Patents

Literature

119results about "AC/DC convertors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

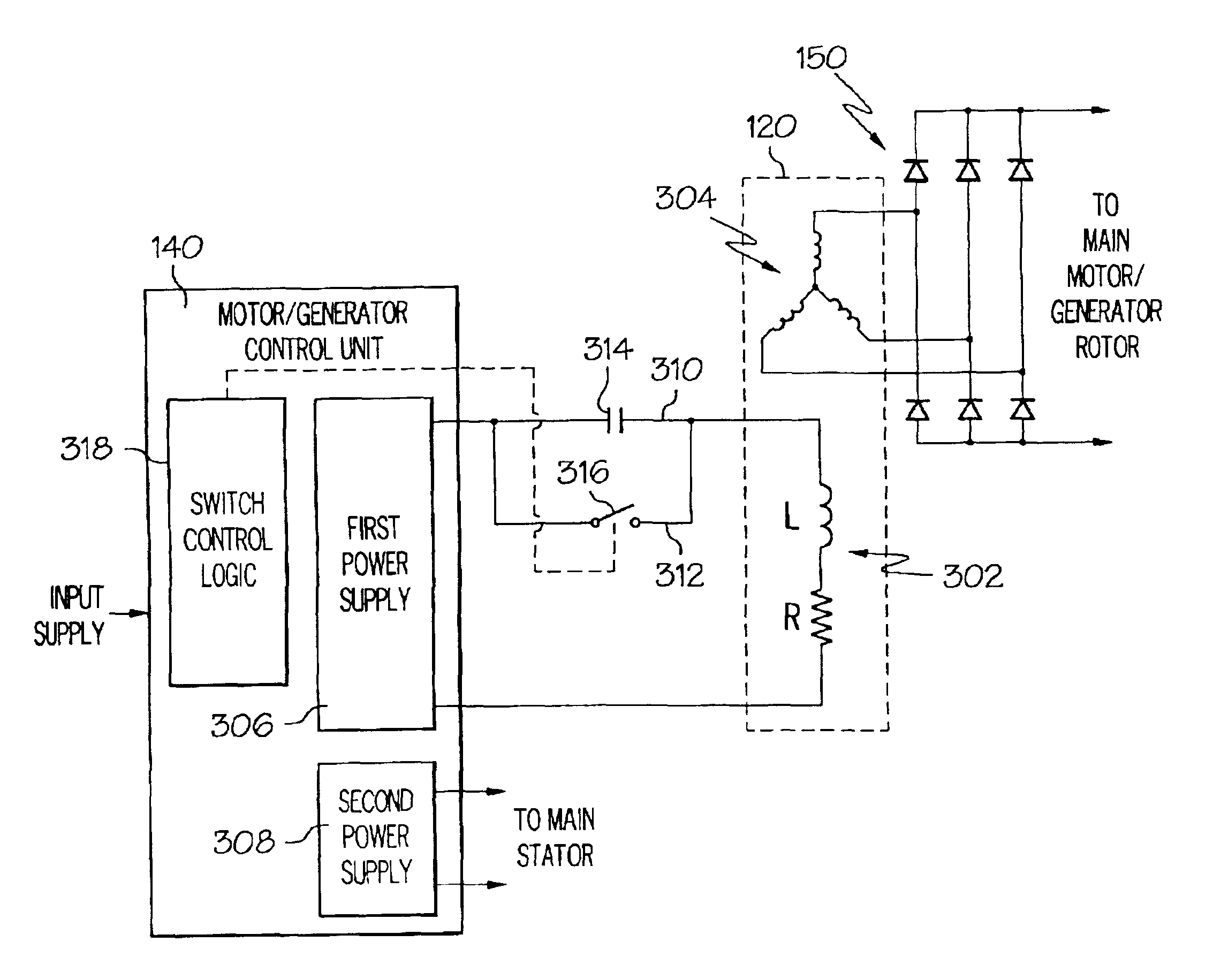

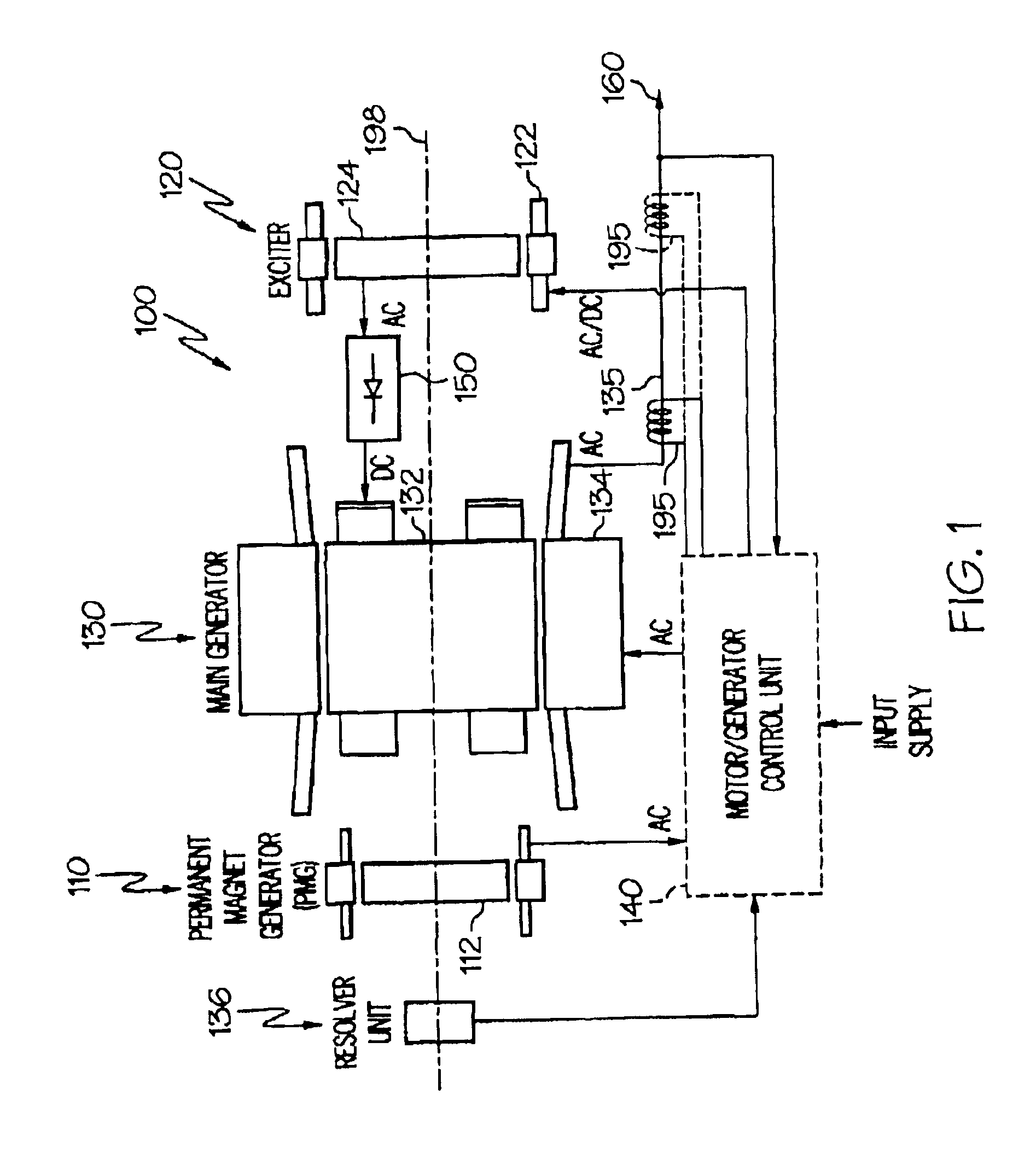

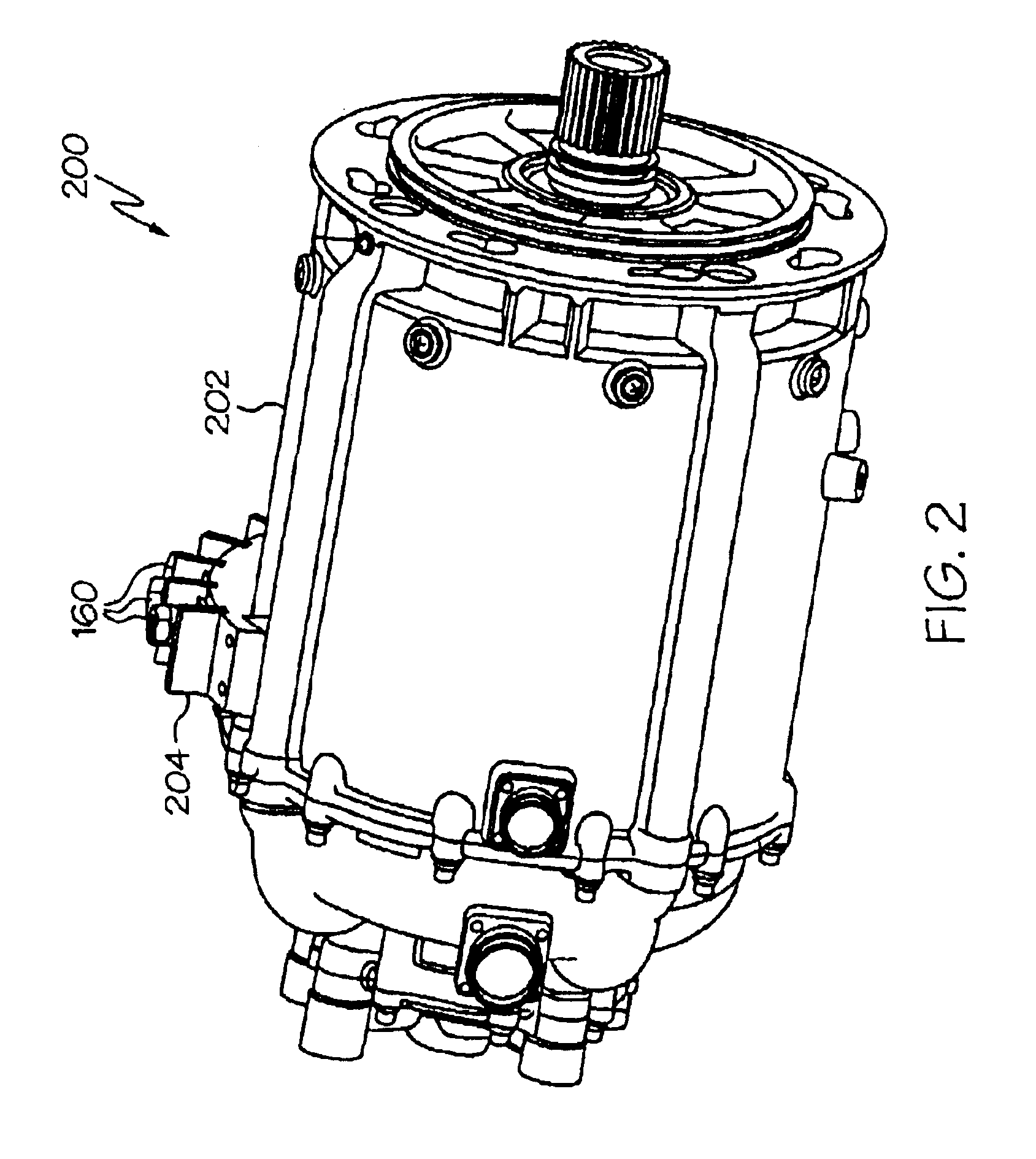

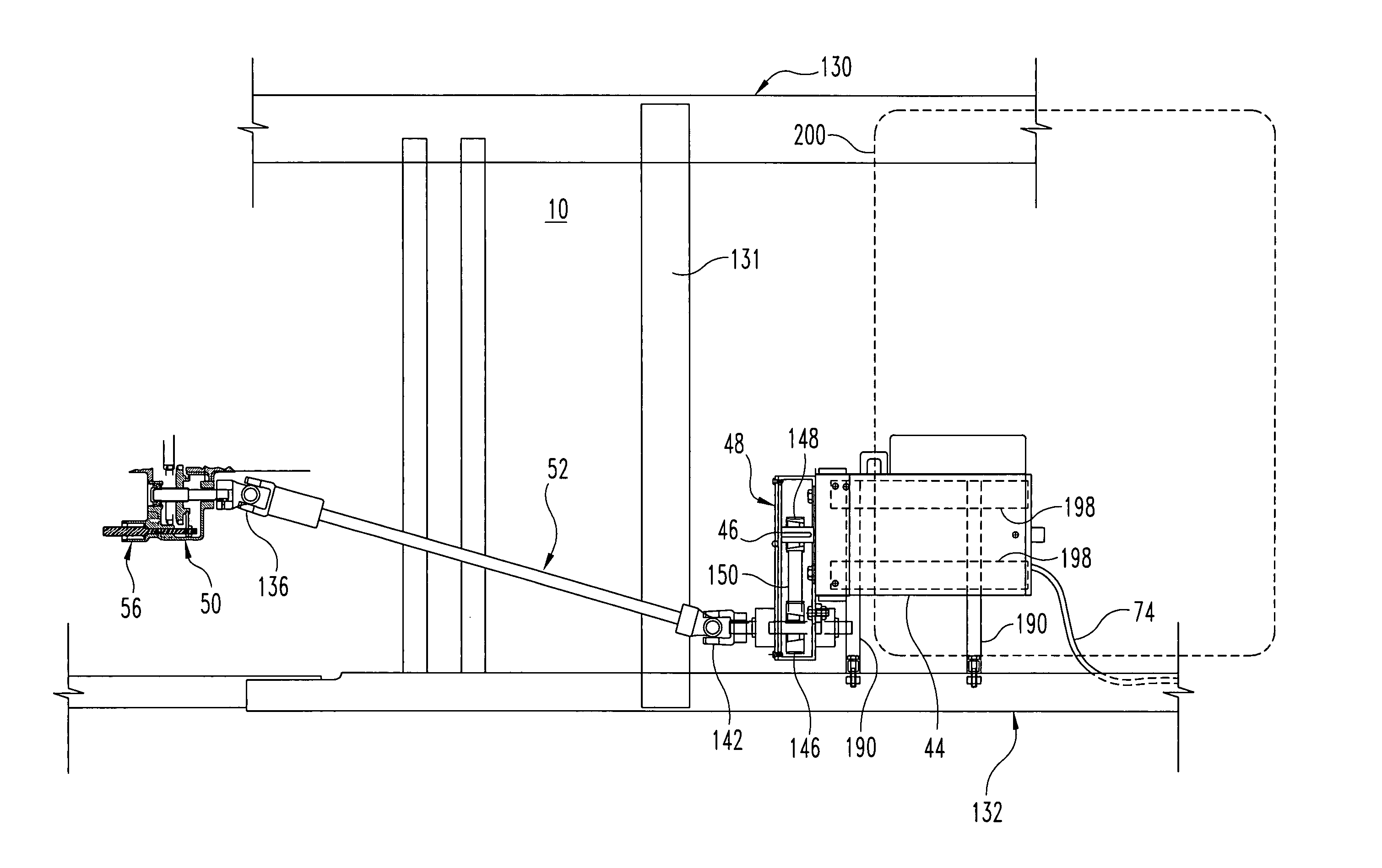

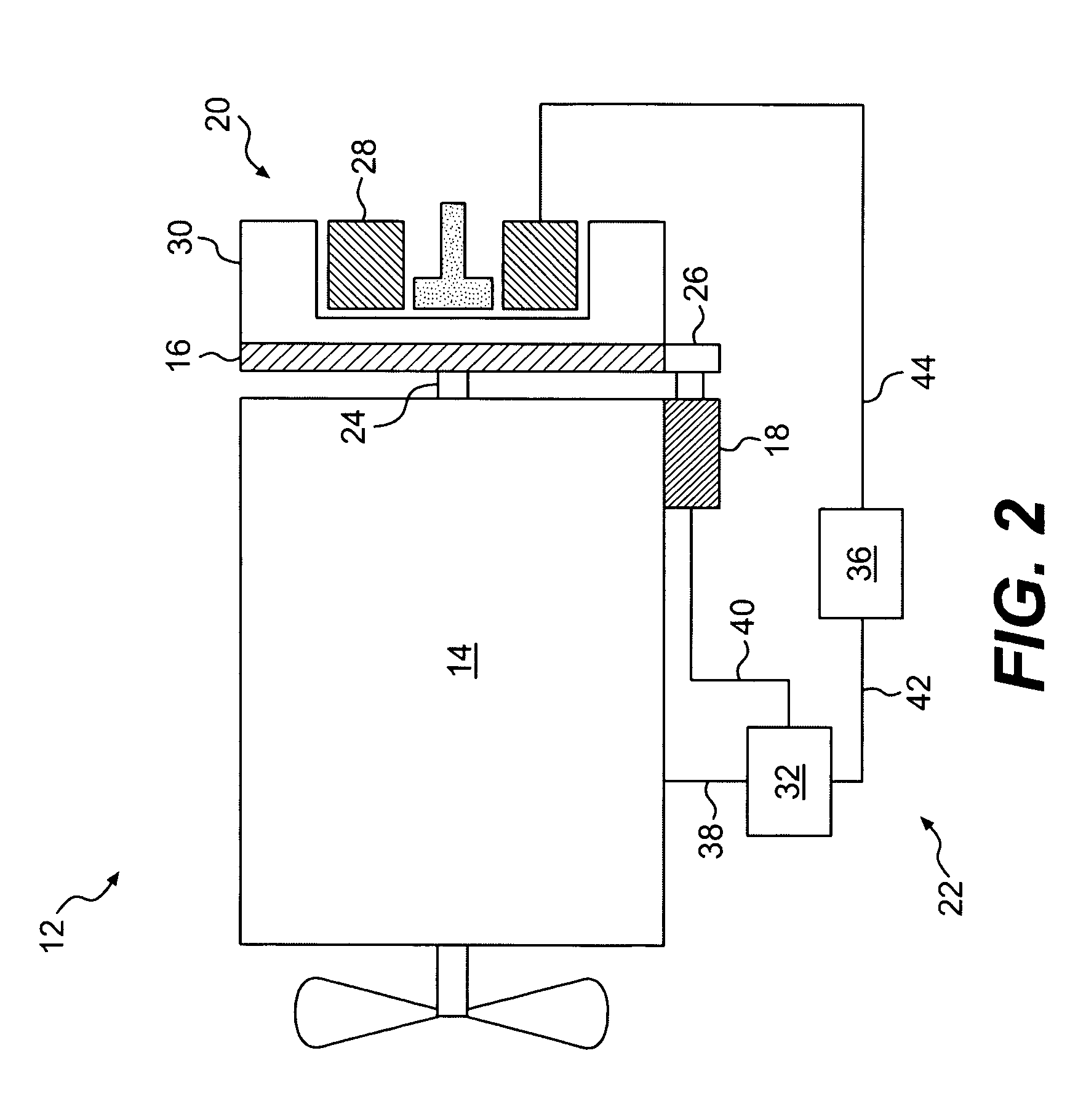

Gas turbine engine starter-generator exciter starting system and method including a capacitance circuit element

A rotating electrical machine, such as an aircraft starter-generator, that includes an exciter that has its stator windings supplied with electrical power from a power supply. One or more switches are electrically coupled between the exciter stator winding and the power supply and are configured and controlled so that a capacitance may be selectively placed electrically in series with the exciter stator windings.

Owner:HONEYWELL INT INC

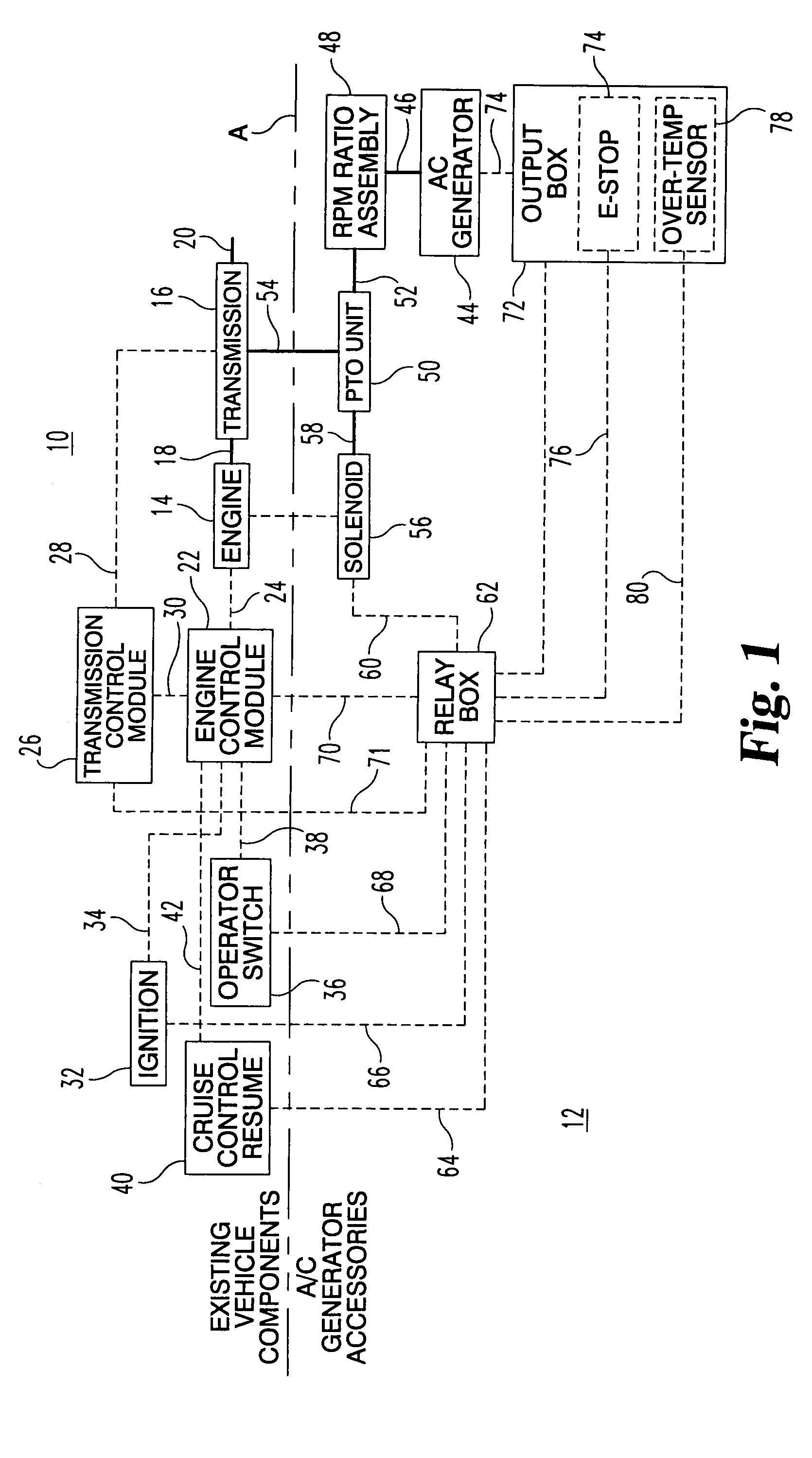

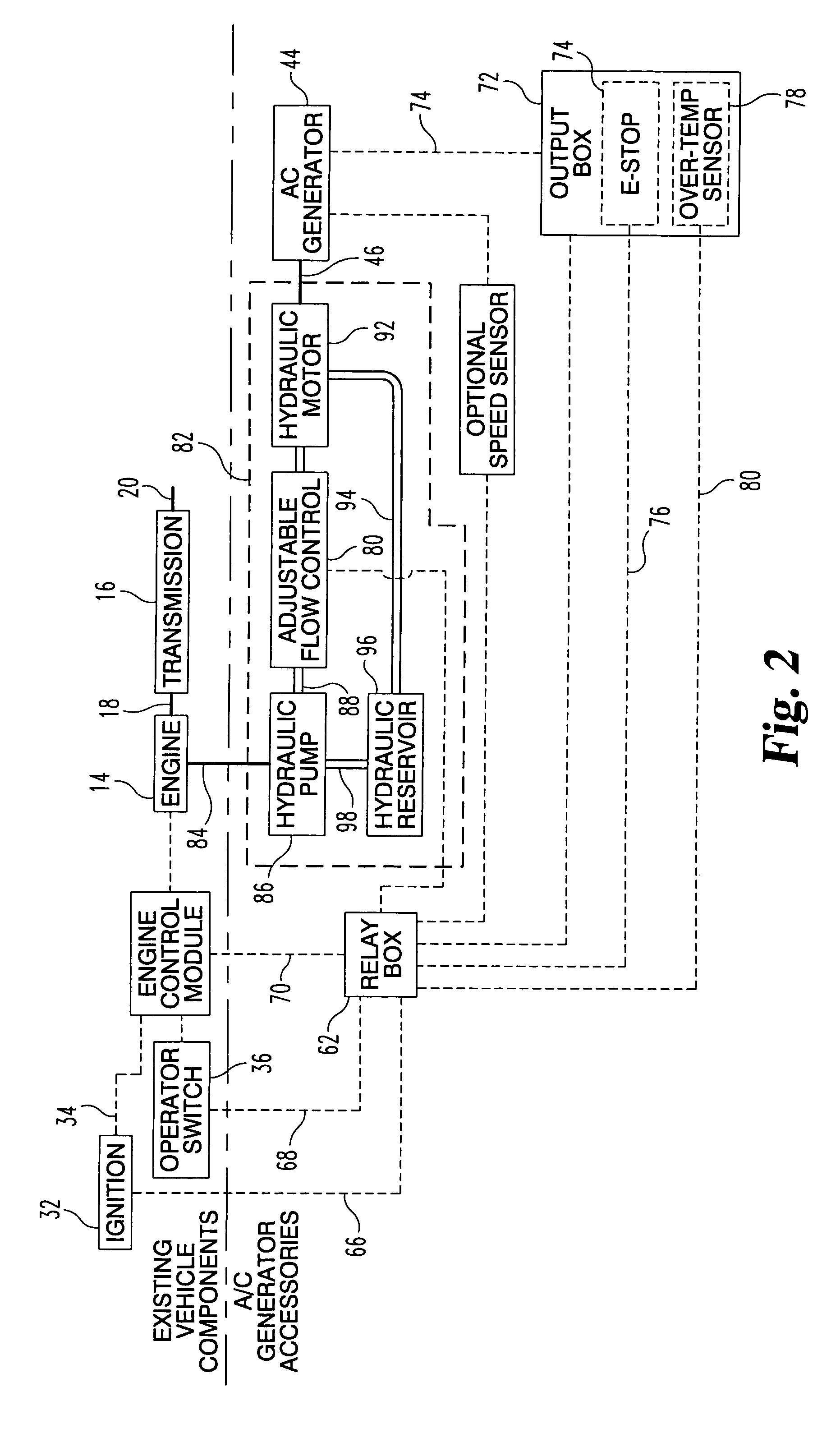

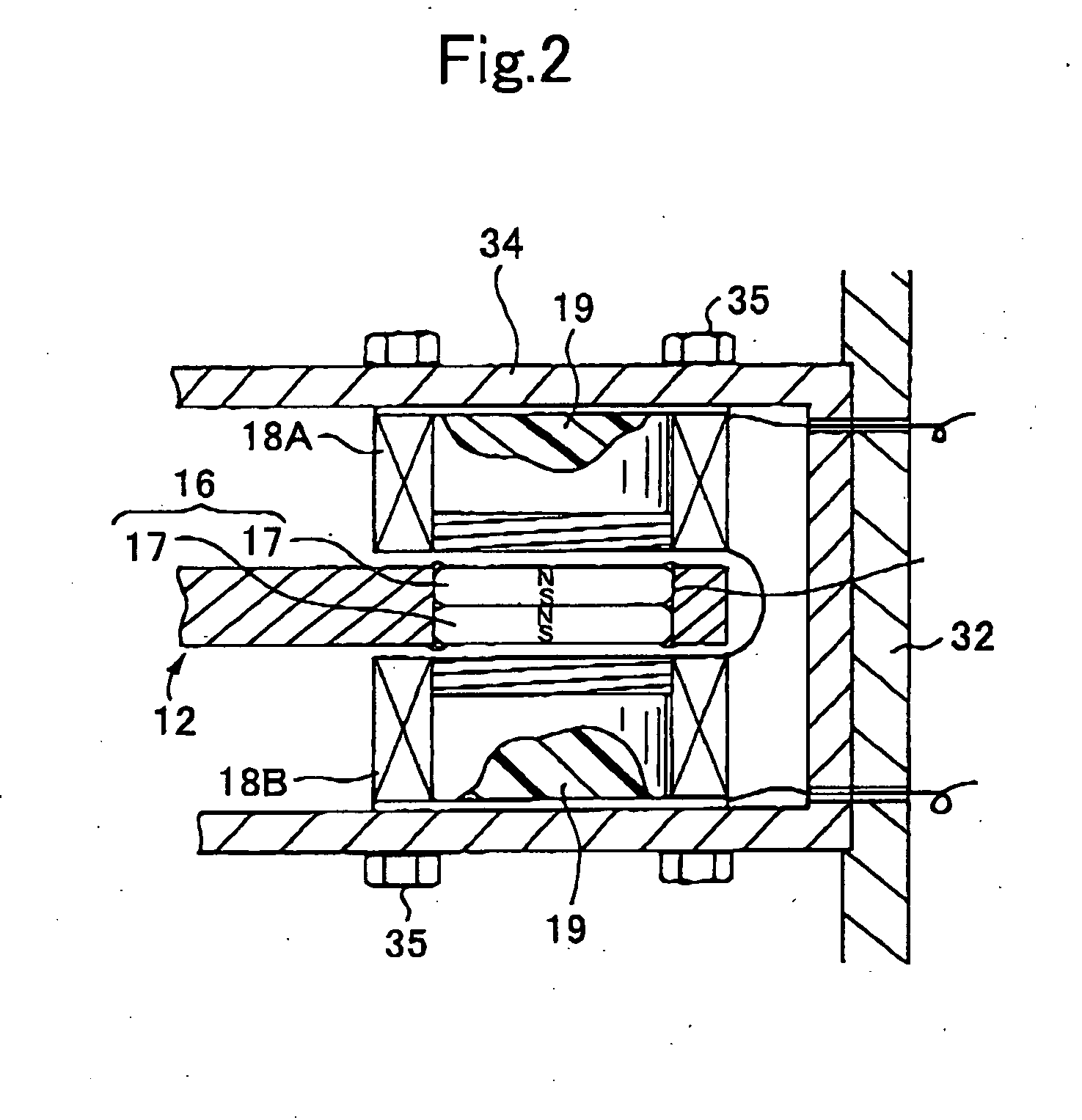

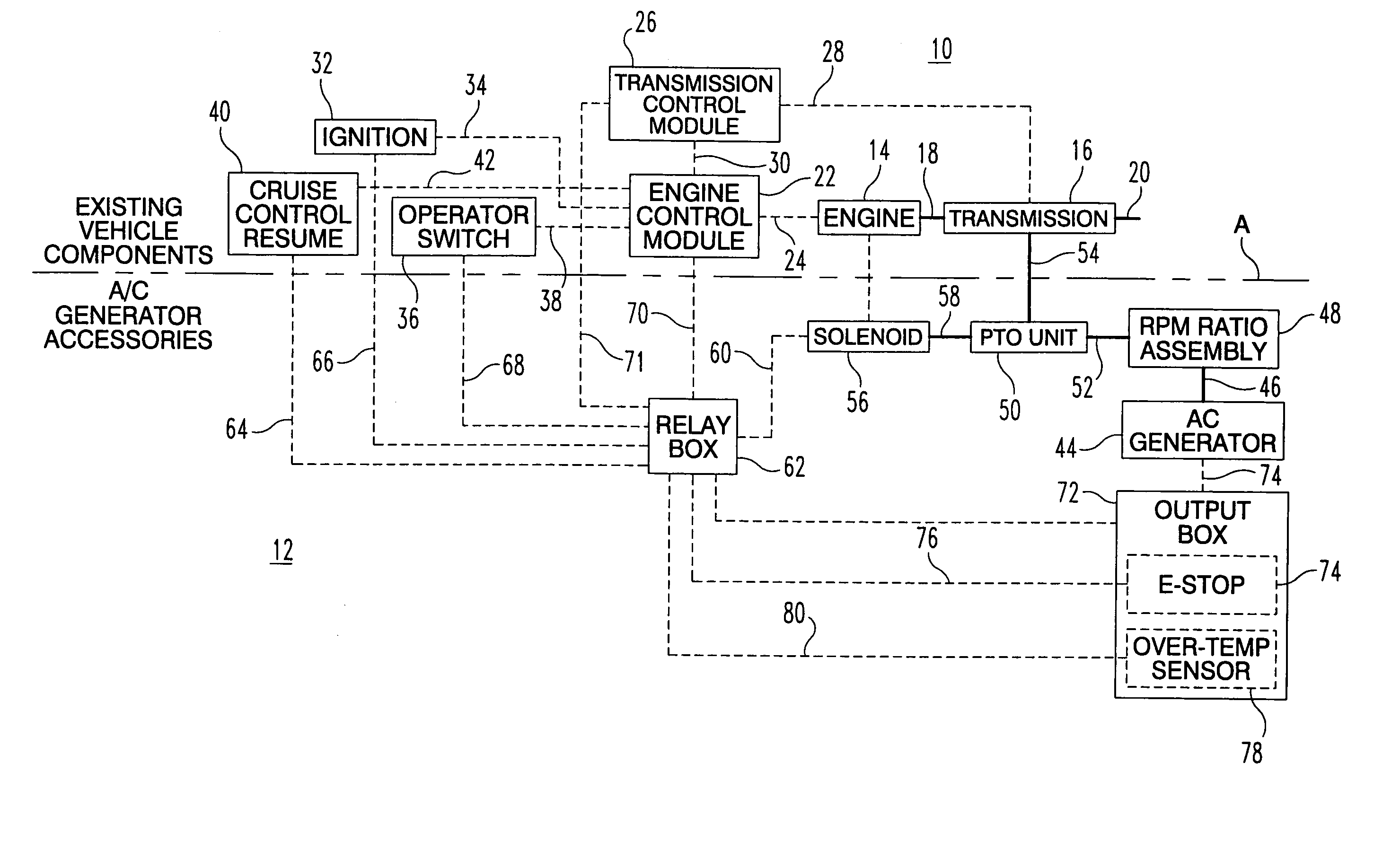

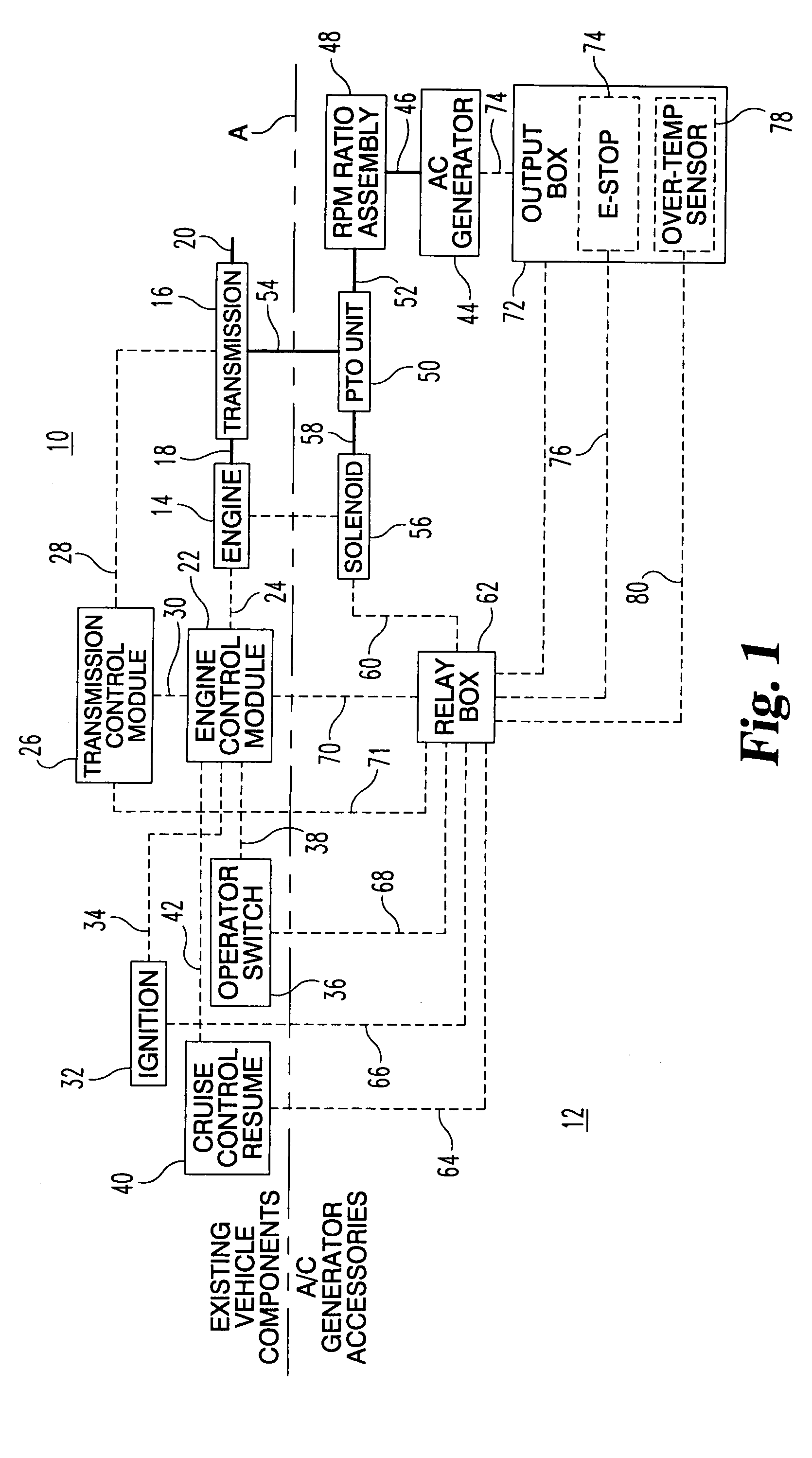

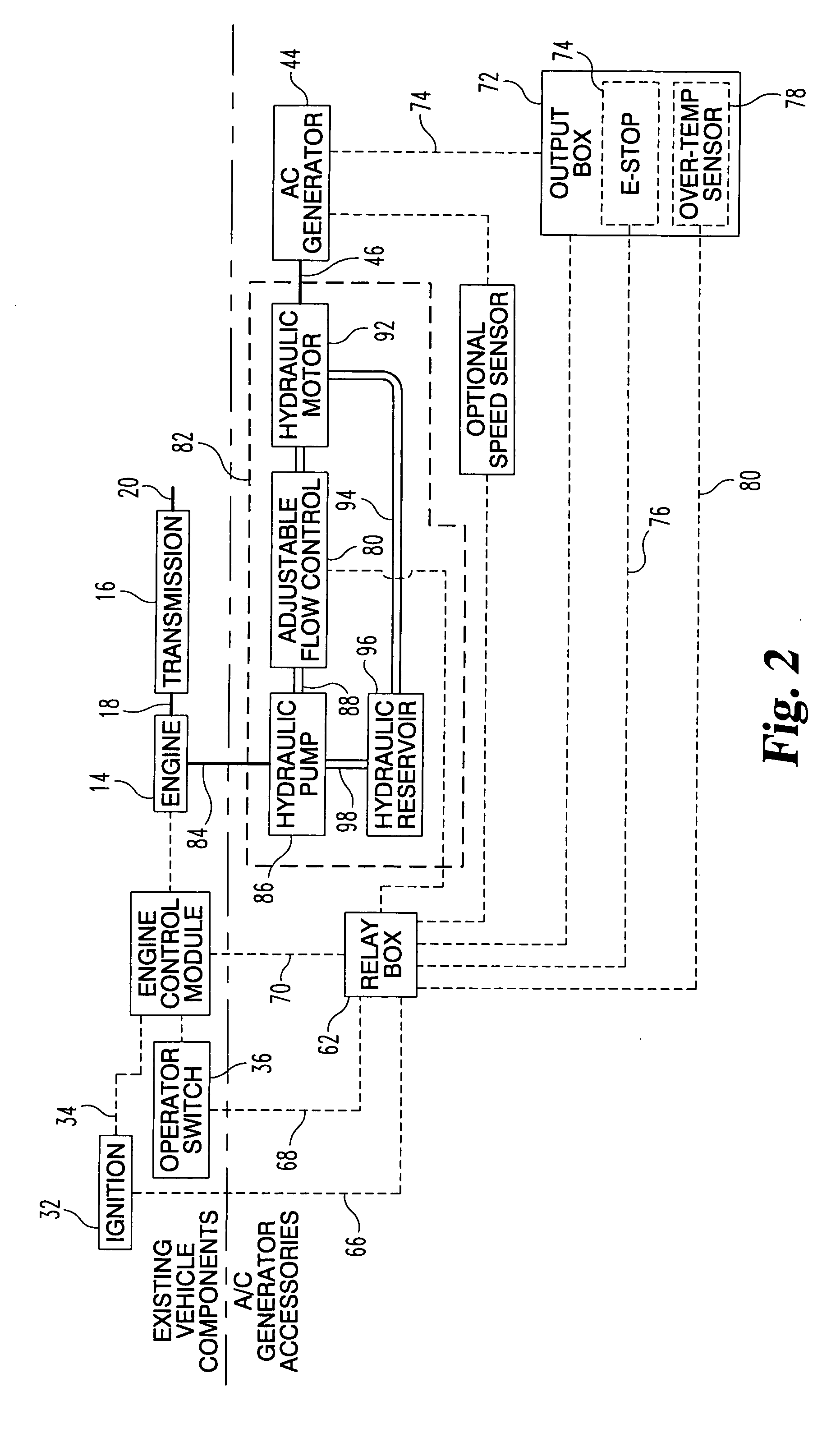

Vehicle mounted electrical generator system

A vehicle mounted AC generator system having an AC generator mounted outside the engine / transmission compartment and connected by drive shaft with universal joints and a belt driven RPM ratio device. The ratio is set to provide accurate AC generator RPM at a preselected engine RPM. The AC generator is mechanically engageable when certain conditions are met and is disconnected when other conditions are present, including an operator emergency stop switch.

Owner:CONTOUR HARDENING

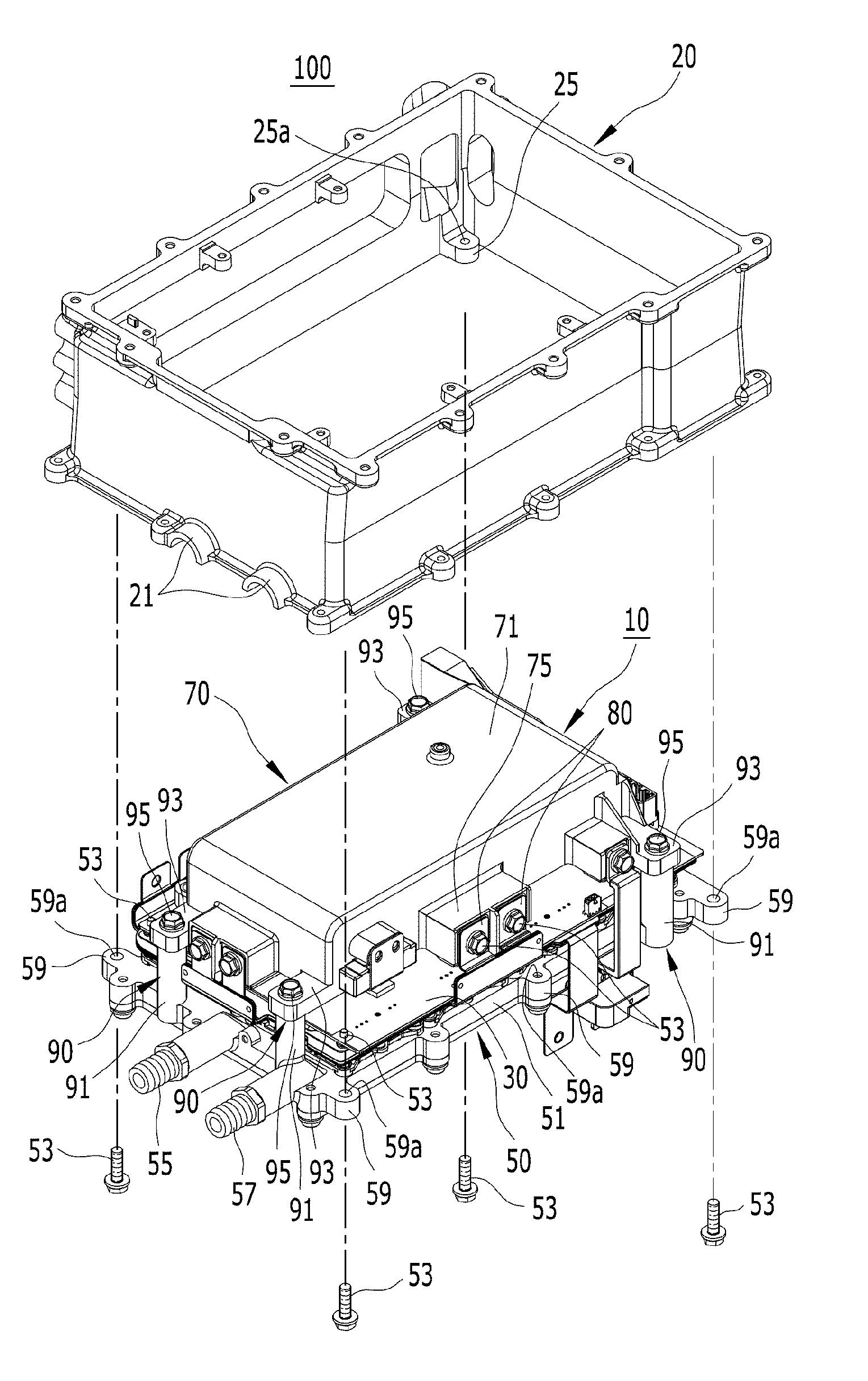

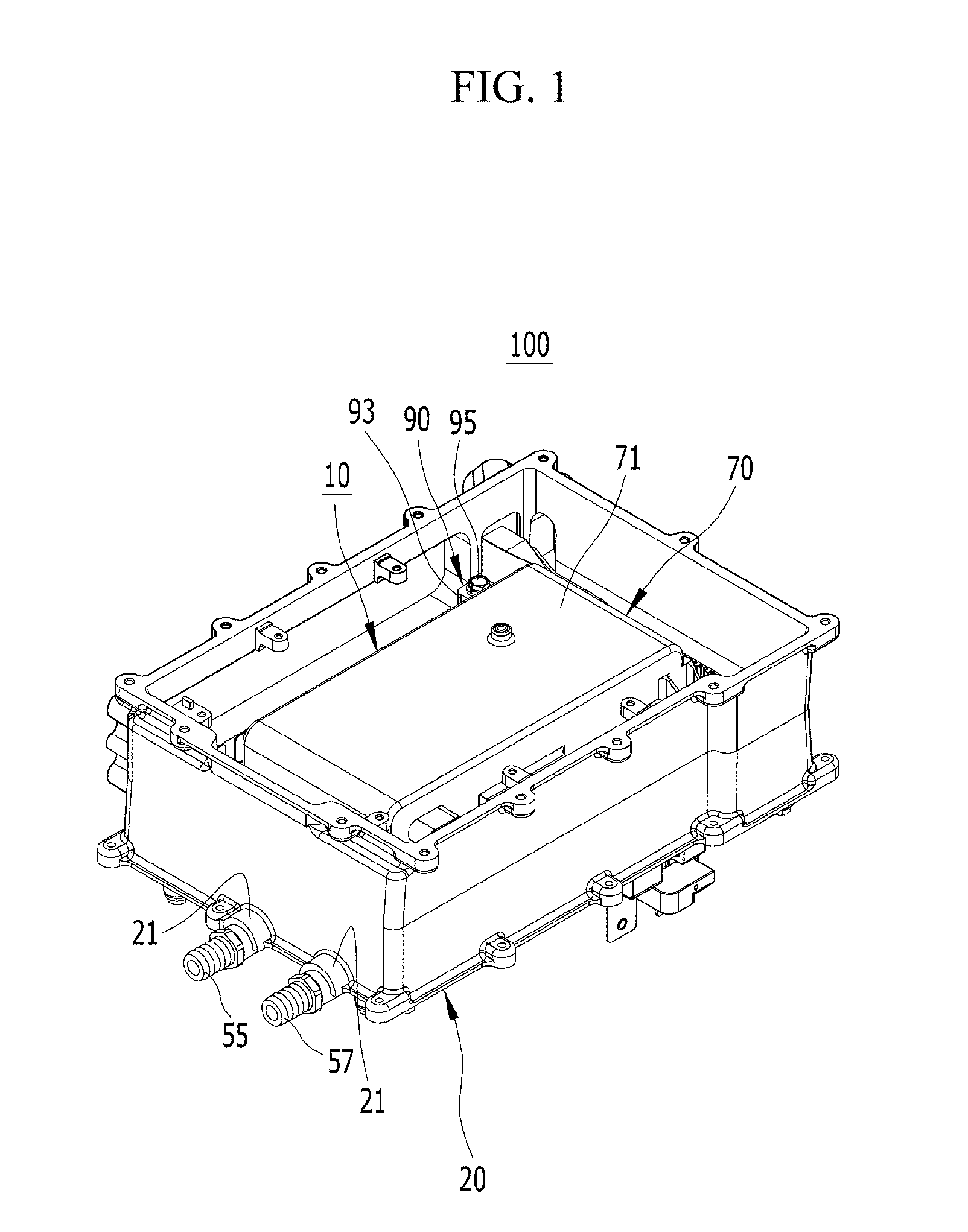

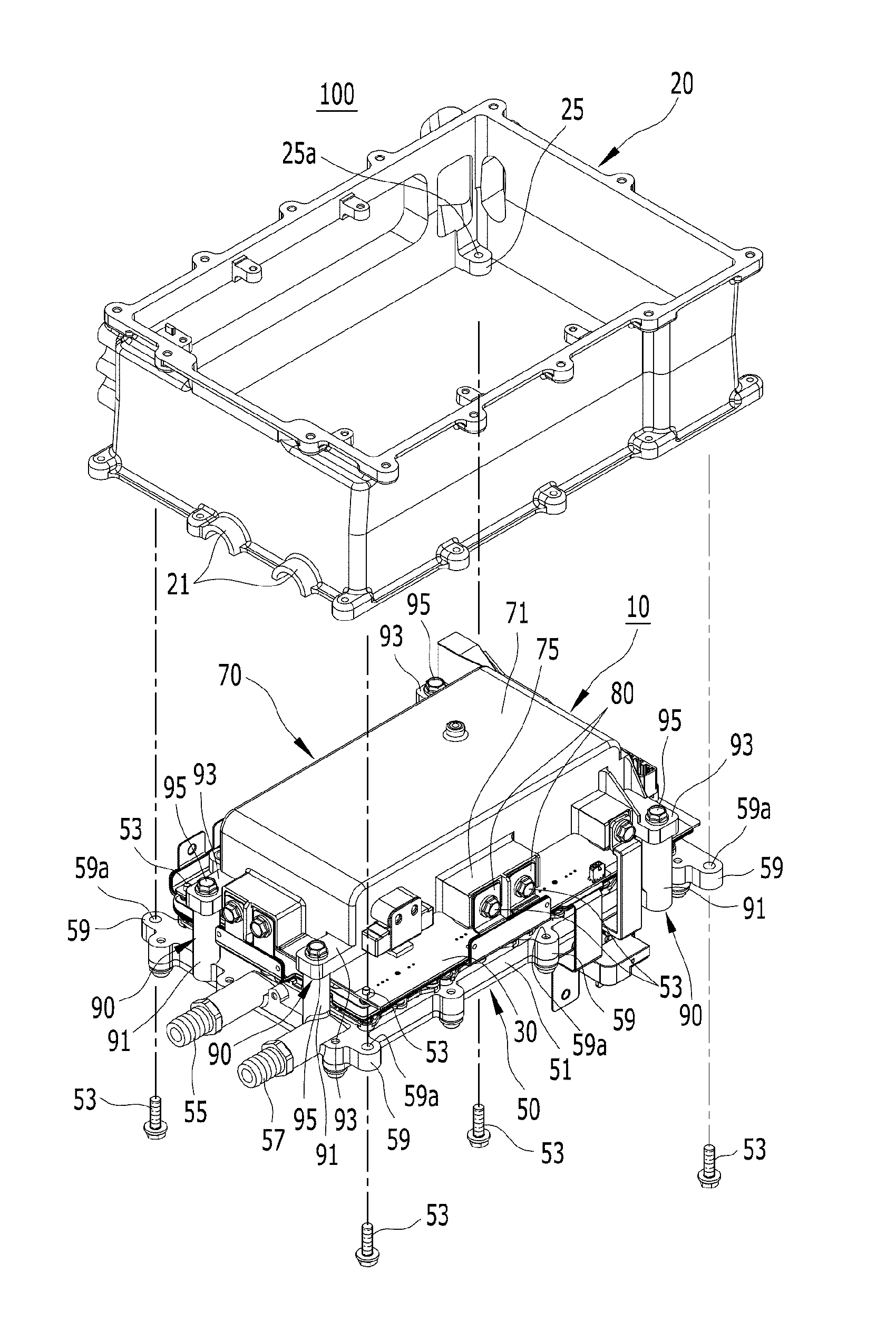

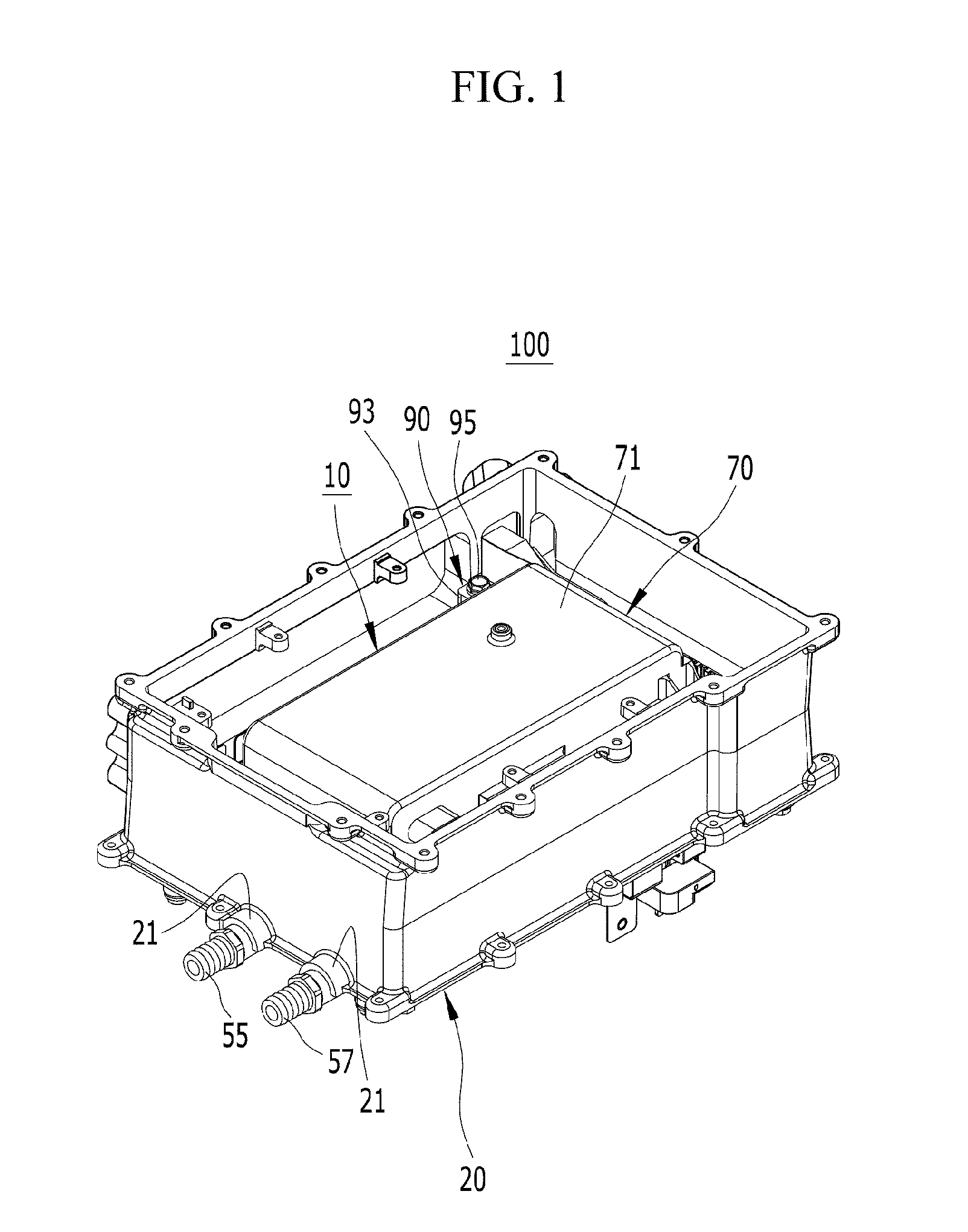

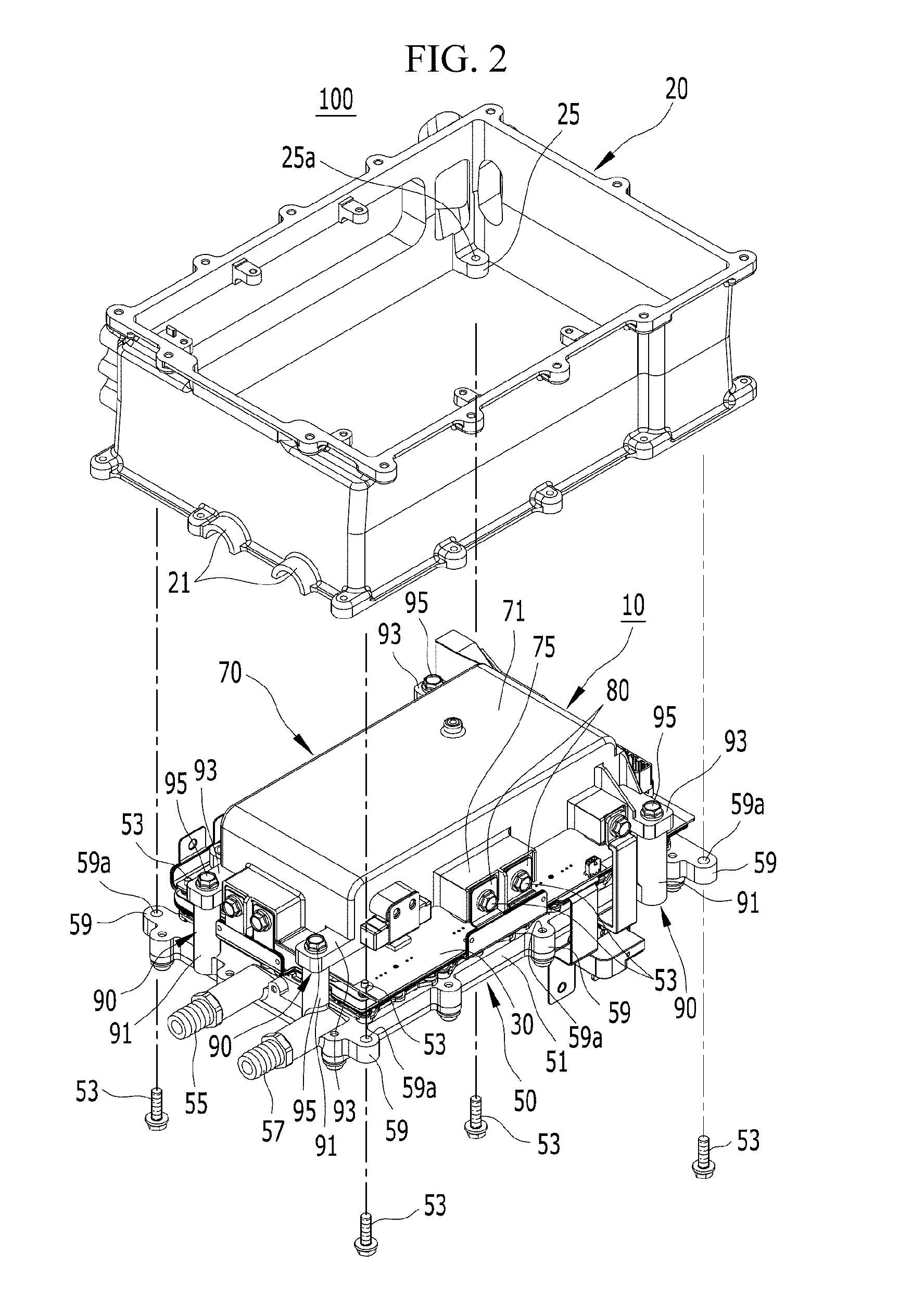

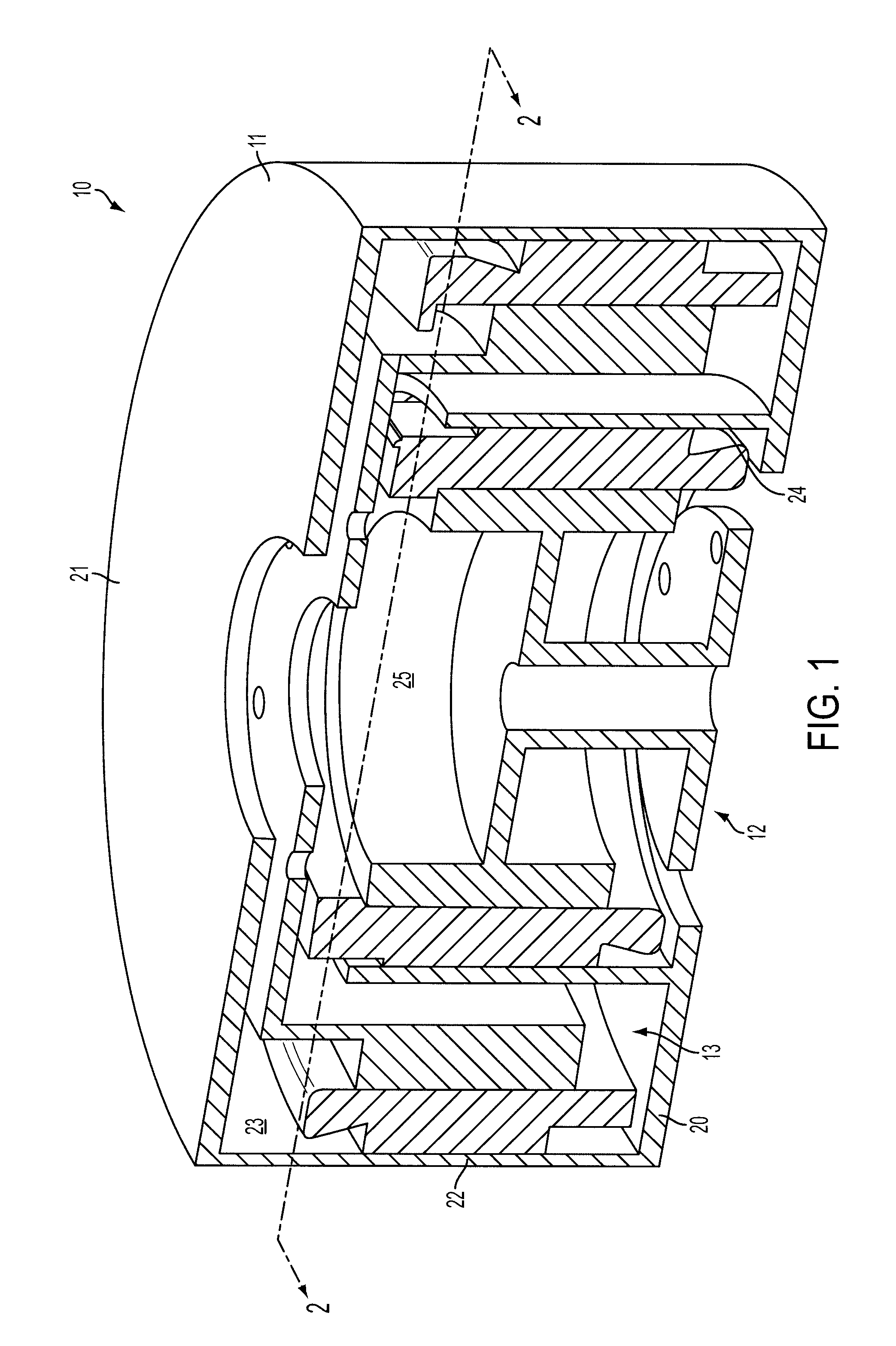

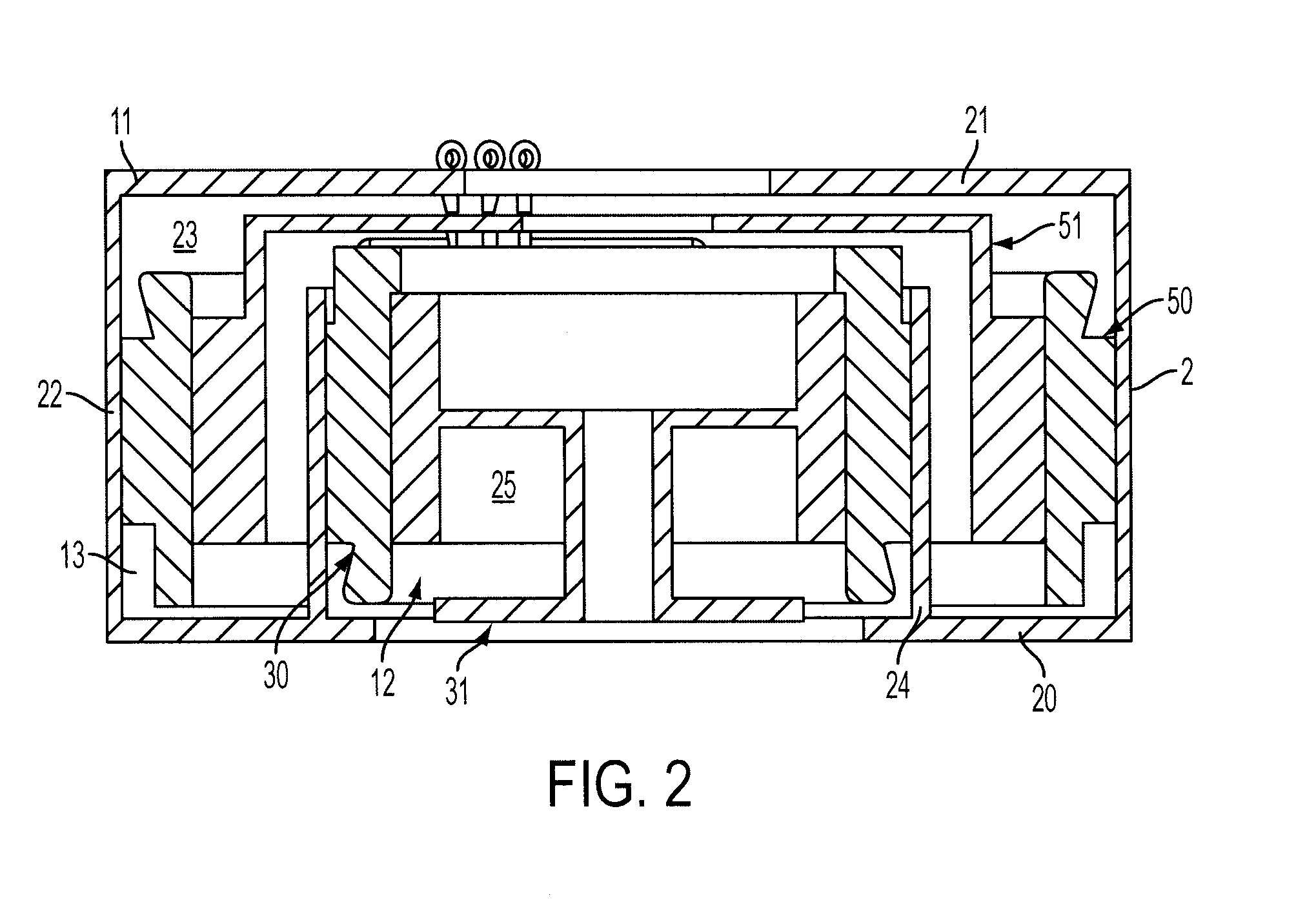

Inverter for vehicle

InactiveUS20130039009A1Improve structural rigidityAC/DC convertorsConversion constructional detailsPower semiconductor deviceFrequency changer

An inverter for a vehicle is disclosed. The inverter for the vehicle illustratively includes: a power module provided with a power semiconductor device; a cooling module coupled to the power module and flowing a coolant therethrough; and a capacitor module mounted at the cooling module through a mounting unit and adapted to absorb a ripple current of the power module.

Owner:HYUNDAI MOTOR CO LTD

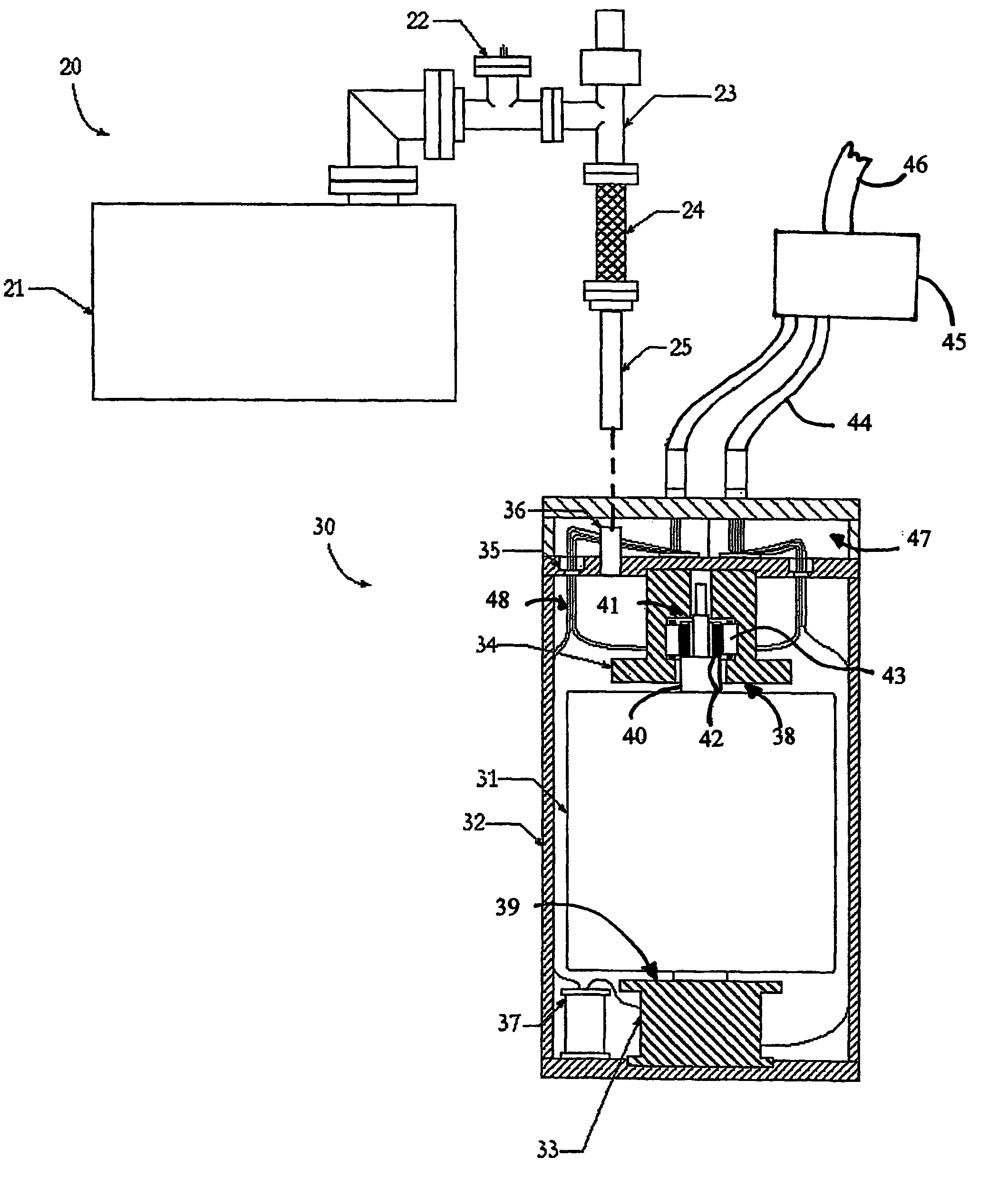

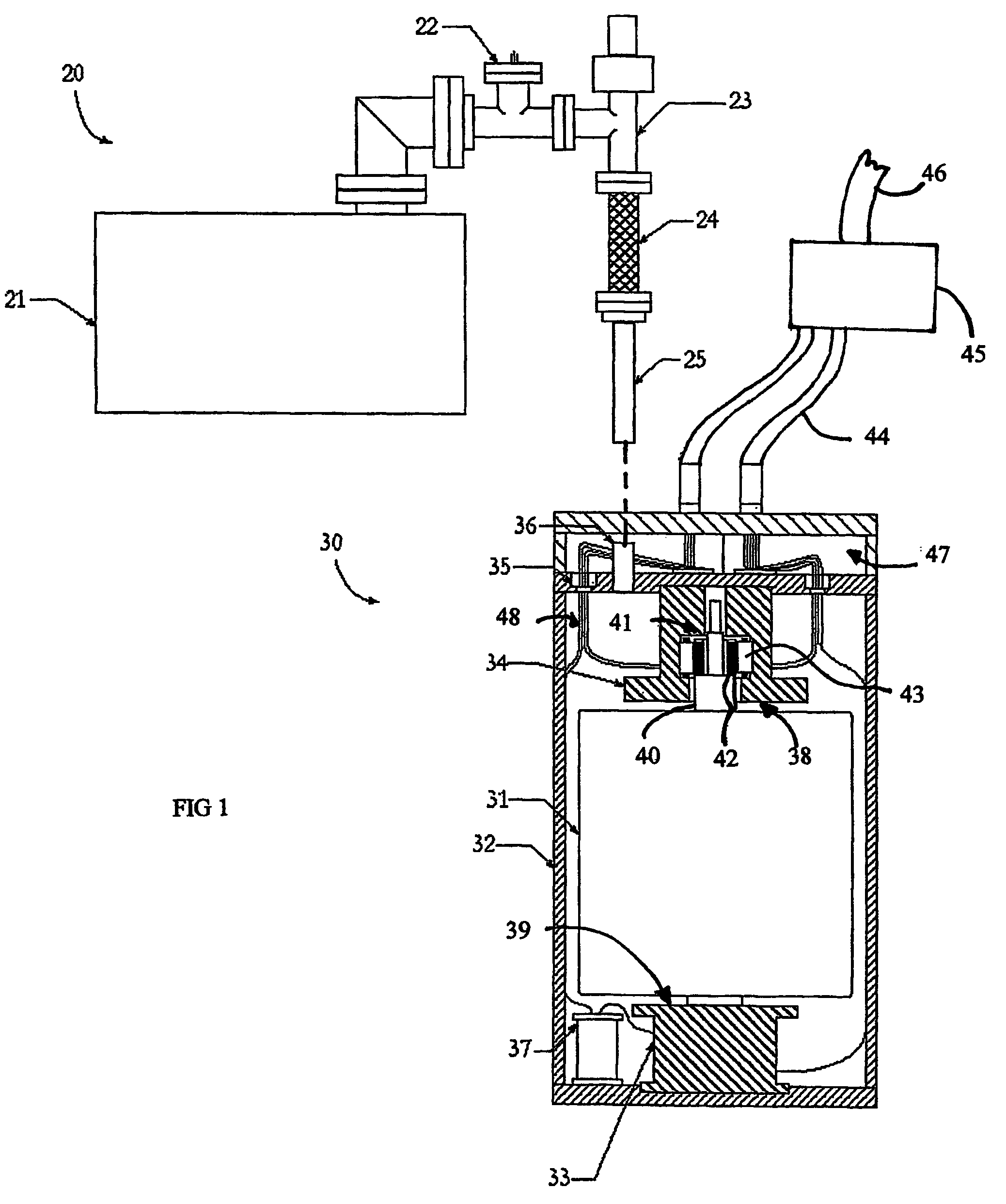

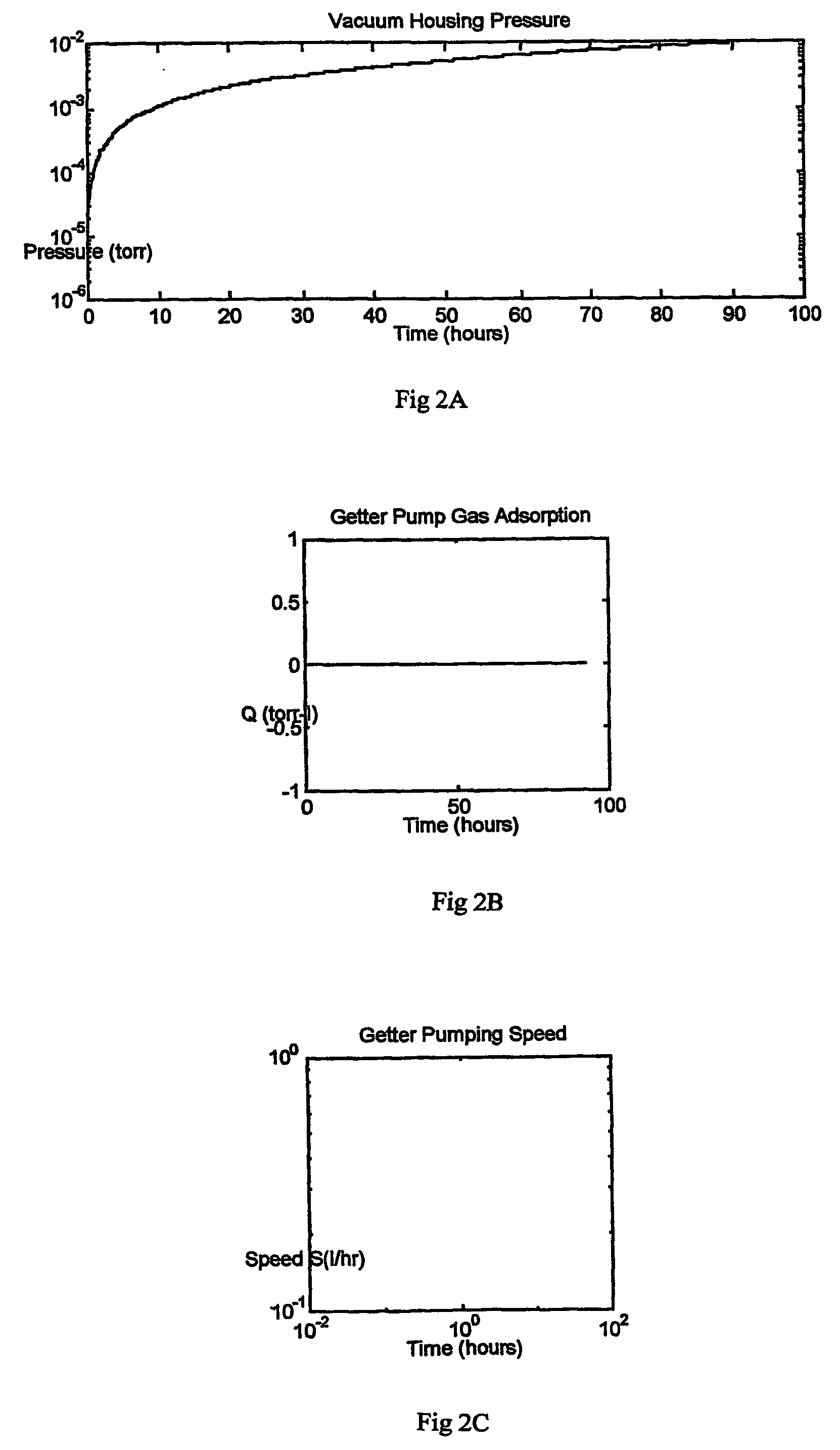

Long-life vacuum system for energy storage flywheels

InactiveUS7053589B2Improve adsorption capacityIncrease chanceAC/DC convertorsFlywheelsAlloyEngineering

The invention, intended primarily for use in a steel flywheel power source (30), provides a vacuum system and a method of maintaining a vacuum inside a flywheel chamber (32) for the life of the power source (30). The vacuum system combines the use of cleaning and de-gassing treatments in the chamber (32) and vacuum tempering of the steel flywheel (31) with the use of a chemical type metal alloy nonevaporable getter, such as zirconium-vanadium-iron, that cooperatively matches the outgassing of the flywheel (31) and chamber (32) by sorbing those gases that are released. The getter may be reactivated throughout the life of the flywheel system by reheating it with an integral heater that is triggered by a timer instead of a vacuum gauge to increase the system reliability, using power taken directly from the energy stored in the flywheel. The electronics (45) of the flywheel power source are used to signal an alarm or prevent achieving or maintaining full speed of the flywheel when the vacuum in the chamber degrades.

Owner:INDIGO ENERGY INC

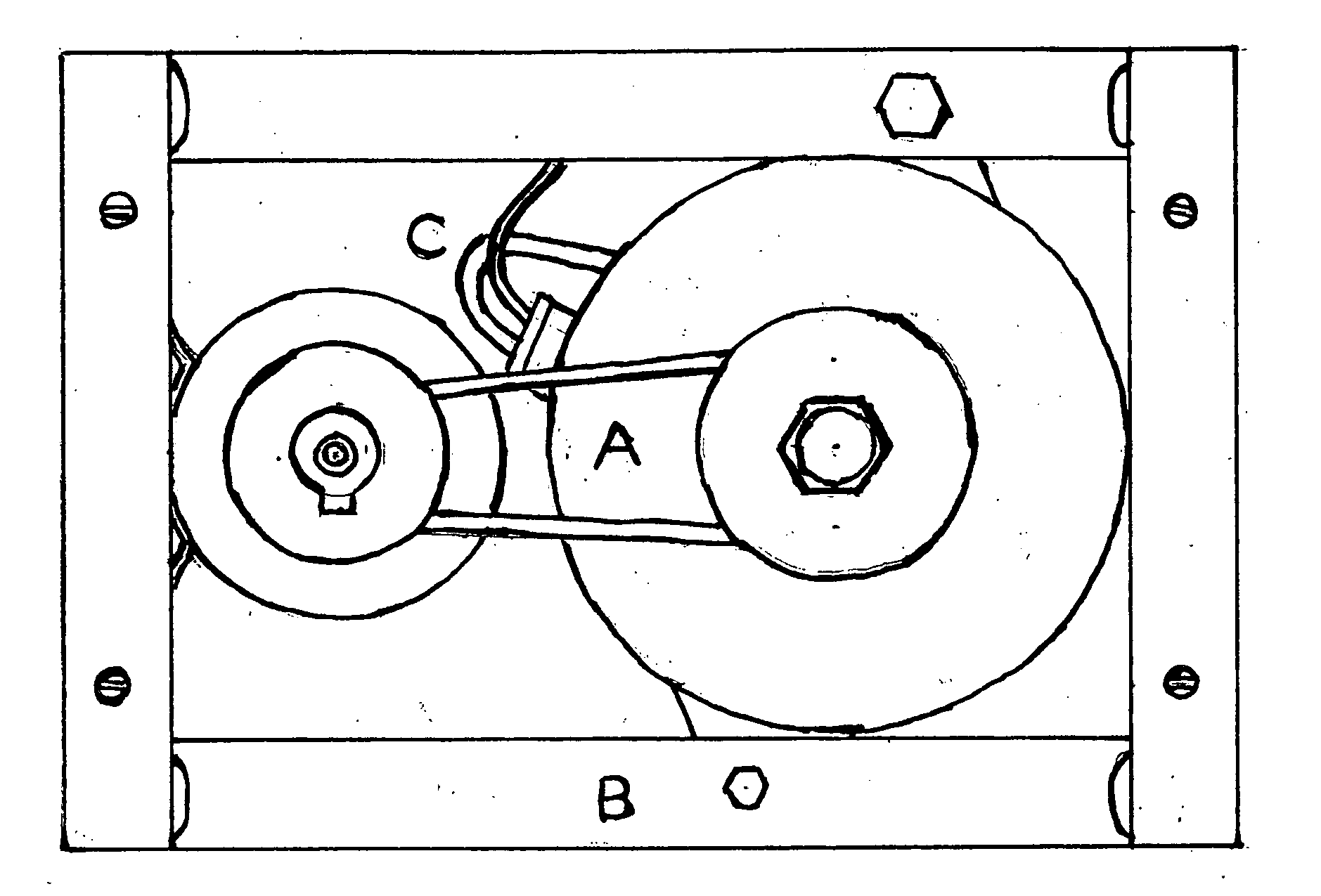

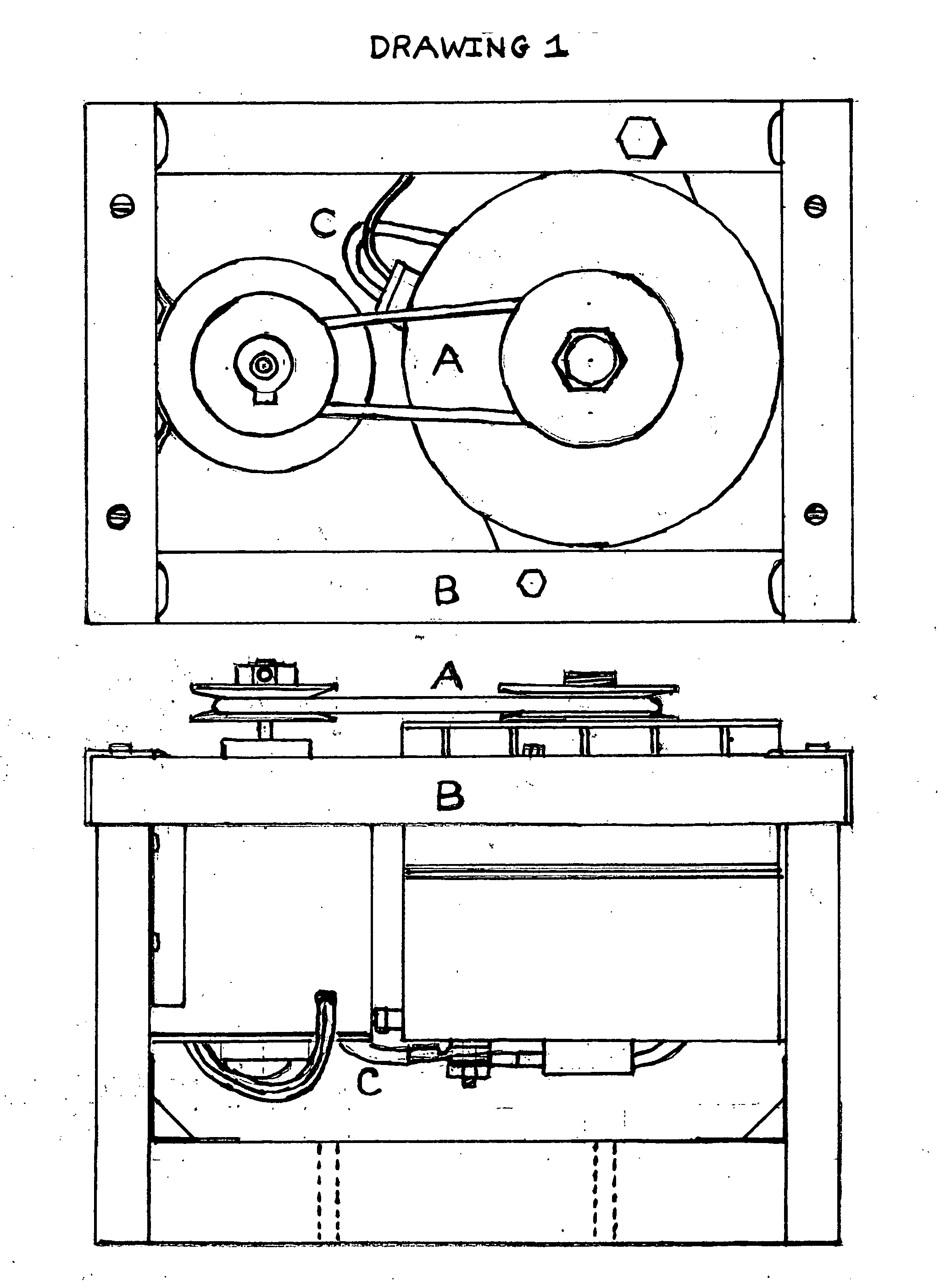

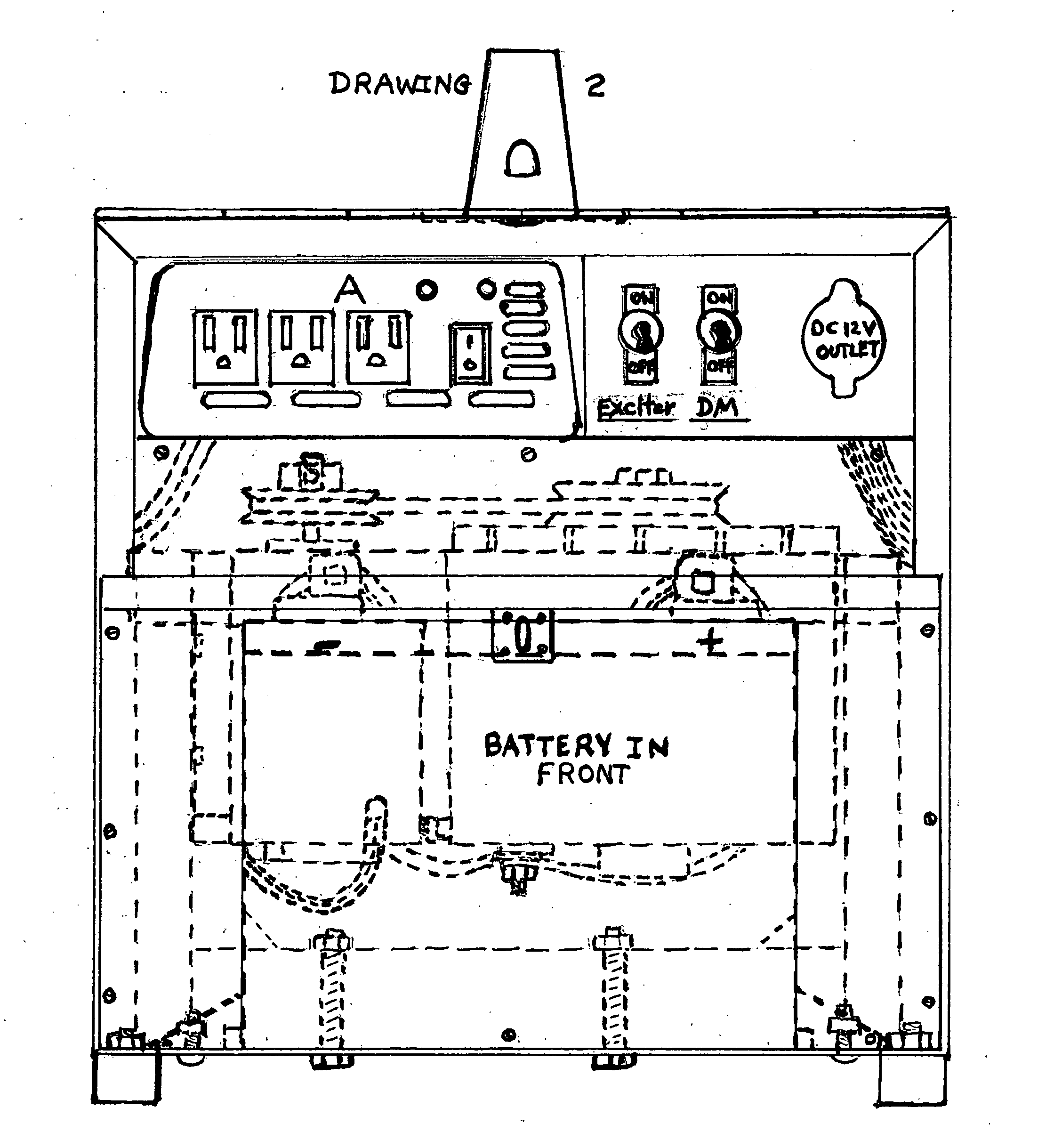

Electric surplus power generator

InactiveUS20060087122A1Little physical effortMinimal costAC/DC convertorsMachines/enginesAlternating currentElectric power

The Enviromentally Clean Rechargable Power Supply is a small portable totally electric rechargable source of both 12 volt DC 15 amp electricity and up to 700 watts and 6.5 amps of 110 volt AC electricity. Invention can be recharged with a conventional battery charger. Invention is enviromentally clean and can be operated indoors or outdoors. Uses include but but are not limited to emergency power to light homes and apartments, back up power to operate computers in homes and offices, power for lighting boats and RVs, power to operate trolling motors, charge automotive and marine batteries and provide a source of electricity for camp lighting, radios etc. Larger models can provide power to operate small scooters, go karts etc. with electric drive motors.

Owner:SHEFFIELD KENT SAUNDERS

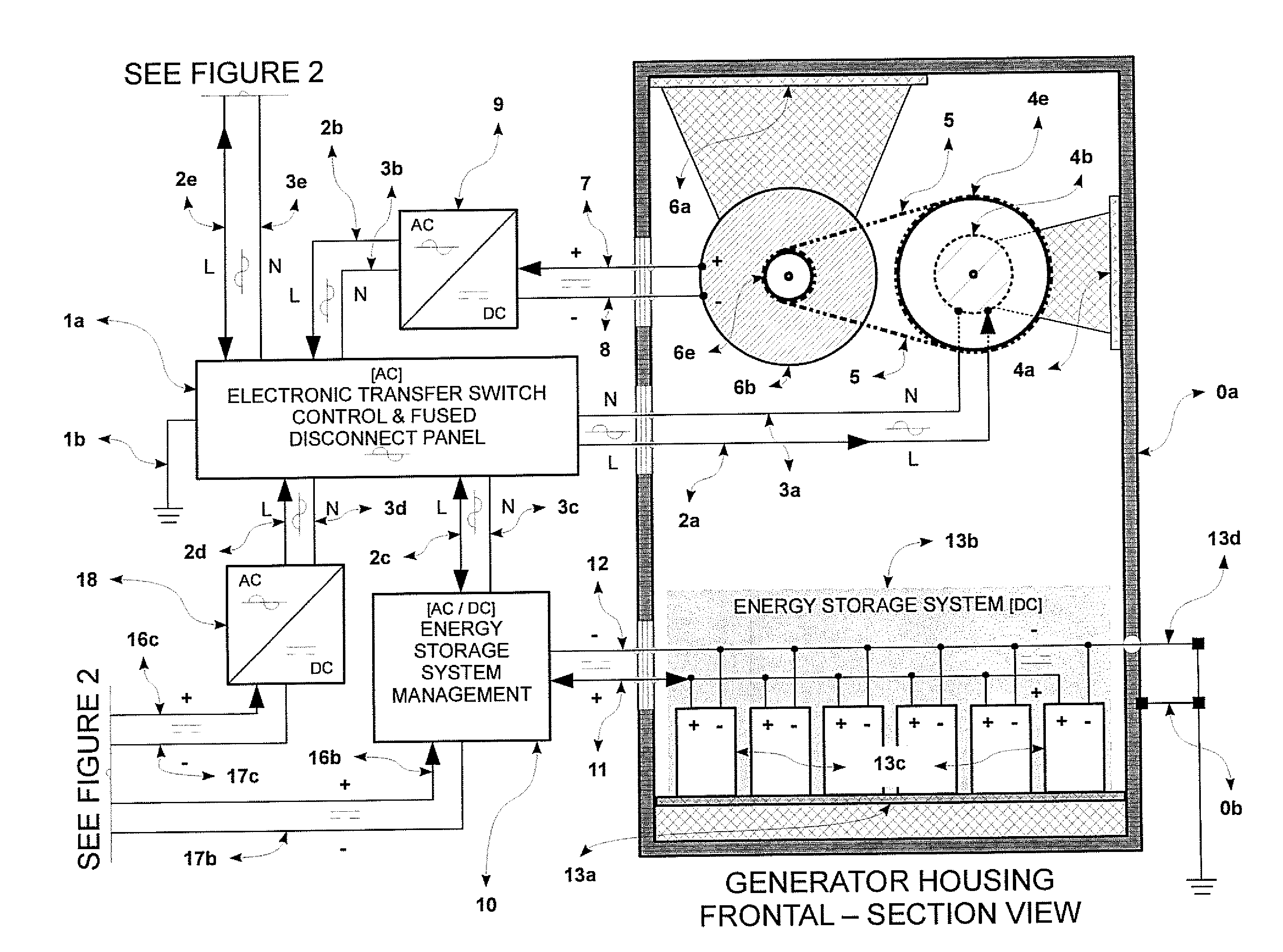

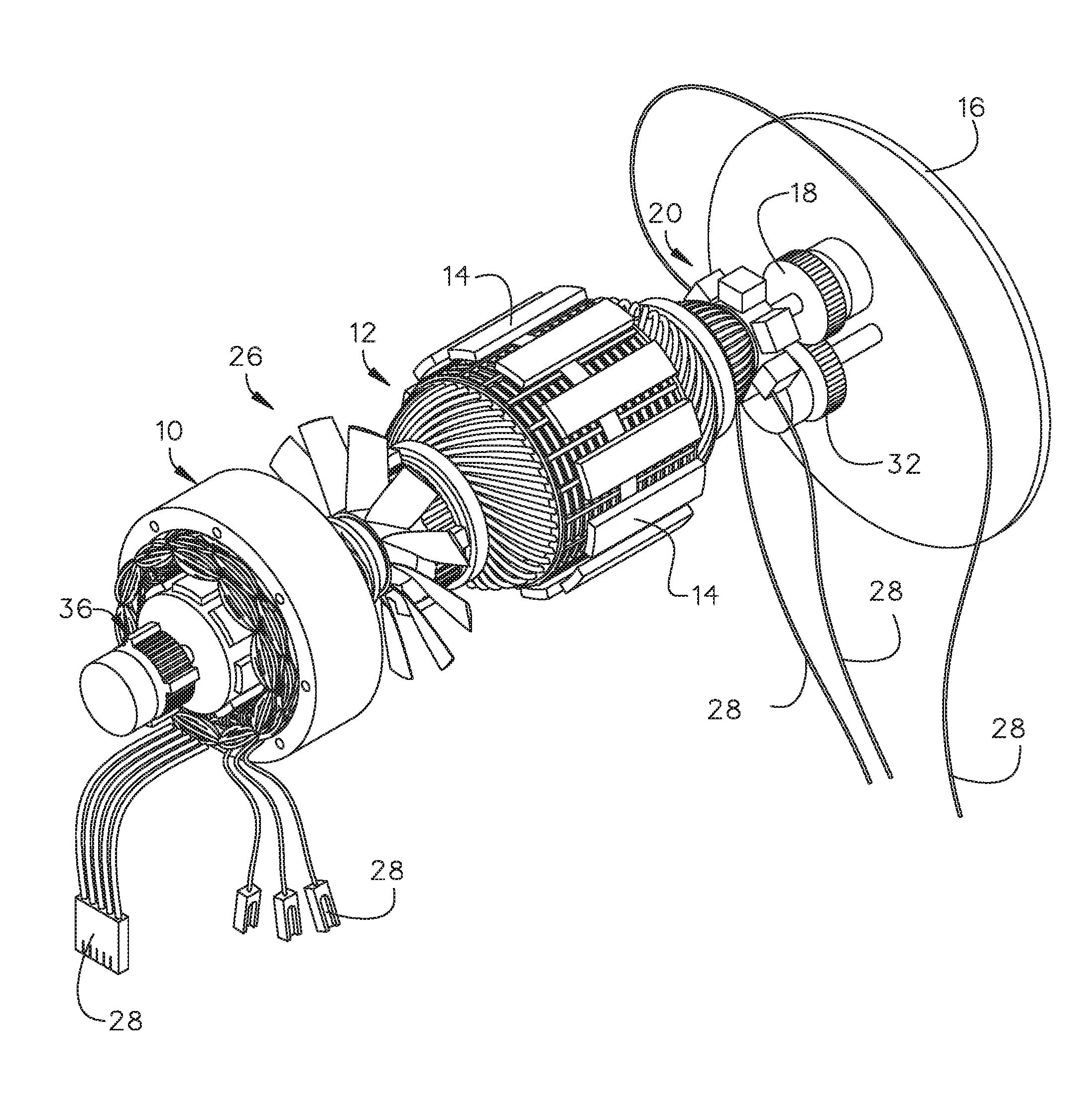

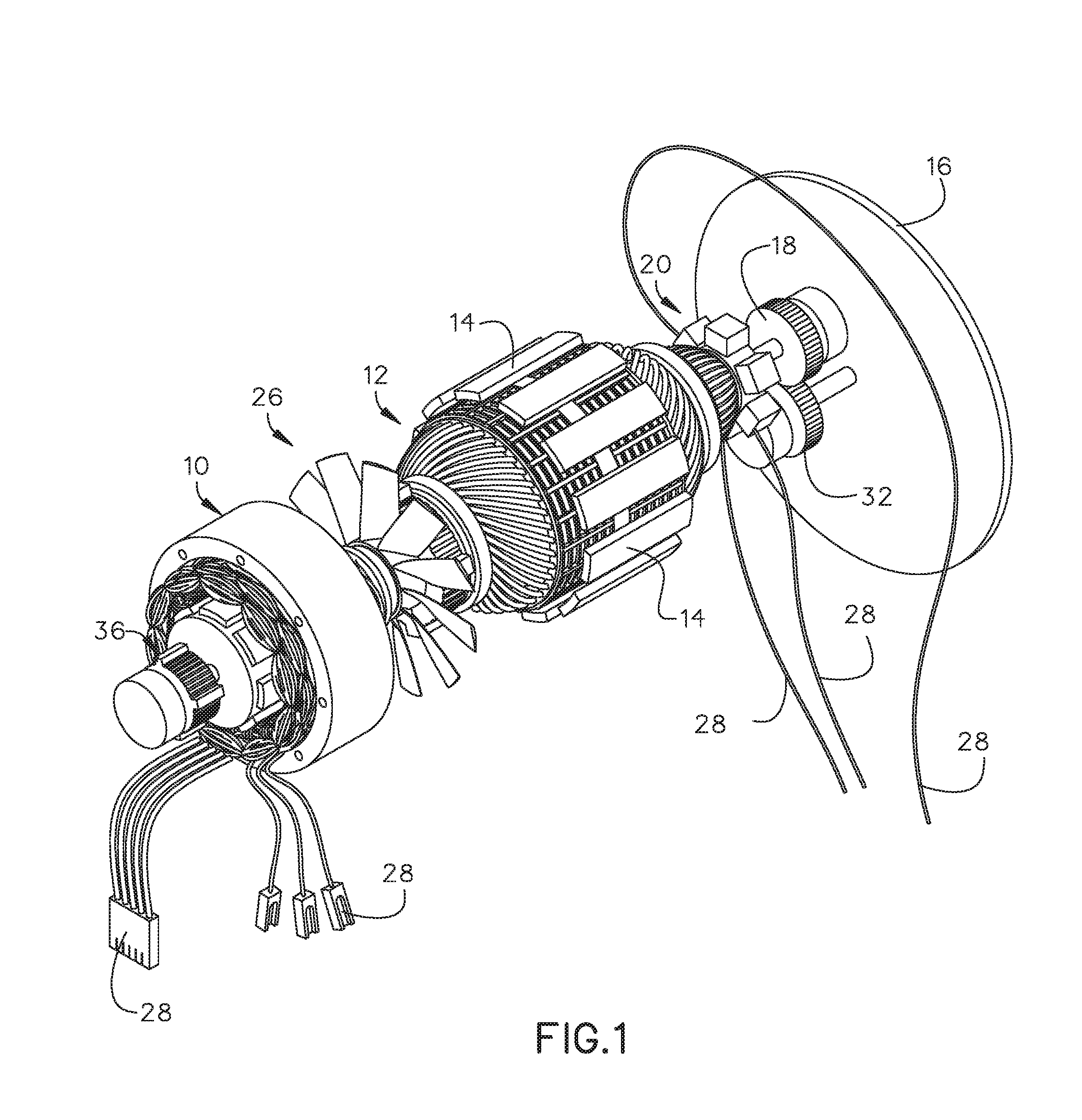

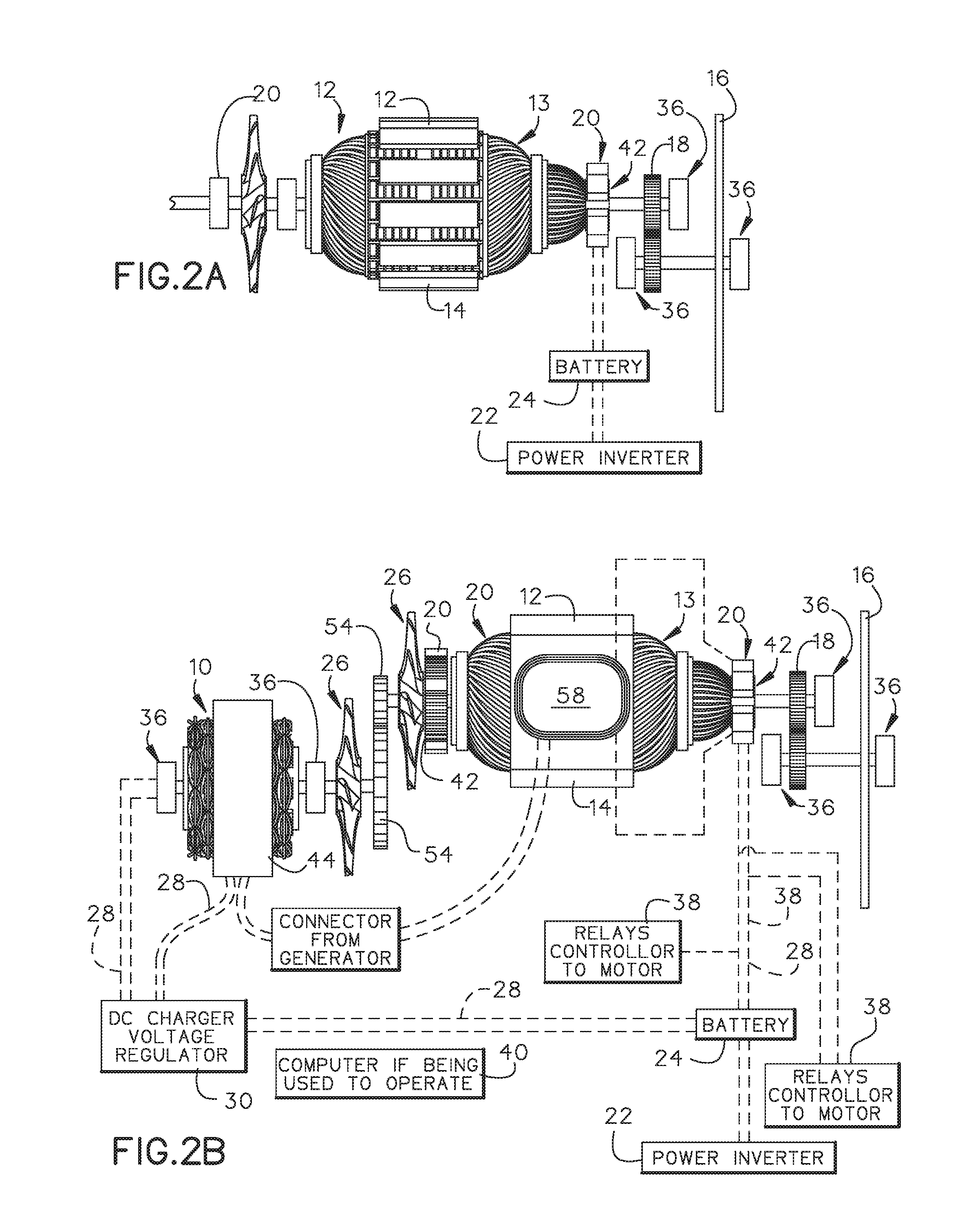

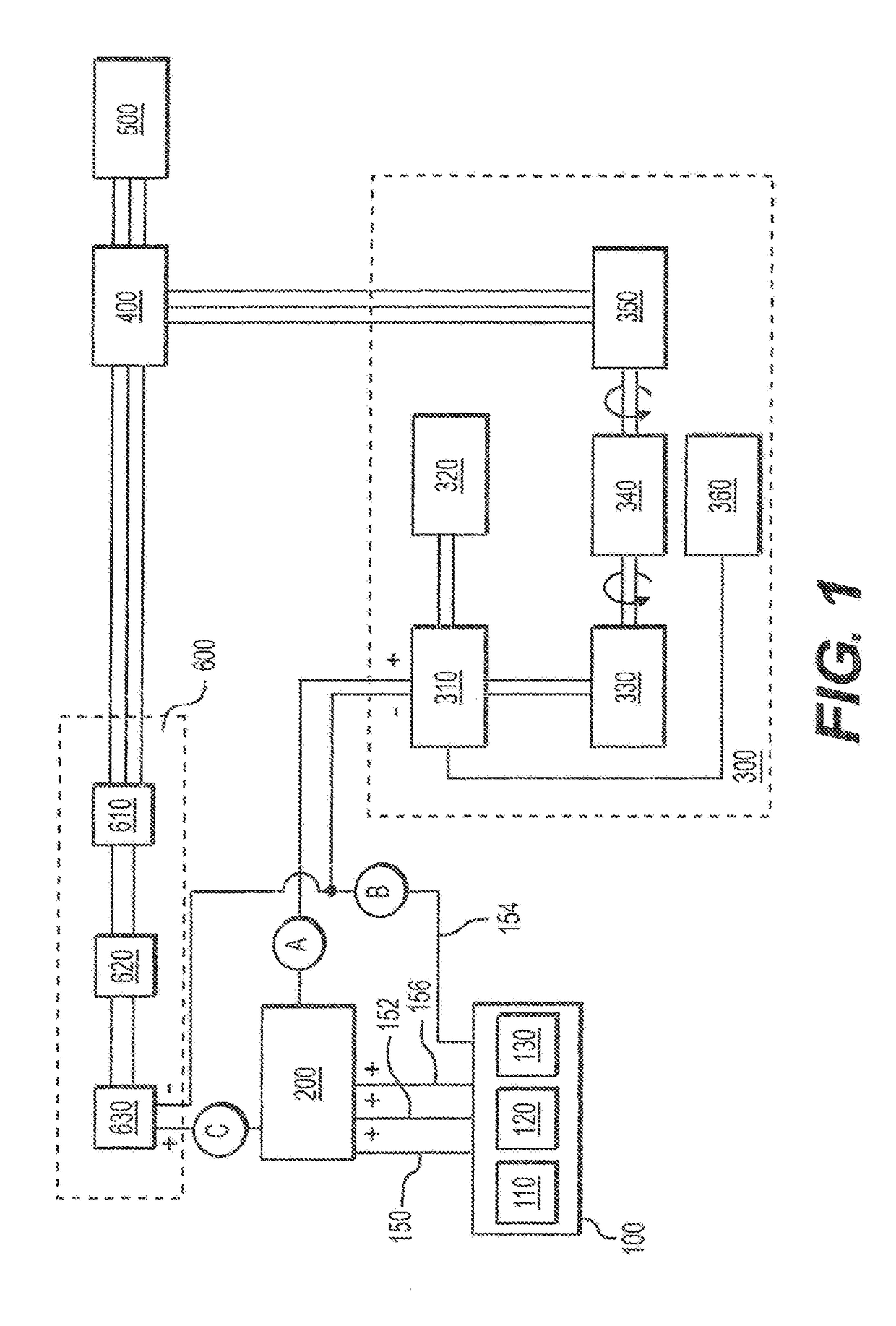

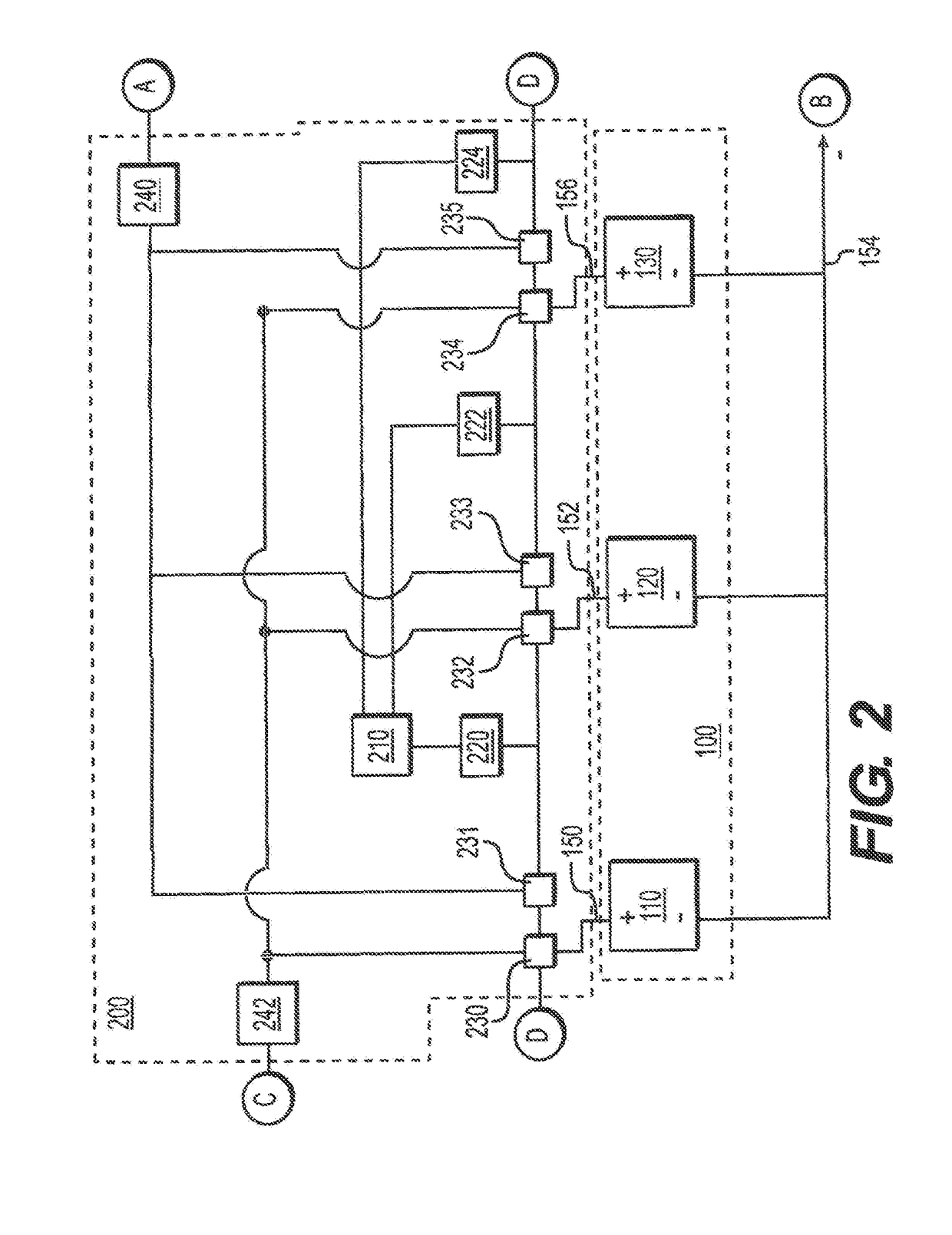

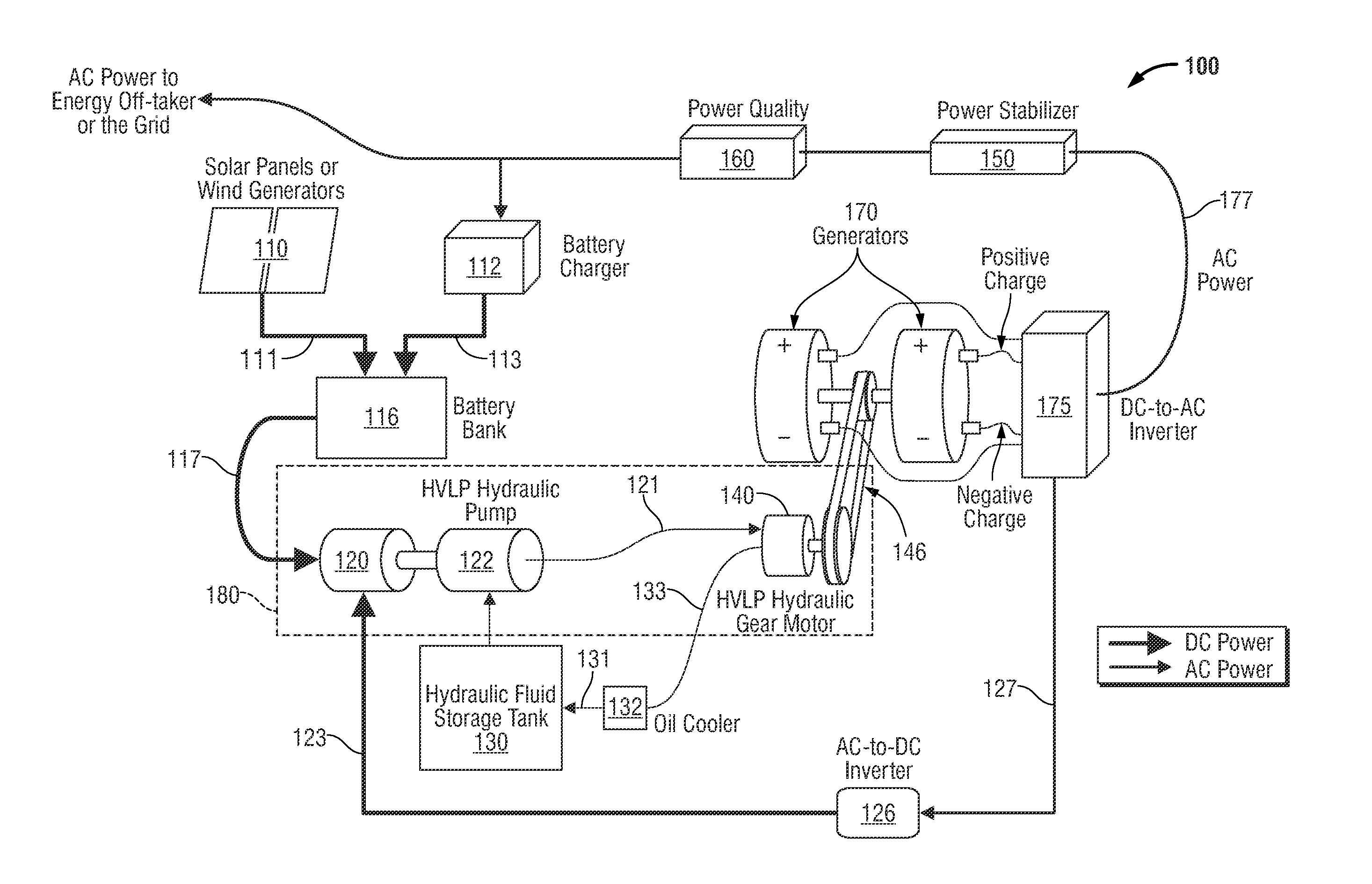

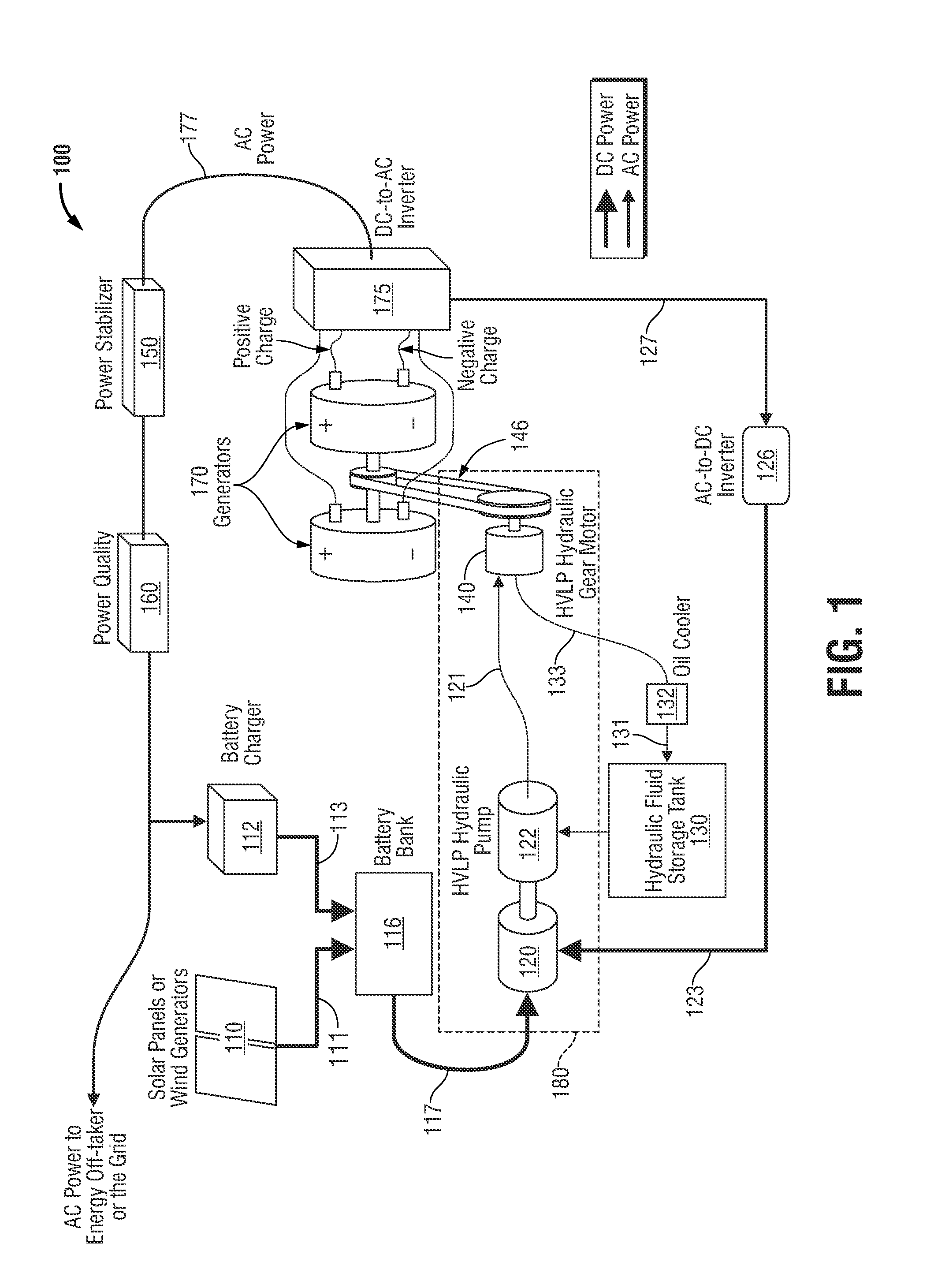

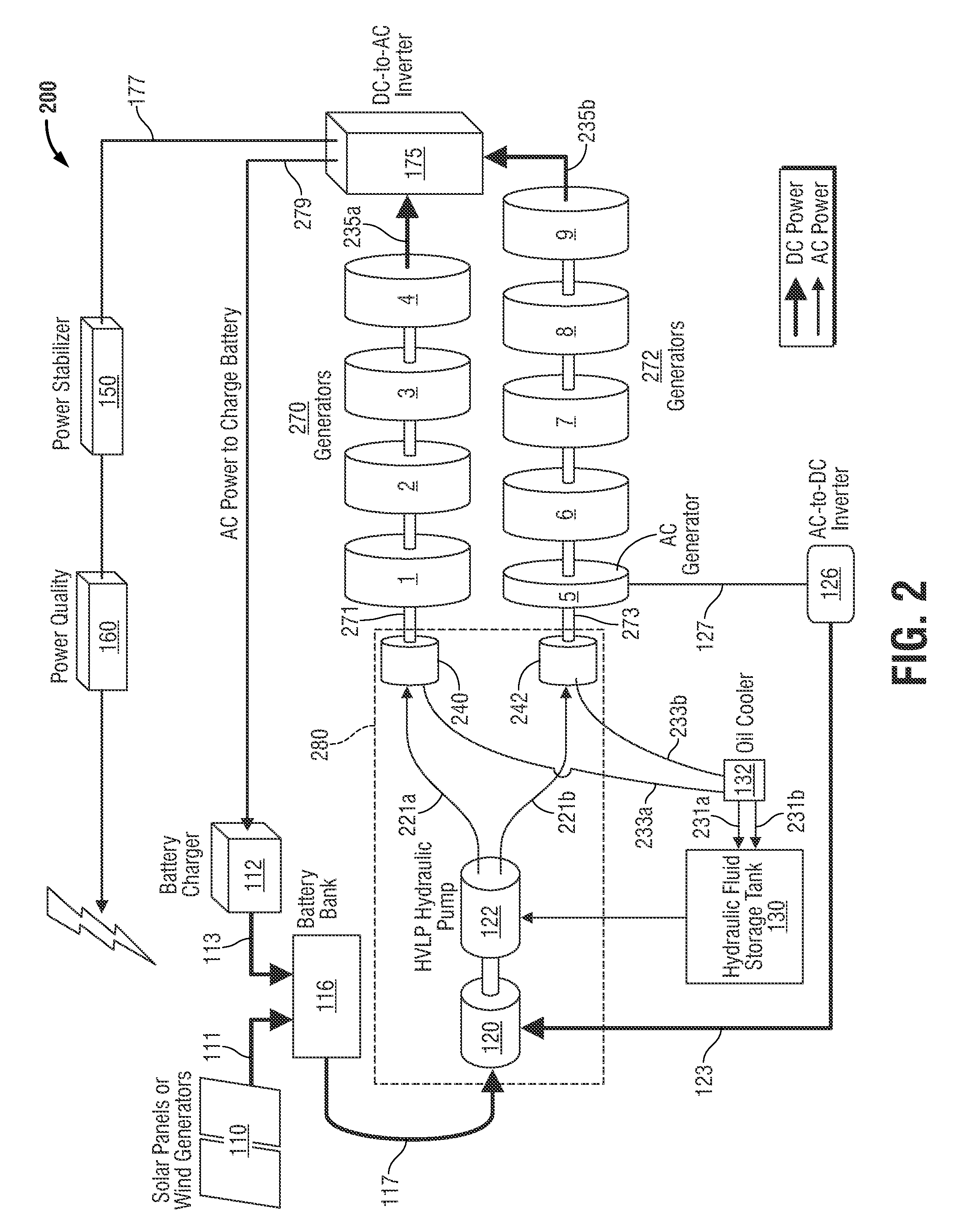

Regenerative Power Supply System and Method

A regenerative power supply system and method comprises a dynamo-electric generator, an electric drive motor coupled to the generator, a transmission device coupling the generator to the electric drive motor, and an energy storage device configured to provide a backup power supply to the regenerative power supply system. An electronic control device is configured to control a flow of electricity to the electric drive motor. An energy storage management device is configured to control a flow of electricity between the electronic control device and the energy storage device.

Owner:CONSTRUCTIVE IND

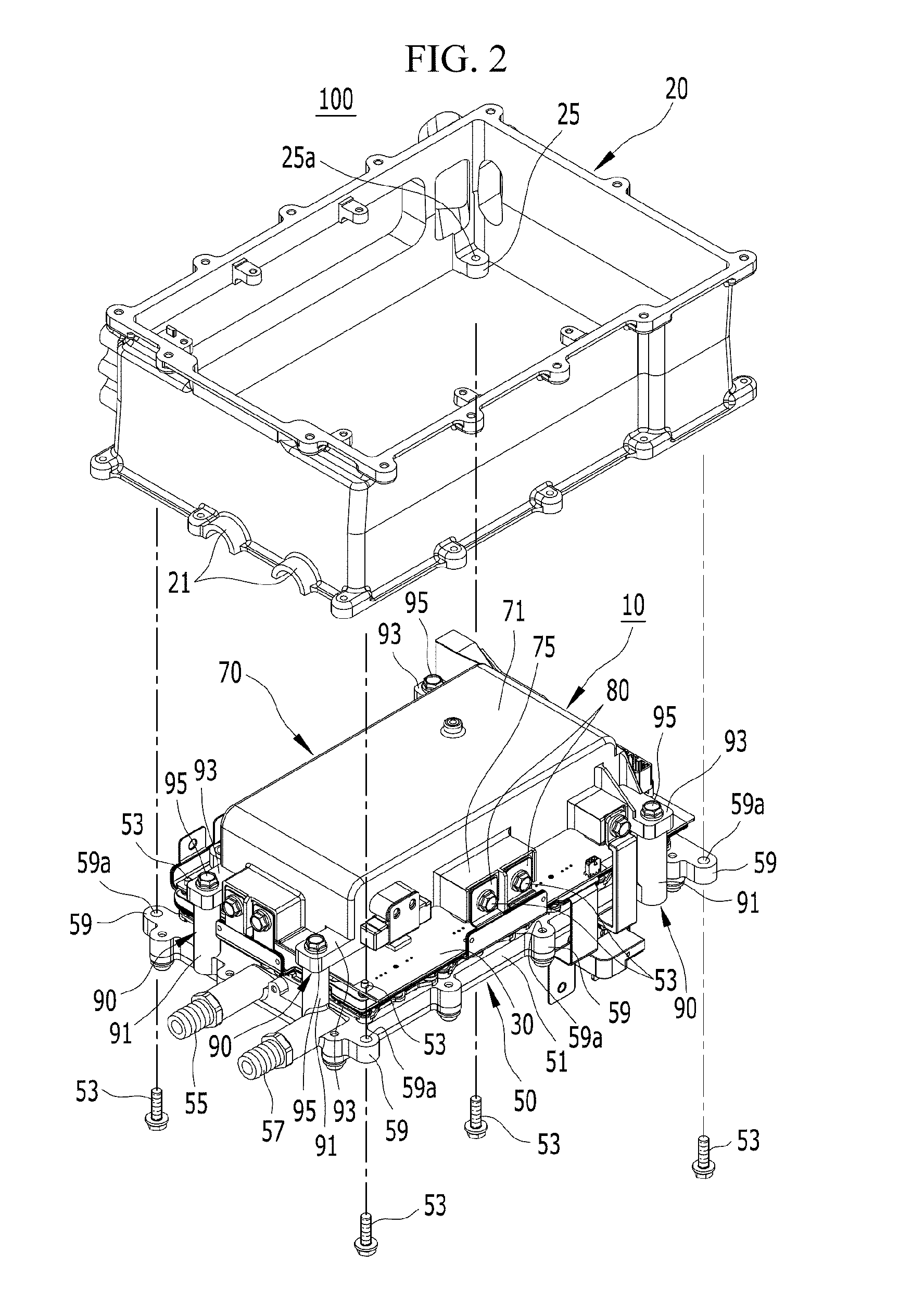

Inverter for vehicle

InactiveUS8848370B2Improve structural rigidityDigital data processing detailsConversion constructional detailsFrequency changerPower semiconductor device

An inverter for a vehicle is disclosed. The inverter for the vehicle illustratively includes: a power module provided with a power semiconductor device; a cooling module coupled to the power module and flowing a coolant therethrough; and a capacitor module mounted at the cooling module through a mounting unit and adapted to absorb a ripple current of the power module.

Owner:HYUNDAI MOTOR CO LTD

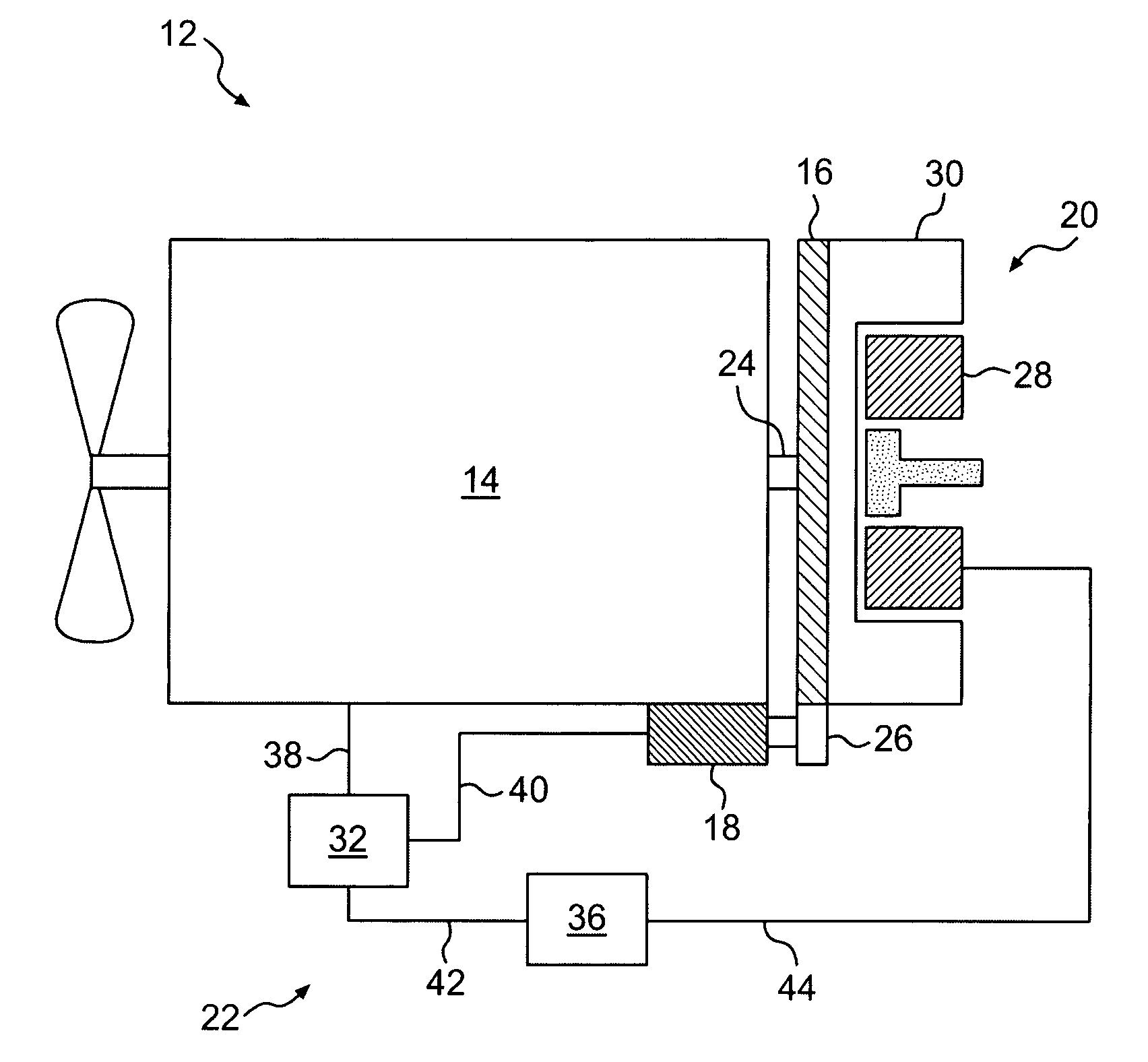

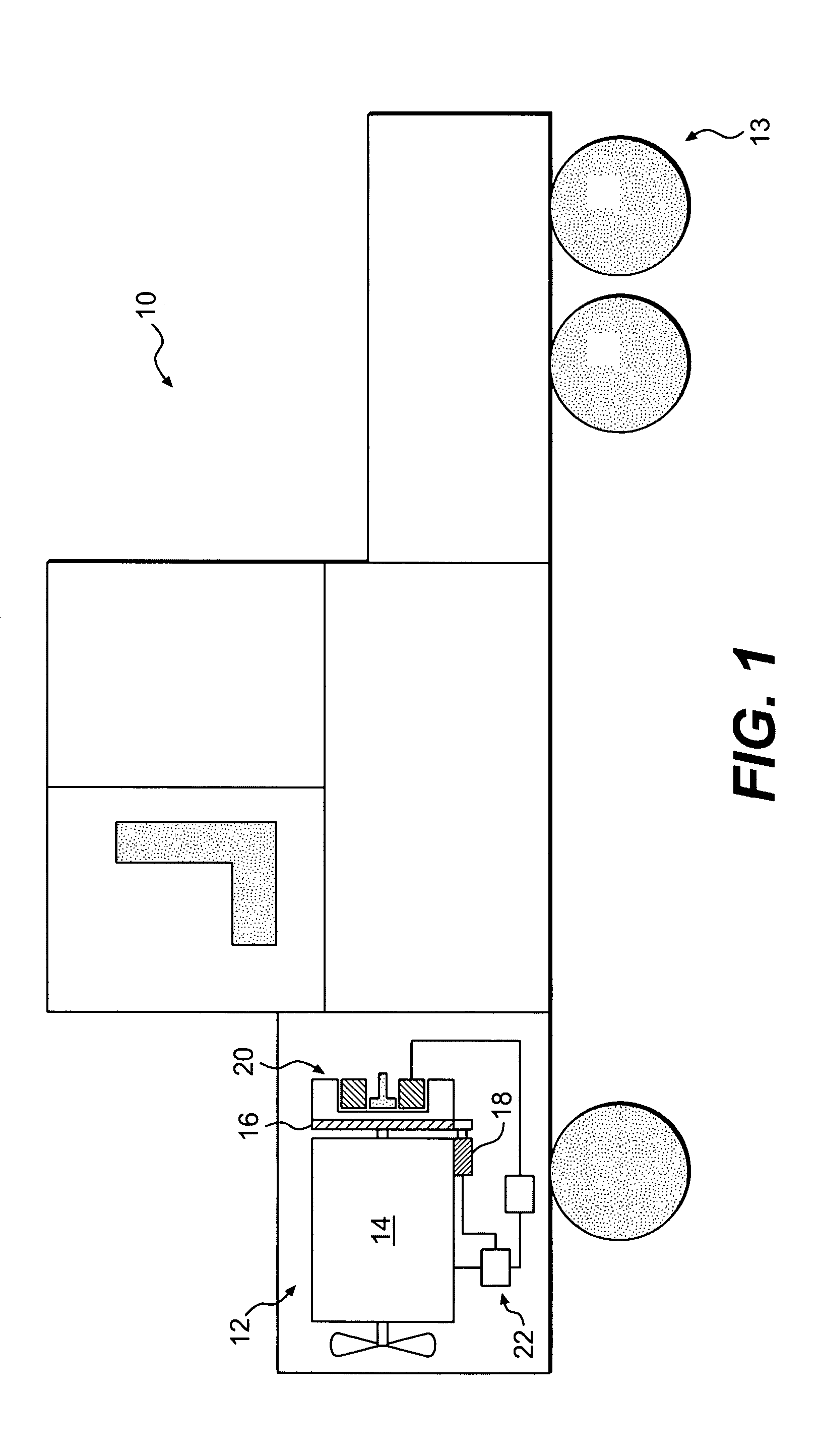

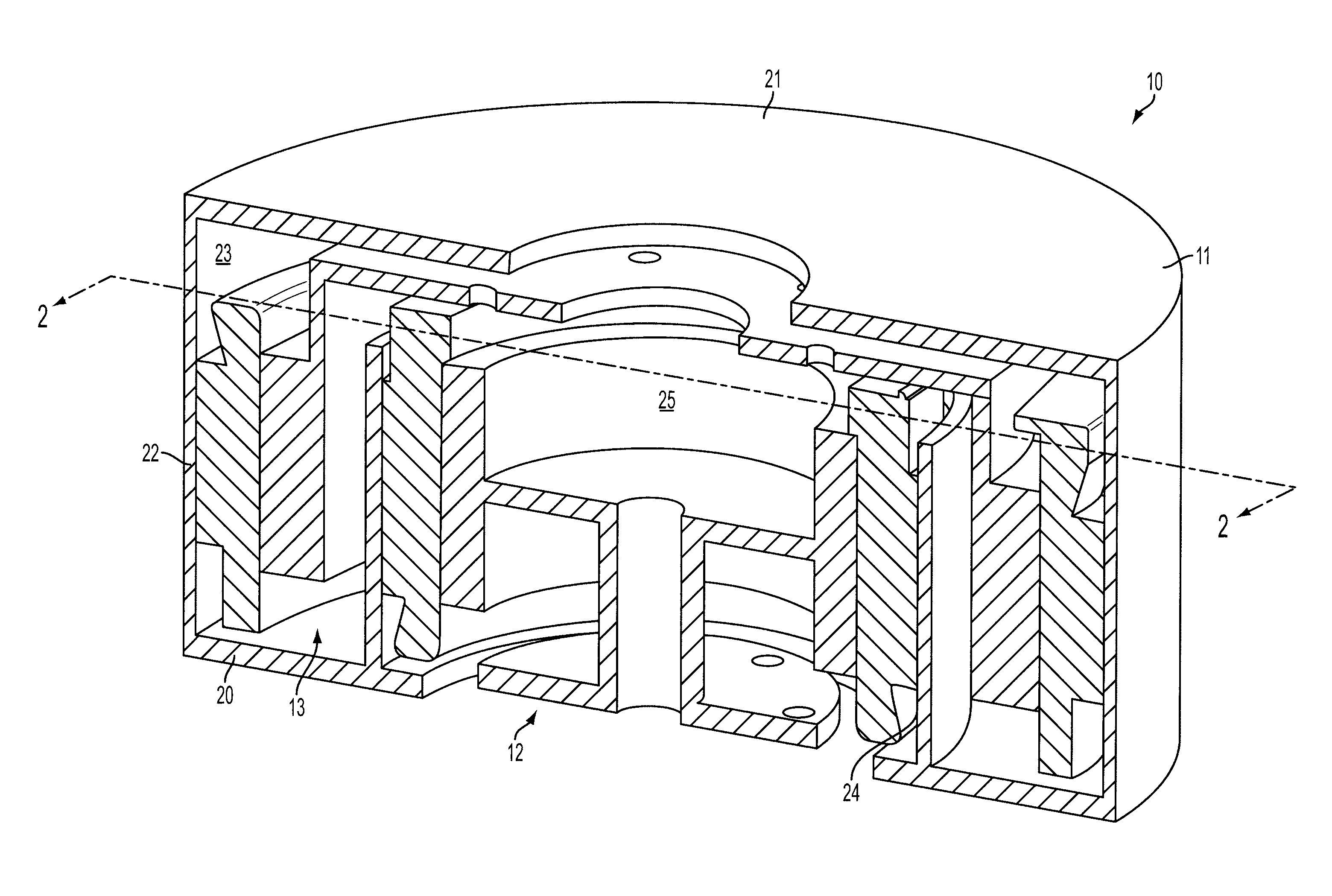

Power generator and torque amplifier

InactiveUS20050140231A1Simple structureEfficiently obtainedMagnetic circuit rotating partsAC/DC convertorsRotational axisAudio power amplifier

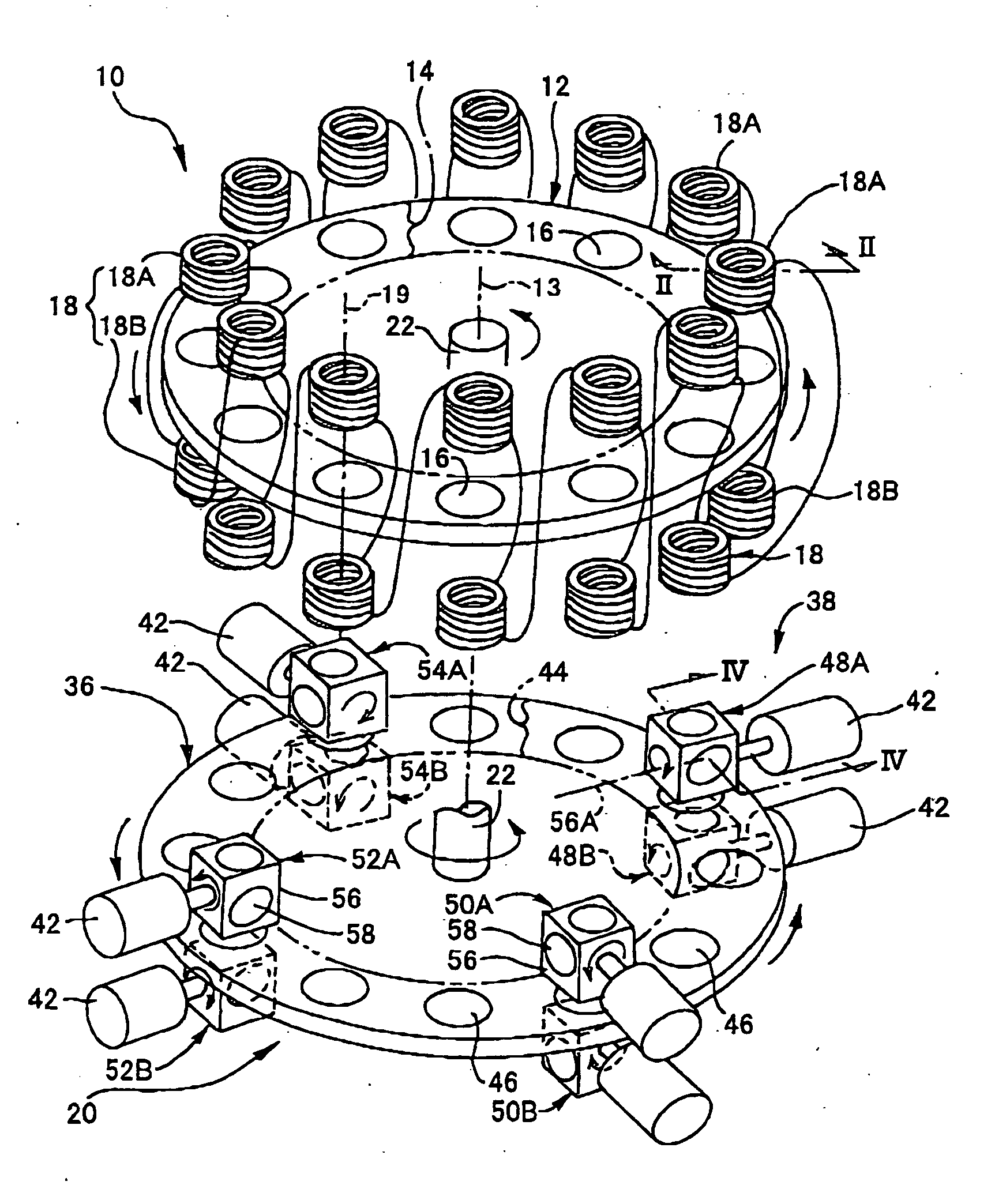

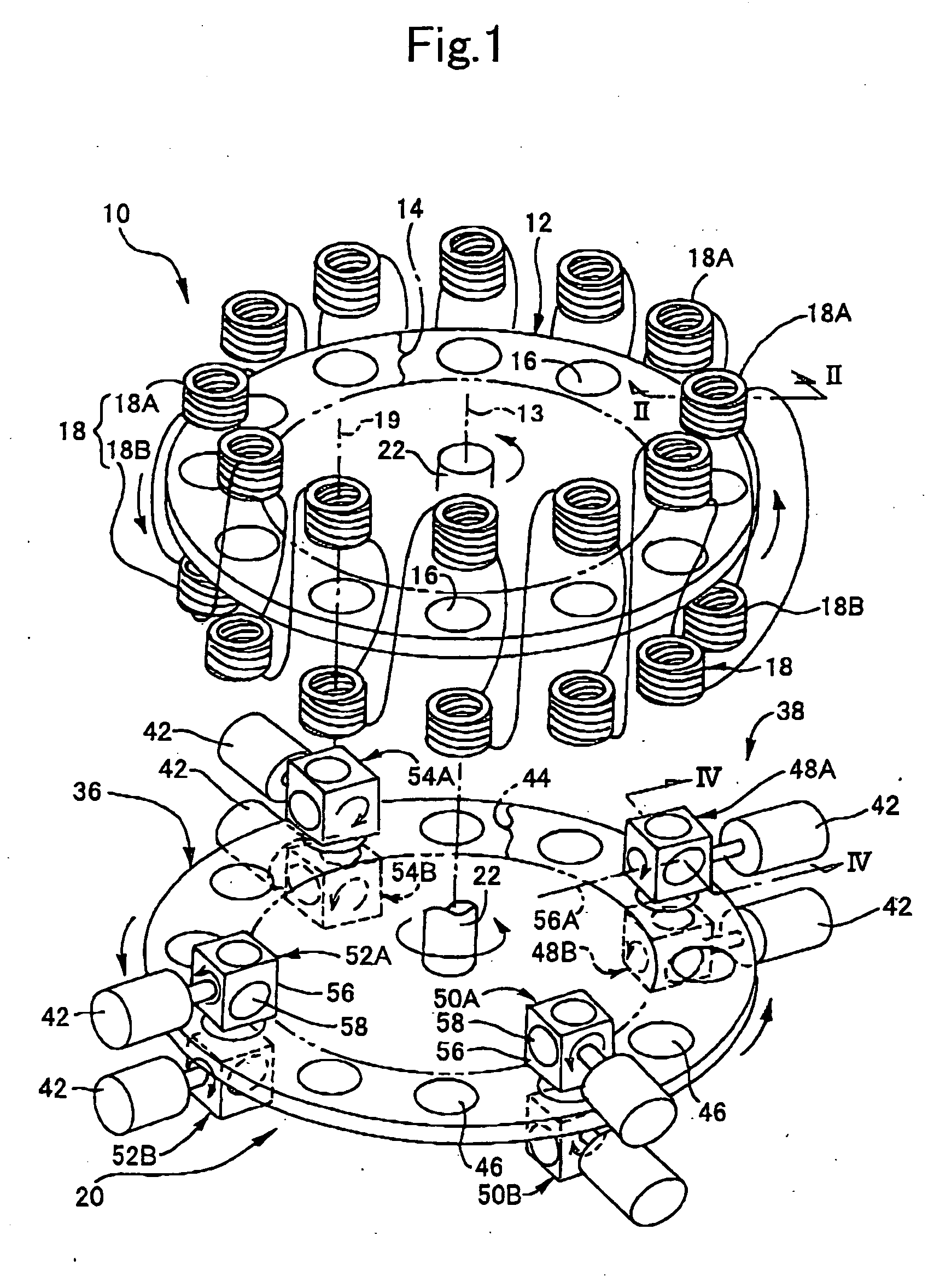

Disclosed is a power generator adapted to provide an electrical power greater than an input power by means of a permanent magnet. The power generator 10 comprises a rotatable rotor 12, a plurality of permanent magnets 16, and a plurality of coreless coils 18. The rotor 12 has a surface including an annular zone 14 formed around the rotational axis 13 thereof. The permanent magnets 16 are disposed along the annular zone 14 at constant intervals in the circumferential direction of the rotor 12 to form an annular array, while uniformly orienting their polarities in a direction orthogonal to the annular zone 14. The coreless coils 18 are supported by a stationary member 11 and disposed along the annular zone to form an annular array, while allowing the respective axes 19 of the coils to intersect with the annular zone 14. The permanent magnets 16 are moved along the coreless coils 18 in conjunction with the rotation of the rotor 12 induced by a rotational force supplied through a center shaft 22 from a torque amplifier 20 disposed below the rotor 12, so as to obtain an output power from the coreless coils 18.

Owner:OGOSHI MAKOTO

Vehicle mounted electrical generator system

A vehicle mounted AC generator system having an AC generator mounted outside the engine / transmission compartment and connected by drive shaft with universal joints and a belt driven RPM ratio device. The ratio is set to provide accurate AC generator RPM at a preselected engine RPM. The AC generator is mechanically engageable when certain conditions are met and is disconnected when other conditions are present, including an operator emergency stop switch.

Owner:CONTOUR HARDENING

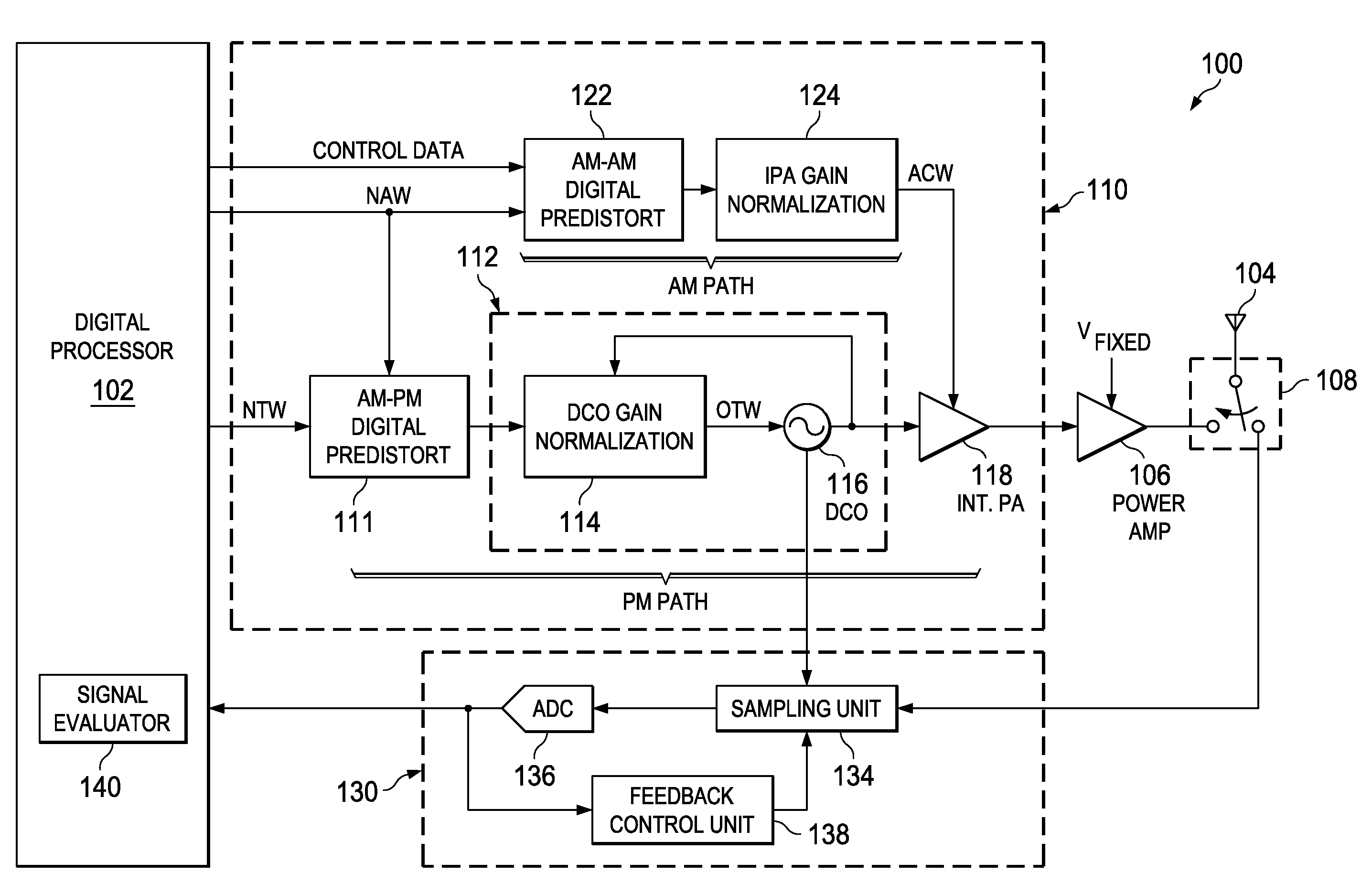

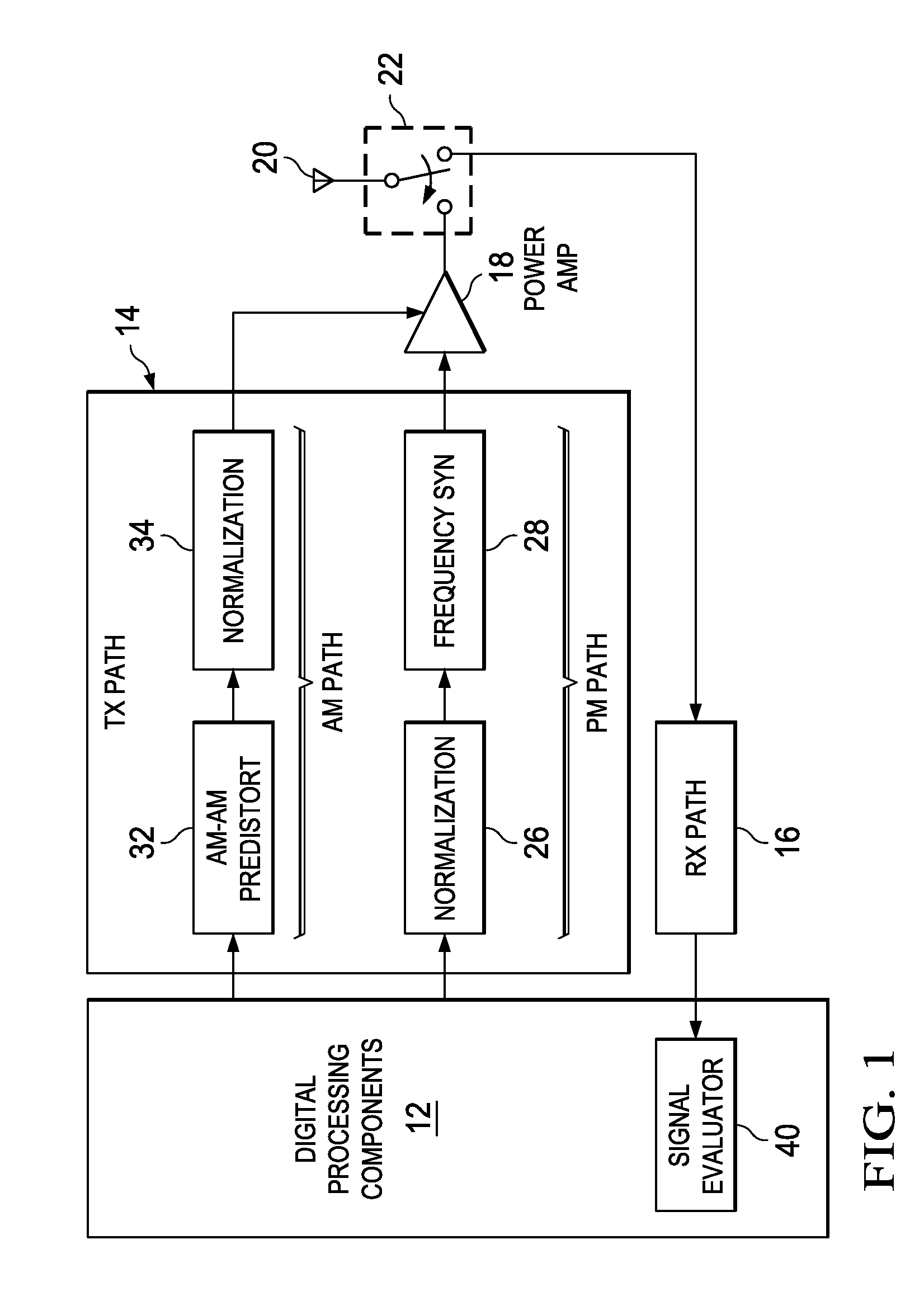

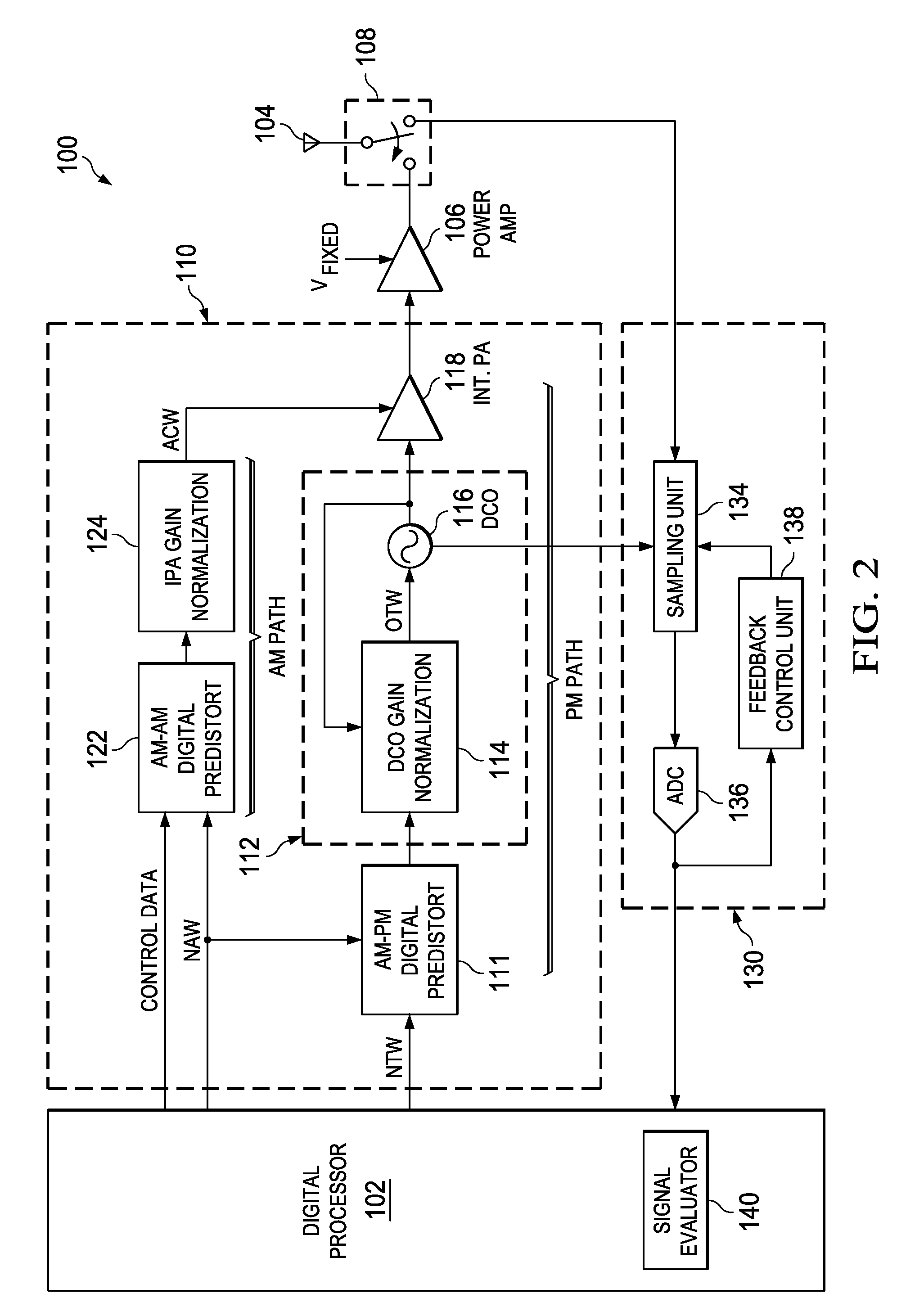

Predistortion calibration in a transceiver assembly

ActiveUS7555057B2Reduce non-linearityMultiple-port networksAmplifier modifications to reduce non-linear distortionTransceiverAudio power amplifier

Systems and methods are provided for calibrating a digital predistorter in an integrated transceiver circuit. A digital transmitter path provides a signal from a digital input. The transmitter path includes a digital predistorter that predistorts the digital input to mitigate nonlinearities associated with a power amplifier. The integrated transceiver circuit further includes a receiver path associated with the digital transmitter path. A coupling element provides the signal from the transmitter path to the receiver path. A signal evaluator determines values for at least one parameter associated with the digital predistorter based on the signal.

Owner:TEXAS INSTR INC

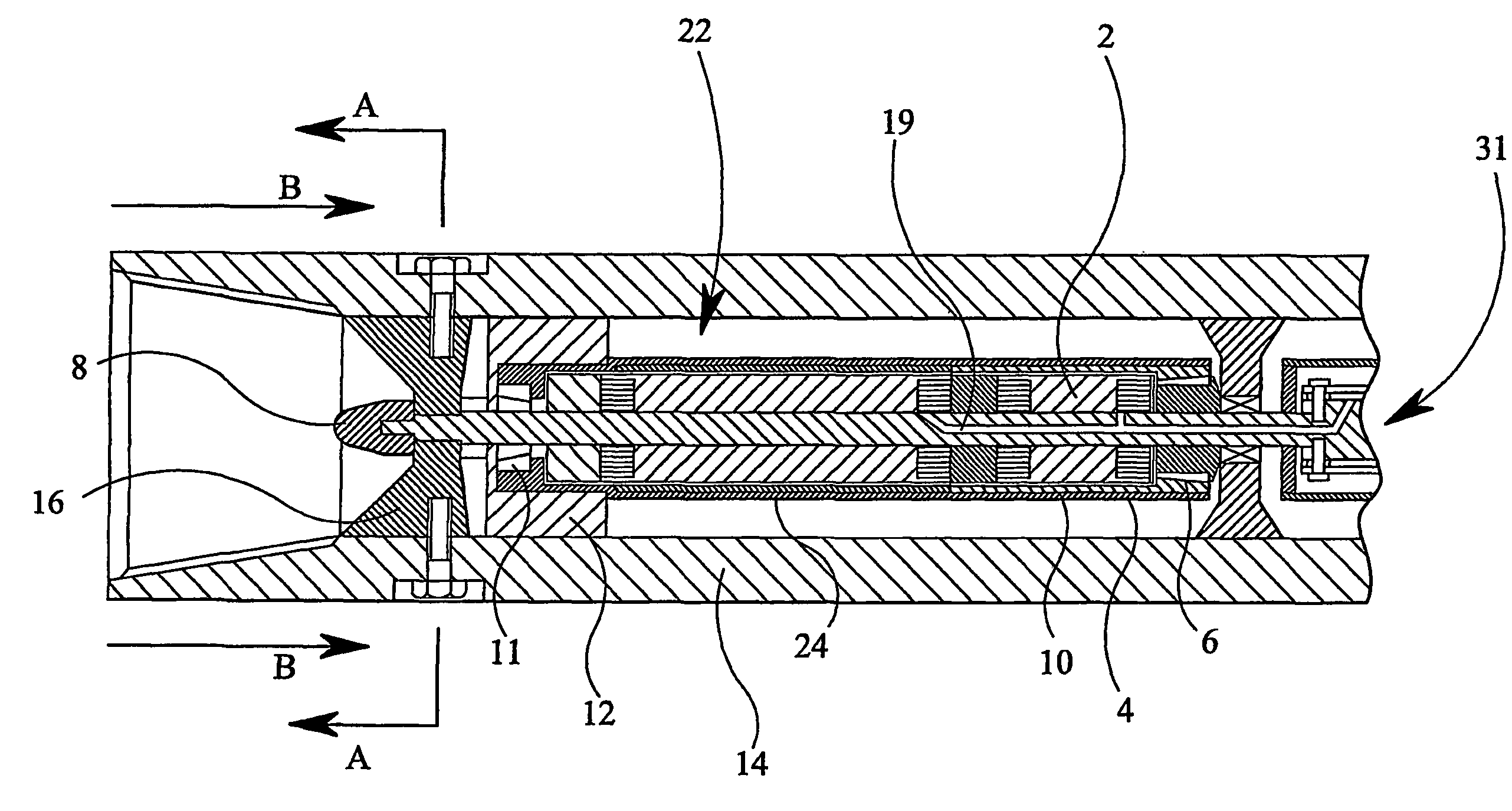

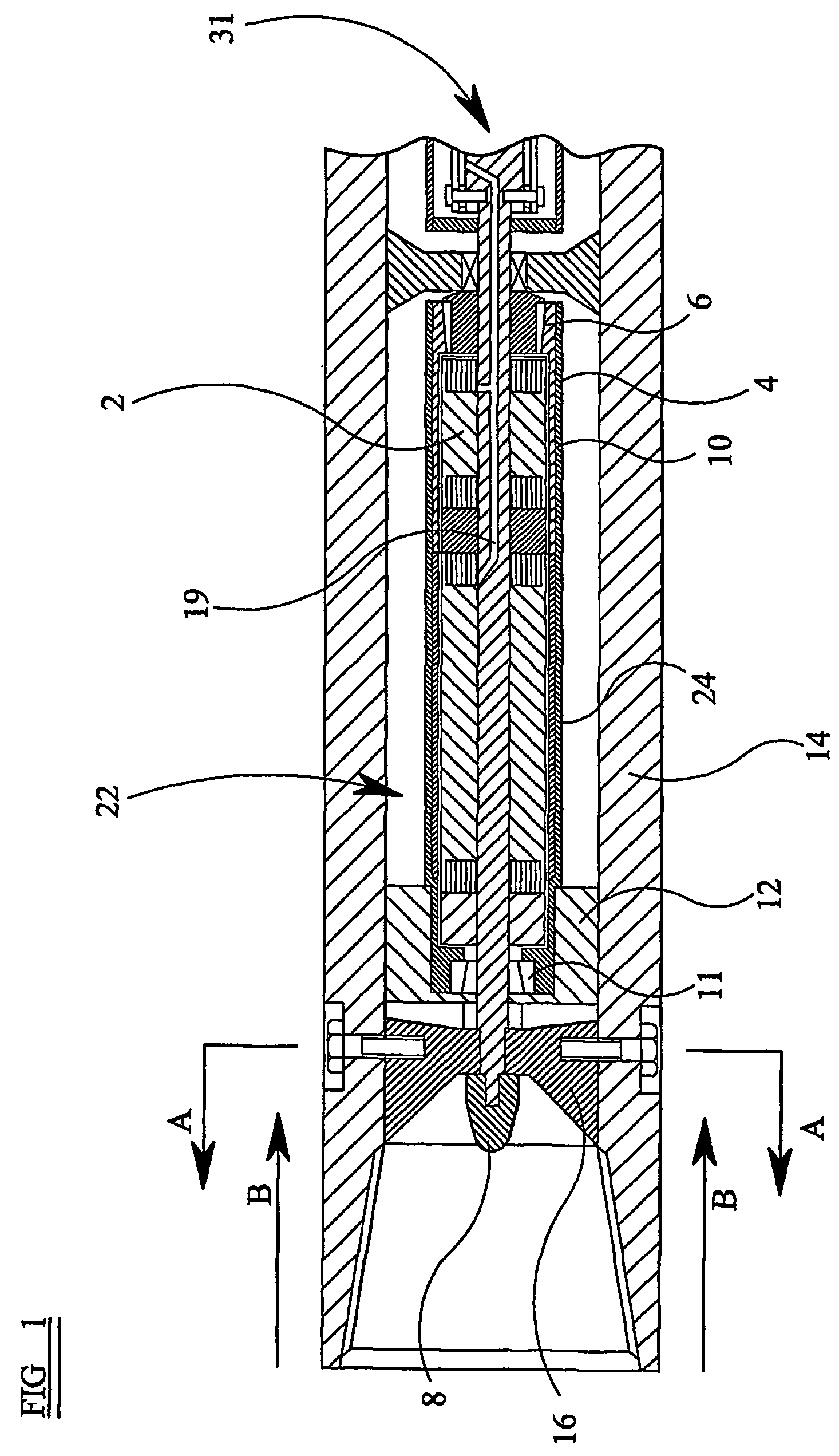

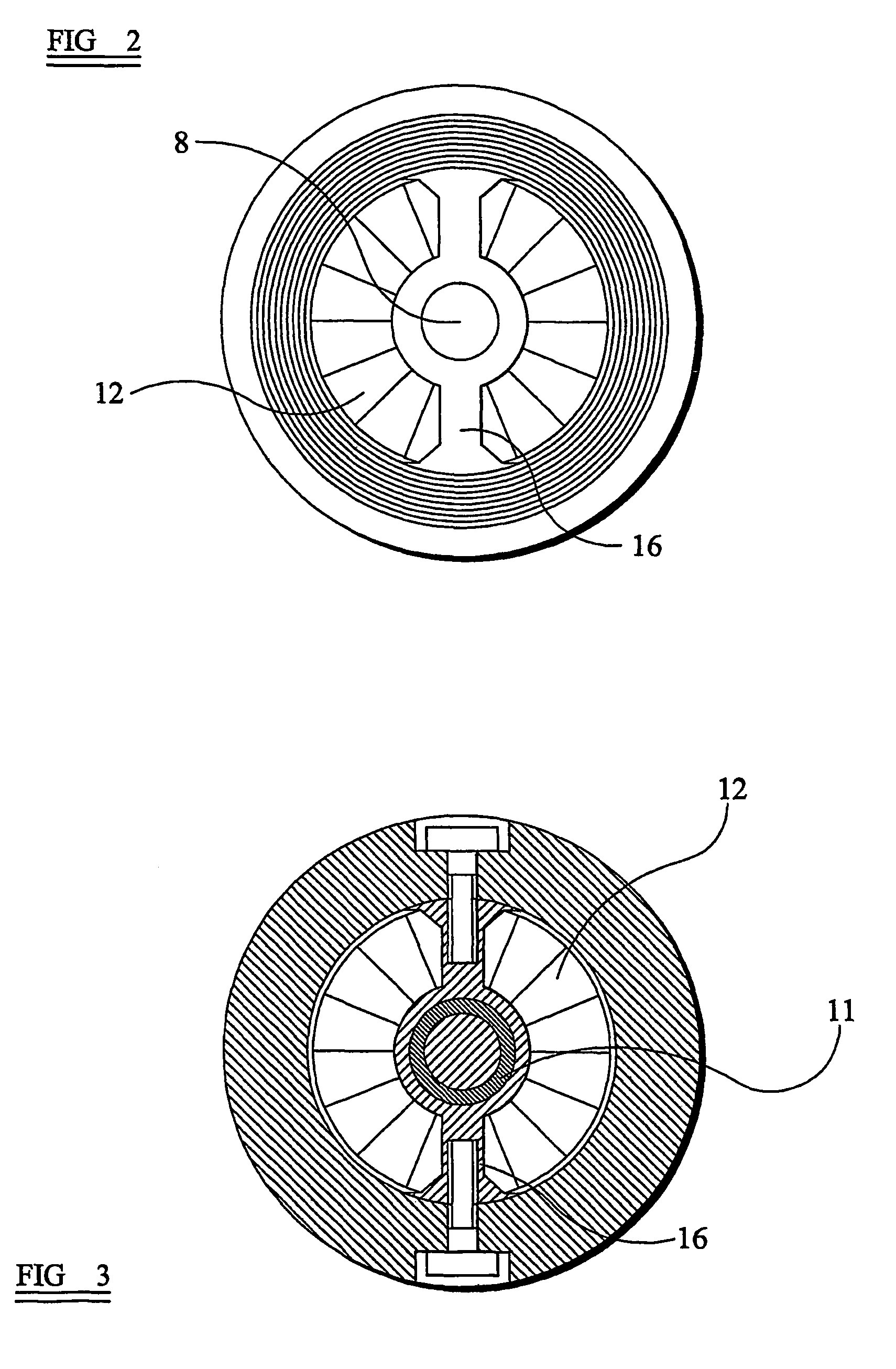

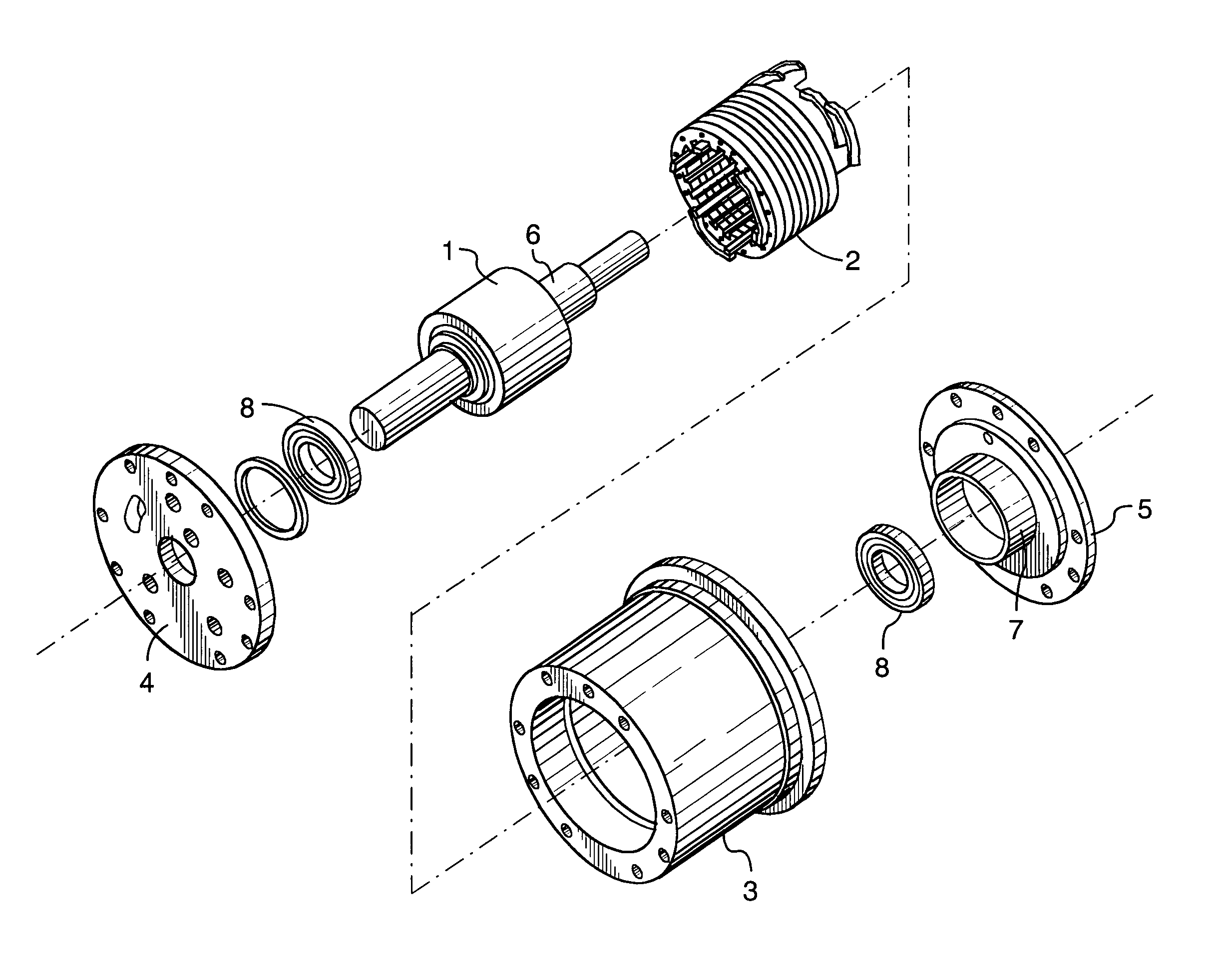

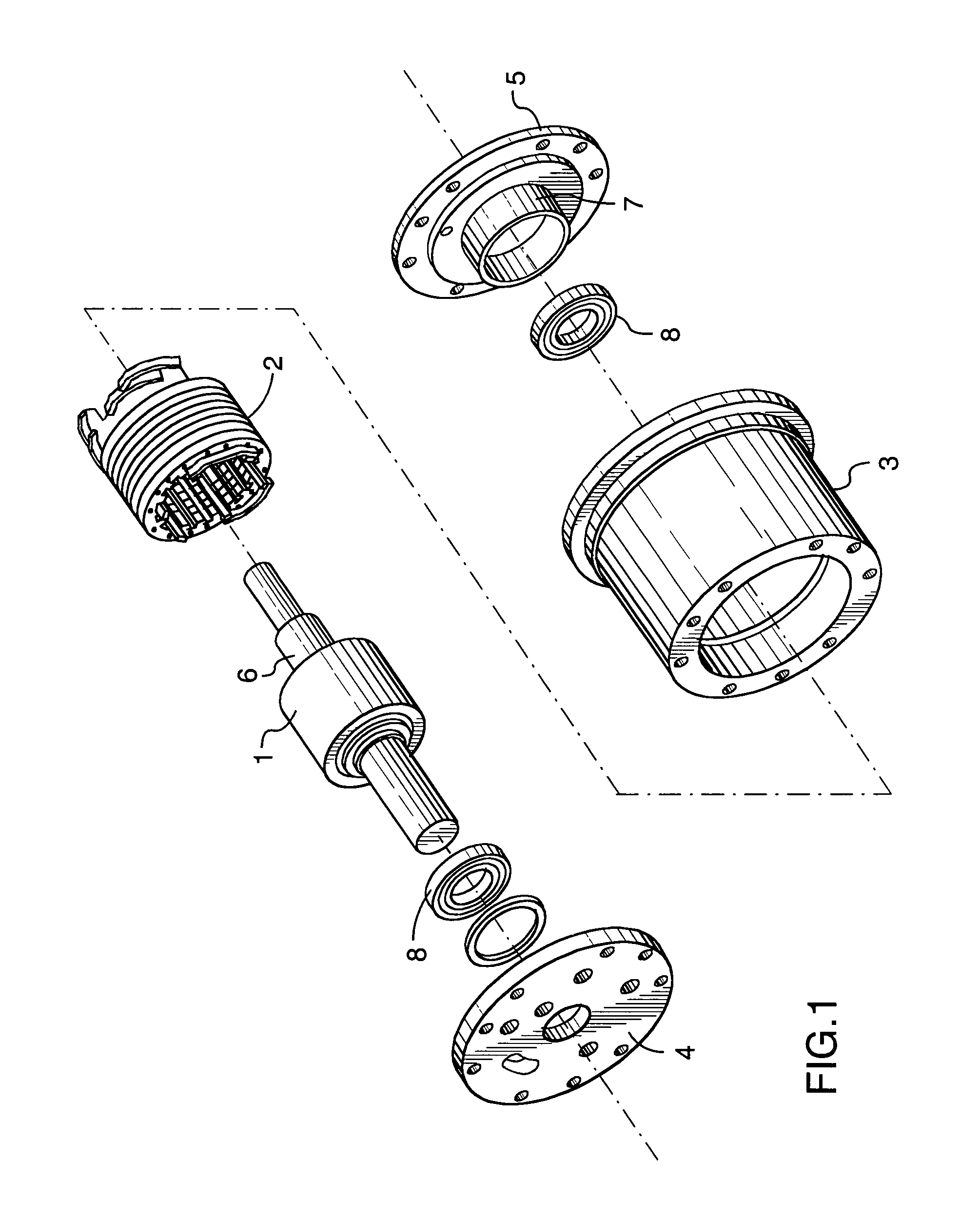

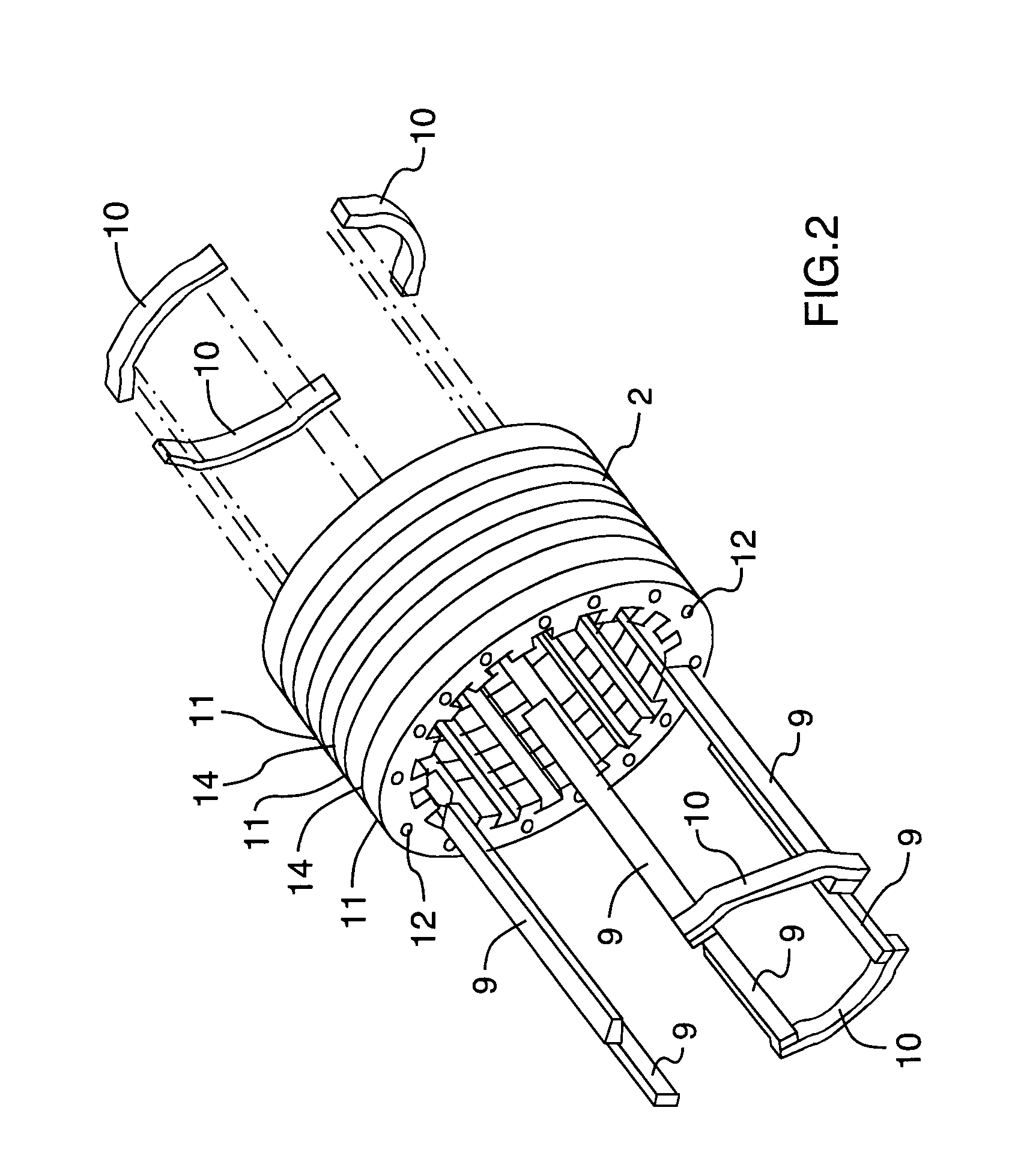

Downhole torque-generating and generator combination apparatus

InactiveUS7141901B2Avoid excessive power outputAC/DC convertorsAsynchronous induction motorsAlternatorDc current

A combination of a torque-generating apparatus with an alternator / generator. The torque-generating apparatus comprises a first assembly (10, 25) including a generally cylindrical member of magnetically soft material and having a longitudinal axis, and a second assembly (2) arranged coaxially within the first assembly and including an electromagnetic winding (4). The first assembly (10, 25) and the second assembly (2) are rotatable relative to each other about the axis. Relative rotation between the first (10, 25) and second (2) assemblies induces a magnetic field which generates rotational torque between the first and second assemblies. Rectification means (31) is provided to convert alternating current electrical output from the alternator / generator (22) to provide D.C. current to the electromagnetic windings (4) of the torque generating apparatus to generate an electromagnetic braking effect.

Owner:TURBINE DYNAMICS

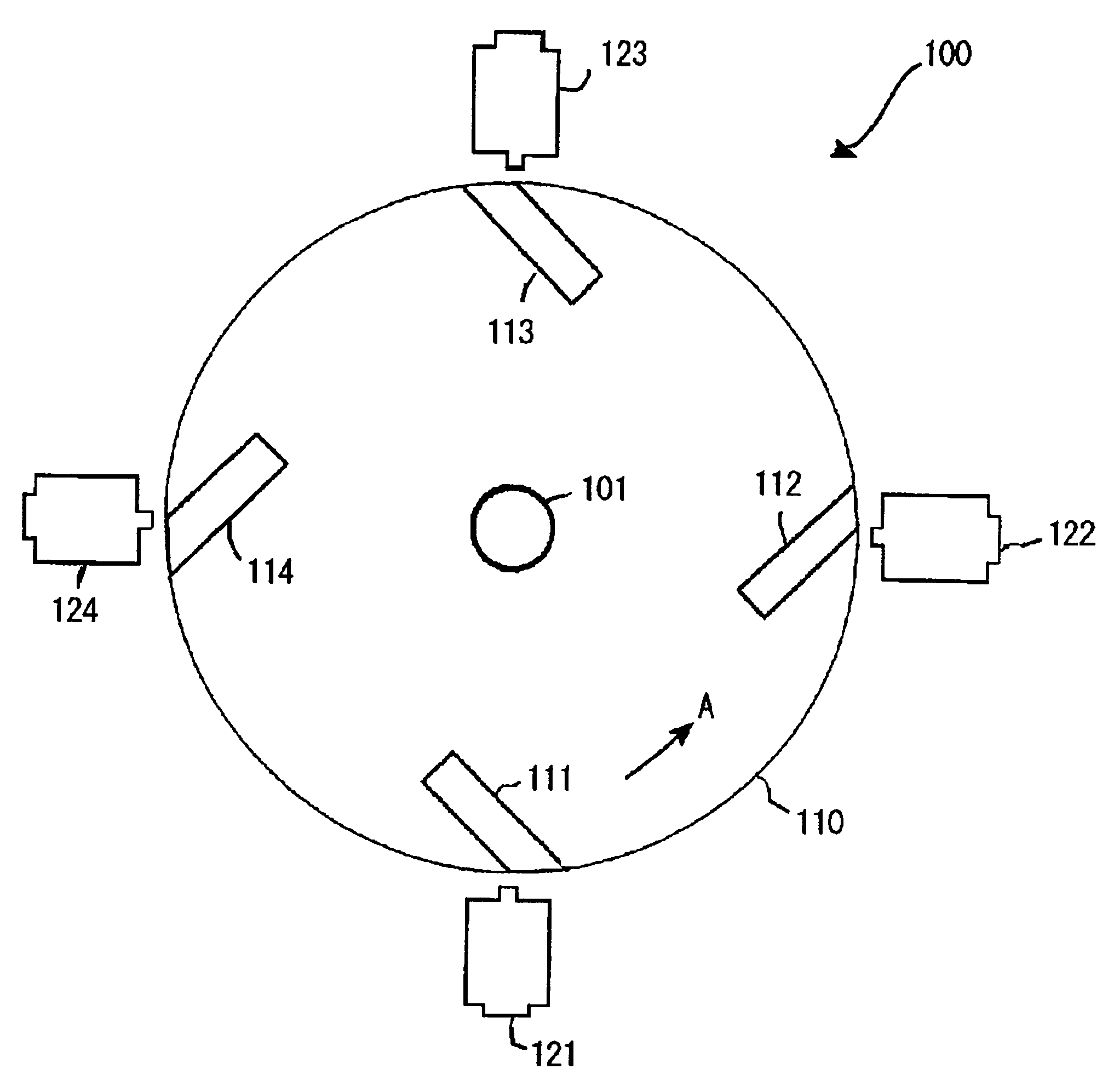

Magnetic rotating motor generator

A magnetic rotating motor generator of the present invention comprises a rotating portion which is made of a non-magnetic substance whose periphery is provided with a group of permanent magnets tilted at a predetermined angle in an embedded manner; a group of electromagnets that are disposed adjacently to the rotating portion so as to oppose the group of permanent magnets; a positional sensor for detecting positions of the group of permanent magnets; a controller for applying an electric current to the electromagnet on the basis of a detected signal from the positional sensor; and a power generating section for obtaining power from a coil of the electromagnet. A rotation mode and a power generation mode are repeated, so that power generation is performed while a function as a motor is exhibited.

Owner:FOREST PINE ELECTRIC

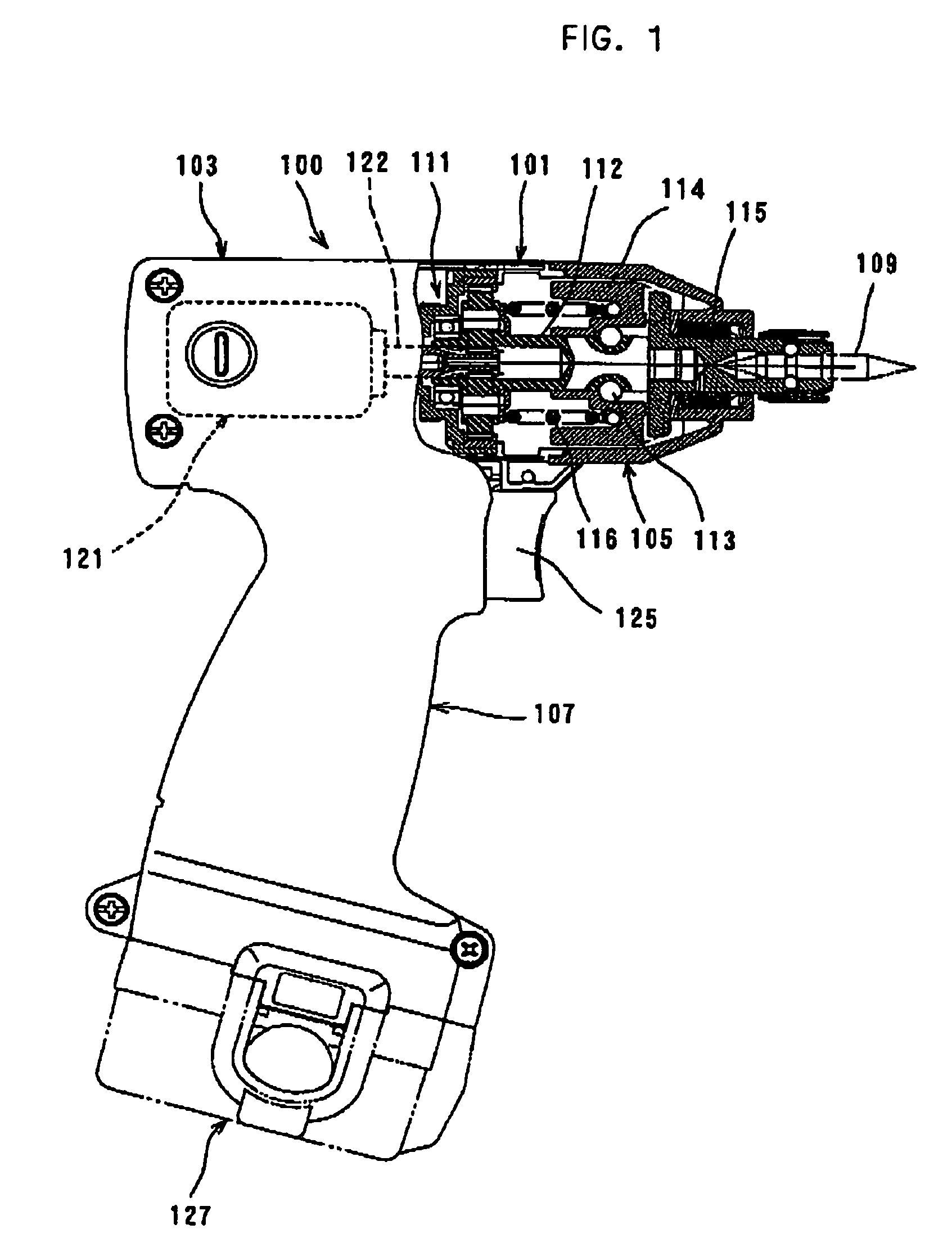

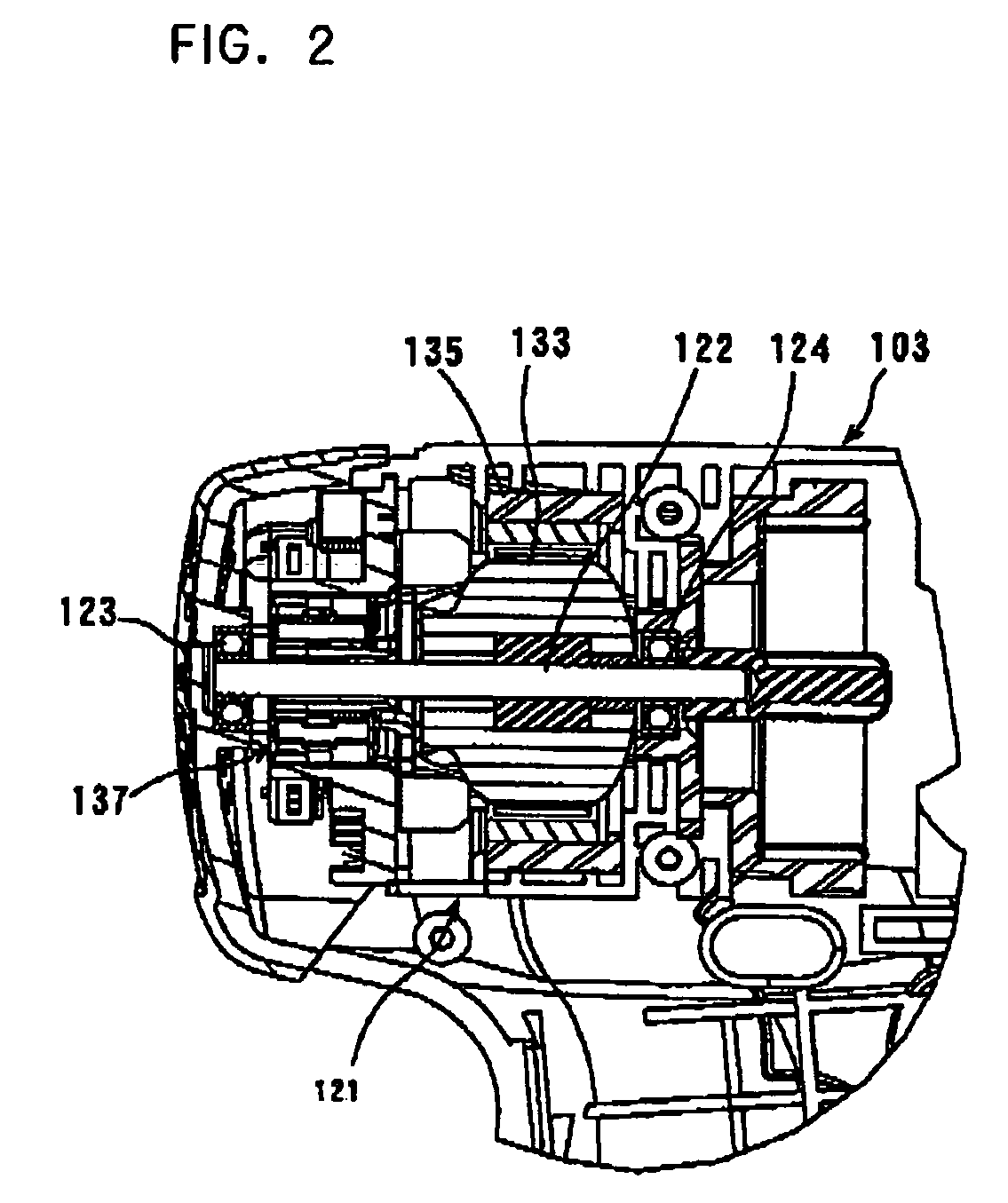

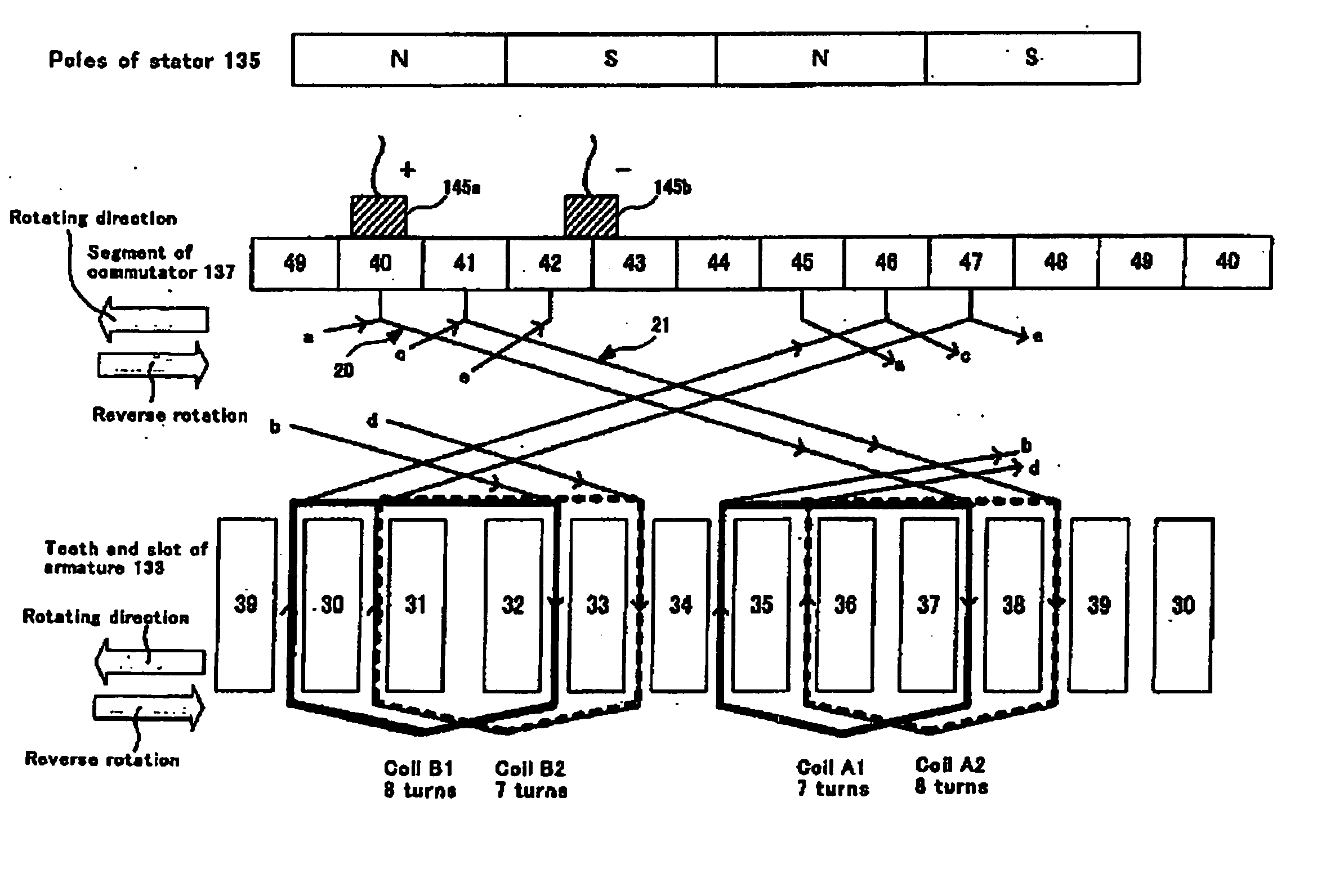

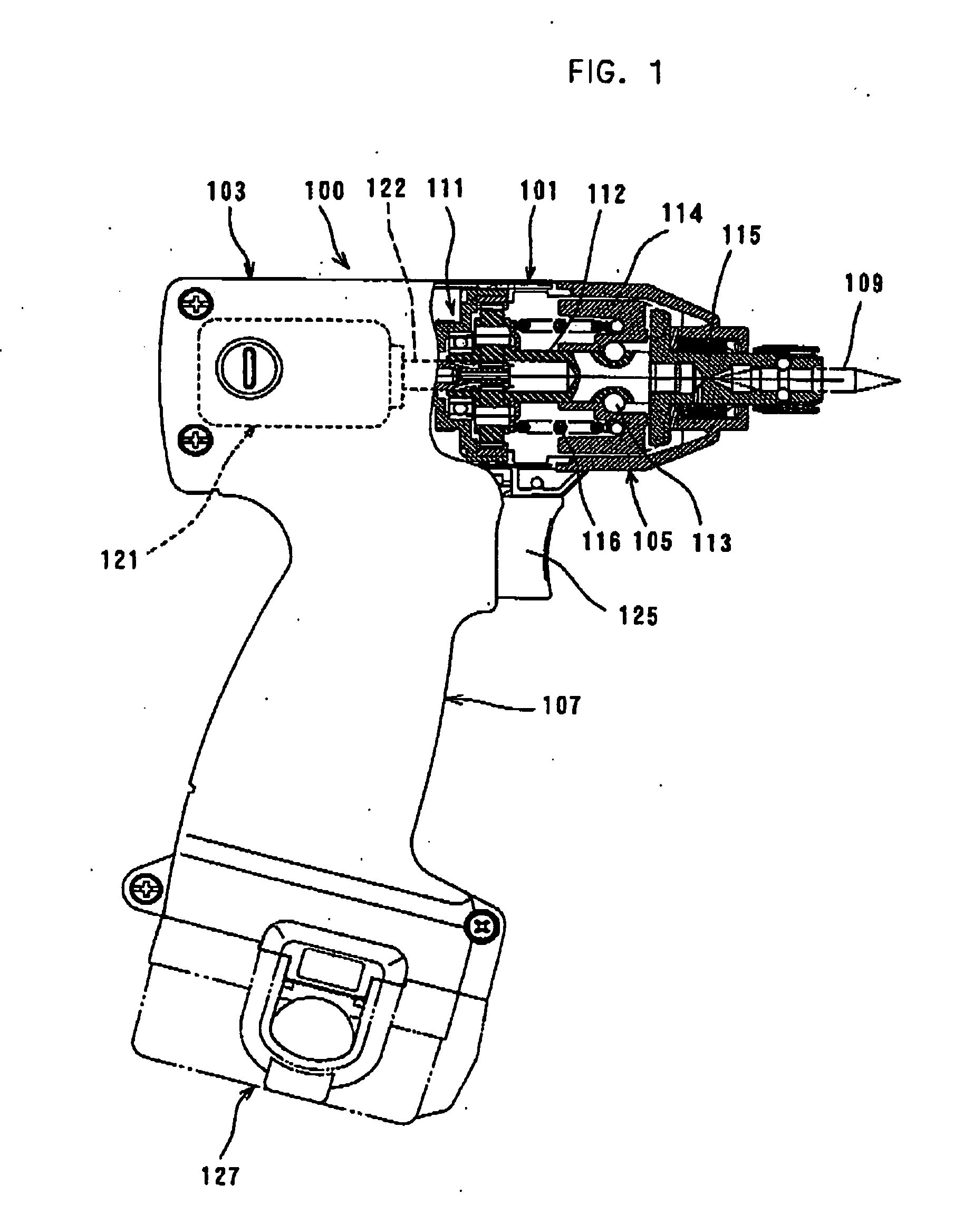

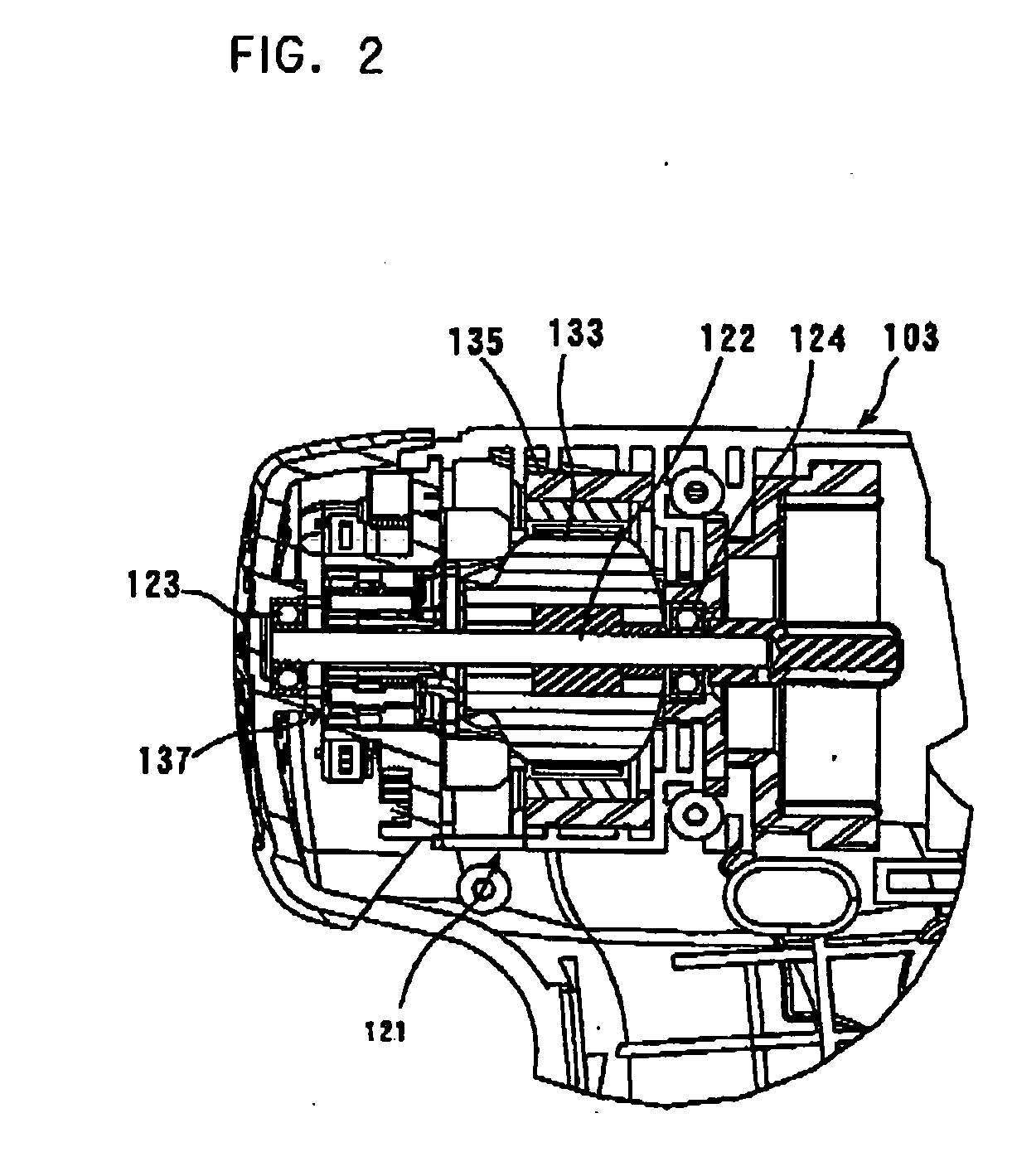

Power tool

ActiveUS7388312B2Simple technologyNot perishableSynchronous generatorsAC/DC convertorsMotor drivePower tool

It is an object of the invention to provide an improved technique for controlling the output characteristic of a motor. Representative power tool includes a tool bit and a motor. The motor drives the tool bit and includes an armature, a coordinator, a plurality of segments and a plurality of armature windings. The armature has a plurality of slots. The communicator rotates together with the armature. Plurality of segments is provided on the communicator. Respective armature windings are connected at the both ends of the segments. Each of the armature windings is defined by coils that are wound between respective pairs of the slots of the armature. Each of the armature windings is formed by at least two coils connected in series. At least one of the coils defining the armature winding has a different number of turns of a wire wound between the associated slots from the other coils in the same armature winding. On the same time, the total number of turns of the coils of each of the armature windings is the same. Thus, as a result, the magnetic field around each of the armature windings can be kept substantially the same while providing fine adjustment of the numbers of turns in the armature windings.

Owner:MAKITA CORP

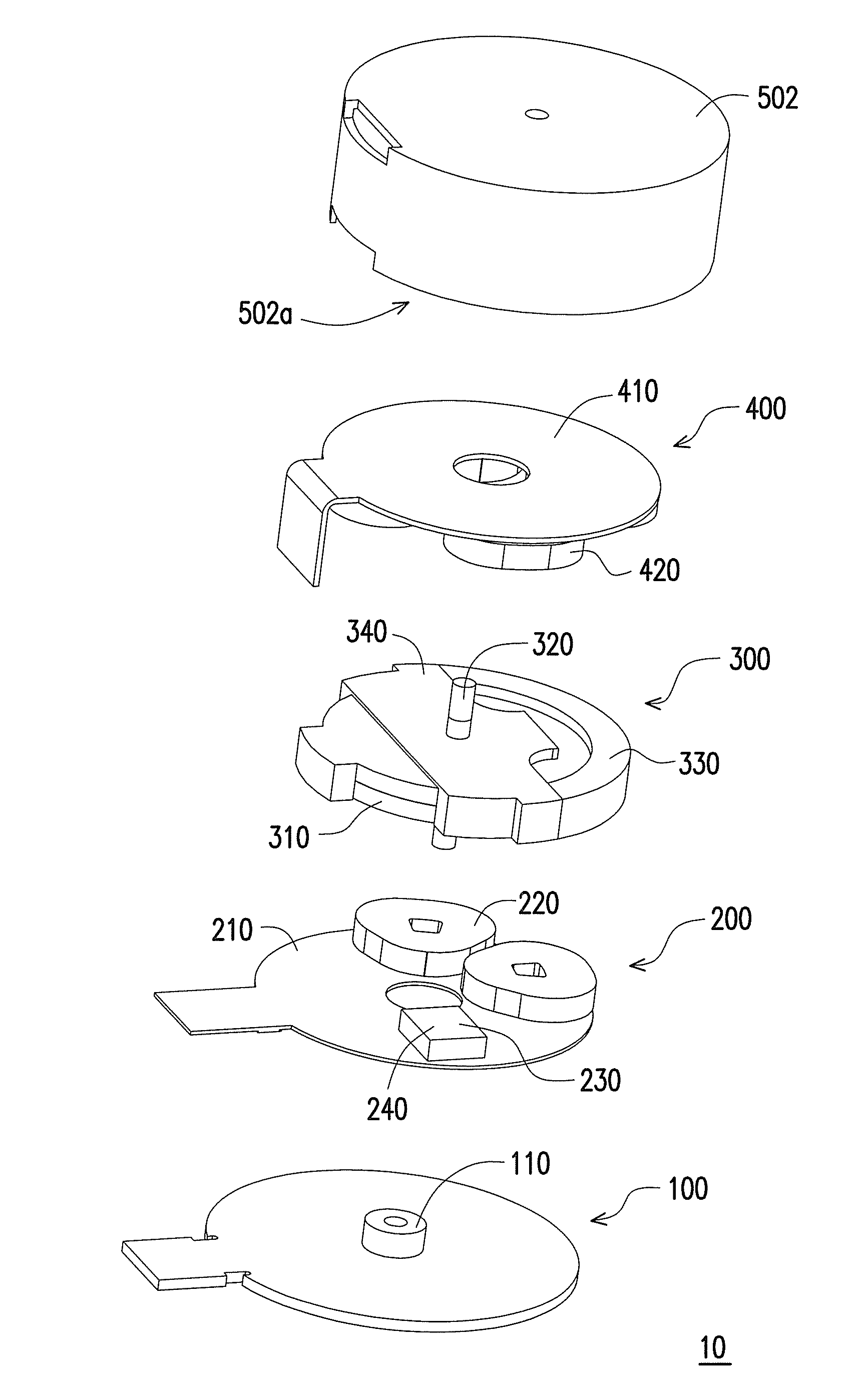

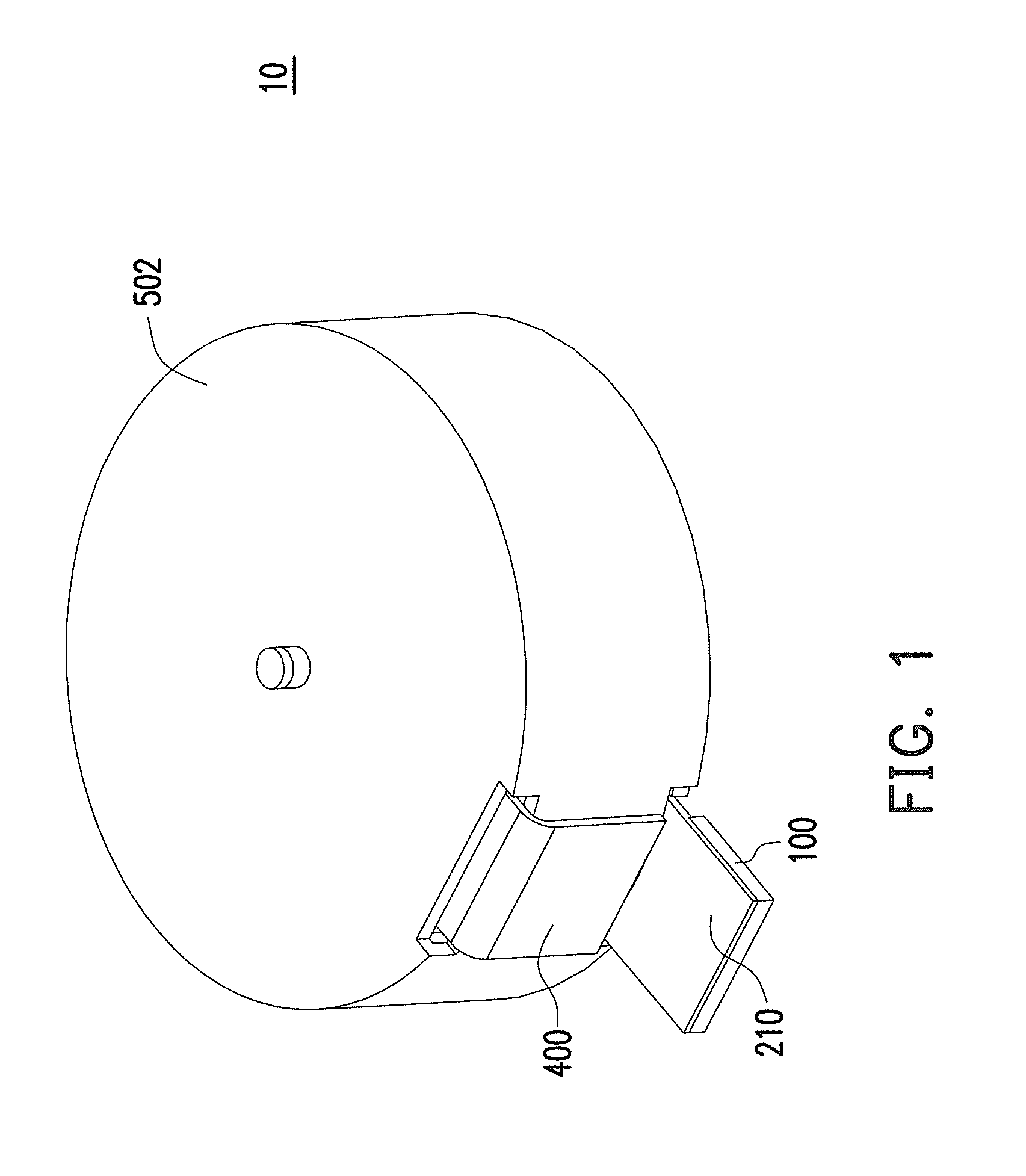

Power generating device

ActiveUS20110012459A1Smooth rotationPiezoelectric/electrostriction/magnetostriction machinesFrom muscle energyElectromagnetic fieldElectrical and Electronics engineering

Owner:SILICON TOUCH TECH INC

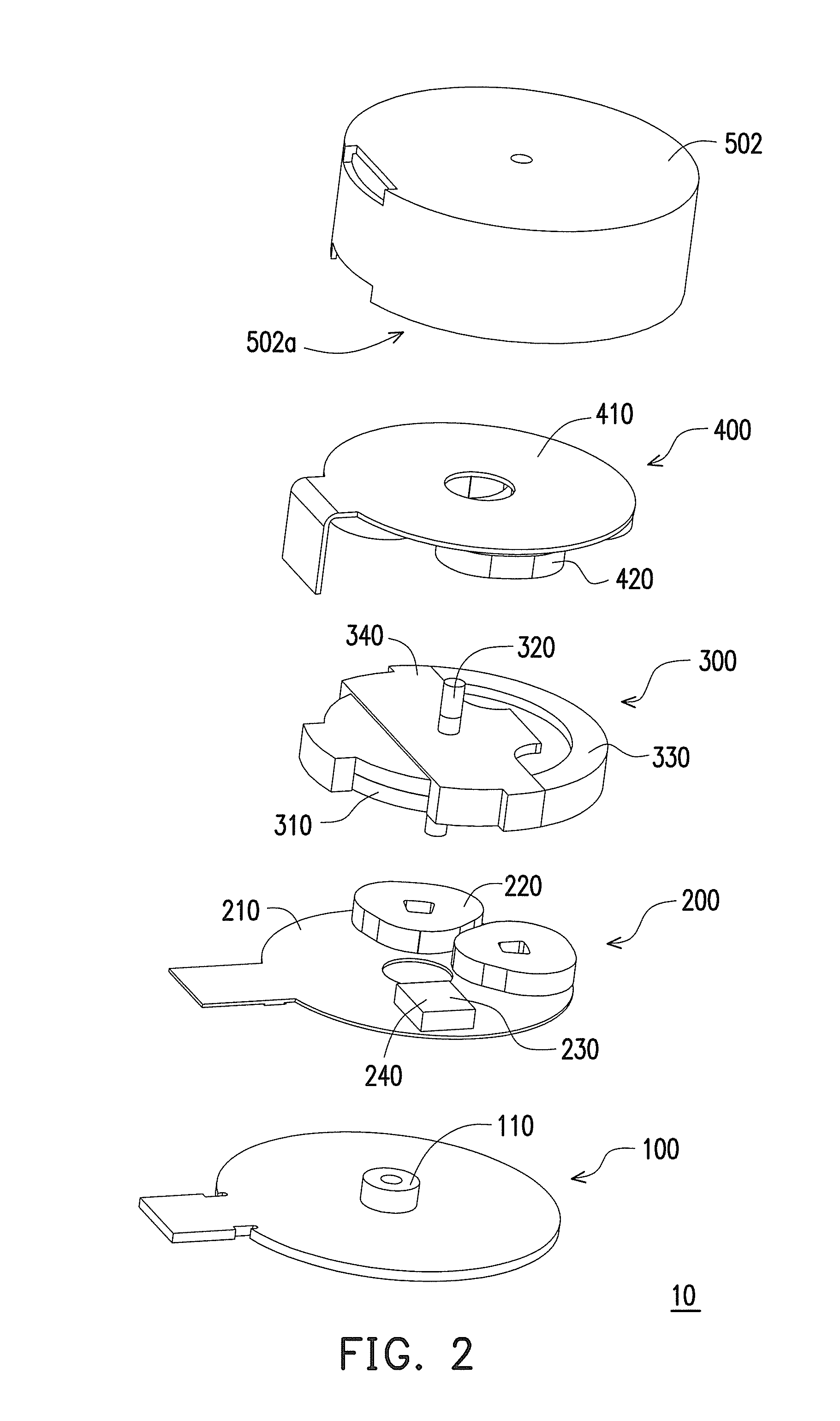

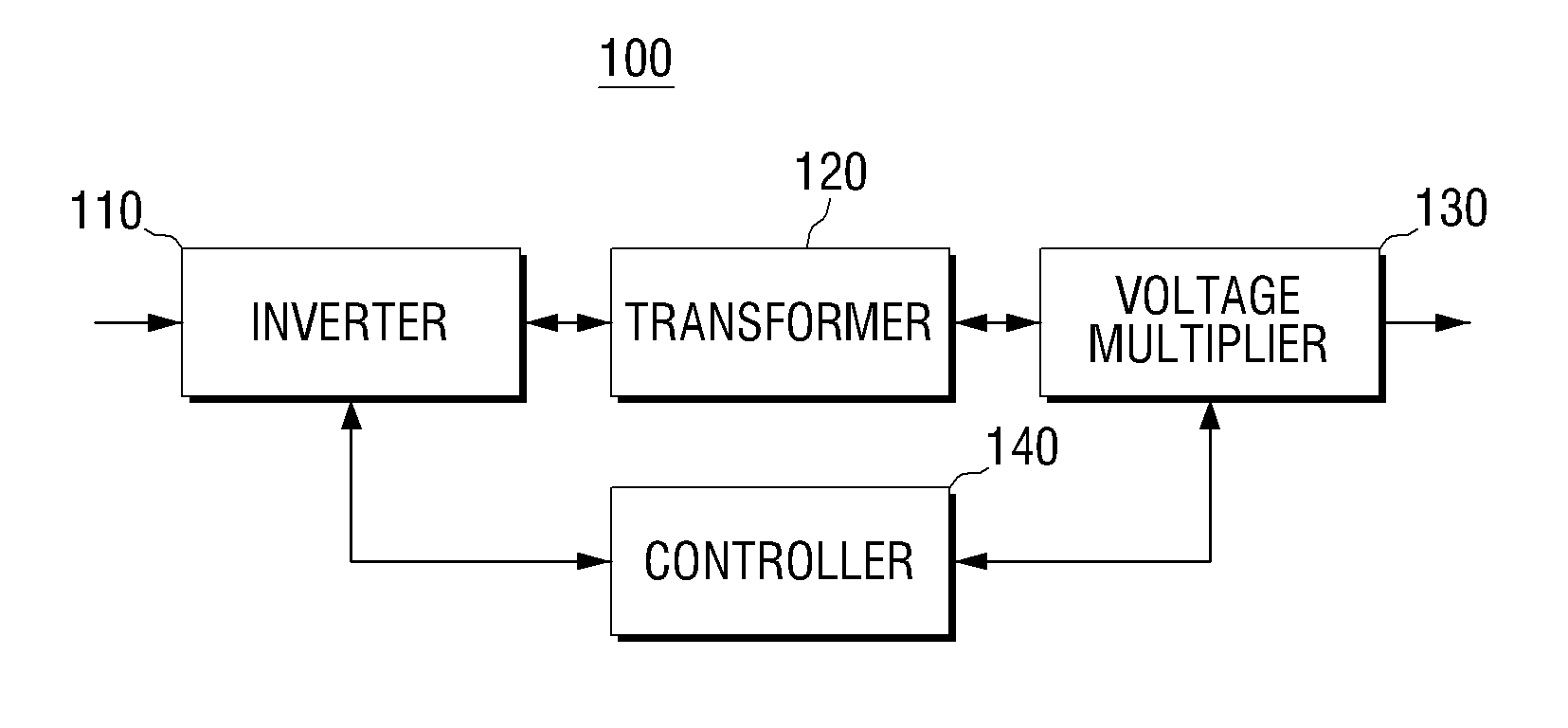

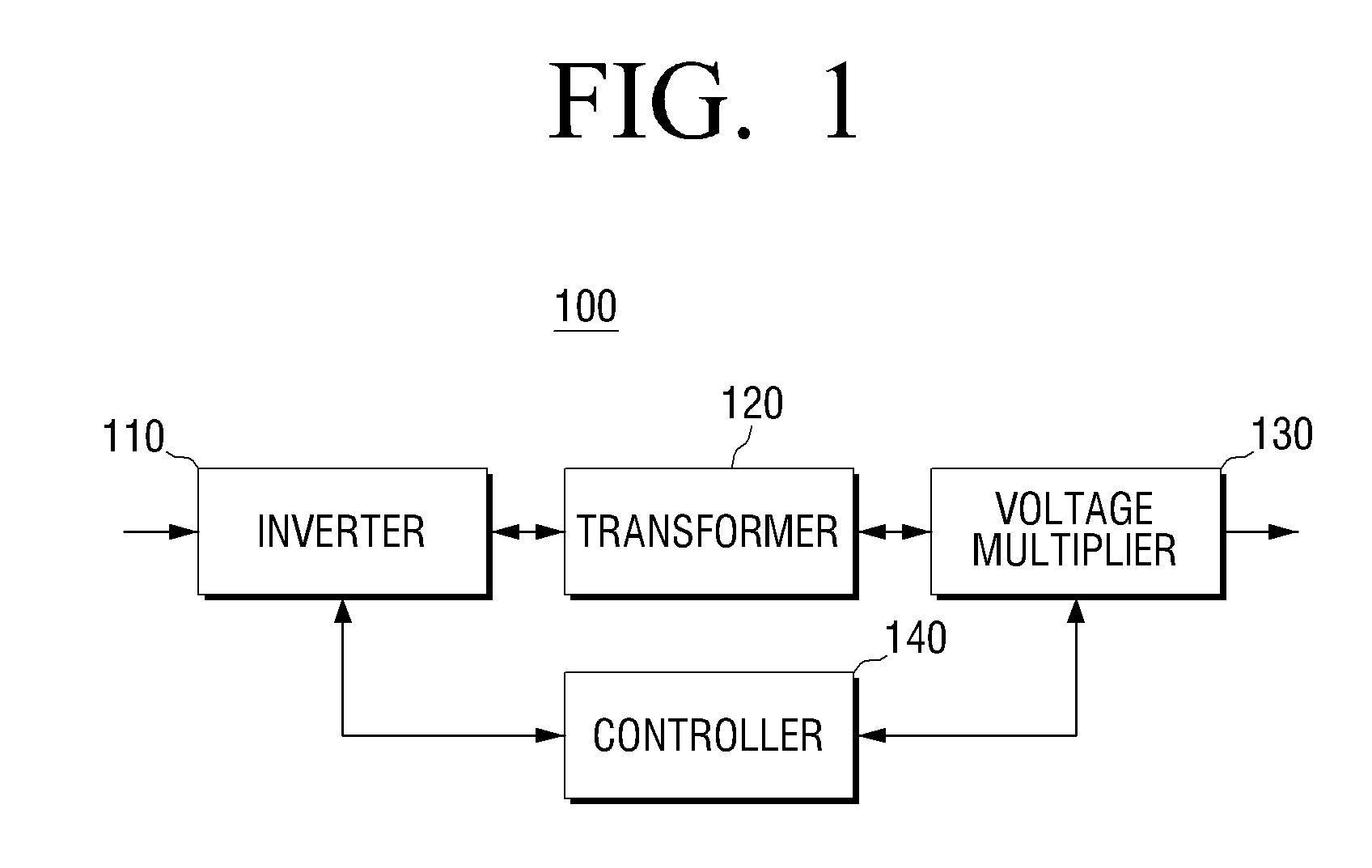

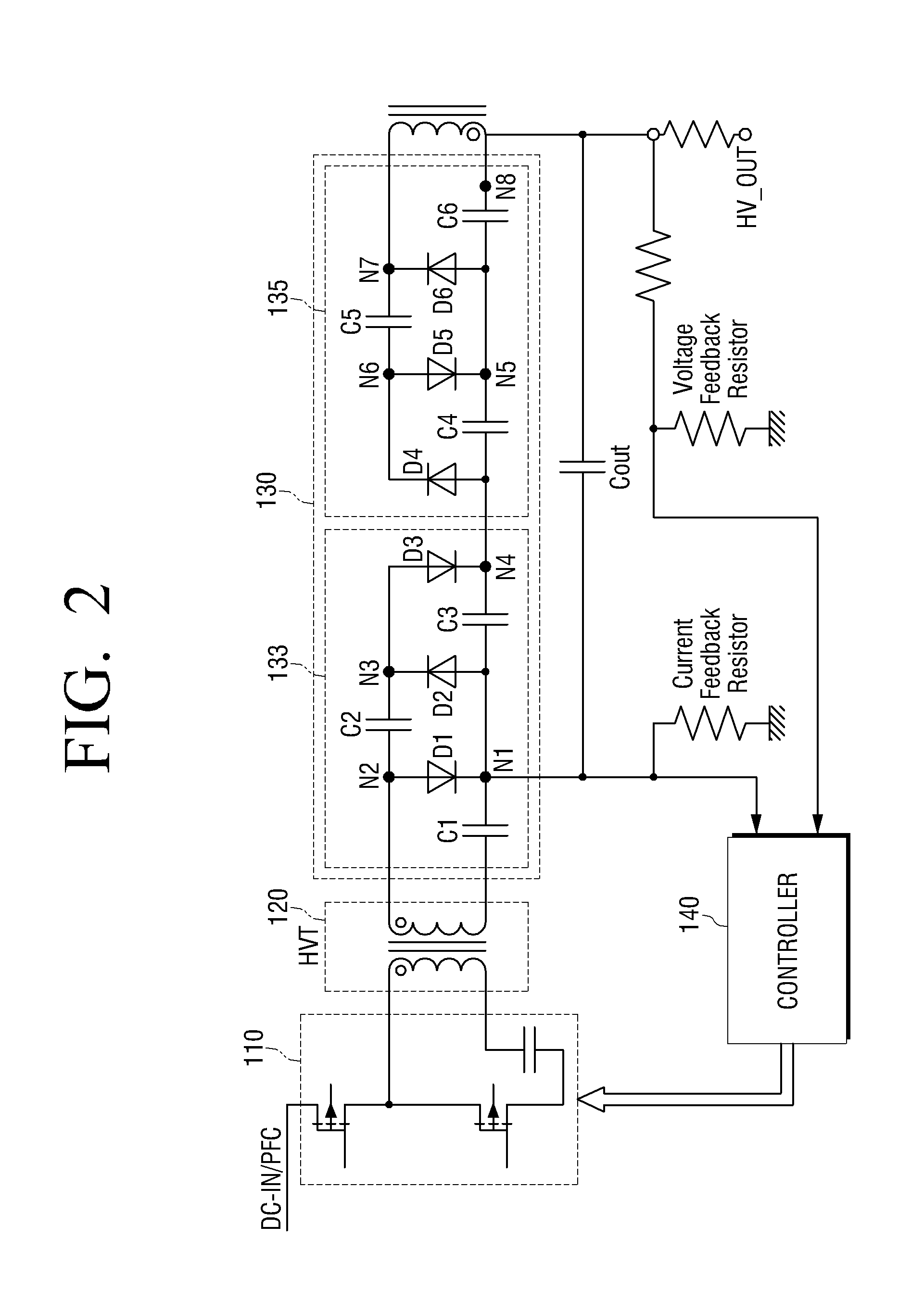

High voltage power supply

InactiveUS20110242853A1Ac-dc conversion without reversalAC/DC convertorsVoltage multiplierTransformer

A high voltage power supply is provided. The high voltage power supply includes an inverter which converts a DC voltage input to the high voltage power supply into a first AC voltage, a transformer including an input winding unit and a plurality of output winding units, wherein the input winding unit receives the first AC voltage from the inverter and the plurality of output winding units generates and outputs a second AC voltage, and a voltage multiplier unit which boosts the second AC voltage output by the transformer and outputs a boosted voltage, and the voltage multiplier unit includes a plurality of voltage multipliers which are connected to each other in series and the plurality of voltage multipliers may be connected to the plurality of output winding units respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

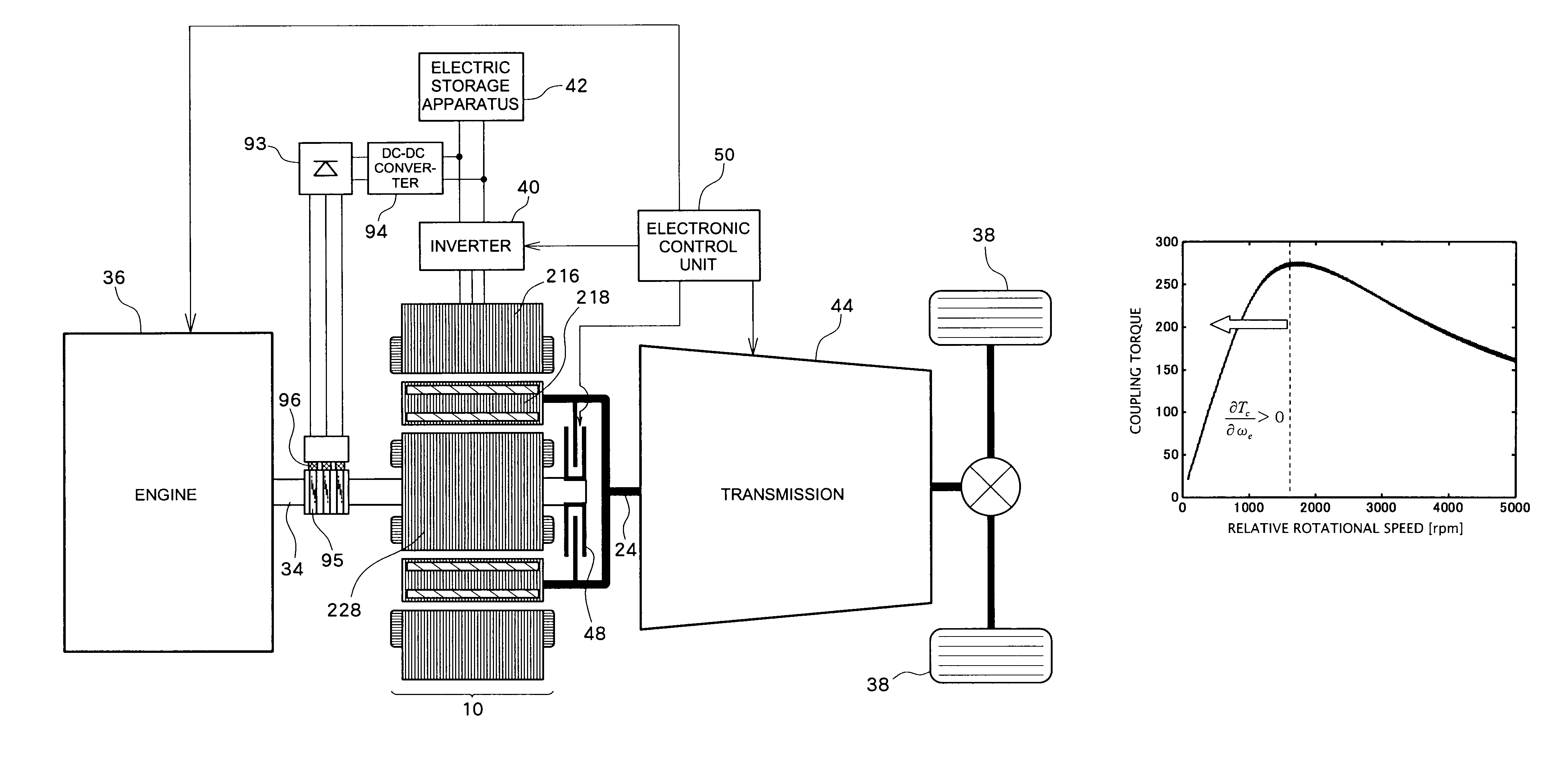

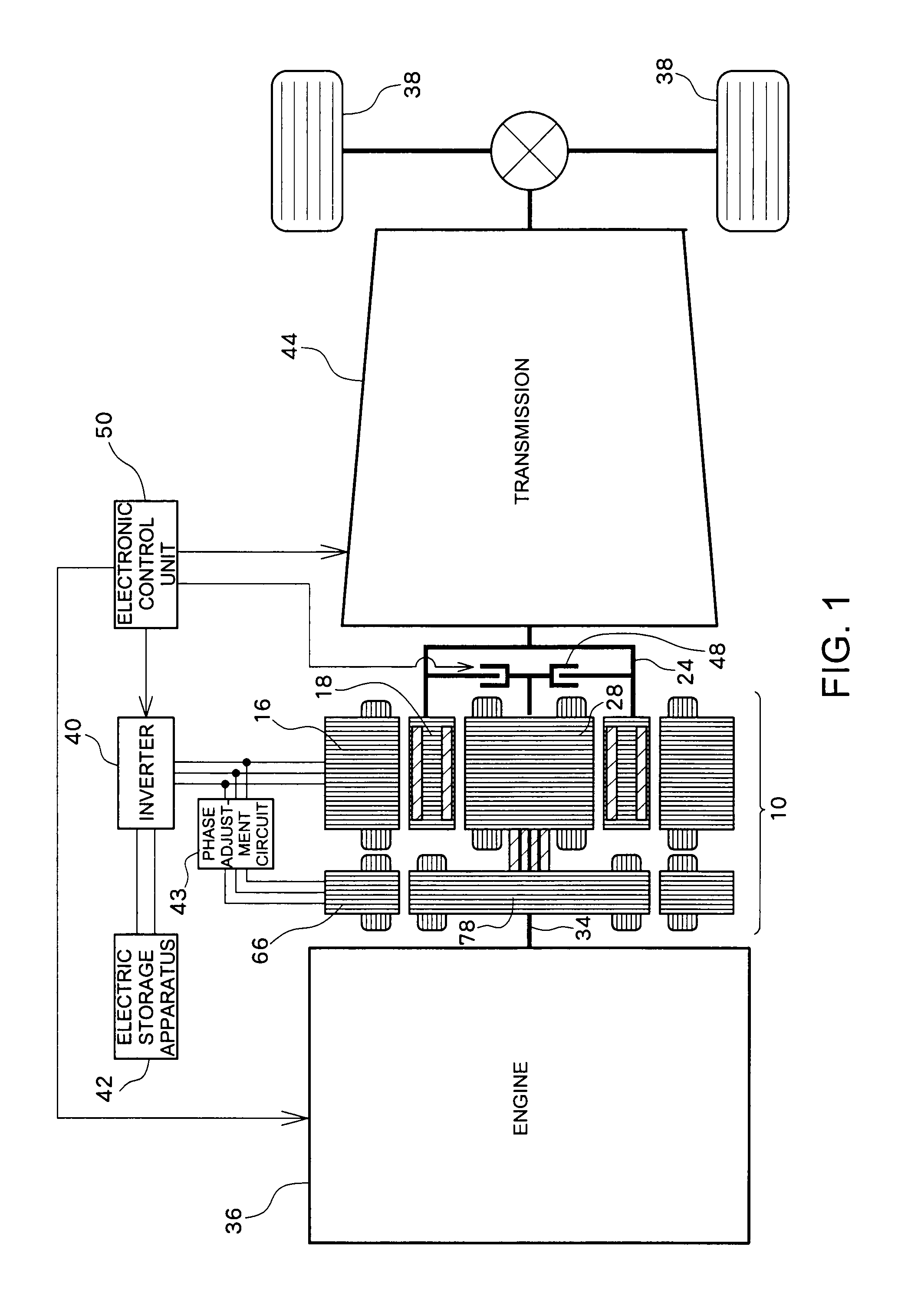

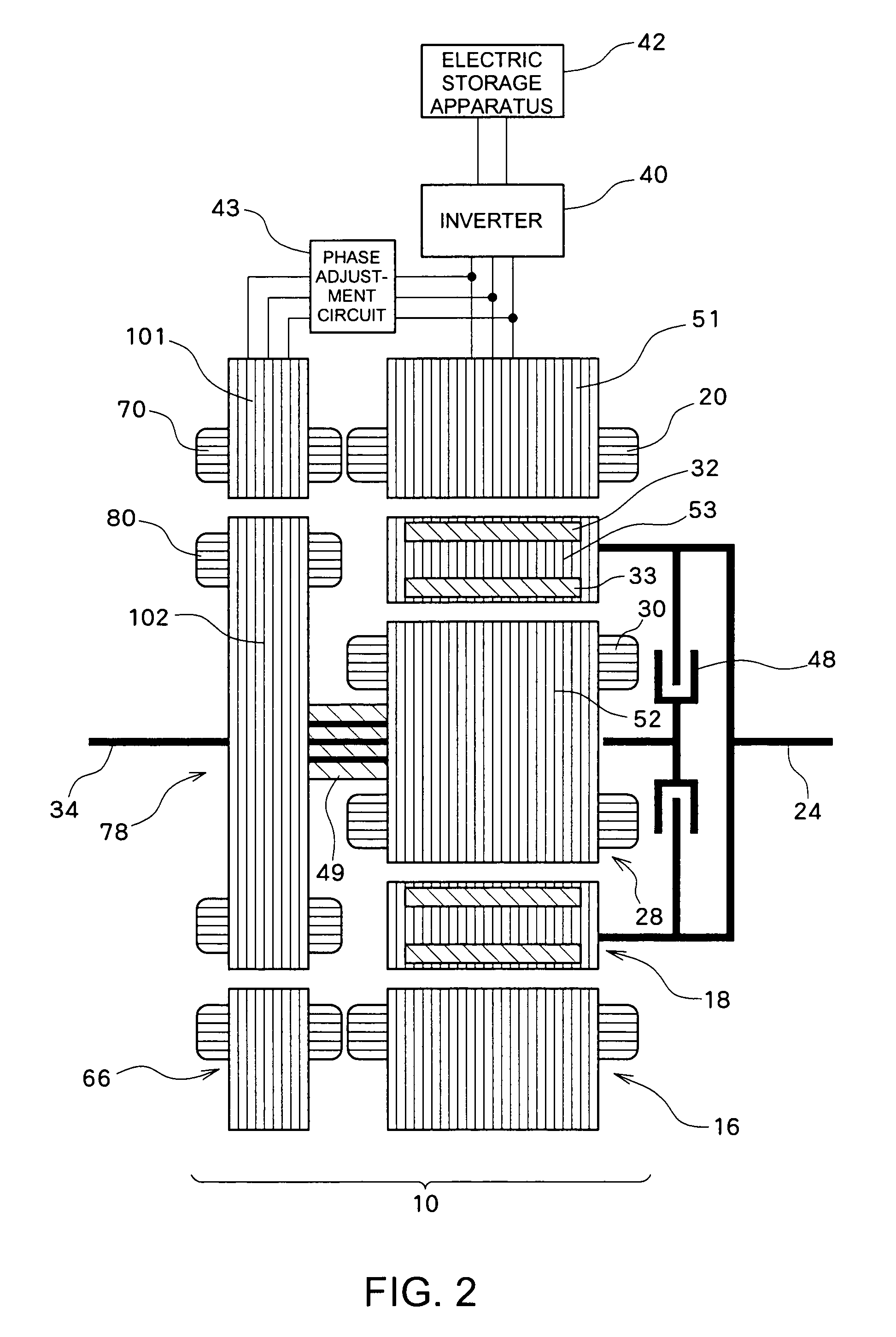

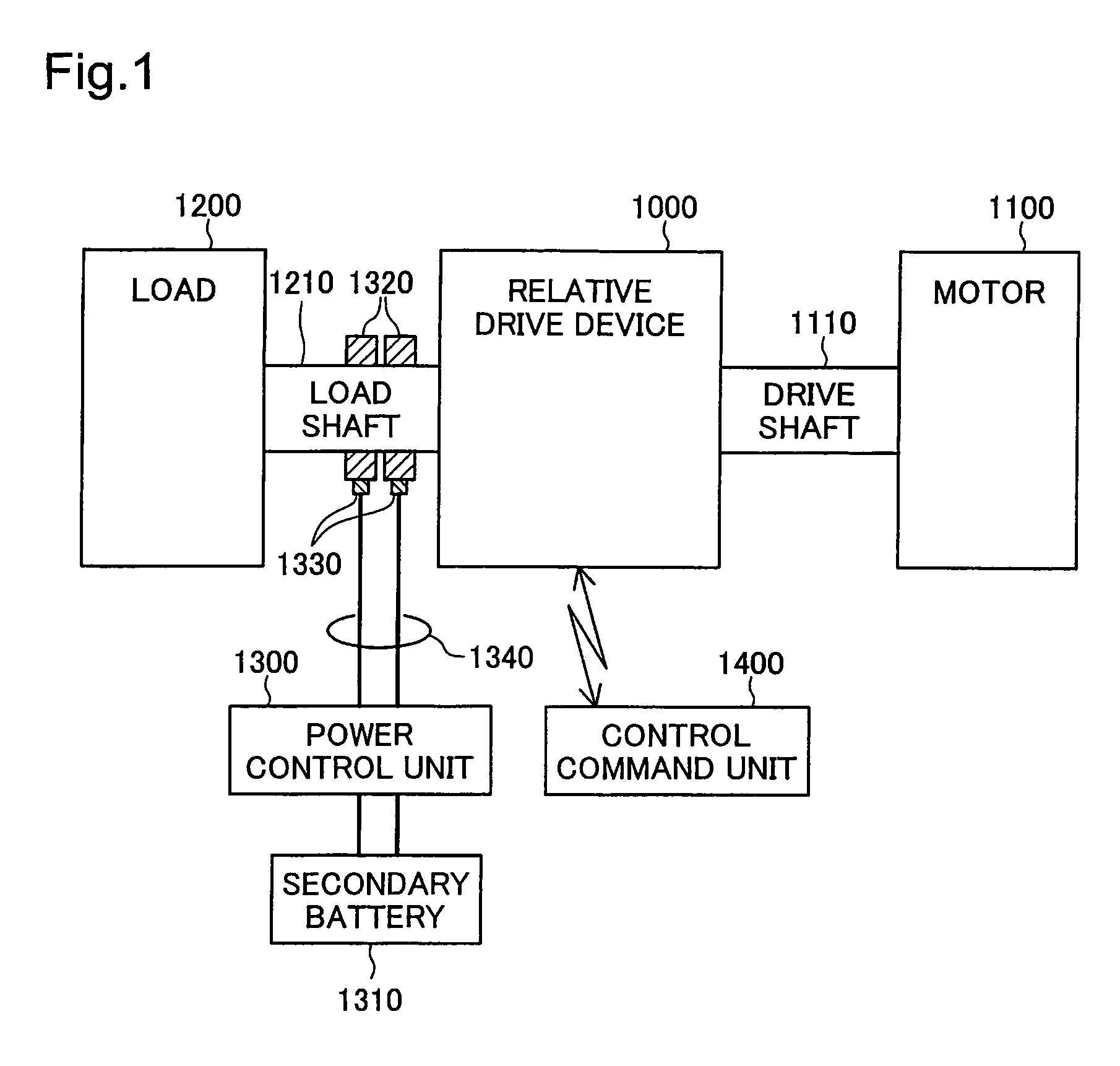

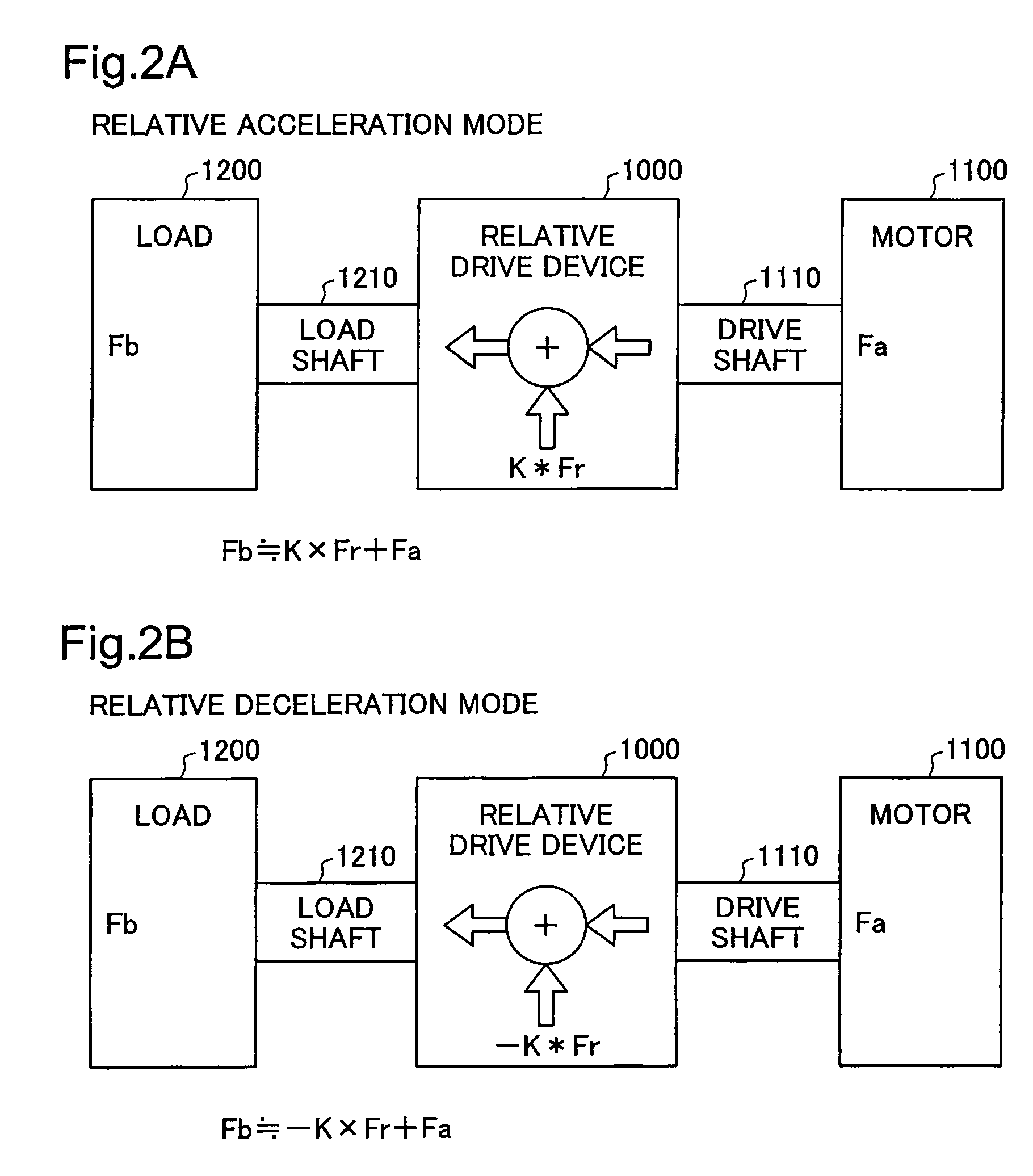

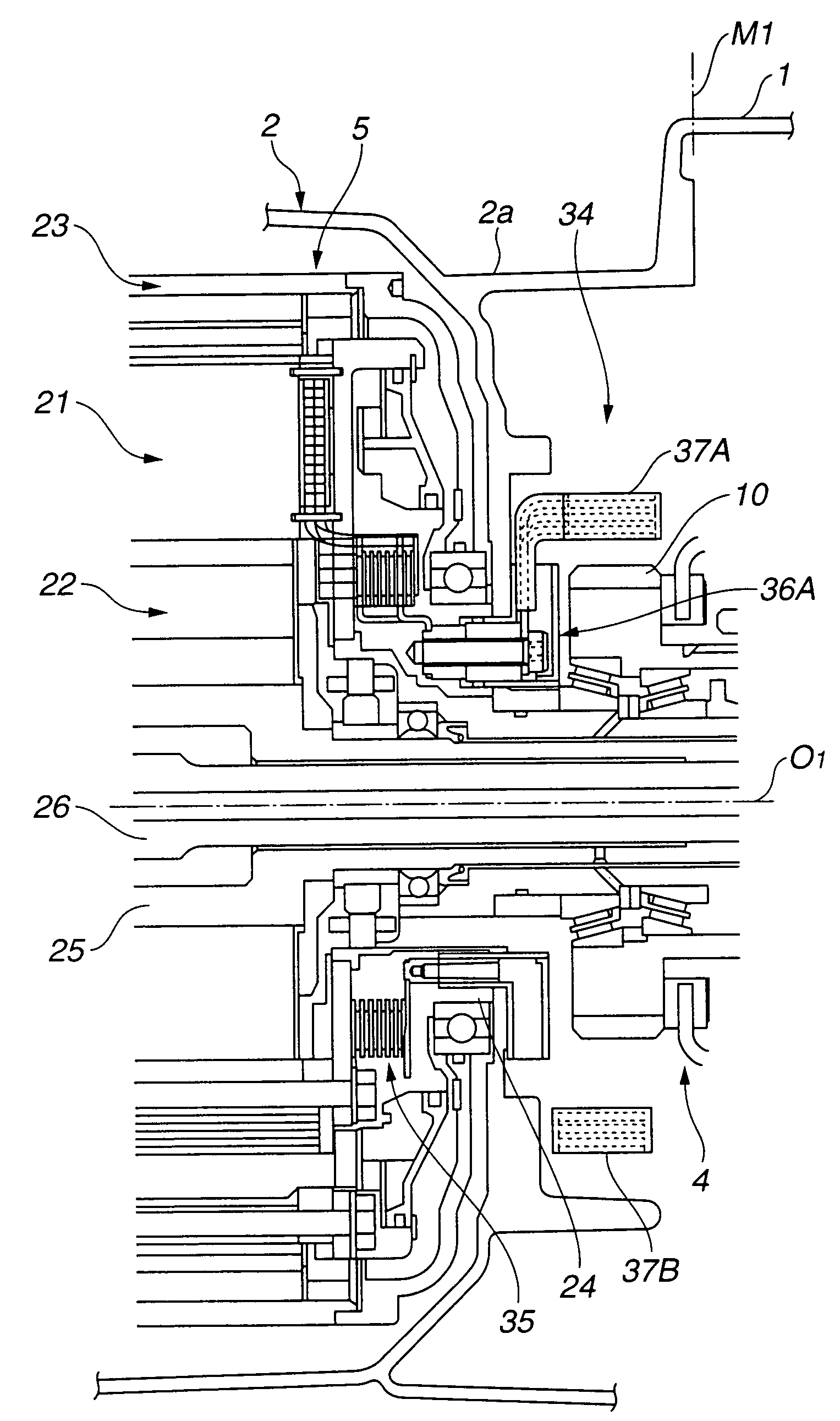

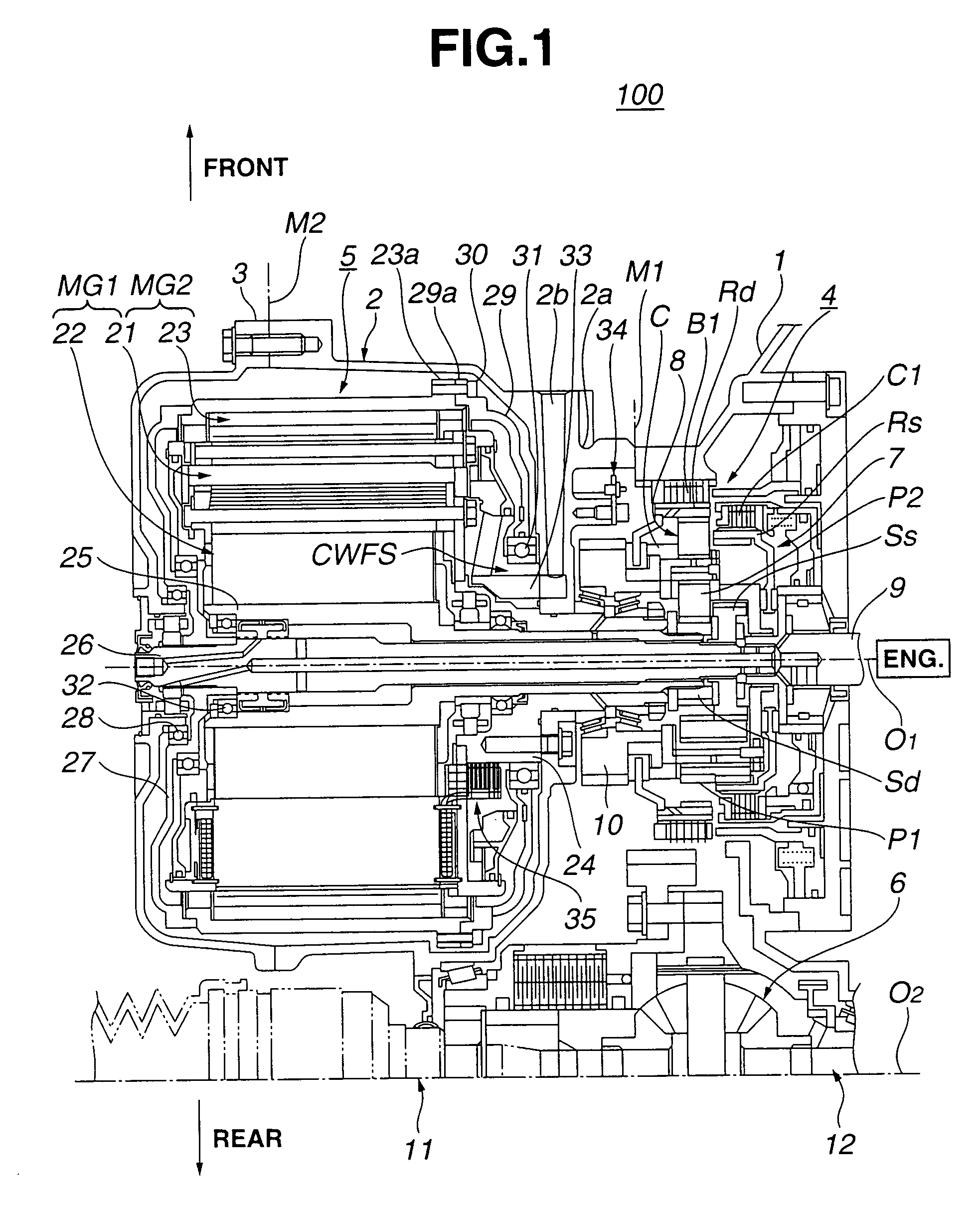

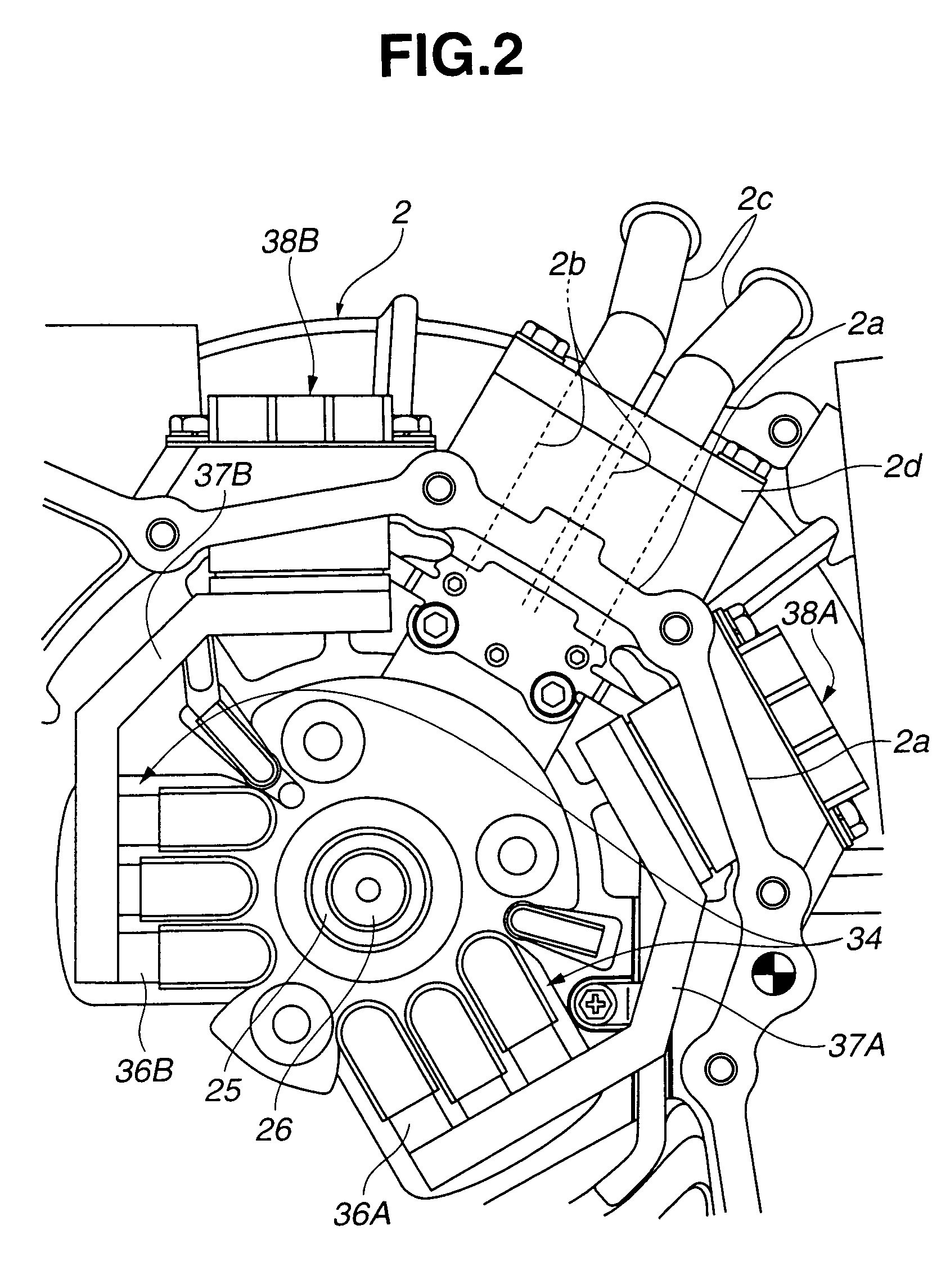

Power transmission apparatus

ActiveUS8733480B2Increased torque transfer capabilityAvoid problemsAuxillary drivesAsynchronous induction motorsElectromotive forceConductor Coil

Owner:TOYOTA JIDOSHA KK +1

Concentric motor power generation and drive system

An apparatus is provided and includes a hub, including first and second opposing faces, a first sidewall fixed at opposite ends thereof to the first and second opposing faces to define a first interior between the first and second opposing faces and a second sidewall fixed to one of the first and second opposing faces to define a second interior within the first interior, a first assembly, disposed within the second interior, to generate current from input mechanical energy and a second assembly, electrically coupled to the first assembly and disposed within the first interior, to generate mechanical energy from current associated with the current generated by the first assembly.

Owner:BORGWARNER INC

Enhanced thermal conductivity ferrite stator

ActiveUS7119461B2Increase speedQuick closeAC/DC convertorsEfficient propulsion technologiesPermanent magnet rotorHeat conducting

A permanent magnet electric machine (i.e.: motor / generator) having a magnetic flux circuit including a stator and a permanent magnet rotor mounted for rotation about an axis relative to the stator. The stator has an electric circuit with windings electro-magnetically coupled to the magnetic circuit. The stator is of material having a Curie temperature, wherein magnetic flux circulation through the stator material is impeded when the stator material acquires a temperature above the Curie temperature. The stator includes heat conducting layers and magnetic flux conducting layers, where the thermal conductivity of the heat conducting layers is greater than the thermal conductivity of the magnetic flux conducting layers. By this means the overall thermal conductivity of the stacked stator assembly is improved and means for quickly effecting shutdown of the electric machine are provided with a heat exchanger thermally coupled to the stator, thereby regulating magnetic flux circulation through the stator material. Preferably the magnetic flux conducting layers are manganese zinc ferrite, and the heat conducting layers are: insulated copper sheets; insulated aluminum sheets; thermally conductive polymer sheets; sheet metal; or plated metal layers deposited on associated magnetic flux conducting layers.

Owner:PRATT & WHITNEY CANADA CORP

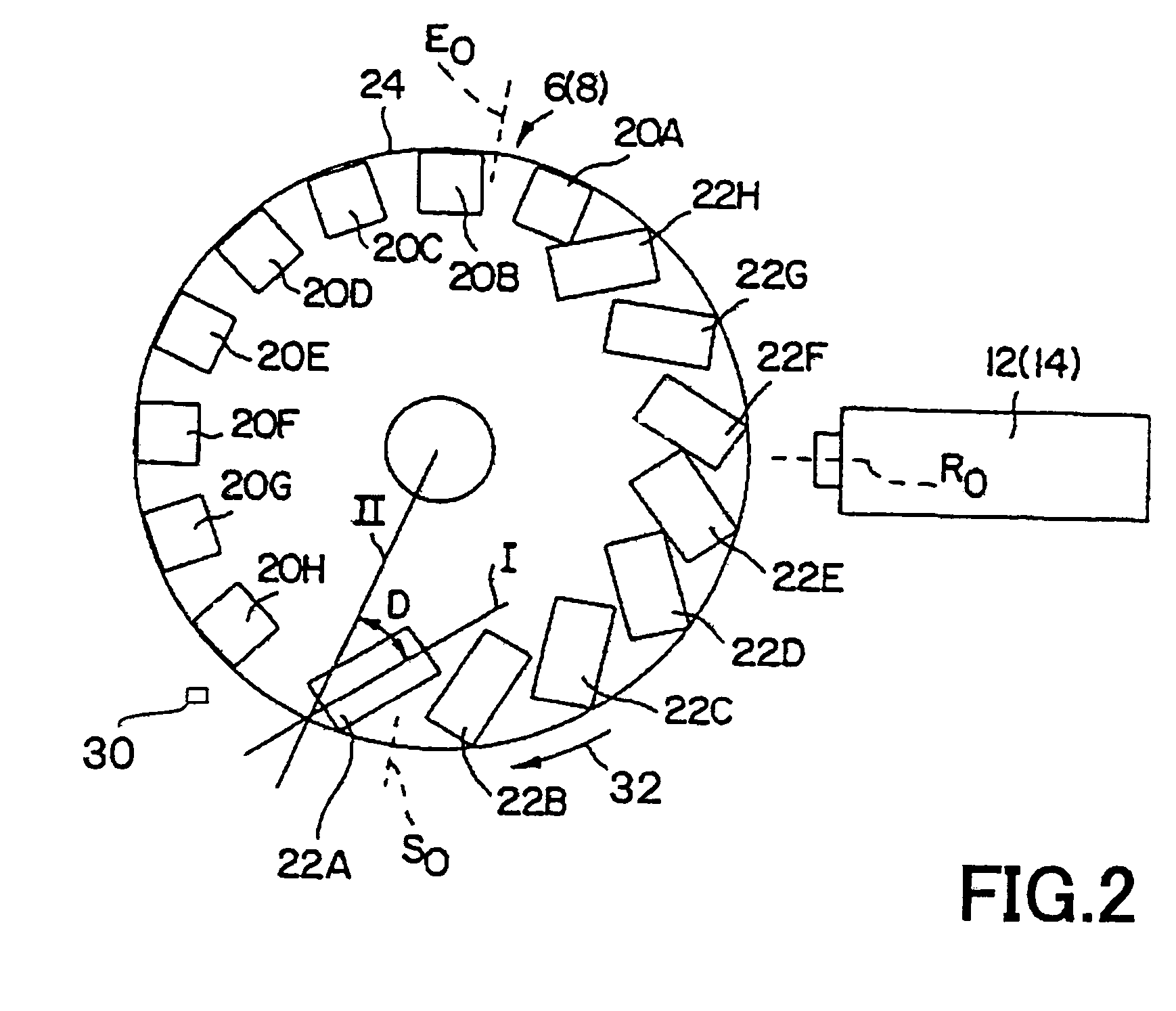

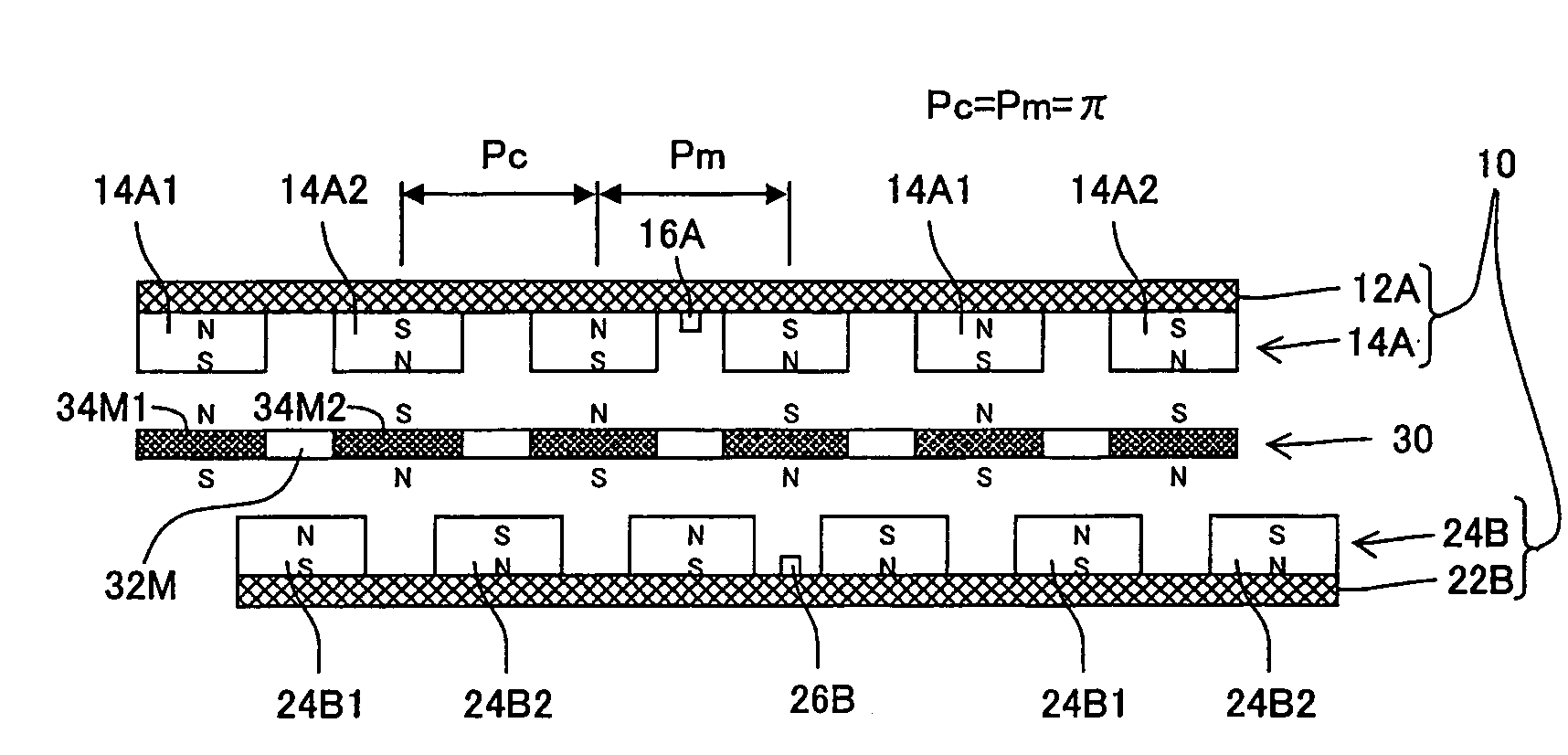

Relative drive device

InactiveUS7479722B2Smooth and stable relative drivingImprove efficiencyMotor/generator/converter stoppersAC motor controlMagnetic circuitOut of phase

A small, lightweight relative drive device is provided, which is capable of producing large torque. The relative drive device of a two-phase magnetic excitation type according to an aspect of the invention comprises first and second coil groups and a magnet group. The magnet group includes magnets disposed with alternating north and south poles facing the first and second coil groups. The first and second coil groups are disposed at positions that are out of phase with each other by an odd multiple of π / 2 in electrical angles. The coils in the first and second coil groups have substantially no magnetic material cores, and the relative drive device has substantially no magnetic material yoke for forming a magnetic circuit.

Owner:TAKASHI KENJO +1

Hybrid transmission

Owner:NISSAN MOTOR CO LTD

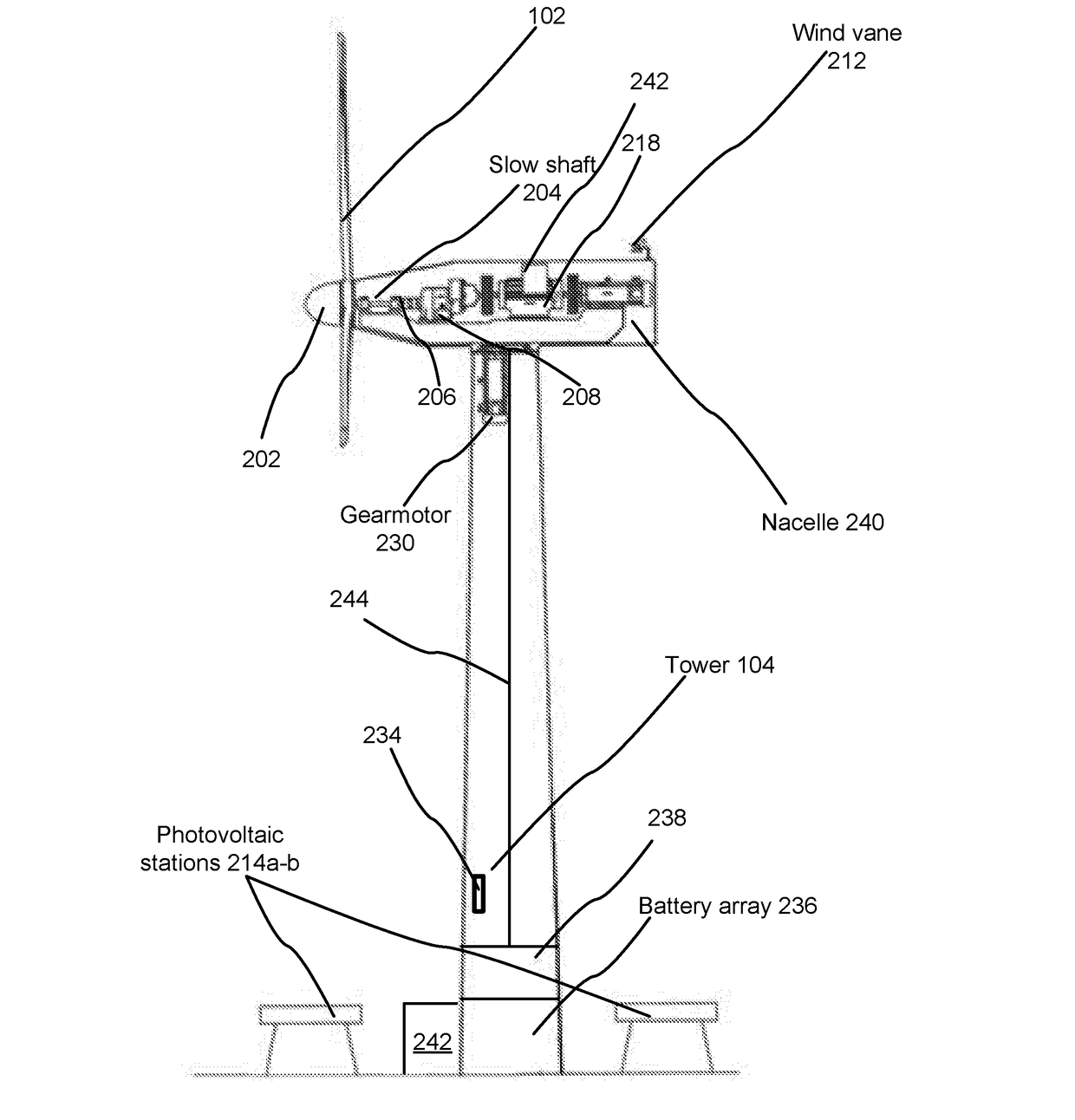

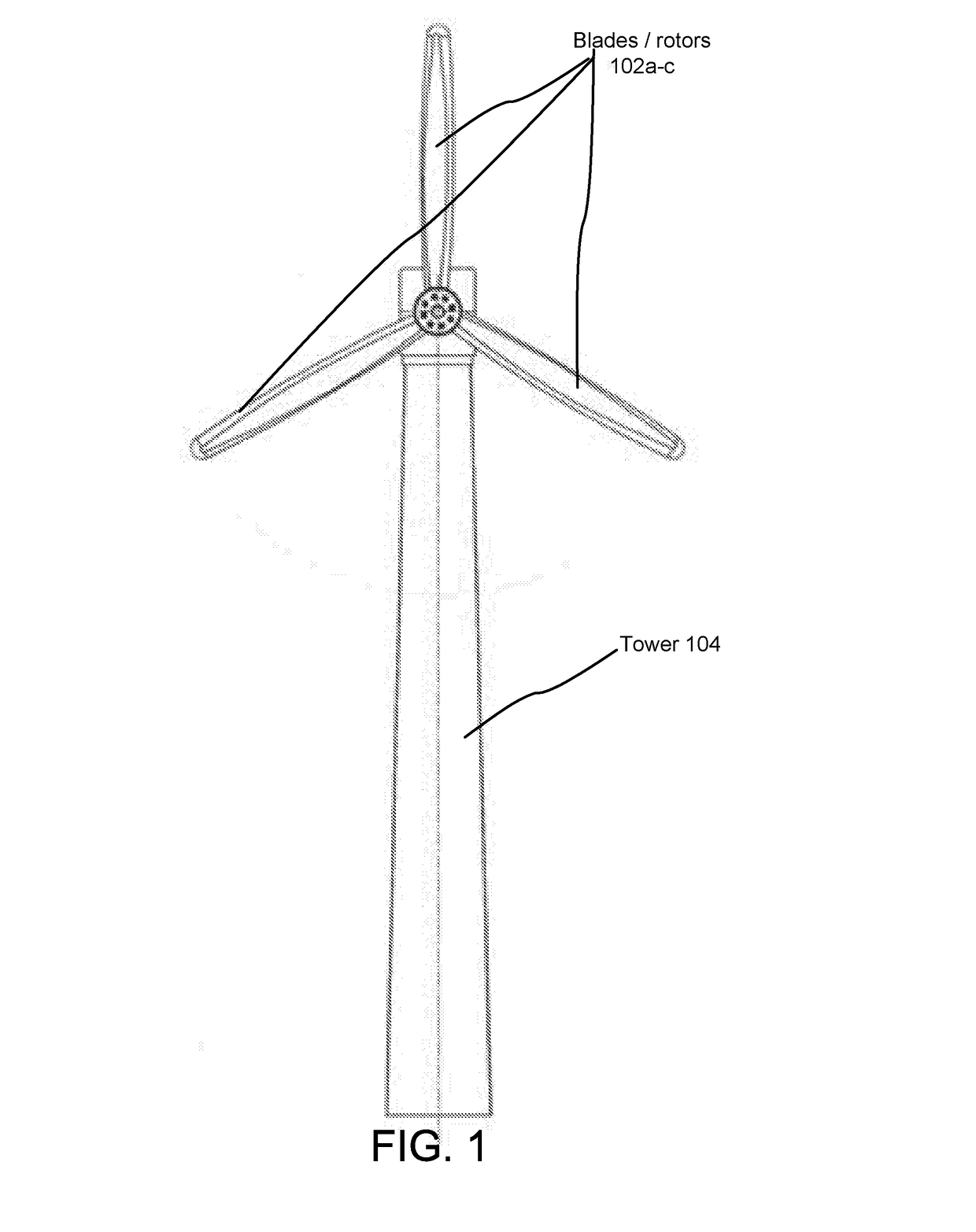

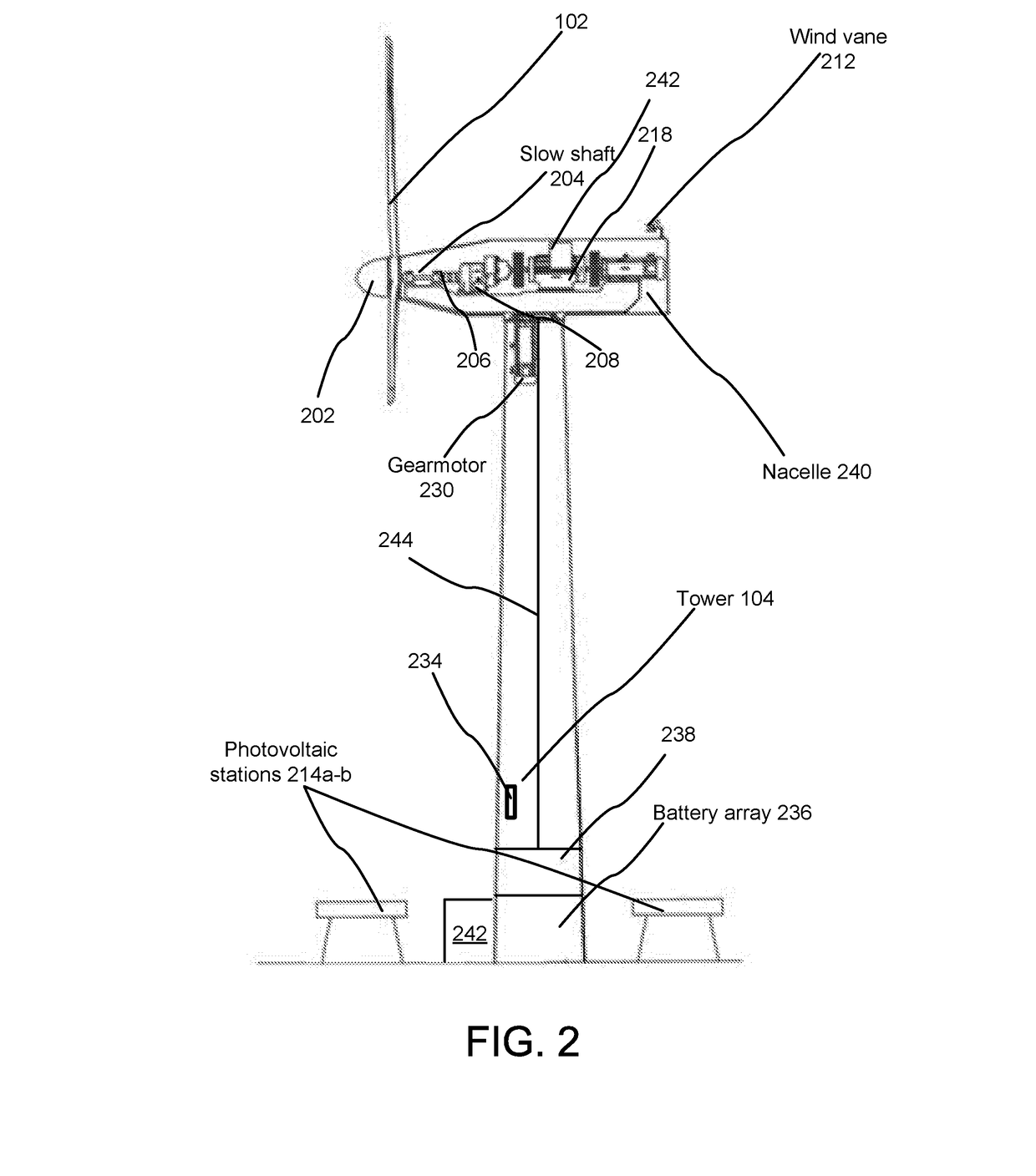

Hybrid wind turbine for power output in low and zero wind conditions

InactiveUS20180112648A1Lower center of gravityEasy maintenance and operationWind motor with solar radiationWind motor controlReciprocating motionTower

A hybrid wind turbine having comprising photovoltaic cells, an induction generator and batteries, adapted to output power in low wind conditions and stored power in zero wind conditions, with heavy components disposed in the base of the tower to facilitate maintenance operations, with an alternative reciprocating liquid-nitrogen engine for assisting with drive torque in low wind conditions.

Owner:BOND JAMES

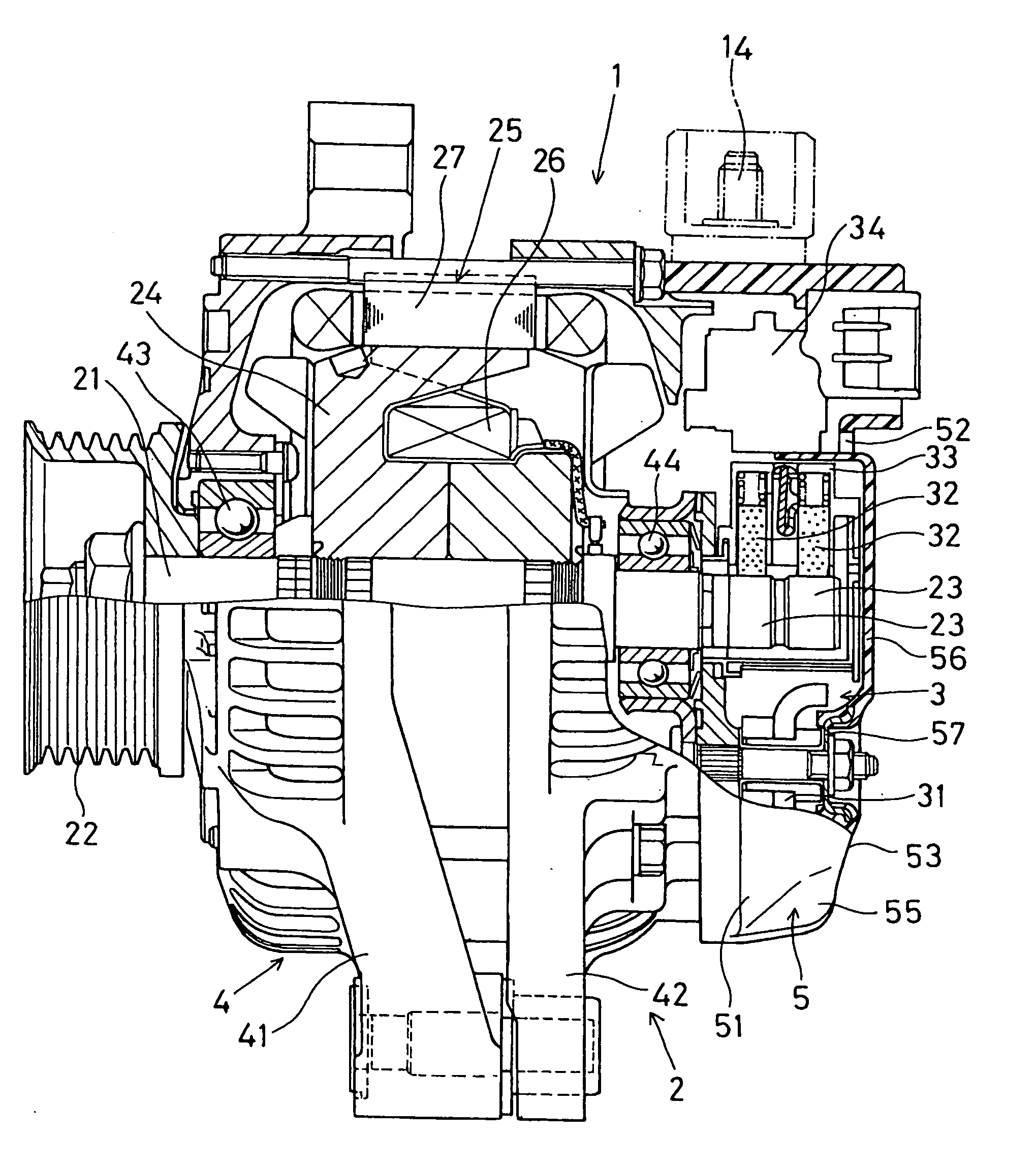

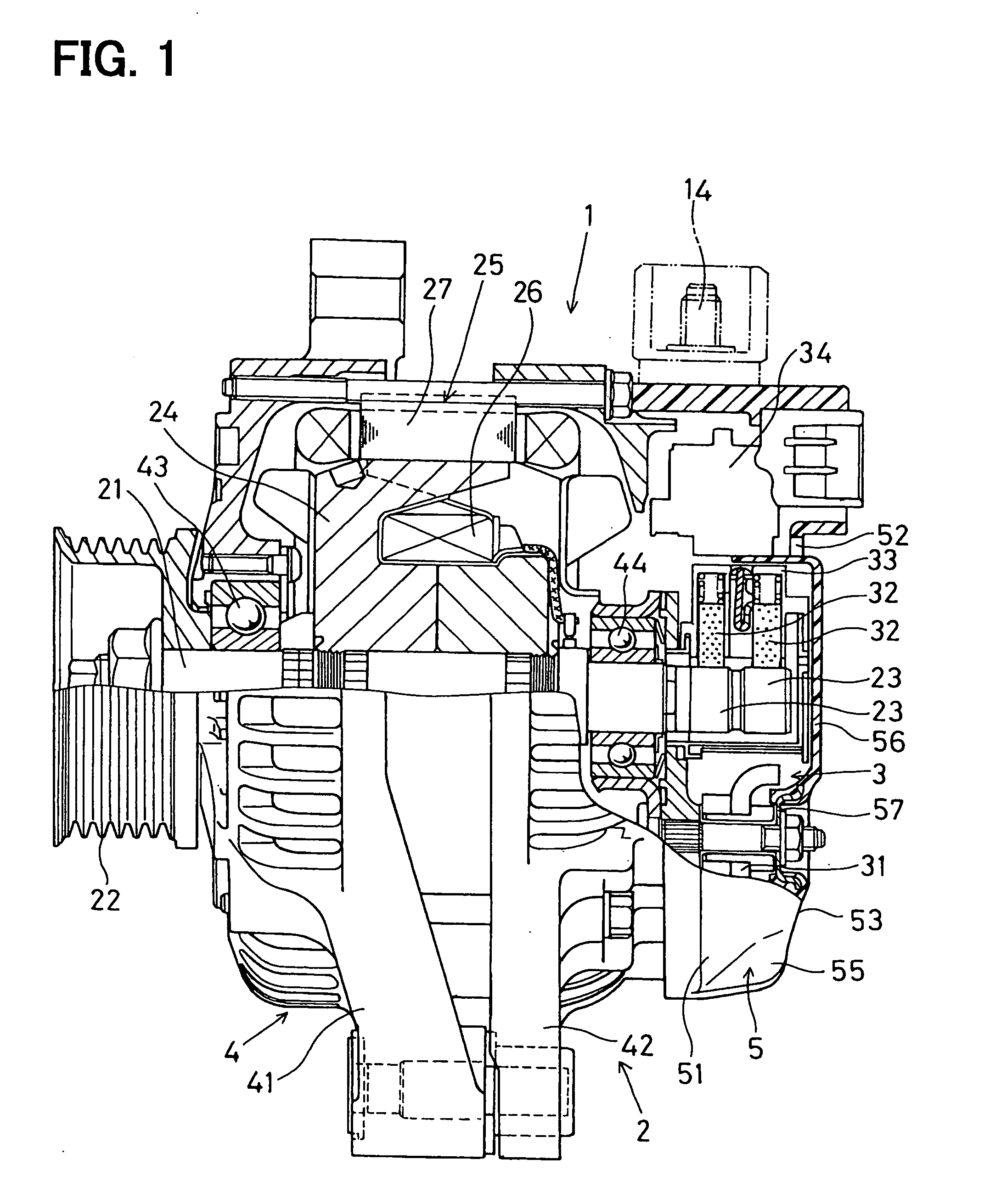

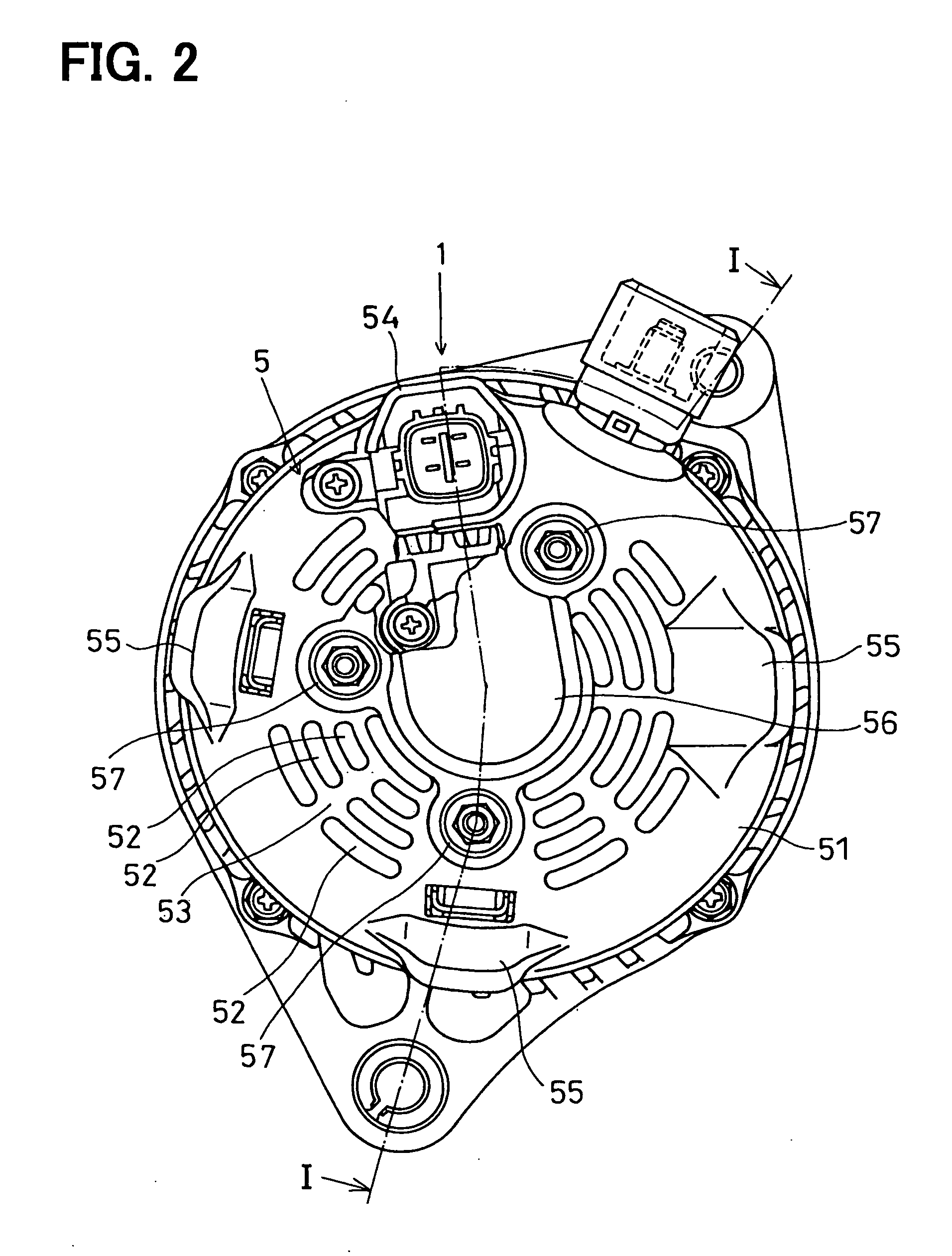

Vehicle generator having circuit protective cover

ActiveUS20050151435A1Improve securityMaking safeSynchronous generatorsAC/DC convertorsElastomerPolyamide

The vehicle generator having a circuit protective cover of present invention comprises a housing, an electric circuit device and a protective cover. The housing encloses a stator on which an armature coil is wound and a rotor located inside the stator to face each other. The electric circuit device is located outside the housing for rectifying AC induced in the armature coil to DC. The protective cover covers the electric circuit device. The protective cover is made of a composite material including a polyamide and an elastomer. It is desirable that the protective cover has a mechanical properties including: a maximum elongation of 10% or higher; and a Charpy impact strength with notch of 78 kJ / m2 or higher.

Owner:DENSO CORP

Power generator

A power generator is provided. The power generator may include a battery, a motor and an electrical generator. The motor is powered by the battery which rotates a first rotating shaft. The first rotating shaft rotates a second rotating shaft of the electrical generator, which generates electricity. An electrical wiring may run from the electrical generator to a voltage regulator. An electrical wiring may run from the voltage regulator to the battery, thereby keeping the battery charged. A power inverter may be electrically connected to the battery.

Owner:MILLER RAYMOND F

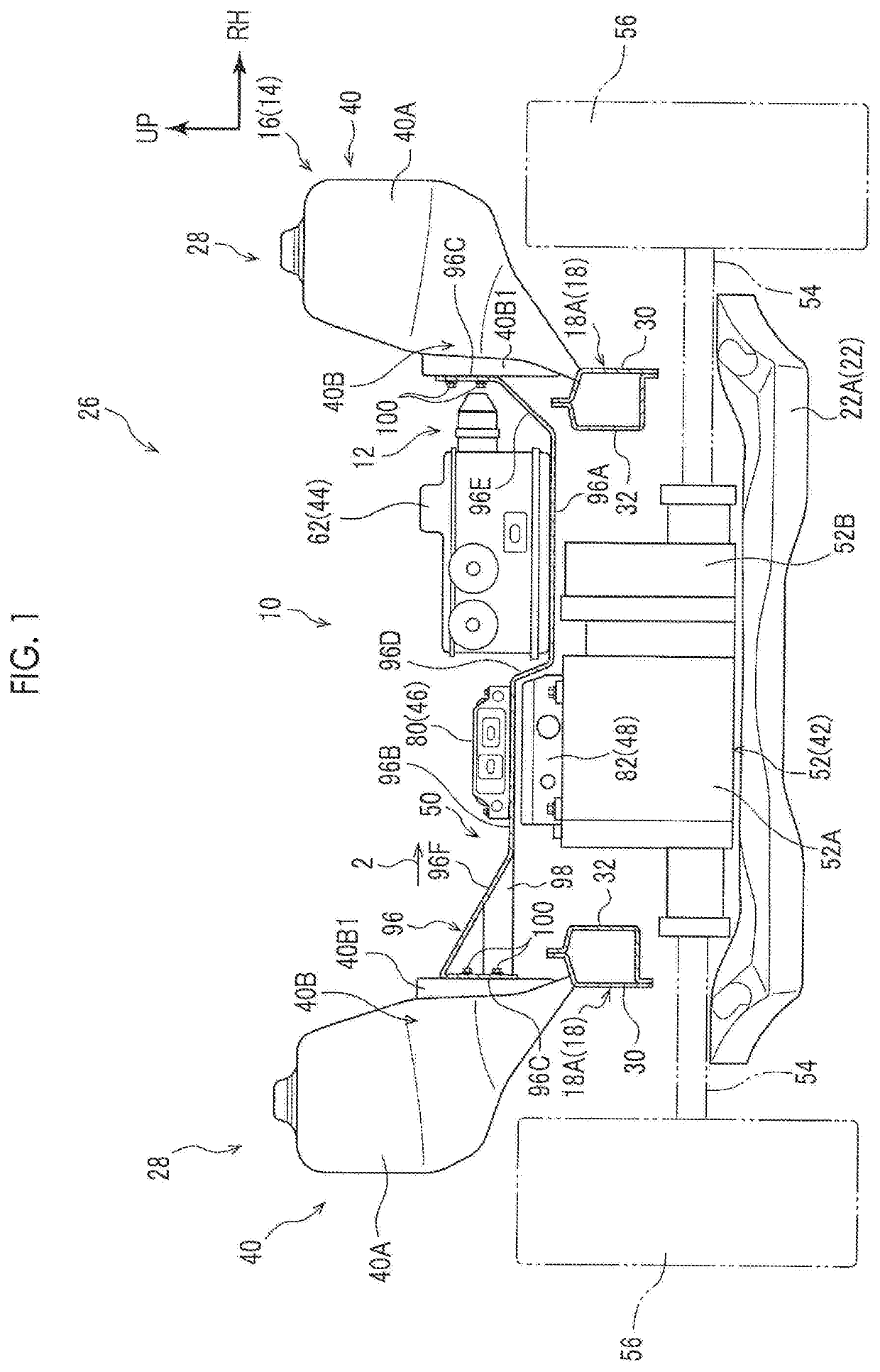

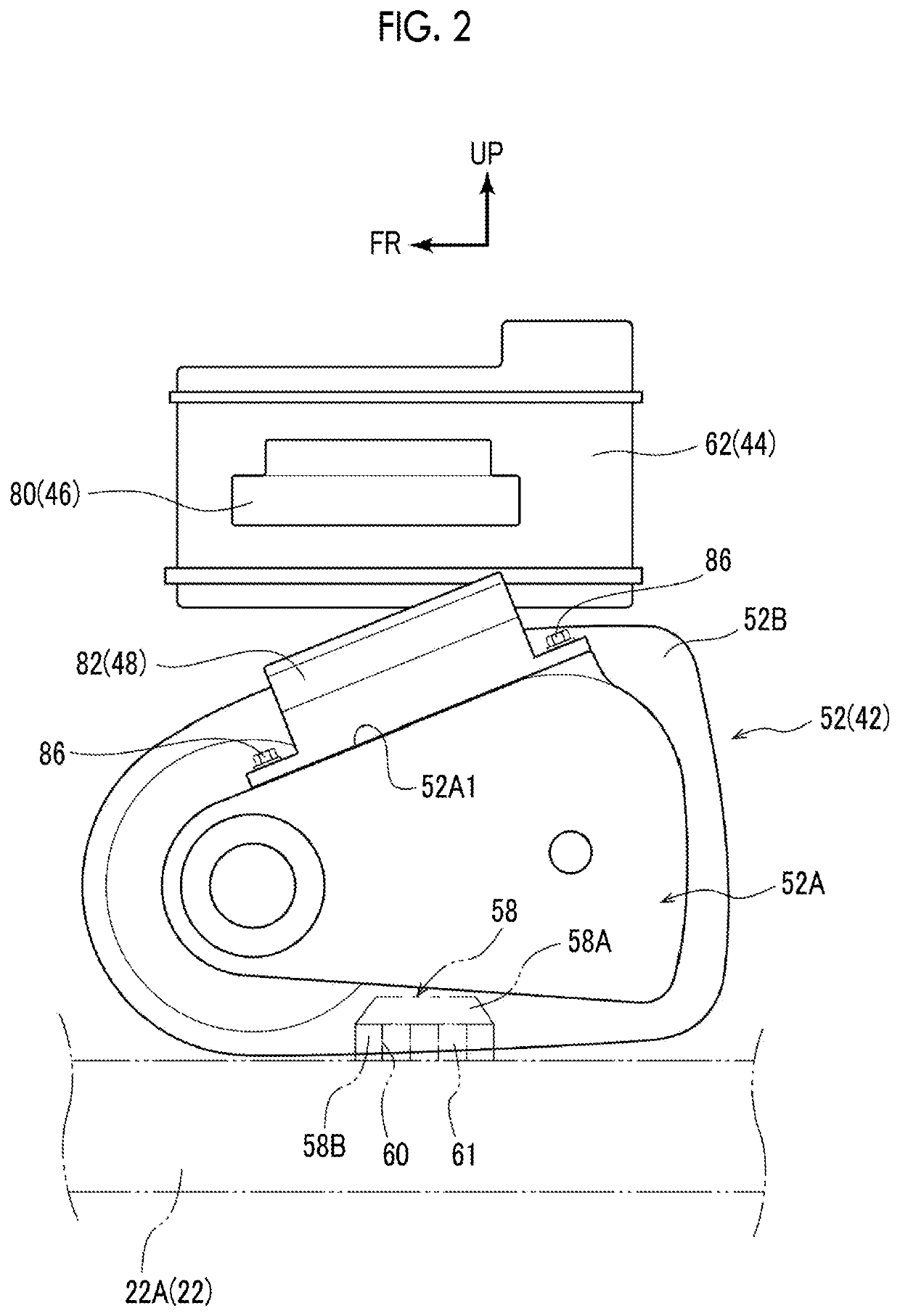

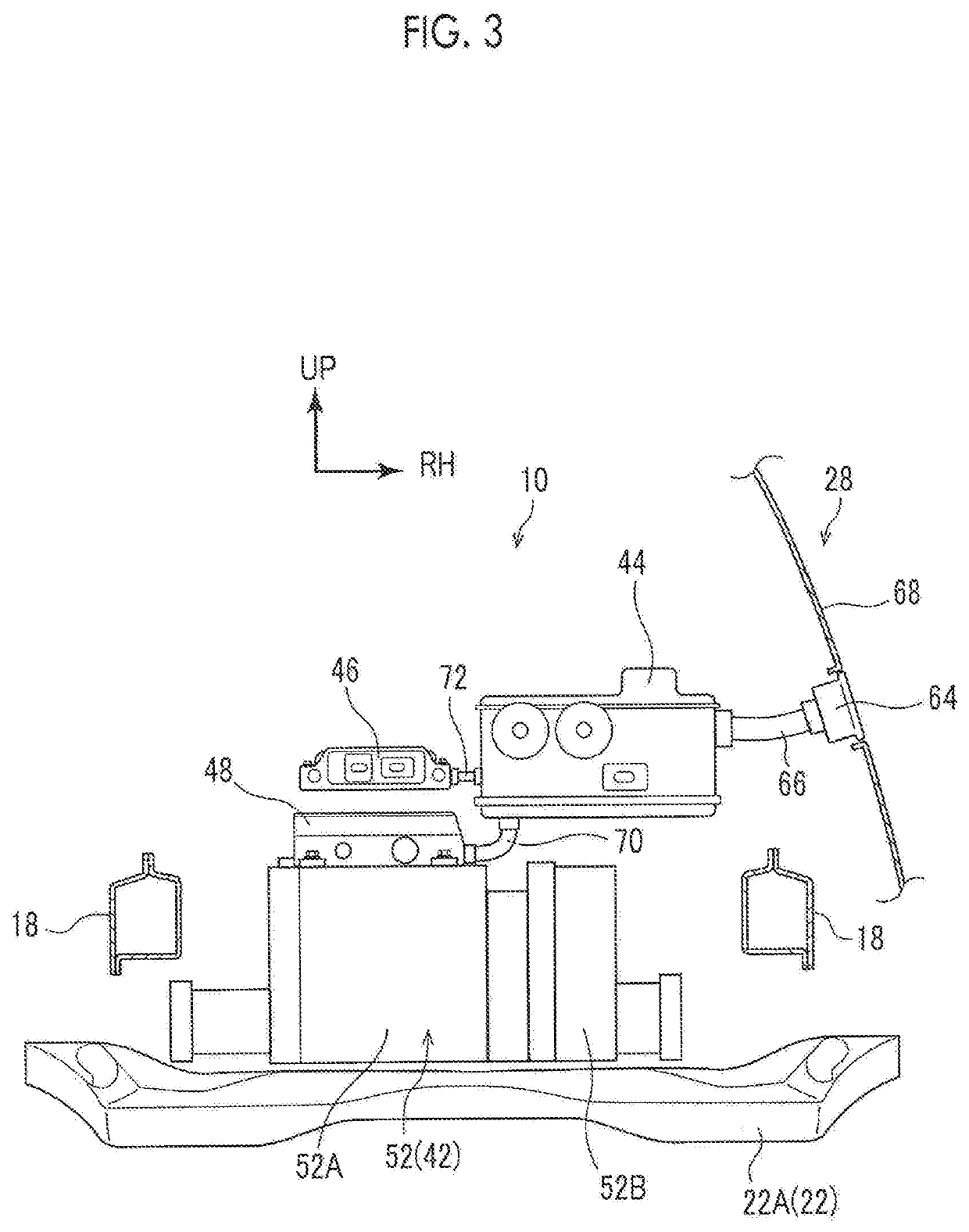

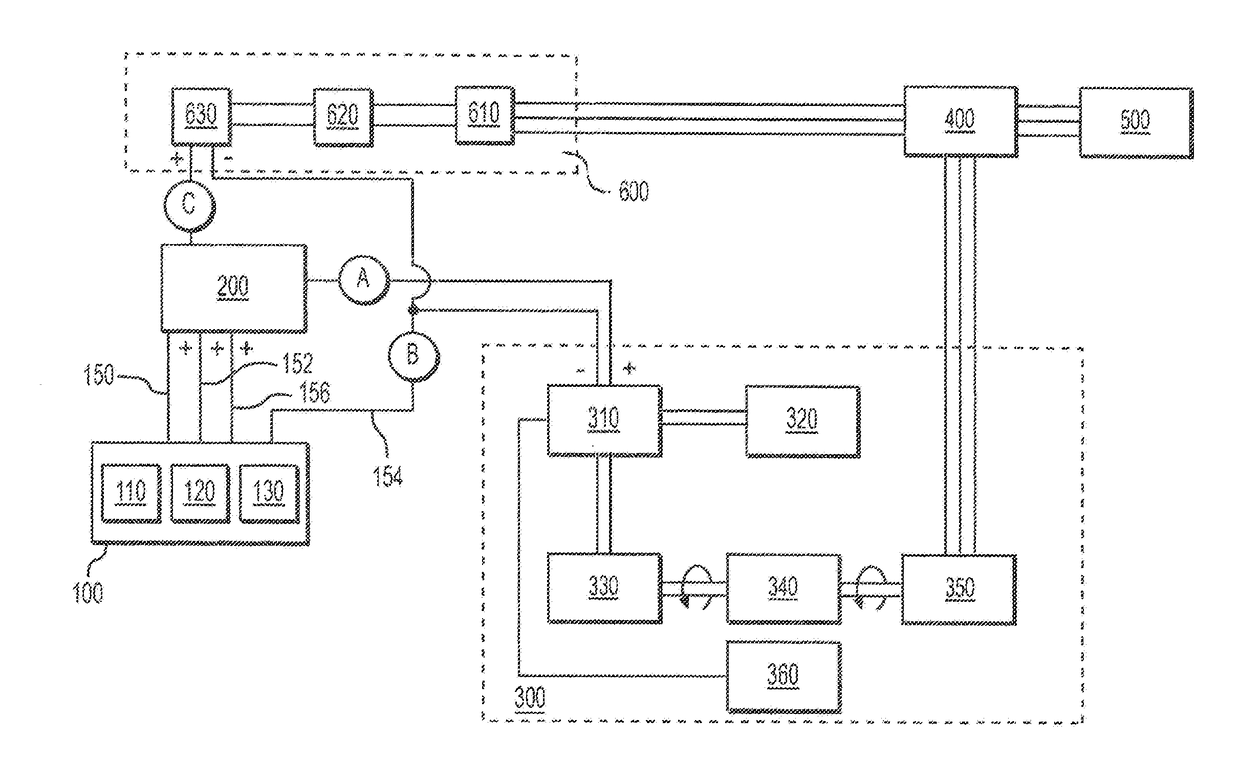

Power unit structure for vehicle

ActiveUS20200076270A1Reduce power lossReduce in quantityUnderstructuresSuperstructure subunitsConvertersDrive wheel

A power unit structure for a vehicle includes a motor disposed in a power unit room of the vehicle and configured to transmit a driving force to drive wheels of the vehicle, an electric power converter disposed in the power unit room of the vehicle, and an electric power distributor disposed in the power unit room of the vehicle. The electric power converter is configured to convert supplied electric power into electric power to be supplied to the motor and is disposed on an upper side of the motor. The electric power distributor is configured to distribute electric power supplied from a power supply to the electric power converter and is disposed at a position where at least a part of the electric power distributor overlaps the electric power converter in an up-down direction of the vehicle when viewed from a vehicle front-rear direction or a vehicle width direction.

Owner:TOYOTA JIDOSHA KK

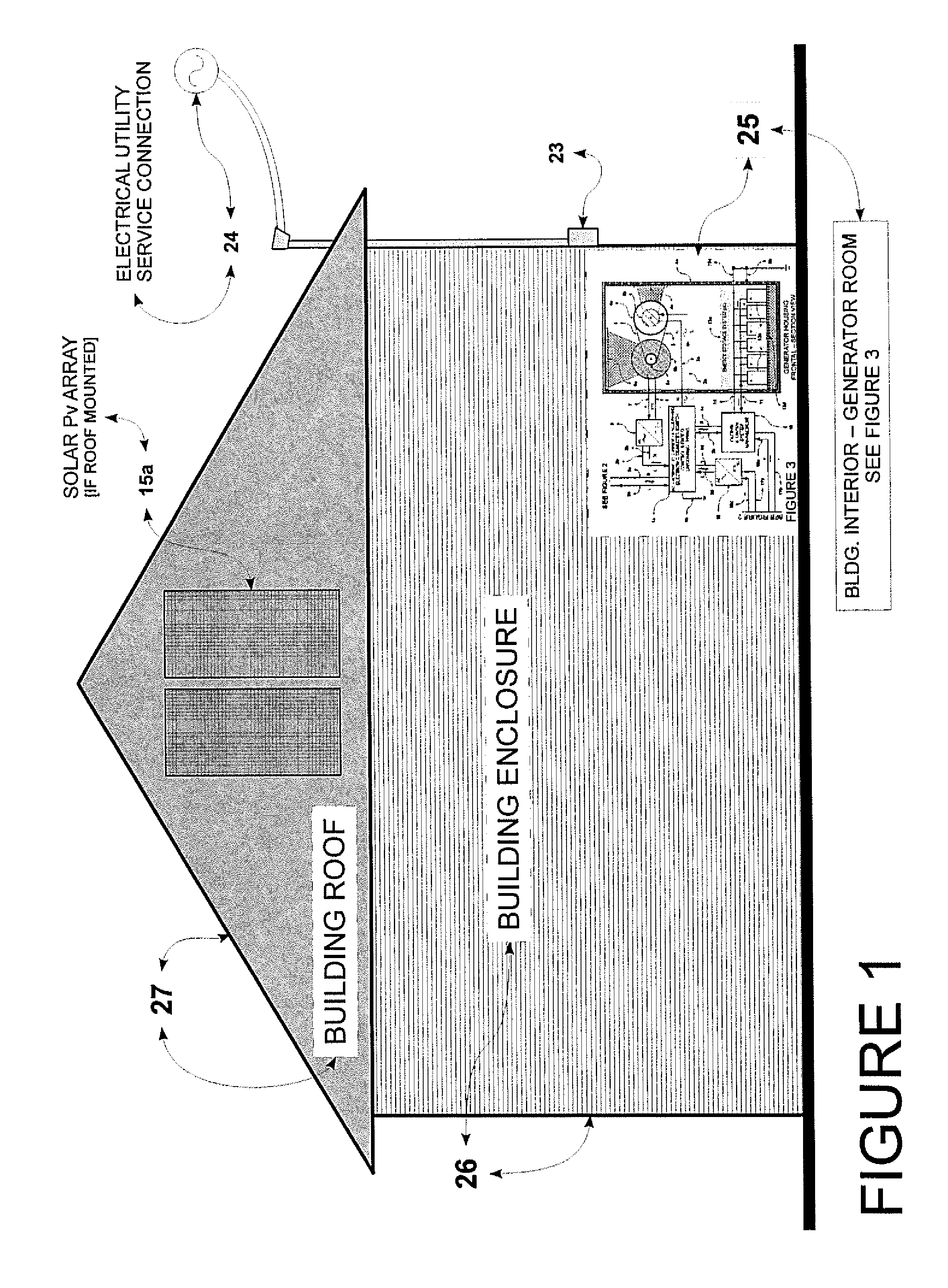

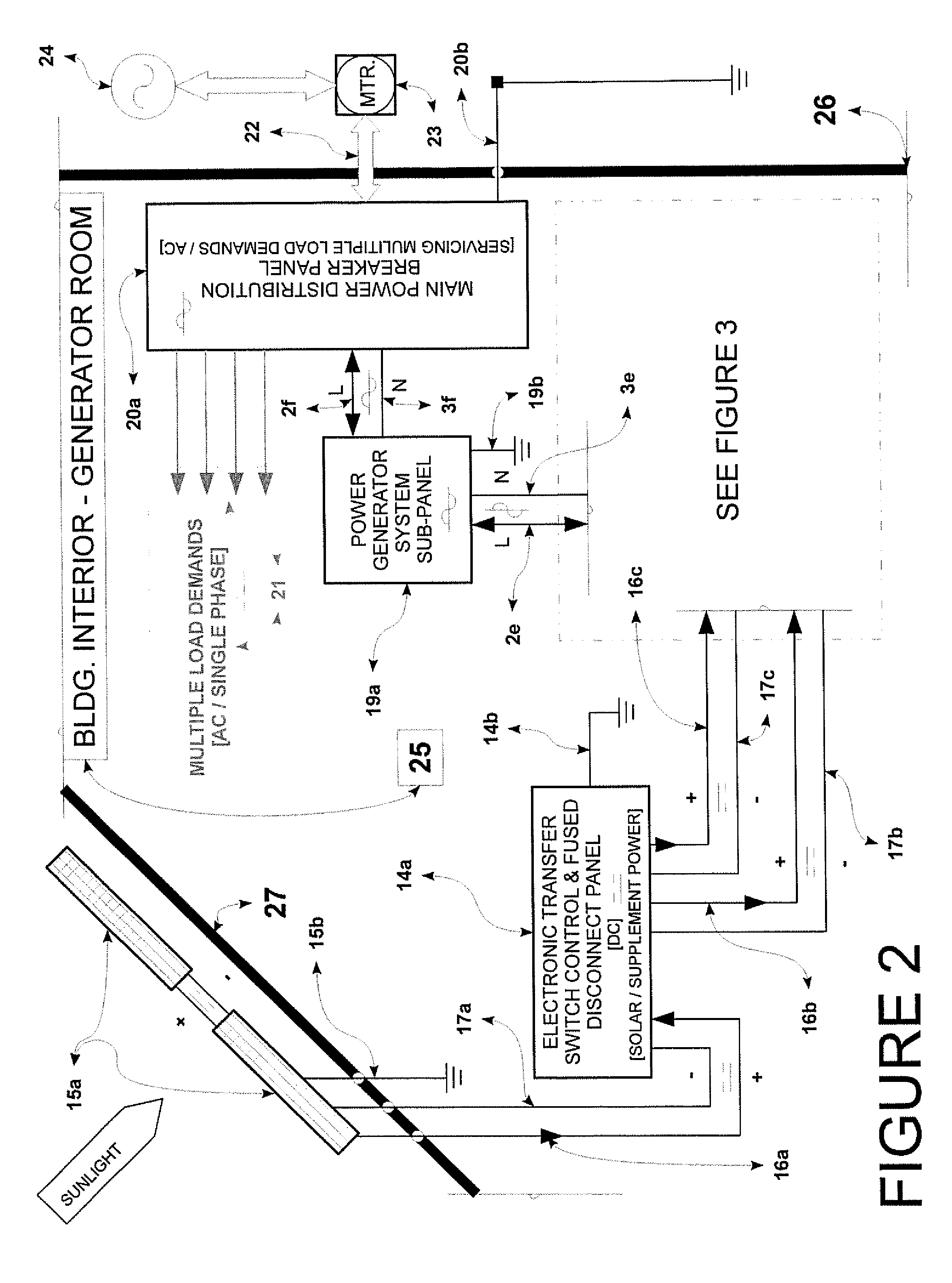

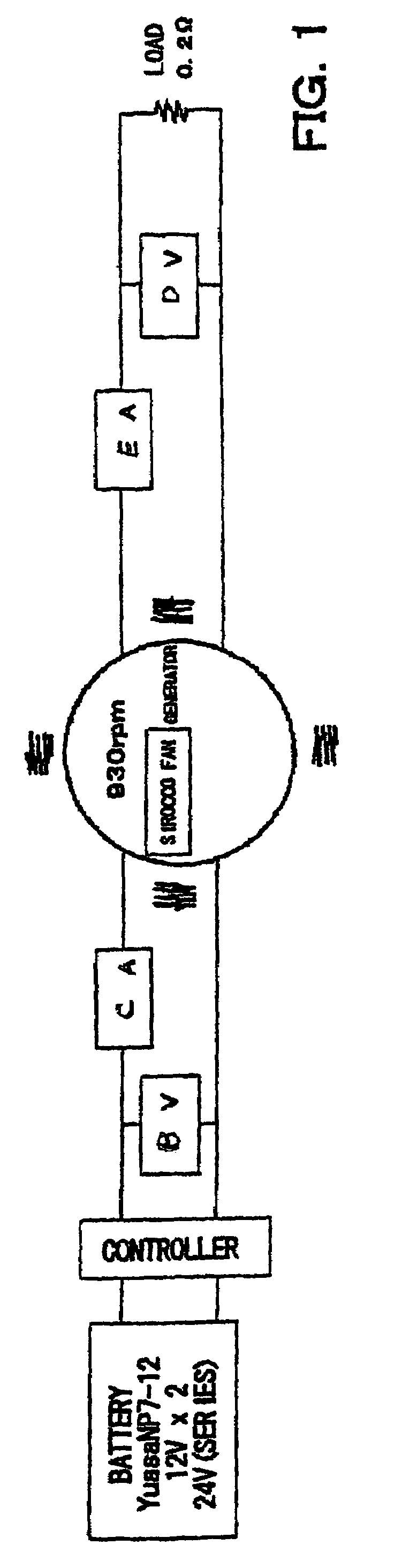

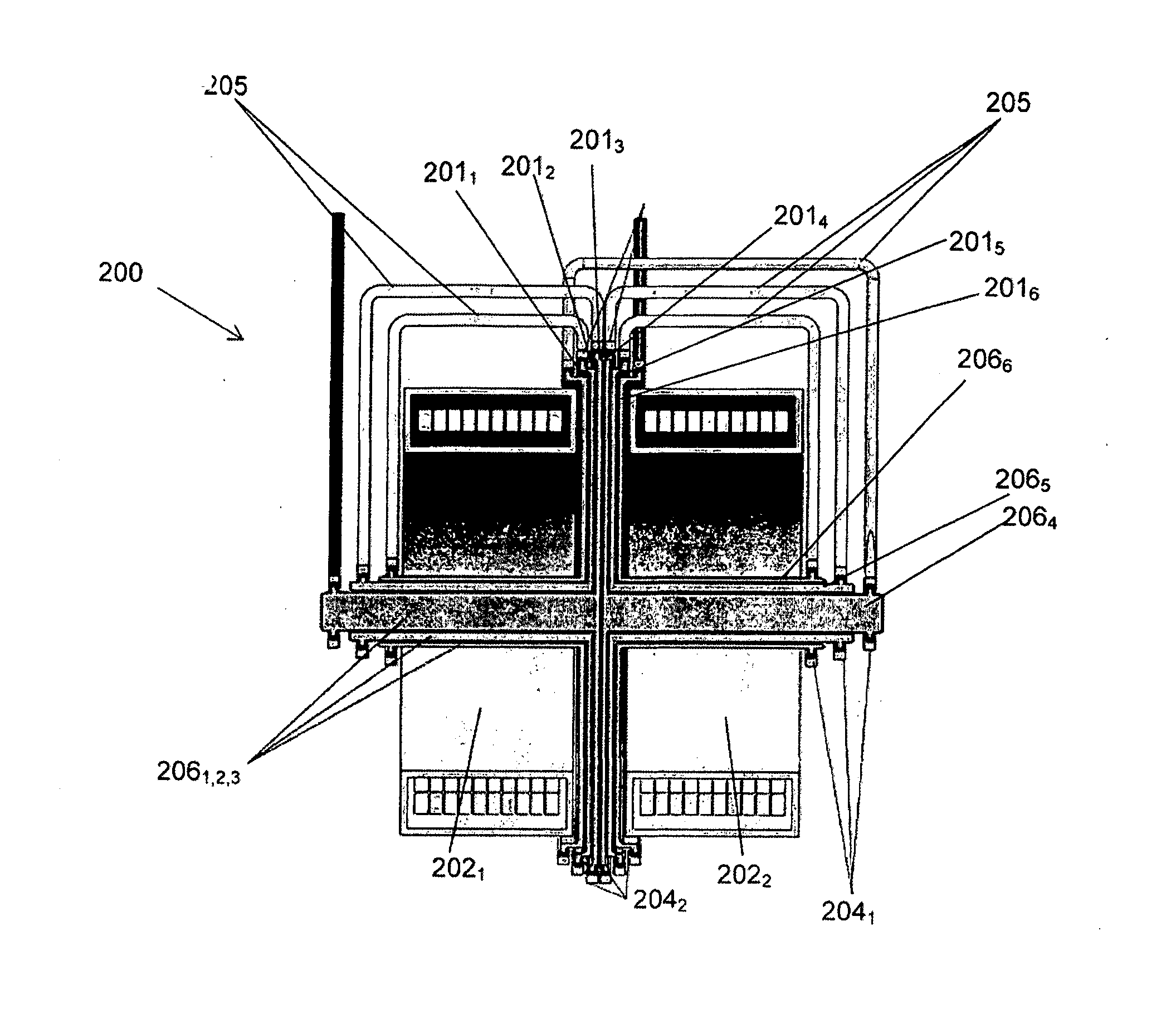

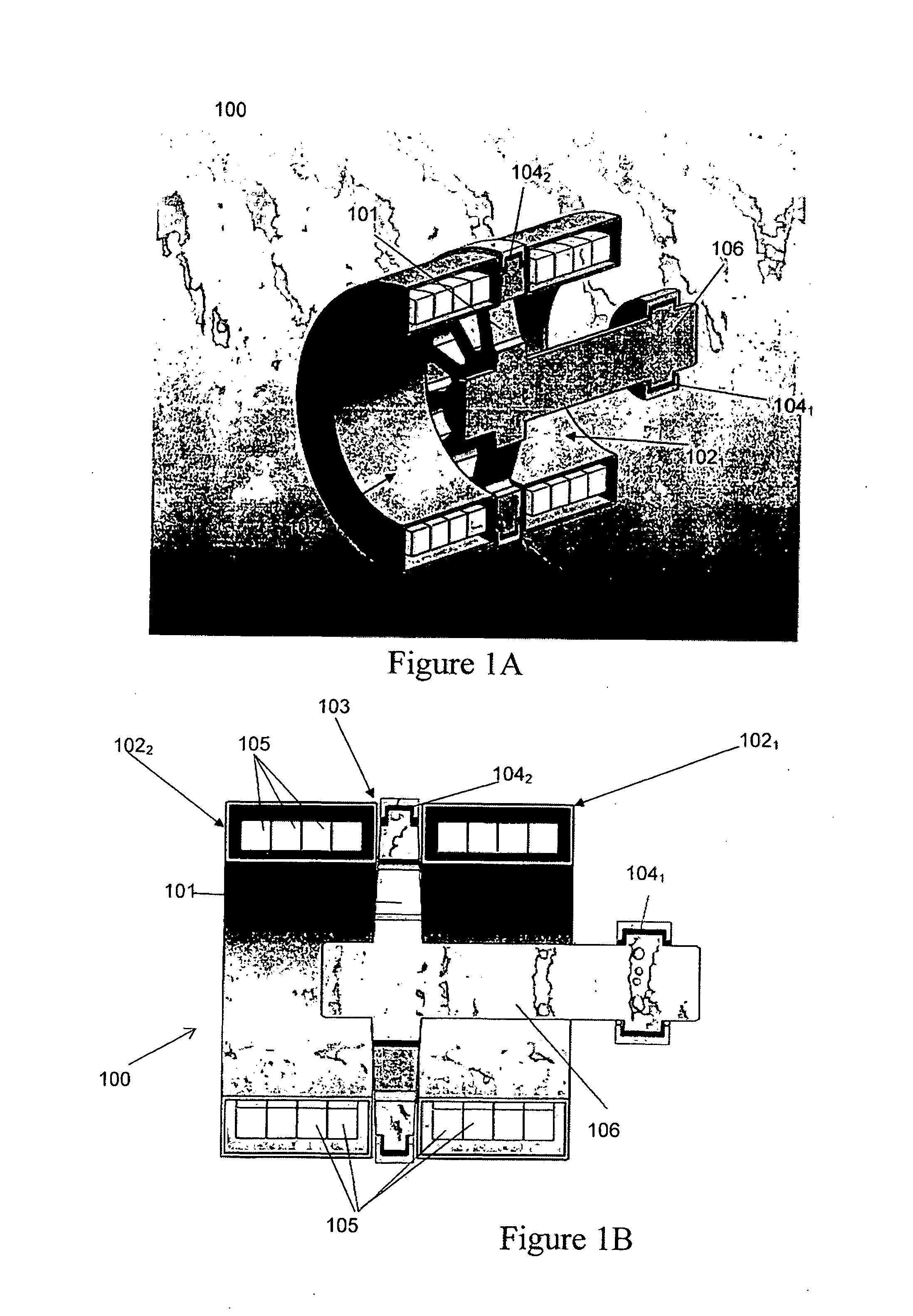

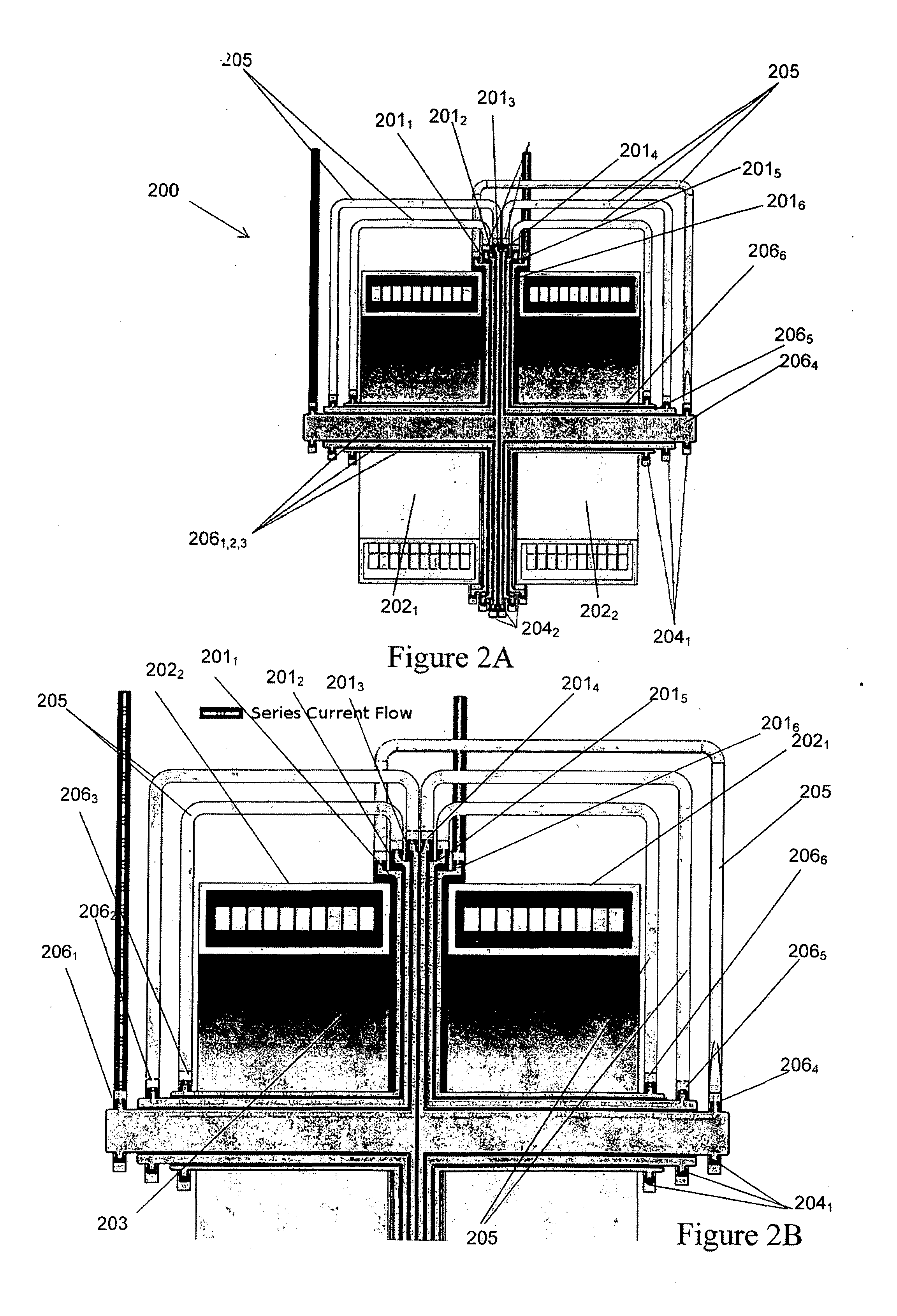

Electrical power generation and distribution

Systems and methods of generating, storing and / or distributing electric power are disclosed. The system may include two or more direct current battery subsystems, a direct current motor / alternating current generator combination, an electric power distribution network, and battery recharging elements. One battery subsystem may power an alternating current generator while the other battery subsystem charges using a portion of the generated power. Excess power may service other electric loads. The roles of the battery subsystems may be switched periodically between charging and powering, repeatedly. A gear box may connect the electric motor and generator to adjust the relative rotational speeds of each for optimal performance of the system.

Owner:ENERGY PRODUCING SYST OF AMERICA LLC

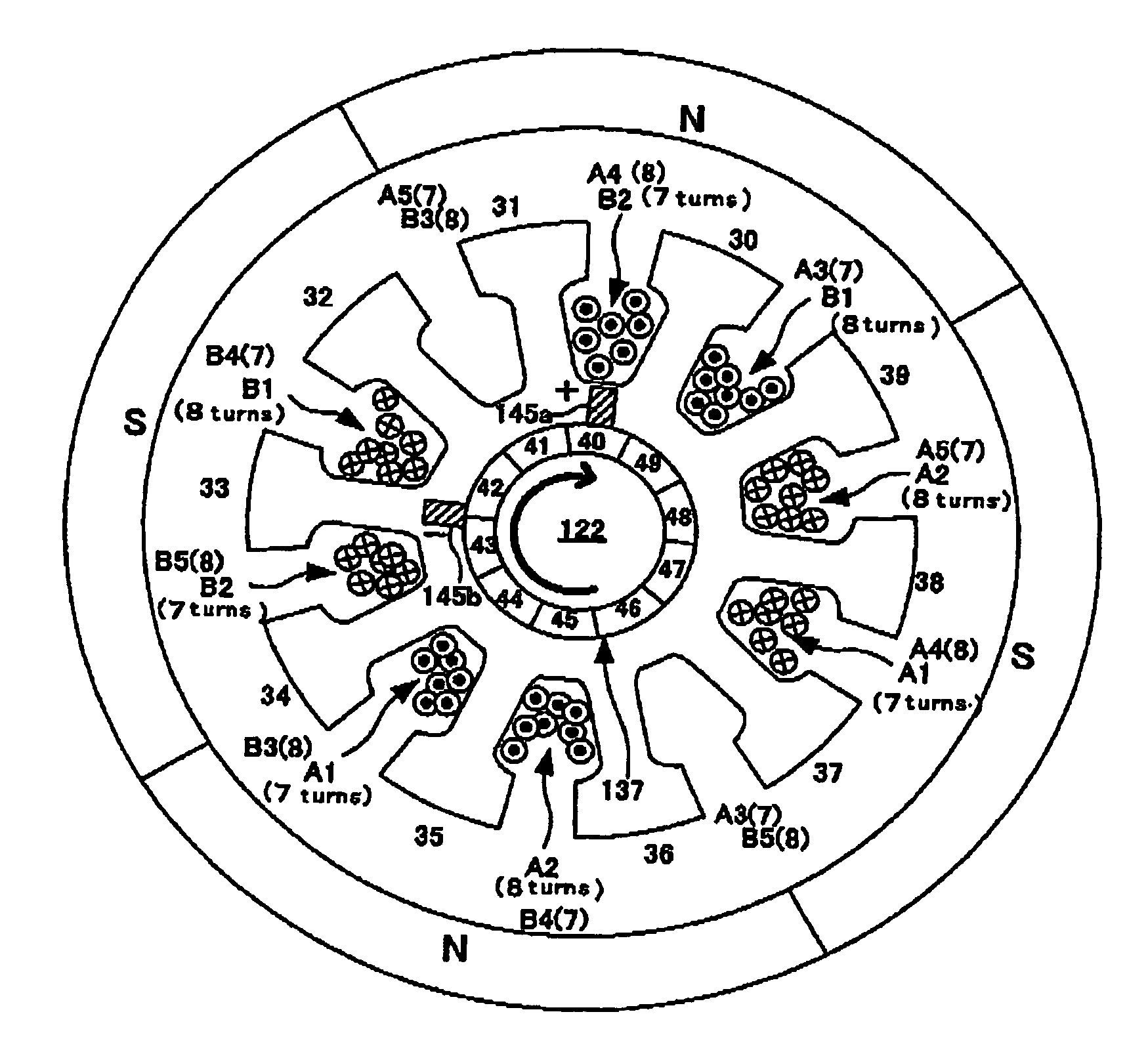

Power tool

ActiveUS20060087193A1Readily keep high commutating performanceNot perishableSynchronous generatorsRotary current collectorMotor drivePower tool

It is an object of the invention to provide an improved technique for controlling the output characteristic of a motor. Representative power tool includes a tool bit and a motor. The motor drives the tool bit and includes an armature, a coordinator, a plurality of segments and a plurality of armature windings. The armature has a plurality of slots. The communicator rotates together with the armature. Plurality of segments is provided on the communicator. Respective armature windings are connected at the both ends of the segments. Each of the armature windings is defined by coils that are wound between respective pairs of the slots of the armature. Each of the armature windings is formed by at least two coils connected in series. At least one of the coils defining the armature winding has a different number of turns of a wire wound between the associated slots from the other coils in the same armature winding. On the same time, the total number of turns of the coils of each of the armature windings is the same. Thus, as a result, the magnetic field around each of the armature windings can be kept substantially the same while providing fine adjustment of the numbers of turns in the armature windings.

Owner:MAKITA CORP

Electromagnetic turbine

InactiveUS20150214824A1Improve the immunityReduce contact resistanceSynchronous generatorsAC/DC convertorsPower flowDrive shaft

A generator including a first magnetic assembly and a second magnetic assembly wherein the first and second magnetic assemblies are arranged in parallel for the production of a magnetic field and a null magnetic field region, a rotor positioned between the first and second magnetic assemblies the rotor being coupled to a drive shaft extending through the first and second magnetic assemblies wherein a portion of the rotor is positioned in the null field region, a least one current transfer mechanism coupled to the rotor in the null field region and at least one current transfer mechanism coupled to the shaft, a drive mechanism attached to the shaft, whereby actuation of the drive mechanism causes rotation of the rotor in the magnetic field to produce a electric potential between the first and second current transfer mechanisms.

Owner:HERON ENERGY

Power generation systems

The present disclosure is directed to several embodiments or variations of a power generation system. Several of these variations use the same power generators and also include one or more prime movers that supply mechanical power to the generators. In a first embodiment of the power generation system, two single drive through-shaft generators adapted to produce electric power are configured to be driven by a common prime mover. In a second, alternative embodiment of the power generation system, a plurality of generators is arranged into first and second generator groups. Each of the first and second generator groups is operably associated with an independent motor, which allows the power output to be controlled via adjustment to the applied power of the independent motors.

Owner:POWER PARTNERS INT LLC

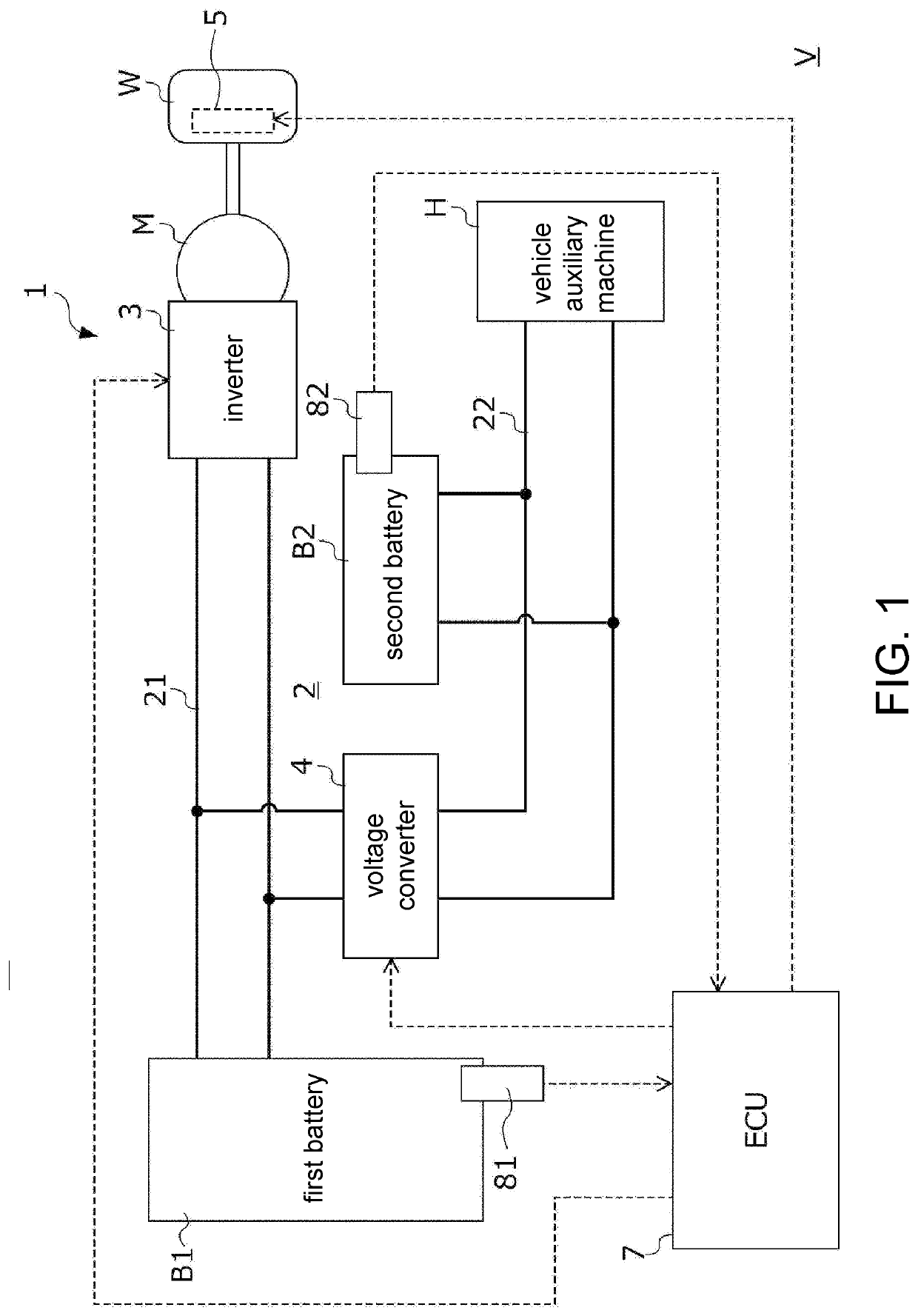

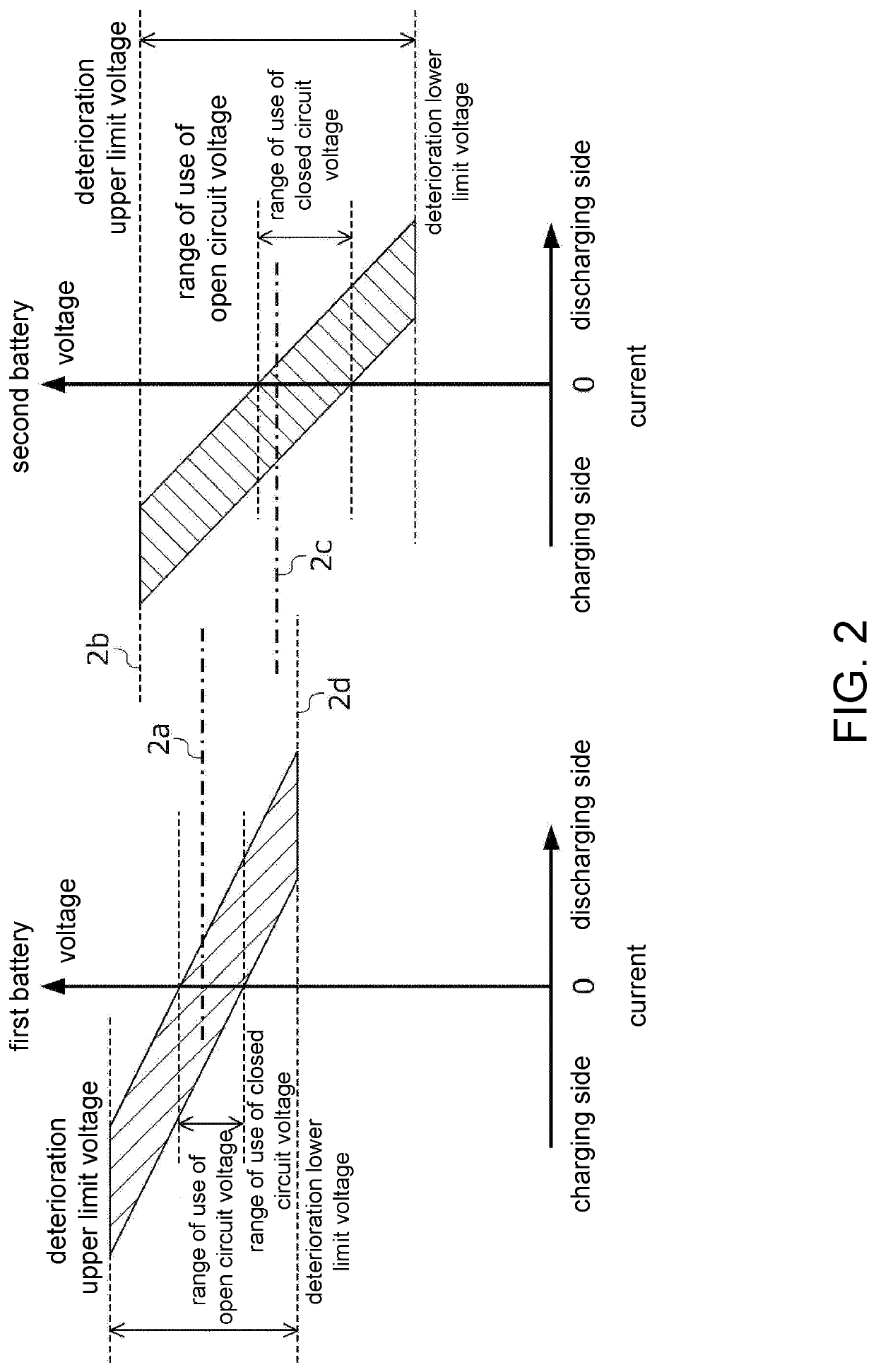

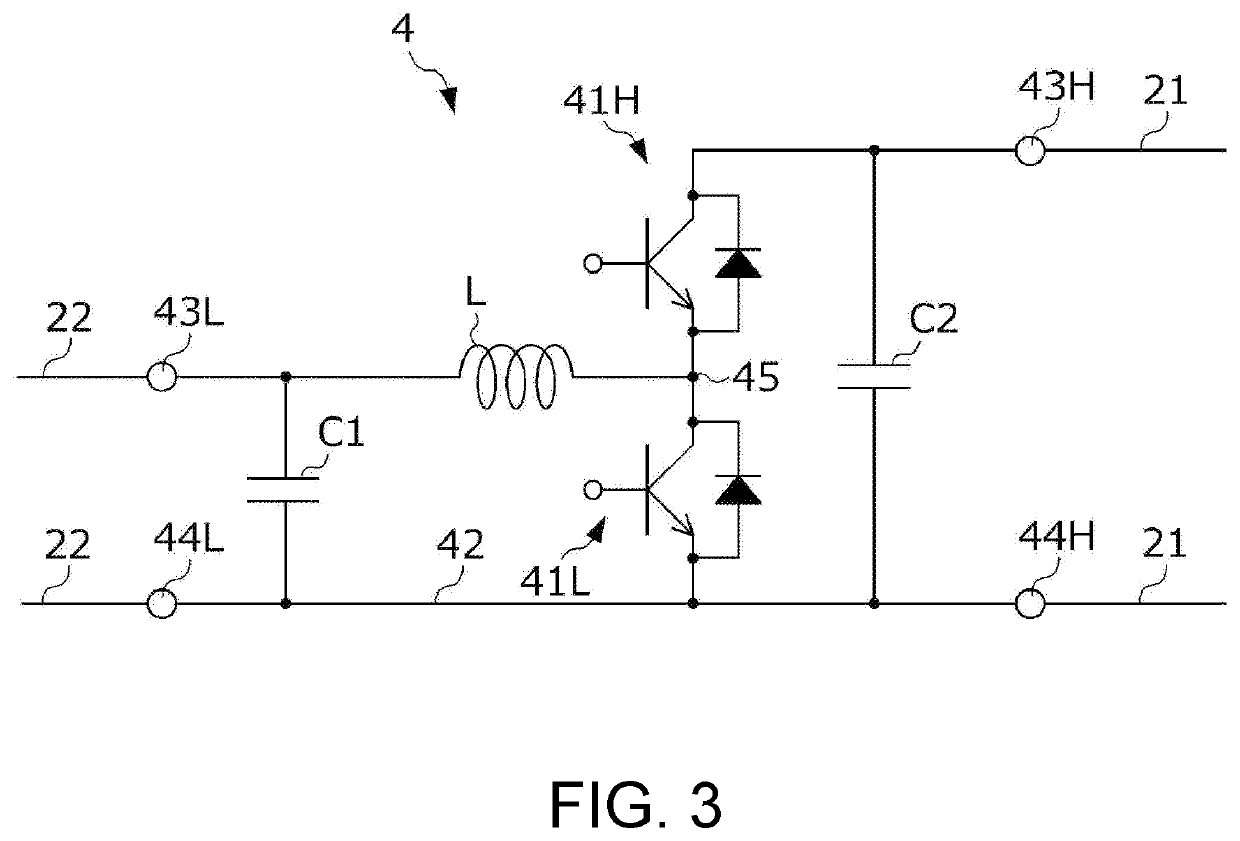

Electrically driven vehicle

A vehicle includes an inverter, a first battery, a first power line, a second battery, a second power line, and a voltage converter. Ranges of use with respect to open circuit voltages of the first battery and the second battery do not overlap each other, and ranges of use with respect to closed circuit voltages of the first and the second batteries overlap each other. When a regenerative power output from the inverter to the first power line is supplied to the second power line via the voltage converter, and the second battery is charged, an ECU calculates a maximum regenerative power with respect to the regenerative power output from the inverter to the first power line based on the open circuit voltage of the first battery and controls the inverter and the voltage converter such that the regenerative power does not exceed the maximum regenerative power.

Owner:HONDA MOTOR CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com