Patents

Literature

2439 results about "Pressure swing adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure swing adsorption (PSA) is a technology used to separate some gas species from a mixture of gases under pressure according to the species' molecular characteristics and affinity for an adsorbent material. It operates at near-ambient temperatures and differs significantly from cryogenic distillation techniques of gas separation. Specific adsorbent materials (e.g., zeolites, activated carbon, molecular sieves, etc.) are used as a trap, preferentially adsorbing the target gas species at high pressure. The process then swings to low pressure to desorb the adsorbed material.

High frequency pressure swing adsorption

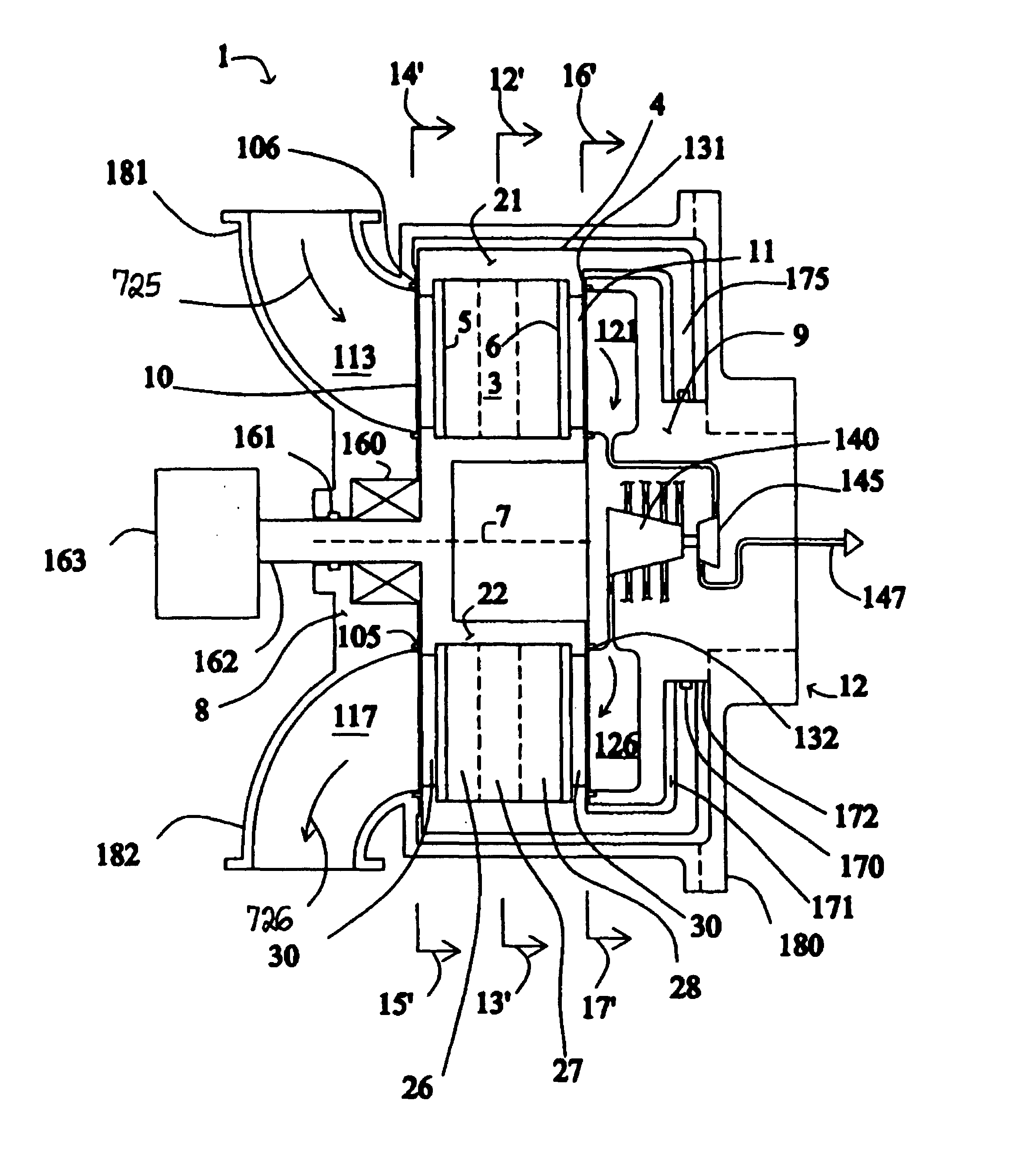

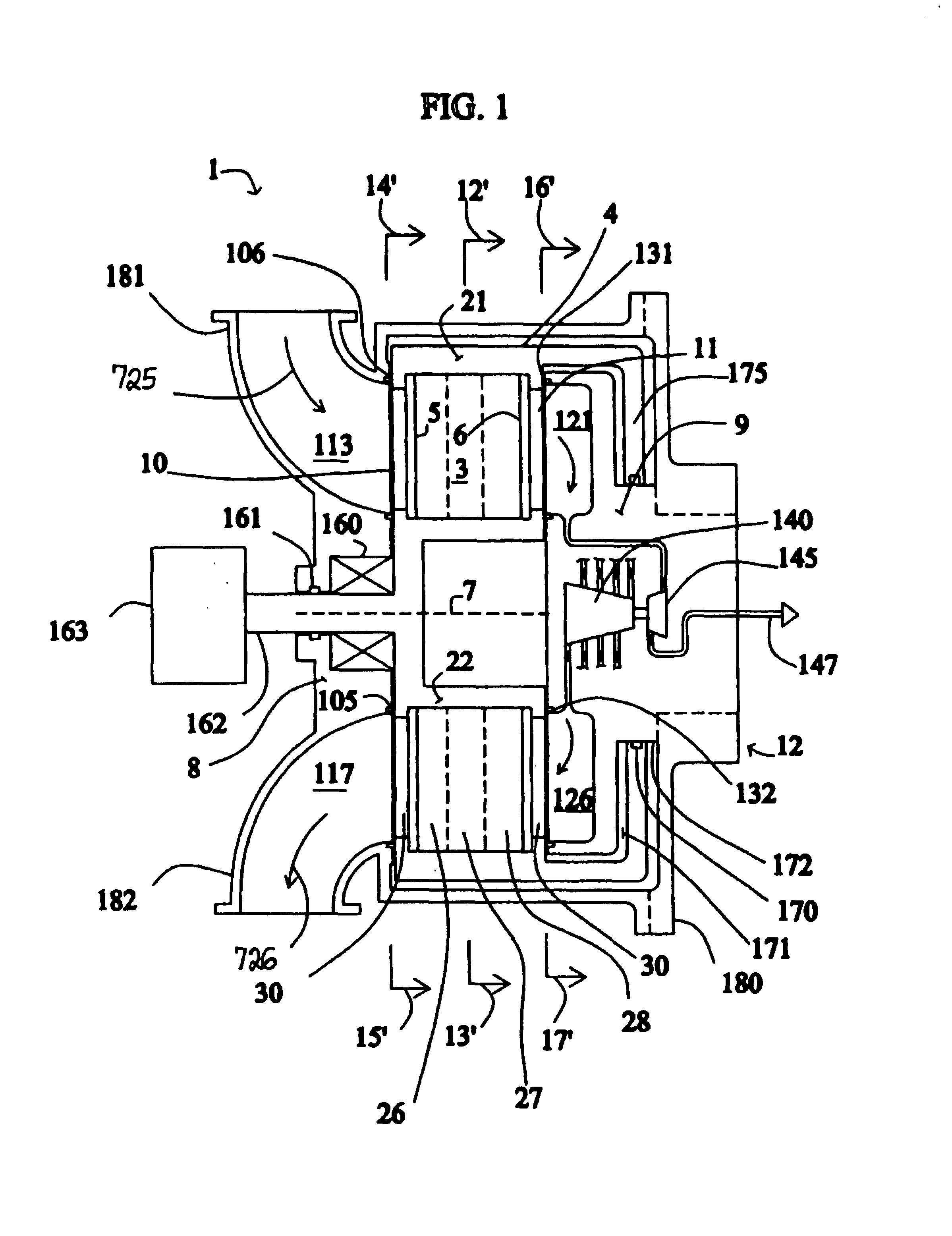

InactiveUS6176897B1High purityRecoverable expansion workNitrogen purification/separationGas treatmentSorbentEngineering

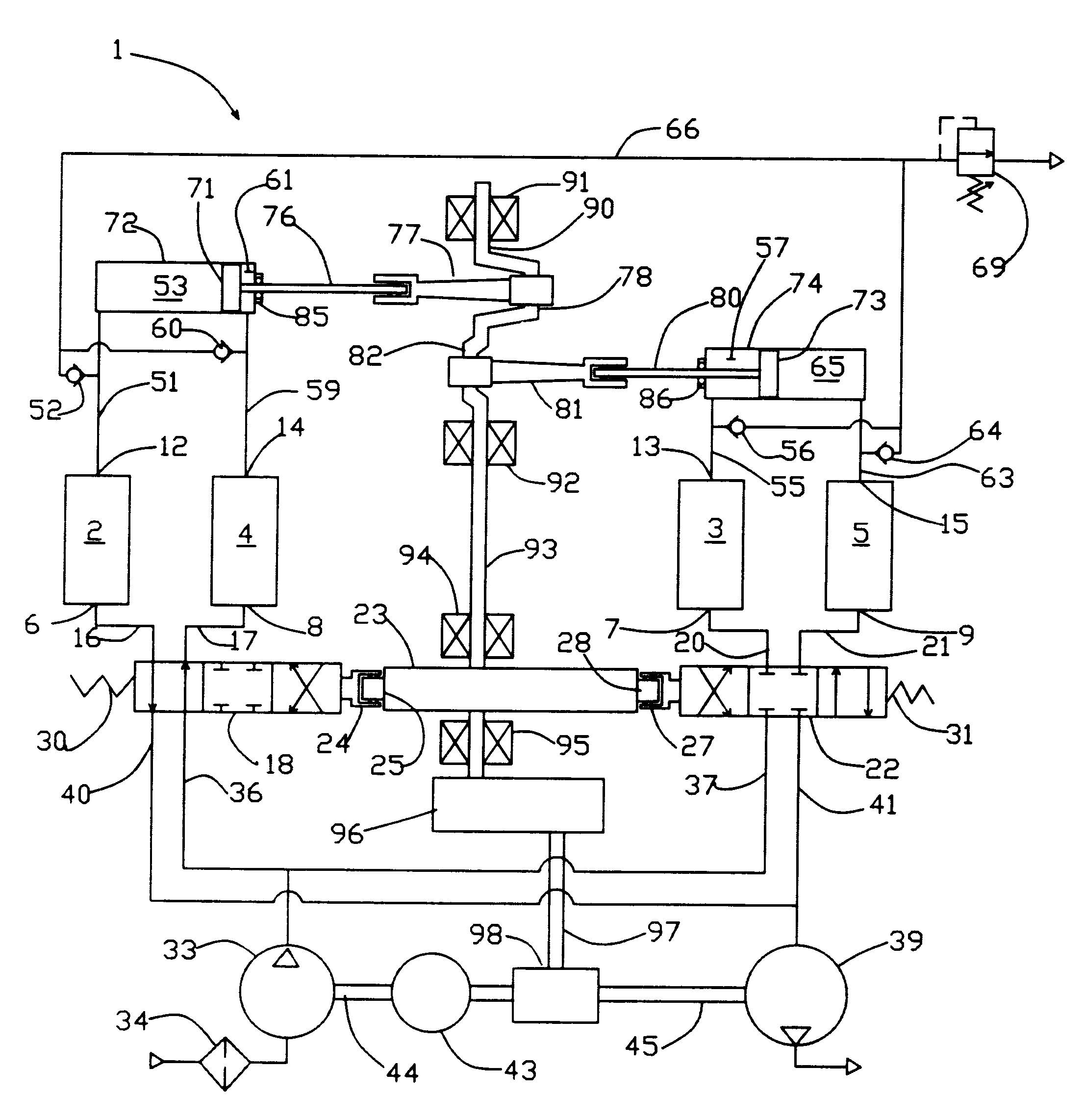

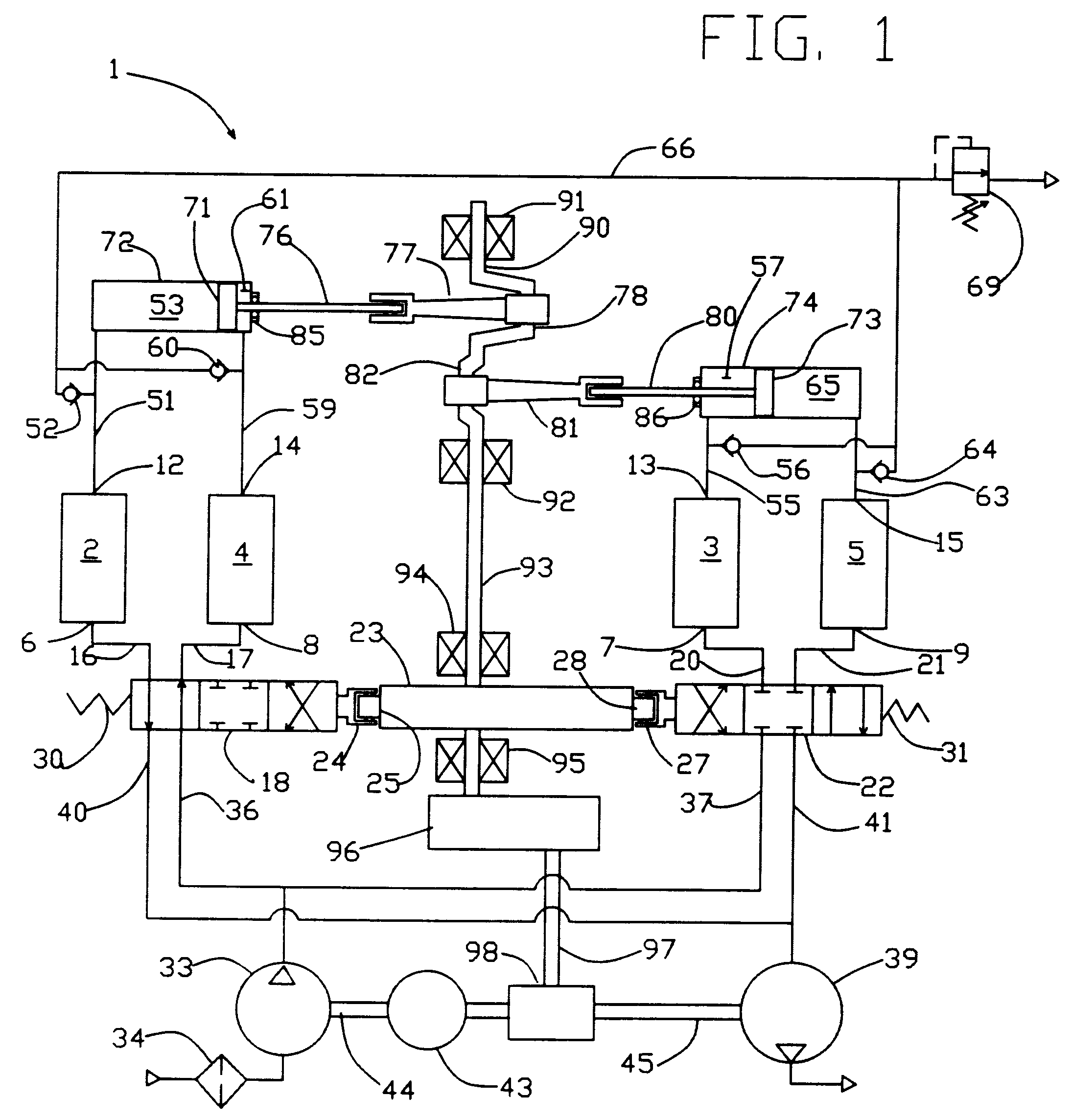

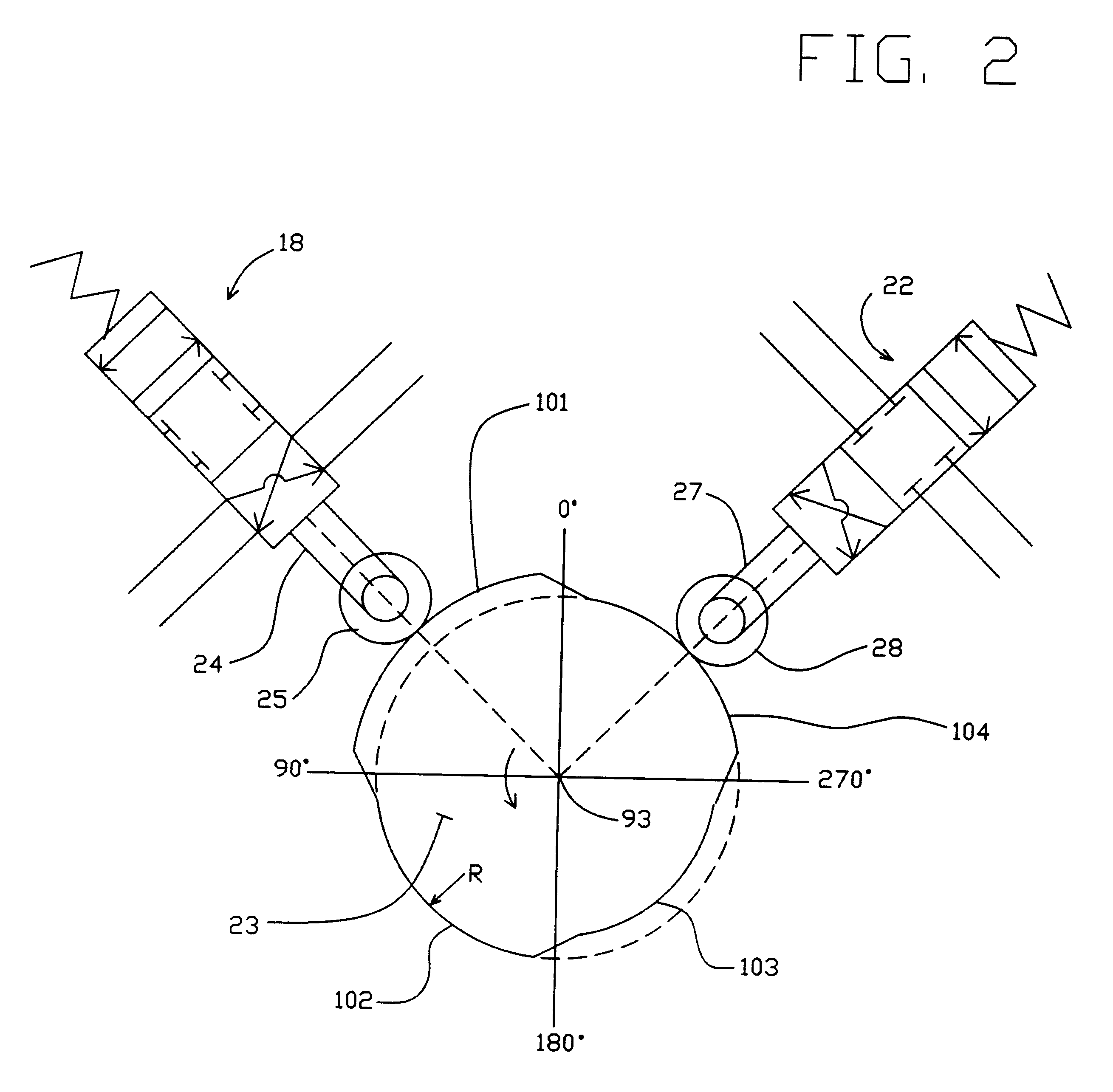

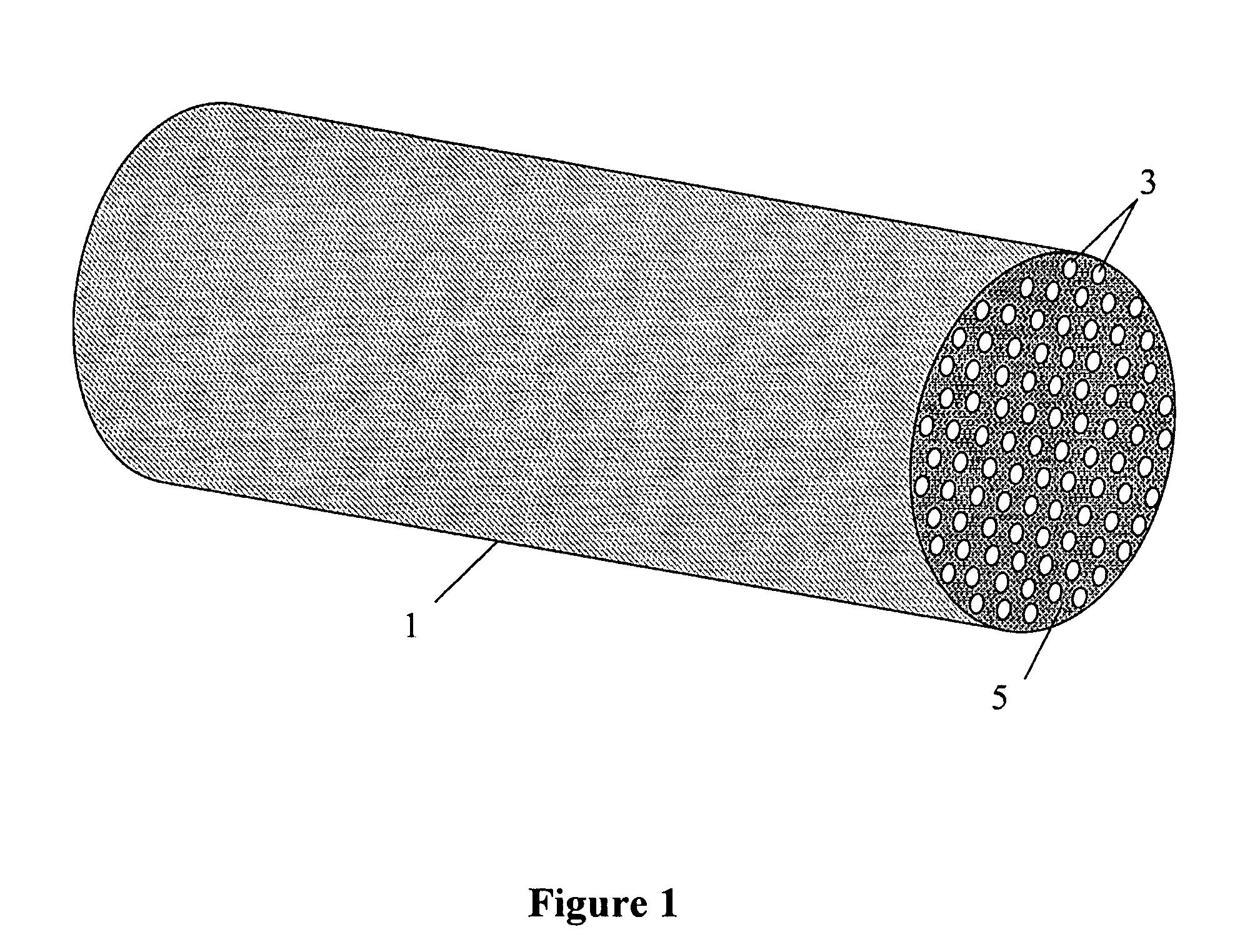

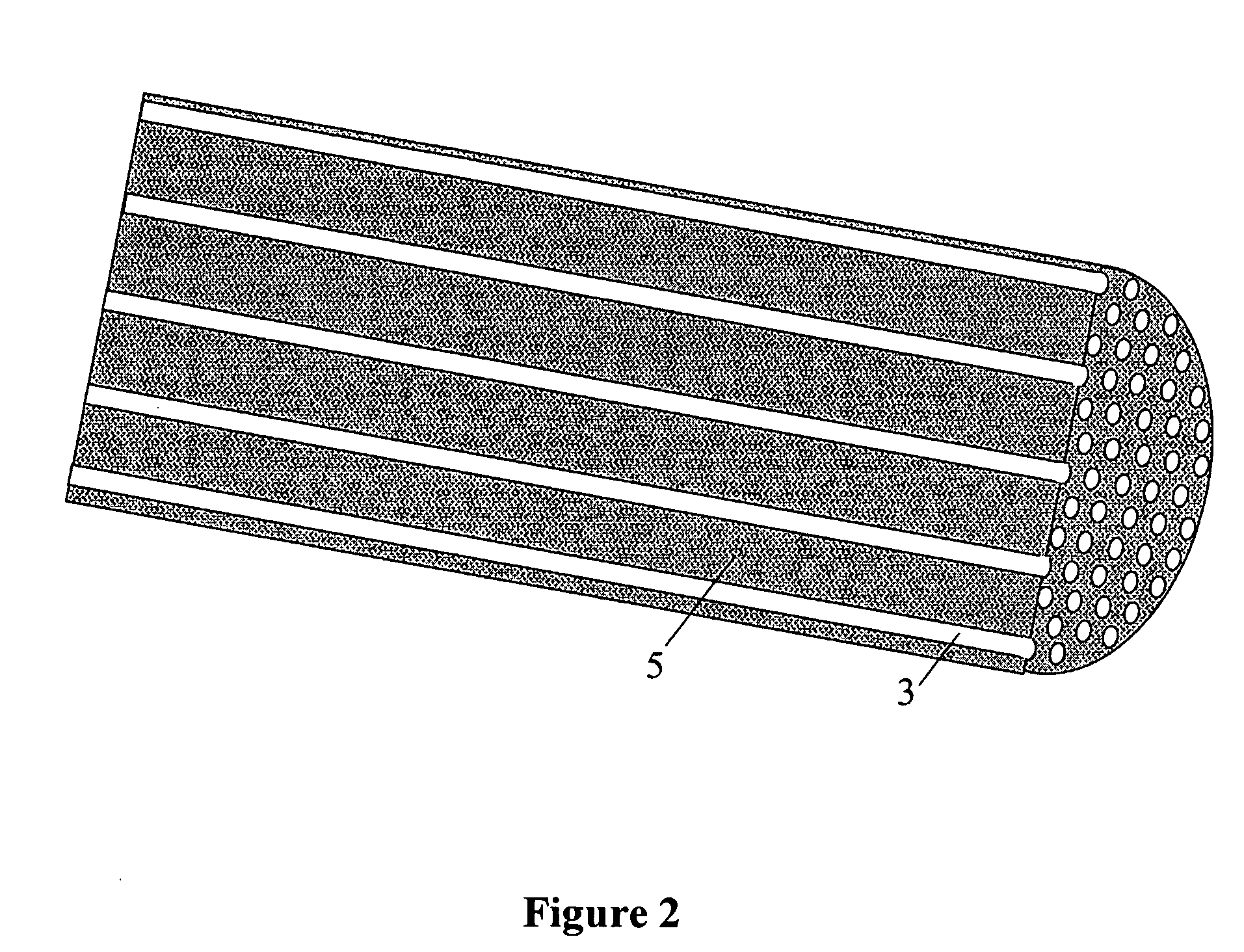

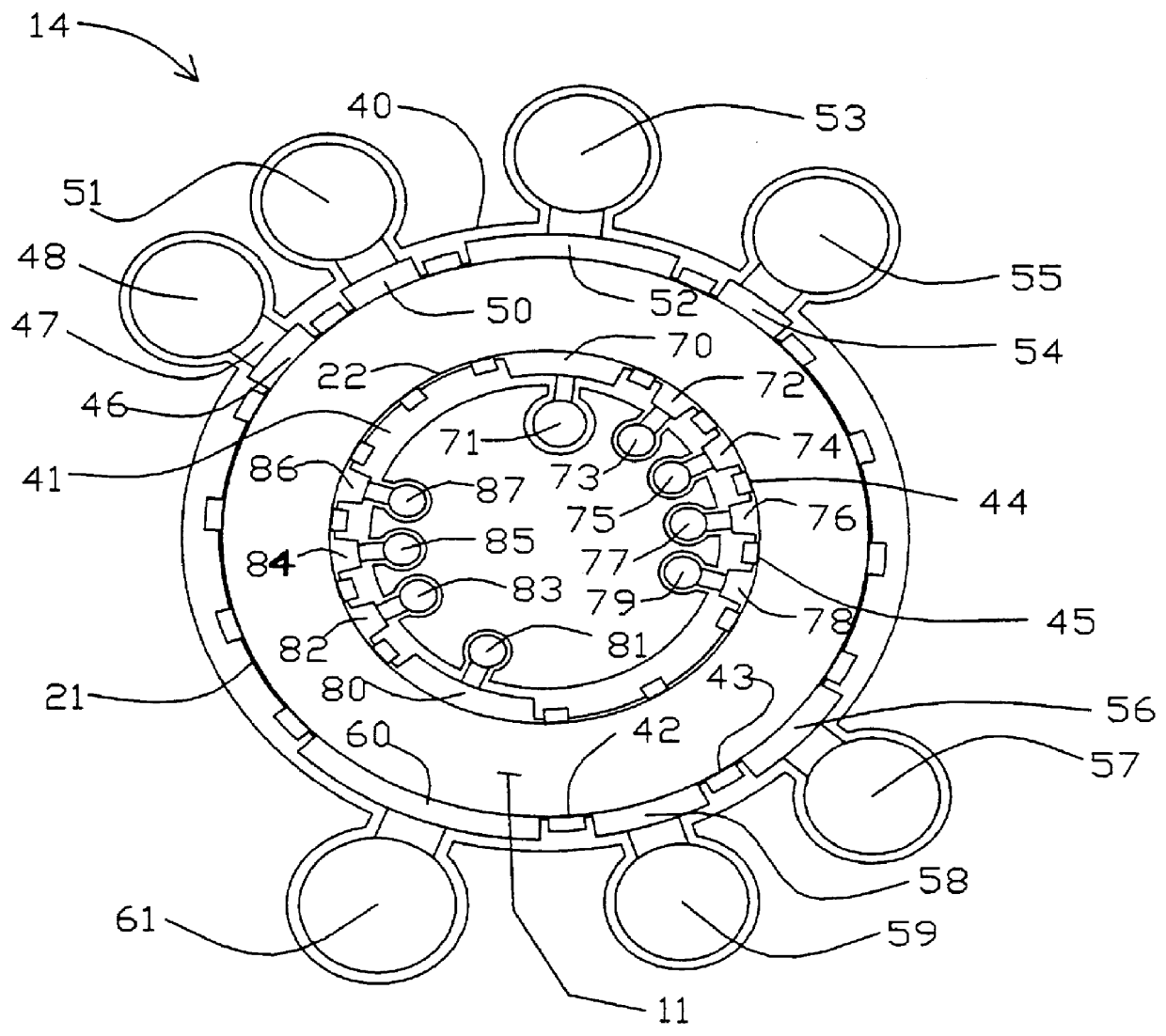

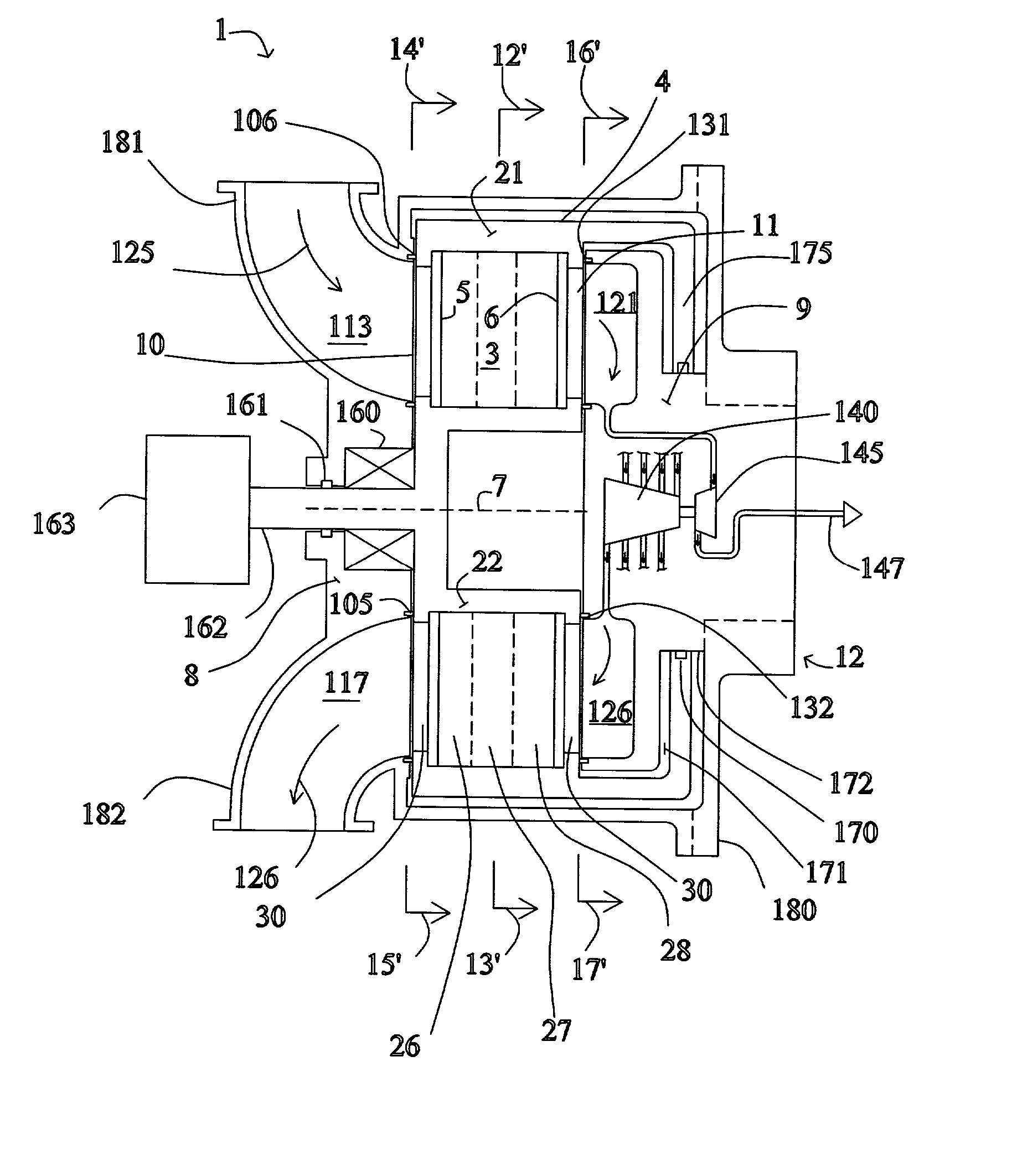

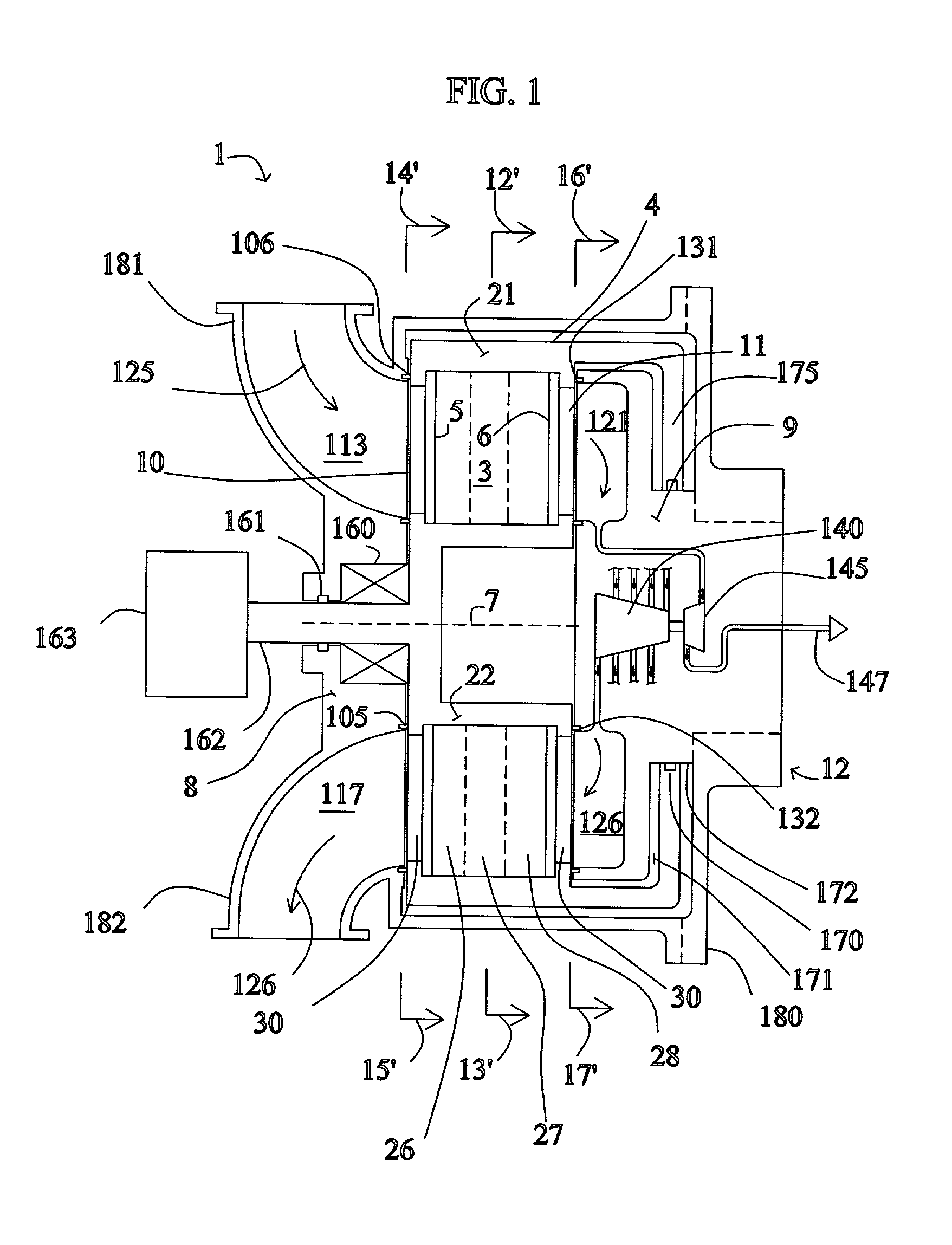

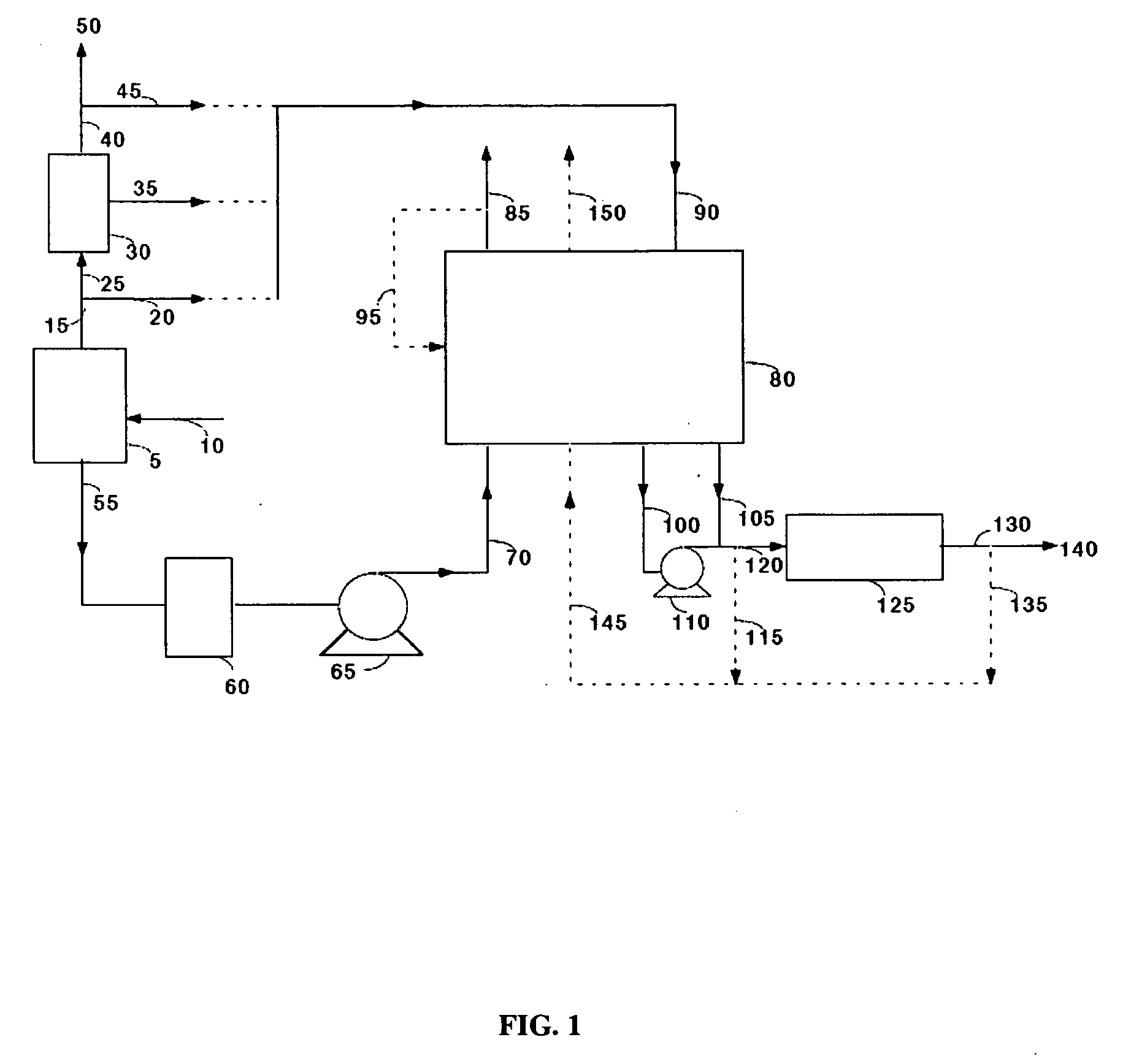

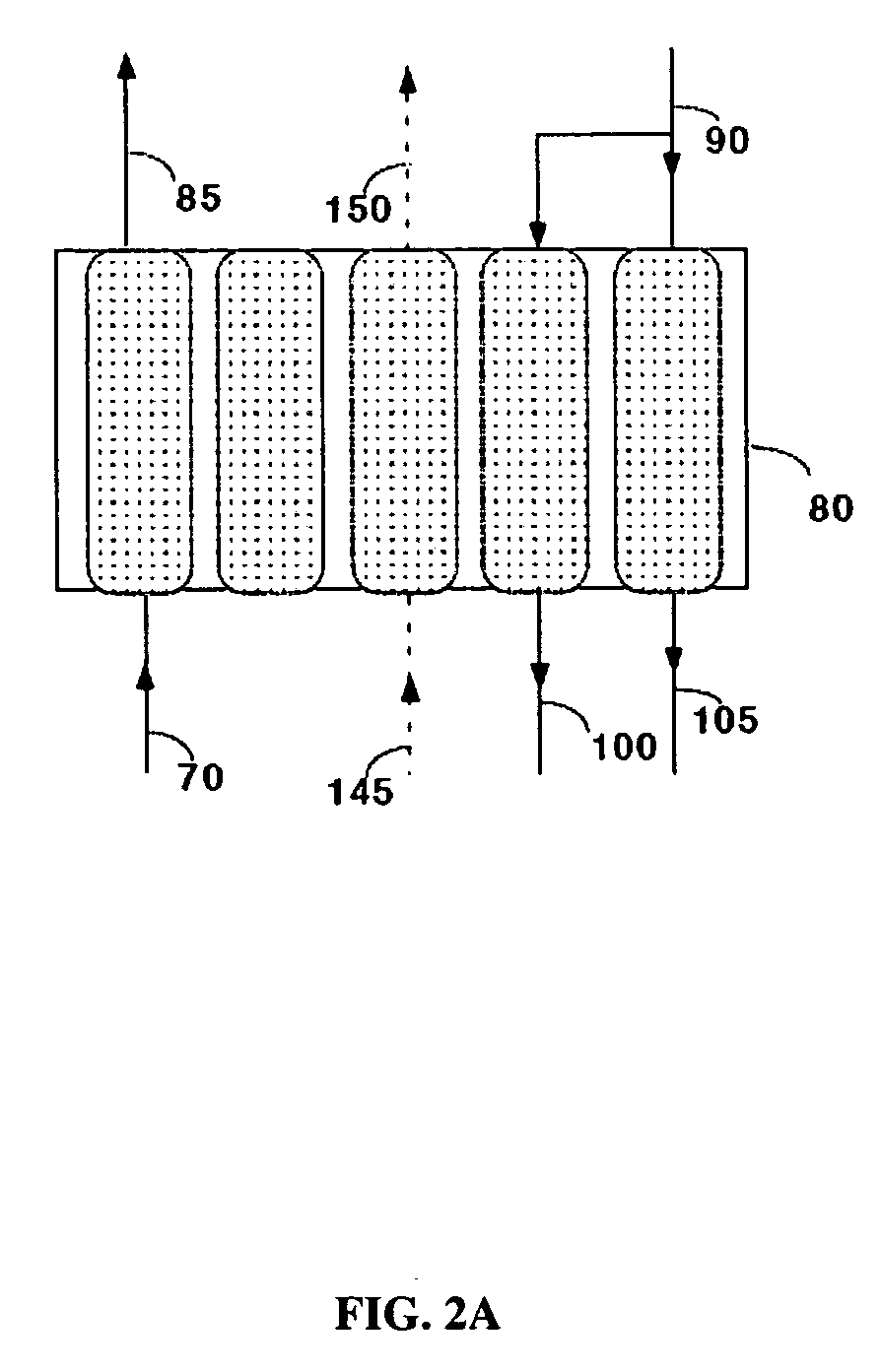

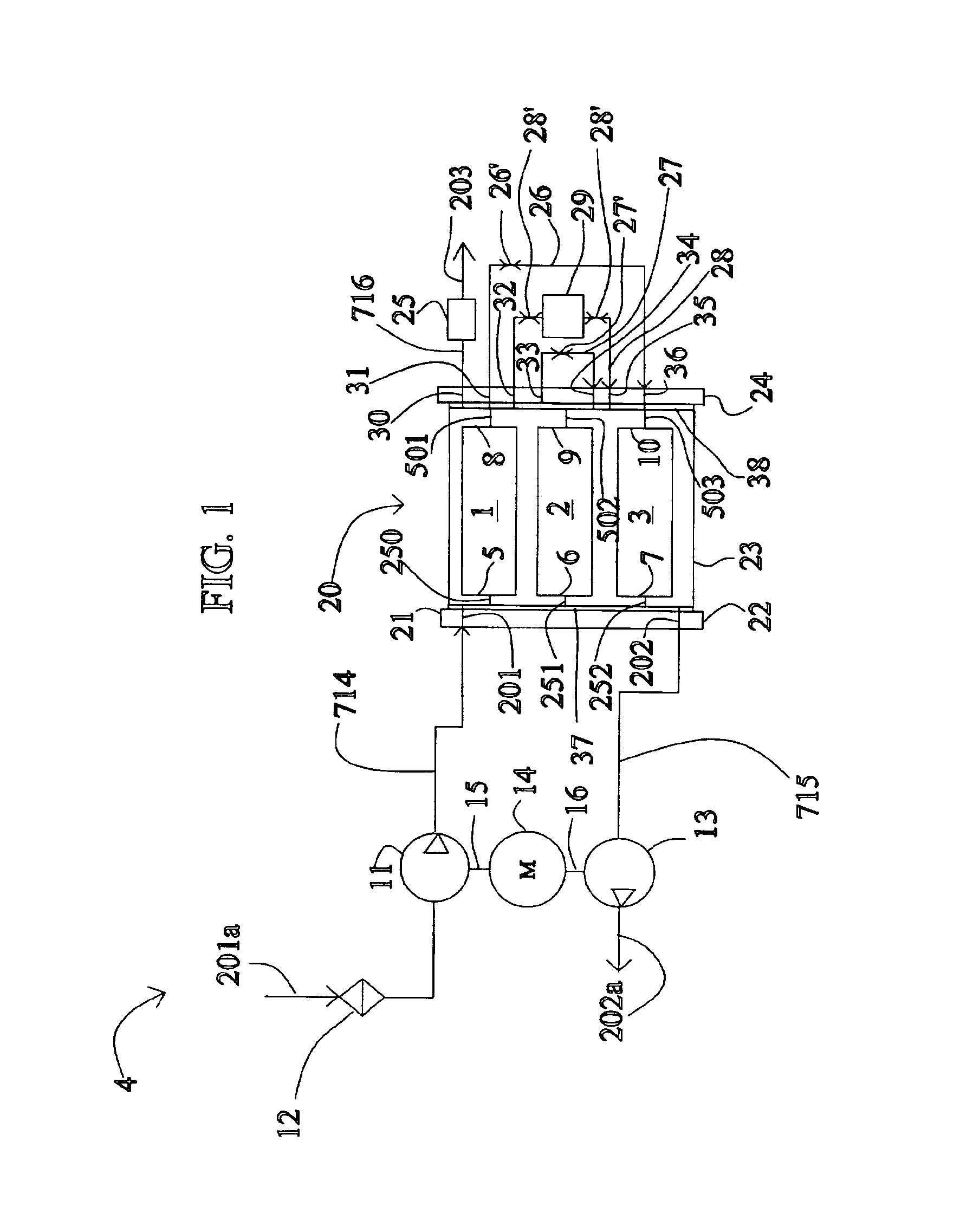

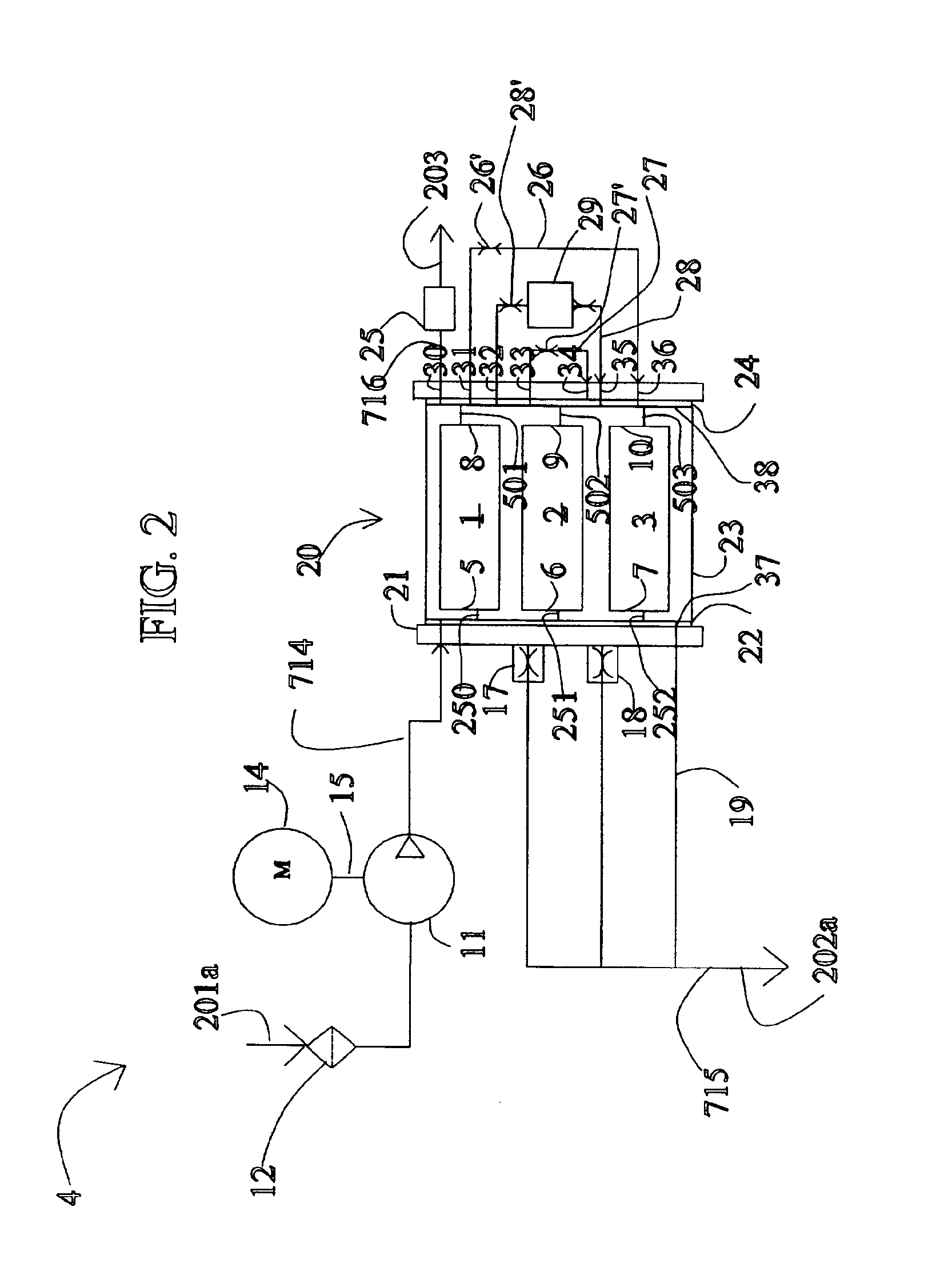

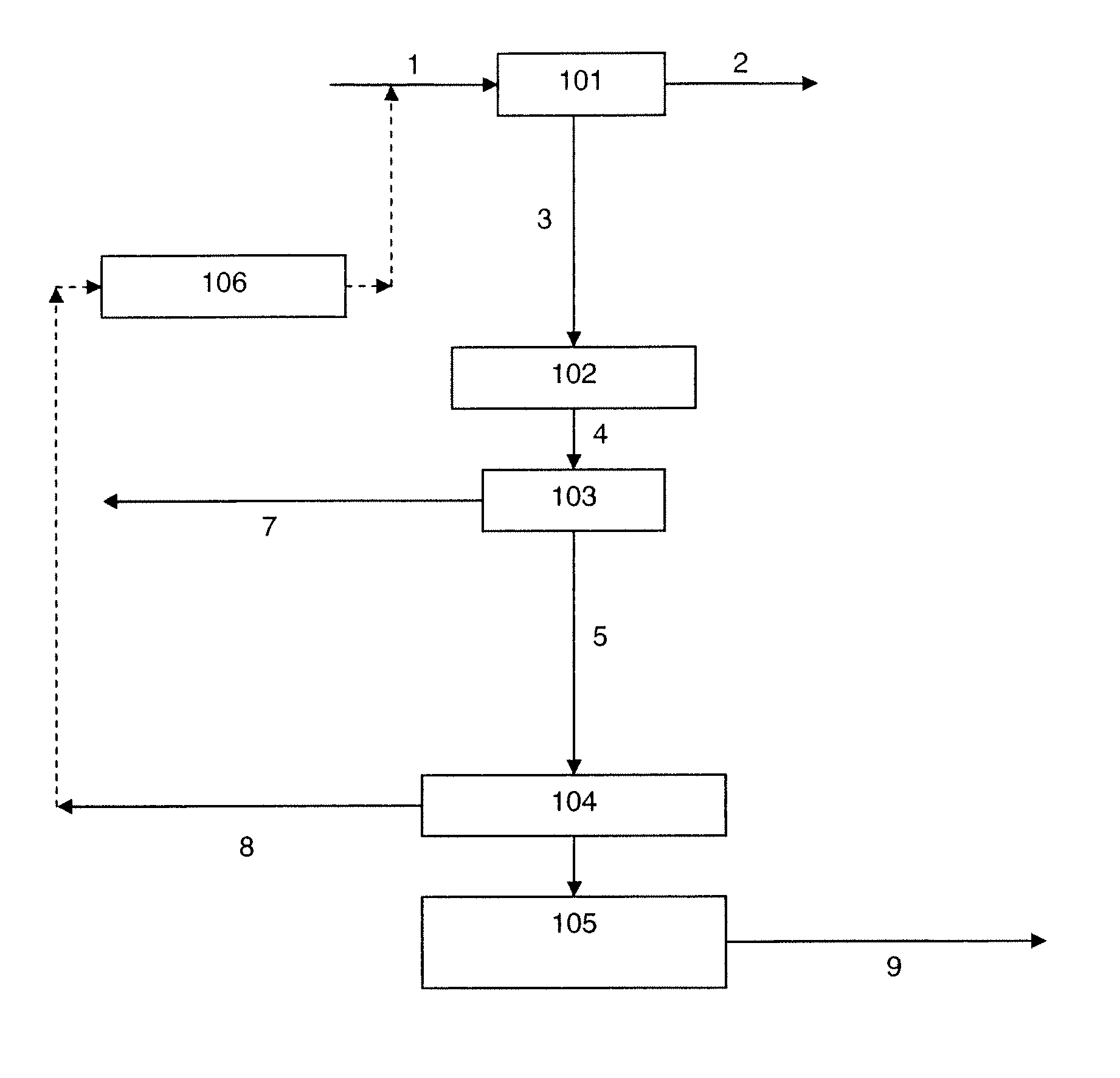

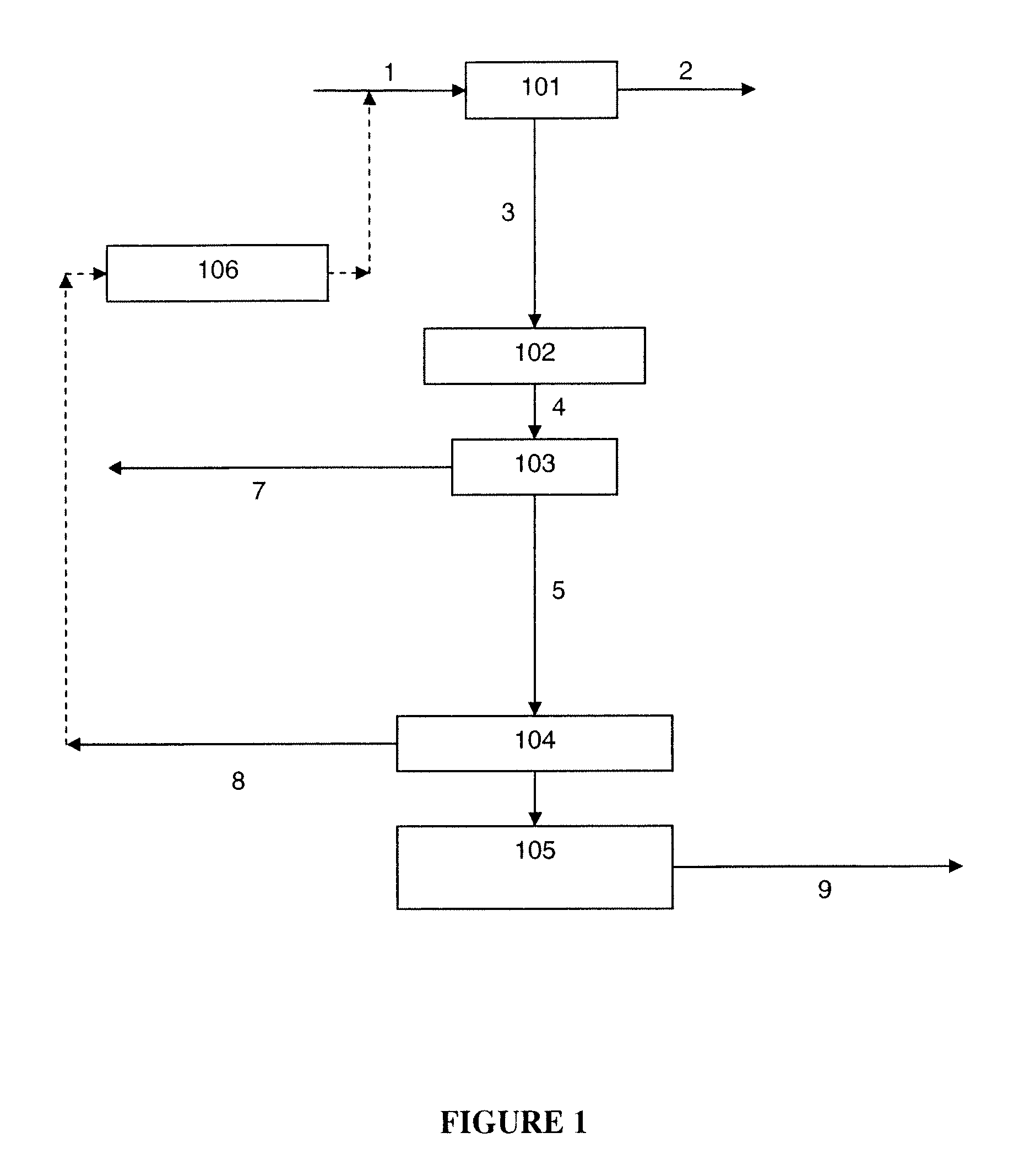

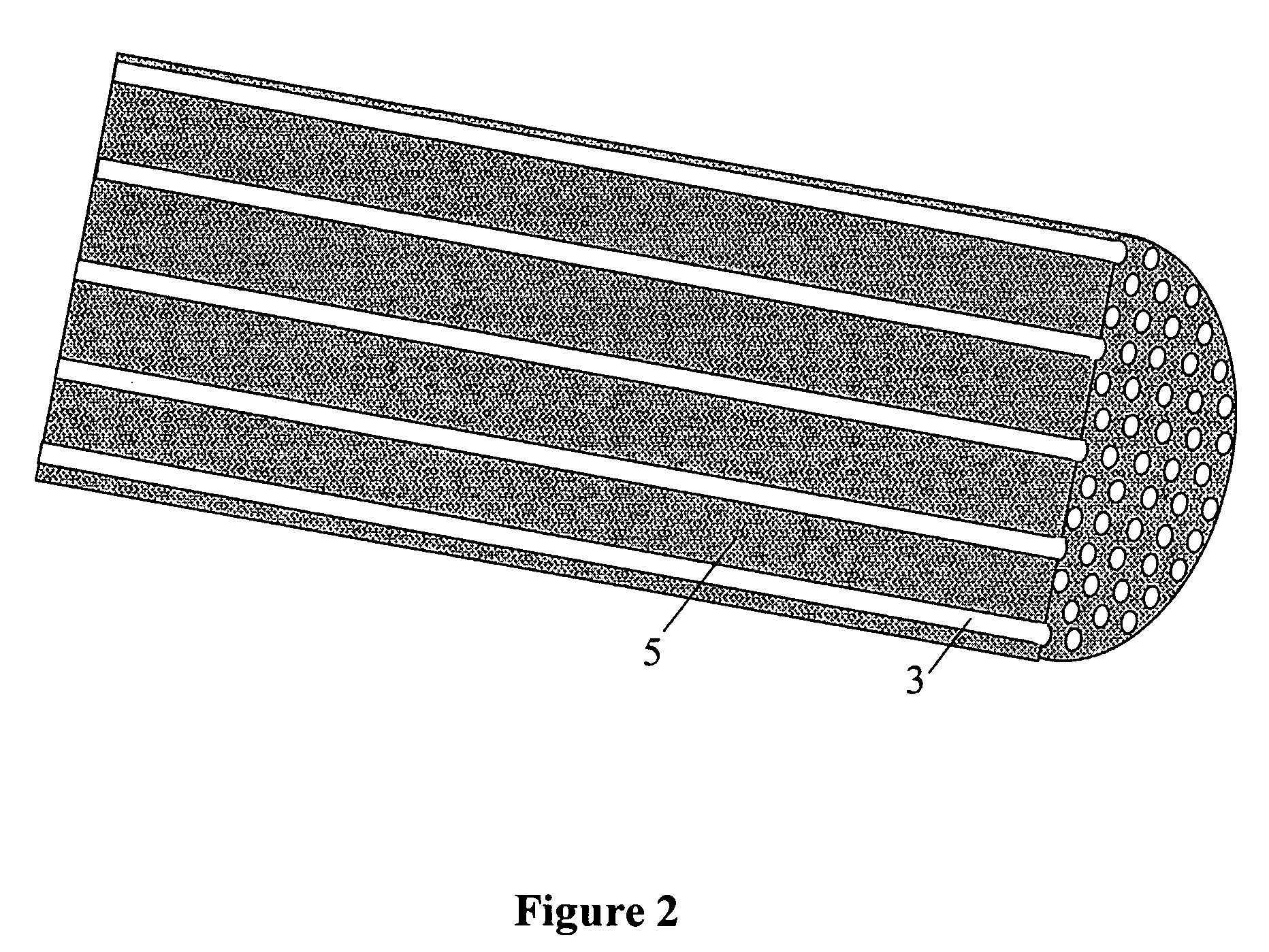

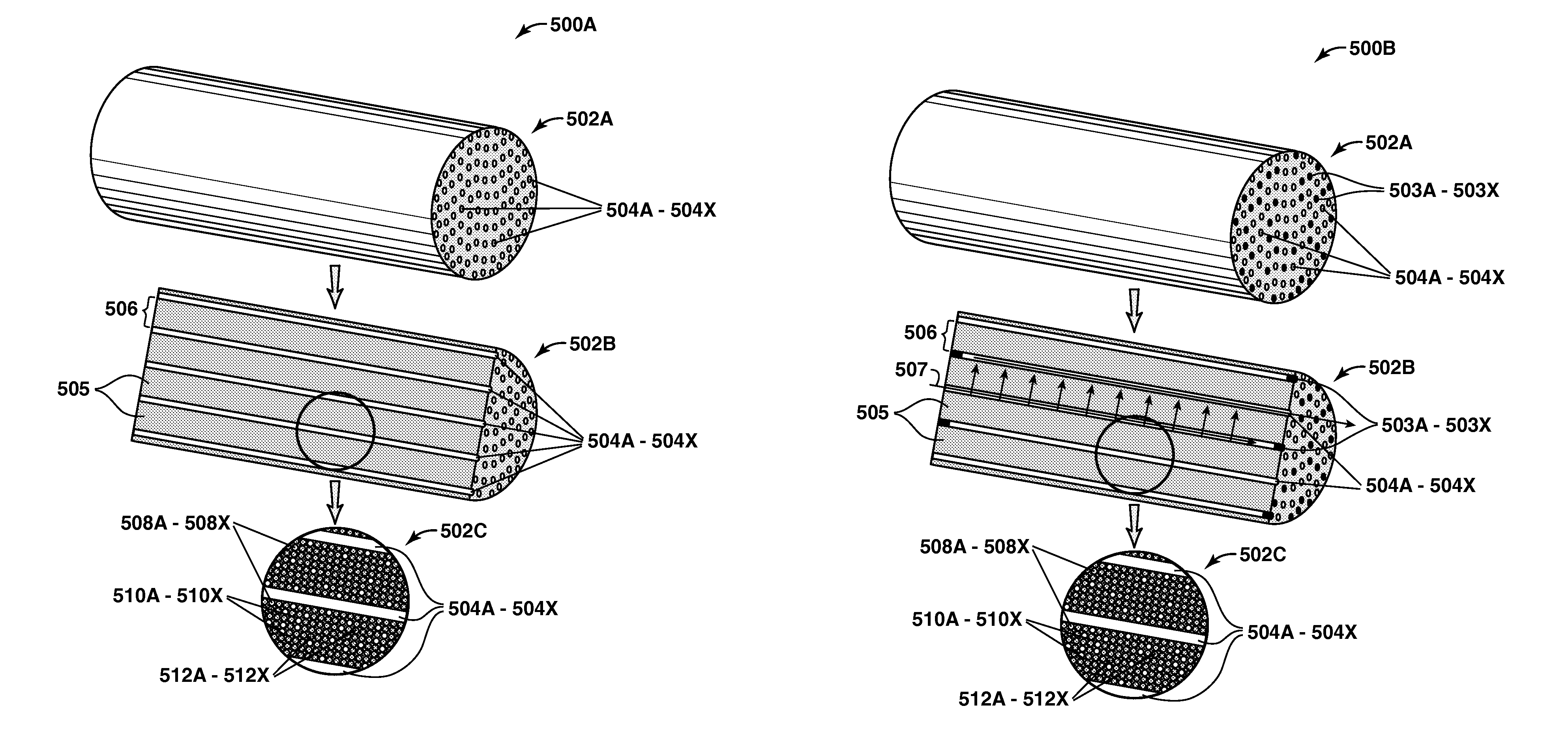

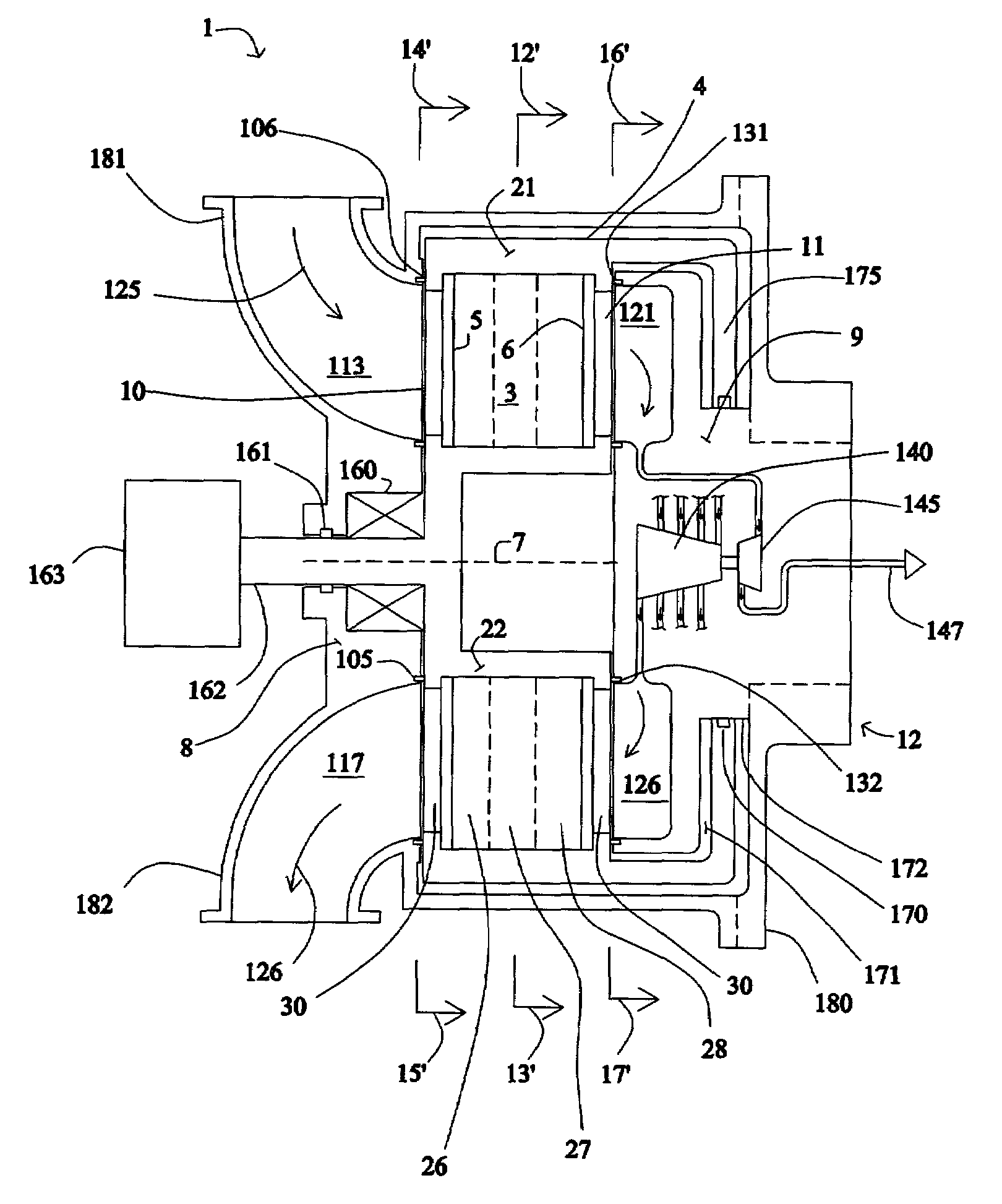

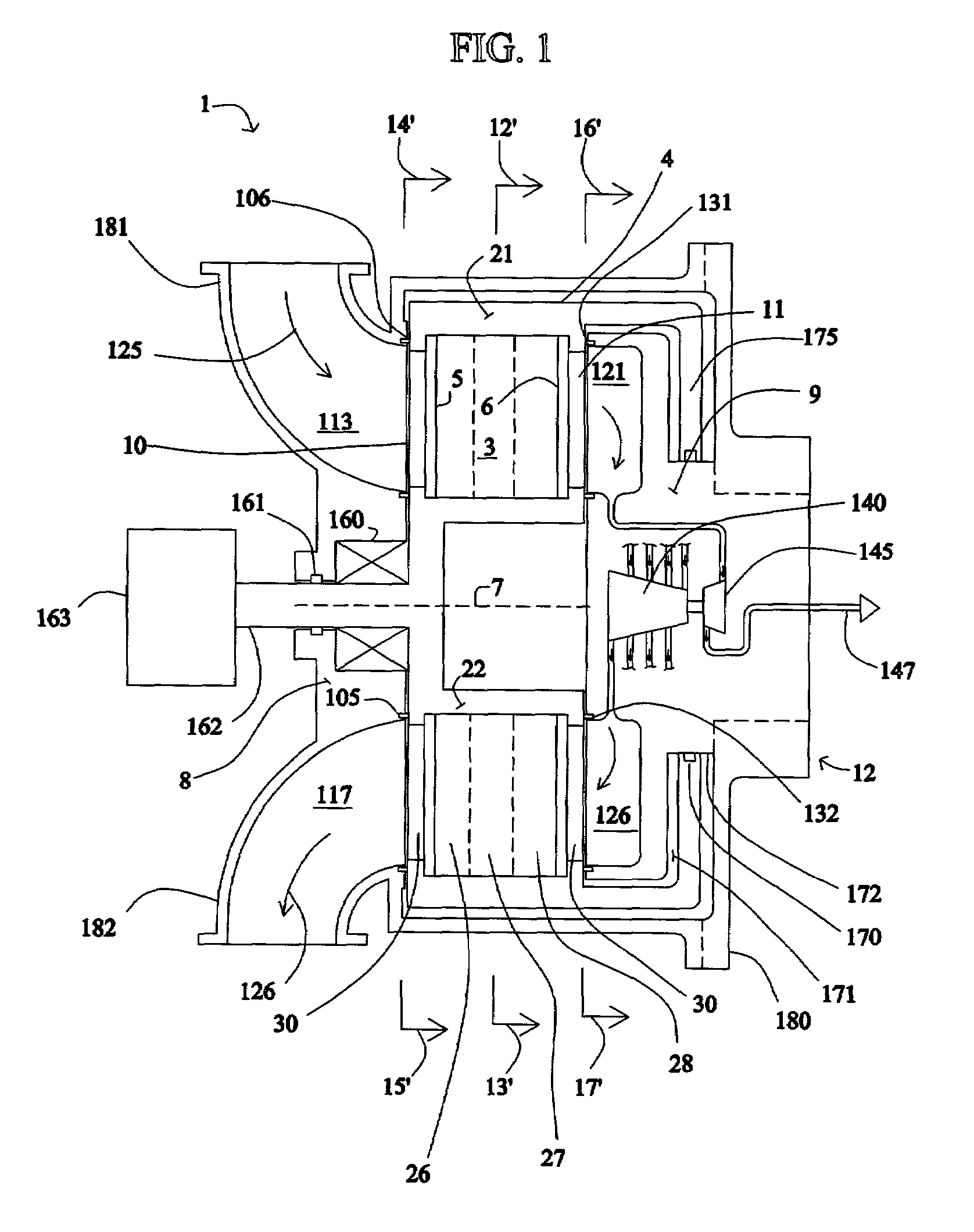

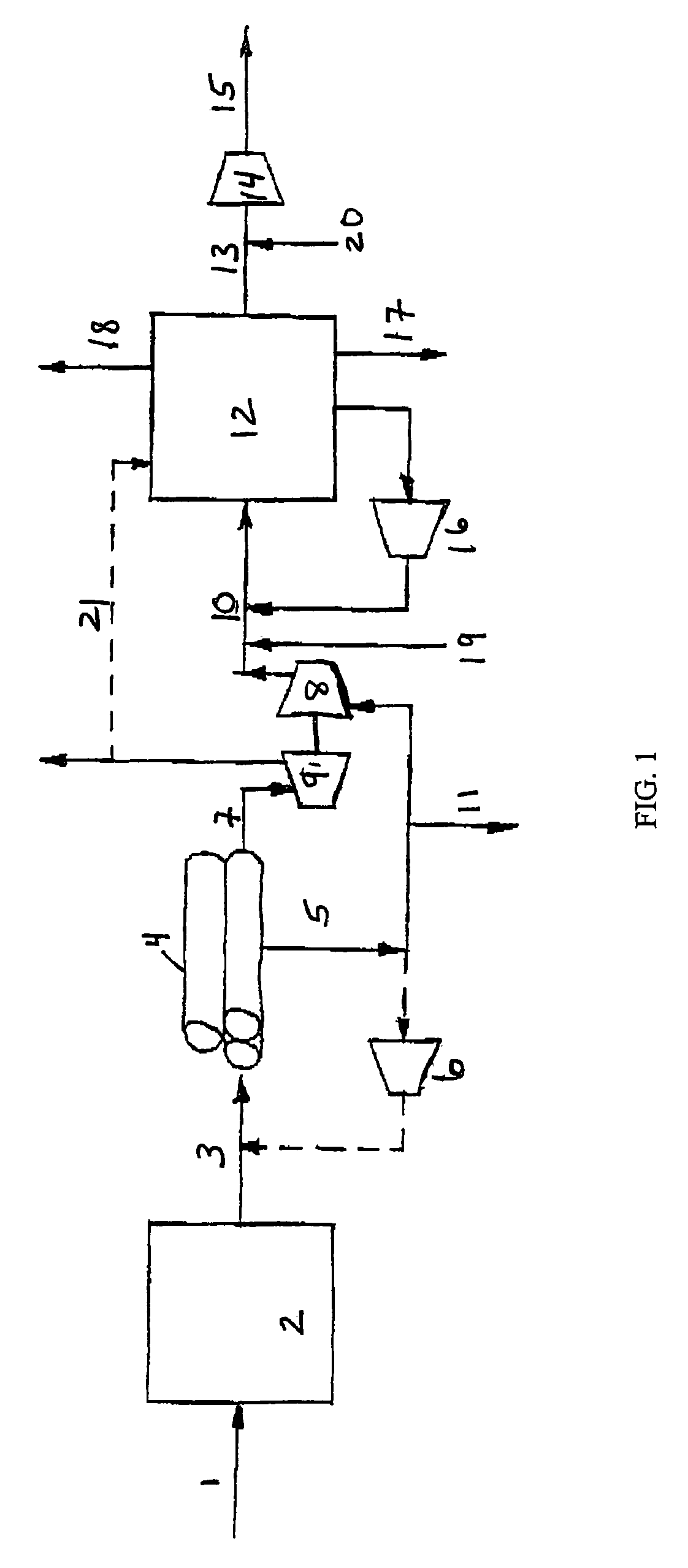

Pressure swing adsorption separation of a feed gas mixture, to obtain a purified product gas of the less strongly adsorbed fraction of the feed gas mixture, is performed in a plurality of preferably an even number of adsorbent beds, with each adsorbent bed communicating at its product end directly to a variable volume expansion chamber, and at its feed end by directional valves to a feed compressor and an exhaust vacuum pump. For high frequency operation of the pressure swing adsorption cycle, a high surface area layered support is used for the adsorbent. The compressor and vacuum pump pistons may be integrated with the cycle, reciprocating at twice the cycle frequency. Alternative configurations of the layered adsorbent beds are disclosed.

Owner:AIR PROD & CHEM INC

Low mesopore adsorbent contactors for use in swing adsorption processes

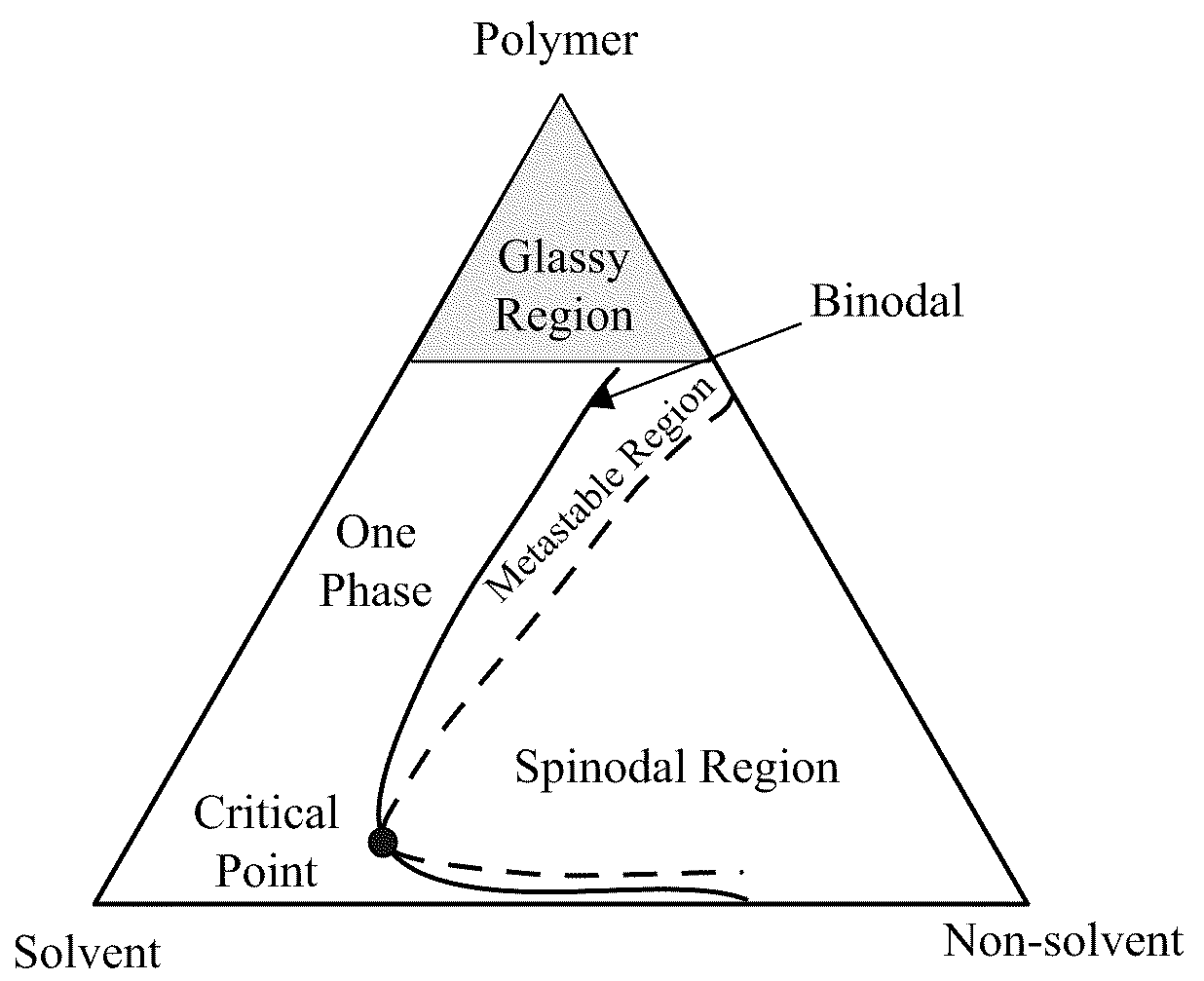

The present invention relates to engineered structured adsorbent contactors for use in pressure swing adsorption and thermal swing adsorption processes. Preferably, the contactors contain engineered and substantially parallel flow channels wherein 20 volume percent or less of the open pore volume of the contactor, excluding the flow channels, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

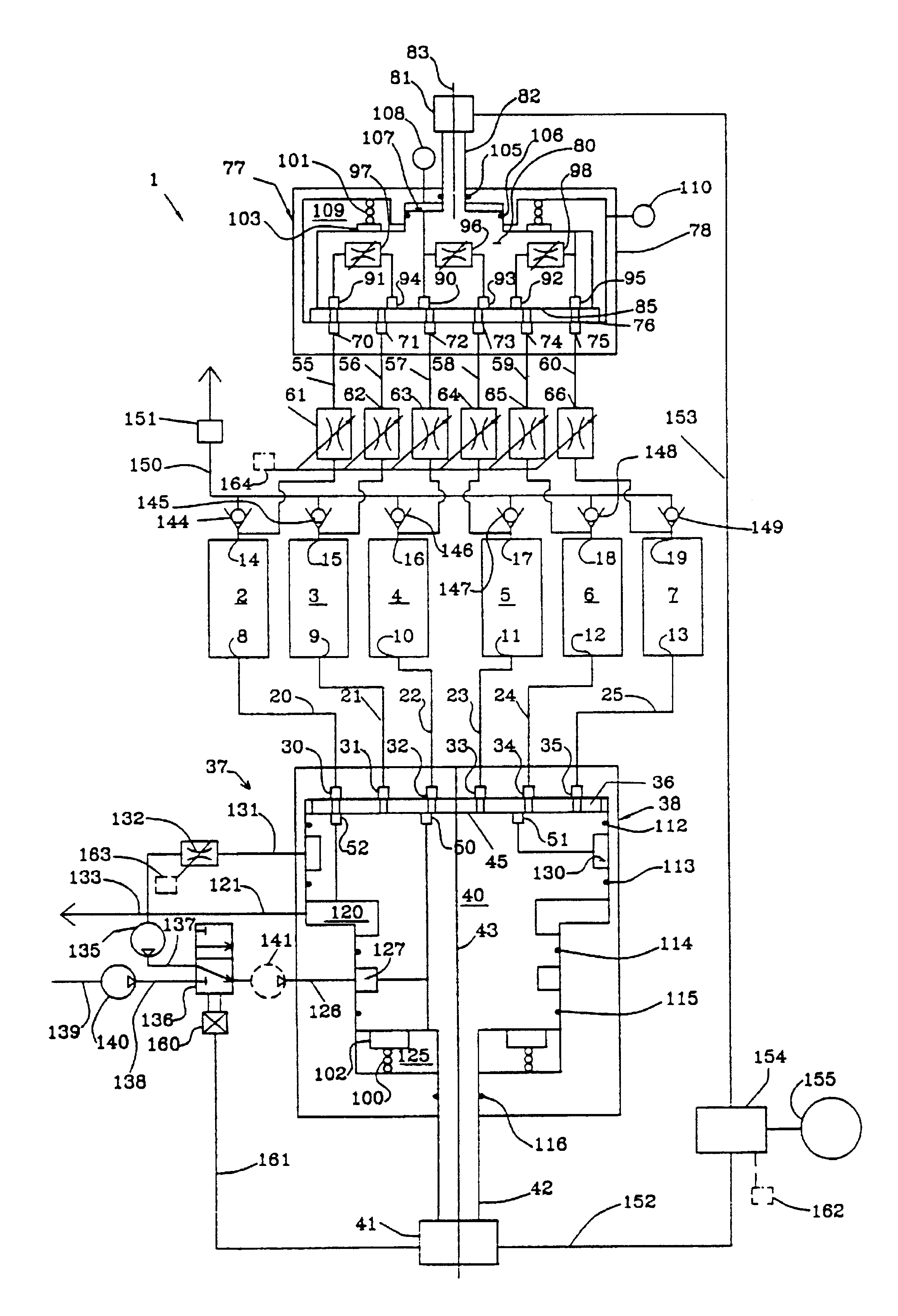

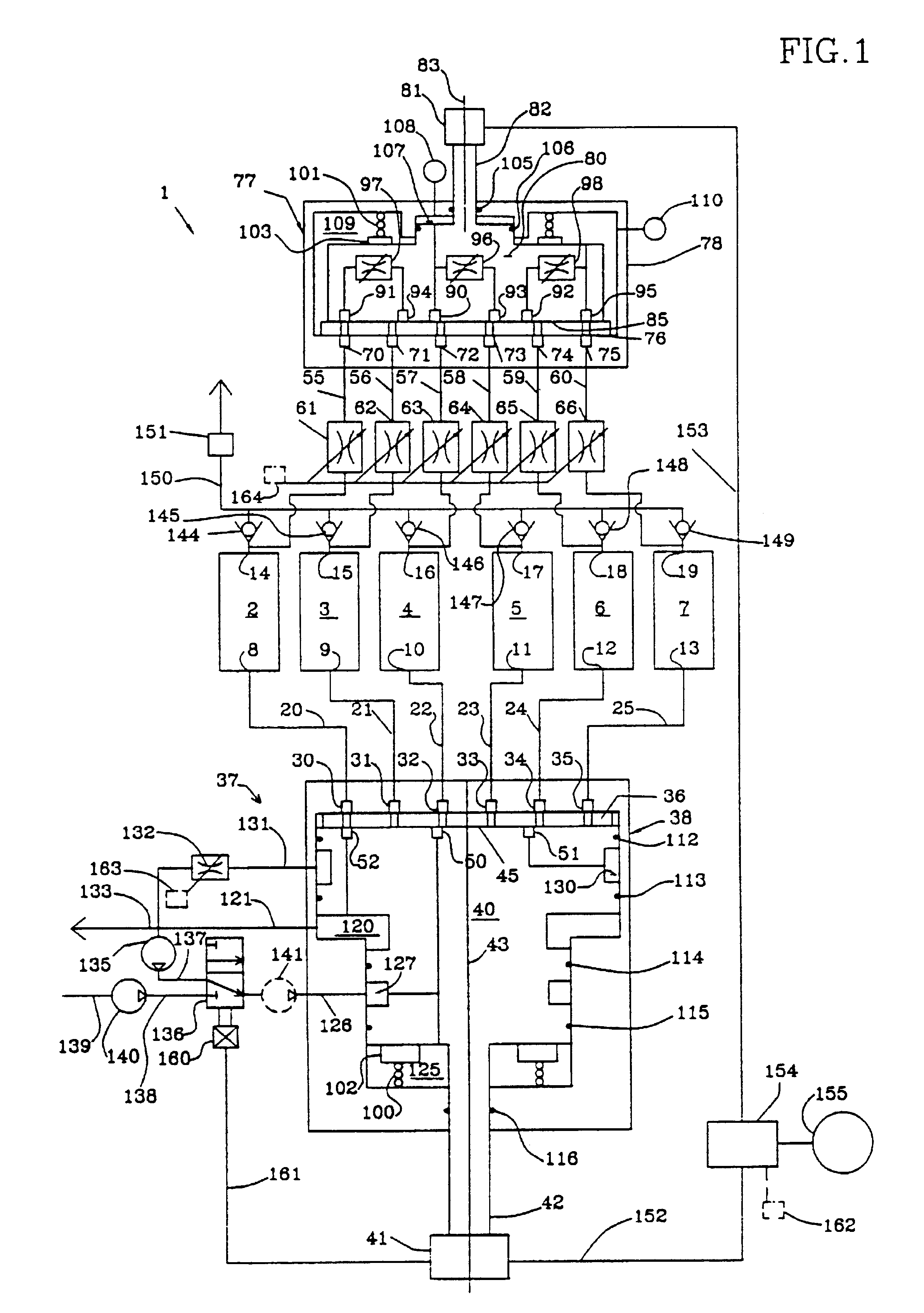

Modular pressure swing adsorption with energy recovery

InactiveUS6051050AHigh-frequency operationCompact equipmentIsotope separationRefluxProcess engineering

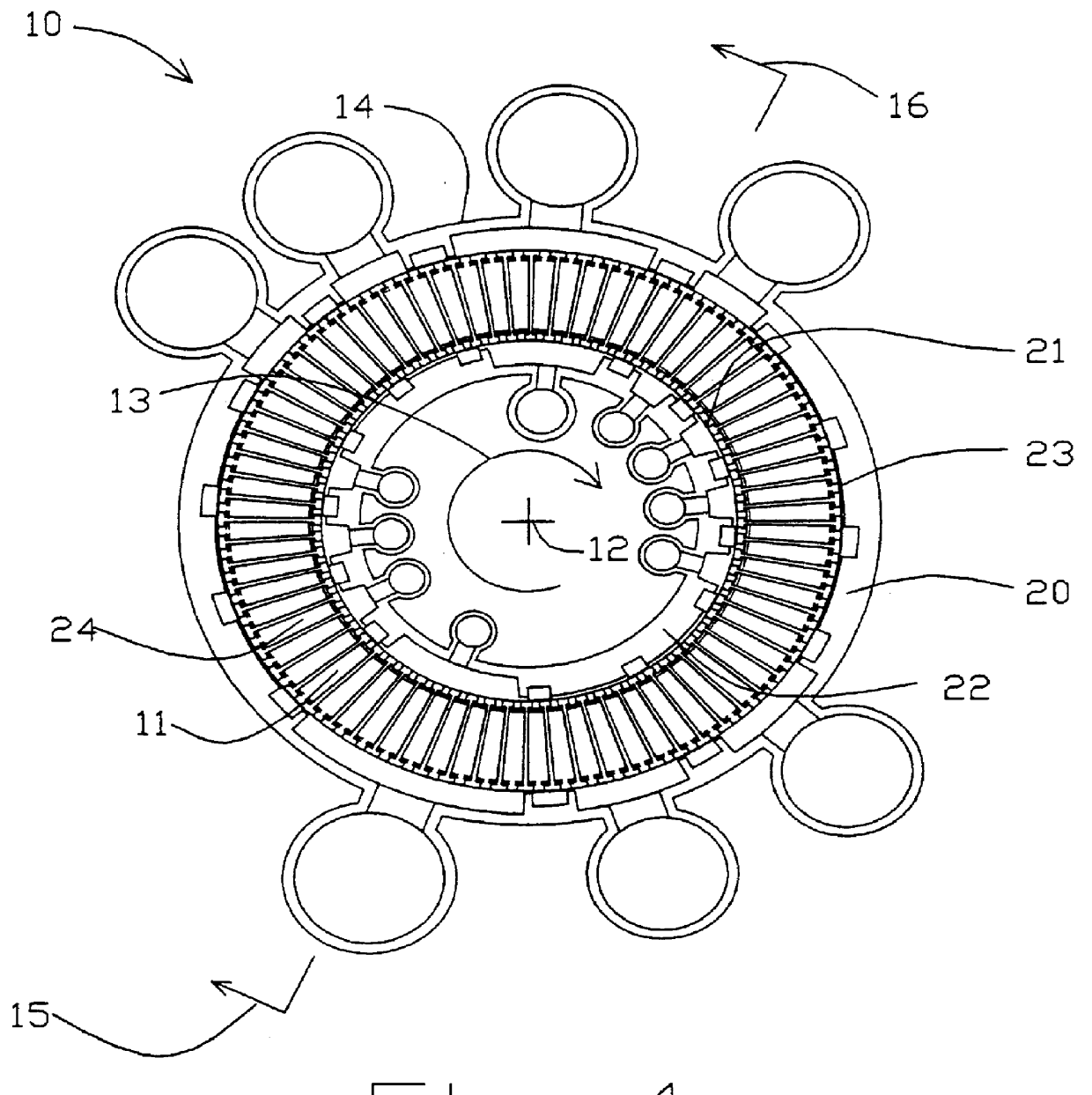

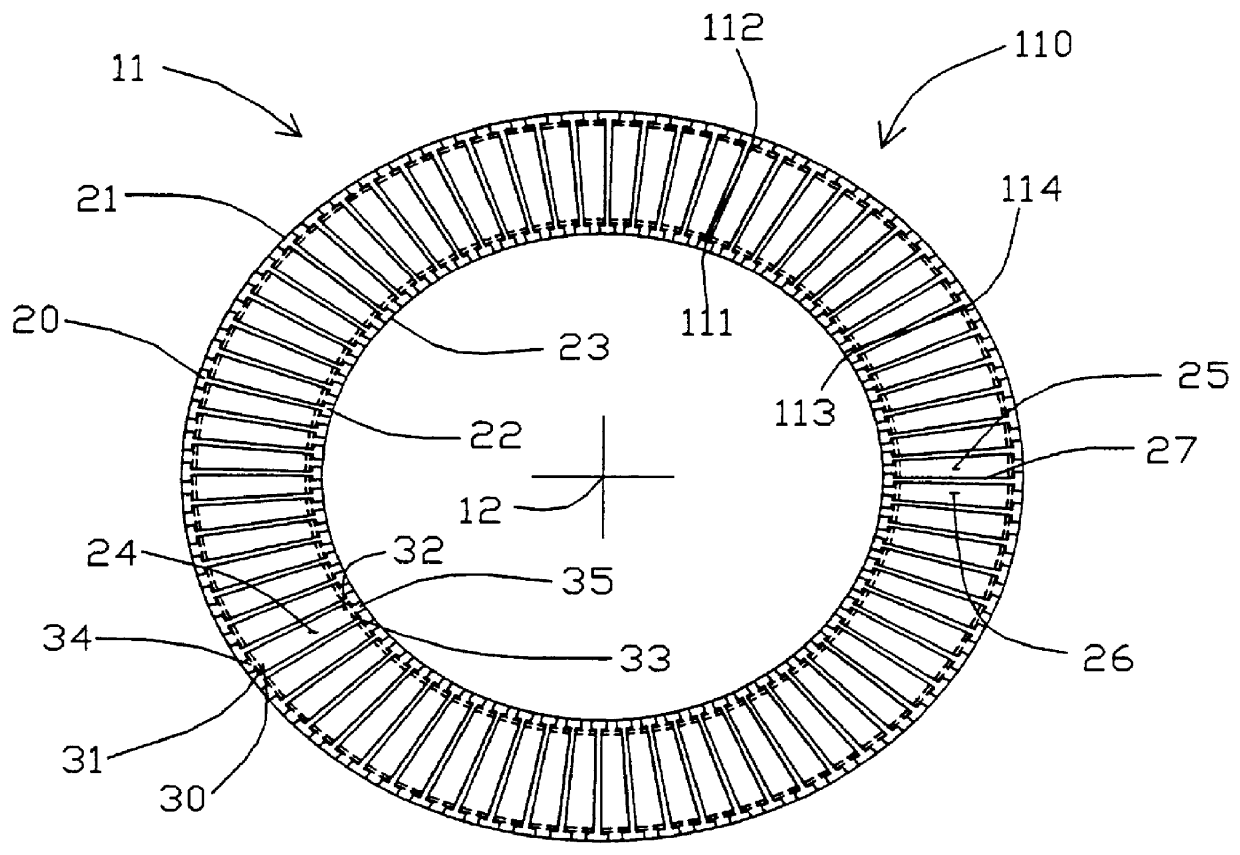

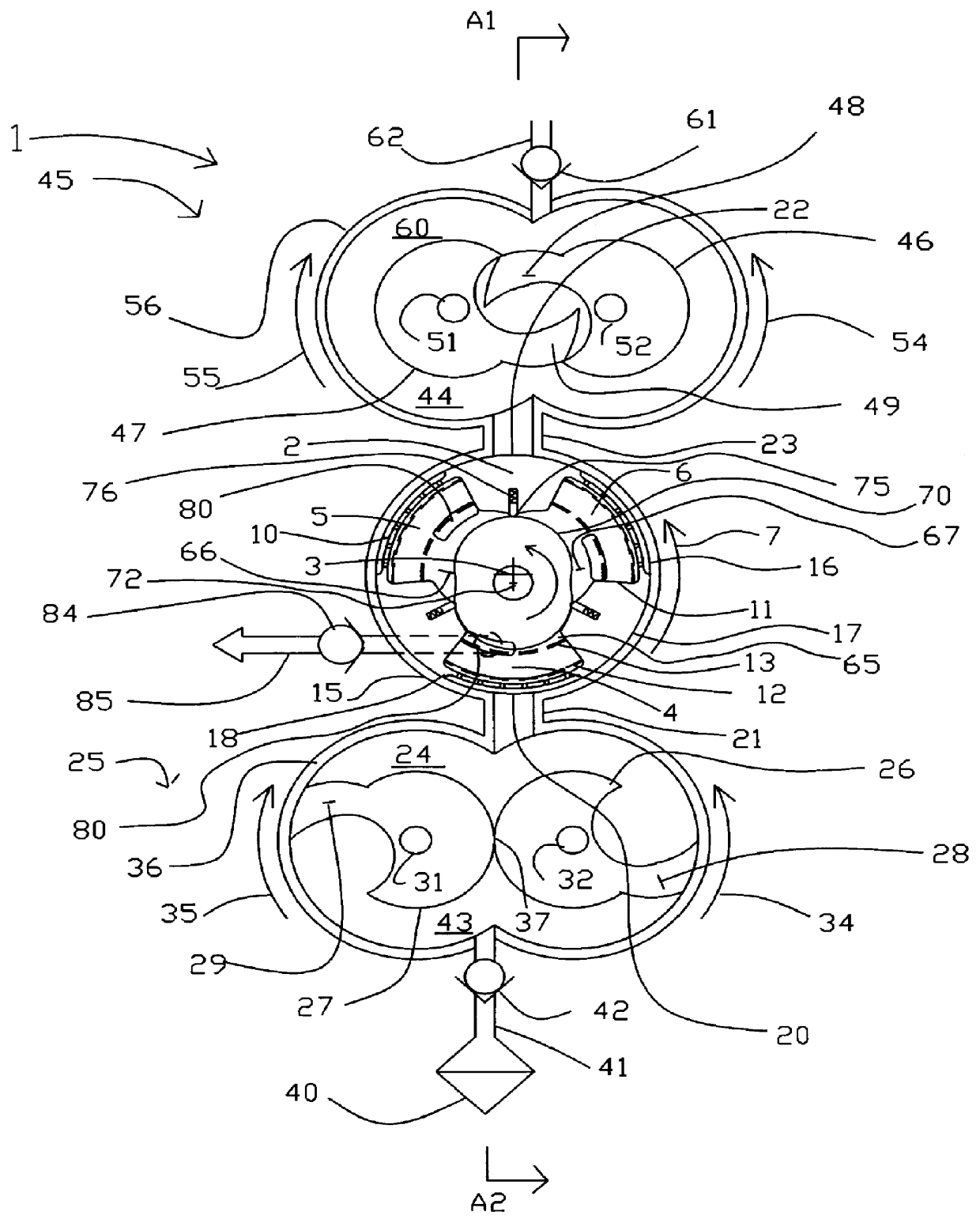

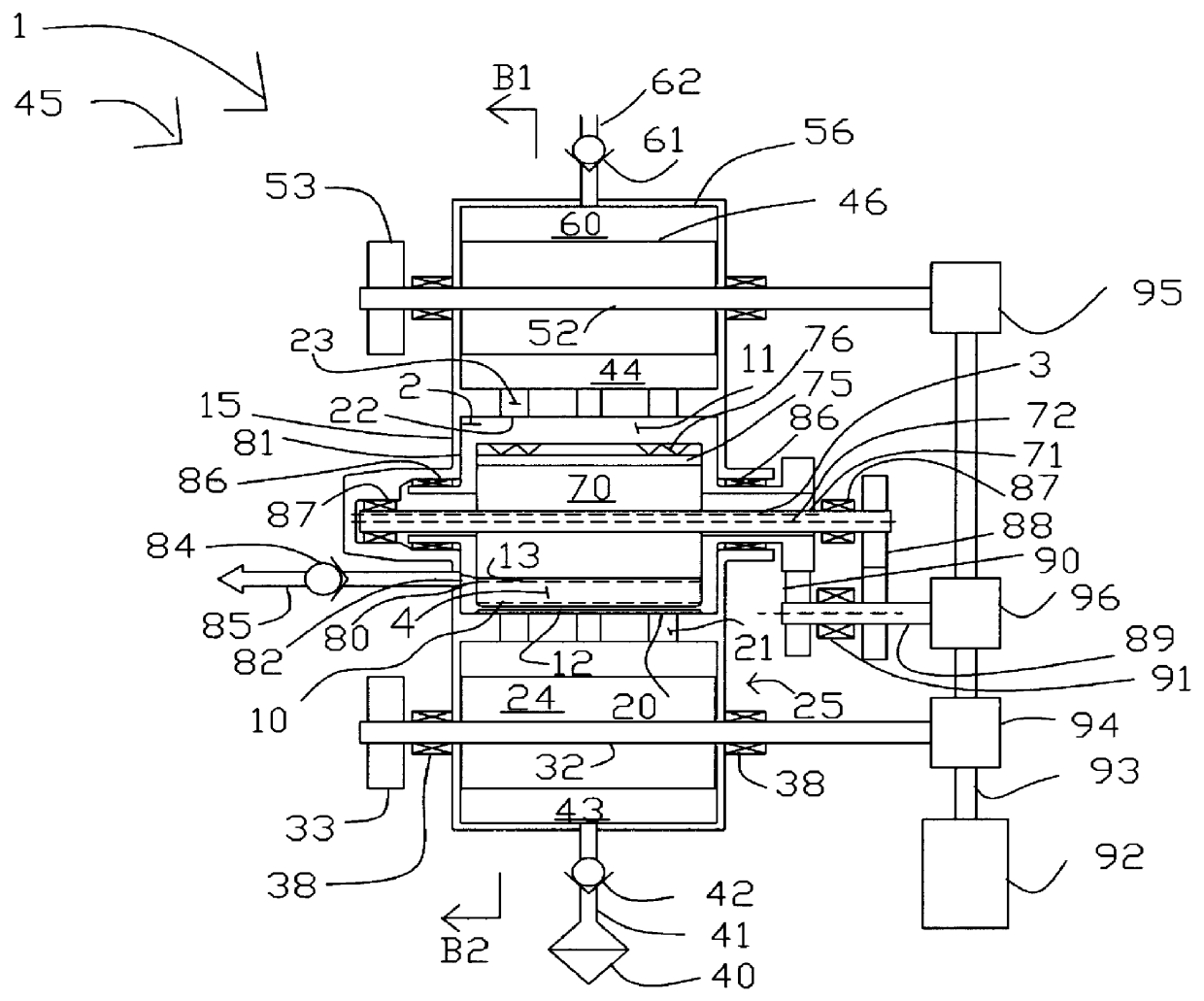

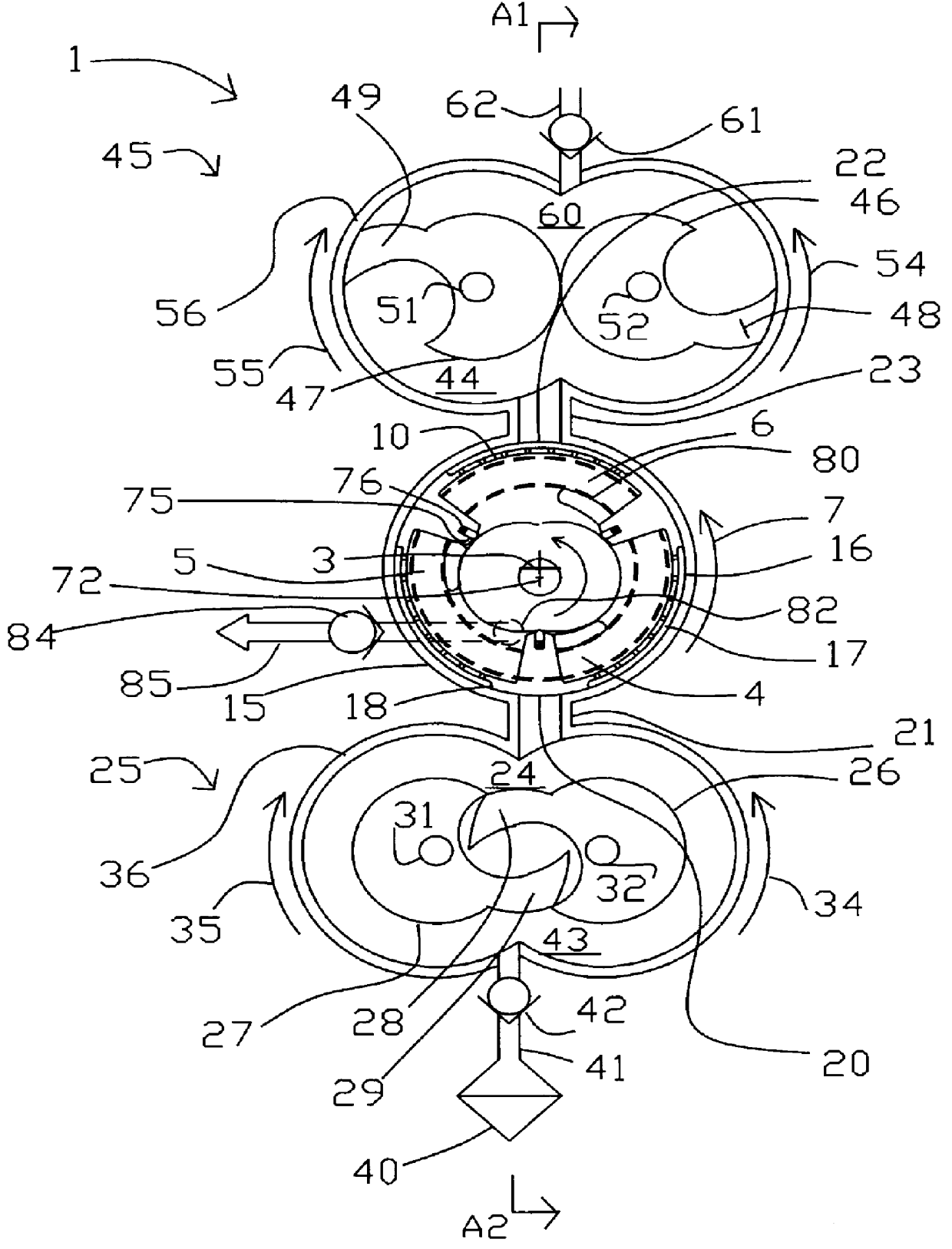

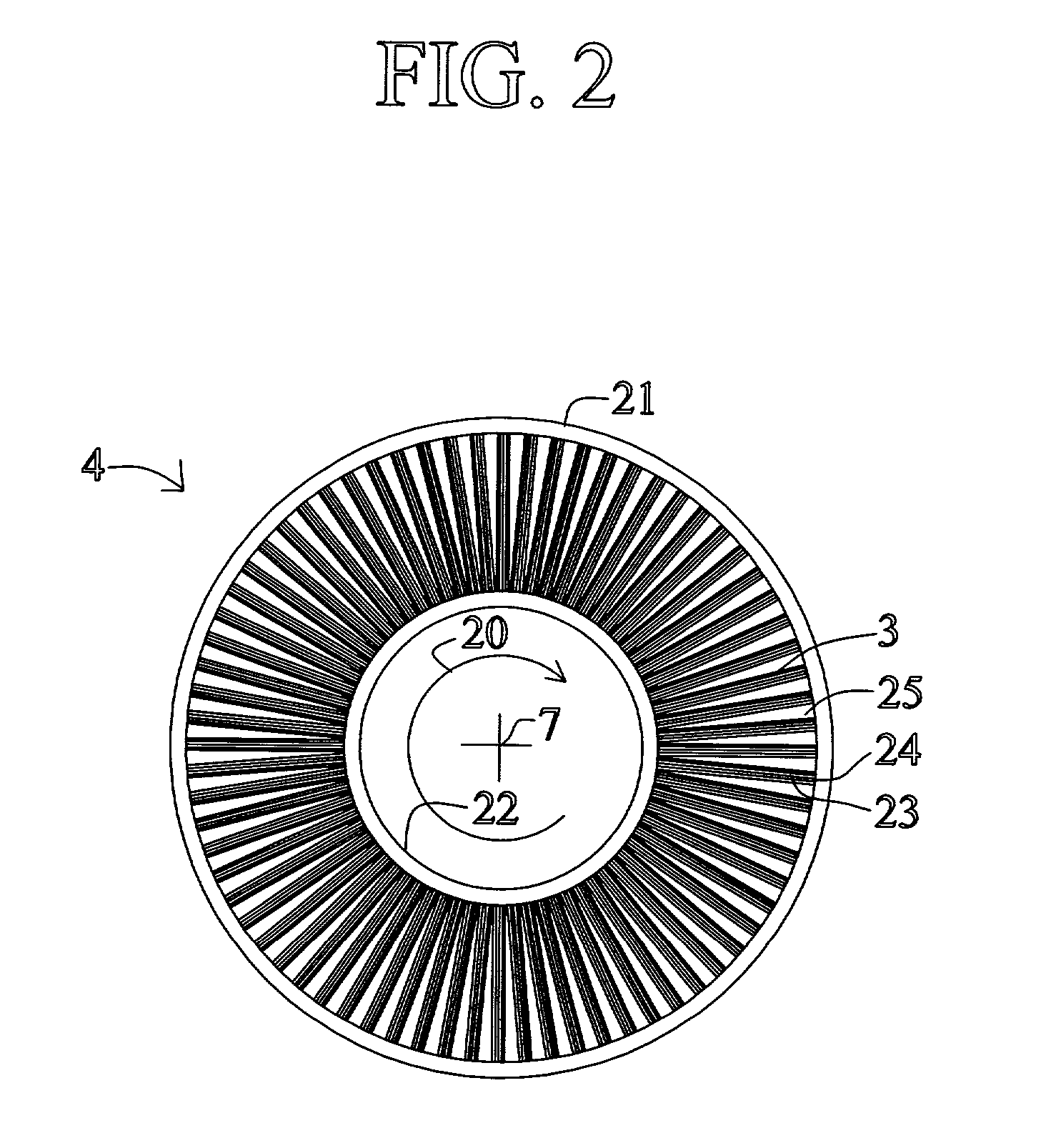

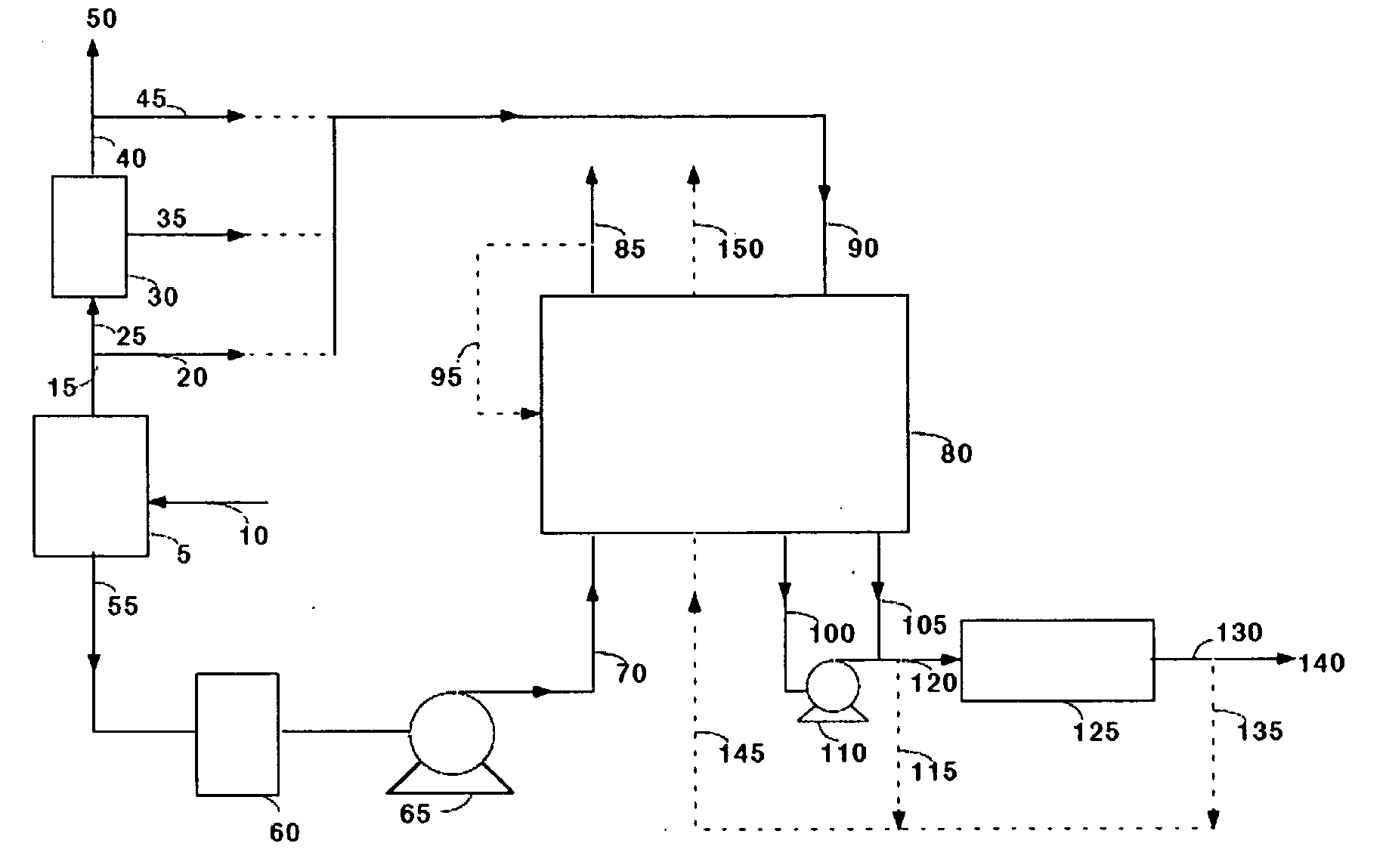

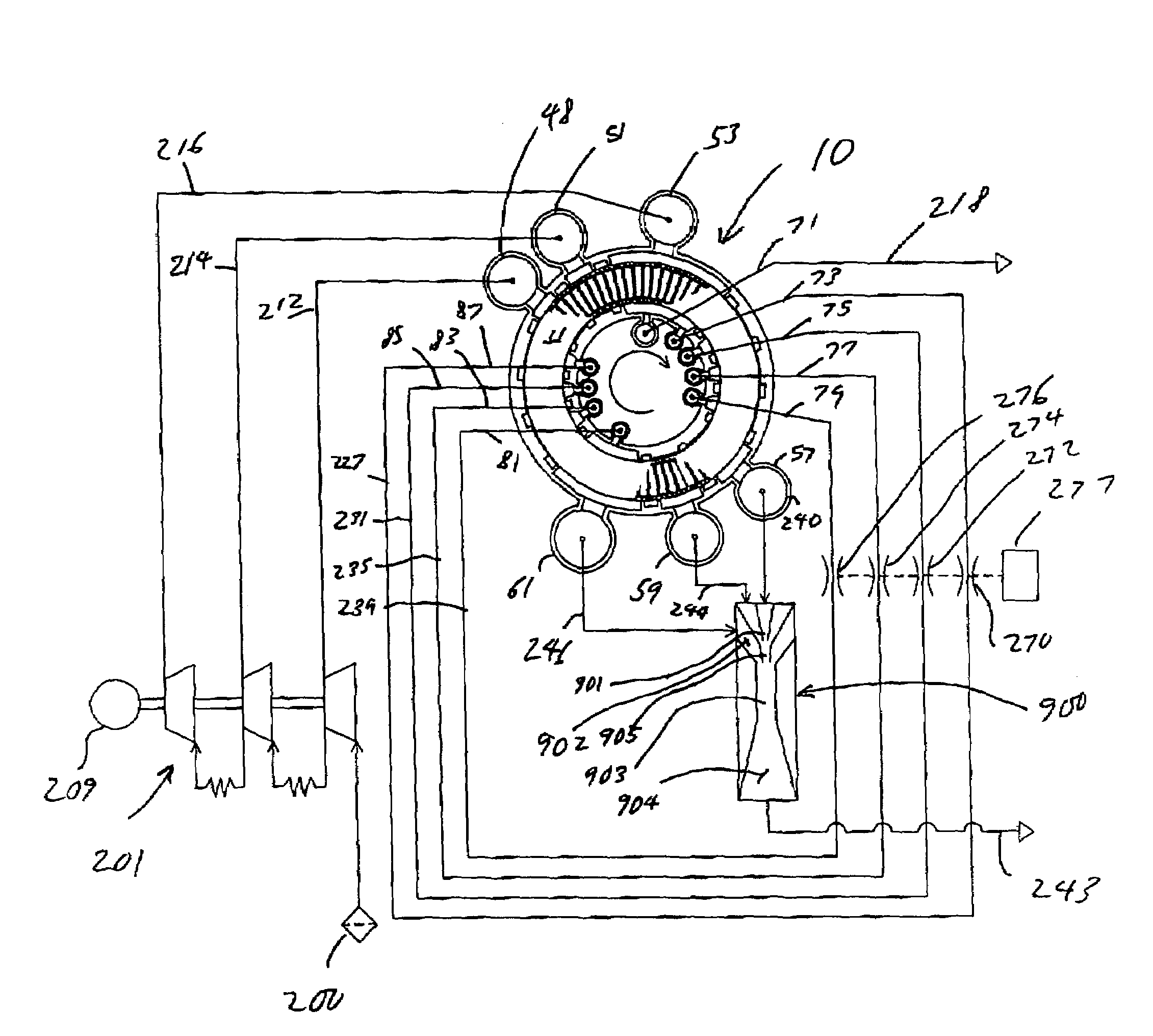

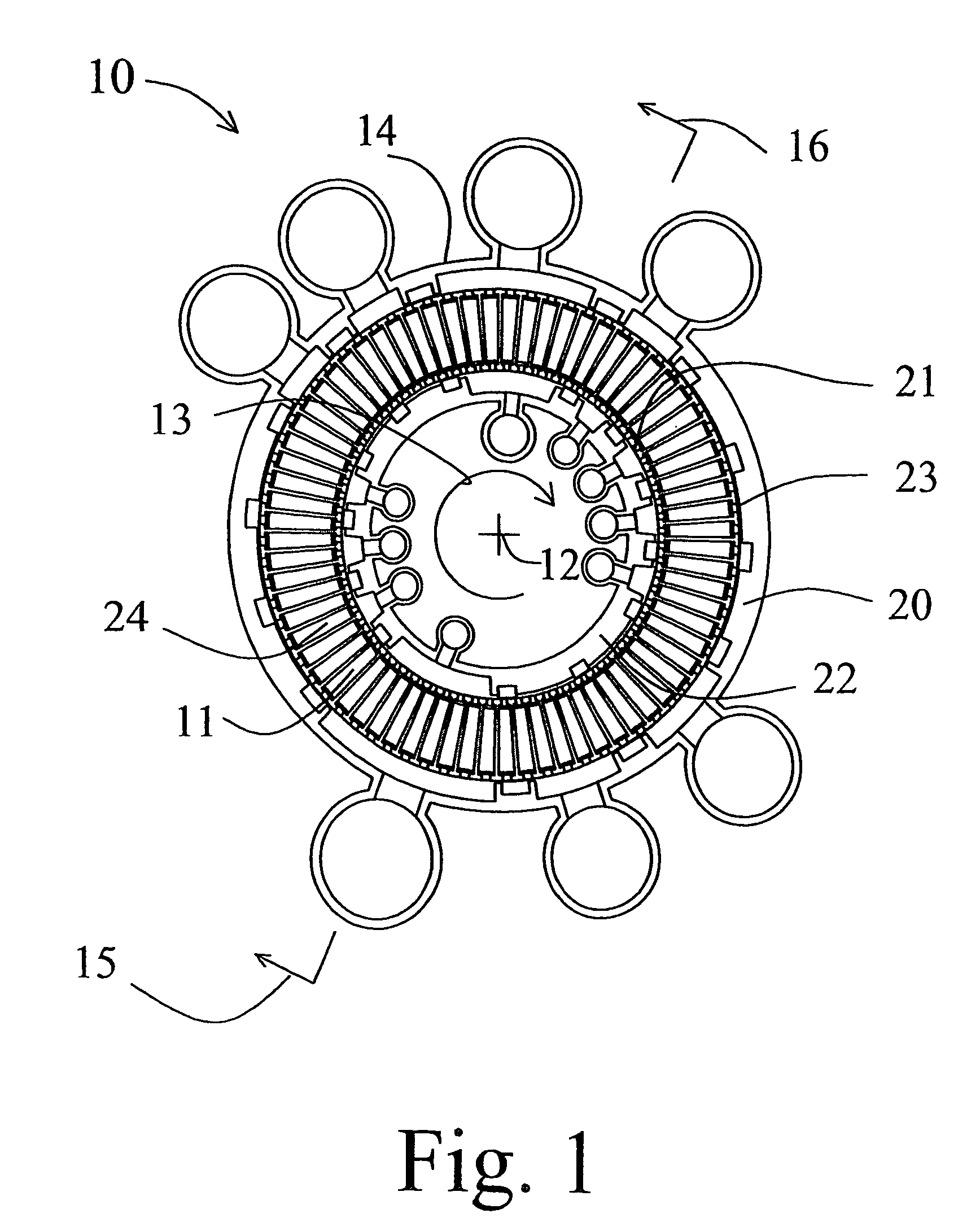

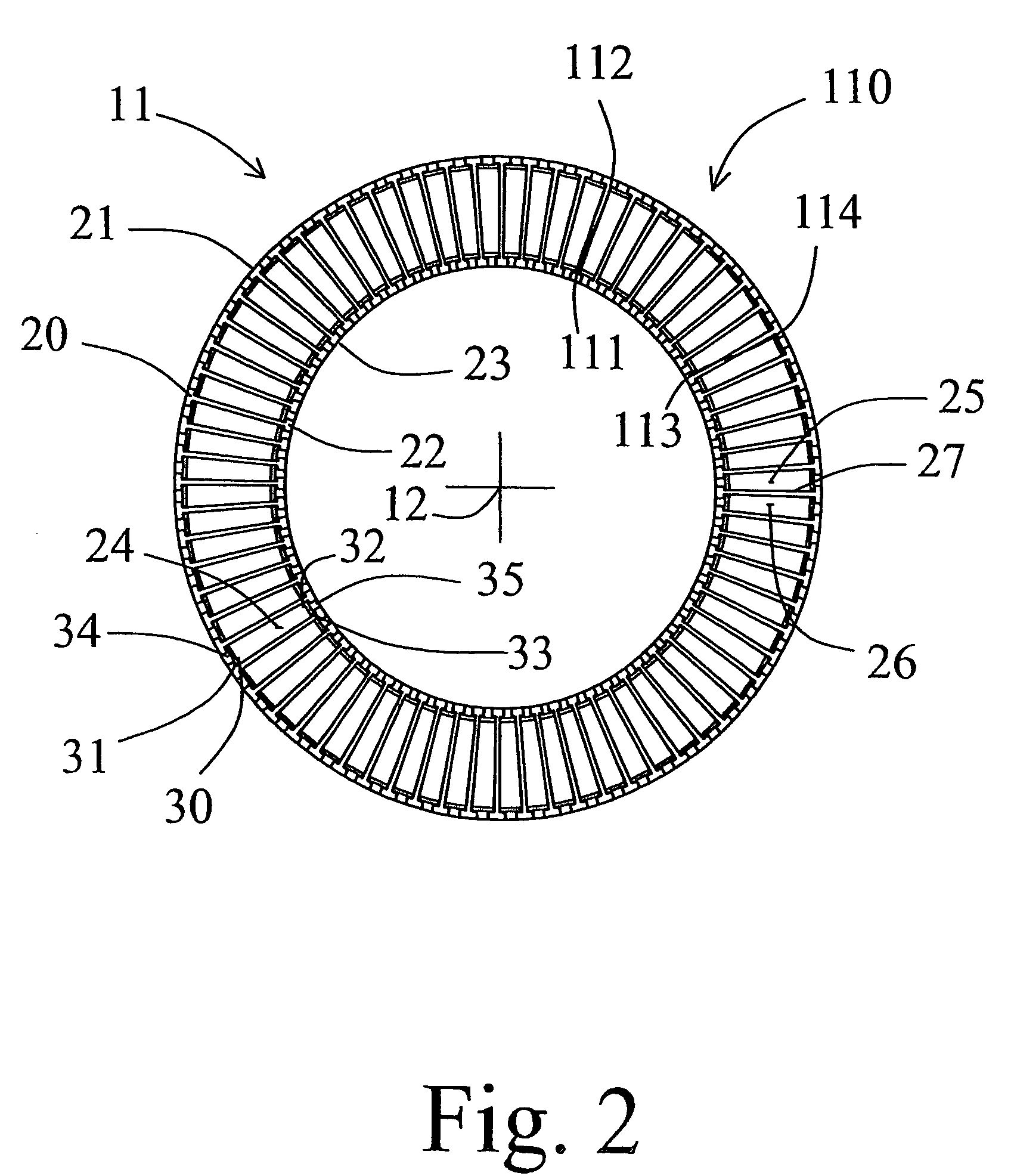

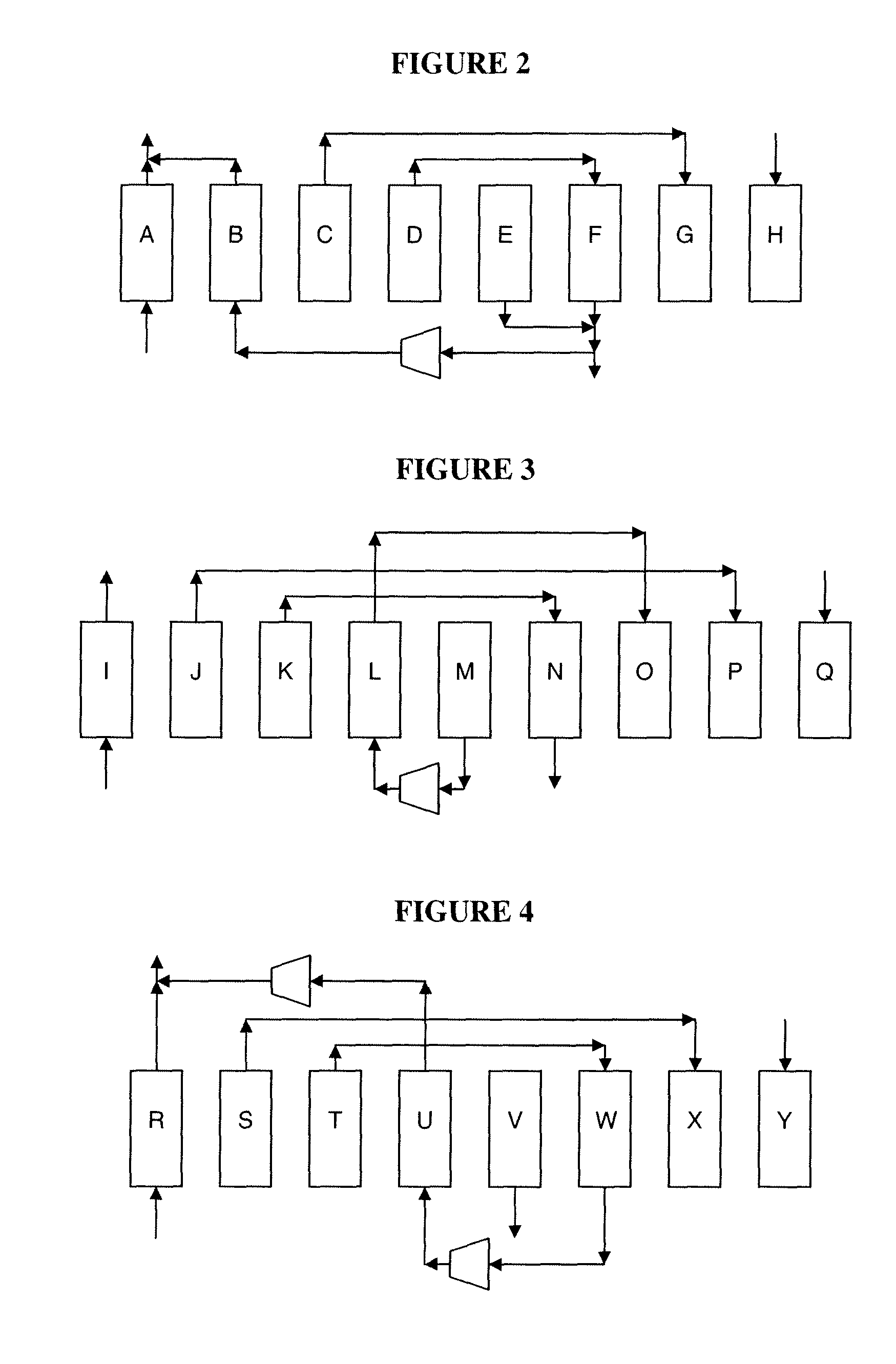

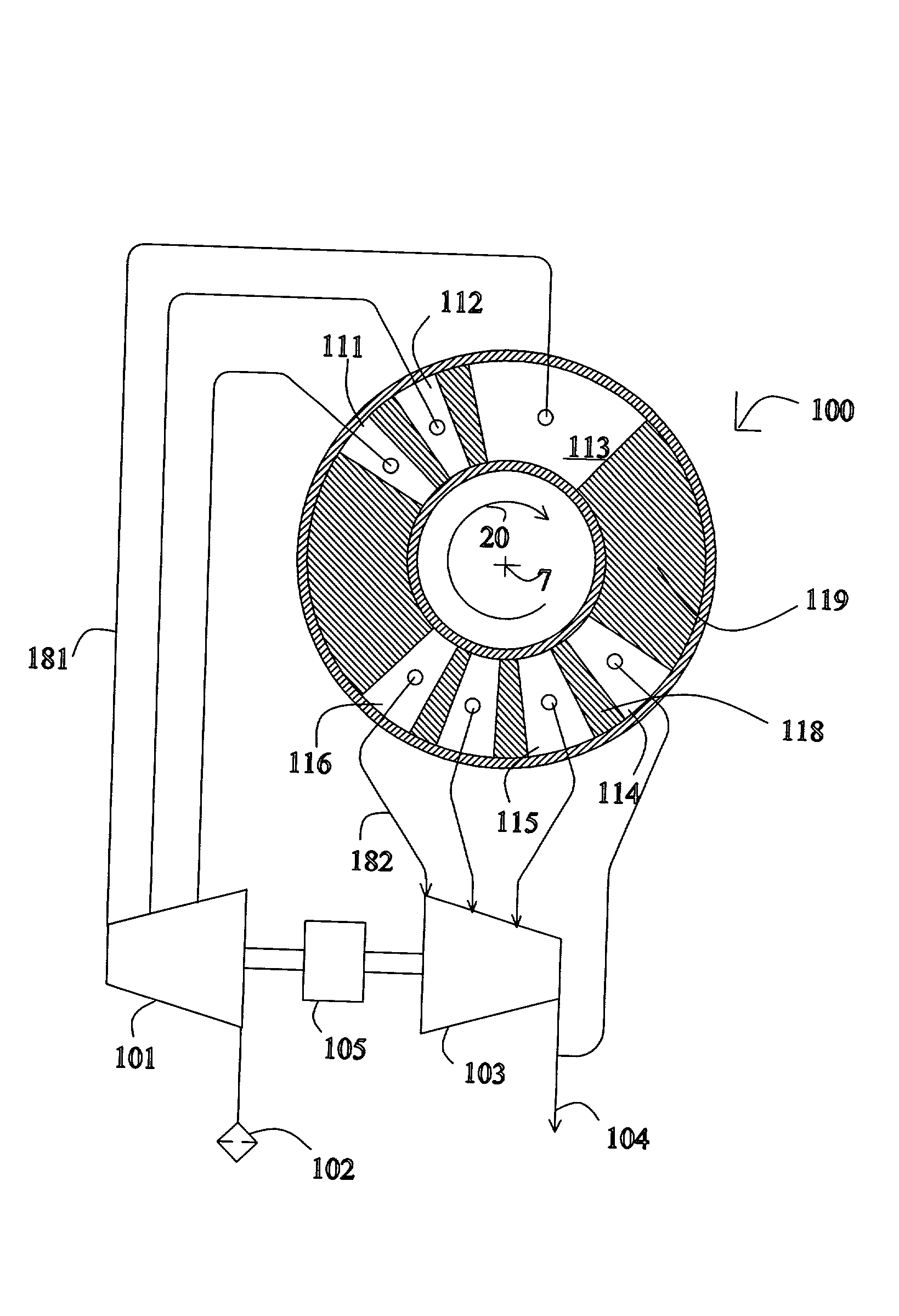

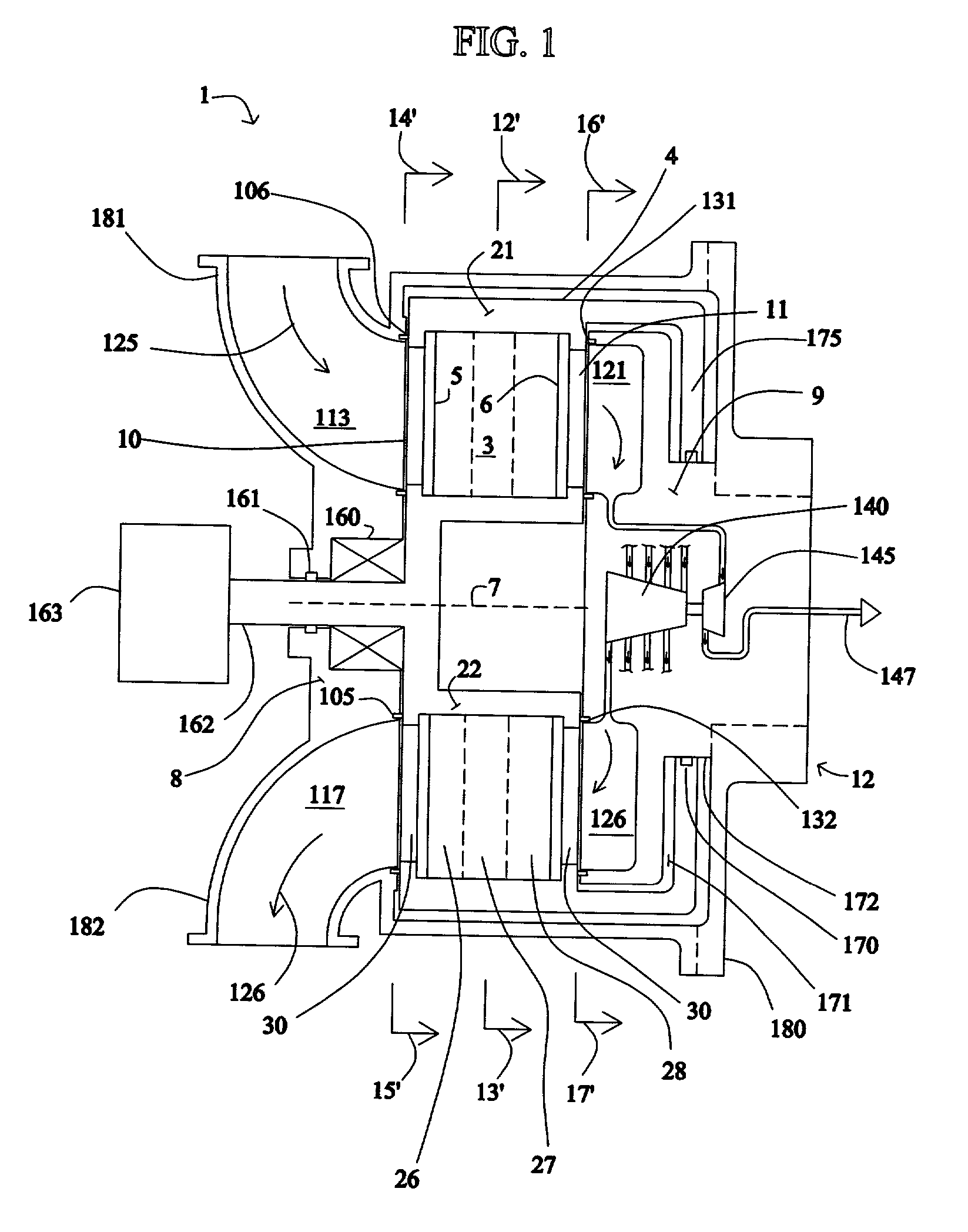

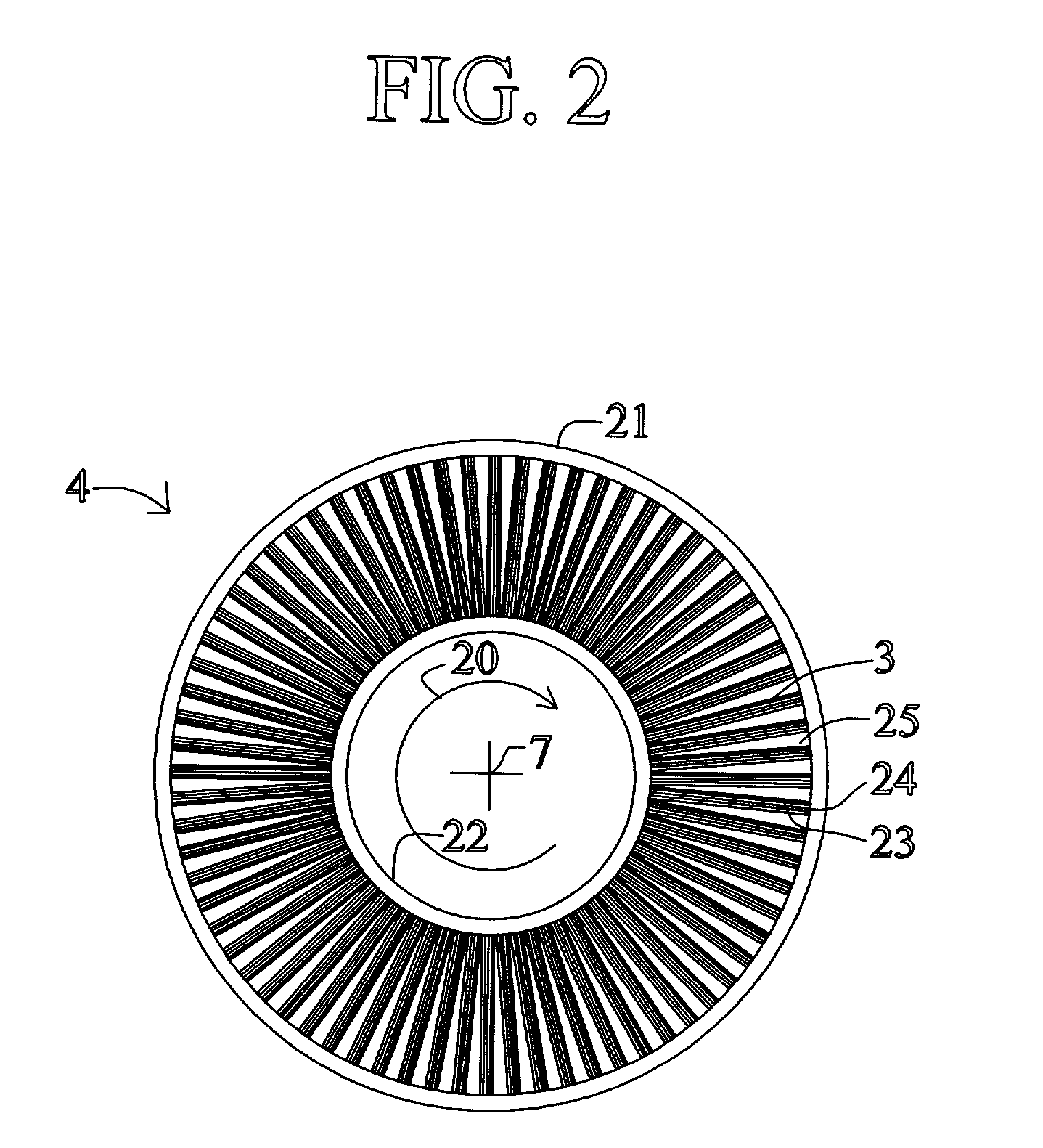

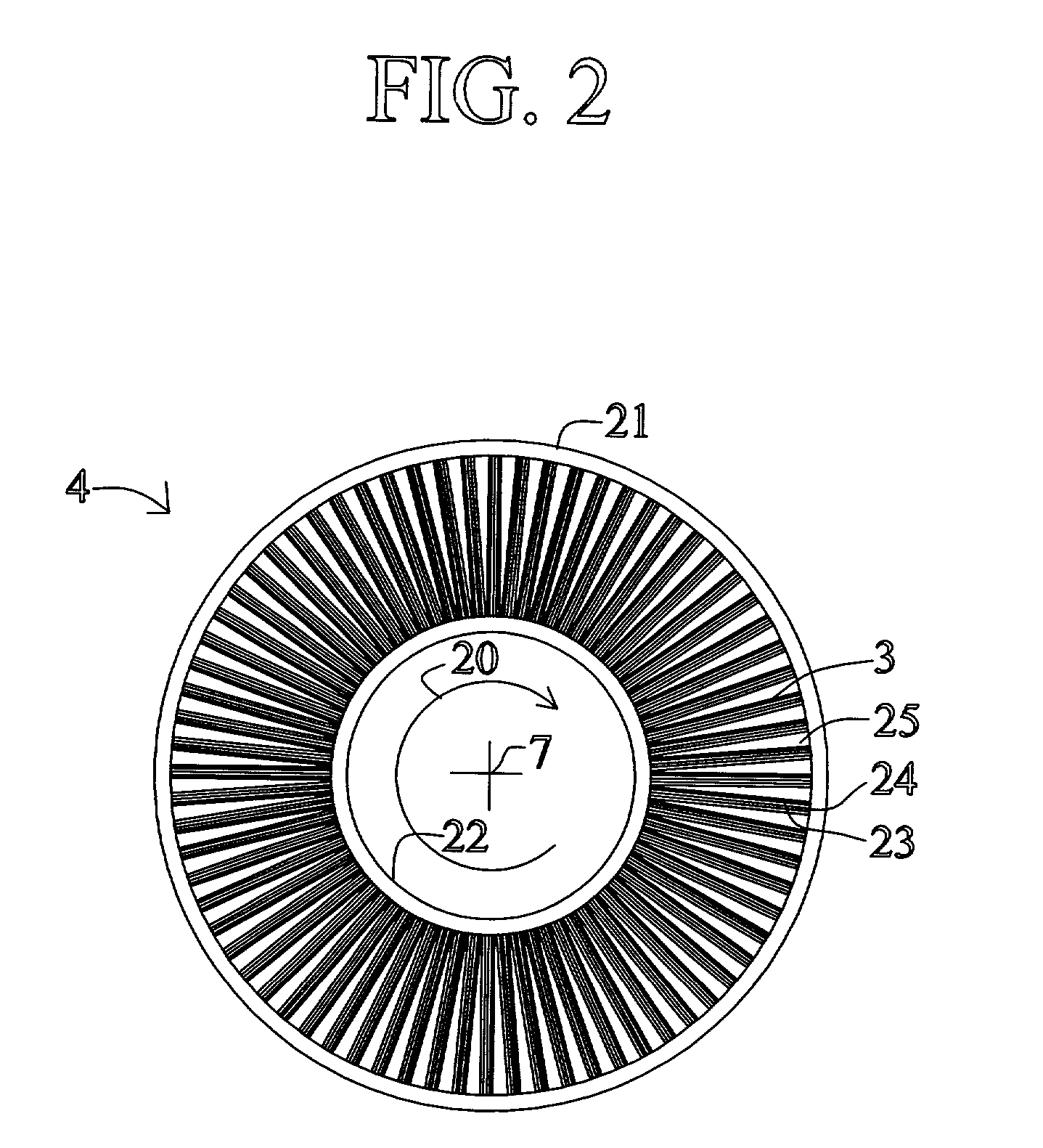

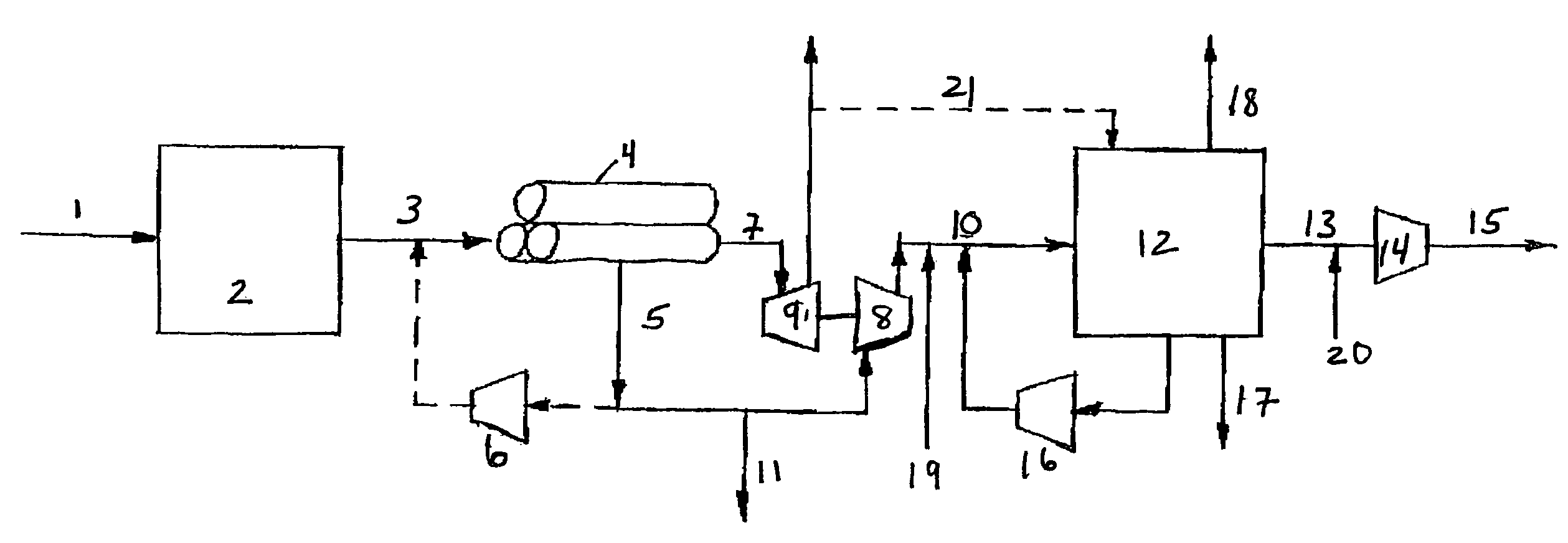

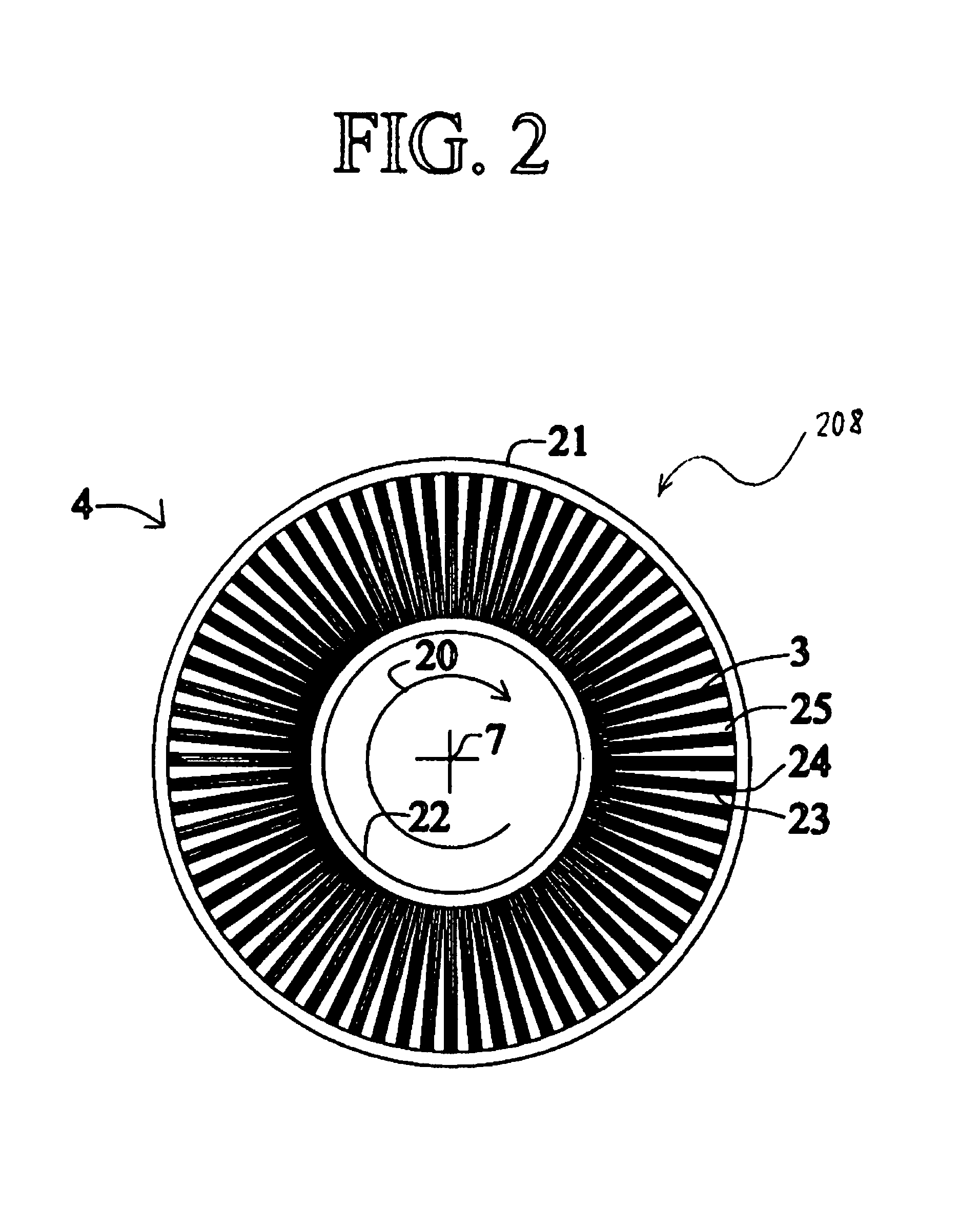

Pressure swing adsorption (PSA) separation of a feed gas mixture is performed within an apparatus having typically a single prime mover powering a feed compressor for one or multiple rotary PSA modules in parallel, each module including a rotor with a large number of angularly spaced adsorber elements, with valve surfaces between the rotor and a stator so that individual adsorber elements are opened to compartments for staged pressurization and blowdown, with thermally boosted energy recovery from staged expansion of countercurrent blowdown and light reflux gases, and a plurality of adsorber elements opened at any instant to each compartment so that each compressor and expander stage operates under substantially steady conditions of flow and pressure.

Owner:AIR PROD & CHEM INC

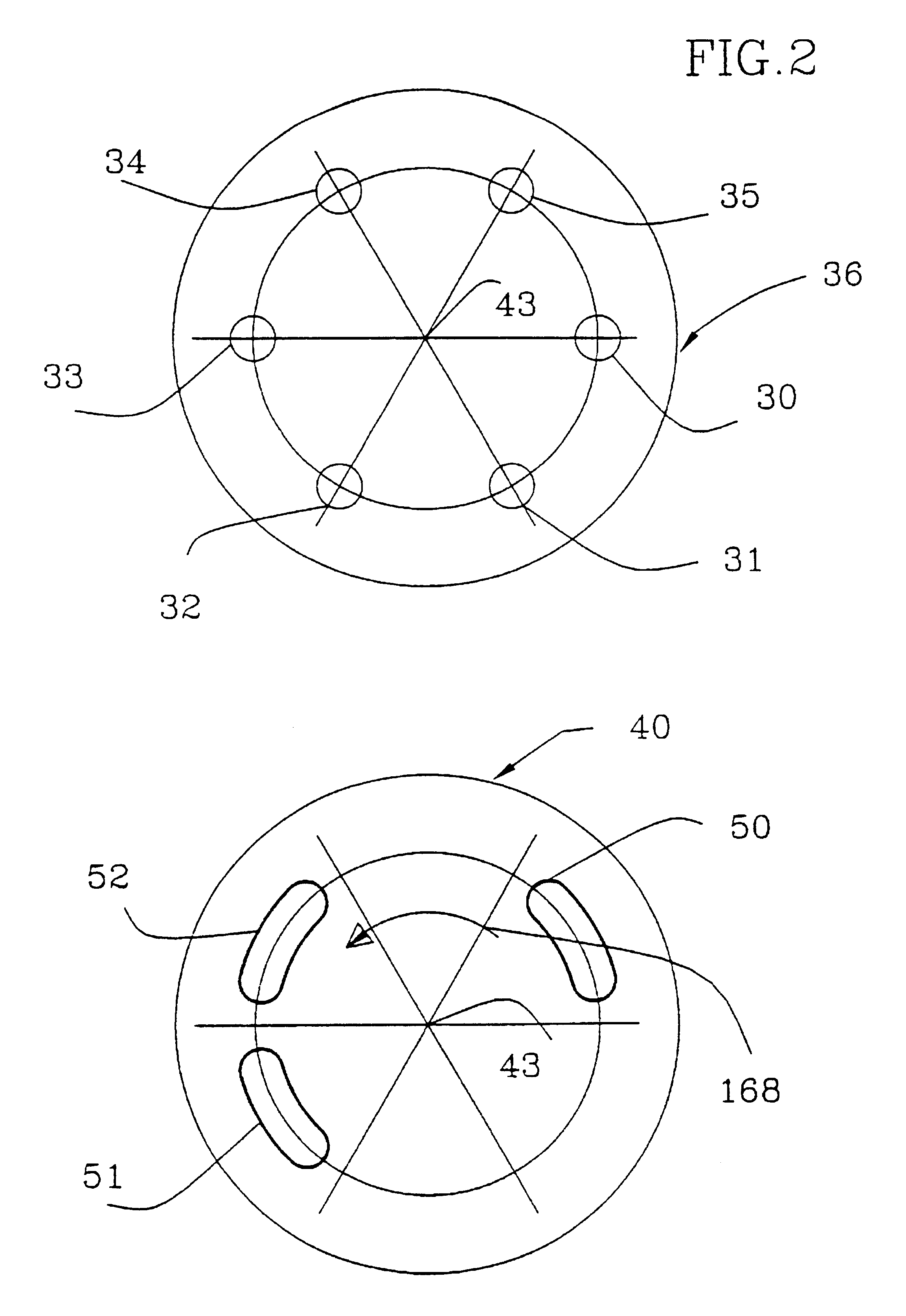

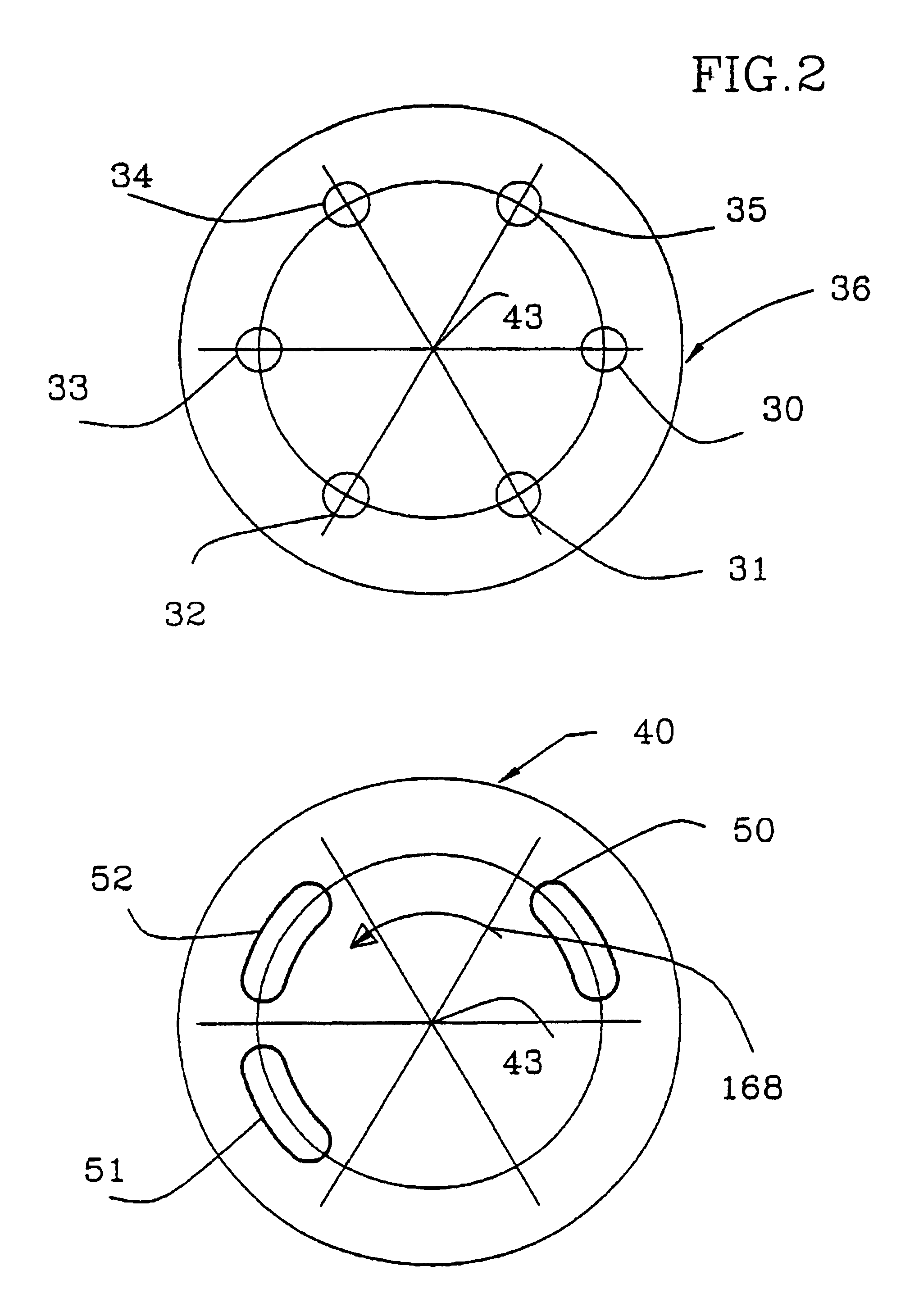

High frequency rotary pressure swing adsorption apparatus

InactiveUS6056804AHigh-frequency operationCompact equipmentGas treatmentIsotope separationProduct gasDistributor

Pressure swing adsorption separation of a feed gas mixture, to obtain a purified product gas of the less strongly adsorbed fraction of the feed gas mixture, is performed with a cooperating set of "N" adsorbers in a rotary assembly, with each adsorber communicating at its product end directly to a rotary cyclic displacement chamber, and at its feed end by rotary distributor valve ports to a rotary piston feed compressor and a rotary piston exhaust vacuum pump. The compressor and vacuum pump are integrated with the cycle, and rotate at "N" times the cycle frequency. Alternative adsorber configurations for high frequency operation are disclosed.

Owner:AIR PROD & CHEM INC +1

Energy efficient gas separation for fuel cells

InactiveUS20020142208A1Improve efficiencyReduce the ratioFuel cell heat exchangeFused electrolyte fuel cellsEngineeringDelivery system

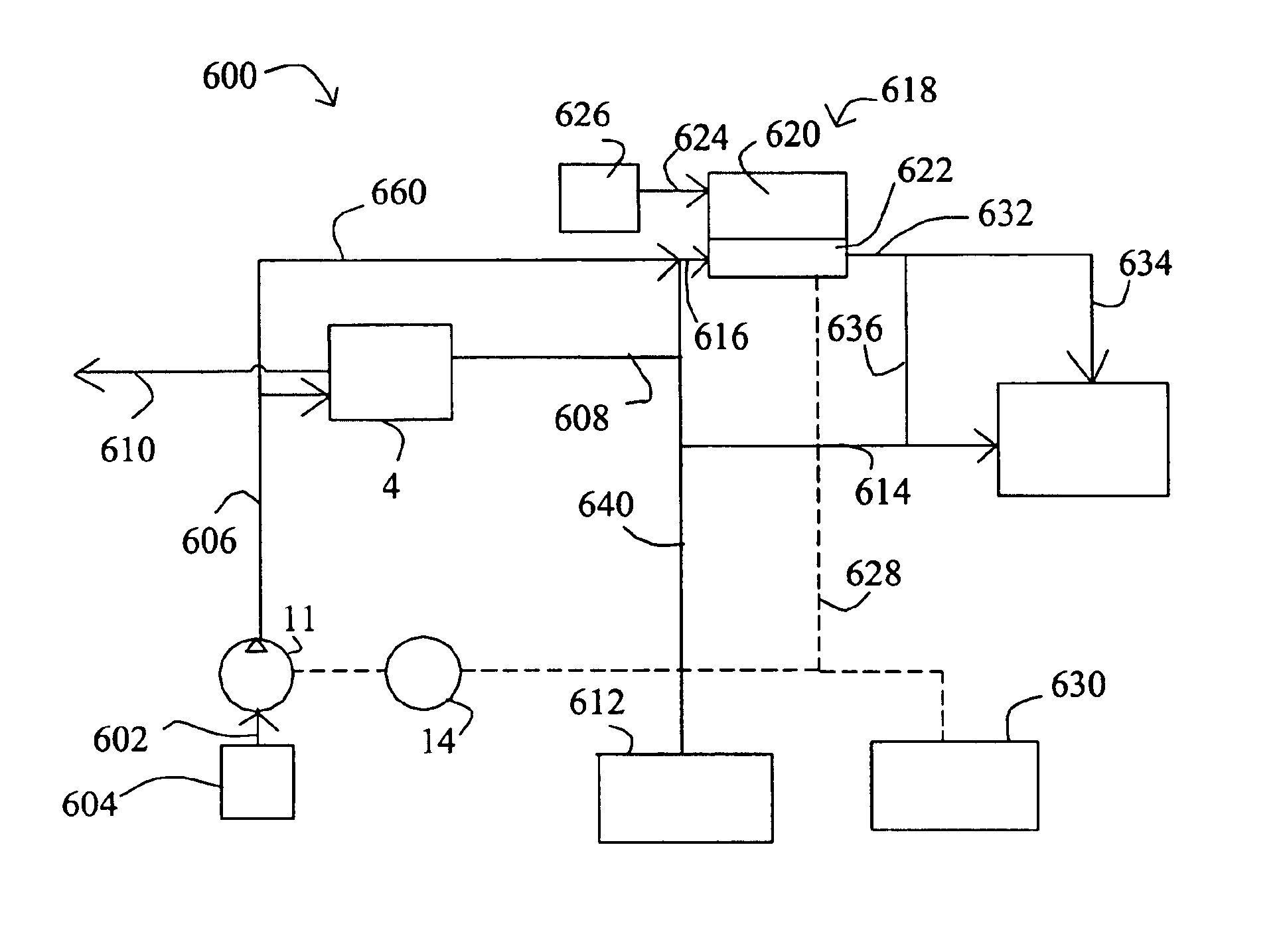

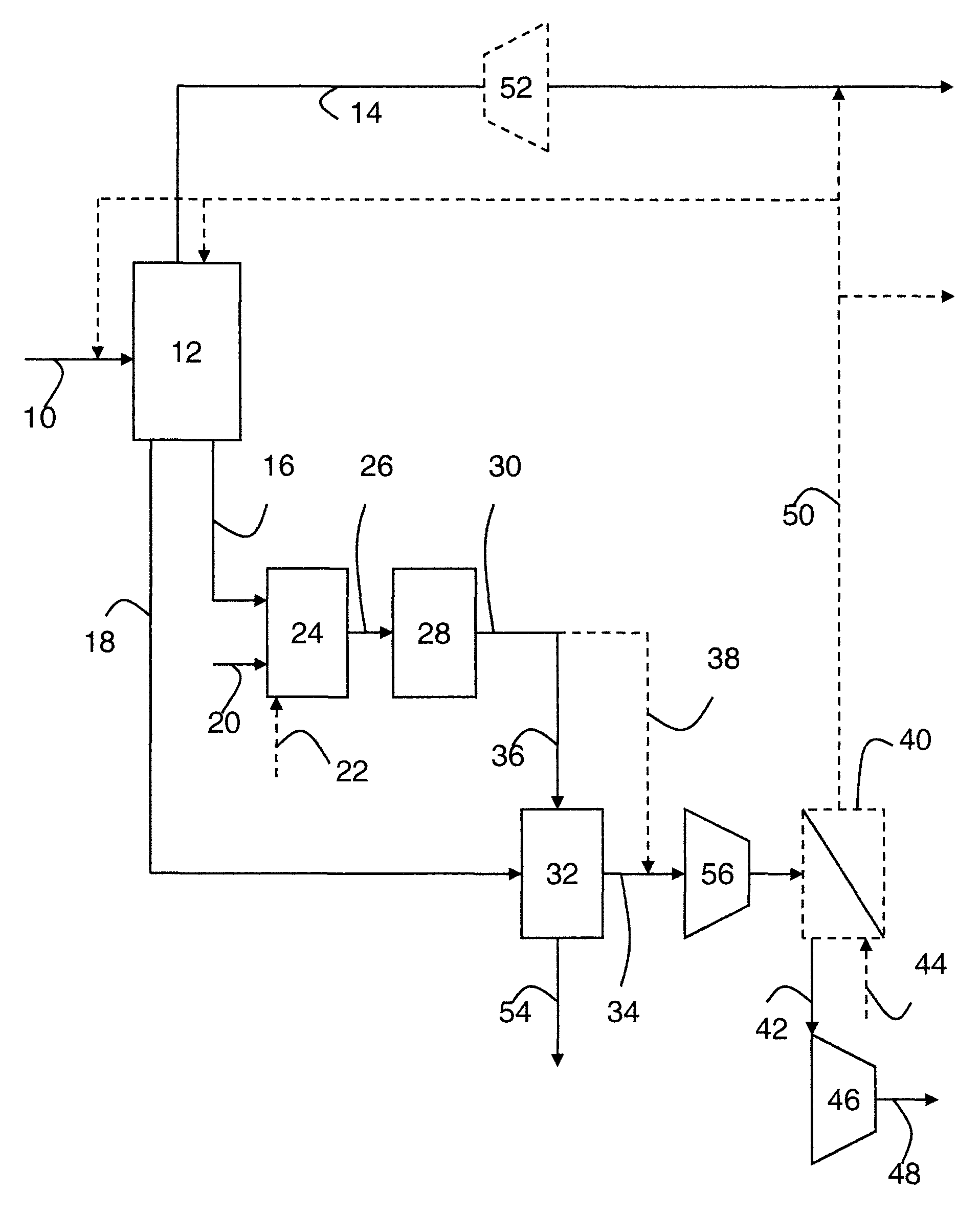

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

Carbon Dioxide Recovery

Disclosed herein is a method and system for separating carbon dioxide (CO2) from a CO2 containing gas stream containing water vapor and additional impurities, for example, nitrogen, oxygen, sulfur oxides, nitrogen oxides, and mercury. The CO2 is captured by subjecting the CO2 gas feed stream to a temperature swing adsorption step. The temperature swing adsorption step comprises an adsorption step for producing a substantially dry carbon dioxide-depleted stream, and an adsorbent regeneration step comprising heating the adsorbent bed to produce a substantially water vapor-free carbon dioxide stream. Moisture from the gas stream containing CO2 is optionally removed by pressure swing adsorption, temperature swing adsorption, membrane separation, or absorption prior to CO2 capture.

Owner:INNOSEPRA LLC

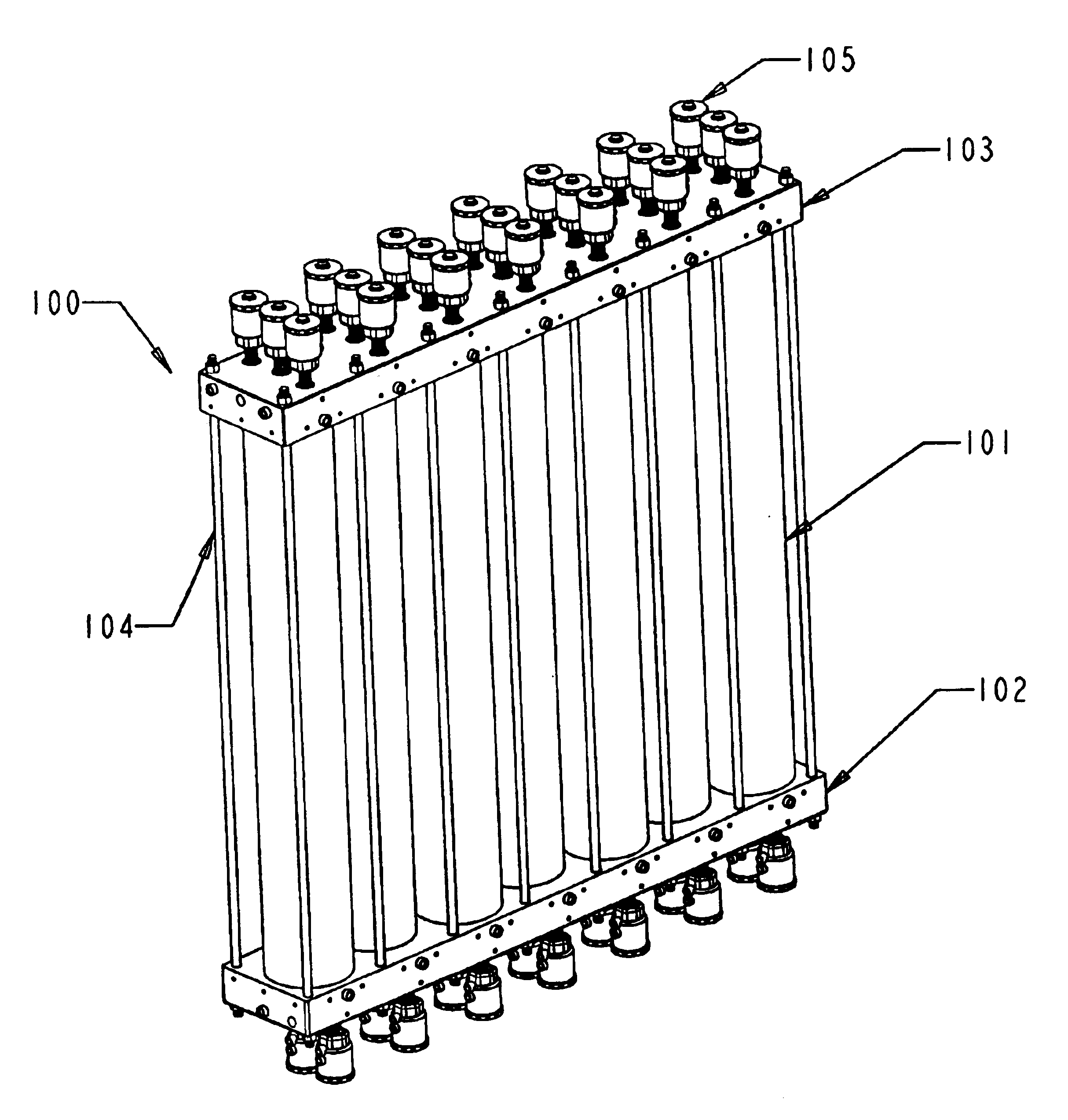

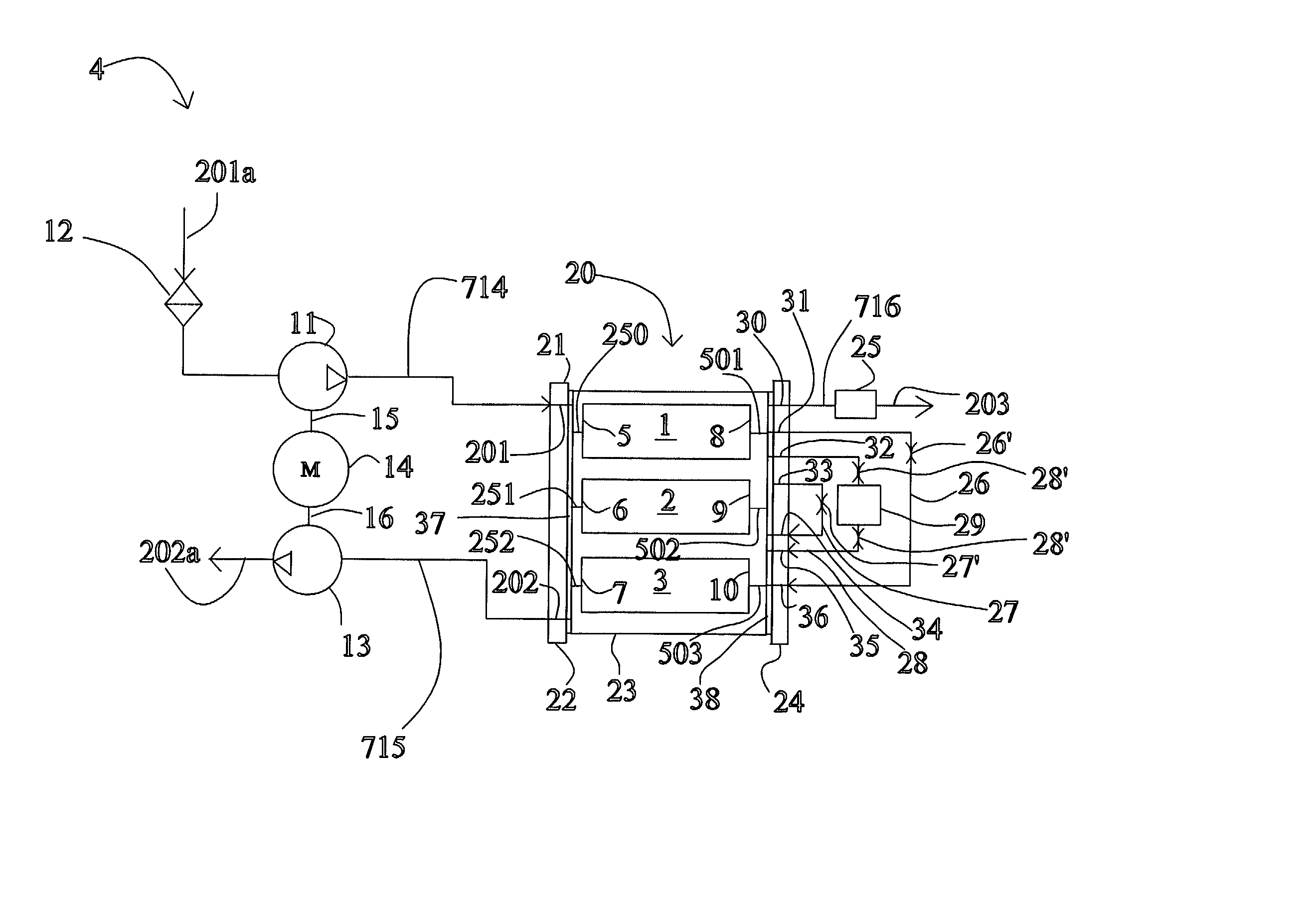

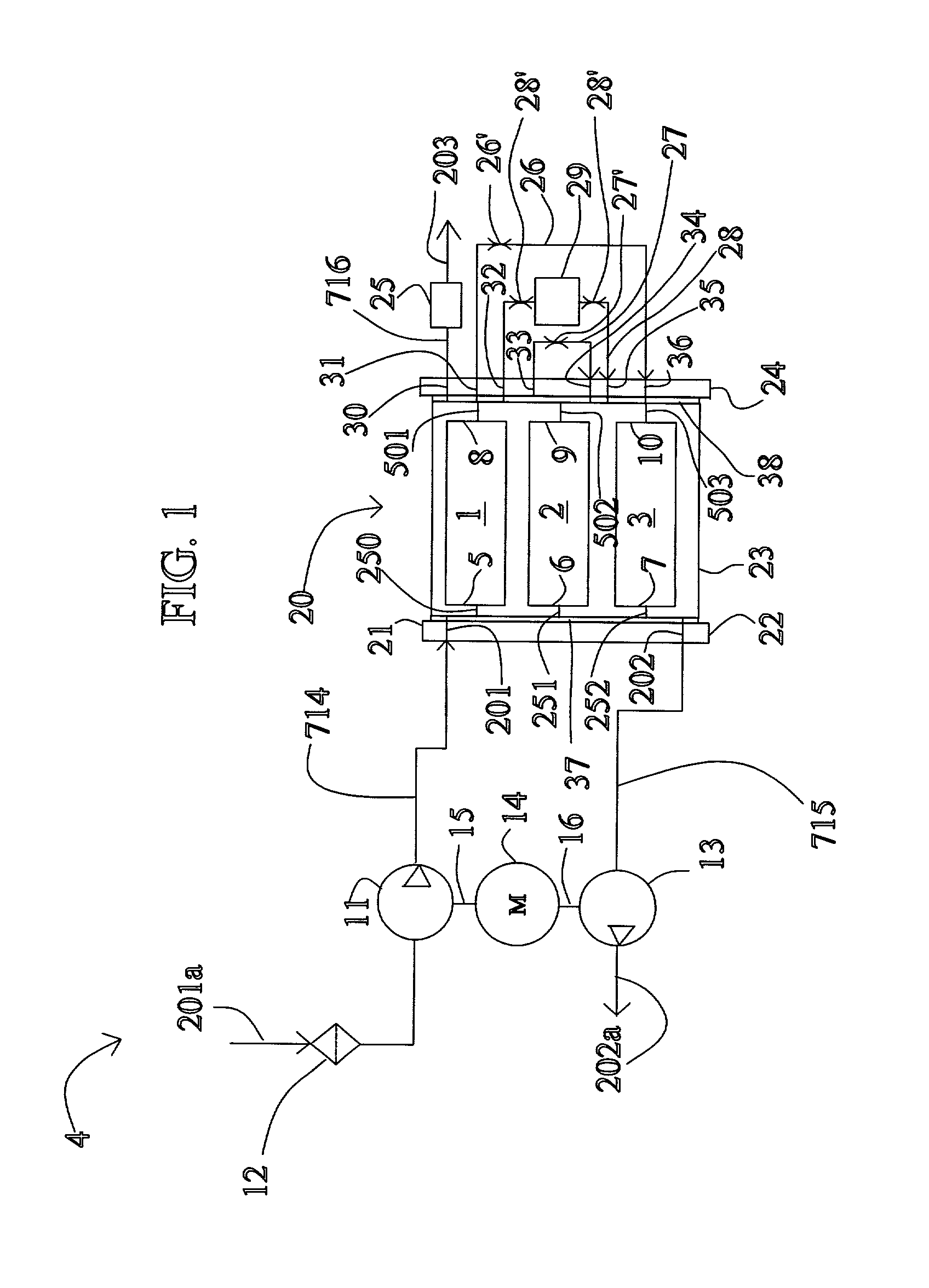

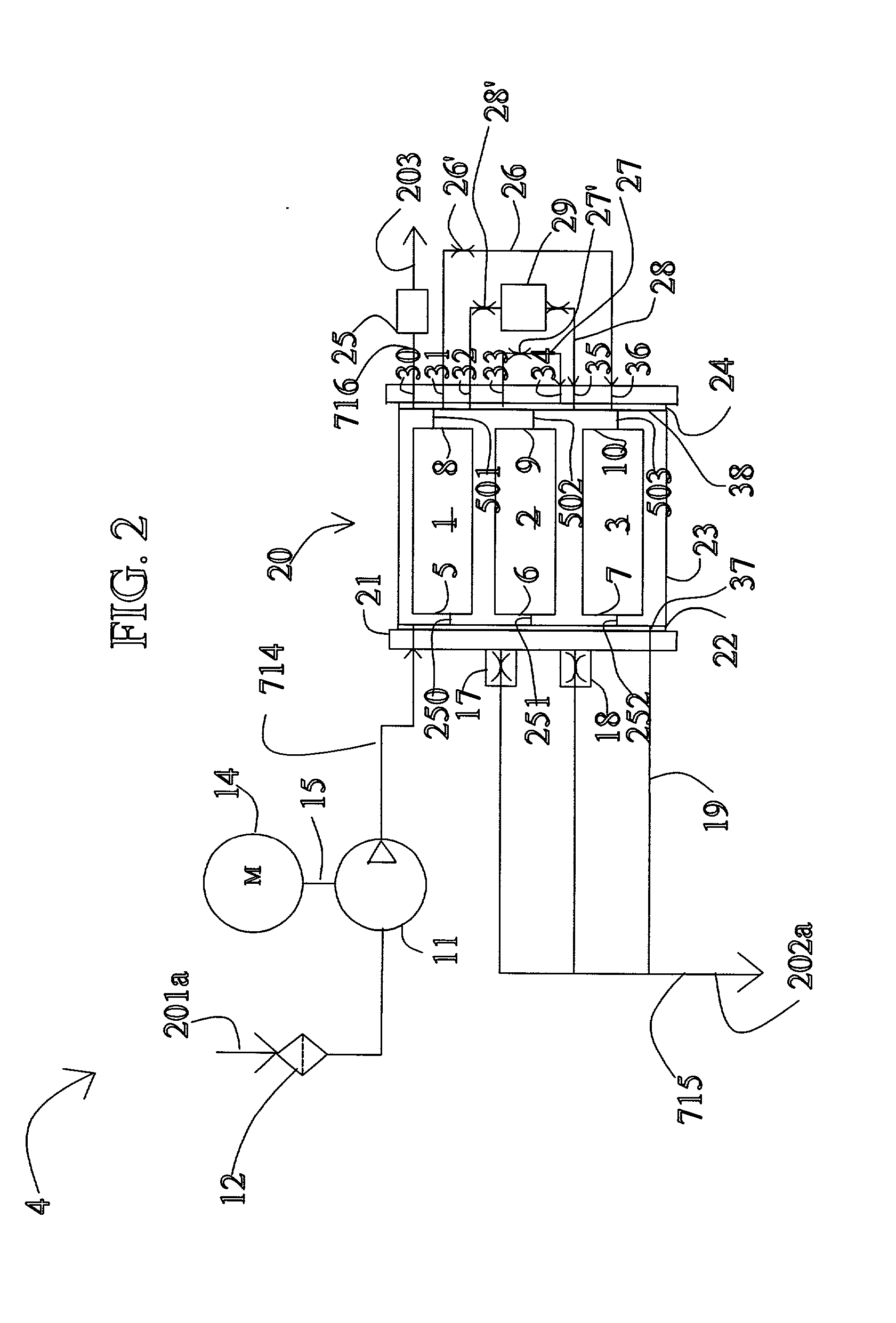

Modular pressure swing adsorption apparatus

InactiveUS7094275B2Improve energy efficiencyGas treatmentIsotope separationEngineeringPressure level

Owner:AIR PROD & CHEM INC

Methods and apparatuses for gas separation by pressure swing adsorption with partial gas product feed to fuel cell power source

Various systems, method and apparatuses are disclosed that include a pressure swing adsorption apparatus coupled to a fuel cell, wherein the fuel cell receives at least a portion of a product gas from the pressure swing adsorption and powers the pressure swing adsorption apparatus. Also disclosed is a portable gas separator that include a housing that houses a rotary pressure swing adsorption apparatus.

Owner:AIR PROD & CHEM INC

Separation of a sour syngas stream

A feed stream, comprising hydrogen sulphide (H2S), carbon dioxide (CO2), hydrogen (H2) and, optionally, carbon monoxide (CO), is separated into at least a CO2 product stream and an H2 or H2 and CO product stream. The stream is separated using a pressure swing adsorption system, an H2S removal system and a further separation system, which systems are used in series to separate the stream. The method has particular application in the separation of a sour (i.e. sulphur containing) syngas, as for example produced from the gasification of solid or heavy liquid carbonaceous feedstock.

Owner:AIR PROD & CHEM INC

Method and apparatus for treating a sour gas

Owner:AIR PROD & CHEM INC

Adsorbents for rapid cycle pressure swing adsorption processes

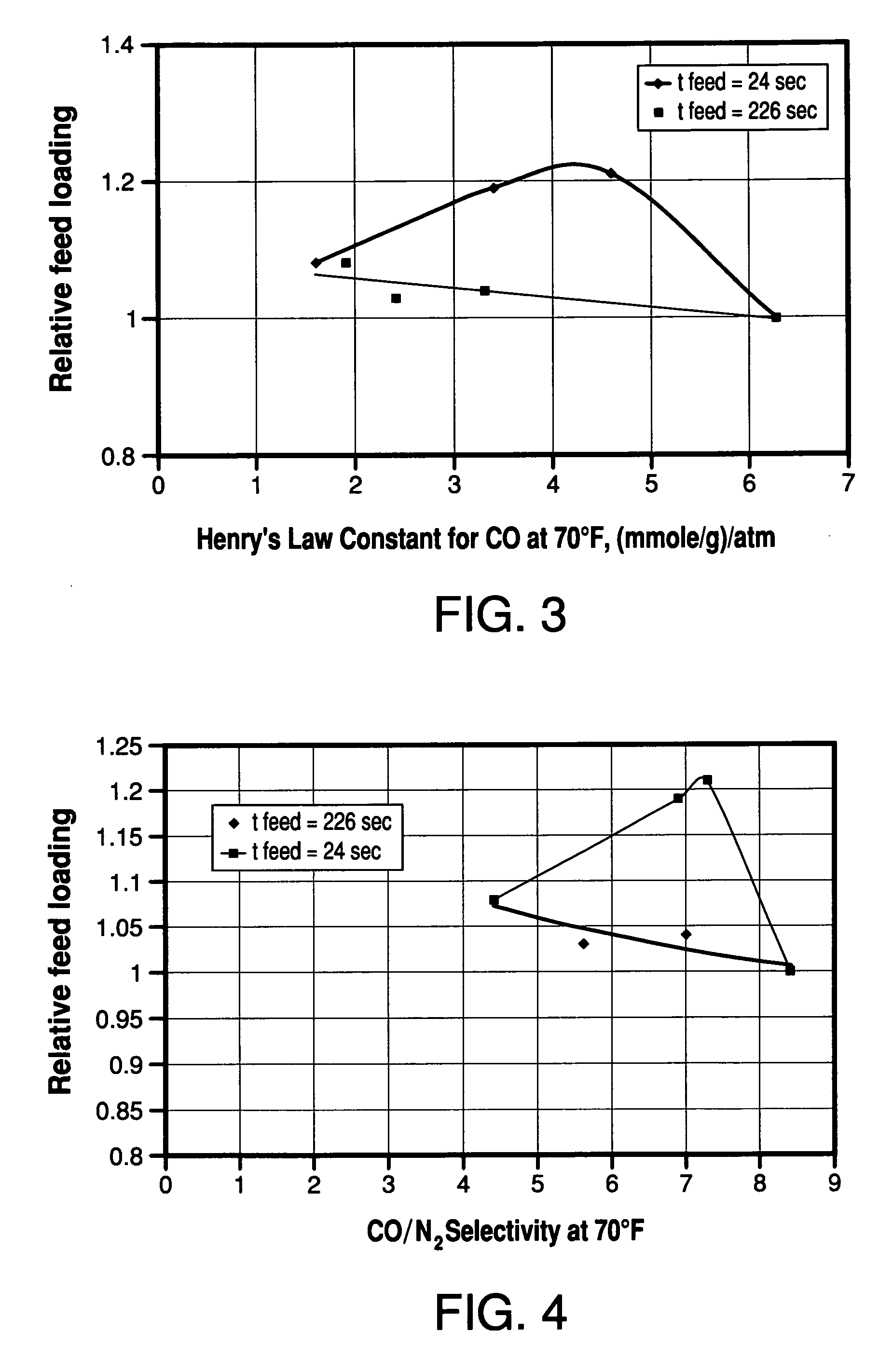

Method for the separation of a gas mixture comprising providing a PSA system with at least one adsorber vessel containing adsorbent material that is selective for the adsorption of carbon monoxide and nitrogen, passing a feed gas mixture containing at least hydrogen and carbon monoxide and optionally containing nitrogen through the adsorbent material in a feed step and withdrawing a purified hydrogen product from the adsorber vessel, wherein the feed step has a duration or feed time period of about 30 seconds or less. The adsorbent material is characterized by any of (1) a Henry's law constant for carbon monoxide between about 2.5 and about 5.5 (mmole / g) / atm; (2) a carbon monoxide heat of adsorption between about 6.0 and about 7.5 kcal / gmole; (3) a Henry's law constant for nitrogen greater than about 1.5 (mmole / g) / atm; and (4) a selectivity of carbon monoxide to nitrogen between about 5.0 and about 8.0.

Owner:AIR PROD & CHEM INC

Systems and processes for providing hydrogen to fuel cells

InactiveUS20020098394A1Minimized in sizeMaximize energy efficiencyFuel cell auxillariesHydrogen/synthetic gas productionFuel cellsInternal combustion engine

A process and system for providing a hydrogen-containing gas stream to a fuel cell anode that includes providing a hydrogen-containing gas stream that includes carbon monoxide, introducing the hydrogen-containing gas stream into a pressure swing adsorption module that includes at least one carbon monoxide-selective adsorbent to produce a purified hydrogen-containing gas stream, and introducing the purified hydrogen-containing gas stream to the fuel cell anode. The pressure swing adsorption module can also include a second adsorbent and / or catalyst. Also disclosed is a fuel cell system coupled to an internal combustion engine and a fuel cell system that utilizes fuel cell waste heat for vaporizing a hydrocarbon / water mixture.

Owner:AIR PROD & CHEM INC

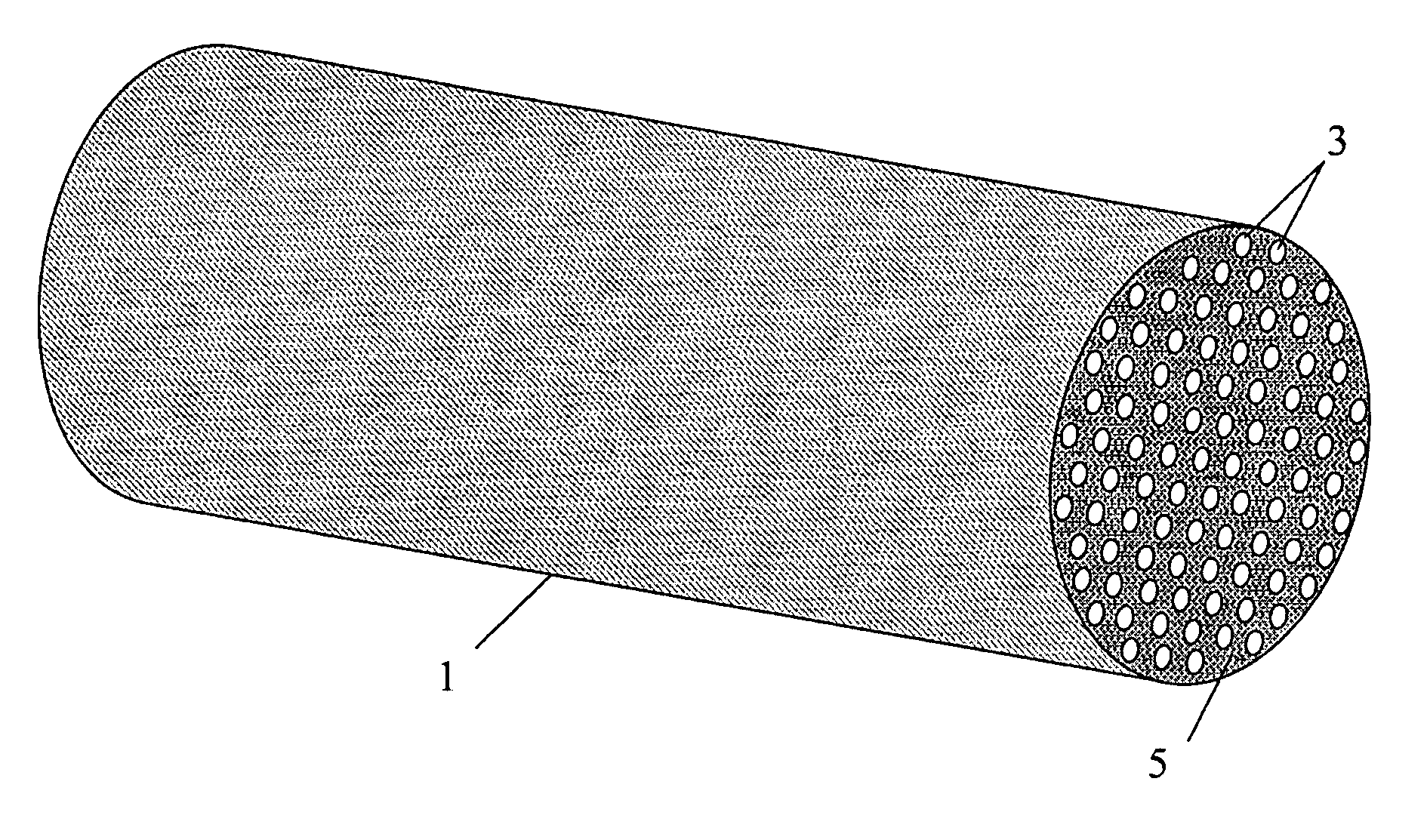

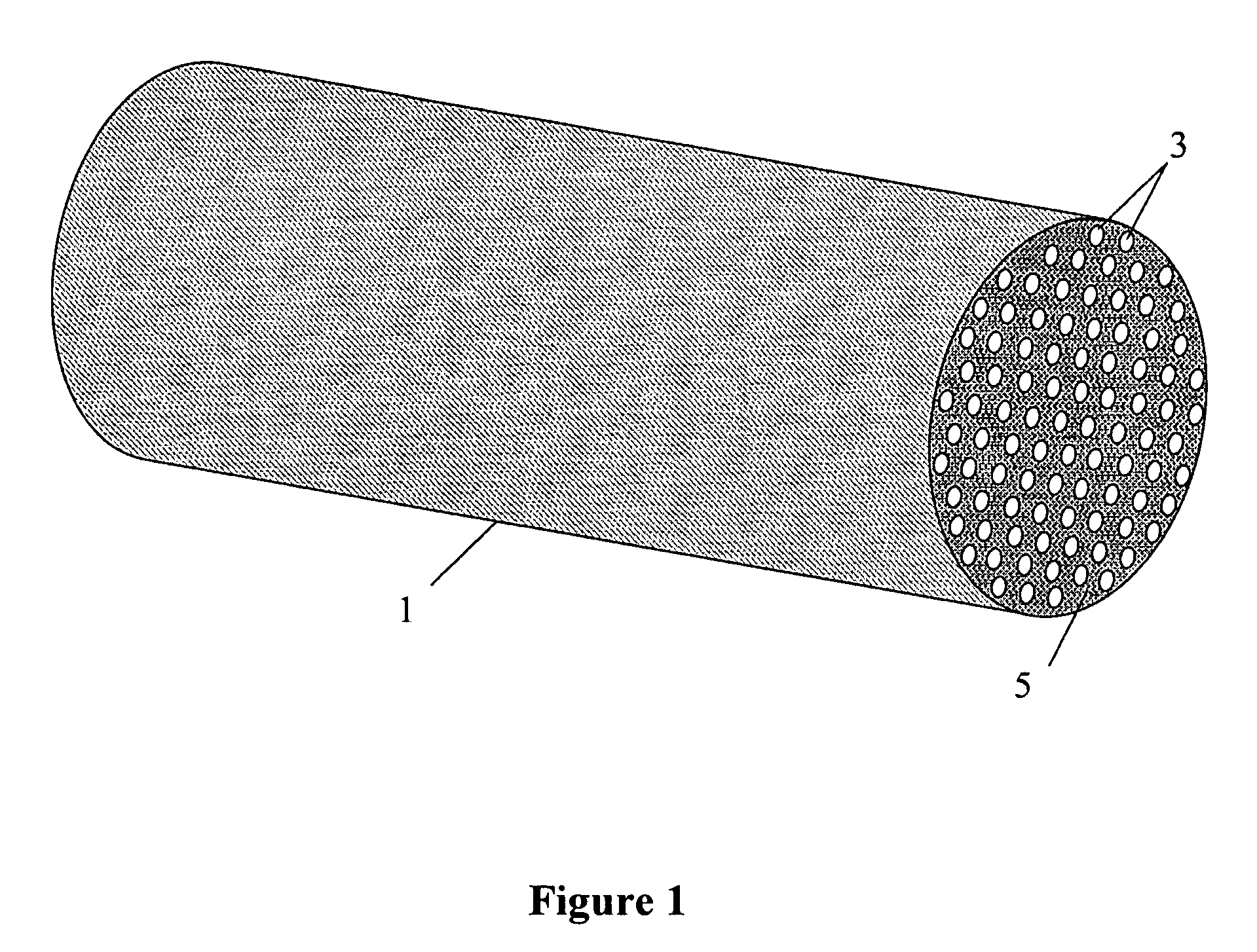

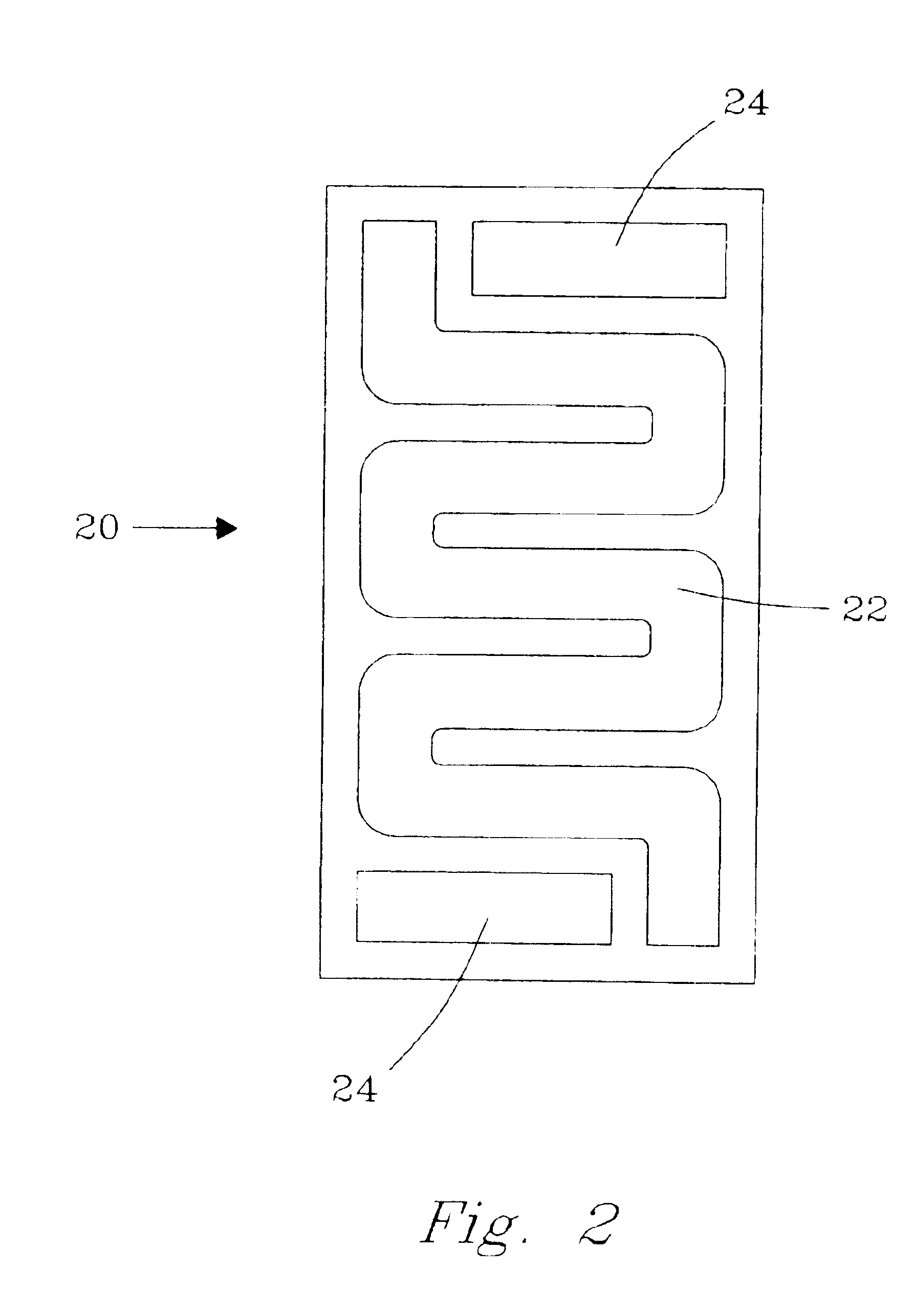

Adsorbent sheet material for parallel passage contactors

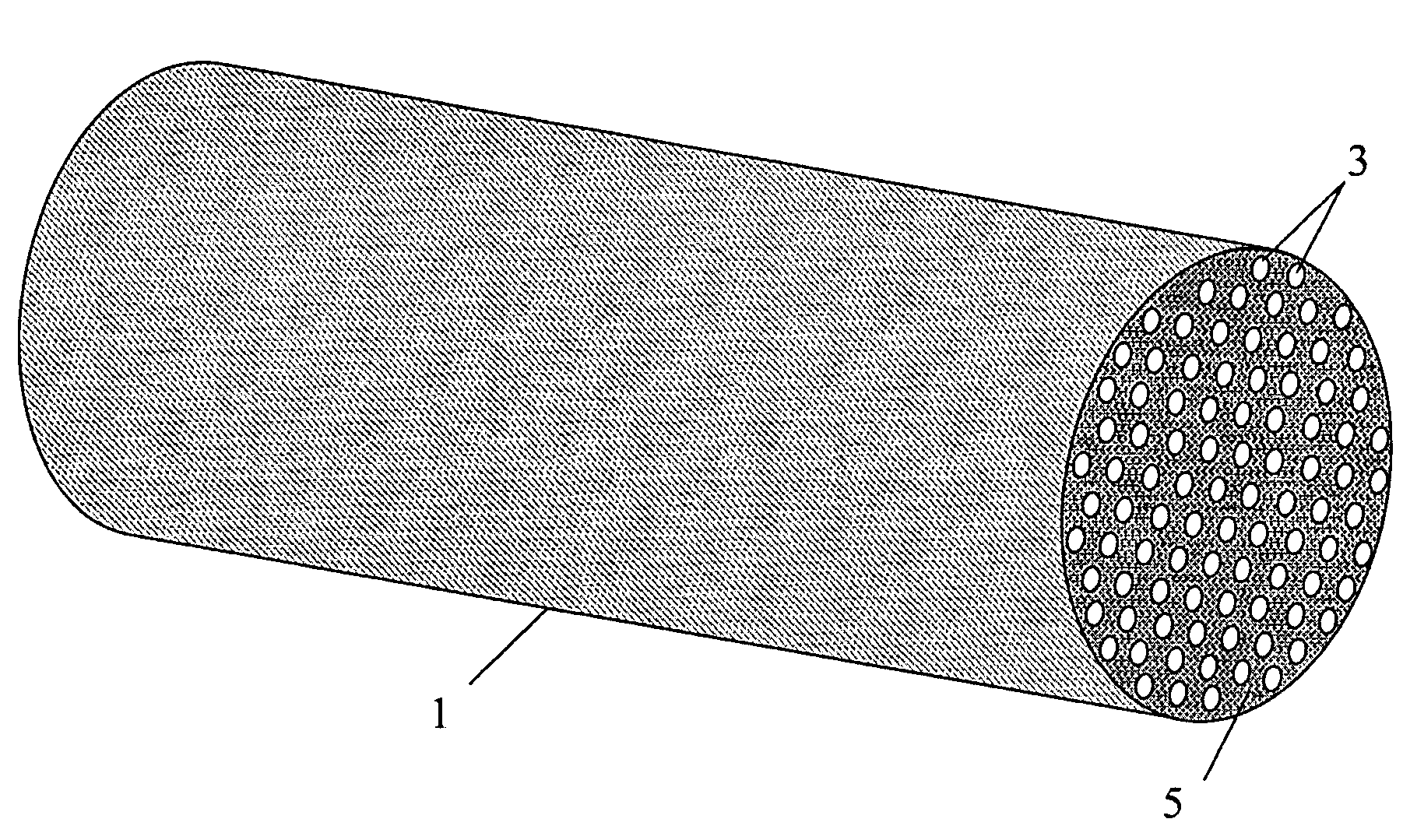

ActiveUS7077891B2Maximize capacityImprove efficiencyMaterial nanotechnologyOther chemical processesParticulatesSorbent

An adsorbent material fabricated into a reinforcement-free, self-supported coherent thin sheet and configured for use as a parallel passage contactor element in adsorption / separation applications with gases and liquids is disclosed. The adsorbent sheet material is obtained by enmeshing fine adsorbent particulates in a polymer binder. Particulates include but are not limited to carbon particles, inorganic oxides particles, or ceramic particles, or synthetic polymer resin particles. The adsorbent sheet advantageously contains a large volume percentage of active adsorbent particles. The parallel passage contactor device fabricated from the adsorbent sheet material is characterized by minimal mass transfer resistance and better separation efficiency expressed as height equivalent to a theoretical plate, while it maintains most of the adsorptive properties of the starting particulates, and can be used in gas separation applications with short adsorption cycles, such as rapid pressure swing adsorption, rotary concentrators, rapid electric swing adsorption.

Owner:AIR PROD & CHEM INC

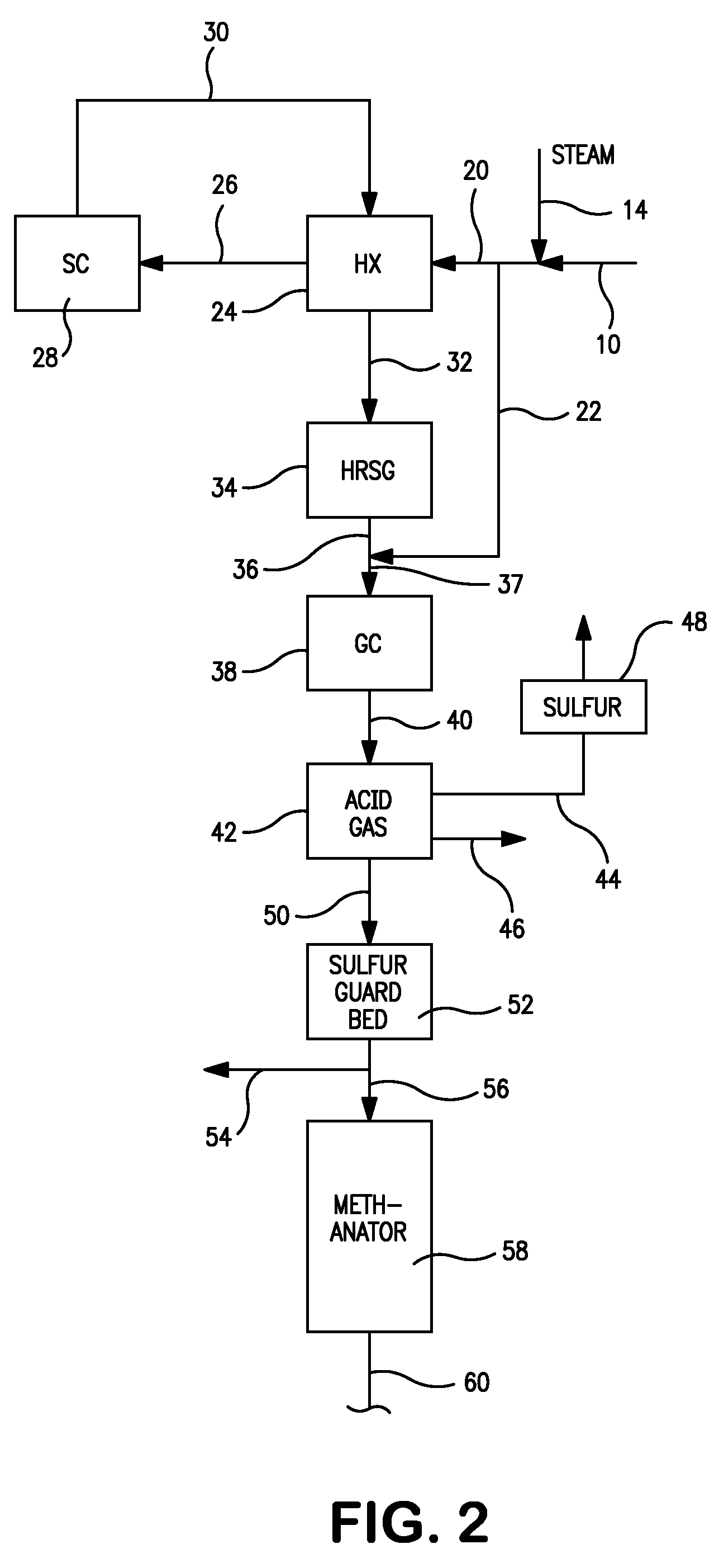

Hydrogen production method

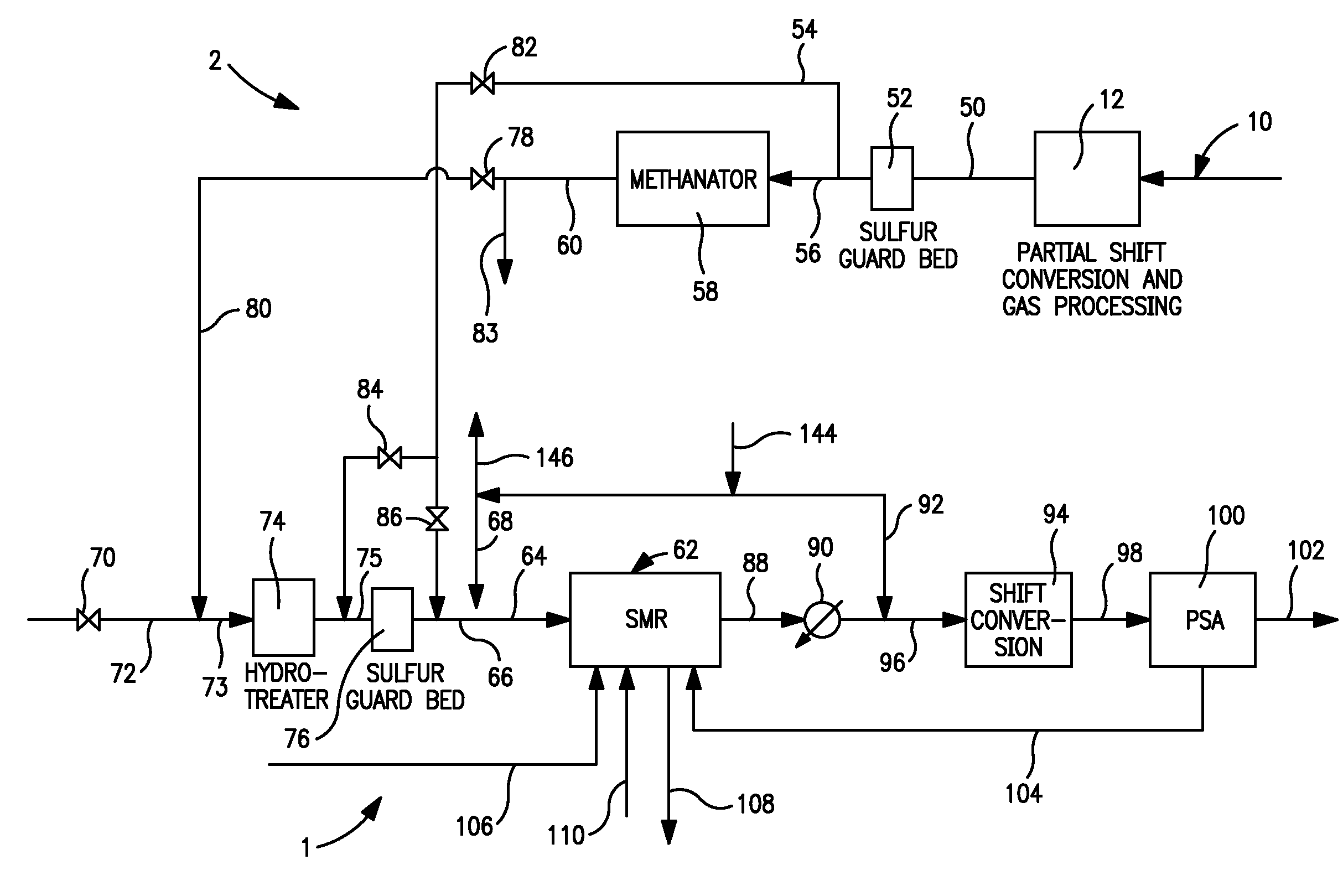

ActiveUS7931888B2Maximize productionSteam flow rate essentially constantHydrogenCombustible gas catalytic treatmentMethane reformerMethane

A method of producing a hydrogen product stream in which a steam stream is reacted with a hydrocarbon containing stream within a steam methane reformer. The resulting product stream is subjected to a water gas shift reaction and then to pressure swing adsorption to produce the hydrogen product stream. The hydrocarbon stream is alternatively formed from a first type of feed stream made up of natural gas, refinery off-gas, naphtha or synthetic natural gas or combinations thereof and a second type that is additionally made up of a hydrogen and carbon monoxide containing gas. During use of both of the types of feed streams, the flow rate of the steam stream is not substantially changed and reformer exit temperatures of both the reactant and the flue gas side are held essentially constant.

Owner:PRAXAIR TECH INC

Low mesopore adsorbent contactors for use in swing adsorption processes

Owner:EXXON RES & ENG CO

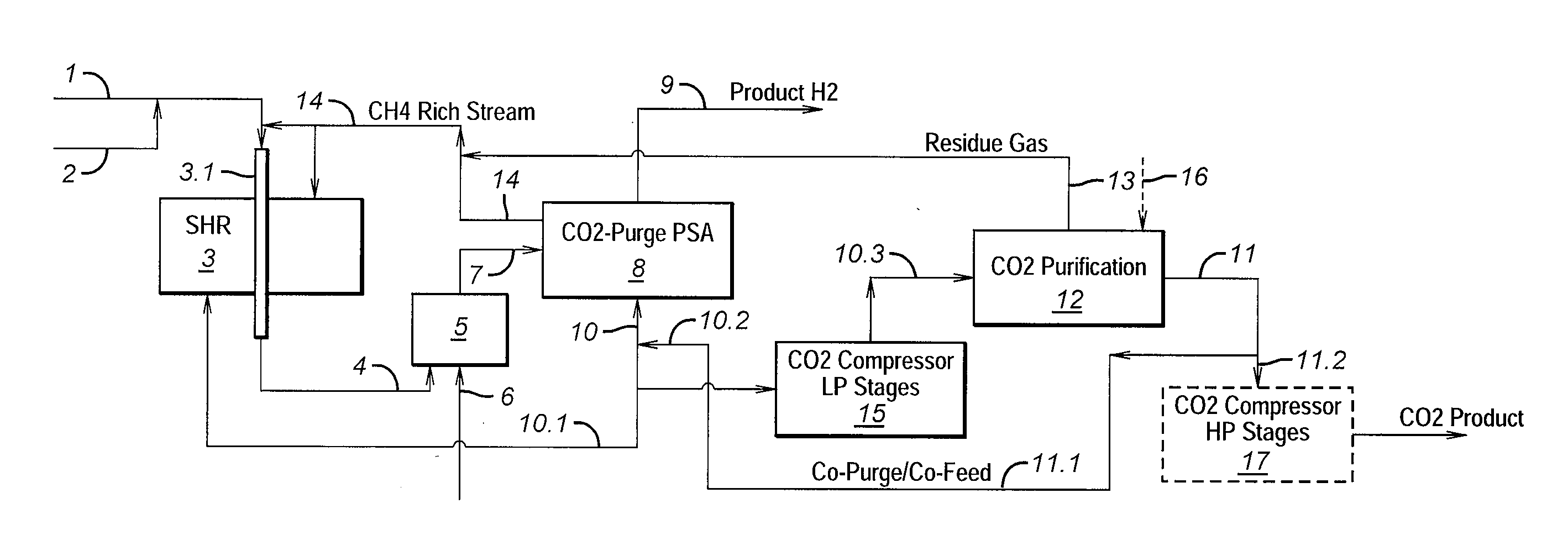

Carbon dioxide production method

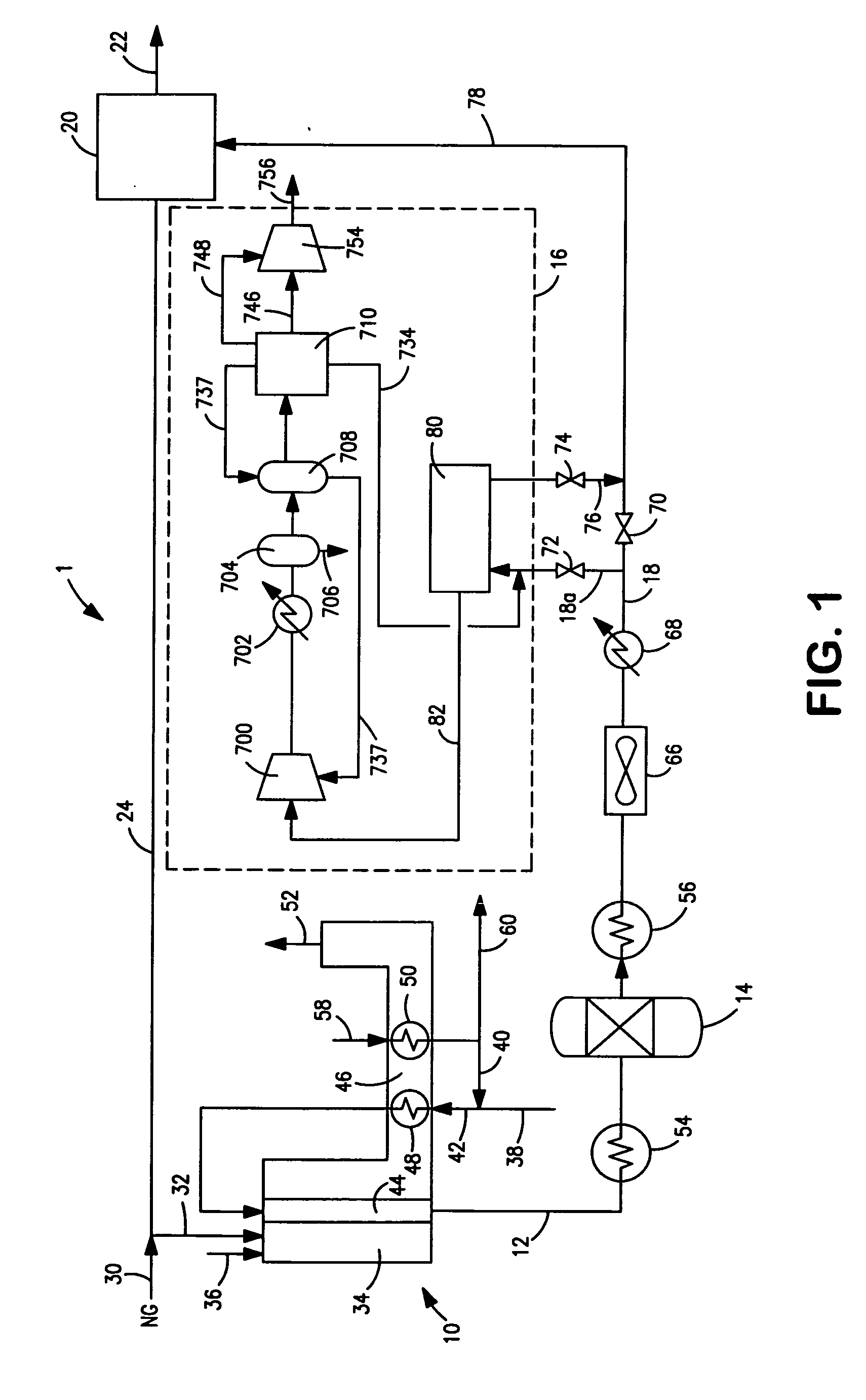

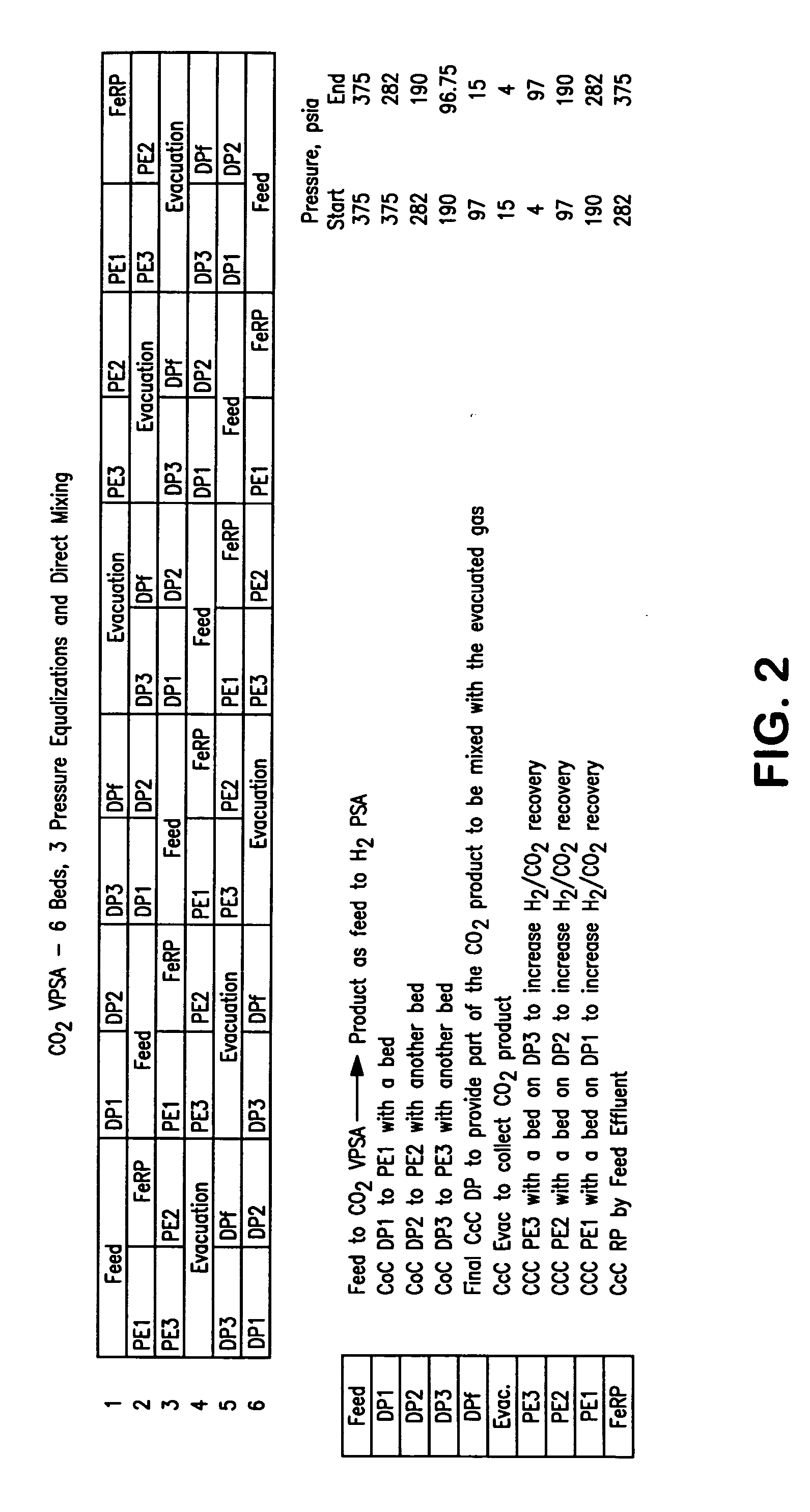

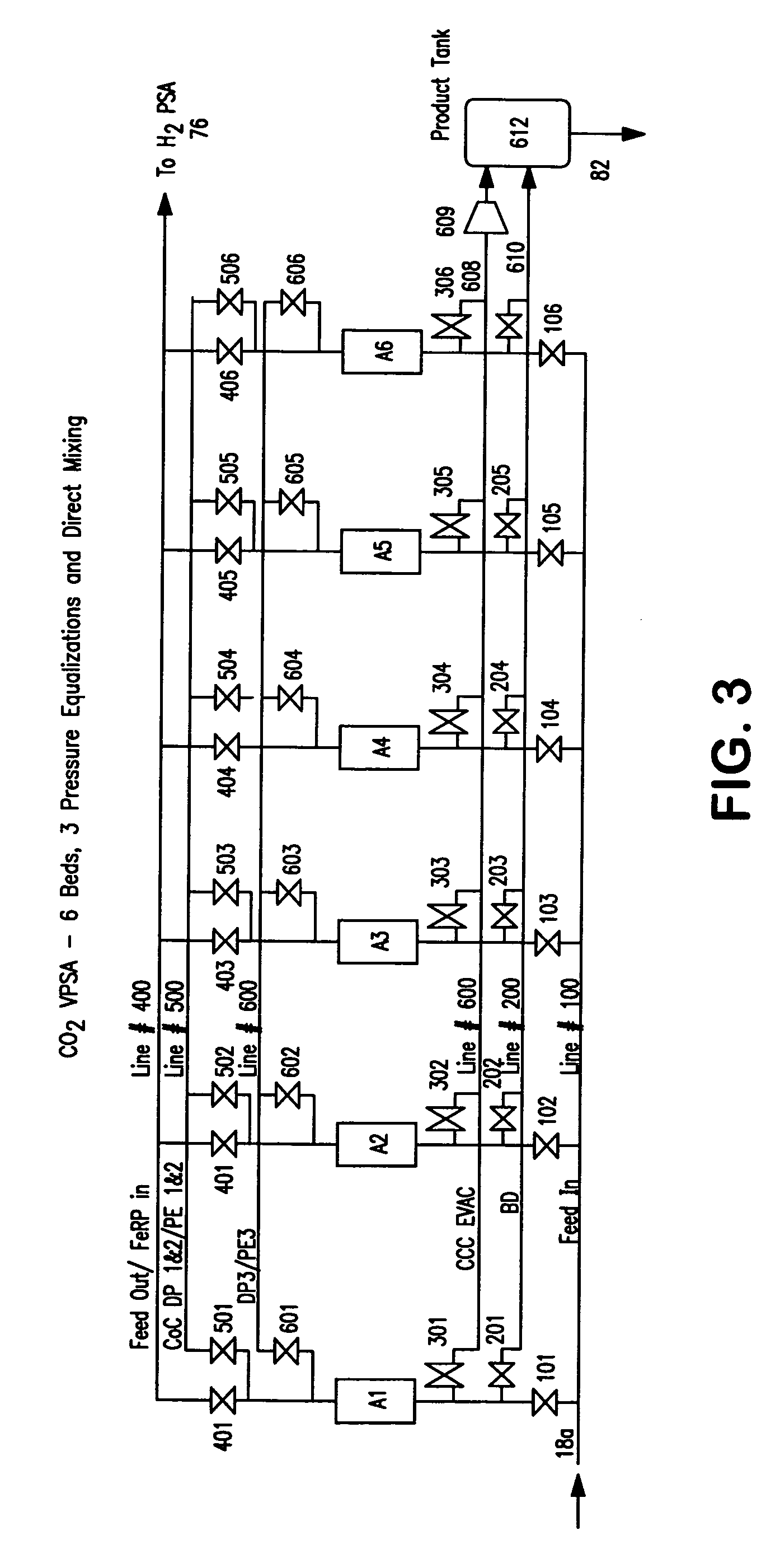

ActiveUS20070232706A1Increased hydrogen recoveryPromote recoverySolidificationLiquefactionVacuum pressureCarbon dioxide production

A method of producing a carbon dioxide product stream from a synthesis gas stream formed within a hydrogen plant having a synthesis gas reactor, a water-gas shift reactor, located downstream of the synthesis gas reactor to form the synthesis gas stream and a hydrogen pressure swing adsorption unit to produce a hydrogen product recovered from the synthesis gas stream. In accordance with the method the carbon dioxide from the synthesis gas stream by separating the carbon dioxide from the synthesis gas stream in a vacuum pressure swing adsorption system, thereby to produce a hydrogen-rich synthesis gas stream and a crude carbon dioxide stream and then purifying the crude carbon dioxide stream by a sub-ambient temperature distillation process thereby to produce the carbon dioxide product. A hydrogen synthesis gas feed stream to the hydrogen pressure swing adsorption unit is formed at least in part from the hydrogen rich stream.

Owner:PRAXAIR TECH INC

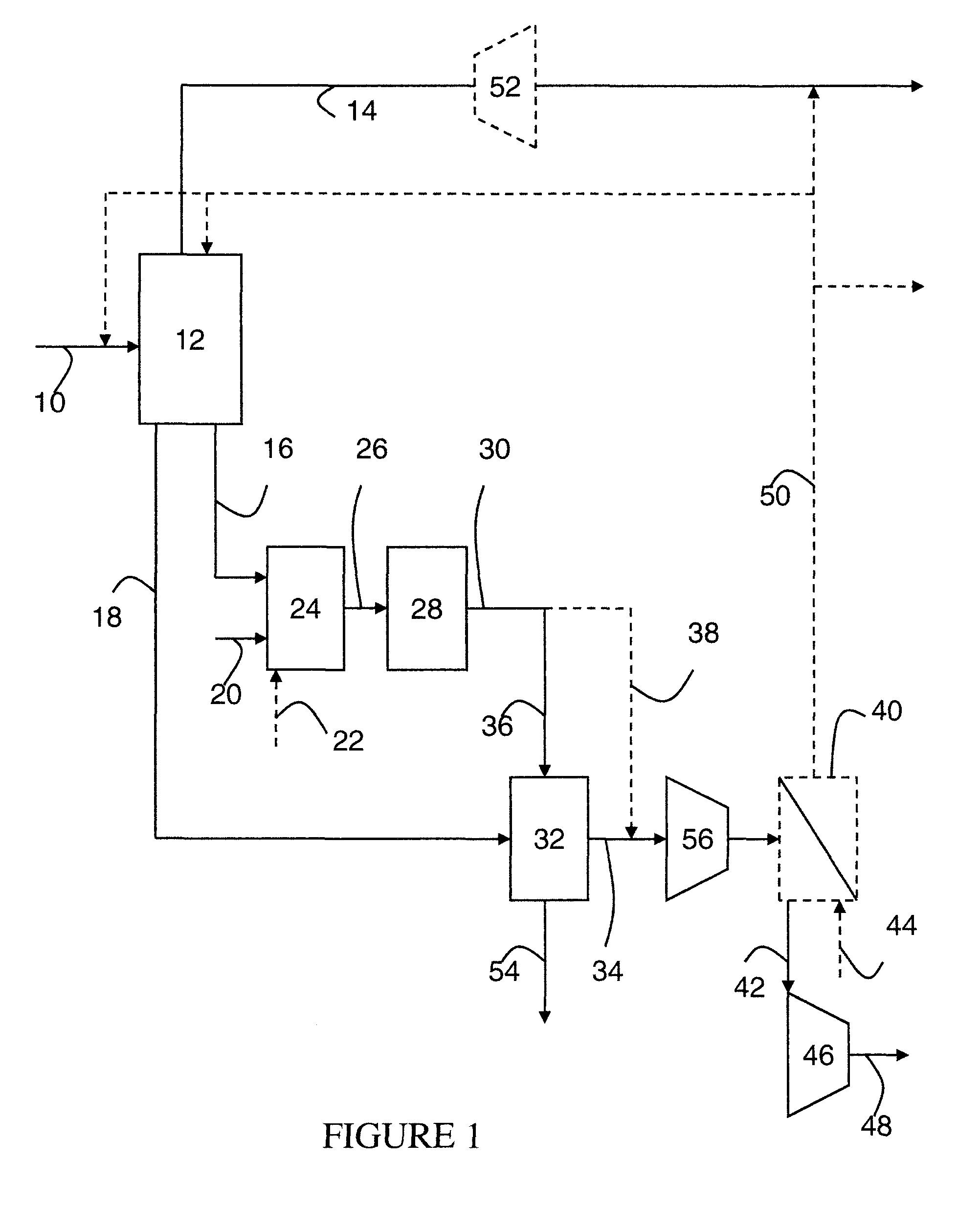

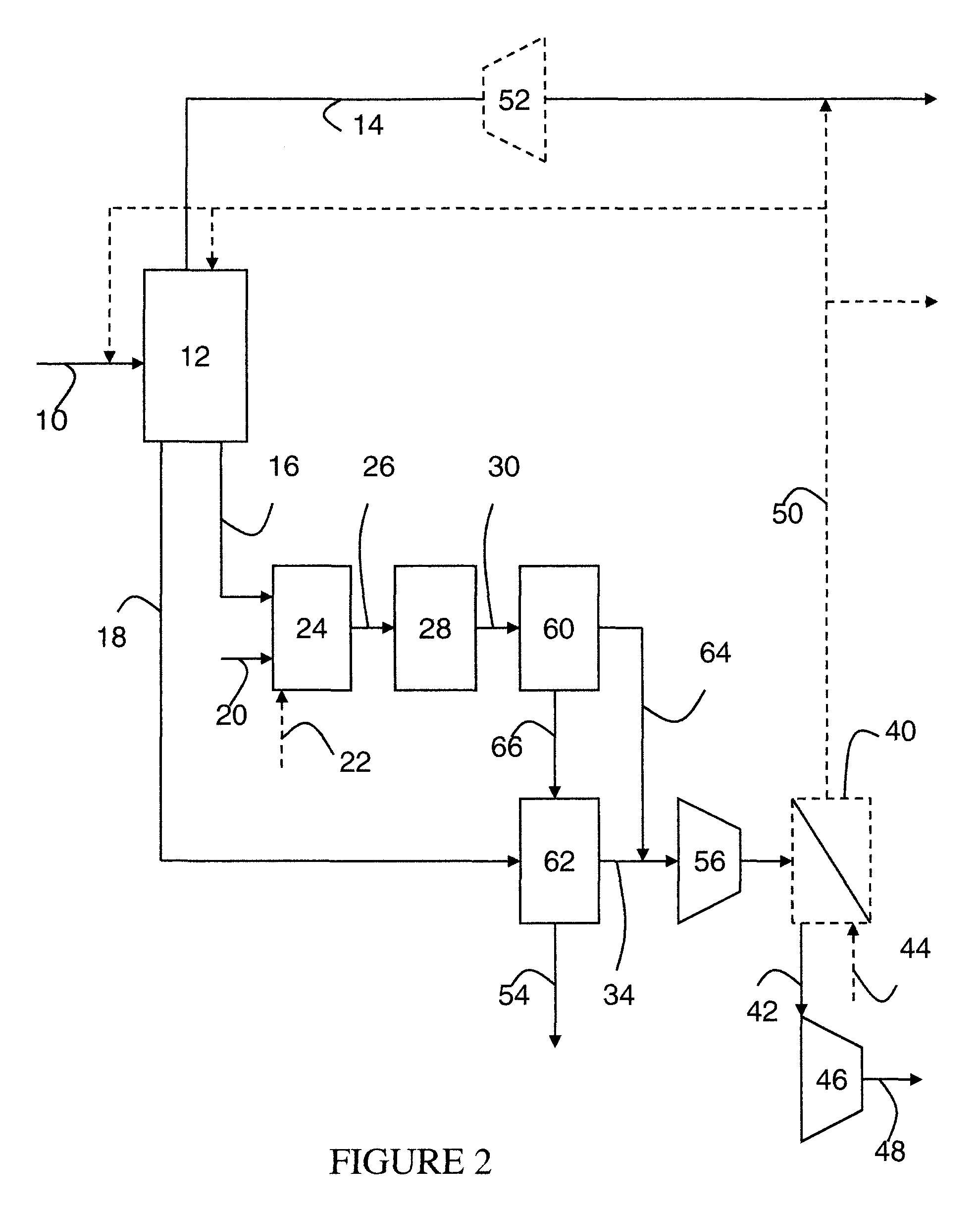

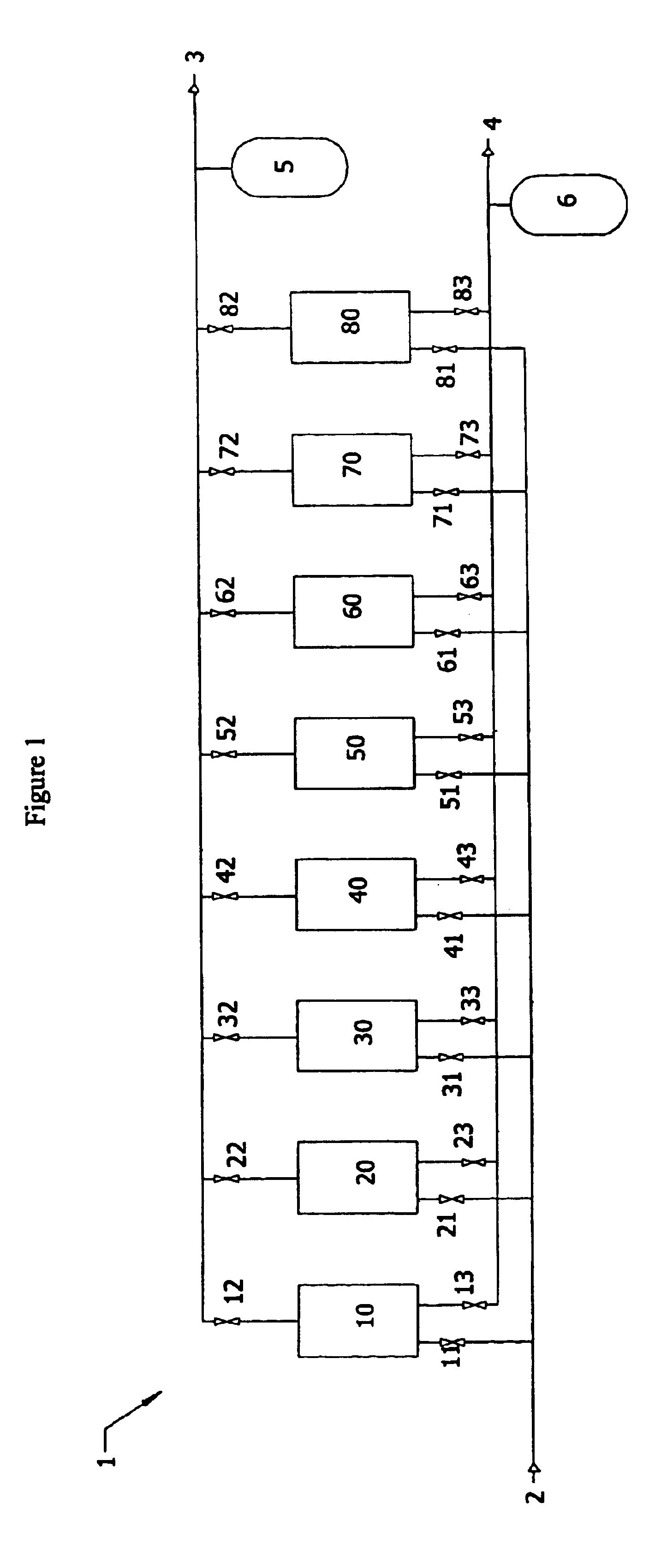

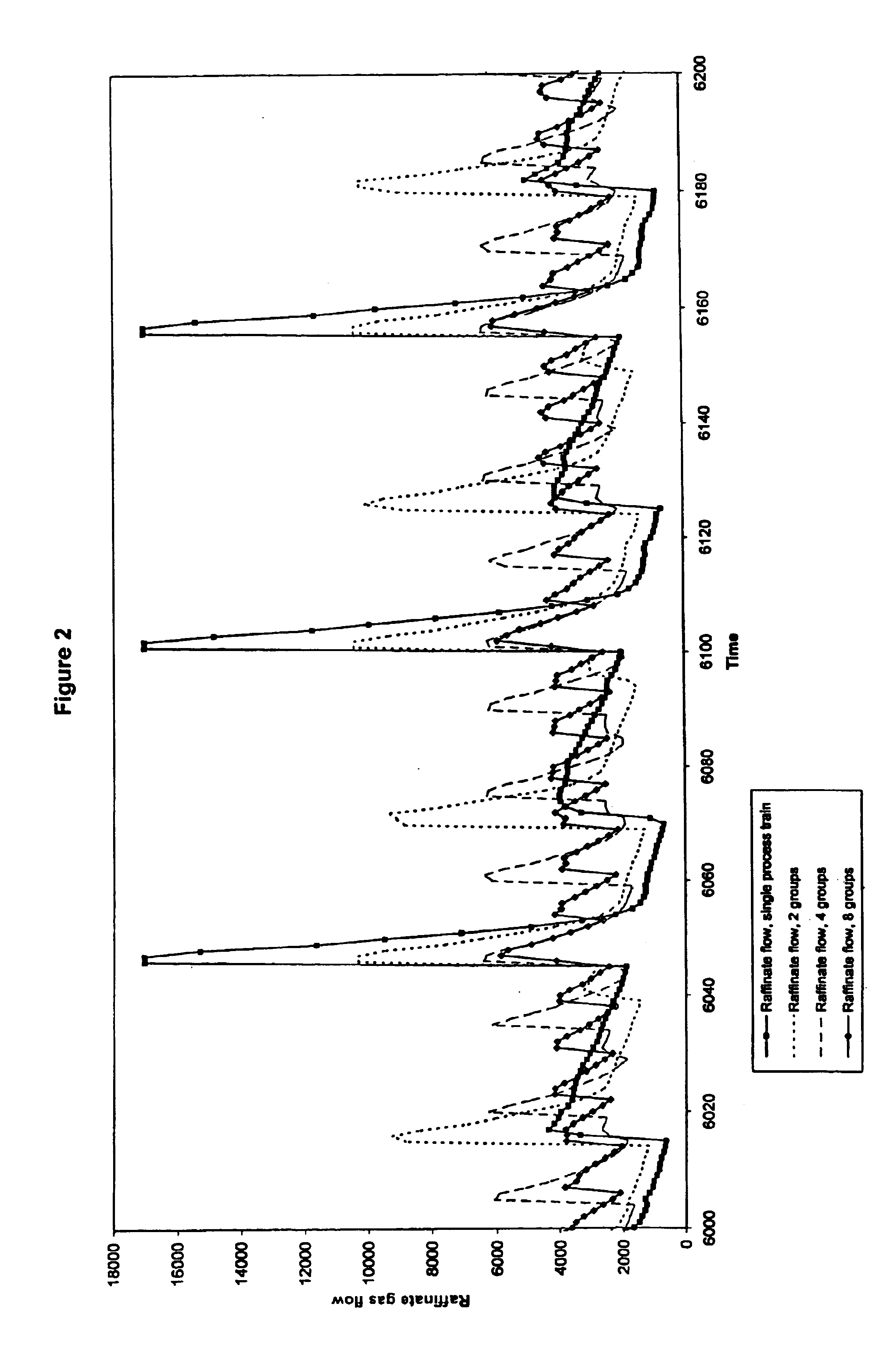

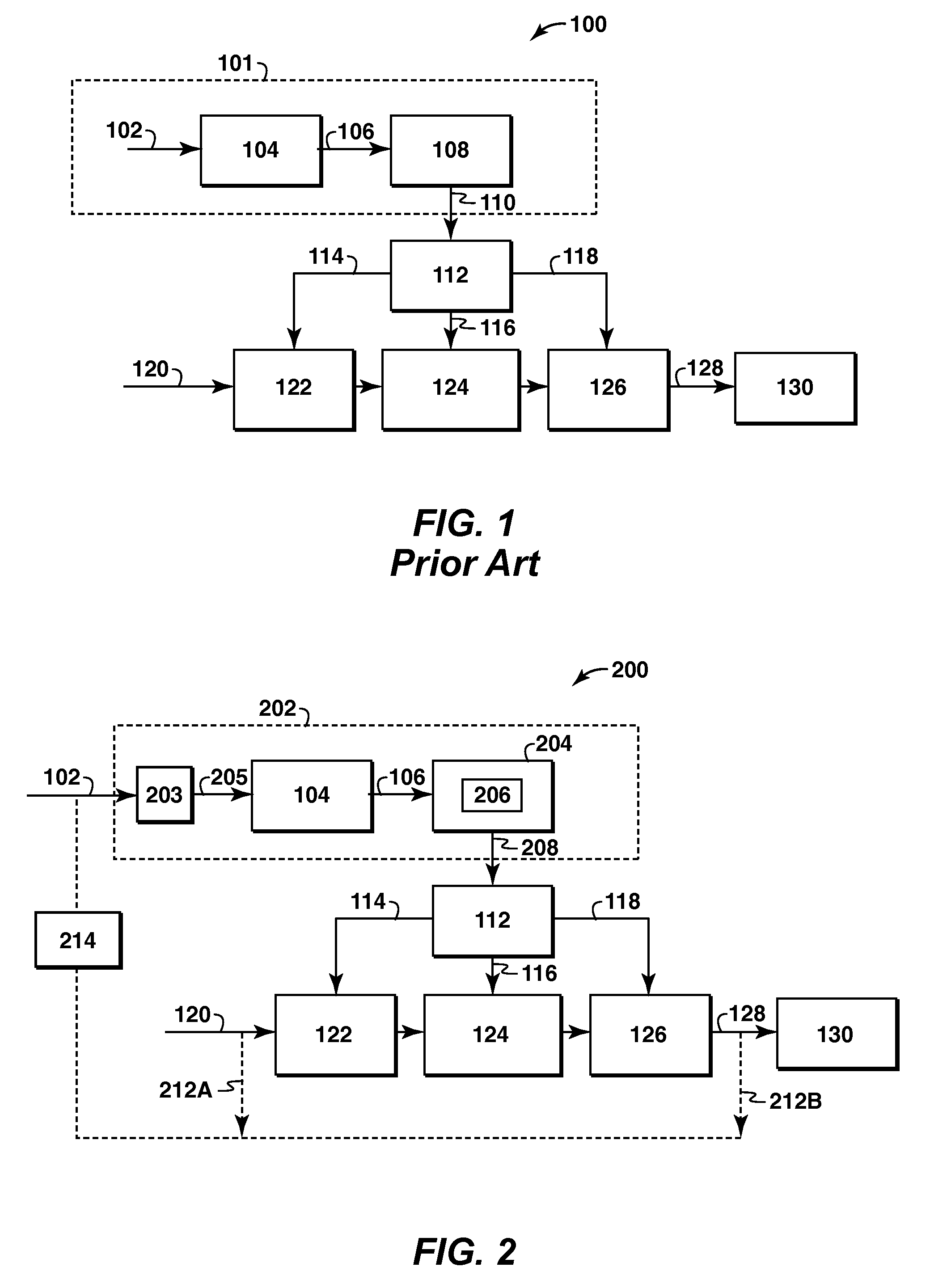

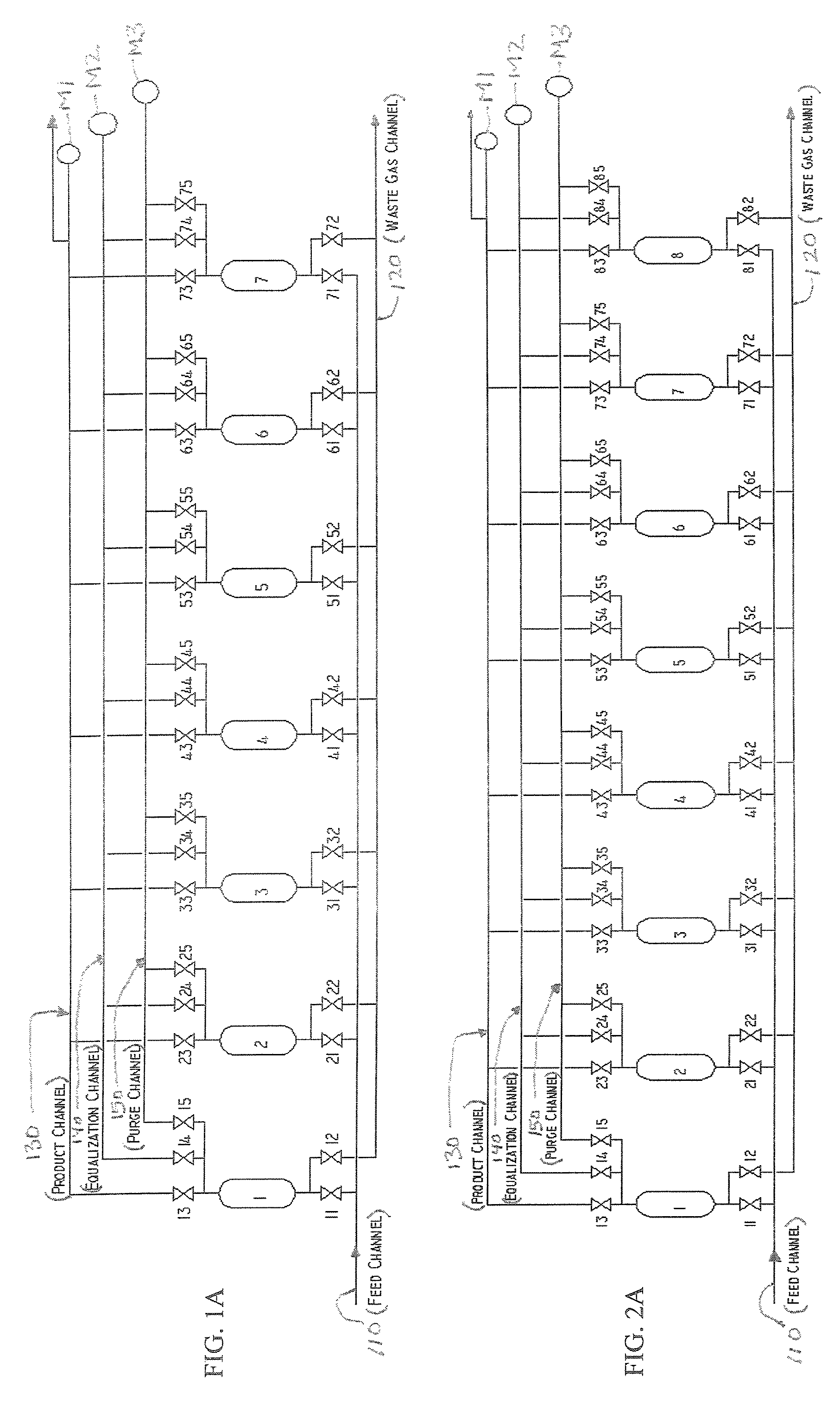

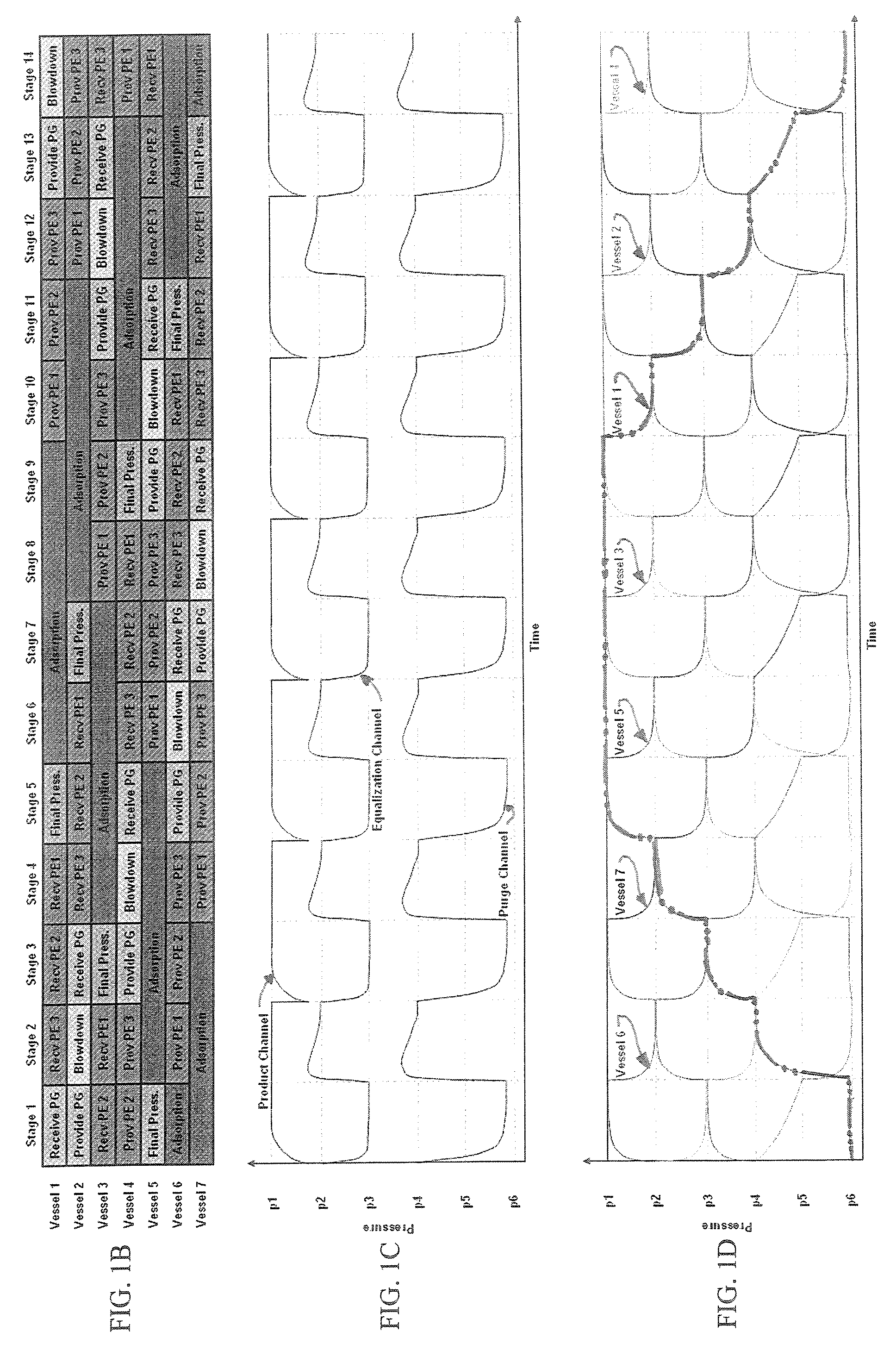

Modular pressure swing adsorption process and apparatus

InactiveUS6918953B2Reduce flowImprove reliabilityGas treatmentWaste based fuelProcess engineeringRigid structure

A pressure swing adsorption (PSA) system including a first group of PSA modules having a plurality of first PSA modules, and a second group of PSA modules having a plurality of second PSA modules. The system includes a feed gas manifold, a product manifold, and a waste manifold connected to the first PSA modules and the second PSA modules. Each first PSA module operates on a first PSA cycle in synchronization with the other first PSA modules, and each second PSA module operates on a second PSA cycle in synchronization with the other second PSA modules. The first PSA cycle is offset from the second PSA cycle. The PSA modules include a plurality of pressurized adsorbent chambers, an inlet manifold, and an outlet manifold. A rigid structure is provided that connects the inlet manifold to the outlet manifold, and structurally joins the inlet and outlet manifolds to the adsorbent chambers.

Owner:LUMMUS TECH INC

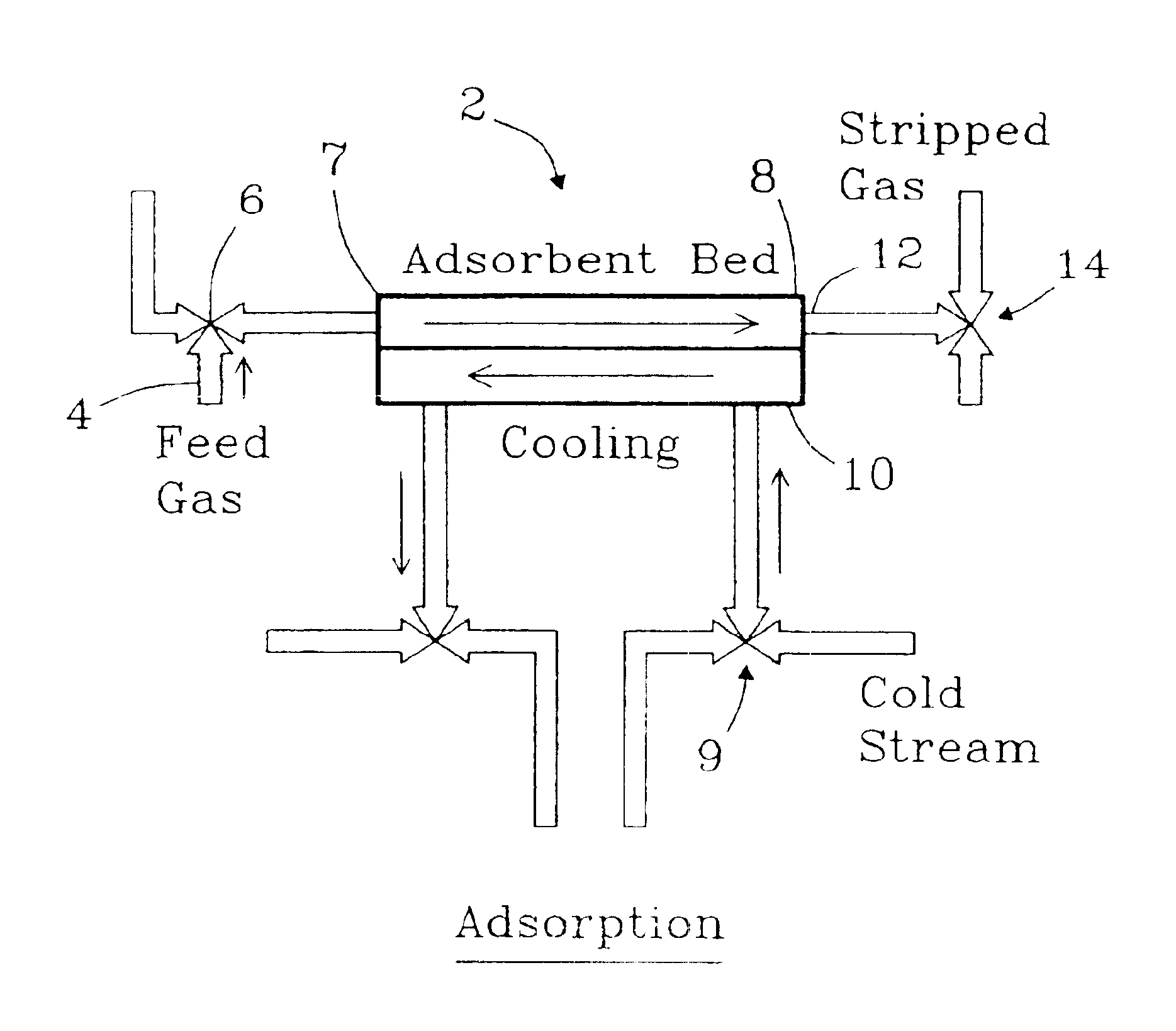

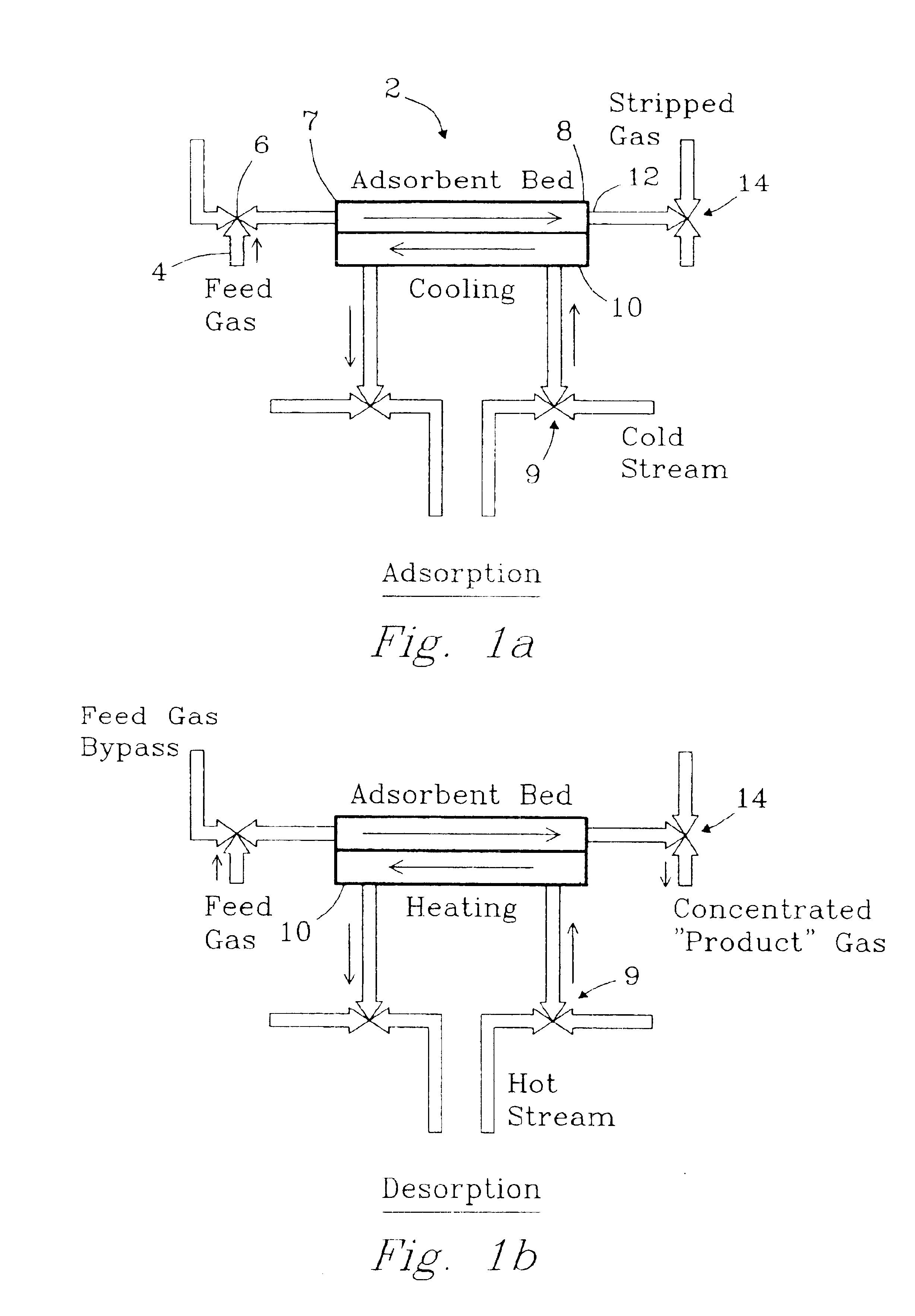

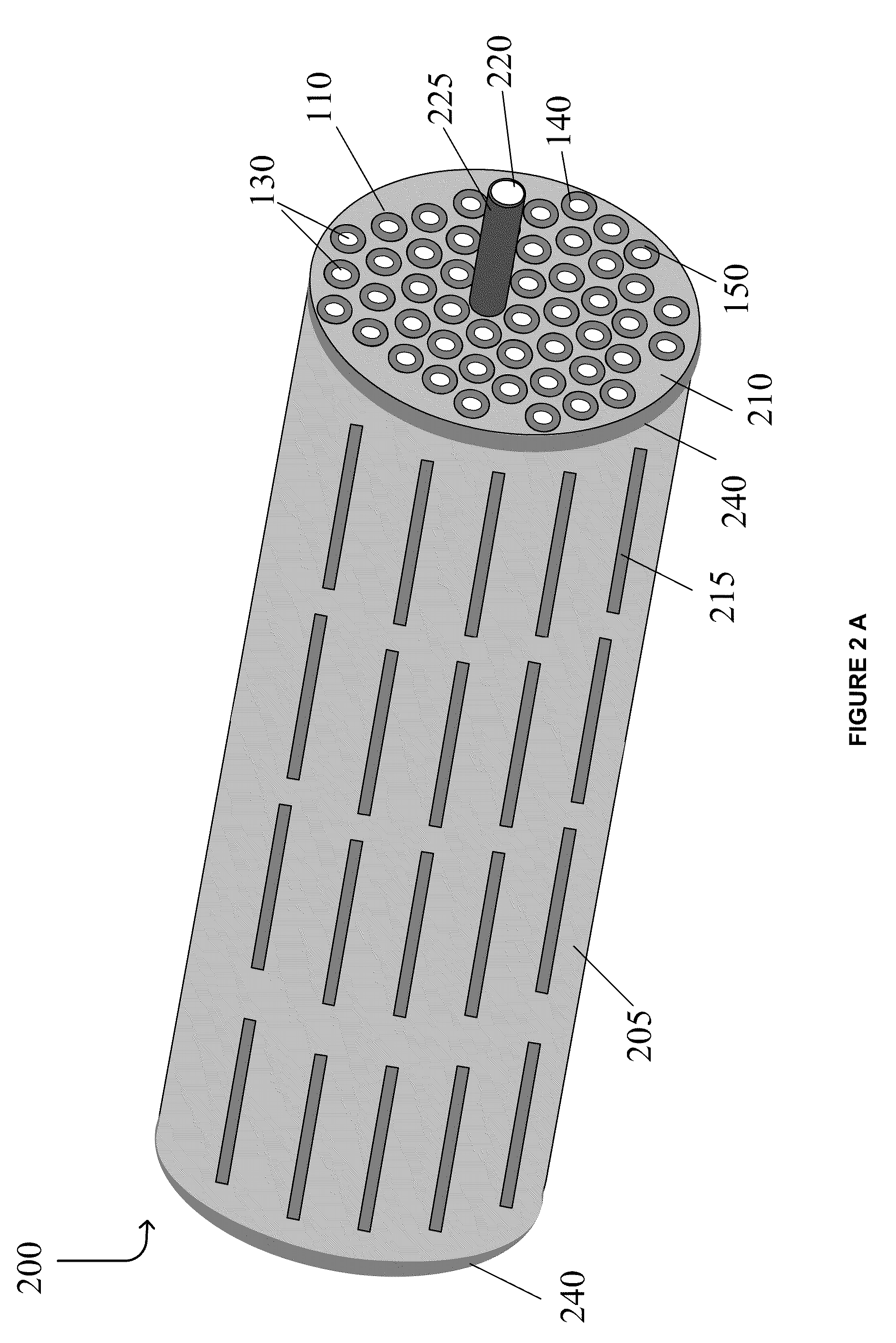

Apparatus for thermal swing adsorption and thermally-enhanced pressure swing adsorption

The present invention provides compact adsorption systems that are capable of rapid temperature swings and rapid cycling. Novel methods of thermal swing adsorption and thermally-enhanced pressure swing adsorption are also described. In some aspects of the invention, a gas is passed through the adsorbent thus allowing heat exchangers to be very close to all portions of the adsorbent and utilize less space. In another aspect, the adsorption media is selectively heated, thus reducing energy costs. Methods and systems for gas adsorption / desorption having improved energy efficiency with capability of short cycle times are also described. Advantages of the invention include the ability to use (typically) 30-100 times less adsorbent compared to conventional systems.

Owner:BATTELLE MEMORIAL INST

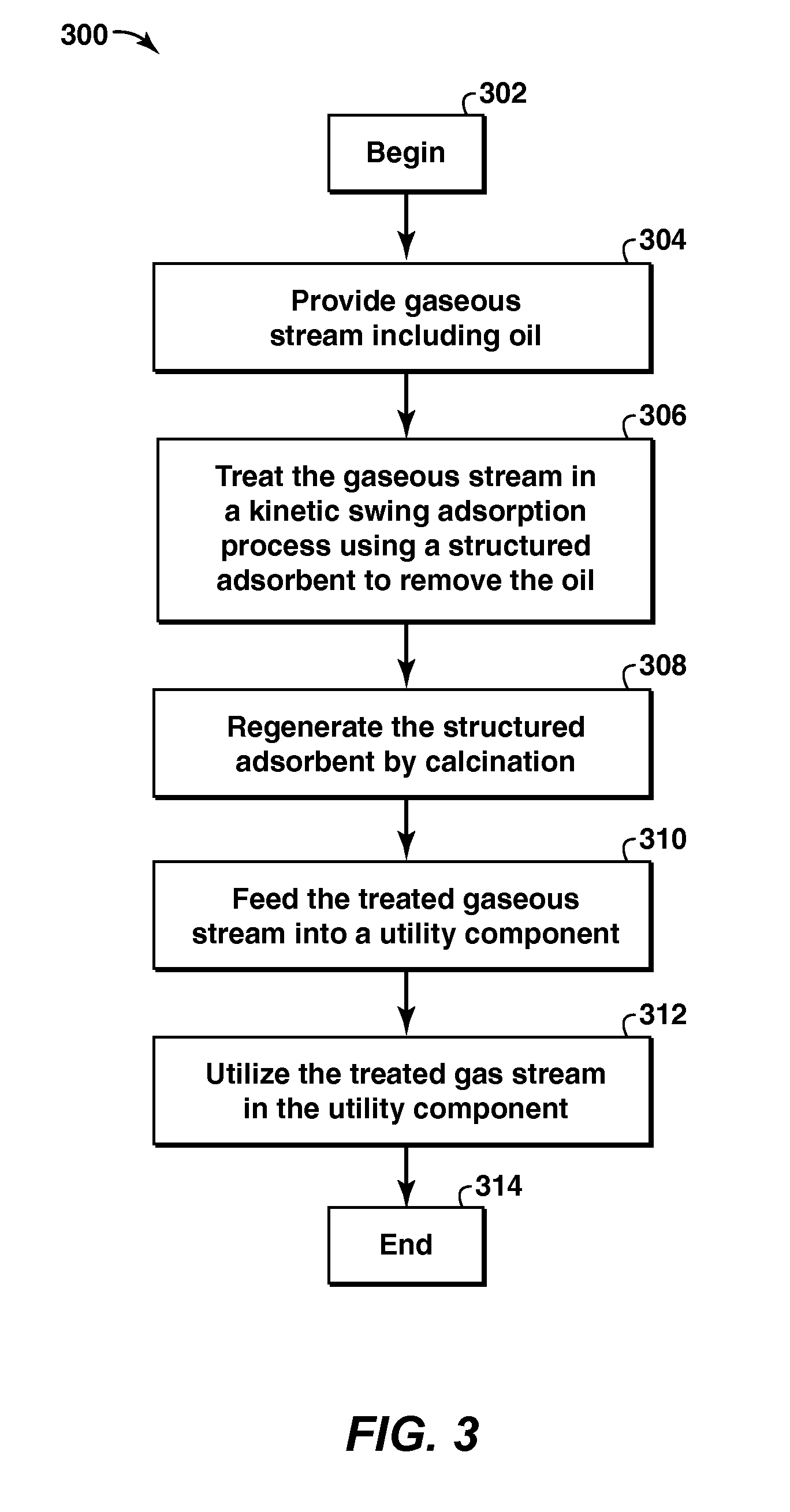

Method and Apparatus For Removal Of Oil From Utility Gas Stream

The present application is directed to a method and system for preparing gaseous utility streams from gaseous process streams, particularly, removing oil contamination from such streams prior to use in a dry gas seal. The methods and systems may include at least one kinetic swing adsorption process including pressure swing adsorption, temperature swing adsorption, calcination, and inert purge processes to treat gaseous streams for use in dry gas seals of rotating equipment such as compressors, turbines and pumps and other utilities. The adsorbent materials used include a high surface area solid structured microporous and mesoporous materials.

Owner:EXXONMOBIL UPSTREAM RES CO

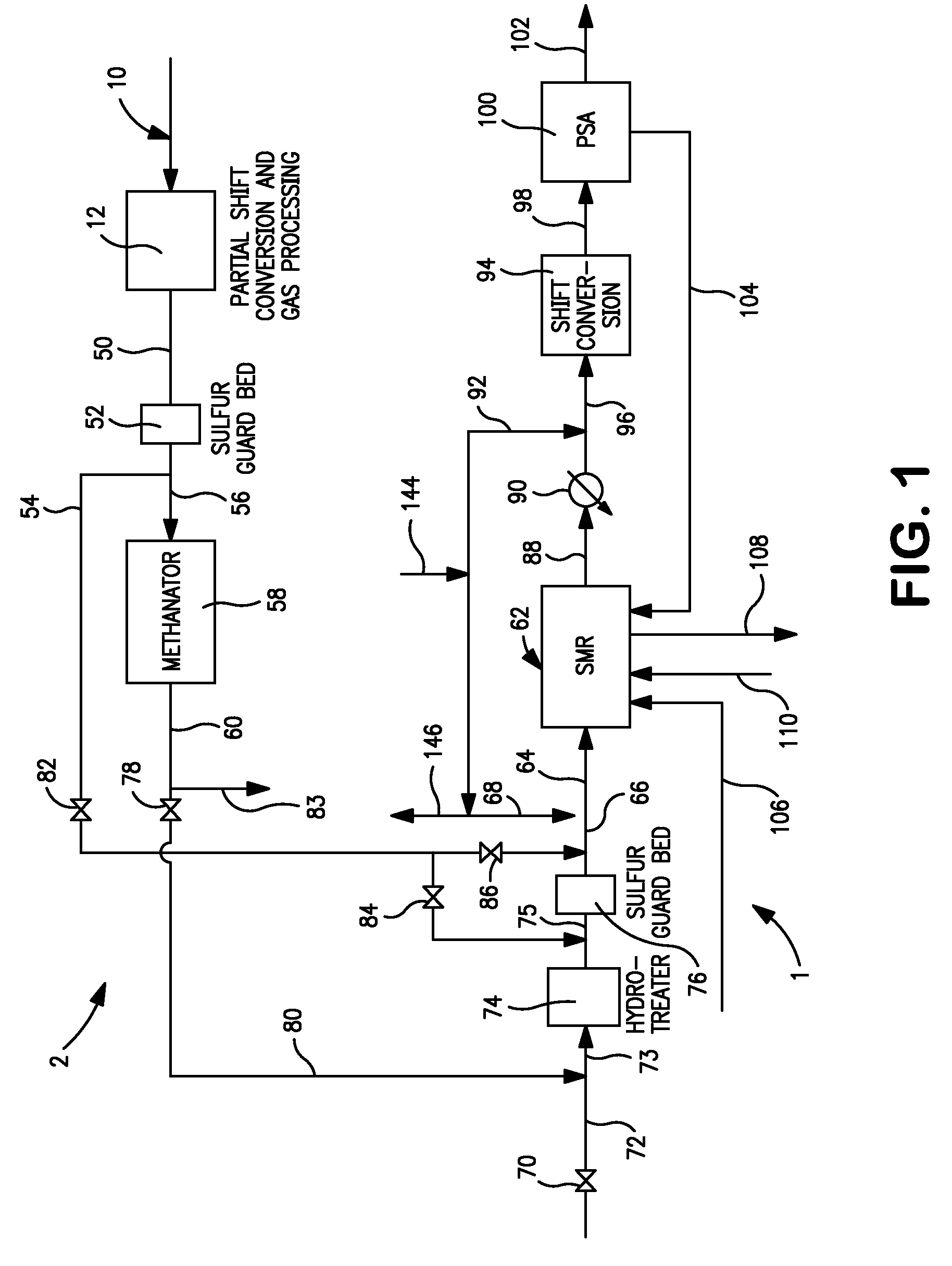

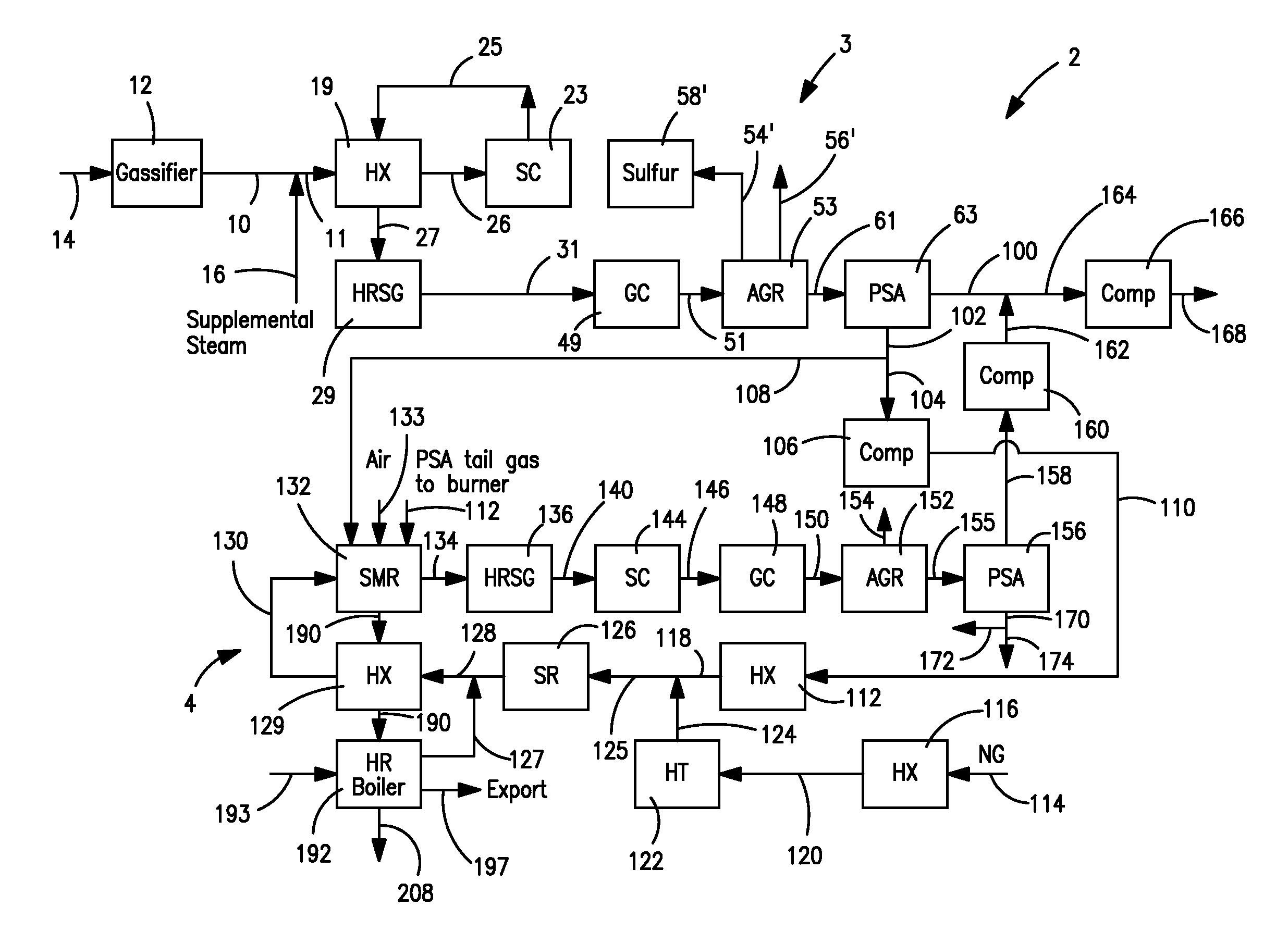

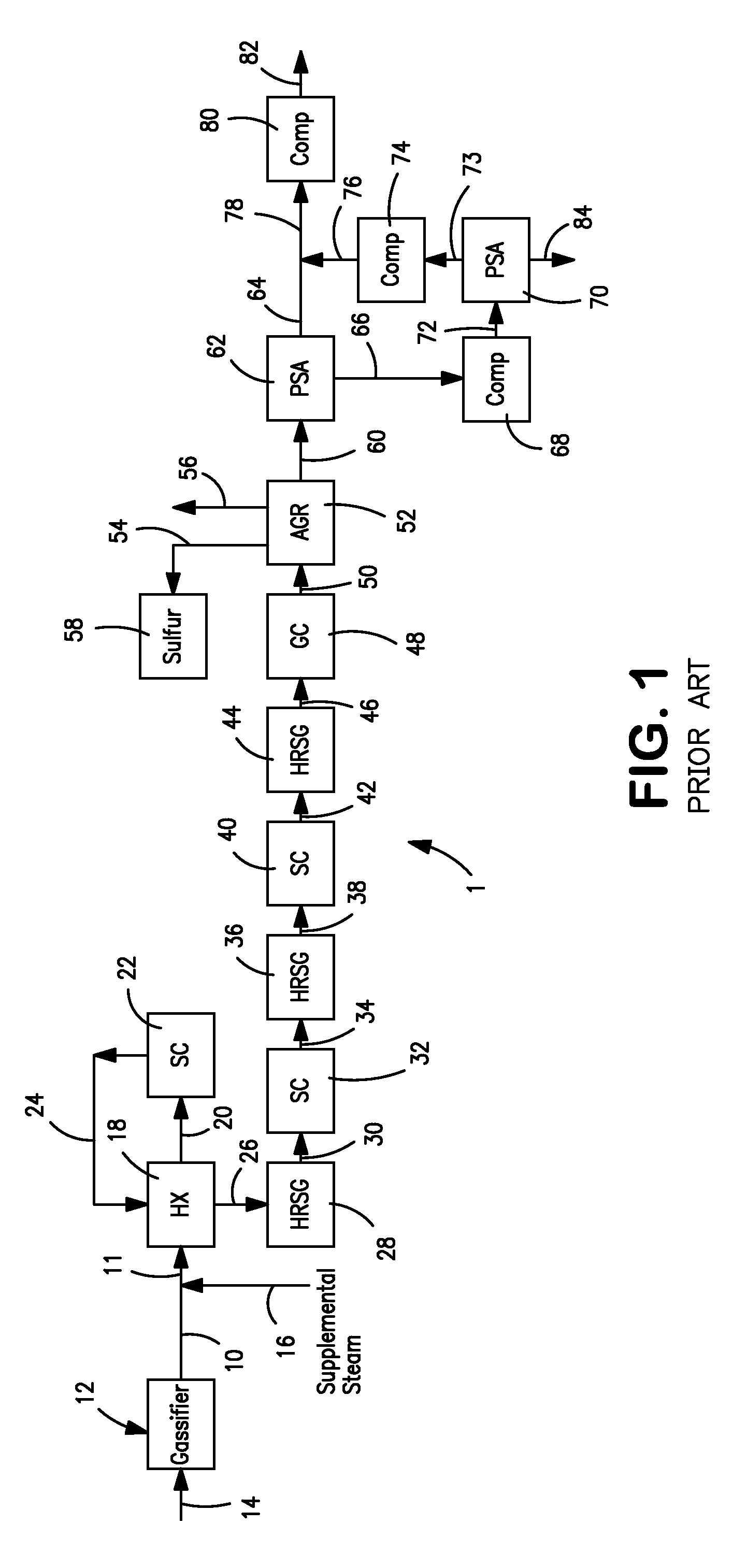

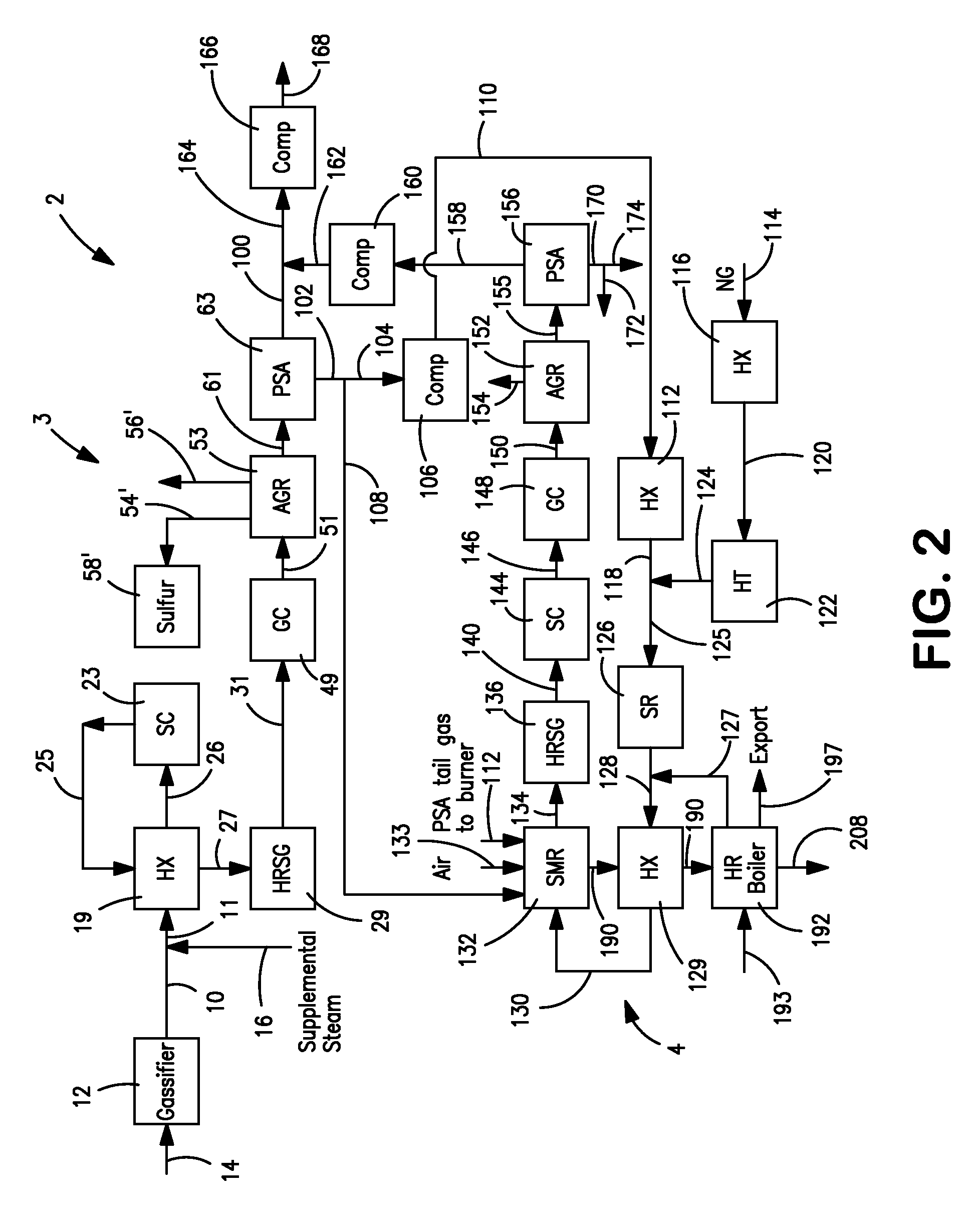

Hydrogen production method and facility

ActiveUS7985399B2High trafficHydrogen separation using solid contactHydrogen separation using liquid contactSyngasHydrocarbon

A hydrogen production method and facility in which a synthesis gas stream produced by the gasification of a carbonaceous substance is processed within a synthesis gas processing unit in which the carbon monoxide content is reacted with steam to produce additional hydrogen that is removed by a pressure swing adsorption unit. The tail gas from the pressure swing adsorption unit is further reformed with the addition of a hydrocarbon containing stream in a steam methane reforming system, further shifted to produce further additional hydrogen. The further hydrogen is then separated in another pressure swing adsorption unit.

Owner:PRAXAIR TECH INC

Systems and processes for providing hydrogen to fuel cells

InactiveUS7041272B2Minimized in sizeMaximize energy efficiencyFuel cell auxillariesHydrogen/synthetic gas productionFuel cellsInternal combustion engine

Owner:AIR PROD & CHEM INC

Process to remove nitrogen and/or carbon dioxide from methane-containing streams

A process for the removal of inert gases, such as nitrogen and carbon dioxide, from methane-containing gases, such as natural gas, including a first stage removal which lowers the total combined inert content to about less than 30% and a second stage removal utilizing a pressure swing adsorption process comprising one or more adsorbent beds comprising contracted titanosilicate-1 adsorbent, wherein the purified methane-containing gas contains less than about 6% total combined inerts.

Owner:REG SYNTHETIC FUELS LLC +1

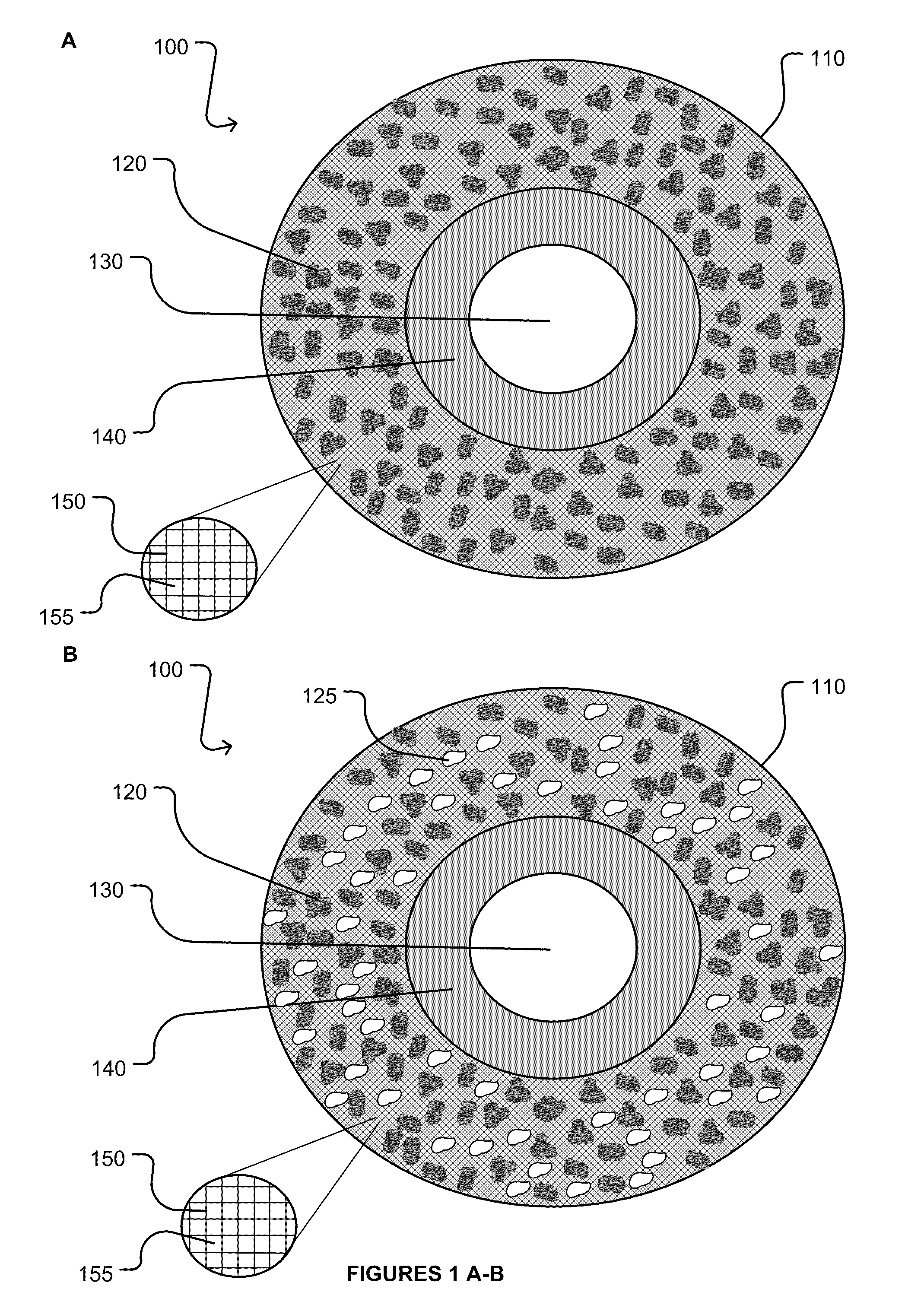

Sorbent fiber compositions and methods of temperature swing adsorption

The various embodiments of the present invention relate to compositions, apparatus, and methods comprising sorbent fibers. More particularly, various embodiments of the present invention are directed towards sorbent fiber compositions for temperature swing adsorption processes. Various embodiments of the present invention comprise sorbent fiber compositions, apparatus comprising a plurality of sorbent fibers, and methods of using the same for the capture of at least one component from a medium, for example CO2 from flue gas.

Owner:GEORGIA TECH RES CORP +1

Energy efficient gas separation for fuel cells

InactiveUS7087331B2Intuitive effectFully purifiedFuel cell heat exchangeFused electrolyte fuel cellsDelivery systemSolid oxide fuel cell

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

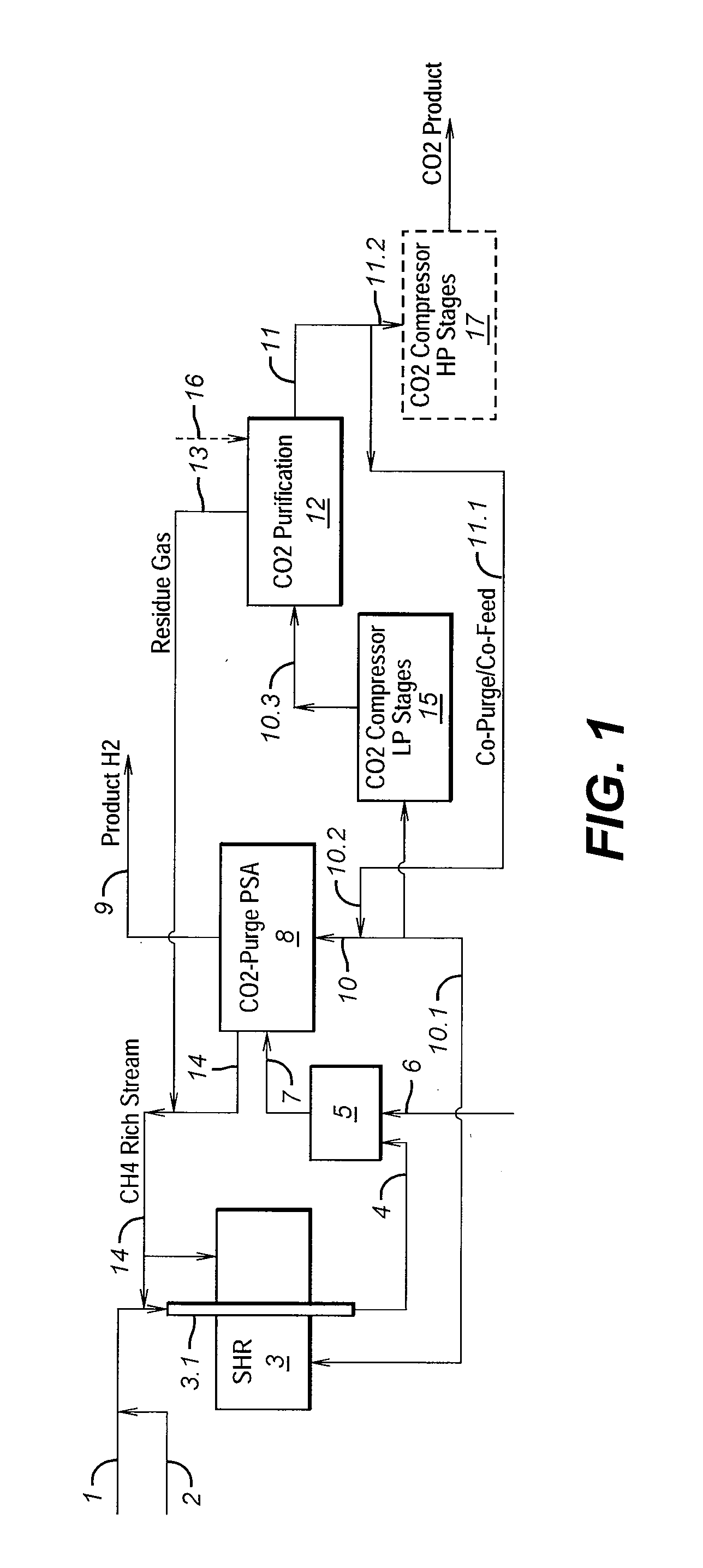

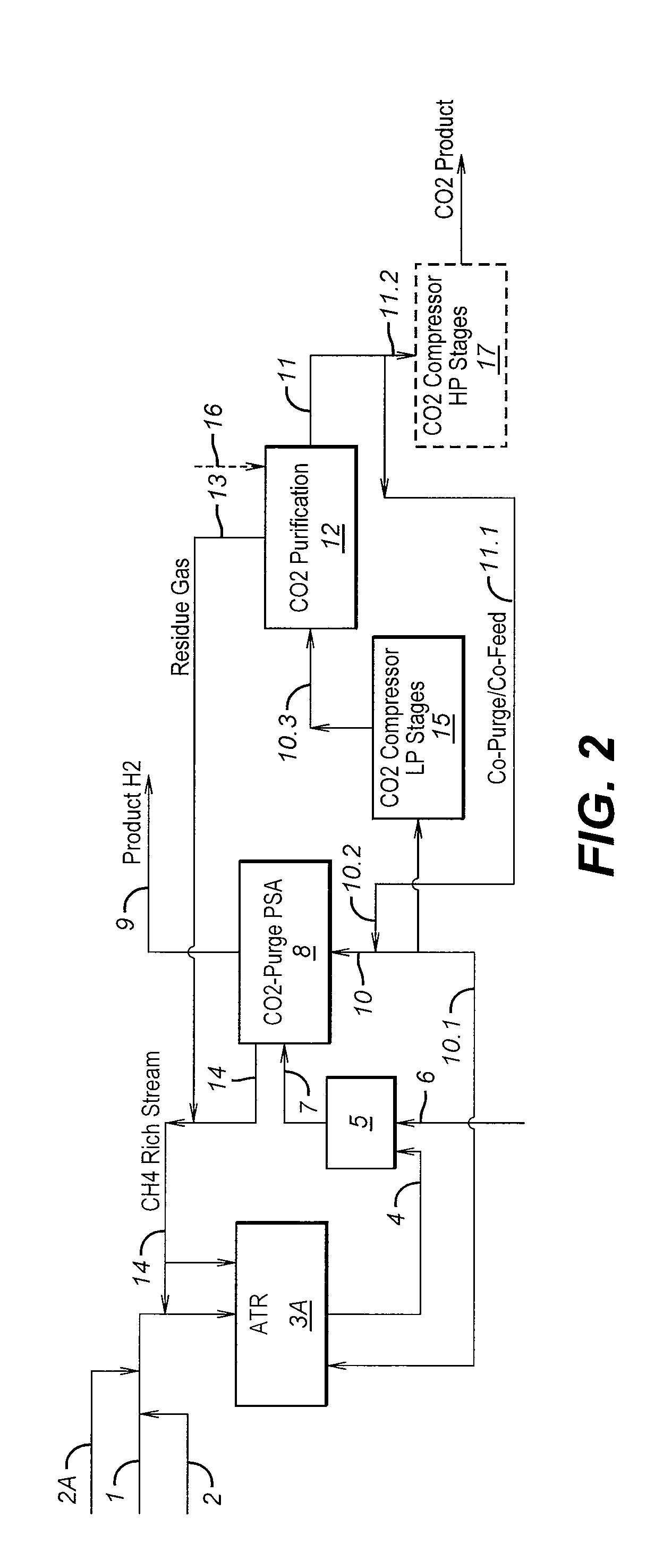

Process For The Production Of Carbon Dioxide Utilizing A Co-Purge Pressure Swing Adsorption Unit

The present invention provides a process for recovering gaseous hydrogen and gaseous carbon dioxide from a mixture of hydrocarbons by utilizing a system that includes a reformer unit, an optional water gas shift reactor, and a pressure swing adsorption unit in conjunction with a carbon dioxide purification unit such as a cryogenic purification unit or a catalytic oxidizer. In this process, purified CO2 from the CO2 purification unit is used as a co-feed / co-purge in the pressure swing adsorption unit in order to produce a CO2 tail gas that includes a higher concentration of CO2.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Methods and apparatuses for gas separation by pressure swing adsorption with partial gas product feed to fuel cell power source

Various systems, method and apparatuses are disclosed that include a pressure swing adsorption apparatus coupled to a fuel cell, wherein the fuel cell receives at least a portion of a product gas from the pressure swing adsorption and powers the pressure swing adsorption apparatus. Also disclosed is a portable gas separator that include a housing that houses a rotary pressure swing adsorption apparatus.

Owner:AIR PROD & CHEM INC

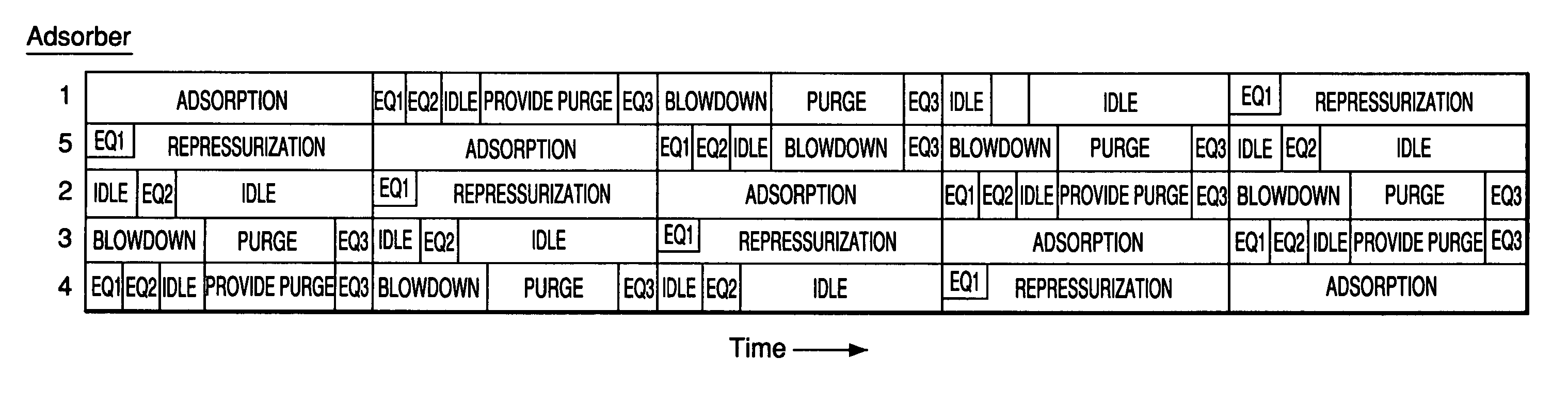

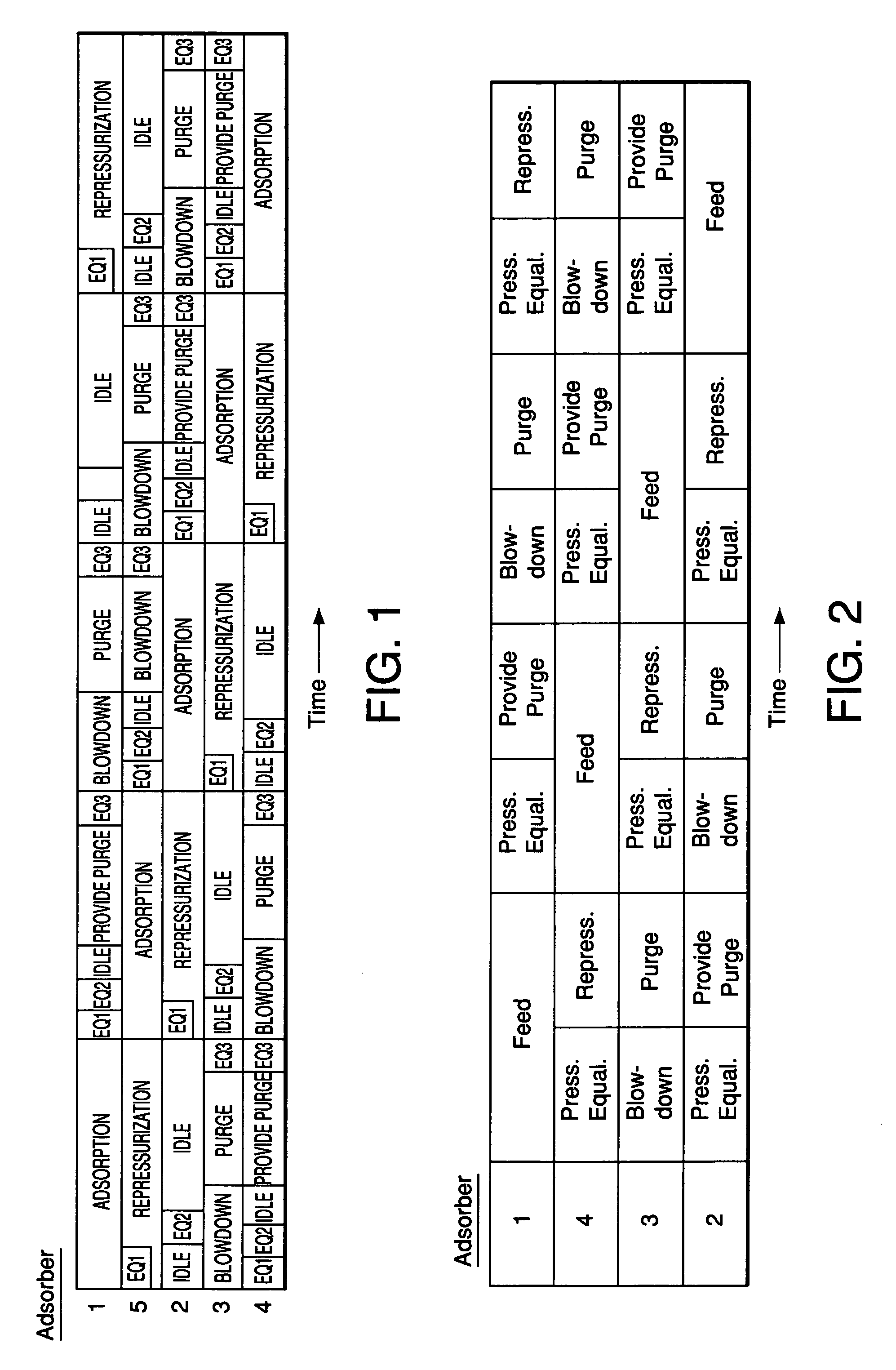

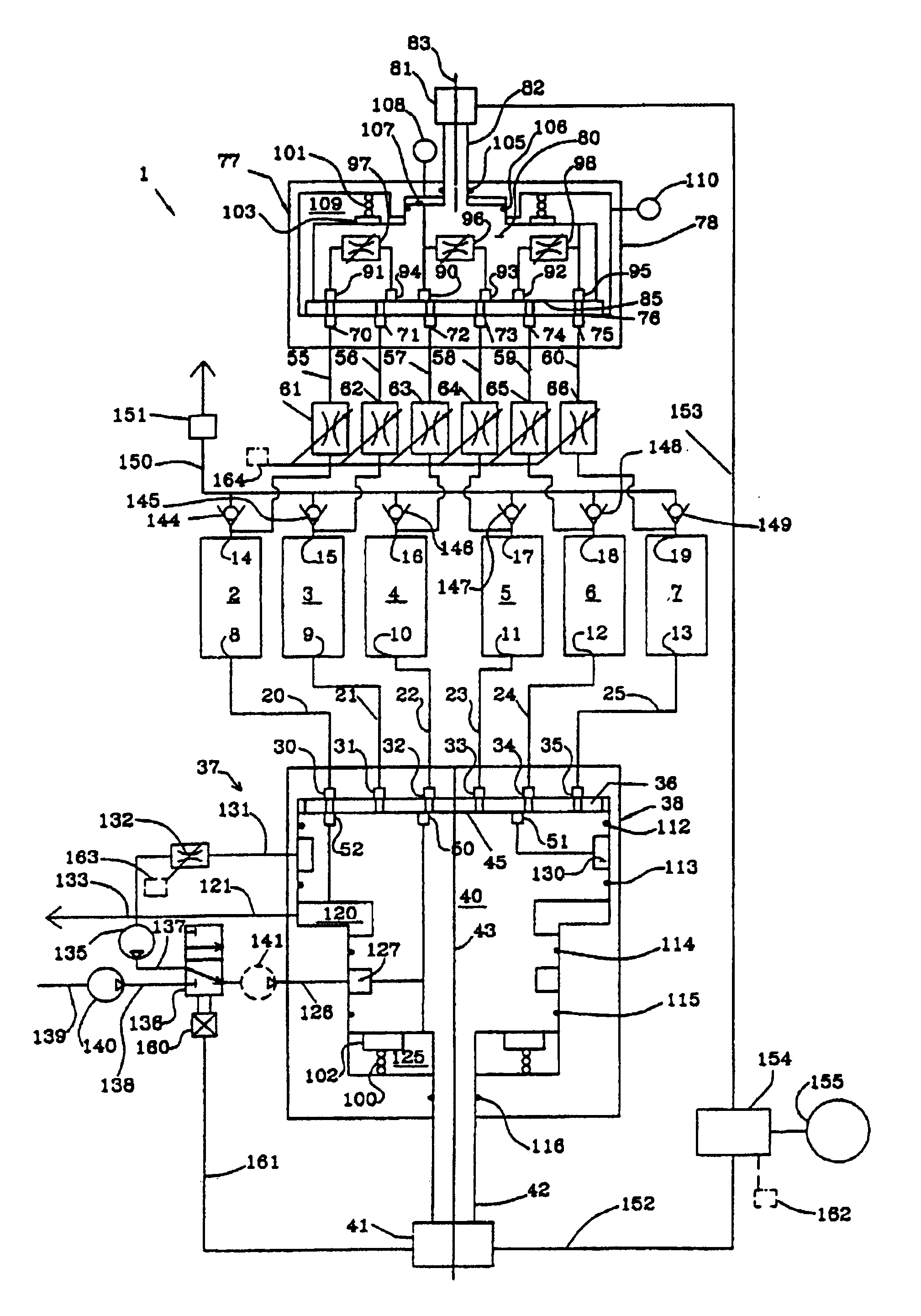

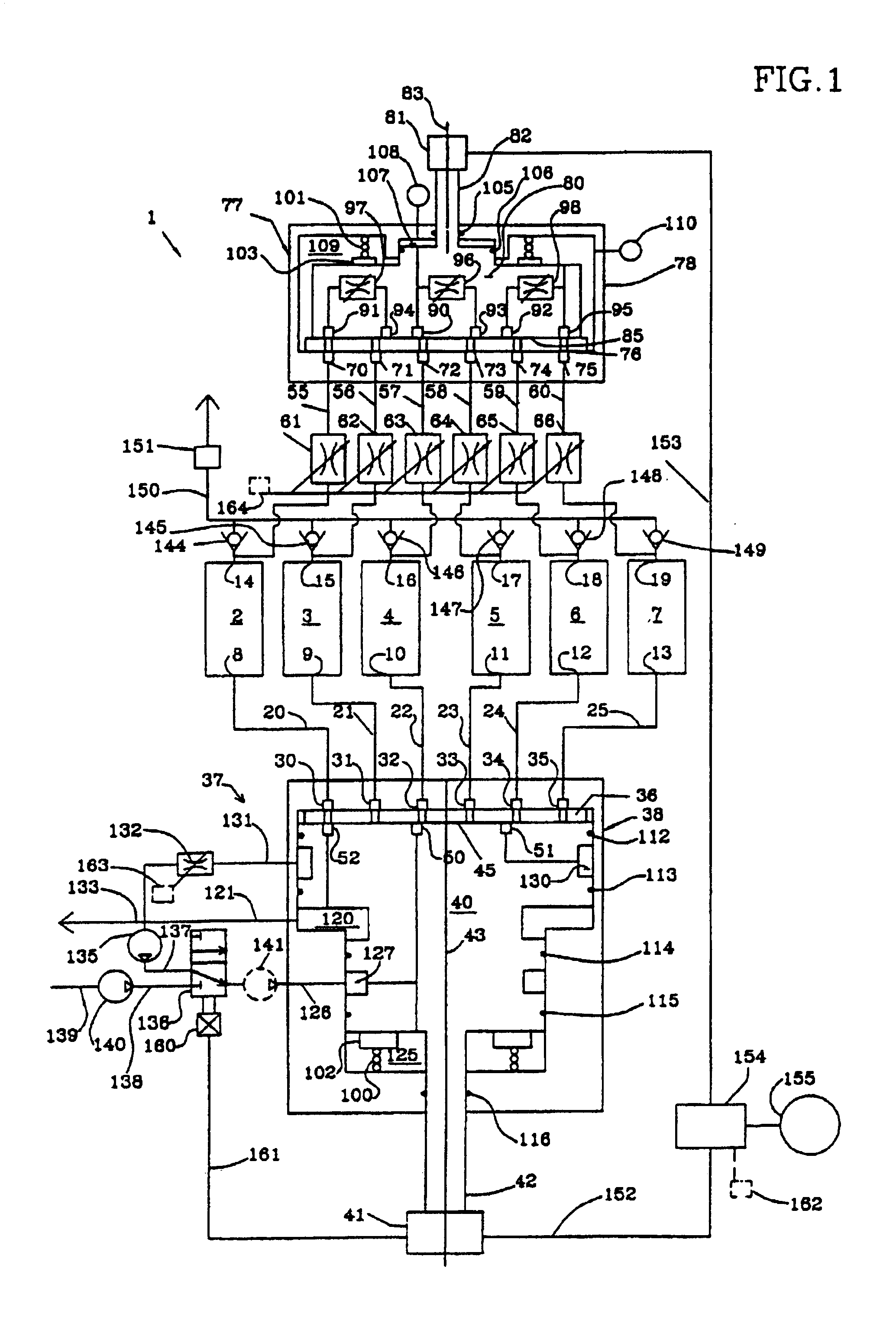

Flow regulated pressure swing adsorption system

InactiveUSRE38493E1Satisfactory operationGas treatmentIsotope separationSystem pressureProcess engineering

Pressure swing adsorption (PSA) separation of a gas mixture is performed in an apparatus with a plurality of adsorbent beds. The invention provides rotary multiport distributor valves to control the timing sequence of the PSA cycle steps between the beds, with flow controls cooperating with the rotary distributor valves to control the volume rates of gas flows to and from the adsorbent beds in blowdown, purge, equalization and repressurization steps.

Owner:AIR PROD & CHEM INC

Performance Stability in Shallow Beds in Pressure Swing Adsorption Systems

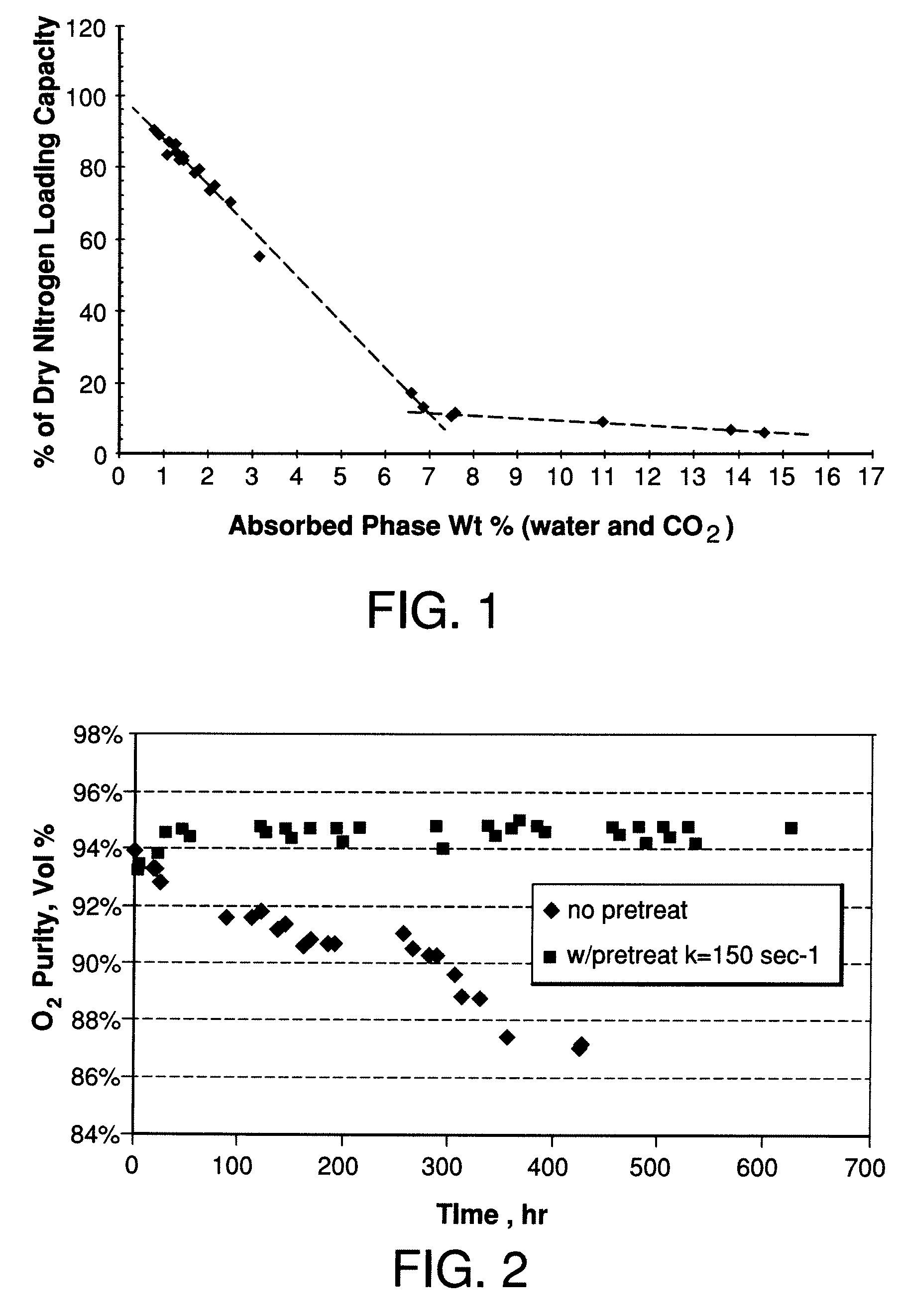

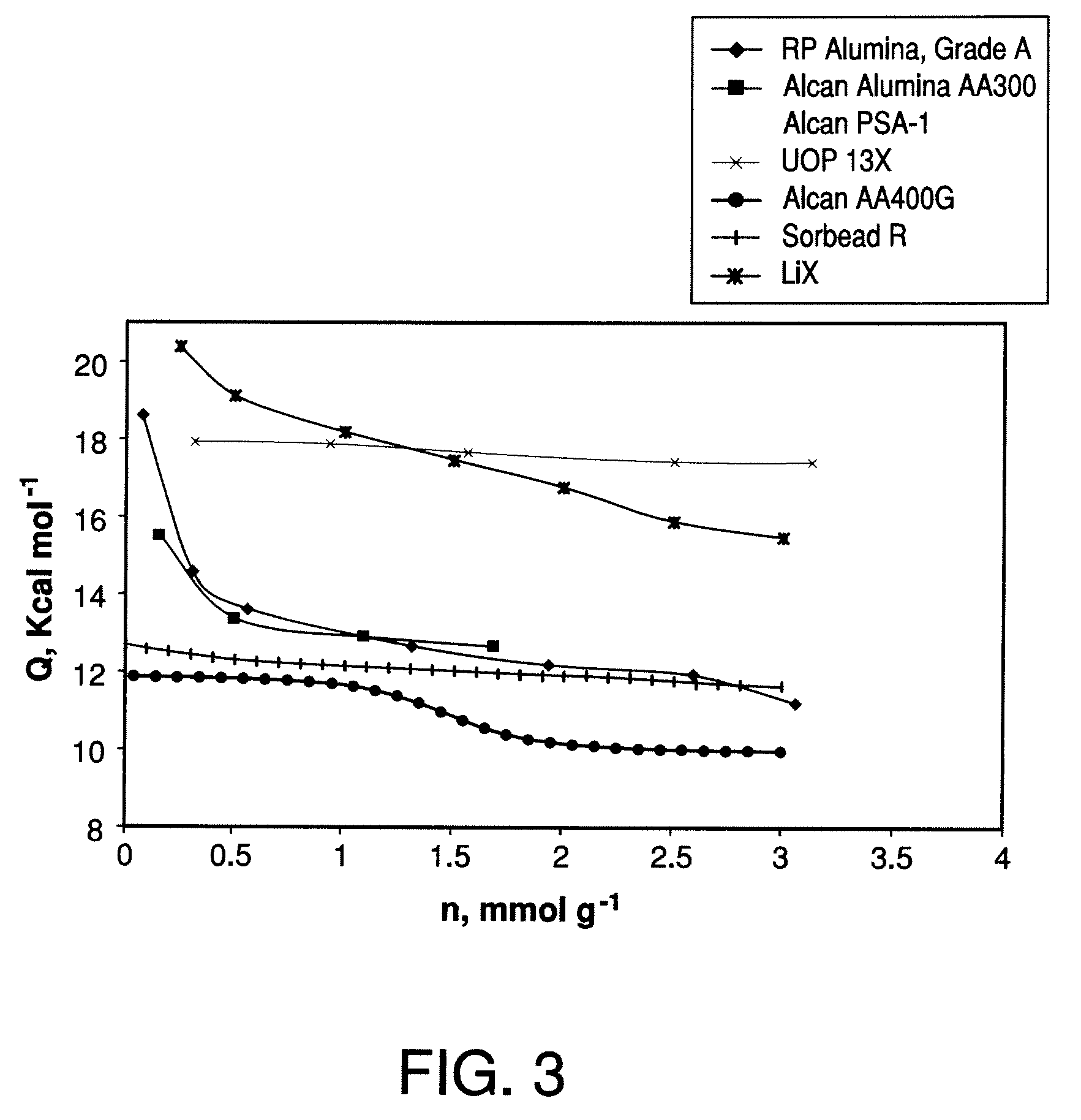

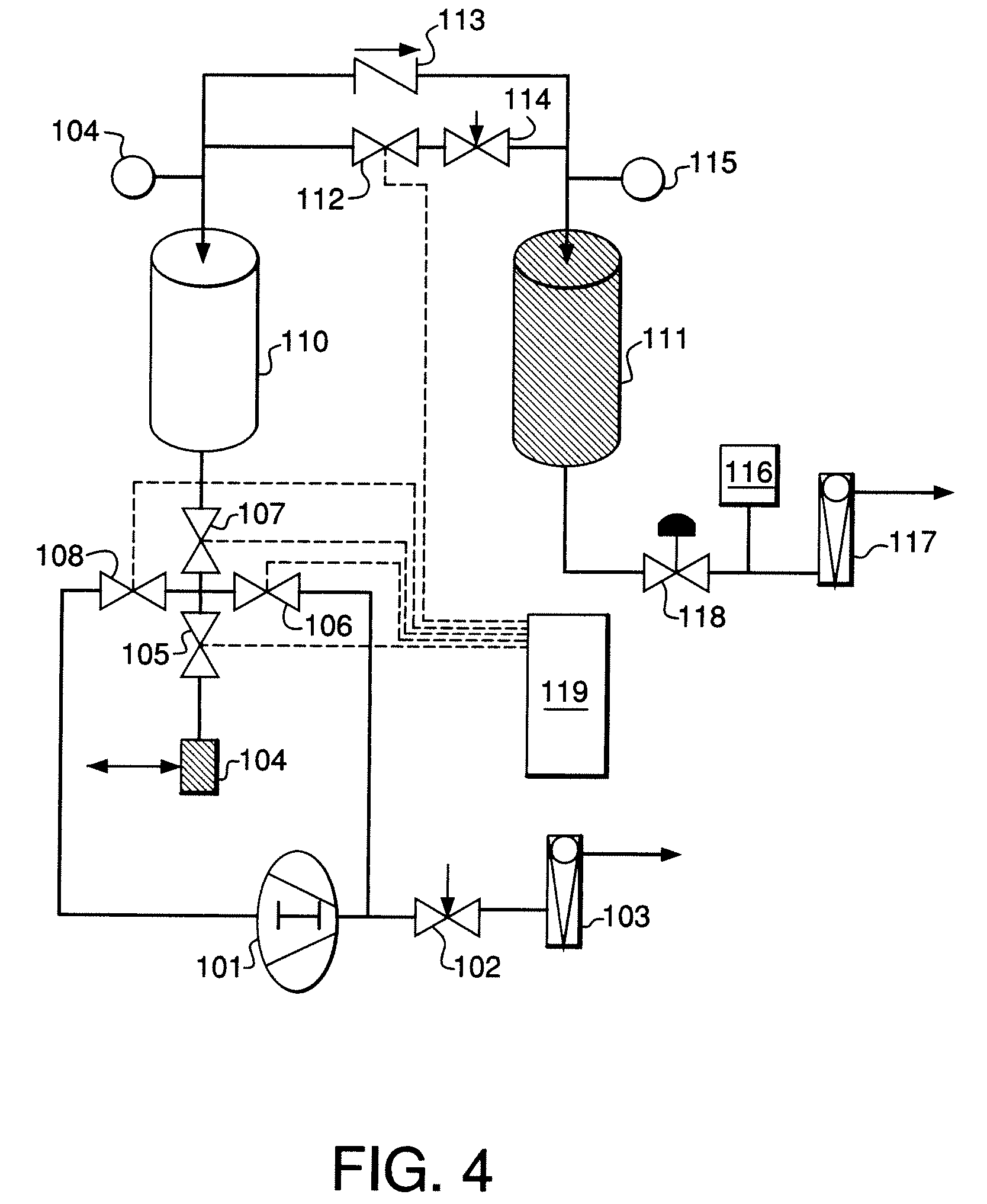

PSA process for oxygen production comprising (a) providing an adsorber having a first layer of adsorbent selective for water and a second layer of adsorbent selective for nitrogen, wherein the heat of adsorption of water on the adsorbent in the first layer is equal to or less than about 14 kcal / mole at water loadings less than about 0.05 mmol per gram; (b) passing a feed gas comprising at least oxygen, nitrogen, and water successively through the first and second layers, adsorbing water in the first layer of adsorbent, and adsorbing nitrogen in the second layer of adsorbent, wherein the mass transfer coefficient of water in the first layer is in the range of about 125 to about 400 sec−1 and the superficial contact time of the feed gas in the first layer is between about 0.08 and about 0.50 sec; and (c) withdrawing a product enriched in oxygen from the adsorber.

Owner:AIR PROD & CHEM INC

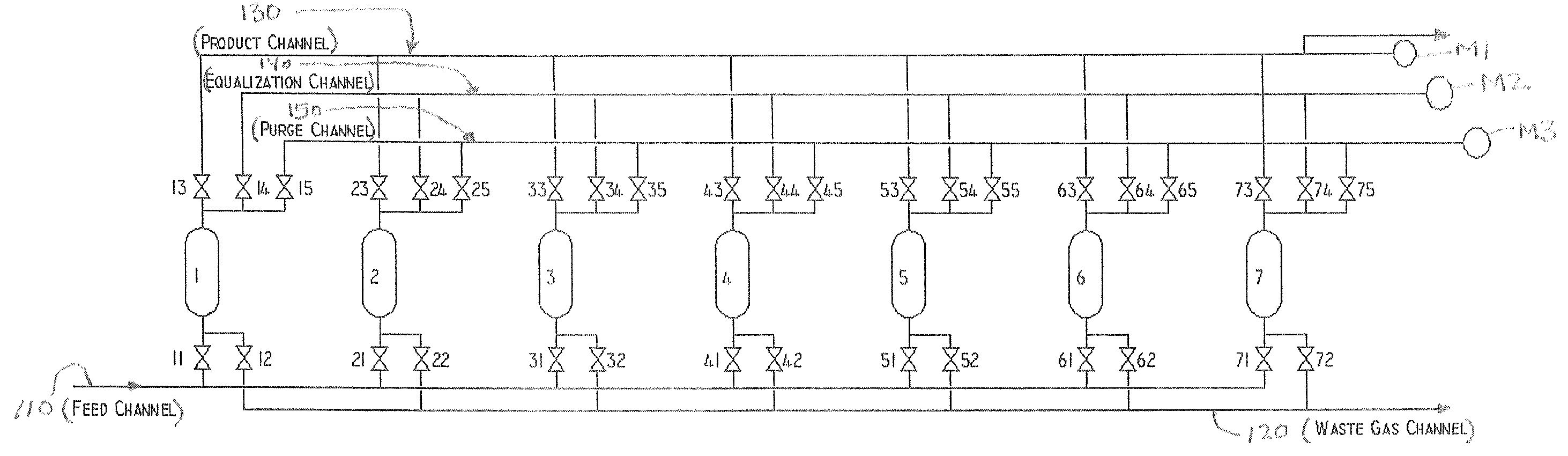

PSA pressure measurement and control system

A pressure swing adsorption system including a plurality of vessels having one or more layers of adsorbent material therein, a feed gas channel, a waste channel, and a product channel. The system also includes at least one parallel channel connected to each of the vessels via a respective conduit with a valve. At least one pressure measuring device i configured to measure a pressure within the parallel channel. And, a controller is provided that is configured to monitor the at least one pressure measured by the at least one pressure measuring device during a PSA cycle performed within the PSA system, in order to determine the performance of the cycle and monitor proper operation of the system.

Owner:LUMMUS TECH INC

Flow regulated pressure swing adsorption system

Pressure swing adsorption (PSA) separation of a gas mixture is performed in an apparatus with a plurality of adsorbent beds. The invention provides rotary multiport distributor valves to control the timing sequence of the PSA cycle steps between the beds, with flow controls cooperating with the rotary distributor valves to control the volume rates of gas flows to and from the adsorbent beds in blowdown, purge, equalization and repressurization steps.

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com