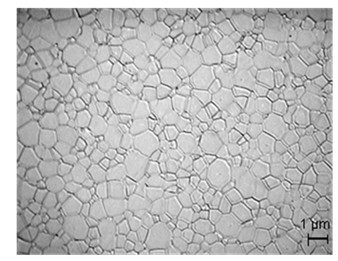

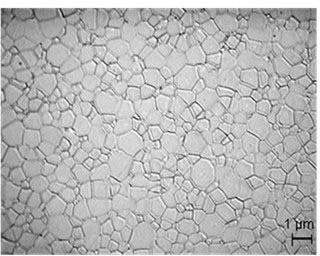

Fine-crystal transparent alumina ceramic material and preparation method

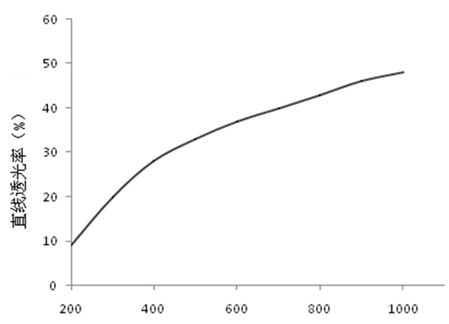

An alumina ceramic and transparent technology, which is applied in the field of fine-grained transparent alumina ceramic materials and preparation, can solve the problems of low linear transmittance and coarse grains, and achieve the effect of uniform grain size and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0018] The present invention prepares the operating steps of a preferred embodiment of fine-grained transparent alumina ceramics as follows:

[0019] (1) Preparation of slurry: 99.91 parts of Al with a purity of 99.99% 2 o 3 Powder, 0.07 parts of MgO, 0.01 parts of ZrO 2 , 0.01 part of La 2 o 3 Put it into a ball mill, add deionized water and alumina balls, use nitric acid solution to adjust the pH to 4, then add 1.5 parts of Dolapix CE64 as a dispersant, and carry out roller milling for 24 hours to prepare a slurry with a solid content of 70-80% material; add 0.5 part of polyvinyl alcohol to the ball-milled slurry, and continue ball-milling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com