Patents

Literature

408results about How to "Uniform grain size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of hydrocracking catalyst

ActiveCN103055923AUnlimited capacityGood dispersionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveDispersity

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, and then adding the acidic mixed solution A, the alkaline solution B and CO2 to a reaction tank filled with clear water in parallel to prepare gel; and then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering, drying and forming the mixture, and then washing, drying and roasting the product, thus preparing the hydrocracking catalyst. The method has the beneficial effects that a clean preparation method is adopted, so not only can the catalyst be easily formed and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased and the dispersity of metals in the catalyst can be improved, thus the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst prepared by the method can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

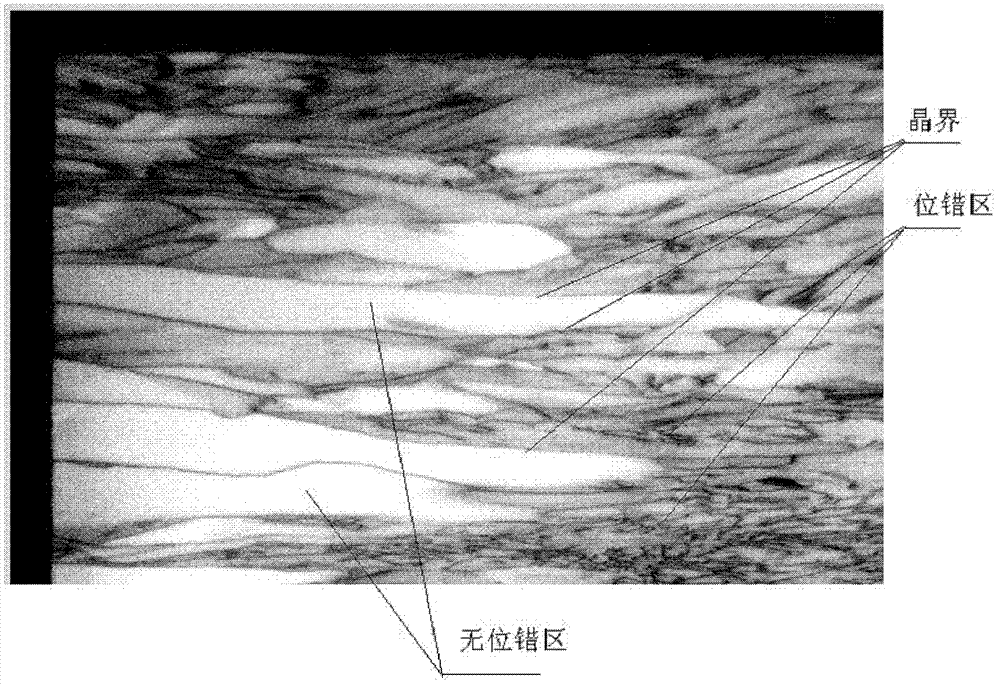

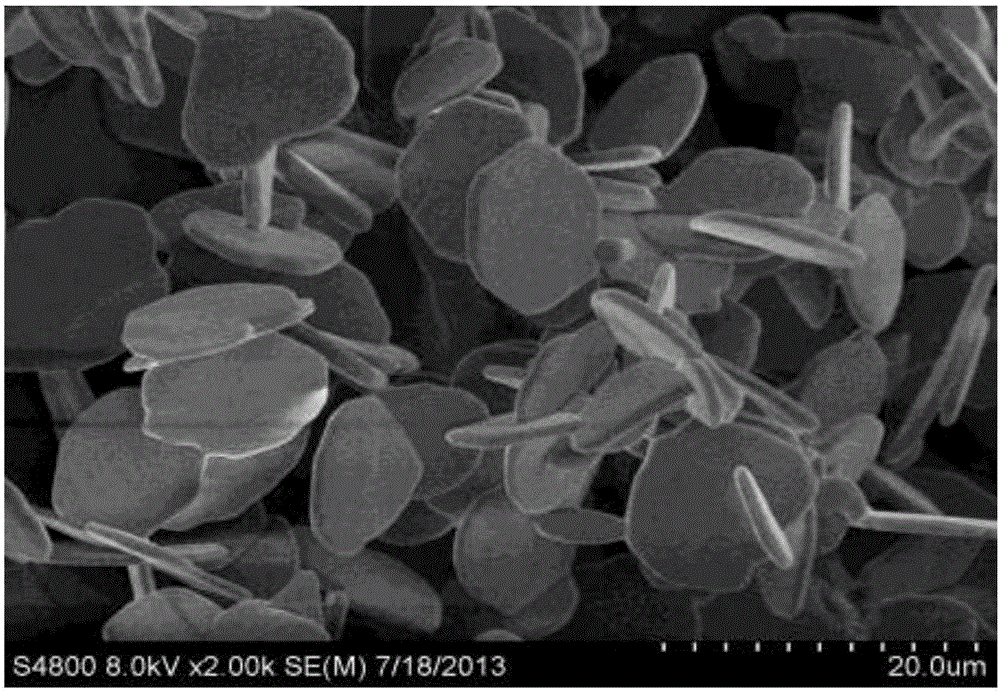

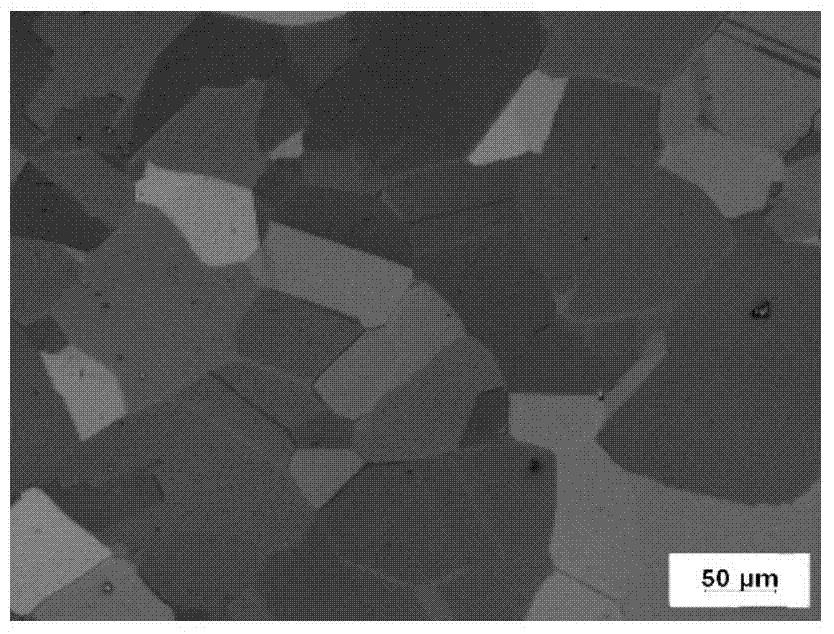

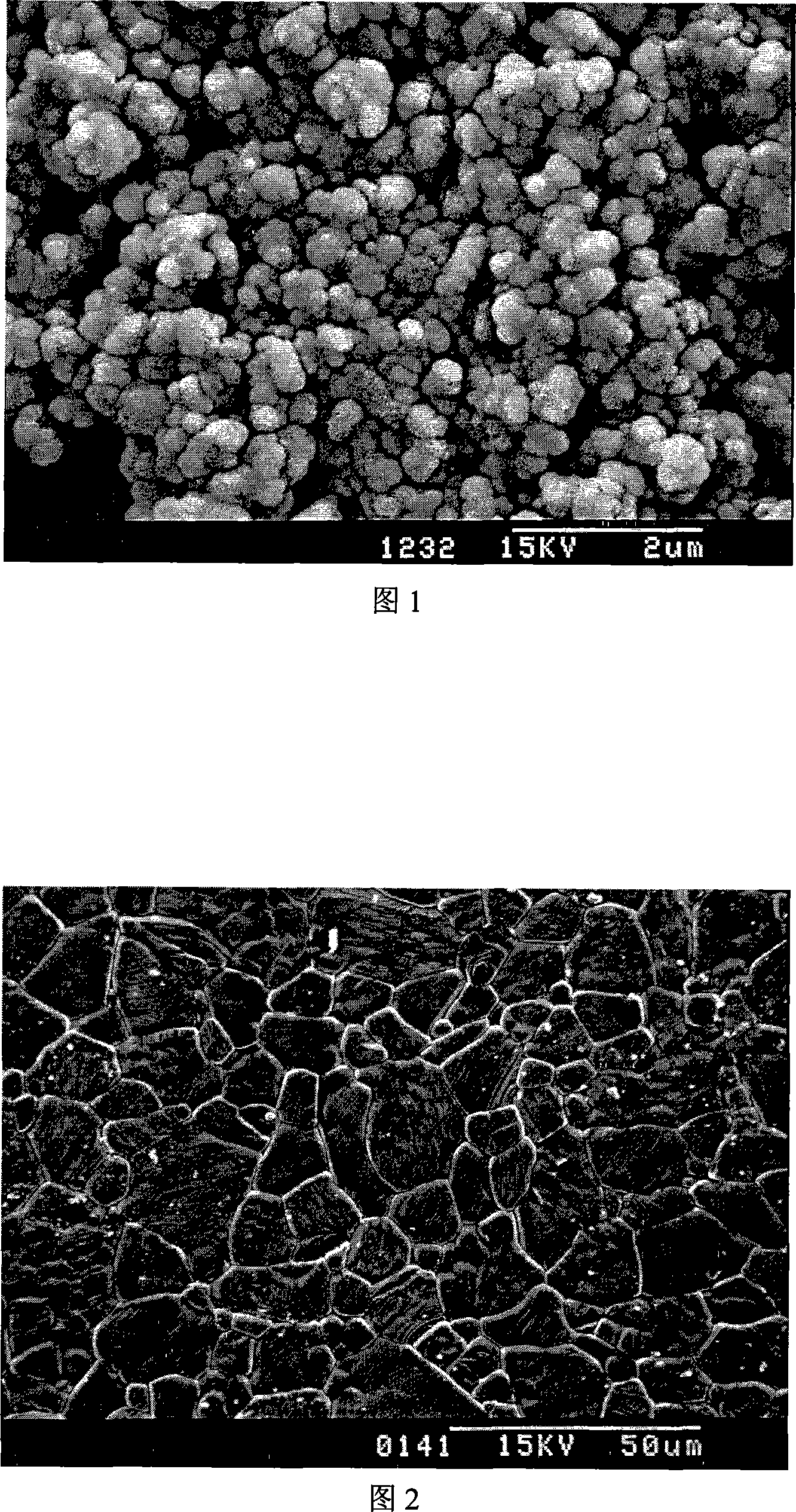

Polycrystalline silicon ingot, preparation method of polycrystalline silicon ingot, polycrystalline silicon slice and crucible for polycrystalline silicon ingot casting

ActiveCN102776561APromote nucleationUniform grainPolycrystalline material growthSingle crystal growth detailsMolten stateCrucible

The invention provides a preparation method of a polycrystalline silicon ingot. The preparation method comprises the following steps that a core source is arranged at the bottom of a crucible, and a core source layer is formed; silicon materials in a molten state are arranged on the core source layer; and the temperature in the crucible is controlled to gradually rise in a direction vertical to the upward direction form the bottom of the crucible, the temperature gradient is formed, the silicon materials in the molten state form core crystallization by utilizing the core source, and the polycrystalline silicon ingot is prepared. The invention also provides high-quality polycrystalline silicon ingot obtained by the preparation method, a polycrystalline silicon slice obtained through the preparation of the polycrystalline silicon ingot and the crucible for polycrystalline silicon ingot casting. The polycrystalline silicon ingot prepared by the preparation method has the advantages that the crystalline size is uniform and regular, the dislocation density is low, and in addition, no obvious pine-tree crystals or twin crystals exist.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

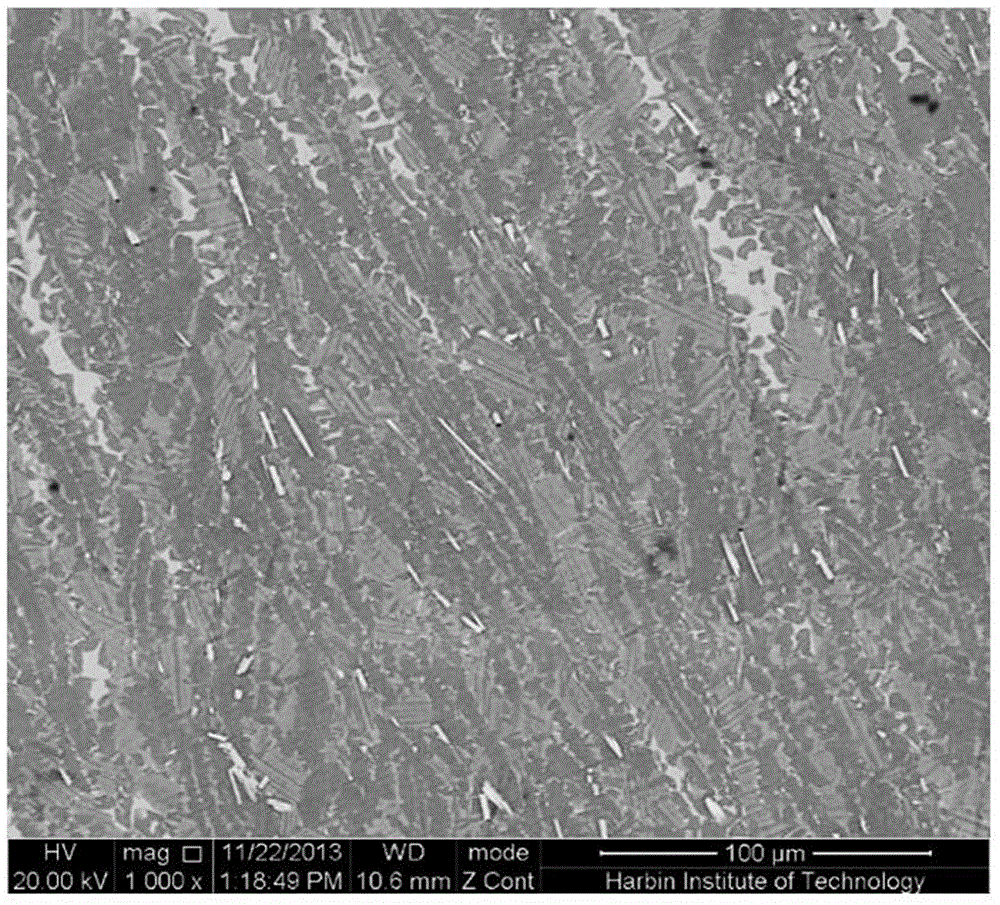

Preparation method of high-toughness boride-carbide composite ceramic

A preparation method of a high-toughness boride-carbide composite ceramic relates to a preparation method of a boride-carbide composite ceramic and solves the problems that in the conventional preparation of the boride-carbide composite ceramic, due to high sintering temperature and high sintering pressure, the preparation cost is high and the prepared boride-carbide composite ceramic is poor in mechanical property and fracture toughness. The preparation method of the high-toughness boride-carbide composite ceramic comprises the following steps : adding a dispersing medium into boride and carbide; uniformly mixing the dispersing medium, the boride and the carbide; pressing the mixture into a blank material; and sintering the blank material in a two-section pressure-free sintering way at alow temperature and a high temperature sequentially. The sizes and the distribution of grain crystals in the boride-carbide composite ceramic which is prepared under the low-temperature pressure-freeconditions are uniform; the fracture toughness is as high as 5.0-13MPa.m<-1 / 2>; and the bending strength is as high as 400-1000 MPa; the boride-carbide composite ceramic with excellent comprehensive mechanical property can be prepared; the preparation cost is reduced; and the application range is widened.

Owner:吉林长玉特陶新材料技术股份有限公司

Aluminum-scandium alloy target blank and preparation method and application thereof

InactiveCN107841639ALow oxygenMeet the characteristic requirements of sputteringVacuum evaporation coatingSputtering coatingCrystalliteScandium

The invention relates to an aluminum-scandium alloy target blank and a preparation method and application thereof. The aluminum-scandium alloy target blank comprises, by weight part, 0.1-15 parts of scandium and 85-99.9 parts of aluminum, and the oxygen content of the aluminum-scandium alloy target blank is smaller than or equal to 160 ppm. The aluminum-scandium alloy target blank has the beneficial effects that the oxygen content is low, then the prepared target blank cannot generate abnormal discharge or particle splashing scars, and later high-quality film forming can be guaranteed; and inaddition, the aluminum-scandium alloy target blank is even in target blank crystal particle size.

Owner:GEMCH MATERIAL TECH SUZHOU

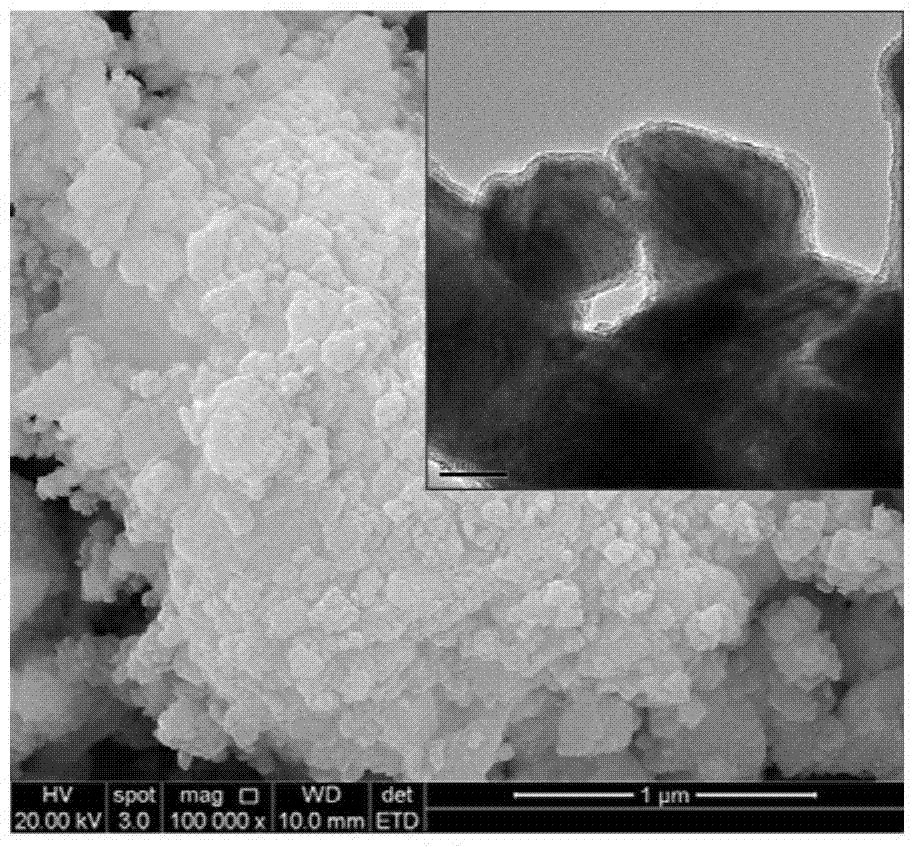

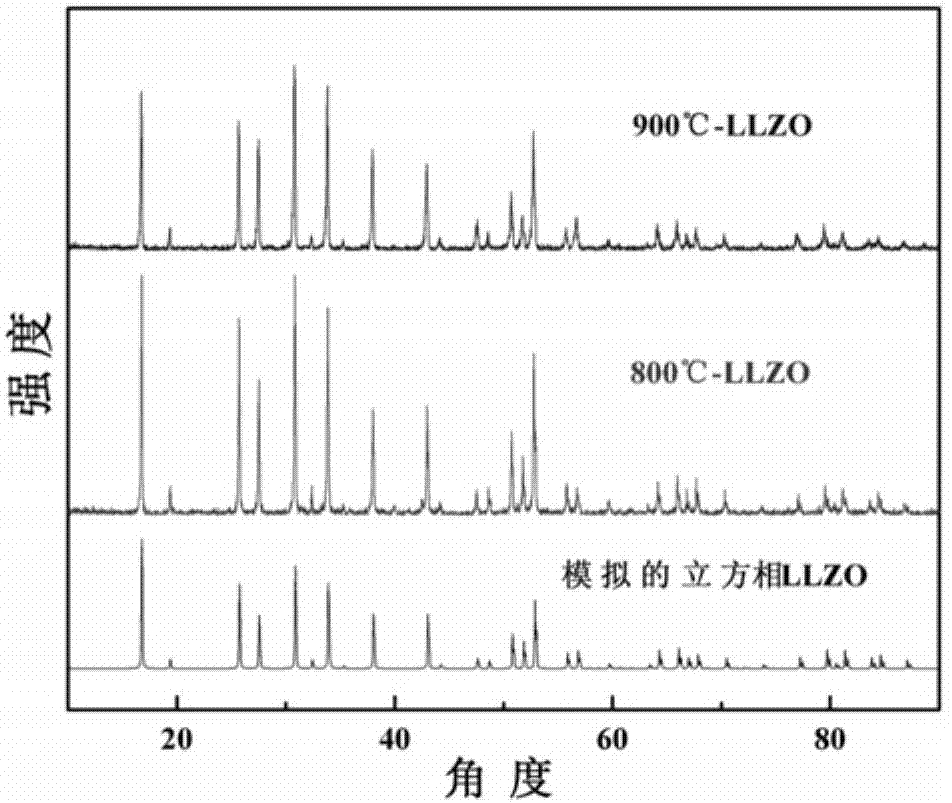

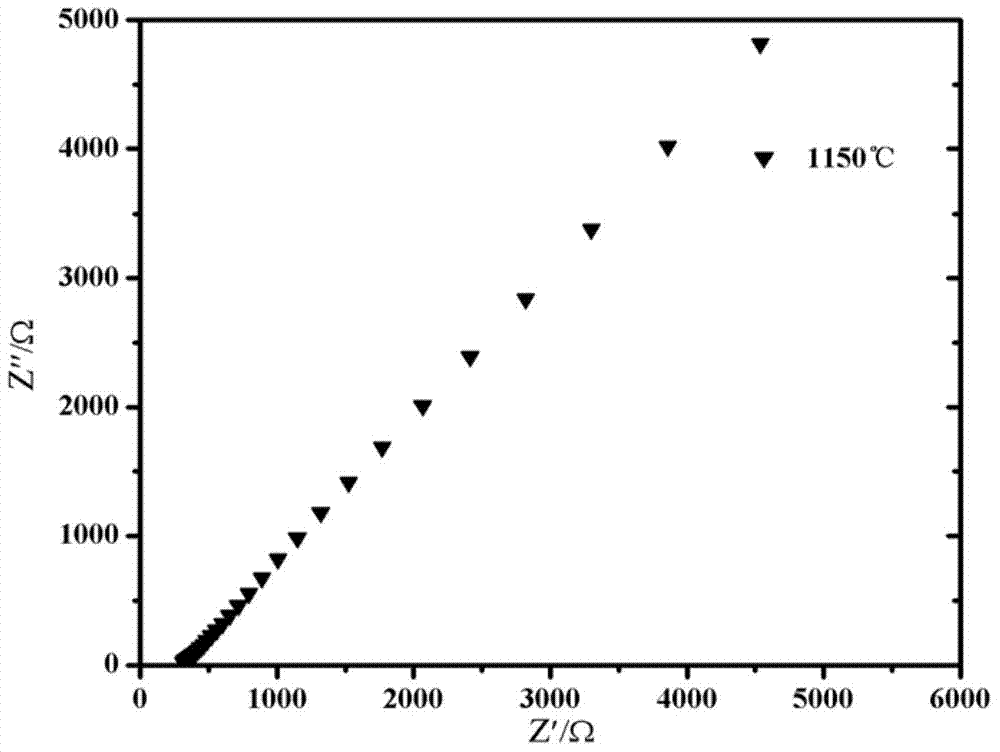

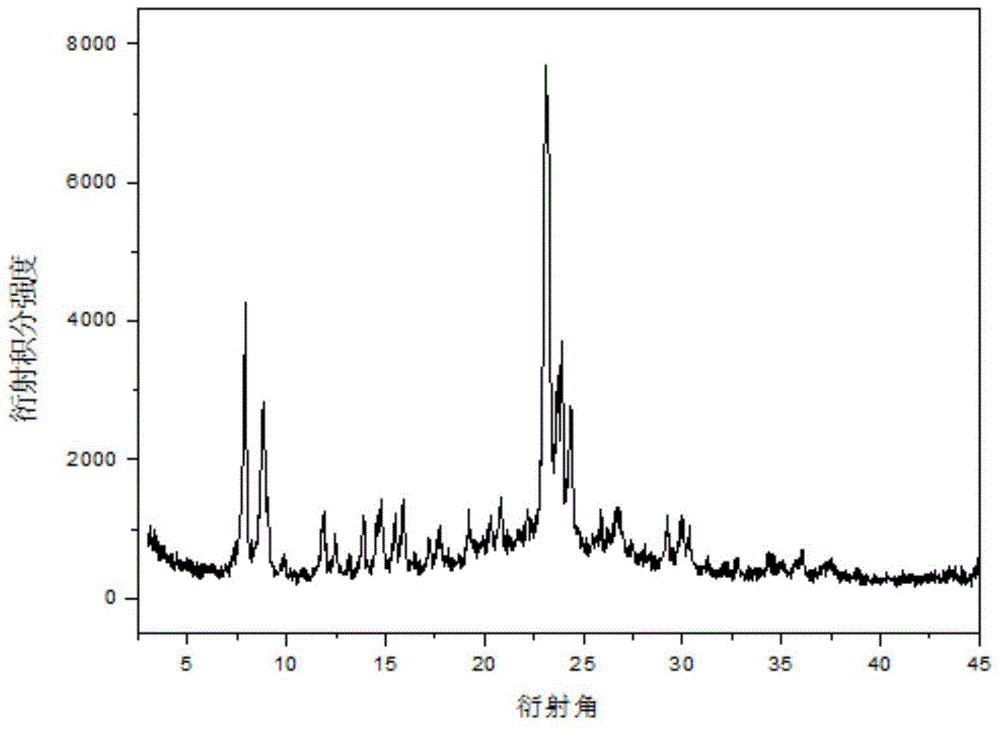

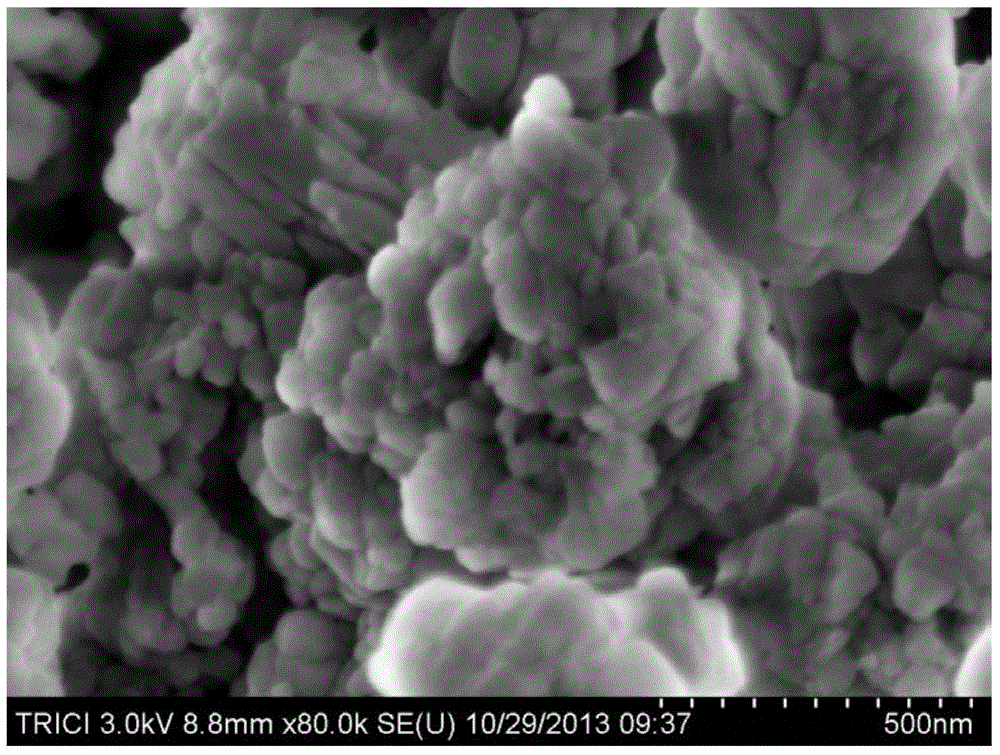

Method for preparing solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder

ActiveCN104124467ACalcination temperature is lowHigh sintering activitySecondary cellsElectrical batteryElectrochemistry

The invention discloses a method for preparing a solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder. The method specifically comprises the steps of dissolving a certain amount of lanthanum nitrate and zirconium nitrate into water, adding a precipitator, namely ammonium carbonate, controlling the pH value to ensure that La<3+> and Zr<4+> ions are simultaneously precipitated, and filtering and washing the precipitate; weighing a certain amount of lithium oxalate, dissolving lithium oxalate into water, adding the precipitate into the lithium oxalate solution, stirring, evaporating, crystallizing, and separating out lithium oxalate crystal on the surface of the precipitate to form precursor powder with a coated structure. The prepared powder has the advantages of uniform mixing, fine grains, high purity and the like; through the formed specific coated structure, the calcination temperature of the powder is low, the sintering time of the powder is short, and the room-temperature lithium ion electric conductivity of the sintered lithium lanthanum zirconium oxide is more than 2.2*10<-4>S / cm. According to the method, the process is simple, the cost is low, the preparation conditions are easy to control, and the prepared solid electrolyte is good in electrochemical stability and high in electric conductivity and can be used for preparing all-solid-state lithium ion batteries.

Owner:WUHAN UNIV OF TECH

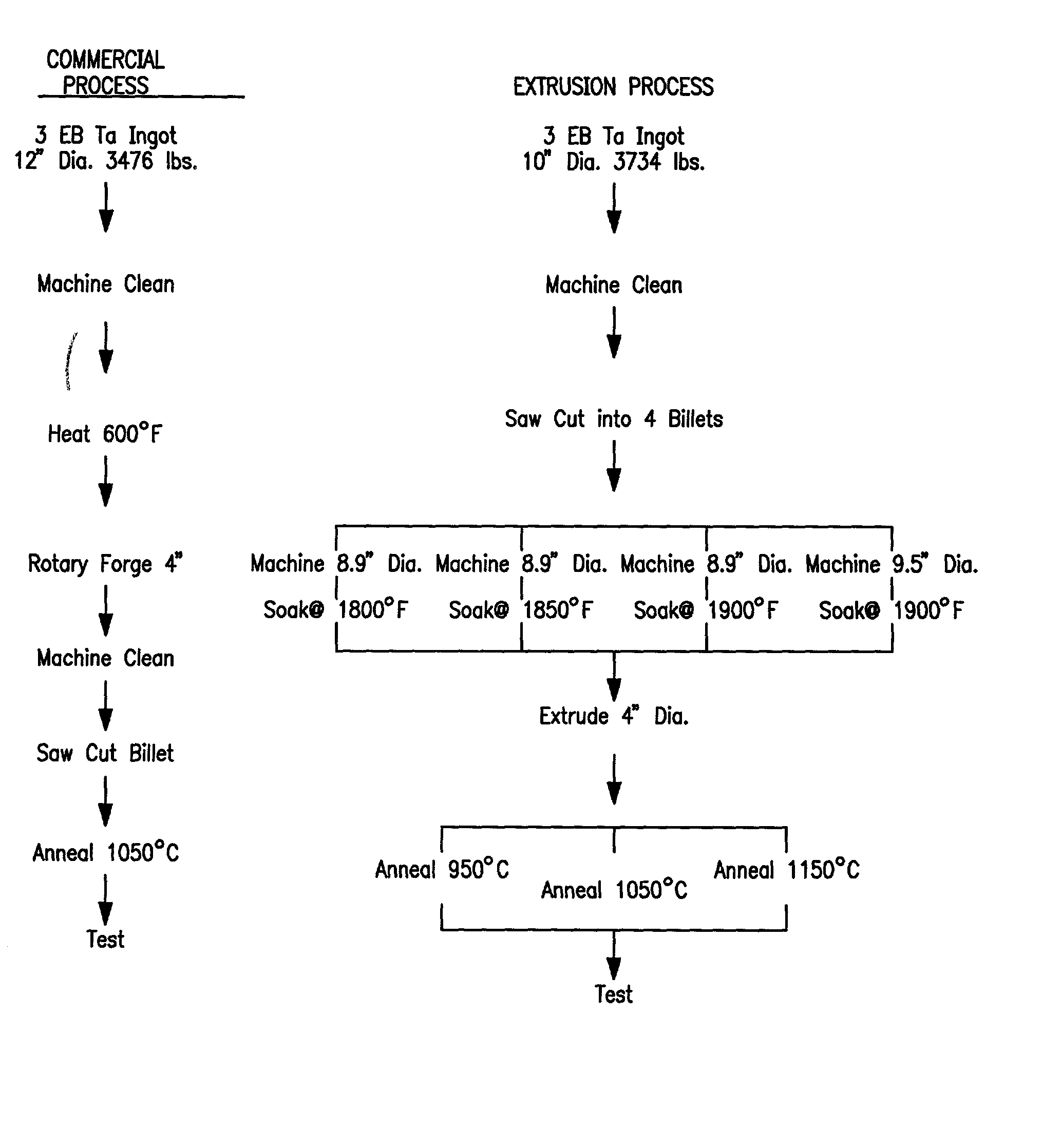

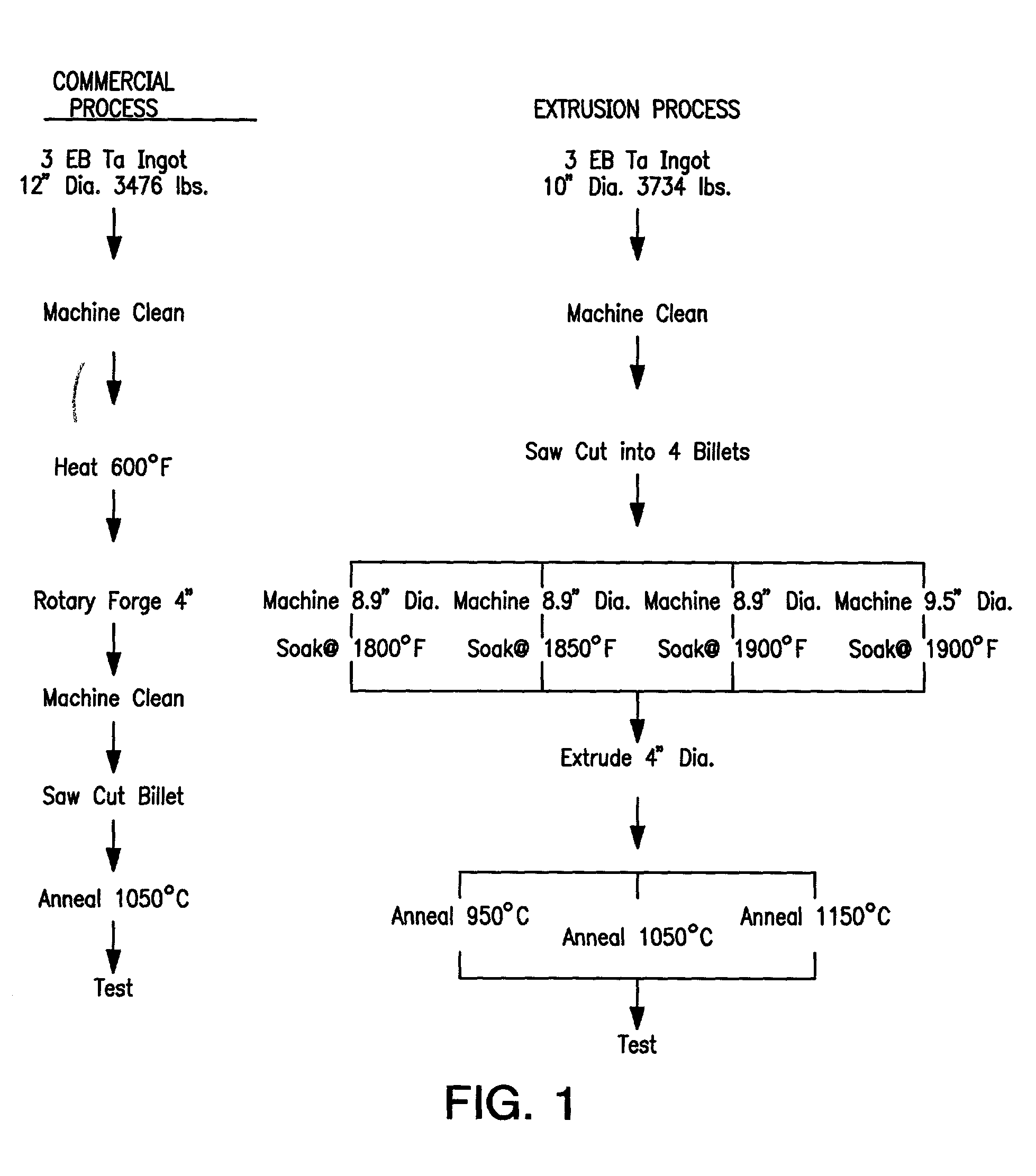

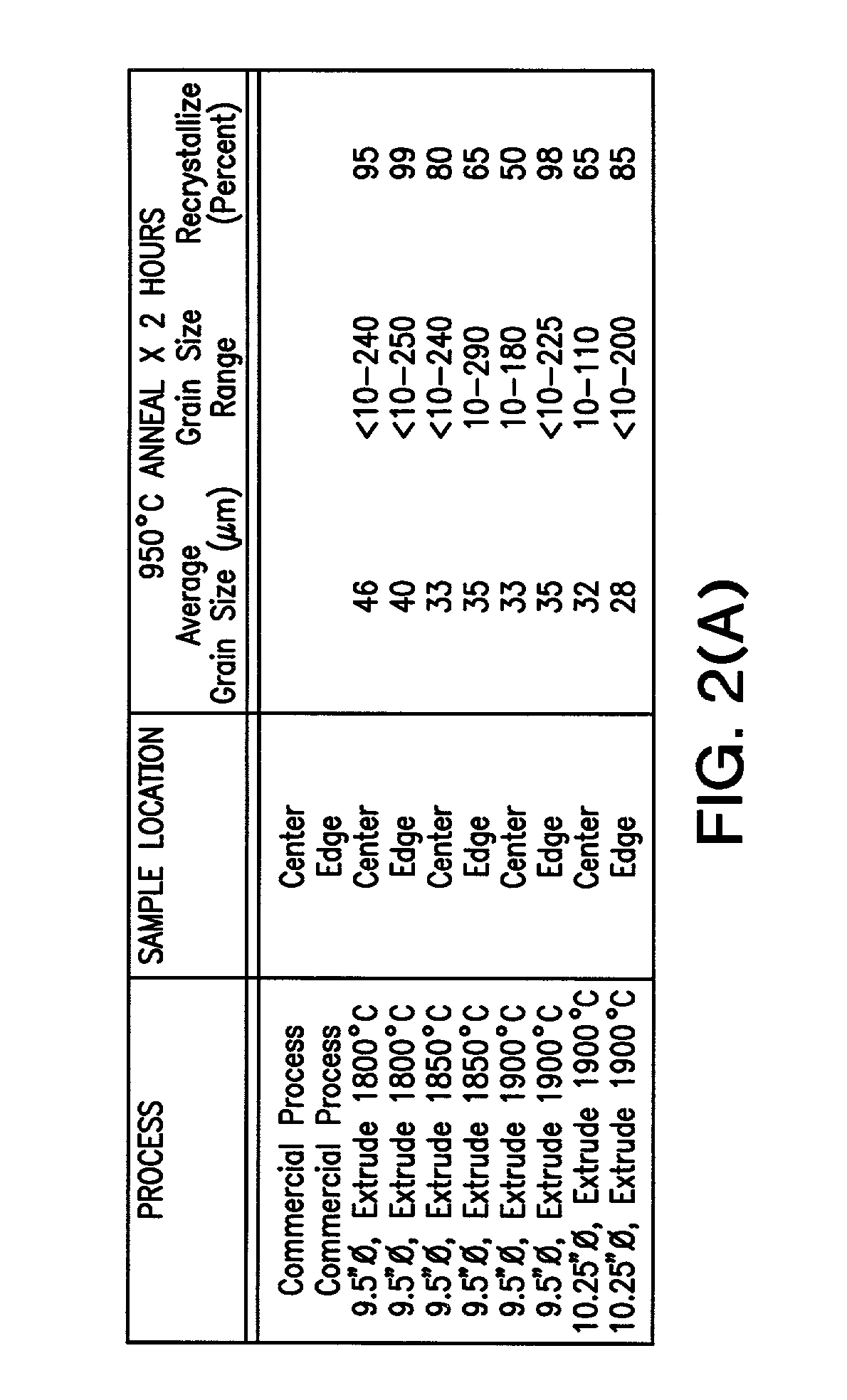

Tantalum and niobium billets and methods of producing the same

InactiveUS20020157736A1Uniform grain sizeUniform particle sizeCellsVacuum evaporation coatingCrystalliteSufficient time

Extruded tantalum billets and niobium billets are described having a substantially uniform grain size and preferably an average grain size of about 150 microns or less and more preferably an average grain size of about 100 microns or less. The extruded billet can then be forged or processed by other conventional techniques to form end use products such as sputtering targets. A process for making the extruded tantalum billets or niobium billets is also described and involves extruding a starting billet at a sufficient temperature and for a sufficient time to at least partially recrystallize the billet and form the extruded billet of the present invention.

Owner:GLOBAL ADVANCED METALS USA

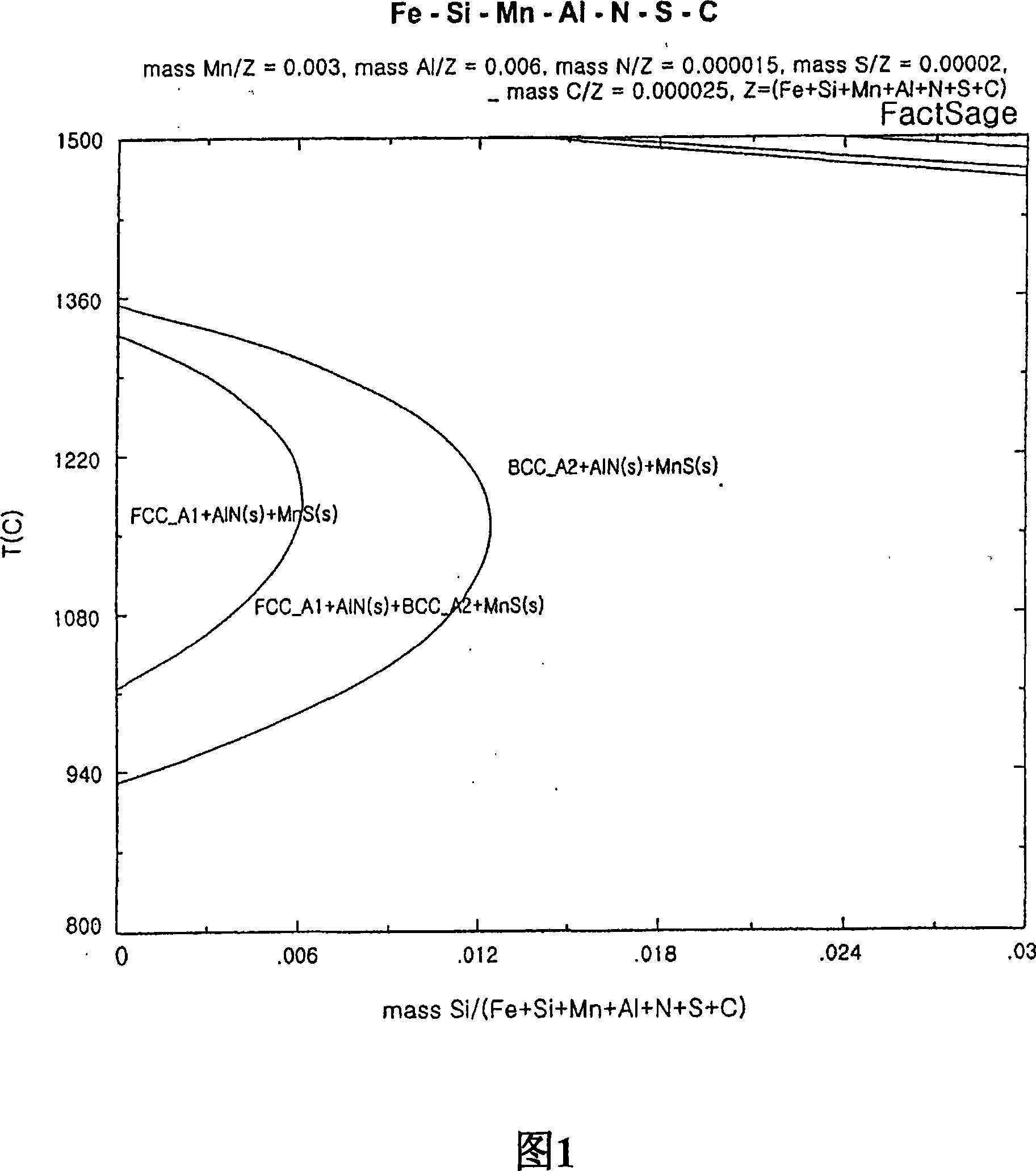

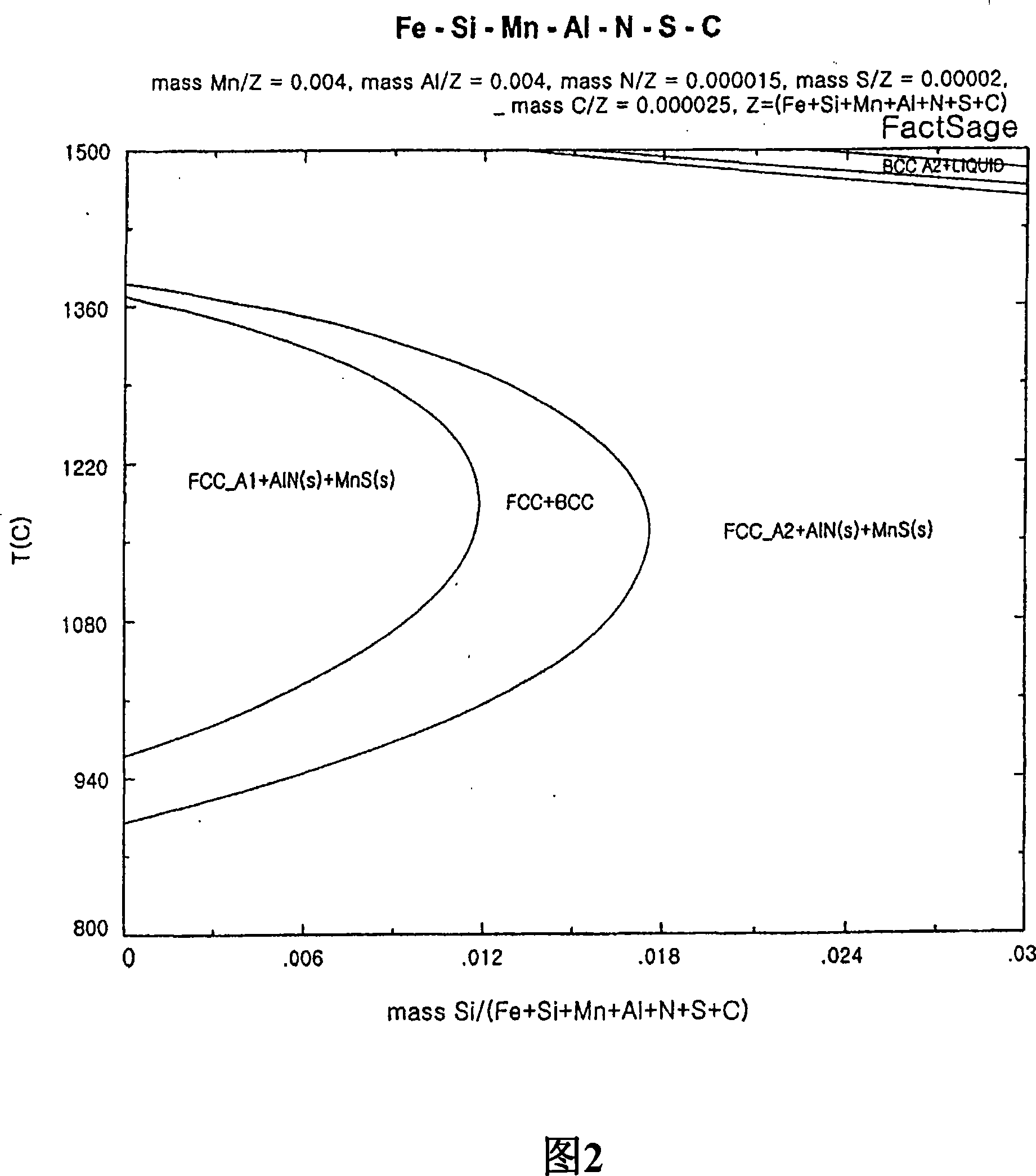

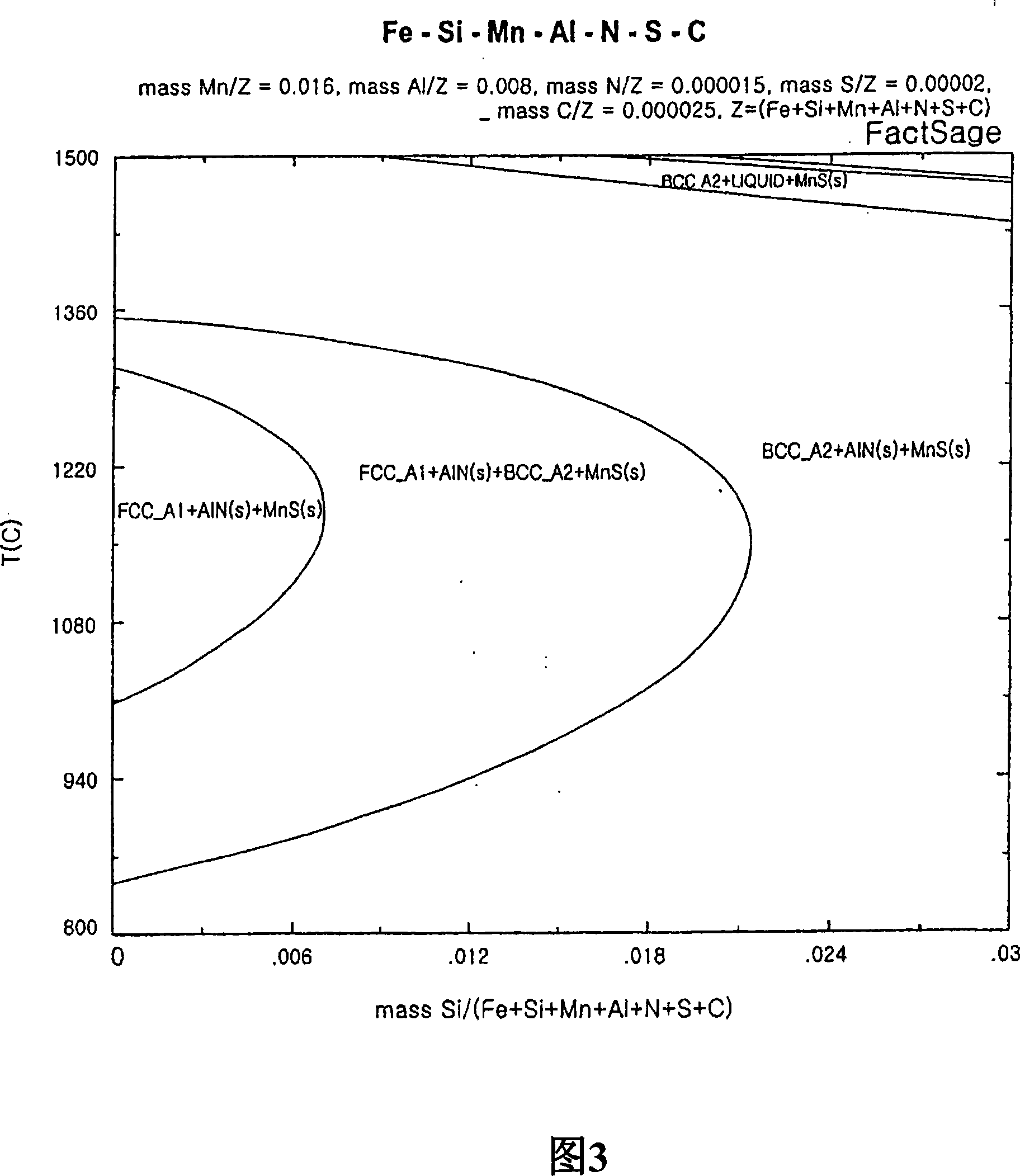

Non-oriented electrical steel sheets with excellent magnetic properties and method for manufacturing the same

InactiveCN101084322AUniform grain sizeInhibition formationInorganic material magnetismFurnace typesSheet steelElectrical steel

The present invention relates to technology for manufacturing electrical steel sheets having excellent magnetic properties through the control of a hot-rolled texture using the phase transformation of steel. More particularly, it relates to a non-oriented electrical steel sheet that has reduced iron loss and increased magnetic flux density by controlling alloy component elements and optimizing hot-rolling conditions, even though hot-rolled sheet annealing is not carried out, as well as a manufacturing method thereof. More specifically, the invention provides a non-oriented electrical steel sheet which has excellent magnetic properties while hot-rolled sheet annealing can be omitted, the steel sheet being comprised of 0.005 wt% or less of C, 1.0-3.0 w% of Si, 0.1-2.0 wt% of Mn, 0.1 wt% or less of P, 0.1-1.5 wt% of Al, and a remainder of Fe and other inevitable impurities, in which the relationship between the elements Mn and Al satisfies an equation of -0.2 < m (=Mn-Al) < 1.0, and a slab for the steel sheet, when reheated, has a two-phase region of austenite + ferrite at a temperature ranging from ArI to 1250 DEG C.

Owner:POHANG IRON & STEEL CO LTD

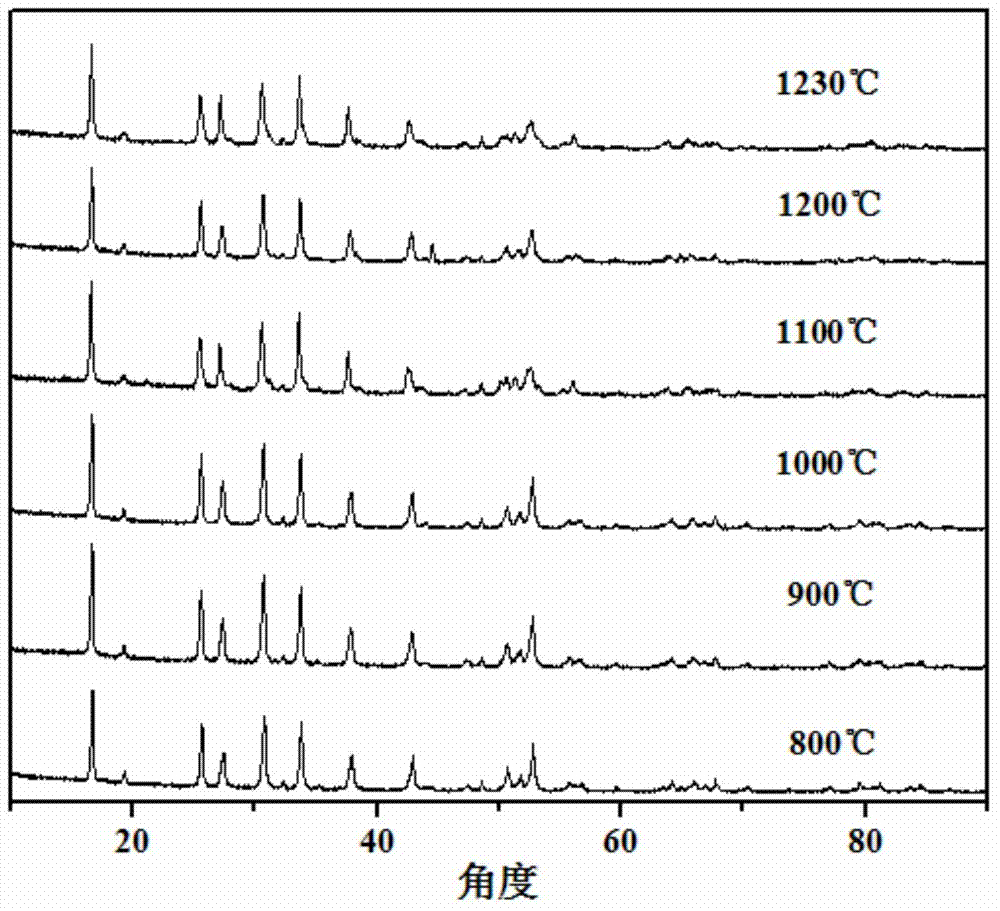

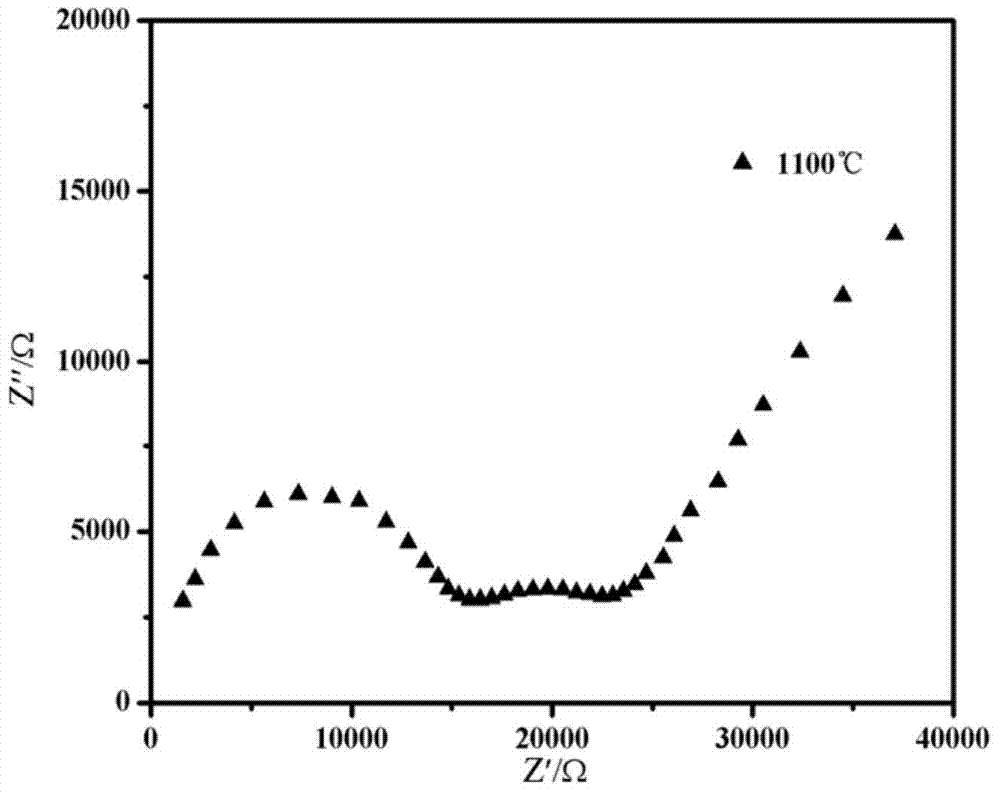

Electric field activated sintering method of solid electrolyte material

The invention provides an electric field activated sintering method of a solid electrolyte material Li7La3Zr2O12 (LLZO). The electric field activated sintering method comprises the following specific steps: ball-milling with a ball and mixing Li2O, La2O3 and ZrO2 powder, the mass percents of which are respectively 9.2-15.5%, 56.2-60.4% and 28.3-30.4%, wherein a zirconium oxide ball is used as a ball-milling medium, isopropanol is used as a solvent, and the ball-milling time is 12-36 hours; carrying out vacuum drying on ball-milling milled powder for 6-12 hours at the temperature of 80 DEG C; and carrying out electric field activated sintering, wherein the temperature is in the range from 800 to 1230 DEG C, the pressure is 0-100 MpaMPa, and a sintered sample has the room-temperature lithium-ion conductivity greater than 6*10<-4S>S / cm. Compared with a conventional solid-phase synthesis method, the electric field activated sintering method has the advantages that the synthesis reaction and the sintering compact process are completed in one step, the synthetic efficiency is improved to a large extent, the preparation technology is simplified, and the LLZO with the high lithium-ion conductivity is obtained.

Owner:WUHAN UNIV OF TECH

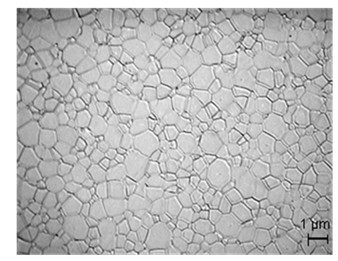

Fine-crystal transparent alumina ceramic material and preparation method

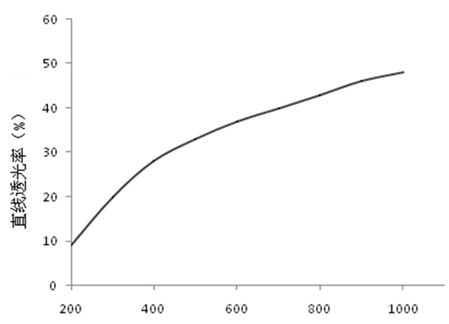

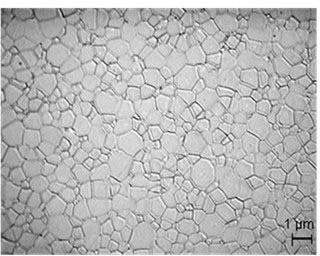

InactiveCN102627450ABreak through the phenomenon that the bending strength is less than 300MPaUniform grainHydrogen atmosphereMicrometer

The invention discloses a fine-crystal transparent alumina ceramic material and a preparation method. A formula of the material comprises the following constituents by weight percentage: 99.6-99.98% of Al2O3 and 0.02-0.4% of MgO, ZrO2 and La2O3. The particle size of the ceramic is at the range of 0.8 micrometer to 1.5 micrometer, and the linear light transmission at the 640-nanometer position is larger than 37%. High-purity alumina powder is used to be formed by cold isostatic compaction and sintered at hydrogen atmosphere, and temperature rises to 1,300 DEG C, then decreases to 1,150 DEG C and is preserved. By means of the method, the fine-crystal transparent alumina ceramic material is high in compactness, excellent in mechanical property, high linear transmission and suitable for ceramic metal halide lamp tubes, key components of semiconductor devices, high temperature observation and the like.

Owner:SUZHOU KEY MATERIALS TECH

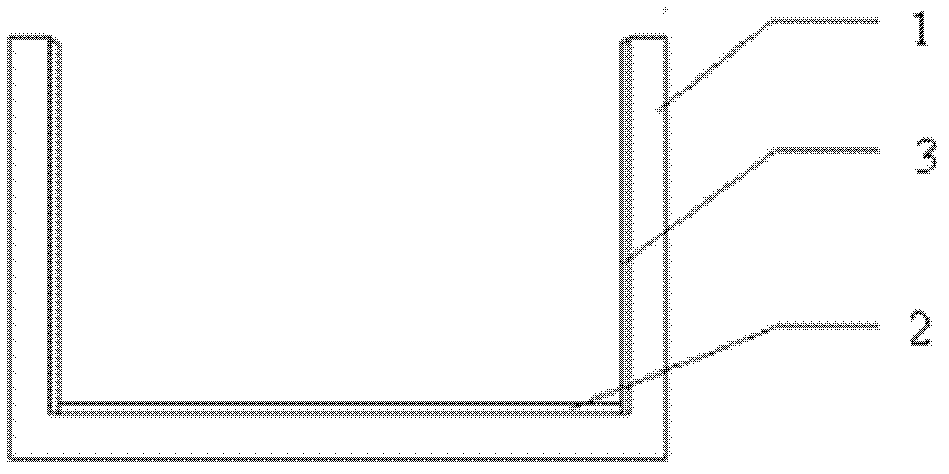

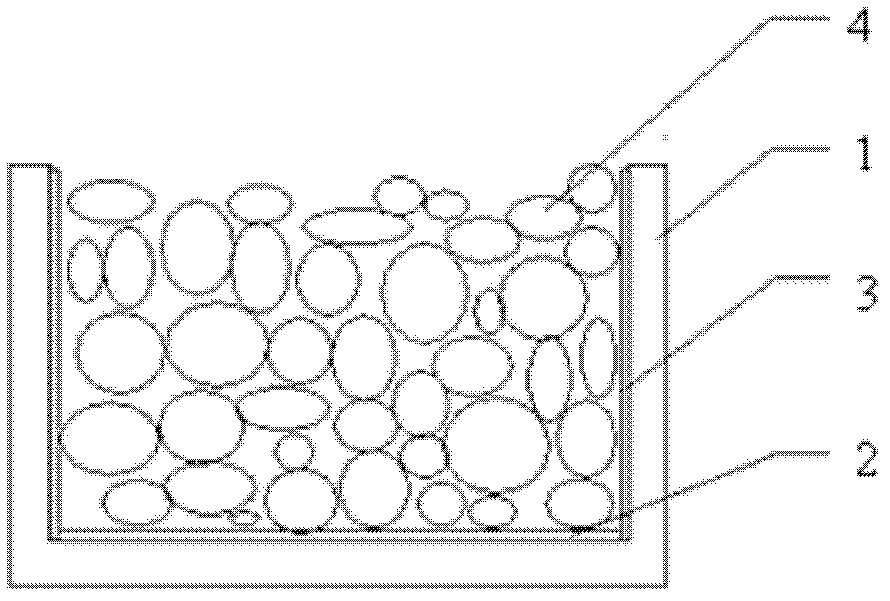

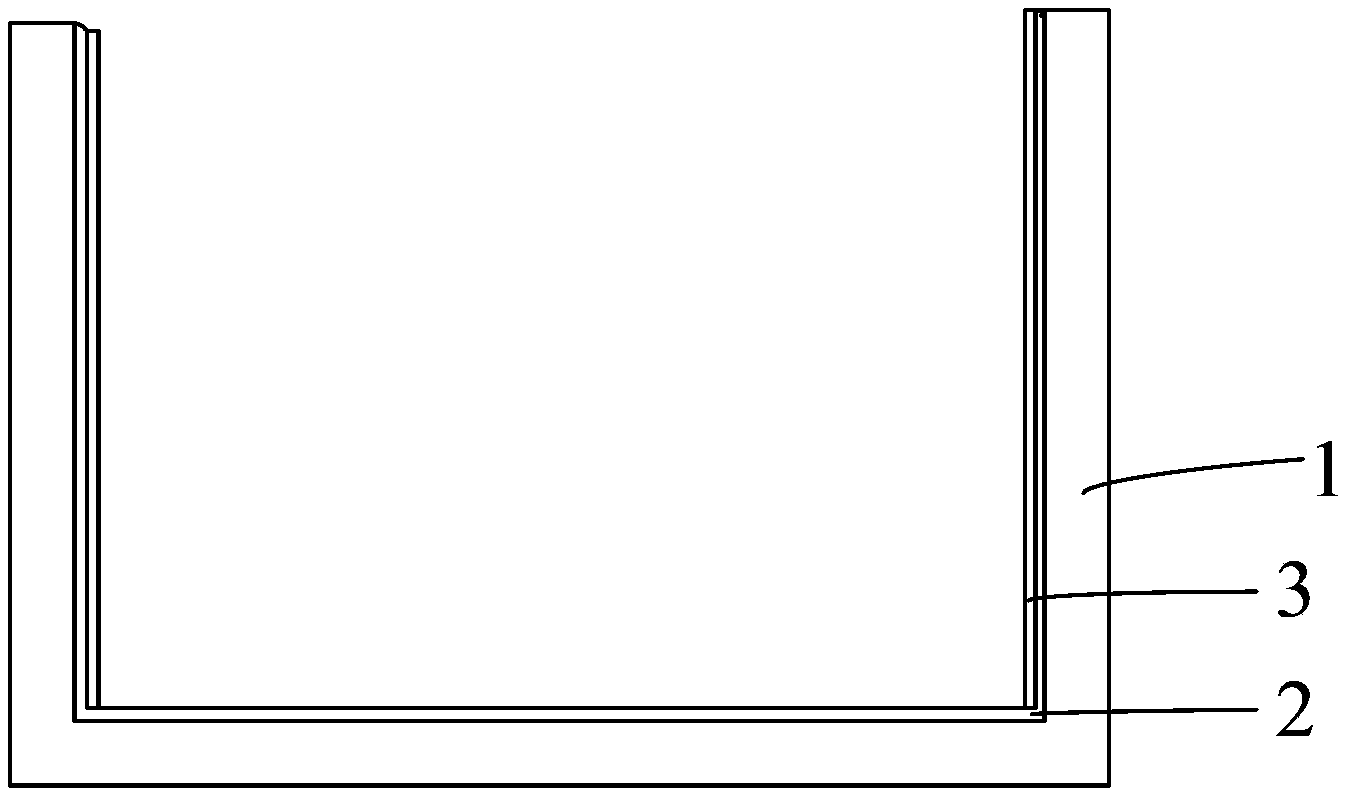

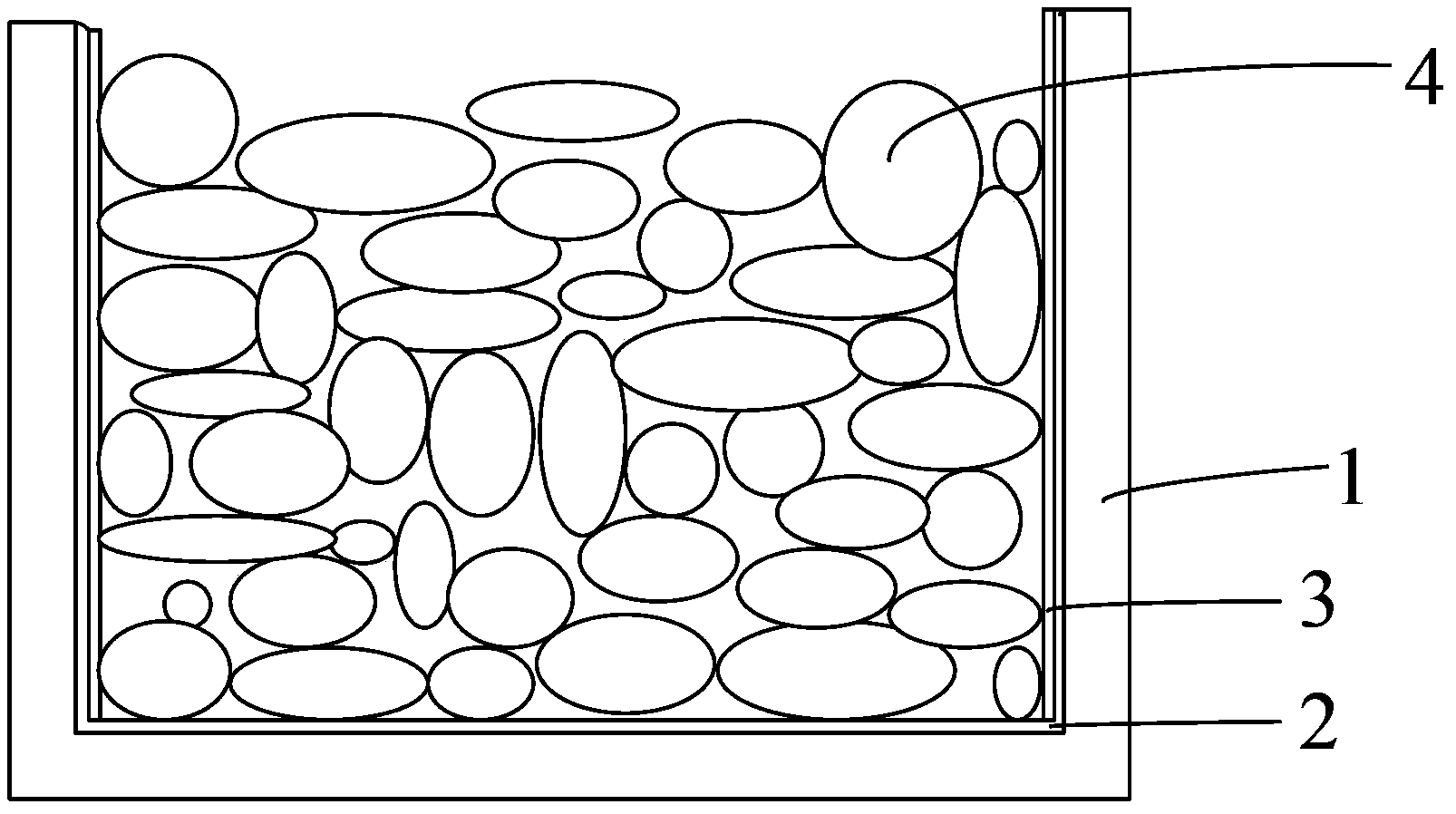

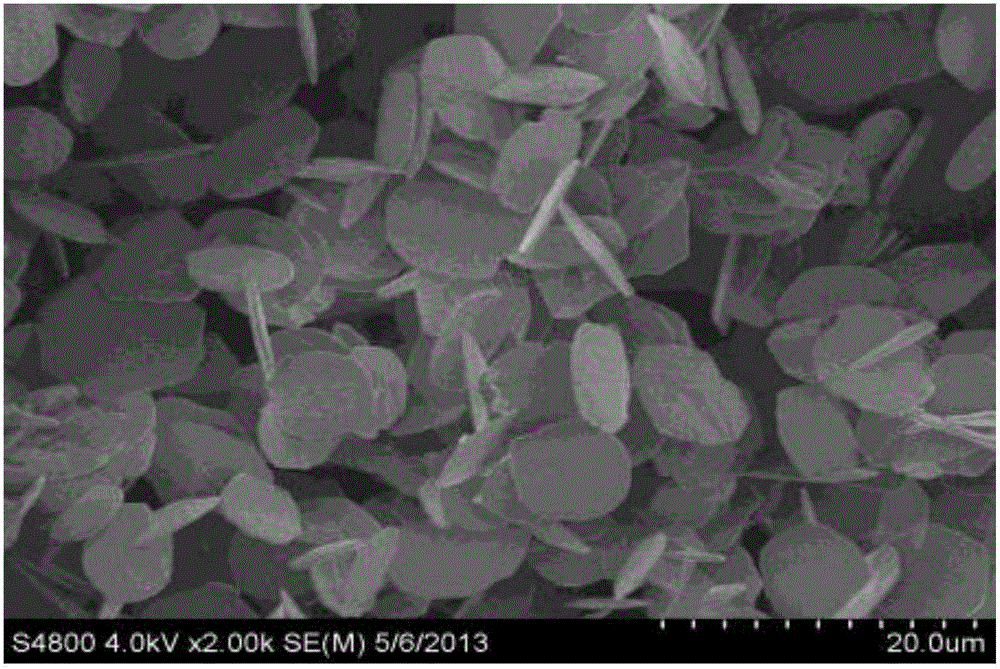

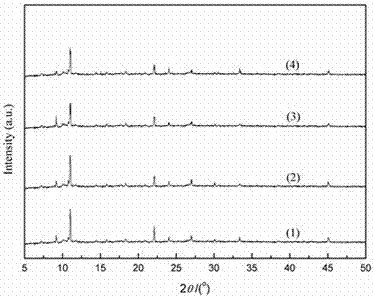

Polycrystalline silicon ingots and preparation method thereof, polycrystalline silicon chips and polycrystalline silicon ingot casting crucible

ActiveCN103361722AUniform grain sizeGrain rulePolycrystalline material growthAfter-treatment detailsMolten stateDislocation

The invention provides a preparation method of polycrystalline silicon ingots. The preparation method comprises the following steps: before or after the inner wall of a crucible is sprayed with a silicon nitride layer, a barrier layer is arranged on the inner side of the side wall of the crucible, wherein the barrier layer is a silicon powder coating layer, or a quartz powder coating layer, or a silicon powder and quartz powder mixed coating layer, and purities of silicon powder and quartz powder are above 99.99%; then a molten silicon material is arranged in the crucible; temperature in the crucible is controlled to increase gradually, along a direction which is perpendicular to the bottom of the crucible and is upward, to form a temperature gradient to make the molten silicon material to begin crystallization; and after the crystallization is finished, and the polycrystalline silicon ingots are obtained through annealing and cooling . The invention also provides the high quality polycrystalline silicon ingots obtained by the preparation method, and polycrystalline silicon chips prepared from the polycrystalline silicon ingots and the polycrystalline silicon ingot casting crucible. The polycrystalline silicon ingots prepared by the preparation method are characterized in that crystalline grains near areas of crucible wall are smaller, uniform and regular, dislocation density is low, and impurities is less.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

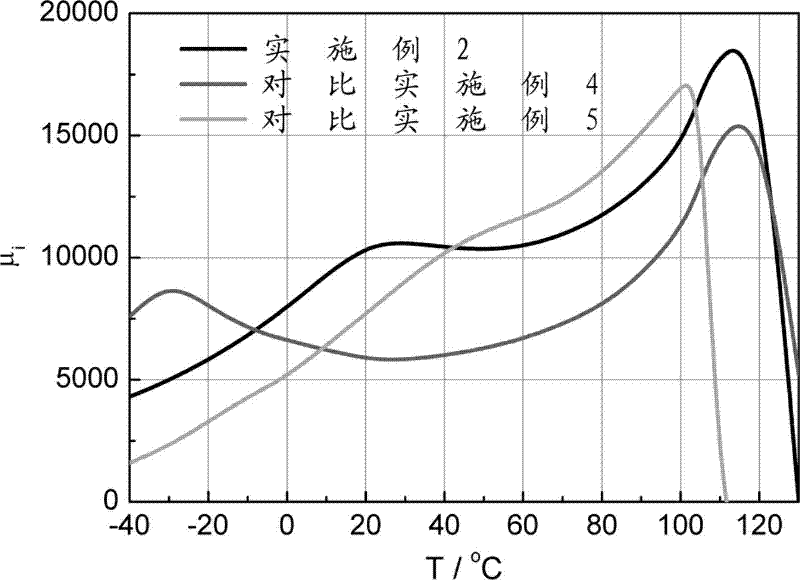

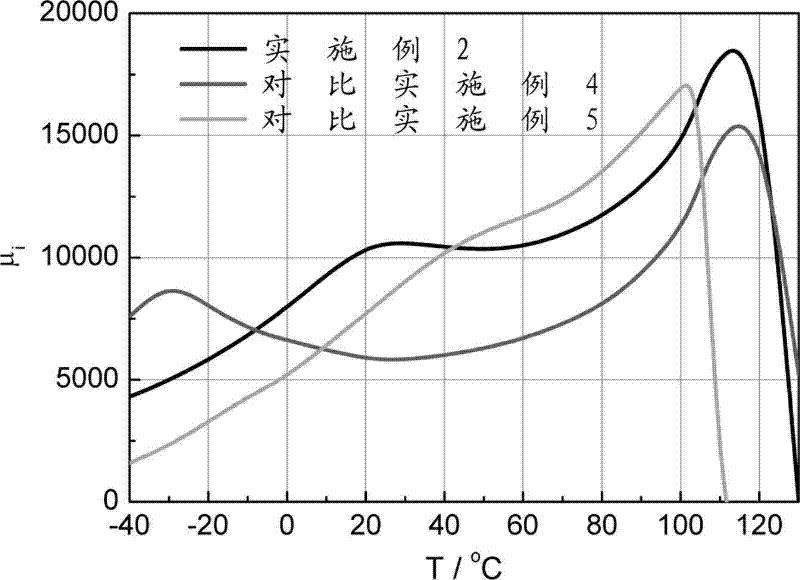

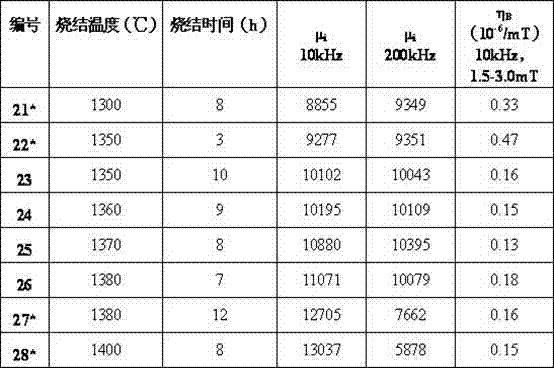

Low-total harmonic distortion (THD) wideband high-permeability MnZn ferrite material and manufacturing method thereof

InactiveCN102231312AAccurate and efficient establishmentGood temperature characteristicsInorganic material magnetismHysteresisCompression molding

The invention provides a low-total harmonic distortion (THD) wideband high-permeability MnZn ferrite material, which comprises the following principal components of: 51.5 to 53 mol percent of Fe2O3, 22 to 27.5 mol percent of Mn3O4 based on MnO, and 20 to 25 mol percent of ZnO; and auxiliary components are at least four of TiO2 (or SnO2), Co2O3, MoO3, Bi2O3, SiO2, CaCO3 and Nb2O5, wherein the total weight of the auxiliary components is 0.02 to 0.04 weight percent of that of the principal components. In the low-THD wideband high-permeability MnZn ferrite material, an initial permeability at a low frequency of 10kHz and a high frequency of 200kHz at the temperature of 25 DEG C is not less than 10,000, and a hysteresis constant etaB is less than 0.2*10<-6> / mT. The invention also provides a method for manufacturing the low-THD wideband high-permeability MnZn ferrite material, which comprises the following steps of: mixing, drying, presintering, ball milling, pelleting, compression molding and sintering. The method has the advantages of simple process and low cost.

Owner:江门安磁电子有限公司

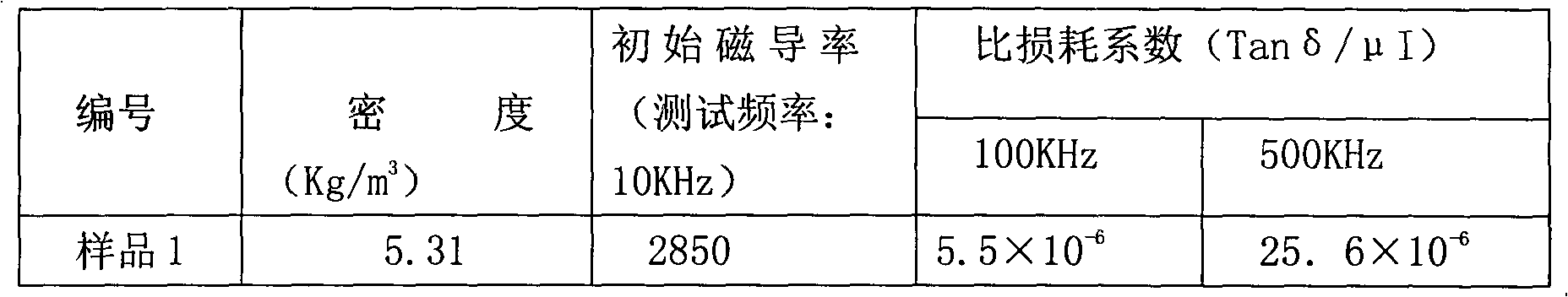

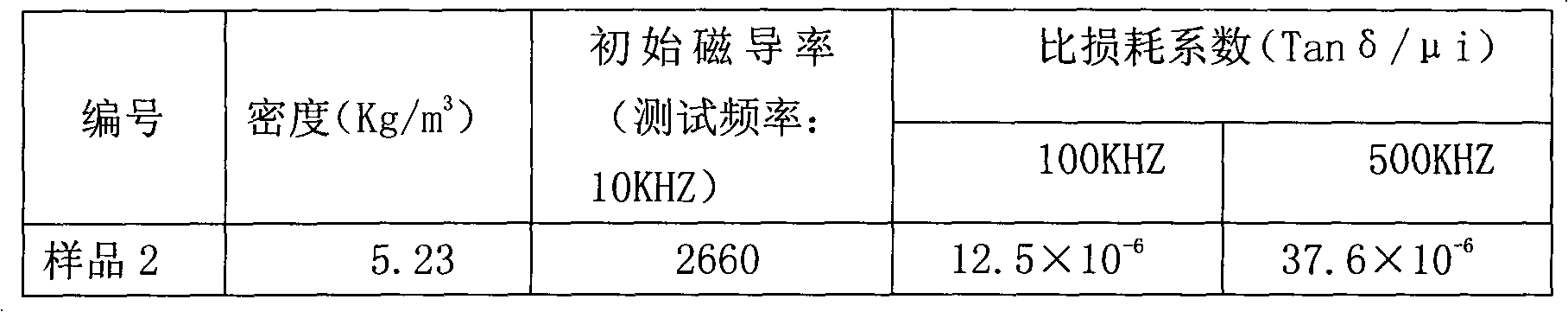

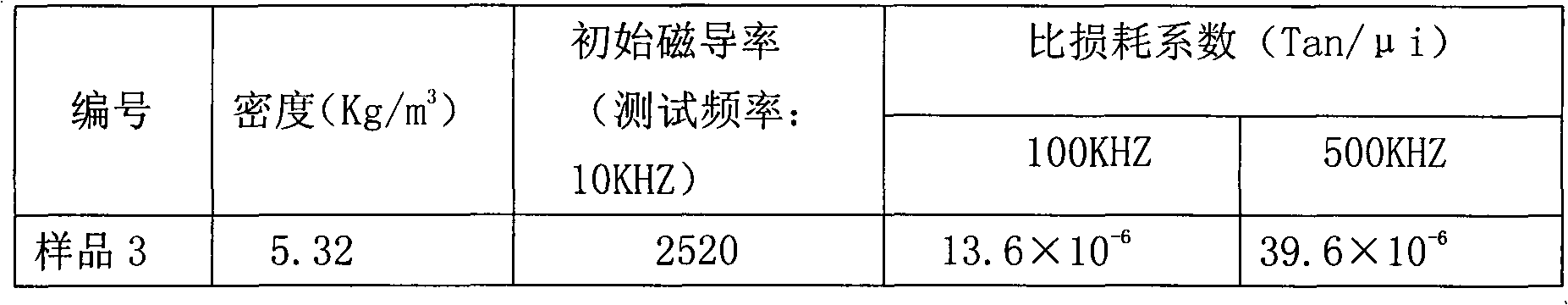

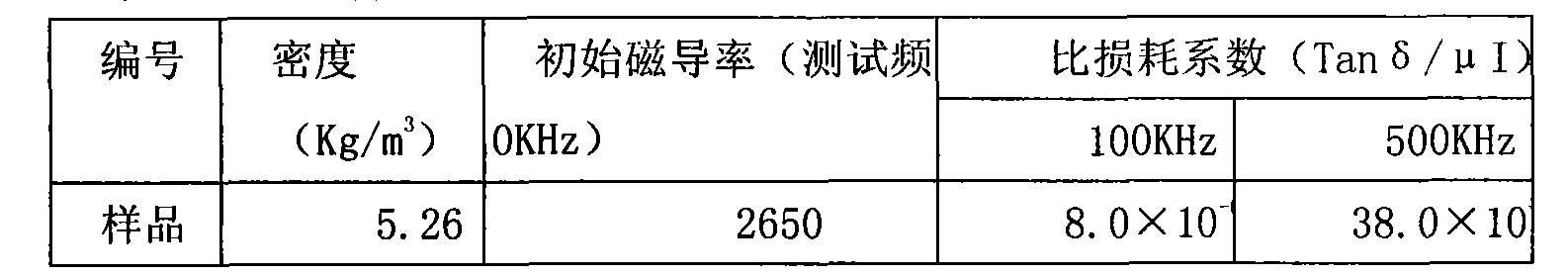

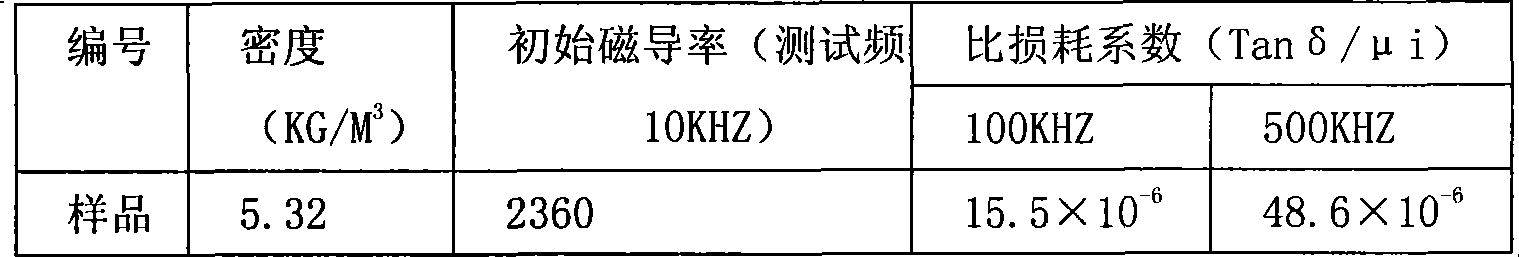

Low-temperature sintered high-permeability NiCuZn ferrite material

The invention discloses a low-temperature sintered high-permeability NiCuZn ferrite material for a wire wound chip inductor and a preparation method of the ferrite material. The ferrite material comprises the following main components based on oxide content: 40.5 to 49.6 moles percent of Fe2O3, 30 to 47 moles percent of ZnO, 5 to 20 moles percent of CuO and the balance of NiO. The preparation method comprises the following steps of: (1) mixing raw materials, (2) performing primary sanding, (3) performing primary spray drying and granulation, (4) pre-sintering, (5) adding trace elements, (6) performing secondary sanding, (7) performing secondary spray drying and granulation, (8) molding and (9) sintering. By adding auxiliary components such as NaCO3, B2O3, Ta2O5 and the like, the sintering temperature is greatly reduced, the sintering temperature is below 900 DEG C, the high-frequency electromagnetic performance of the material is greatly improved, the sintering density of the material is improved, the mechanical strength of the material is improved, and the manufacturing process requirement of the wire wound chip inductor is met; and on the other hand, energy is saved, and the producing and manufacturing costs are greatly reduced. The initial permeability of the material is 2,850; the specific loss coefficient of the material is less than 5.5*10<-6> under the test conditions of 100 kHz and 0.25mT; and the specific loss coefficient of the material is less than 25.6*10<-6> under the test conditions of 500 kHz and 0.25mT.

Owner:TAIXING ZHONGHENG BUILDING DECORATION ENGCO

Casting method for polycrystalline silicon ingot

ActiveCN104562192AImprove photoelectric conversion efficiencyShorten the production cyclePolycrystalline material growthSingle crystal growth detailsIngot castingCrucible

The invention discloses a casting method for a polycrystalline silicon ingot. The casting method comprises a crucible pretreatment process and an ingot casting process, wherein the crucible pretreatment process comprises the steps of preparing silicon nitride slurry from silicon nitride powder, silica sol and water, spraying the silicon nitride slurry at the side wall and bottom of a crucible, and spraying other silicon nitride slurry at the bottom of the crucible; and soaking silicon powder in an acid solution with strong oxidizing property for 30-60 minutes, then, separating, washing to be neutral, drying the washed silicon powder, next, preparing slurry from the dried silicon powder, the silica sol and the water, spraying the slurry at the bottom of the obtained crucible, and sintering the treated crucible; and the melting stage of the ingot casting process comprises the step of immediately opening a cage to cool when a silicon material floats from the bottom of the crucible. The polycrystalline silicon ingot produced by using the casting method disclosed by the invention has the characteristics of short production period, low cost, long silicon ingot minority carrier lifetime, high primary silicon material utilization ratio and the like, and the obtained polycrystalline silicon wafer has the characteristics of uniform grain size, small defect density, high photoelectric conversion efficiency and the like.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

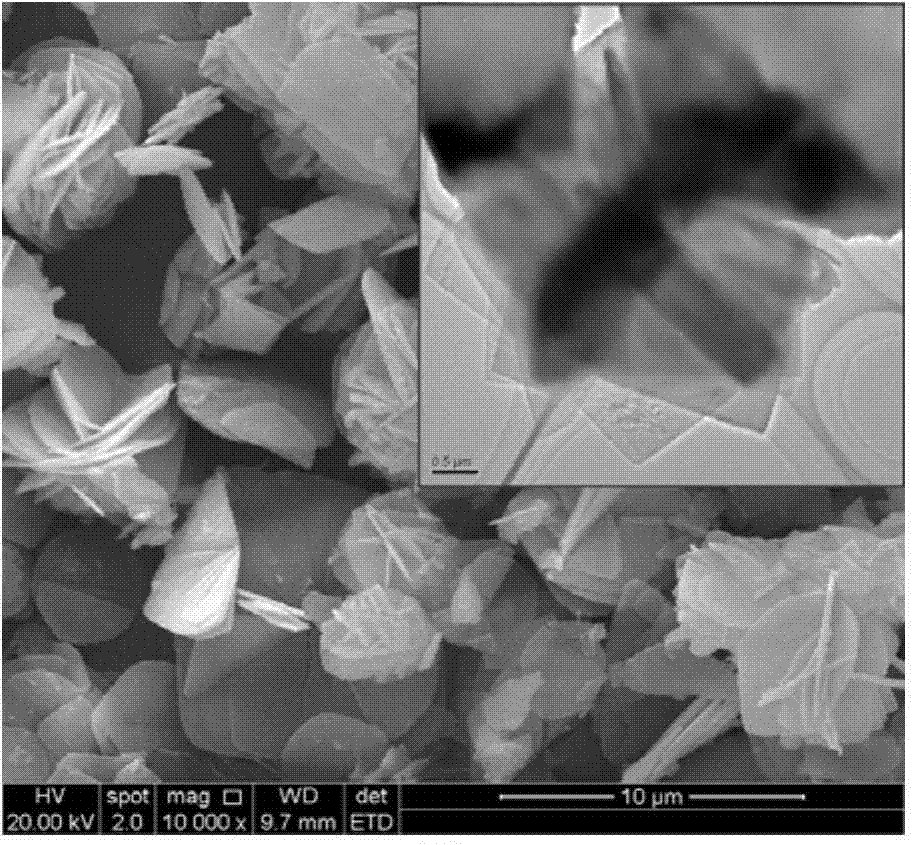

Preparation method for high-purity flaky alumina

ActiveCN105347377AHigh purityImprove doping uniformityAluminium hydroxide preparationAluminium oxides/hydroxidesAluminium isopropoxideAmmonium bifluoride

The invention discloses a preparation method for high-purity flaky alumina, belonging to the technical field of preparation of special powder. The preparation method comprises the following steps: with high-purity aluminum isopropoxide with a purity of 99.999%, pure water and isopropanol as main raw materials and ammonium bifluoride or ammonium fluoride as a crystal morphology controlling agent, dissolving the high-purity aluminum isopropoxide in isopropanol to prepare a solution A; preparing a solution B from pure water, isopropanol and ammonium bifluoride; then gradually adding the solution A into the solution B drop by drop at a certain addition speed; carrying out a reaction under the conditions of heating and stirring so as to produce hydrated alumina; and then successively carrying out filtering, drying and roasting so as to obtain the high-purity flaky alumina. The high-purity flaky alumina prepared by using the method has crystal grain thickness of no more than 1.0 [mu]m, a radial size of 5 to 20 [mu]m, a smooth surface, a flaky shape, no agglomeration and crystal twinning, and good dispersibility, and can be used in fields like cosmetics, pearlescent pigment, high-grade coatings and fine ceramics.

Owner:SHENGNUO OPTOELECTRONICS TECH QH CO LTD

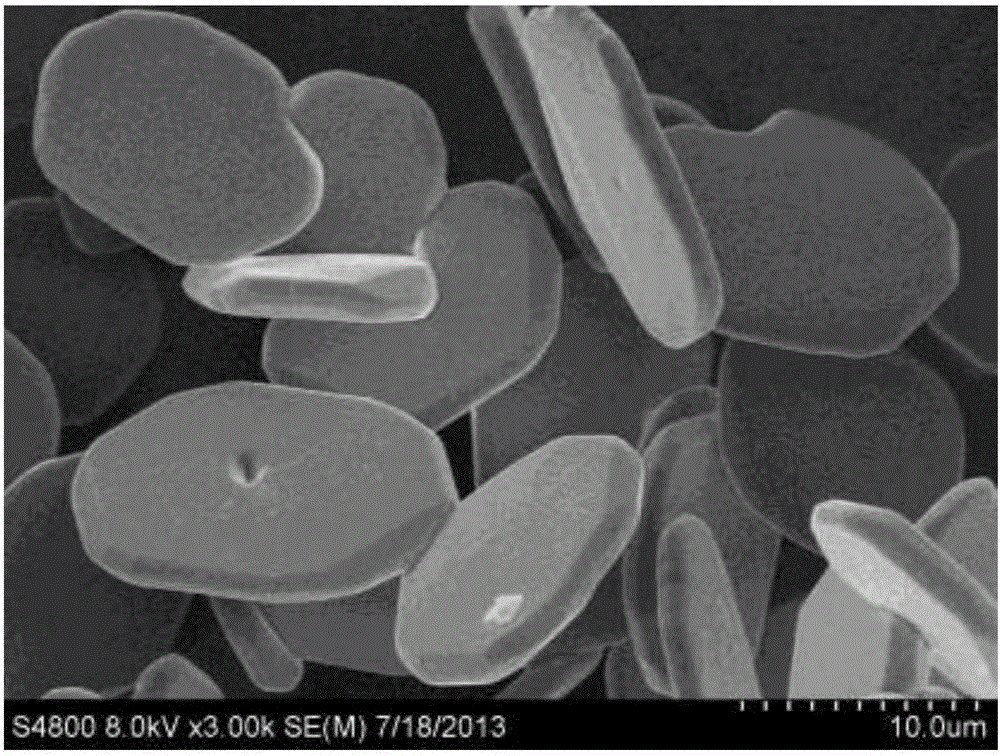

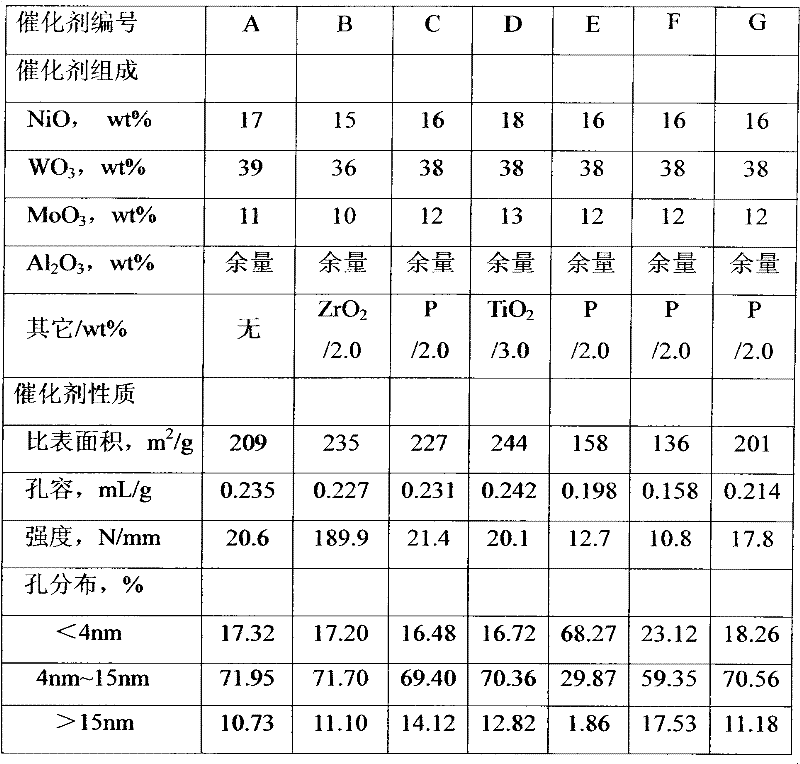

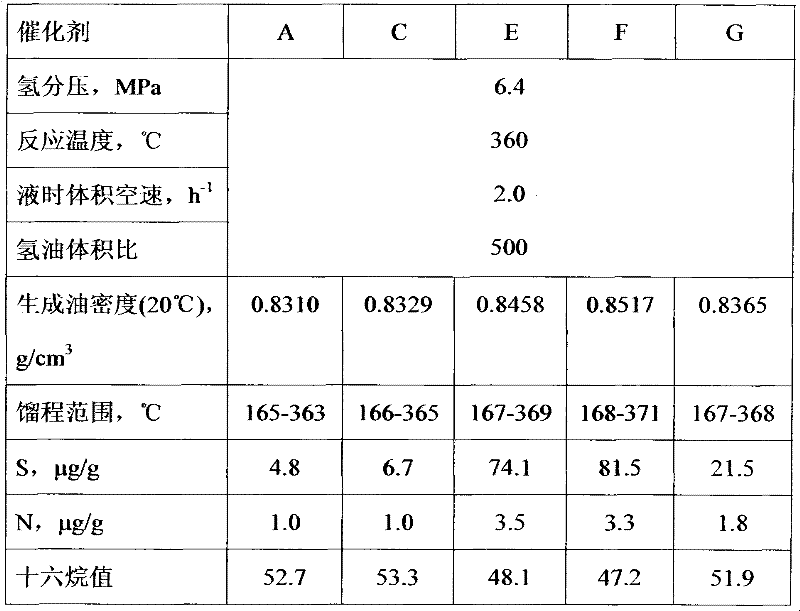

Preparation method of hydrotreatment catalyst composition

ActiveCN102451705AImprove adhesionEasy to shapeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAluminateOrganic solvent

The invention discloses a preparation method of a hydrotreatment catalyst composition. According to the method, during preparation of a mixture of NixWyOz composite oxide precursor and Al2O3 precursor, sodium meta aluminate is employed as an aluminium source, and sodium meta aluminate and CO2 gas are added with swing addition during a gelatinizing process; after gelatinization, the mixture, molybdena and organic solvent are beaten, mixed, moulded and dried to obtain the catalyst. Particles prepared by the method are large and uniform to improve physical and chemical properties of the catalyst; the catalyst has characteristics of large pore volume, large specific surface area, reasonable aperture distribution and high effective utilization rate of active metal, etc.; and the method solves a problem of difficulty in forming of bulk phase catalyst. The catalyst prepared by the method of the invention is especially suitable for super-deep desulphurization reaction in production of super-cleaning diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing perovskite film, and perovskite solar cell device

ActiveCN108899420AEnhanced carrier mobility and diffusion lengthEnhanced charge transport capabilitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellCrystallite

The invention discloses a method for preparing a perovskite film and a perovskite solar cell device, wherein the method for preparing a perovskite film comprises the following steps: (1) preparing a perovskite precursor solution, then adding anti-solvent diethyl ether to the perovskite precursor solution, and uniformly mixing the anti-solvent diethyl ether and the perovskite precursor solution; (2) dropping the perovskite precursor solution containing the diethyl ether onto the surface of a substrate, performing spin coating, and dropping anti-solvent toluene during the spin coating in order to wash the surface of perovskite; (3) after the spin coating, subjecting an obtained perovskite film intermediate product to thermal annealing treatment to obtain the perovskite film. Adding the diethyl ether to the perovskite precursor solution can control the growth of a perovskite crystal, can prepare a perovskite film having a uniform grain size and low surface roughness, and is beneficial toimproving carrier mobility, a diffusion length, and a charge transport capacity. The perovskite film, when used as an active layer of the perovskite solar cell device, can effectively improve the photovoltaic performance of the device.

Owner:NANJING UNIV OF POSTS & TELECOMM

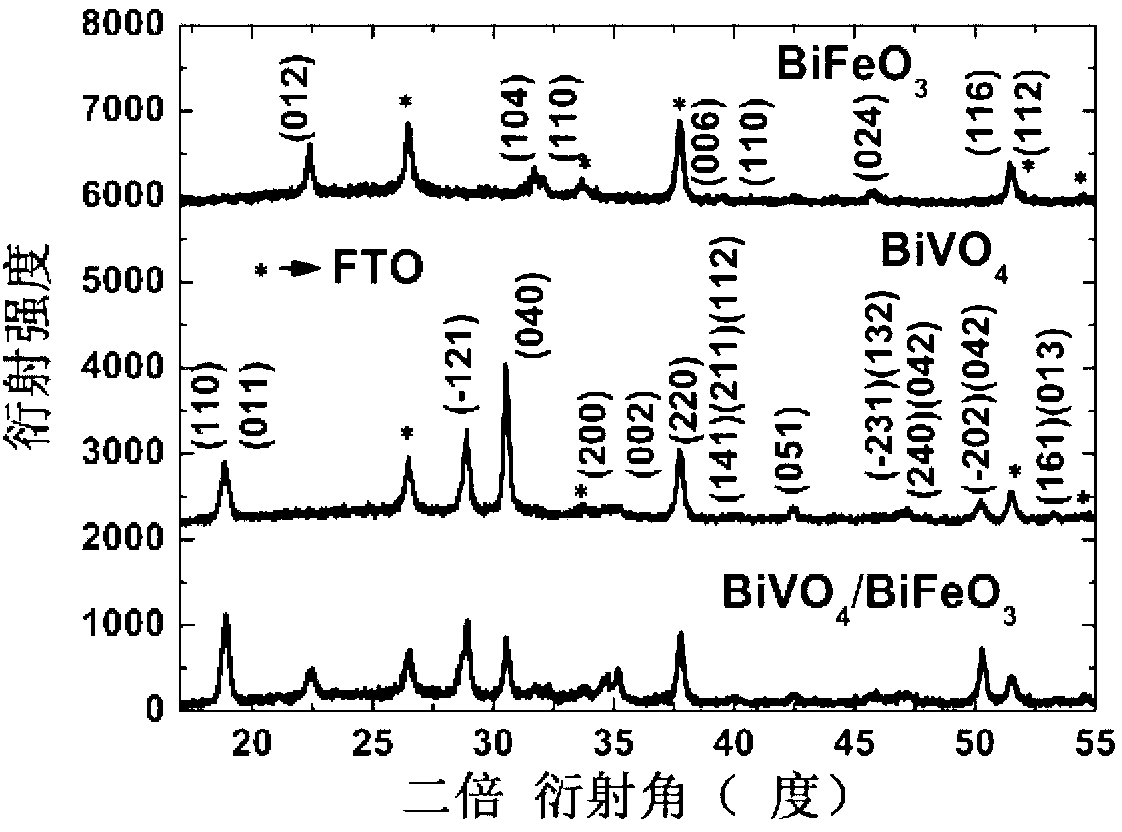

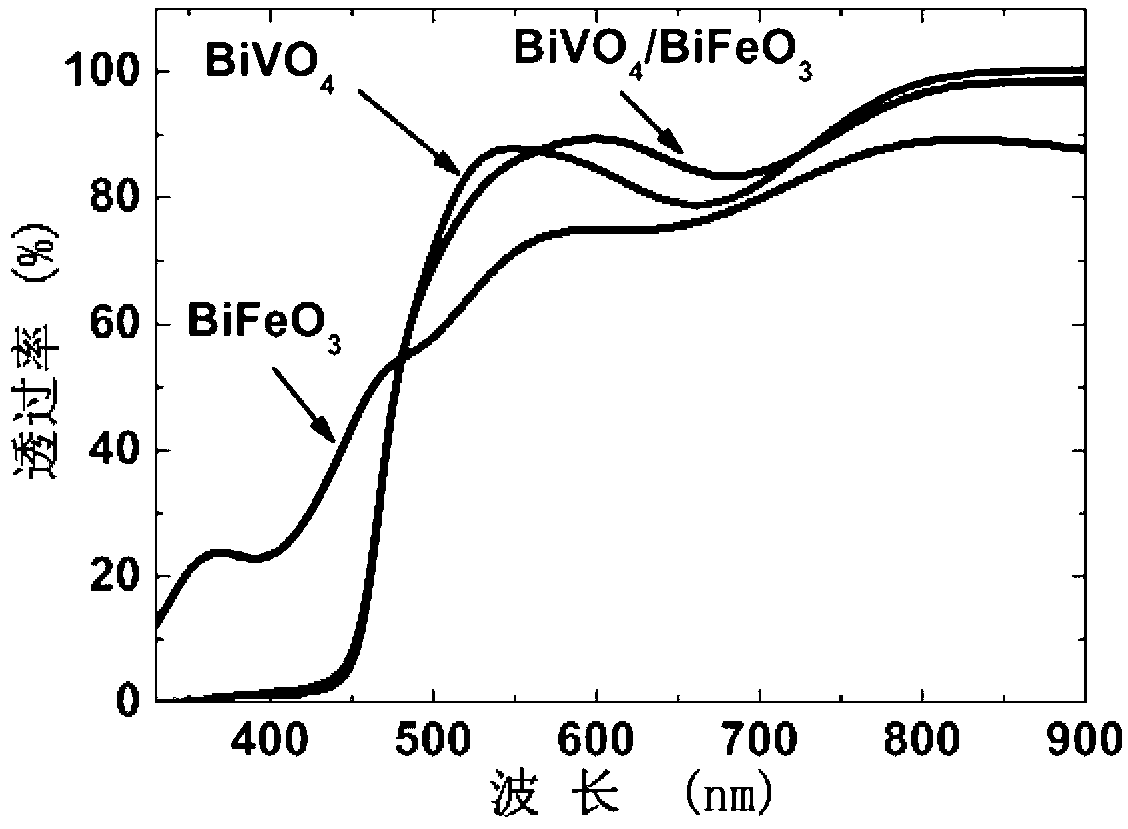

Method for preparing bismuth vanadate/bismuth ferrite heterojunction film solar cells

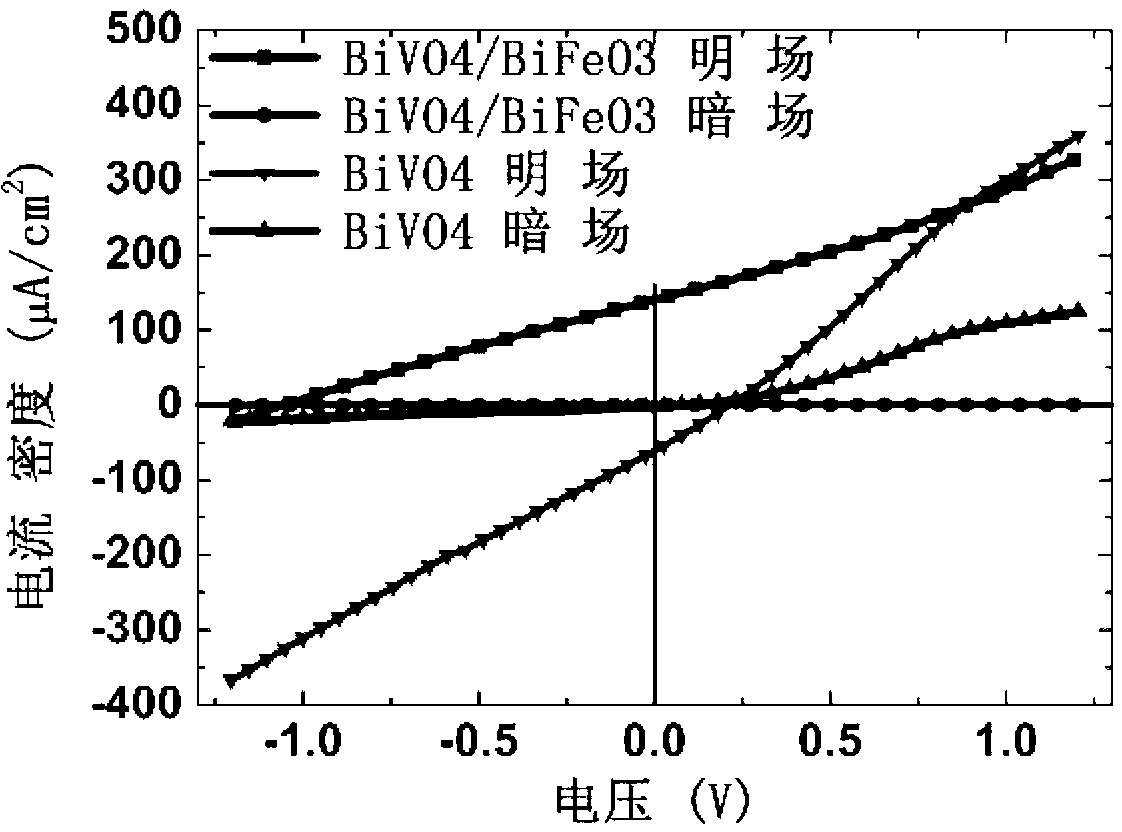

InactiveCN103078013ANo impurityReduce manufacturing costRenewable energy productsSemiconductor devicesHeterojunctionBismuth vanadate

The invention relates to a method for preparing bismuth vanadate / bismuth ferrite heterojunction film solar cells on a glass substrate. The method comprises the following steps: selecting FTO (Fluorinedoped Tin Oxide) conductive glass as a base, preparing a perovskite-structure bismuth vanadate / bismuth ferrite heterojunction film with a chemical solution deposition method, and then preparing a top electrode on the film with a physical sputtering method to obtain the solar cells. The photovoltaic effect of the bismuth vanadate film can be increased and is reversed by utilizing an ultra-thin bismuth ferrite layer. The method can prepare the bismuth vanadate / bismuth ferrite heterojunction film with high consistency and good repeatability on the glass substrate with a low cost. The prepared heterojunction film has good photovoltaic properties, the diode direction of the heterojunction film is opposite to the diode direction of a pure bismuth vanadate film, and ultra-thin bismuth ferrite ferroelectric films and similar bismuth vanadate / bismuth ferrite heterojunction films have a wide application prospect in the fields of solar cells and photoelectric devices due to the good properties.

Owner:SHANGHAI JIAO TONG UNIV

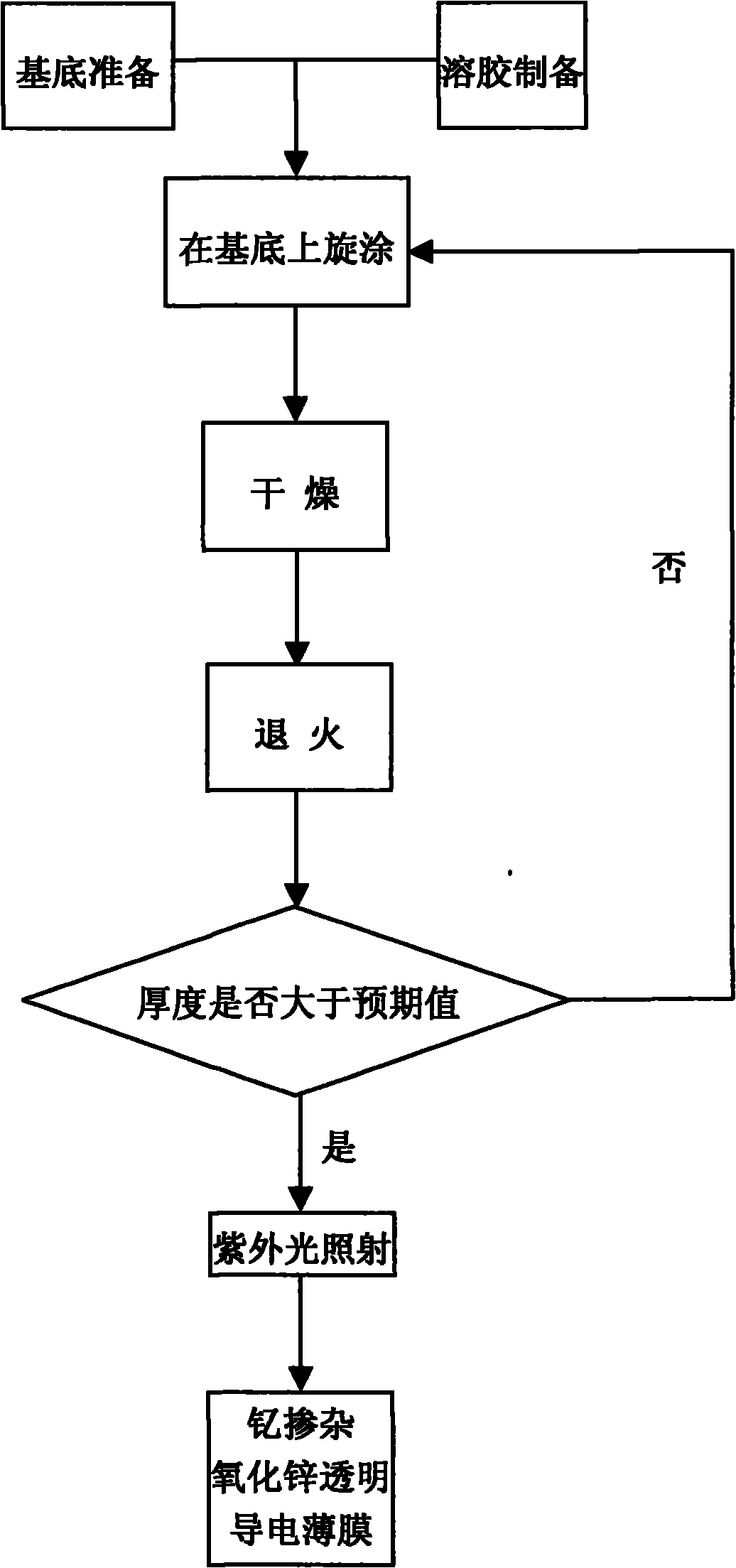

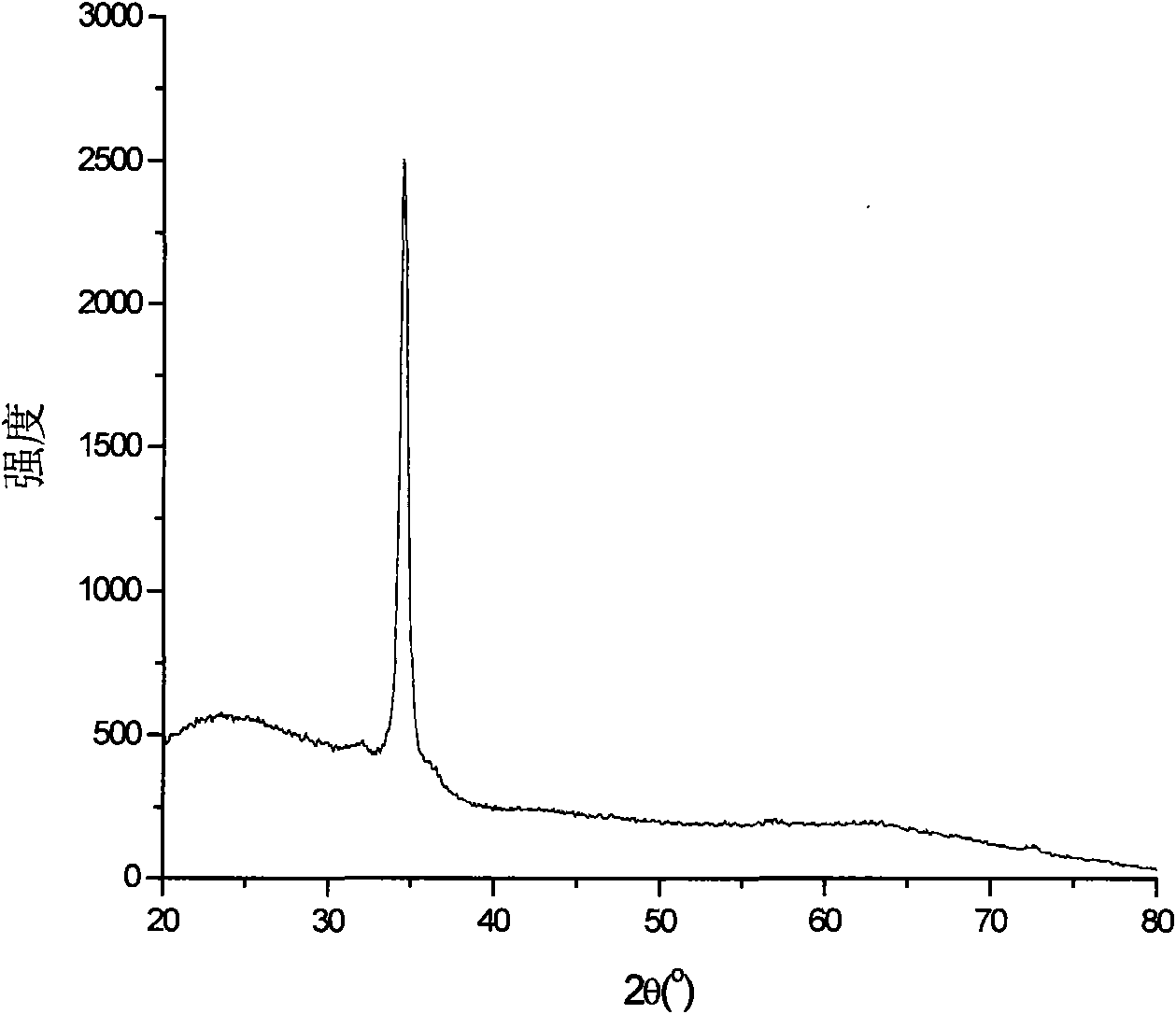

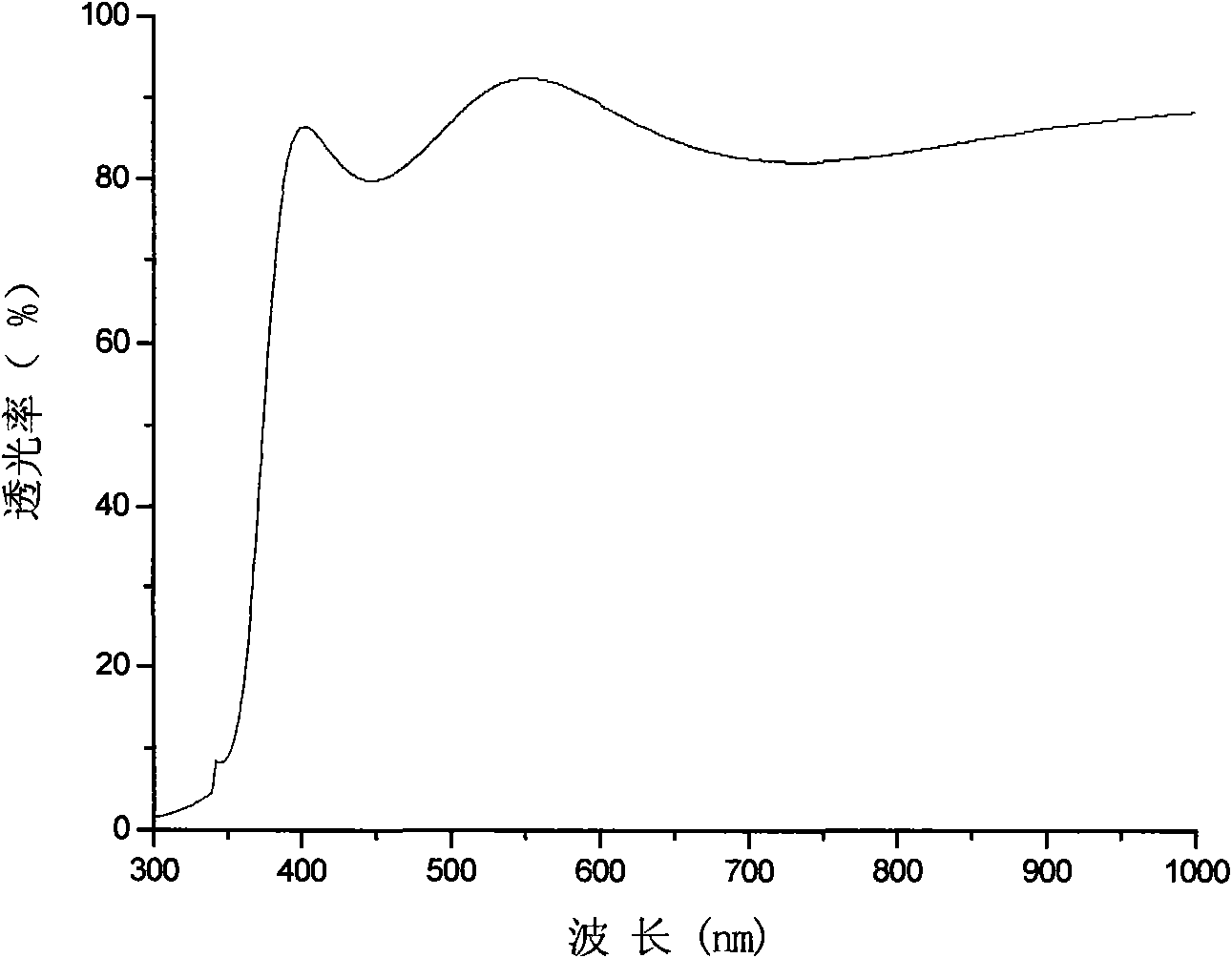

Preparation method of photoassisted sol-gel of yttrium doped zinc oxide transparent conductive film

InactiveCN101994103AUniform grain sizeClosely arrangedLiquid/solution decomposition chemical coatingSolventChemistry

The invention belongs to the technical field of material surface chemical coating, in particular relating to a preparation method of a photoassisted sol-gel of a yttrium doped zinc oxide transparent conductive film. In the invention, the sol-gel is prepared by adopting a photoassisted sol-gel method and a hierarchic annealing method, and taking zinc acetic acid and yttrium nitric acid as raw materials, ethylene glycol monoemethyl ether as a solvent, and ethanolamine as a stabilizer; and by regulating the doping amount of the yttrium, controlling the temperature and the time of drying and annealing, and irradiating by ultraviolet, the control on the electricity performance of the yttrium doped zinc oxide transparent conductive film is achieved. In the invention, the prepared yttrium doped zinc oxide transparent conductive film has the resistivity within 2.1*10<-2> omega.cm to 8.1*10<-2> omega.cm, the light transmission ratio (including substrate) of a visible light area is more than 85%; in addition, the film consists of zinc oxide nano-crystals with a hexagonal wurtzite structure, wherein the crystal sizes are even, and the crystals are arranged compactly and have C-axis preferable growth orientation.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

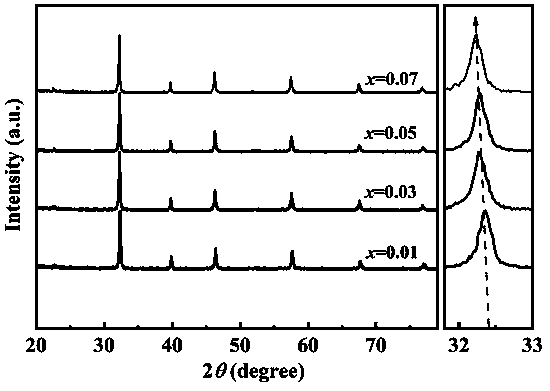

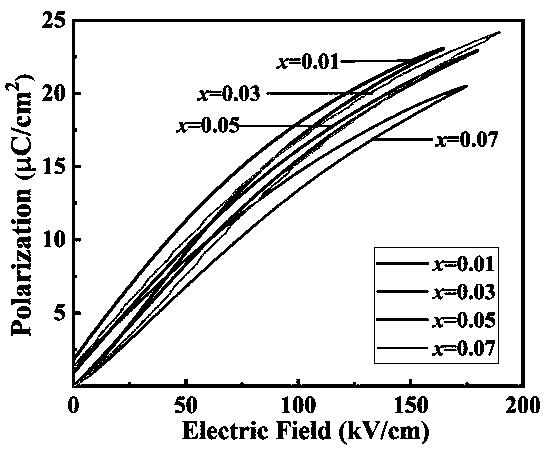

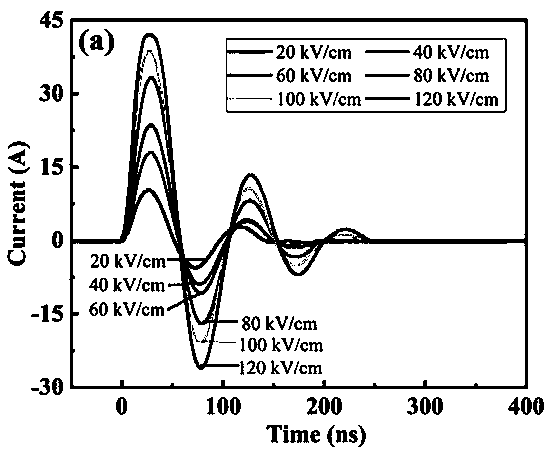

Sn-doped high-entropy perovskite oxide ceramic material with high power density, and preparation method thereof

ActiveCN111039672AHigh breakdown strengthGrowth inhibitionFixed capacitor dielectricOxide ceramicFree energies

The invention discloses a Sn-doped high-entropy perovskite oxide ceramic material with high power density. The preparation method of the material comprises the following steps: taking Na2CO3, Bi2O3, BaCO3, SrCO3, CaCO3, TiO2 and SnO2 as raw materials according to a chemical formula (Na0.2Bi0.2Ba0.2Sr0.2Ca0.2)Ti[1-x]Sn[x]O3, carrying out wet ball-milling mixing on the powder, pre-firing the dried powder at 900 DEG C for 2 hours, carrying out secondary ball-milling, sieving and molding, and finally sintering at 1250 DEG C for 2 hours to obtain the single-phase high-entropy perovskite oxide ceramic material. According to the invention, the high-entropy ceramic material prepared by the invention is simple in preparation process and low in manufacturing cost, the discharge energy storage density can reach 1.74 J / cm<3> and the power density can reach 51.4 MW / cm<3> by selecting a proper x value, and a new lead-free energy storage material matrix is provided.

Owner:SHAANXI UNIV OF SCI & TECH

Aluminum-scandium alloy target blank and preparation method and application thereof

InactiveCN107841643ALow oxygenScandium content is highVacuum evaporation coatingSputtering coatingScandiumAlloy

The invention relates to an aluminum-scandium alloy target blank and a preparation method and application of the aluminum-scandium alloy target blank. The aluminum-scandium alloy target blank comprises, by weight, 16-50 parts of scandium and 50-84 parts of aluminum. The oxygen content of the aluminum-scandium alloy target blank is smaller than or equal to 160 ppm. The aluminum-scandium alloy target blank is high in scandium content and low in oxygen content, so that the prepared target blank cannot generate abnormal discharge or particle sputtering scars, and follow-up high-quality firm formation can be guaranteed.

Owner:GEMCH MATERIAL TECH SUZHOU

Polycrystalline silicon film, preparation method thereof, array substrate and display device

ActiveCN102856173ALarge grainUniform grain sizeSolid-state devicesSemiconductor/solid-state device manufacturingCharge carrierDisplay device

The invention discloses a polycrystalline silicon film and a preparation method thereof, an array substrate and a display device, belonging to the technical field of semiconductors. The preparation method of the polycrystalline silicon film comprises the following steps of: (1) forming a graphene layer and a noncrystalline silicon layer which are adjacent; and (2) enabling noncrystalline silicon to crystallize and form polycrystalline silicon and obtaining the polycrystalline silicon film. The polycrystalline silicon in the polycrystalline silicon film has the advantages of no pollution and low defect density, the crystal grain size of the polycrystalline silicon is uniform in size, the arrangement is ordered, the crystal grain is larger, and further the surface flatness is better. The speed rate of current carriers in the polycrystalline silicon film prepared by the method is increased, and the element performance of a polycrystalline silicon film transistor is improved.

Owner:BOE TECH GRP CO LTD

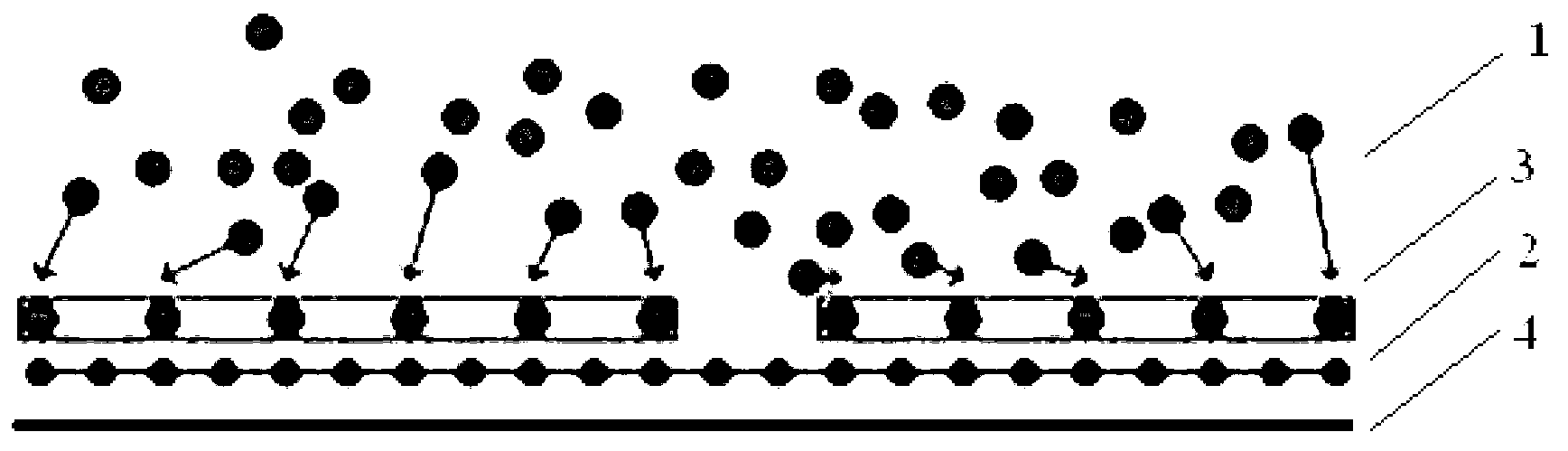

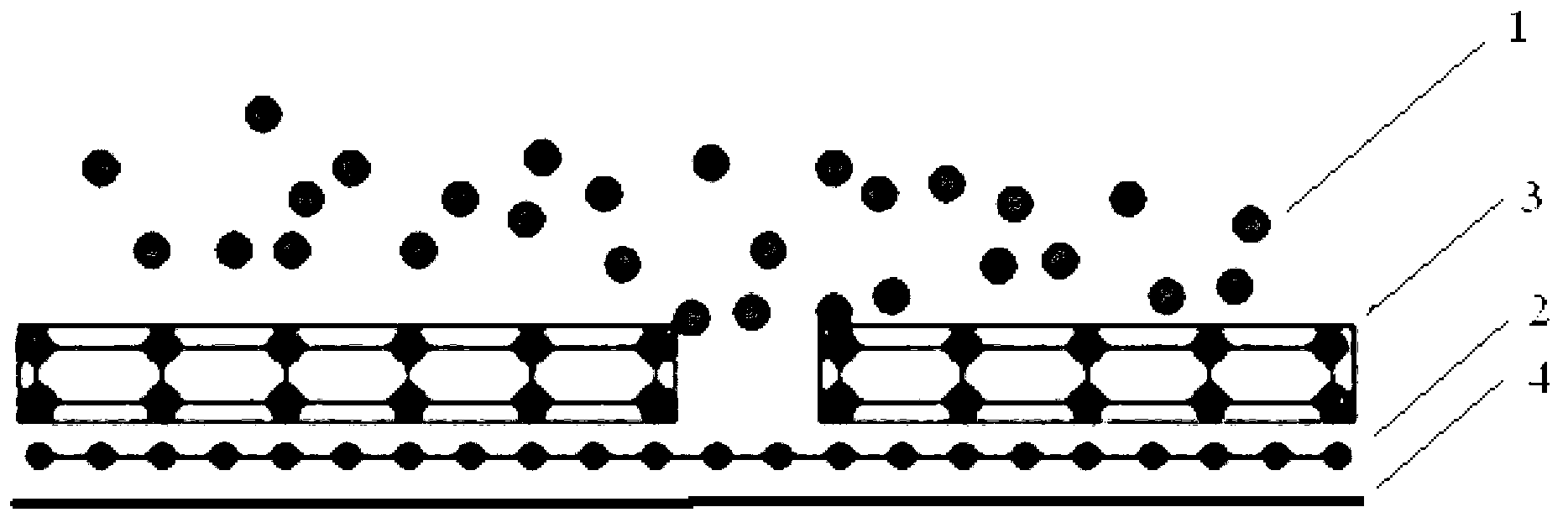

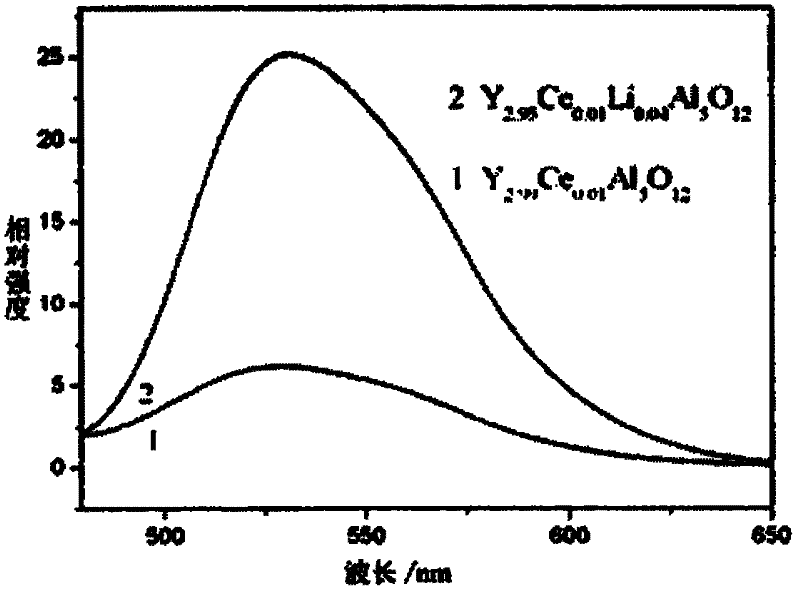

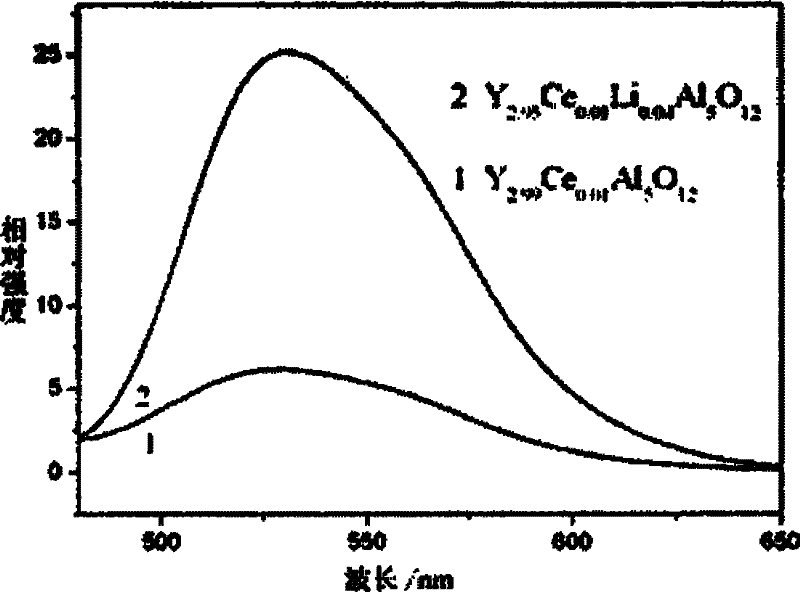

Transparent ceramic for high brightness white light-emitting diode and preparation method thereof

The invention discloses transparent ceramic for the high brightness white light-emitting diode (LED) and a preparation method thereof. The chemical formula of the transparent ceramic is (Y3-x-y-zCexLiyRz)(Al5-nMn)O12, wherein R is at least one of La, Pr, Sm, Gd, Tb and Dy; M is at least one of Sc, Ti, V, Cr and Mn; and x is larger than or equal to 0.003 and less than or equal to 0.06, y is larger than or equal to 0.003 and less than or equal to 0.06, z is larger than or equal to 0 and less than or equal to 0.75, and n is larger than or equal to 0 and less than or equal to 0.75. The raw material powder prepared by the solid-phase ball milling method or wet chemical method is used for preparing the transparent ceramic which has the advantages of fine crystal particle, uniform size and ultralow porosity through moulding, cold isostatic pressing and vacuum sintering. The transparent ceramic has the characteristics of high transmissivity and thermal conductivity, good chemical stability and thermal stability and high fluorescence conversion efficiency.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

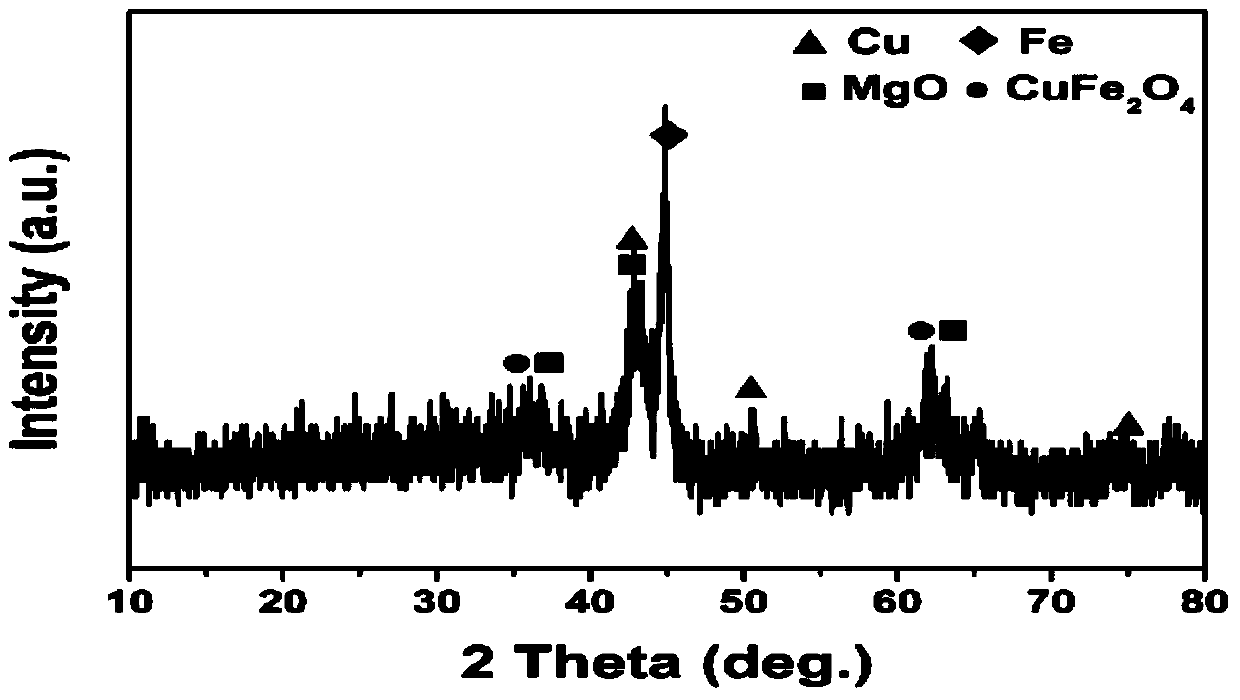

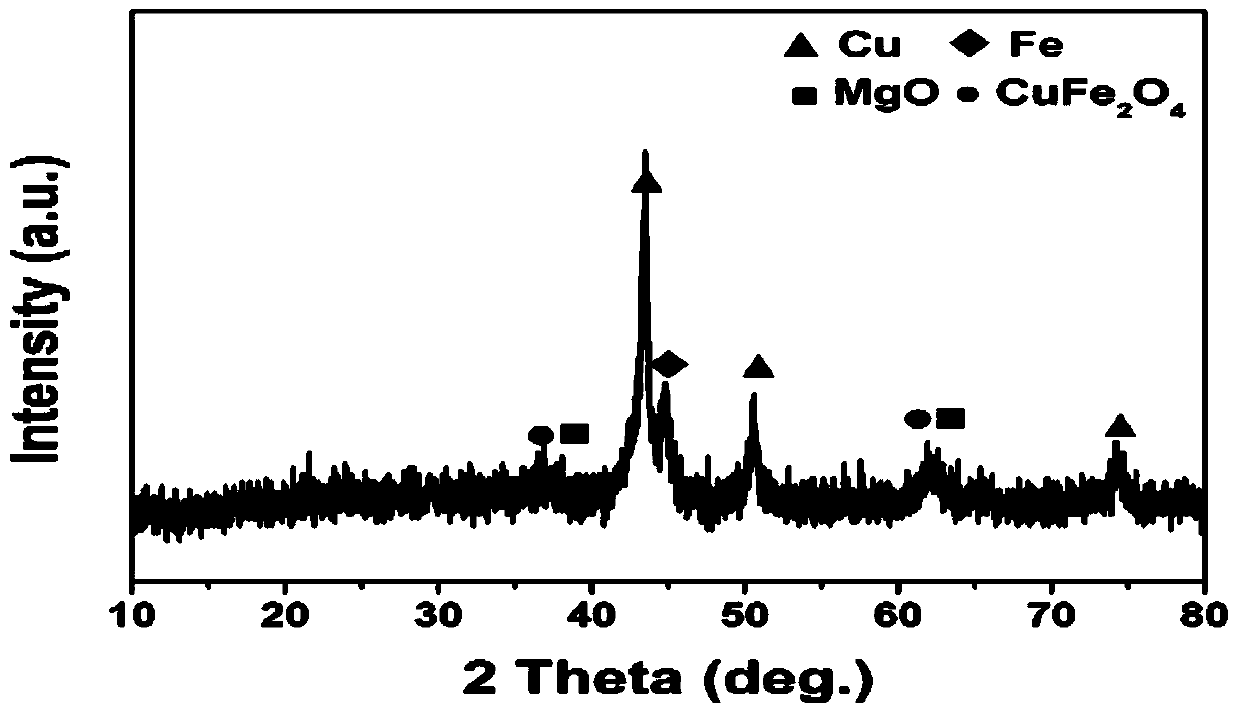

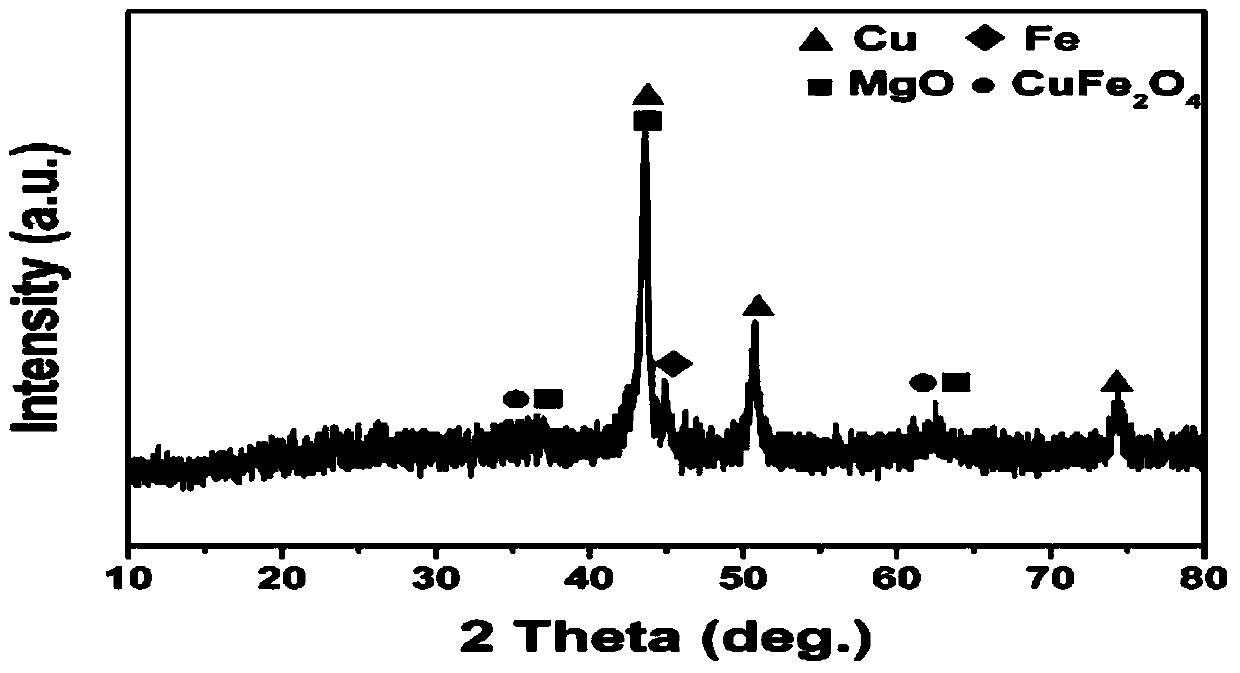

Copper-iron based catalyst and application thereof in preparing low mixed alcohols by catalyzing synthesis gas

InactiveCN103464159ATo achieve co-precipitation reactionGuaranteed uniformityOrganic compound preparationHydroxy compound preparationPtru catalystAlcohol

The invention discloses a copper-iron based catalyst in the technical field of catalyst preparation and application thereof in preparing low mixed alcohols by catalyzing synthesis gas. According to the invention, a copper-magnesium-iron hydrotalcite precursor is prepared by a nucleation-crystallization isolating method, and then the copper-magnesium-iron hydrotalcite precursor is roasted and then subjected to reduction treatment to obtain the copper-iron based catalyst of highly dispersed nanoparticles. The catalyst has the characteristics that the catalytic active ingredients are highly dispersed, the catalytic active ingredients have strong interaction with one another, and are high in stability, and as a result, the activity and selectivity of the catalyst are improved. After the copper-iron based catalyst is applied to preparing low mixed alcohols from the synthesis gas, the CO conversion rate is high, and the selectivity and space time yield of the low mixed alcohols are also improved; besides, the conversion rate of CO for synthesizing low mixed alcohols through CO hydrogenation is 56.89% and the selectivity of alcohols is 49.07%.

Owner:BEIJING UNIV OF CHEM TECH

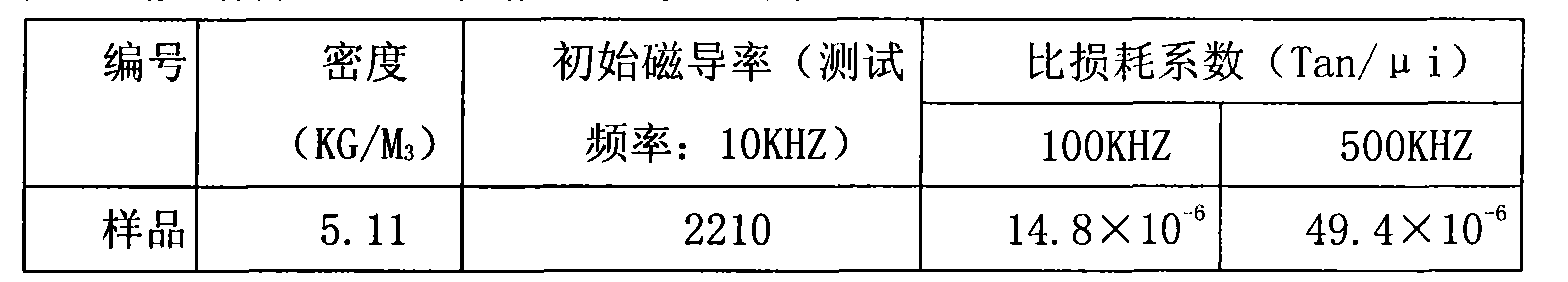

High magnetic conductive low temperature sintered NiCuZn ferrite material

InactiveCN101388268AUniform grain sizeClear grain boundariesInorganic material magnetismOxideMaterials science

The invention relates to a NiCuZn ferrite material with high magnetic permeability and low-temperature sintering, whose main phase is a spinel structure, the compositions which are calculated through oxide content are that Fe2O3 is 41-52.8mol%, ZuO is 20-45mol%, and CuO is 1-14mol%, NiO is 2-15mol%. MoO3 and In2O3 are used as additive based on the above materials, MoO3: 0.15wt%-0.25wt% is added, and In2O3: 0.12wt%-0.45wt% is added. Ferrite blanks which are prepared are put in a furnace to be sintered, the sintering temperature is 910-950 DEG C, the sintering time is 6-20 hours, and the temperature is kept for 2-4 hours.

Owner:SHANDONG ZHONGRUI ELECTRONICS

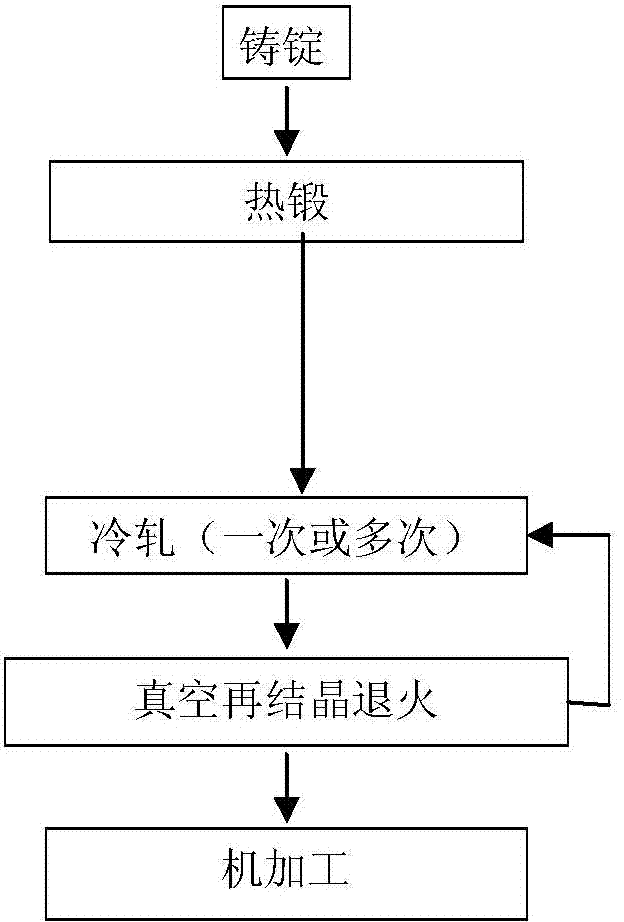

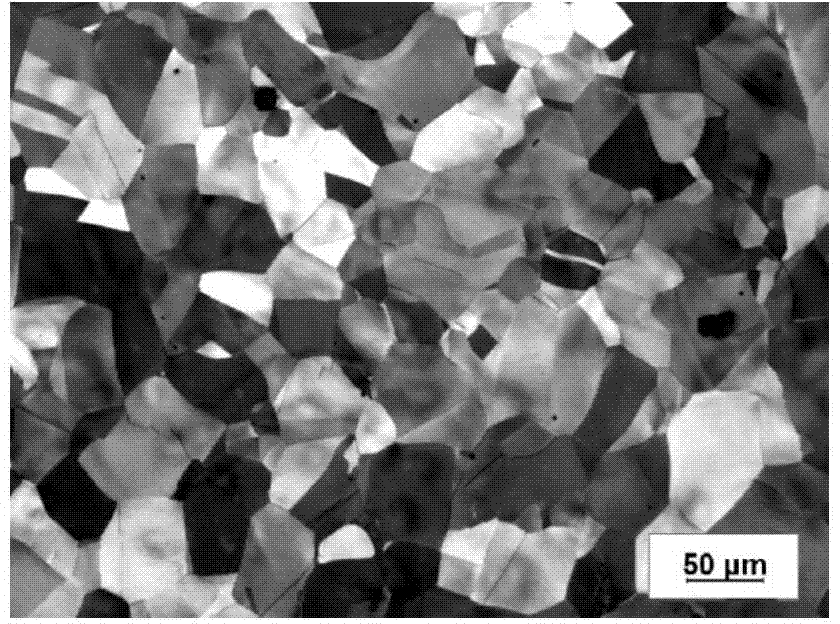

High purity NiPt alloy target material and preparation method thereof

InactiveCN104726829AFine grainUniform grainVacuum evaporation coatingSputtering coatingMaterials preparationAlloy

Belonging to the technical field of target material preparation, the invention discloses a high purity NIPT alloy target material and a preparation method thereof. The method is characterized by: conducting cogging by hot forging, and combining cold rolling and recrystallization heat treatment to control the alloy microstructure. The specific technological process includes: hot forging, cold rolling, vacuum heat treatment, finish machining and the like. The high purity NIPT alloy target material obtained by the method has fine and uniform grains, and the grain orientation of the target material sputtering surface is in random distribution.

Owner:GRIKIN ADVANCED MATERIALS

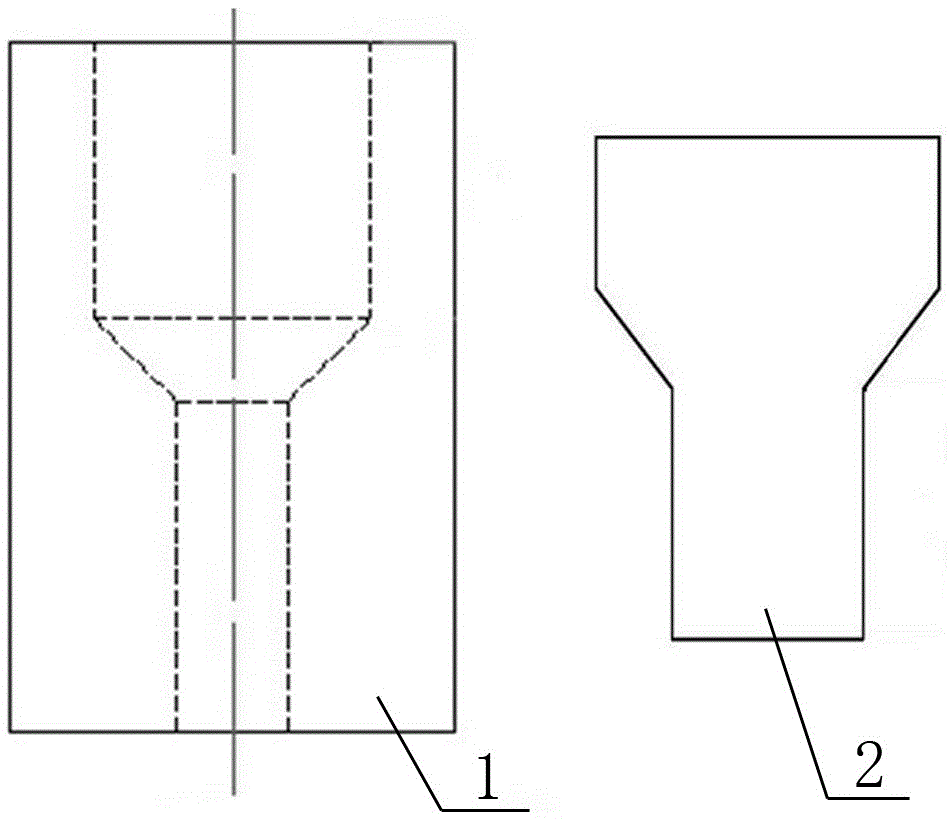

Preparation method for TiAl alloy bar

ActiveCN106636741ASolve the problem of severe segregationPrevent surface oxidationExtrusion diesIngotSkull

The invention discloses a preparation method for a TiAl alloy bar and relates to a preparation method for a bar. The preparation method for the TiAl alloy bar aims at solving the problems that according to a TiAl alloy bar prepared through an existing method, the preparation process is complex, the surface of the bar cracks, the diameter is nonuniform, the bar structure grain size is nonuniform, and TiAl alloy reacts with package materials and is molten when the extrusion temperature is too high. The preparation method for the TiAl alloy bar comprises the specific steps that 1, all raw material components are weighed; 2, a cast ingot is prepared through water cooling copper crucible induction skull melting; 3, pretreatment is conducted on an extrusion blank; and 4, bar extrusion is conducted, and thus the TiAl alloy bar can be obtained. The surface of the TiAl alloy bar obtained through the preparation method is free of cracking, the diameter is uniform, the bar structure grain size is uniform, and the process is simple.

Owner:山西中工重型锻压有限公司

Thermal treatment method used for improving duplex stainless steel welded structure

InactiveCN102560065AImprove pitting resistanceControl volumeFurnace typesHeat treatment furnacesHeat-affected zoneElectrical impulse

The invention discloses a thermal treatment method used for improving a duplex stainless steel welded structure, which comprises the following steps: 1) heating by an electric oven at the temperature lower or close to duplex stainless steel phase transition when a duplex stainless steel weld seam and a heat affected zone are heated by a thermal treatment technology, simultaneously carrying out electric pulse heating; 2) insulating for 10-60 minutes after heating, cooling with three phases, wherein in a first phase, the temperature of the welded structure is 850 DEG C and the cooling speed is controlled at 1-30 DEG C / s, simultaneously providing pulse current; in a second phase: the temperature is decreased to 800-500 DEG C, the cooling speed is controlled at 5-50 DEG C / s, and the cooling speed is greater than that of the first phase; in a third phase: the temperature is decreased below 500 DEG C and the cooling speed is controlled more than 30 DEG C / s. The thermal treatment for duplex stainless steel welded seam and the heat affected zone can control the volume fraction and existence form of ferrite, avoid the precipitation of a brittleness phase in ferrite / austenite, ferrite / ferrite crystal boundary, and enhance the capability of pitting corrosion resistance of the duplex stainless steel.

Owner:WENGFU (GRP) CO LTD

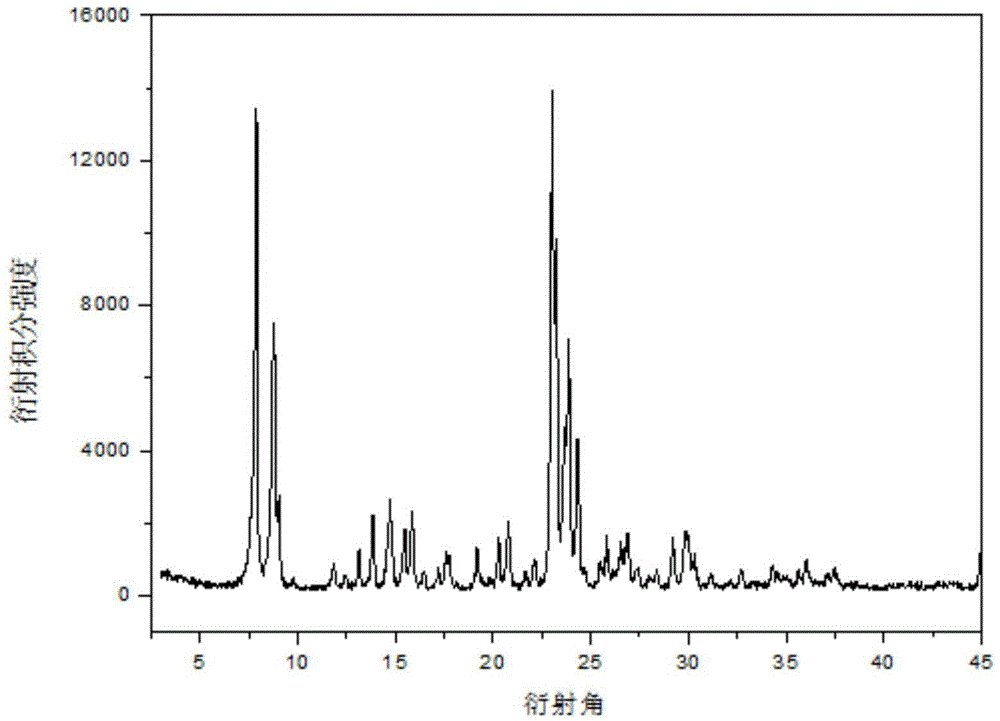

Synthesis method of ultralow-sodium high-silicon nano ZSM-5 molecular sieve

ActiveCN104386707AHarm reductionEmission reductionMaterial nanotechnologyPentasil aluminosilicate zeoliteFiltrationSynthesis methods

The invention relates to a synthesis method of an ultralow-sodium high-silicon nano ZSM-5 molecular sieve, which is characterized by comprising the following steps: 1) dissolving NaOH in water, slowly adding a silicon source selected from silica sol, wherein the Na2O:SiO2:H2O mole ratio is (0.08-0.2):1:(20-26), and the dropwise addition speed of the silica sol is controlled at about 50g / minute; 2) after the silica sol in the step 1) is uniformly dispersed in the alkali, respectively dissolving a template agent and an aluminum source in a small amount of water, adding into the sol in the step 1) while slowly stirring, and aging at room temperature for 8 hours, wherein the silica-alumina ratio is 80-240, and the mole ratio of the template agent to the silicon oxide is 0.05-0.1; 3) transferring the sol in the step 2) into a reaction kettle for hydrothermal crystallization, heating at the rate of 2 DEG C / minute, pre-crystallizing at 110-130 DEG C for 3 hours, heating to the crystallization temperature of 180+ / -10 DEG C, crystallizing for 40-80 hours, and mechanically stirring; and carrying out conventional filtration, washing, drying and roasting to obtain the product.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for synthesizing metal-organic framework material Co-MOF-71

InactiveCN107099038AUniform grain sizeImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixture productionReactive siteMetal-organic framework

The invention relates to successful preparation of a Co-MOF-71 nano-material. According to the invention, preparation process conditions are optimized; the prepared Co-MOF-71 nano-material is uniform in crystal grain size and has good stability; and when Co utilizes the acidic catalysis reaction of MOF framework metal ions, the metal ions are active sites and the supporting points of a framework, and metal ions undergo coordination in the process of catalysis. The prepared Co-MOF-71 material has high metal content and completely exposed metal sites; more Lewis acid site Co-MOF-71 materials can be provided; and the material is beneficial for total activation of reactant molecules and has good catalytic activity.

Owner:NINGXIA UNIVERSITY

Multi-component doping high-performance beryllium oxide ceramic material and preparation method

The invention belongs to the technical field of electronic materials. Multi-element doped high-performance beryllium oxide ceramic material, in addition to beryllium oxide, also includes 0.2-0.6% by mass of multi-element dopant; said multi-element dopant is composed of MgO, Al2O3, SiO2, CaO, ZnO and rare earth oxides , the mass percentage content of each component is: MgO: 5-60%, Al2O3: 0-40%, SiO2: 20-95%, CaO: 0.1-0.5%, ZnO: 0-0.5%, containing Y, La, Single or random mixed rare earth oxides of Ce or Sm: 0.01-0.5%. The multi-element dopant is prepared by a sol-gel method, and then mixed with a high-purity beryllium oxide raw material, shaped and sintered at a high temperature to obtain the multi-element doped high-performance beryllium oxide ceramic material of the present invention. The multi-component doped high-performance beryllium oxide ceramic material provided by the invention has lower sintering temperature, higher density, thermal conductivity and mechanical properties; its microstructure has the characteristics of compactness, uniform crystal grains and few pores. The preparation method has simple process, low production cost and good repeatability, and is suitable for industrialized production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com