Lunar-environment-simulated cutting test device

A cutting test and environmental technology, applied in the field of deep space exploration, can solve the problems of work failure, poor thermal conductivity of lunar soil, high temperature of drill pipe and drill bit, and achieve the effect of simple structure, convenient operation and wide application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

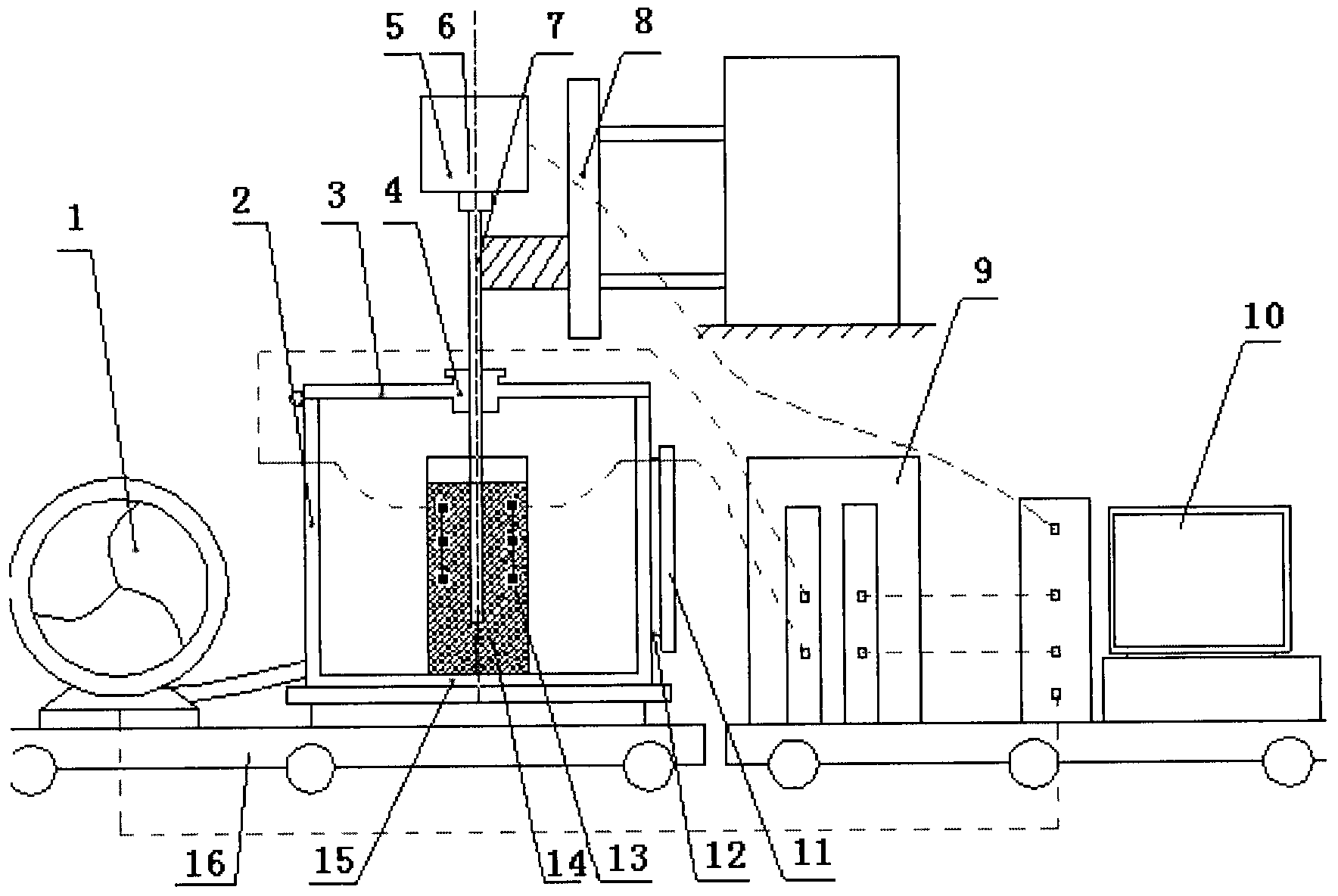

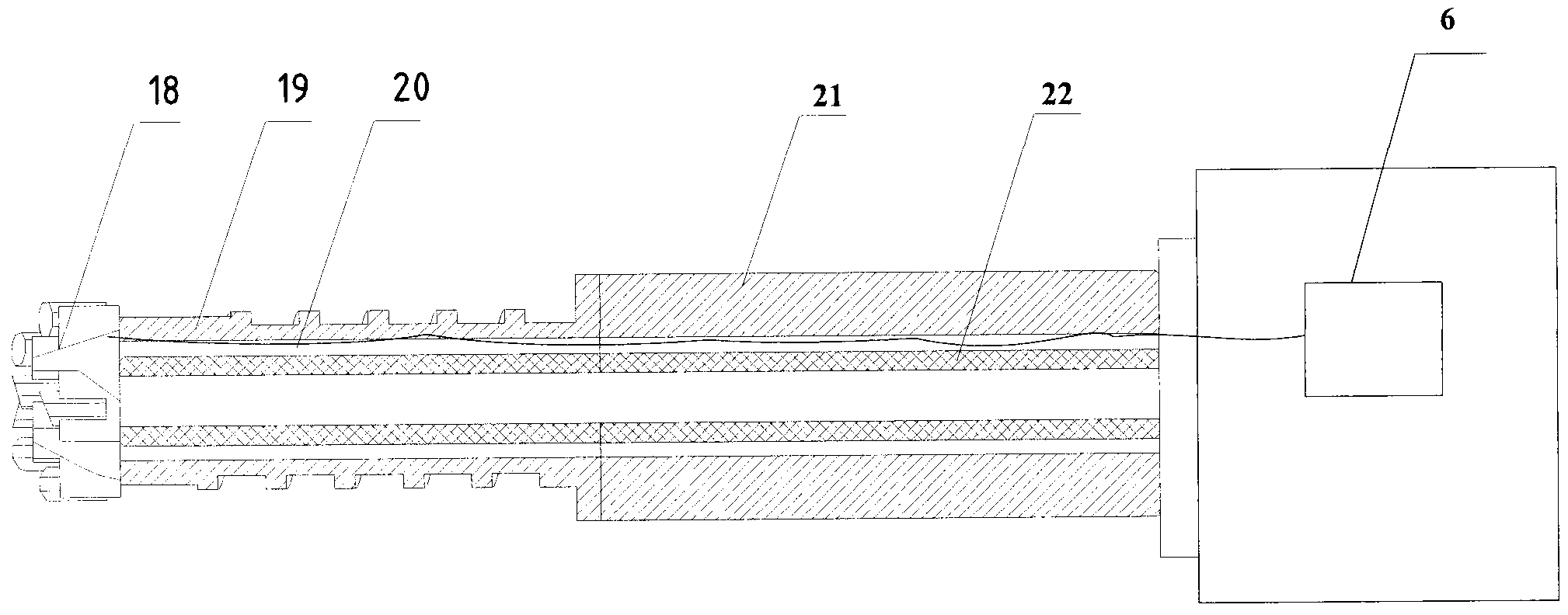

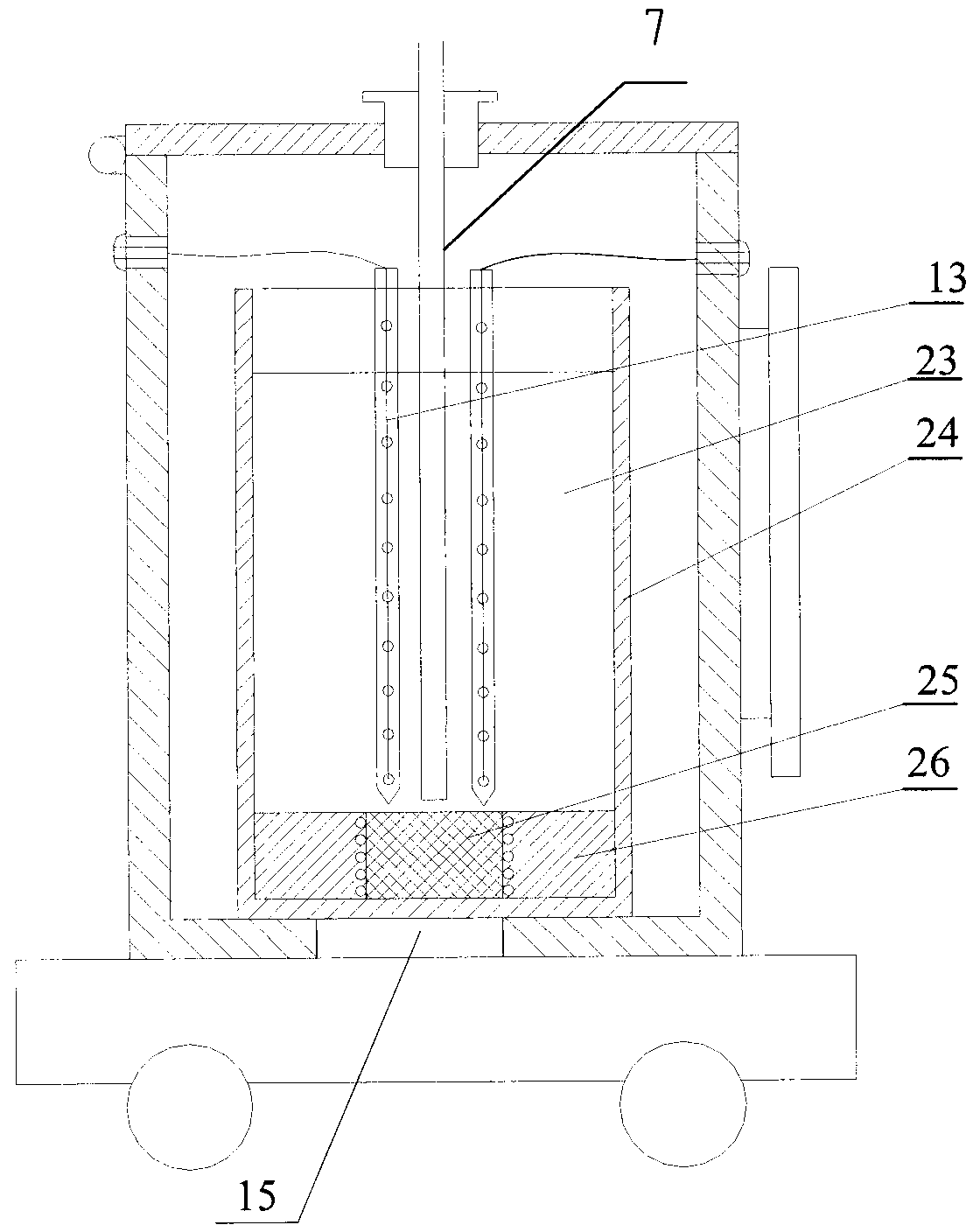

[0015] Such as figure 1 As shown, the vacuum pump 1 of the present invention, the vacuum tank 2, the vacuum tank cover 3, the dynamic seal 4, the drilling drive device 5, the measuring chip 6, the drilling tool 7, the drilling tool supporting platform 8, the data acquisition system 9, and the control computer 10 , observation window 11, static seal 12, temperature sensor 13, drilling load 14, heating and constant temperature device 15 and support platform 16, vacuum pump 1 and vacuum tank 2 are installed on the support platform 17, vacuum pump 1 and vacuum tank 2 are connected as The vacuum tank 2 provides a vacuum power source, the vacuum tank cover 3 is installed on the top of the vacuum tank 2 through a hinge structure, the drilling load 14 is arranged in the vacuum tank 2 for simulating lunar soil and rocks on the lunar surface, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com