Motor unit, manufacturing method therefor and recording disk driving apparatus

a technology of recording disk and motor unit, which is applied in the direction of bearing unit rigid support, magnetic circuit shape/form/construction, instruments, etc., can solve the problems of not cured ultraviolet curing adhesive, poor productivity, and long time-consuming cure time of adhesive, etc., and achieve high adhesive strength and good productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Overall Construction of Spindle Motor

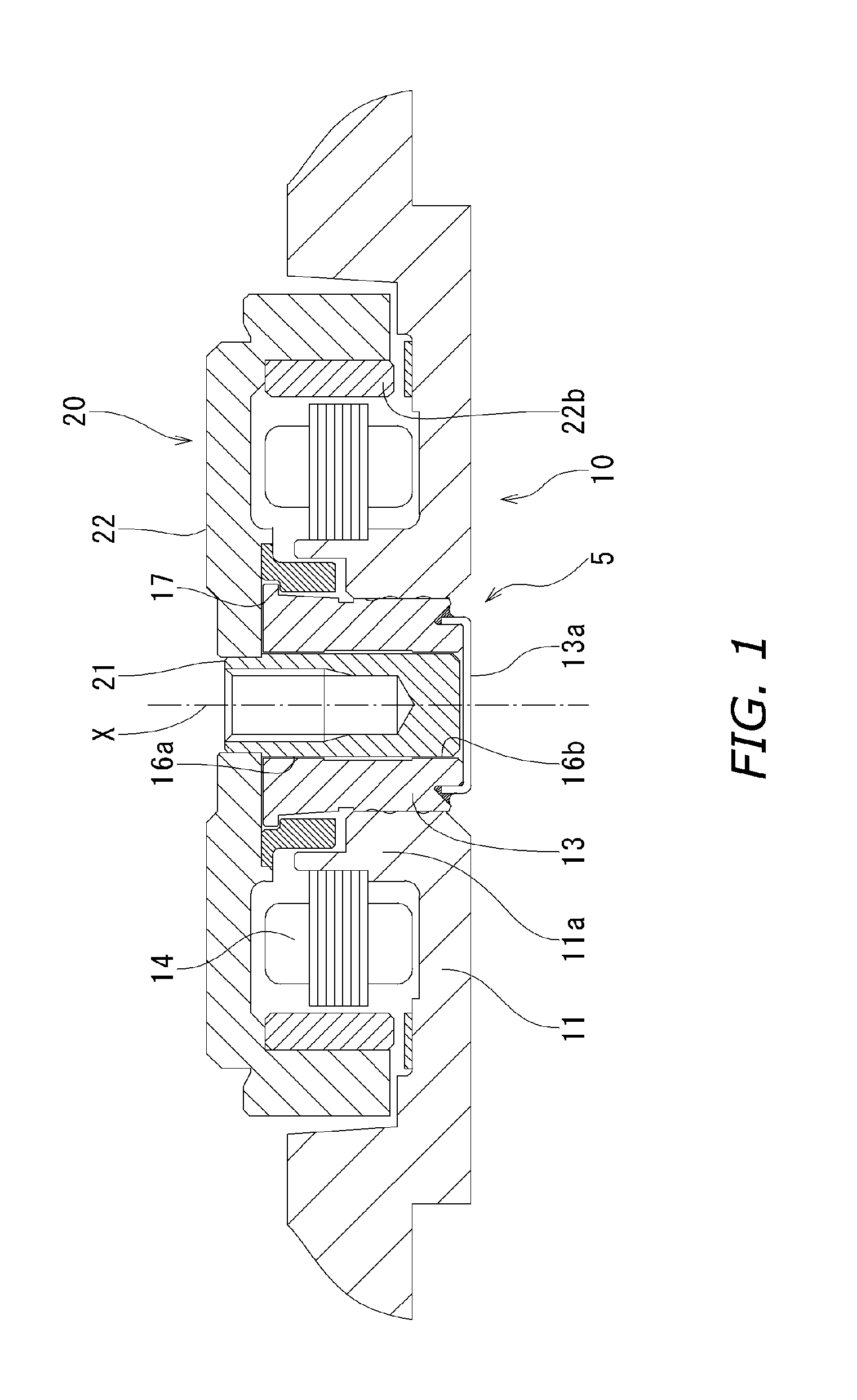

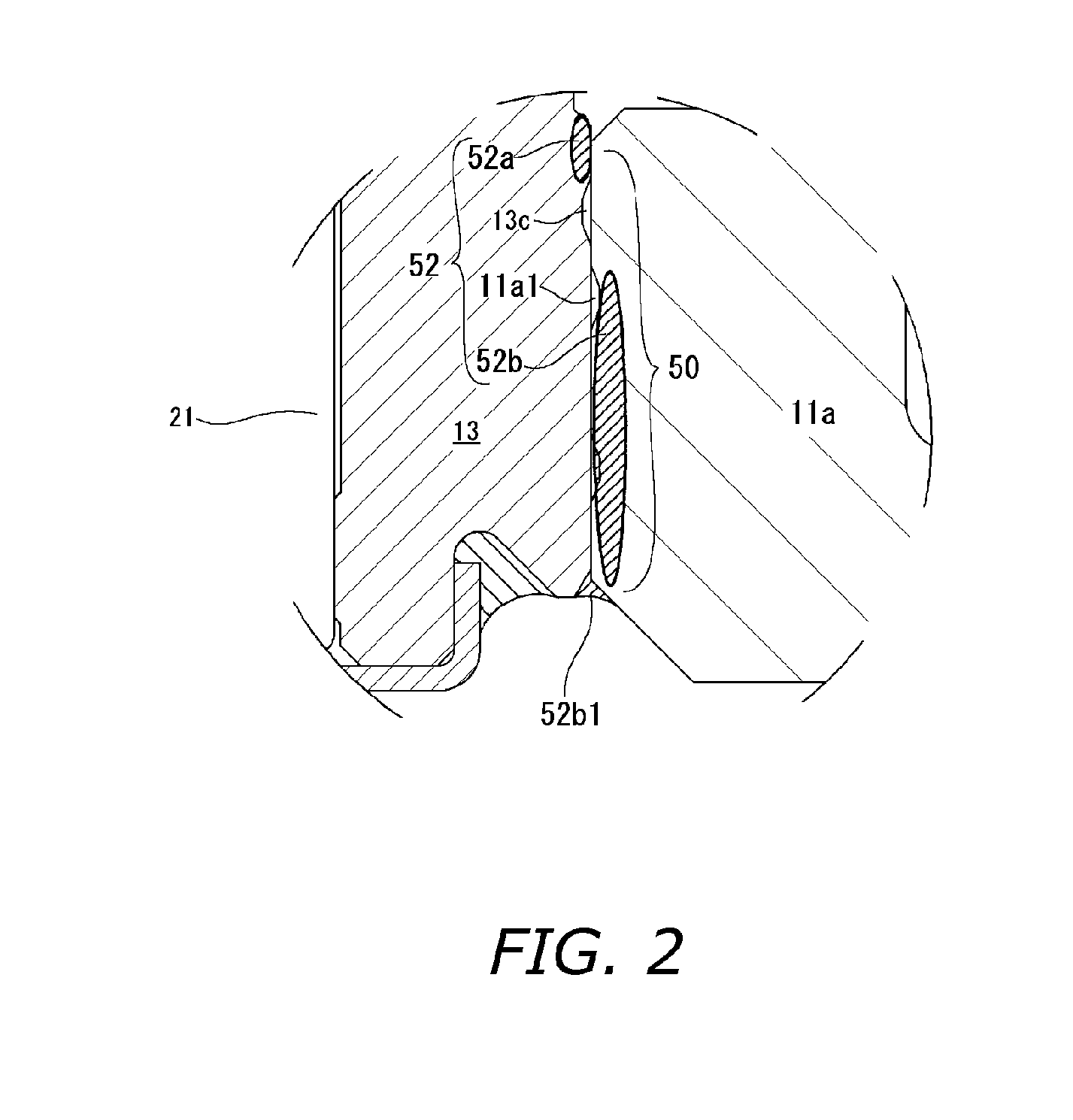

[0026]A spindle motor shown in FIG. 1 includes: a first housing member 11; a bearing assembly 5; and a rotor assembly 20. A hollow cylindrical section 11a is formed in the middle of the first housing member 11 approximately coaxially with the central axis X. The bearing assembly 5 is securely held by plural adhesives described later on an inner circumferential portion of the hollow cylindrical section 11a and a stator 14 is held on an outer circumferential portion of the hollow cylindrical section 11a.

[0027]The bearing assembly 5 includes: a sleeve 13 having a hollow cylindrical shape which made of a copper-based material such as phosphor bronze; a cover member 13a closing the lower end of the sleeve 13 in the axial direction thereof; and a shaft 21 facing an inner circumferential portion of the sleeve 13 with a micro gap interposed therebetween and rotating around the central axis X.

[0028]The rotor assembly 20 includes: the shaft 21; a rotor hu...

second embodiment

[0049]Description will be given of a second embodiment of the present invention with the reference to FIG. 6. Since a motor unit of the second embodiment is equivalent to that of the first embodiment in basic structure, corresponding parts are indicated with numbers in the hundreds so as to make clear correspondence between parts and description will be given only of different points.

[0050]An expanded clearance 111a2 open downward in the axial direction is, as shown in FIG. 6, formed in a lower portion in the axial direction of the hollow cylindrical section 111a of the first housing member 111. With the construction adopted, ultraviolet can be irradiated as deeply as the interior, thereby, enabling not only a highly rigid joint with higher precision to be realized, but also tilting of the shaft 121 to be prevented more.

[0051]The second embodiment as well has an action and effect similar to those of the first embodiment.

third embodiment

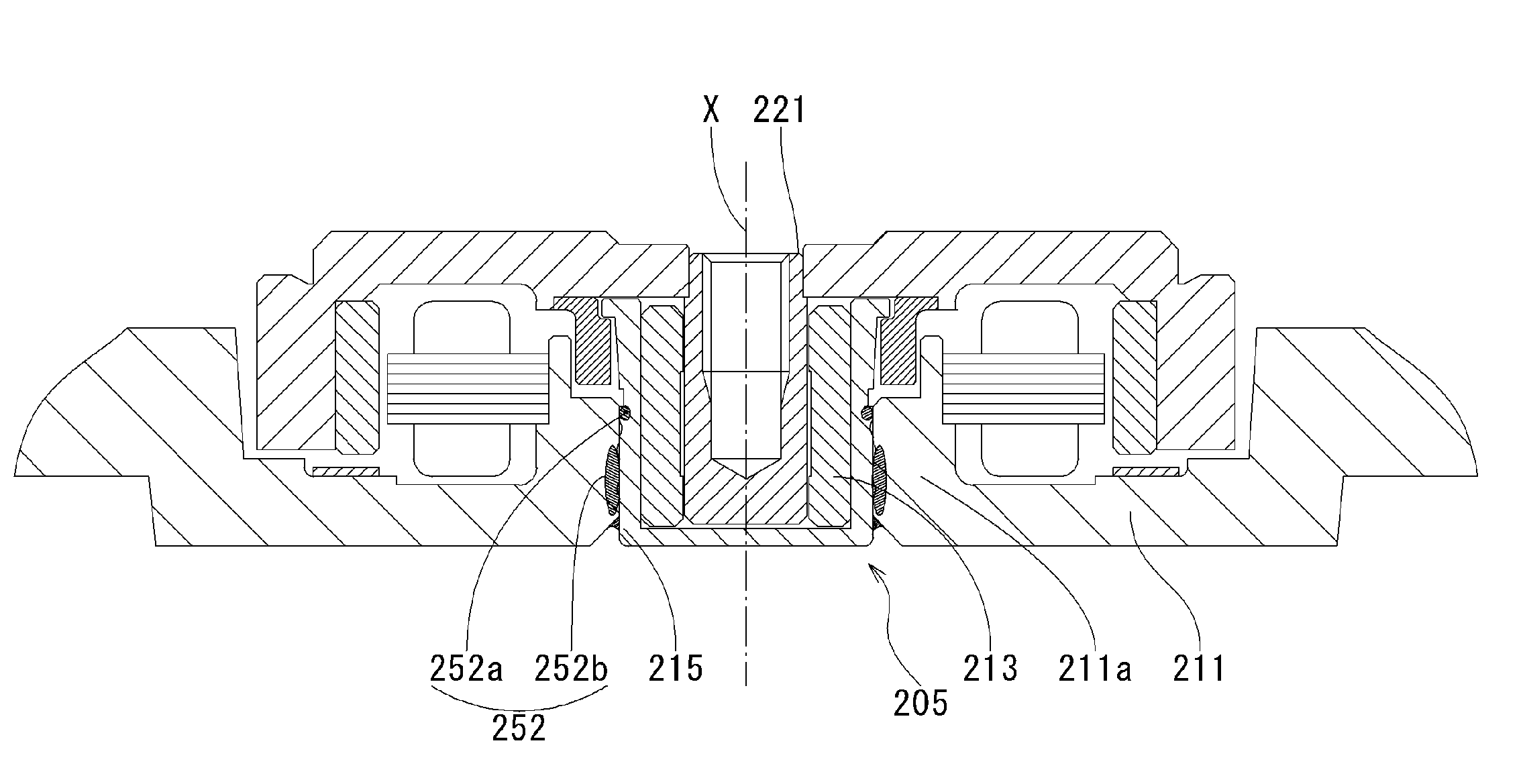

[0052]Description will be given of a third embodiment of the present invention with reference to FIG. 7. Since a motor unit of the third embodiment is equivalent to that of the first embodiment in basic construction, corresponding parts are indicated with numbers in the two hundreds to make clear correspondence between parts and description will be given only of different points.

[0053]A hollow cylindrical section 211a is provided in the middle of a first housing member 211 and a bearing assembly 205 is securely held on an inner circumferential portion of the hollow cylindrical section 211a with an adhesive section 252 interposed therebetween.

[0054]A bearing assembly 205 includes: a bearing holder 215 having a bottomed cylindrical shape; a sleeve 213 press fit in a space surrounded with an inner circumferential portion of the bearing holder 215 and securely held thereon by means such as adhesion; and a shaft 221 facing the inner circumferential portion of the sleeve 213 with a micro ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com