Process for producing high-nodularity fastener wire rod

A fastener wire and production process technology, which is applied in the field of high-spheroidization fastener wire production technology, can solve the problems of high forging cost, poor dimensional stability, unreasonable annealing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

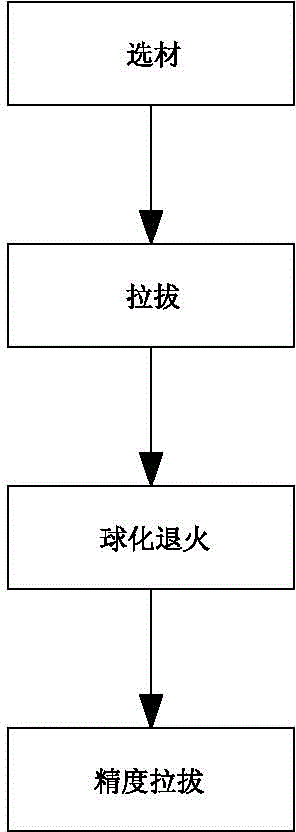

[0022] (1) Material selection: Select the steel wire of model SWRCH22A.

[0023] (2) Drawing: the steel wire is drawn by using a drawing machine, and the compression rate is controlled at 50% in this embodiment.

[0024] (3) Spheroidizing annealing: Hang the steel wire into the atmosphere protection furnace, which is added with a protection atmosphere. The protection atmosphere is methanol, and the flow rate of methanol gas is 10ml / min, and then the steel wire is heated to the austenite transformation temperature Above 20°C, heat preservation for 4 hours, then slowly cool at 10°C / hour to 30°C below the austenite transformation temperature, heat preservation for 3 hours, then cool with the furnace until it comes out of the furnace, the austenite transformation temperature is 720°C.

[0025] (4) Precision drawing: the steel wire is drawn again by using a drawing machine. In this embodiment, the compression rate is controlled at 10%.

[0026] The steel wire treated in this embod...

Embodiment 2

[0028] (1) Material selection: Select the steel wire of model SWRCH22A.

[0029] (2) Drawing: use a drawing machine to draw the steel wire, and in this embodiment, the compression ratio is controlled at 51%.

[0030] (3) Spheroidizing annealing: Hang the steel wire into the atmosphere protection furnace, which is added with a protection atmosphere. The protection atmosphere is methanol, and the flow rate of methanol gas is 10ml / min, and then the steel wire is heated to the austenite transformation temperature Above 25°C, keep warm for 5 hours, then slowly cool at 10°C / hour to 25°C below the austenite transformation temperature, keep hold for 3.5 hours, then cool with the furnace until it comes out of the furnace, the austenite transformation temperature is 720°C.

[0031] (4) Precision drawing: the steel wire is drawn again with a drawing machine. In this embodiment, the compression rate is controlled at 8%.

[0032] The steel wire treated in this embodiment is inspected for ...

Embodiment 3

[0034] (1) Material selection: Select the steel wire of model SWRCH22A.

[0035] (2) Drawing: use a drawing machine to draw the steel wire, and in this embodiment, the compression rate is controlled at 55%.

[0036] (3) Spheroidizing annealing: Hang the steel wire into the atmosphere protection furnace, which is added with a protection atmosphere. The protection atmosphere is methanol, and the flow rate of methanol gas is 10ml / min, and then the steel wire is heated to the austenite transformation temperature Above 30°C, heat preservation for 6 hours, then slowly cool at 10°C / hour to 20°C below the austenite transformation temperature, heat preservation for 4 hours, then cool with the furnace until it comes out of the furnace, the austenite transformation temperature is 720°C.

[0037] (4) Precision drawing: the steel wire is drawn again with a drawing machine, and in this embodiment, the compression rate is controlled at 6%.

[0038] The steel wire treated in this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com