Amylum category complete biodegradable material and preparation method thereof

A technology for biodegradable materials and starch, which is applied in the field of completely biodegradable starch materials and their preparation, can solve the problems that the comprehensive performance needs to be further improved, the dispersing effect and plasticizing effect of starch fillers are not ideal, and the like, and complete biodegradation is achieved. performance, excellent blow molding processability, and the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

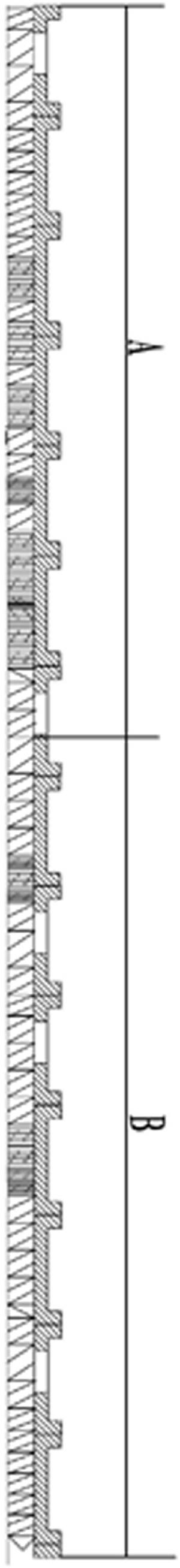

Method used

Image

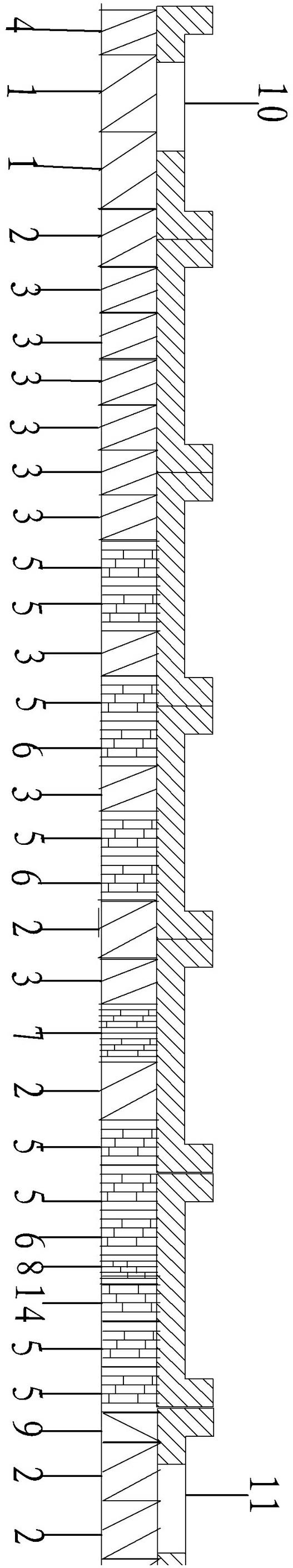

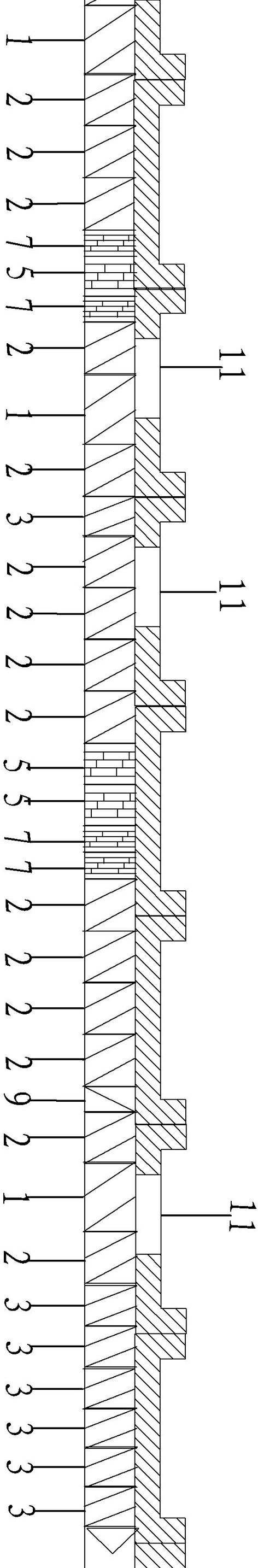

Examples

Embodiment 1

[0045] Weigh each component according to the following weight percentages:

[0046] Composition Proportion% PBSA 60 corn starch 20 glycerin 10 calcium carbonate 5 DOA 2 Toluene diisocyanate 1 1,4-phenyl-bis(2-oxawaline) 1.5 bisphenol A phosphite 0.1 dodecylthiopropyl ester 0.1 Oleamide 0.1 Ethylene bis stearamide 0.2

[0047] The preparation process is as follows:

[0048] Mix glycerin and DOA evenly and transfer to liquid metering pump;

[0049] Put PBSA, cornstarch, and calcium carbonate into the frequency conversion high-speed mixer according to the ratio and mix them evenly. At the same time, turn on the liquid metering pump to accurately measure and inject oil and mix for 135 seconds.

[0050] Use weighing scales to accurately measure and feed into the extruder;

[0051] The length-to-diameter ratio of the extruder is 56:1, and the main engine is designed with 4 exhaust ports;

[00...

Embodiment 2

[0058] Weigh each component according to the following weight percentages:

[0059] Composition Proportion% PCL 50 corn starch 30 glycerin 10 calcium carbonate 5 water 2 Toluene diisocyanate 1 Diglycidyl esters, bis(2-oxaline) 1.5 bisphenol A phosphite 0.1 dodecylthiopropyl ester 0.1 Oleamide 0.1 Ethylene bis stearamide 0.2

[0060] The preparation process is as follows:

[0061] Mix glycerin and water evenly and transfer to liquid metering pump;

[0062] Put PCL, cornstarch, and calcium carbonate into the frequency conversion high-speed mixer according to the ratio and mix evenly. At the same time, turn on the liquid metering pump to accurately measure and inject oil and mix for 135 seconds. After adding the additives, turn to high speed and mix for 40 seconds.

[0063] Use a weighing scale to accurately measure and feed the extruder;

[0064] The length-to-diameter ratio of the extruder is 5...

Embodiment 3

[0070] Weigh each component according to the following weight percentages:

[0071] Composition Proportion% PHAs 70 corn starch 20 glycerin 5 calcium carbonate 1 DOA 2 Toluene diisocyanate 1 Diglycidyl esters, bis(2-oxaline) 0.5 bisphenol A phosphite 0.1 dodecylthiopropyl ester 0.1 Oleamide 0.1 Ethylene bis stearamide 0.2

[0072] The preparation process is as follows:

[0073] Mix glycerin and DOA evenly and transfer to liquid metering pump;

[0074] Put PHA, cornstarch, and calcium carbonate into the frequency conversion high-speed mixer according to the ratio and mix them evenly. At the same time, turn on the liquid metering pump to accurately measure and inject oil and mix for 135 seconds. After adding the additives, turn to high speed and mix for 40 seconds.

[0075] Use a weighing scale to accurately measure and feed the extruder;

[0076] The length-to-diameter ratio of the extruder is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com