Patents

Literature

395 results about "Hydrogen synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen makes up 75% of the mass of the universe but the element in its standard state, H2, is rare on Earth. It makes up about 1 part per million of the atmosphere. Hydrogen was first synthesized by the oxidation-reduction reaction of metals with acids.

Carbon dioxide production method

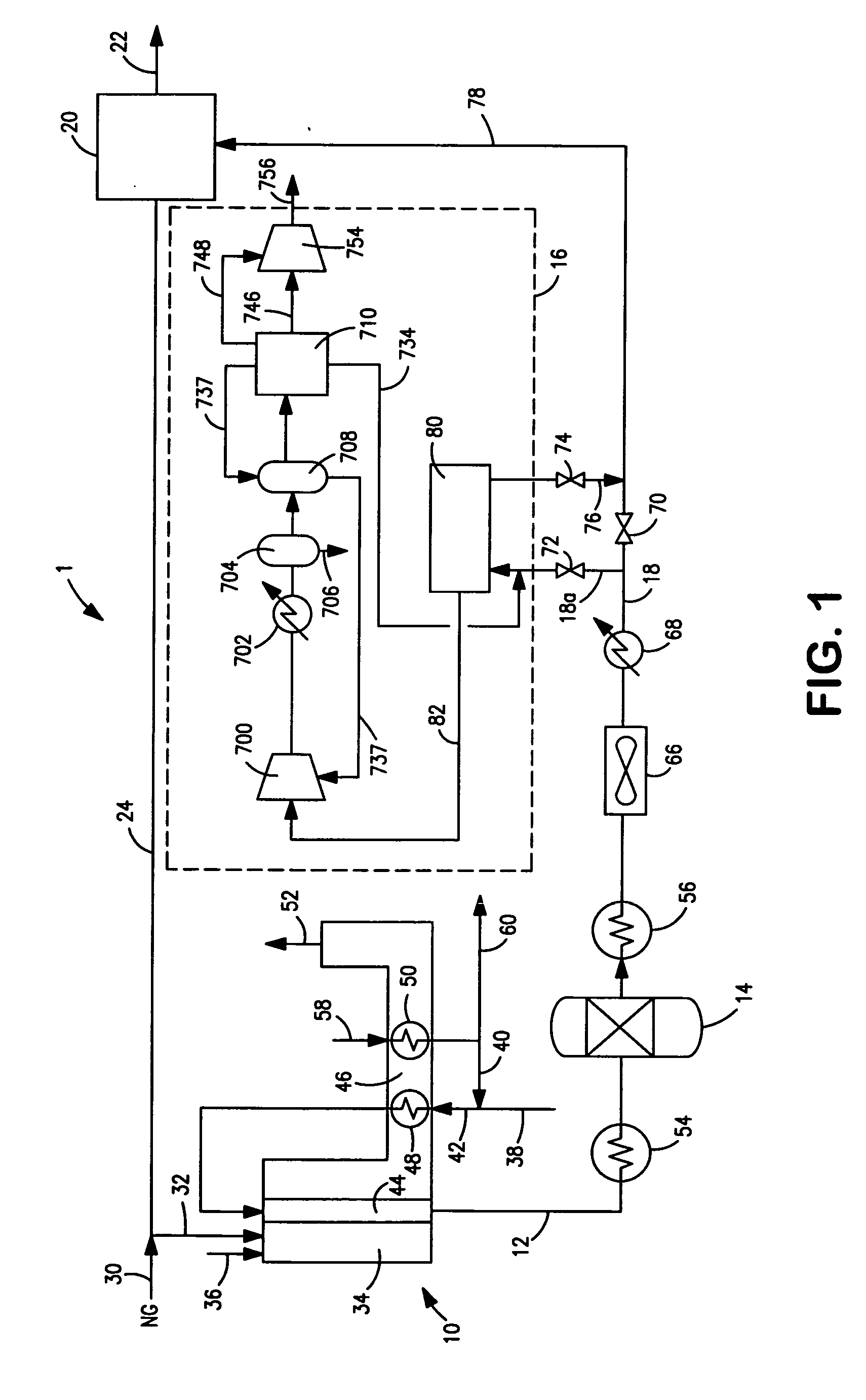

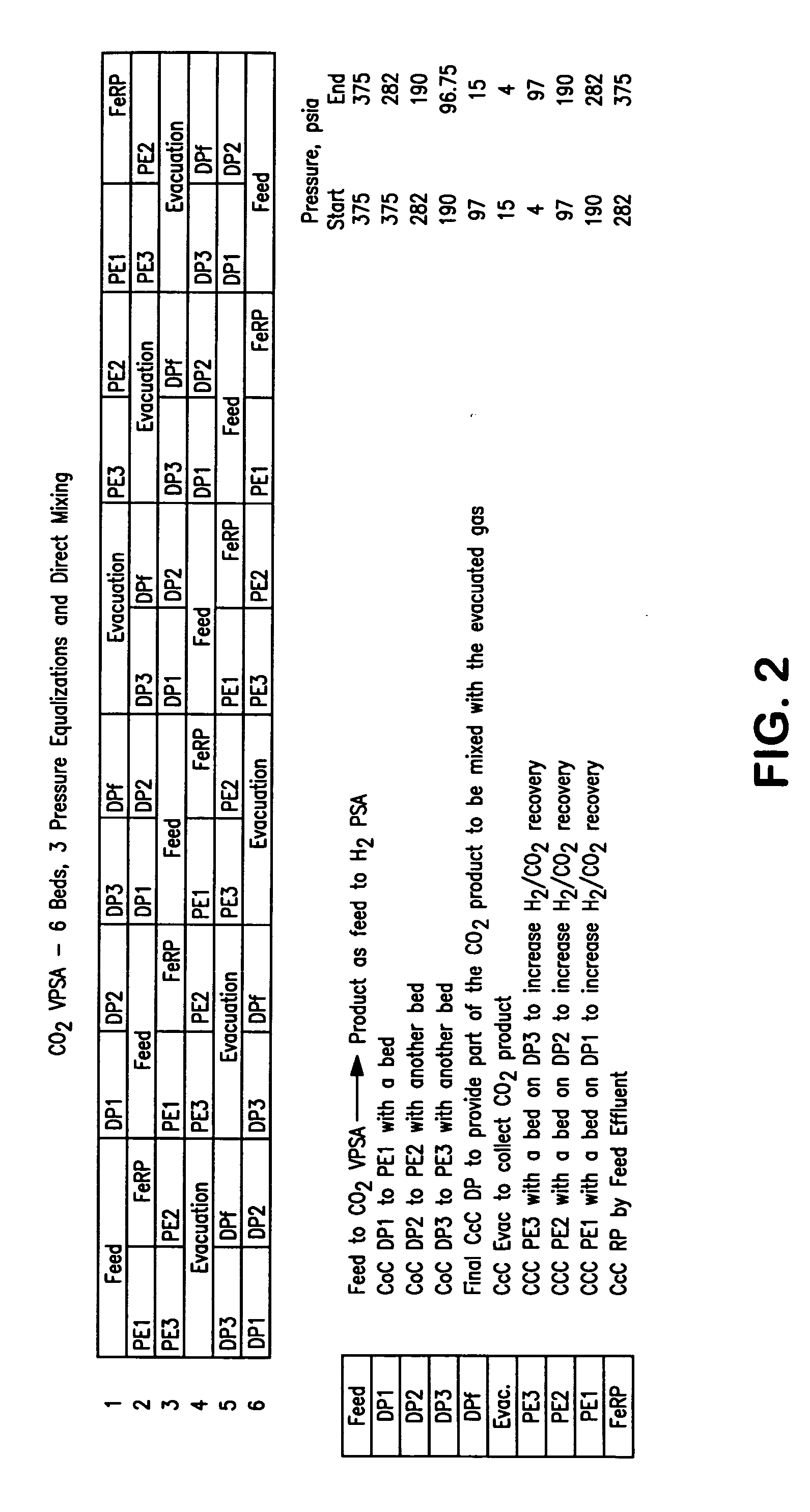

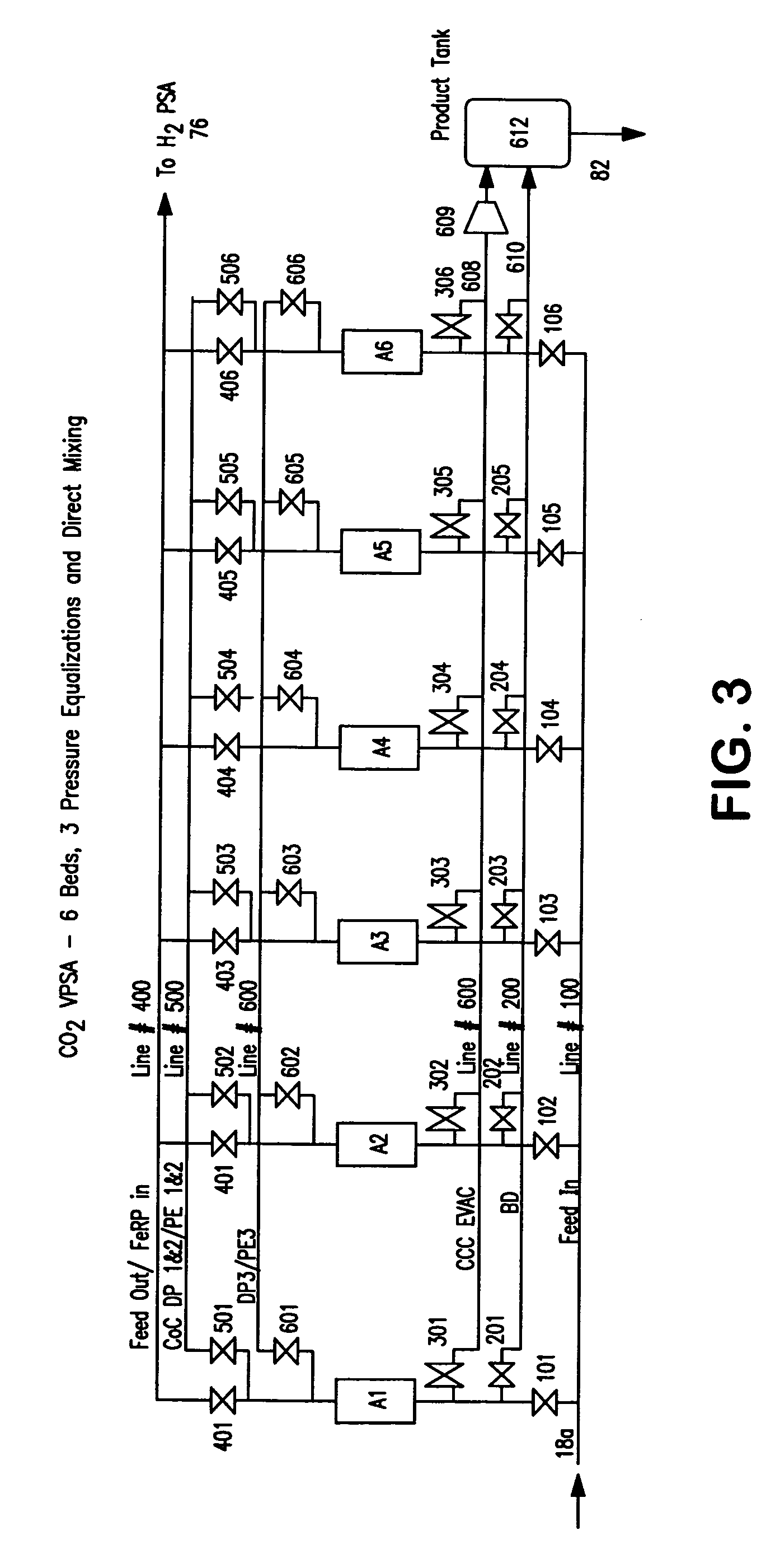

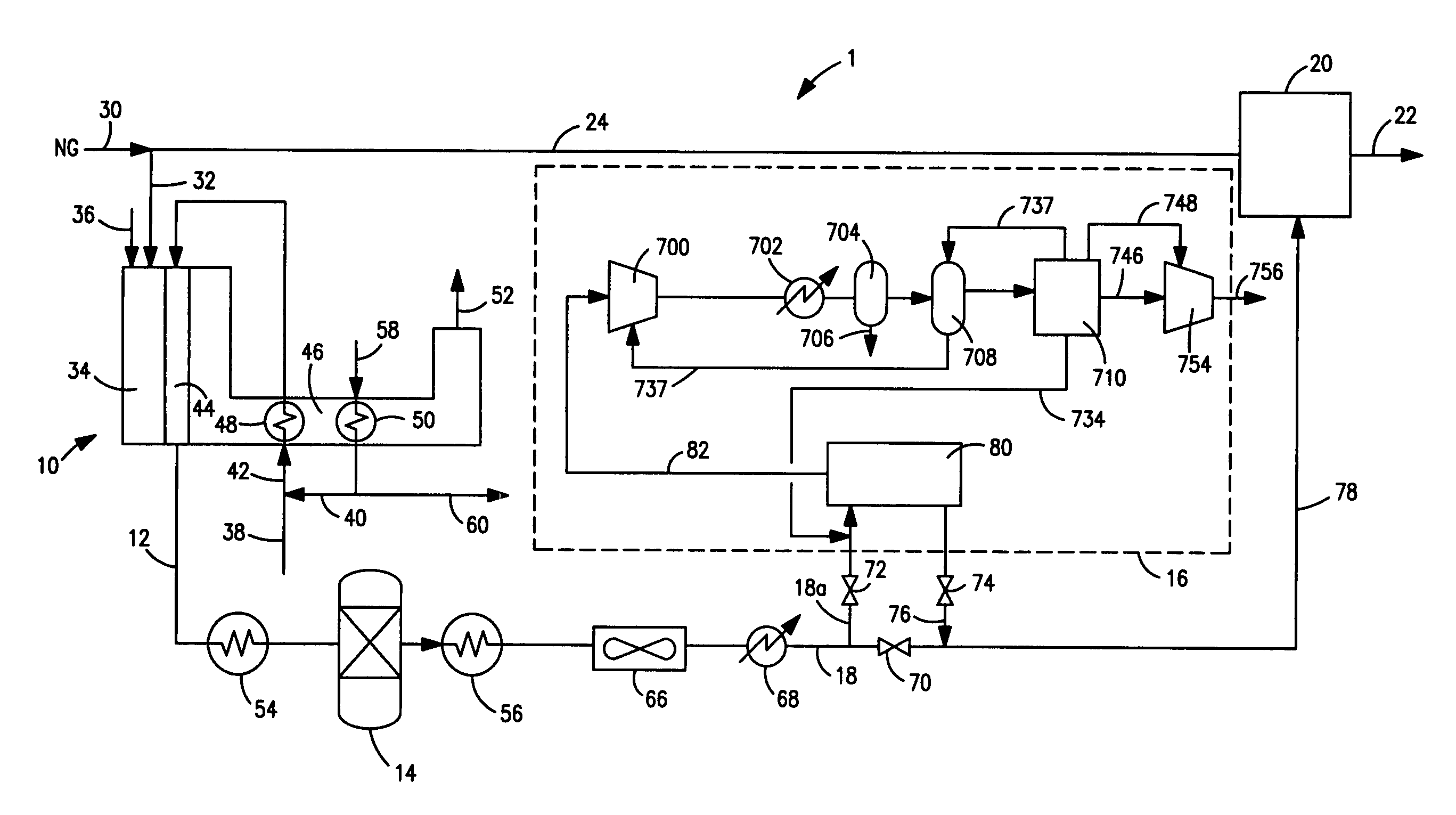

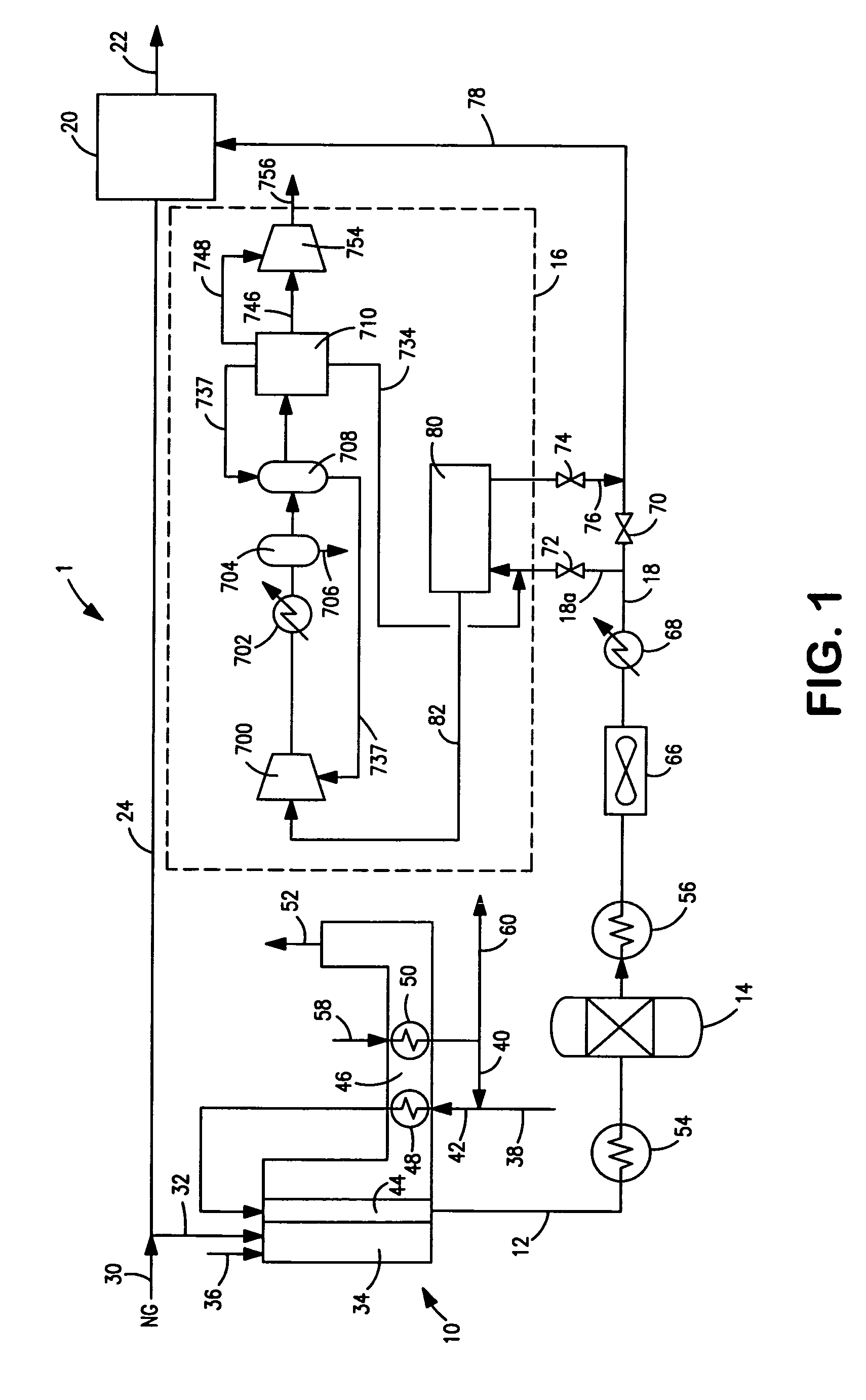

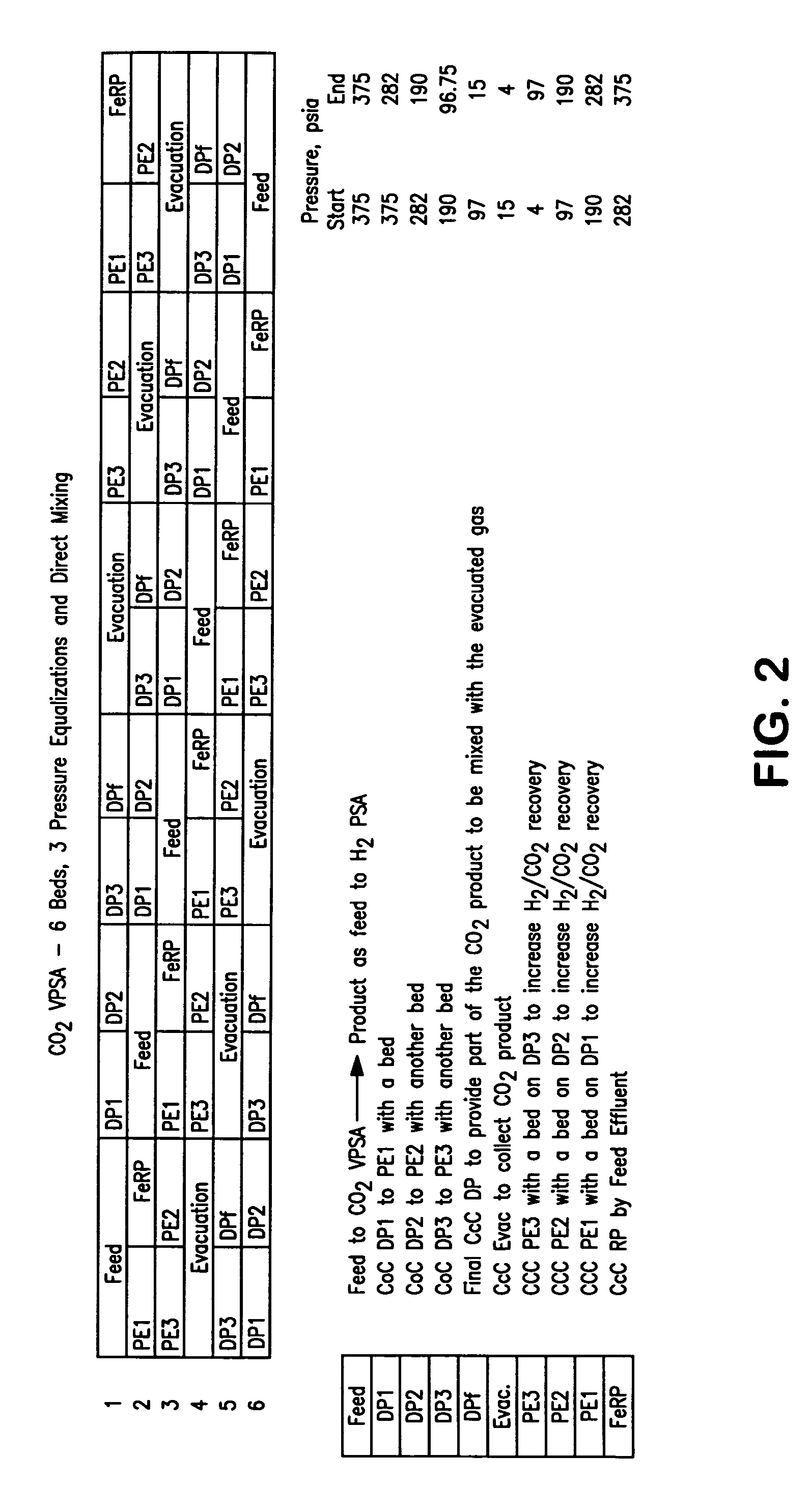

ActiveUS20070232706A1Increased hydrogen recoveryPromote recoverySolidificationLiquefactionVacuum pressureCarbon dioxide production

A method of producing a carbon dioxide product stream from a synthesis gas stream formed within a hydrogen plant having a synthesis gas reactor, a water-gas shift reactor, located downstream of the synthesis gas reactor to form the synthesis gas stream and a hydrogen pressure swing adsorption unit to produce a hydrogen product recovered from the synthesis gas stream. In accordance with the method the carbon dioxide from the synthesis gas stream by separating the carbon dioxide from the synthesis gas stream in a vacuum pressure swing adsorption system, thereby to produce a hydrogen-rich synthesis gas stream and a crude carbon dioxide stream and then purifying the crude carbon dioxide stream by a sub-ambient temperature distillation process thereby to produce the carbon dioxide product. A hydrogen synthesis gas feed stream to the hydrogen pressure swing adsorption unit is formed at least in part from the hydrogen rich stream.

Owner:PRAXAIR TECH INC

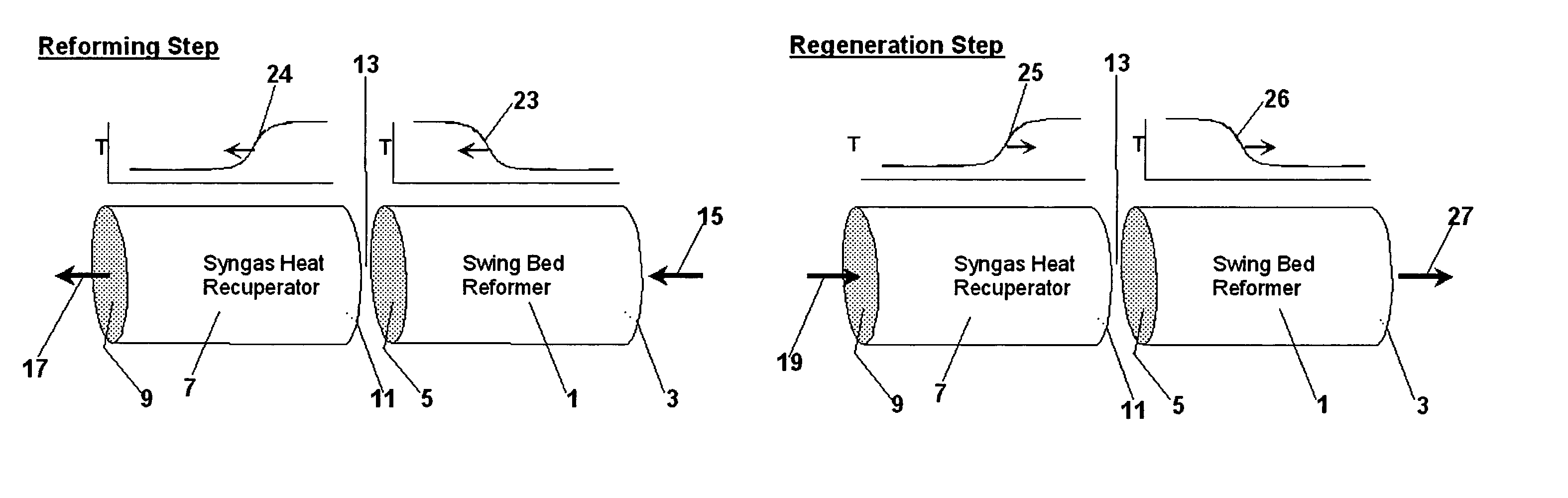

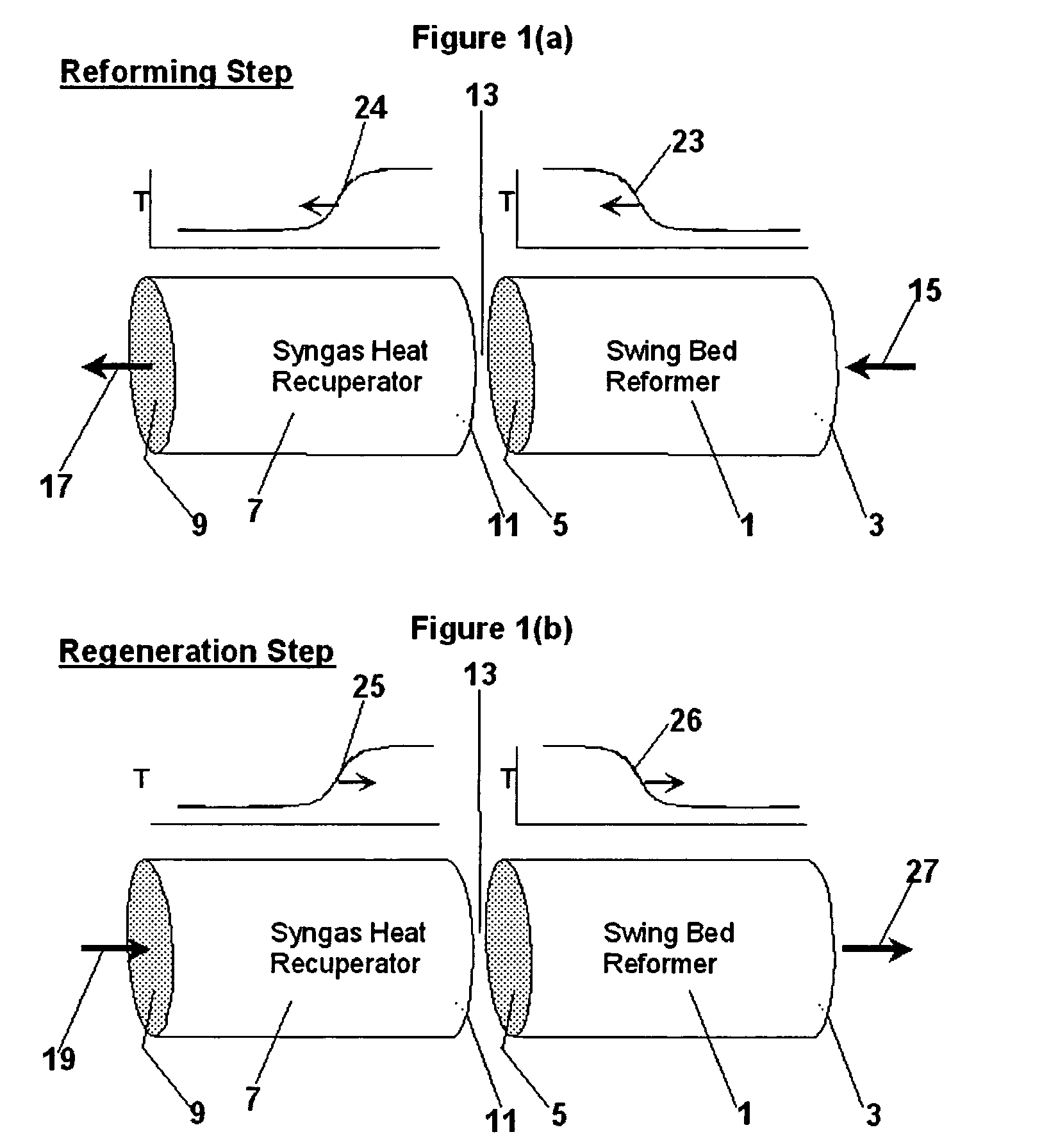

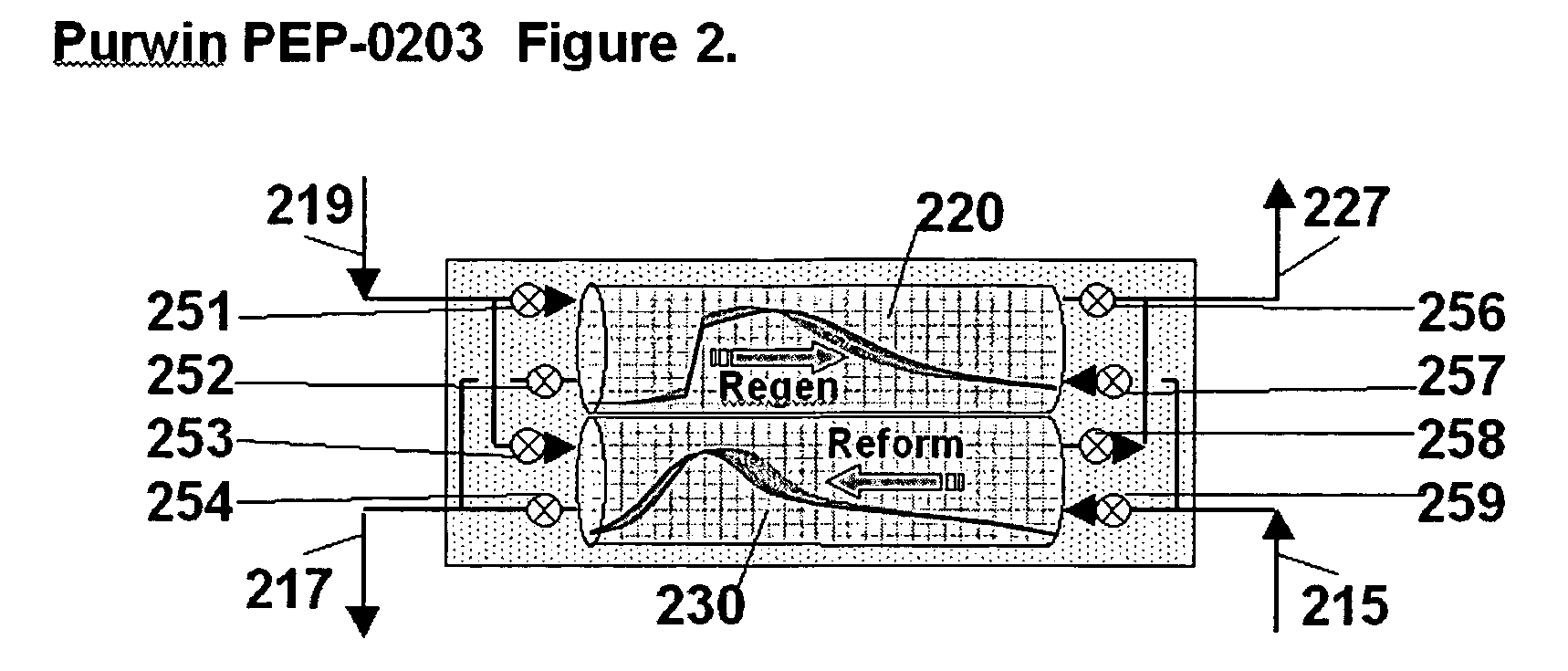

Pressure swing reforming for fuel cell systems

Owner:EXXON RES & ENG CO

Hybrid catalyst for hydrocarbon synthesis via hydrogenation of carbon dioxide

InactiveUS6376562B1High yieldHigh selectivityMolecular sieve catalystsOrganic compound preparationCarbon numberCarbon source

The present invention provides a hybrid catalyst which is prepared by mixing a methanol synthesis catalyst with SAPO-type zeolite as a methanol conversion catalyst, and a process for the preparation of hydrocarbons from carbon dioxide by using the hybrid catalyst. The hybrid catalyst of the invention can be used for preparing hydrocarbons having a carbon number of more than 2 from carbon dioxide under a relatively on the hydrocarbons produced. Therefore, the hybrid catalyst may be used for preparing various high-valued hydrocarbons from an ubiquitous carbon source of carbon dioxide.

Owner:KOREA ADVANCED INST OF SCI & TECH

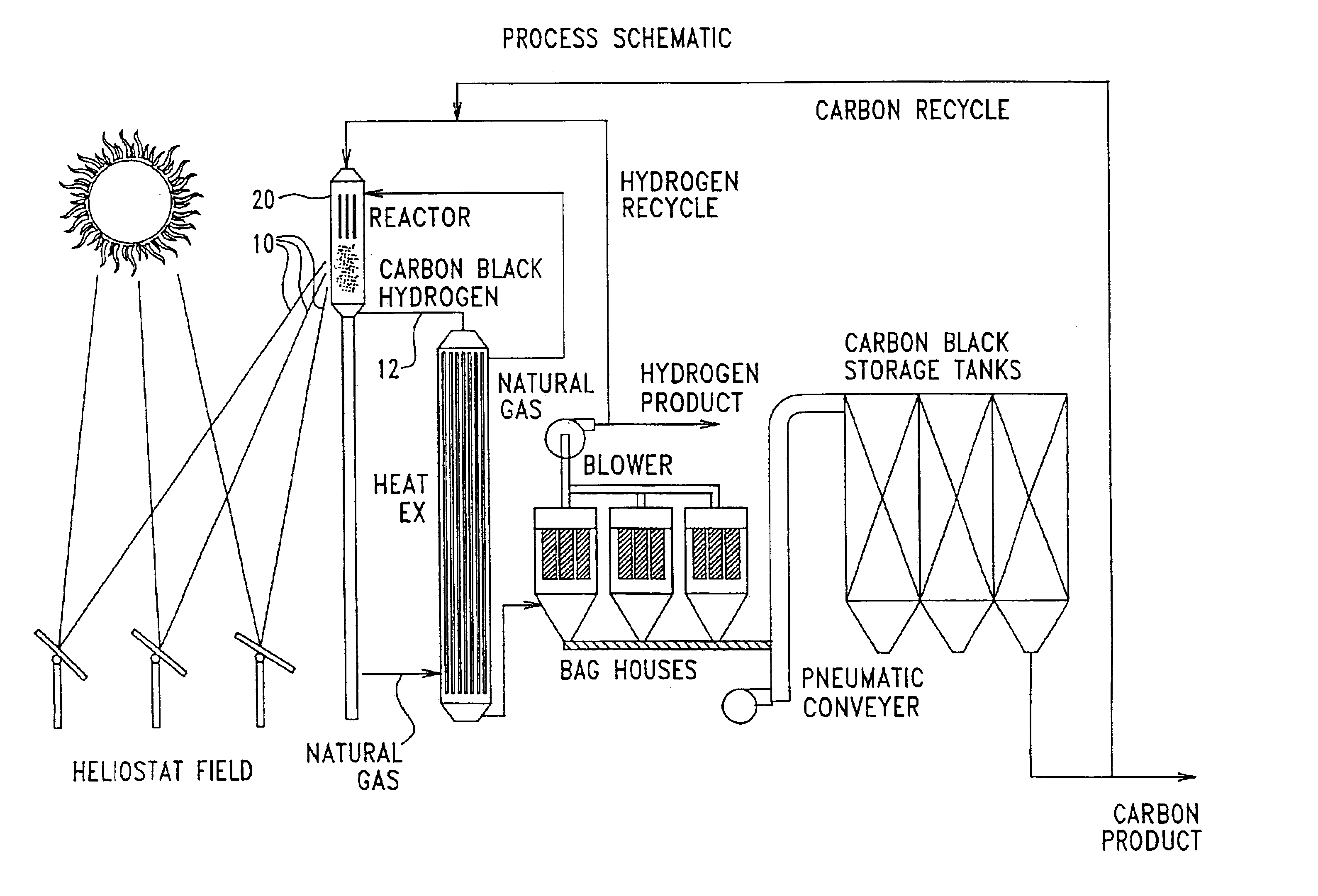

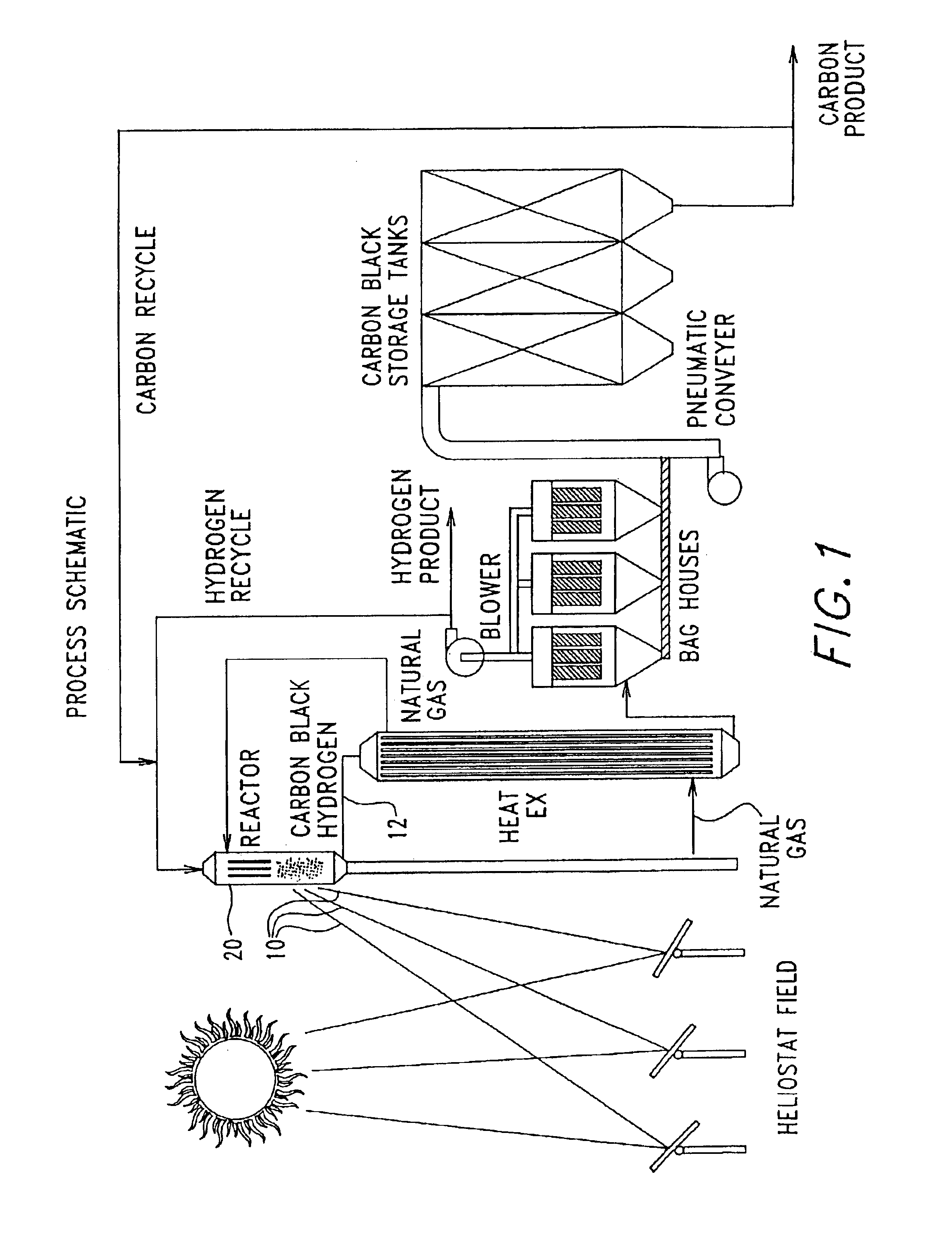

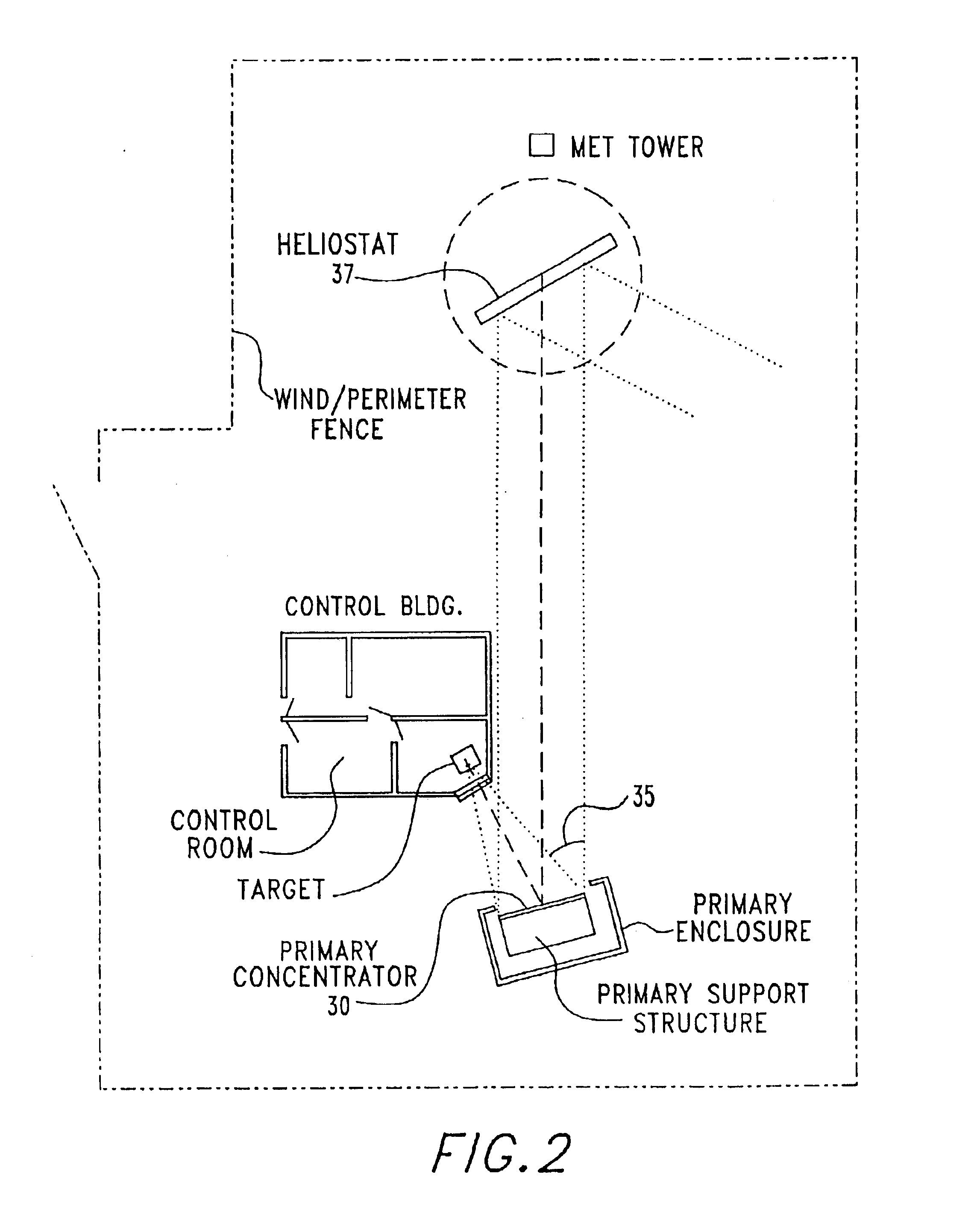

Solar thermal aerosol flow reaction process

InactiveUS6872378B2Short stayCost-effectiveSolar heating energyHydrocarbon from carbon oxidesForming gasChemical reaction

Owner:UNIV OF COLORADO THE REGENTS OF +1

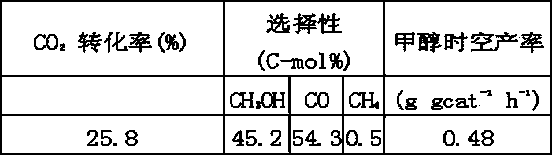

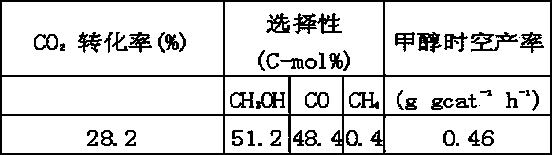

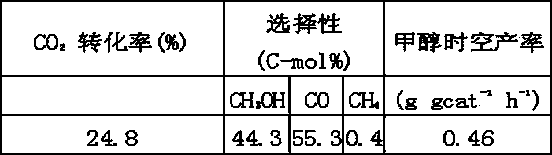

Catalyst for synthesizing methanol through carbon dioxide hydrogenation as well as preparation method and application thereof

InactiveCN103263926AImprove performanceLarge specific surface areaOrganic compound preparationHydroxy compound preparationDivalent metal ionsHigh carbon dioxide

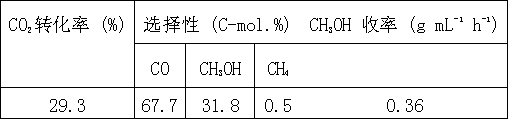

The invention discloses a catalyst for synthesizing methanol through carbon dioxide hydrogenation, which is composed of oxides, wherein measured by metals, the mole ratio of various metals is as follows: [n(Cu)+n(Zn)+n(MA)]:[n(Al)+n(MB)]=2-15, n(Cu):n(Zn)=0.5-4, n(MA):n(Zn)=0-1, and n(MB):n(Al)=0-9, MA represents monovalent or divalent metal ions, and MB represents trivalent or tetravalent metal ions. The catalyst has the advantages of high carbon dioxide conversion ratio, good methanol selectivity and high methanol yield.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

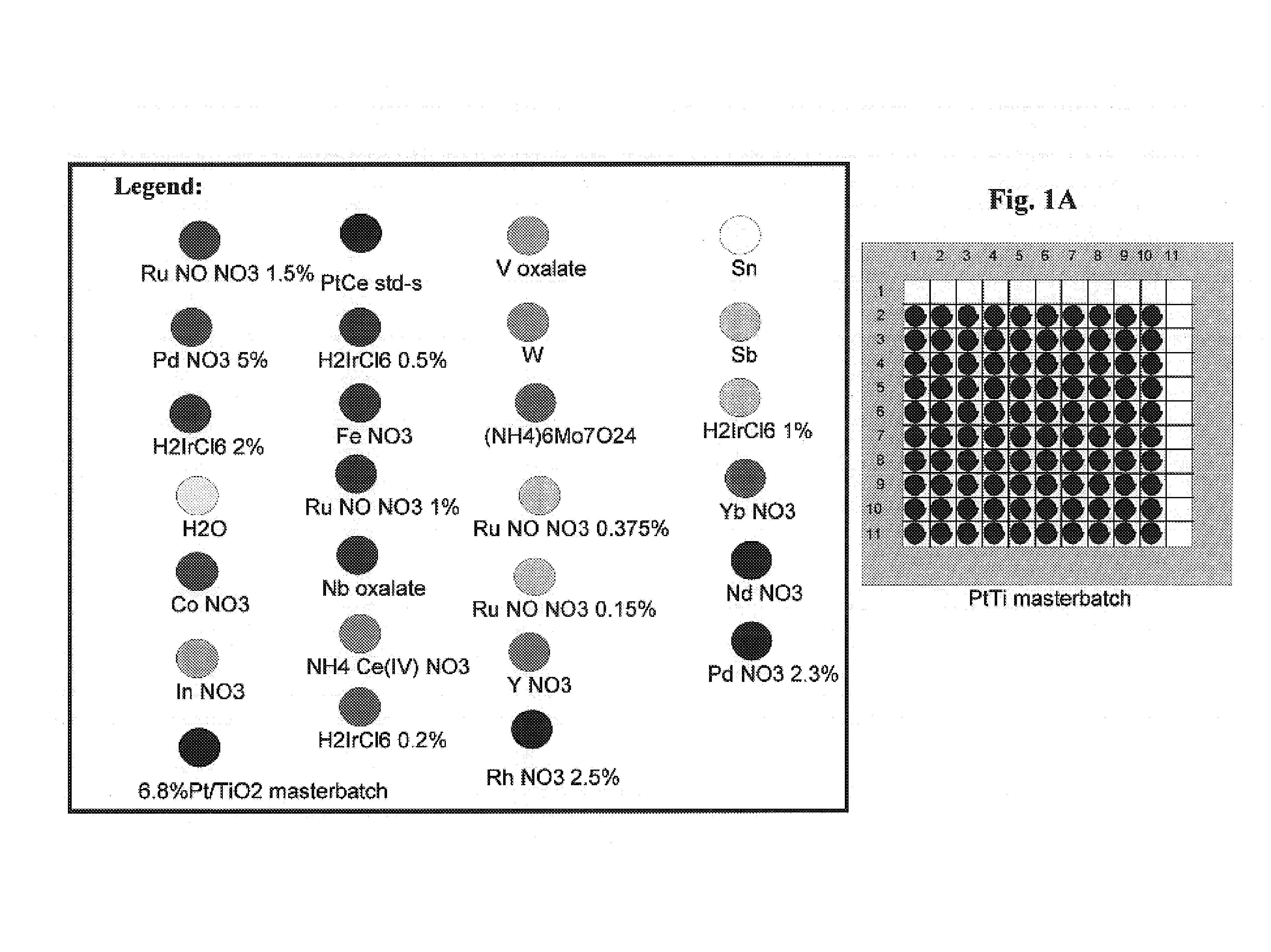

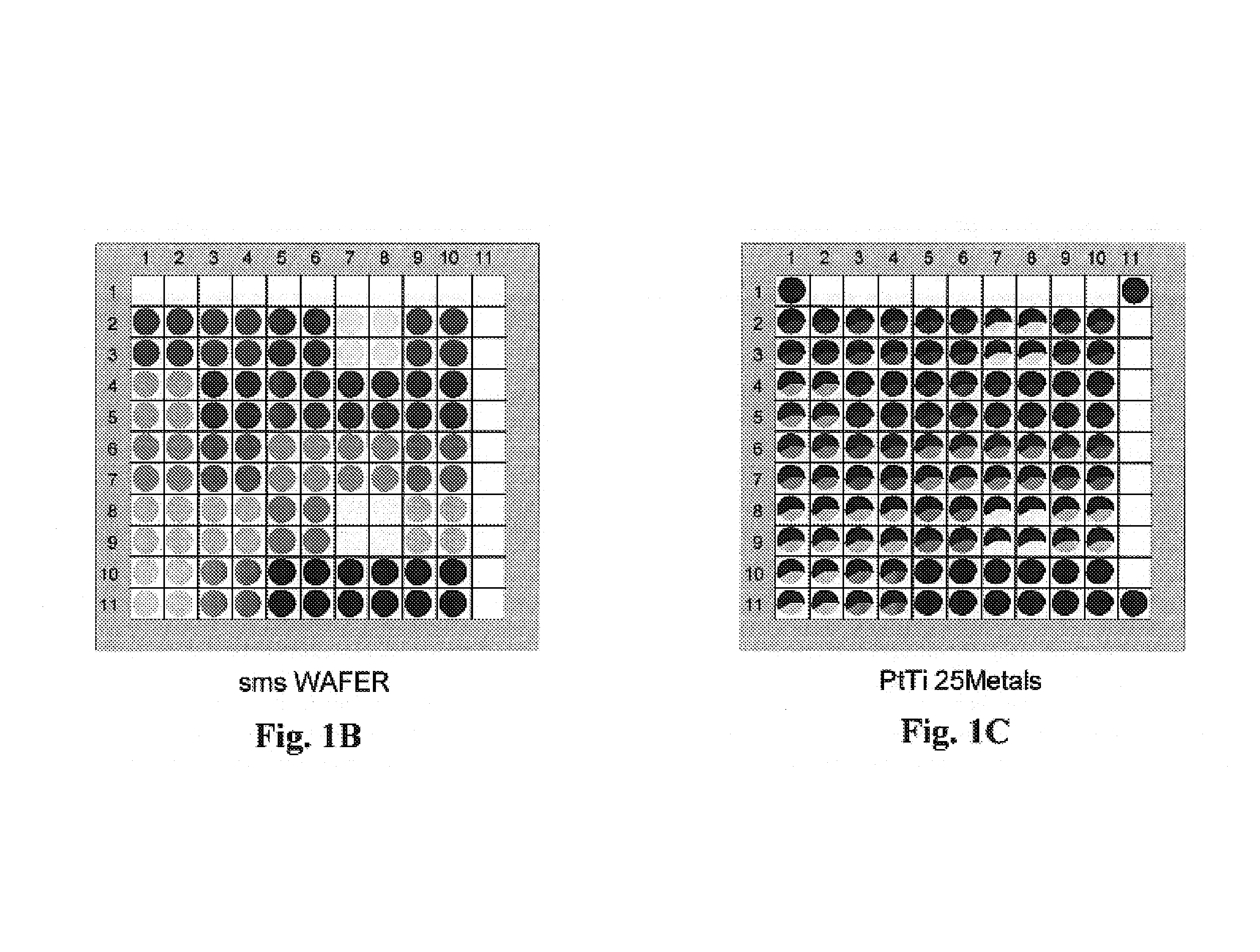

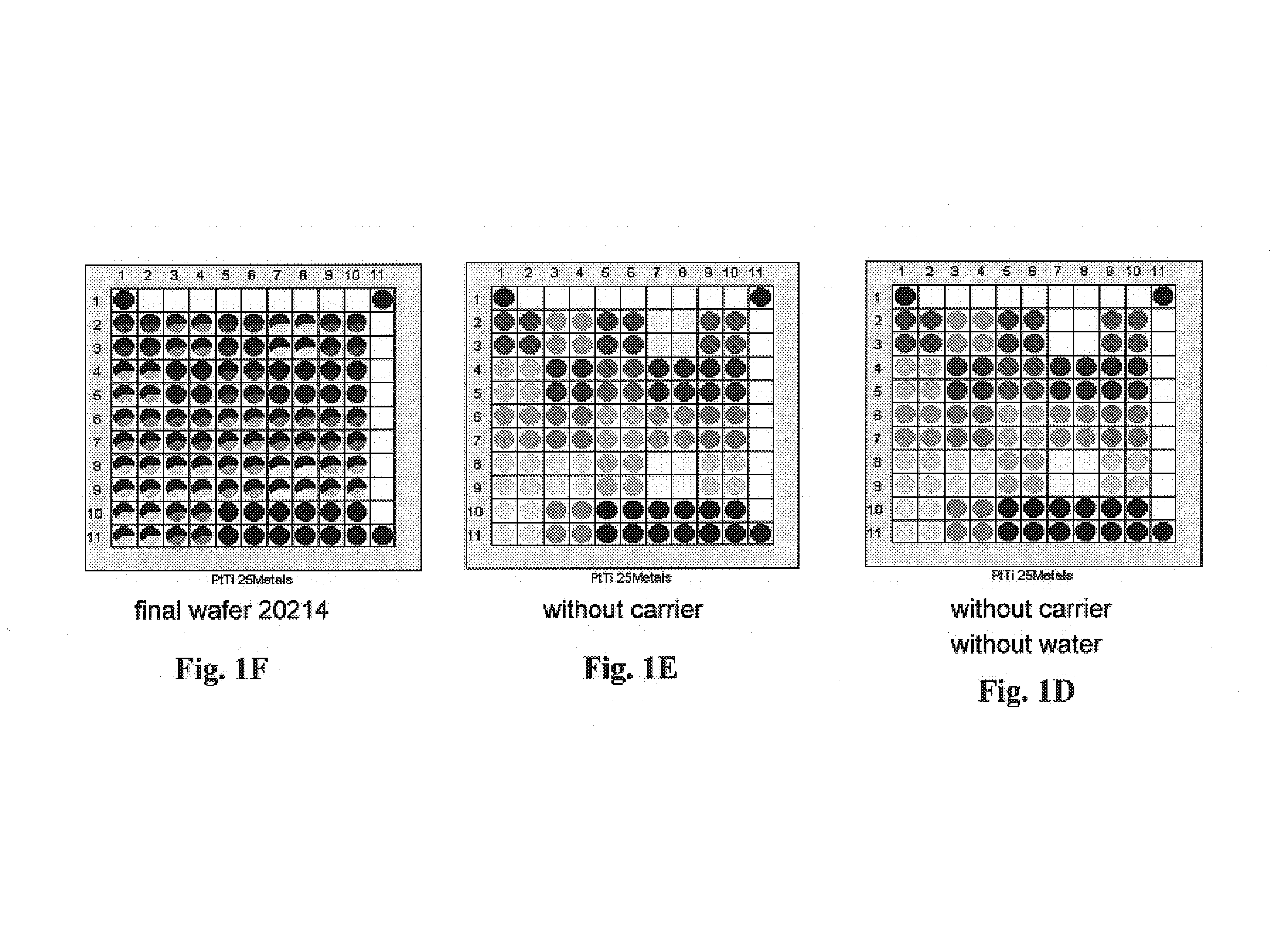

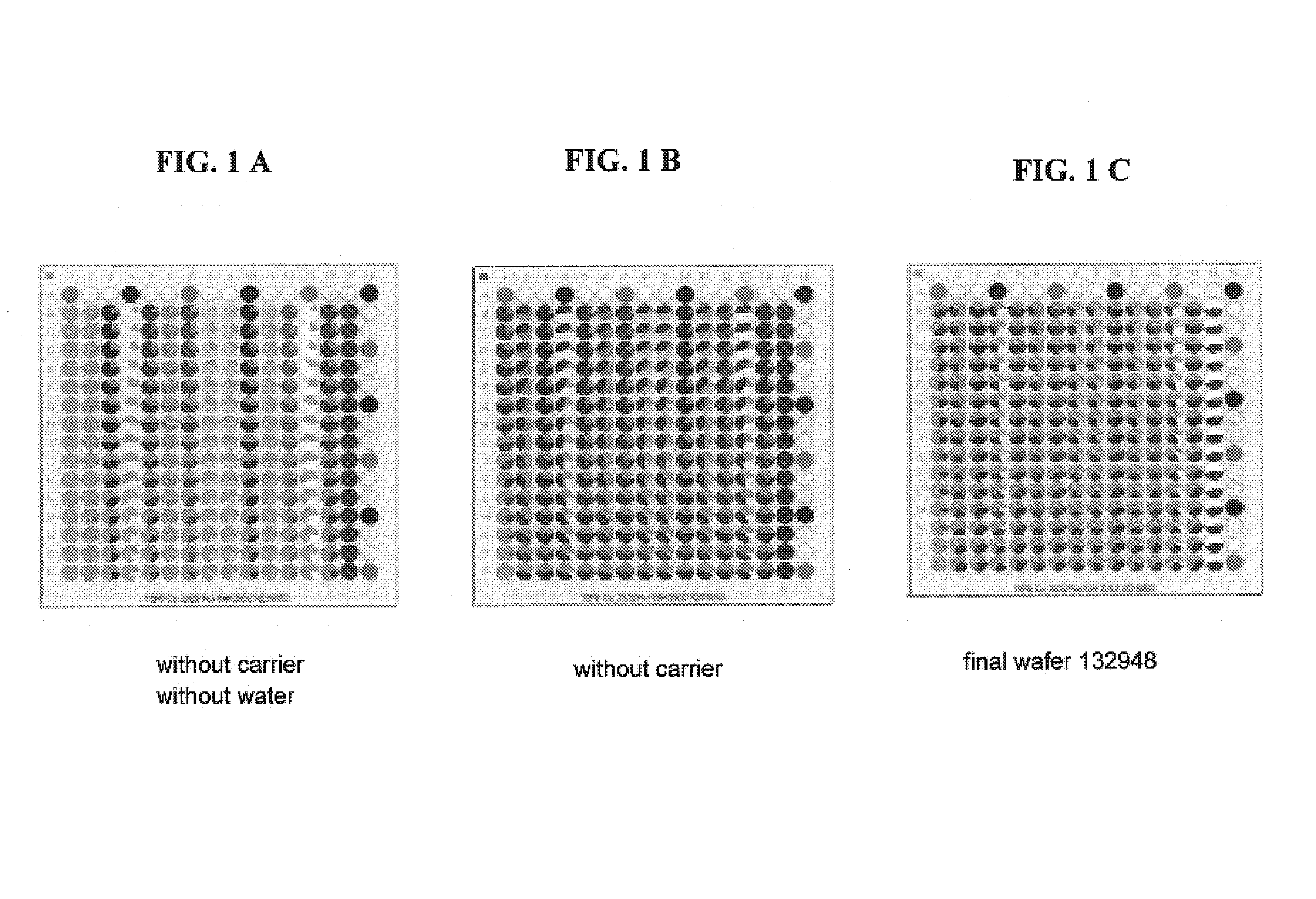

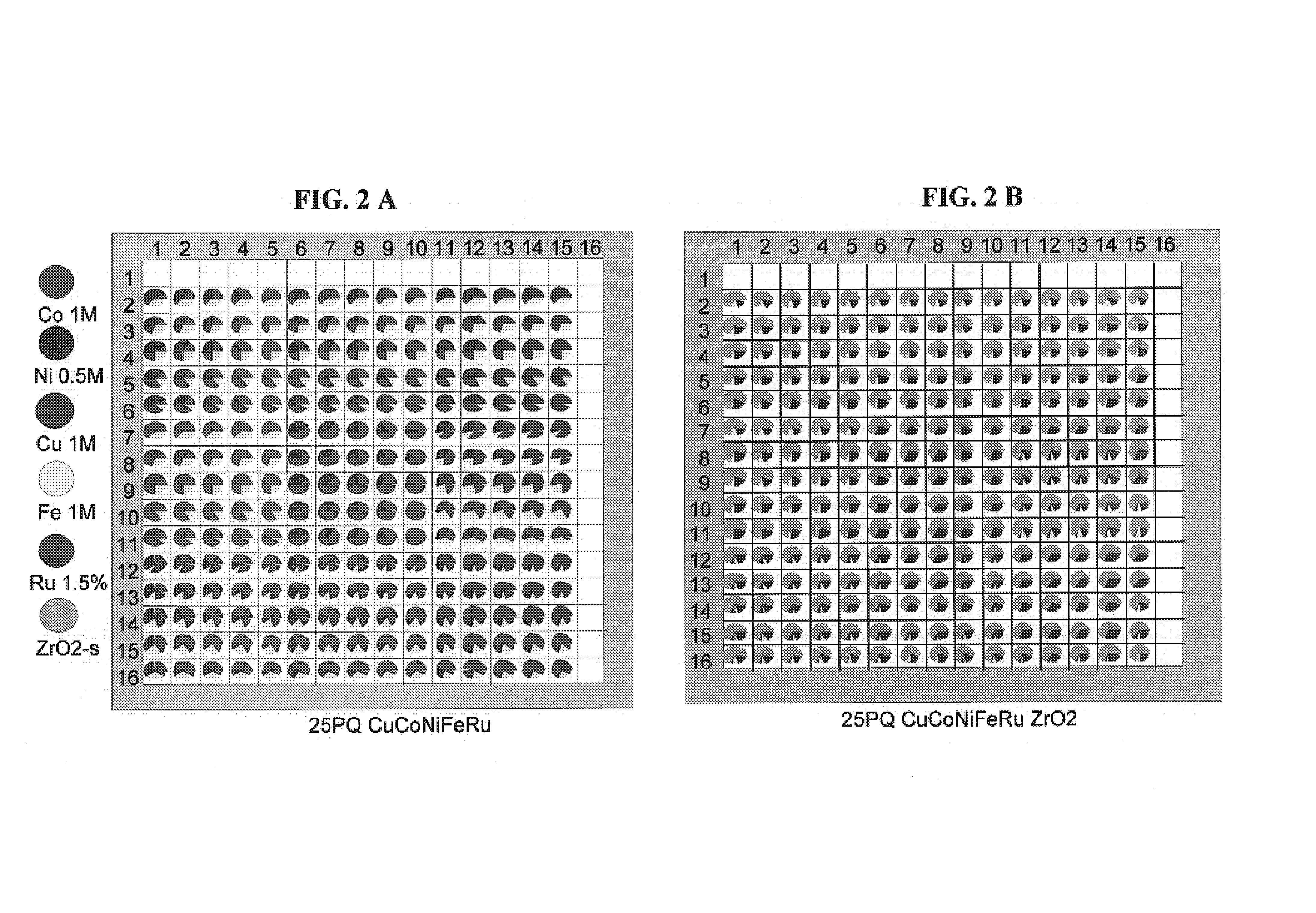

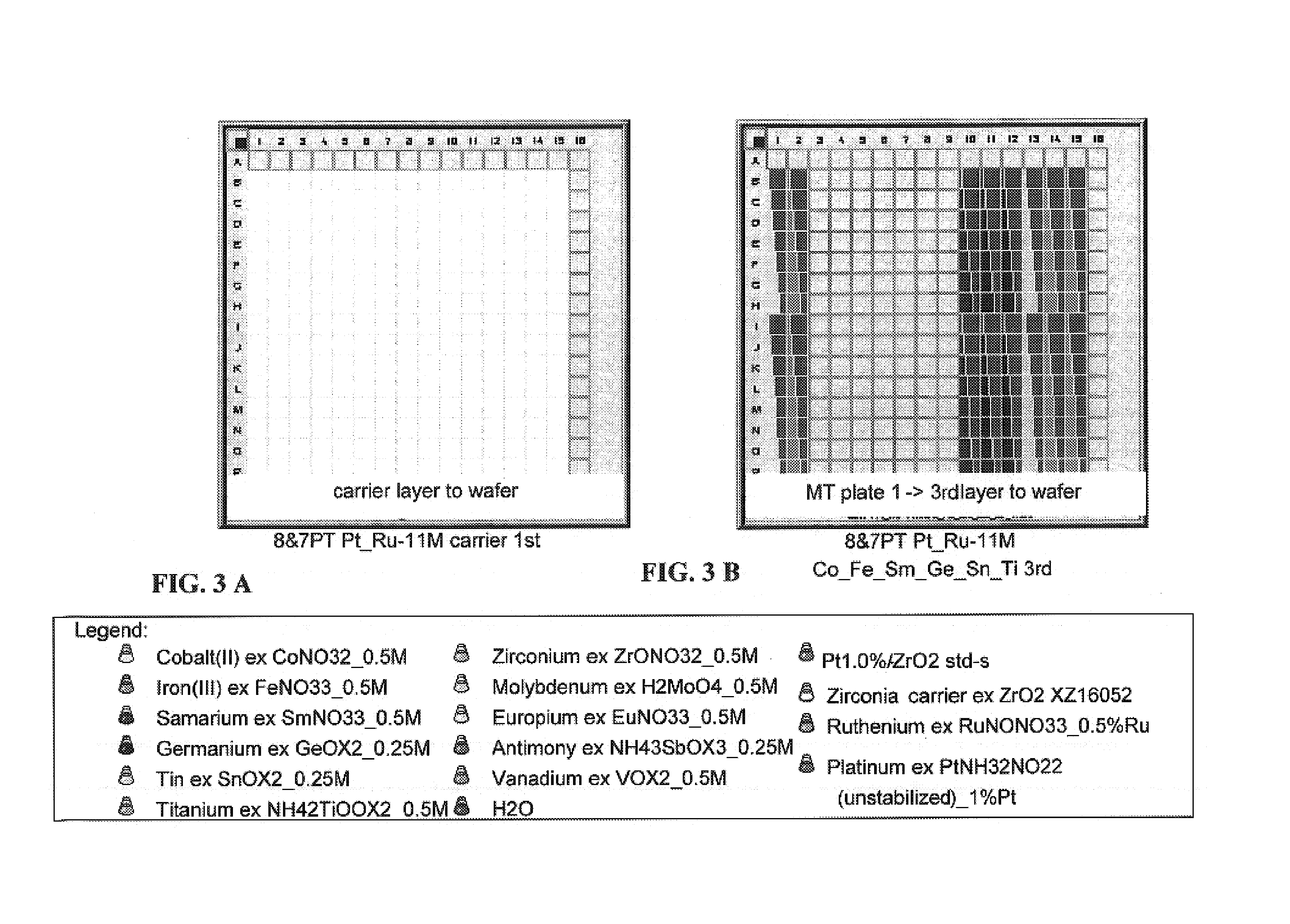

Platinum-ruthenium containing catalyst formulations for hydrogen generation

A method and catalysts for producing a hydrogen-rich syngas are disclosed. According to the method a CO-containing gas contacts a water gas shift (WGS) catalyst, optionally in the presence of water, preferably at a temperature of less than about 450° C. to produce a hydrogen-rich gas, such as a hydrogen-rich syngas. Also disclosed is a water gas shift catalyst formulated from:a) Pt, its oxides or mixtures thereof;b) Ru, its oxides or mixtures thereof; andc) at least one of Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Sc, Y, Ti, Zr, V, Mo, Mn, Fe, Co, Rh, Ir, Ge, Sn, Sb, La, Ce, Pr, Sm, and Eu. Another disclosed catalyst formulation comprises Pt, its oxides or mixtures thereof; Ru, its oxides or mixtures thereof; Co, its oxides or mixtures thereof; and at least one of Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Sc, Y, Ti, Zr, V, Mo, Mn, Fe, Rh, Ir, Ge, Sn, Sb, La, Ce, Pr, Sm, and Eu, their oxides and mixtures thereof. The WGS catalyst may be supported on a carrier, such as any one member or a combination of alumina, zirconia, titania, ceria, magnesia, lanthania, niobia, zeolite, perovskite, silica clay, yttria and iron oxide. Fuel processors containing such water gas shift catalysts are also disclosed.

Owner:FREESLATE +1

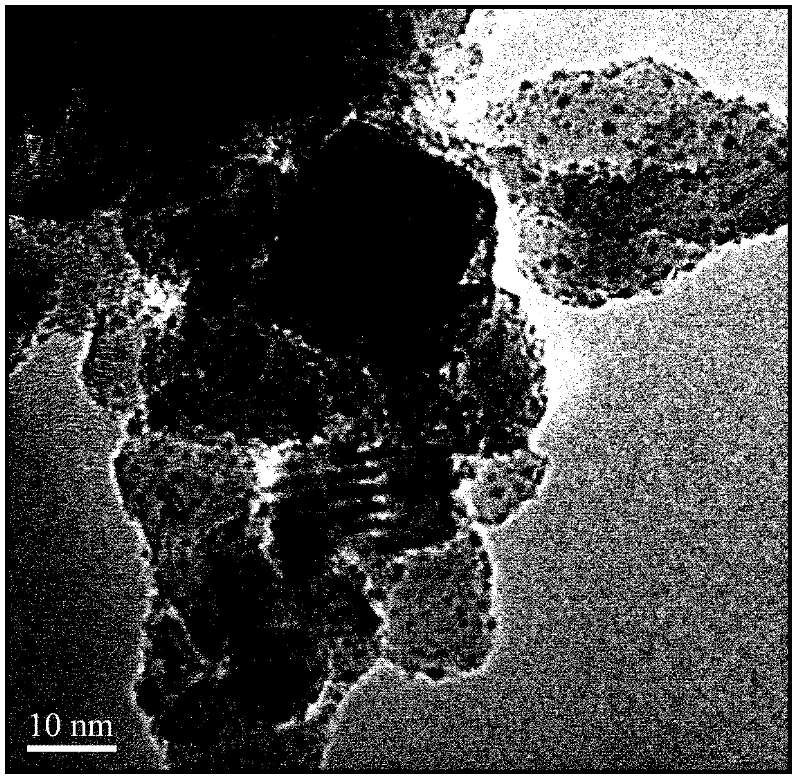

Preparation method and application of titanium dioxide loaded ruthenium catalyst

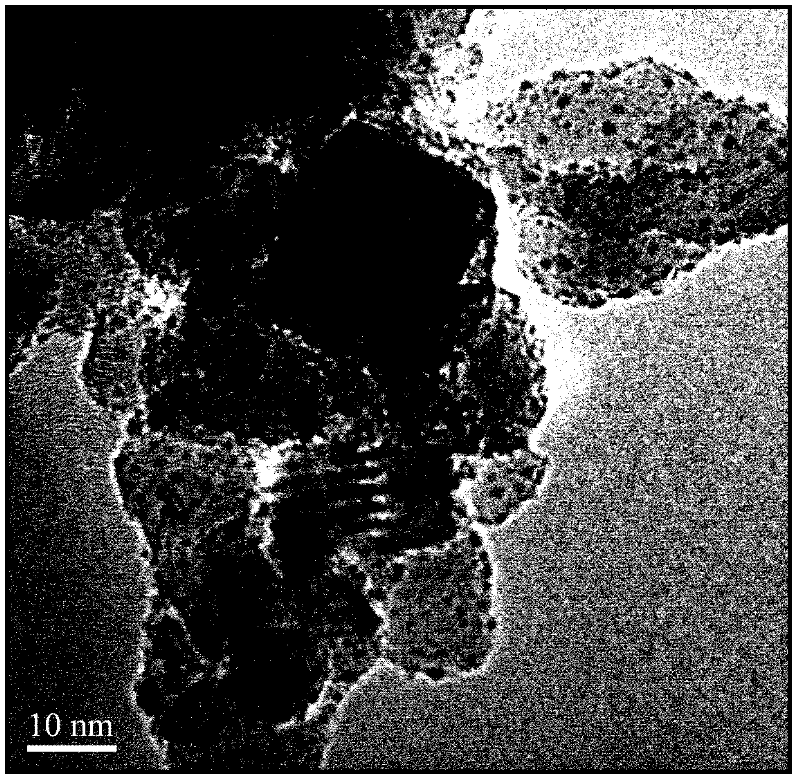

InactiveCN102513102AEnhanced interactionIncrease dispersionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsChemistryCarbon dioxide

The invention discloses a preparation method of a low-load-capacity and high-activity load type ruthenium catalyst using titanium dioxide as a carrier. According to the invention, the titanium dioxide is used as the carrier, an ageing solution is illuminated by using ultraviolet rays in a precipitation and deposition ageing process, thus interaction of a ruthenium precursor and the titanium dioxide is enhanced, the dispersion degree of the precursor is improved, and further the high-dispersion titanium dioxide loaded ruthenium catalyst is obtained. The preparation method has the advantages of simple equipment and process, high yield, and convenience for industrialized production; and the prepared ruthenium catalyst has the advantages of small ruthenium granularity and good reproducibility. The ruthenium catalyst is applied to a process for synthesizing methane by carbon dioxide through hydrogenation, and has high reactant transformation rate, high selectivity and good stability.

Owner:BEIJING UNIV OF CHEM TECH

Carbon dioxide production method

A method of producing a carbon dioxide product stream from a synthesis gas stream formed within a hydrogen plant having a synthesis gas reactor, a water-gas shift reactor, located downstream of the synthesis gas reactor to form the synthesis gas stream and a hydrogen pressure swing adsorption unit to produce a hydrogen product recovered from the synthesis gas stream. In accordance with the method the carbon dioxide from the synthesis gas stream by separating the carbon dioxide from the synthesis gas stream in a vacuum pressure swing adsorption system, thereby to produce a hydrogen-rich synthesis gas stream and a crude carbon dioxide stream and then purifying the crude carbon dioxide stream by a sub-ambient temperature distillation process thereby to produce the carbon dioxide product. A hydrogen synthesis gas feed stream to the hydrogen pressure swing adsorption unit is formed at least in part from the hydrogen rich stream.

Owner:PRAXAIR TECH INC

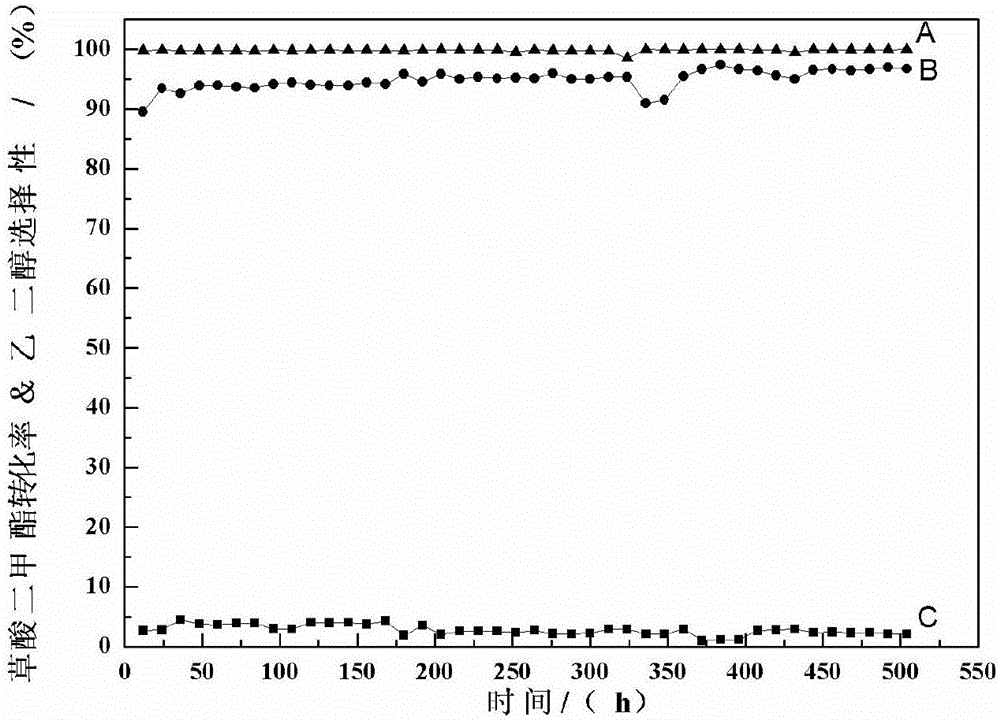

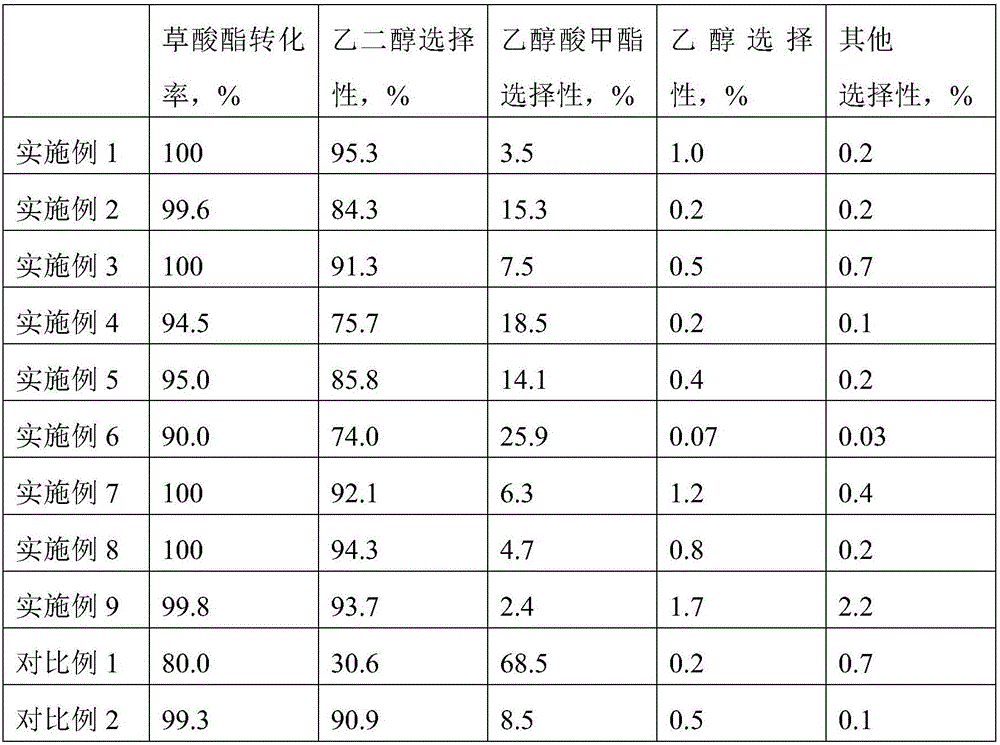

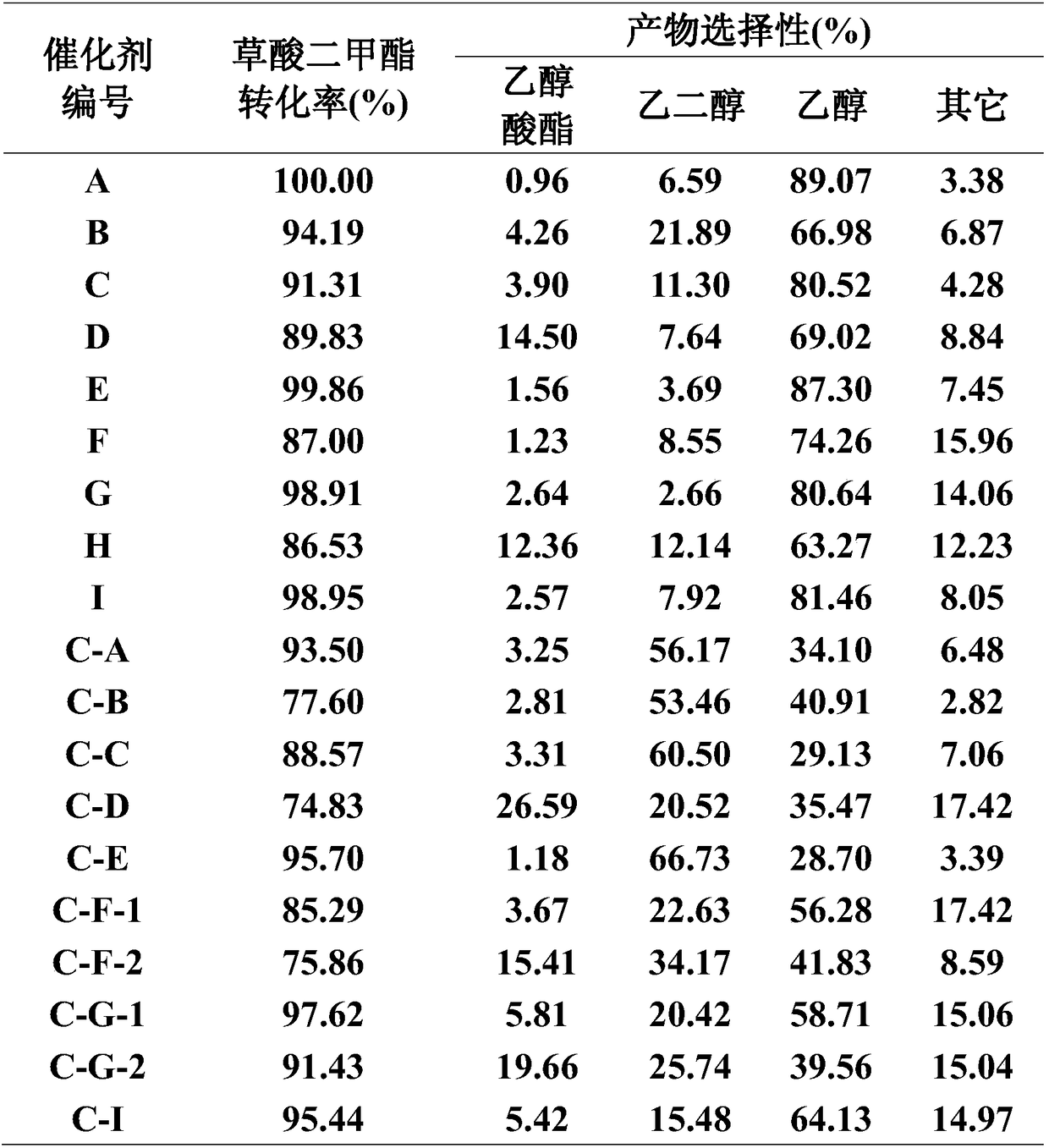

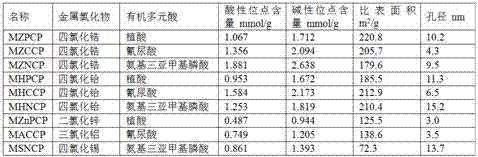

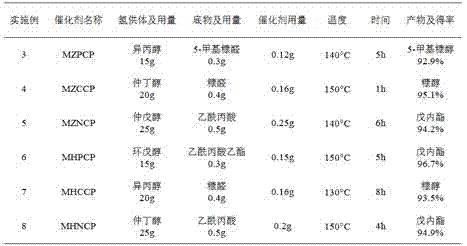

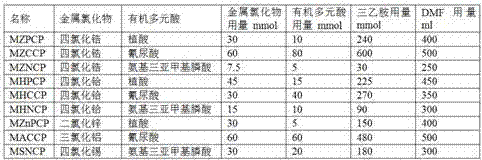

Catalyst for synthesizing ethylene glycol by oxalate hydrogenation, and preparation method and application method of catalyst

ActiveCN106563449AGood dispersionHigh activityOrganic compound preparationCarboxylic acid esters preparationDispersityReaction temperature

The invention provides a catalyst for synthesizing ethylene glycol by oxalate hydrogenation, and a preparation method and an application method of the catalyst. The preparation method comprises the steps of taking copper nitrate and copper acetate as copper sources, taking alkaline silica gel as a silicon source, and taking urea and ammonia water as a precipitant; adding a multi-hydroxyl organic matter; and preparing a Cu / SiO2 catalyst with a deposition-precipitation method. According to the method, the dimension and dispersity of copper species are adjusted and controlled by adding the multi-hydroxyl organic matter in the preparation process, and the aggregation of the copper species is inhibited by utilizing carbon deposition, so that the problem of easy sintering of the copper species at a high temperature is better solved. The application method for applying the catalyst to the synthesis of ethylene glycol by oxalate hydrogenation comprises the steps of firstly enabling the organic matter on the catalyst to form the carbon deposition at a relatively high temperature in an inert atmosphere; secondly switching inert gas to hydrogen in a cooling process after carbon deposition formation; and finally when the temperature is reduced to a reaction temperature, performing subsequent hydrogenation synthesis. The method has the characteristics that the catalyst does not need to be pre-roasted before use, and hydrogen pre-reduction does not need to be carried out for a long time, so that the preparation and use costs of the catalyst can be reduced.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

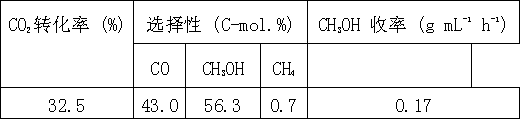

Preparing method of high-performance catalyst for hydrogenation of carbon dioxide for synthesizing methyl alcohol

InactiveCN104383928ALarge specific surface areaStable structureOrganic compound preparationHydroxy compound preparationPtru catalystHigh activity

The invention discloses a preparing method of a high-performance catalyst for hydrogenation of carbon dioxide for synthesizing methyl alcohol, belonging to the technical field of catalysts. The catalyst comprises mixed oxides of Cu, Zn and M, wherein M refers to Al, Nb, Mg or Zr; the molar ratio of CuO to ZnO to MxOy in the catalyst is 8 to 4-5 to 1-2; the preparing method comprises the following steps: performing parallel-flow precipitation on a saline solution containing active matters and a precipitator in a certain ratio to prepare an active component sizing agent A; performing parallel-flow precipitation on a saline solution containing carrier components and the precipitator to prepare a carrier sizing agent B; adding the sizing agent A to the sizing agent B, and violently beating; adding the saline solution containing the active matters and the precipitator in a certain ratio to prepare a catalyst sizing agent; and filtering, washing, drying and roasting to obtain the catalyst powder. The catalyst has a specific surface area as large as 160 m<2> / g, and is stable in structure, and the components are in close contact and achieve high synergistic effect, so that the catalyst has high activity and selectivity.

Owner:大连瑞克科技股份有限公司

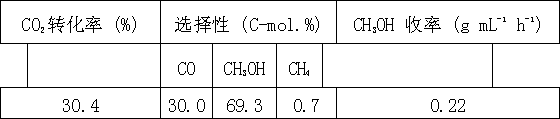

Catalyst for synthesizing methanol through CO2 hydrogenation as well as preparation method and application

ActiveCN103721719ALarge specific surface areaGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystHalogen

The invention discloses a catalyst for synthesizing methanol through CO2 hydrogenation, comprising Cu, Zn, Al, X, halogen and oxygen elements, oxides and halides, wherein the molar ratio of [Cu+Zn+MA] to [Al+Mb] is 2-18; the molar ratio of Cu to Zn is 0.5-5; the molar ratio of MA to [Cu+Zn] is 0-5; the molar ratio of MB to Al is 0-9; the molar ratio of halogen to Al is 0.05-5; MA and MB cannot be 0 at the same time; MA represents a mono-valent or divalent metal ion in X; MB represents a trivalent and / or tetravalent metal ion in X; X is one or a combination of more elements of Li, K, Mg, B, Ga, In, transition metal elements and rare-earth metal elements. The catalyst has the advantages of high carbon dioxide conversion rate, good methanol selectivity and high methanol yield.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

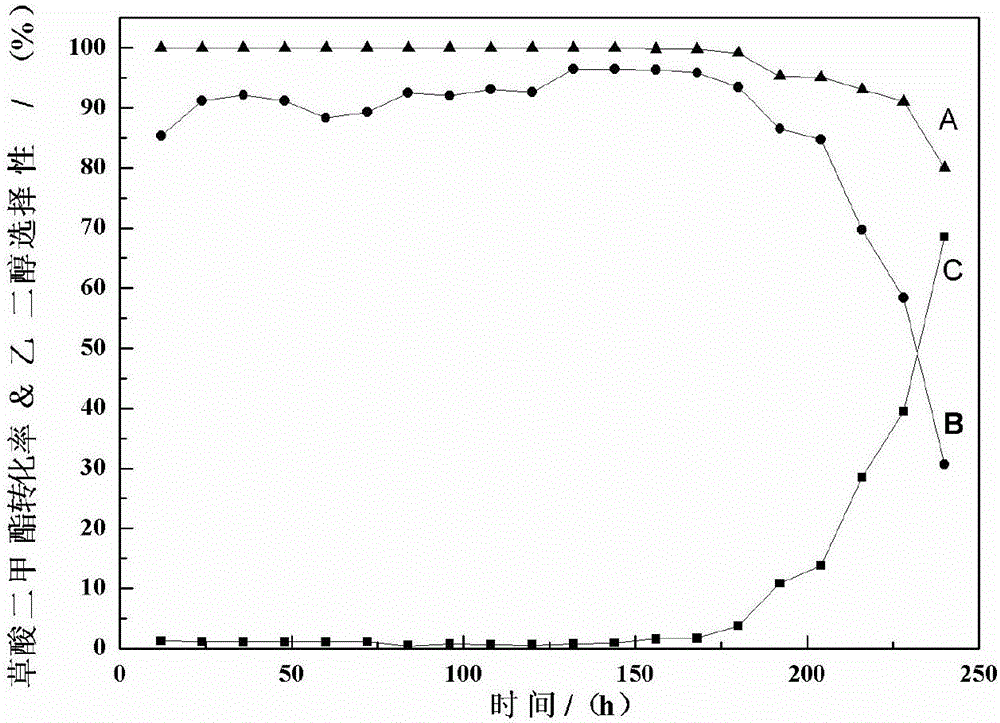

Catalyst for ethylene glycol synthesis through gas phase hydrogenation of dimethyl oxalate, preparation method and applications thereof

InactiveCN106582652AHigh activityImprove overall lifespanOrganic compound preparationHeterogenous catalyst chemical elementsSal ammoniacCopper salt

The present invention relates to a catalyst for ethylene glycol synthesis through gas phase hydrogenation of dimethyl oxalate, a preparation method and applications thereof. The catalyst comprises CuO, a metal auxiliary agent oxide and silica, wherein the Cu element accounts for 10-50% of the total weight of the catalyst, and the metal auxiliary agent element accounts for 1-10% of the total weight of the catalyst. The invention further discloses the preparation method of the catalyst. According to the present invention, a soluble copper salt and a metal auxiliary agent soluble salt are used and are added with ammonia water to form an ammonia complex aqueous solution, aging-ammonia evaporation and co-precipitating are performed, and the obtained material and silica form the gel so as to form the stable chemical structure, such that the stability of the catalyst is substantially improved; during the preparation process, the organic modifier is added so as to effectively improve the pore structure and the specific surface area of the catalyst, and improve the activity of the catalyst and the ethylene glycol selectivity; and with the application of the catalyst in the dimethyl oxalate hydrogenation reaction, the service life is more than one year, the average conversion rate of dimethyl oxalate is more than 99.9%, and the ethylene glycol selectivity is more than 95%.

Owner:SHANGHAI HUAYI ENERGY CHEM

Preparation method of copper based hydrogenation catalyst

InactiveCN104549299AImprove conversion rateHigh selectivityOrganic compound preparationHydroxy compound preparationPtru catalystPhysical chemistry

The invention relates to a preparation method of a copper based hydrogenation catalyst, and belongs to the technical field of catalyst preparation. The catalyst is prepared by adopting a staged precipitation method and is divided into two parts of a main body part and a surface auxiliary agent, the catalyst main body is composed of oxides of Cu, Zn and Al and is prepared by a co-precipitation method; the surface auxiliary agent includes one or more of Mg, Ba, Zr, Mn, Ga, Ce, La and Ti and is introduced to the surface of the catalyst main body by the chemical method. The prepared catalyst has the characteristics of high auxiliary agent utilization rate, high mechanical strength, and large number of strong alkaline sites in the surface, is used as a catalyst for a reaction for CO2 hydrogenation synthesis of methanol, and has high CO2 conversion rate and methanol selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

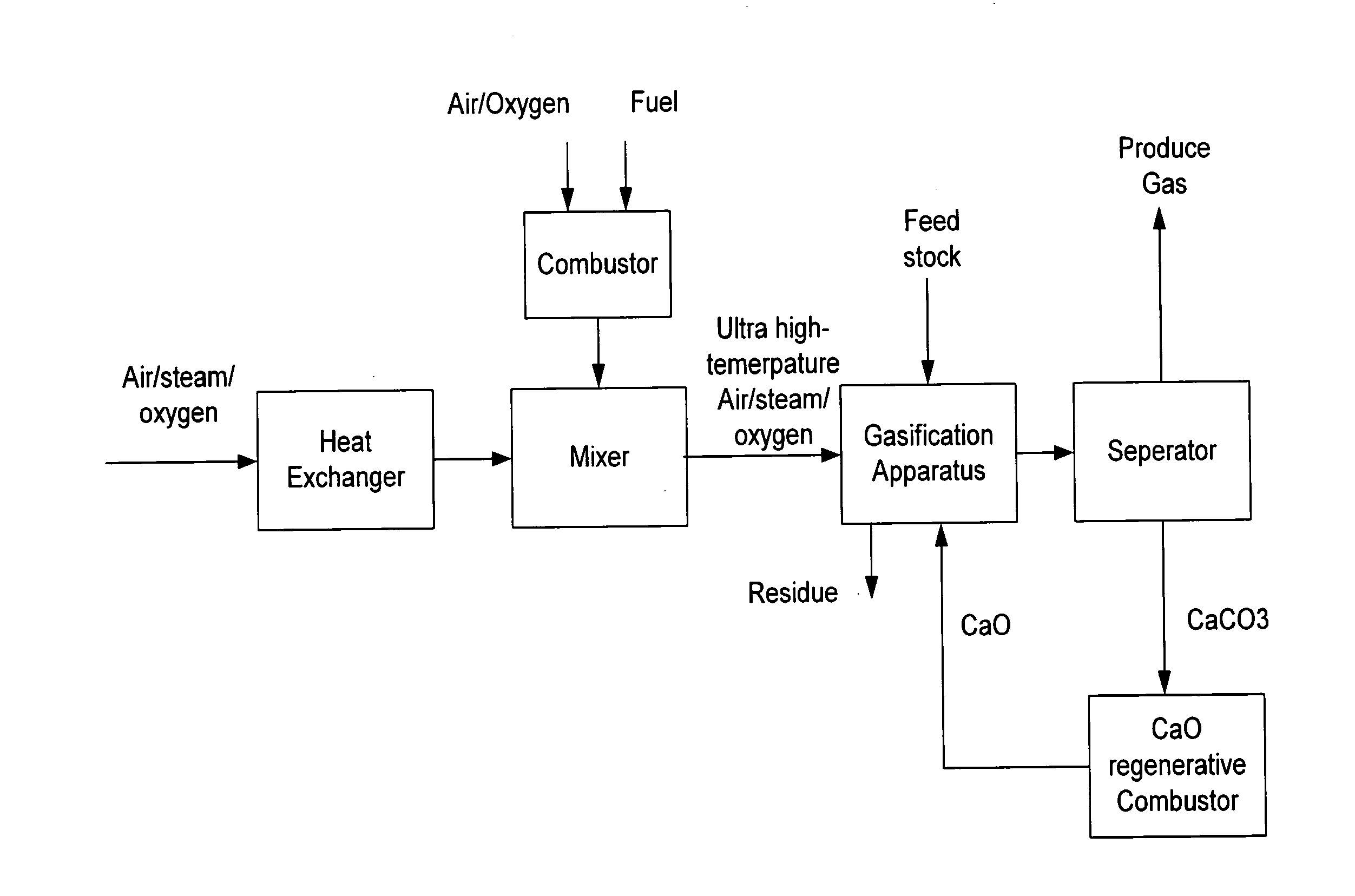

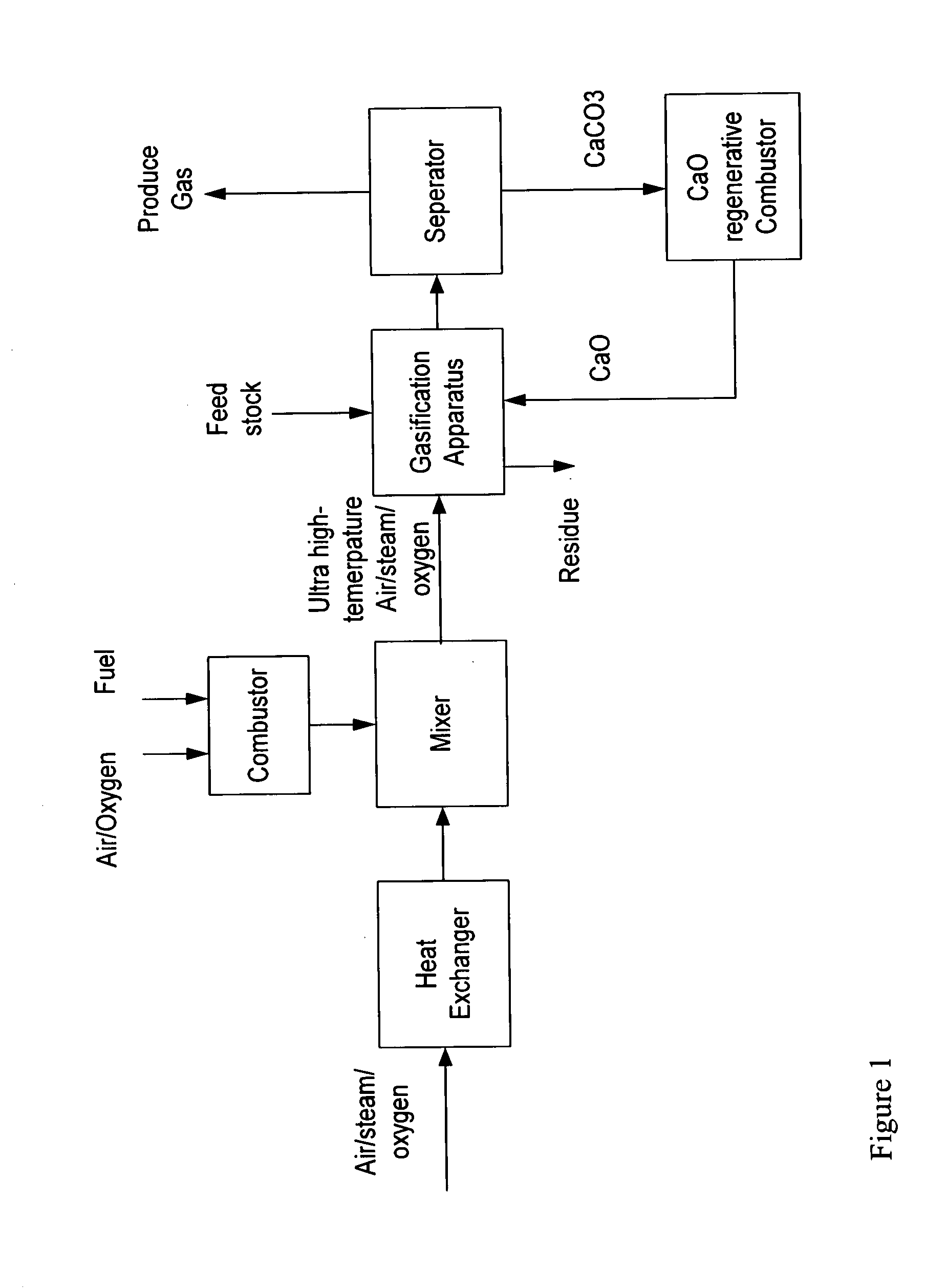

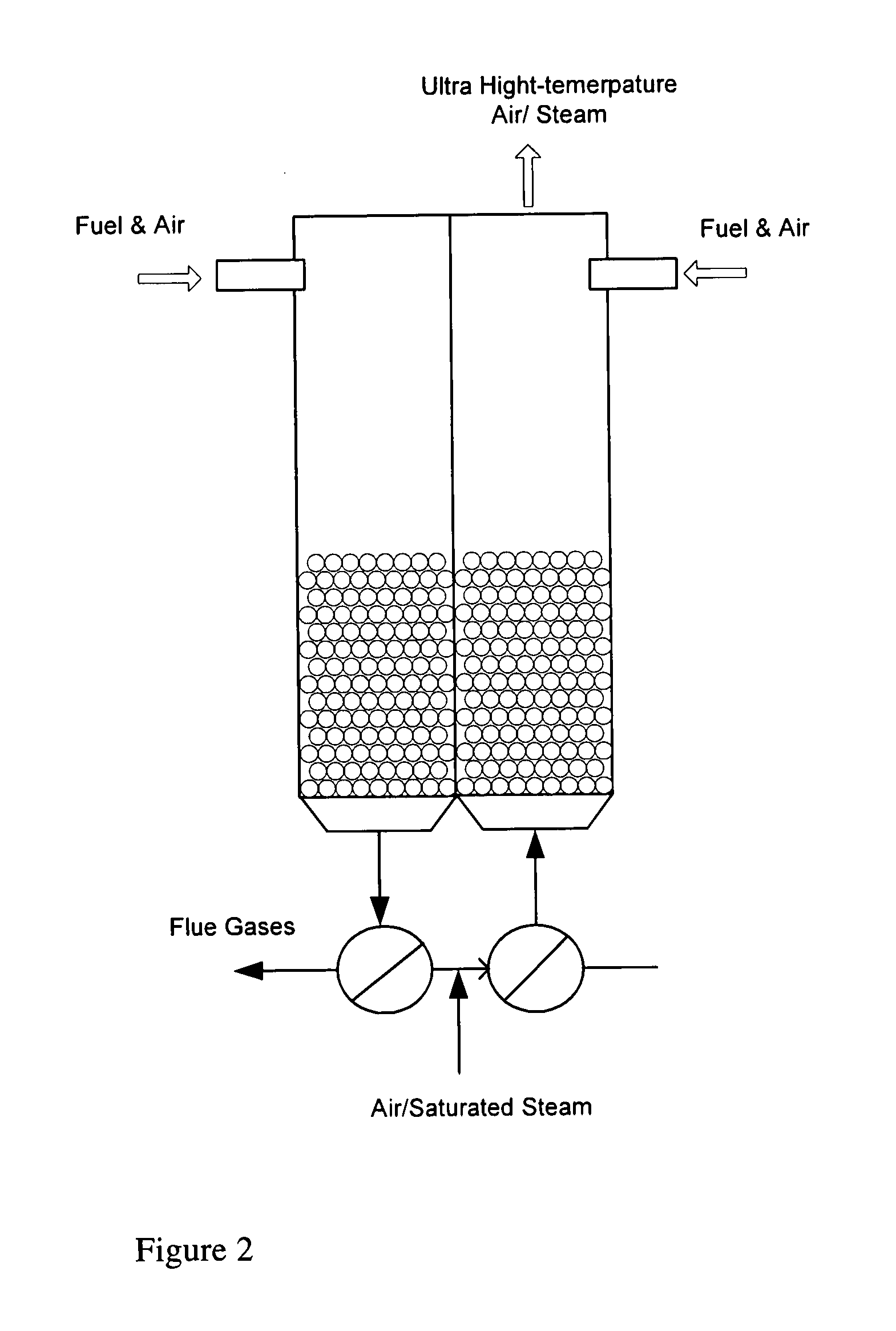

Biomass gasification method and apparatus for production of syngas with a rich hydrogen content

InactiveUS20100301273A1Satisfactory efficiencyMedium and high LCV valueHydrocarbon from carbon oxidesCombustible gas catalytic treatmentSyngasChemical reaction

A biomass gasification method and apparatus for production of syngas with arich hydrogen content. In the gasification process the gasification energy is supplied by the sensible heat carried by a high temperature agent combined with the heat released by the chemical reaction between calicined lime and carbon dioxide.

Owner:BOSON ENERGY

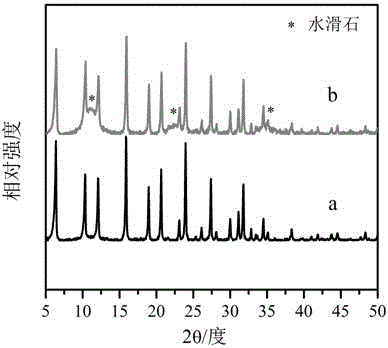

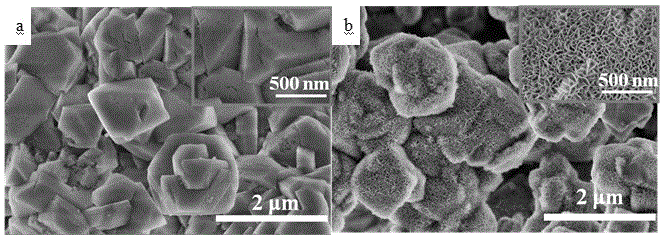

Core shell catalyst by taking hydrotalcite as shell and molecular sieve as core as well as preparation and application thereof

ActiveCN106475134AGood dispersionImprove stabilityMolecular sieve catalystsOrganic compound preparationMolecular sieveDivalent metal

The invention discloses a core shell catalyst by taking hydrotalcite as a shell and a molecular sieve as a core as well as a preparation and an application thereof. According to the invention, divalent metal source and aluminum species in a core-shell molecular sieve are used for forming a hydrotalcite compound on the surface of the molecular sieve, and the core-shell structure molecular sieve by taking the molecular sieve as the core and the petal hydrotalcite as the shell is formed; after the molecular sieve is reduced, the nano-grade metal-modified molecular sieve catalyst having uniform size, high dispersibility, excellent heat stability and high universality is obtained, and can be used for a catalytic reaction for hydrogenation synthesis of m-dinitrobenzene to obtain m-phenylenediamine. compared with the prior art, the preparation process is simple, the metal atom utilization rate is high, applied metal source is almost completely reacted, no loss is generated, cost is reduced, and pollution on environment is reduced, industrial production is easy, and a series of different metal-modified molecular sieve catalysts can be prepared according to the modifiable character of the composition elements of the hydrotalcite and diversity of a topological structure of the molecular sieve.

Owner:EAST CHINA NORMAL UNIV

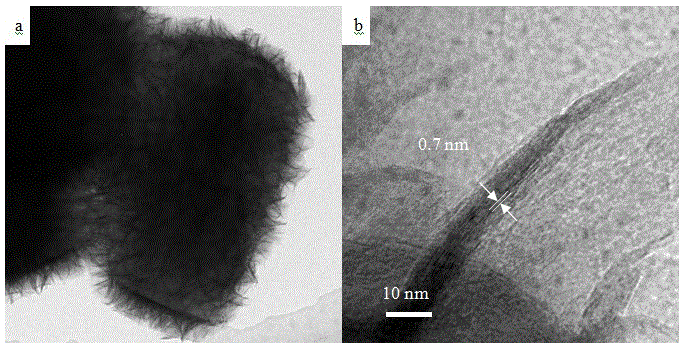

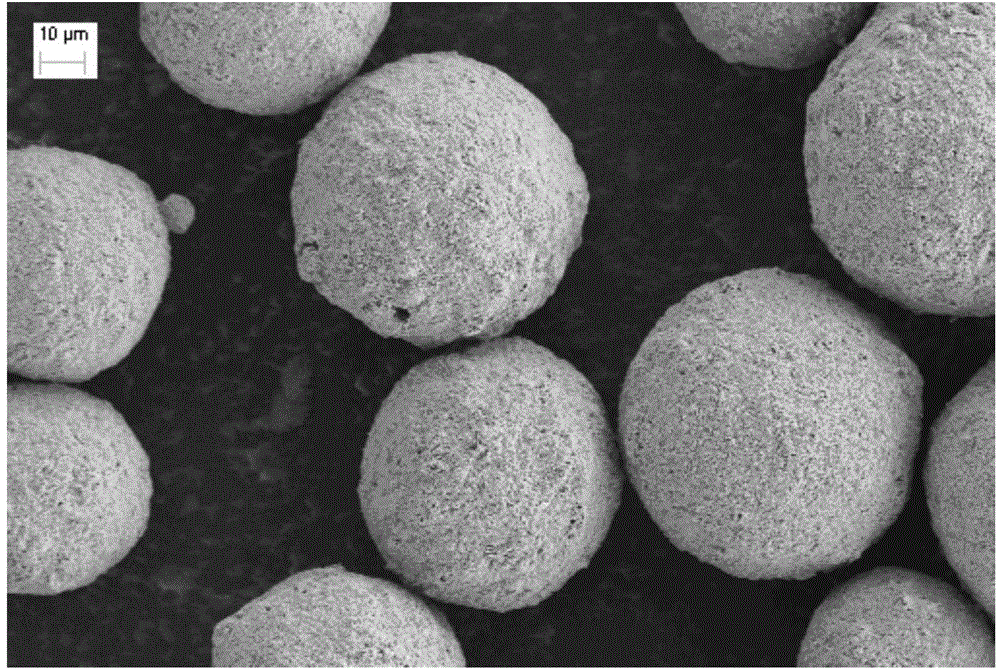

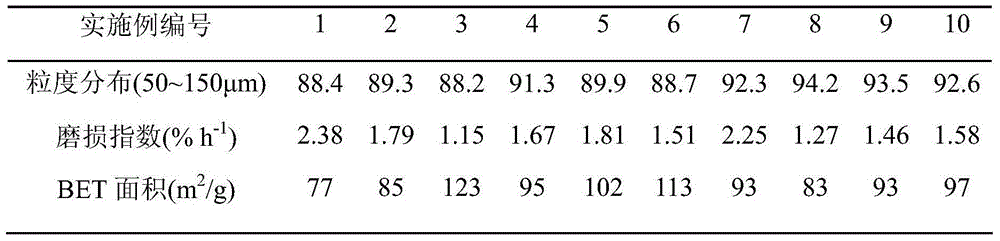

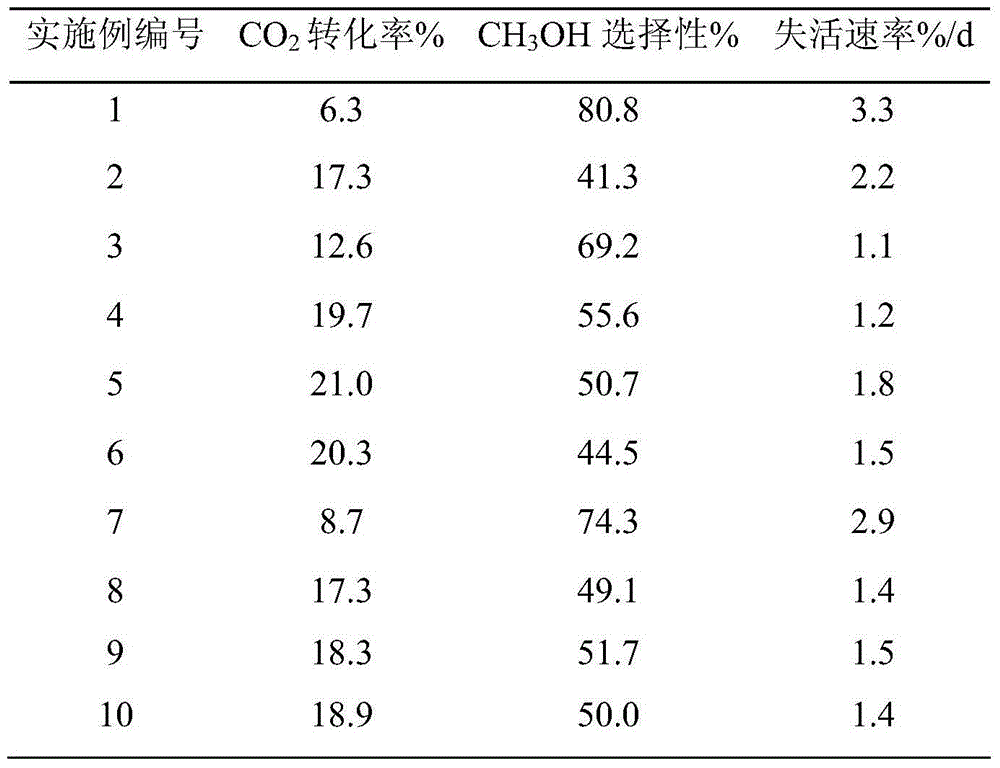

Catalyst for methanol synthesis via CO2 hydrogenation on slurry bed reactor, preparation method and application

InactiveCN104959143AUniform particle size distributionLarge specific surface areaOrganic compound preparationHydroxy compound preparationHydrogenation reactionSlurry

The invention provides a catalyst for methanol synthesis via CO2 hydrogenation on a slurry bed reaction. The catalyst comprises the following components in percentage by weight: 30%-50% of CuO, 15%-30% of ZnO, 10%-25% of Al2O3, 2%-10% of transition metal oxides and 5%-40% of structural promoters. The catalyst has the advantages that the degree of sphericity of particles is high, the particles are distributed uniformly, the specific surface area is large, the wear resistance is high, the service life is long, the performance of the catalyst is stable in CO2 hydrogenation reaction, low-temperature activity, transformation activity and selectivity are high, the catalyst can be operated at low temperature ranging from 180-220 DEG C, the cost is low, and the catalyst is easy and convenient to prepare and can be industrially amplified easily. The CO2 single-pass conversion rate of the catalyst can be high at the temperature of 220 DEG C, and the wear resistance of the catalyst is quite high.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Preparation method of catalyst used for synthesizing ethyl alcohol through hydrogenation on dimethyl oxalate, catalyst obtained by adopting preparation method and application thereof

ActiveCN108236955AHigh selectivityImprove conversion rateMolecular sieve catalystsOrganic compound preparationPtru catalystAlcohol

The invention relates to a method for preparing a catalyst used for synthesizing ethyl alcohol through hydrogenation on dimethyl oxalate. The catalyst contains a carrier, a catalytic active componentloaded on the carrier, and an optional catalytic promoter, concretely the catalyst contains: (A) based on element, 1-50wt% of elements which are selected from Cu, Fe, Ni, Co, Ag and Au and taken as the catalytic active component; (B) based on element, 0-10wt% of elements which are selected from third main group elements, transition elements and lanthanide elements and taken as the catalytic promoter; and (C) the carrier. The catalyst is prepared by adopting a urea-assisted hydrothermal synthesis method, and CO2 supercritical drying is adopted, so that high ethyl alcohol selectivity can be obtained, and high dimethyl oxalate conversion rate also can be obtained when the prepared catalyst is used for producing ethyl alcohol through hydrogenation on dimethyl oxalate. The invention also relates to the catalyst prepared by adopting the method provided by the invention and application of the catalyst in production of ethyl alcohol through hydrogenation on dimethyl oxalate.

Owner:HIGHCHEM

Method for synthesizing 2,5-furandimethanol by selective hydrogenation of 5-hydroxymethylfurfural

ActiveCN107442177AHigh acid-base strengthPolyacid-base siteOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholHydrogenation reaction

The invention discloses a method for synthesizing 2,5-dihydroxymethylfuran by selective hydrogenation of 5-hydroxymethylfurfural. The method is characterized in that a magnetic metal-organic coordination polymer is used as an acid and base bifunctional catalyst, low-price and easily-obtained low carbon alcohol is used as an in-situ hydrogen donor, and the 5-hydroxymethylfurfural is efficiently transformed into the 2,5-dihydroxymethylfuran by a selective transfer hydrogenation reaction under mild operation conditions and the maximum yield of the 2,5-dihydroxymethylfuran can be up to 98.6 percent. The magnetic metal organic coordination polymer used in the method disclosed by the invention has the advantages of relatively-high acid-base strength, more acid-base sites, relatively-large specific surface area and suitable pore size; in addition, the magnetic metal organic coordination polymer is simple in preparation process, is easy to separate and recover and shows excellent catalytic activity and catalytic stability. Furthermore, the low carbon alcohol is used as the in-situ hydrogen donor in the invention, so that the use of molecular hydrogen is avoided and the safety of the reaction process is improved; besides, the low carbon alcohol can be used as a reaction solvent and the introduction of exogenous substances is reduced, and thereby the production cost can be further reduced.

Owner:HUAIYIN TEACHERS COLLEGE

Preparation method of catalyst of carbon dioxide hydrogenation methanol synthesis

InactiveCN102500381AImprove conversion rateHigh selectivityOrganic compound preparationHydroxy compound preparationPtru catalystHydrogen synthesis

The invention provides a preparation method of catalyst of carbon dioxide hydrogenation methanol synthesis, which belongs to the technical field of preparation of catalyst. The preparation method includes adding dispersing agent in Cu(NO3)2, Zn(NO3)2 and Zr(NO3)4 so as to prepare mixed liquor, then titrating the mixed liquor into Na2CO3 liquor, adjusting the pH (potential of hydrogen) of the liquor to range from 7 to 8, allowing the liquor to stand after sufficient reaction so that the liquor is aged to obtain solid precipitate, and roasting the solid precipitate to obtain methanol catalyst after the roasted solid precipitate is cooled naturally. On the basis of preparing catalyst by a coprecipitation method, the dispersing agent is added so as to prepare the methanol catalyst. The preparation method has the advantages that the preparation method is simple in technological process and easy to realize industrialization, carbon dioxide conversion rate and methanol selectivity of products are high, and the like. The obtained catalyst is applicable to carbon dioxide hydrogenation catalytic reaction under medium and low pressure.

Owner:KUNMING UNIV OF SCI & TECH

Catalyst for synthetizing compound of dicarbon containing oxygen by CO hydrogenation

InactiveCN1724151AIncreased space-time yieldHigh activityOrganic compound preparationHydroxy compound preparationPtru catalystPhysical chemistry

A catalyst Rh-Mn-Ti-M1-M2 / SiO2, where M1 is alkali metal (Li or Na) and M2 is chosen from Ru, Fe and Ir features that the wt ratio of Rh is 0.1-3%, Mn / Rh is 0.5-12, Ti / Rh is 0.001-3, M1 / Rh is 0.01-1 and M2 / Rh is 0.1-1. Its advantage is high catalytic activity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

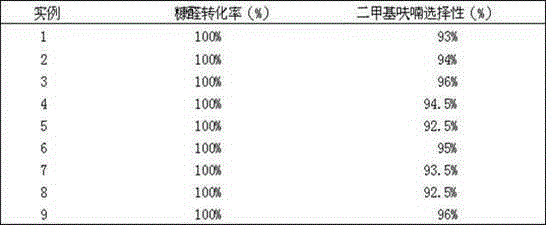

Environment-friendly 2-methyl furan catalyst and preparation method thereof

InactiveCN102614883AGood dispersionImprove performanceOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFuranPtru catalyst

The invention provides an environment-friendly 2-methyl furan catalyst and a preparation method thereof and relates to a hydrogenation catalyst and a preparation method thereof. The catalyst is prepared by a colloid precipitation method and the active component Cu is dispersed highly. The catalyst mainly comprises the following components as per percentage by weight: 15 to 50 percent of CuO and 40 to 80 percent of silicon oxide or aluminum oxide. The catalyst is applied to preparation of 2-methyl furan through furfural gas phase hydrogenation, wherein the conversion rate of the furfural is 100 percent and the selectivity of the 2-methyl furan reaches over 92 percent. By the colloid precipitation method, sol can be effectively bound with Cu and aid; the Cu can be dispersed on the surface of the carrier highly; and the catalyst has high activity and stability in the reaction of synthesizing the 2-methyl furan by hydrogenating the furfural. The catalyst applied to preparation of the 2-methyl furan by hydrogenating the furfural has simple components and does not comprise Cr so as to avoid the environmental pollution caused by pretreatment on the Cr-containing industrial catalyst and treatment on the waste catalyst.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

2-methyl furan catalyst and preparation method thereof

InactiveCN104383929AHigh activityHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsFuranAlkaline earth metal

The invention discloses a 2-methyl furan catalyst and a preparation method thereof, and relates to a catalyst and a preparation method thereof. The catalyst comprises active ingredients, such as 30-50 mass percent of CuO, 40-60 mass percent of aluminum oxide or silicon oxide, and aids selected from CaO, BaO, Na2O, K2O, Sr2O and ZnO, wherein the total mass percent of one or two of the aids is 5-10. The 2-methyl furan catalyst is synthesized by virtue of furfural hydrogenation. The preparation method comprises the following steps: dissolving a metal copper salt and an alkali metal or alkaline-earth metal salt in alumina sol or silica sol; enabling the salts to react with a precipitator so as to obtain a precipitate, aging for 1-4 hours after the precipitation is finished, washing, drying, molding and roasting; and finally preparing an oxidation state precursor of the catalyst, wherein an addition mode of reacting a salt solution and the precipitator refers to a positive addition method, a back addition method or a parallel addition method. The component of the catalyst does not contain Cr, and the catalyst is green; and moreover, the catalyst has the high activity and the high selectivity, the furfural conversion rate is 100 percent, and the selectivity of the 2-methyl furan is over 90 percent.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Platinum-free ruthenium-cobalt catalyst formulations for hydrogen generation

ActiveUS7160534B2Maintain good propertiesHydrogenSequential/parallel process reactionsPlatinumRuthenium

A method and catalysts and fuel processing apparatus for producing a hydrogen-rich gas, such as a hydrogen-rich syngas are disclosed. According to the method, a CO-containing gas, such as a syngas, contacts a platinum-free ruthenium-cobalt water gas shift (“WGS”) catalyst, in the presence of water and preferably at a temperature of less than about 450° C., to produce a hydrogen-rich gas, such as a hydrogen-rich syngas. Also disclosed is a platinum-free ruthenium-cobalt water gas shift catalyst formulated from:a) Ru, its oxides or mixtures thereof;b) Co, Mo, their oxides or mixtures thereof; andc) at least one of Li, Na, K, Rb, Cs, Ti, Zr, Cr, Fe, La, Ce, Eu, their oxides and mixtures thereof. The WGS catalyst may be supported on a carrier, such as any one member or a combination of alumina, zirconia, titania, ceria, magnesia, lanthania, niobia, zeolite, perovskite, silica clay, yttria and iron oxide. Fuel processors containing such water gas shift catalysts are also disclosed.

Owner:HONDA MOTOR CO LTD +1

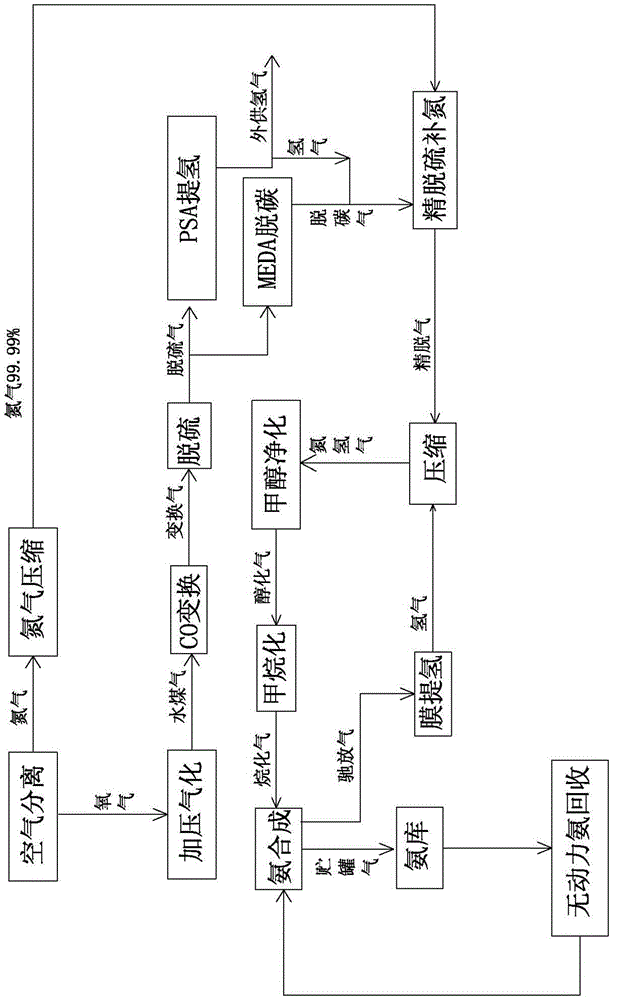

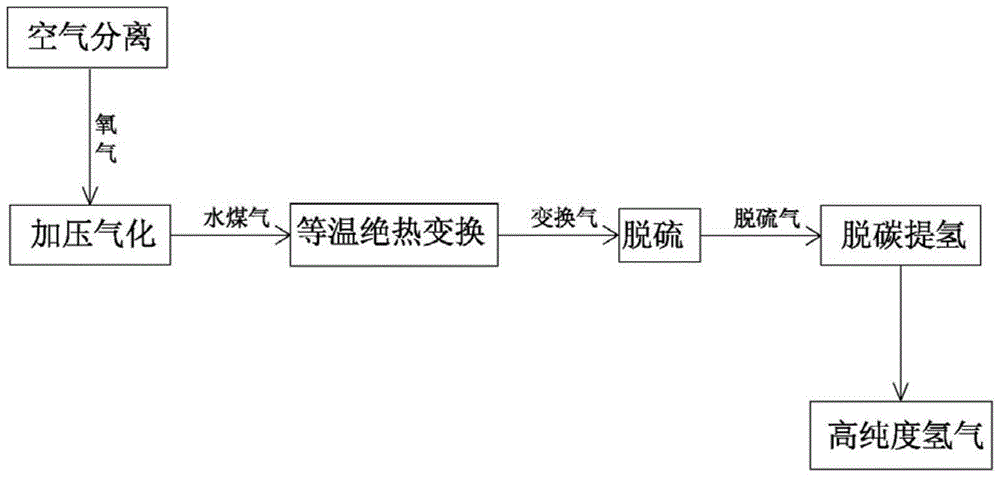

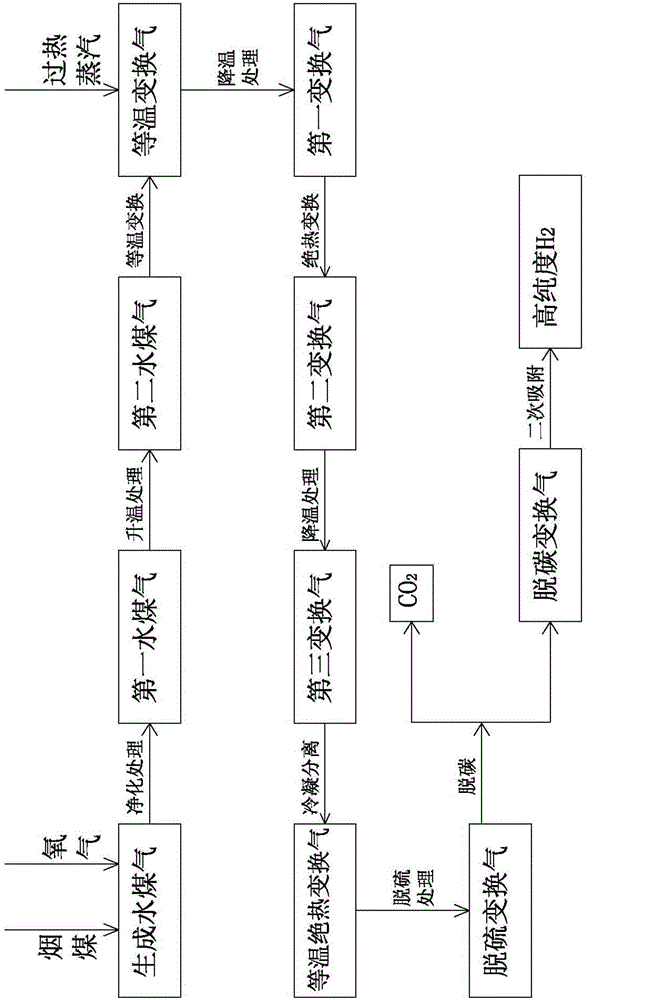

Production process and system of high-purity hydrogen and ammonia synthesis process and system

ActiveCN104560201AShort production processReduce resistanceHydrogen separation by selective and reversible uptakeHydrogen separation using solid contactOperating costOperating environment

The invention provides a production process and system of high-purity hydrogen and an ammonia synthesis process and system. The production process of high-purity hydrogen comprises the steps of generating water gas by using bituminous coal, generating shifted gas by using the water gas, desulfurizing the shifted gas, and carrying out decarbonization and hydrogen extraction on the shifted gas; the ammonia synthesis process comprises the steps of hydrogen nitrogen-feeding and deoxygenization, nitrogen-hydrogen compression and ammonia synthesis. The production system of high-purity hydrogen comprises a water gas generating part, a shifted gas generating part, a shifted gas desulfurizing part and a shifted gas decarbonization and hydrogen extraction part; and the ammonia synthesis system also comprises a hydrogen nitrogen-feeding and deoxygenization part, a nitrogen-hydrogen compression part and an ammonia synthesis part. The production process of high-purity hydrogen disclosed by the invention is short in flow, small in resistance, low in power consumption and low in operating cost; and the production system of high-purity hydrogen disclosed by the invention is high in degree of automation, less in catalyst consumption, less in species, less in operators, good in operating environment, low in operating cost and remarkable in energy saving and consumption reducing effect.

Owner:蓝星工程有限公司

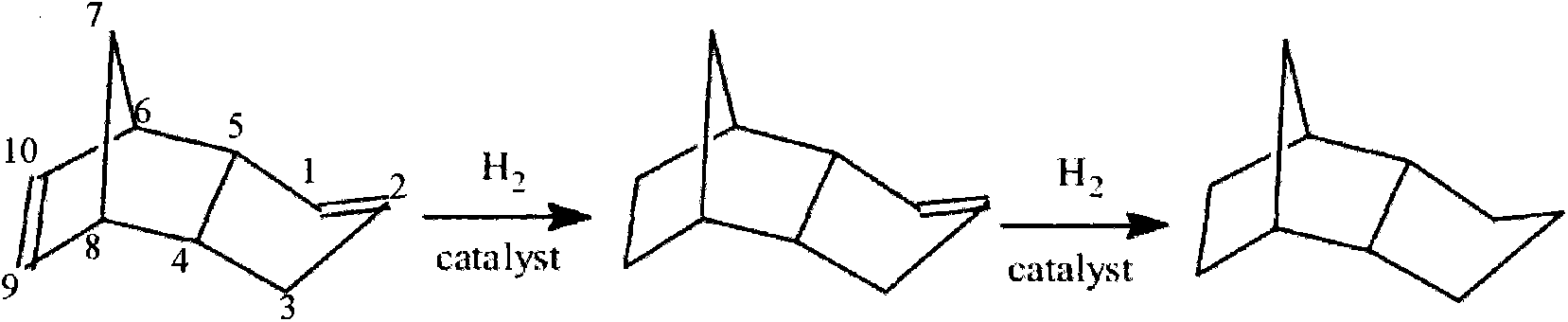

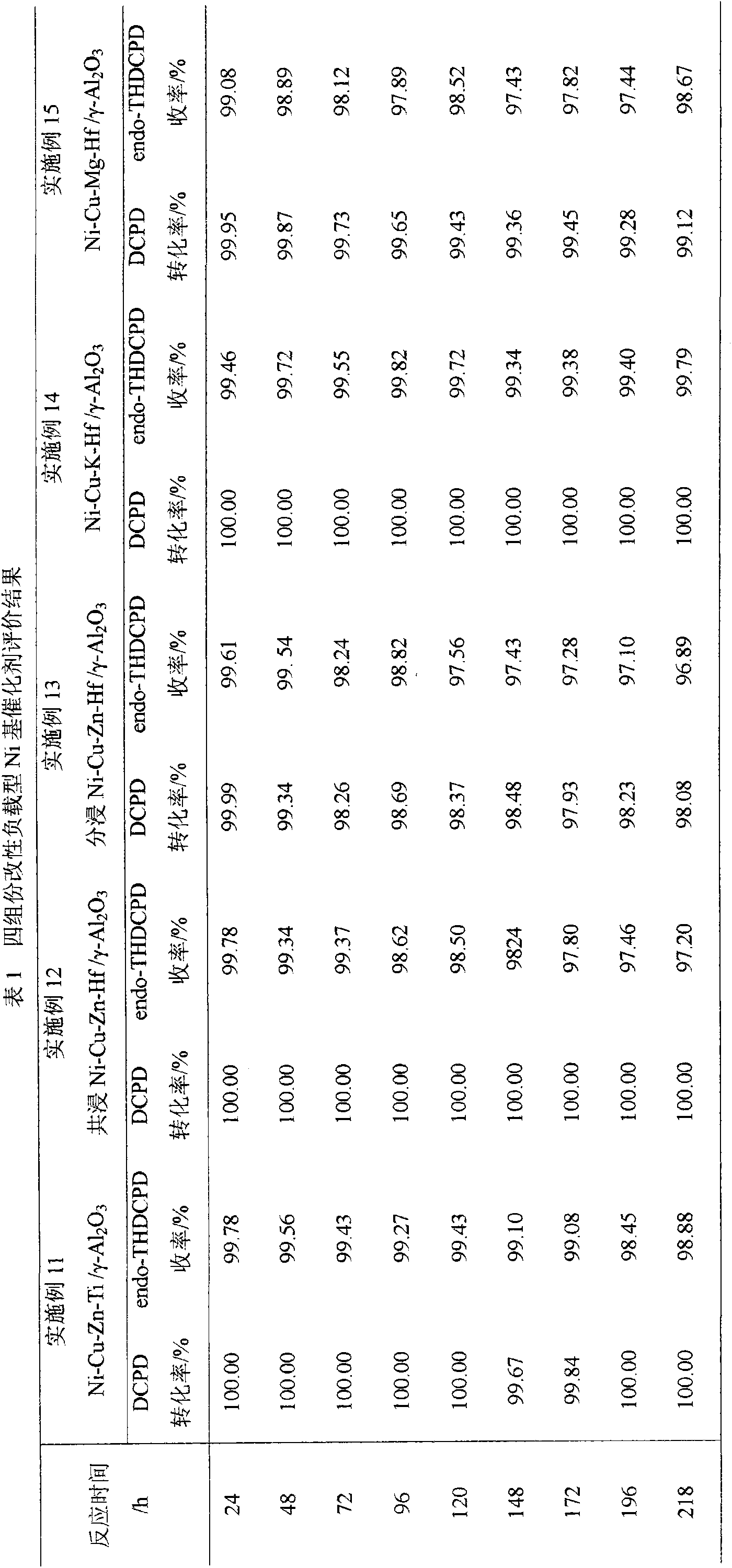

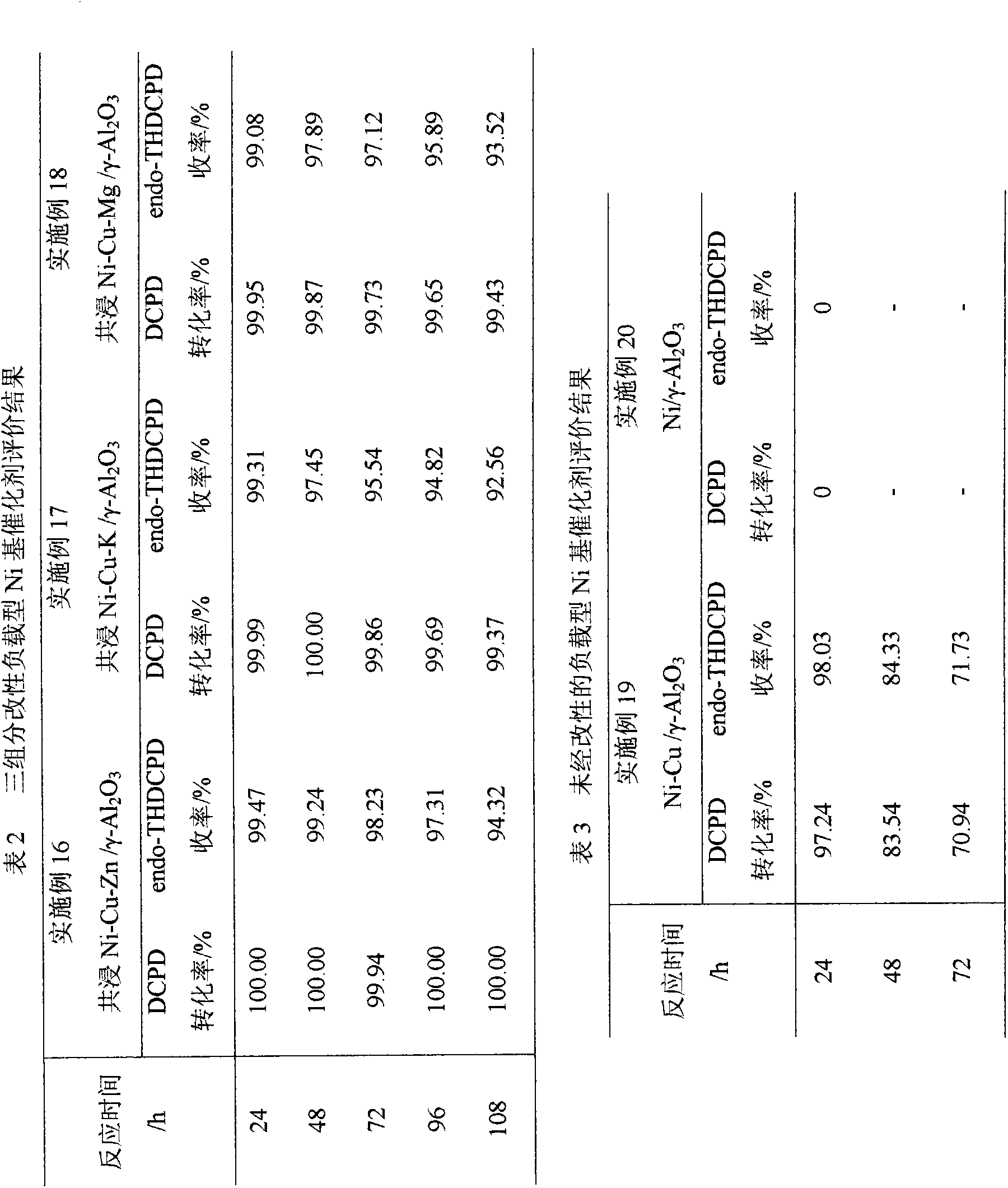

Supported Ni-based catalyst for DCPD (dicyclopentadiene) continuous hydrogenation and hydrogenating method

ActiveCN103877982AEasy to makeLow reduction temperatureHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionSalt solution

The invention relates to a Ni-based catalyst for continuous hydrogenation of a DCPD fixed bed and a hydrogenating method for DCPD continuous hydrogenation to synthesize endo-tetrahydrodicyclopentadiene (endo-THDCPD), overcoming the problems of complex operation, low synthetic efficiency, rapid catalyst deactivation and difficulty in separation of the catalyst and a product for the existing intermittent synthetic reaction. The Ni-based catalyst is prepared from the following components by weight percentage: 5%-40% of NiO, 1-15% of CuO, 0.2%-5% of basic metallic oxide, 0.2%-5% of transition metallic oxide and the balance of a carrier gamma-Al2O3. The catalyst is prepared from a soluble salt solution of reactive metal and auxiliary metal by an impregnation method, and is subjected to drying, calcination and reduction for continuous hydrogenation reaction of a DCPD fixed bed. The Ni-based catalyst is prepared by a co-impregnation method, and also can be prepared by a substep impregnation method, the required reduction temperature is low, the reaction condition is mild, the one-step hydrogenation activity is high, the yield and the selectivity of the endo-THDCPD are high and the activity stability is good.

Owner:军事科学院系统工程研究院军事新能源技术研究所

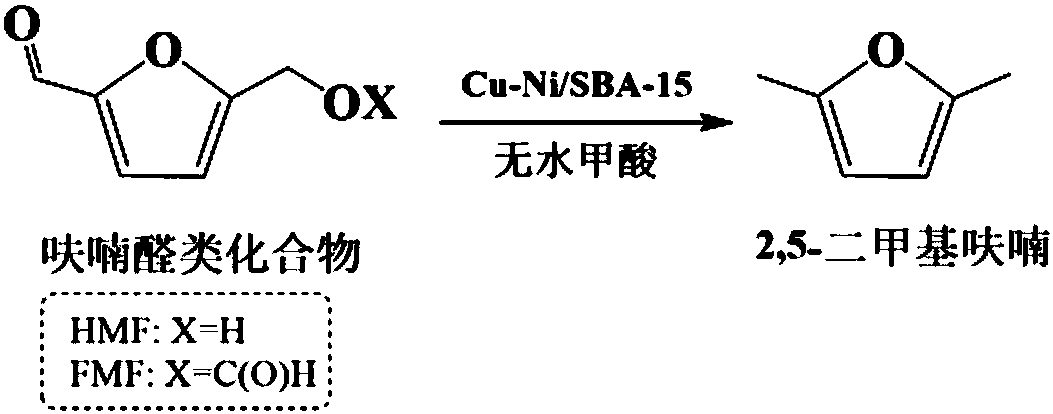

Preparation method of 2, 5-dimethylfuran

InactiveCN108047174AHigh activityHigh selectivityOrganic chemistryMolecular sieve catalystsSolubilityFuran

The invention discloses a preparation method of 2,5-dimethylfuran and relates to 2,5-dimethylfuran. A furan aldehyde compound serving as a substrate is added into an organic solvent to prepare a reaction substrate solution; the reaction substrate solution, anhydrous formic acid and a non-precious-metal catalyst are mixed and put into a reaction kettle, nitrogen gas is used for replacing dischargedair, heating and stirring are conducted for hydrodeoxygenation, and 2,5-dimethylfuran is obtained. The prepared supported non-precious-metal Ni-Cu / SBA-15 serves as a catalyst, formic acid serves as ahydrogen donor, and the furan aldehyde compound is subjected to catalytic transfer hydrogenation to synthesize DMF. The whole process is simple and easy to operate, the cost is low, the reaction system is green, the catalyst is high in activity, the selectivity of DMF is high, the yield is high, and the method has a wide industrial application prospect. Direct use of H2 is avoided, formic acid isused as a hydrogen source, 2,5-dimethylfuran is convenient to store and use, the requirement of a reaction solvent for the hydrogen solubility is reduced, the hydrogenation effect is good, the synthesis method is simple, the method is easy to operate, and energy consumption is low.

Owner:XIAMEN UNIV

Iron-based SCR (Selective Catalytic Reduction) catalyst and preparation method thereof

ActiveCN104226361AExcellent purificationLow costMolecular sieve catalystsDispersed particle separationOxygen cycleOxygen

The invention discloses an SCR (Selective Catalytic Reduction) catalyst containing synthetic zeolite and iron, and particularly relates to an SCR catalyst which always has an NOx purifying property in a low-temperature region after being subjected to relatively long-term action of hot water and relatively long-term action of sulfur oxides. A preparation method of the SCR catalyst, disclosed by the invention, comprises the following steps: crystallizing a hydrogenised synthetic zeolite with maximal oxygen cycle number of 8-12 and a three-dimensional structure by using a mixing procedure, and blending with a ferric nitrate (III) water solution or ferric chloride (III) water solution with a pH value of 0.1-0.7 to obtain the SCR catalyst without a filtering procedure and a cleaning procedure.

Owner:清华大学苏州汽车研究院(吴江) +1

Copper-iron based catalyst and application thereof in preparing low mixed alcohols by catalyzing synthesis gas

InactiveCN103464159ATo achieve co-precipitation reactionGuaranteed uniformityOrganic compound preparationHydroxy compound preparationPtru catalystAlcohol

The invention discloses a copper-iron based catalyst in the technical field of catalyst preparation and application thereof in preparing low mixed alcohols by catalyzing synthesis gas. According to the invention, a copper-magnesium-iron hydrotalcite precursor is prepared by a nucleation-crystallization isolating method, and then the copper-magnesium-iron hydrotalcite precursor is roasted and then subjected to reduction treatment to obtain the copper-iron based catalyst of highly dispersed nanoparticles. The catalyst has the characteristics that the catalytic active ingredients are highly dispersed, the catalytic active ingredients have strong interaction with one another, and are high in stability, and as a result, the activity and selectivity of the catalyst are improved. After the copper-iron based catalyst is applied to preparing low mixed alcohols from the synthesis gas, the CO conversion rate is high, and the selectivity and space time yield of the low mixed alcohols are also improved; besides, the conversion rate of CO for synthesizing low mixed alcohols through CO hydrogenation is 56.89% and the selectivity of alcohols is 49.07%.

Owner:BEIJING UNIV OF CHEM TECH

Catalyst for methane synthesis through carbon dioxide hydrogenation and preparation method thereof

InactiveCN102941098AImprove electronic statusHigh activityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementPtru catalyst

The invention discloses a catalyst for methane synthesis through carbon dioxide hydrogenation and a preparation method of the catalyst for methane synthesis through carbon dioxide hydrogenation. The catalyst for methane synthesis through carbon dioxide hydrogenation is a composite oxide Eu2O3-Co3O4-ZrO2, wherein the molar ratio of Co and Zr is 4:6, and the quantity of rare earth element Eu is 1-10% of the molar total quantity of Co and Zr. The preparation method comprises the following steps of: adopting citric acid as fuel, and preparing the composite oxide Eu2O3-Co3O4-ZrO2 through a combustion method. The obtained composite oxide Eu2O3-Co3O4-ZrO2 is used for catalyzing carbon dioxide hydrogenation to synthesize methane and shows a good catalytic performance. The preparation method has the characteristics that the process is simple and quick, the environmental-friendly chemical concept can be conformed, and the industrial production can be easily realized.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

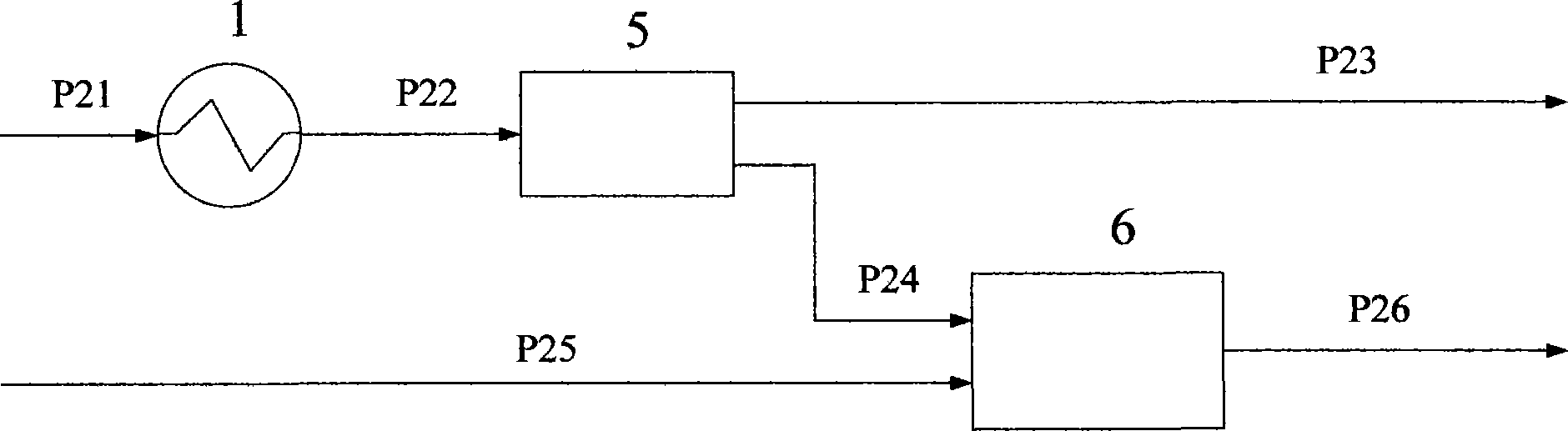

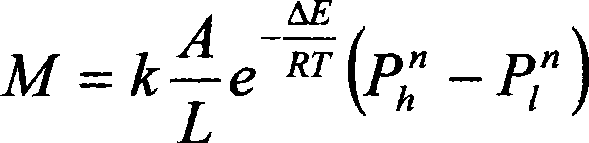

Method and apparatus for producing hydrogen from hydrogen-containing synthesis gas using palladium membrane

InactiveCN101372314ASituations that reduce separation efficiencyHigh separation efficiency of hydrogenHydrogen separationSyngasVapor–liquid separator

The invention relates to a method which adopts a palladium membrane to produce high-purity hydrogen from hydrogen-containing synthetic gas and a device. In the method, synthetic gas which contains water vapor and hydrogen and is produced by an upstream hydrogen making reactor is firstly sent to a cooler, the cooled synthetic gas enters a gas-liquid separator, after dehydration, the synthetic gas enters a primary heater and is heated in the heater, the heated synthetic gas enters a secondary heater and heated to the temperature of 450-600 DEG C, the heated synthetic gas enters a palladium membrane separator, and most of hydrogen in the synthetic gas permeates the palladium membrane separator to become the high-purity finished hydrogen. A pipeline of the device which connects a heat exchanger and the palladium membrane separator is sequentially provided with the gas-liquid separator, the primary heater and the secondary heater, the palladium membrane separator is connected with a burner by the primary heater, and the burner is also connected with the secondary heater. The invention has simple design and high hydrogen separation efficiency of the palladium membrane and provides a new technical method for efficient production of high-purity hydrogen.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com