Patents

Literature

458results about How to "Guaranteed bonding performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of bast fiber nonwoven fabric

InactiveCN101324012AEasy to manufactureAvoid breakingNon-woven fabricsAdhesivesNonwoven fabricMaterials science

The invention discloses a production method of a fibrilia non-woven fabric and comprises following steps: (1) opening and mixing: the fibrilia is opened once, bonding fiber and other fibers are opened for two or more times, and the opened fibrilia, bonding fiber and other fibers are mixed; (2) the mixed fibers are processed into a meshwork; (3) prickling shaping: the fiber meshwork that is obtained from step (2) is prickled by a needle machine; (4) hot rolling shaping: the fiber meshwork that is obtained after the prickling is transmitted onto a roll squeezer to be rolled, and the hot rolling shaping is implemented. The production method of the fibrilia non-woven fabric is simple, and the opening times of the fibrilia is limited, thus avoiding fibrilia break that is caused by a plurality of opening times, and consequently ensuring the length of the fibers and being convenient for the production of the non-woven fabric; simultaneously the opening of other fibers excluding the fibrilia is implemented for two or more times, thus ensuring full opening of the fibers and being convenient for the production of the non-woven fabric.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

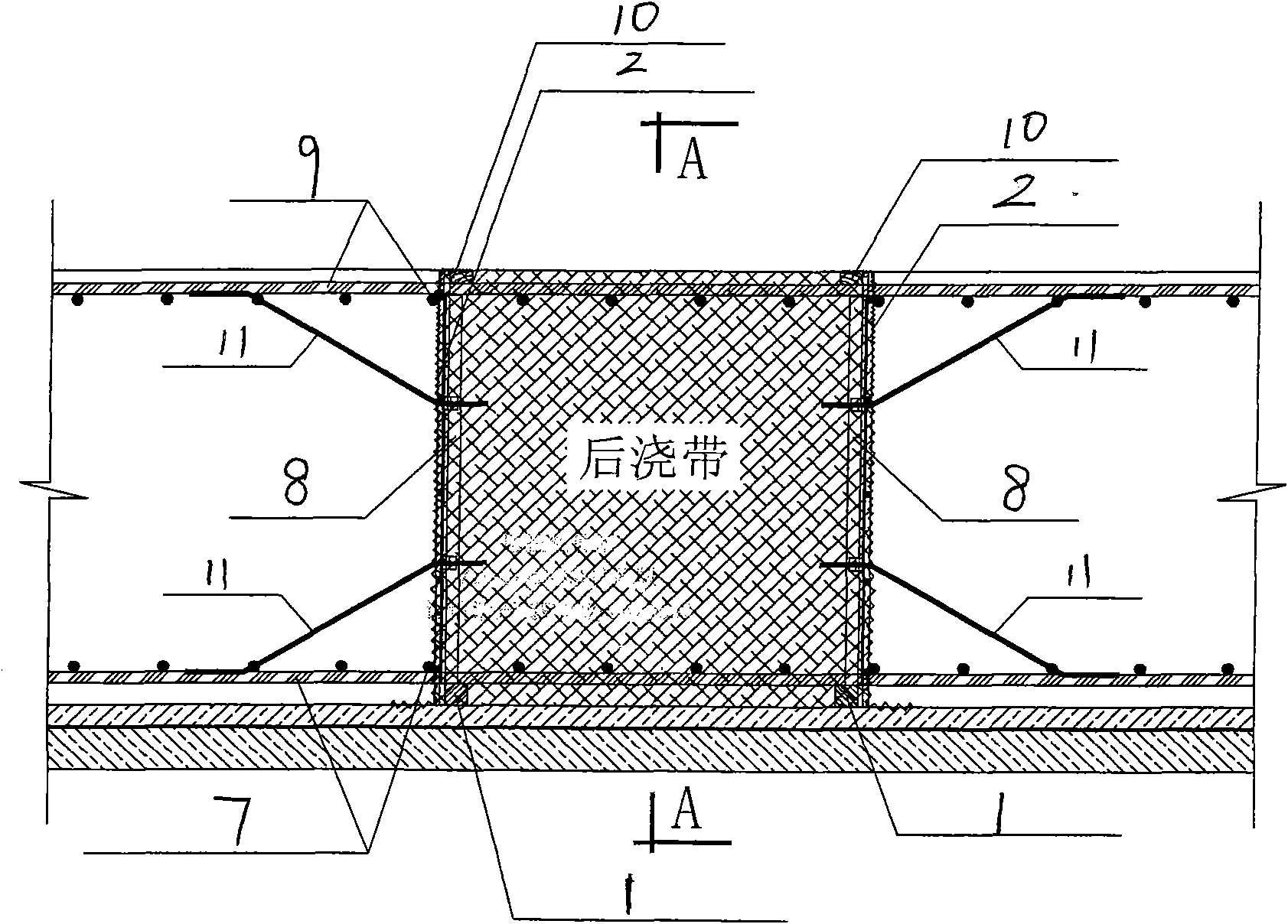

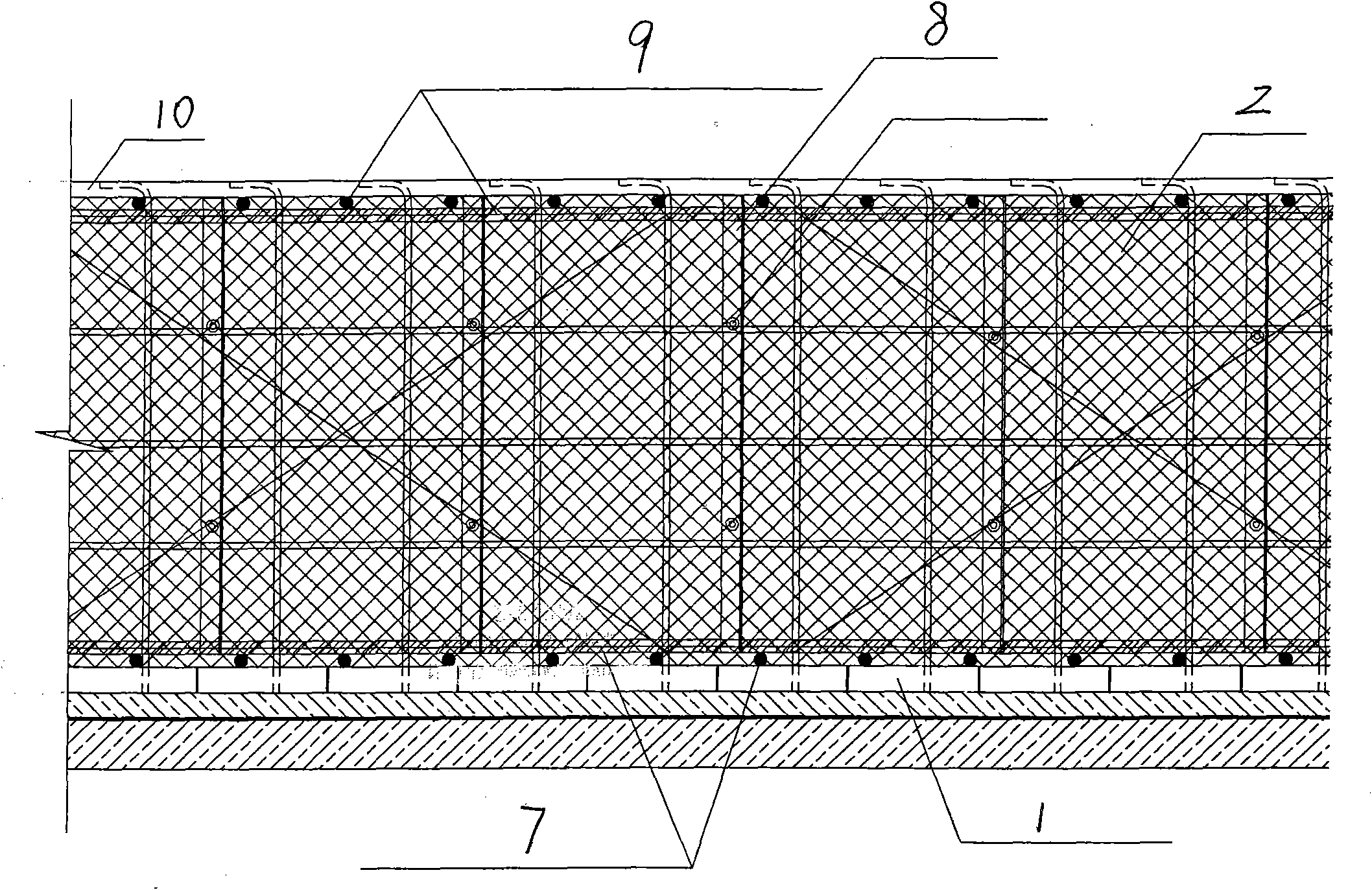

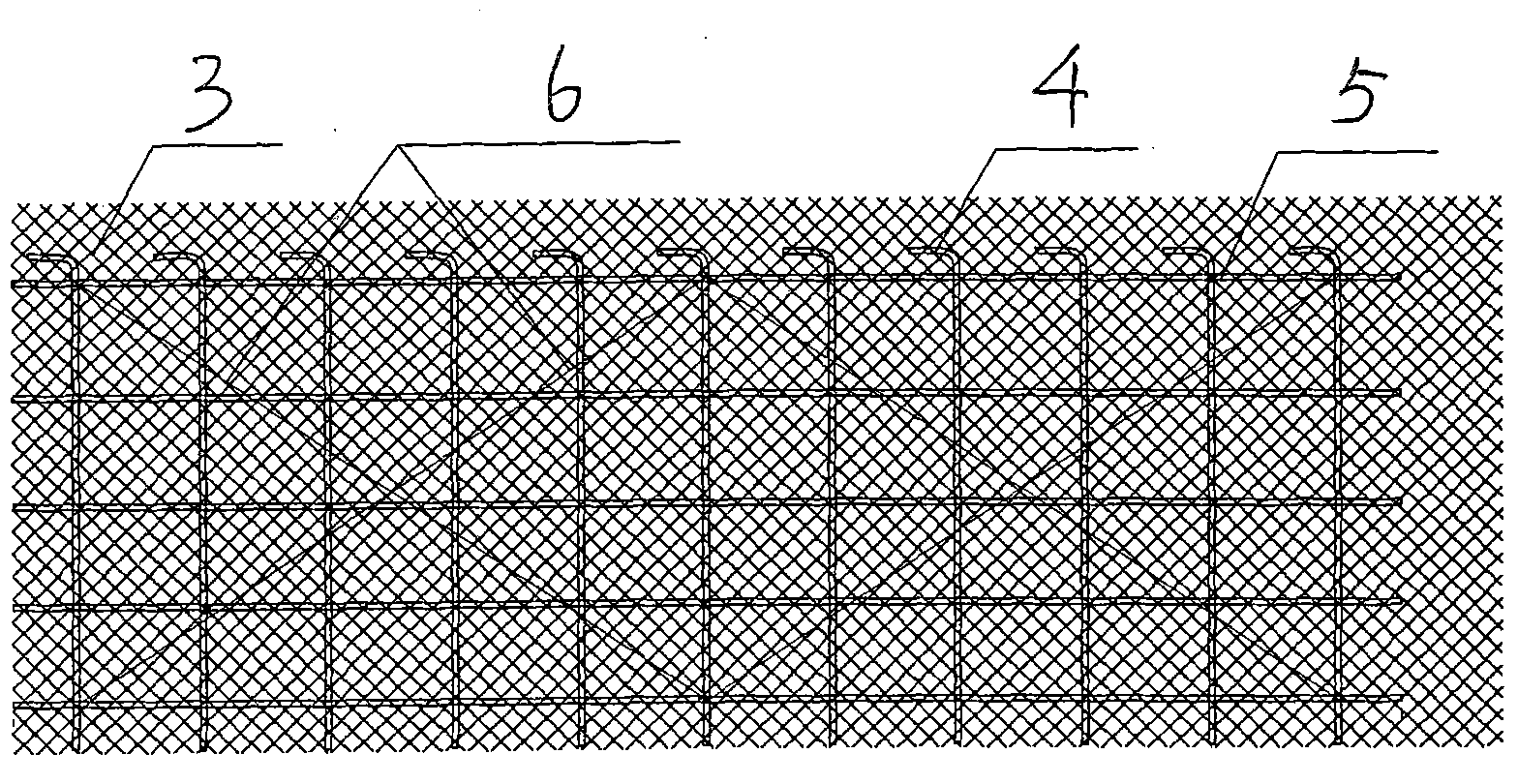

Construction method of sole plate post-poured strip form bracing system

ActiveCN101832026AGuarantee the construction qualityEasy constructionBuilding material handlingForm treatmentRebarSheet steel

The invention discloses a sole plate post-poured strip form bracing system, applicable to sole plate post-poured strip form bracing of basement in constructional engineering. The form bracing system is mainly composed of components of a steel screen mould, a cable-stayed bolt and structural steel back plank, a precast slurry baffle concrete strick and a slurry baffle wood block. The invention utilizes a sole plate reinforcing mattress as a main bracing body, side pressure of concrete at the two sides of the post-poured strip can be effectively braced, the cavity of the formed post-poured strip is clean, tidy and clear and has no concrete pouring oozing or laitance pollution, most materials in the post-poured strip form bracing system are available and can be dismantled and recycled, and design function of post-poured strip can be effectively realized.

Owner:南通建工集团股份有限公司

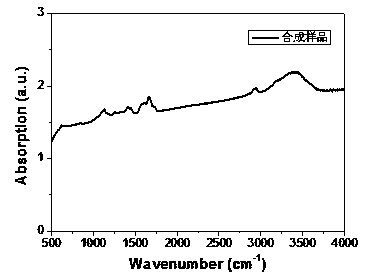

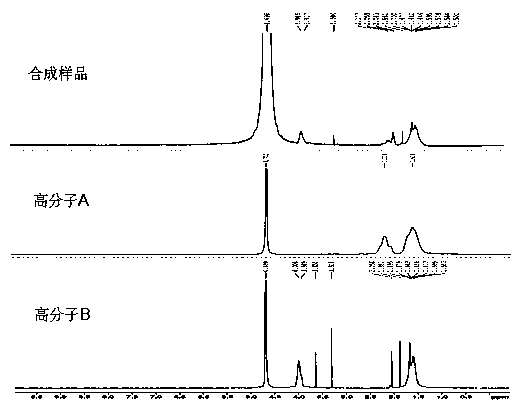

Lignin-base auxiliary agent for phenolic resin adhesive and its preparation method and application

InactiveCN101104782AImprove environmental performanceGuaranteed bonding performanceMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSulfonateUltrafiltration

Belonging to the technical field of macromolecule binder, the invention relates to the preparation and application of a lignin additive for phenolic resin adhesive. The lignin additive is composed of hydroxylmethylated lignin with a molecular weight over 10000 and auxiliary components, wherein the raw material lignin is sulfonate lignin and the auxiliary components are Na3PO4, Na2HPO4, urea and NaOH. The preparation steps comprise the ultrafiltration treatment and hydroxylmethylation of lignin and the mixing of lignin with the auxiliary components. By adding the additive into the phenolic resin adhesive, the environmental protection performance of the resin adhesive is largely improved and the product cost is reduced.

Owner:上海复爱绿色化学技术有限公司 +1

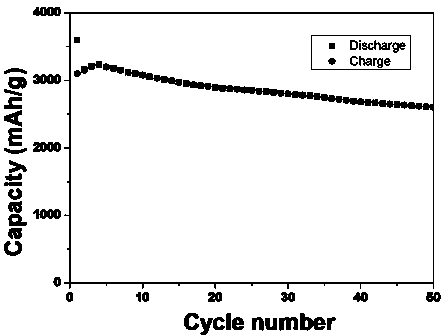

Adhesive for lithium battery and preparation method thereof

ActiveCN103427083APromote circulationImproved high-magnification performanceCell electrodesPolymer scienceAdhesive

The invention relates to adhesive for a lithium battery and a preparation method thereof. The adhesive is aqueous and is prepared through polymer A containing carboxyl functional groups and polymer B containing hydroxyl functional groups. The preparation method includes dissolving and placing the polymer A containing the carboxyl functional groups and the polymer B containing the hydroxyl functional groups in a reactor in proportion, then adding reaction initiator C to stir without a break for 10 to 12 hours at the constant temperature ranging from 40 to 70 DEG C, and cooling to the room temperature to obtain the adhesive. The adhesive has high-strength adhesion and excellent plasticity, prepared slurry can be preserved for long time without phase separation and can be mass produced, so that a battery producing process is easier and more facilitated, and consistence of battery quality can be guaranteed.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

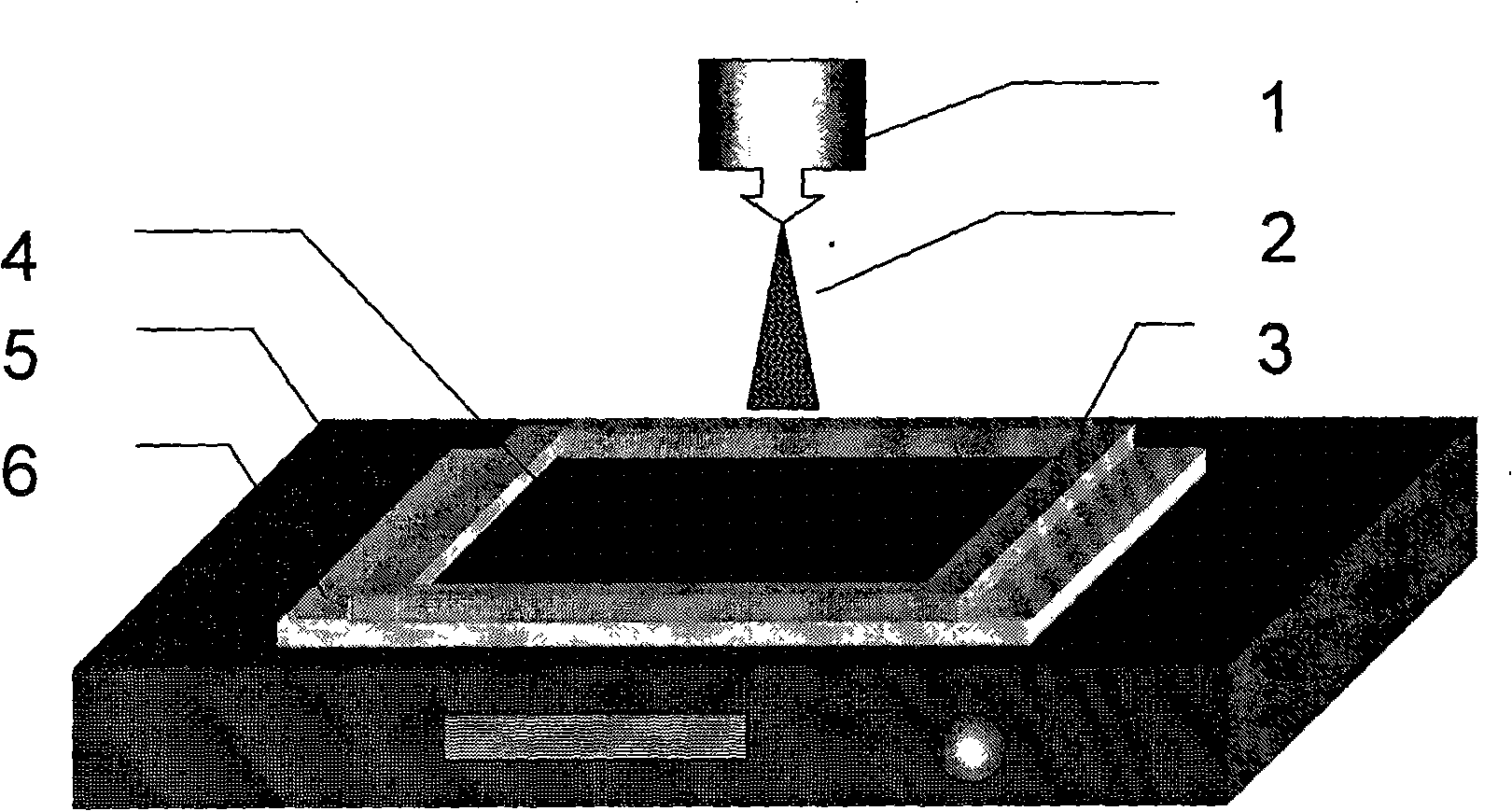

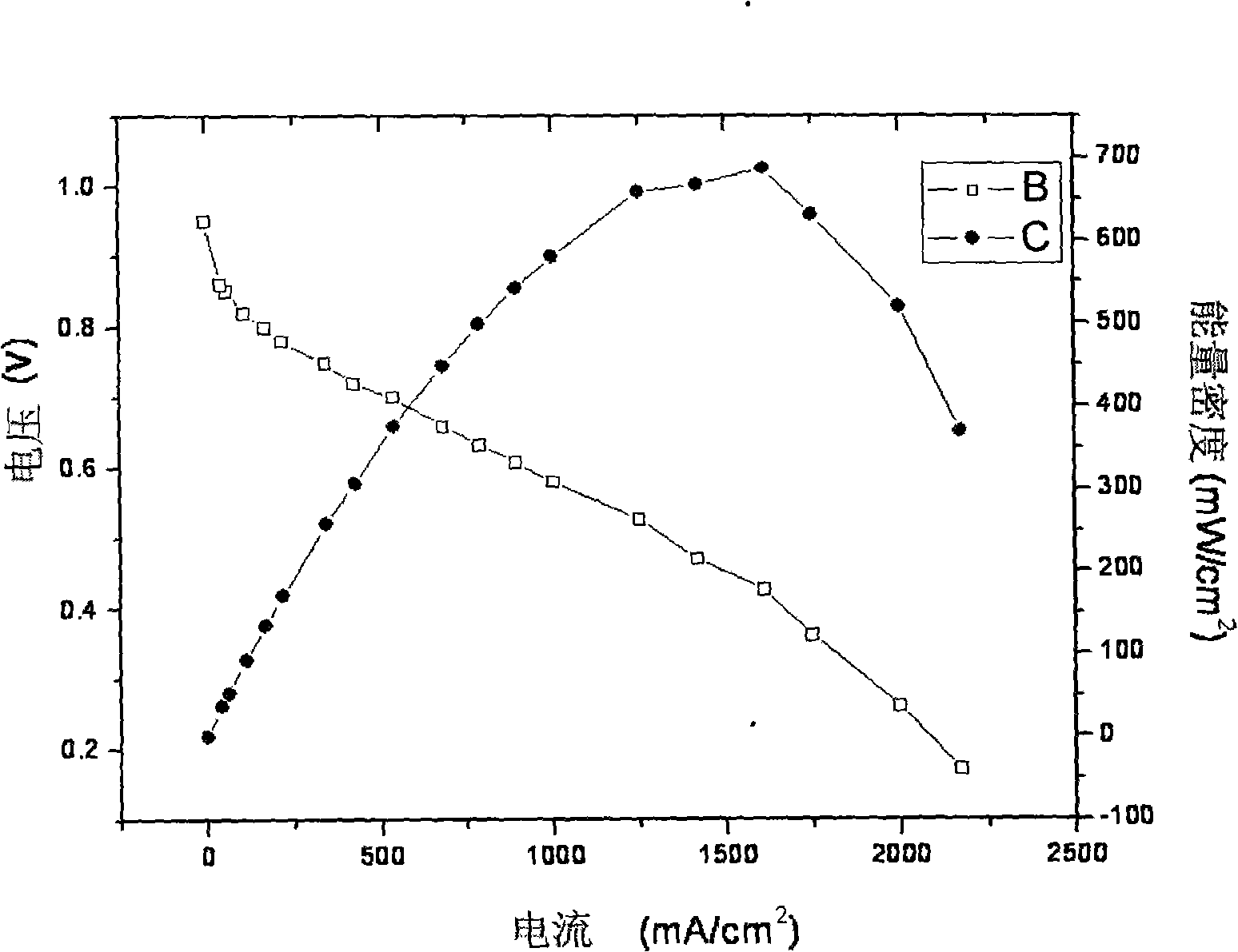

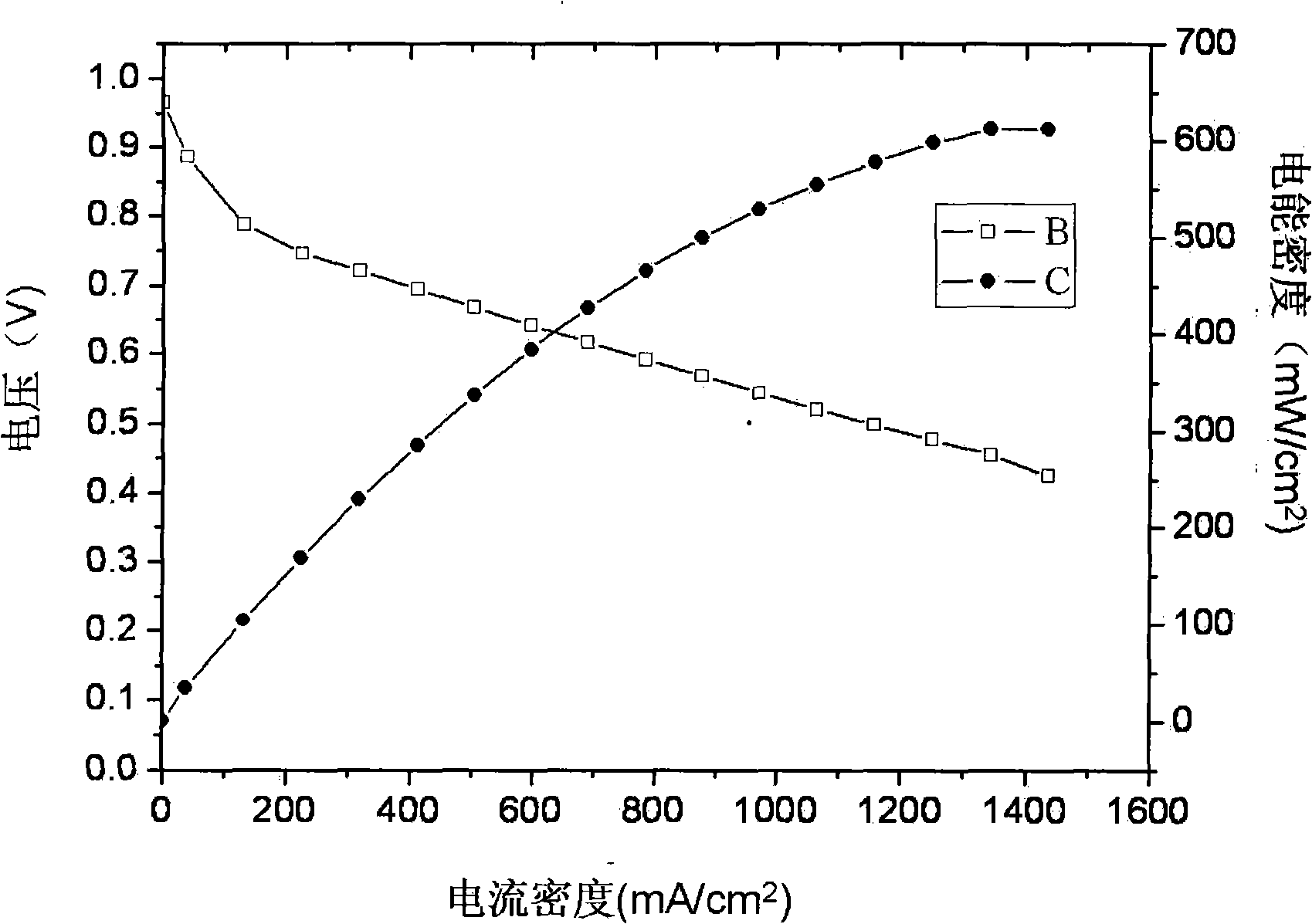

Preparation technique for membrane electrode of proton exchange film fuel cell

ActiveCN101276919AImprove solubilityNo pollution in the processFinal product manufactureCell electrodesState of artSpray coating

The invention relates to a technology that prepares a proton exchange membrane fuel cell electrode, comprising three parts of a pre-process of the proton exchange membrane, a preparation of a catalyst slurry and spray coating of a membrane electrode. The technology provided by the invention solves the problems that in prior art preparation process, the proton exchange membrane swells and rucks and the dosage of the catalyst is high and the preparation process is complicated. The prepared proton exchange resin has great elasticity and adhesive property, which is beneficial for improving adhesion of the catalyst layer and the proton exchange membrane and improves utilization ratio of the catalyst.

Owner:辽宁沐与康中氢燃料电池有限公司

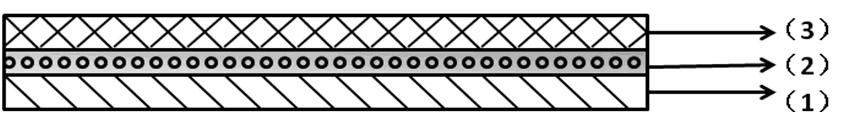

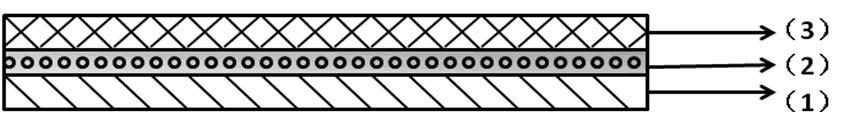

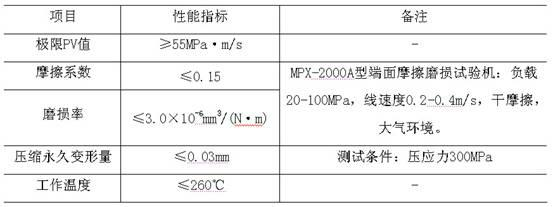

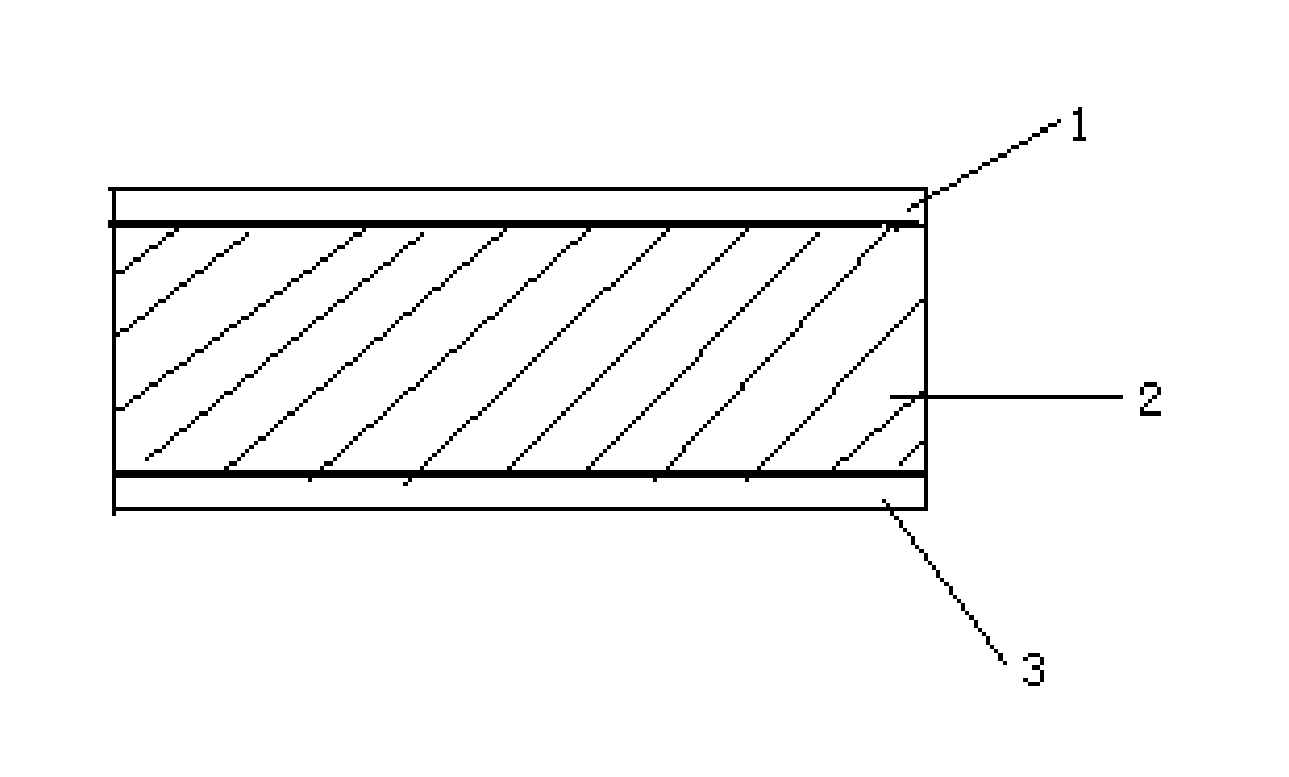

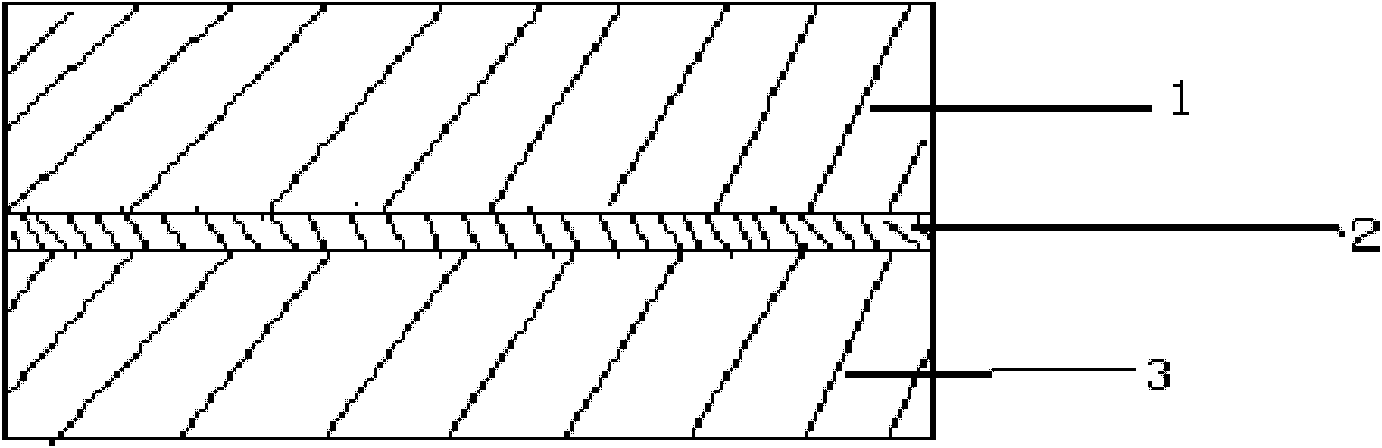

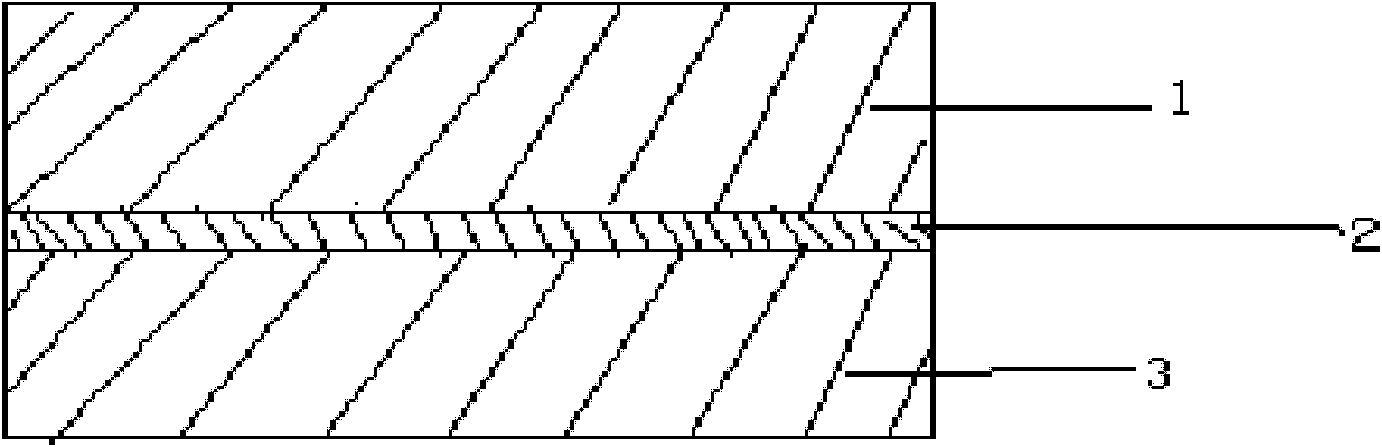

Composite material of high-temperature resistant metal-fabric/resin self-lubricating bearing and preparation method of composite material

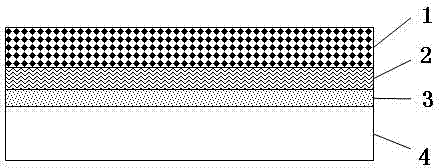

InactiveCN102145556AGuaranteed bonding performanceSolve the problem of low bonding strengthSynthetic resin layered productsMetal layered productsPoly ether ether ketoneResin composite

The invention belongs to the technical field of polymer composite materials and in particular relates to a composite material of a high-temperature resistant metal-fabric / resin self-lubricating bearing and a preparation method of the composite material. The composite material comprises three layers, wherein the bottom layer is a metal plate; the middle layer is a porous sintered tin bronze powder layer, and self-lubricating wear-resisting resin is impregnated in a pore; the surface layer is made of the composite material of mixed fabric and self-lubricating wear-resisting resin; the mixed weaved fabric is the composition of at least two materials of polytetrafluoroethylene fiber, carbon fiber, aramid fiber, polybenzimidazole fiber and glass fiber; and the self-lubricating wear-resisting resin is the blend of one or more of polyphenylene sulfide, polytetrafluoroethylene, polyether-ether-ketone and nylon. The composite material of the bearing has good high-temperature resistance, high loading capacity, good wear resistance and good self-lubricating property, solves the problems of high wear rate, poor wear resistance, low-temperature resistance and the like of the material of a DU bearing, and realizes the excellent frictional property and using reliability under high temperature of the material of the bearing. The composite material is applicable to the self-lubricating bearings in the fields of aeronautics and astronautics, machinery, automobiles, home appliances, office facilities and the like.

Owner:FUDAN UNIV

Method for forming Pt-modified NiAl+Ni3Al thermal barrier adhering layer on surface of nickel-based super alloy

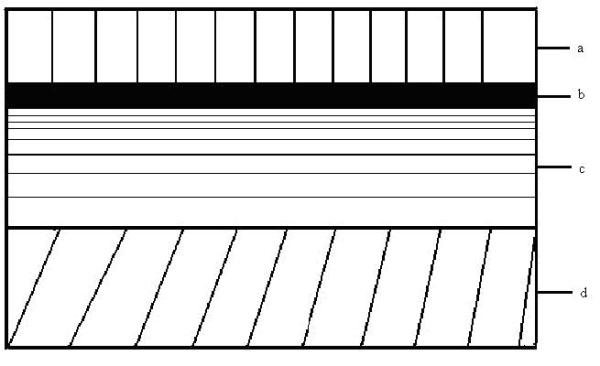

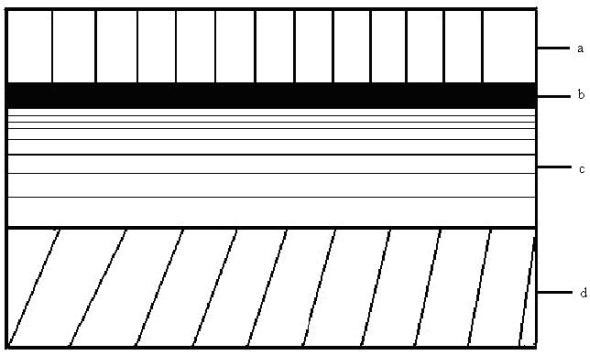

InactiveCN102181860APrevent oxidationGuaranteed bonding performanceSolid state diffusion coatingSuperimposed coating processMartensite transformationCoated surface

The invention relates to a method for forming a Pt-modified Beta-NiAl+Gamma'-Ni3Al thermal barrier coating adhering layer on the surface of nickel-based super alloy (c). Specially speaking, the surface (a) of a coating is a Pt+Beta-NiAl phase, and the inner part (b) of the coating is a Pt-Gamma-Ni+Gamma'-Ni3Al phase Due to the double-phase structure, the problem of martensite phase transformation in the traditional thermal barrier coating adhering layer is solved as the difference between the coating and the base aluminum is larger, and the aluminum diffuses rapidly, the oxidation resistance of the coating is guaranteed and simultaneously, the adhering property of the coating and the base is combined, and compared with the traditional adhering-layer material, the adhering layer has superior advantages. In the invention, the Pt+Beta-NiAl+Gamma'-Ni3Al coating is formed in a powder embedding and aluminizing way. The specific implementation process is as follows: plating a layer of Pt on the super alloy base, then heating and diffusing the super alloy base, and finally conducting powder embedding and aluminizing on the Pt-plated base diffused uniformly, thus obtaining the coating with the structure and the phase by aluminizing control process.

Owner:SHANGHAI UNIV

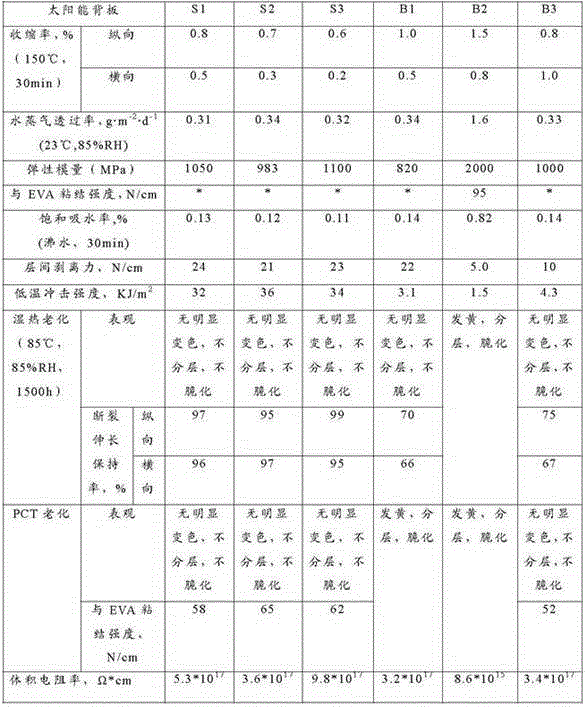

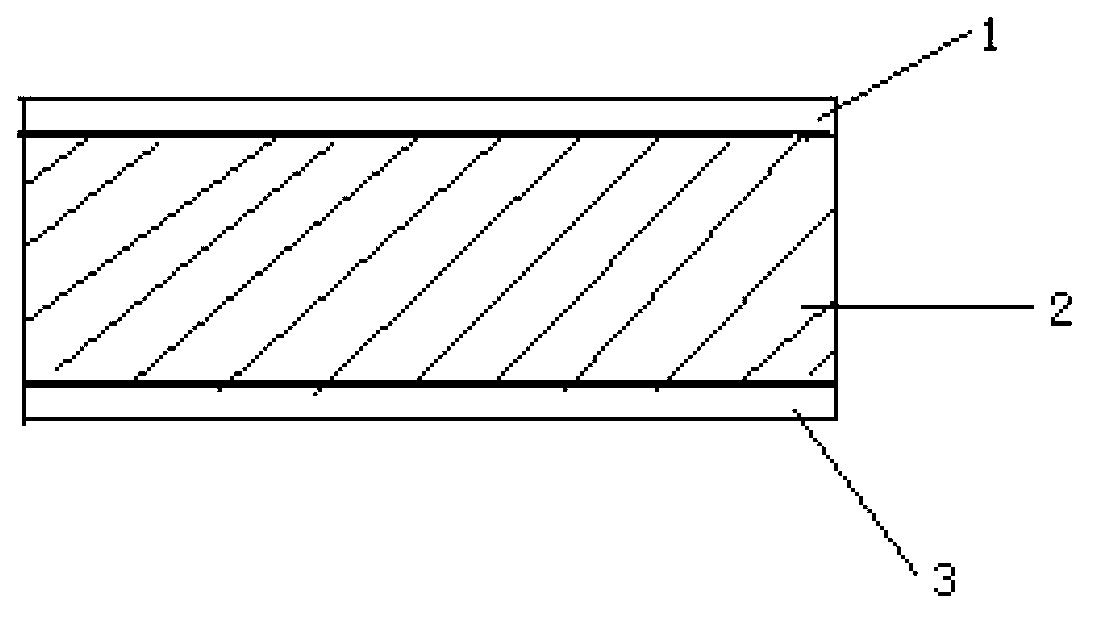

Extrusion type solar energy backboard and manufacturing method thereof

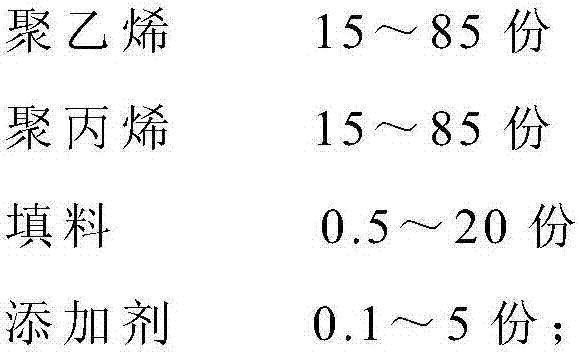

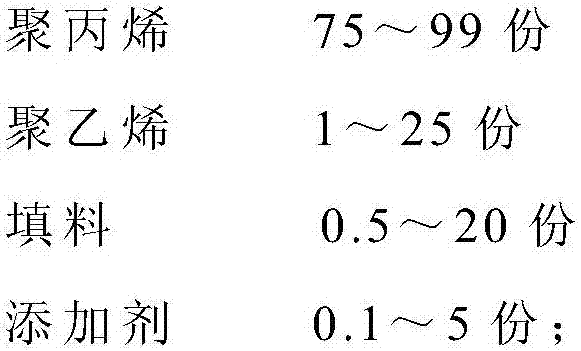

InactiveCN107275429AGuaranteed bonding performanceImprove adhesionSynthetic resin layered productsElectrical equipmentEngineeringSilica gel

The invention discloses an extrusion type solar energy backboard. The extrusion type solar energy backboard sequentially comprises an inner layer, a middle layer and an outer layer from inside to outside, wherein mass ratios of the inner layer, the middle layer and the outer layer are respectively 10-40:40-80:10-40, and total thickness of the extrusion type solar energy backboard is 0.1-0.6mm. The extrusion type solar energy backboard is advantaged in that polypropylene having relatively large rigidity is added to the inner layer, not only can adhesion stress between the backboard and a glue film be guaranteed, but also interlayer adhesion force between the inner layer and the middle-layer polypropylene material is further improved, moreover, polyethylene or copolymer of the polyethylene is added between the middle layer and the outer layer material, excellent adhesion with polyethylene of the inner-layer material can be realized, and interlayer adhesion force and low temperature impact strength of the backboard are further improved; the grafting material is added, uniformity and interlayer adhesion stress of products can be improved, surface tension of the backboard after corona processing can be improved, adhesion force between the backboard and sealing silica gel employed during solar energy cell frame sealing can be enhanced, and sealing performance is better.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

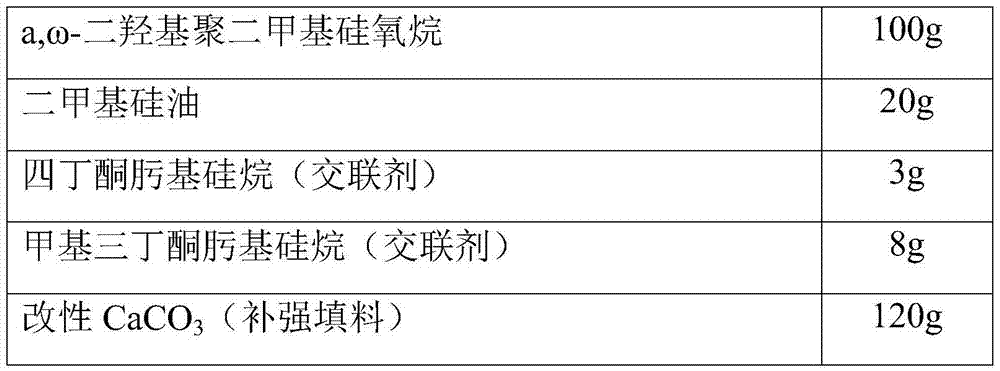

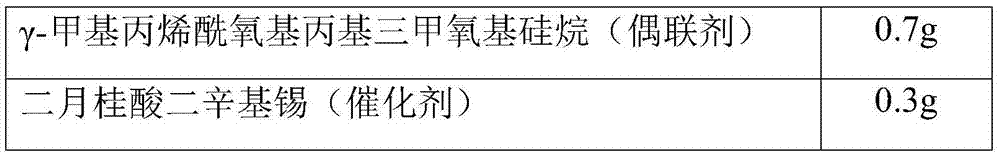

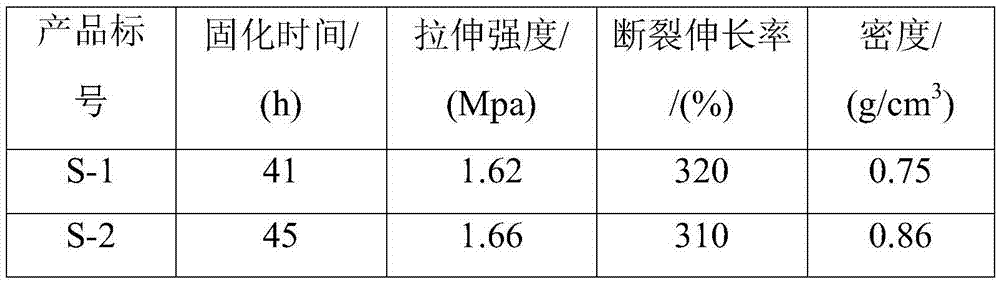

Low-density deketoxime type silicone sealant and preparation method thereof

ActiveCN105441019ALow densityImprove stabilityNon-macromolecular adhesive additivesThermal expansionLow density

The invention discloses a low-density deketoxime type silicone sealant. The sealant comprises components in parts by weight as follows: 100 parts of alpha, omega-dyhydroxyl polydimethylsiloxane, 1-40 parts of dimethyl silicone oil, 0.1-4 parts of thermal expansion microcapsules, 1-25 parts of a cross-linking agent, 20-180 parts of reinforcing filler, 0.01-5 parts of a coupling agent and 0.005-1 part of a catalyst. The invention further discloses a preparation method of the low-density deketoxime type silicone sealant. The low-density deketoxime type silicone sealant has excellent mechanical property and adhesive property, the density of the sealant is remarkably reduced, the foaming effect is excellent, and the stability is high. According to the preparation method, a process is simple and easy to implement, equipment is conventional, operation is facilitated, and industrial large-scale production is facilitated.

Owner:浙江中天东方氟硅材料股份有限公司

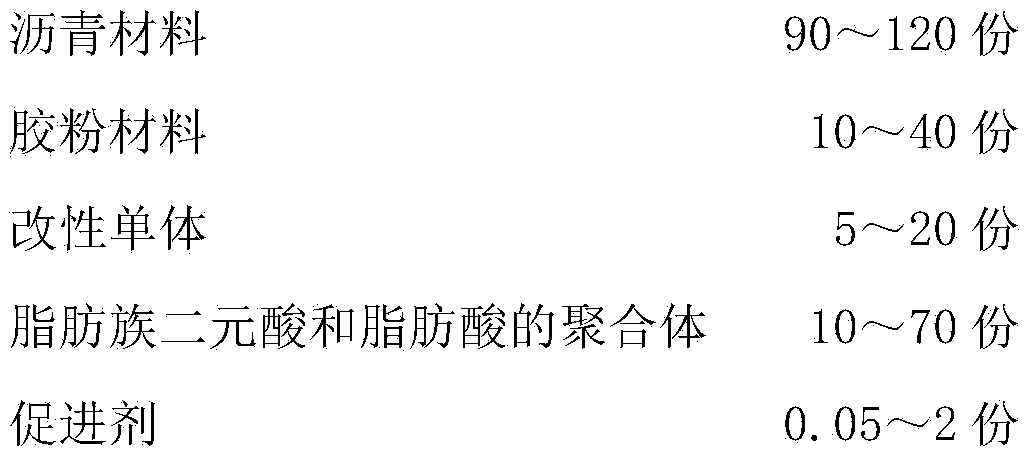

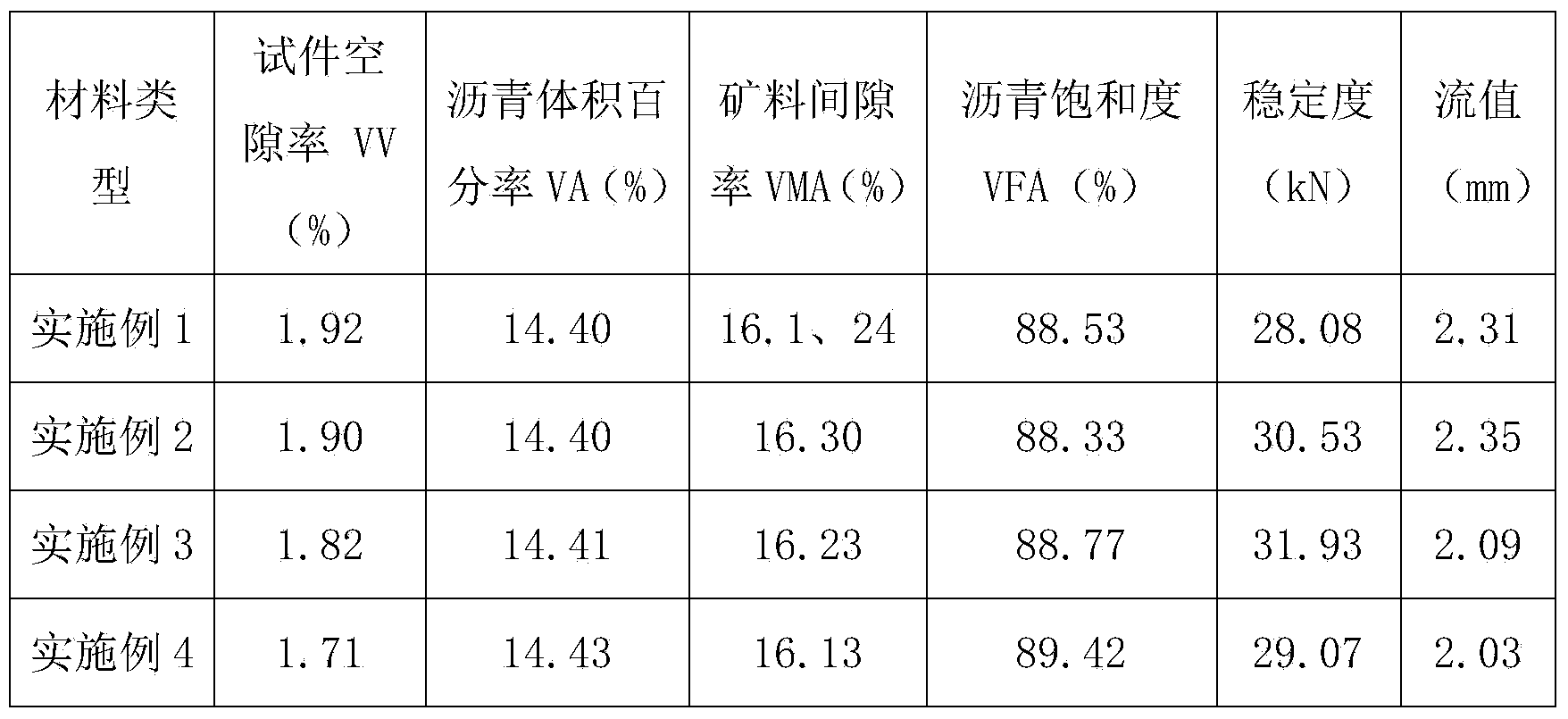

Rubber powder epoxy resin asphalt material as well as preparation method and using method thereof

ActiveCN103396673AProduction environmental protectionReduce energy consumptionIn situ pavingsBridge structural detailsEpoxyPolymer science

The invention discloses a rubber powder epoxy resin asphalt material, as well as a preparation method and a using method thereof. Modified asphalt comprises an A component and a B component, wherein a weight ratio of the A component to the B component is 1:(2-20); the A component comprises 100 parts of epoxy resin by weight; and the B component comprises 90-120 parts of asphalt material, 10-40 parts of rubber powder material, 5-20 parts of modified monomer, 10-70 parts of fatty group binary acid and fatty acid polymer and 0.05-2 parts of accelerant. According to the rubber powder epoxy resin asphalt material, the rubber powder material is adopted, so that the unit price of the epoxy resin asphalt material can be reduced, the low-temperature flexibility of the epoxy resin asphalt material can be improved, and waste rubber can be fully used; and the rubber powder epoxy resin asphalt material, the preparation method and the using method are energy-saving and environment-friendly. The rubber powder epoxy resin asphalt material can serve as a cementing material of a bonding layer and a waterproof layer of a deck and a pavement, asphalt concrete in road engineering, top dressing and the like, and can also be used for waterproofness and anticorrosion of a structure and a building.

Owner:黄卫 +1

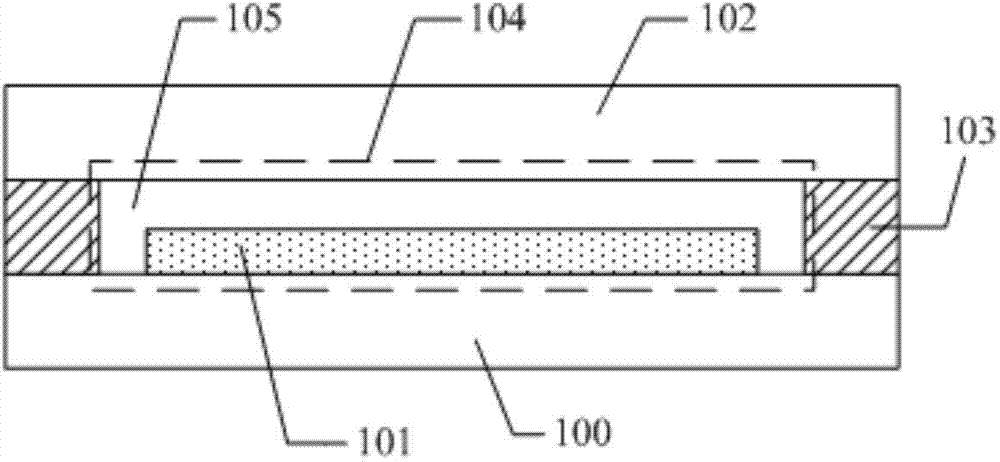

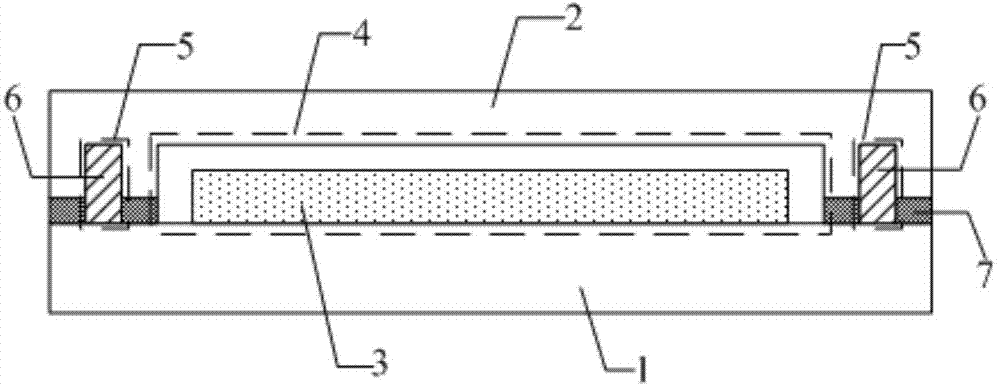

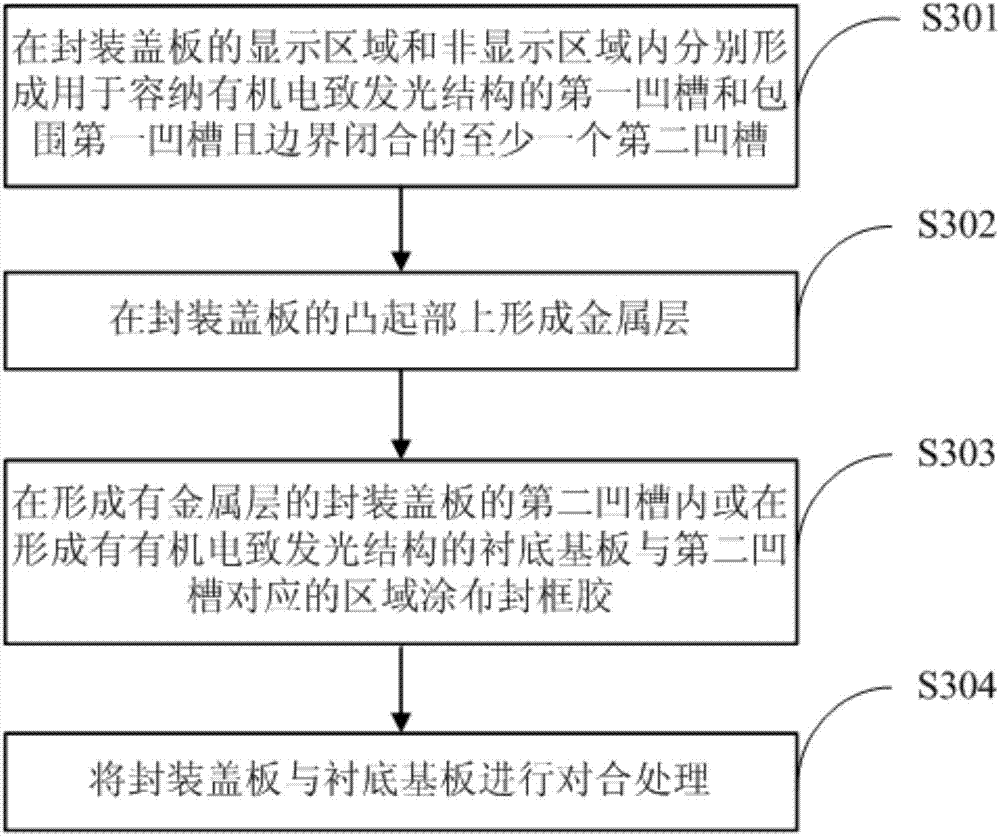

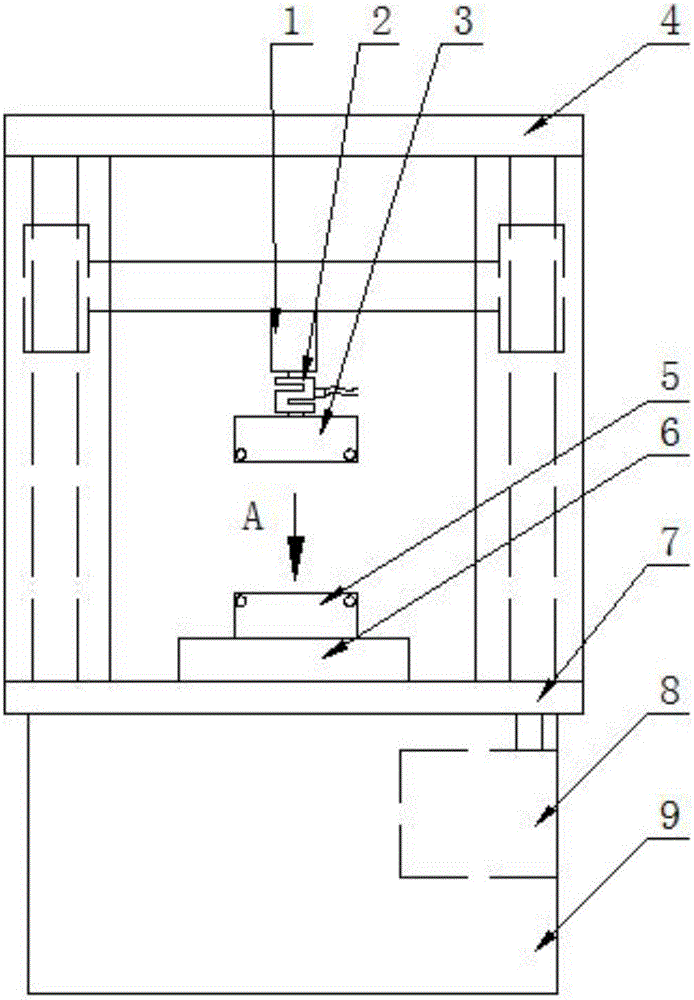

Organic electroluminescent display panel and manufacturing method thereof, and display apparatus

ActiveCN104851904AImprove sealingImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOxygen

The invention discloses an organic electroluminescent display panel and a manufacturing method thereof, and a display apparatus. According to the organic electroluminescence display panel, a first groove for accommodating an organic electroluminescent structure is formed in a display area of a packaging cover plate; and at least one second groove encircling the first groove is formed in a non-display area of the packaging cover plate, wherein the boundary of the second groove is closed. A metal layer enables a protruding part of the packaging cover plate to be bonded with a substrate. Because the protruding part of the packaging cover plate and the metal layer located between the protruding part and the substrate have high molecular densities, a high-efficiency water and oxygen blocking effect can be realized. Moreover, frame sealing glue is accommodated by the second groove and the substrate and the packaging cover plate can be bonded well based on cooperation of the frame sealing glue. Therefore, the packaging cover plate and the substrate can be bonded well based on the metal layer and the frame sealing glue. And under the circumstances the bonding between the packaging cover plate and the substrate is guaranteed, the sealing performance of the organic electroluminescent display panel can be effectively improved.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Testing method of interlayer bonding power of asphalt pavement

InactiveCN106644933AGuaranteed bonding performanceEffective simulation of cohesionUsing mechanical meansMaterial analysisPower parameterDisplay device

The invention relates to a testing method of interlayer bonding power of an asphalt pavement. The testing method comprises the following steps: preparing a test piece: bonding a lower-layer cement concrete test piece with upper-layer asphalt concrete through bonding layer oil; (2) mounting the test piece: putting a test piece to be tested into a lower clamp and slowly lowering a pressing head; continually lowering the pressing head so as to tightly stick an upper mold and the lower mold; and tightly fixing the upper and lower clamps with the test piece respectively; (3) starting to test: starting a pressure machine and adjusting the speed; starting to carry out a pulling test to enable a force value and displacement on a display device to be changed; and when the test piece is pulled to be opened and the force value reaching a peak valve, recording. According to the testing method of the interlayer bonding power of the asphalt pavement, a vertical load of the asphalt pavement can be really simulated and bonding power parameters are obtained; and evaluation of bonding performances of an interlayer material is convenient to realize.

Owner:CHANGAN UNIV +1

Extrusion type solar backboard and preparing method thereof

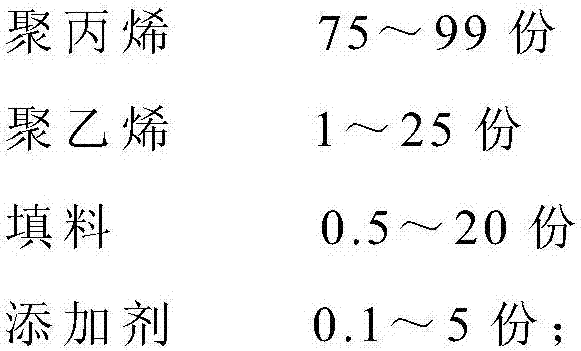

InactiveCN106279904AGuaranteed bonding performanceImprove adhesionSynthetic resin layered productsElectrical equipmentMass ratioEngineering

The invention discloses an extrusion type solar backboard. The extrusion type solar backboard comprises an inner layer, a middle layer and an outer layer from inside to outside in sequence, wherein the mass ratio of the inner layer to the middle layer to the outer layer is (10-40):(40-80):(10-40). The total thickness of the extrusion type solar backboard is 0.1-0.6 mm. By adding high-rigidity polypropylene to the inner layer, cohesive force between the backboard and an adhesive film is guaranteed, and interlayer cohesive force between the backboard and a polypropylene material of the middle layer is improved; meanwhile, by adding polyethylene or copolymers thereof to the material of the middle layer and the outer layer to enable the middle layer and the outer layer to be well bonded with polyethylene in the material of the inner layer, interlayer cohesive force and low-temperature impact resistance of the backboard are improved.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Tatami bed core and preparation method thereof

InactiveCN103054382AGood against insectsGood antibacterialStuffed mattressesSpring mattressesHemp fiberSurface layer

The invention discloses a tatami bed core. The tatami bed core comprises at least one middle layer and a surface layer which is arranged on the upper surface or the lower surface of the middle layer, wherein the surface layer is a non-woven layer which comprises the following components in percentage by weight: 15-40% of low melting point fibers and 60-85% of raw bamboo fibers and / or hemp fibers; and the middle layer comprises the following components in percentage by weight: 5-85% of alpinia fibers, 15-40% of low melting point fibers and the balance of other fibers. The invention further discloses a preparation method of the tatami bed core; and the preparation method comprises the following steps: respectively preparing each layer including an upper surface layer, a lower surface layer and the middle layer; laying the upper surface layer, the lower surface layer and the middle layer in sequence; drying the upper surface layer, the lower surface layer and the middle layer in a drying box; and coldly rolling, cooling, cutting, inspecting and packaging the upper surface layer, the lower surface layer and the middle layer to obtain the tatami bed core. Through adoptions of the tatami bed core and the preparation method thereof disclosed by the invention, technical problems of mildews, insects, easiness for layering and cracking, insufficient elasticity, poor ventilating property and the like in a current bed mattress are solved.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

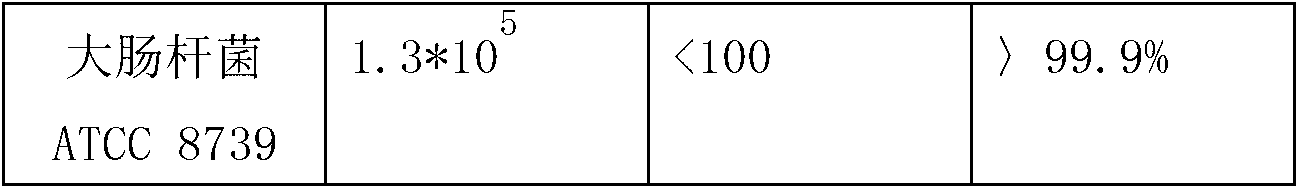

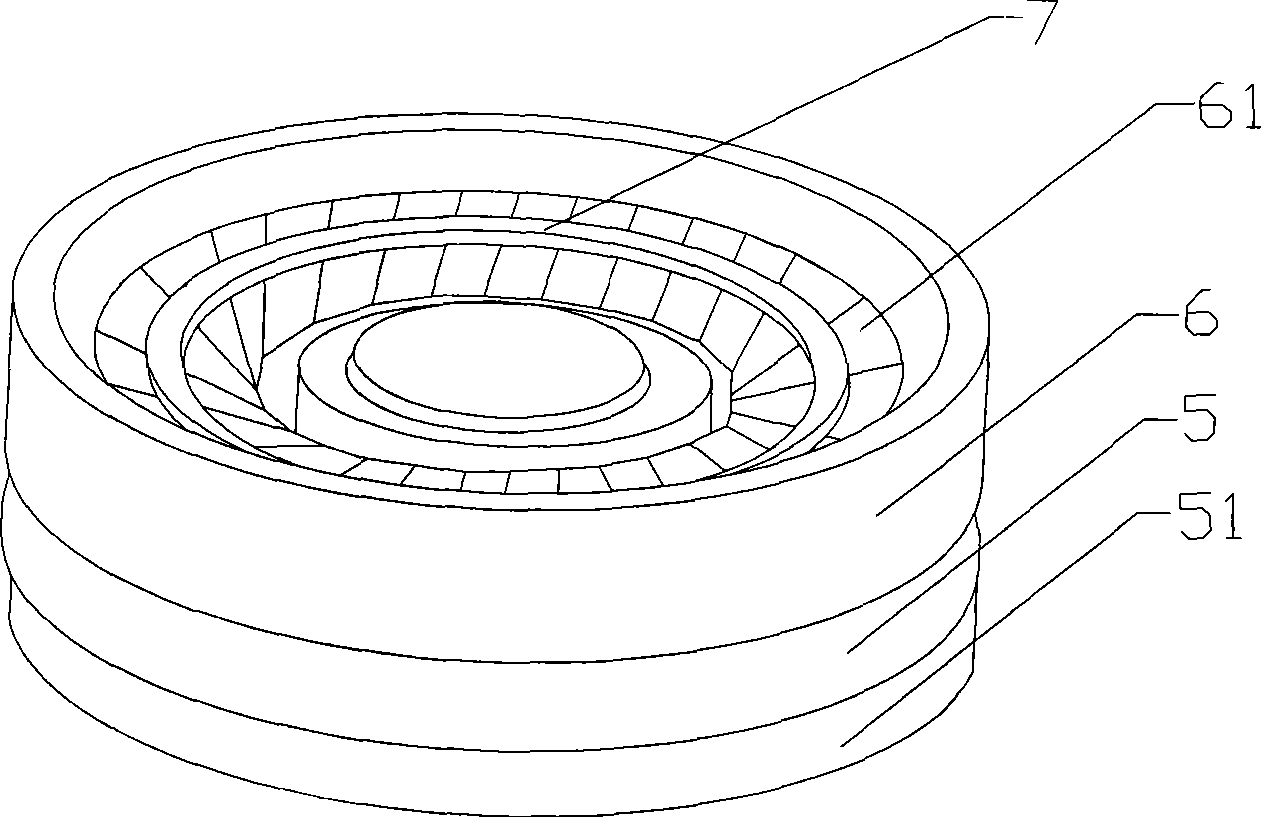

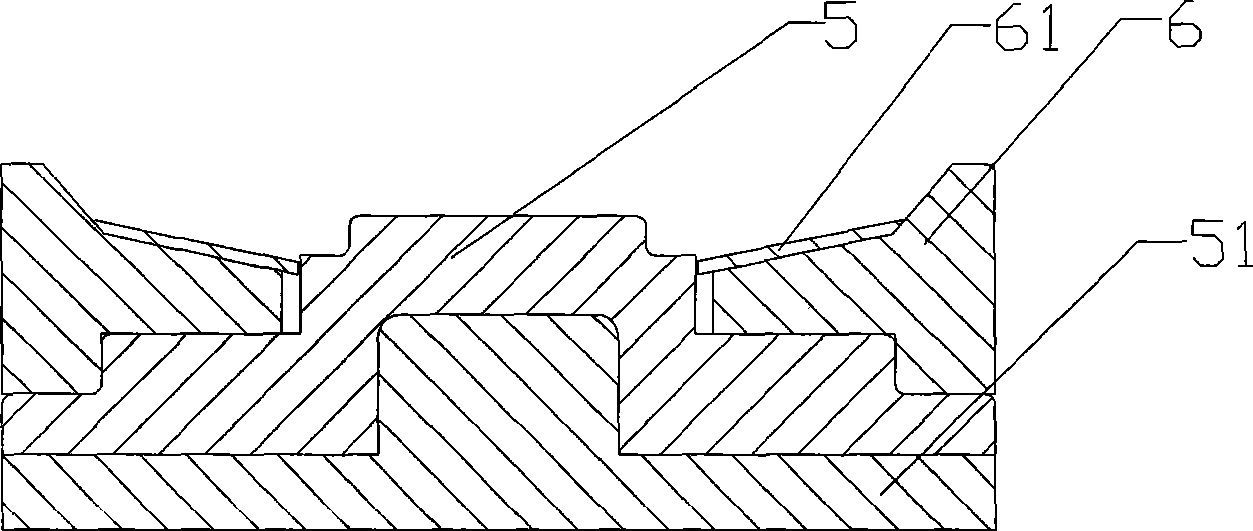

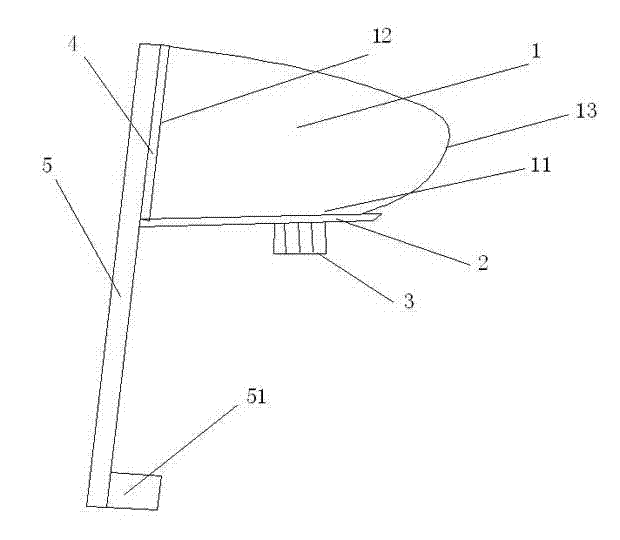

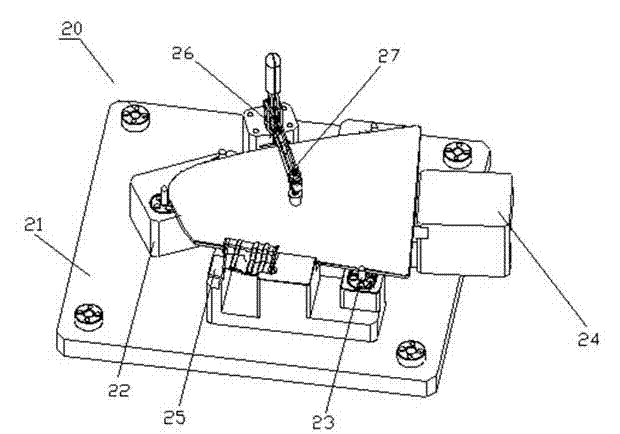

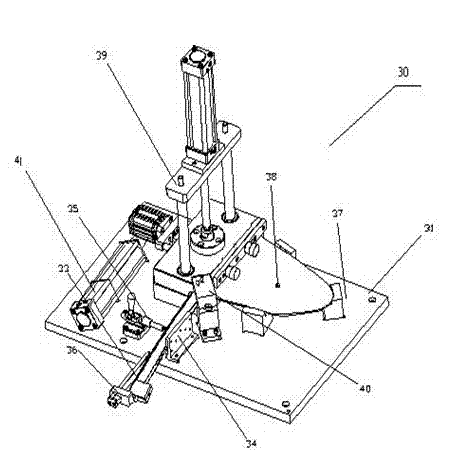

Flow production line of flap disc

ActiveCN101480789AReduce processGuaranteed bonding performanceFlexible-parts wheelsGrinding devicesProduction lineAdhesive

The invention discloses a set of sand-shale disc ring-shaped flow production line which comprises moulds, a gluing device, a filature, a rotator, a clamping device and a stand body, wherein the gluing device and the filature are sequentially distributed on the stand body, the moulds are arranged on the stand body and the rotator, and one mould is driven by the rotator to circularly operate. The sand-shale disc ring-shaped flow production line treats the work arrangement during the production according to a principle of specialized labor division, one operator takes charge of one piece of work so as to greatly shorten the manufacturing process of the sand-shale disc and enhance the production efficiency, the filature is used for replacing the manual screwing of nuts, and the pressure on the adhesive of the sand-shale disc is greatly larger than the pressure of manual operation, thereby the invention ensures the adhesive relation of a sand shale and a base body, enhances the quality and effectively reduces the defective rate and the cost.

Owner:广东小太阳砂磨材料有限公司

Production process and equipment for corner window glass edge-cladding assembly

ActiveCN102529650AGood bonding effectEnsure stabilityWindowsEngine sealsSecondary bondingEngineering

The invention relates to a production process and equipment for a corner window glass edge-cladding assembly, wherein the production process employs the bonding process for two times and is characterized by positioning by first tooling equipment firstly and then bonding the corner window glass with a positioning supporting iron block by single-component polyurethane glue; performing solidification after the first bonding; performing secondary bonding by second tooling equipment after finishing the solidification; during the secondary bonding, adjusting and fixing all the parts in place according to the designed limit requirements; injecting bi-component polyurethane into the clearance of each part by a high-pressure ejector so as to performing solidification; and finishing the processing of the corner window glass edge-cladding assembly after reaching to corresponding solidification time. The technical scheme of the invention makes full use of different bonding properties of the bi-component polyurethane glue and the single-component polyurethane glue to finish the processing by bonding for two times, and the bonding speed of the secondary bonding is accelerated by the high-pressure ejecting molding machine so as to achieve a good bonding effect. Therefore, the production process and the device for the corner window glass edging assembly are efficient and practical.

Owner:瀚德(中国)汽车密封系统有限公司

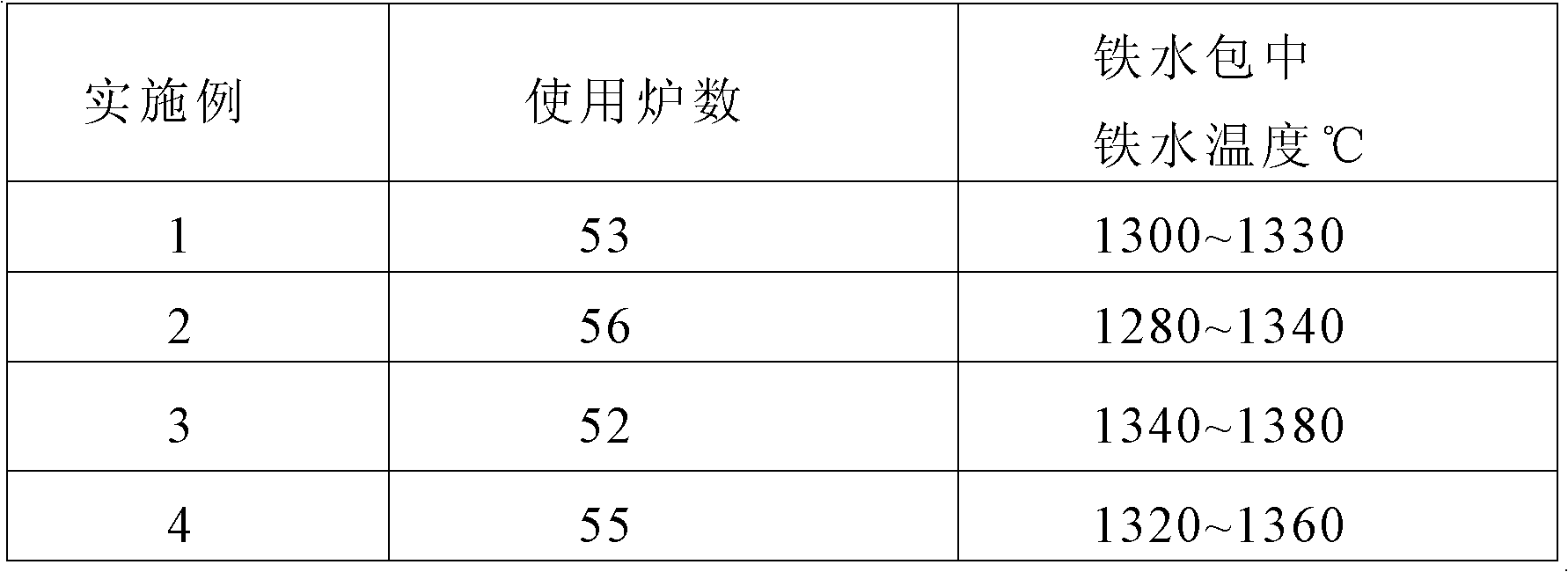

Castable for ladle deslagging plate, and preparation method and applicable of castable

The invention discloses a castable for a ladle deslagging plate, and a preparation method and an applicable of the castable. The castable for the ladle deslagging plate comprises the following components in parts by weight: 50-70 parts of mullite, 10-20 parts of andalusite, 10-20 parts of bauxite powder, 3-5 parts of pure calcium aluminate cement, 4-6 parts of aluminum oxide micropowder, 3-5 parts of silicon carbide micropowder and 2-3 parts of compound additive, wherein the compound additive is a combination of two or more of organic fiber, steel fiber, and sodium tripolyphosphate or sodium hexametaphosphate. When the castable is cast on the outer surface of the ladle deslagging plate, the service life of the ladle deslagging plate can be prolonged and the preparation cost can be reduced; and the preparation method of the castable for the ladle deslagging plate is simple, and easy to operate.

Owner:WUGANG REFRACTORY CO LTD

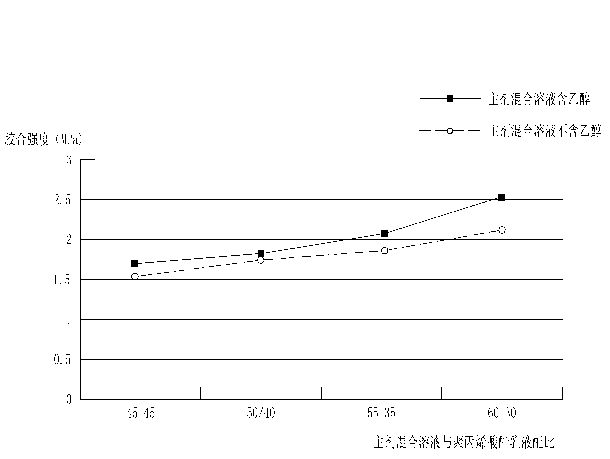

Aqueous polymer-isocyanate adhesive and preparation method thereof

InactiveCN102936471AImprove solubilityGood compatibilityNon-macromolecular adhesive additivesEster polymer adhesivesPolymer sciencePolyvinyl alcohol

The present invention discloses a preparation method of an aqueous polymer-isocyanate adhesive. The aqueous polymer-isocyanate adhesive comprises a main agent and a cross-linking agent, wherein the main agent comprises polyvinyl alcohol, deionized water, ethanol and a polyacrylate emulsion, the cross-linking agent comprises polyaryl polymethylene isocyanate and dioctyl phthalate, and the main agent components and the cross-linking agent components are respectively subjected to dissolving mixing to prepare the aqueous polymer-isocyanate adhesive. According to the present invention, solubility of polyvinyl alcohol in water is increased, compatibility of isocyanate and a hydroxyl polymer is increased, use cost and price are reduced, the adhesive does not contain free phenol and free aldehyde, and provides a bonding strength of 1.71-2.59 MPa for wood when use, and a working life is more than 40 min.

Owner:青州市天源化工有限公司

Flexible pole piece, preparation method of flexible pole piece, flexible battery and flexible mobile phone

InactiveCN106356505AHigh mechanical strengthImprove bendabilityFinal product manufactureElectrode carriers/collectorsFiberCellulose

The invention relates to a flexible pole piece, a preparation method of the flexible pole piece, a flexible battery using the flexible pole piece and a flexible mobile phone using the flexible battery. The preparation method of the flexible pole piece comprises the following steps: (1) mixing and stirring an active material, a conductive agent, an adhesive and a solvent to form a uniformly-dispersed suspension; (2) adding cellulose into the suspension, and stirring to obtain a viscous slurry; and (3) laying the viscous slurry on a metal net via a film rolling process, drying and then obtaining the flexible pole piece. According to the embodiment of the invention, the battery pole piece is prepared from the active material, the conductive agent, the adhesive, the solvent and cellulose; the cellulose can achieve a support effect and can ensure that the pole piece is high in flexibility and mechanical strength; the metal net can achieve an effect of a current collector, so that the mechanical strength of the pole piece can be further improved; a structure of combining the metal net and the slurry with support fiber can ensure that the pole piece still has high flexibility, the bending part is free of bending marks, and the material cannot fall off in the bending process.

Owner:武汉艾特米克超能新材料科技有限公司

Healthcare environment-friendly mattress and preparation method thereof

ActiveCN102517796AGood moisture absorption and air permeabilityLight in massNon-woven fabricsCooking & bakingCarding

The invention discloses a healthcare environment-friendly mattress, which comprises the following ingredients of: 5%-50% of low-melting-point fiber and 5%-65% of bastose. The invention further discloses a preparation method of the healthcare environment-friendly mattress, and the preparation method comprises the following steps of: weighing the ingredients according to the required proportion; carrying out loosening and mixing; carrying out pre-laying; carding; carrying out air laying; entering a baking oven; carrying out cold rolling; cooling; and cutting, checking and packaging, wherein thespeed of the processes of pre-laying, carding and air laying is 0-20 m / min, the temperature of the baking oven is 180-230 DEG C, the temperature of cold rolling is 5-20 DEG C, and the cooling temperature is 0-25 DEG C. With the adoption of the healthcare environment-friendly mattress and the preparation method of the healthcare environment-friendly mattress, disclosed by the invention, the problem that the traditional mattress is easily mildewed due to wetting, deteriorated due to worms and easily delaminated is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

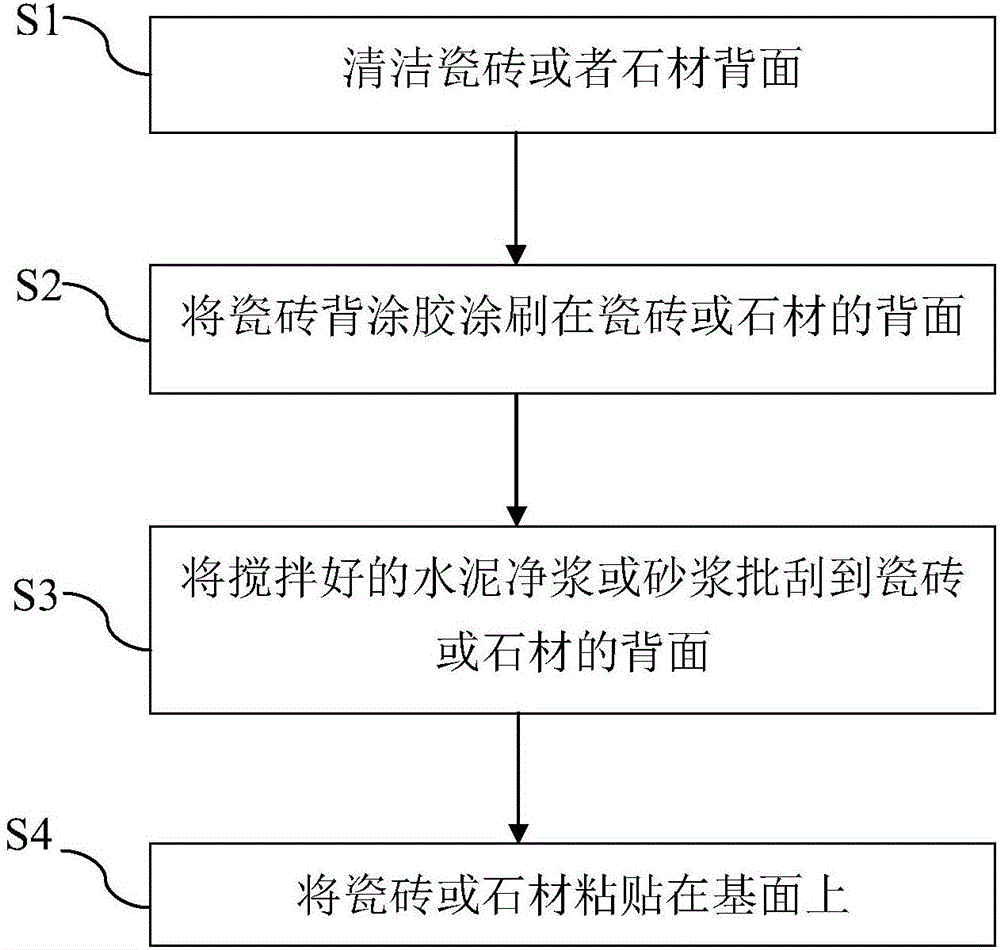

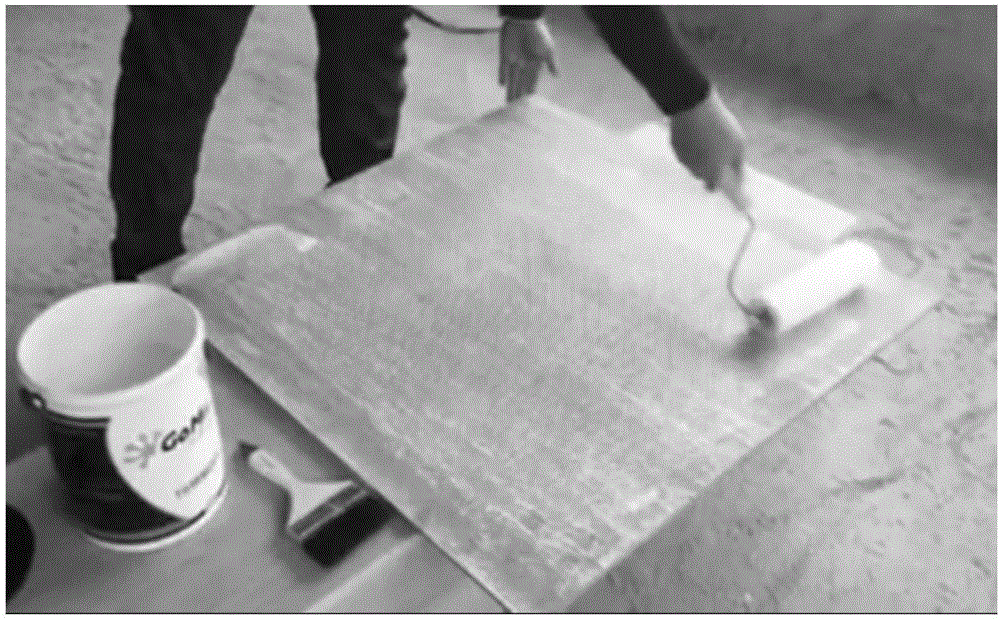

Ceramic tile back coating glue and preparation method thereof, and tile adhering method

InactiveCN106244055AImprove water resistance bond strengthImprove high temperature resistanceNon-macromolecular adhesive additivesCovering/liningsBrickButadiene-styrene rubber

The invention discloses a ceramic tile back coating glue and a preparation method thereof, and a tile adhering method. The ceramic tile back coating glue comprises, by mass, 30-55% of a styrene-butadiene rubber latex, 40-65% of an acrylic emulsion, 3-8% of nanometer calcium carbonate, 0.4-0.8% of a chelating coupling agent, and 0.09-0.25% of a bactericide. According to the present invention, during the tile adhering, the ceramic tile back coating glue is uniformly coated and brushed on the back surface of the ceramic tile or stone material, stirred cement paste or mortar is scraped onto the back surface of the ceramic tile or stone material, and the ceramic tile or stone material is adhered on the base surface requiring the adhering after the flat scraped surface is achieved; and the ceramic tile back coating glue has characteristics of high adhesion strength, water resistance, aging resistance, freezing-thawing resistance, effectively improved construction efficiency and yield of the tile adhering process, and construction cost reducing.

Owner:阁美仕(广东)建材有限公司

A non-earthing composite structure for a waterproof pavement layer of a top plate for a road tunnel

InactiveCN104264561AImprove waterproof performanceImprove impact performanceIn situ pavingsEpoxyMaterials science

The invention relates to a non-earthing composite structure for a waterproof pavement layer of a top plate for a road tunnel. The structure comprises the following structural layers from top to bottom: a rubber pitch protective layer, a waterproof layer, an epoxy resin priming coat and a cement concrete top plate. The invention provides a composite structure for a waterproof pavement layer of a top plate capable of efficiently resisting drying and watering cycle and impact load of the surface load. The composite structure for a waterproof pavement layer of a top plate has superior waterproof performance and capacity of resisting the impact load, greatly improves the integrity and effectiveness of the waterproof system of the road tunnel, enhances the structural durability and satisfies the waterproof requirement of the top plate of the road tunnel.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

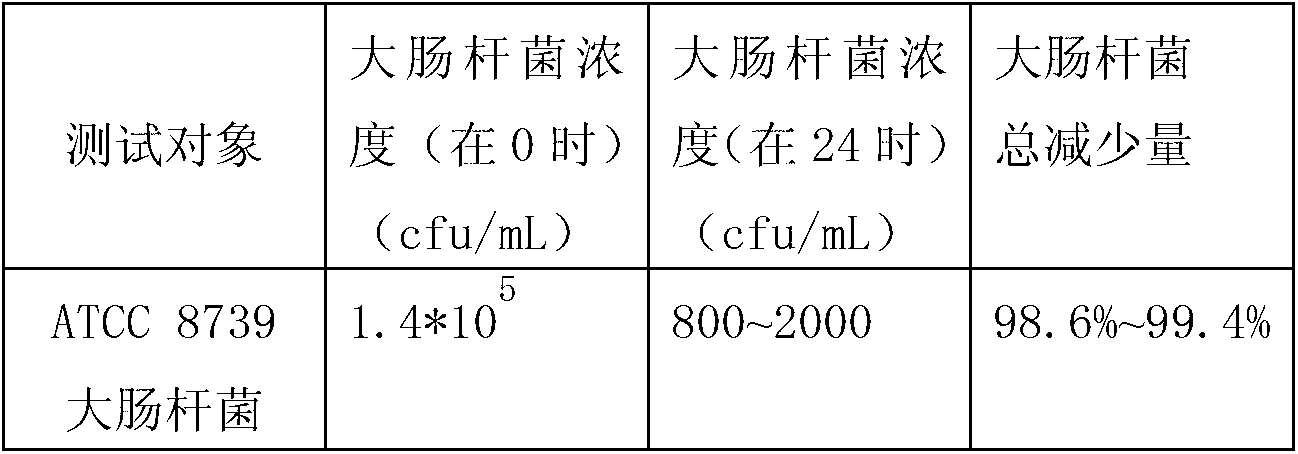

Antibacterial and odor removing fiber bed core and preparation method thereof

InactiveCN103054388AImprove bulkIncrease elasticityStuffed mattressesSpring mattressesFiberPolyester

The invention discloses an antibacterial and odor removing fiber bed core. The fiber bed core comprises at least one middle layer and a surface layer which is arranged on the upper surface or the lower surface of the middle layer, wherein the surface layer comprises a non-woven fabric prepared from the following components in percentage by weight: 15-40% of low melting point fibers and 60-85% of polyester fibers; and the middle layer comprises the following components in percentage by weight: 60-85% of raw bamboo fibers and 15-40% of low melting point fibers. The invention further discloses a preparation method of the fiber bed core; and the preparation method comprises the following steps: respectively preparing each layer including an upper surface layer, a lower surface layer and the middle layer; laying the upper surface layer, the lower surface layer and the middle layer in sequence; drying the upper surface layer, the lower surface layer and the middle layer in a drying box; and coldly rolling, cooling, cutting, inspecting and packaging the upper surface layer, the lower surface layer and the middle layer. The fiber bed core disclosed by the invention has the advantages as follows: antibacterial and odor removing properties, elasticity and bulkiness, healthcare property, ultraviolet resistance, moisture absorbing and removing properties and environment friendliness of the fiber bed core are greatly improved when being compared with those of a traditional mattress.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

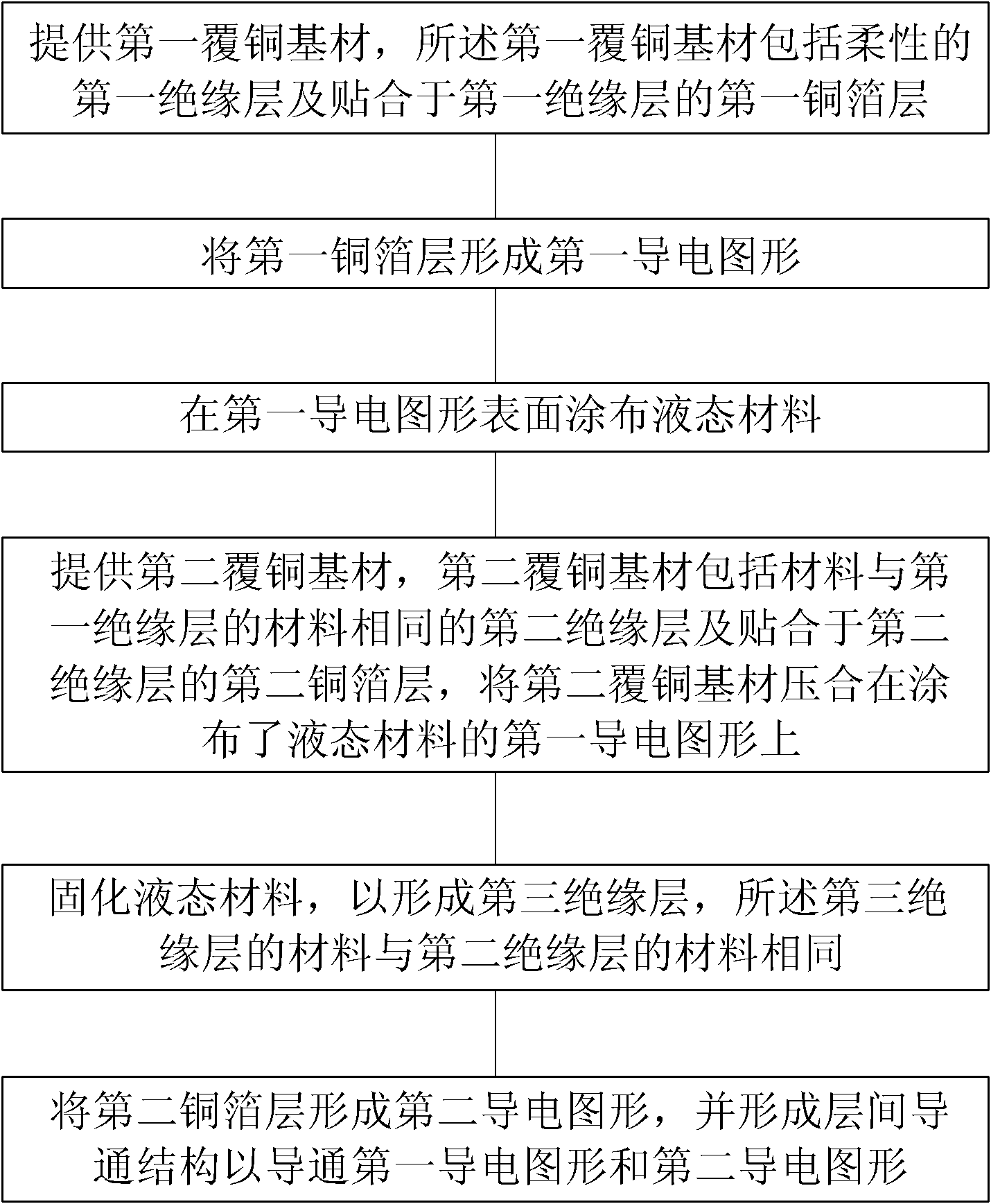

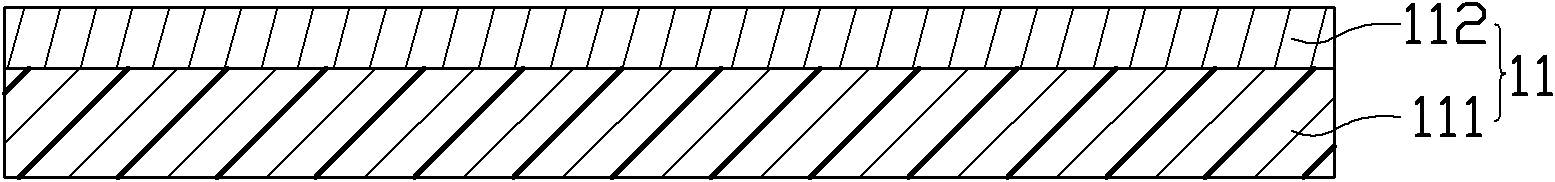

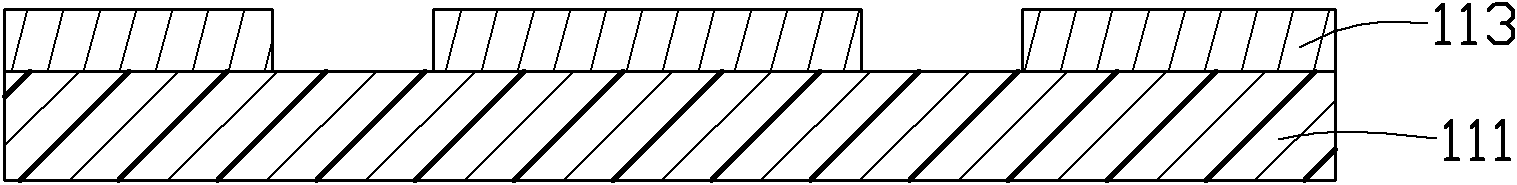

Manufacturing method of flexible multi-layer circuit board

ActiveCN102340937AImprove performanceImprove yieldMultilayer circuit manufactureInsulation layerCopper foil

The invention provides a manufacturing method of a flexible multi-layer circuit board, which comprises the steps that: a first flexible copper clad laminate is provided, and the first copper clad laminate comprises a first insulation layer and a first copper foil layer; the first copper foil layer is formed into a first conductive pattern; a liquid material is applied on the surface of the first conductive pattern; a second copper clad laminate which comprises a second insulation layer and a second copper foil layer is provided, the material of the second insulation layer is the same with that of the first insulation layer, the second copper clad laminate is pressed on the first conductive pattern, and the second insulation layer is contacted with the liquid material; the liquid material is cured so that a third insulation layer is formed, and the material of the third insulation layer is the same with that of the second insulation layer; and the second copper foil layer is formed into a second conductive pattern, and an interlamination communicating structure is formed to communicate the first conductive pattern with the second conductive pattern. The materials of the insulation layers in the multi-layer circuit board which is manufactured through the method are same, so that the adverse conditions when communicating holes are manufactured can be avoided.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Wet-mixed masonry mortar prepared by adopting aggregate chips

ActiveCN104496327AEasy to get materialsLow priceSolid waste managementCarboxymethyl celluloseSodium Bentonite

The invention discloses wet-mixed masonry mortar prepared by adopting aggregate chips. The wet-mixed masonry mortar comprises the following components in parts by weight: 18-22 parts of cement, 6-8 parts of pulverized fuel ash, 5-7 parts of mineral powder, 22-25 parts of water, 135-145 parts of aggregate chips and 0.5-2.0 parts of a mortar admixture, wherein the particle size of the aggregate chips is not more than 4.75mm; the mountain flour in the aggregate chips accounts for 2-3 percent by weight; the mortar admixture serves as a thickening agent; the thickening agent comprises the following components in parts by weight: 2-4 parts of a sulfonic acid type air entraining agent, 10-20 parts of a melamine water reducing agent, 1-3 parts of soft sugar, 1-3 parts of a water repellent, 4-6 parts of sodium carboxymethyl cellulose and 40-60 parts of sodium bentonite. The machine-made sand and river sand are replaced by residual aggregate chips after stone processing, the aggregate chips are readily available and low in price, the resources are reasonably utilized, the environmental pollution caused by waste aggregate chips is reduced, and the production cost of the mortar is reduced.

Owner:青岛磊鑫混凝土有限公司

Compound health protection bed core and preparation method thereof

InactiveCN103054386ANot easy to layerNot easy to be environmentally friendlyUpholstery manufactureStuffed mattressesSurface layerNatural fiber

The invention discloses a compound health protection bed core. The bed core comprises at least one intermediate layer and a surface layer arranged on the upper surface or the lower surface of the intermediate layer, wherein the surface layer is a non-woven layer comprising the following components in percentage by weight: 15-40% of low-melting point fiber and 60-85% of bamboo hemp fiber; the bamboo hemp fiber consists of bamboo fiber and fibrilia; the intermediate layer comprises the following components in percentage by weight: 60-85% of compound natural fiber and 15-40% of low-melting point fiber; the compound natural fiber consists of coconut fiber, bamboo fiber and fibrilia; and the content ratio of the coconut fiber to the bamboo fiber to the fibrilia is 1: 1: (1-3): 2: 1. The invention further comprises a preparation method for the compound health protection bed core; the method comprises the following steps of: respectively preparing various layers which comprise the upper surface layer, the lower surface layer and the intermediate layer, laying the layers sequentially, and preparing the bed core through procedures of oven, cold rolling, cooling, cutting, examining and packaging. The compound health protection bed core and the preparation method thereof solve the technical problems, such as high possibility of layering and rupture, weak elasticity, weak air permeability, mustiness and the like in the existing mattresses.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Natural fiber composite plate and manufacturing method thereof

InactiveCN102514255AGood moisture absorption and air permeabilityLight in massLaminationLamination apparatusMetallurgyNatural fiber

The invention discloses a natural fiber composite plate, which comprises an upper layer, a lower layer and a bonding layer for bonding the upper layer and the lower layer, wherein the upper layer and the lower layer are nonwoven layers comprising the following components: 5 to 50 percent of low melting point fibers and 5 to 65 percent of jute fibers; and the bonding layer is a nonwoven layer comprising 50 to 100 percent of low melting point fibers. The invention also discloses a method for manufacturing the natural fiber composite plate, which comprises the following steps of: respectively preparing various layers, namely the upper layer, the lower layer and the bonding layer; and sequentially spreading the layers, drying in an oven, performing cold rolling, cooling, cutting, checking and packaging to obtain the natural fiber composite plate. By the natural fiber composite plate and the method for manufacturing the natural fiber composite plate, the problem that the conventional mattress is easily moulded with damp, goes bad due to moths and is easily layered is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

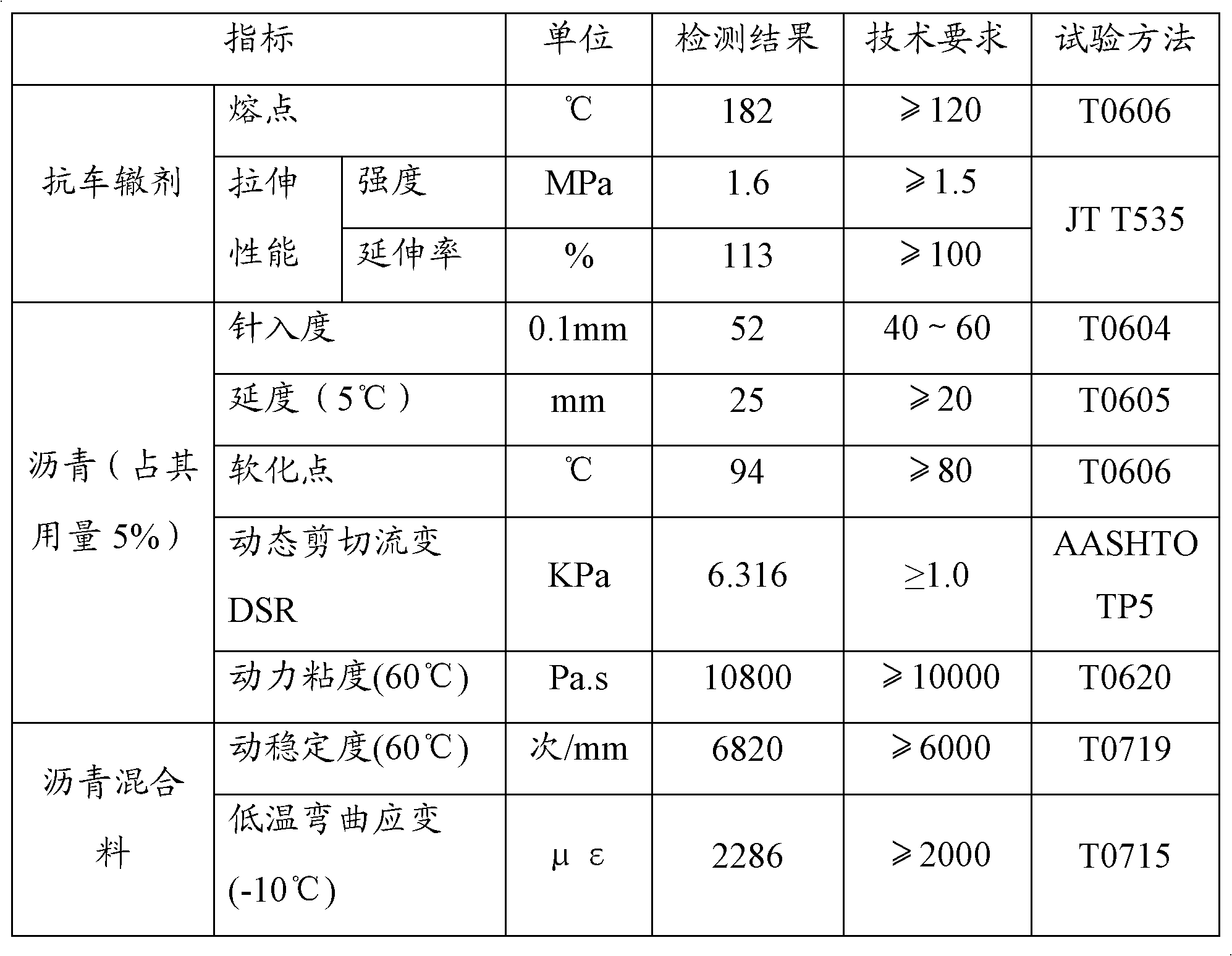

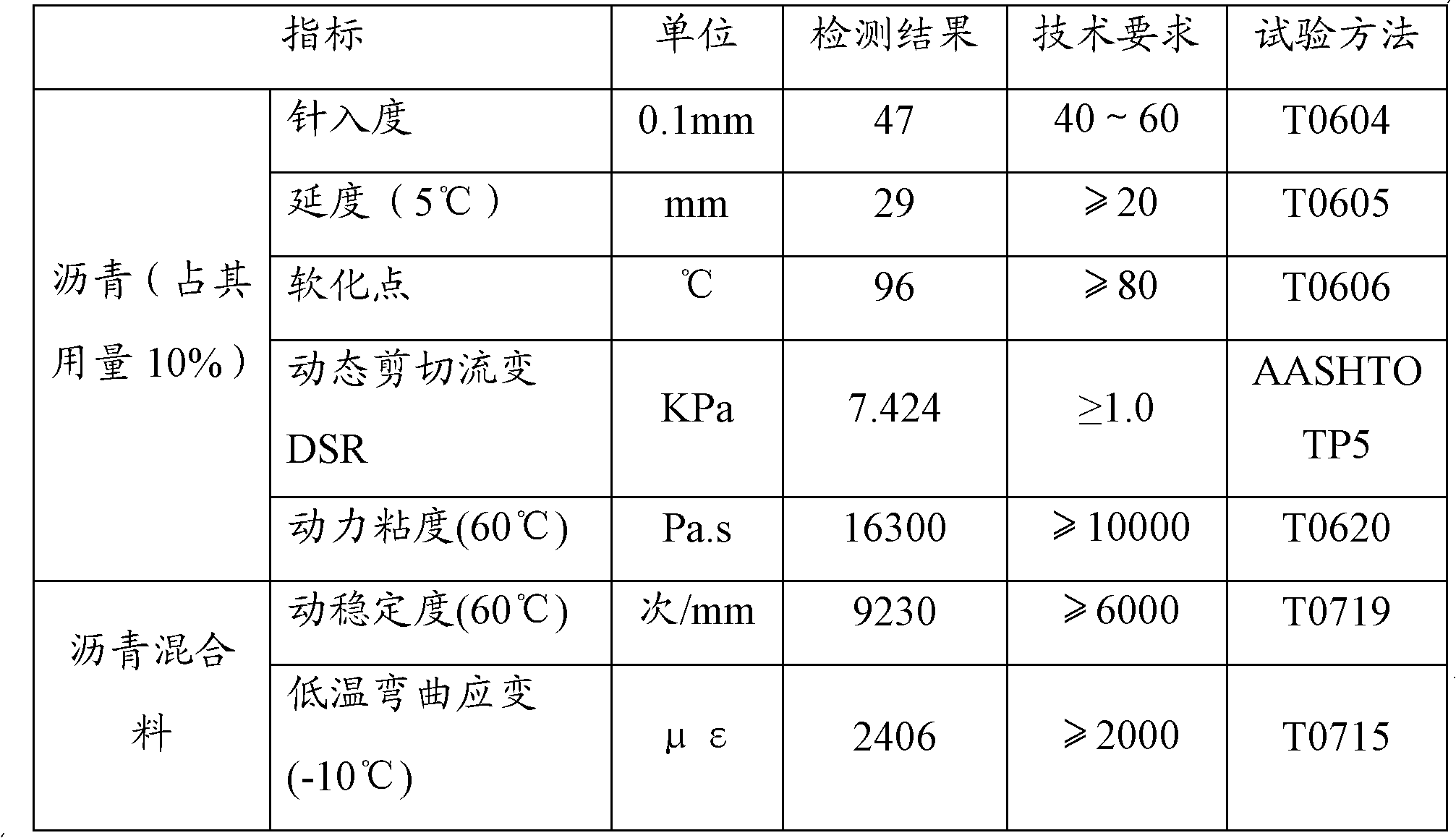

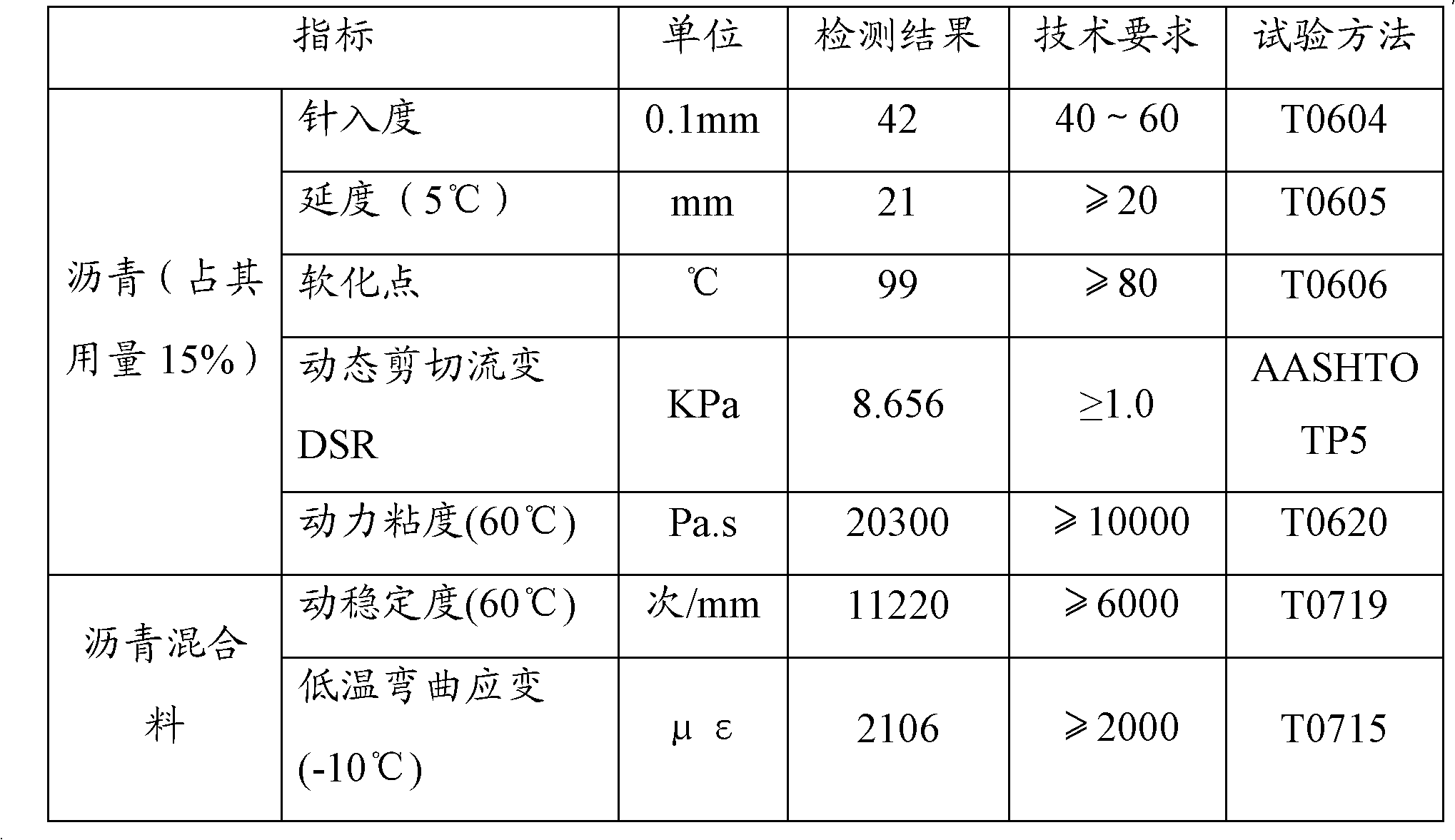

Anti-rutting agent, asphalt material and preparation method

ActiveCN102181134AImprove high temperature performanceImprove high temperature stabilityBuilding insulationsPolymer scienceBituminous materials

The invention discloses an anti-rutting agent, an asphalt material and a preparation method. The anti-rutting agent is mainly prepared from the following raw materials in percentage by weight: 30.0 to 40.0 percent of polyurethane, 40.0 to 50.0 percent of polyethylene terephthalate, 5.0 to 10.0 percent of polymethacrylonitrile and 5.0 to 10.0 percent of calcium carbonate. The polyurethane is a block copolymer formed by condensation polymerization of diphenylmethane diisocyanate and propylene glycol. The invention also discloses the asphalt material, which contains the anti-rutting agent in an amount which is 5 to 15 percent of the total weight of asphalt. The invention also discloses the preparation method of the anti-rutting agent and the asphalt material. The high-temperature performance of the asphalt can be improved by adopting the anti-rutting agent, and the low-temperature performance of the asphalt of the anti-rutting agent is coordinated at the same time, so that the high-temperature performance of the mixture blended by using the asphalt is improved; the dynamic stability of high-temperature rutting resistance reaches 10,000 times per millimeter; and the asphalt material has strong adhesive property.

Owner:ROADMAINT CO LTD

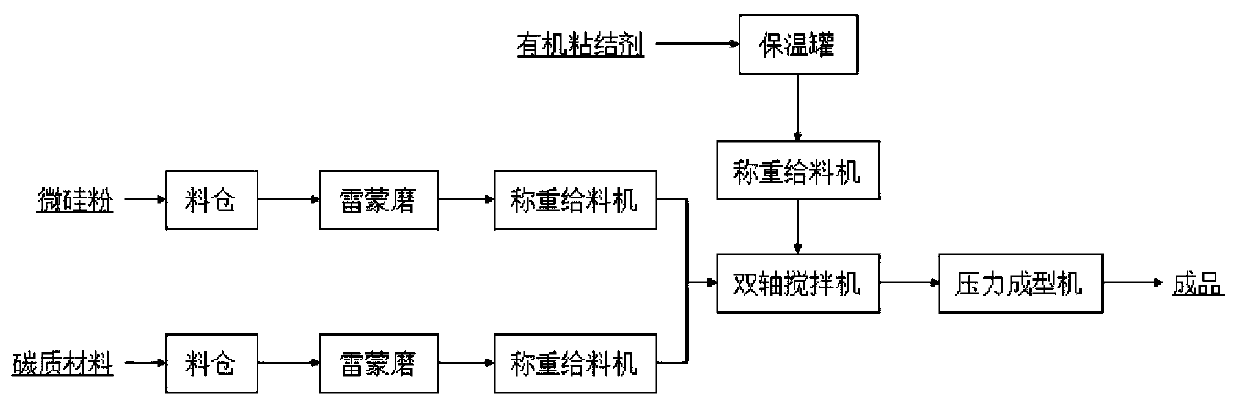

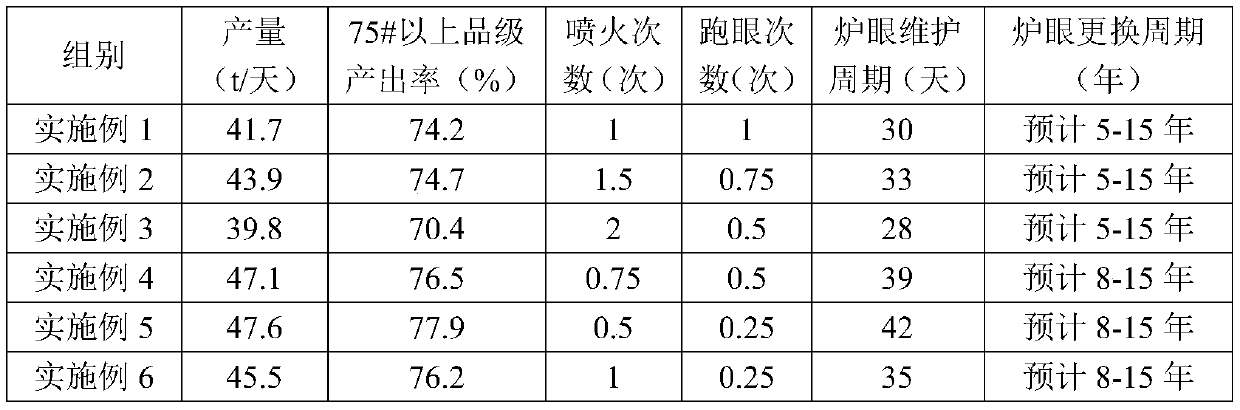

Window blocking material used for high silicon alloy smelting electric furnace

ActiveCN110243185AAvoid pollutionReduce maintenance timesCharge manipulationBrickElectric arc furnace

The invention discloses a window blocking material used for a high silicon alloy smelting electric furnace, and relates to the field of chemical materials. The window blocking material comprises, by weight percent, 10 to 30% of a solid-state inorganic binder, 40 to 60% of a carbon material and 10 to 30% of a liquid-state organic binding agent. The window blocking material can effectively avoid the pollution to the high silicon alloy, it is ensured that the redox reaction of anhydrous steam and the carbon material causes the furnace window carbon brick erosion, and in the use process, the furnace window is repaired, so that the furnace window carbon brick damage speed is effectively reduced; the maintaining period of the furnace window is prolonged to 28 to 42 days, and the furnace window repair cost is reduced; the furnace window replacing frequency is reduced, the coil base yield and the product quality are improved, and the economic benefit is improved; and the window blocking material can be used in cooperation with a high silicon alloy smelting electric furnace window opening and blocking machine, the automation level is improved, operation is easy, and labor force and time are reduced.

Owner:内蒙古鄂尔多斯电力冶金集团股份有限公司 +1

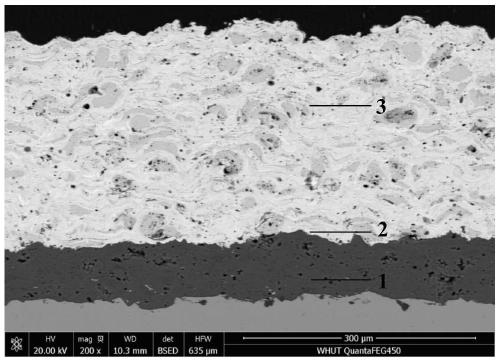

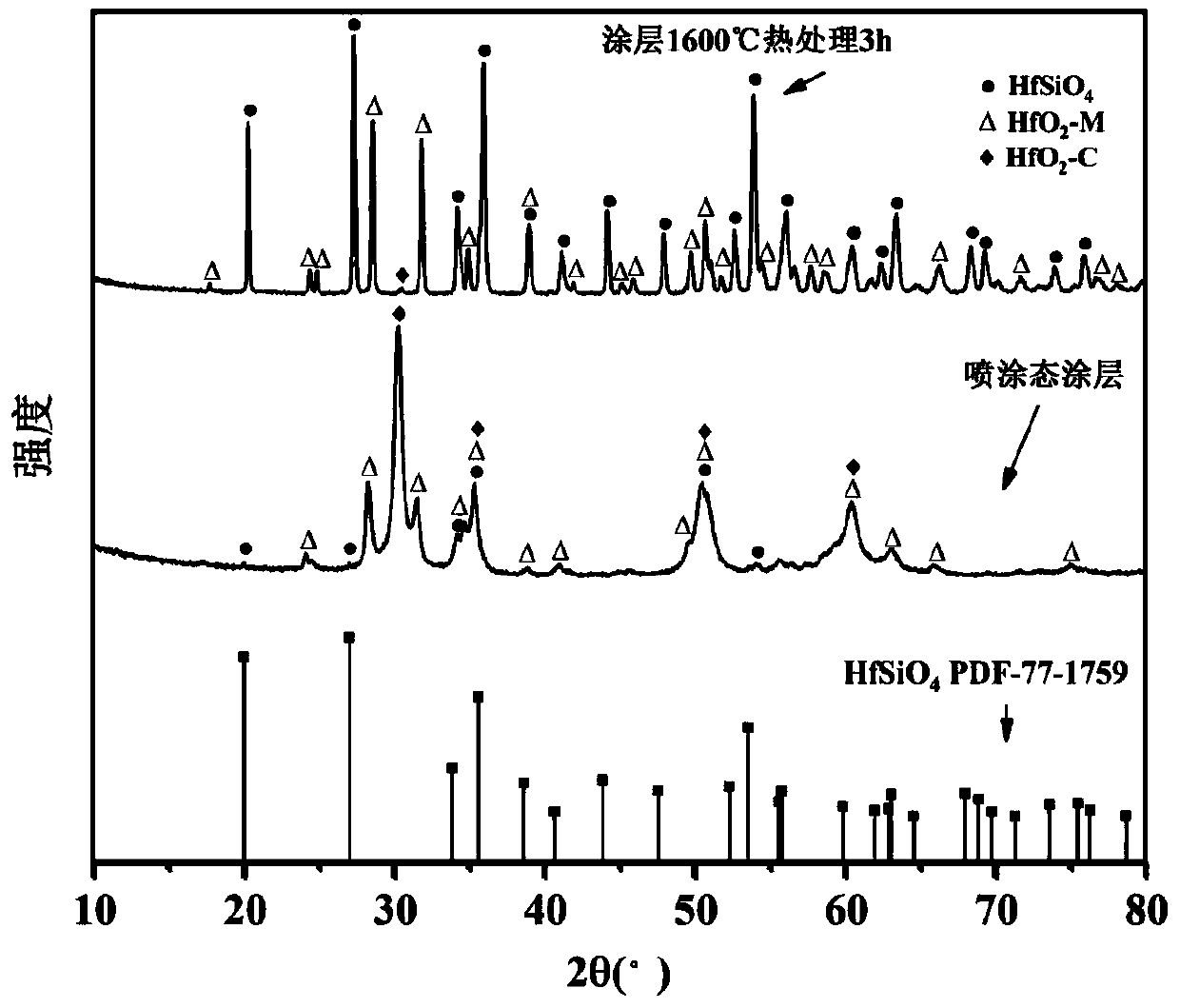

Hafnium silicate environment barrier coating for ceramic-based composite material matrix and preparation method thereof

The invention provides a hafnium silicate environment barrier coating for a ceramic-based composite material matrix and a preparation method thereof. The preparation method comprises the following steps: (1) mixing HfO2 and SiO2, carrying out wet mixing and ball milling on a ball mill, drying, grinding, sieving, sintering, and carrying out a high-temperature solid-phase reaction; (2) after the high-temperature solid-phase reaction is finished, adding deionized water for slurry preparation, then performing ball milling, and performing spray granulation to obtain an HfSiO4 powder material; (3) firstly spraying a Si layer on the surface of a ceramic-based composite matrix as a priming coat, and then spraying the HfSiO4 powder material on the surface of the priming coat as a surface layer to form a multi-layer coating; and (4) carrying out a heat treatment on the multi-layer coating to obtain the environmental barrier coating. Due to the added heat treatment, the crystallinity of the HfSiO4 surface layer is improved, the binding force of each layer of the coating is better, the stability is higher, and the water and oxygen resistance of the environment barrier coating is greatly improved. The provided preparation method is simple and easy to control, and is easy for industrial production and application.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com