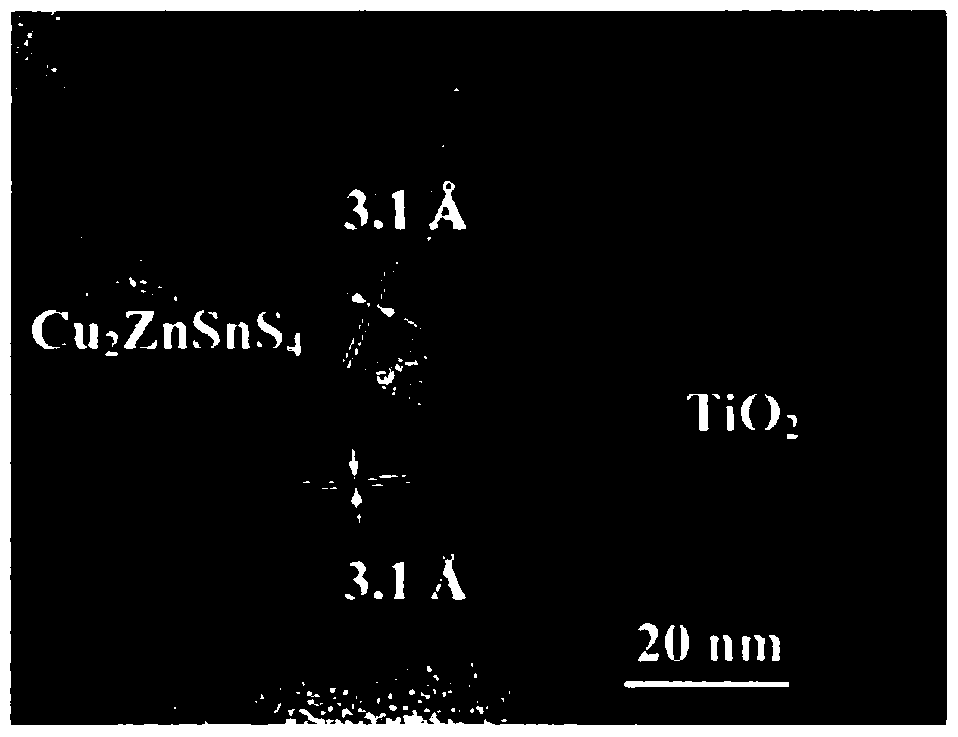

cu2znsns4 sensitized tio2 photoanode and its in situ preparation method and application

An in-situ preparation and photoanode technology, which is applied in the direction of photosensitive equipment, can solve the problems of high cost and inability to improve the separation efficiency of photogenerated electrons and holes, and achieve low production cost, avoid the formation of single metal sulfide, and easy size The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

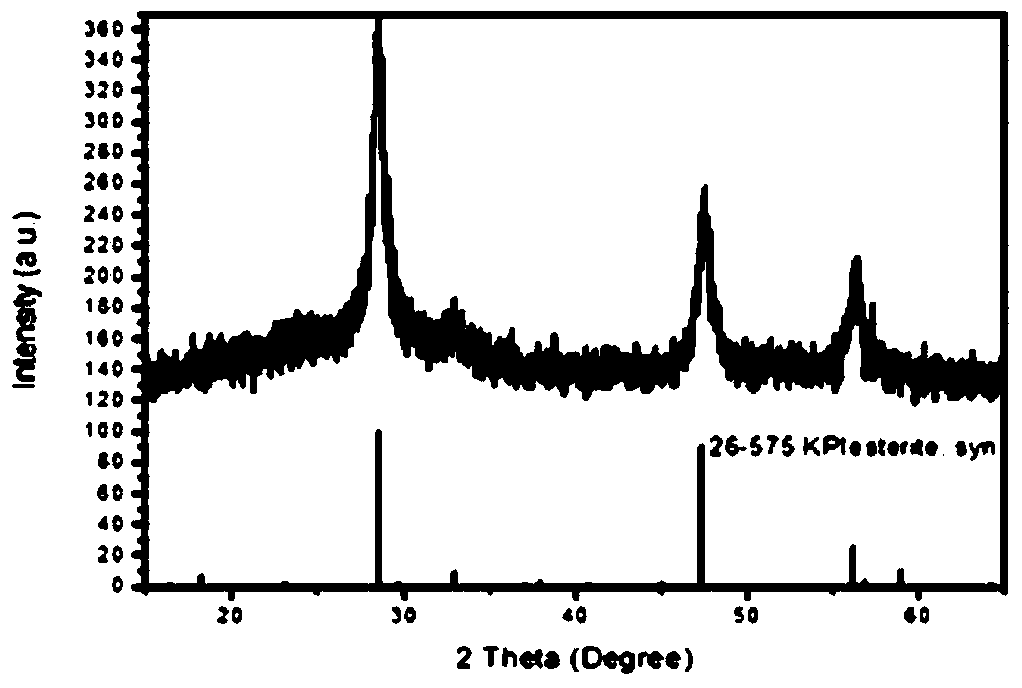

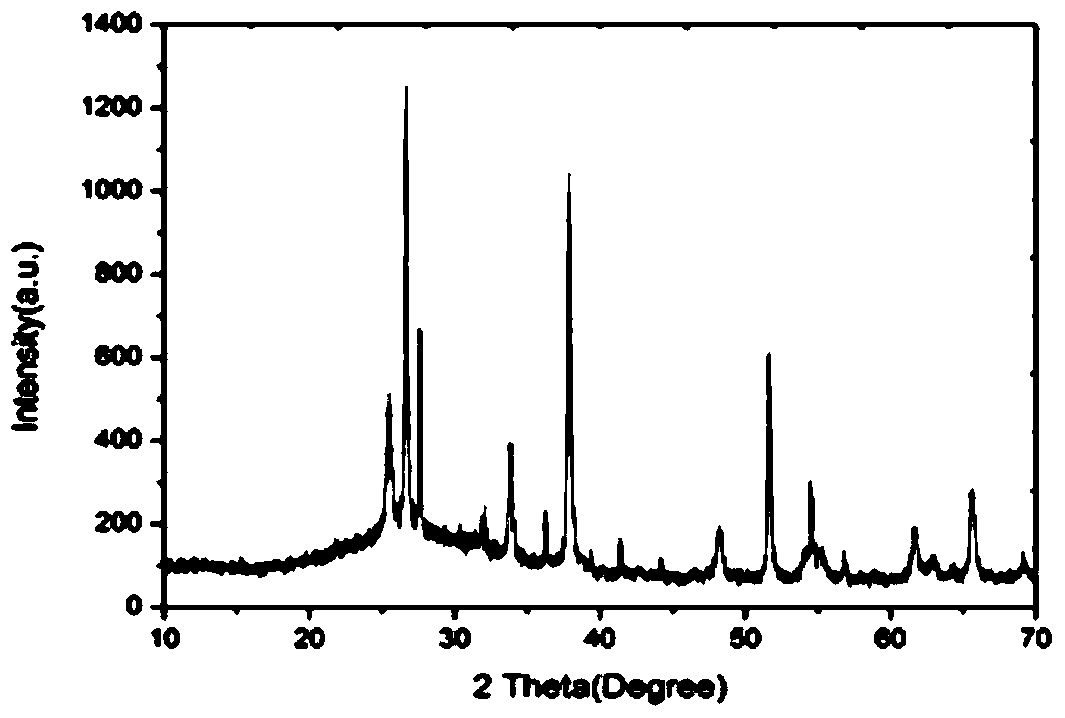

[0038] Cu 2 ZnSnS 4 Sensitized TiO 2 The in situ preparation method of the photoanode adopts the following steps:

[0039] (1) Weigh the raw materials, express the amount of the substance in millimoles, and add the copper salt, zinc salt, tin salt, reducing agent and modifier together with the sulfur source in a millimolar ratio of 2:1:1.2:x:y into a polytetrafluoroethylene reactor, then add water to dissolve, and form a precursor solution with a concentration of 0.01-0.5M, where x is the amount of reducing agent, x=1-15, and y is the amount of modifier, y=1-35; the amount of sulfur source is 1-20 times of the sum of copper salt, zinc salt and tin salt;

[0040] (2) Add the prepared titanium dioxide nanostructure photoanode material in the configured precursor solution;

[0041] (3) Seal the reactor, control the reaction temperature inside the reactor to be 100-200° C., and react for 1-24 hours. After the reaction, cool the reactor to room temperature naturally, take out t...

Embodiment 1

[0052] (1) represent the amount of substance in millimoles, join copper acetate, zinc acetate and thioacetamide together in the 50mL polytetrafluoroethylene reactor with the millimolar ratio of 0.8:0.4:15.2 respectively, then add 40mL water, Stir and ultrasonically dissolve, then add 3 mL of mercaptopropionic acid and 2 mL of triethanolamine to adjust the pH to 10-11, wherein triethanolamine is the reducing agent and mercaptopropionic acid is the modifier. Finally, add 12mL tin tetrachloride solution having a concentration of 0.04M (mol / liter), and stir evenly.

[0053] (2) Put the prepared titanium dioxide nanostructured photoanode substrate into the prepared precursor solution.

[0054] (3) The reaction kettle is sealed, and the reaction temperature is controlled to be 200° C., and the reaction time is 12 hours; after the reaction is completed, the reaction kettle is naturally cooled to room temperature, and the synthesized photoanode material is washed several times with ab...

Embodiment 2

[0057] The steps are the same as in Example 1, except that the reducing agent triethanolamine in Example 1 is replaced by ascorbic acid to obtain Cu 2 ZnSnS 4 Sensitized solar cell photoanode materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com