Visual measuring device and method of flame frontal surface structure of movable fire source

A measuring device and flame front technology, which is applied in the field of visual measuring devices for the flame front structure of a moving fire source, can solve problems such as uncontrollable, acceleration a cannot be adjusted in a large range, and the fire source point cannot move and run at a speed, etc., to achieve applicable Wide range, simple device structure, and improved speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

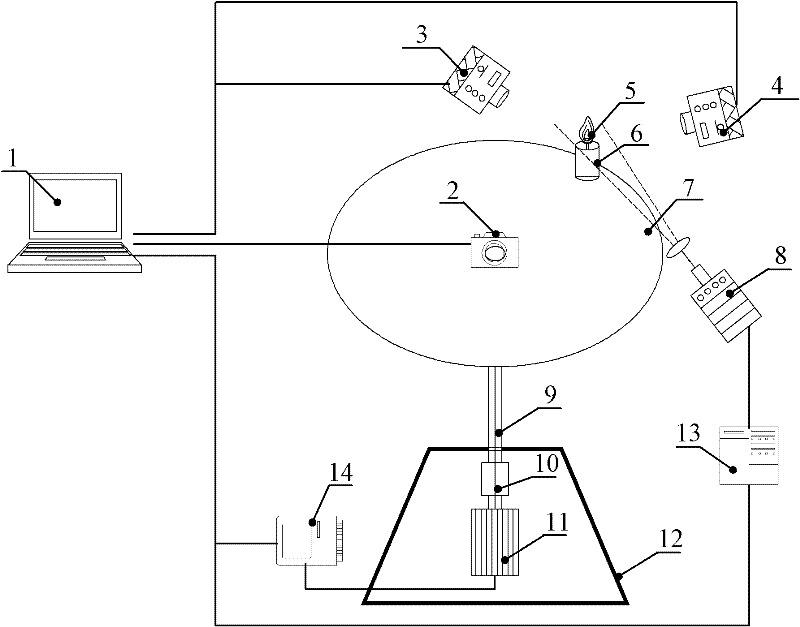

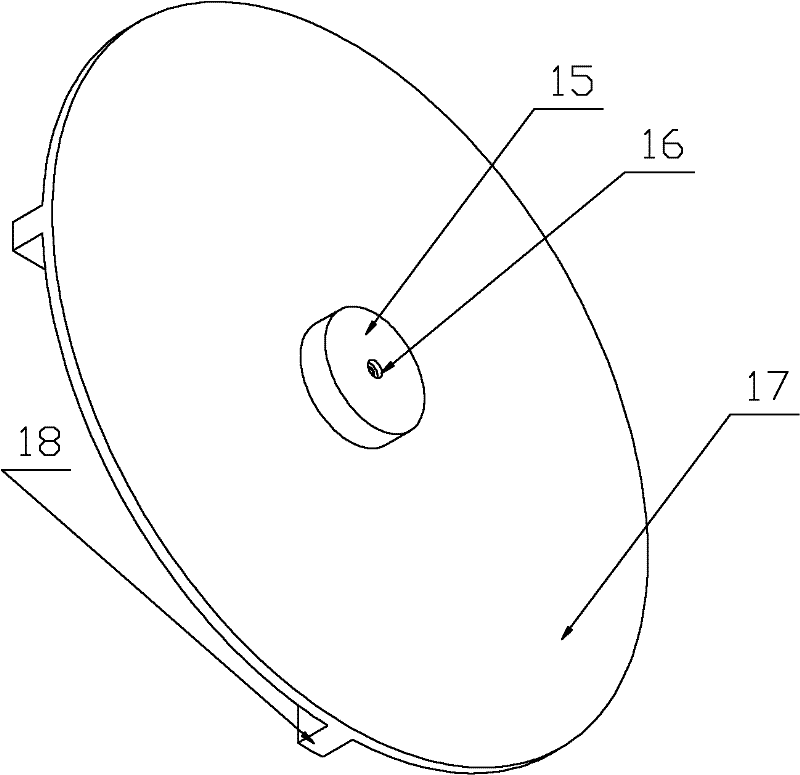

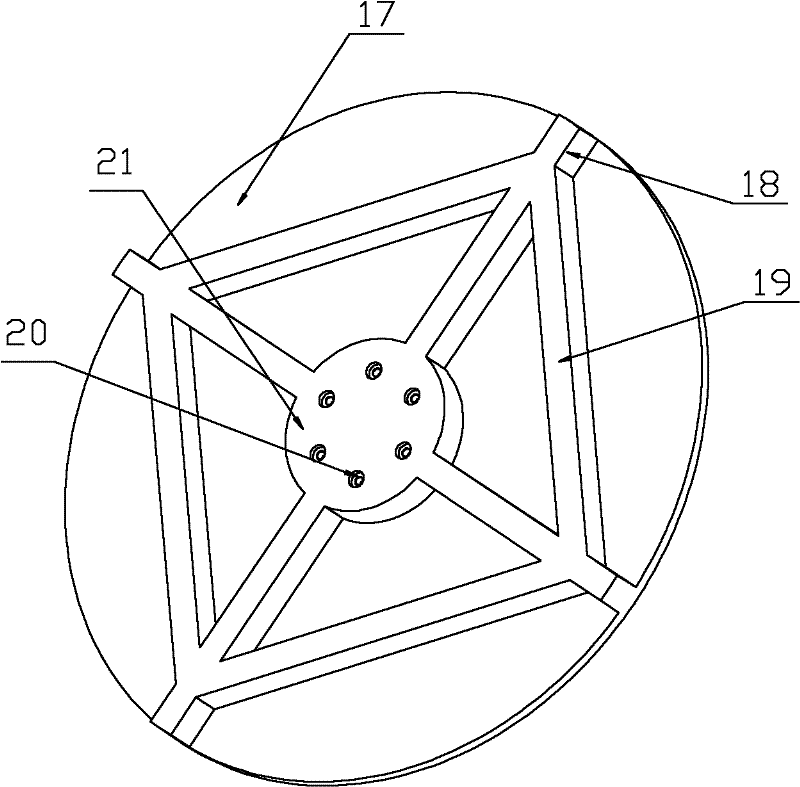

[0037] Figure 1 to Figure 4 Shows the specific structural schematic diagram of this embodiment, such as figure 1 As shown, the visual measurement device for the flame front structure of the moving fire source includes a control computer 1, a burner 6, a turntable mechanism 7, an image acquisition device, a turntable drive device and a support seat 12, and the burner 6 is connected to the turntable mechanism 7 Above, the turntable mechanism 7 is arranged on the support seat 12; the turntable drive device is placed in the support seat 12, and connected to the turntable mechanism 7 through the rotating shaft 9; the turntable drive device and the image acquisition device are respectively connected to the control computer 1; The image acquisition device is connected with the turntable mechanism 7 and is set corresponding to the position of the burner 6 .

[0038] Before the test, according to the fuel type of the flame 5 generated by combustion, select one of the solid fuel burne...

Embodiment 2

[0063] This embodiment has the same structure as Embodiment 1 except the following features: the outer diameter of the turntable body is 800mm.

[0064] The fuel of the burner is liquid fuel.

[0065] In order to detect the influence of the volume force field that the flame is subjected to on the flame front structure produced by the combustion of liquid fuel, its test process: according to the preparations before the experiment described in Example 1, the burner is replaced by a burner of liquid fuel , adjust the opening of the nozzle in the burner to control the height of the flame to 0.15m. This experiment presents images of flame structures under different volumetric force fields. The variable frequency controller is used to adjust the speed of the variable frequency motor, so that the volumetric force field, that is, the centrifugal acceleration a suffered by the flame is 2g, 10g, 20g, 50g, 100g, 200g, 500g, 1000g, 1500g, 2500g. Start various image acquisition devices a...

Embodiment 3

[0067] This embodiment has the same structure as Embodiment 1 except the following features: the outer diameter of the turntable body is 1000 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com