Modified alkyd resin for laminated board and preparation method and usage thereof

A technology for phenolic resin and laminate, which is applied in the field of modified phenolic resin for laminate and its preparation, can solve the problems of free phenol and aldehyde volatilization, environmental pollution, etc., and achieves the improvement of crosslinking density, reduction of precipitation and emission, and curing speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 200 parts by weight of 2,4-di-tert-butylphenol were added with 37 parts by weight of formaldehyde and 2 parts by weight of barium hydroxide under nitrogen protection state, heated to 80°C under stirring, and stirred for 5 hours. The reaction solution was in a transparent state; the gel time was determined to be 3 to 4 minutes, and the water produced by the reaction was collected and removed by distillation under reduced pressure. The molecular weight of the resin was determined to be between 450 and 600, and the temperature was lowered to 40°C, and 240 parts by weight of alcohol was added to dilute. Stir and react for 1 hour to obtain a uniform and transparent modified phenolic resin with a number average molecular weight between 450 and 600.

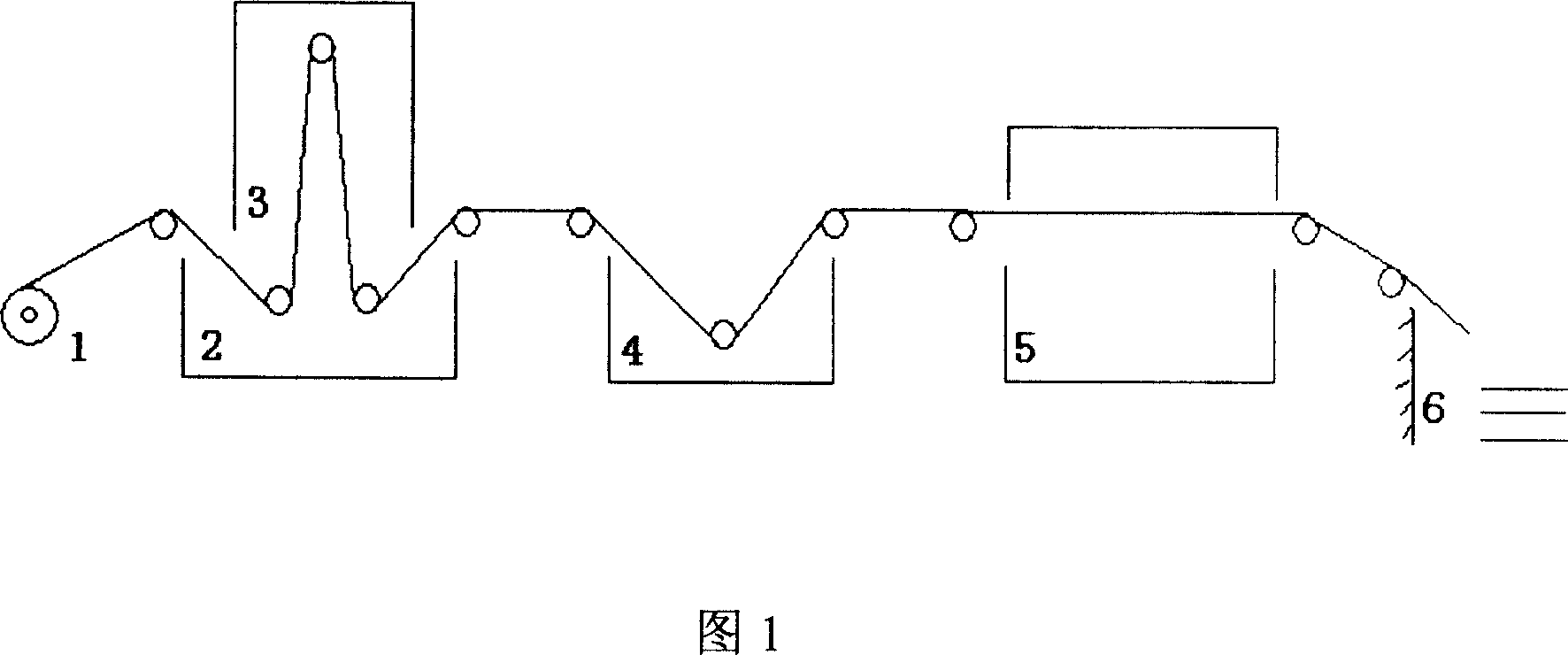

[0026] According to the preparation process route of the phenolic paper laminated board shown in Figure 1, the phenolic paper laminated board for electrical engineering was prepared.

[0027] (1). In a continuous manner, kraft pa...

Embodiment 2

[0034] 180 parts by weight of hexylphenol was added with 37 parts by weight of formaldehyde and 2 parts by weight of barium hydroxide under the protection state of nitrogen filling, heated to 80°C under stirring, and stirred and reacted for 5 hours, and the reaction solution was in a transparent state; The gelation time is 3-4min, distilled under reduced pressure, collect and remove the water produced by the reaction, measure the molecular weight of the resin between 450-600, cool down to 40°C, add 200 parts by weight of alcohol, stir for 1 hour, and get the number average Uniform and transparent modified phenolic resin with a molecular weight between 450 and 600.

[0035] According to the preparation process route of the phenolic paper laminated board shown in Figure 1, the phenolic paper laminated board for electrical engineering was prepared.

[0036] (1). In a continuous manner, kraft paper is impregnated with modified phenolic resin through a vertical dipping tank, and th...

Embodiment 3

[0043] 180 parts by weight of nonylphenol were added with 37 parts by weight of formaldehyde and 2 parts by weight of magnesium hydroxide under nitrogen protection, heated to 80°C under stirring, and stirred for 5 hours, and the reaction solution was transparent; Measure the gelation time at 3 to 4 minutes, distill under reduced pressure, collect and remove the water produced by the reaction, measure the molecular weight of the resin between 450 and 600, cool down to 40°C, add 200 parts by weight of methanol, and stir for 1 hour to obtain the number Uniform and transparent modified phenolic resin with an average molecular weight between 450 and 600.

[0044] In the way of continuous impregnation, impregnate the prepared modified phenolic resin with glass cloth, and bake it at 120°C for 7-10 minutes to obtain a prepreg. 2 Hot-press molding under pressure to prepare a phenolic glass cloth laminated board for electrical engineering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com