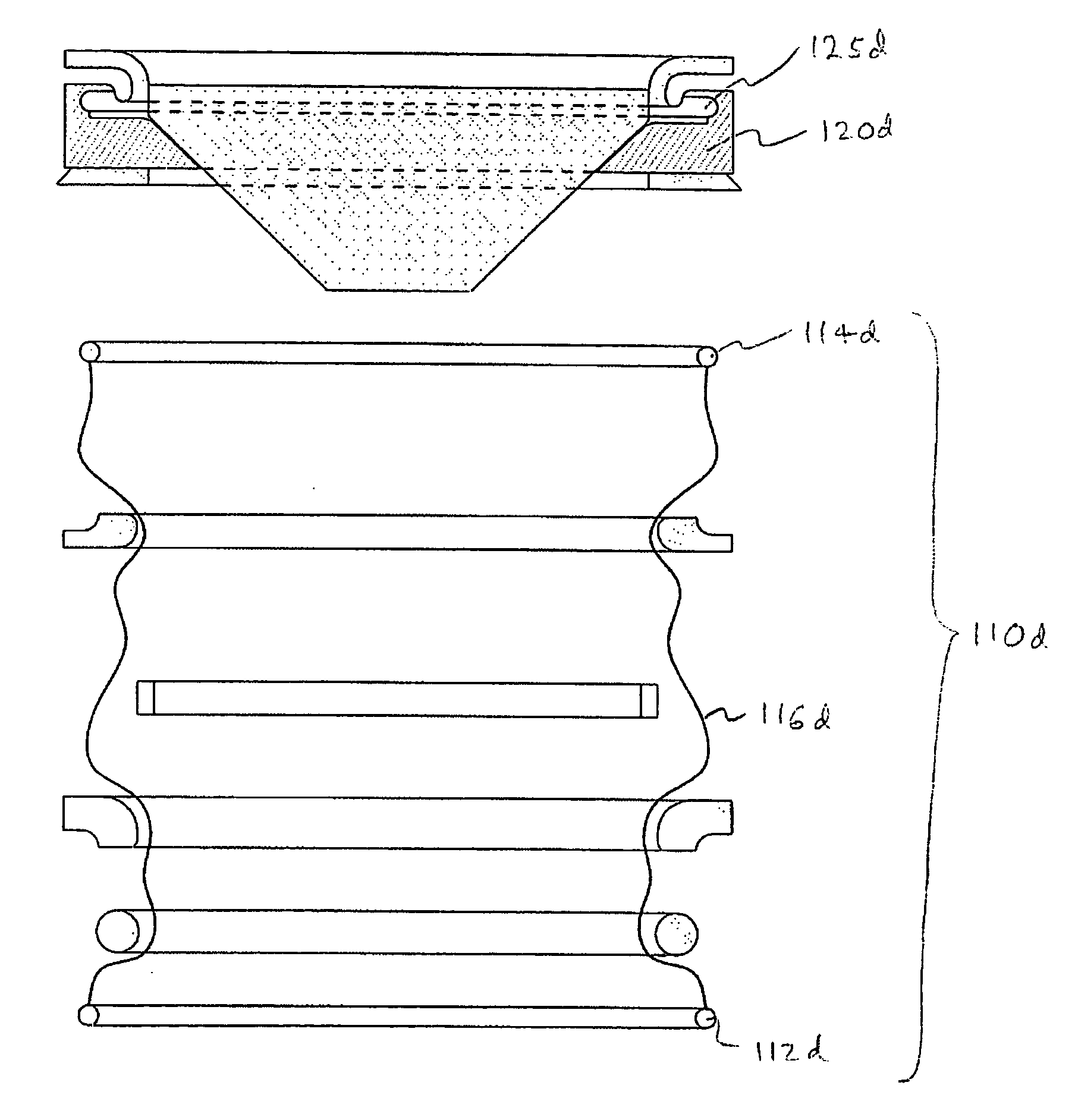

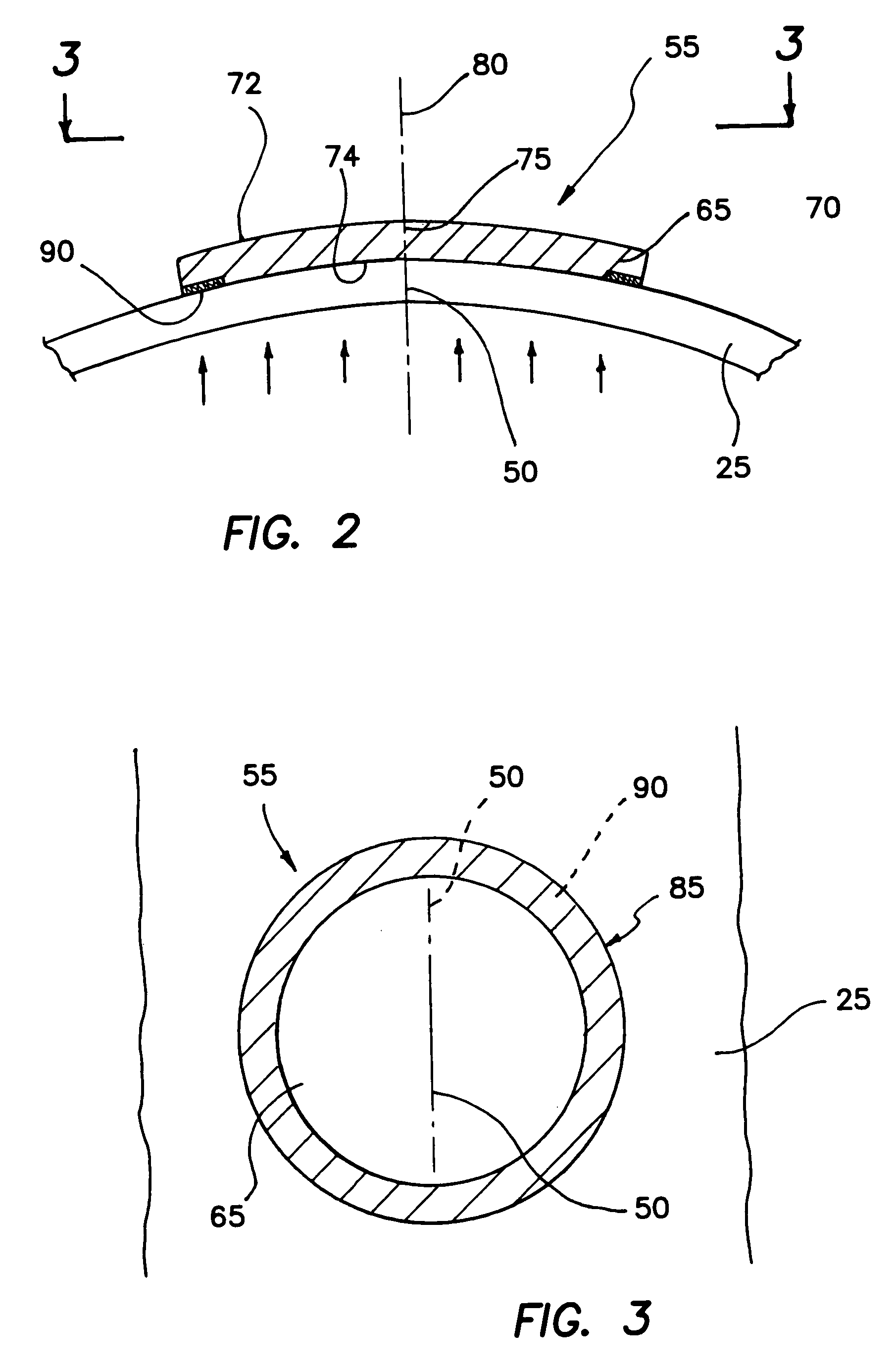

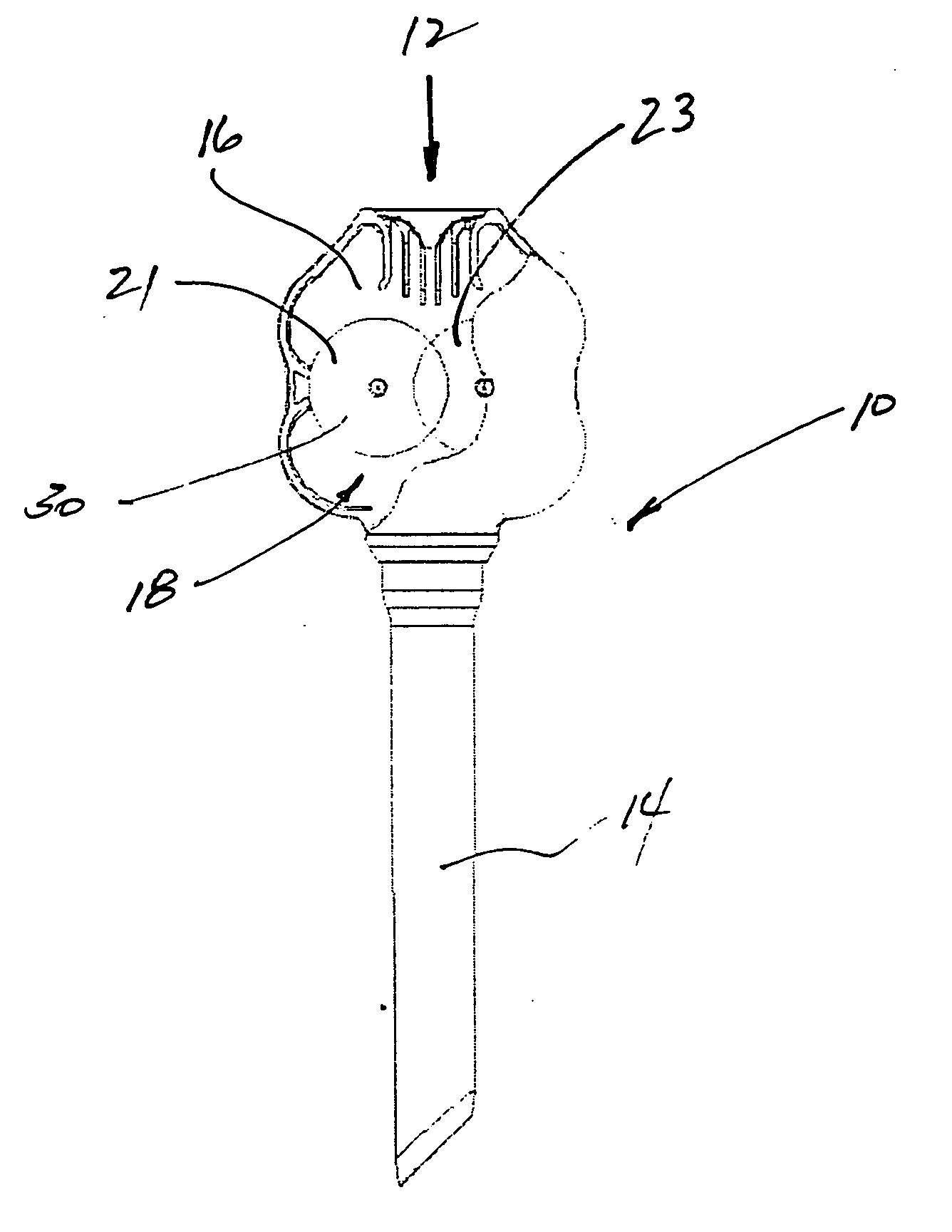

A surgical access device includes a single valve that forms a seal with a body wall and provides an access channel into a body cavity. The valve has properties for creating a zero seal in the absence of an instrument as well as an instrument seal for an instrument having a diameter up to about 37 mm. The valve can include a gel material and the access channel can include a protective sleeve to provide for wound protection during insertion and withdrawal of a sharp surgical instrument. The valve further comprises a cap ring which may be inserted or molded with the gel material. The protective sleeve may be bonded or molded around an inner diameter of the cap ring. The protective sleeve may be a single tubular member, or may comprise a plurality of axially extending sleeve members having a plurality of axial slits. The protective sleeve and the cap ring may comprise of the same or different materials. The surgical access device further comprises at least one support ring disposed circumferentially of the valve forming a hollow space, and a wound retractor operatively placed in the hollow space. The wound retractor includes an inner ring, an outer ring, and a flexible sleeve connecting the inner ring and the outer ring.

Owner:APPL MEDICAL RESOURCES CORP

Surgical access apparatus and method

Owner:APPL MEDICAL RESOURCES CORP

Surgical access system

ActiveUS20060084842A1High tear strengthLow durometerCannulasSurgical needlesSurgical departmentVALVE PORT

The invention is directed to a hand access system that provides hand access to a surgical area while maintaining pneumoperitoneum during laparoscopic surgery. The hand access system comprises a sheath retractor adapted to dilate a wound stretchable to a desired diameter, the sheath retractor includes a first ring being adapted for disposition interiorly of the wound, a second ring being adapted for disposition exteriorly of the wound, and a sheath being disposed in a generally cylindrical form between the first ring and the second ring and operable to exert a radial retraction force on the wound. The hand access system further comprises a detachable hand seal adapted to be removable from the second ring of the sheath retractor. The sheath retractor may be formed of an elastomeric material, and the hand seal may be formed of a gel material and includes a slit providing an instrument seal in the presence of an instrument or hand and a zero seal in the absence of the instrument or hand. In another aspect, there is disclosed a surgical access device adapted for disposition relative to an incision in a patient comprising a valve including a plurality of overlapping sheets defining an access channel, and a ring having an inner diameter for holding the valve by fixing each of the overlapping sheets along a portion of the perimeter, the access channel extends into communication with the incision in the patient. Each of the overlapping sheets includes a portion of the perimeter that is not fixed to the inner diameter of the ring, which provide open edges defining the access channel. The open edges slightly overlap at the center of the ring. The open edges may have different shapes including at least one of a straight edge, concave, convex and a cross-configuration. The hand access device may further comprise a septum seal formed at the proximal and distal ends of the ring.

Owner:APPL MEDICAL RESOURCES CORP

Surgical device with tack-free gel and method of manufacture

InactiveUS20050033246A1Significant drag forceImprove complianceCannulasSurgical needlesMolten stateLow-density polyethylene

A process of making a tack-free gel is disclosed comprising the steps of providing a mold defining a mold cavity, the mold cavity comprising a plastic material; pouring or injecting a molten gel having a high molding temperature into the mold cavity; and forming the tack-free gel as a thin layer of plastic of the mold cavity is melted over the gel. The forming step further comprises cooling the gel from the molten state to a solidified state. The melting temperature of the plastic material is lower than the molding temperature of the gel; and the higher the temperature differential, the greater the melting of the plastic material and the thicker the layer of the plastic material on the surface of the gel. The mold may be formed of low-density polyethylene (LDPE). With the process of the invention, the heat of the molten gel at its molding temperature is transferred to the surface of the LDPE mold so as to melt a thin layer of the LDPE. The mold may comprise a mold base having a plurality of mold holes forming a plurality of mold cavities, each of the mold holes comprising an axial pin to mold an axial hole through a center of the gel, an LDPE cylinder providing a predetermined inside diameter for the mold, and an LDPE disc mounted on the axial pin and disposed at the bottom of each mold cavity in the mold base. The process may further comprise the step of dabbing the gel in a low-friction powder such as polytetrafluoroethylene (PTFE) and a lubricant. The mold may further comprise a mold top disposed axially of the mold base and comprises a plurality of holes forming a plurality of cavities, each of the mold top holes is adapted to receive the LDPE cylinder, and a second LDPE disc disposed at the top of each mold cavity of the mold top.

Owner:APPL MEDICAL RESOURCES CORP

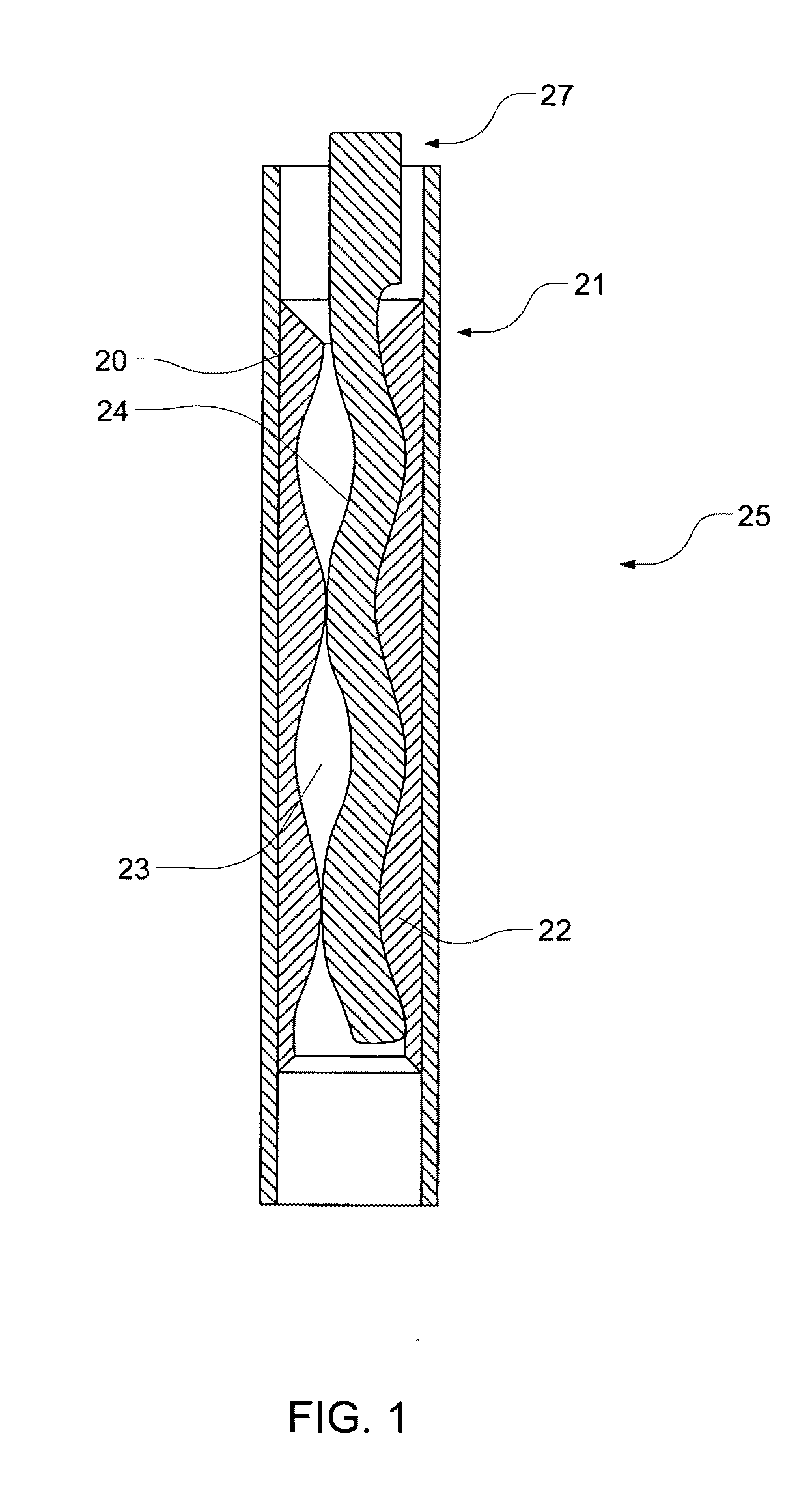

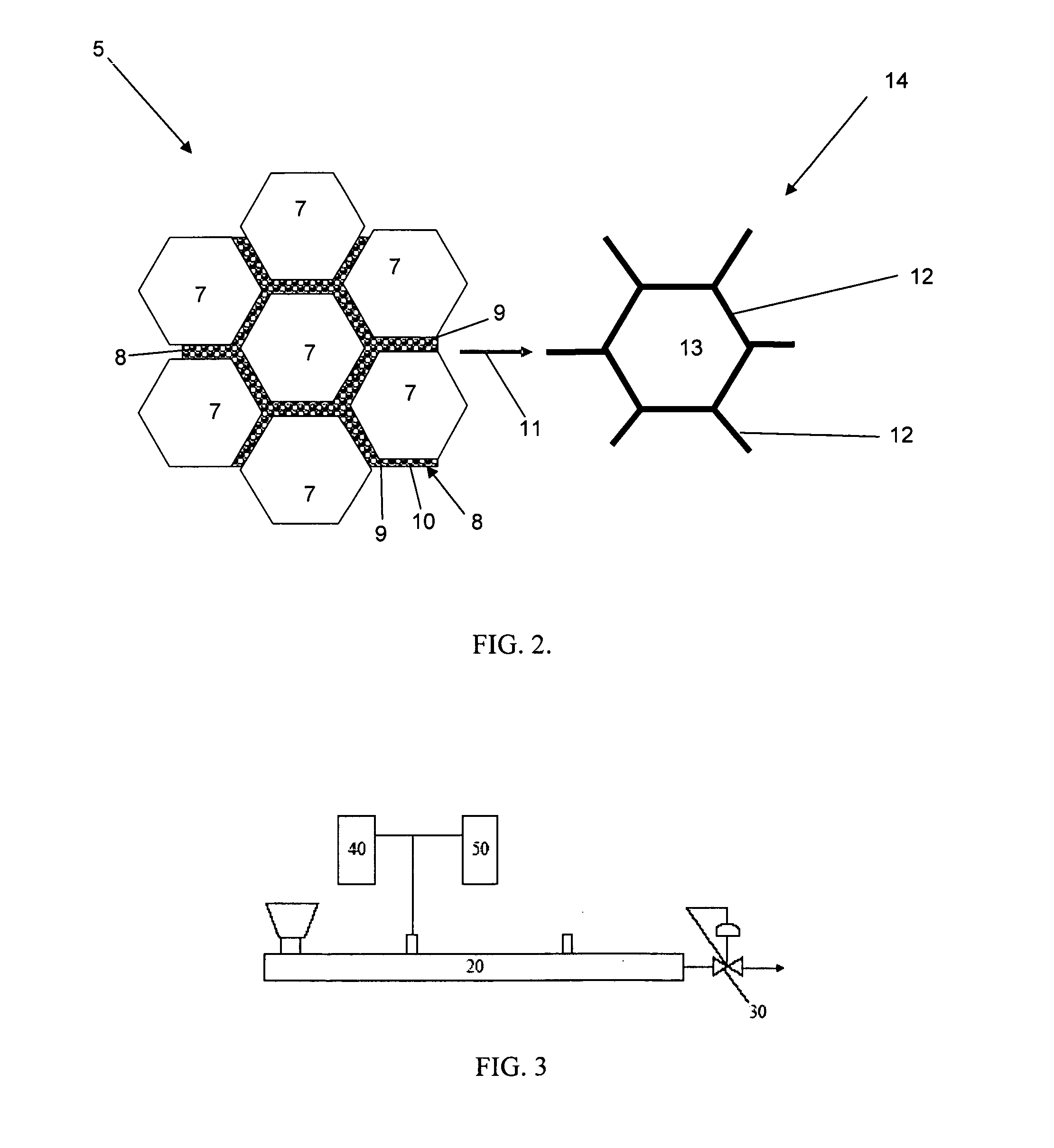

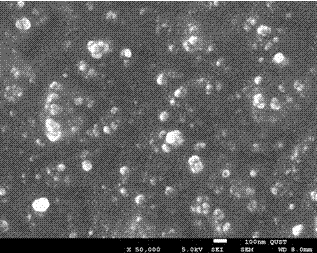

Nano particle reinforced polymer element for stator and rotor assembly

InactiveUS20090152009A1Interfacial interaction be improveImprove resistanceEngine of arcuate-engagement typeOscillating piston enginesNanometreNano sized particle

A nano particle reinforced polymer element of a stator and rotor assembly for a power section of a positive displacement fluid motor or a progressive cavity pump. Nano-sized particles are blended with an uncured polymer to improve the physical and chemical properties of the polymer. The use of nano-sized particles reduces the quantity of reinforcement material required to manufacture the polymer for the stator and rotor assembly and lowers the viscosity of the uncured polymer to improve manufacturing characteristics. The use of chemically functionalized nano particles improves the chemical and physical characteristics of the polymer.

Owner:HALLIBURTON ENERGY SERVICES INC

Artificial neural canal

InactiveUS6090117AStay in shapePrevent intrusionTubular organ implantsTissue regenerationMedicineBlood capillary

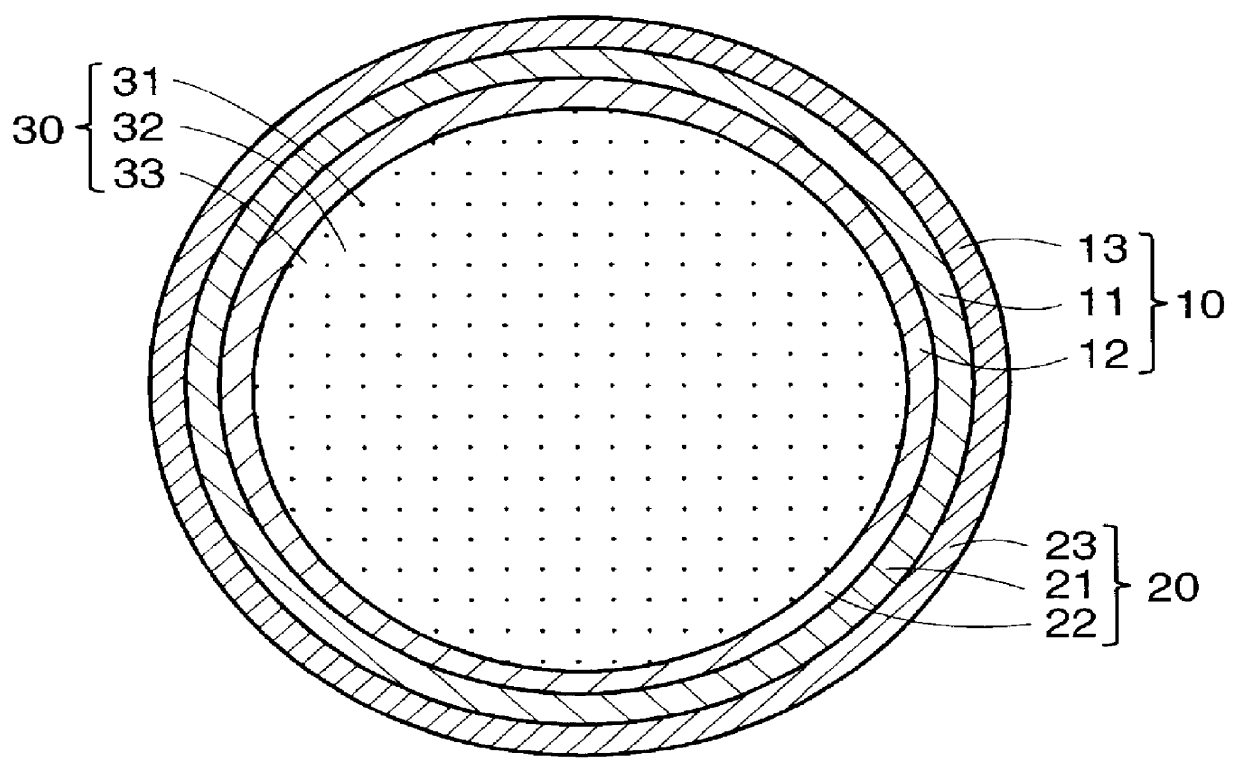

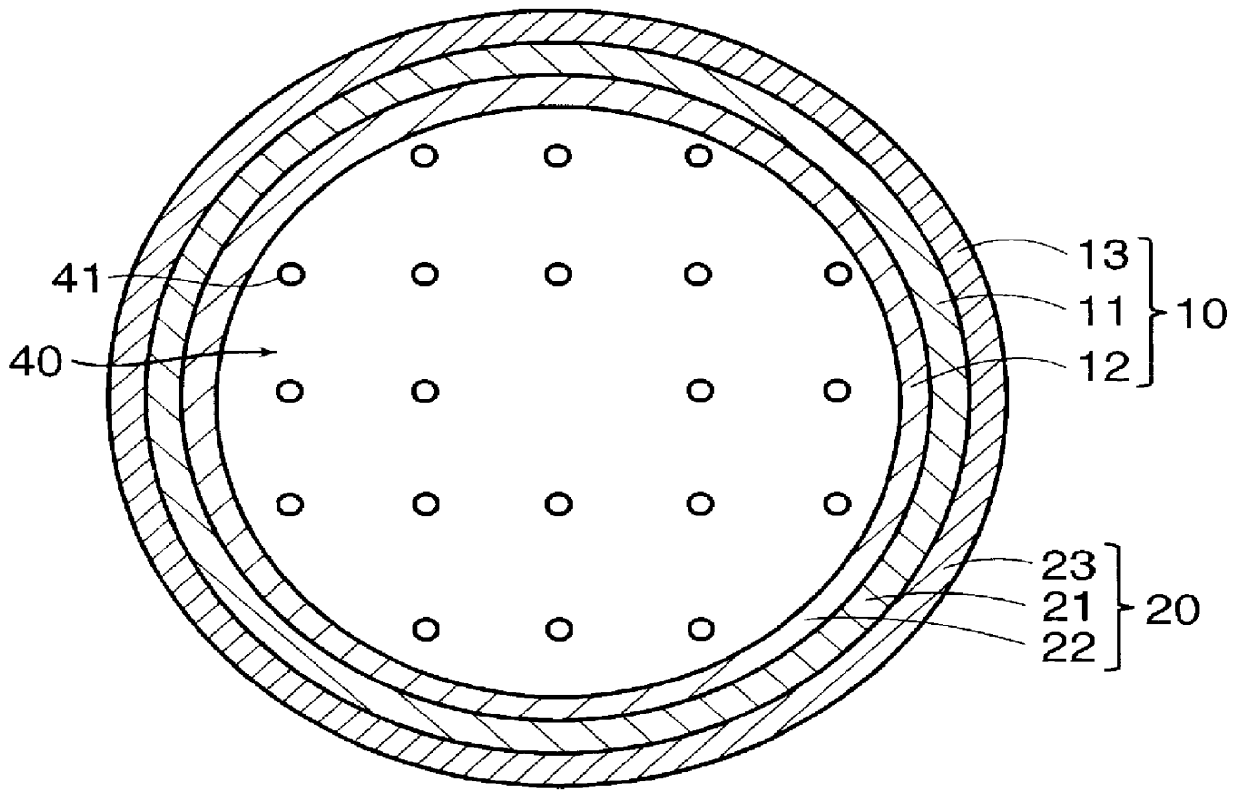

PCT No. PCT / JP97 / 04203 Sec. 371 Date May 20, 1999 Sec. 102(e) Date May 20, 1999 PCT Filed Nov. 19, 1997 PCT Pub. No. WO98 / 22155 PCT Pub. Date May 28, 1998The present invention offers an artificial tube for nerve which can remain in the body until the nerve regenerates while does not remain as a foreign body in the body following nerve regeneration, and which induces axons regenerated from severed nerve stumps, can promote infiltration of blood capillaries from the body and regeneration of nerve tissue. The present invention comprises a tube 10 or 20 having coating layers 12, 13 or 22, 23 composed of gelatin or collagen on the inner and outer surfaces of a tube 11 or 21 composed of a material being biodegradable and absorbable in vivo, and a collagen body 30 or 40 having cavities 32, 33 or 41 which pass through said tube so as to be substantially parallel to the axis of said tube; wherein, said cavities are filled with a matrix gel.

Owner:TAPIC INT

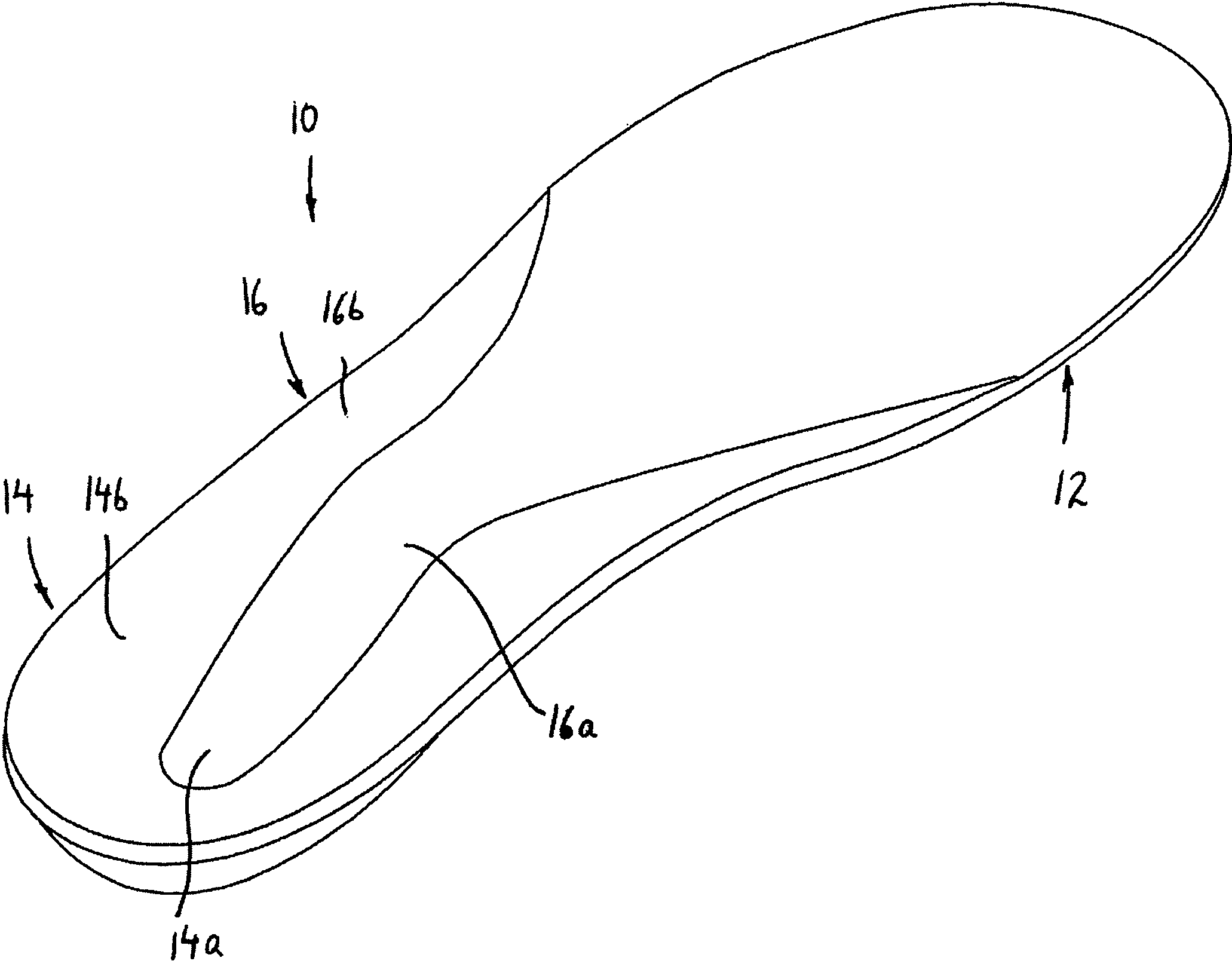

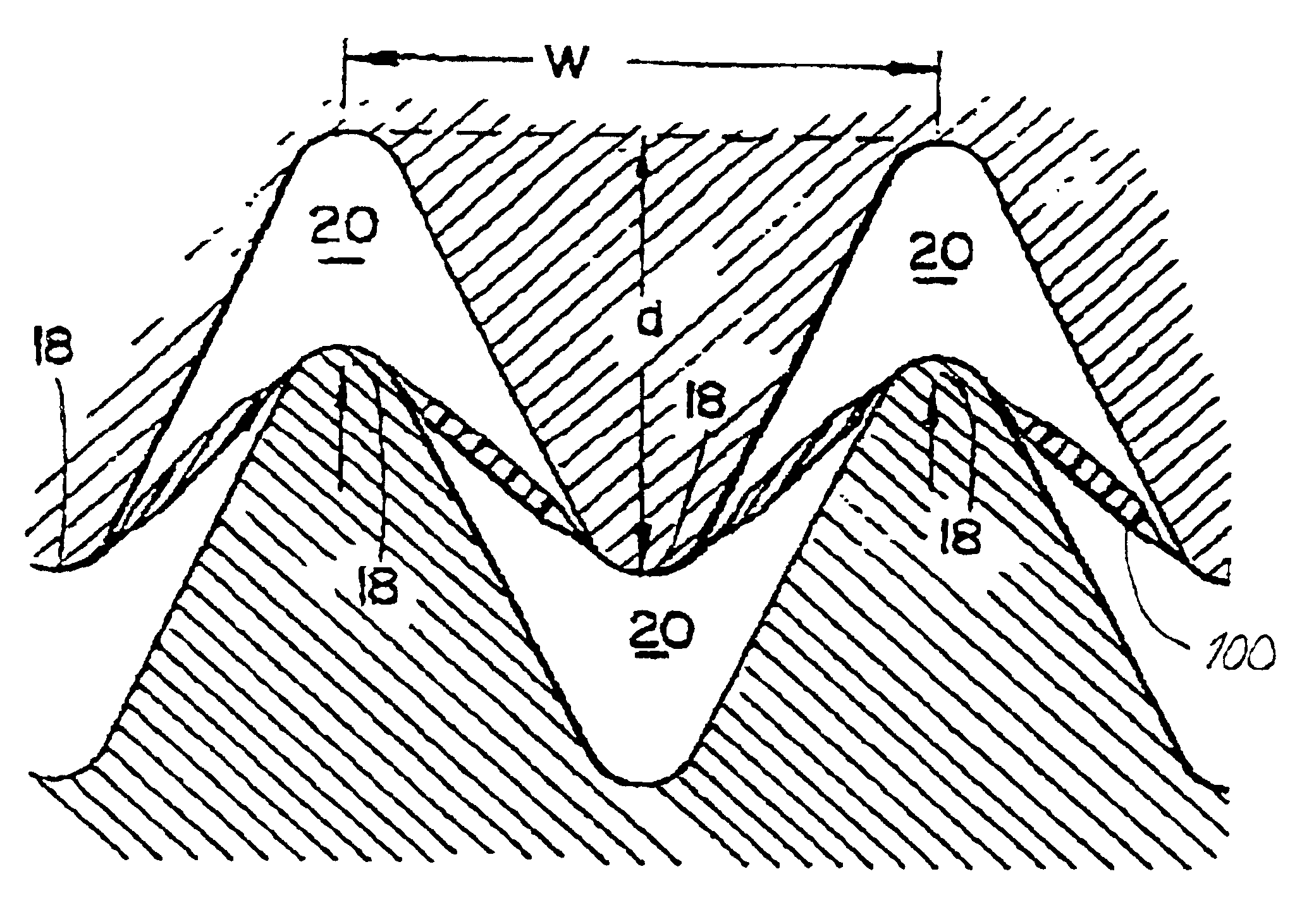

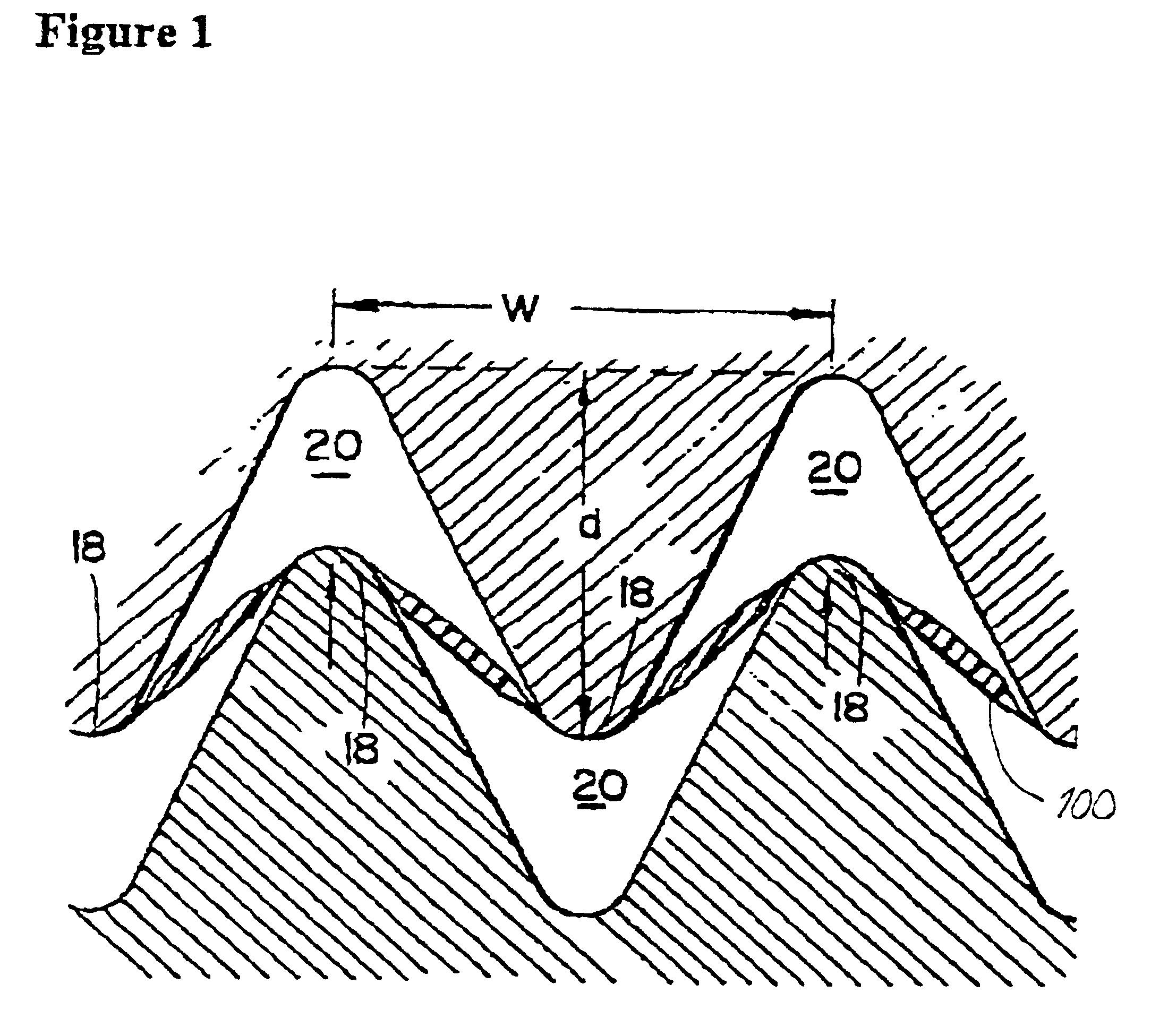

Additive Manufactured Metal Sports Performance Footwear Components

ActiveUS20160051009A1Wearing comfort without impairing the bending stiffness of the soleHigh tear strengthAdditive manufacturing apparatusLastingSports PerformancesMechanical engineering

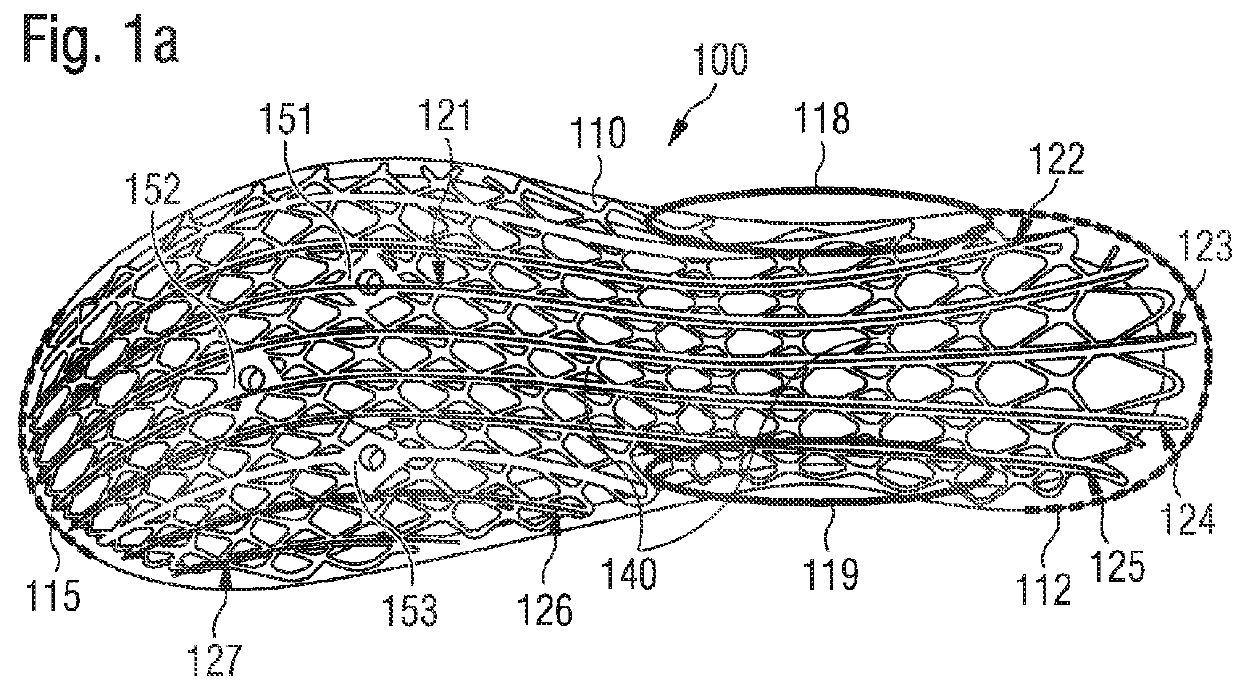

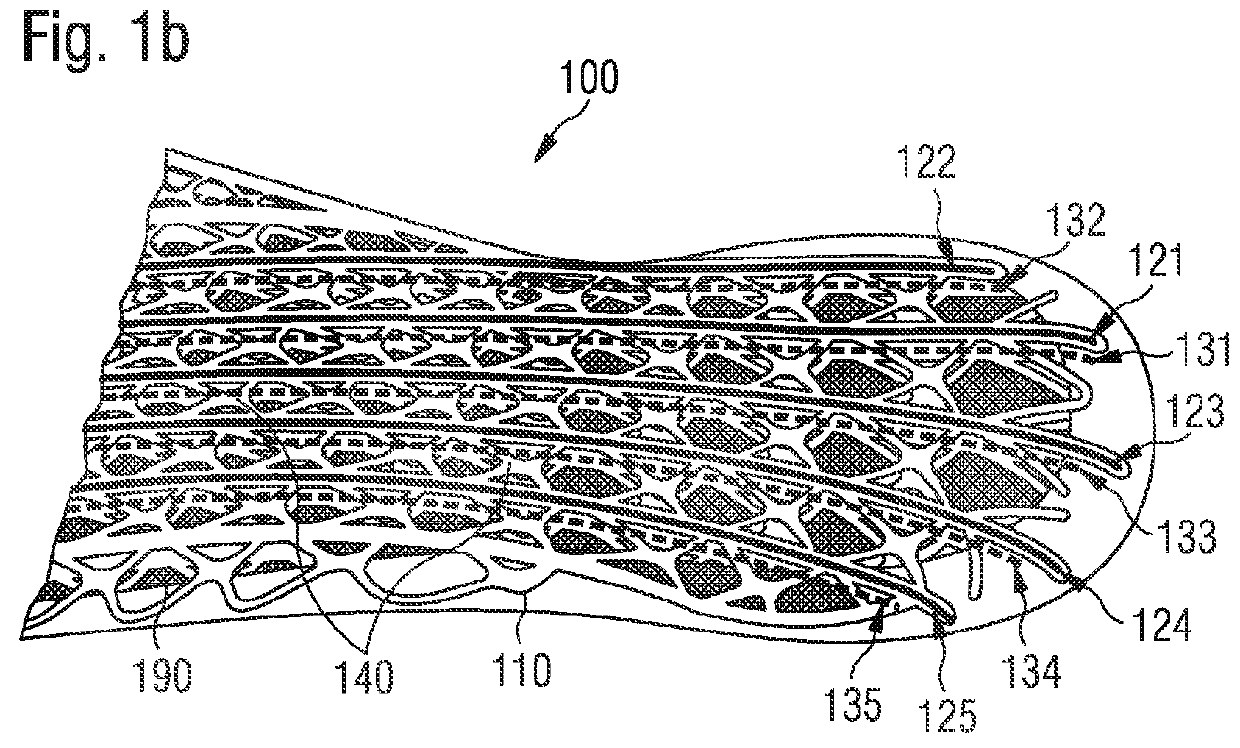

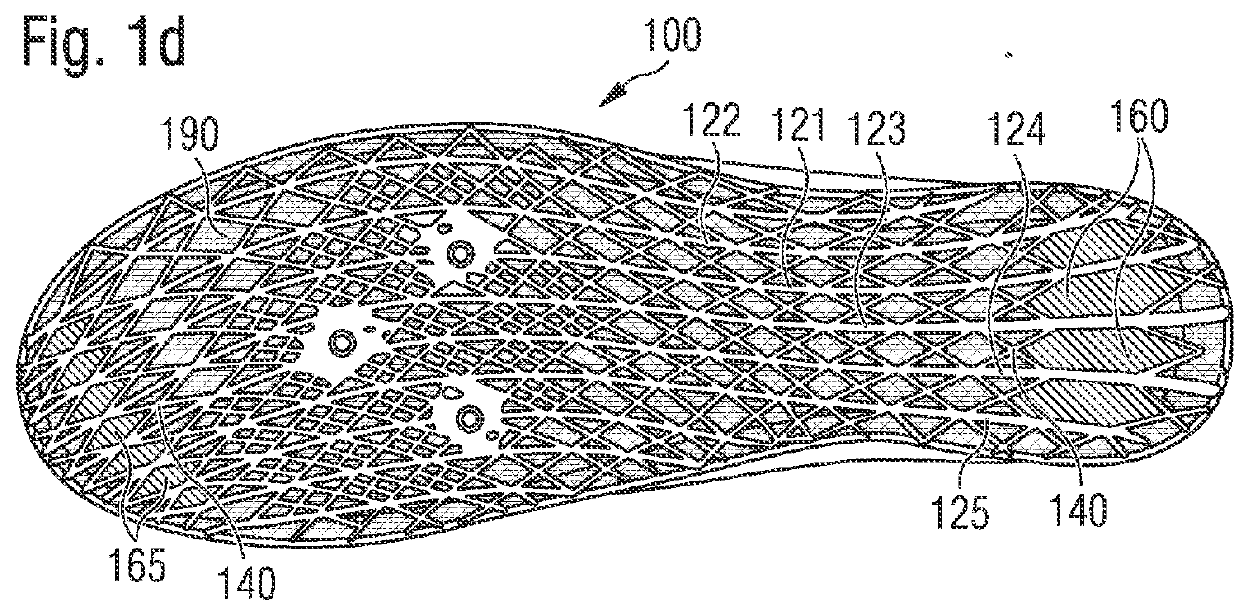

The present invention relates to a sole (100; 200) for a shoe (300), in particular for a cycling shoe (300), comprising: (a.) a three-dimensionally shaped rim (110); and (b.) a plurality of first reinforcing struts (121-127; 221-222), wherein (c.) at least two (122-125; 221-222) of the plurality of first reinforcing struts (121-127; 221-222) extend from a heel region (112) of the rim (110) of the sole (100; 200) to a toe region (115) of the rim (110) of the sole (100; 200), and wherein (d.) the rim (110) of the sole (100; 200) and the plurality of first reinforcing struts (121-127; 221-222) are integrally manufactured as a single piece in an additive manufacturing process.

Owner:ADIDAS

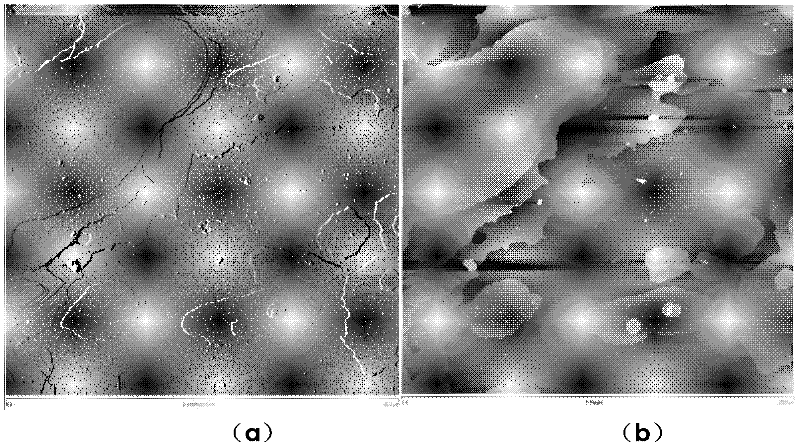

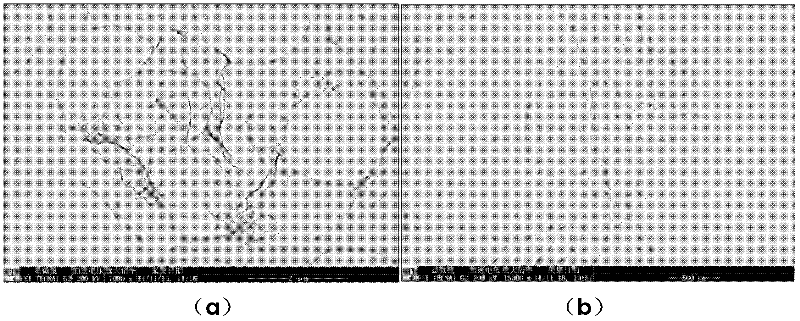

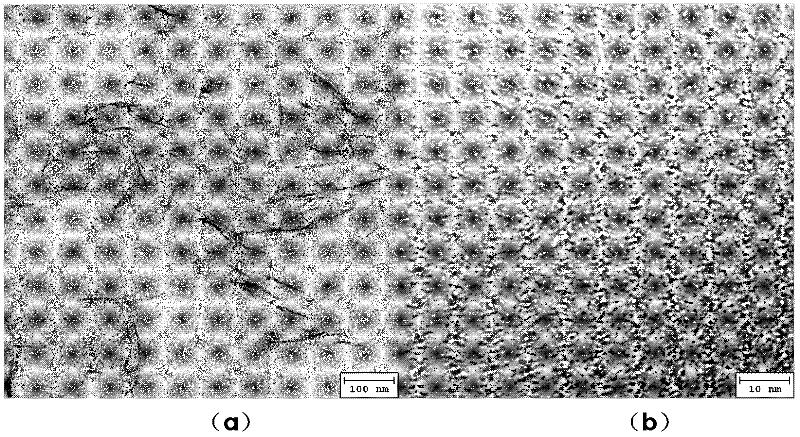

Preparation method of completely peeled oxidation graphene/ rubber nanometer composite material

A preparation method of completely peeled oxidation graphene / rubber nanometer composite material adopts combination of emulsion compounding and flocculation processes or combination of emulsion compounding and spraying drying processes. The preparation method retains the phase state structure of the oxidation grapheme / rubber composite emulation in the liquid state and obtains the phase-state structure which is highly dispersed, highly peeled and dispersed in nanometer scale dispersion. Simultaneously, substances capable of acting with generating ionic bond effect or chemical bond effect with an oxidation graphene surface functional group are added into the oxidation graphene / hydrosol to serve as an interface agent, thereby improving interface combination effect of oxidation graphene and rubber. Vulcanized rubber prepared by the composite material of the preparation method through follow-up mixing and vulcanizing has mechanical property such as high tensile strength, stretching stress and tearing strength and is capable of greatly improving abrasion resistance and gas separation performance of the vulcanized rubber. The preparation method is simple, easy, low in cost, apt to industrialization and wide in suitable aspect, saves energy and has better economical and social benefits.

Owner:JIANGSU LVYUAN RUBBER RESOURCE RECYCLING INNOVATION CENT CO LTD

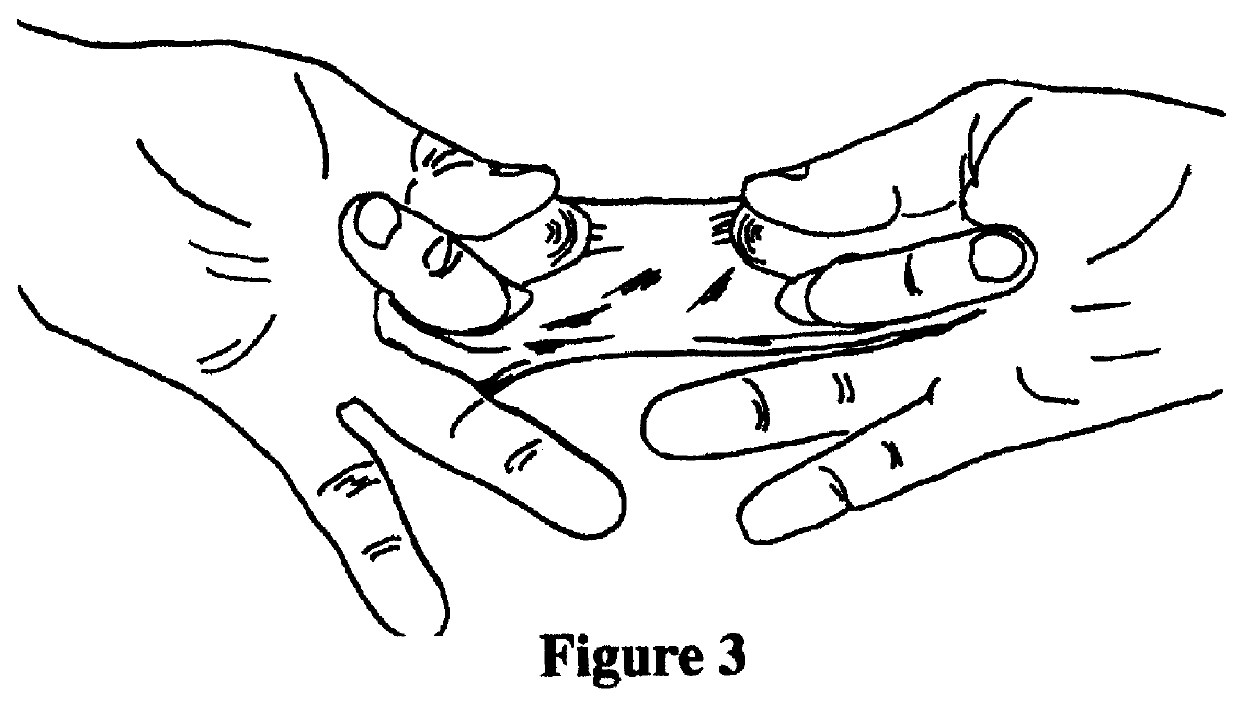

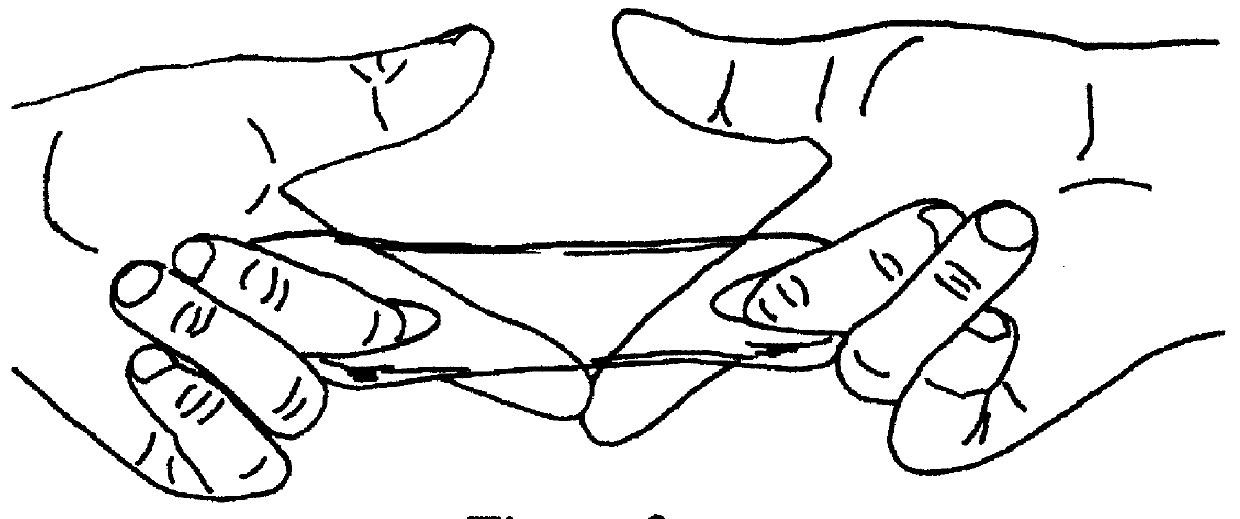

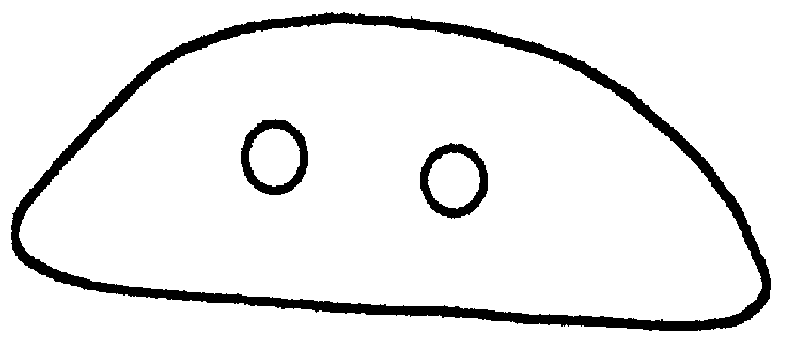

Crystal gels useful as dental floss with improved high tear, high tensile, and resistance to high stress rupture properties

InactiveUS6161555AHigh tear strengthHigh tensile strengthGum massageDental flossEngineeringConstriction

PCT No. PCT / US97 / 17534 Sec. 371 Date Feb. 3, 1999 Sec. 102(e) Date Feb. 3, 1999 PCT Filed Sep. 30, 1997 PCT Pub. No. WO98 / 14133 PCT Pub. Date Apr. 9, 1998A novel dental floss and gum massager made in the form of a strand, a tape or a sheet of polymeric material, said sheet having selectively positioned multiple sized holes for inserting though and holding by the fingers of the hands. The floss provides substantially very little constriction of blood flow surrounding the fingers as the floss is held taught and the peripheral edge of the floss is being manipulated and worked by the gripping, pulling, pushing, deforming, and guilding back and forth actions of the fingers during massaging of the gums and flossing of the teeth.

Owner:APPLIED ELASTOMERICS

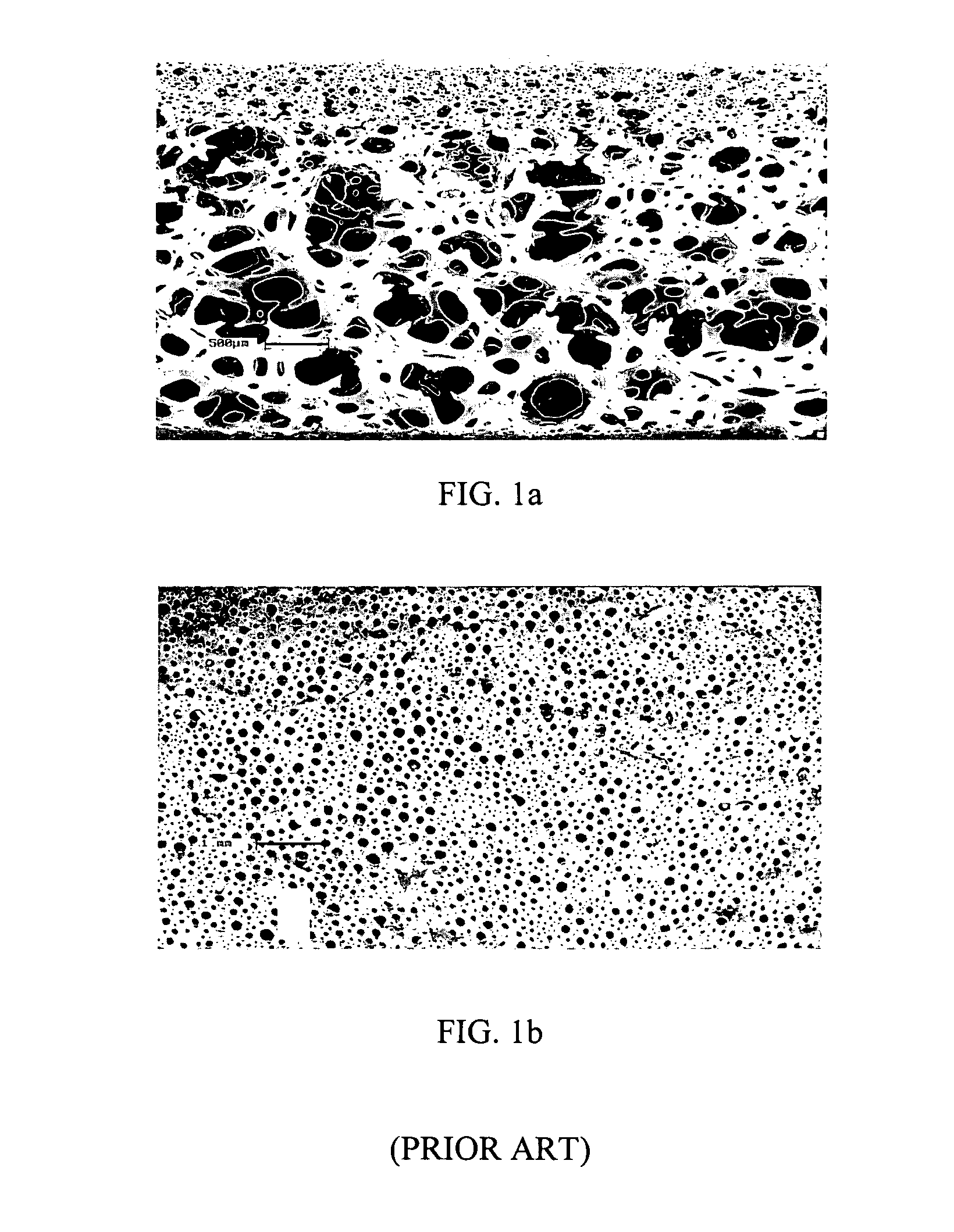

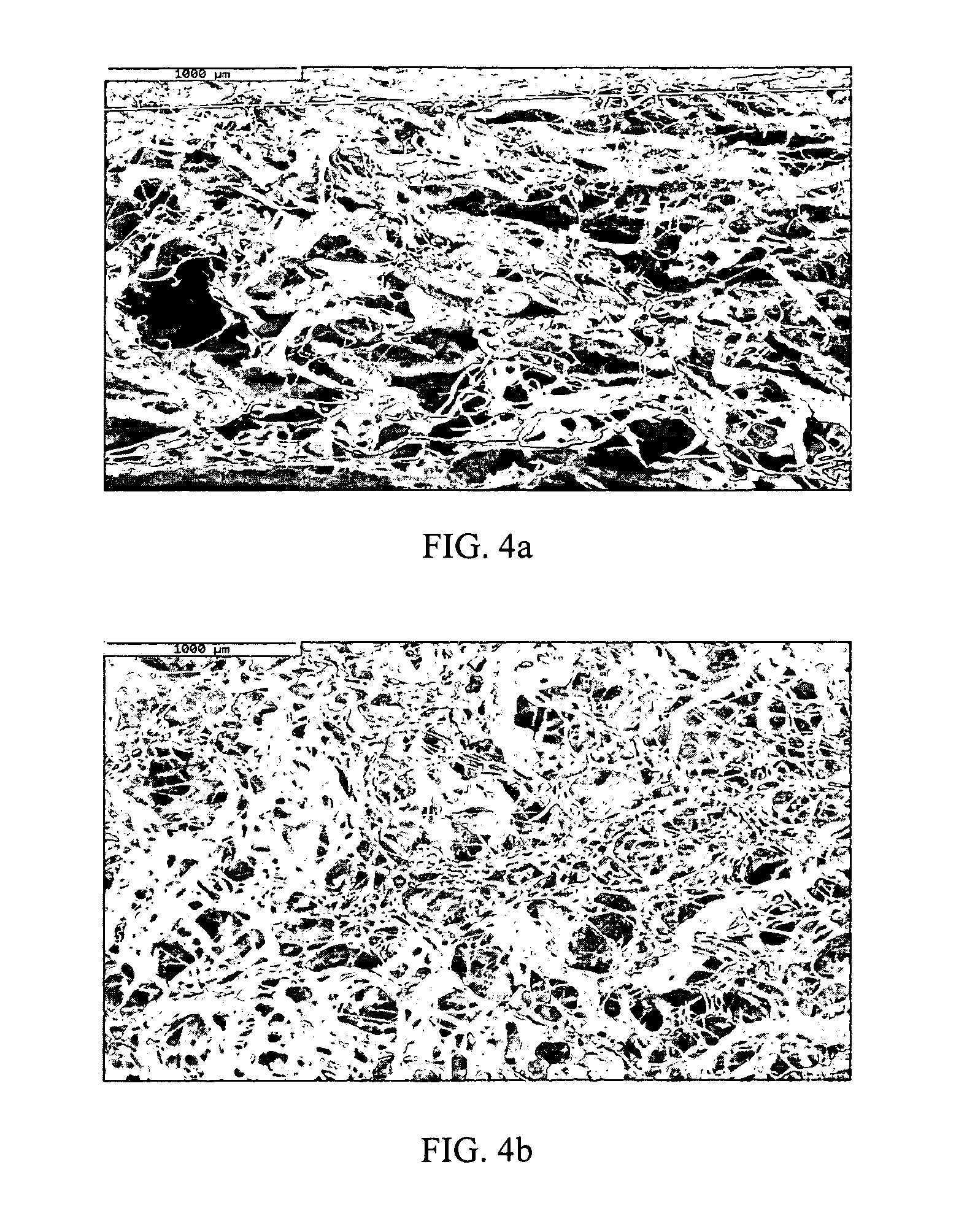

Fibrillated polyolefin foam

ActiveUS20080076844A1Improve heat resistanceLow compression setAbsorbent padsBandagesThermoplasticFiber

A method for generating a thermoplastic foam from an aqueous dispersion, the aqueous dispersion comprising a thermoplastic resin, water, and a dispersion stabilizing agent, the method including: adding at least one froth stabilizing surfactant to the aqueous dispersion to form a mixture; adding a fiber to the mixture; and frothing the mixture to create a froth, removing at least a portion of the water in the froth to create a foam, wherein the foam generated has a non-cellular fibrillated morphology. In another aspect, embodiments disclosed herein relate to a foam having a thermoplastic-based, fibrillated, non-cellular structure, wherein the foam has an average density of about 0.02 g / cm3 to about 0.07 g / cm3. In certain embodiments, the foam may be used in an absorbent article.

Owner:DOW GLOBAL TECH LLC

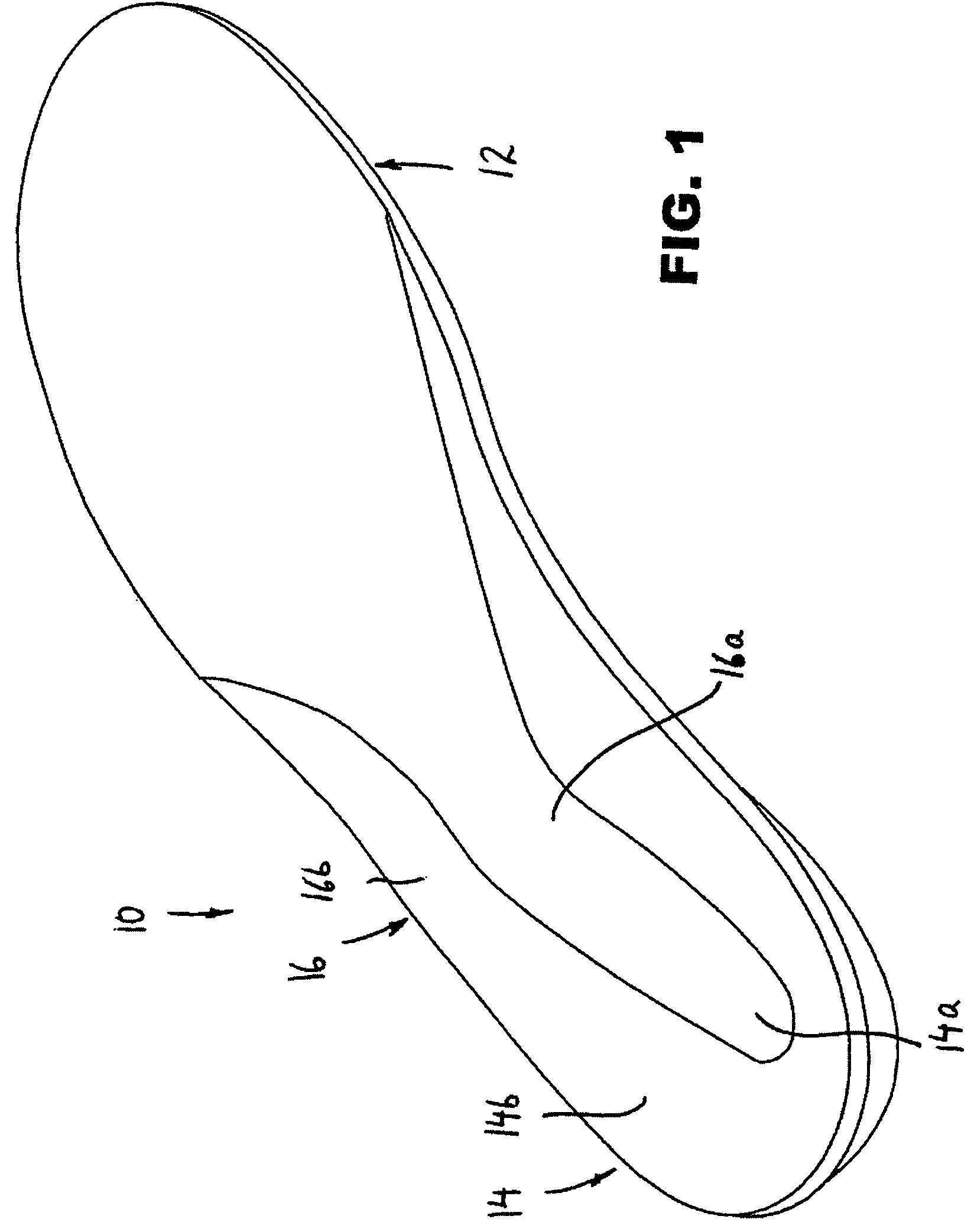

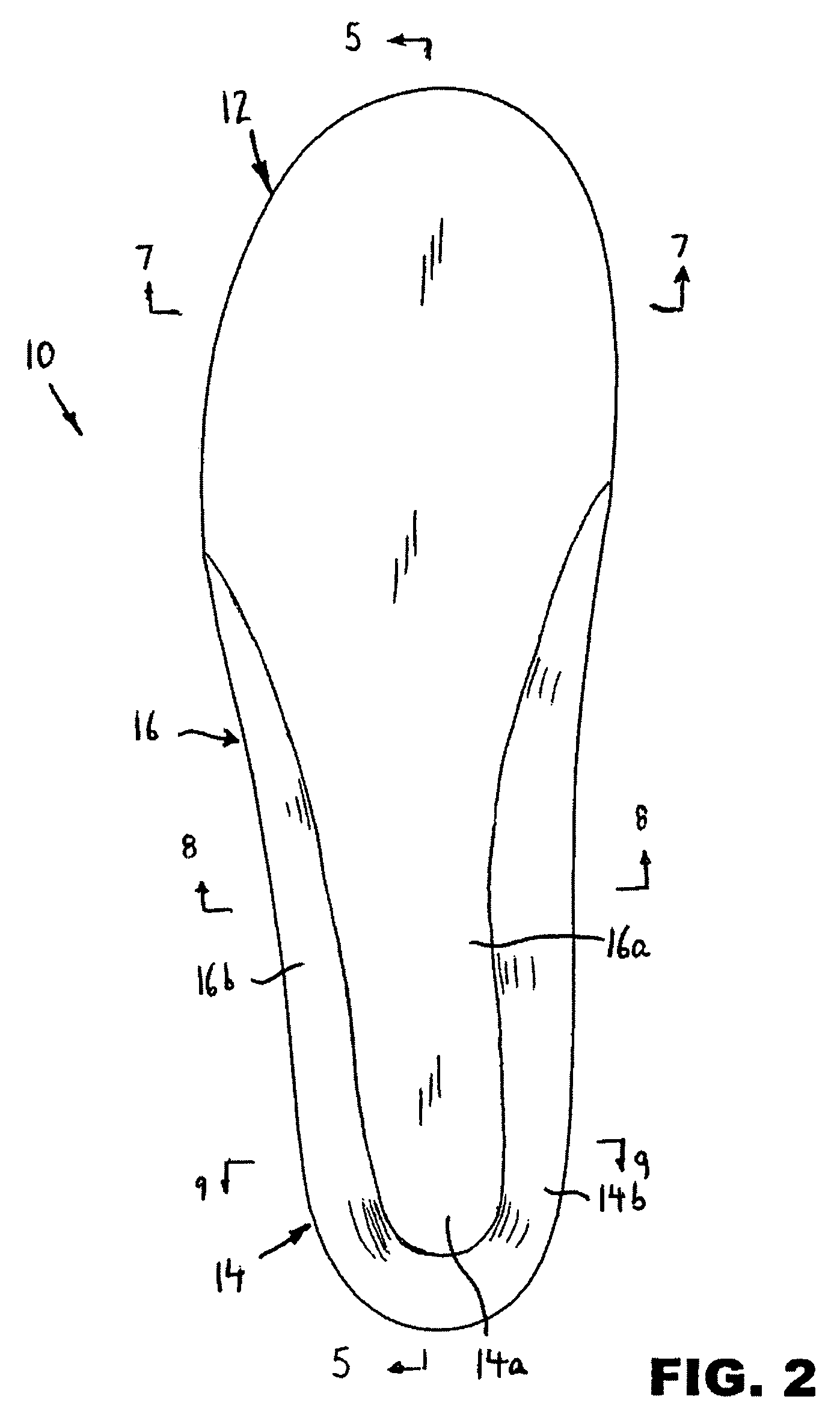

Heel insert

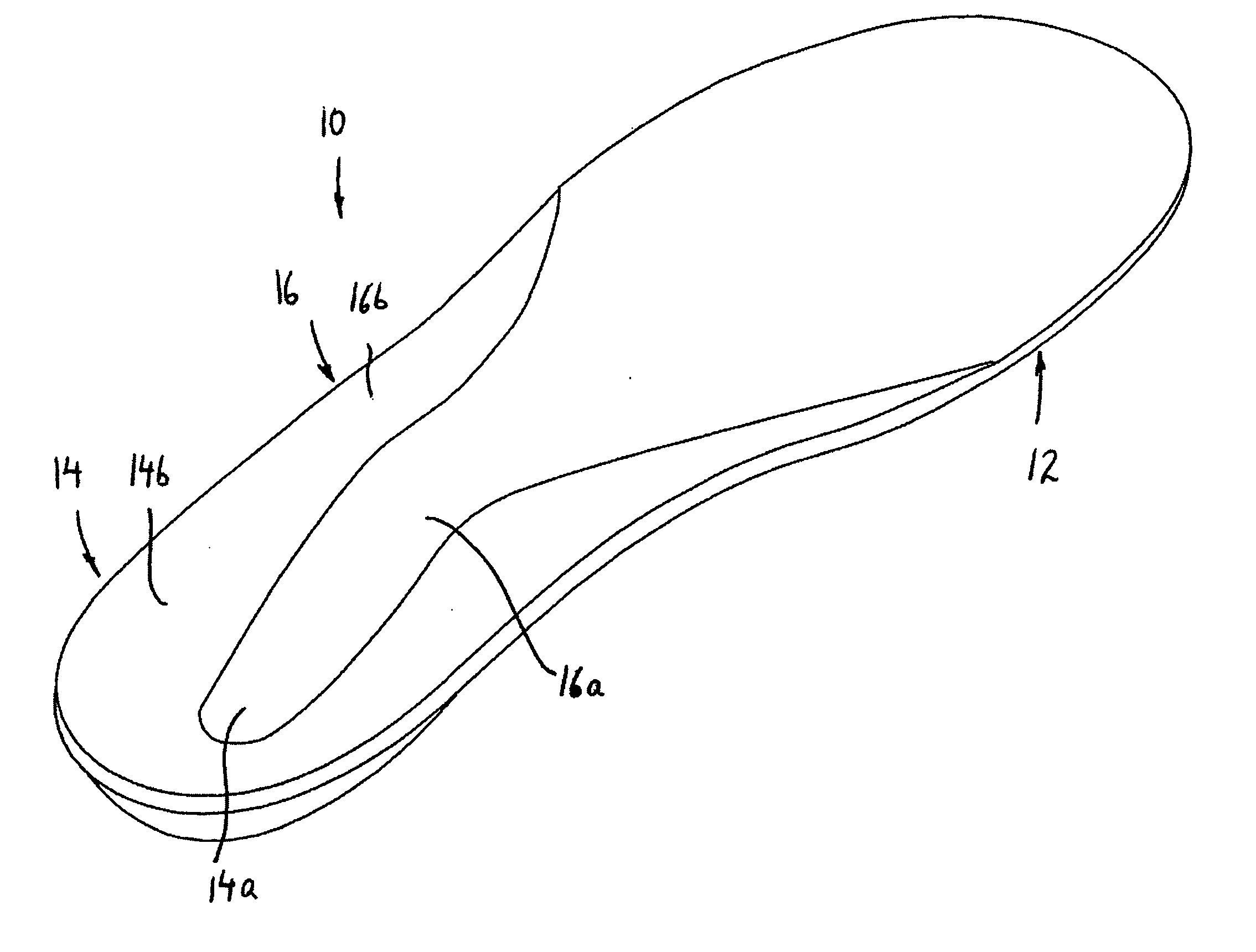

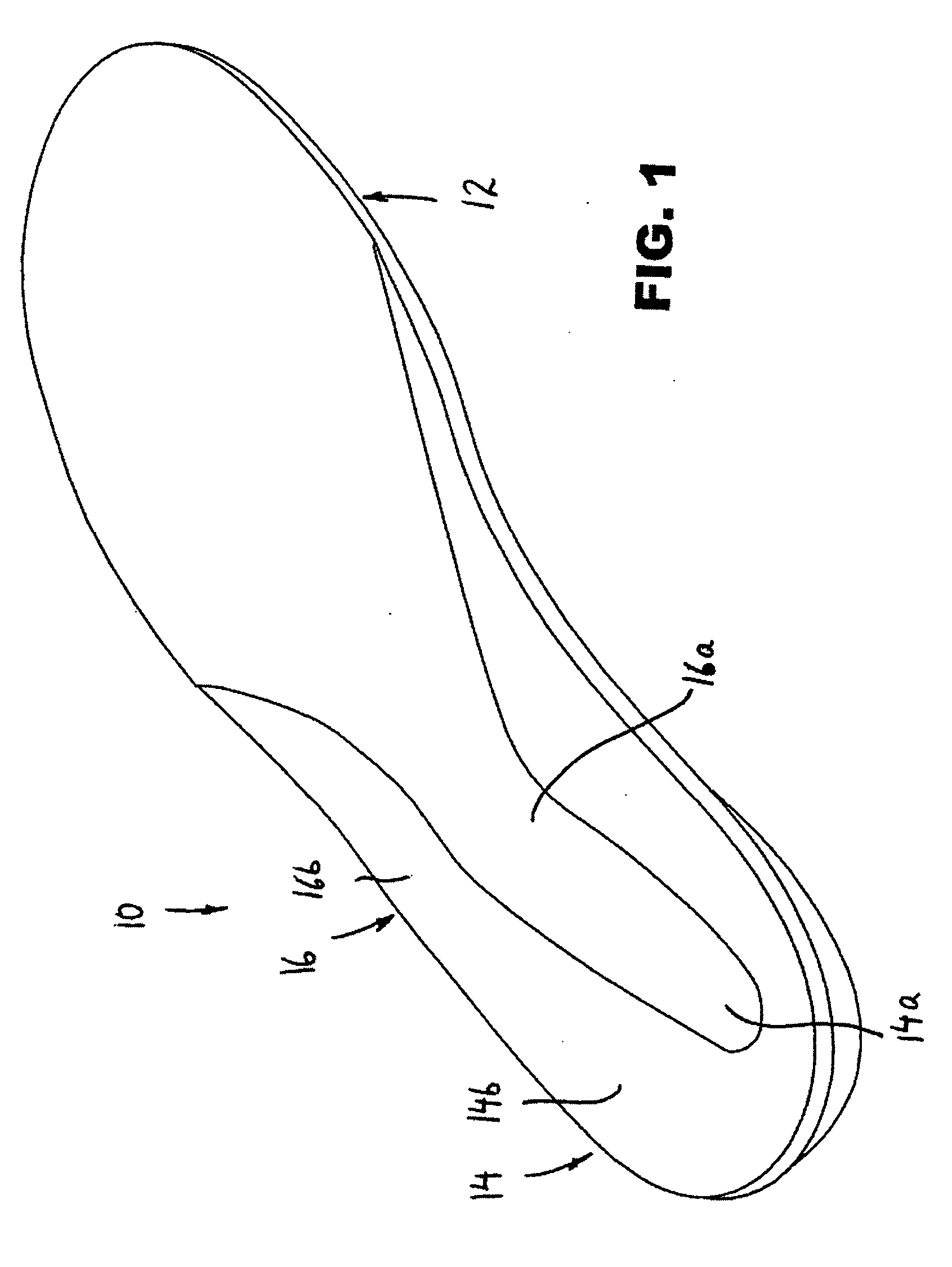

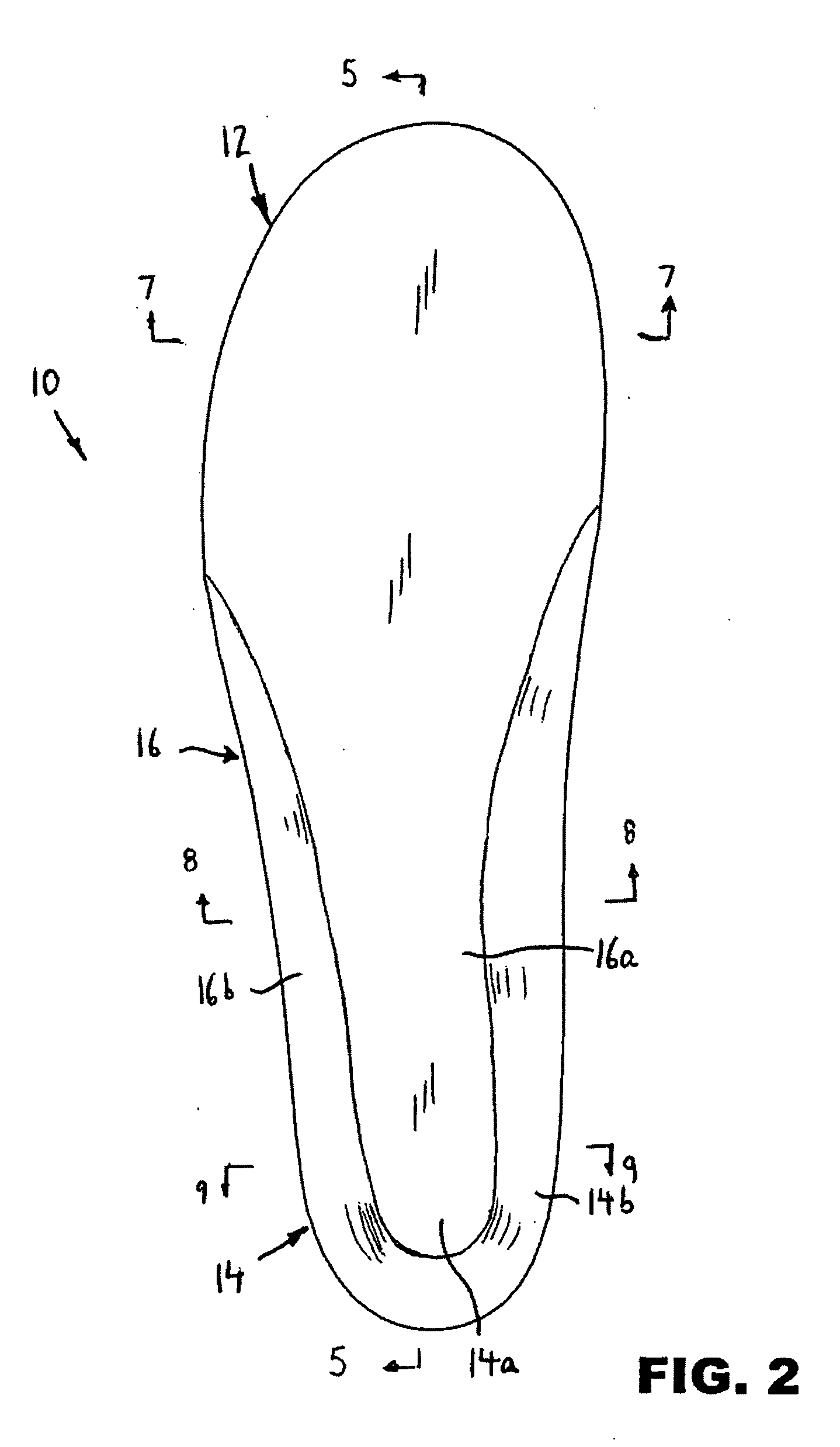

A removable insole for insertion into footwear, includes a forefoot portion, a heel portion, and an arch portion connecting together the forefoot and heel portions. At least one of the forefoot portion, heel portion and arch portion is formed by a lower layer of a resilient material which provides a cushioning function, and an upper layer positioned and secured on top of the lower layer and formed of a material having a Shore “000” hardness of less than about 45, and a tear strength greater than about 6.3 lb / in.

Owner:MSD CONSUMER CARE INC

High-temperature resisting methyl vinyl silicone rubber

The invention discloses high-temperature resisting methyl vinyl silicone rubber as well as a prescription and a preparation process thereof. The high-temperature resisting modified silicon rubber material which has more than 300 DEG C of application temperature and can not crack when according with requirements of 550 DEG C, 4mm distance and high-temperature radiation for more than 12 minutes is prepared by adopting the following steps of: adding cerium oxide and polymide into the prescription in which methyl vinyl silicon crude rubber is taken as a rubber raw material to improve the heat-resisting temperature, adding hydroxy silicone oil, dimethyl silicon oil and a silane coupling agent to improve the oil-resisting performance, adding precipitation method white carbon black and gas-phase method white carbon black to improve the tearing-resistance strength, adding quartz power and kieselguhr to improve the tensile strength and matching technical schemes of the preparation process. The high-temperature resisting methyl vinyl silicone rubber overcomes the problems and the defects of poor high-temperature and aging resistance performance and short service life of the common silicone rubber in the prior art, satisfies the special requirements for the heat-resisting performance, the electrical strength and the mechanical strength of automotive rubber products, and ensures that the silicone rubber products achieve the aims of improving the high-temperature resistance performance and prolonging the service life.

Owner:NINGBO GUANGMING RUBBER & PLASTIC

Tire components having improved tear strength

InactiveUS6255372B1High tear strengthLess susceptible to chippingSpecial tyresPolypropyleneEngineering

A tire having improved tear strength including at least one component comprising a vulcanized elastomer from about 5 to about 50 parts by weight polypropylene per one hundred parts by weight elastomer, and from about 0.05 to about 2.0 parts by weight of an anhydride compatibilizing agent per one hundred parts by weight elastomer.

Owner:BRIDGESTONE CORP

Method of making microporous breathable film

InactiveUS6953510B1High tear strengthGood extrusion processing performanceLamination ancillary operationsLaminationPolymer sciencePolyolefin

A polyolefin microporous breathable film having improved tear and impact strength as well as a soft feel is provided by a film including a polypropylene precursor film and a filler. Other embodiments include a second polymer component.

Owner:TREDEGAR FILM PROD CORP

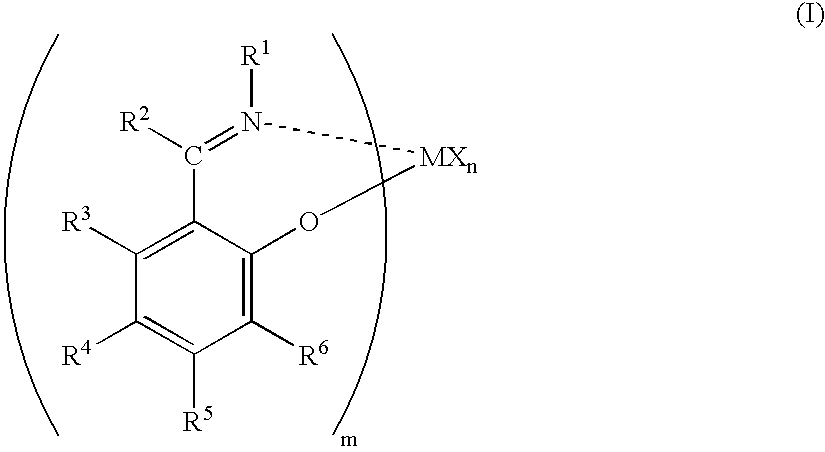

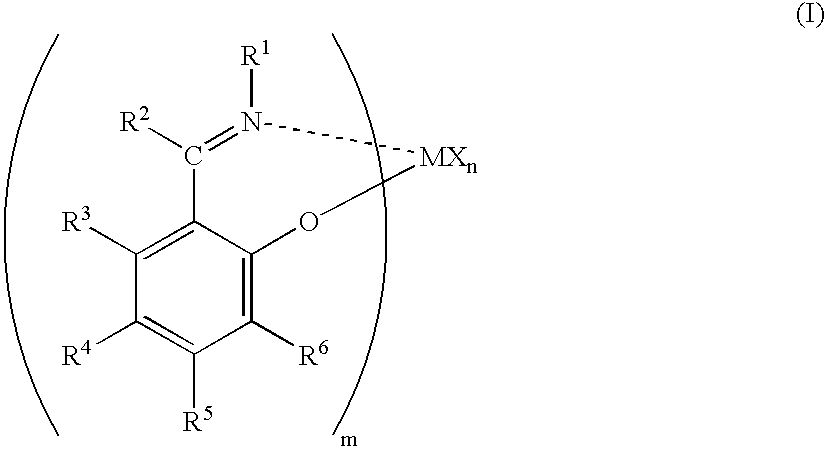

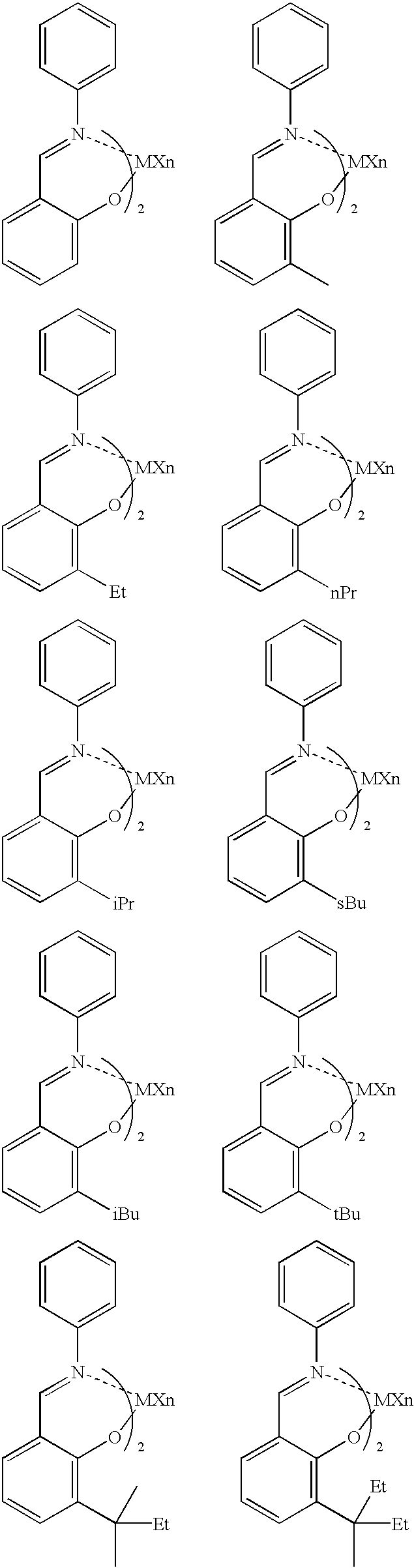

Ethylene copolymer and process for producing the same, resin composition containing the copolymer, and uses of these

InactiveUS6462136B1High tear strengthUniform processElectric/magnetic detectionAcoustic wave reradiationPolymer scienceActivation energy

The present invention is intended to provide an ethylene copolymer having excellent mechanical properties and moldability, a process for preparing the copolymer, a resin composition containing the copolymer and uses thereof. The ethylene copolymer has the following properties: the copolymer comprises 90 to 99% by mol of ethylene constituent units and 1 to 60% by mol of C3-20 alpha-olefin constituent units; the ratio (Mz / Mw) of a Z average molecular weight (Mz) to a weight-average molecular weight (Mw), each molecular weight being measured by GPC, is in the range of 10 to 30, and said ratio (Mz / Mw) and the ratio (Mw / Mn) of a weight-average molecular weight (Mw) to a number-average molecular weight (Mn), each molecular weight being measured by GPC, satisfy the relation (Mz / Mw)>(Mw / Mn); the intrinsic viscosity is in the range of 0.5 to 9 dl / g; the ratio (n*0.01 / n*8) of a melt viscosity (eta*0.01) at a shear rate of 0.01 rad / sec, as measured at 190° C., to a melt viscosity (eta*8) at a shear rate of 8 rad / sec, as measured at 190° C., and the intrinsic viscosity (eta) satisfy the relation (eta*0.01 / eta*8)>=0.893x(eta)+1.0; and the absolute value of an activation energy (Ea) of a shift factor of melt viscoelasticity is not more than 4x104 J / mol.K.

Owner:MITSUI CHEM INC

Heel insert

A removable insole for insertion into footwear, includes a forefoot portion, a heel portion, and an arch portion connecting together the forefoot and heel portions. At least one of the forefoot portion, heel portion and arch portion is formed by a lower layer of a resilient material which provides a cushioning function, and an upper layer positioned and secured on top of the lower layer and formed of a material having a Shore “000” hardness of less than about 45, and a tear strength greater than about 6.3 lb / in.

Owner:MSD CONSUMER CARE INC

Spray polyurea high-performance waterproof paint and preparation method thereof

InactiveCN101818019AFast curingHigh strengthPolyurea/polyurethane coatingsDiluentUltimate tensile strength

The invention relates to a spray polyurea high-performance waterproof paint which is characterized by comprising component A and component B, wherein the component A comprises semi-prepolymer formed by the reaction between 70-35 parts of polyisocyanate and 30-50 parts of polyether glycol, and 0-15 parts of diluent based on parts by weight; the component B comprises 50-70 parts of amine-terminated polyether, 20-40 parts of amine chain extender and 5-10 parts of filler; and the volume ratio between the component A and the component B is 1:1. Compared with the common spray polyurea high-performance waterproof paint, the spray polyurea high-performance waterproof paint has higher tensile strength, elongation at break, tearing strength and other physical properties, and not only is applicable to waterproof projects of common building projects, basic facilities and the like, but also is especially suitable for high-difficulty waterproof projects of large basic facility construction such as a high speed railway, a subway, a tunnel, water conservancy project and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

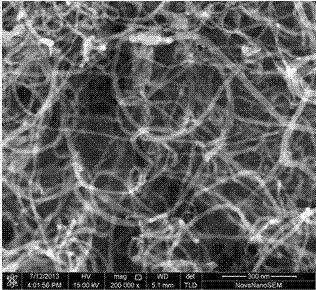

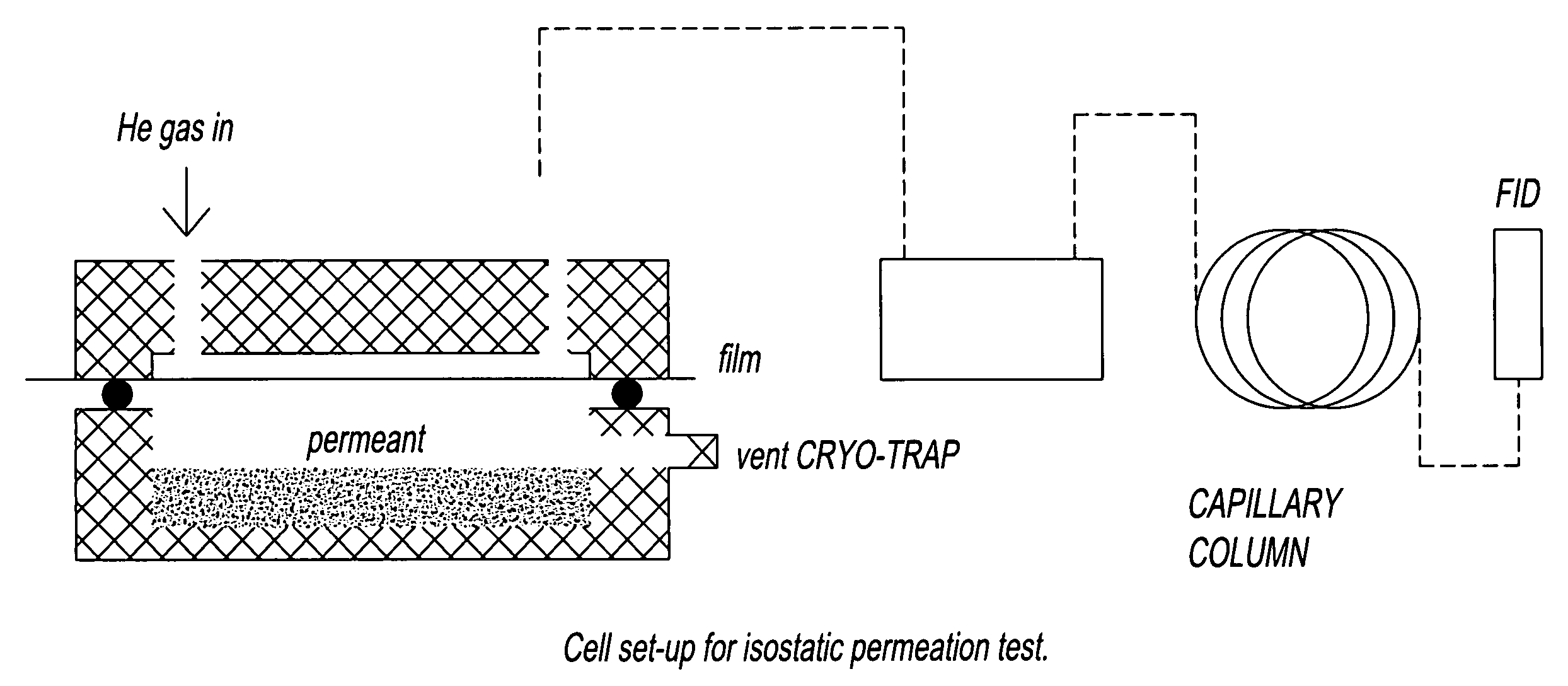

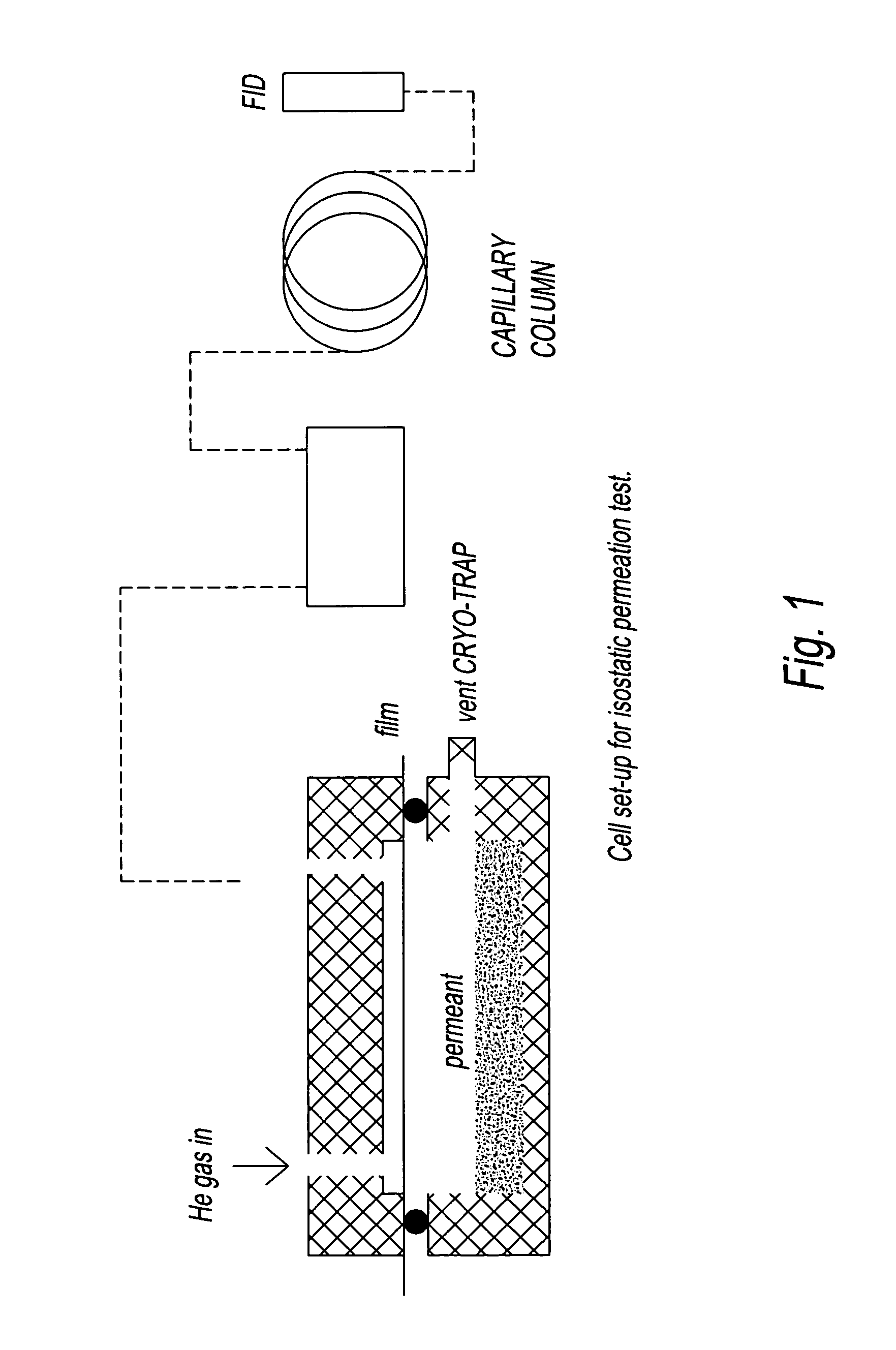

Preparation method of pre-dispersed carbon nano-tube rubber masterbatches

ActiveCN104513410AHigh tear strengthWear volume reductionSpecial tyresMicron scaleHigh concentration

The invention belongs to the field of materials and specifically relates to a preparation method of pre-dispersed carbon nano-tube rubber masterbatches. The method is characterized in that the rubber masterbatches comprise the following ingredients, by weight, 5-100 parts of carbon nano-tube, 5-100 parts of rubber, 5-100 parts of wax, 0.5-50 parts of a dispersing aid, 0.5-5 parts of an anti-aging agent and 0.1-10 parts of an activator. The preparation method of the rubber masterbatches comprises the following specific steps: carrying out high-speed shearing on the above ingredients, mixing, carrying out in situ activated modification on carbon nano-tube such that carbon nano-tube is uniformly dispersed and has no micron-scale aggregate, and pelleting so as to obtain the pre-dispersed high-concentration carbon nano-tube rubber masterbatches. By the use of the pre-dispersed carbon nano-tube rubber masterbatches prepared by the above formula and method, tear strength of tire tread rubber can be raised by about 5-10% and even more, wear volume of Akron is reduced by about 30% and even more, volume resistivity is minimized by two orders of magnitudes, and mechanical properties such as tensile strength, elongation at break and the like are basically unchanged or increased a little.

Owner:SHANDONG DAZHAN NANO MATERIALS

Odor control cassette

InactiveUS7073311B2Reduce odorInexpensive and easy to manufactureLayered productsCharge supportsHigh densityMagnetic tape

A film is provided for use in a cassette. Preferably, the cassette is used in a waste disposal system. The film is a high density polyethylene film resin having both a low melt index and a high density, thereby providing improved odor control capabilities and enhanced tear strength and assembly strength.

Owner:WELLS FARGO BANK NAT ASSOC

Articles prepared from certain hydrogenated block copolymers

InactiveUS20100056721A1High tensile strengthHigh tear strengthFilm/foil adhesivesOrganic dyesPolymer scienceEthylene Homopolymers

The present invention relates to articles prepared from novel anionic block copolymers of mono alkenyl arenes and conjugated dienes, and to blends of such block copolymers with other polymers. The block copolymers are selectively hydrogenated and have the structure C-A-B2-A-C or (C-A-B)nX, where the molecular weight of B2 is twice that of B, n is an integer between 2 and about 30, X is the residue of a coupling agent, and wherein prior to hydrogenation each A block is a mono alkenyl arene homopolymer block, each B block is a polymer block of at least one conjugated diene and each C block is a polymer block of (i) ethylene, (ii) alpha olefins of 3 to 10 carbon atoms; or (iii) monomers of 1,3-butadiene having a vinyl content less than 10 mol percent prior to hydrogenation. The block copolymer may be blended with at least one other polymer selected from the group consisting of olefin polymers, styrene polymers and amorphous resins.

Owner:KRATON POLYMERS US LLC

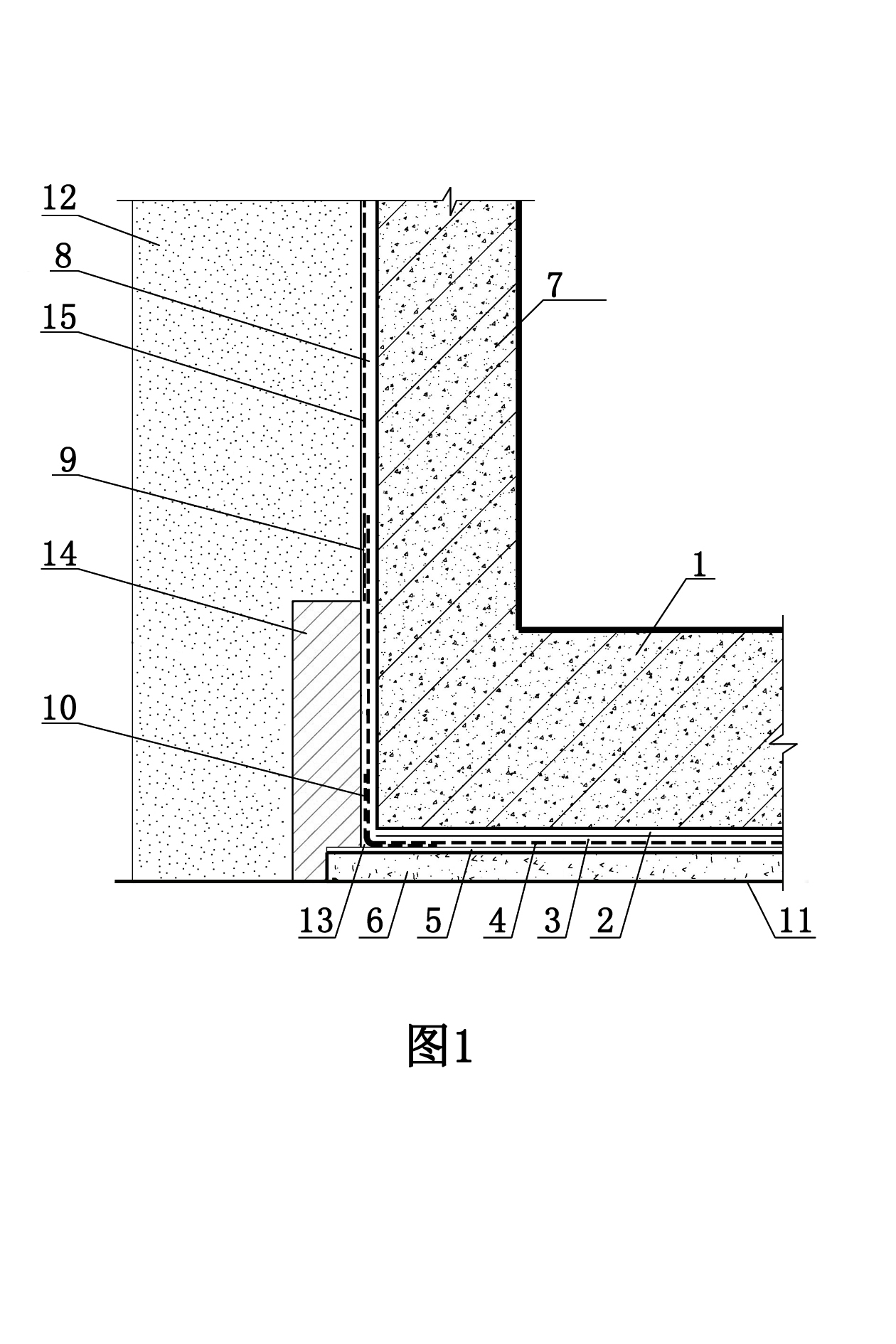

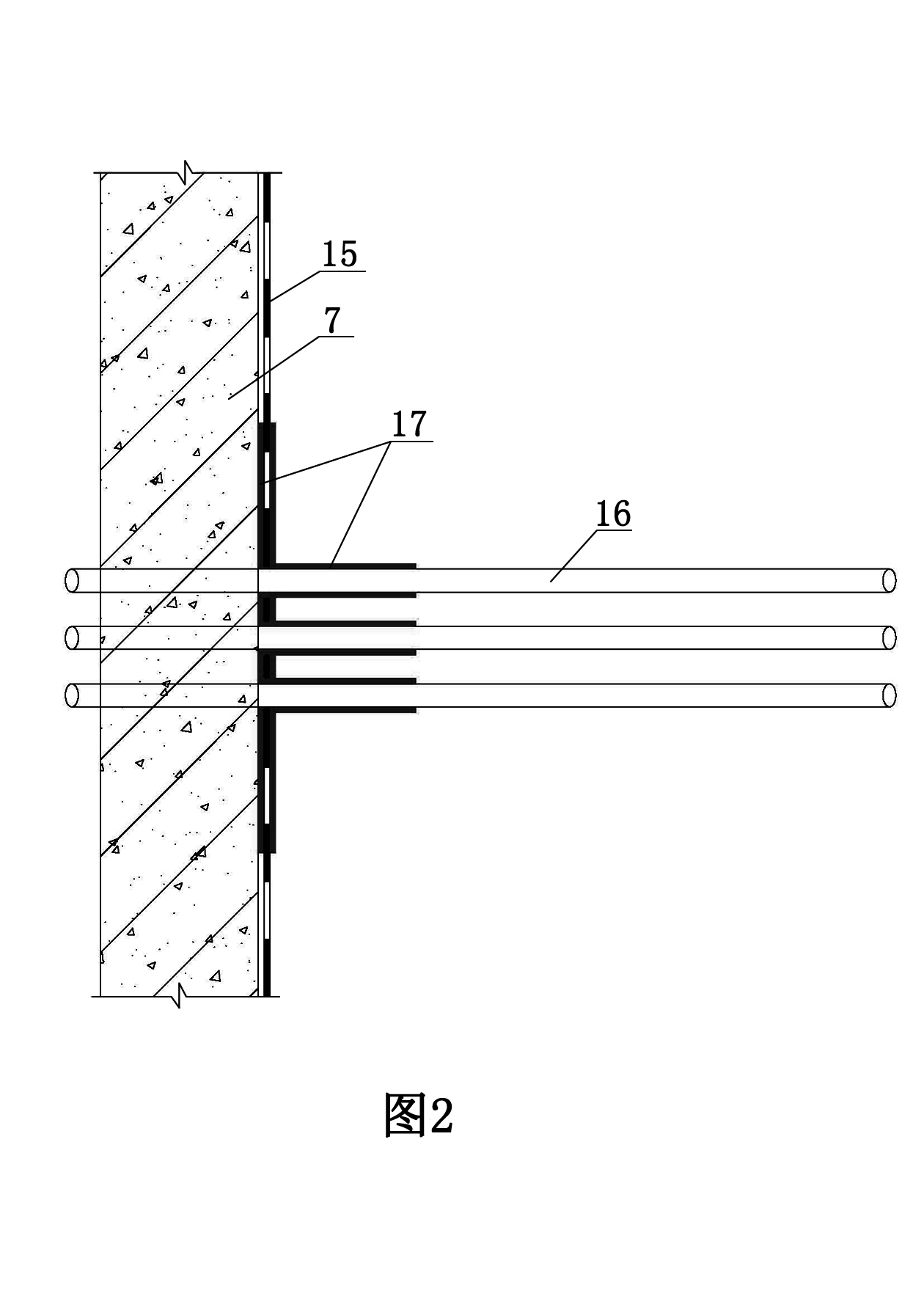

Waterproof system for basement bottom board and wall surface and construction method thereof

InactiveCN101914927AReduce weightHigh tensile strengthArtificial islandsBuild-up roofsBasementBituminous waterproofing

The invention relates to a waterproof system for a basement bottom board and a wall surface and a construction method thereof. The construction method comprises the steps of: horizontally spreading and pasting a self-adhesive rubber bituminous waterproof sheet material on a concrete base layer, and building up a brick permanent protection wall outside a preset position of a basement wall surface, wherein the bottom of the brick permanent protection wall is vertically connected with the concrete base layer, the self-adhesive rubber bituminous waterproof sheet material spreads over corners of the basement wall surface and then is upward folded to be spread and pasted on the water attaining surface of the brick permanent protection wall, then the self-adhesive rubber bituminous waterproof sheet material is lapped with another self-adhesive rubber bituminous waterproof sheet material pasted above the brick permanent protection wall, a self-adhesive rubber bituminous waterproof sheet material is pasted on an outer vertical surface of the basement wall surface. The construction method has the advantages of strong construction continuity, fast speed, good construction environment, low cost and the like, eliminates the hidden danger of fire since the heating is avoided in the construction process, is safe and reliable, completely changes and improves the traditional waterproof construction environments and the waterproof construction technology. The waterproof system can be widely applied in basements, underground structures and roofs.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Electrosurgical tool cover

ActiveUS9138284B2High tear strengthSufficient flexibilityDiagnosticsSurgical instruments for heatingRobot end effectorEngineering

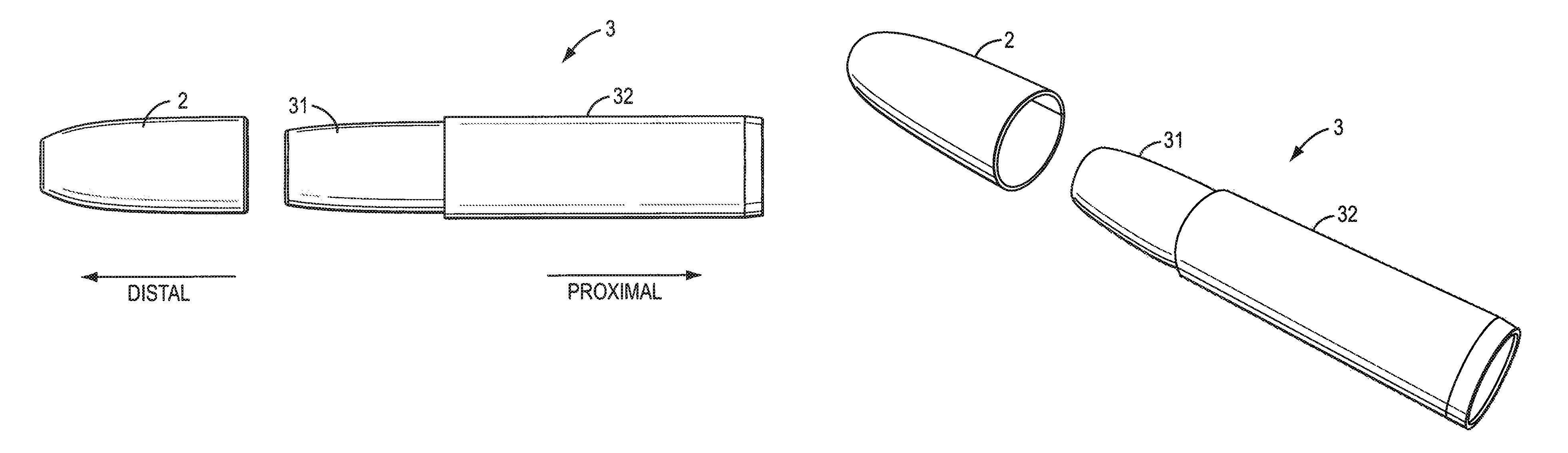

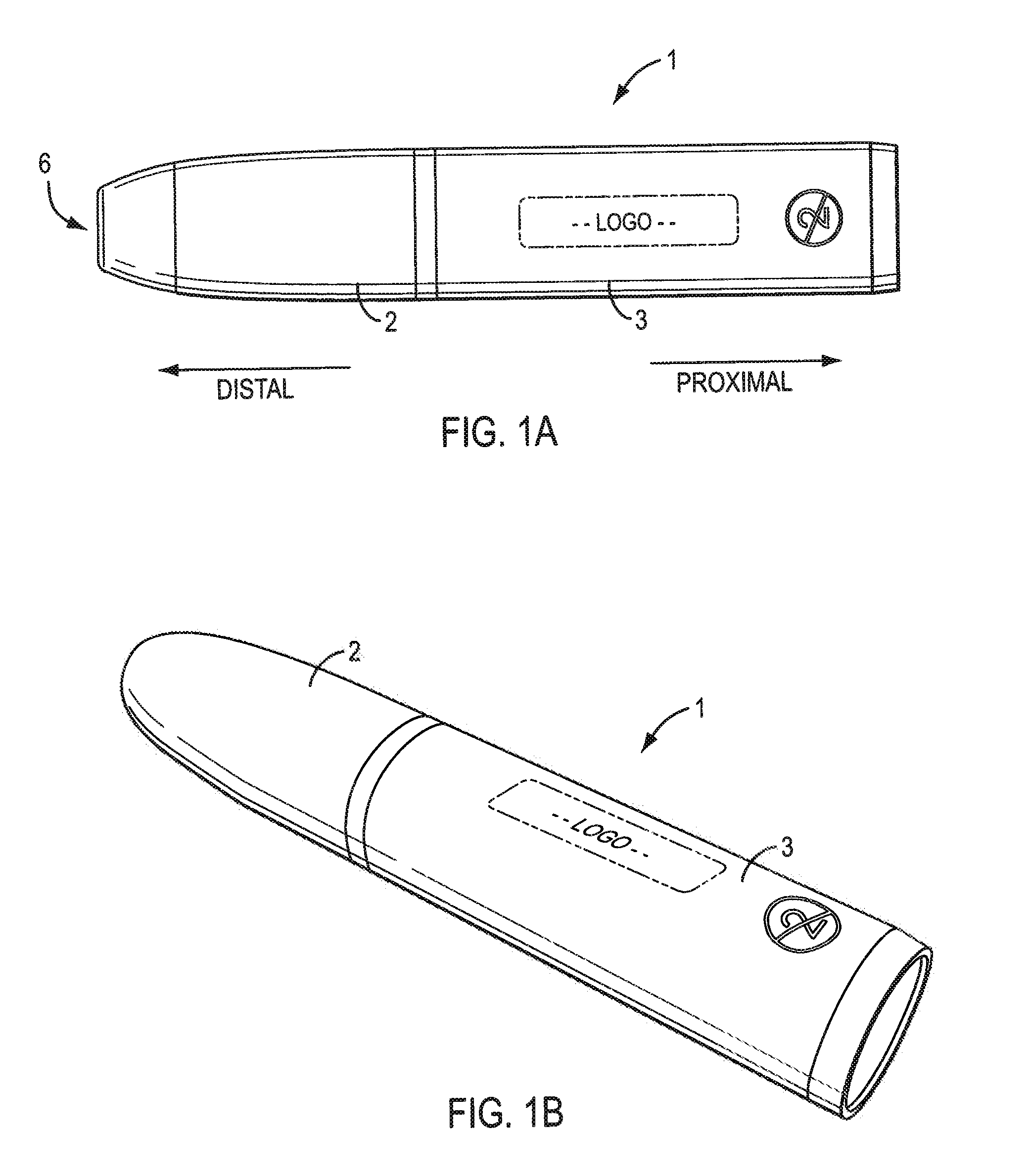

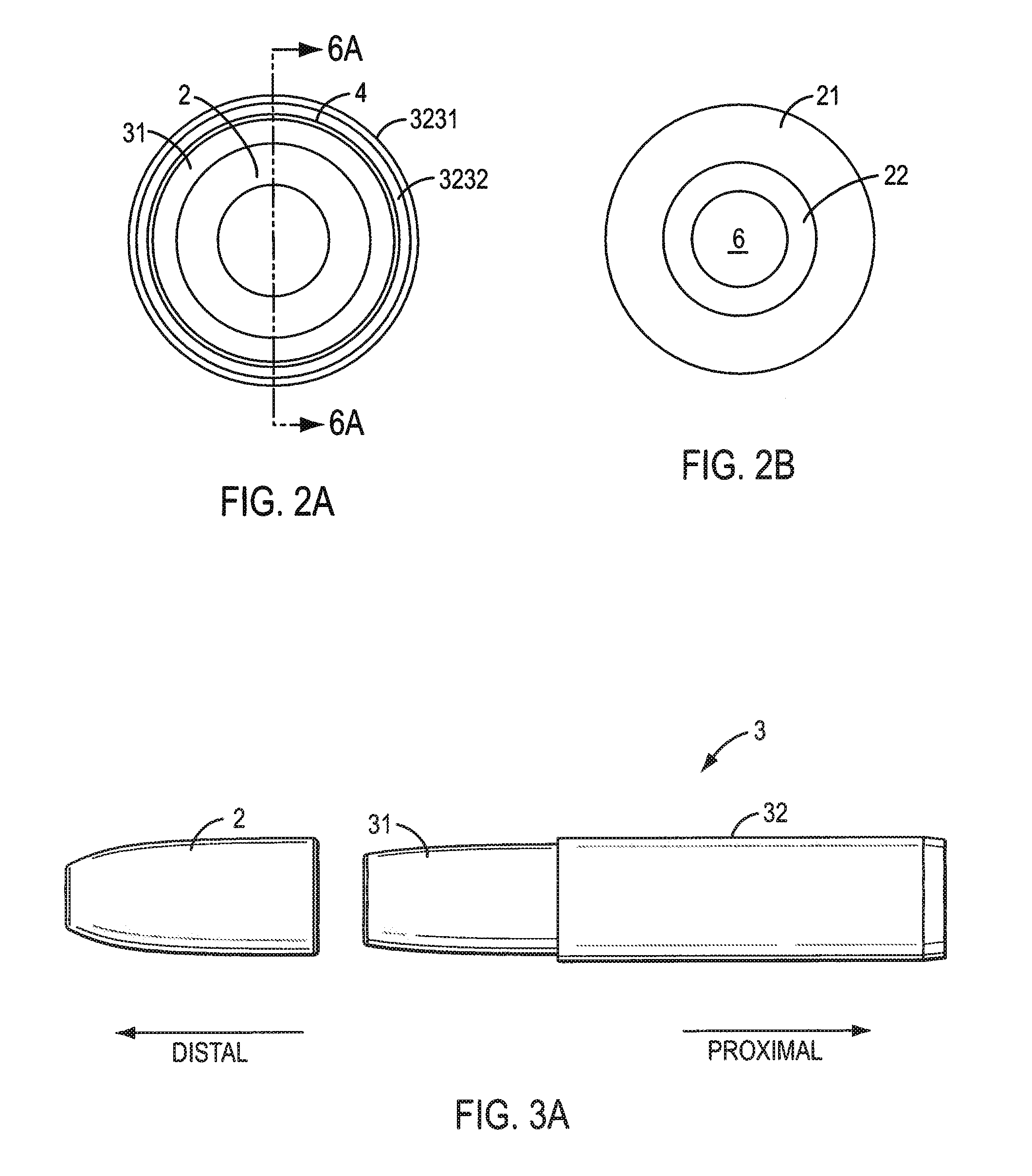

A cover for an electrosurgical instrument having a wrist structure and an end effector is provided. The cover includes a hollow elongated structure, which includes a tip cover portion and a base cover portion integrally connected to the tip cover portion. The tip cover portion has a distal end with an opening therethrough sized to receive the end effector of the electrosurgical instrument and is composed of a first, electrically insulative material having a flexibility sufficient to allow the end effector to be manipulated while the end effector is received in the opening. The base cover portion is composed of a second material having a higher tear strength than the first material. The tip cover portion and the base cover portion overlap at an overlap region configured to receive the wrist structure of the electrosurgical instrument when the end effector is received in the opening.

Owner:INTUITIVE SURGICAL OPERATIONS INC

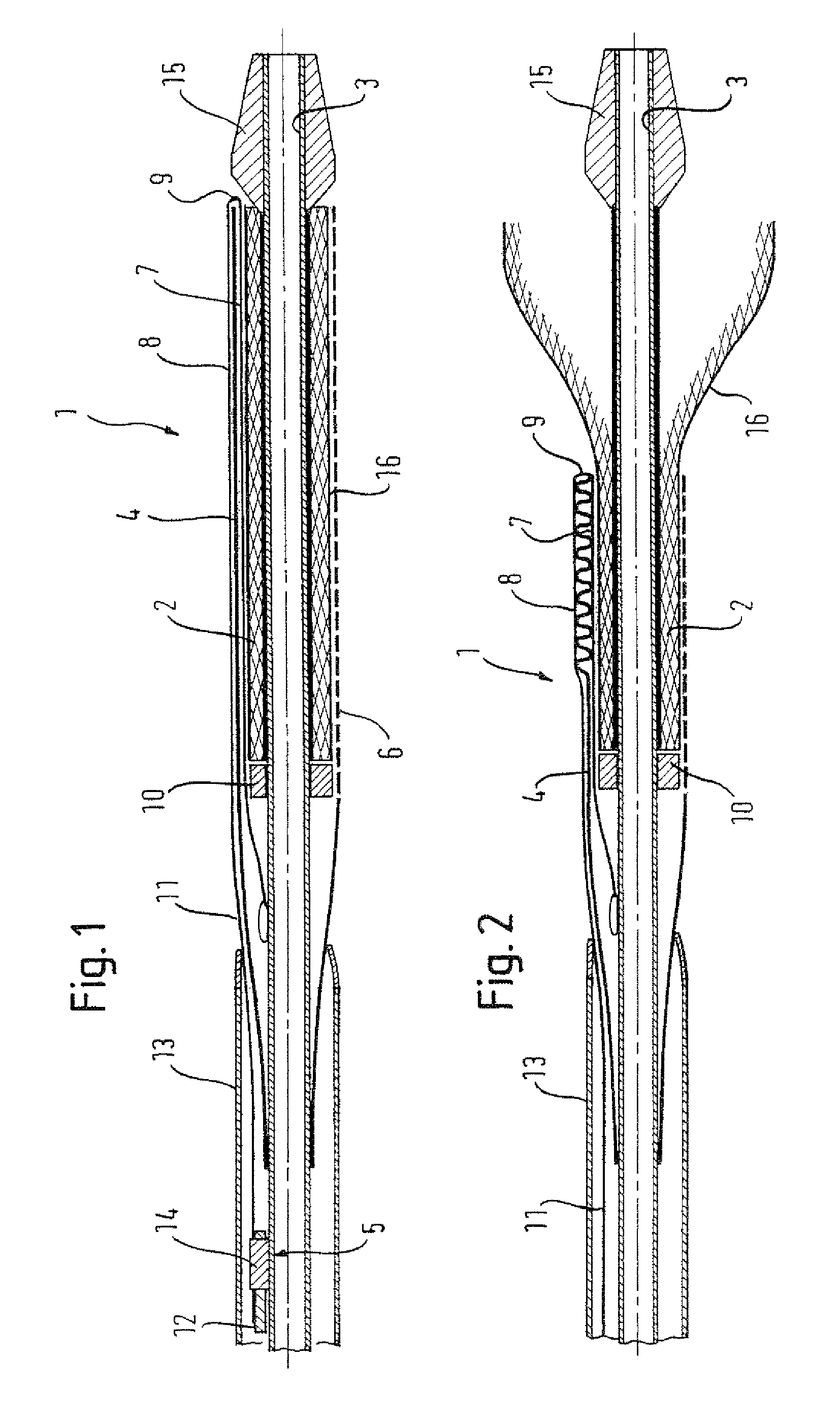

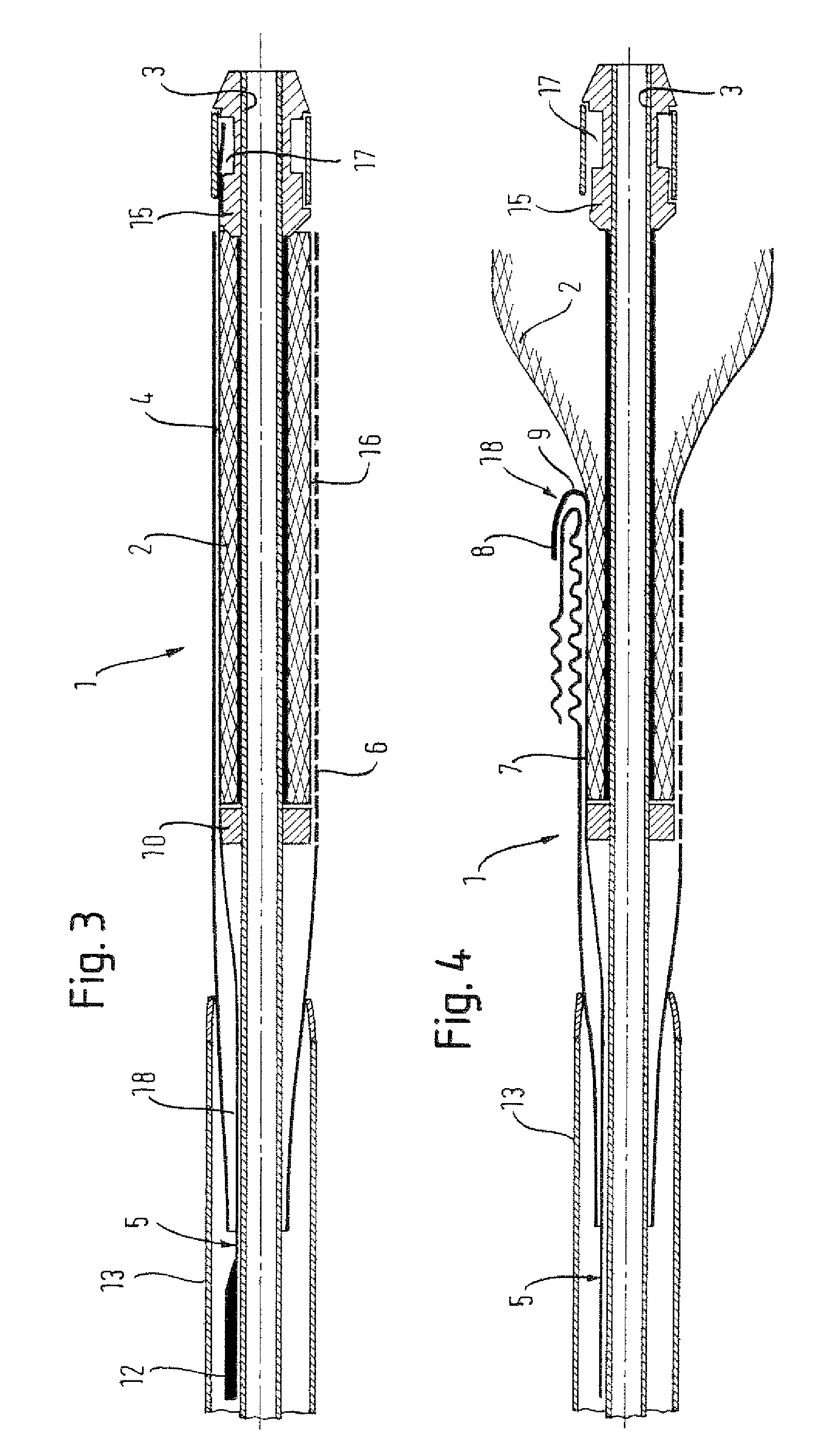

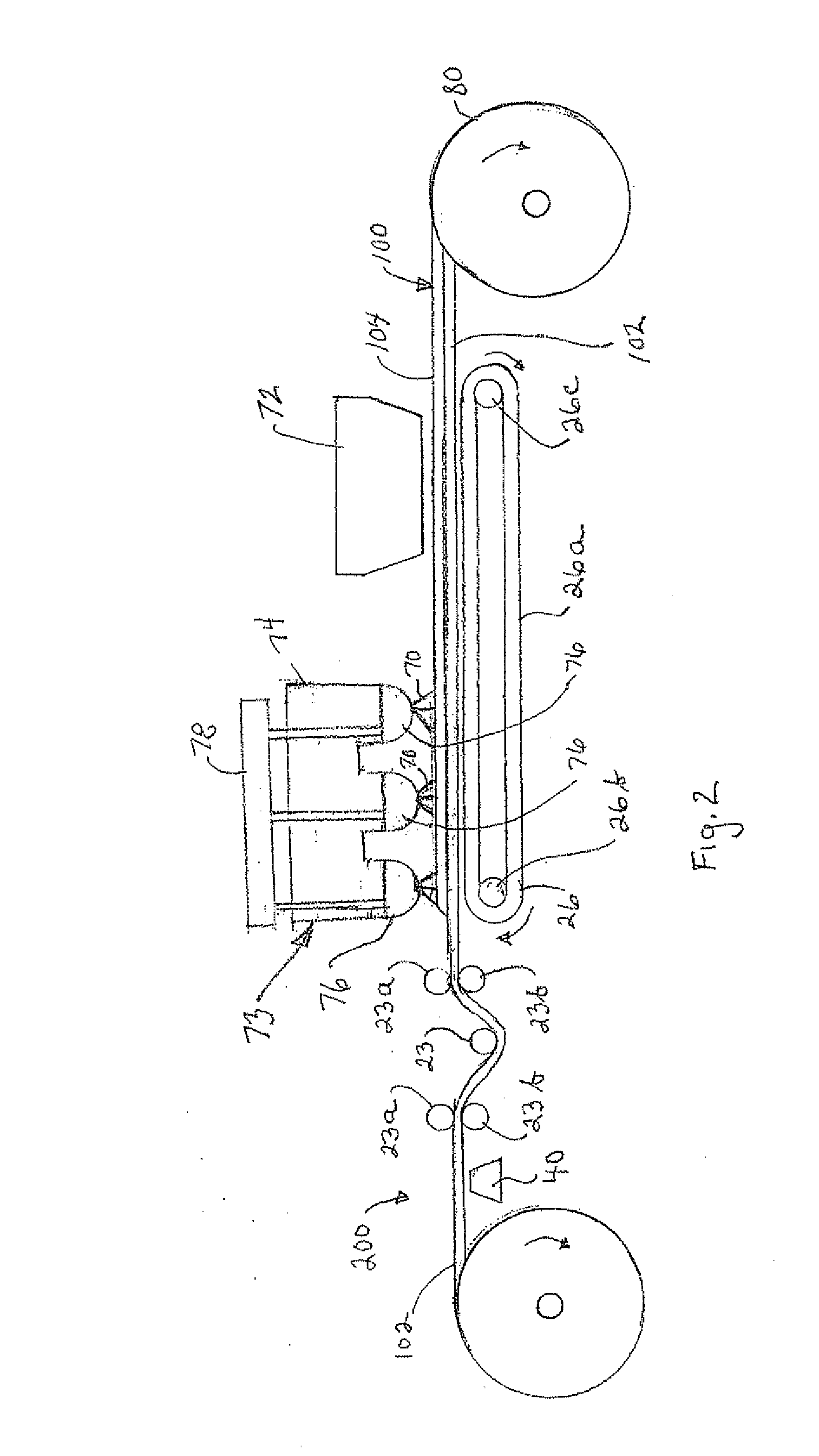

Stent delivery device

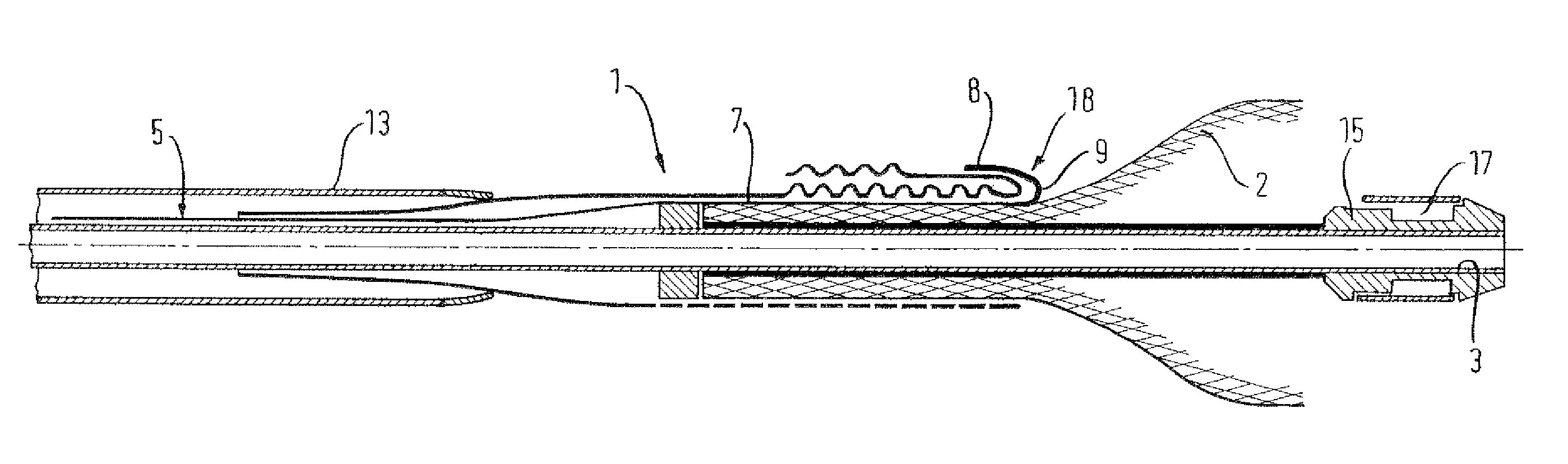

A delivery device is provided for delivering a stent device. The stent device (2) is radially expandable from a radially reduced, delivery configuration to a radially expanded, deployment configuration. A restraining sheath (4) is mounted coaxially over the stent device for maintaining the stent device in the delivery configuration. The restraining sheath has a line of weakness (6) extending axially therealong. A pull member is provided, which is to be pulled so as to split the restraining sheath at the line of weakness and withdraw the restraining sheath from over the stent device. The pull member and the line of weakness are located on opposing sides of the restraining sheath. The pull member (5) is wrapped around a distal end of the restraining sheath. The wrap around portion may be formed by a hook of a metal pull member. The wrap around portion may be formed by an open loop of polymer thread. Both ends of the open loop may extend proximally from the restraining sheath and the stent device with one of the ends being fixed to the delivery device and the other being moveable to provide a pull end.

Owner:CR BARD INC

Reinforced Humidity Adaptive Vapor Retarding Film and Method of Manufacture

InactiveUS20080145681A1Minimum tear strengthTear strengthLiquid surface applicatorsSynthetic resin layered productsFiberUltimate tensile strength

A reinforced humidity adaptive, vapor retarding film and a method of manufacture thereof includes, a combination of a thin film and melt bonded thermoplastic fibers, the combination having a tear strength greater than that of the thin film alone and at least the same as a minimum tear strength required to withstand shipping, handling and installation of an unreinforced thicker film of the same material as the thin film.

Owner:CERTAINTEED CORP

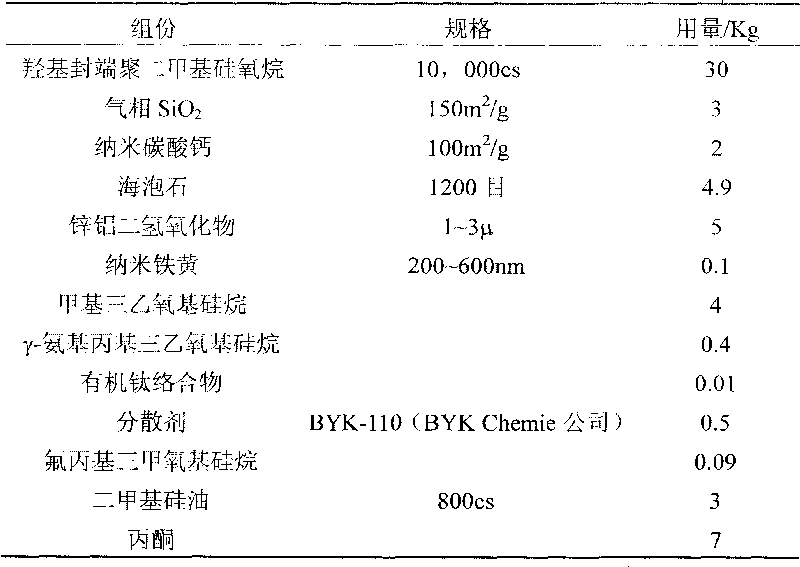

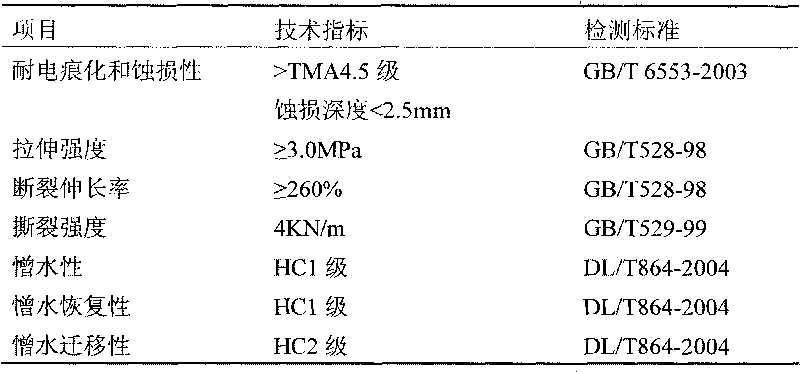

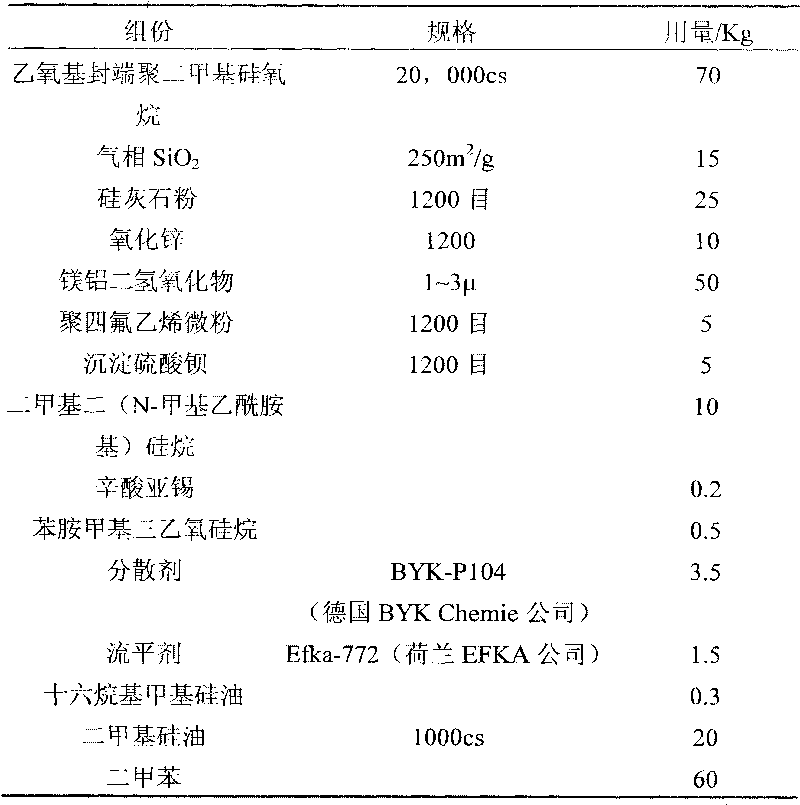

Tracking-proof corrosion-proof room temperature silicon disulfide rubber composite

ActiveCN101747630AHigh tensile strengthHigh elongation at breakPlastic/resin/waxes insulatorsCoatingsRoom temperatureDiluent

The invention relates to a tracking-proof corrosion-proof room temperature silicon disulfide rubber composite which has the following formula: 30-70 parts of polysiloxane by weight, 5-40 parts of reinforced filler by weight, 10-70 parts of electric corrosion resistance stabilizer by weight, 5-15 parts of auxiliary agent by weight and 10-80 parts of diluent by weight. The tracking-proof corrosion-proof room temperature silicon disulfide rubber composite provided by the invention has favourable tracking-proof corrosion-proof performance, has higher tensile strength, breaking elongation and tearing strength as well as favourable surface hydrophobicity, hydrophobicity transference and hydrophobicity restoration and is a functional composite capable of effectively preventing and curing pollution flashover.

Owner:CHINA ELECTRIC POWER RES INST +3

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

Oilfield ultrahigh-pressure acid-resistant rubber seal material and preparation method thereof

ActiveCN103396591AOvercome leaksOvercoming extrusion edge tearing phenomenonOther chemical processesPolymer scienceAntioxidant

An oilfield ultrahigh-pressure acid-resistant rubber seal material comprises, by weight, 85-65 parts of hydrogenated butadiene-acrylonitrile rubber, 15-35 parts of butadiene-acrylonitrile rubber, 5-7 parts of zinc oxide, 1-4 parts of stearic acid, 1-2 parts of an antioxidant, 50-65 parts of nanometer carbon black, 15-25 parts of white carbon black, 5-10 parts of a phenolic resin, 5-10 parts of a softener, 3-6 parts of a peroxide vulcanizing agent, 6-8 parts of a vulcanizing aid, 1-3 parts of sulfur, and 2-4 parts of a promoter, wherein the sum of the weight parts of the hydrogenated butadiene-acrylonitrile rubber and the butadiene-acrylonitrile rubber is 100. A seal ring made through adopting the rubber seal material can satisfy the seal of oilfield high-pressure acid-resistant liquid (hydrochloric acid or hydrofluoric acid) pipelines, and overcomes the leakage and torn edge extrusion phenomena of seal members under a high hydraulic pressure.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Conductive paste for crystalline silicon solar cell and preparation method of conductive paste

ActiveCN104078090AHigh tear strengthImprove adhesion strengthNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteConductive paste

The invention provides conductive paste for a crystalline silicon solar cell. The conductive paste comprises the following components in parts by weight: 100 parts of conductive metal powder, 1.0-10 parts of inorganic binder, 10-65 parts of organic carrier and 0.05-5.0 parts of conductive carbon. The conductive paste is excellent in conductivity; the photoelectric conversion efficiency of the cell is not influenced; and widely applied conductive paste for the crystalline silicon solar cell such as front-side silver paste, front-side seed layer silver paste, back-side silver paste and back electric field aluminum paste can be prepared.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com