Visual simulation system for airplane assembly site

A technology for assembly simulation and simulation system, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve the problems affecting the progress and quality of aircraft development, long process design optimization cycle, and large amount of rework and repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

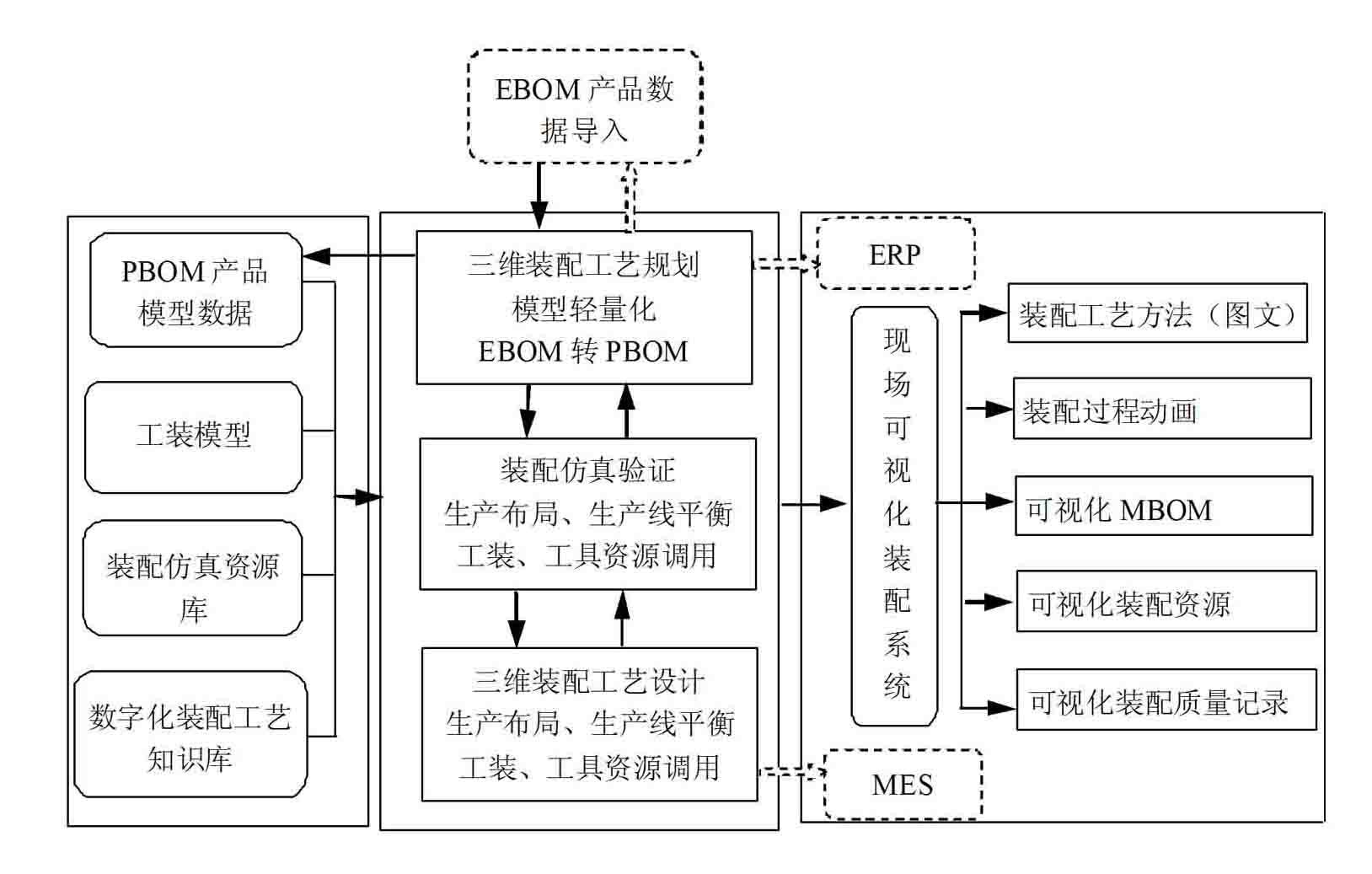

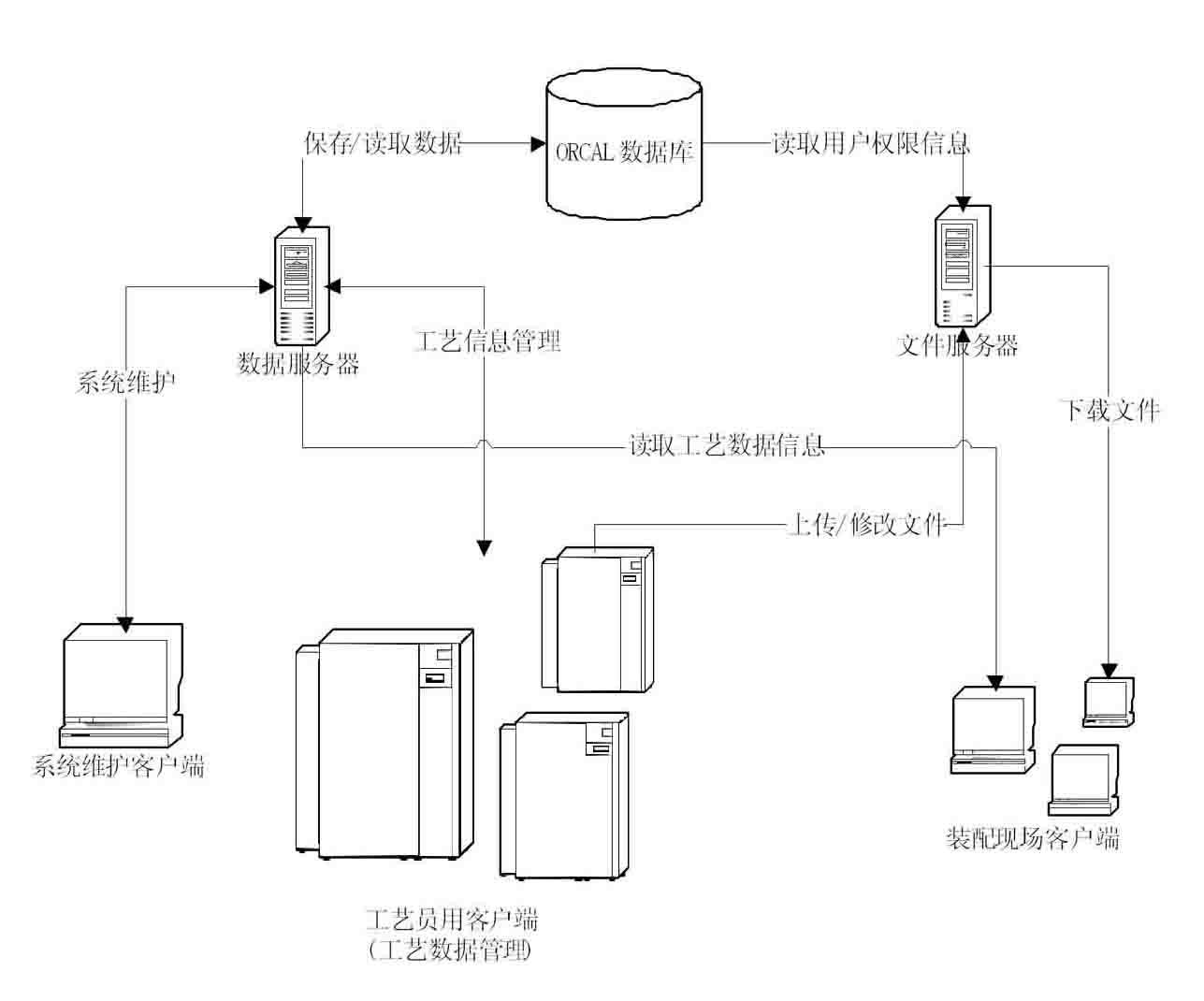

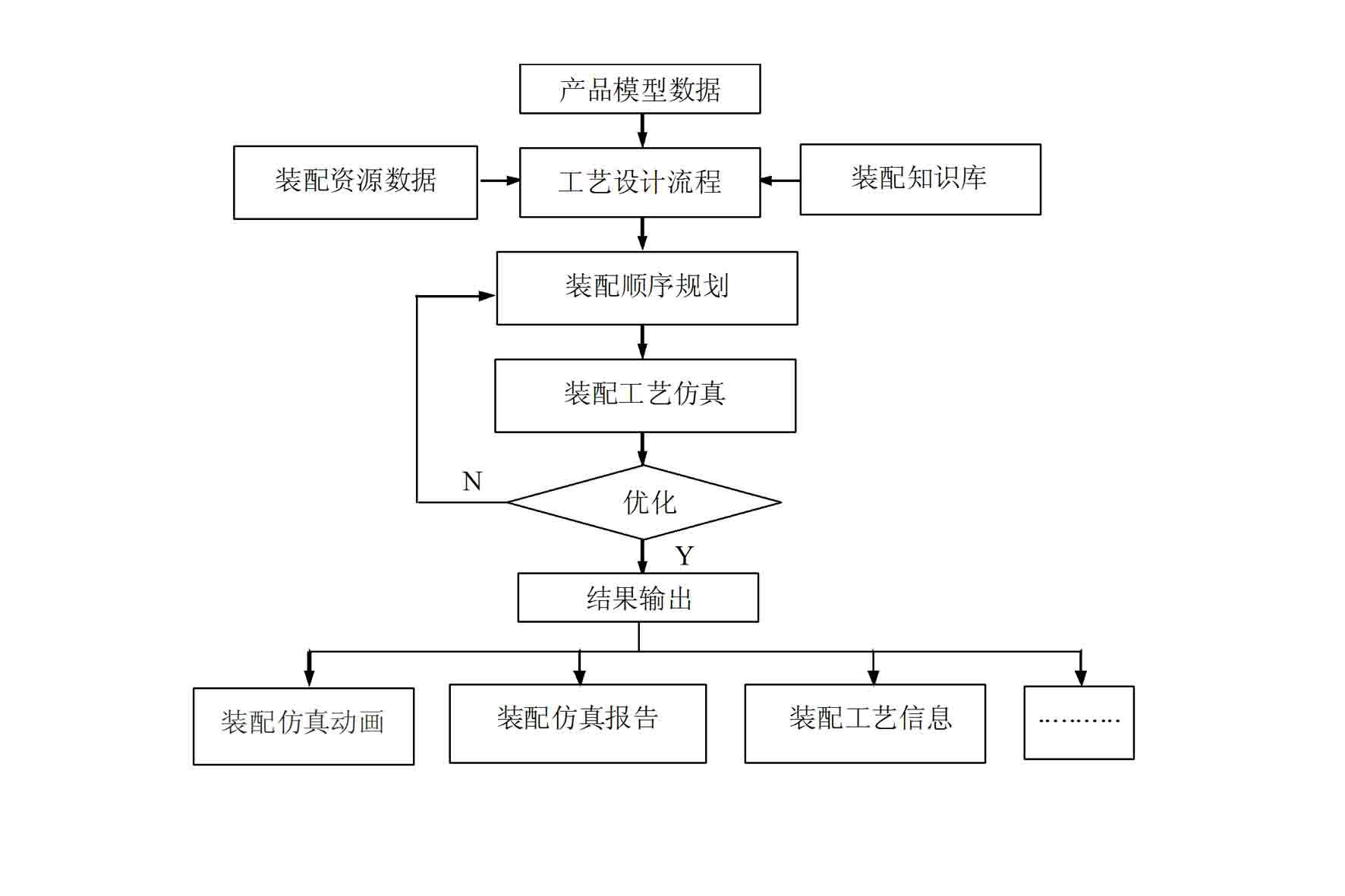

[0010] Such as figure 1 As shown, a visual simulation system for aircraft assembly site includes an assembly simulation database module, an assembly simulation technology module and an assembly visualization expression system module; the assembly simulation technology module can call the data of the assembly simulation database module; the assembly simulation technology The modules include 3D assembly process planning module, assembly simulation verification module and 3D assembly process design module. The data and results between the three modules can be called mutually; the data of the assembly simulation technology module can be output to the assembly visual expression system for visual simulation, The assembly visual expression system is a networked system supported by the C / S (Client / Server) structure model, which can realize the functions of 3D model preview of parts, assembly process demonstration, assembly process information display and other functions.

[0011] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com