Aqueous polymer-isocyanate adhesive and preparation method thereof

A water-based polymer and isocyanate technology, applied in the direction of non-polymer adhesive additives, ester copolymer adhesives, adhesive types, etc., can solve the problem of weakening the reaction between hydroxyl groups and wood surface hydroxyl groups and crosslinking, and increasing Problems such as the amount of crosslinking agent and the decrease of bonding strength can be achieved to strengthen the reaction and crosslinking effect, reduce the cost and price of use, and ensure the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

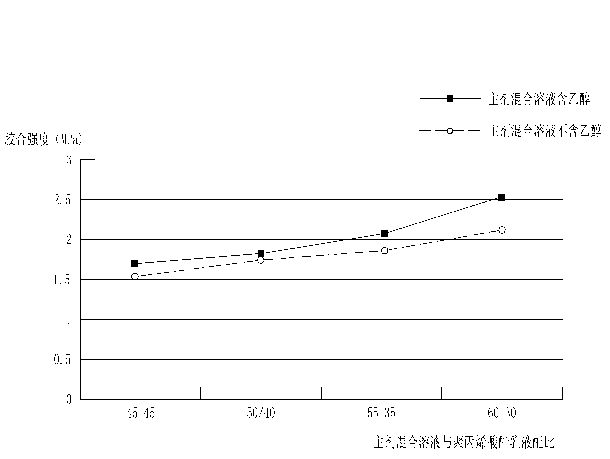

Image

Examples

Embodiment 1

[0031] As shown in the accompanying drawing, a water-based polymer-isocyanate adhesive includes a main agent and a crosslinking agent, wherein the main agent is made of the following raw materials in parts by mass:

[0032] 45 parts by mass of the mixed solution of polyvinyl alcohol, deionized water and ethanol

[0033] 45 parts by mass of polyacrylate emulsion;

[0034] The crosslinking agent is made of polymethylene polyphenyl polyisocyanate and dioctyl phthalate in a mass ratio of 1:1;

[0035] The mass ratio of main agent and crosslinking agent is 100:15.

[0036] The mass ratio of polyvinyl alcohol, deionized water and ethanol in the mixed solution of polyvinyl alcohol, deionized water and ethanol is polyvinyl alcohol: deionized water: ethanol is 20:62.8:17.2.

[0037] The preparation method of the water-based polymer-isocyanate adhesive comprises steps:

[0038] (1) In parts by mass, mix polyvinyl alcohol, deionized water and ethanol according to the mass ratio of pol...

Embodiment 2

[0043] As shown in the accompanying drawing, a water-based polymer-isocyanate adhesive includes a main agent and a crosslinking agent, wherein the main agent is made of the following raw materials in parts by mass:

[0044] 60 parts by mass of a mixed solution of polyvinyl alcohol, deionized water and ethanol

[0045]30 parts by mass of polyacrylate emulsion;

[0046] The crosslinking agent is made of polymethylene polyphenyl polyisocyanate and dioctyl phthalate in a mass ratio of 1:1;

[0047] The mass ratio of main agent and crosslinking agent is 100:15.

[0048] The mass ratio of polyvinyl alcohol, deionized water and ethanol in the mixed solution of polyvinyl alcohol, deionized water and ethanol is polyvinyl alcohol: deionized water: ethanol is 20:62.8:17.2.

[0049] The preparation method of the water-based polymer-isocyanate adhesive comprises steps:

[0050] (1) In parts by mass, mix polyvinyl alcohol, deionized water and ethanol according to the mass ratio of polyvi...

Embodiment 3

[0055] As shown in the accompanying drawing, a water-based polymer-isocyanate adhesive includes a main agent and a crosslinking agent, wherein the main agent is made of the following raw materials in parts by mass:

[0056] 50 parts by mass of a mixed solution of polyvinyl alcohol, deionized water and ethanol

[0057] 40 parts by mass of polyacrylate emulsion;

[0058] The crosslinking agent is made of polymethylene polyphenyl polyisocyanate and dioctyl phthalate in a mass ratio of 1:1;

[0059] The mass ratio of main agent and crosslinking agent is 100:15.

[0060] The mass ratio of polyvinyl alcohol, deionized water and ethanol in the mixed solution of polyvinyl alcohol, deionized water and ethanol is polyvinyl alcohol: deionized water: ethanol is 20:62.8:17.2.

[0061] The preparation method of the water-based polymer-isocyanate adhesive comprises steps:

[0062] (1) In parts by mass, mix polyvinyl alcohol, deionized water and ethanol according to the mass ratio of polyv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com