Joint optimized scheduling method for multiple types of generating sets of self-supply power plant of iron and steel enterprise

A generator set and joint optimization technology, applied in the energy industry, instruments, sustainable manufacturing/processing, etc., can solve problems such as high cost, low power supply cost, and high energy consumption in power production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical scheme proposed by the invention can adopt computer software technology to realize the automatic operation process. The present invention will be further described in detail below in conjunction with the accompanying drawings.

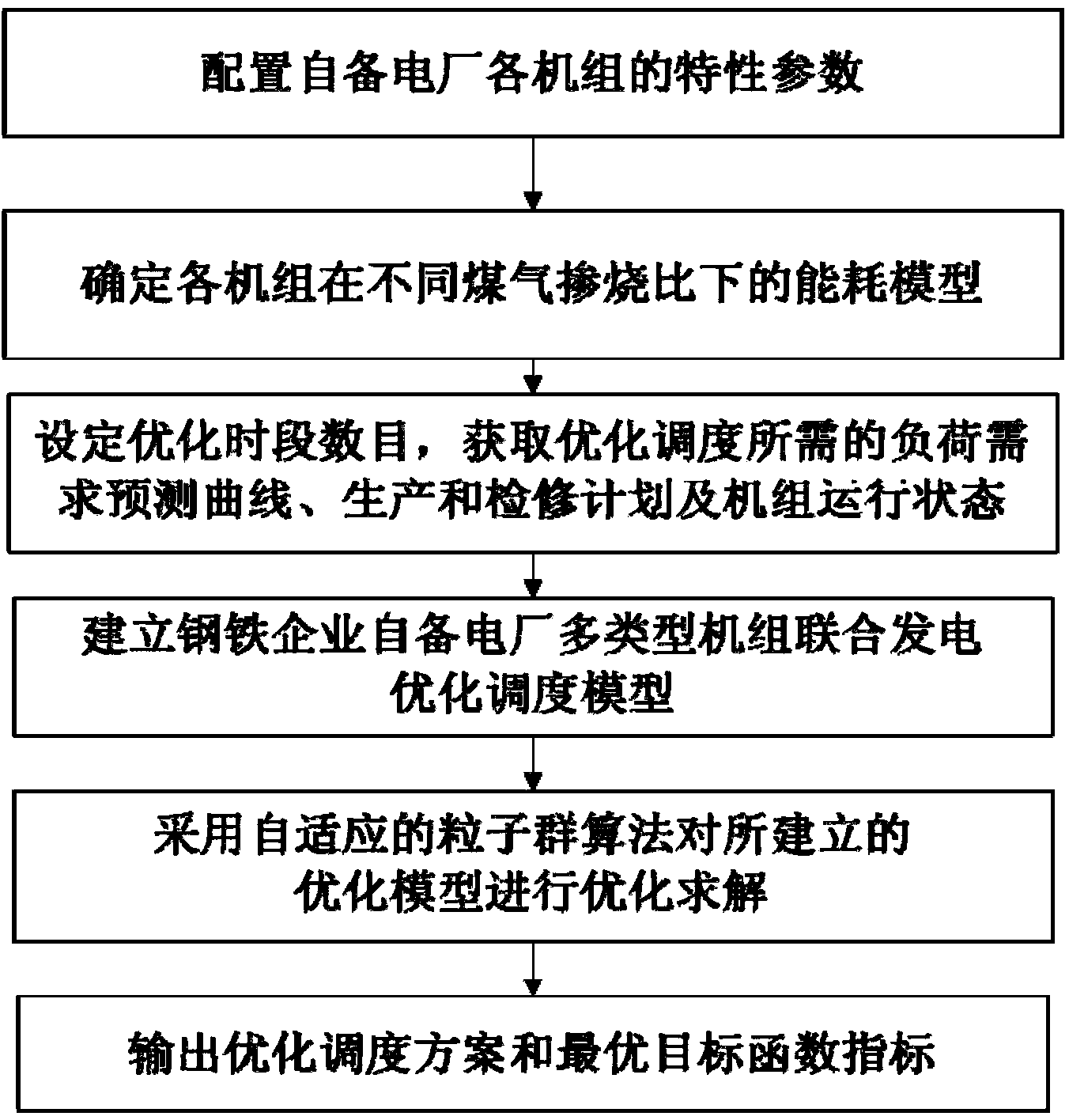

[0059] see figure 1 , figure 1 In order to provide a flow chart of an embodiment of the method for joint optimal scheduling of multi-type generating sets in self-provided power plants of iron and steel enterprises in this application, it includes the following steps:

[0060] Step 1: Obtain the following characteristic parameters of each unit in the self-provided power plant: maximum active output, minimum active output, maximum load increase speed, maximum load decrease speed, fuel consumption range, and upper limit of gas blending ratio.

[0061] The second step is to determine the energy consumption model of the self-provided power plant unit under different gas blending ratios.

[0062] The historical operation data needed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com