Patents

Literature

382 results about "Free phenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for silicon-carbon composite material, prepared silicon-carbon composite material, lithium ion battery anode containing silicon-carbon composite material and battery

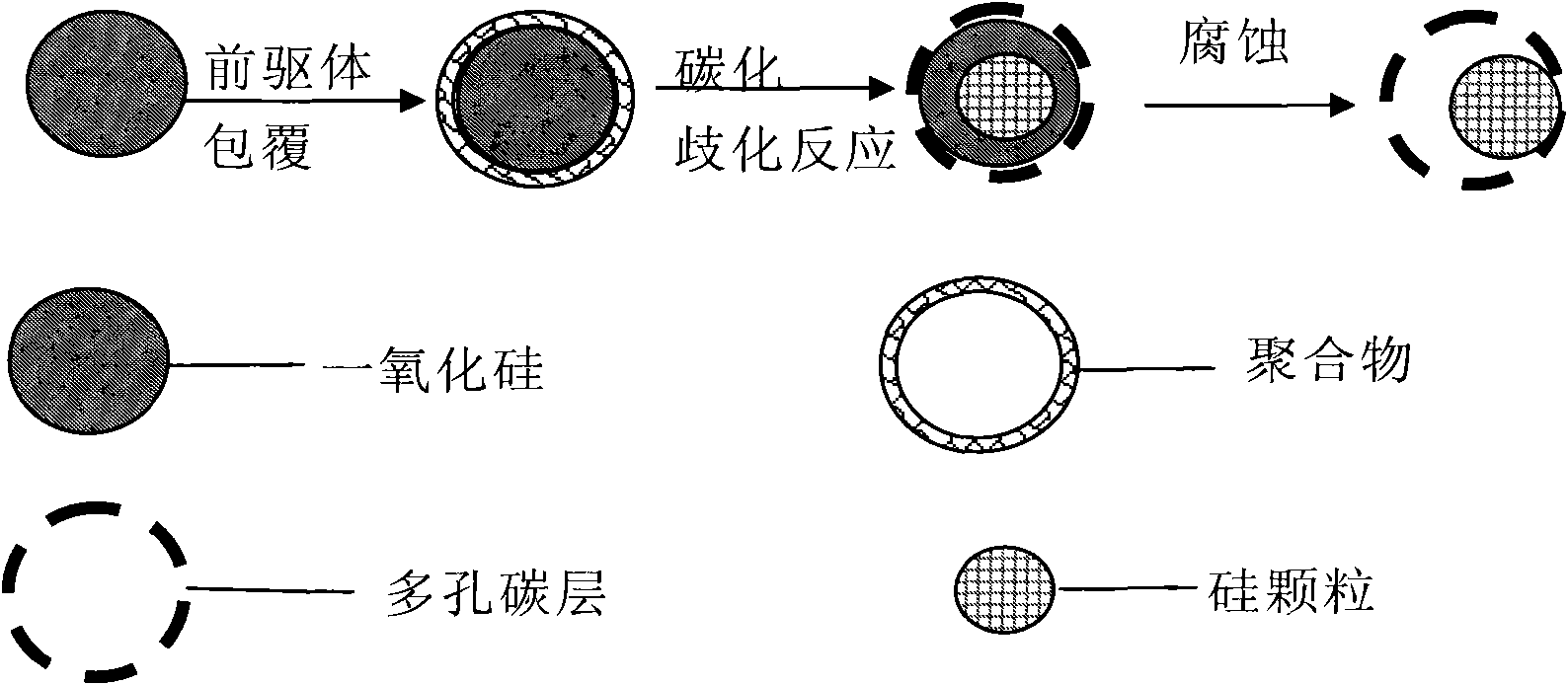

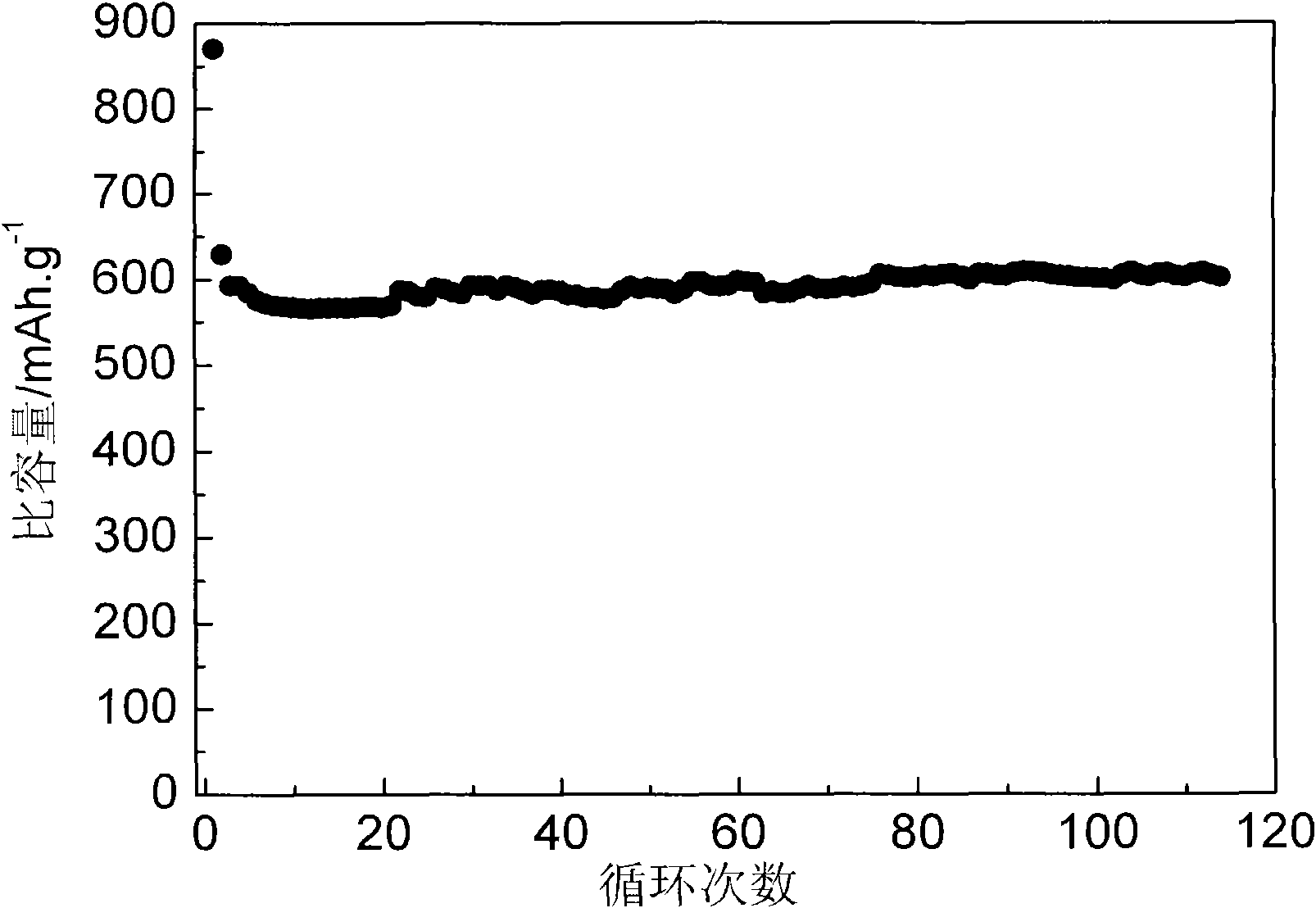

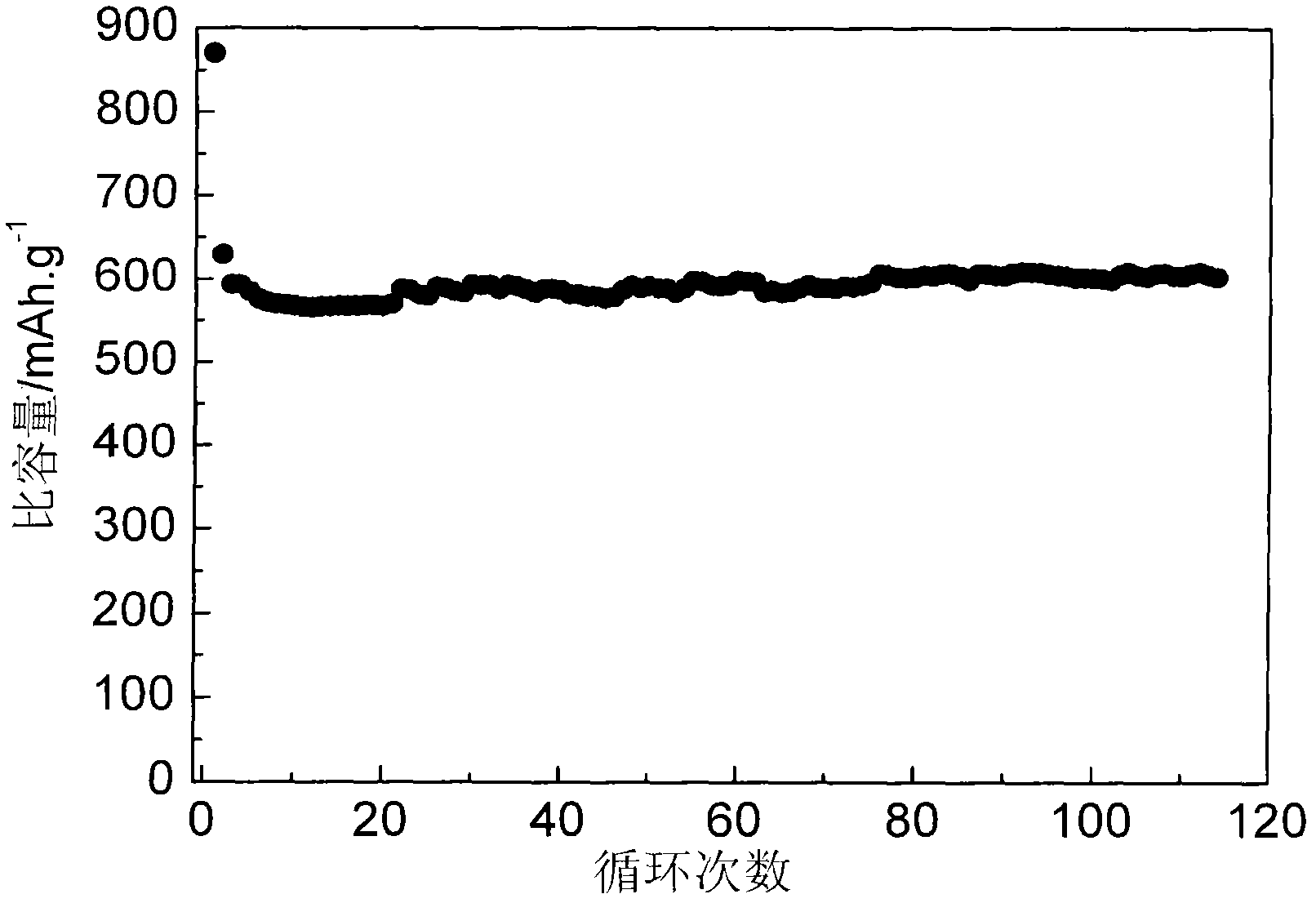

ActiveCN102437318AIncrease the embedding positionImproved silicon volume effectSecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon compositesSilicon monoxide

The invention provides a preparation method for a silicon-carbon composite material, the prepared silicon-carbon composite material, a battery anode prepared from the material and a lithium ion battery. The preparation method comprises the following steps of: directly mixing free phenol, free aldehyde and silicon monoxide, performing polymerization reaction under certain conditions to obtain a mixture of a phenolic resin and the silicon monoxide which is coated by the phenolic resin, and performing thermal treatment and corrosion to obtain the silicon-carbon composite material with a core shell structure. The preparation method is simple. The prepared silicon-carbon composite material has the advantages of high specific capacity and high cycle performance.

Owner:CHERY AUTOMOBILE CO LTD

Phenol-formaldehyde novolac resin having low concentration of free phenol

ActiveUS20080280787A1Synthetic resin layered productsCellulosic plastic layered productsPHENOL LIQUIDShell molding

A phenol-formaldehyde novolac resin having a low concentration of free phenol prepared by distilling residual phenol from a molten novolac resin and replacing at least a portion of the phenol with a solvent having a volatility equal to or less than phenol. Such modified novolac resins are suitable for the production of resin coated molding sands for shell molding and sand cores, as well as for the production of resin coated proppants for use in oil and gas recovery operations.

Owner:GEORGIA PACIFIC CHEM LLC

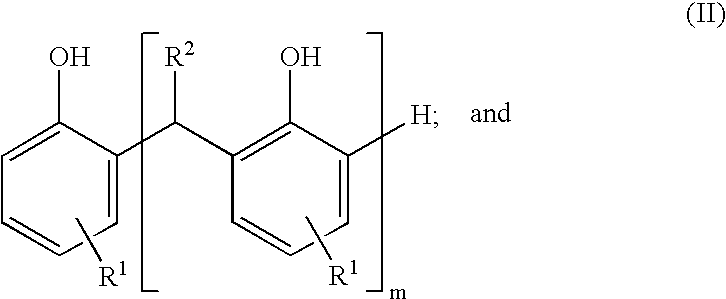

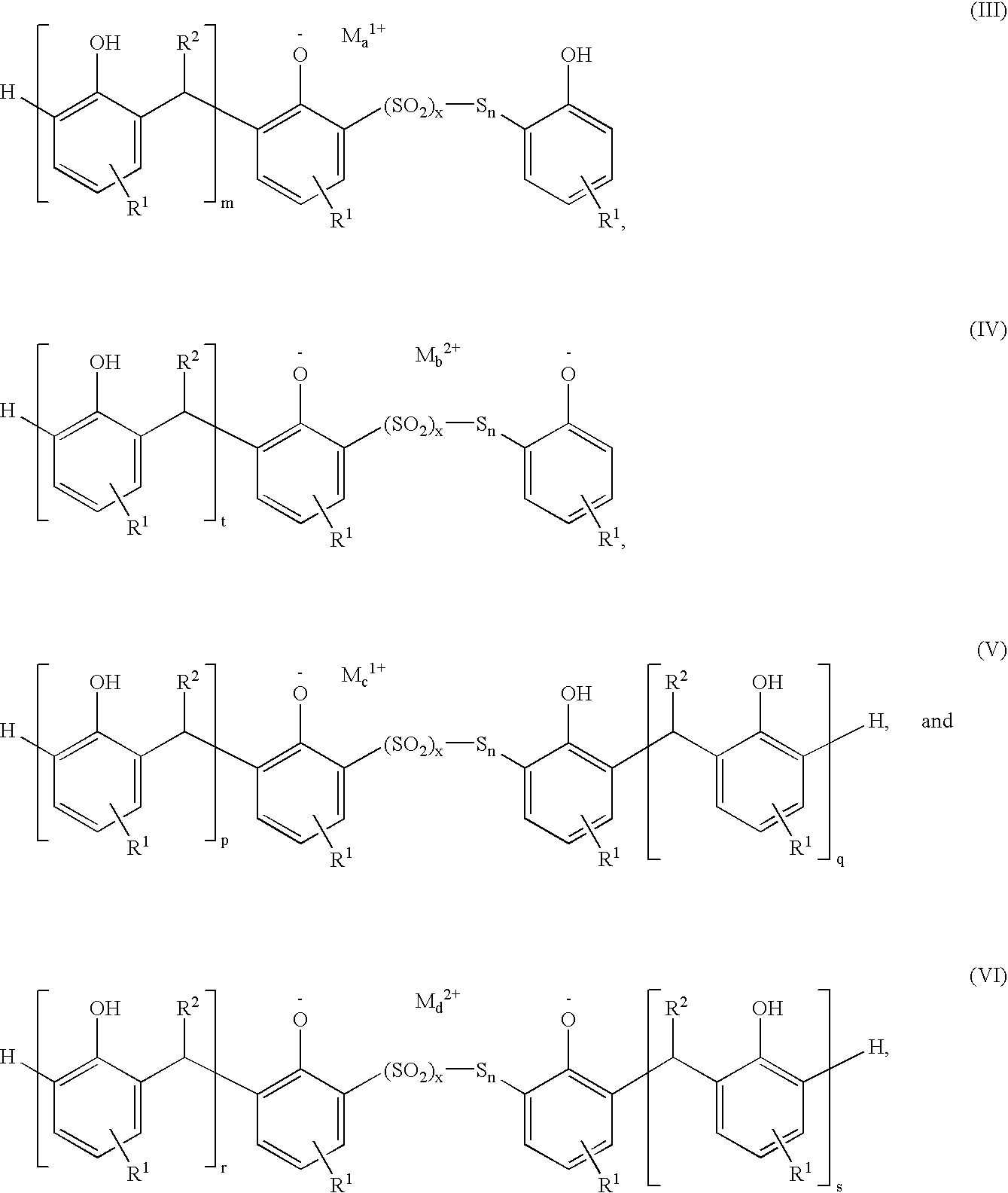

Sulfurized metal alkyl phenate compositions having a low alkyl phenol content

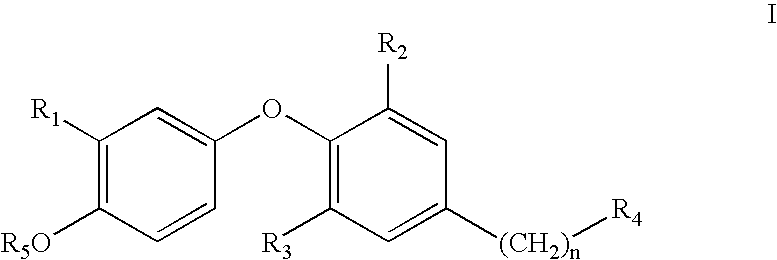

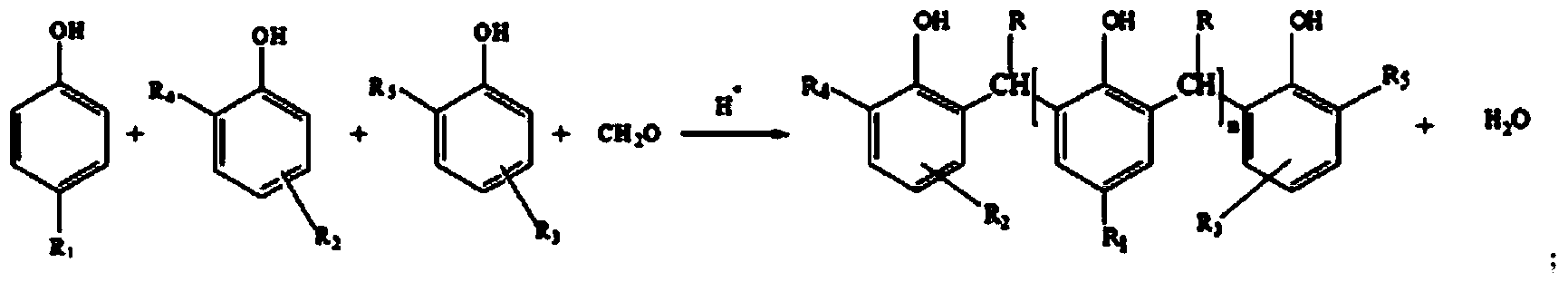

Provided herein are sulfurized metal alkyl phenate compositions having a low alkyl phenol content. The sulfurized metal alkyl phenate compositions can be prepared by reacting a phenol compound of Formula (I) disclosed herein with an aldehyde to form a phenolic resin of Formula (II) disclosed herein and then by reacting the phenolic resin simultaneously with a metal base and a first sulfurizing agent. The sulfurized metal alkyl phenate compositions and the overbased sulfurized metal alkyl phenate compositions disclosed herein may be used as detergents for formulating lubricating oil compositions. The lubricating oil compositions disclosed herein have a reduced amount of the free phenol compound and a salt thereof.

Owner:CHEVRON ORONITE CO LLC

Production of high-quality protein isolates from defatted meals of Brassica seeds

The present invention provides a method for processing defatted oil seeds, comprising the steps of: (a) solubilizing at least a portion of the protein contained in the oil seeds to produce suspended residual solids and a first solution comprising protein, phenolic-protein complexes, and free phenolic compounds; (b) separating at least a portion of the free phenolic compounds from the first solution and recovering a free phenolic reduced solution; and (c) treating the free phenolic reduced solution to precipitate at least a portion of the protein as a precipitated protein isolate and recovering a treated solution containing a soluble protein isolate. Novel protein products are also disclosed. Food and drink products containing the novel protein products are also disclosed.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

Thyroid receptor ligands and method II

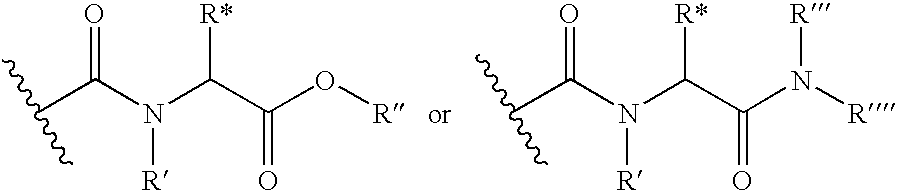

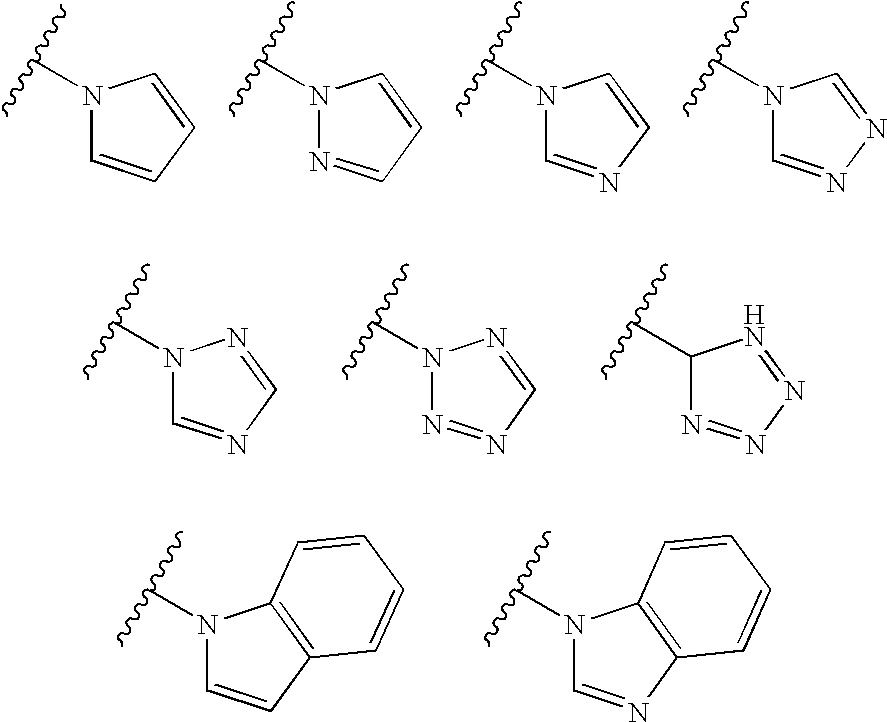

New thyroid receptor ligands are provided which have general formula (I) in which: n is an integer from 0 to 4; R1 is halogen, trifluoromethyl, or alkyl of 1 to 6 carbons or cycloalkyl of 3 to 7 carbons; R2 and R3 are the same or different and are hydrogen, halogen, alkyl of 1 to 4 carbons or cycloalkyl of 3 to 5 carbons, at least one of R2 and R3 being other than hydrogen; R4 is a carboxylic acid amide (CONR′R″) or an acylsulphonamide (CONHSO2R′) derivative, or a pharmaceutically acceptable salt thereof, and all stereoisomers thereof; or when n is equal to or greater than one, R4 may be a heteroaromatic moiety which may be substituted or unsubstituted, or an amine (NR′R″). R5 is hydrogen or an acyl (such as acetyl or benzoyl) or other group capable of bioconversion to generate the free phenol structure (wherein R5=H). In addition, a method is provided for preventing, inhibiting or treating a disease associated with metabolism dysfunction or which is dependent upon the expression of a T3 regulated gene, wherein a compound as described above is administered in a therapeutically effective amount. Examples of such diseases associated with metabolism dysfunction or are dependent upon the expression of a T3 regulated gene include obesity, hypercholesterolemia, atherosclerosis, cardiac arrhythmias, depression, osteoporosis, hypothyroidism, goiter, thyroid cancer as well as glaucoma, congestive heart failure and skin disorders.

Owner:KARO BIO AB

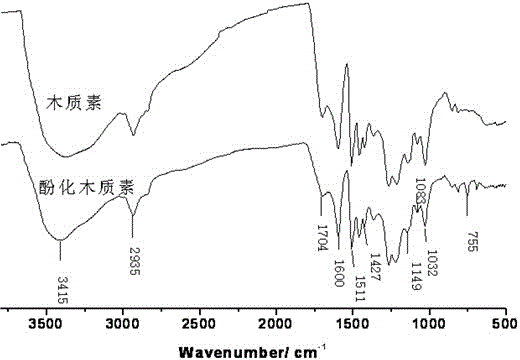

Preparation method of phenolated lignin amine cationic emulsifier

ActiveCN104592530AImprove surface activityImprove stabilityBuilding insulationsEmulsionRoad engineering

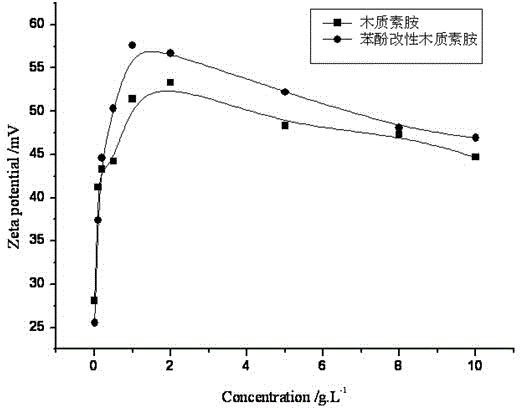

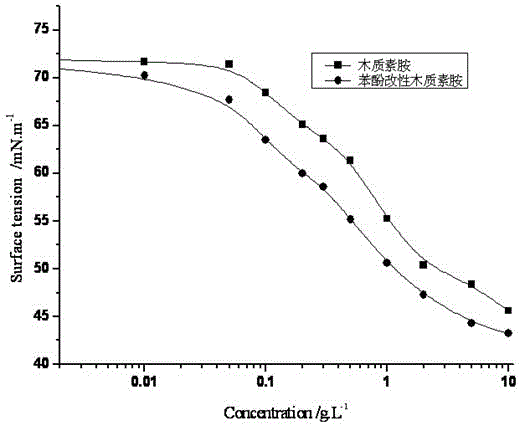

The invention discloses a preparation method of a phenolated lignin amine cationic emulsifier. The method comprises the following steps: heating an alkaline liquid of alkali lignin and a proper amount of phenol to 70-100 DEG C and reacting for 1-3h, then, acidizing a reaction liquid to realize pH=2.5 with 1 mol / L hydrochloric acid, performing suction filtration, washing with hot water at 80-100 DEG C until free phenol disappears completely, thus obtaining phenolated lignin; dissolving the phenolated lignin in a NaOH liquid with mass fraction of 10% and regulating pH to 10.5-12, then, further adding a mixed liquid of a certain amount of small molecule polyamine and 37% formaldehyde, reacting for 3-5h at 90 DEG C, then, introducing amine methyl hydrophilic groups into the phenolated lignin, thereby obtaining the cationic emulsifier which has positive electricity under the condition of diluted acid. In comparison with the cationic emulsifier modified by the lignin which is not phenolated, the emulsifier provided by the invention has higher surface activity, stronger Zeta potential and stronger emulsion stability, and can be widely used in the fields of road engineering, building waterproofing, material corrosion prevention, water conservancy construction, and so on.

Owner:GUANGXI UNIV FOR NATITIES

Cashew shell modified alkyd resin and preparation method thereof

The invention relates to a production method of cashew nut oil modified phenolic resin. Phenol and cashew nut oil are sufficiently mixed under the acidic or alkaline environment, wherein, the main ingredient of the cashew nut oil is the polyhydric phenol of C8-C27, the weight of the cashew nut oil accounts for twenty to thirty percent (weight percentage) of the total weight of the cashew nut oil and the phenol, and the acidic environment is obtained by using catalyst, the addition amount of which is one to three percent (one to two percent for the alkaline environment); the mixture is mixed with formaldehyde, temperature is raised, reaction lasts until the synthesis of the phenolic resin is finished, and wherein, the molar ratio of the formaldehyde is 1:0.72 to 0.78 (1:1.2 to 1.4 for the alkaline environment. the catalyst must be ammonia). The thermoplastic phenolic resin prepared by the invention is characterized in low free phenol and high molecular weight and can be applied to not only molding materials but also friction materials; meanwhile, the production process of the modified phenolic moulding materials is simple, the use amount of phenol and formaldehyde is reduced, the concentration of wastewater is lowered, and therefore environment is protected; moreover, the plant oil applied by the preparation method of the invention is a regenerative resource.

Owner:浙江南方塑胶制造有限公司

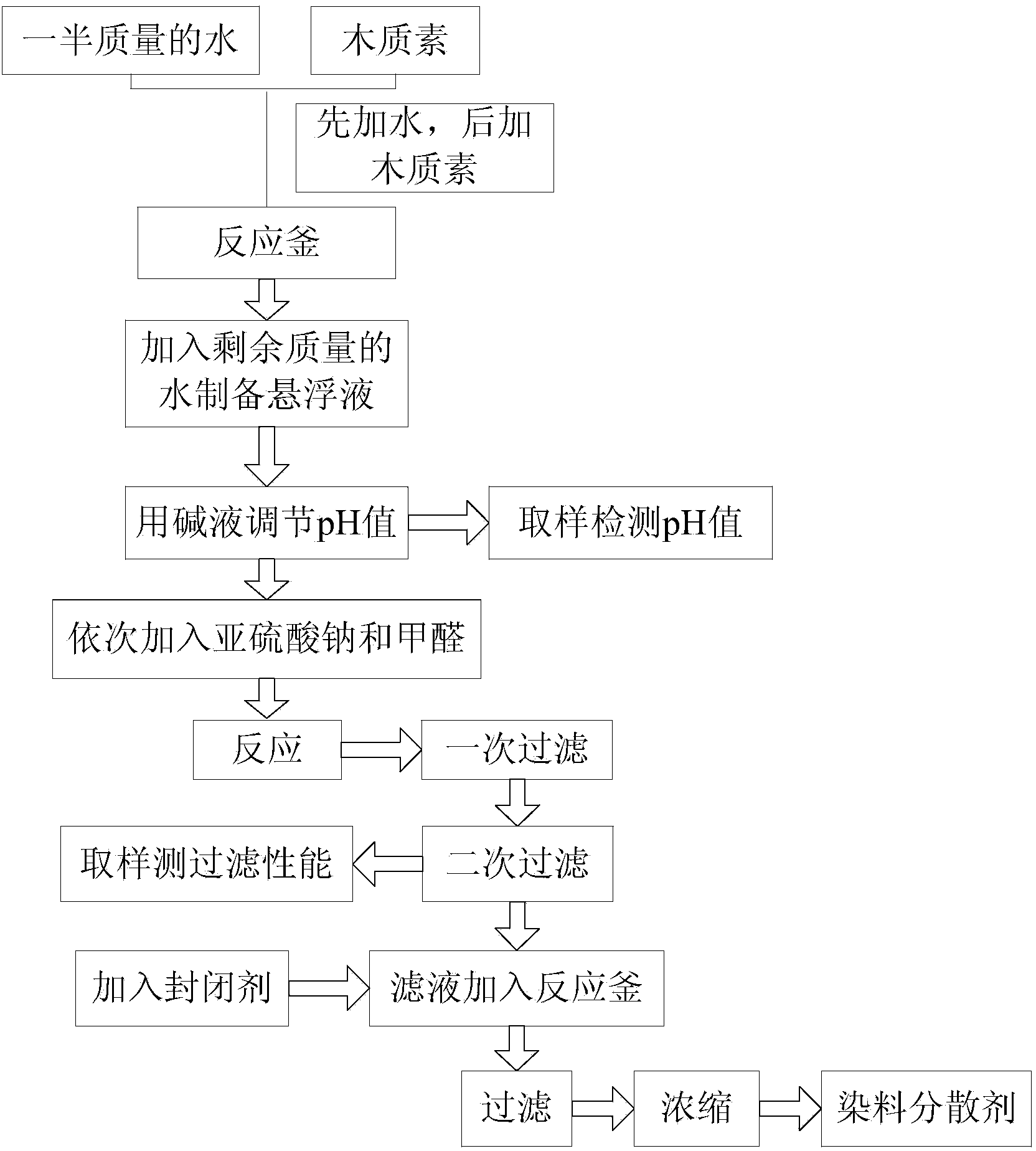

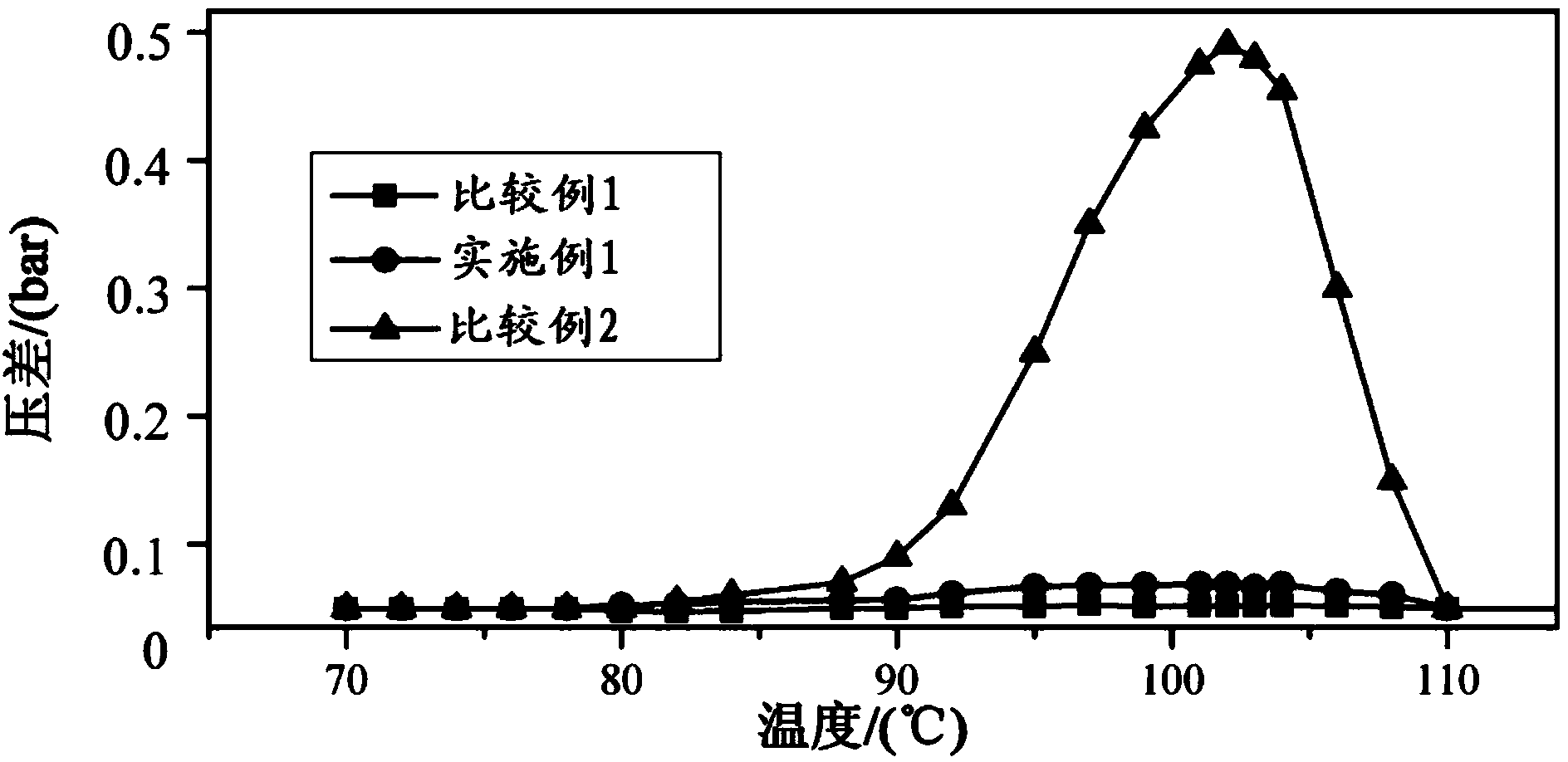

Method for preparing sodium lignosulfonate and application of sodium lignosulfonate as a dye dispersant

InactiveCN103910890AEvenly dispersedImprove heat stabilityOrganic dyesDyeing processSulfite saltSodium lignosulfonate

The invention provides a method for preparing sodium lignosulfonate. The method comprises the following steps: (A) providing a lignin suspension; (B) regulating the pH value of the suspension to 4.8-8.5; (C) sequentially adding sodium sulfite and formaldehyde to the suspension with pH value of 4.8-8.5, reacting and filtering to obtain filtrate; (D) mixing the filtrate with a sealant and reacting to obtain sodium lignosulfonate. The method provided by the invention has the advantages that the reaction between lignin and sodium sulfite and formaldehyde is controlled by controlling the adding order of sodium sulfite and formaldehyde; the filtrate obtained through filtering after reaction is reacted with the sealant to react with the free phenol hydroxyl, so that obtained sodium lignosulfonate has good dispersion property, excellent performance when used as the dye dispersant and little textile staining while having high heat stability.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

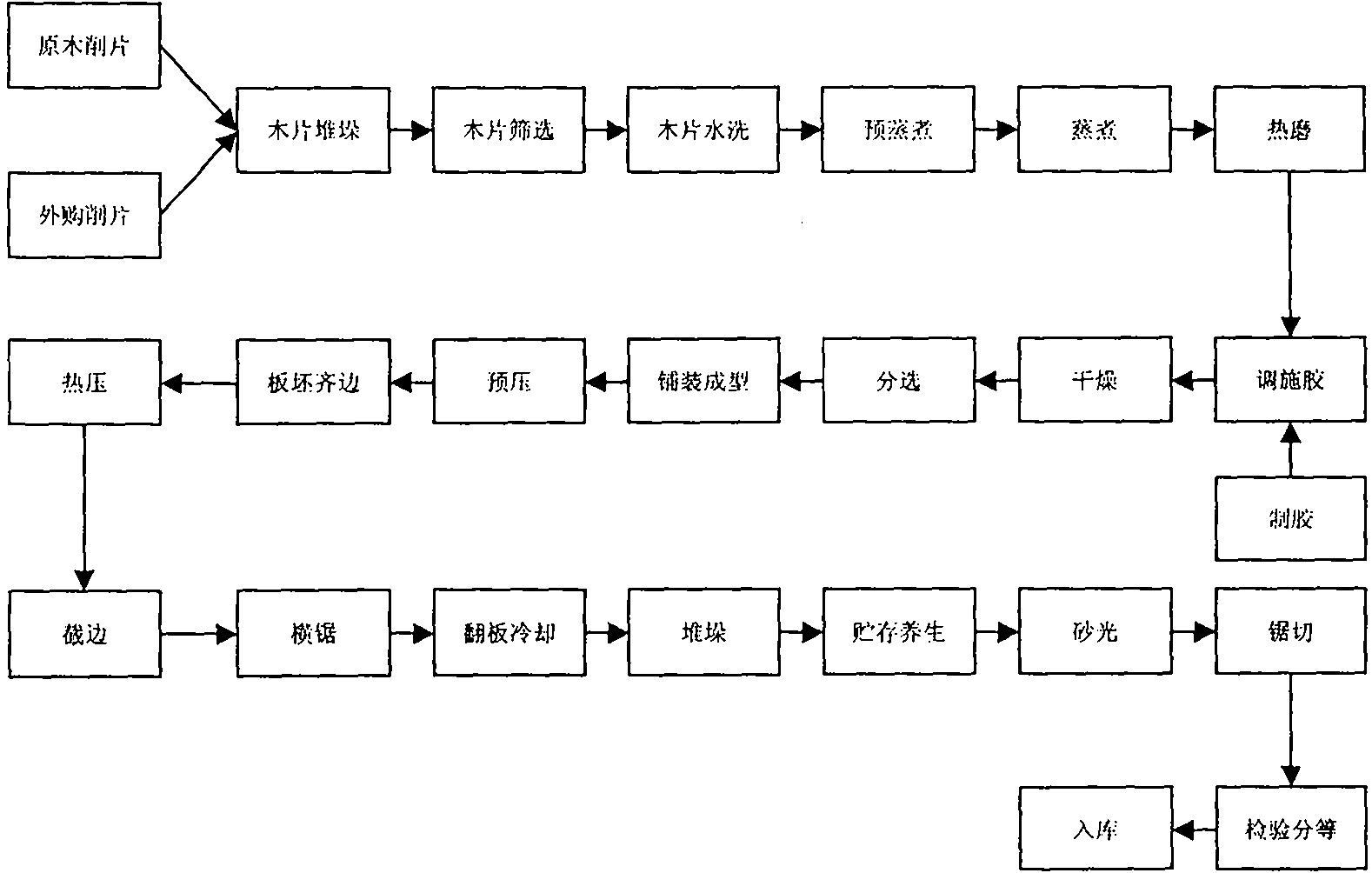

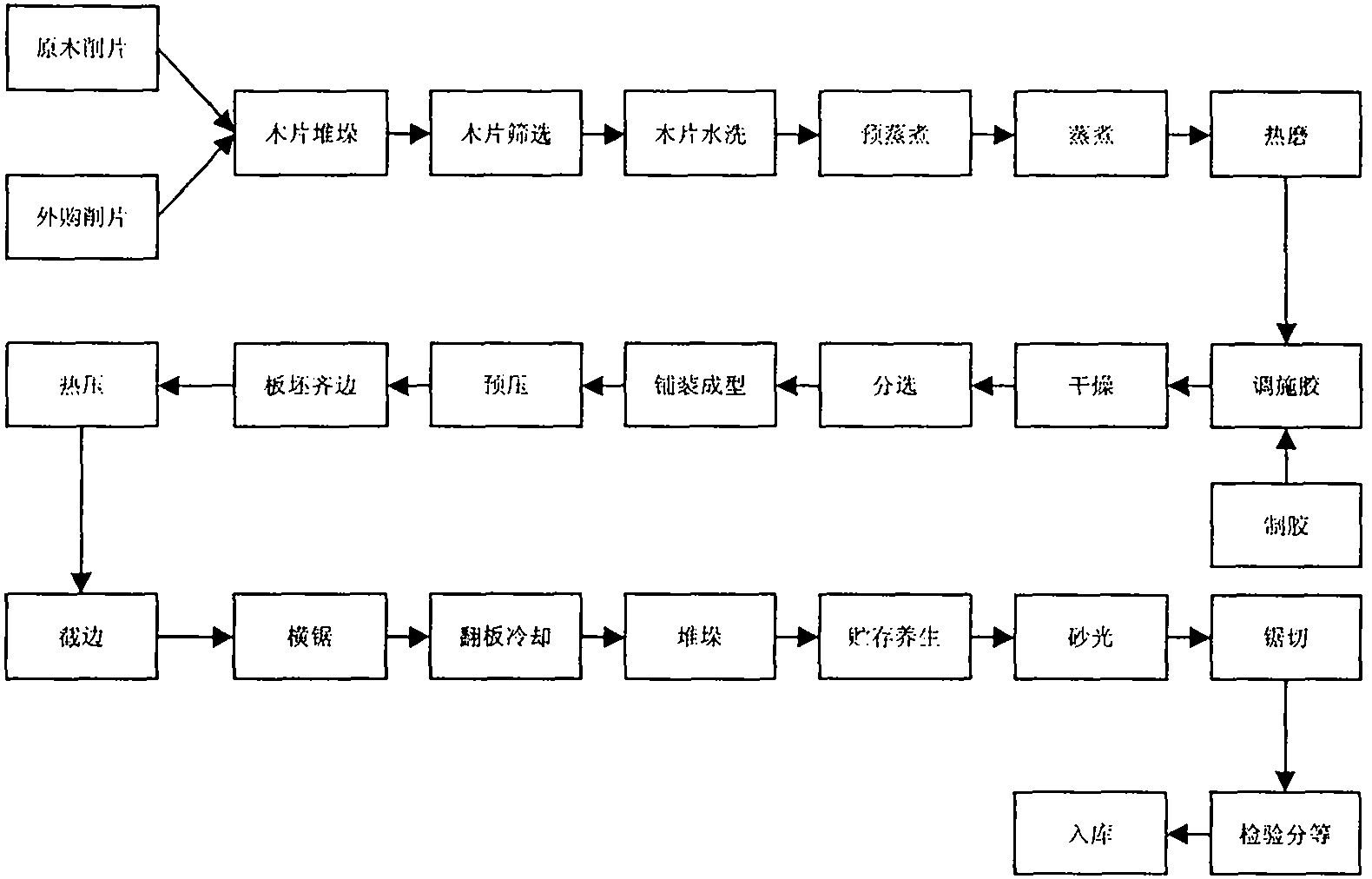

Processing method of high-strength E0 grade middle-high density plate

InactiveCN101863062AStable productionEasy to controlWood treatment detailsWood dampingFiberHigh density

The invention relates to a processing method of a high-strength E0 grade middle-high density plate, comprising the following steps of: controlling the pressure and the time in the stewing and softening working procedure based on the traditional processing method; controlling the pressure of a grinding chamber in the hot rolling work procedure; mixing phenolic resin adhesive with paraffin and a liquid formaldehyde tapping agent in the sizing work procedure; and controlling the dried fiber water-containing rate, the hot-pressing temperature, hot-pressing factors, the density control and other conditions and innovating. The invention particularly provides a preparation method for improving the phenolic resin adhesive, thereby having the specific advantages that the phenolic resin adhesive isstable in the production process and is easy to control and the contents of free aldehyde and free phenol of adhesive liquid are low. The formaldehyde release quantity of a fiber board produced by using modified phenolic resin reaches the European E0 standard; various indexes reach national standard; and the invention has favorable weather resistance and can be used outdoors.

Owner:DONGYING ZHENGHE WOOD IND

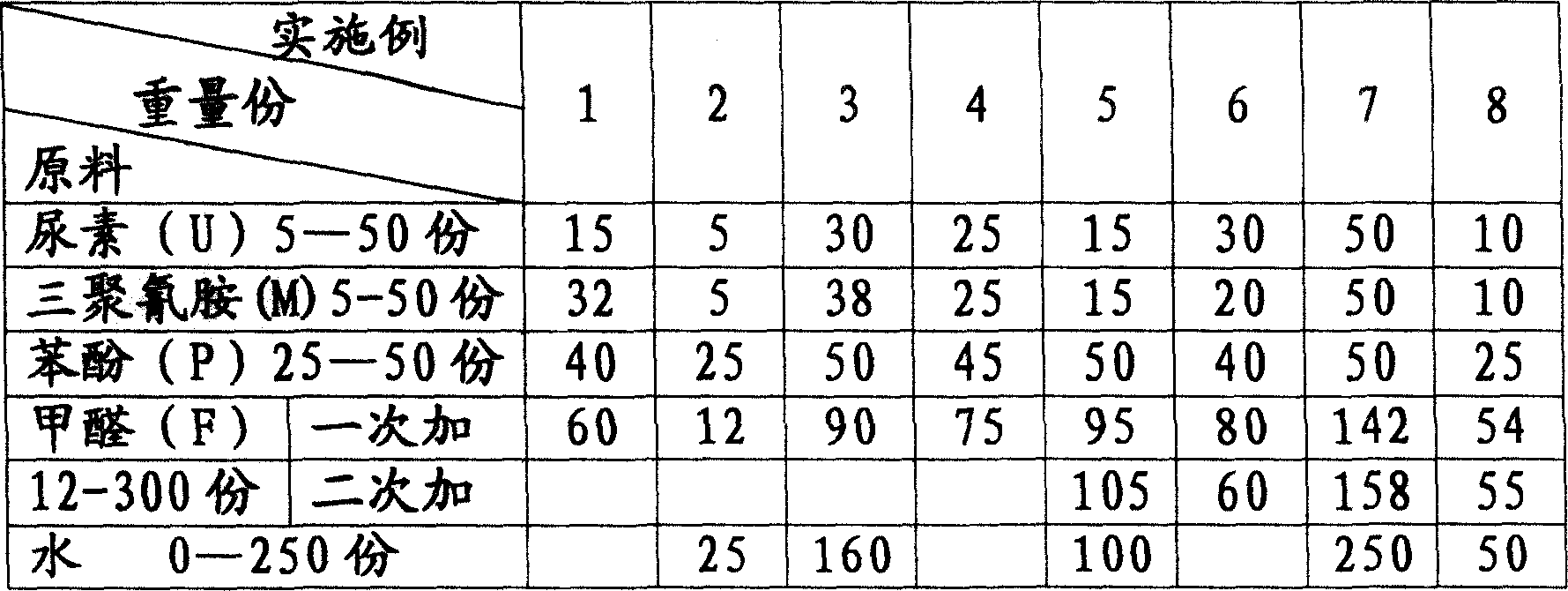

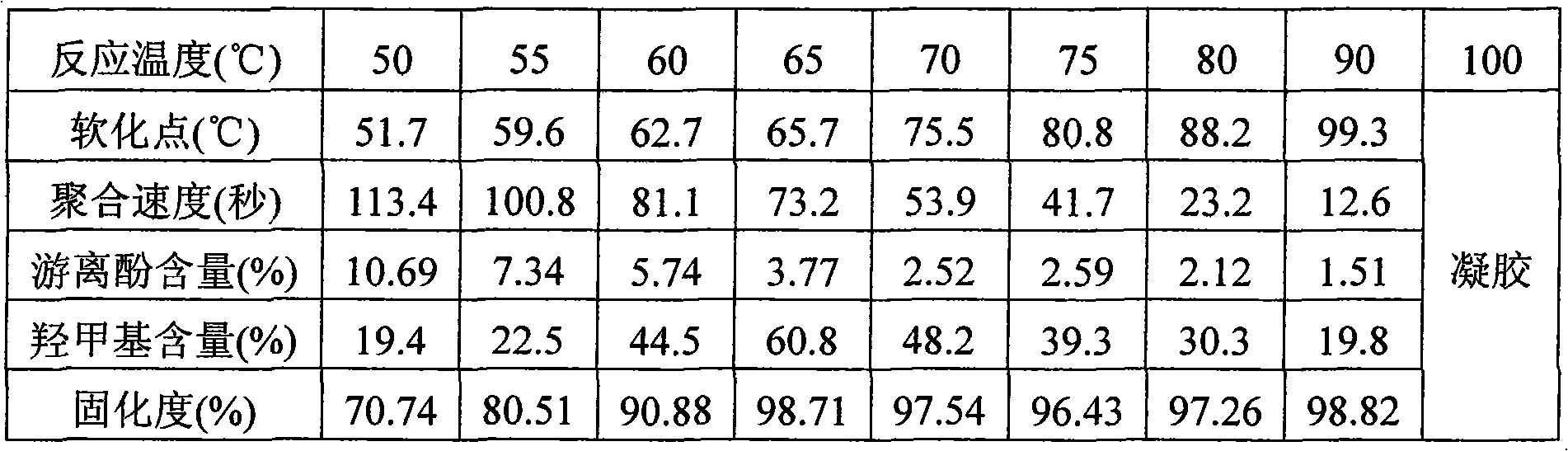

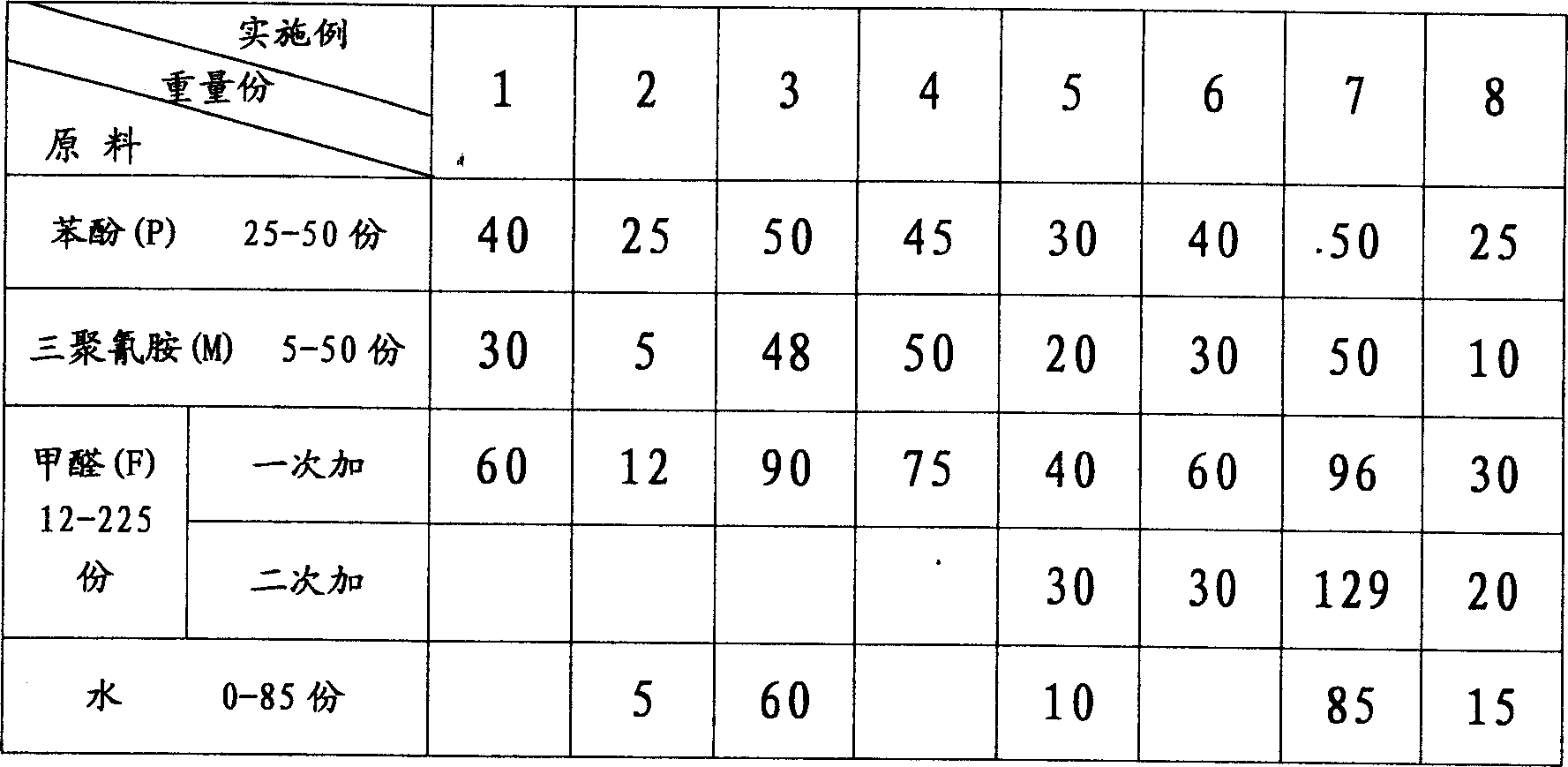

Melamine and urea modified phenolic resin and its production process

The present invention is melamine and urea modified resin and its production process. The material includes urea in 5-50 weight portions, melamine in 5-50 weight portions, phenol in 25-50 weight portions, formaldehyde in 12-300 weight portions and water in 0-250 weight portions. The production process includes the following steps: smelting phenol in the reaction kettle, adding formaldehyde, urea and melamine, regulating pH to 6-8, heating to 75-100 deg.c, maintaining for 30-100min, regulating pH to 3.0-5.5 for condensation reaction at viscosity not lower than 20S, regulating pH to 7.5-12, adding water and formaldehyde optionally, controlling temperature in 80-95 deg.c to react to terminal. The melamine and urea modified resin is yellow or brown transparent colloid liquid with pH 7.5-12, free phenol in 0.5-10 %, free aldehyde less than 2.0 %, and solid content 30-75 % and storage life over 1 month. It is used as adhesive for timber, friction plate, etc.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Non-phenols overlay film sand and producing method thereof

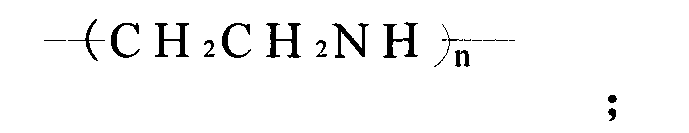

InactiveCN101249545AReduce free phenolHigh melting pointFoundry mouldsFoundry coresChemical reactionHexamethylenetetramine

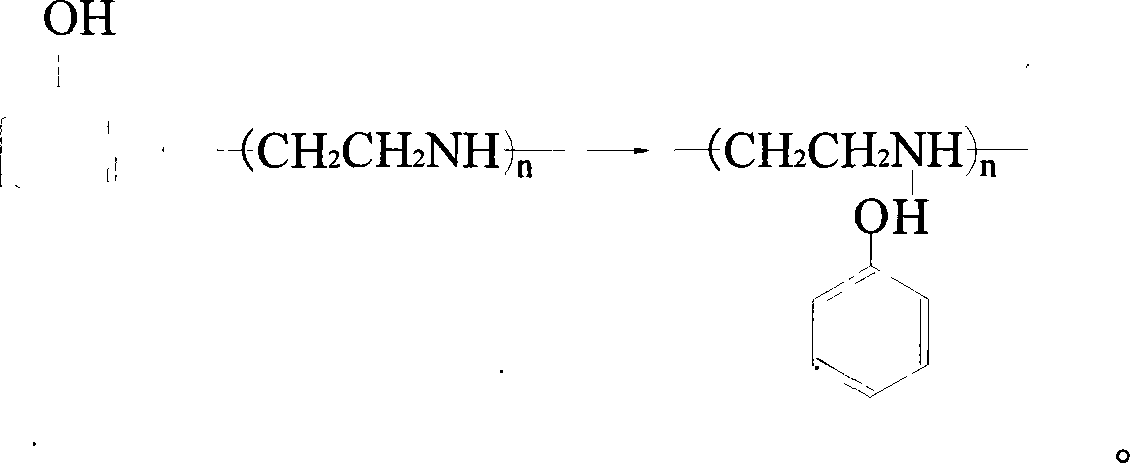

A phenol-free coated sand is characterized in that the coated sand is prepared from silicon sand, phenol-formaldehyde resin, urotropine, calcium stearate and macromolecular substances containing amino groups. The preparation method comprises the following steps of: (1) heating the silicon sand to 140 to 160 DEG C; (2) adding the phenol-formaldehyde resin and additives; (3) adding aqueous solution of the urotropine; (4) adding the calcium stearate; and (5) sieving to obtain the phenol-free coated sand. The phenol-free coated sand has the advantages that a material for reducing the content of free phenols and improving sand core performance is the reaction resultant of the macromolecular substances containing amino groups and the free phenols, which is an intermediate substance with a certain chemical reaction activity and can crosslink with each other to form macromolecules in hot curing reaction for core manufacture or formation. The macromolecules have infusibility and melting resistance, good thermal stability, no phenol volatilization and less production of smoke, and can increase the strength and the toughness of sand core or sand mold and improve the melting point of the coated sand by a certain degree, thus greatly improving the performance of the sand core.

Owner:TIANJIN YABU NEW TECH

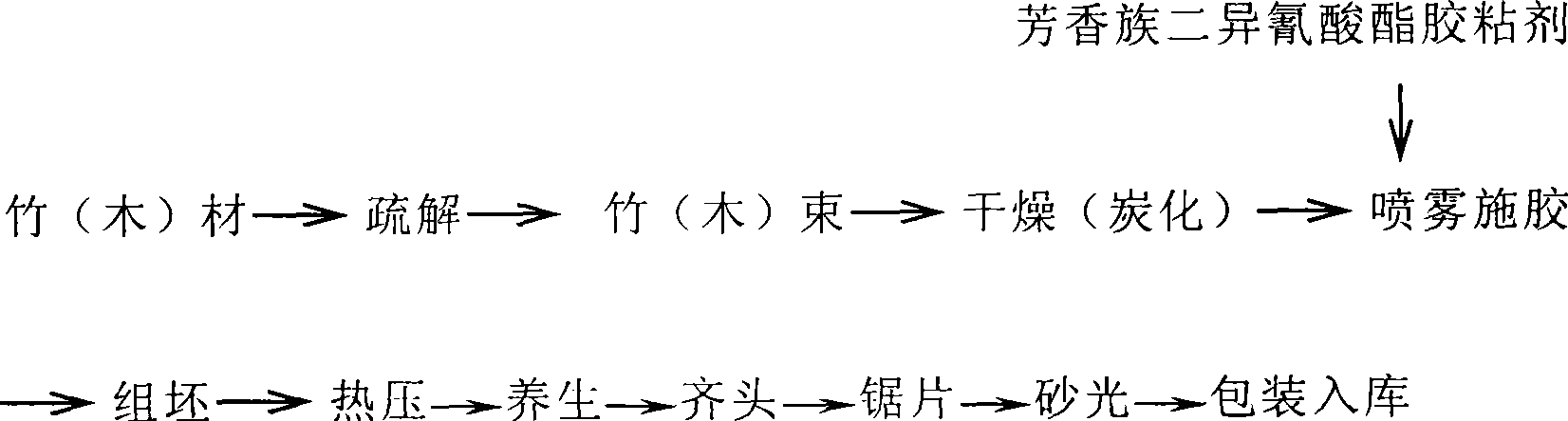

Non-aldehyde recombinant material and manufacturing method thereof

ActiveCN101486215AStrong solid woodExcellent adhesionFlat articlesDomestic articlesAdhesiveApplication procedure

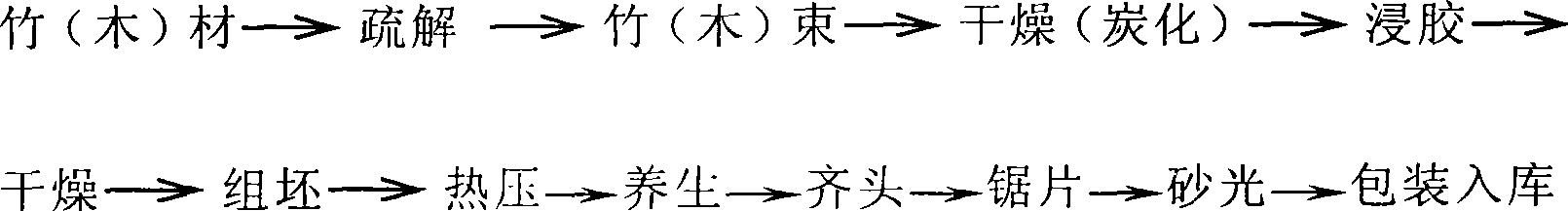

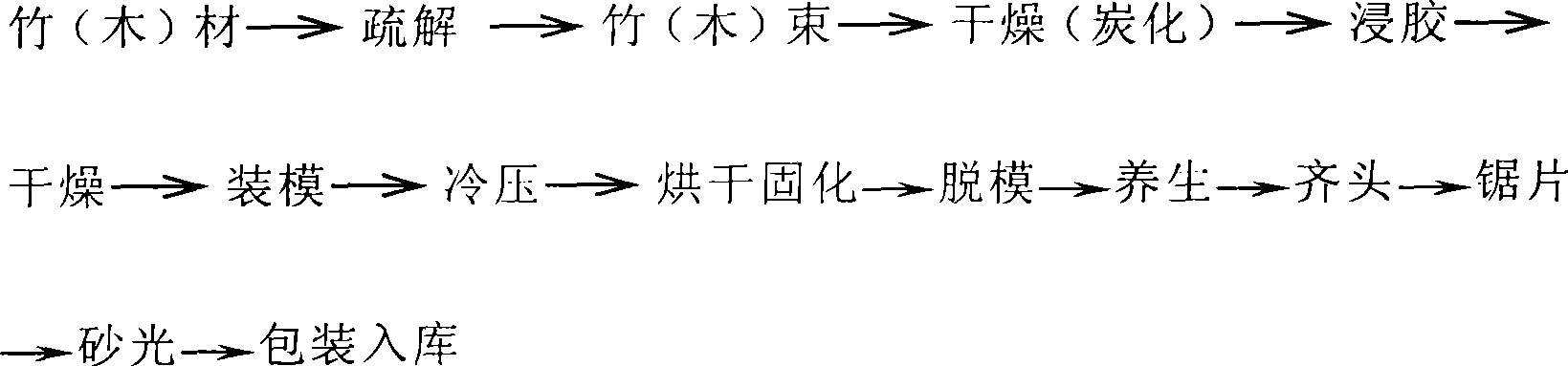

The invention provides an aldehydeless heavy component material. The material comprises a plurality of bamboo (wood) bundles formed by a cis-grain parallel structure; an adhesive layer is arranged between the adjacent bamboo (wood) bundles and in the gap of each bamboo (wood) bundle; and an adhesive of the adhesive layer is aromatic diisocyanate. The adhesive application amount is 5 to 20 percentof absolute dry weight of the bamboo (wood) bundle. The invention also provides a method for manufacturing the heavy component material; the method comprises working procedures of the manufacture of the bamboo (wood) bundle, drying, adhesive application, assembly, curing molding, and post treatment, and the like. In the adhesive application procedure, the used adhesive is the aromatic diisocyanate; and the adopted adhesive application method is an adhesive application method through spraying. The method adopts the aromatic diisocyanate adhesive, so that formaldehyde release amount and free phenol detection value of the heavy component material are the same as the detection value of a bamboo (wood) base material, and the heavy component material has good bonding performance and strengthensthe mechanical performance of the heavy component material; the adhesive application method is adopted adhesive spraying in the process, so the manufacturing method greatly reduces the adhesive application amount, and application of the aromatic diisocyanate adhesive with high cost to the heavy component material has feasibility of implementation.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Modified phenol formaldehyde resin and preparation method thereof

ActiveCN102690403AReduce contentEnergy saving and environmental protectionAldehyde/ketone condensation polymer adhesivesWood impregnation detailsAlkaline waterPolymer science

The invention discloses a modified phenol formaldehyde resin which is synthesized from the following raw materials: 4-25% of phenol, 30-60% of formaldehyde water solution, 2-15% of urea, 2-15% of melamine, 3-8% of alkaline water solution and 10-30% of water. The preparation method comprises the following steps: after adding the formaldehyde water solution, adding the urea, phenol and melamine by stages in an alkaline environment, and controlling the viscosity or water solubility of the intermediate product and the final product in the preparation process, thereby obtaining the modified phenol formaldehyde resin. The raw materials of the modified phenol formaldehyde resin are added by stages to perform sufficient reaction, thereby improving the comprehensive properties of the phenol formaldehyde resin, including lower contents of free aldehyde and free phenol, lighter resin color, higher water boiling property and better wettability. The invention is more suitable for manufacturing of recombined bamboo, and is also applicable to the fields of dipping treatment of paper wood, bamboo, wood and fabric bases as well as manufacturing of grinding tools.

Owner:DYNEA GUANGDONG

Modified phenol formaldehyde resin and preparation method thereof

ActiveCN102757618AImprove toughnessHigh strengthAldehyde/ketone condensation polymer adhesivesToughnessPhenol formaldehyde resin

The invention discloses a modified phenol formaldehyde resin and a preparation method thereof, relating to the field of phenol formaldehyde resins. The preparation method comprises the following steps: reacting 100 parts of phenol, 10-200 parts of lignin and 1-20 parts of acidic catalyst at 80-200 DEG C for 2-8 hours to form a reaction liquid; regulating the temperature of the reaction liquid to 60-110 DEG C, adding 50-200 parts of formaldehyde and 2-20 parts of composite catalyst, and reacting for 1-5 hours to form a sticky matter; washing the sticky matter in 60-70 DEG C water 2-5 times, and dehydrating to obtain a lignin phenol formaldehyde resin; and pulverizing the lignin phenol formaldehyde resin to 200 meshes, and evenly mixing with 2-20 parts of powder nitrile-butadiene rubber to obtain the modified phenol formaldehyde resin. The free phenol content of the modified phenol formaldehyde resin is 2-5%, the thermal decomposition temperature is 400-490 DEG C, the toughness and strength are high, and the friction material prepared from the modified phenol formaldehyde resin has high adhesive property and frictional property.

Owner:HUANGSHI JINZHAOYANG POWDER MATERIALS

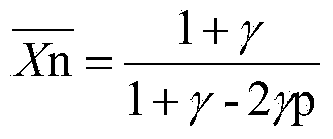

Dual catalyst system thermoplastic phenolic resin preparation method and application for preparing coated sand thereof

InactiveCN101619125AFast aggregationHigh yieldFoundry mouldsFoundry coresOrganic acidRoom temperature

A dual catalyst system thermoplastic phenolic resin preparation method comprises the steps of proportioning, refluxing and reacting, and drying; the raw materials comprises phenol or m-cresol and aldehydes compound, water, organic acid or inorganic acid and bivalent acetate in a molar ratio of 1:0.5-0.9:0-3.0:0.001-0.040:0.001-0.020; wherein, acetate is used as first catalyst and organic acid or inorganic acid is used as second catalyst in reaction process. The invention adopts phenolic aldehyde addition-condensation reaction in dual catalyst system to prepare the thermoplastic phenolic resin; the method has the advantage of rapid polymerization rate, high yield and low content of free phenols; the thermoplastic phenolic resin can be applied for preparing the coated sand and the prepared coated sand has higher hot tensile strength and tensile strength at room temperature.

Owner:SHAANXI NORMAL UNIV

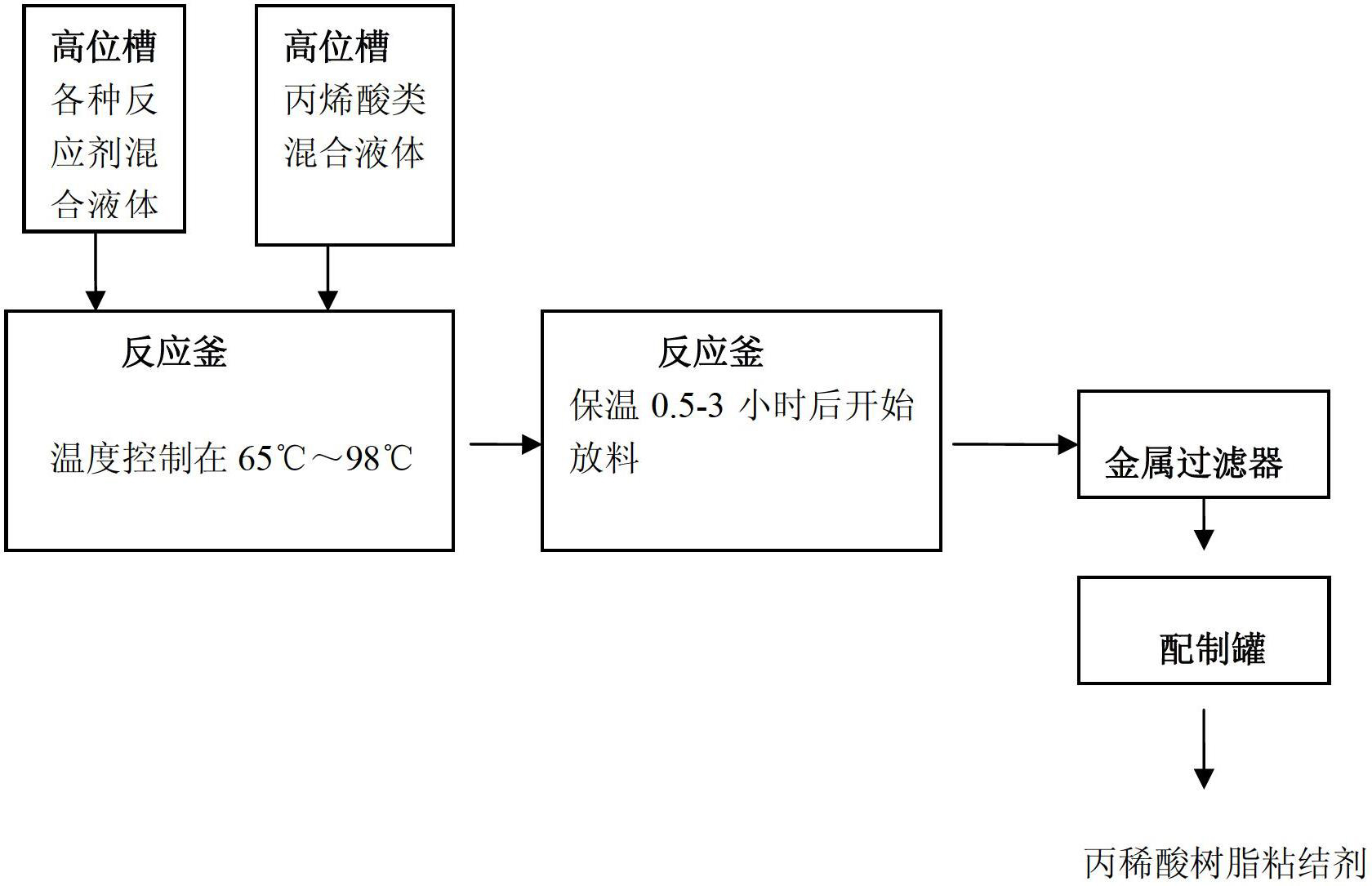

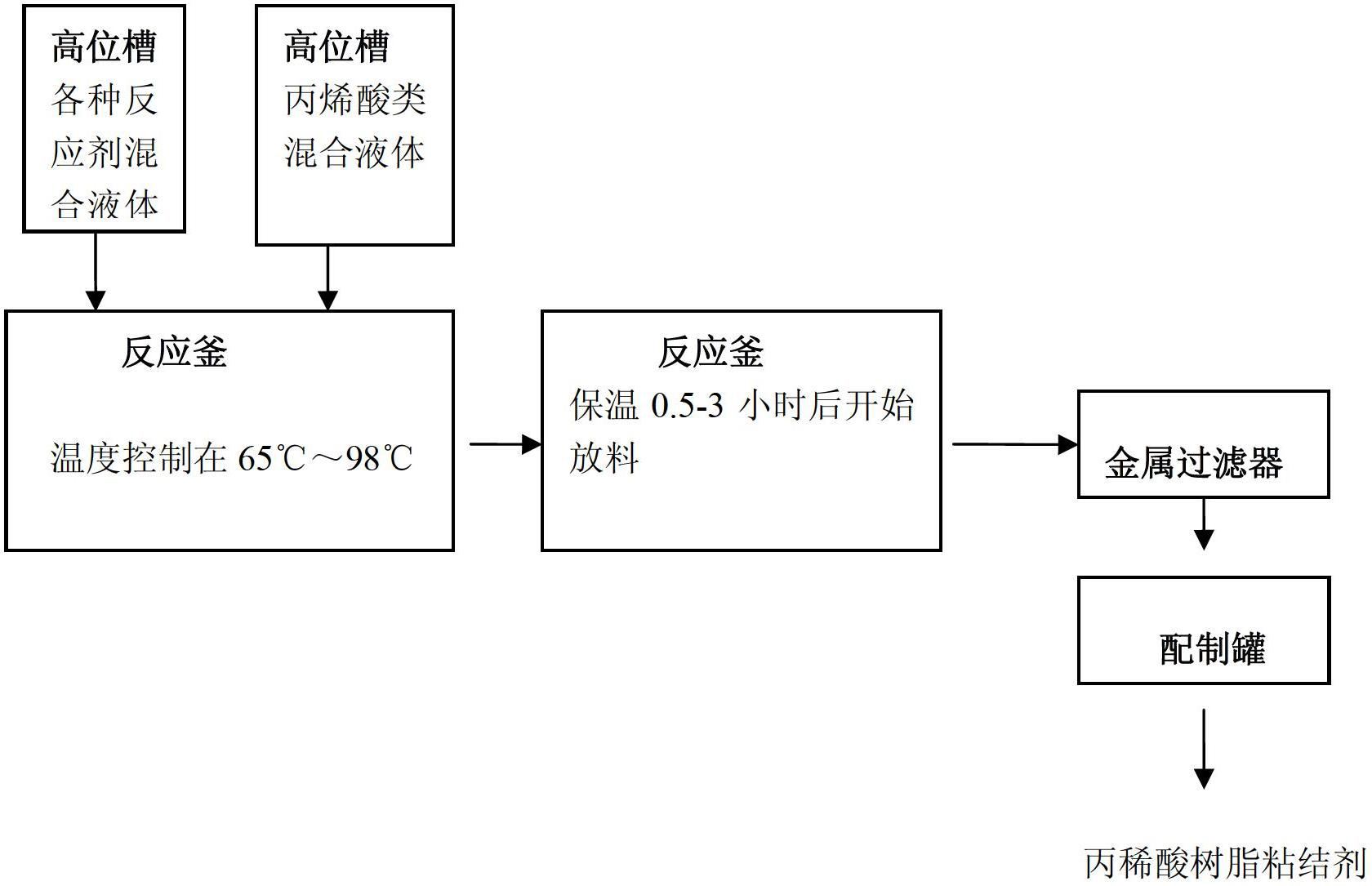

Preparation method of thermosetting acrylic resin binder

ActiveCN102690618AReduce intensityLow moisture absorptionNon-macromolecular adhesive additivesGraft polymer adhesivesPolyesterAcrylic resin

The invention discloses a preparation method of a thermosetting acrylic resin binder which does not contain formaldehyde. The preparation method comprises the following steps: carrying out graft copolymerization reaction on a acrylic acid type compound and an acrylic acid polyester compound under the action of an initiator, a chain transfer agent and a retarder so as to obtain a thermosetting acrylic resin; subsequently adding a softening agent, a curing agent, an emulsifying agent and a mildew preventive; stirring uniformly and filtering so as to prepare the thermosetting acrylic resin binder used for glass wool. The binder prepared by using the method does not contain free formaldehyde and free phenol, so the product does not release free aldehyde during the application process and is an environment-friendly green binder.

Owner:CHENGDU HANJIANG NEW BUILDING MATERIAL +1

High-glue content adhesive for flexible glass fiber felt

InactiveCN102618197AReduce releaseHarm reductionNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolubilityEnvironmental resistance

The invention discloses a high-glue content adhesive for a flexible glass fiber felt. The adhesive is composed of a water-solubility phenolic resin with high free formaldehyde content, urea, melamine, emulsified silicon oil, softened water, a silane coupling agent, a curing agent, a PH conditioning agent and the like. The water-solubility phenolic resin which has low smoke density, good flowing performance, adhesive property and flame retardant property and high free formaldehyde content is adopted in the adhesive to serve as the main raw material; the weather resistance performance and the heat resistance performance of the modified resin are increased; and the felt which has 13-22% of glue content and can be crimped and formed can be obtained. Simultaneously, the invention relates to a synthetic method of the formaldehyde-free glass fiber felt. The adhesive product provided by the invention has the excellent bonding strength, flexibility, water resistant performance, ageing resistant performance, high temperature resistant performance, corrosion resistant performance and flame retardant property, is free of the release of formaldehyde and free phenol and reduces the damage on human bodies, thereby meeting the requirement of environmental protection.

Owner:周介明 +1

Synthesis method of thermosetting phenol-formaldehyde resin in solid at normal temperature

InactiveCN101597364AAvoid the presence of excess hydroxymethyl groupsAvoid formingCresolSynthesis methods

A synthesis method of thermosetting phenol-formaldehyde resin in solid at normal temperature comprises mixing, reflux reaction, and vacuum dehydration. The invention adopts phenol or cresol and aldehyde compound as reactant and alkali as catalyst, preparation parameters is regulated and hydroxymethyl generation speed is controlled to avoid excessive hydroxymethyl existing in the reaction system and gel production, and the thermosetting phenol-formaldehyde resin in solid at normal temperature with 0.4-0.6 hydroxymethyl content is prepared. Compared with the prior preparation method of phenol-formaldehyde resin, the invention has the advantages that gel production is difficult in synthesis process, the synthetic thermosetting phenol-formaldehyde resin is high in hydroxymethyl content, low in free phenol content and is solid at normal temperature, and environmental pollution is less, storage period is long, transportation and use are convenient, etc. The method of the invention can be used for synthesizing solid thermosetting phenol-formaldehyde.

Owner:SHAANXI NORMAL UNIV

Plastic of phenolic aldehyde mould in no ammonia type, and manufacturing method

This invention relates to a method for preparing ammonia-free phenol formaldehyde molding material. The ammonia-free phenol formaldehyde molding material comprises: acid-catalyzed thermoplastic phenol formaldehyde resin 20-50%, curing agent 10-45%, curing accelerator 0.5-4%, organic filler 10-40%, and inorganic filler 10-40%, and lubricant 1-3%. The curing agent is at least one of melamine formaldehyde resin and urea formaldehyde resin. The curing agent is at least one of melamine formaldehyde resin and urea formaldehyde resin. The curing accelerator is at least one of MgO, Mg (OH) 2, CaO and Ca (OH) 2. The organic filler is fiber powder of at least one of wood, bamboo, cotton and hemp. The inorganic filler is at least one of CaCO3, talcum, mica, quartz and asbestos powder. The lubricant is at least one of stearic acid, zinc stearate and ethylene stearamide. The method has such advantages as simple process and low cost. The product has such advantages as no free ammonia, stable quality and long storage period, and can be used to manufacture instrument components.

Owner:厦门柯依达工贸有限公司

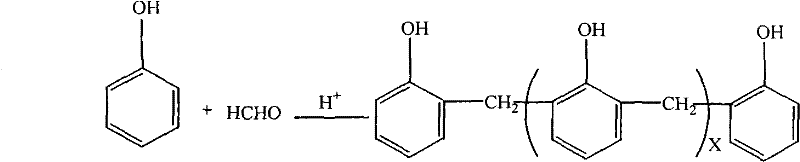

Copolymerized resin of melamine phenol and formaldehyde and its production method

Owner:ZHEJIANG FORESTRY UNIVERSITY

Scrimber and manufacturing method thereof

ActiveCN101642924AQuality improvementNo pollution in the processWood treatment detailsDomestic articlesFiberAdhesive

The invention discloses a scrimber and a manufacturing method thereof. The scrimber is prepared by the following steps: taking braches as raw materials, and cutting, peeling and grinding the branchesinto bunchy macrofiber; removing hemicelluloses and pectin; dipping a water soluble phenol formaldehyde adhesive; extracting free phenol and water content of the free phenol in vacuum; warmly pressinginto sections; performing curing; and performing after curing. The physical and mechanical properties of the scrimber are as follows: the density is between 0.9 and 1.3g / cm<3>; the hardness is between 60 and 120MPa; the static bending strength is between 90 and 150MPa; the water-absorbing expansion rate is between 0.3 and 2 percent; and the formaldehyde emission is between 0.1 and 0.4mg / L. The invention has the advantages that: the invention provides a scrimber product with no mold, no crack and no horizontal warpage; the manufacturing method for the scrimber has reasonable process, high efficiency, low energy consumption and no environmental pollution, the production flow has strong continuity and high connection degree, and the scrimber can be produced on a large scale; and the prospectof fully utilizing branch resources is better.

Owner:仇峰

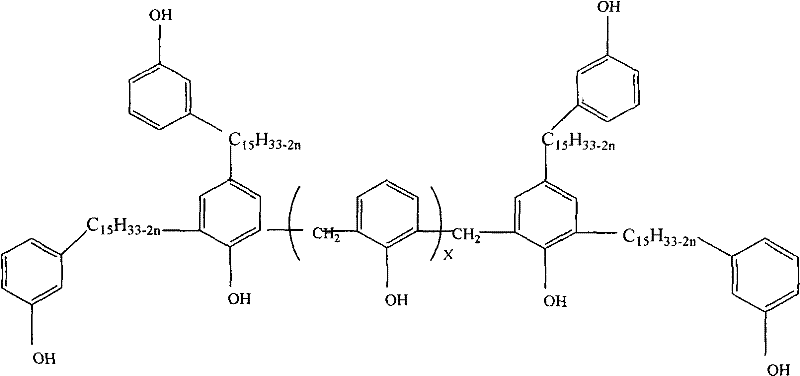

Cashew nut oil-modified phenolic resin and preparation method thereof

The invention discloses cashew nut oil-modified phenolic resin and a preparation method thereof. The method comprises the following steps of: making phenol and formaldehyde react under the condition of an acid catalyst to prepare a phenol-formaldehyde polycondensate; and adding cashew nut oil into the phenol-formaldehyde polycondensate, controlling the reaction temperature at 150-220 DEG C, keeping reacting for 1-5 hours, distilling under reduced pressure at the vacuum degree of between -0.03 MPa and -0.1MPa till the softening point of resin is 70-120 DEG C, and neutralizing the acid catalyst with a neutralizer to obtain the cashew nut oil-modified phenolic resin, wherein the molar ratio of the formaldehyde to the phenol is (0.5-0.76):1; the acid catalyst is alkylbenzenesulfonic acid, p-toluenesulfonic acid, oxalic acid, hydrochloric acid or sulfuric acid; and the cashew nut oil-modified phenolic resin is C15 polyatomic phenol of which the side chain is provided with unsaturated double bonds. According to the preparation method of the cashew nut oil-modified phenolic resin provided by the invention, the problem of easiness in gelling a product in the prior art is solved, and the resin has the characteristic of low free phenol content. When taken as a reinforcing agent of rubber and a tire, the cashew nut oil-modified phenolic resin better contributes to improving the reinforcing performance of a sizing material than unmodified phenol-formaldehyde resin.

Owner:BEIJING RED AVENUE INNOVA

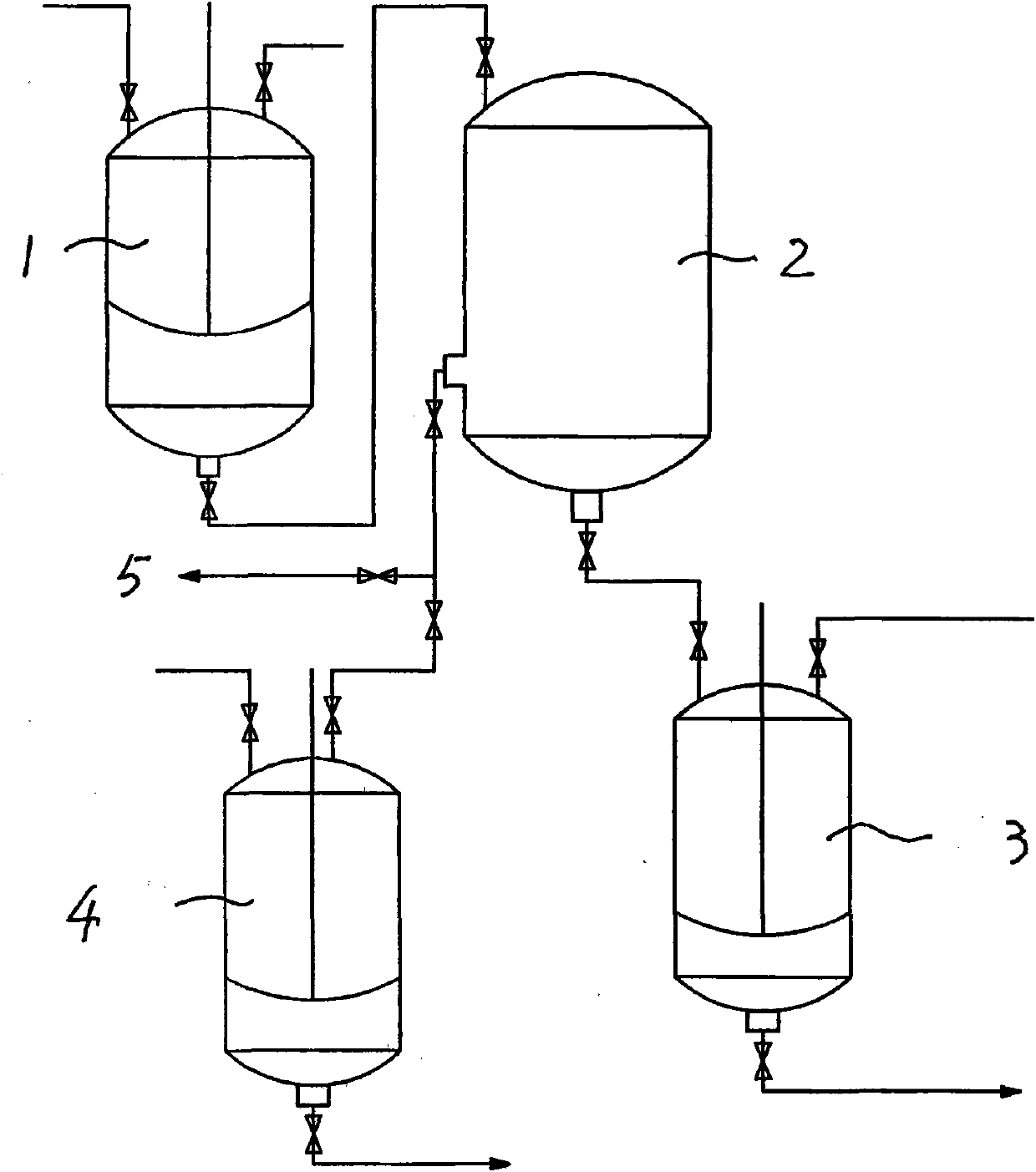

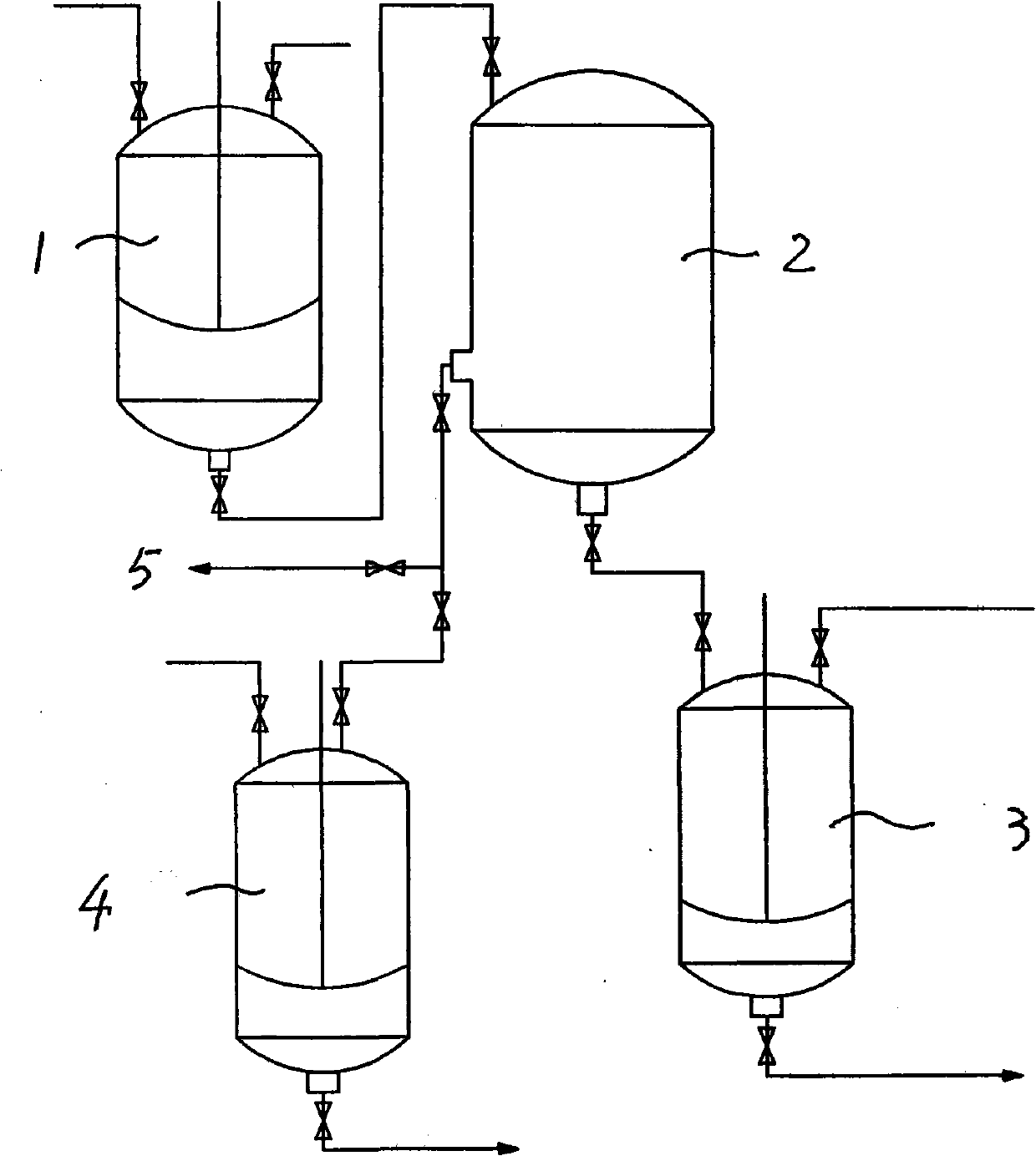

Comprehensive utilization method of phenolic resin wastewater

InactiveCN101906196AShort production processHigh yieldMultistage water/sewage treatmentCarbonyl compound separation/purificationFree phenolWater soluble

The invention discloses a comprehensive utilization method of phenolic resin wastewater, belonging to the technical field of processing wastewater produced in the fine chemical engineering industry. The comprehensive utilization method comprises the steps of: adding the phenolic resin wastewater, an acid catalyst and formaldehyde in a condensation polymerization kettle according to the proportion, raising the temperature until the phenolic resin wastewater, the acid catalyst and the formaldehyde are boiled, preserving temperature for reaction; then reducing the temperature in the kettle, pumping materials in the condensation polymerization kettle into a settlement separation kettle by using a pump to reduce the temperature and settle and demix; flowing a lower layer resin material of a settlement formed by demixing into a resin synthesis kettle through a pipeline, adding the acid catalyst and the formaldehyde, raising temperature and boiling for reaction, vacuum dewatering to obtain thermoplastic phenolic resin; and injecting one part of wastewater with content of the free phenol formed after the settlement formed in the condensation polymerization kettle, which is reduced to be below 1 percent, into a water borne resin synthesis kettle to be used for reducing water soluble resin, absorbing the formaldehyde in a primary and a secondary absorption towers one part of which is injected with industrial formaldehyde, and forming the industrial formaldehyde. The invention realizes the purpose that the phenolic resin industrial wastewater achieves zero emission.

Owner:河北泽田化工有限公司

Preparation method of styrenated hindered phenol or styrenated phenol antioxidant product

ActiveCN102267876AImprove antioxidant capacityAvoid pollutionOrganic chemistryOrganic compound preparationTert butyl phenolButadiene-styrene rubber

The invention discloses a preparation method of a styrenated hindered phenol or styrenated phenol antioxidant product, belonging to the field of preparation process methods of polymer antioxidant products. The preparation method is characterized in that: o-tert-butyl phenol or phenol, p-cresol, o-cresol and m-cresol are used as raw materials, styrene is used as an alkylation reagent, an organic acid compound is used as a catalyst, a small amount of polymerization inhibitor is added, and the styrenated hindered phenol product or styrenated phenol product is prepared through catalytic alkylation reaction; a neutralizing and decolorizing agent is added to the styrenated product to deactivate the acidic catalyst and remove the coloring source material, thus obtaining a white-like or light yellow viscous liquid namely the styrenated phenol antioxidant product which has clear and transparent appearance, pH value of 6.5-7.5, storage stability and high use efficiency; and the styrenated phenol antioxidant product is free of water-soluble pollutants such as free phenol or methyl phenol, thereby solving the problem of environmental pollution caused by the use of the product in styrene butadiene rubber latex.

Owner:CHANGZHOU UNIV

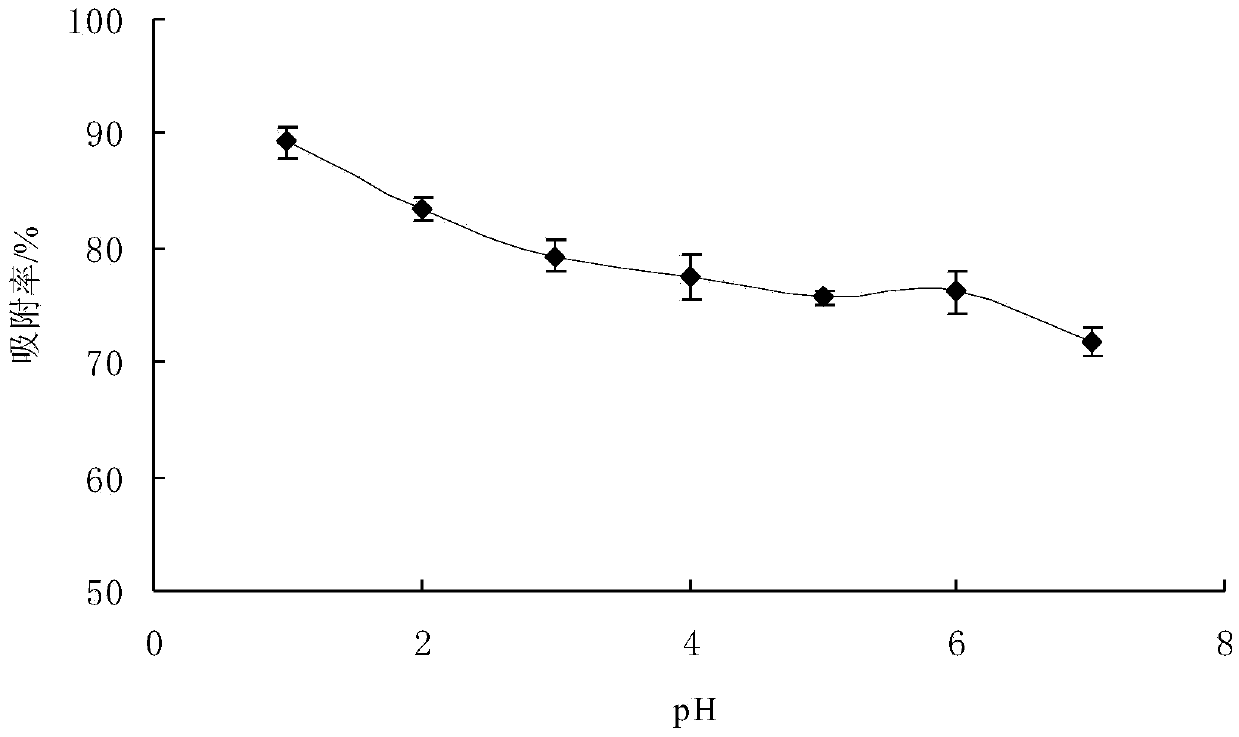

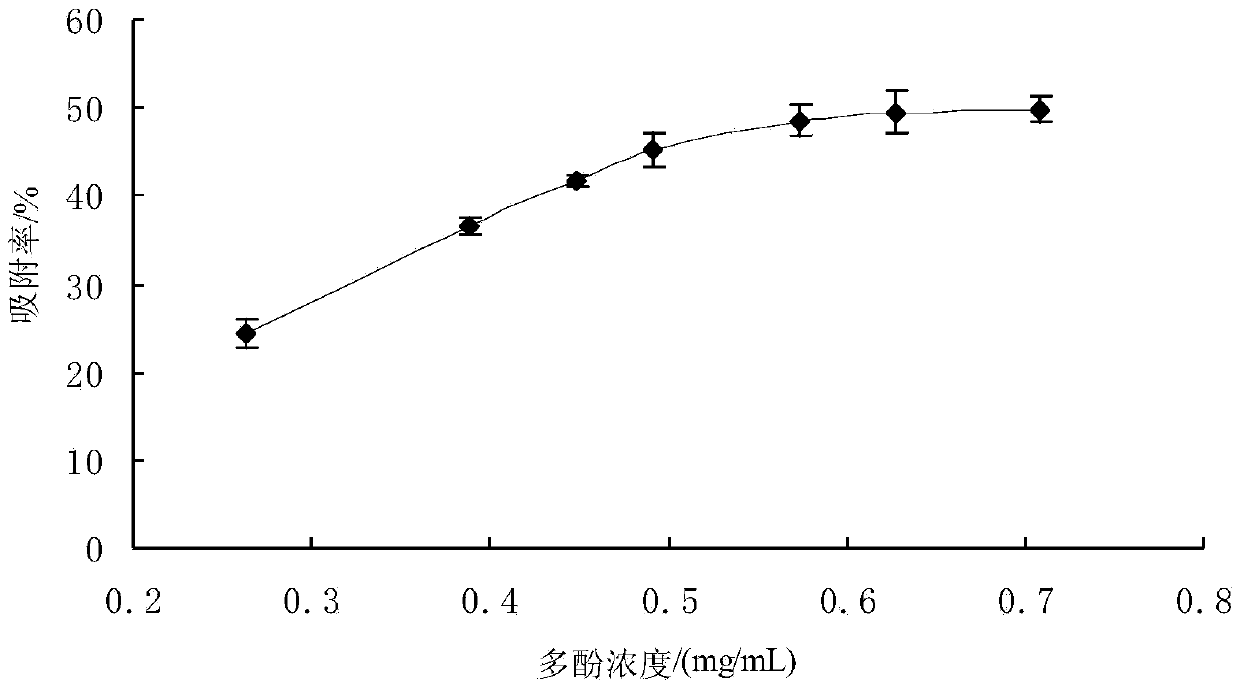

Method for separation purification of walnut green seedcase polyphenol substances by macroporous resin

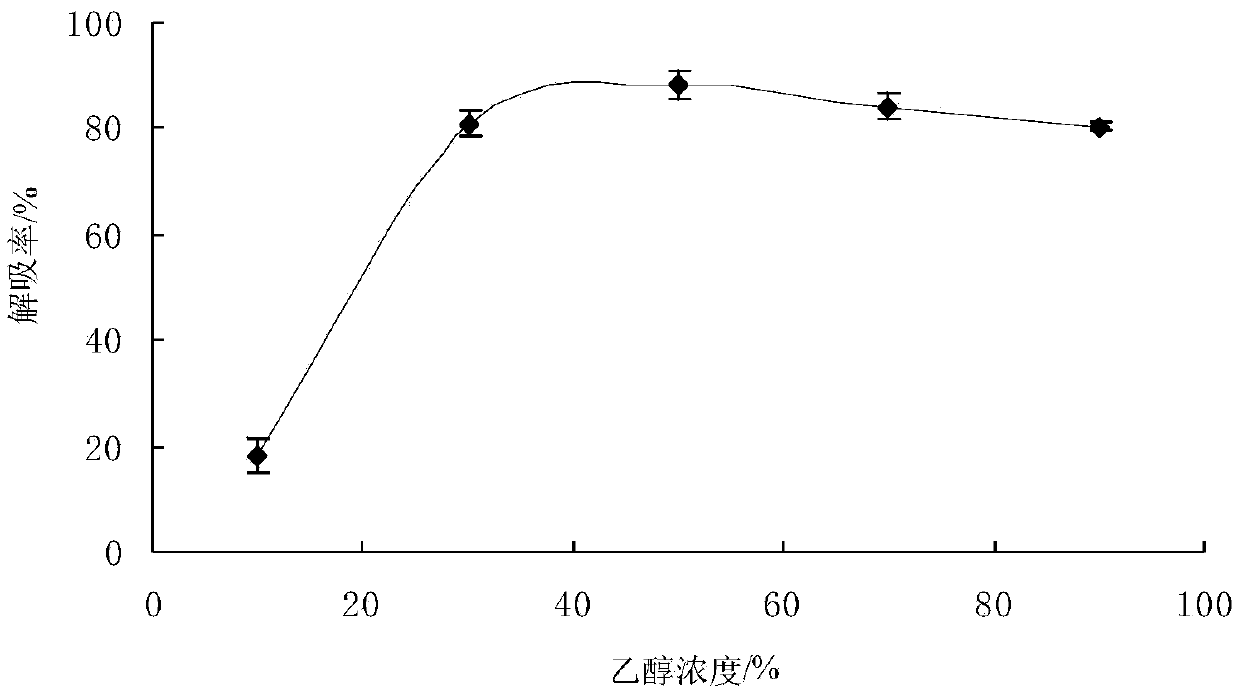

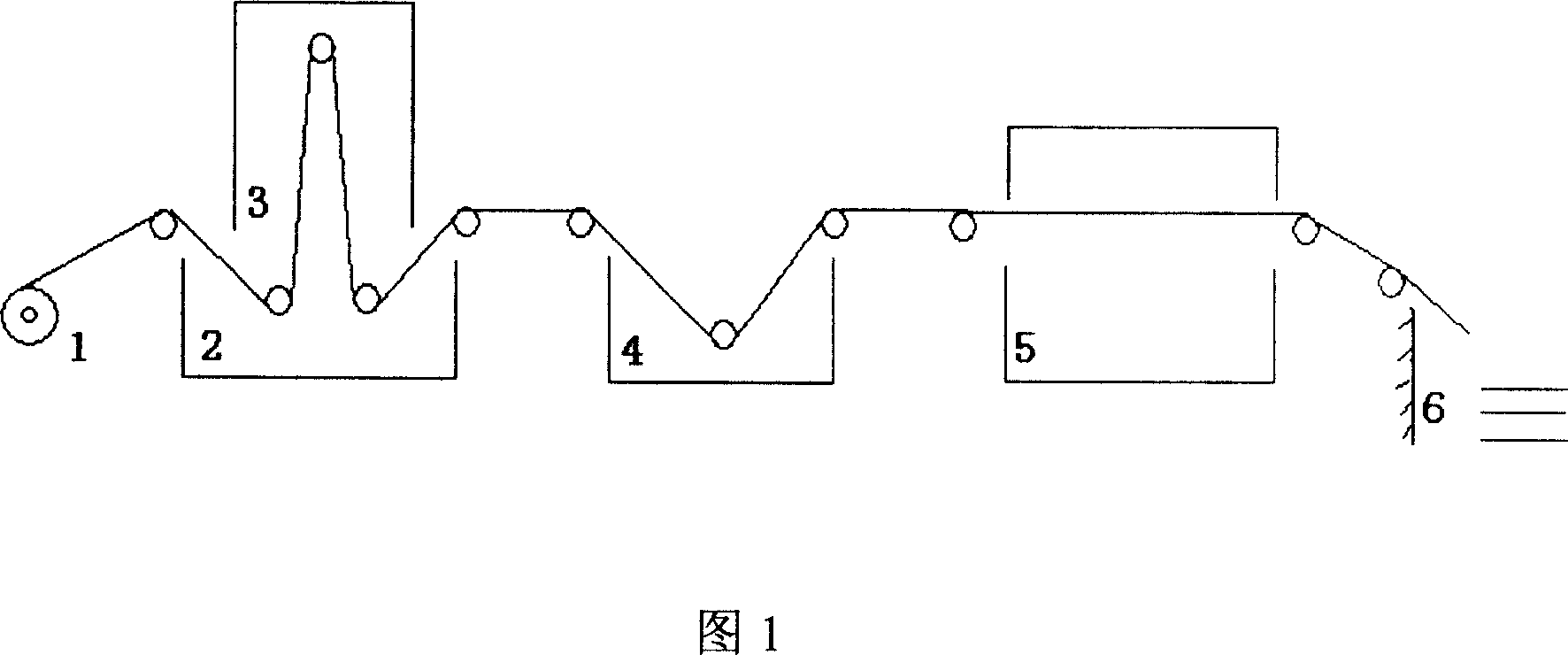

The invention discloses a method for separation purification of walnut green seedcase polyphenol substances by macroporous resin. The method comprises 1, carrying out extraction on walnut green seedcase dry powder at a temperature of 35-40 DEG C through ethanol with content of 50% under ultrasonic action many times, carrying out vacuum filtration on the extract, evaporating the filtrate to obtain walnut green seedcase polyphenol crude extract, diluting the walnut green seedcase polyphenol crude extract until a desired concentration is obtained, and carrying out refrigeration for next use, 2, determining total polyphenol content of walnut green seedcase by a Folin-Ciocaileu method, 3, carrying out macroporous resin pretreatment, 4, carrying out macroporous resin static adsorption and desorption, 5, carrying out macroporous resin dynamic adsorption and desorption, and 6, through a HPLC method, determining free phenol content and composition of the walnut green seedcase polyphenol extract obtained by the macroporous resin separation purification so that the whole separation purification process is finished. The method provides the novel approach for separation purification of walnut green seedcase polyphenol substances, can be operated simply and realizes high separation purification quality and efficiency.

Owner:HENGSHAN COUNTY HONGMENGYUAN TECH IND CO LTD

Modified alkyd resin for laminated board and preparation method and usage thereof

InactiveCN101062971AFast curingReduce precipitationLamination ancillary operationsLaminationAldehyde formationMonomer

The invention discloses a modified alkyd resin of laminated board, preparing method and usage in phenol resin domain, which is characterized by the following: adopting organic phenol monomer with linear hydrocarbon group and aldehydes monomer under the function of activator; getting the product; making the resin as transparent liquid with low viscosity and high dipping property; setting the number average molecular weight between 450 and 600 (GPC detection); decreasing evolution and discharge of free phenol effectively; adopting compatible diluent system. This resin possesses good storing stability, which is fit for dipping paper, cotton fabric and fiberglass cloth and so on reinforced materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Phenol-Formaldehyde Novolac Resin Having Low Concentration of Free Phenol

A phenol-formaldehyde novolac resin having a low concentration of free phenol prepared by distilling residual phenol from a molten novolac resin and replacing at least a portion of the phenol with a solvent having a volatility equal to or less than phenol. Such modified novolac resins are suitable for the production of resin coated molding sands for shell molding and sand cores, as well as for the production of resin coated proppants for use in oil and gas recovery operations.

Owner:GEORGIA PACIFIC CHEM LLC

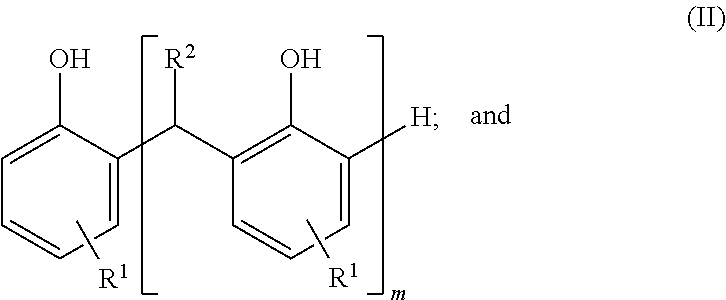

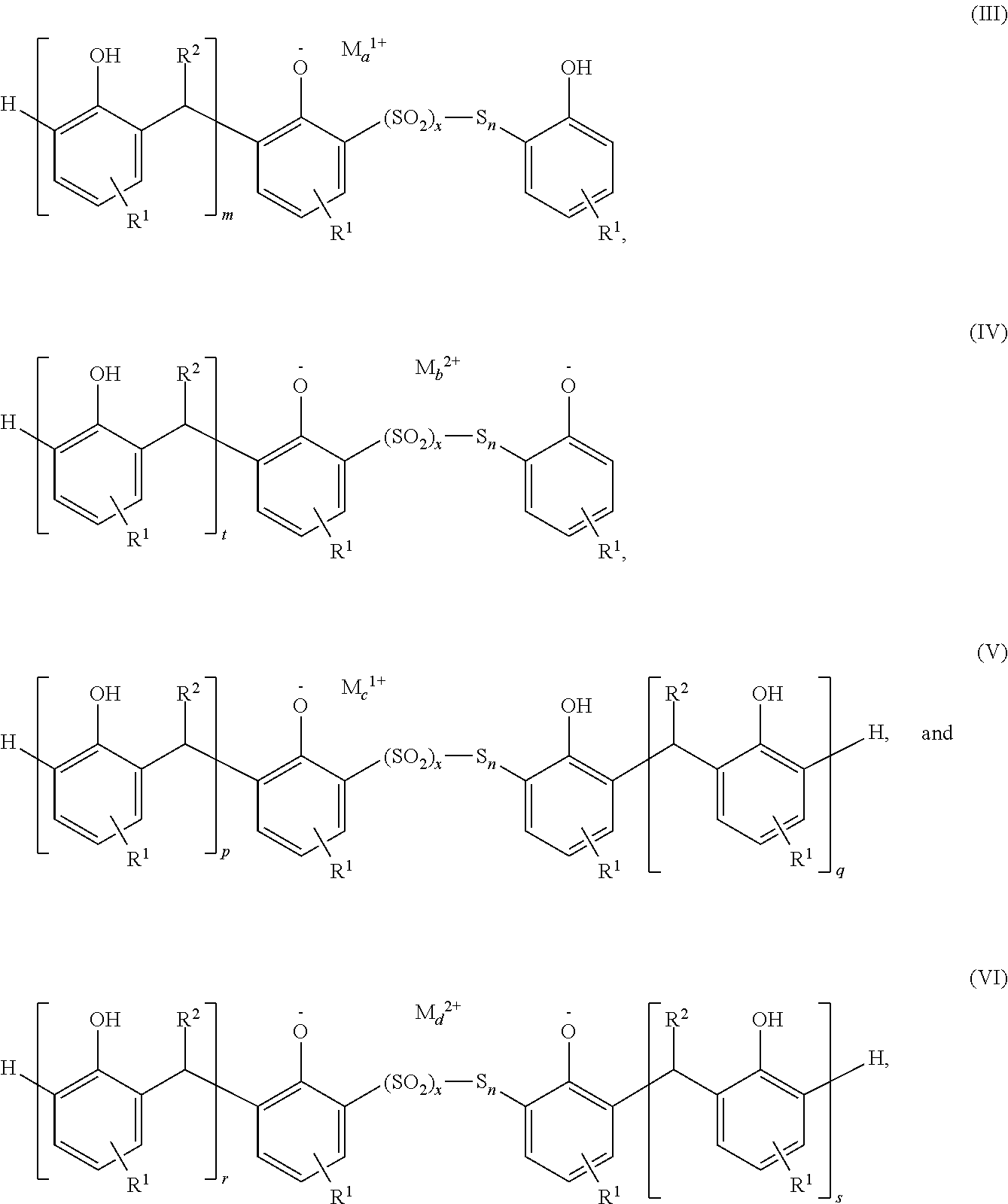

Sulfurized metal alkyl phenate compositions having a low alkyl phenol content

Provided herein are sulfurized metal alkyl phenate compositions having a low alkyl phenol content. The sulfurized metal alkyl phenate compositions can be prepared by reacting a phenol compound of Formula (I) disclosed herein with an aldehyde to form a phenolic resin of Formula (II) disclosed herein and then by reacting the phenolic resin simultaneously with a metal base and a first sulfurizing agent. The sulfurized metal alkyl phenate compositions and the overbased sulfurized metal alkyl phenate compositions disclosed herein may be used as detergents for formulating lubricating oil compositions. The lubricating oil compositions disclosed herein have a reduced amount of the free phenol compound and a salt thereof.

Owner:CHEVRON ORONITE CO LLC

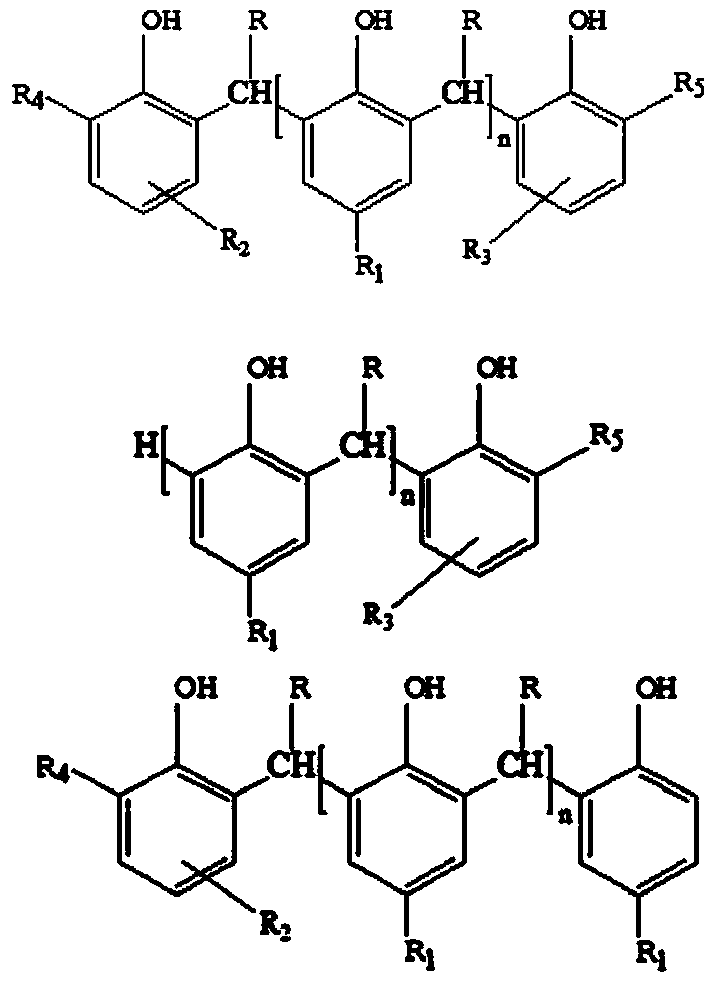

Synthesis method of alkyl phenol aldehyde resin

The invention discloses an alkyl phenol aldehyde resin and a synthesis method thereof. The synthesis method comprises the following steps: adding raw materials mono-substituted alkyl phenol and di-substituted alkyl phenol into a reactor, reacting with aldehyde under the action of an acidic catalyst, heating for dehydration, adding aldehyde, and reacting to obtain the alkyl phenol aldehyde resin. Compared with like alkyl phenol aldehyde resins, the alkyl phenol aldehyde resin disclosed by the invention has obviously higher tackifying effect and lower free phenol content. The invention also discloses application of the alkyl phenol aldehyde resin in production manufacturing of tires and rubber products.

Owner:RACHEM CHINA CO LTD

Preparation method of toughening-modified phenolic resin and phenolic foam

The invention provides a preparation method of a toughening-modified phenolic resin and phenolic foam. The preparation method of the phenolic resin comprises the following steps: adding phenol and an alkali catalyst into a reaction kettle, heating to 65-75 DEG C while stirring, and adding a mixture 1, wherein the mol ratio of phenol to alkali catalyst to mixture 1 is 24.6:(0.03-0.09):(16-26.8). The preparation method of the phenolic foam comprises the following step: adding toughener-containing mineral inorganic powder capable of adsorbing and degrading free formaldehyde and free phenol in the resin, a foaming agent, a curing agent and a foam stabilizer into the prepared phenolic resin, thereby obtaining the phenolic foam. The phenolic resin prepared by the method provided by the invention has the advantages of high toughness, favorable flame retardancy, low contents of free formaldehyde and free phenol, and no waste water discharge in the production process. The phenolic resin foam prepared by the method provided by the invention has the advantages of low heat conductivity coefficient, high percentage of close area, favorable toughness, high oxygen index (up to higher than 50), no cracking, no shedding, no dropping, low smoke and no toxicity.

Owner:单成敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com