Patents

Literature

3396 results about "Gas blending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas blending is the process of mixing gases for a specific purpose where the composition of the resulting mixture is specified and controlled. A wide range of applications include scientific and industrial processes, food production and storage and breathing gases.

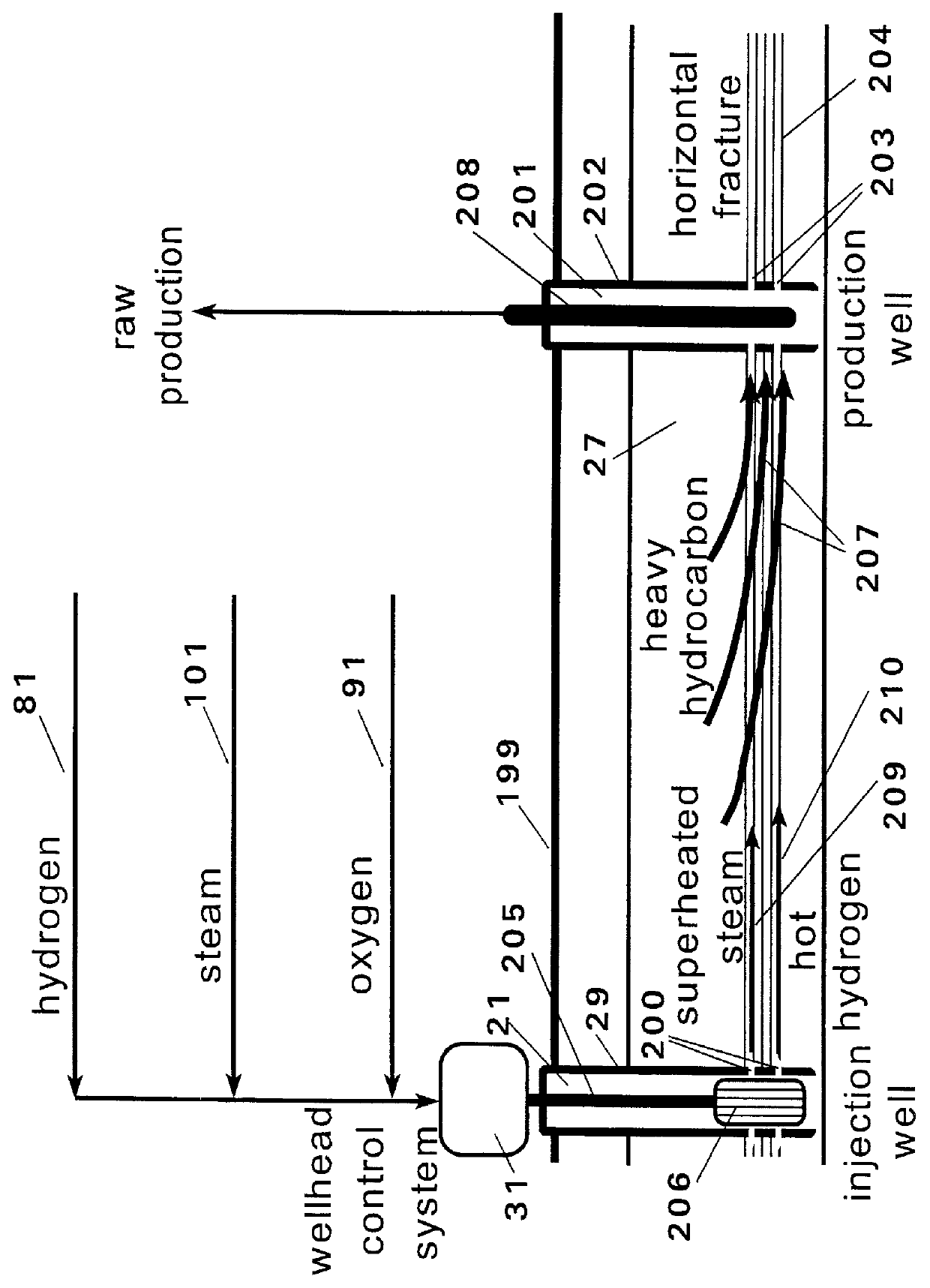

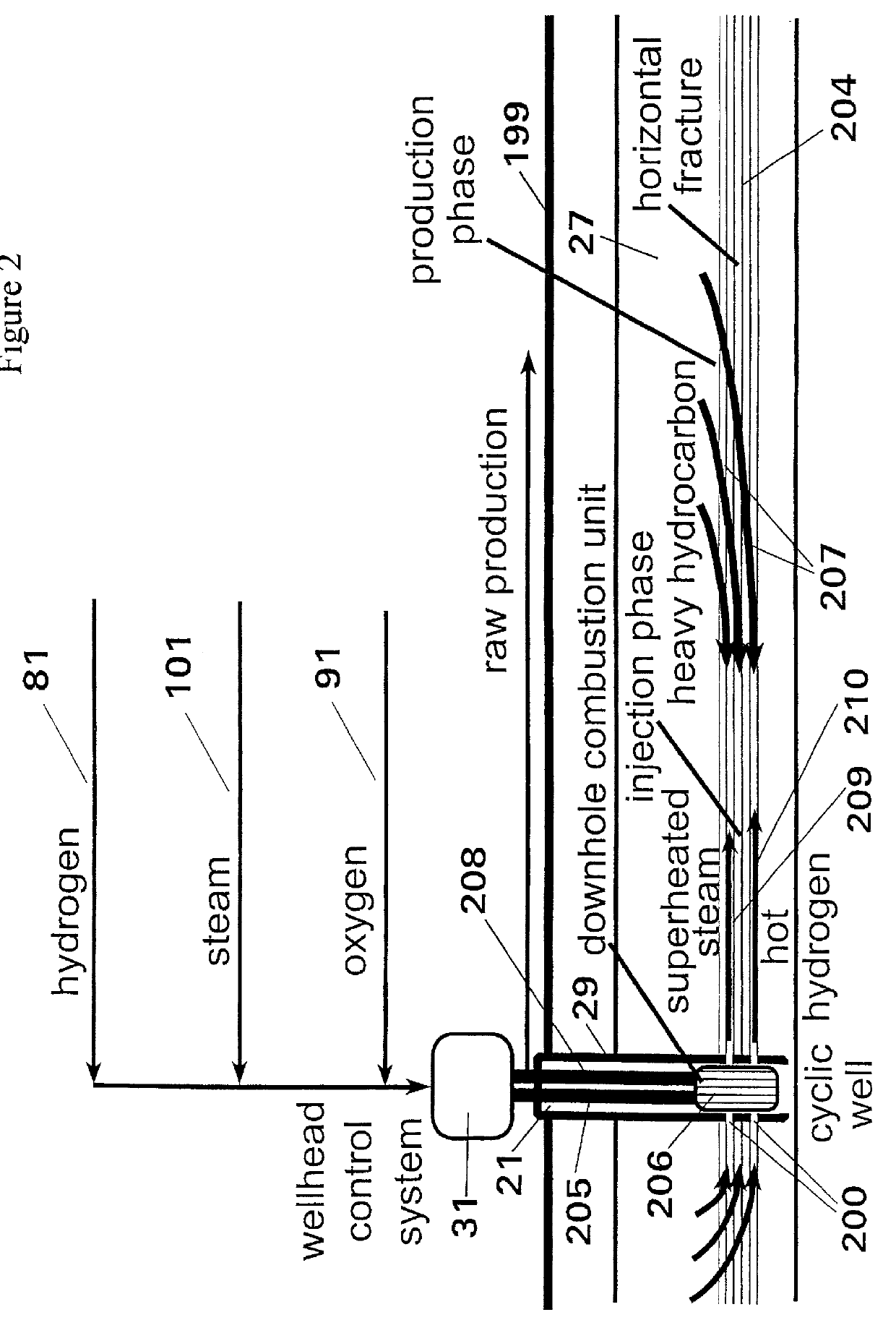

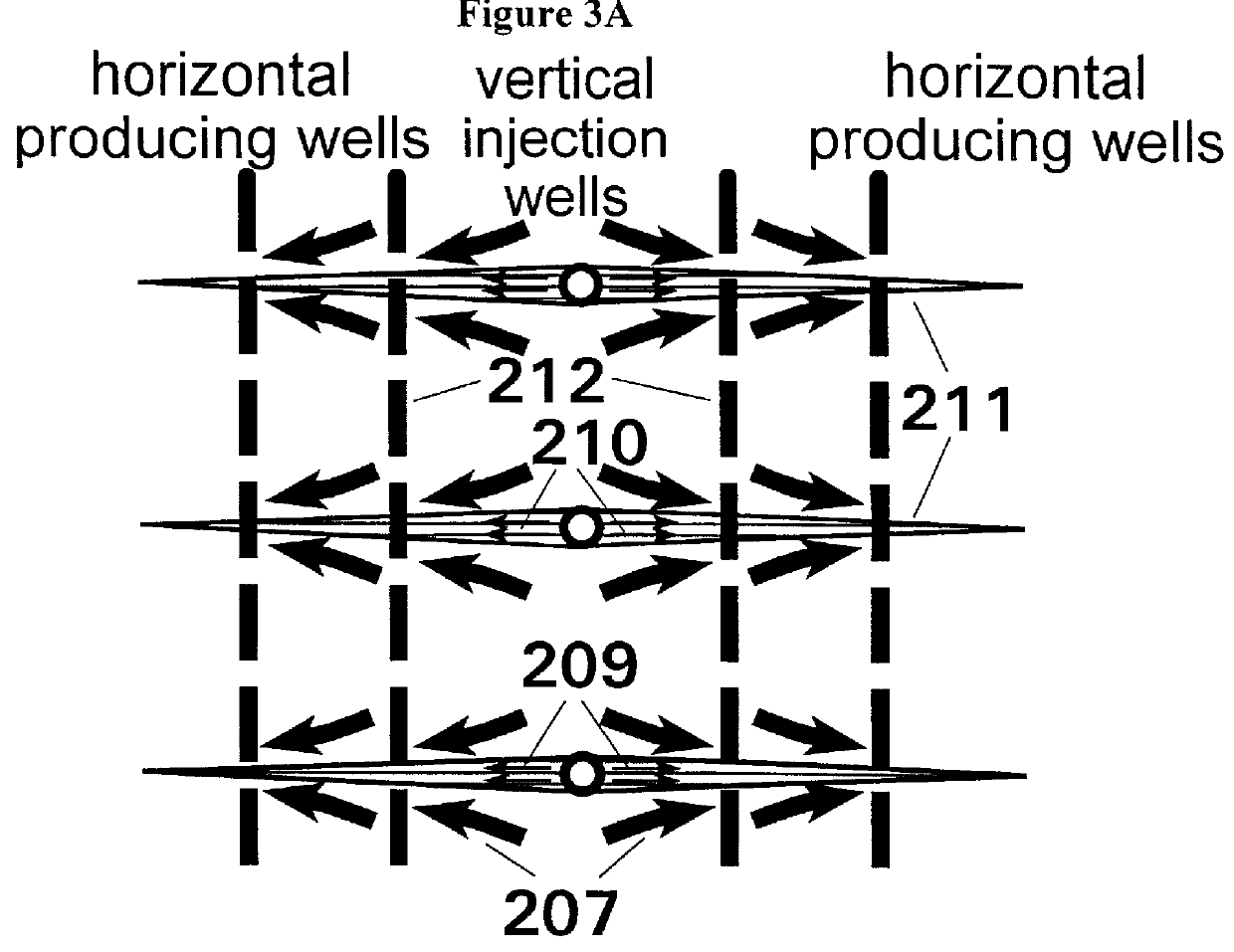

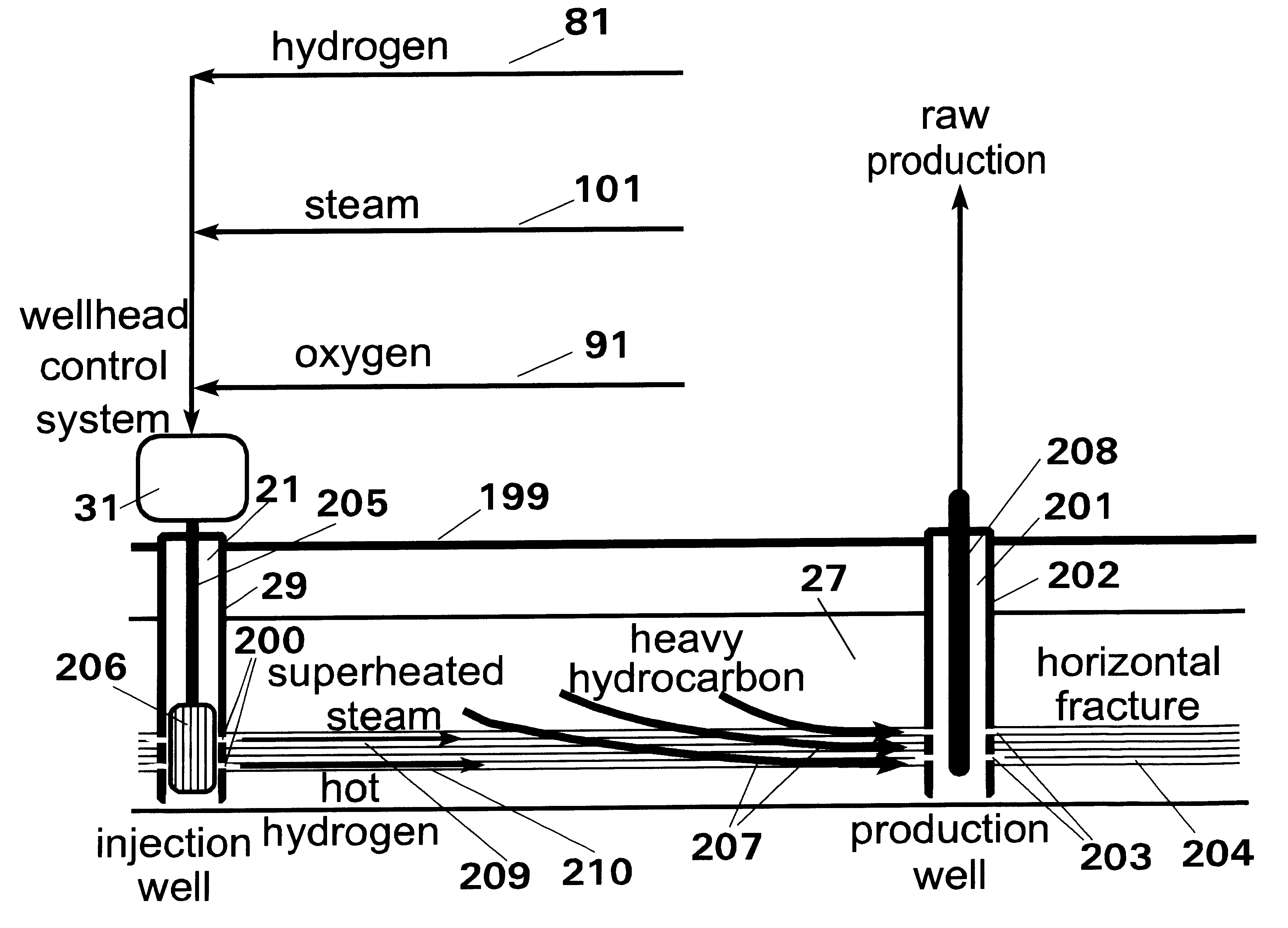

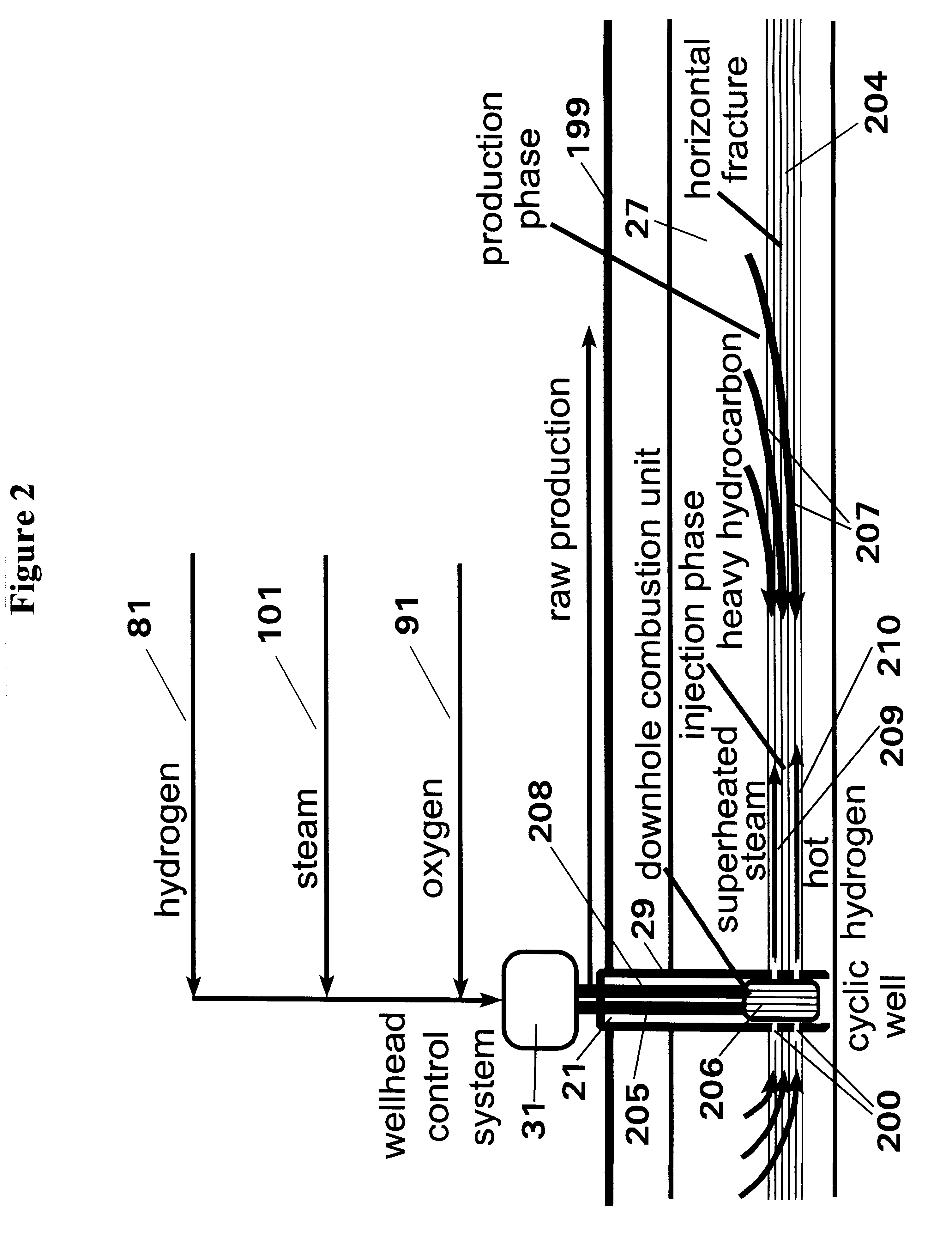

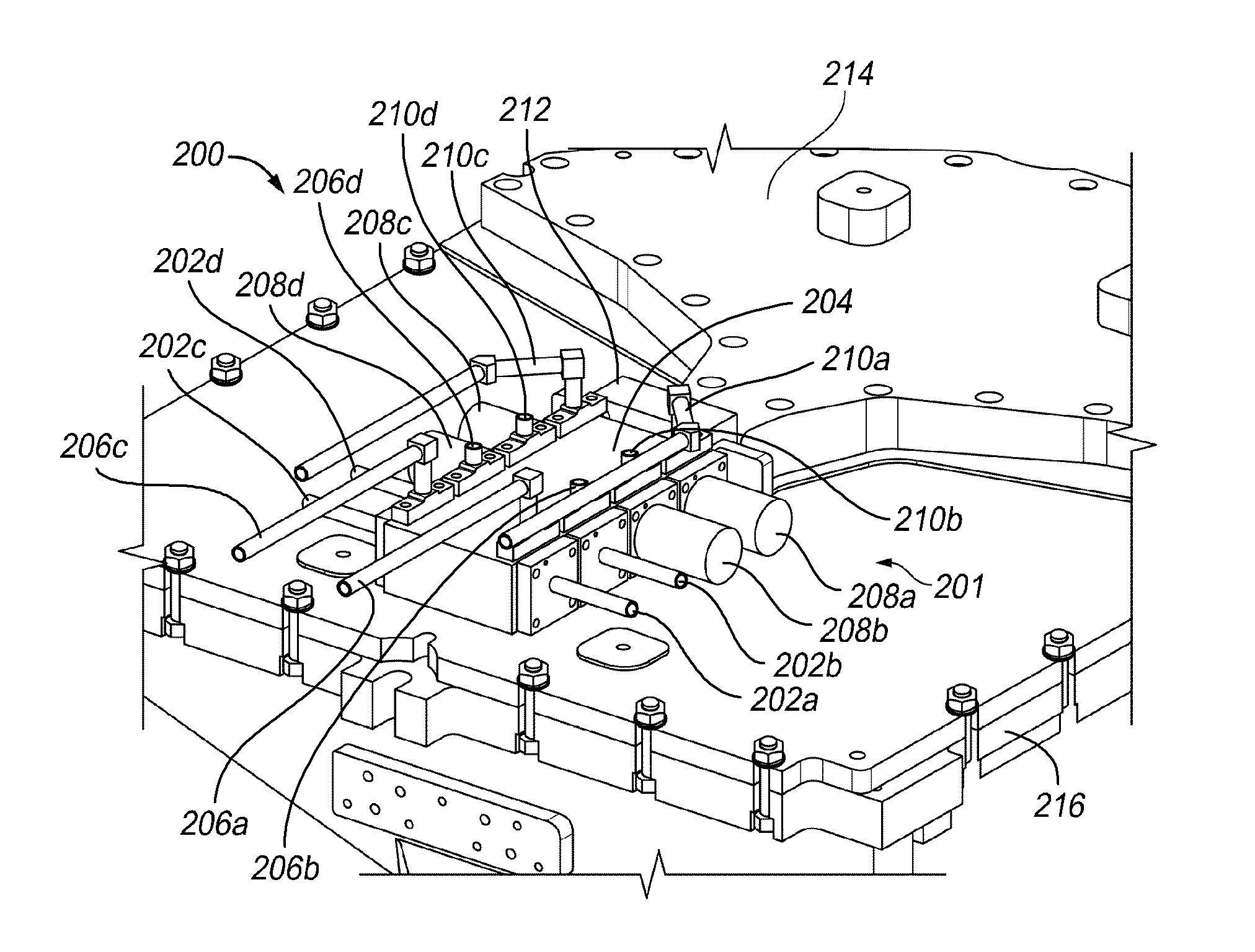

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more injection and production boreholes, which may include horizontal boreholes, or a cyclic operation whereby both injection and production occur in the same boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing or related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

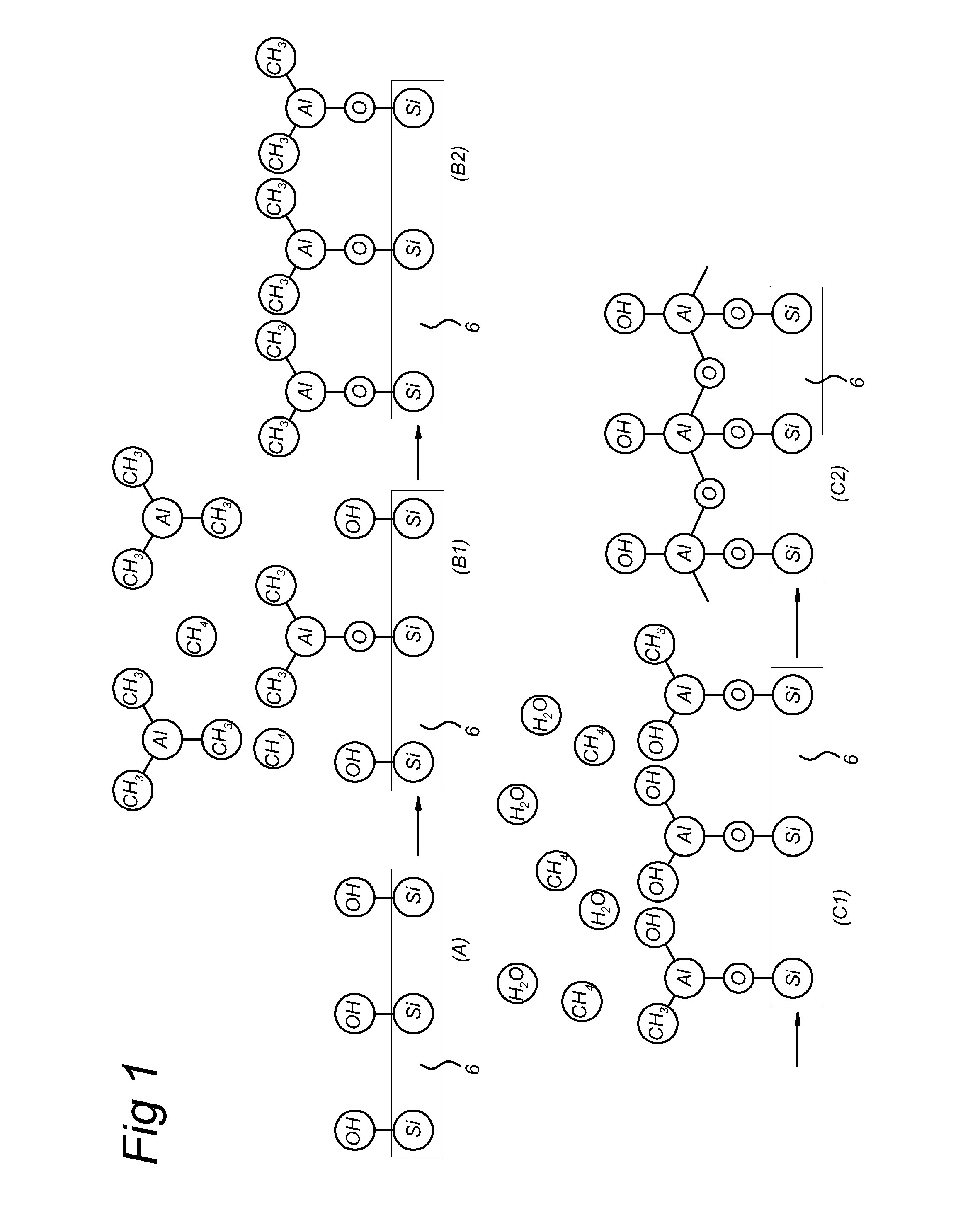

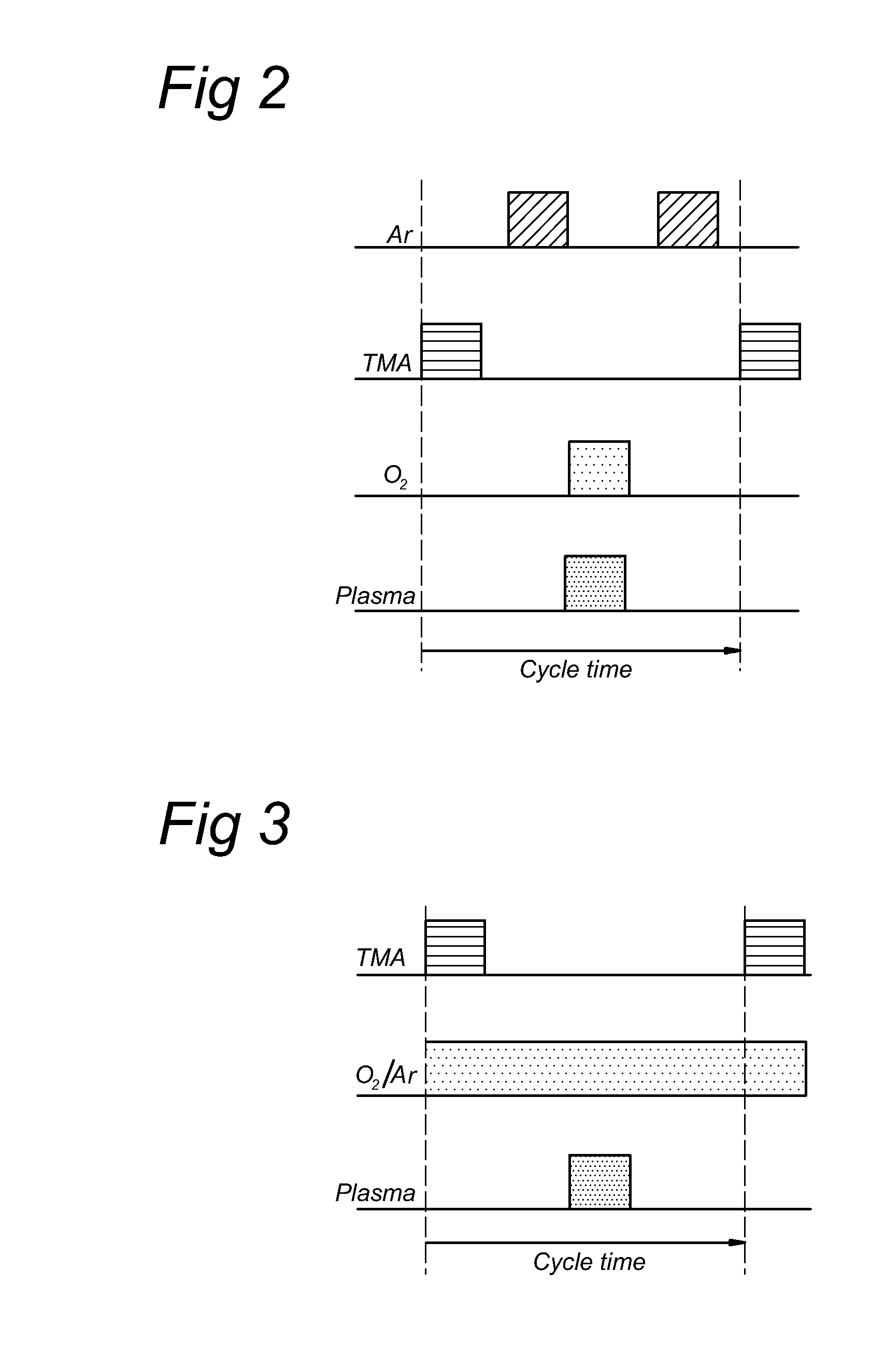

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20100255625A1Comparable and good performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPlasma generatorProduct gas

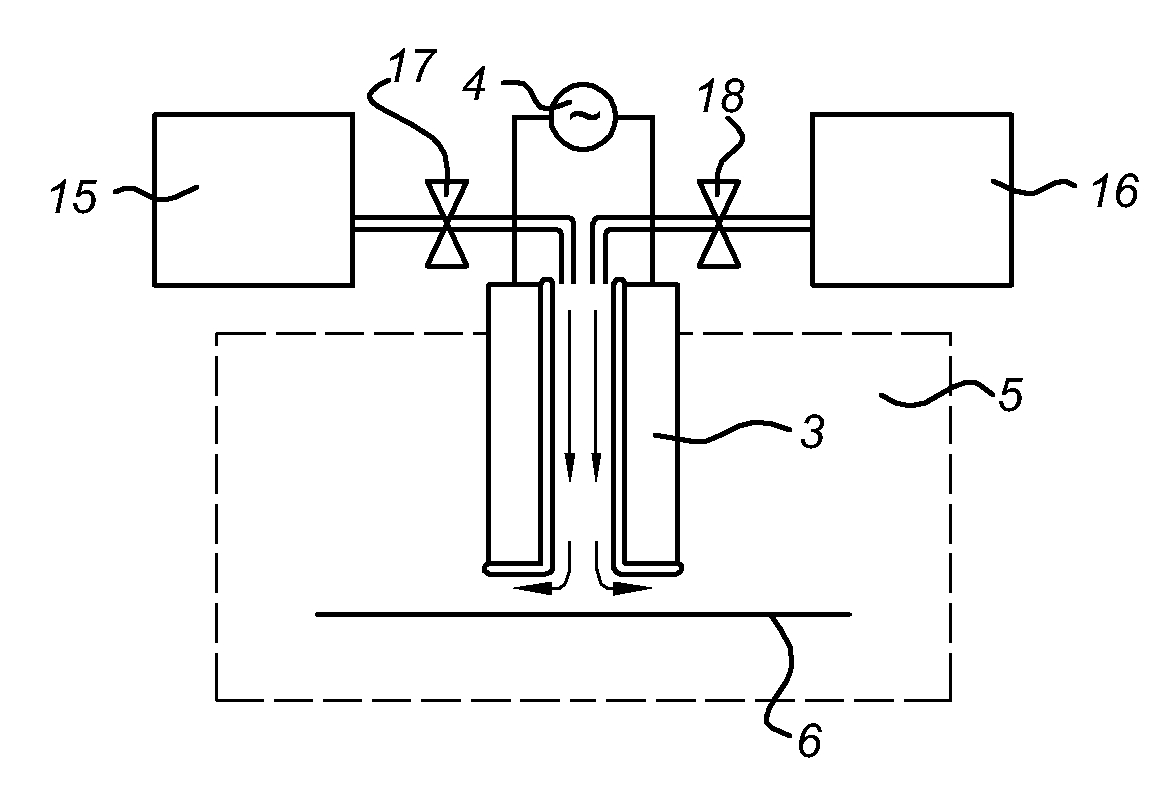

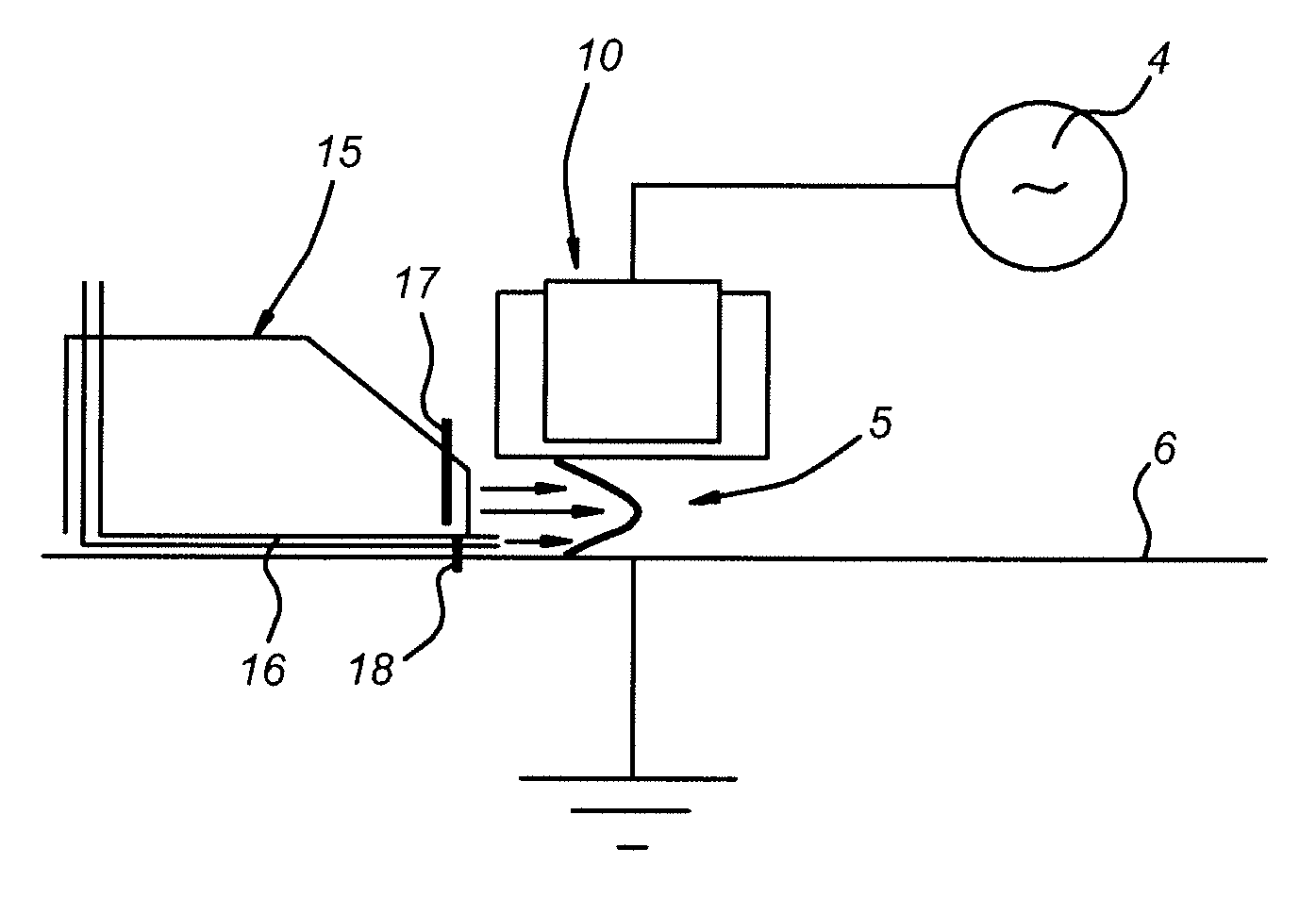

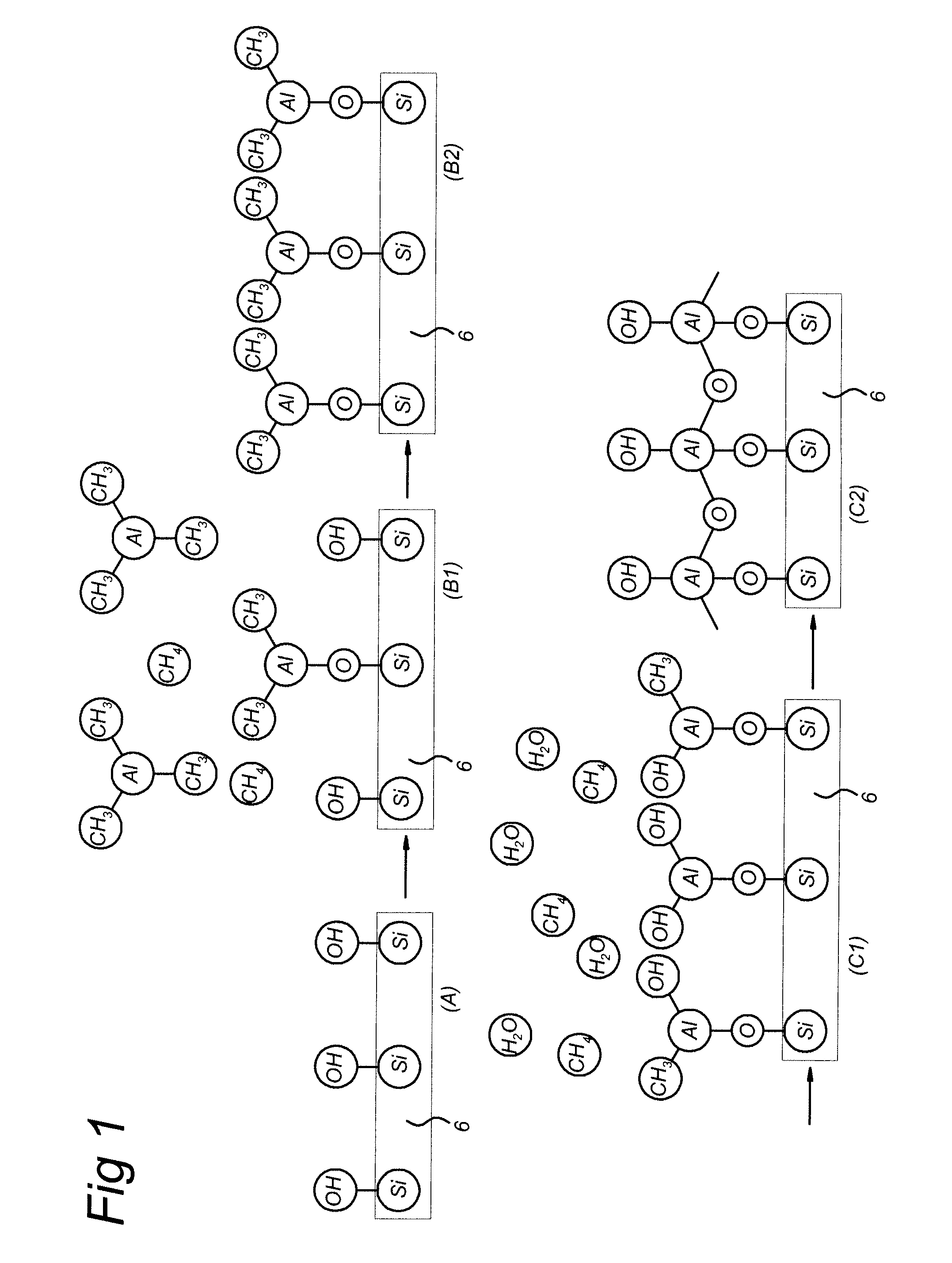

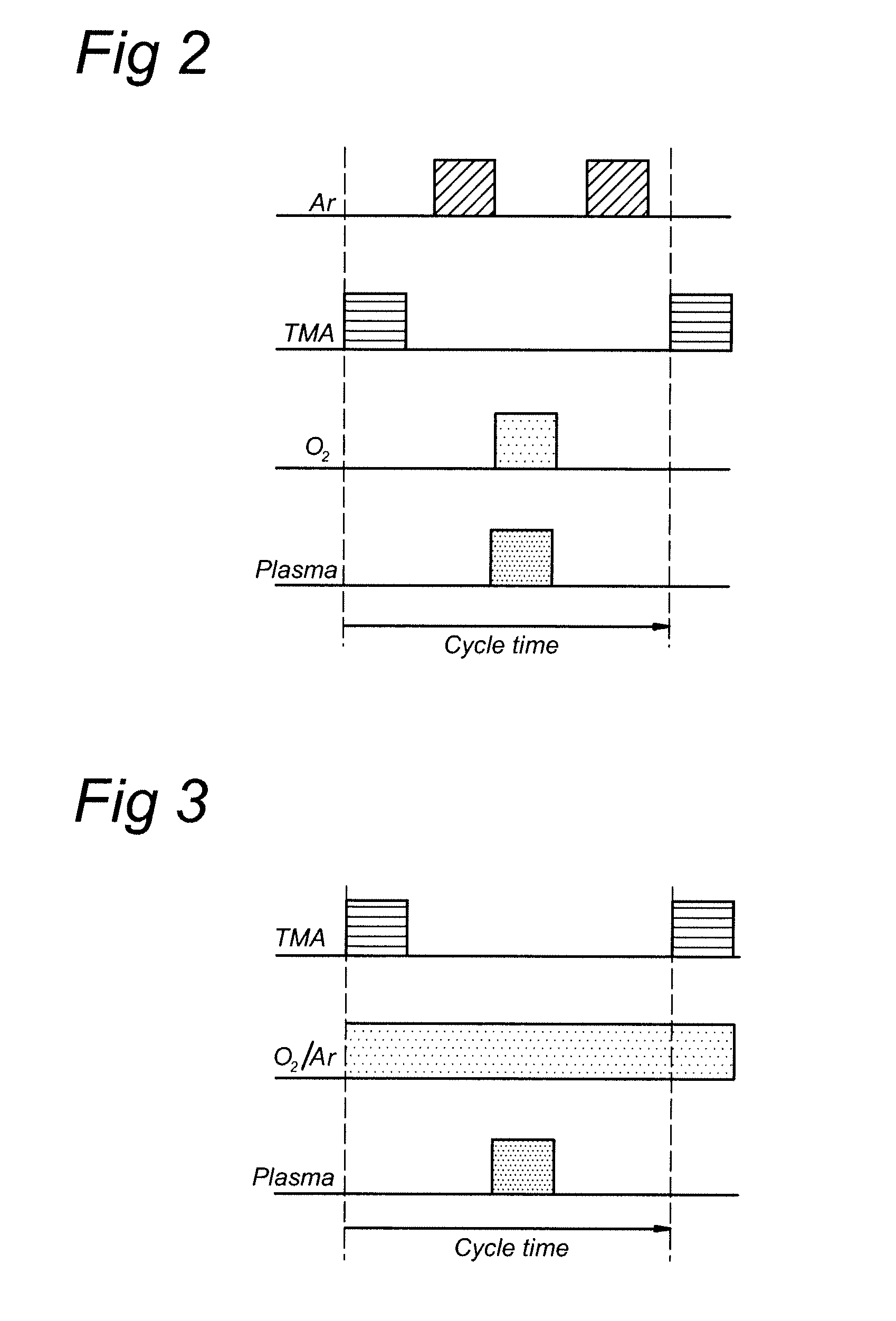

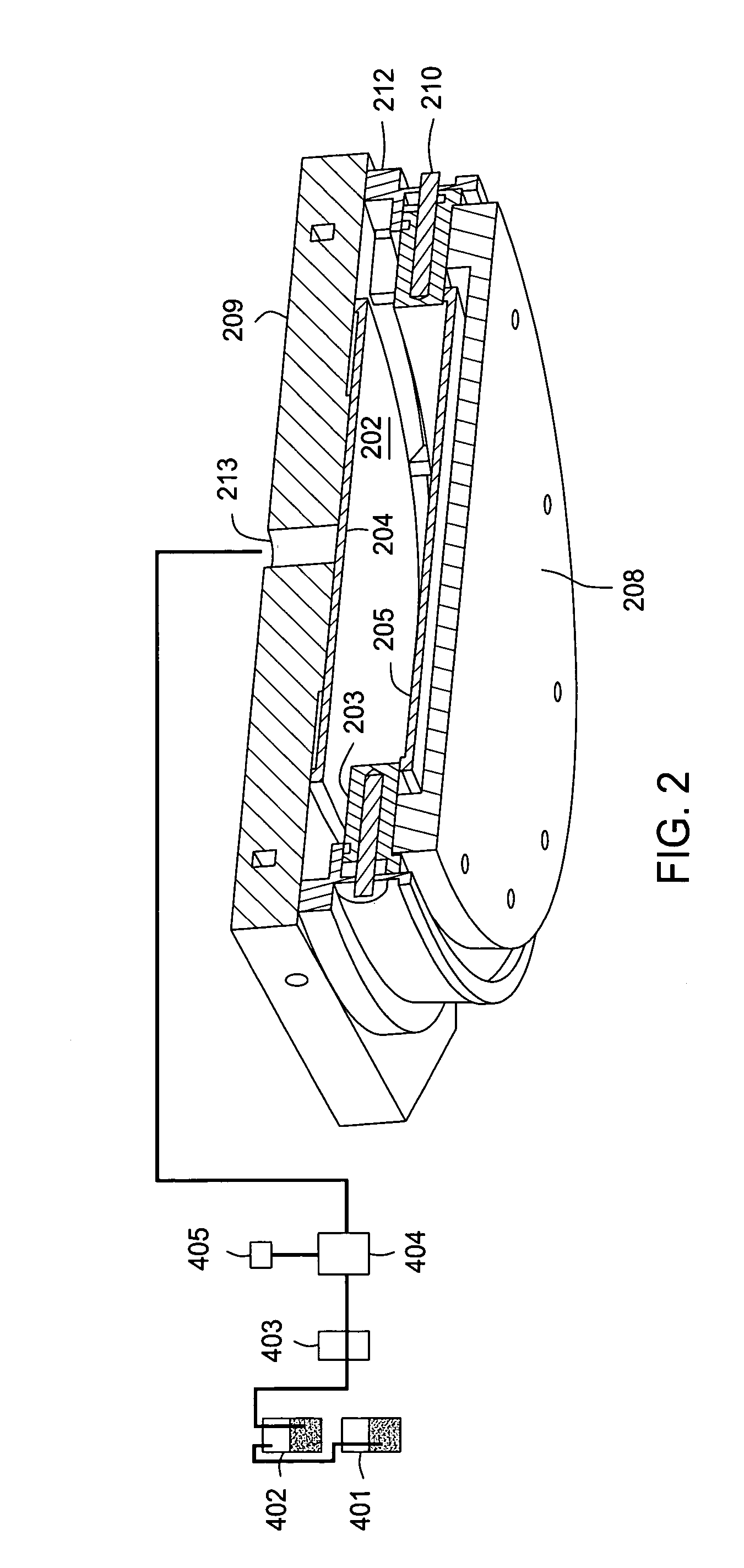

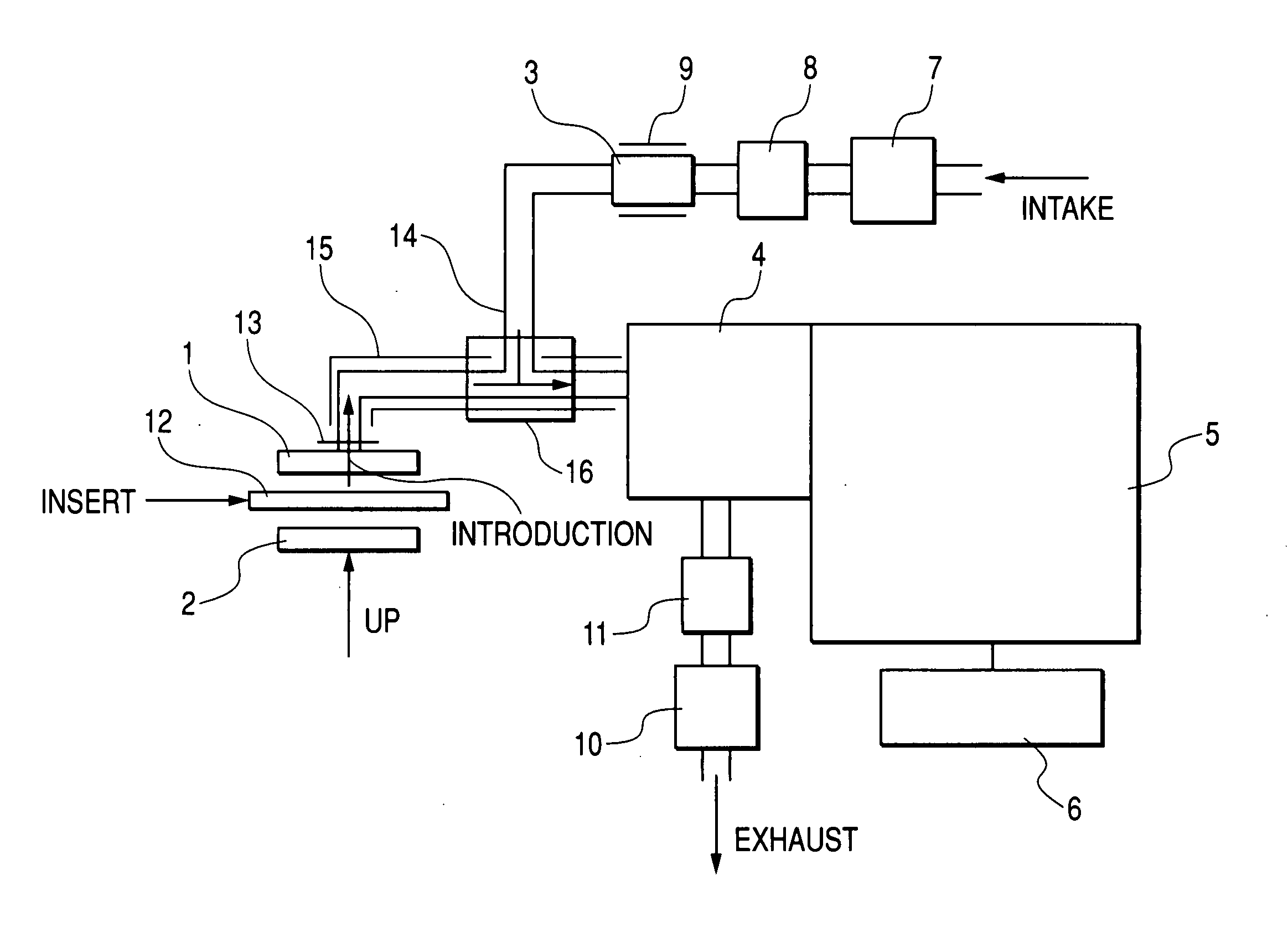

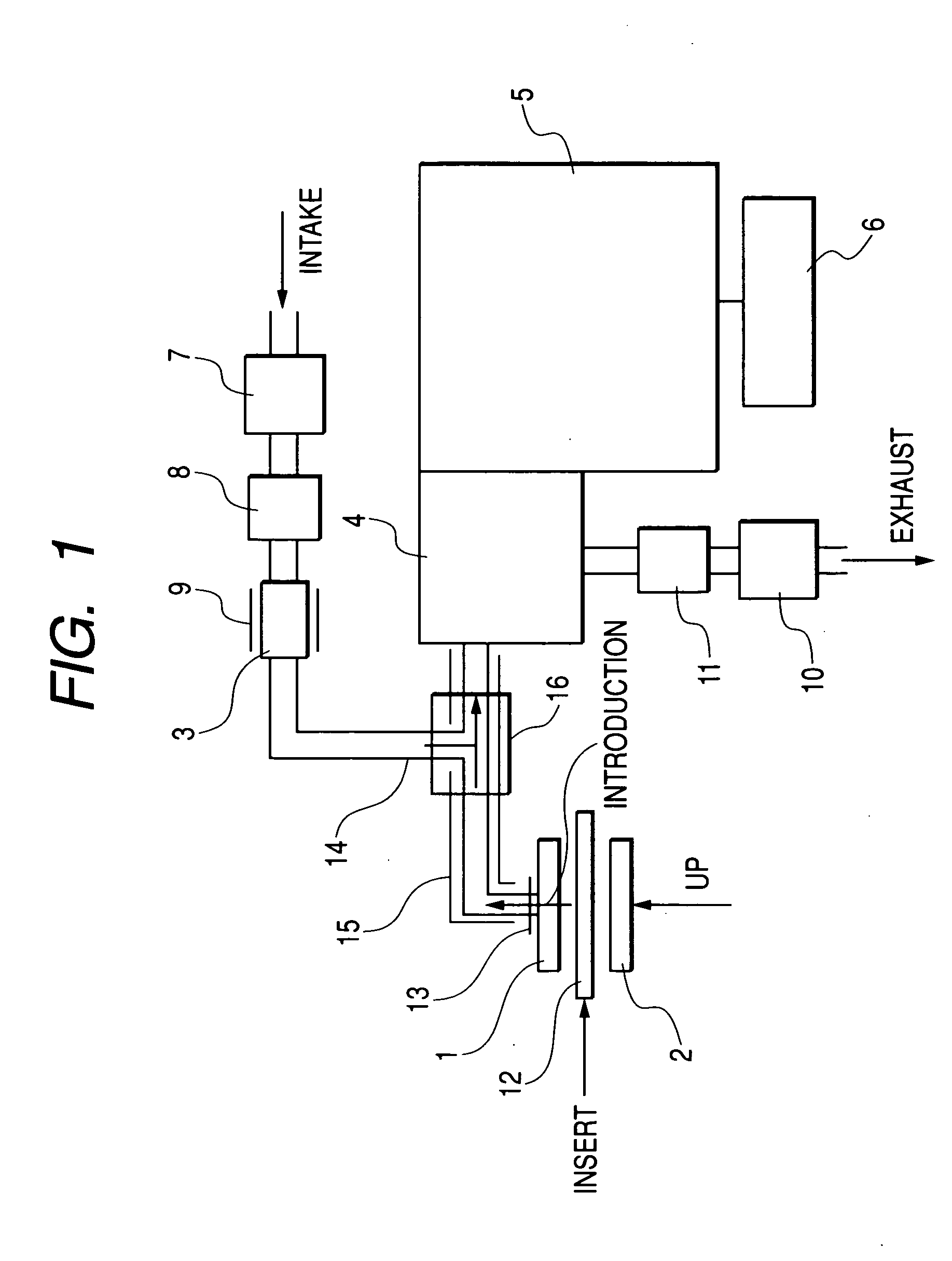

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space (1, 2). The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent, the plasma generator being arranged remote from the treatment space (1, 2).

Owner:FUJIFILM MFG EURO

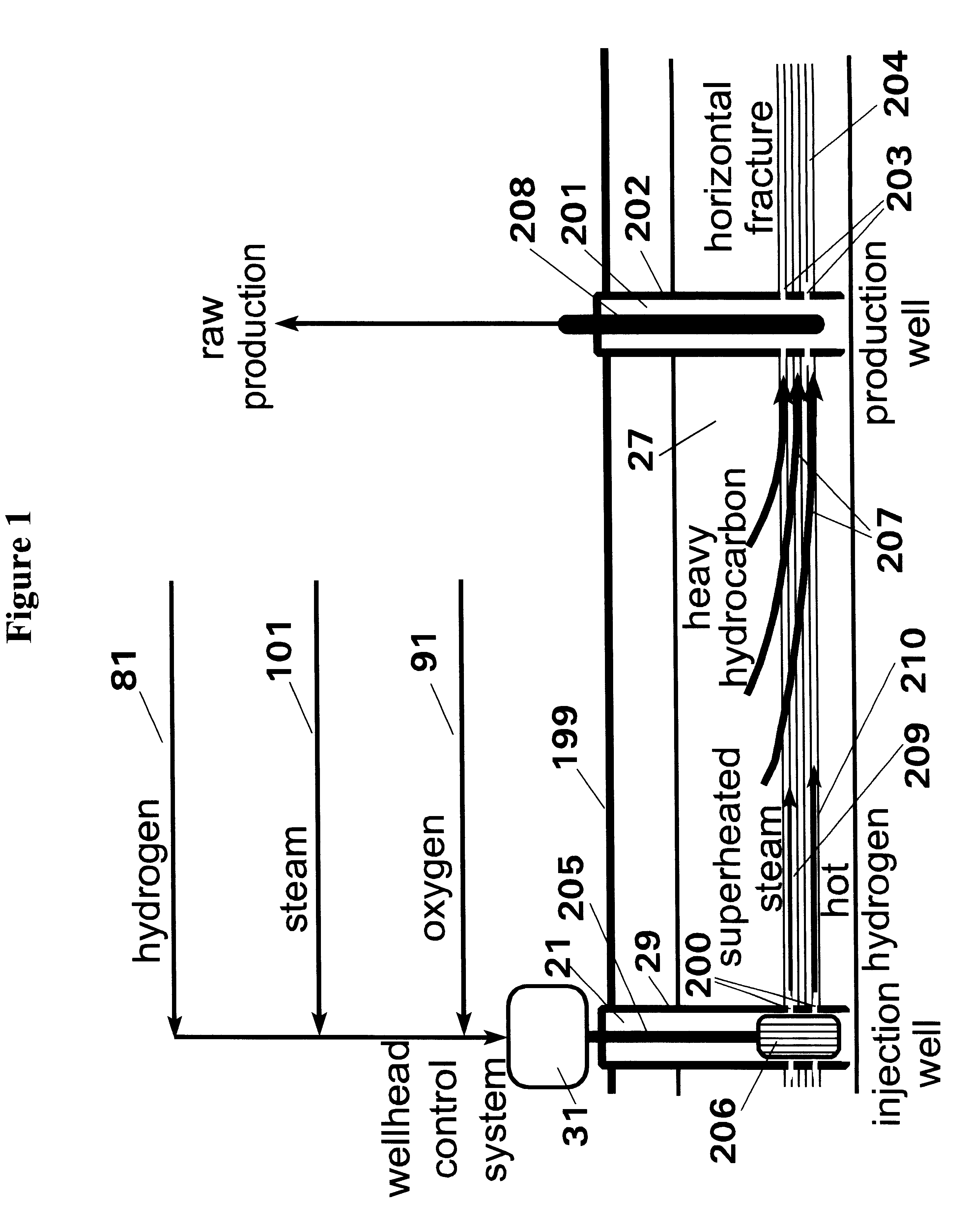

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more vertical injection boreholes and one or more vertical production boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes, or a cyclic operation whereby both injection and production occur in the same vertical boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing, multiple horizontal boreholes extending from vertical boreholes, or other related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

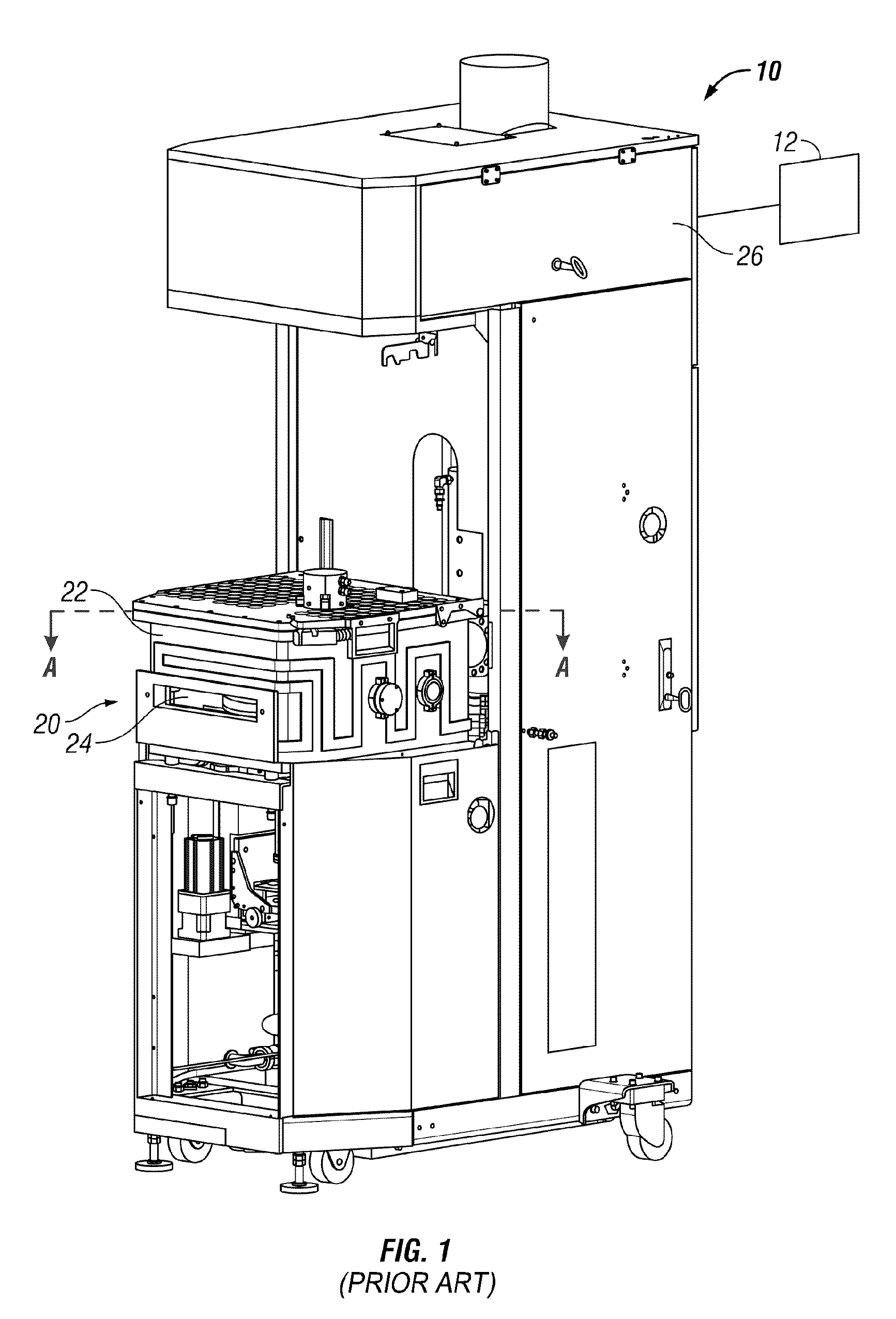

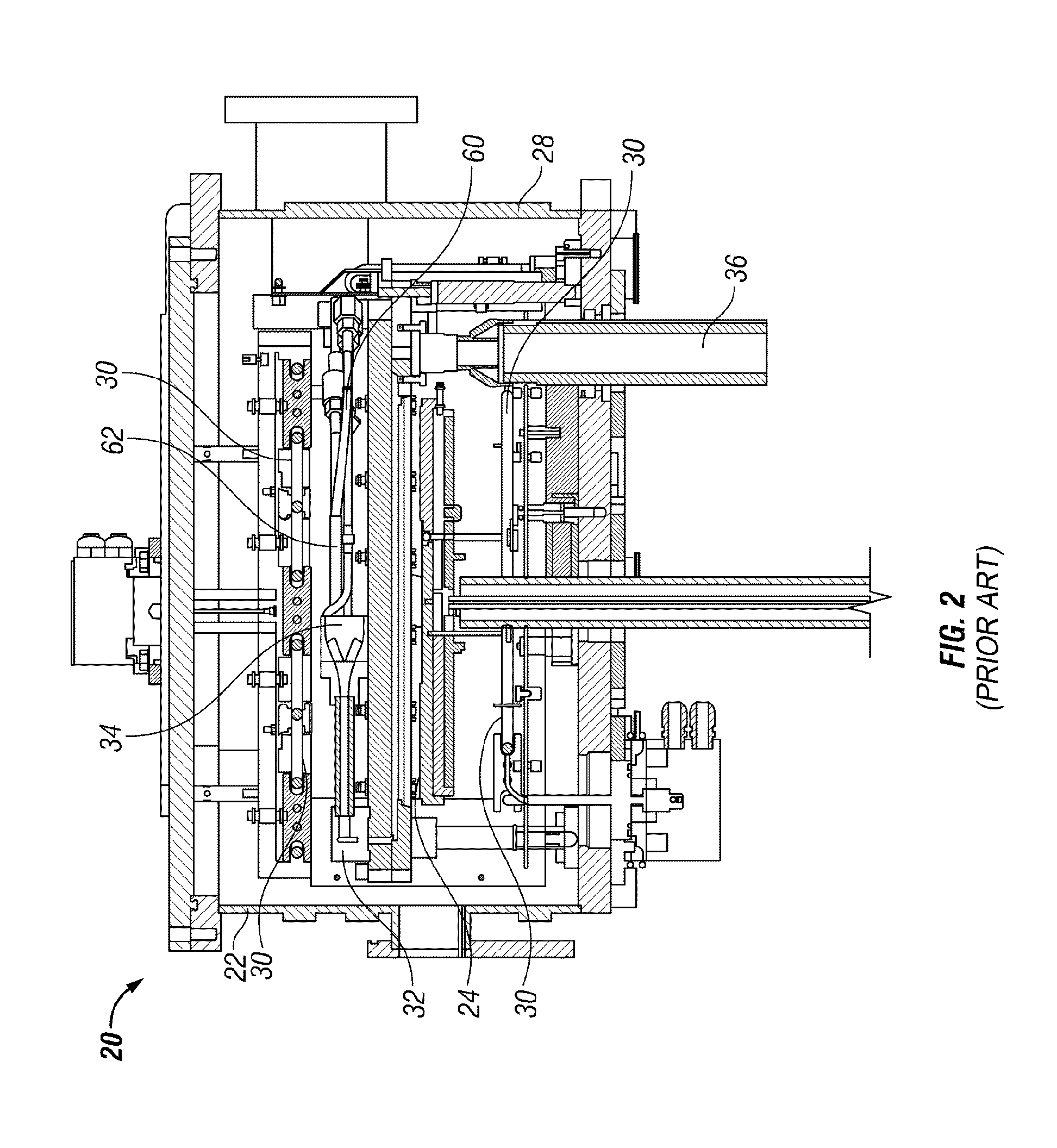

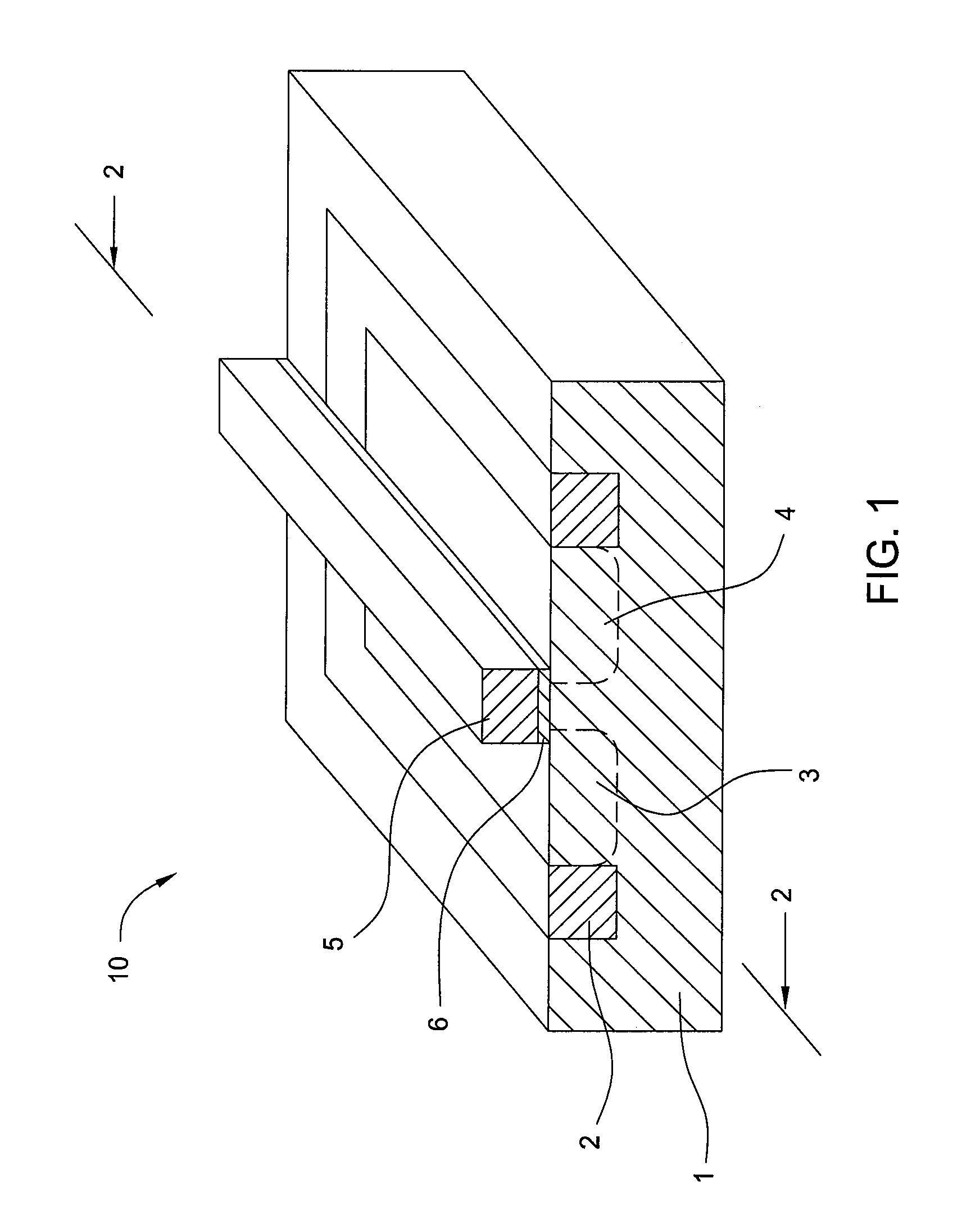

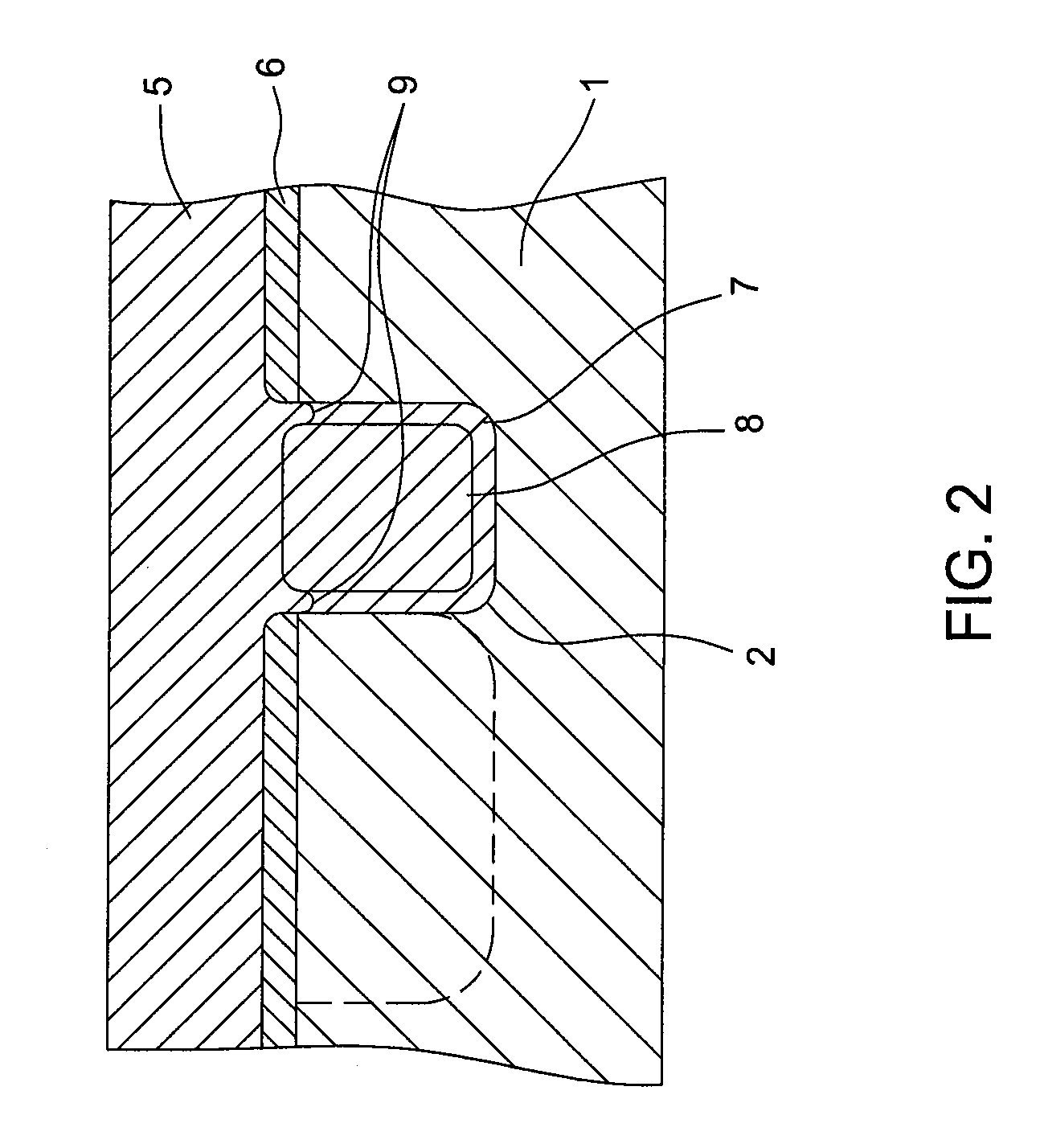

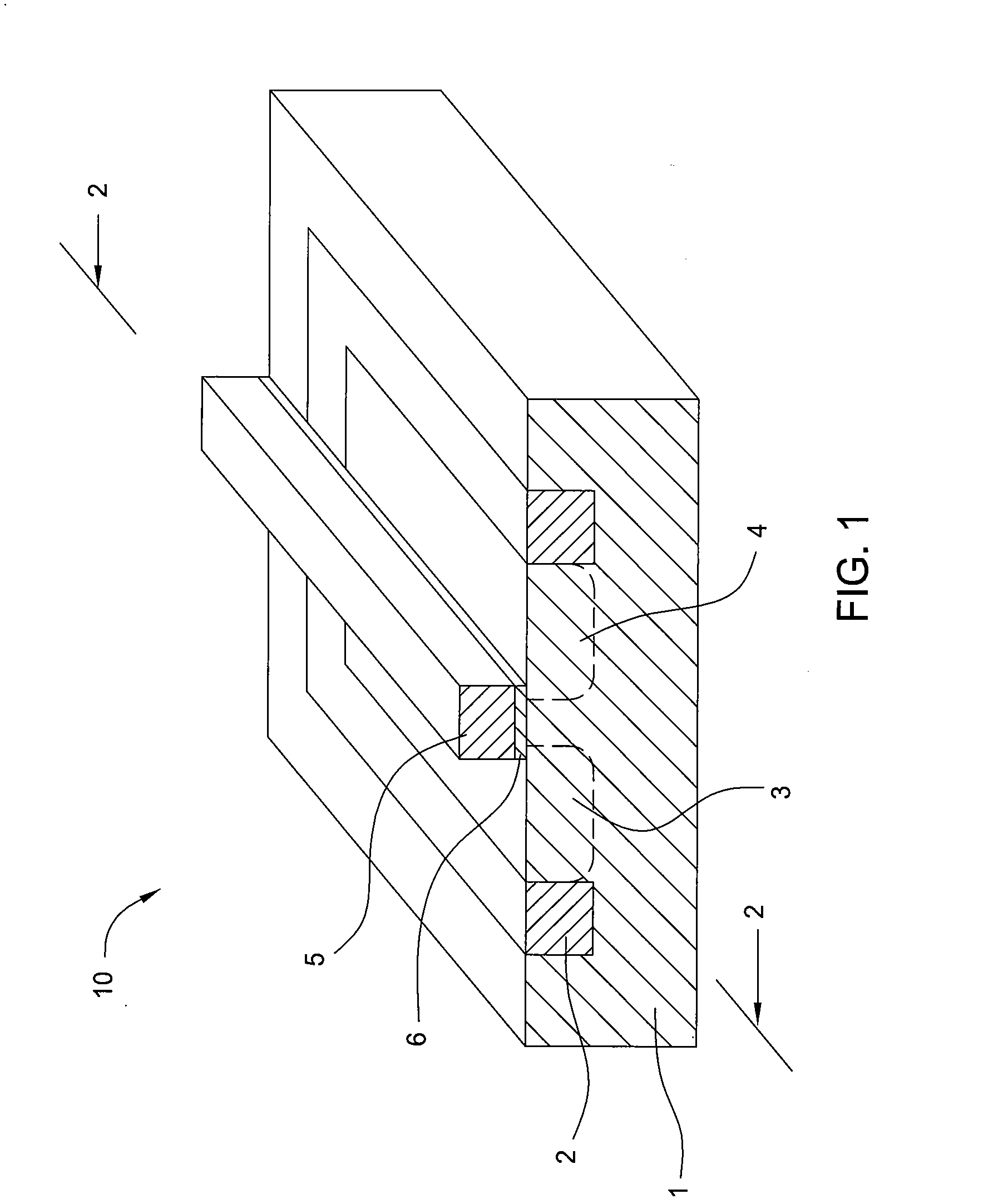

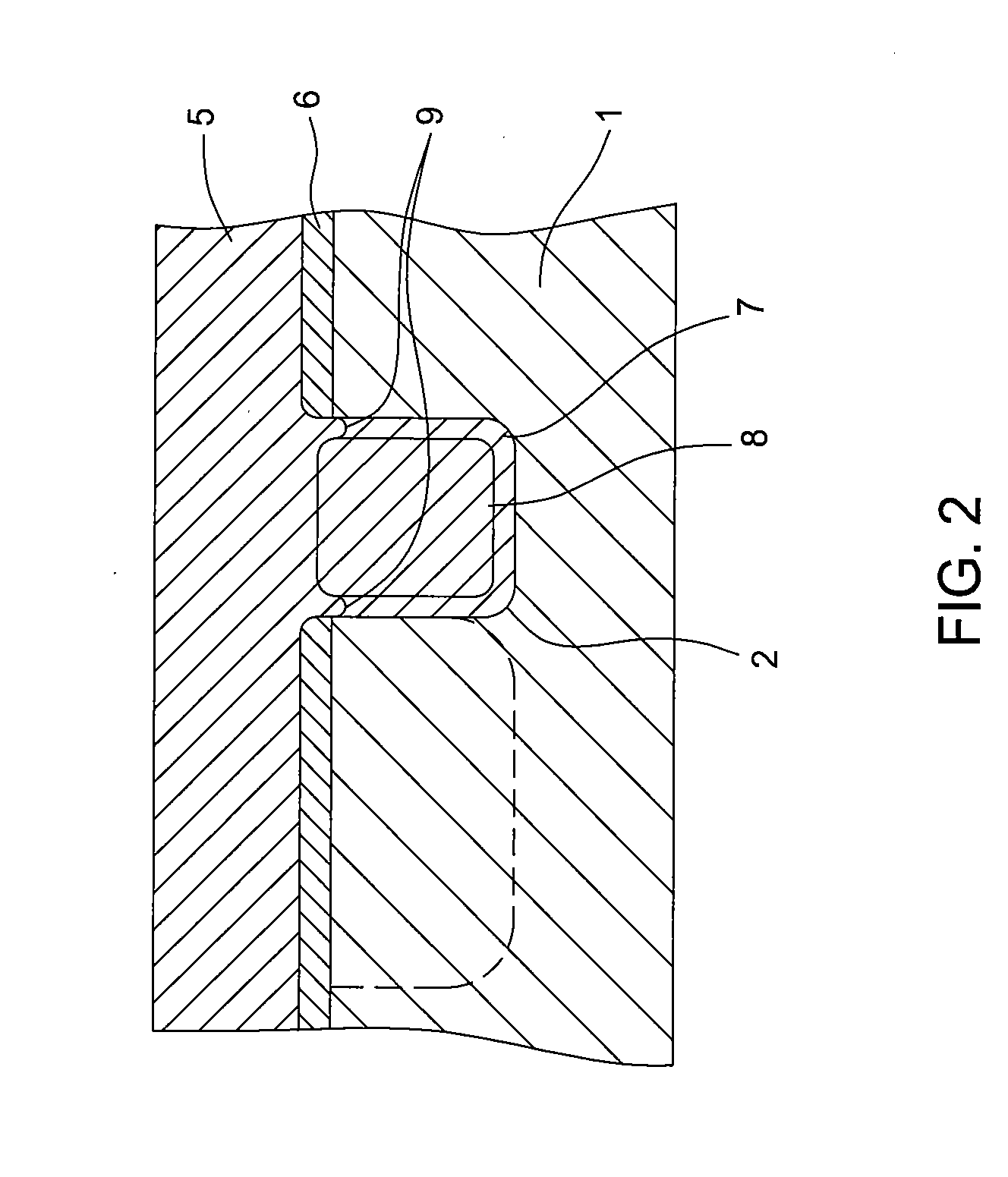

Vapor flow control apparatus for atomic layer deposition

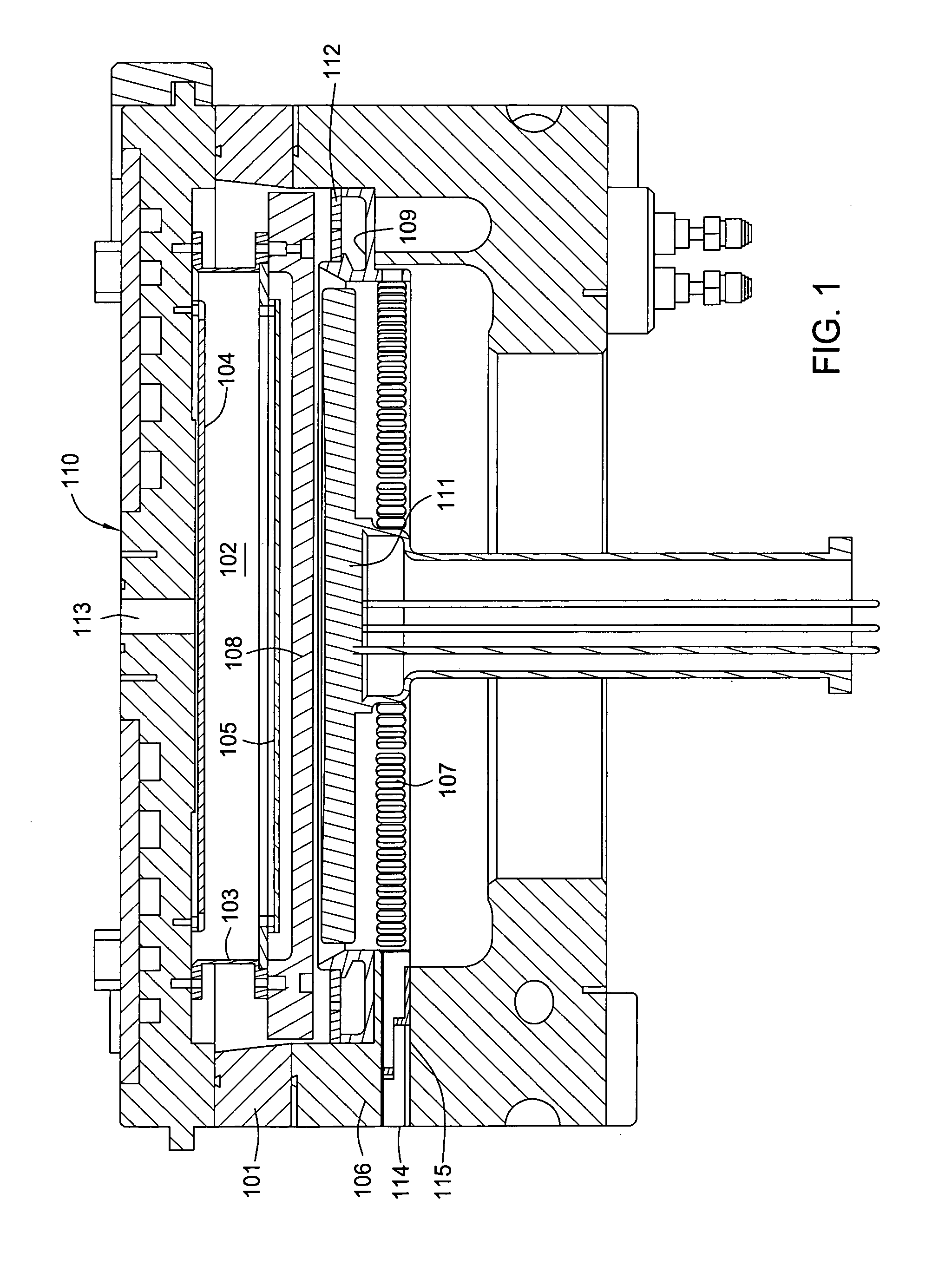

A device for performing ALD includes a housing having a vacuum chamber that surrounds a horizontal flow reactor. The device further includes a gas distribution system for delivering gases to the reactor. The gas distribution system includes at least one of a high temperature valve and a high temperature filter disposed inside the vacuum chamber. The high temperature valve (and / or filter) controls (and / or filters) a supply of a precursor / reactant gas, inert gas, or precursor / reactant and inert gas mixture before it enters the horizontal flow reactor.

Owner:ASM IP HLDG BV

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20090324971A1Increase response rateImprove productivitySynthetic resin layered productsChemical vapor deposition coatingPlasma generatorProduct gas

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space. The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent.

Owner:FUJIFILM MFG EURO

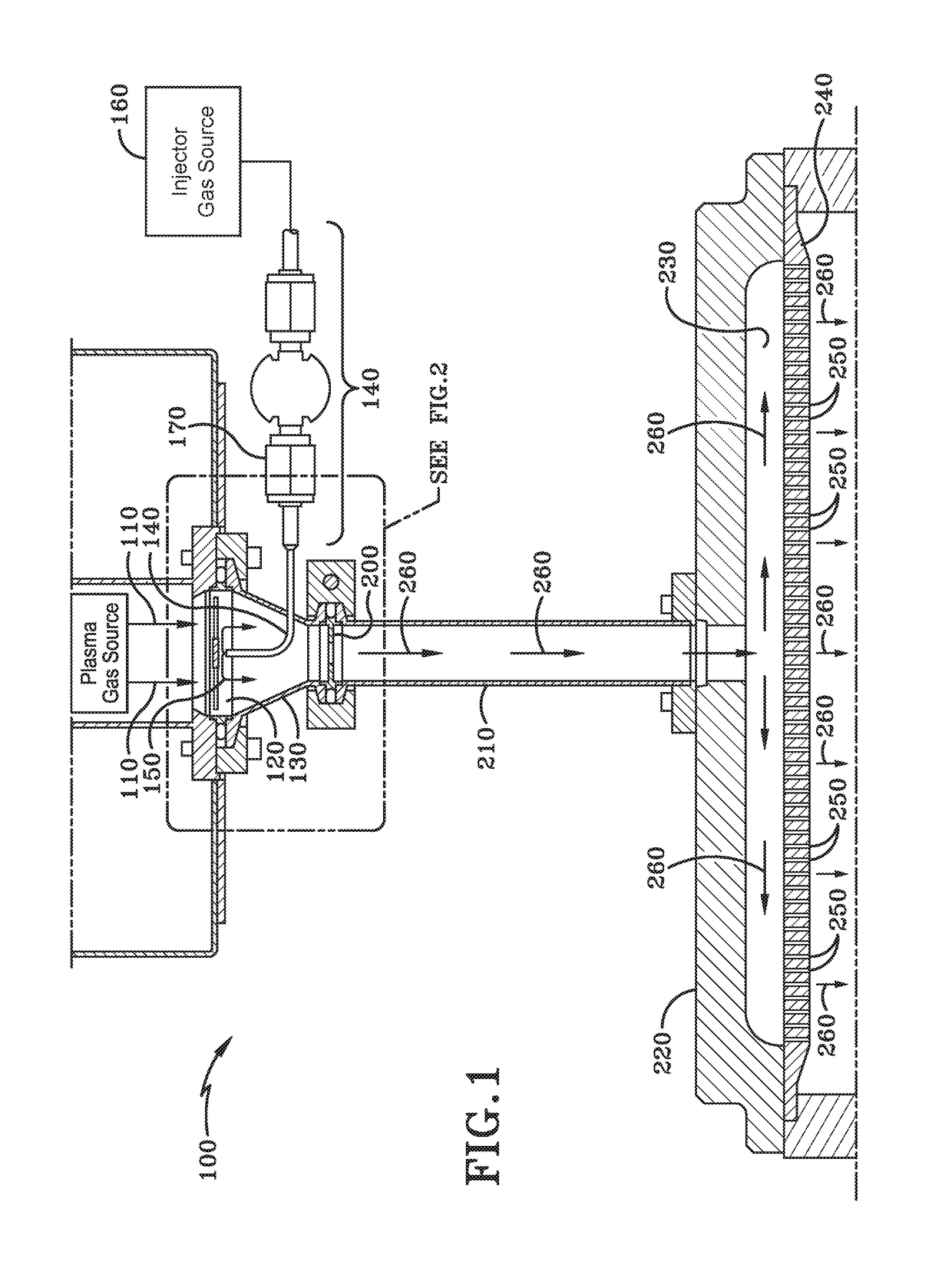

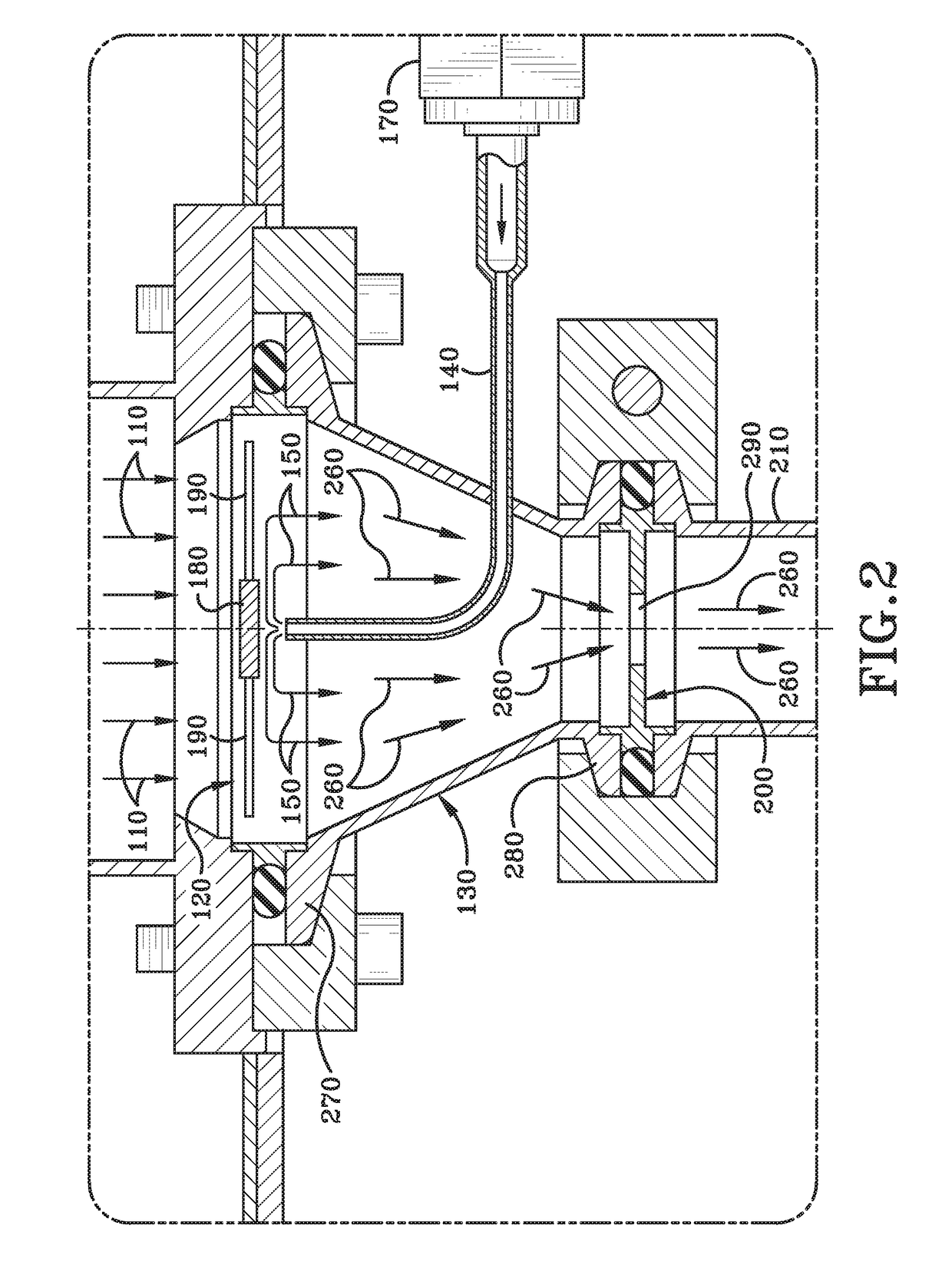

Counter flow mixer for process chamber

A counterflow mixing device for a process chamber is disclosed, comprising an injection tube that introduces a fluid in a manner counter to a flow of a post-plasma gas mixture traveling downward from a plasma source. The invention allows for proper mixing of the fluid as well as avoiding recombination of generated ions and radicals.

Owner:ASM IP HLDG BV

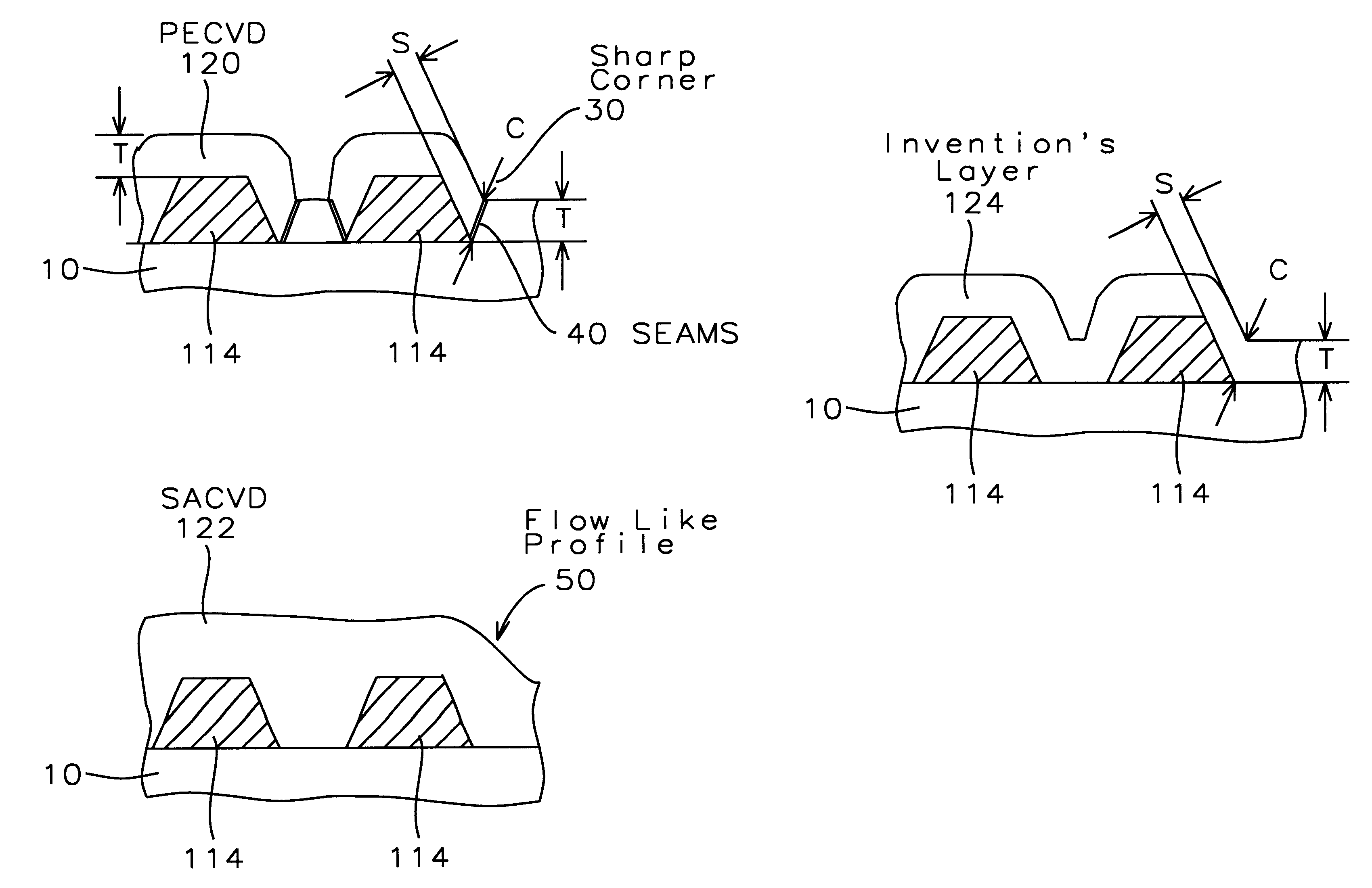

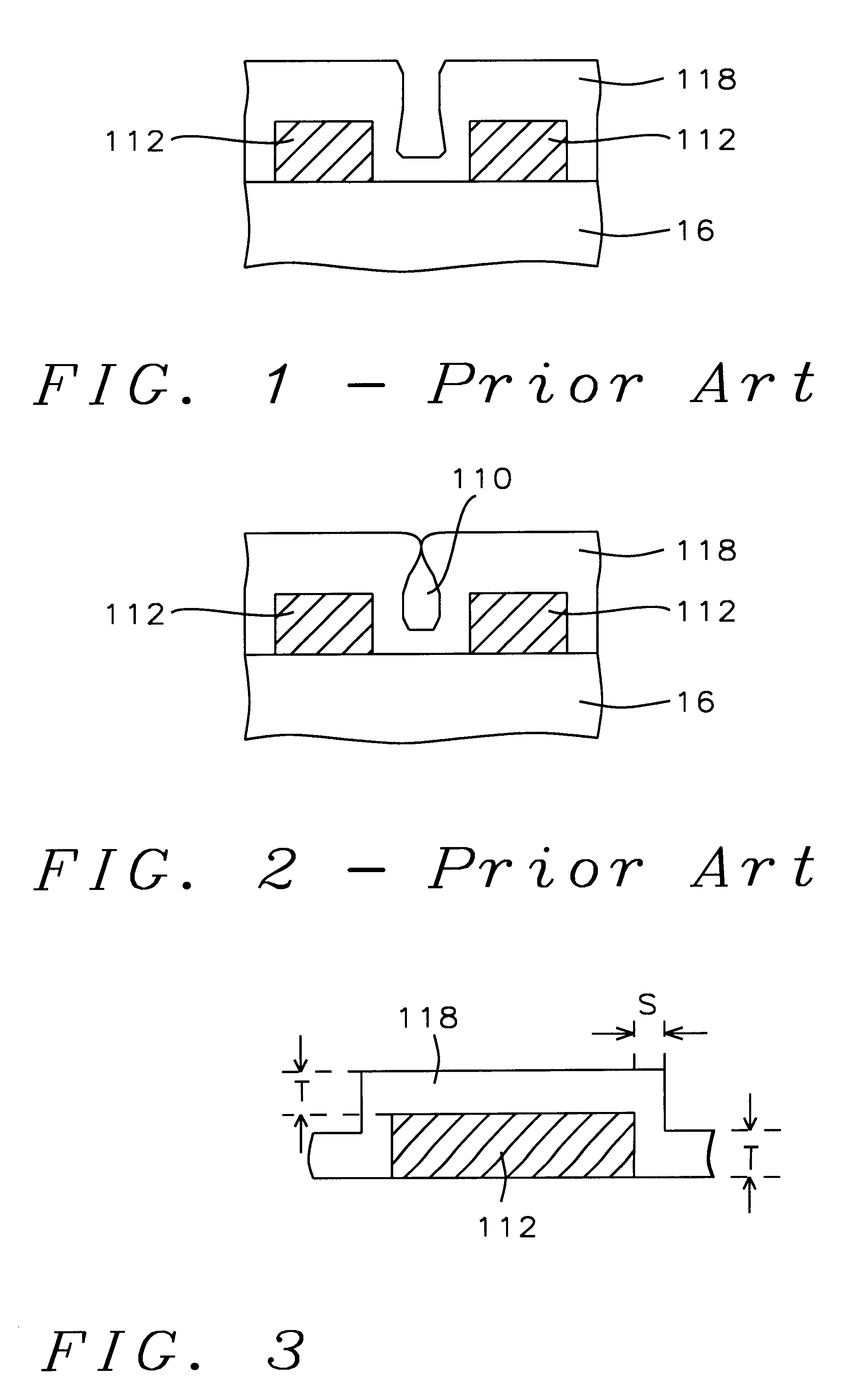

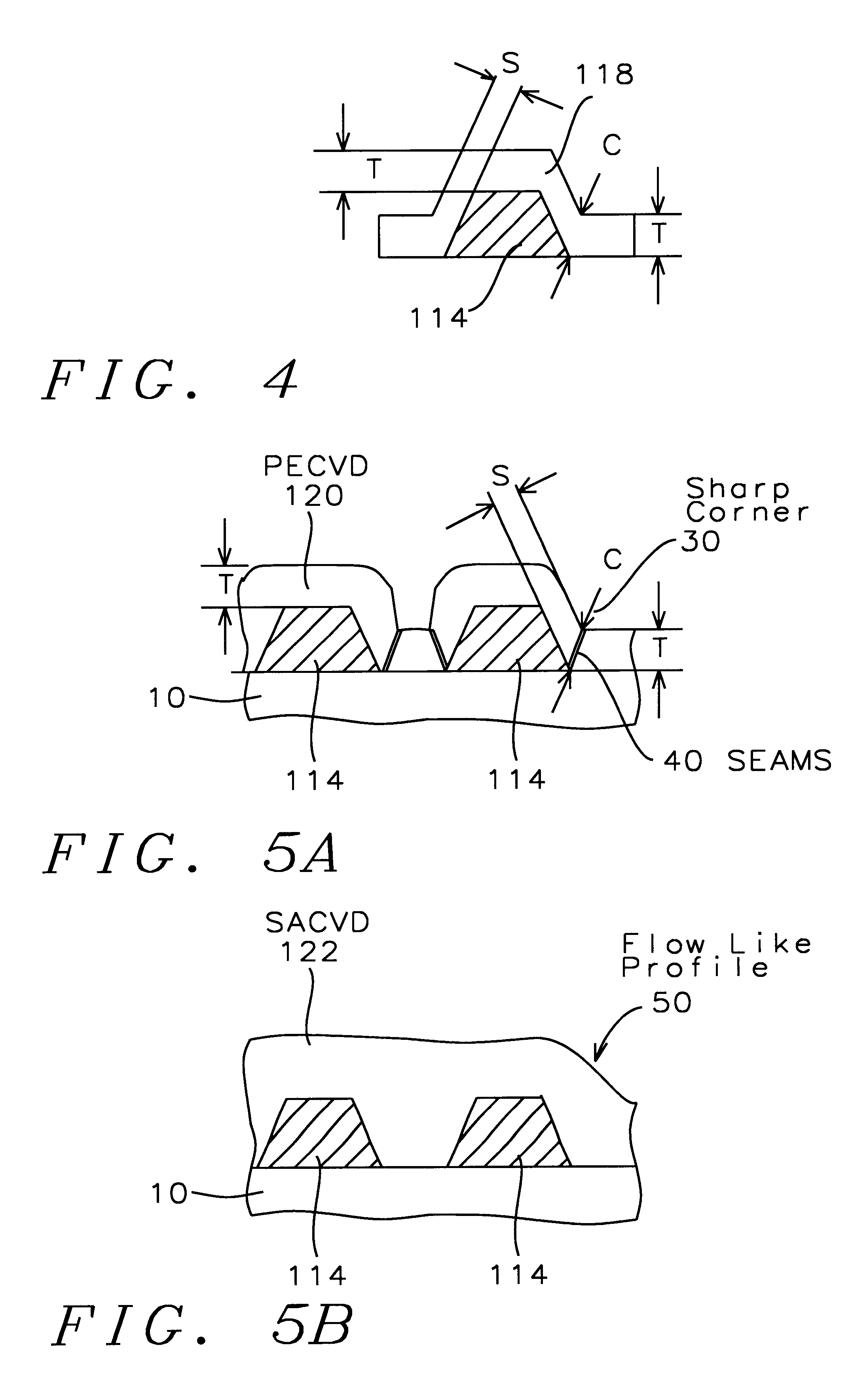

Method of silicon oxide and silicon glass films deposition

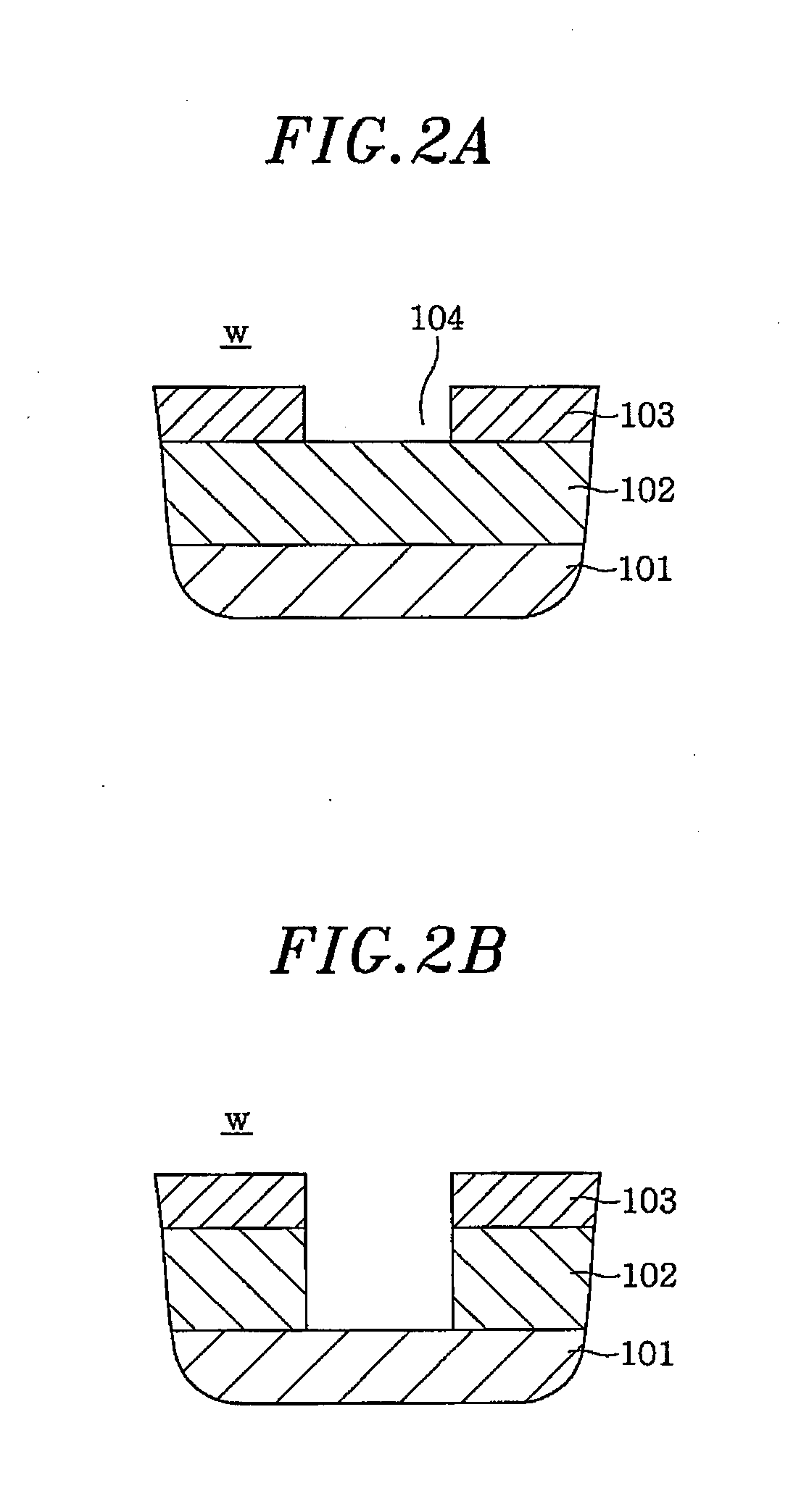

InactiveUS6197705B1Good step coverageImprove integrityPretreated surfacesSemiconductor/solid-state device manufacturingDielectricPlasma density

A method for fabricating a silicon oxide and silicon glass layers at low temperature using soft power-optimized Plasma-Activated CVD with a TEOS-ozone-oxygen reaction gas mixture (TEOS O3 / O2 PACVD) is described. It combines advantages of both low temperature Plasma-Enhanced Chemical Vapor Deposition (PECVD) and TEOS-ozone Sub-Atmospheric Chemical Vapor Deposition (SACVD) and yields a coating of silicon oxide with stable and high deposition rate, no surface sensitivity, good film properties, conformal step coverage and good gap-fill. Key features of the invention's O3 / O2 PACVD process are: a plasma is maintain throughout the entire deposition step in a parallel plate type reactor chamber, the precise RF plasma density, ozone concentration in oxygen and the deposition temperature. These features provide the reaction conditions for the proper O3 / O2 reaction mechanism that deposits a conformal silicon oxide layer. The process has significant implication for semiconductor device manufacturing involving the deposition of a dielectric over a conducting non-planar surface.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

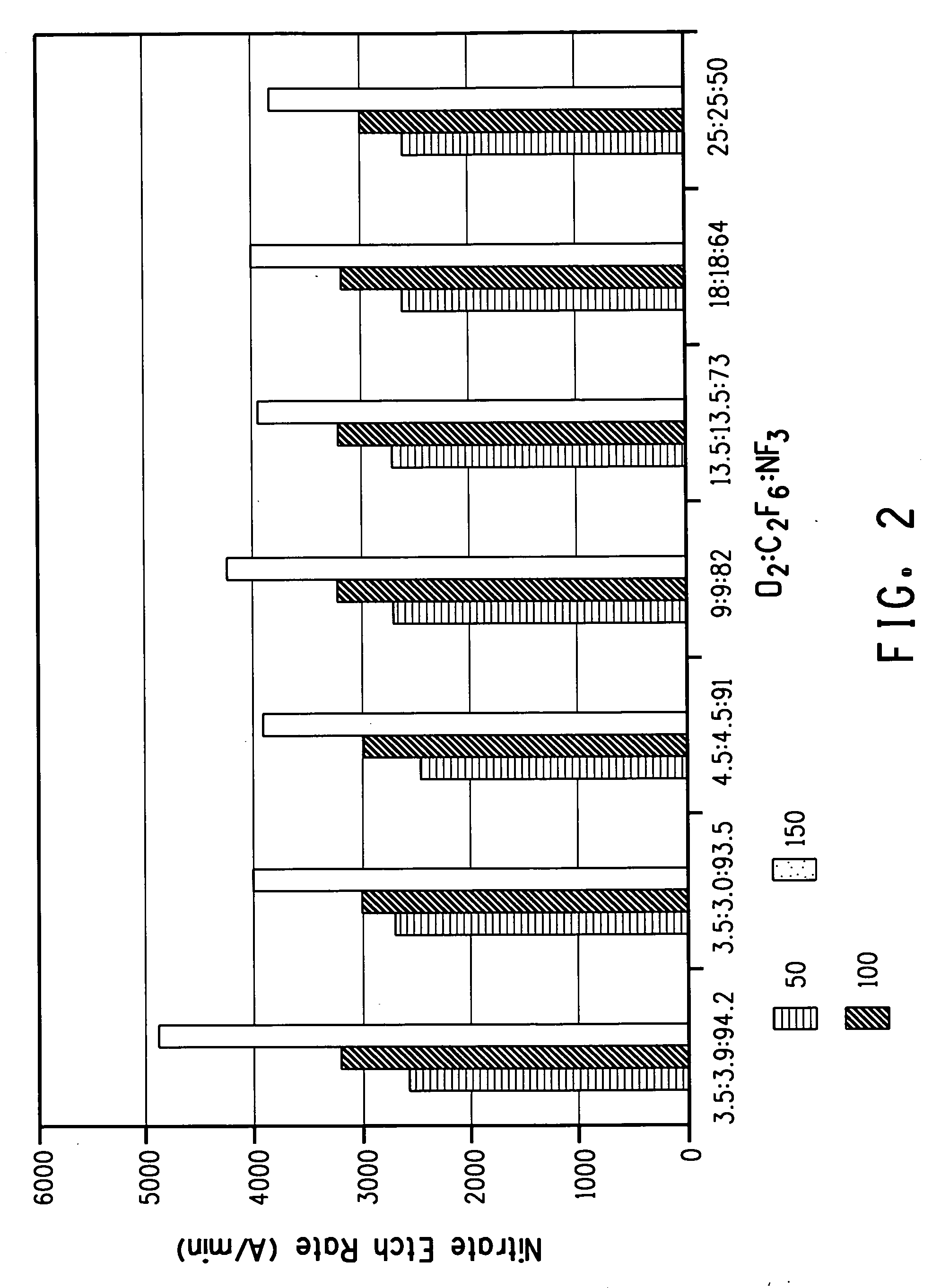

Oxide etch with nh4-nf3 chemistry

InactiveUS20070123051A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSemiconductorAnalytical chemistry

The present invention generally provides apparatus and methods for selectively removing various oxides on a semiconductor substrate. One embodiment of the invention provides a method for selectively removing an oxide on a substrate at a desired removal rate using an etching gas mixture. The etching gas mixture comprises a first gas and a second gas, and a ratio of the first gas and a second gas is determined by the desired removal rate.

Owner:APPLIED MATERIALS INC

High frequency pressure swing adsorption

InactiveUS6176897B1High purityRecoverable expansion workNitrogen purification/separationGas treatmentSorbentEngineering

Pressure swing adsorption separation of a feed gas mixture, to obtain a purified product gas of the less strongly adsorbed fraction of the feed gas mixture, is performed in a plurality of preferably an even number of adsorbent beds, with each adsorbent bed communicating at its product end directly to a variable volume expansion chamber, and at its feed end by directional valves to a feed compressor and an exhaust vacuum pump. For high frequency operation of the pressure swing adsorption cycle, a high surface area layered support is used for the adsorbent. The compressor and vacuum pump pistons may be integrated with the cycle, reciprocating at twice the cycle frequency. Alternative configurations of the layered adsorbent beds are disclosed.

Owner:AIR PROD & CHEM INC

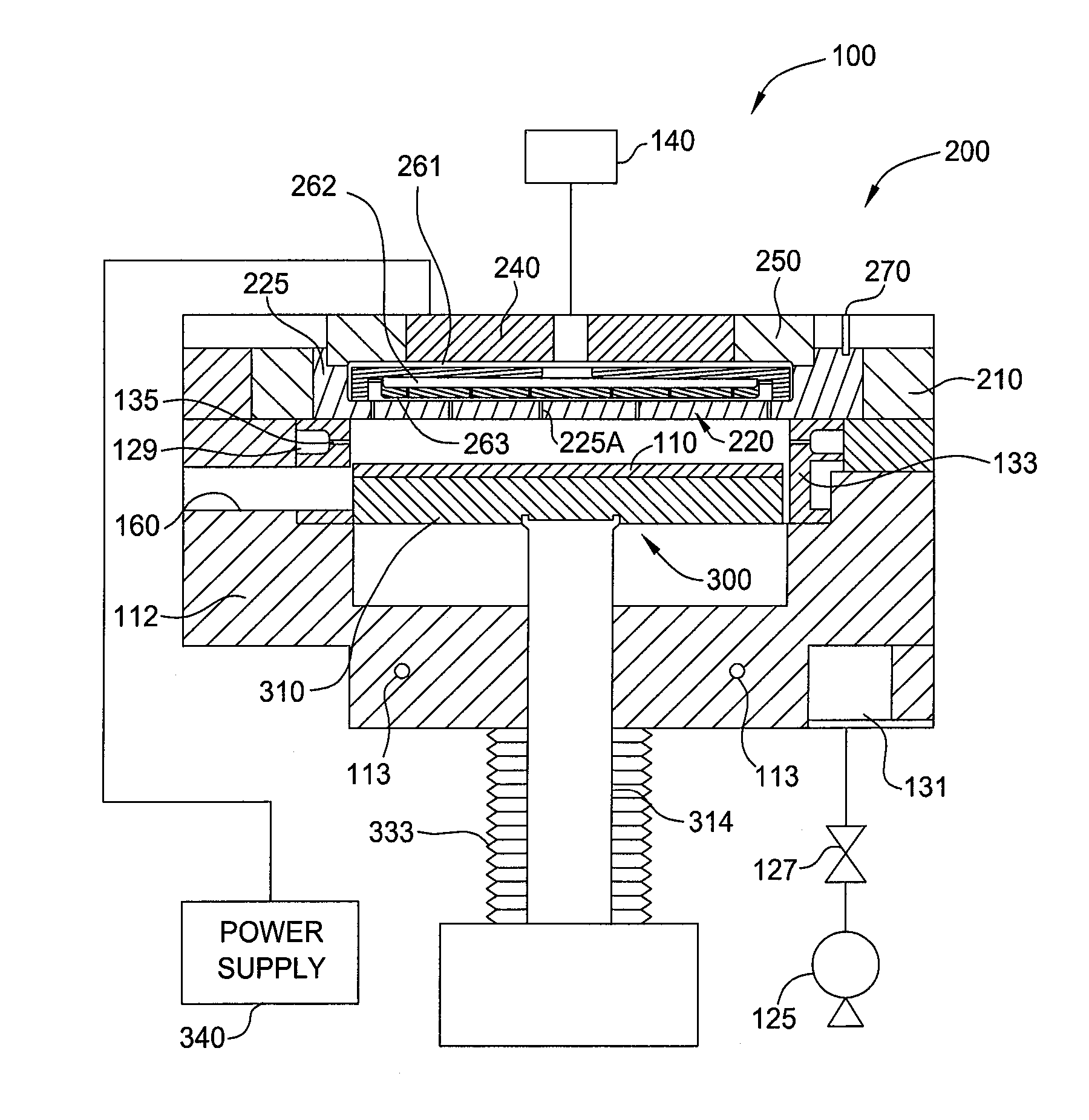

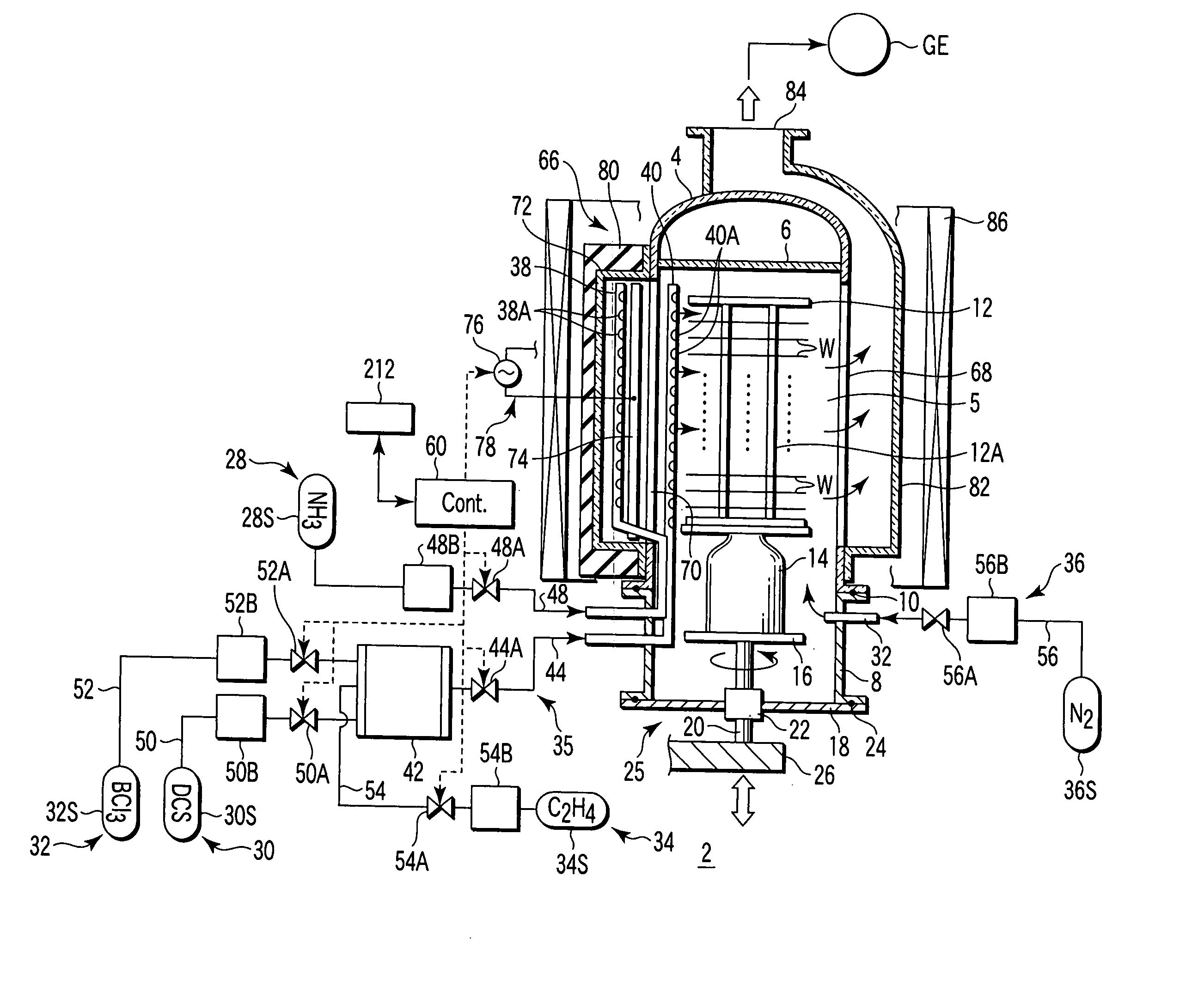

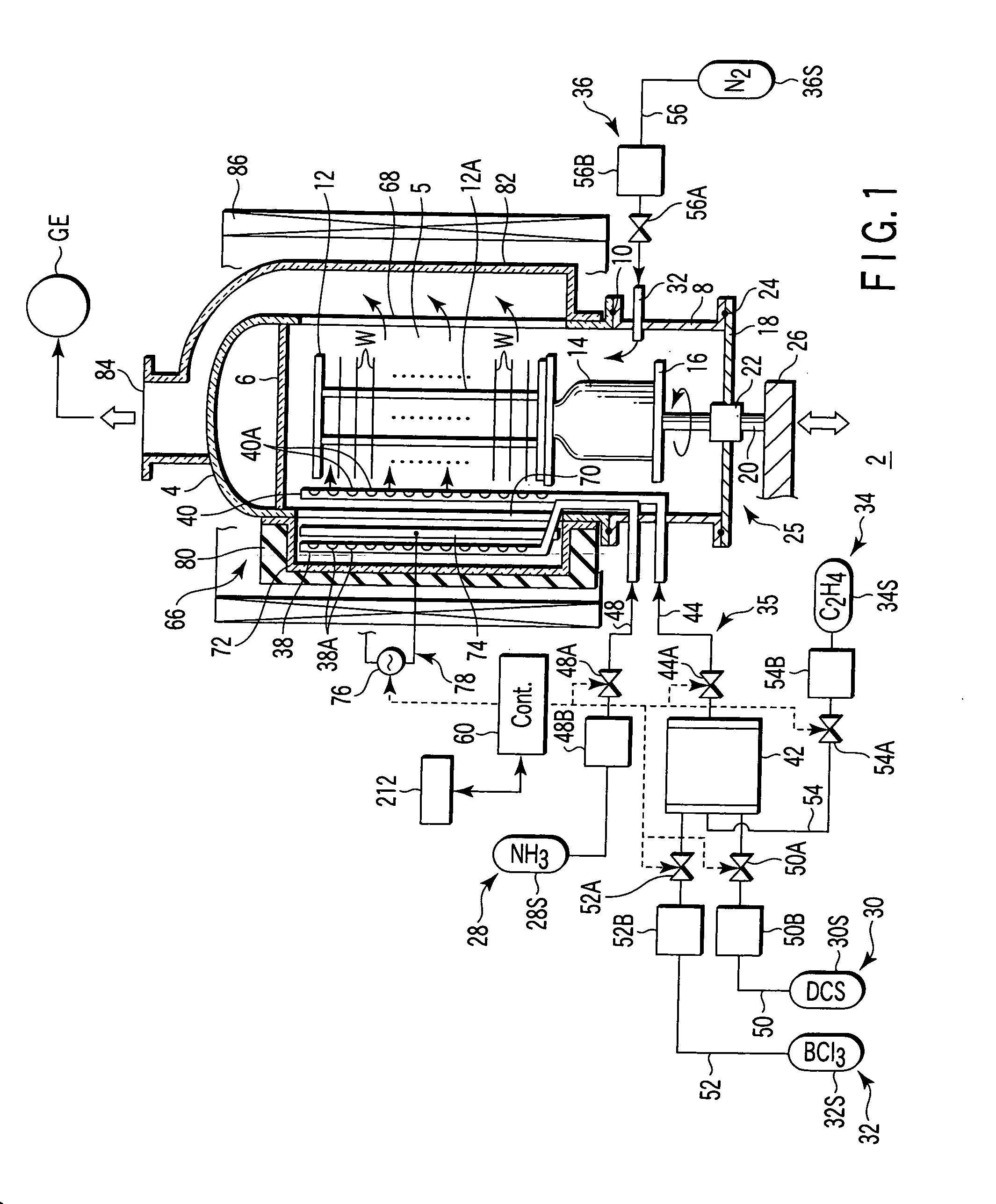

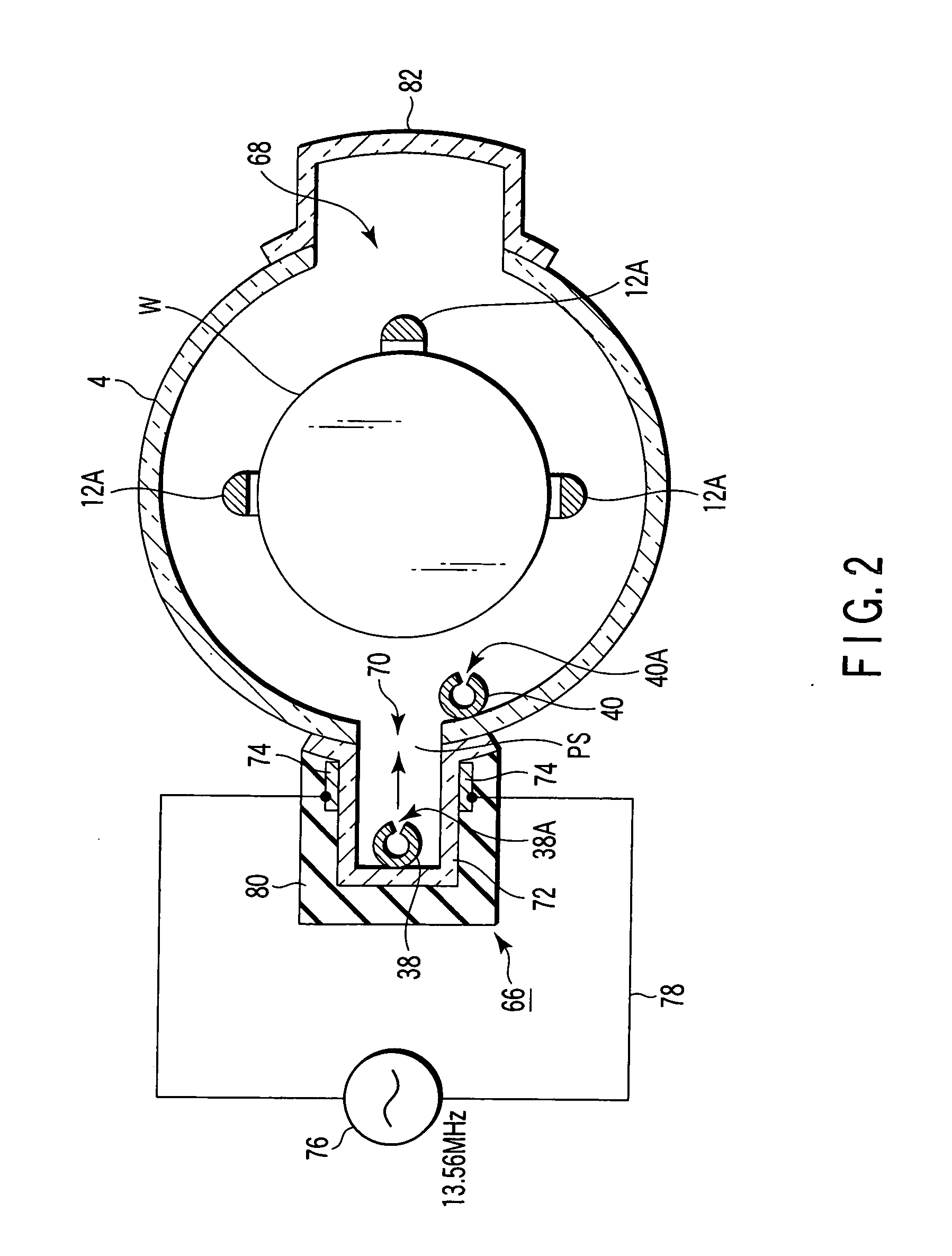

Apparatus and method for the deposition of silicon nitride films

InactiveUS20060102076A1Evenly distributedResidue reductionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCompound (substance)Process engineering

A method and apparatus for a chemical vapor deposition (CVD) chamber provides uniform heat distribution, uniform distribution of process chemicals in the CVD chamber, and minimization of by-product and condensate residue in the chamber. The improvements include a processing chamber comprising a chamber body, a base, and a chamber lid defining a processing region, a substrate support disposed in the processing region, a gas delivery system mounted on a chamber lid, the gas delivery system comprising an adapter ring and two blocker plates that define a gas mixing region, and a face plate fastened to the adapter ring, an exhaust system mounted at the base, a heating element positioned to heat the adapter ring; and a heating element positioned to heat a portion of the exhaust system.

Owner:APPLIED MATERIALS INC

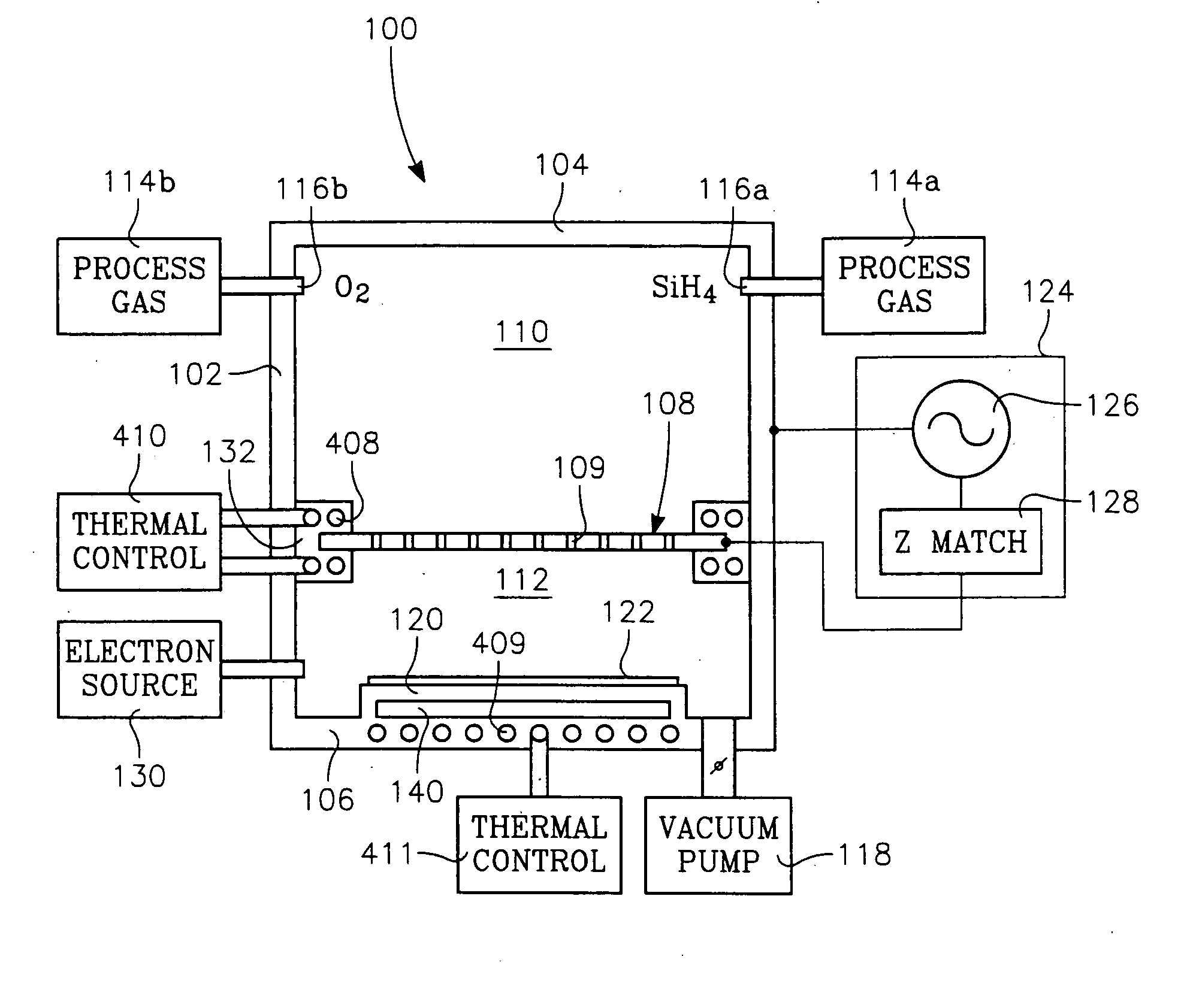

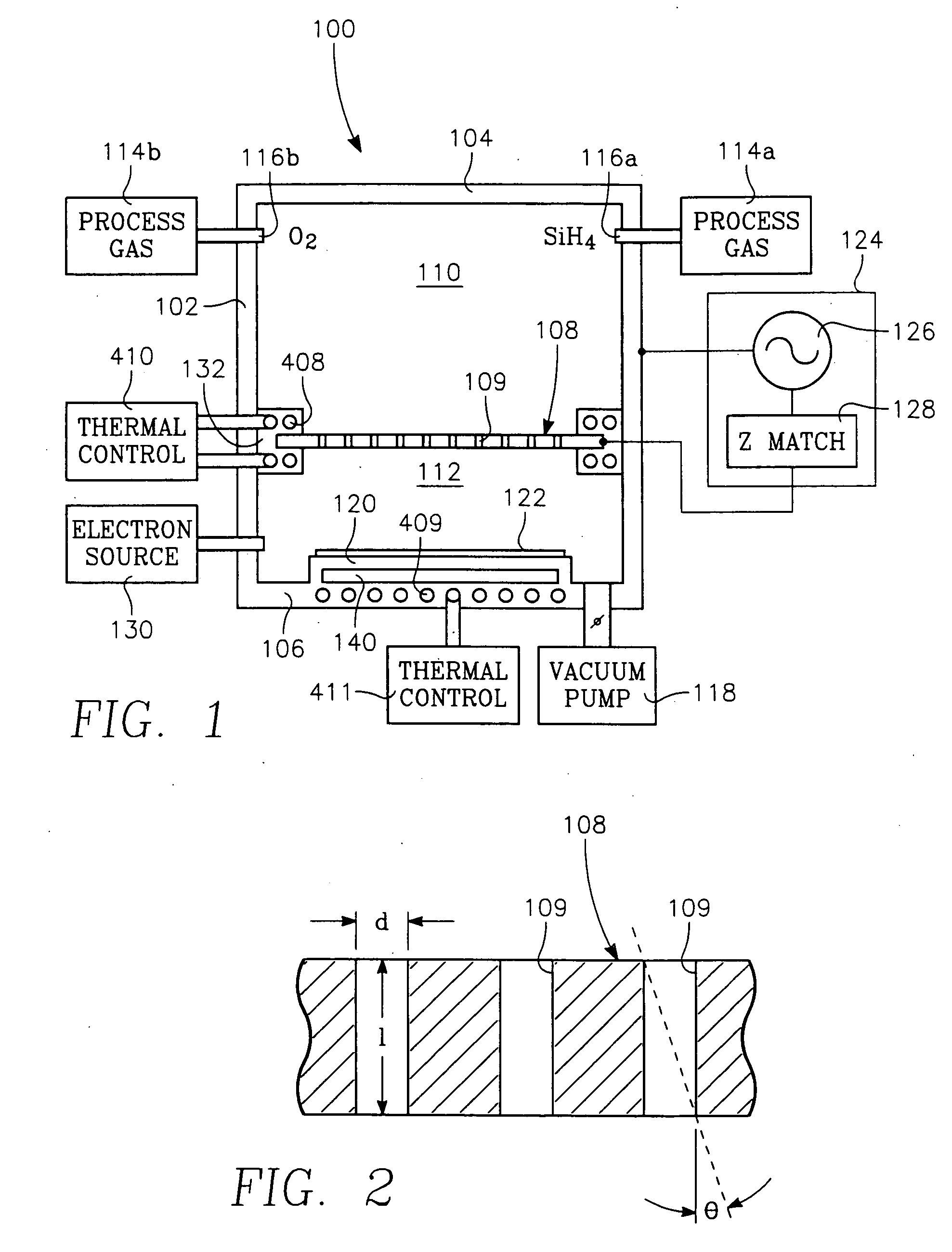

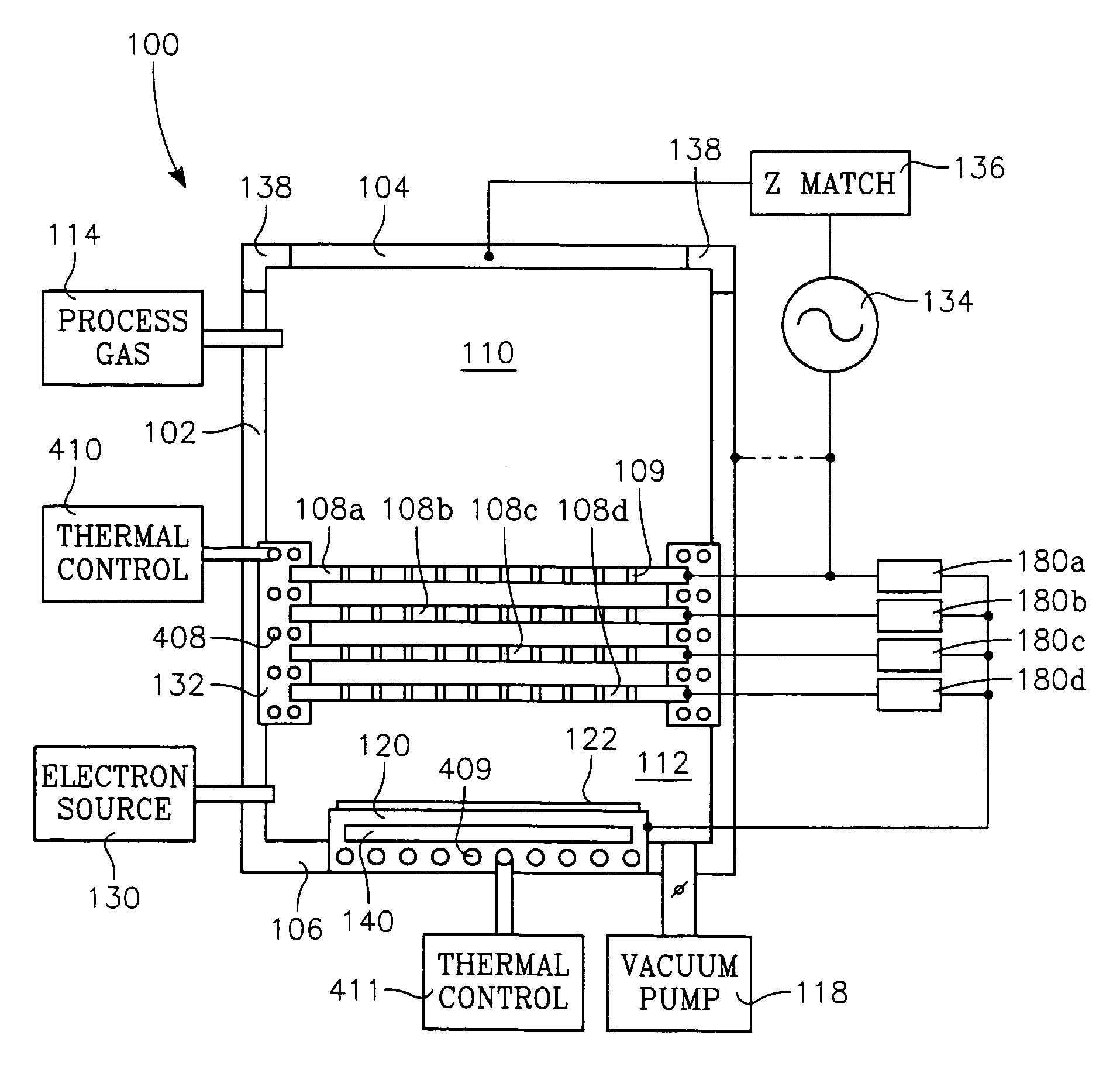

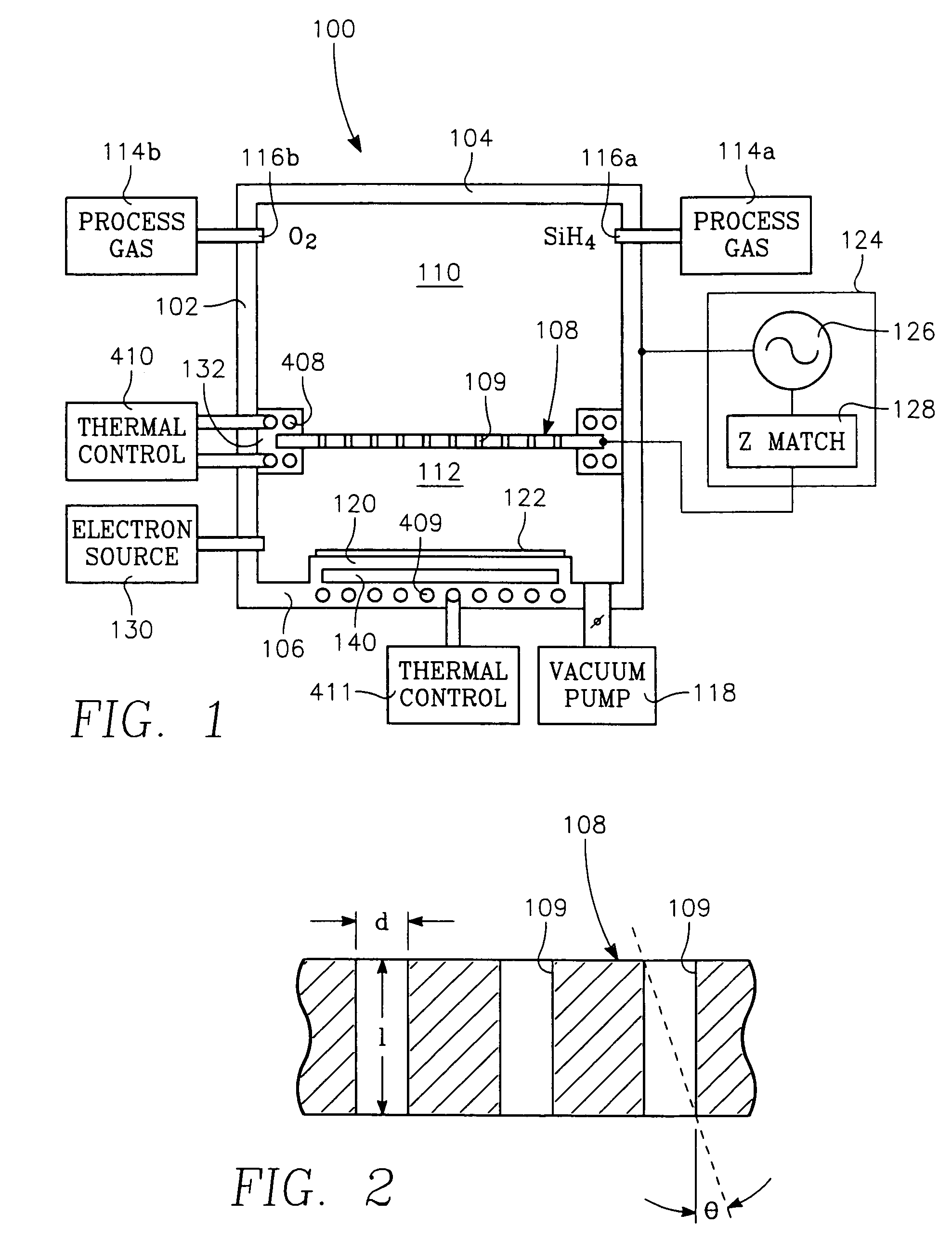

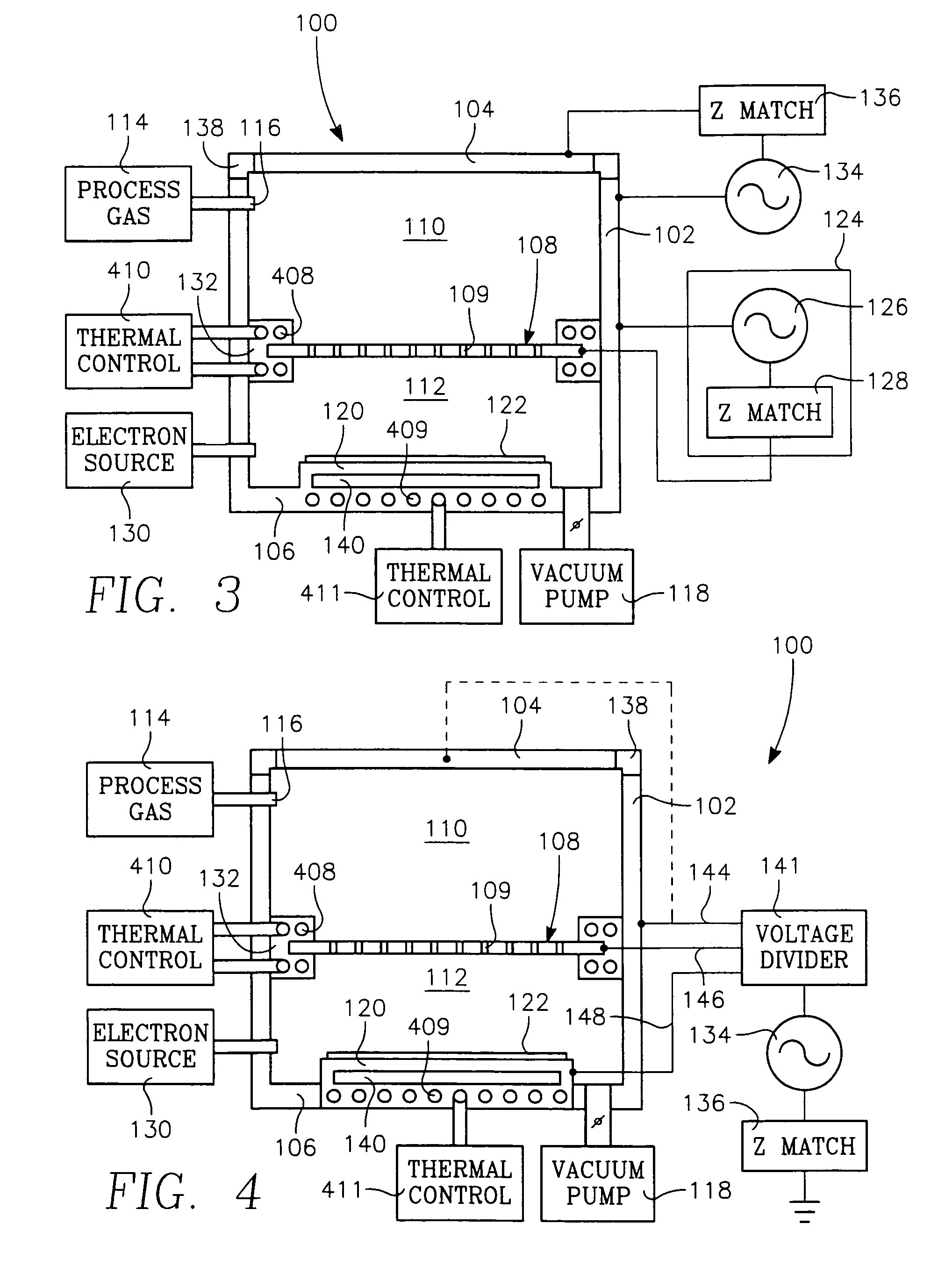

Chemical vapor deposition plasma process using an ion shower grid

A chemical vapor deposition process is carried out in a reactor chamber with an ion shower grid that divides the chamber into an upper ion generation region and a lower process region, the ion shower grid having plural orifices oriented in a non-parallel direction relative to a surface plane of the ion shower grid. A workpiece is placed in the process region facing the ion shower grid, the workpiece having a workpiece surface generally facing the surface plane of the ion shower grid. A gas mixture is furnished comprising deposition precursor species into the ion generation region and the process region is evacuated at an evacuation rate sufficient to create a pressure drop across the ion shower grid from the ion generation region to the process region whereby the pressure in the ion generation region is at least several times the pressure in the process region. A layer of material of a desired thickness is deposited on the workpiece by: (a) applying plasma source power to generate a plasma of the deposition precursor species in the ion generation region, and (b) applying a grid potential to the ion shower grid to create a flux of ions from the plasma through the grid and into the process region.

Owner:APPLIED MATERIALS INC

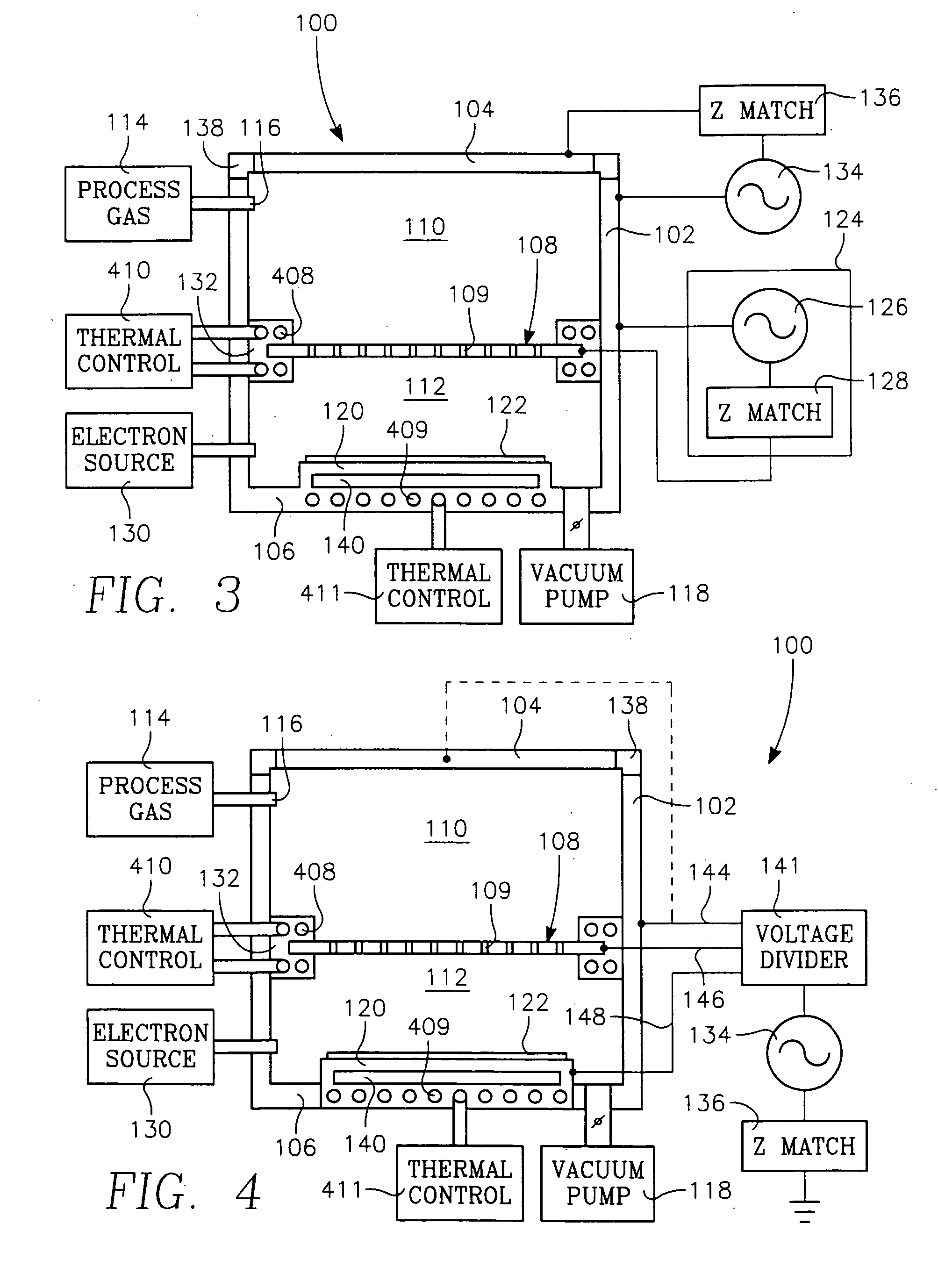

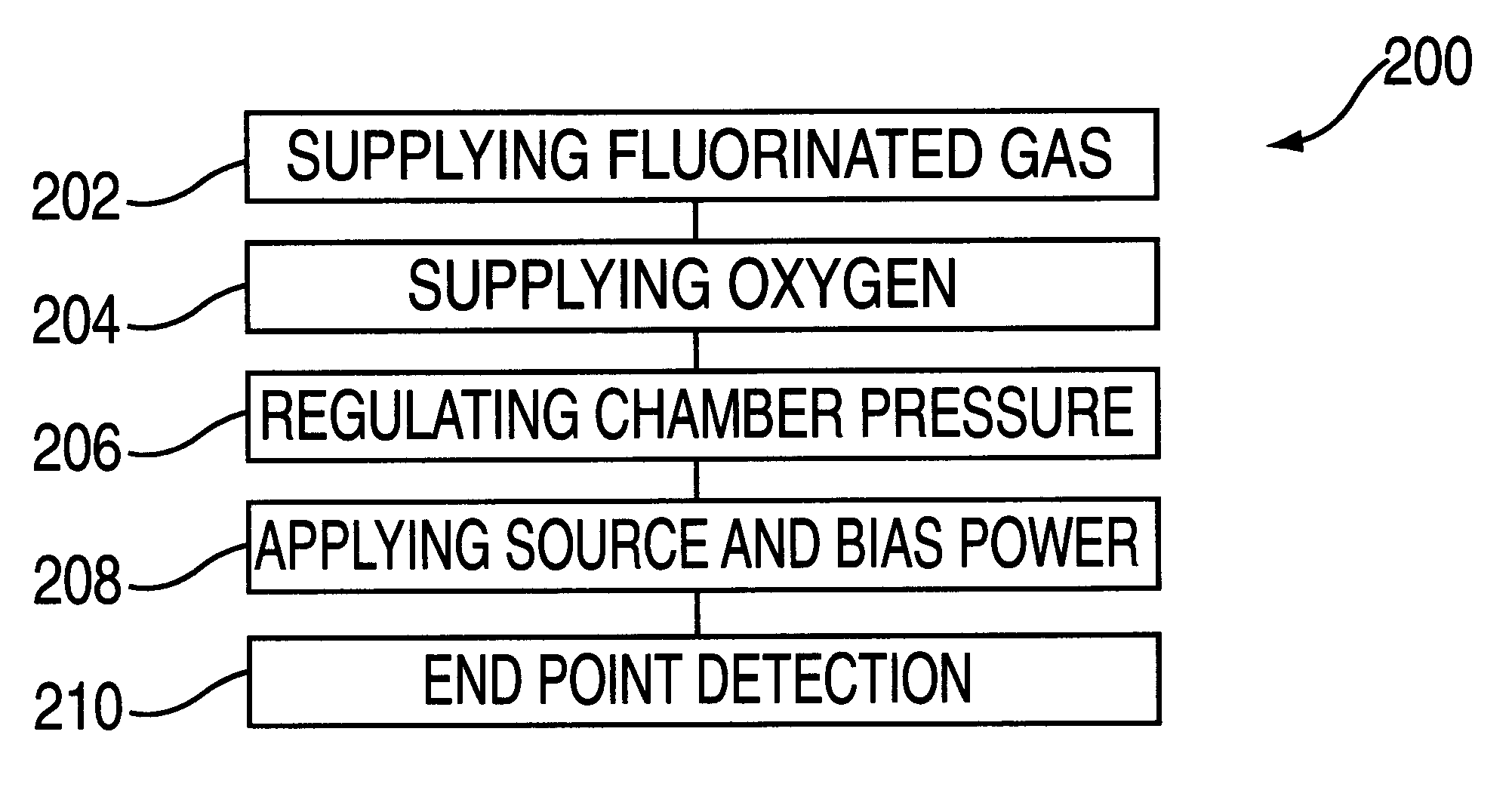

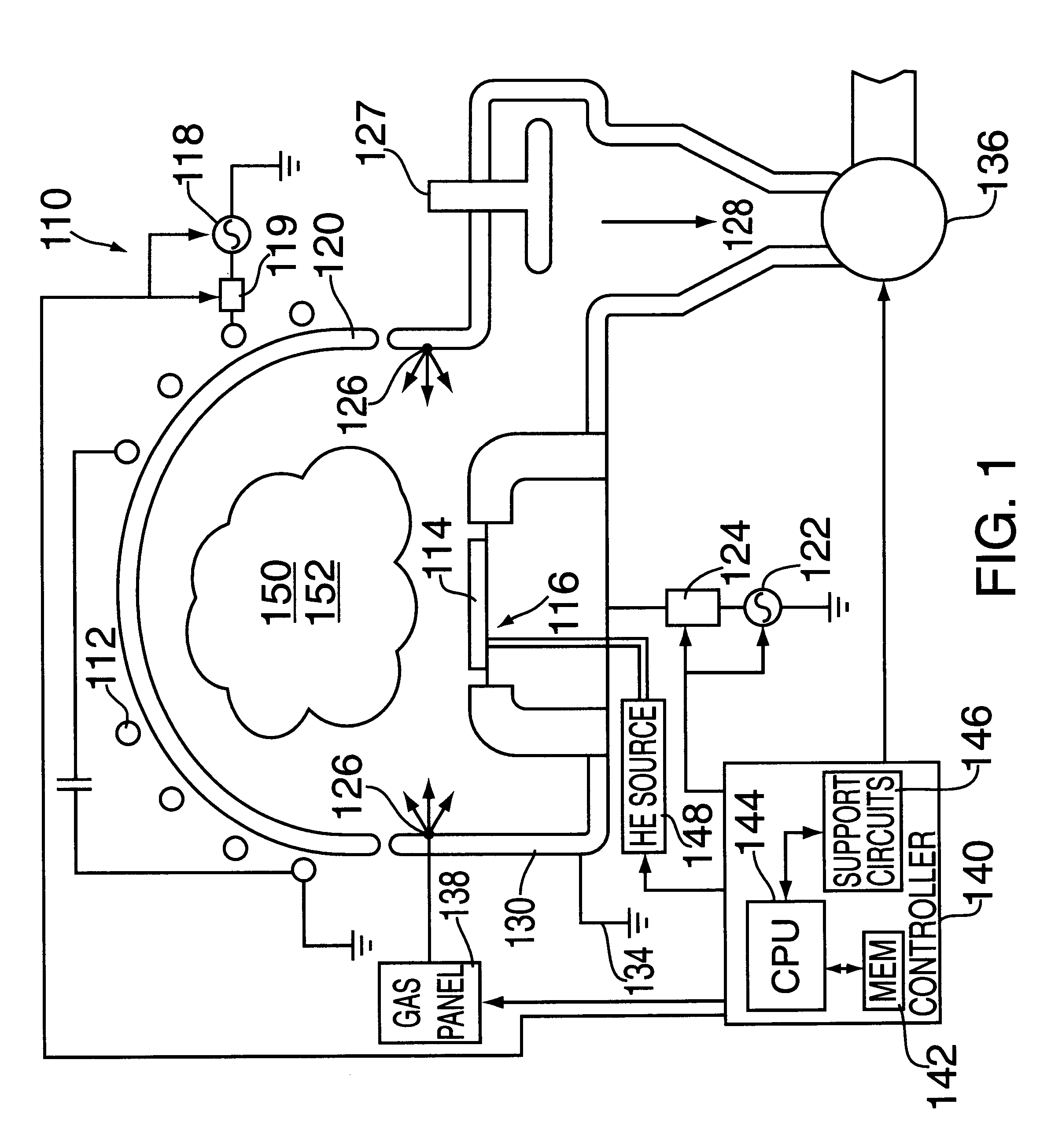

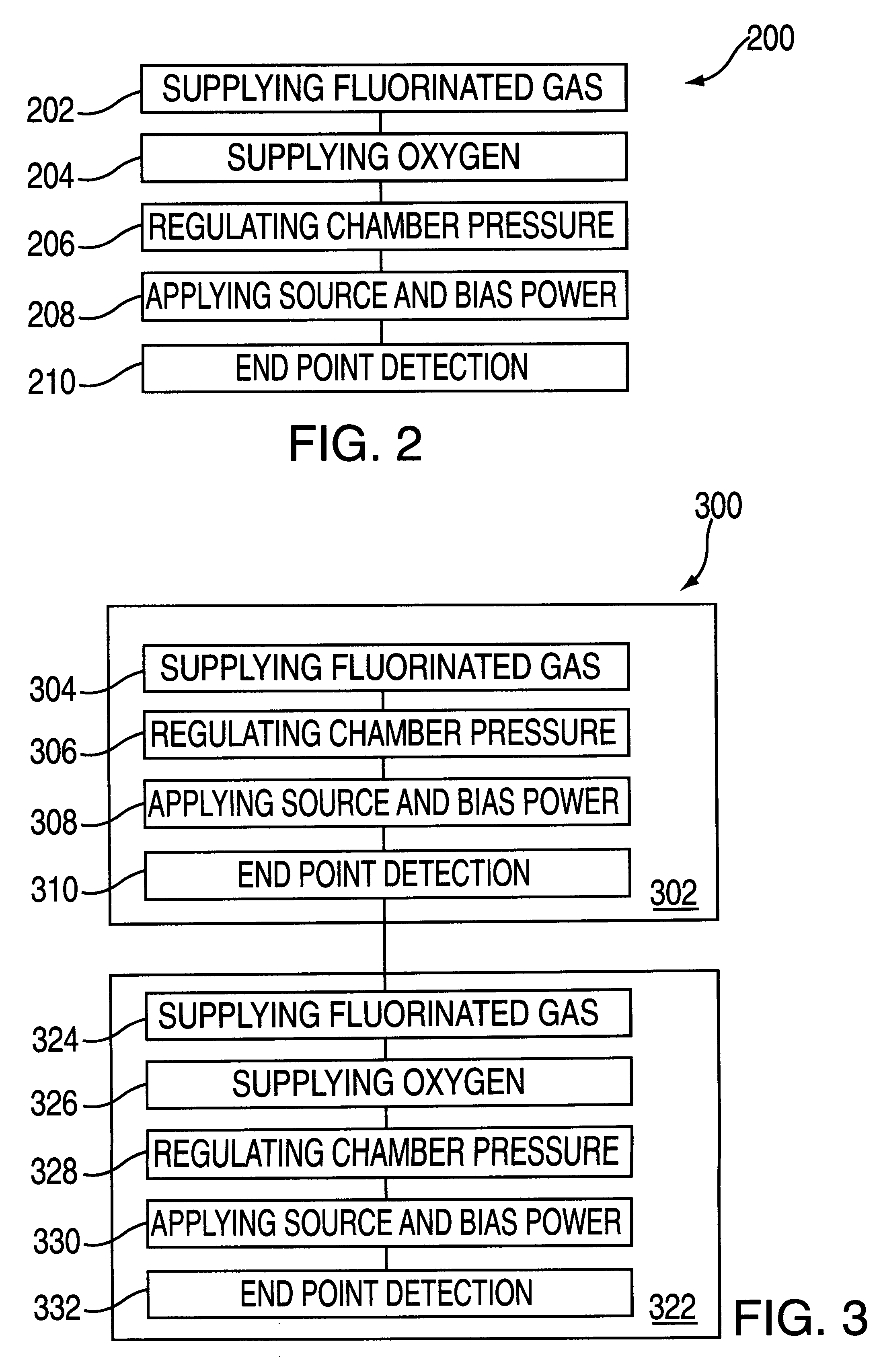

Plasma processing of tungsten using a gas mixture comprising a fluorinated gas and oxygen

InactiveUS6277763B1Good choiceElectric discharge tubesVacuum gauge using ionisation effectsFluorinated gasesProduct gas

Owner:APPLIED MATERIALS INC

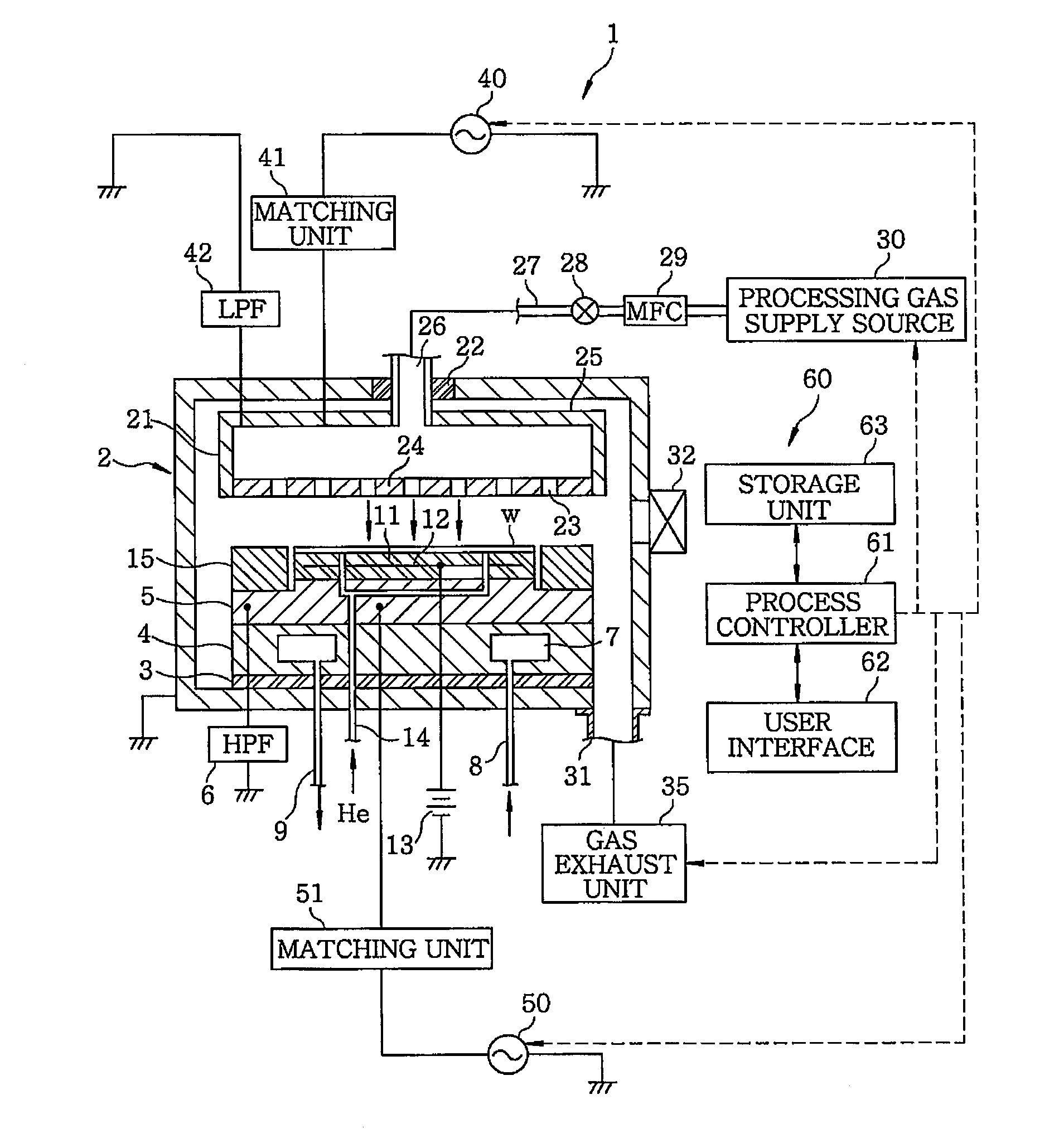

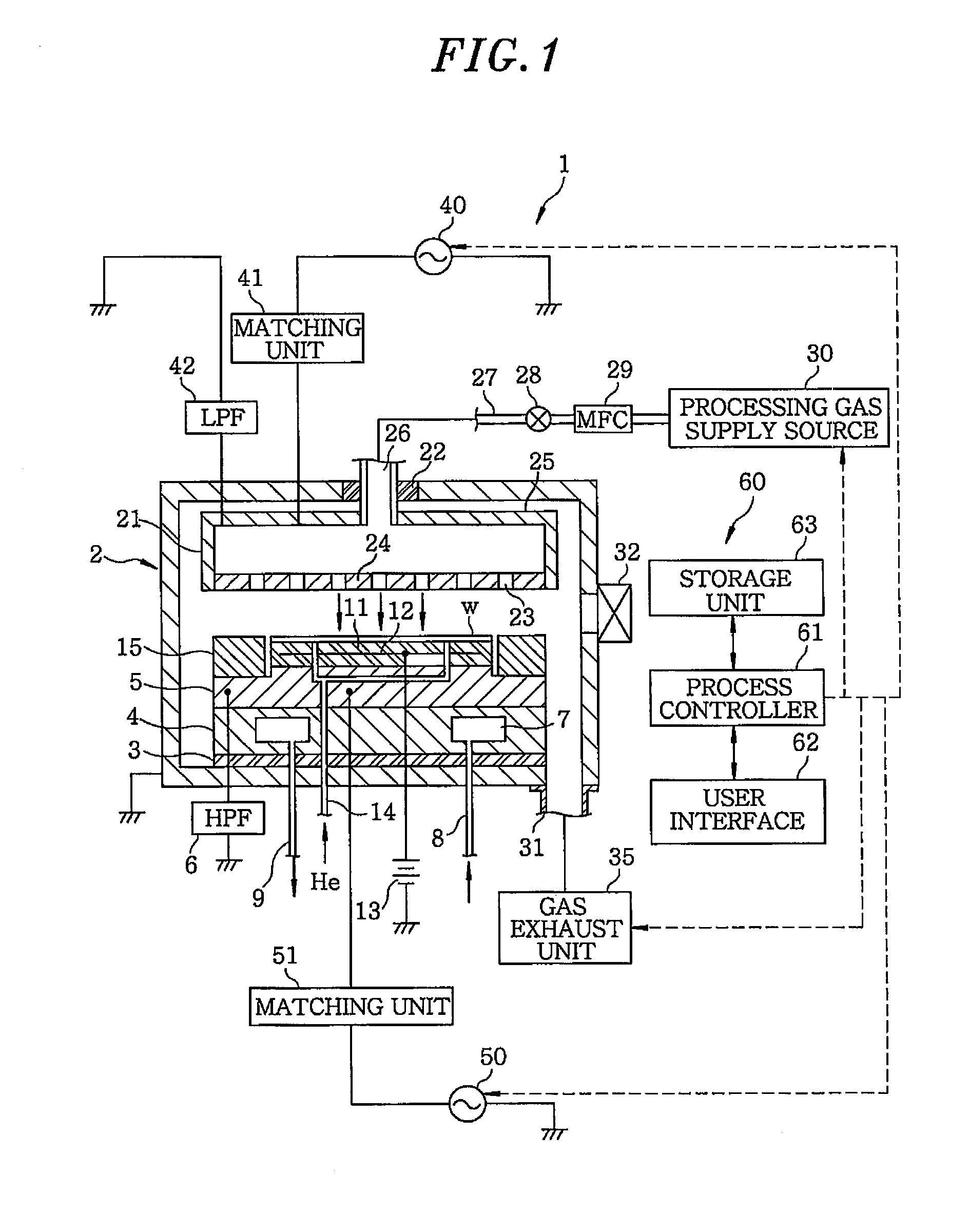

Film formation method and apparatus for semiconductor process

InactiveUS20060207504A1Improving inter-substrate uniformity in compositionUniform supplySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringEngineering

A film formation apparatus for a semiconductor process includes a process gas supply system configured to supply process gases. The process gas supply system includes a gas mixture tank configured to mix first and third process gases to form a mixture gas, a mixture gas supply line configured to supply the mixture gas from the gas mixture tank to a process field, a second process gas supply circuit having a second process gas supply line configured to supply a second process gas to the process field without passing through the gas mixture tank, and first and second switching valves disposed on the mixture gas supply line and the second process gas supply line, respectively. A control section controls the first and second switching valves to be opened and closed so as to alternately and pulse-wise supply the mixture gas and the second process gas to the process field.

Owner:TOKYO ELECTRON LTD

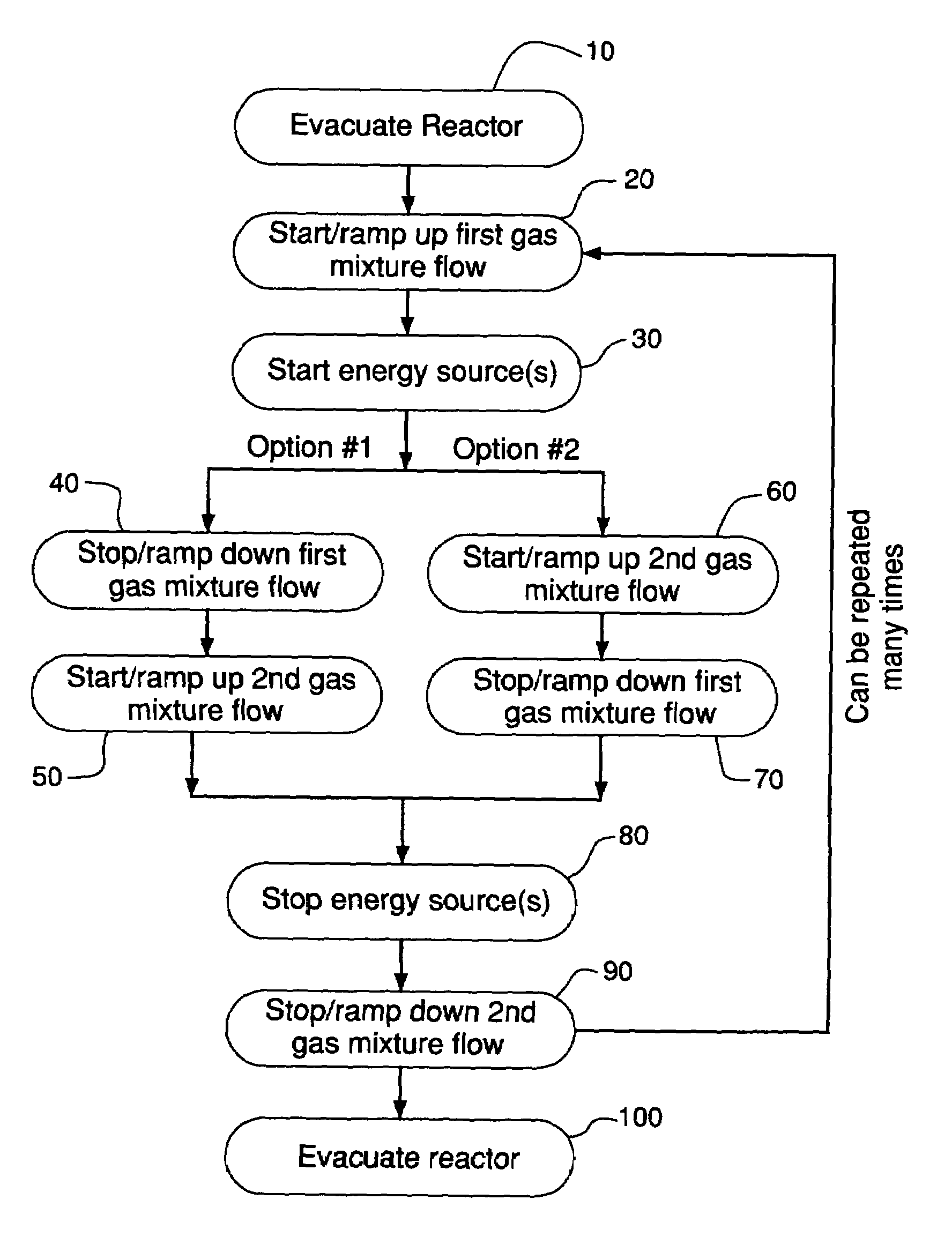

Method for cleaning deposition chambers for high dielectric constant materials

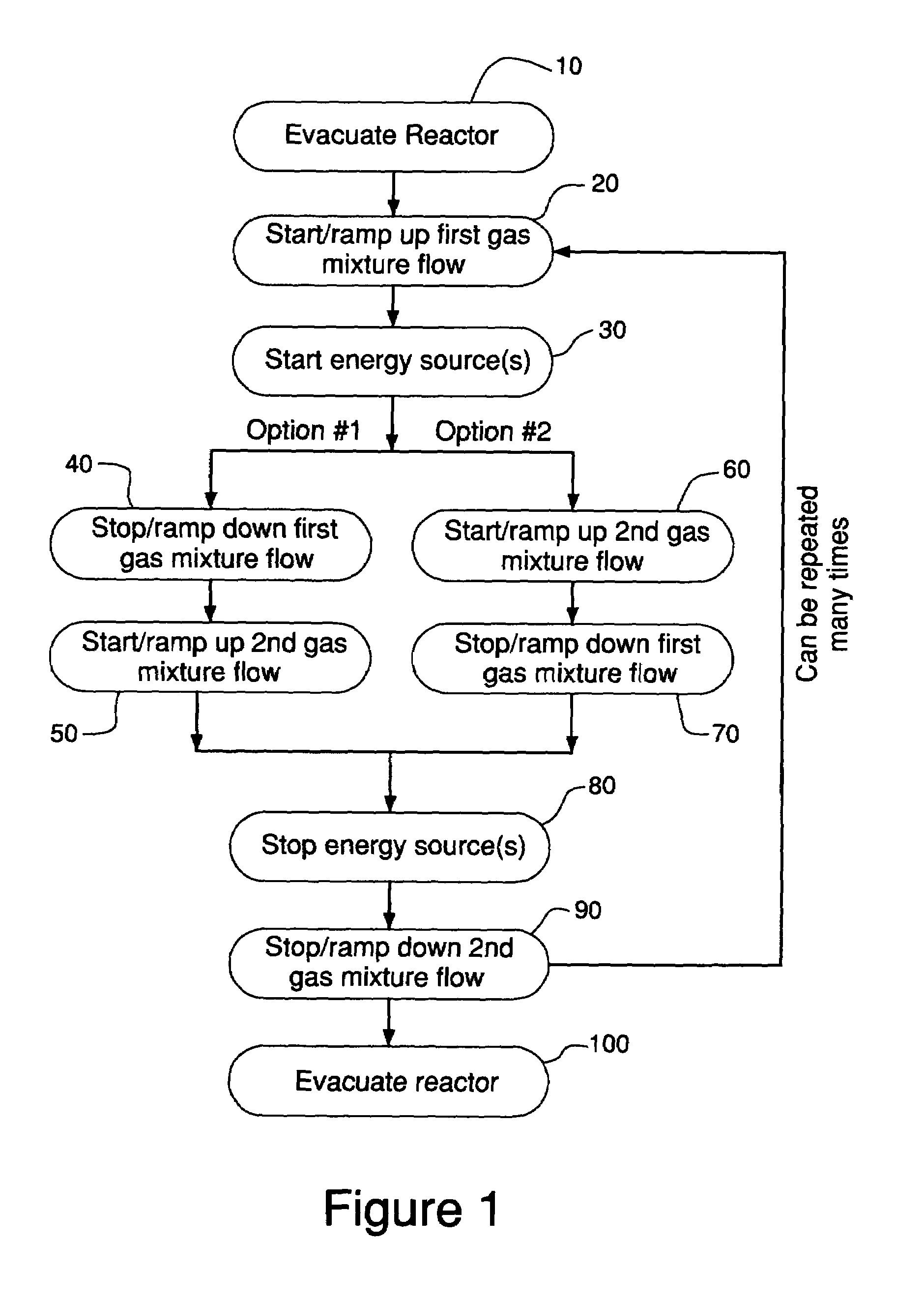

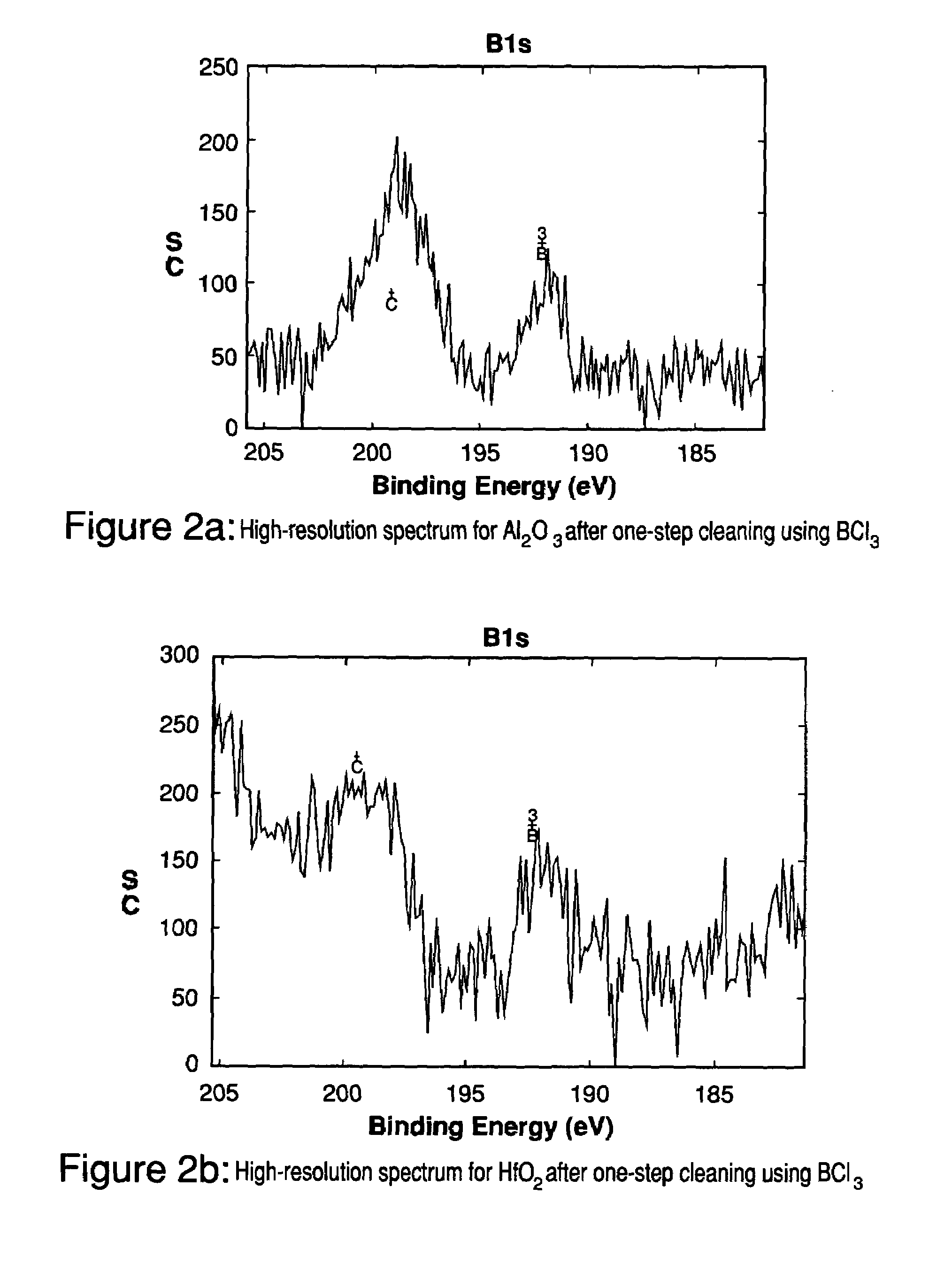

A method for dry etching and chamber cleaning high dielectric constant materials is disclosed herein. In one aspect of the present invention, there is provided a process for cleaning a substance comprising a dielectric constant greater than the dielectric constant of silicon dioxide from at least a portion of a surface of a reactor comprising: introducing a first gas mixture comprising a boron-containing reactive agent into the reactor wherein the first gas mixture reacts with the substance contained therein to provide a volatile product and a boron-containing by-product; introducing a second gas mixture comprising a fluorine-containing reactive agent into the reactor wherein the second gas mixture reacts with the boron-containing by-product contained therein to form the volatile product; and removing the volatile product from the reactor.

Owner:AIR PROD & CHEM INC

Apparatus for detecting chemical substances and method therefor

ActiveUS20050061964A1High detection sensitivityPrevent false detectionStability-of-path spectrometersAnalysis using chemical indicatorsNon detectionData treatment

An apparatus for detecting chemical substances which is high in sensitivity and selectivity is provided. An organic acid or an organic acid salt is used to generate an organic acid gas from an organic acid gas generator 3 to be mixed with a sample gas for introduction into an ion source 4 for ionization, thereby obtaining a mass spectrum by a mass analysis region 5. A data processor 6 determines the detection or non-detection of a specific m / z of an organic acid adduct ion obtained by adding a molecule generated from the organic acid to a molecule with specific m / z generated from a target chemical substance to be detected based on the obtained mass spectrum. When there is an ion peak with the m / z of the organic acid adduct ion, the presence of the target chemical substance to be detected is determined, and an alarm is sounded. False detection can be prevented.

Owner:HITACHI LTD

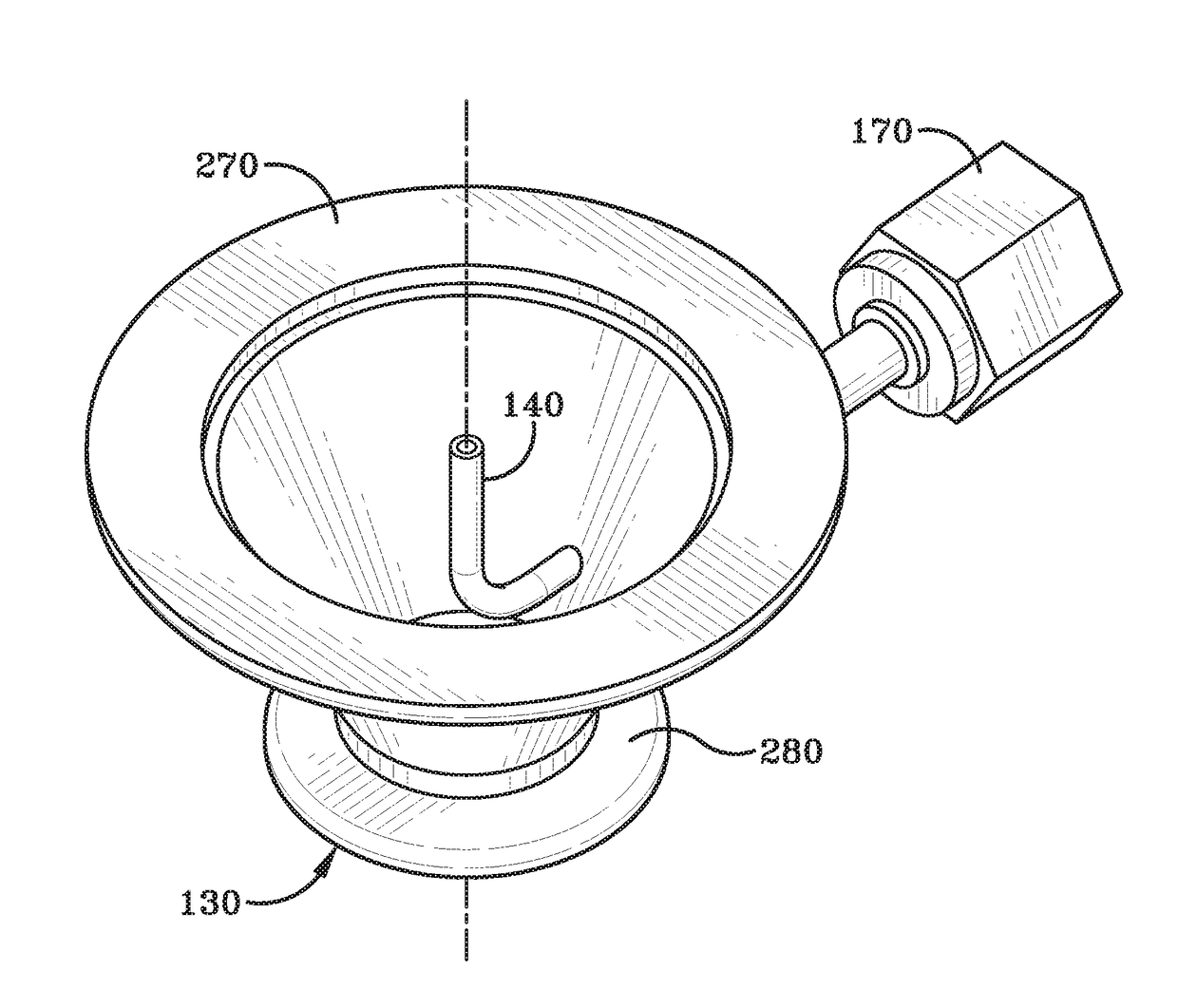

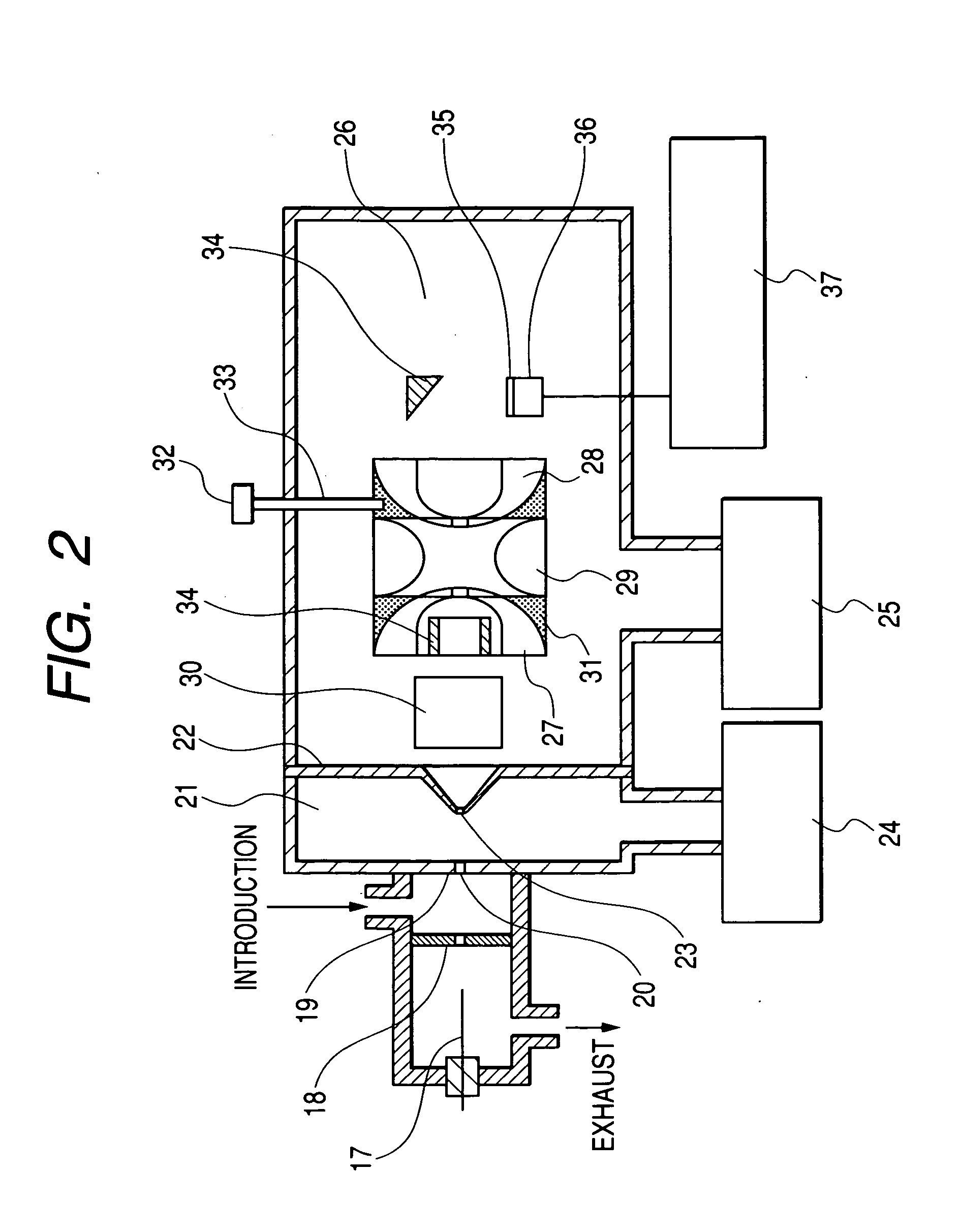

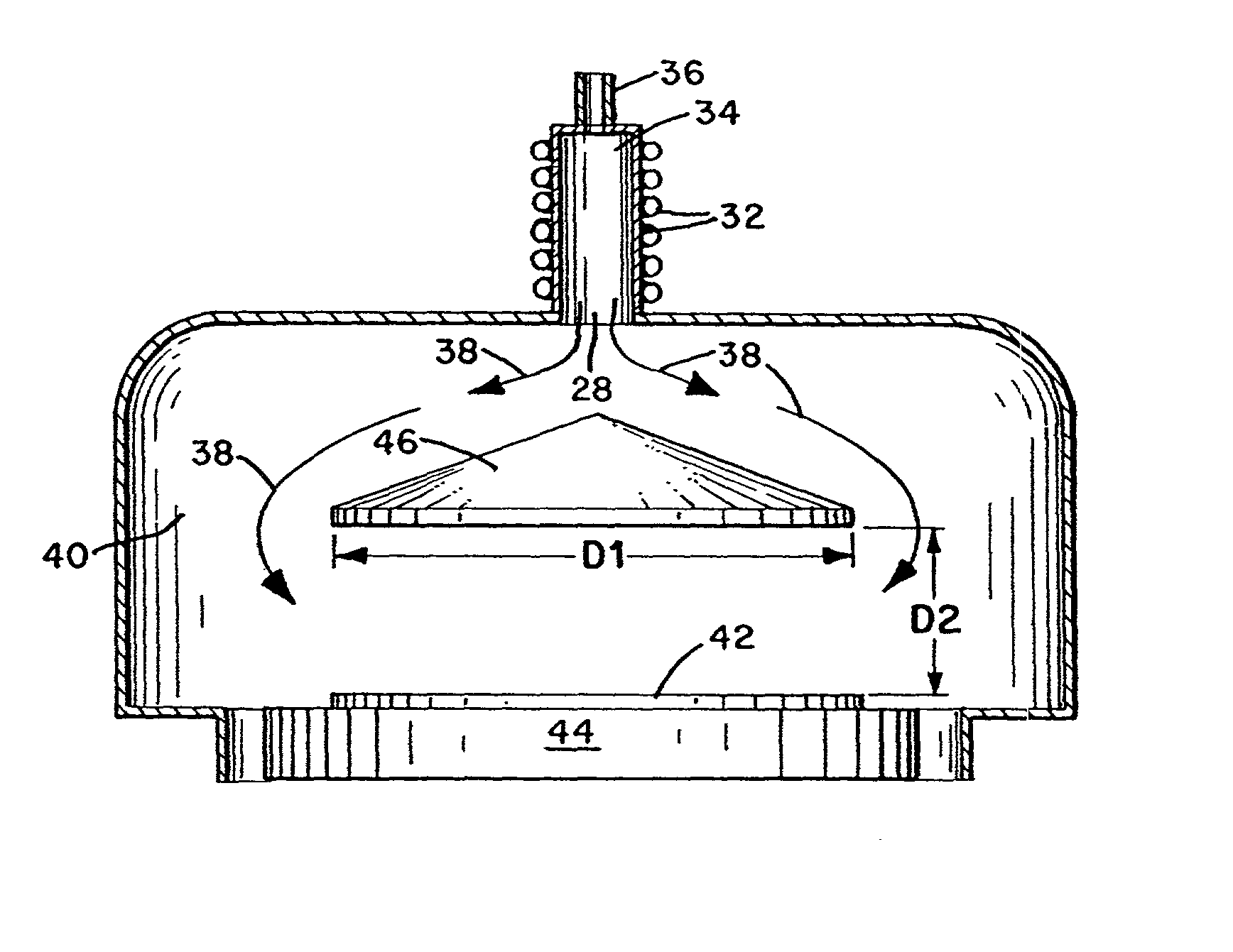

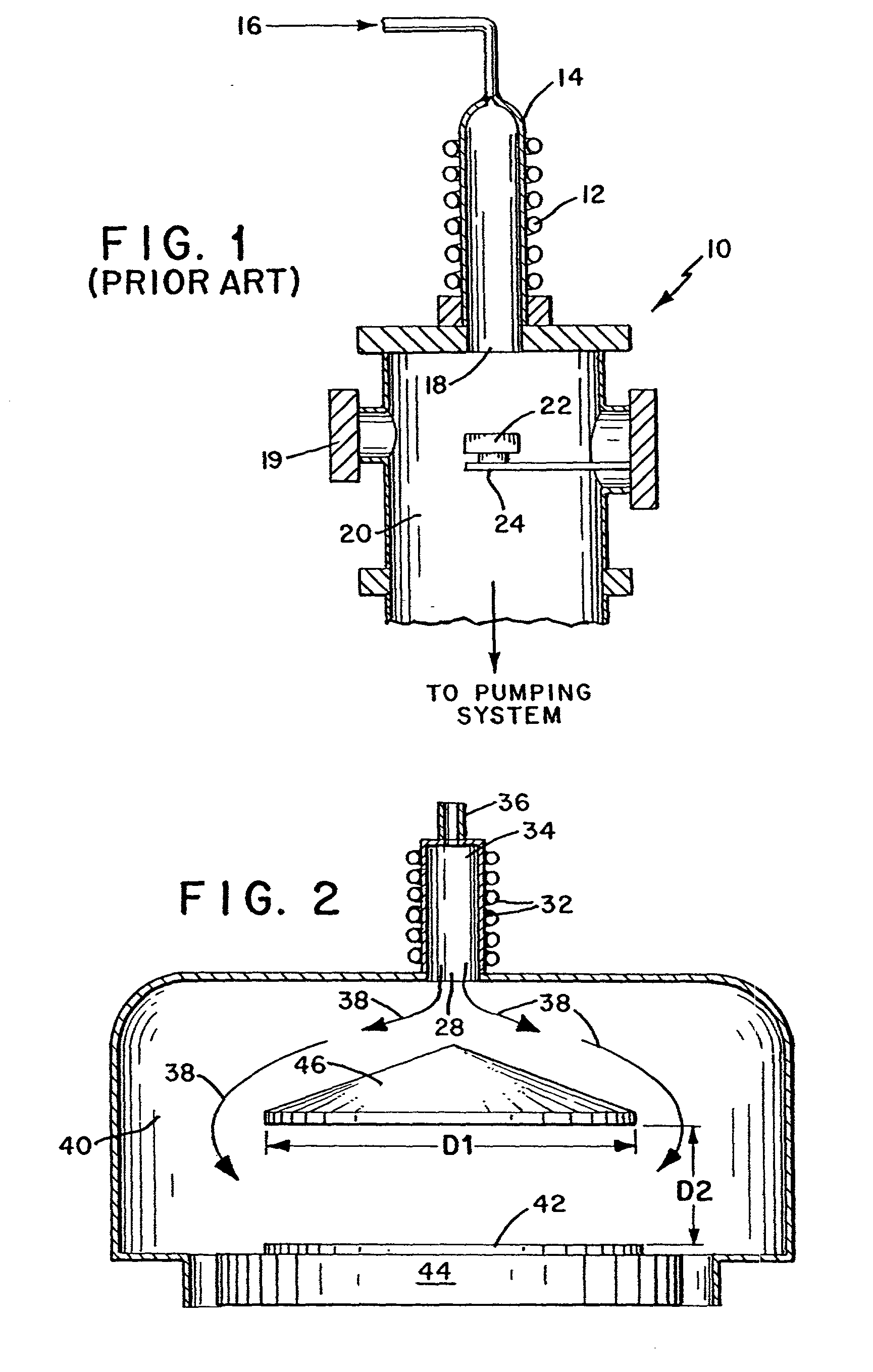

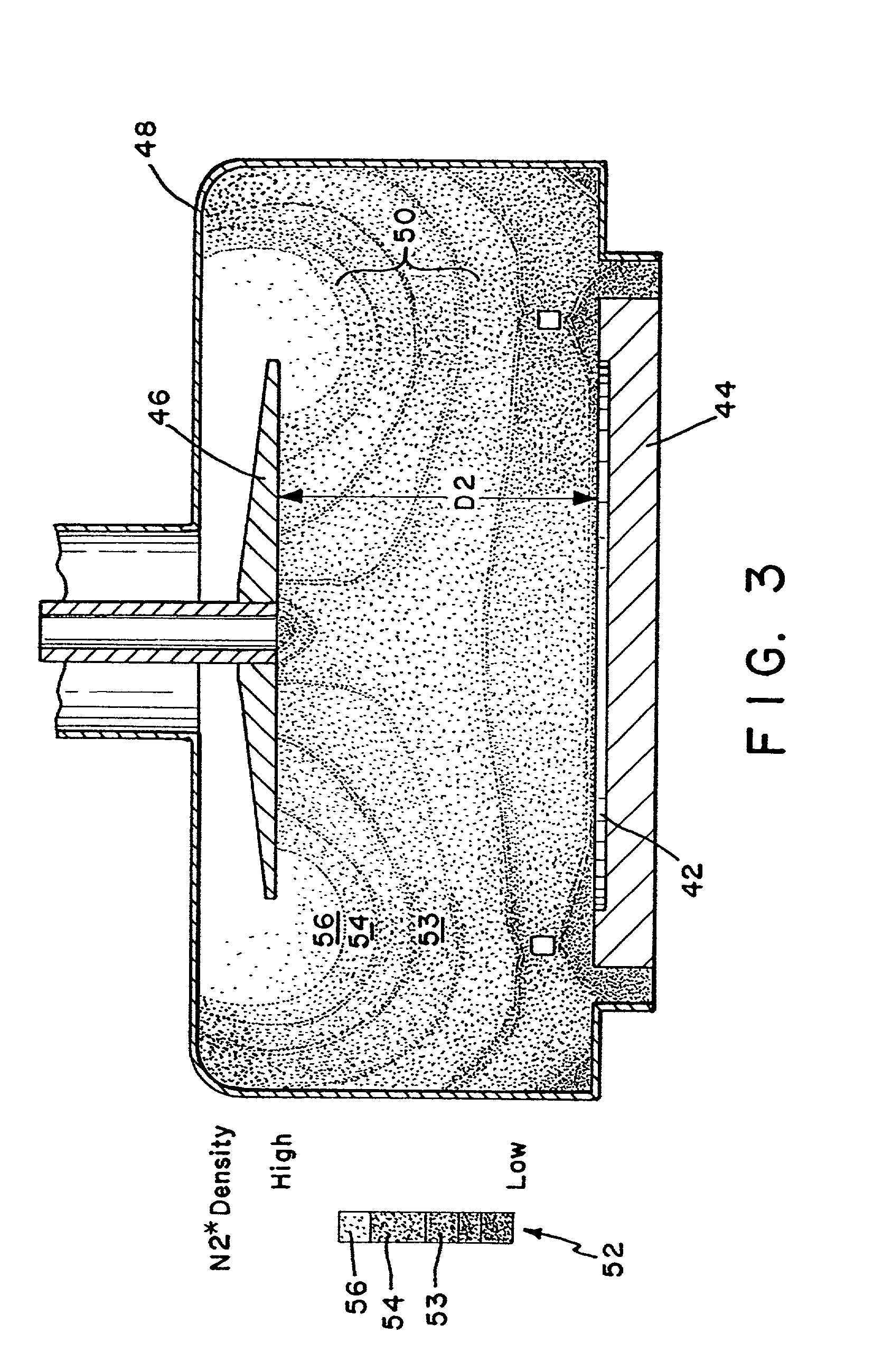

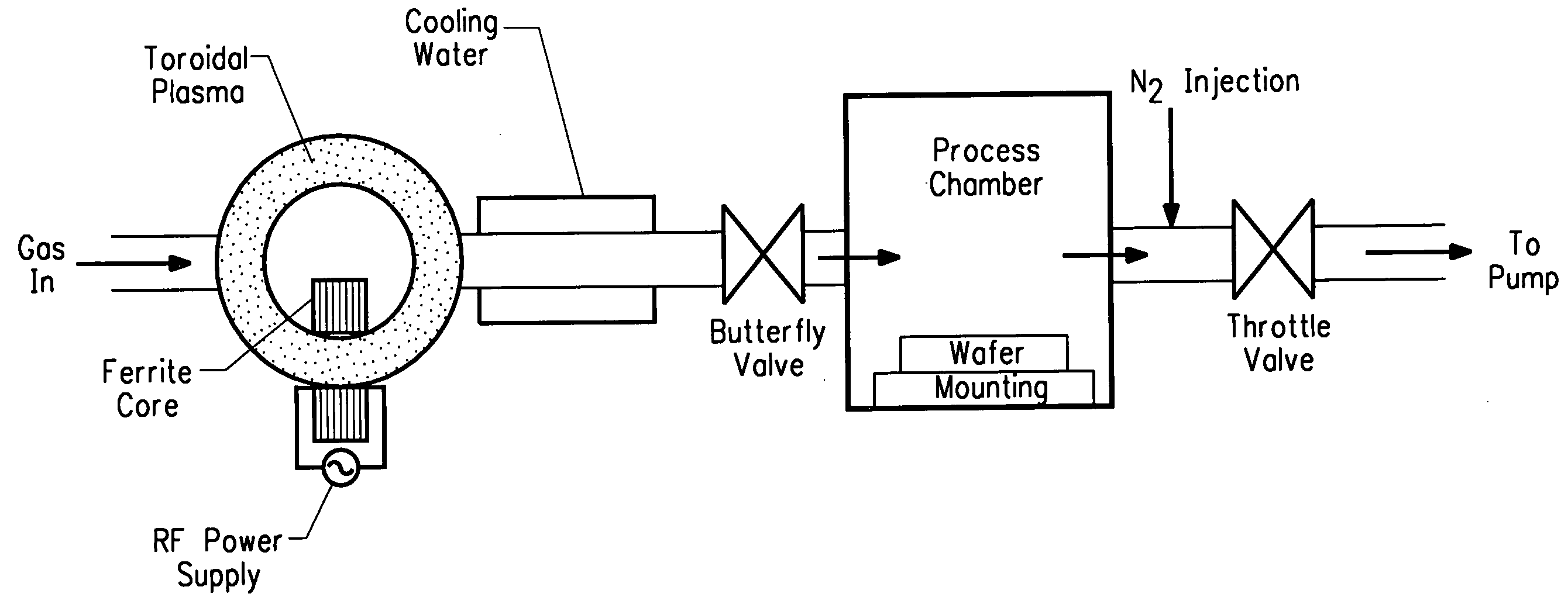

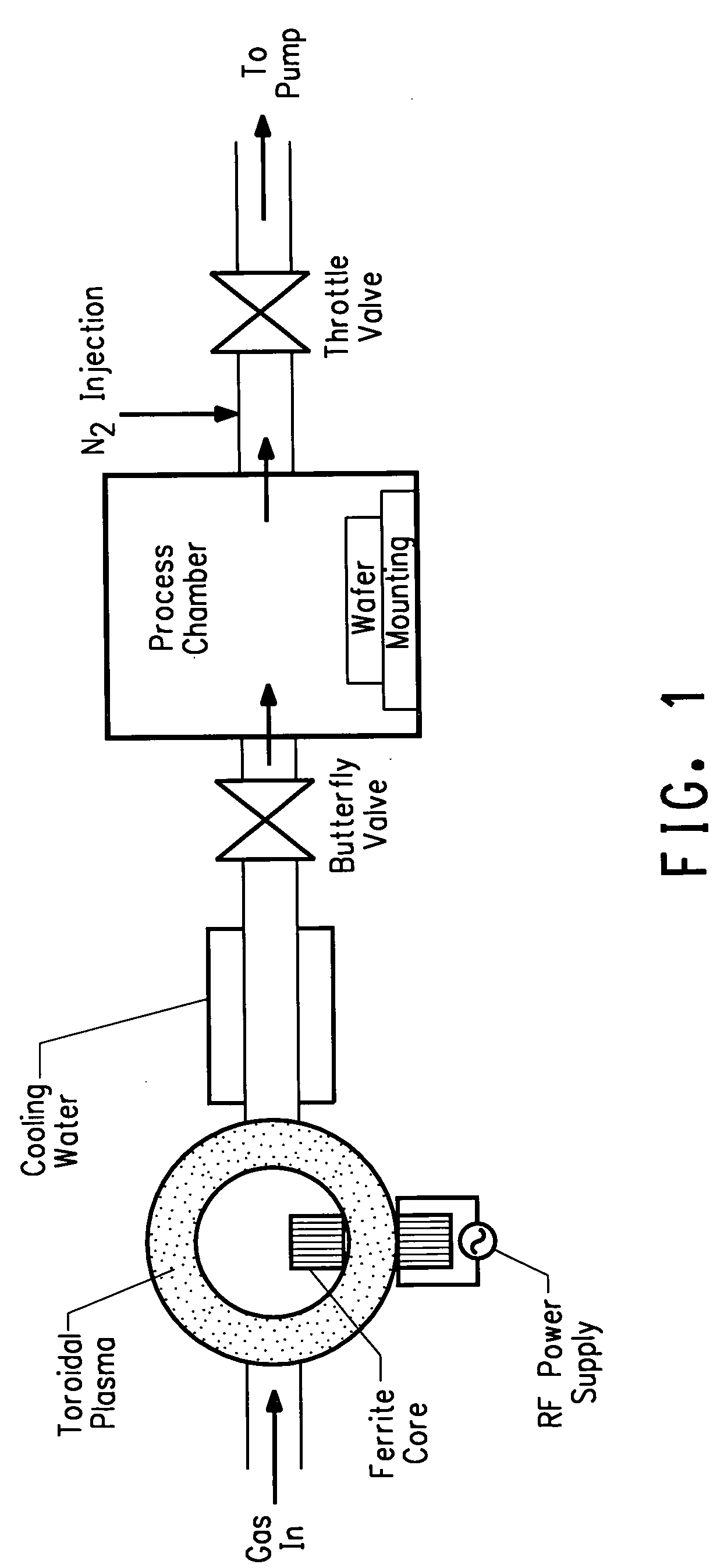

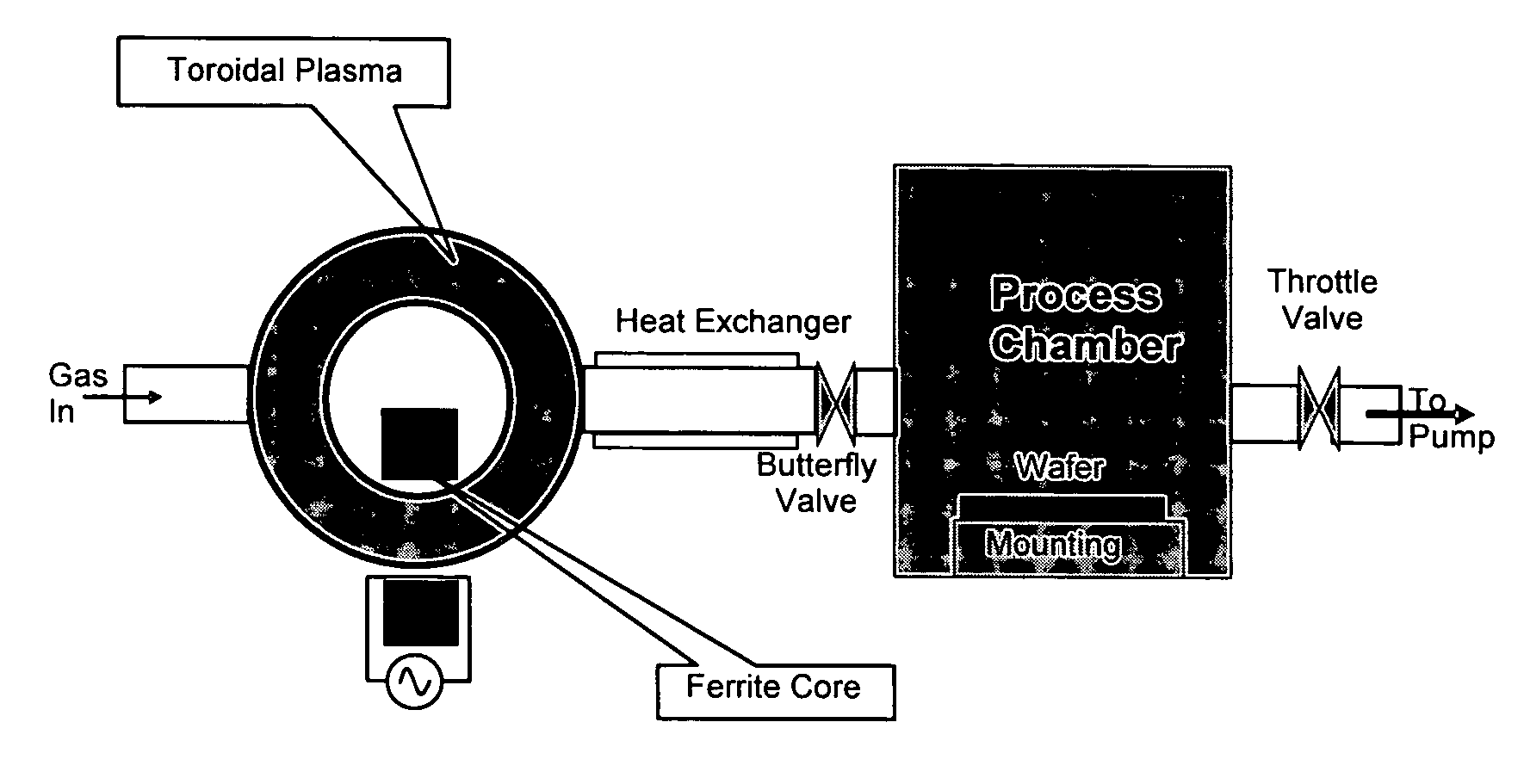

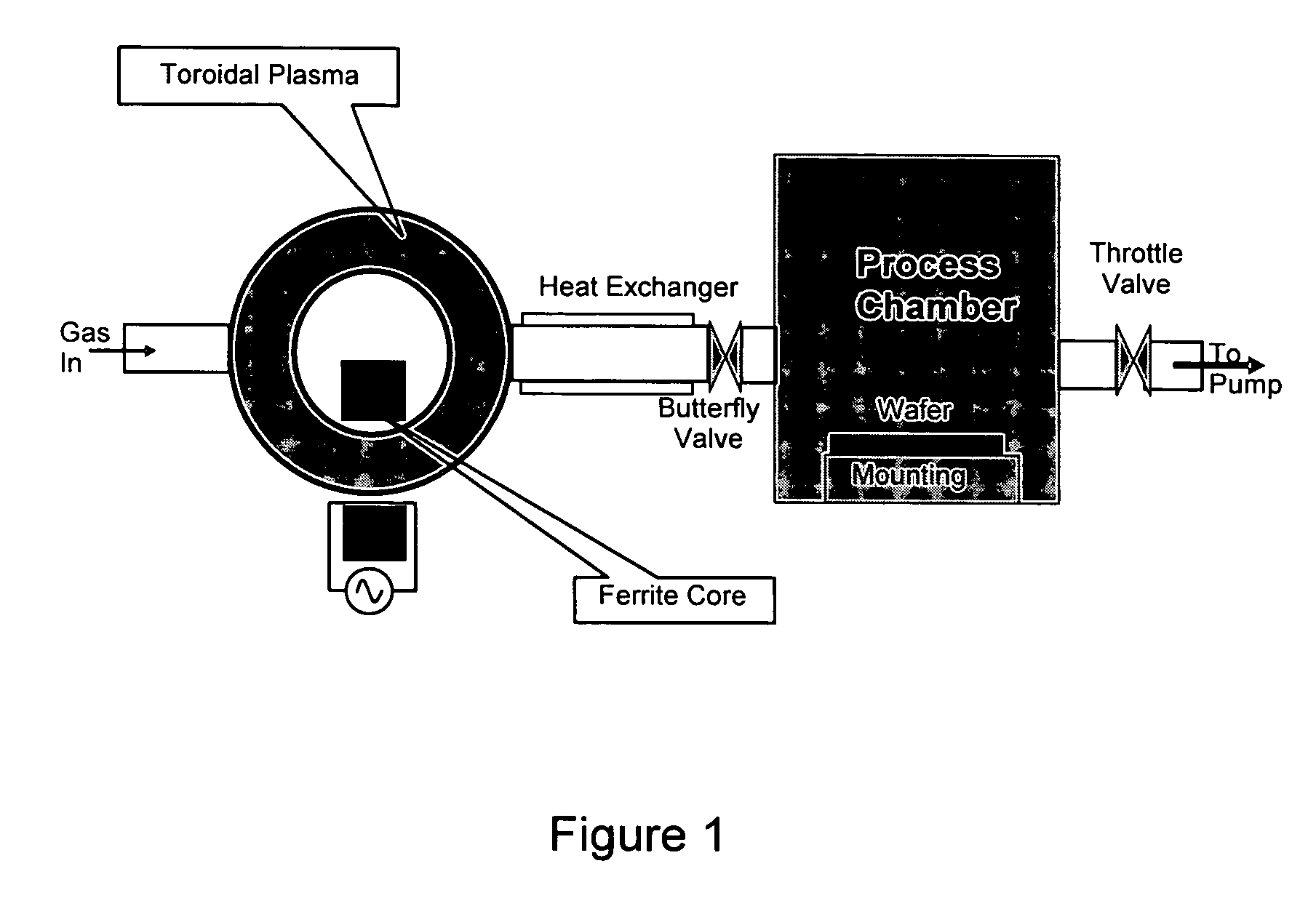

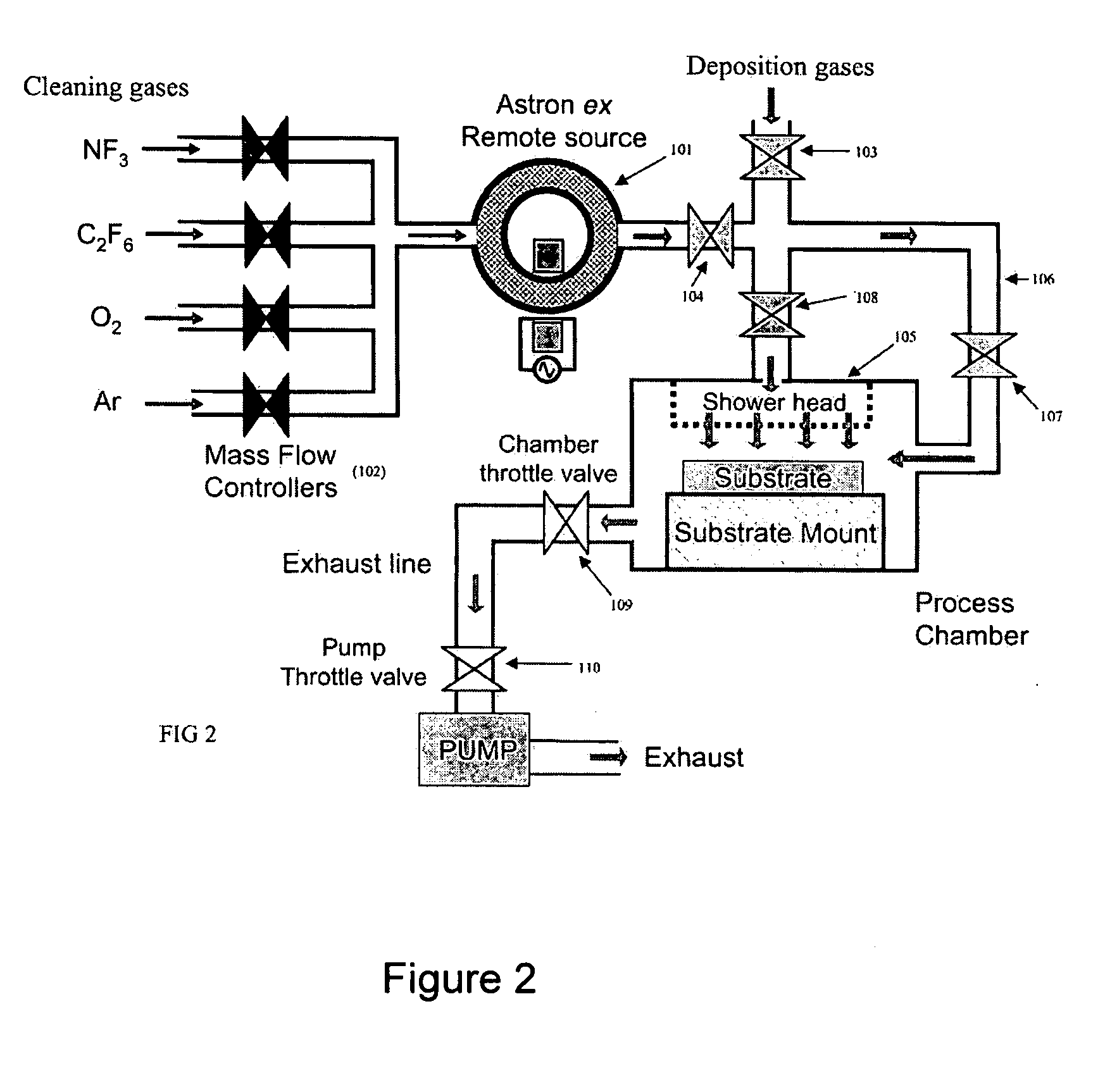

Apparatus and method for injecting and modifying gas concentration of a meta-stable or atomic species in a downstream plasma reactor

InactiveUS20020029747A1Reduce lossesElectric discharge tubesChemical vapor deposition coatingGas passingActive matter

This invention provides an apparatus and method for injecting gas within a plasma reactor and tailoring the distribution of an active species generated by the remote plasma source over the substrate or wafer. The distribution may be made more or less uniform, wafer-edge concentrated, or wafer-center concentrated. A contoured plate or profiler is provided for modifying the distribution. The profiler is an axially symmetric plate, having a narrow top end and a wider bottom end, shaped to redistribute the gas flow incident upon it. The profiler is situated below an input port within the plasma reactor chamber and above the wafer. The method for tailoring the distribution of the active species over the substrate includes predetermining the profiler diameter and adjusting the profiler height over the substrate. A coaxial injector tube, for the concurrent injection of activated and non-activated gas species, allows gases (or gas mixtures) to be delivered in an axially symmetric manner whereby one gas can be excited in a high density RF plasma, while the other gas can be prevented from excitation and / or dissociation caused by exposure to the plasma or heated surfaces in the source apparatus. The gas admixture that is not to be excited or dissociated prior to contact with the wafer surface is shielded from direct exposure to the RF field surrounding the plasma confinement tube. The tube walls are also shielded from the infrared energy emitted from the plasma. The profiler is used in conjunction with the coaxial injector tube for redistributing the excited gases emerging from the injector tube, while allowing the non-excited gases to pass through its center.

Owner:NOVELLUS SYSTEMS

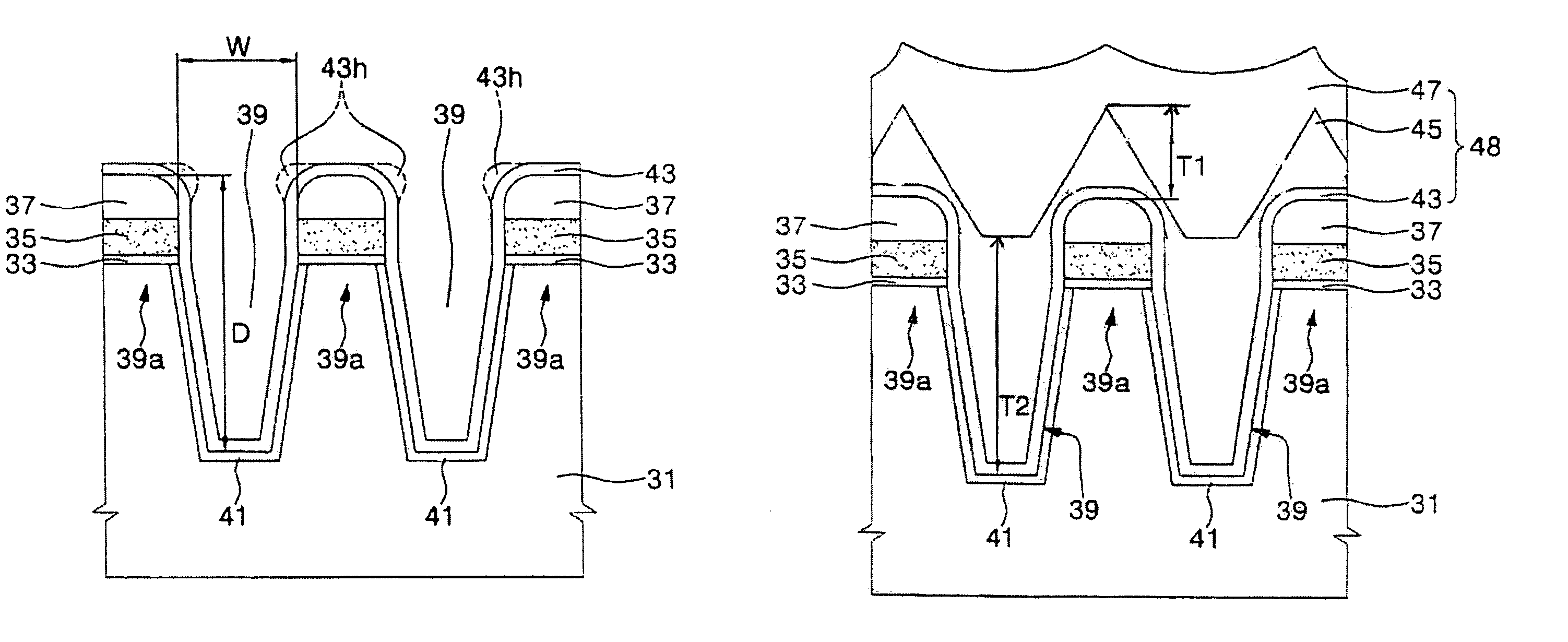

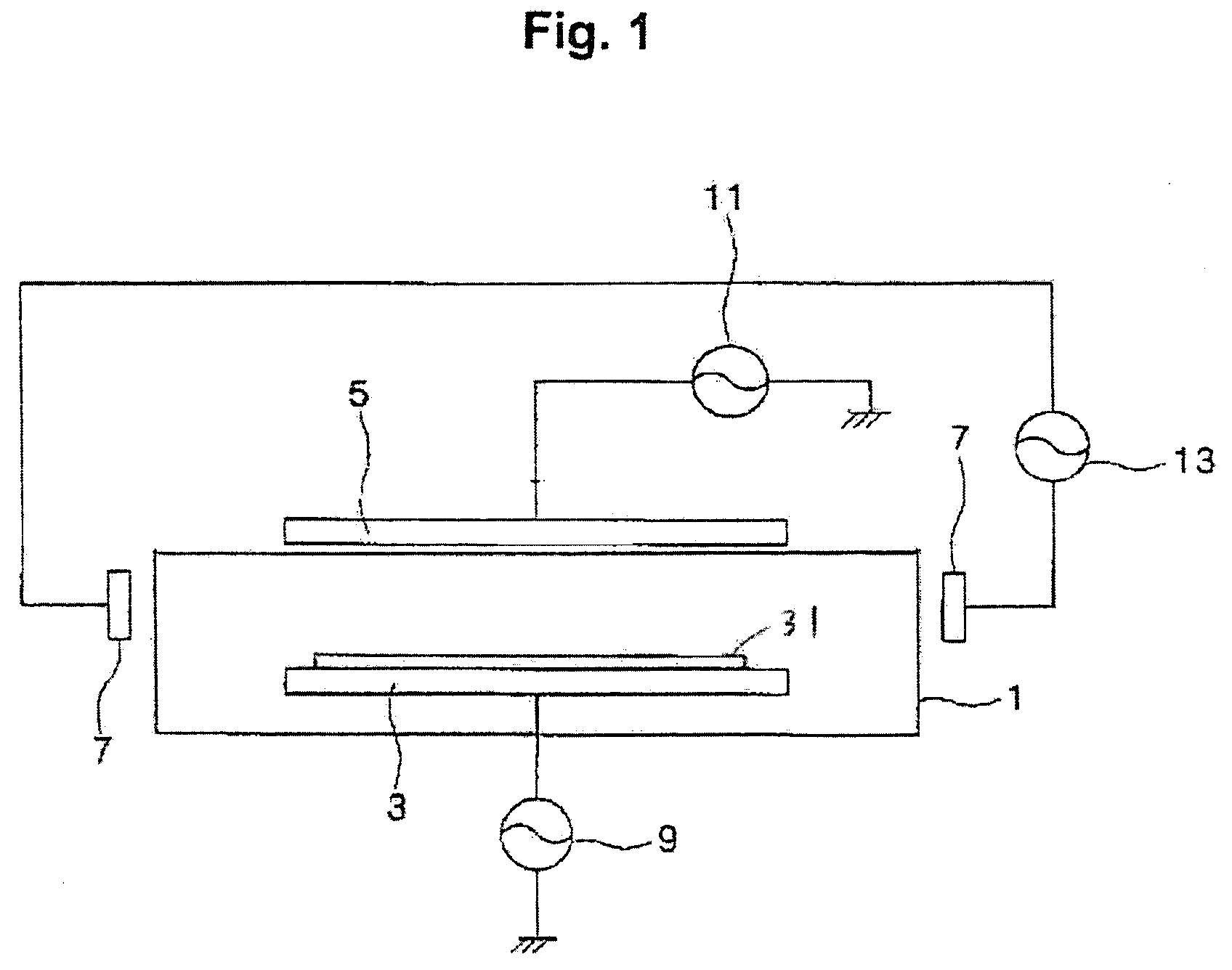

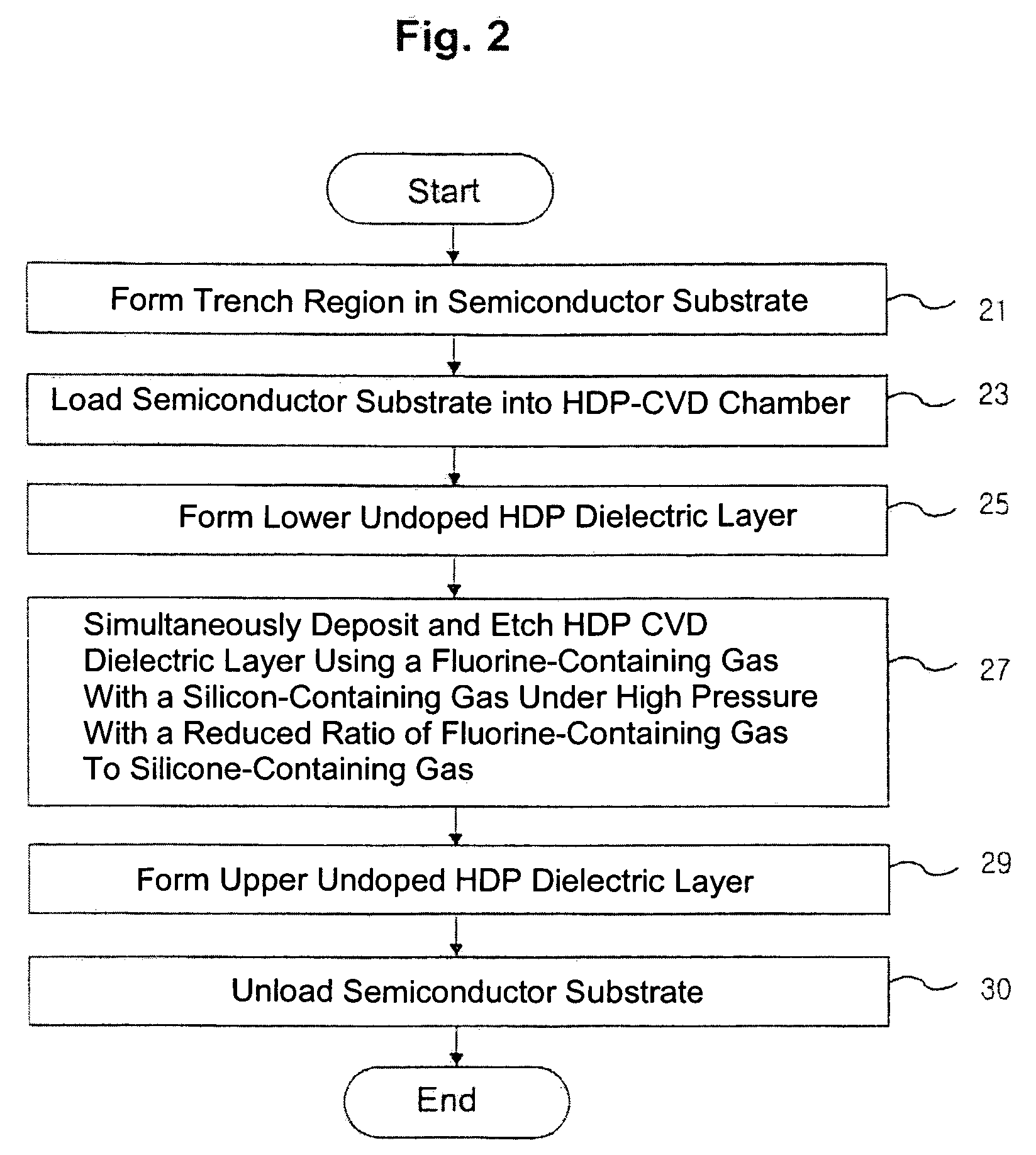

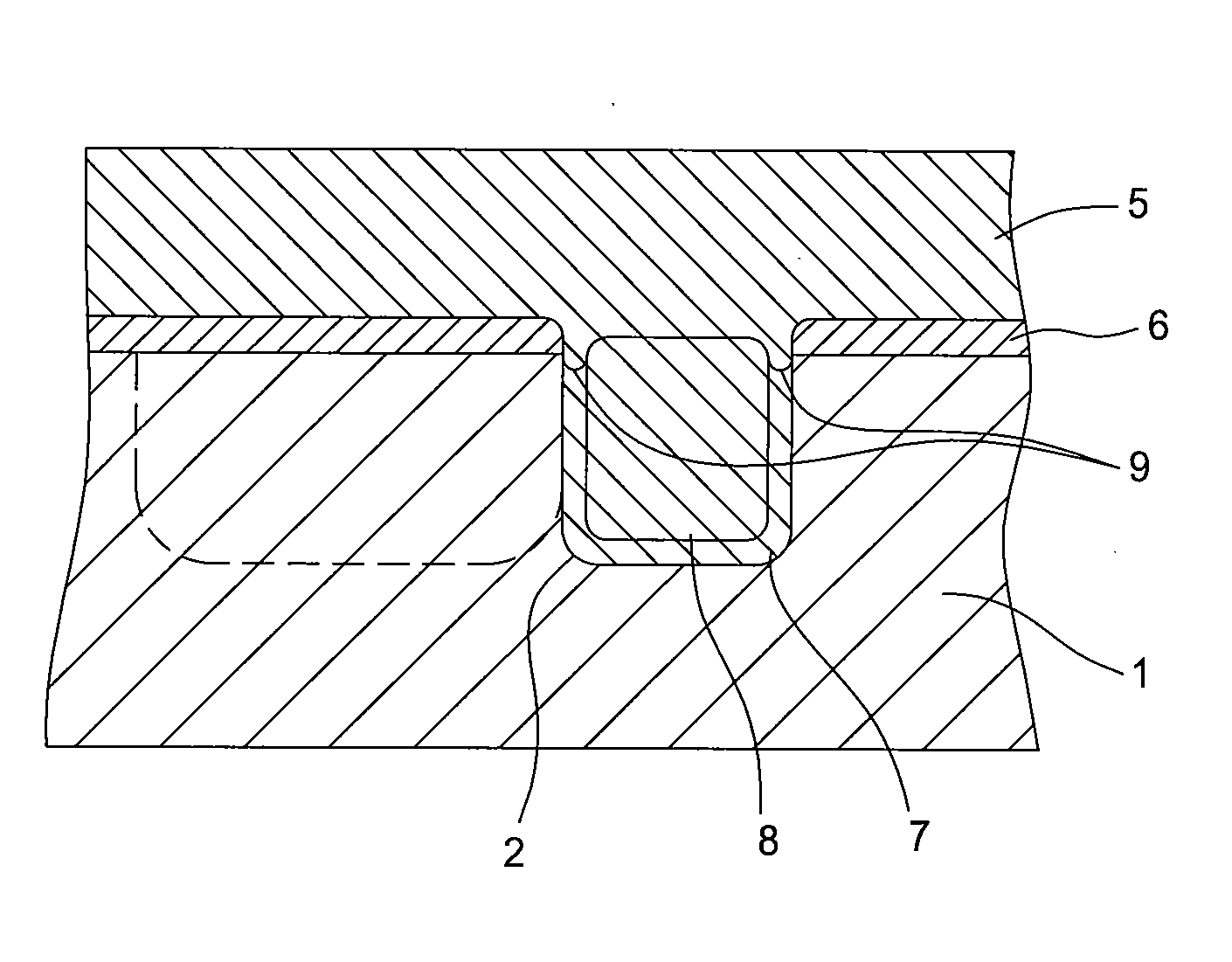

High-density plasma (HDP) chemical vapor deposition (CVD) methods and methods of fabricating semiconductor devices employing the same

InactiveUS7183214B2Reduce amountStrong Gap Filling CapabilitySemiconductor/solid-state device manufacturingPackaging toiletriesGas phaseDevice material

In one embodiment, a semiconductor substrate is placed into a process chamber. A gas mixture including a silicon-containing gas, a fluorine-containing gas, an inert gas, and an oxygen gas is introduced into the chamber at a pressure range of from about 30 mTorr to about 90 mTorr. During this time, deposition and etching processes are concurrently performed using a plasma to form a high-density plasma (HDP) insulating layer on the semiconductor substrate. A ratio of deposition to etching is from about 3:1 to about 10:1. A ratio of a flow rate of the fluorine-containing gas to a flow rate of the silicon-containing gas is less than about 0.9.

Owner:SAMSUNG ELECTRONICS CO LTD

Oxide etch with nh4-nf3 chemistry

ActiveUS20100093151A1Semiconductor/solid-state device testing/measurementDecorative surface effectsSemiconductorAnalytical chemistry

Owner:APPLIED MATERIALS INC

Method of using NF3 for removing surface deposits from the interior of chemical vapor deposition chambers

InactiveUS20070107750A1Efficient methodElectrostatic cleaningChemical vapor deposition coatingRemote plasmaOxygen

The present invention relates to a remote plasma cleaning method for removing surface deposits from a surface, such as the interior of a depositions chamber that is used in fabricating electronic devices. The process involves activating a gas stream comprising an oxygen source, NF3, and a fluorocarbon and contacting the activated gas mixture with surface deposits to remove the surface deposits.

Owner:MASSACHUSETTS INST OF TECH

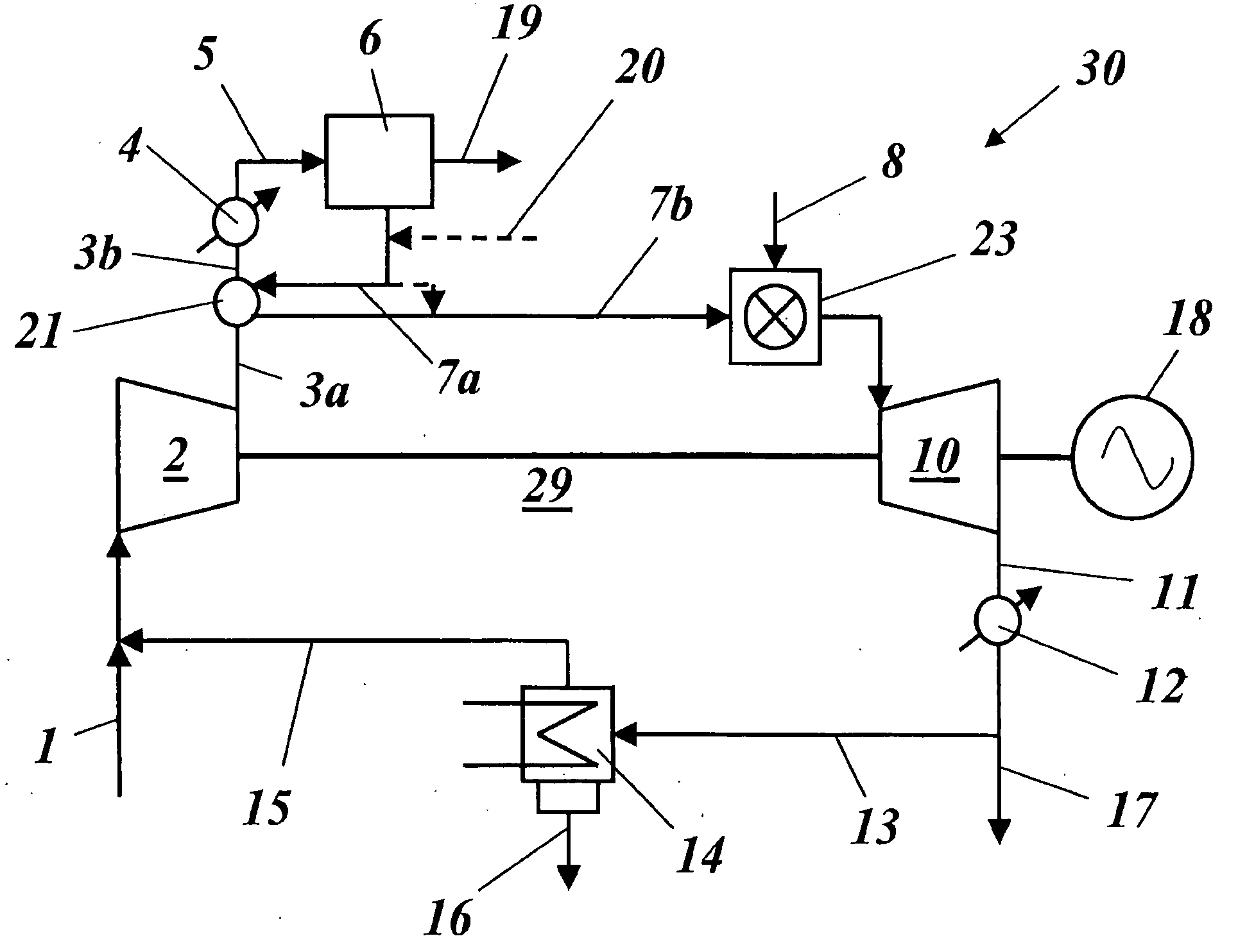

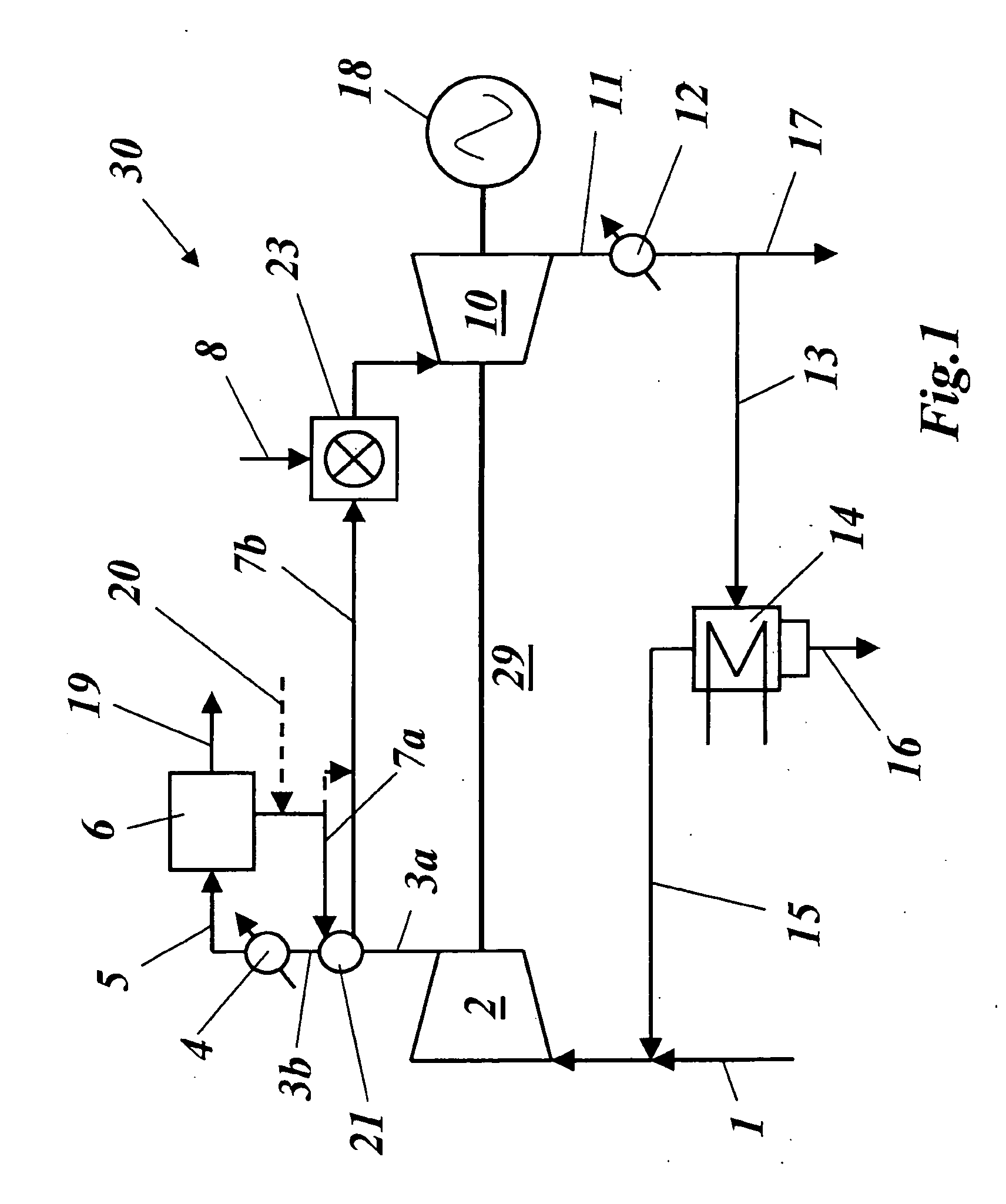

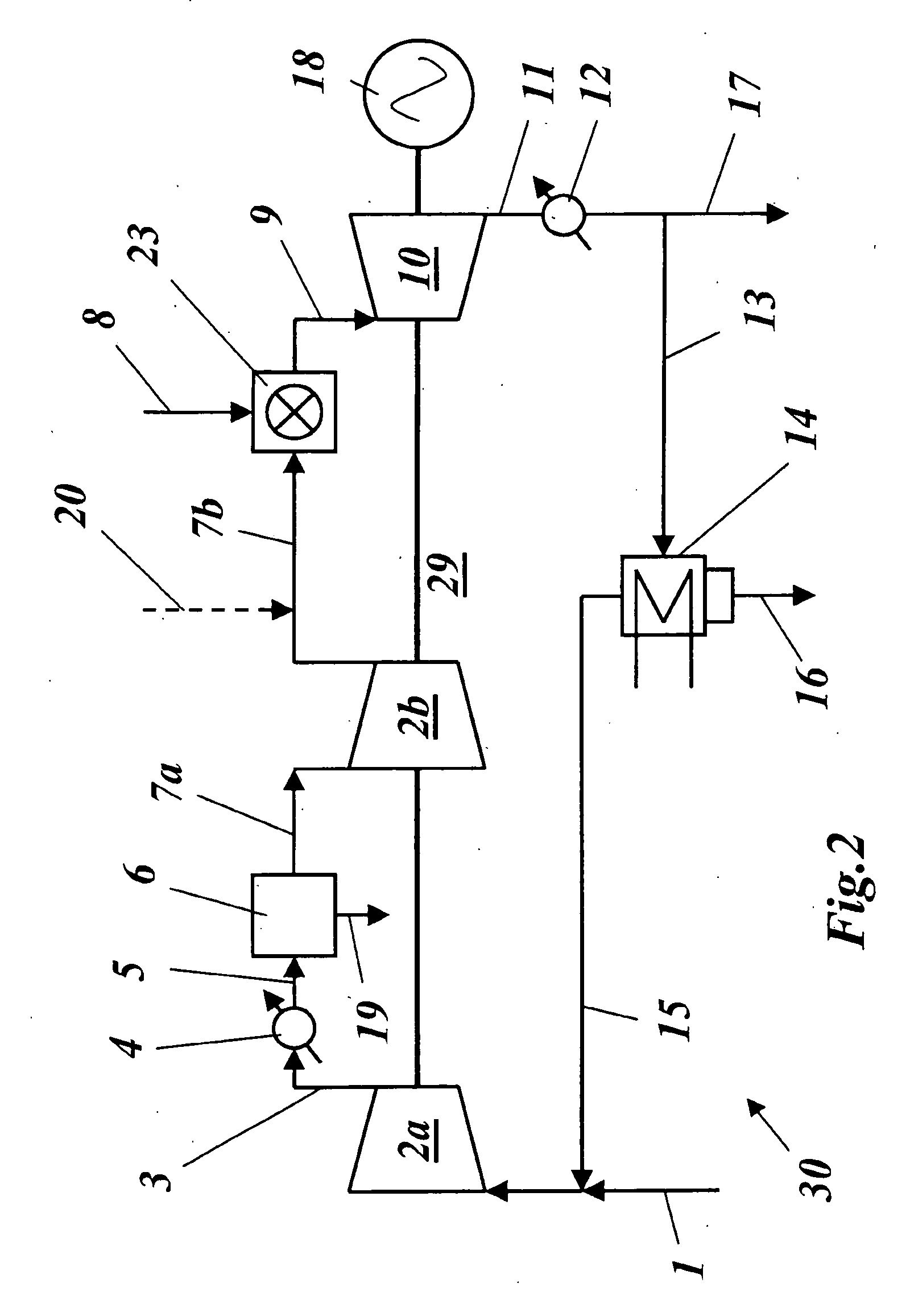

Method of generating energy in a power plant comprising a gas turbine, and power plant for carrying out the method

InactiveUS20050028529A1Small sizeLow costContinuous combustion chamberDispersed particle separationPower stationCombustor

A method of generating energy in a power plant (30) having a gas turbine (29), includes a first step a gas containing air (1) is compressed in a first compressor (2) of the gas turbine (29), a second step the compressed gas (3, 3a, 3b; 5; 7a, 7b) is fed to a combustion process with the addition of fuel (8) in a combustor (23), a third step the hot flue gas (9) from the combustor (23) is expanded in an expander or a turbine (10), driving a generator (18), of the gas turbine (29) while performing work, and a fourth step a partial flow of the expanded flue gas (11) is recirculated to the inlet of the first compressor (2) and admixed with the gas containing air (1). Carbon dioxide (CO2) is separated from the compressed gas (3, 3a, 3b; 5; 7a, 7b) in a CO2 separator (6) before the third step. In such a method, the overall size and energy costs are reduced by virtue of the fact that, to permit increased CO2 concentrations in the CO2 separator (6), not more than about 70% of the carbon dioxide contained in the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b) is removed from the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b).

Owner:ALSTOM TECH LTD

Method for removing surface deposits and passivating interior surfaces of the interior of a chemical vapor deposition reactor

InactiveUS20090047447A1Efficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsGas phaseSulfur

The present invention relates to plasma cleaning methods for removing surface deposits from a surface, such as the interior of a depositions chamber that is used in fabricating electronic devices. The present invention also provides gas mixtures and activated gas mixtures which provide superior performance in removing deposits from a surface. The methods involve activating a gas mixture comprising a carbon or sulfur source, NF3, and optionally, an oxygen source to form an activated gas, and contacting the activated gas mixture with surface deposits to remove the surface deposits wherein the activated gas mixture acts to passivate the interior surfaces of the apparatus to reduce the rate of surface recombination of gas phase species.

Owner:MASSACHUSETTS INST OF TECH

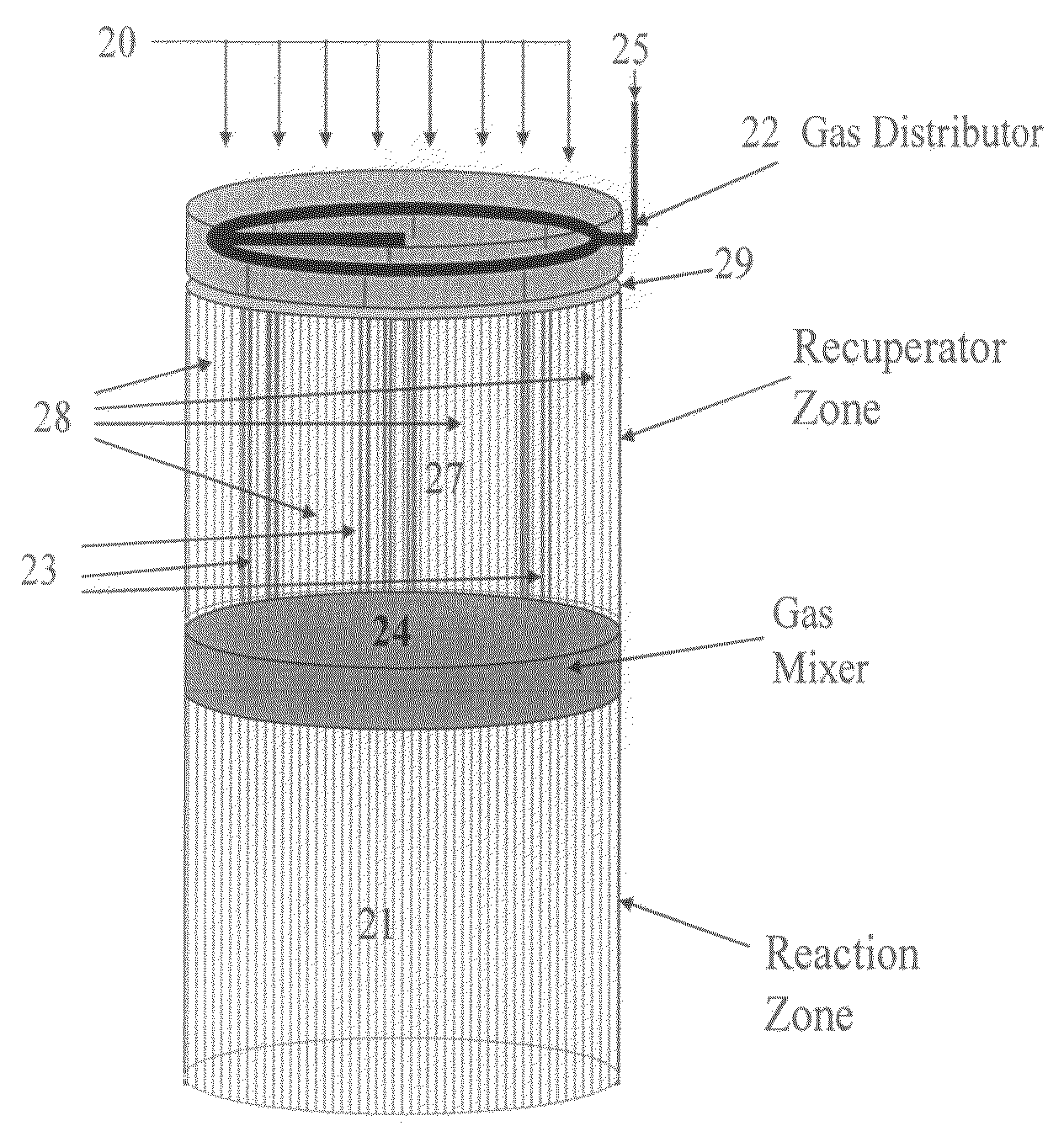

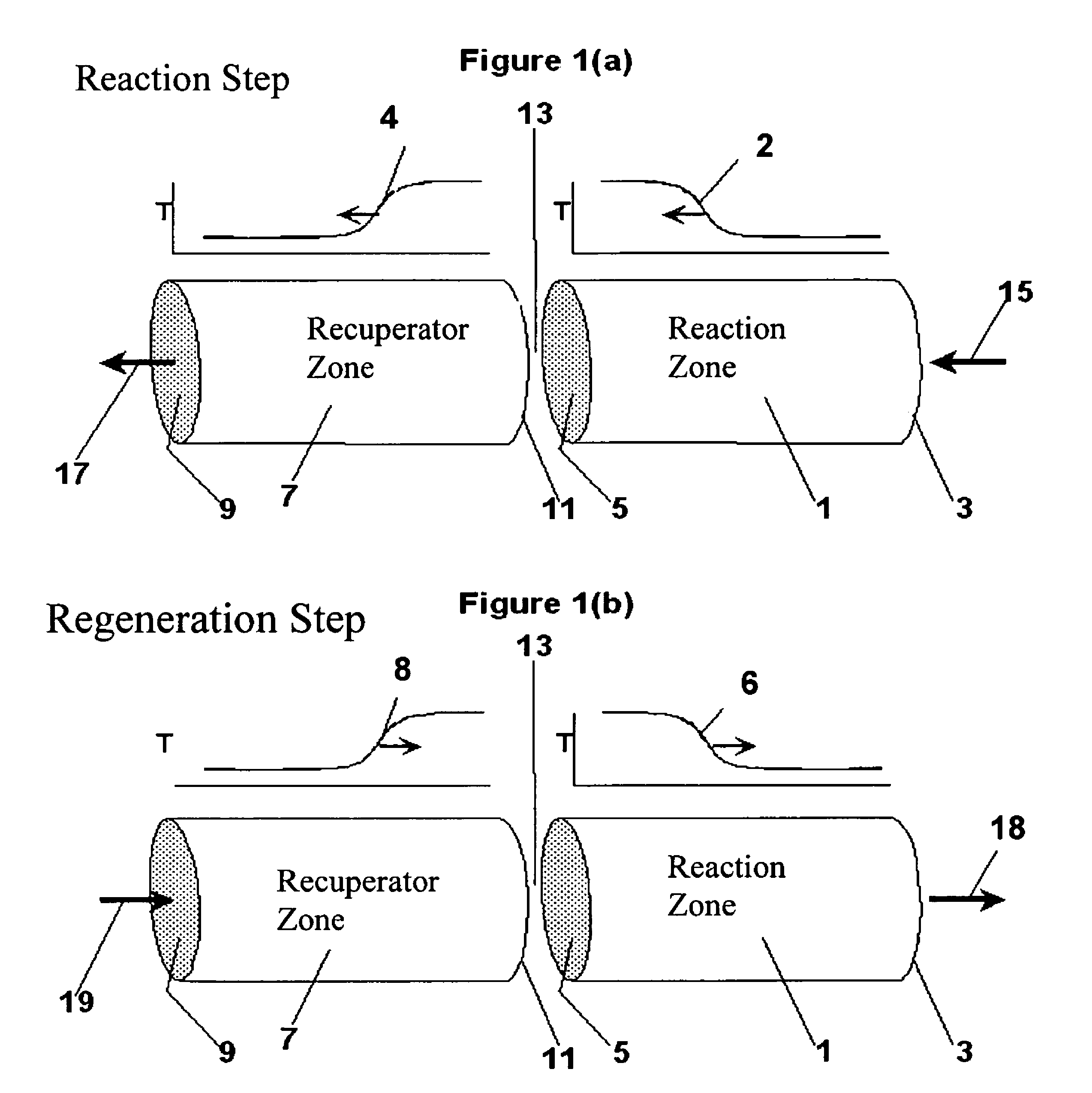

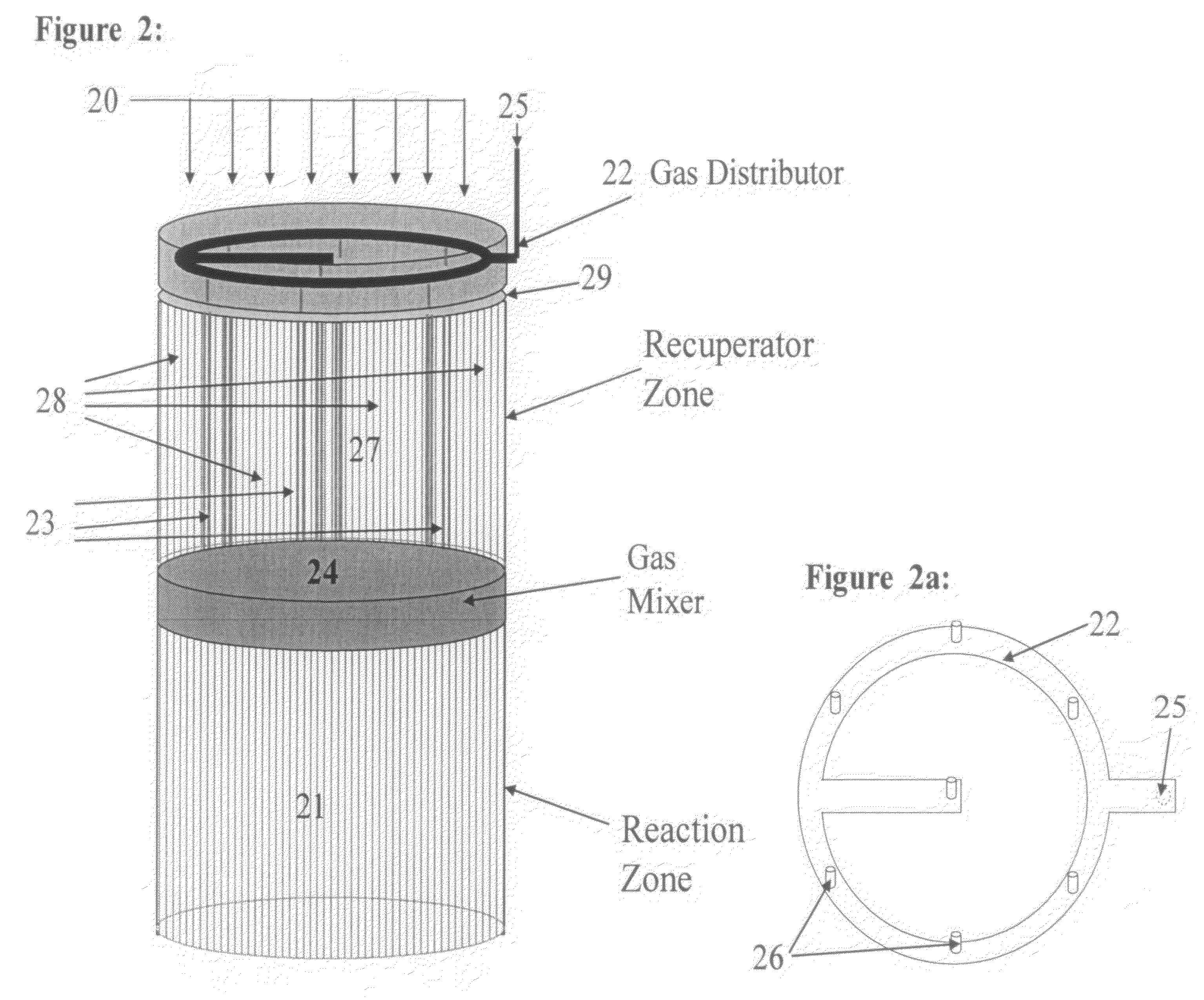

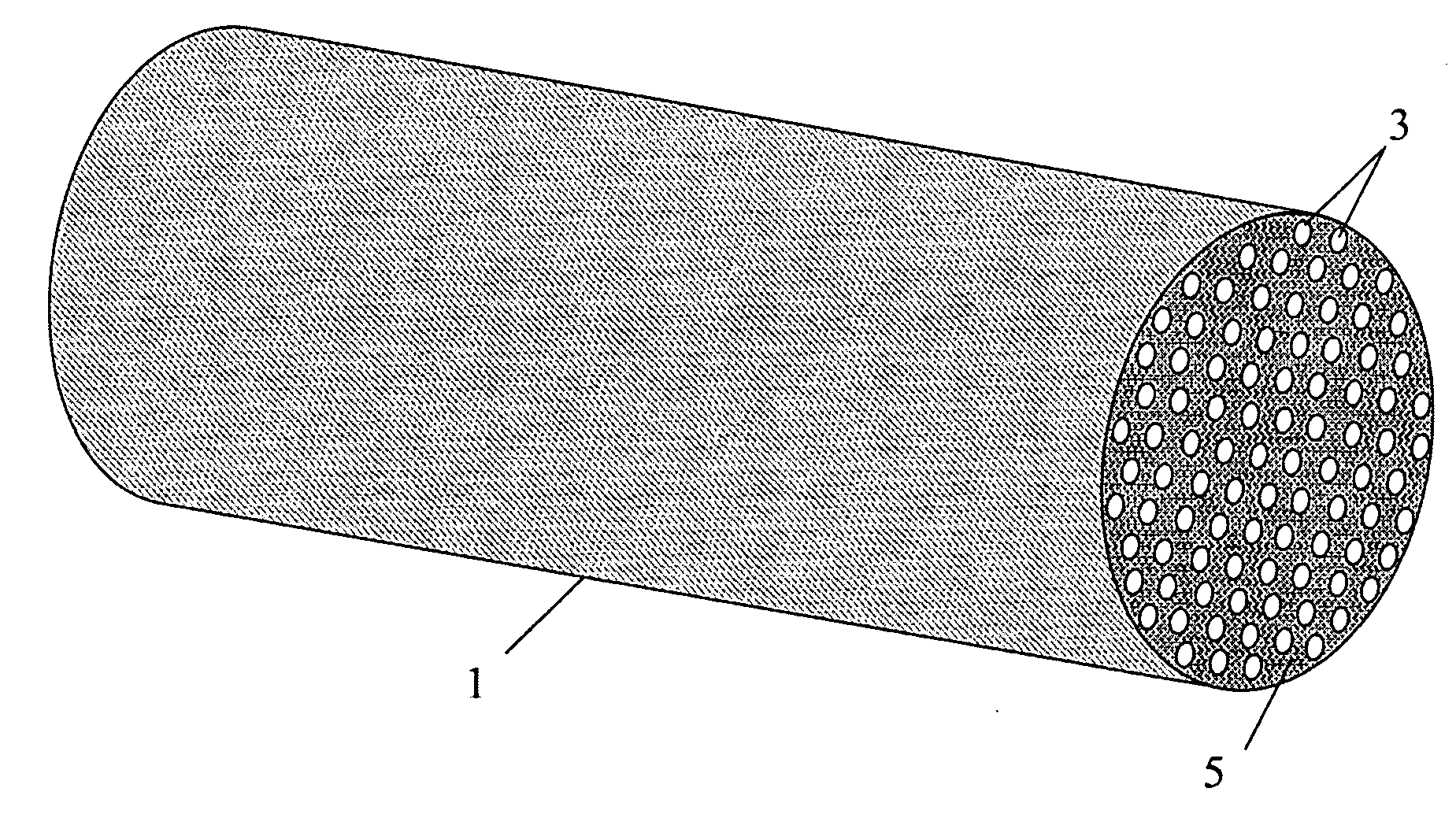

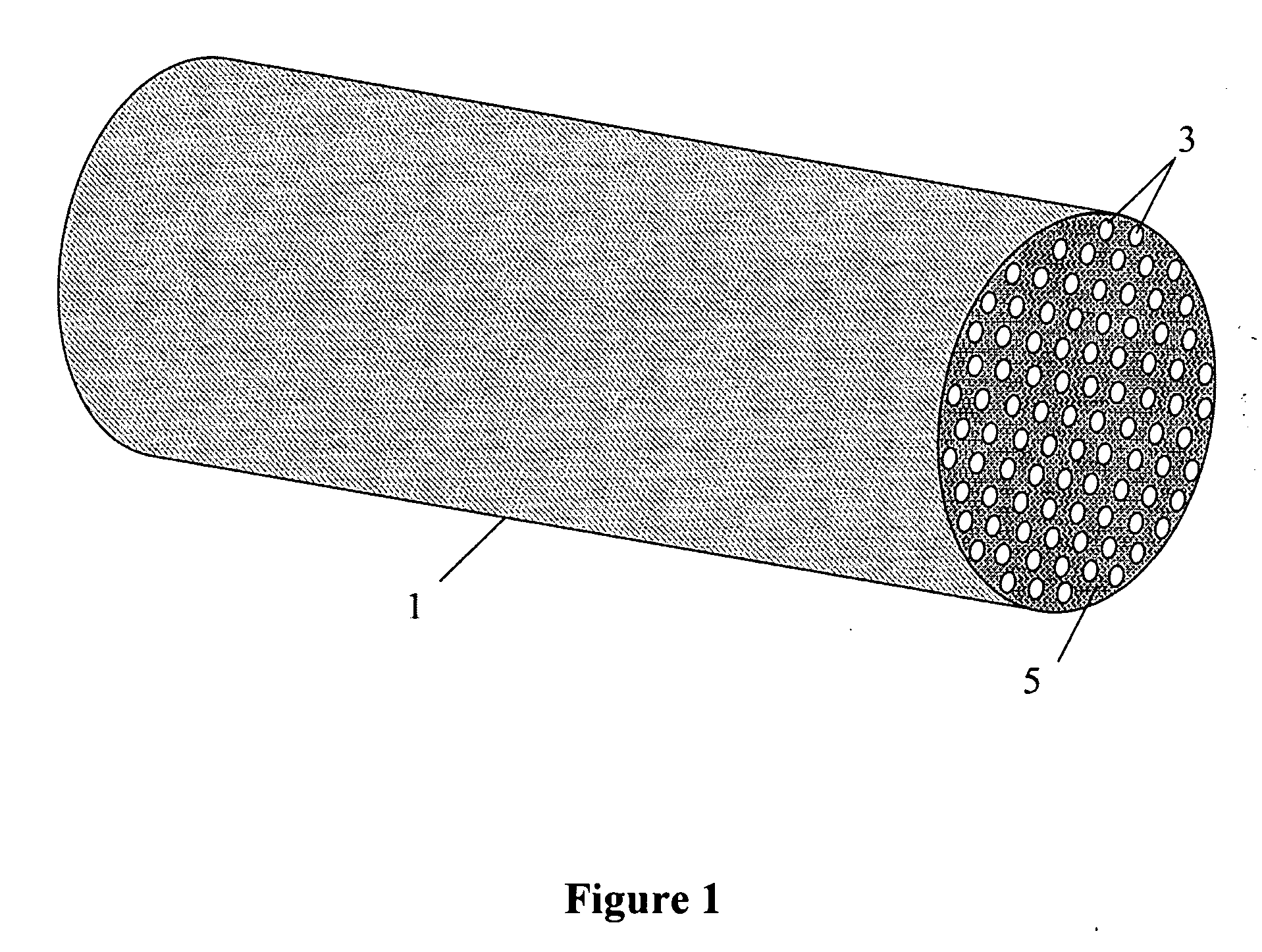

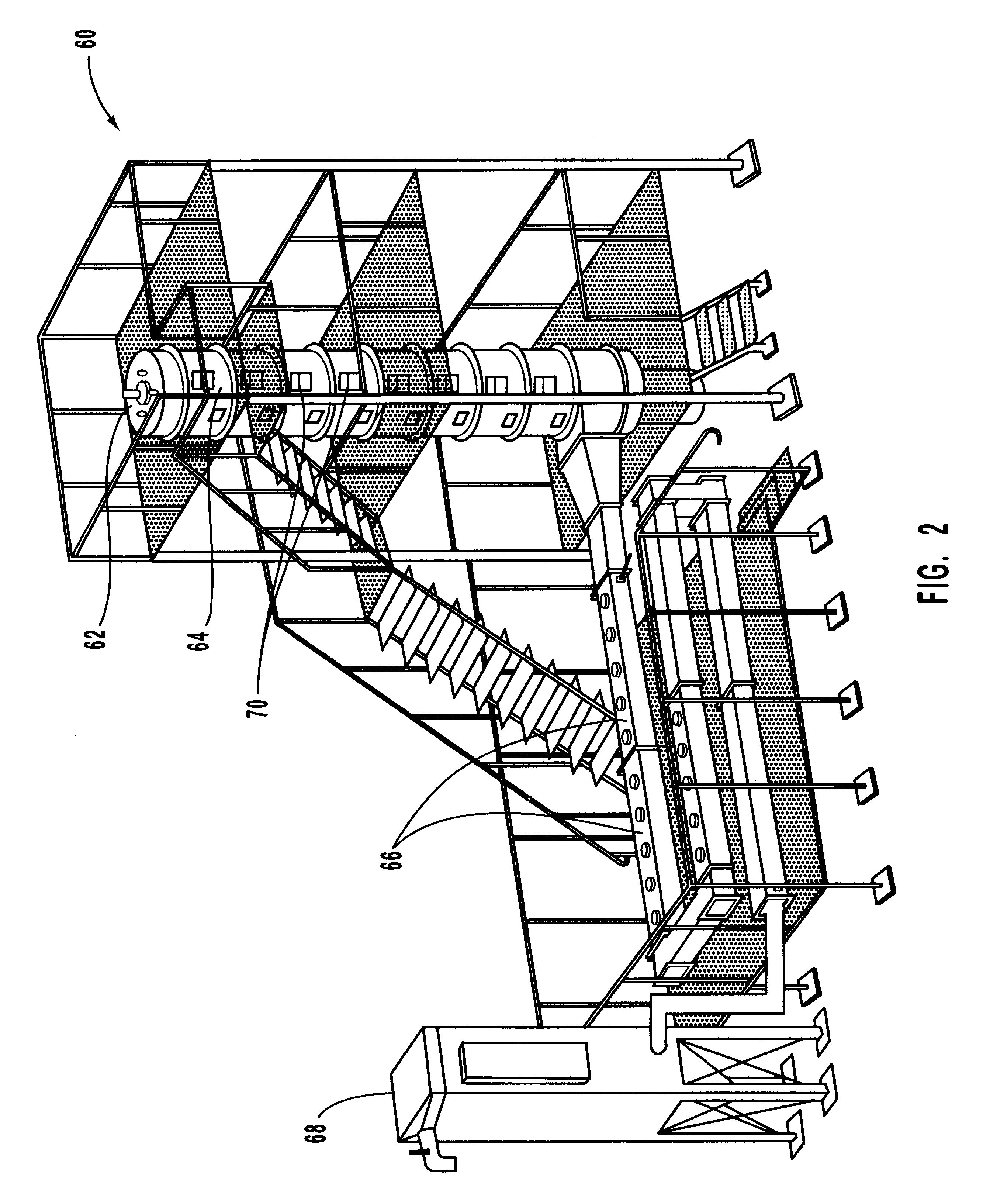

Controlled combustion for regenerative reactors with mixer/flow distributor

ActiveUS7815873B2Efficient transferEvenly distributedHydrocarbon by dehydrogenationFlow mixersReactor systemCombustion

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

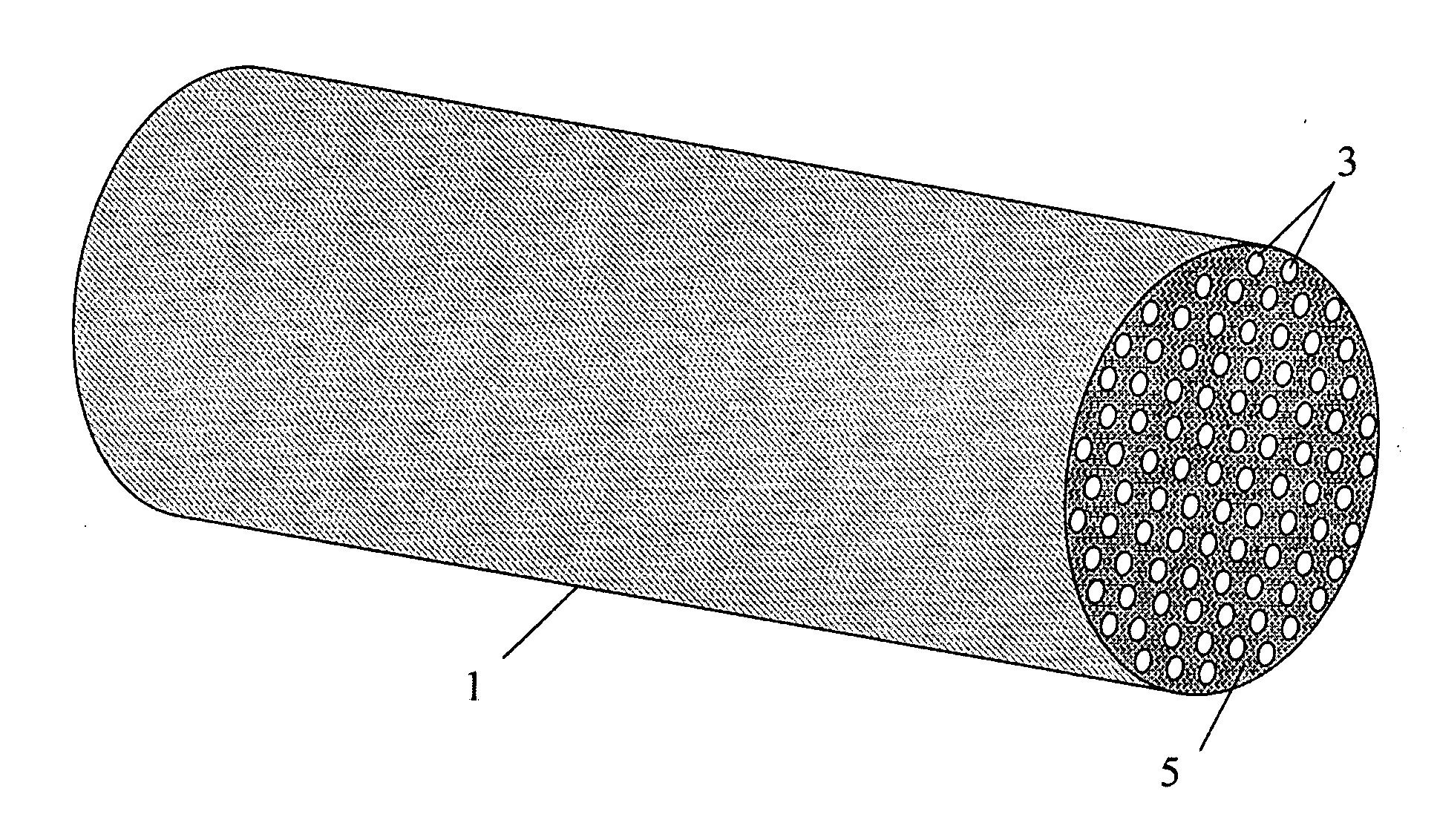

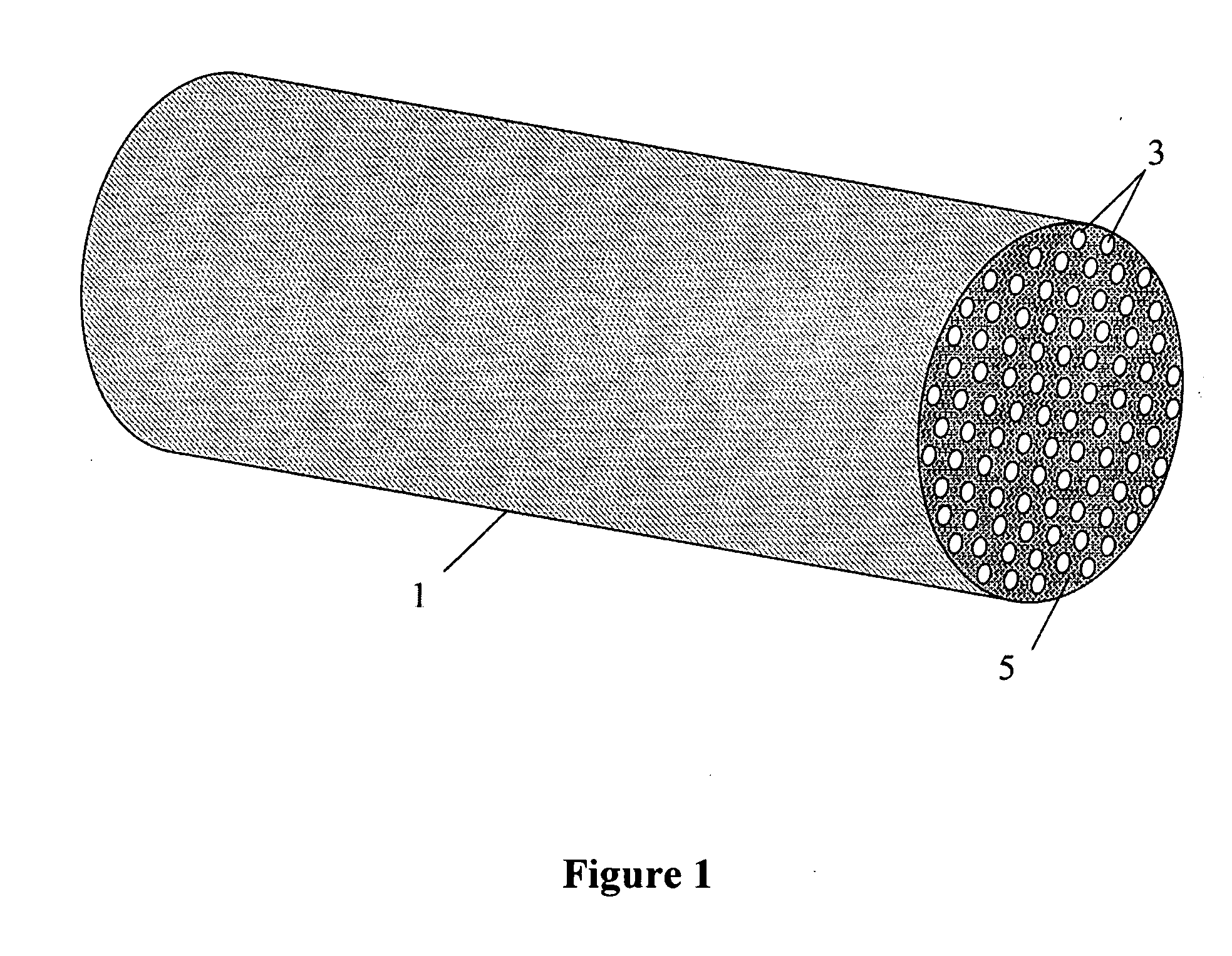

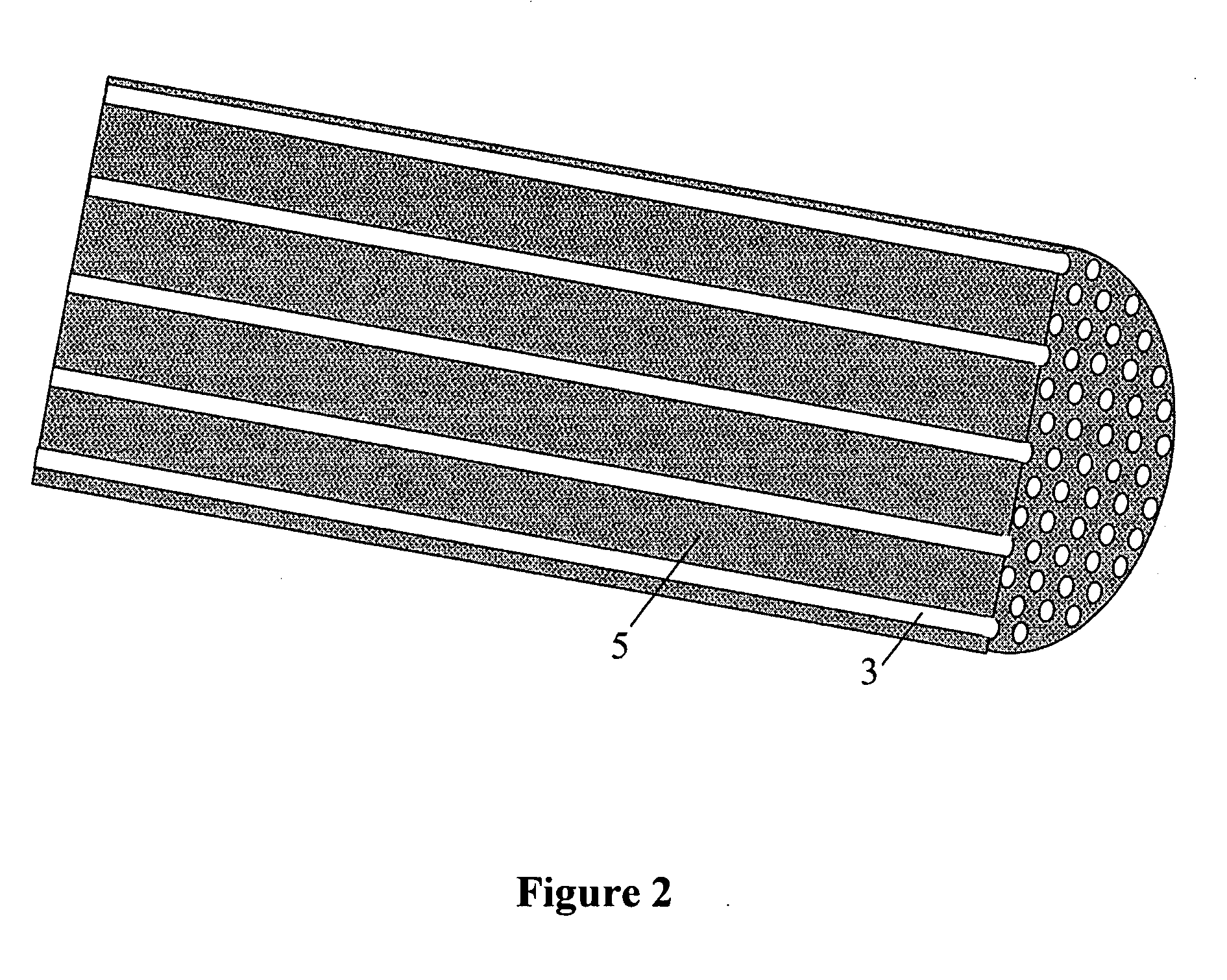

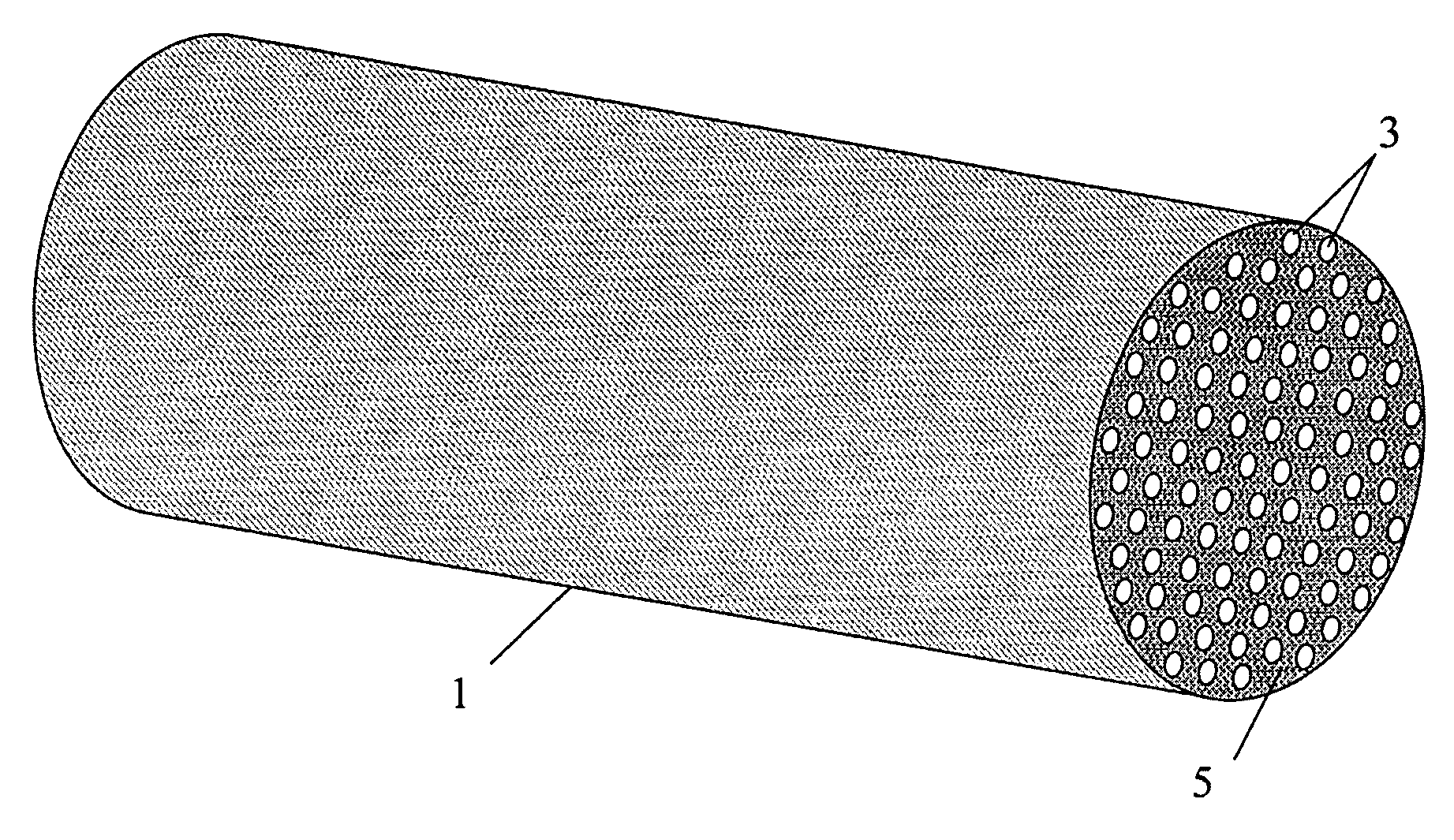

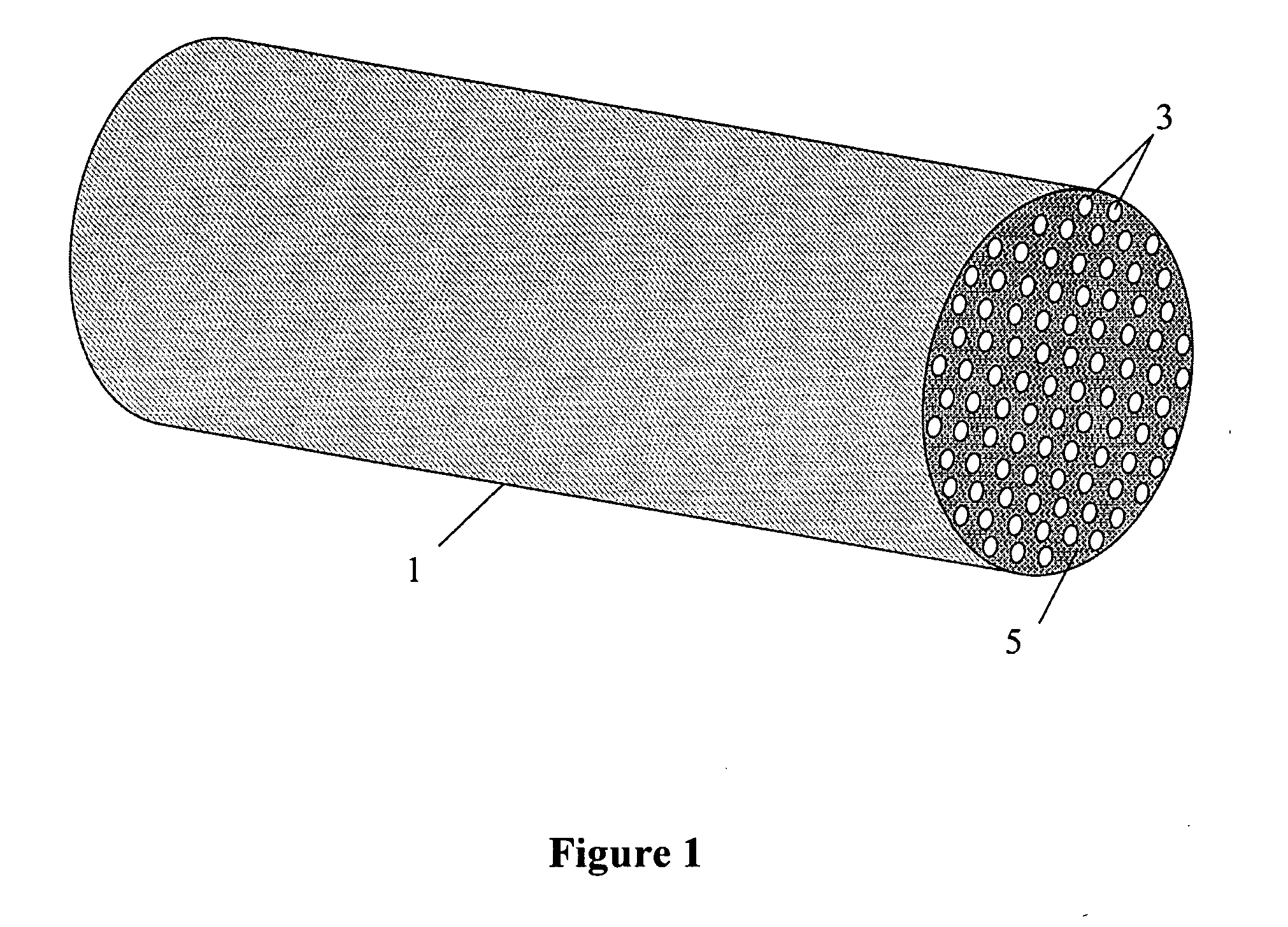

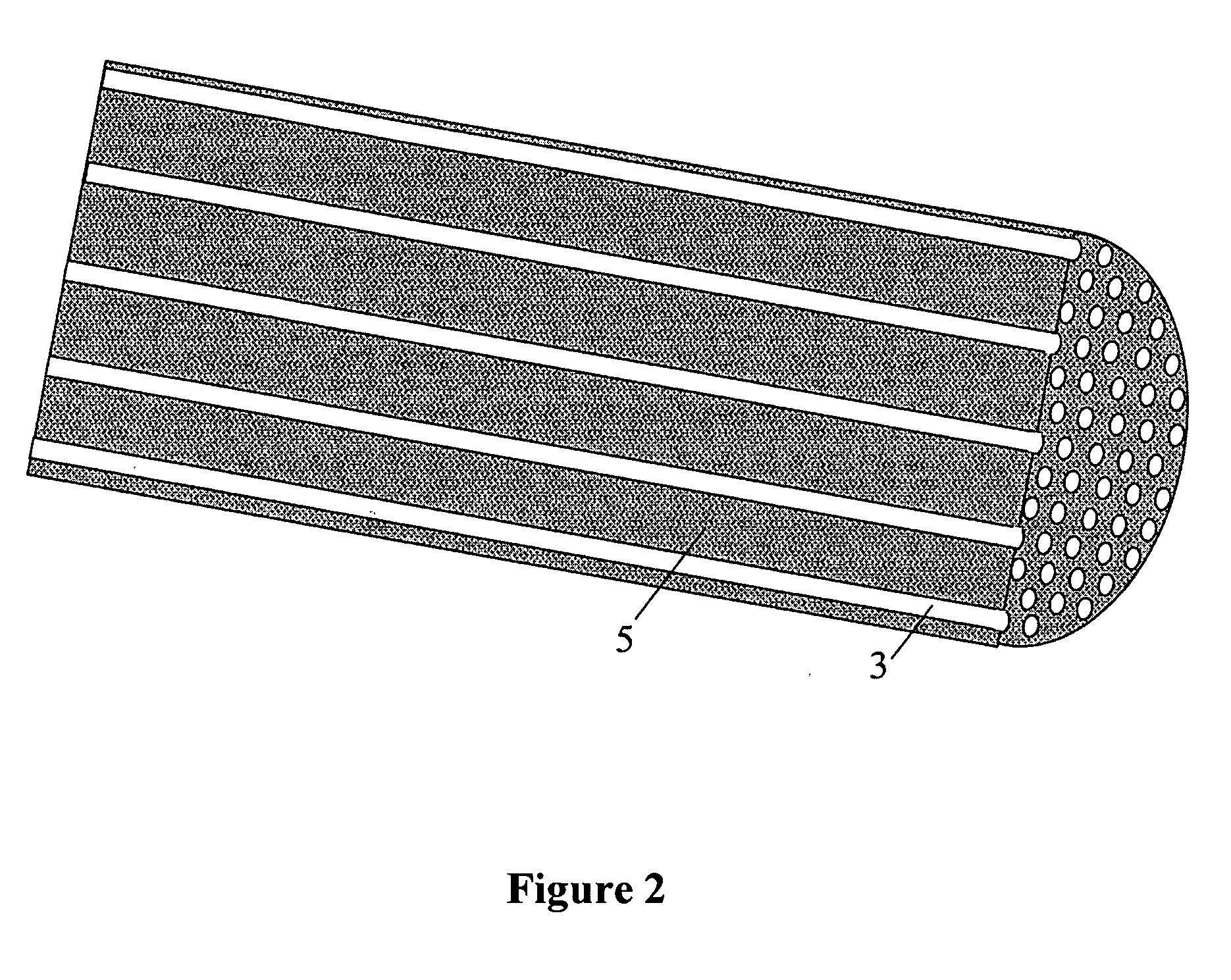

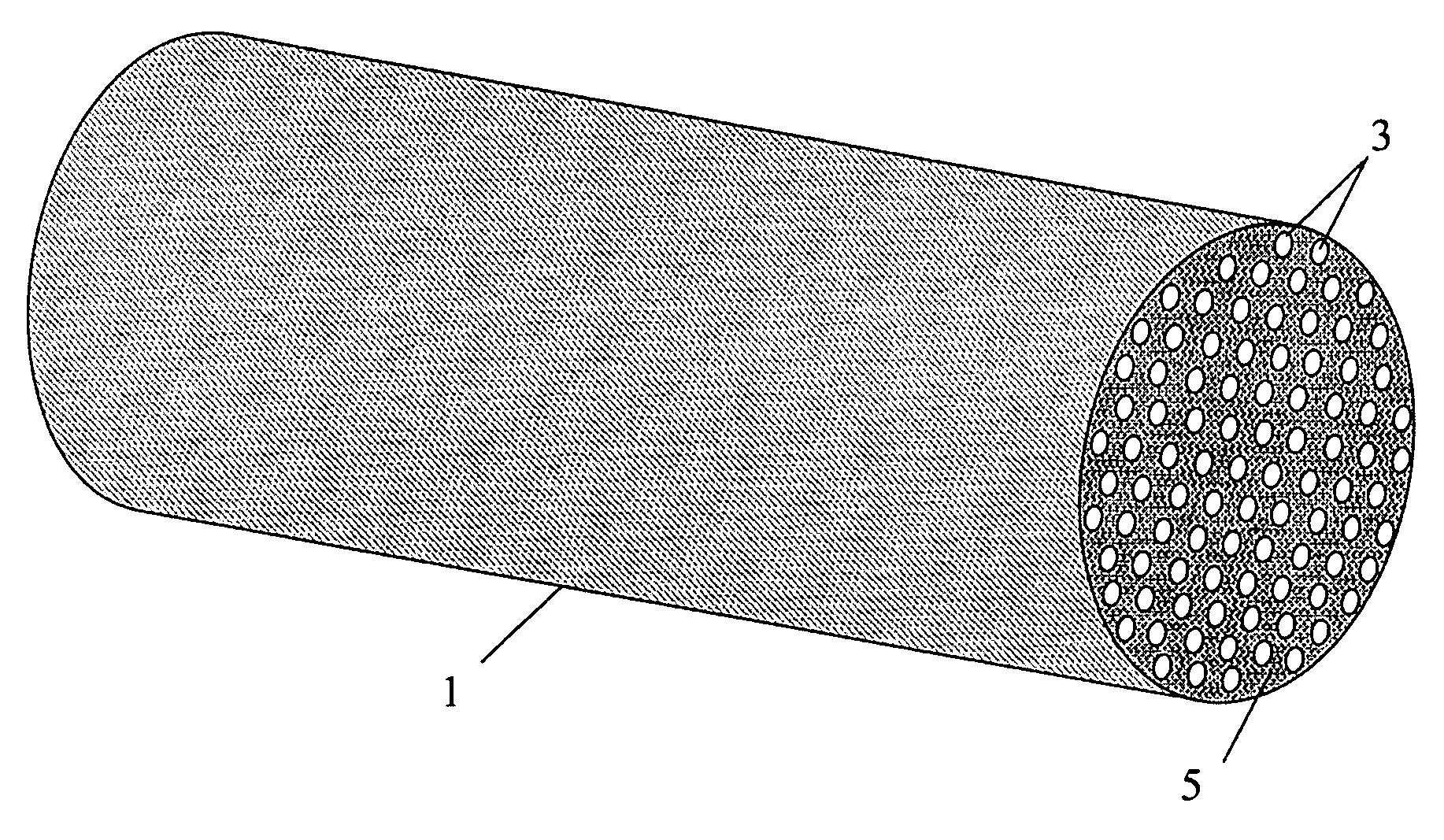

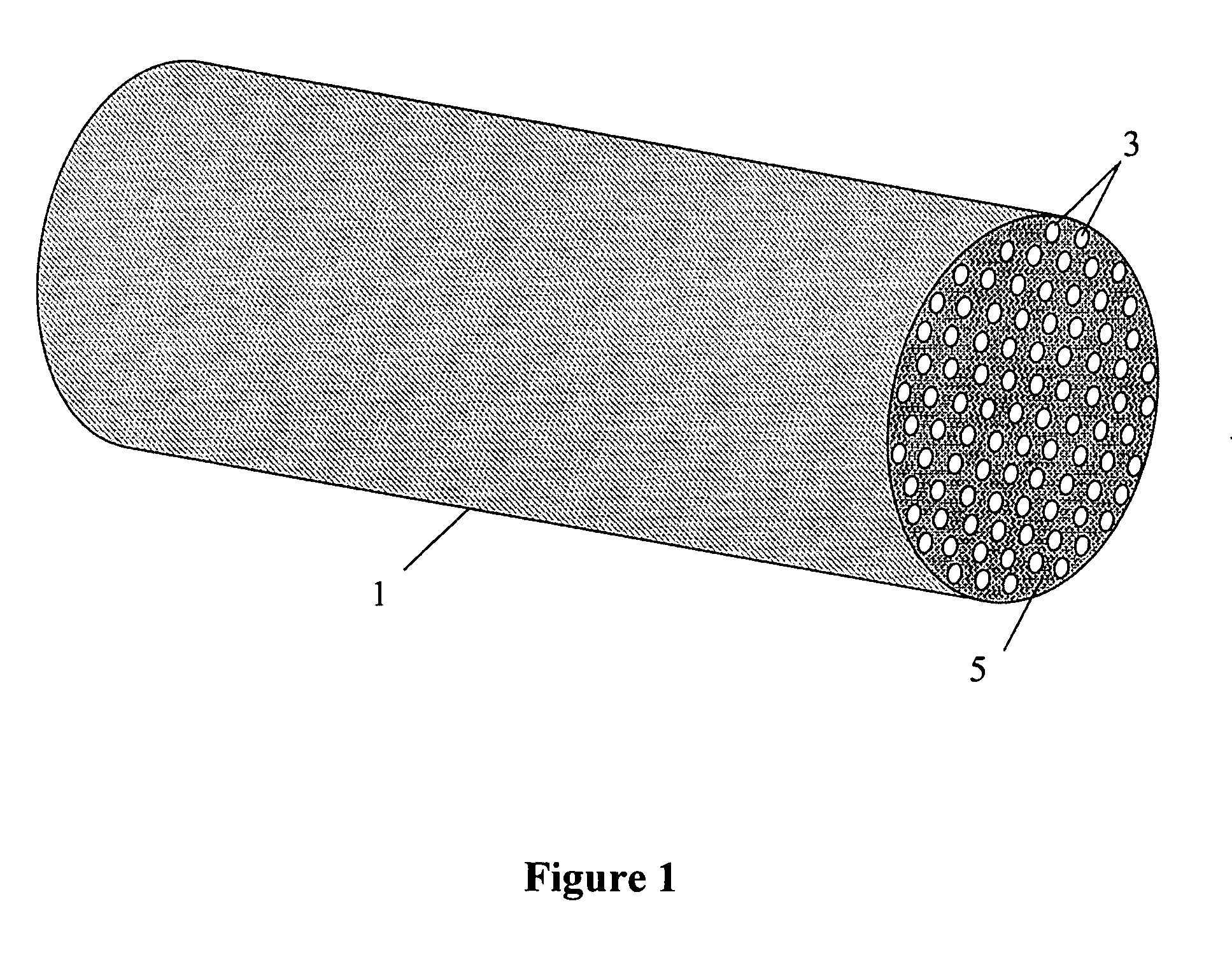

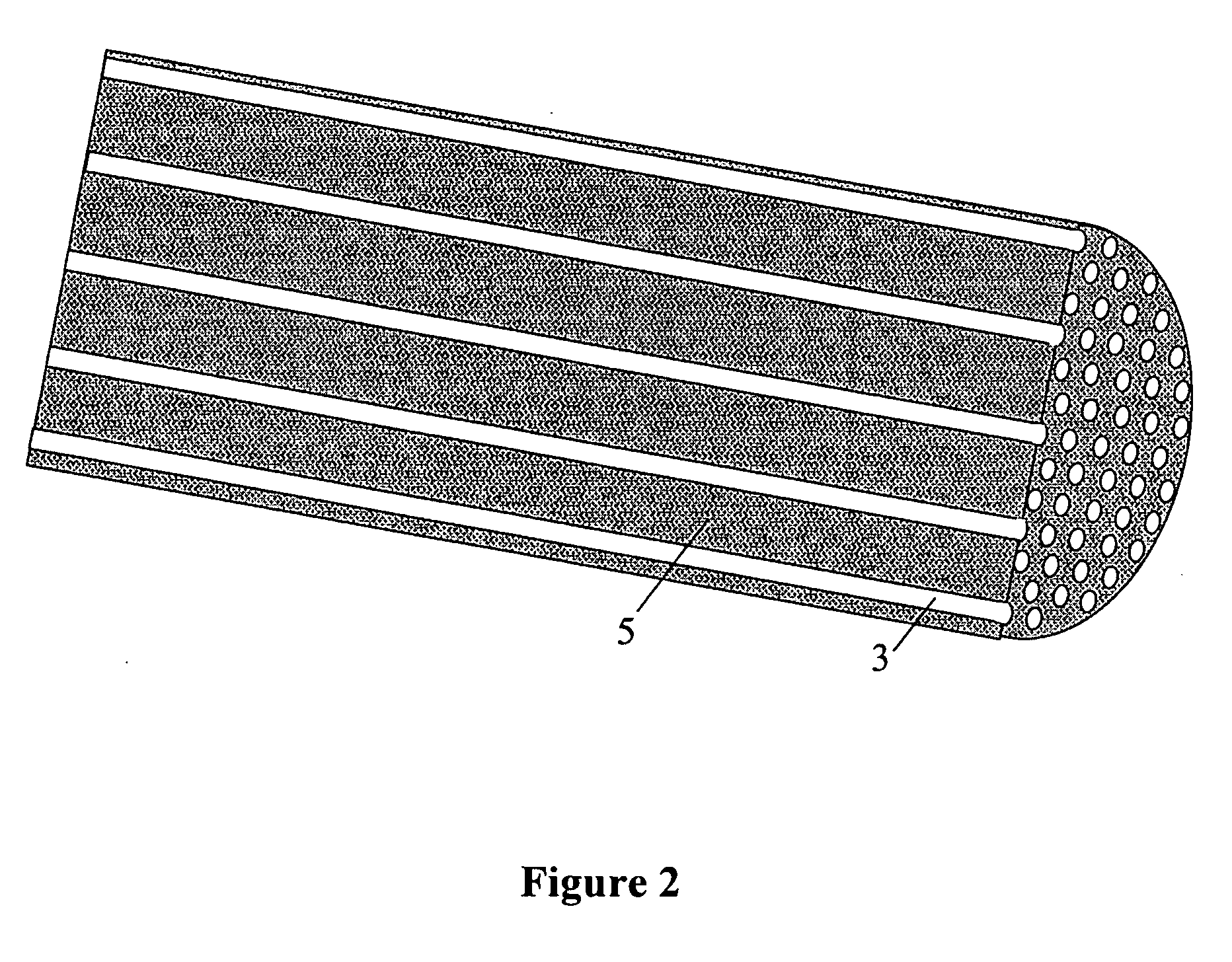

Removal of CO2, N2, or H2S from gas mixtures by swing adsorption with low mesoporosity adsorbent contactors

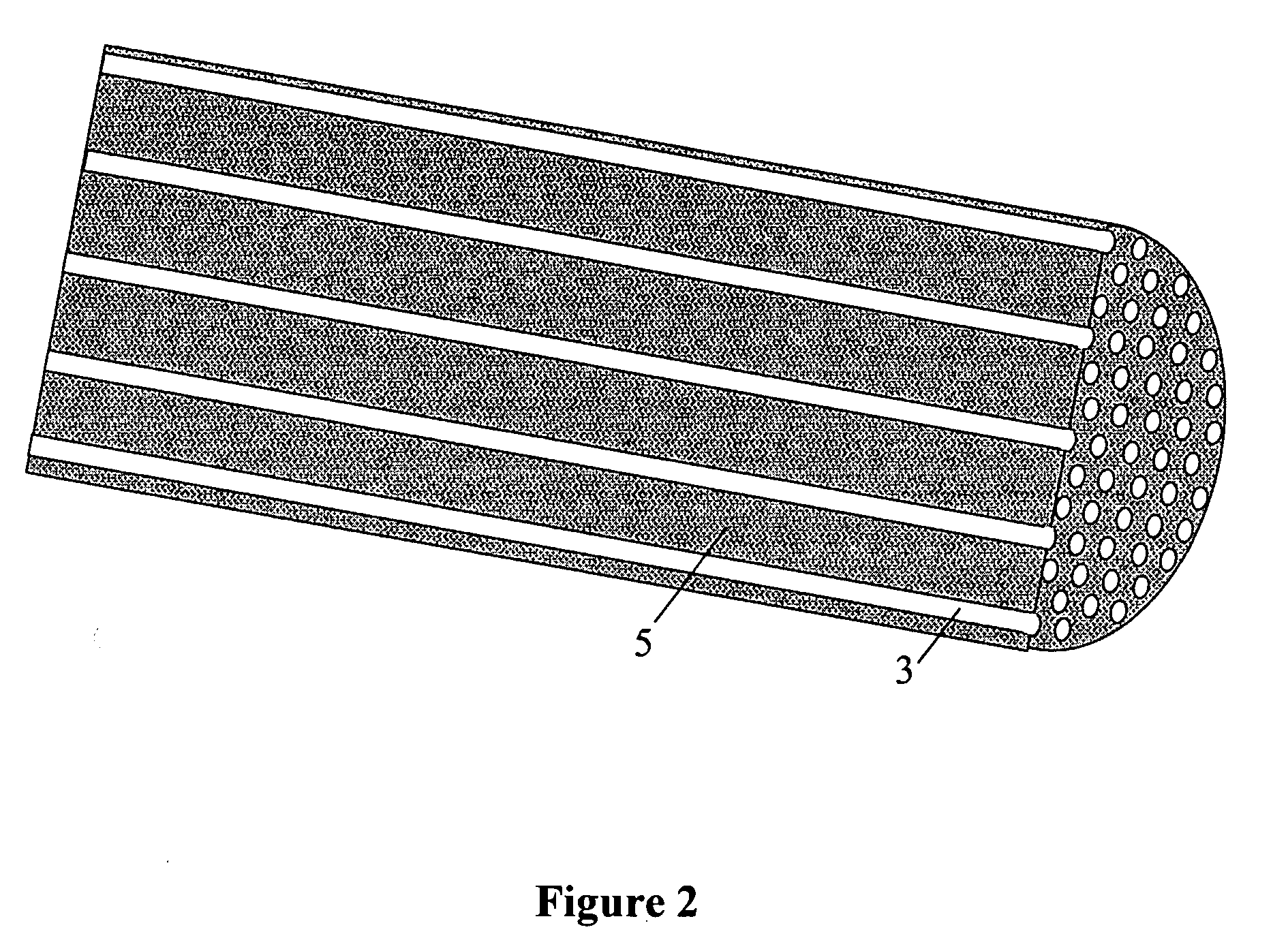

The present invention relates to the separation of one or more of CO2, N2, and H2S gas components from a gas mixture containing at least a second gas using a swing adsorption process unit. The adsorbent contactors of the swing adsorption process unit are engineered structured adsorbent contactors having a plurality of flow channels wherein 20 volume percent or less of the open pore volume of the contactors is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

Chemical vapor deposition plasma process using an ion shower grid

A chemical vapor deposition process is carried out in a reactor chamber with an ion shower grid that divides the chamber into an upper ion generation region and a lower process region, the ion shower grid having plural orifices oriented in a non-parallel direction relative to a surface plane of the ion shower grid. A workpiece is placed in the process region facing the ion shower grid, the workpiece having a workpiece surface generally facing the surface plane of the ion shower grid. A gas mixture is furnished comprising deposition precursor species into the ion generation region and the process region is evacuated at an evacuation rate sufficient to create a pressure drop across the ion shower grid from the ion generation region to the process region whereby the pressure in the ion generation region is at least several times the pressure in the process region. A layer of material of a desired thickness is deposited on the workpiece by: (a) applying plasma source power to generate a plasma of the deposition precursor species in the ion generation region, and (b) applying a grid potential to the ion shower grid to create a flux of ions from the plasma through the grid and into the process region.

Owner:APPLIED MATERIALS INC

Removal of heavy hydrocarbons from gas mixtures containing heavy hydrocarbons and methane

A process for the separation of one or more heavy hydrocarbon gases from a gas mixture containing heavy hydrocarbon gas components and methane. The process is conducted in swing adsorption apparatus containing adsorbent contactor having a plurality of flow channels and wherein 20 volume percent or less of the open pore volume of the contactors, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

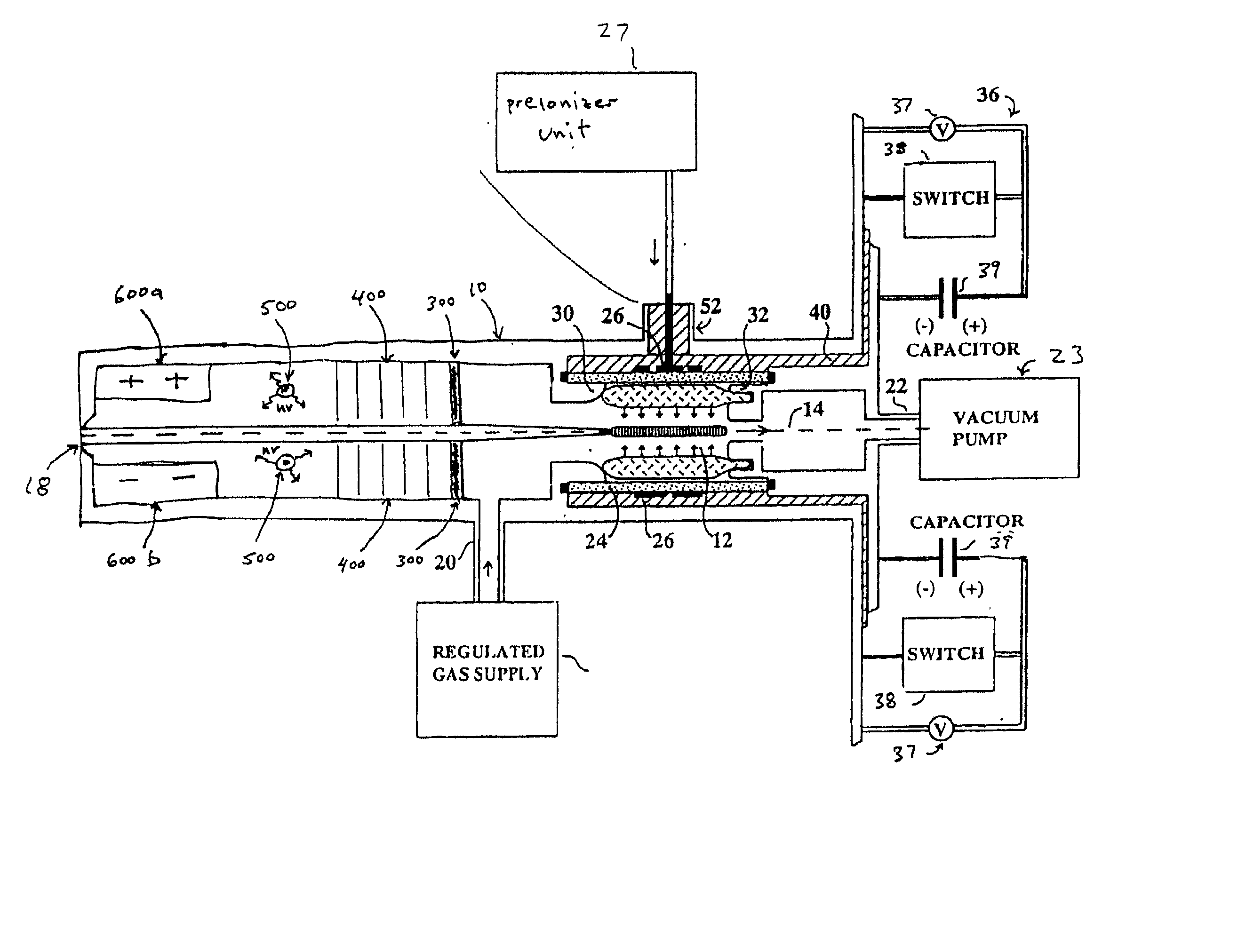

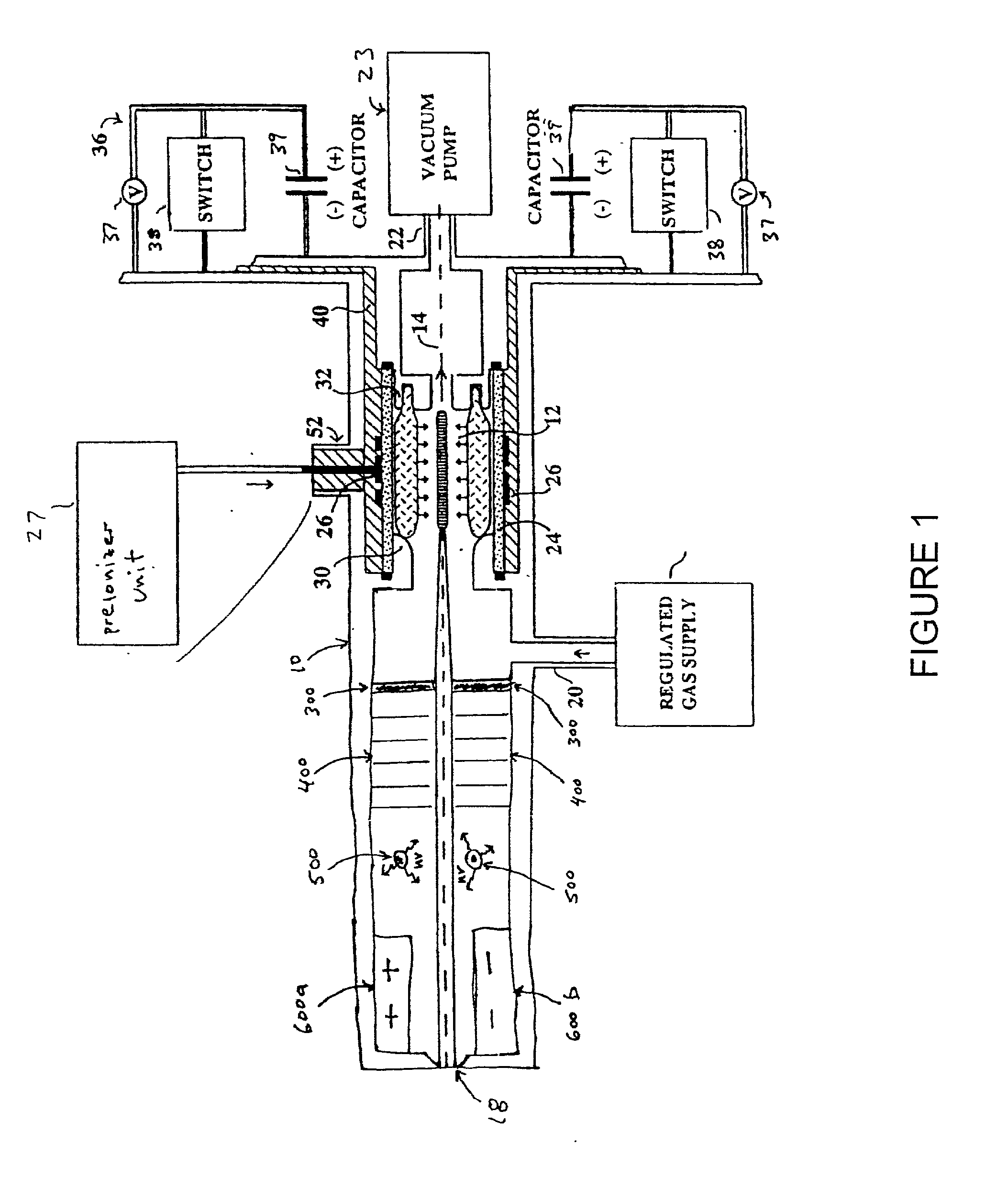

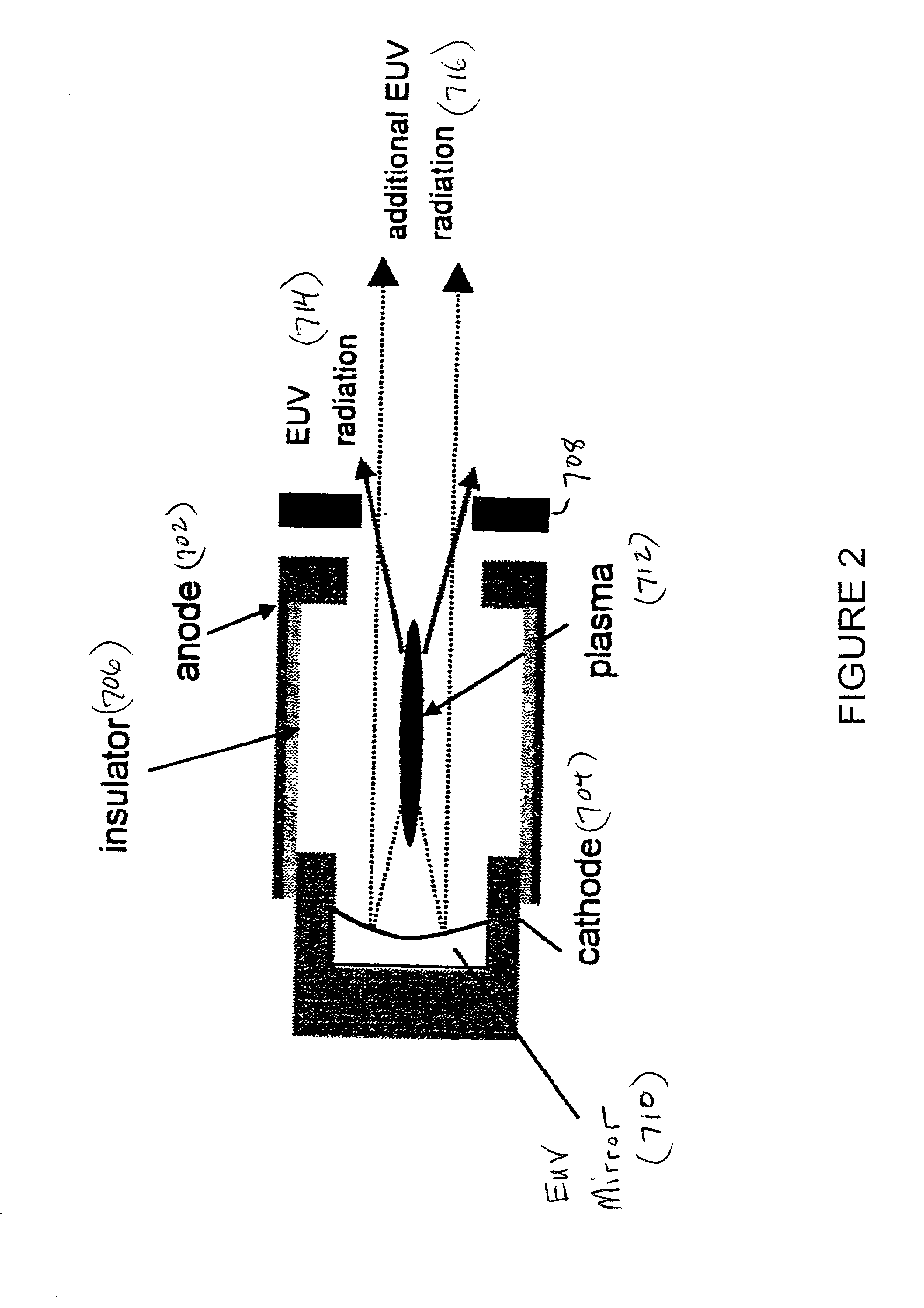

Method and apparatus for generating high output power gas discharge based source of extreme ultraviolet radiation and/or soft x-rays

InactiveUS20020168049A1Avoid reflectionsReduce reflectionRadiation/particle handlingNanoinformaticsSoft x rayUltraviolet radiation

An EUV photon source includes a plasma chamber filled with a gas mixture, multiple electrodes within the plasma chamber defining a plasma region and a central axis, a power supply circuit connected to the electrodes for delivering a main pulse to the electrodes for energizing the plasma around the central axis to produce an EUV beam output along the central axis, and a preionizer for ionizing the gas mixture in preparing to form a dense plasma around the central axis upon application of the main pulse from the power supply circuit to the electrodes. The EUV source preferably includes an ionizing unit and precipitator for collecting contaminant particulates from the output beam path. A set of baffles may be disposed along the beam path outside of the pinch region to diffuse gaseous and contaminant particulate flow emanating from the pinch region and to absorb or reflect acoustic waves emanating from the pinch region away from the pinch region. A clipping aperture, preferably formed of ceramic and / or Al2O3, for at least partially defining an acceptance angle of the EUV beam. The power supply circuit may generates the main pulse and a relatively low energy prepulse for homogenizing the preionized plasma prior to the main pulse. A multi-layer EUV mirror is preferably disposed opposite a beam output side of the pinch region for reflecting radiation along the central axis for output along the beam path of the EUV beam. The EUV mirror preferably has a curved contour for substantially collimating or focusing the reflected radiation. In particular, the EUV mirror may preferably have a hyperbolic contour.

Owner:USHIO DENKI KK

Dry etching method for metal film

ActiveUS20130098868A1Decorative surface effectsSemiconductor/solid-state device manufacturingHalogenNoble gas

A method for performing dry etching on a metal film containing Pt via a mask layer includes performing dry etching on the metal film by generating a plasma of an etching gas including a gaseous mixture of H2 gas, CO2 gas, methane gas and rare gas. With the dry etching method, it is possible to make a vertical sidewall of a hole or trench more vertical without using a halogen gas.

Owner:TOKYO ELECTRON LTD

Removal of CO2, N2, and H2S from gas mixtures containing same

The removal of one or more of the gases CO2, N2 and H2S from gas mixtures containing at least one of said gases with use of an 8-ring zeolite having a Si:Al ratio from about 1:1 to about 1000:1. The preferred gas mixture is a natural gas feedstream and the preferred 8-ring zeolite is DDR.

Owner:EXXON RES & ENG CO

Process for removing a target gas from a mixture of gases by swing adsorption

The present invention relates the separation of a target gas from a mixture of gases through the use of engineered structured adsorbent contactors in pressure swing adsorption and thermal swing adsorption processes. Preferably, the contactors contain engineered and substantially parallel flow channels wherein 20 volume percent or less of the open pore volume of the contactor, excluding the flow channels, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

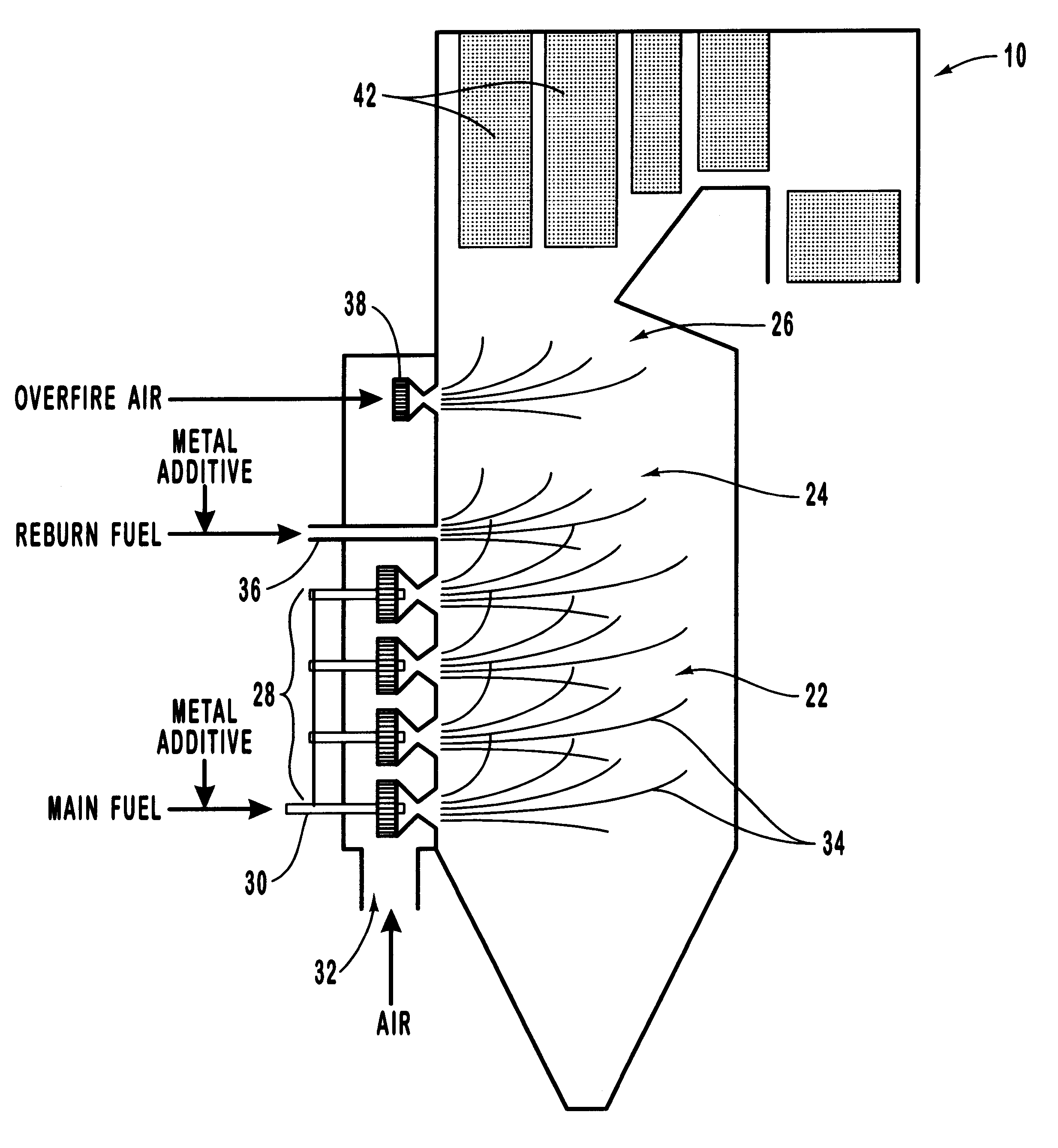

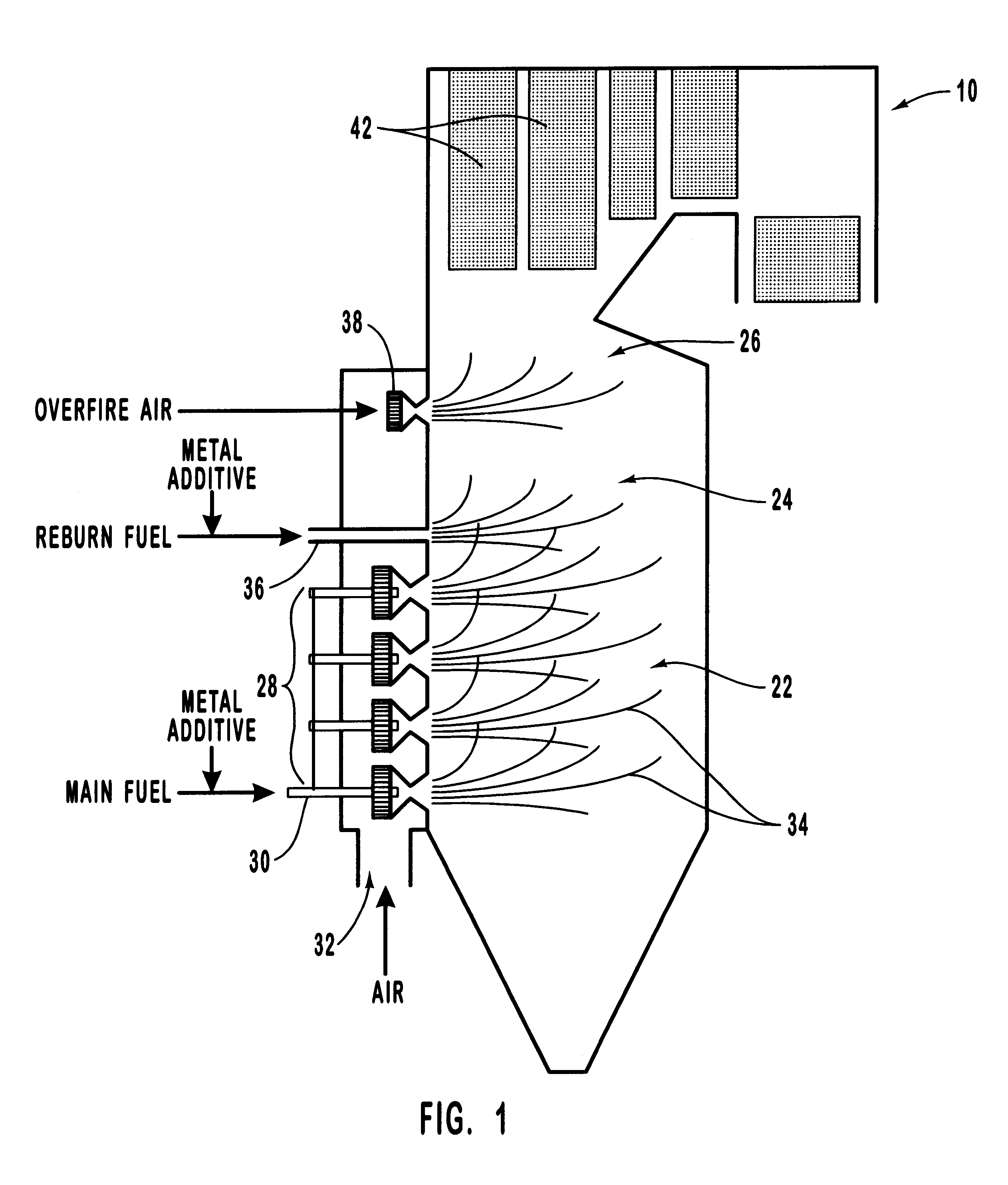

Method for reducing NOX in combustion flue gas using metal-containing additives

InactiveUS6206685B1Improved control deviceSure easyDispersed particle separationSolid fuel combustionAtmospheric airNitric oxide

Various methods for decreasing the amount of nitrogen oxides released to the atmosphere as a component of combustion gas mixtures are provided. The methods specifically provide for the removal of nitric oxide and nitrogen dioxide (NOx) from gas mixtures emitted from stationary combustion systems. In particular, methods for improving efficiency of nitrogen oxide reduction from combustion systems include injecting metal-containing compounds into the main combustion zone and / or the reburning zone of a combustion system. The metal containing compounds react with active combustion species, and these reactions change radical concentrations and significantly improve NOx conversion to molecular nitrogen. The metal-containing additives can be injected with the main fuel, in the main combustion zone, with secondary or reburning fuel addition, or at several locations in the main combustion zone and reburning zone. Optionally, nitrogenous reducing agents and / or overfire air can be injected downstream to further increase NOx reduction.

Owner:GE ENERGY & ENVIRONMENTAL RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com