Patents

Literature

171 results about "Outgassing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Outgassing (sometimes called offgassing, particularly when in reference to indoor air quality) is the release of a gas that was dissolved, trapped, frozen, or absorbed in some material. Outgassing can include sublimation and evaporation (which are phase transitions of a substance into a gas), as well as desorption, seepage from cracks or internal volumes, and gaseous products of slow chemical reactions. Boiling is generally thought of as a separate phenomenon from outgassing because it consists of a phase transition of a liquid into a vapor of the same substance.

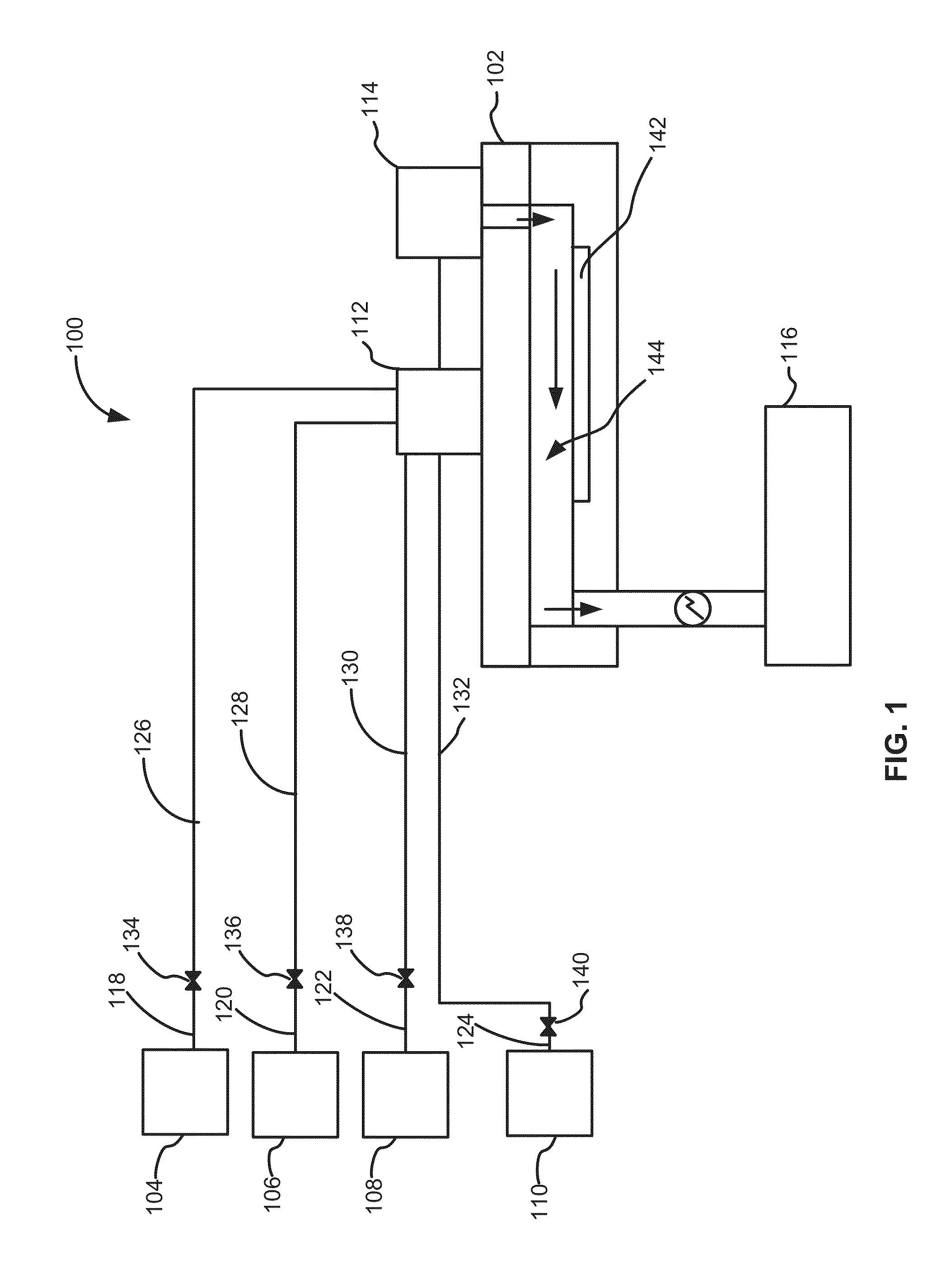

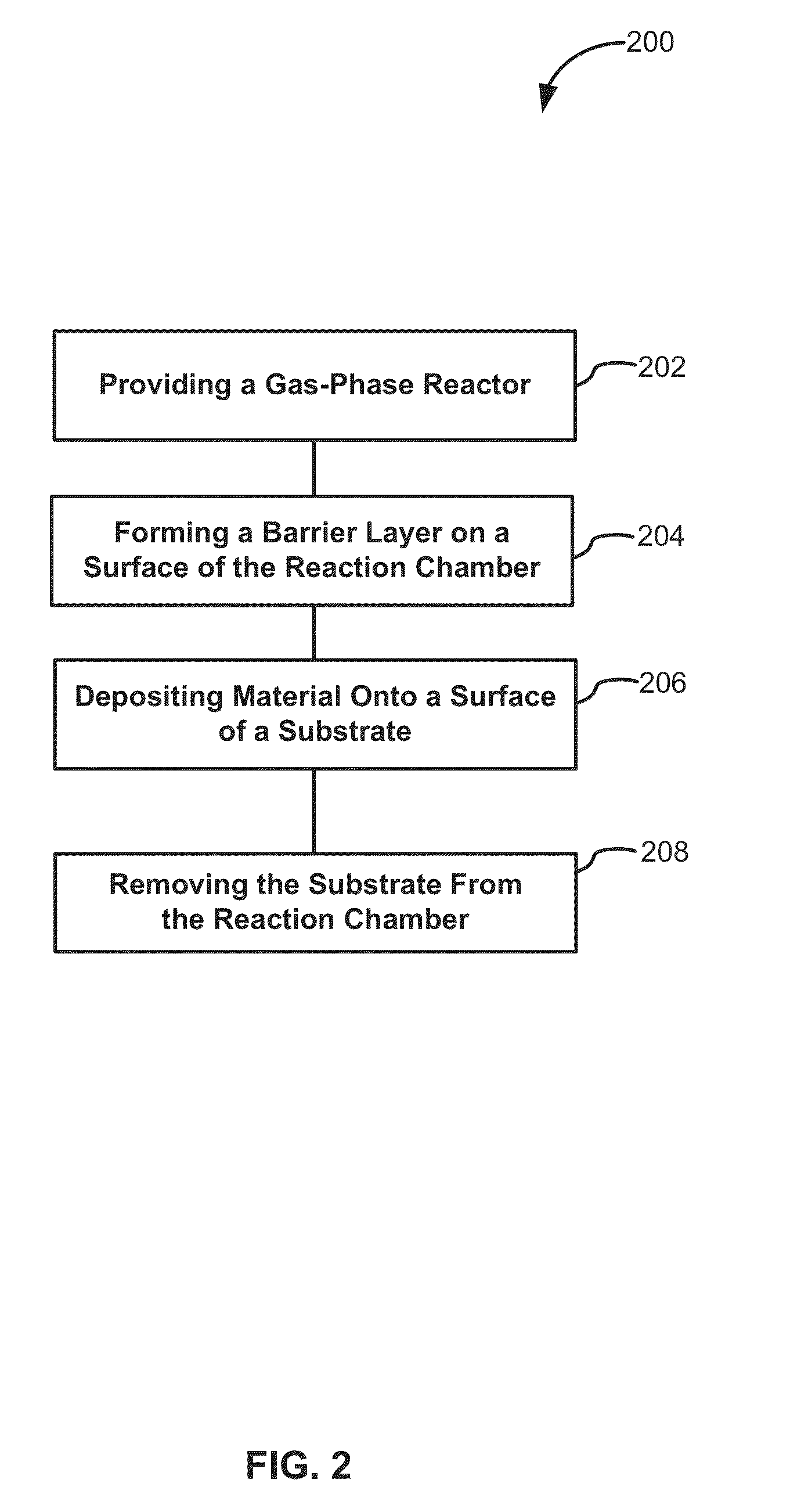

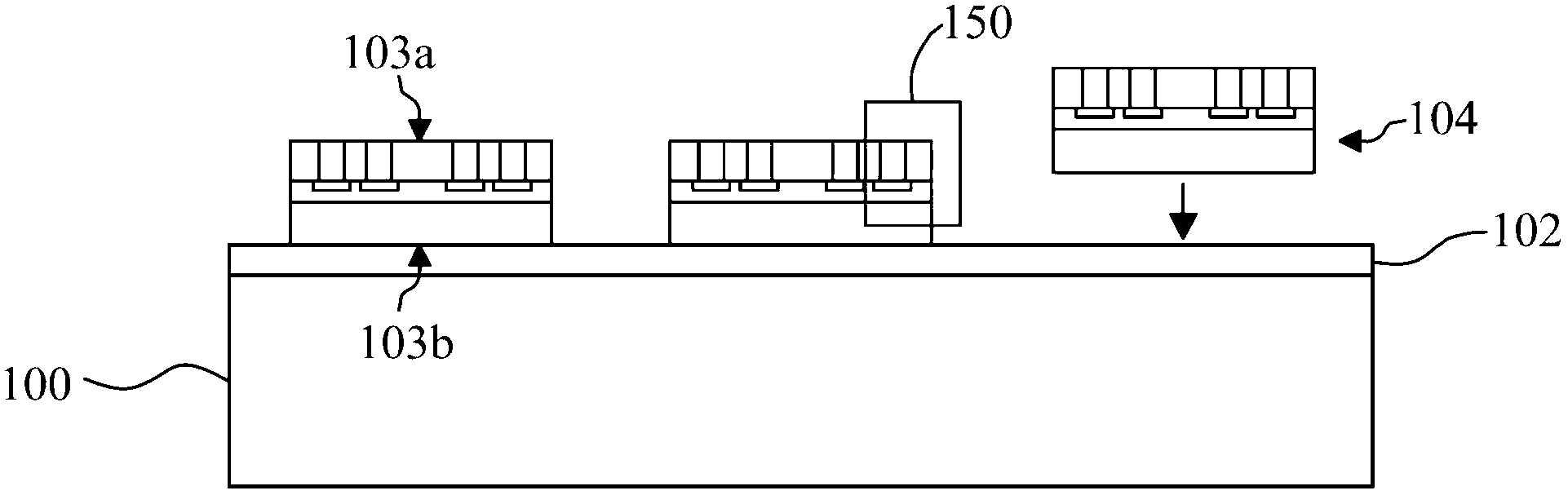

Method and system to reduce outgassing in a reaction chamber

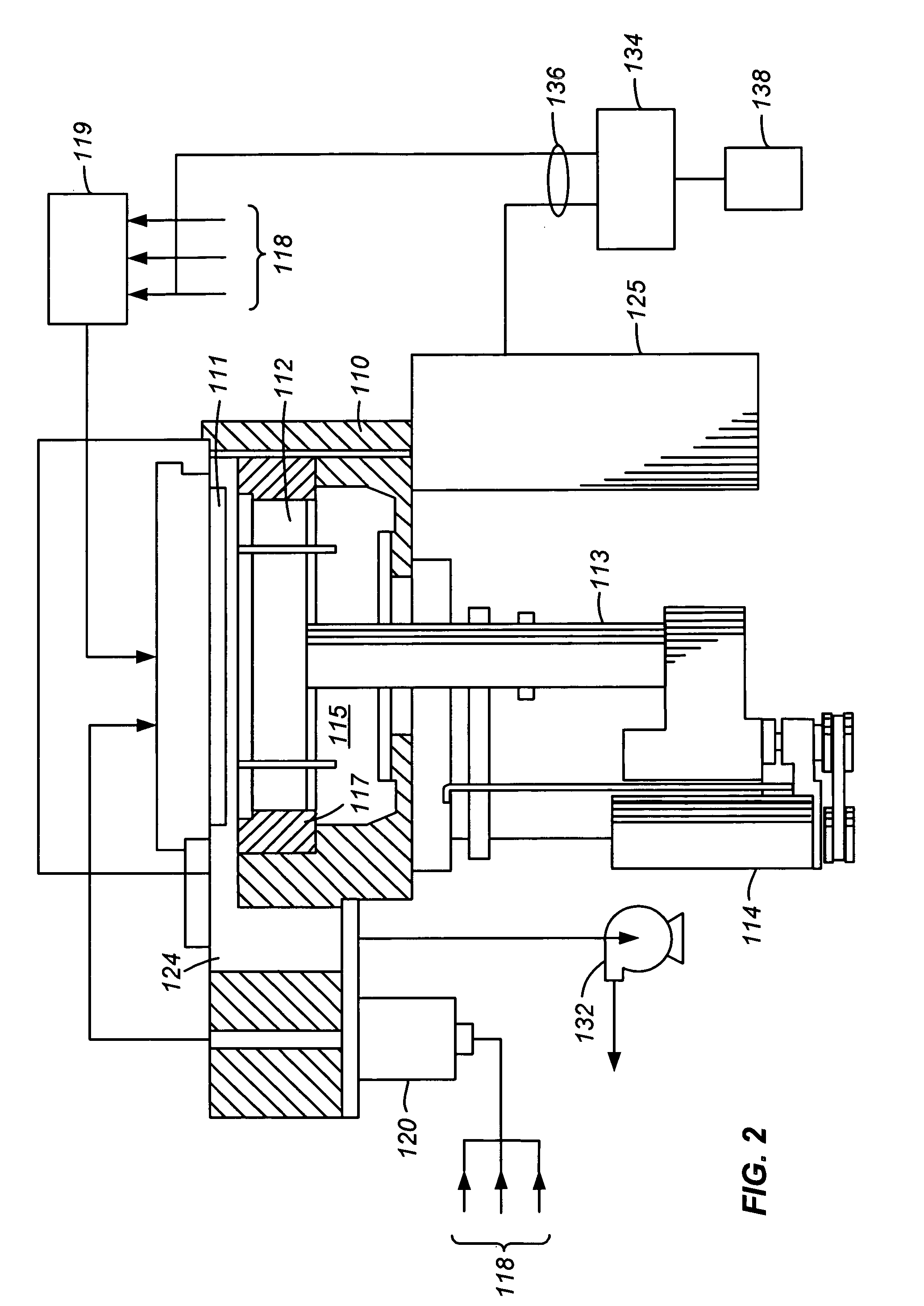

ActiveUS20150140210A1Reduce outgassingImprove thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingOutgassingGas phase

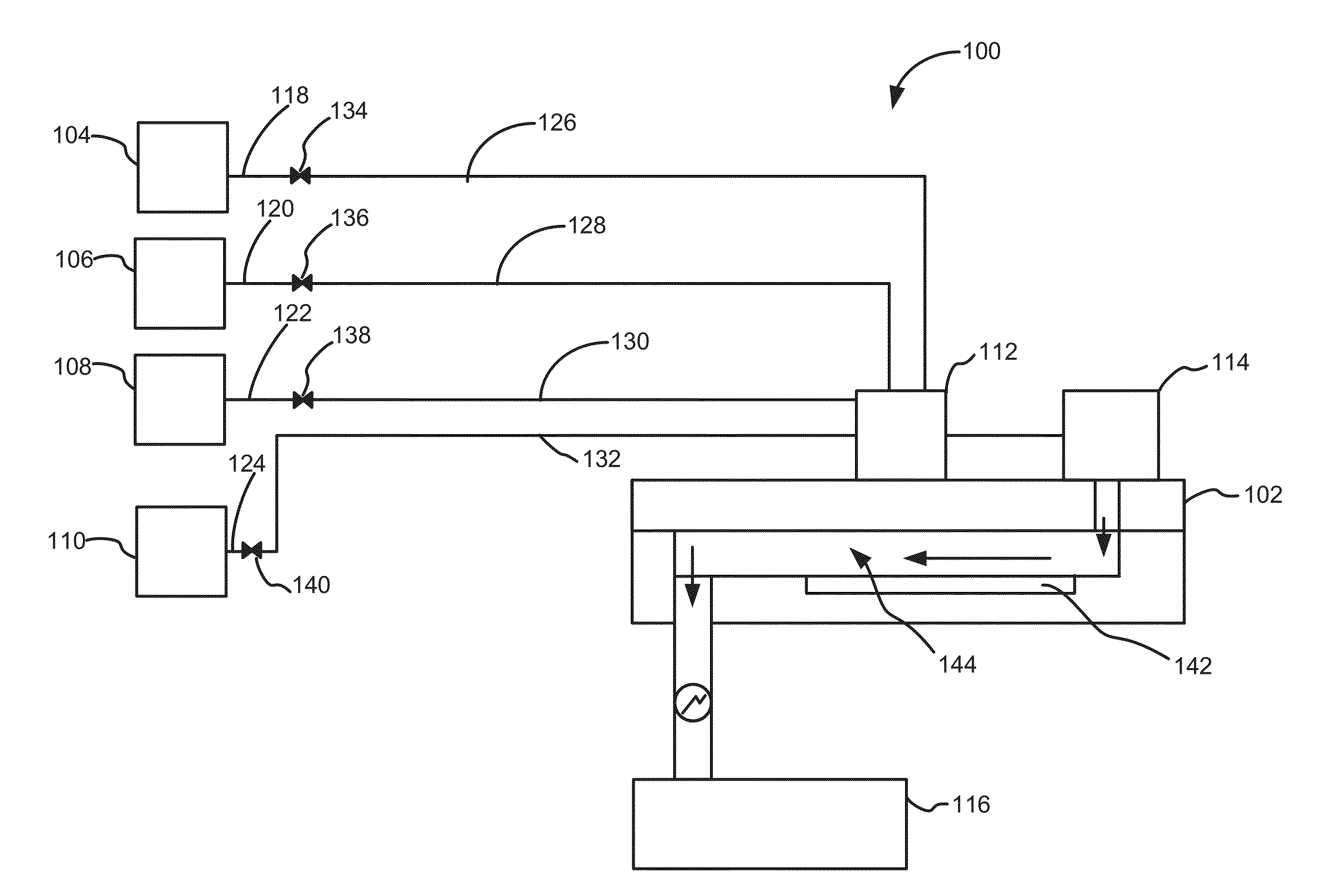

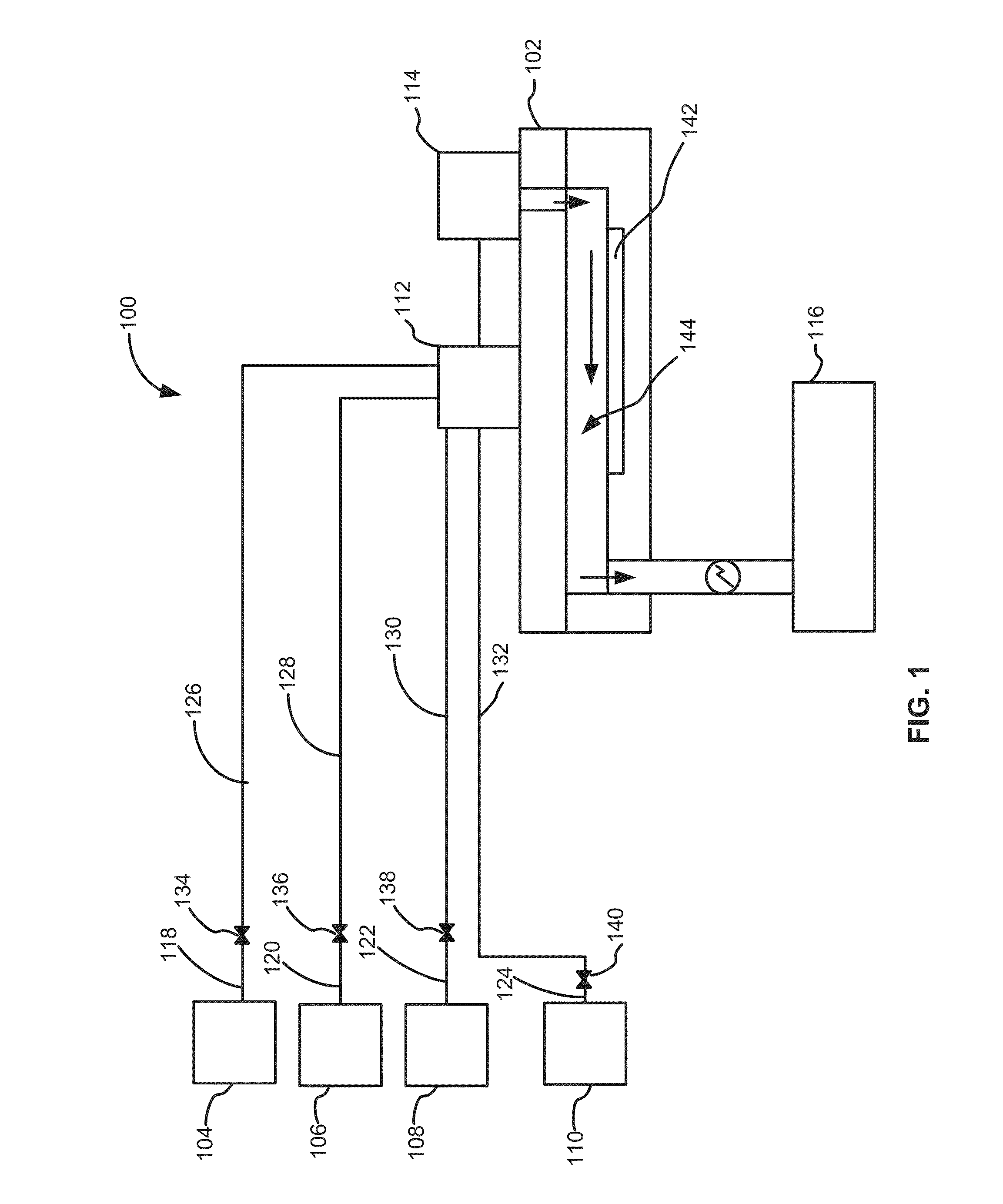

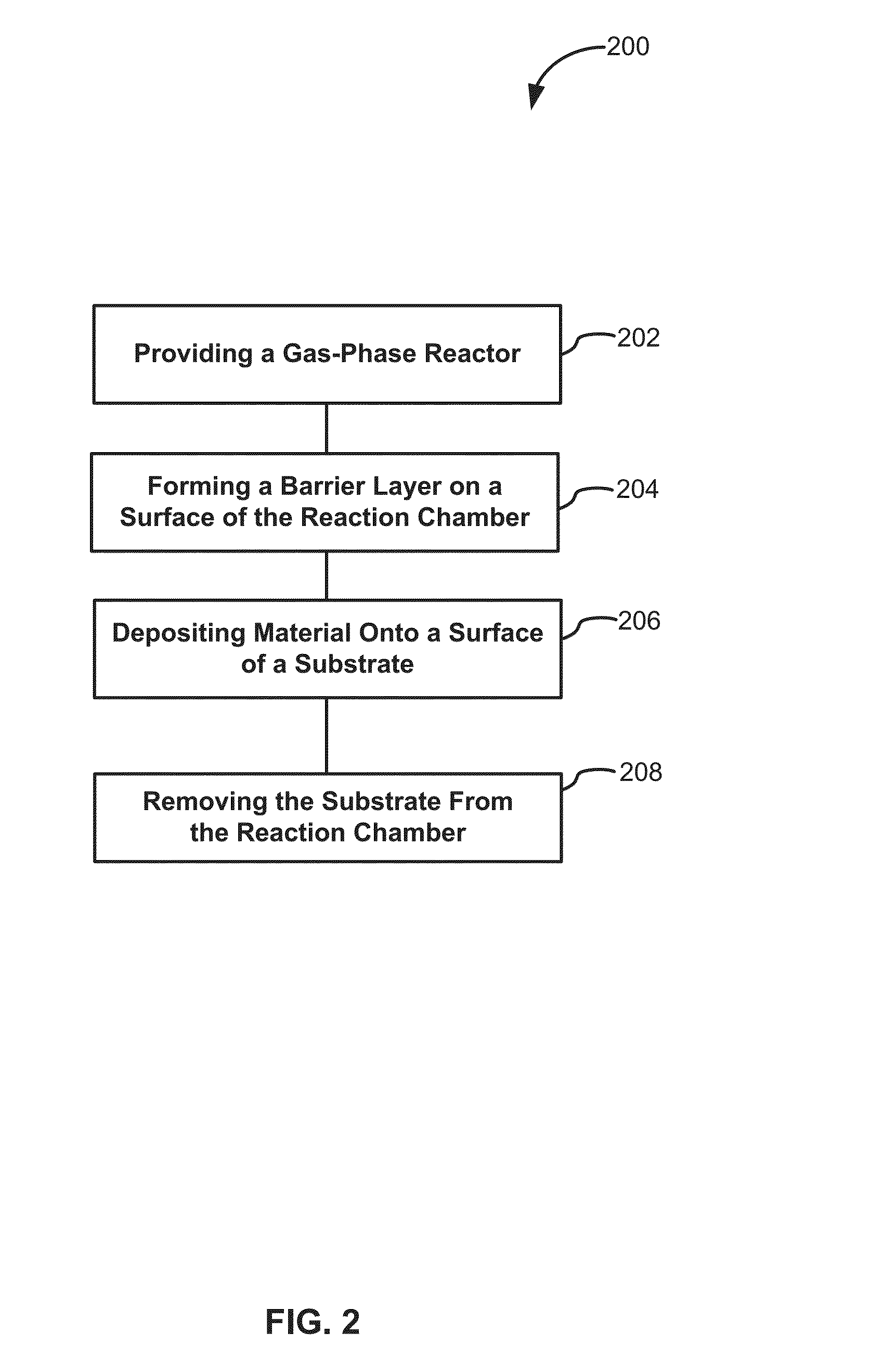

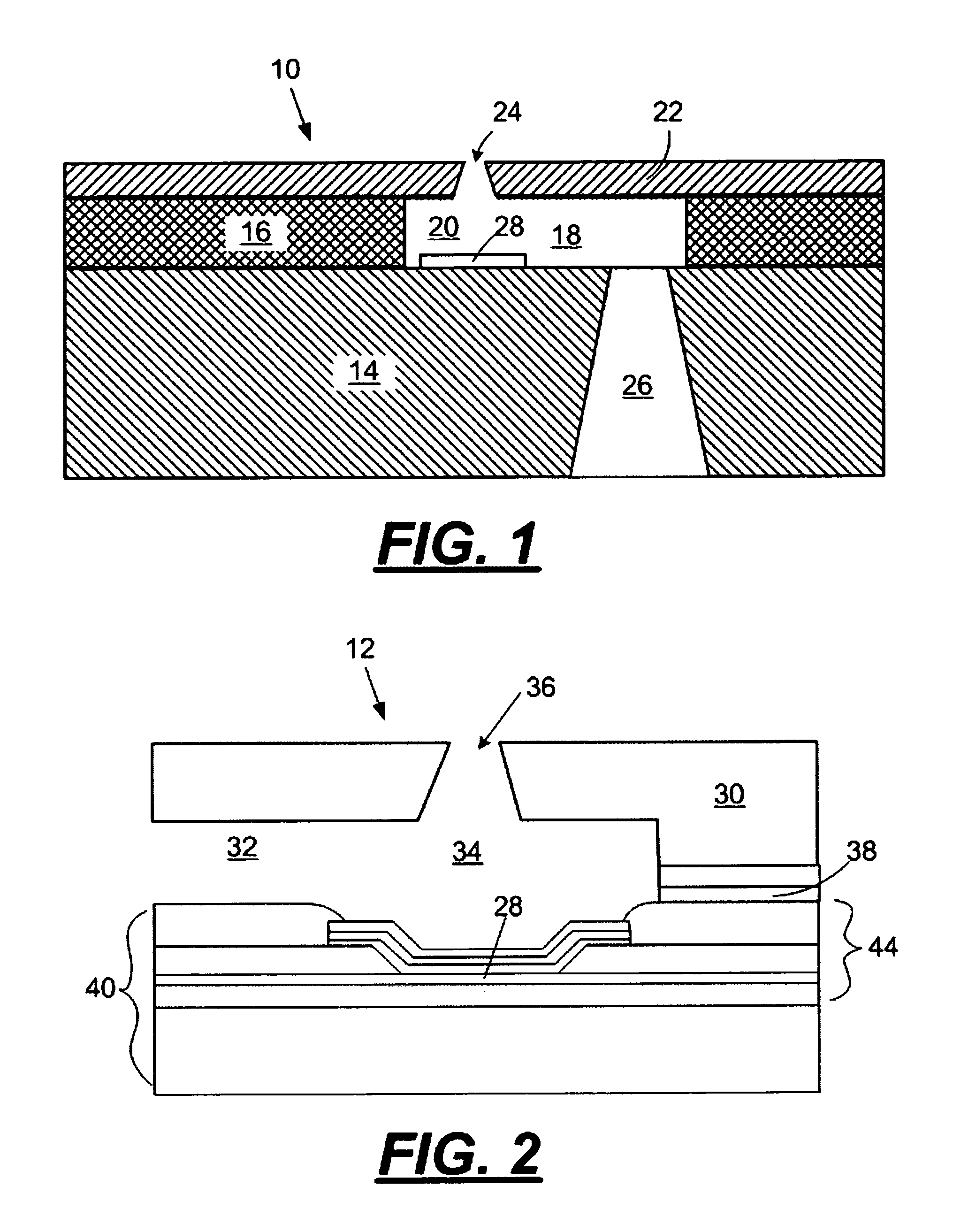

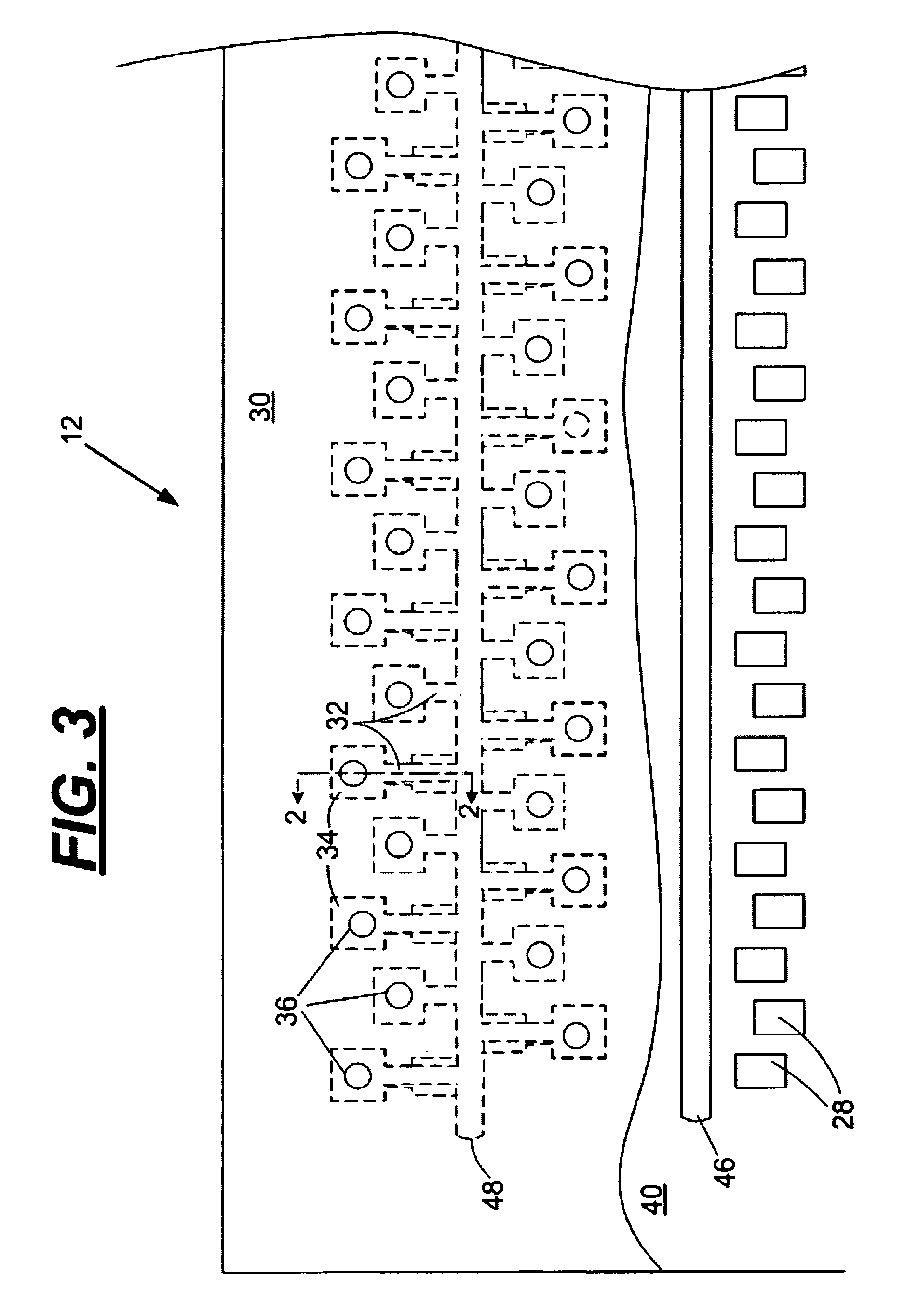

Systems and methods of reducing outgassing of a substance within a reaction chamber of a reactor are disclosed. Exemplary methods include depositing a barrier layer within the reaction chamber and using a scavenging precursor to react with species on a surface of the reaction chamber. Exemplary systems include gas-phase deposition systems, such as atomic layer deposition systems, which include a barrier layer source and / or a scavenging precursor source fluidly coupled to a reaction chamber of the system.

Owner:ASM IP HLDG BV

Method and system to reduce outgassing in a reaction chamber

ActiveUS8993054B2Reduce outgassingImprove thickness uniformityChemical vapor deposition coatingSemiconductor/solid-state device manufacturingGas phaseOutgassing

Systems and methods of reducing outgassing of a substance within a reaction chamber of a reactor are disclosed. Exemplary methods include depositing a barrier layer within the reaction chamber and using a scavenging precursor to react with species on a surface of the reaction chamber. Exemplary systems include gas-phase deposition systems, such as atomic layer deposition systems, which include a barrier layer source and / or a scavenging precursor source fluidly coupled to a reaction chamber of the system.

Owner:ASM IP HLDG BV

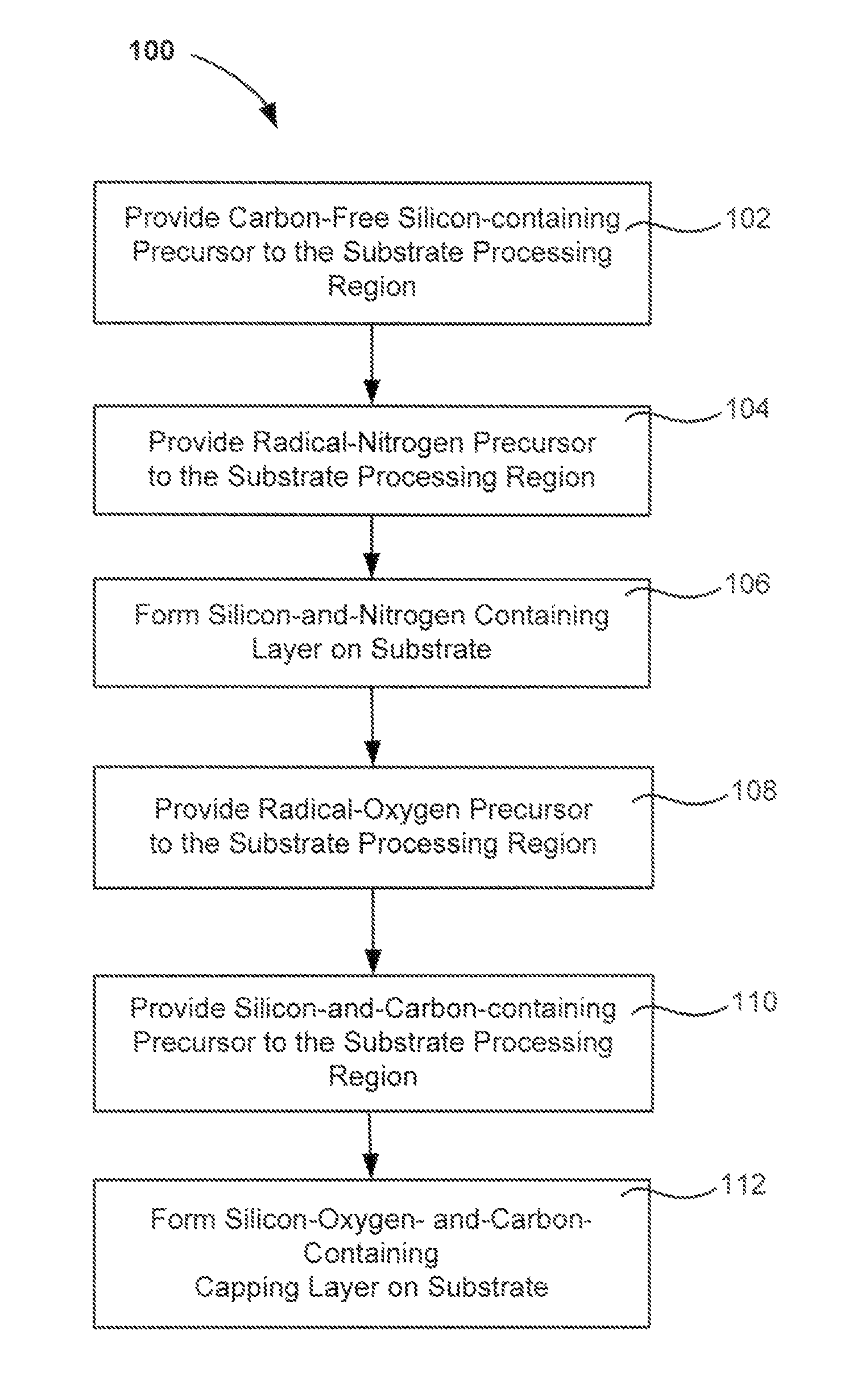

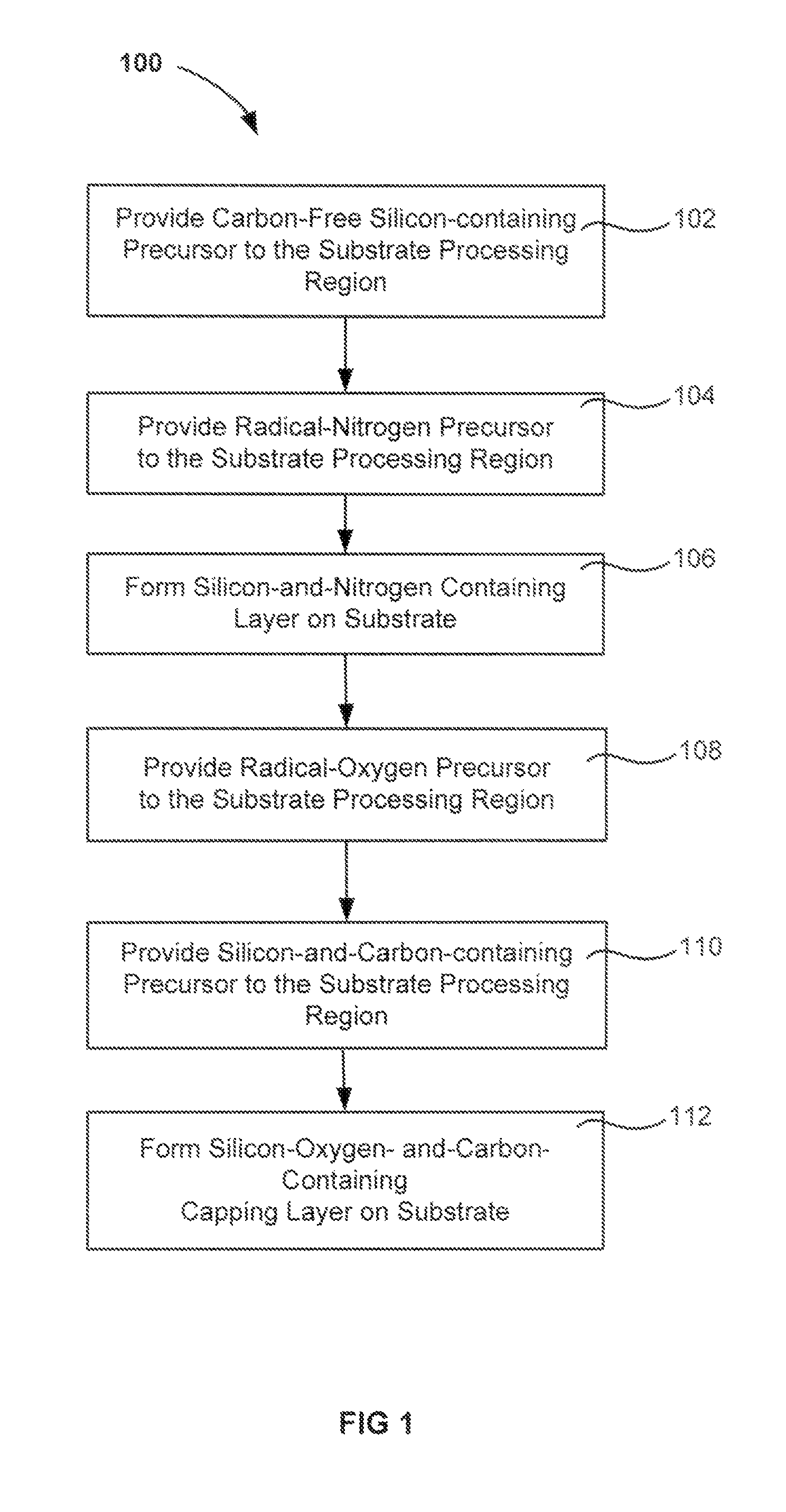

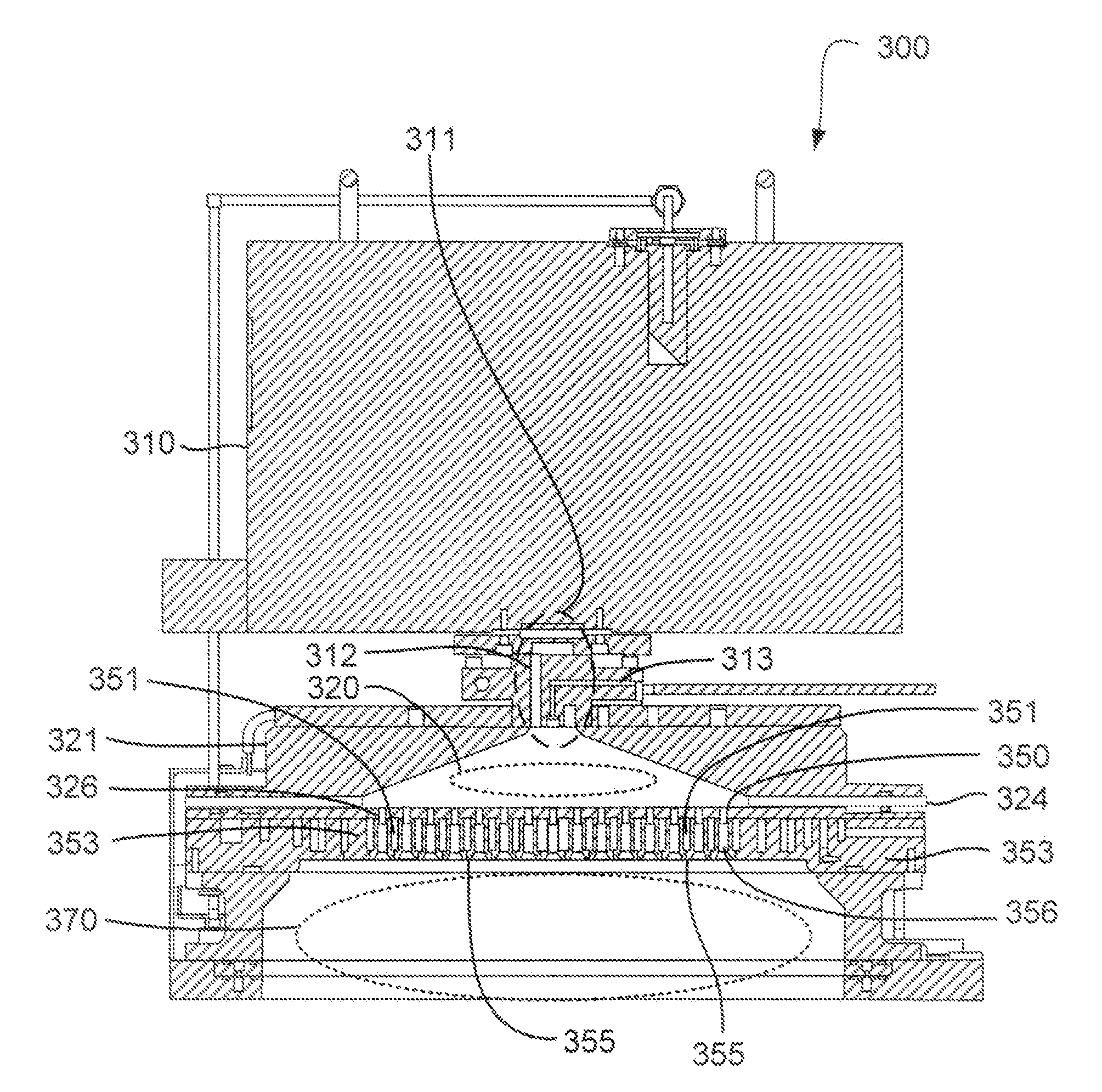

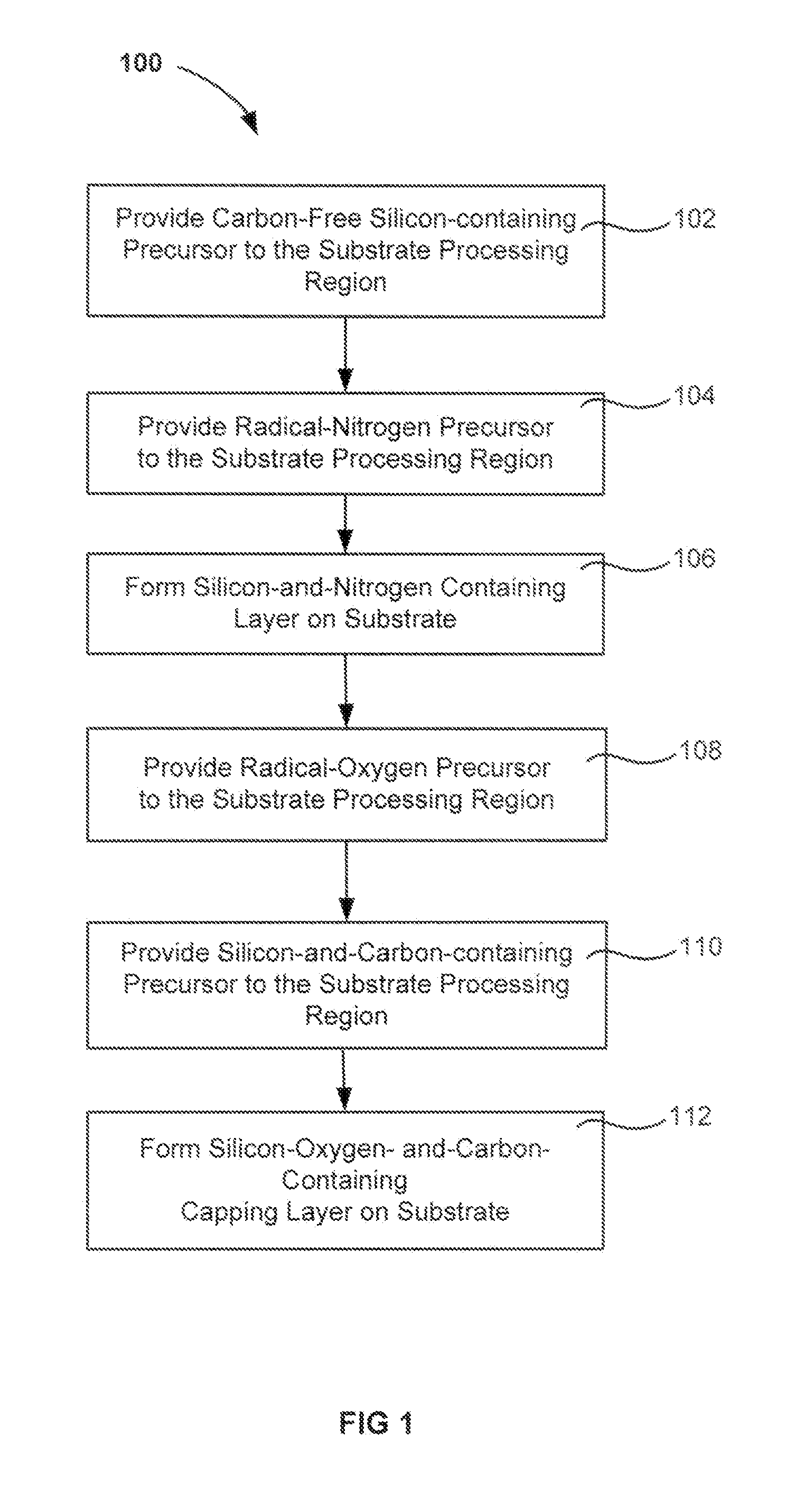

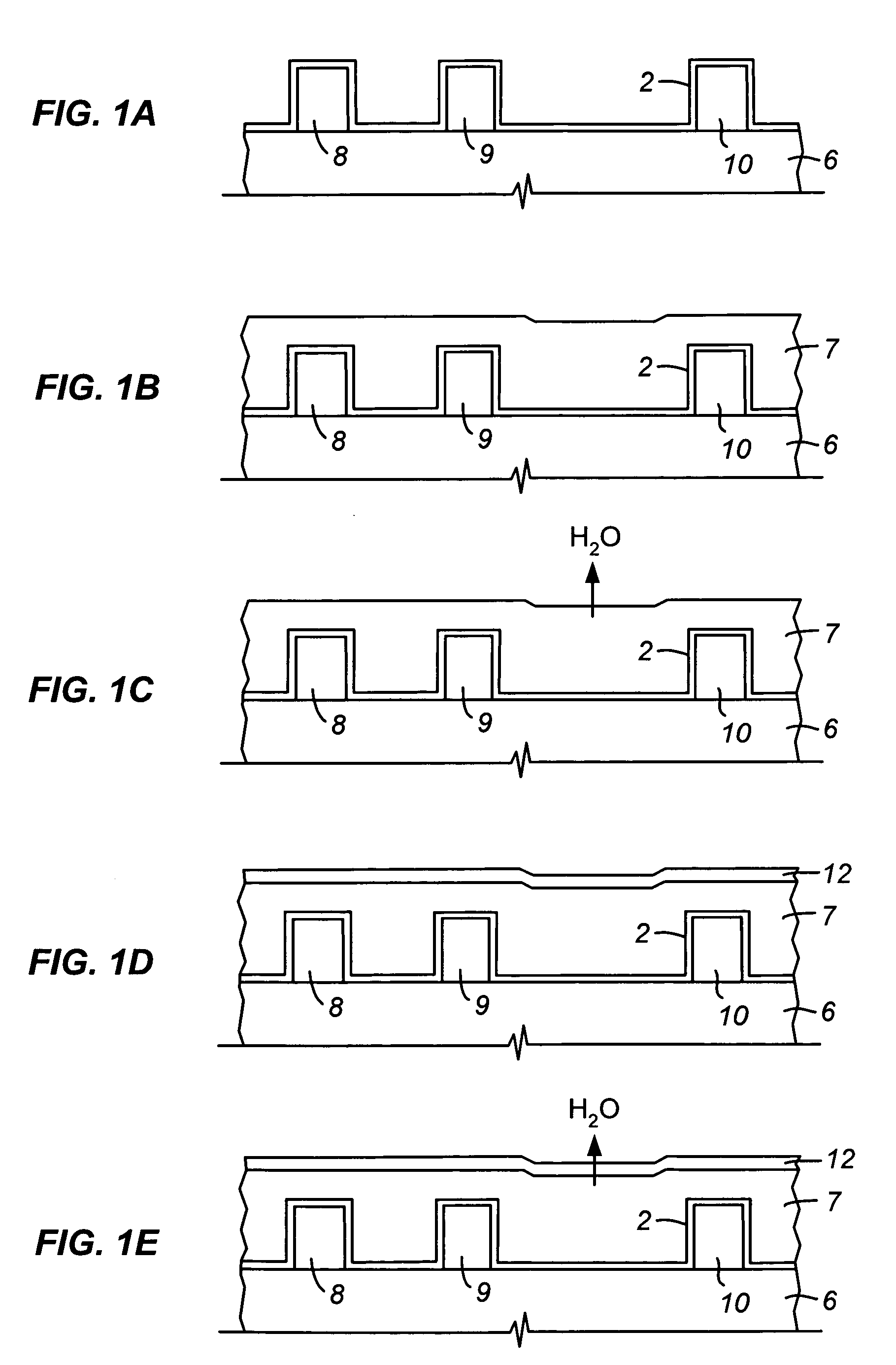

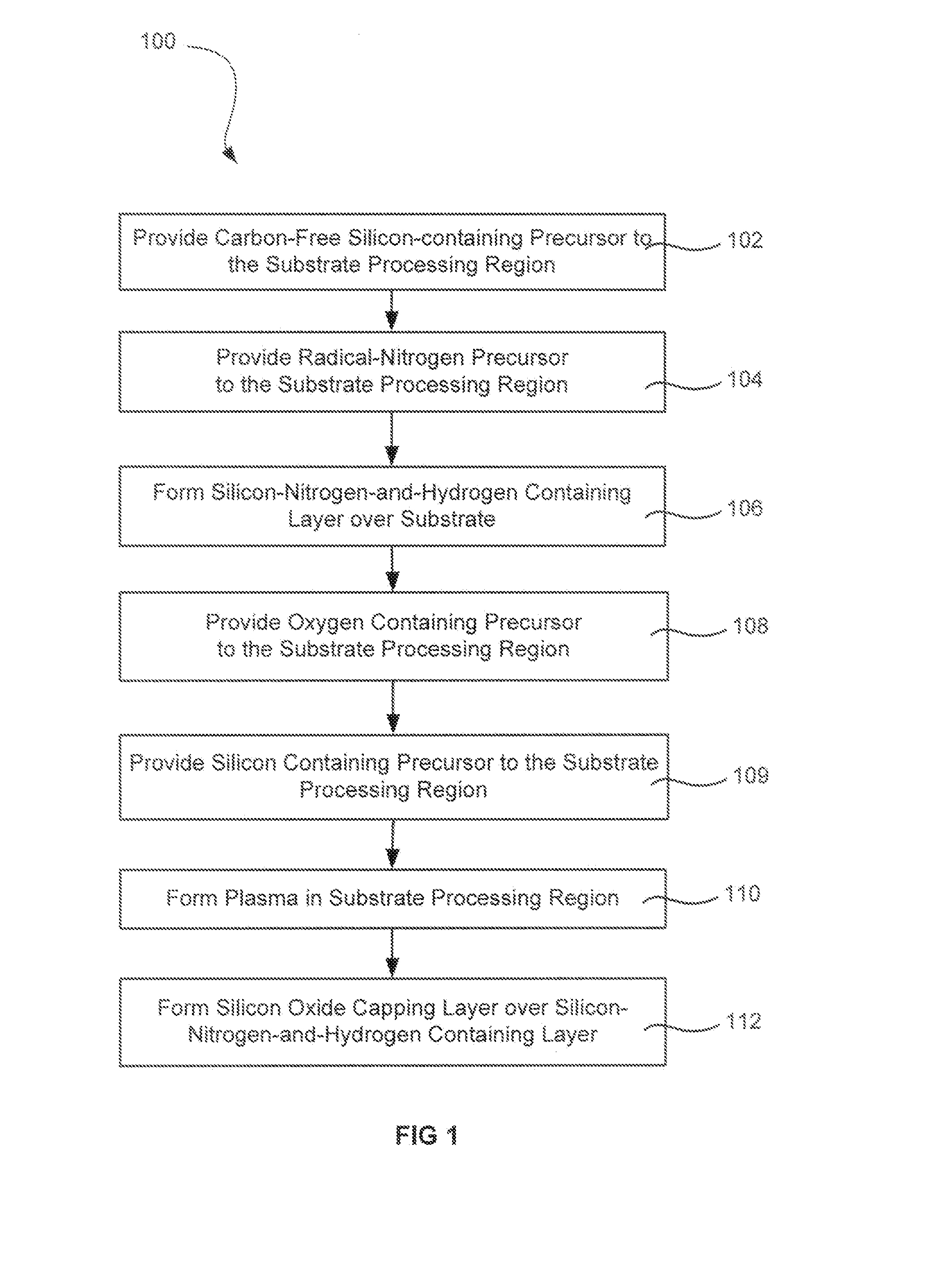

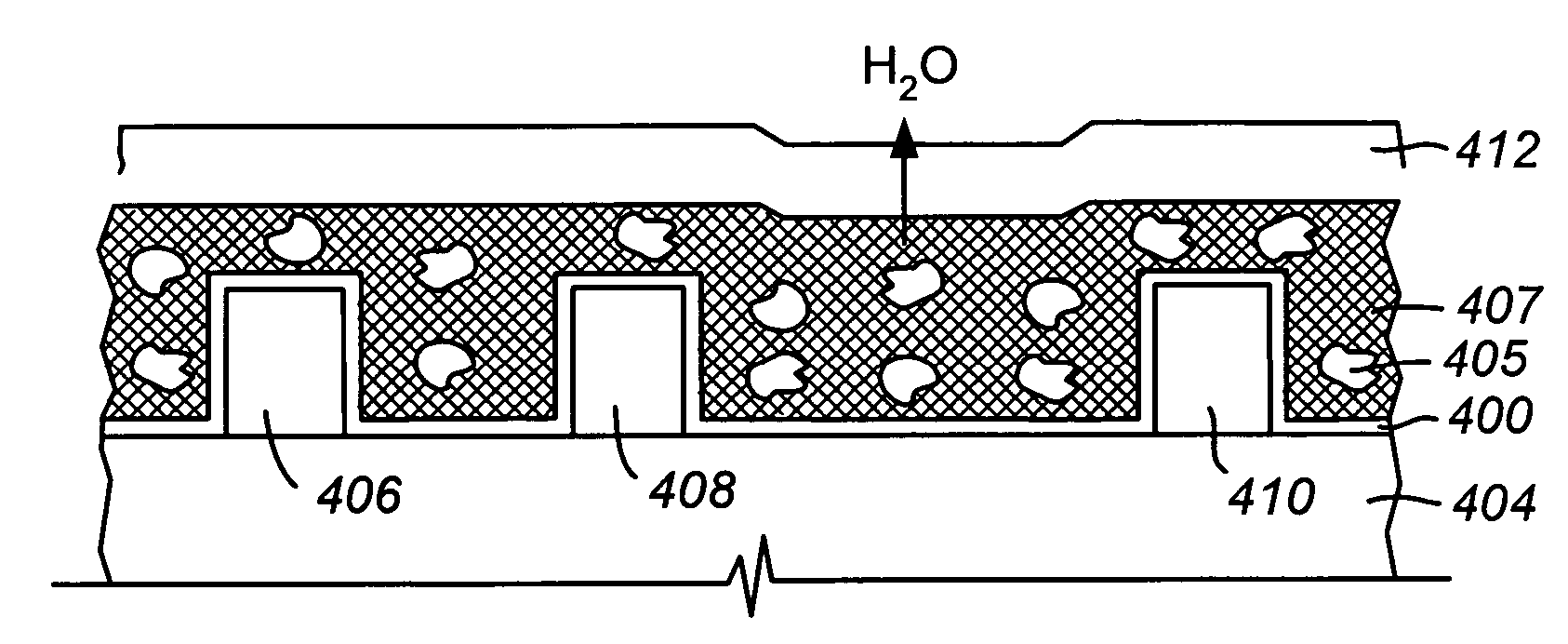

Capping layer for reduced outgassing

InactiveUS8466073B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaHydrogen

A method of forming a silicon oxide layer is described. The method first deposits a silicon-nitrogen-and-hydrogen-containing (polysilazane) film by radical-component chemical vapor deposition (CVD). The silicon-nitrogen-and-hydrogen-containing film is formed by combining a radical precursor (excited in a remote plasma) with an unexcited carbon-free silicon precursor. A capping layer is formed over the silicon-nitrogen-and-hydrogen-containing film to avoid time-evolution of underlying film properties prior to conversion into silicon oxide. The capping layer is formed by combining a radical oxygen precursor (excited in a remote plasma) with an unexcited silicon-and-carbon-containing-precursor. The films are converted to silicon oxide by exposure to oxygen-containing environments. The two films may be deposited within the same substrate processing chamber and may be deposited without breaking vacuum.

Owner:APPLIED MATERIALS INC

Capping layer for reduced outgassing

InactiveUS20120309205A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaHydrogen

Owner:APPLIED MATERIALS INC

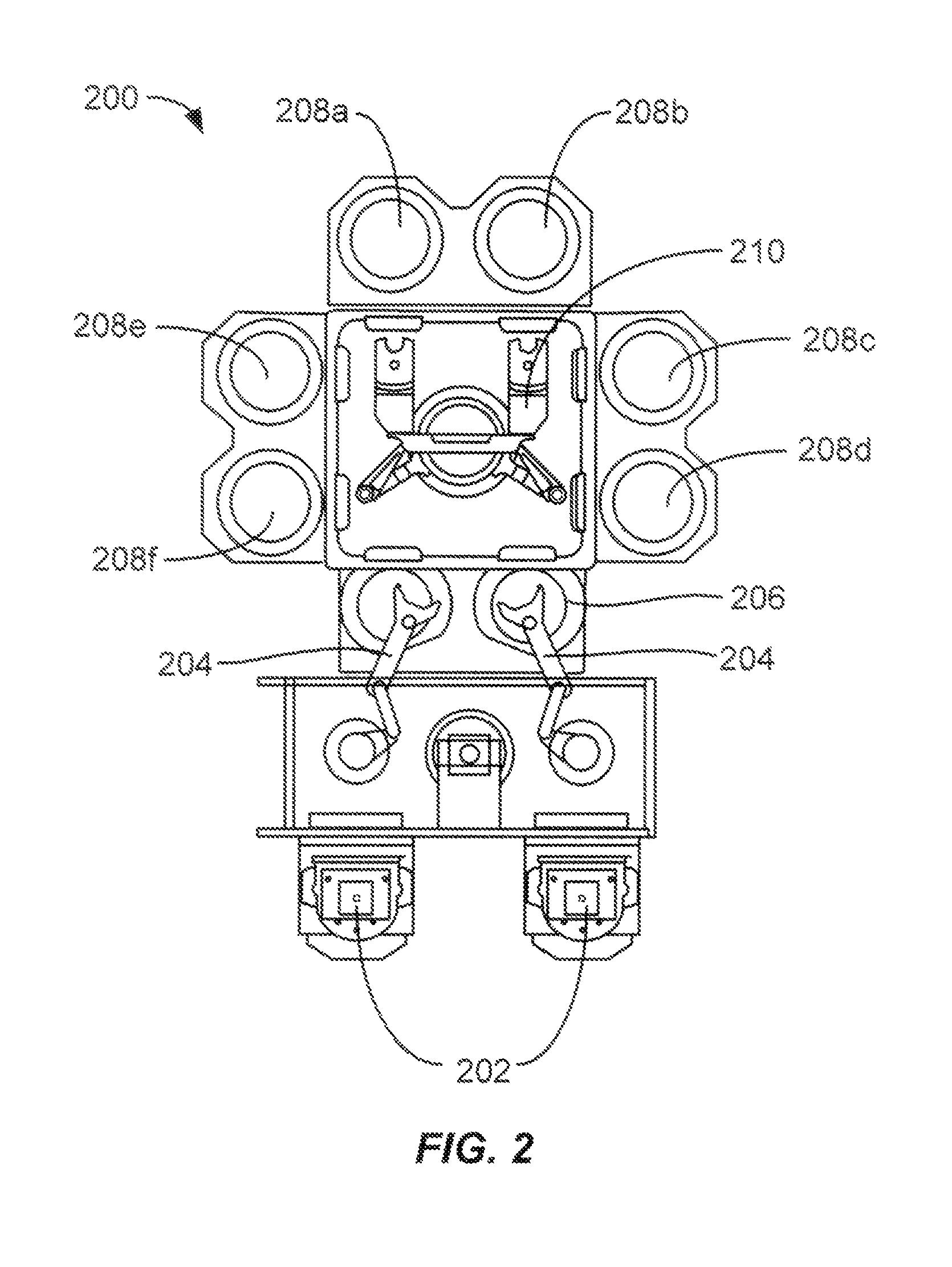

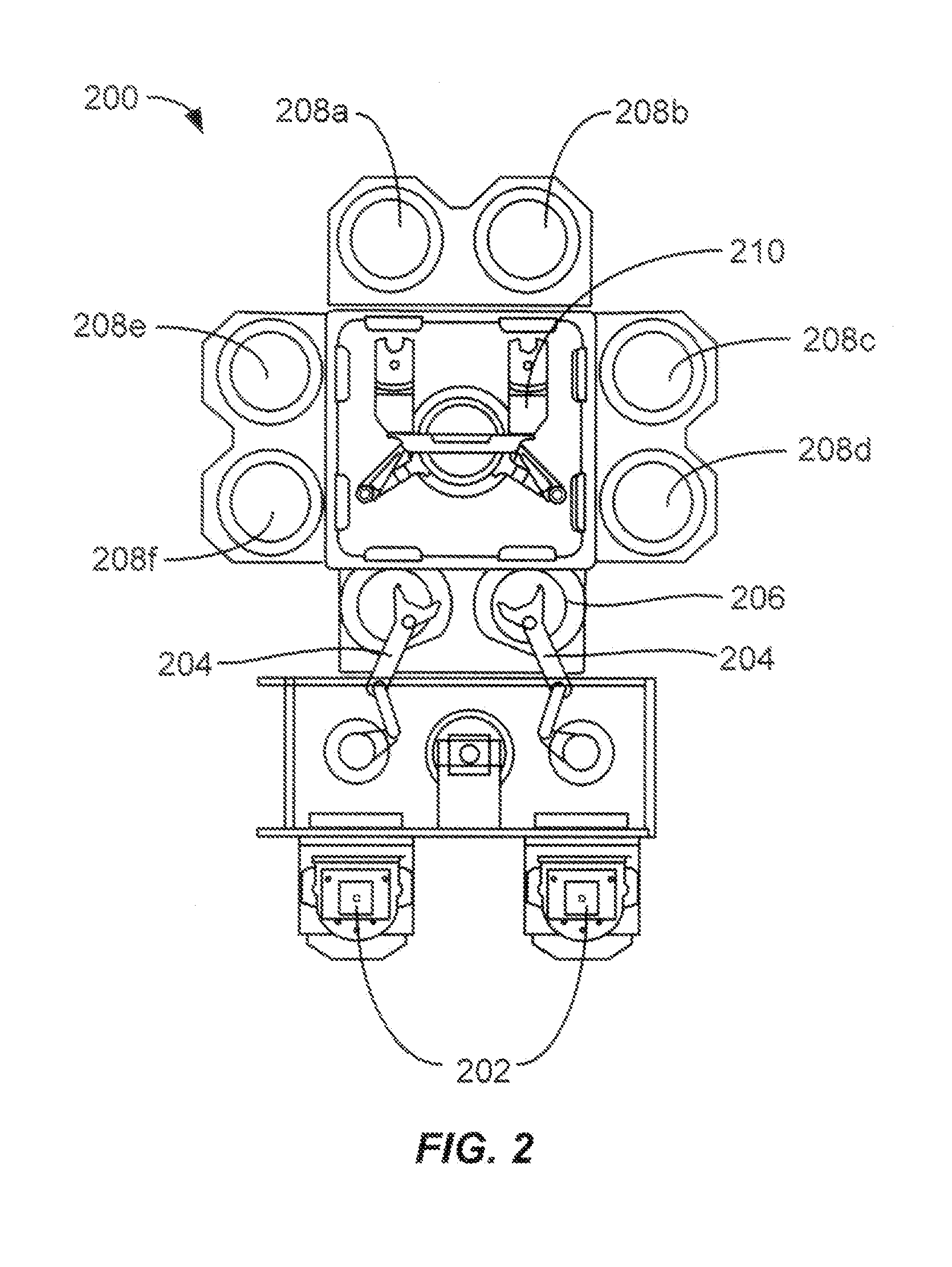

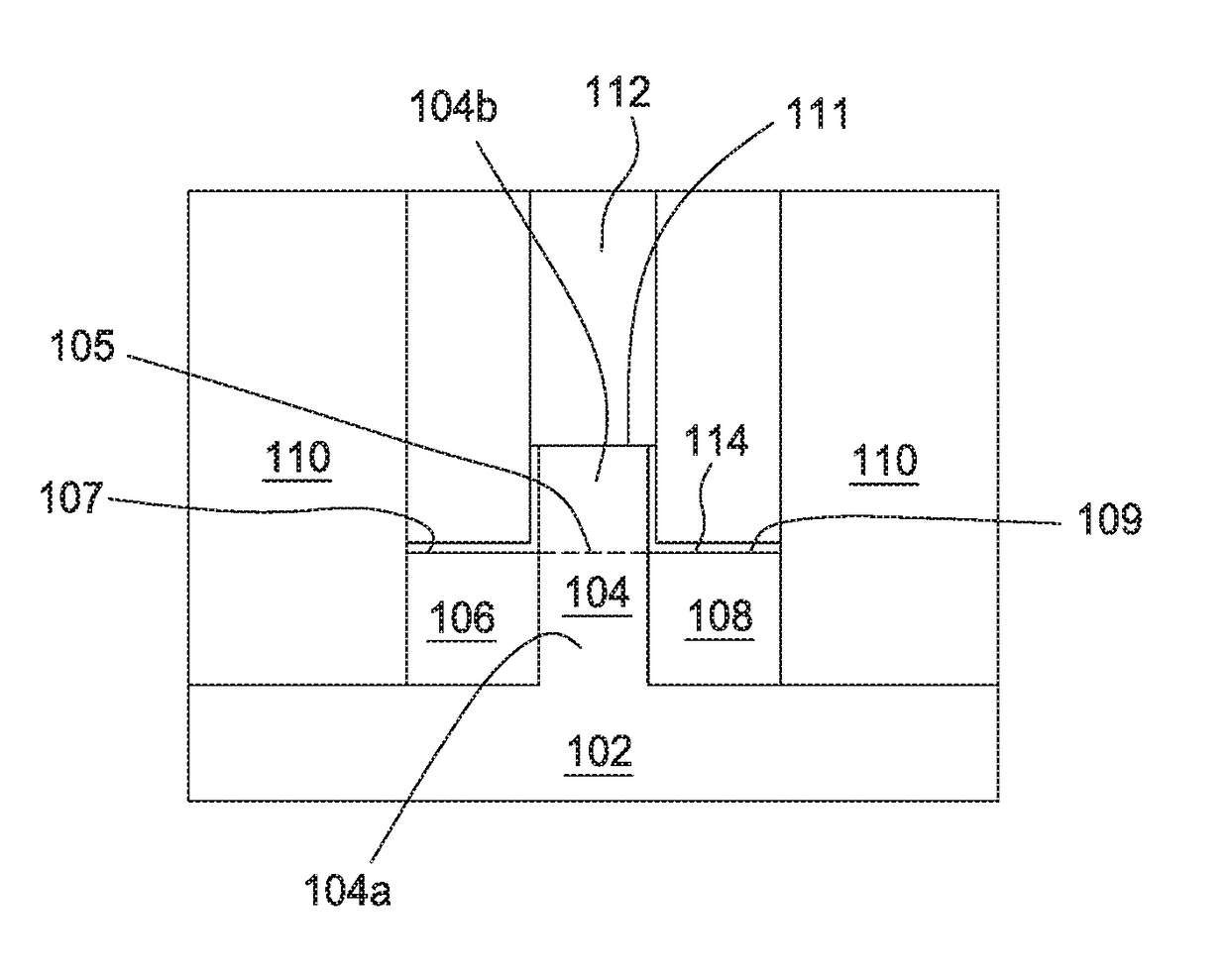

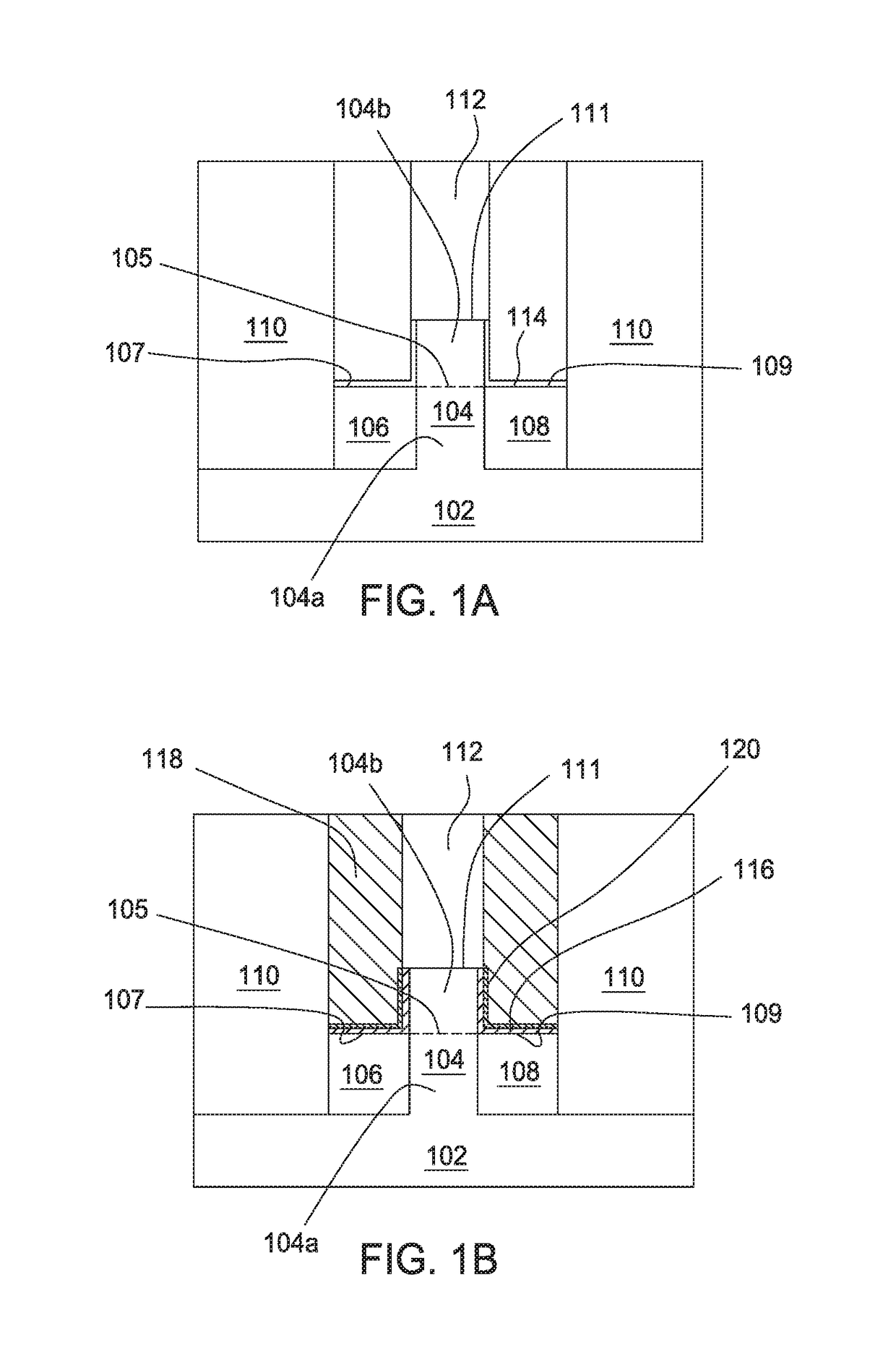

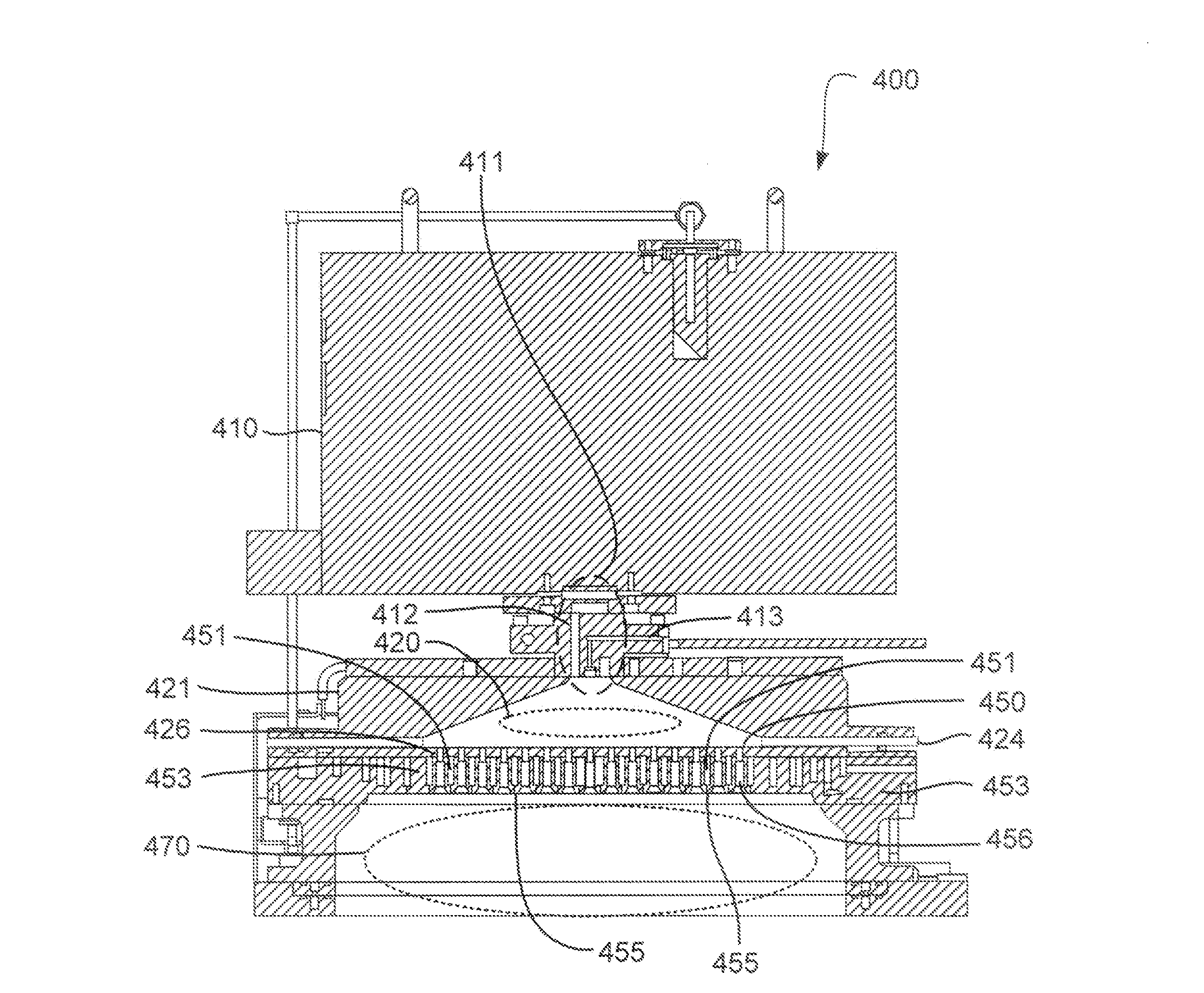

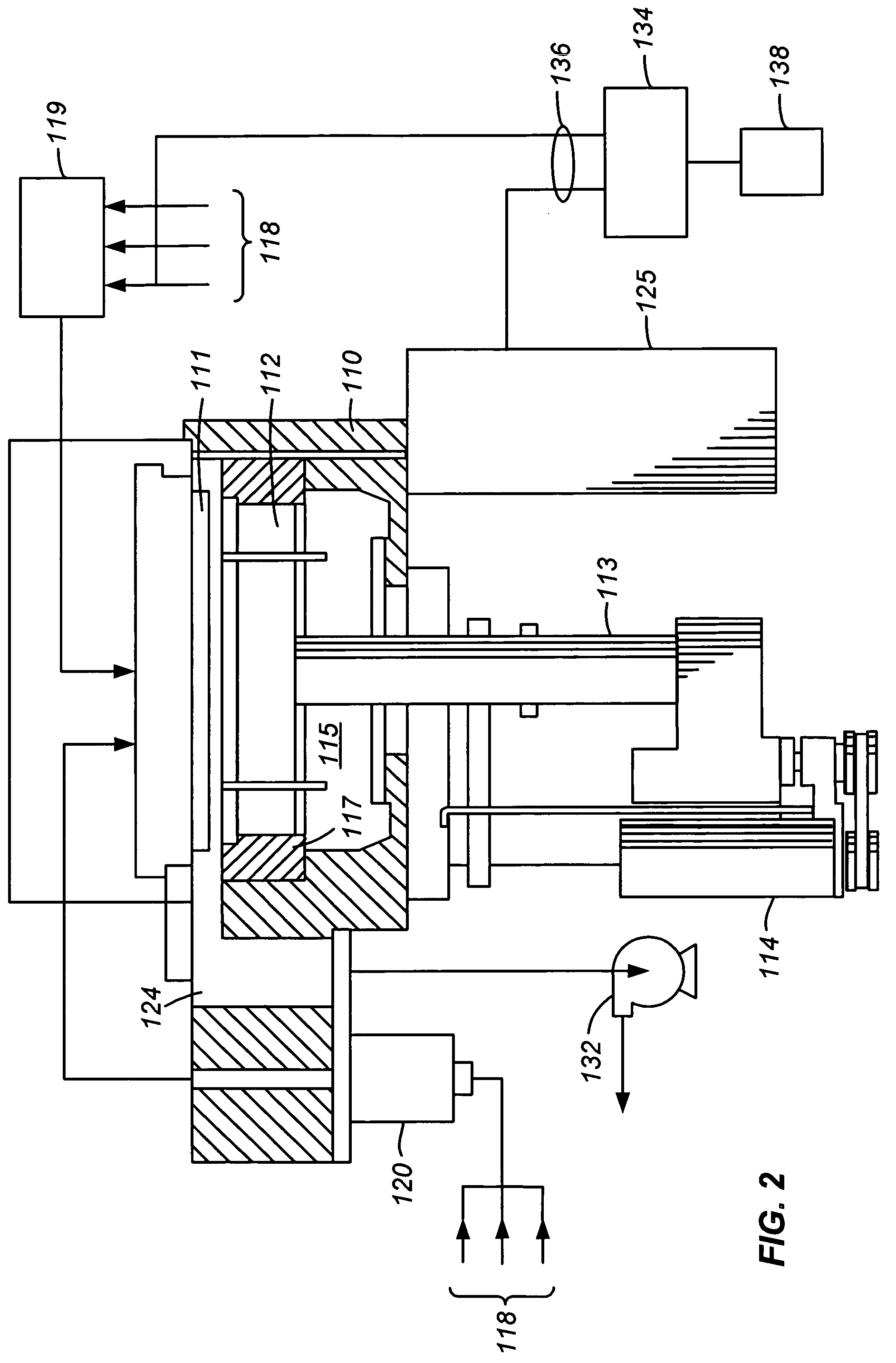

Integrated method for wafer outgassing reduction

Implementations disclosed herein relate to methods for controlling substrate outgassing. In one implementation, the method includes removing oxides from an exposed surface of a substrate in an inductively coupled plasma chamber, forming an epitaxial layer on the exposed surface of the substrate in an epitaxial deposition chamber, and performing an outgassing control of the substrate by subjecting the substrate to a first plasma formed from a first etch precursor in the inductively coupled plasma chamber at a first chamber pressure, wherein the first etch precursor comprises a hydrogen-containing precursor, a chlorine-containing precursor, and an inert gas, and subjecting the substrate to a second plasma formed from a second etch precursor in the inductively coupled plasma chamber at a second chamber pressure that is higher than the first chamber pressure, wherein the second etch precursor comprises a hydrogen-containing precursor and an inert gas.

Owner:APPLIED MATERIALS INC

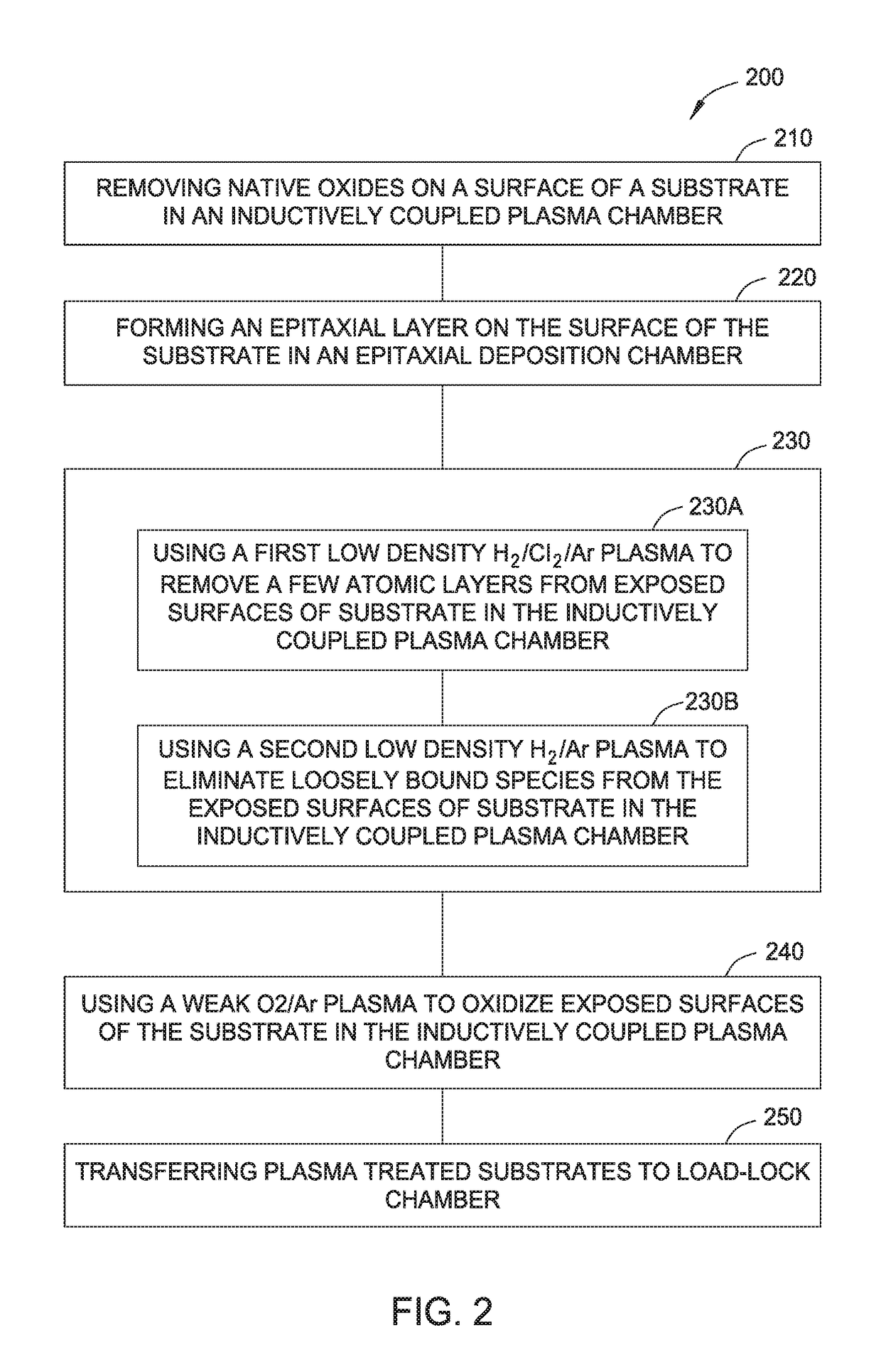

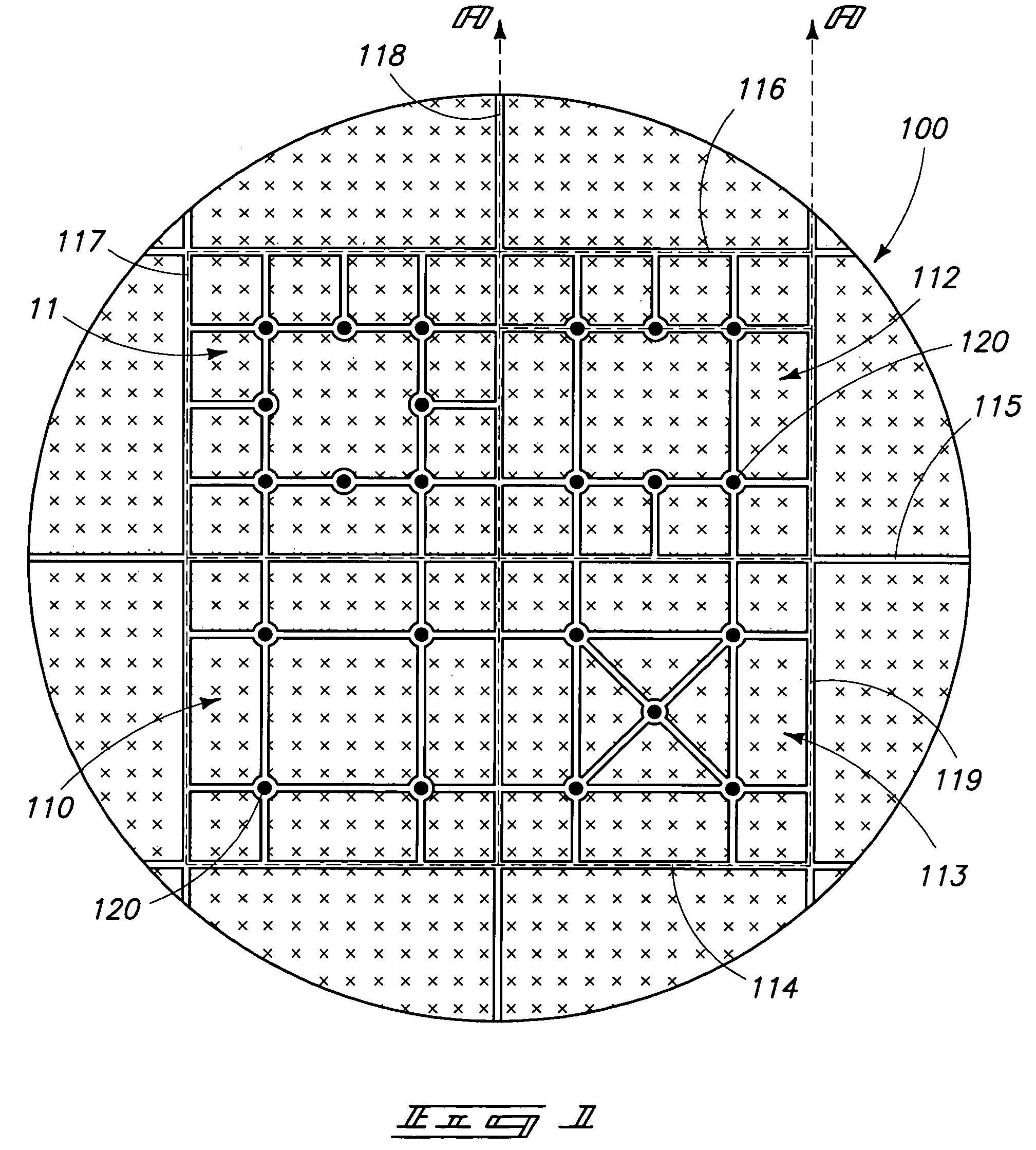

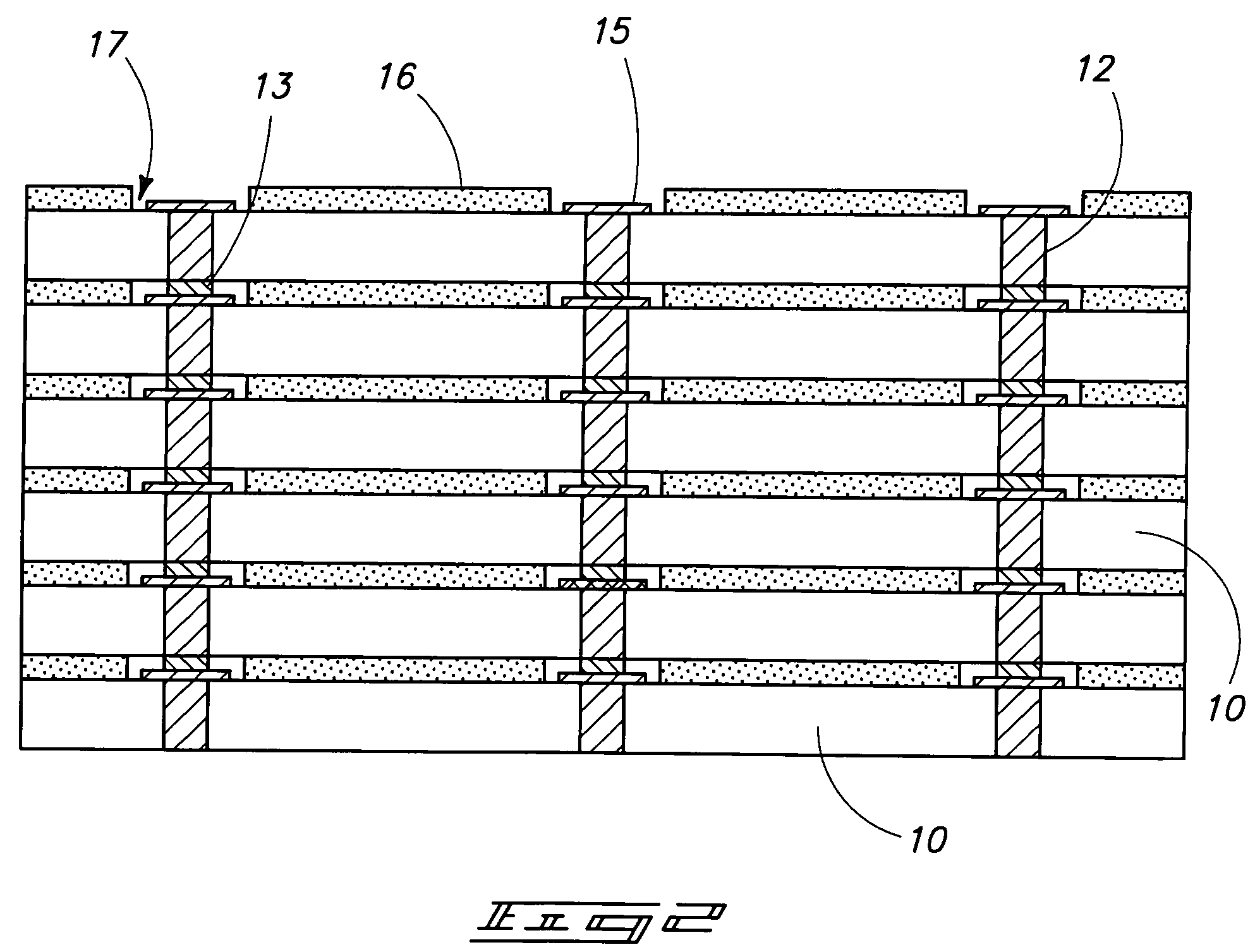

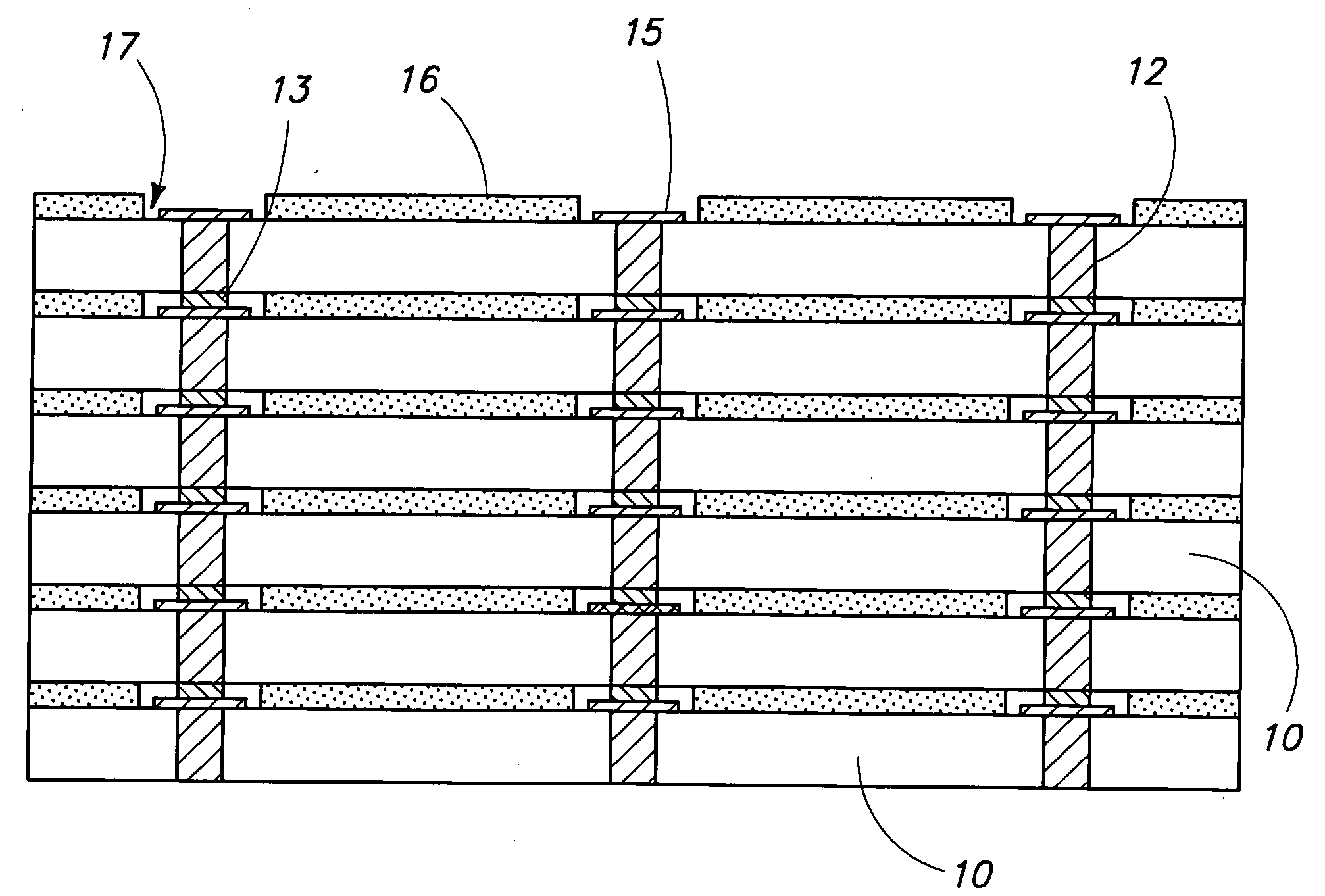

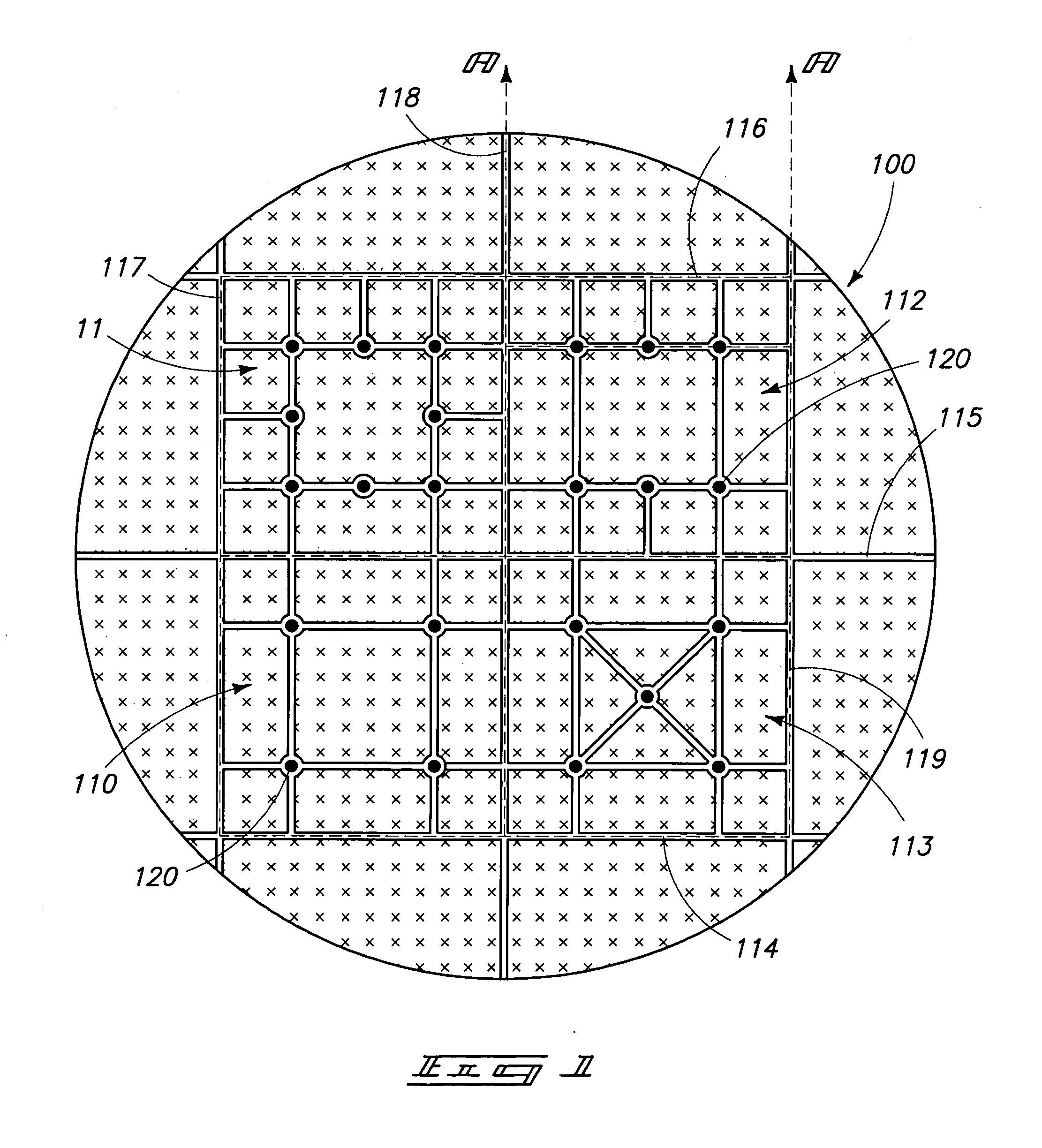

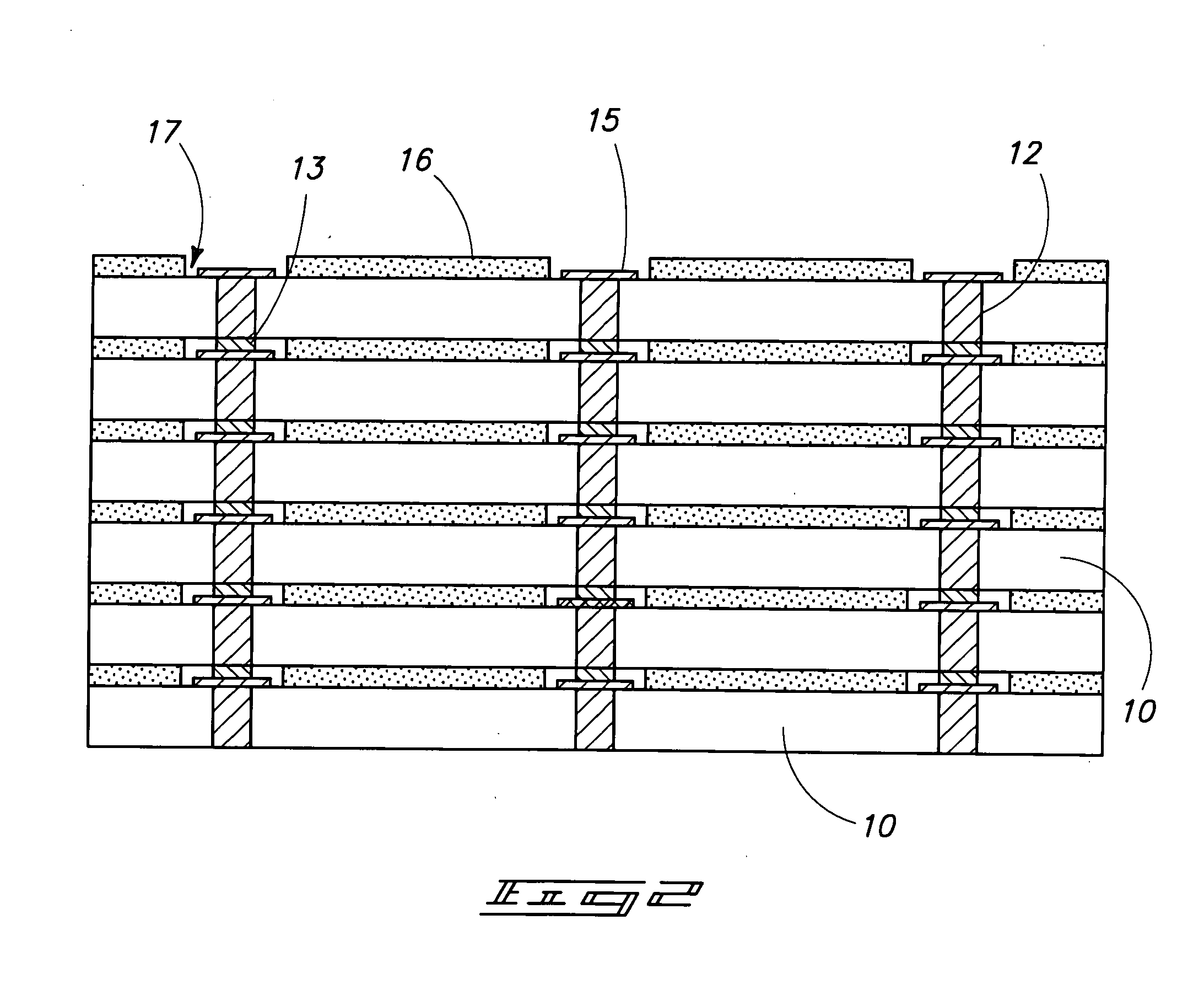

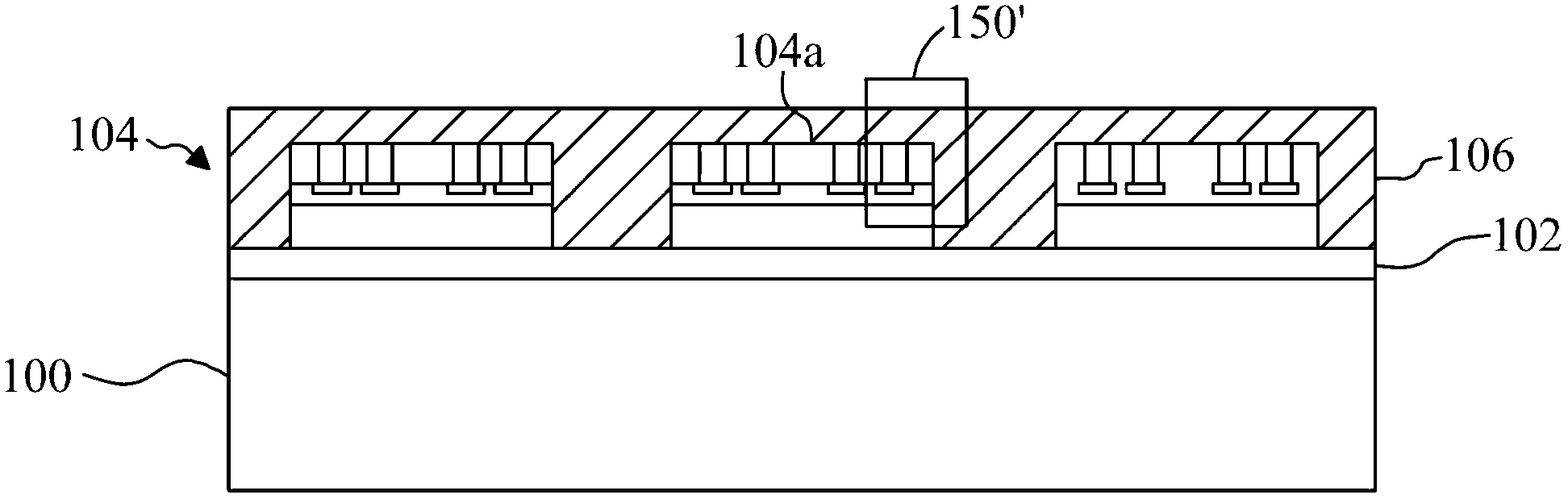

Bonding method for through-silicon-via based 3D wafer stacking

ActiveUS7683459B2Semiconductor/solid-state device detailsSolid-state devicesOutgassingWafer stacking

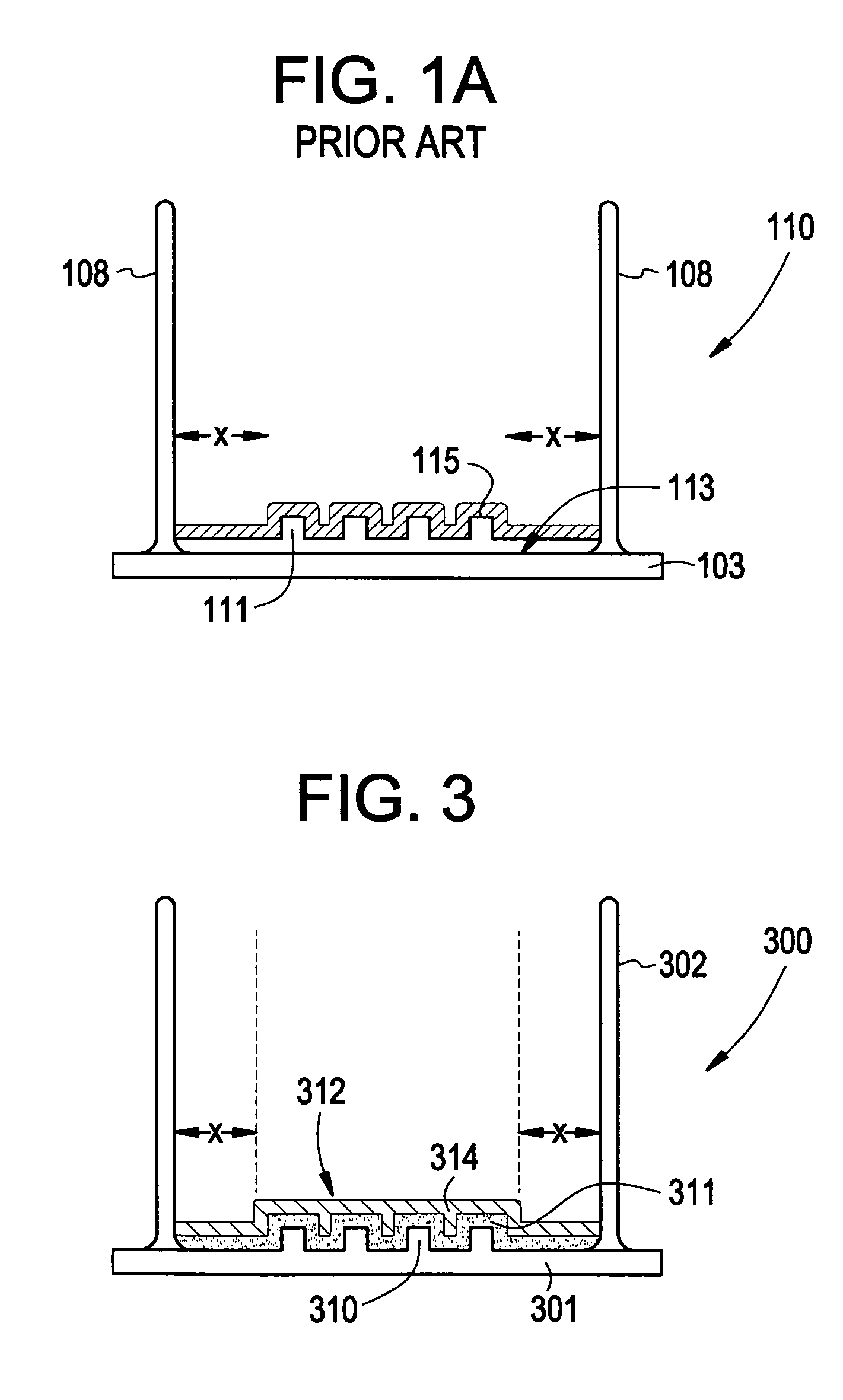

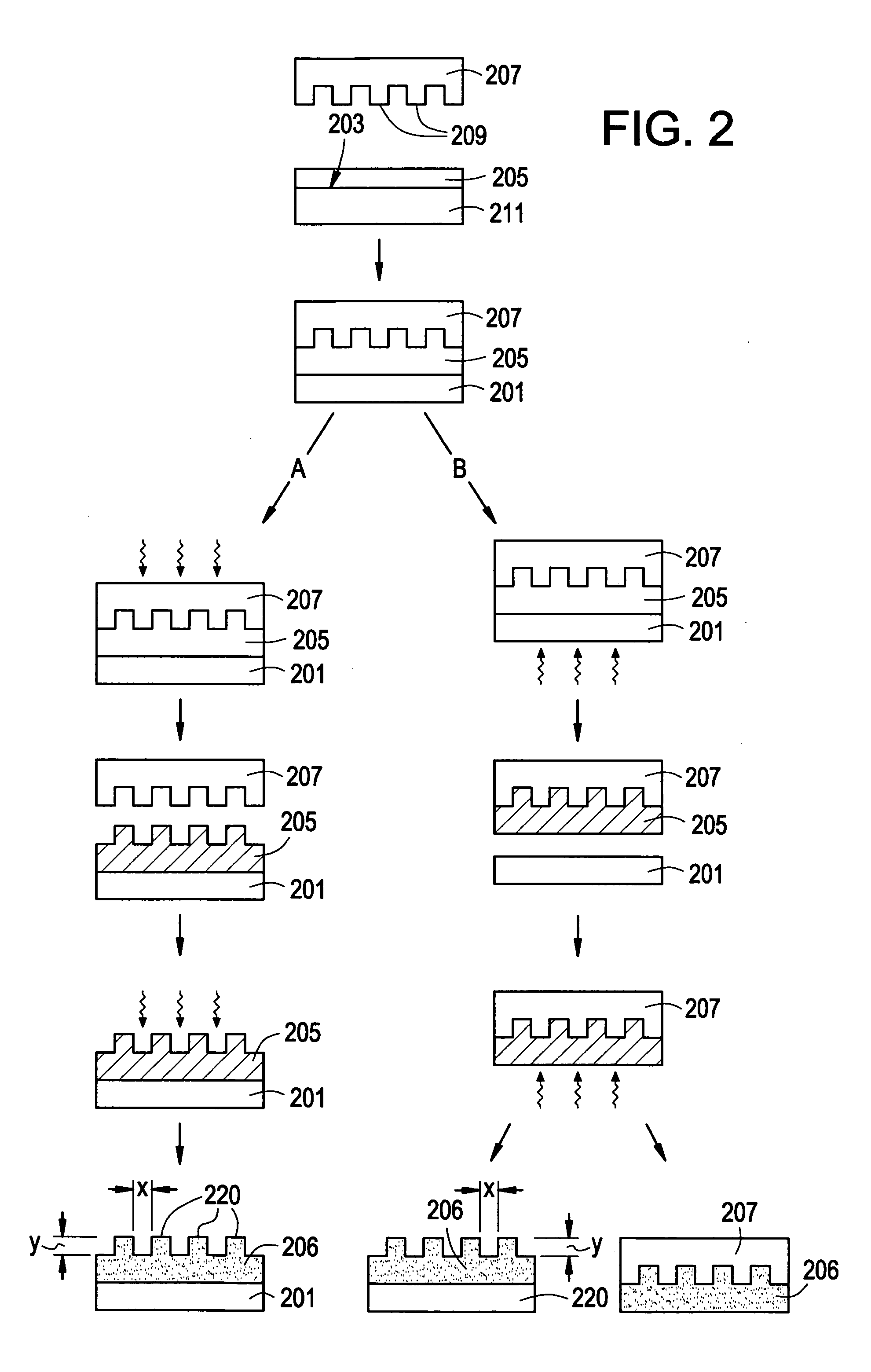

There is described a hybrid bonding method for through-silicon-via based wafer stacking. Patterned adhesive layers are provided to join together adjacent wafers in the stack, while solder bonding is used to electrically connect the vias. The adhesive layers are patterned to enable outgassing and to provide stress relief.

Owner:HONG KONG APPLIED SCI & TECH RES INST

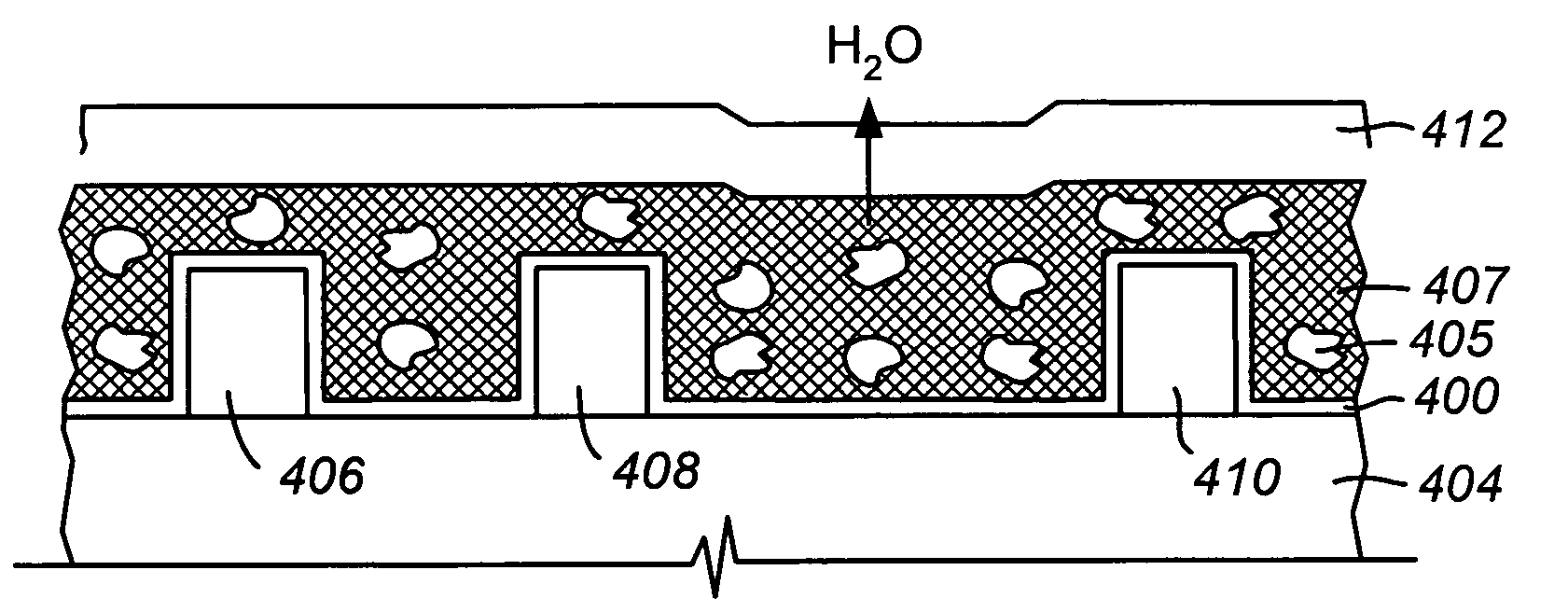

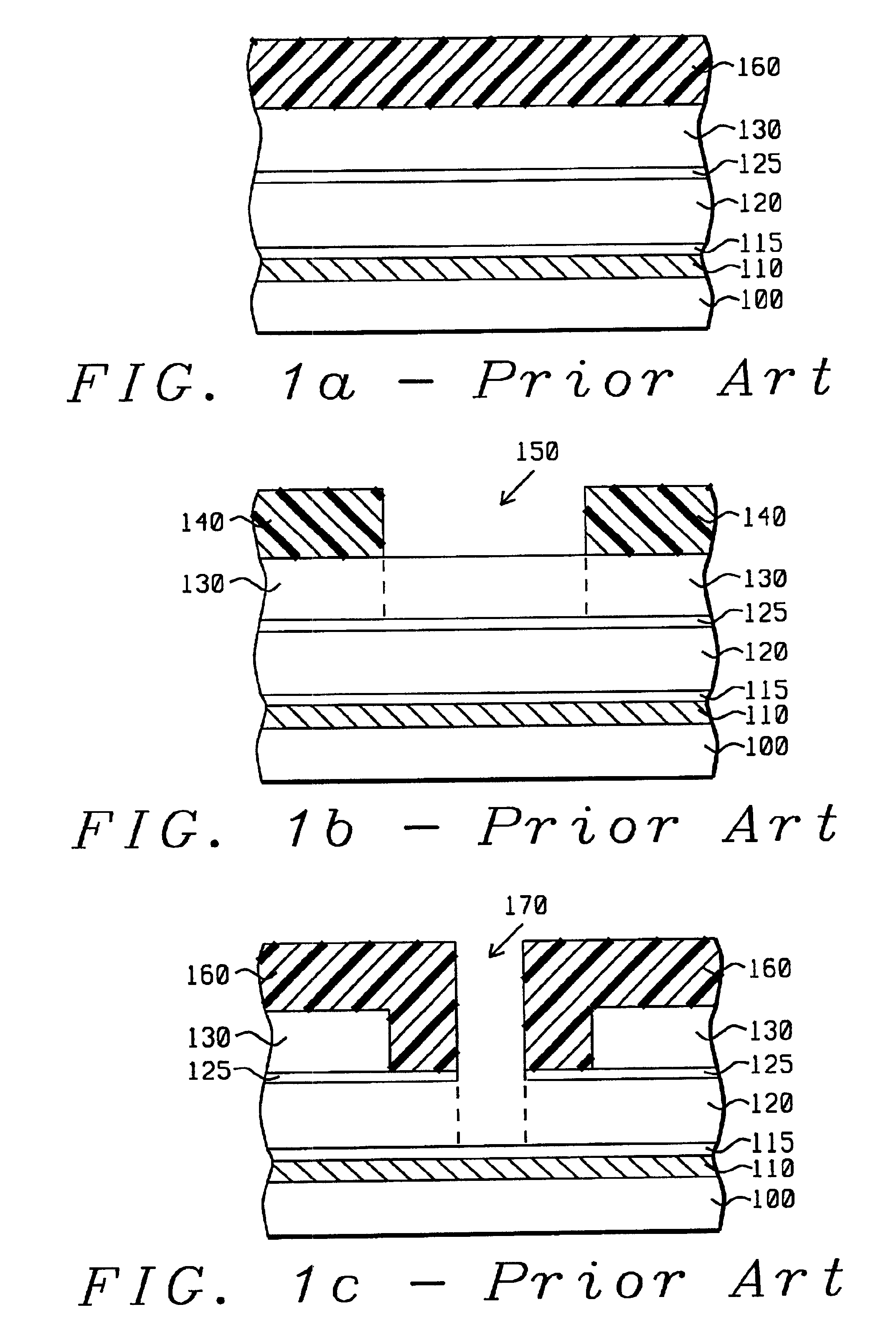

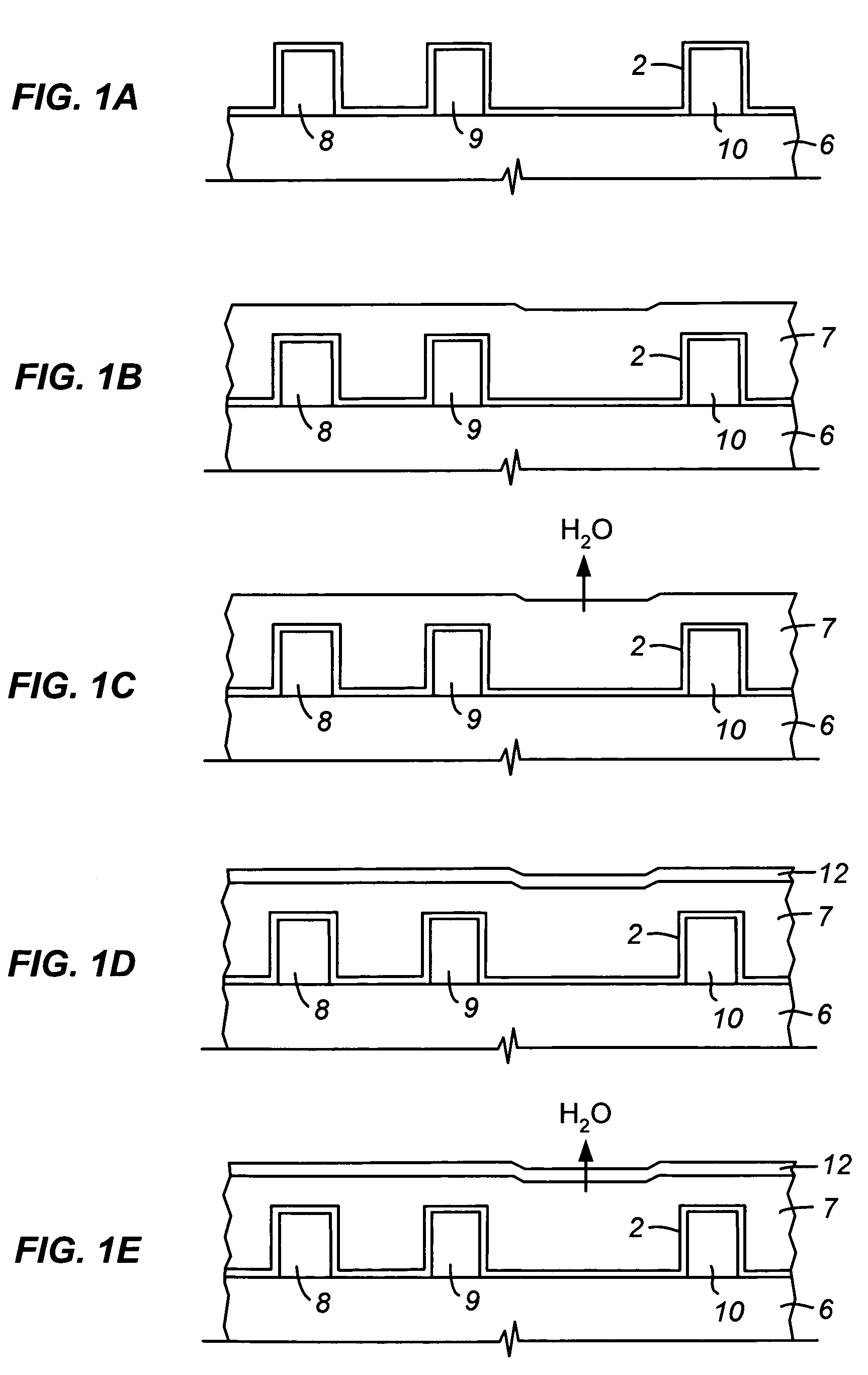

Multi-stage curing of low K nano-porous films

InactiveUS20050230834A1Semiconductor/solid-state device detailsSolid-state devicesThermal energyGas phase

Embodiments in accordance with the present invention relate to multi-stage curing processes for chemical vapor deposited low K materials. In certain embodiments, a combination of electron beam irradiation and thermal exposure steps may be employed to control selective outgassing of porogens incorporated into the film, resulting in the formation of nanopores. In accordance with one specific embodiment, a low K layer resulting from reaction between a silicon-containing component and a non-silicon containing component featuring labile groups, may be cured by the initial application of thermal energy, followed by the application of radiation in the form of an electron beam.

Owner:APPLIED MATERIALS INC

Higher organic inks with good reliability and drytime

InactiveUS6497479B1High solventReduce moistureMeasurement apparatus componentsInksOutgassingEngineering

An inkjet ink is provided that has a greater organic content than prior art inks. However, it is not simply enough to increase the organic content; other factors must be considered as well. These include controlling viscosity and surface tension, as well as maintaining acceptable drytime. An inkjet ink composition that evidences reduced outgassing and reduces paper cockle and curl comprises about 25 to 50 wt % of one or more organic co-solvents, has a viscosity of 10 cp or less, and has a surface tension of 40 dyne / cm or less. Advantageously, using a higher solvent ink reduces cockle and curl. Cockle and curl are also reduced as the water content of the ink is reduced. The present invention uses the higher solvent inks in combination with underprinting. In underprinting, a fixer solution is first "printed" on the print medium, followed by printing the inkjet ink thereon. There is a synergism to this combination. Together, weaknesses of both approaches are addressed. The advantages are a longer life pen, due to the reduction of outgassing of the ink, and reduced cockle and curl.

Owner:HEWLETT PACKARD DEV CO LP

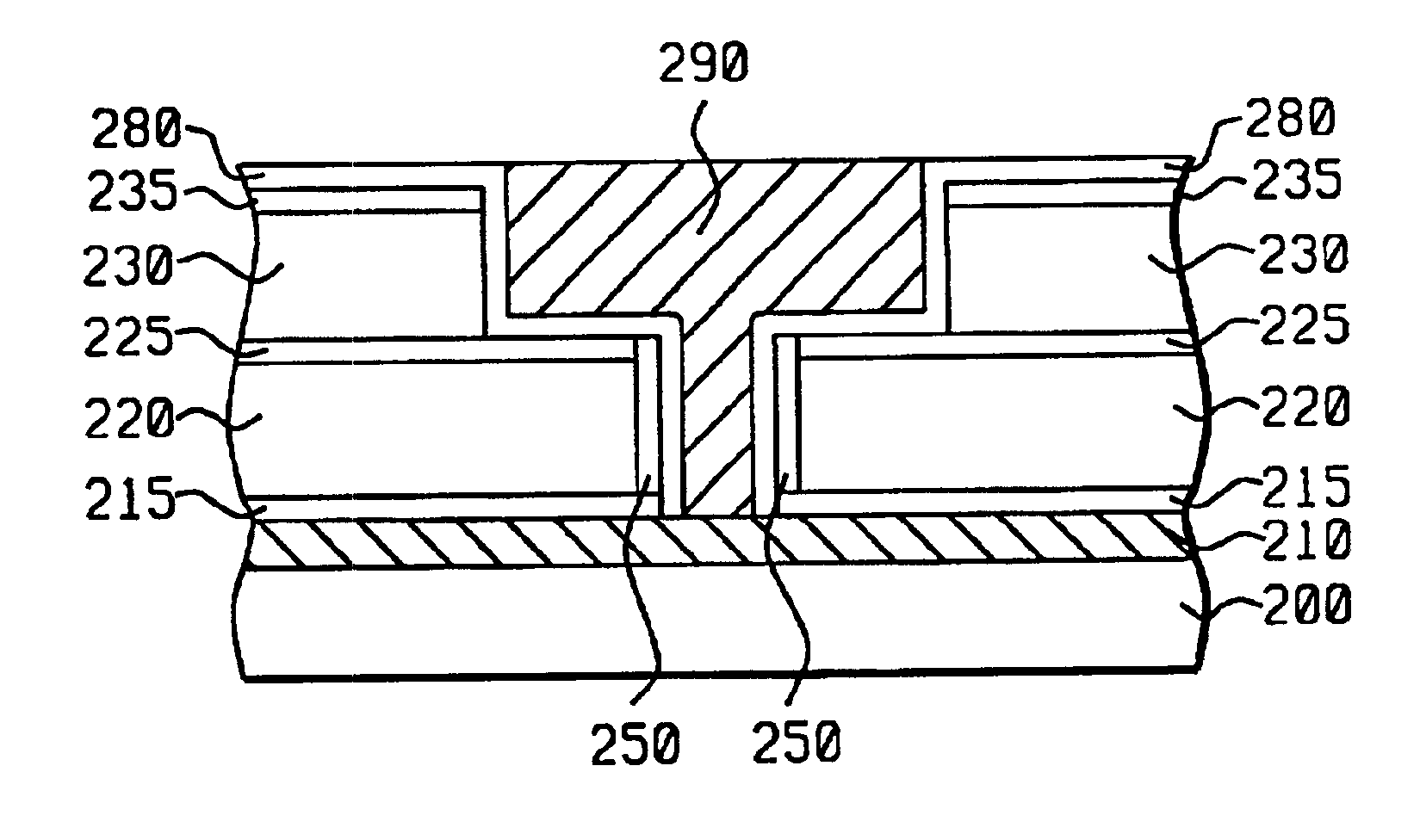

Method to solve via poisoning for porous low-k dielectric

InactiveUS6878615B2Avoid deflationSolid-state devicesSemiconductor/solid-state device manufacturingOutgassingCopper

A method of forming a via in a low-k dielectric material and without the attendant via poisoning problem, or a dual damascene structure formed in the same dielectric and without the same problem are disclosed. The vertical walls of the via opening are first lined with a low-k protection layer and then covered with a barrier layer in order to prevent outgassing from the low-k dielectric material when copper is deposited into the via opening. In the case of a dual damascene structure, it is sufficient that the hole opening underlying the trench opening is first lined with the low-k protection layer. The resulting via or dual damascene structure is free of poisoned metal and, therefore, more reliable.

Owner:TAIWAN SEMICON MFG CO LTD

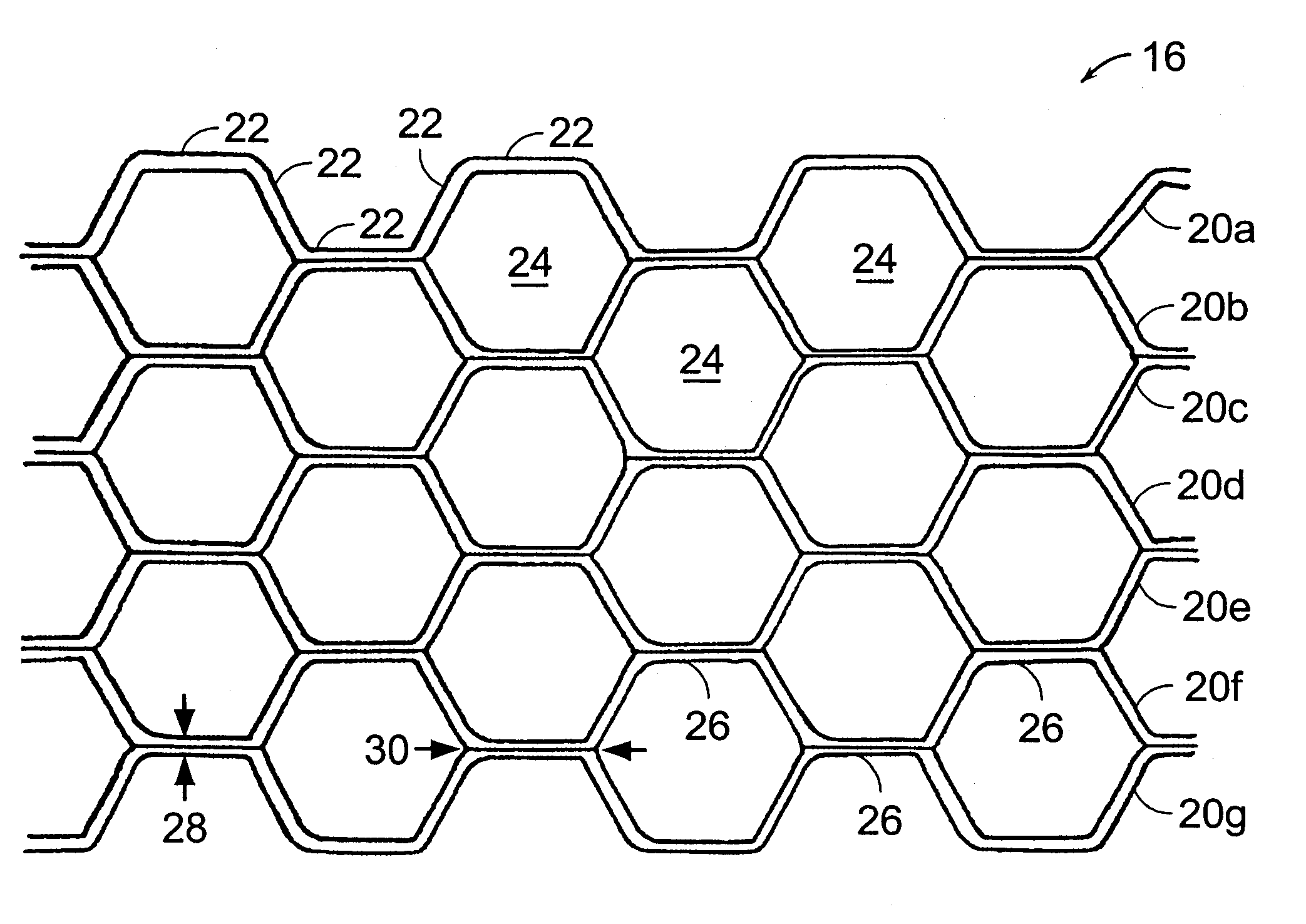

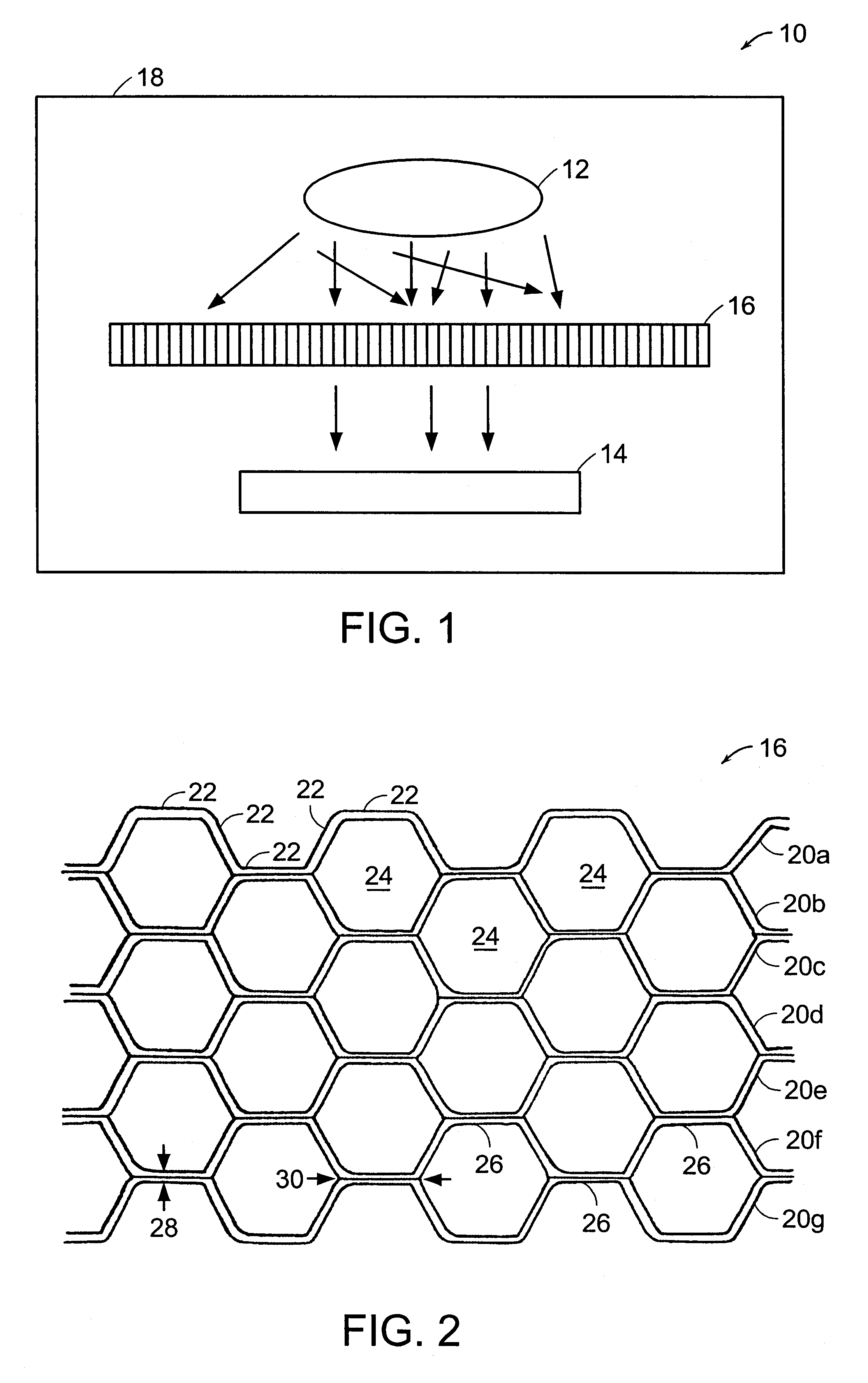

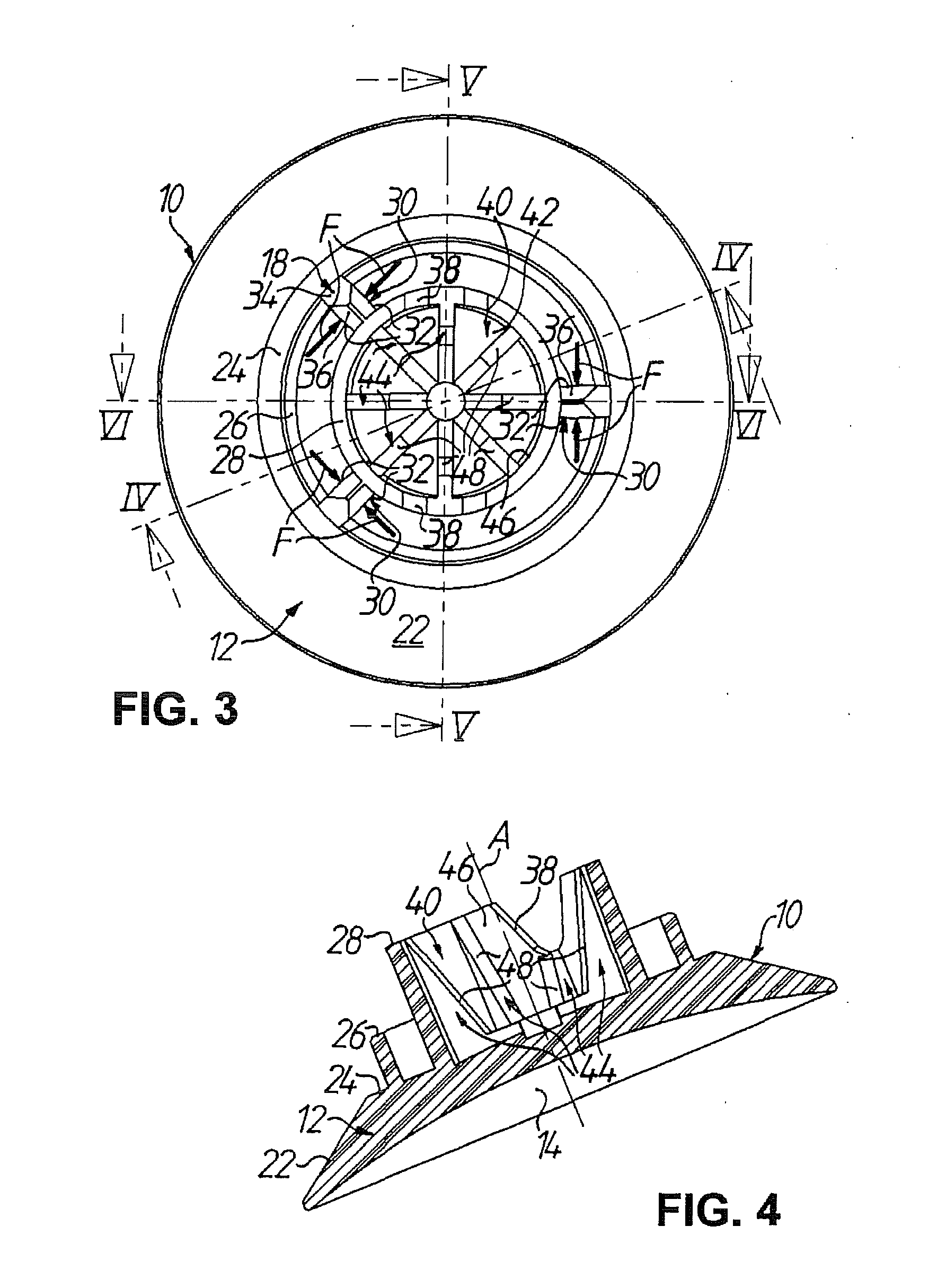

Brazed honeycomb collimator

A collimator filter for a physical vapor deposition apparatus useful for coating semiconductor wafers includes a plurality of corrugated ribbons attached at abutting double-walled nodes by resistance spot welding. The nodes are sealed by application of a braze material to diverging wall portions of the nodes by extrusion or spraying, followed by heating in a vacuum furnace. Alternatively, the nodes may be sealed by application of a braze material foil to a top and a bottom surface of the collimator followed by heating in the vacuum furnace. By sealing the nodes, a significant reduction may be achieved in outgassing and generation of particulate contaminants.

Owner:INNOVENT

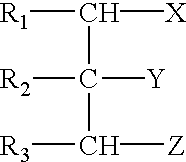

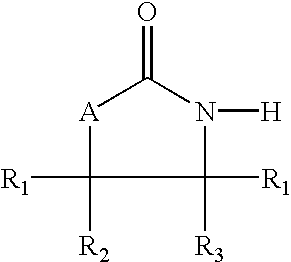

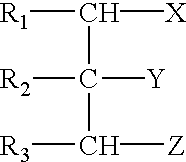

Device comprising low outgassing photo or electron beam cured rubbery polymer material

Owner:CORNING INC

Bonding method for through-silicon-via based 3D wafer stacking

ActiveUS20090294916A1Semiconductor/solid-state device detailsSolid-state devicesOutgassingWafer stacking

There is described a hybrid bonding method for through-silicon-via based wafer stacking. Patterned adhesive layers are provided to join together adjacent wafers in the stack, while solder bondng is used to electrically connect the vias. The adhesive layers are patterned to enable outgassing and to provide stress relief.

Owner:HONG KONG APPLIED SCI & TECH RES INST

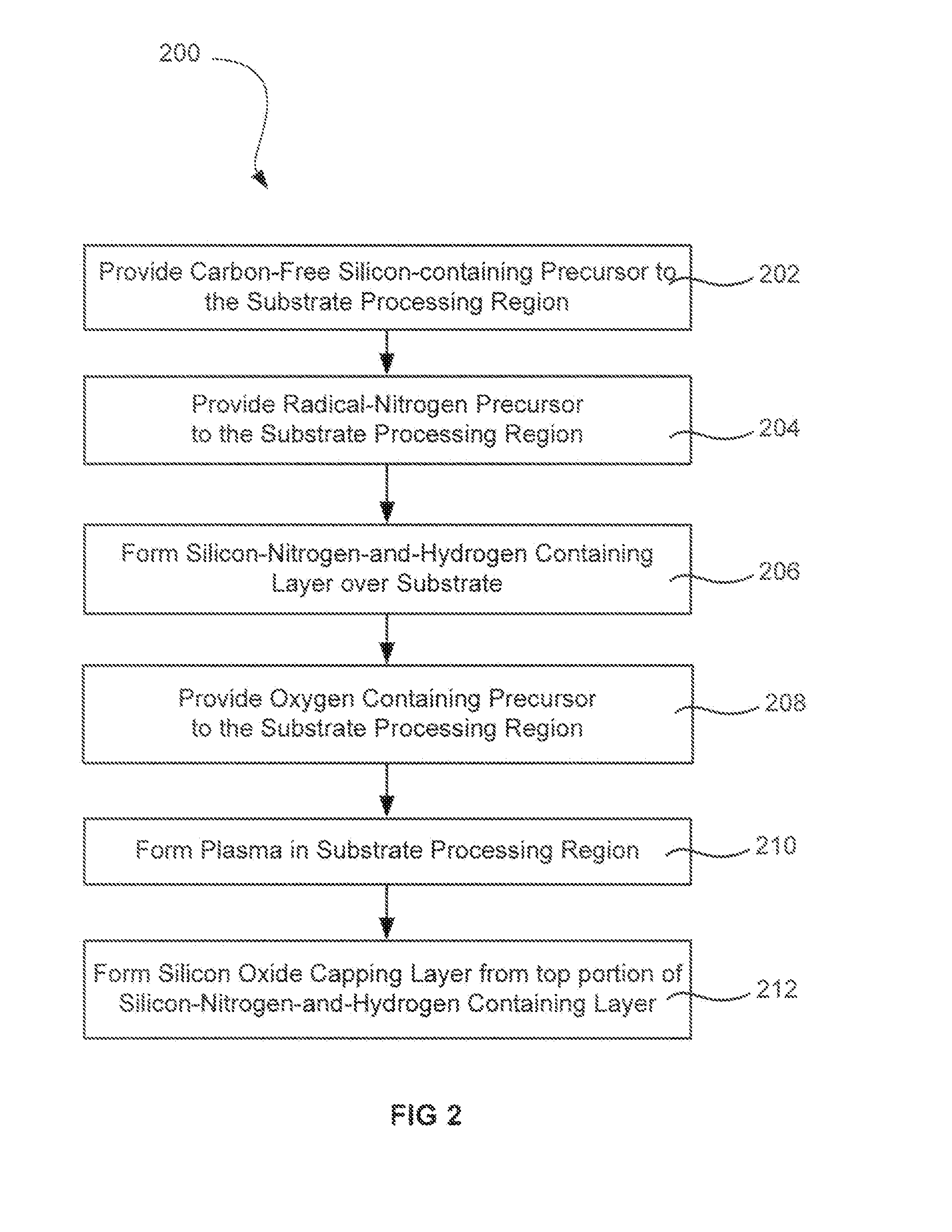

Surface treatment and deposition for reduced outgassing

InactiveUS20130149462A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaHydrogen

A method of forming a dielectric layer is described. The method first deposits a silicon-nitrogen-and-hydrogen-containing (polysilazane) layer by radical-component chemical vapor deposition (CVD). The silicon-nitrogen-and-hydrogen-containing layer is formed by combining a radical precursor (excited in a remote plasma) with an unexcited carbon-free silicon precursor. A silicon oxide capping layer may be formed from a portion of the carbon-free silicon-nitrogen-and-hydrogen-containing layer to avoid time-evolution of underlying layer properties prior to conversion into silicon oxide. Alternatively, the silicon oxide capping layer is formed over the silicon-nitrogen-and-hydrogen-containing layer. Either method of formation involves the formation of a local plasma within the substrate processing region.

Owner:APPLIED MATERIALS INC

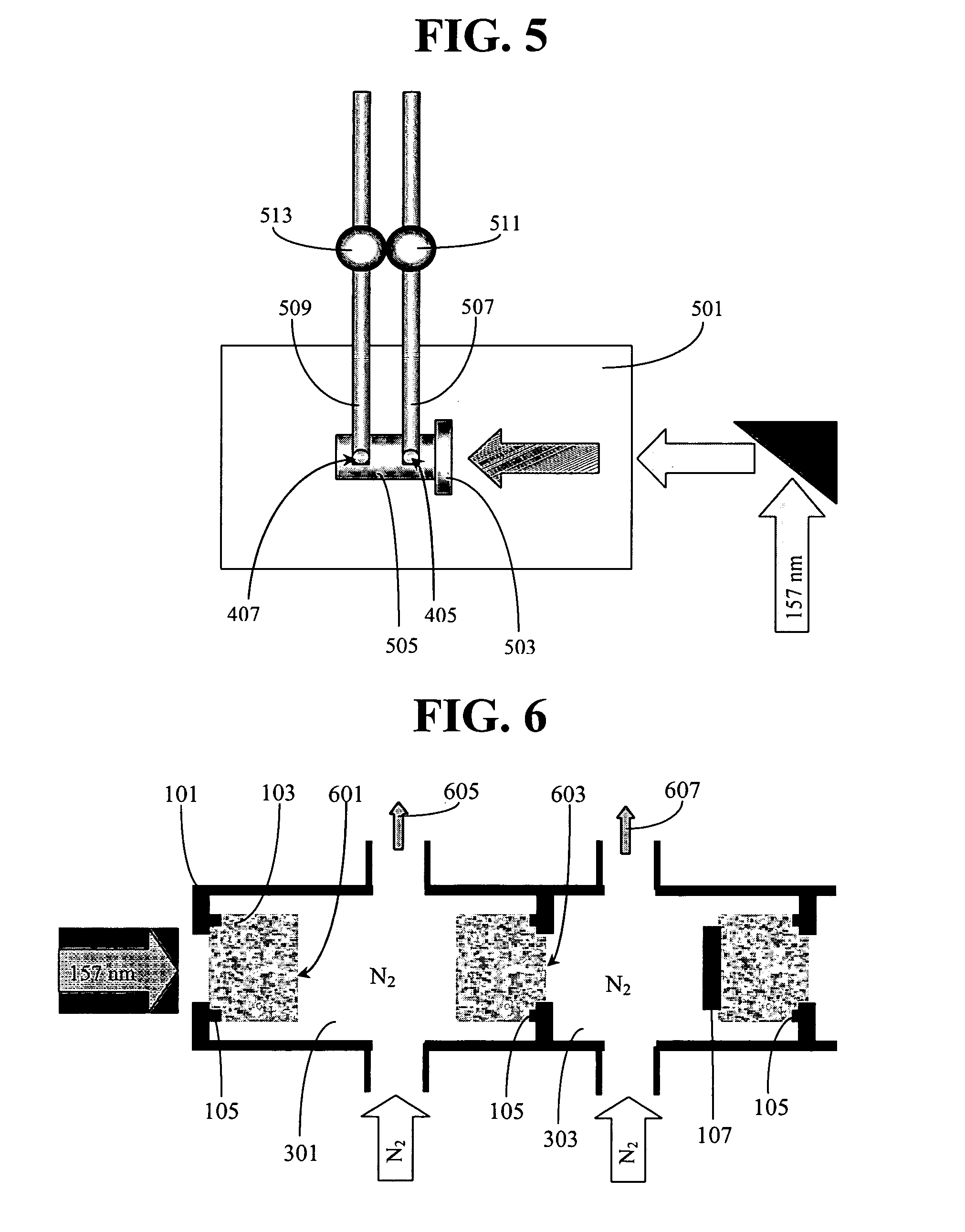

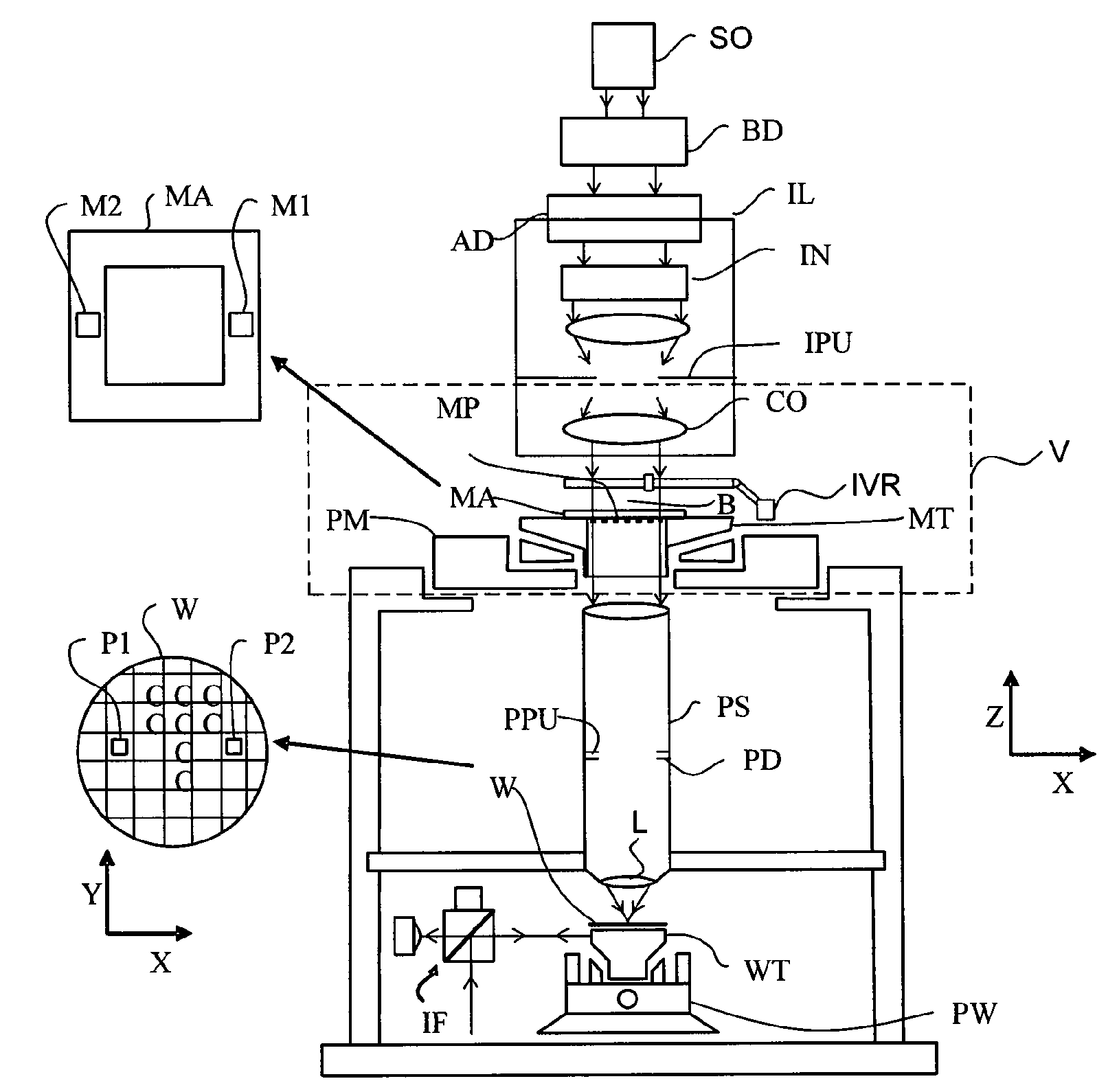

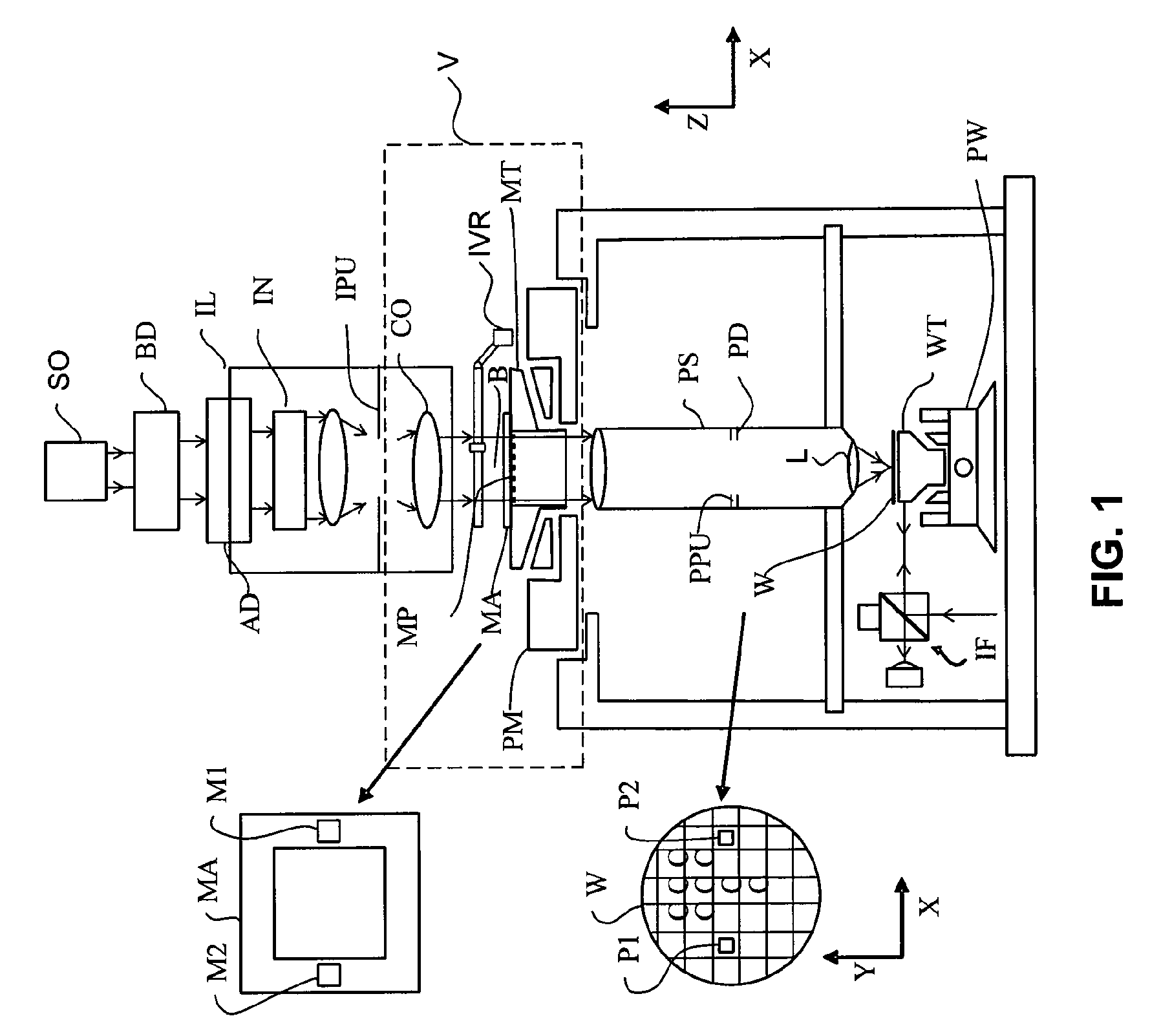

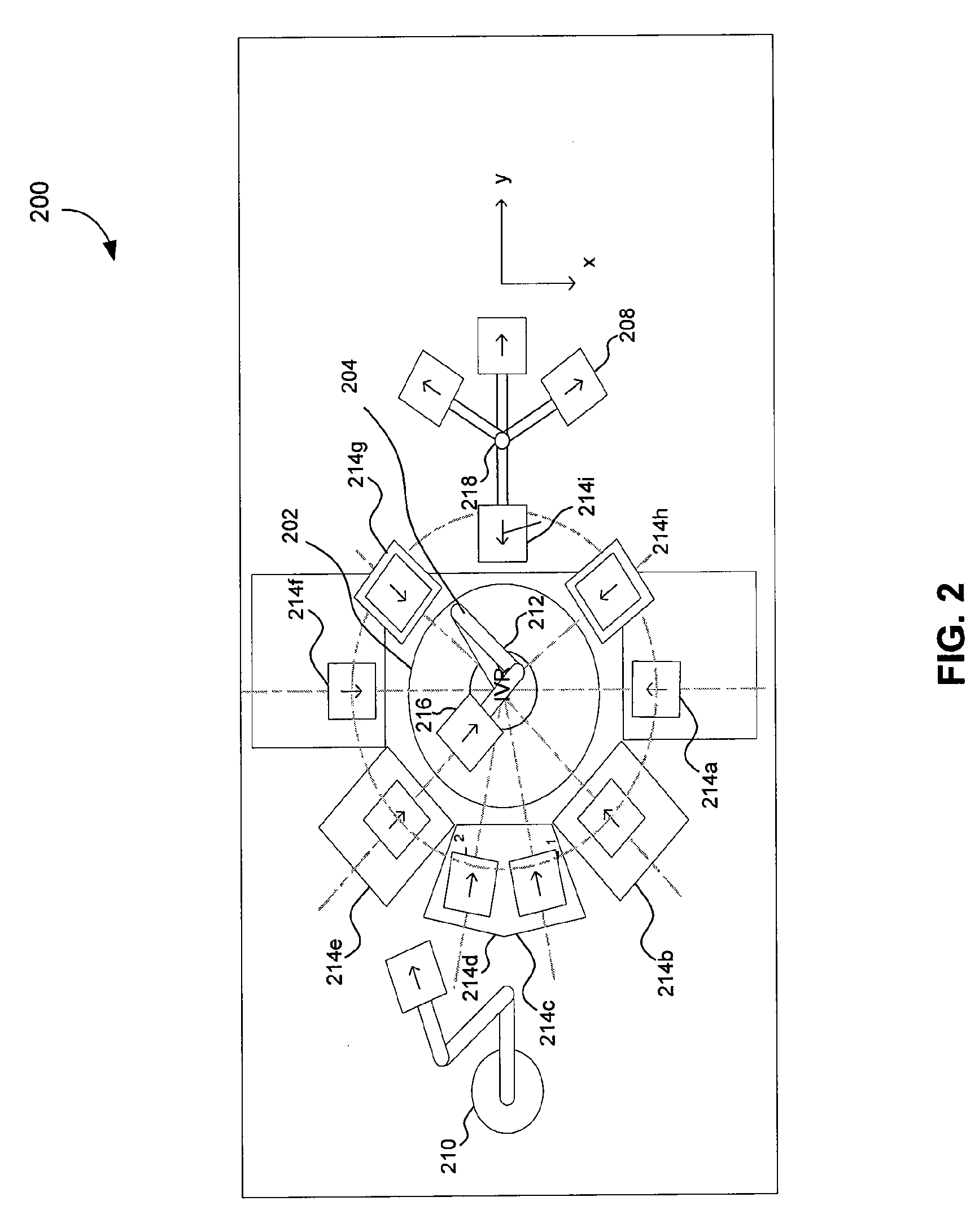

Robot Position Calibration Tool (RPCT)

InactiveUS20090259337A1Minimizes repeated particle generationQuick calibrationProgramme controlProgramme-controlled manipulatorLithographic artistOutgassing

A Robot Position Calibration Tool (RPCT) is used to accurately calibrate a robot position for a reticle hand-off to a transfer station in a lithography tool with minimized particle generation and outgassing. Method(s), system(s) and computer program product(s) are described to calibrate the robot with minimal sensor usage and minimal slippage of a payload leading to minimized particle generation and outgassing inside a vacuum chamber of a lithography tool.

Owner:ASML HLDG NV

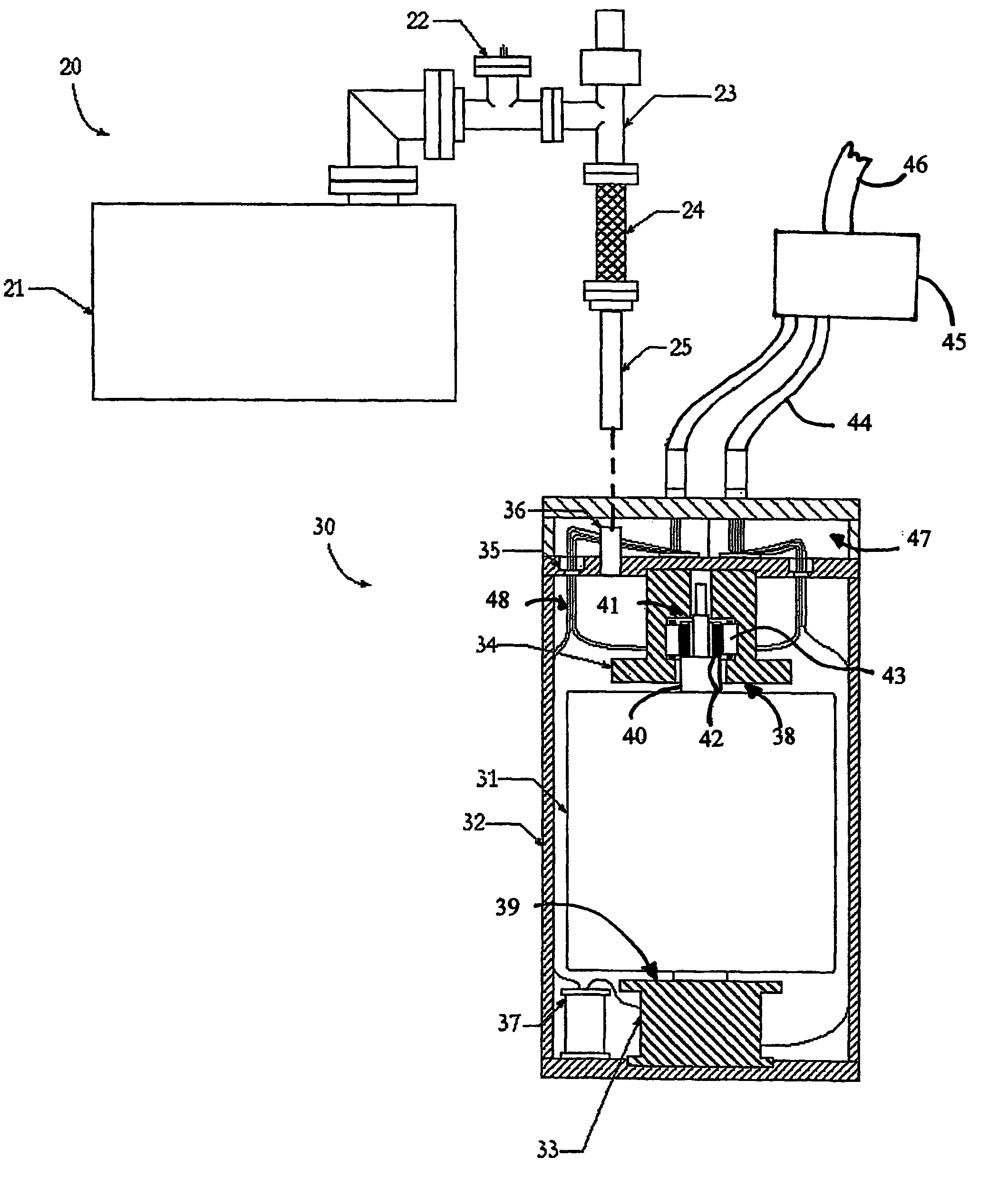

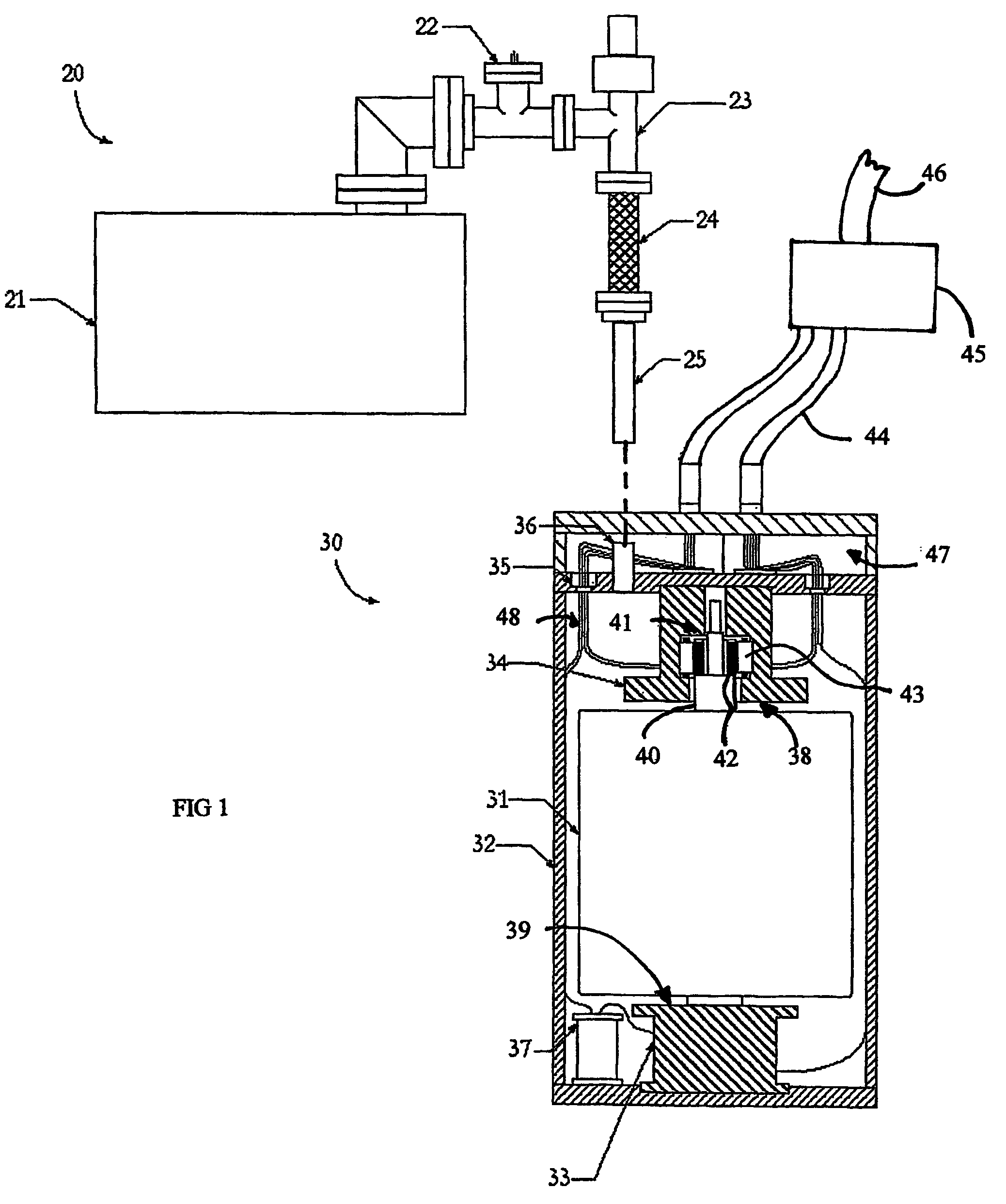

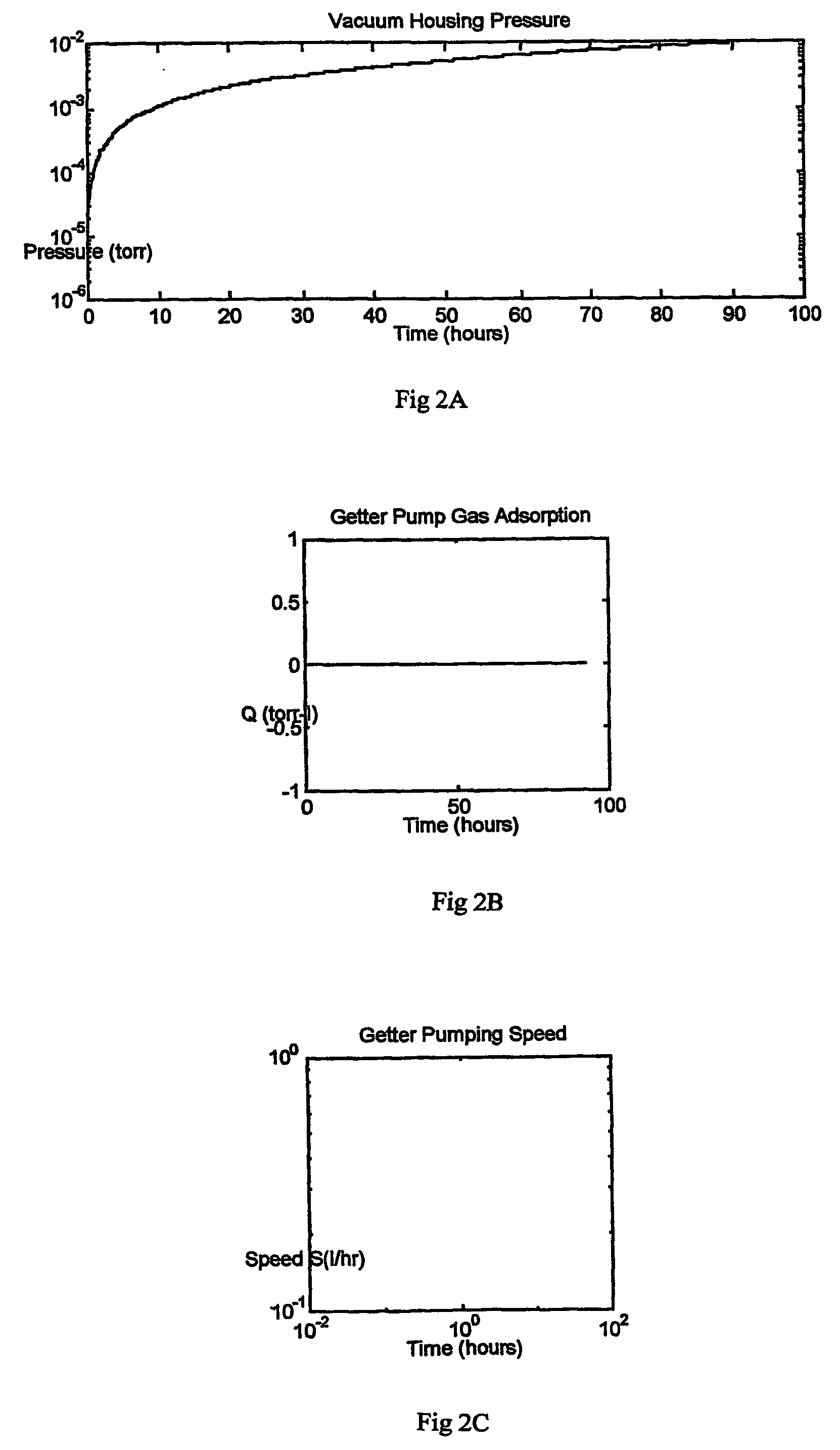

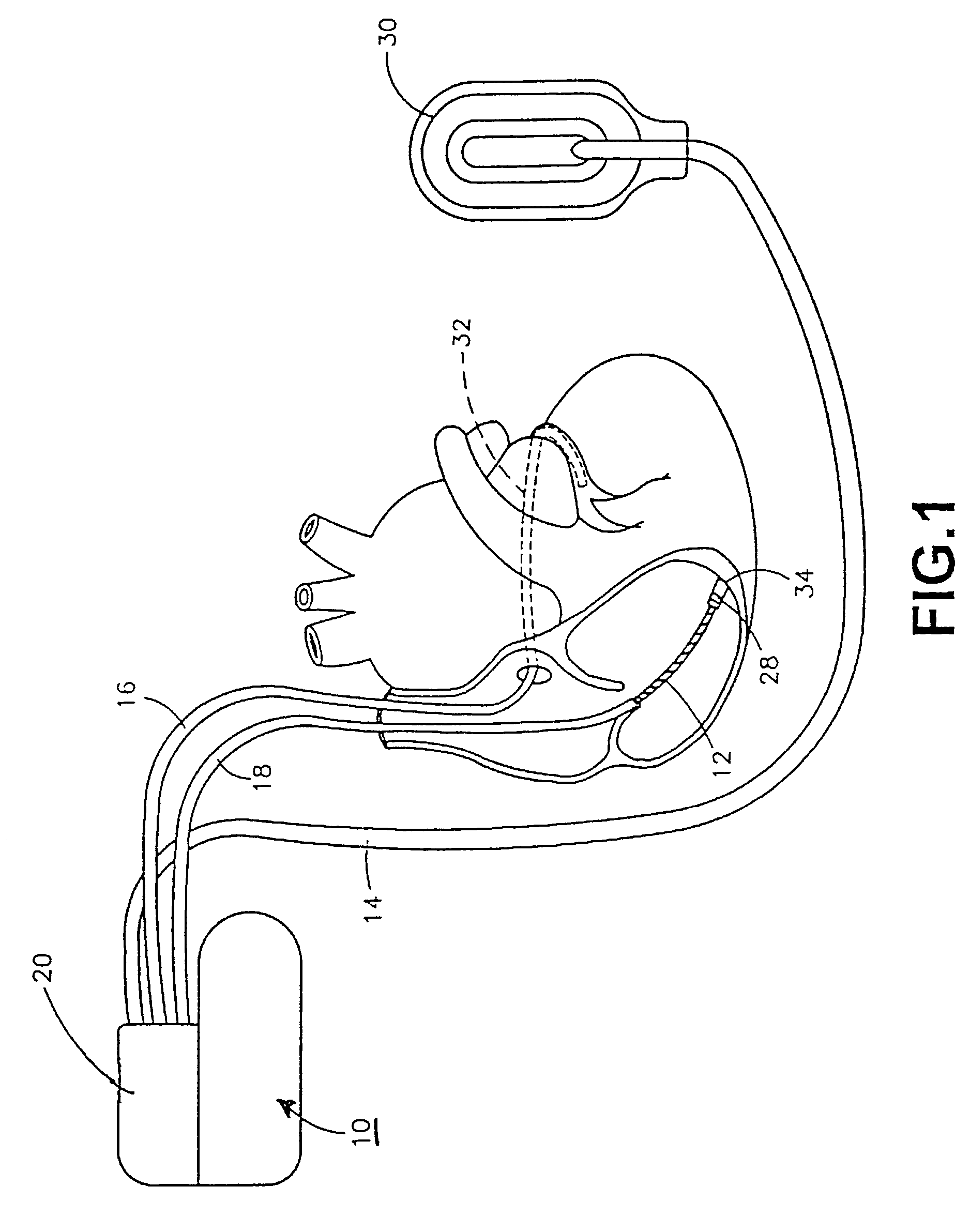

Long-life vacuum system for energy storage flywheels

InactiveUS7053589B2Improve adsorption capacityIncrease chanceAC/DC convertorsFlywheelsAlloyEngineering

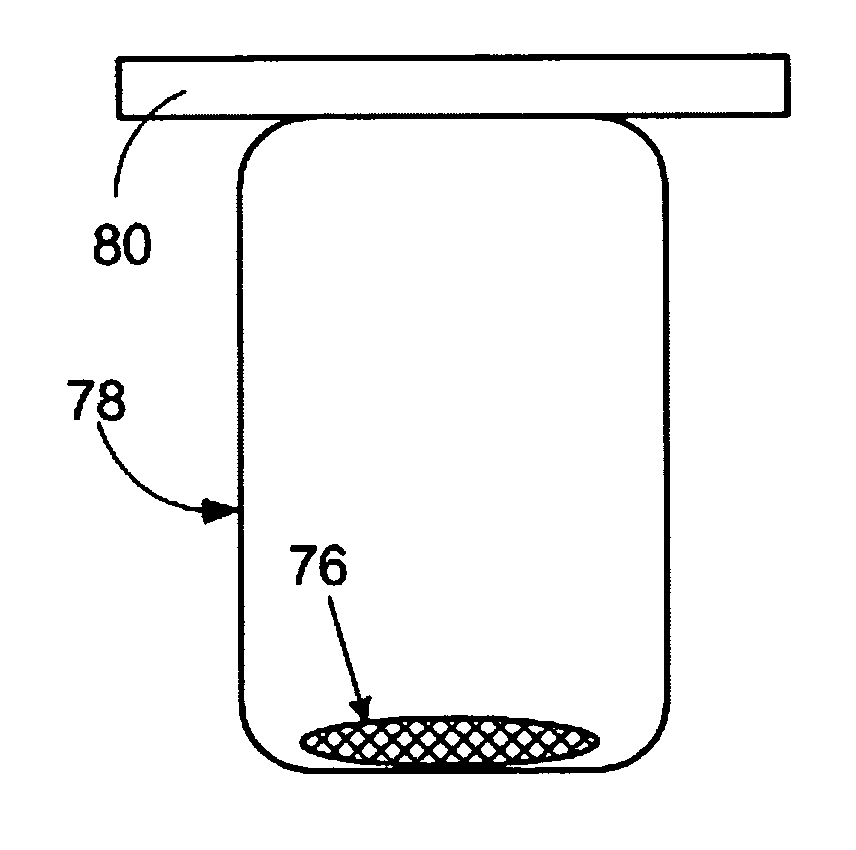

The invention, intended primarily for use in a steel flywheel power source (30), provides a vacuum system and a method of maintaining a vacuum inside a flywheel chamber (32) for the life of the power source (30). The vacuum system combines the use of cleaning and de-gassing treatments in the chamber (32) and vacuum tempering of the steel flywheel (31) with the use of a chemical type metal alloy nonevaporable getter, such as zirconium-vanadium-iron, that cooperatively matches the outgassing of the flywheel (31) and chamber (32) by sorbing those gases that are released. The getter may be reactivated throughout the life of the flywheel system by reheating it with an integral heater that is triggered by a timer instead of a vacuum gauge to increase the system reliability, using power taken directly from the energy stored in the flywheel. The electronics (45) of the flywheel power source are used to signal an alarm or prevent achieving or maintaining full speed of the flywheel when the vacuum in the chamber degrades.

Owner:INDIGO ENERGY INC

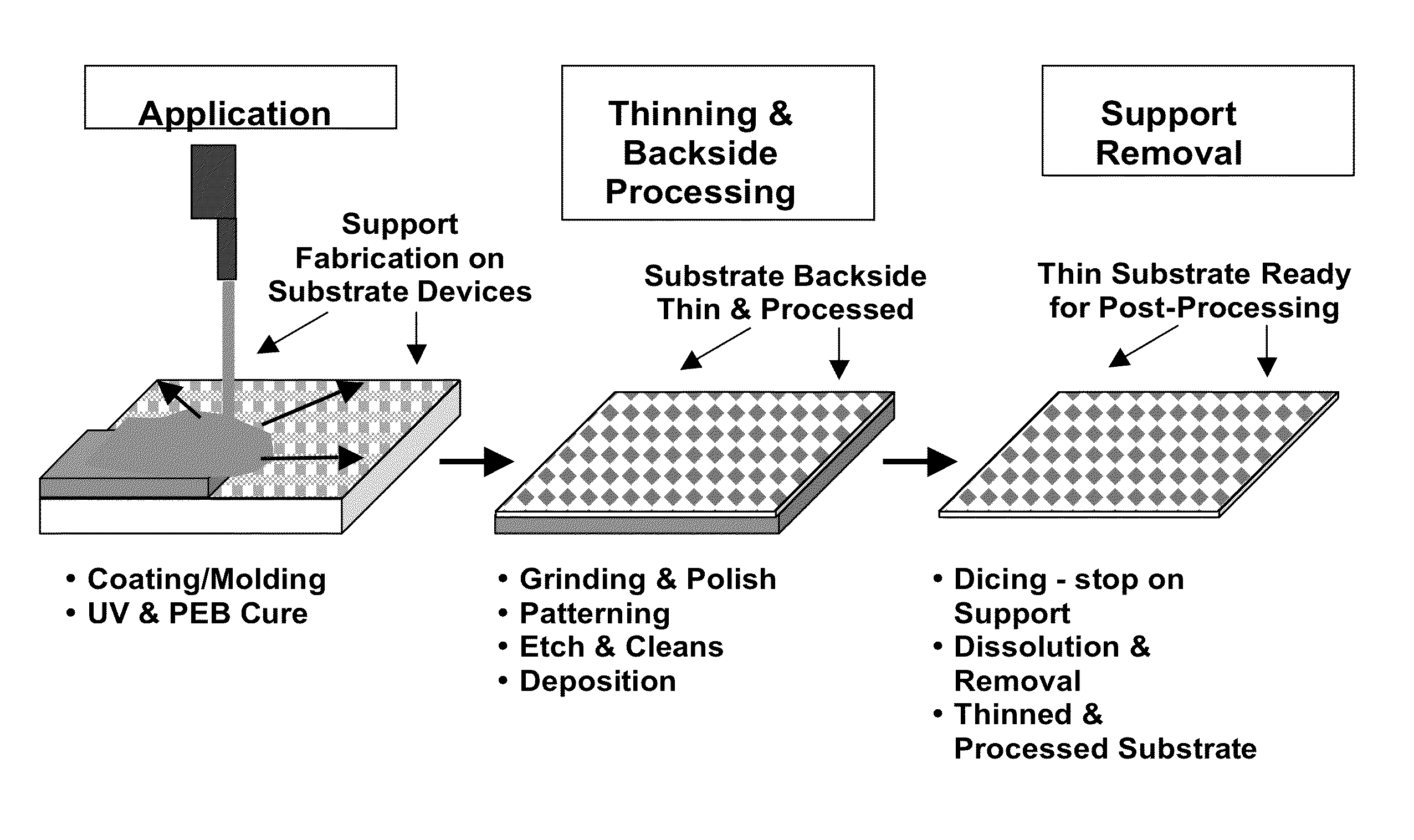

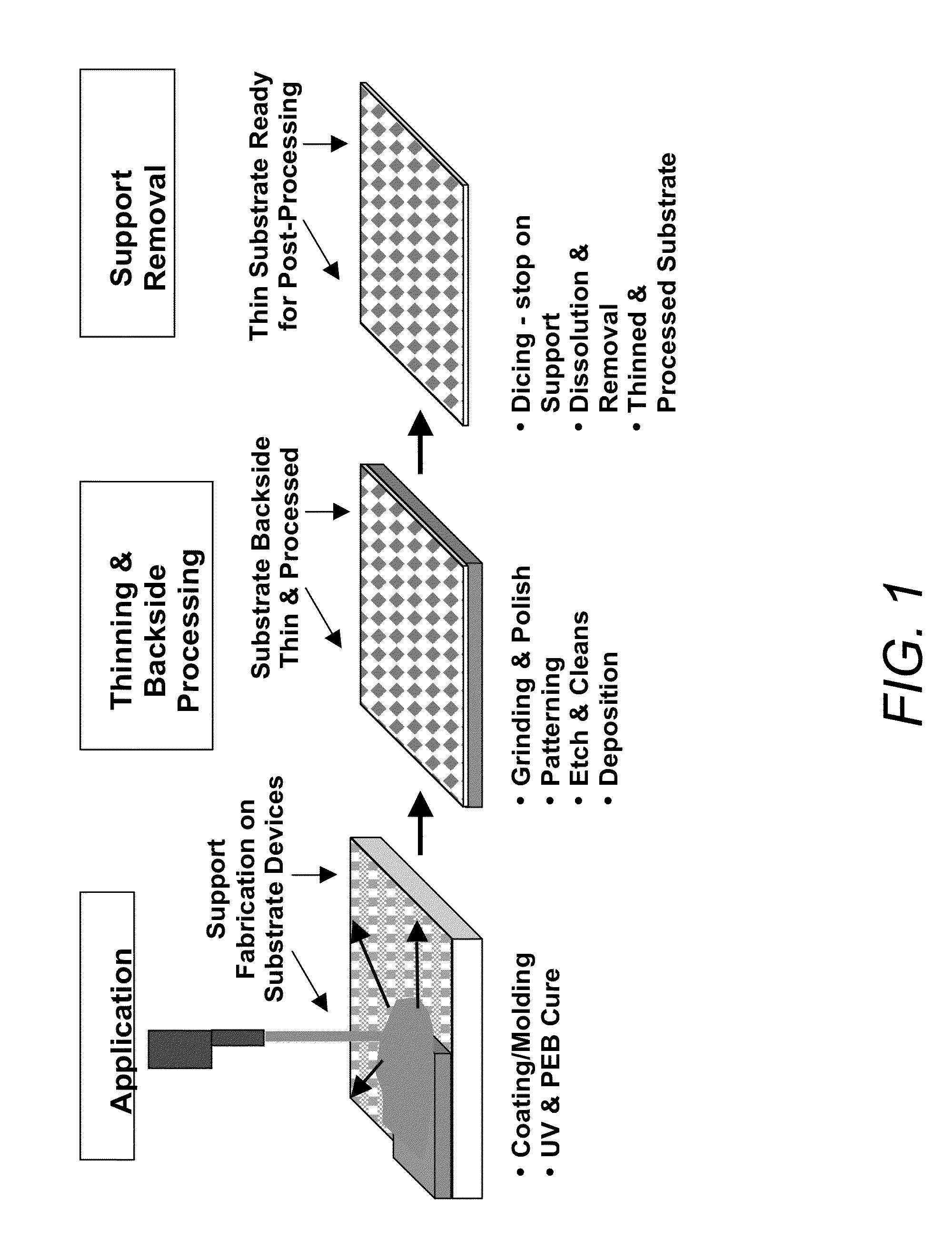

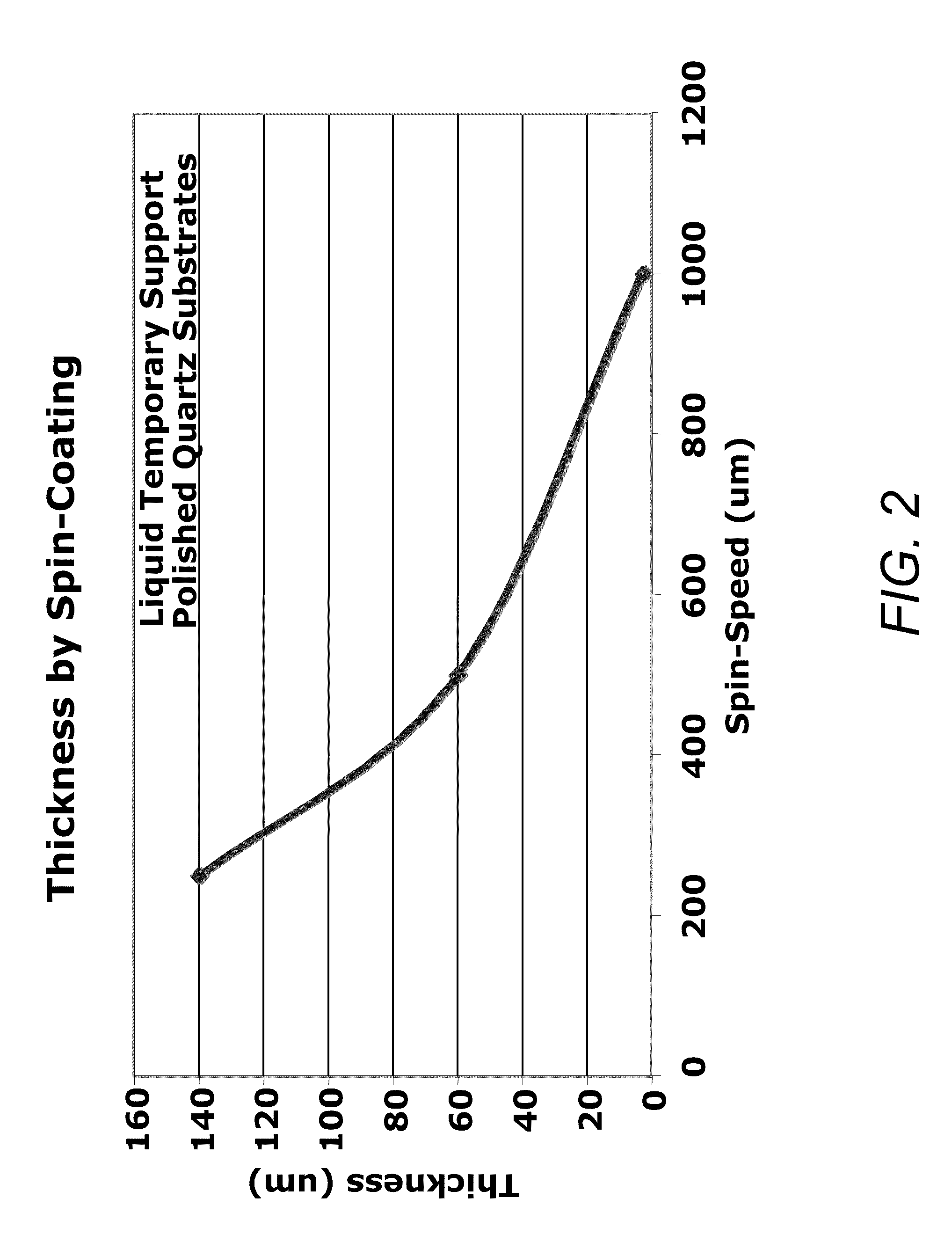

Rapid fabrication of a microelectronic temporary support for inorganic substrates

InactiveUS20100264566A1Eliminate useEliminate damageLiquid surface applicatorsSemiconductor/solid-state device detailsLiquid layerOutgassing

A method for fabricating a rigid temporary support used for supporting inorganic substrates during processing includes providing an inorganic substrate comprising a first surface to be processed and a second surface opposite to the first surface. Next, applying a liquid layer to the second surface of the inorganic substrate and then curing the applied liquid layer and thereby forming a rigid temporary support attached to the second surface of the inorganic substrate. Next, processing the first surface of the inorganic substrate while supporting the inorganic substrate upon the rigid temporary support. The curing includes first exposing the applied liquid layer to ultraviolet (UV) radiation and then performing a post exposure bake (PEB) at a temperature sufficient to complete the curing of the applied liquid layer and to promote outgassing of substances.

Owner:SUSS MICRO TEC LITHOGRAPHY

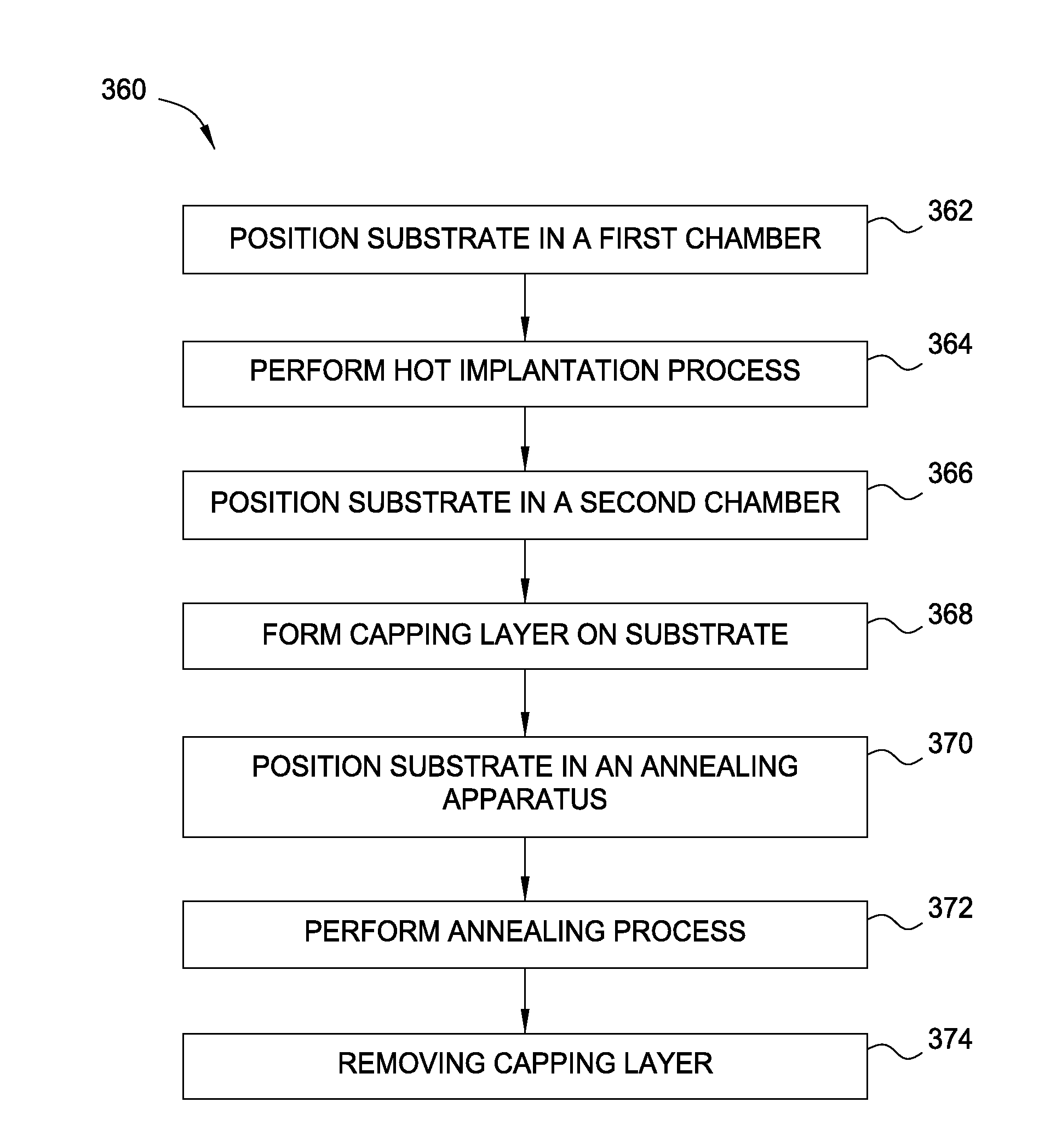

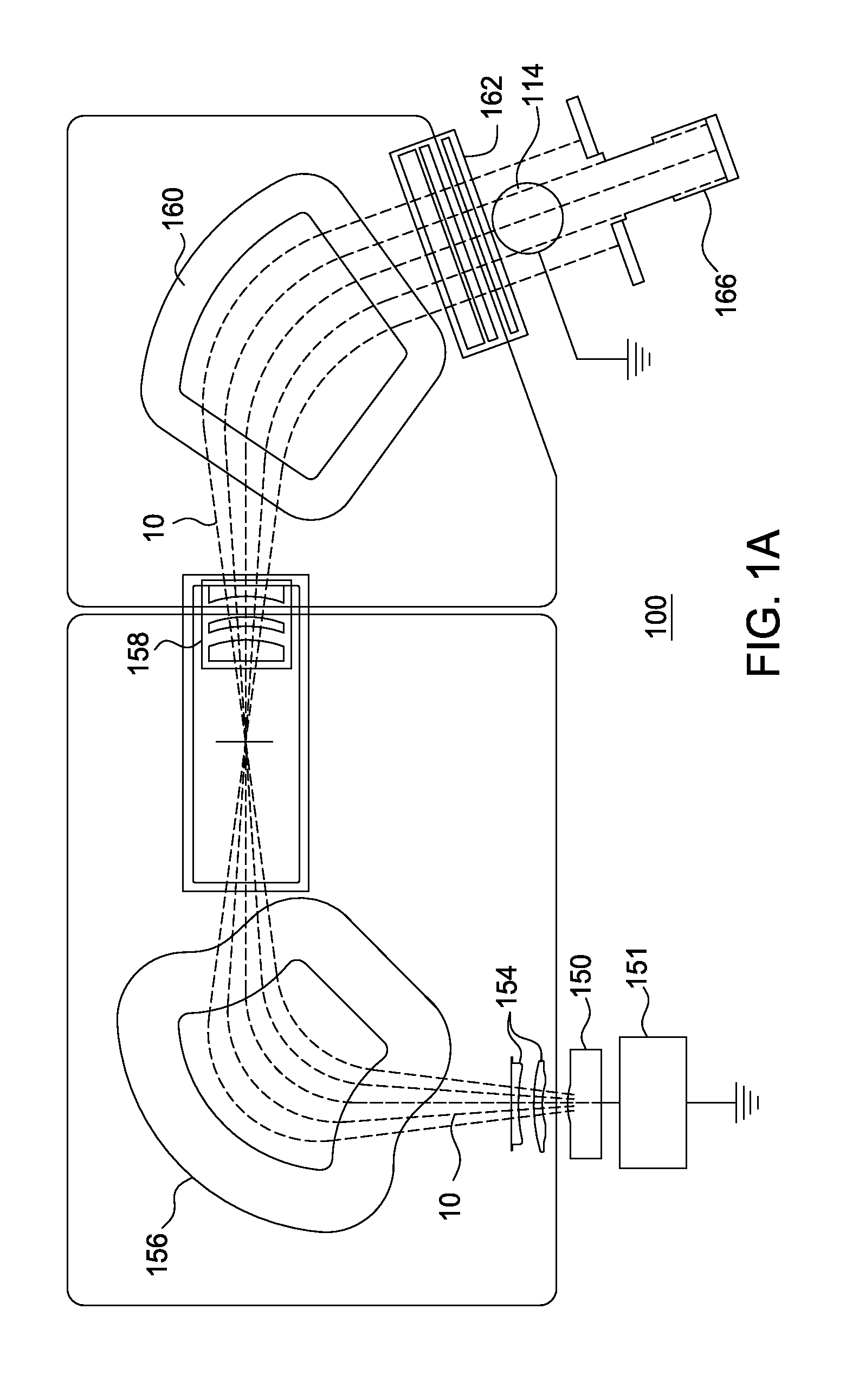

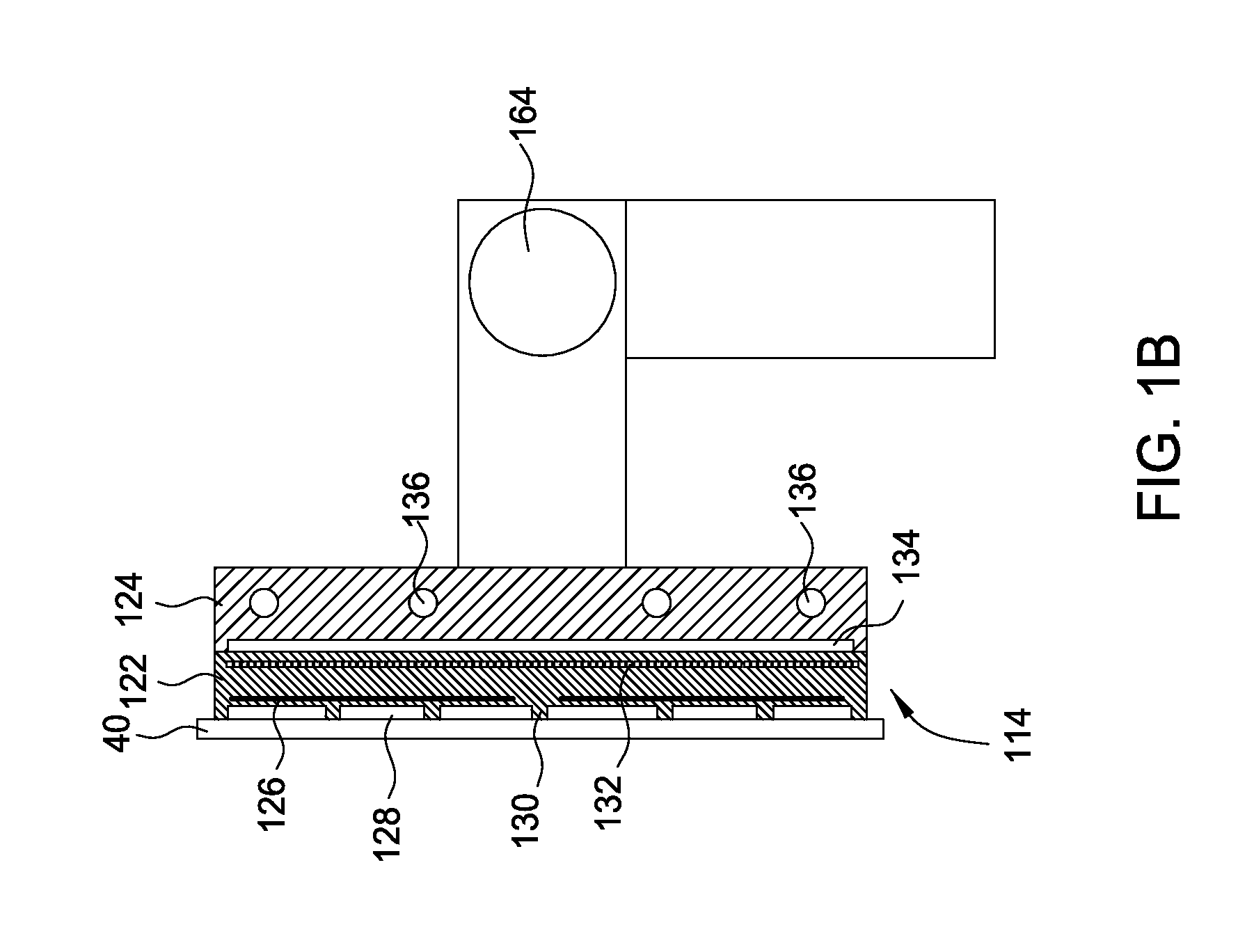

Enabling high activation of dopants in indium-aluminum-galium-nitride material system using hot implantation and nanosecond annealing

InactiveUS20150099350A1Reduce lattice damageReduce outgassingSemiconductor/solid-state device manufacturingDopantElectricity

Embodiments of the present disclosure generally relate to doping and annealing substrates. The substrates may be doped during a hot implantation process, and subsequently annealed using a nanosecond annealing process. The combination of hot implantation and nanosecond annealing reduces lattice damage of the substrates and facilitates a higher dopant concentration near the surface of the substrate to facilitate increased electrical contact with the substrate. An optional capping layer may be placed over the substrate to reduce outgassing of dopants or to control dopant implant depth.

Owner:APPLIED MATERIALS INC

Photo or electron beam curable compositions

InactiveUS7799885B2Photosensitive materialsPhotosensitive materials for photomechanical apparatusGratingOutgassing

Owner:CORNING INC

Block Piece for Holding an Optical Workpiece, in Particular a Spectacle Lens, for Processing Thereof, and Method for Manufacturing Spectacle Lenses According to a Prescription

ActiveUS20110033615A1Low costImprove optical qualityOptical surface grinding machinesOptical articlesOutgassingEyewear

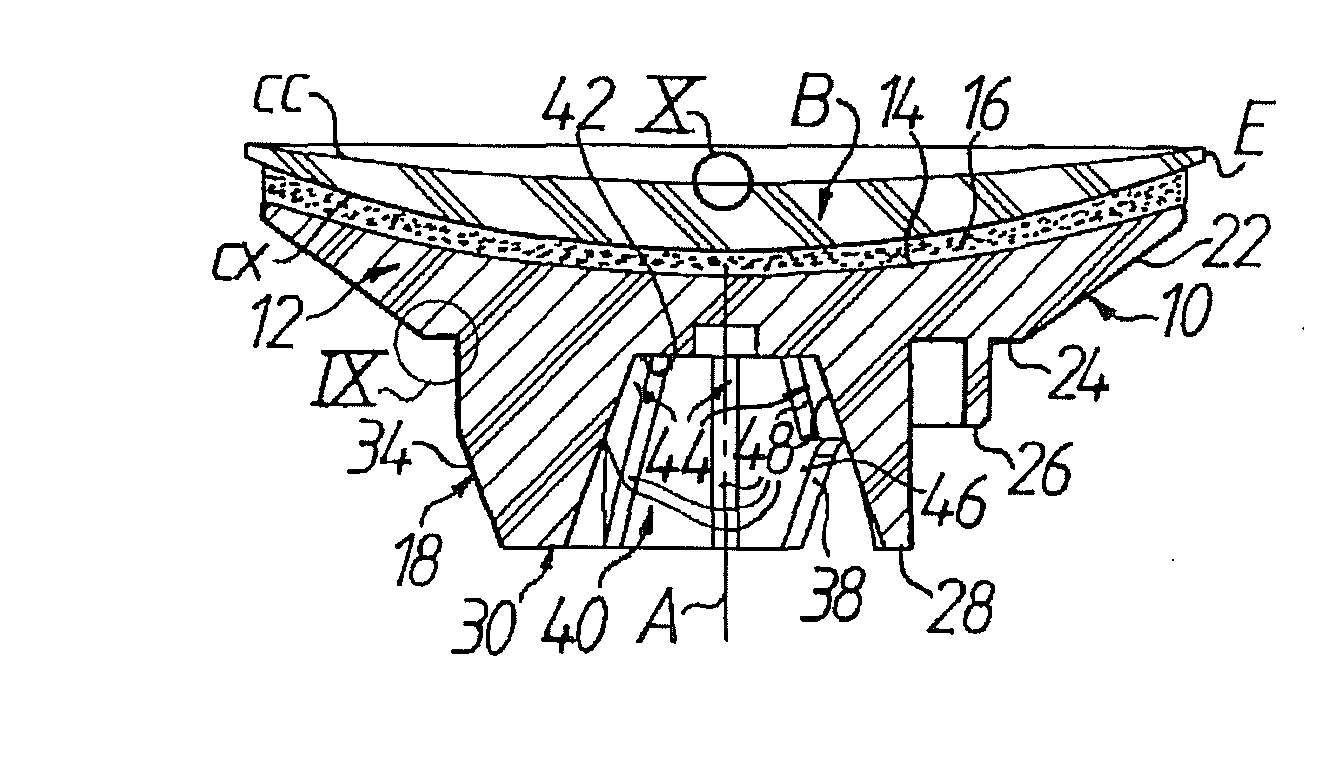

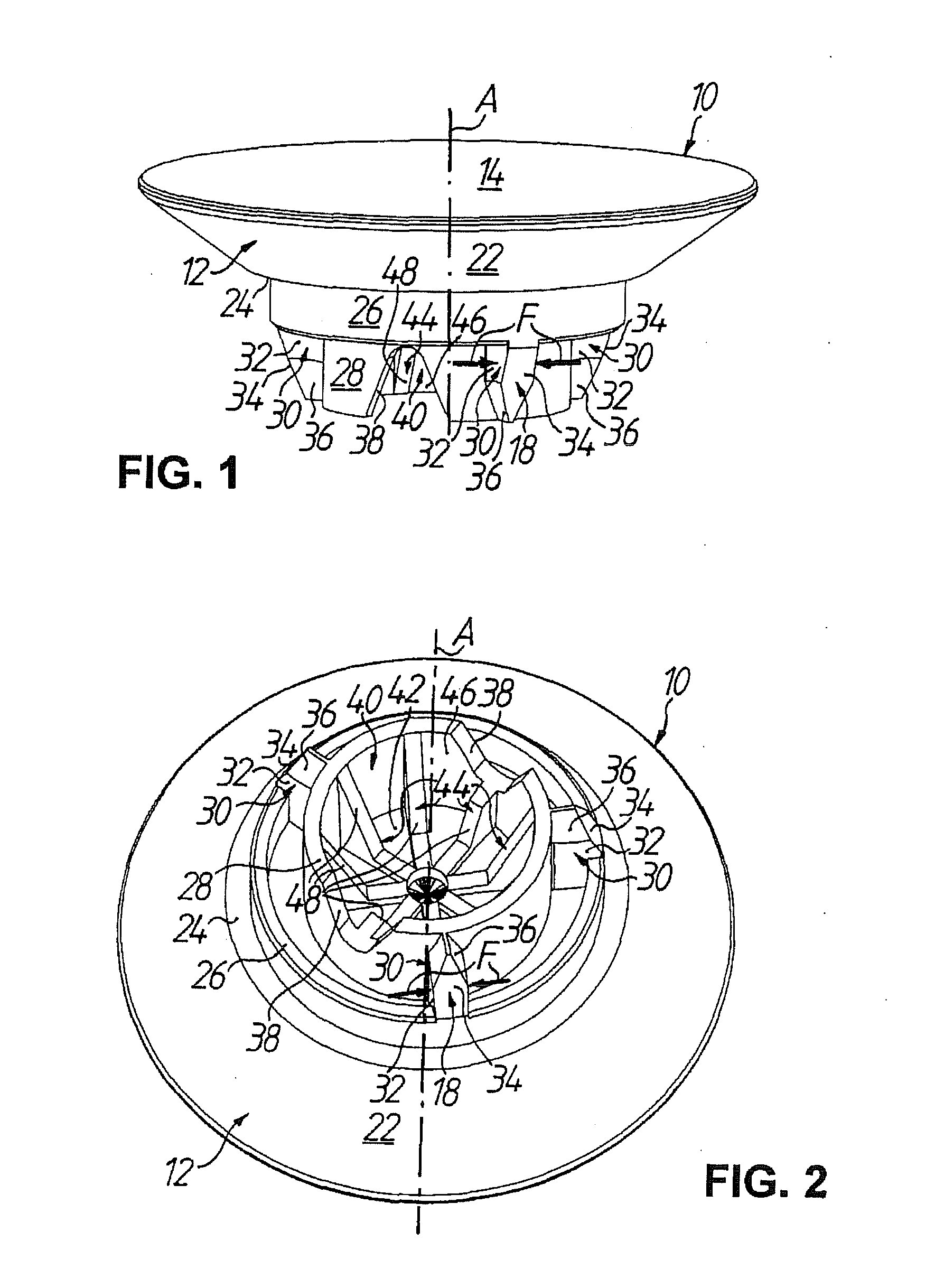

A block piece for holding a spectacle lens blank has a basic body with a workpiece mounting face portion against which the workpiece can be blocked with a blocking material, and a clamping portion via which the blocked workpiece can be fixed in a machine / apparatus for processing it. The basic body is made substantially of a material having a defined low water absorption and / or is sealed to at least reduce outgassing of water moisture under vacuum conditions, so that the block piece can be used also in vacuum coating processes. Alternatively or in addition, the clamping portion is constructed to be clamped by forces directed essentially perpendicular to the radial direction to cancel out each other and not deform the basic body, and / or the workpiece mounting face portion is provided with a predetermined amount of prism.

Owner:SATISLOH AG

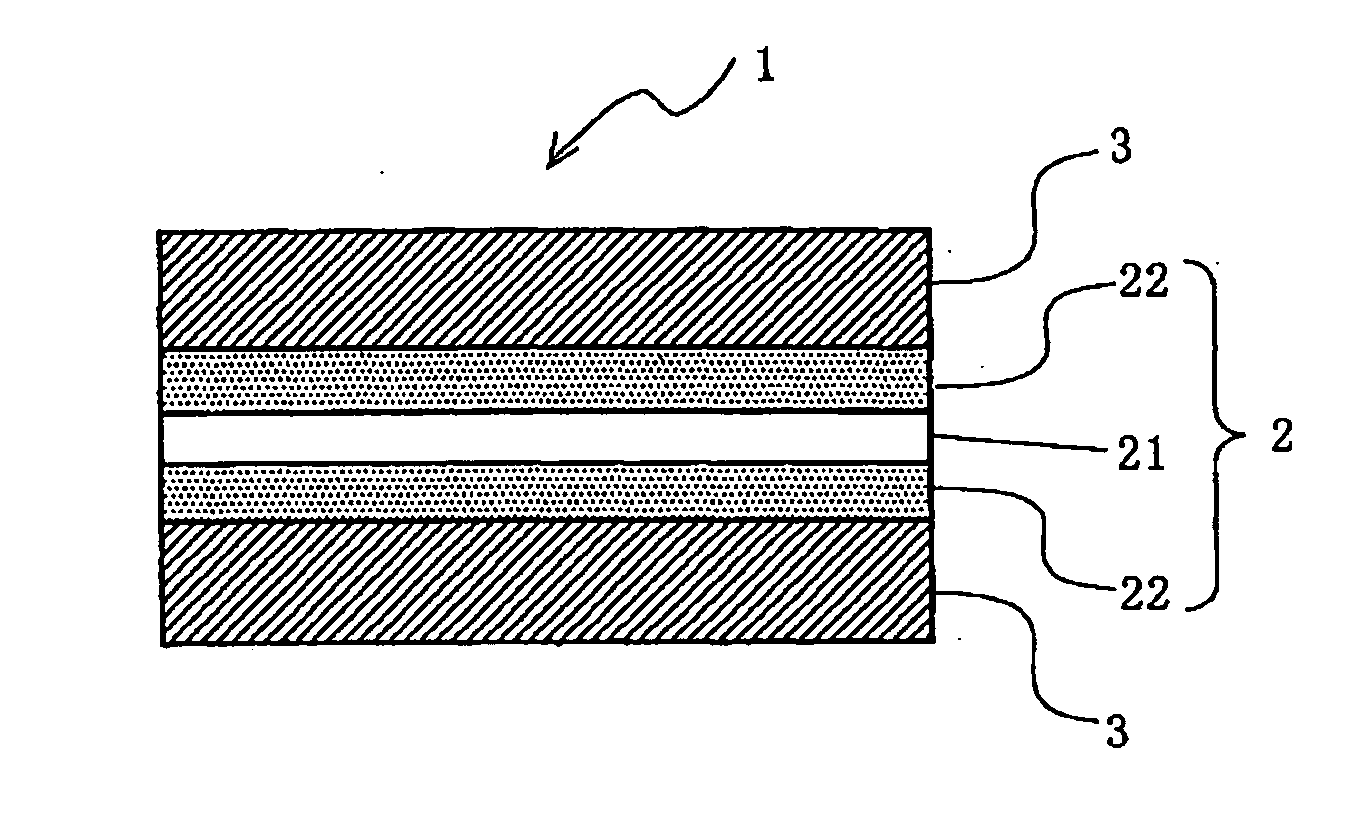

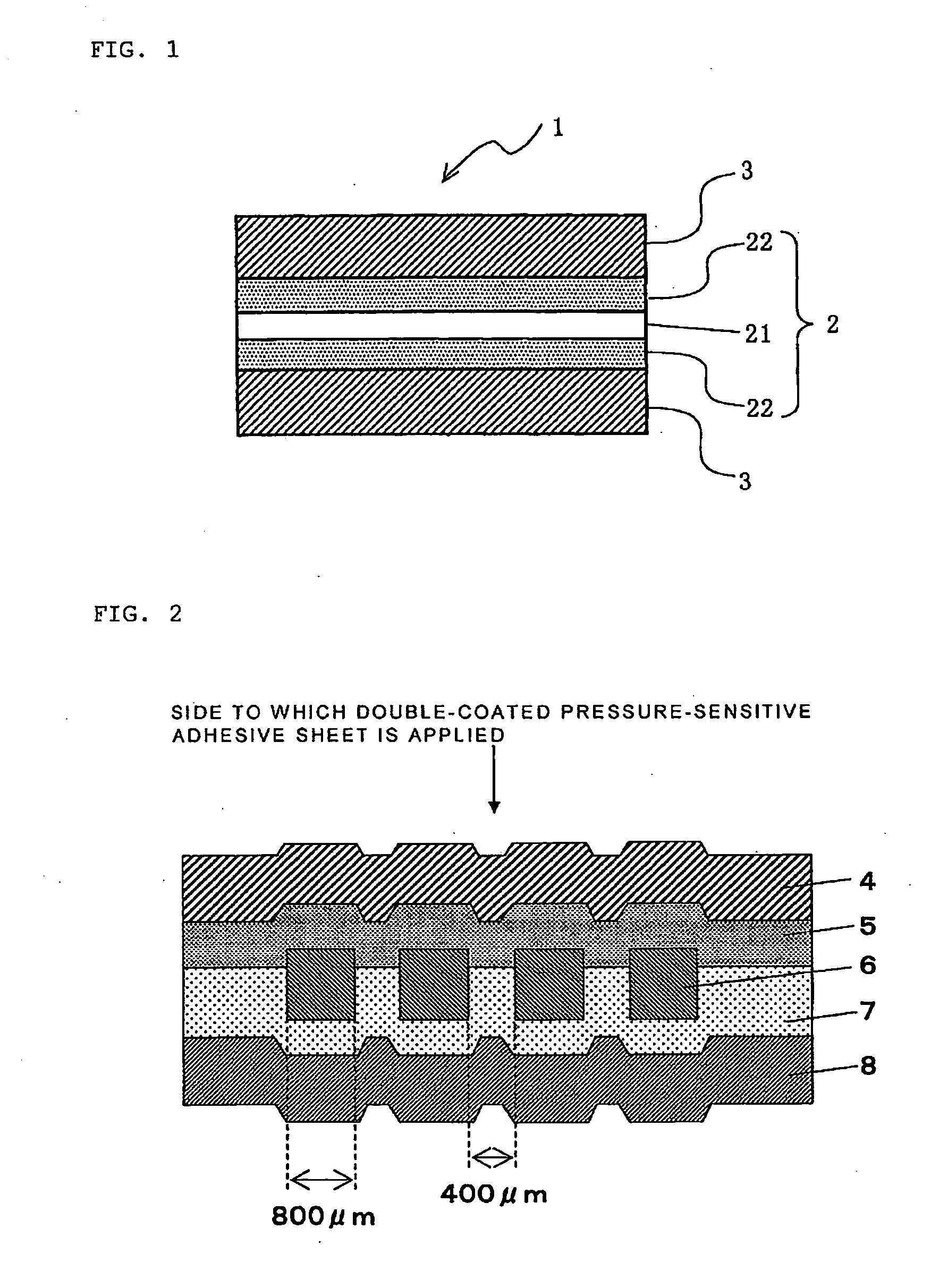

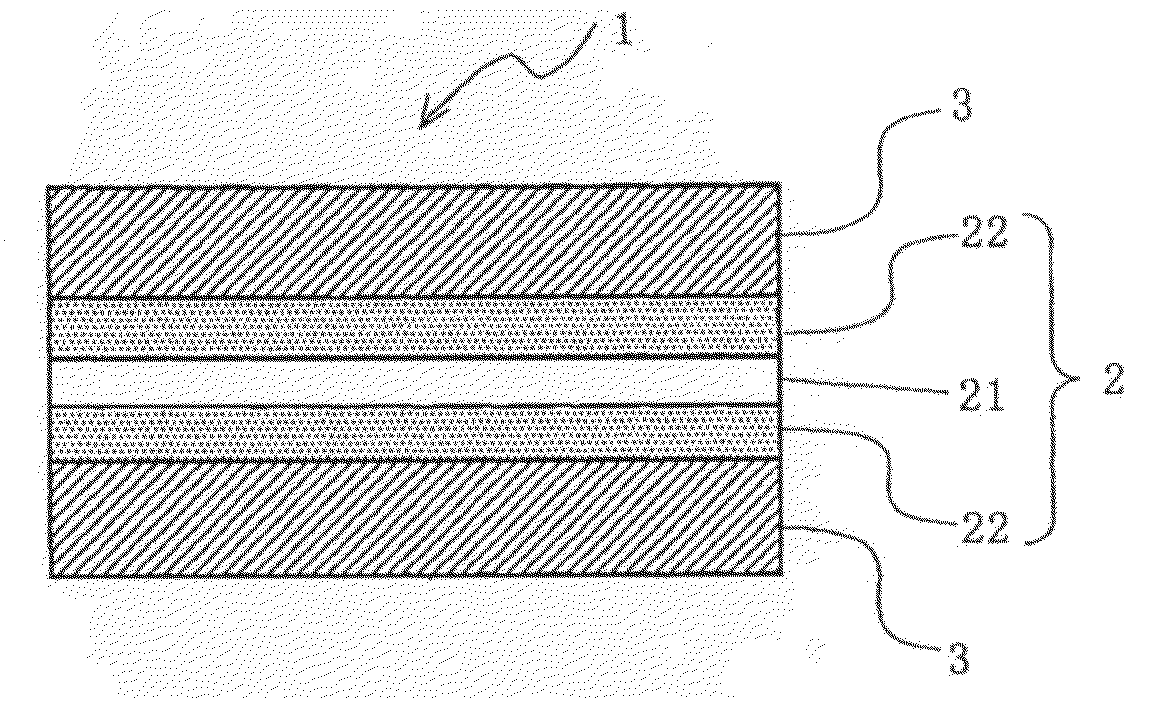

Double-coated pressure sensitive adhesive sheet for fixing flexible printed circuit board

InactiveUS20100183872A1Insufficient adhesivenessImprove adaptabilityLaminating printed circuit boardsSolid-state devicesMeth-Outgassing

Disclosed is a double-coated pressure-sensitive adhesive sheet for fixing a flexible printed circuit board, which includes at least a pressure-sensitive adhesive unit including a plastic base film having a thickness of 13 μm or less, and pressure-sensitive adhesive layers on both sides of the plastic base film. The pressure-sensitive adhesive layers are formed from an acrylic polymer containing, as essential monomer components, a polar-group-containing monomer and an alkyl (meth)acrylate whose alkyl moiety being a linear or branched-chain alkyl group having 2 to 14 carbon atoms. The pressure-sensitive adhesive unit has a thickness of 60 μm or less, the double-coated pressure-sensitive adhesive sheet shows an outgassing of 1 μg / cm2 or less when heated at 120° C. for 10 minutes, and shows a split distance (lifting) of 1.5 mm or less.

Owner:NITTO DENKO CORP

Methods for improving flow through fluidic channels

Methods for improving fluid flow in one or more flow features of a micro-fluid ejection head and micro-fluid ejection heads having improved fluid flow. One method includes bonding a substrate having a flow feature layer to an ejection head body using a relatively low stress, substantially flexible adhesive containing a relatively volatile polar organic compound. The adhesive is cured under conditions sufficient to induce outgassing of at least a portion of the relatively volatile polar organic compound on at least a portion of a flow feature surface sufficient to increase fluid wetting of the flow feature surface.

Owner:FUNAI ELECTRIC CO LTD

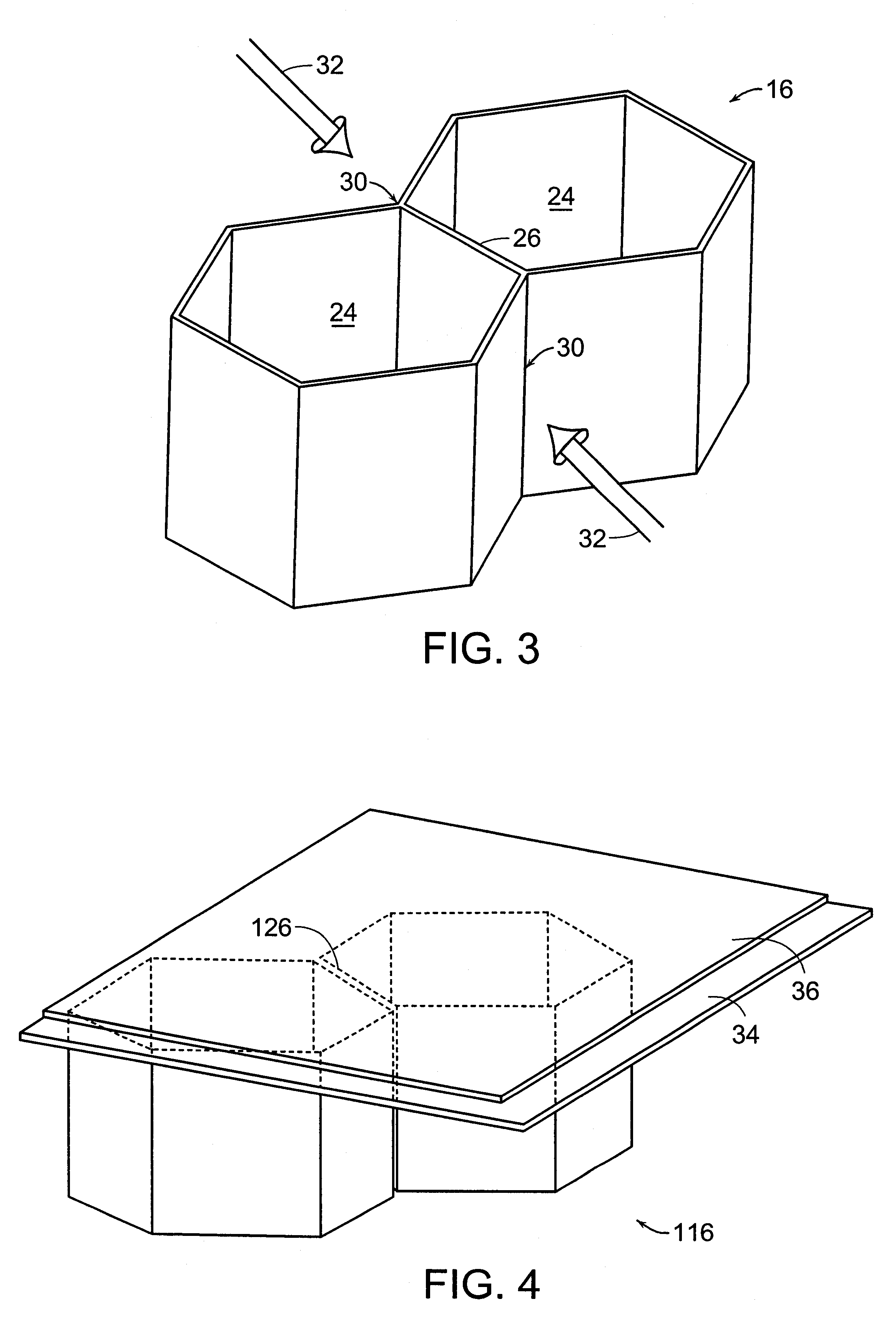

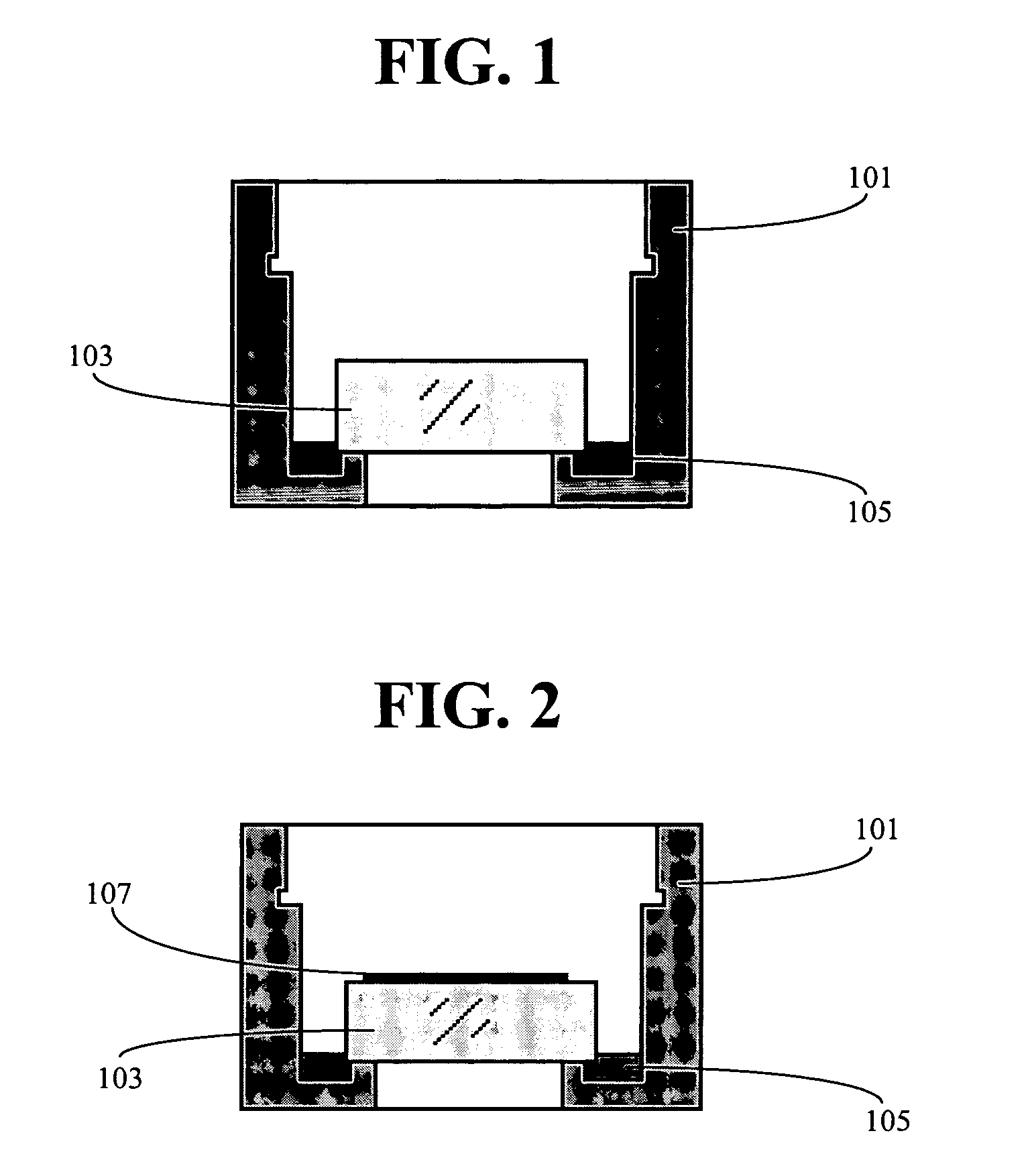

Packaged semiconductor device and method of packaging the semiconductor device

ActiveCN103187388ASemiconductor/solid-state device detailsSolid-state devicesInterfacial delaminationContact pad

The mechanisms of forming a molding compound on a semiconductor device substrate to enable fan-out structures in wafer-level packaging (WLP) are provided. The mechanisms involve covering portions of surfaces of an insulating layer surrounding a contact pad. The mechanisms improve reliability of the package and process control of the packaging process. The mechanisms also reduce the risk of interfacial delamination, and excessive outgassing of the insulating layer during subsequent processing. The mechanisms further improve planarization end-point. By utilizing a protective layer between the contact pad and the insulating layer, copper out-diffusion can be reduced and the adhesion between the contact pad and the insulating layer may also be improved.

Owner:TAIWAN SEMICON MFG CO LTD

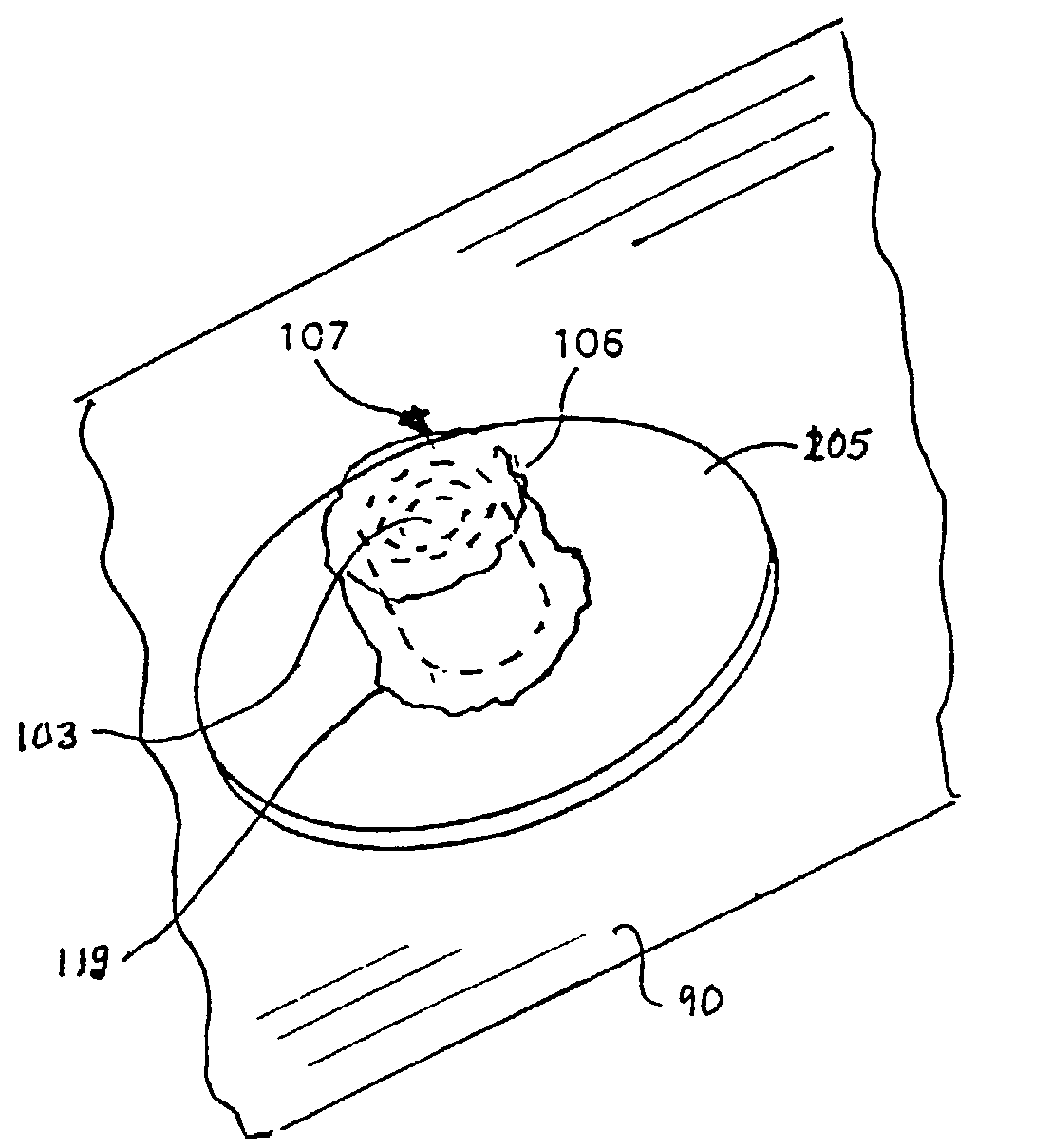

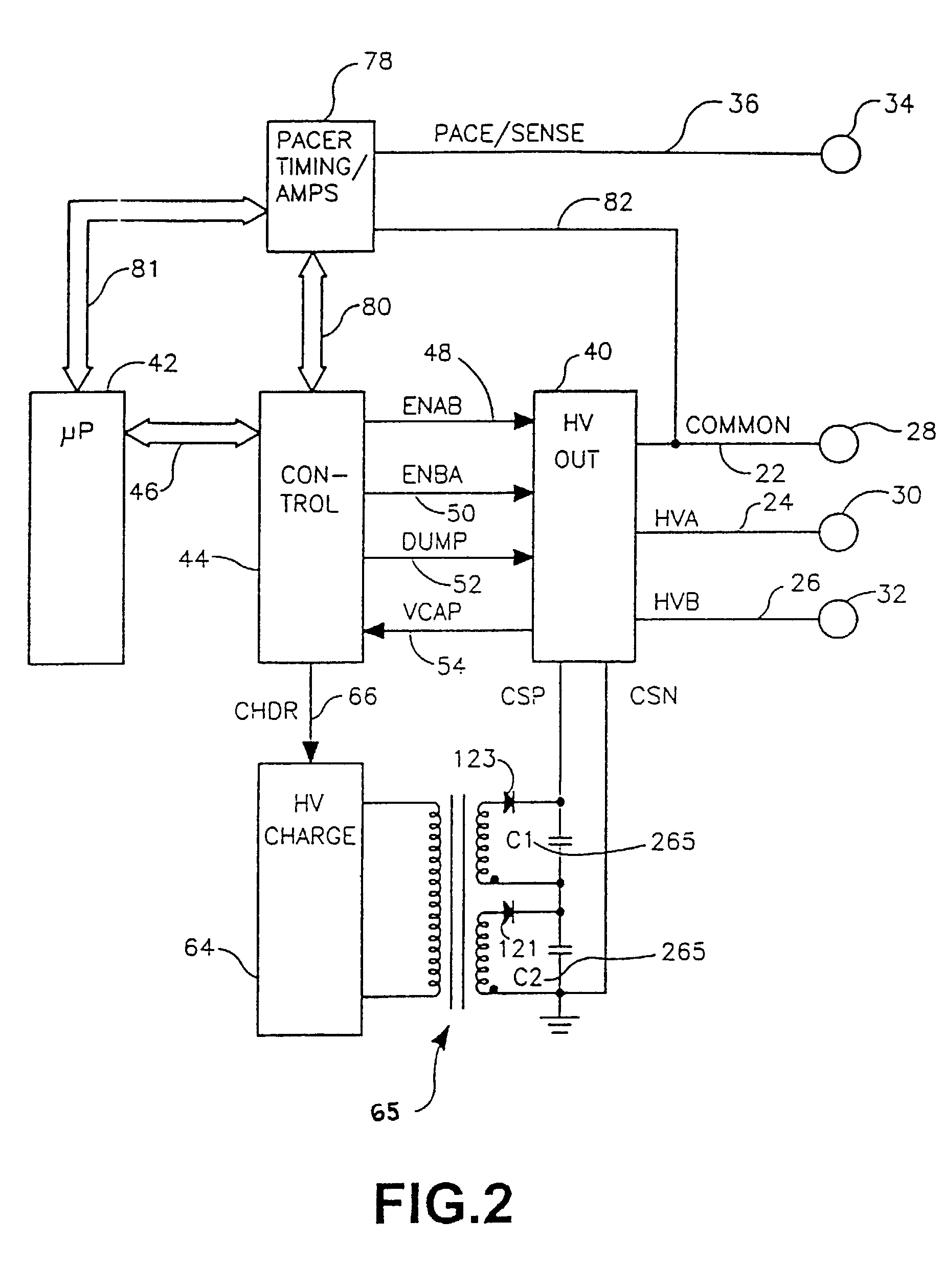

Implantable medical device having flat electrolytic capacitor with porous gas vent within electrolyte fill tube

InactiveUS7177140B2Prevent electrolyte leakageClosuresLiquid electrolytic capacitorsElectrolysisEngineering

Implantable medical devices (IMDs) and their various components, including flat electrolytic capacitors for same, and methods of making and using same and providing for outgassing of gases released during capacitor charge and discharge cycles are disclosed. A gas vent and liquid electrolyte barrier into the electrolyte fill tube lumen that is used to fill the interior case chamber with electrolyte and then needs to be closed to prevent leakage of electrolyte. The fill port is shaped to comprise a fill port tube having interior and exterior tube ends and a fill port ferrule intermediate the ends of the fill port tube and comprising a fill port ferrule flange extending transversely to and away from the fill port tube. The fill port ferrule is mounted in an opening disposed in one of the case wall and the cover wall with the ferrule flange in sealing engagement therewith to locate the exterior tube end extending outwardly away from the fill port ferrule flange and the interior tube end within the interior case chamber. A microporous plug is injected into and fills the fill port lumen, the plug formed of a microporous material allowing the escape of gas released from the liquid electrolyte during capacitor charging while preventing escape of liquid or vaporized electrolyte.

Owner:MEDTRONIC INC

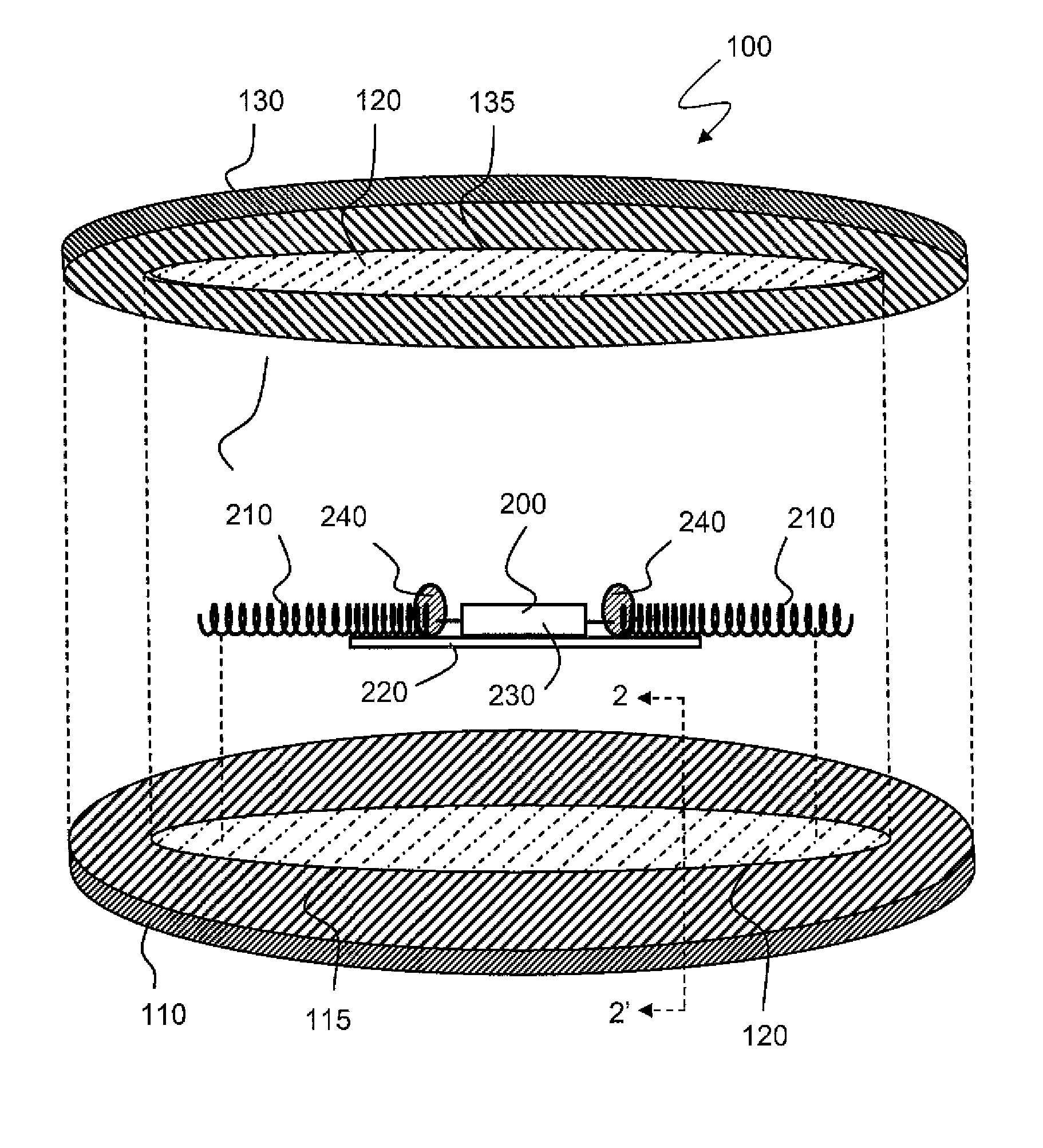

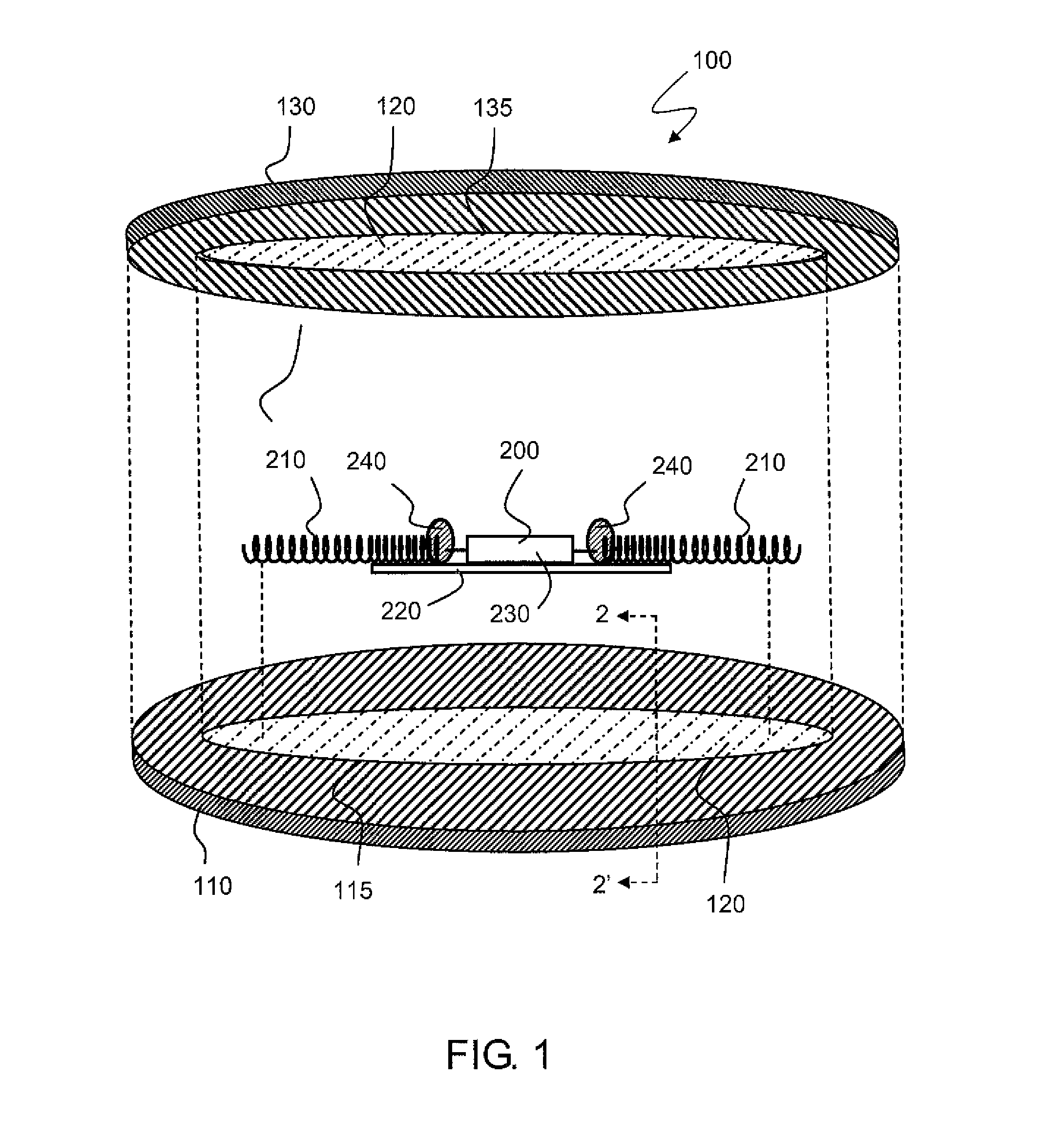

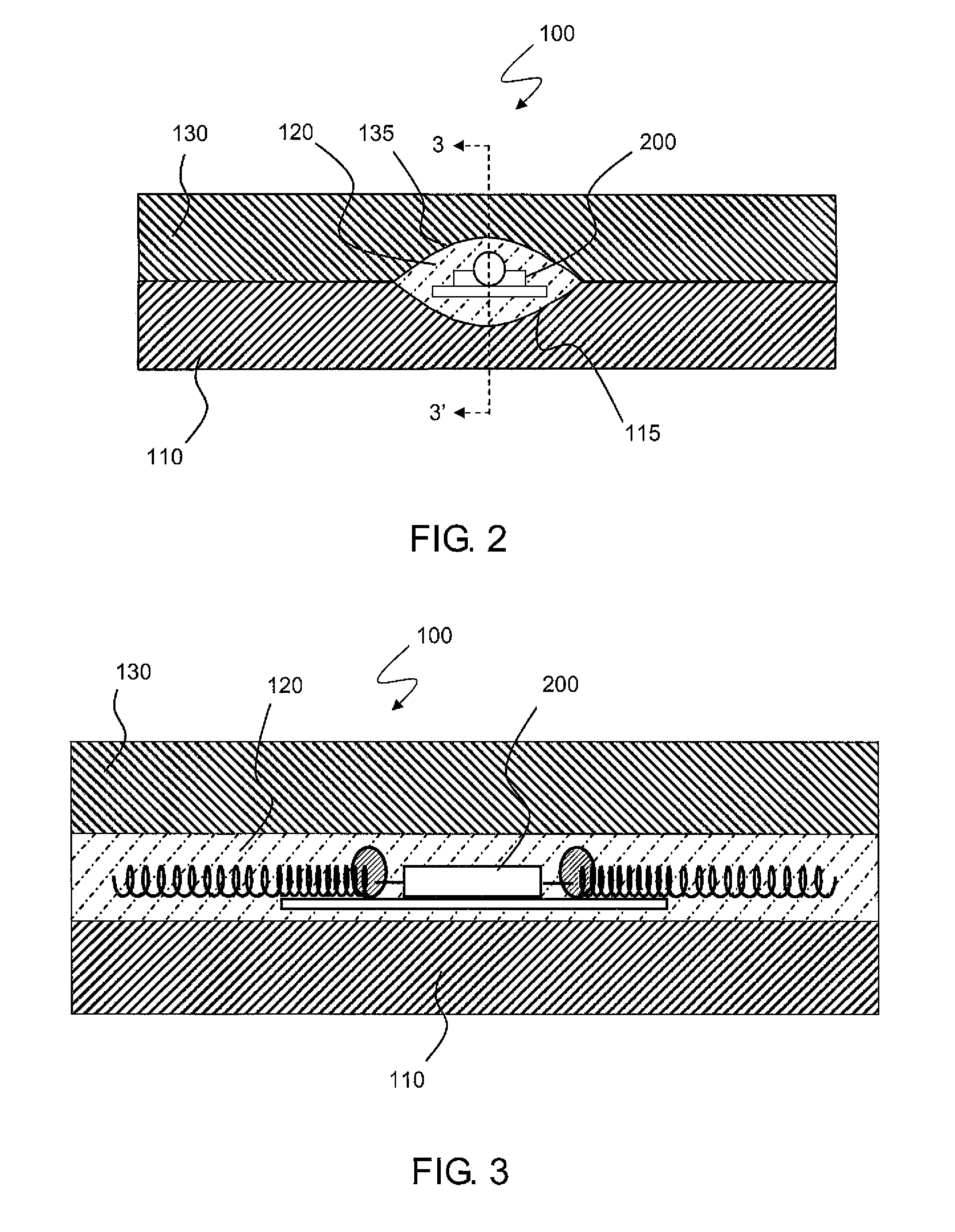

Flexible middle layer for RFID patch on tires

A tire mountable apparatus and a method of fabricating a tire mountable apparatus is disclosed. The tire mountable apparatus includes a first layer, a second layer and a middle layer disposed between the first layer and the second layer. The tire mountable apparatus further includes an electrical device embedded in the middle layer of the tire mountable apparatus. The middle layer of the tire mountable apparatus completely surrounds the electrical device and is formed from a potting compound. The potting compound does not require exposure to heat, air, moisture, or light to cure and does not require solvent evaporation or outgassing of reaction products to cure. The tire mountable apparatus may be constructed by curing the potting compound between the first layer and the second layer.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

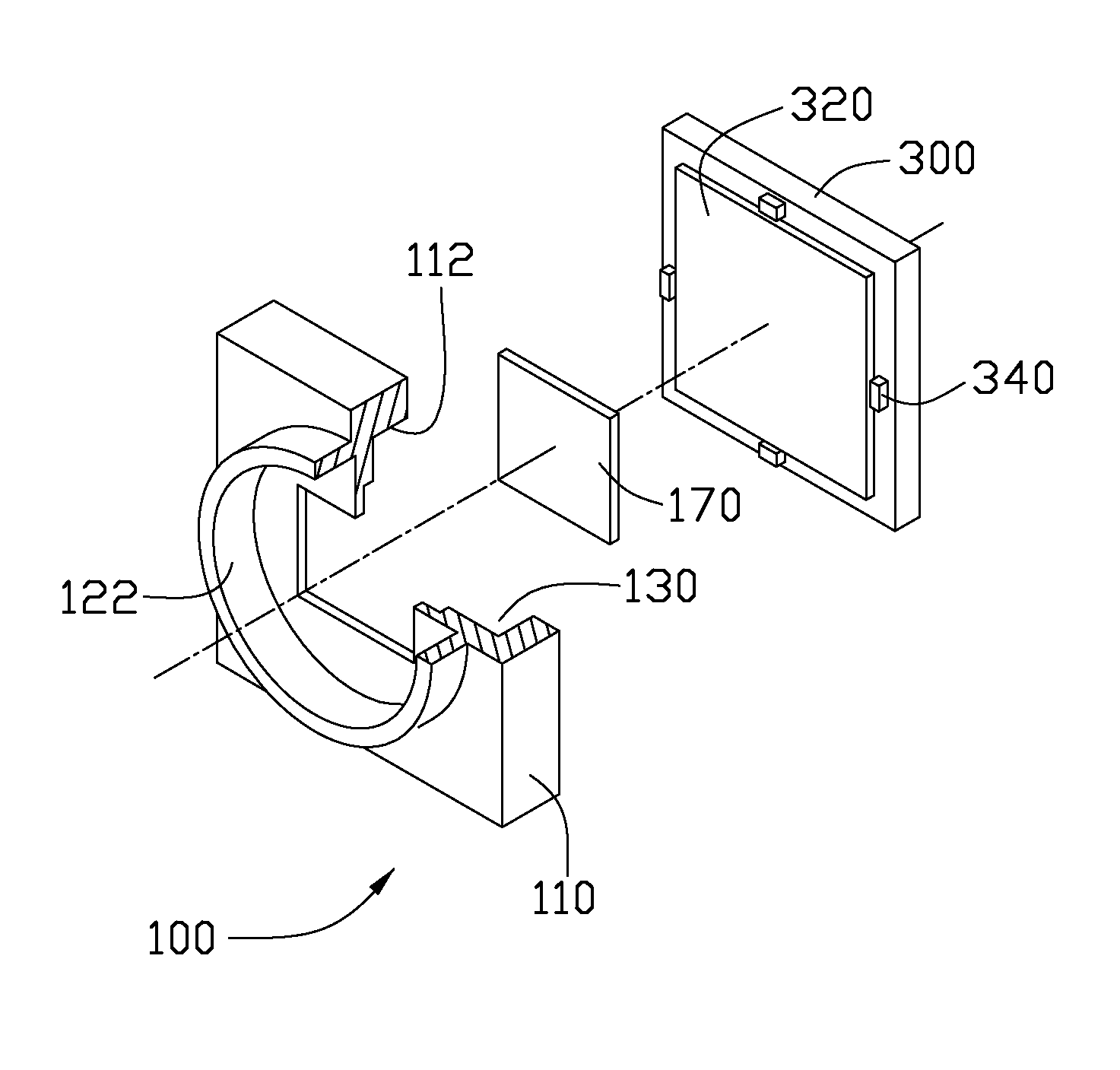

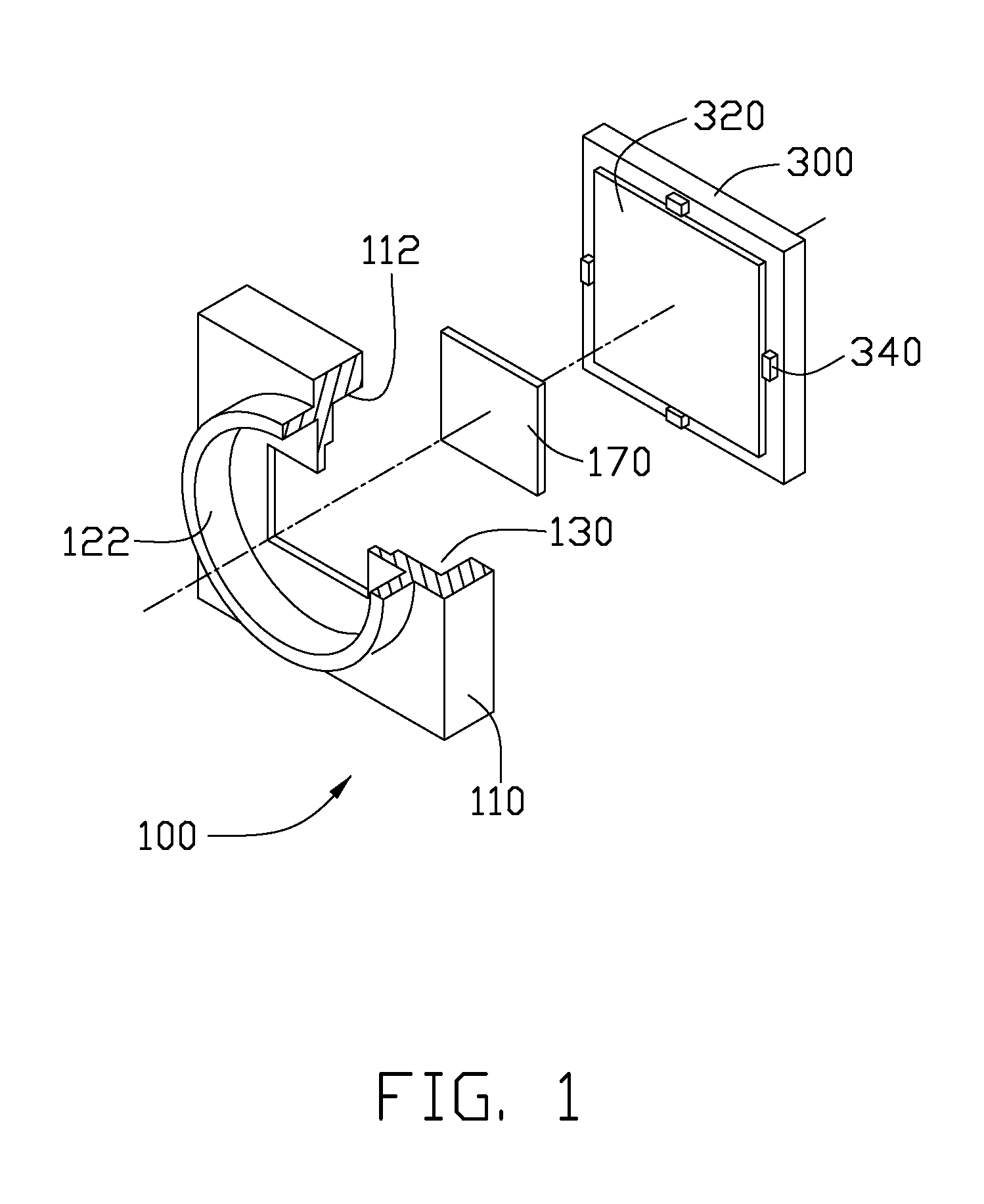

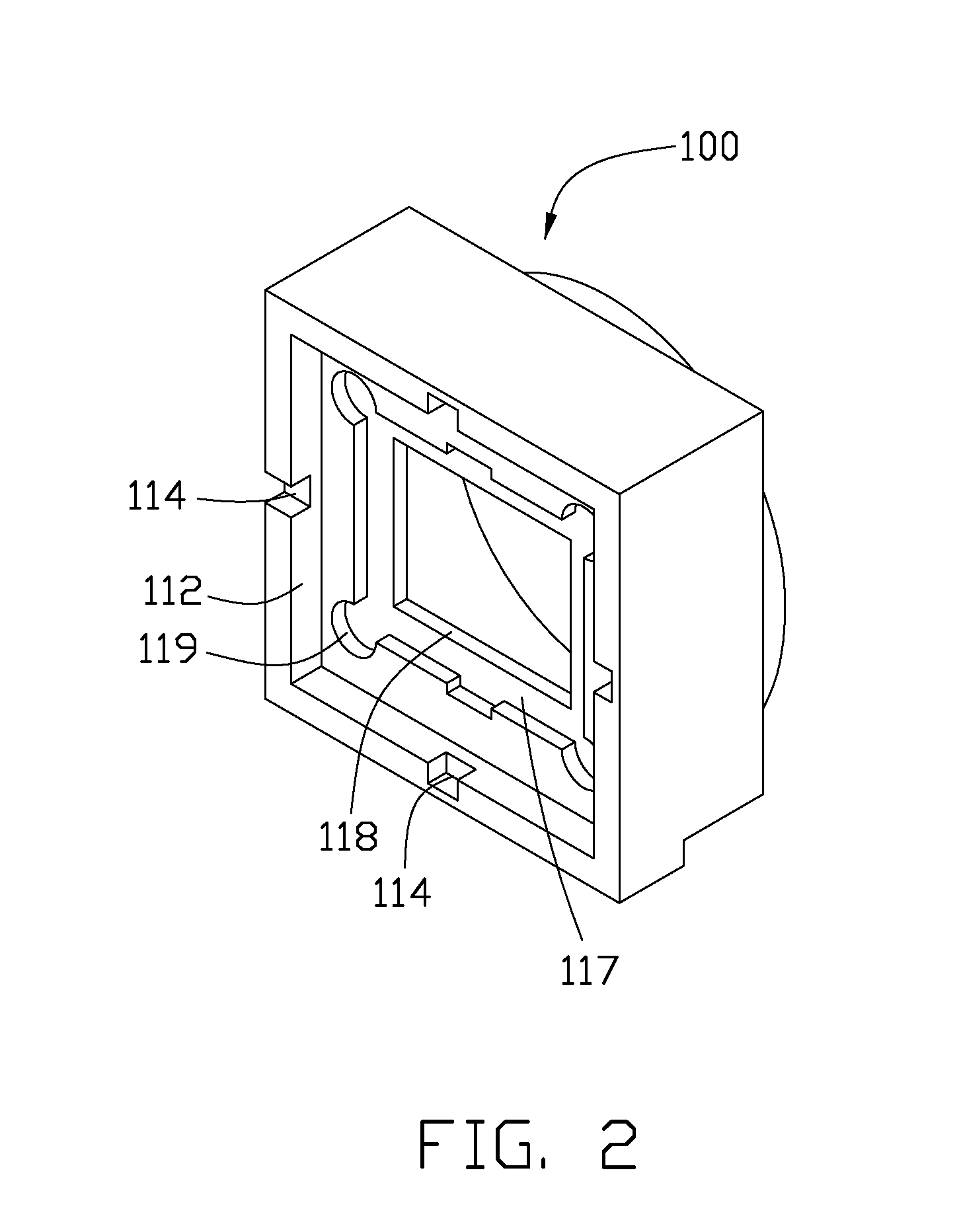

Objective holder for camera module

InactiveUS20090052887A1Effective coolingTelevision system detailsColor television detailsOutgassingAdhesive

An exemplary objective holder engages with a PCB substrate having an image sensor and several passive components arranged thereon. The passive components surround the image sensor. The objective includes a lens barrel extending from a side of a base, and a plurality of walls extending from an opposite side of the base. The walls enclose a chamber thereamong for receiving the image sensor and define notches therein for receiving the passive components therein. A transparent cover is received in the objective holder between the lens barrel and the chamber. An adhesive is used to connect the objective holder to the PCB substrate. The PCB substrate is rested on the walls. At least one of the notches communicates the chamber to an exterior for outgassing and is sealed by a mass of sealing material after a heating process of the adhesive.

Owner:POLIGHT TECH LTD

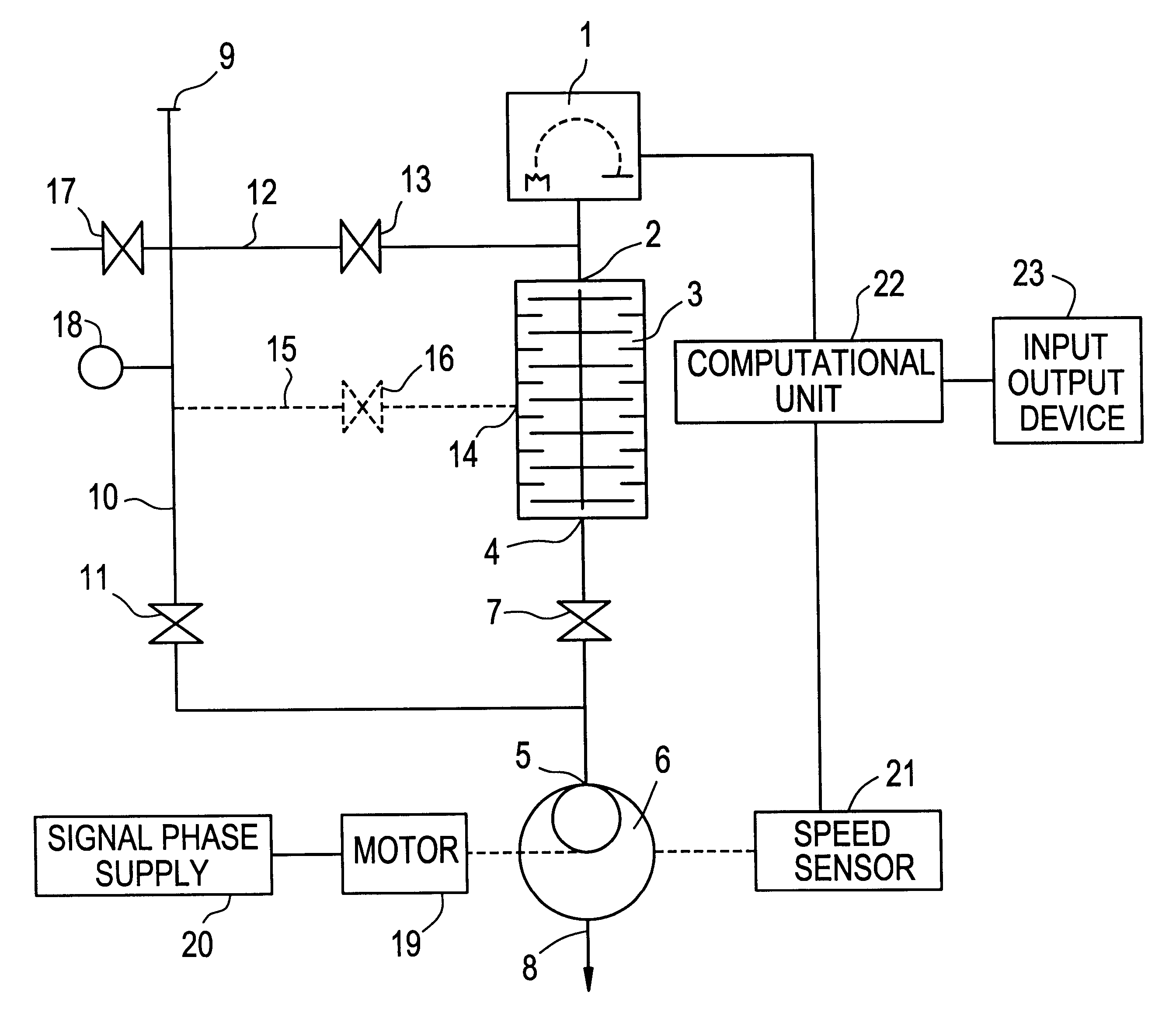

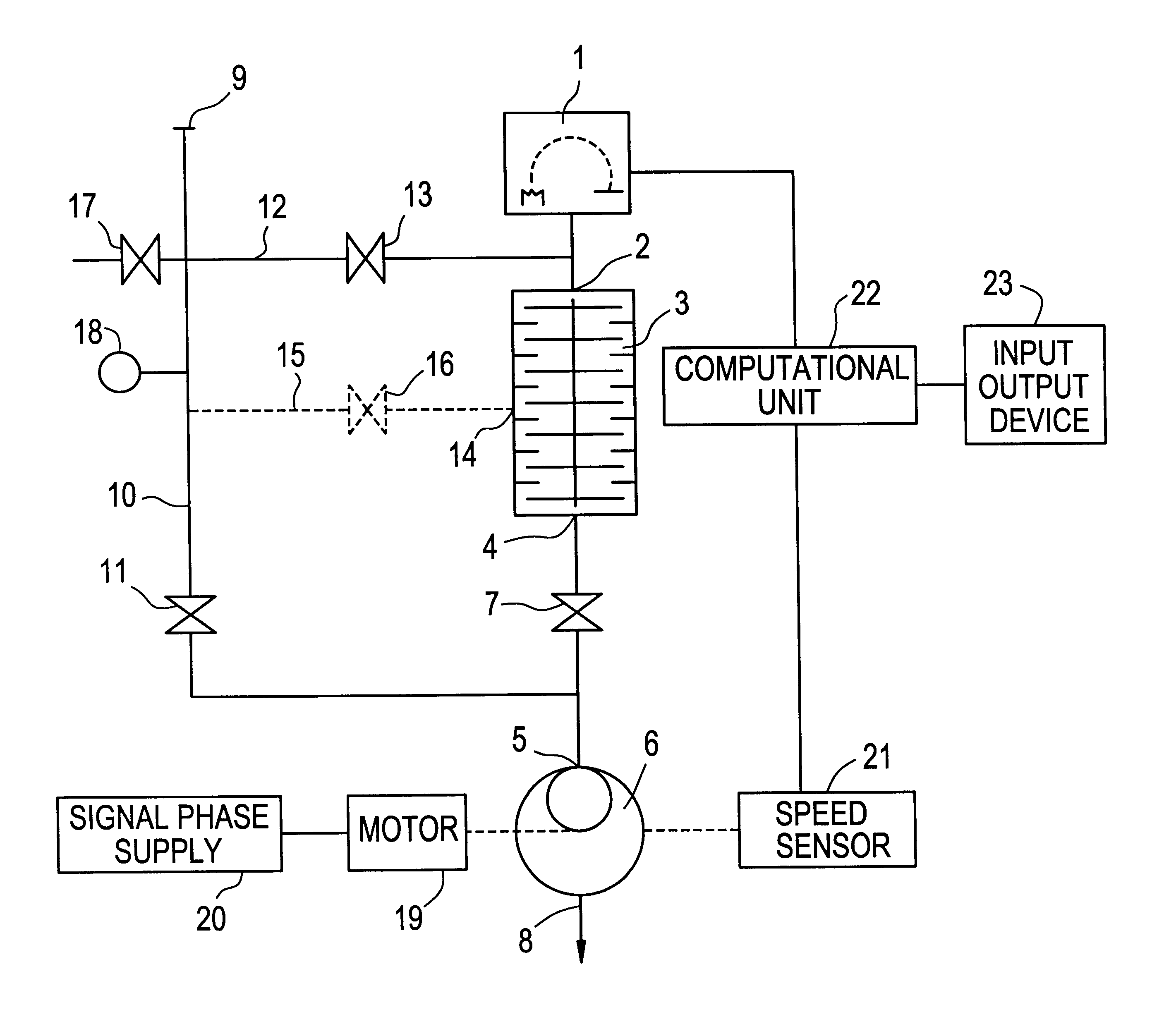

Variable speed primary pumping in a tracer gas leak detector

InactiveUS6354141B1Reducing pre-evacuation timeShorten the timeDetection of fluid at leakage pointOutgassingControl valves

In a system in accordance with the invention for detecting leaks, a mass spectrometer is connected to the aspiration side of a secondary pump whose discharge side is connected to the aspiration side of a primary pump driven by a rotational drive system adapted to vary the rotation speed of the primary pump between at least two different rotation speeds. An aspiration inlet is selectively connected by control valves either to the aspiration side of the primary pump or to the aspiration side or an intermediate area of the secondary pump. Variation of the rotation speed of the primary pump is used to perform faster pre-evacuation before the test, to detect grosser leaks, to compensate for a high level of outgassing or to adapt the sensitivity of the device, and equally to eliminate helium background noise from the primary pump.

Owner:ALCATEL LUCENT SAS

Multi-stage curing of low K nano-porous films

InactiveUS7611996B2Semiconductor/solid-state device detailsSolid-state devicesThermal energyGas phase

Embodiments in accordance with the present invention relate to multi-stage curing processes for chemical vapor deposited low K materials. In certain embodiments, a combination of electron beam irradiation and thermal exposure steps may be employed to control selective outgassing of porogens incorporated into the film, resulting in the formation of nanopores. In accordance with one specific embodiment, a low K layer resulting from reaction between a silicon-containing component and a non-silicon containing component featuring labile groups, may be cured by the initial application of thermal energy, followed by the application of radiation in the form of an electron beam.

Owner:APPLIED MATERIALS INC

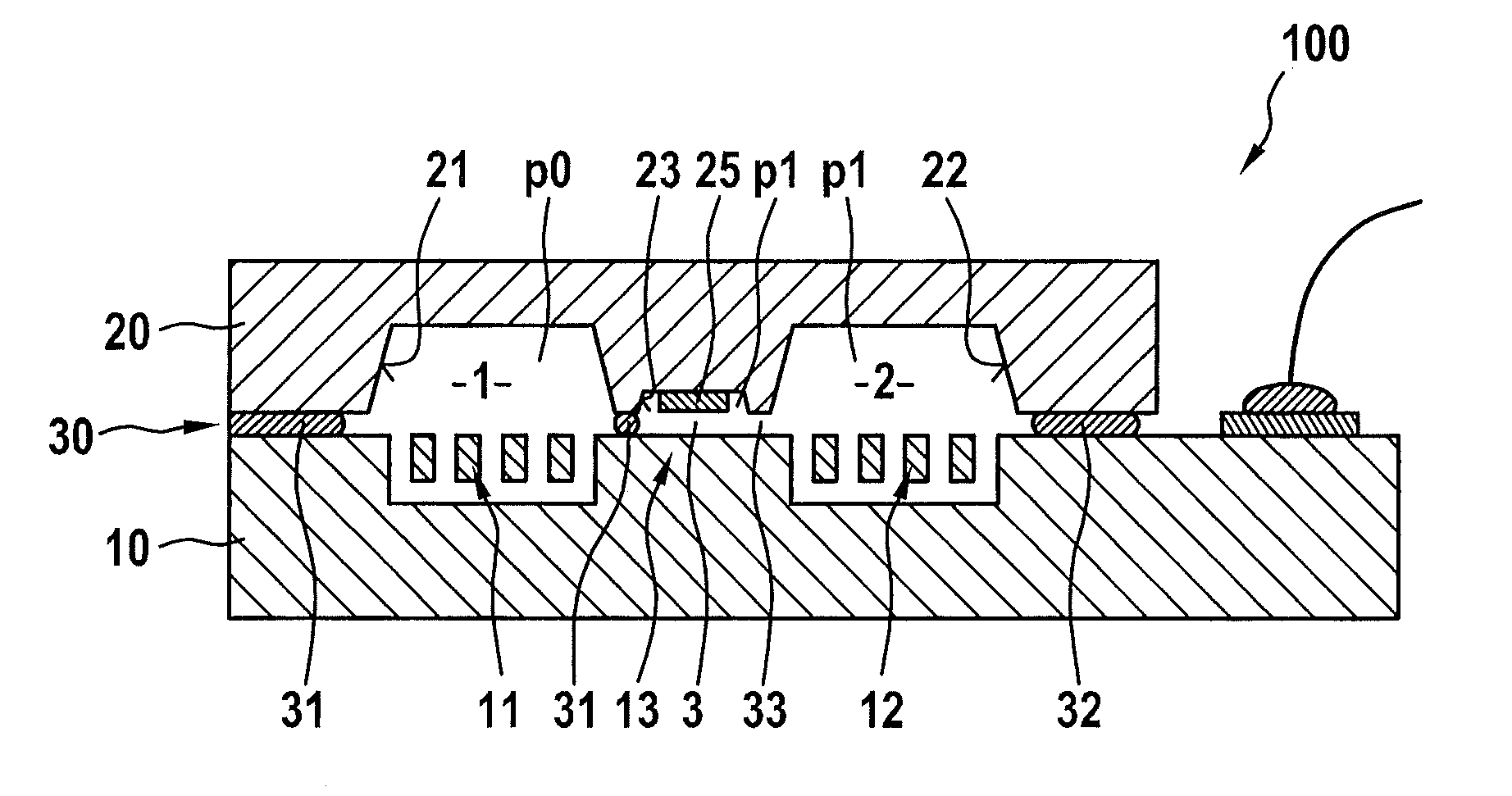

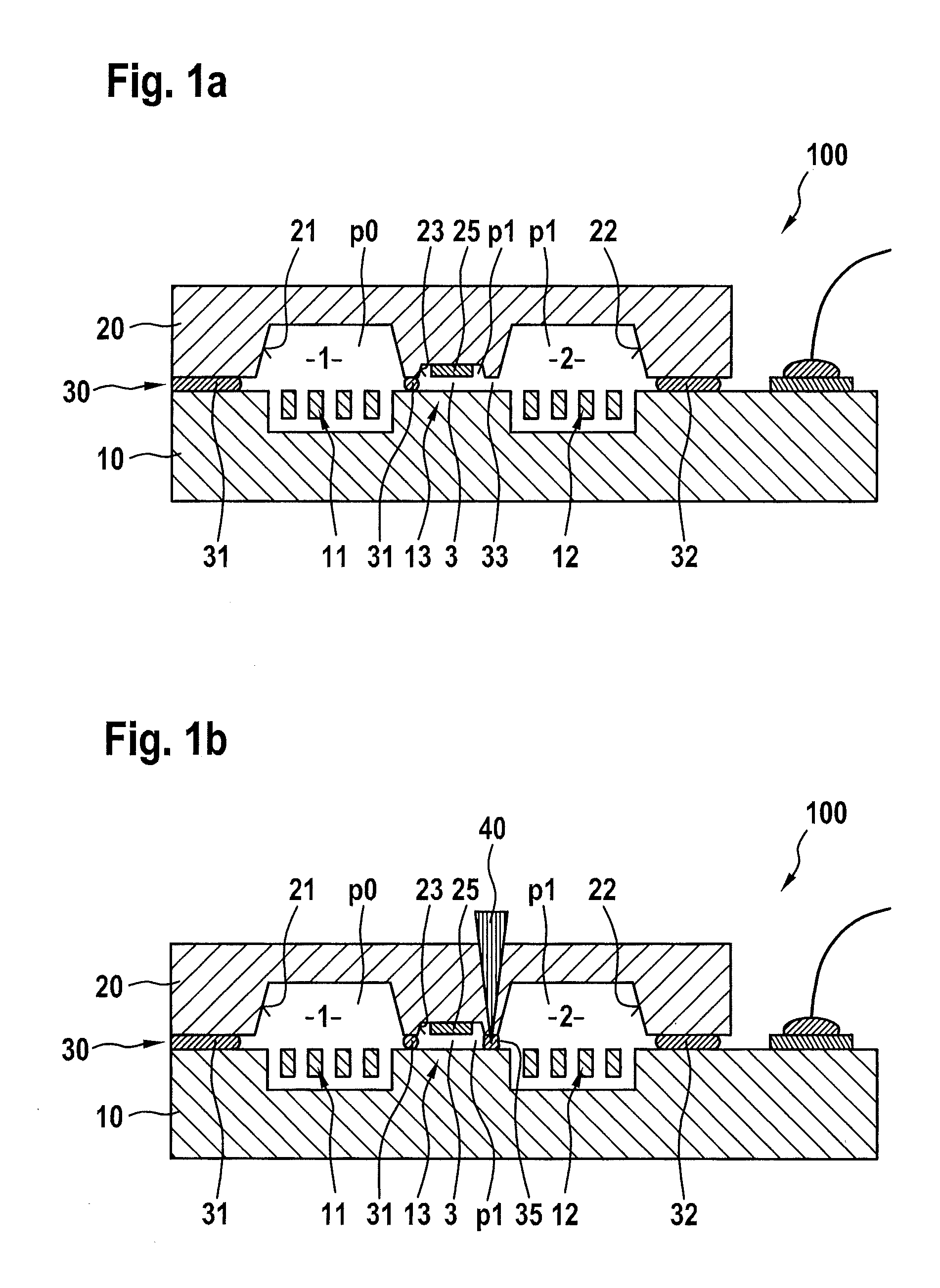

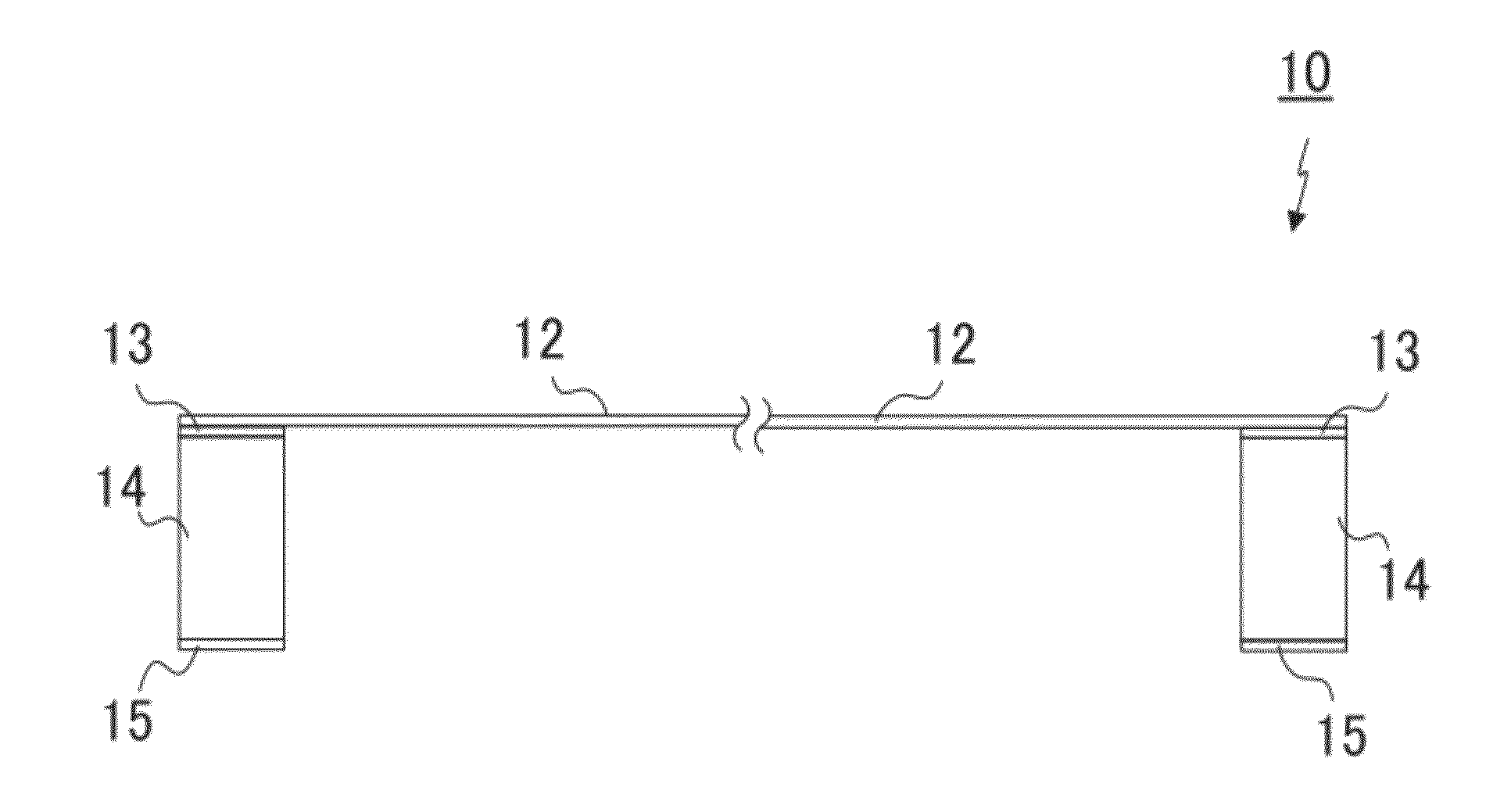

Component including two semiconductor elements between which at least two hermetically tightly sealed cavities having different internal pressures are formed and method for manufacturing such a component

ActiveUS20150353346A1FocusEasy to useDecorative surface effectsSemiconductor/solid-state device detailsOutgassingGetter

For the targeted influencing of the internal pressure within a cavity between two elements of a component, a getter material or an outgassing material is situated in an additional cavity between the two elements. After the two elements are bonded to one another, the additional cavity is still to be joined via a connecting opening to the cavity. The getter material or the outgassing material is then activated so that gasses are bound in the additional cavity and in the connected cavity, or an outgassing takes place. Only when the sought internal pressure has established itself in the connected cavity is the connecting opening to the additional cavity closed. In this way, the getter material or the outgassing material is only used for establishing a defined internal pressure, but no longer has any influence on the internal pressure within the cavity during ongoing operation of the component.

Owner:ROBERT BOSCH GMBH

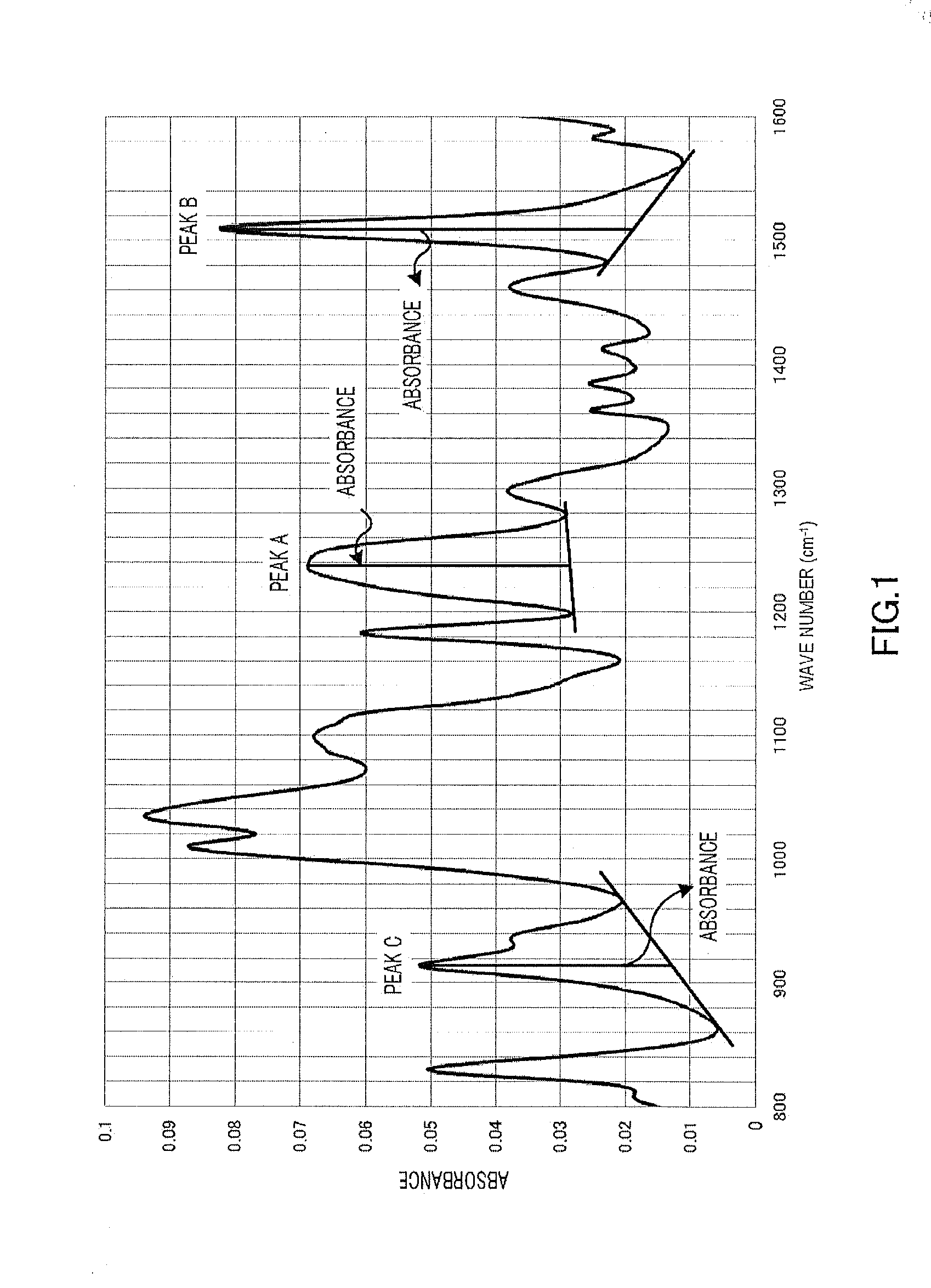

Pellicle frame and pellicle containing same

ActiveUS20120122025A1Moderate film strengthGood chemical resistanceSynthetic resin layered productsRecord information storageEpoxyHigh resistance

Provided is a pellicle that has appropriate membrane strength, high resistance to chemicals, and a low degree of sulfate ion generation and outgassing. A provided pellicle frame supports the outer rim of a pellicle membrane, and an epoxy resin coating is formed on the surface of the pellicle frame. In the infrared absorption spectrum of said epoxy resin coating, the ratio of the absorbance of a peak in the range between 1450 cm−1 and 1550 cm−1 to the absorbance of a peak in the range between 1200 cm−1 and 1275 cm−1 is at least 0.5 and at most 3; also, the ratio of the absorbance of a peak in the range between 1450 cm−1 and 1550 cm−1 to the absorbance of a peak in the range between 905 cm−1 and 930 cm−1 is at least 1 and less than 7.

Owner:MITSUI CHEM INC

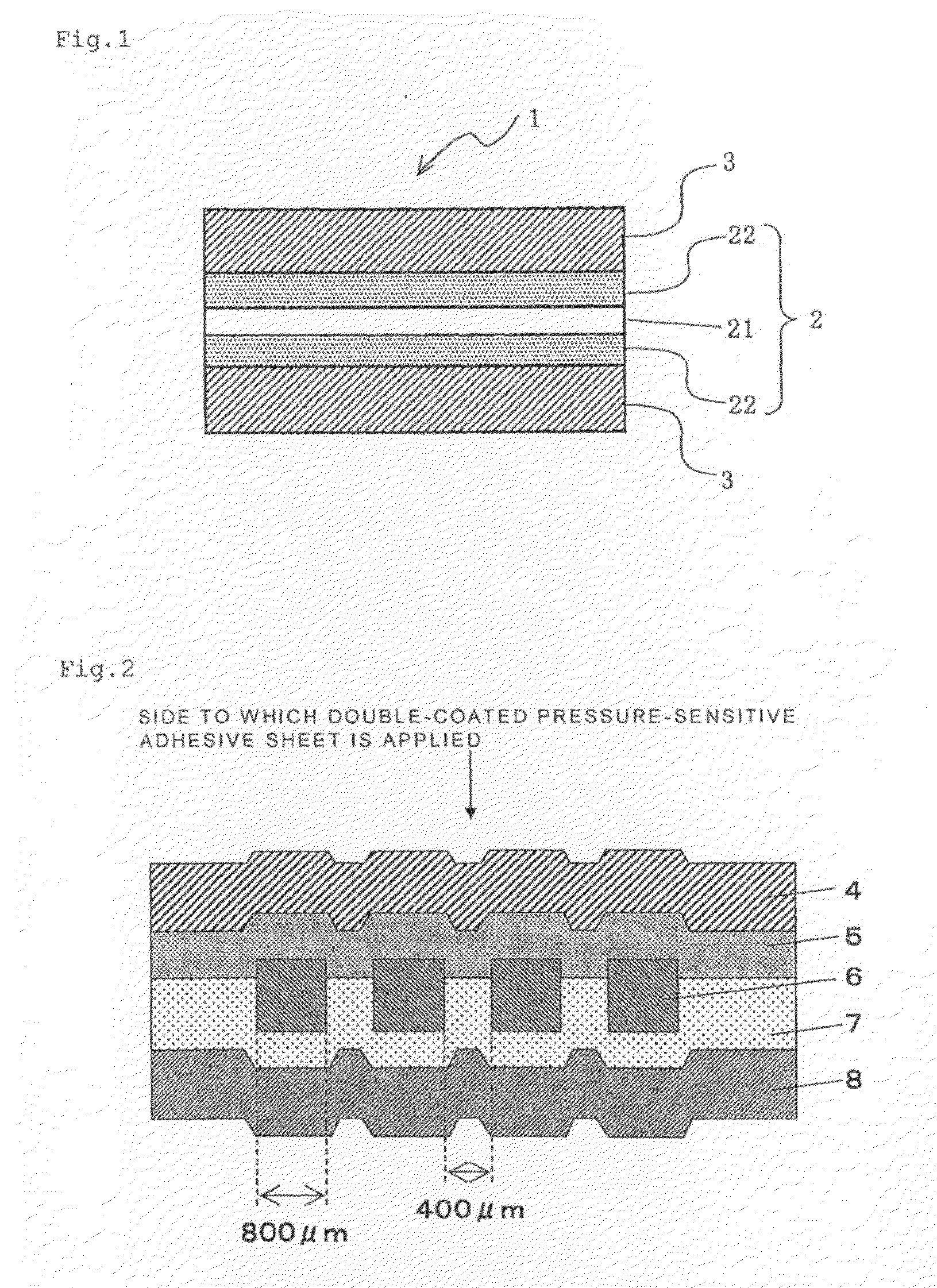

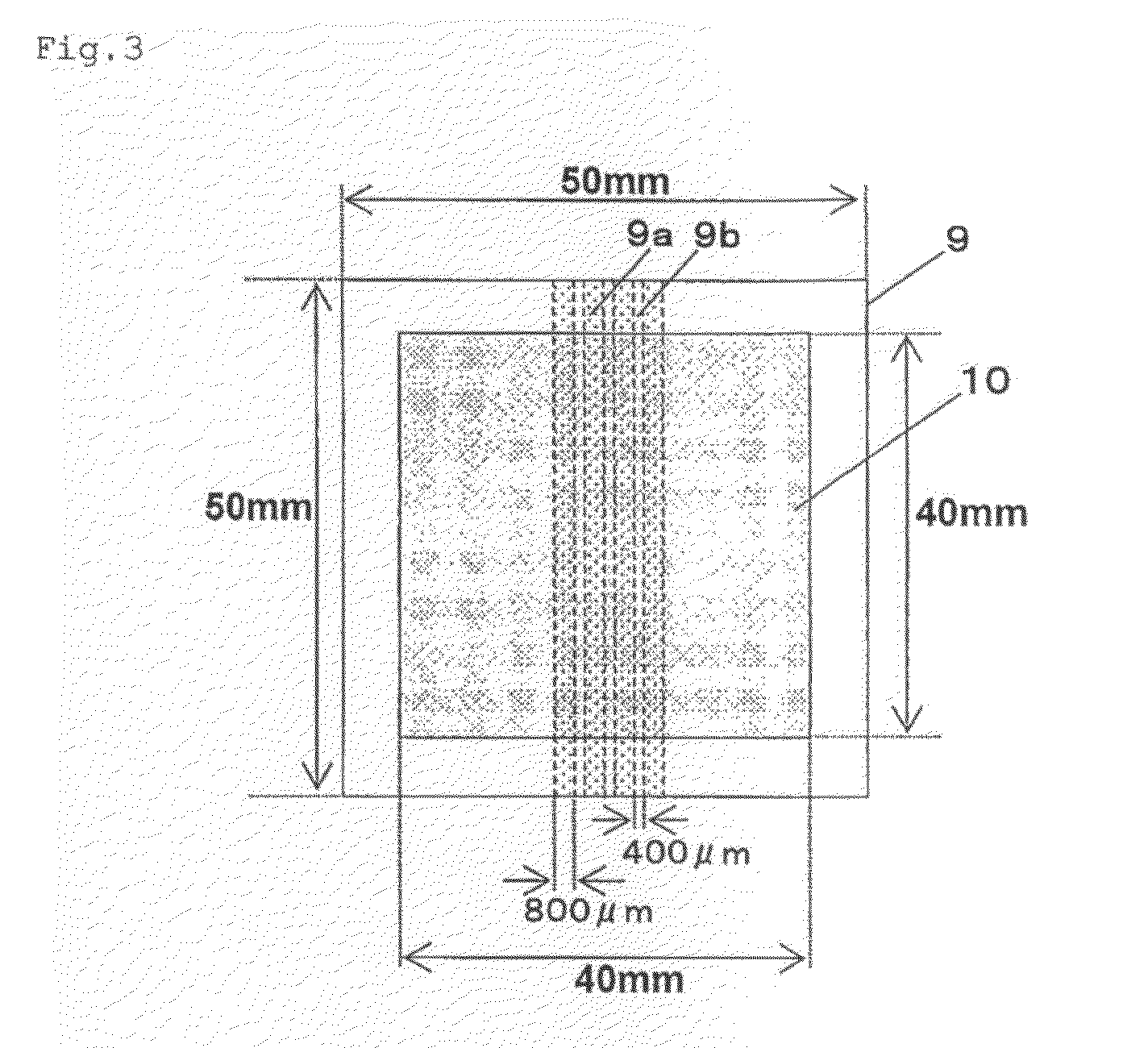

Double-coated pressure sensitive adhesive sheet for fixing hard disk drive component and hard disk drive

InactiveUS20100124627A1Improve machinabilityLess pollutionFilm/foil adhesivesLayered productsHard disc driveOutgassing

Disclosed is a double-coated pressure-sensitive adhesive sheet adopted to fix a hard disk drive component, which includes a pressure-sensitive adhesive unit including a plastic film base having a thickness of 20 μm or less and pressure-sensitive adhesive layers arranged on or above both sides of the plastic film base; and non-silicone release liners arranged on both surfaces of the pressure-sensitive adhesive unit. The pressure-sensitive adhesive unit has a thickness of 60 μm or less, and the double-coated pressure-sensitive adhesive sheet shows an outgassing of 1 μg / cm2 or less when the double-coated pressure-sensitive adhesive sheet is heated at a temperature of 120° C. for 10 minutes. The double-coated pressure-sensitive adhesive sheet is free from silicone, thereby causes less contamination, evolves less outgas, and is superior in workability. It has further improved followability to difference in level by controlling the thickness of the plastic film base to 13 μm or less. Additionally, it becomes resistant to “lifting” from an adherend even when subjected to a heating process after affixation, by specifying the gel fraction of the pressure-sensitive adhesive layer within a range of 10% to 60%.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com