Patents

Literature

5237 results about "Tool bit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tool bit is a non-rotary cutting tool used in metal lathes, shapers, and planers. Such cutters are also often referred to by the set-phrase name of single-point cutting tool, as distinguished from other cutting tools such as a saw or water jet cutter. The cutting edge is ground to suit a particular machining operation and may be resharpened or reshaped as needed. The ground tool bit is held rigidly by a tool holder while it is cutting.

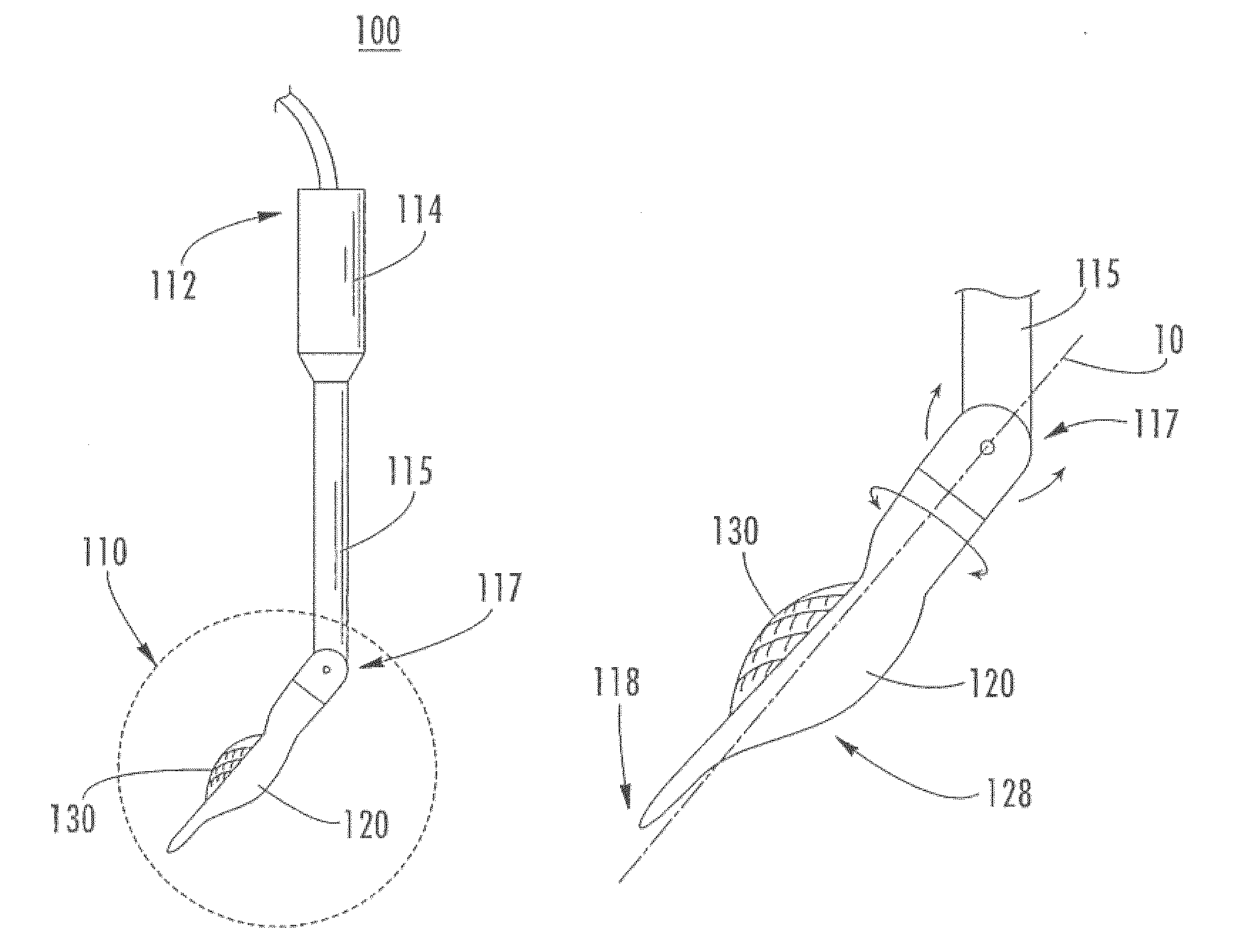

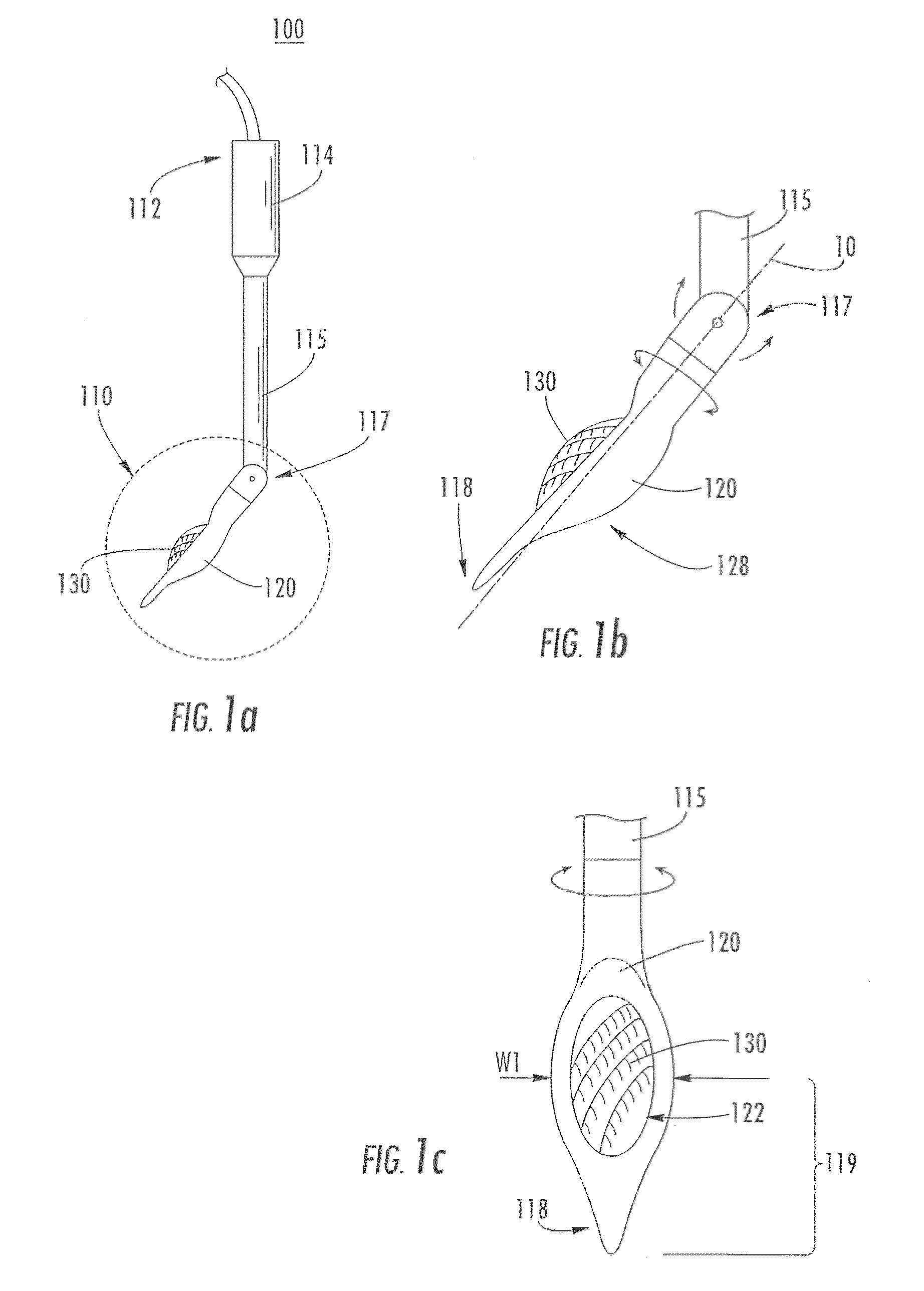

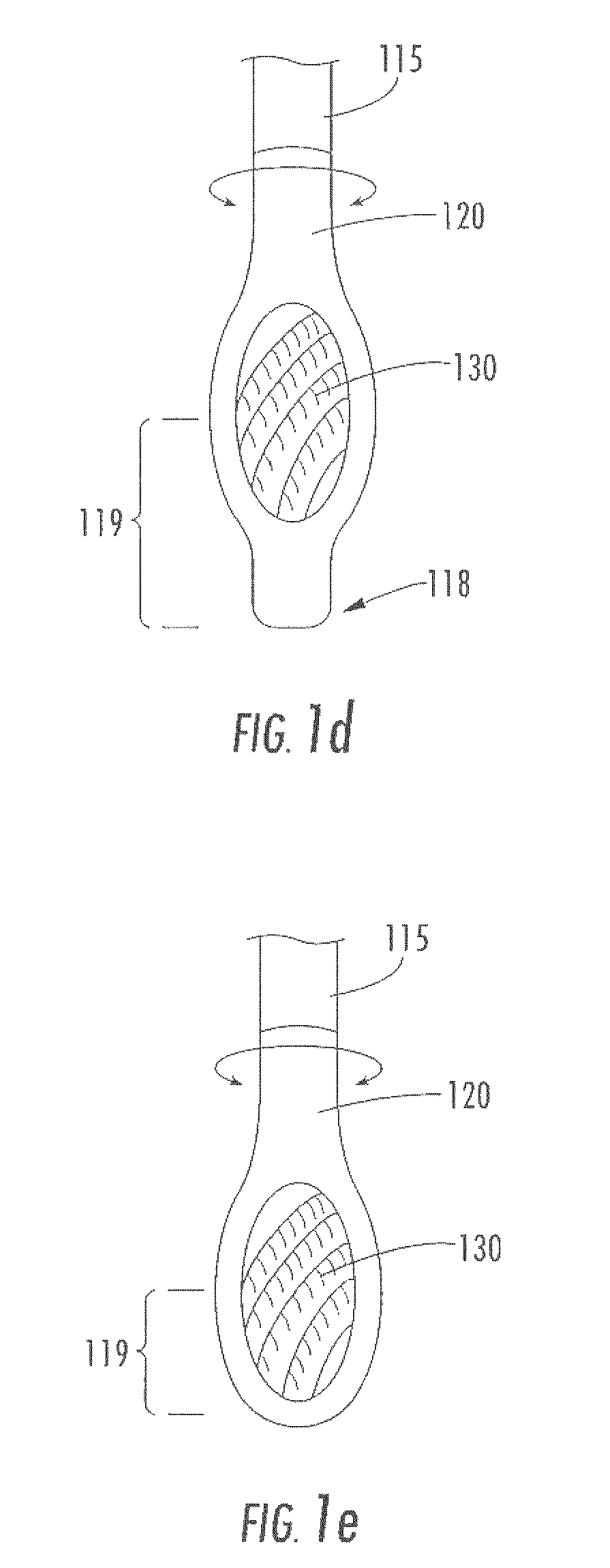

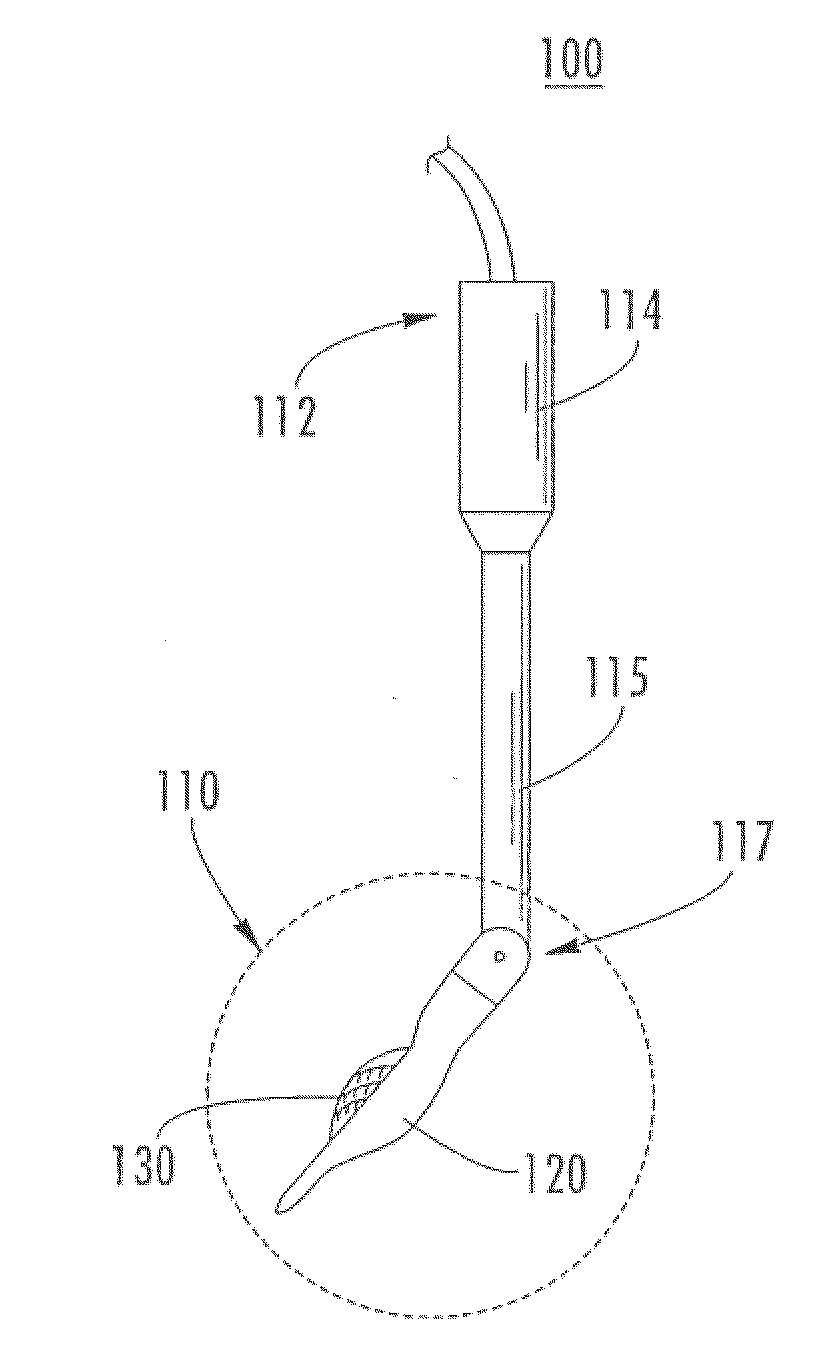

Surgical instrument for orthopedic surgery

ActiveUS8221424B2Safe foraminal decompressionDiagnosticsEndoscopic cutting instrumentsTool bitSurgical instrumentation

Owner:GLOBUS MEDICAL INC

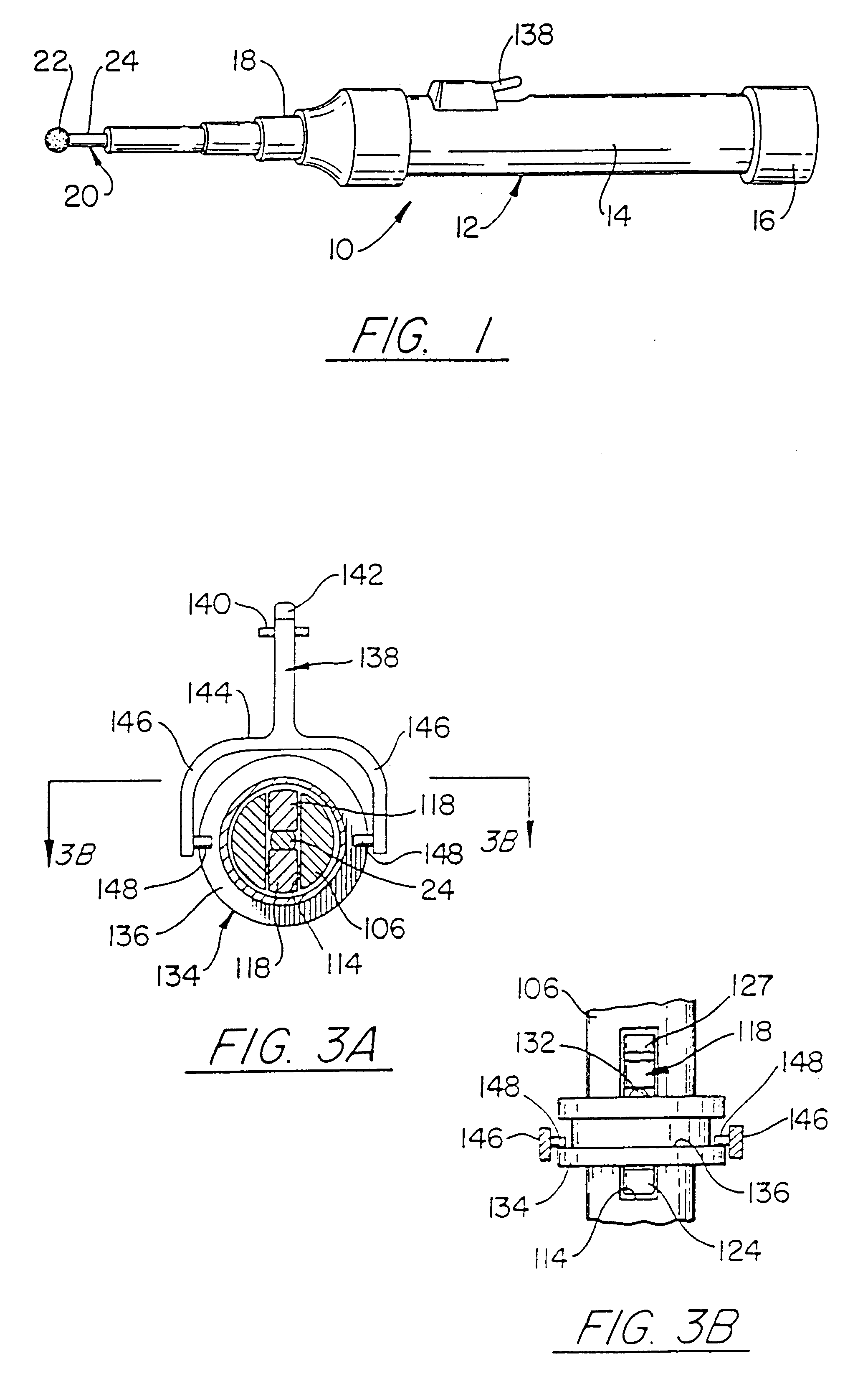

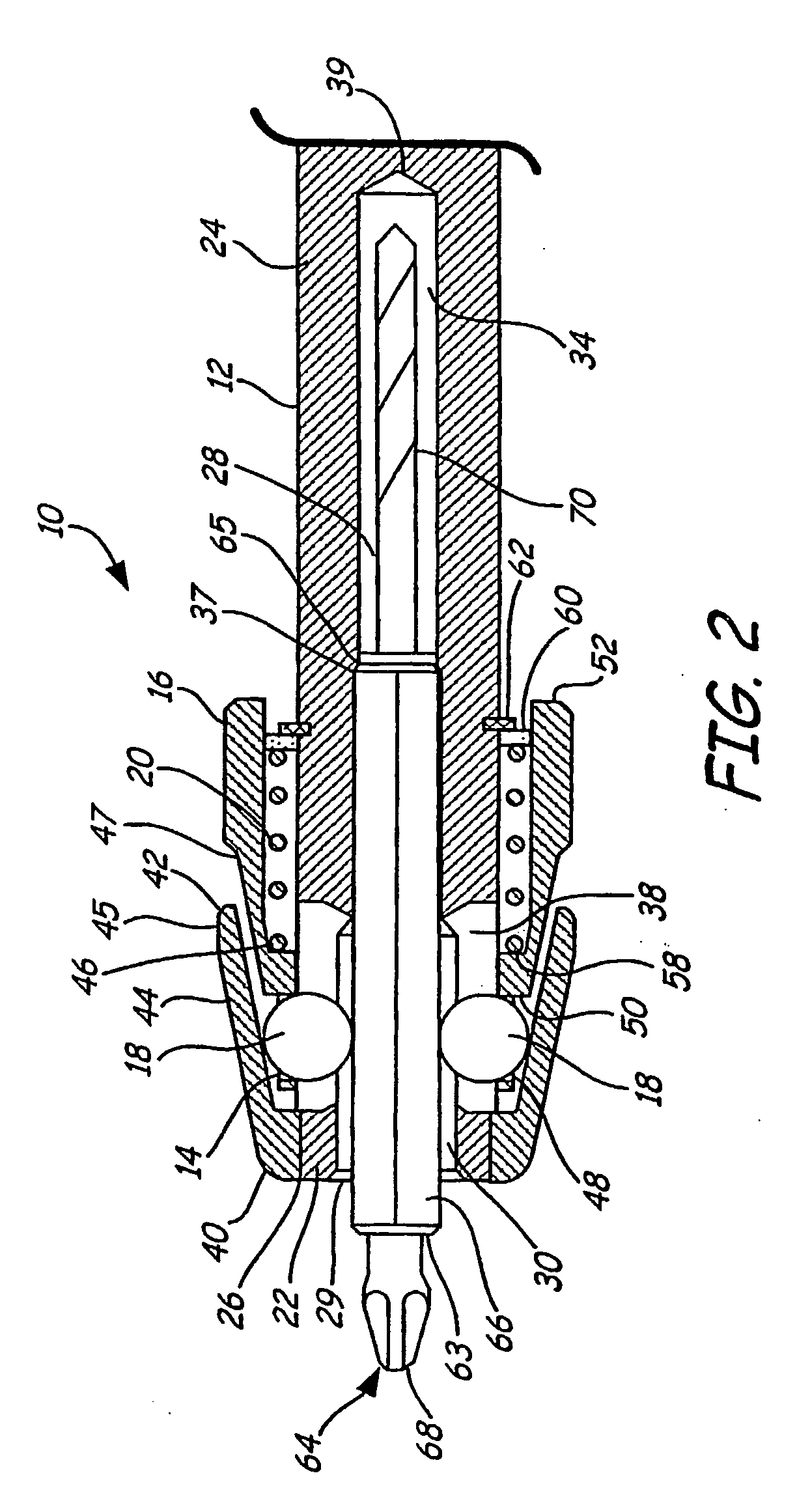

Surgical instrument for orthopedic surgery

ActiveUS20100057087A1Safe foraminal decompressionDiagnosticsEndoscopic cutting instrumentsTool bitPlastic surgery

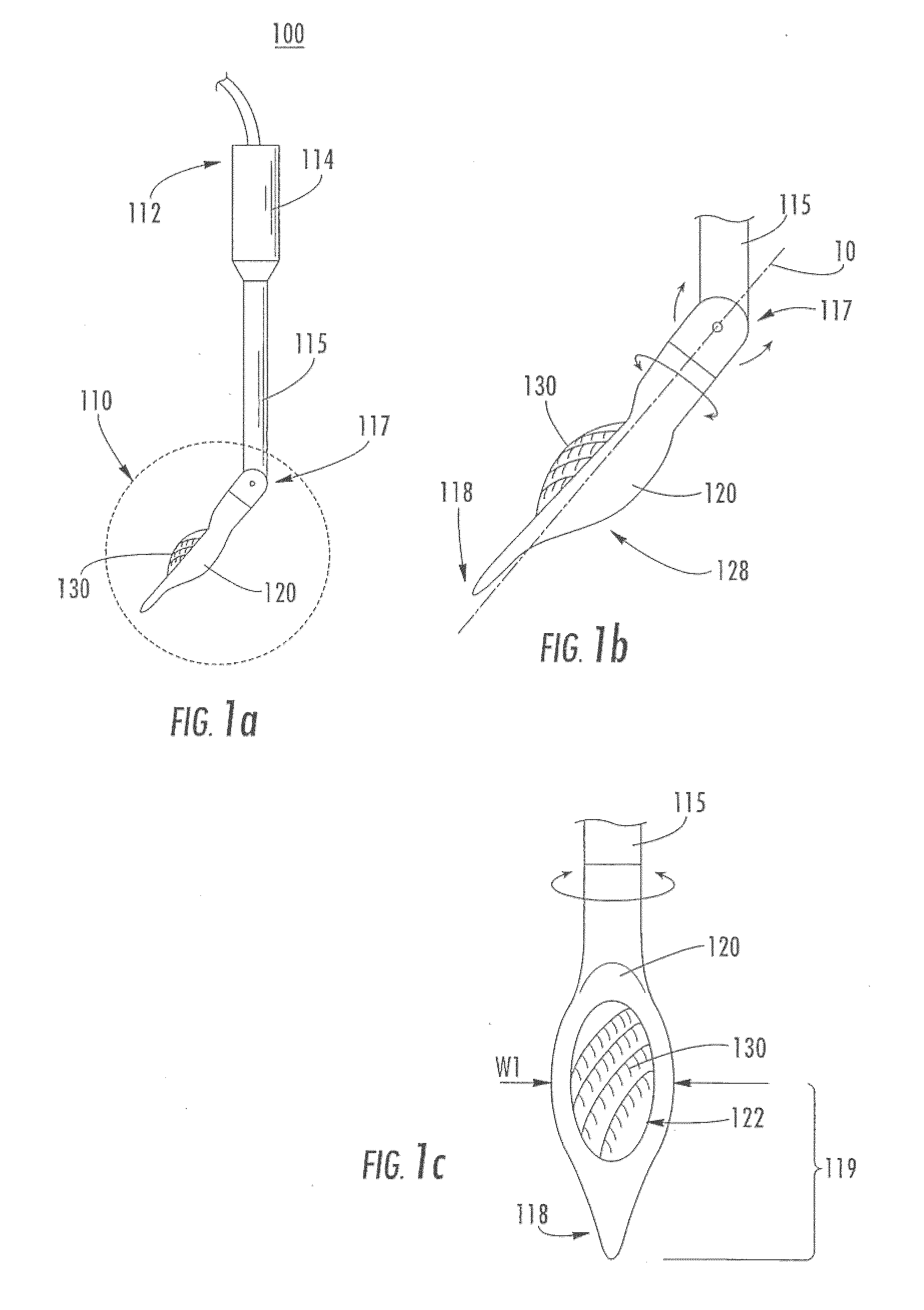

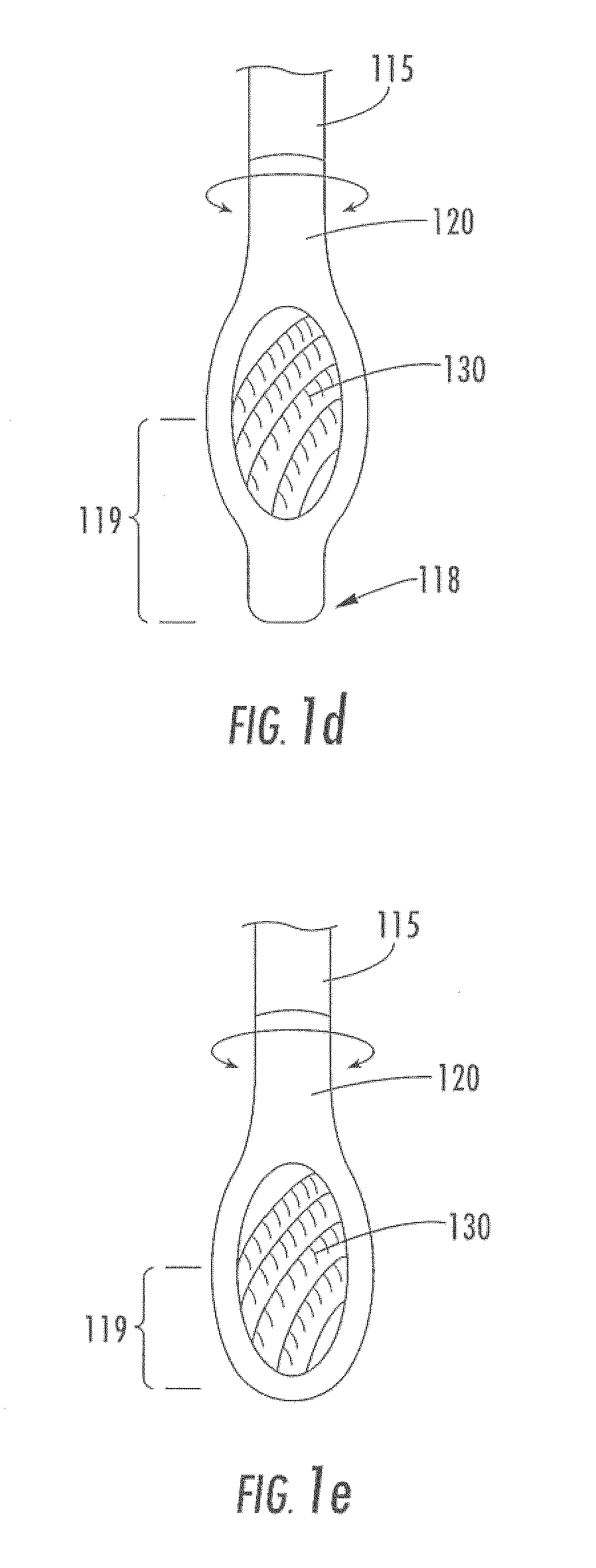

A rotatable surgical instrument having a protective hood with articulating bendable distal end is provided to improve and enable various orthopedic surgical procedures such as arthroscopy. The protective hood surrounds the surgical tool bit exposing only a portion of the tool bit for removing bone or soft tissue material and protects the nerve from the surgical tool bit. The protective hood can be controllably rotated from the instrument's hand piece to control the orientation of the attack angle of the surgical tool bit. Additionally, the bending of the distal end of the instrument can be controlled from the hand piece.

Owner:GLOBUS MEDICAL INC

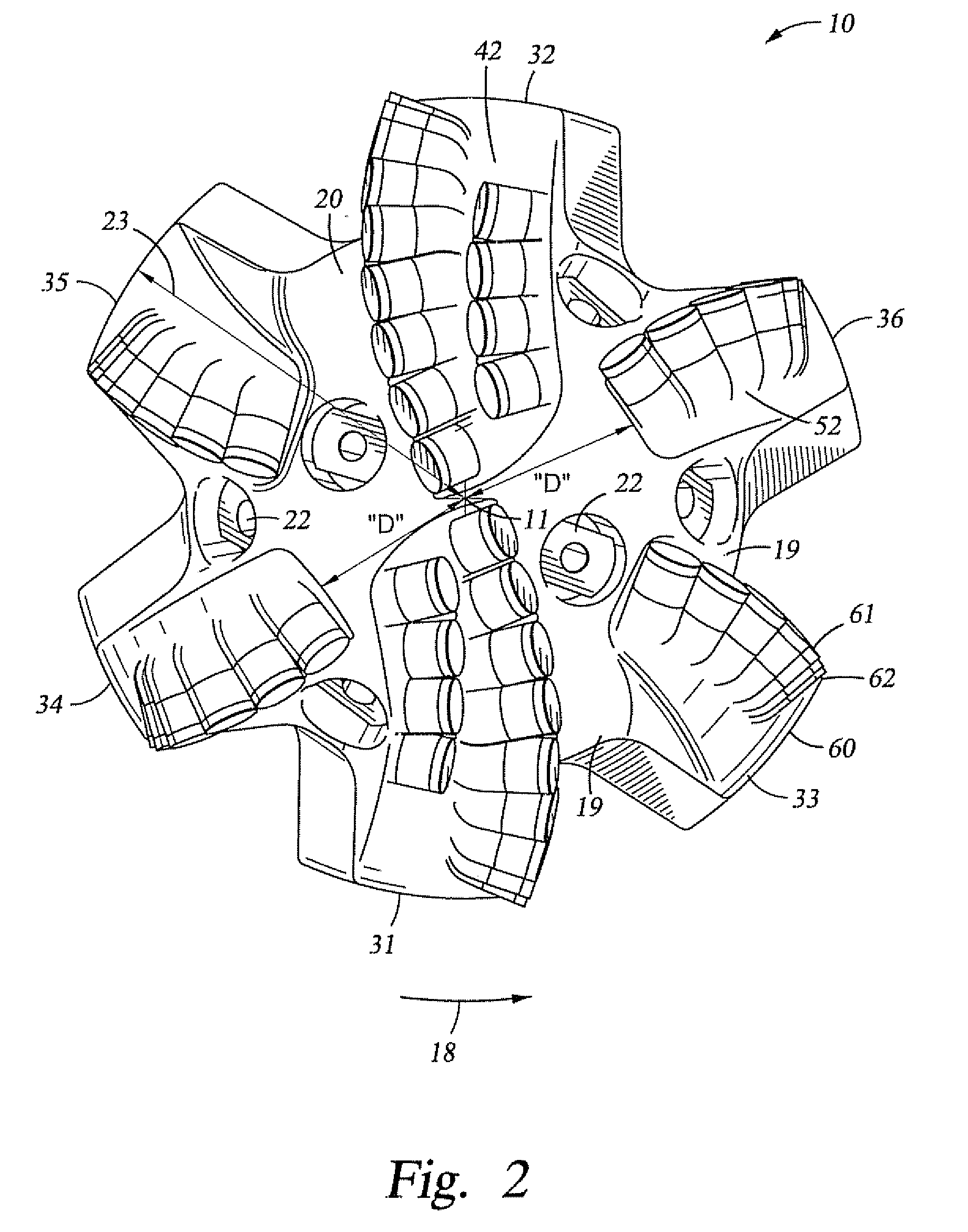

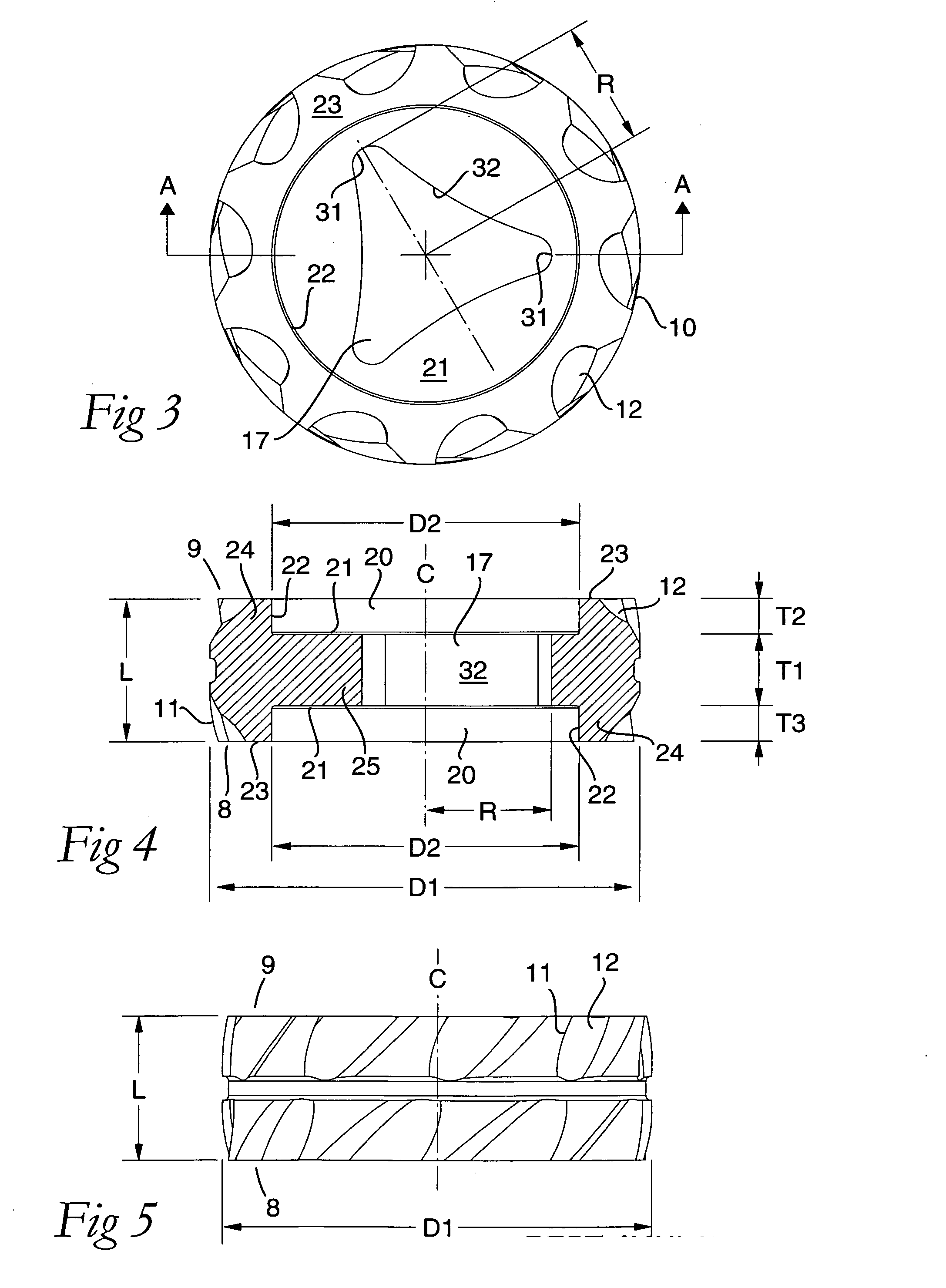

Fixed Cutter Bit With Centrally Positioned Backup Cutter Elements

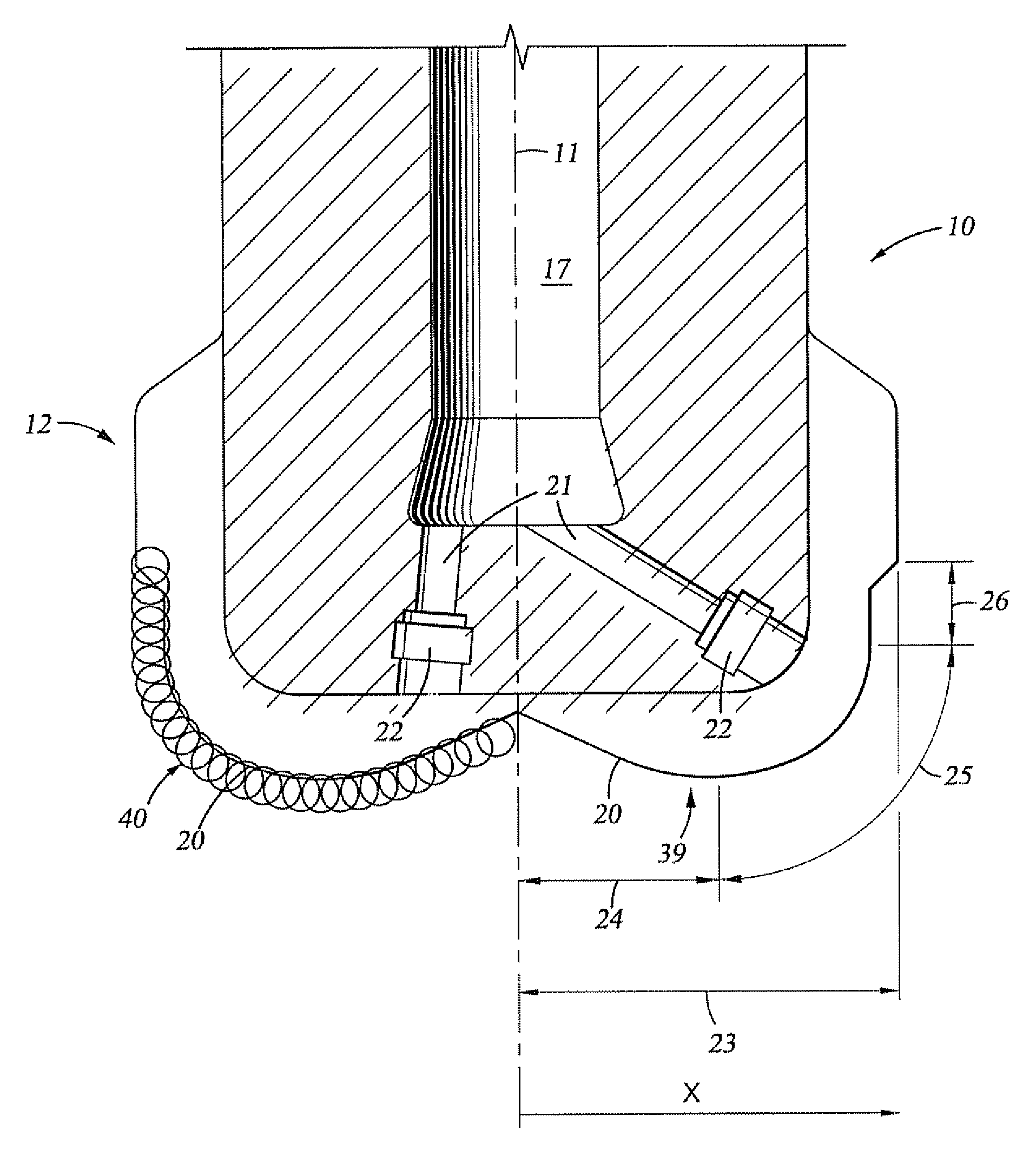

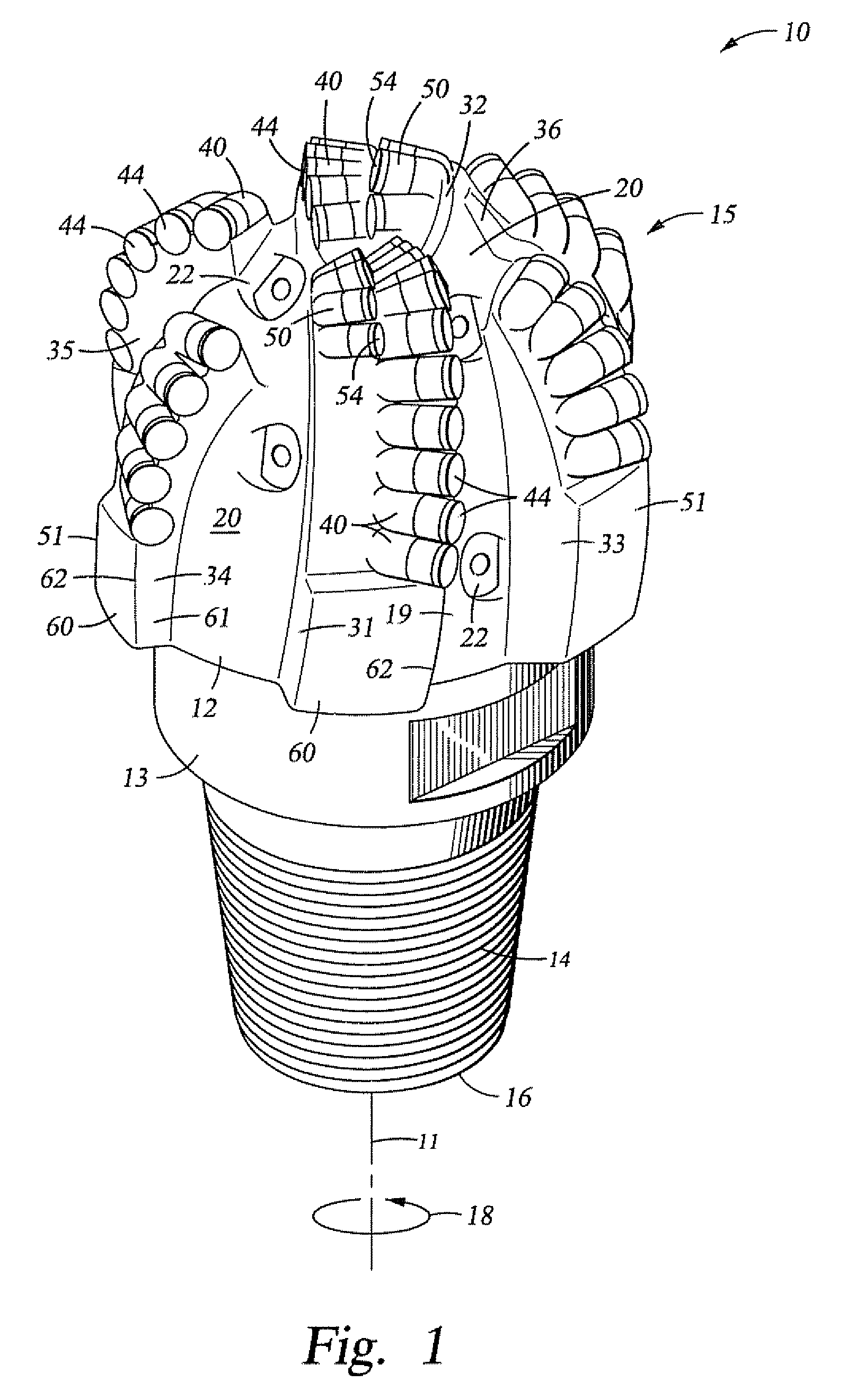

A drill bit for drilling a borehole in earthen formations. In an embodiment, the bit comprises a bit body having a bit face comprising a cone region, a shoulder region, and a gage region. In addition, the bit comprises at least one primary blade disposed on the bit face, wherein the at least one primary blade extends into the cone region. Further, the bit comprises a plurality of primary cutter elements mounted on the at least one primary blade in the cone region. Still further, the bit comprises a plurality of backup cutter elements mounted on the at least one primary blade in the cone region, wherein the at least one primary blade has a cone backup cutter density and a shoulder backup cutter density, and wherein the cone backup cutter density of the at least one primary blade is greater than the shoulder backup cutter density of the at least one primary blade.

Owner:SMITH INT INC

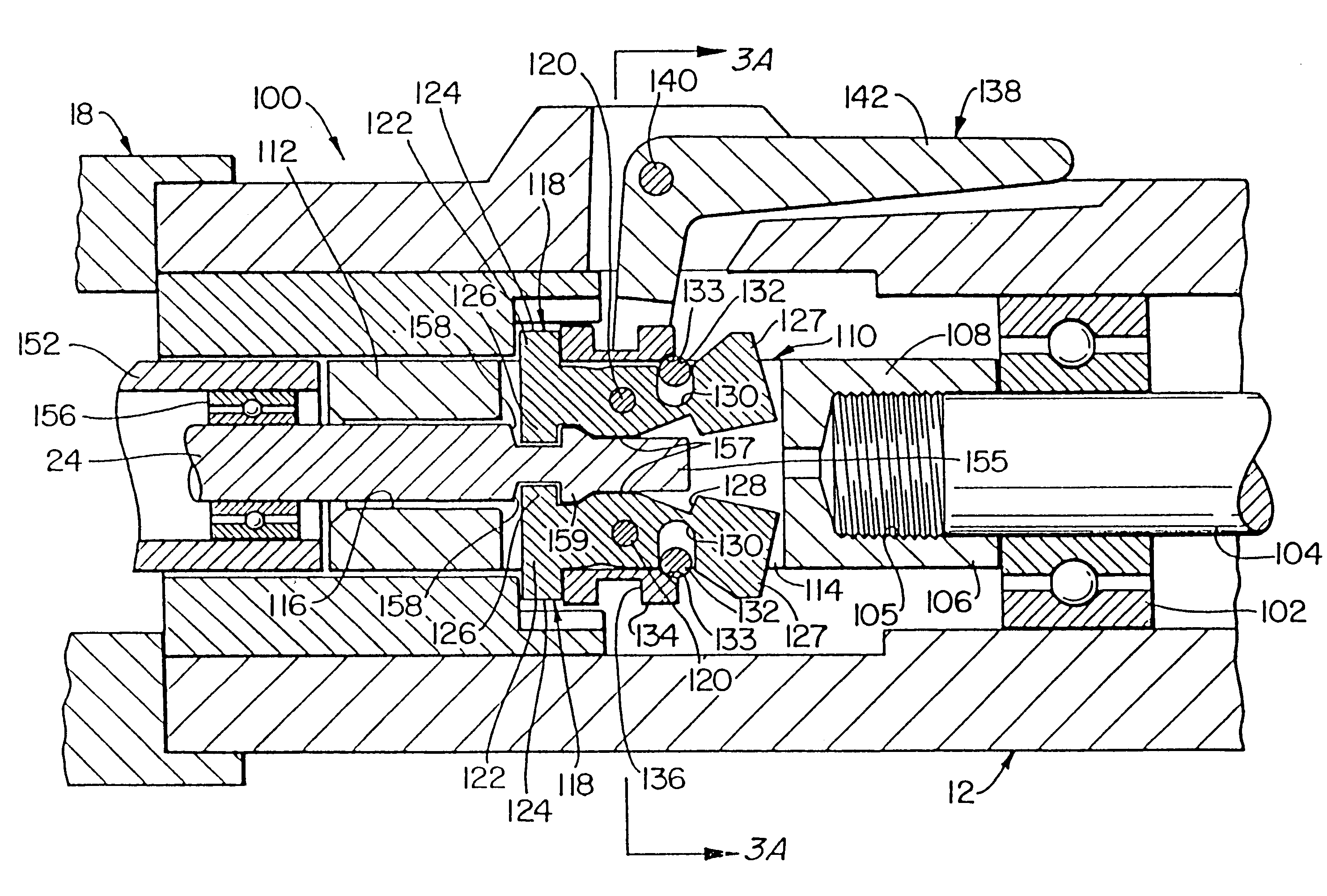

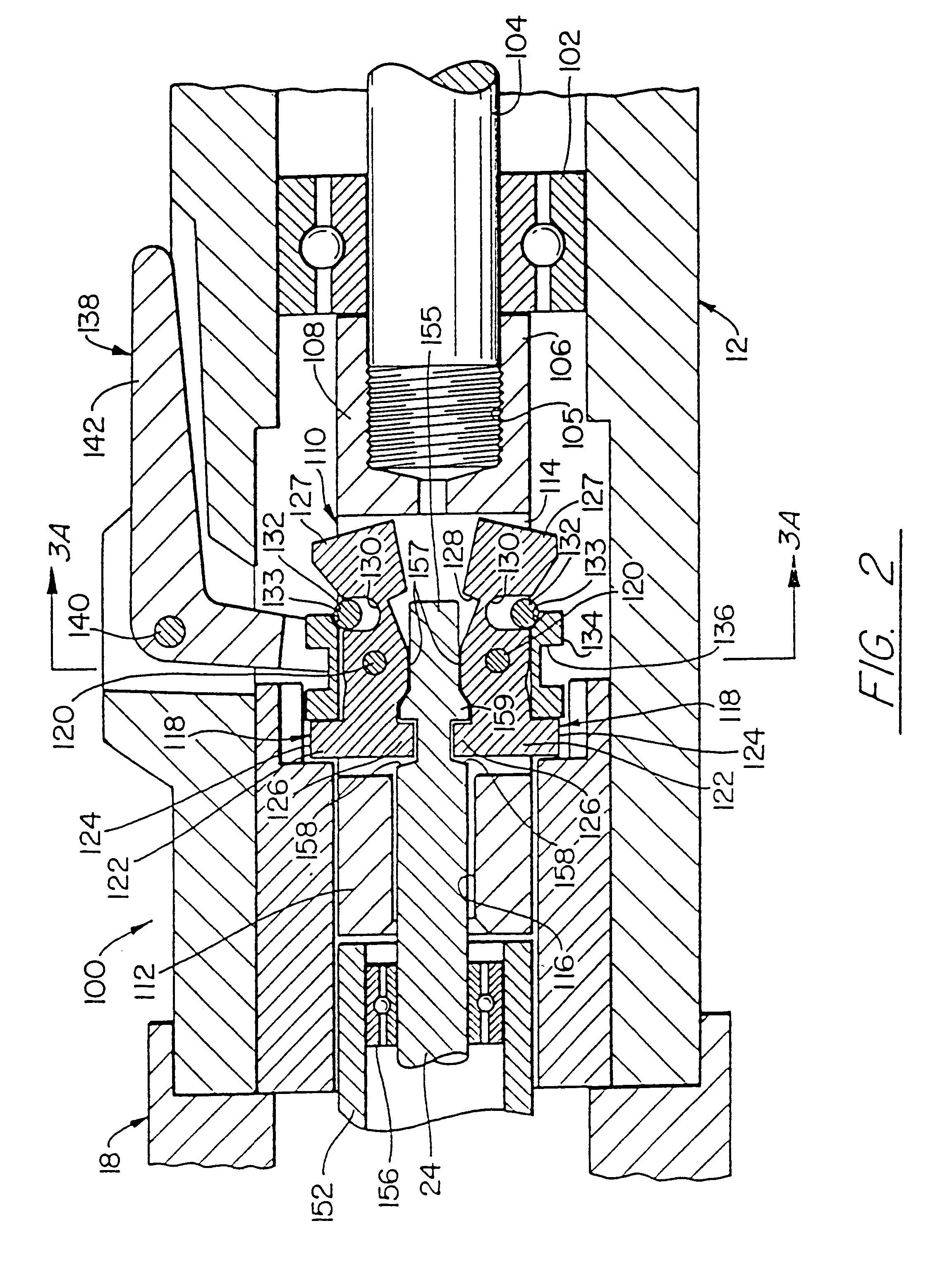

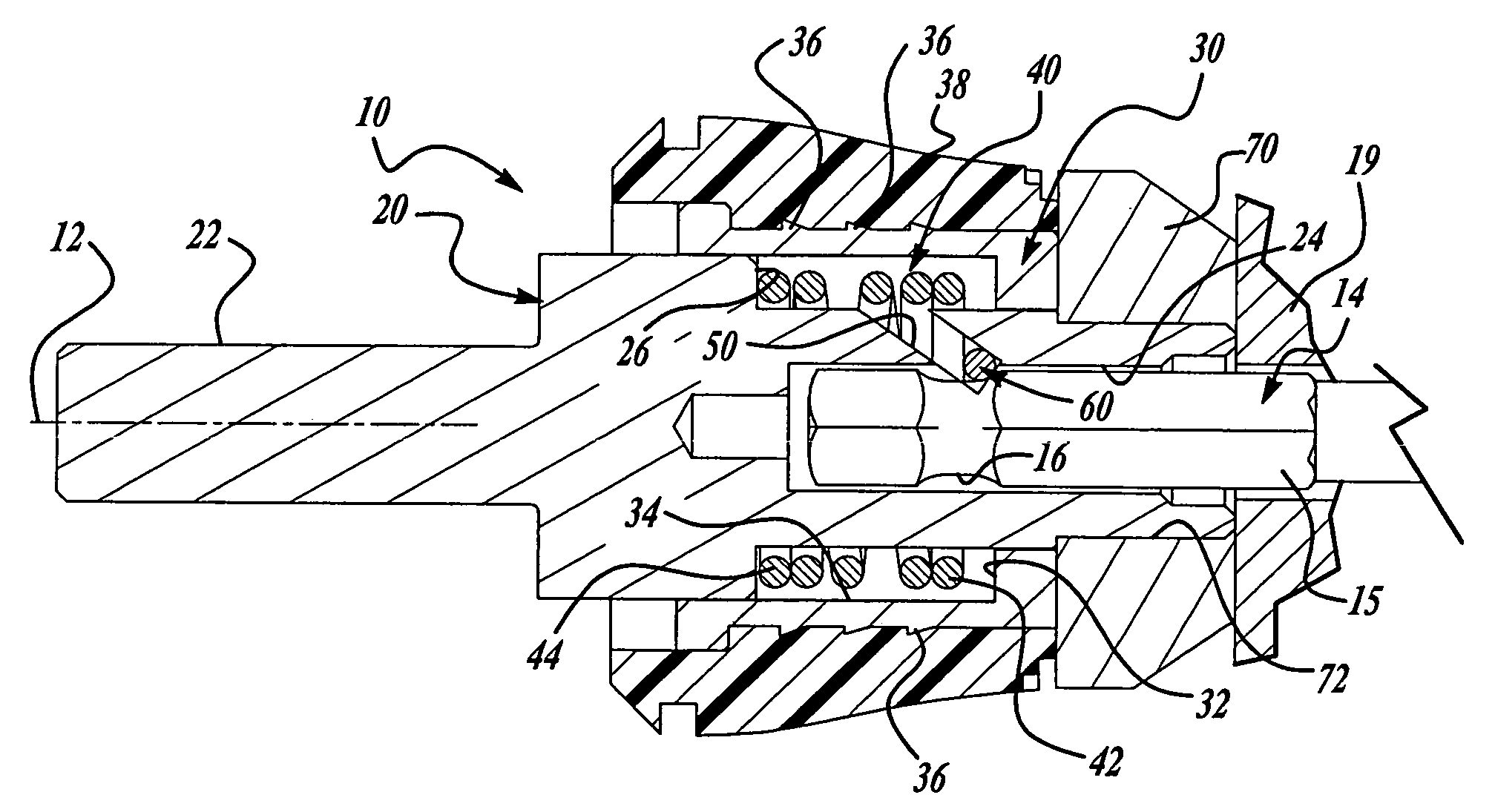

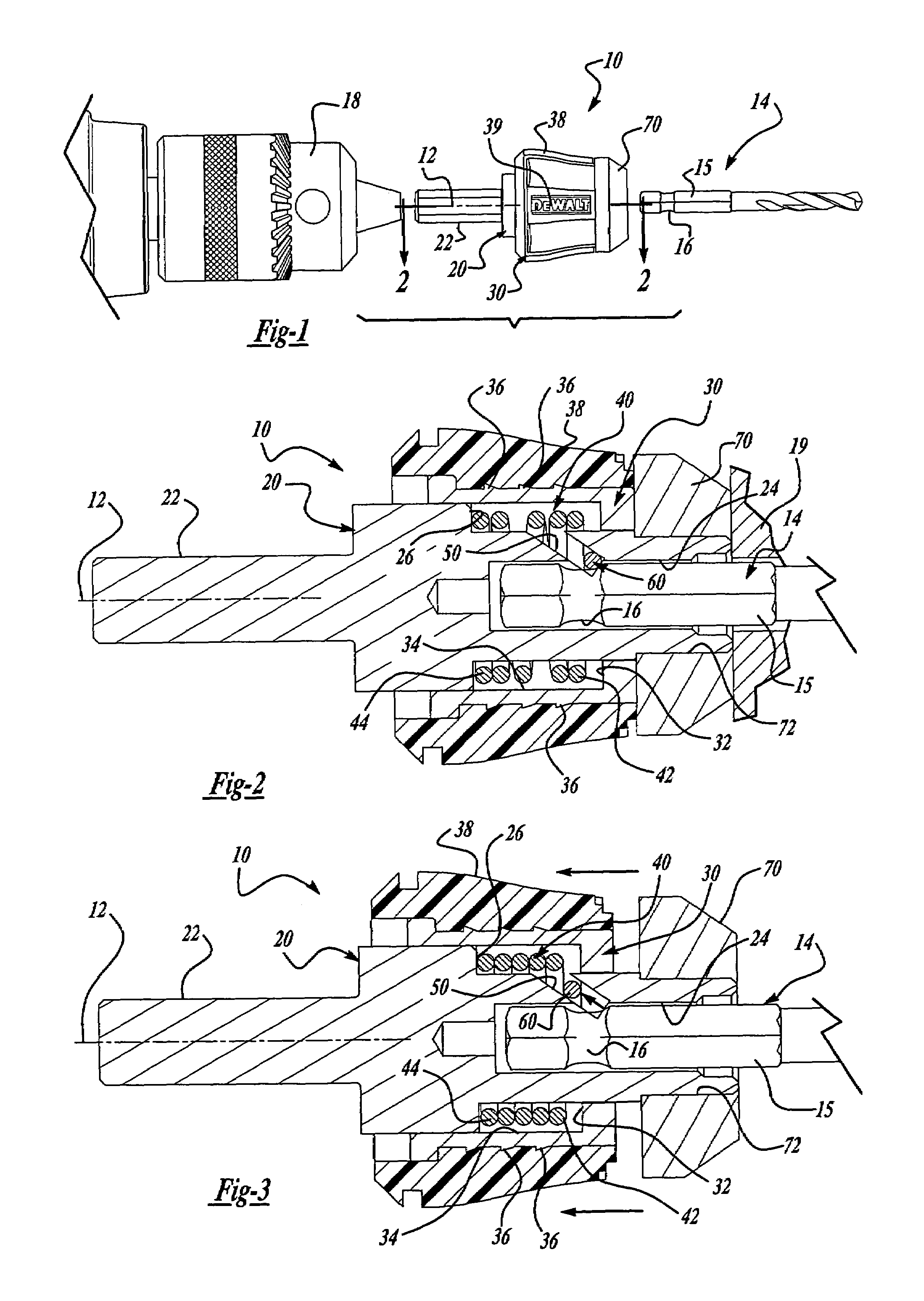

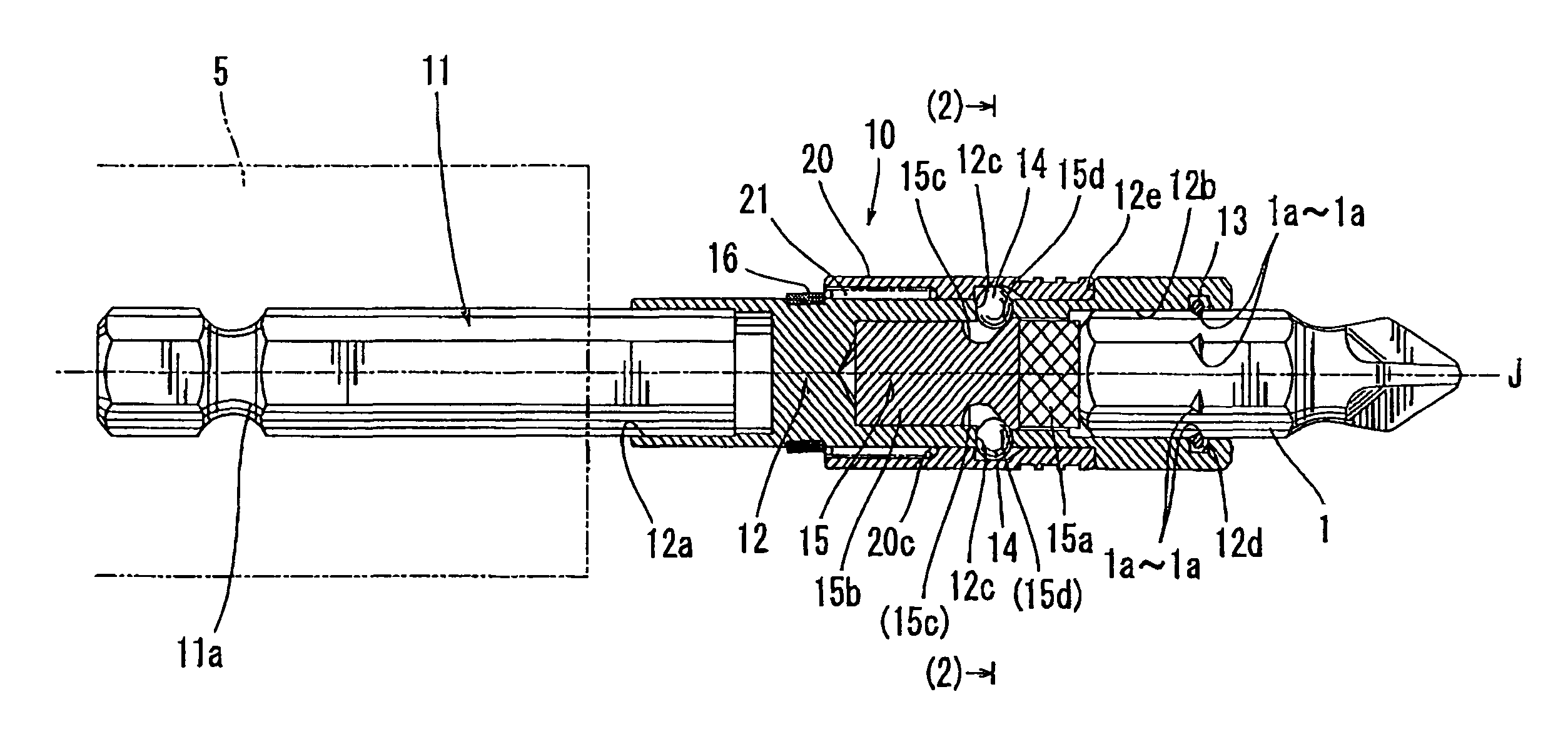

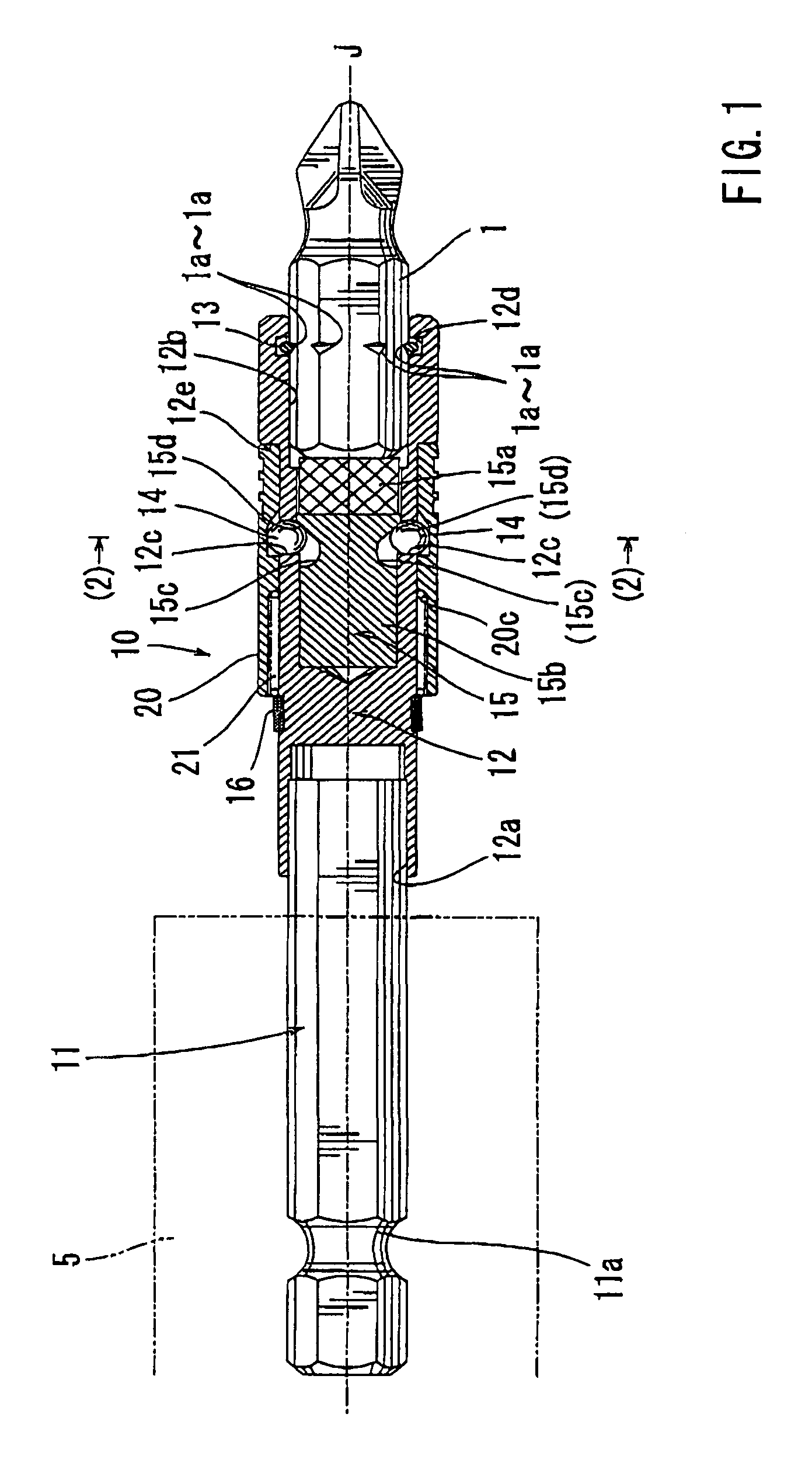

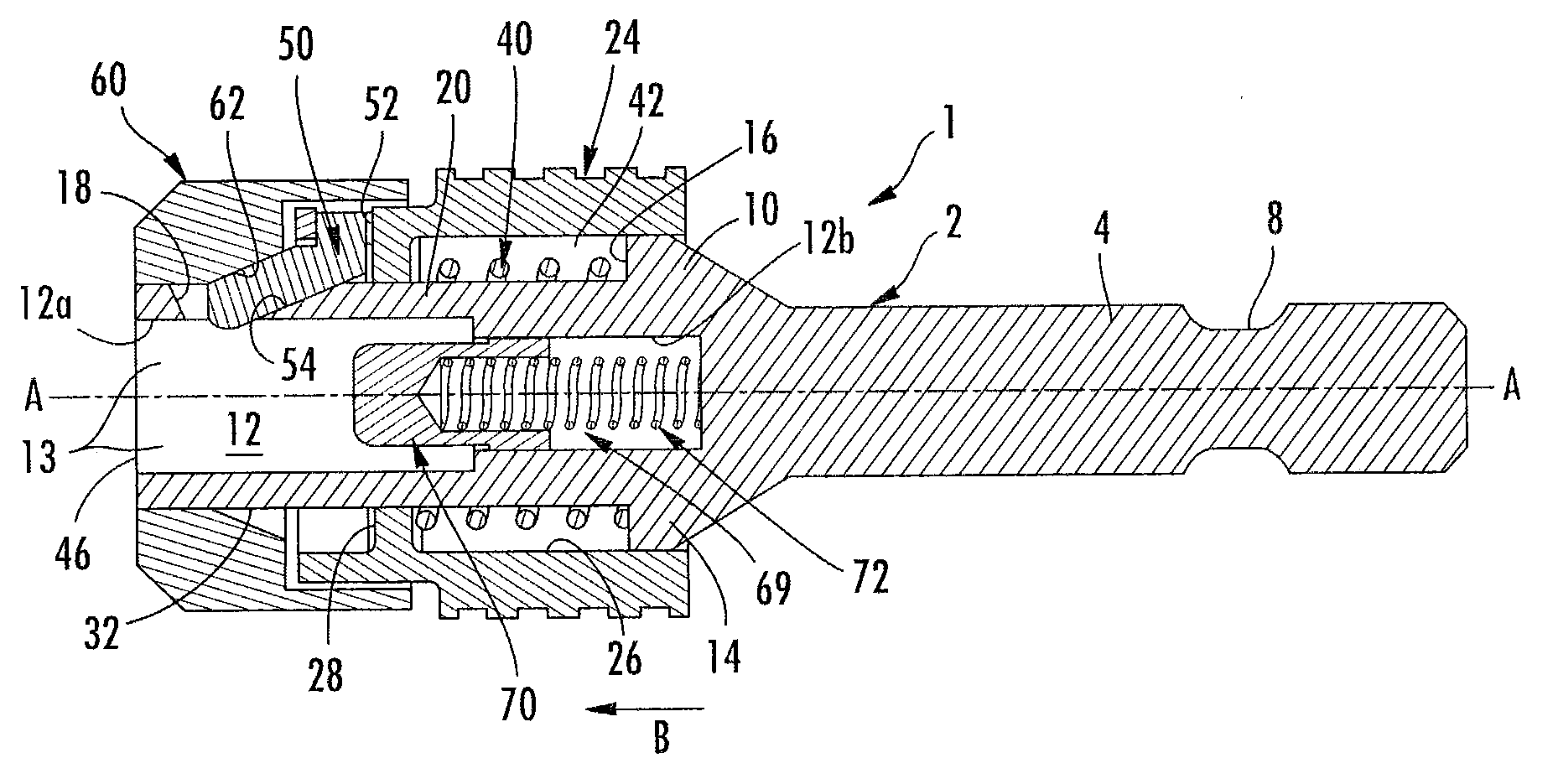

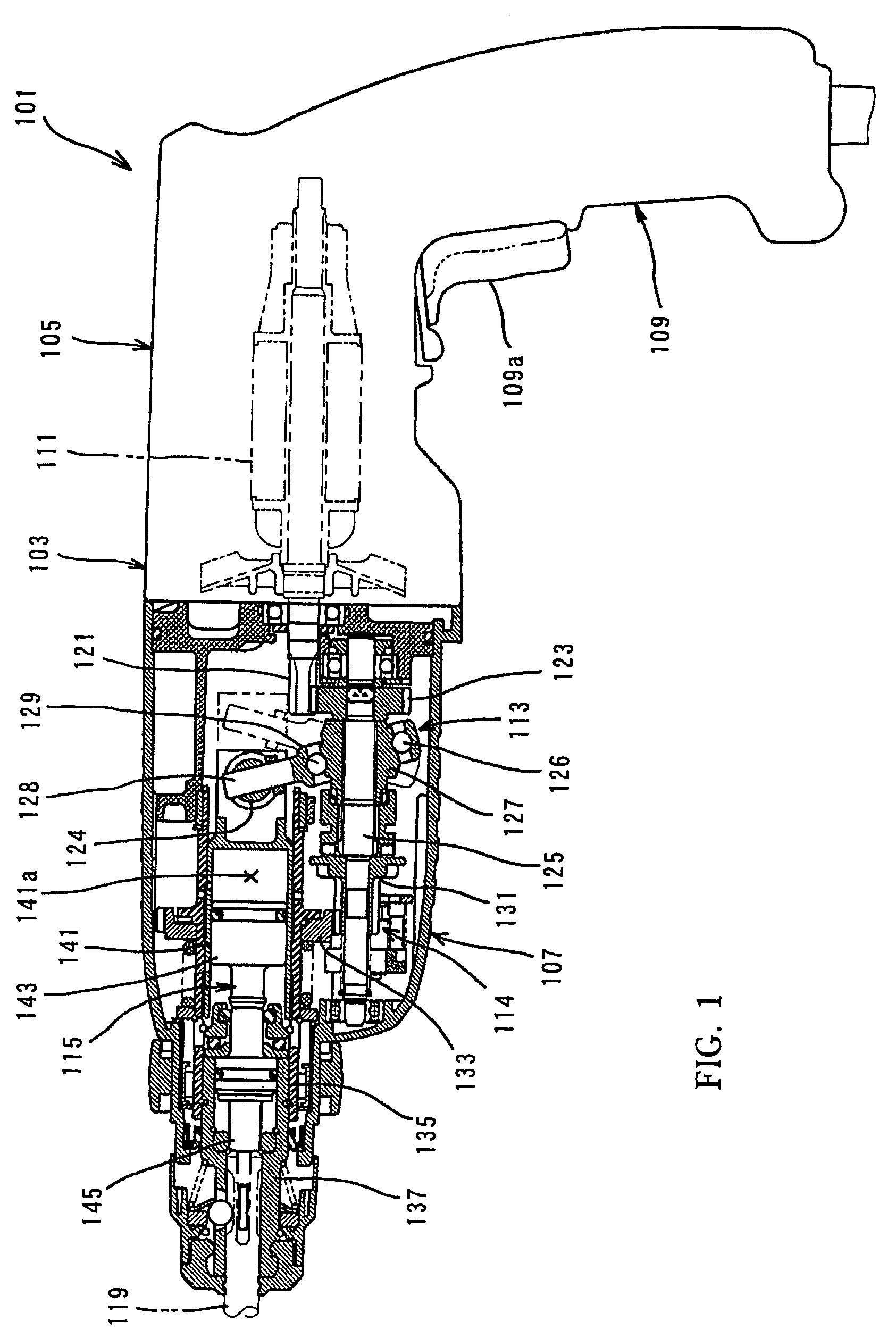

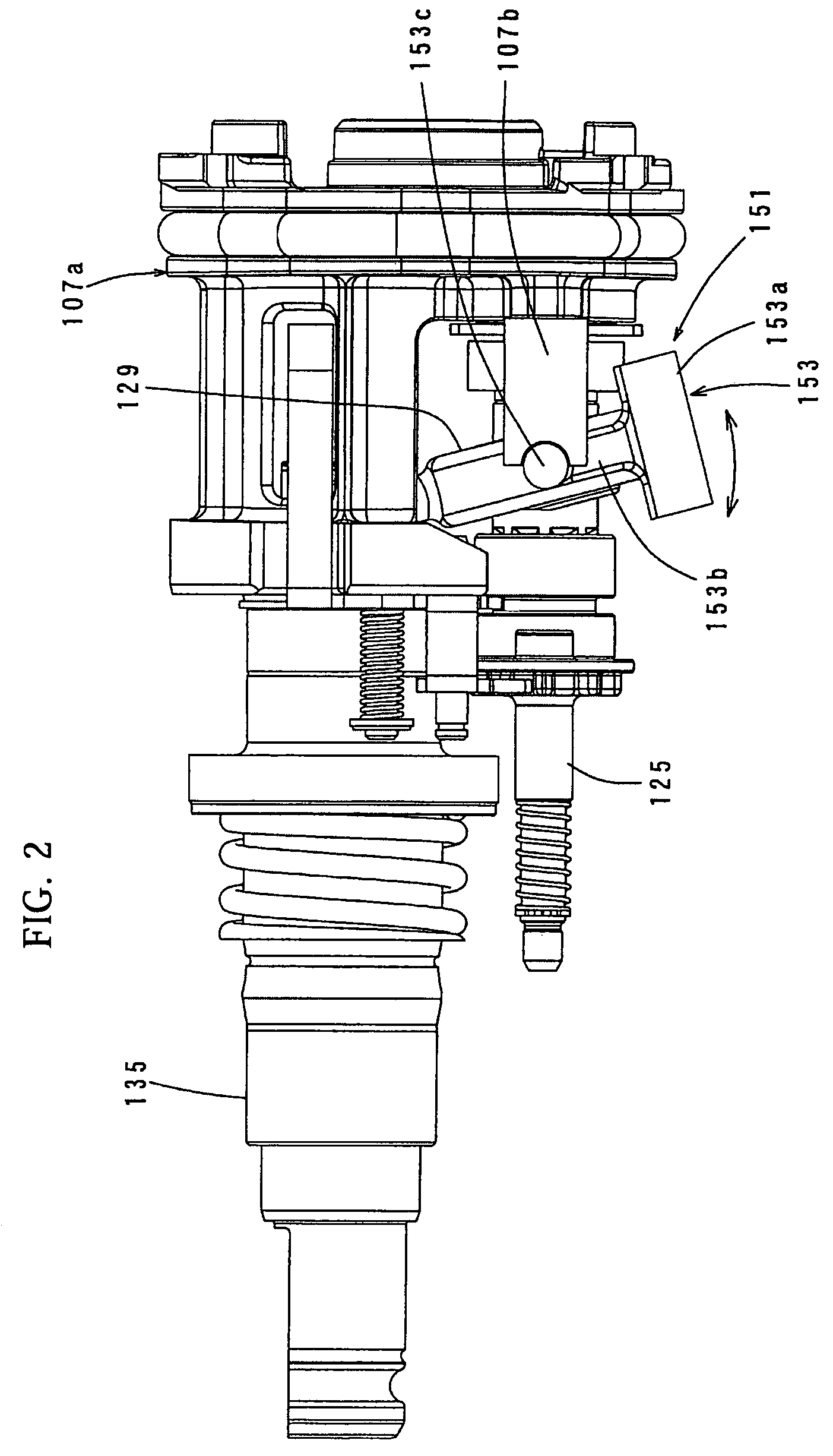

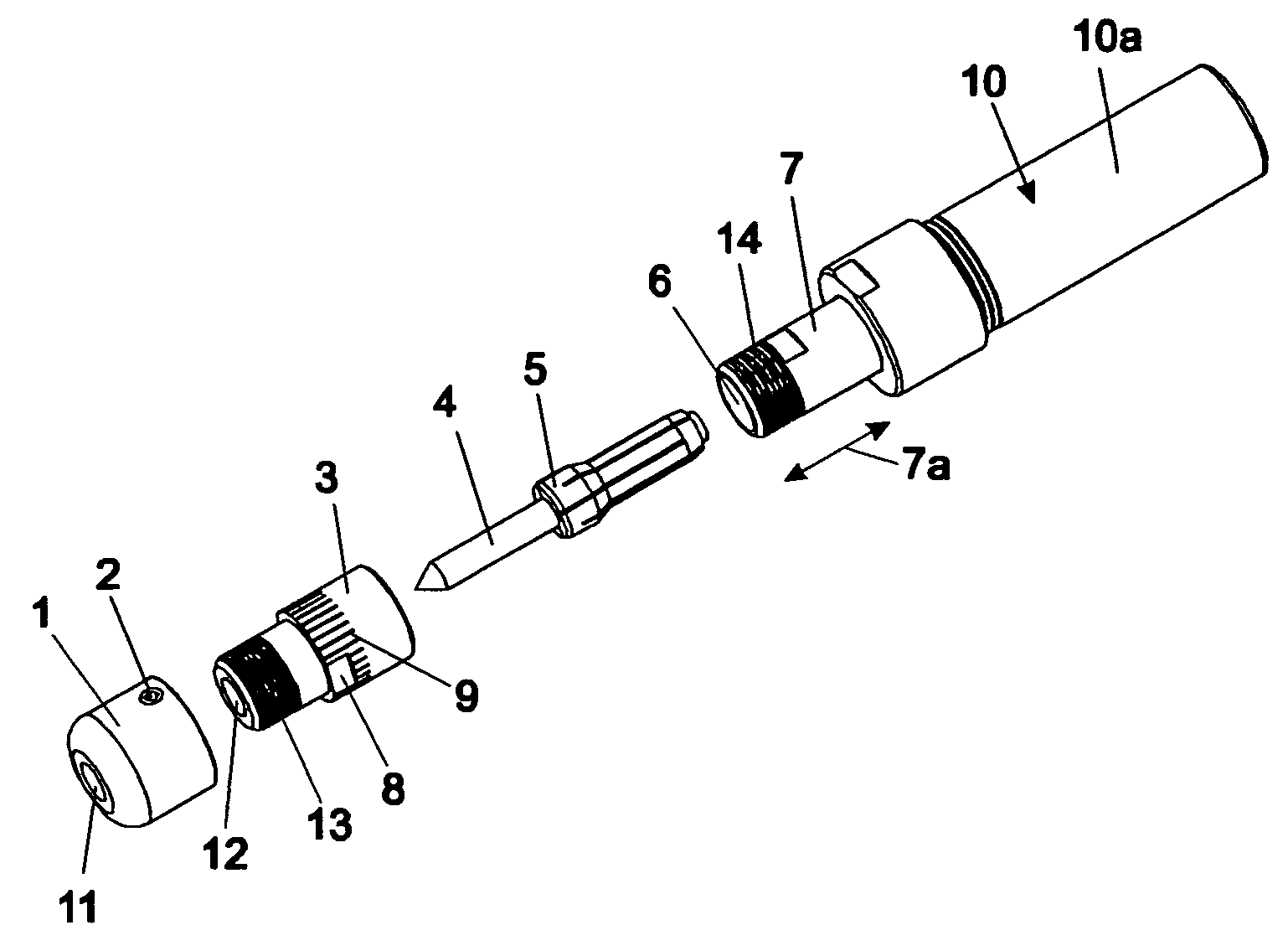

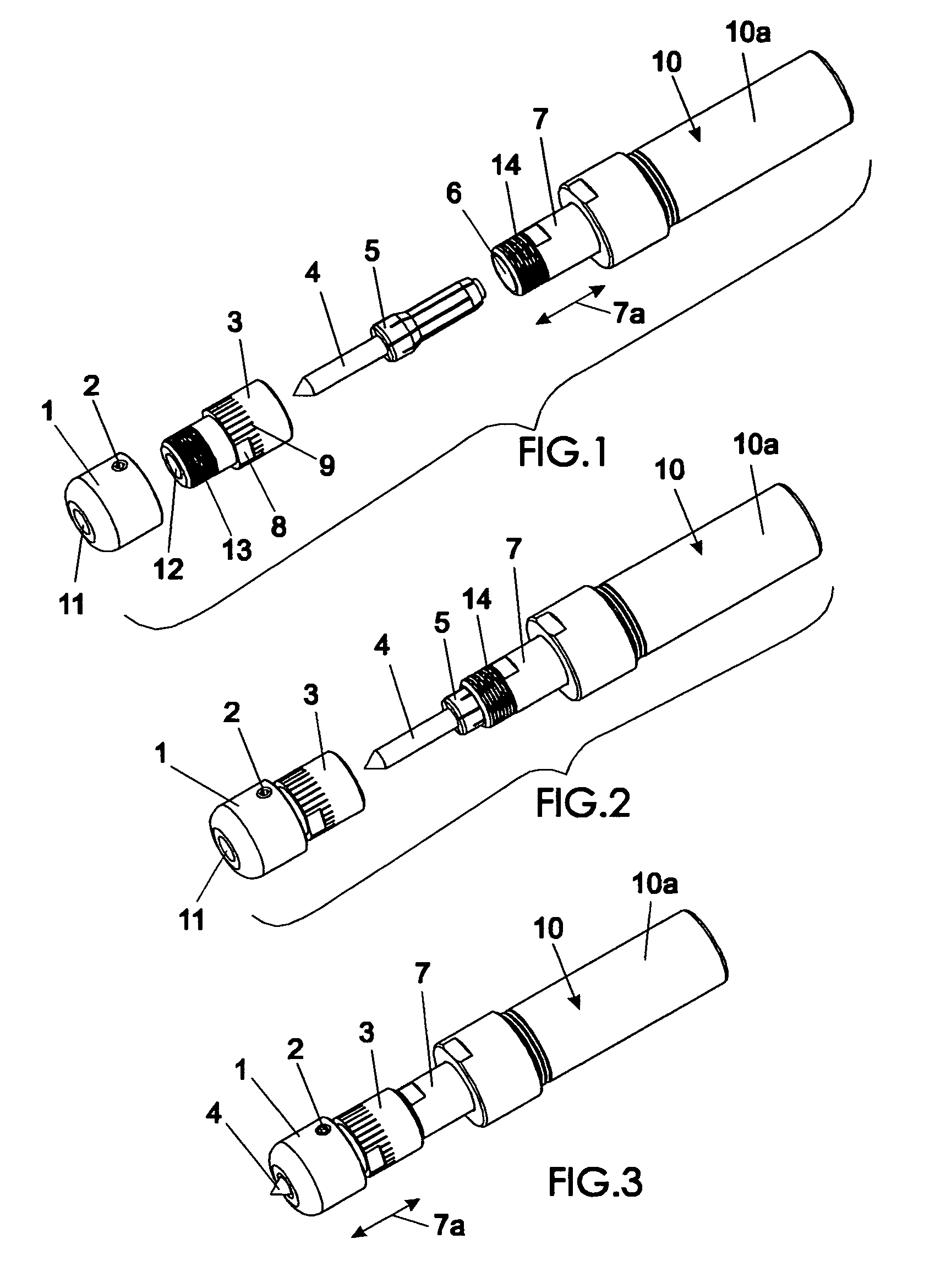

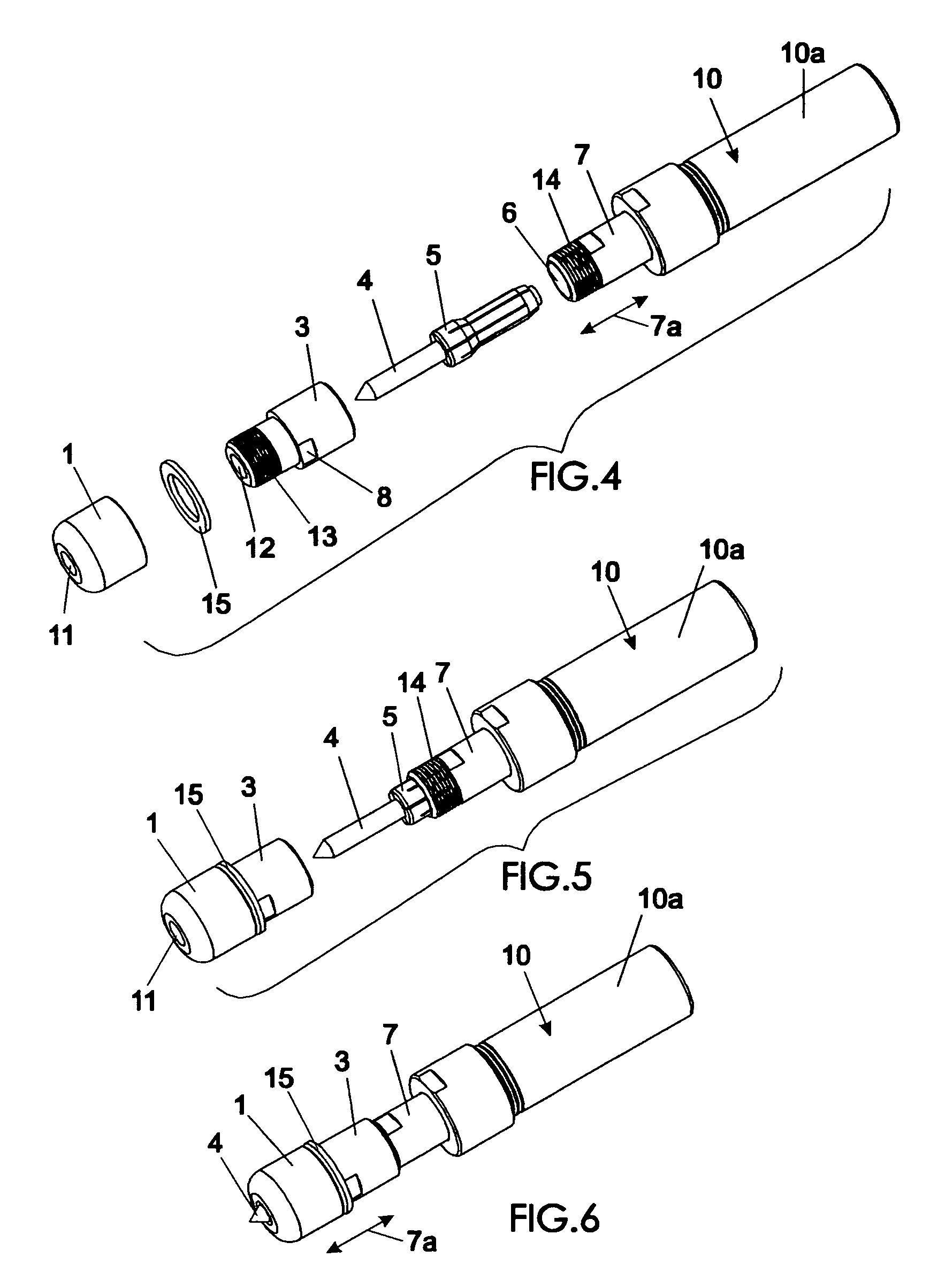

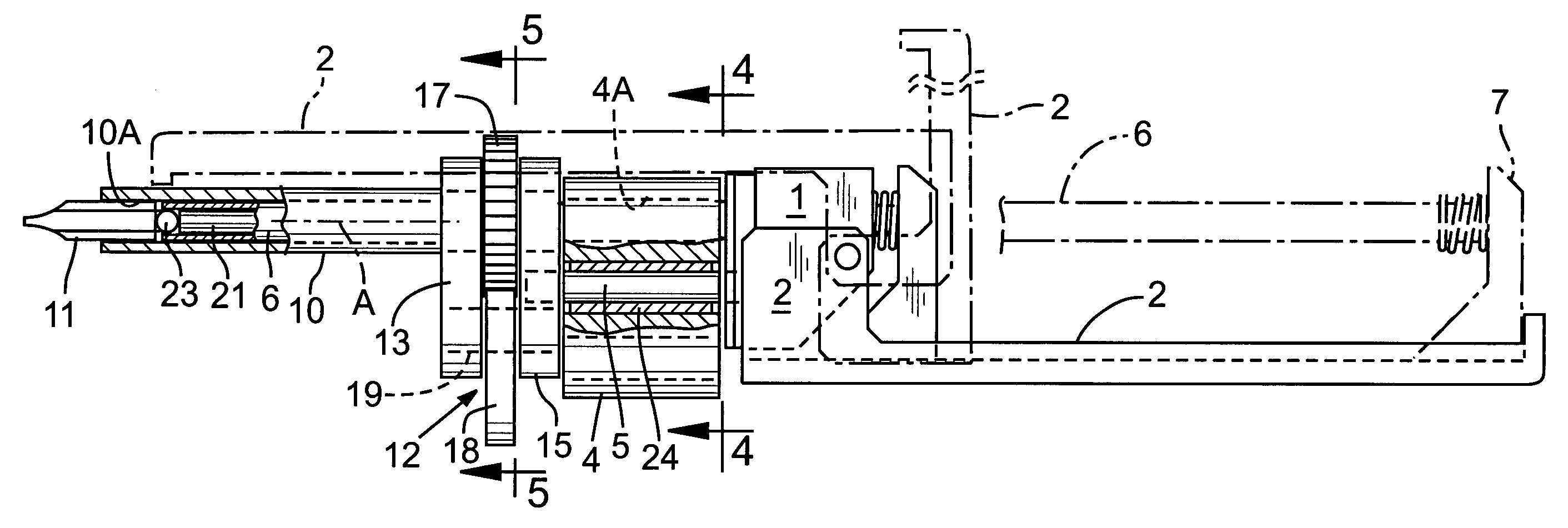

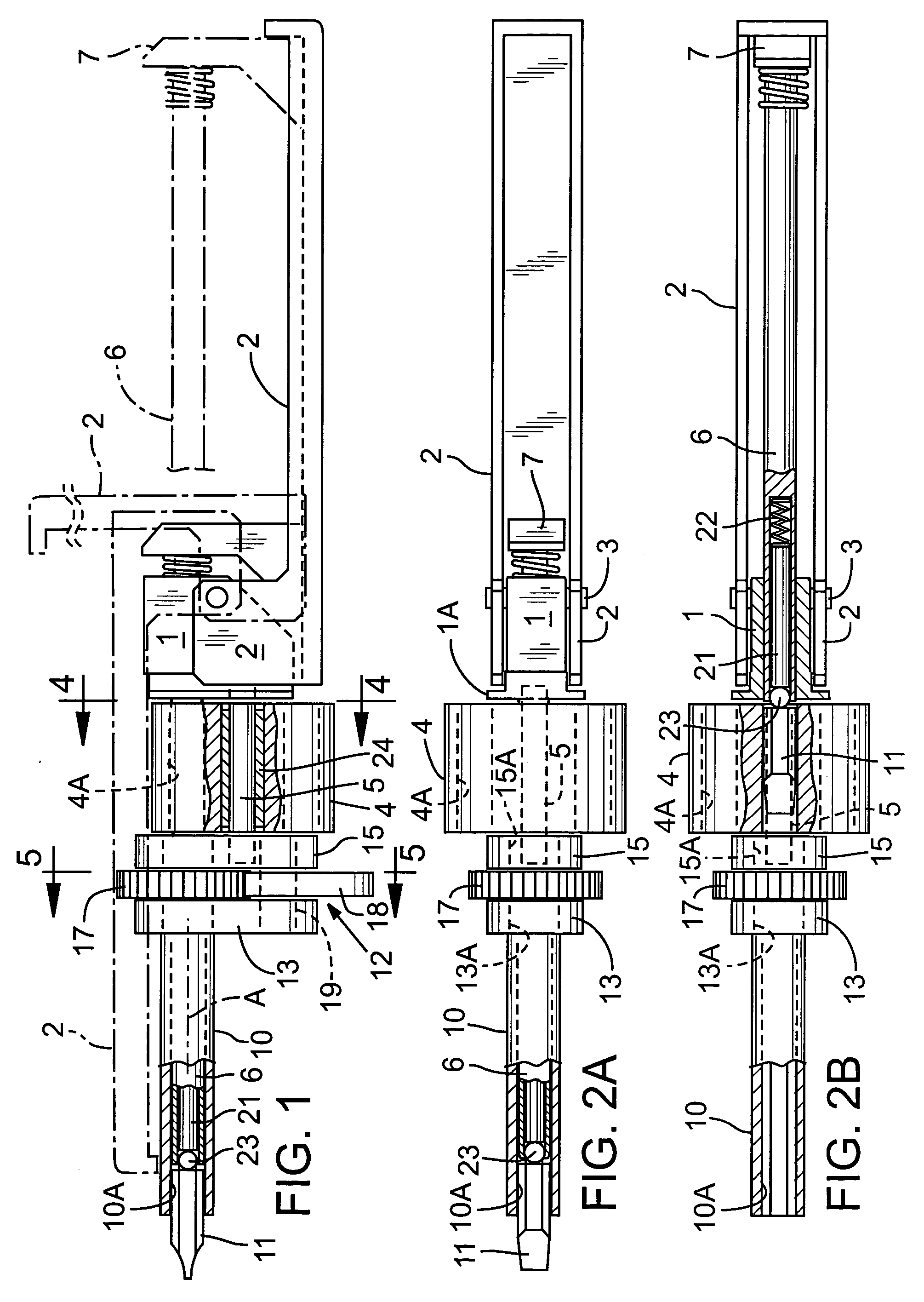

Tool holding mechanism for a motor driven surgical instrument

InactiveUSRE37358E1Eliminate usePrevent rotationSleeve/socket jointsWood turning toolsTool bitMotor drive

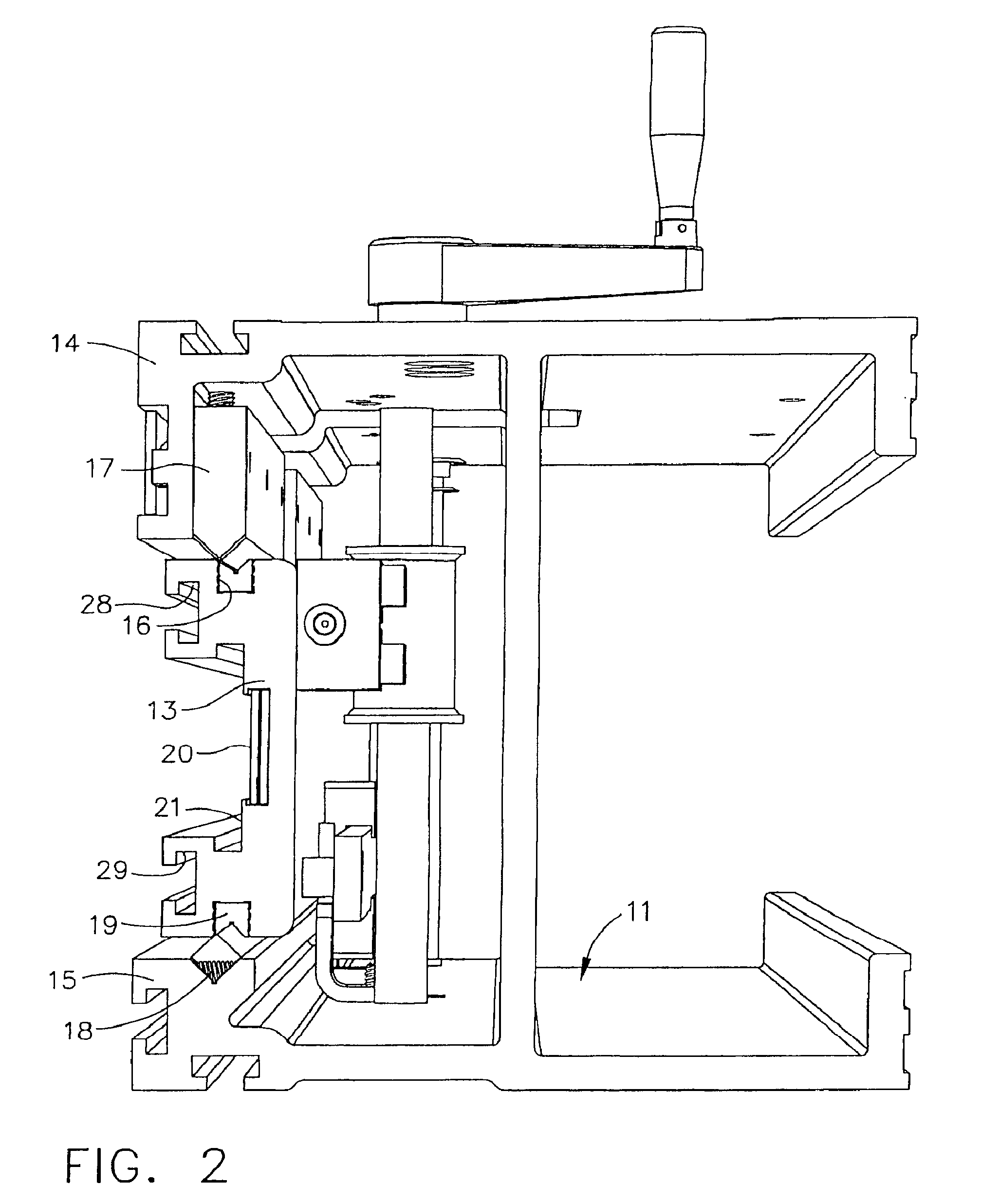

A surgical instrument has a housing which contains a motor that drives a spindle. A tool bit is attached to the motor by a holder that includes a body with a first end portion connected to the spindle, a central portion with a cavity therein, and a second end portion having an aperture through which a shaft of the tool bit passes into the cavity. A pair of lock pawls are pivotally mounted in the cavity with each one having a first tab that enters a slot in the shaft when the lock pawls are in a first position to hold the tool bit in the instrument. The first tabs retract from the slot when the lock pawls are in a second position for changing the tool bit. The lock pawls have second tabs that engage a restrainer only in the second position to prevent the body from rotating. A ring extends around the body and pivots the lock pawls between the first and second positions when the ring moved longitudinally along the body. A manually operable shift lever is pivotally coupled to the housing and move the ring longitudinally along the body.

Owner:ANSPACH EFFORT

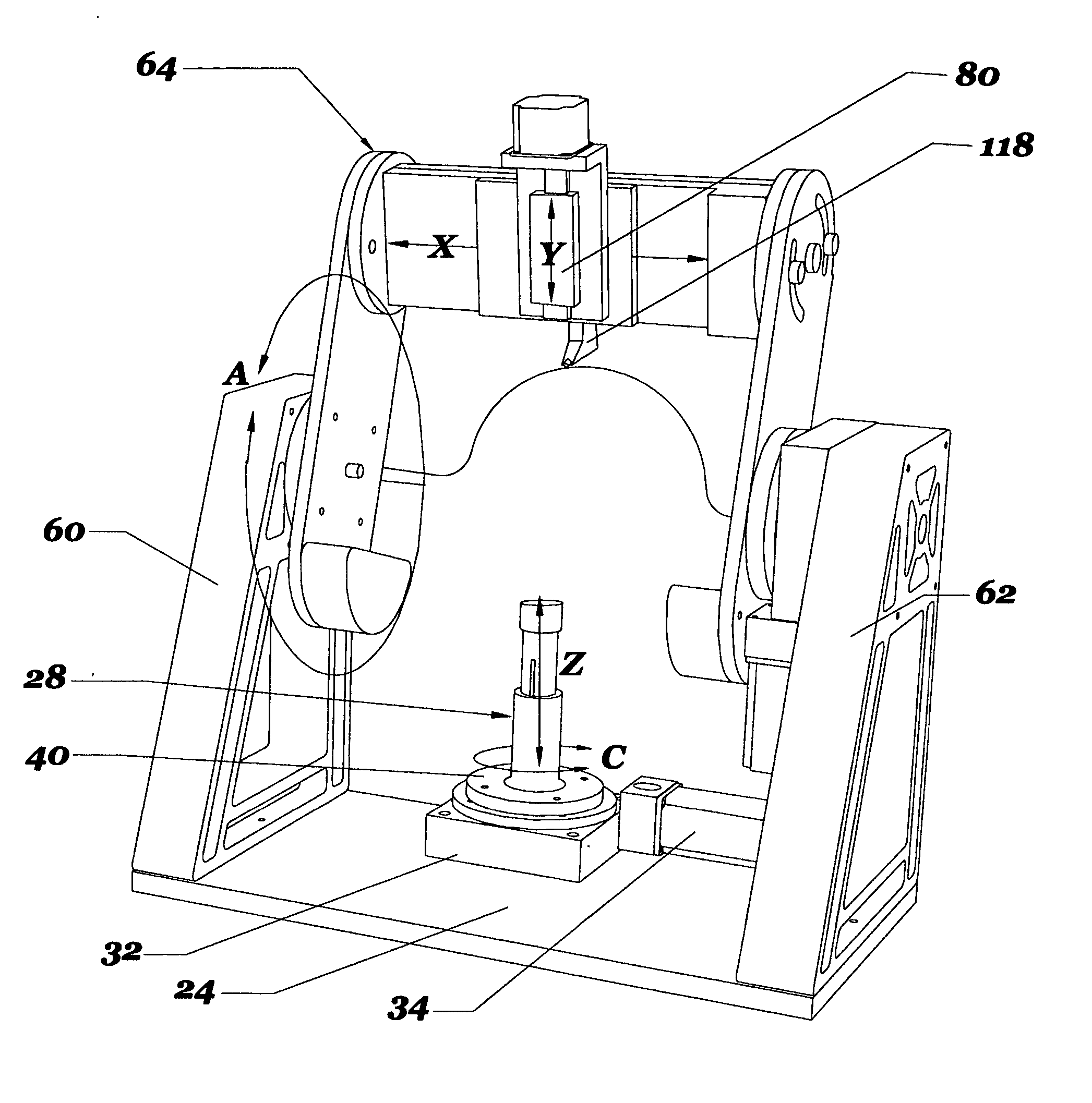

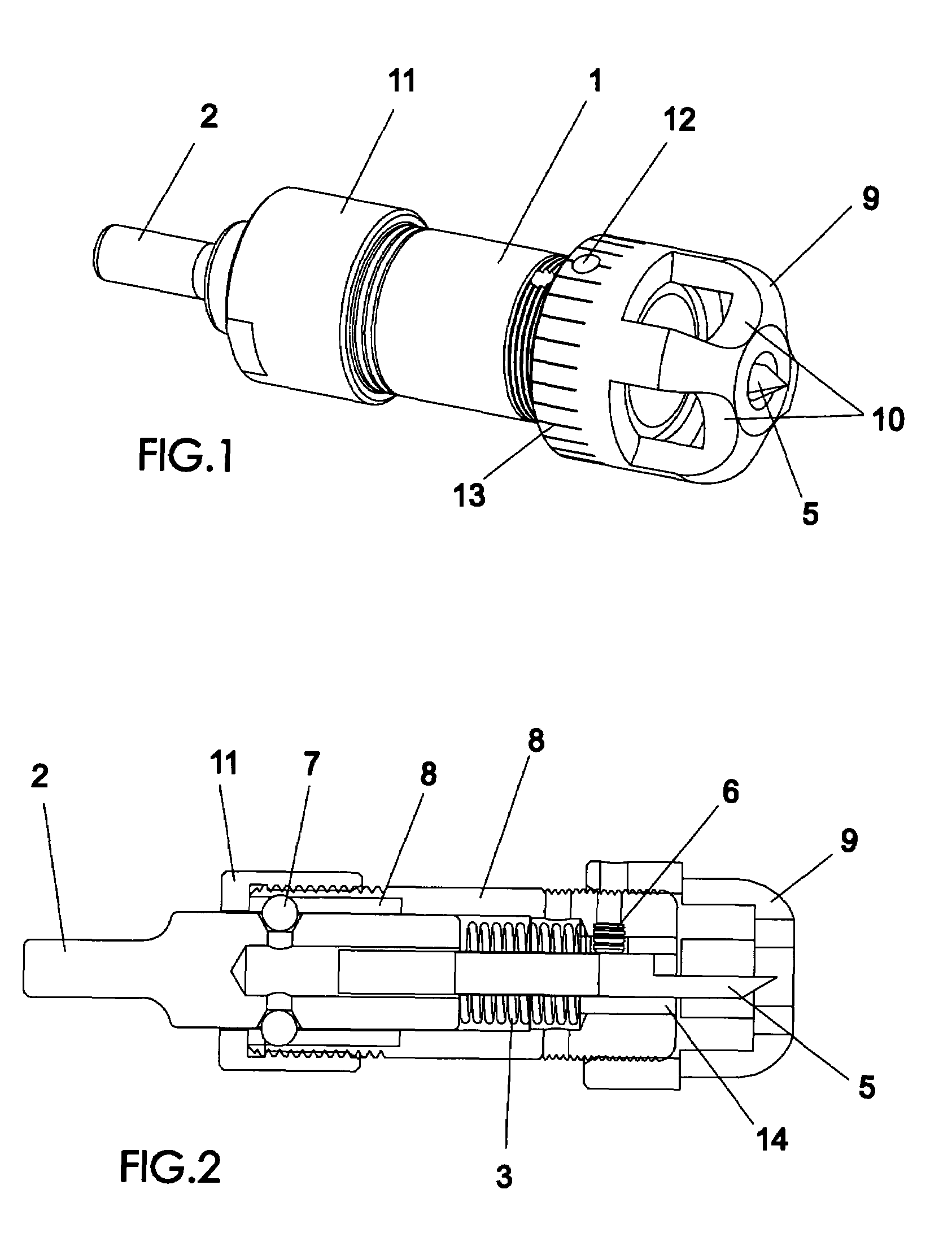

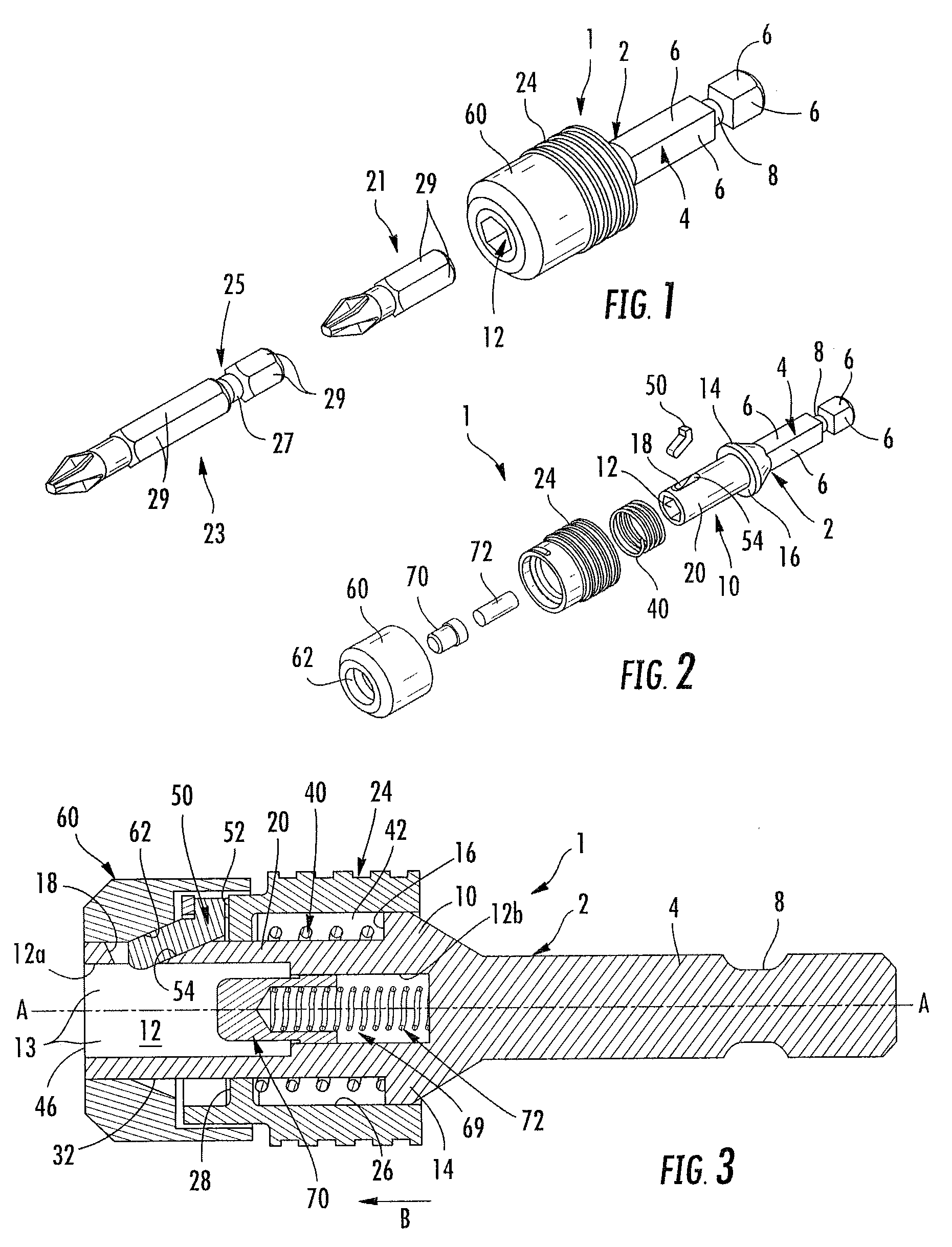

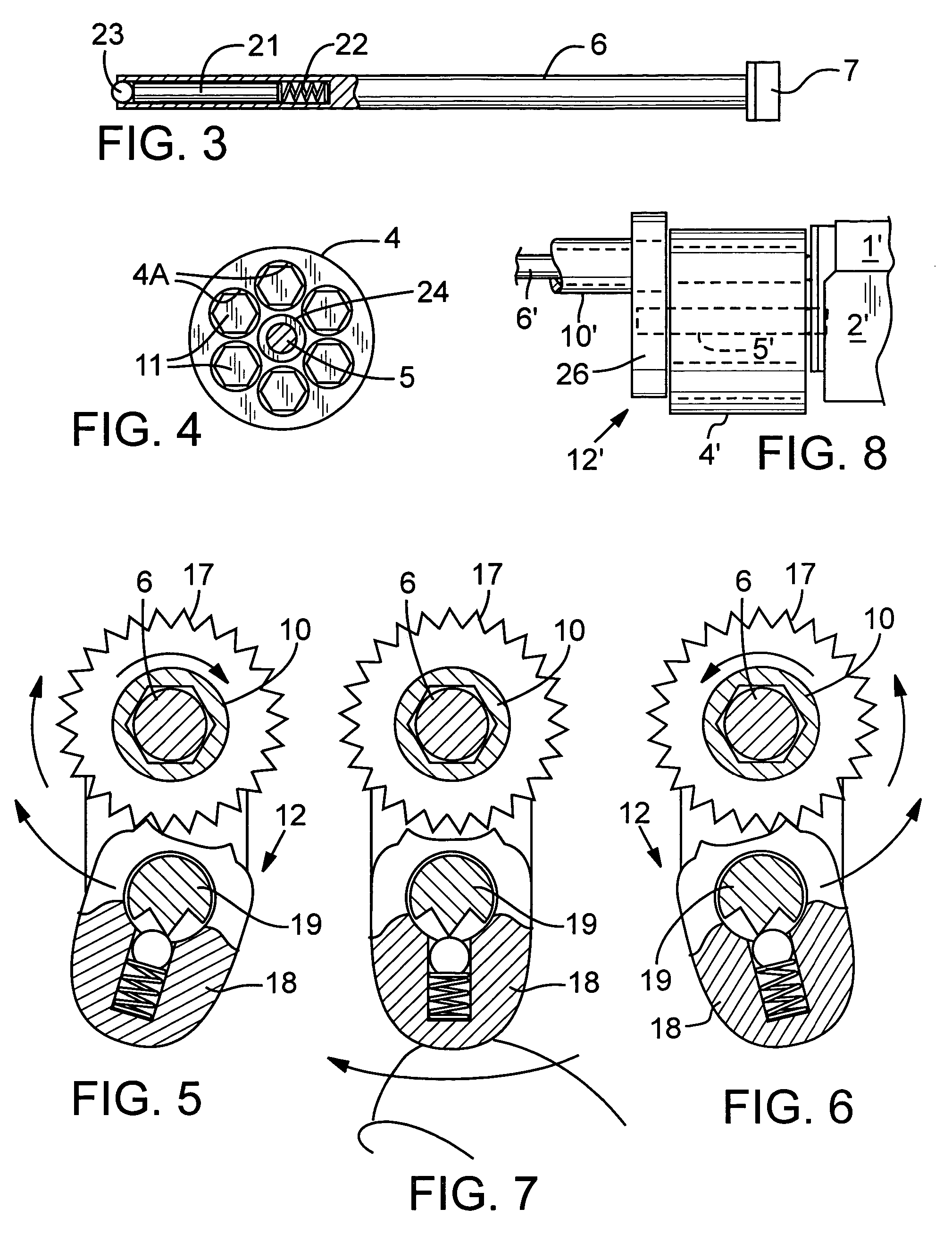

Quick-acting tool bit holder

InactiveUS7086813B1Minimize off-axis “ cocking ”Prevent over-retractionThread cutting machinesTransportation and packagingTool bitCoil spring

A “snap-in” bit chuck assembly for a rotary hand or powered tool, includes an elongated body having a hex shank at its rearward end, an elongated retraction collar slidably disposed on the body, and an outer retaining collar fixed to the forward end of the body. The body has a coaxial hex socket formed therein to allow a reversible tool to be inserted thereinto. A slot is formed in the body, between the outer surface of the body and the internal hex socket. A coil spring surrounds the body, inside the retraction collar, and normally biases the retraction collar forwardly and biases a retaining clip toward the bottom of the angular slot. The retaining clip slides outwardly in the angular slot, against the bias of the coil spring, as the reversible tool is inserted, where a recess on the reversible tool is engaged and retained by the clip. The tool is removed by sliding the retraction collar rearwardly, to compress the coil spring and allow the retaining clip to retract back up the slot. The clip is directly engaged by the coil spring and has two legs extending about the body so that the clip is self-retaining. The clip legs extend around the body such that the retraction force on the coil spring is directed through the center of the coil spring to keep it coaxially aligned with the body.

Owner:BLACK & DECKER INC

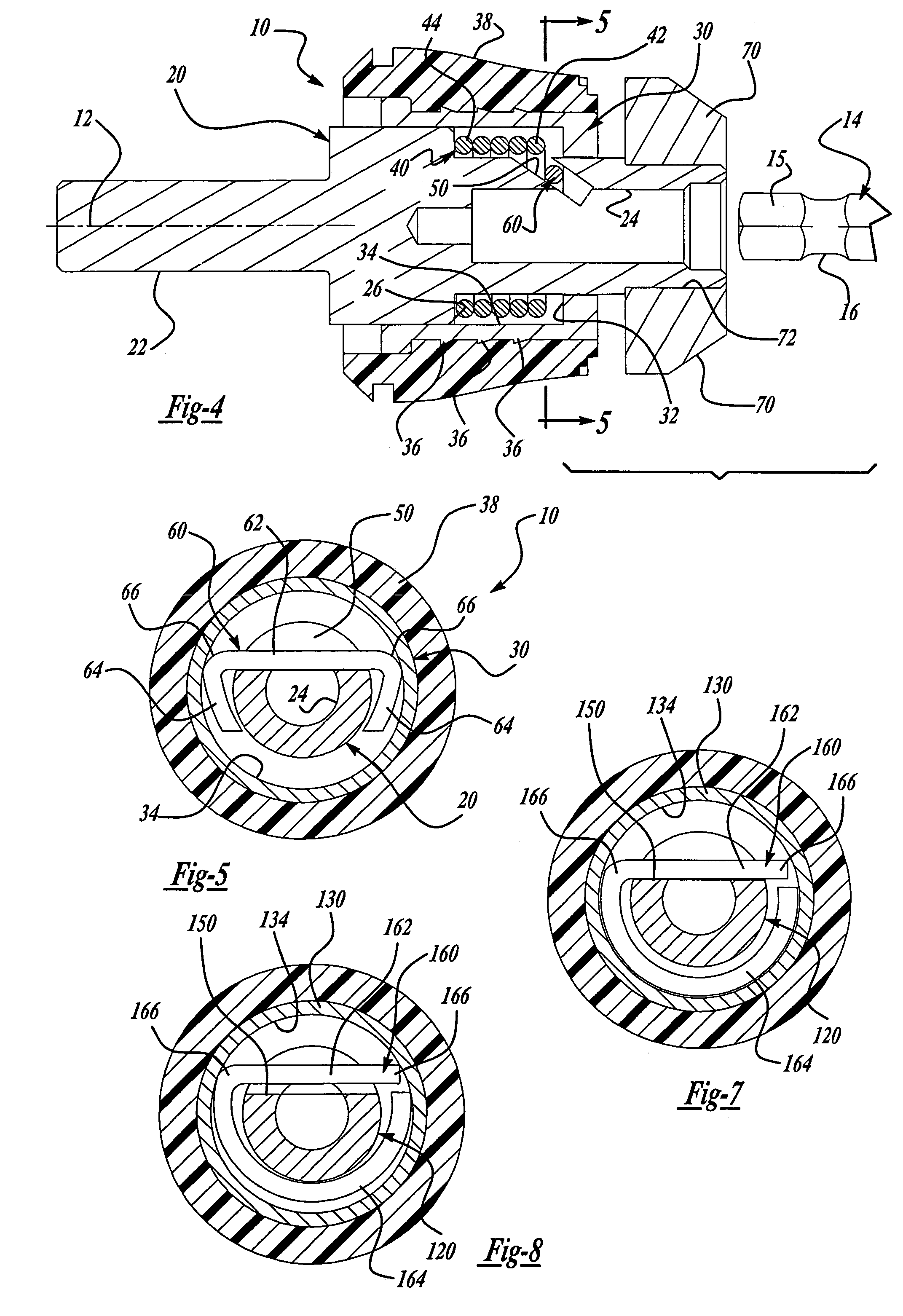

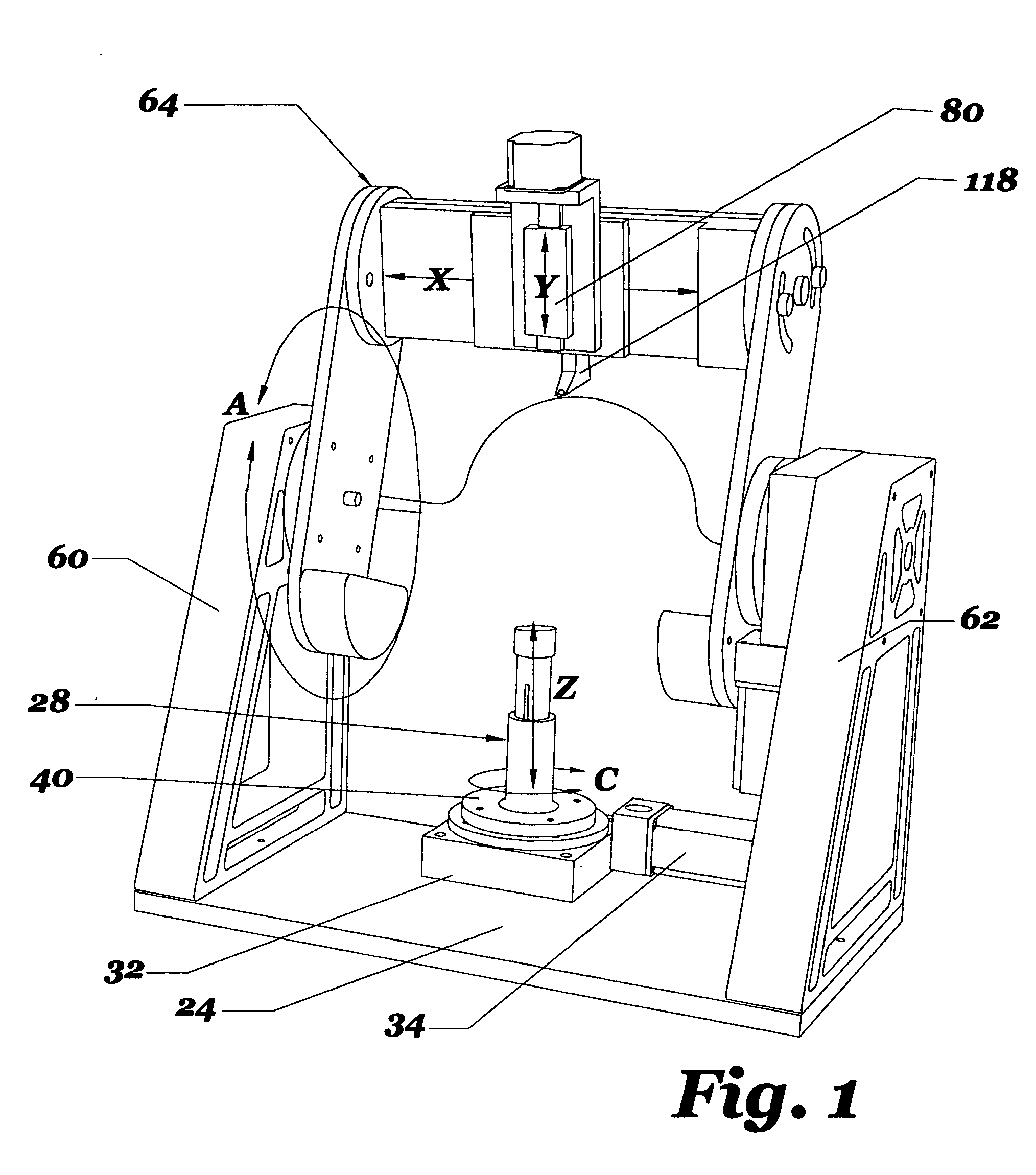

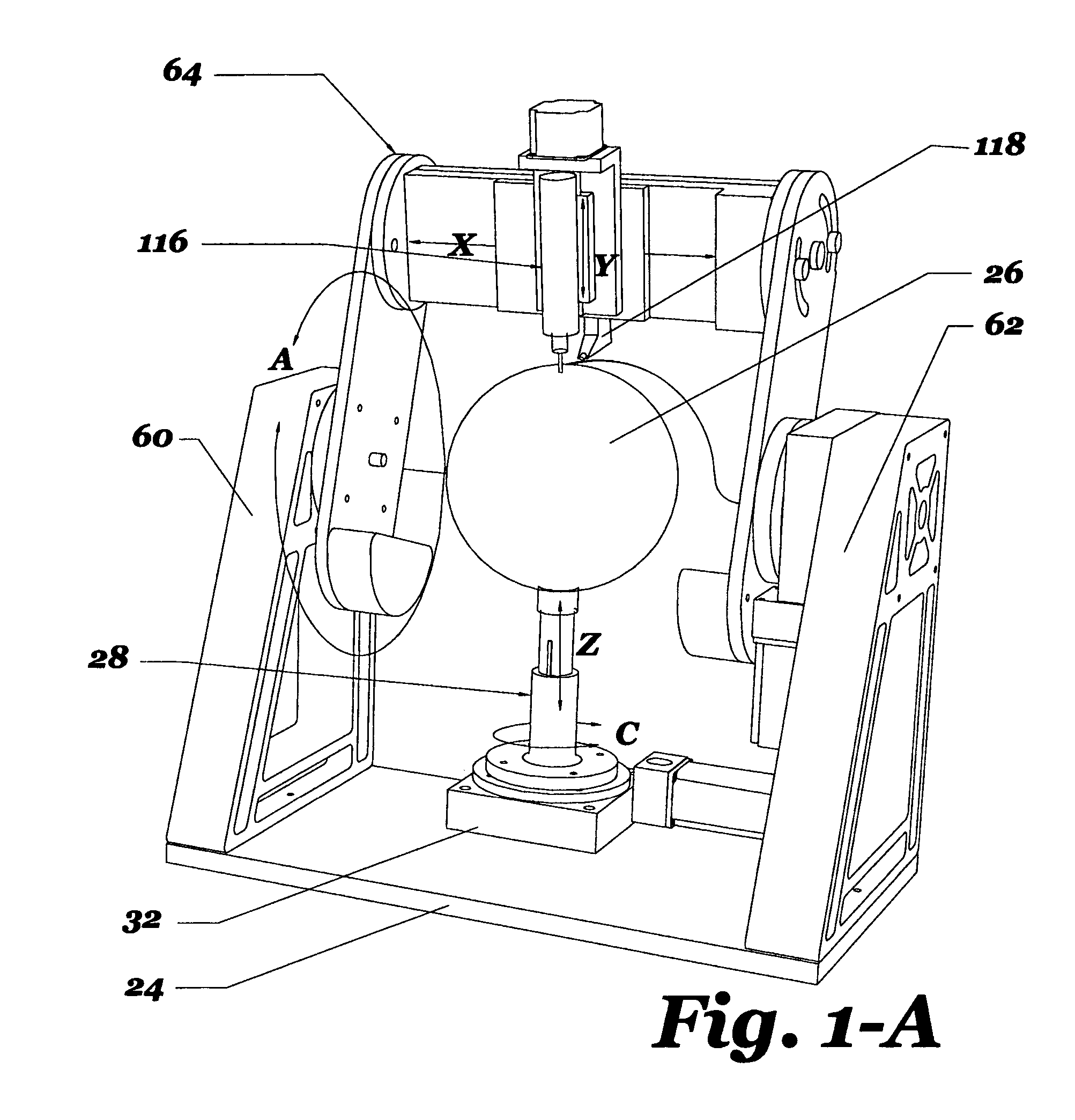

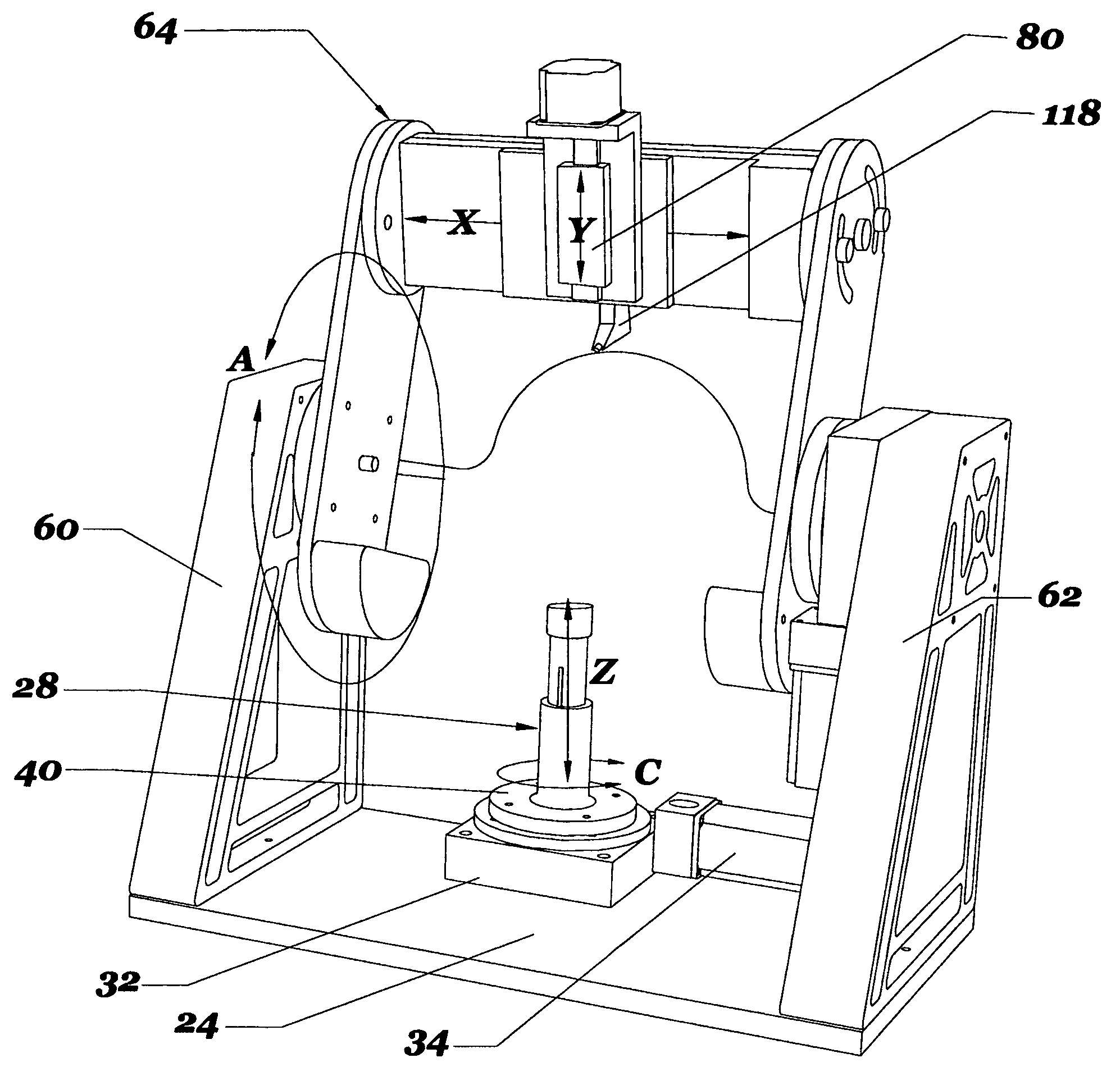

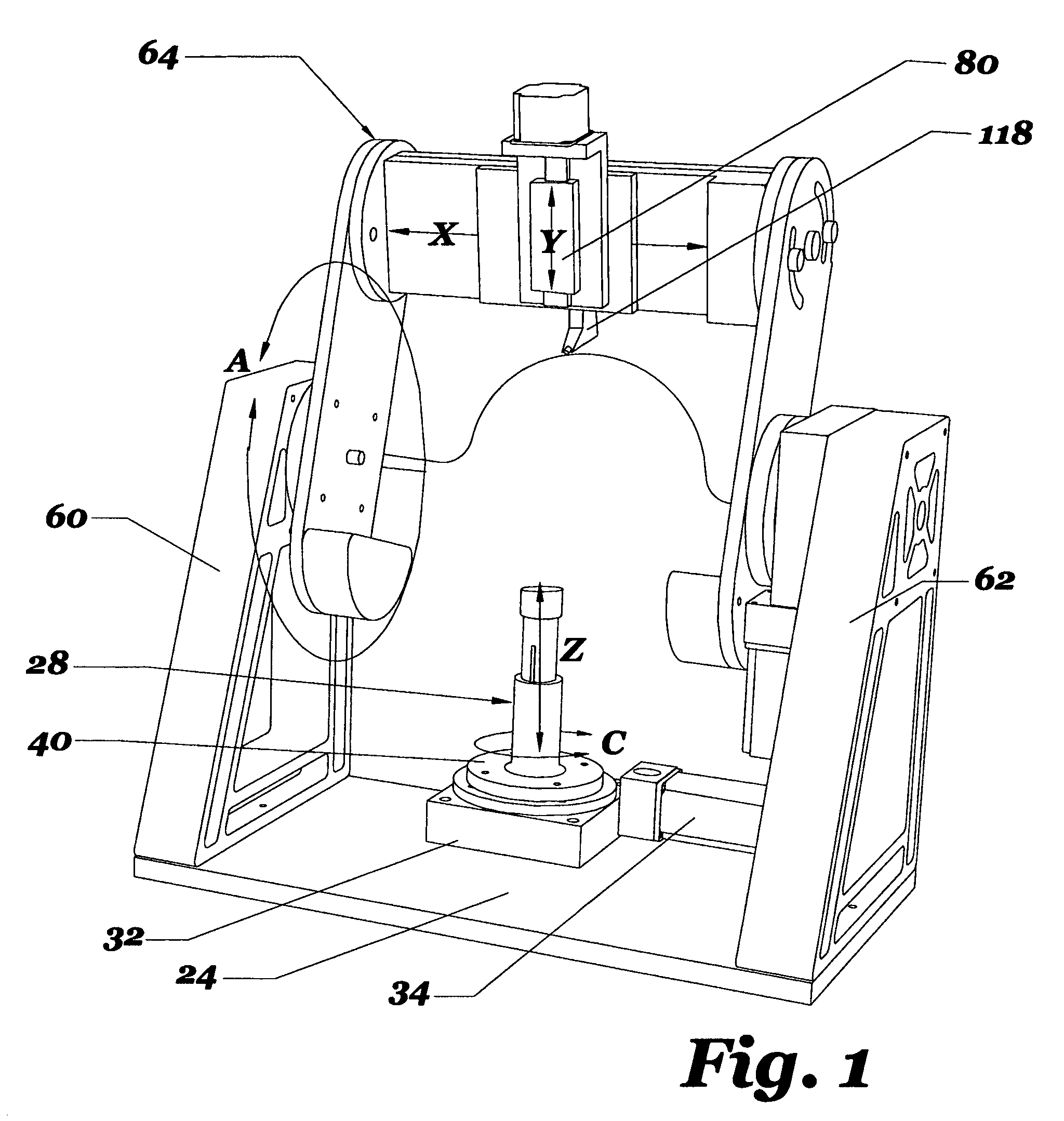

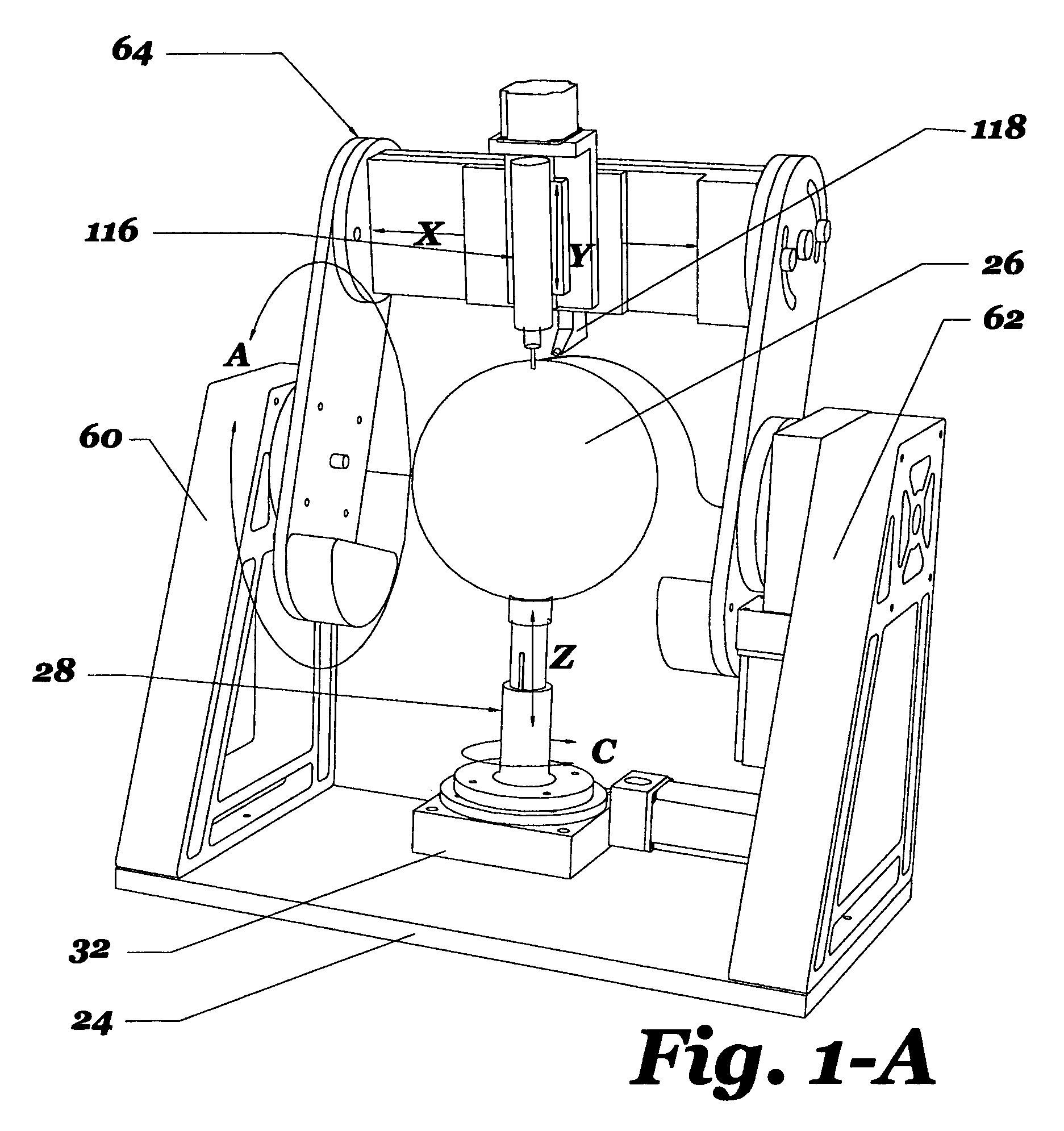

Multi-axis, processor-controlled, toolhead positioner

InactiveUS20060242818A1Programme-controlled manipulatorPlaning/slotting machinesRotational axisEngineering

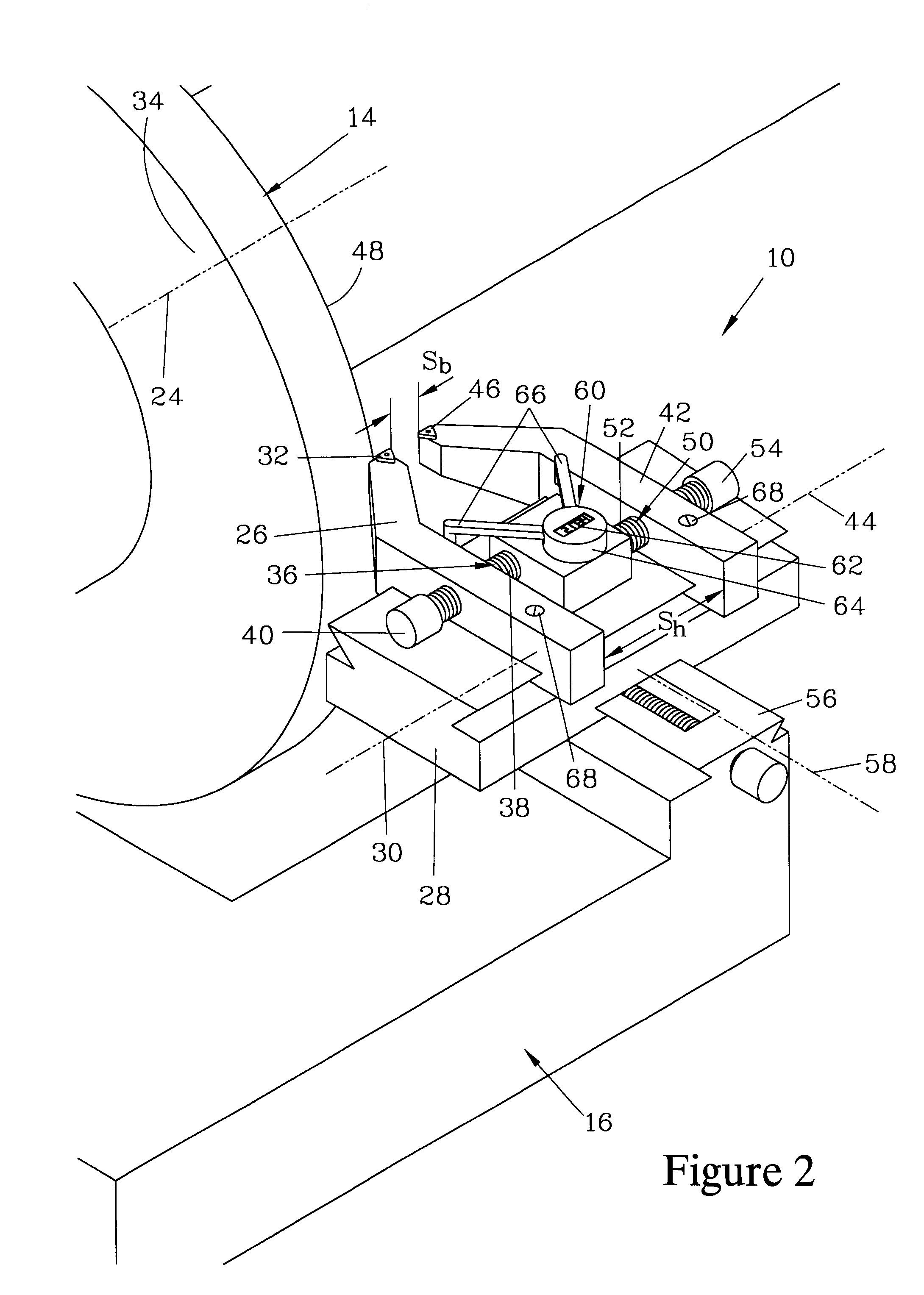

A multi-axis, computerized numerically-controlled (CNC) toolhead positioning device with six degrees of freedom of movement while utilizing only five axes of movement, comprising a rotating workpiece mount assembly (28) and a rotating gantry (64) with a mounted toolhead assembly base (80). Perpendicular rotational axes about a mounted workpiece (26) provide the capability to perform specific toolhead operations on the arcuate surface of the workpiece (26), subject to the type of mounted toolhead assembly. The computer (120) uses CNC software to integrate operator instructions, machining operations, and the sequence of operations into an automatic and coherent machining package.

Owner:PRECISION SPHERICAL

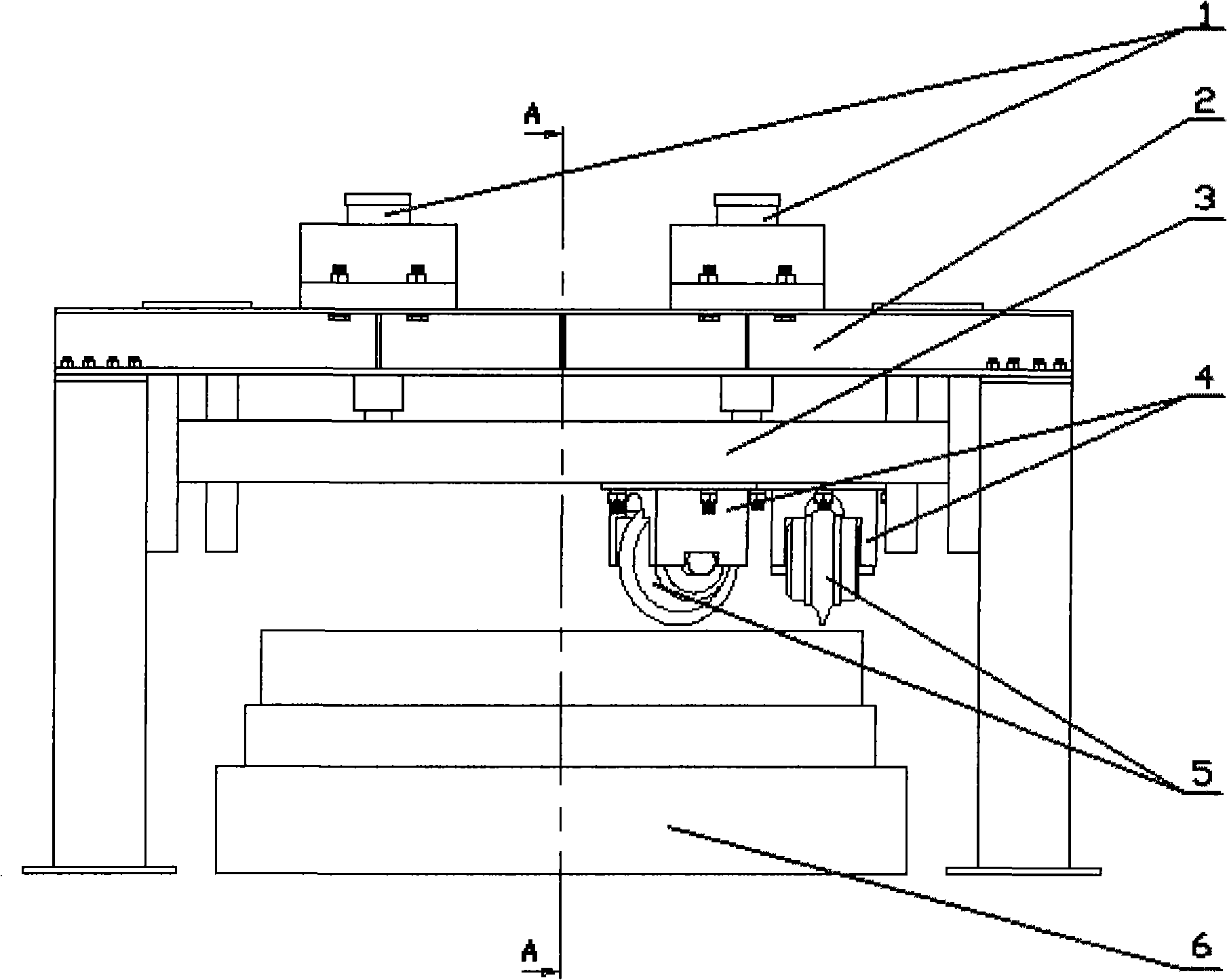

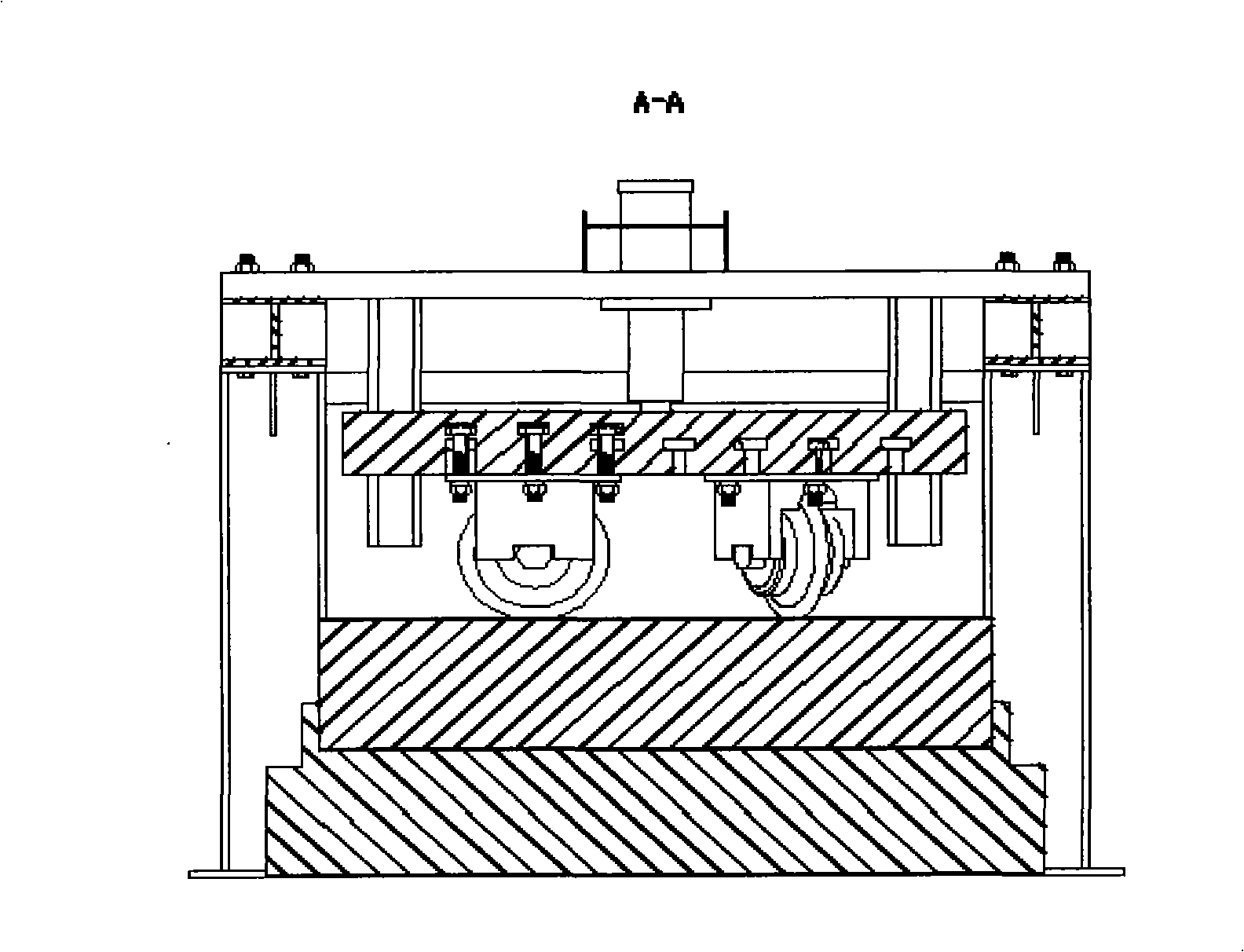

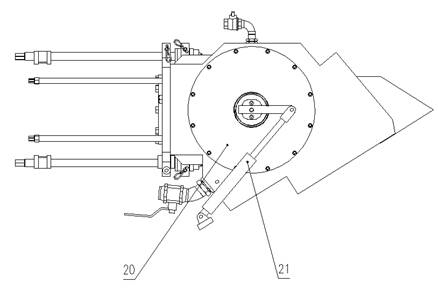

Tool bit rock breaking mechanism and abrasion tester

InactiveCN101299013AIdea novel scienceFunction increaseInvestigating abrasion/wear resistanceInvestigating machinabilityTool bitHydraulic cylinder

The present invention provides a cutter rock-breaking mechanism which is applied in the technical field of the cutter experiment and an abrasion resistant tester thereof. The abrasion resistant tester comprises a hydraulic cylinder, a structural frame, a bearing plate, a cutter support, a disc-shaped hob and a rotation worktable. When the cutter rock-breaking mechanism and the abrasion resistant tester work, the disc-shaped hob is connected with the cutter support through a bolt. The cutter support is jointed and fixed on the bearing plate through the bolts. The hydraulic cylinder exerts a certain load to impact the disc-shaped hob to the rock sample on the worktable and generate a certain penetration. Afterwards the worktable is rotated through a power system to execute cutting test to the rock passively. The cutter rock-breaking mechanism and the abrasion resistant tester execute cutting with a single cutter to do the abrasion resistance test of the cutter. The bearing plate is provided with a groove. The regulation to the cutter space and the phase angle is realized through the variation of the jointing position of the cutter support on the bearing plate. The regulation to the inner deflection angle of the cutter is realized by changing the cutter supports with different angles. The positioning and rotation of the rock are realized through the rotating worktable. The designing of the device is novel and scientific. The knife angle, phase angle and inner deflection angle which affect larger to the rock breaking and abrasion of cutter are researched. The device settles the problem that two hob cutters simultaneously cut the rock.

Owner:NORTHERN HEAVY IND GRP CO LTD

Tool head for a modular shank tool

Owner:KENNAMETAL INC

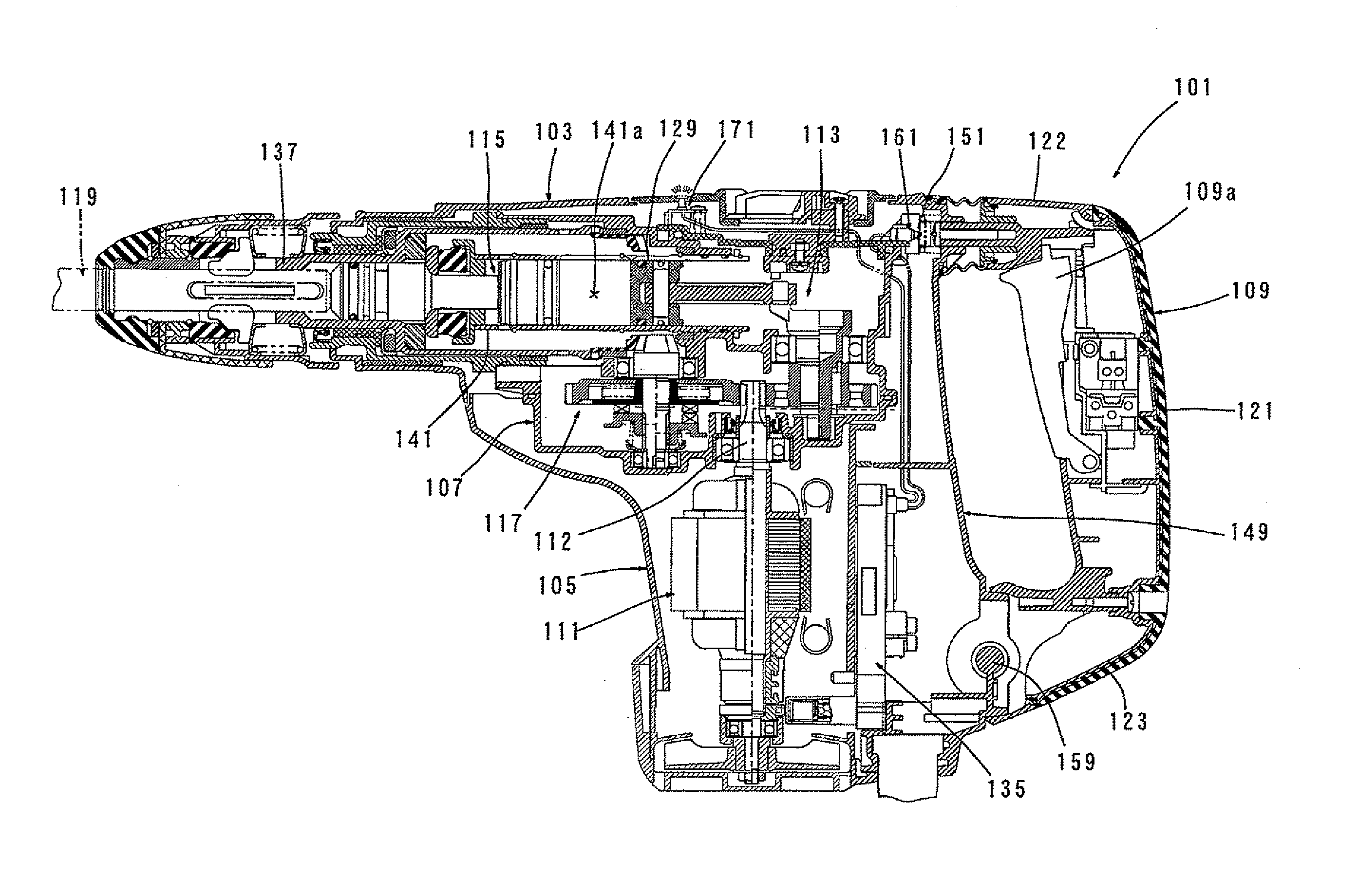

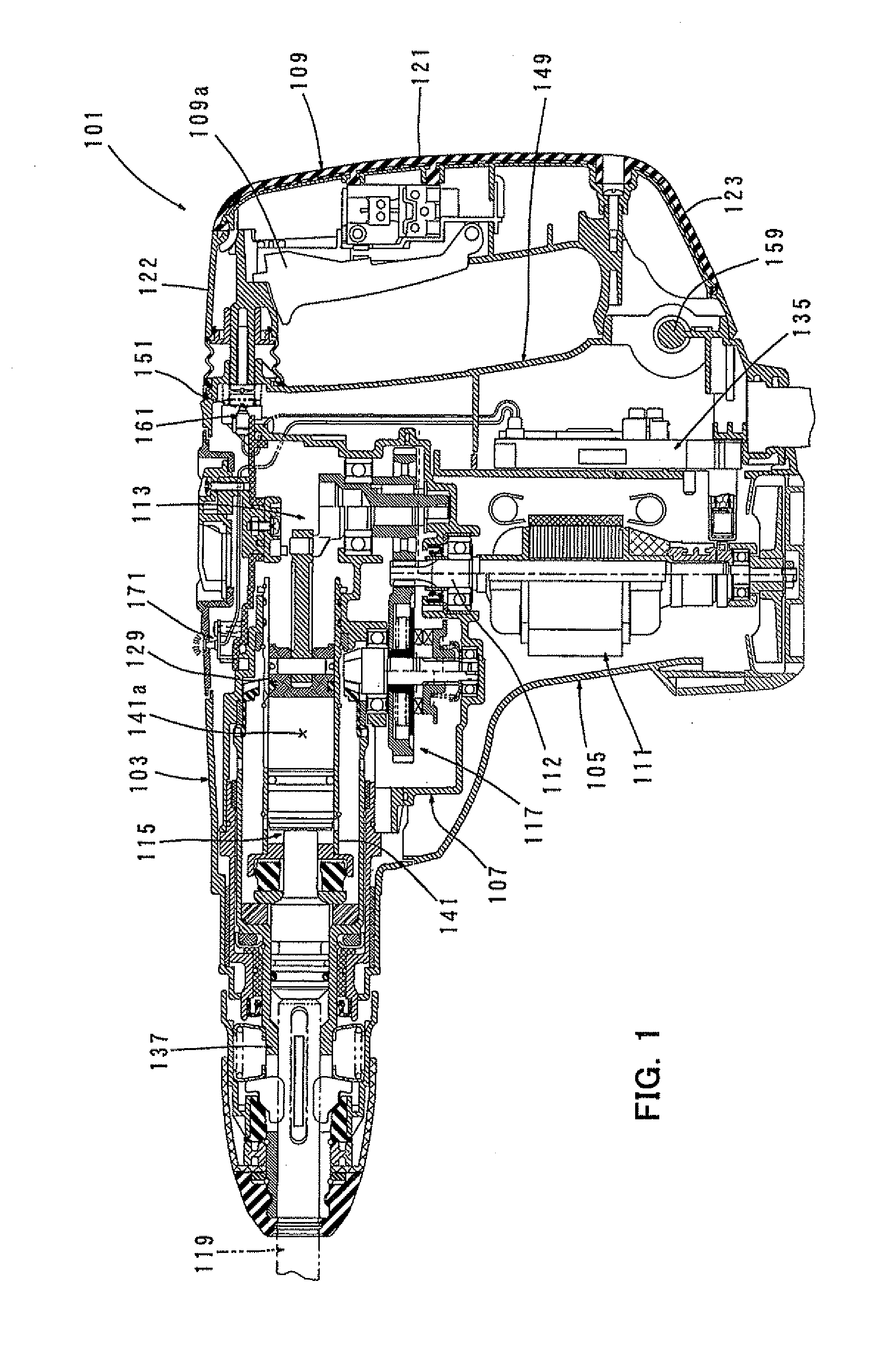

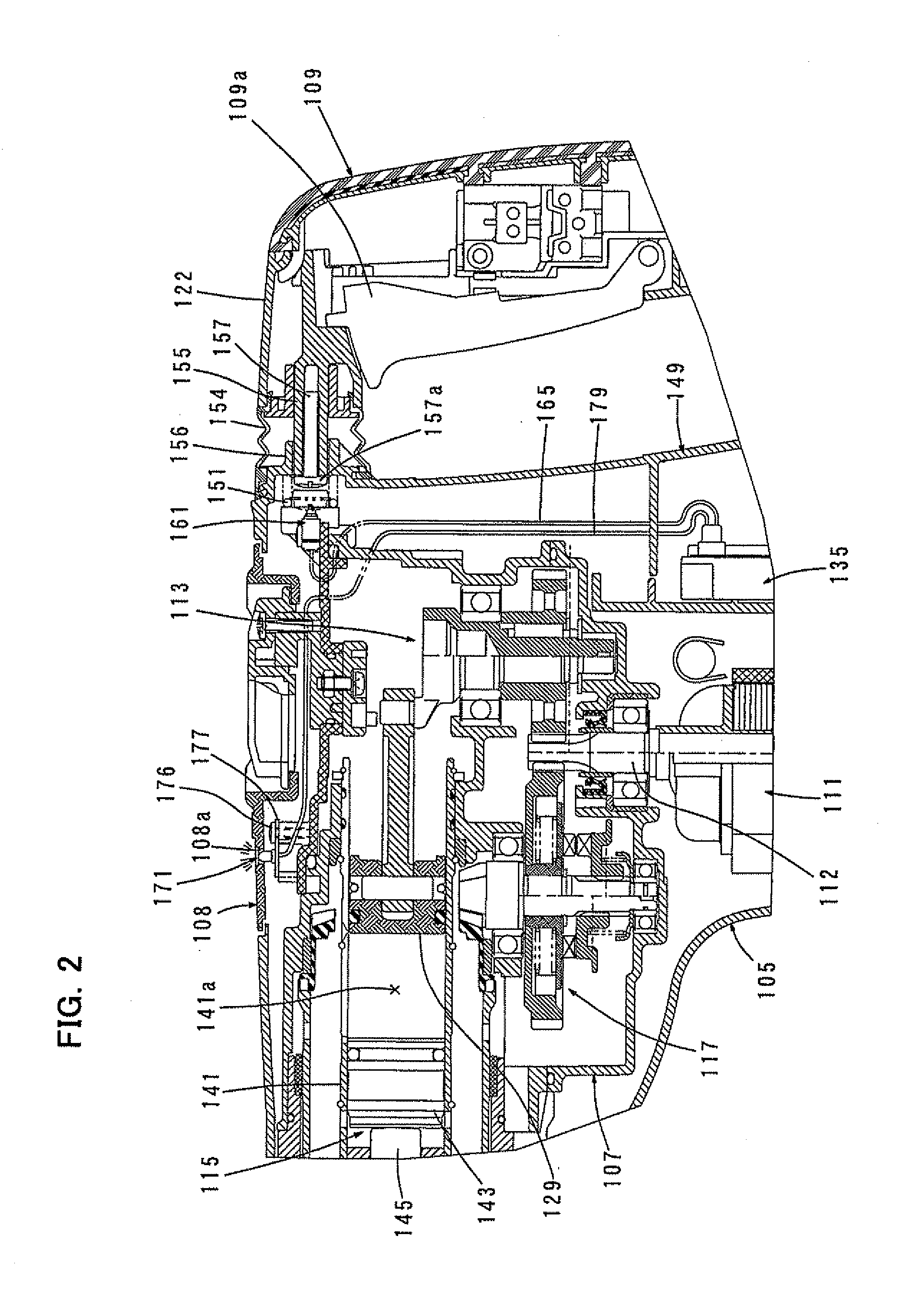

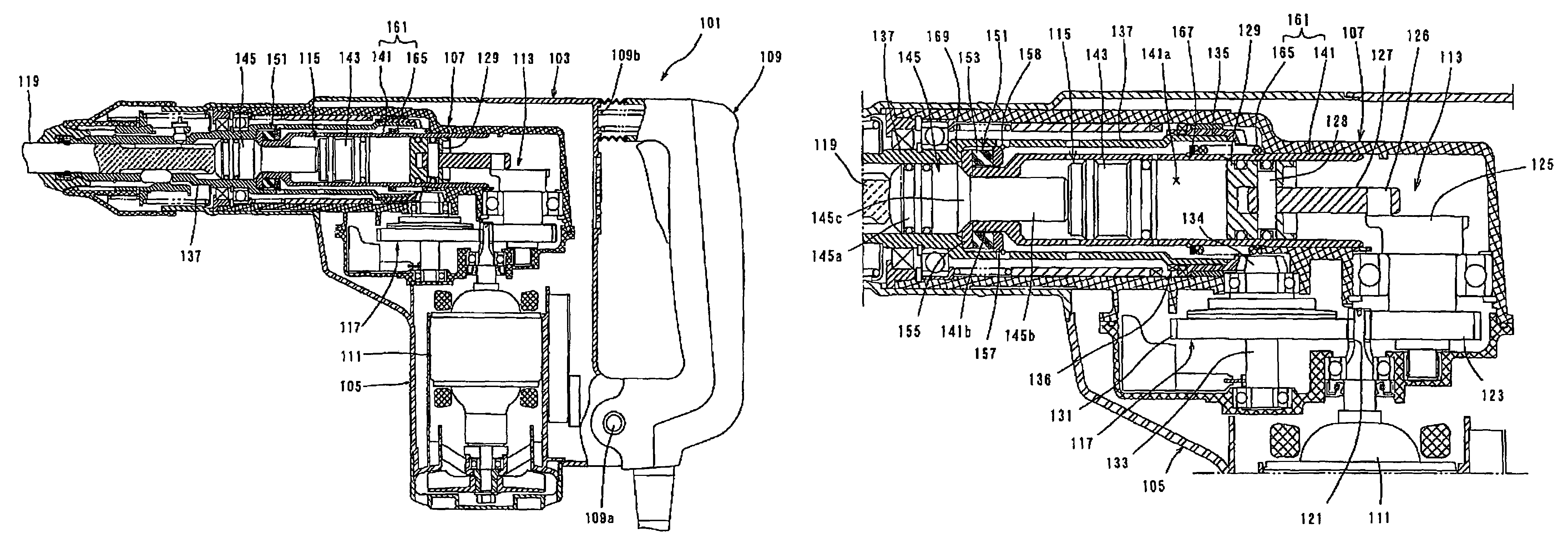

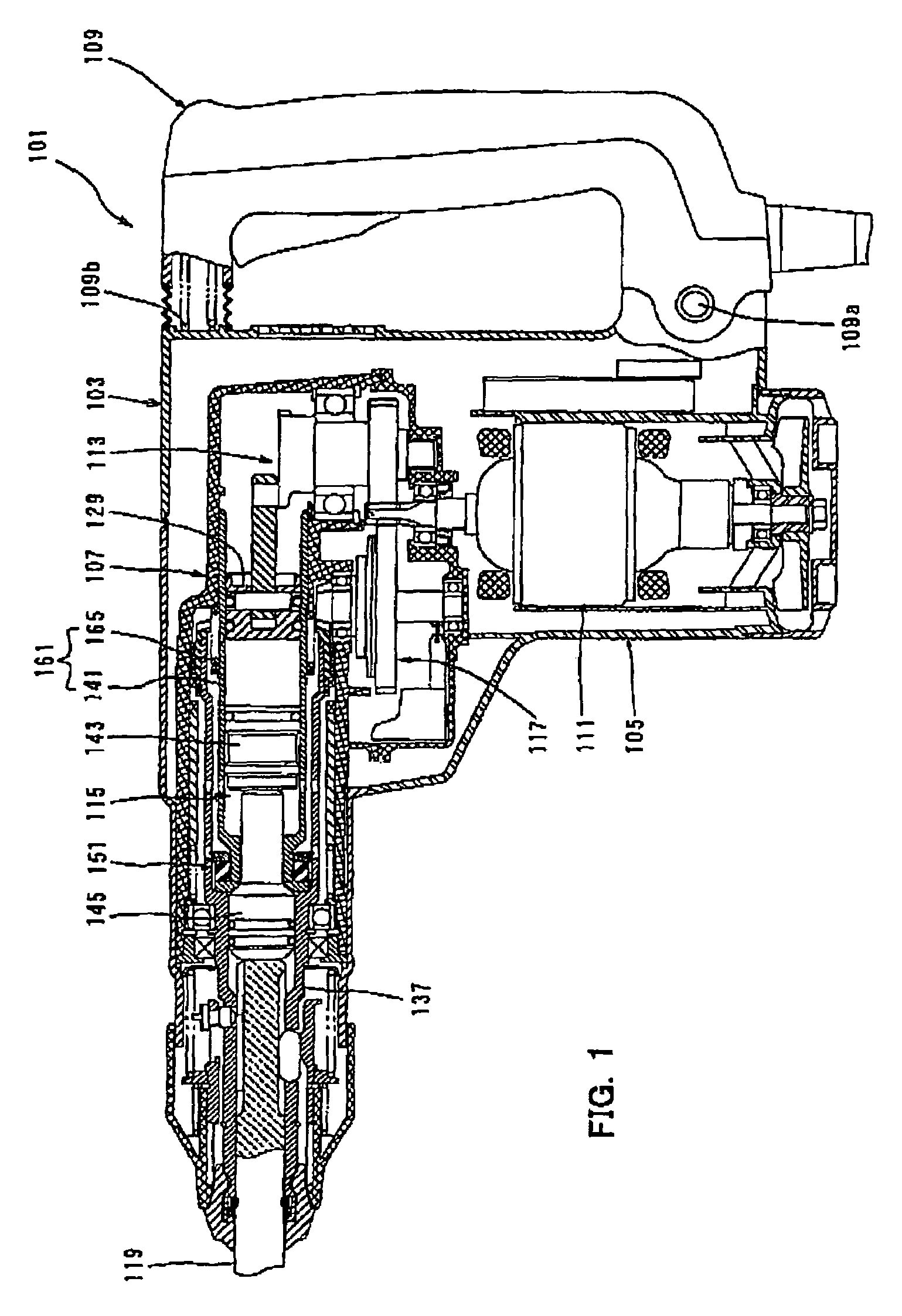

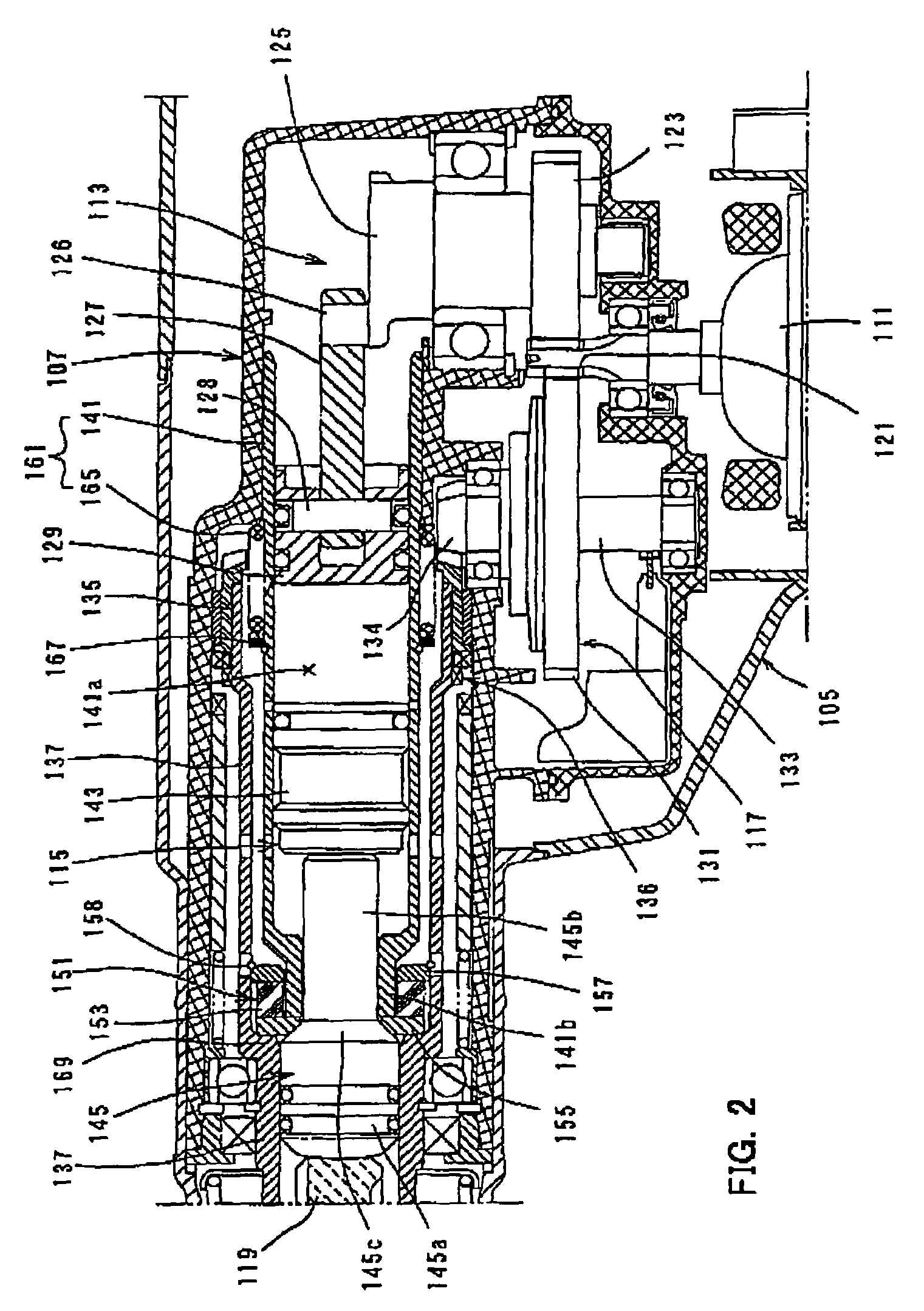

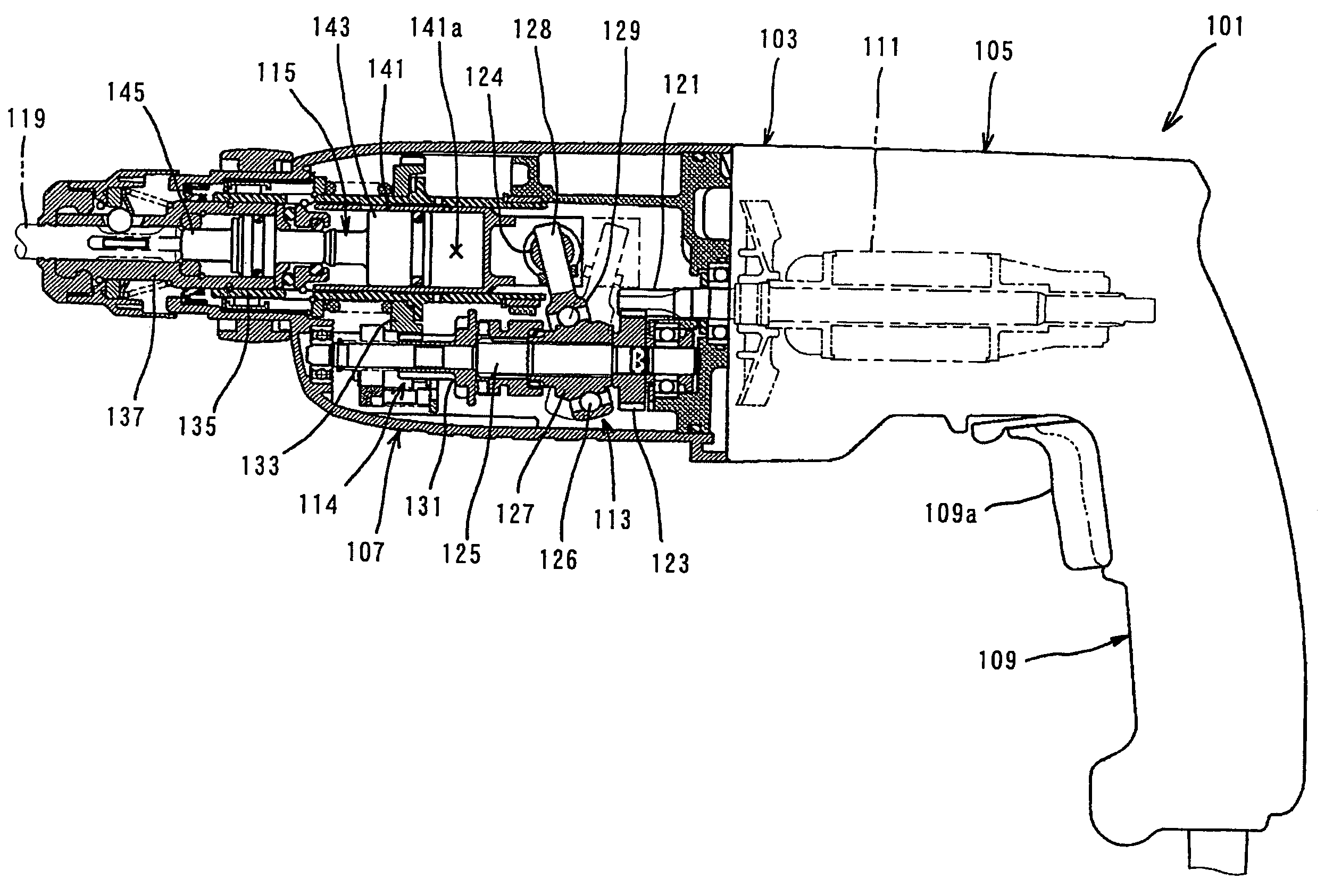

Hand-held tool

ActiveUS20110114347A1Accurate detectionReduce usageAutomatic control devicesDerricks/mastsHand heldControl theory

An effective technique for detecting several load conditions different in presence or absence and magnitude of load applied to a tool bit is provided in a hand-held tool. A hand-held tool 101 performs a predetermined operation while pressing a tool bit 119 mounted in a front end region of a tool body 103 against a workpiece. A plurality of detecting sensors 161 of different kinds detect several load conditions different in presence or absence and magnitude of load applied to the tool bit 119. The hand-held tool 101 includes at least one of an indicating device 171 which indicates the load conditions based on a result detected by the detecting sensors 161, and a driving control device 135 which controls driving of the tool bit 119 based on the detected result.

Owner:MAKITA CORP

Spring loaded tool with floating depth control for countersinking holes or engraving

ActiveUS7607871B1Avoid damageAvoid scratchesThread cutting toolsDrilling/boring measurement devicesTool bitSpray nozzle

A floating tool-bit depth controlling nosepiece for a spring loaded tool holder is used to countersink holes of equal size when the height of the work piece material changes. The floating tool-bit depth controlling nosepiece, driven by a cnc machine, is rigidly coupled to the floating portion of the tool holding element. The floating depth controlling nosepiece has a bearing on the end to allow an area of the nosepiece to stop rotating when the nosepiece is pressed against the work-piece surface. Since the area of the nosepiece that comes into contact with the work-piece is no longer spinning in relationship with the work-piece, the possibility of scratching the work-piece surface is reduced. Additionally, the nosepiece has cutouts therein to expel machined chips during countersinking of holes.

Owner:NELSON LANCE

Multi-axis, processor-controlled, toolhead positioner

InactiveUS7185412B2Programme-controlled manipulatorPlaning/slotting machinesRotational axisEngineering

Owner:PRECISION SPHERICAL

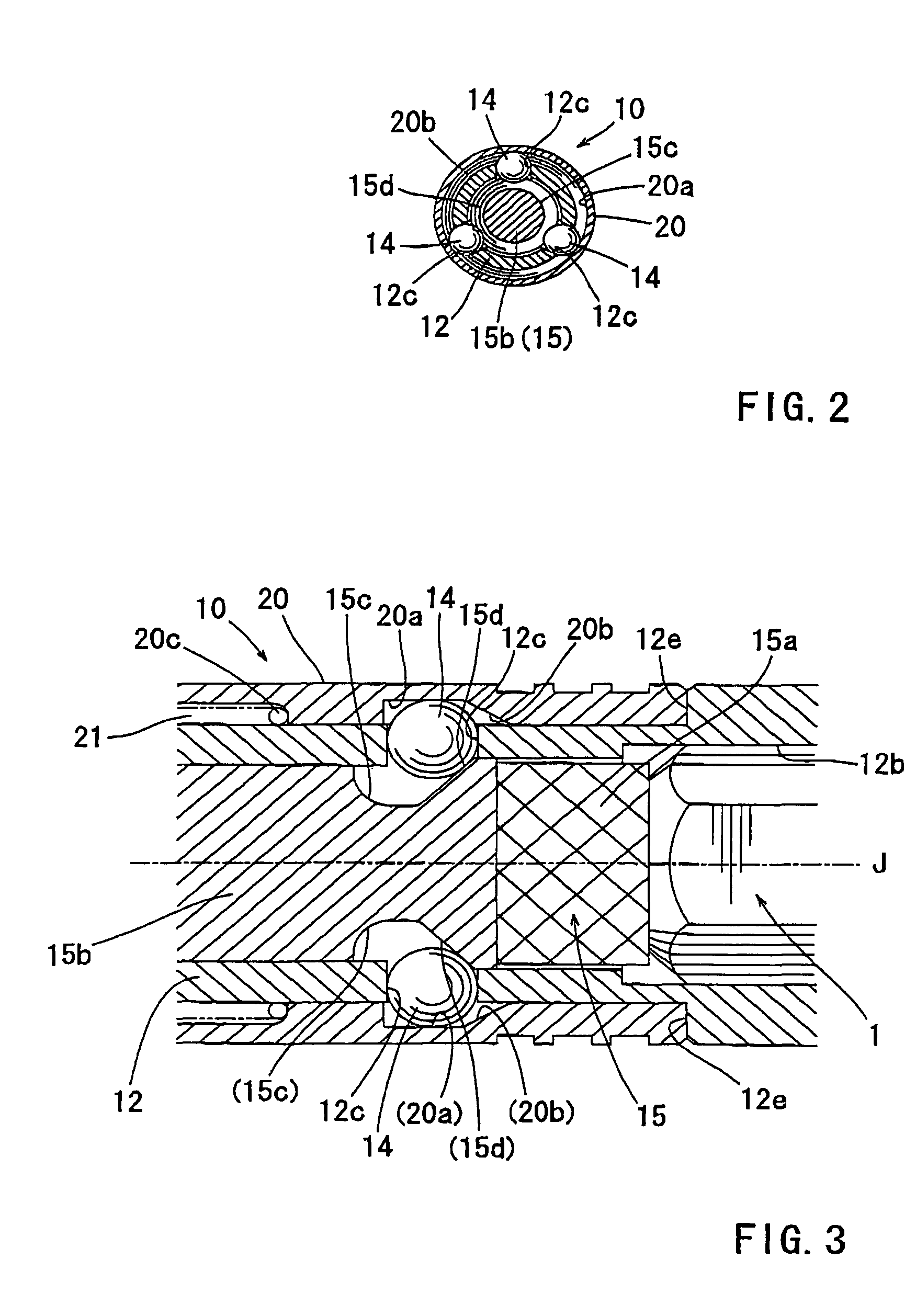

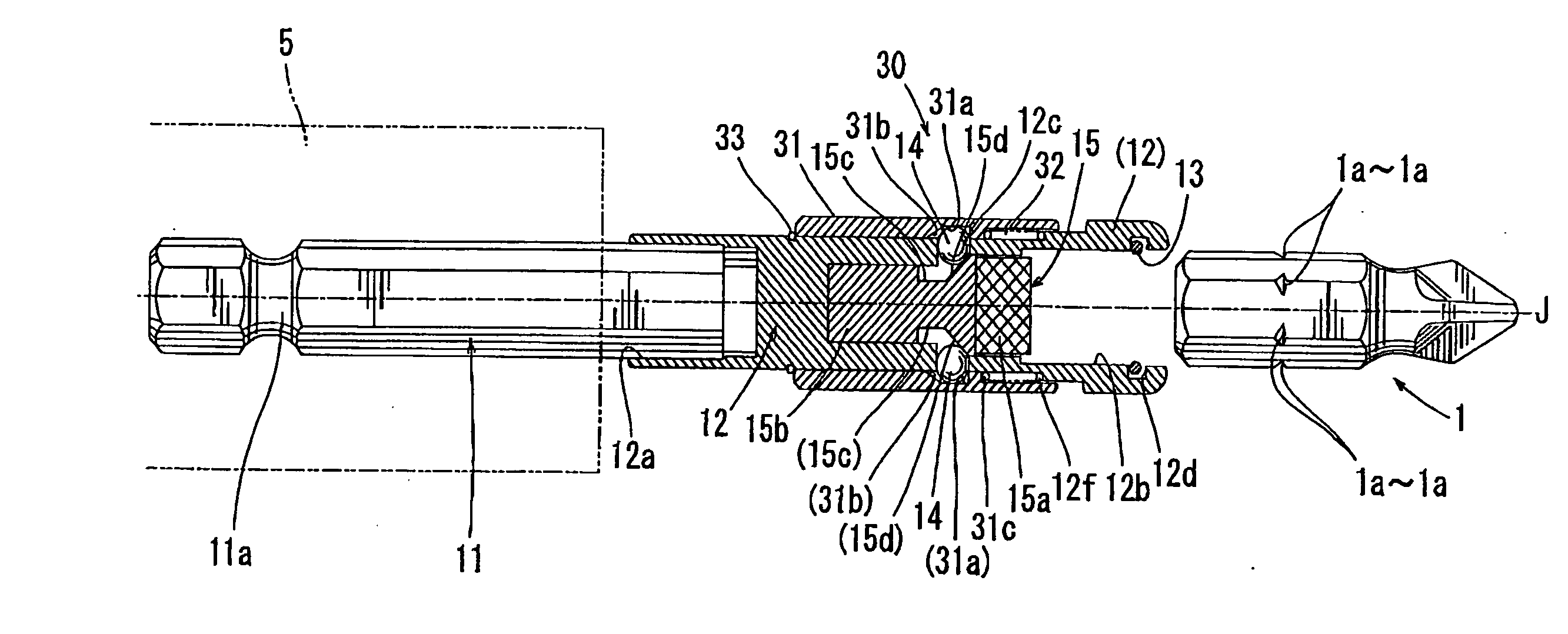

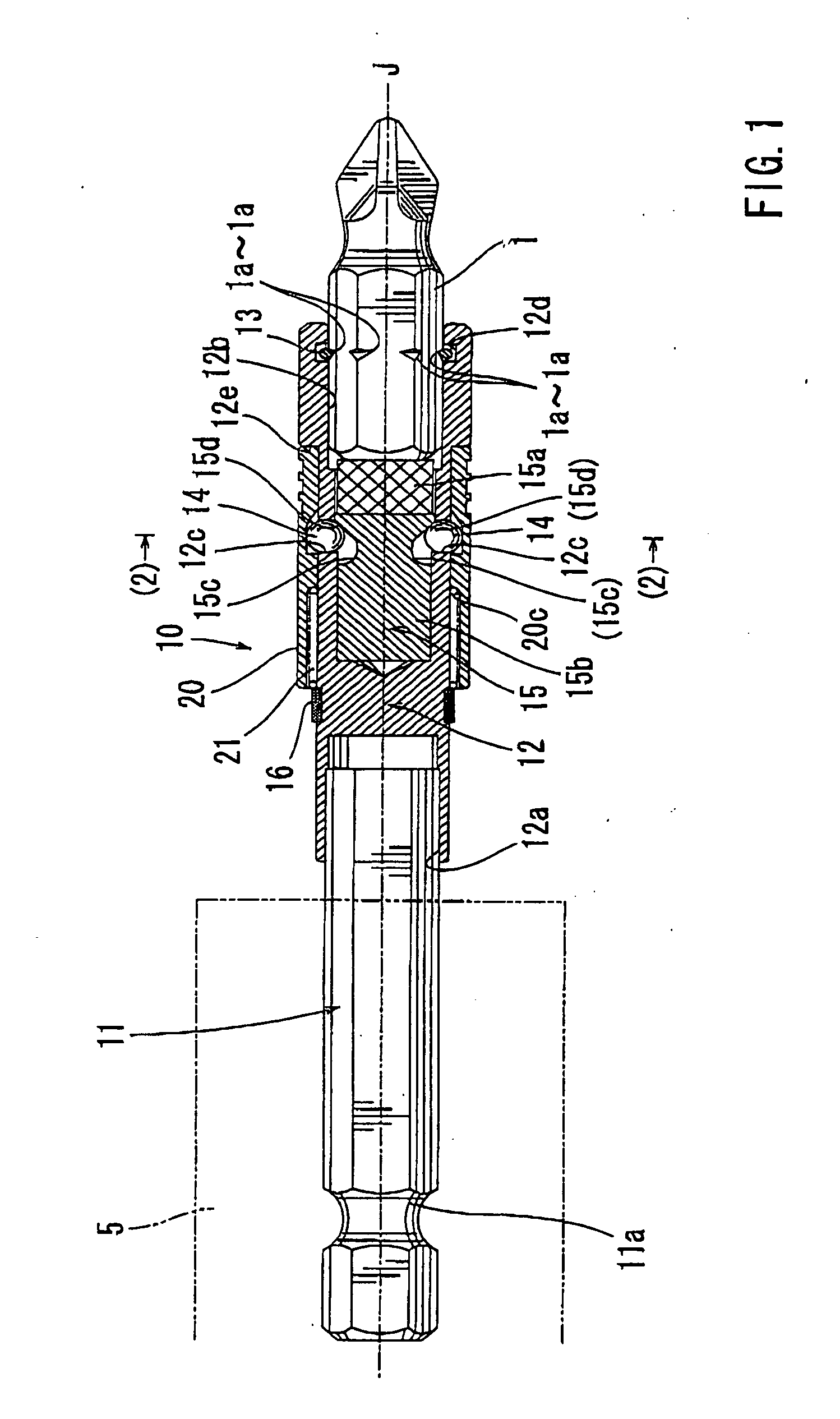

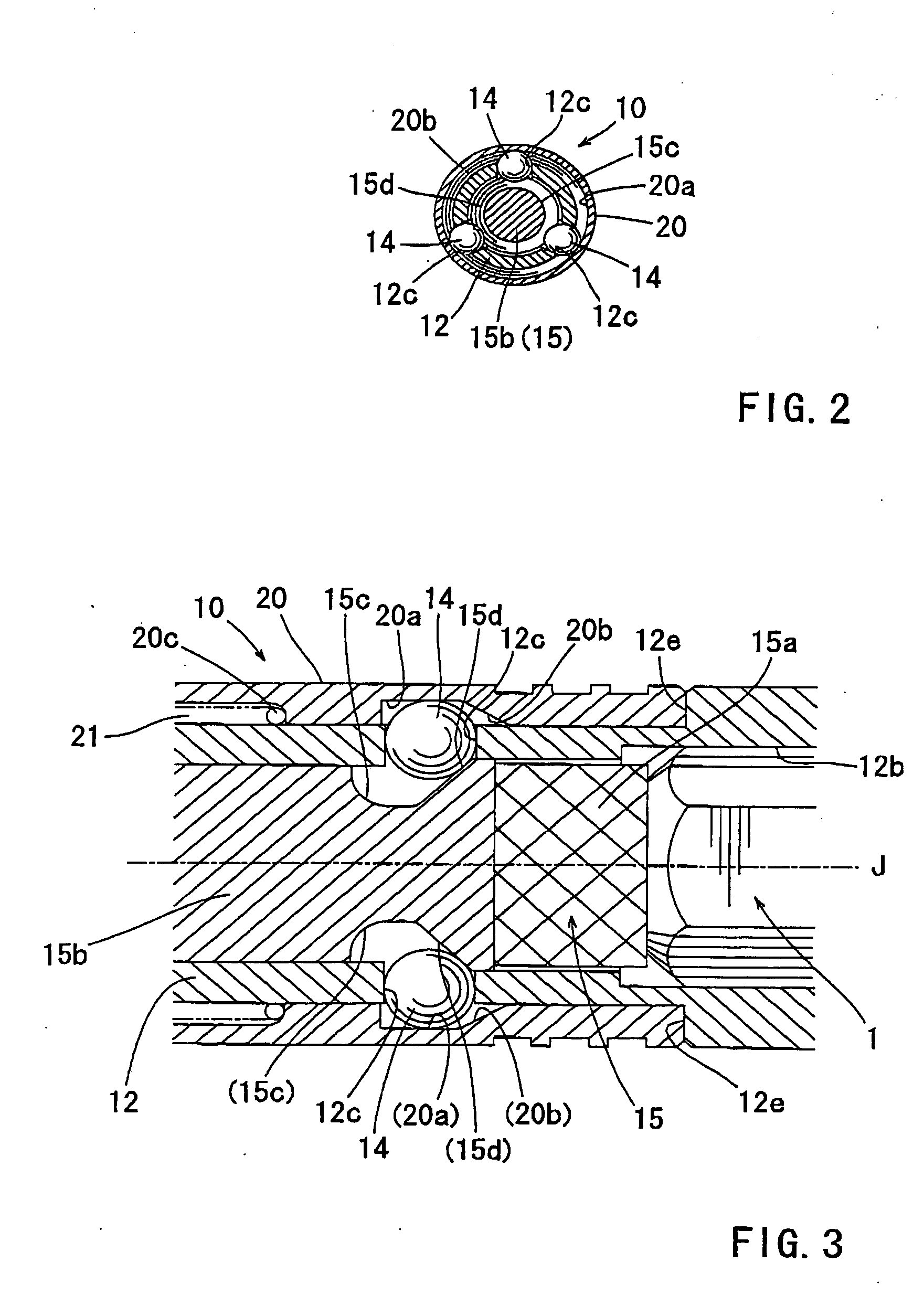

Bit mounting devices

InactiveUS8172236B2Compatibility of bit can be ensuredRestrict movementSleeve/socket jointsSpannersTool bitEngineering

A bit mounting device includes a holder that may be mounted to a spindle of the power tool or may be a part of the spindle. A bit push member is disposed within a bit receiving hole that is formed in the holder for receiving a tool bit. The movement of the operation member is transmitted to the bit push member via a transmission mechanism, so that the tool bit is pushed in a removing direction from the bit receiving hole by the bit push member.

Owner:MAKITA CORP

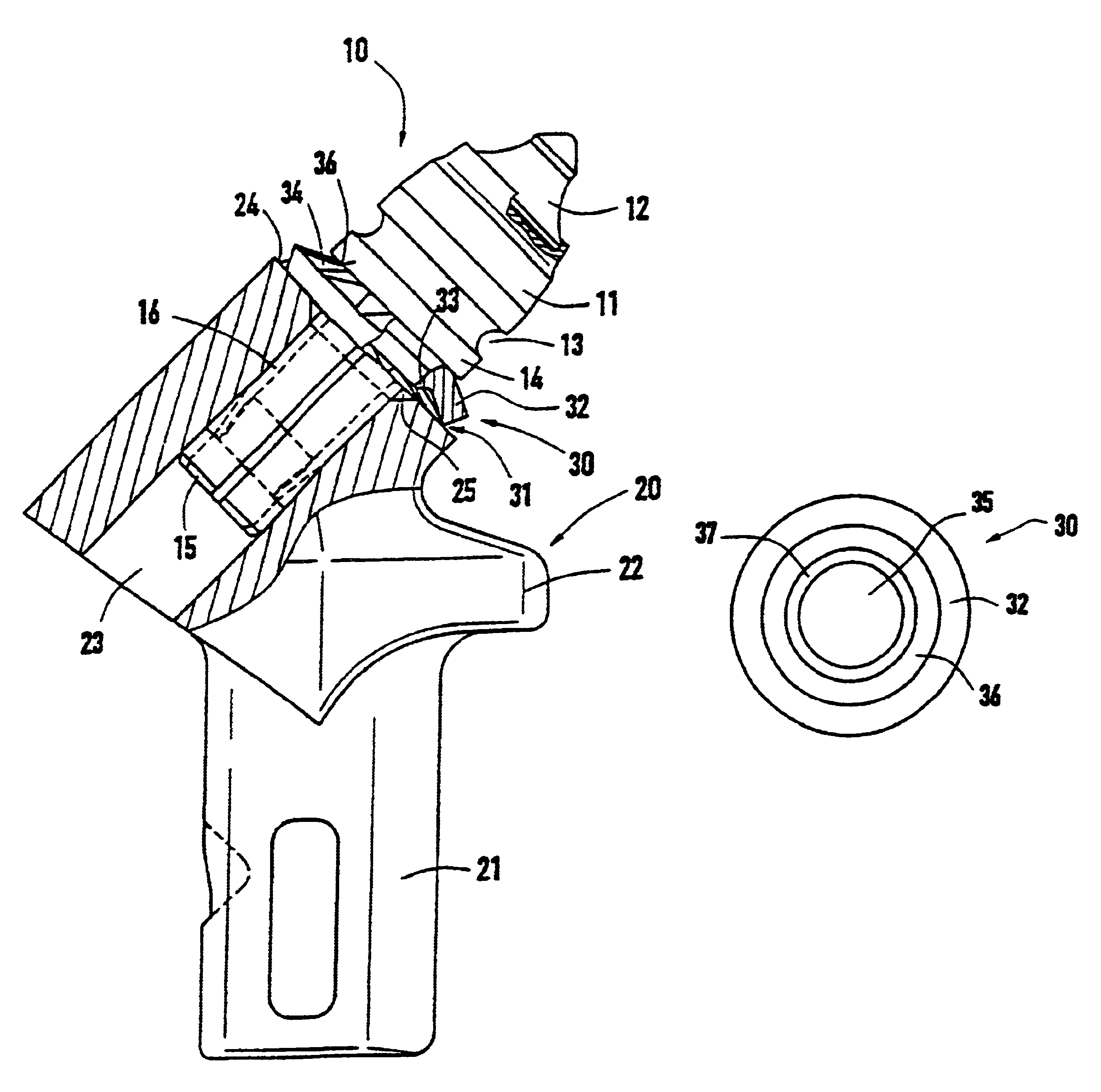

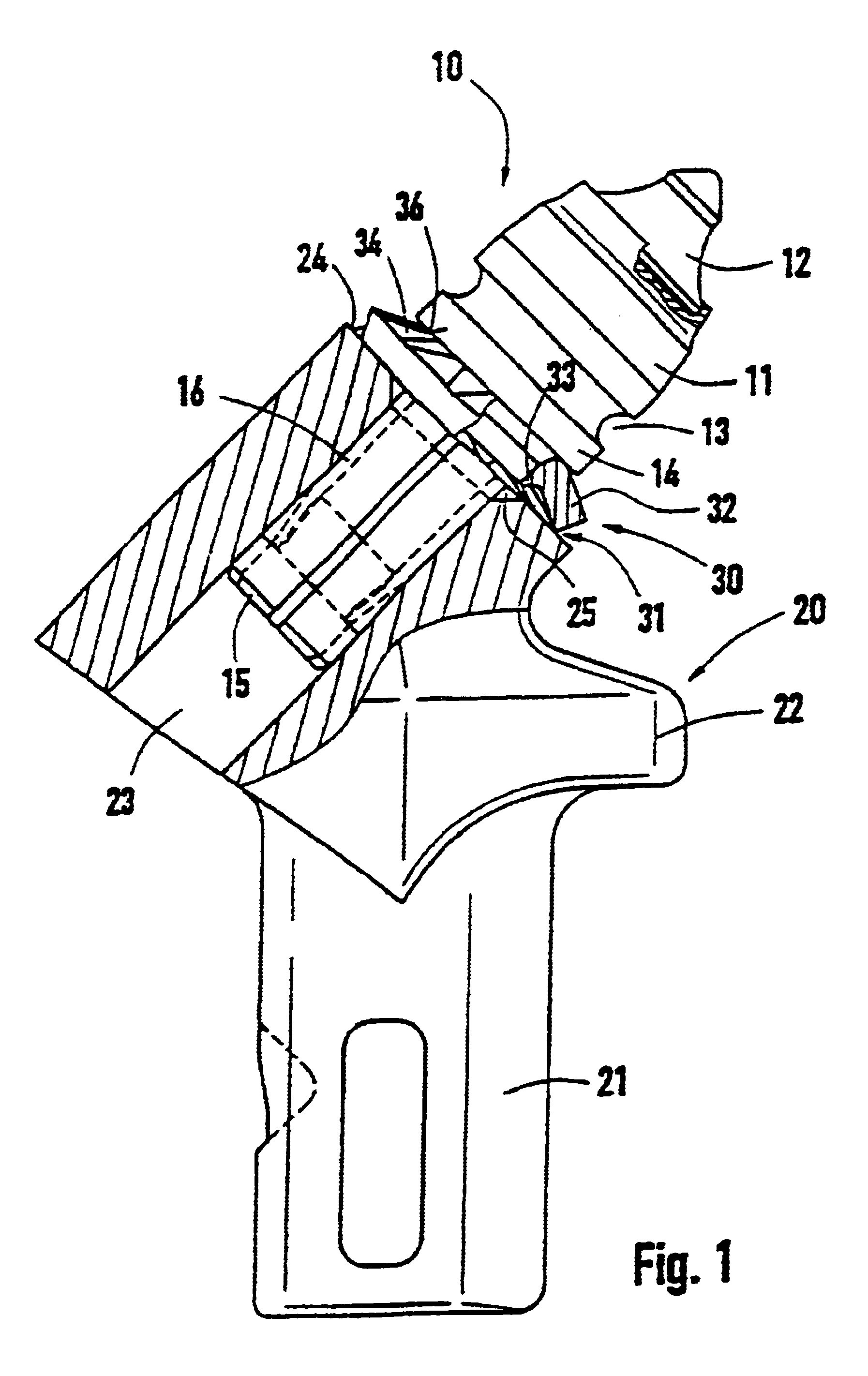

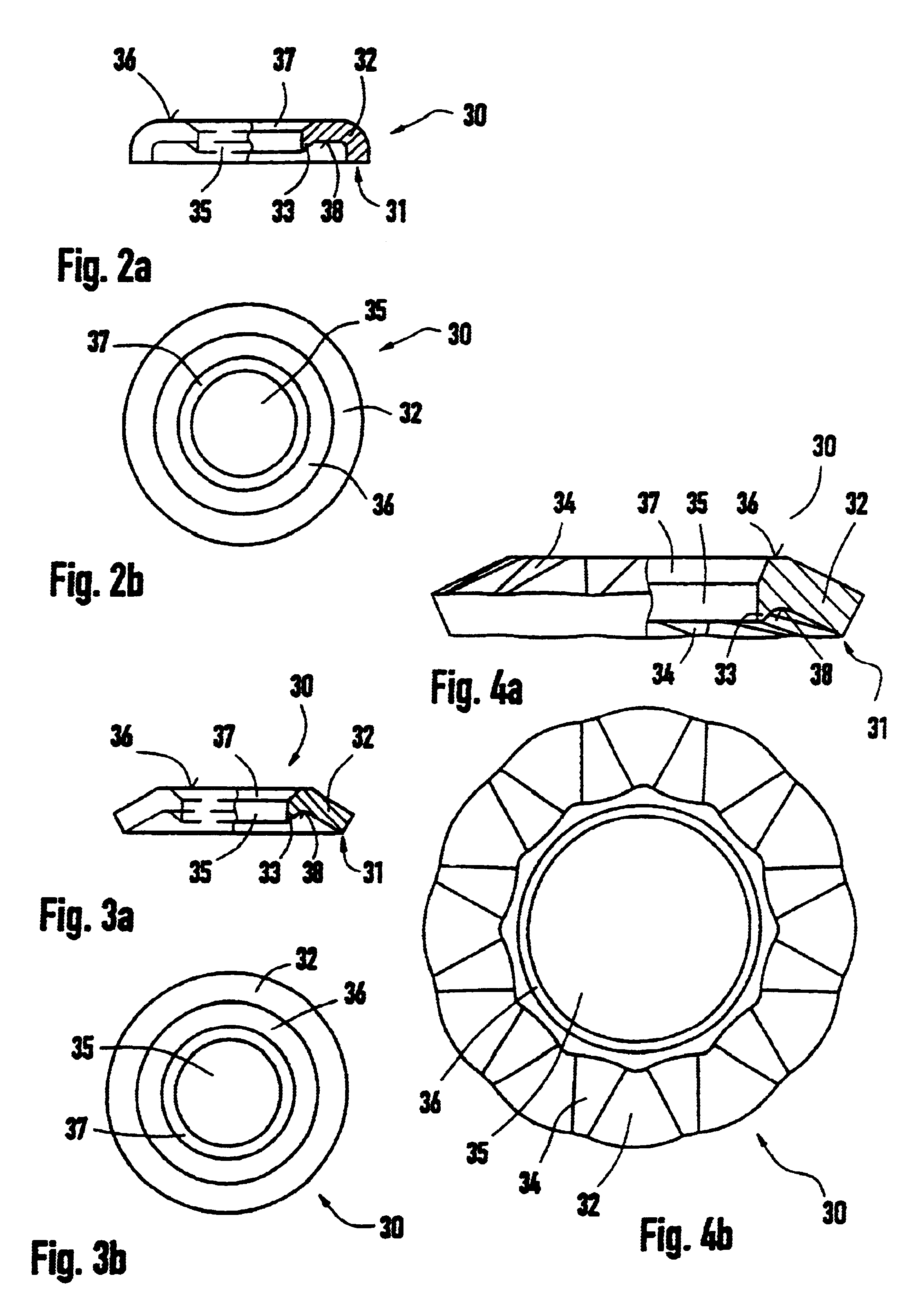

Tool for a street milling, coal-cutting or mining machine

A tool for a street milling, coal-cutting mining machine or the like which includes a chisel with a chisel head and a chisel stem. The chisel stem is rotatably mounted in a receiver of a chisel holder. A perforated wearing protection element is mounted on the chisel head. The chisel head sits closely on the chisel holder while embracing the interposed wearing protection element. This invention achieves improved wearing protection behavior of such a tool. Thus, the inventive wearing protection element has one or more spring elements that elastically support the chisel head by way of the chisel holder.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

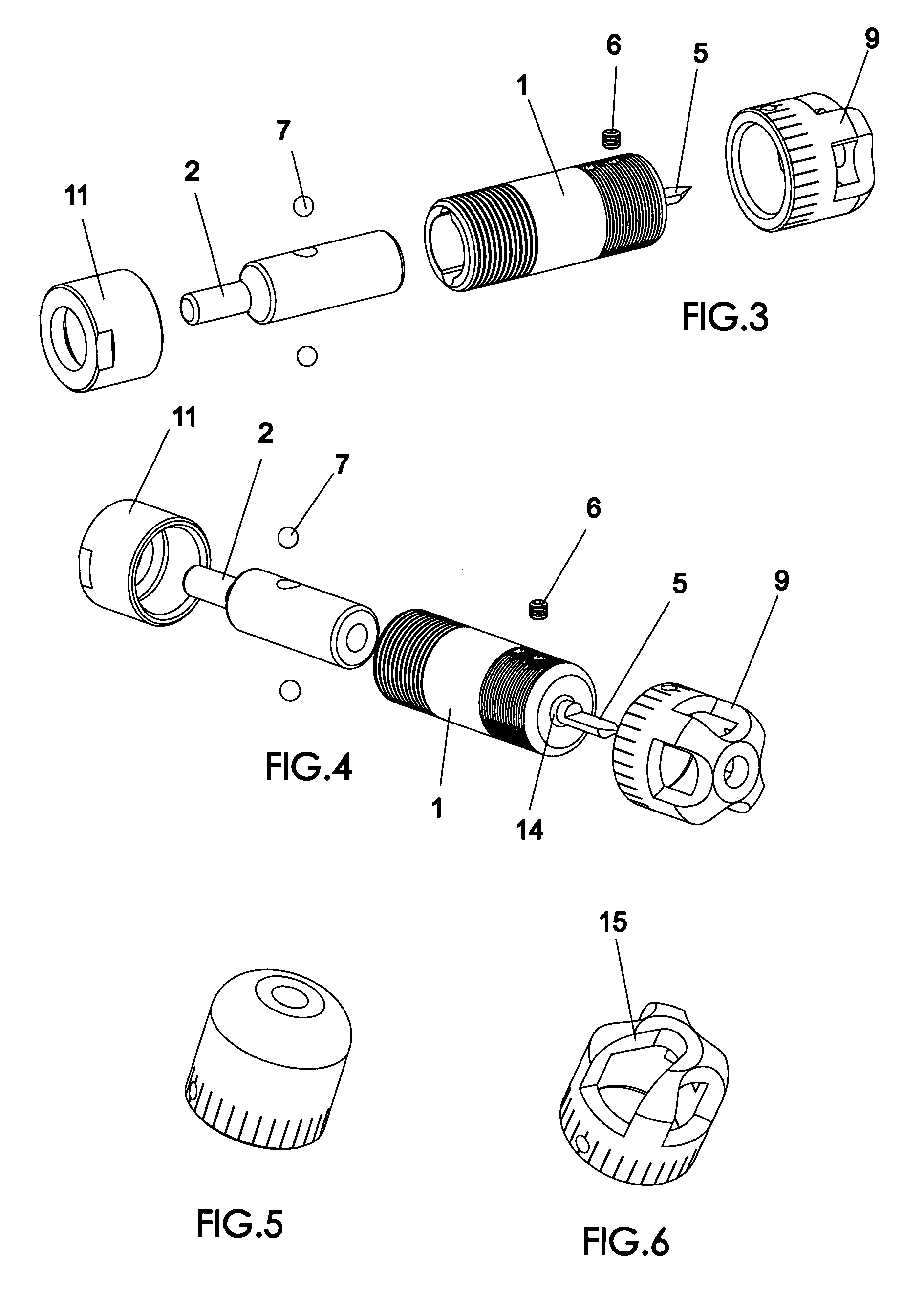

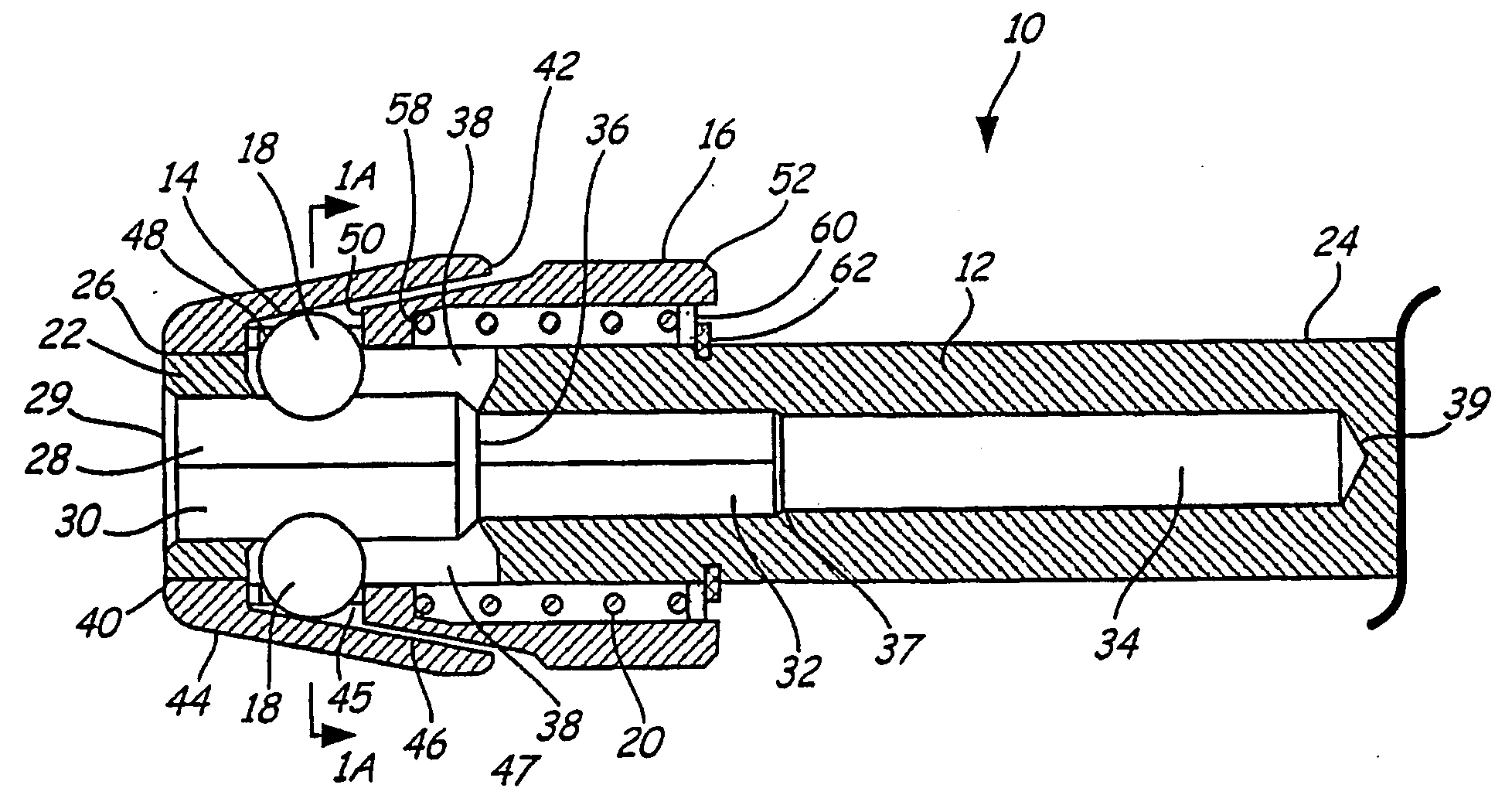

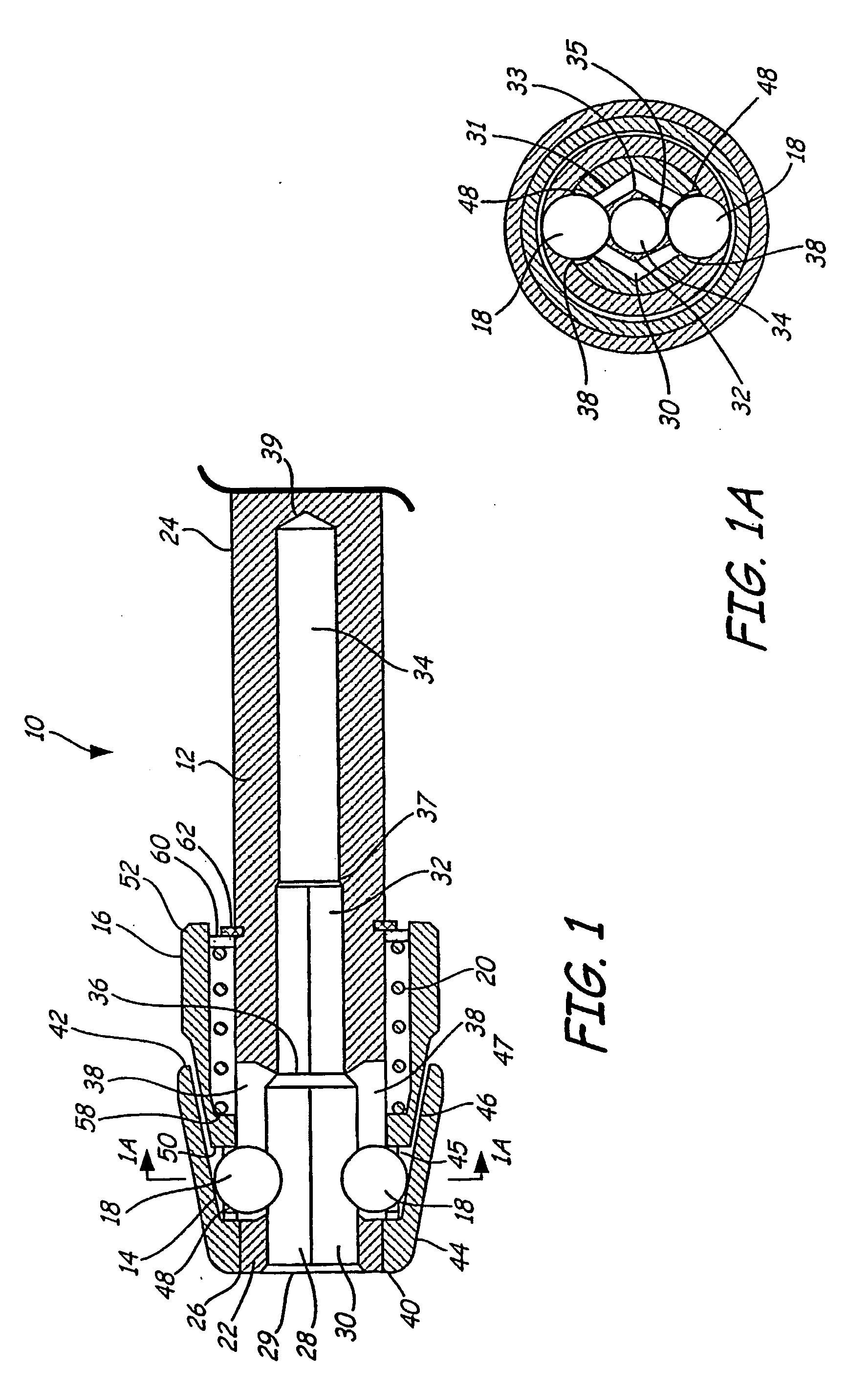

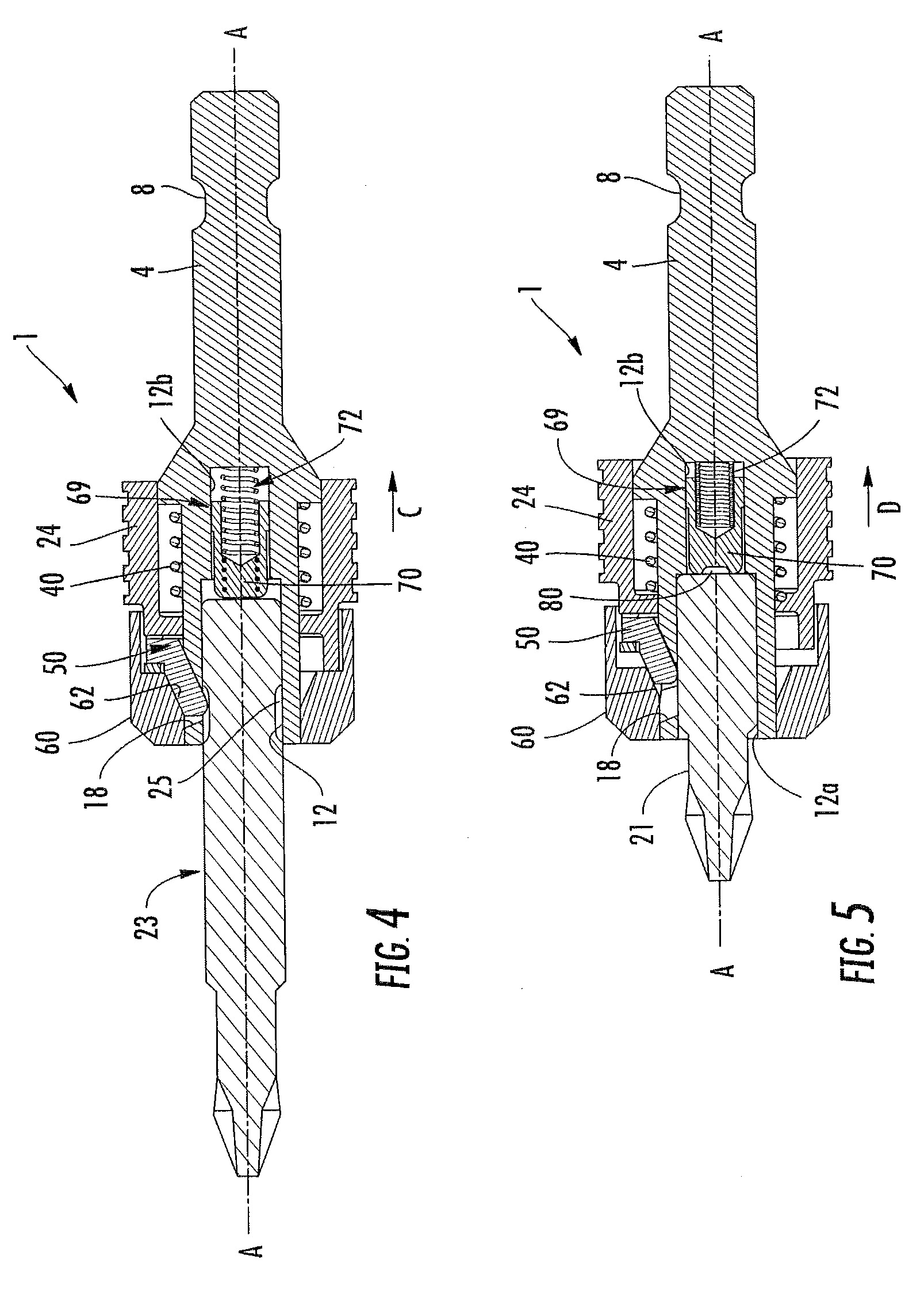

Dual Size Tool-Bit Holder

A tool-bit holder (10) for varying tool-bit shank profiles comprising a hub (12) having a longitudinal bore (28) adapted for receiving a tool-bit shank (66, 70, 80). The hub (12) has a plurality of radial slots (38) communicating with the first section (30) of the longitudinal bore (28). The tool-bit holder (10) has a collar (14) fixedly attached to the hub (12) adjacent the open (29) and disposed annularly about the hub (12). A sleeve (16) is axially slideably mounted and disposed annularly about the hub (12). The sleeve (16) has a plurality of radial bores (48), each being in communication with a respective radial slot (38) of the hub (12) with a detent ball (18) disposed within each. A spring (20) is provided for biasing the sleeve (16) towards the open end (29) wherein the detent ball (18) engages an inner ramp face (46) of the collar (14).

Owner:INSTY BIT

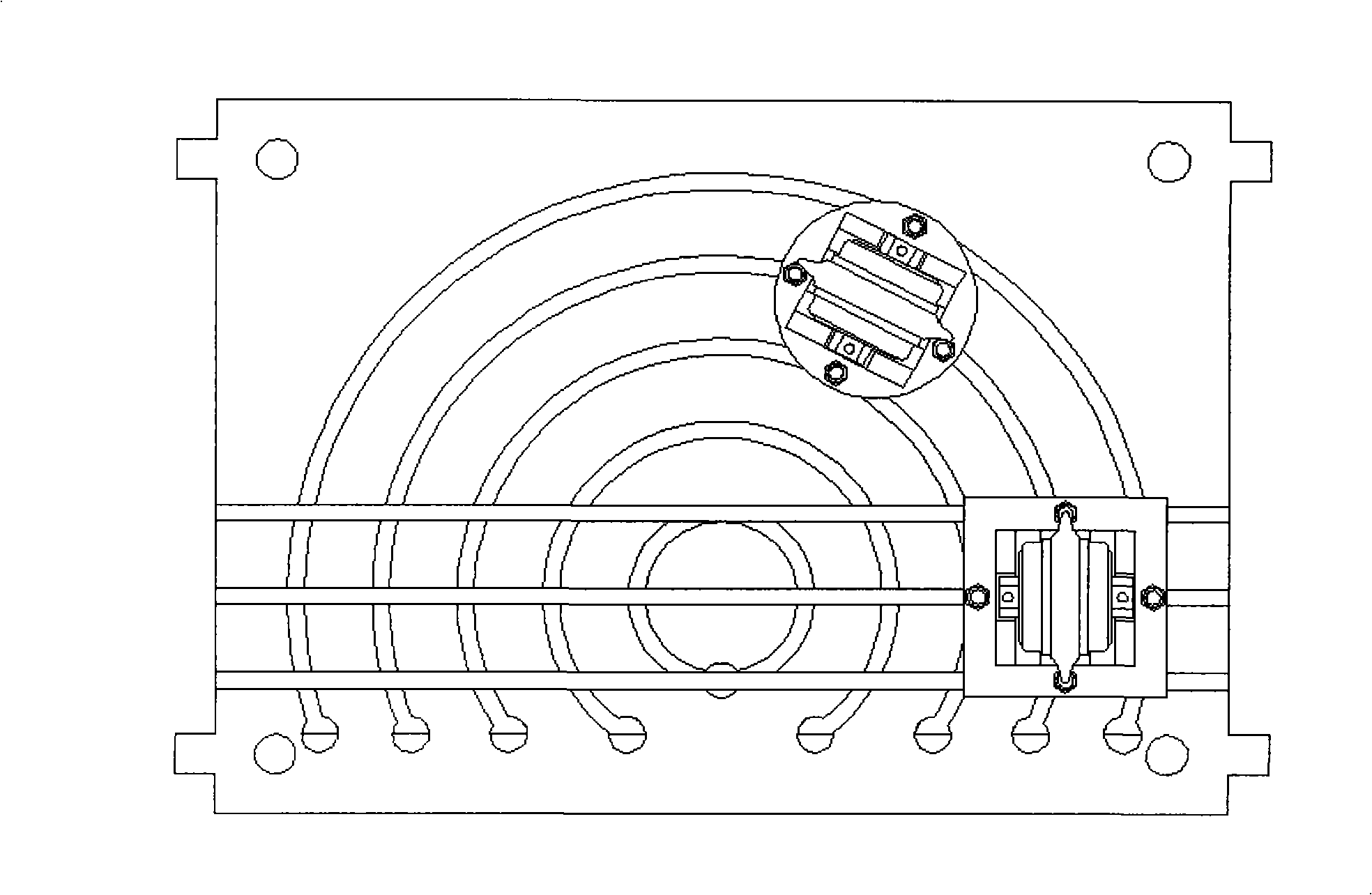

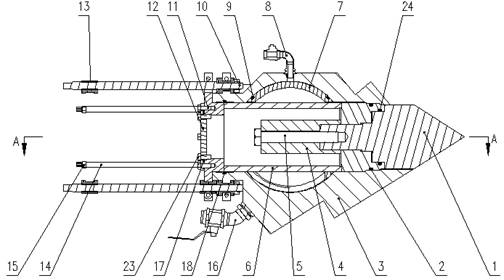

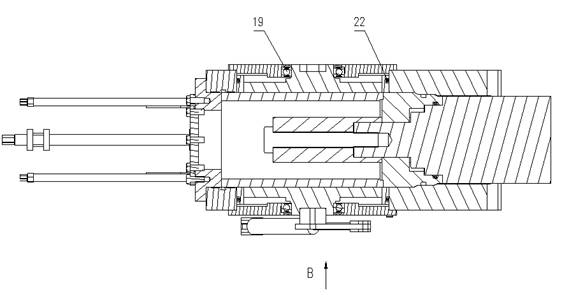

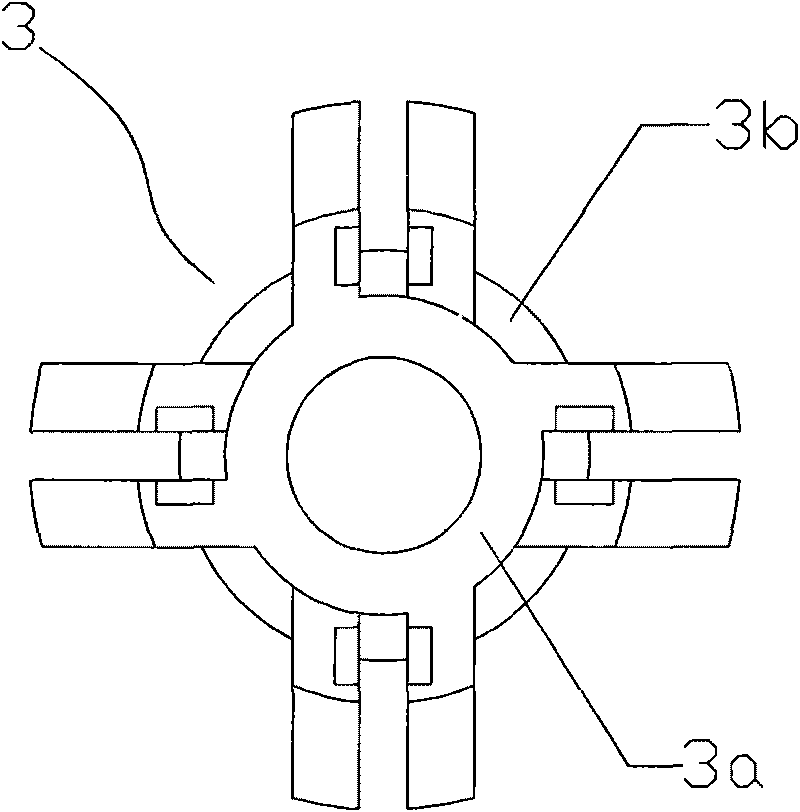

Tool pan back-loading type device for changing tool of slurry-balanced shield machine under normal pressure

The invention relates to a tool pan back-loading type device for changing a tool of a slurry-balanced shield machine under normal pressure, which is applied to the technical field of shield machine engineering machinery. The tool pan back-loading type device for changing the tool of the slurry-balanced shield machine under normal pressure comprises a tool bit, a first seal ring, a tool post, a tool bit fixing sleeve, a tool bit fixing bolt, a tool bar, a cylindrical gate, a grease injection valve, a flushing valve, a third seal ring, a fourth seal ring, a bearing, a large end cover, an oil cylinder and the like; when the tool is in the working state, the tool bit is fixed on the tool bar through the tool bit fixing sleeve and the tool bit fixing bolt; the first seal ring is mounted at thefront end of the tool bar, and the tool bar is matched with the front end of the tool post and is sealed through the first seal ring; the tool bar is fixed on the tool post by the rear end of the tool bar and the tool post through a first fixing screw; the cylindrical gate is fixed on the tool post through the bearing and the large end cover; the grease injection valve and the flushing valve are installed on the tool post; and a serial number is arranged between the cylindrical gate and the tool post. The tool pan back-loading type device for changing the tool of the slurry-balanced shield machine under normal pressure has the advantages of simple structure, reliable working, and capability of conveniently and quickly changing a worn tool under normal pressure (atmospheric pressure) in the shield construction process.

Owner:SHENYANG HEAVY MACHINERY GROUP

Bit mounting devices

InactiveUS20080217870A1Compatibility of bit can be ensuredRestrict movementSleeve/socket jointsSpannersPower toolTool bit

A bit mounting device includes a holder that may be mounted to a spindle of the power tool or may be a part of the spindle. A bit push member is disposed within a bit receiving hole that is formed in the holder for receiving a tool bit. The movement of the operation member is transmitted to the bit push member via a transmission mechanism, so that the tool bit is pushed in a removing direction from the bit receiving hole by the bit push member.

Owner:MAKITA CORP

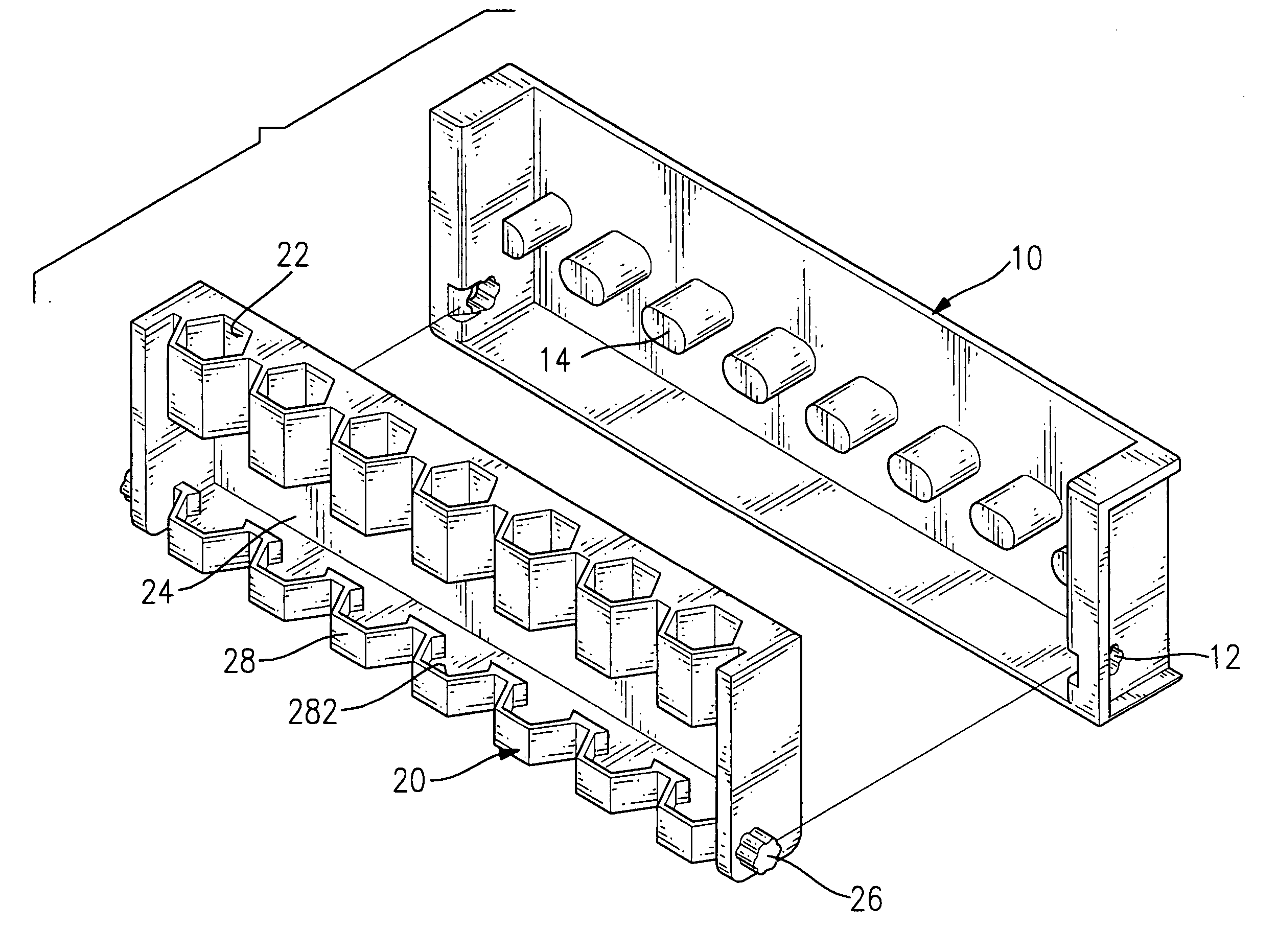

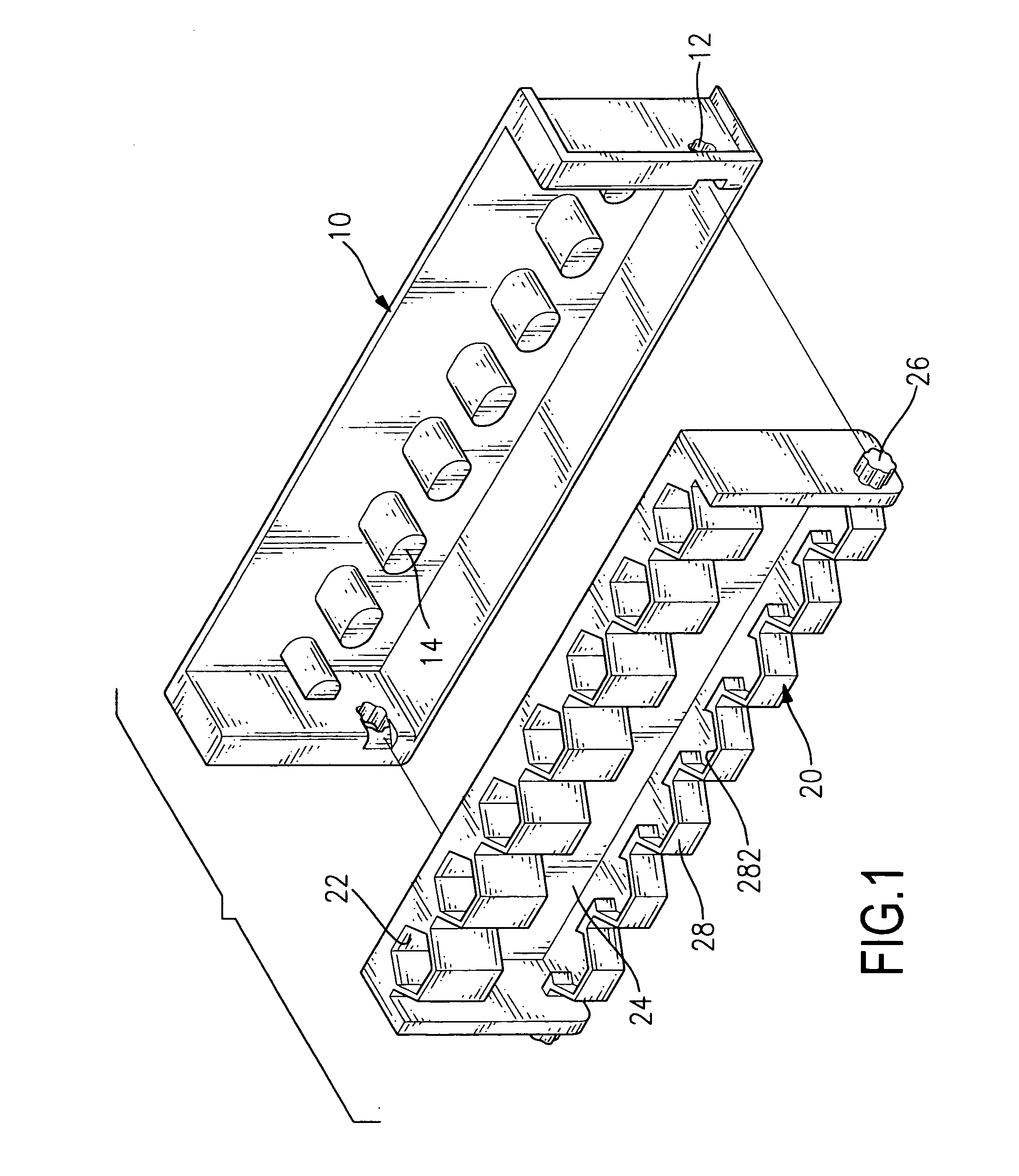

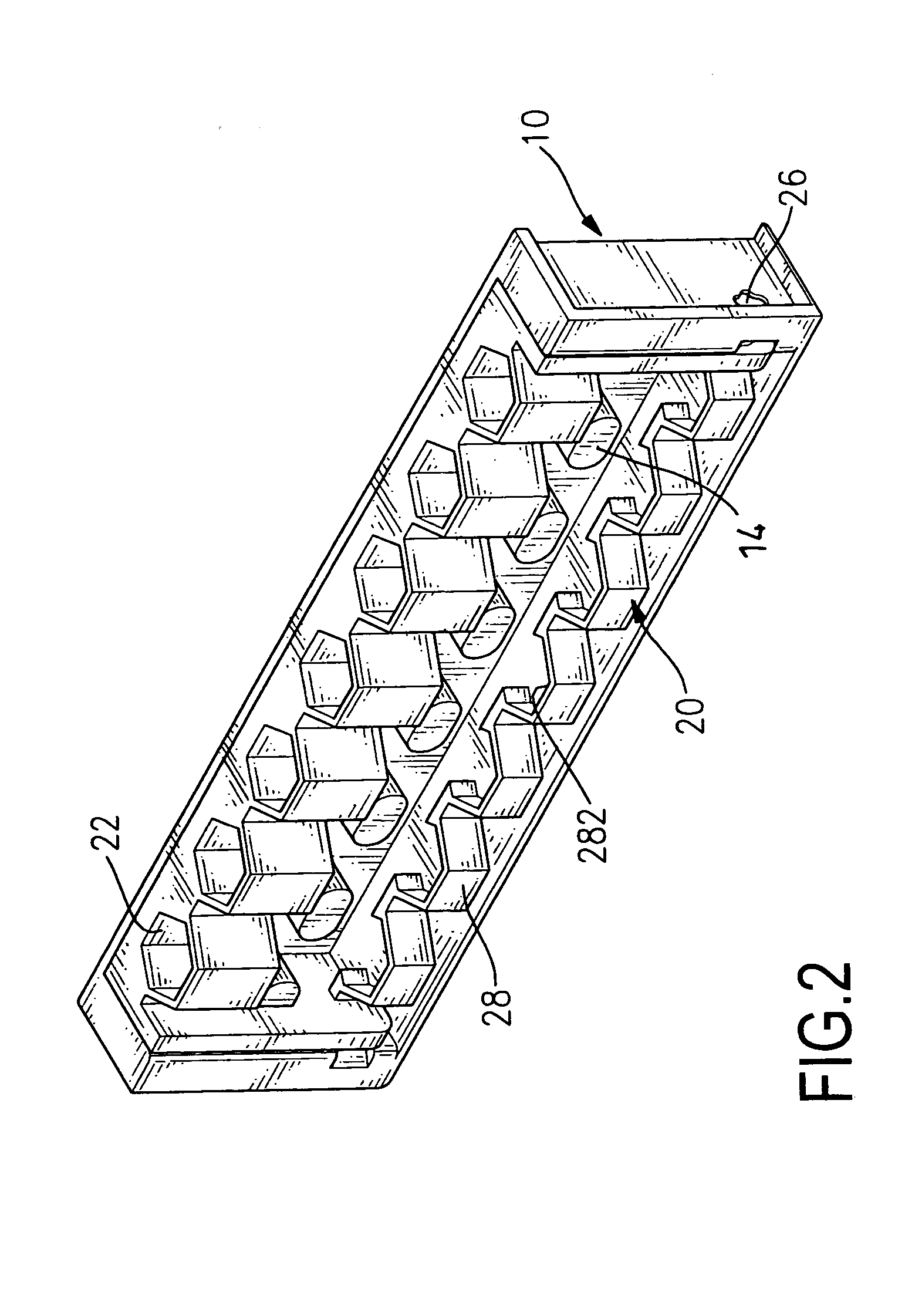

Tool bracket for storing tool bits

Owner:CHEN KUN CHEN

Quick change tool bit holder

The quick change tool bit holder comprises a bore for receiving a bit. A retaining tooth, or plurality of teeth, is movable into engagement with the bit when the bit is inserted into the bore to retain the bit in the bore. An ejector ejects the bit from the bore when the retaining tooth is moved out of engagement with the bit. The ejector may comprise a spring that is compressed when the bit is inserted in the bore and a push button is biased by the spring into engagement with the bit. A sleeve forces the retaining tooth into engagement with the bit when said sleeve is in the locking position where the tooth moves at an angle relative to a longitudinal axis into contact with the bit. A method of operating the quick change tool bit holder is also disclosed.

Owner:BLACK & DECKER INC

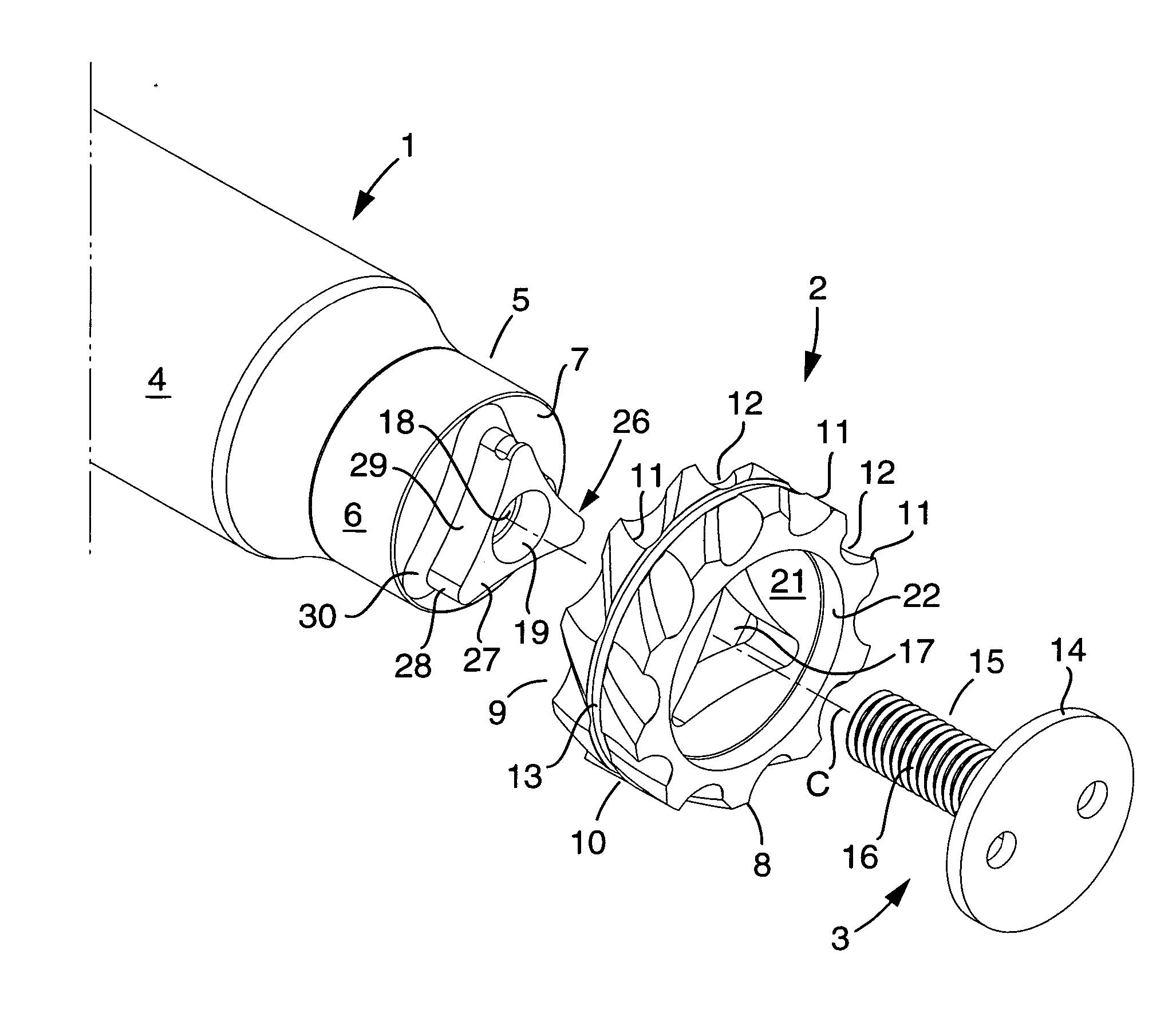

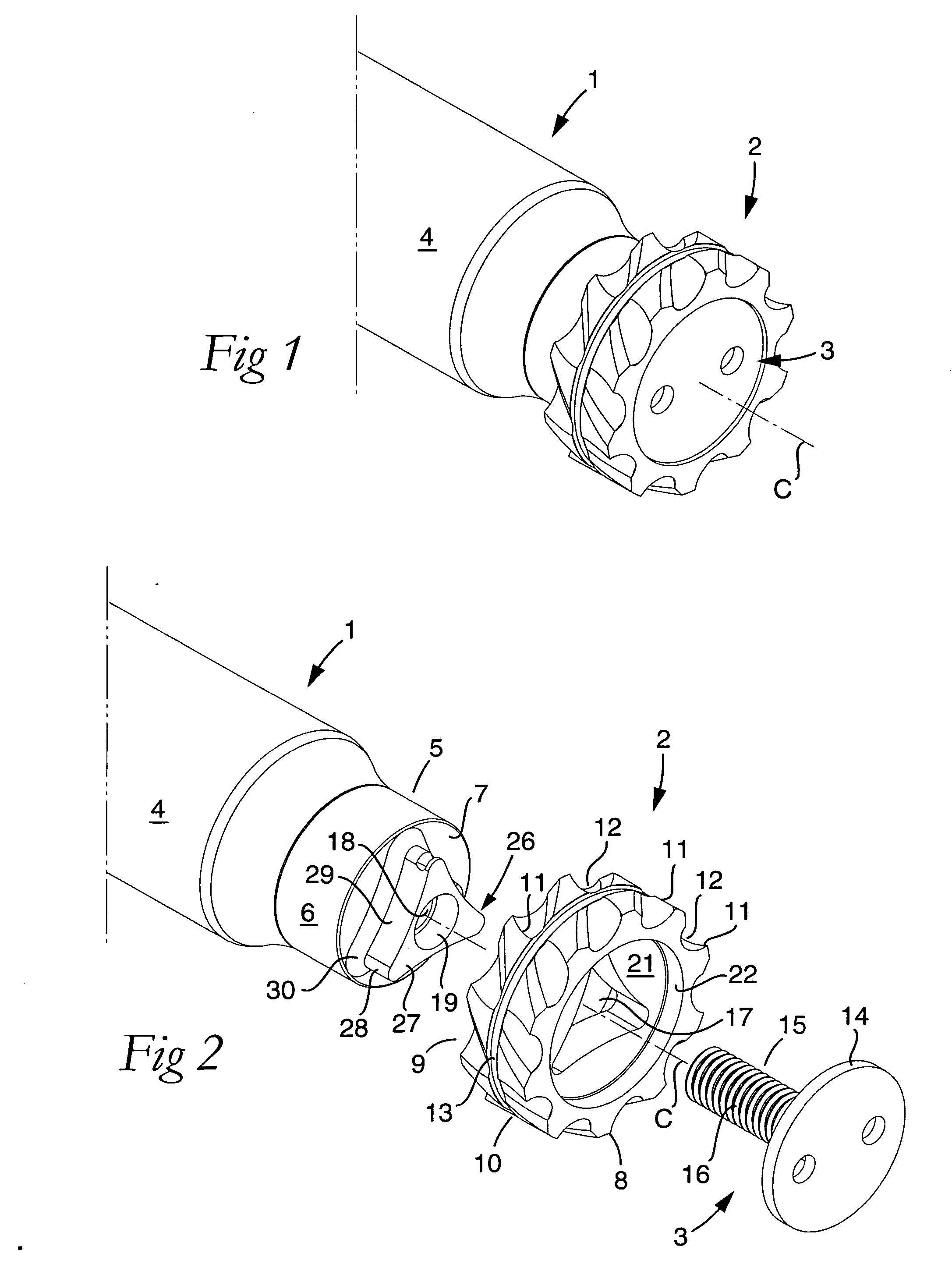

Milling cutter head and a milling cutter tool

InactiveUS20070081873A1Large formatEliminate shortcomingsMilling cuttersAttachable milling devicesFluteTool bit

A milling cutter head in the form of a body, which has an external envelope surface having a rotationally symmetrical basic shape in respect of a central axis, and includes a plurality of peripherally spaced-apart cutting edges and chip flutes. The cutter head includes two axially spaced-apart ends in which hollow spaces open, which are arranged to receive male elements included in a basic body, and are spaced-apart by a partition wall in which a through hole is formed. The through hole mouths in bottom surfaces in the hollow spaces. The cross-section area of each individual hollow space, in a plane perpendicular to the center axis, amounts to at least 25% of the total cross-section area of the body, as defined by the greatest diameter of the envelope surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

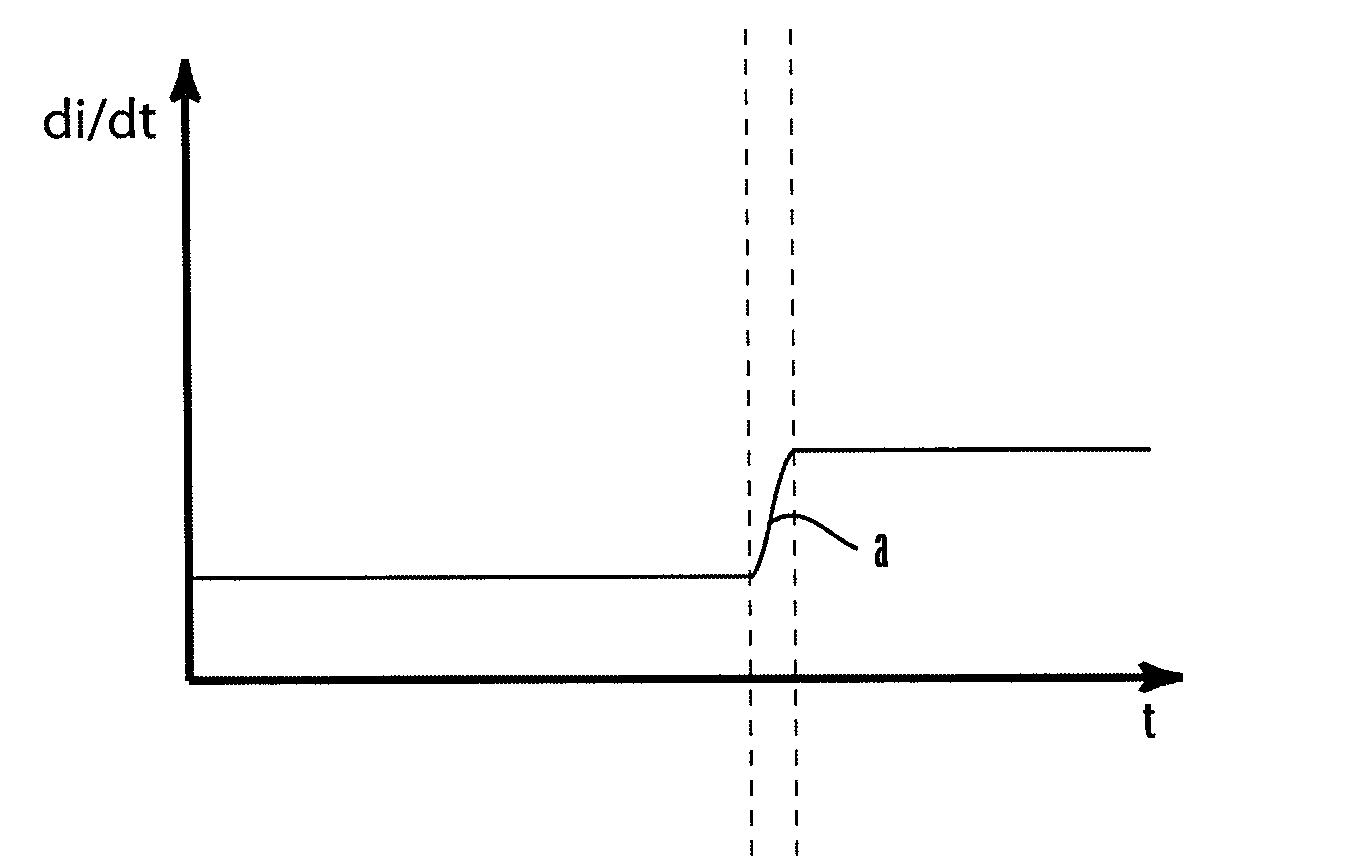

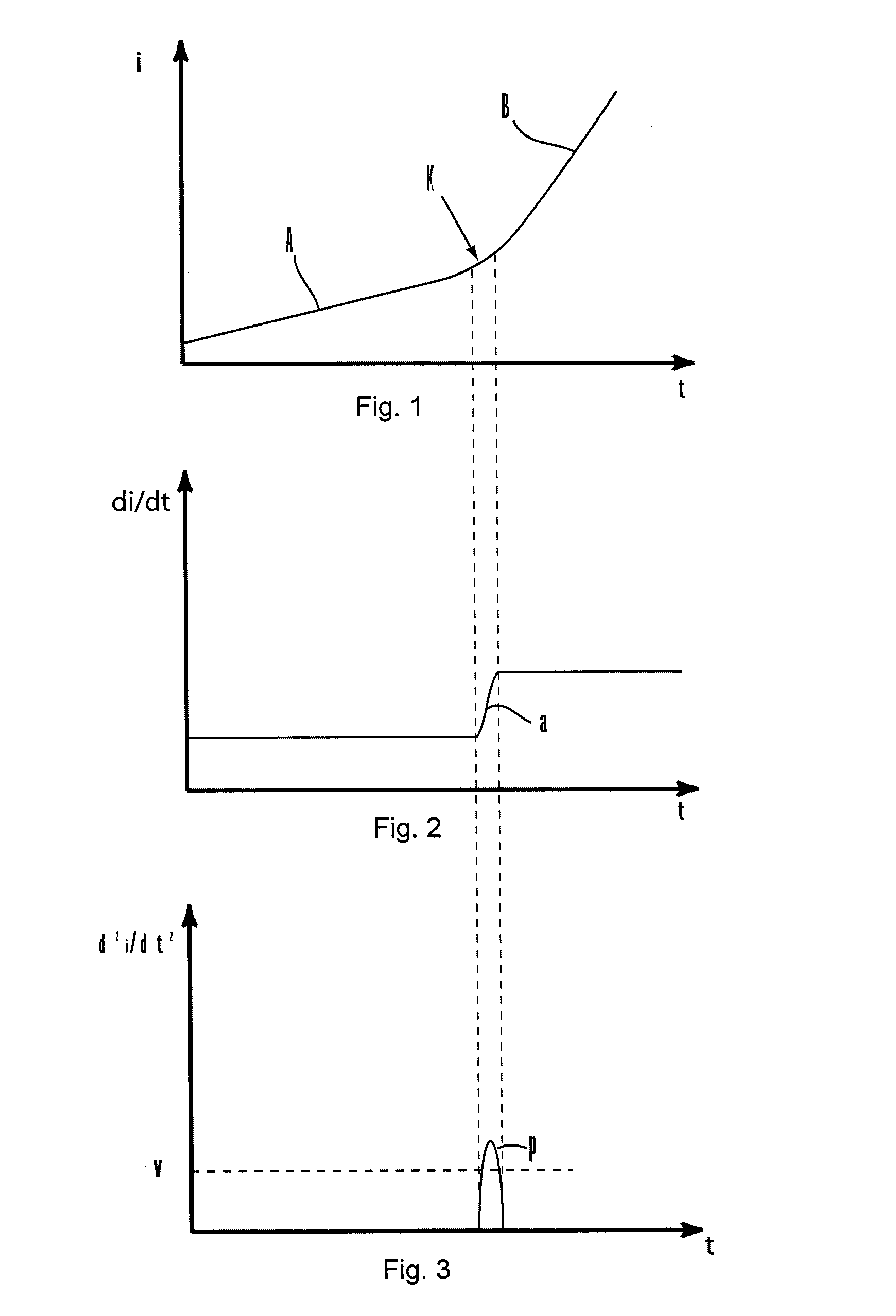

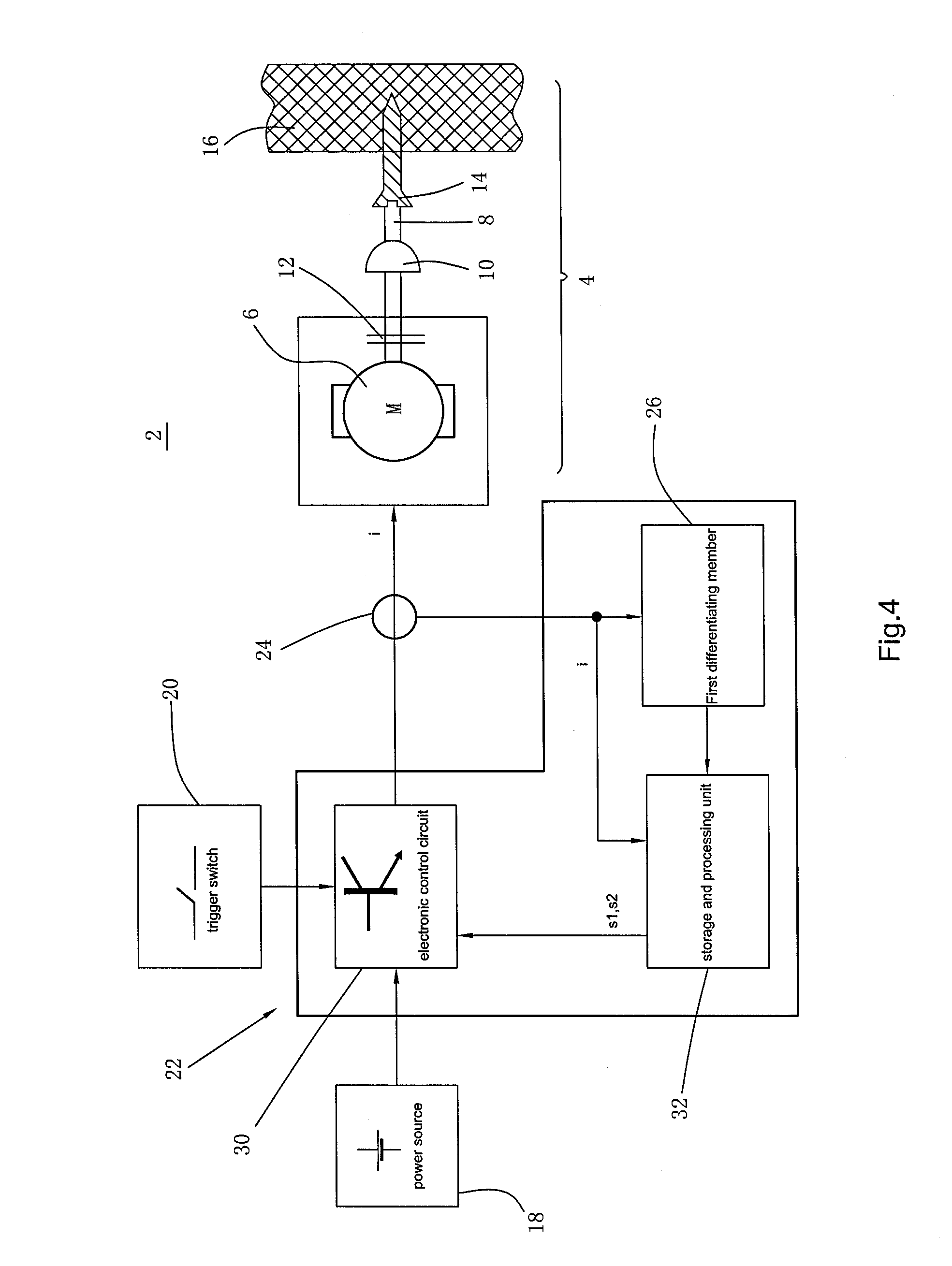

Controlling method of electric tool and electric tool carrying out the controlling method

InactiveUS20100089600A1Simple processLow costDC motor speed/torque controlDerricks/mastsControl signalRotation velocity

The invention relates to a power tool, which comprises a motor for driving a tool bit rotating, the motor attains a rotational speed, a source for supplying an electric current to said motor, a sensor for measuring said current, and a control device. The control device fulfills the task of detection of a variation of the slope of the current in the course of time, and generates a control signal. The rotational speed of the tool is reduced in response to the control signal. The present invention automatically detects whether the work piece operated by the tool bit reaches a predetermined position by providing electronic control means. It may make sure that the screw is driven into a piece of wood and does not go beyond the predetermined position once detect that the work piece reaches the position and carries out the changing action.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

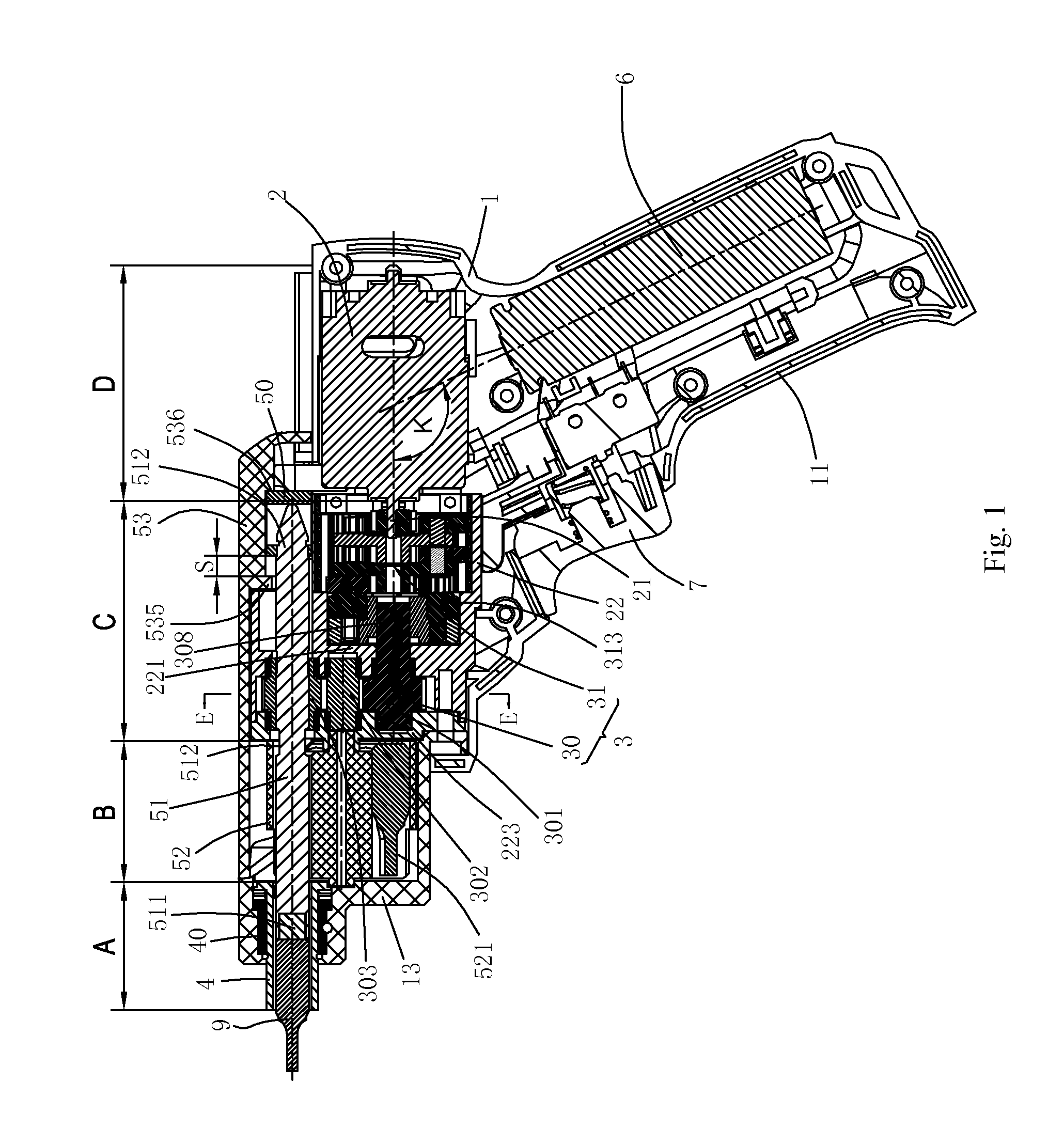

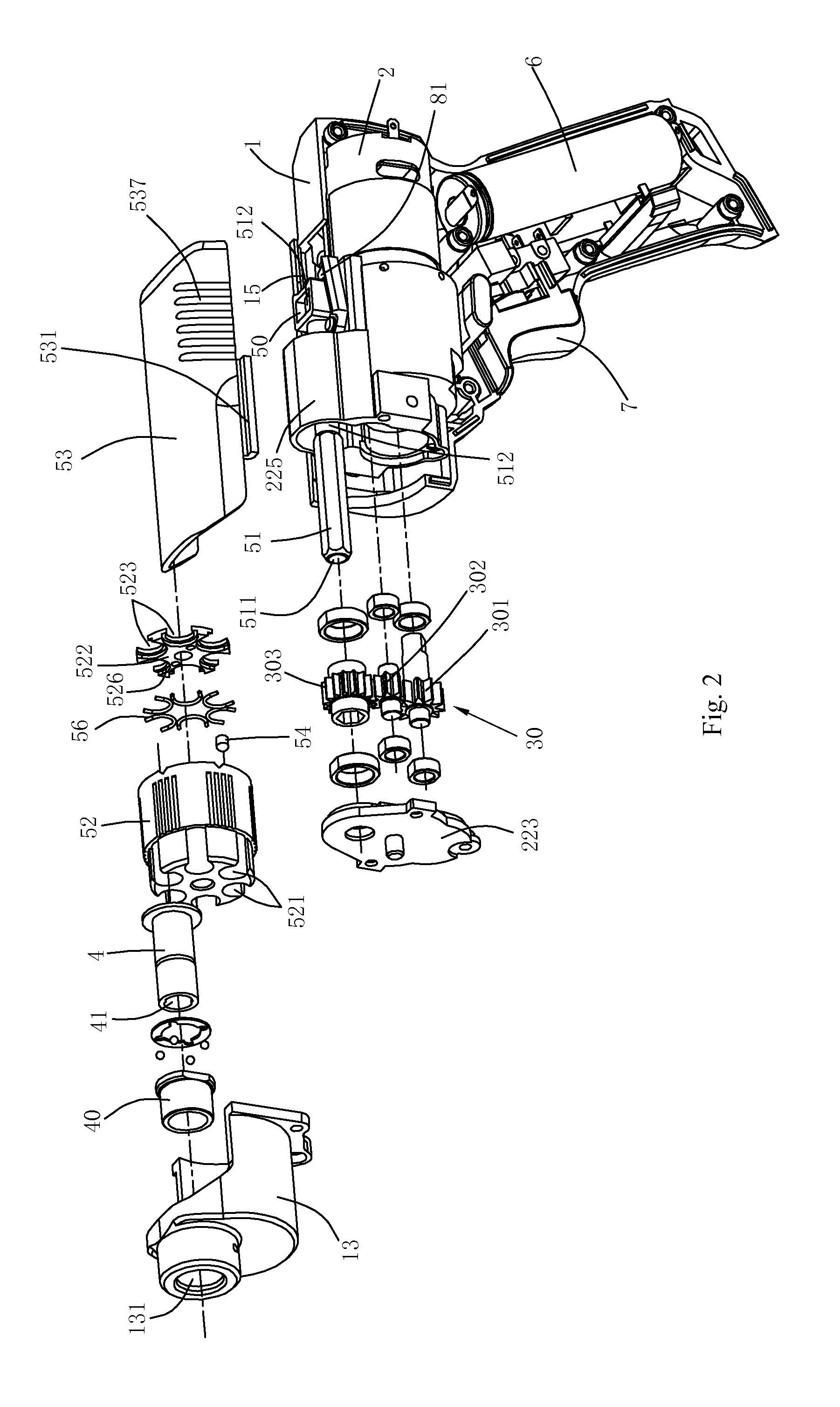

Impact power tool

InactiveUS7523791B2Reduce impactReduce shock vibrationReciprocating drilling machinesConstructionsEngineeringPower tool

An object of the invention is to provide an improved technique for lessening an impact force caused by rebound of a tool bit after its striking movement in an impact power tool. The representative impact power tool comprises a tool body, a hammer actuating member, a tool holder, a driving mechanism, a weight placed in contact with the hammer actuating member to move rearward by a reaction force transmitted from the hammer actuating member when the hammer actuating member performs a hammering operation on the workpiece and an elastic element elastically deformed when the weight moves rearward in the tool body to push the elastic element such that the elastic element absorbs the reaction force transmitted to the weight. The weight is defined one or both of the cylinder and the tool holder.

Owner:MAKITA CORP

Power impact tool

ActiveUS7588097B2Improve vibration damping effectDrilling rodsReciprocating drilling machinesRotational axisEngineering

It is an object of the invention to provide a technique for further improving the vibration reducing performance in a power impact tool that linearly drives a tool bit by using a swinging mechanism. According to the invention, a representative power impact tool is provided with a motor, a rotating shaft, a swinging member, a tool driving mechanism and a counter weight. The swinging member is supported by the rotating shaft to swing in the axial direction of the rotating shaft by rotation of the rotating shaft. The counter weight is disposed in a region higher than a lower end region of the swinging member in the vertical direction to intersect with the axis of the rotating shaft, and a lower end of the counter weight is connected to the lower end region of the swinging member. The counter weight extends upward from the connection between the counter weight and the swinging member and has a pivot point in the extending end portion, and when the swinging member swings, the counter weight is driven by the swinging member to rotate in the axial direction of the tool bit, thereby reducing vibration caused in the axial direction of the tool bit.

Owner:MAKITA CORP

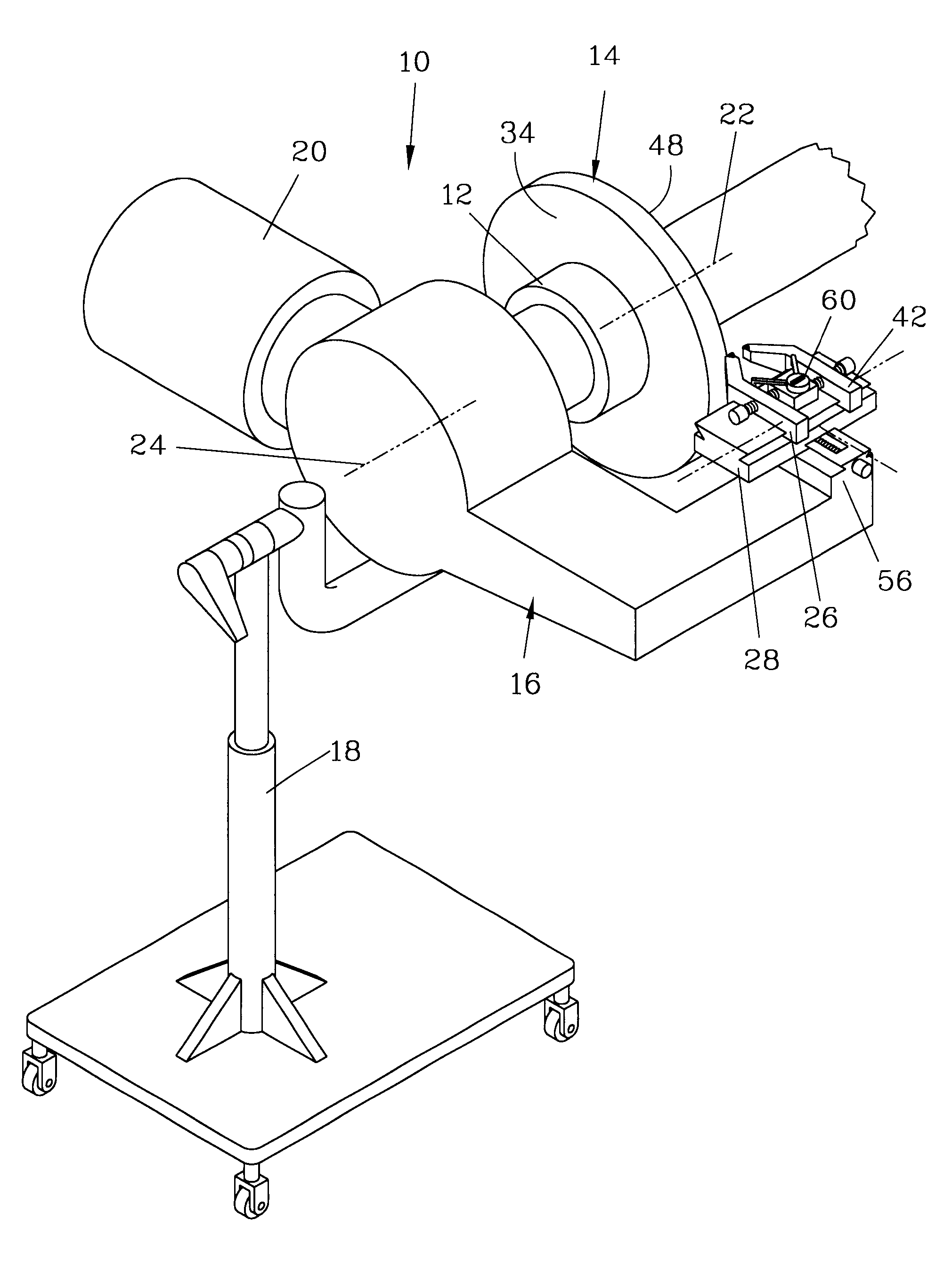

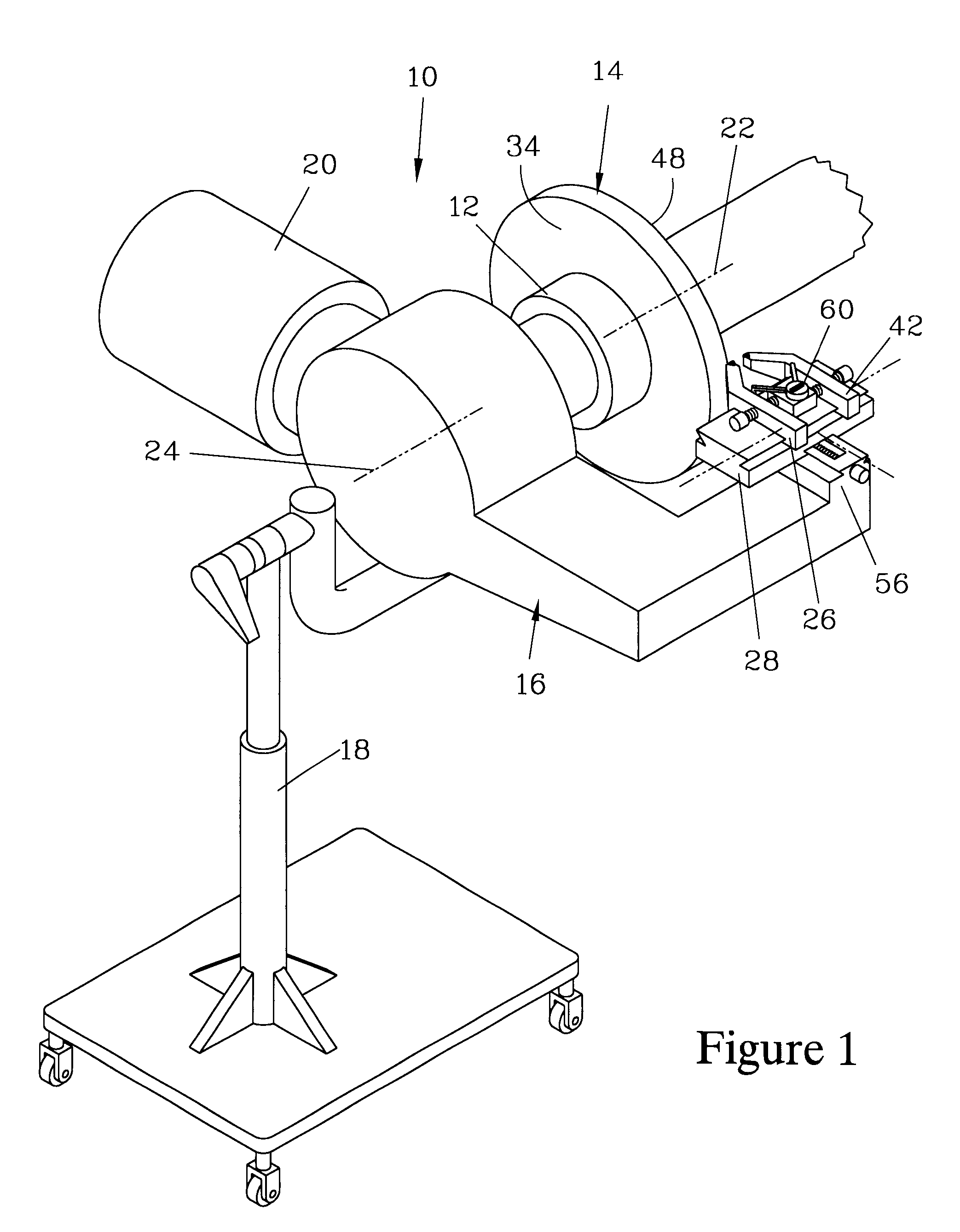

On-vehicle disk brake lathe

InactiveUS6363821B1Easy to adjustEasy to measureTurning machine accessoriesMeasurement/indication equipmentsTool bitEngineering

A disk brake lathe has a pair of tool bits mounted to tool holders which are translatable parallel to a lathe axis to adjust the separation of the tool bits from a brake disk. A displacement gauge responds to changes in the separation between the tool holders. When the tool bits are in continuous contact with the disk, the separation indicates the thickness which would result from machining the disk. This separation can be compared to a specification to determine whether to machine or discard the disk. A method for machining a disk starts by mounting and aligning the lathe to a wheel hub on which the disk is mounted. The tool bits are each advanced until they are in continuous contact the disk surfaces, when the separation of the tool bits is measured and preferably compared to a specification. When the tool bits are sequentially advanced, variation in the separation can be used to determine depth of cut for each tool bit. A system employing a brake lathe has a microprocessor which receives signals responsive to the separation between the tool bits of the lathe. One or more contact sensors indicate contact of the tool bits with the other tool bit or the brake disk, and the microprocessor can implement instructions to practice the above method. A surface displacement gauge can be employed to allow the system to measure the thickness and lateral run-out of the disk prior to machining.

Owner:BONITA IP

Wood Working Machine

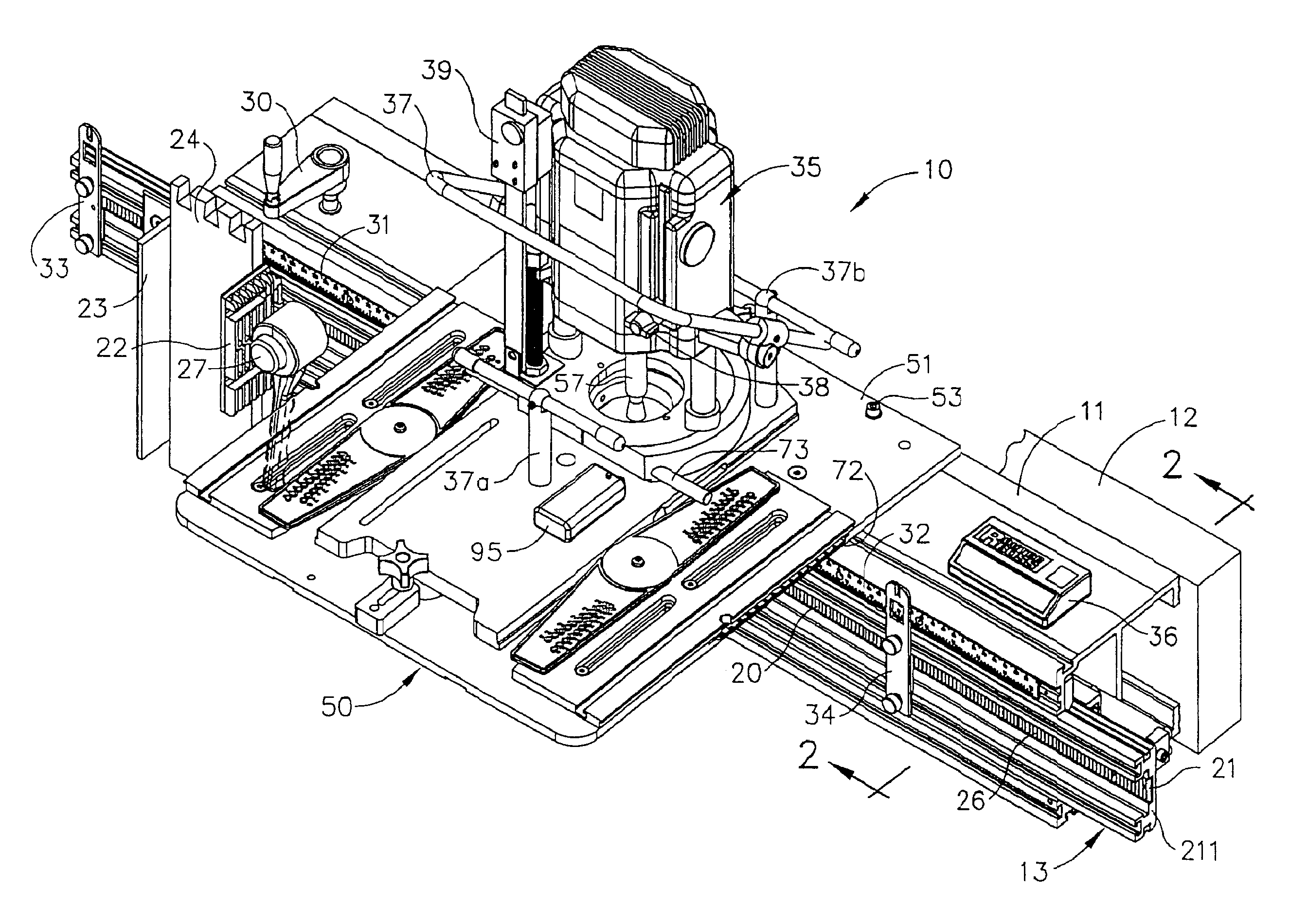

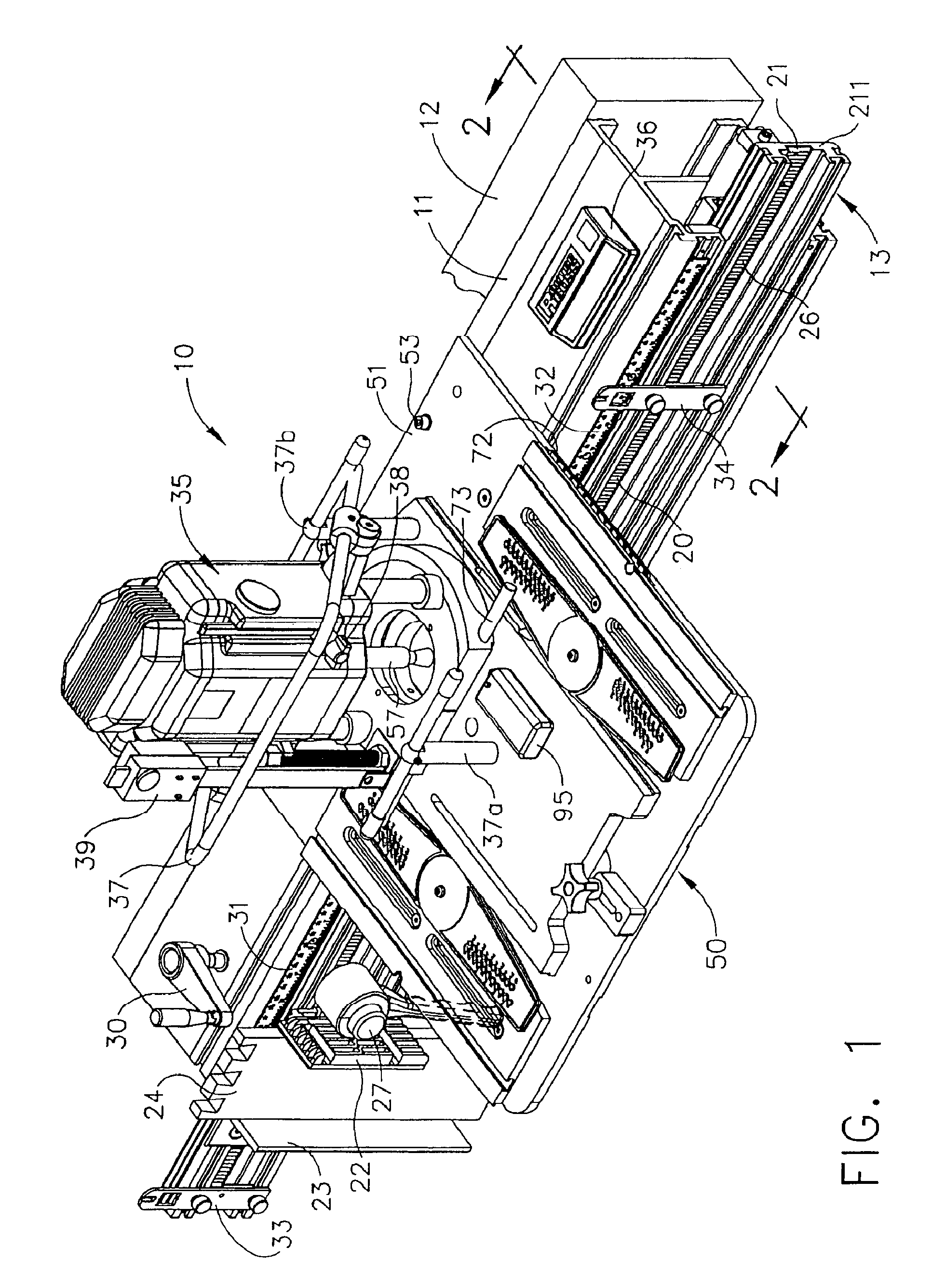

InactiveUS20090188584A1Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workWoodworking machineLaser source

A wood working machine is described that includes a mounting plate assembly for supporting a cutting tool, the mounting plate assembly including a base plate, first and second spaced apart intermediate plates on the base plate, and first and second guide plate elements pivotally supported on respective first and second intermediate plates, and a cutting tool support plate slidably disposed between the first and second guide plate elements, the guide plate elements including means defined therein for positioning each of the guide plate elements at selected angular intervals with respect to the respective first and second intermediate plates, whereby the cutting tool support plate is slidably movable on the base plate between the guide plate elements at a prescribed angle. The mounting plate assembly may include laser sources providing crossed laser beams for accurately positioning the tool bit of the cutting tool near a work piece, and light sources for illuminating the tool bit. A digital sensor may be included for precise positioning of the work piece held beneath the base plate on a movable carrier.

Owner:STEPP LEWIS E

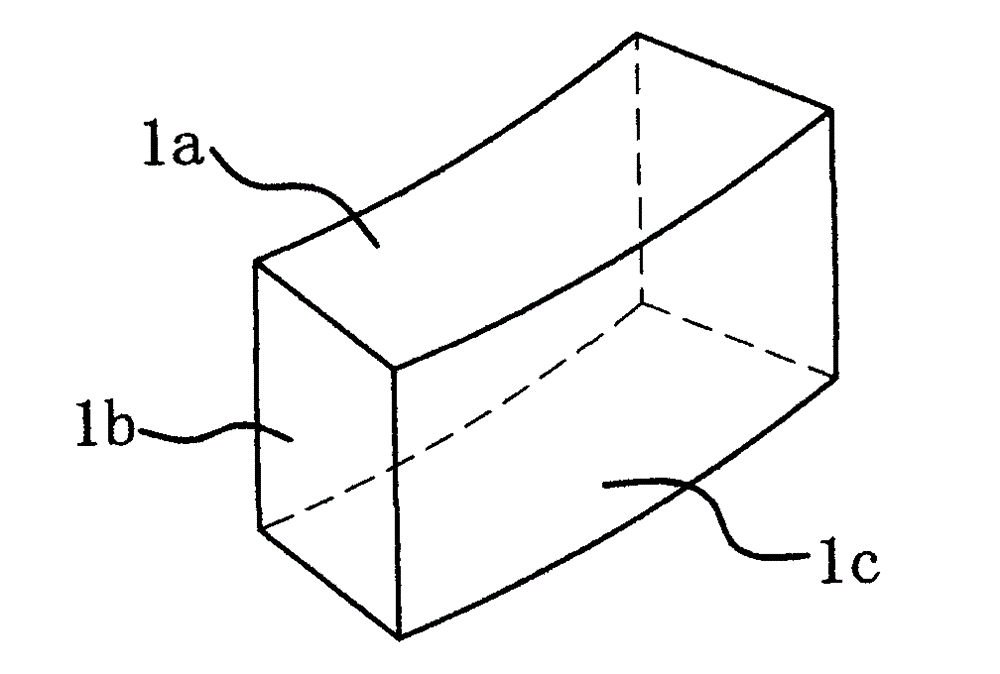

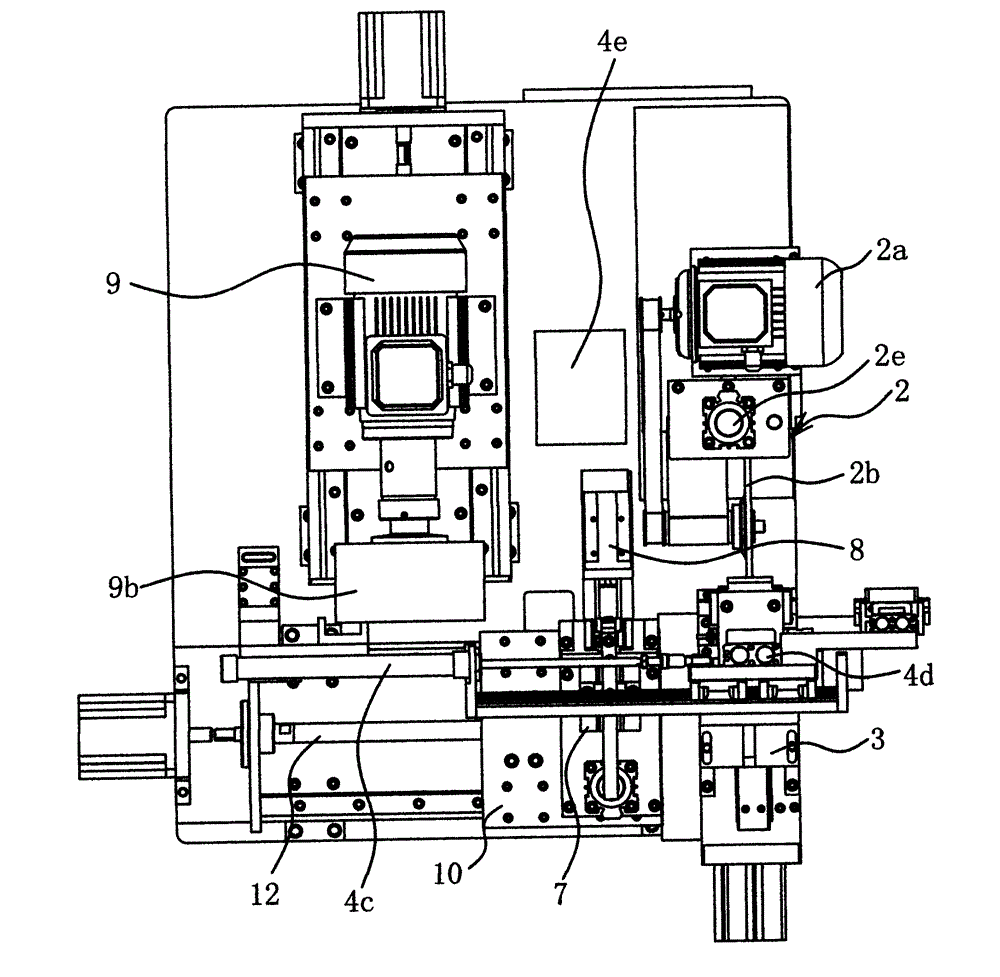

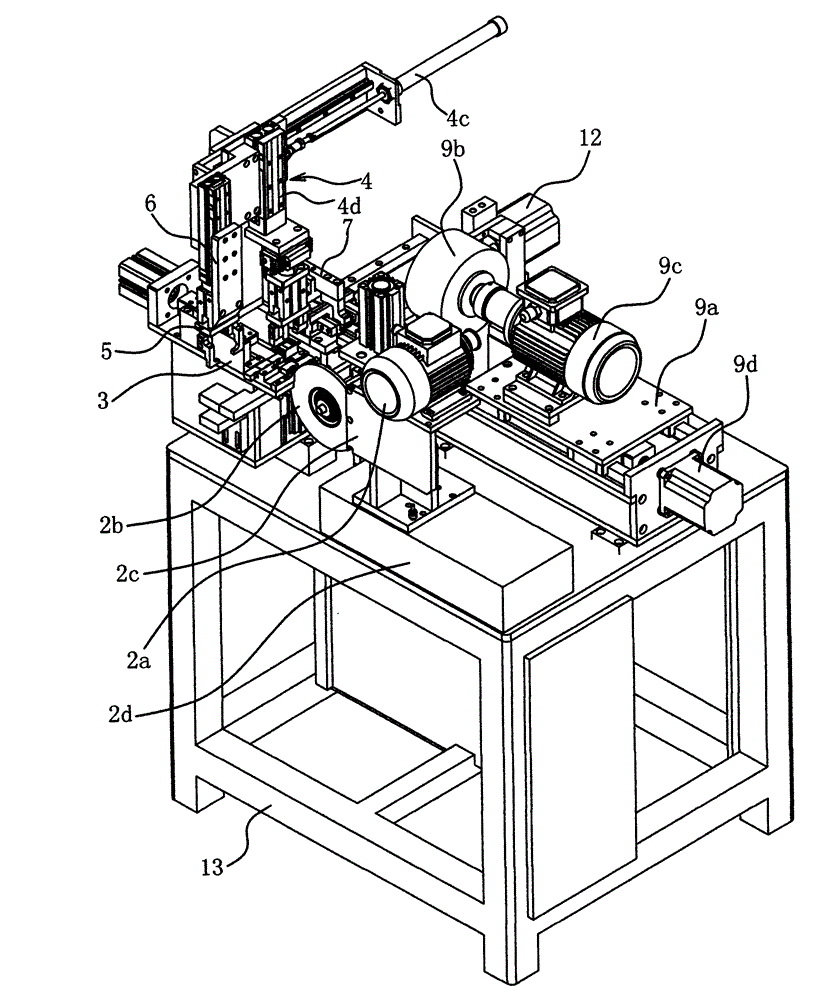

Diamond tool bit bottom surface grinding device

ActiveCN103331488AEasy to produceLabor savingSawing tools dressing arrangementsDrilling toolsTool bitSurface grinding

The invention provides a diamond tool bit bottom surface grinding device, which belongs to the technical field of the operation. The problem that the traditional diamond tool bit bottom surface grinding has low production efficiency because of grinding by a common machine tool is solved. The diamond tool bit bottom surface grinding device comprises a rack, wherein the rack is provided with a first grinding mechanism, a transfer discrimination mechanism and a second grinding mechanism, wherein the first grinding mechanism can be used for grinding the certain end surface of a diamond tool bit into a bright surface; the transfer discrimination mechanism can be used for transferring out the diamond tool bit capable of grinding the certain end surface of the diamond tool bit into the bright surface, can be used for judging whether the bright surface is positioned on the bottom surface or a tool surface and enables the diamond tool bit to face to the same direction according to the judgment result; and the second grinding mechanism can be used for bearing the diamond tool bit with the same facing direction of the transfer discrimination mechanism and can be used for grinding the diamond tool bit bottom surface. The diamond tool bit bottom surface grinding device has the advantages of convenience in production, labor force saving, high automation degree and high efficiency. According to the test, the diamond tool bit bottom surface grinding device can be used for grinding ten diamond tool bit bottom surfaces in one minute.

Owner:ZHEJIANG BANNINGER FLUID CONTROL CO LTD

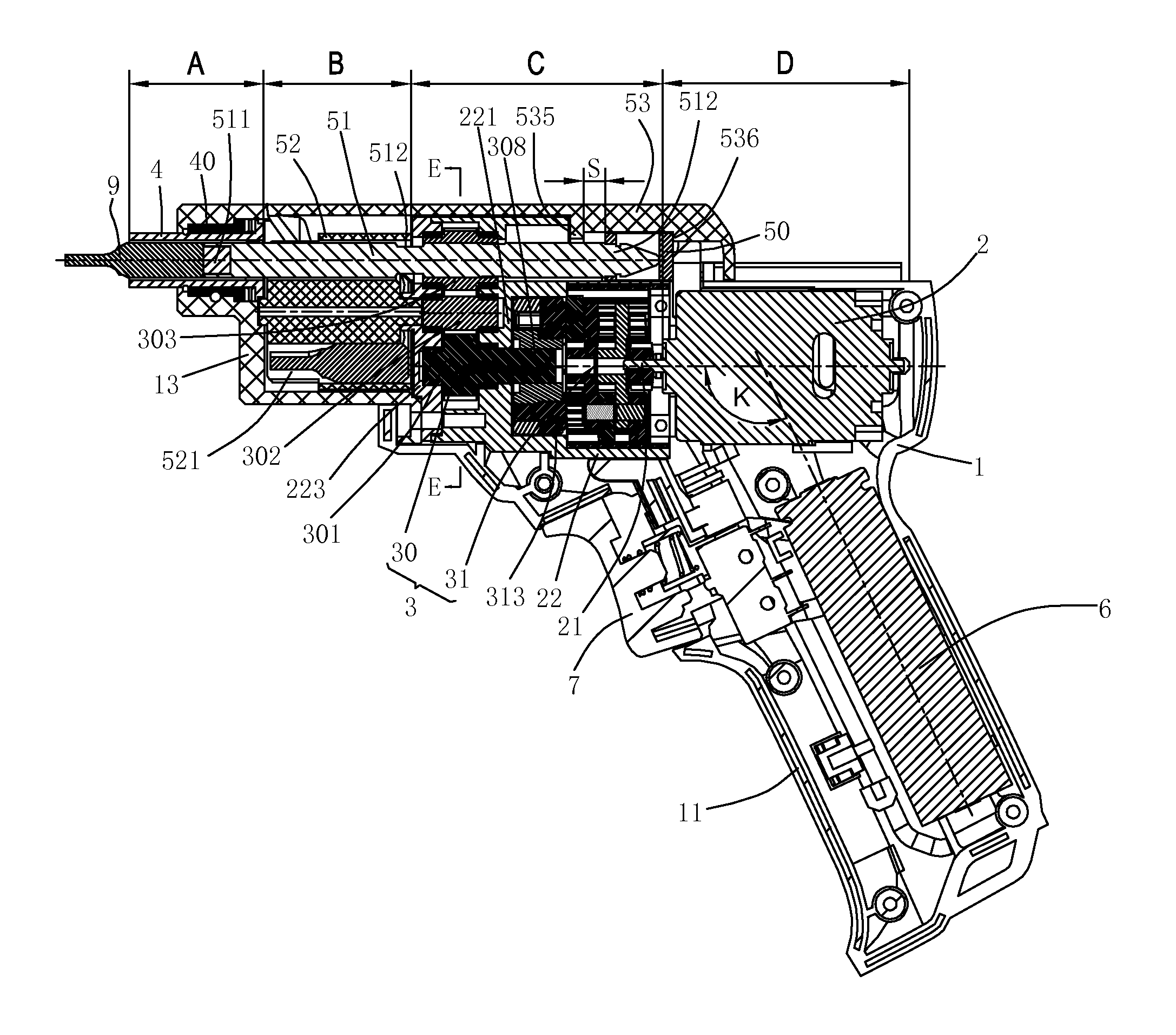

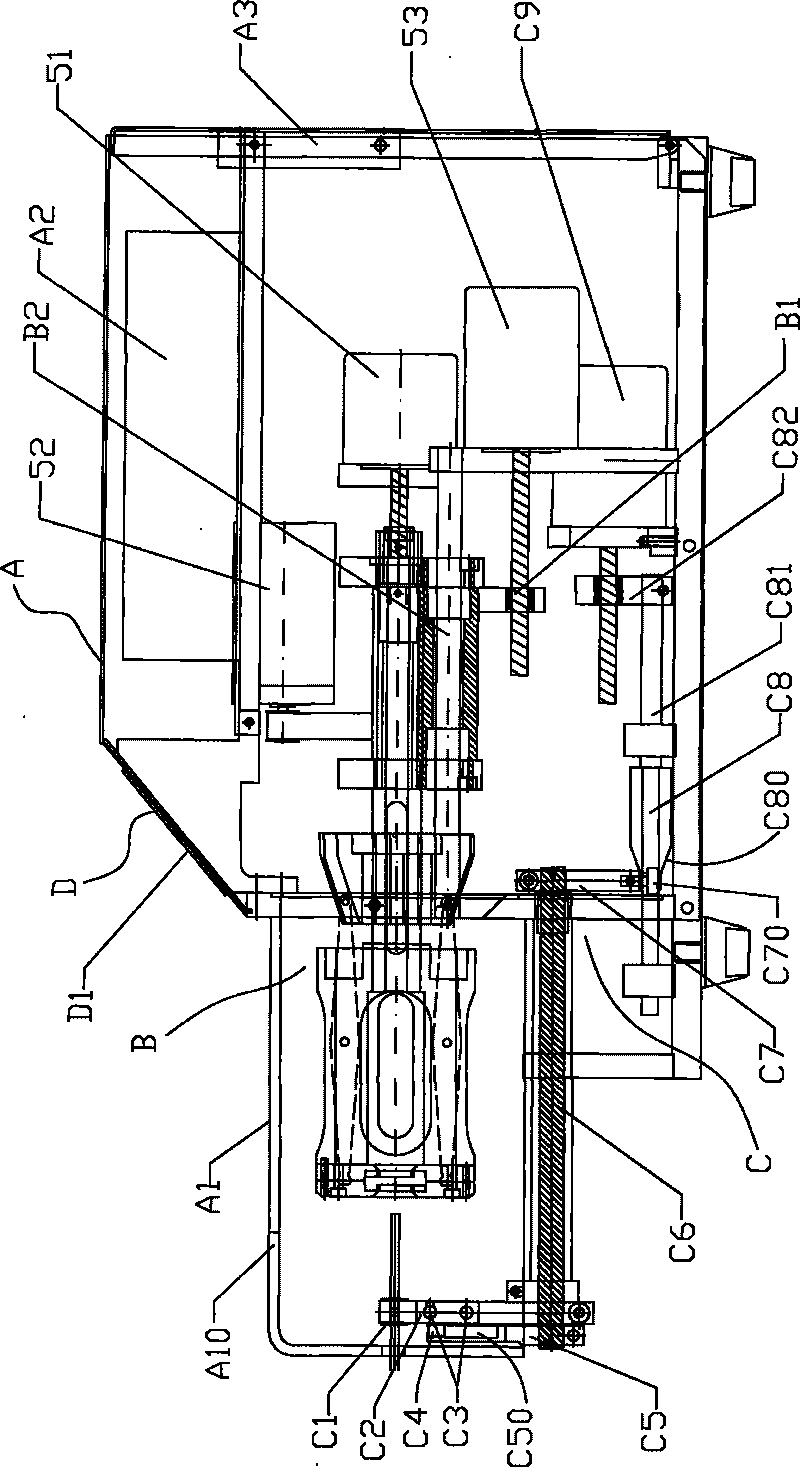

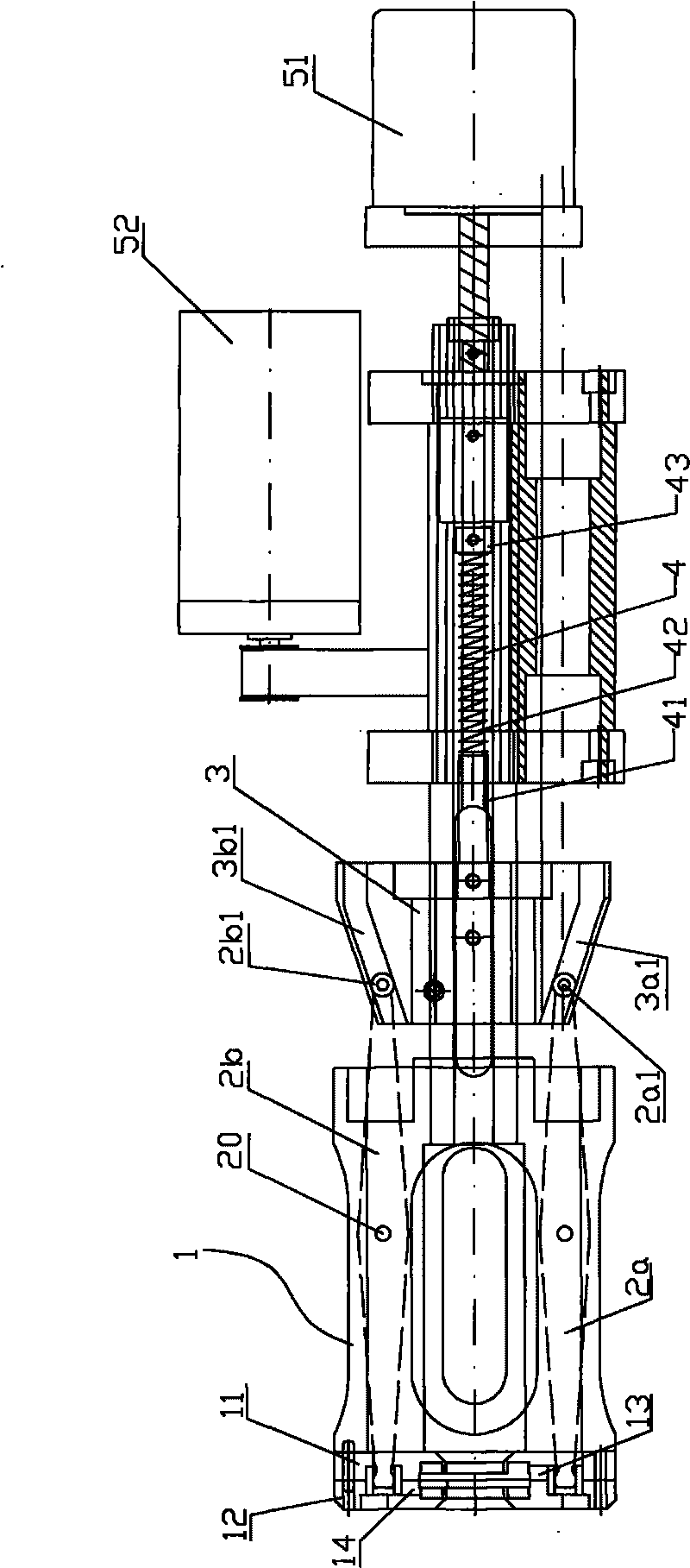

Power tool and operation method for the power tool

ActiveUS20130032368A1Easy to useFast typingDrilling rodsConstructionsPower toolMoving between two positions

A power tool, including: a housing, a motor, arranged in the housing and outputting rotary force, a connecting shaft, adapted to one of a plurality of tool bits, a transmission mechanism, arranged between the motor and the connecting shaft and transmitting the rotary force from the motor to the connecting shaft, a cartridge, the cartridge includes a tool chamber for receiving the plurality of tool bits, the connecting shaft being capable of moving axially between a working position wherein the connecting shaft is adapted to the tool bits and a release position wherein the connecting shaft is separated from one of the plurality of tool bits, and a restricting member, the restricting member operable to move between two positions; at a first position, the restricting member limits the movement of the connecting shaft; and at a second position, the restricting member allows the connecting shaft to move.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Coaxial line stripping machine

ActiveCN101764379APrevent deviationEnsure positioning accuracyLine/current collector detailsApparatus for removing/armouring cablesTool bitCoaxial cable

The invention relates to a coaxial line stripping machine, which is provided with a case. A tool bit unit, a line clamping unit and a control unit are arranged in the case; the tool bit unit is provided with a rotating tool bit seat which is provided with a cutter arm and a positioning tool arm; the middle parts of the cutter arm and the positioning tool arm are pivoted to the rotating tool bit seat together; and the tool bit unit is also provided with a tool-pushing seat which is formed by detachably embedding a blade tool-pushing seat and a positioning blade tool-pushing seat along the axial line. The invention can control the tool bit unit and the line clamping unit by using a control system of the control unit and can flexibly control whether various motors need to simultaneously run or not, the running speed and the like according to the requirement, thereby realizing the operations of stripping in a multilayer, layer by layer, rotating and other ways. The invention solves the problems of inaccurate cable positioning, low cutting precision and the like of a traditional coaxial line stripping machine.

Owner:DONGGUAN WINGUD MECHANICAL EQUIP CO LTD

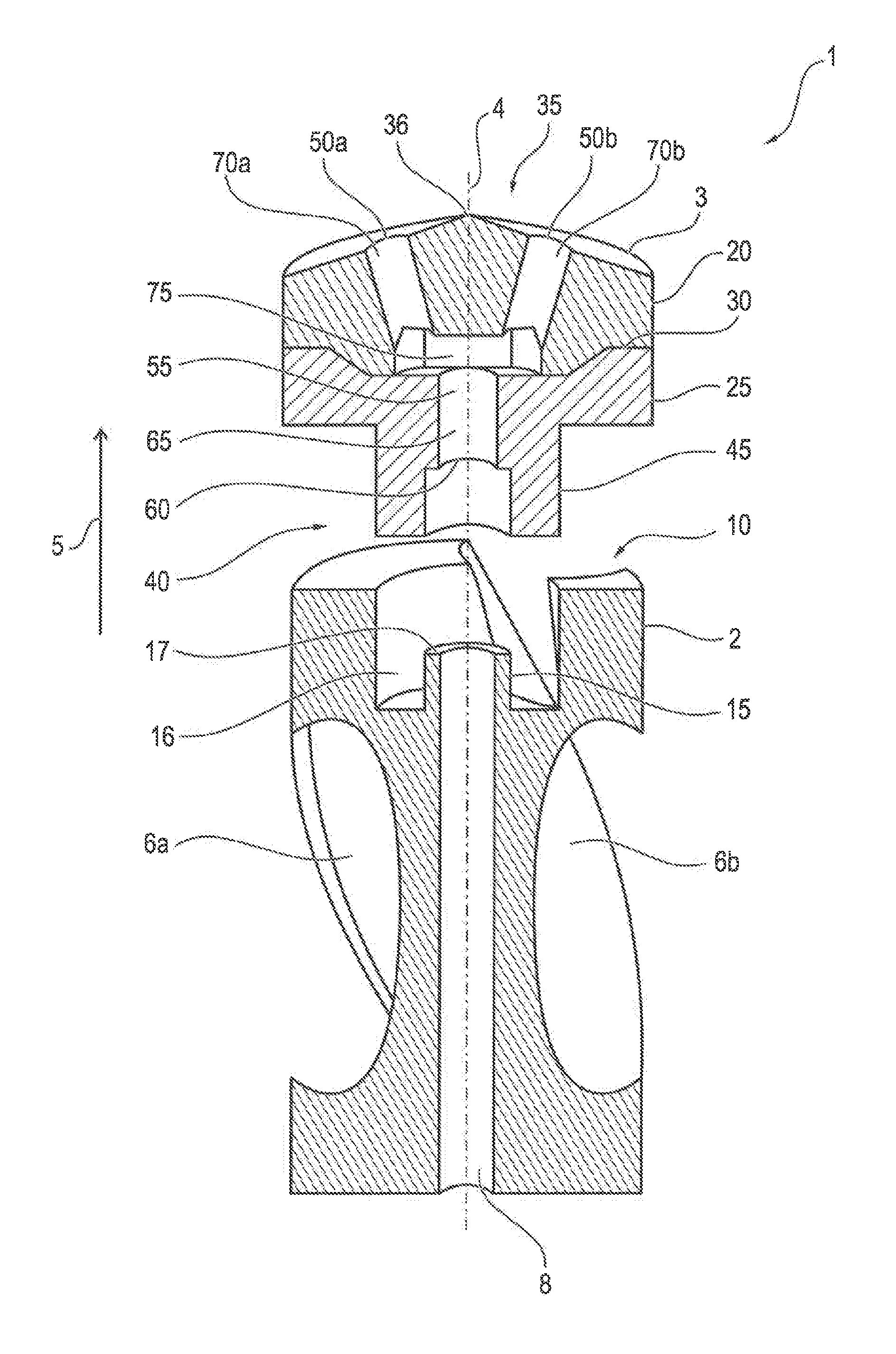

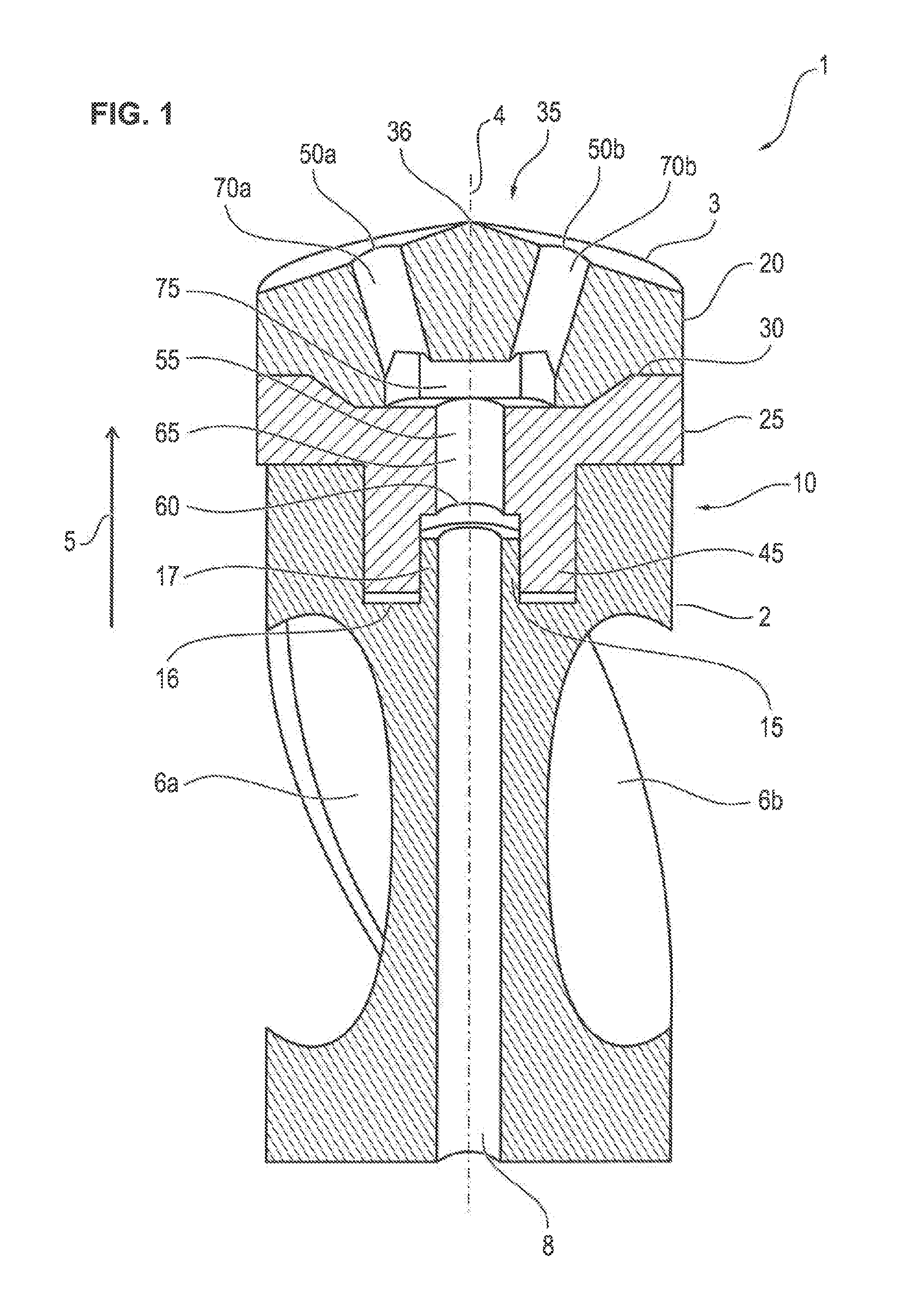

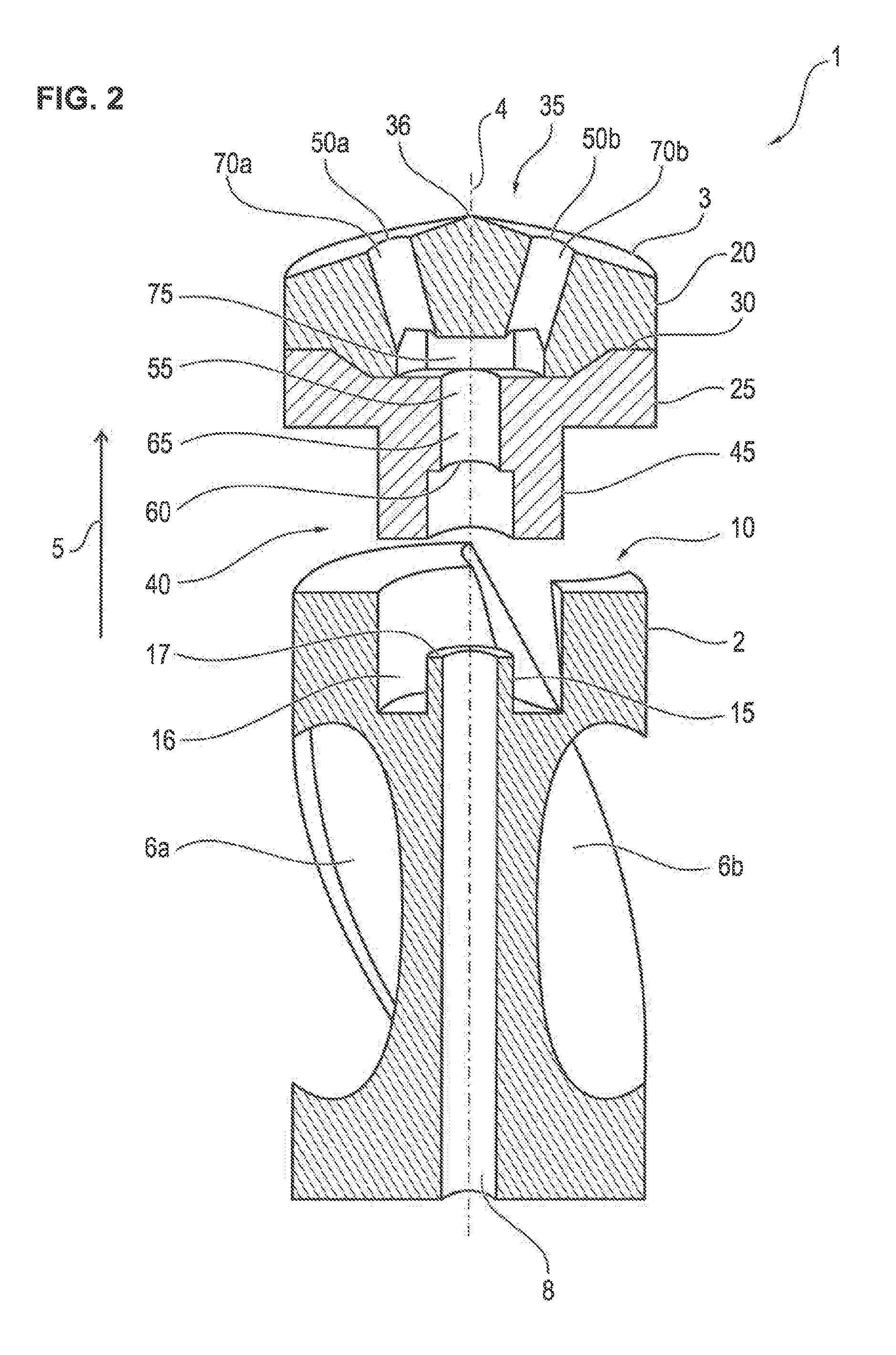

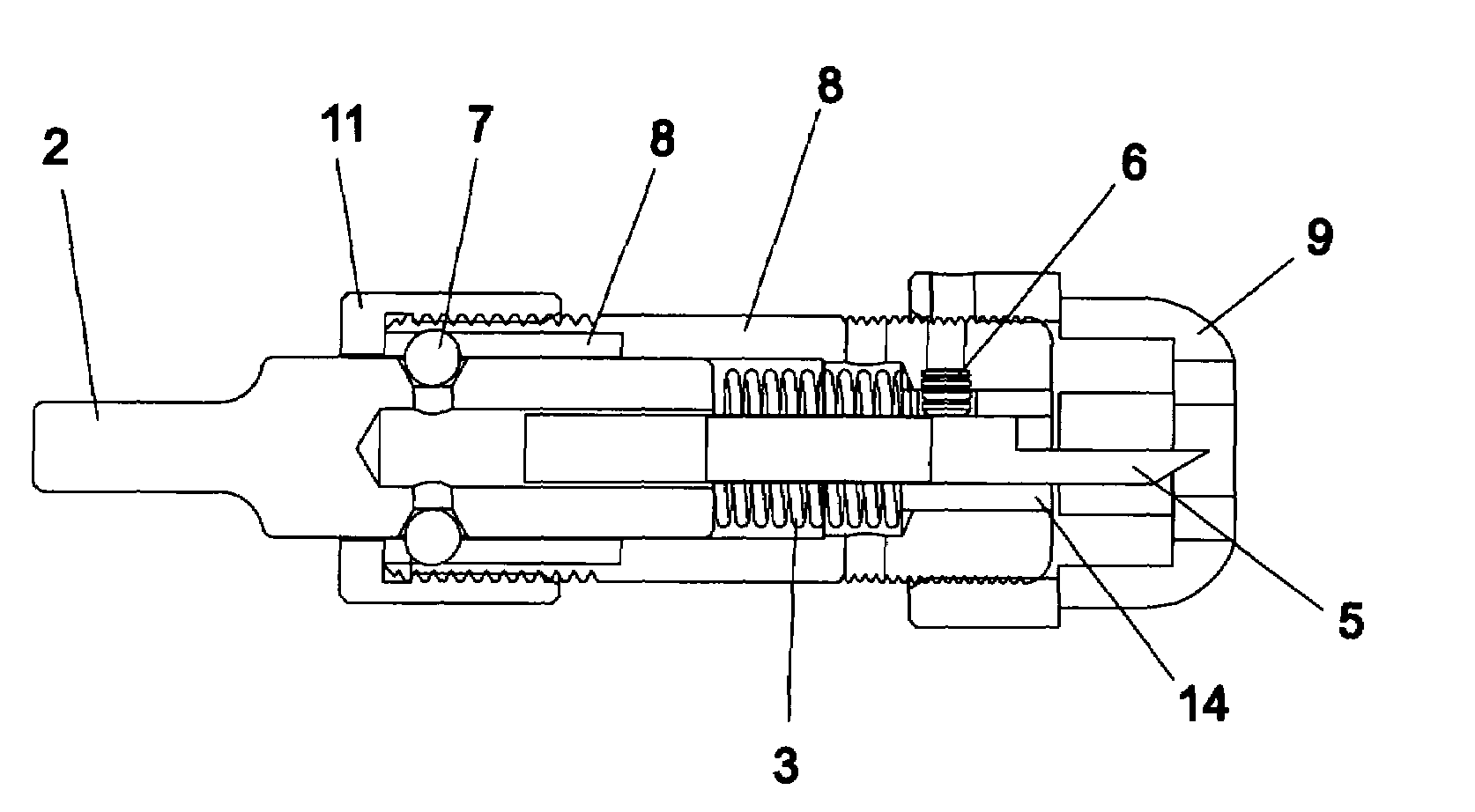

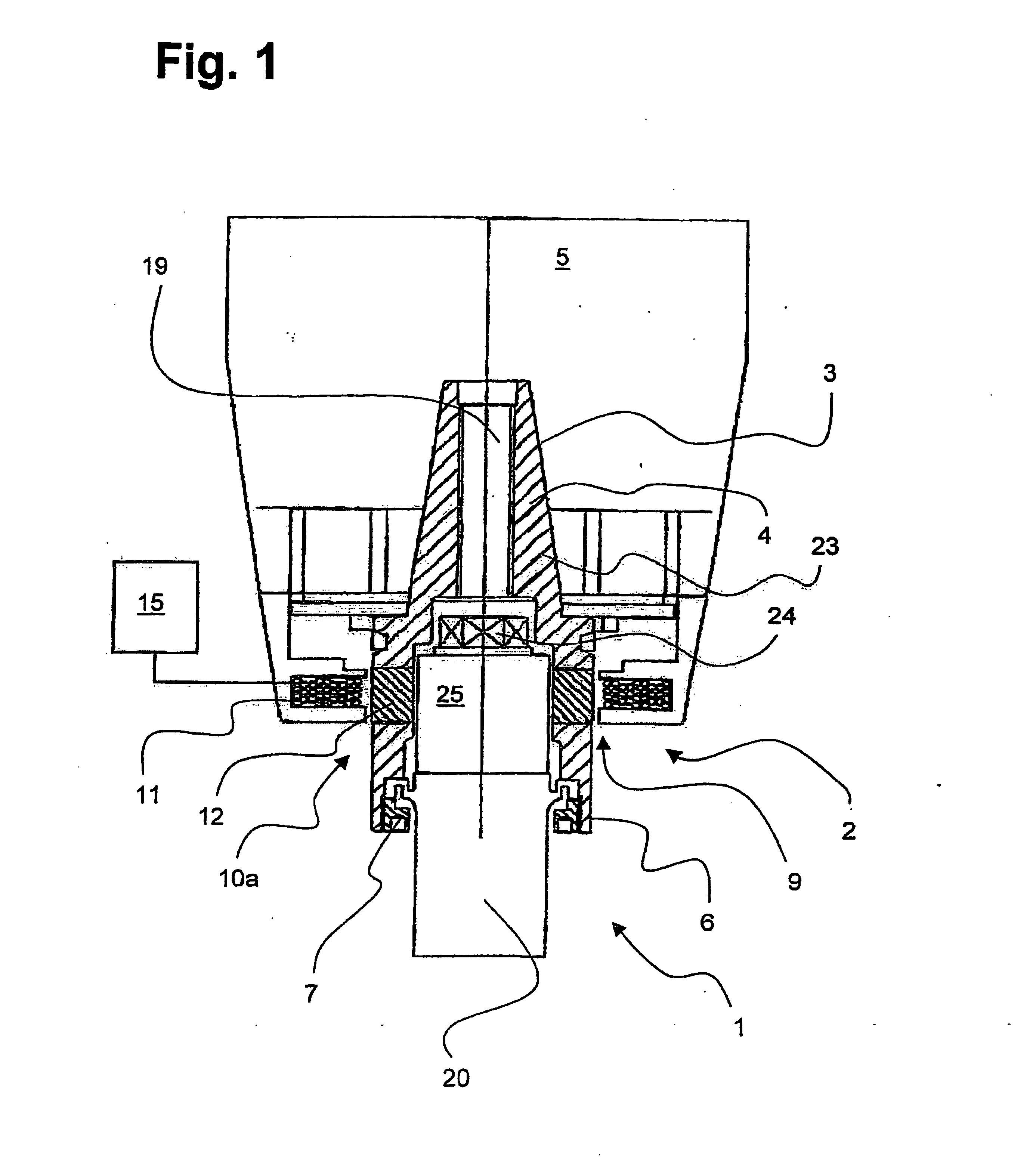

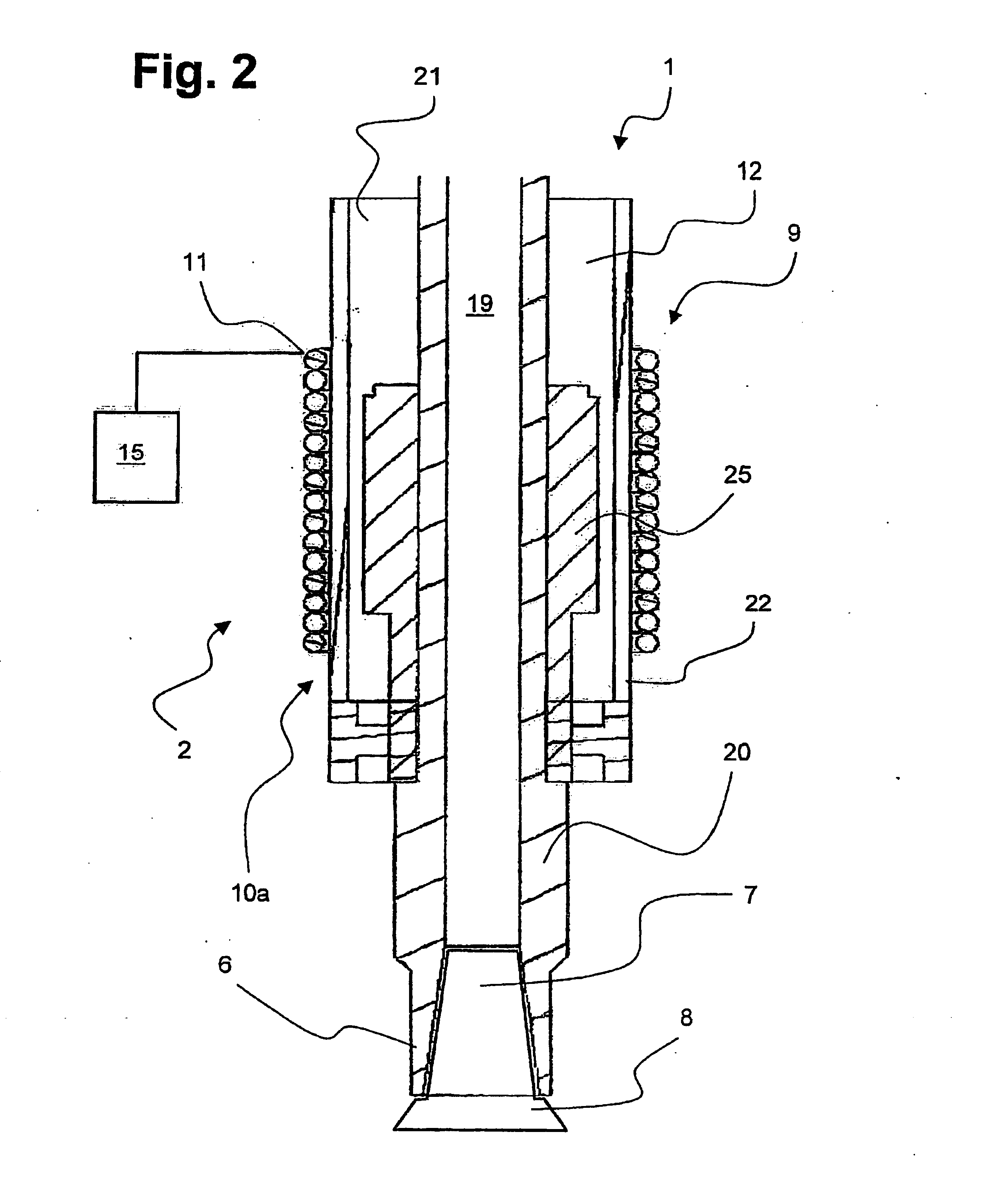

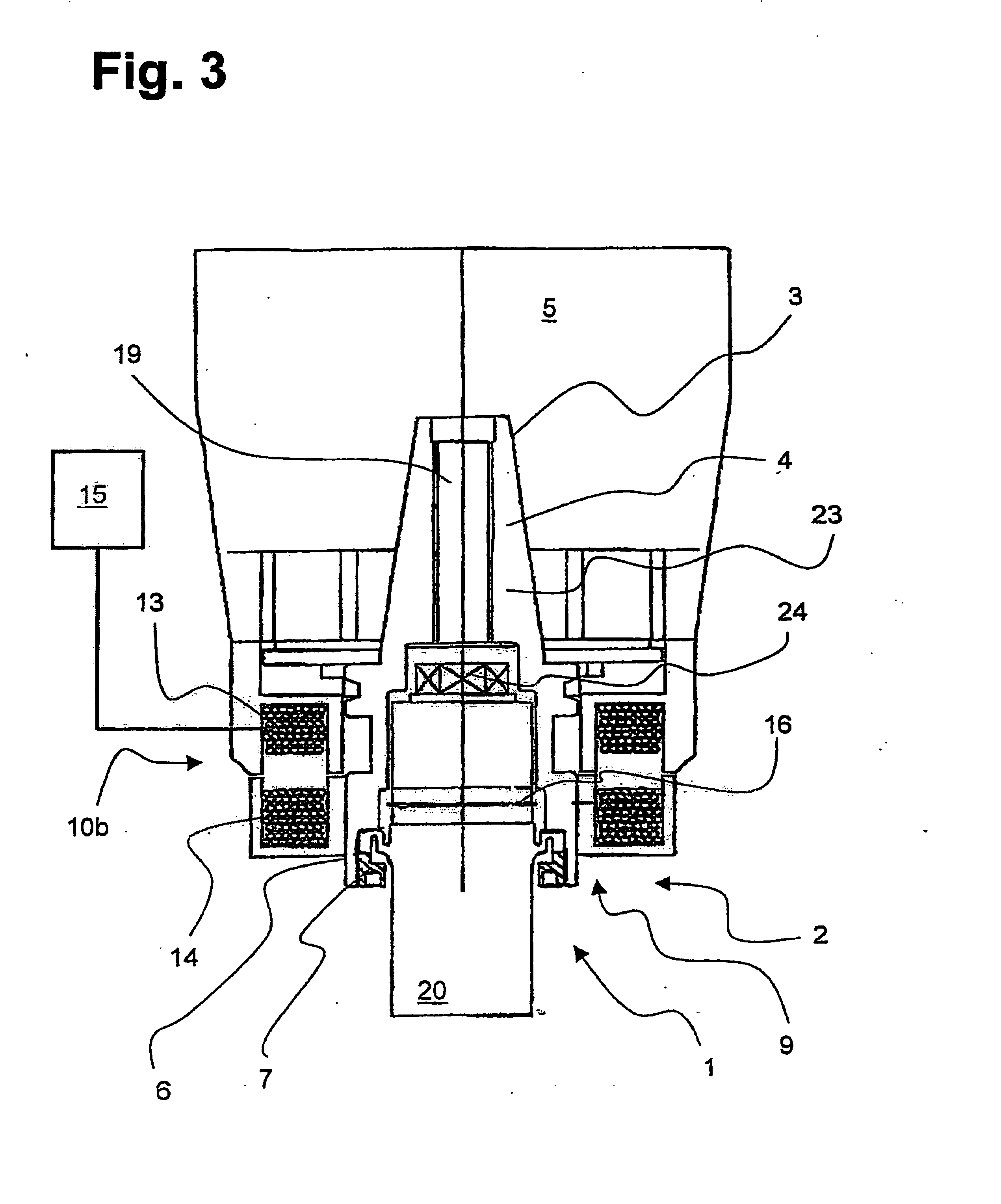

Tool with an Oscillating Head

ActiveUS20080041604A1Low-wear operationSusceptibility is insufficientDrilling rodsConstructionsTool bitMachine

The invention relates to a tool (1) comprising a tool holder (2), which has on a first end (3) a tool holder recess (4) that is adapted to the contours of a rotating spindle driver (5) and a tool recess (7) on a second end that lies opposite the first end (6). The tool holder also comprises a tool head (8) that can be inserted into the tool recess (7). For the optimal machining of a workpiece, attempts were previously made to provide an oscillating unit in the spindle of the machine, to initiate oscillations in the tool head. The disadvantage of said known constructions is that all available tools have to be synchronized with the oscillation unit. The invention overcomes said disadvantage by equipping the tool holder (2) with an oscillating motor (9).

Owner:SAUER GMBH

Engraving tool depth control nosepiece for enhancing line uniformity

Engraving tool bit depth controlling nosepiece adjustment devices establish a precise protrusion distance that an engraving tool bit protrudes from the end of the nosepiece of a spring loaded engraving tool, that is in turn inserted within and driven by a standard machine tool such as a cnc type milling machine. One rotational adjustment device establishes the axial position of the nosepiece with respect to a collet nut of the engraving tool and another adjustment device employs annular ring spacers in the form of washers between the nosepiece and collet nut to precisely establish the desired engraving tool bit protrusion distance from the end of the nosepiece. This modification of a spring loaded engraving tool beneficially prevents the engraving tool bit from being able to plunge too deeply into the workpiece, particularly at the start of each engraved line, to thus ensure that all the lines will be consistent.

Owner:NELSON LANCE

Screw driver with bit storage cylinder

A base carries a positionable hand grip. A cylinder is rotatably mounted on the base and carries multiple bits for driving various types of fasteners. An ejector rod on the base propels a selected bit from the cylinder through a drive tube to an exposed position. A base carried spindle imparts rotational movement to drive component and the drive tube. Magnetic components assist in positioning and retention of the screw driver bits.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com