Patents

Literature

112results about How to "Good extrusion processing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

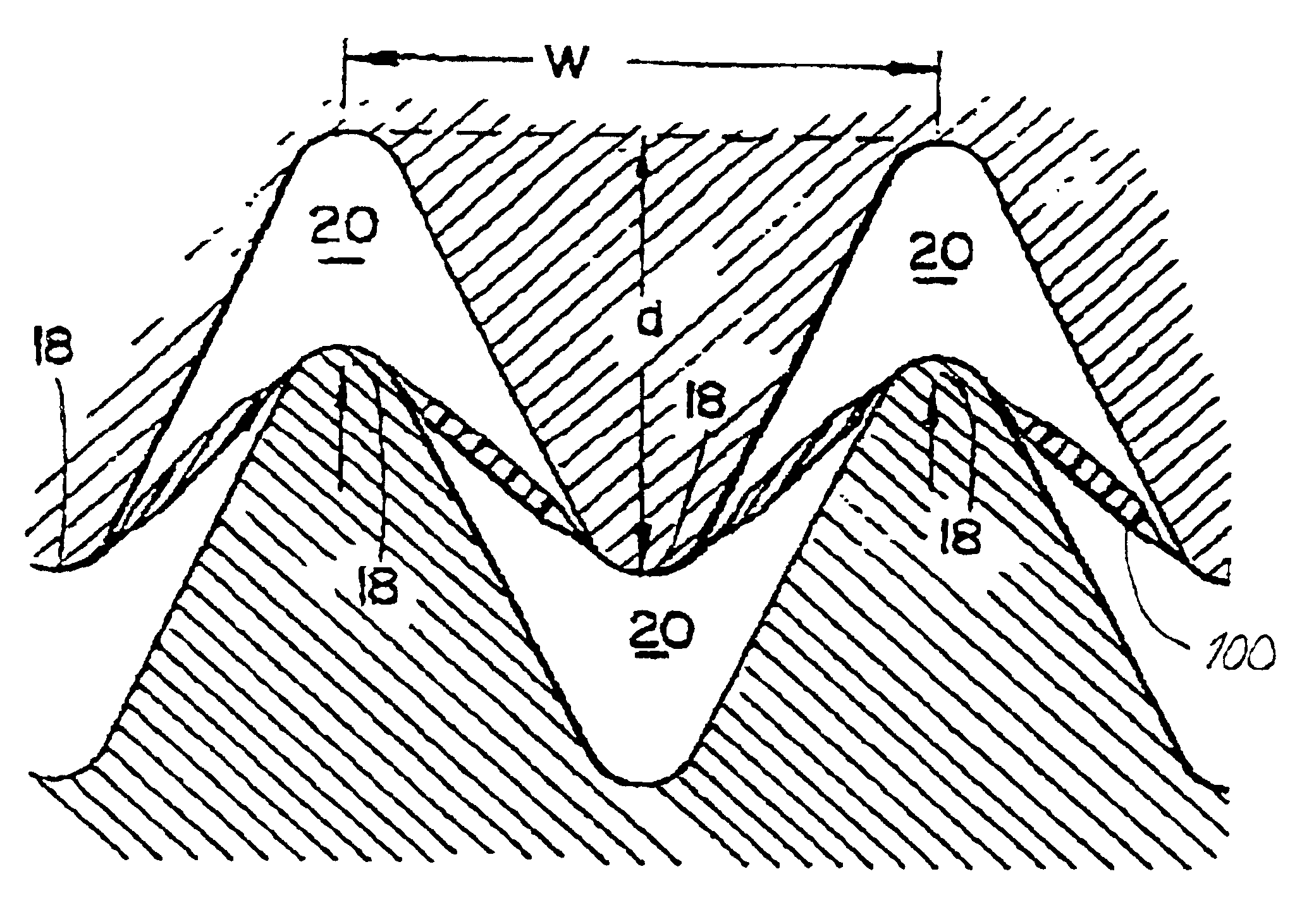

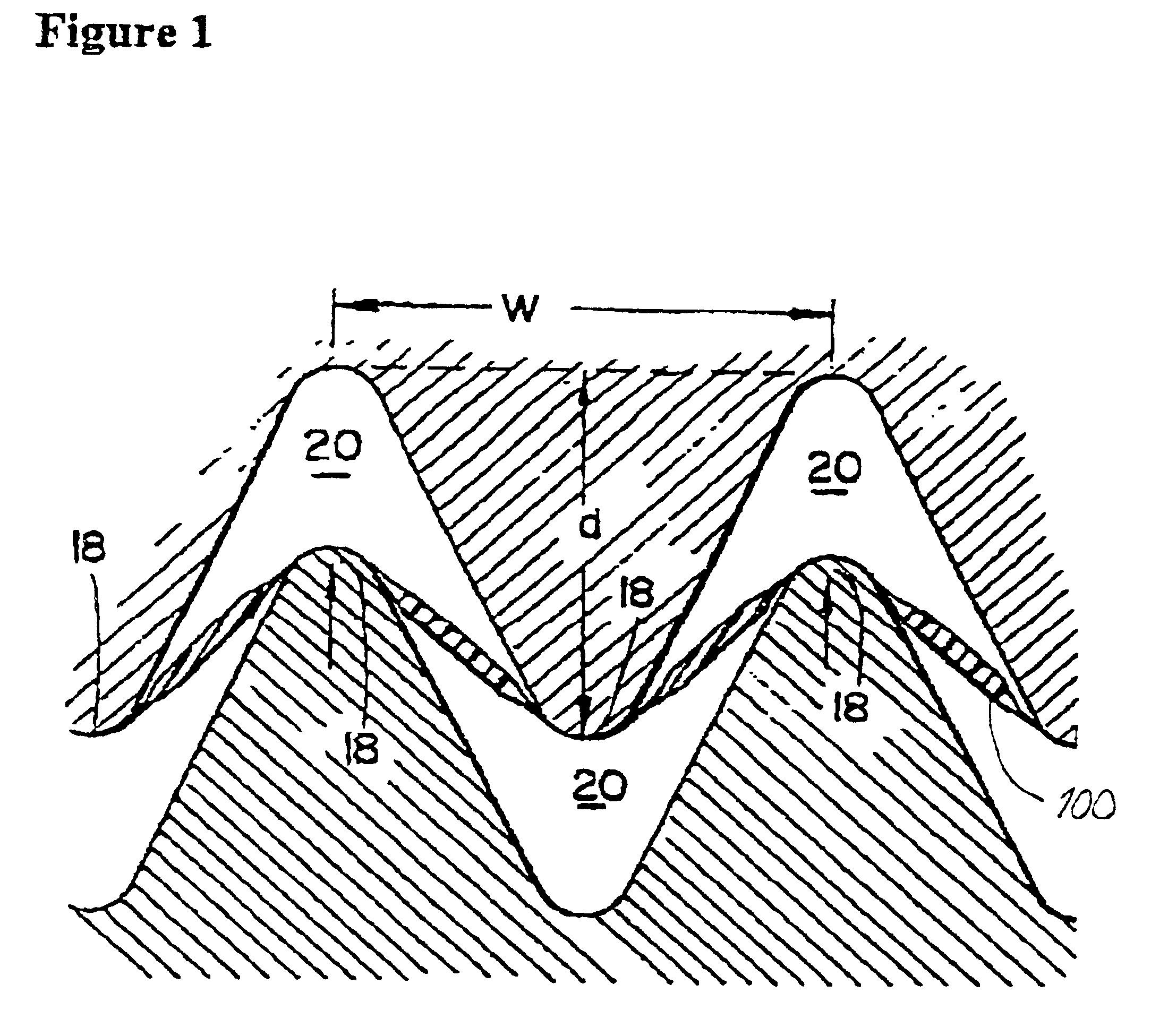

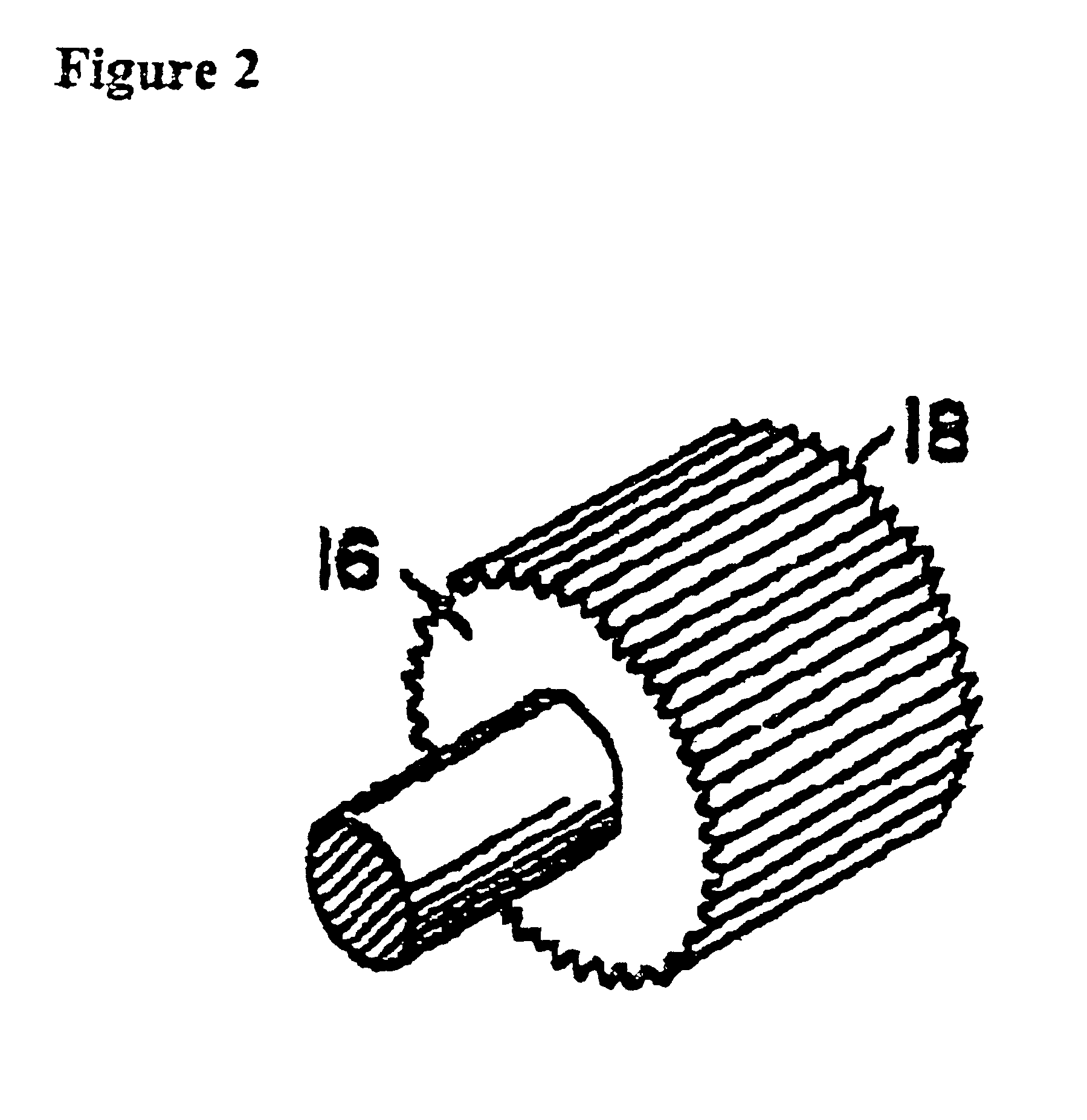

Method of making microporous breathable film

InactiveUS6953510B1High tear strengthGood extrusion processing performanceLamination ancillary operationsLaminationPolymer sciencePolyolefin

A polyolefin microporous breathable film having improved tear and impact strength as well as a soft feel is provided by a film including a polypropylene precursor film and a filler. Other embodiments include a second polymer component.

Owner:TREDEGAR FILM PROD CORP

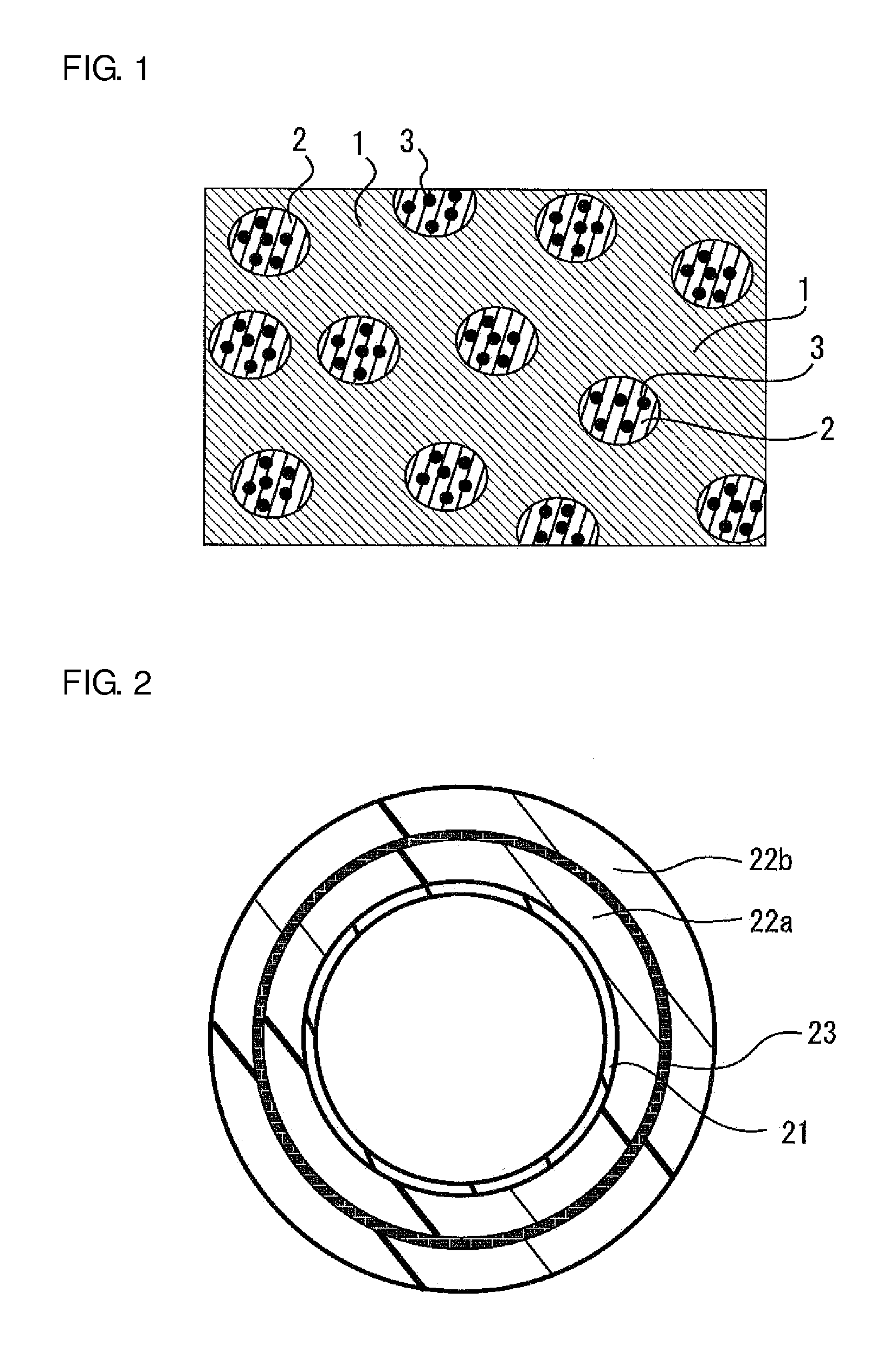

Resin-reinforced elastomer, process for producing same and pneumatic tire using same

There are disclosed a resin-reinforced elastomer which comprises as principal components, a rubber and a polyolefin having an average particle diameter of at most 1 .mu.m, and in which the rubber and the polyolefin are linked together; a process for producing the resin-reinforced elastomer by melt kneading a polyolefin, a No.1 rubber and a binding agent to prepare a thermoplastic composition, adding a No.2 rubber to the resultant thermoplastic composition and melt kneading the mixture thus formed to disperse the polyolefin in the rubber components; and a pneumatic tire using the resin-reinforced elastomer in its tread. The above resin-reinforced elastomer has a uniform modulus and a low density, is minimized in directionality, and is excellent in tensile strength, fatigue resistance and abrasion resistance.

Owner:BRIDGESTONE CORP +1

Rubber composition for tire and pneumatic tire

InactiveUS20120296027A1Improve responseImprove economySpecial tyresRolling resistance optimizationAlkylphenolEngineering

Provided are a rubber composition for a tire which can achieve good handling stability, good fuel economy, good elongation at break, and good steering response in a balanced manner while maintaining good extrusion processability; and a pneumatic tire produced using the rubber composition. The rubber composition includes: 100 parts by mass of a rubber component; 0.5 to 20 parts by mass of an alkylphenol resin; and 0.04 to 10 parts by mass of a methylene donor, wherein the alkylphenol resin is produced from formaldehyde and at least two compounds selected from the group consisting of a 2-alkylphenol, a 3-alkylphenol, and a 4-alkylphenol, and a total amount of the free 2-alkylphenol, 3-alkylphenol, and 4-alkylphenol in the alkylphenol resin is not more than 3% by mass.

Owner:SUMITOMO RUBBER IND LTD

Linear low-density polyethylene composition

ActiveCN102477180AUniform viscosityEliminate cracksLow-density polyethyleneLinear low-density polyethylene

The invention relates to a linear low-density polyethylene composition comprising components of, by weight: 50-98 parts of linear low-density polyethylene with a density of 0.918-0.922g / cm<3> and a melt flow index of 0.1-10g / 10min, 0.5-45 parts of low-density polyethylene with a density of 0.910-0.925g / cm<3> and a melt flow index of 0.1-30g / 10min, 0.5-45 parts of high-density polyethylene with a density of 0.941-0.970g / cm<3> and a melt flow index of 0.5-10g / 10min, 0.5-45 parts of polypropylene with a density of 0.830-0.910g / cm<3> and a melt flow index of 0.5-50g / 10min, 0.1-20 parts of an ethylene-vinyl acetate copolymer with a density of 0.926-0.939g / cm<3>, 0.01-1 part of a rheology modifying agent, and 0.5-20 parts of a compatibilizing agent with a melt flow index of 0.5-50g / 10min. With the composition, extrusion processing performance can be effectively improved, a melt fracture phenomenon can be eliminated, and the compatibility can be improved. With the composition, the strength, flexibility and aging resistance of a product can be improved. The composition can be used for producing films, drip irrigation tapes, and pipes with various specifications.

Owner:XINJIANG TIANYE WATER SAVING IRRIGATION SYST

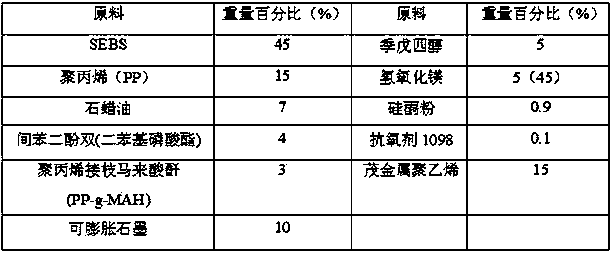

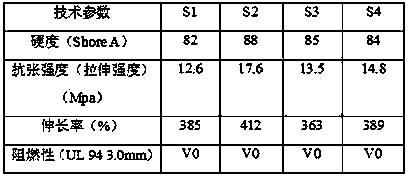

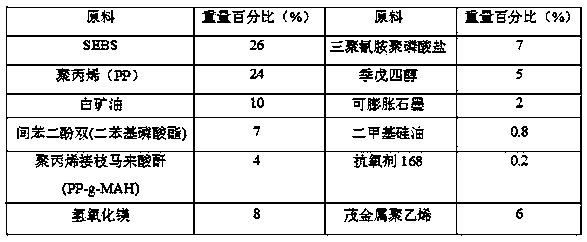

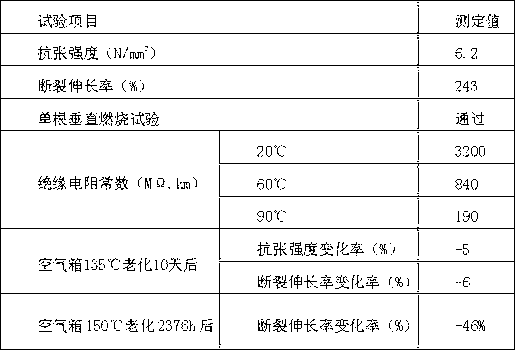

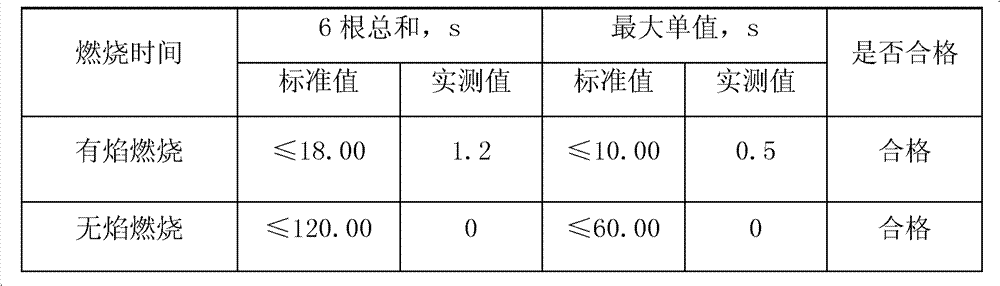

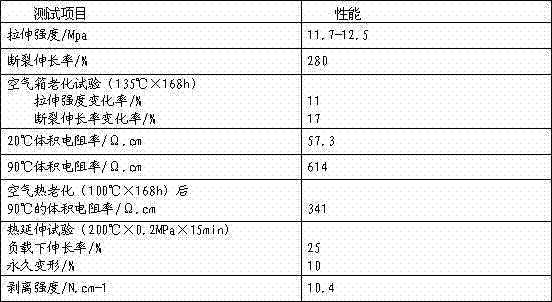

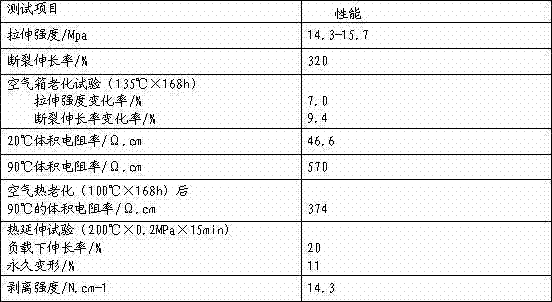

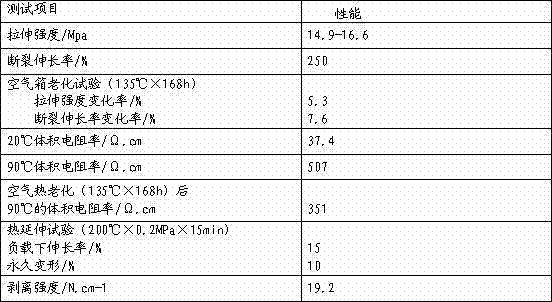

Halogen-free flame retardant thermoplastic elastomer composite material and preparation method thereof

ActiveCN103435955AImprove mechanical propertiesImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolymer science

The invention belongs to the technical field of high polymer materials and particularly relates to a halogen-free flame retardant thermoplastic elastomer composite material. The halogen-free flame retardant thermoplastic elastomer composite material comprises the following components in percentage by weight according to a raw material formula: 25-45 percent of SEBS (Styrenic Block Copolymer), 15-25 percent of polypropylene, 5-15 percent of metallocene polyethylene, 5-15 percent of a flame retardant synergist, 5-15 percent of a soften plasticizer, 15-25 percent of a flame retardant, 3-5 percent of a compatilizer, 0.1-1 percent of an antioxidant and 0.5-2 percent of a processing aid, wherein the flame retardant is a mixture of an inorganic flame retardant and an organic flame retardant; the organic flame retardant is at least one of melamine cyanurate, melamine pyrophosphate, organic hypophosphite and pentaerythritol; the inorganic flame retardant is at least one of zinc borate, magnesium hydroxide and expansible graphite; the mass ratio of the inorganic flame retardant to the organic flame retardant is (0.1-10):1. The composite material disclosed by the invention has the advantages of favorable flame-retardant performance and mechanical property and easiness for processing and forming.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Amylum category complete biodegradable material and preparation method thereof

The invention discloses an amylum category complete biodegradable material and a preparation method thereof. The amylum category complete biodegradable material comprises, by weight, the long-chain branch aliphatic polyester or long-chain branch aliphatic series- aromatic copolyesters 50-70%, the starch 20-30%, the chain extender 0.1-3% and the balance chain extender 9-17%. The preparation method comprises the steps of enabling all components to be mixed in a high speed mixer, feeding in a twin-screw extruder after accurate measurement by means of a measurement scale, and extruding and prilling by adjusting a built-up sequence of a screw and designing different exhaust ports. The amylum category complete biodegradable material and the preparation method of the amylum category complete biodegradable material solve the problems of dispersing, plasticizing and exhausting of starch filler in the twin-screw extruder, and obtained amylum complete biodegradation material not only has complete biodegradation performance, but also has excellent mechanical property and good extrusion molding working quality.

Owner:KINGFA SCI & TECH CO LTD +2

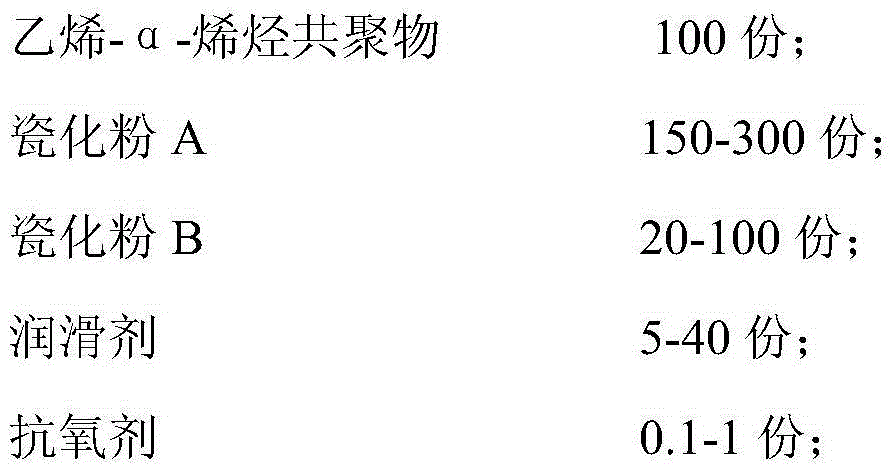

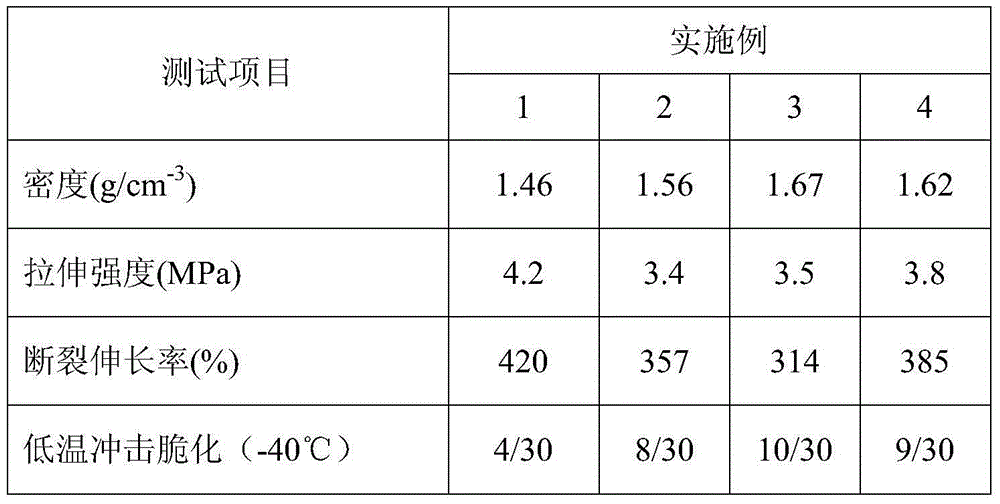

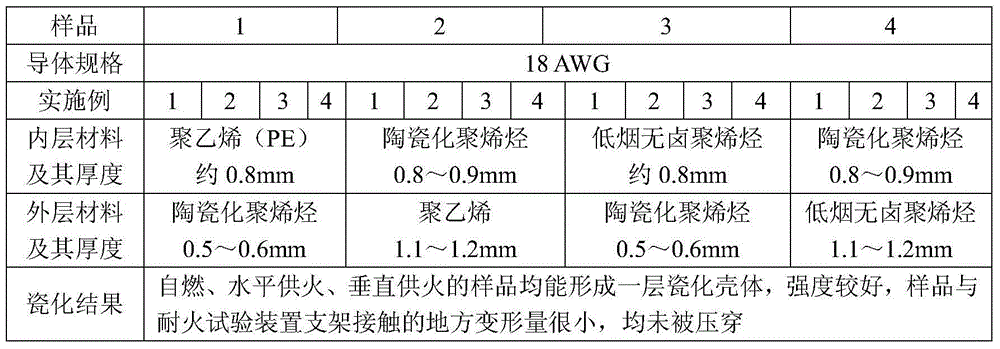

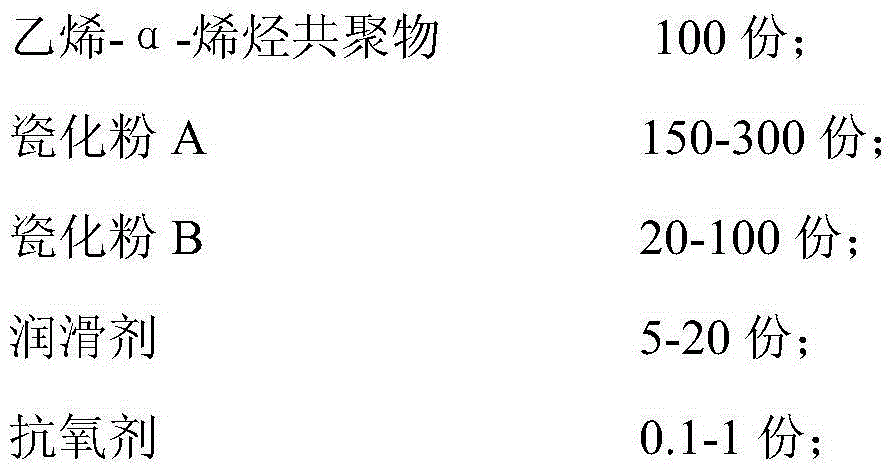

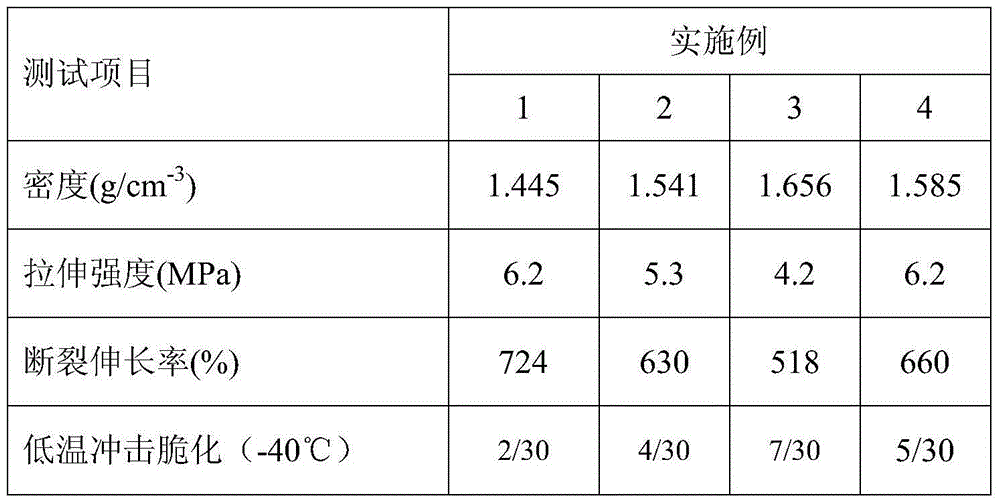

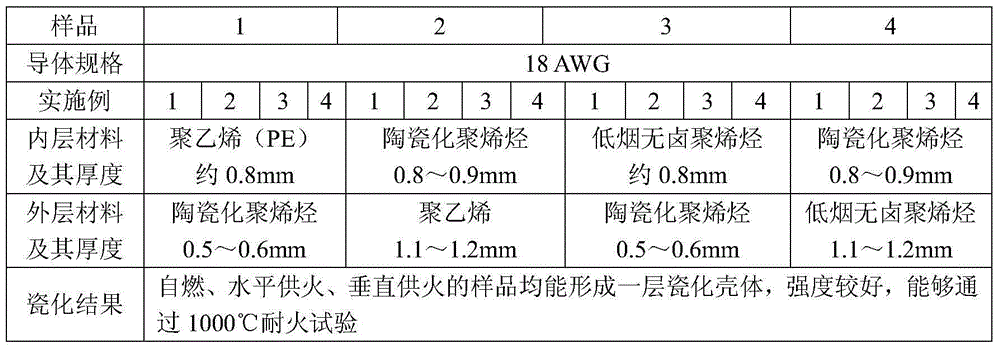

Ceramized polyolefin material and preparation method thereof

InactiveCN104558804AHigh strengthReduce the temperaturePlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses a ceramized polyolefin material and a preparation method thereof, belonging to the field of electric wire and cable materials. The ceramized polyolefin material comprises the following raw material components: 100 parts of an ethylene-alpha-olefin copolymer, 150-300 parts of ceramized powder A, 20-100 parts of ceramized powder B, 5-40 parts of a lubricating agent and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefin copolymer is one or more selected from an ethylene and alpha-propylene copolymer, an ethylene and alpha-butylene copolymer, an ethylene and alpha-hexylene copolymer and an ethylene and alpha-octene copolymer; the ceramized powder A is one or a combination of more than one selected from layered inorganic powder, fibrous inorganic powder and needle-like inorganic powder; the ceramized powder B is at least one selected from borax, ammonium borate, a zinc borate and boron frit, phosphate glass powder with a low melting point, borate glass powder with a low melting point and silicate glass powder with a low melting point; and the antioxidant is at least one selected from 1010, 1076, 168, 626, 300 and DSTDP. The ceramized polyolefin material is reasonable in raw material and proportion, capable of ensuring normal operation of a route, good in flexibility, simple in process and low in cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

Preparation method for conductive polymer sheathing material

InactiveCN102153878AImprove mechanical propertiesGood compatibilityInsulated cablesNon-conductive material with dispersed conductive materialFiberCarbon fibers

The invention belongs to the technical field of organic materials, relating to a preparation method for a conductive polymer sheathing material. The conductive polymer sheathing material comprises the following components in percent by mass: 60-30 percent of thermoplastic polymer resin, 25-30 percent of nanometer conductive carbon black, 5-14 percent of conductive carbon fiber or conductive agent, 10-18 percent of flexibilizer and 0.5-1.5 percent of processing aid and 1-3 percent of dispersing agent. The preparation method comprises the steps of: mixing and stirring well the raw materials of all the components and forming a product by melting, extruding, cooling, granulating, drying and packaging with a double-screw extruder; or adding a mixture consisting of the raw materials of all the components into an internal mixer for complete kneading, mixing and dispersing, then conducting mixing, rolling, laminating and crushing with a double-roller open mill and forming the product by melting, extruding, cooling, granulating, drying and packaging with a single-screw extruder. The preparation method has a simple process, and the conductive polymer sheathing material has the advantages of good electrical properties, low cost and production environment protection performance.

Owner:QINGDAO WEDONK POLYMER MATERIAL

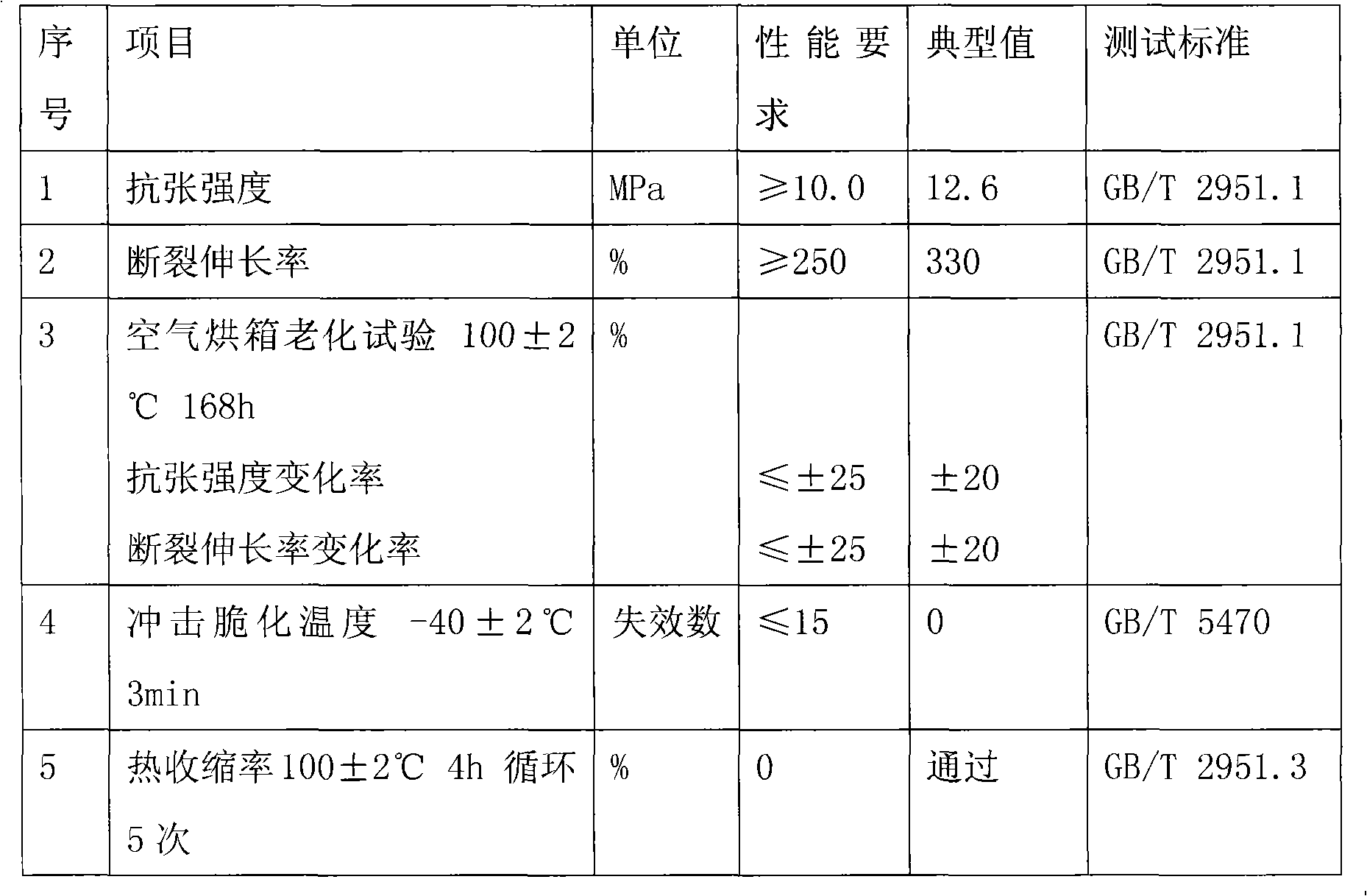

High strength aluminum alloy for electronic product shell and preparation method of high strength aluminum alloy

The invention discloses a high strength aluminum alloy for an electronic product shell and a preparation method of the high strength aluminum alloy. The alloy comprises, by mass percentage, 6.1-6.8% of Zn, 1.1-1.7% of Mg, 0.1-0.5% of Cu, 0.015-0.03% of Ti, 0.0006-0.0012% of B, smaller than 0.1% of Fe, smaller than 0.1% of Si and the balance Al and other inevitable impurities, wherein the mass sum of Zn, Mg and Cu is: 7.5%<=Zn+Mg+Cu<=8.4%, the single content of the other inevitable impurities is smaller than 0.01%, and the total amount is smaller than 0.05%. The aluminum alloy prepared through the preparation method has high strength, good extruding and machining performance, low quenching sensitiveness and good oxidizing coloring effect, can meet the requirement of the portal electronic product shell for the high strength aluminum alloy, and has wide application prospects.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

Halogen-free flame retardant high-tear-resistance wire and cable compound for electric vehicles and wire and cable production method

InactiveCN105038087AAchieve heat resistanceImprove mechanical propertiesPlastic/resin/waxes insulatorsButadiene DioxideTear resistance

The invention discloses a halogen-free flame retardant high-tear-resistance wire and cable compound for electric vehicles. The wire and cable compound comprises the following components in parts by weight: 100 parts of styrene-ethylene / butadiene-styrene block copolymer (SEBS), 20-60 parts of polypropylene, 5-20 parts of alkene polymer, 0.3-3 parts of antioxidant, 40-90 parts of halogen-free flame retardant, 20-60 parts of charring agent, 0.5-3 parts of processing aids and 15-80 parts of softening and plasticizing agent. The invention also discloses a production method for preparing wires and cables with the wire and cable compound. Through radiation micro-crosslinking, the wire and cable products prepared with the cable compound have excellent tear resistance, higher physical and mechanical properties and good electric insulation property, achieve excellent flame retardance under the premise of satisfying environmental protection, also have the advantage of high production efficiency and can be widely applied to the field of new energy, such as cables used for electric vehicles.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

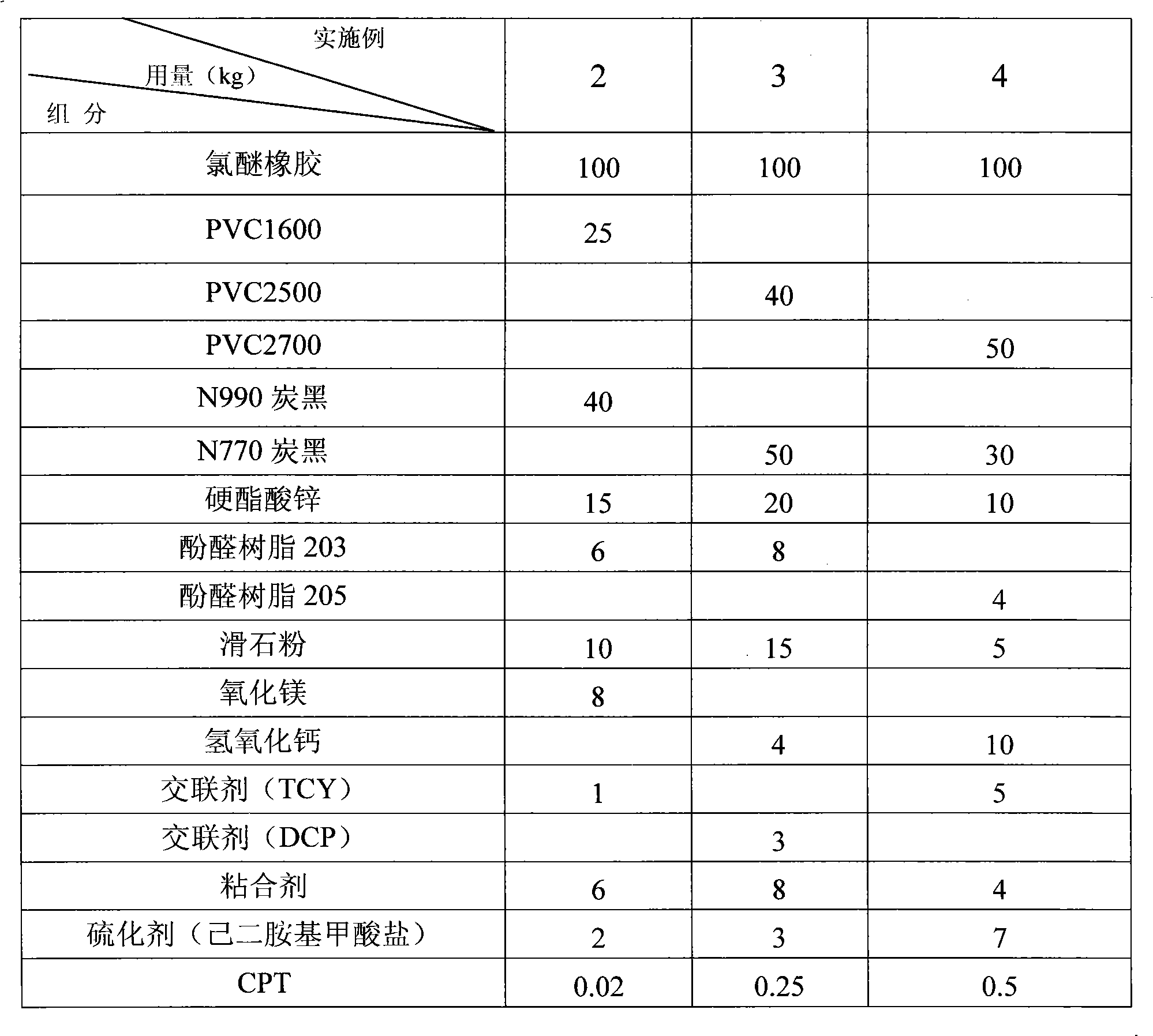

Material for anti-seepage rubber layer of inner tube of air conditioning hose and method for preparing same

The invention discloses a material for an anti-seepage rubber layer of an inner tube of an air conditioning hose and a method for preparing the same. The material comprises the following components in part by mass: 100 parts of epichlorohydrin rubber, 20 to 50 parts of PVC1300-2700, 10 to 20 parts of stabilizer, 5 to 15 parts of anti-aging agent, 4 to 8 parts of phenolic resin, 2 to 8 parts of barium / tin stabilizer, 30 to 50 parts of carbon black, 5 to 15 parts of talcpowder, 4 to 10 parts of acid acceptor, 1 to 5 parts of cross-linking agent, 4 to 8 parts of adhesive and 1 to 4 parts of vulcanizing agent. The method comprises the following steps of: placing the PVC and the components except the cross-linking agent and the adhesive in an internal mixer and plasticating the components for 8 to 16 minutes at the temperature of between 150 and 160 DEG C; placing the materials in an open mill, adding the cross-linking agent and the adhesive into the materials under the condition that the roller temperature is less than or equal to 60 DEG C, allowing the mixture to pass through the roller for 3 to 4 times in small thickness, triangularly packaging the mixture for 5 to 6 times and discharging sheets. The rubber material provided by the formula of the invention has the characteristics of freon resistance, novel refrigerant resistance, hot oil resistance, aging resistance and the like; and meanwhile, the process is simple and the manufacturing cost is low.

Owner:仝国磊

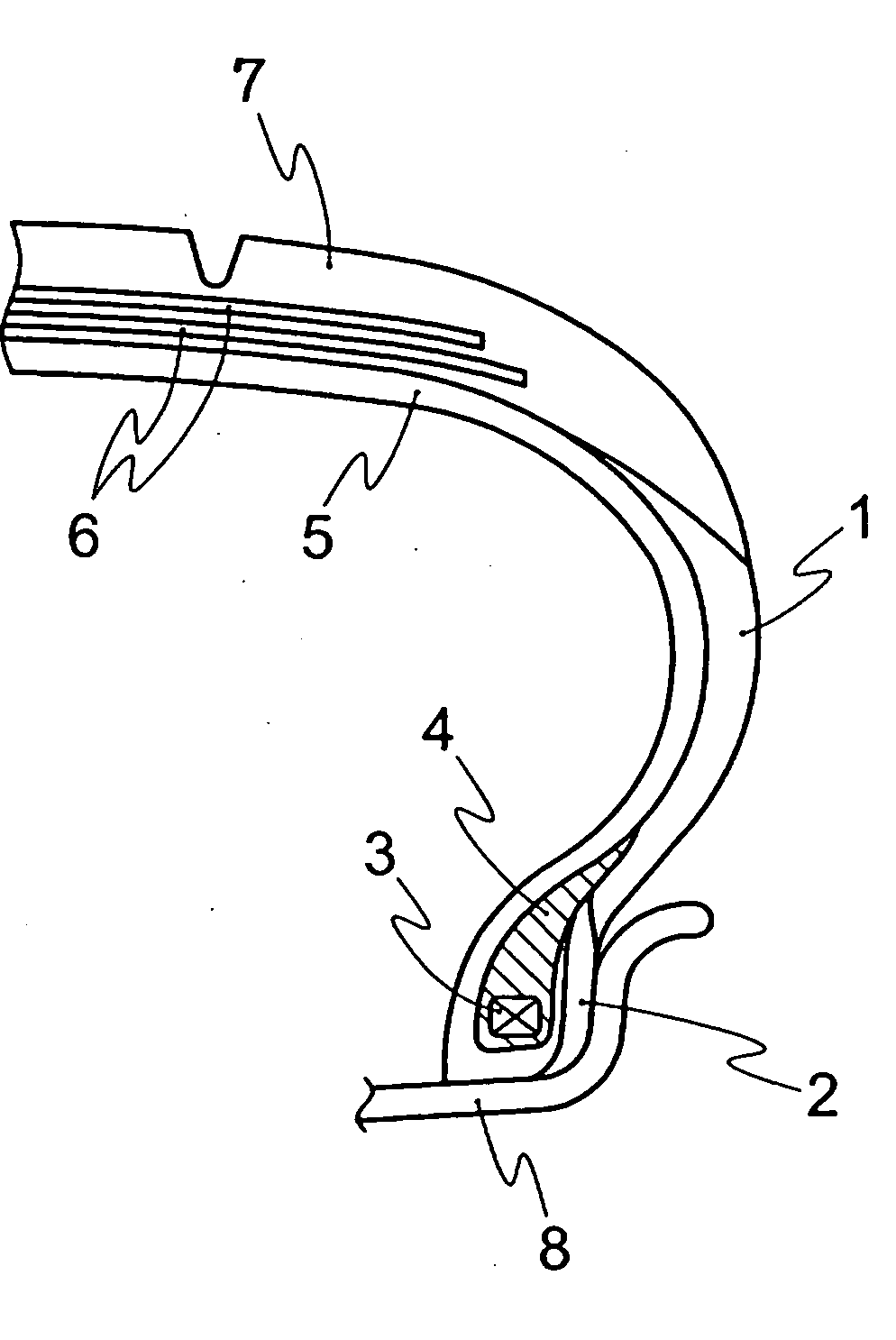

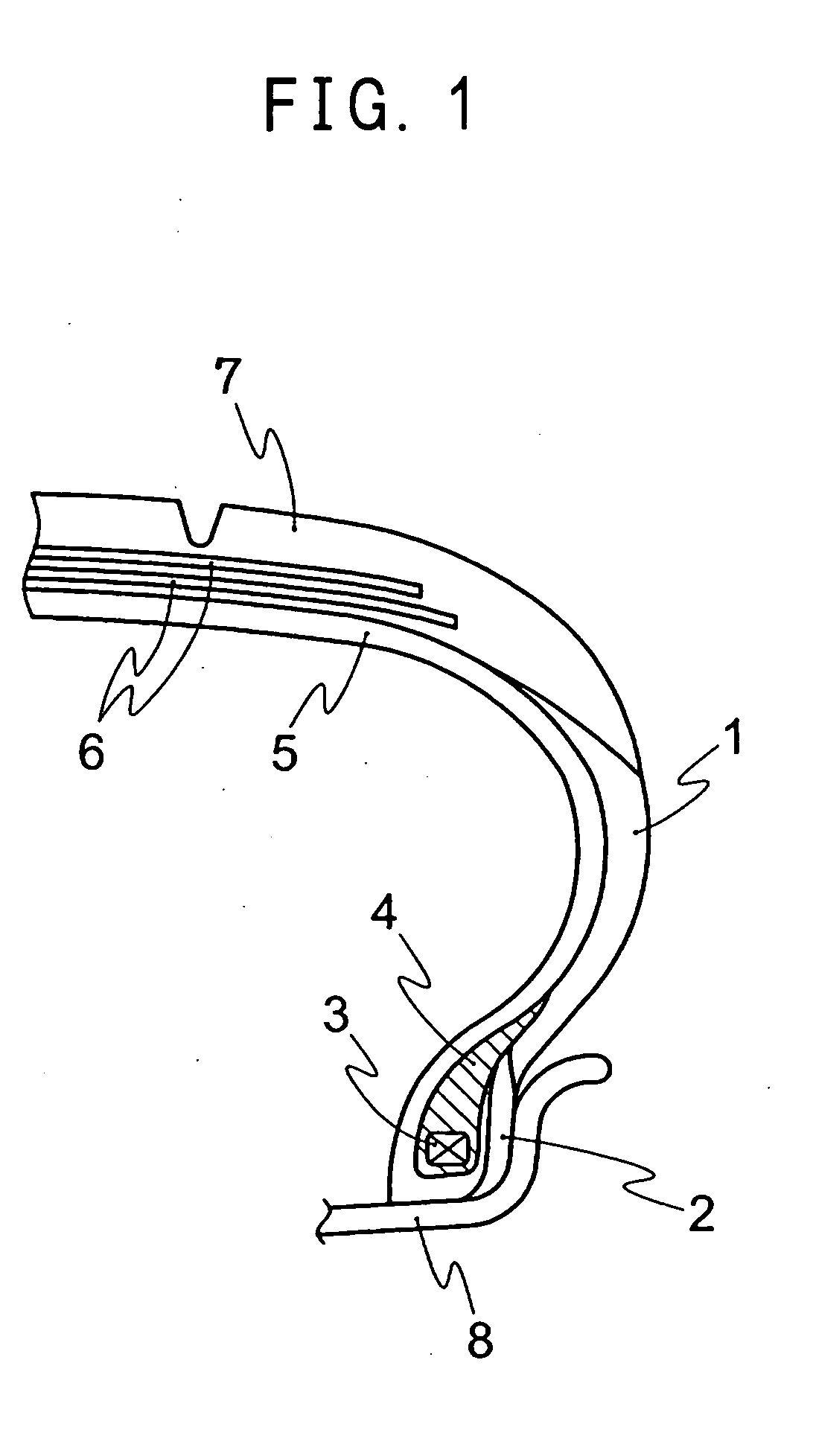

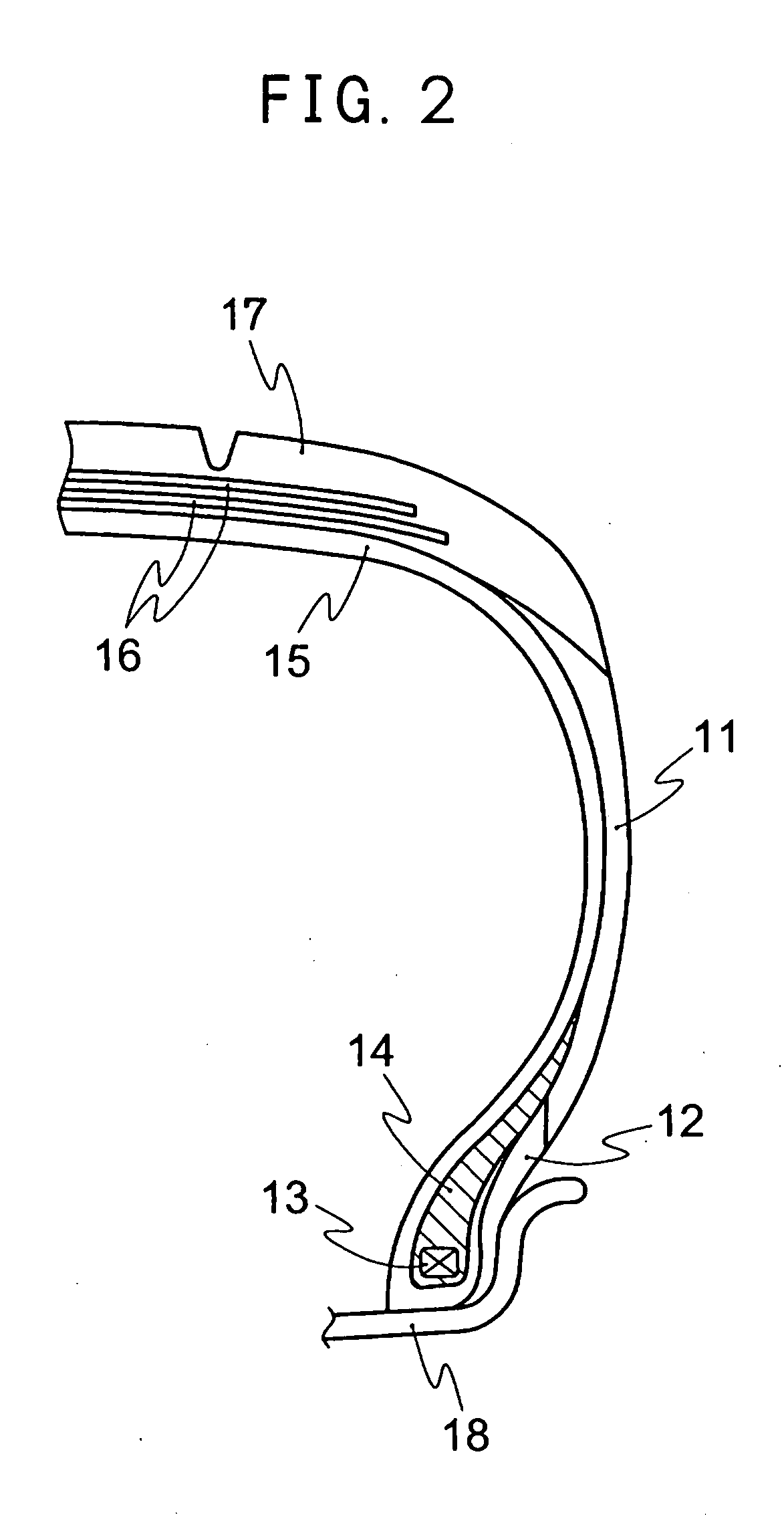

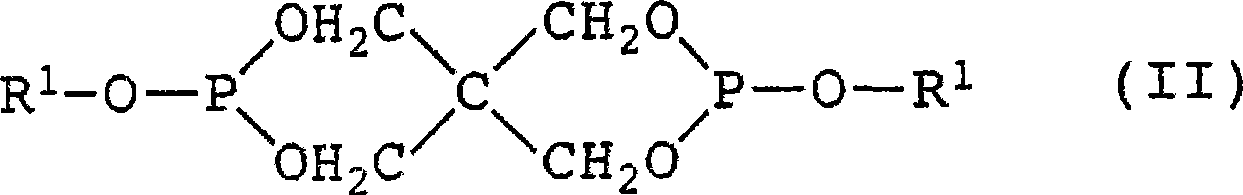

Rubber Composition for Bead Apex and Tire Having Bead Apex Prepared Using Same

InactiveUS20090151844A1Good extrusion processing performanceImprove rigidityLayered productsSpecial tyresRolling resistanceVulcanization

There is provided a rubber composition for a bead apex which can enhance extrusion processability by optimizing a rate of vulcanization during a vulcanization process, and can improve rigidity, steering stability and a low fuel consumption property, a tire having a bead apex prepared by using the rubber composition for a bead apex and being capable of enhancing steering stability and reducing rolling resistance and a tire for a sports utility vehicle (SUV) having further enhanced durability. The rubber composition for a bead apex comprises a diene rubber, a phenol resin and / or a modified phenol resin, sulfur, hexamethylenetetramine, a vulcanization accelerator, and at least one kind of vulcanization acceleration auxiliary selected from the group consisting of a citraconimide compound, a condensate of alkyl phenol and sulfur chloride, an organic thiosulfate compound and a compound represented by the general formula: R1—S—S-A-S—S—R2.

Owner:SUMITOMO RUBBER IND LTD

Halogen-free low-smoke flame retardant double-layer insulating outer layer material for area-1 cable of AP1000 nuclear power station and preparation method thereof

ActiveCN103275401AImprove radiation resistanceImprove flame retardant performanceRubber insulatorsEthylene propylene rubberMaterials science

The invention discloses a halogen-free low-smoke flame retardant double-layer insulating outer layer material for an area-1 cable of an AP1000 nuclear power station and a preparation method thereof, belonging to the technical field of cables. The material comprises a base body consisting of ethylene propylene diene monomer, ethylene propylene monomer and ethylene vinyl acetate copolymer rubber, a halogen-free flame retardant smoke suppression system consisting of magnesium hydroxide, aluminum hydroxide, zinc borate pentahydrate, microcapsule-coated ammonium polyphosphate and siloxane, an anti-radiation system consisting of nano cerium dioxide and lead monoxide, a vulcanization system consisting of 98% bis(tert-butylperoxyisopropyl)benzene and N,N'-m-phenylene dimaleimide, a protection system consisting of 2-mercapto benzimidazole zinc salt, para, para'-diisopropylphenyl diphenylamine and nano zinc oxide, a coupling agent composed of vinyltri(beta-methoxyethyoxy)silane, and a lubricating and softening system consisting of stearic acid and microcrystalline wax. The material disclosed by the invention has the advantages of good radiation resistance, excellent mechanical properties and good electrical insulation properties; and the service life of the material reaches 60 years.

Owner:BAOSHENG SCI & TECH INNOVATION

Resin composition for refrigerant-transporting hose and method of producing the resin composition, and refrigerant-transporting hose

ActiveUS20130056107A1Improve the immunityReduce crystallization rateMaterial nanotechnologyLayered productsElastomerAramides

A resin composition for a refrigerant-transporting hose, including: a semi-aromatic polyamide resin (A) as a main component; an aliphatic polyamide resin (B); and an elastomer (C), in which the aliphatic polyamide resin (B) is dispersed in a phase formed of the semi-aromatic polyamide resin (A) and the elastomer (C), which is not crosslinked, is incorporated in the form of particles into the dispersed aliphatic polyamide resin (B). Thus, excellent refrigerant permeation resistance and acid resistance, and at the same time, for example, extrusion processability and flexibility, are obtained.

Owner:SUMITOMO RIKO CO LTD

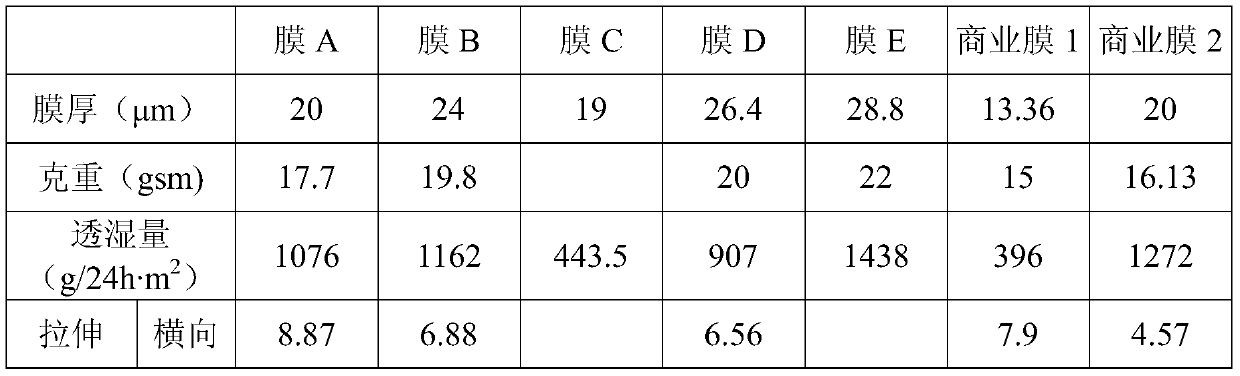

Raw material composition for preparing blown breathable film, blown breathable film and preparation of blown breathable film

The invention provides a raw material composition for preparing a blown breathable film, a blown breathable film and preparation of the blown breathable film. The raw material composition comprises the following ingredients in percentage by weight (100% in total): 50-70% of inorganic filler coated with a coupling agent on the surface, 25-50% of linear low density polyethylene and 0.2-1.0% of antioxidant, wherein linear low density polyethylene comprises 1-3 kinds of linear low density polyethylene in different densities; density distribution of linear low density polyethylene in the differentdensities is 0.910-0.935g / cm<3>; and melting index distribution at 190 DEG C is 2.5-0.5g / 10min. The invention further provides a masterbatch of the blown breathable film, which is prepared from the raw material composition. The invention further provides a blown breathable film which is prepared by blowing the masterbatch to form a film by a film blowing method and then performing unilateral stretching on the film. The blown breathable film is excellent in comprehensive performance and lower in cost.

Owner:RENOLIT PLASTICS TECH BEIJING CO LTD

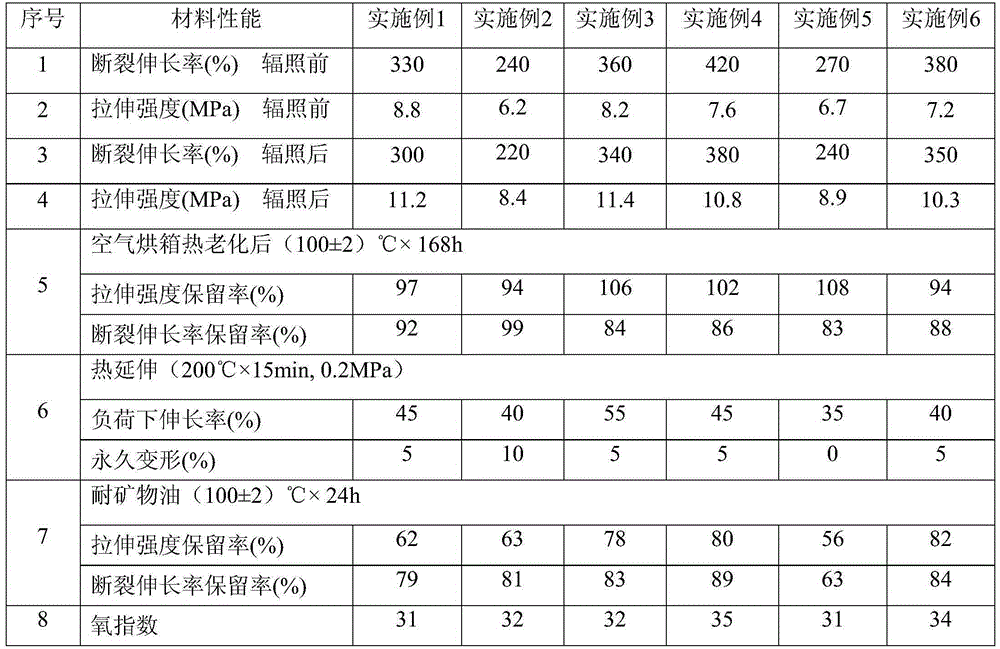

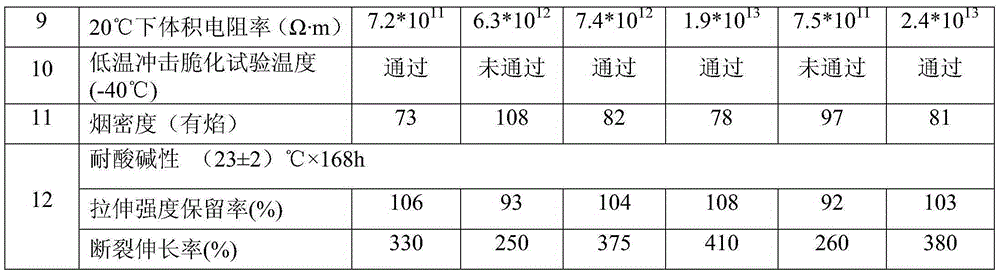

An irradiation-crosslinked oil-resistant type low-smoke halogen-free flame-retardant material used for cables of motor train units and a preparing method thereof

InactiveCN106554547AImprove flame retardant performanceGood oil resistancePlastic/resin/waxes insulatorsEngineeringFire retardant

The invention relates to the field of flame retardant materials and particularly relates to an irradiation-crosslinked oil-resistant type low-smoke halogen-free flame-retardant material used for cables of motor train units and a preparing method thereof. Raw materials of the material include, by weight, 50-85 parts of substrate resin, 10-45 parts of a compatilizer, 70-125 parts of a flame retardant, 10-35 parts of a synergistic flame retardant, 0.35-1.45 parts of an antioxidant, 1.5-6 parts of a lubricant, 1-3 parts of a crosslinking sensitizing agent and 3-9 parts of black color master batch. The material has good flame retardant effects, good resistance to mineral oil, chemical resistance and high elongation at break, can meet torsion-resisting requirements of wire cables used for motor train units and has good production and extrusion processing properties.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

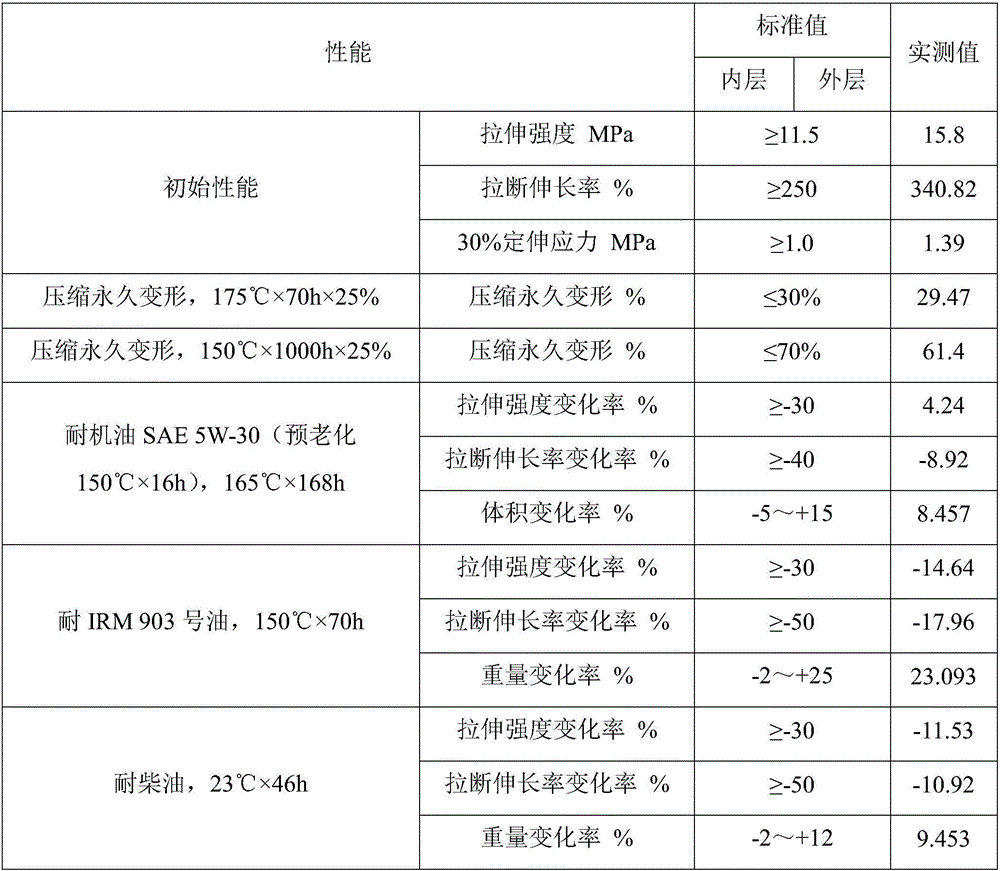

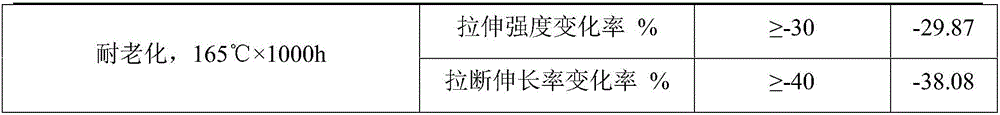

Rubber composition for preparing external and internal layers of automotive turbocharged hose and production method thereof

The invention relates to a rubber composition for preparing external and internal layers of an automotive turbocharged hose. The rubber composition comprises 100 parts of ethylene acrylate rubber, 1.0-3.0 parts of anti-aging agent, 1.0-3.0 parts of processing agent, 10.0-20.0 parts of plasticiser, 50.0-70.0 parts of carbon black, 0.5-1.5 parts of internal releasing agent, 2.0-3.0 parts of vulcanization activator and accelerator and 1.0-2.0 parts of vulcanizing agent. The invention further provides a preparation method for the rubber composition. The rubber composition improves high temperature resistance and oil resistance, reduce compression permanent sets, and is not prone to scorching, good in processing characteristics, and can serve as the external layer and the internal layer of the automotive turbocharged hose.

Owner:QINGDAO SUNSONG CO LTD

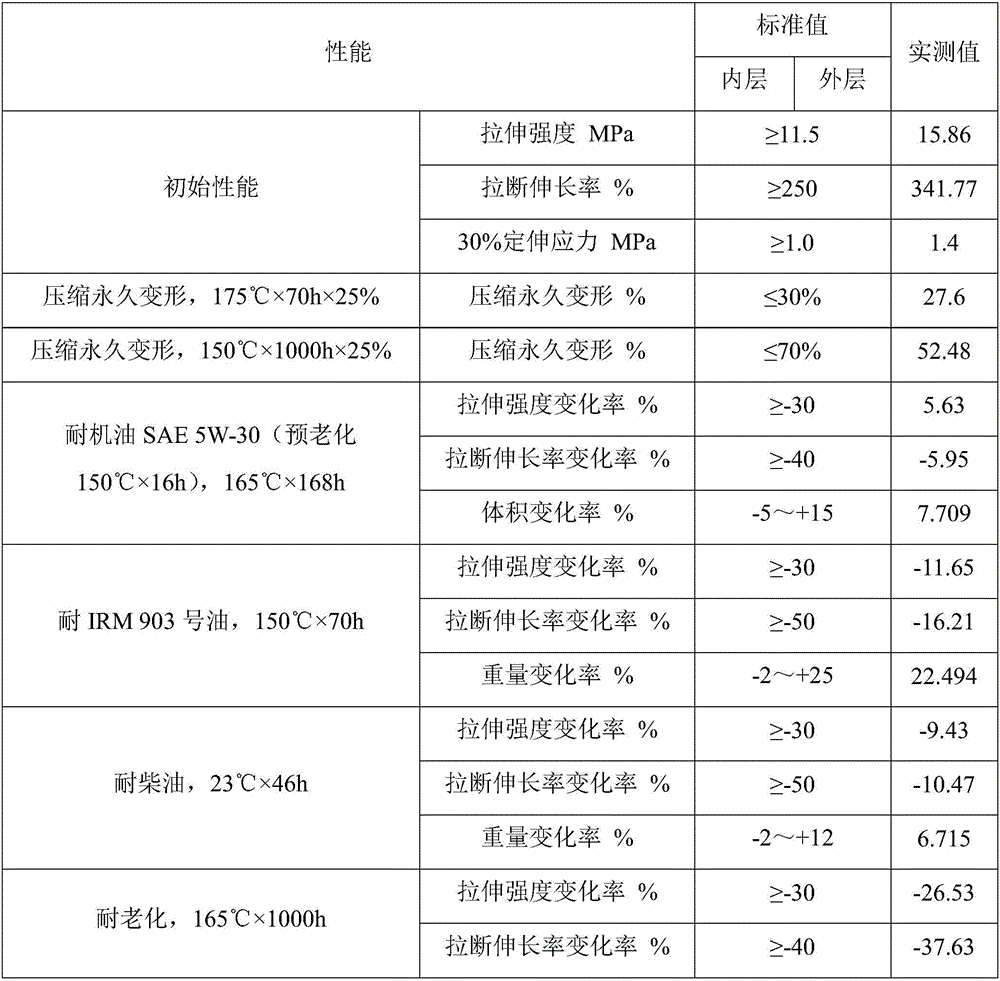

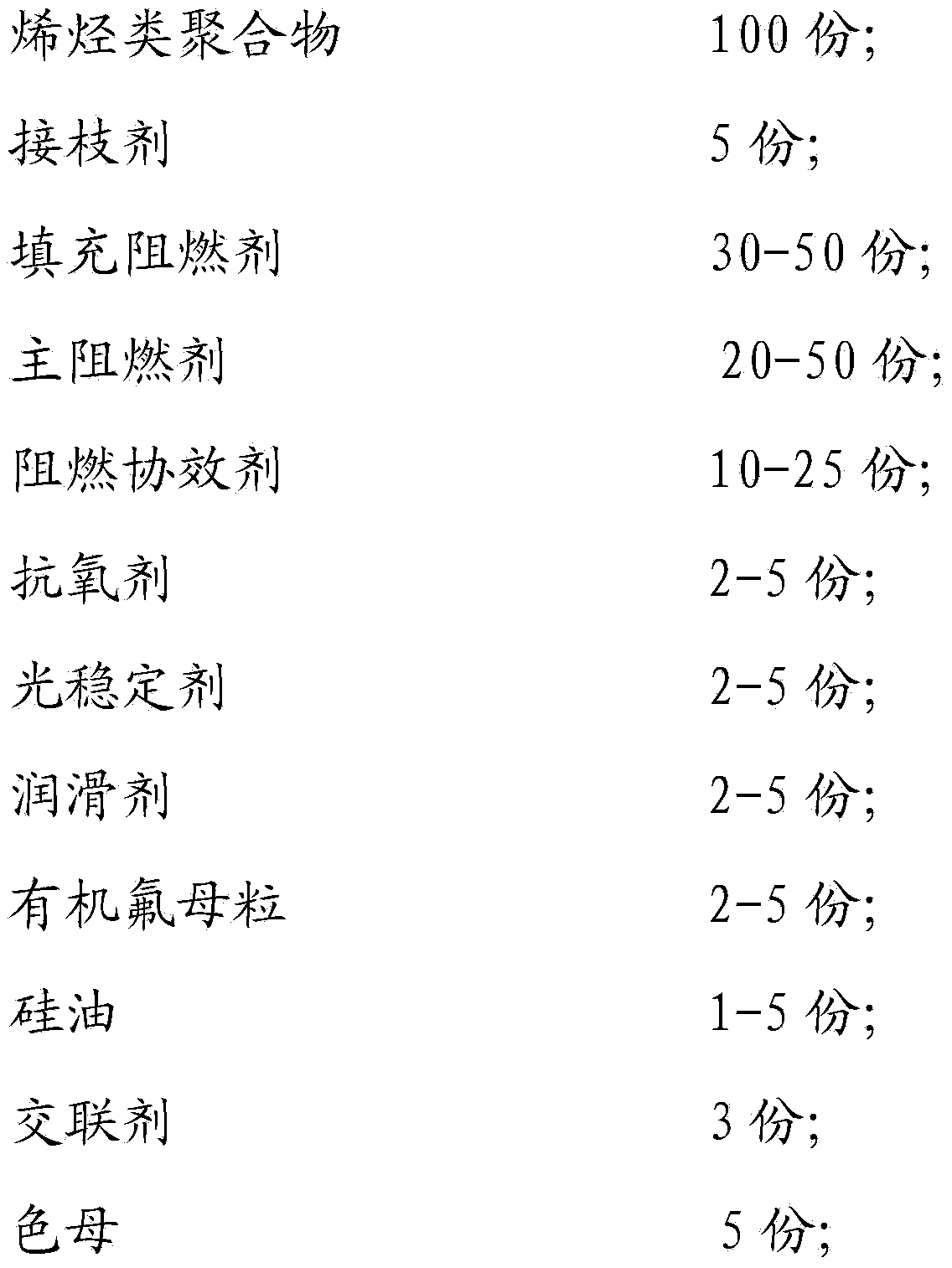

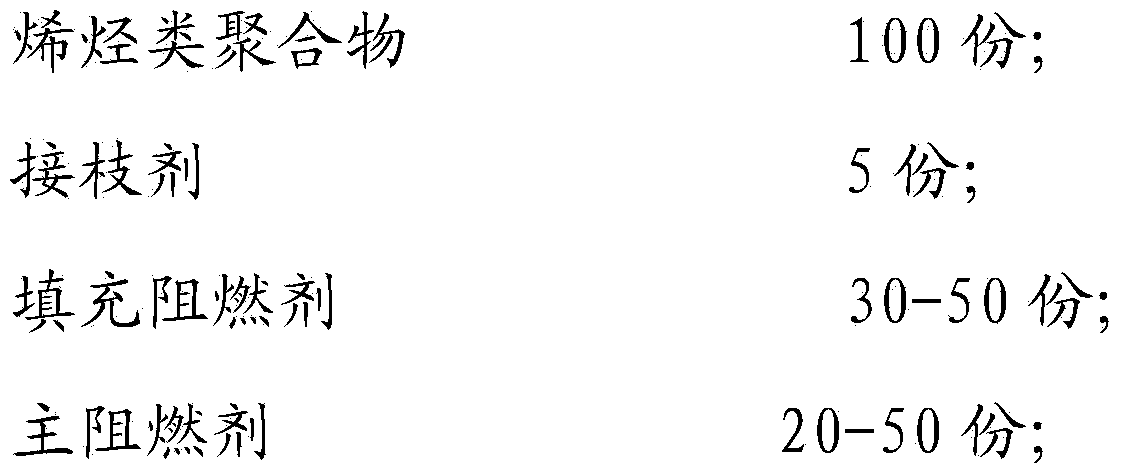

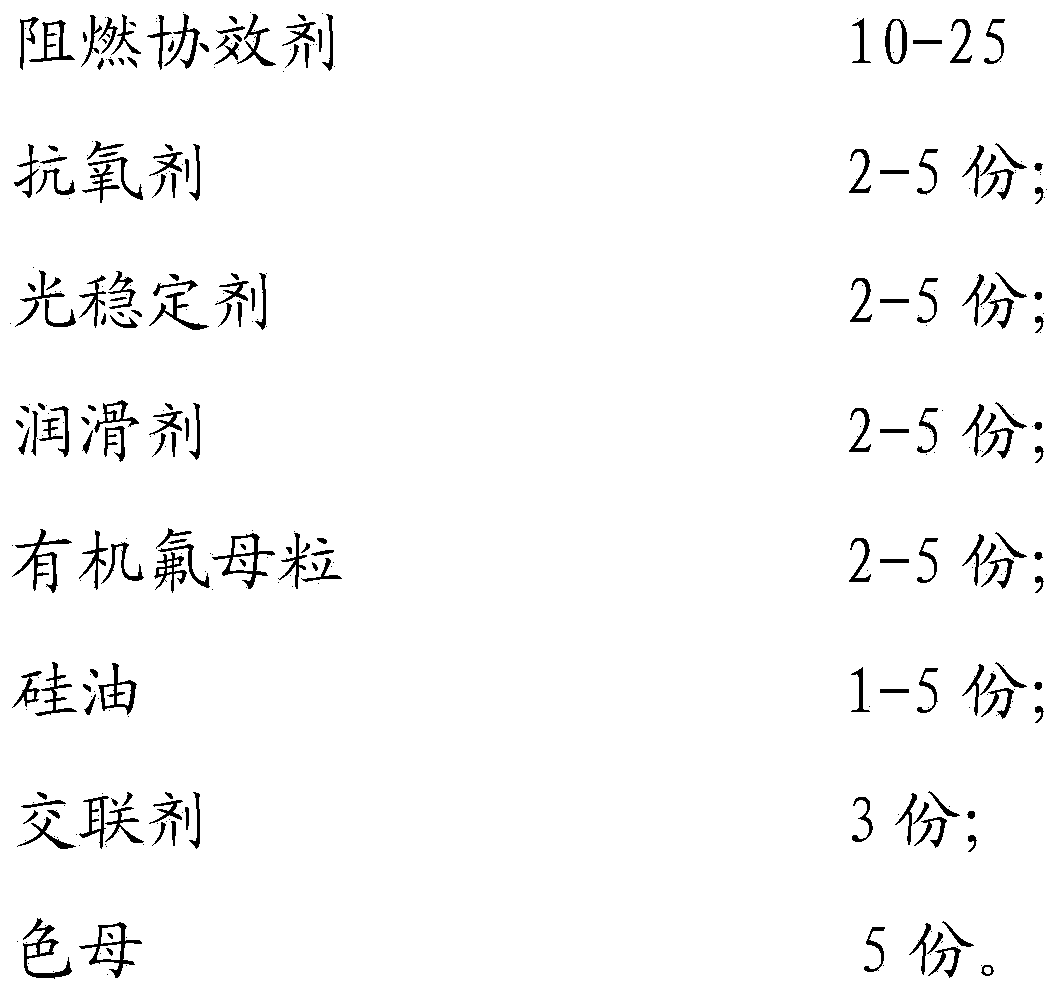

135 DEG C irradiation-crosslinked polyolefin heat-shrinkable tube

The invention relates to a 135 DEG C irradiation-crosslinked polyolefin heat-shrinkable tube which is composed of the following components in parts by weight: 100 parts of olefin polymer, 5 parts of grafting agent, 30-50 parts of filling flame retardant, 20-50 parts of main flame retardant, 10-25 parts of flame-retardant synergistic agent, 2-5 parts of antioxidant, 2-5 parts of light stabilizer, 2-5 parts of lubricant, 2-5 parts of organic fluorine master batch, 1-5 parts of silicon oil, 3 parts of crosslinking agent and 5 parts of color master batch. The heat-shrinkable tube produced according to the formula above completely satisfies the requirements in UL242 and Grade 135 DEG C in MIL-DTL-23053-5, does not have the adhesion phenomenon in the shrinkage process, and can be widely used in the fields of locomotives, ships, aerospace, nuclear power, war industry and the like.

Owner:长园科技集团股份有限公司 +2

Microencapsulation red phosphorus fire retardation antistatic polyethylene pipe composition

InactiveCN103087380AImprove flame retardant performanceReduce dosageRigid pipesAntioxidantMechanical property

The present invention relates to a microencapsulation red phosphorus fire retardation antistatic polyethylene pipe composition, and belongs to the technical field of plastic processing. The composition comprises the following raw materials, by weight, 45-60 parts of a polyethylene resin, 30 parts of an electric conduction carbon black master batch, 6-10 parts of microencapsulation red phosphorus, 6-10 parts of a melamine isocyanurate, 1.0-3.0 parts of a coupling agent, 0.1-0.3 part of an antioxidant, and 1.0-3.0 parts of a dispersing agent. With the present invention, the problem of not good fire retardation effect during fire retardation of polyethylene through single microencapsulation red phosphorus is solved; a synergetic fire retardation agent MCA is added so as to reduce the amount of the red phosphorus and improve a fire retardation effect of the composition; the microencapsulation red phosphorus fire retardation antistatic polyethylene pipe composition is an environmental protection type material, and has characteristics of good extrusion processability and good mechanical property; and compared with the bromine-antimony fire retardation system, the composition has characteristics of low raw material cost, low density, good economic benefits, and good market application prospects.

Owner:山东远洋塑胶工业有限公司

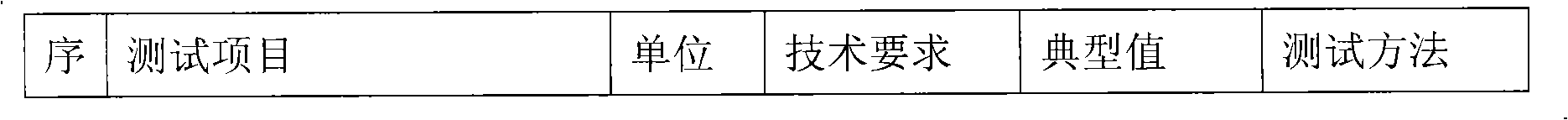

Strippable semi-conductive shielding material for ethylene propylene rubber cable

InactiveCN102558660AExcellent performance indexSemi-conductive and stableInsulated cablesInsulated conductorsVulcanizationPolymer science

The invention discloses a strippable semi-conductive shielding material for an ethylene propylene rubber cable. The shielding material is prepared by mixing the following raw materials in part by weight: 70 parts of ethylene vinyl acetate, 30 parts of chlorinated polyethylene, 50 to 70 parts of conductive carbon black, 5 to 15 parts of coarse-particle carbon black, 5 to 10 parts of metal oxide, 20 to 40 parts of mineral filler, 3 to 20 parts of dispersing agent, 2 to 6 parts of cross-linking agent, 4 to 6 parts of cross-linking aid, 2 to 5 parts of anti-ageing agent and 15 to 20 parts of plasticizer. The defects that the shielding material has overhigh volume resistivity, and insufficient adhesion with an ethylene propylene insulation layer, and is difficult to strip, the shielding material and the ethylene propylene insulation layer cannot be synchronously vulcanized, and the like in the prior art are overcome, and the strippable semi-conductive shielding material for the ethylene propylene rubber cable has high semi-conductivity, high extrusion processability, and moderate adhesion with the insulation layer, is easy to strip and has a vulcanization rate equivalent to that of ethylene propylene rubber.

Owner:重庆鸽牌电线电缆有限公司

Ceramic polyolefin cable material and preparation method thereof

InactiveCN104558806AHigh strengthReduce the temperaturePlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses a ceramic polyolefin cable material and a preparation method thereof, and belongs to the technical field of a wire / cable material. The ceramic polyolefin cable material consists of the following raw material components in parts by weight: 100 parts of an ethylene-alpha-olefine copolymer, 150-300 parts of ceramic powder A, 20-100 parts of ceramic powder B, 5-20 parts of a lubricant and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefine copolymer is a mixture of ethylene and any one or more of alpha-propylene, alpha-butylene, alpha-hexylene and alpha-octylene copolymers according to any proportions by weight; the ceramic powder A is any one or any combinations of lamellar inorganic powder, fibrous inorganic powder and acicular inorganic powder; the ceramic powder B is at least one of borax, ammonium borate, zinc borate, boron frit, low-melting-point phosphate glass powder, low-melting-point borate glass powder and low-melting-point silicate glass powder; and the antioxidant is at least one of 1010, 1076, 168, 626, 300 and DSTDP.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

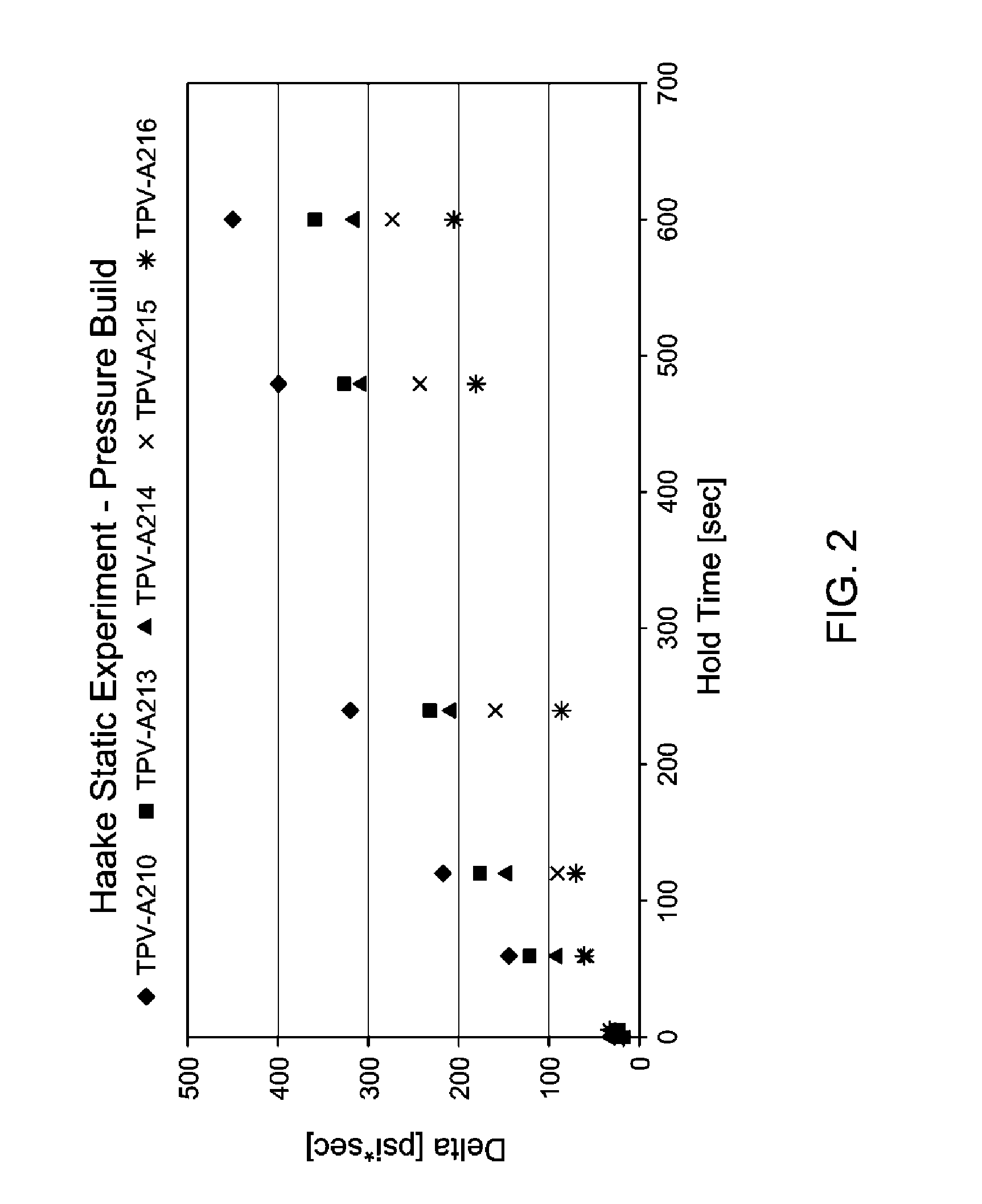

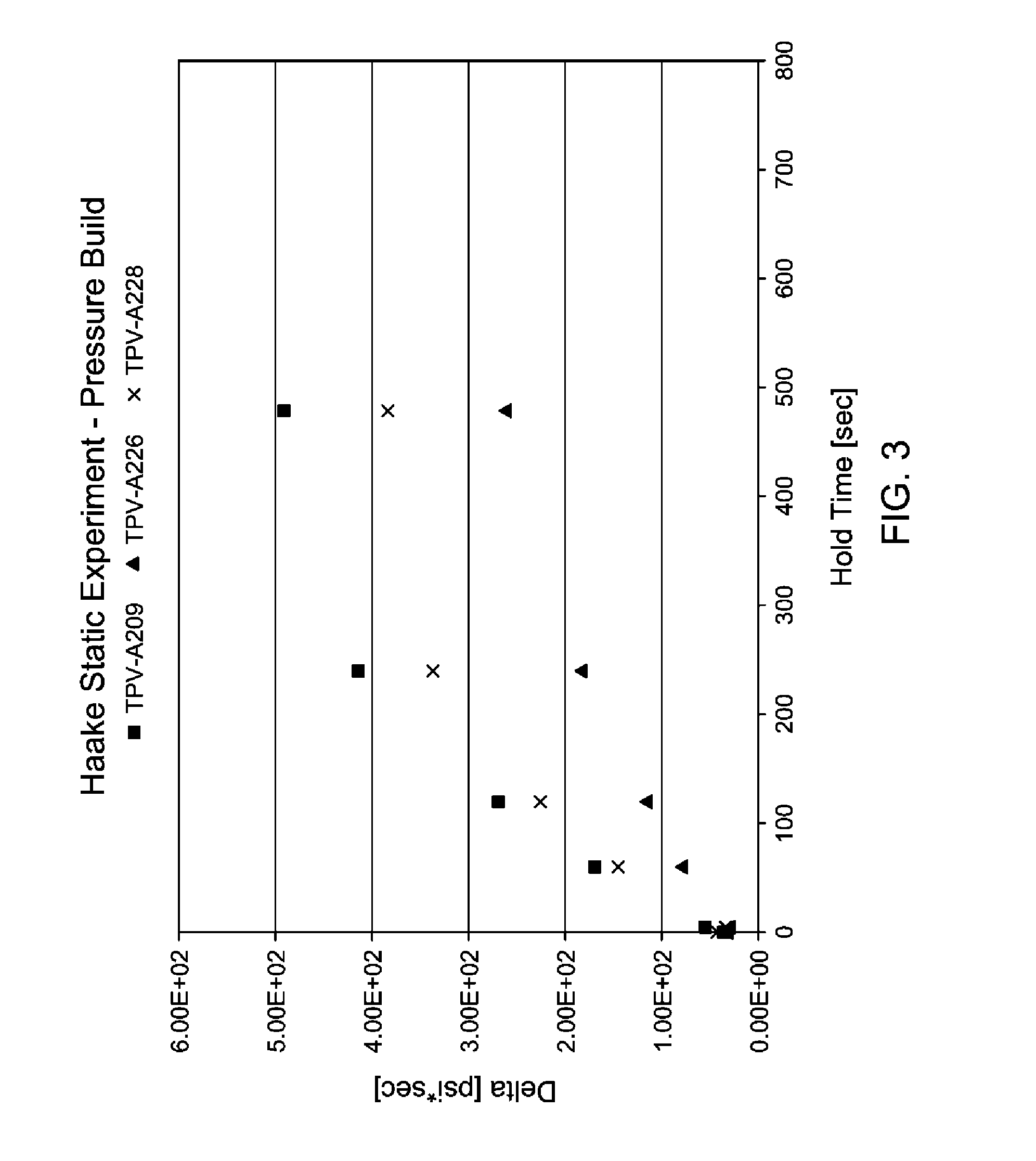

Thermoplastic Vulcanizates Comprising Propylene-Based Elastomers and Methods for Making the Same

InactiveUS20160340480A1Good extrusion processing performanceImprove surface qualityDomestic articlesElastomerPolymer chemistry

Described herein are thermoplastic vulcanizates comprising propylene-based elastomers and methods for producing the same. The thermoplastic vulcanizates comprise rubber, at least 10 wt % of thermoplastic resin, from 1 to 9 wt % of propylene-based elastomer, oil, and at least 5 wt % of one or more fillers. The thermoplastic vulcanizates are made by a method where the propylene-based elastomer is introduced to the extrusion reactor before the curative is introduced to the extrusion reactor.

Owner:CELANESE INT CORP

Thermoplastic resin composition and resin molding

Disclosed is a thermoplastic resin composition which comprises: an aromatic polycarbonate resin (component A) (which may comprise an aromatic polycarbonate resin (component A1) and a thermoplastic resin other than an aromatic polycarbonate resin (component A2)); a granulated talc (component B) which comprises a talc having an average particle diameter of 0.1 to 10 [mu]m, wherein the talc is so granulated as to have a bulk density of 0.4 to 1.5 g / ml; a rubbery polymer (component C, an optional component); a flame retardant (component E, an optional component); and a fluorinated polyolefin (component F, an optional component); wherein the granulated talk (component B) has such a grain size that the ratio of granules trapped on a 500 [mu]m-mesh sieve is 55% by weight or more. Also disclosed is a resin molded article formed by molding the thermoplastic resin composition. The thermoplastic resin composition and the resin molded article are excellent in extrusion moldability, stiffness, flame retardancy, impact resistance and thermal stability and show excellent balance among physical properties.

Owner:MITSUBISHI ENG PLASTICS CORP

High-melt-strength high-bonding-property thermoplastic elastomer and preparation method thereof

InactiveCN107118495AIncrease molecular weight and degree of branchingImprove melt strengthChemistryPolypropylene

The invention discloses a high-melt-strength high-bonding-property thermoplastic elastomer and a preparation method thereof. The high-melt-strength high-bonding-property thermoplastic elastomer contains the following components in parts by weight: 25-35 parts of a high molecular weight styrene copolymer, 20-30 parts of polypropylene, 6-14 parts of thermoplastic polyurethane, 5-12 parts of a chain extender, 3-8 parts of a tackifier 1, 2-9 parts of a tackifier 2, 14-20 parts of tackifier filling oil, 3-14 parts of a compatilizer and 2-6 parts of an antioxidant. The preparation method comprises the following steps: weighing the materials in the formula in parts by weight; uniformly mixing the materials; inputting the mixed raw materials into a feeding hopper of a twin-screw extruder; and performing melt extrusion and granulation. The thermoplastic elastomer disclosed by the invention is high in melt strength, good in mechanical strength, difficult to shrink and good in encapsulating adhesive property, and is suitable for the fields of toy tires, bathroom hoses and automobile sealing strips, etc.

Owner:泉州盈创新材料技术开发有限公司

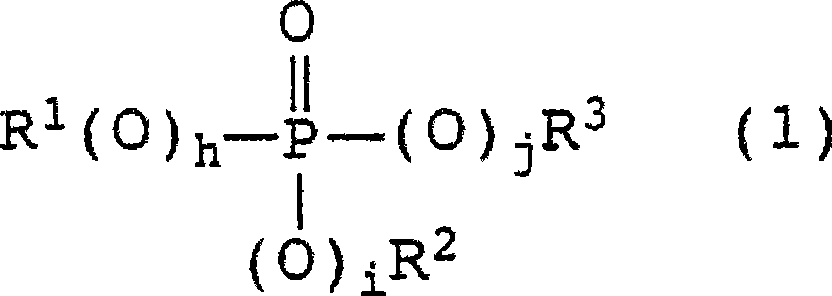

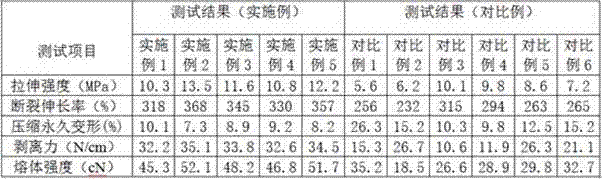

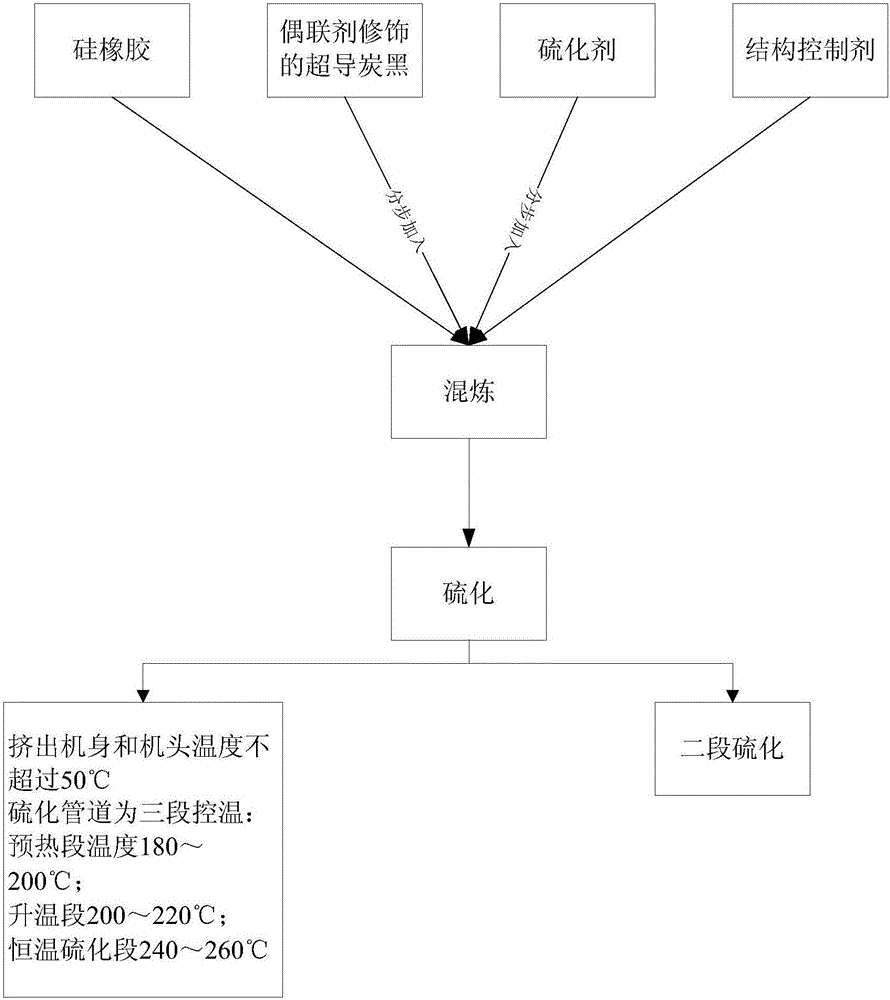

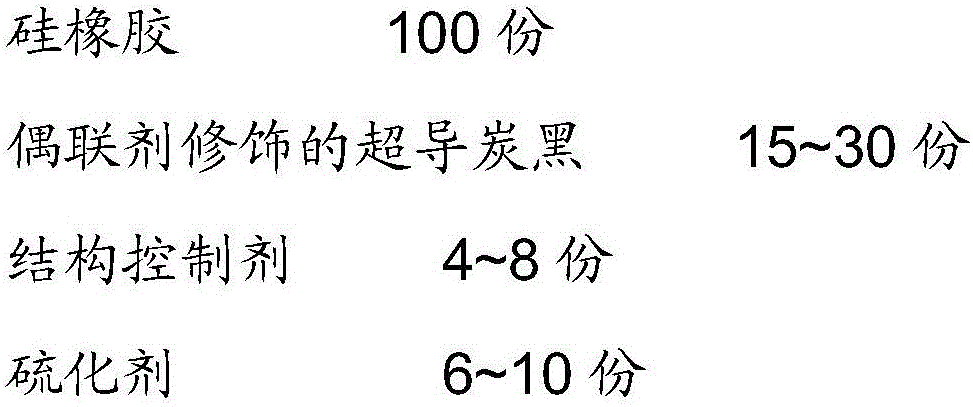

Preparation method of ageing-resistant and high-resilience extruded carbon black filled conductive shielding silicone rubber

The invention discloses a preparation method of ageing-resistant and high-resilience extruded carbon black filled conductive shielding silicone rubber. The preparation method comprises the steps that 1, 100 parts of silicone rubber, 15-30 parts of coupling agent modified superconductive carbon black, 4-8 parts of a structure control agent and 6-10 parts of vulcanizing agent are prepared by mass; 2, the raw materials in the step 1 are mixed on a mixing mill or a kneading machine at room temperature; 3, the rubber material obtained in the step 2 is subjected to vulcanization treatment, and the vulcanization treatment process is divided into two stages. The prepared conductive shielding silicone rubber has good extrusion processing performance. A preparation process is simple, and the costs are low. The silicone rubber prepared by means of the preparation method has good ageing-resistant performance and elasticity and is suitable for use by serving as a high-performance sealant material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Rubber composition and golf ball including the same as rubber base material

InactiveUS20090215552A1High hardnessGood extrusion processing performanceGolf ballsSolid ballsPolymer scienceMooney viscosity

A rubber composition comprises a rubber component. The rubber component contains (A) 1-70 weight parts of polybutadiene rubber having a Mooney viscosity (ML) of 35-50 and composed of (a) 1-9 weight % of a boiled n-hexane insoluble fraction having a melting point of 180° C. or higher and (b) 99-91 weight % of a boiled n-hexane soluble fraction. The rubber component also contains (B) 99-30 weight parts of diene-based rubber other than (A). A crosslinking coagent (C) is mixed in the rubber component.

Owner:UBE IND LTD

Process for producing polybutadiene rubber and rubber composition

A process for producing a vinyl-cis-polybutadiene rubber, including mixing (A) vinyl-cis-polybutadiene obtained by (1) a step of adding a cis-1,4-polymerization catalyst obtainable from an organoaluminum compound and a soluble cobalt compound to a mixture containing 1,3-butadiene and a hydrocarbon-based organic solvent as the major components and having an adjusted water content, thereby subjecting the 1,3-butadiene to cis-1,4-polymerization and subsequently, (2) a step of making a catalyst obtainable from a soluble cobalt compound, an organoaluminum compound represented by the general formula, AlR3 (wherein R represents an alkyl group having from 1 to 6 carbon atoms, a phenyl group, or a cycloalkyl group), and carbon disulfide present in the resulting polymerization reaction mixture, thereby subjecting the 1,3-butadiene to 1,2-polymerization; and (B) cis-polybutadiene obtained by a step of adding the foregoing cis-1,4-polymerization catalyst, thereby subjecting the 1,3-butadiene to cis-1,4-polymerization and a rubber composition containing the resulting rubber.

Owner:UBE IND LTD

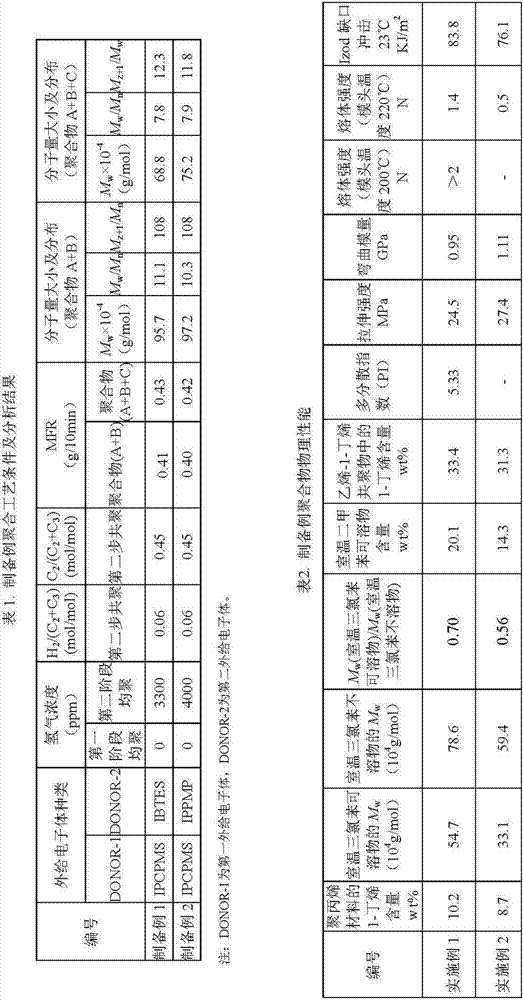

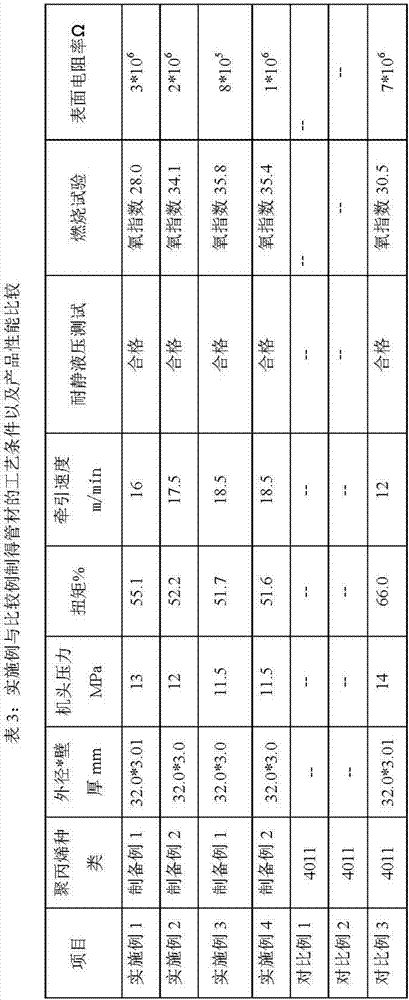

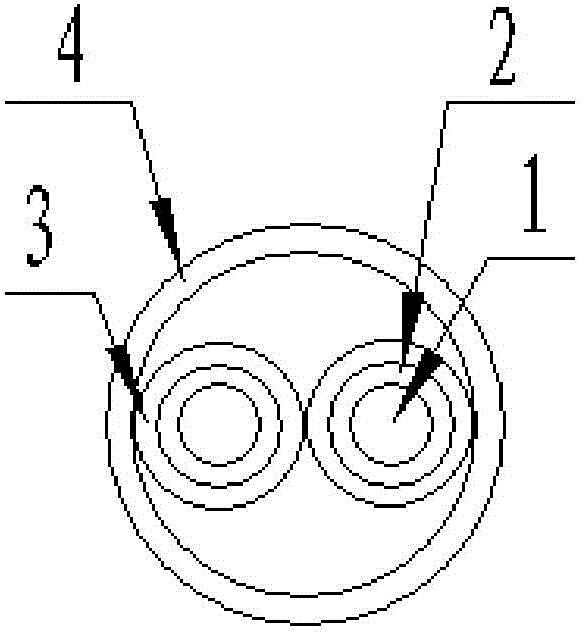

Polypropylene composition and high performance flame retardant antistatic polypropylene pipe

ActiveCN107325394AExcellent flame retardant, antistatic and impact resistanceSmooth inner wallRoom temperatureEthylene Homopolymers

The invention relates to a flame retardant antistatic polypropylene composition and a pipe prepared therefrom. The composition comprises basic polypropylene resin, a fire retardant, and a conductive filling material. The basic polypropylene resin comprises a propylene homopolymer component and ethylene-1-butene copolymer; wherein the propylene homopolymer component at least comprises first propylene homopolymer and second propylene homopolymer. In the basic polypropylene resin, the ratio of the Mw of a substance, which is soluble in trichlorobenzene at a room temperature, to the Mw of a substance, which is insoluble in trichlorobenzene at a room temperature, is greater than 0.5 and less than 1; preferably in a range of 0.5 to 0.8. At a room temperature, the content of a substance, which is soluble in xylene at a room temperature, is in a range of 10 wt% to 30 wt%. The content of 1-butene is 5 to 20 wt%. The provided pipe has a good antistatic and flame retardant performance, moreover, the melt strength is high, and the impact resistant property is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

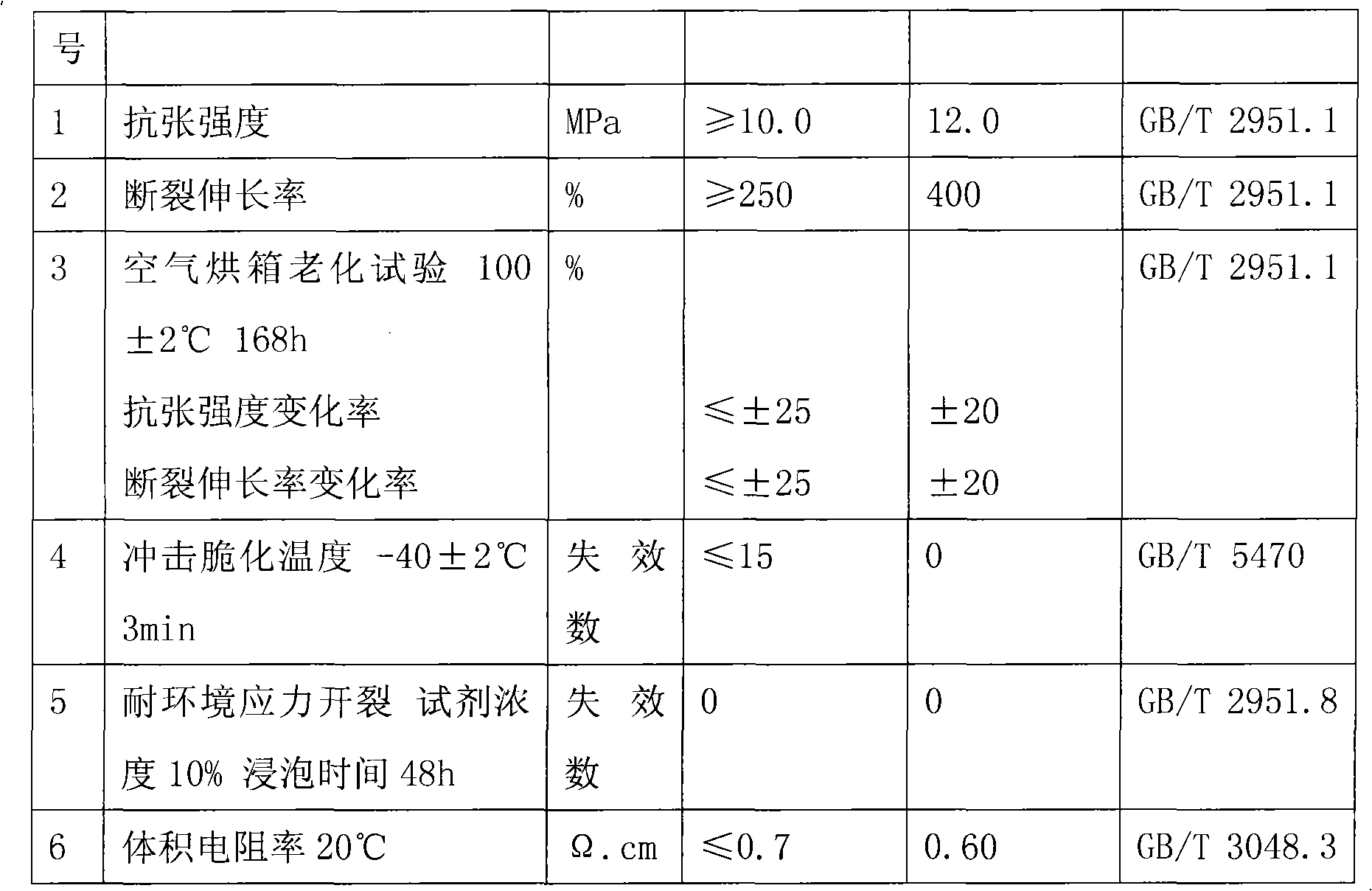

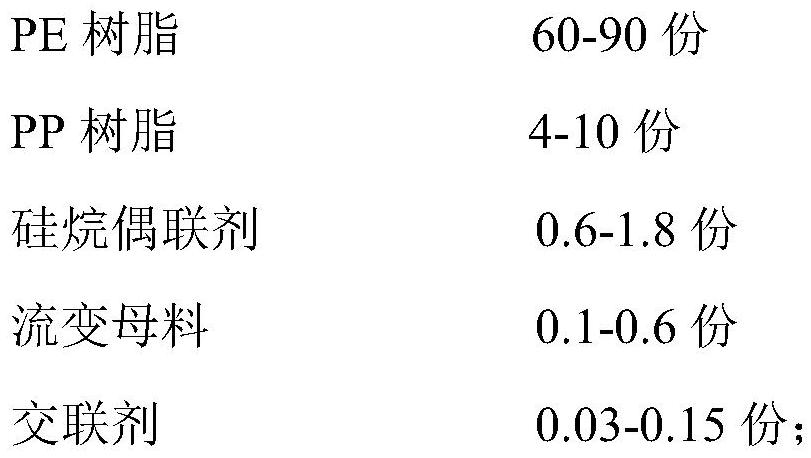

Cross-linked polyethylene insulating material universal for large and small wires of 3KV and below, and preparation method thereof

PendingCN112375284AExtrusion stabilityEasy to processPlastic/resin/waxes insulatorsPolymer sciencePtru catalyst

The invention discloses a cross-linked polyethylene insulating material universal for large and small lines of 3KV and below, and a preparation method thereof. The cross-linked polyethylene insulatingmaterial comprises PE resin, PP resin, a silane coupling agent, a rheological master batch, a cross-linking agent and a catalyst, wherein extruding by a double-step screw, extruding granulation by asingle screw, conveying with water, drying and packaging are performed to obtain a finished product. According to the cross-linked polyethylene insulating material universal for large and small linesof 3KV and below, and the preparation method thereof, the PE resin and the PP resin are compounded to improve the problem of unqualified thermal shrinkage of the small wire, the reaction rate is reduced and the extrusion processability of the small-wire-diameter cable is optimized through the vinyltrimethoxyethoxysilane, the dibutyltin dilaurate catalyst can catalyze a hydrolytic condensation reaction of the grafted material A and water to generate a three-dimensional reticular structure, and the obtained silane cross-linked polyethylene insulating material has more excellent processability, is universal for large and small lines, is stable in extrusion and good in surface extrusion, and meets JB / T 10437-2004 standard requirements and customer processing technology requirements.

Owner:SUZHOU HENGLI COMM MATERIAL

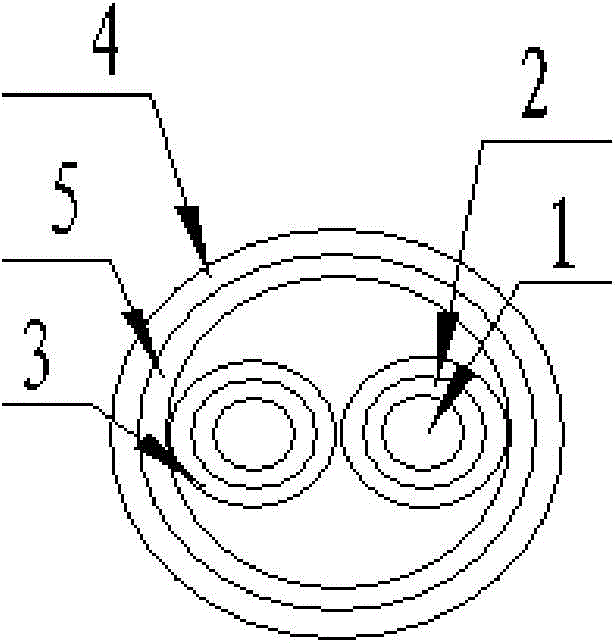

Anti-interference low-noise cable for medical use

InactiveCN105989928ALow priceConvenient sourceInsulated cablesNon-conductive material with dispersed conductive materialLow noiseDisplay device

The invention relates to an anti-interference low-noise cable for medical use. The cable is connected with the displays of multiple medical devices and at least one emitter. The cable comprises a two pair-twisted wire cores, flexible PVC polymer layers coating the pair-twisted wire cores, insulating layers coating the flexible PVC polymer layers, and a sheath coating the two pair-twisted wire core structures. Compared with the prior art, the anti-interference low-noise cable for medical use has the advantages of low cost, good mechanical performance, good high temperature resistance, and the like.

Owner:SHANGHAI XINYI ELECTRICAL CIRCUIT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com