Copper-iron based catalyst and application thereof in preparing low mixed alcohols by catalyzing synthesis gas

A low-carbon mixed alcohol and catalyst technology, which is applied in the preparation of hydroxyl compounds, organic compounds, physical/chemical process catalysts, etc., can solve the problem of insufficient activity, selectivity, stability and economy, poor catalyst stability, and product alcohol Low selectivity and other issues, to achieve the effects of increased selectivity, space-time yield, easy operation, and strong interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Weigh Cu(NO 3 ) 2 ·3H 2 O4g, Mg(NO 3 ) 2 ·6H 2 O12.8g, Fe(NO 3 ) 3 9H 2 O13.4g was dissolved in 100ml deionized water by stirring to make it completely dissolved; respectively weighed NaOH6.4g, NaOH 2 CO 3 7.1g in 100ml deionized water, stir to dissolve completely;

[0025] 2. Add the two solutions obtained in step 1 into the rotating liquid film reactor at a certain flow rate to nucleate rapidly, and circulate for 2 minutes, then place the mixed solution in a hydrothermal kettle, and crystallize at a temperature of 100°C for 48 hours. Then wash the filtrate with deionized water to make the pH value of the washing water less than 8, and then dry at 60° C. for 24 hours to obtain the copper-magnesium-iron hydrotalcite precursor.

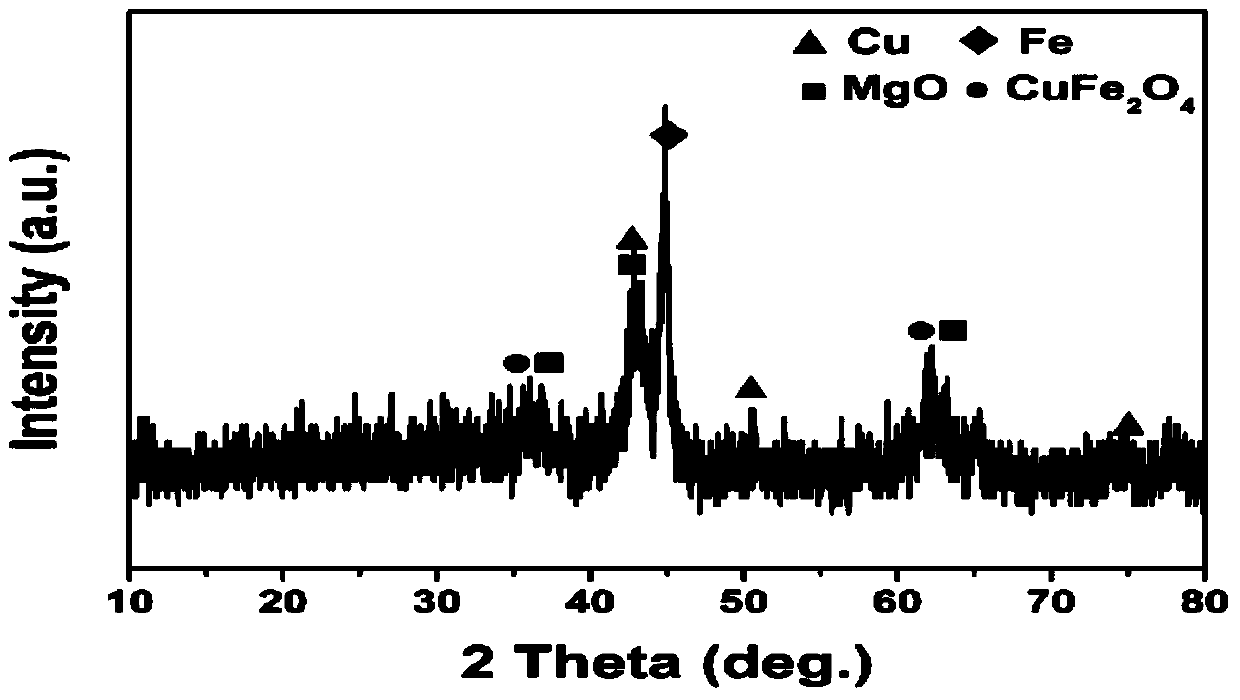

[0026] 3. Put the copper-magnesium-iron hydrotalcite precursor prepared in step 2 in a muffle furnace, raise the temperature to 500°C at 2°C / min, keep it warm for 6h, and cool down to room temperature naturally; then perform reducti...

Embodiment 2

[0030] 1. Weigh Cu(NO 3 ) 2 ·3H 2 O9.1g, Mg(NO 3 ) 2 ·6H 2 O9.6g, Fe(NO 3 ) 3 9H 2 O10.1g in 100ml deionized water, stirred to make it completely dissolved; Weigh respectively NaOH6.4g, NaOH 2 CO 3 5.3g in 100ml deionized water, stir to dissolve completely;

[0031] 2. Add the two solutions obtained in step 1 into the rotating liquid film reactor at a certain flow rate to quickly nucleate, and circulate for 2 minutes, then place the mixed solution in a hydrothermal kettle, and crystallize at a temperature of 100°C for 48 hours. Then wash the filtrate with deionized water to make the pH value of the washing water less than 8, and then dry at 60° C. for 24 hours to obtain the copper-magnesium-iron hydrotalcite precursor.

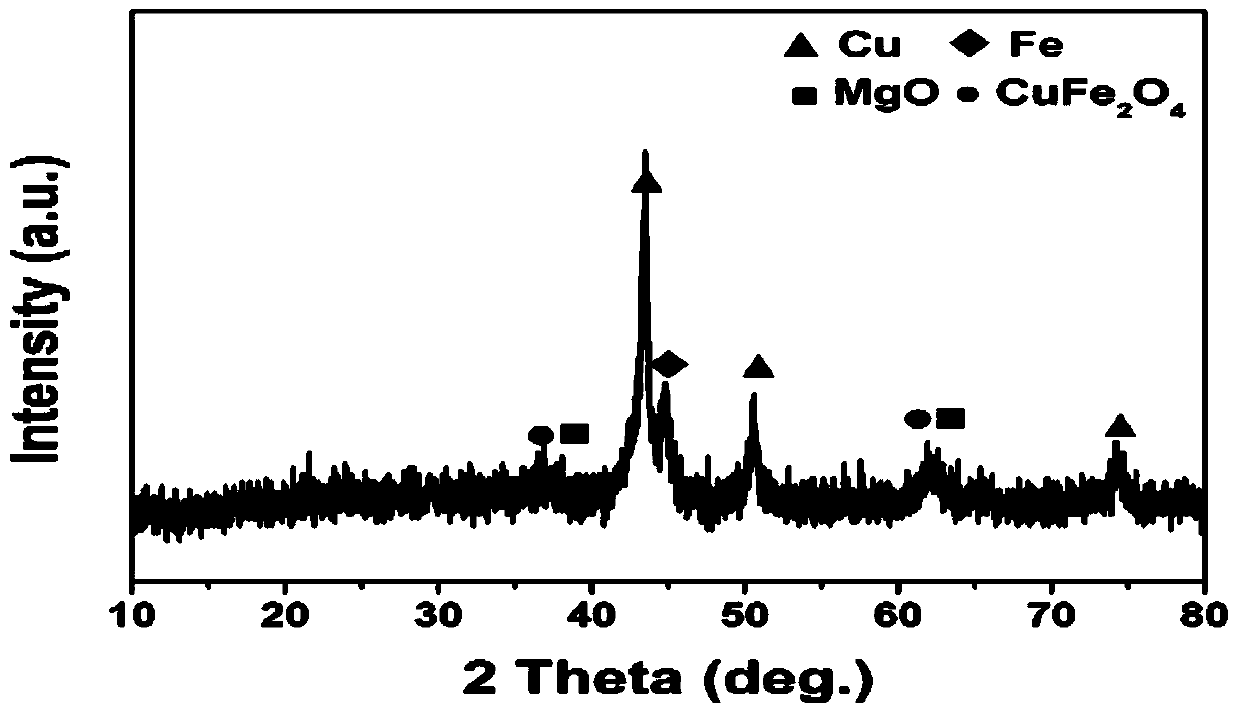

[0032] 3. Place the copper-magnesium-iron hydrotalcite precursor prepared in step 2 in a muffle furnace, raise the temperature to 500°C at 2°C / min, keep it warm for 6h, and cool down to room temperature naturally; then perform reduction treatment, th...

Embodiment 3

[0036] 1. Weigh Cu(NO 3 ) 2 ·3H 2 O12.1g, Mg(NO 3 ) 2 ·6H 2 O7.7g, Fe(NO 3 ) 3 9H 2 O8.1g in 100ml deionized water, stirred to make it completely dissolved; Weigh respectively NaOH6.4g, NaOH 2 CO 3 4.2g in 100ml deionized water, stir to dissolve completely;

[0037] 2. Add the two solutions obtained in step 1 into the rotary liquid film reactor to nucleate at the same time, and after circulating for 2 minutes, put the mixed solution in a hydrothermal kettle and crystallize at 100°C for 48 hours. Then use deionized The filtrate was washed with water to make the pH value of the washing water less than 8, and then dried at 60° C. for 24 hours to obtain a copper-magnesium-iron hydrotalcite precursor.

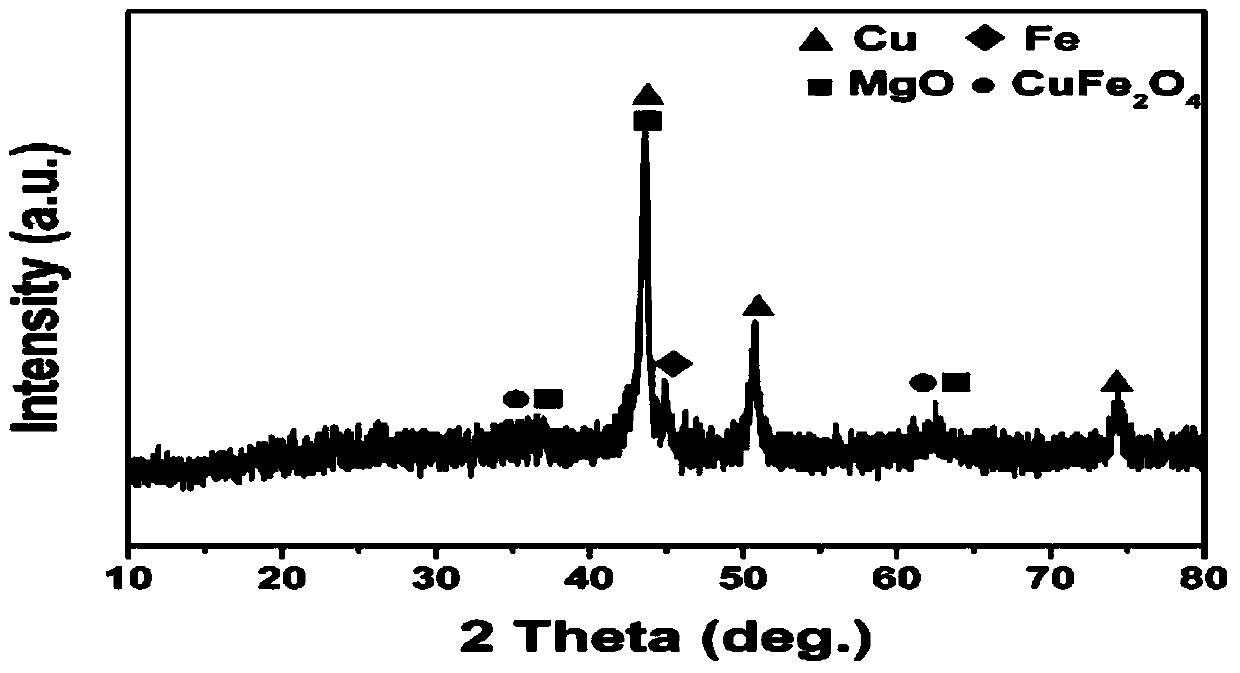

[0038] 3. Place the copper-magnesium-iron hydrotalcite precursor prepared in step 2 in a muffle furnace, raise the temperature to 500°C at 2°C / min, keep it warm for 6h, and cool down to room temperature naturally; then perform reduction treatment, the reduction condition i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com