Patents

Literature

463results about "Investigating machinability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

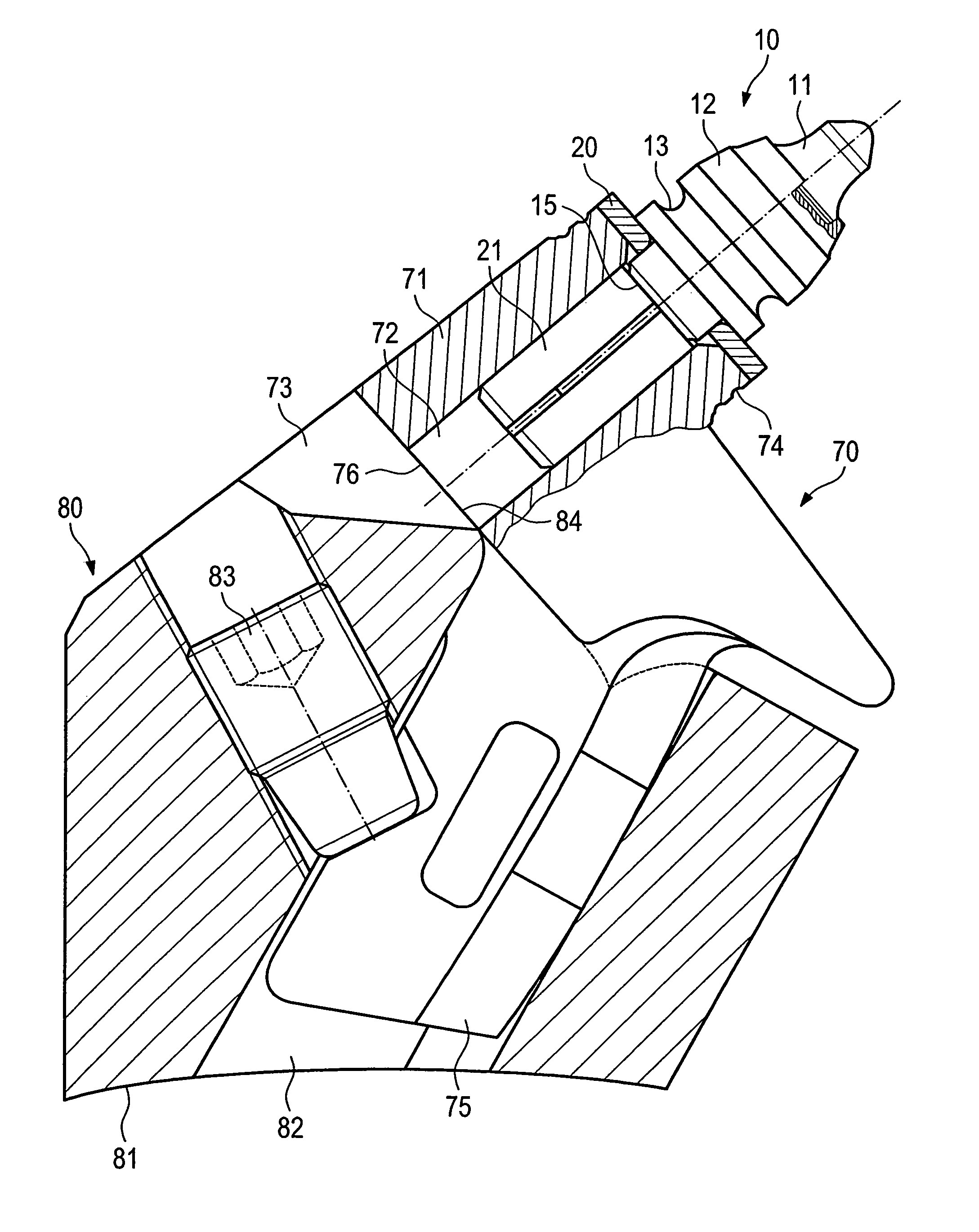

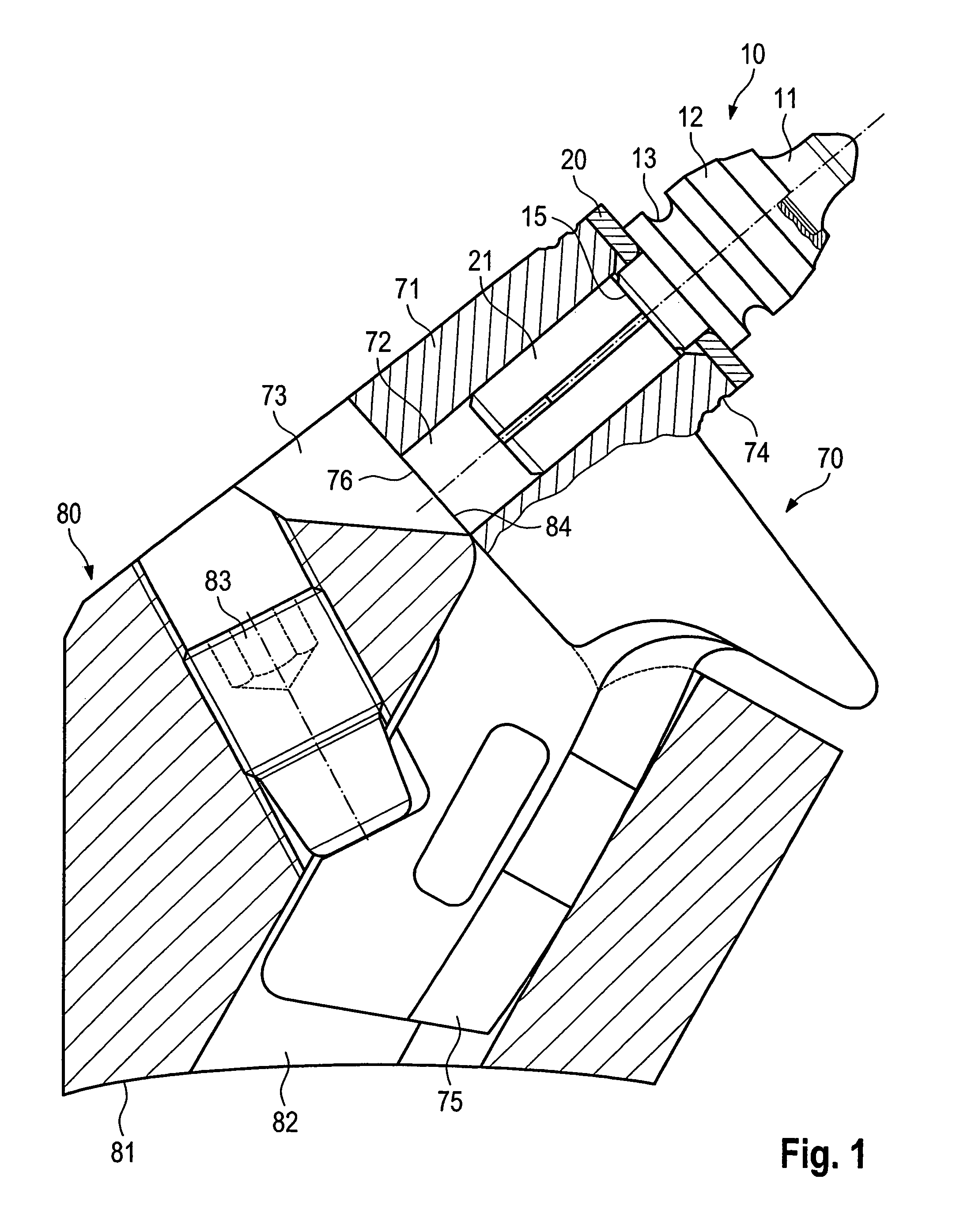

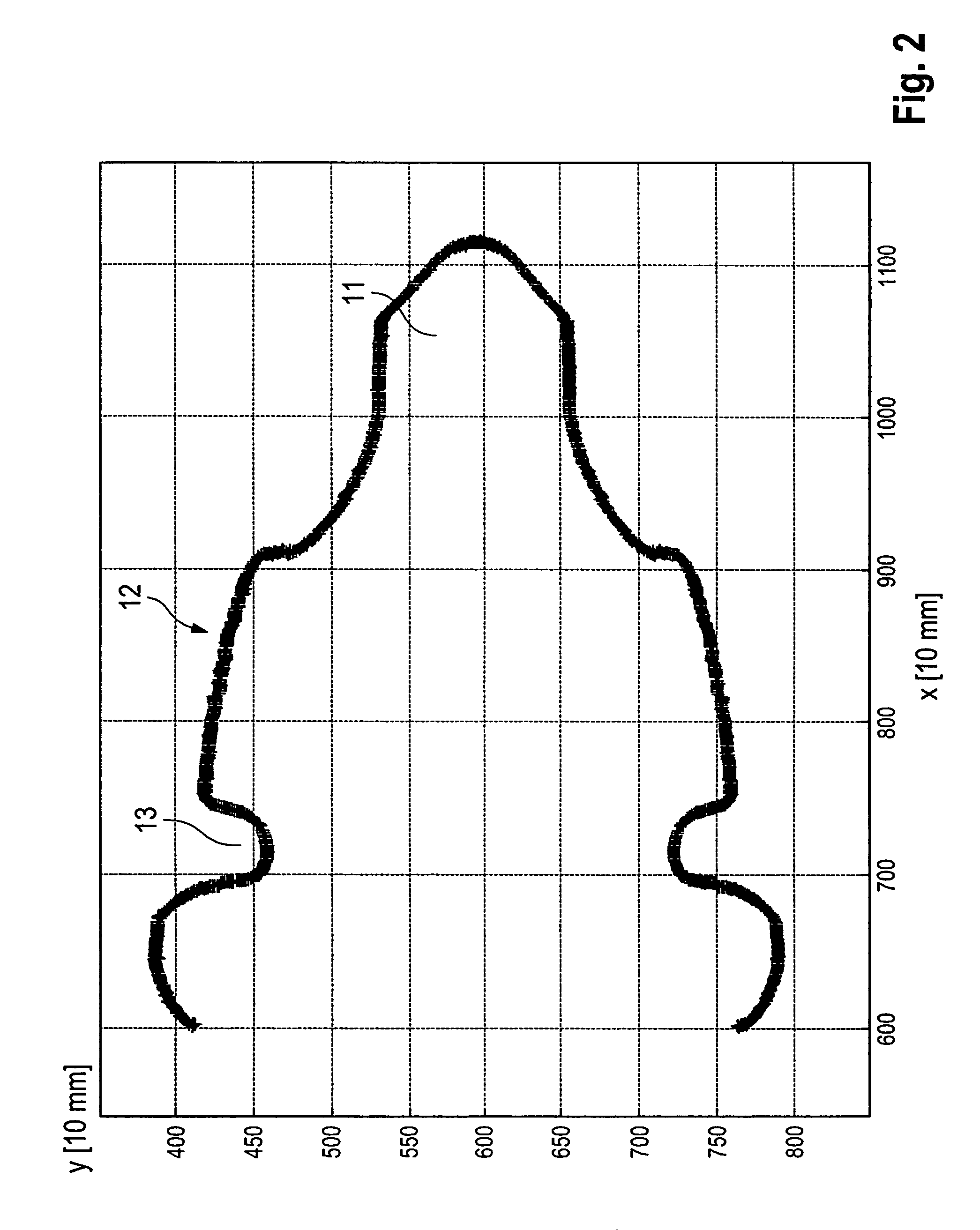

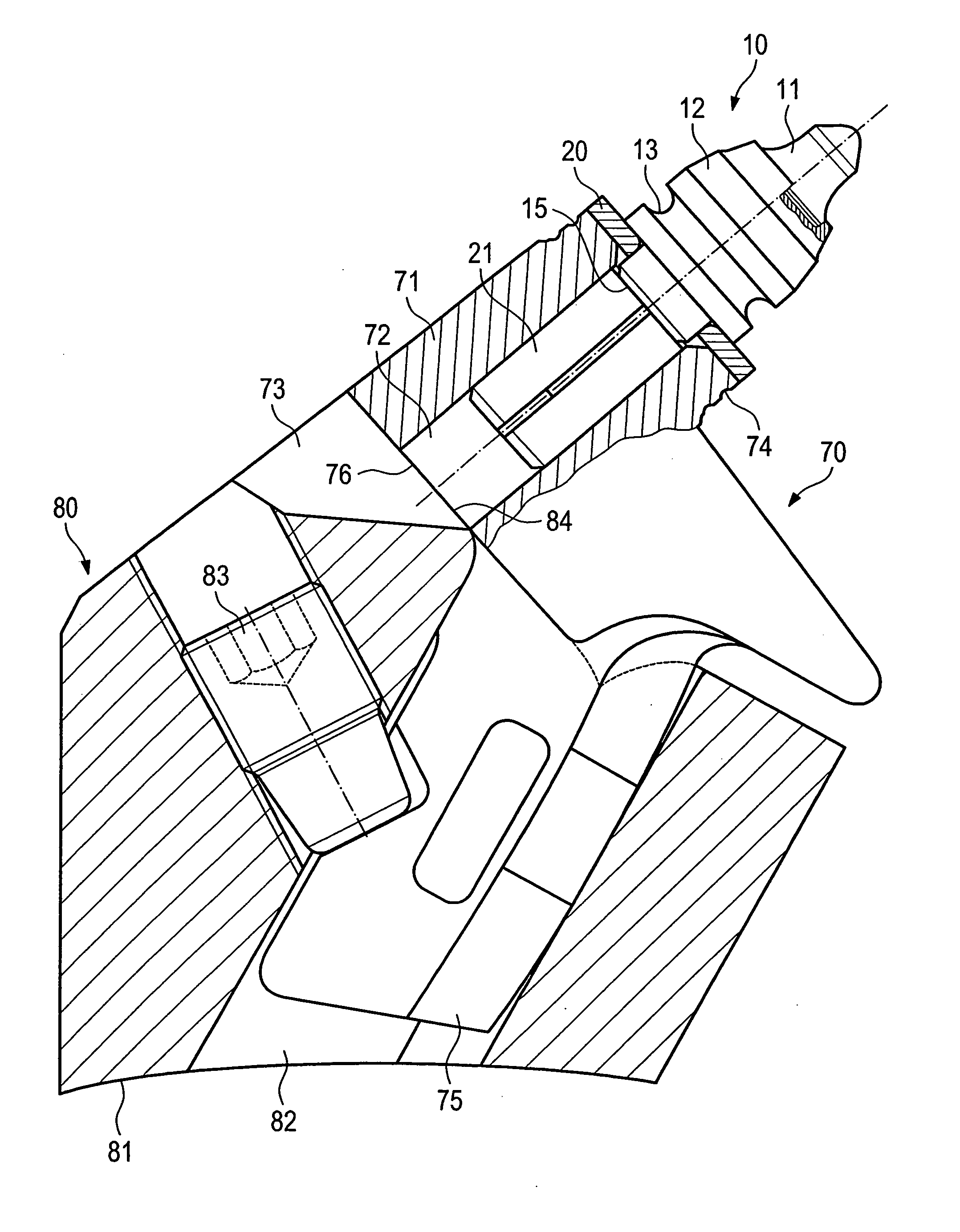

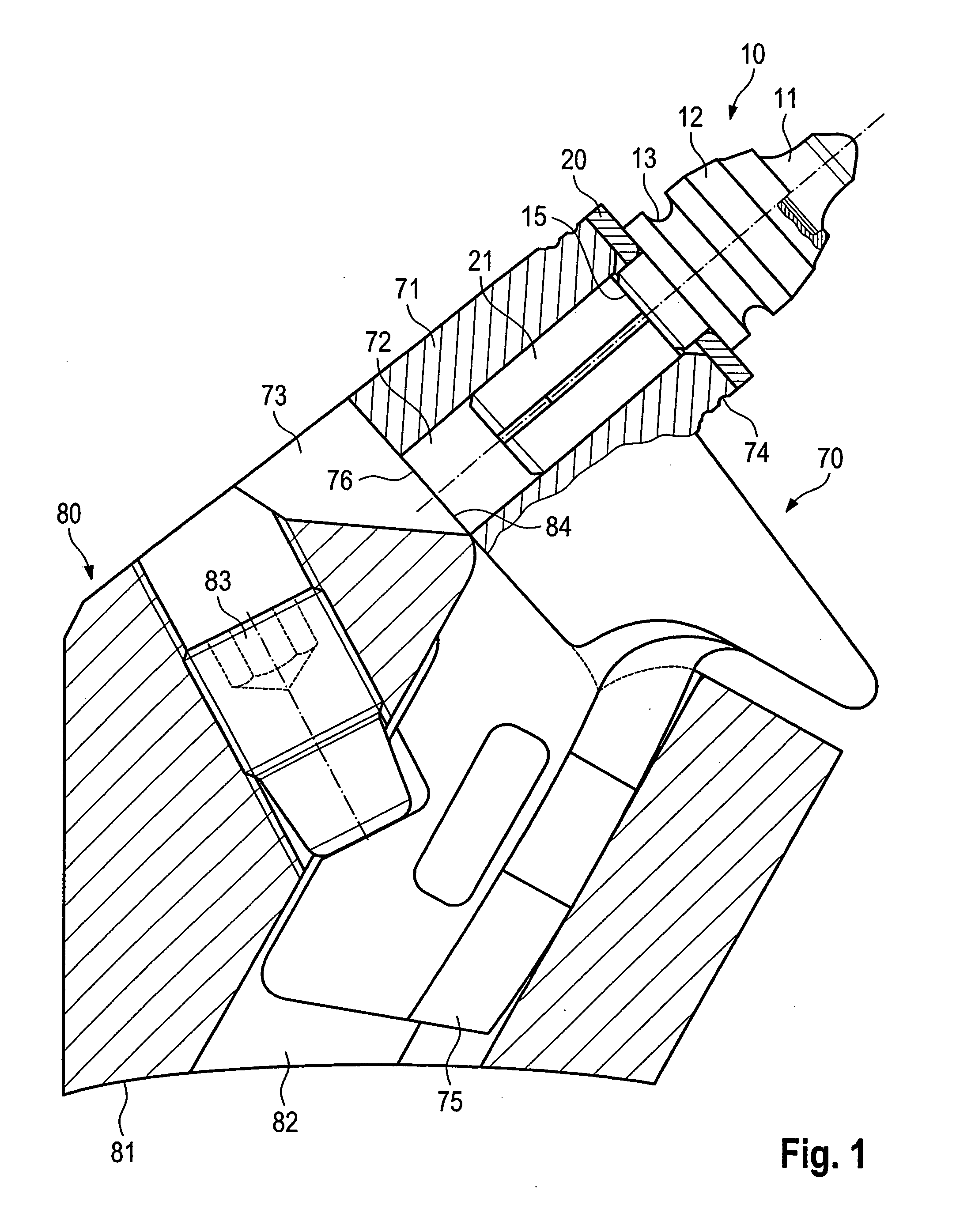

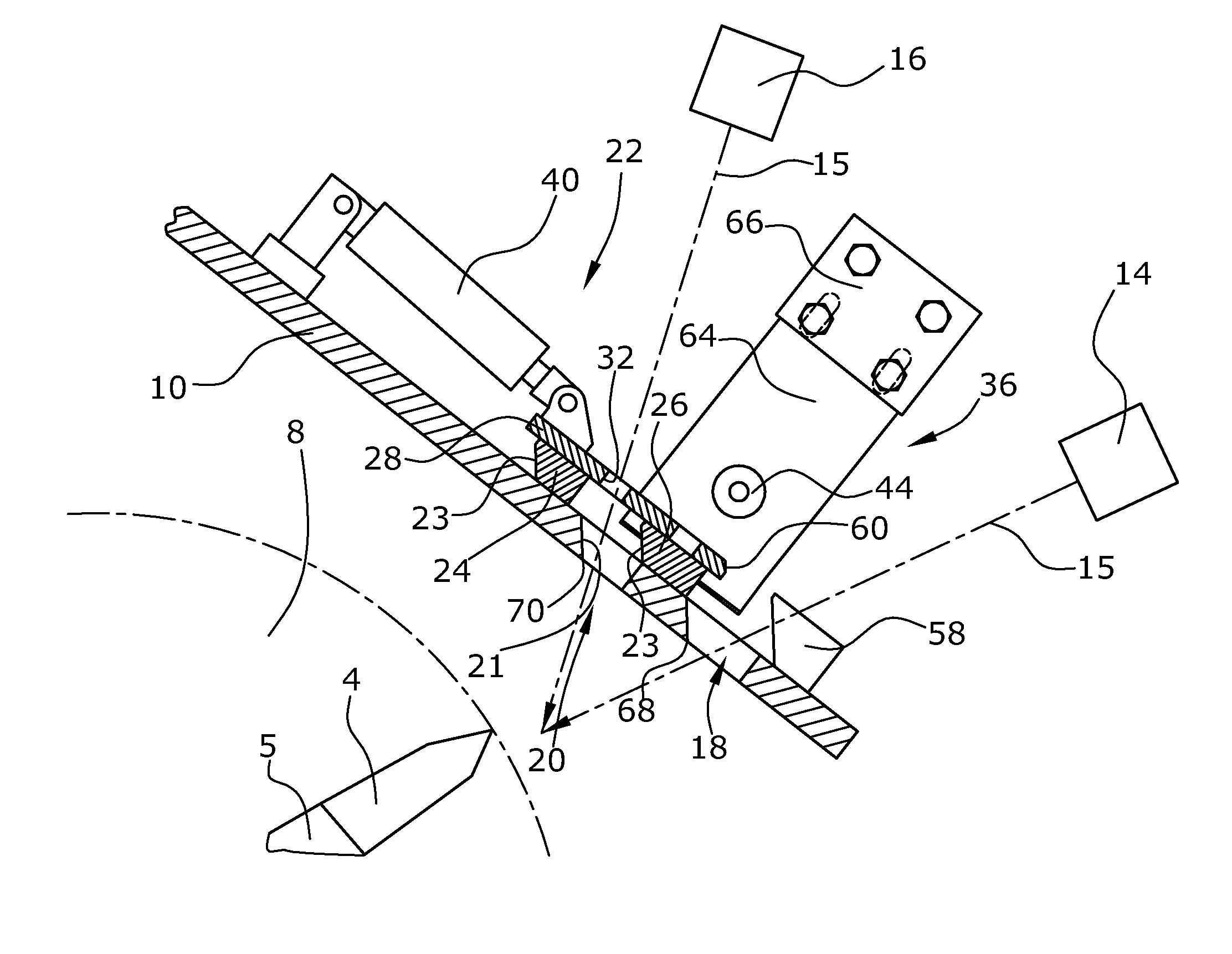

Method for determining the wear state

This invention relates to a method for determining a wear state of a chisel, a chisel holder, and / or a chisel holder replacement system equipped with a chisel and chisel holder. For this method to give the user qualitative and quantitative information about the wear, according to one embodiment of this invention, a position of at least one point of the chisel and / or the chisel holder is determined by a contactless measurement method and a corresponding measurement result is compared in a switching unit to a reference value stored in a memory device.

Owner:WIRTGEN GMBH

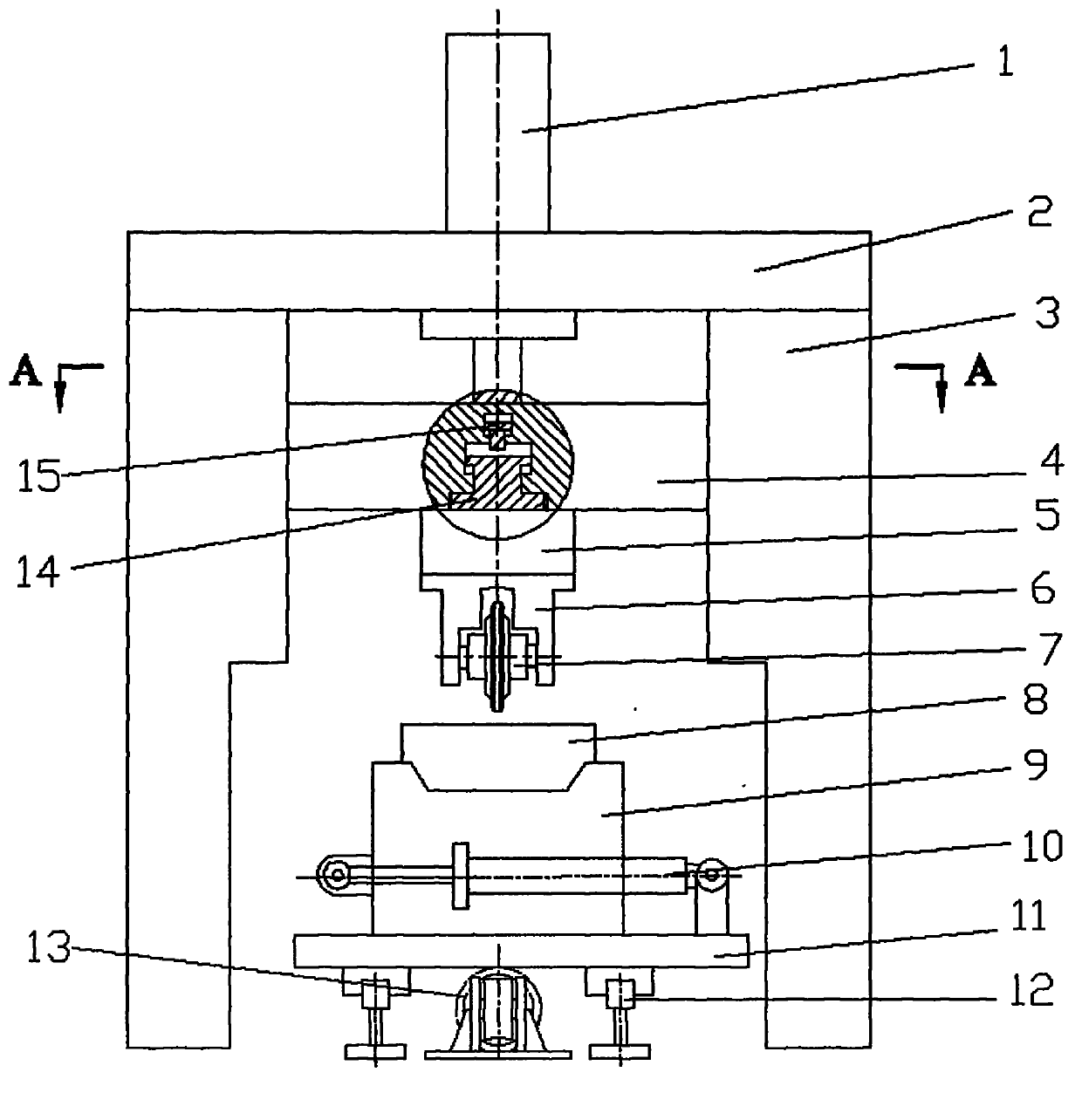

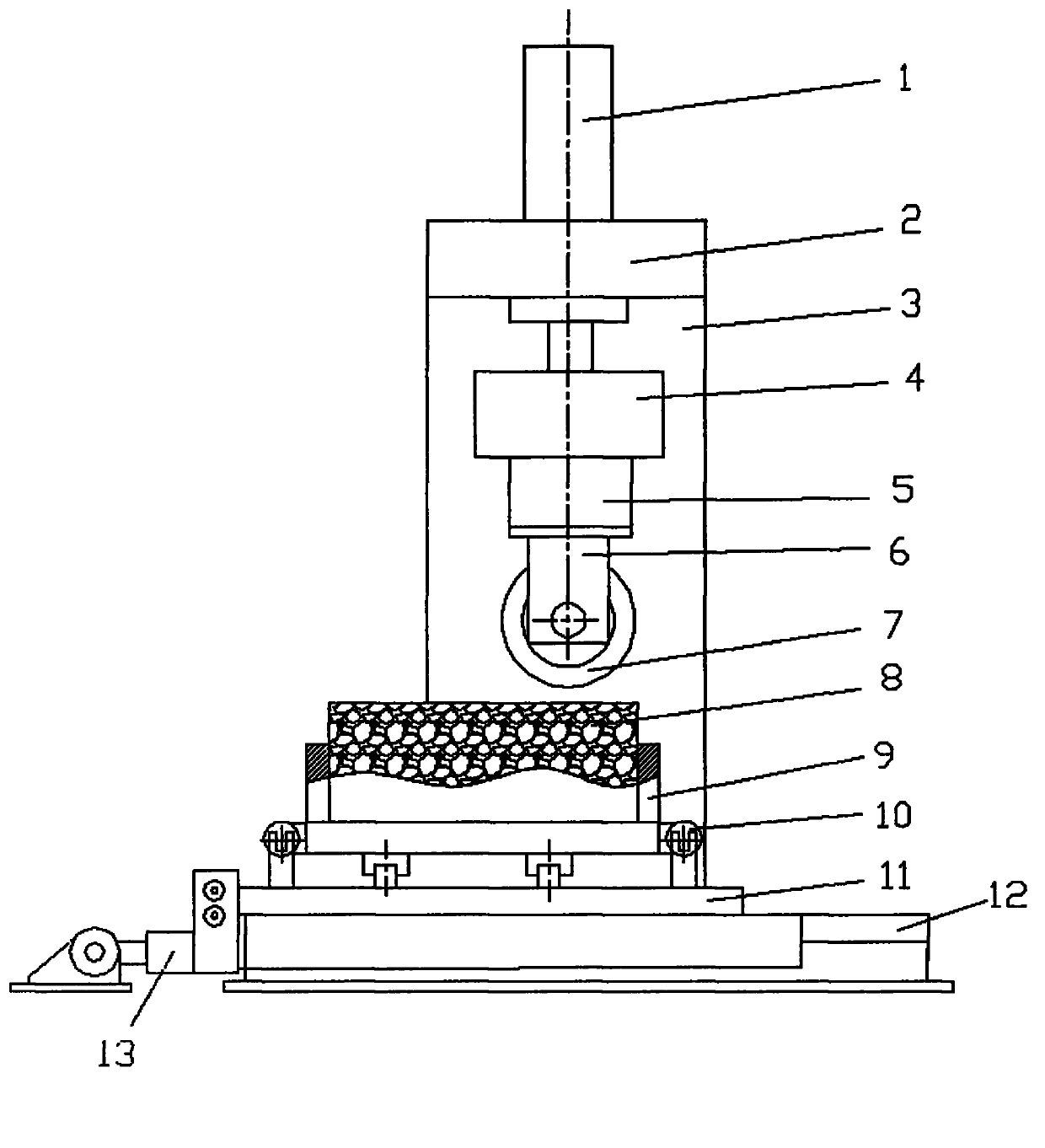

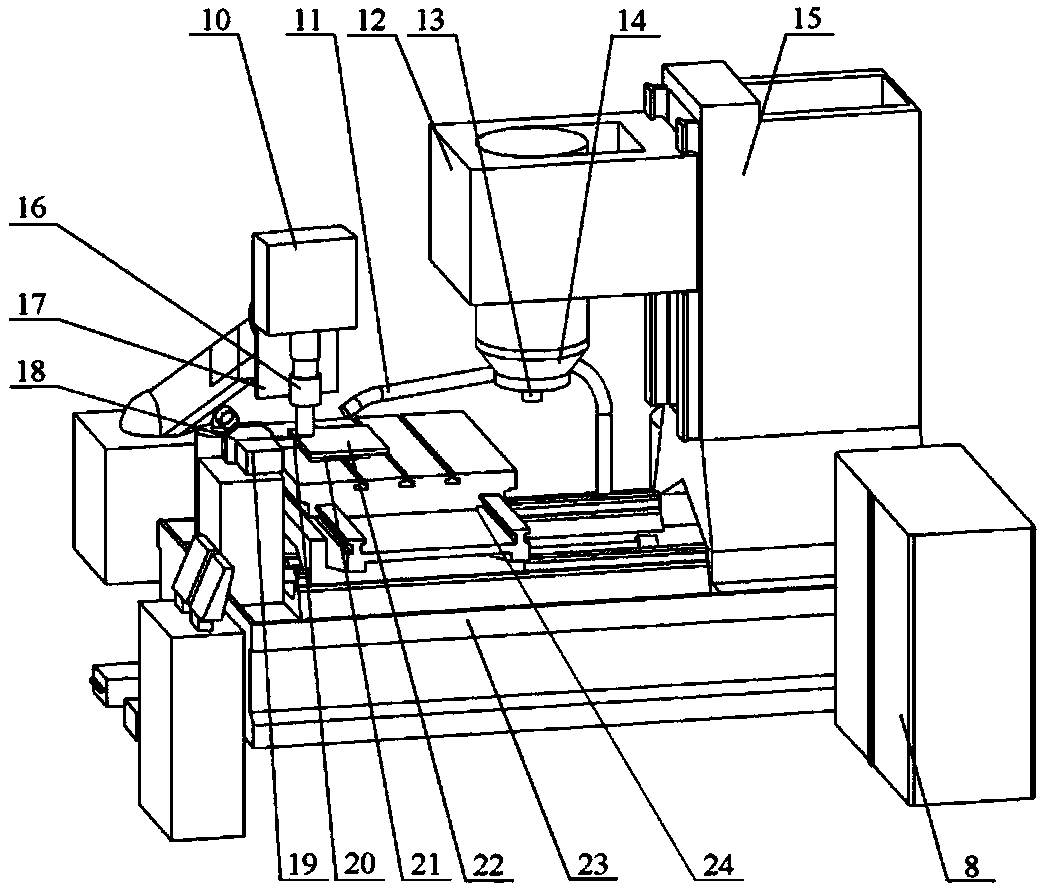

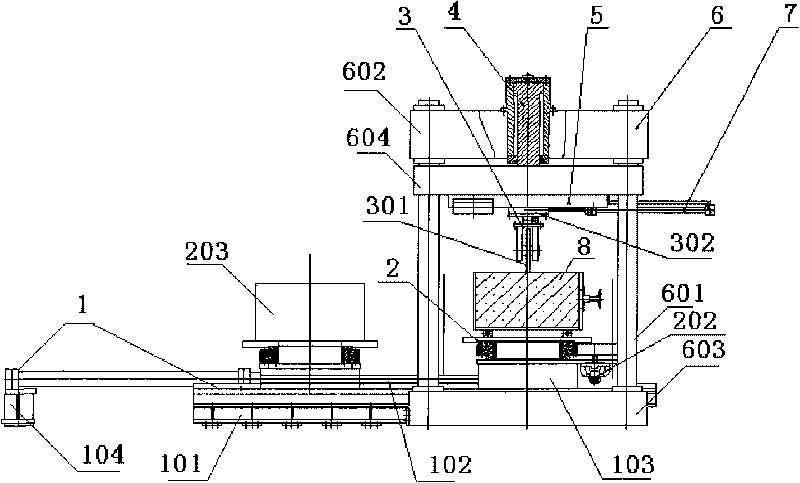

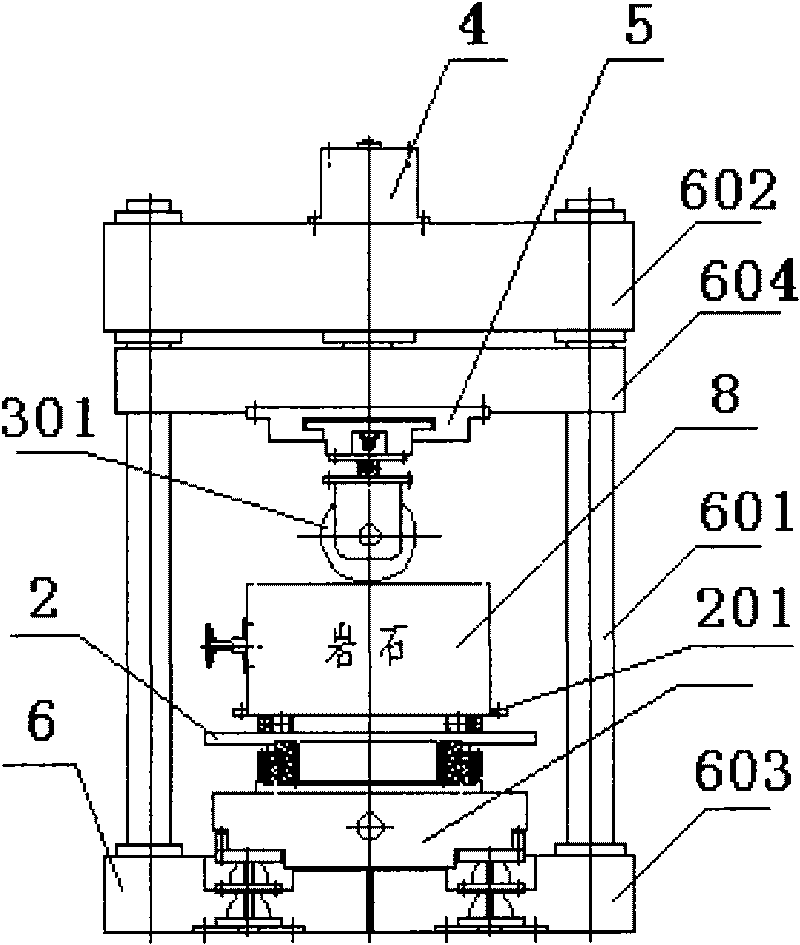

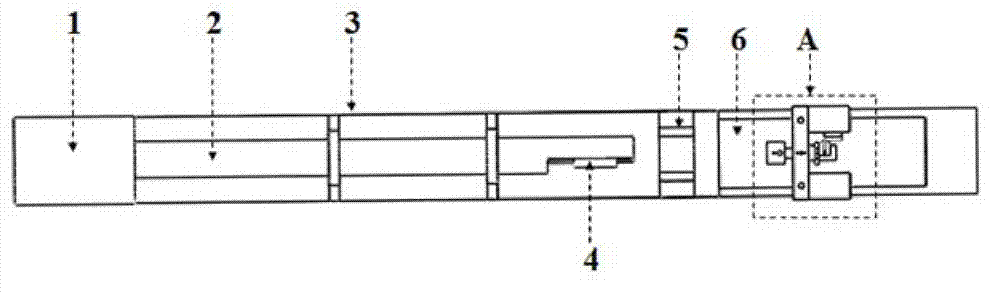

A hard rock hobbing cutter rock breaking characteristic testing device

InactiveCN103969141AObservable breakage featuresInvestigating abrasion/wear resistanceInvestigating machinabilityHobbingData acquisition

A hard rock hobbing cutter rock breaking characteristic testing device used in the field of tunnel engineering is provided. A rock silo supporting seat is positioned on a guide rail pair and realizes longitudinal motion by a longitudinal-moving hydraulic cylinder; a rock silo is positioned on the rock silo supporting seat and realizes lateral movement by lateral moving hydraulic cylindersfixed on the rock silo supporting seat; rock samples are positioned inside the rock silo. Two columns are vertically arranged at both sides of the rock silo, top ends of the columns are connected by a beam and thus a gantry structure is formed. A vertical hydraulic cylinder is fixed on the beam, and the lower part of the vertical hydraulic cylinder is connected with a walking beam. Under the walking beam, a hobbing cutter is installed to simulate the process of hobbing cutter rock breaking, or a similar hobbing cutter wearing module is installed to simulate the process of similar hobbing cutter wearing. An industrial computer, a data acquisition card, a three-axis force sensor, an acoustic emission device and a high-speed digital camera system are used to monitor the processes of hobbing cutter rock breaking and wearing. The device is capable of simulating the process of rolling-type rock breaking of the hobbing cutter, the process of rolling and impact-combined type rock breaking of the hobbing cutter and the process of similar hobbing cutter wearing.

Owner:CENT SOUTH UNIV

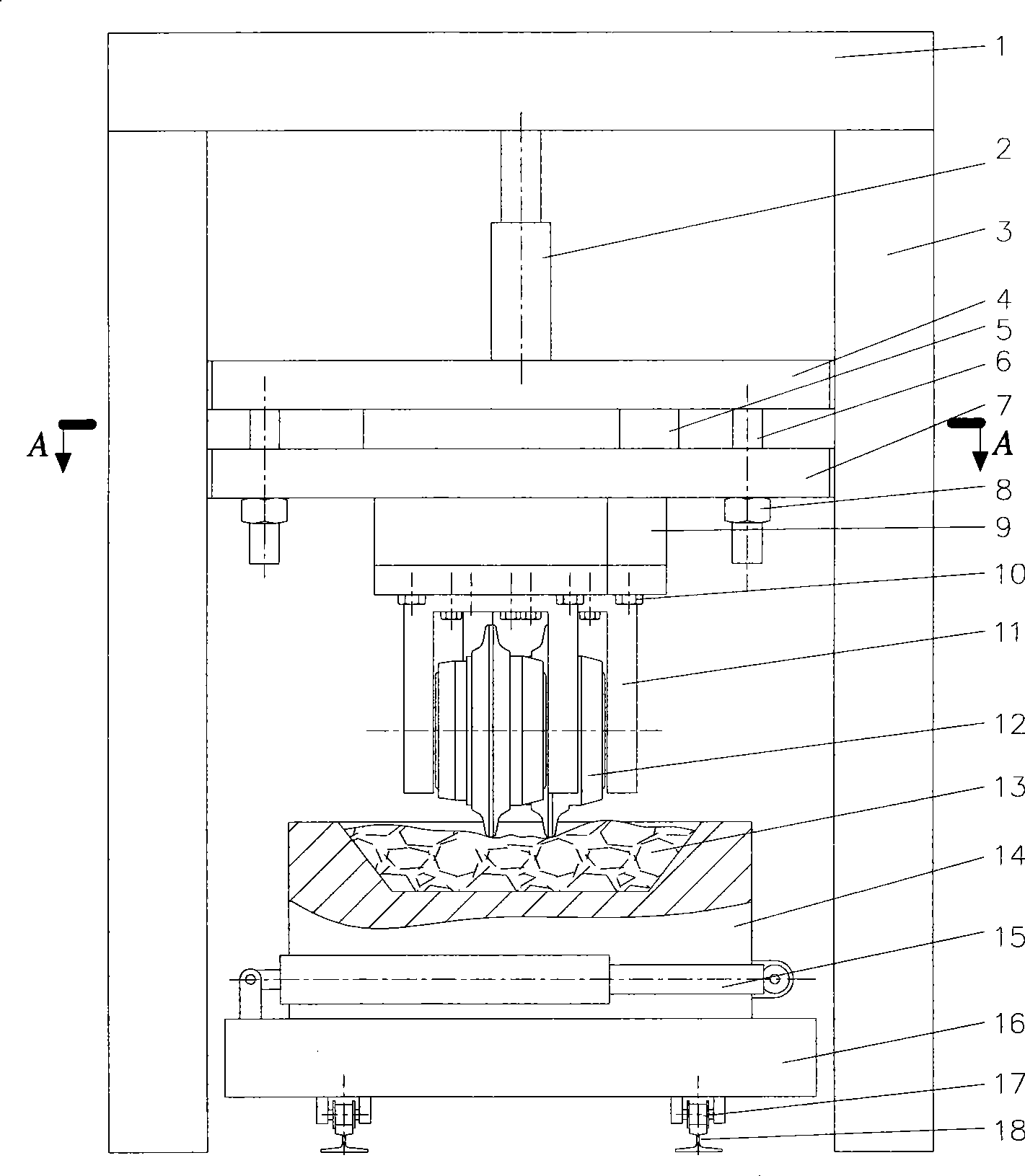

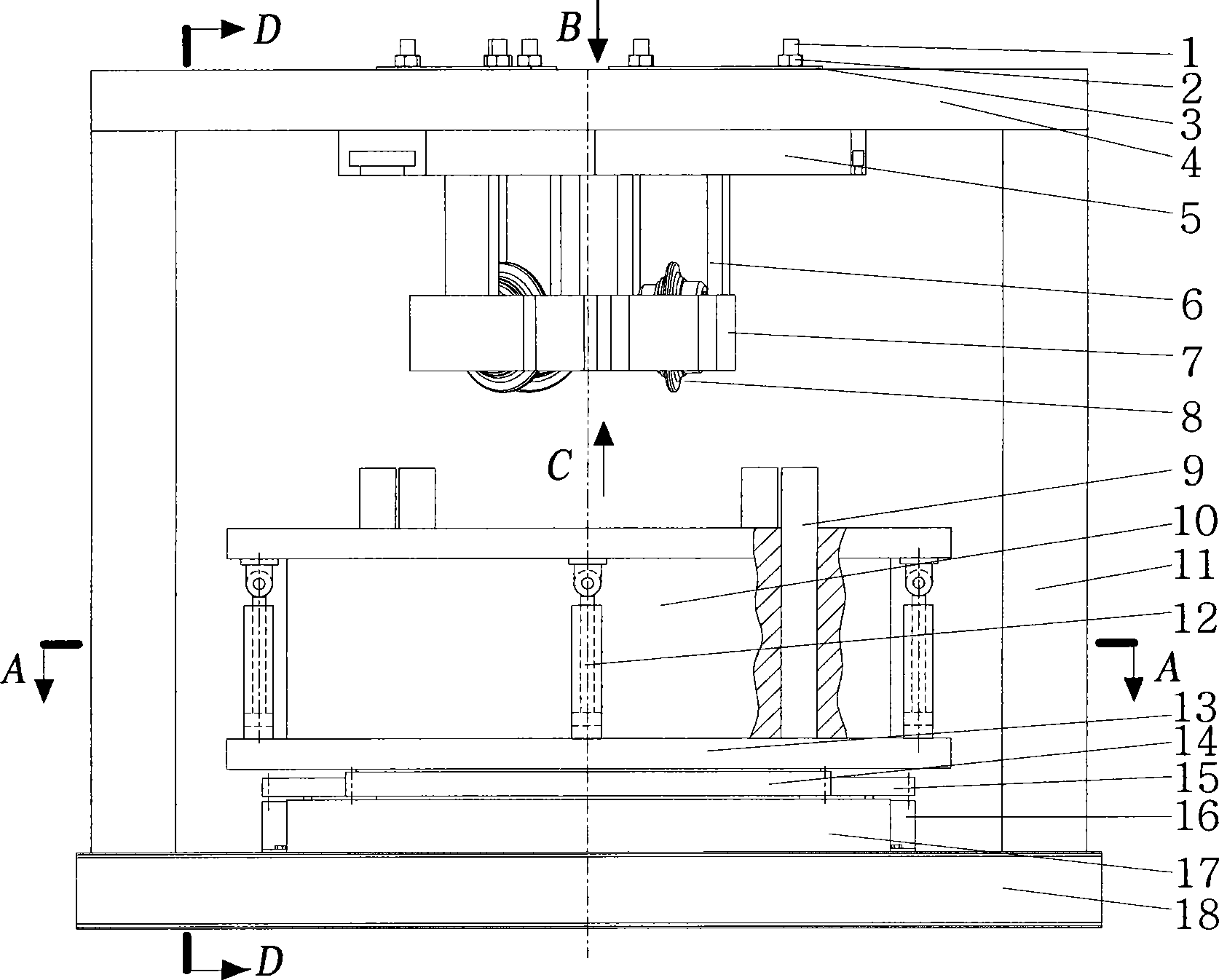

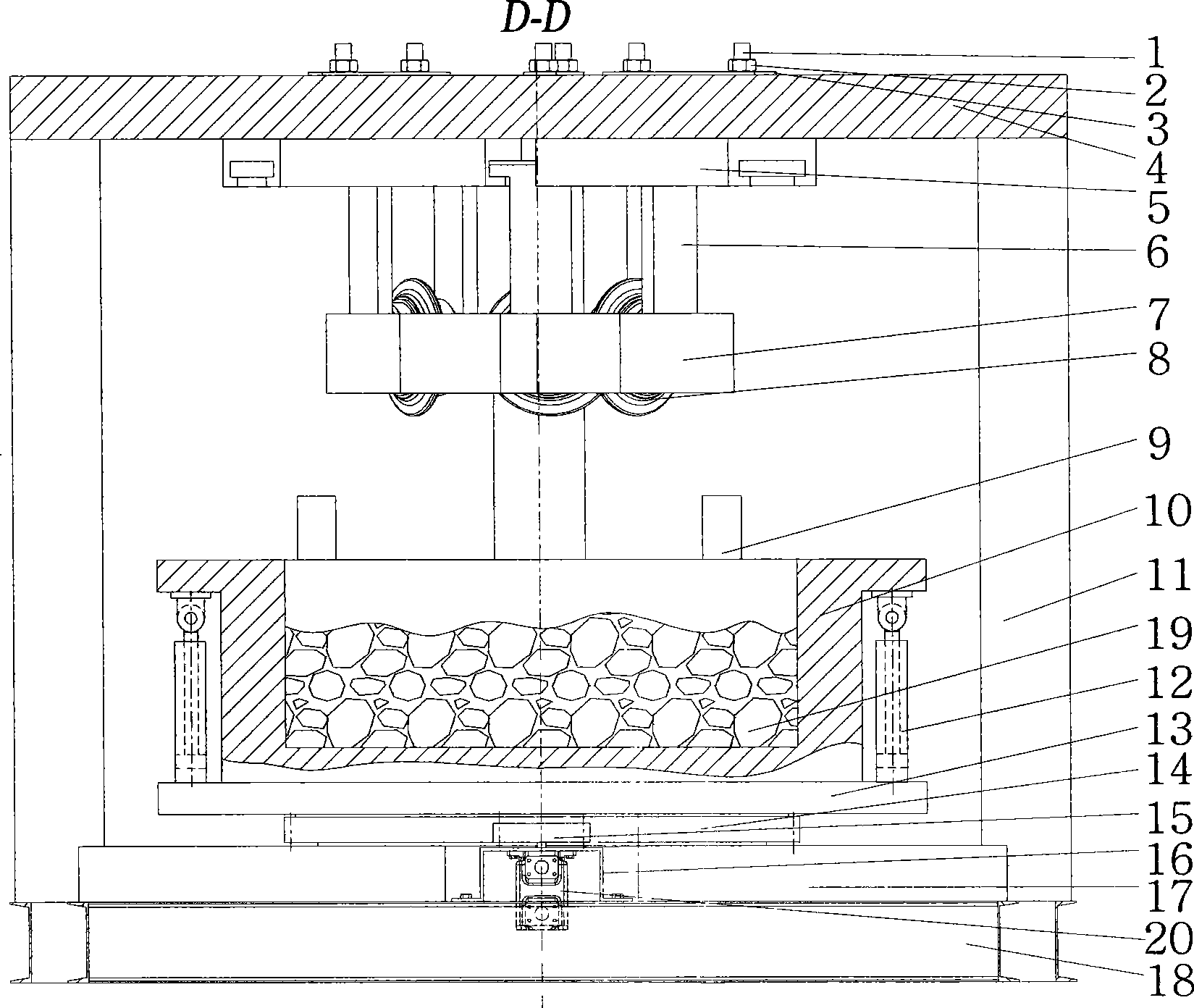

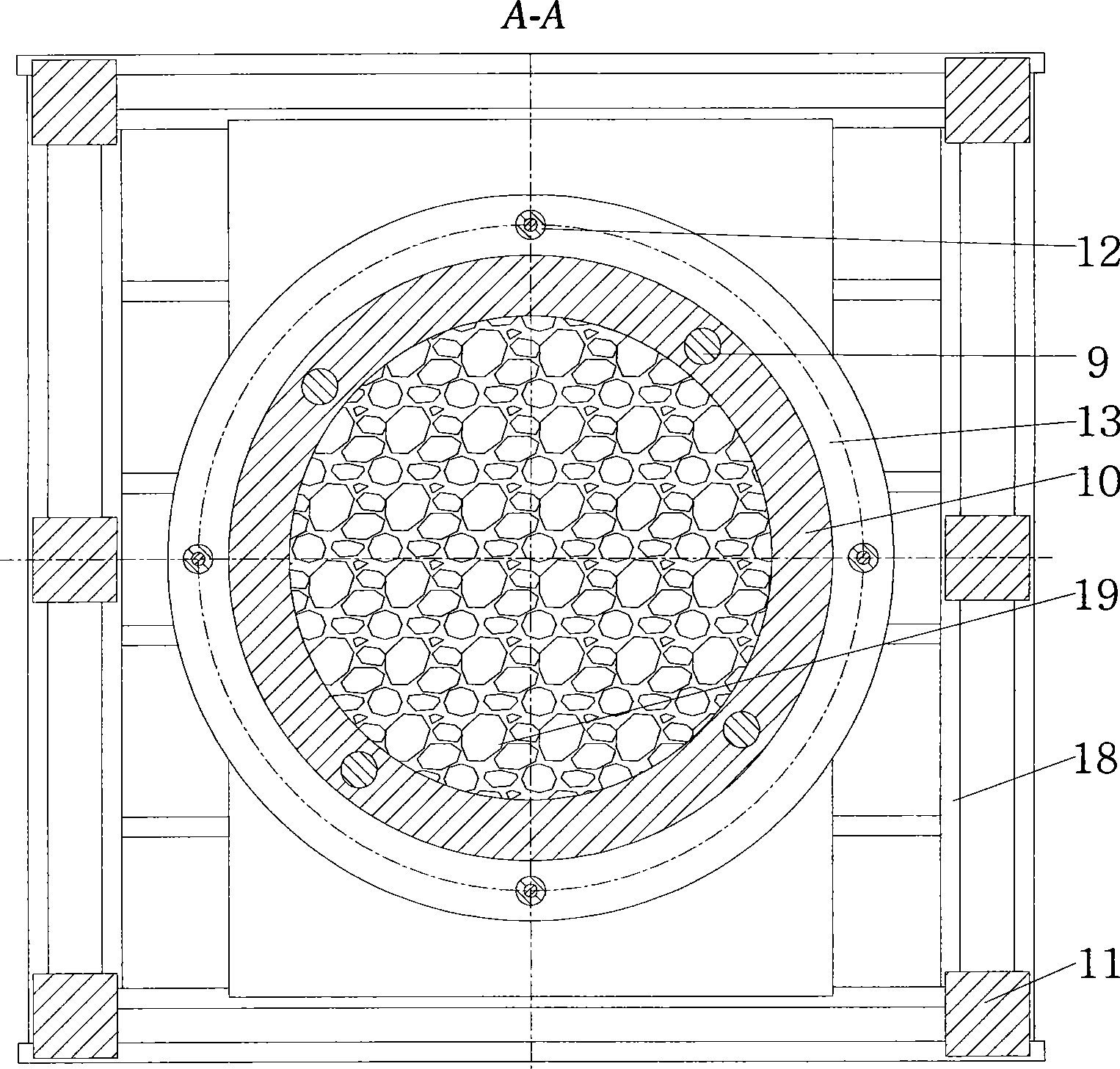

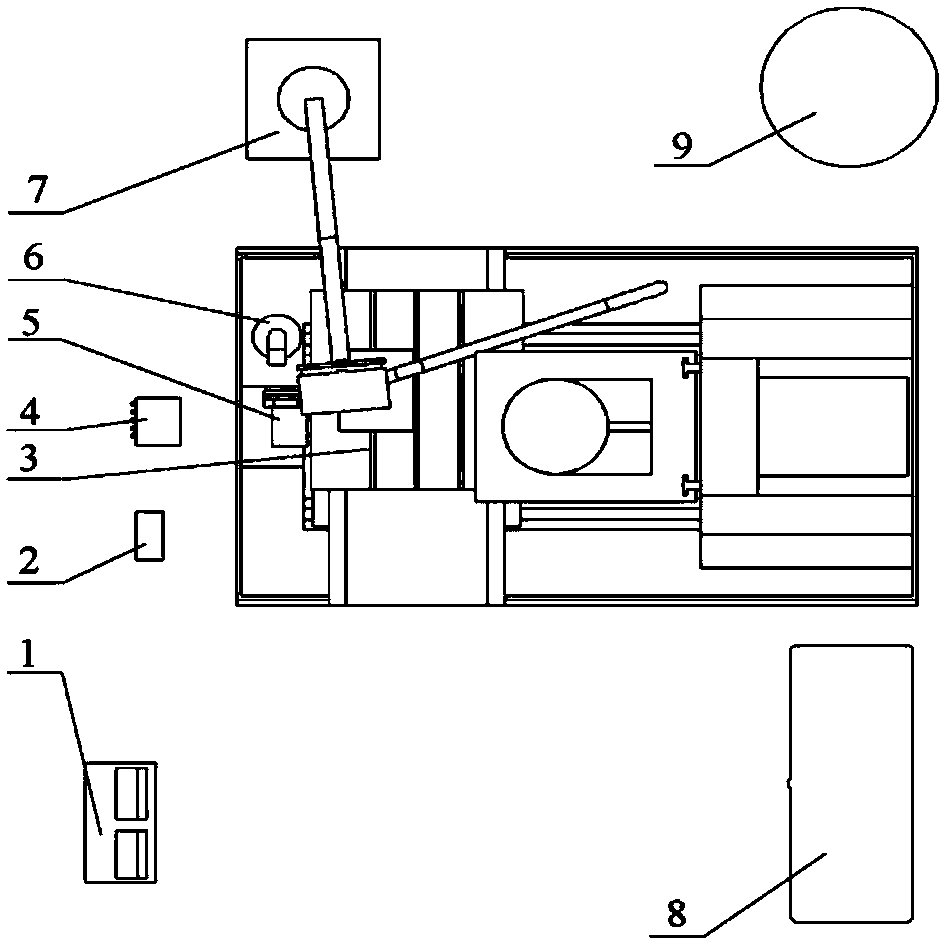

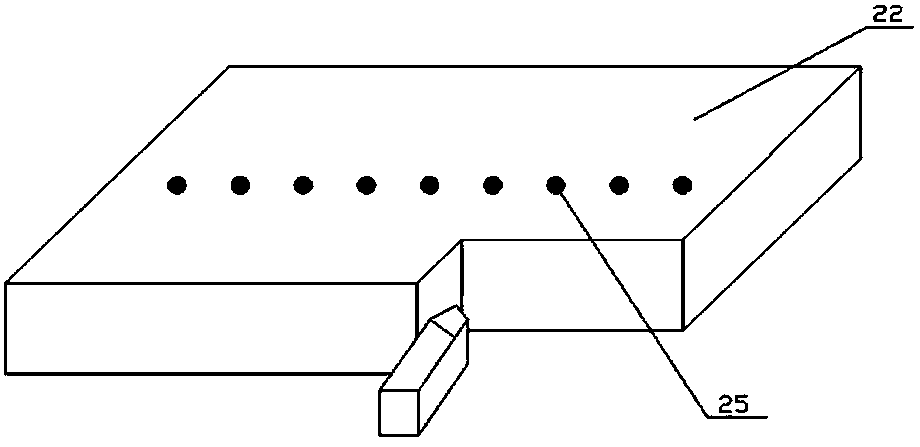

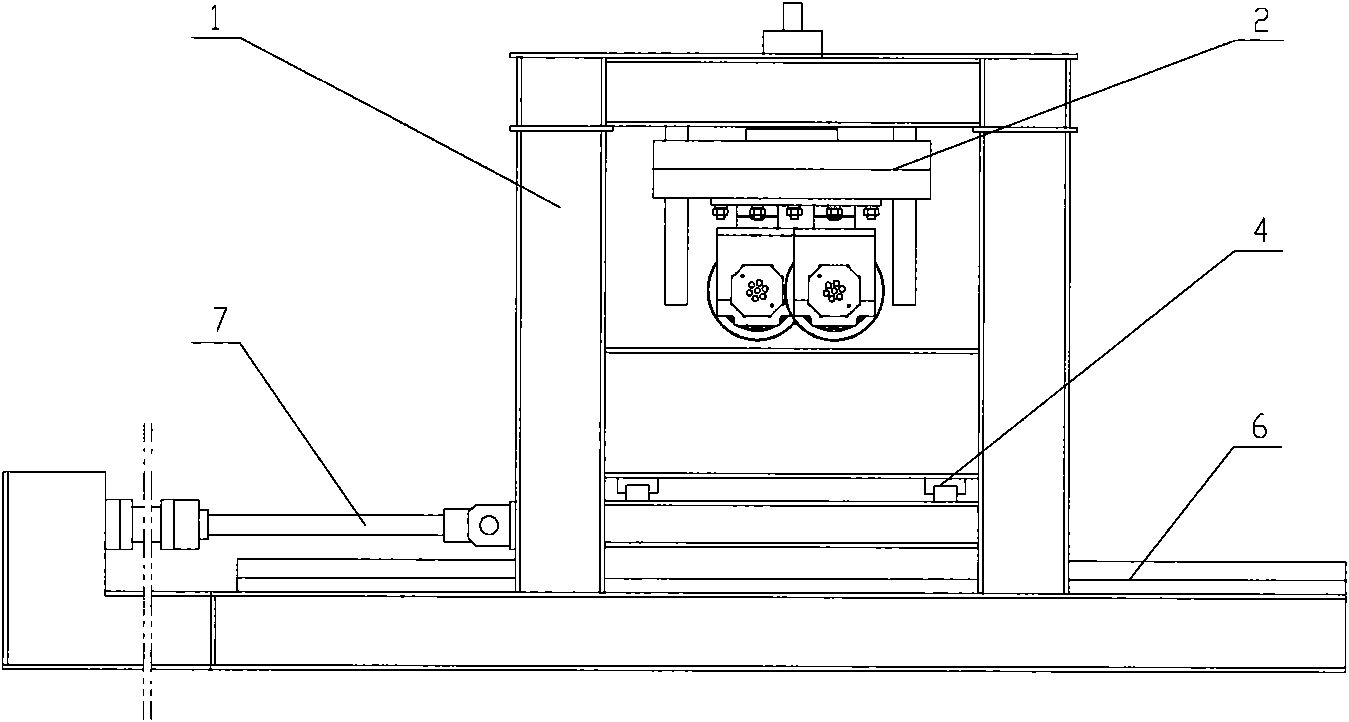

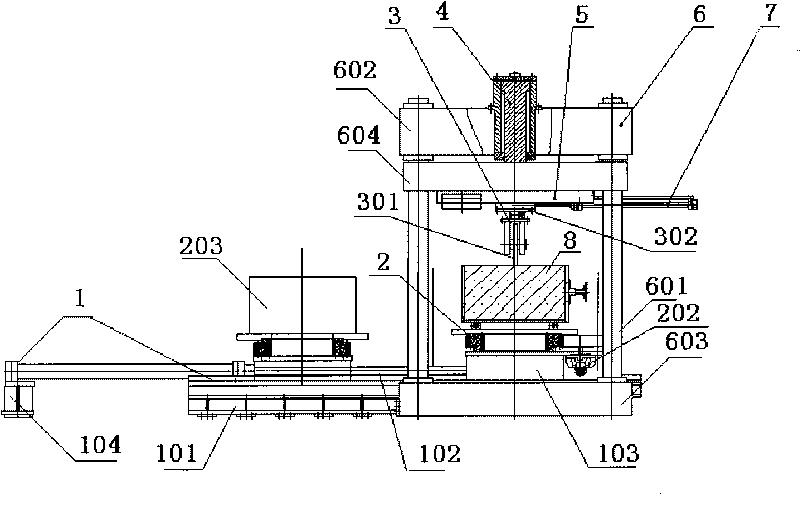

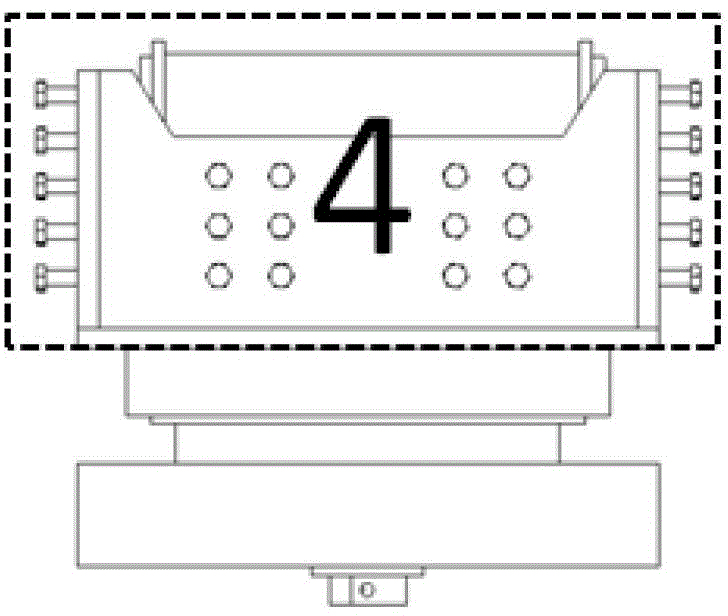

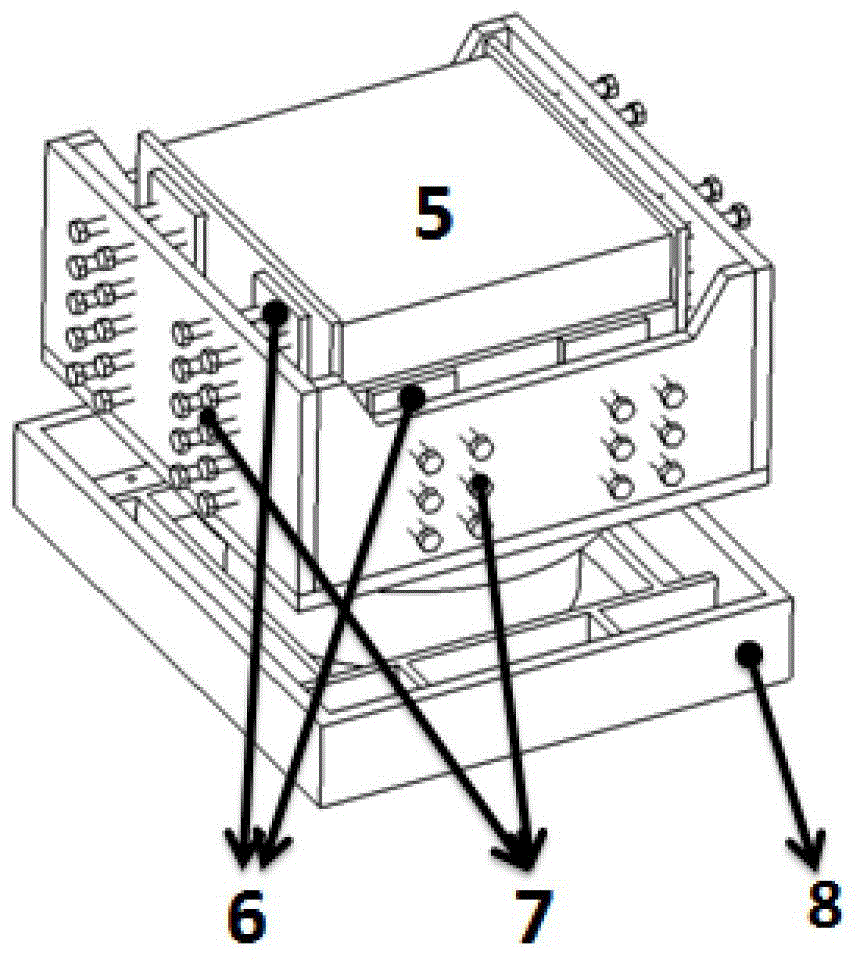

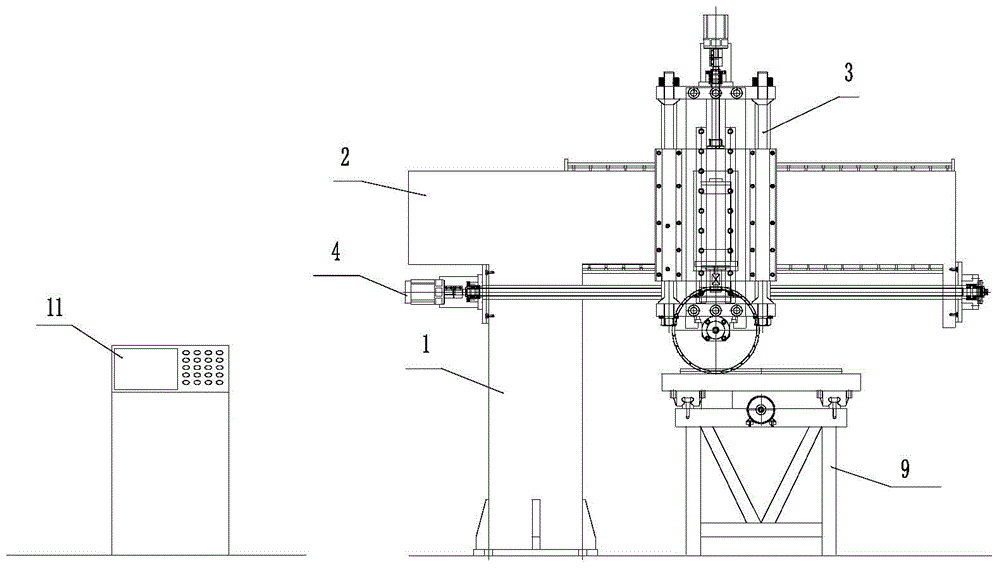

Adjustable multi-hob rock cutting fragmentation test means

InactiveCN101446537AImprove cutting lifeExperimental accuracyInvestigating machinabilityHydraulic cylinderSoil characteristics

The invention relates to an adjustable multi-hob rock cutting fragmentation test device for the field of tunnel project. Being characterized in that the soil warehouse is provided on a guiding track achieving the vertical movement by the vertically-moving hydraulic cylinder; the soil warehouse is provided on the soil warehouse supporting base for achieving the transverse movement by the transverse hydraulic cylinder fixed on the soil warehouse base; the soil warehouse has the rock soil samples; two sides of the soil warehouse are provided with four pillars leaning against the beams and forming a rectangular frame structure. The lower position of the fixed beams of the vertical movement of two synchronized hydraulic cylinders for the realization of the vertical plate hob feed, vertical hydraulic cylinder mounting bracket for the following connection hob, for the realization of more than the fixed plate hob; mounting bracket Three-axis with the following sensors, hob plate connected to the force sensor in the bottom three of the hob seat, using industrial computer, data acquisition cards, the pressure of traffic and other sensors, such as high-speed digital camera system to test the disk-shaped roll knife load rock, broken rock and soil characteristics.

Owner:CENT SOUTH UNIV

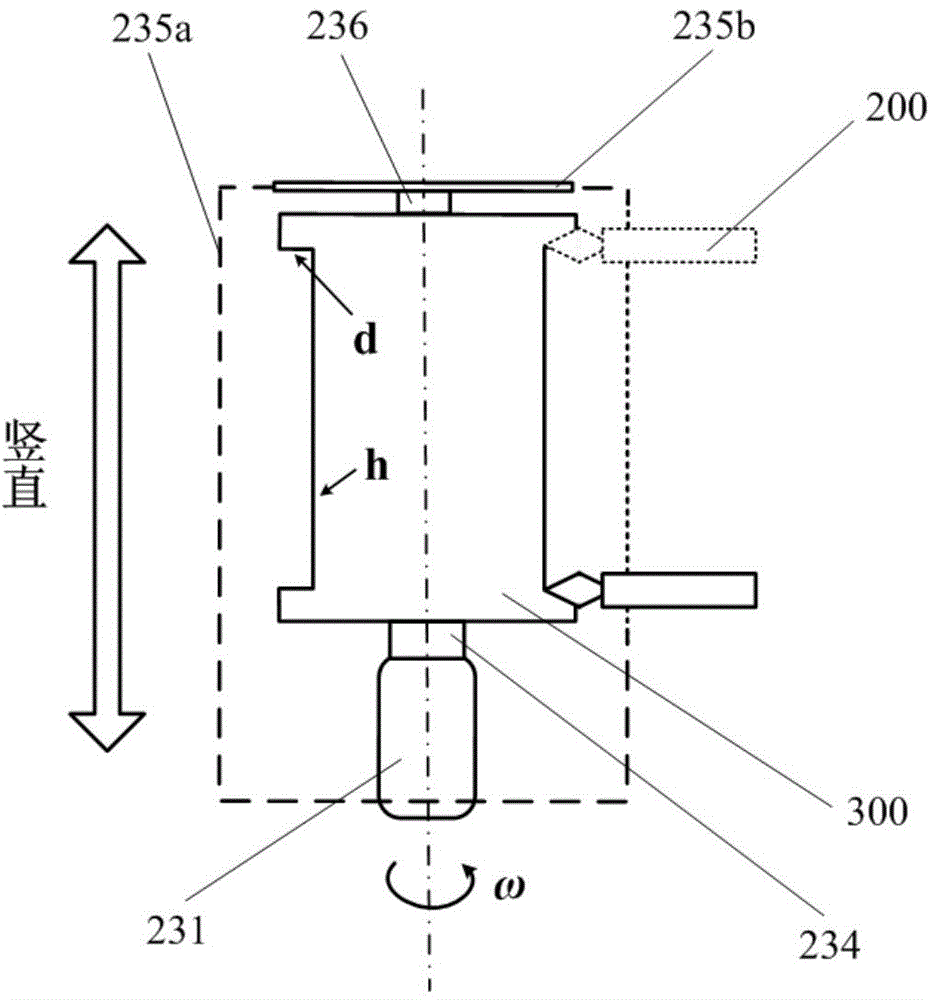

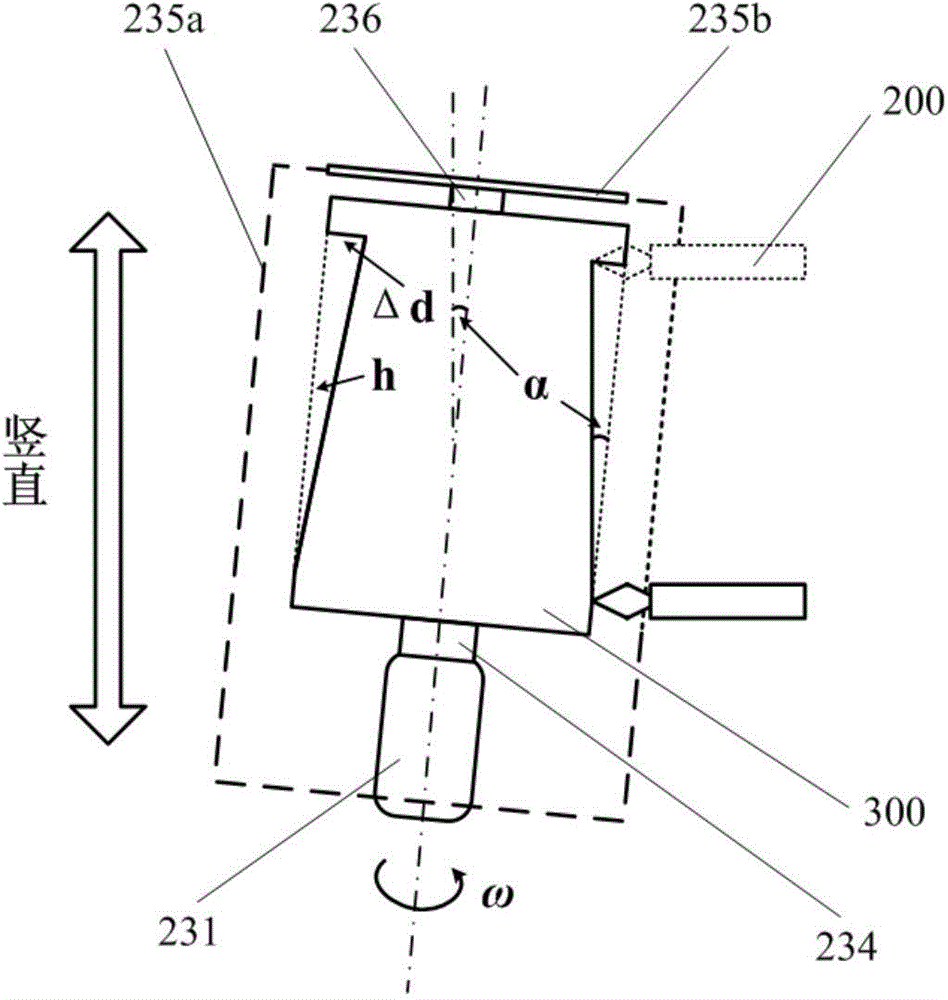

Tool bit rock breaking mechanism and abrasion tester

InactiveCN101299013AIdea novel scienceFunction increaseInvestigating abrasion/wear resistanceInvestigating machinabilityTool bitHydraulic cylinder

The present invention provides a cutter rock-breaking mechanism which is applied in the technical field of the cutter experiment and an abrasion resistant tester thereof. The abrasion resistant tester comprises a hydraulic cylinder, a structural frame, a bearing plate, a cutter support, a disc-shaped hob and a rotation worktable. When the cutter rock-breaking mechanism and the abrasion resistant tester work, the disc-shaped hob is connected with the cutter support through a bolt. The cutter support is jointed and fixed on the bearing plate through the bolts. The hydraulic cylinder exerts a certain load to impact the disc-shaped hob to the rock sample on the worktable and generate a certain penetration. Afterwards the worktable is rotated through a power system to execute cutting test to the rock passively. The cutter rock-breaking mechanism and the abrasion resistant tester execute cutting with a single cutter to do the abrasion resistance test of the cutter. The bearing plate is provided with a groove. The regulation to the cutter space and the phase angle is realized through the variation of the jointing position of the cutter support on the bearing plate. The regulation to the inner deflection angle of the cutter is realized by changing the cutter supports with different angles. The positioning and rotation of the rock are realized through the rotating worktable. The designing of the device is novel and scientific. The knife angle, phase angle and inner deflection angle which affect larger to the rock breaking and abrasion of cutter are researched. The device settles the problem that two hob cutters simultaneously cut the rock.

Owner:NORTHERN HEAVY IND GRP CO LTD

Position adjustable multi-hob rotary cutting test-bench

InactiveCN101446536AFacilitate the study of the microscopic mechanism of rock breakingAchieve regulationInvestigating machinabilityHydraulic cylinderHydraulic motor

The invention relates to a position adjustable multi-hob rotary cutting test-bench. The soil warehouse base fixed on the soil warehouse and a rectangular base fixed on the ground frame are supported by a looping support and looped by two hydraulic motors synchronously. Periphery of the soil warehouse is provided with flanges, which is provided with four guiding pillars evenly and four hydraulic cylinders; the four hydraulic cylinders driven synchronous vertical position into the soil to the campaign from the four columns to orientation and direction of torque transmission. 6 shelves uniform foundation column layout, fixed a column to open the top 4 at the top ring groove of the frame, forming a rectangular frame; connected at the top of the bottom bracket has three slide rail and the knife block, plate hob installed in the Seat knife. Using IPC test, data acquisition cards, the pressure of the flow velocity sensor, dynamic strain gauge, high-speed digital camera system on the cutting process of geotechnical monitoring. The test-bench is mainly used for the multi-hob and rotary cutting of rock mechanical properties of the relevant test.

Owner:CENT SOUTH UNIV

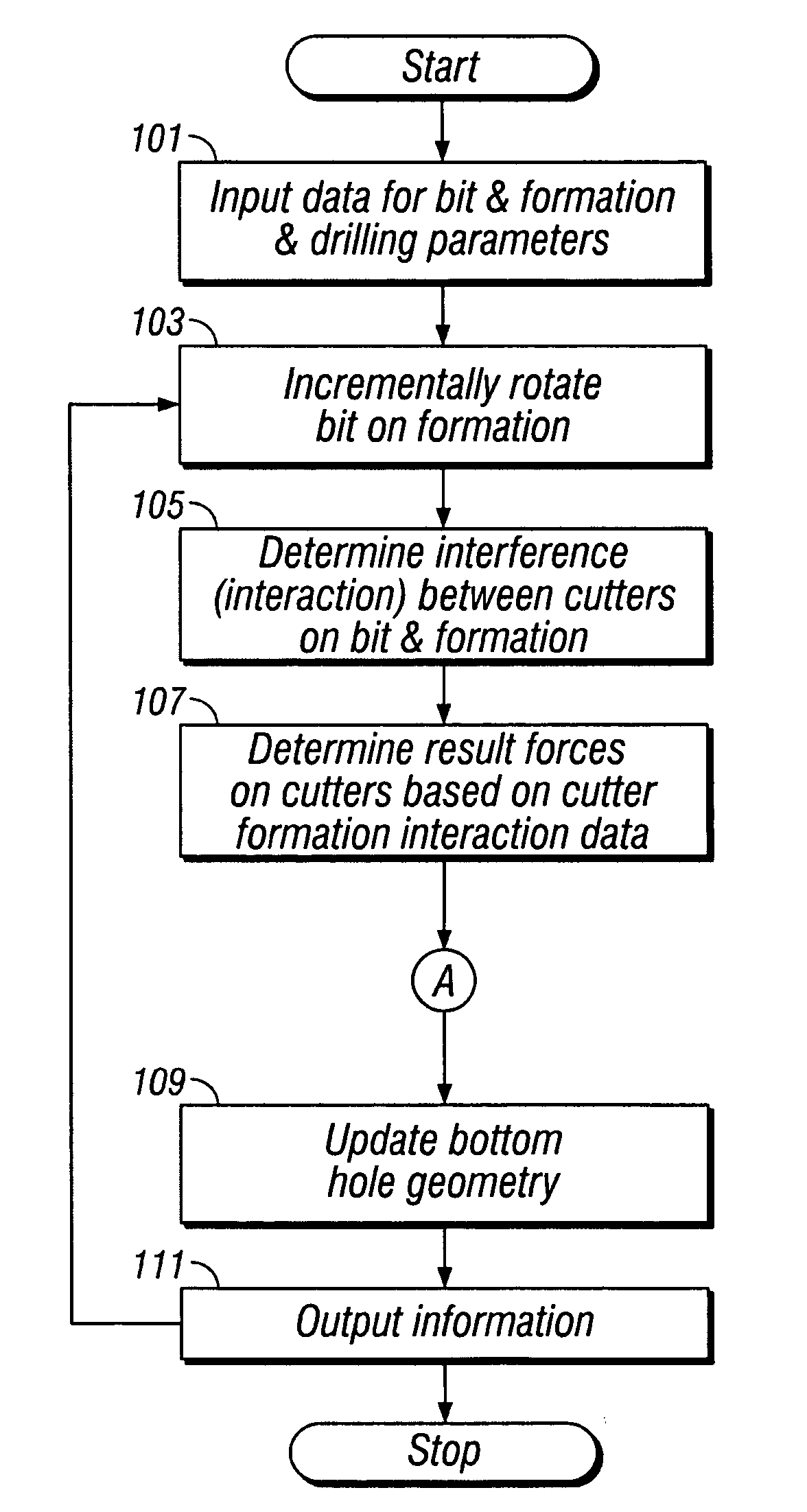

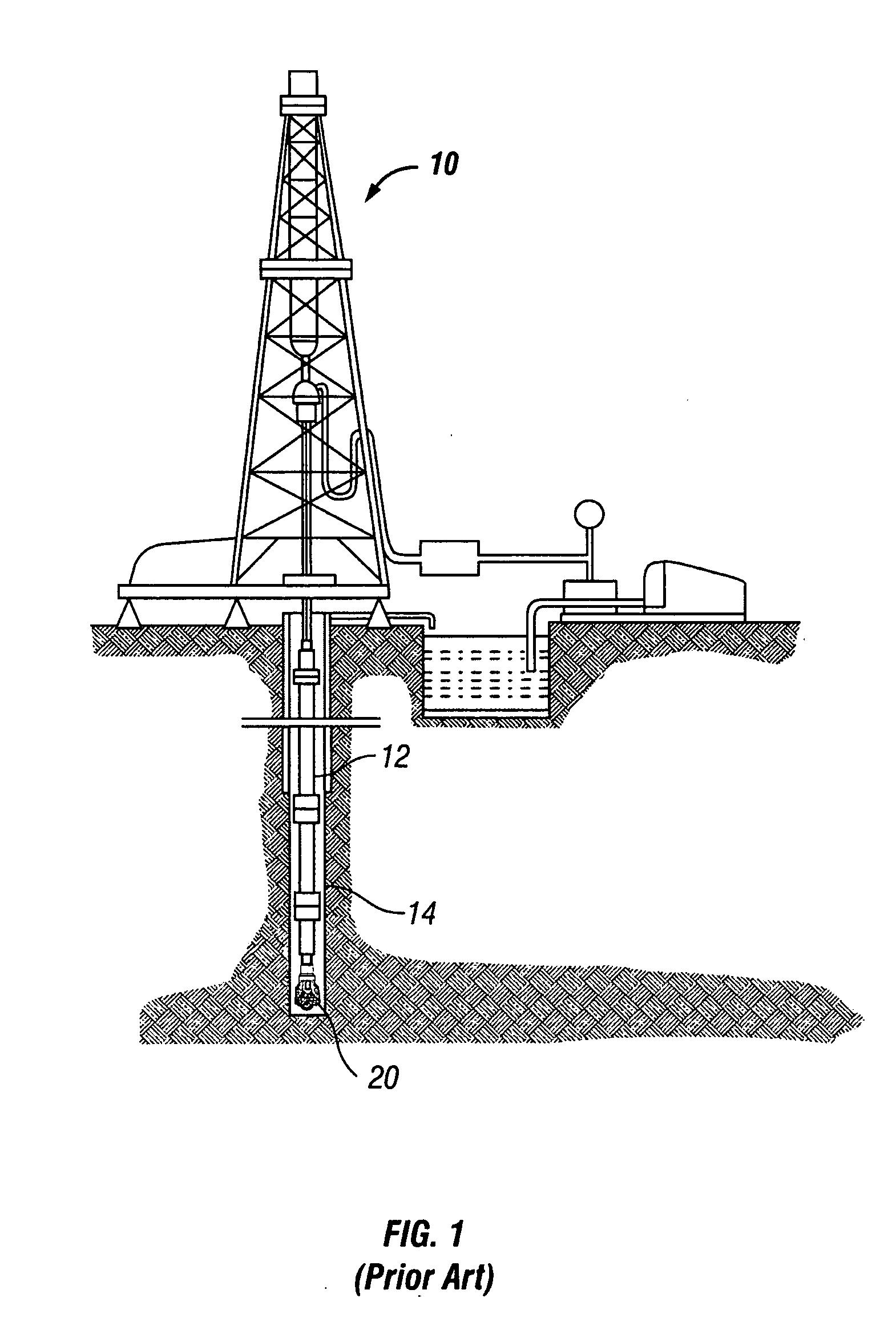

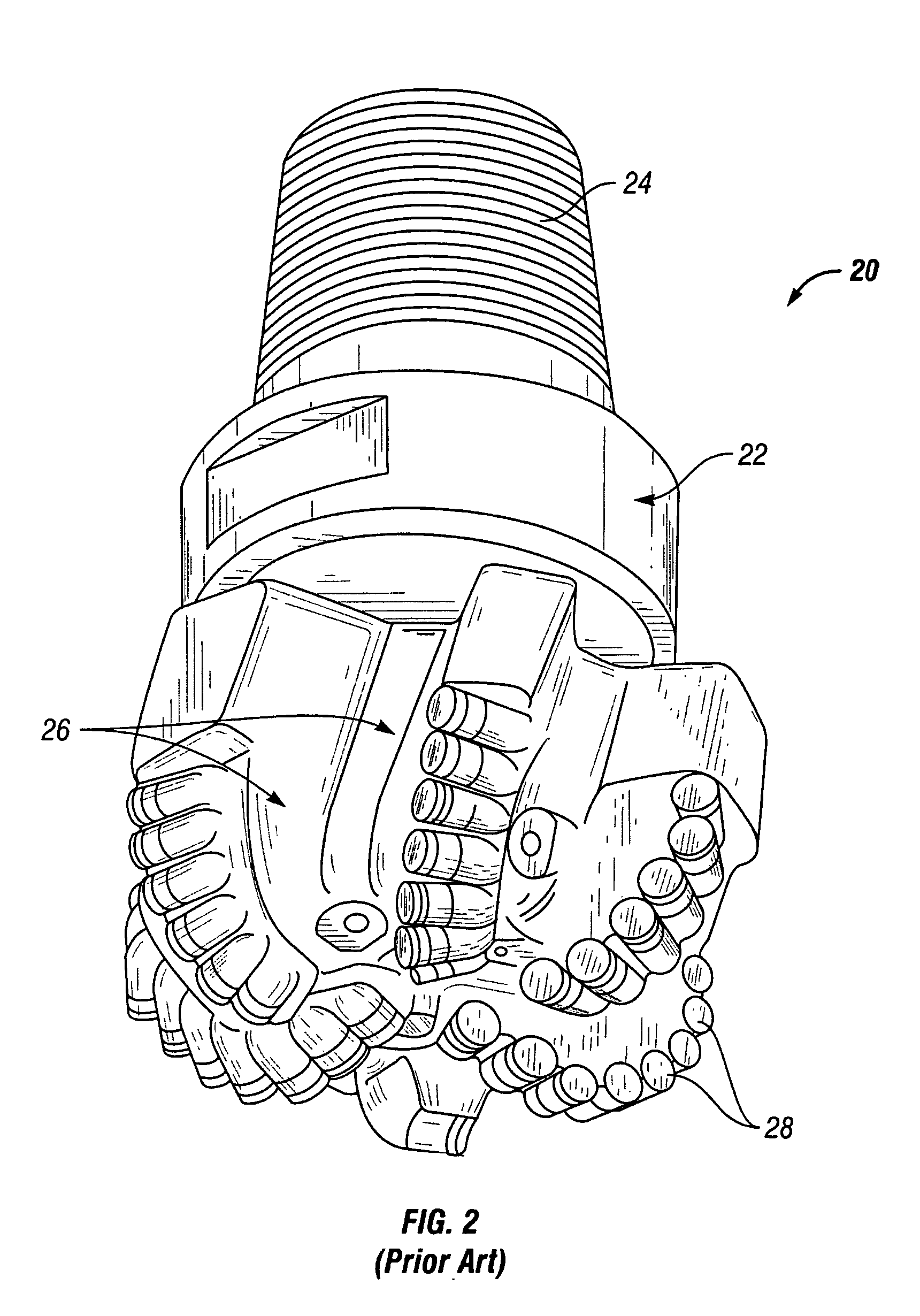

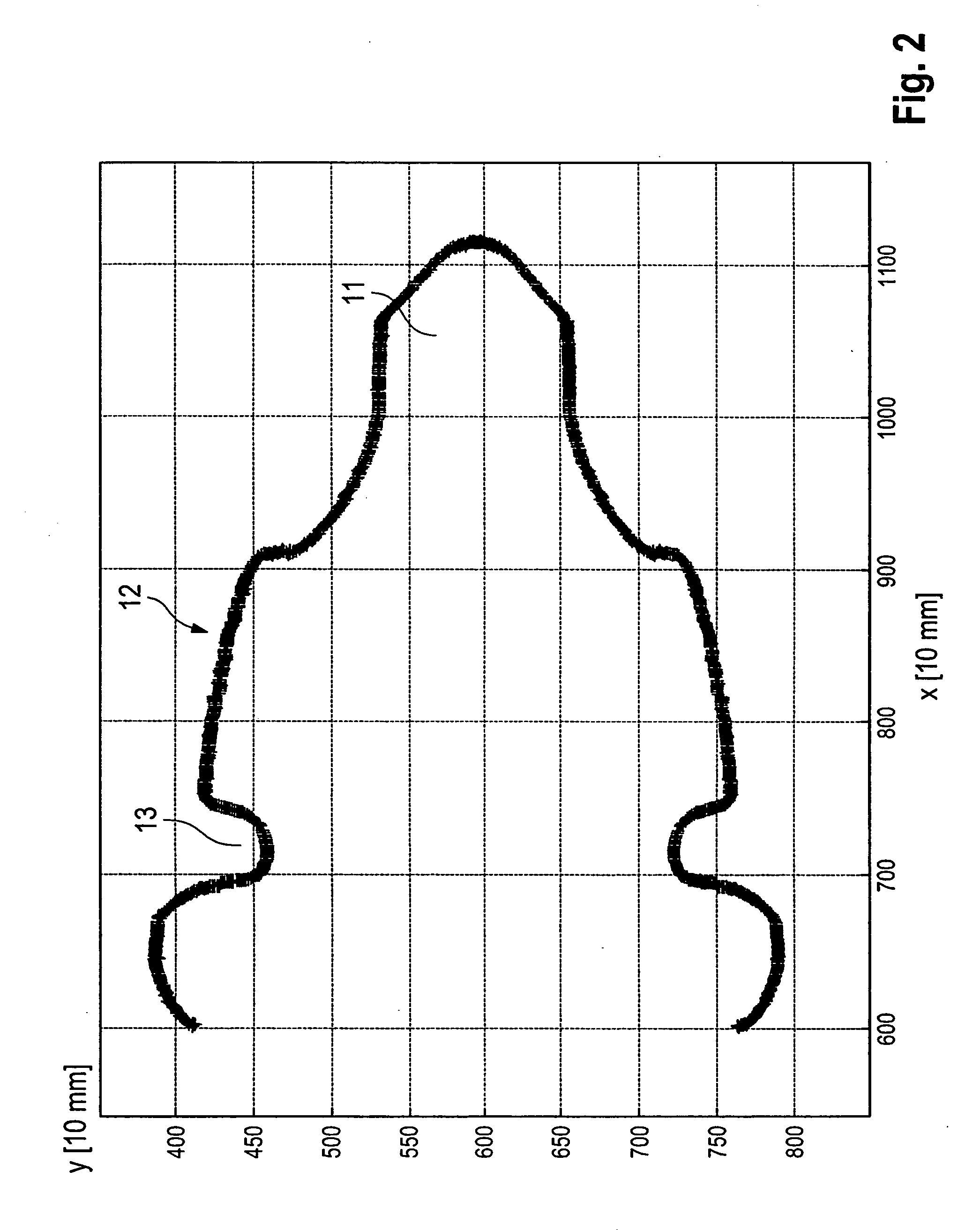

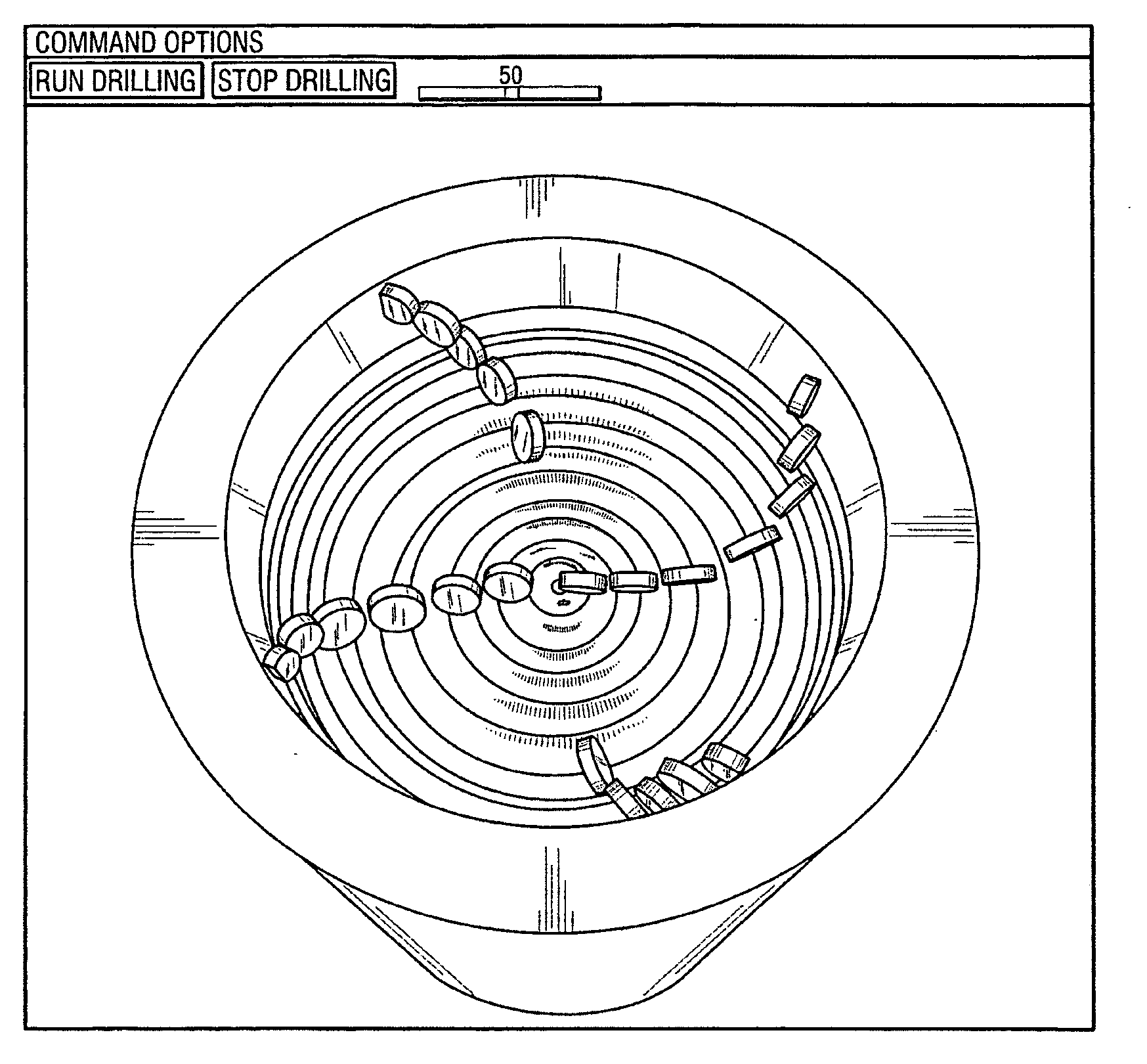

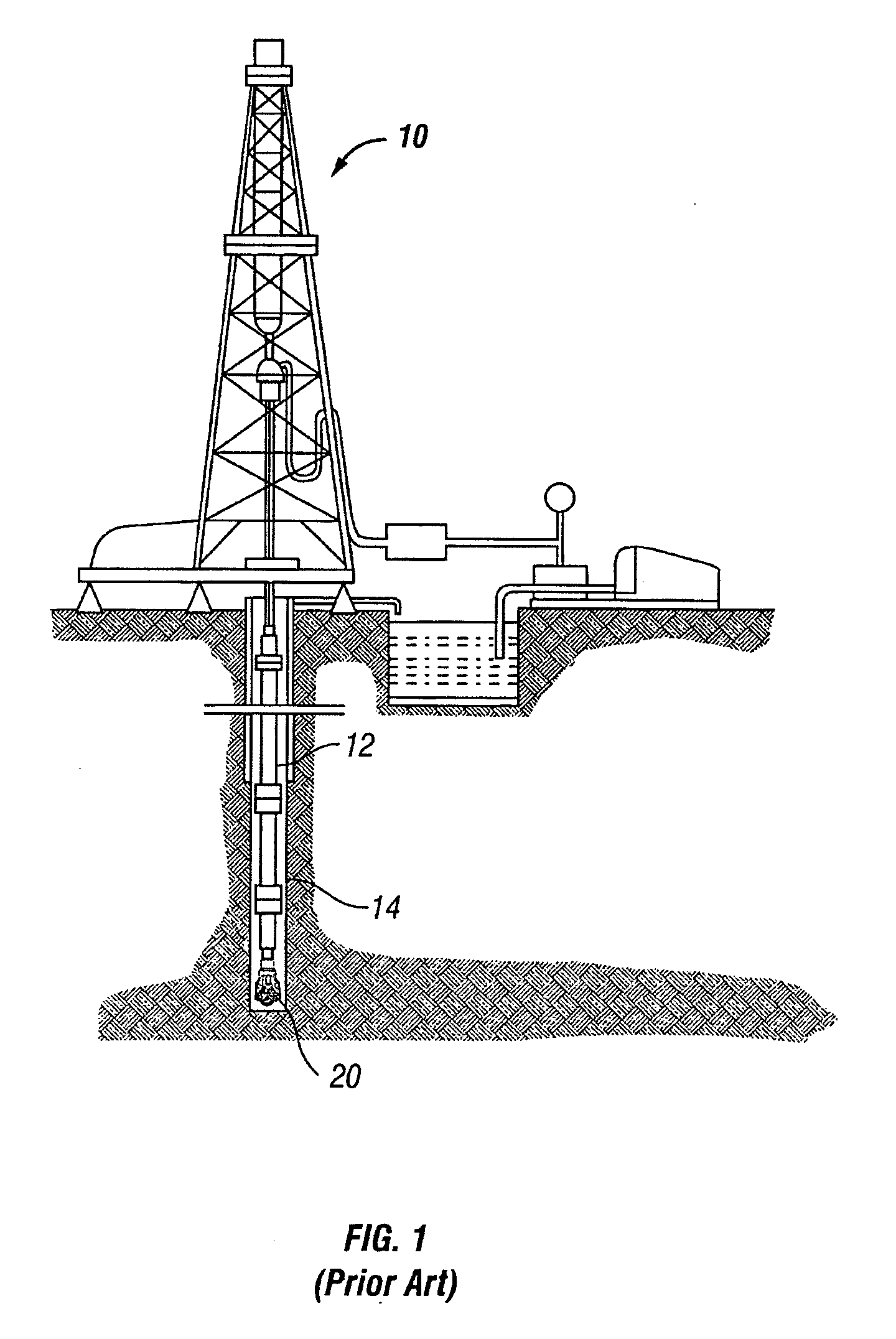

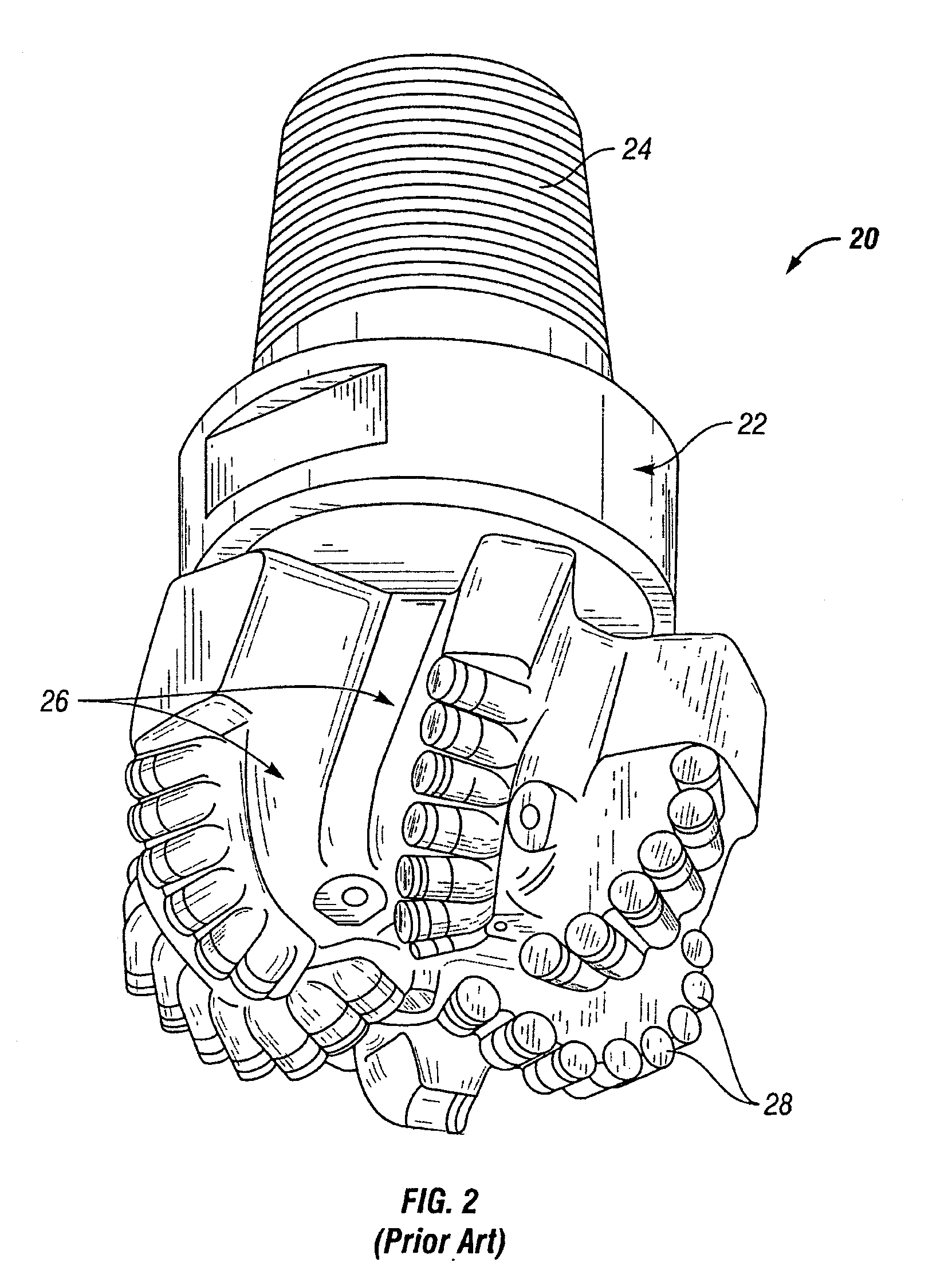

Methods for designing fixed cutter bits and bits made using such methods

In one aspect, the invention provides a method for modeling the dynamic performance of a fixed cutter bit drilling earth formations. In one embodiment, the method includes selecting a drill bit and an earth formation to be represented as drilled, simulating the bit drilling the earth formation. The simulation includes at least numerically rotating the bit, calculating bit interaction with the earth formation during the rotating, and determining the forces on the cutters during the rotation based on the calculated interaction with earth formation and empirical data.

Owner:SMITH INT INC

Method for determining the wear state

This invention relates to a method for determining a wear state of a chisel, a chisel holder, and / or a chisel holder replacement system equipped with a chisel and chisel holder. For this method to give the user qualitative and quantitative information about the wear, according to one embodiment of this invention, a position of at least one point of the chisel and / or the chisel holder is determined by a contactless measurement method and a corresponding measurement result is compared in a switching unit to a reference value stored in a memory device.

Owner:WIRTGEN GMBH

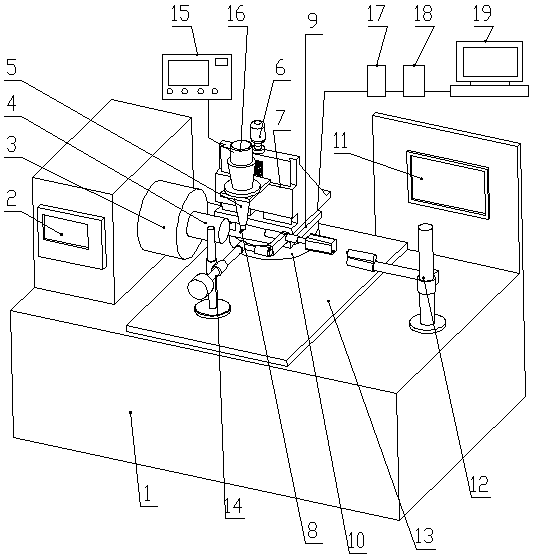

Device and method for single abrasive grain grinding experiments under assistance of ultrasonic vibration

ActiveCN104002220ASimulated machinabilityRealize online dynamic observationGrinding feed controlGrinding machinesData processing systemStress conditions

A device for single abrasive grain grinding experiments under the assistance of ultrasonic vibration comprises a super precision machine tool, a tool setting system, an ultrasonic vibration system, a force measurement system, a high-speed camera shooting system and a data processing system. A method for the single abrasive grain grinding experiments under the assistance of ultrasonic vibration comprises the steps of installing a workpiece in an air floatation spindle clamp of the super precision machine tool; utilizing the tool setting system to rapidly accurately perform tool setting; dismantling the tool setting system, starting the super precision machine tool and the ultrasonic vibration system, utilizing the force measurement system to perform on-line detection and recording on single abrasive grain stress conditions in the experiment processing, and transmitting data to a computer; and utilizing the high-speed camera shooting system to perform on-line observation and recording on a abrasive grain movement trail in the grinding process, the microscopic changing process and the material removing process. The device and the method genuinely reflect the grinding process of a whole grinding wheel and can particularly reflect the abrasive grain cutting process under the conditions of ultrasonic grinding and can provide valuable experimental data for manufacture and research of the grinding wheel and a cutting mechanism of the grinding wheel.

Owner:CONPROFE TECH GRP CO LTD +1

Experimental device for cutting off carbon fiber composite material

InactiveCN103837422ASave spaceThe cutting experiment is orderly and accurateInvestigating machinabilityTemperature controlMaterial removal

The invention provides an experimental device for cutting off a carbon fiber composite material, and belongs to the field of research on hardly machined material cutting devices. The experimental device is provided with experiment functional devices by taking a cutting device as a basic structure, wherein the experiment functional devices comprise a work piece quick assembling-clamping and temperature control device, a high-speed micro-examination device, a temperature and cutting force online measuring device and a dust remover. In the high-speed micro-examination device, a lens is connected with a high-speed camera, the high-speed camera is arranged on a single-axis precision displacement platform pedestal which is arranged on a camera support, a light source is aligned to a cutting area and the high-speed camera is connected with a computer system. The experimental device for cutting off the carbon fiber composite material, which is disclosed by the invention, can effectively realize the observation on a cutting process, precisely measures the temperature and the cutting force in real time, controls the temperatures of a sample and a cutter, and studies on material breakage forms, material removal mechanisms and cutter abrasion mechanisms under different cutting conditions, so as to provide experimental support for the explanation of the carbon fiber composite material cutting basic theory.

Owner:DALIAN UNIV OF TECH

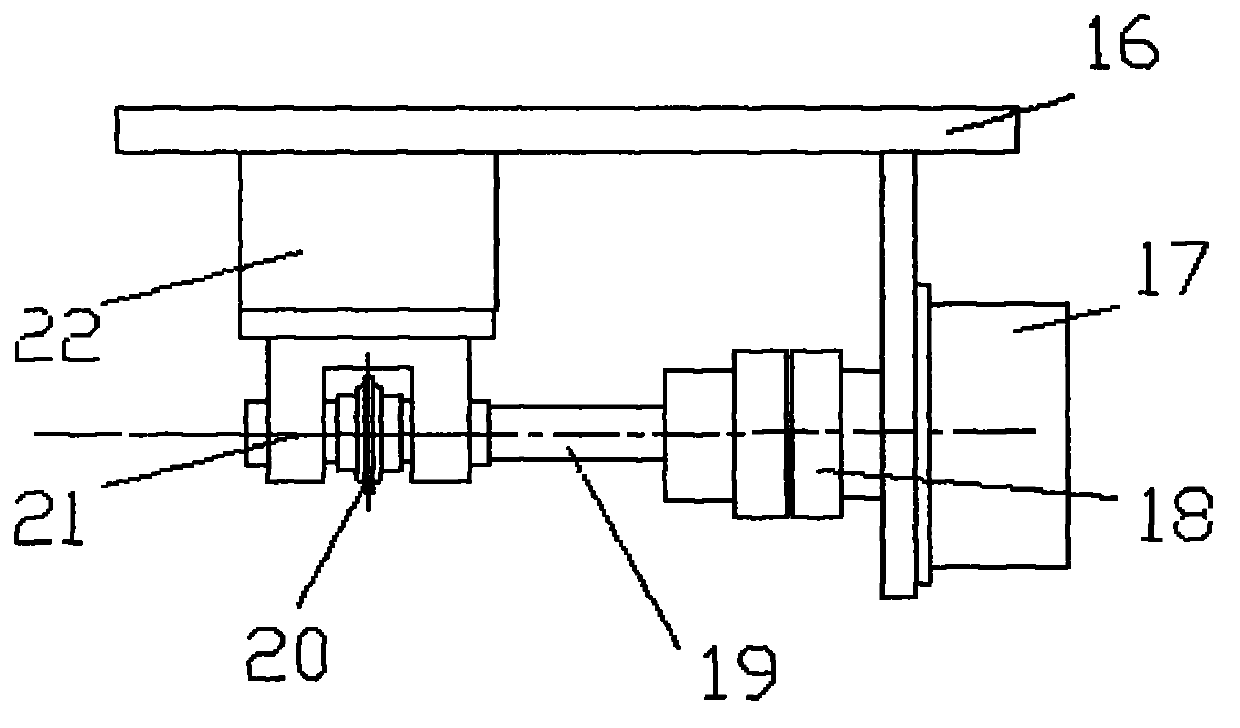

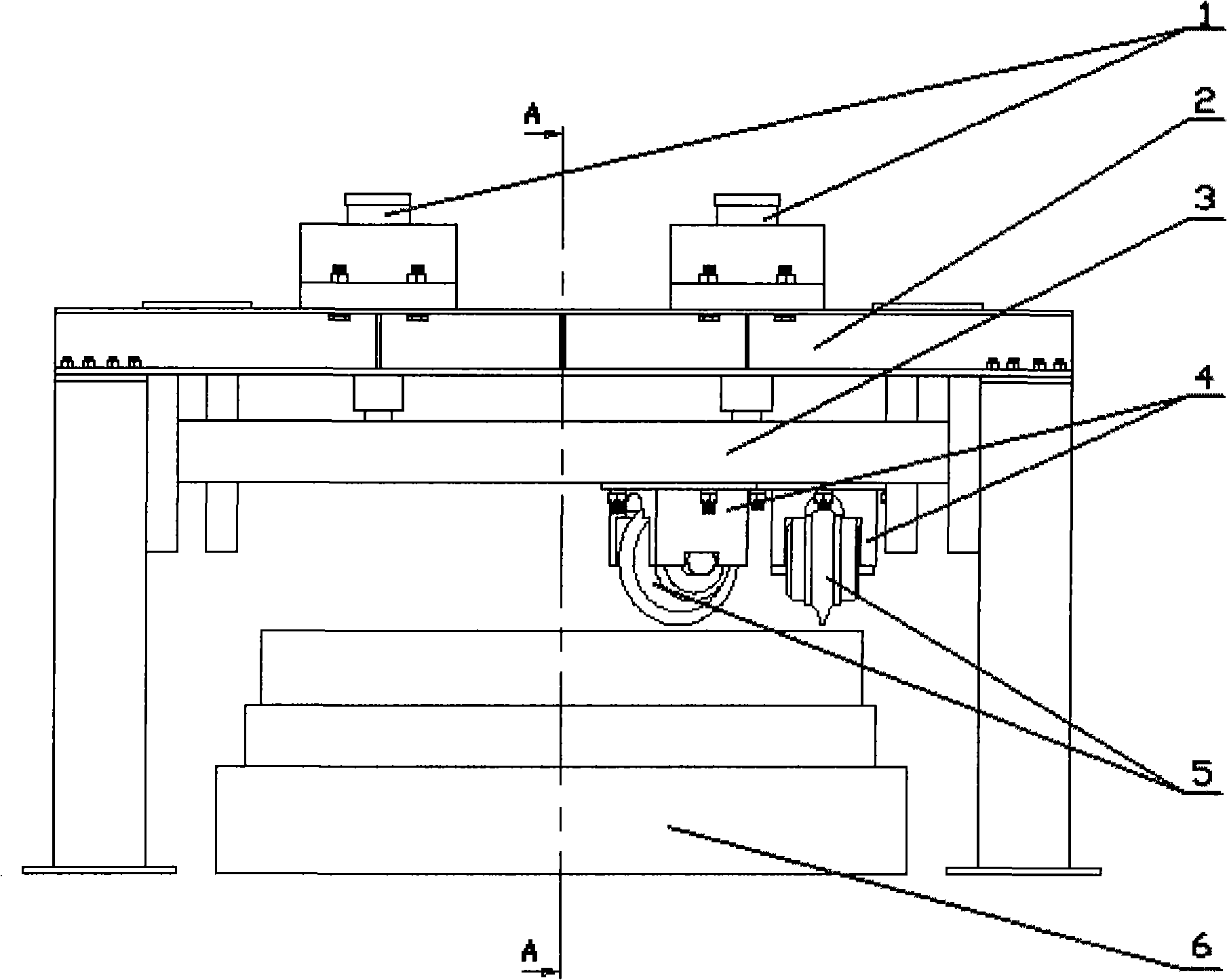

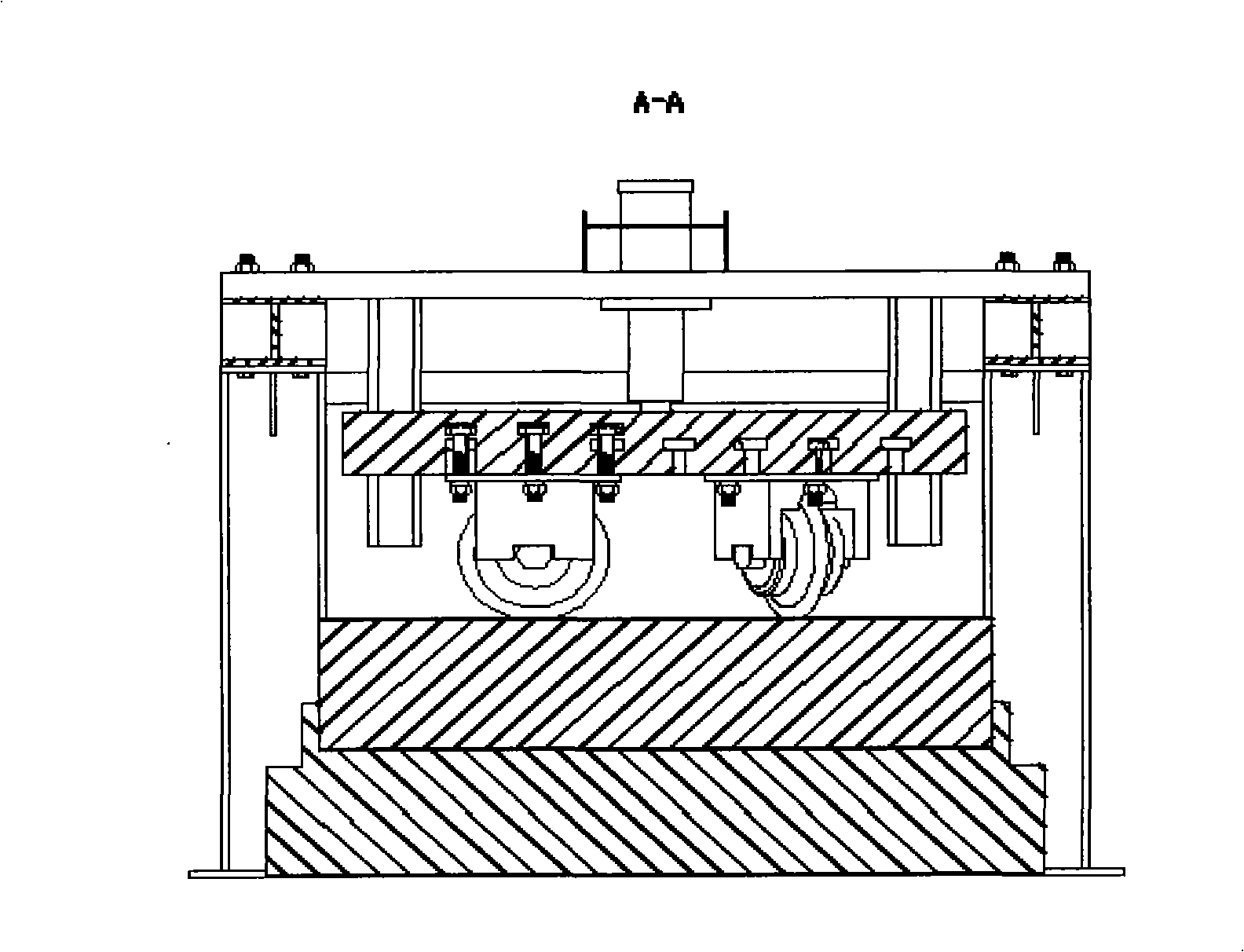

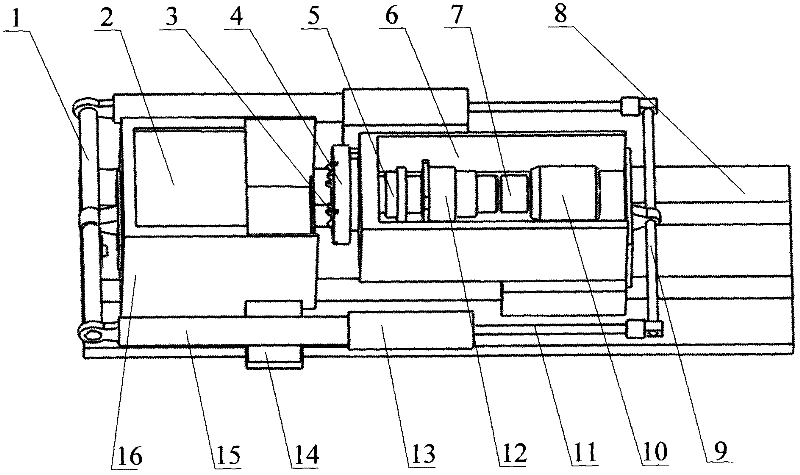

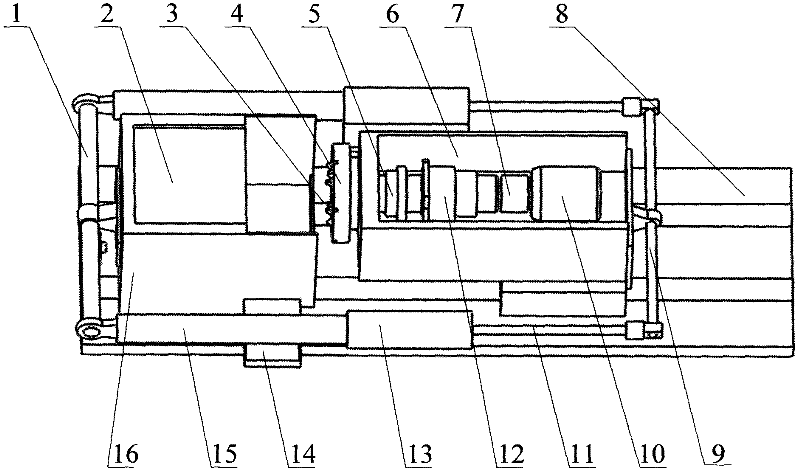

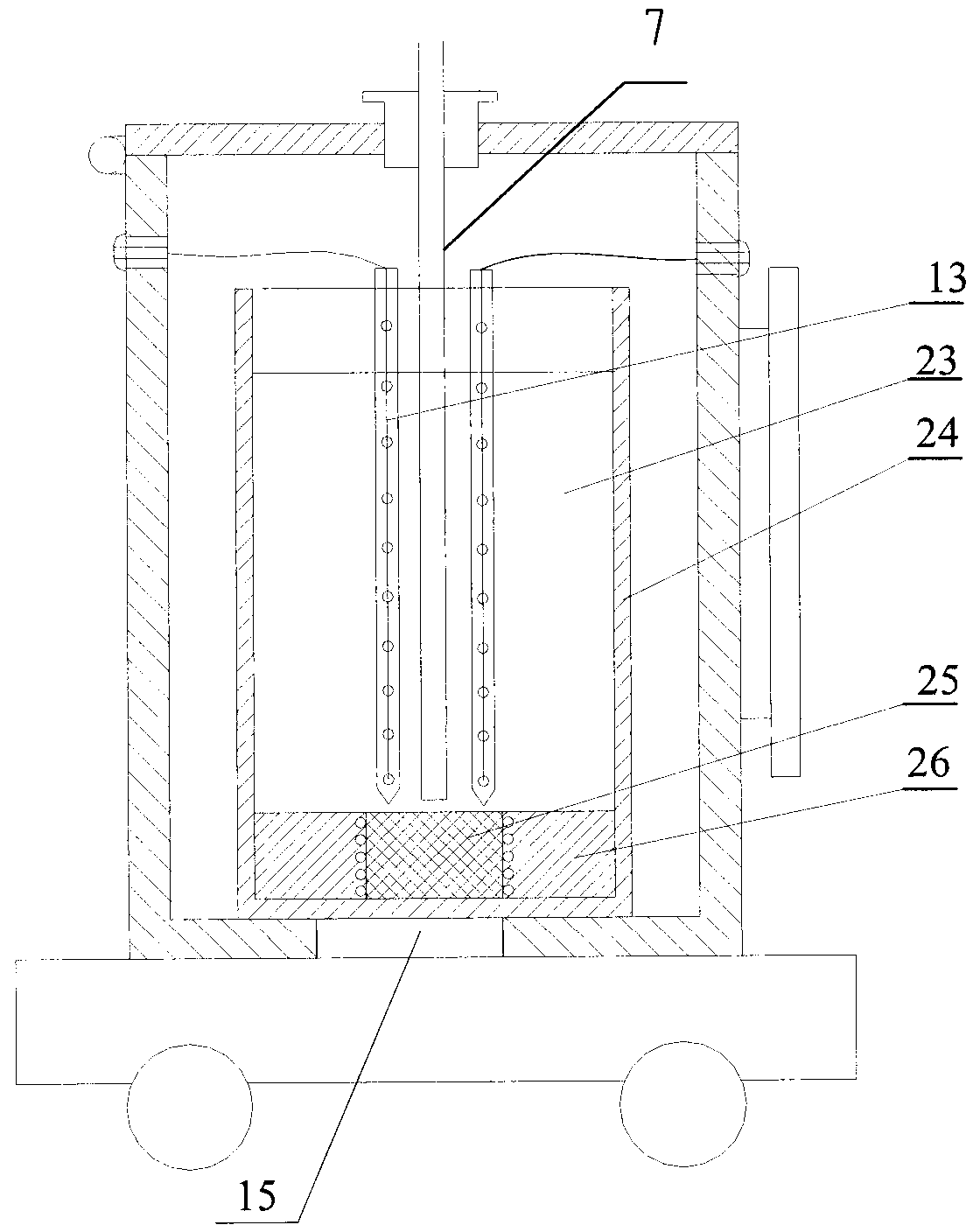

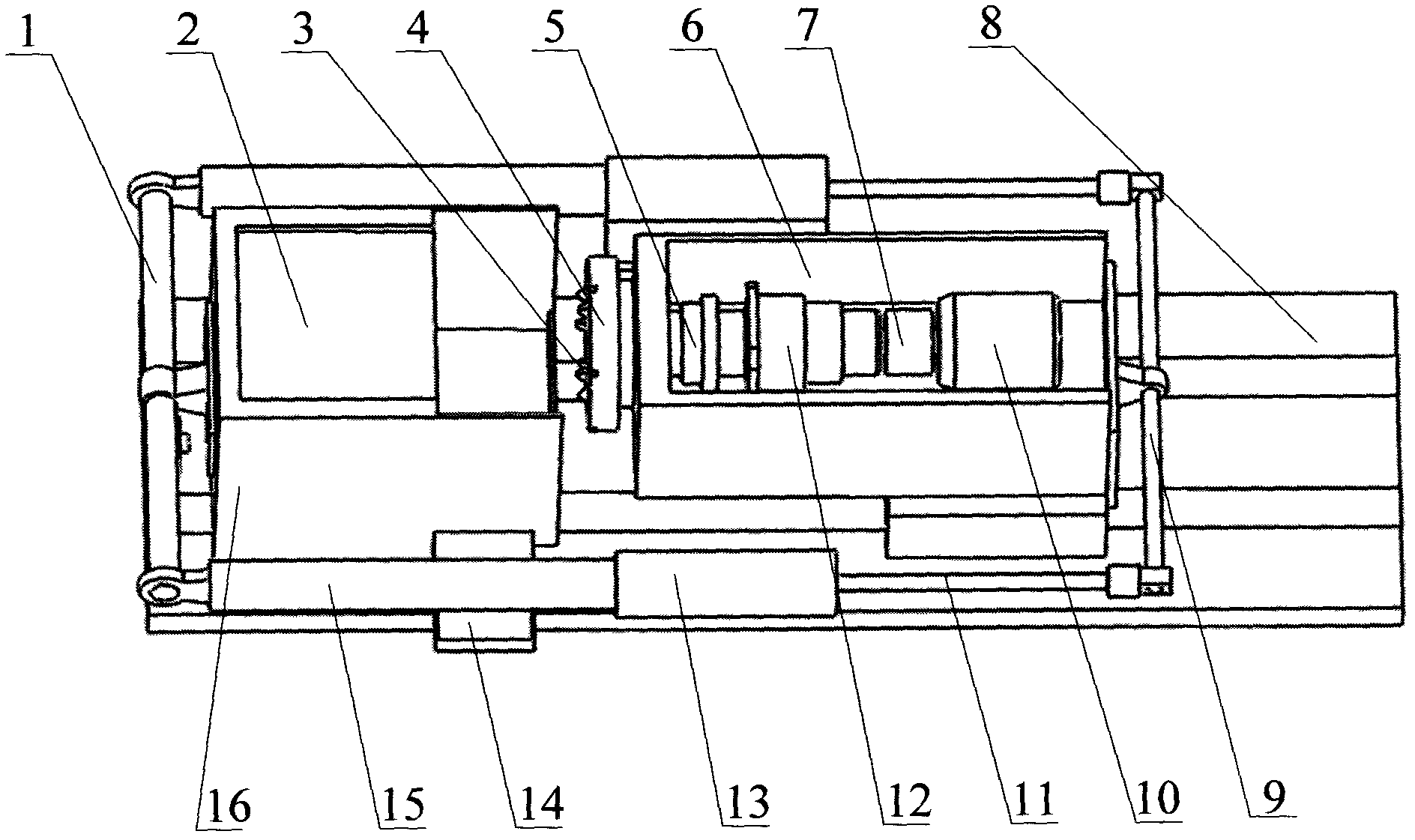

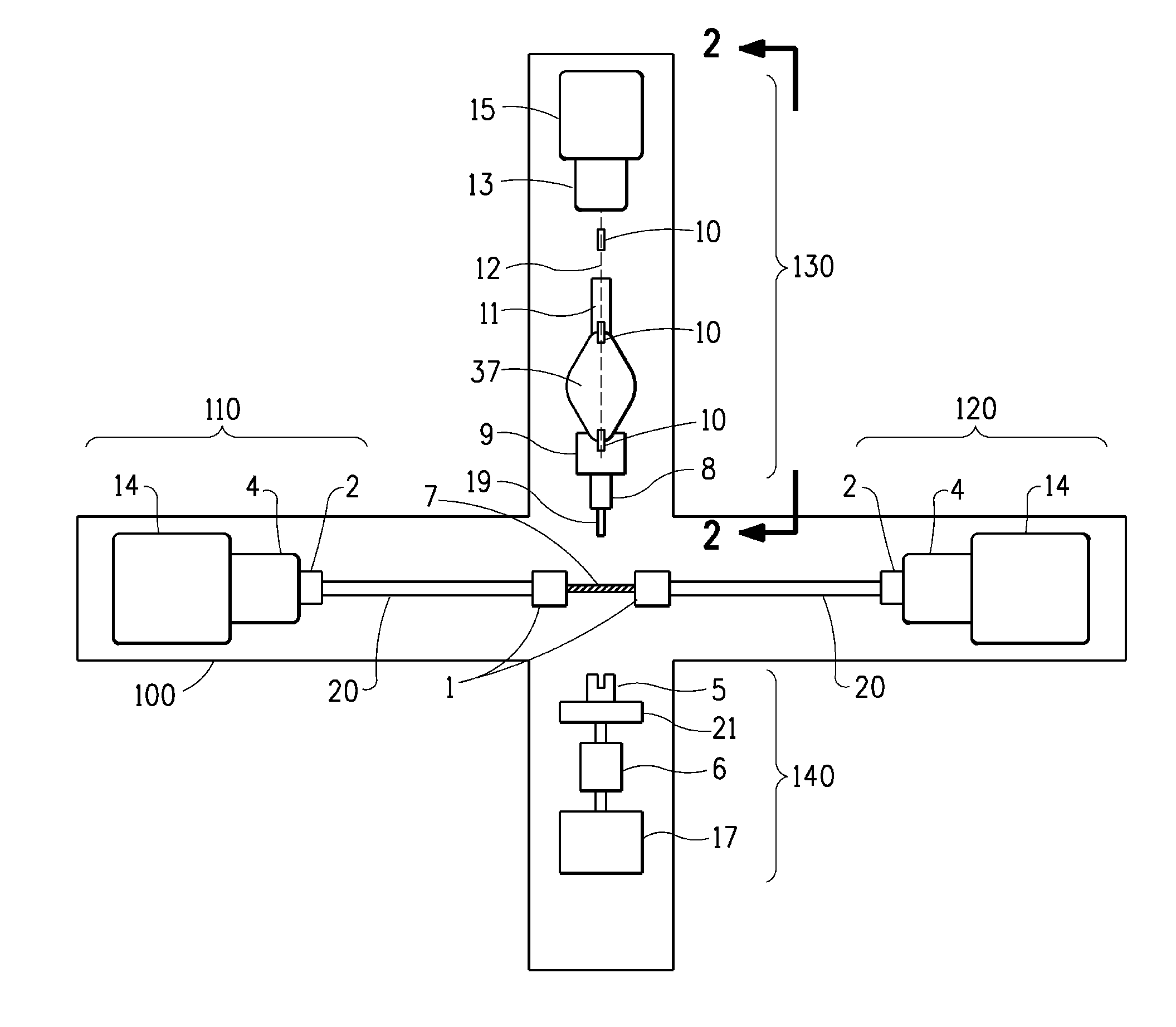

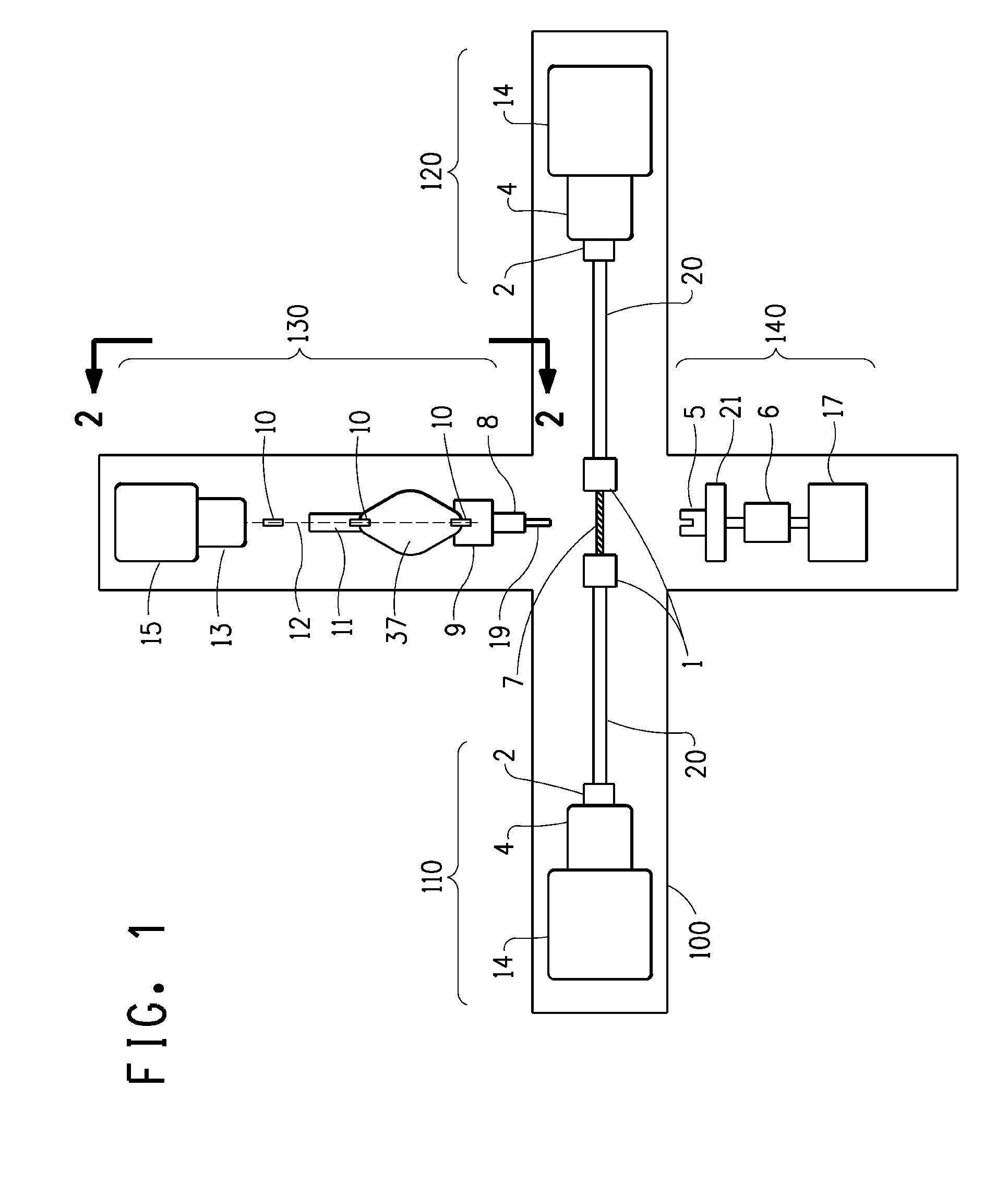

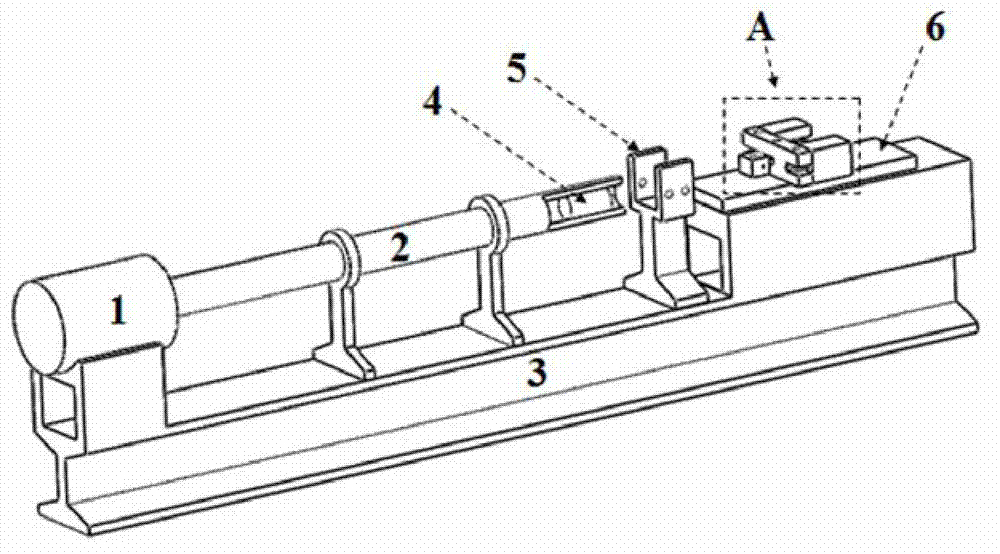

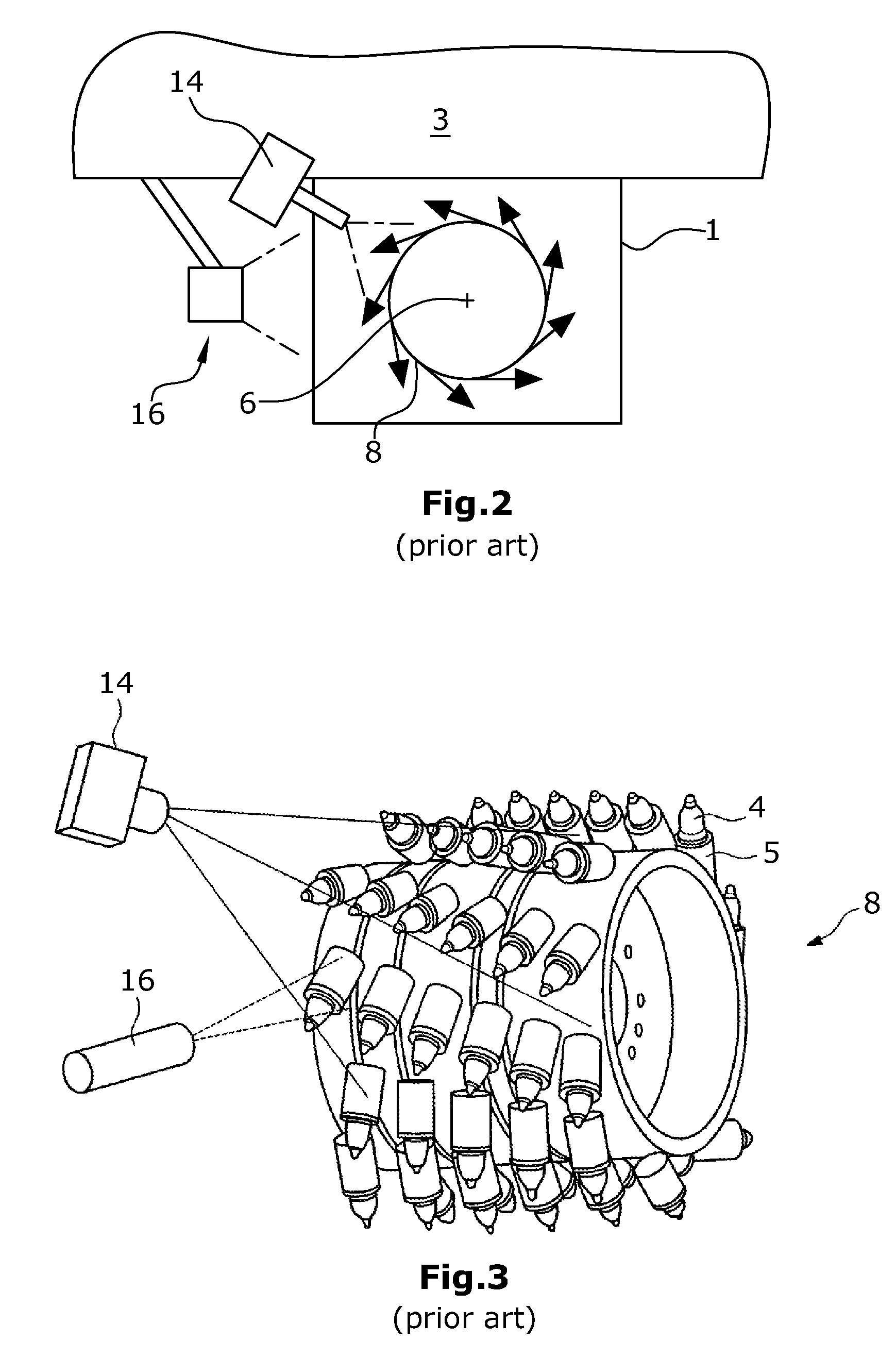

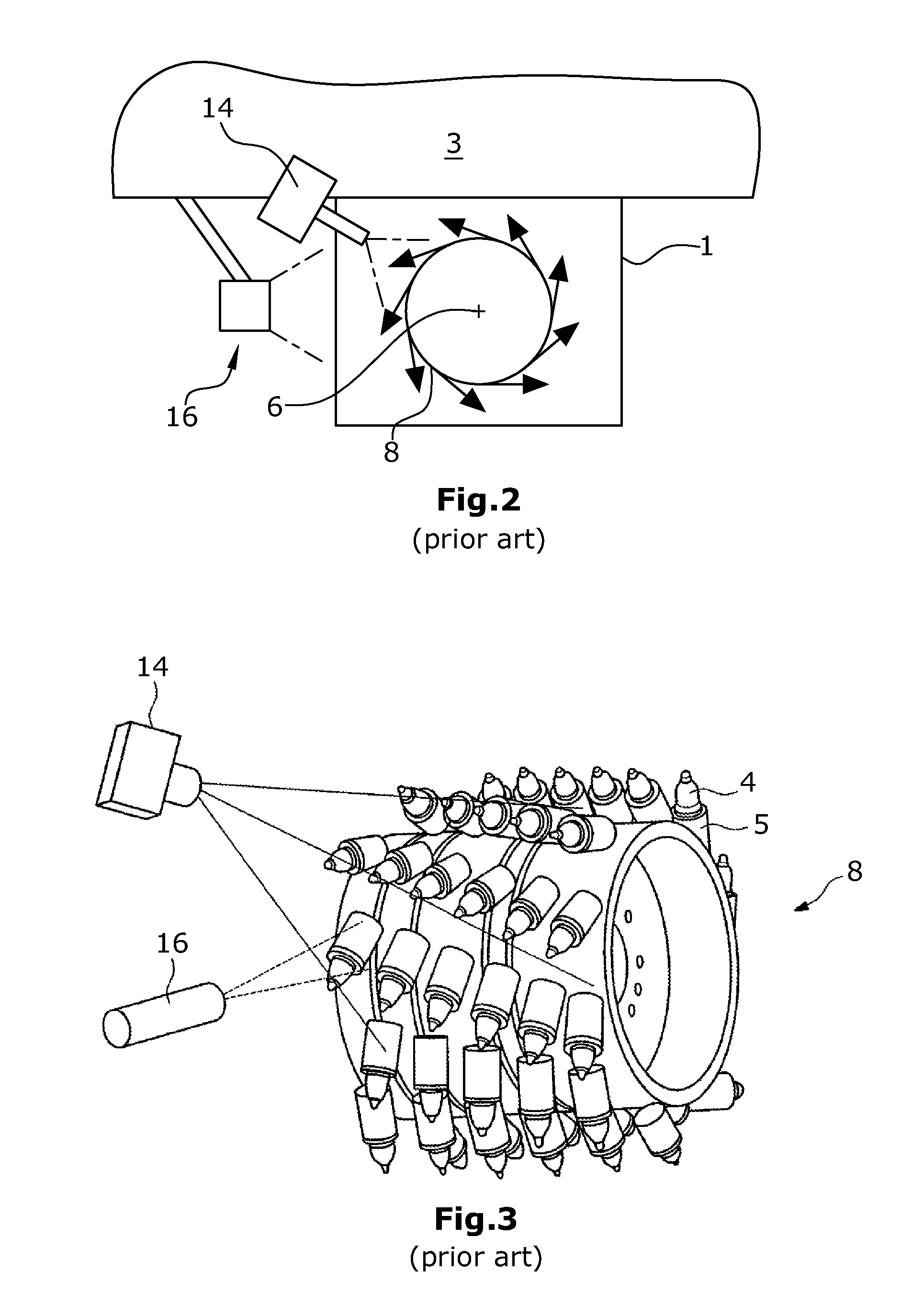

TBM rock breaking test apparatus

ActiveCN102359919AThere is no fixed problemImprove reliabilityMachine part testingInvestigating abrasion/wear resistanceCouplingEngineering

The TBM rock breaking test apparatus provided by the invention comprises a wheel box (6), a rock box (16), a cutterhead (4) and a worktable (8). The wheel box is provided with a motor (10), a torque speed sensor (7) and a decelerator (12); two ends of the torque speed sensor are connected with the motor and the decelerator respectively; the decelerator is connected with the cutterhead arranged onthe wheel box; a cutter (3) is arranged on the cutterhead; and the wheel box and the rock box are slidingly connected with the worktable. A rear distance rod (1) is connected to an external side of the rock box; a front distance rod (9) is connected to an external side of the wheel box; thrust mechanisms are symmetrically arranged on the worktable on two sides of the rock box and the wheel box; rear ends of the thrust mechanisms are connected with the rear distance rod, and front ends of the thrust mechanisms are connected with the front distance rod; the wheel box and the rock box are pushedto simultaneously carry out compressing or loosening movement on the worktable to realize tool feed and retracting. The apparatus can simulate real working process of the cutter to measure a plurality of key parameters of the cutter, such as cutting force, axial thrust, penetration and cutter space.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

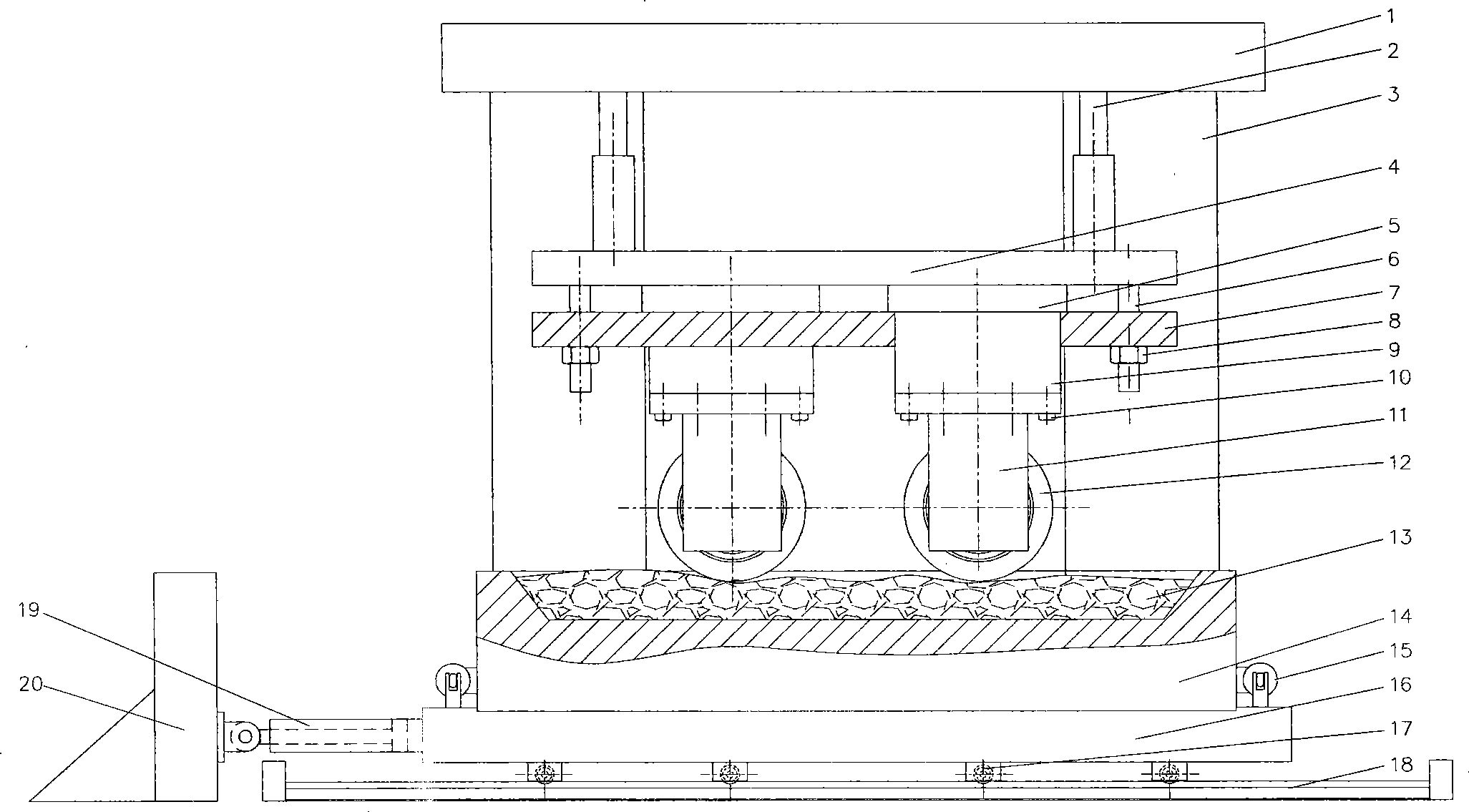

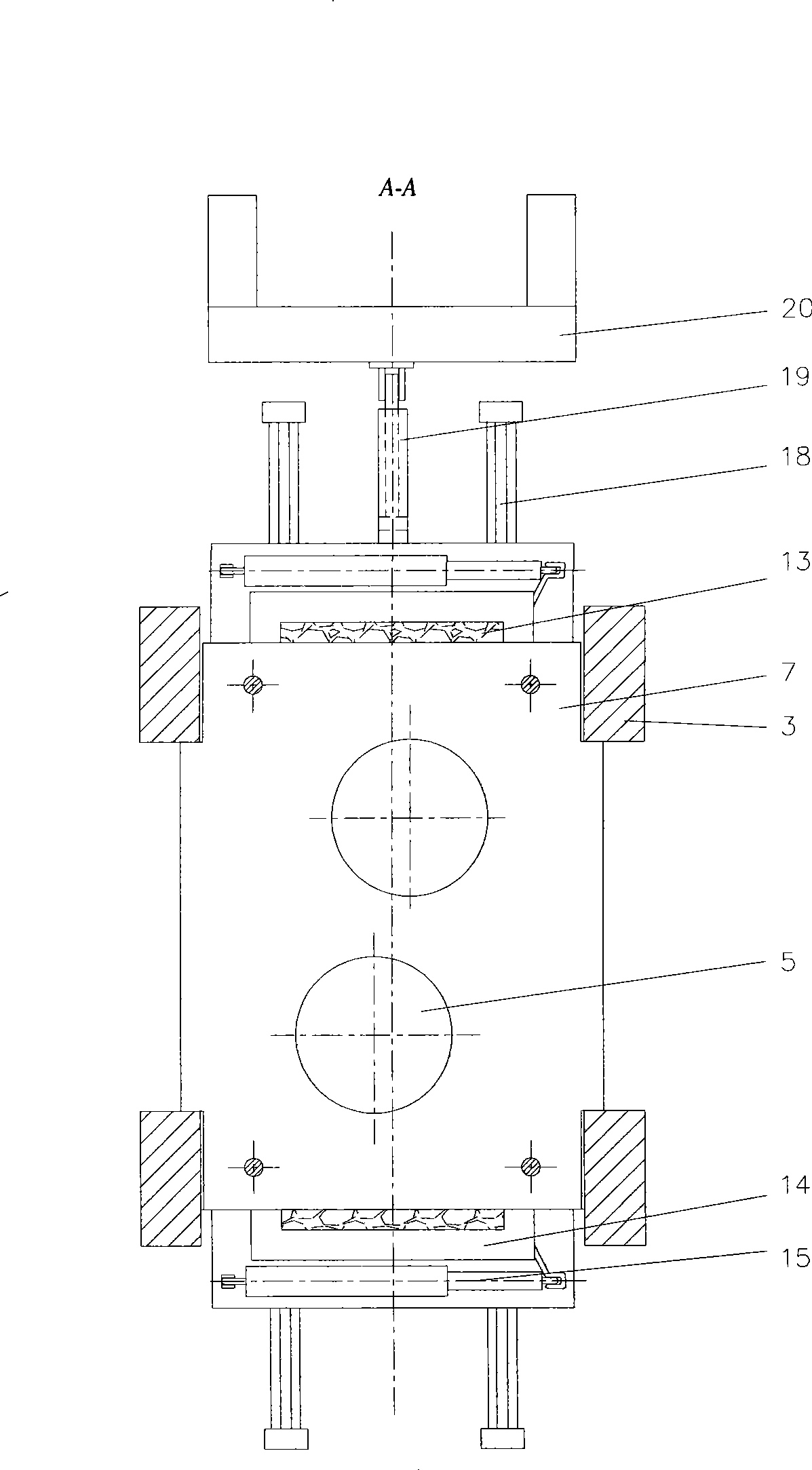

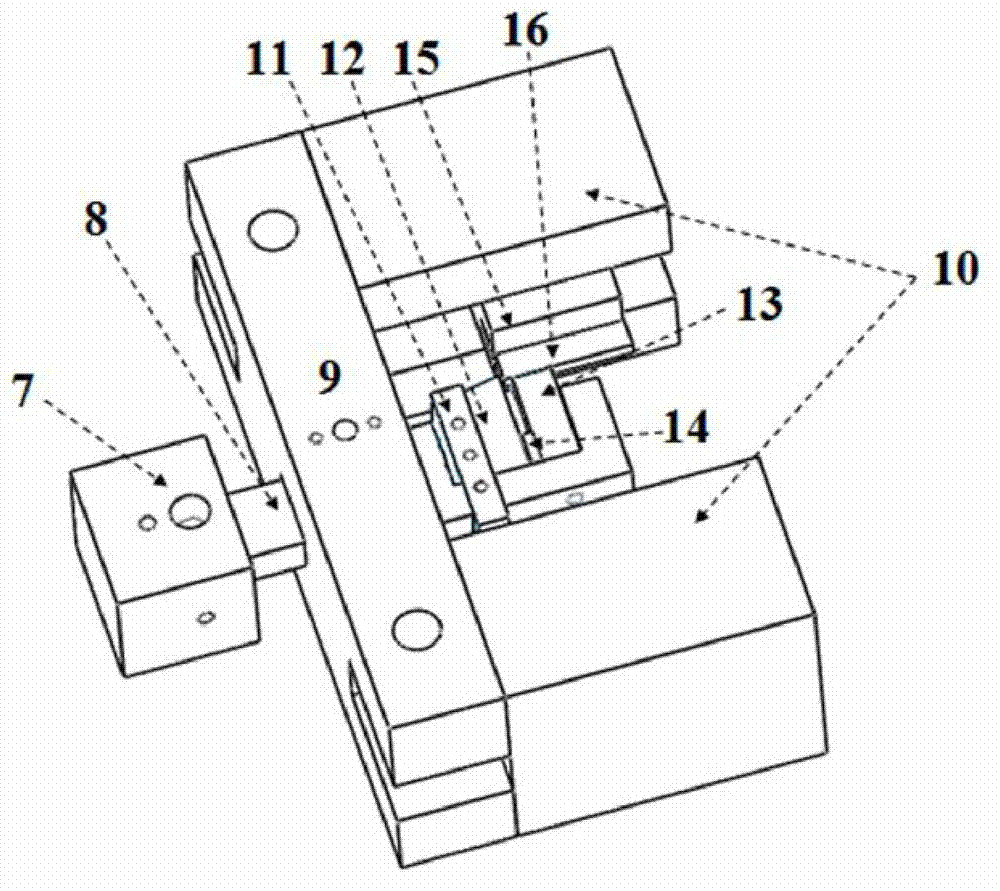

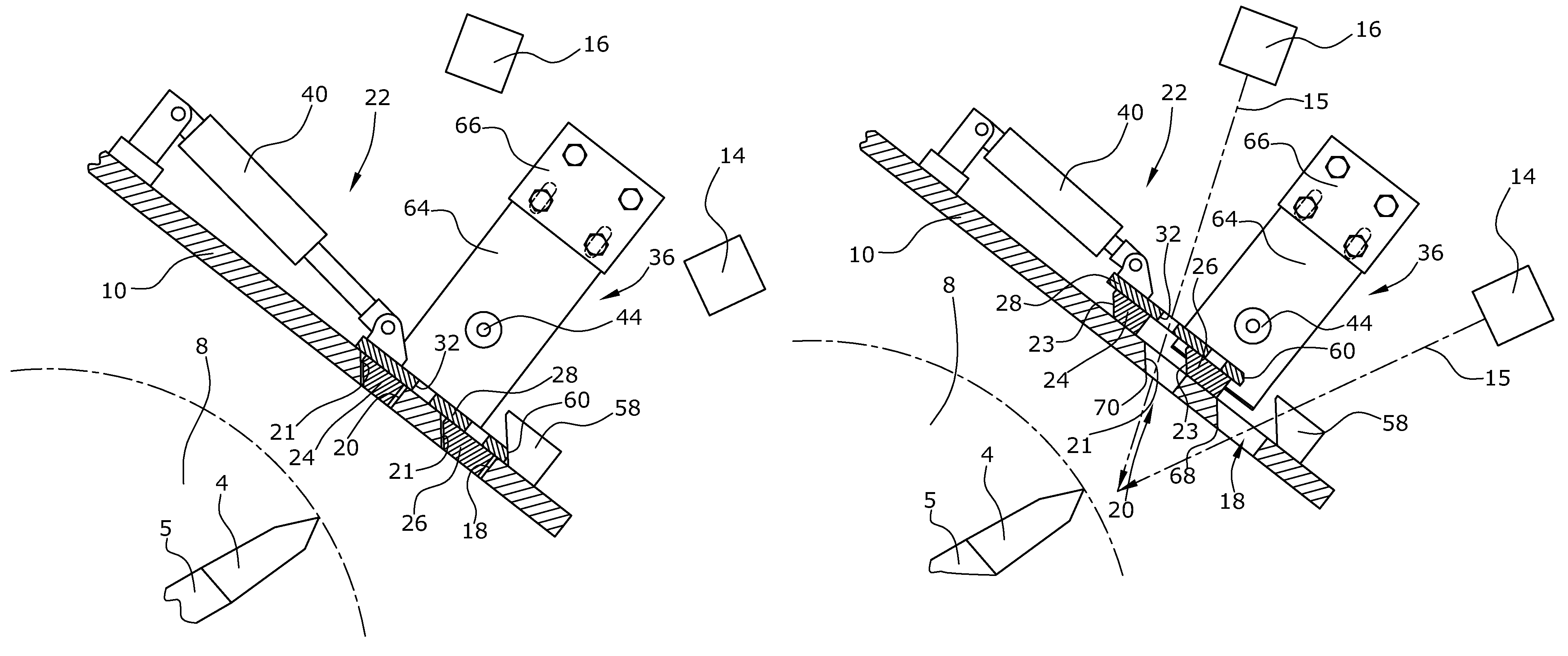

Synchronous detection test device for multi-item parameters of linear TBM hobs

InactiveCN101592533ARock breaking test data is accurateShorten the development and design cycleForce measurementMechanical clearance measurementsHydraulic cylinderPhase difference

The invention provides a synchronous detection test device for multi-item parameters of linear TBM hobs applied in the full-section hard-rock tunneling machine industry. The whole device consists of a self-counterforce frame, a regulate tool rest, an X-direction moving worktable, an X-direction linear guide rail, a Y-direction moving worktable, a Y-direction linear guide rail, an X-direction hydraulic cylinder, a rock sample, a hob, a four-rod guide mechanism, three-direction pressure sensors, a Z-direction hydraulic cylinder and the like, wherein the lateral movement direction of the rock sample is set as an X axis; the axial direction of the hob is set as a Y axis; the direction perpendicular to the surface of the rock sample is set as a Z axis; the rock sample is fixed on a trolley; the regulate tool rest is arranged on the four-rod guide mechanism; the X-direction moving worktable and the Y-direction moving worktable are arranged on a horizontal linear guide rail; the hob is arranged in a hob seat and is connected with the regulate tool rest through the three-direction pressure sensors; the rock sample is arranged and clamped on the X-direction moving worktable; and the three direction hydraulic cylinders are fixed with the fixed self-counterforce frame respectively. The device has the advantage of more precise function of simulating the process of breaking rocks through the hob, and is used for the synchronous detection of three-direction force, tool interval, penetration degree, wear degree, phase difference and other parameters of the hob in the states of linear paths and high-speed rotation of a plurality of hobs.

Owner:SHENYANG HEAVY MACHINERY GROUP

Methods for modeling, displaying, designing, and optimizing fixed cutter bits

ActiveUS20100211362A1Electric/magnetic detection for well-loggingEarth drilling toolsEngineeringDesign methods

In one aspect, the invention provides a method for modeling the performance of a fixed cutter bit drilling an earth formation. In one embodiment, the method includes selecting a drill bit and an earth formation to be represented as drilled, simulating the bit drilling the earth formation, displaying the simulating, and adjusting at least one parameter affecting the performance. The method of design is used to make a fixed cutter drill bit. In another embodiment the method includes numerically rotating the bit, calculating bit interaction with the earth formation during the rotating, and determining the forces on the cutters during the rotation based on the calculated interaction with earth formation and empirical data.

Owner:SMITH INT INC

Tool wear monitoring and predicting method

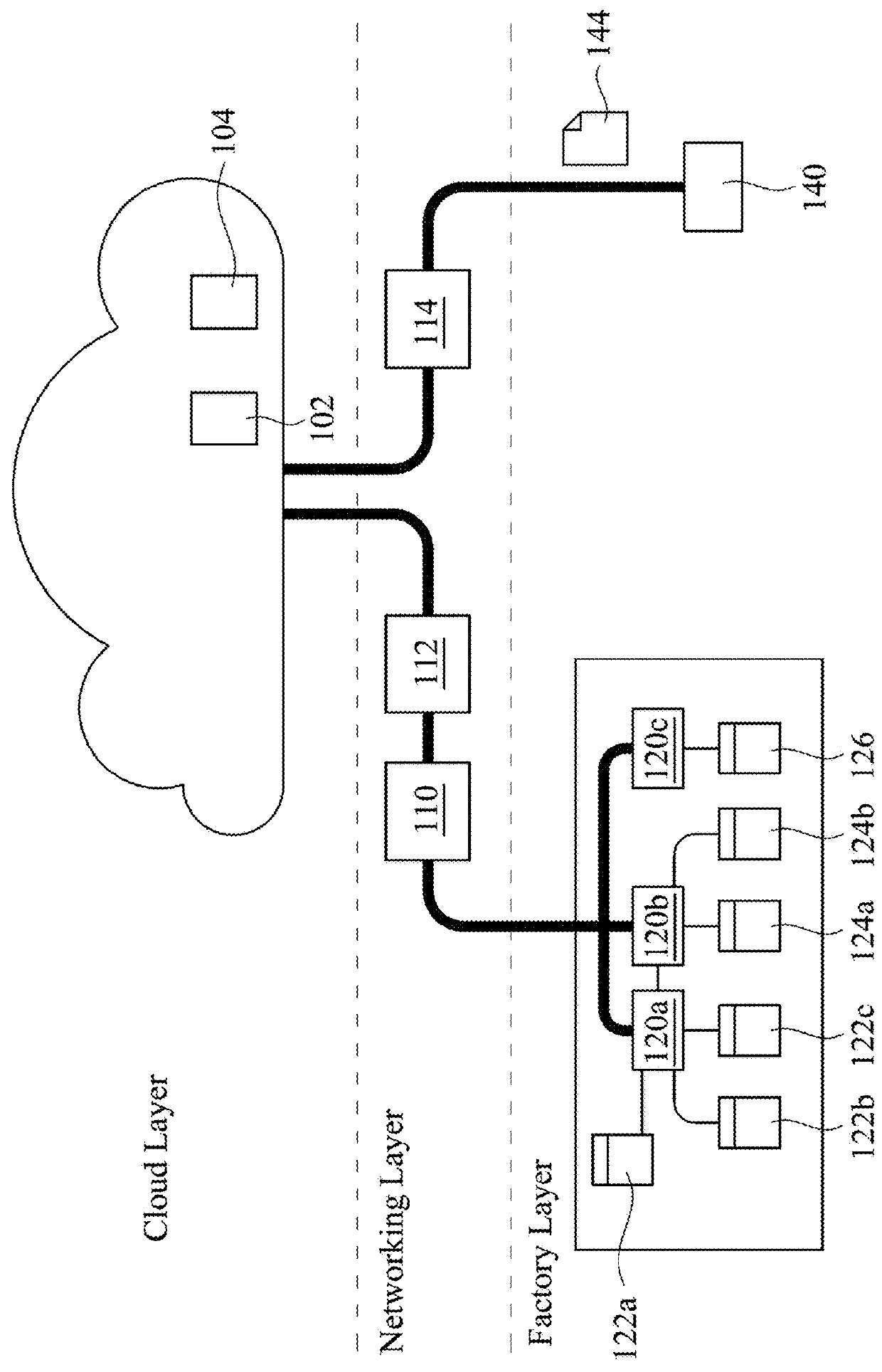

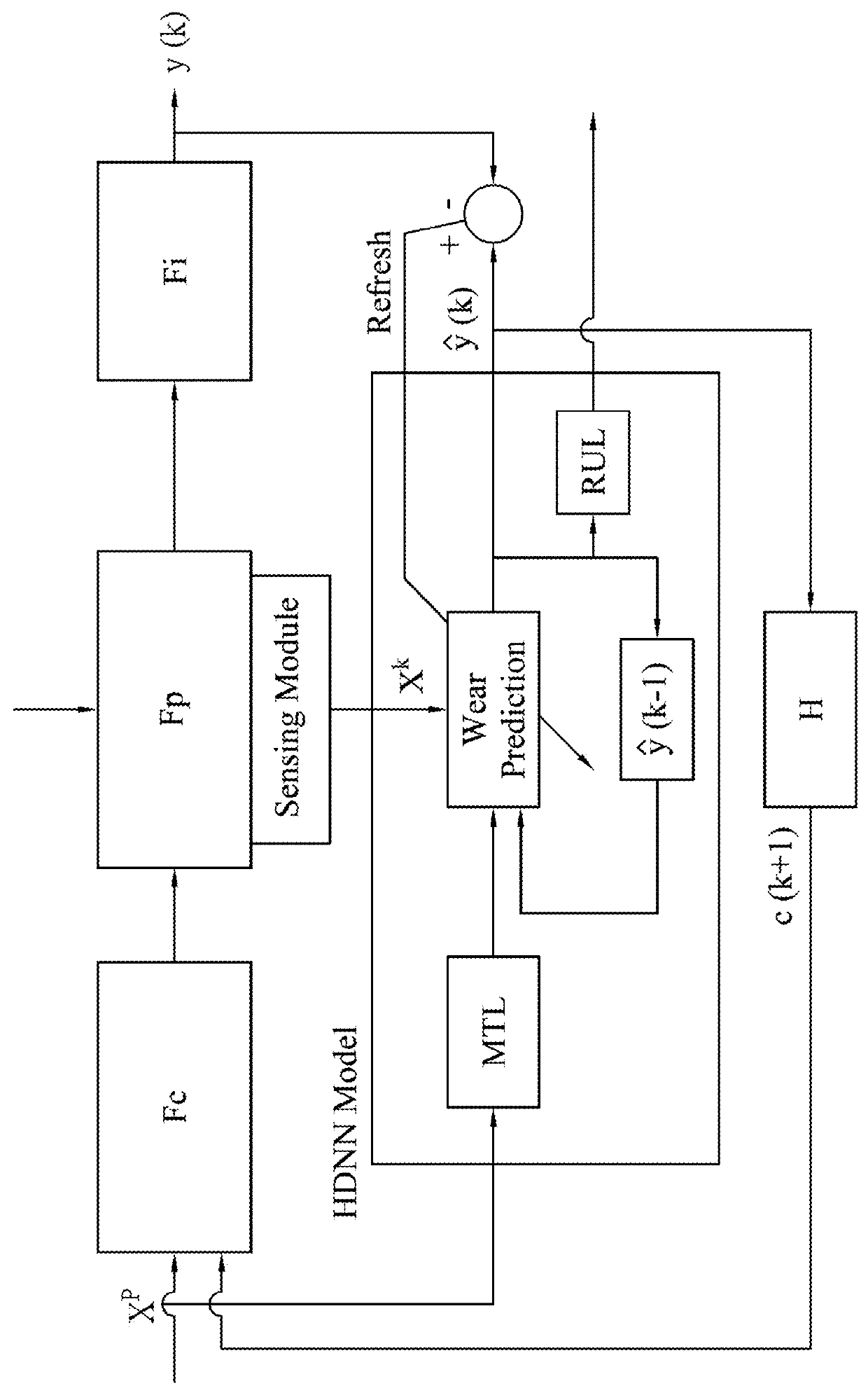

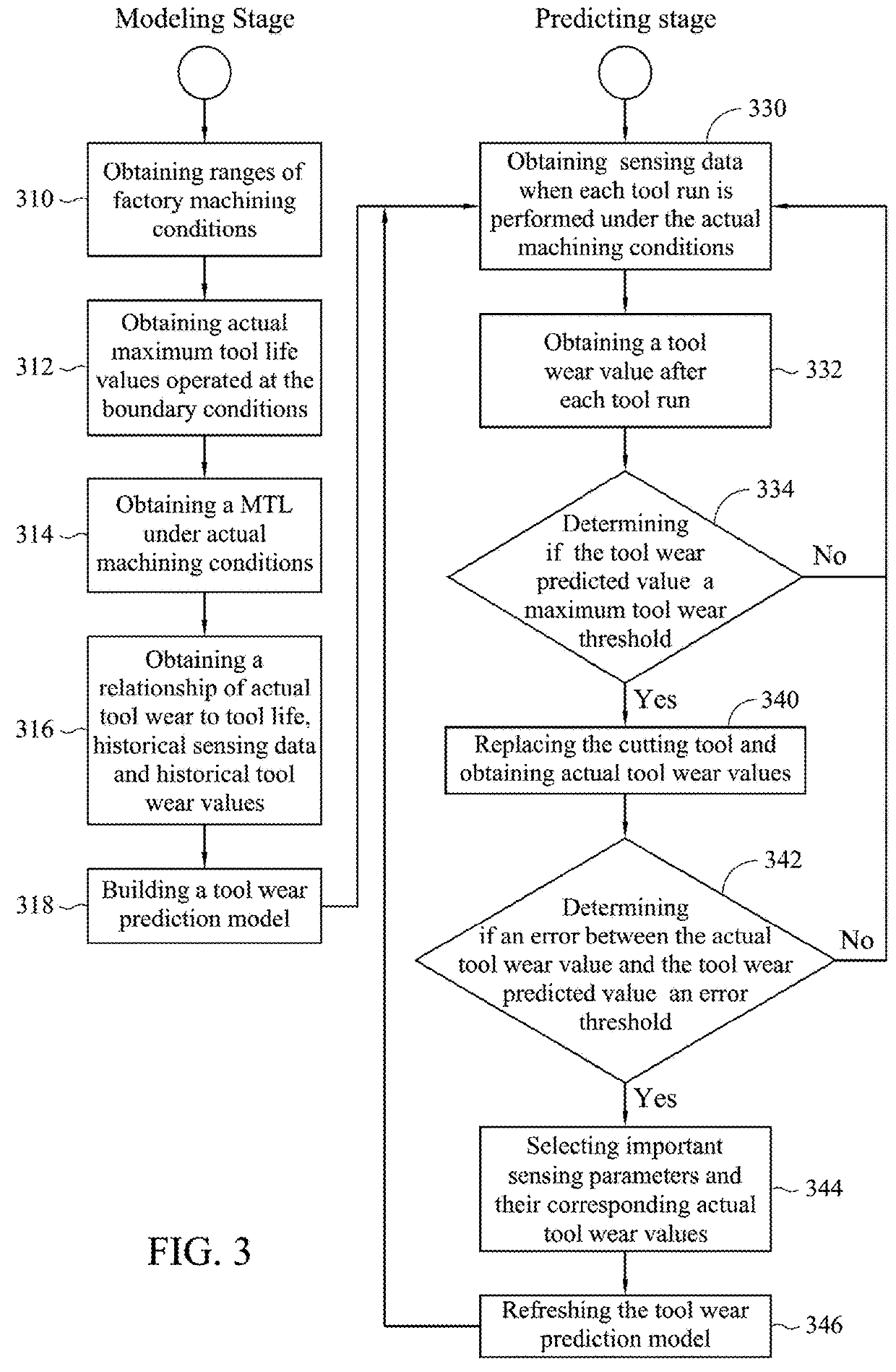

A tool wear monitoring and predicting method is provided, and uses a hybrid dynamic neural network (HDNN) to build a tool wear prediction model. The tool wear prediction model adopts actual machining (cutting) conductions, sensing data detected at the current tool run of operation and the predicted tool wear value at the previous tool run of operation to predict a predicted tool wear value at the current tool run. A cyber physical agent (CPA) is adopted for simultaneously monitoring and predicting tool wear values of plural machines of the same machine type.

Owner:NAT CHENG KUNG UNIV

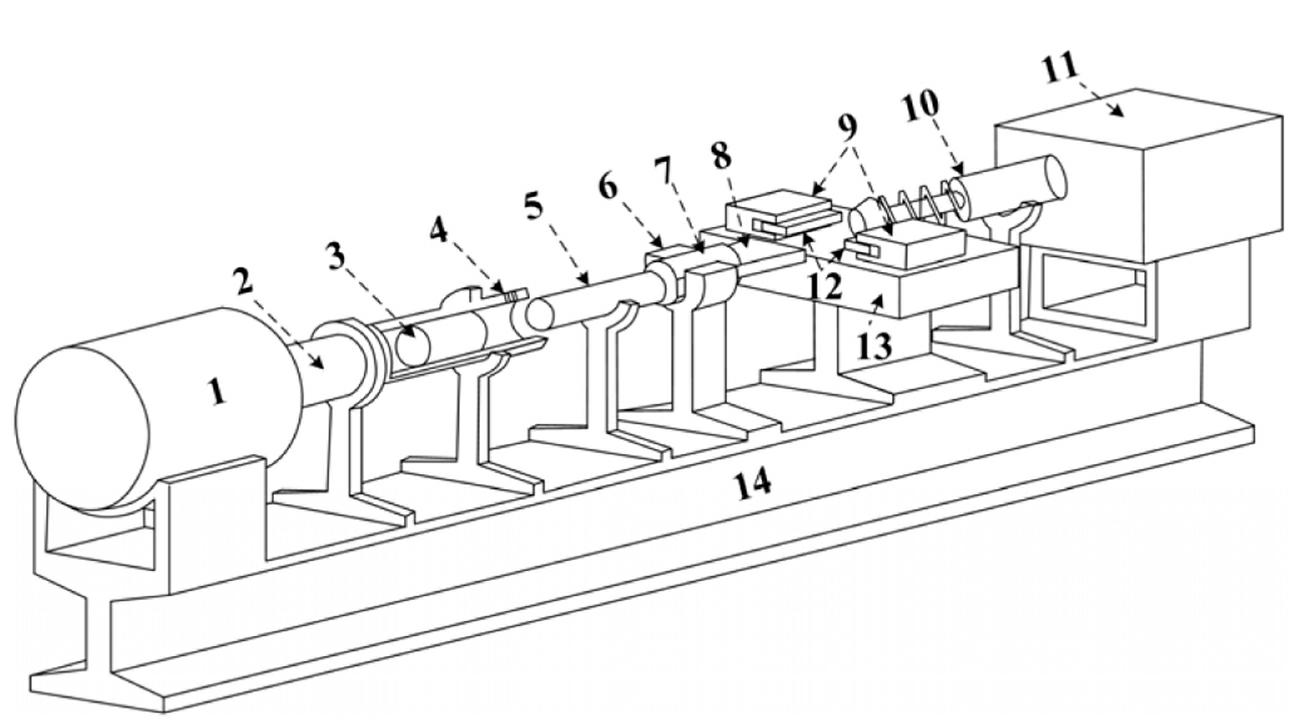

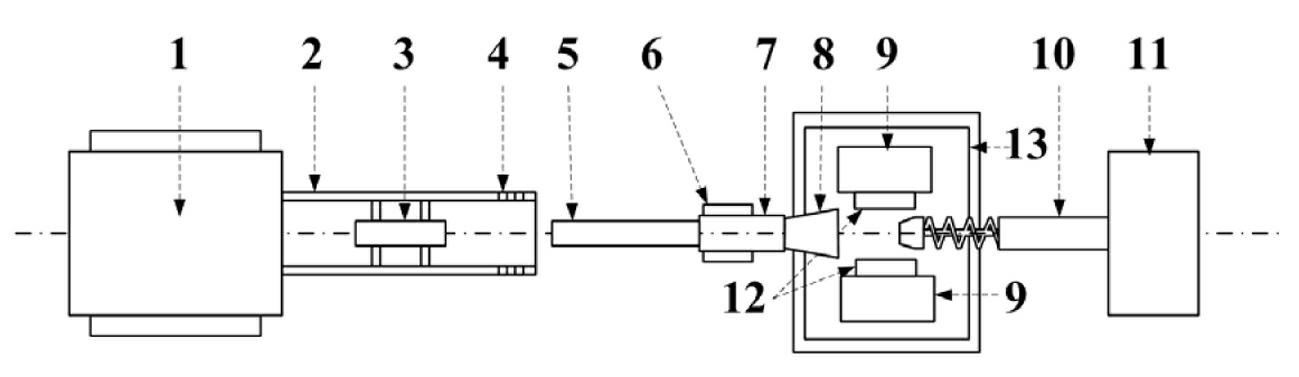

High-speed cutting experiment device based on Hopkinson pressure lever loading technology

ActiveCN102175549AMeet the requirements of high-speed cutting experimentsWide cutting speedInvestigating machinabilityLoading TechniqueMechanical engineering

The invention discloses a high-speed cutting experiment device based on a Hopkinson pressure lever loading technology. The device comprises a power mechanism, a cutting mechanism, a fixing mechanism and a collecting mechanism which are arranged in sequence along an axis, wherein the power mechanism is used for shooting a bullet to the cutting mechanism; an incident bar of the cutting mechanism isdriven to move forwards when the bullet is collided with the cutting mechanism; along with the forward movement of the incident bar, a cutter at the front end of the incident bar cuts a workpiece fixed on the fixing mechanism; and the collecting mechanism is used for resisting the forward incident bar to stop the incident bar quickly. The entire experiment device is built on the basis of the Hopkinson pressure lever loading technology, the entire cutting process is quick and short, and the impact energy is far greater than the energy needed by cutting, so that a stable process is achieved andpreconditions are provided for the stable cutting process.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

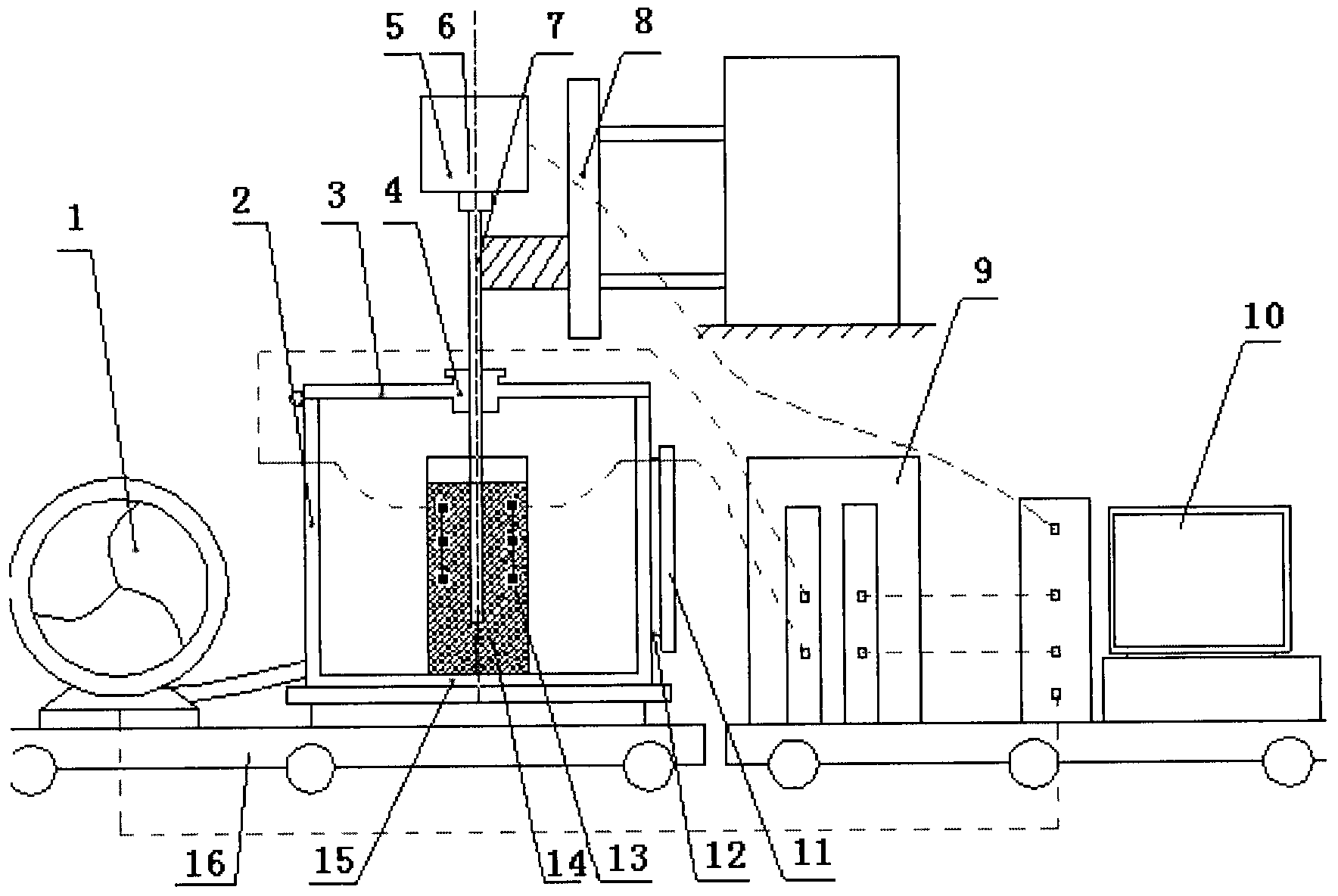

Lunar-environment-simulated cutting test device

ActiveCN102798577ARealize visualizationExtended testInvestigating machinabilityDeep space explorationEngineering

The invention discloses a lunar-environment-simulated cutting test device. According to the lunar-environment-simulated cutting test device, a vacuum environment existing during lunar surface drilling is simulated by adopting a vacuum tank, the structure of a lunar surface is simulated by adopting a drilling load, and a heat-insulating drilling load in a lunar vacuum environment is simulated more really by using a heat insulation technology; the control on drilling parameters and procedures is carried out on drilling sampling during the process of cutting, the drilling parameters and drilling temperature can be monitored, acquired and analyzed, the temperature distribution and the highest temperature limit of a drilling tool are determined, and the vacuum seal for a drilling sampling device during the process of drilling is realized through a magnetofluid sealing device; and the visualization of a vacuum device is realized by adopting an observation window. The lunar-environment-simulated cutting test device also can be applied to the test and development of other drilling unmanned autonomous samplers for deep space exploration in an expanding manner; and in addition, the lunar-environment-simulated cutting test device also has a wide application prospect in the field of vacuum sealing and precise measurement.

Owner:BEIJING SATELLITE MFG FACTORY

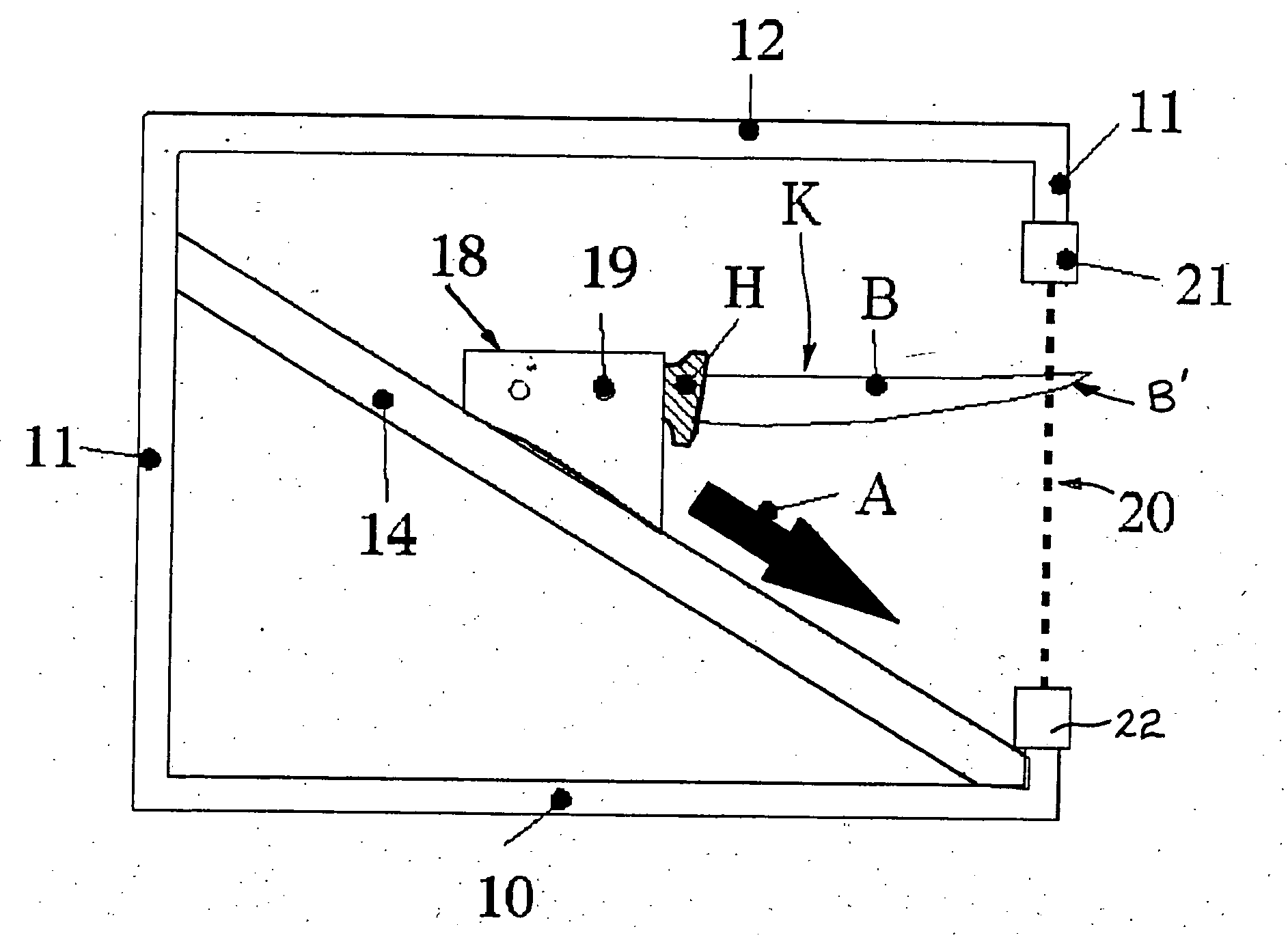

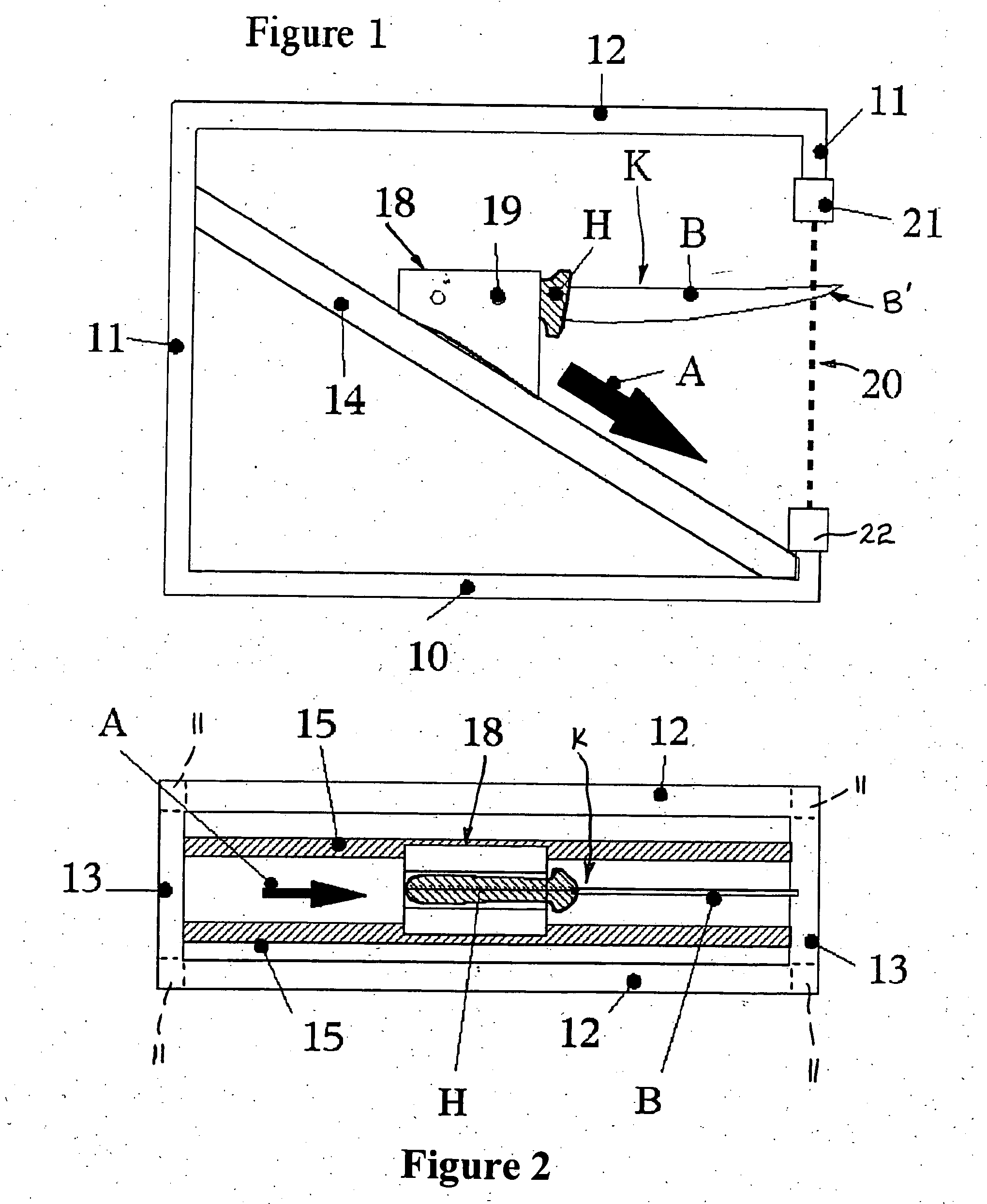

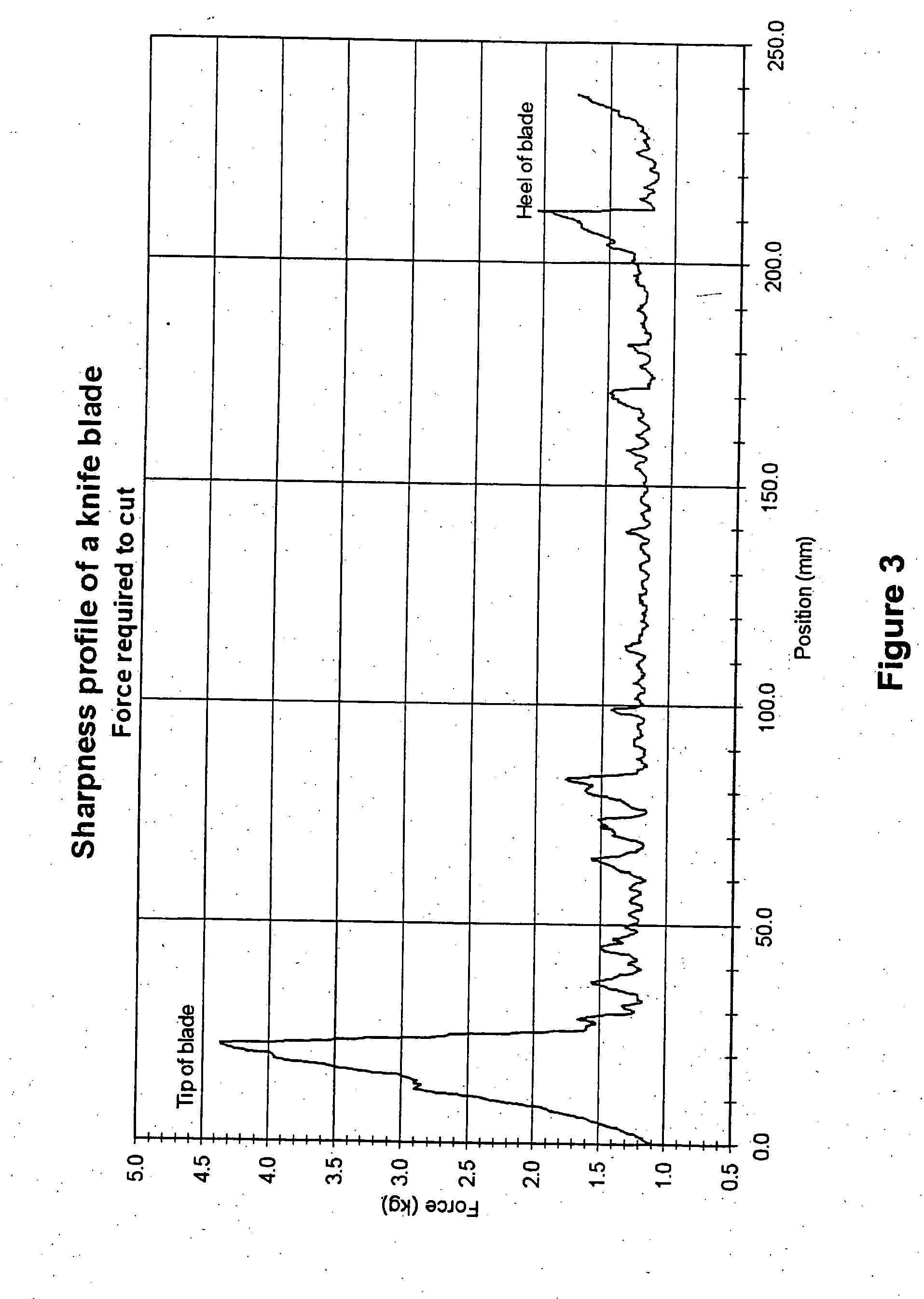

Sharpness tester

ActiveUS20060201237A1Minimal damageMeasurement/indication equipmentsElectric/magnetic roughness/irregularity measurementsMechanical engineeringLinear distance

A sharpness tester for testing the sharpness of a blade. The tester has a blade holder 19 and a mounting arrangement 21, 22 for mounting a cuttable material 20. The blade holder 19 is mounted by a carriage 18 which is moveable on a track 14 so that the blade can move relative to the material 20 and contact the material. A linear distance measuring device and a force measuring device 21 enable the tester to determine the force required by part of the blade B to cut the material 20.

Owner:DOWD PETER CHRISTOPHER

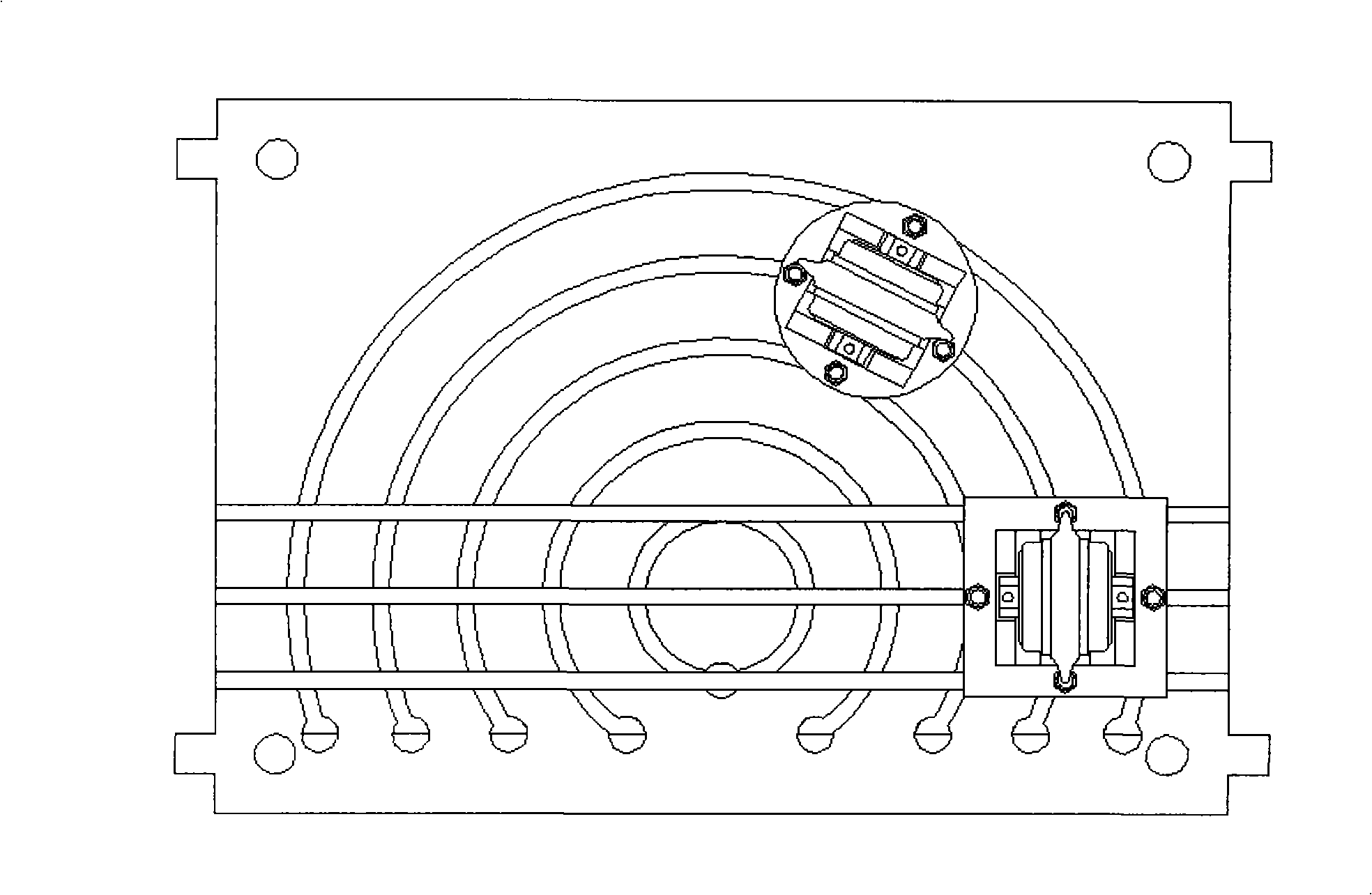

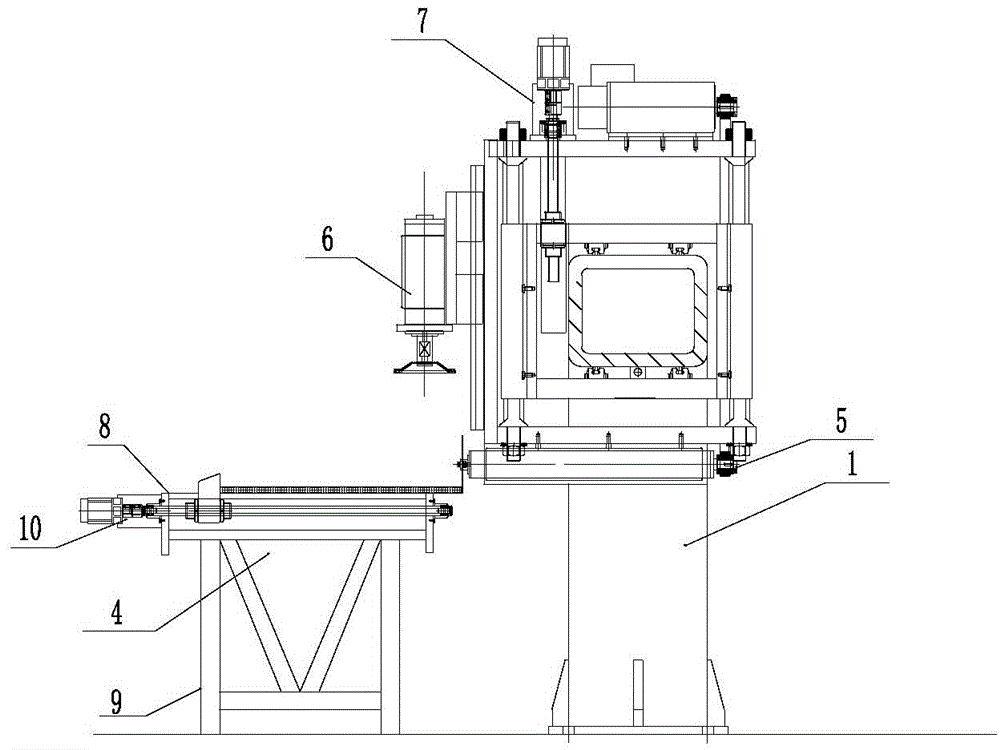

Cutting test method for rock-cutting tool

InactiveCN101713719AAffect the normal service lifeImprove stabilityInvestigating machinabilityHydraulic cylinderPresent method

The invention belongs to the field of hardware tools or tunnel boring machines, and in particular to a cutting test method for a rock-cutting tool. The cutting test method for the rock-cutting tool is characterized in that: a cutting test device for the rock-cutting tool comprises a storage box moving device, a storage box turning device, a cutting tool device, a screw-down oil cylinder device, a cutting tool moving device, a whole frame and a cutting tool locking device; the whole frame is formed by connecting an upper crossbeam, a lower crossbeam and a middle crossbeam by four prestressed pull rods; the whole frame is in rigid connection with the storage box moving device which is connected with a foundation; the storage box moving device at least comprises a pedestal, a guide rail, an operating platform and a hydraulic cylinder; the storage box turning device is arranged on the operating platform which is fixed on the guide rail on the pedestal; and the storage box turning device is moved to a working area to work by pushing the operating platform by the hydraulic cylinder. The cutting test method for the rock-cutting tool can really simulate the actual working condition of a tunnel boring machine (TBM) so as to systematically analyze the rock breaking and wearing processes of the rock-cutting tool.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

TBM rock breaking test apparatus

ActiveCN102359919BEasily measure cutting forceEasily measure axial thrustMachine part testingInvestigating abrasion/wear resistanceCouplingReduction drive

The TBM rock breaking test apparatus provided by the invention comprises a wheel box (6), a rock box (16), a cutterhead (4) and a worktable (8). The wheel box is provided with a motor (10), a torque speed sensor (7) and a decelerator (12); two ends of the torque speed sensor are connected with the motor and the decelerator respectively; the decelerator is connected with the cutterhead arranged onthe wheel box; a cutter (3) is arranged on the cutterhead; and the wheel box and the rock box are slidingly connected with the worktable. A rear distance rod (1) is connected to an external side of the rock box; a front distance rod (9) is connected to an external side of the wheel box; thrust mechanisms are symmetrically arranged on the worktable on two sides of the rock box and the wheel box; rear ends of the thrust mechanisms are connected with the rear distance rod, and front ends of the thrust mechanisms are connected with the front distance rod; the wheel box and the rock box are pushedto simultaneously carry out compressing or loosening movement on the worktable to realize tool feed and retracting. The apparatus can simulate real working process of the cutter to measure a plurality of key parameters of the cutter, such as cutting force, axial thrust, penetration and cutter space.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Apparatus for determining cut resistance

ActiveUS20100300195A1Tension measurementInvestigating abrasion/wear resistanceElastomerBiomedical engineering

An apparatus and a method of using the apparatus for measuring the cut resistance of polymeric and elastomeric materials having specimen holding and tensioning devices arranged on a common axis; a blade cutting device located orthogonally to the axis of the first and second specimen tensioning devices and a cutting block assembly located on the same axis as the cutting device and on the opposite side of the specimen tensioning device.

Owner:DUPONT SAFETY & CONSTR INC

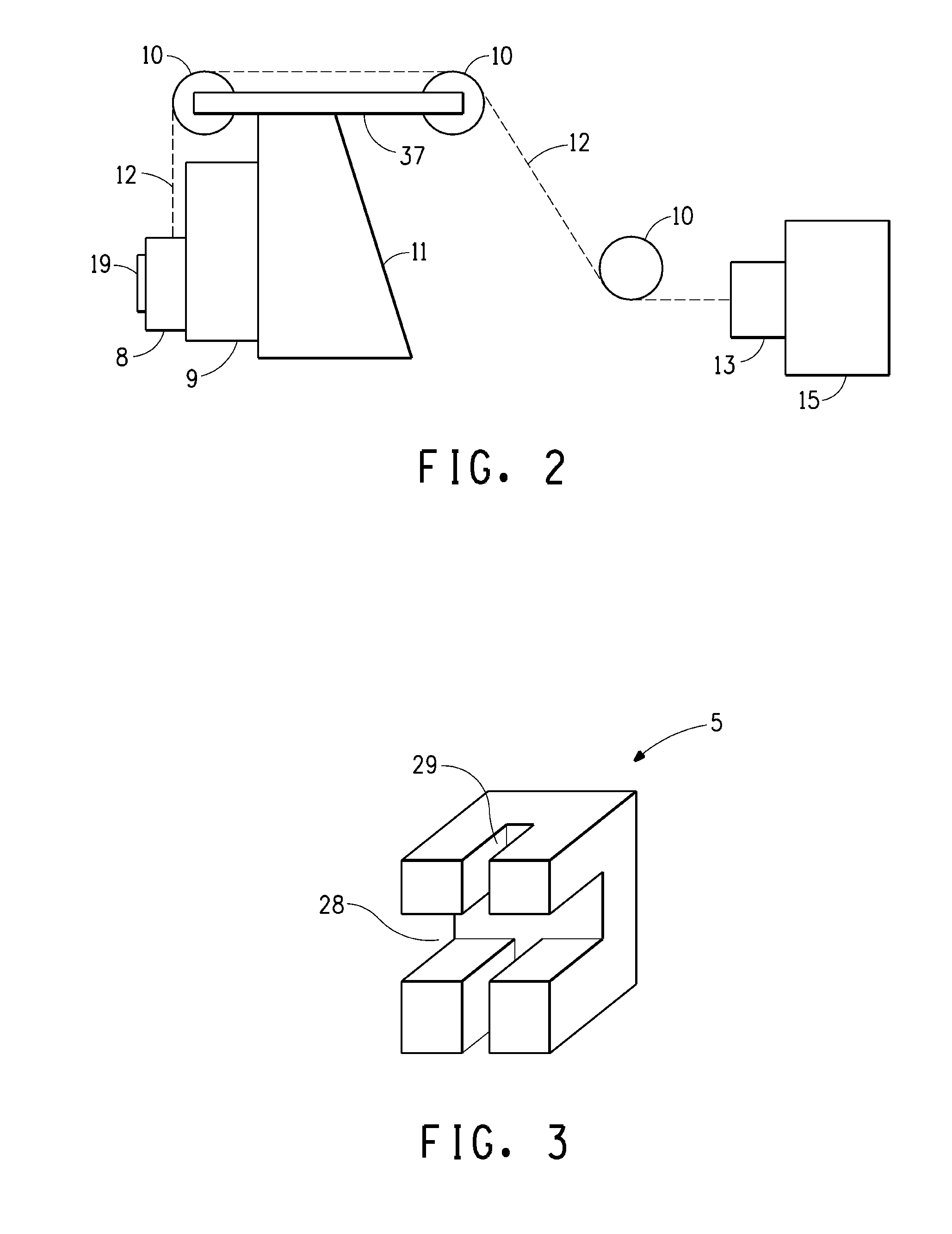

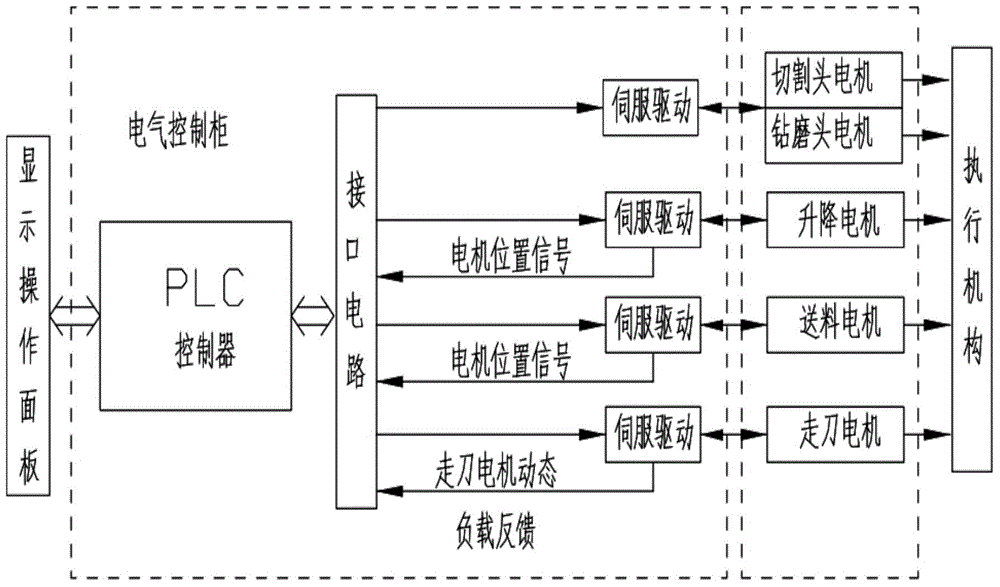

Tool cutting and grinding tester

The invention discloses a tool cutting and grinding tester, which comprises a tool movement system, a workpiece movement system, a sensor detection system and a circuit control system, wherein the tool movement system comprises a horizontal drive device, a rotary drive device and a tool clamping part; the horizontal drive device is connected with the tool clamping part; the rotary drive device is connected with the tool clamping part; the workpiece movement system comprises a vertical drive device, an oscillating drive device and a main shaft device for driving a workpiece to rotate; the vertical drive device is connected with the oscillating drive device, and is capable of driving the oscillating drive device to move along the vertical direction; the oscillating drive device is connected with the main shaft device to drive the main shaft device to oscillate relative to the vertical drive device; the sensor detection system comprises various sensors; the circuit control system is connected with the tool movement system, the workpiece movement system and the sensor detection system to control the tool movement system, the workpiece movement system and the sensor detection system to start and stop; and the circuit control system comprises a human-computer interaction interface to at least input an instrument and output a detection result. The tool cutting and grinding tester is high in test efficiency, good in measurement accuracy and wide in application range.

Owner:TSINGHUA UNIV

Apparatus to determine the operational effectiveness of a machine tool and method therefor

InactiveUS6041271ADetect presenceGood flexibilityProgramme controlComputer controlOperational effectivenessEngineering

To determine whether a machine tool is operating effectively, the present invention system, instead of directly measuring the operating parameters of the machine tool, monitors the presence or absence of any holes made by the machine tool and the quality of those holes, if made. The operational effectiveness of the machine tool is then correlated with the data thus monitored.

Owner:FINN POWER INT

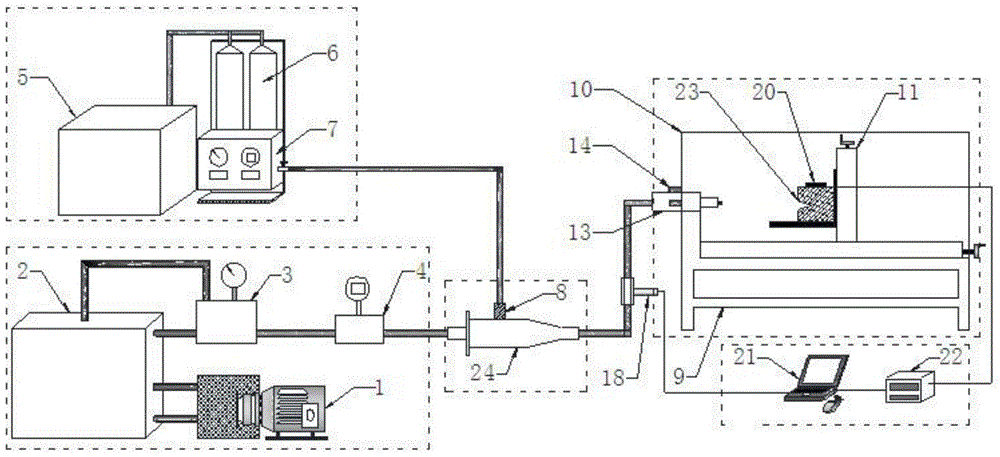

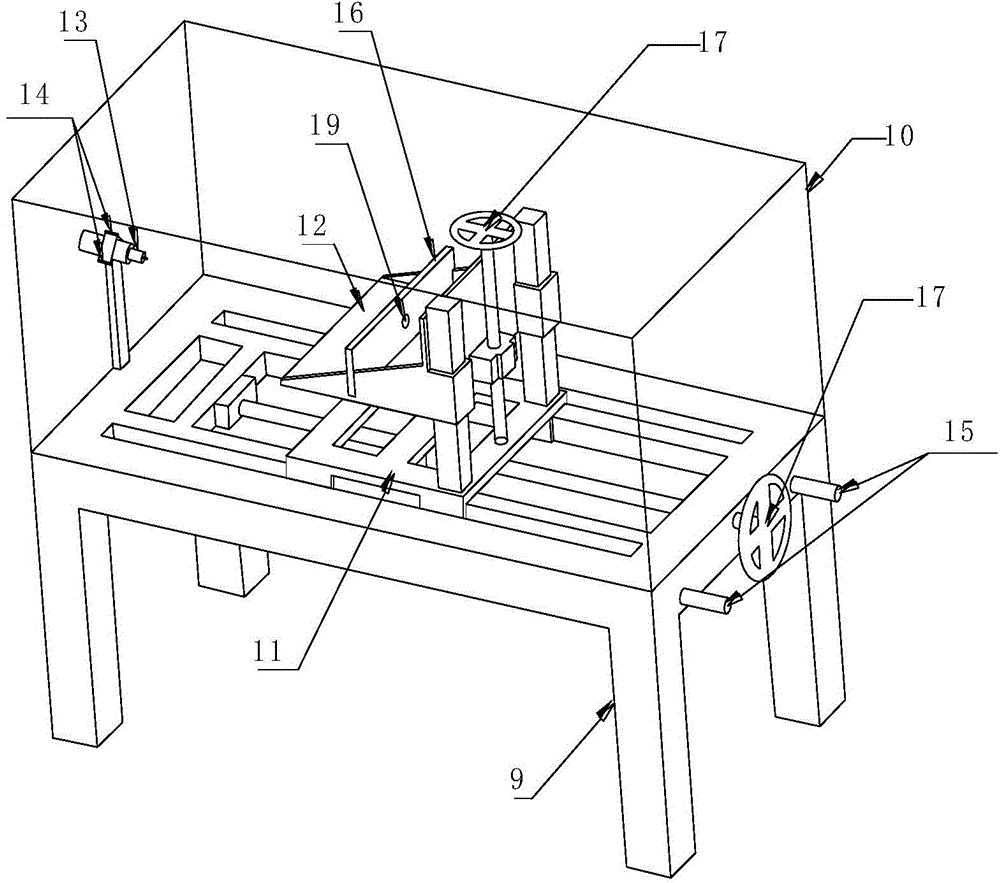

High-pressure multi-phase jet-flow cutting performance test system and method

ActiveCN104634687APracticalSimple structureInvestigating machinabilityEngineeringHigh pressure water

The invention provides a high-pressure multi-phase jet-flow cutting performance test system and a high-pressure multi-phase jet-flow cutting performance test method. The test system comprises a high-pressure water supply system, a high-pressure air supply system, an air-liquid mixing device, a test platform and a test monitoring system. By utilizing the high-pressure water supply system, the high-pressure air supply system and the air-liquid mixing device, a high-pressure water jet flow or a high-pressure air-liquid two-phase jet flow can be formed, and the pressure and air content of the jet flow can be controlled; by utilizing the test platform and the test monitoring system, the impact force and the erosion damage capacity of the high-pressure jet flow can be tested. By utilizing the high-pressure multi-phase jet-flow cutting performance test system, the high-pressure water jet flow or air-liquid two-phase jet flow impact test of parameters including different pressure, air contents, spray nozzle diameter, target distance and the like under a submergence or non-submergence condition can be carried out, important significance for analyzing a relation between various jet-flow erosion rock breaking properties and characteristic parameters and optimizing a hydraulic slot unloading anti-reflection technology can be realized; moreover, the high-pressure multi-phase jet-flow cutting performance test system is high in practicability, simple in structure, convenient to operate, safe and reliable.

Owner:CHINA UNIV OF MINING & TECH

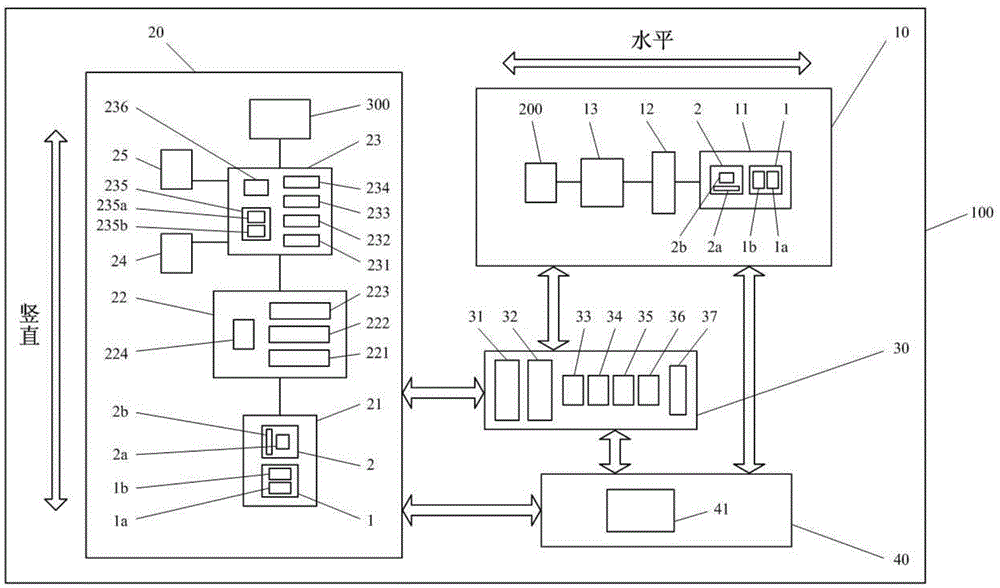

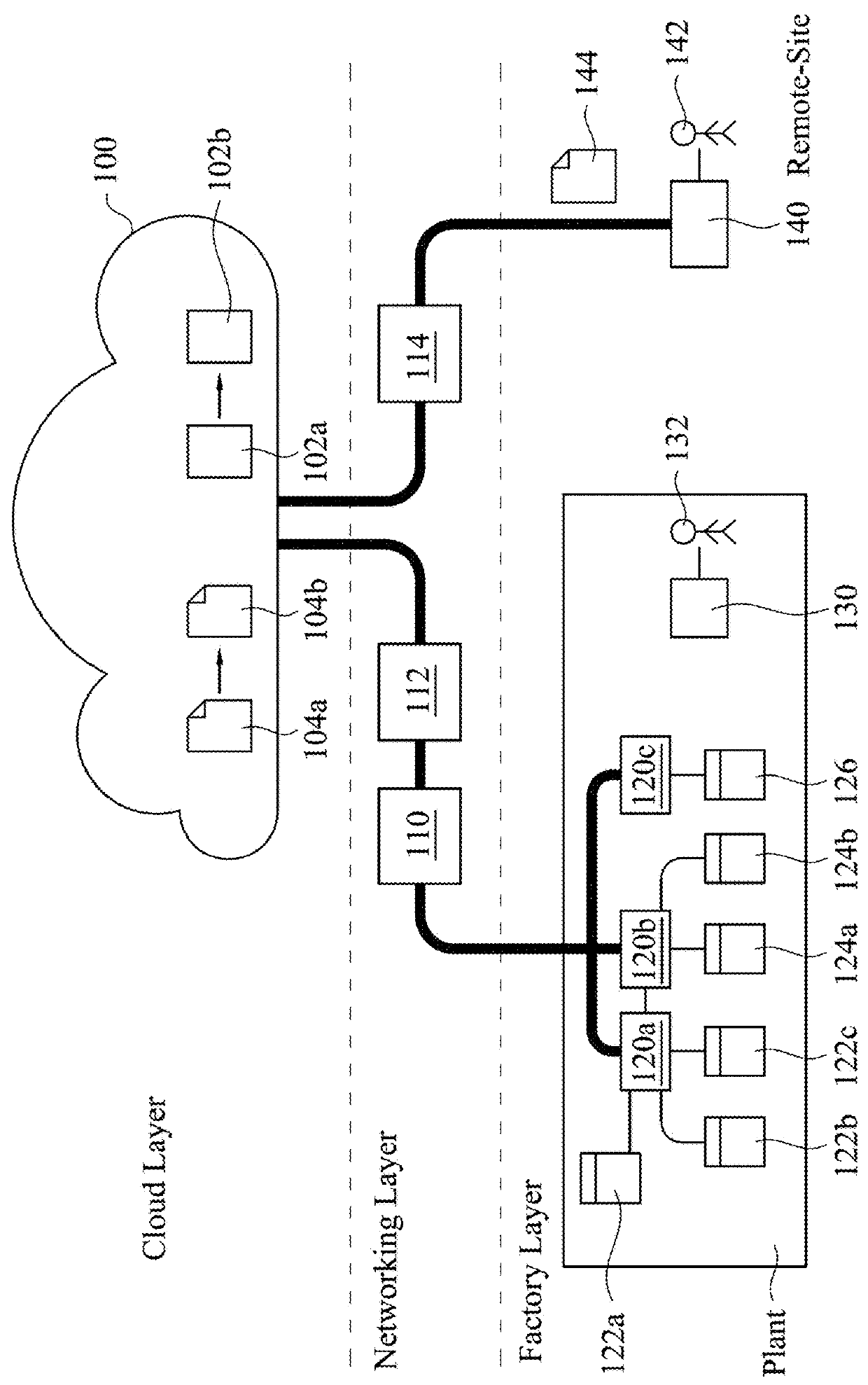

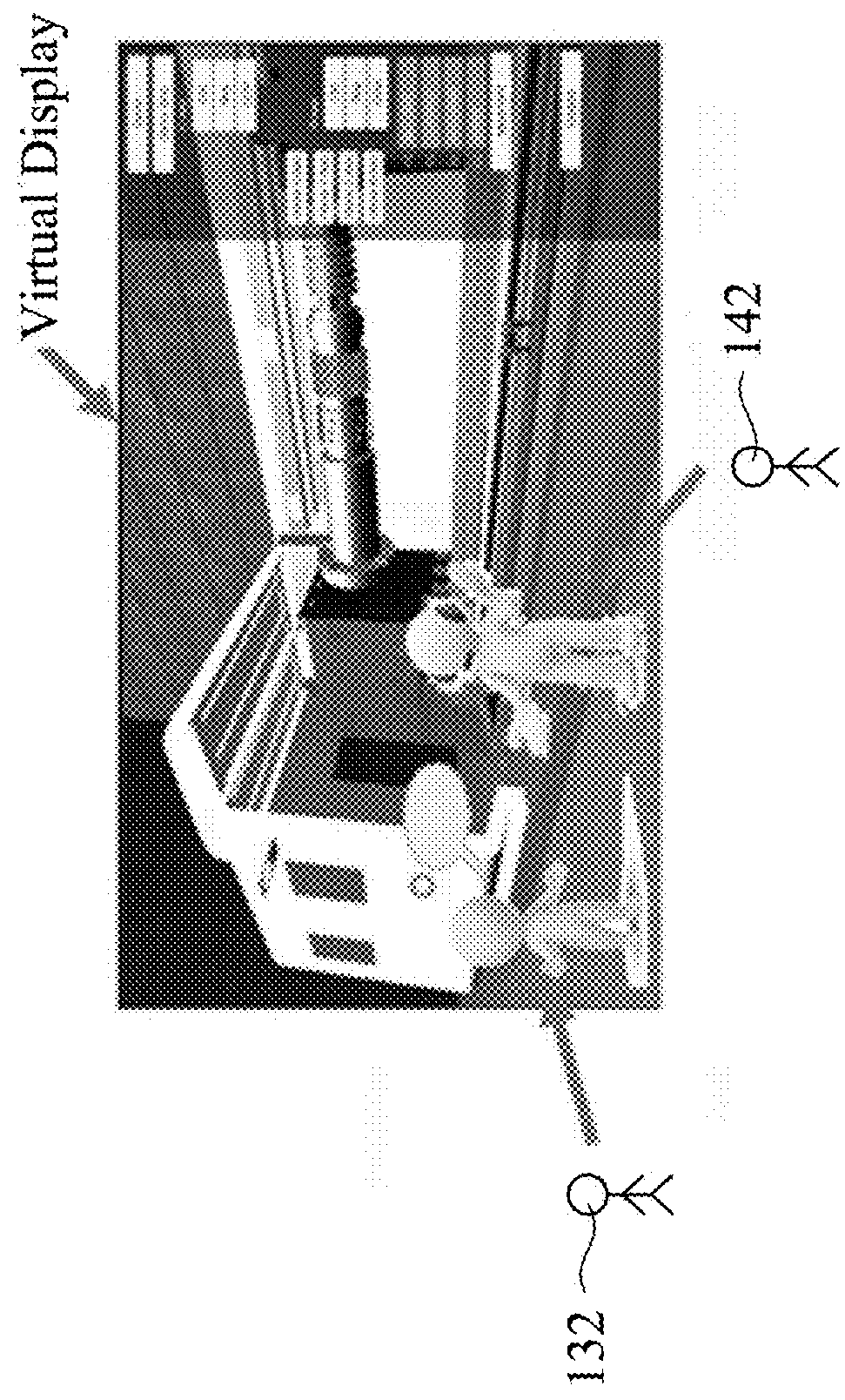

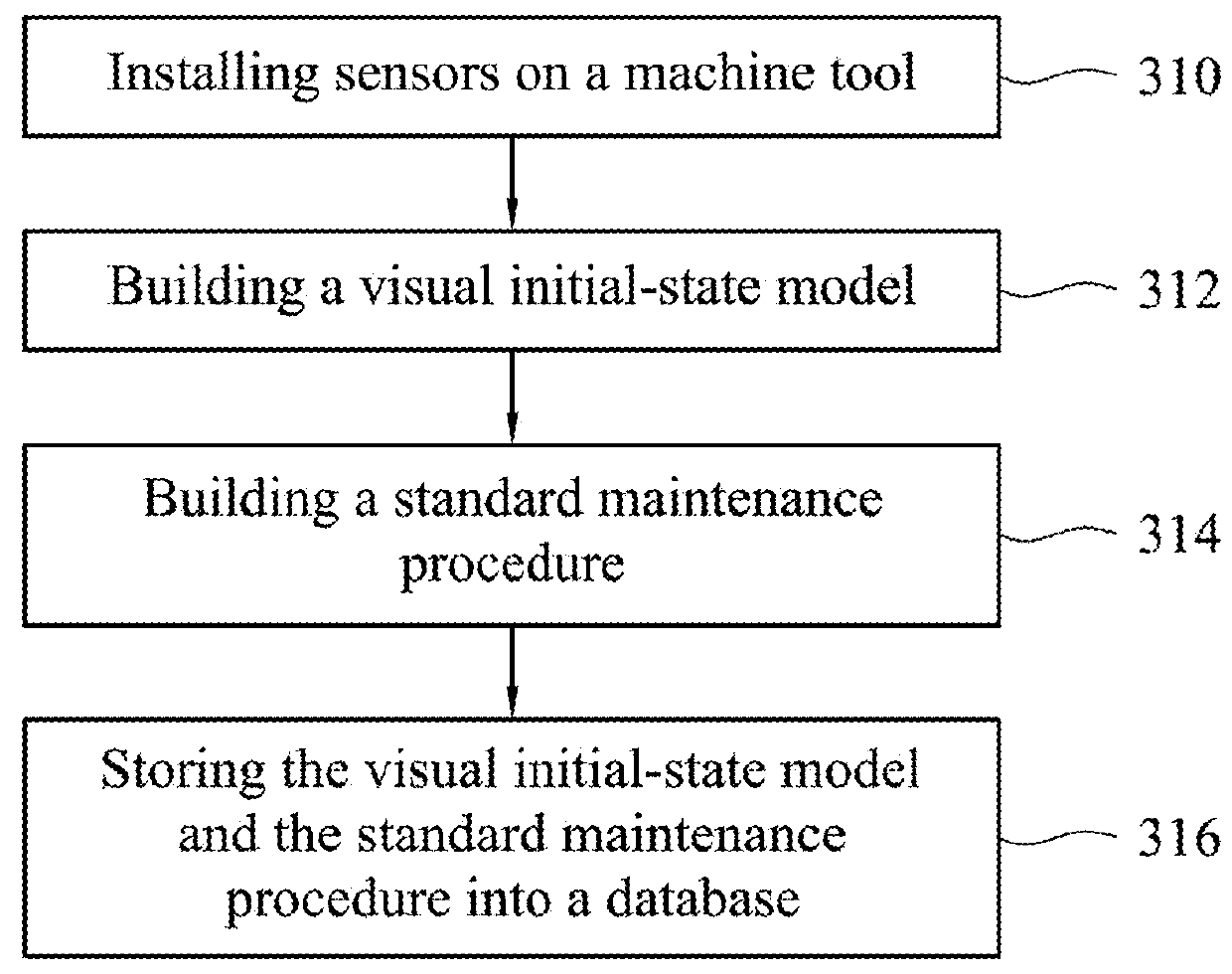

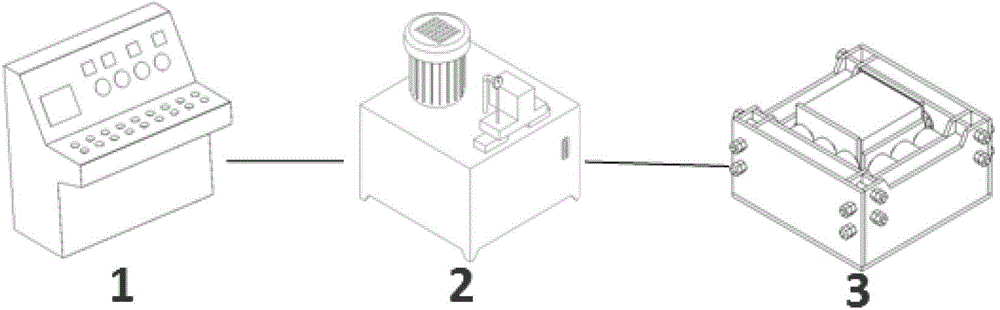

System and method for machine tool maintenance and repair

InactiveUS20180275630A1Shorten maintenance timeProgramme controlComputer controlPhysical agentsEngineering

A system and a method for machine tool maintenance and repair is provided for allowing an expert at a remote site to collaborate with an on-site personnel to maintain or repair a physical machine in a manner of combining the physical machine with a virtual reality (VR) model or an augmented reality (AR) model. Two maintenance modes are provided, which are an augmented virtual reality model guided by a standard operation procedure (referred as a SOP-AVR mode), and an augmented virtual reality model guided by an expert operation procedure (referred as an EG-AVR mode). A cyber physical agent (CPA) is adopted for simultaneously monitoring and repairing plural machines of the same machine type.

Owner:NAT CHENG KUNG UNIV

Mechanical rock breaking test machine rotary rock breaking device

ActiveCN103226078BReach the purpose of rotating rock breakingEasy to put in and take outInvestigating machinabilityHydraulic motorControl system

The invention relates to a mechanical rock breaking test machine rotation rock breaking apparatus, and belongs to the technical filed of geotechnical test machines. The apparatus comprises a control system, a hydraulic station and a mechanical portion. The mechanical portion is a main body, and is composed of a steel sample case, a torque transmission mechanism and a vertical force transmission mechanism. A hydraulic system is used for applying a pressure to a sample and comprises a hydraulic motor and the hydraulic station, and the control system is used for controlling the hydraulic system to apply an adjustable torque and an adjustable rotation speed to the sample. Samples having different dimensions and properties can be replaced in tests.

Owner:GUANGZHOU XINOU MACHINERY +1

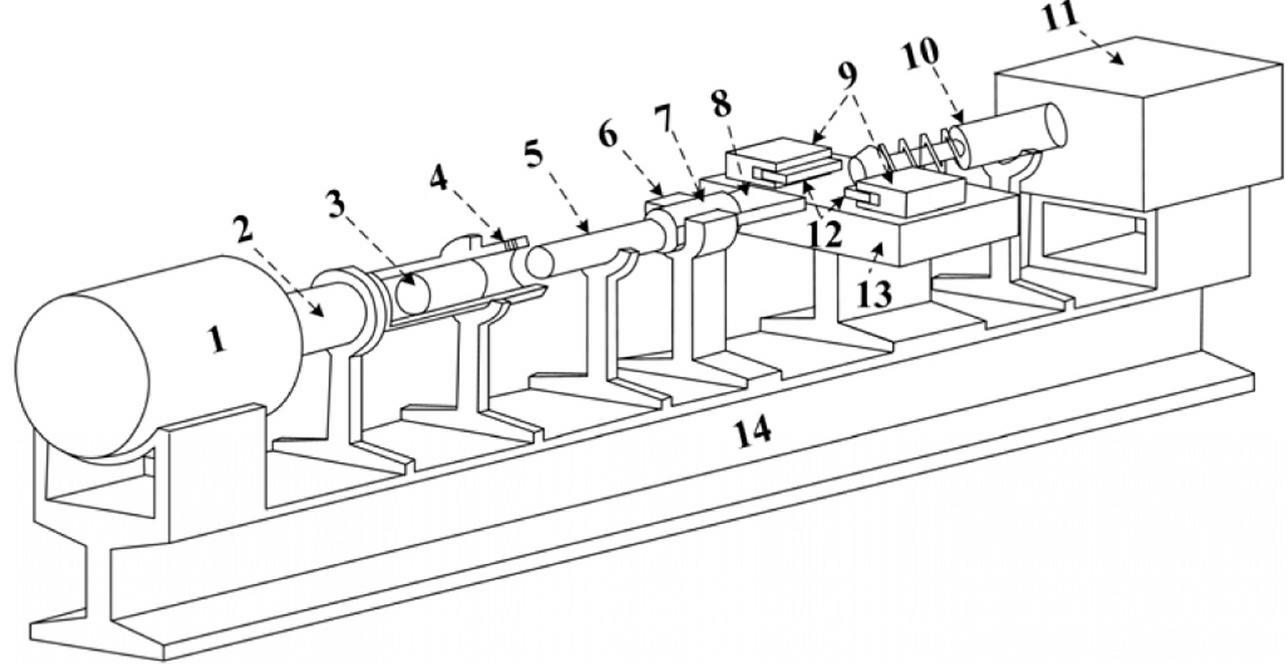

High-speed restrained cutting experimental device based on split Hopkinson pressure bar loading technology

ActiveCN103163037AHigh strain rateConstrained Cutting ExperimentInvestigating machinabilityGun barrelVelocity measurement

The invention discloses a high-speed restrained cutting experimental device based on split Hopkinson pressure bar loading technology. The high-speed restrained cutting experimental device based on the split Hopkinson pressure bar loading technology comprises a Hopkinson pressure bar loading mechanism which is used for pushing a bullet to move along a scheduled track at a scheduled speed, a laser velocity measurement mechanism which is used for measuring a movement speed before the bullet strikes a restrained cutting mechanism, the restrained cutting mechanism which is used for conducting restrained cutting of different plastic deformation degrees on a to-be-processed workpiece, a restrained cutting slideway mechanism which is used for giving a speed direction of restrained cutting, a fixing mechanism which is used for fixing the to-be-processed workpiece and a cutting stopping mechanism which is used for stopping a restrained cutting process. Different cutting speeds are obtained by adjusting pressure of air gun of the Hopkinson pressure bar and an initial position of the bullet in an acceleration gun barrel, different plastic deformation degrees can be obtained by adjusting the space between a tool of the restrained cutting mechanism and a restraining device, the high-speed restrained cutting experimental device based on the split Hopkinson pressure bar loading technology can be utilized to study a material interior microstructure evolution law when the material is with different strain rates and different plastic deformation degrees.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

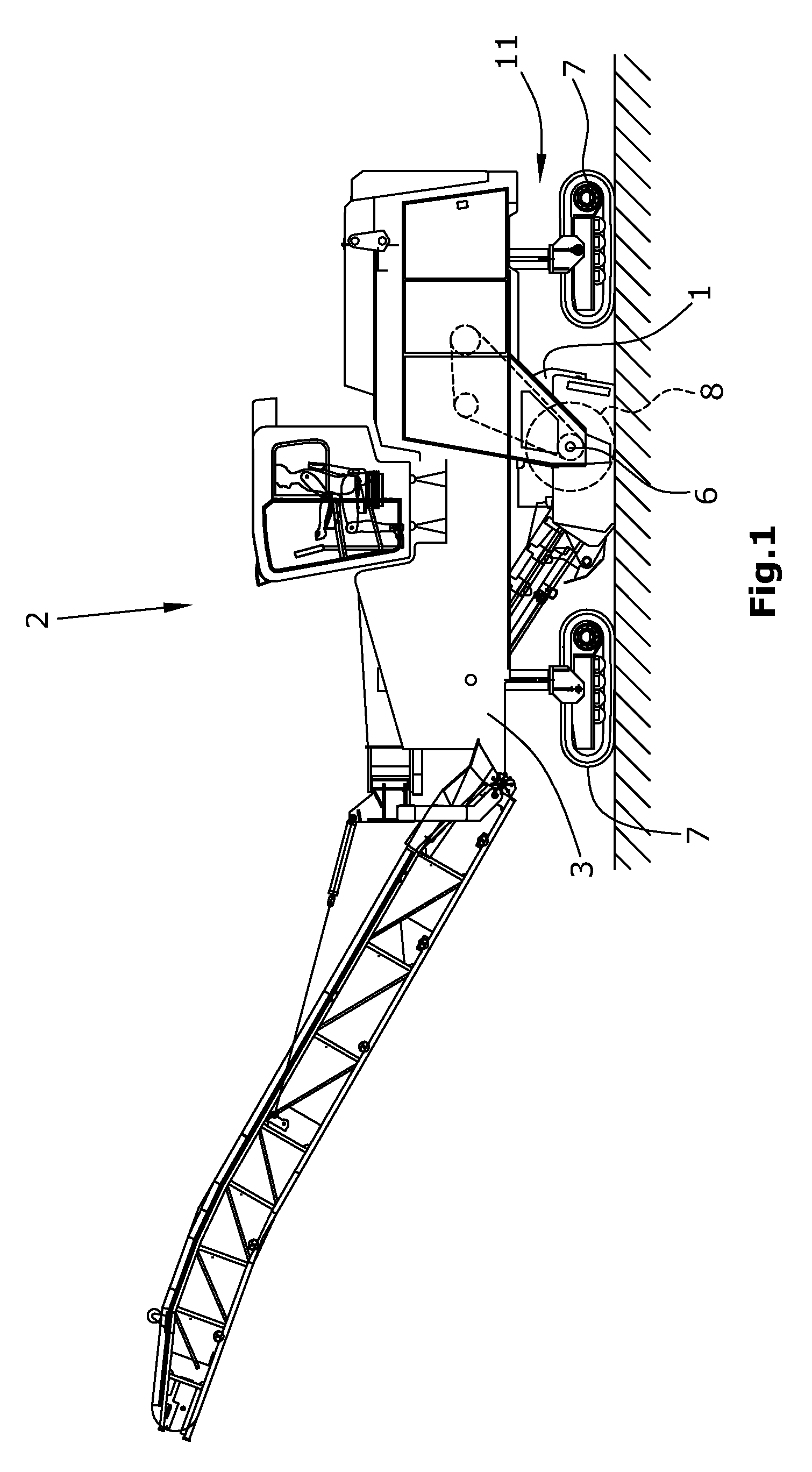

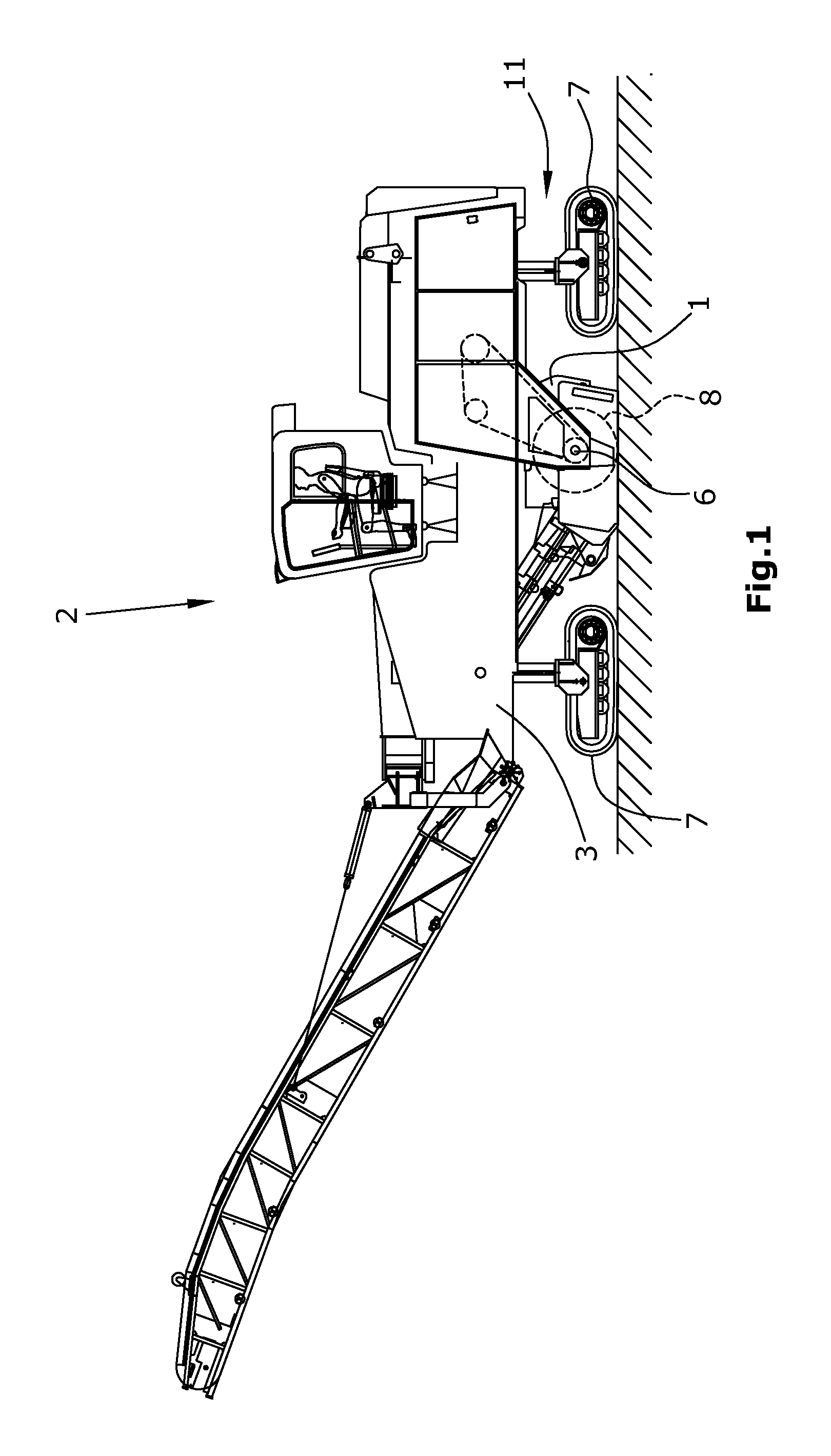

Drum housing for a working drum of a construction machine or mining machine, construction machine or mining machine, as well as method for monitoring the condition of a working drum of a construction machine or mining machine

ActiveUS9175448B2Allows economy timeDisloding machinesUnderground miningEngineeringIndustrial engineering

In a drum housing for a working drum of a construction machine or mining machine, the working drum being provided with tools and rotating about a drum axis, with a housing shell which at least partially encloses the circumference of the working drum, and with at least one inspection opening for a monitoring device arranged in the housing shell, wherein the monitoring device inspects the condition of the working drum or the tools thereof, it is provided for the following features to be achieved: a closing mechanism is arranged on the outside of the housing shell, the closing mechanism enabling closure of the at least one inspection opening.

Owner:WIRTGEN GMBH

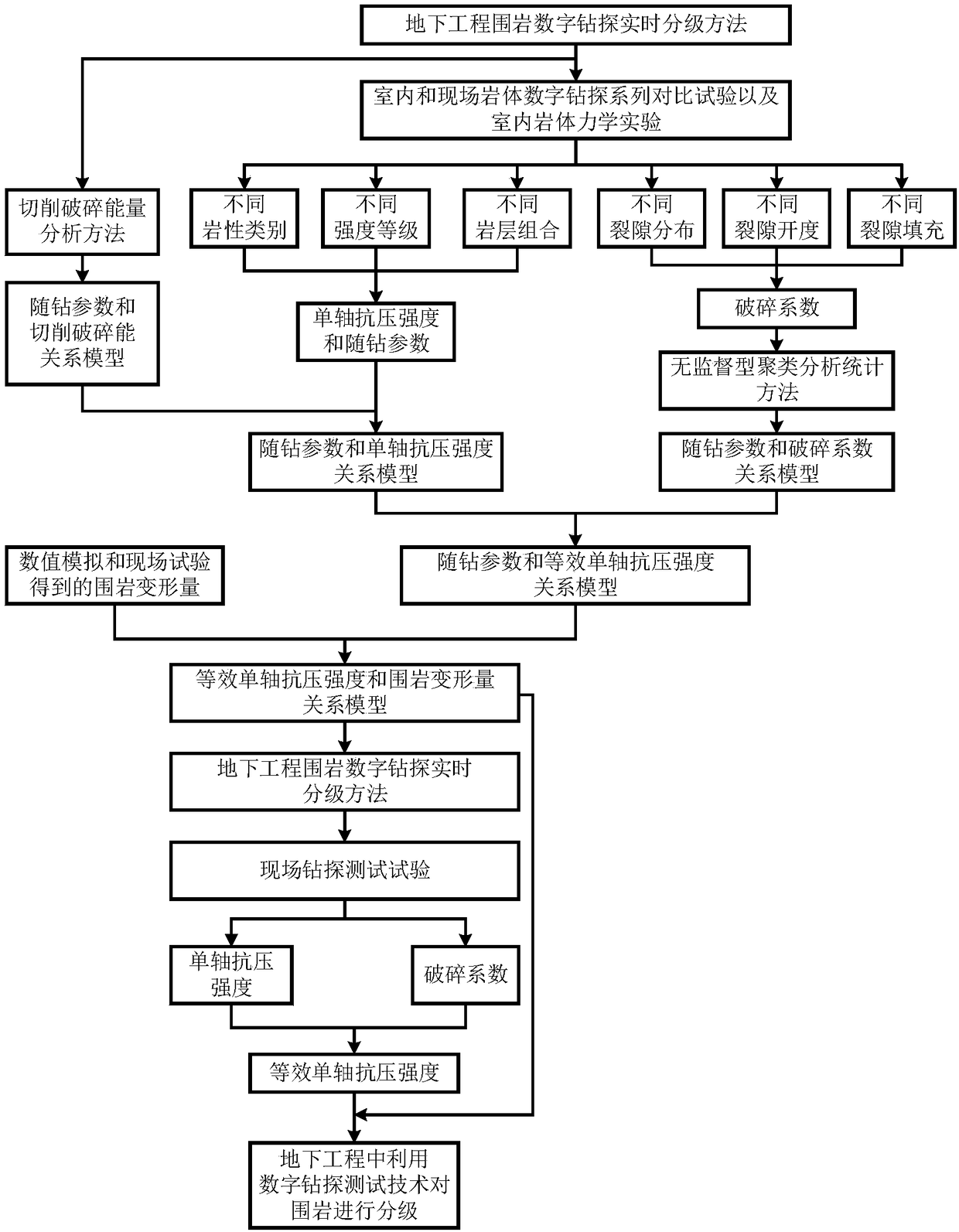

Digital drilling real-time classification method for surrounding rock of underground engineering

ActiveCN108519284AQuick gradingAccurate classificationMaterial strength using tensile/compressive forcesInvestigating machinabilityRelational modelTested time

The invention discloses a digital drilling real-time classification method for a surrounding rock of underground engineering. The method comprises the following steps: making a field drilling test onan underground engineering field to obtain a drilling parameter, obtaining uniaxial compressive strength of a rock body through a model of relationships between drilling parameters and uniaxial compressive strength of rock bodies, obtaining a rock body breaking coefficient on the basis of a model of relationships between drilling parameters and rock body breaking coefficients, obtaining equivalentuniaxial compressive strength from the uniaxial compressive strength of the rock body and the rock body breaking coefficient by use of a uniaxial compressive strength correction formula, obtaining displacement of the surrounding rock by use of a model of relationships between equivalent uniaxial compressive strength and displacement of surrounding rocks, and further classifying the surrounding rock in real time according to the displacement of the surrounding rock. The method has the characteristic of real-time accurate prediction; the displacement of the surrounding rock is reversely deducedaccording to the drilling parameter obtained in field, thereby accurately classifying the surrounding rock in real time by use of the stability of the surrounding rock and providing a basis for design and construction of underground engineering; disturbance in a process of delivering a rock sample to a laboratory is avoided, meanwhile, the test time is shortened to a great extent and manpower andmaterial resources are saved.

Owner:SHANDONG UNIV +1

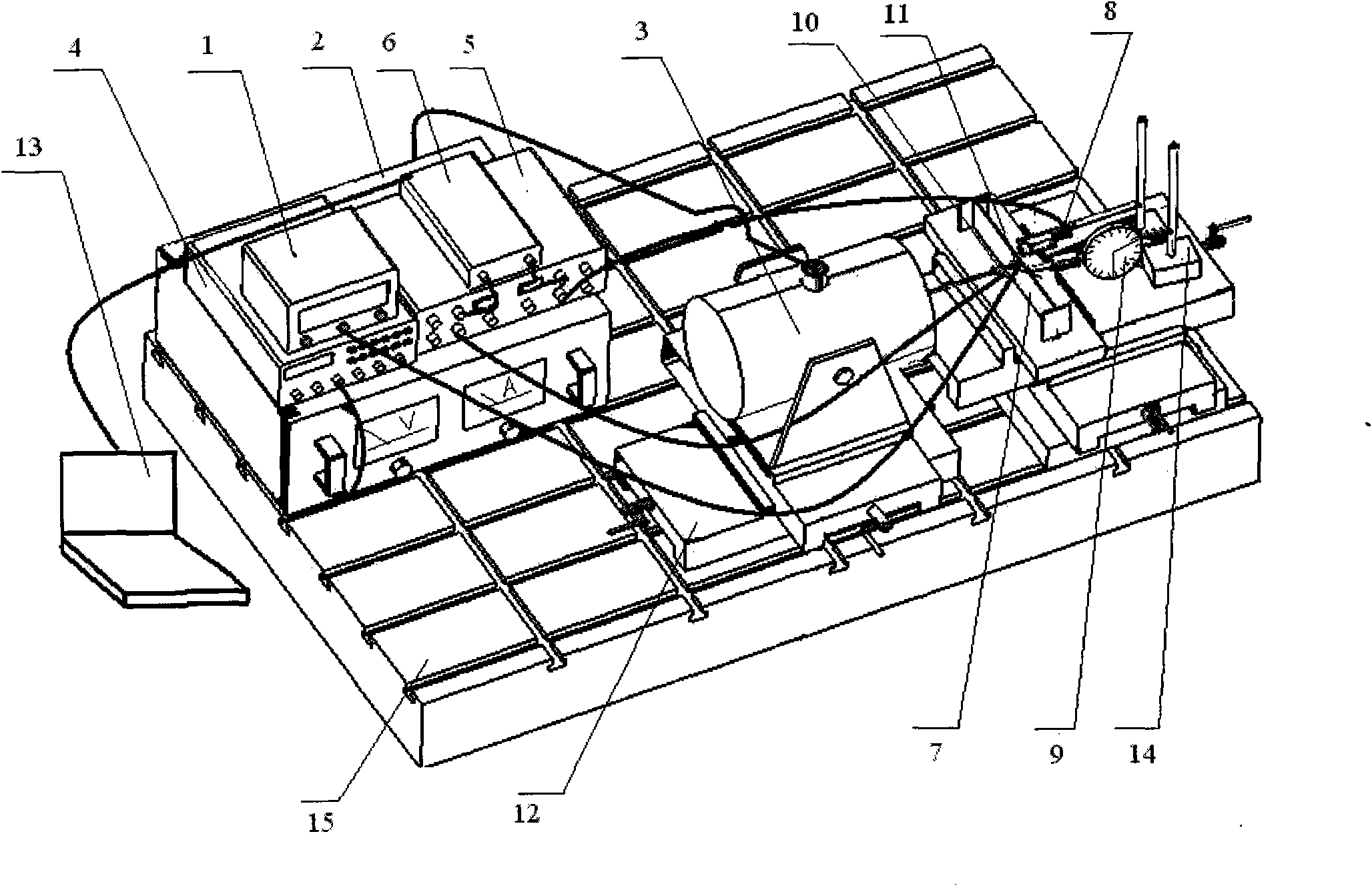

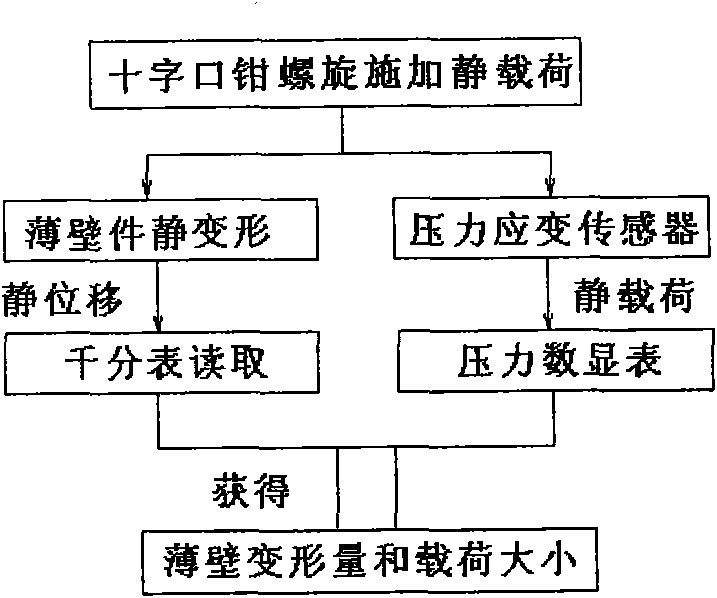

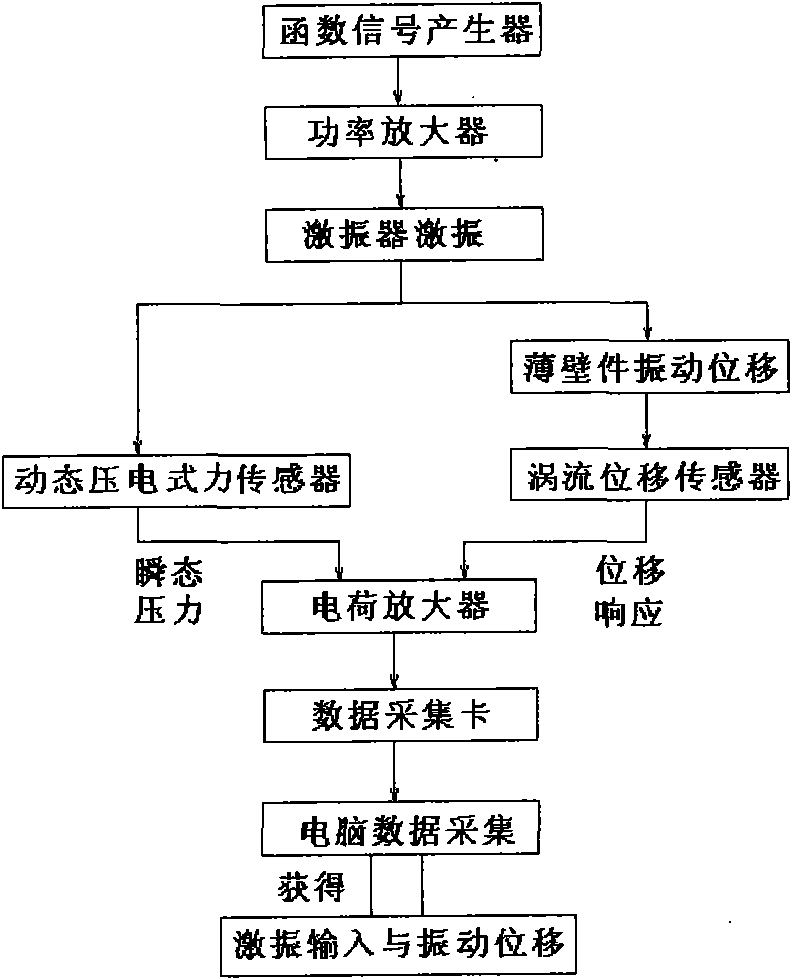

Measure apparatus of machining deformation and dynamic response for thin-wall part of aircraft

A measure apparatus of machining deformation and dynamic response for thin-wall parts of aircraft comprises a pressure signal digital display meter, a power amplifier, a vibration exciter, a function generator, a charge amplifier, a signal collection card, a thin-wall part to be measured, a non-contact eddy current displacement sensor, a dial indicator, a dynamic piezoelectric force sensor, a static pressure sensor, a cross flat-nose pliers assembly, a data acquisition software, a computer system, a magnetic base and an experiment platform. In the measure apparatus, the cross flat-nose pliersand the vibration exciter generate static and dynamic load force; the dial indicator and the dynamic piezoelectric force sensor measure the deformation and dynamic response of the part; the exciting force with required frequency is obtained through the function generator and the power amplifier to simulate the cutting force. The measure apparatus provides a simulation environment and an experiment platform for the parameters selection and optimization during machining process of thin-wall parts. The invention has a good practical value and broad application prospects in fields of high precisemilling study and detection technology.

Owner:BEIHANG UNIV

Drum Housing For A Working Drum Of A Construction Machine Or Mining Machine, Construction Machine Or Mining Machine, As Well As Method For Monitoring The Condition Of A Working Drum Of A Construction Machine Or Mining Machine

ActiveUS20120256470A1Inexpensive and timelyAllows economy timeDisloding machinesUnderground miningIndustrial engineeringBuilding construction

In a drum housing for a working drum of a construction machine or mining machine, said working drum being provided with tools and rotating about a drum axis, with a housing shell which at least partially encloses the circumference of the working drum, and with at least one inspection opening for a monitoring device arranged in the housing shell, wherein said monitoring device inspects the condition of the working drum or the tools thereof, it is provided for the following features to be achieved: a closing mechanism is arranged on the outside of the housing shell, said closing mechanism enabling closure of the at least one inspection opening.

Owner:WIRTGEN GMBH

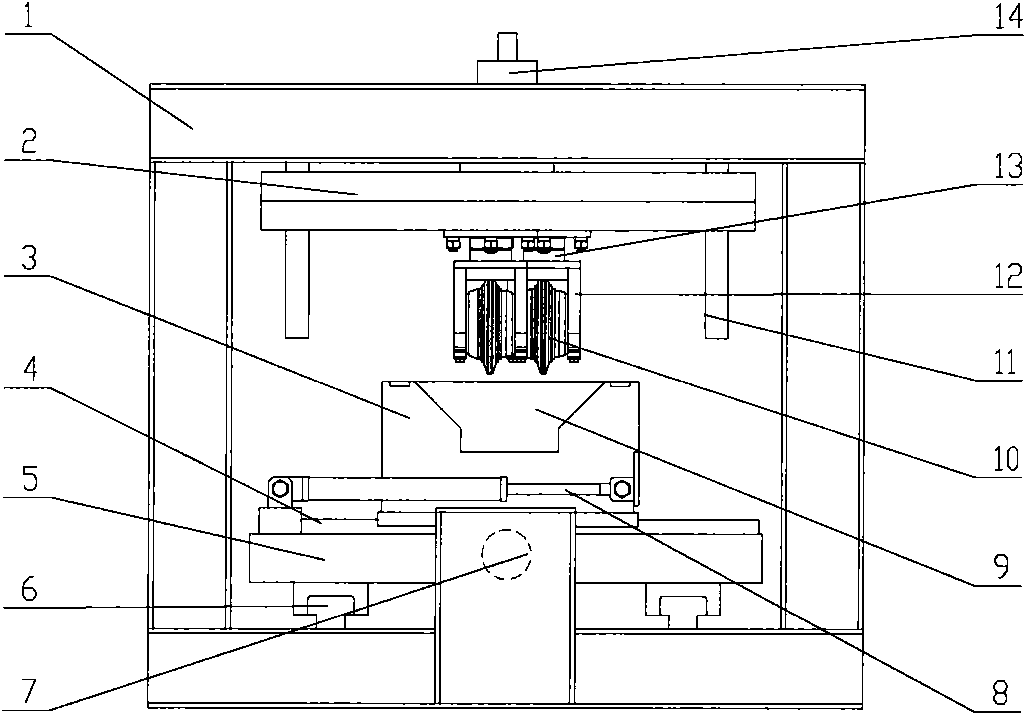

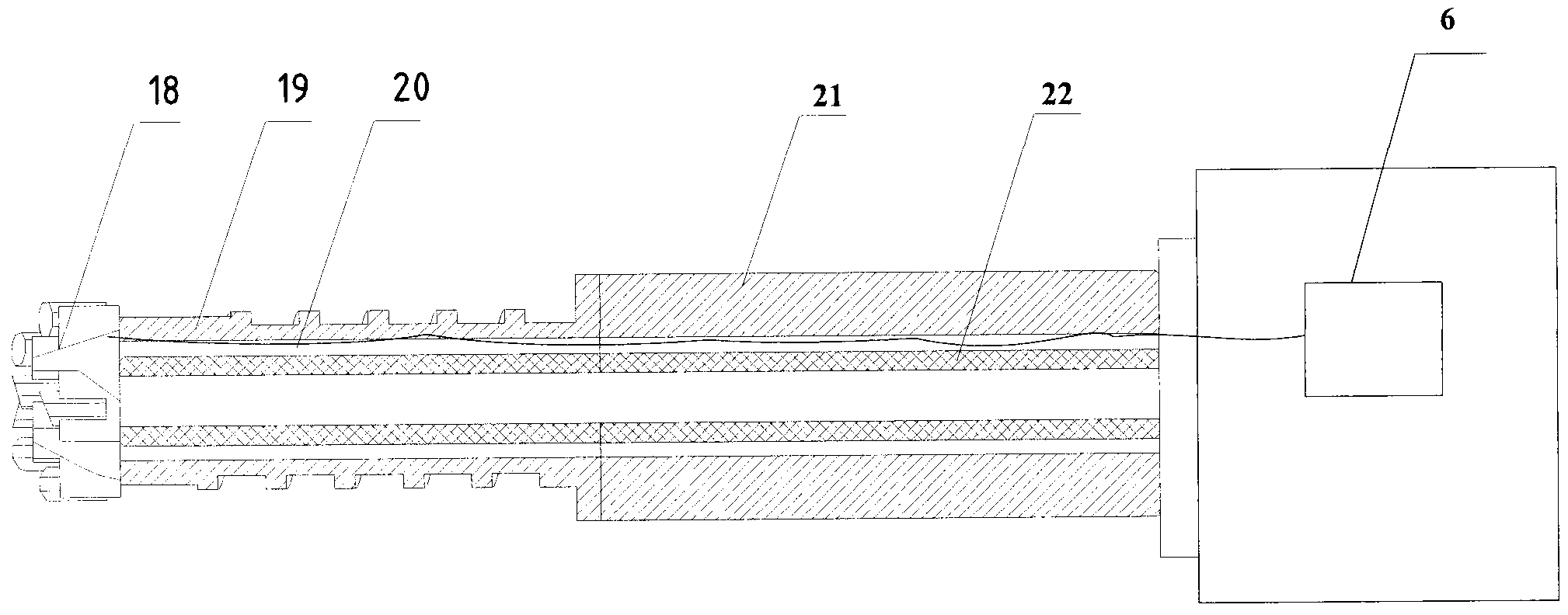

Saw blade cutting performance test machine and test method thereof

ActiveCN104406876AAvoid burnt teethMeet specific needsInvestigating machinabilityFeed drivePolishing

The invention relates to diamond saw blade performance testing, in particular to a saw blade cutting performance test machine and a test method thereof. The test machine comprises a stand column (1), a cross beam (2), a feed frame (3), a feed drive device (4), a cutting power head (5), a drilling polishing power head (6), a power head lifting mechanism (7), a feed carriage (8), a feed rack (9) and a feed drive mechanism (10). The test machine can be used for standardized quantitative verification testing of cutting performance of cutting, drilling and polishing tool products, fills up blank in the industry, has the characteristic of being capable of performing different cutting tests for different plates, not only avoids tooth burning of a test product due to overload but also can prevent the situation that the due efficiency of the test product cannot be reflected due to excessively small load to enable the test product to completely meet the specific requirements of merchants, is also suitable for serving as a process technology research and development test machine, and provides a powerful test verification way for extension of the cutting, drilling and polishing tools to the high-tech field.

Owner:CHENGDU HUIFENG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com