Patents

Literature

278 results about "Fuel type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

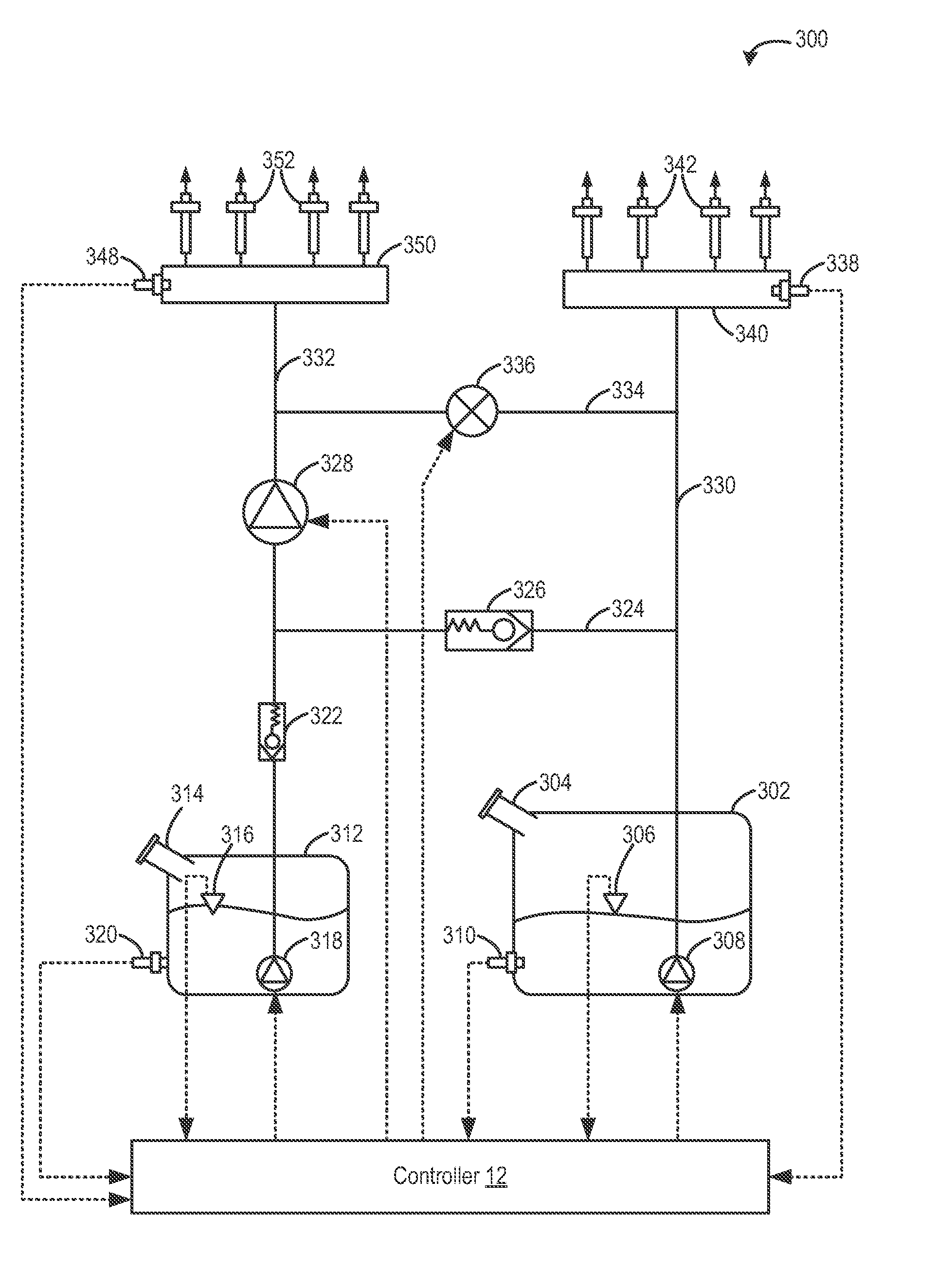

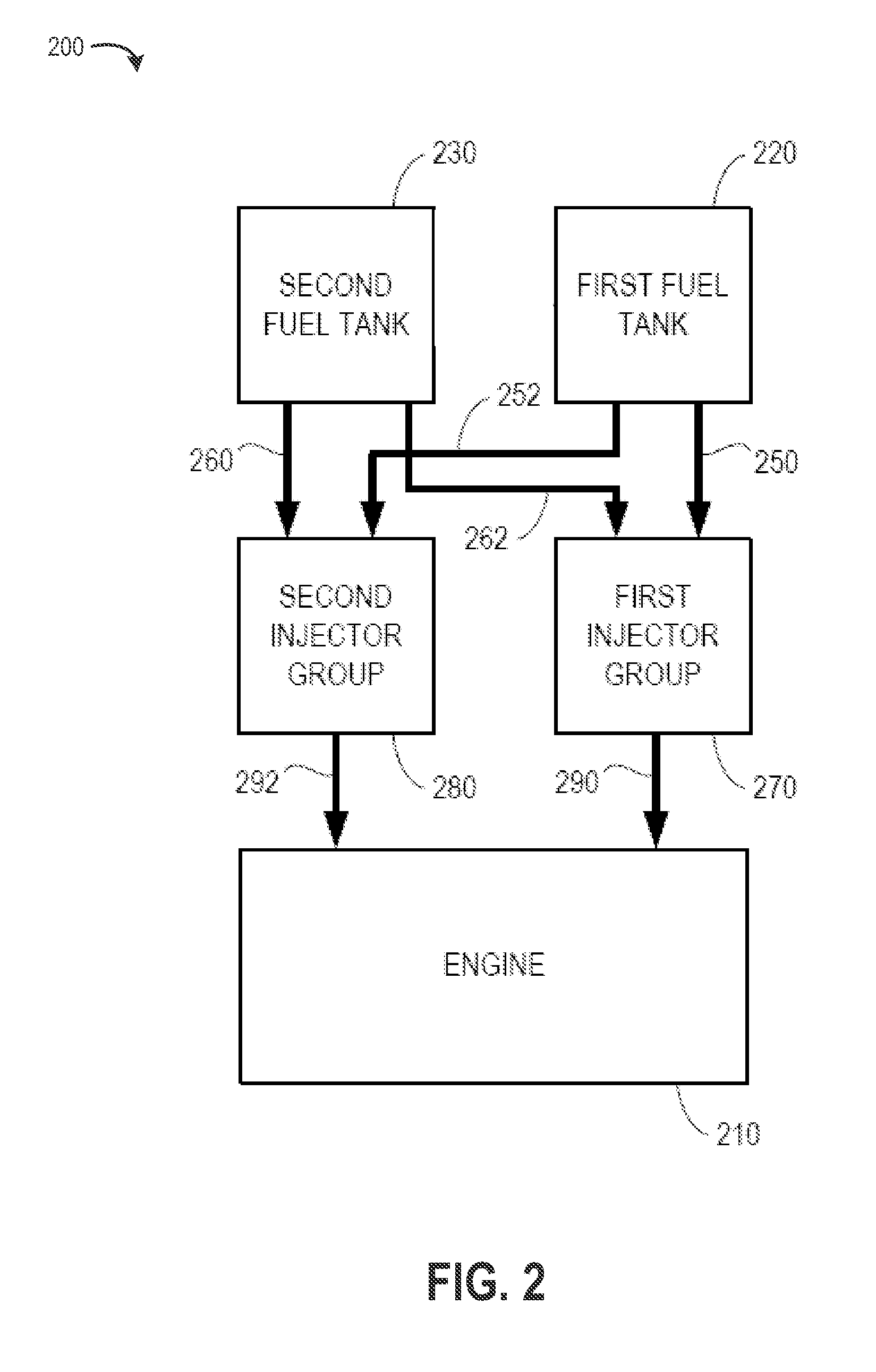

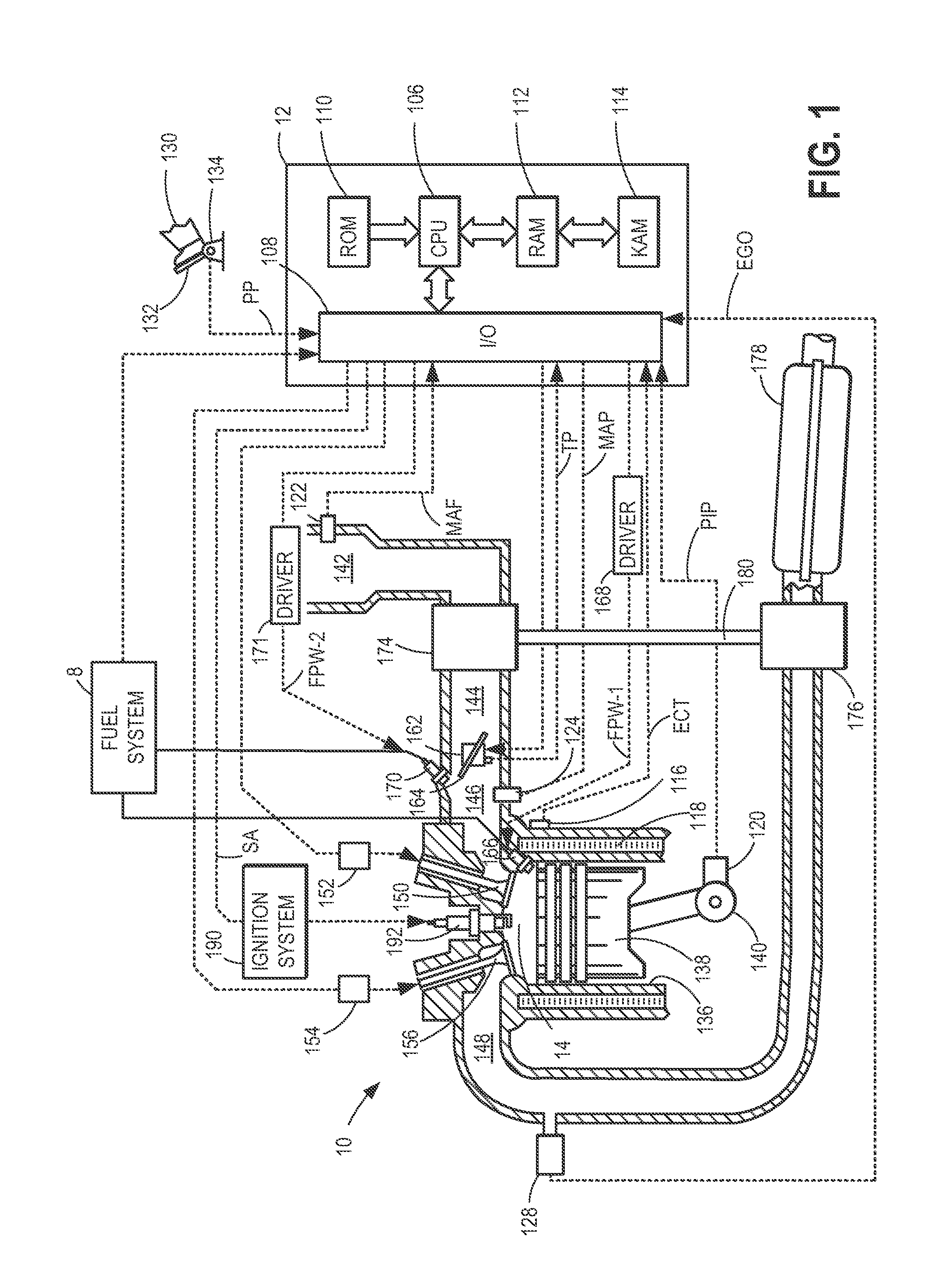

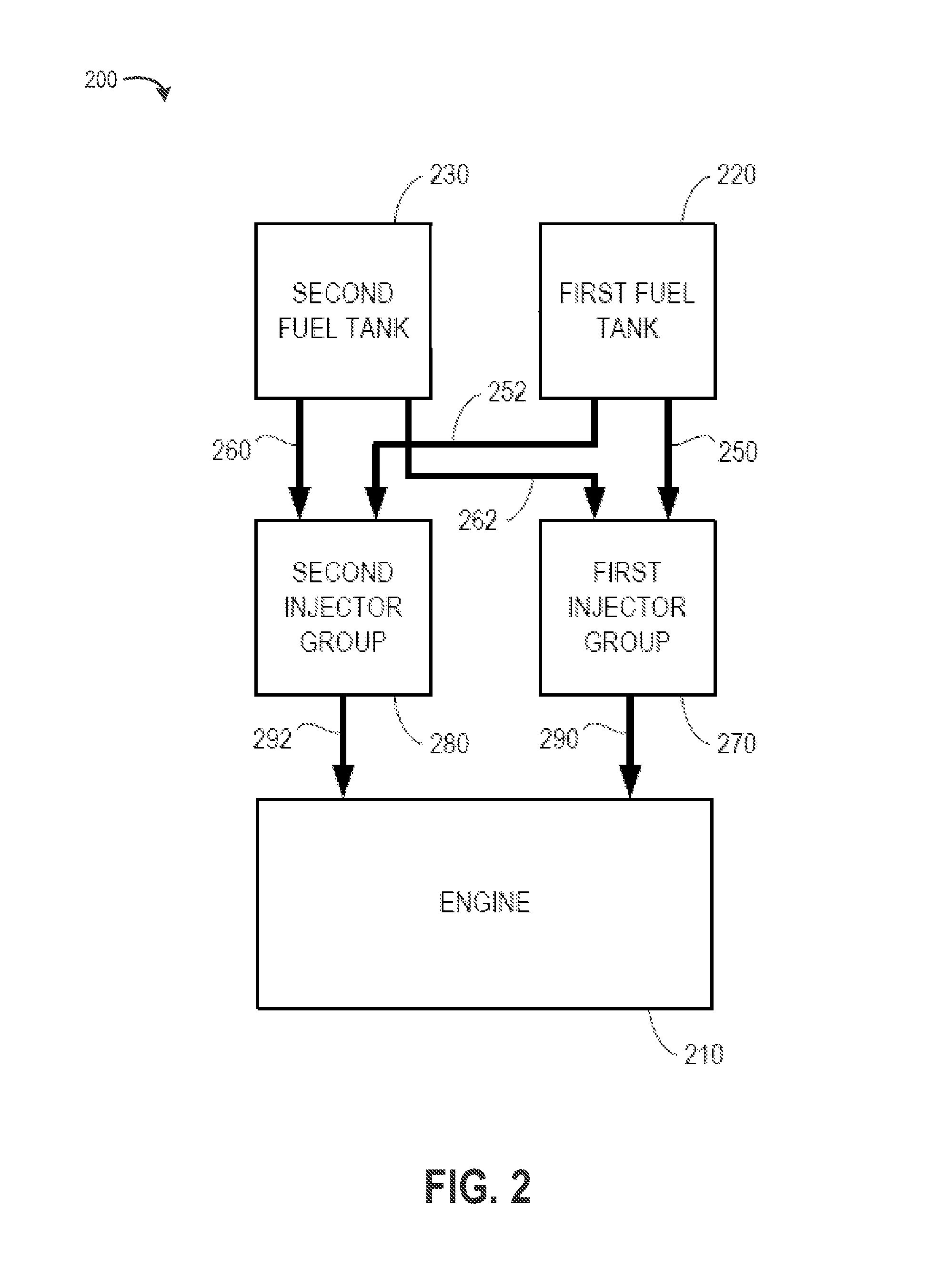

Fuel system for a multi-fuel engine

InactiveUS20120048242A1Reducing high pressure pump degradationReduce degradationElectrical controlInternal combustion piston enginesFuel typeHigh pressure

Methods and systems are provided for operating an engine fuel system including fuels of different fuel types. A first fuel type is delivered for port injection upon circulation through a high pressure pump when direct injection of a fuel is not requested to cool and / or lubricate the high pressure pump.

Owner:FORD GLOBAL TECH LLC

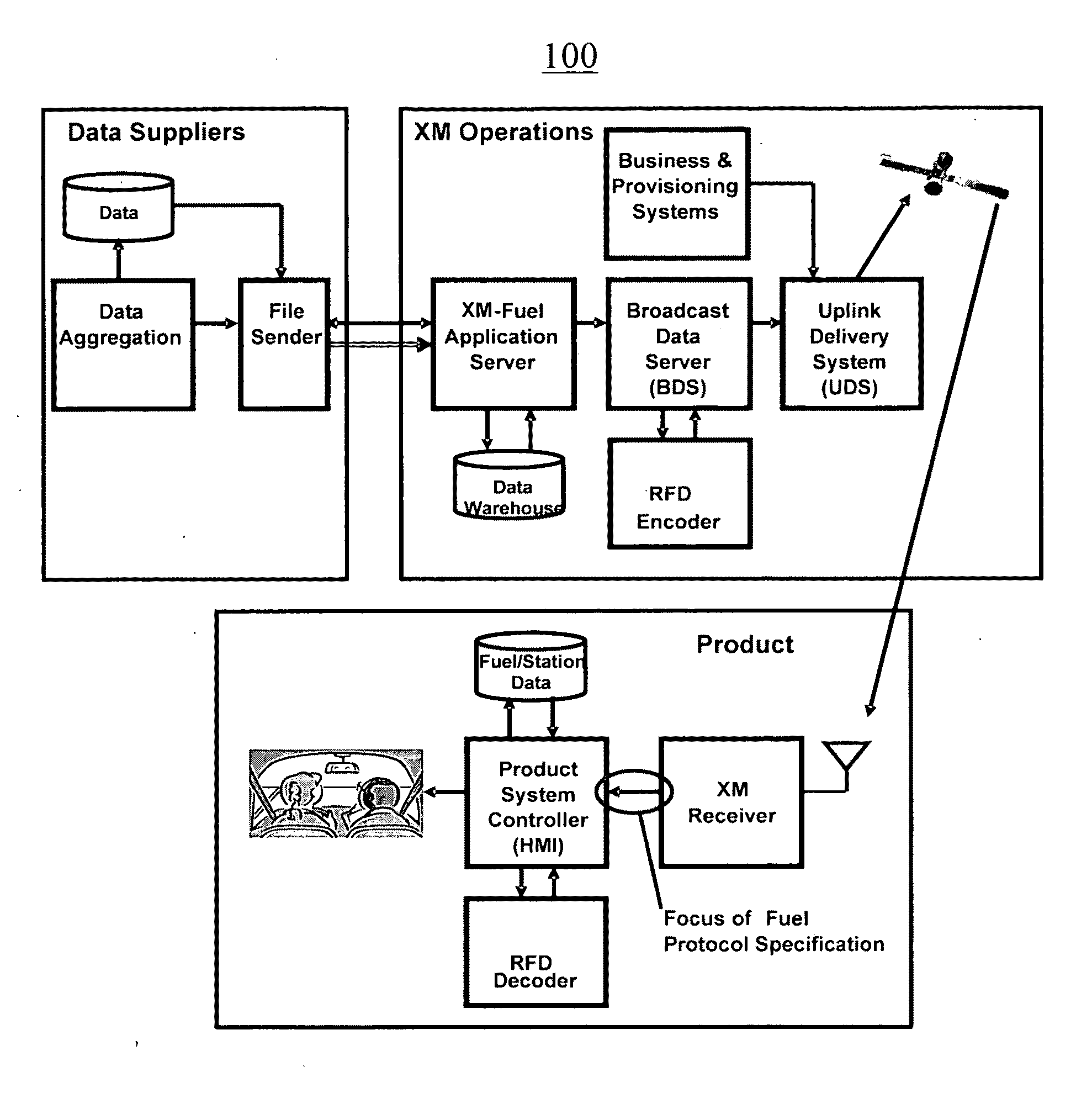

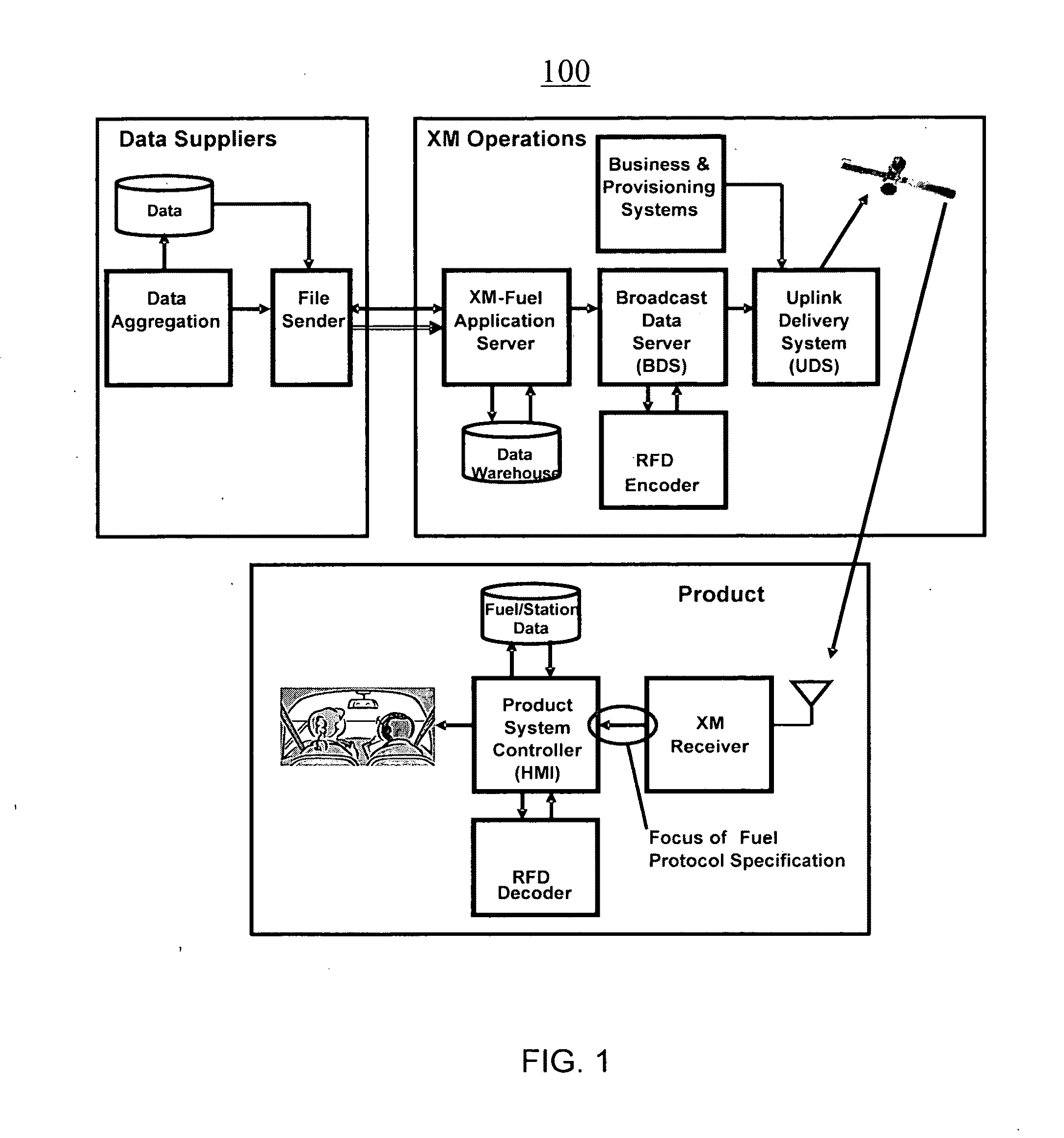

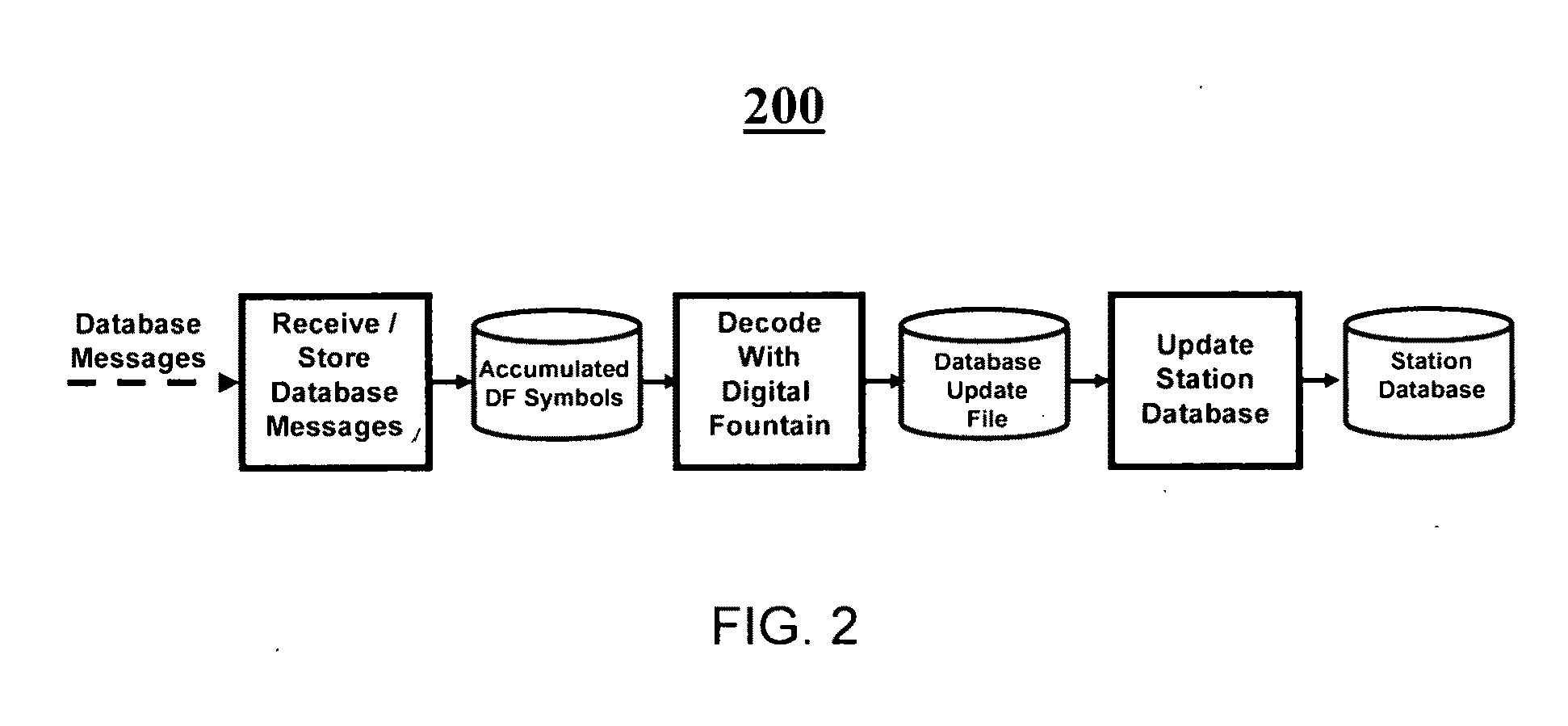

Travel related services via SDARS

InactiveUS20100106514A1Instruments for road network navigationNavigational calculation instrumentsData streamParking space

Systems and methods of for providing various services, such as parking services, flight services, and fuel services, to a user using a satellite digital audio radio system are provided. Each data service can be provided independently or in any combination to a user, and each can be independently subscribed to by a user, in various exemplary business models. In exemplary embodiments of the present invention, a parking data service, providing, for example, information on parking garages near a certain location and the availability of parking spaces in parking garages can be provided. In exemplary embodiments of the present invention, a flight data services, providing, for example, information such as near real-time updates to changes in arrival and departure statuses of one or more commercial airline flights. In exemplary embodiments of the present invention, a fuel data service, providing, for example, information on fueling stations and the prices and fuel types available at fueling stations, can be provided. In exemplary embodiments of the present invention, such data services can be embedded in an SDARS data stream and made available to users on an SDARS receiver.

Owner:SIRIUS XM RADIO INC

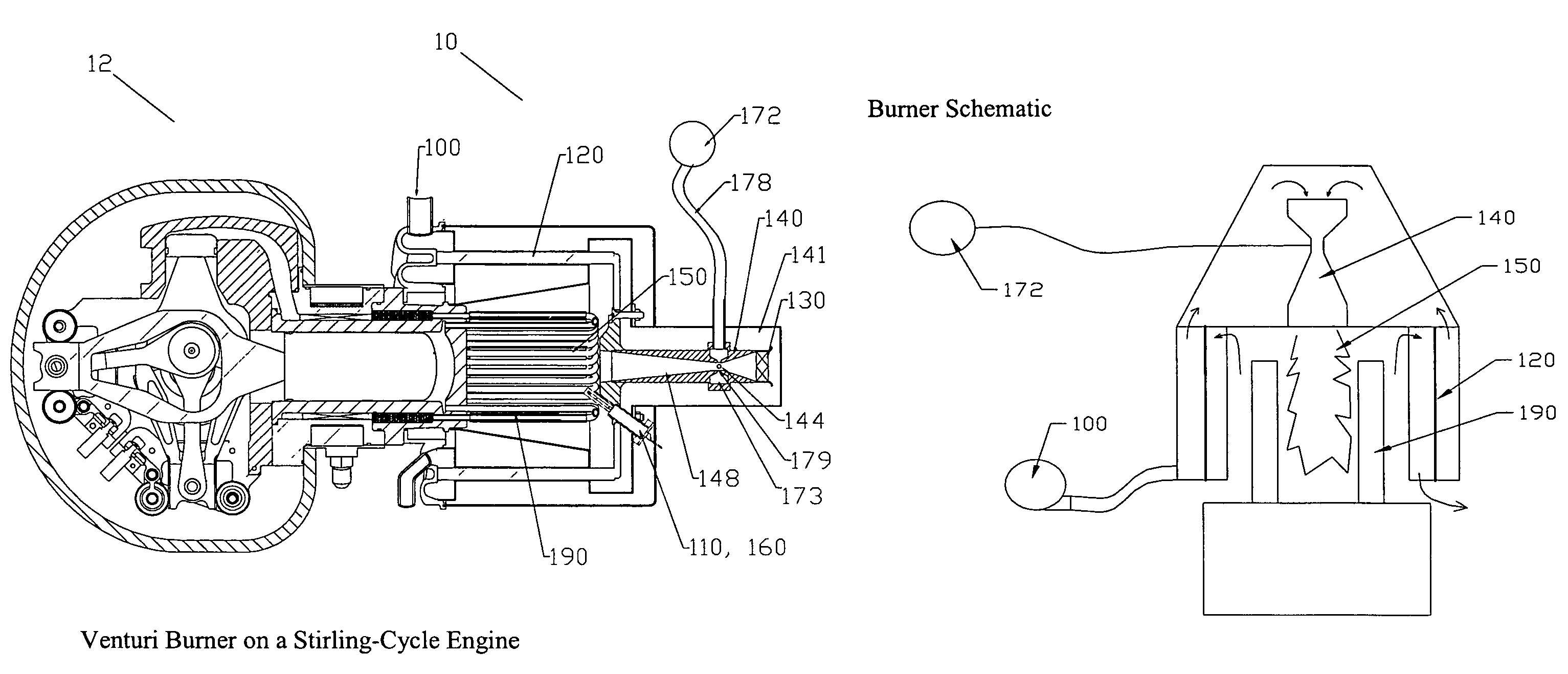

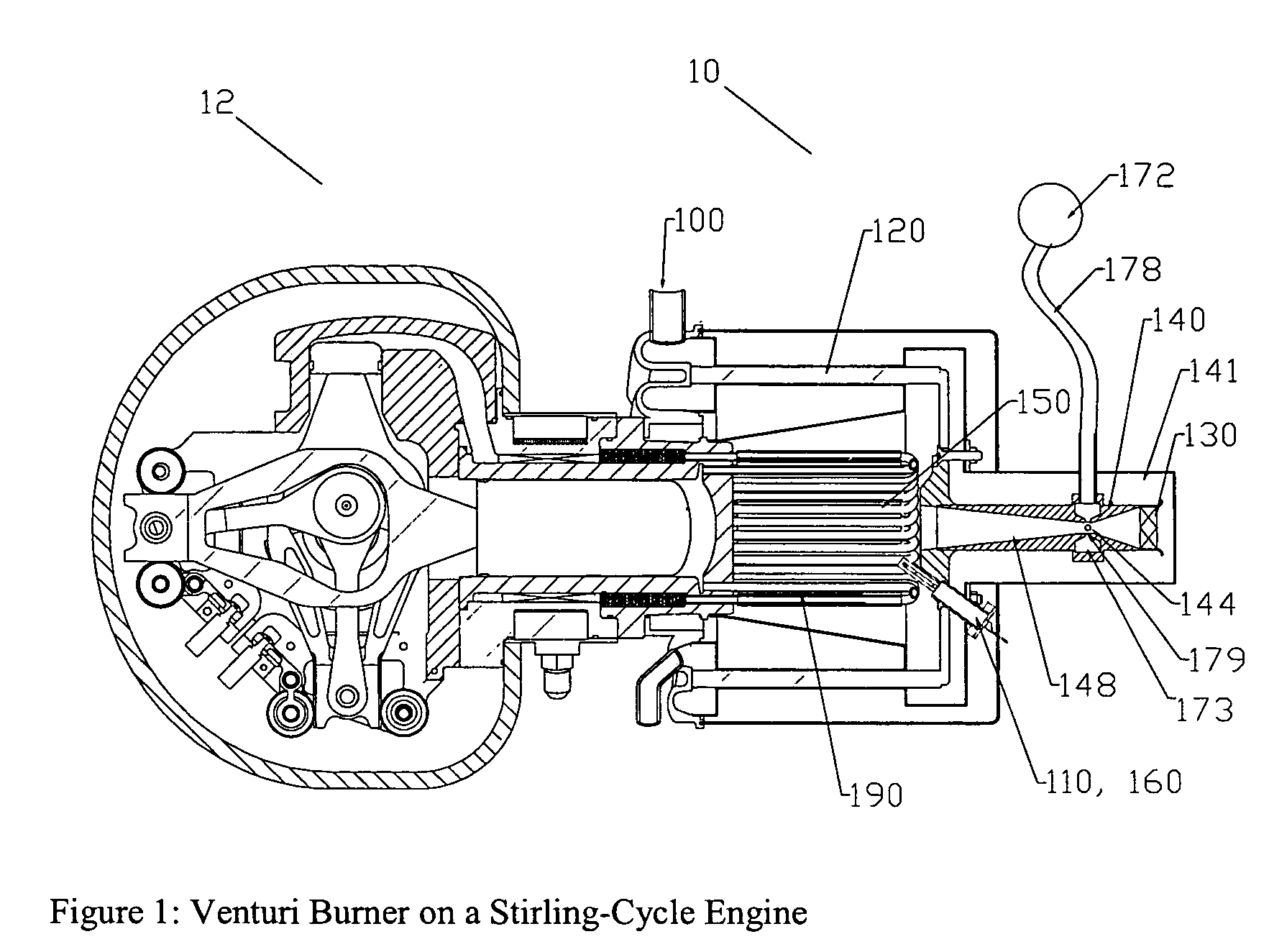

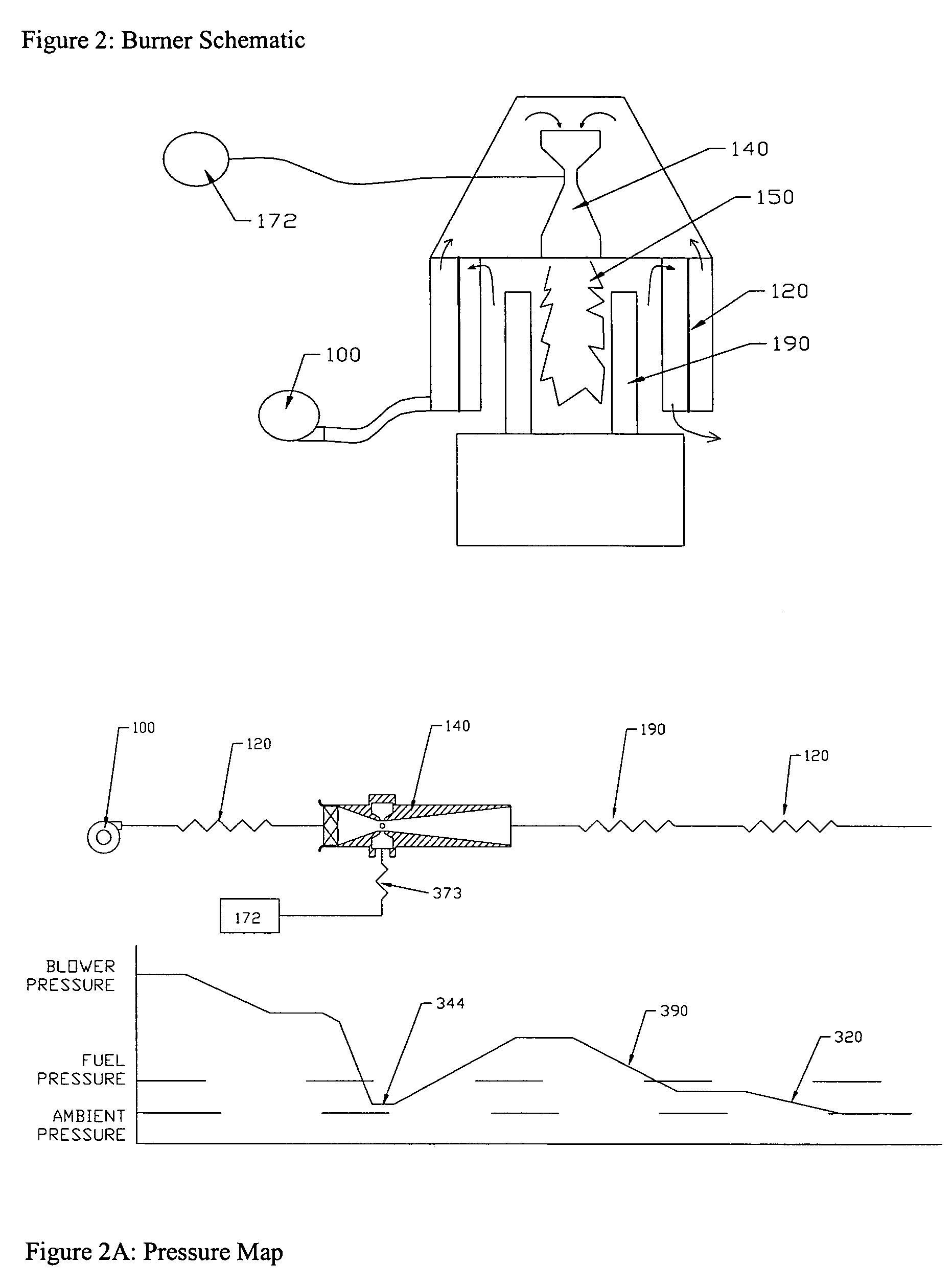

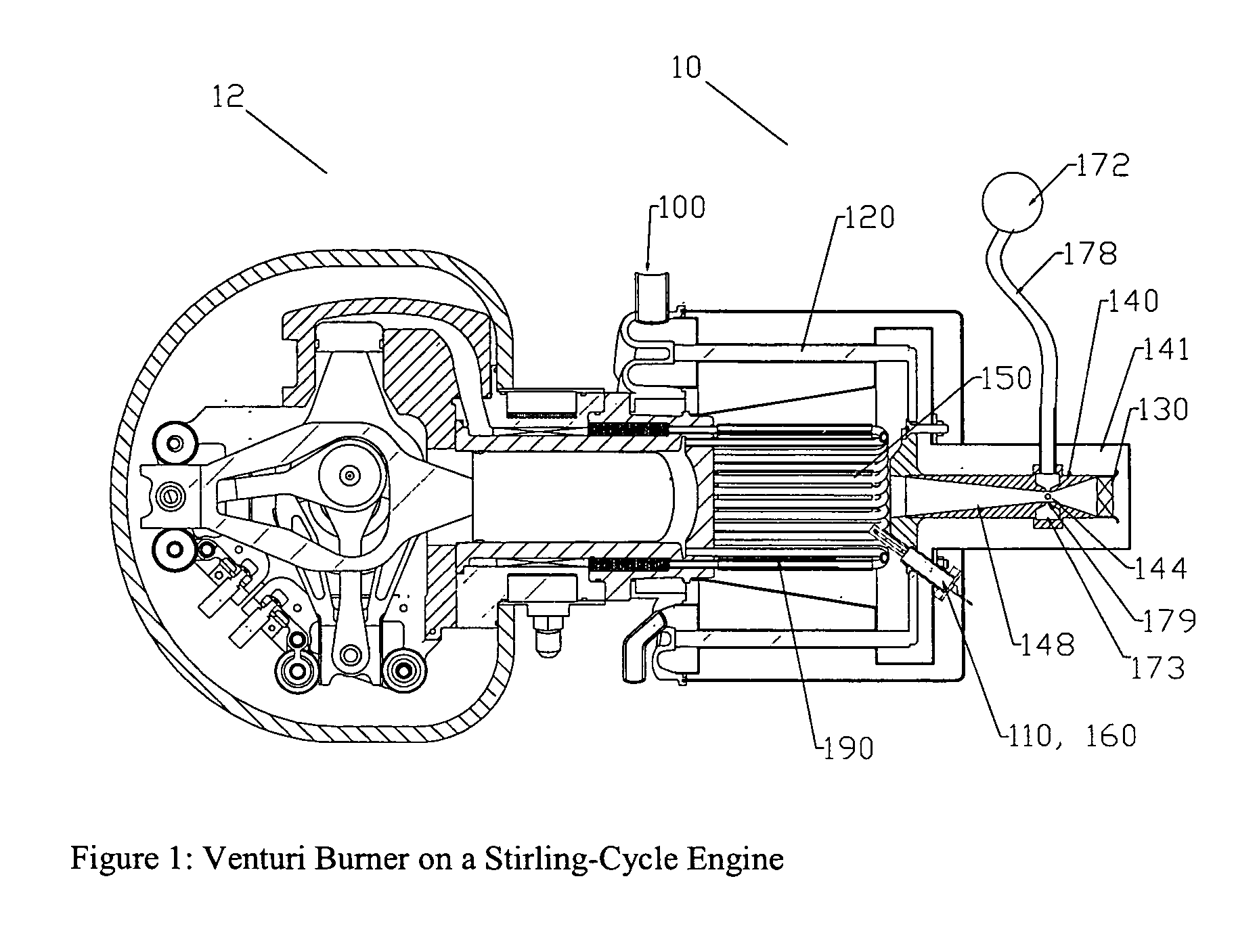

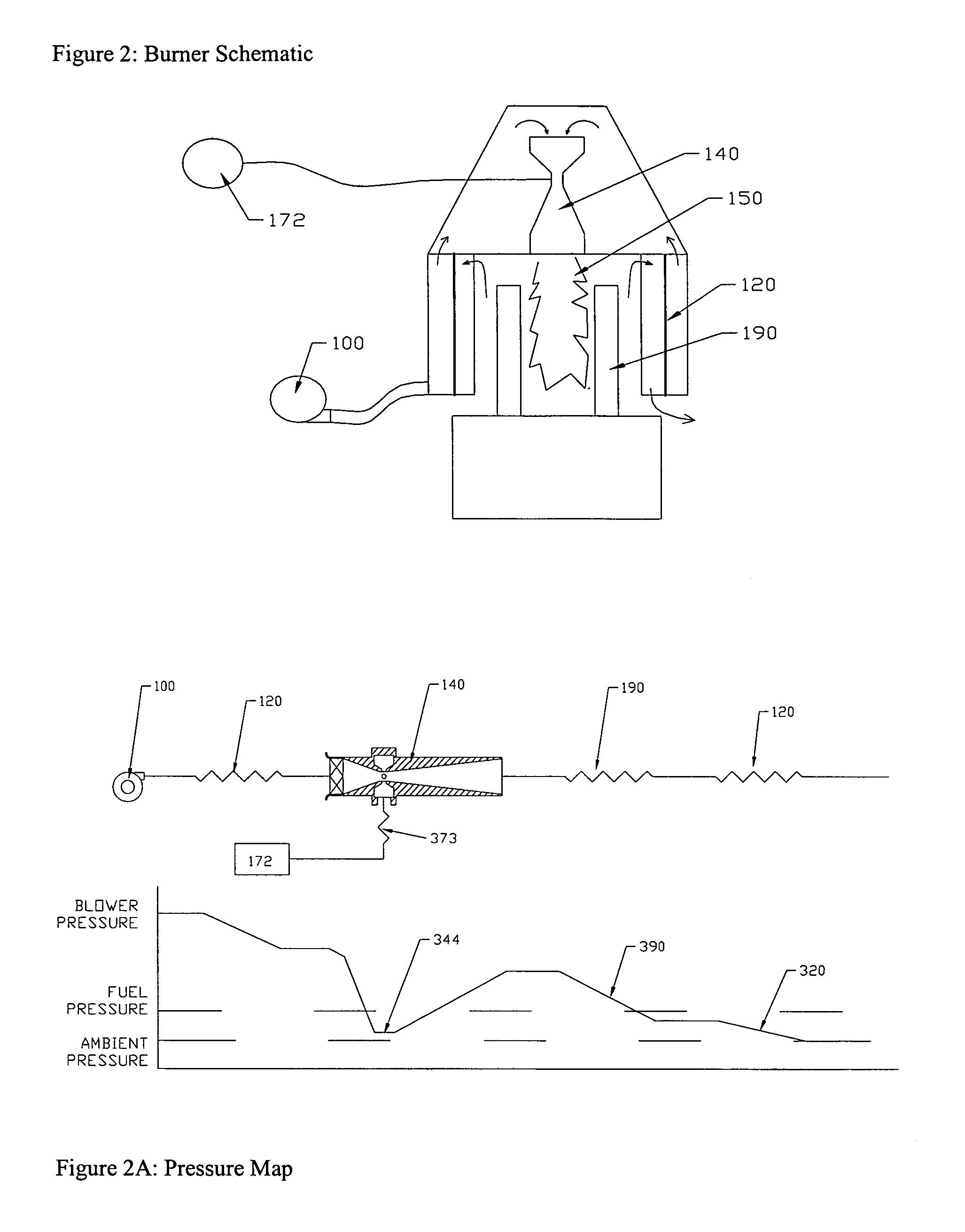

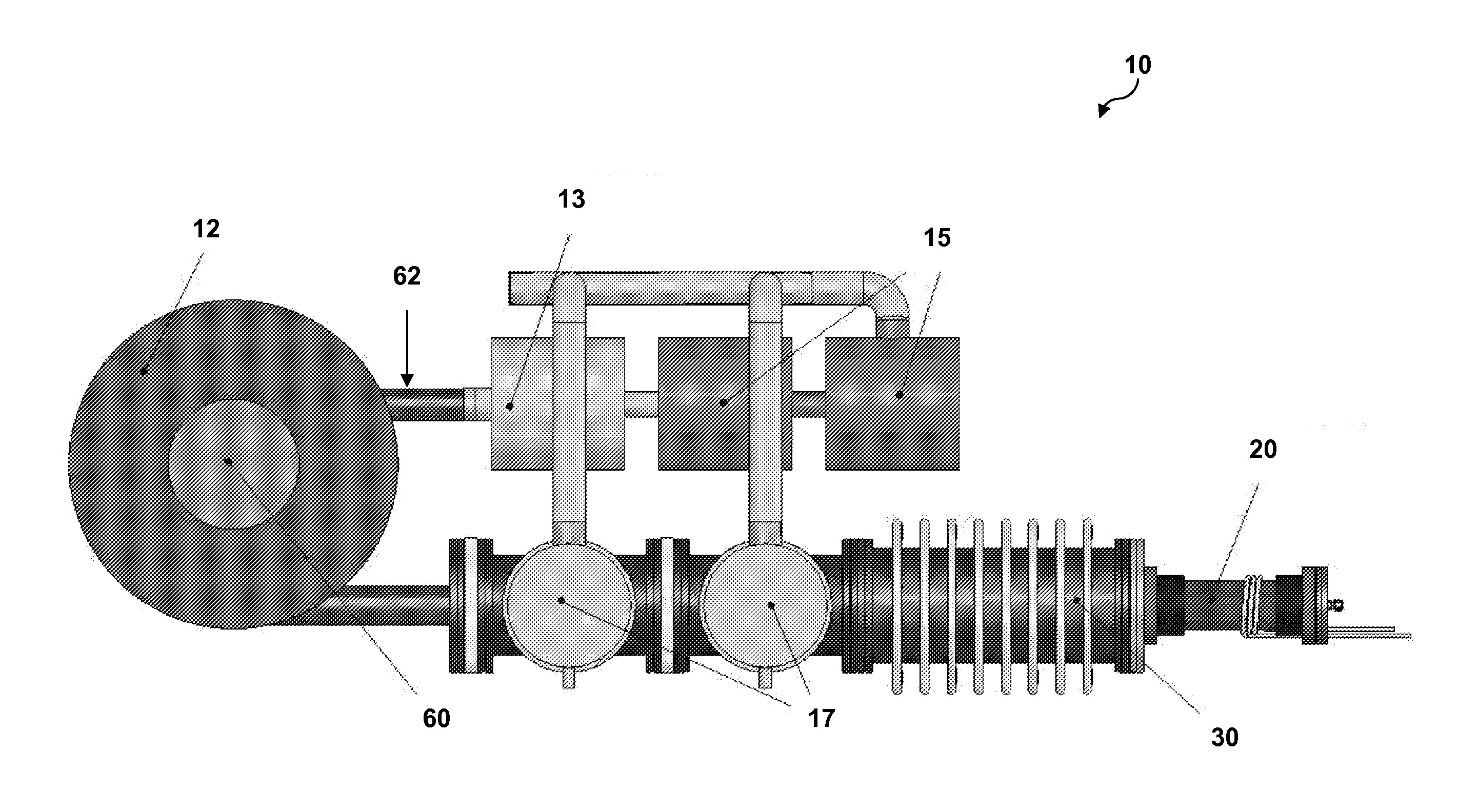

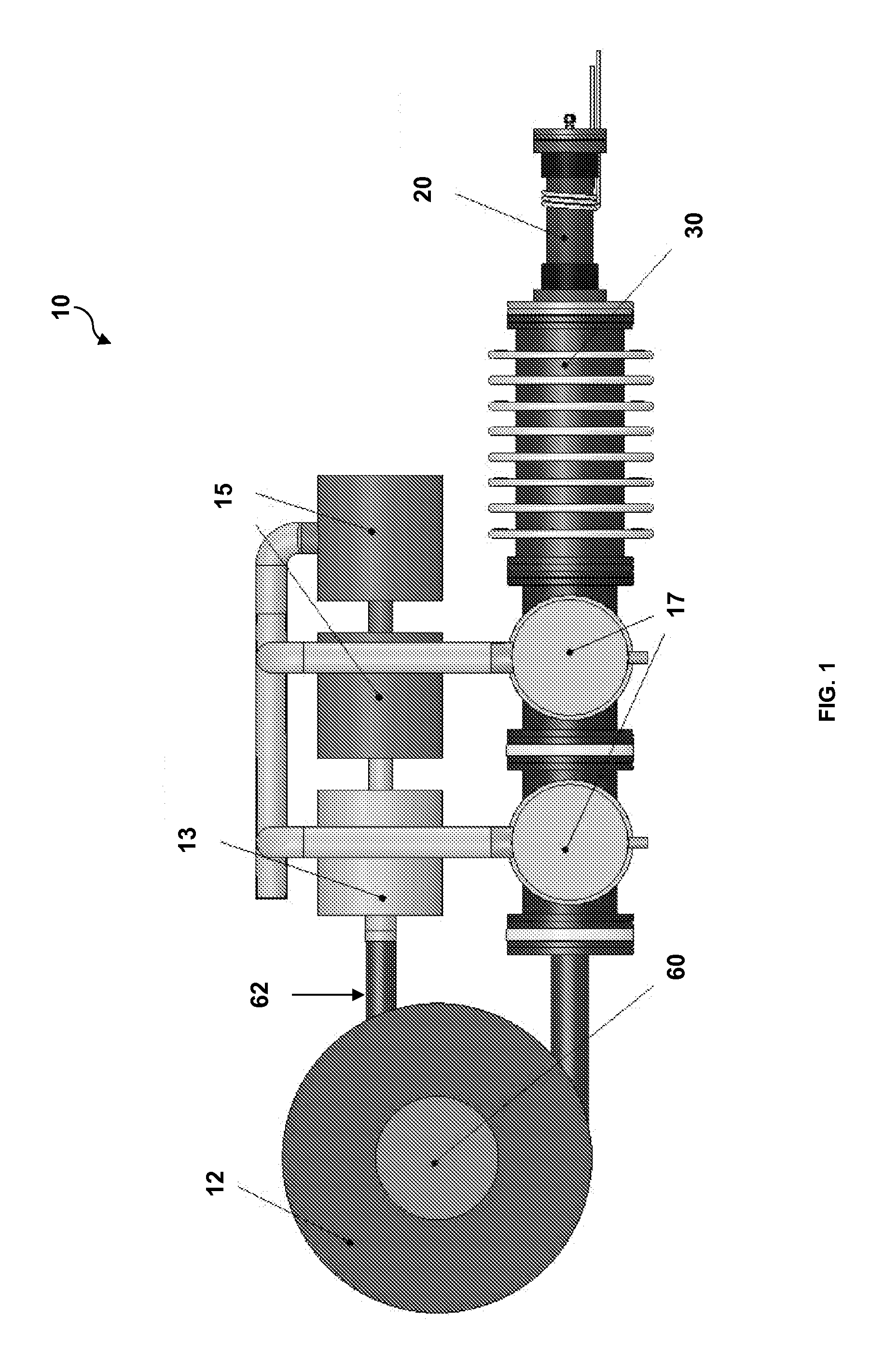

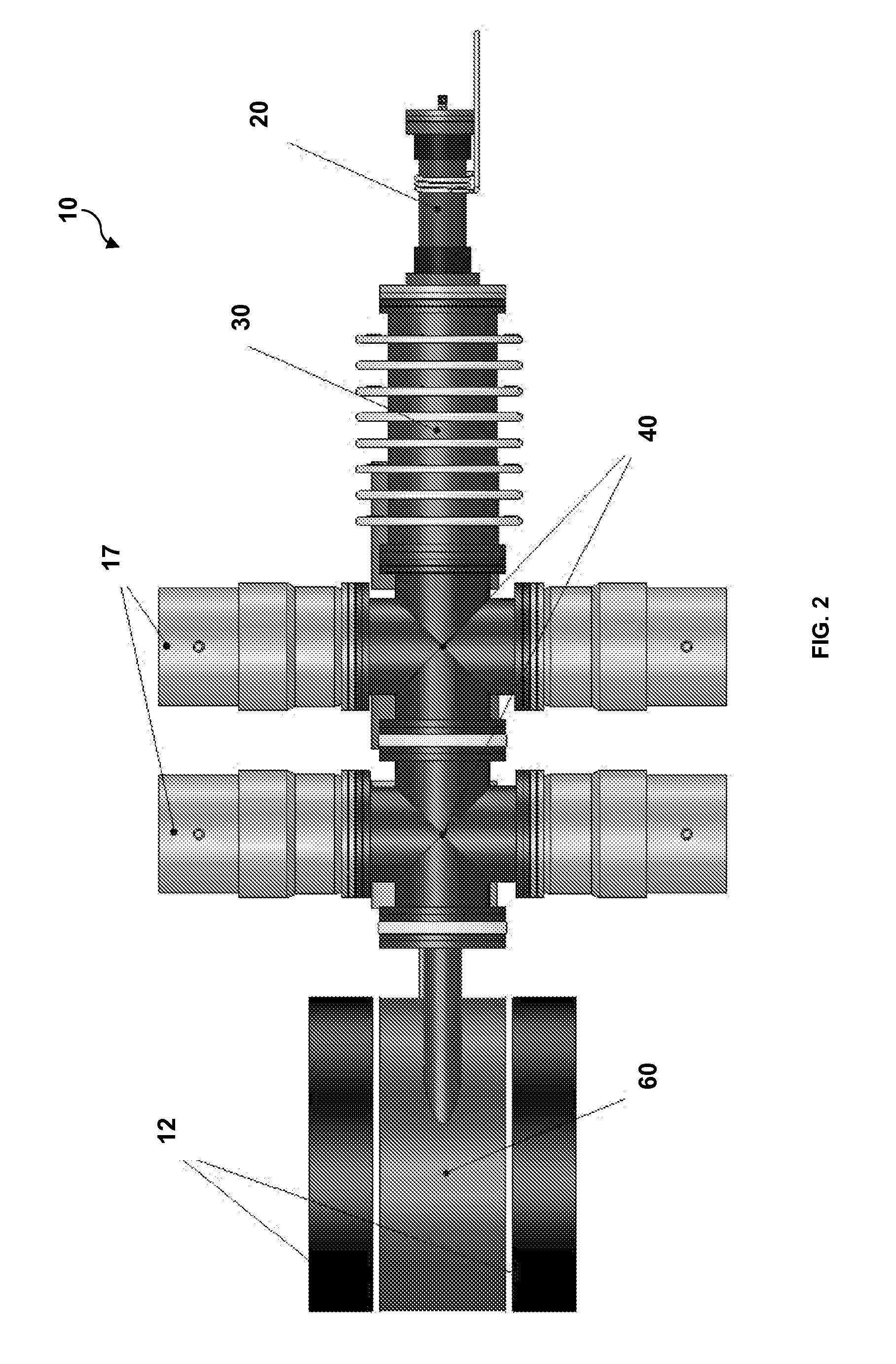

Gaseous fuel burner

ActiveUS7934926B2Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

Owner:NEW POWER CONCEPTS

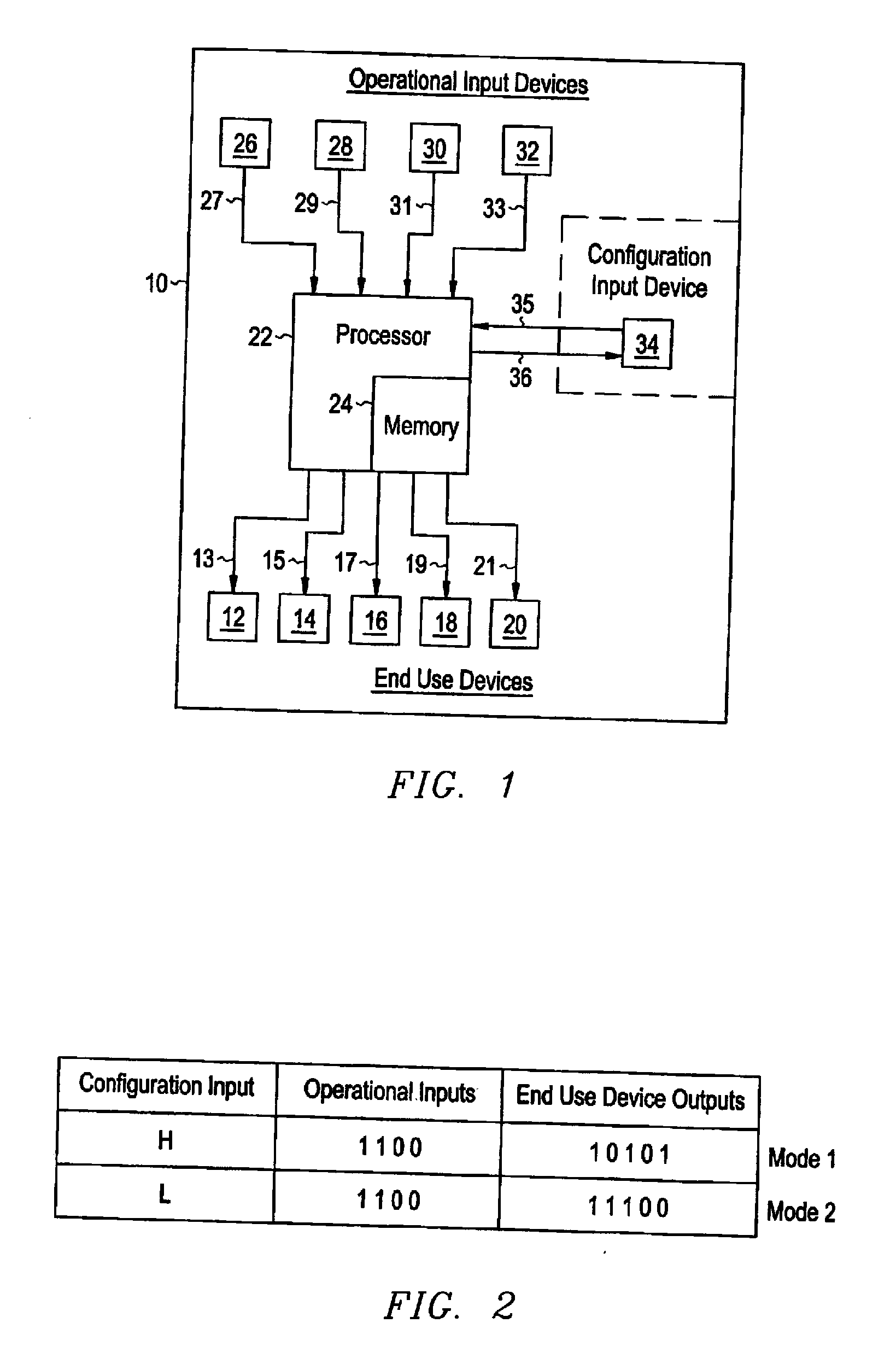

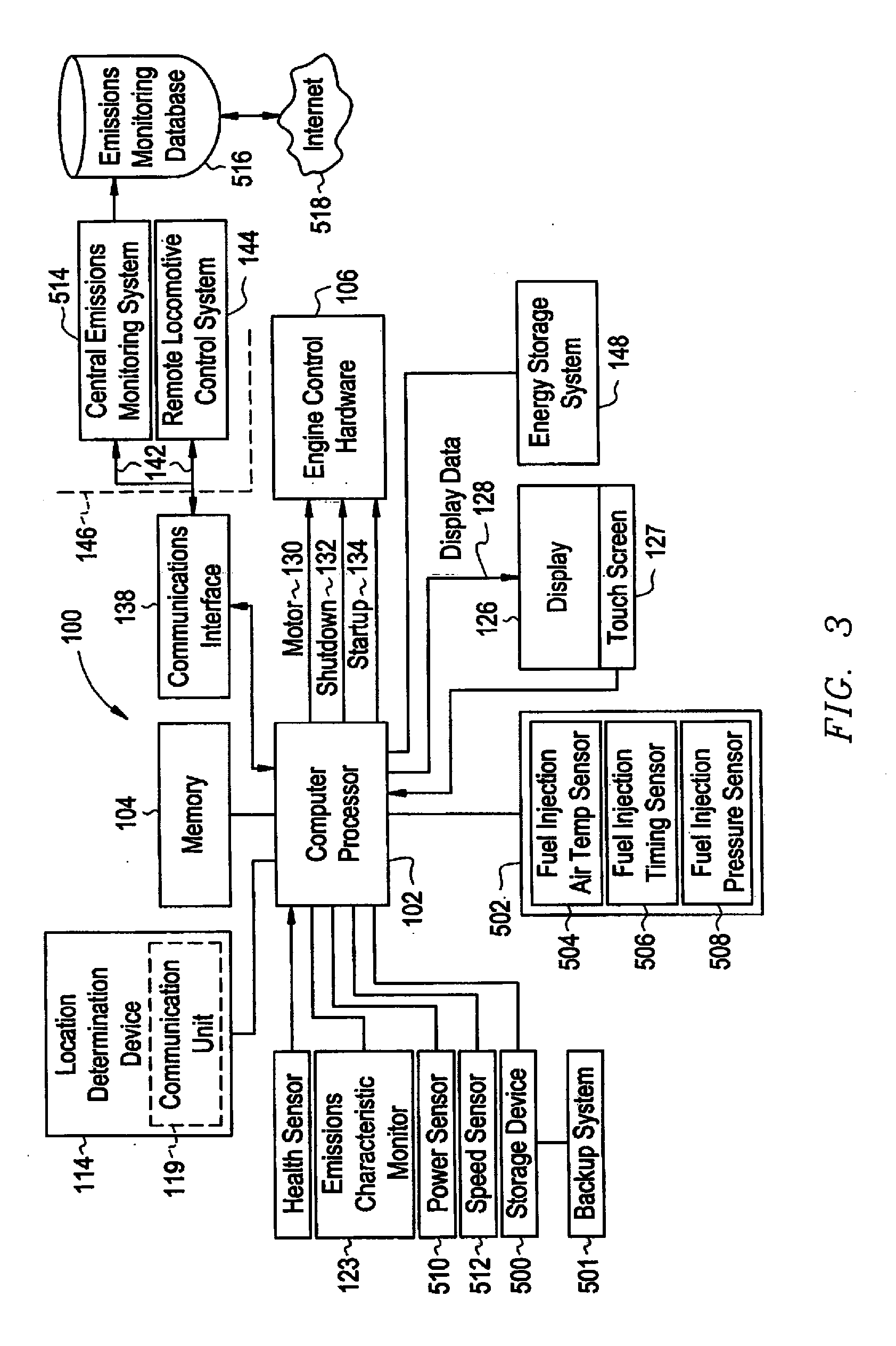

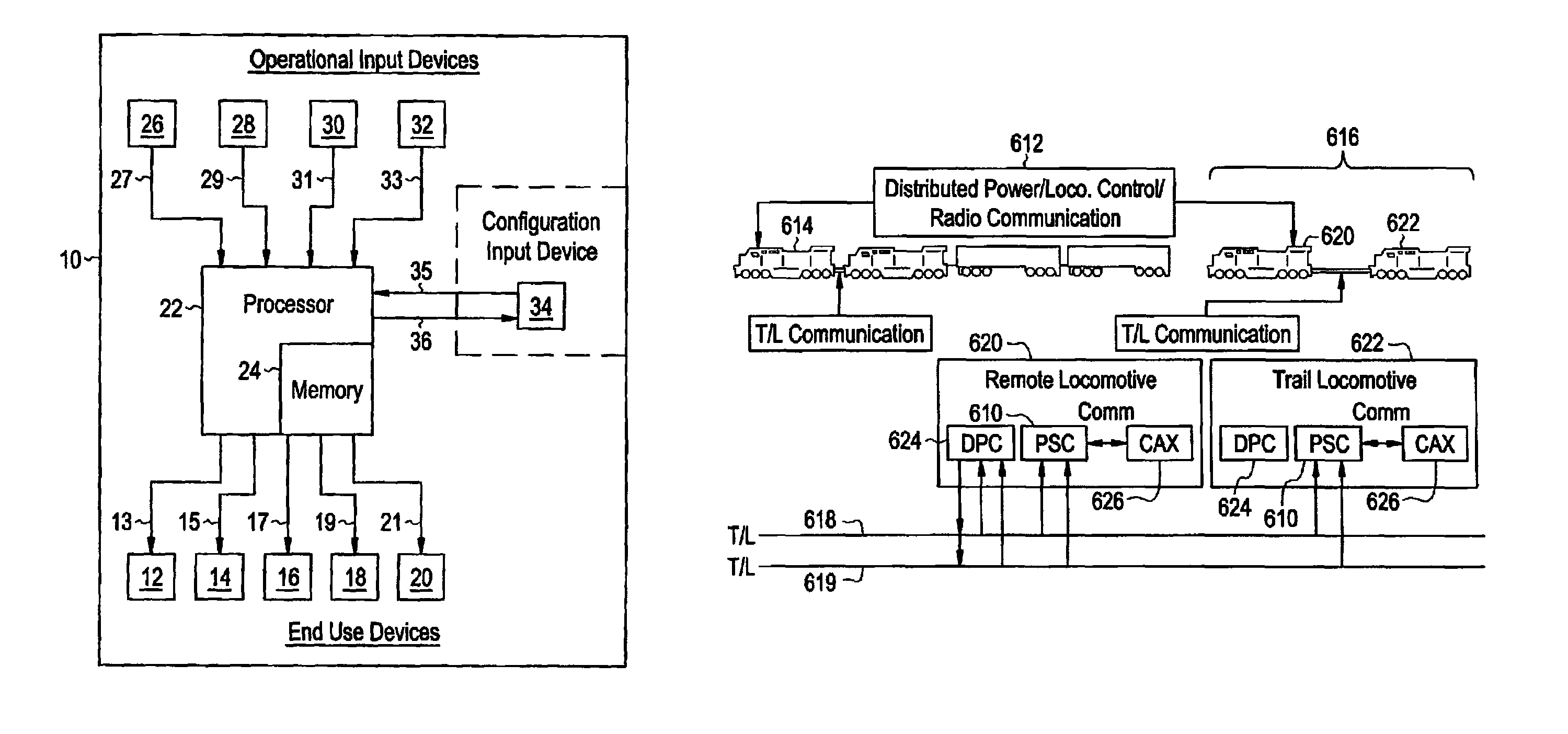

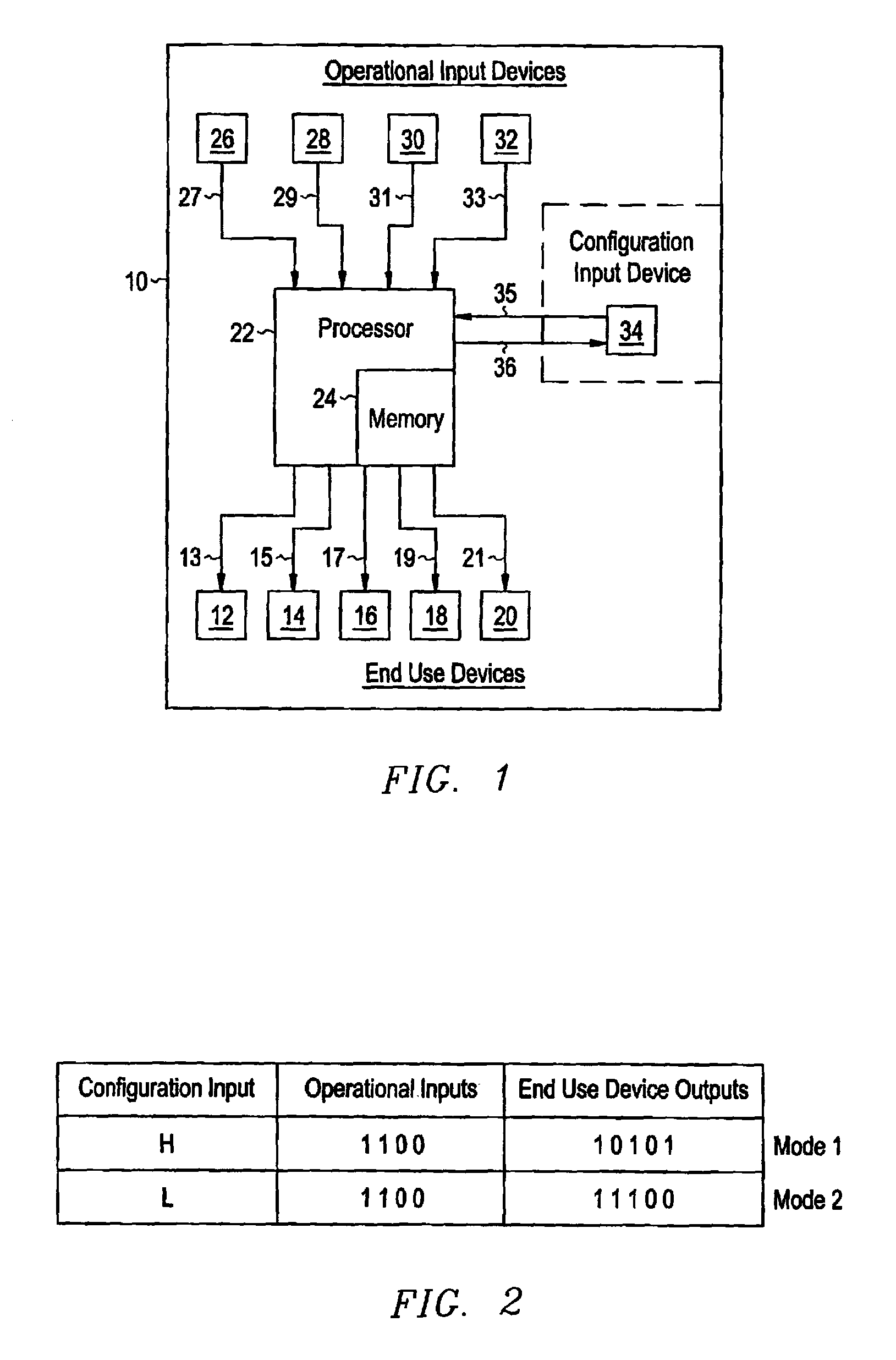

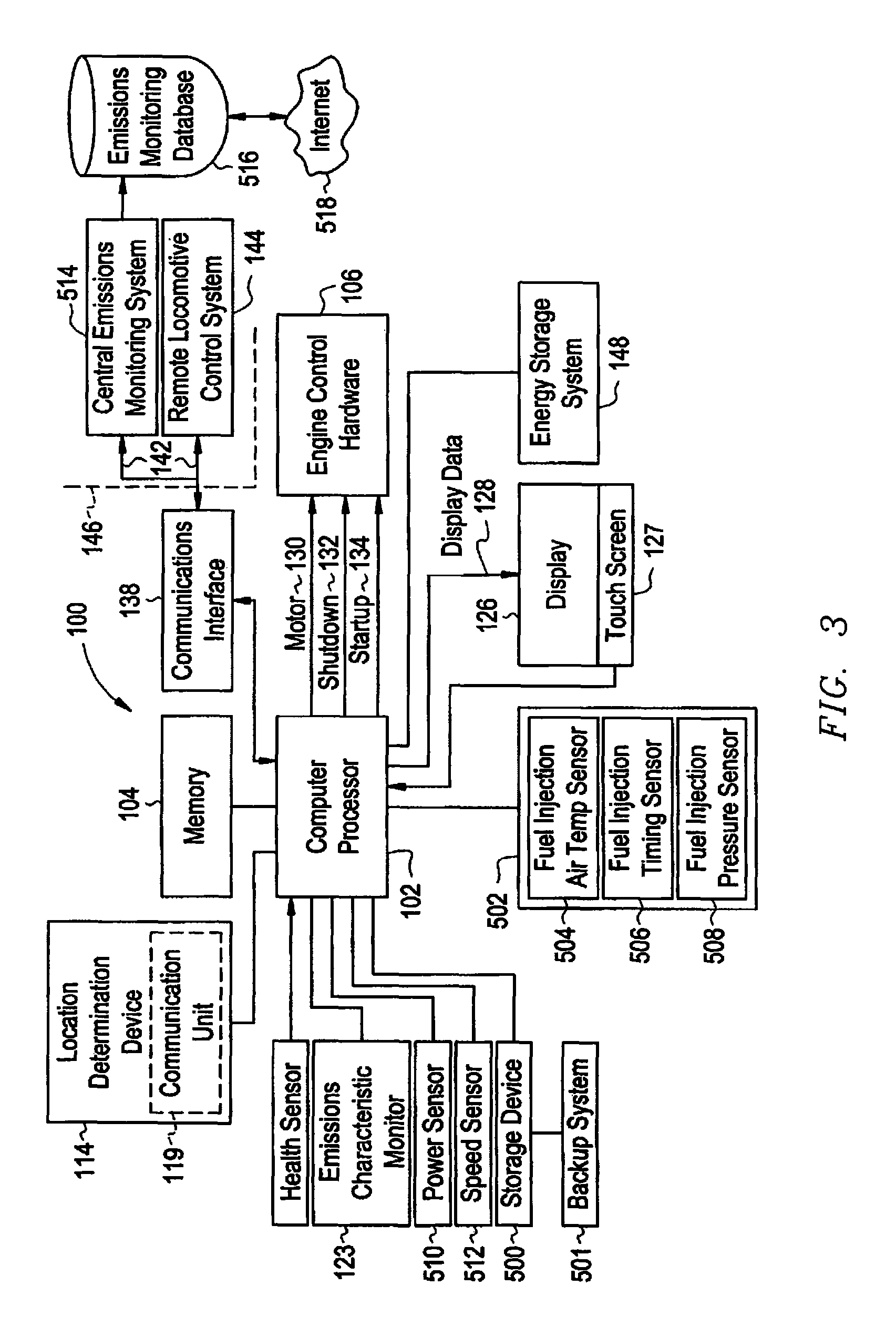

System and Method for Managing Emissions from Diesel Powered Systems

InactiveUS20070137514A1Emission controlElectrical controlInternal combustion piston enginesControl signalFuel tank

A configurable diesel powered system is provided for controlling engine emissions of a diesel-fueled power generating unit. The diesel-fueled power generating unit includes an engine operating on at least one fuel type. The system includes a plurality of operational input devices coupled with a processor to generate operational input signals to the processor. A plurality of end use devices include fuel tanks for each respective fuel type and are controlled by the processor to control the engine emissions. A configuration input device in communication with the processor generates a respective configuration signal for each particular location along the predetermined course comprising a mission. The processor is responsive to the operational input devices and configuration signals to generate a set of control signals to the fuel tanks to limit the total engine emissions of all fuel types to a respective stored engine emission profile for each configuration signal for each particular location along the predetermined course comprising the mission.

Owner:GE GLOBAL SOURCING LLC

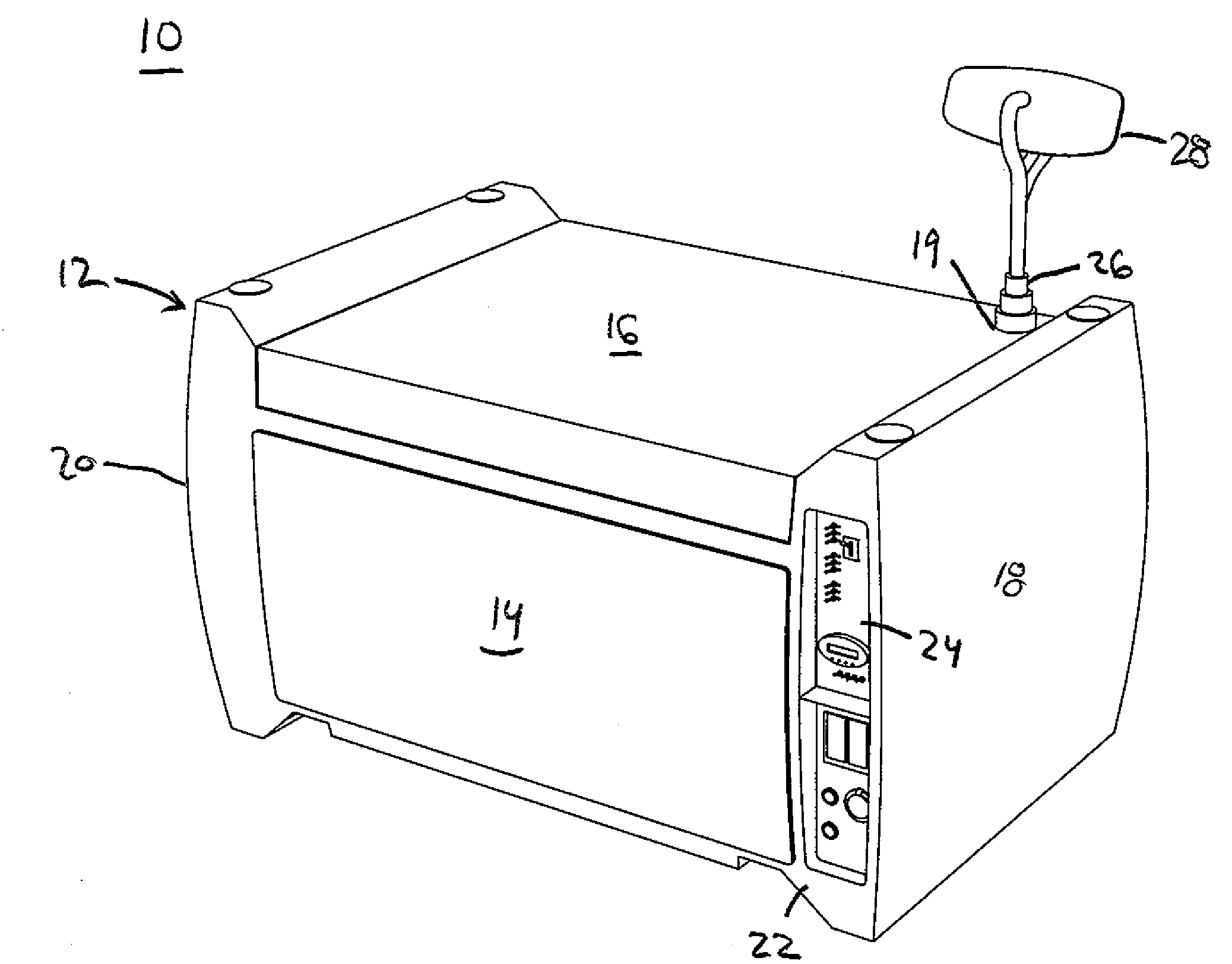

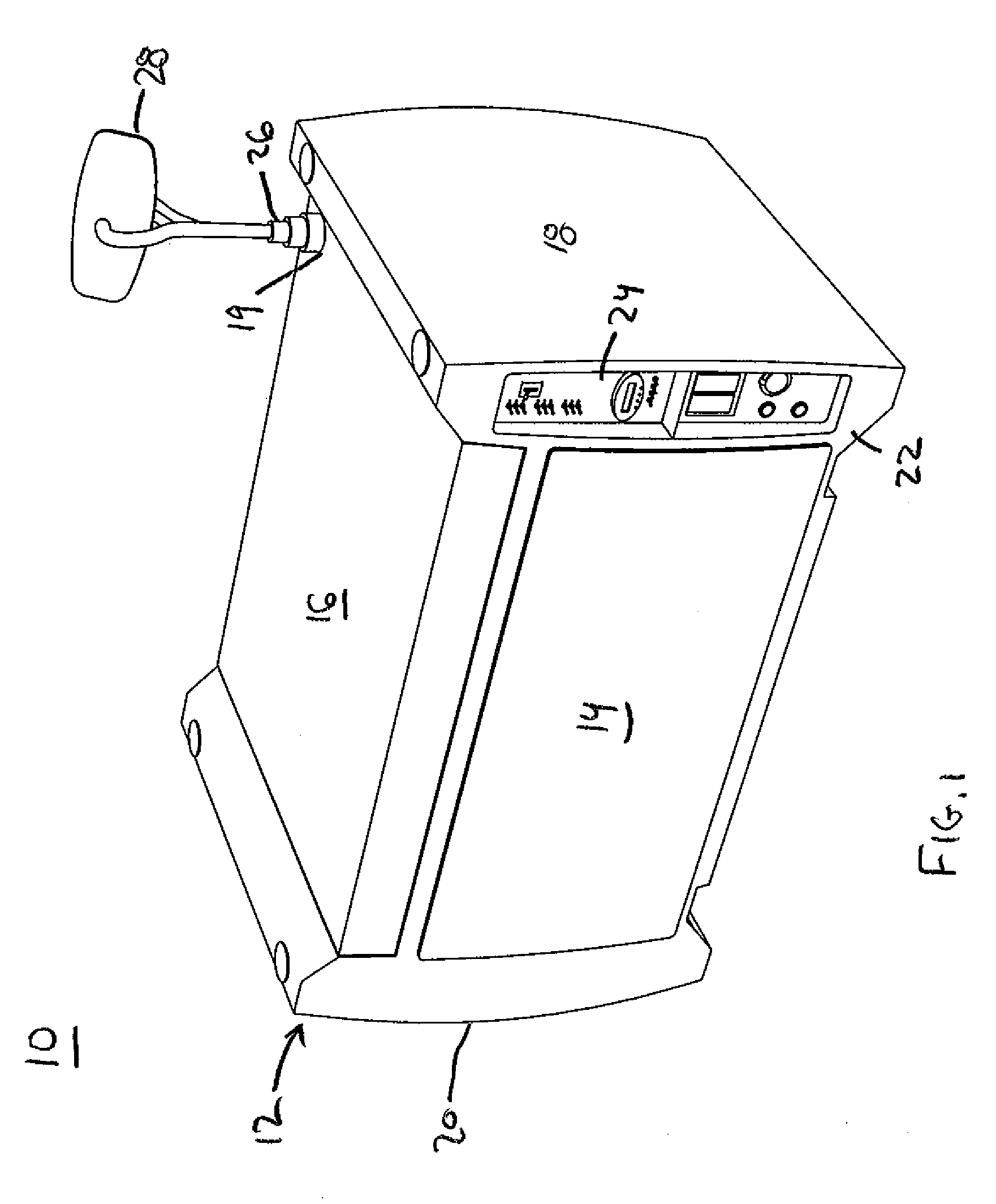

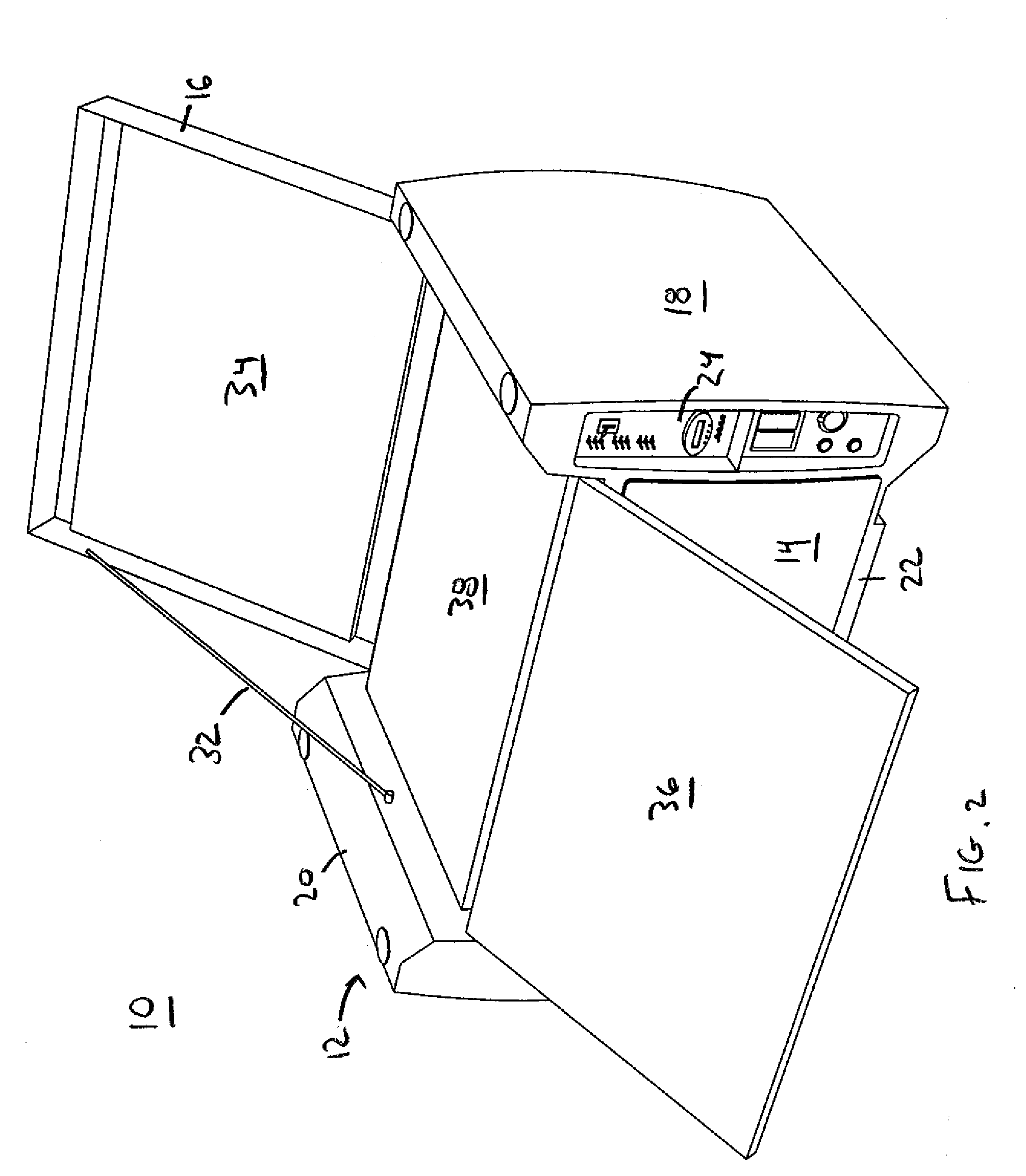

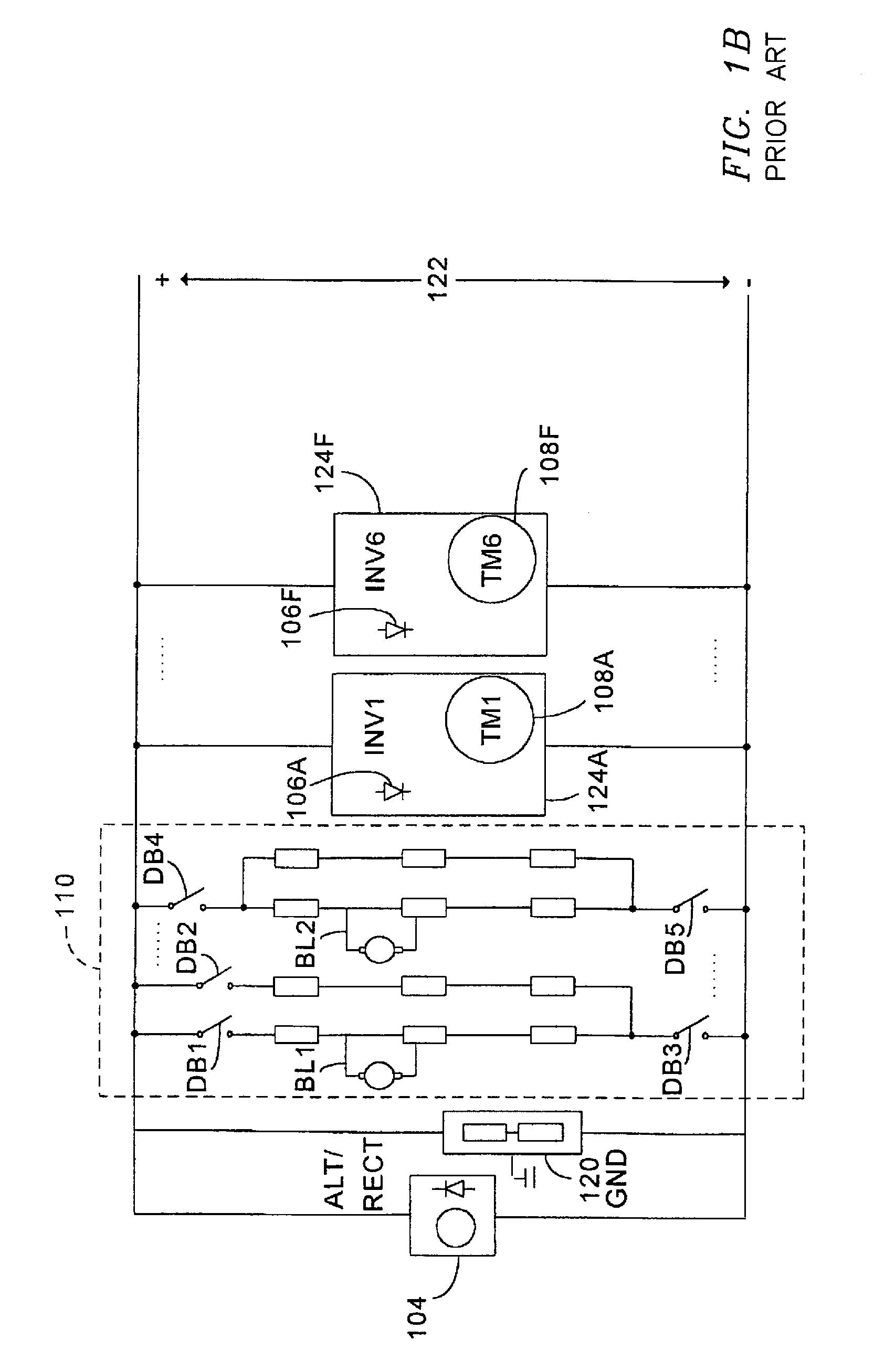

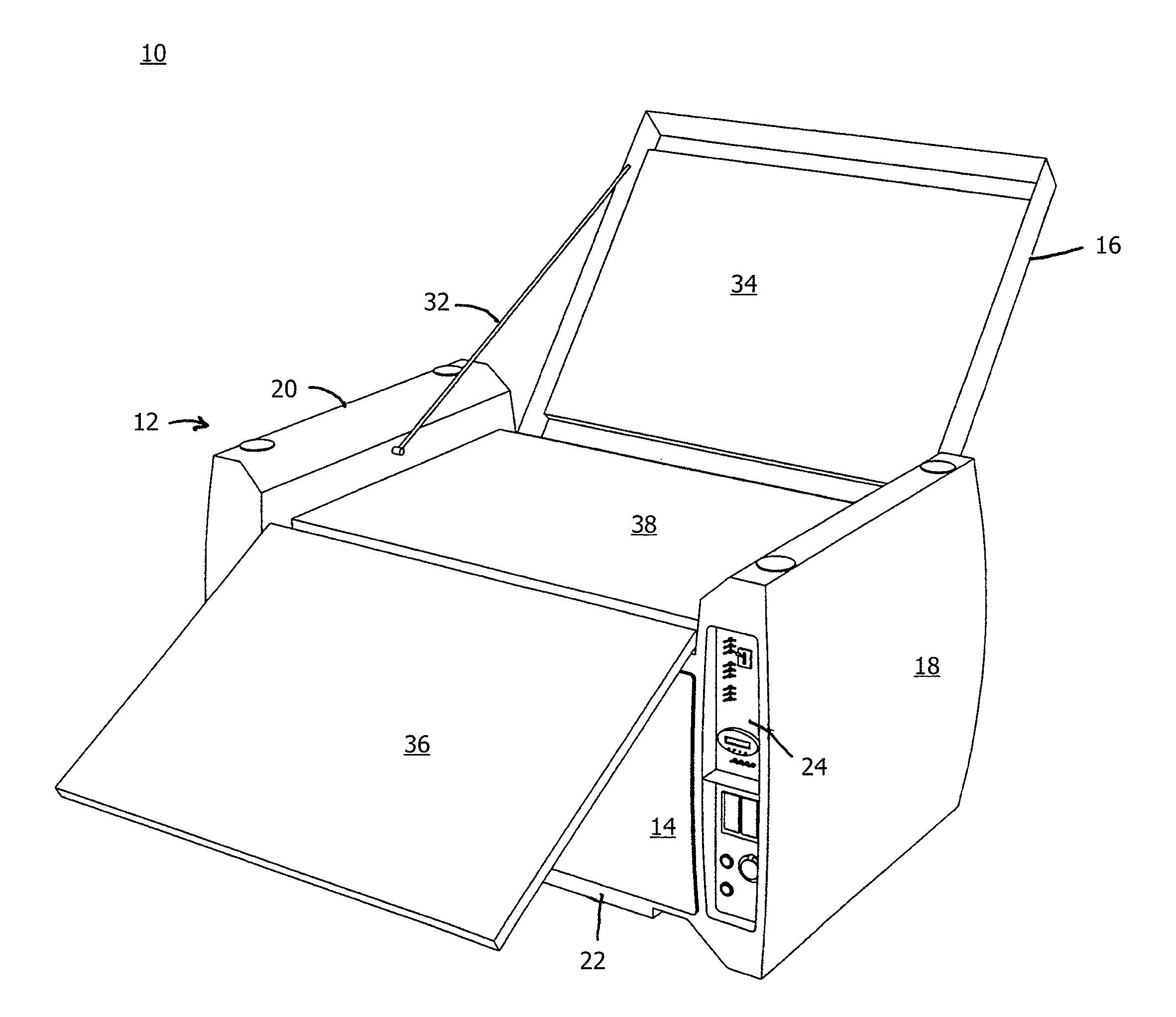

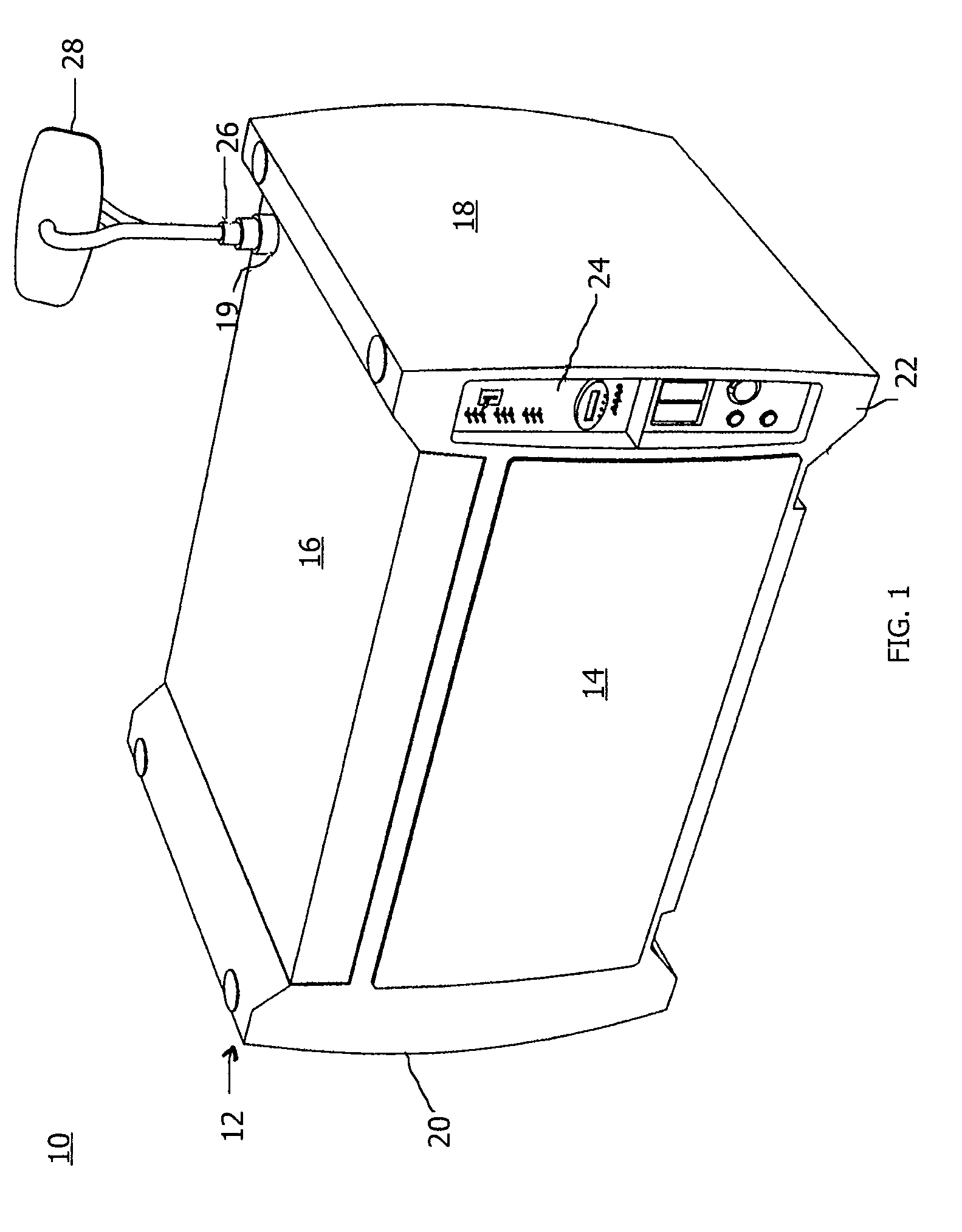

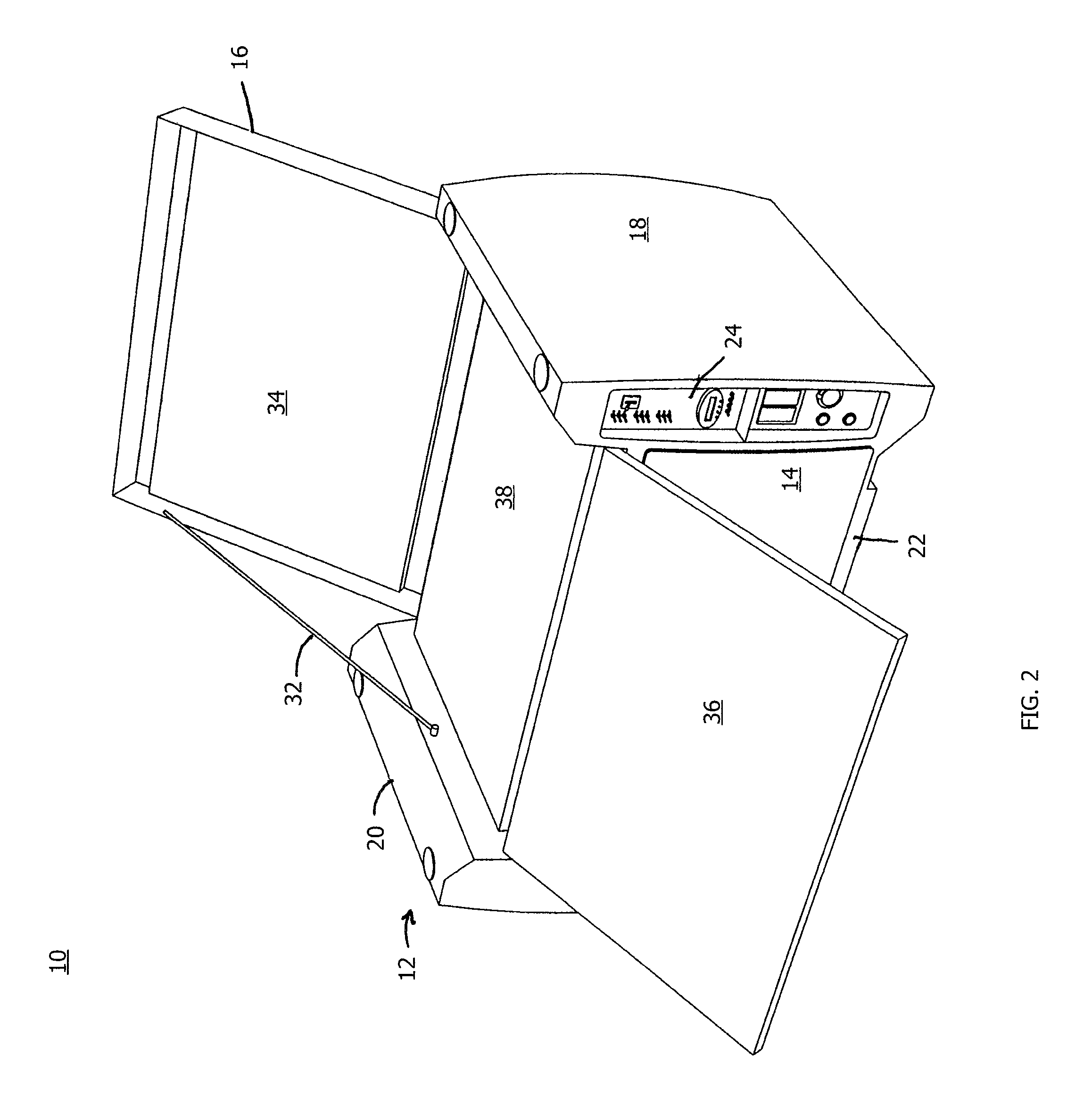

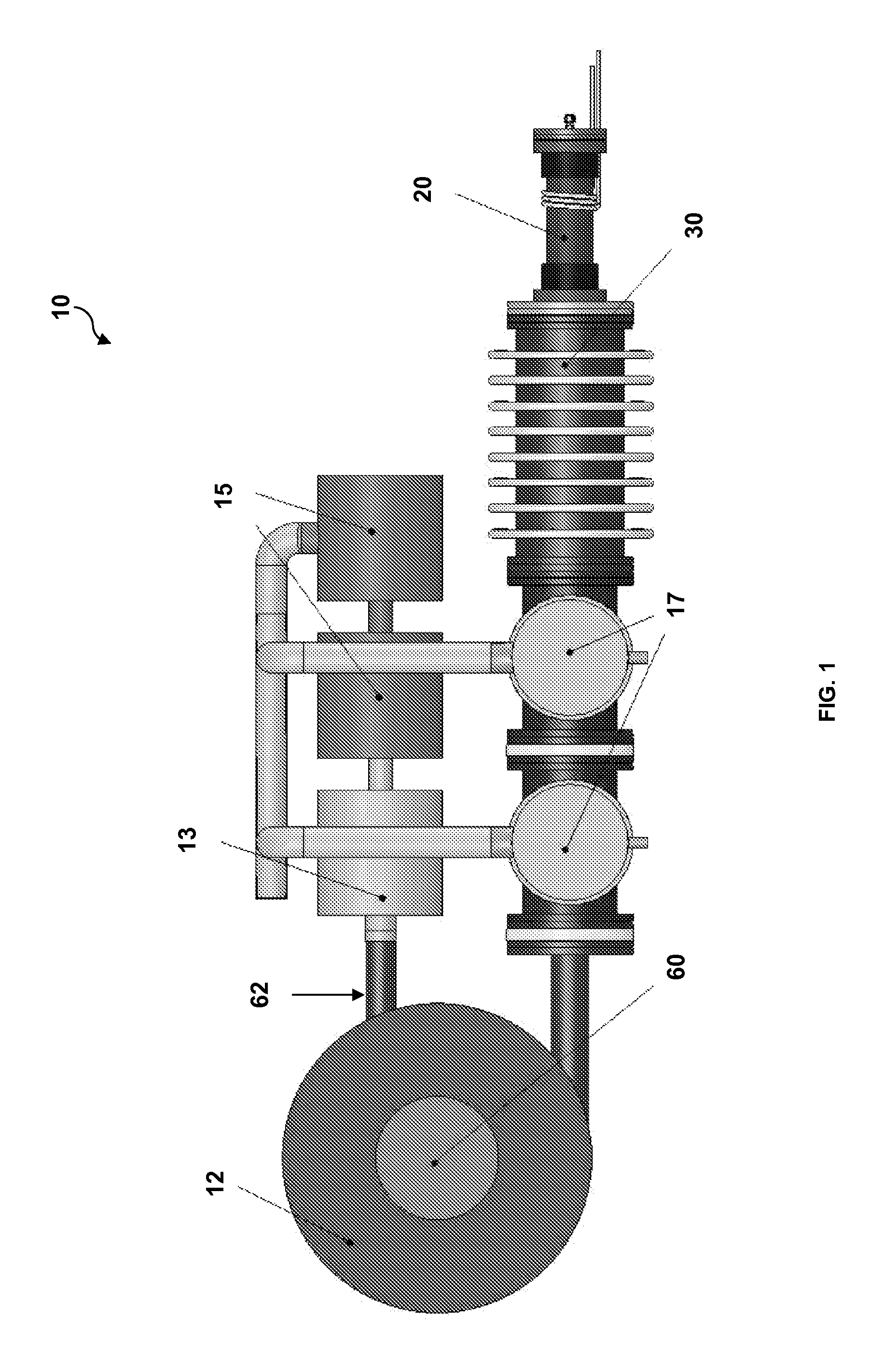

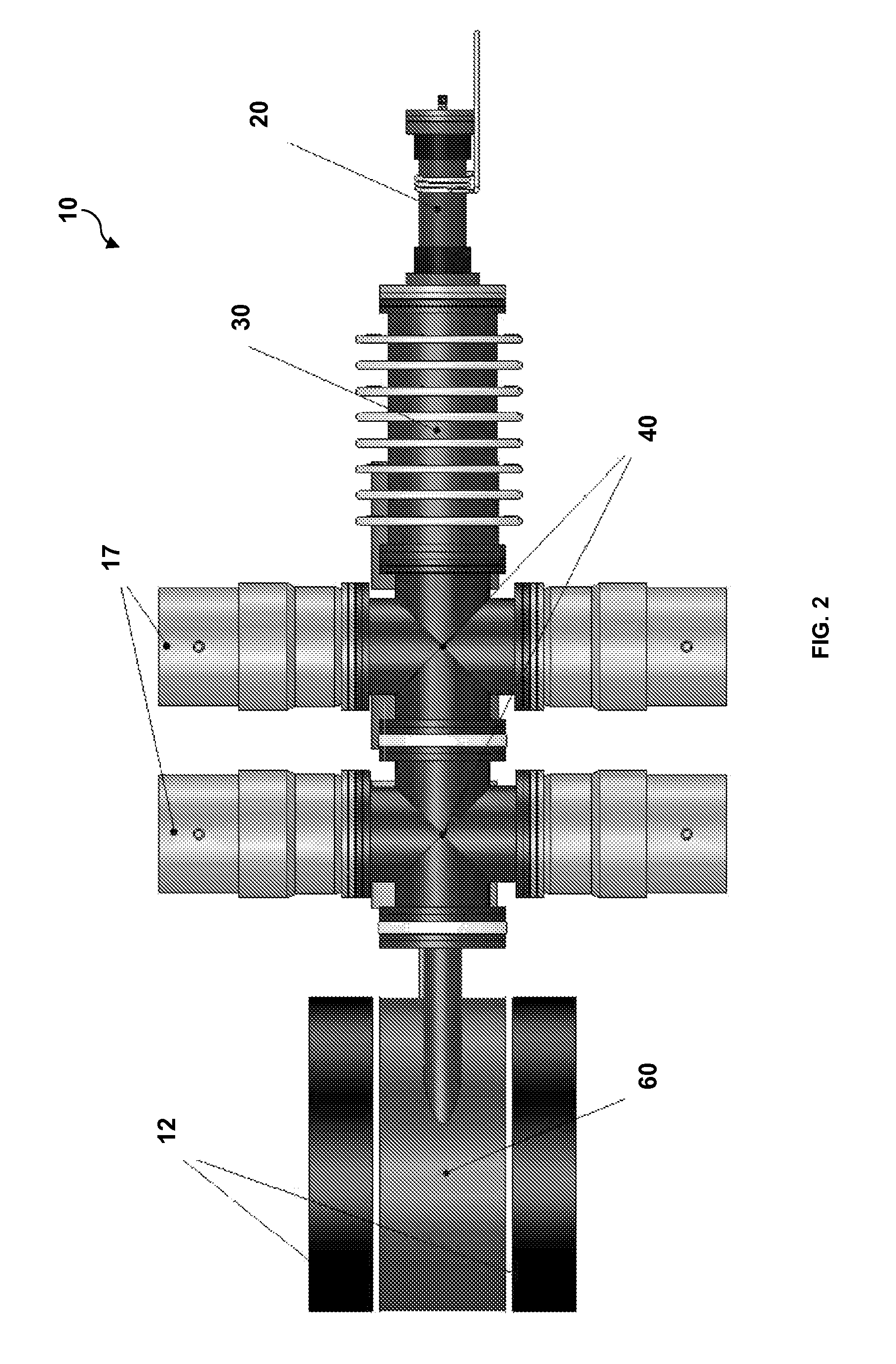

Deployable power supply system

InactiveUS20090039705A1Easy to operateEasy to scaleBatteries circuit arrangementsPV power plantsElectricityRemote system

A self-contained conveyable power unit for producing 12V / 24V, 110V AC, and 220V AC electricity at a desired location independent of external power sources integrates within one weather-resistant molded nonmetallic material based housing a power generating device of a selectable combination of a renewable energy type (e.g., solar), power management devices, power storage devices and management reporting devices. Additional optional power generating devices, renewable or of traditional fuel type, can be contained within or coupled to the housing. The system includes devices or an array of devices contained within the housing for the storage of electrical power. A device for power management is contained within the housing as is networking equipment of wireless or wired type for remote system observation and reporting. The system and housing are modular and configured to produce power using any combination of renewable and non-renewable energy resources. The conveyable power unit may provide easy access to different types of power outputs and inputs and be coupled with like appliances in a ‘daisy chain’ or network of power. Given its molded composite material construction and scaleable design, the appliance may be readily fabricated in a variety of sizes for varied applications. Further, the molded housing of composite material construction is designed for resistance to the elements, light weight and strength.

Owner:ZEROBASE ENERGY

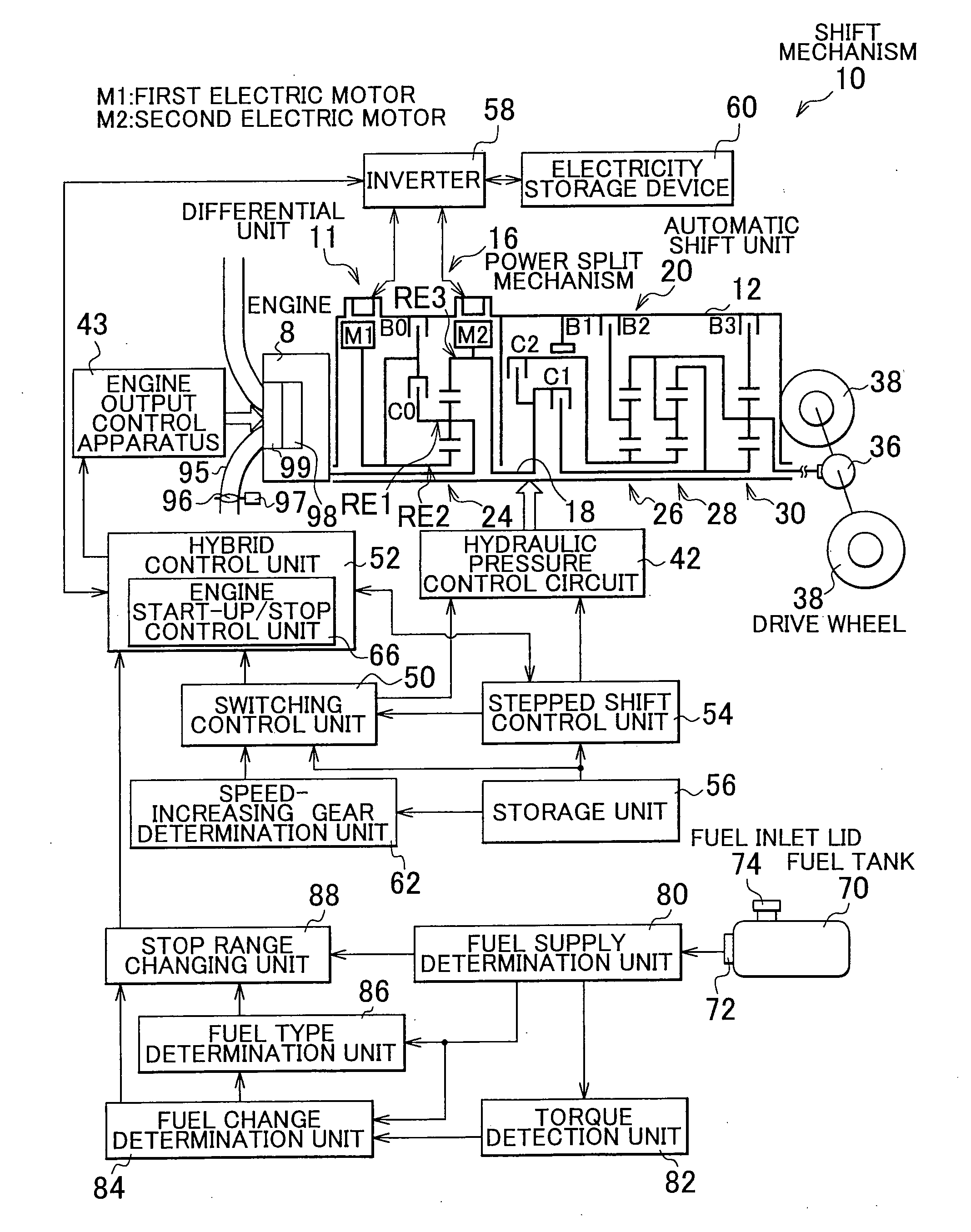

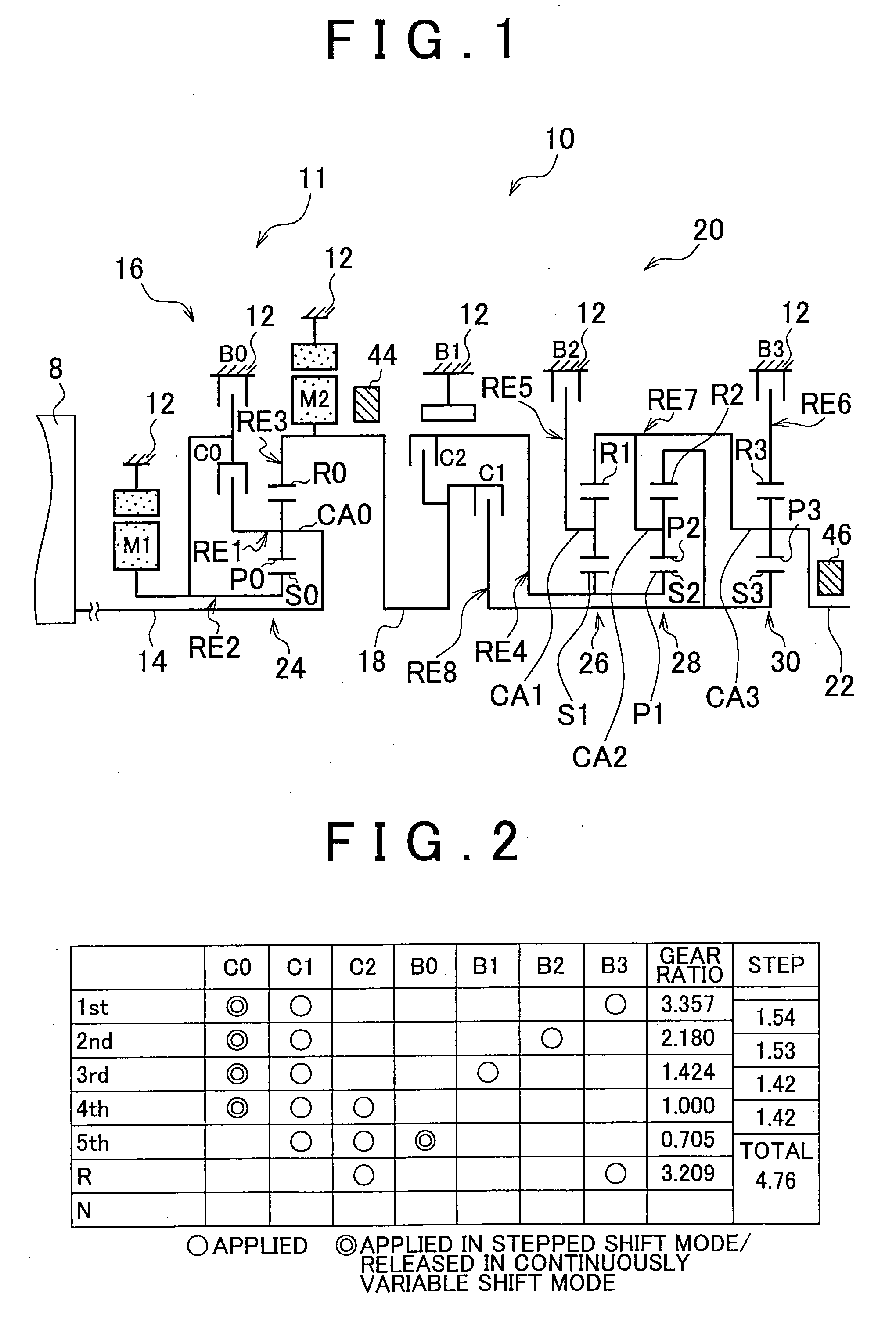

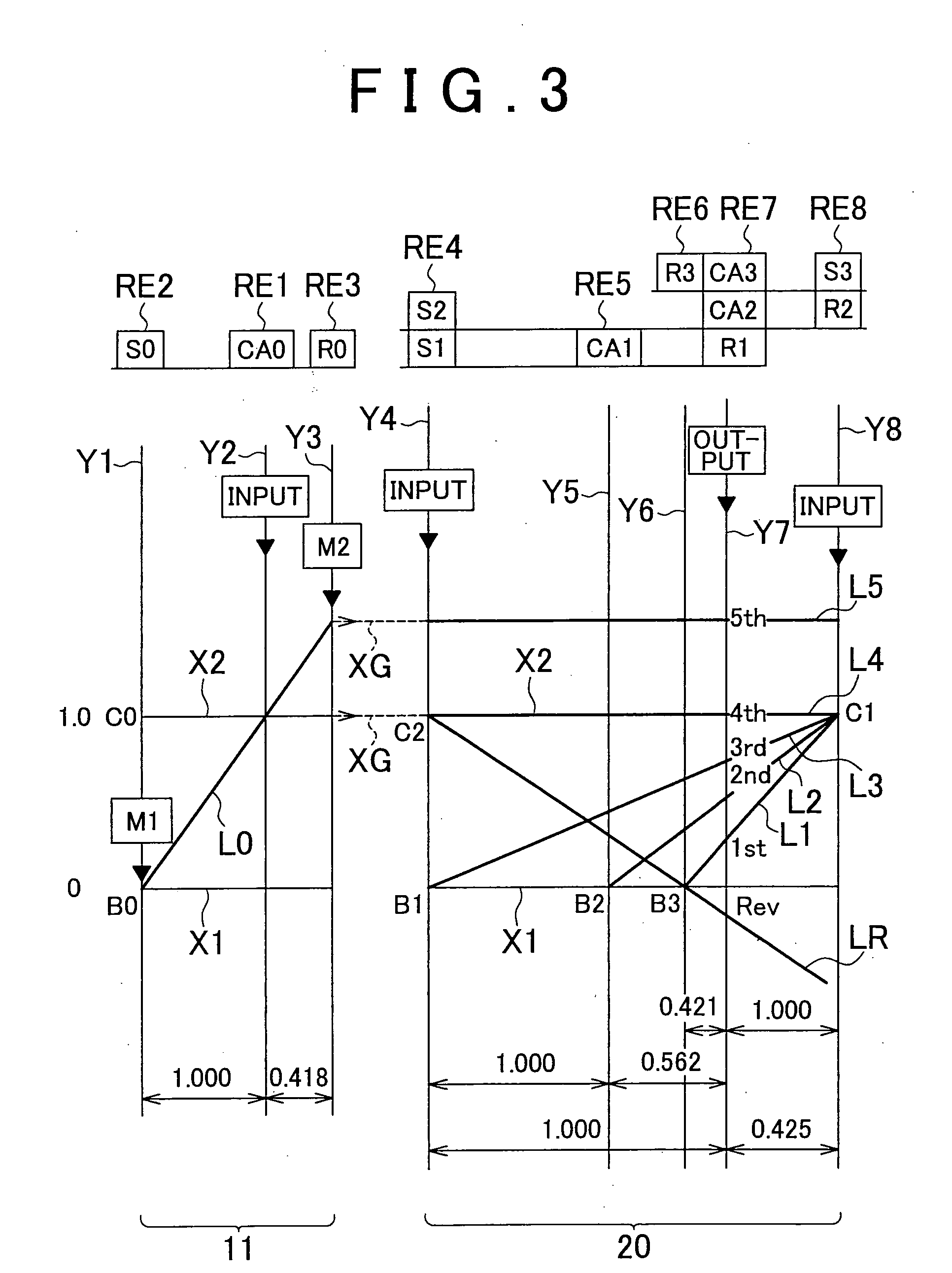

Control apparatus for power transmission system of hybrid vehicle

ActiveUS20100138086A1Unfavorable effectDeterioration of start-up performanceHybrid vehiclesAnalogue computers for vehiclesFuel typeHybrid vehicle

A stop range changing unit changes an engine stop range, which is a cruise range in which an operation of an engine is stopped, based on a type of fuel that is burned in the engine and that is determined by a fuel type determination unit. Therefore, the engine is stopped or started up under a cruise condition that suits the fuel type. Accordingly, even if start-up performance of the engine varies due to variation of the fuel type, unfavorable effects of the variation in the start-up performance of the engine on a smooth motion of a hybrid vehicle is alleviated.

Owner:TOYOTA JIDOSHA KK

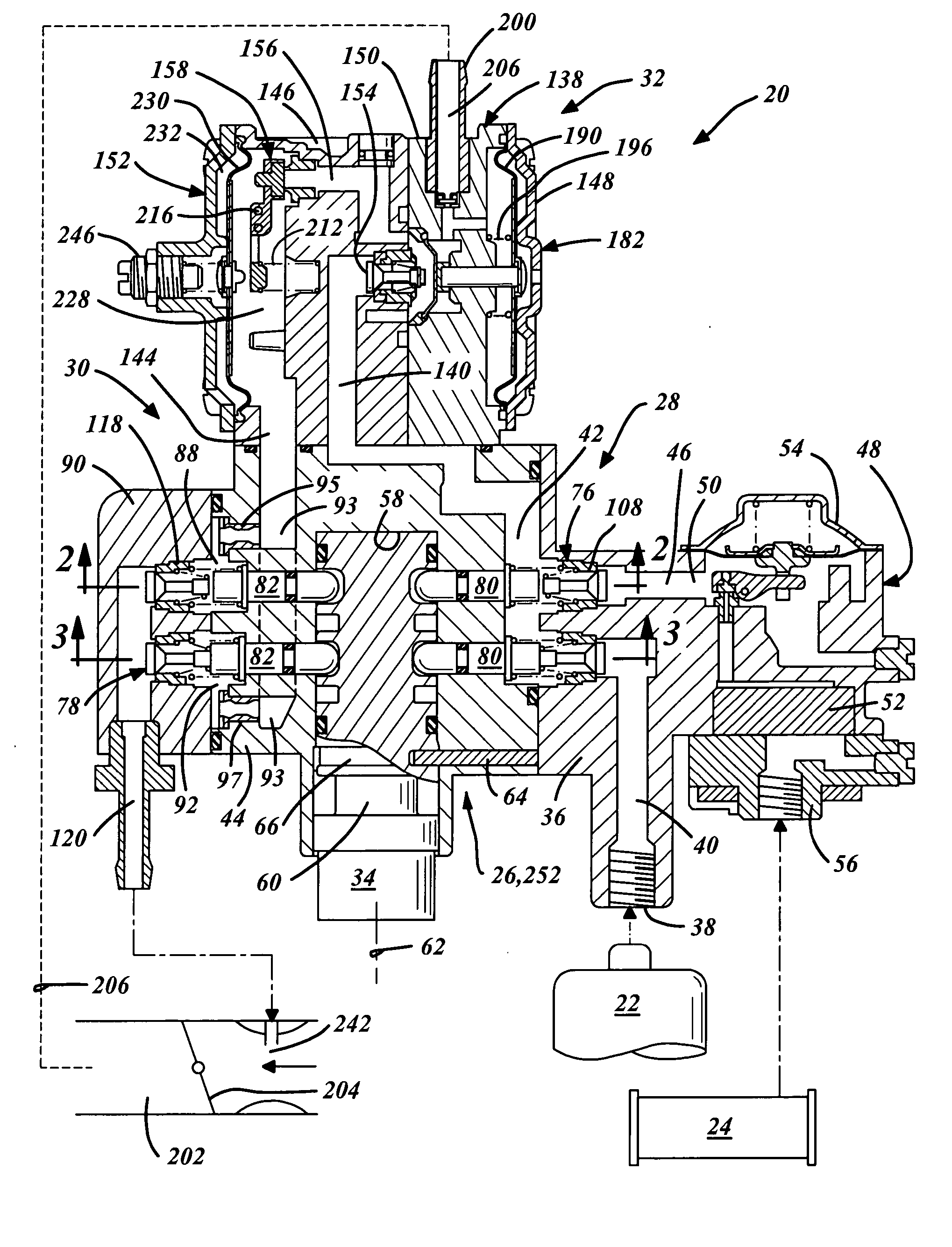

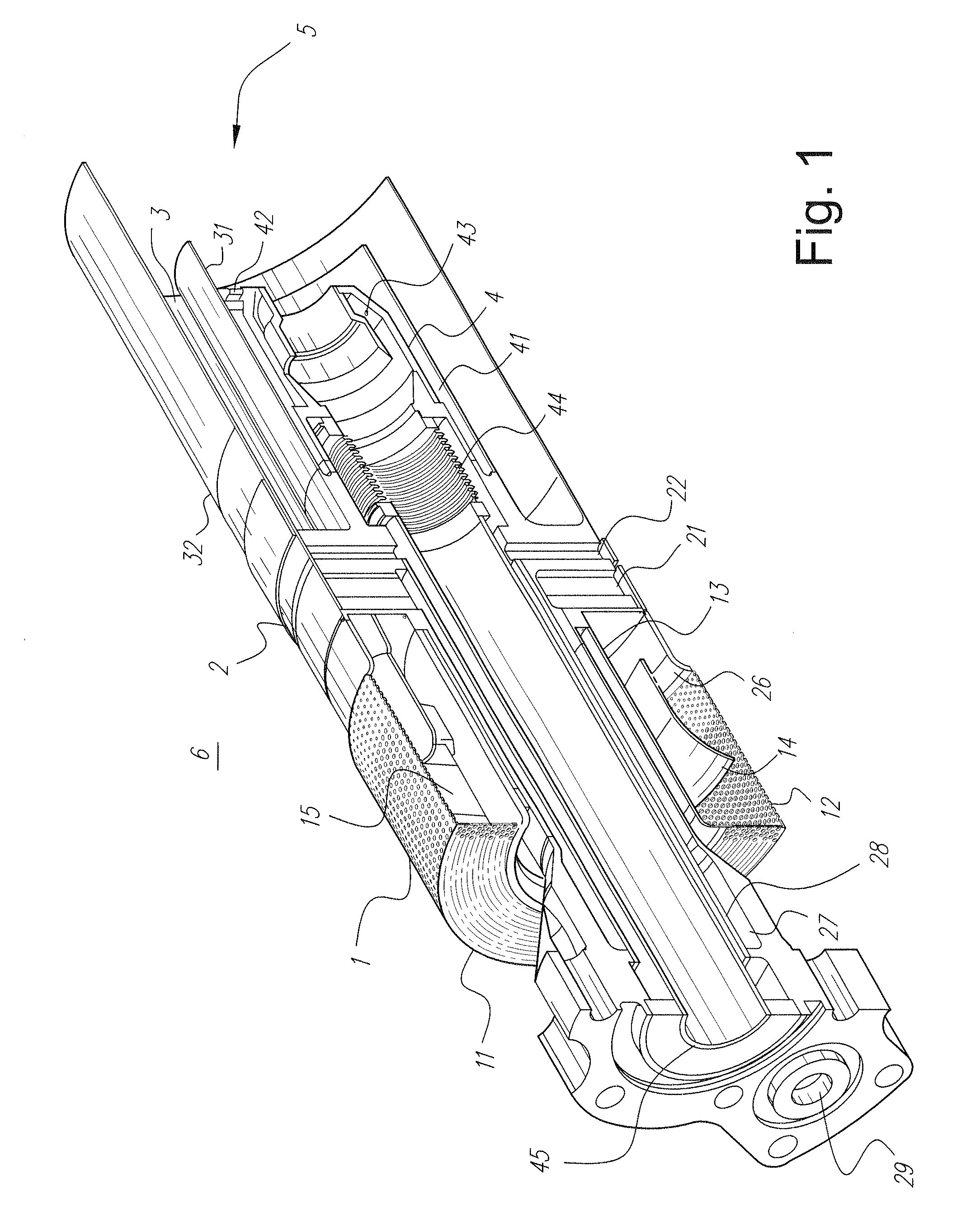

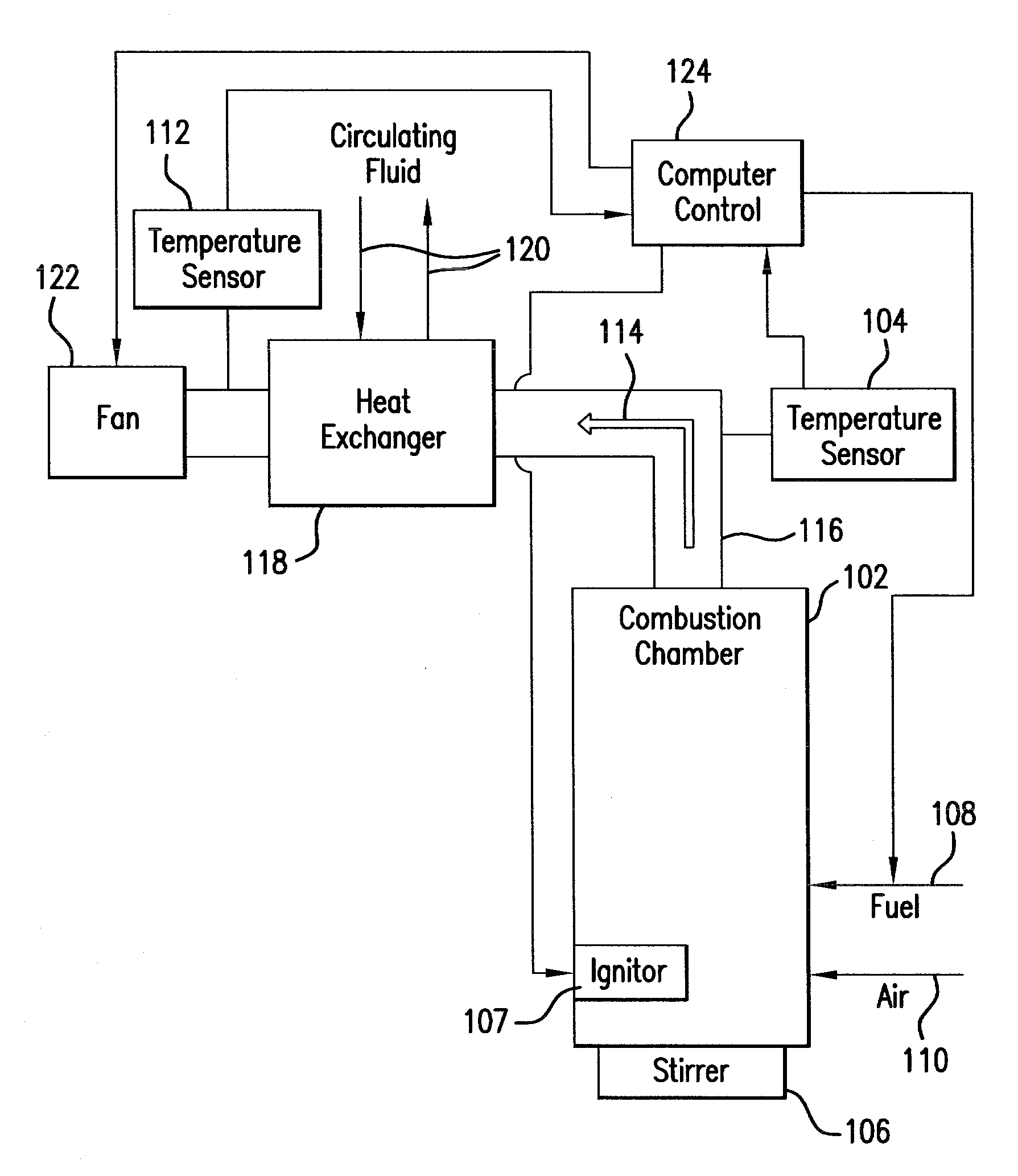

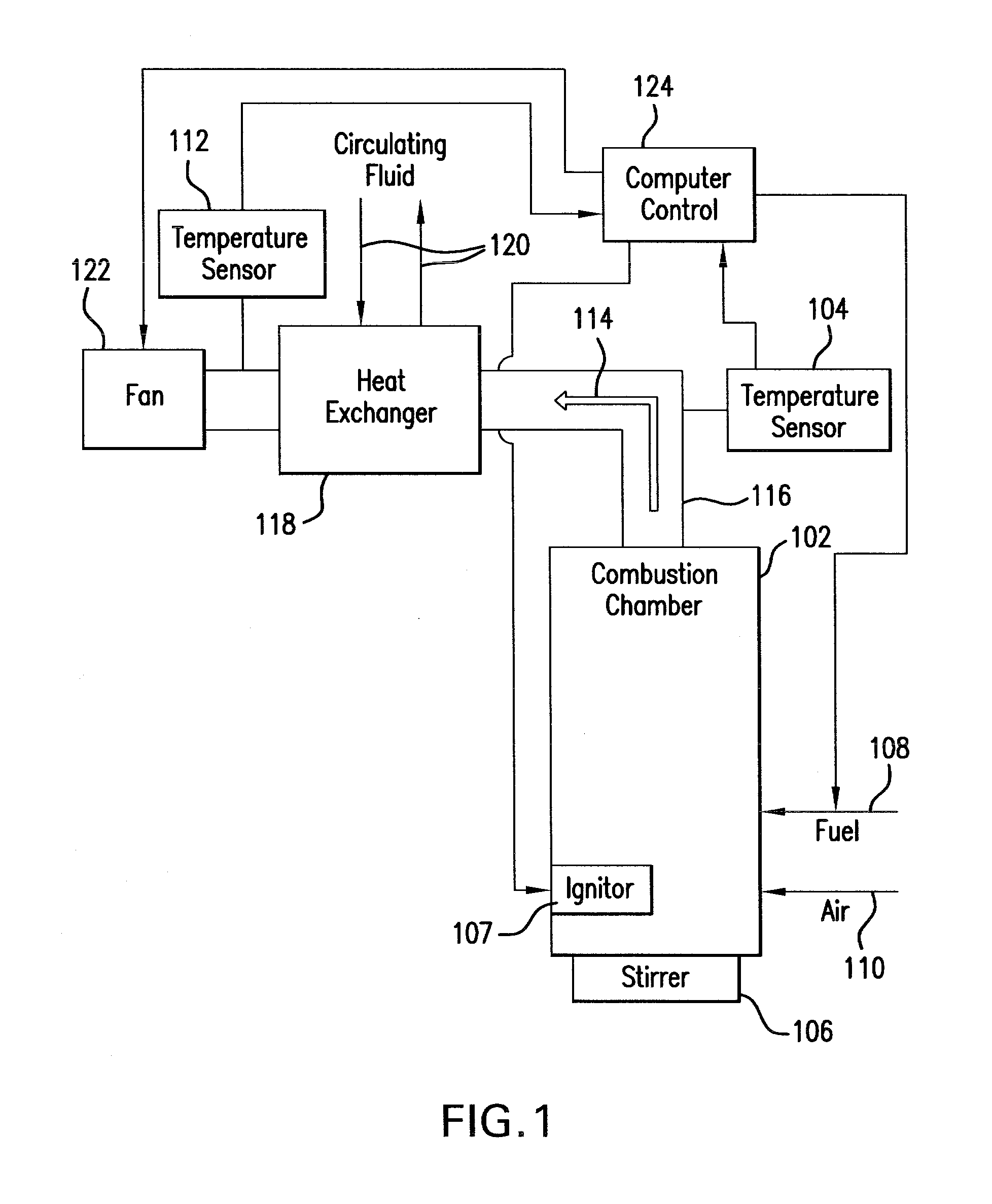

Gaseous fuel burner

ActiveUS20050250062A1Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

An ejector, such as a venturi, facilitates the delivery of gaseous fuel to the combustion chamber of a burner. A blower forces air through the ejector, and the air flow produces a suction that draws fuel from a fuel inlet to produce a fuel-air mixture. The amount of fuel drawn from the fuel inlet is a function of the air flow such that a substantially constant fuel-air ratio is obtained over a range of air flow rates and temperatures without the need for a separate high-pressure fuel pump. The fuel-air mixture may be provided to a combustion chamber for combustion. Air from the blower may be pre-heated prior to entering the ejector, for example, using a heat exchanger that recovers some of the heat from the combusted fuel-air mixture. Air flow through the ejector may be conditioned, for example, by a swirler, to produce a tangential air flow that can increase fuel flow by increasing air velocity across the fuel inlet and / or produce a swirl-stabilized flame in the combustion chamber. The combusted fuel-air mixture may be provided to a thermal load, such as an external combustion engine. Blower speed may be controlled manually or automatically to control power output. Fuel flow to the ejector can be controlled manually or automatically to control fuel-air ratio. The burner can be configured to operate with multiple fuel types, for example, using a fuel selector with fixed or variable restrictors.

Owner:NEW POWER CONCEPTS

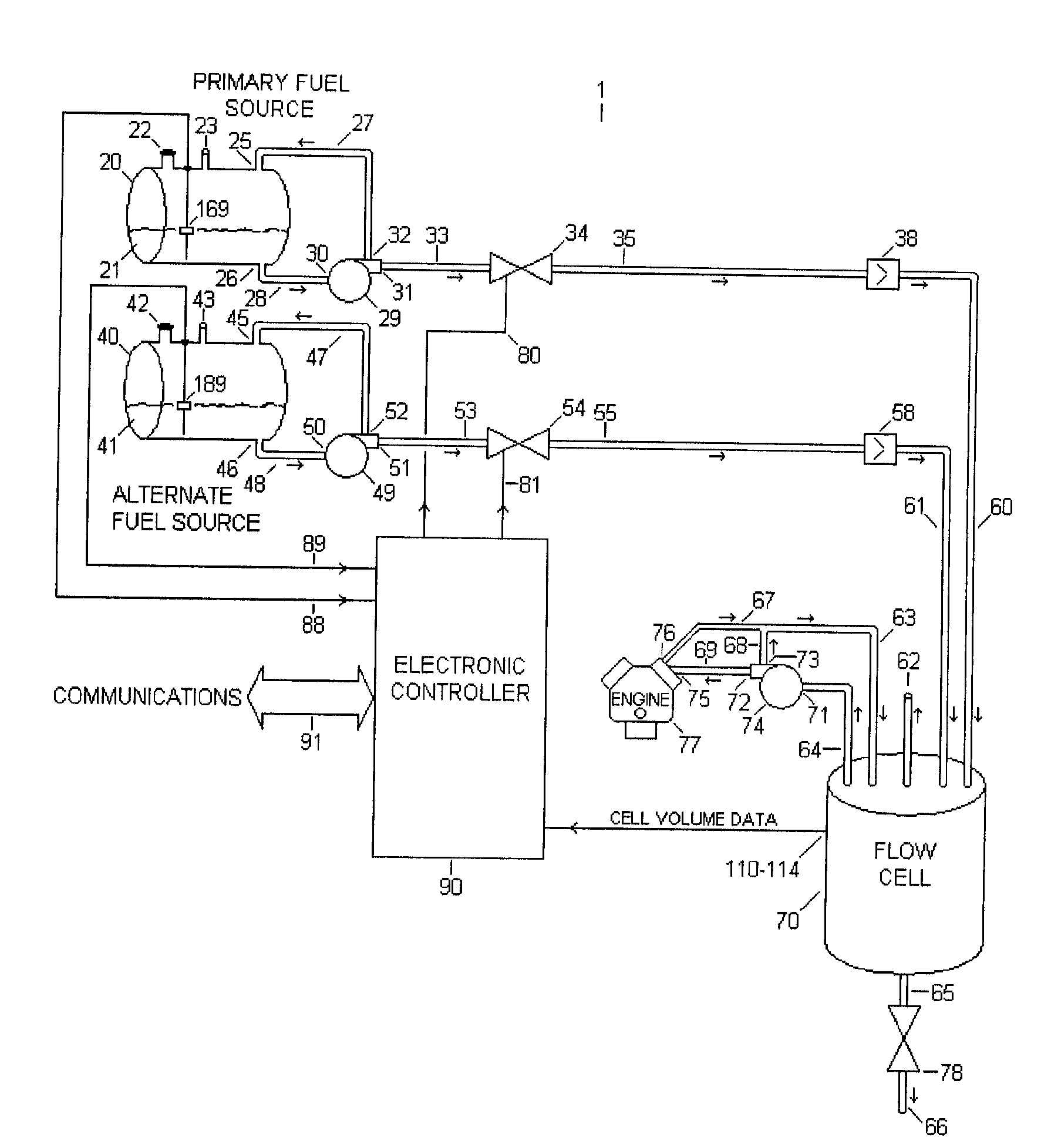

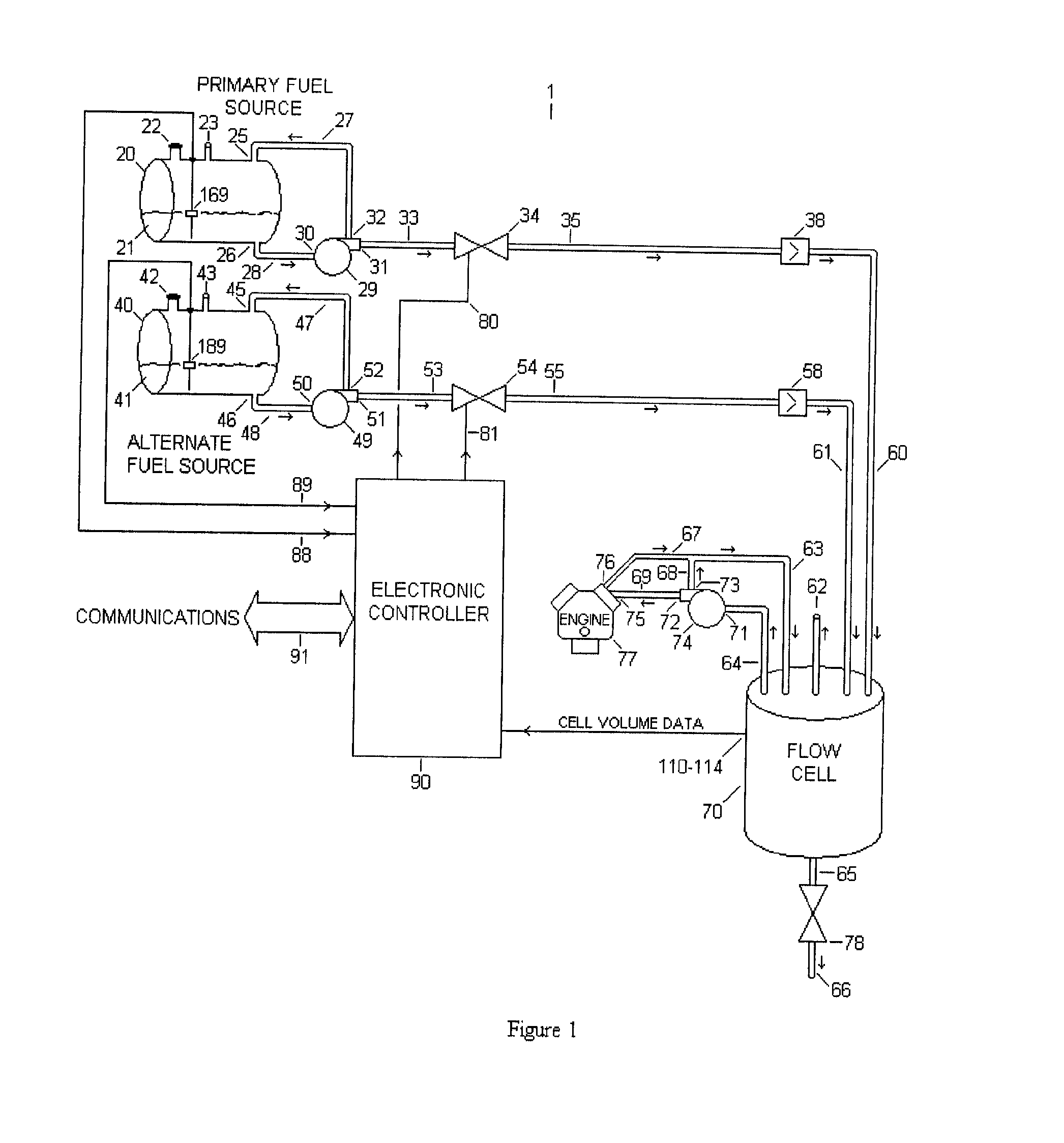

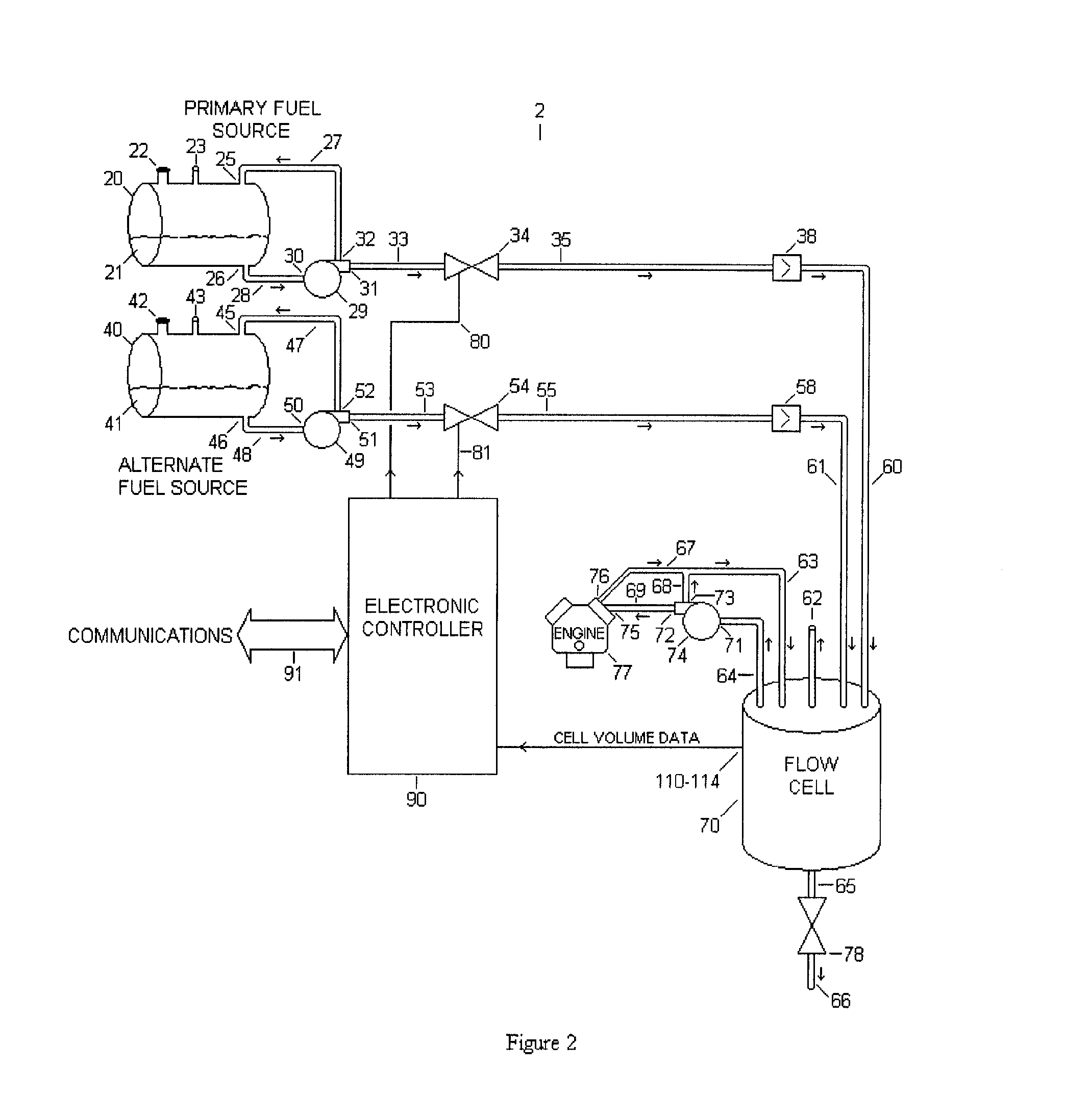

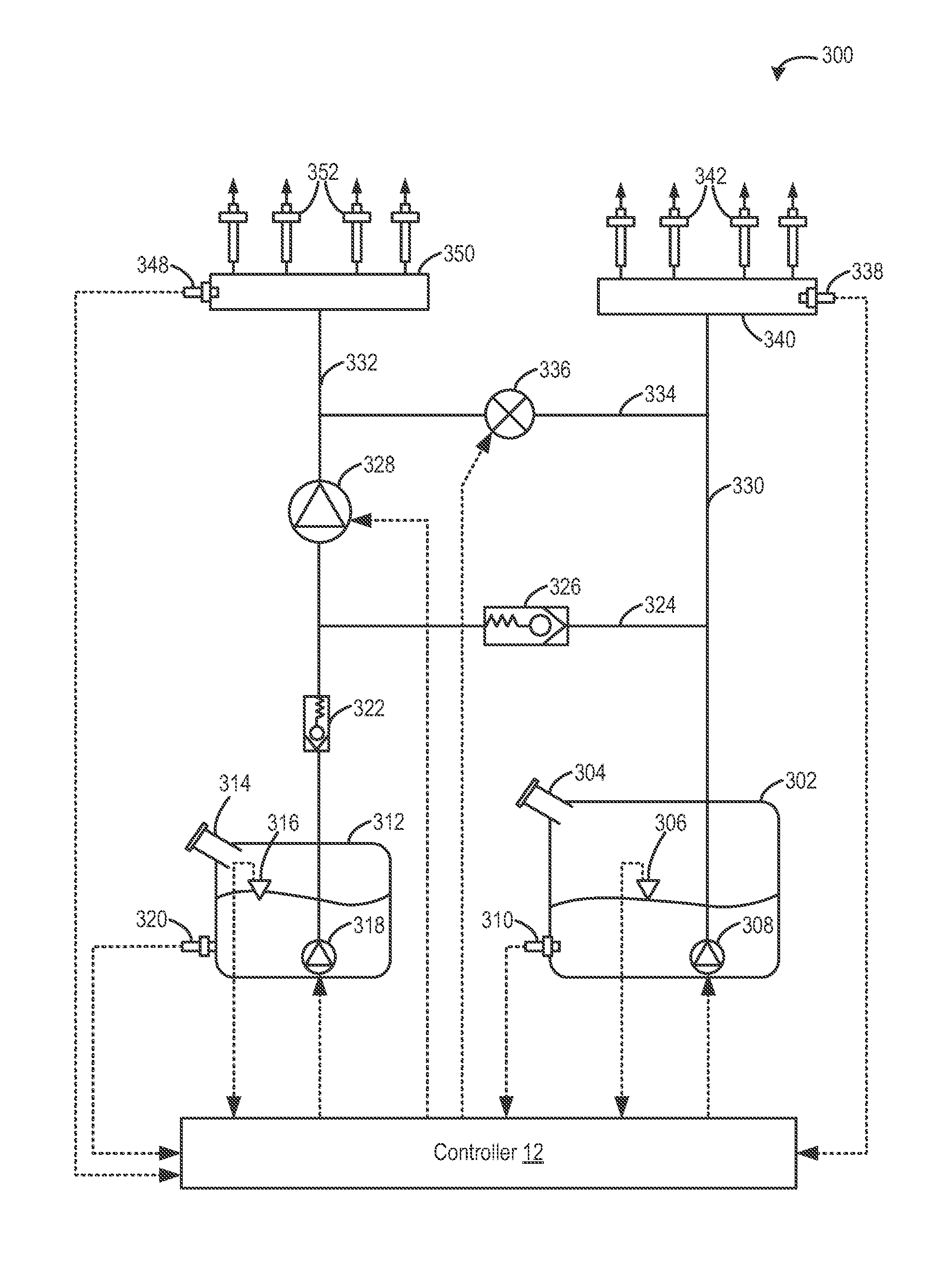

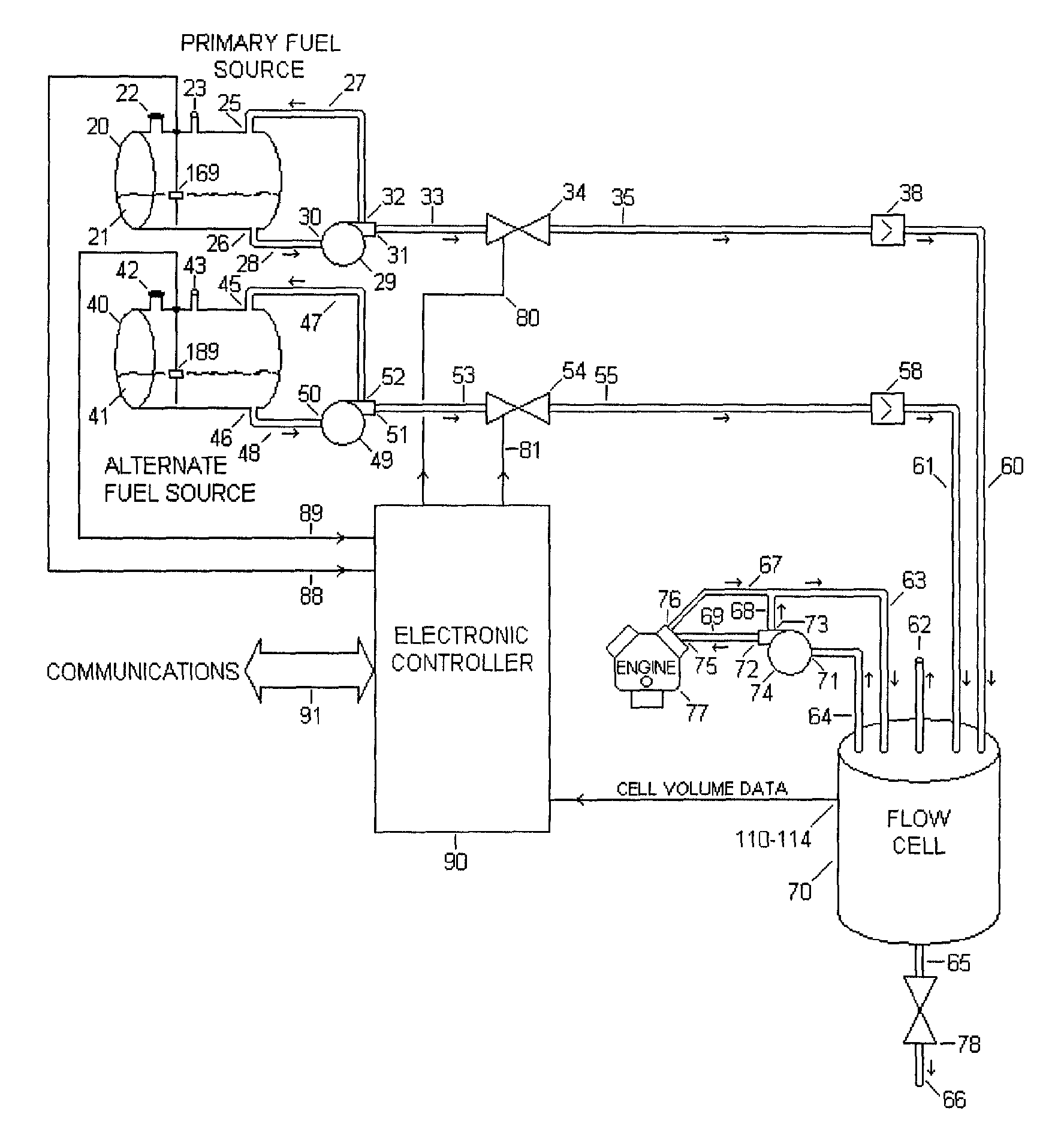

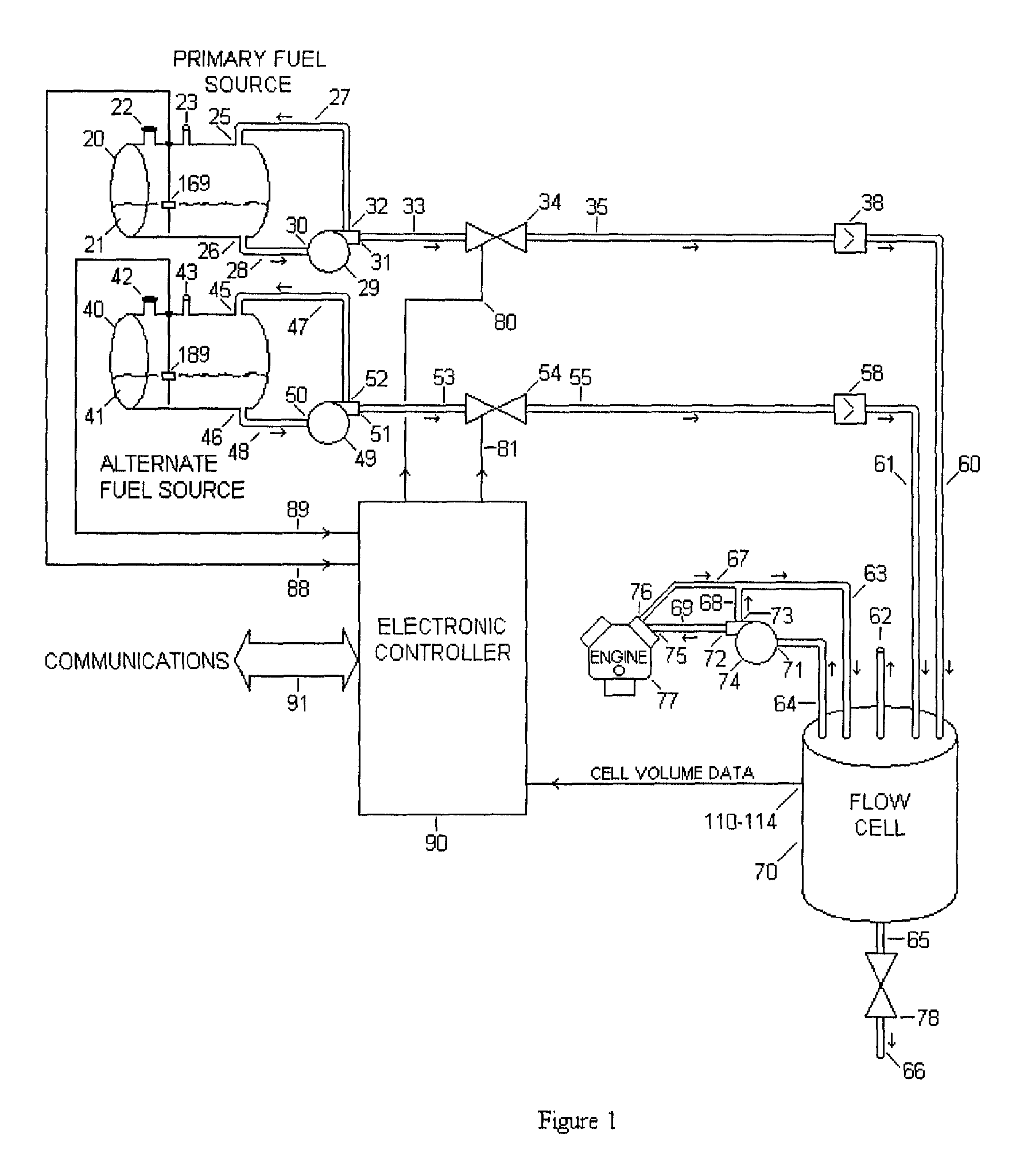

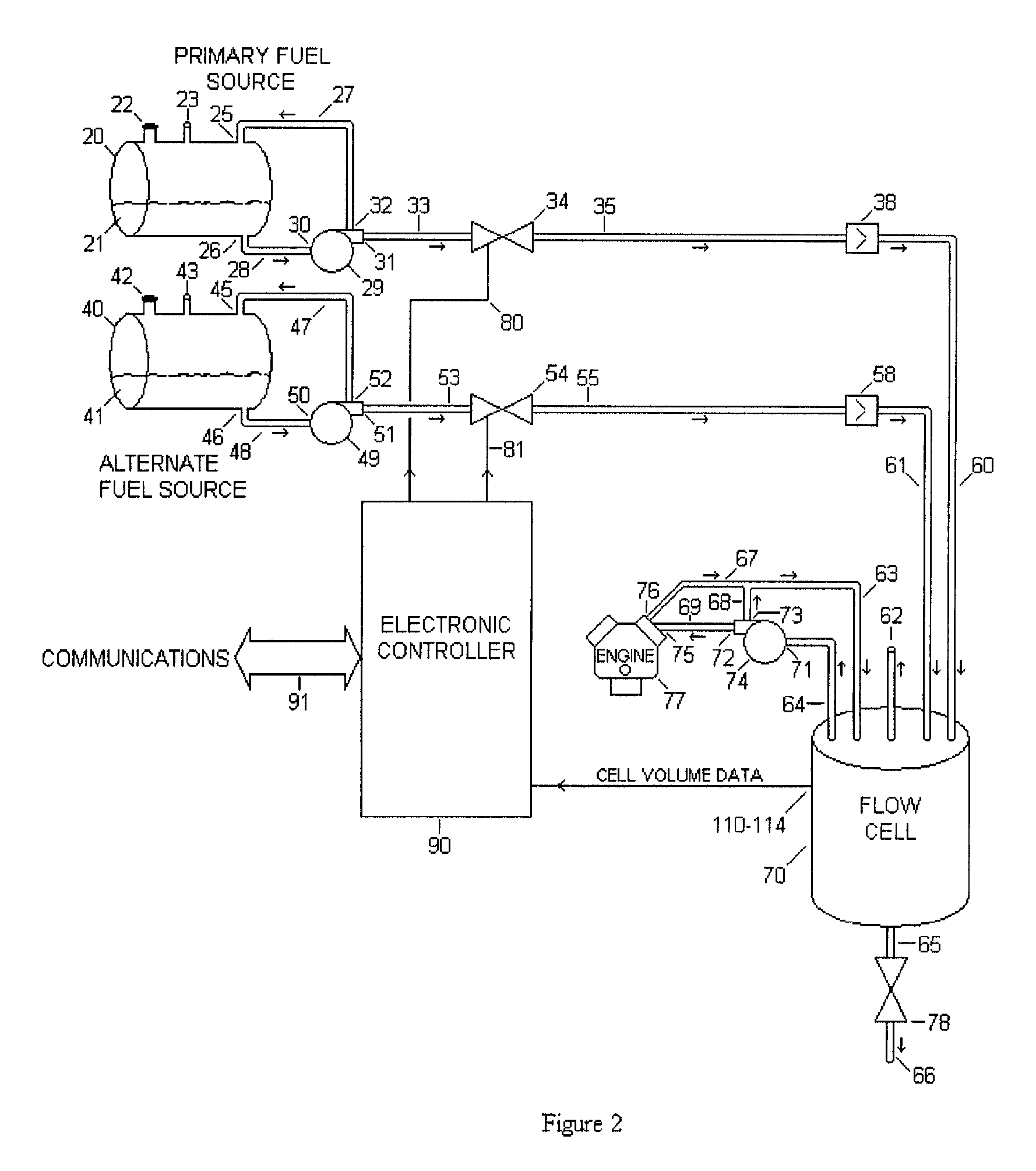

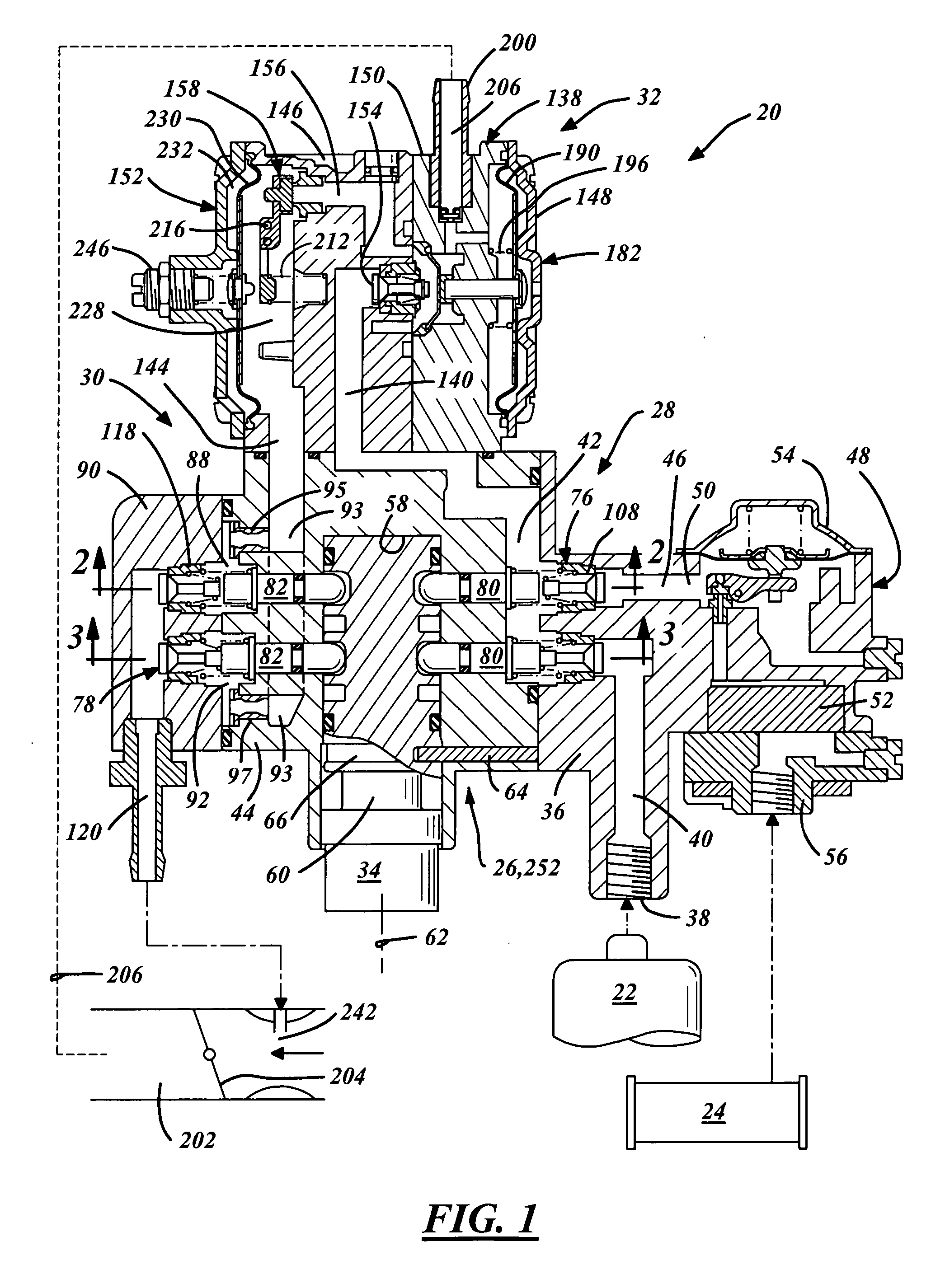

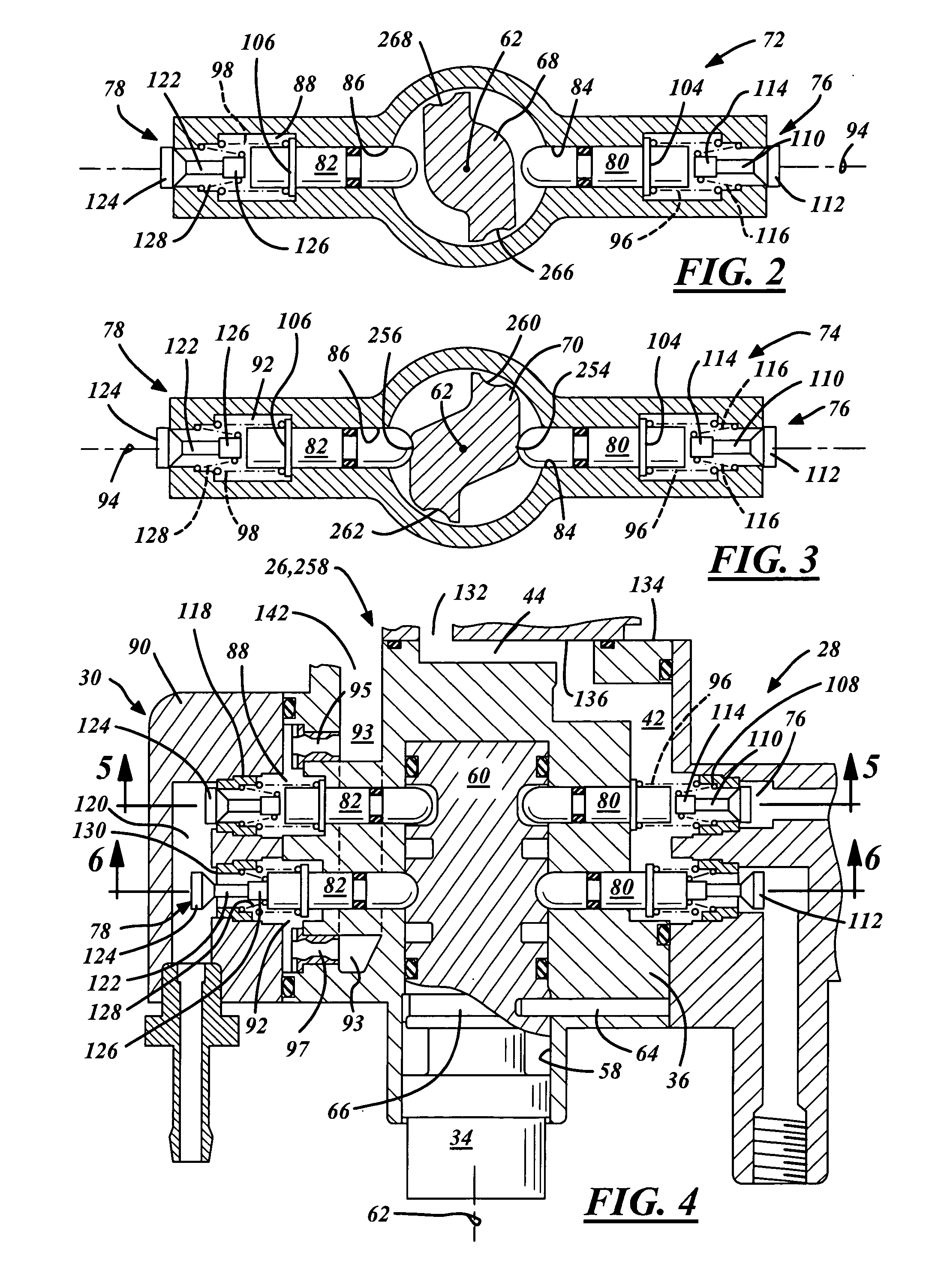

Alternate fuel blending system and associated method

ActiveUS20080262701A1Discounts/incentivesInternal combustion piston enginesAlternative fuelsControl system

A fuel control system for controlling the use of primary fuel and alternate fuel in an internal combustion engine without cross-contamination of fuel types. Cross-contamination of fuel types may eliminate the ability to receive certain benefits or financial incentives associated with use of alternate fuel, including but not limited to RINs, credits, and subsidies. In one embodiment, primary and / or alternate fuel are controllably delivered from sources to a flow cell. If blending is desired, both primary and alternate fuels are delivered to the flow cell. The engine is fed with the resulting primary fuel, alternate fuel, or blended mixture of fuel from the flow cell. The flow cell contains a bypass inlet port adapted to receive excess fuel not consumed by the engine in lieu of the excess fuel being returned to the primary and / or alternate fuel sources. In this manner, cross-contamination of the fuel sources can be avoided.

Owner:GILBARCO

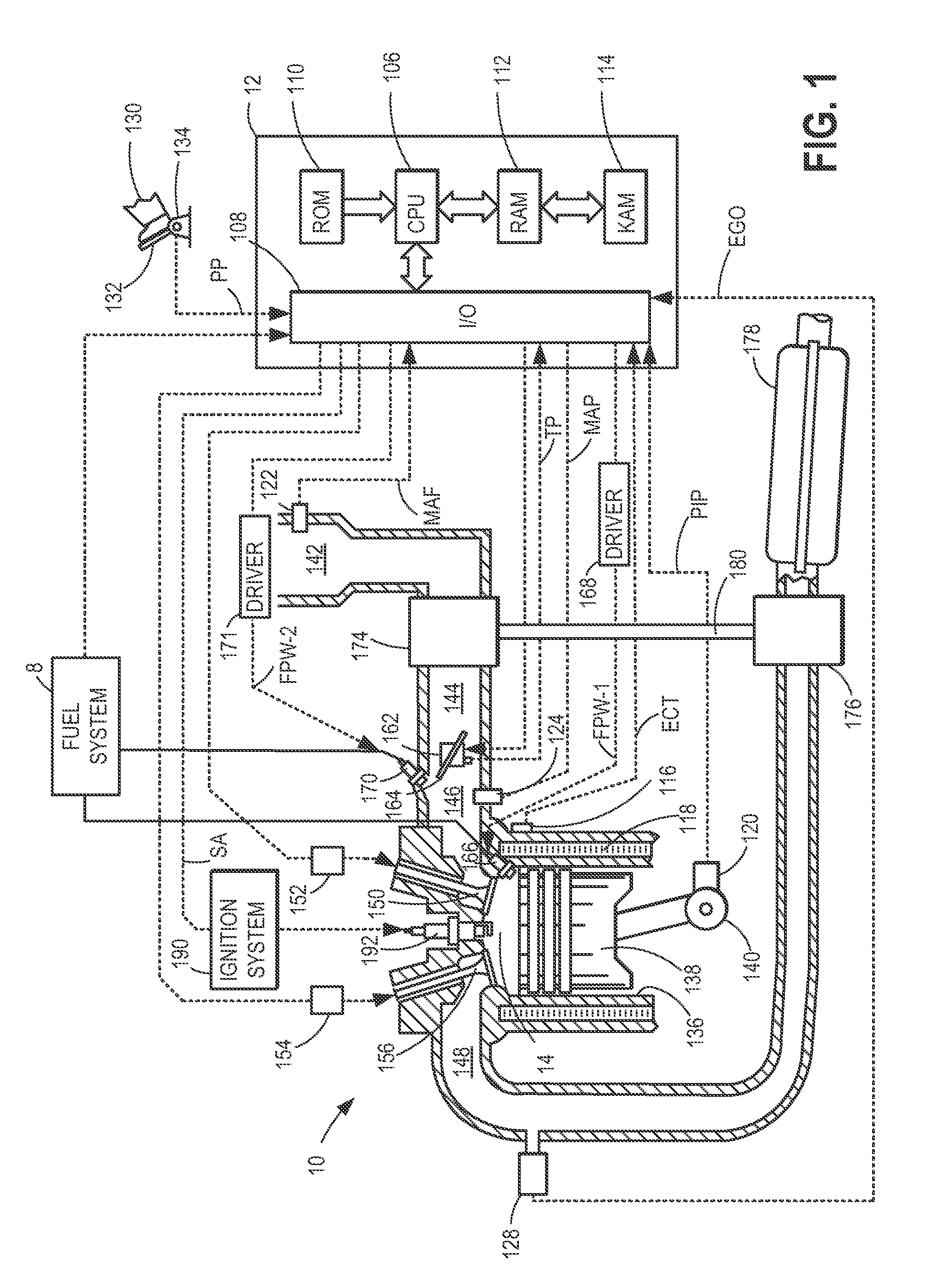

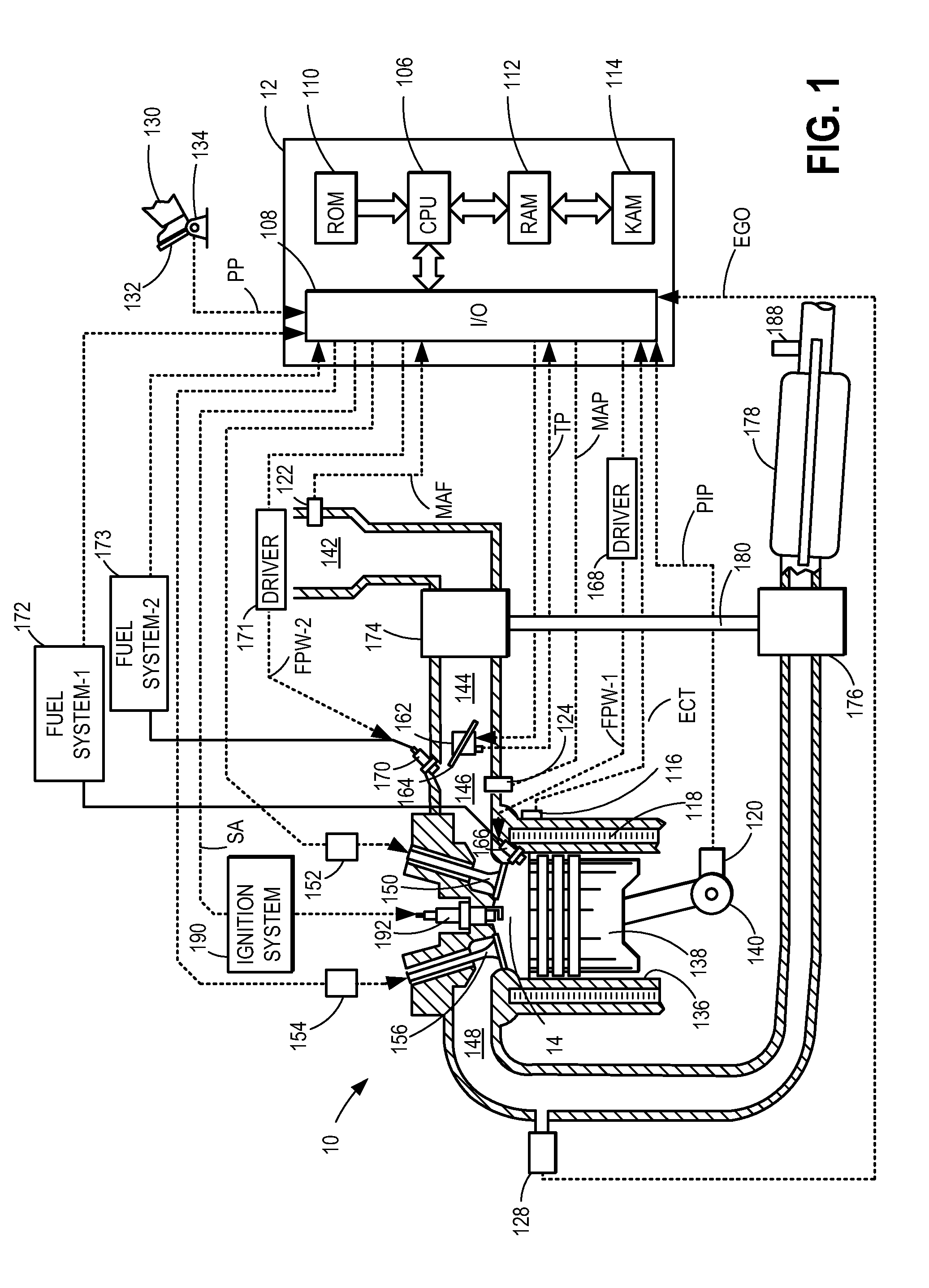

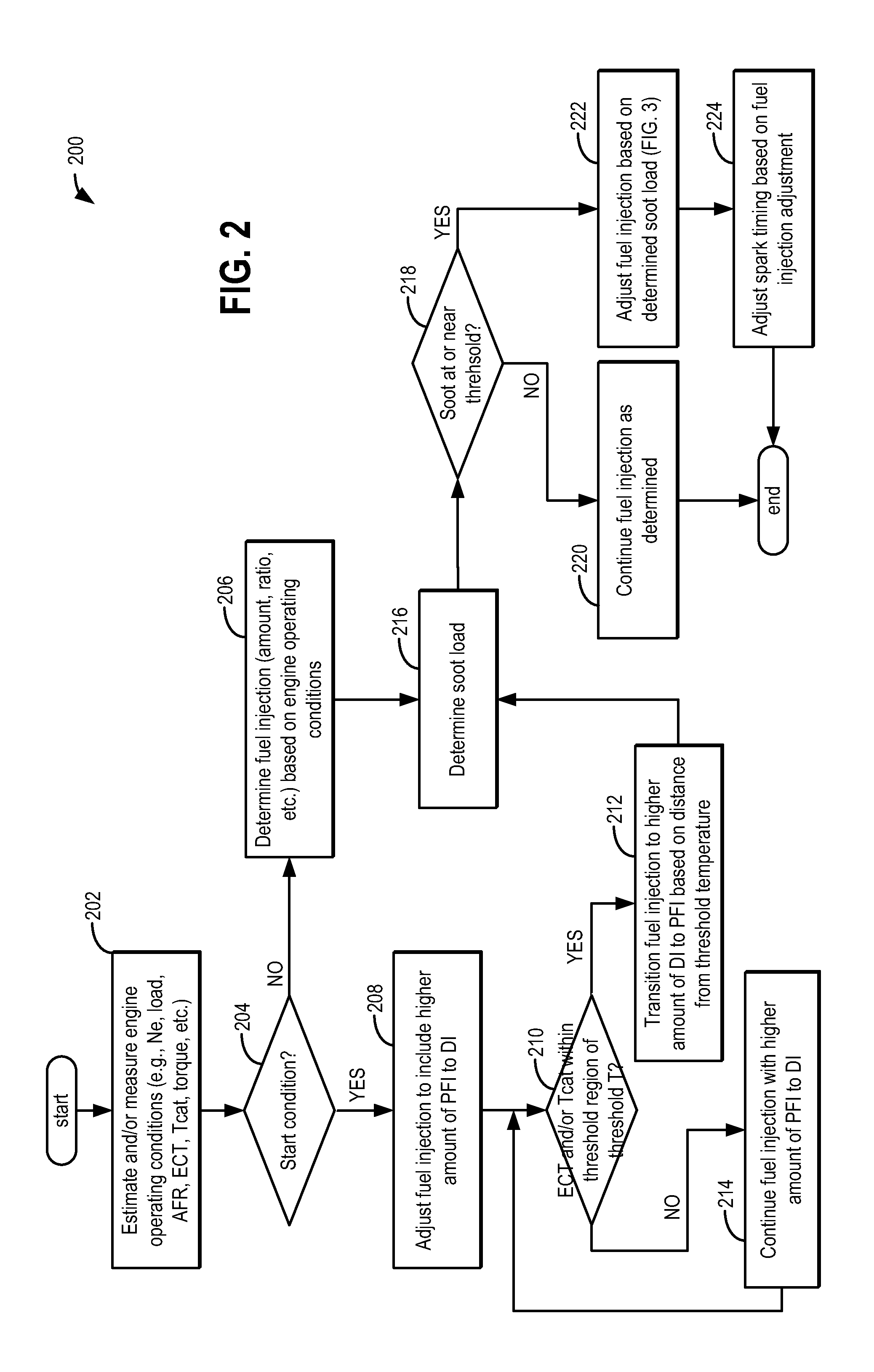

Method and system for engine control

ActiveUS8100107B2Improve cooling effectImprove fuel efficiencyElectrical controlExhaust apparatusExhaust fumesFuel type

Methods and systems are provided for controlling exhaust emissions by adjusting a fuel injection into an engine cylinder from a plurality of fuel injectors based on the fuel type of the injected fuel and further based on the soot load of the engine. Soot generated from direct fuel injection is reduced by decreasing an amount of direct injection into a cylinder as the engine soot load increases.

Owner:FORD GLOBAL TECH LLC

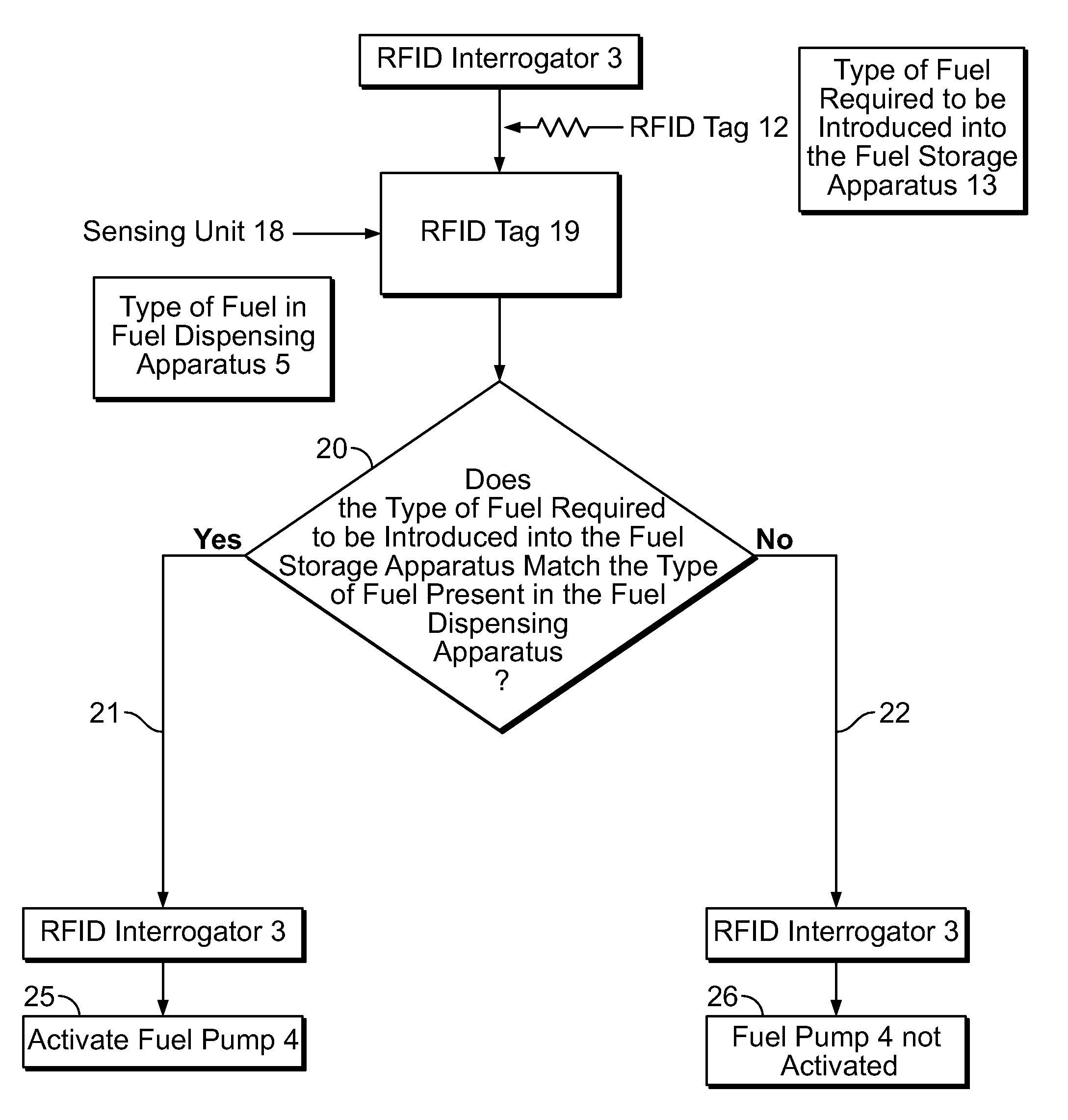

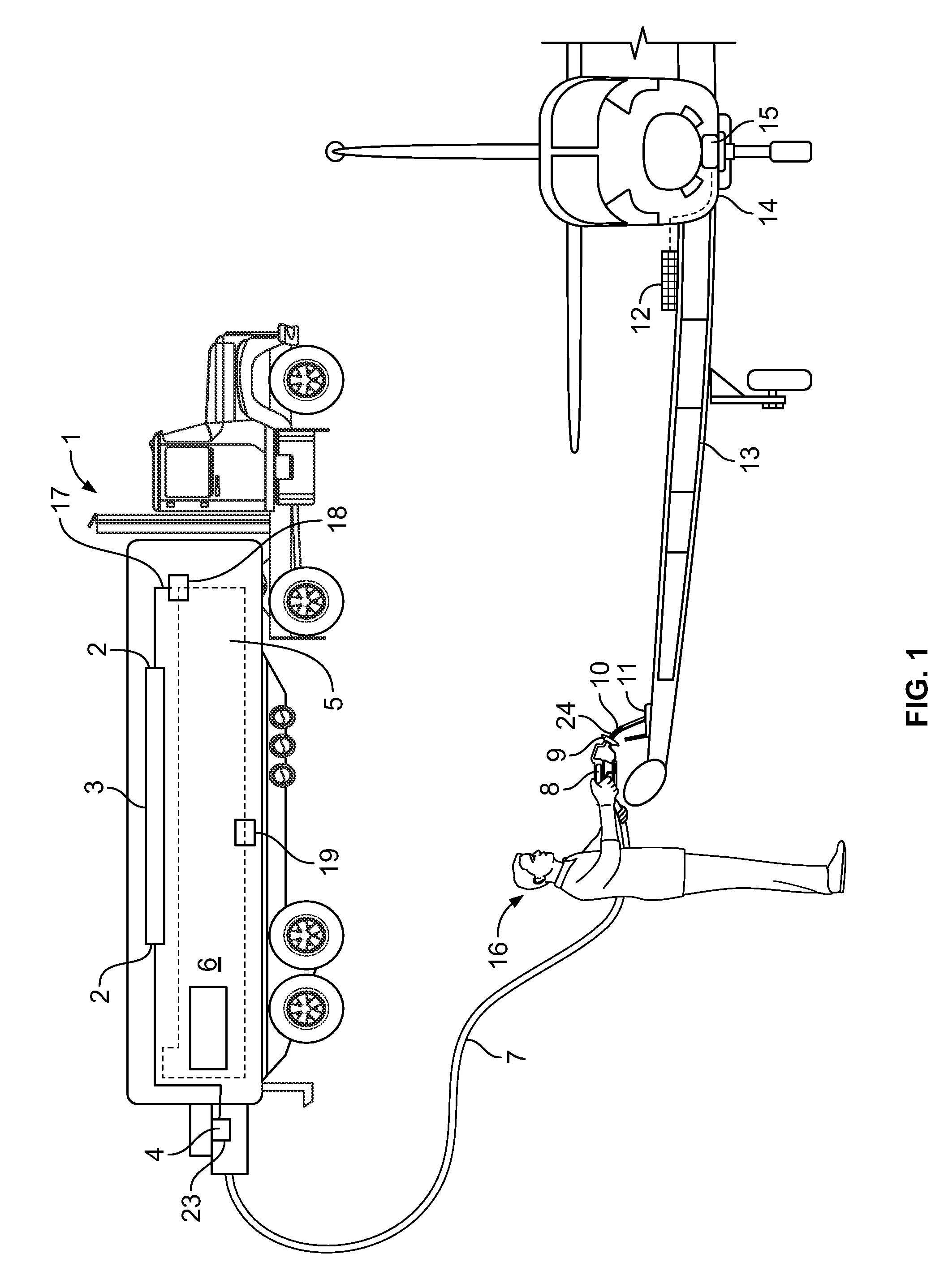

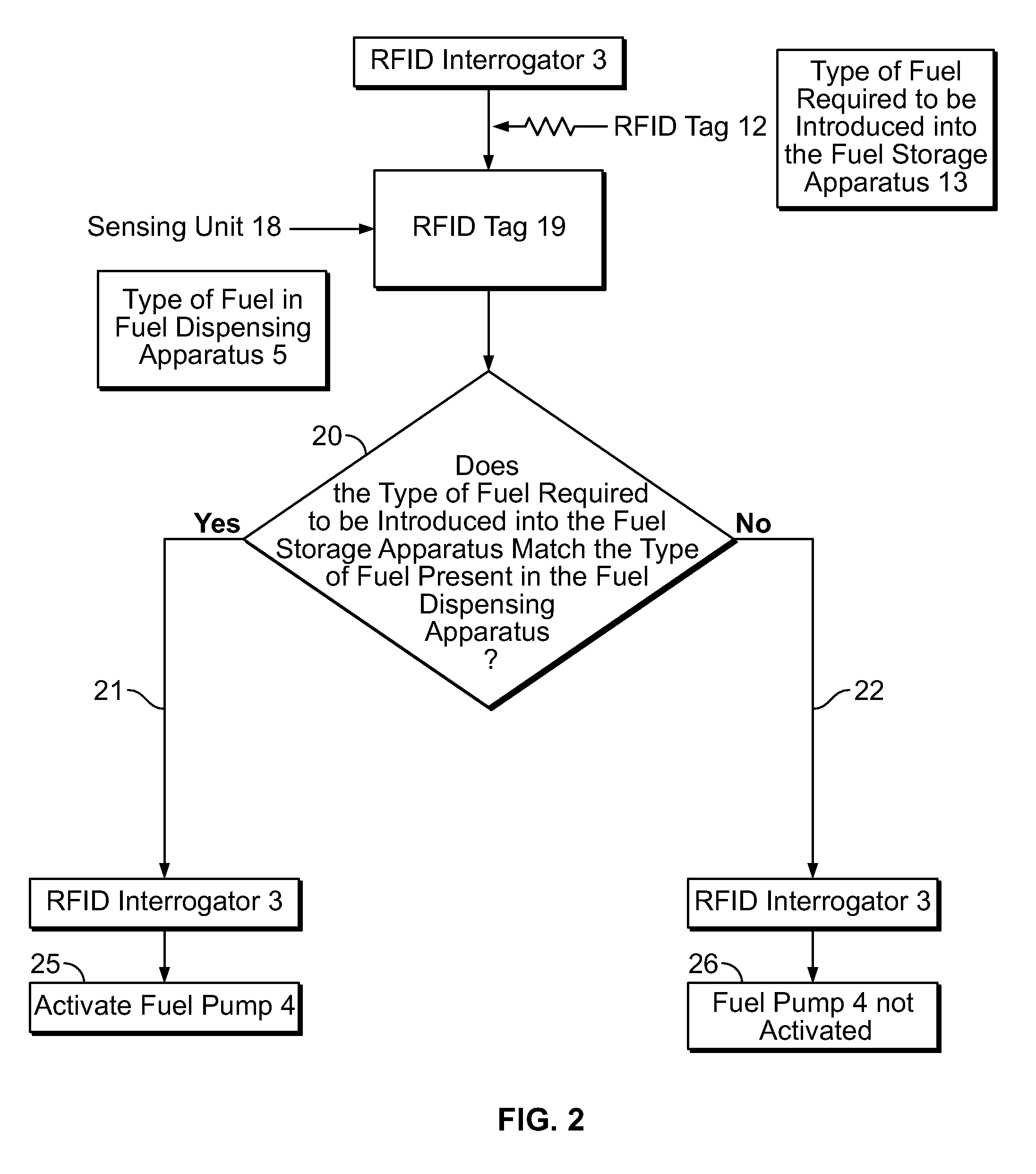

Method and System for Preventing Misfueling

InactiveUS20090315729A1Liquid handling installationsLiquid transferring devicesFuel typeFuel storage

The methods and system of the present invention provide for a means of preventing the introduction of incorrect fuel type into an engine. Data is transmitted wirelessly from a fuel storage apparatus to at least one receiver. In part, the selected data comprises the type of fuel that is required to be introduced into the fuel storage apparatus. Data is also transmitted wirelessly from a fuel dispensing apparatus to the receiver. In this case, the data comprises, in part, the type of fuel present in the fuel dispensing apparatus. The receiver determines whether the type of fuel required to be introduced into the fuel storage apparatus corresponds to the type of fuel present in the fuel dispensing apparatus. If the two types of fuel correspond, i.e., match, fuel is dispensed from the fuel dispensing apparatus into the fuel storage apparatus. If the two types of fuel do not match, the fuel dispensing apparatus is not activated. The receiving apparatus may also provide an indication that the fuel from the fuel dispensing apparatus does not match the type required to be introduced into the fuel storage apparatus. In another embodiment, if the two types of fuel do not match, a cut-off system is activated that stops dispensing of the fuel during the fueling process.

Owner:INHOFFER SCOTT

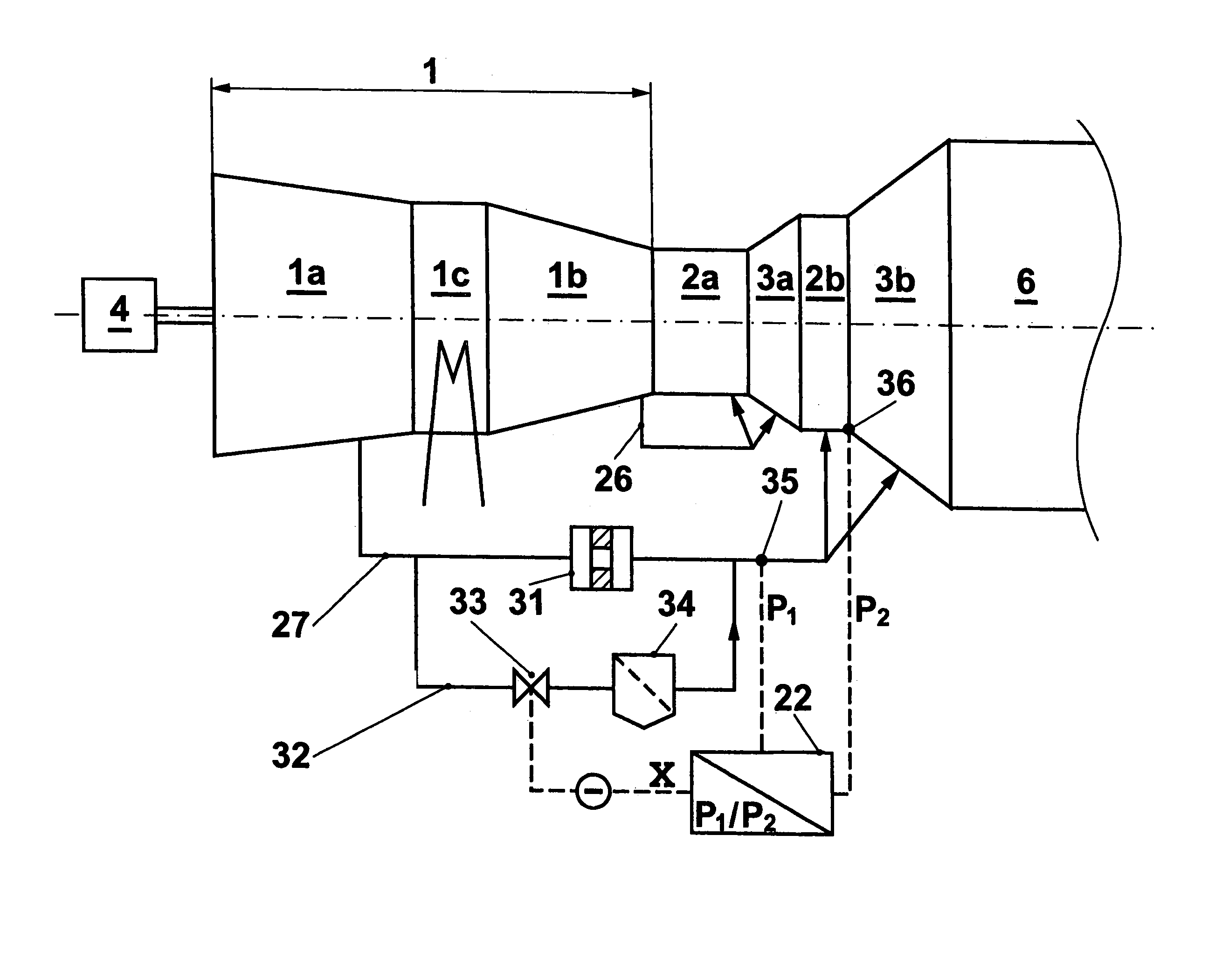

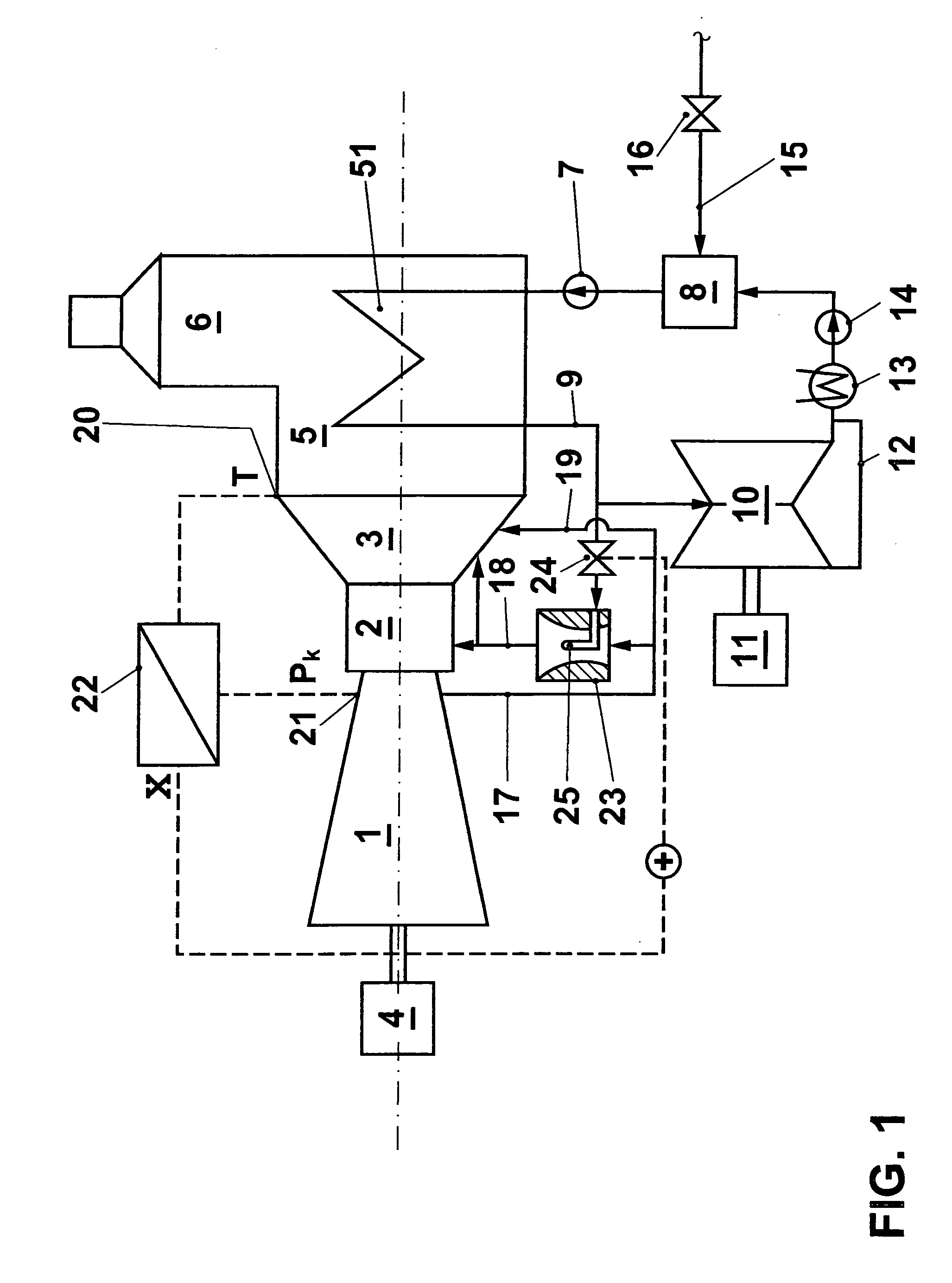

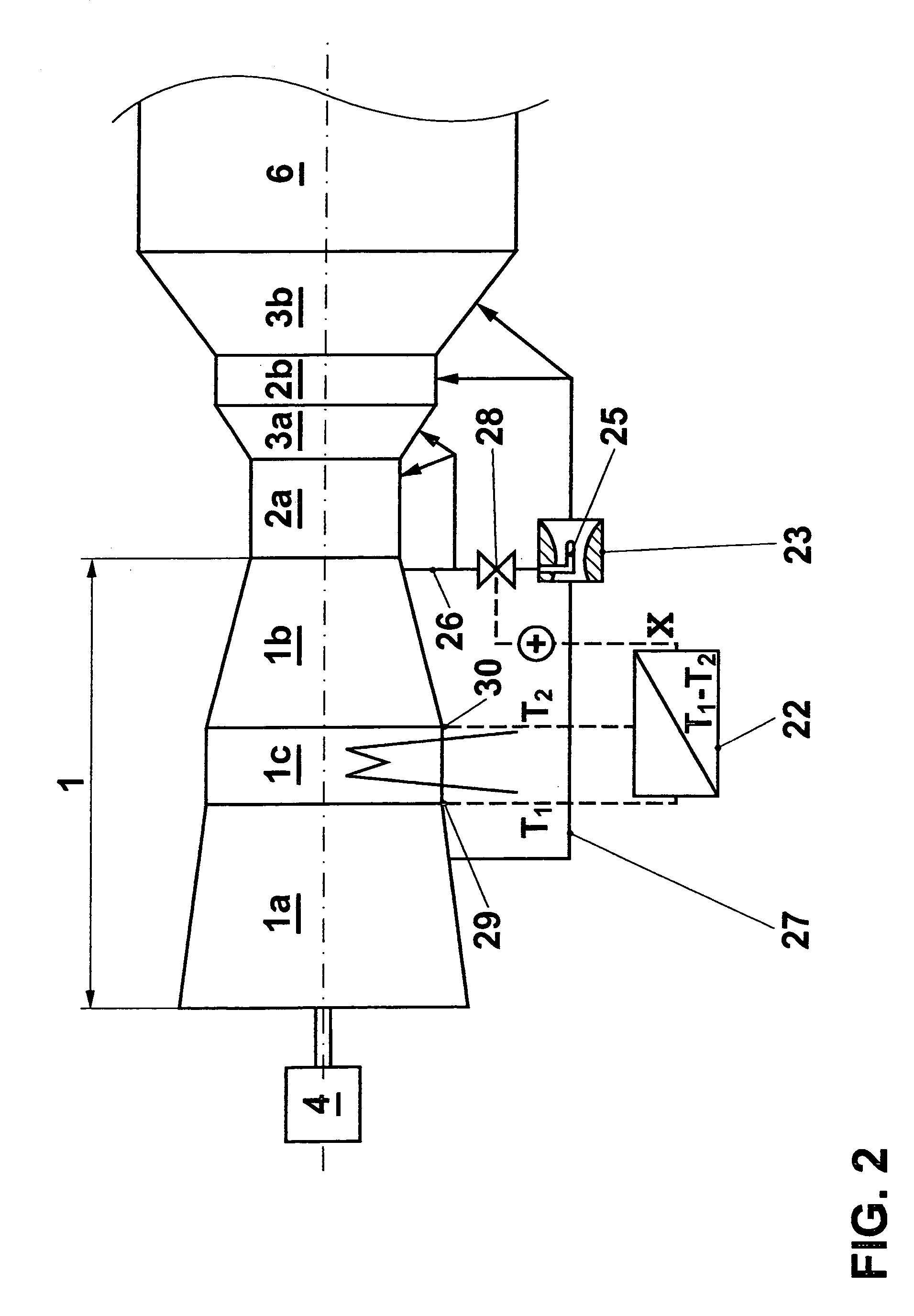

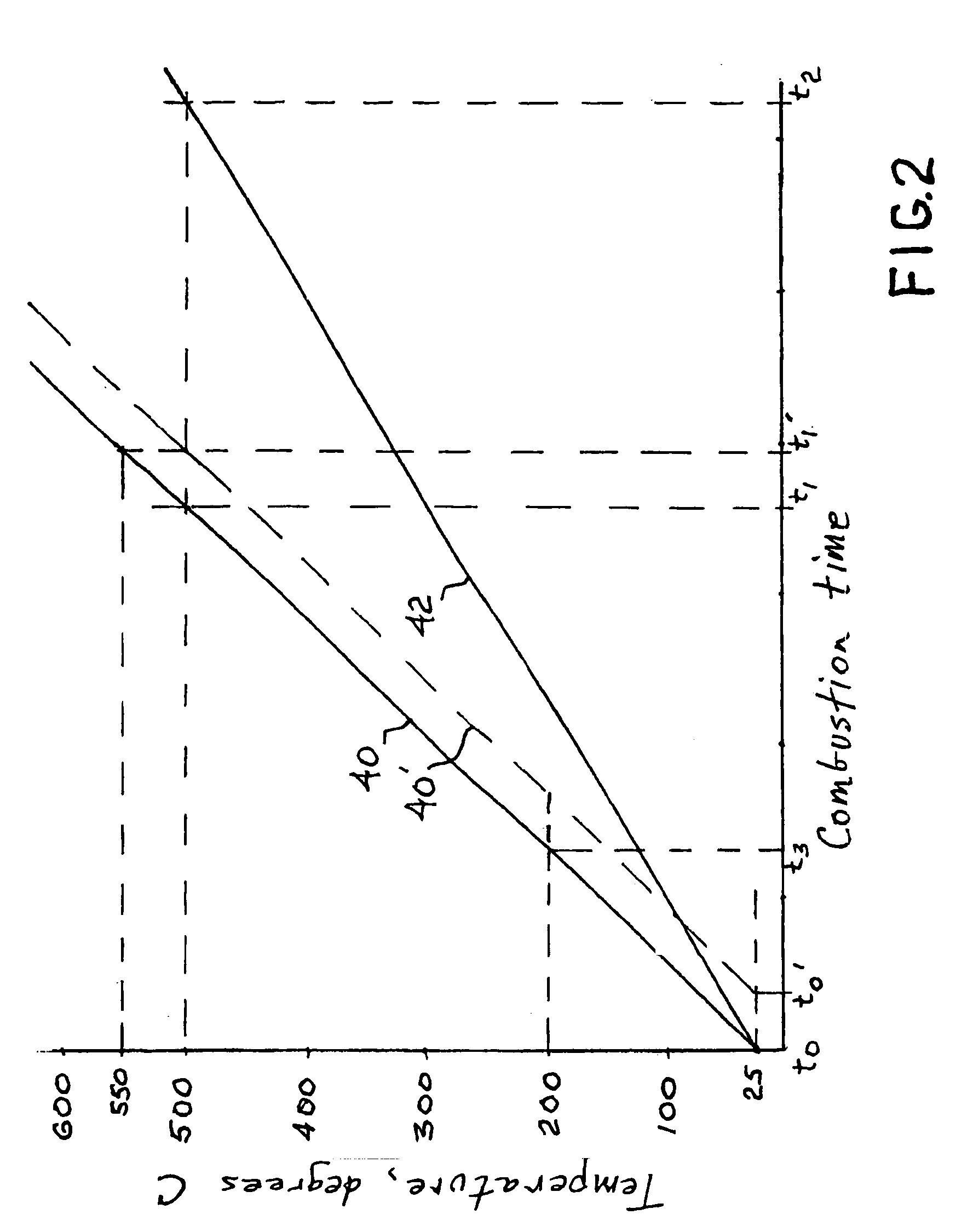

Process for controlling the cooling air mass flow of a gas turbine set

A process is provided for the control of the amount of cooling air of a gas turbine set. Suitable means are provided in the cooling system to enable the amount of cooling air to be varied. The control of this means takes place in dependence on an operating parameter (X). This operating parameter is made dependent on the fuel type used.

Owner:ANSALDO ENERGIA IP UK LTD

System and method for managing emissions from diesel powered systems

A configurable diesel powered system is provided for controlling engine emissions of a diesel-fueled power generating unit. The diesel-fueled power generating unit includes an engine operating on at least one fuel type. The system includes a plurality of operational input devices coupled with a processor to generate operational input signals to the processor. A plurality of end use devices include fuel tanks for each respective fuel type and are controlled by the processor to control the engine emissions. A configuration input device in communication with the processor generates a respective configuration signal for each particular location along the predetermined course comprising a mission. The processor is responsive to the operational input devices and configuration signals to generate a set of control signals to the fuel tanks to limit the total engine emissions of all fuel types to a respective stored engine emission profile for each configuration signal for each particular location along the predetermined course comprising the mission.

Owner:GE GLOBAL SOURCING LLC

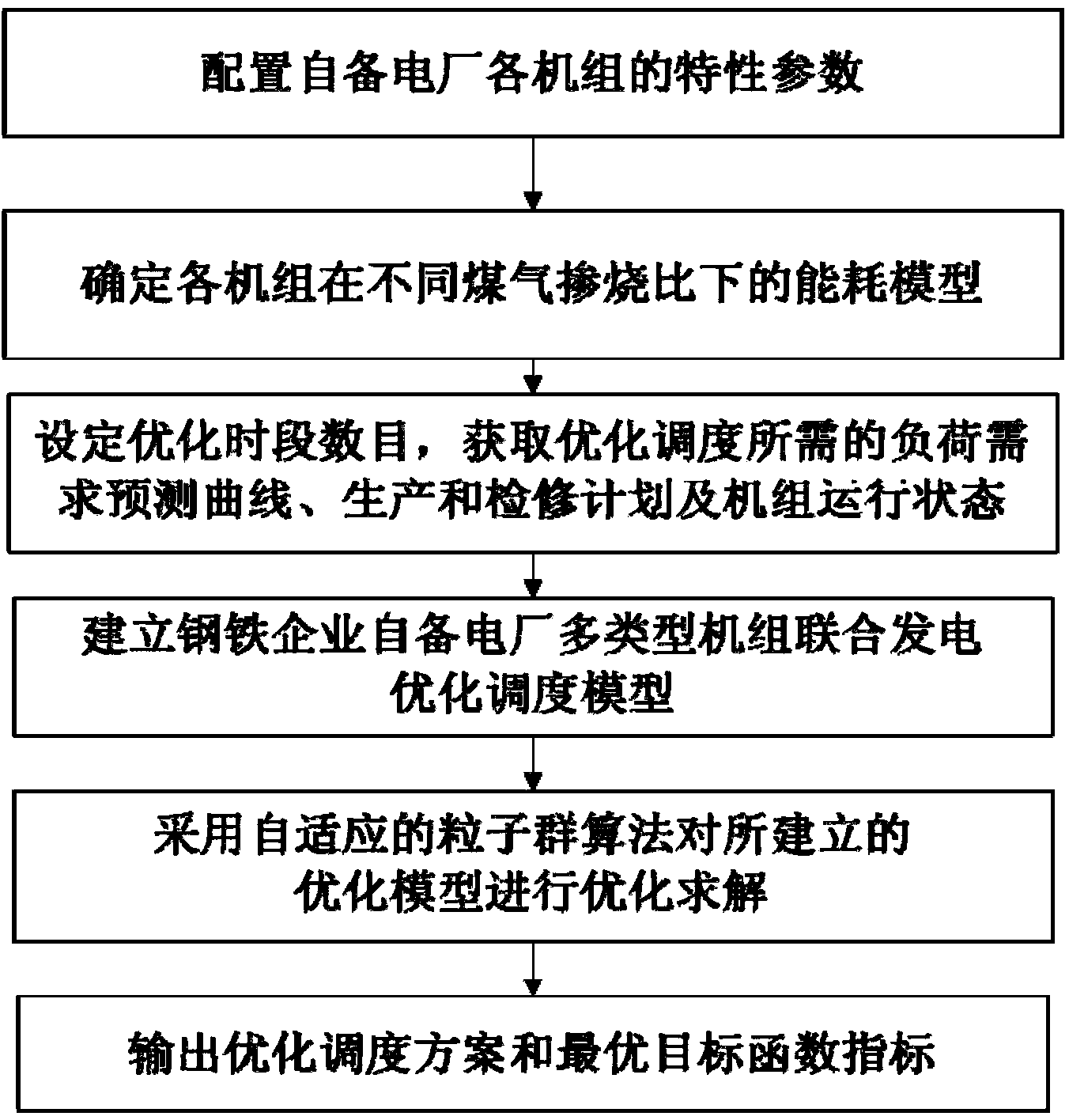

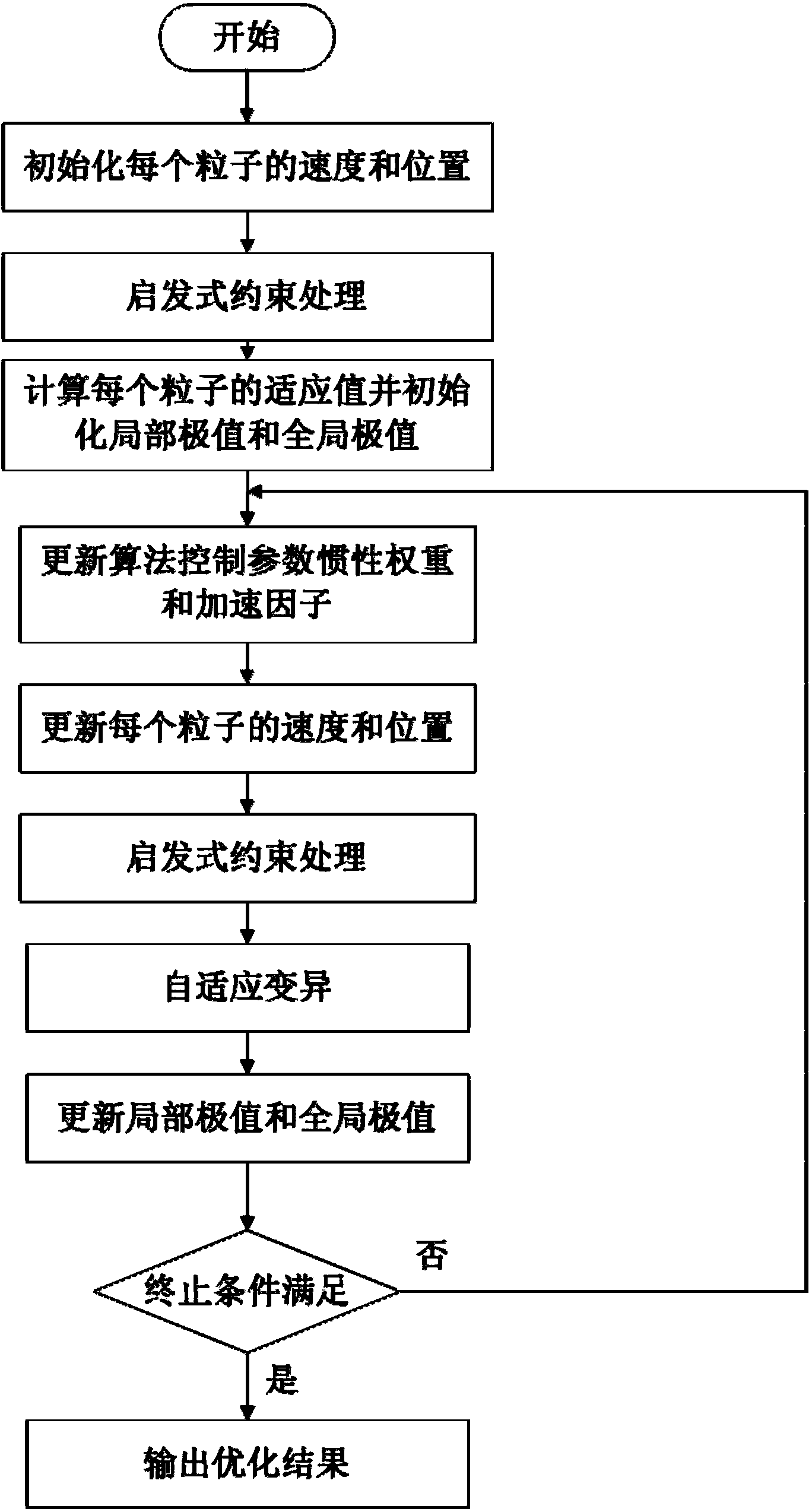

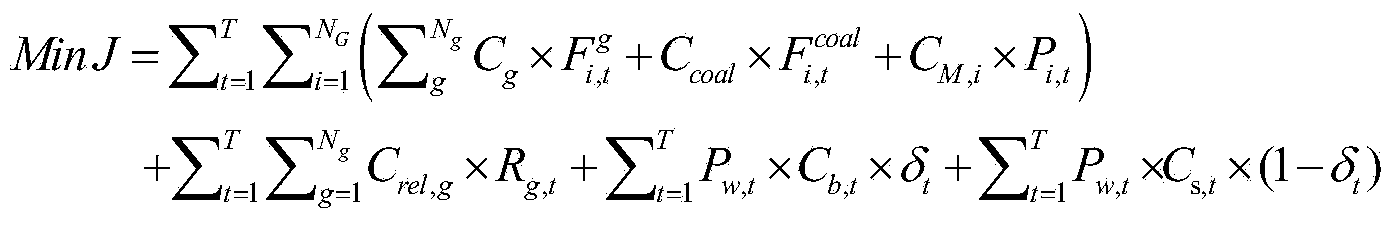

Joint optimized scheduling method for multiple types of generating sets of self-supply power plant of iron and steel enterprise

InactiveCN104392334AImprove accuracyImprove representationEnergy industryResourcesProduction optimizationElectricity price

The invention discloses a joint optimized scheduling method for multiple types of generating sets of a self-supply power plant of an iron and steel enterprise, and belongs to the technical field of energy optimized scheduling of the iron and steel enterprise. Influence of fuel types and gas mixed burning amount on energy consumption of the sets is taken into consideration in construction of a set energy consumption characteristic model, fitting is performed under different gas mixed burning, and the accuracy and representativeness of the model are improved; and influence of the fuel cost, time-of-use power price and surplus gas dynamic change on the generating cost is considered comprehensively in construction of an optimized scheduling model, meanwhile, various constraint conditions including power balance constraint, generating set self-running constraint, purchased power quantity constraint, gas supply constraint, variable load rate limit and the like are considered, and the performability of a generation schedule is guaranteed. Optimization solution is performed on the models by adopting the adaptive particle swarm optimization algorithm, the problems of high dimensionality, nonconvexity, nonlinearity and multiple constraints of the power generation scheduling of the self-supply power plant can be well solved, power production optimization and purchasing rationalization are realized, surplus gas is sufficiently used, and the power supply cost is reduced to the greatest extent.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

Fuel system for a multi-fuel engine

InactiveUS8590510B2Improve fuel vaporizationEmission reductionElectrical controlInternal combustion piston enginesFuel typeEngineering

Owner:FORD GLOBAL TECH LLC

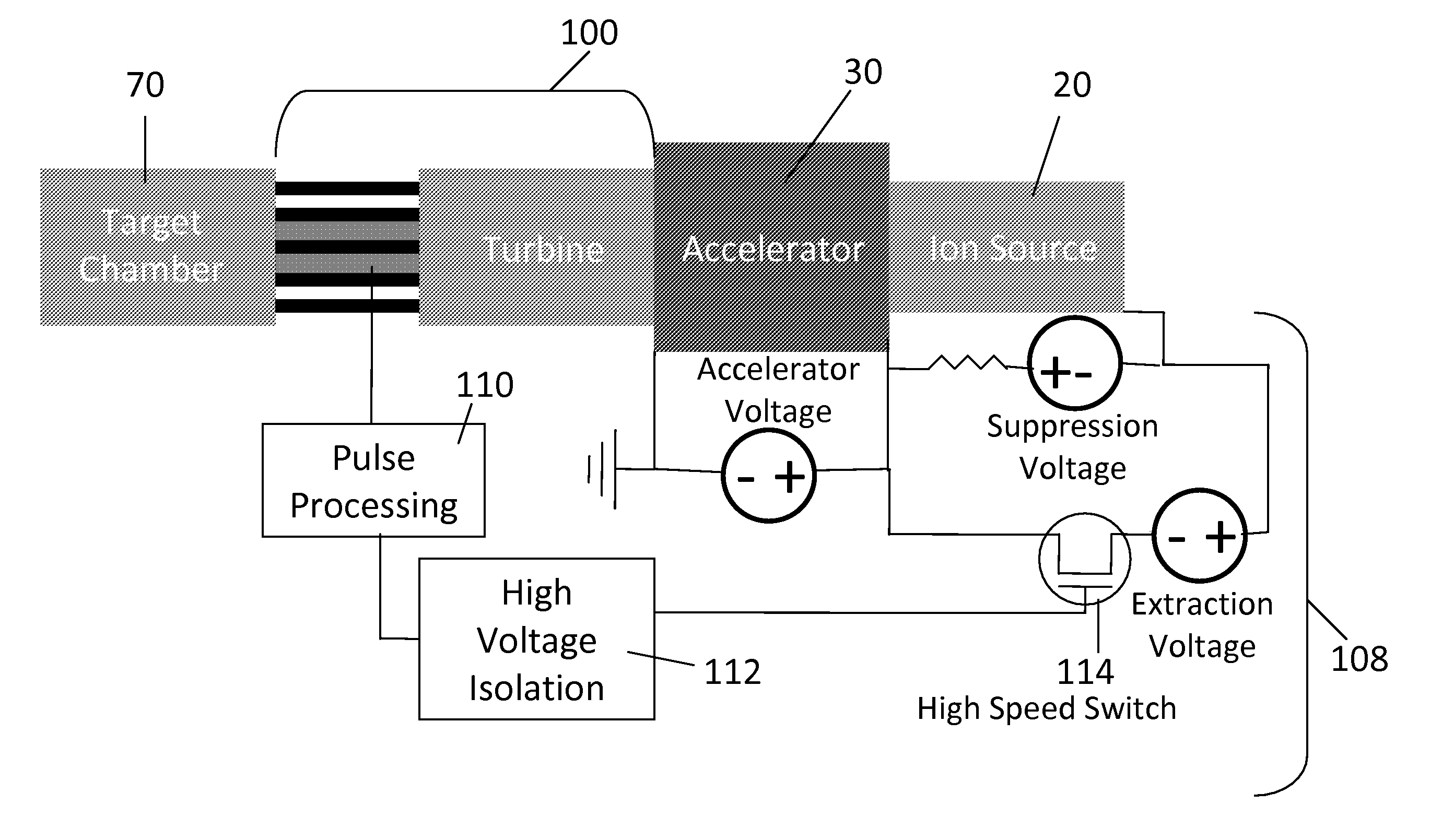

High energy proton or neutron source

ActiveUS20100284502A1Overcome disadvantagesPrevent escapeConversion outside reactor/acceleratorsNuclear targetsHigh fluxIsotope

The invention provides a compact high energy proton source useful for medical isotope production and for other applications including transmutation of nuclear waste. The invention further provides a device that can be used to generate high fluxes of isotropic neutrons by changing fuel types. The invention further provides an apparatus for the generation of isotopes including but not limited to 18F, 11C, 15O, 63Zn, 124I, 133Xe, 111In, 125I, 131I, 99Mo, and 13N.

Owner:SHINE TECH LLC

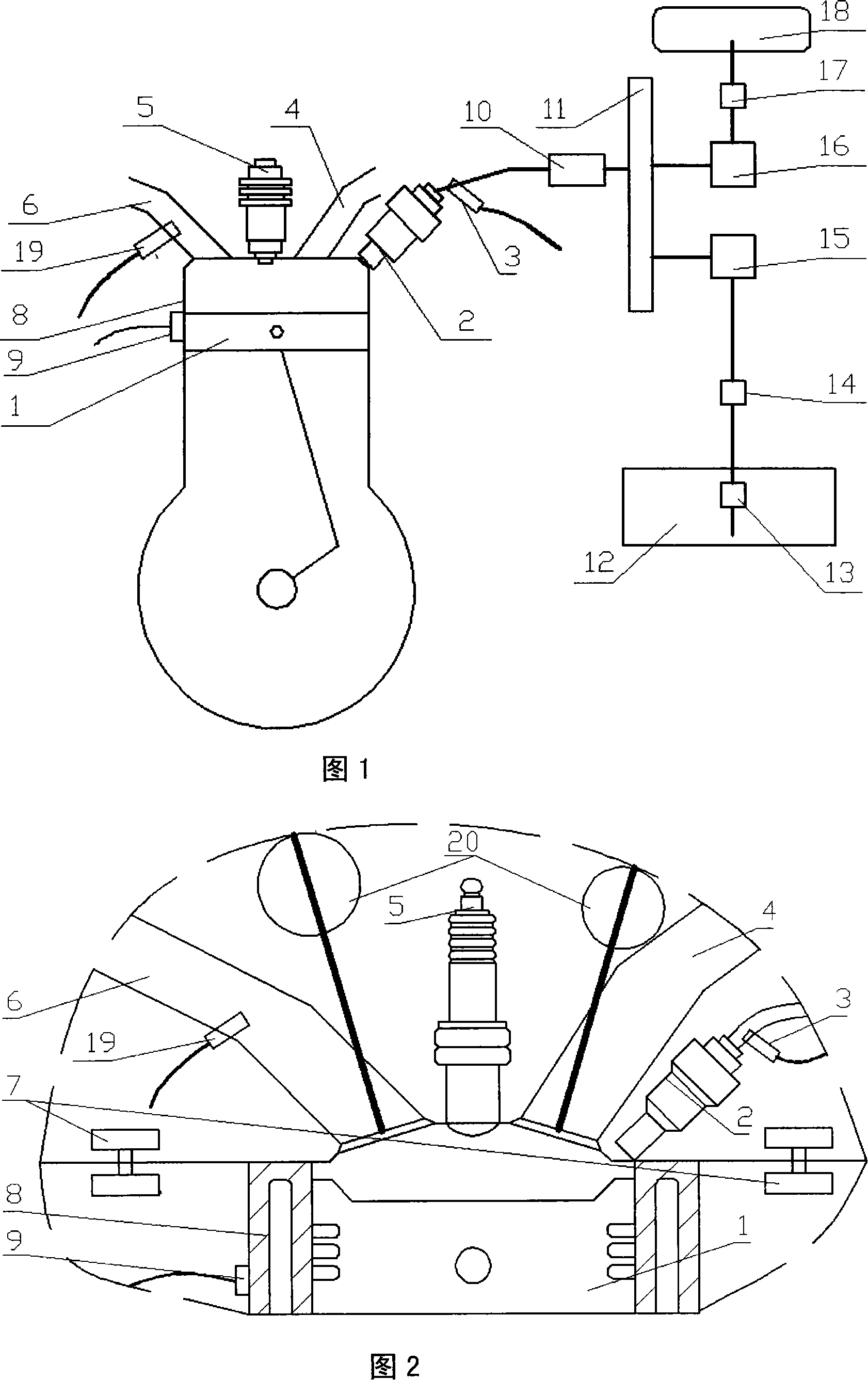

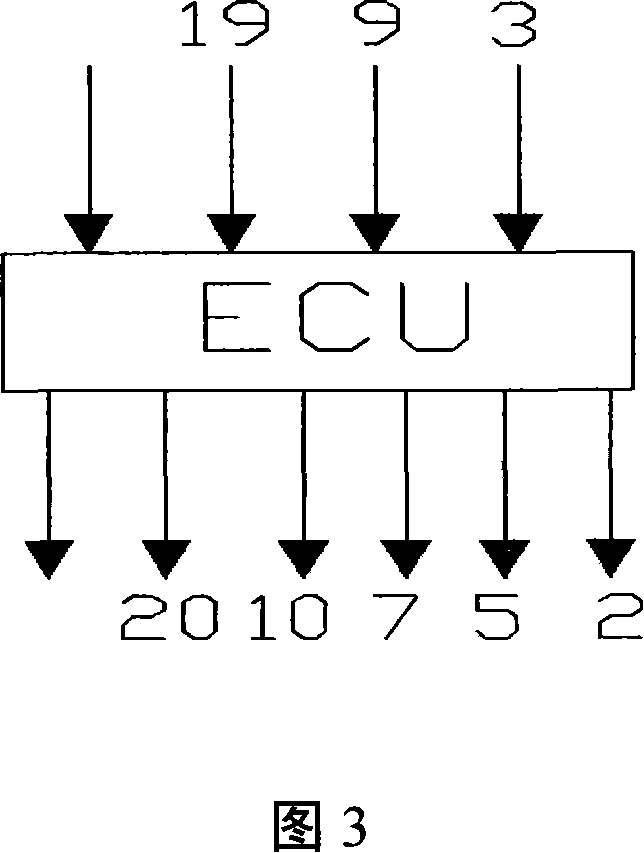

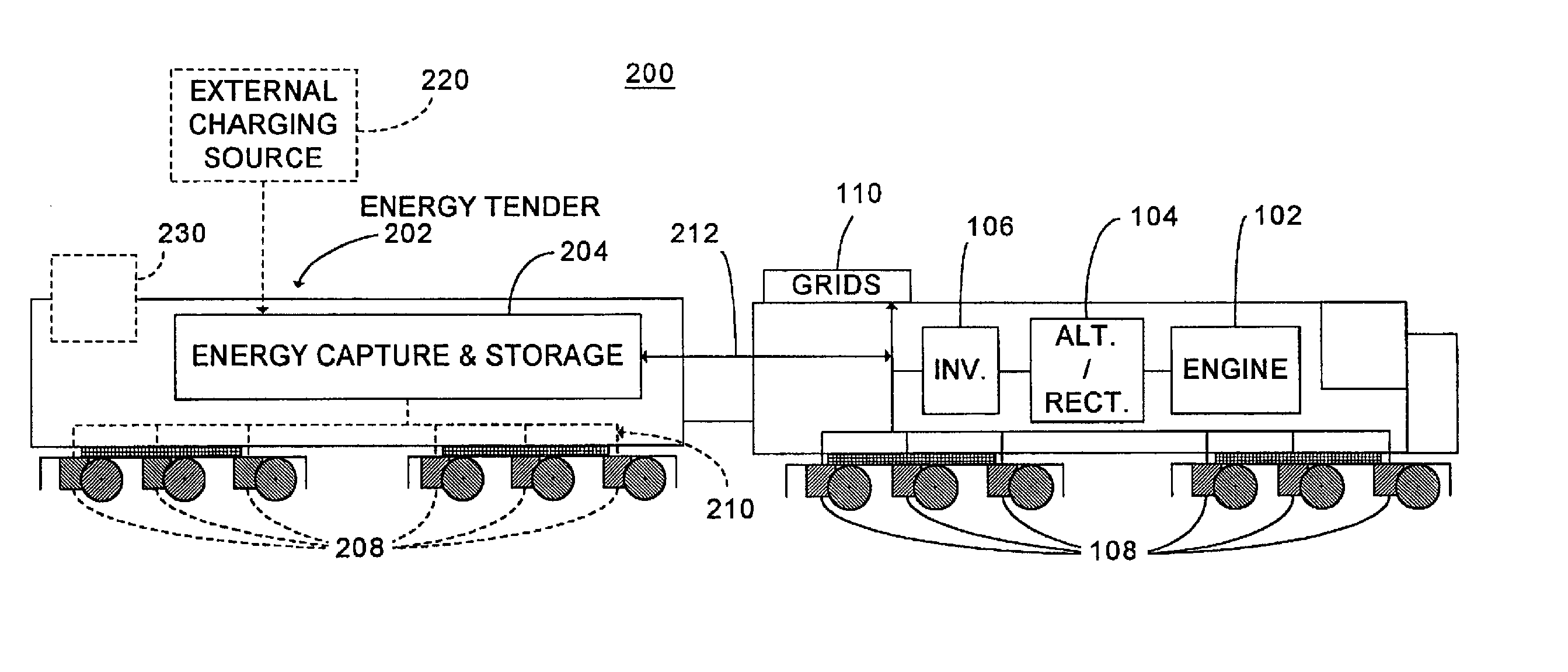

Flexible fuel engine with alterable compression ratio and control method thereof

InactiveCN101131126AValve arrangementsInternal combustion piston enginesCombustion systemVariable valve timing

The present invention discloses one kind of engine with changeable compression ratio and changeable fuel and its control method. The engine includes one combustion system, one fuel pressure regulating system, one liquid fuel providing system, one gas fuel providing system, one changeable gas valve timing mechanism, one electronic control unit and one sensor module. According to the acquired signal, the electronic control unit determines the current fuel type, regulates the compression ratio, combustion controlling strategy and gas distribution phase of the engine and regulates the pressure of the fuel injector, so as to fit the fuel. The engine of the present invention can burn gas fuel, liquid fuel and mixed fuel, and has compression ratio adjustable in 8-18 and high dynamic performance and economic performance in burning different types of fuel.

Owner:CHERY AUTOMOBILE CO LTD

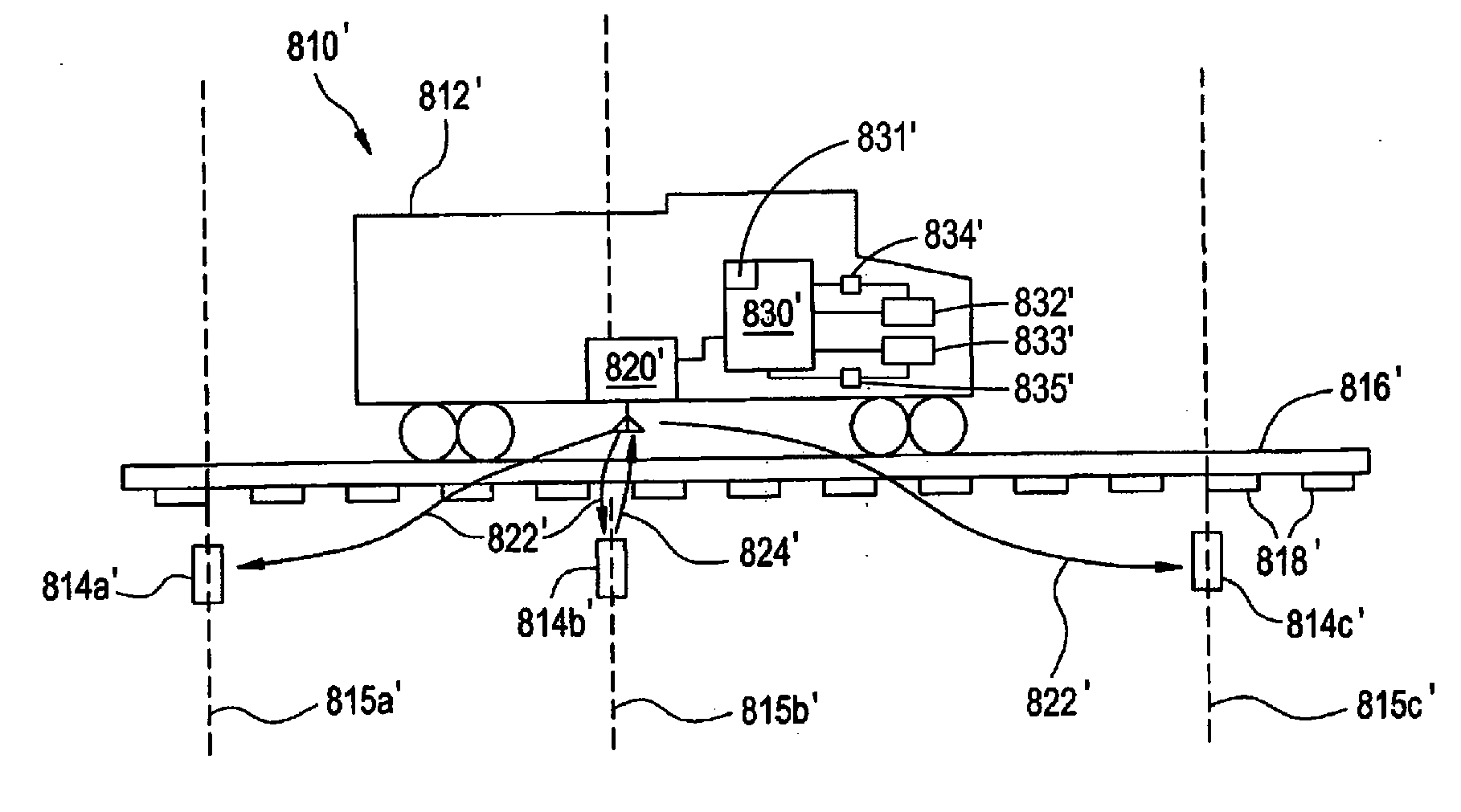

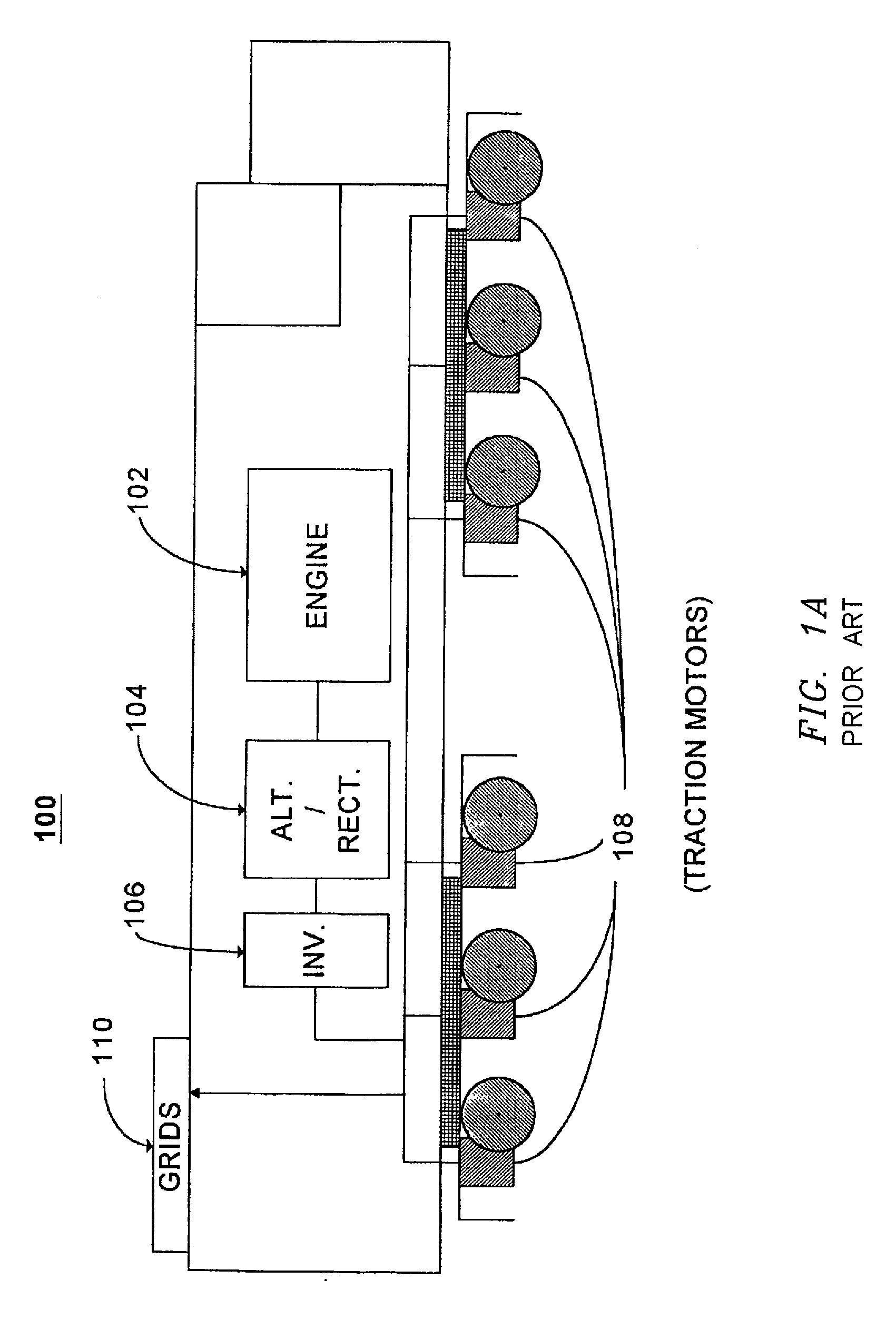

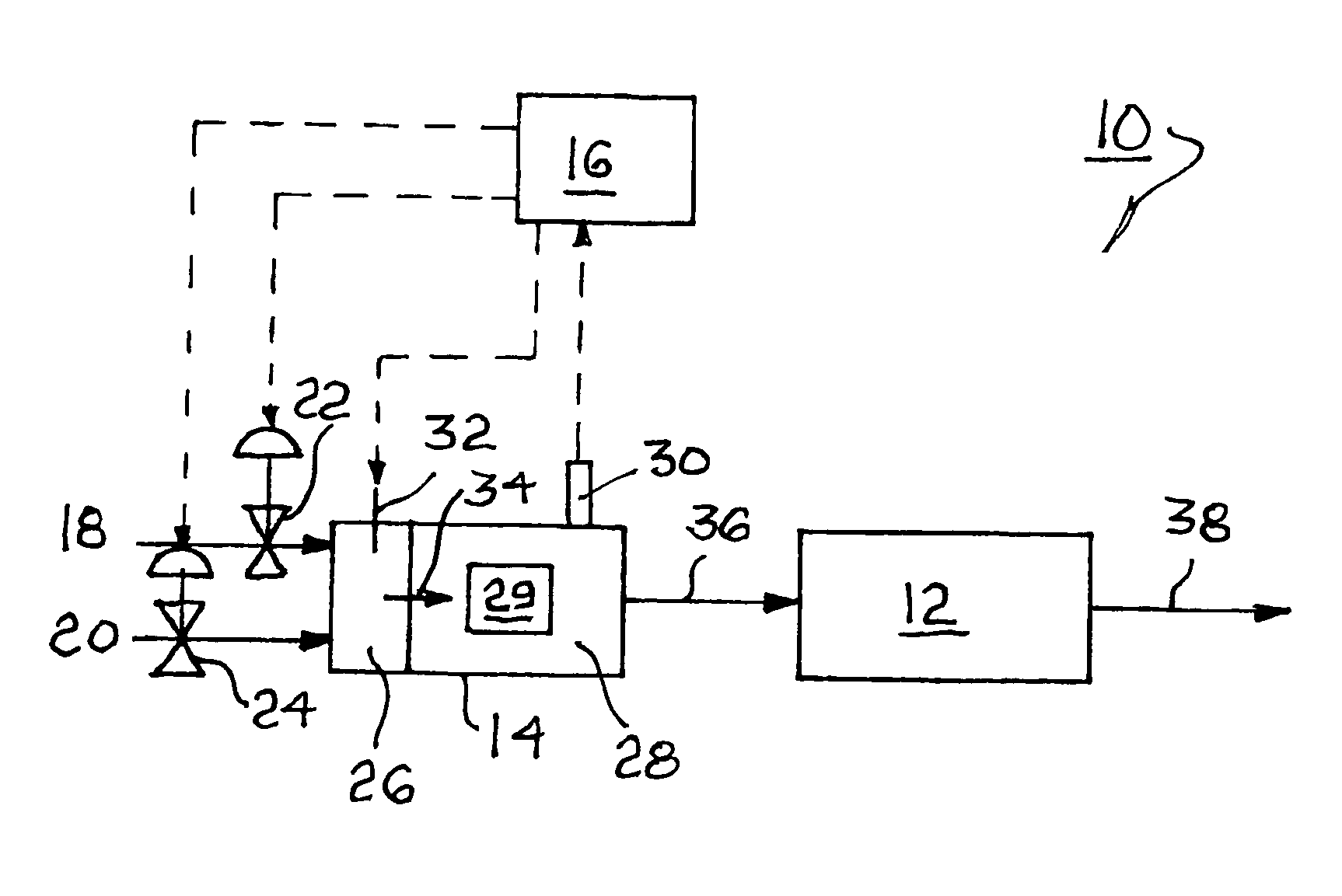

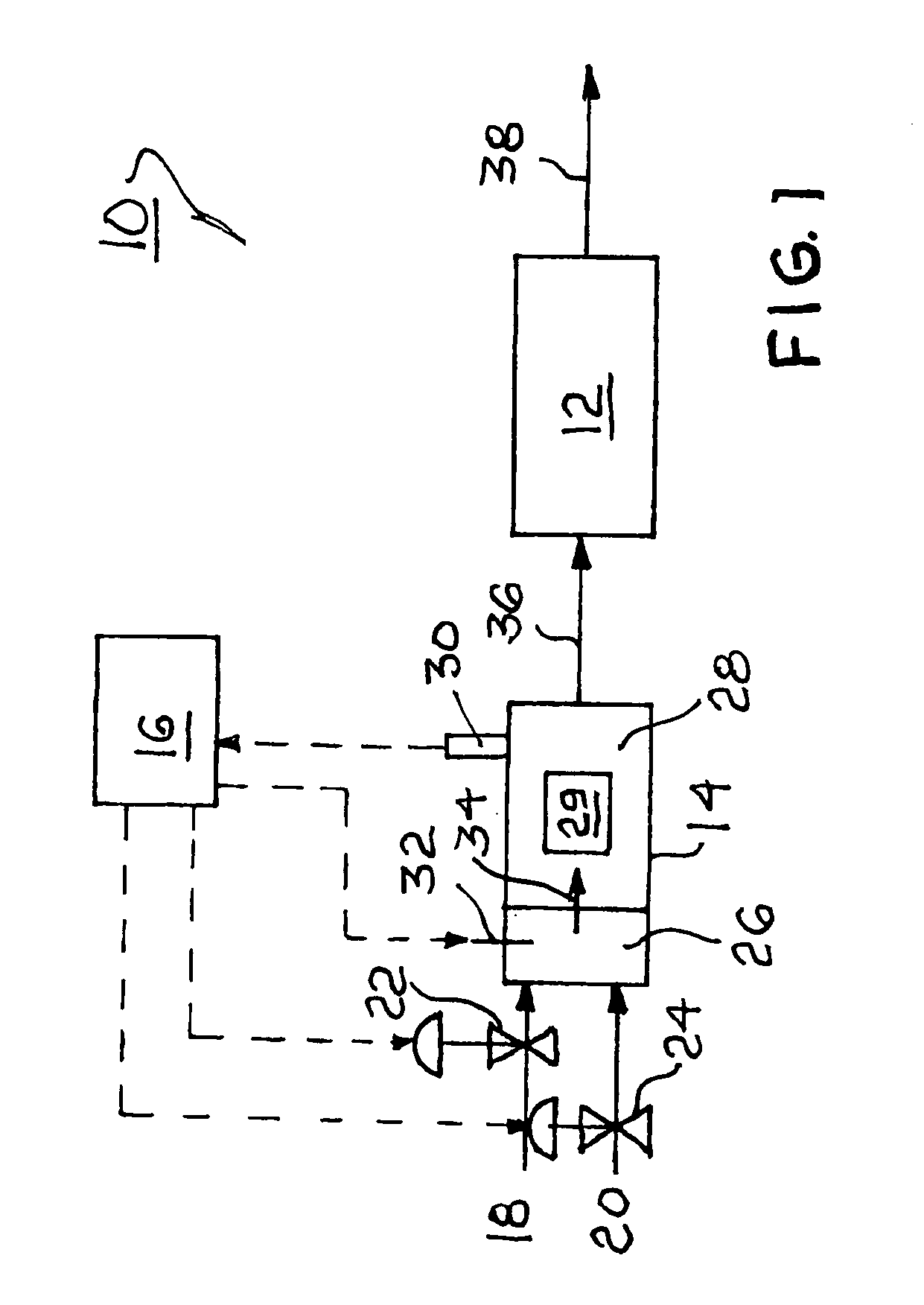

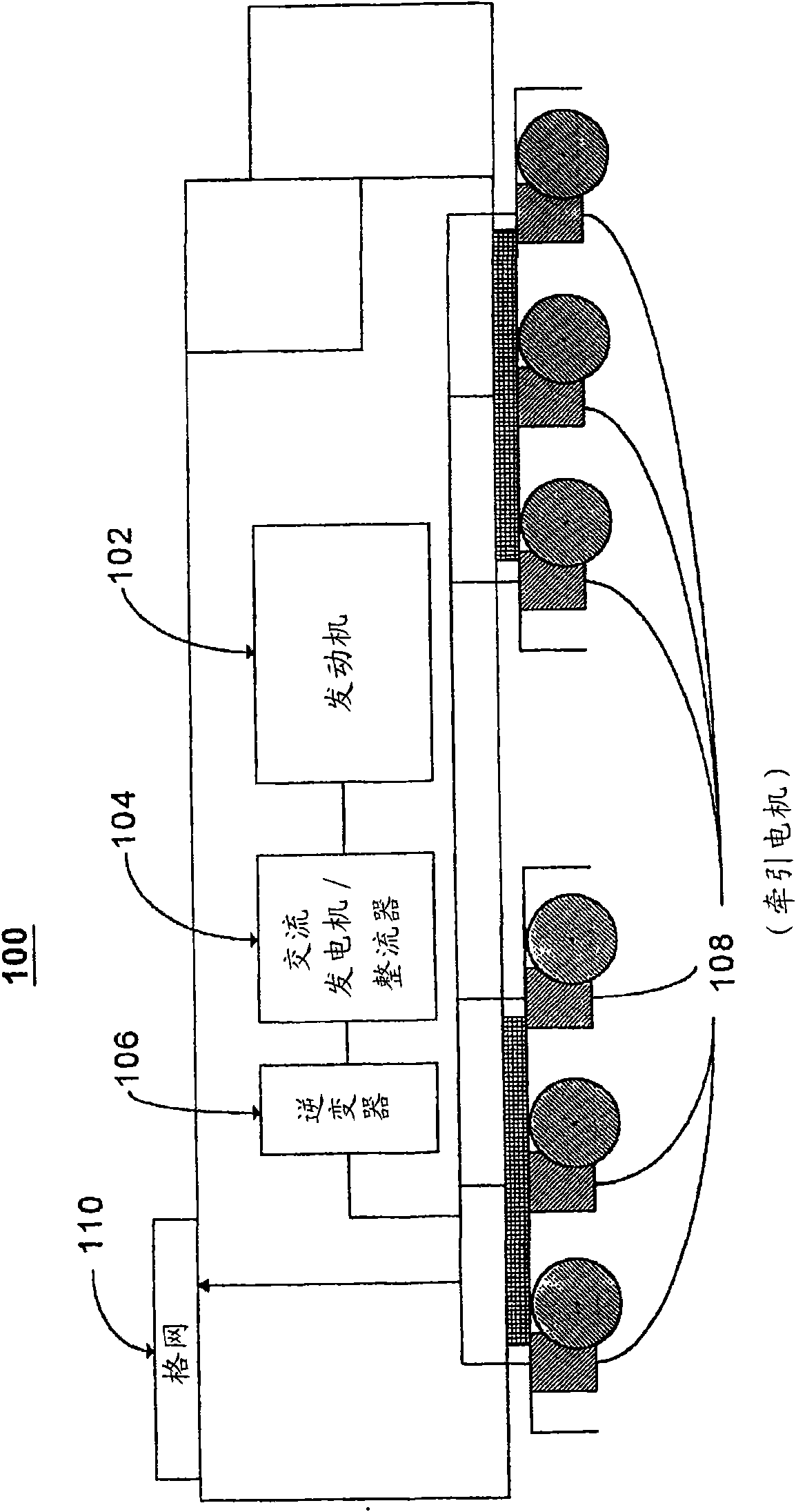

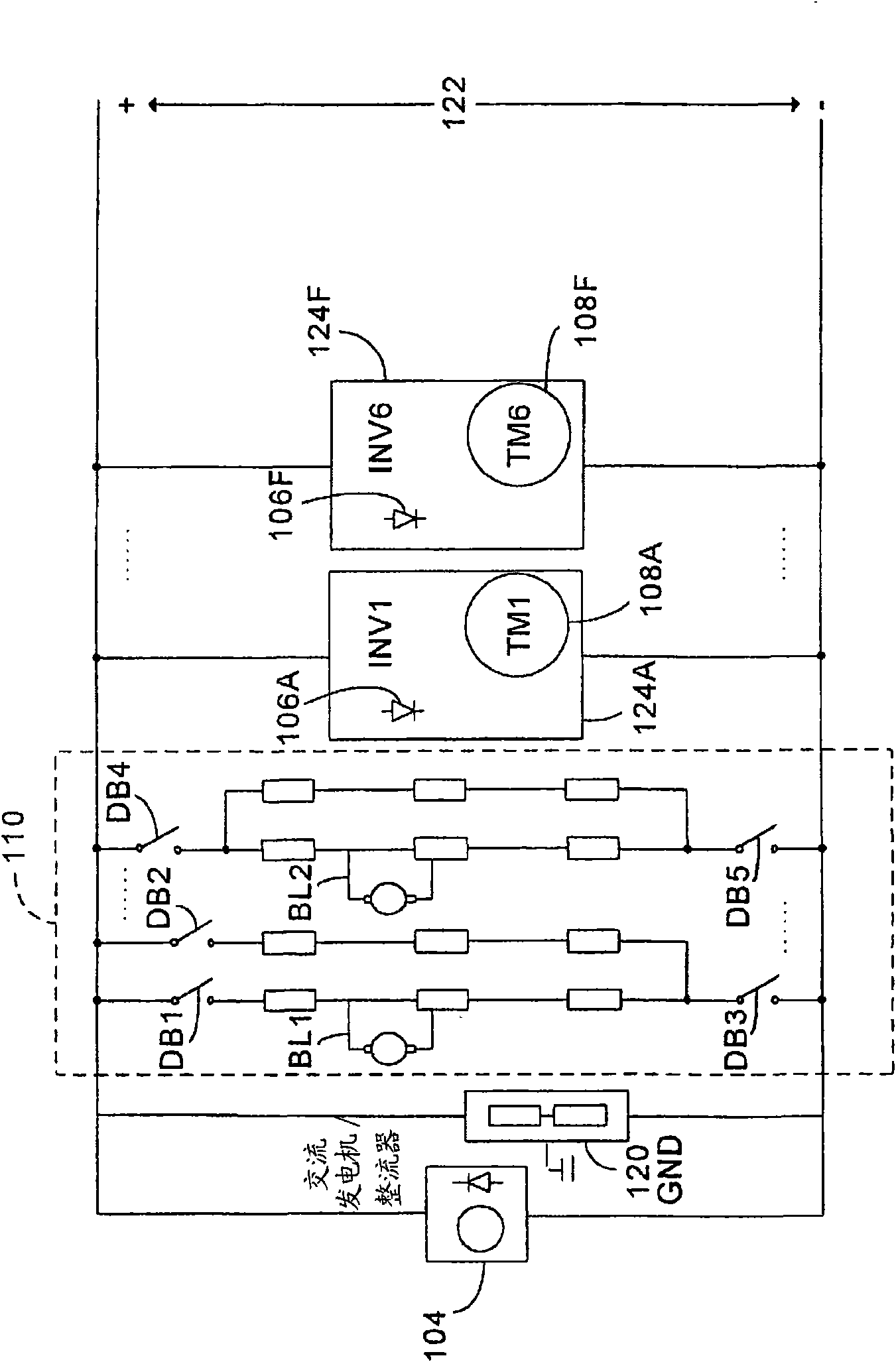

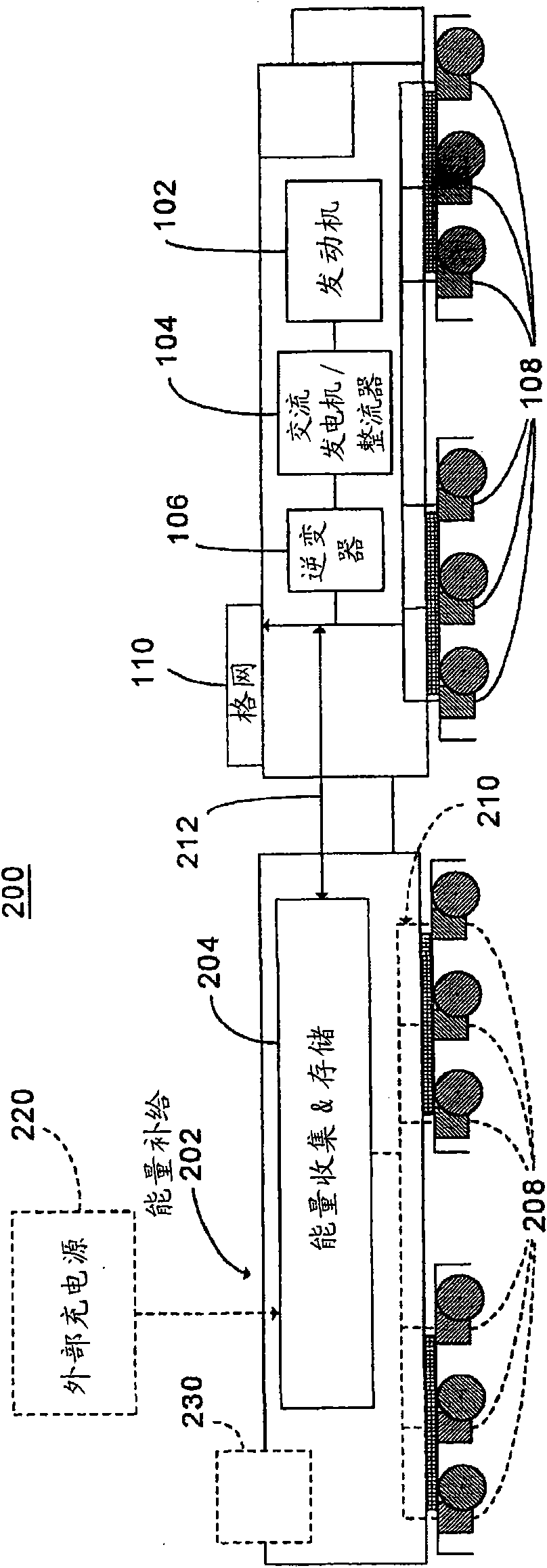

Hybrid Energy Power Management System and Method

ActiveUS20070142985A1Minimize the total fuel consumedElectrical controlInternal combustion piston enginesElectric power transmissionFuel type

An energy management system is provided for use with a hybrid energy off-highway vehicle traveling on a predetermined course. The energy management system includes an energy management processor to determine a power storage parameter, a power transfer parameter, and an engine transfer parameter for each location along the predetermined course to minimize the total fuel consumed of all fuel types during the predetermined course subject to at least one fuel parameter constraint. An energy storage system selectively stores electrical energy available from the traction bus as a function of the power storage parameter and selectively supplies secondary electric power from the stored electrical energy to the traction bus as a function of the power transfer parameter. The engine selectively supplies primary electric power to the traction bus at each location along said predetermined course through selectively using at least one fuel type in response to said engine transfer parameter.

Owner:GE GLOBAL SOURCING LLC

Reformer start-up strategy for use in a solid oxide fuel cell control system

Owner:DELPHI TECH INC

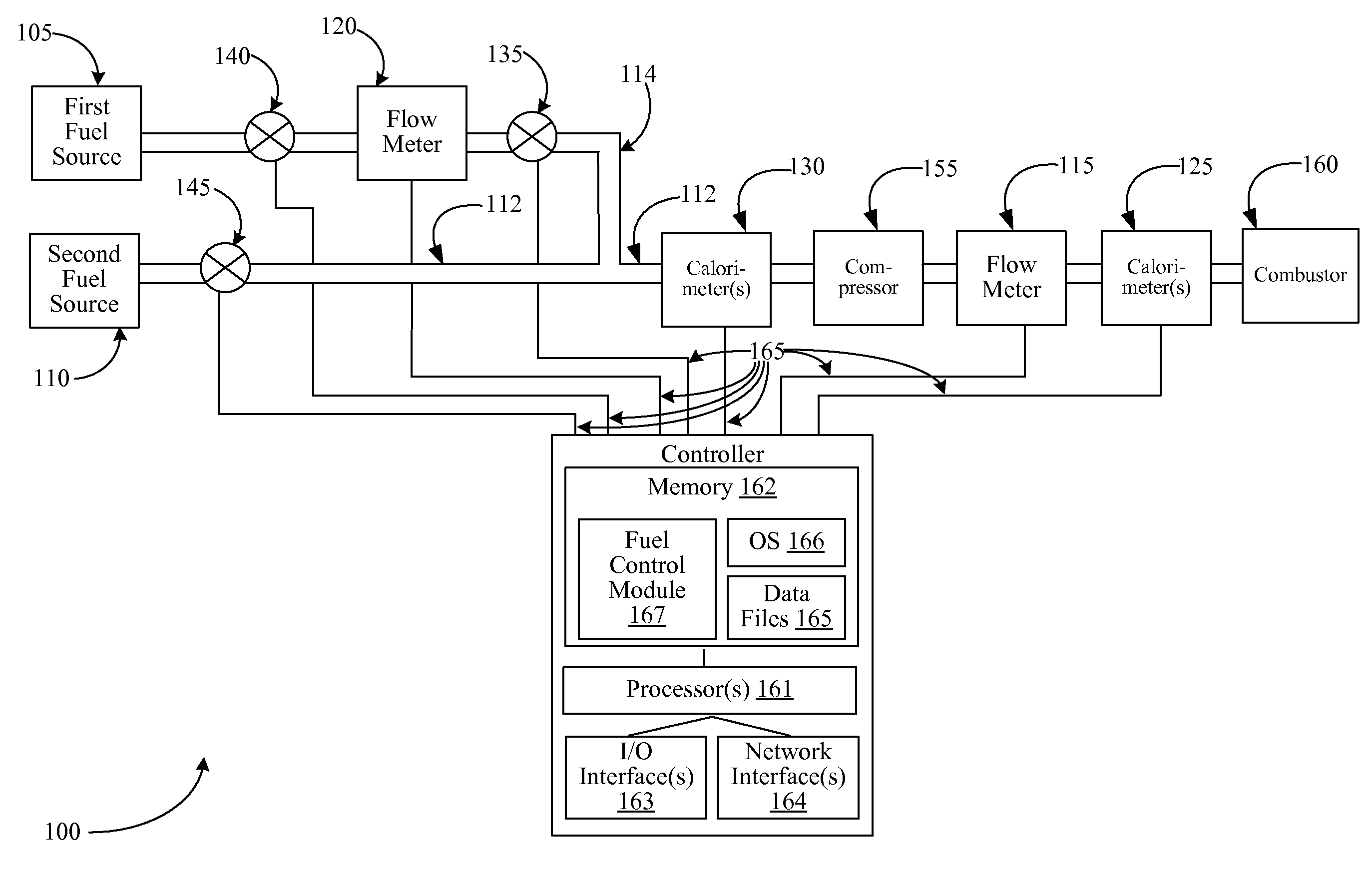

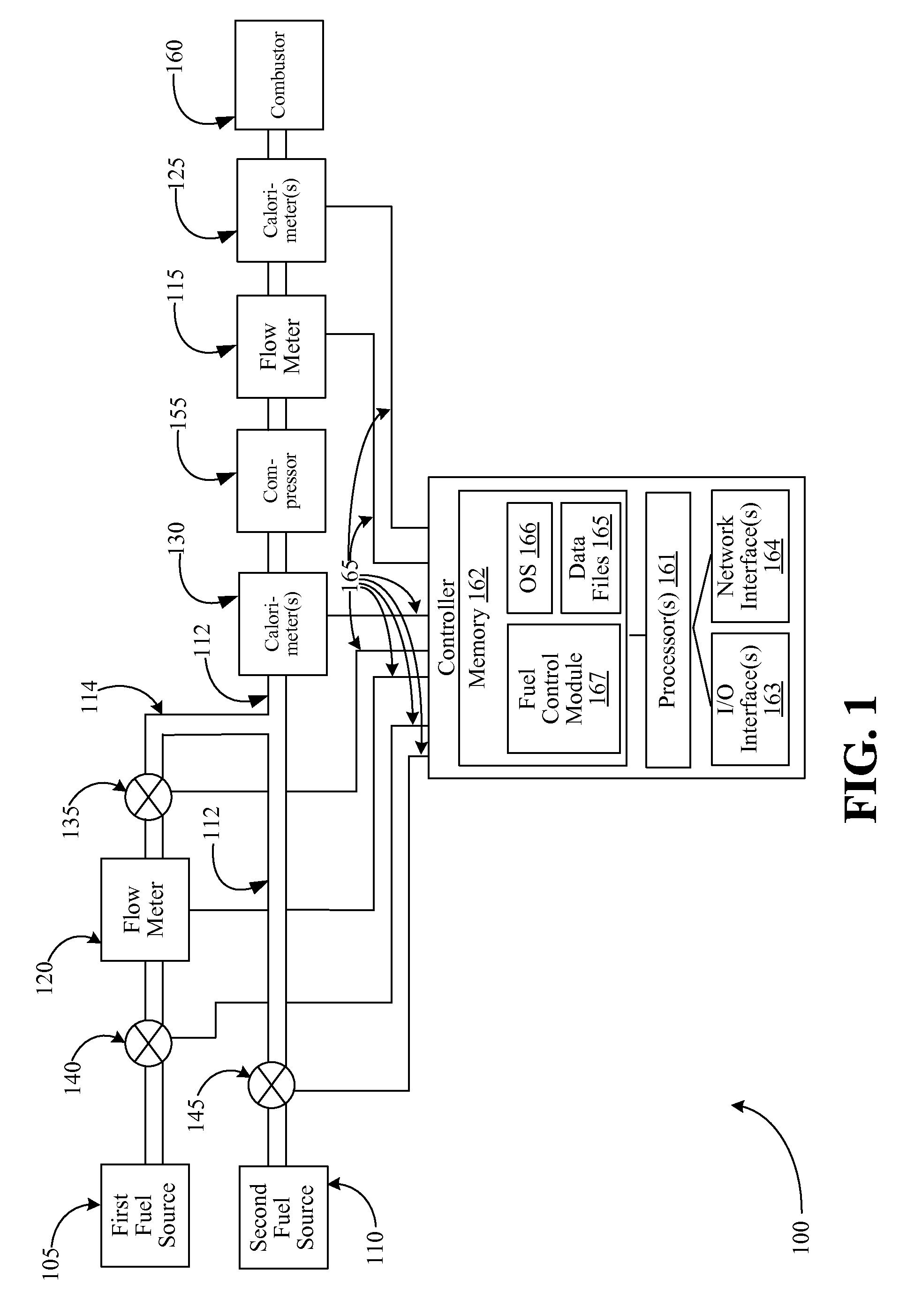

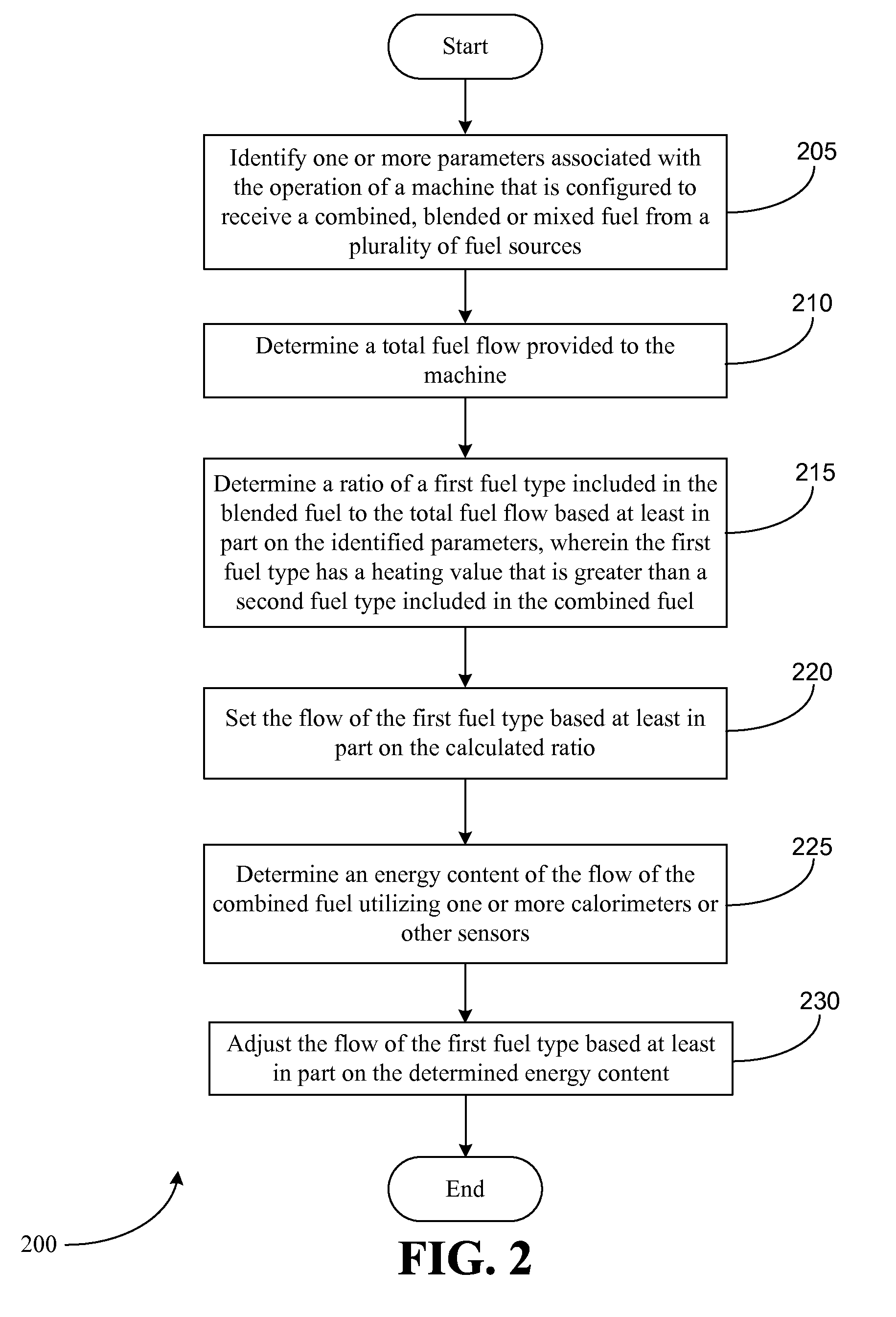

Systems and methods for controlling fuel mixing

InactiveUS20110126545A1Fuel supply regulationContinuous combustion chamberFuel typeAutomotive engineering

Systems and methods for controlling fuel mixing are provided. One or more parameters associated with the operation of a machine configured to receive a combined fuel may be identified. A fuel flow of the combined fuel that is provided to the machine may be determined. Based at least in part on the identified parameters, a ratio of a first fuel type included in the combined fuel to the determined fuel flow may be determined. The first fuel type may have a heating value that is greater than a second fuel type included in the combined fuel. A flow of the first fuel type may be set based at least in part on the ratio. Subsequent to setting the flow of the first fuel type, an energy content of the fuel flow of the combined fuel may be determined, and the flow of the first fuel type may be adjusted based at least in part on the determined energy content.

Owner:GENERAL ELECTRIC CO

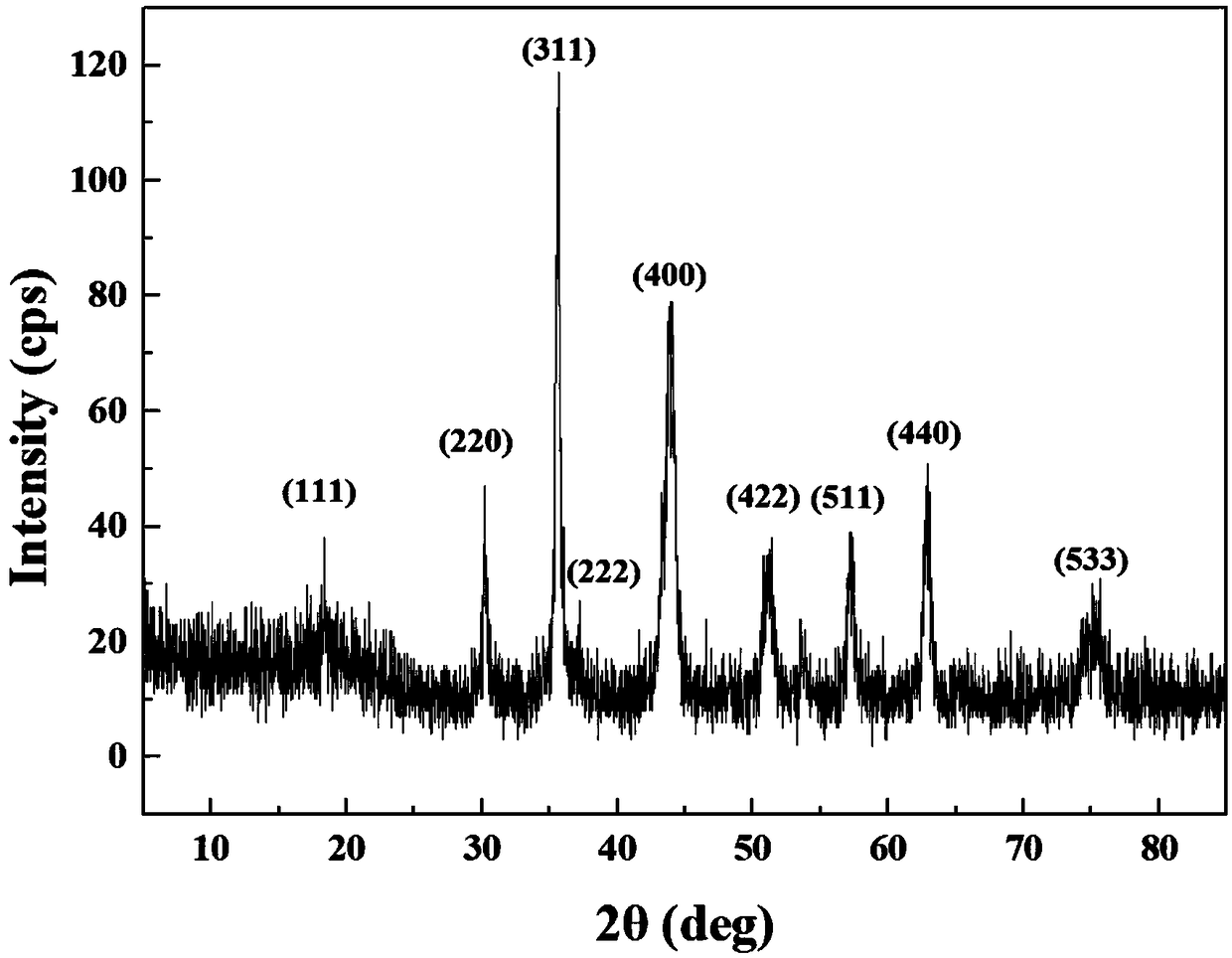

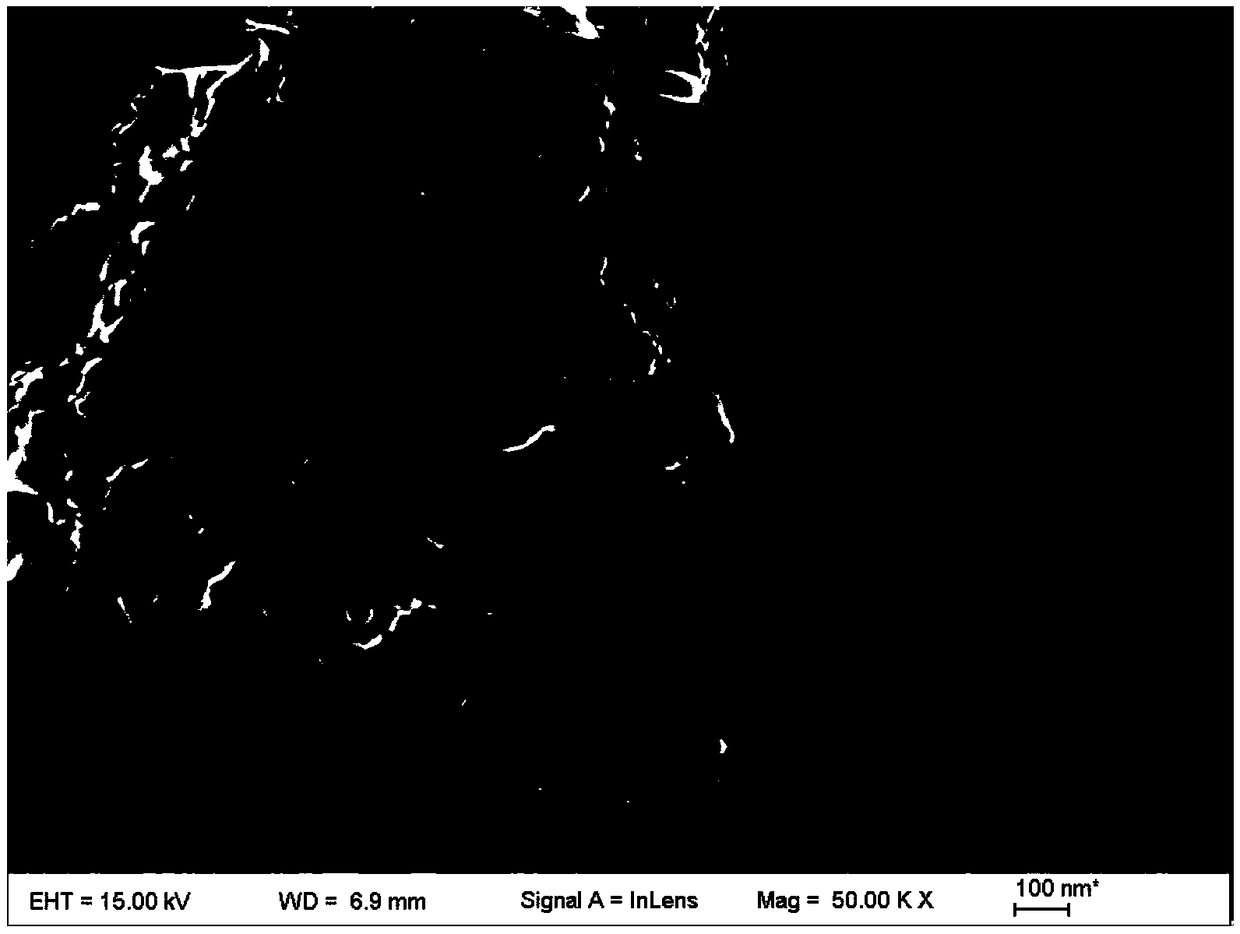

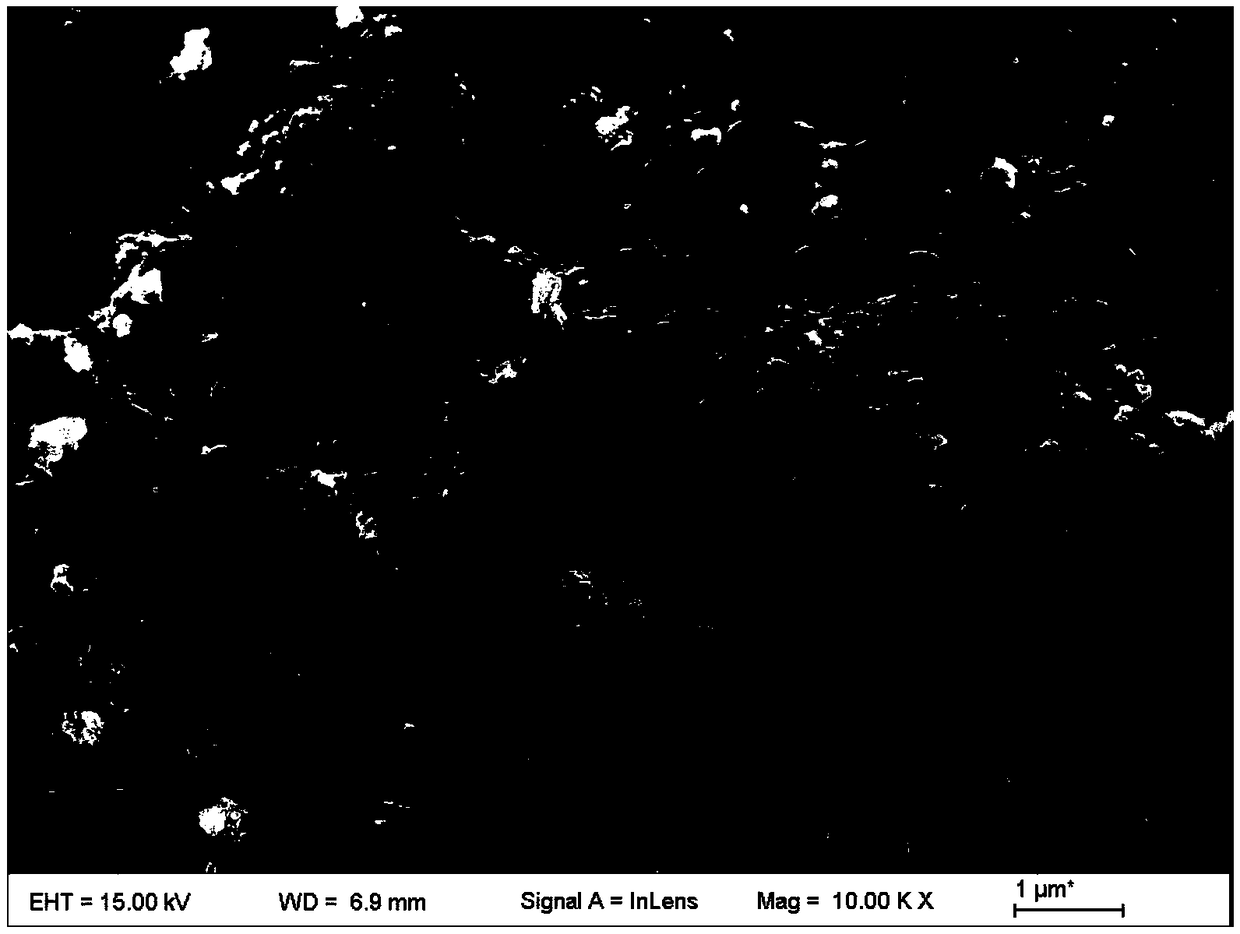

Preparation method of spinel-type porous high entropy oxide material

ActiveCN108821351AAchieving a stoichiometric ratioReduce energy consumptionMaterial nanotechnologyNickel compoundsHexamethylenetetramineSynthesis methods

Belonging to the field of inorganic oxide powder materials, the invention discloses a preparation method of a spinel-type porous high entropy oxide material. The method is low temperature combustion synthesis method. Specifically, a metal nitrate is adopted as the metal source, one of or a mixture of several of citric acid, ethylenediamine tetraacetic acid, hexamethylenetetramine and glucose is adopted as the fuel, by controlling the concentration of the metal salt raw materials, the fuel type and adding amount, the combustion improver type and adding amount, and the ignition way, the granularity, morphology and other characteristics of the spinel-type transition metal high entropy oxide (CoCrFeMnNi)3O4 nanopowder can be regulated. The preparation method adopts liquid phase compounding toensure molecular level uniform mixing of the raw materials, and the product achieves stoichiometric ratio. At the same time, the method has the advantages of energy saving, high production efficiency,green and environmental protection, no need for complicated post-treatment and the like. The high entropy oxide powder prepared by the method provided by the invention has high purity and uniform particle size distribution.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Deployable power supply system

InactiveUS7884502B2Catalyzes diffusion and adoptionEasy usabilityBatteries circuit arrangementsPV power plantsRemote systemMetallic materials

A self-contained conveyable power unit for producing 12V / 24V, 110V AC, and 220V AC electricity at a desired location independent of external power sources integrates within one weather-resistant molded nonmetallic material based housing a power generating device of a selectable combination of a renewable energy type (e.g., solar), power management devices, power storage devices and management reporting devices. Additional optional power generating devices, renewable or of traditional fuel type, can be contained within or coupled to the housing. The system includes devices or an array of devices contained within the housing for the storage of electrical power. A device for power management is contained within the housing as is networking equipment of wireless or wired type for remote system observation and reporting. The system and housing are modular and configured to produce power using any combination of renewable and non-renewable energy resources. The conveyable power unit may provide easy access to different types of power outputs and inputs and be coupled with like appliances in a ‘daisy chain’ or network of power. Given its molded composite material construction and scaleable design, the appliance may be readily fabricated in a variety of sizes for varied applications. Further, the molded housing of composite material construction is designed for resistance to the elements, light weight and strength.

Owner:ZEROBASE ENERGY

Alternate fuel blending system and associated method

ActiveUS7841317B2Discounts/incentivesInternal combustion piston enginesAlternative fuelsControl system

A fuel control system for controlling the use of primary fuel and alternate fuel in an internal combustion engine without cross-contamination of fuel types. Cross-contamination of fuel types may eliminate the ability to receive certain benefits or financial incentives associated with use of alternate fuel, including but not limited to RINs, credits, and subsidies. In one embodiment, primary and / or alternate fuel are controllably delivered from sources to a flow cell. If blending is desired, both primary and alternate fuels are delivered to the flow cell. The engine is fed with the resulting primary fuel, alternate fuel, or blended mixture of fuel from the flow cell. The flow cell contains a bypass inlet port adapted to receive excess fuel not consumed by the engine in lieu of the excess fuel being returned to the primary and / or alternate fuel sources. In this manner, cross-contamination of the fuel sources can be avoided.

Owner:GILBARCO

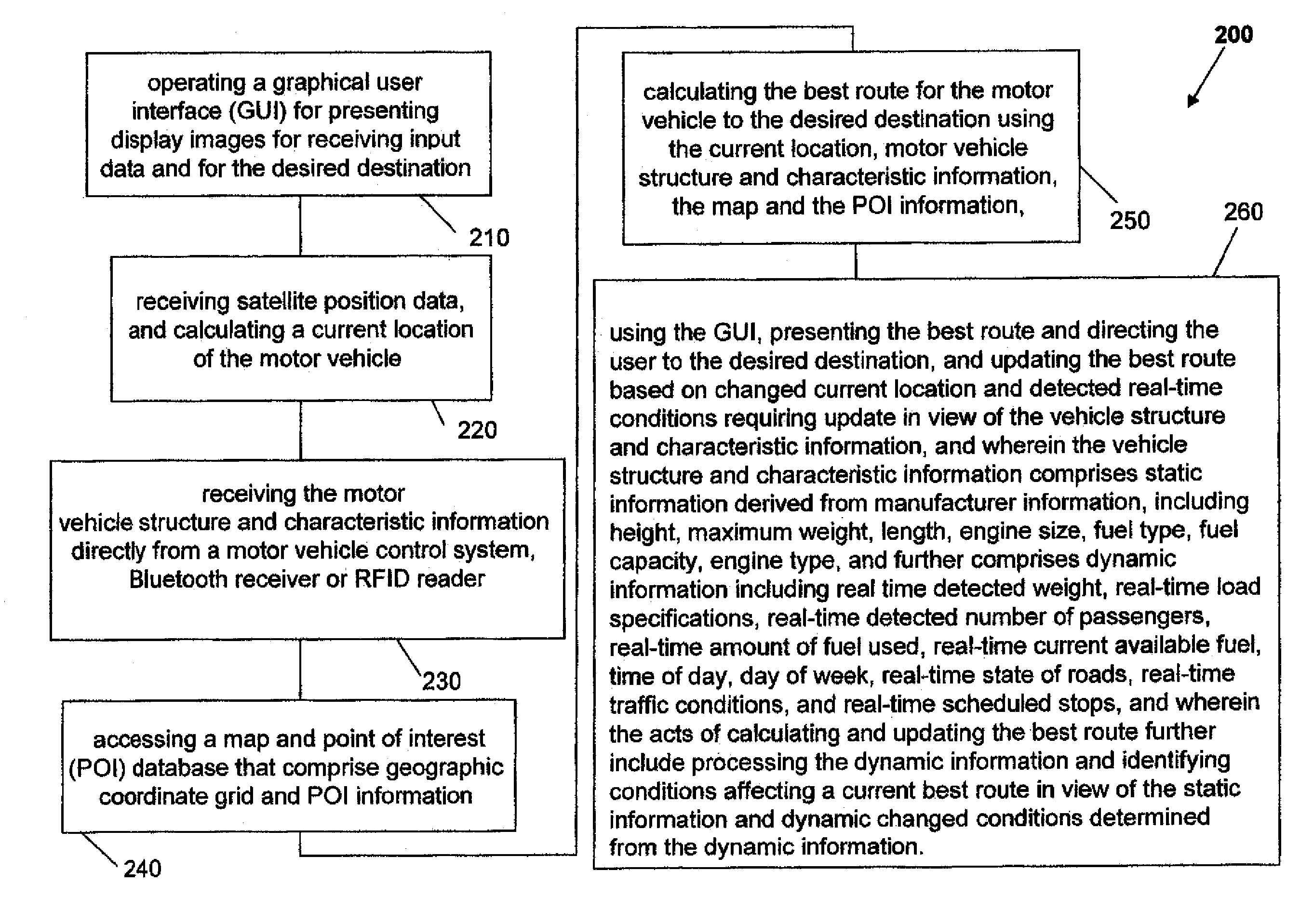

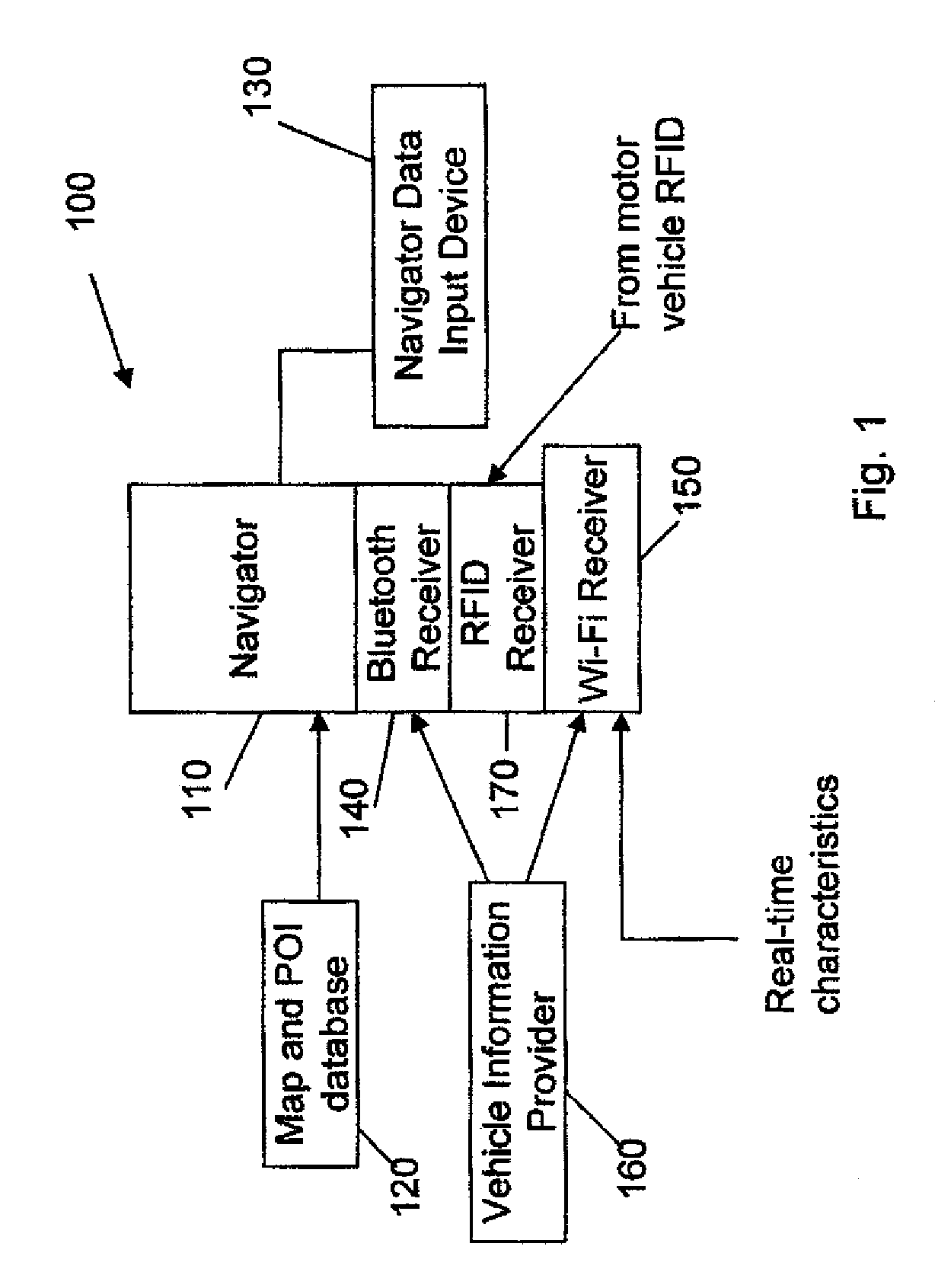

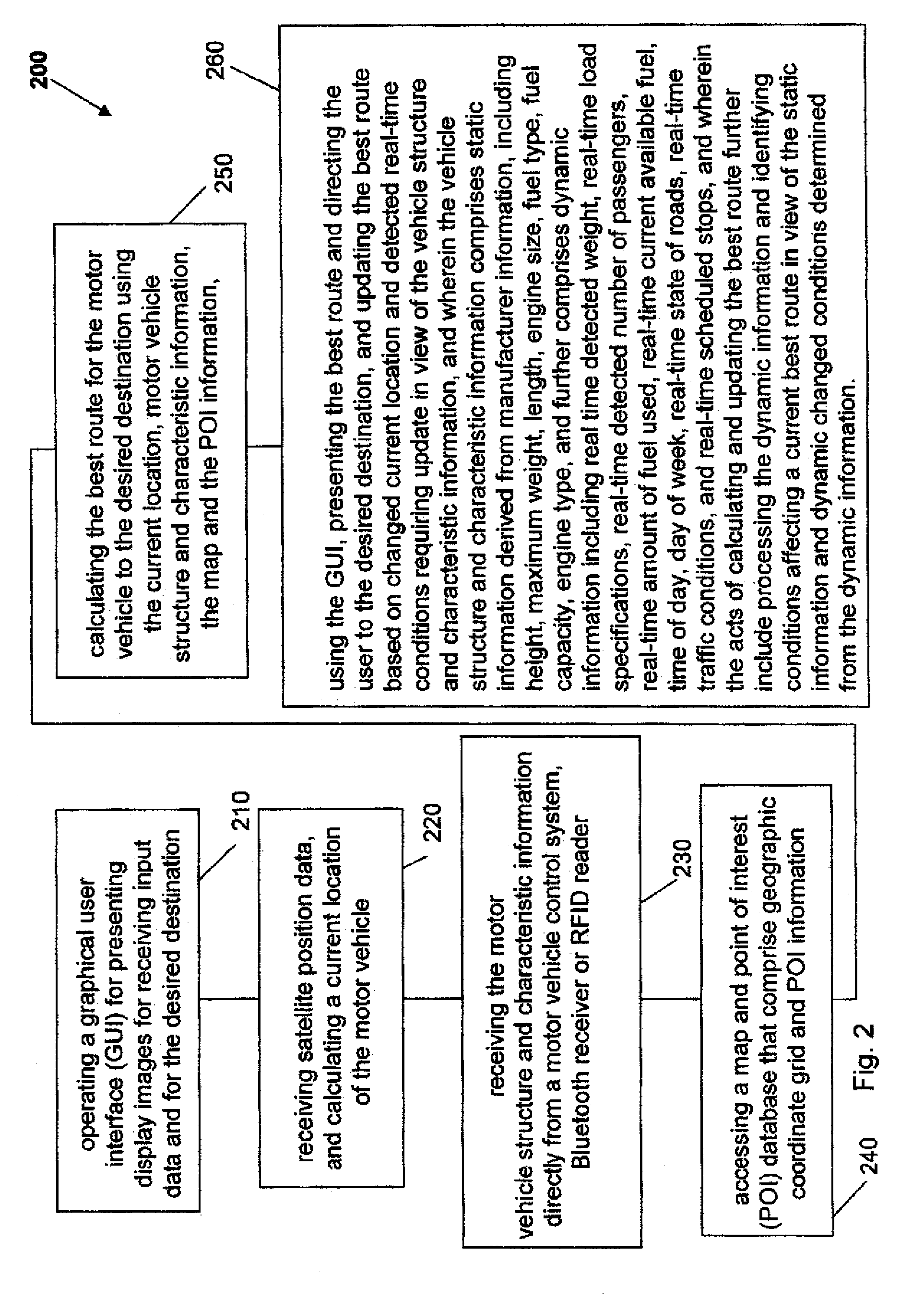

Method and system for selective route search on satellite navigators

ActiveUS7483786B1Instruments for road network navigationRoad vehicles traffic controlEngine efficiencySimulation

A method of operating a motor vehicle satellite navigation system using a motor vehicle's structure and characteristic information to calculate a best route to a desired destination. The method includes operating a graphical user interface (GUI), presenting display images for receiving input data for the desired destination and receiving satellite position data, and calculating a current location of the motor vehicle. The GUI presents a display image requesting motor vehicle structure and characteristic information. The method includes calculating and updating current best routes to a desired destination using map and POI databases comprising geographic coordinate grid and point of interest information from the current location and motor vehicle structure and characteristic information. The motor vehicle structure and characteristic information reflects static vehicle structure and characteristics such as size, fuel type, engine efficiency and fuel capacity, and dynamic information such as current fuel level and real-time traffic and road condition information.

Owner:MAPLEBEAR INC

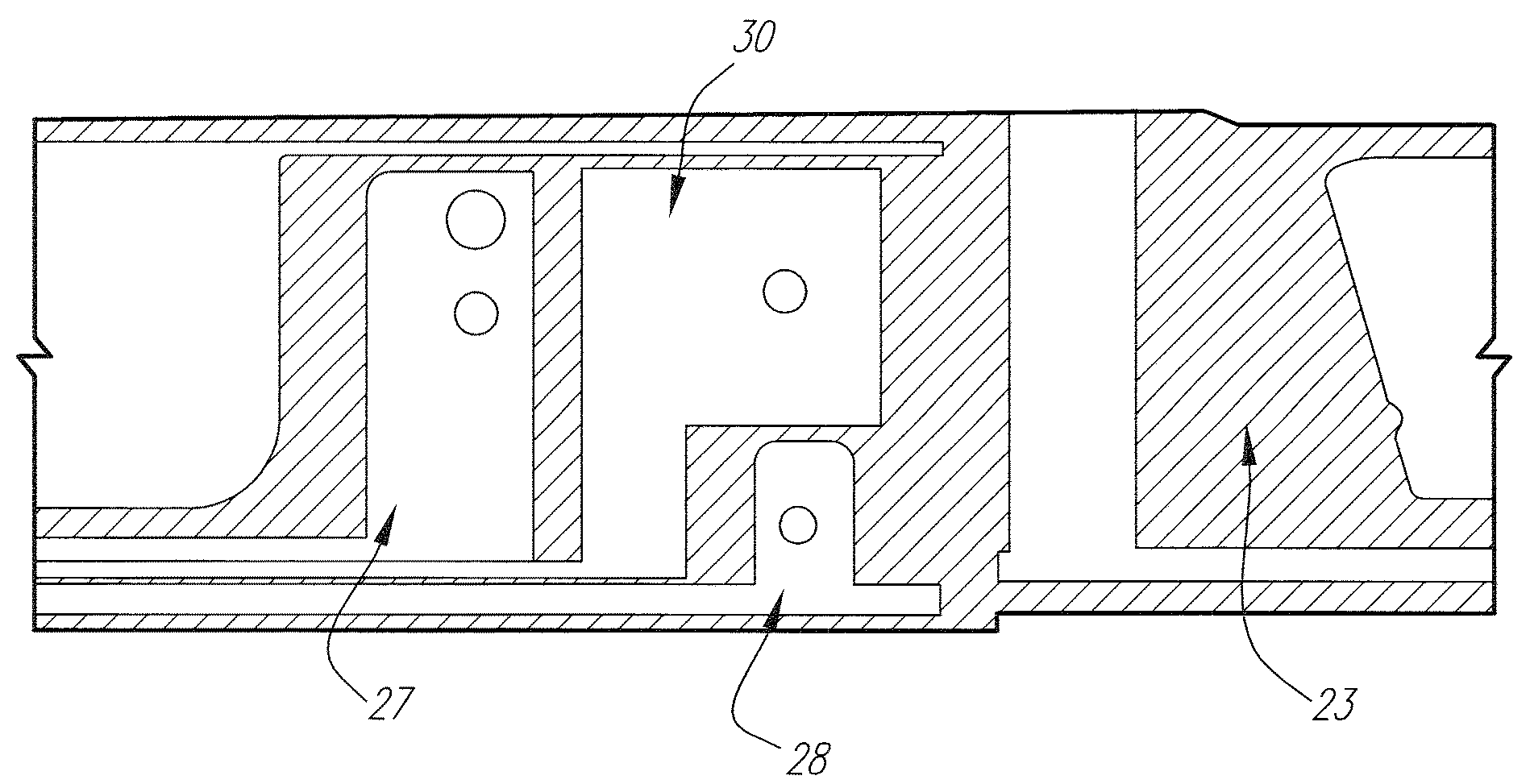

Fuel control device for a combustion engine

InactiveUS20060236986A1Increase rangeIncrease in sizeInternal combustion piston enginesFuel supply apparatusCombustionInlet valve

A fuel control device for a combustion engine capable of running on any one of a plurality of fuels has a fuel selection module with a plurality of fuel type settings for selecting a specific fuel type whereupon the fuel control device controls the outlet pressure of the chosen fuel to a desired fuel pressure corresponding to the calorific properties of the chosen fuel. The fuel selection module preferably operates a plurality of fuel flow circuits each designated for a specific fuel type, and each having a biased closed inlet valve and a biased closed outlet valve. Located preferably between each inlet and outlet valve is a pressure regulator designated for the specific fuel type and controlling the outlet fuel pressure. The device preferably includes a fuel metering apparatus and a shutoff valve that communicate with, and control in part, fuel flow through the fuel flow circuits.

Owner:WALBRO ENGINE MANAGEMENT

Multiple Fuel Circuits for Syngas/NG DLN in a Premixed Nozzle

InactiveUS20100319353A1Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemSyngas

A fuel / air premixer for use in a burner in a combustion system of an industrial gas turbine includes an air inlet, a fixed nozzle geometry, and an annular mixing passage. The fuel / air premixer mixes fuel and air in the annular mixing passage for injection into a combustor reaction zone. A plurality of fuel sources are connected with the fixed nozzle geometry, and each of the fuel sources is cooperable with the fixed nozzle geometry to effect multiple fuel flow variations including variations in fuel type, fuel blend, volumetric flow, and pressure ratios.

Owner:GENERAL ELECTRIC CO

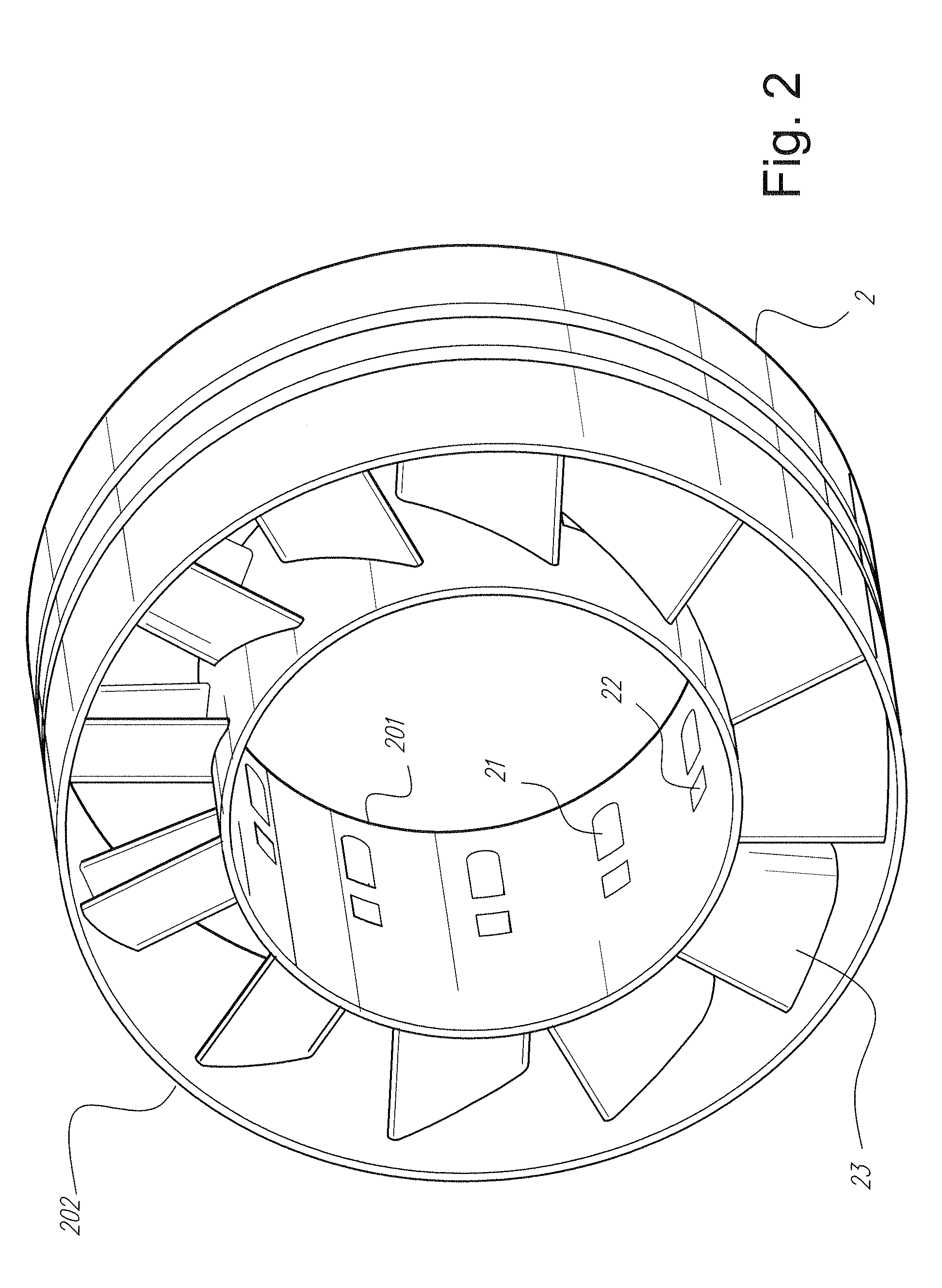

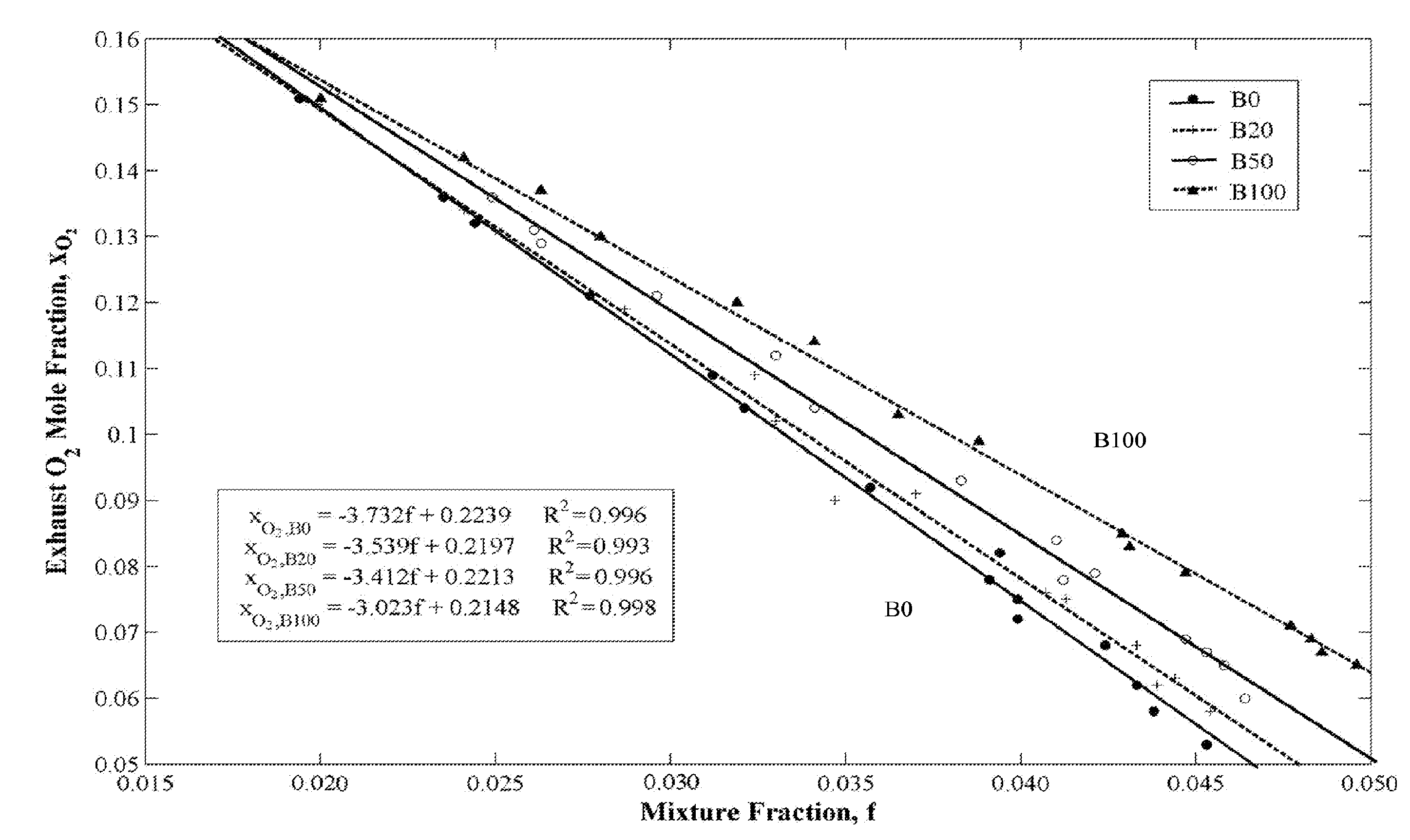

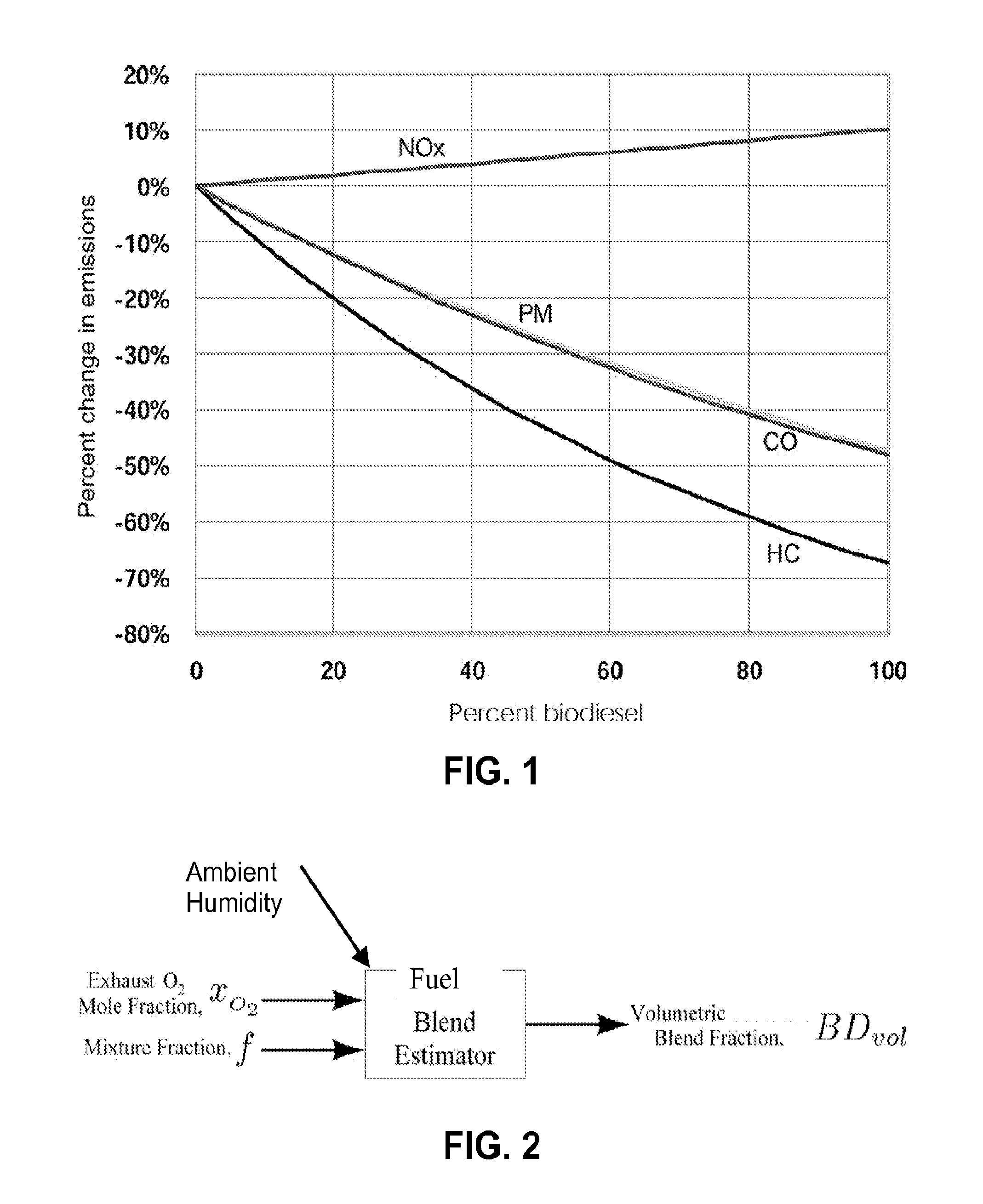

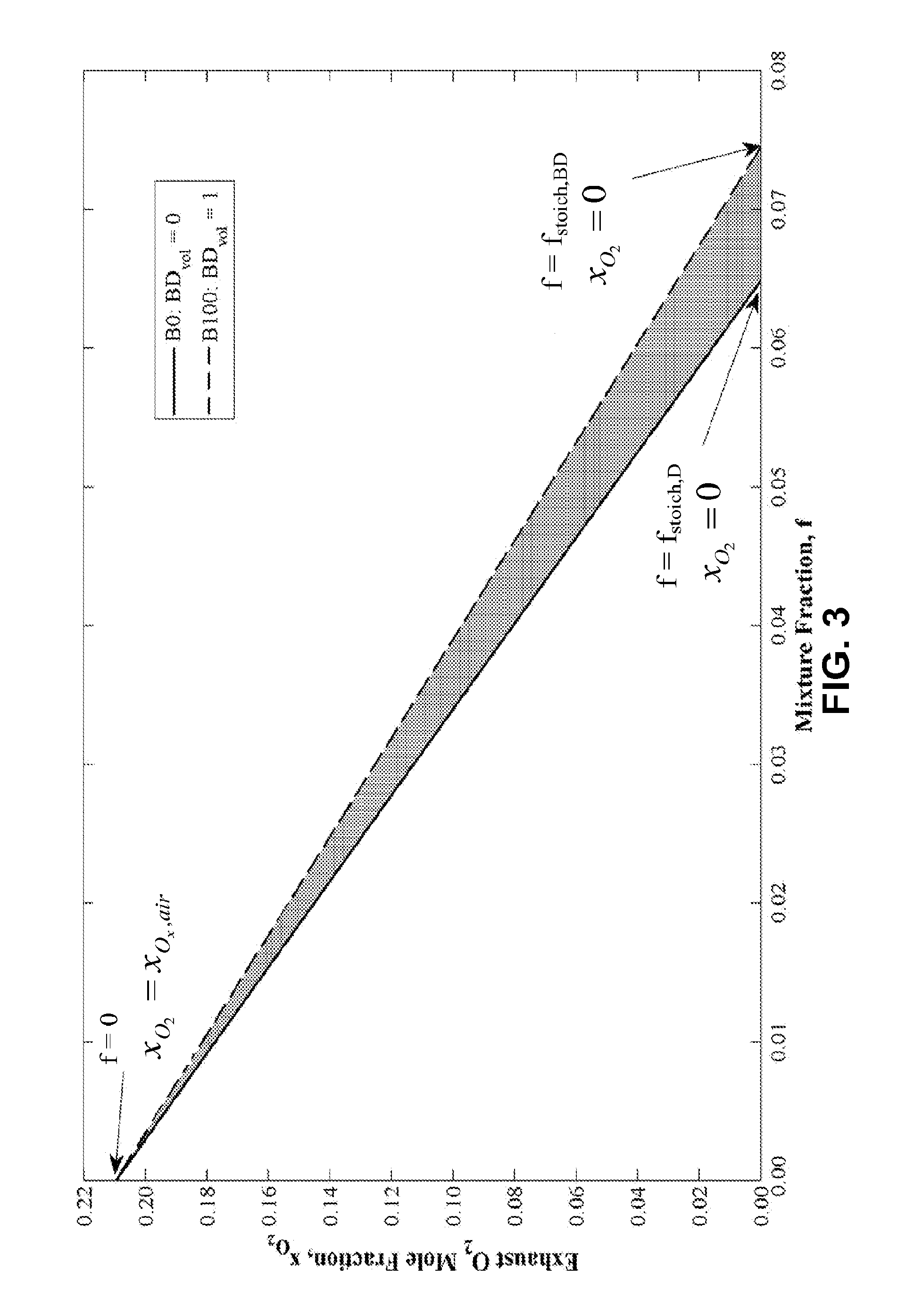

Fuel blend sensing system

Owner:PURDUE RES FOUND INC

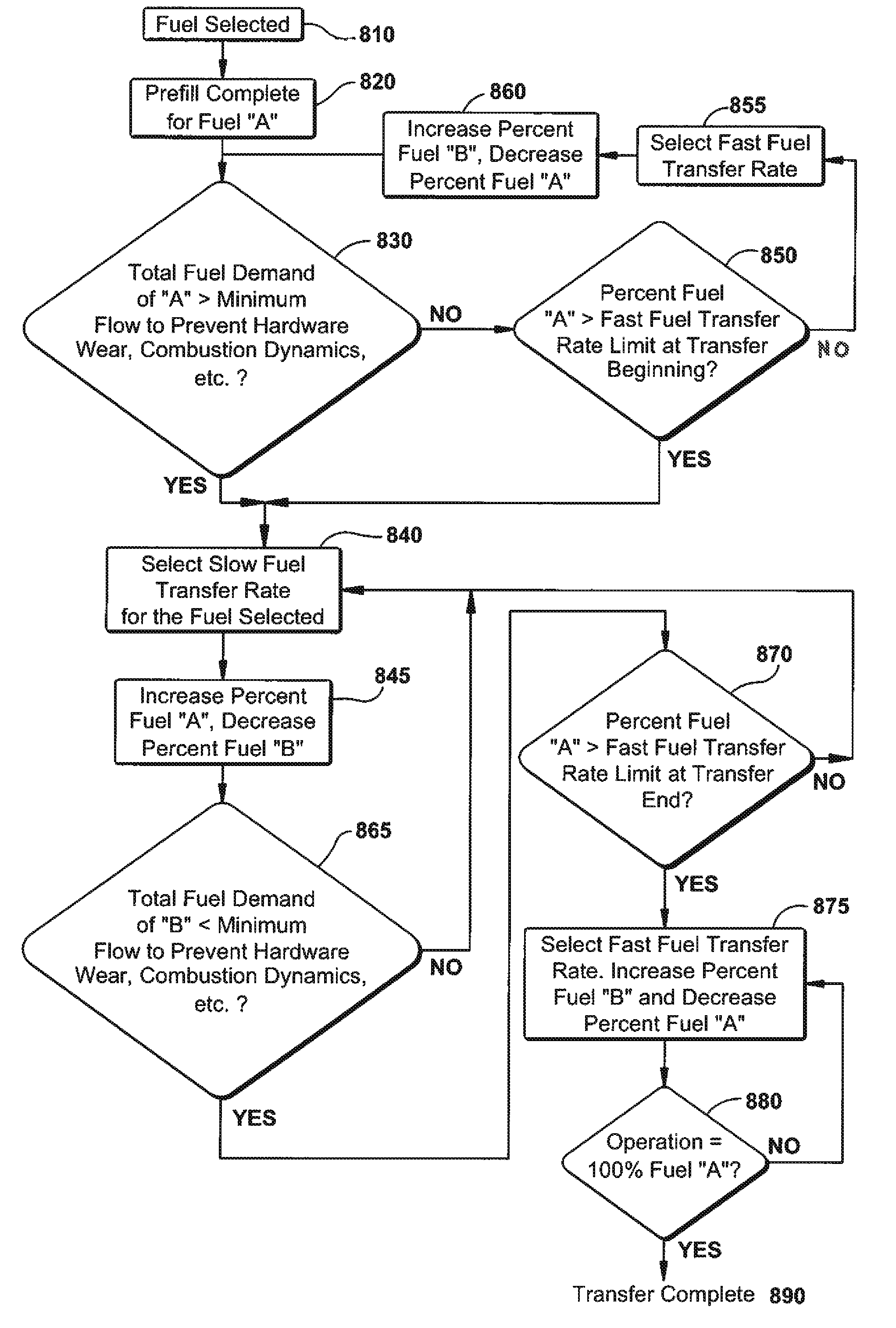

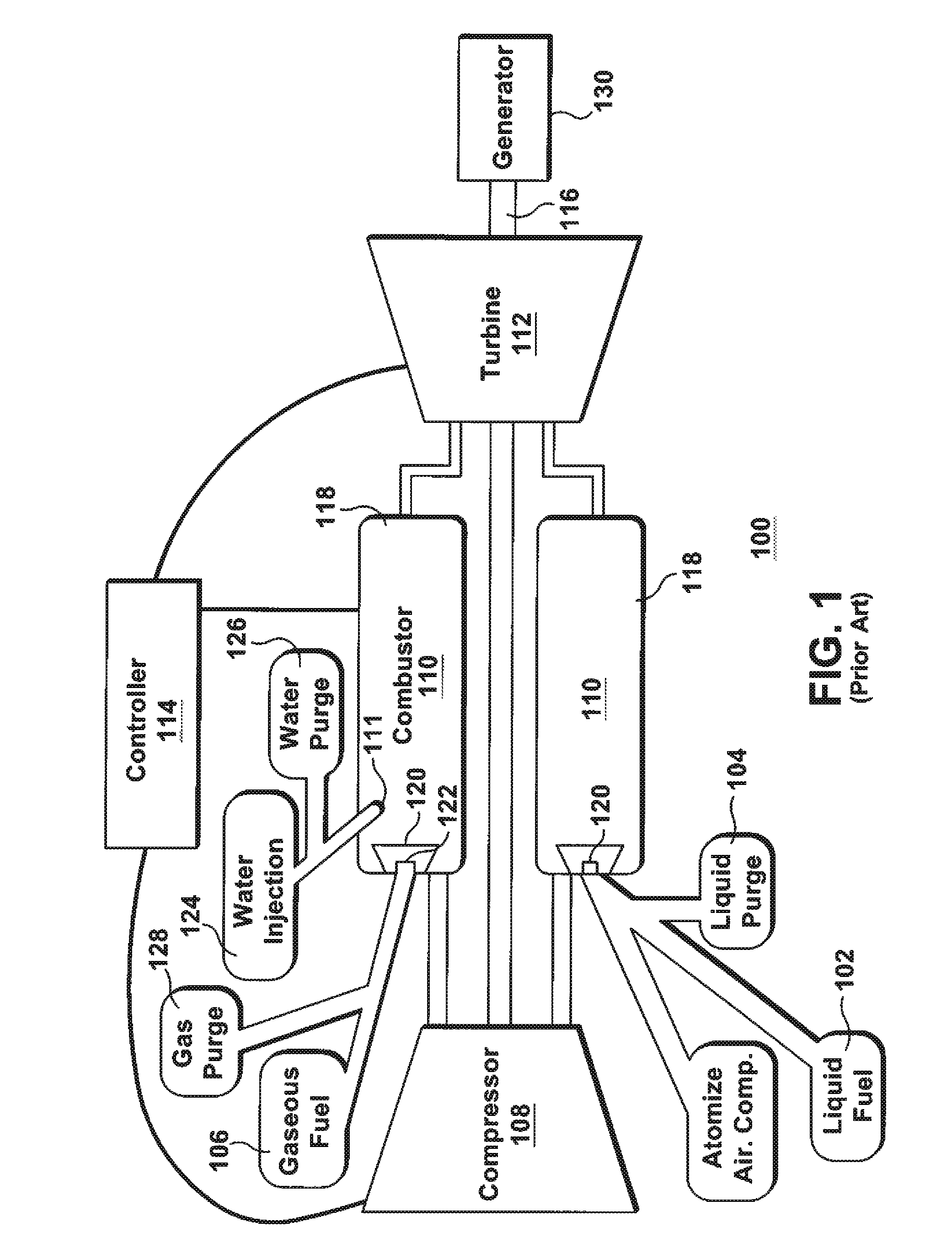

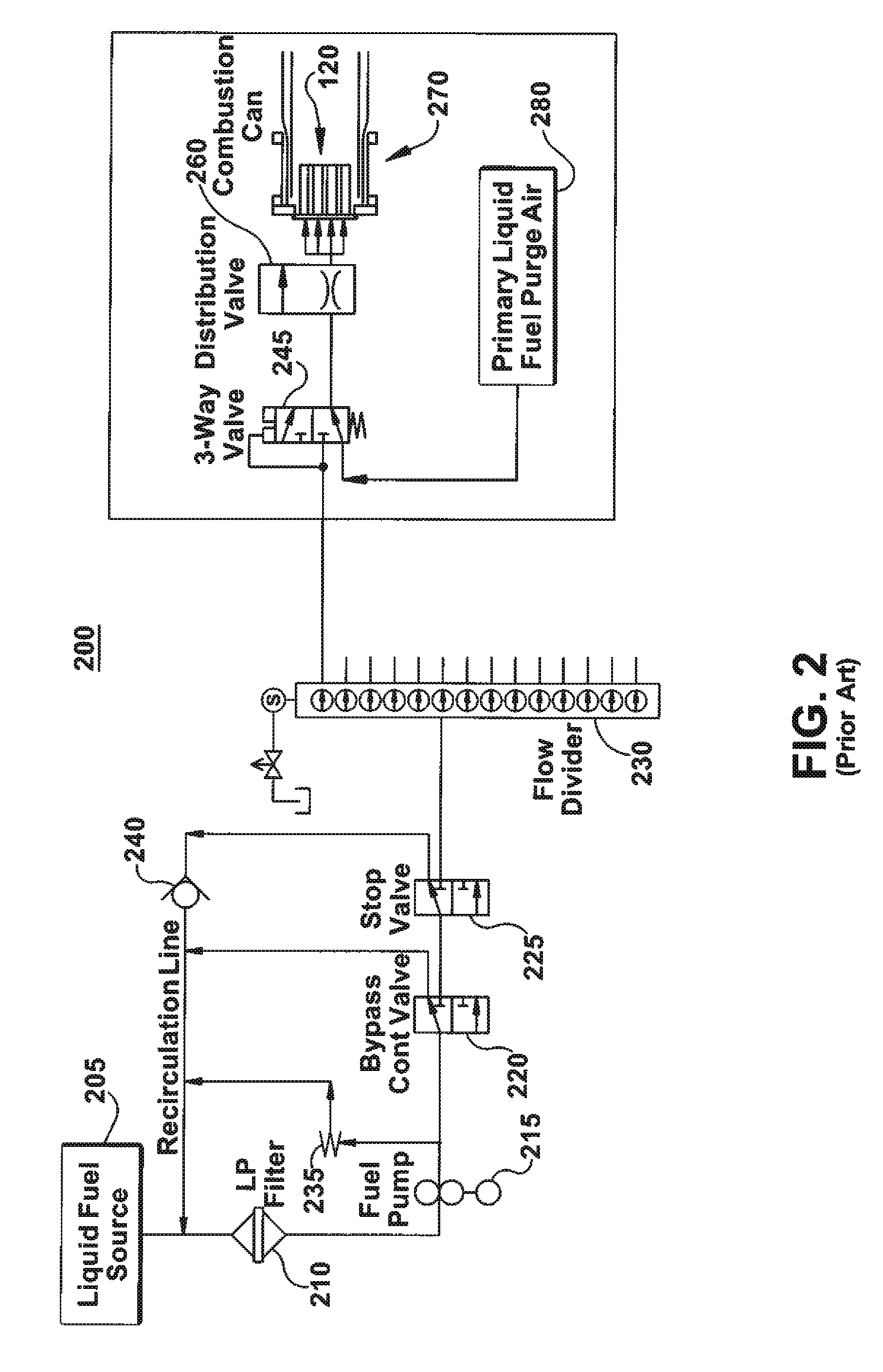

Non-linear fuel transfers for gas turbines

InactiveUS7770400B2Minimize timeDecreasing fuel flowrateAnalogue computers for vehiclesTurbine/propulsion engine ignitionFuel typeLiquid fuel

Owner:GENERAL ELECTRIC CO

High energy proton or neutron source

ActiveUS8837662B2Overcome disadvantagesPrevent escapeConversion outside reactor/acceleratorsDirect voltage acceleratorsHigh fluxEngineering

Owner:SHINE TECH LLC

Hybrid energy power management system and method

An energy management system is provided for use with a hybrid energy off-highway vehicle traveling on a predetermined course. The energy management system includes an energy management processor to determine a power storage parameter, a power transfer parameter, and an engine transfer parameter for each location along the predetermined course to minimize the total fuel consumed of all fuel types during the predetermined course subject to at least one fuel parameter constraint. An energy storage system selectively stores electrical energy available from the traction bus as a function of the power storage parameter and selectively supplies secondary electric power from the stored electrical energy to the traction bus as a function of the power transfer parameter. The engine selectively supplies primary electric power to the traction bus at each location along said predetermined course through selectively using at least one fuel type in response to said engine transfer parameter.

Owner:GENERAL ELECTRIC CO

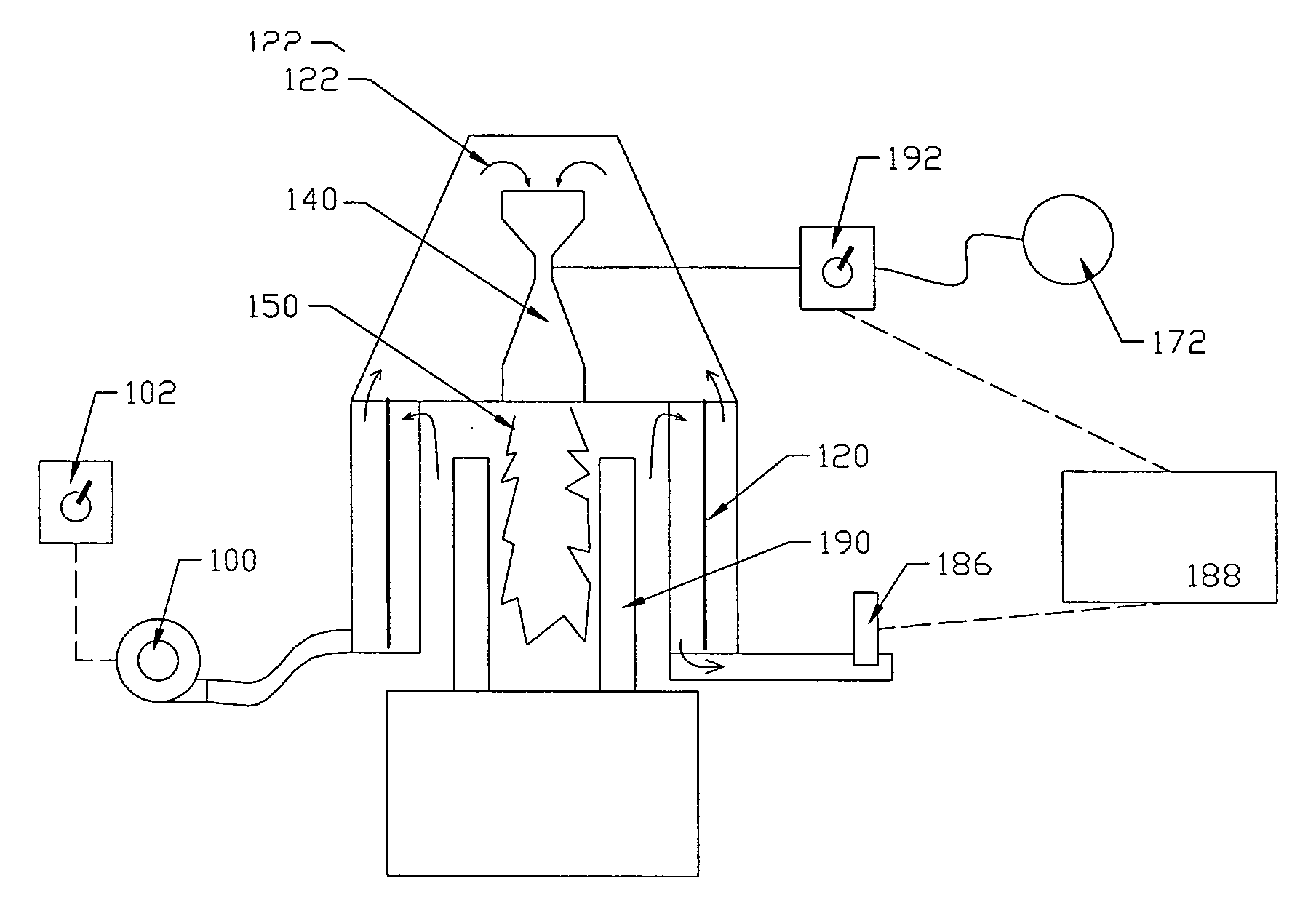

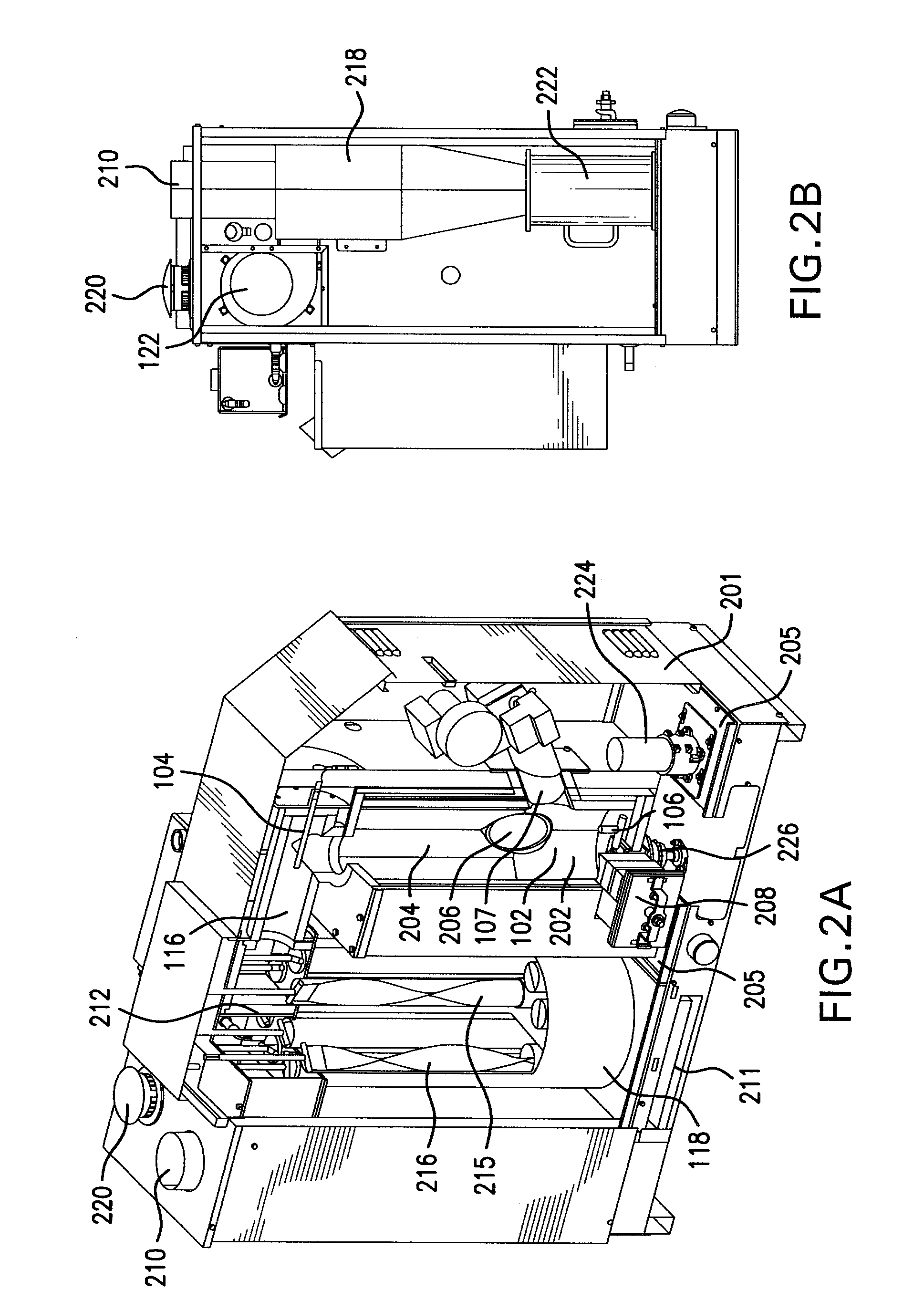

Non-catalytic biomass fuel burner and method

The present invention relates to a non-catalytic biomass burner that may be used to burn a variety of fuel types at high efficiencies. The burner may include a cylindrical combustion chamber with an auxiliary igniter to heat the fuel in the combustion chamber until desirable combustion temperatures are reached. Fuel may be added to the chamber via a fuel feed assembly, and the rate of fuel addition to the chamber by the fuel feed assembly may be controlled by a computer. A fan located on the distal side of a flue pipe from the chamber may also be provided that pulls air into the chamber through one or more air inlets that are designed to encourage cyclonic air and exhaust flow in the chamber. Methods are further provided for controlling the manner of operation of the burner by a computer that may be instructed by a computer program code.

Owner:LASKOWSKI SCOTT +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com