Patents

Literature

11460 results about "Plastic property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick Answer. Some properties of plastics include their light weight, high resistance to various chemicals, thermal and electrical insulation and their wide range of colors, characteristics and potential uses. Plastics are also known as polymers.

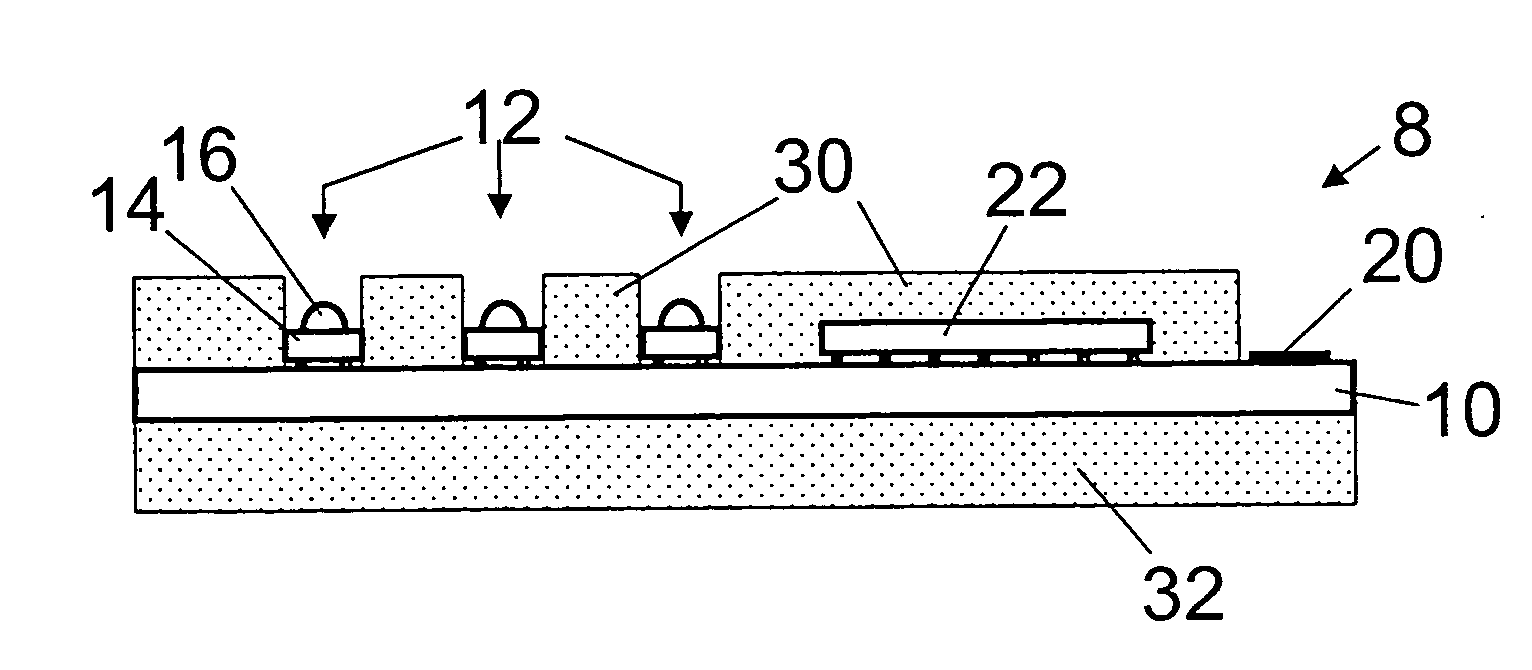

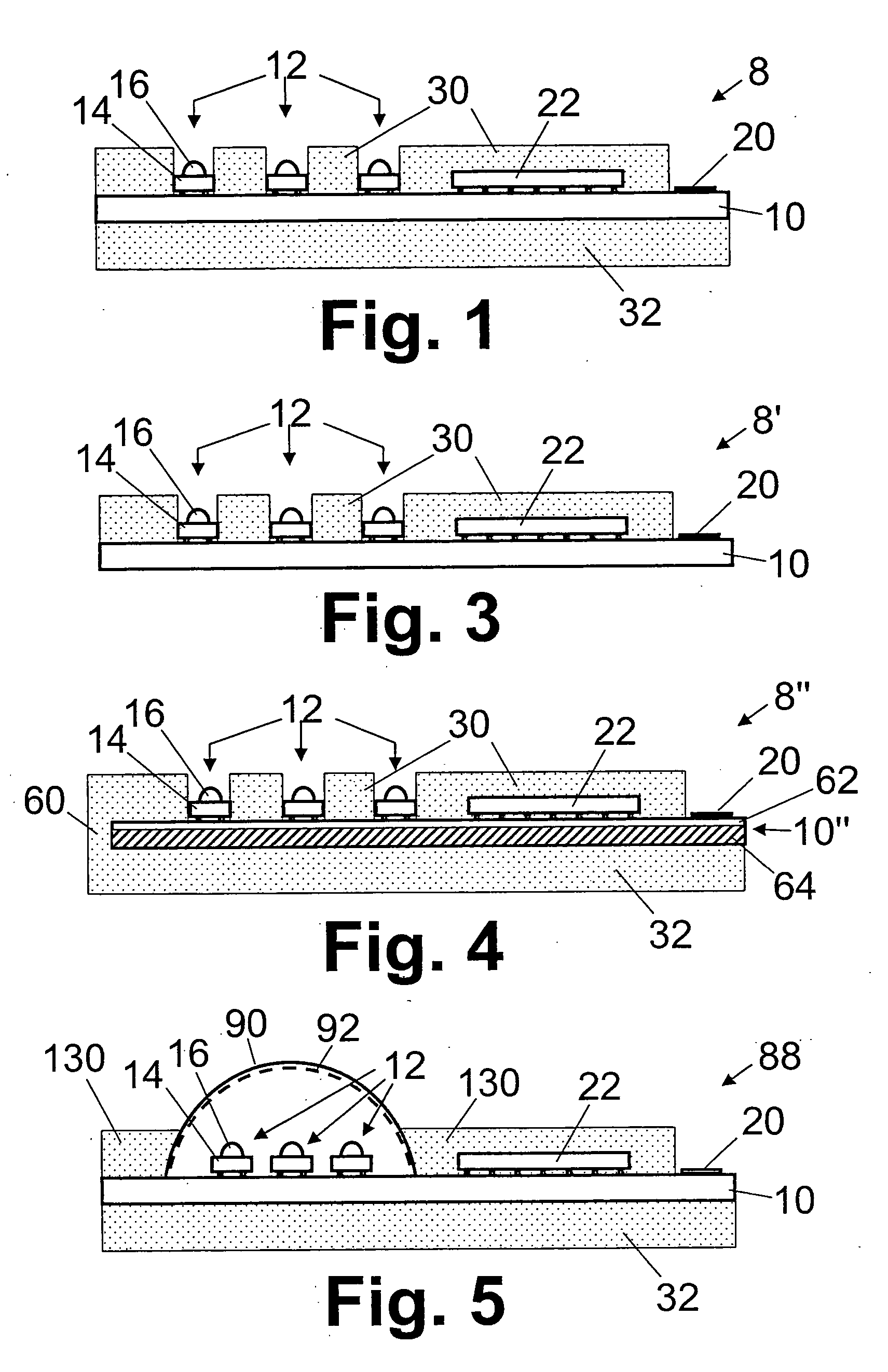

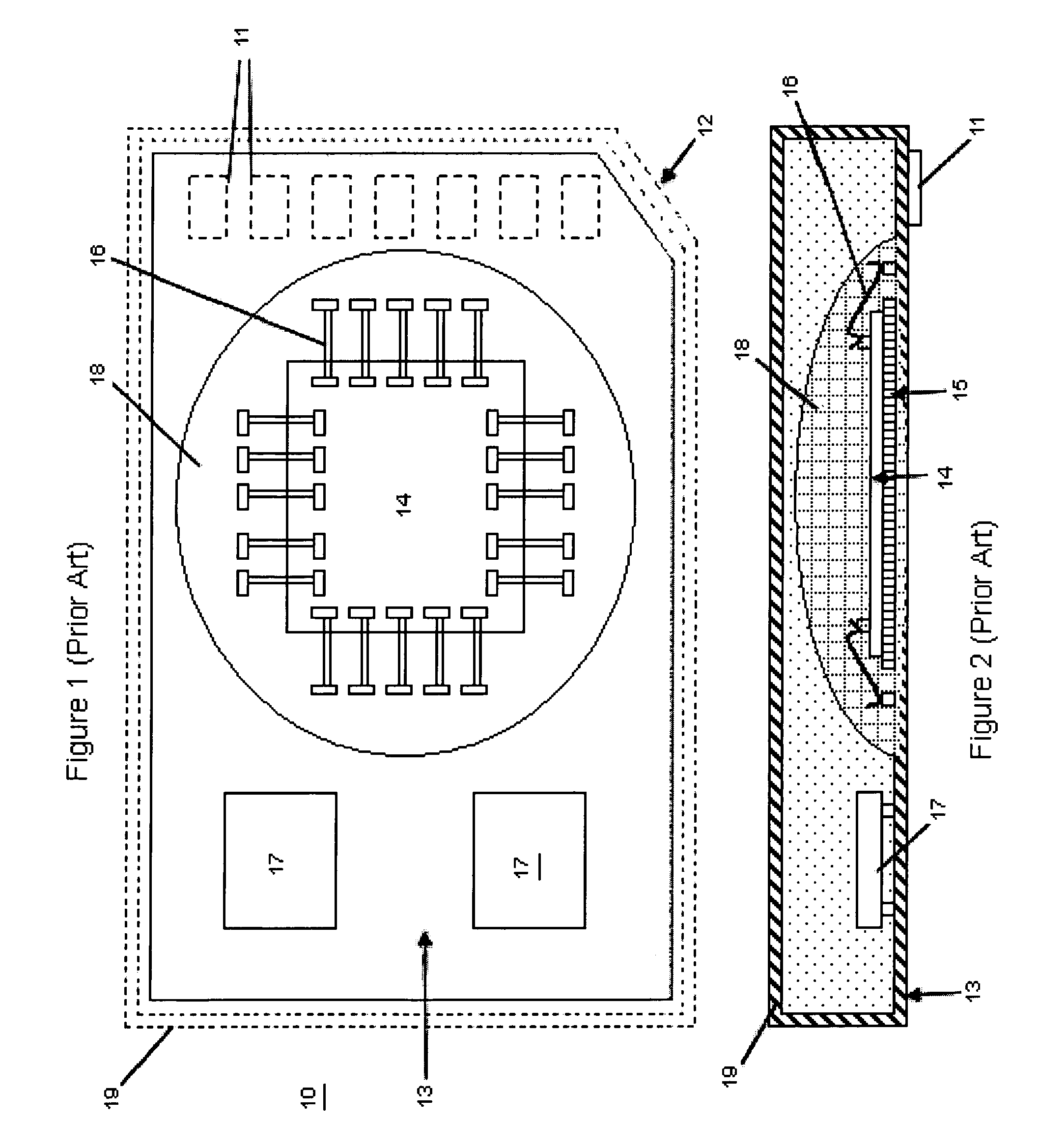

LED lighting assemblies with thermal overmolding

ActiveUS20070121326A1Thermal conductivityPoint-like light sourceElectric circuit arrangementsEffect lightEngineering

One or more light emitting diode diodes (LEDs) are attached to a printed circuit board. The attached LEDs are connectable with a power source via circuitry of the printed circuit board. An overmolding material is insert molded an over at least portions of the printed circuit board proximate to the LEDs to form a free standing high thermal conductivity material overmolding that covers at least portions of the printed circuit board proximate to the LEDs. The free standing high thermal conductivity material has a melting temperature greater than about 100° C. and has a thermal conductivity greater than or about 1 W / m·K. In some embodiments, the free standing high thermal conductivity material is a thermoplastic material.

Owner:GE LIGHTING SOLUTIONS LLC

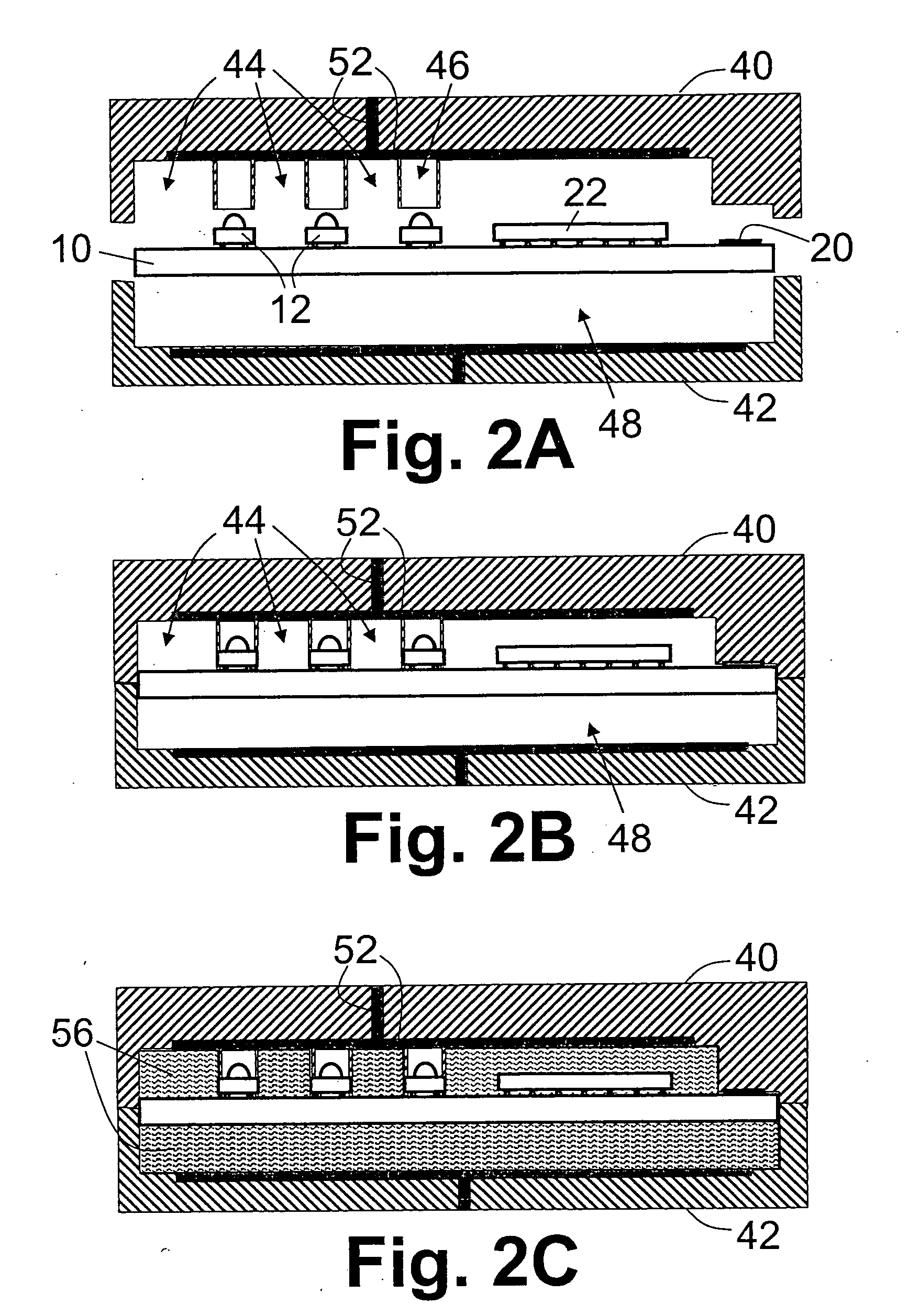

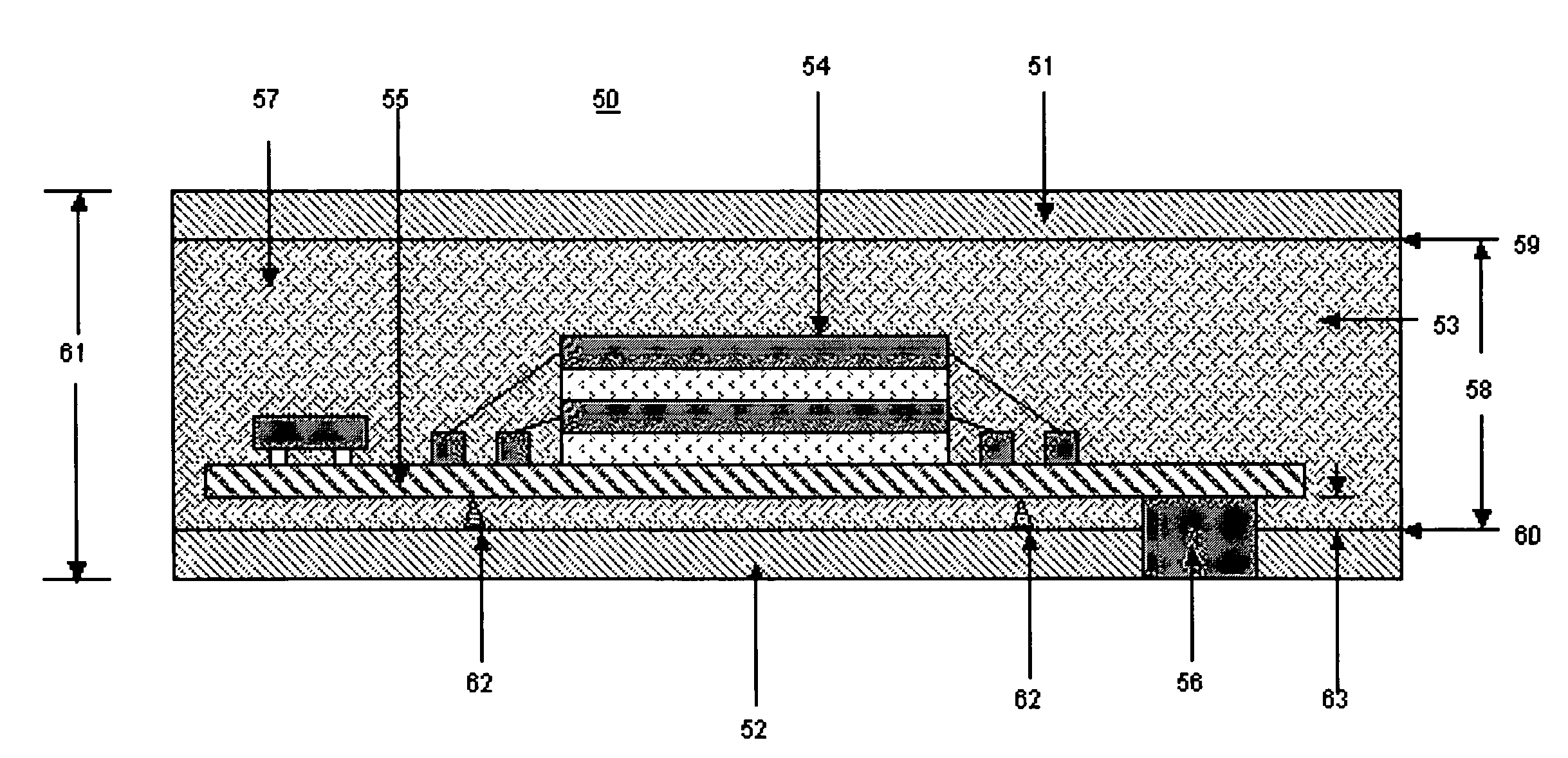

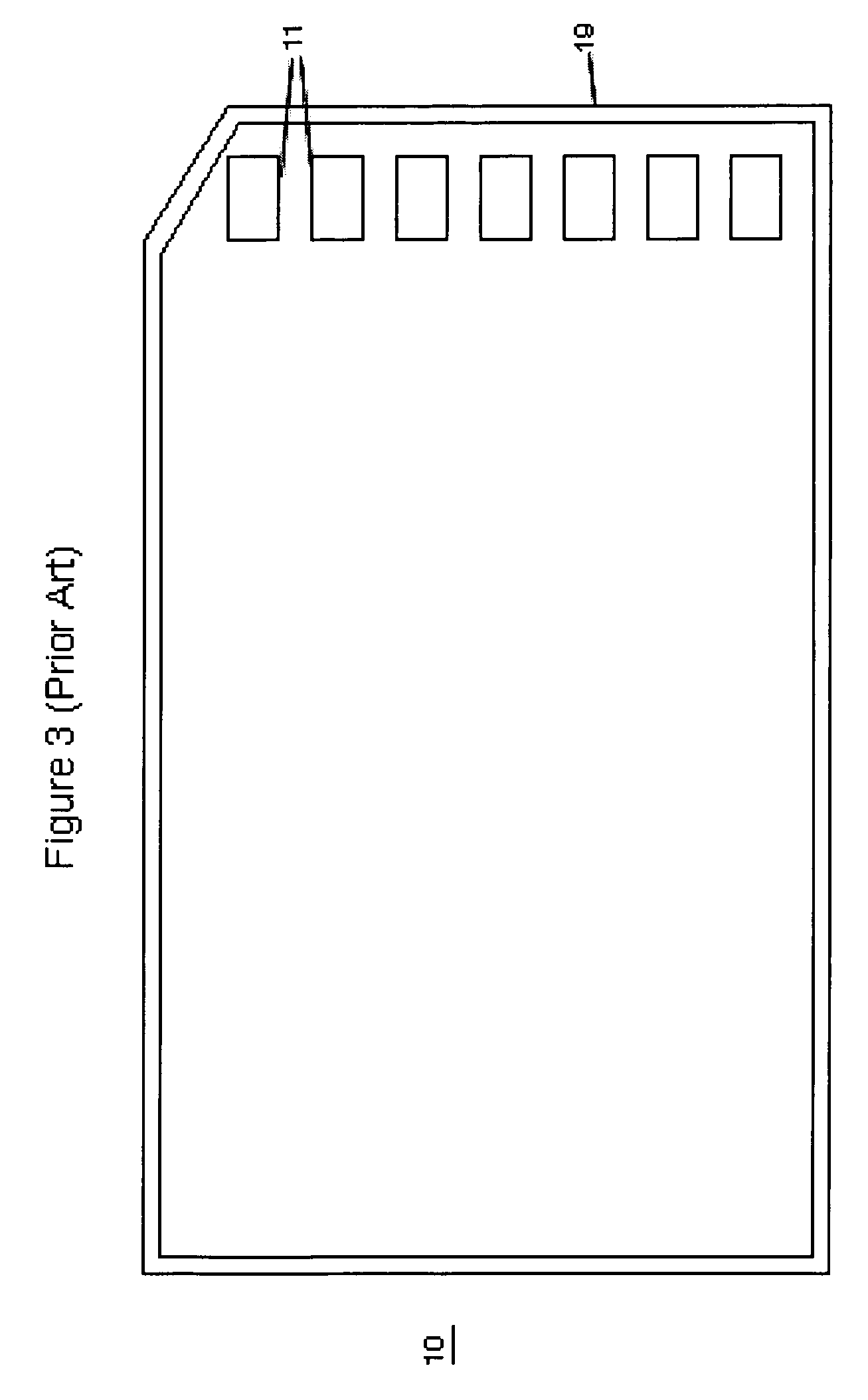

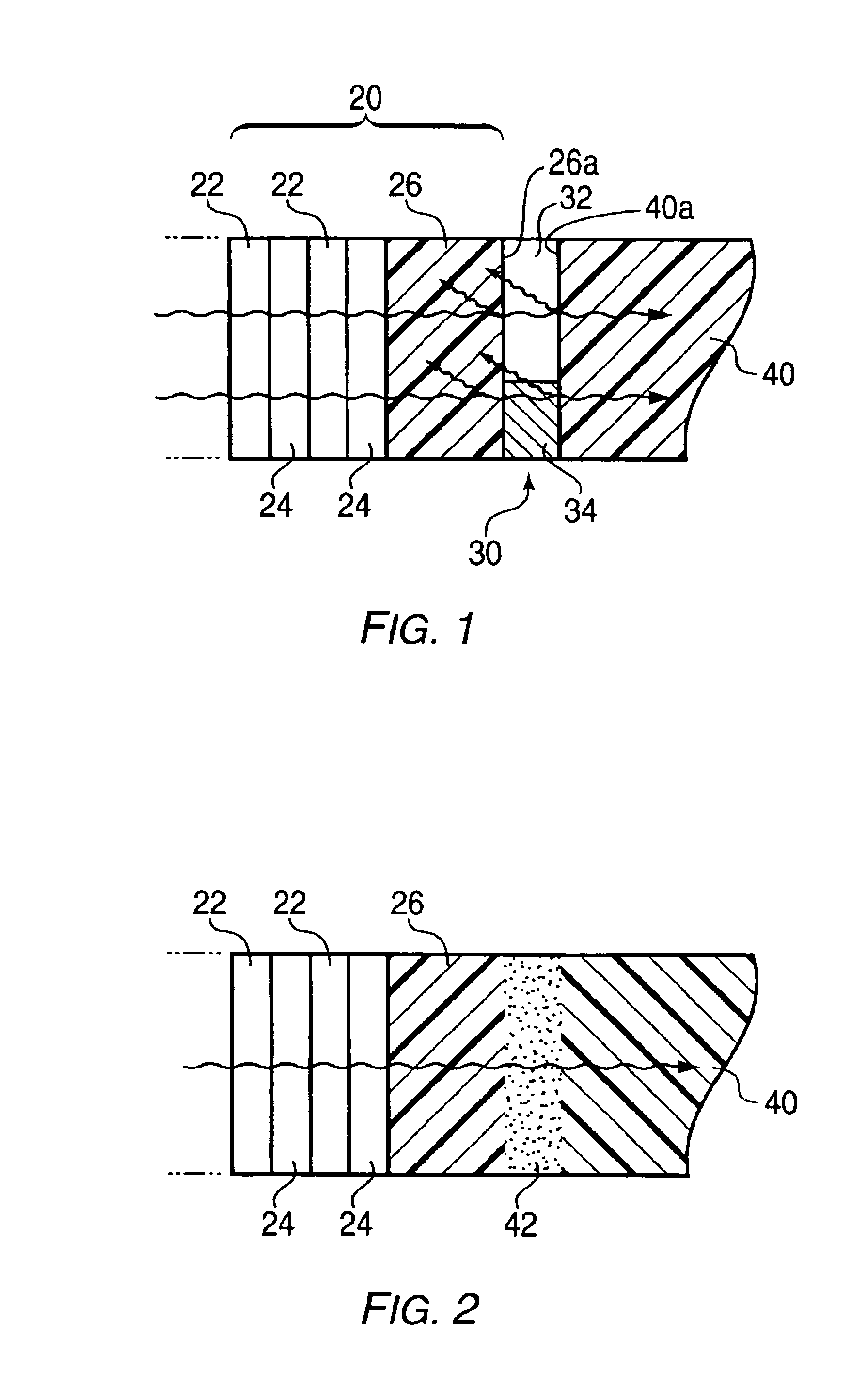

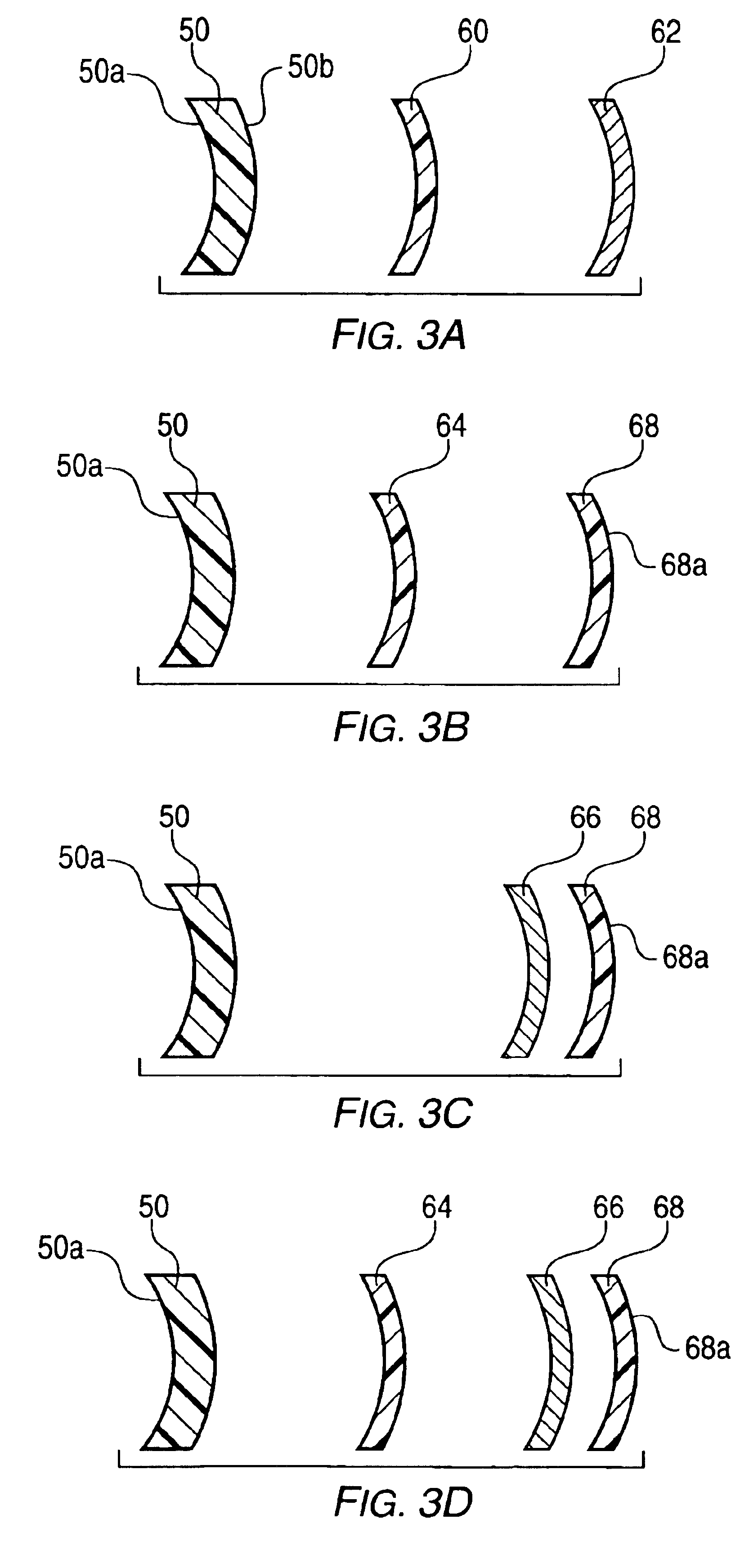

Method for making memory cards and similar devices using isotropic thermoset materials with high quality exterior surfaces

InactiveUS7225537B2Shorten the timeQuality improvementPrinted circuit assemblingLine/current collector detailsEngineeringInjection moulding

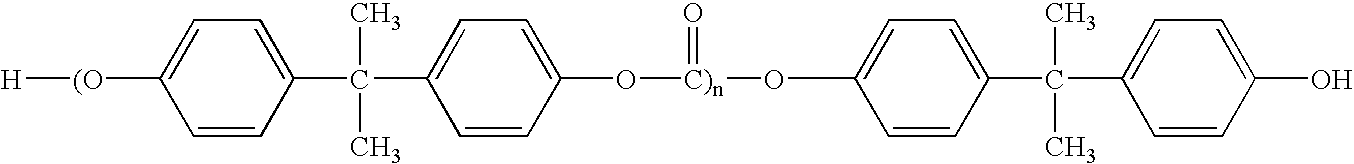

Memory Cards containing Integrated Circuits and other electronic components (e.g. resistors) in a variety of form factors having high quality external surfaces of polycarbonate, synthetic paper (e.g. Teslin), or other suitable material (e.g. PVC) can be made through use of injection molded thermoplastic material or thermosetting material that becomes the core layer of said Memory Cards and similar devices. The object of the invention is to provide the following properties to Memory Cards: rapid production cycle, high volume manufacturing throughput, security, electronics protection, better tamper resistance, durability, and highly reliable complex electronics encapsulation, achieved through a process utilizing low temperature and low pressure.

Owner:CARDXX

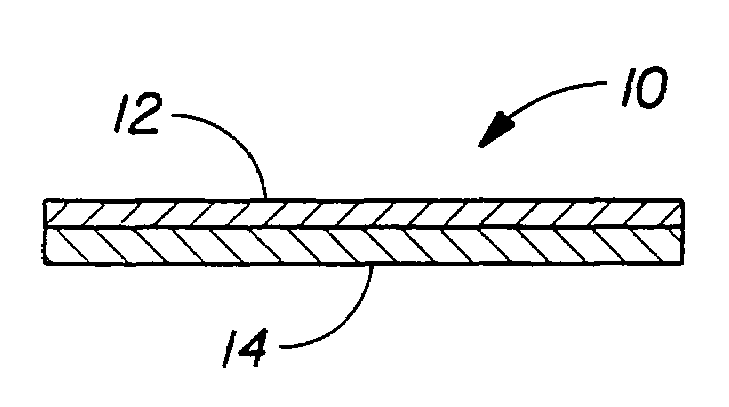

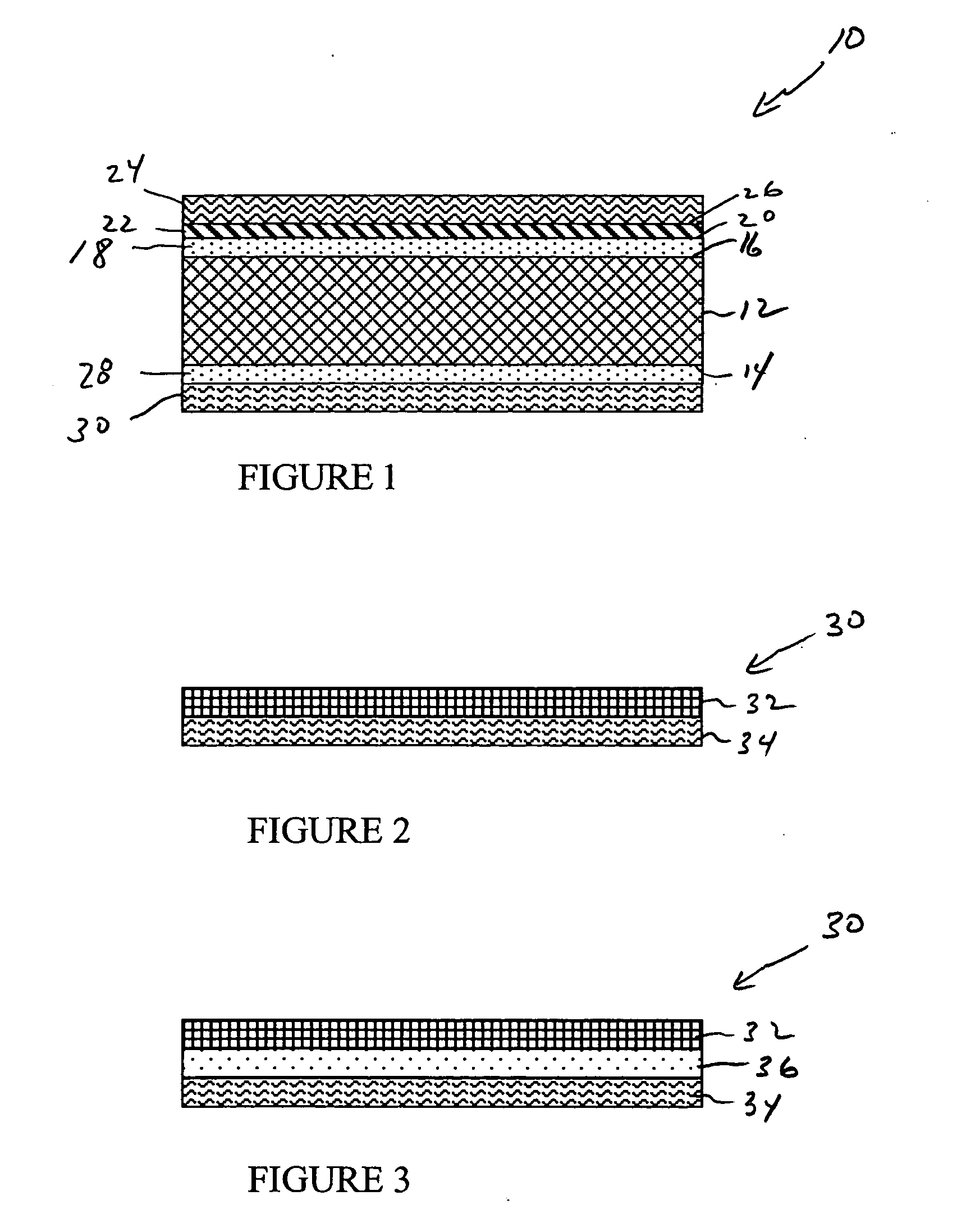

Breathable composite sheet structure and absorbent articles utilizing same

A breathable composite sheet material, a method for making such a sheet material, and an absorbent article utilizing the sheet material are provided. The composite sheet material is comprised of a thermoplastic film adhered directly to a fibrous substrate. The thermoplastic film comprises at least 50% by weight of a polymer material from the group of block copolyether esters, block copolyether amides and polyurethanes. The substrate comprises a fibrous web of at least 50% by weight of polyolefin polymer synthetic fibers. The composite sheet exhibits a peel strength of at least 0.1 N / cm, a dynamic fluid transmission of less than about 0.75 g / m2 when subjected to an impact energy of about 2400 joules / m2, and a moisture vapor transmission rate, according to the desiccant method, of at least 1500 g / m2 / 24 hr. The absorbent article comprises (a) a topsheet; (b) a backsheet; and (c) an absorbent core located between the topsheet and the backsheet; wherein the backsheet comprises the non-porous, substantially fluid impermeable, moisture vapor permeable composite sheet material described above. The composite sheet material is oriented such that the film layer of the composite sheet material faces toward the absorbent core. The absorbent article may comprise a disposable diaper.

Owner:THE PROCTER & GAMBLE COMPANY

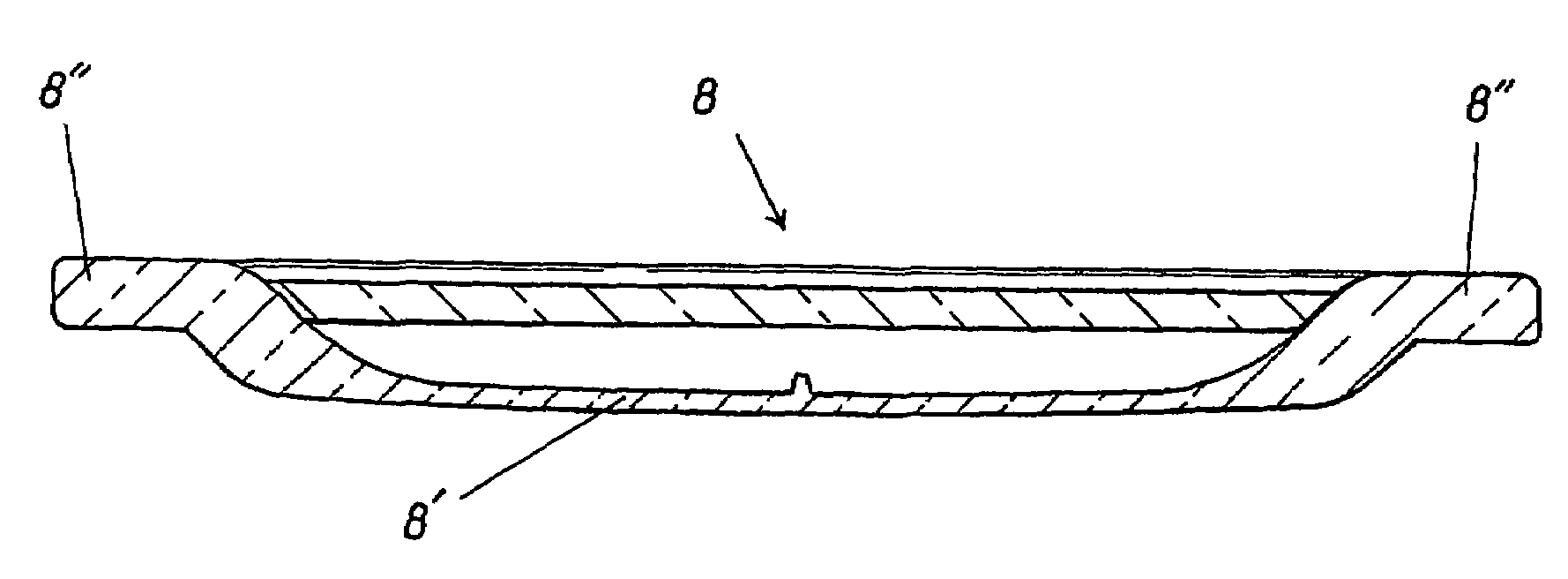

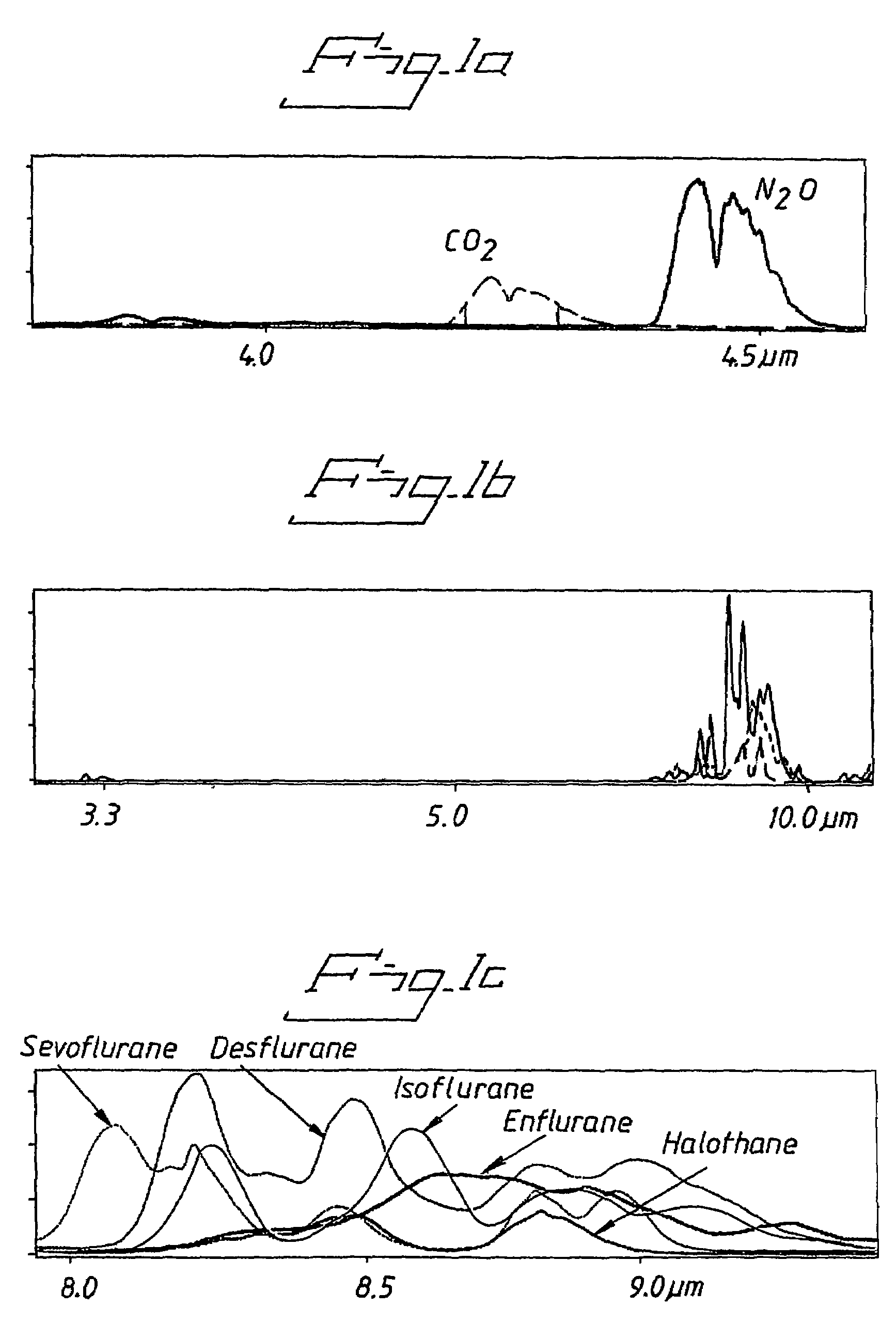

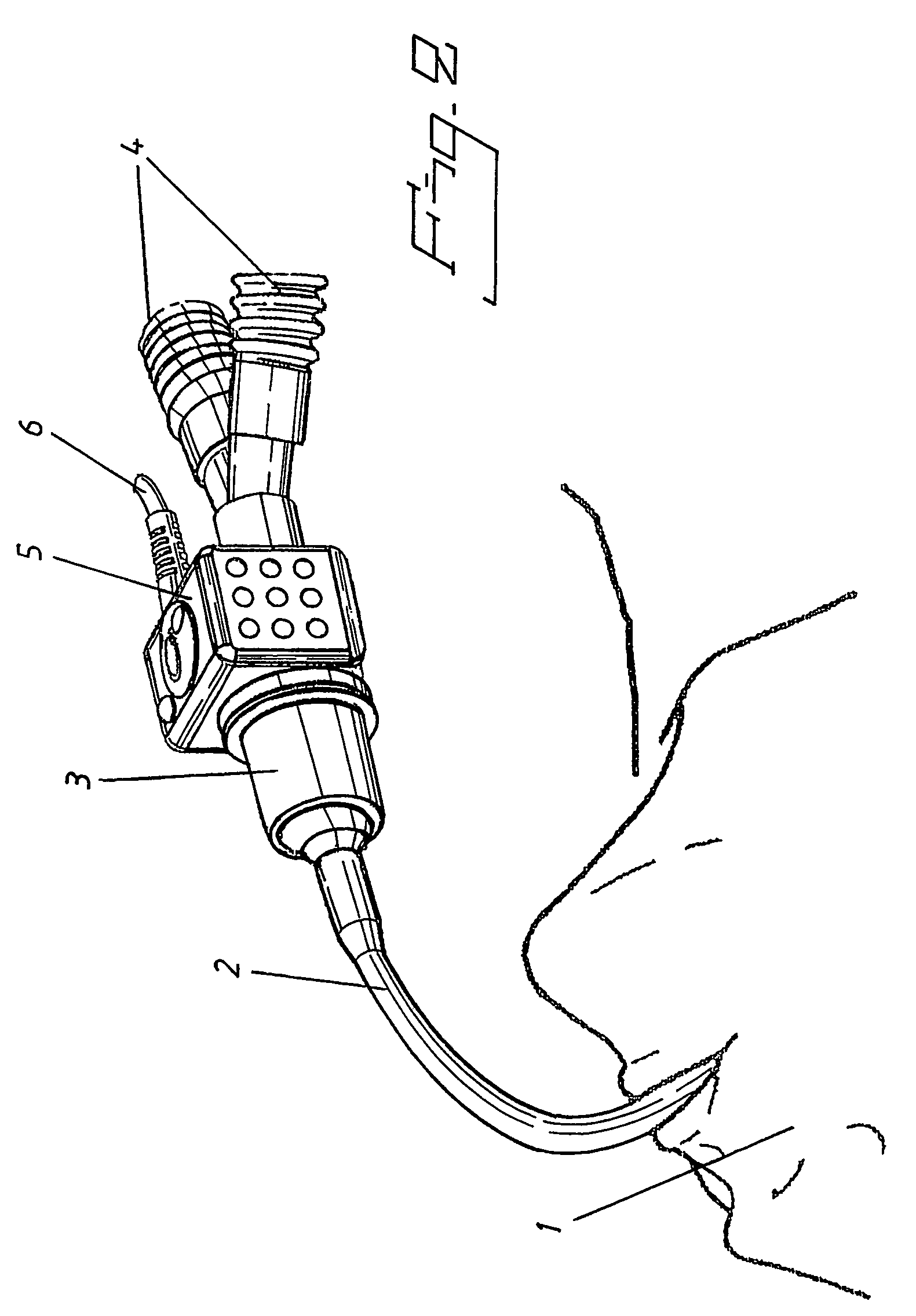

Air gas analyzer window and a method for producing such a window

ActiveUS7629039B2Uniform material thicknessSatisfactory transmission propertyLayered productsRespiratory organ evaluationPlastic materialsLight beam

A window for use in an adapter for an IR gas analyser for analysing breathing gases, where the gases flow through a through-penetrating passageway in the adapter, which includes windows disposed on opposite sides of the passageway so as to enable an IR beam to be sent through the windows and through the passageway containing said breathing gases. Each window is a one-piece structure comprised of plastic material and has a round basic shape that includes a surrounding edge and a central part which is sunken in relation to the surrounding edge and which forms the window through which the IR beams or rays shall be able to pass. A method of producing such a window, by injection moulding a thermoplastic material in a mould where injection of the plastic material is also disclosed.

Owner:PHASEIN

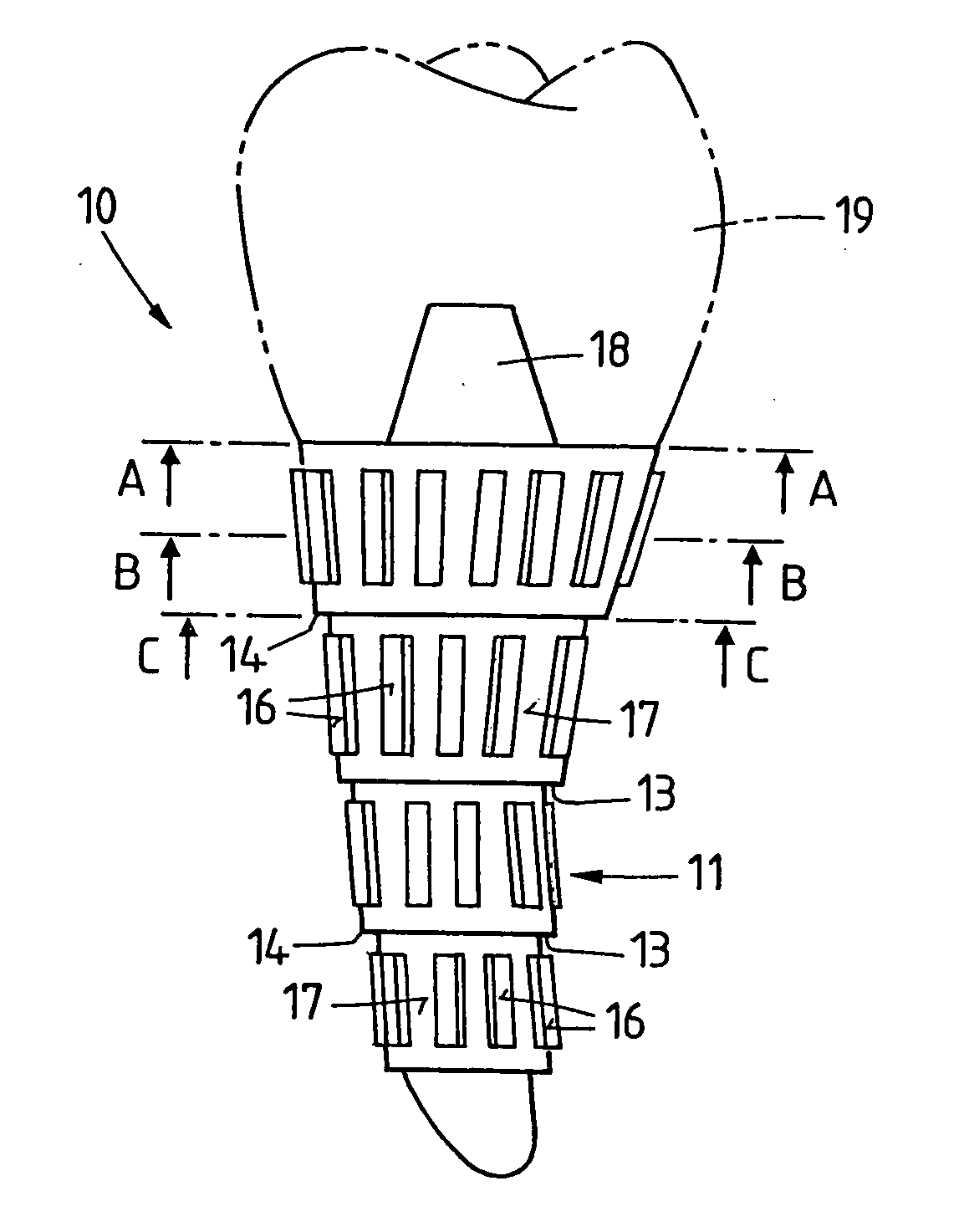

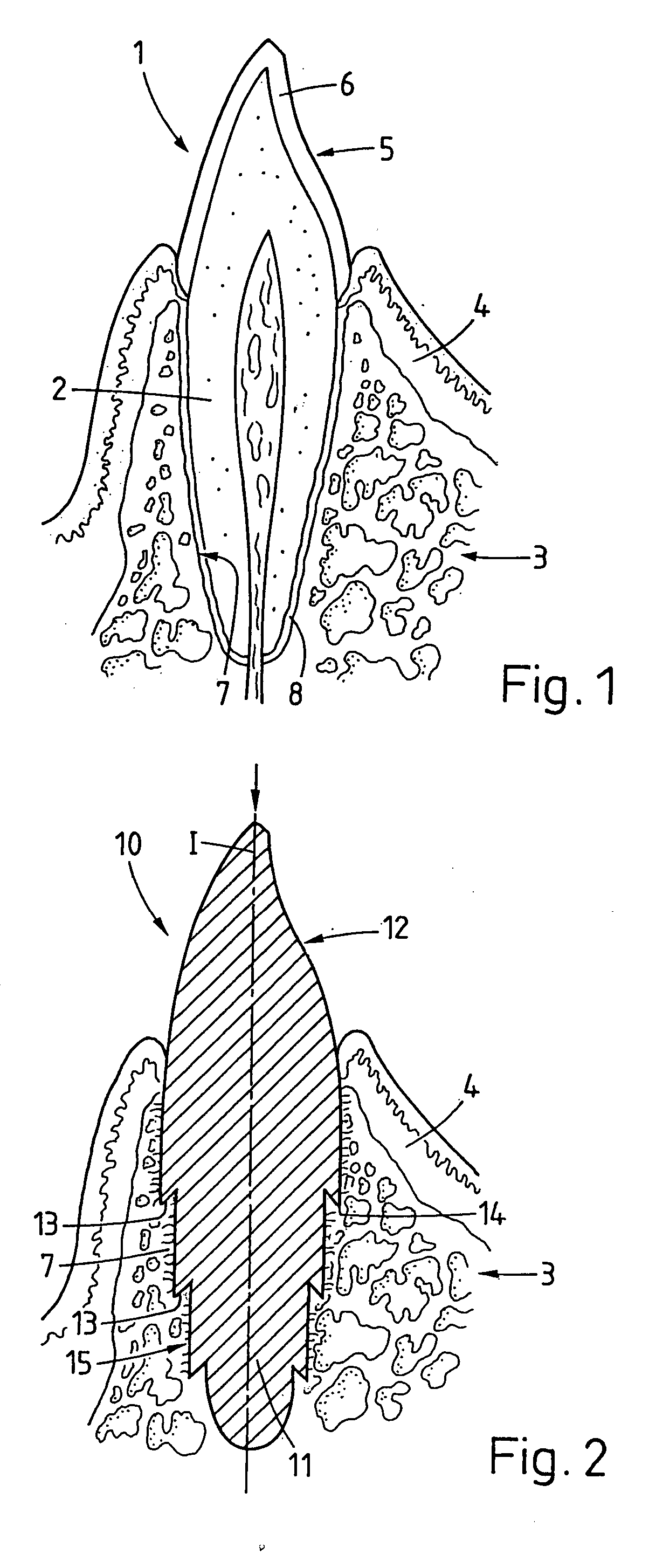

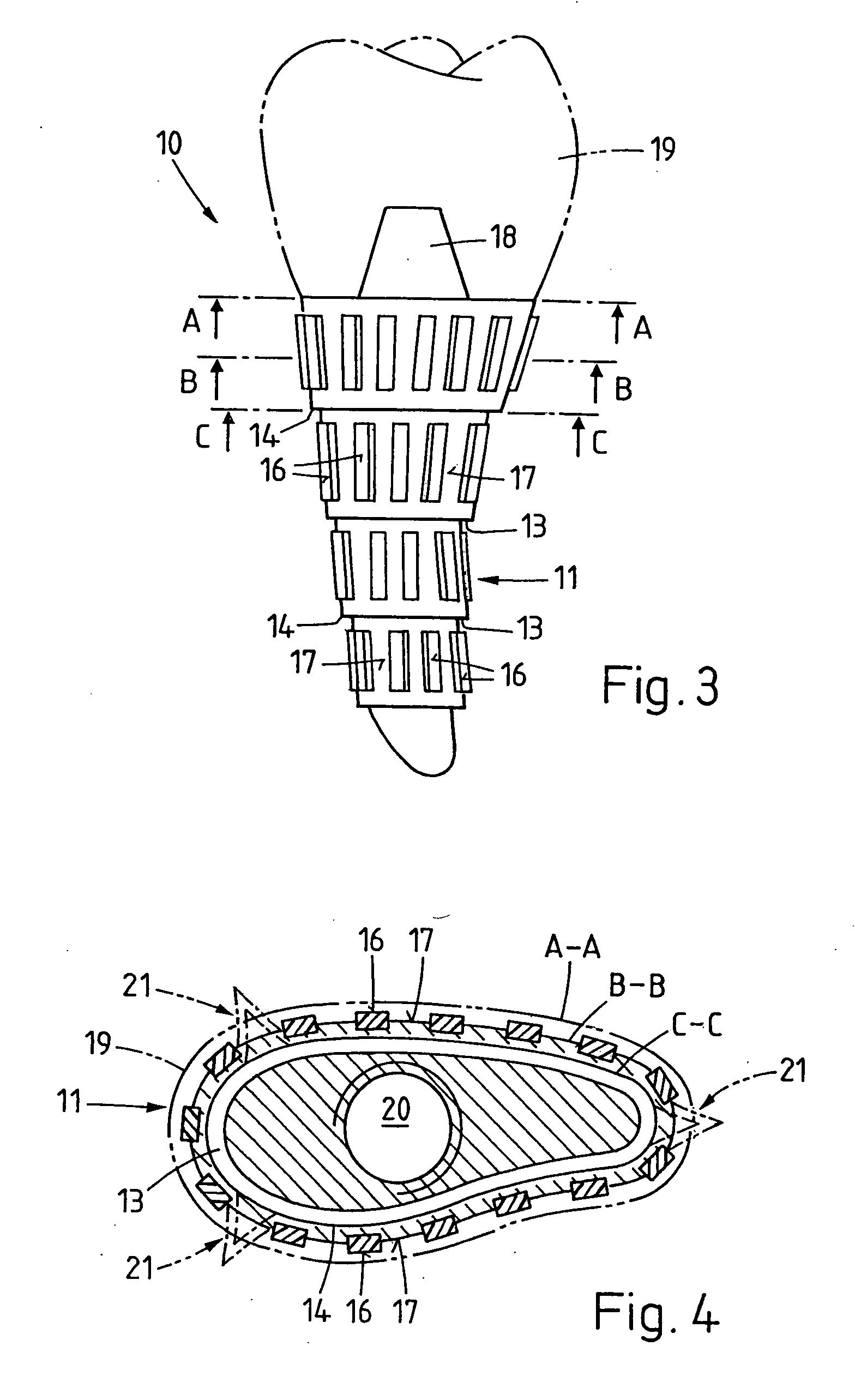

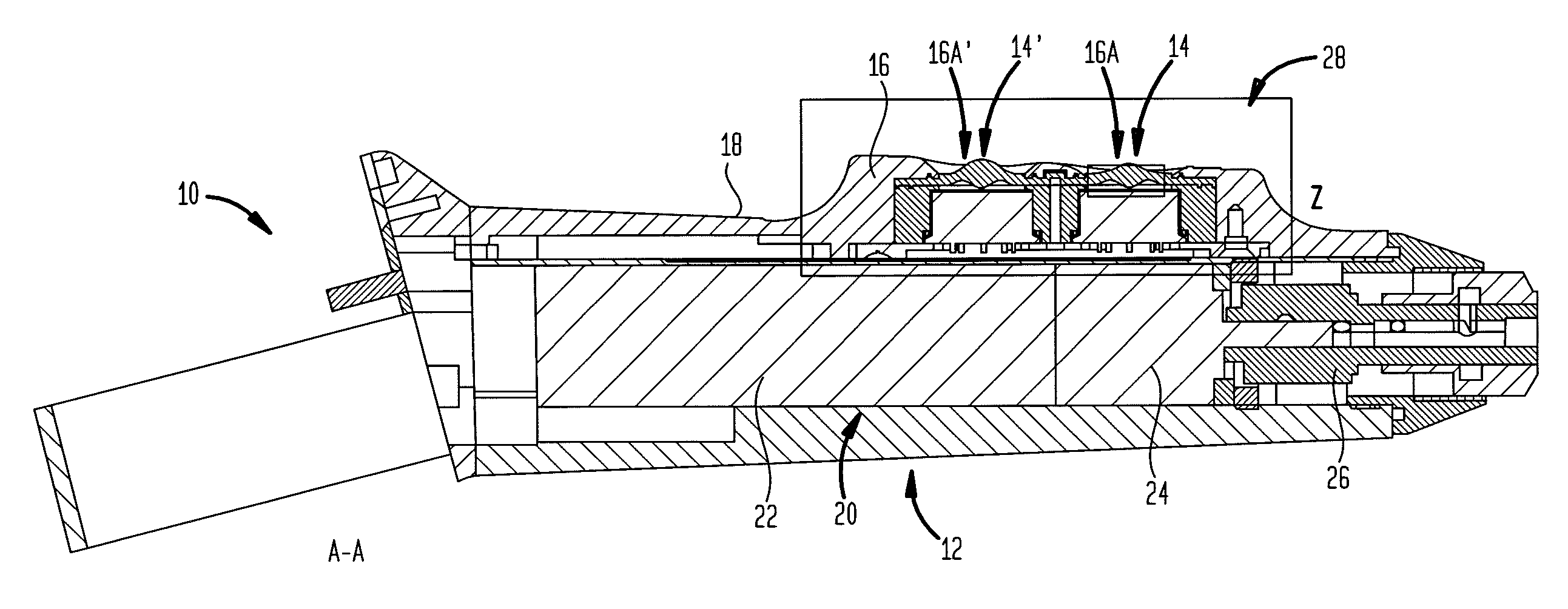

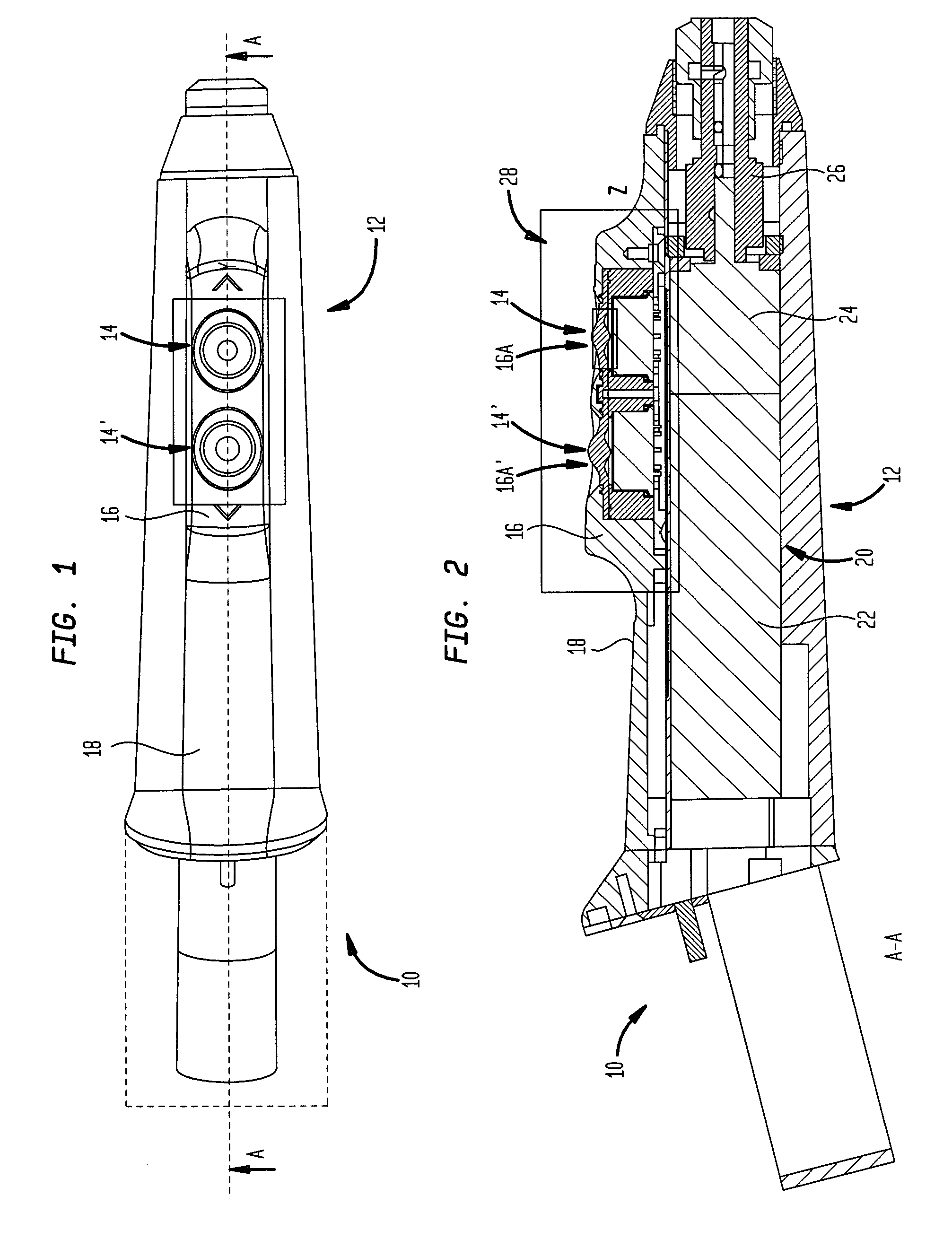

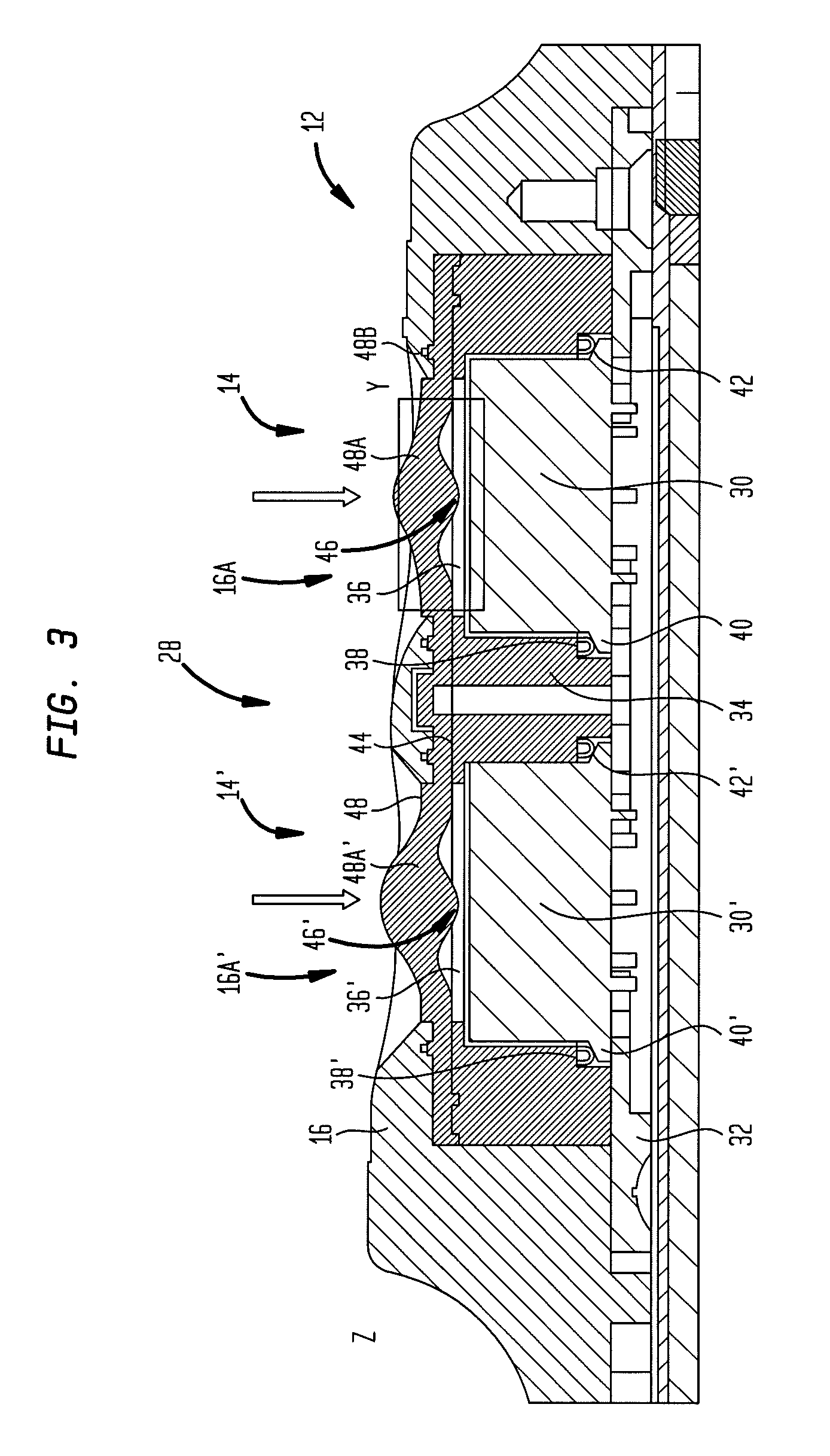

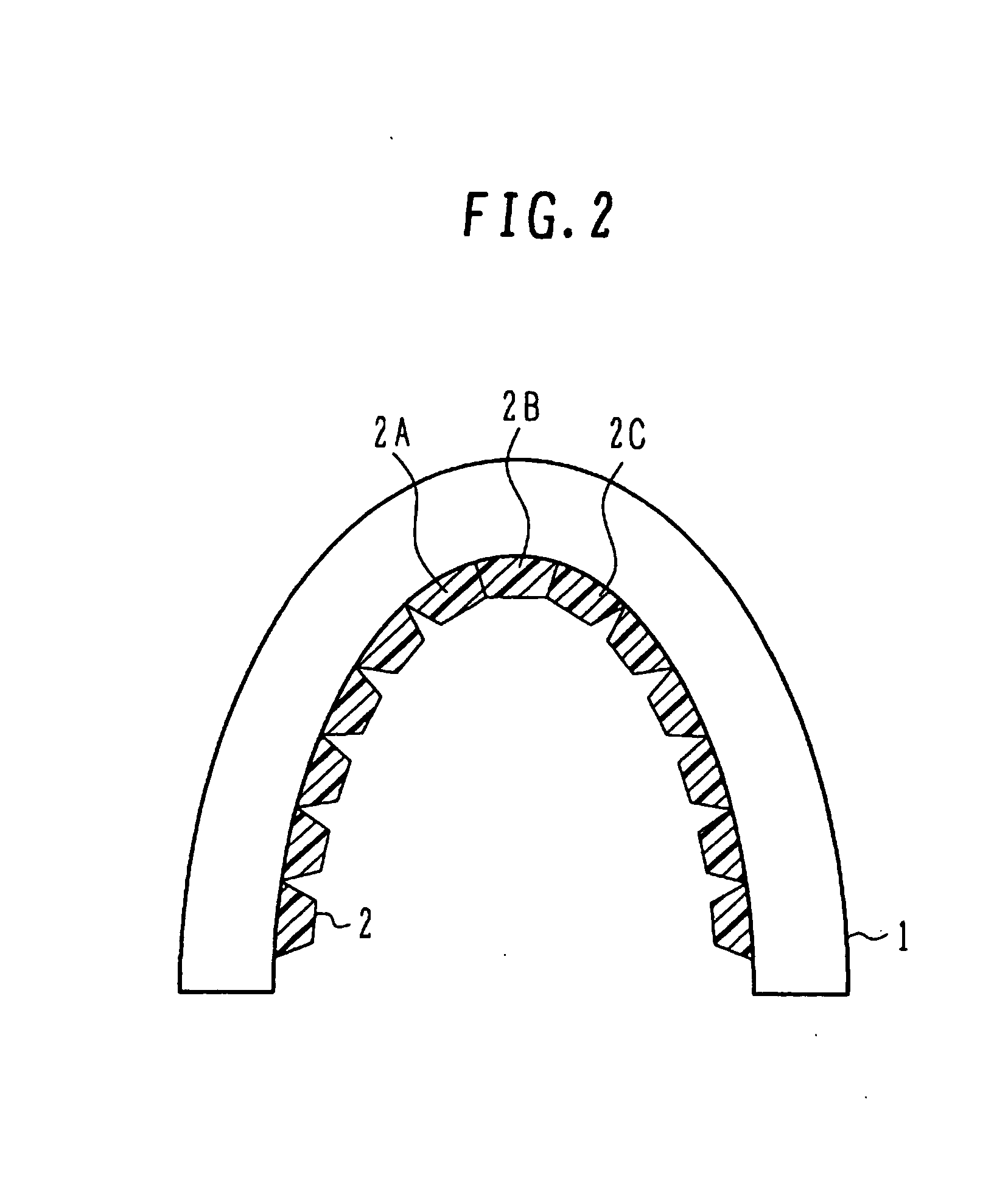

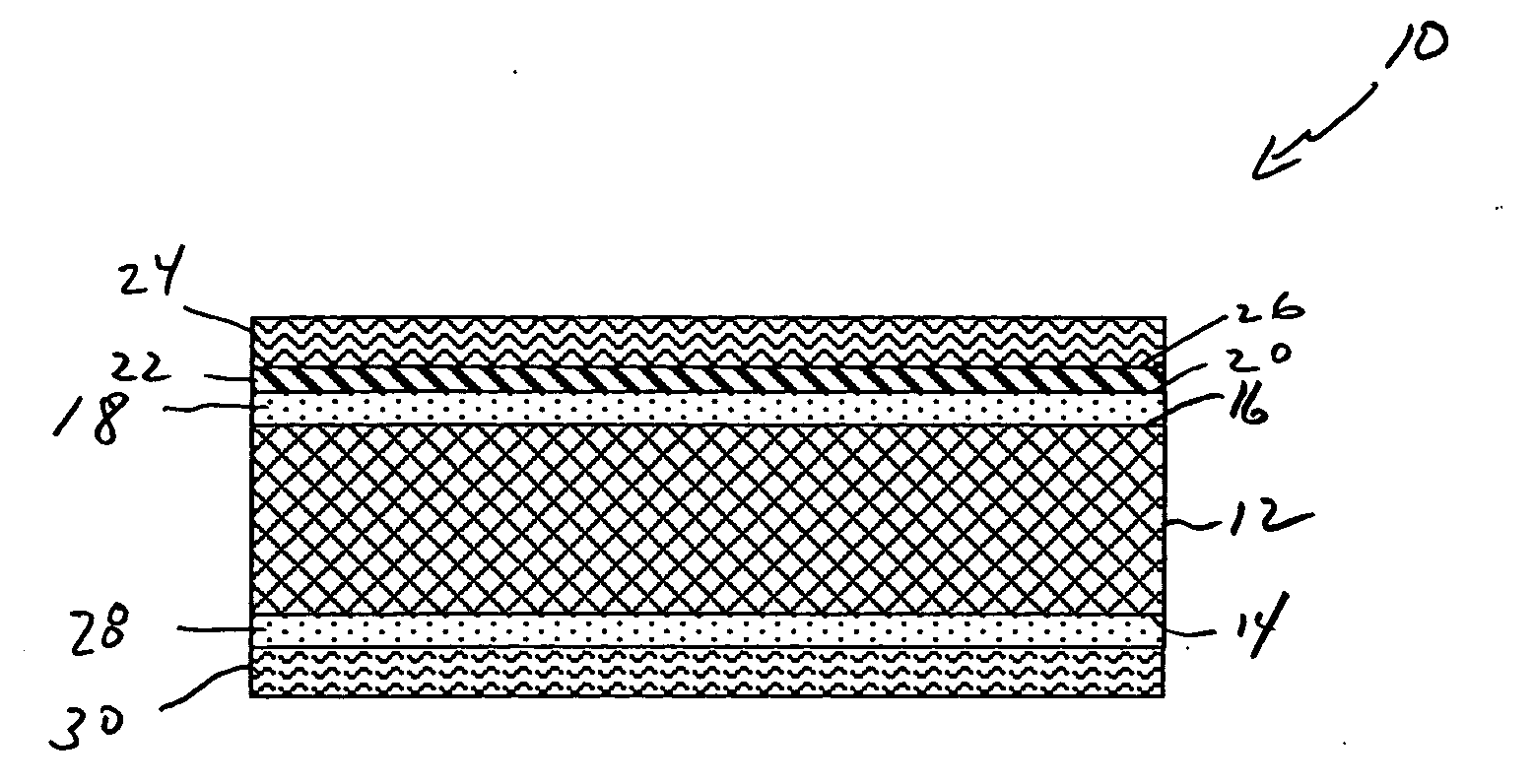

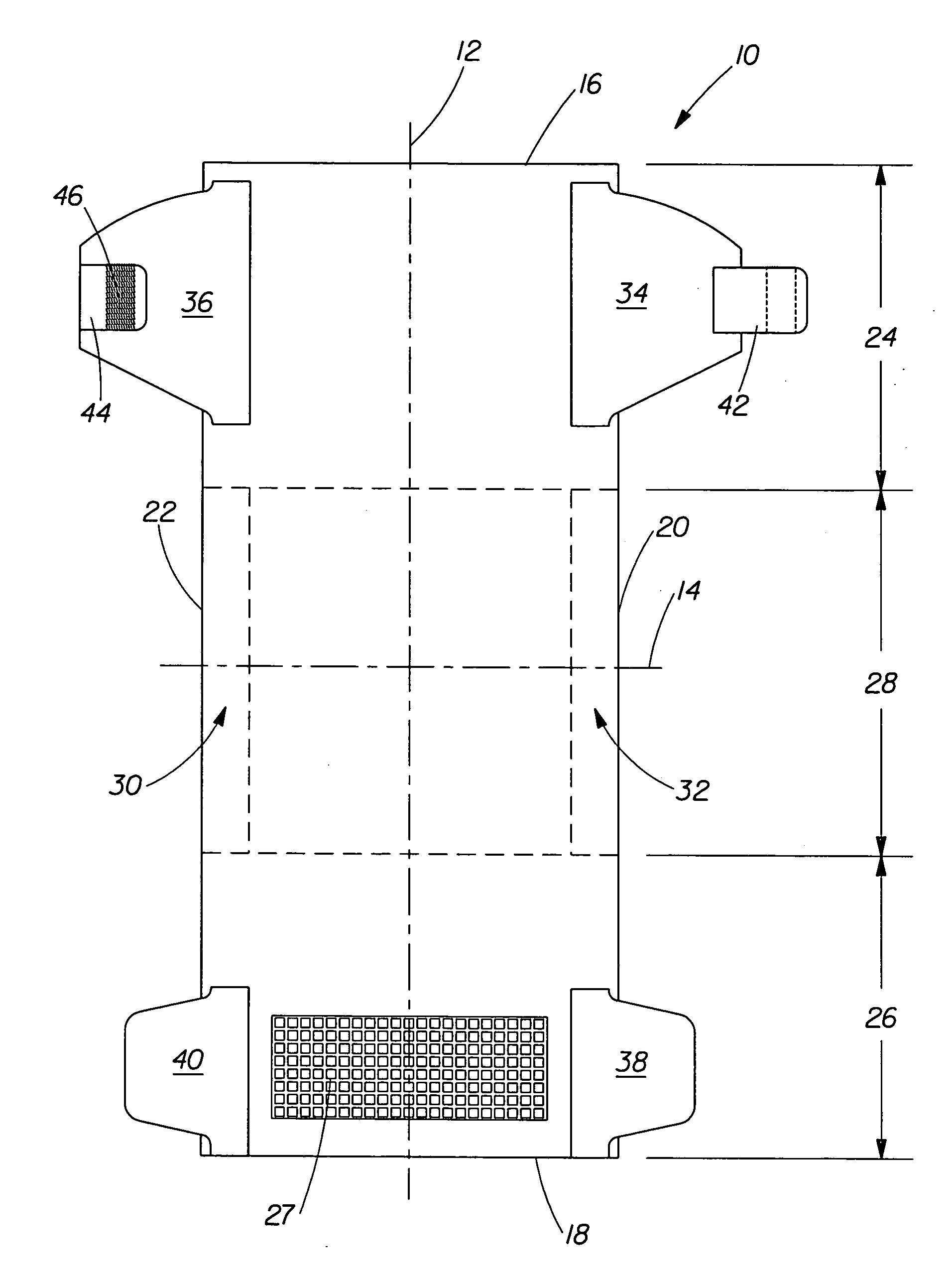

Implant that can be implanted in osseous tissue and method for producing said implant corresponding implant

ActiveUS20060105295A1Strong long-term anchoringProcess stabilityDental implantsInternal osteosythesisBone implantCavity wall

A bone implant (10) is implanted in a cavity parallel to an implant axis (I) and without substantial rotation. The implant includes, on an implant portion to be implanted, cutting edges (14), which do not extend in a common plane with the implant axis and are facing toward the distal end of the implant. The implant also includes surface ranges (16) of a material that is liquefiable by mechanical oscillations. The cutting edges (14) are dimensioned such that they are lodged in the cavity wall after implantation. For implantation, the implant is impinged with mechanical oscillations, resulting in the thermoplastic material being at least partially liquefied and pressed into unevennesses and pores of the cavity wall to form a form-fit and / or material-fit connection between implant (10) and cavity wall, when re-solidified. The cutting edges (14) anchor the implant in the cavity wall.

Owner:WOODWELDING

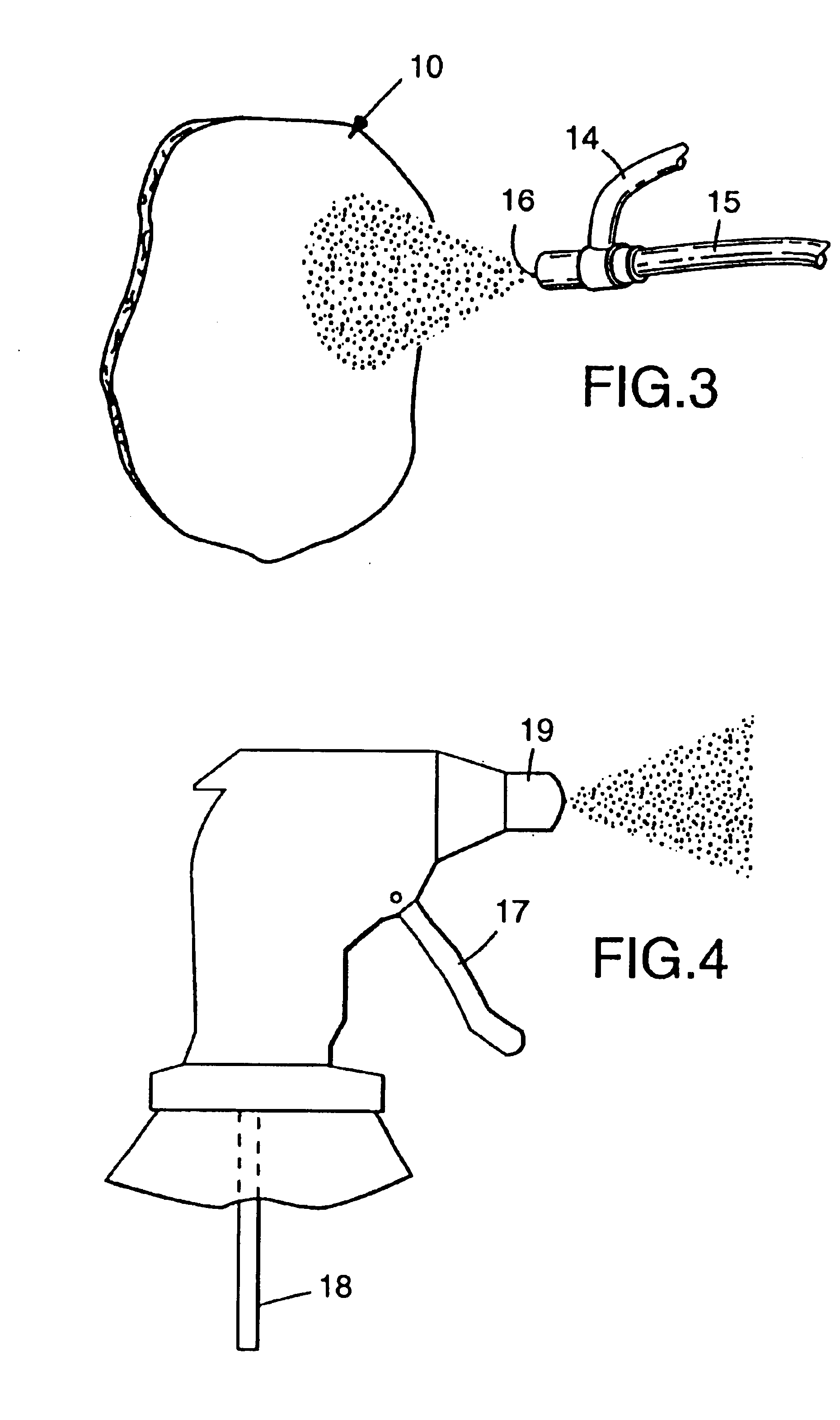

Electret filter media and filtering masks that contain electret filter media

InactiveUS6783574B1Reduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersFilter mediaRespiratory mask

Electret filter media comprising a nonwoven web of thermoplastic nonconductive microfibers having trapped charge, said charge provided by (1) subjecting the nonwoven web to a corona treatment, followed by (2) impingement of jets of water or a stream of water droplets on the web at a pressure sufficient to provide the web with filtration enhancing electret charge and (3) drying the web. This electret filter media may be used in a respiratory mask to provide extraordinarily good filtration properties.

Owner:3M CO

Composite building material

InactiveUS6941720B2Reduce noise transmissionLow acoustic transmissionConstruction materialSolid waste managementArchitectural engineeringPlastic property

This invention generally pertains to a composite building material comprising a lightweight core with a thin fiber cement facing on one side of the core and a second facing material on the other side. The fiber cement facing that is used on at least one of the faces of the building material is 3 / 16″ or less, more preferably ⅛″ or less. The green fiber cement facing is preferably formed by a slurry-dewatering process to form a sheet that is in a plastic, uncured, state prior to manufacture of the composite. The composite building material is assembled in an uncured state and then cured.

Owner:JAMES HARDIE TECH LTD

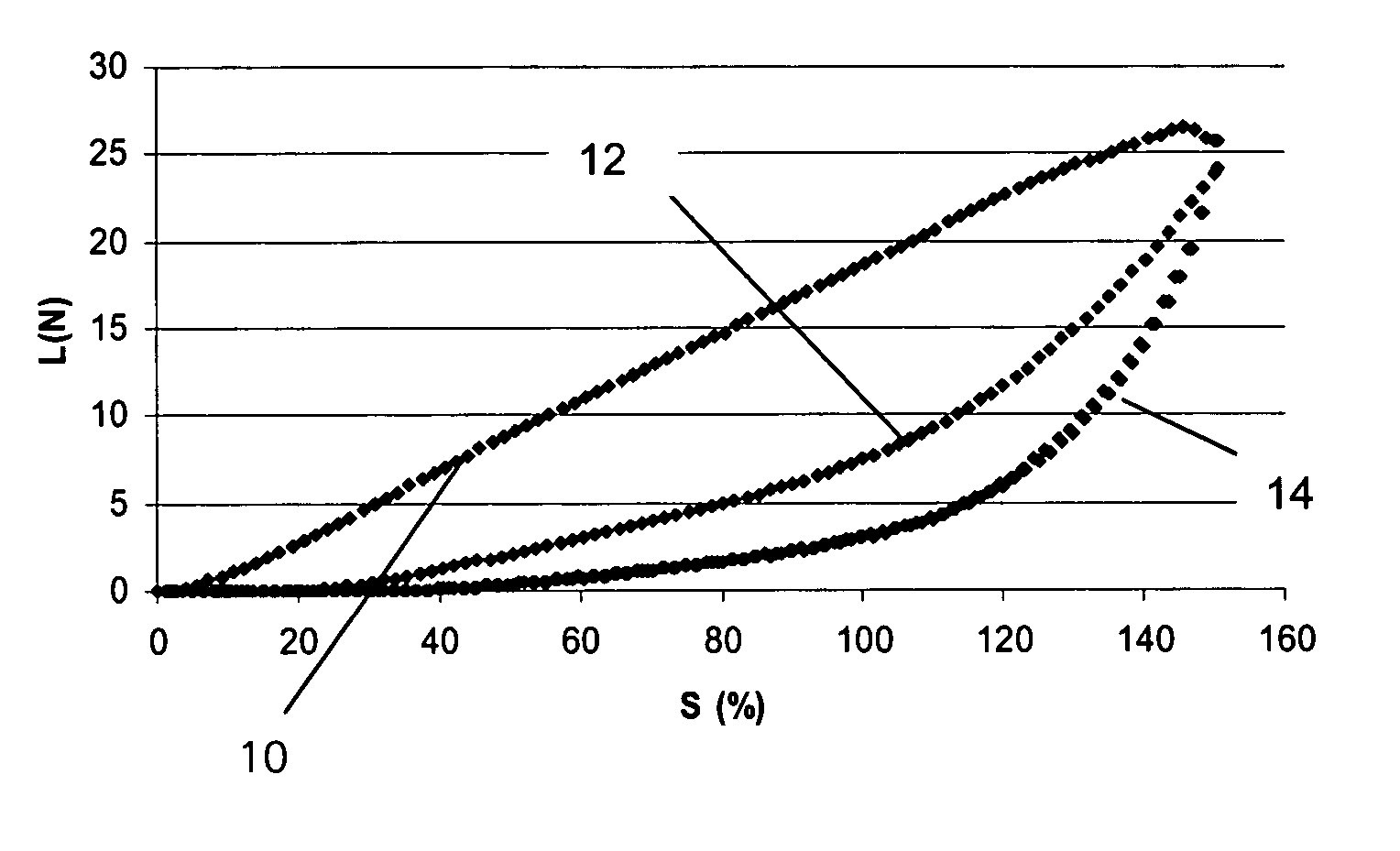

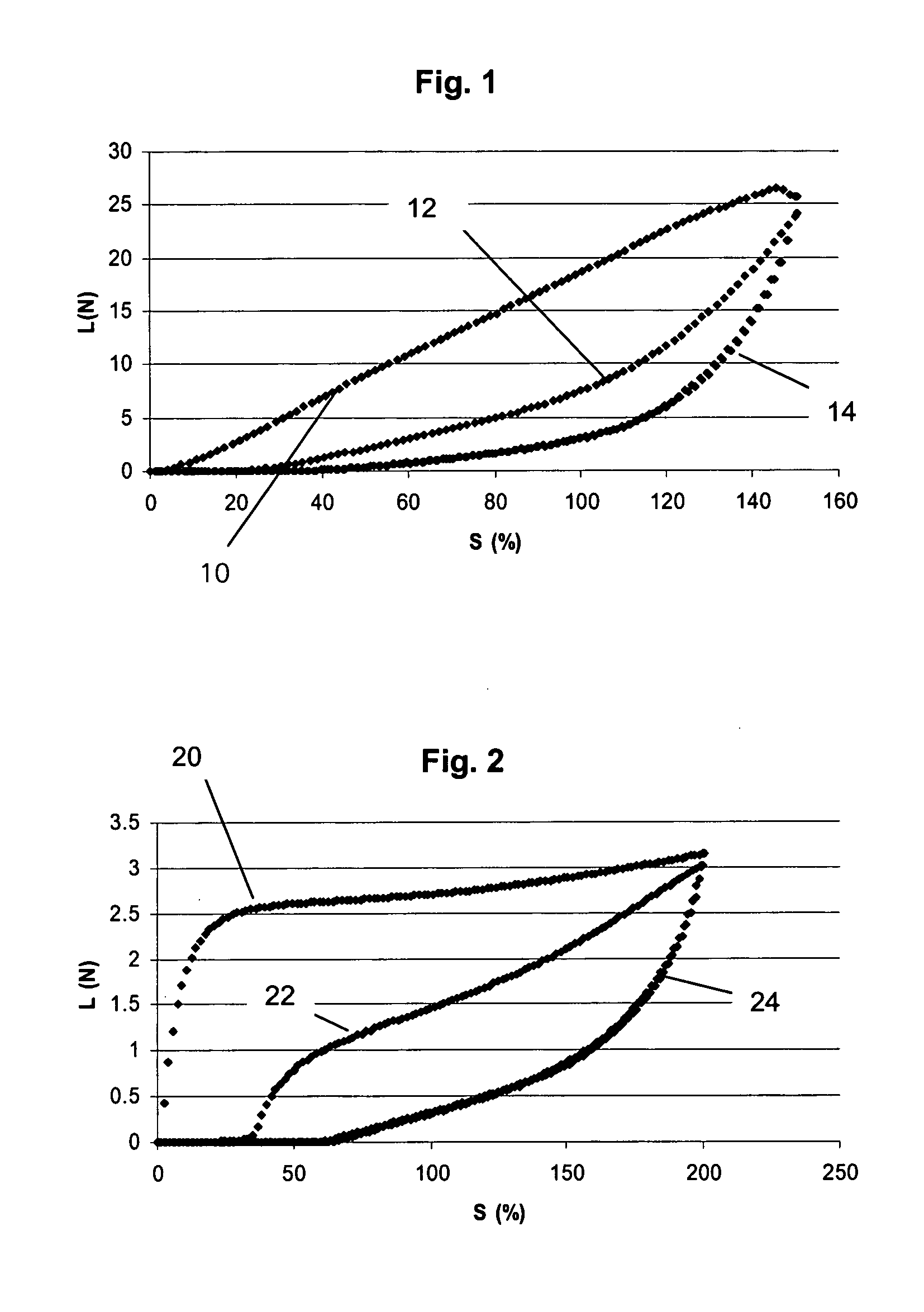

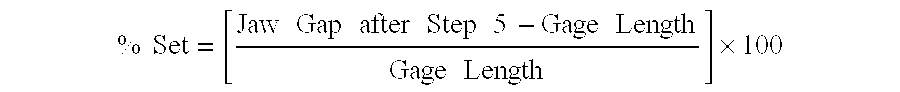

Web materials having both plastic and elastic properties

An extruded web is disclosed. The extruded web can be either a nonwoven material of a films. The web comprises a plasto-elastic material where the plasto-elastic material is a combination of a first polyolefin and a second polyolefin (either a polymeric blends or a polymeric mixture). The claimed combination of polyolefins results in a material that has substantially plastic properties when a sample taken from said web is subjected to an initial strain cycle (such that the web is provided with a set of at least 30% by an initial strain cycle) and substantially elastic properties when a sample taken from the web is subjected to at least a second strain cycle.

Owner:THE PROCTER & GAMBLE COMPANY

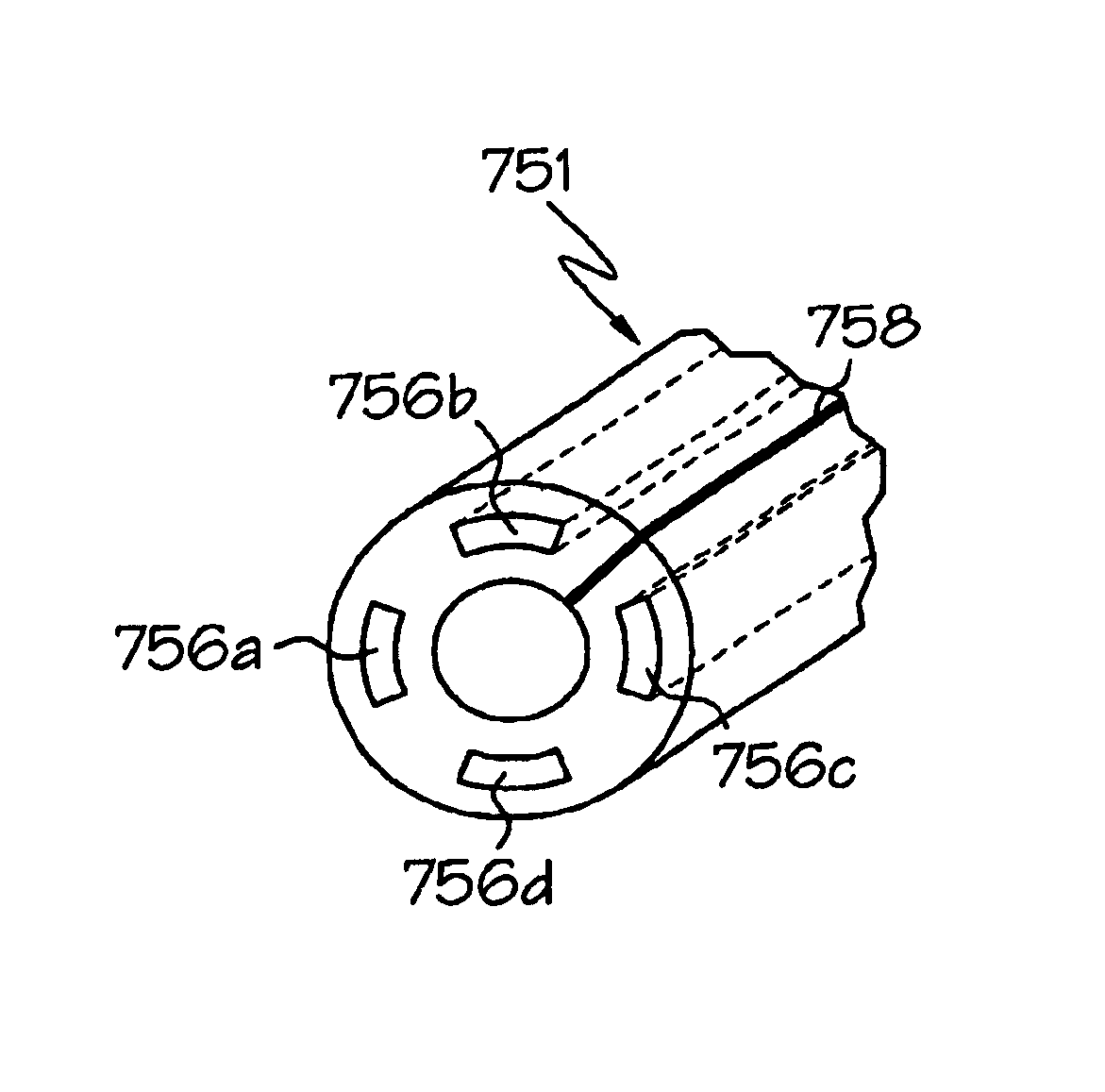

Surgical power tool and actuation assembly therefor

ActiveUS9345490B2Easy to detectEasy to placeEmergency actuatorsEmergency casingsSurgical operationEngineering

A surgical power tool has an actuation assembly for the actuation-force-dependent control of the tool. The actuation assembly includes a force sensor configured to sense the actuation force and a carrier component for the force sensor which is arranged upstream of the force sensor in a direction of force application and is coupled thereto in a force-transmitting manner. A mechanical damping member is arranged upstream of the carrier component in the direction of force application. The damping member protects the carrier component and the force sensor, for example, from impacts and shocks and the accompanying plastic deformations.

Owner:STRYKER EURO OPERATIONS HLDG LLC

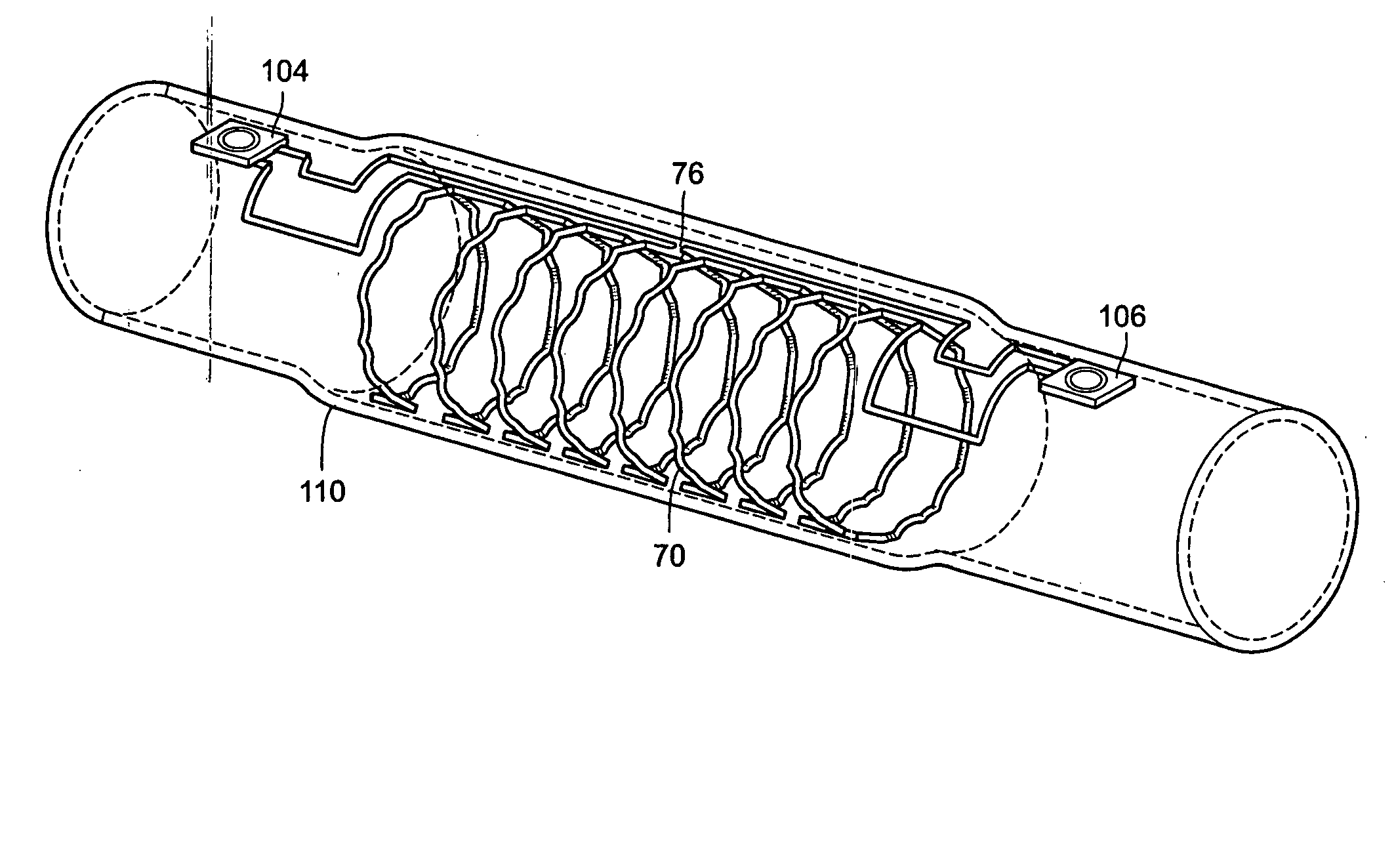

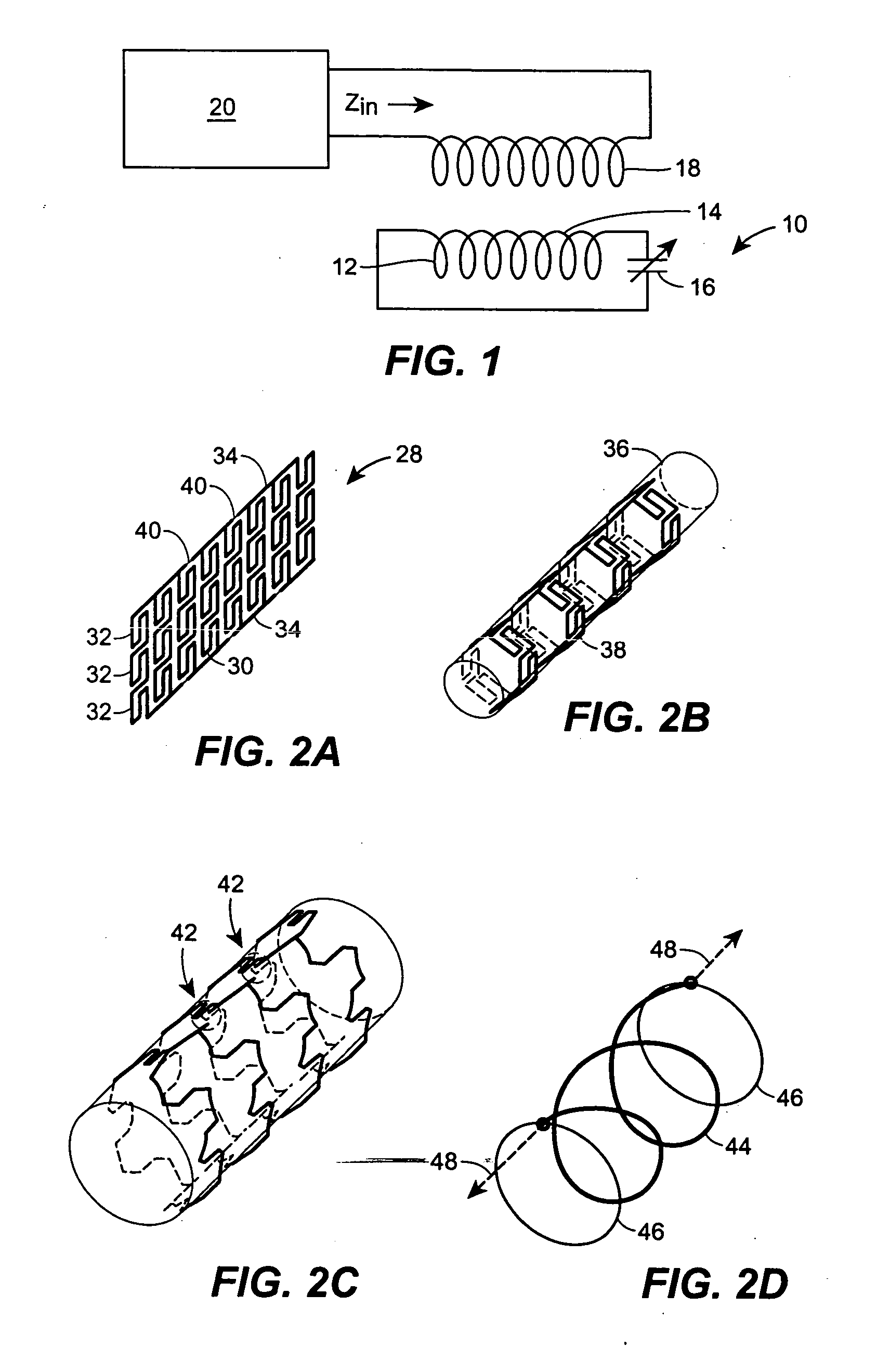

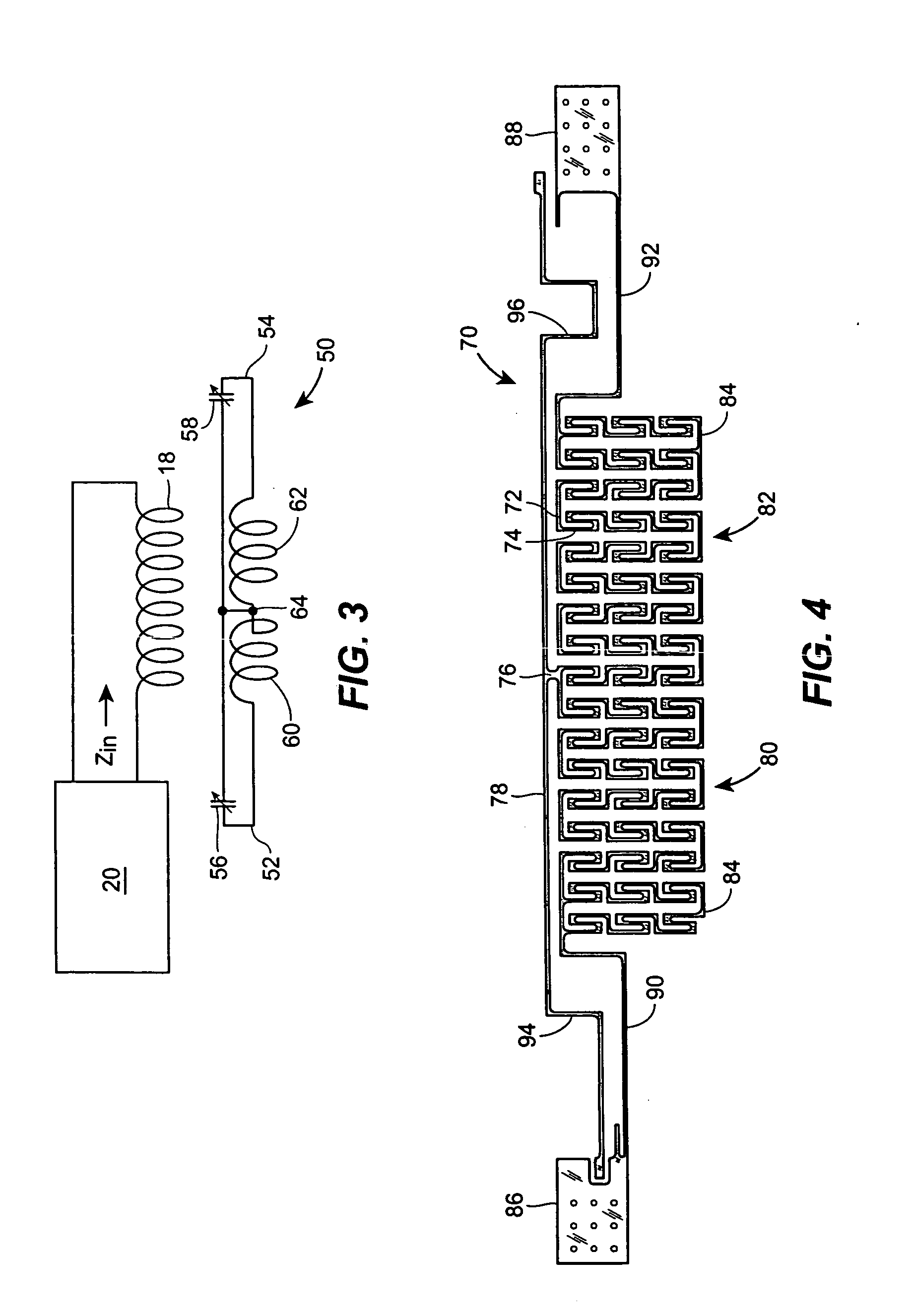

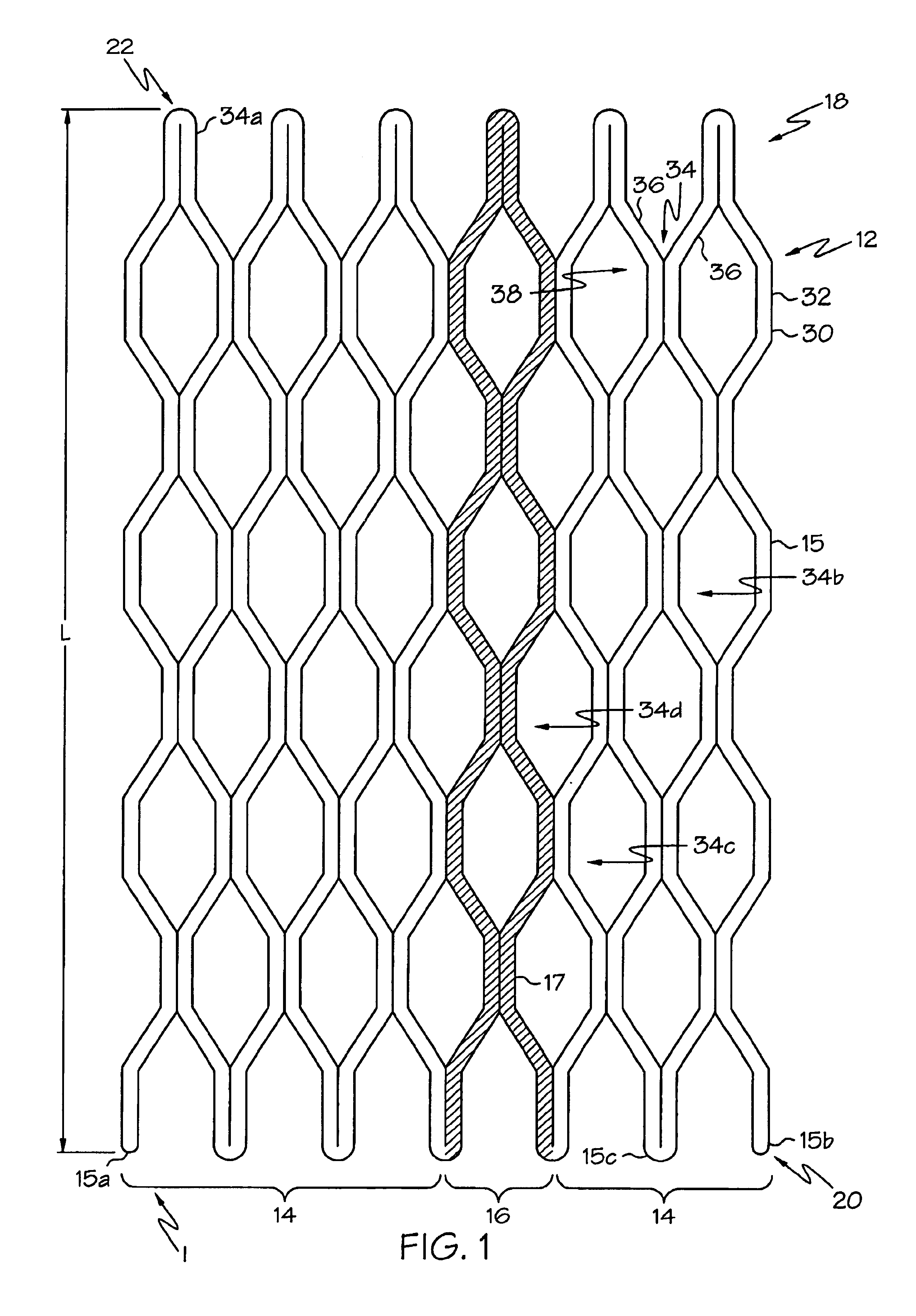

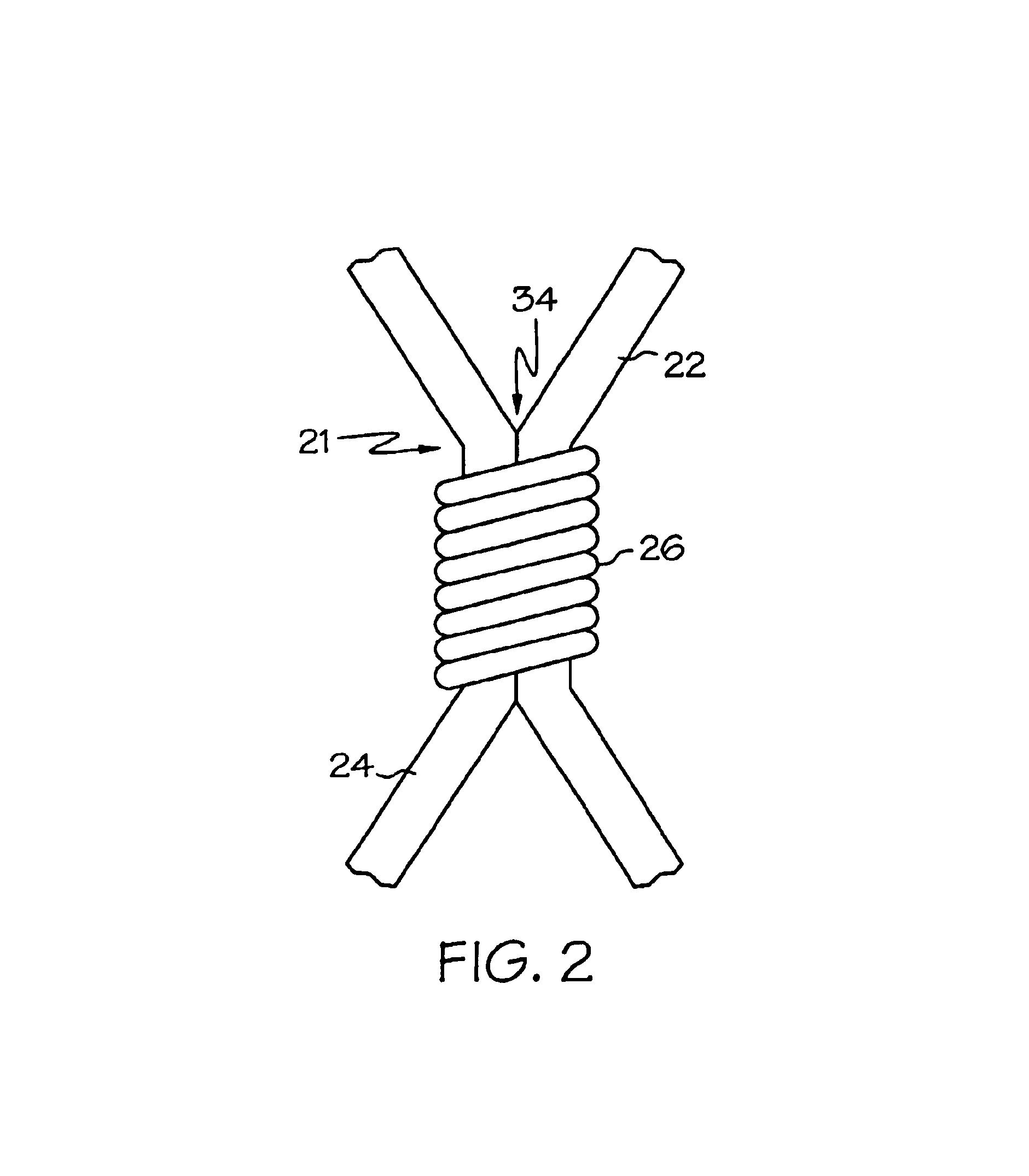

Antenna stent device for wireless, intraluminal monitoring

ActiveUS20050080346A1Keep openMaintaining the patency of the lumenStentsCatheterCapacitanceWireless transmission

Disclosed herein is a stent device useful for maintaining the patency of a lumen while monitoring an intraluminal characteristic. The device includes a structure having a set of extendible bands that are capable of plastic deformation to form a scaffolding having an inductance, and further includes a capacitance coupled to the set of extendible bands and responsive to the intraluminal characteristic. The capacitance and the inductance form a tank circuit after the plastic deformation of the set of extendible bands to enable wireless transmission of an indication of the intraluminal characteristic.

Owner:RGT UNIV OF MICHIGAN OFFICE TECH TRANSFER

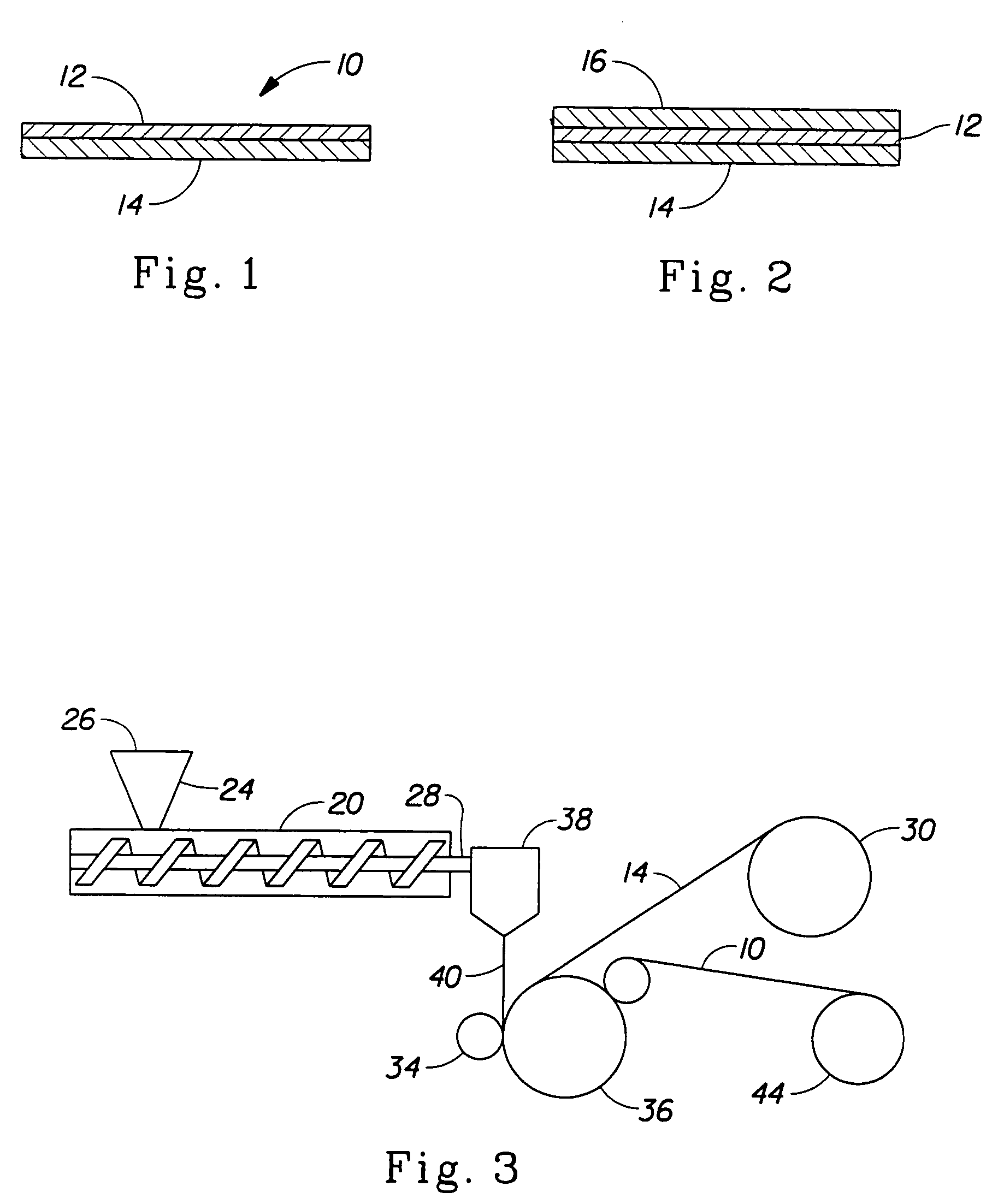

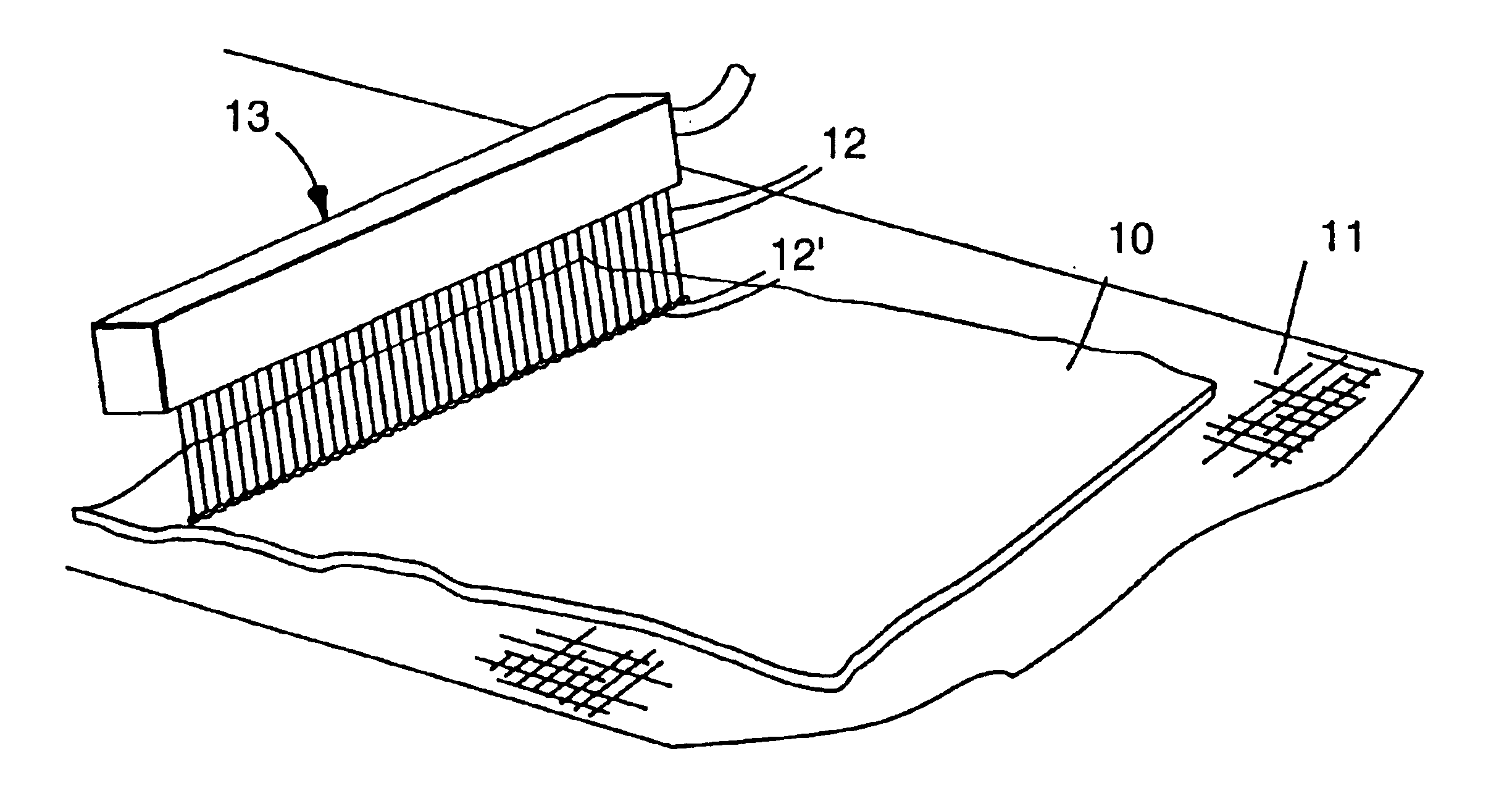

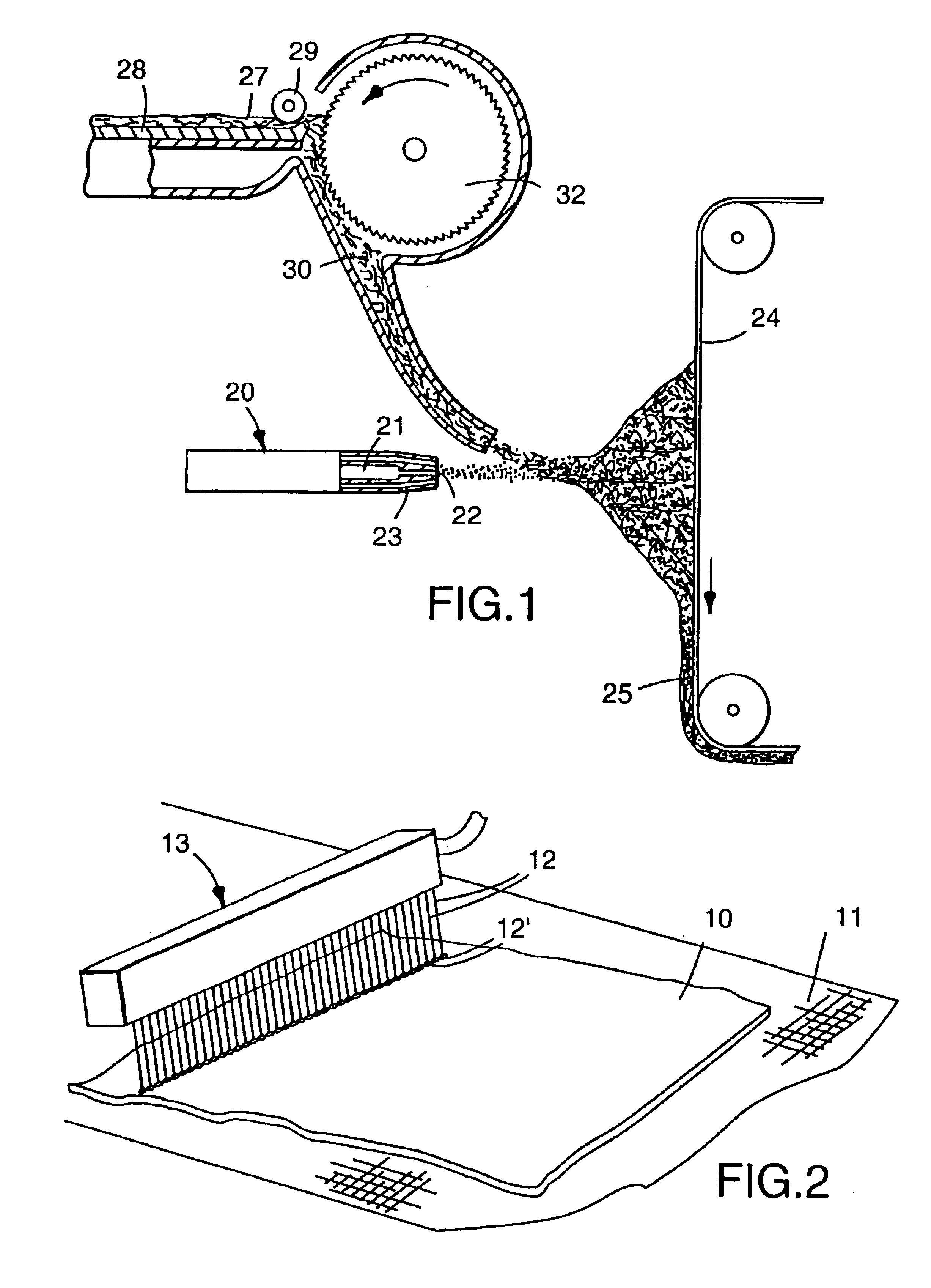

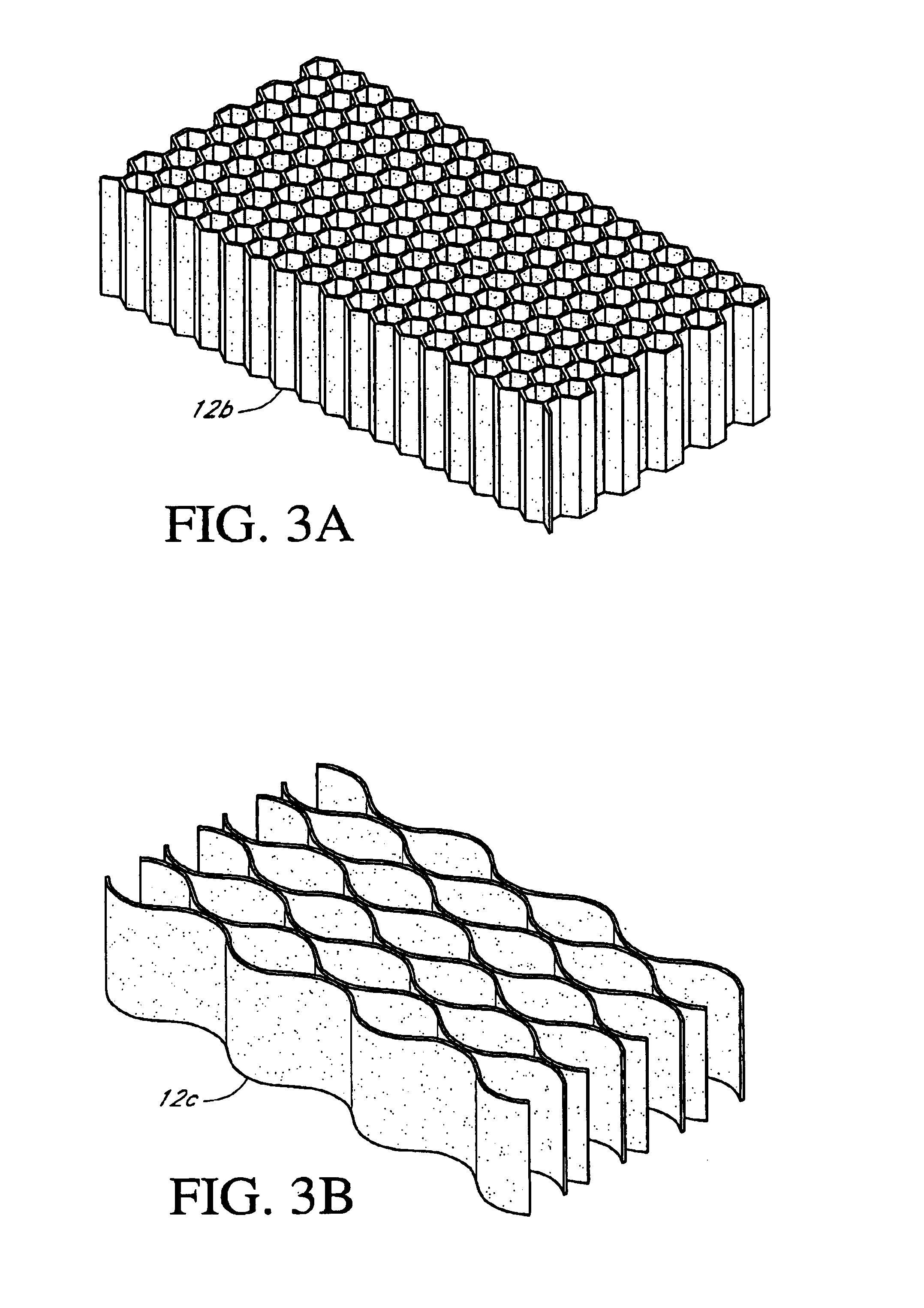

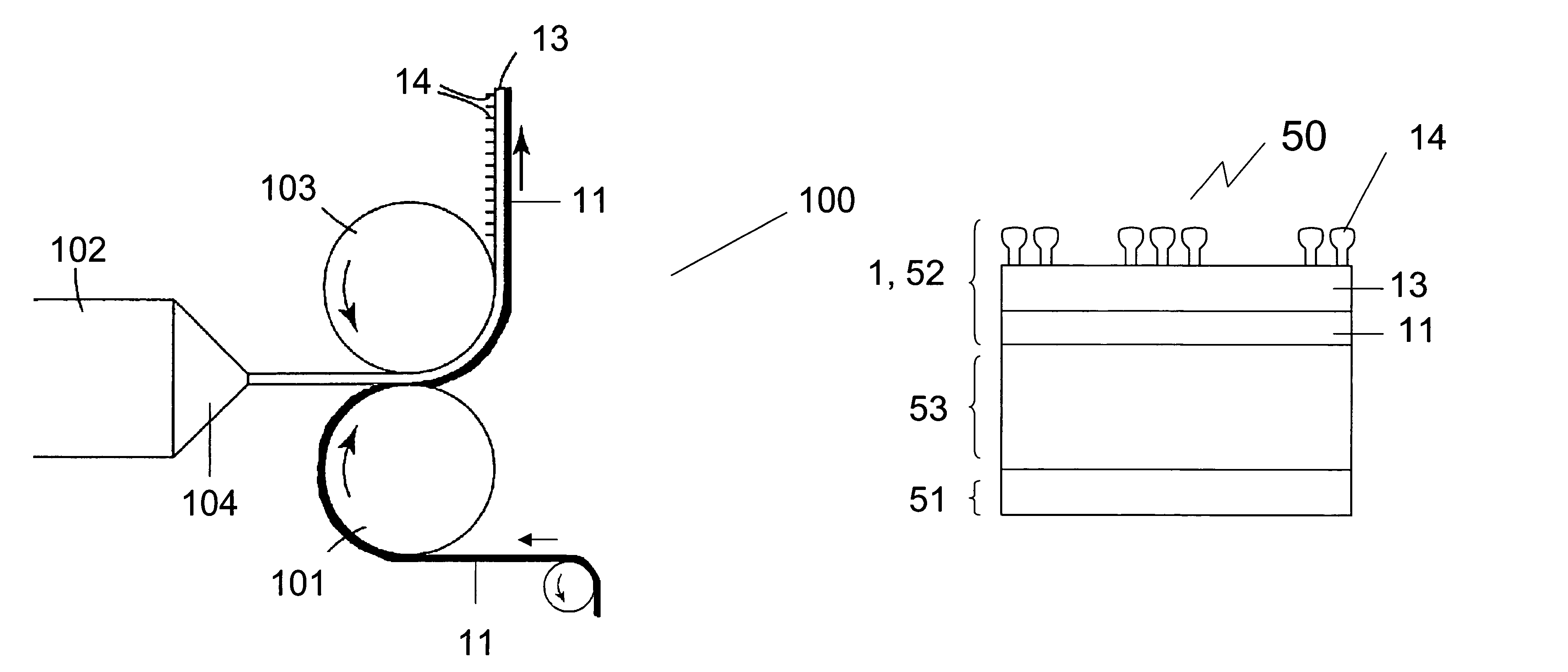

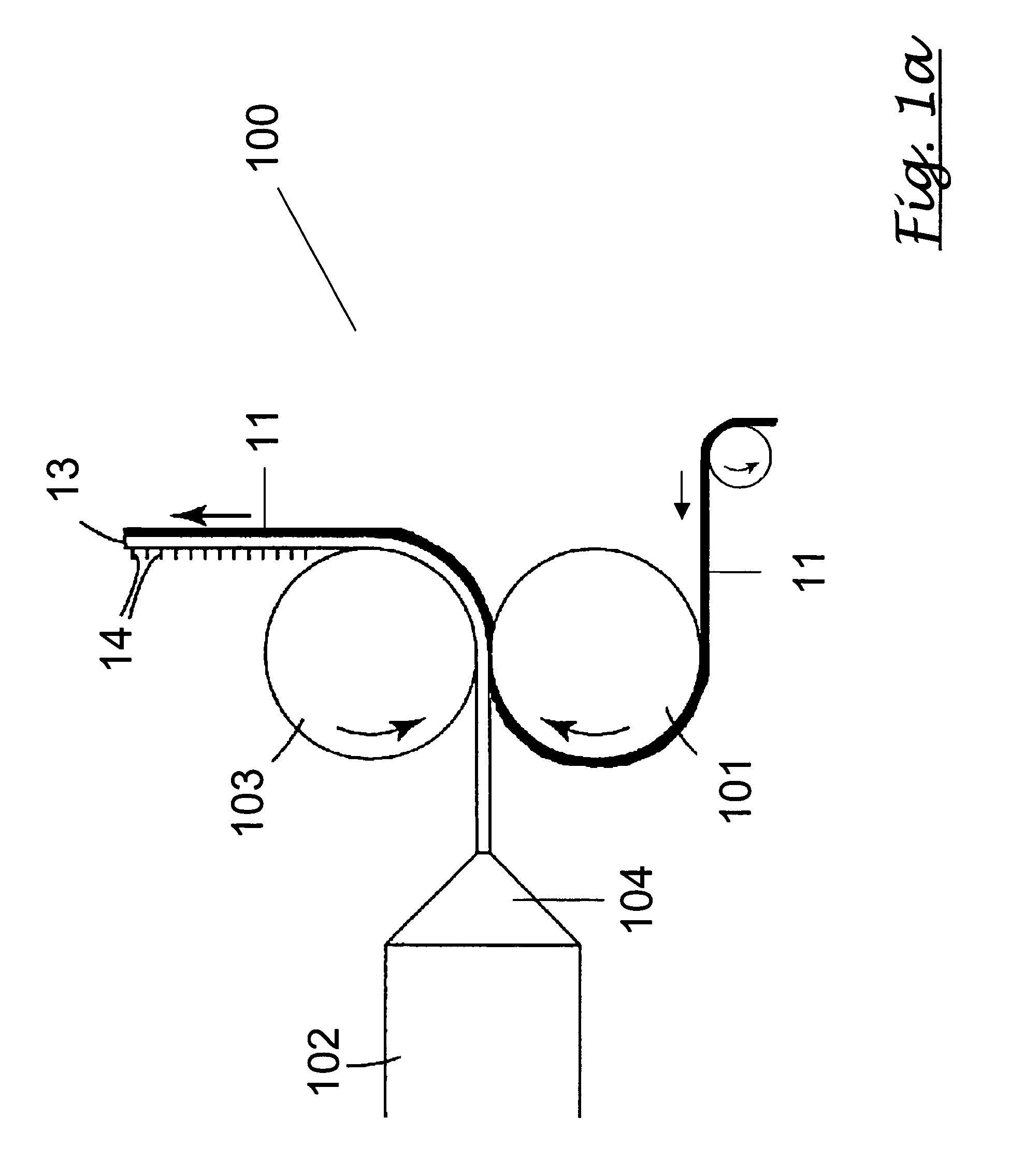

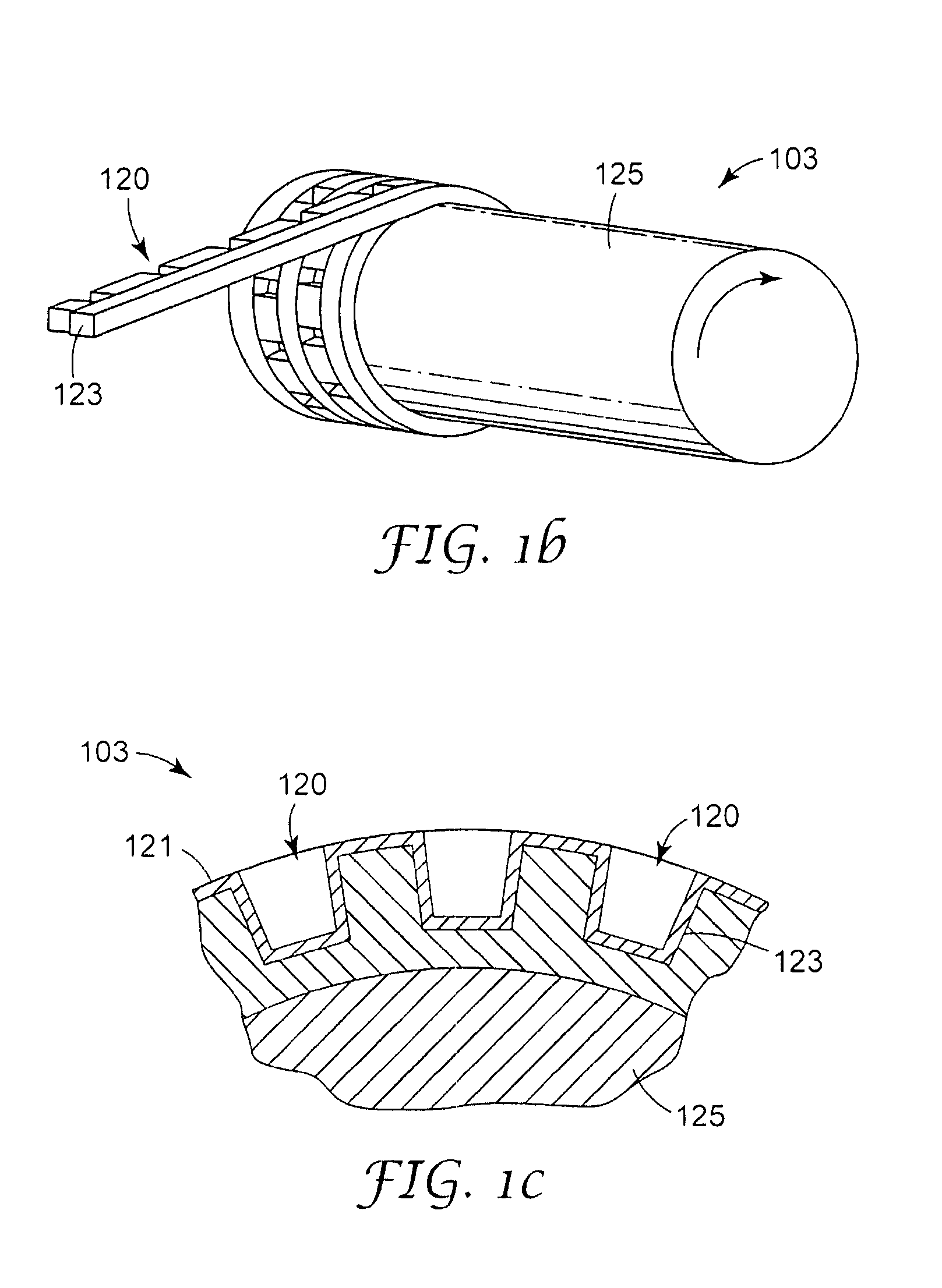

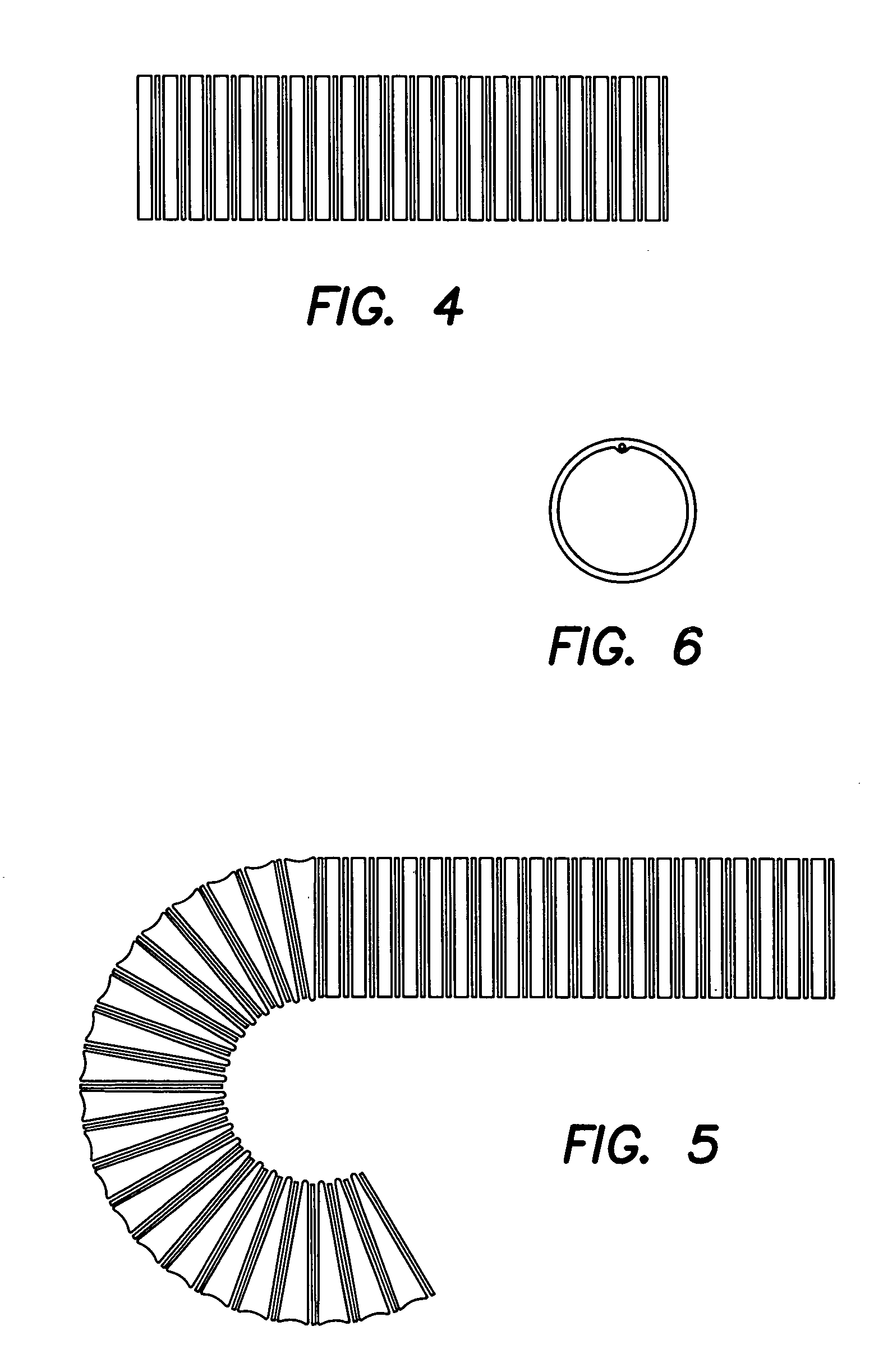

Methods of manufacturing a stretched mechanical fastening web laminate

InactiveUS7897078B2Reduce basis weightSnap fastenersWood working apparatusFiberVolumetric Mass Density

The present invention relates to a method of manufacturing a stretched mechanical fastening web laminate (1) comprising a thermoplastic web layer (13) having two major surfaces, one of the major surfaces bearing a multitude of male fastening elements (14) suitable for engagement with a corresponding female fastening material, and on its other major surface a fibrous web layer (11), said method comprising the steps of(i) providing the fibrous web layer (11) having an initial basis weight,(ii) passing the fibrous web layer (11) through a nip formed by two rolls (101), (103), one of them having cavities (120) that are the negatives of a plurality of male fastening elements (14), introducing a molten thermoplastic resin into the cavities (120) in excess of an amount that would fill the cavities (120) which excess forms the thermoplastic web layer (13), allowing the resin to at least partially solidify and stripping of a precursor web laminate (10) thus formed comprising the fibrous web layer (11) and the thermoplastic web layer (13) bearing a plurality of male fastening elements (14), from the cylindrical roll (103) having cavities (120) whereby the thermoplastic web layer (13) has an initial thickness and an initial hook density, and(iii) stretching the precursor web laminate (10) monoaxially or biaxially thereby decreasing the basis weight of the fibrous web layer (11) and the thickness of the thermoplastic web layer (13) from their respective initial values to provide a stretched mechanical fastening laminate (1) having a basis weight of less than 100 g·m−2.

Owner:3M INNOVATIVE PROPERTIES CO

Flexible Base Material and Flexible Image-Displaying Device Resistant to Plastic Deformation

ActiveUS20080055831A1Restrict further deformationControl deformationSubstation/switching arrangement detailsStatic indicating devicesBiomedical engineeringPlastic property

Owner:UDC IRELAND

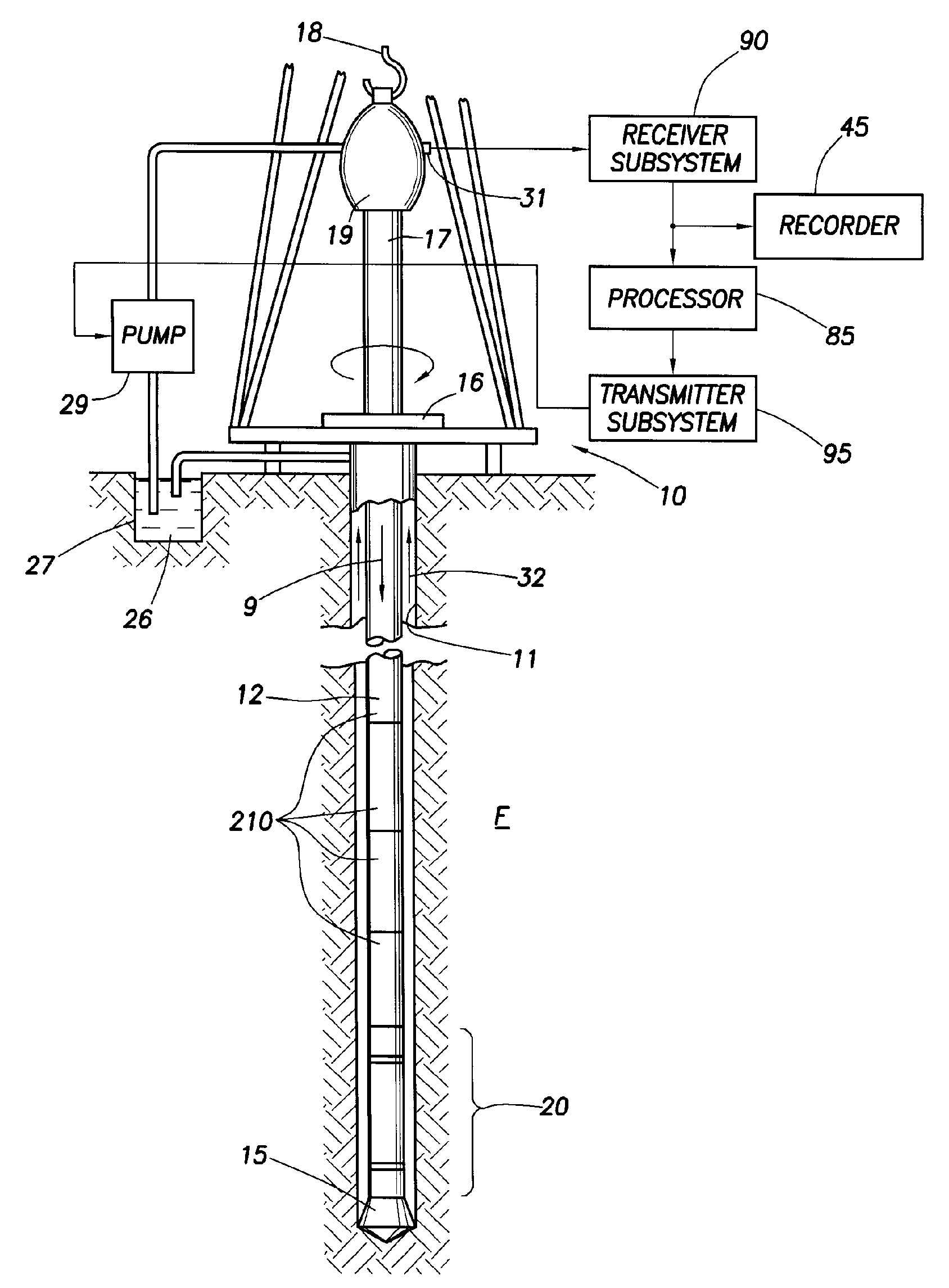

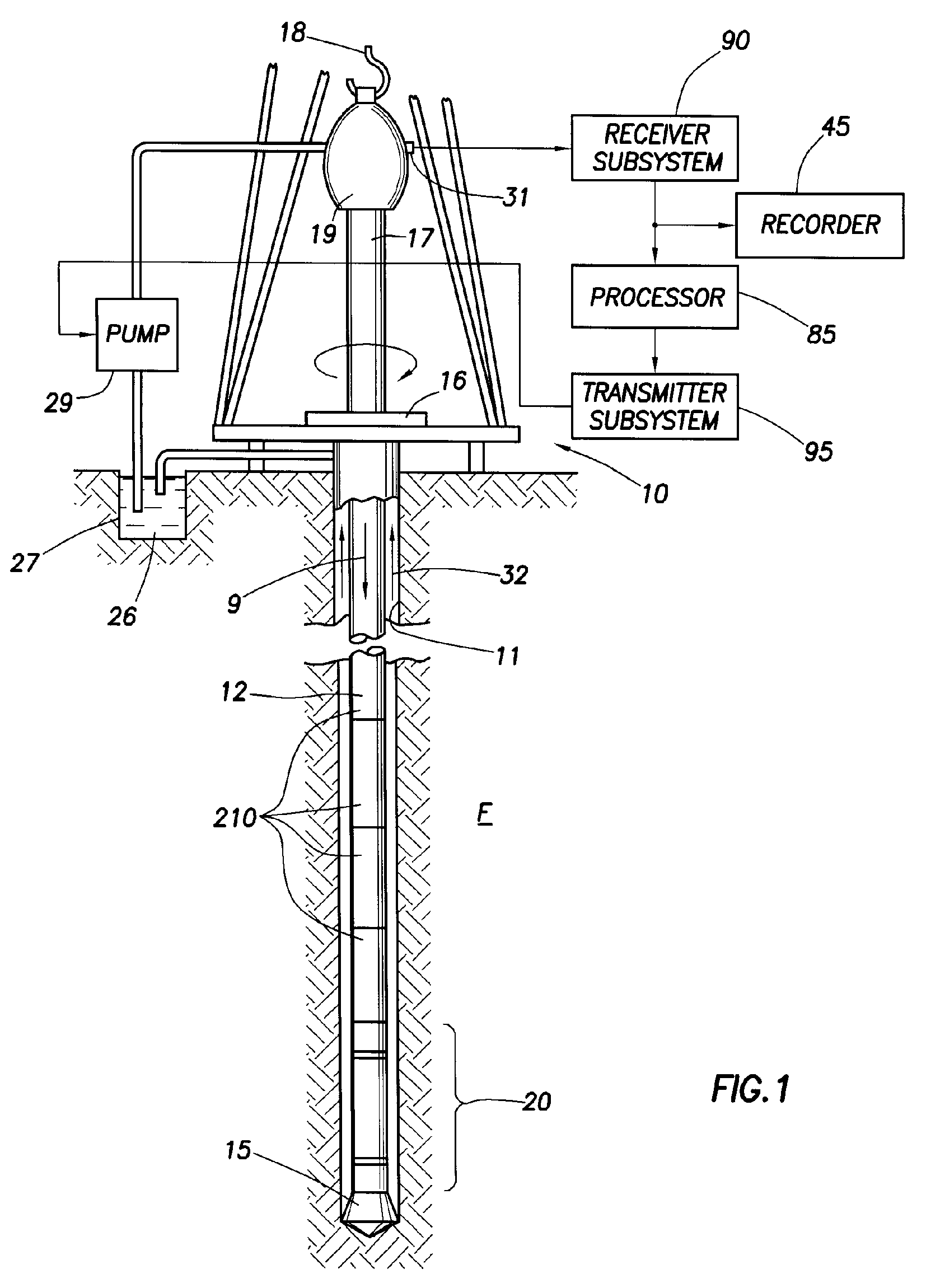

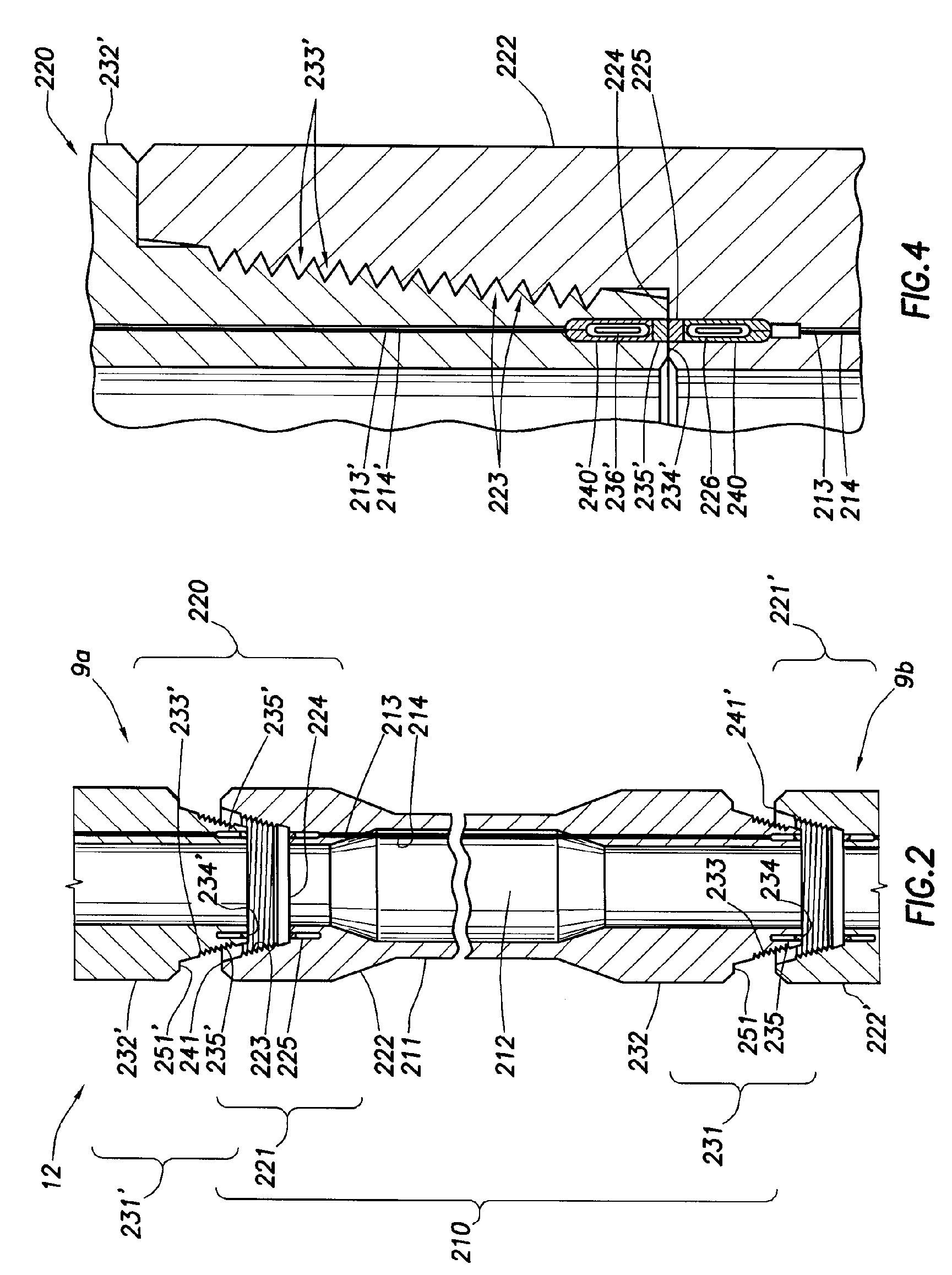

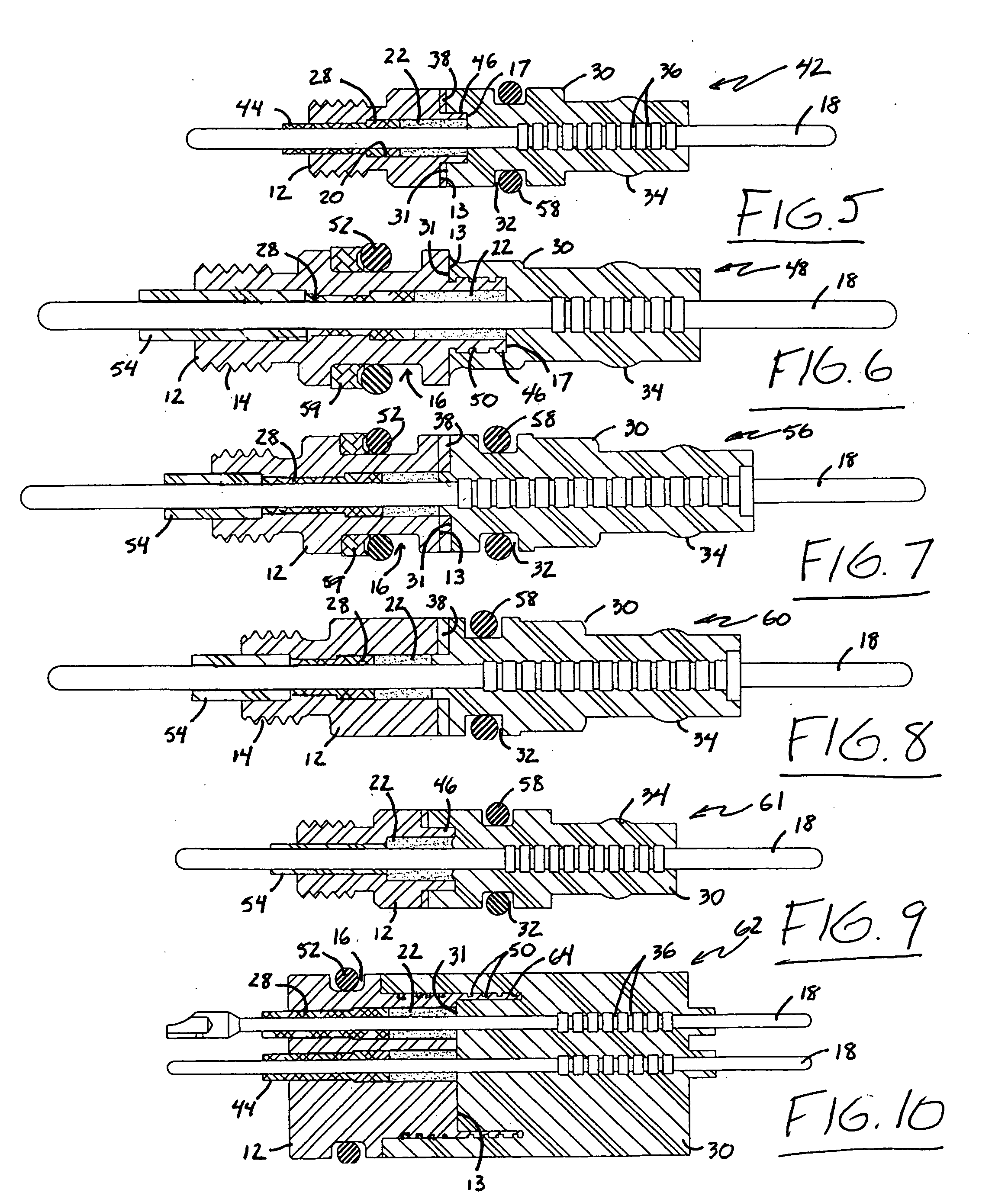

Method and conduit for transmitting signals

ActiveUS20060225926A1Improve scalabilityDrilling rodsInsulated cablesBiomedical engineeringHeat treated

An expandable tubular sleeve having utility for lining a downhole tubular member includes a tubular body having a portion that is predisposed to initiate expansion thereof under the application of internal fluid pressure. The predisposed portion of the body may be a plastically-deformed portion formed, e.g., by application of mechanical force to a wall of the body. The predisposed portion of the body may be defined by a portion of the body having reduced wall thickness. The reduced wall thickness may be achieved, e.g., by reinforcing the wall thickness everywhere except the predisposed portion. The predisposed portion of the body may be formed by modifying the material properties of the body, e.g., by localized heat treatment. The sleeve and related apparatuses and methods are useful for securing and protecting a cable having one or more insulated conductive wires for transmission of signals between locations downhole and at the surface.

Owner:SCHLUMBERGER TECH CORP

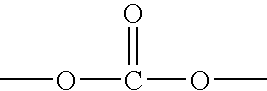

Substrate mounting for organic, dielectric, optical film

A method for optically coupling a thermoplastic material to an outer surface layer of an organic, dielectric, optical film and the resulting optical filter. Initially, a dielectric film is selected that includes (i) repeating optical layers of at least two polymers having different refractive indexes from each other, (ii) an exterior film surface, (iii) a refractive boundary along the exterior film surface, and (iv) a delamination threshold based on total thermal energy delivered to the film. A thermoplastic material which is miscible with the exterior film surface is fused to the refractive boundary with thermal energy below the delamination threshold to form a polydisperse region having a higher optical transmission than the refractive boundary. Add-on filters in the form of hardcoat layers, anti-reflection layers, holograms, metal dielectric stacks and combinations of these may be combined with the thermoplastic-film construct.

Owner:GENTEX CORP

Advanced compatible polymer wood fiber composite

InactiveUS6210792B1Improve compatibilityGood material compatibilitySynthetic resin layered productsCellulosic plastic layered productsThermoplasticFiber

The invention relates to a composition comprising a thermoplastic polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer, the fiber or both can be modified to increase compatibility. The wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

Elastomerically impregnated ePTFE to enhance stretch and recovery properties for vascular grafts and coverings

This invention relates to an elastomerically recoverable PTFE material that includes a longitudinally compressed fibrils of ePTFE material penetrated by elastomeric material within the pores defining the elastomeric matrix. The elastomeric matrix and the compressed fibrils cooperatively expand and recover without plastic deformation of the ePTFE material. This invention was used for various prosthesis, such as a vascular prosthesis like a patch, a graft and an implantable tubular stents. Furthermore, this invention discloses a method of producing the elastomerically recoverable PTFE material which include the steps of: providing the specified ePTFE, defined by the nodes and fibrils, to meet the desired end use; longitudinally compressing the fibrils of the ePTFE, the pore size sufficiently enough to permit penetration of the elastomeric material; applying the elastomeric material within the pores to provide a structurally integral elastomerically recoverable PTFE material defining an elastomeric matrix. The elastomeric material is applied to the ePTFE by dip, brush or spray coating techniques. The compression step and the application steps are interchangeable to produce the desired properties for the end use material. Finally, the elastomeric material is dried within the pores of the longitudinally compressed ePTFE to solidify the elastomeric matrix.

Owner:LIFESHIELD SCI

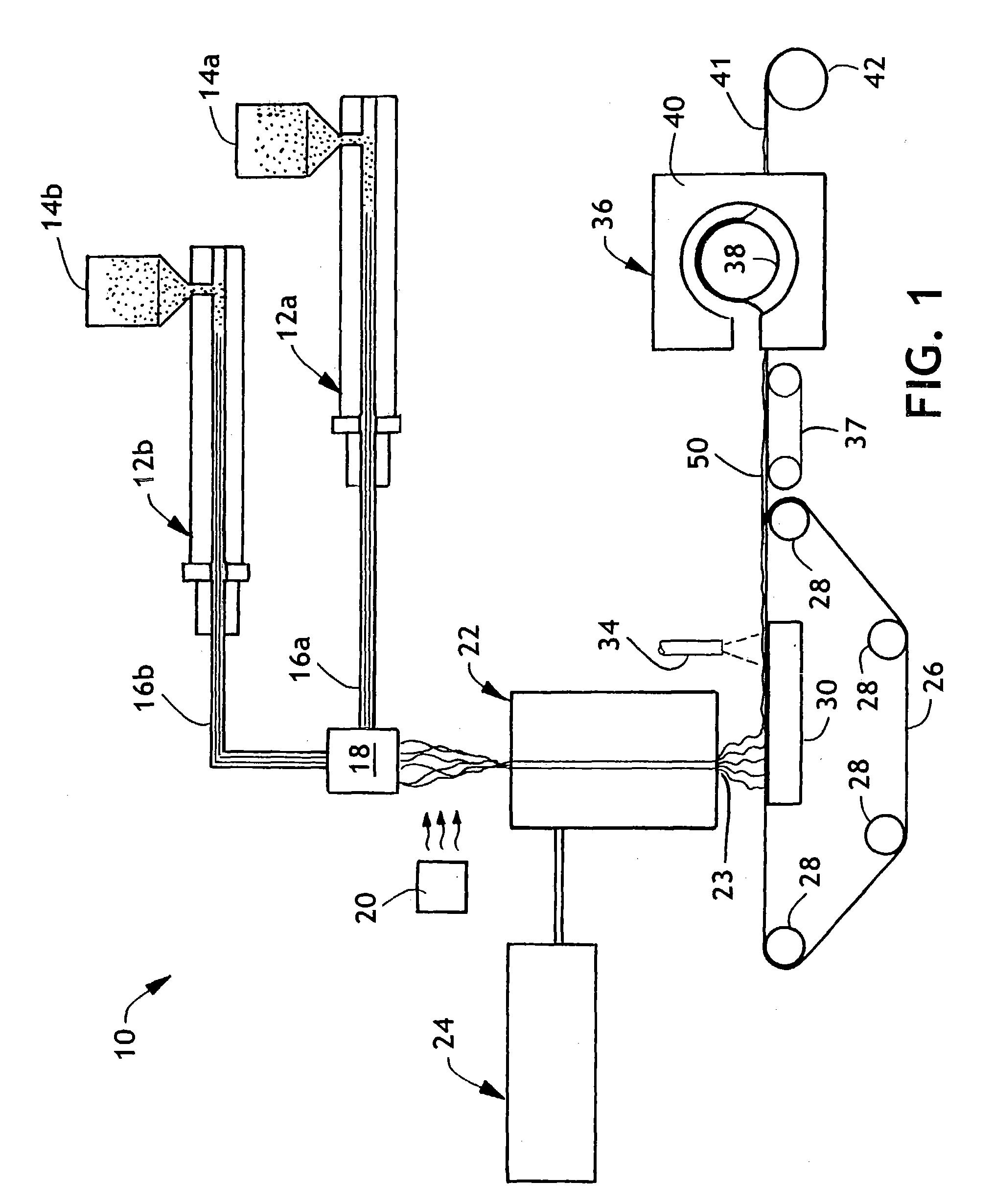

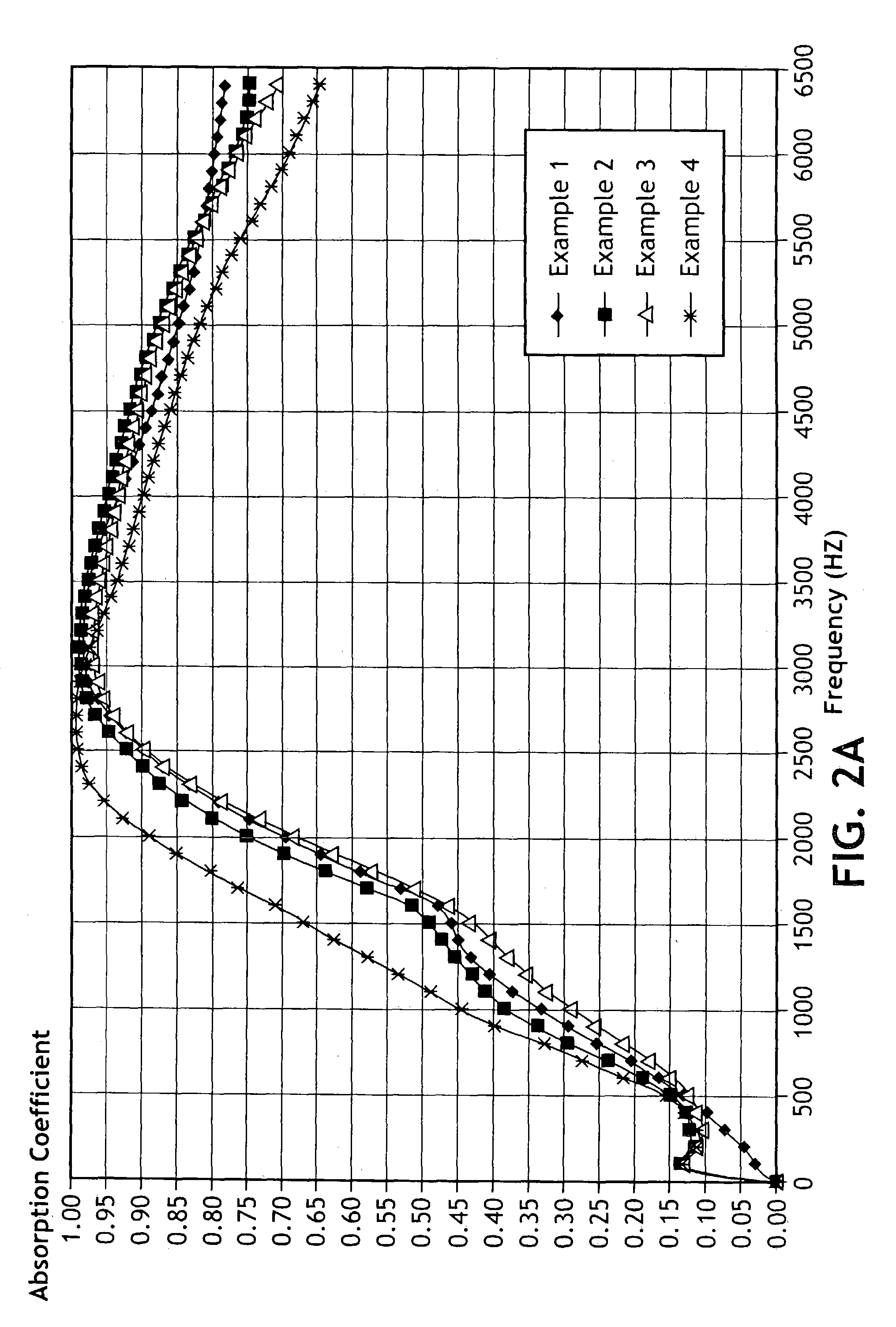

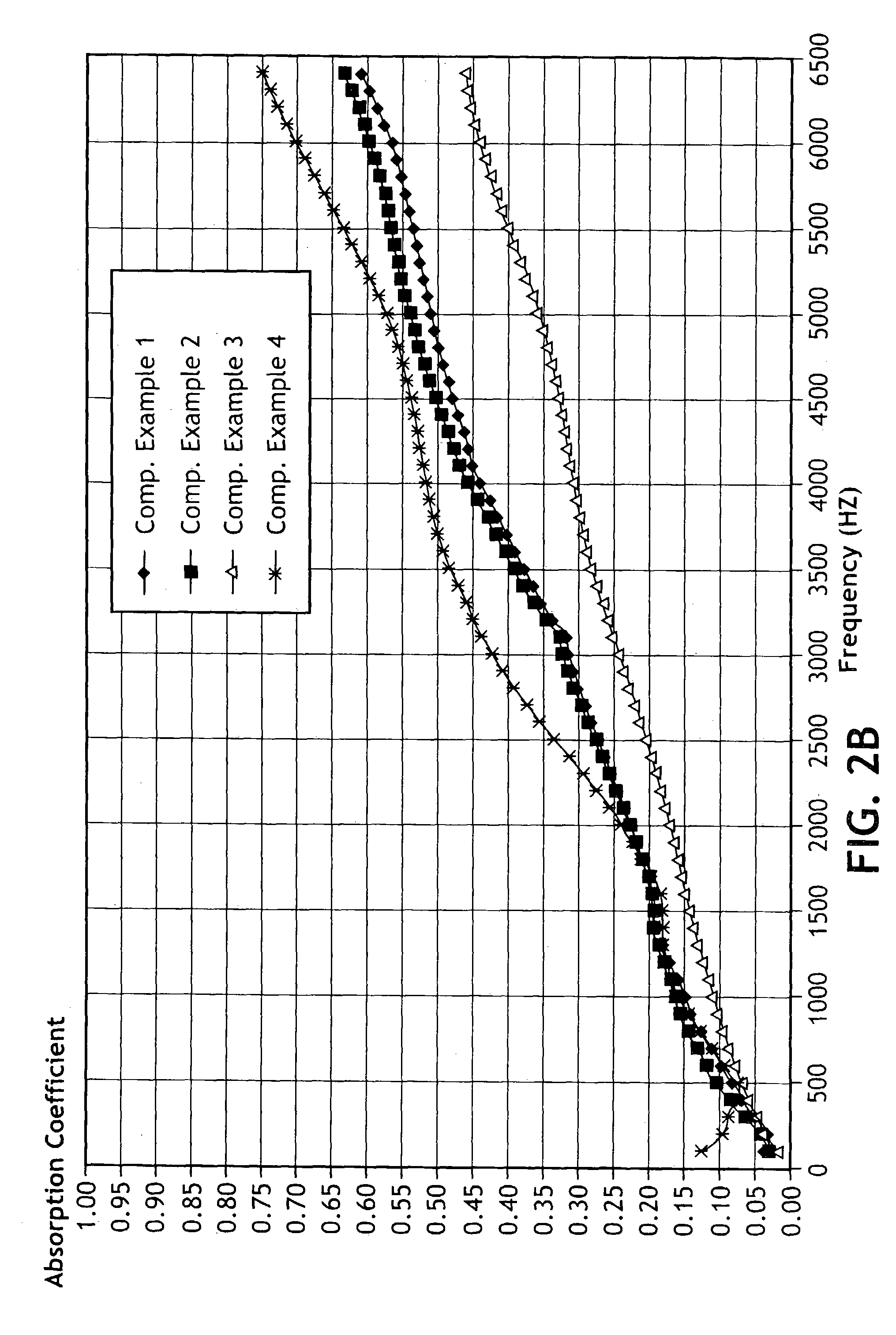

Nonwoven containing acoustical insulation laminate

The present invention relates to an acoustical insulation material containing a first layer formed from a nonwoven web having a density of at least 50 kg / m3 wherein the nonwoven web is formed from thermoplastic [meltblown] fibers having an average fiber diameter of less than about 7 microns; and a second layer of a high loft material. The high loft material of the present invention provides bulk to the first layer and may or may not have sound attenuating properties. Examples of the high loft material include, for example, fiberglass and high loft nonwoven webs. Also disclosed in a method of attenuating sound waves passing from a sound source area to a second area. The method includes positioning an acoustical insulation material containing a first layer formed from a nonwoven web having a density of at least 50 kg / m3 wherein the nonwoven web is formed from thermoplastic [meltblown] fibers having an average fiber diameter of less than about 7 microns; and a second layer of a high loft material, between the sound source area and the second area.

Owner:KIMBERLY-CLARK WORLDWIDE INC

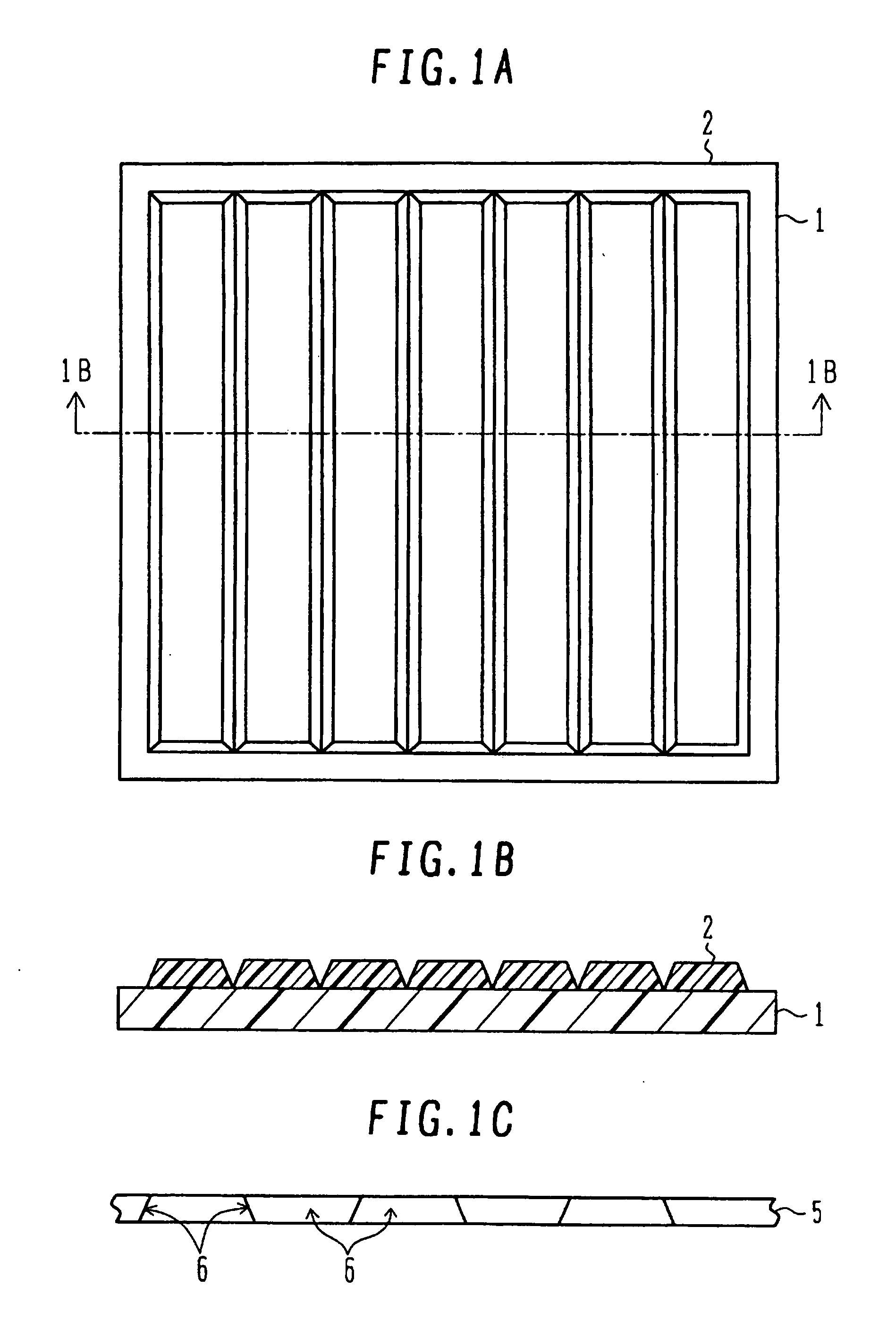

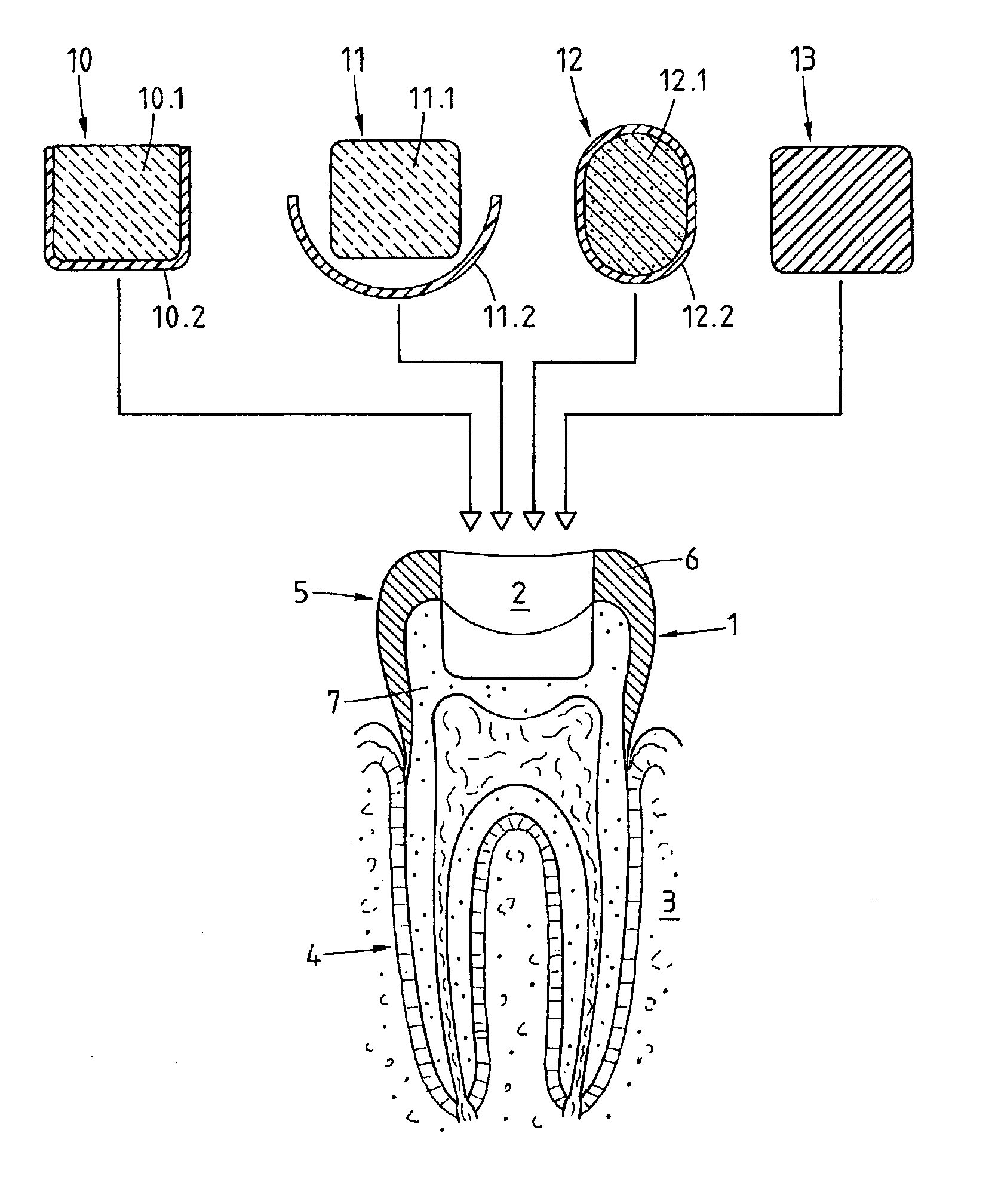

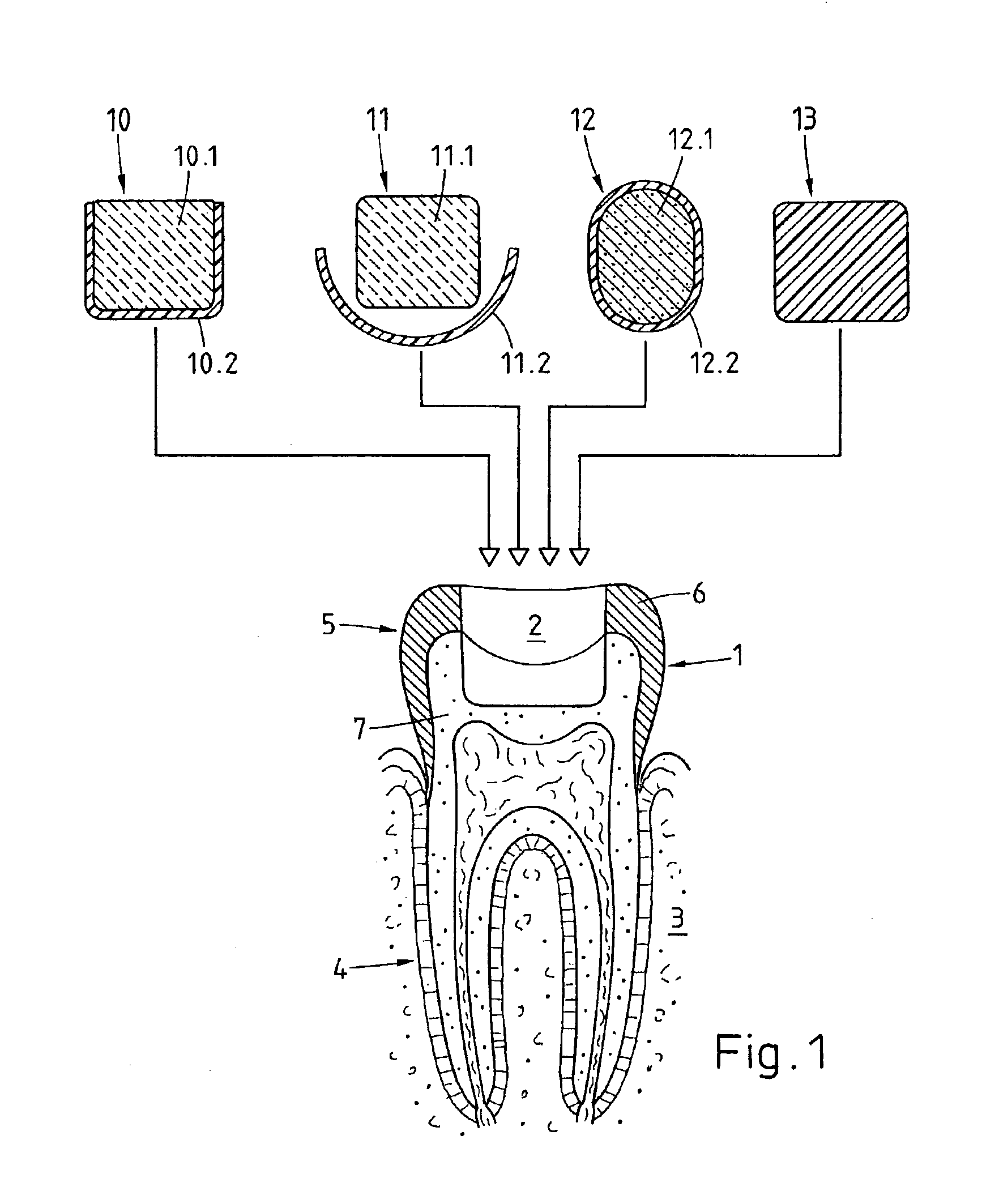

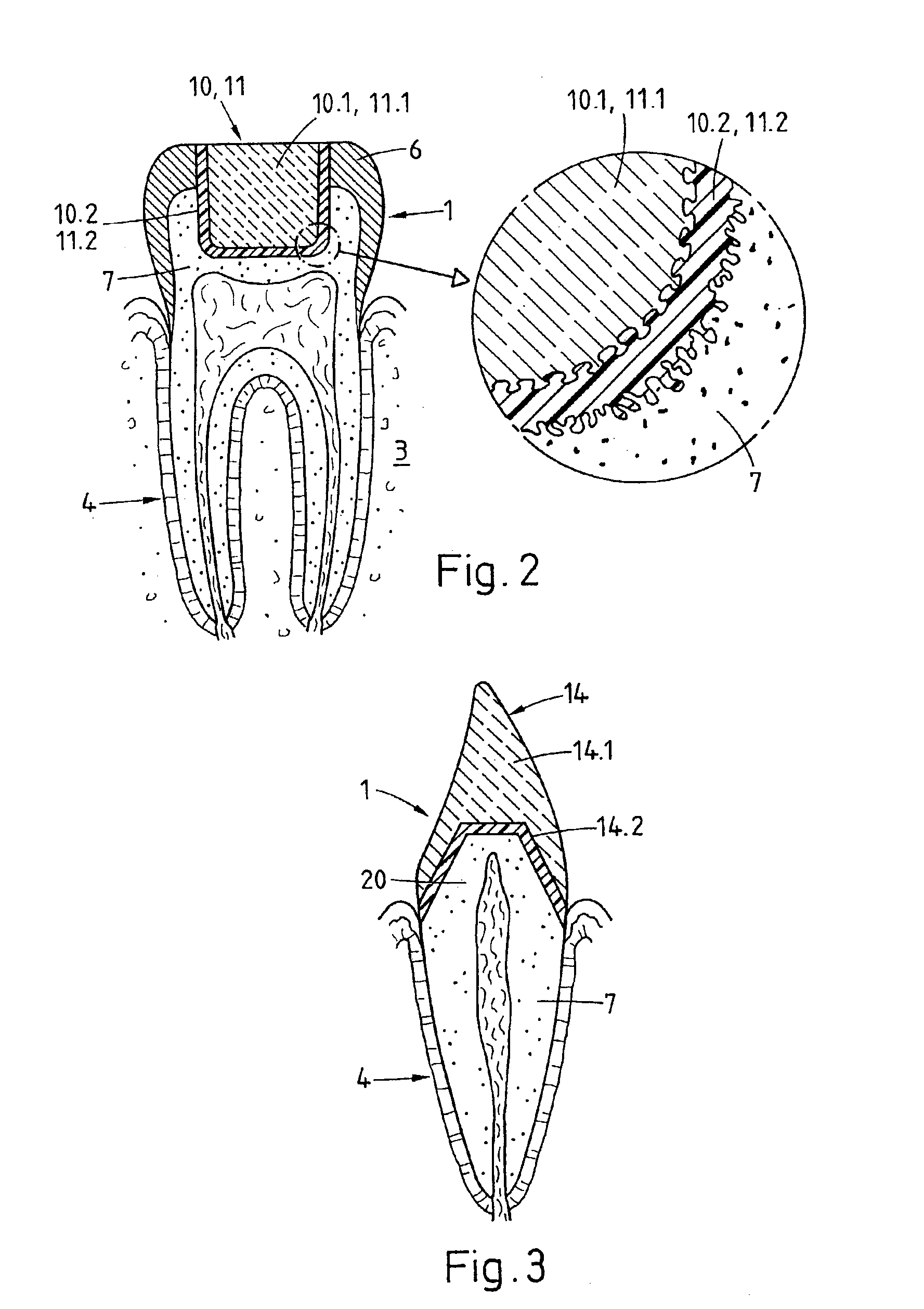

Preparation for being fastened on a natural tooth part or tooth and corresponding fastening method

ActiveUS6955540B2Reduce Shrinkage ProblemsRelieve stressDental implantsImpression capsStress concentrationNatural tooth

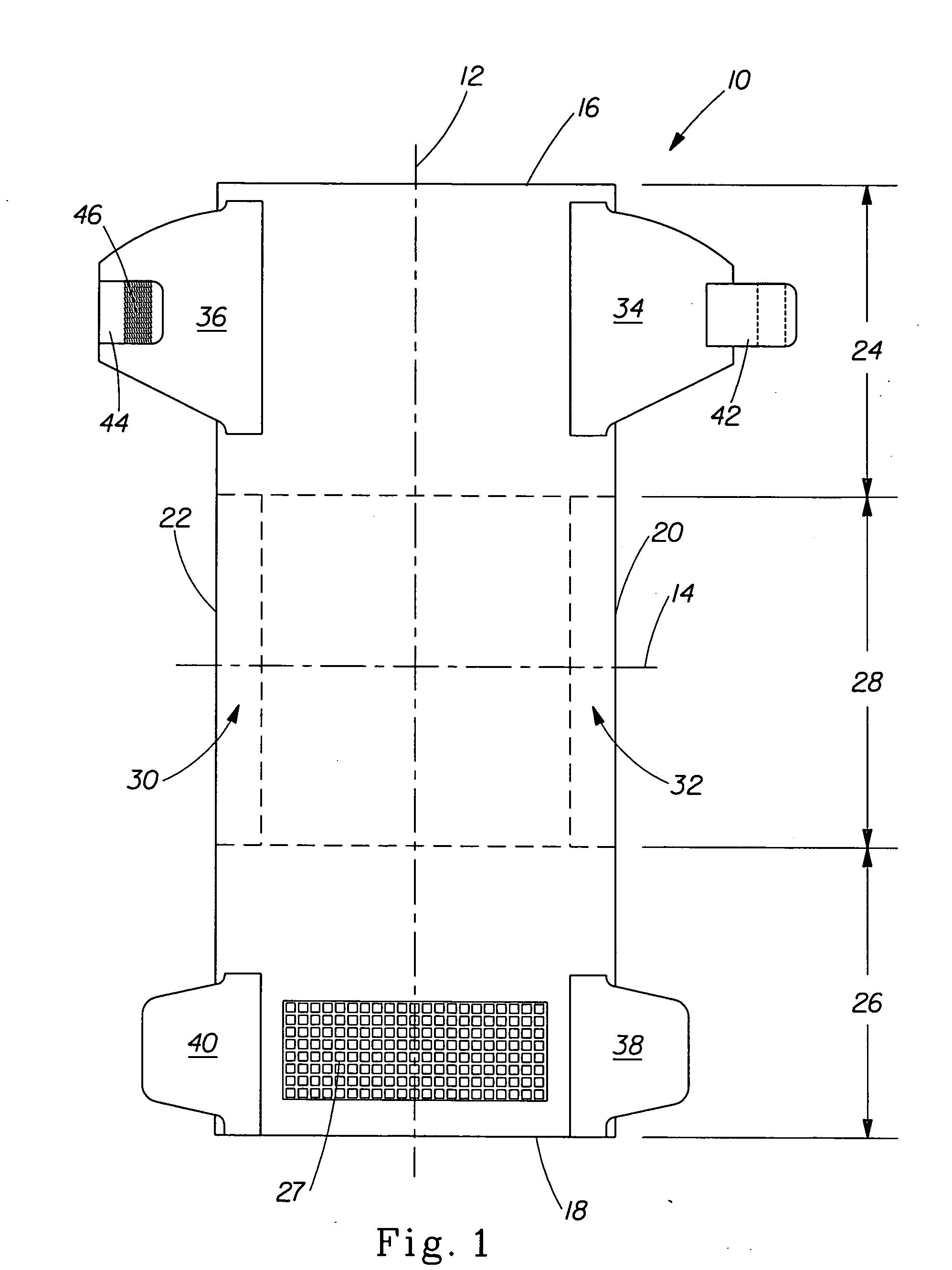

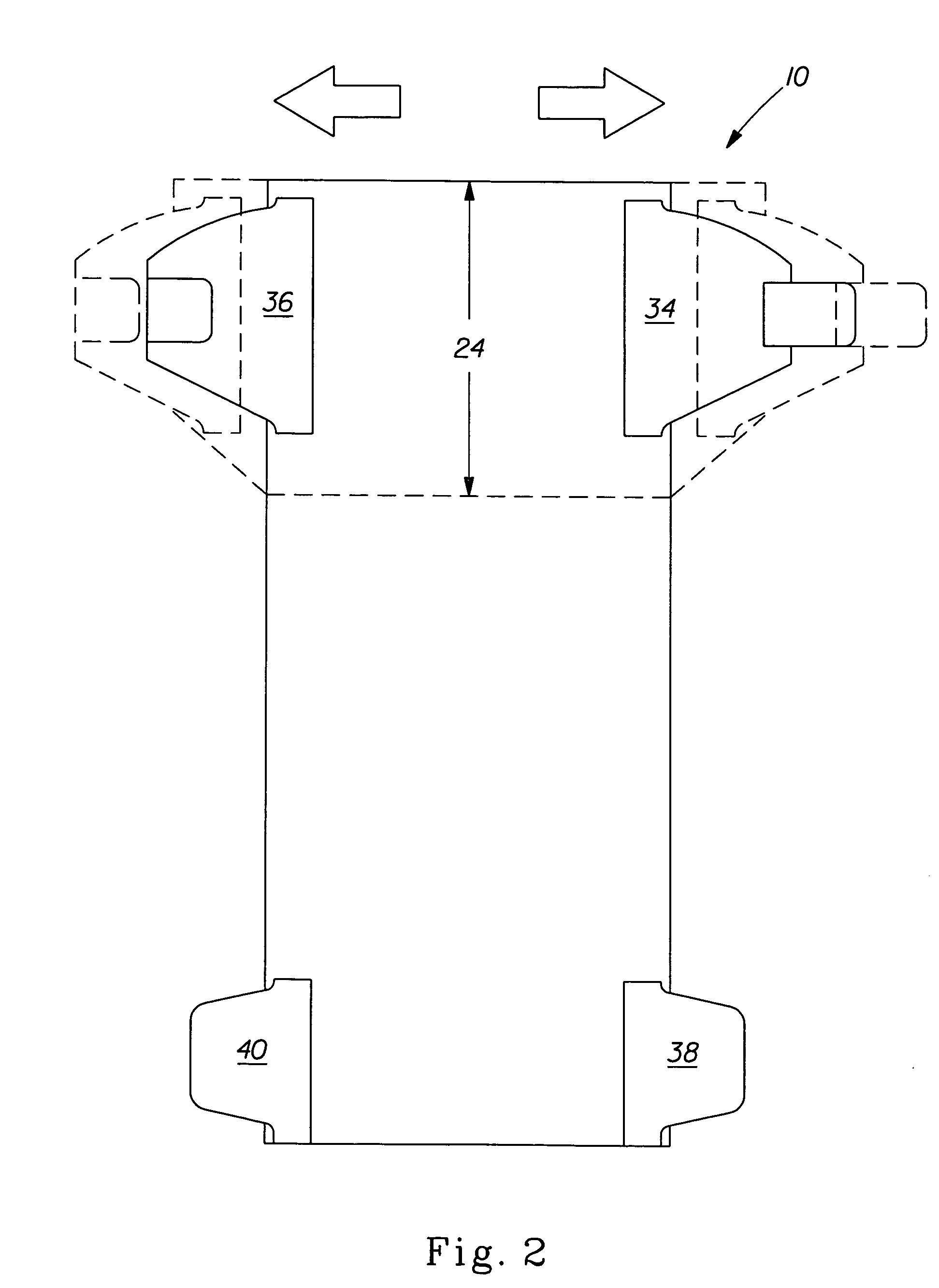

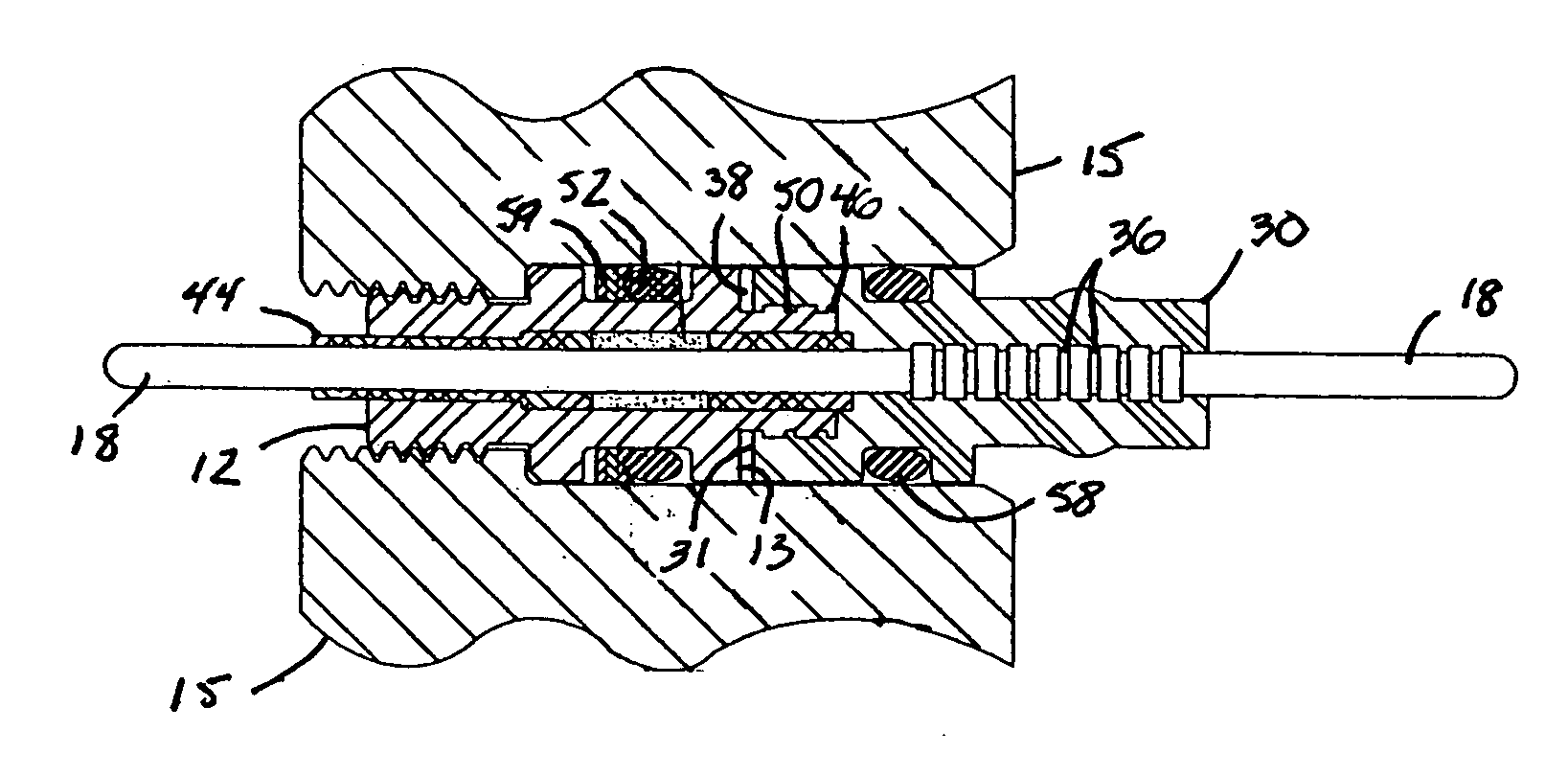

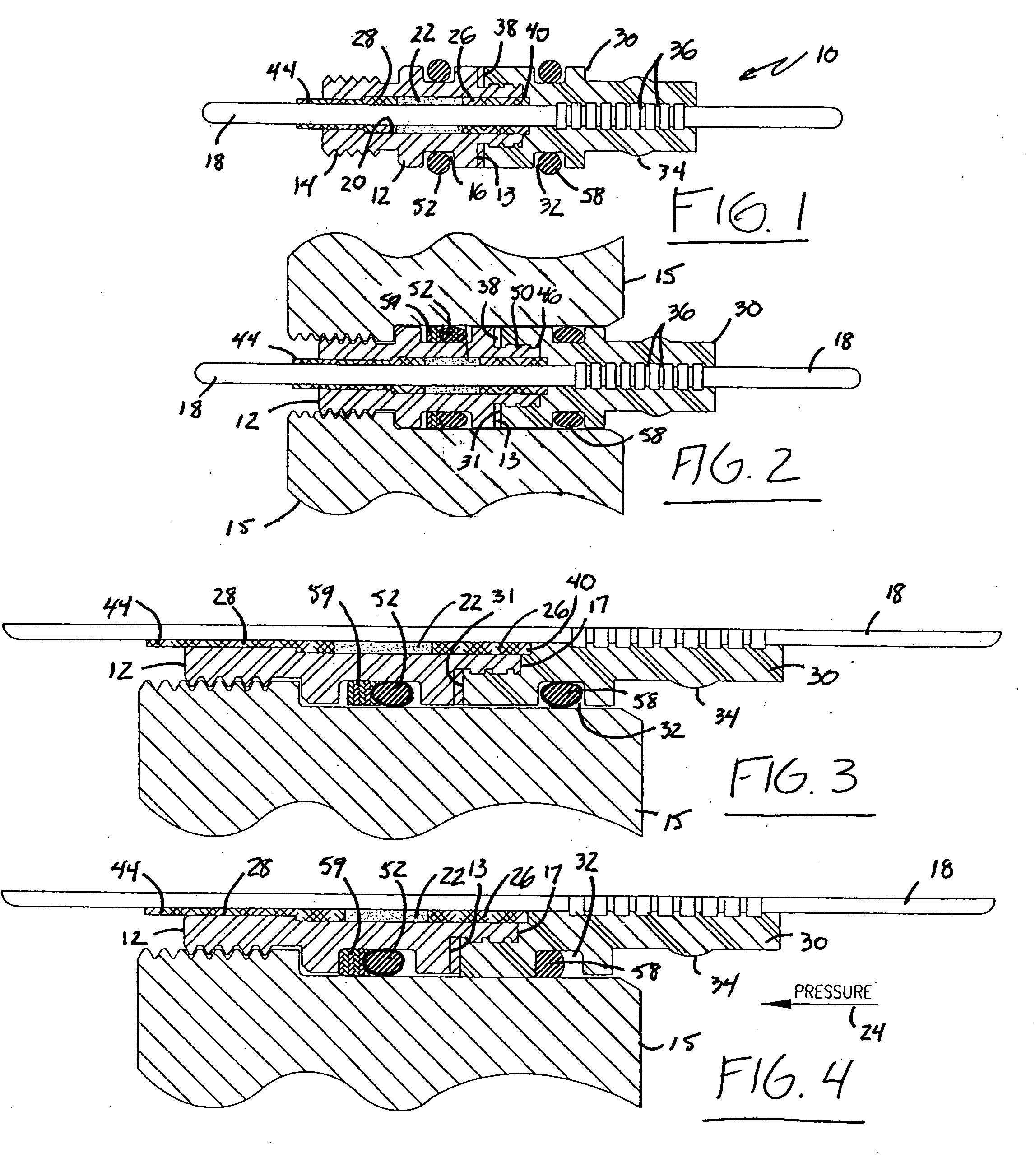

A preparation (10, 11,12,13) to be fixed to a natural tooth part or tooth, in particular for the replacement of a load-bearing tooth part, is for example a filling for a drilled-out tooth (1), a crown, bridge or prosthesis to be placed on a tooth stub, or a tooth pin to be fixed in a tooth root for fastening an artificial tooth, a bridge or a prosthesis. The preparation has surface regions which consist of a material with thermoplastic properties. The preparation (10, 11, 12,13) is designed in a manner such that it has oscillation properties with such low damping losses that for a liquefaction of the material with thermoplastic properties by way of oscillations there are local stress concentrations required, and in a manner such that such stress concentrations only occur in the region of the preparation surface. The preparation is positioned on a suitably prepared natural tooth part in a manner such that the material with the thermoplastic properties is in contact or may be brought into contact with the dentin surface and / or enamel surface. The preparation is then made to mechanically oscillate and is simultaneously pressed against the natural tooth part, whereby the material with the thermoplastic properties is at least partly liquefied and brought into intimate contact with the dentin or enamel surface in a manner such that after solidification it forms a positive fit and / or material fit connection. Teeth restored with such preparations have a high stability and a long life, which in particular is attributed to the fact that the thermoplastic material, in contrast to cements used for the same purpose, shrinks less and has the ability to relieve internal stress by creeping.

Owner:WOODWELDING

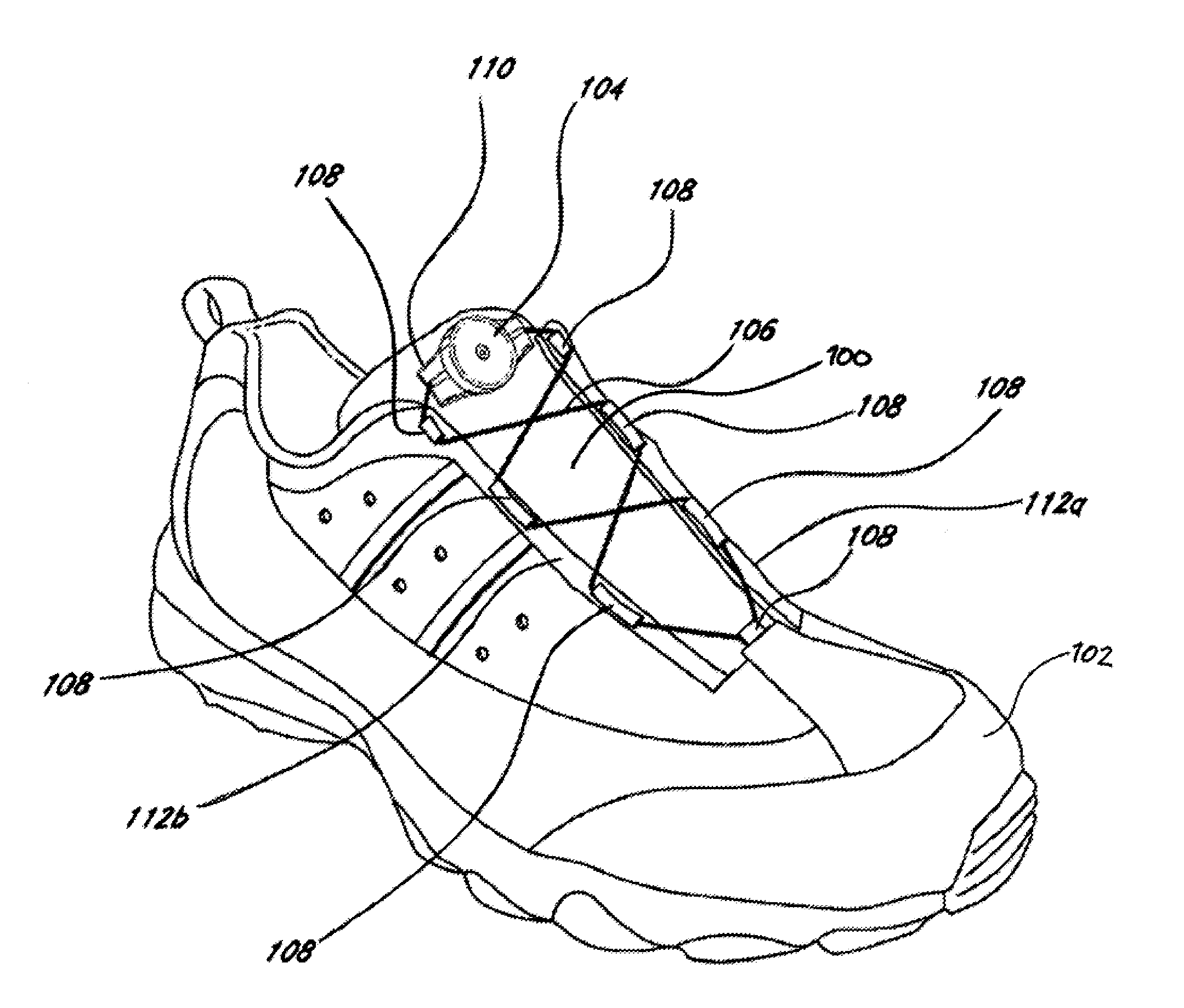

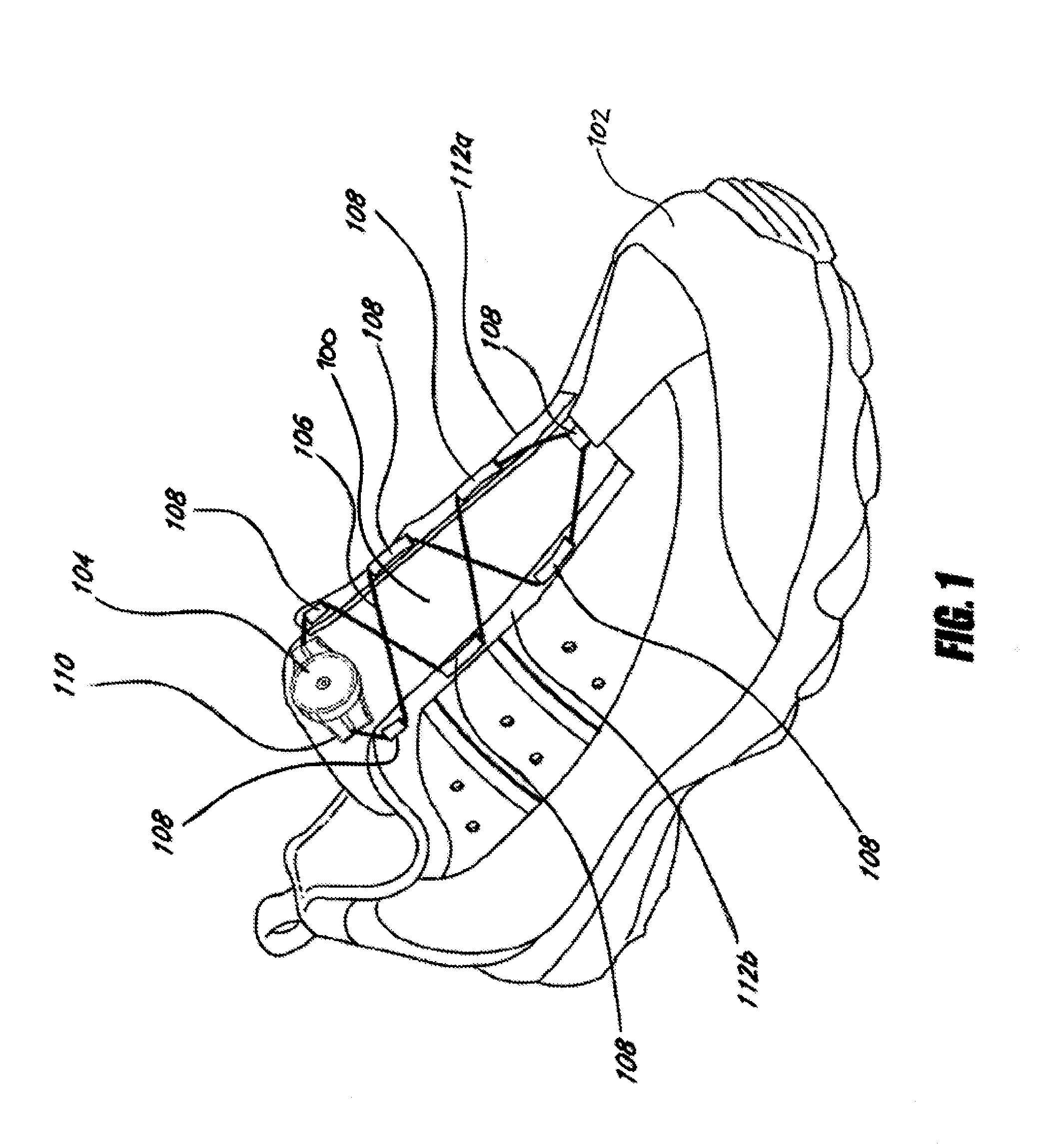

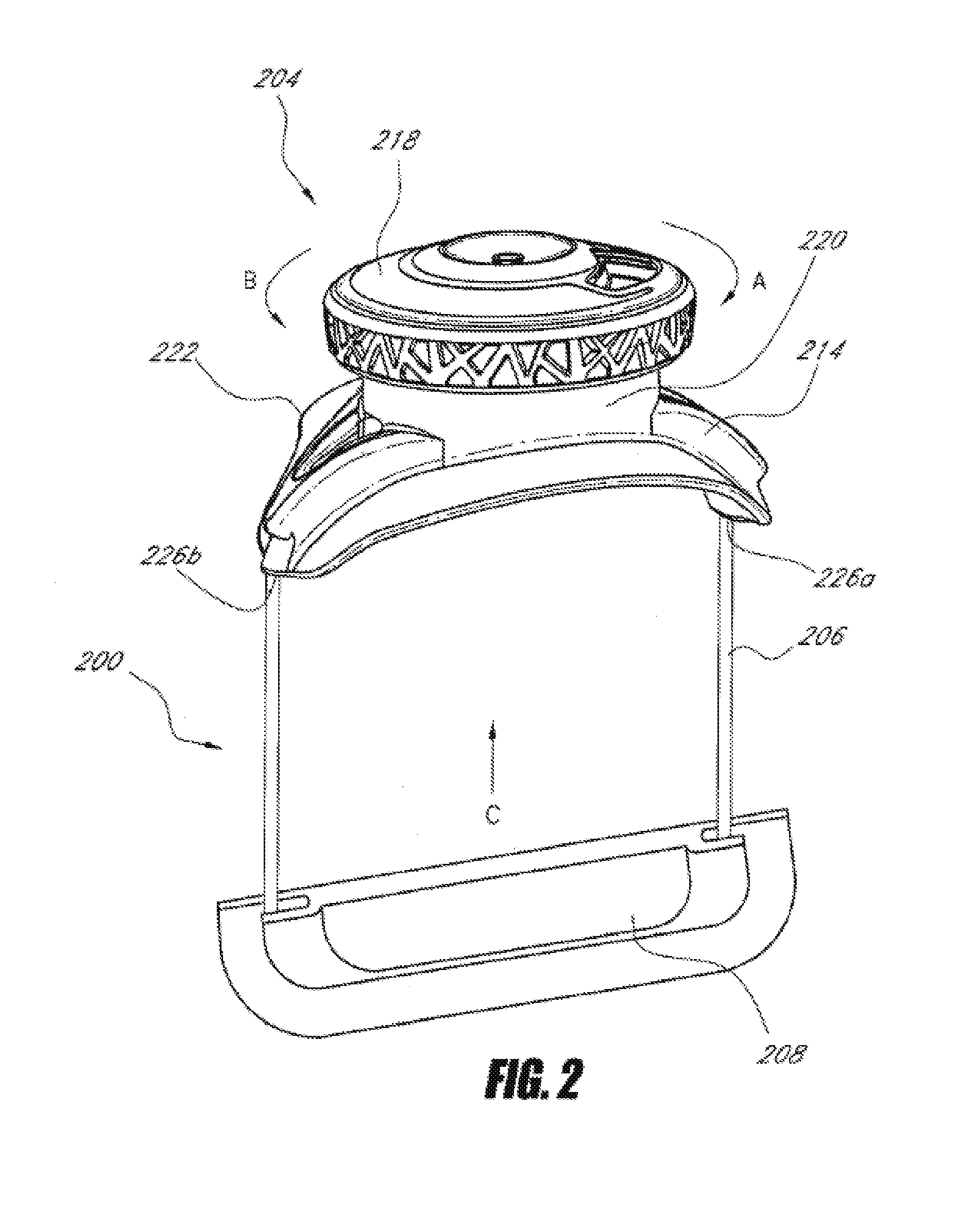

Guides and components for closure systems and methods therefor

ActiveUS20150059206A1Easily and conveniently coupledTighten shoeEyeletsLacing hooksThermoplastic elastomerEngineering

According to an embodiment, a component for attachment to an article includes an upper component that is made of a thermoplastic material having a first melting temperature and a flange member that is molded onto the upper component and made of a thermoplastic elastomer material having a second melting temperature that is lower than the first melting temperature of the upper component. The flange member extends laterally from a bottom end of the upper component so that a bottom surface of the flange member is flush with or positioned axially below a bottom surface of the upper component. The melting temperature of the thermoplastic elastomer material enables the flange member to be directly coupled to the article via heat welding and the like without substantially affecting the upper component.

Owner:BOA TECHNOLOGY

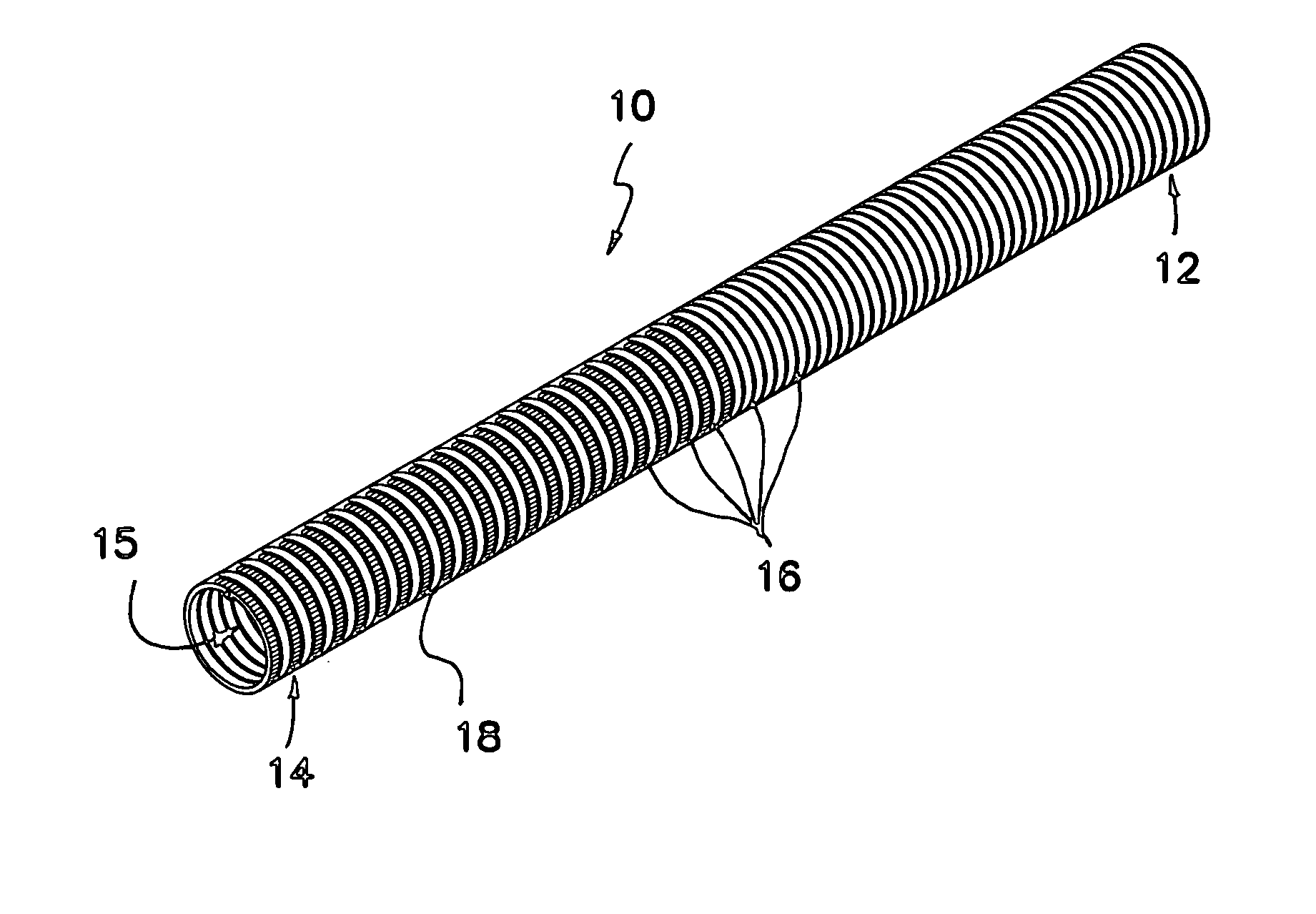

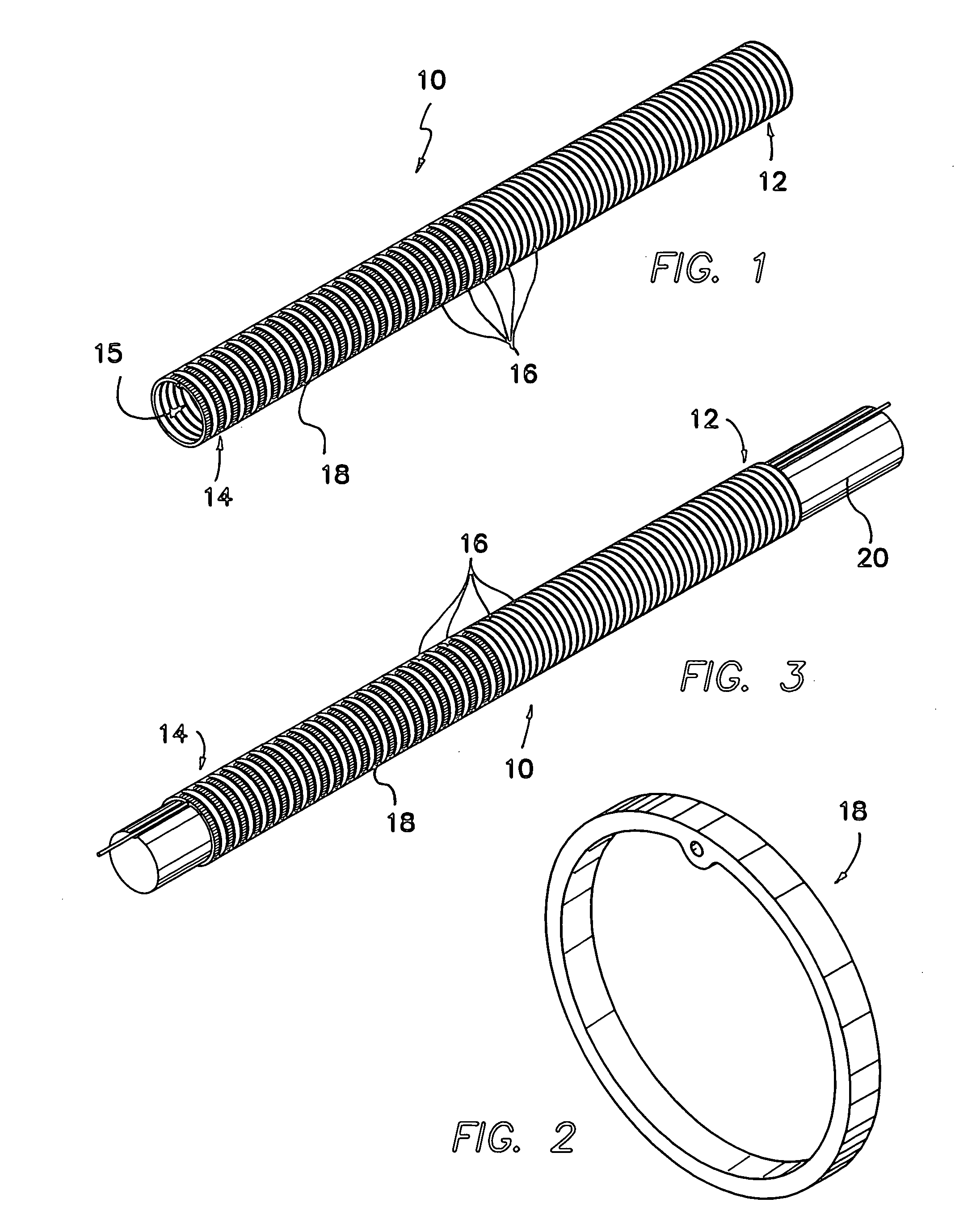

Medical tubing having variable characteristics and method of making same

The invention primarily is directed to a medical tubing adapted for insertion into a body tissue or cavity and method of manufacturing different variations of the tubing along a length of the tubing. The tubing comprises a plurality of individual, discrete, generally ring-shaped elements arranged in series and fused or bonded together forming a continuous tubular structure. The ring-shaped elements may be formed of a thermoplastic or a thermoset material. The ring-shaped elements may include plastic rings, metallic rings, un-reinforced plastic rings and / or metal reinforced plastic rings assembled along the length of the tubular structure to provide variable flexibility and kink-resistance. The tubular structure may have a cross-section of any geometric shape and it may be bent, twisted or curved without kinking. The ring-shaped elements may have different flexural modulus. The ring-shaped elements may include a combination of flexible and rigid ring-shaped elements assembled along different portions or sections of the tubular structure. The ring-shaped elements may be metallic and may be bonded with a resilient, flexible elastomeric adhesive, wherein the ring-shaped elements may have different lengths and may be fused closer or further apart to one another depending on the characteristics of a portion or section of the tubing. In another aspect of the invention, the medical tubing may further comprise a secondary lumen and a pull wire to control the tubular structure. The ring-shaped elements may be truncated to provide a bending bias. In another aspect of the invention, the ring-shaped elements may vary in diameter and / or composition in different portions or sections of the tubular structure. In yet another aspect of the invention, some of the ring-shaped elements may be radiopaque, or the ring-shaped elements may comprise of different colors to operate as indicators along the tubular structure.

Owner:APPL MEDICAL RESOURCES CORP

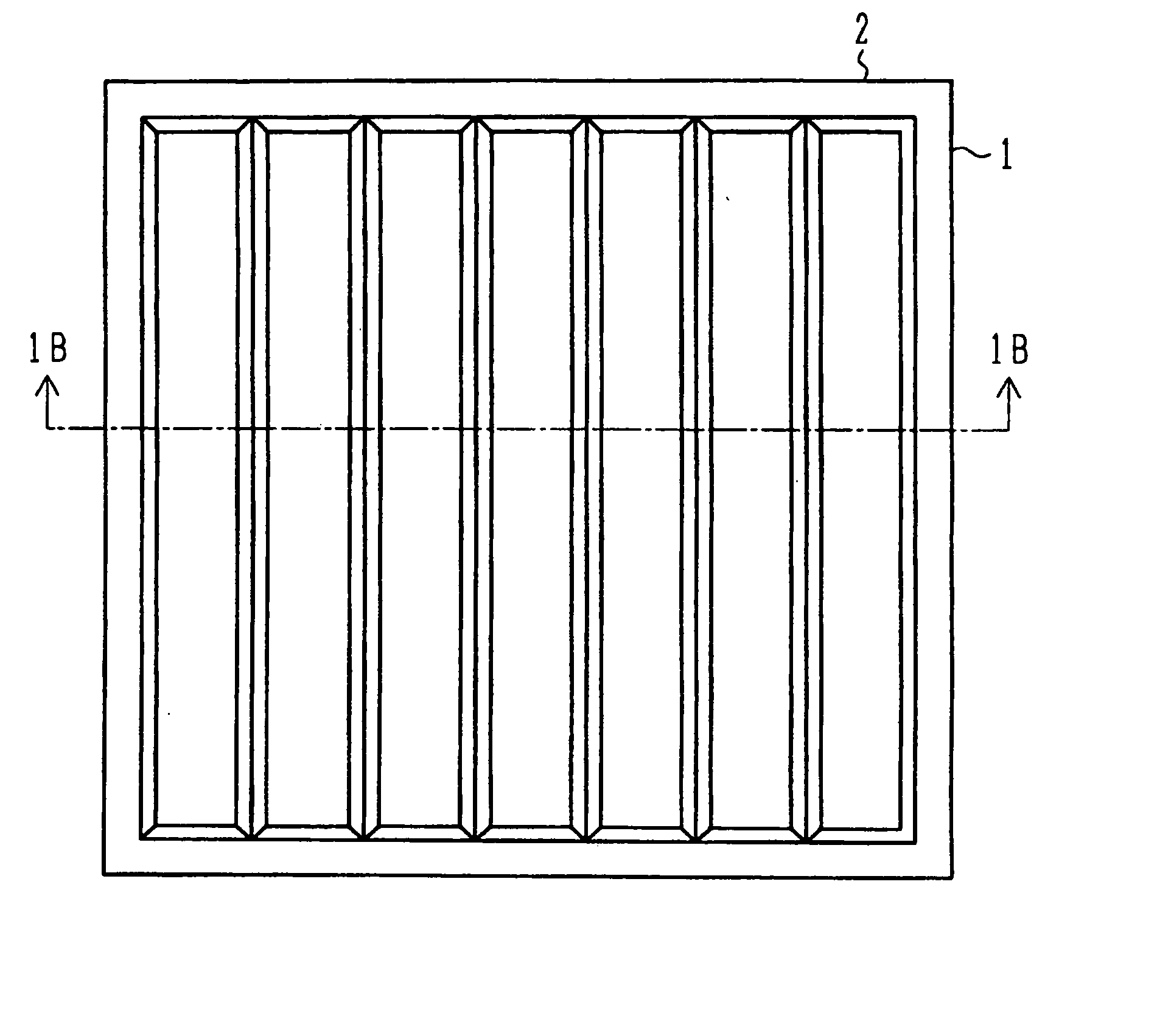

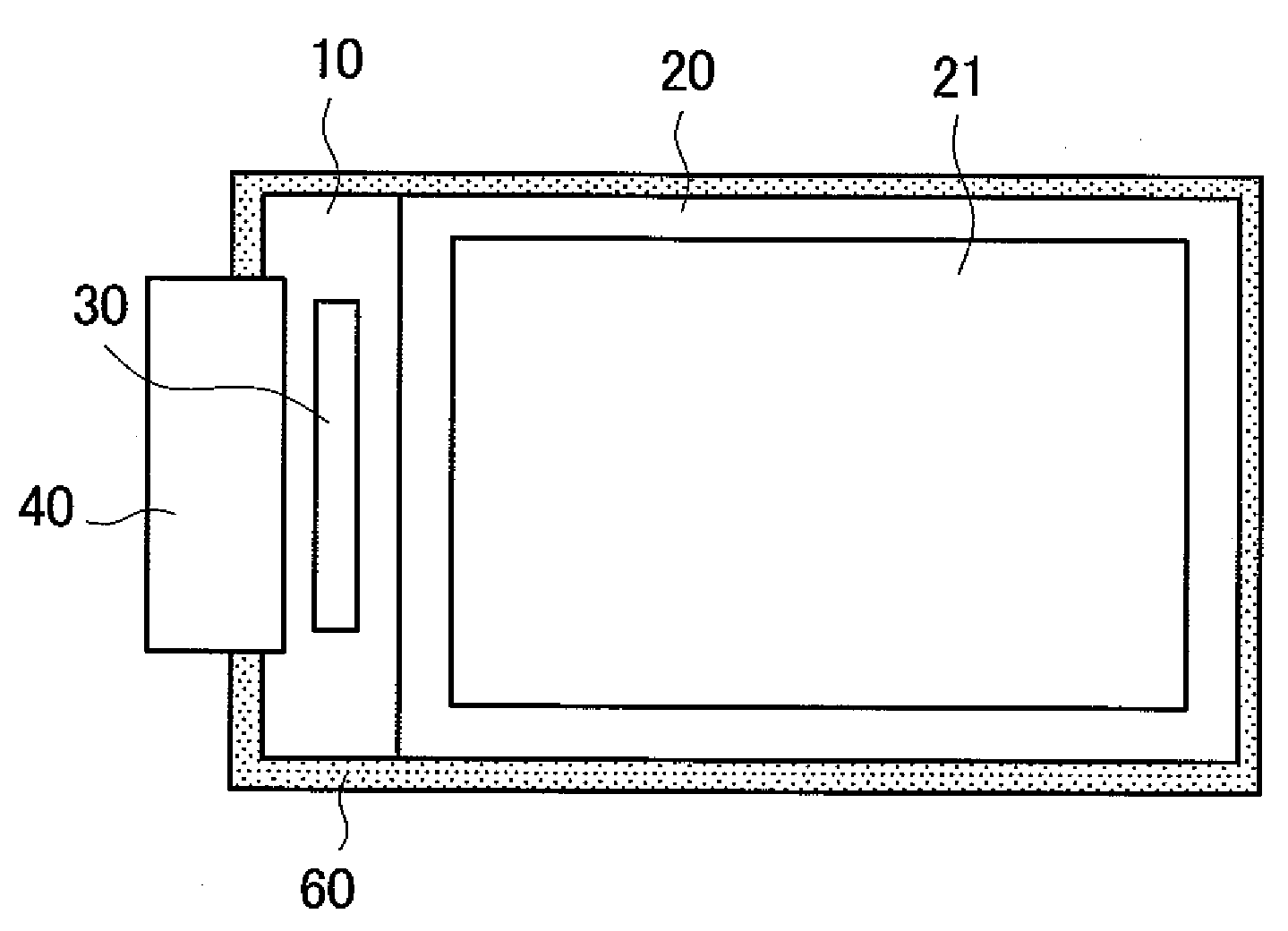

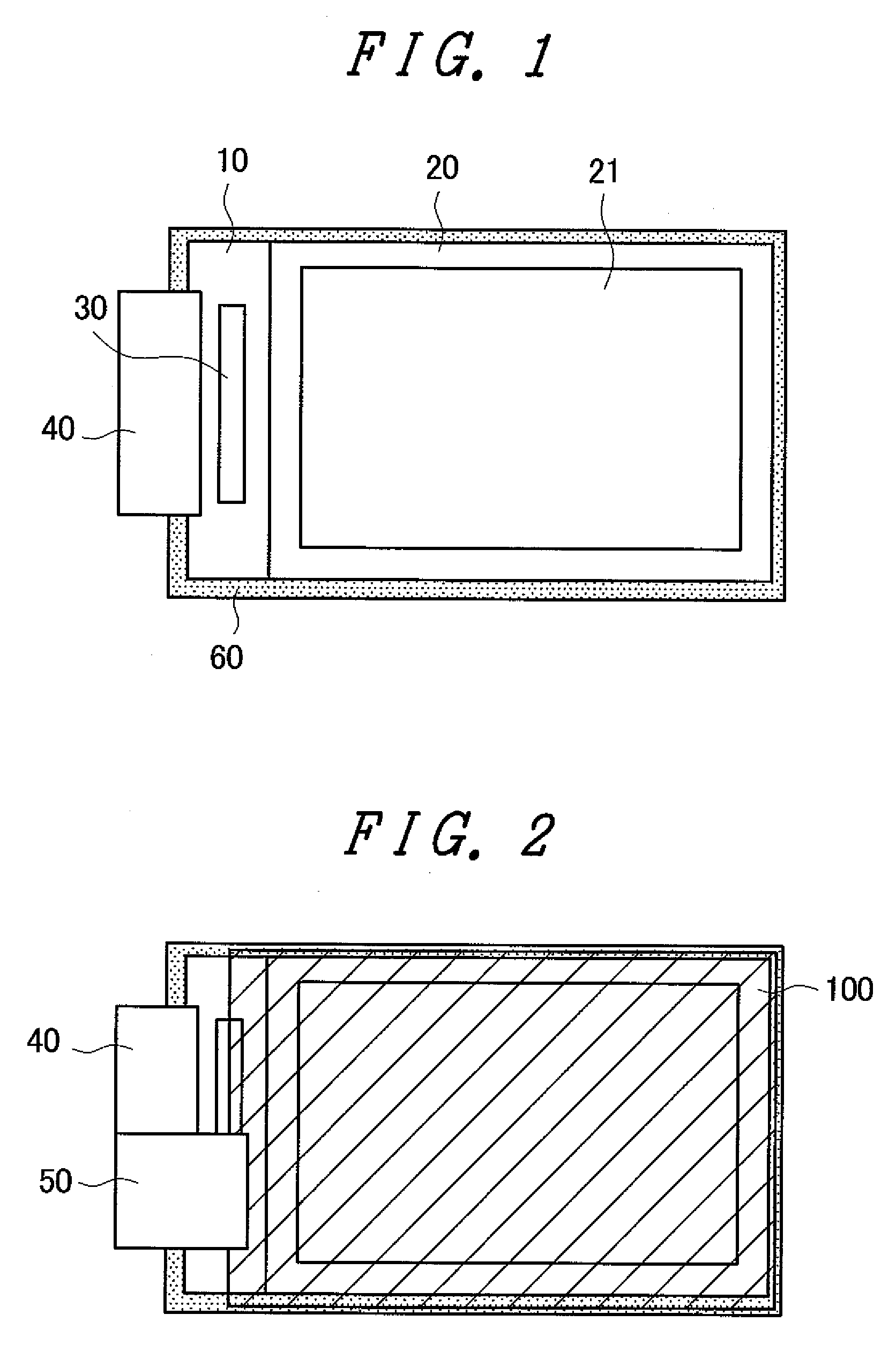

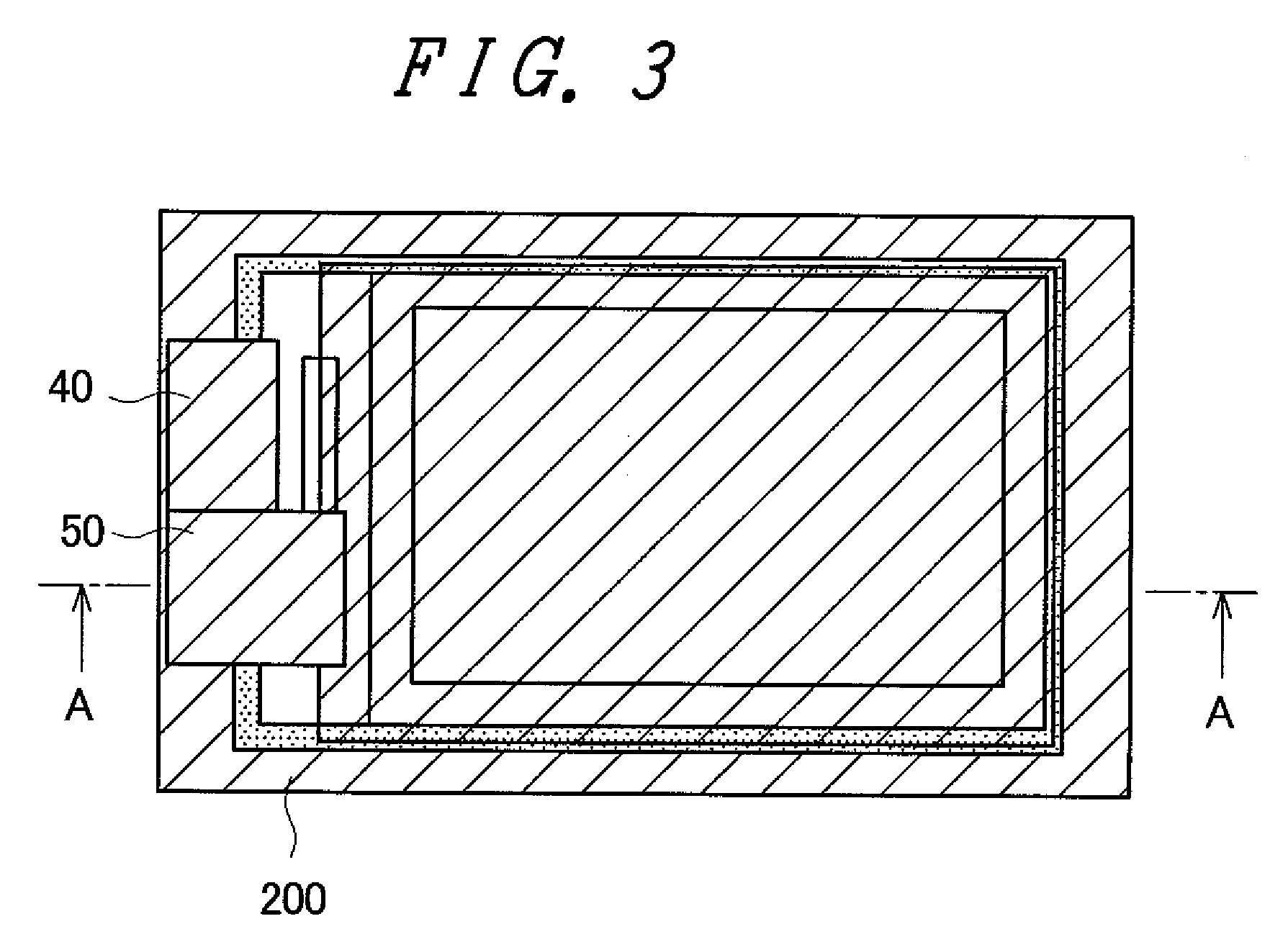

Liquid crystal display device

ActiveUS20100060601A1Small sizeReduce thicknessStatic indicating devicesPrinted circuit aspectsLiquid-crystal displayLight guide

A liquid crystal display device having a touch panel and a front window which can enhance reliability thereof and facilitates repair thereof is provided. The touch panel and the front window are mounted on a liquid crystal display device using a thermoplastic adhesive material. Electronic parts are arranged on a lower side of a touch-panel-use flexible printed circuit board, and electronic parts are arranged on a lower side of a main flexible printed circuit board. The respective electronic parts are covered with the front window in a plan view. A light emitting diode is mounted on the main flexible printed circuit board, and faces a light guide plate in a resin mold. Due to such a constitution, an external shape of the liquid crystal display device can be made small as a whole, and relatively expensive light emitting diodes can be reproduced and reused by repair.

Owner:JAPAN DISPLAY INC +1

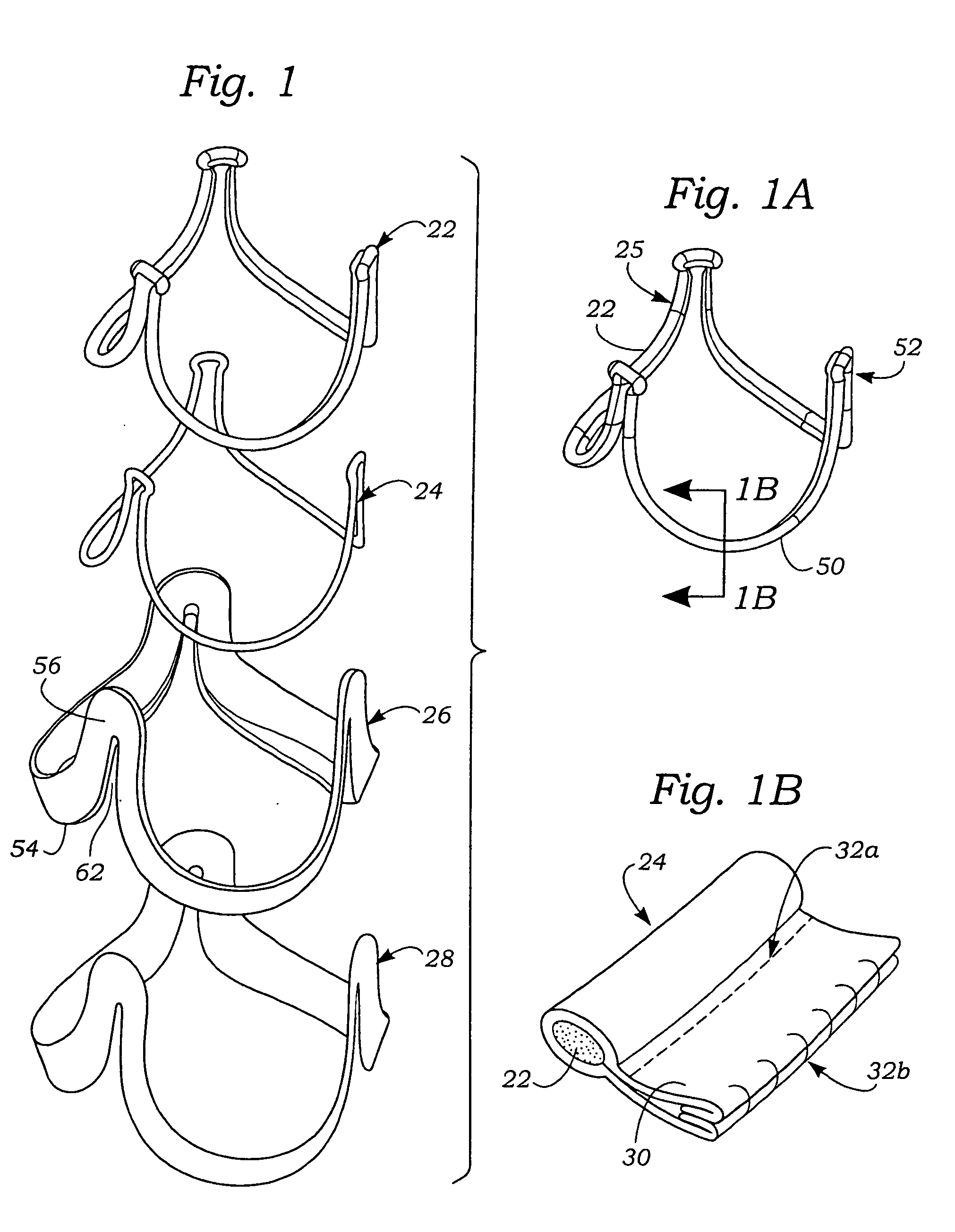

Combination self-expandable, balloon-expandable endoluminal device

An endoluminal device, such as a stent or a vena cava filter, comprising at least one superelastic section and at least one plastically deformable section. The superelastic section may comprise, for example, a superelastic grade of nitinol, whereas the plastically deformable section may comprise, for example, gold, platinum, tantalum, titanium, stainless steel, tungsten, a nickel alloy, a cobalt ally, a titanium alloy, or a combination thereof. Each plastically deformable section may merely comprise a constrained portion of the superelastic section comprising a plastically deformable material, such as gold. The device enables deployment by a method comprising introducing the device into a body lumen with the device radially constrained in a first configuration having a first diameter; allowing the device to self-expand into a second configuration having a second diameter less than or equal to a fully-self-expanded diameter; and then optionally “fine-tuning” the device by forcibly expanding the device into a third configuration having a third diameter in a range between the second diameter and less than or equal to a fully-forcibly-expanded diameter. The superelastic and plastically deformable sections may be tubular sections placed end-to-end, such that the plastically deformable section can be conformed to fit a tapered section of a lumen.

Owner:BOSTON SCI SCIMED INC

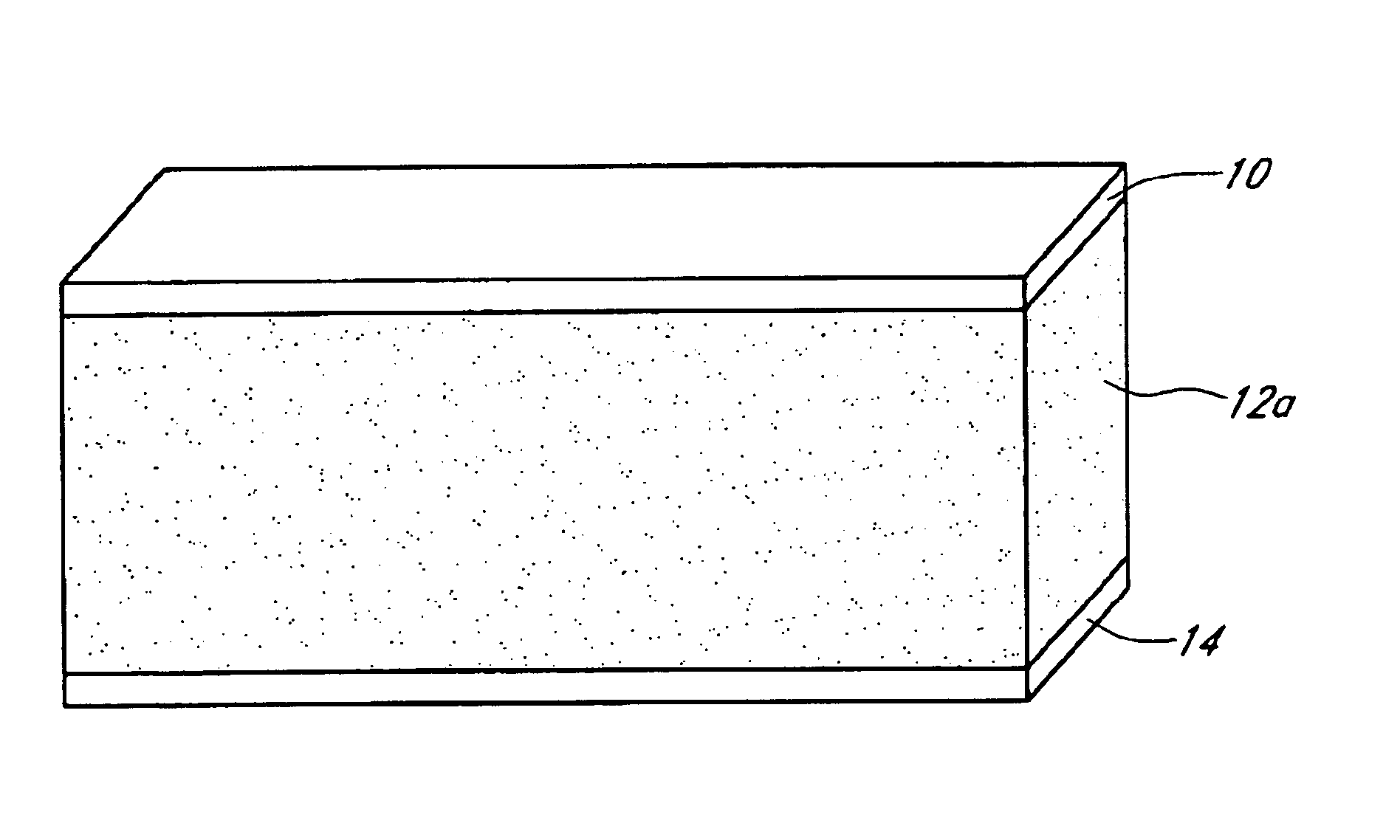

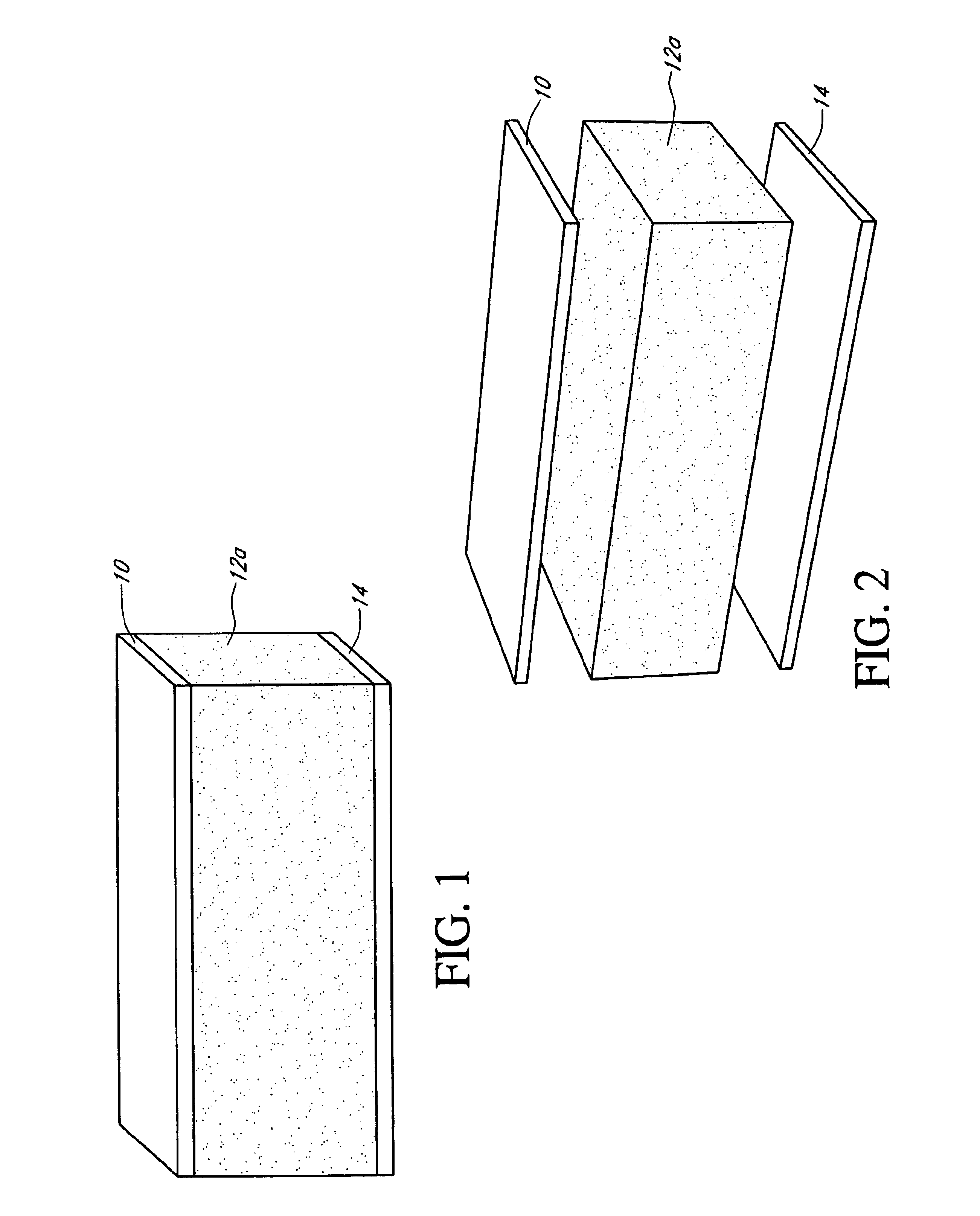

Low-density, open-cell, soft, flexible, thermoplastic, absorbent foam and method of making foam

A soft, flexible, low-density, open-cell, thermoplastic, absorbent foam formed from a foam polymer formula including a balanced amount of a plasticizing agent and a surfactant in combination with a base resin. Thermoplastic elastomers can be added to the foam polymer formula to improve softness, flexibility, elasticity, and resiliency of the resulting foam. The surfactant may be either a single surfactant or a multi-surfactant system. The foam possesses a number of qualities, such as softness and strength, which render the foam particularly suitable for use in a variety of personal care products, medical products, and the like.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Solid golf ball

InactiveUS20080194357A1Improve spin performanceIncrease distanceGolf ballsSolid ballsThermoplasticPolymer science

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a thermoplastic or thermoset polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

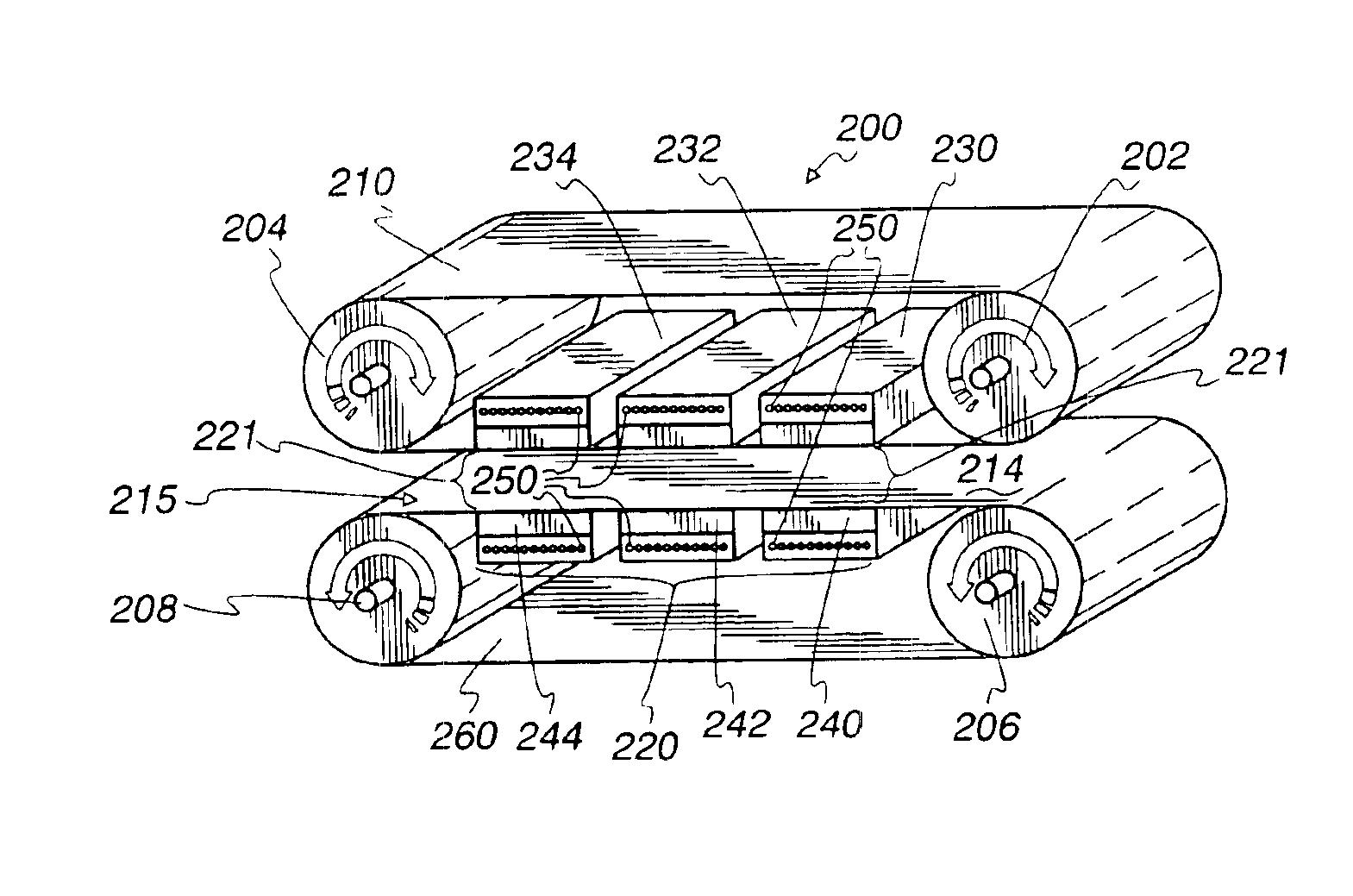

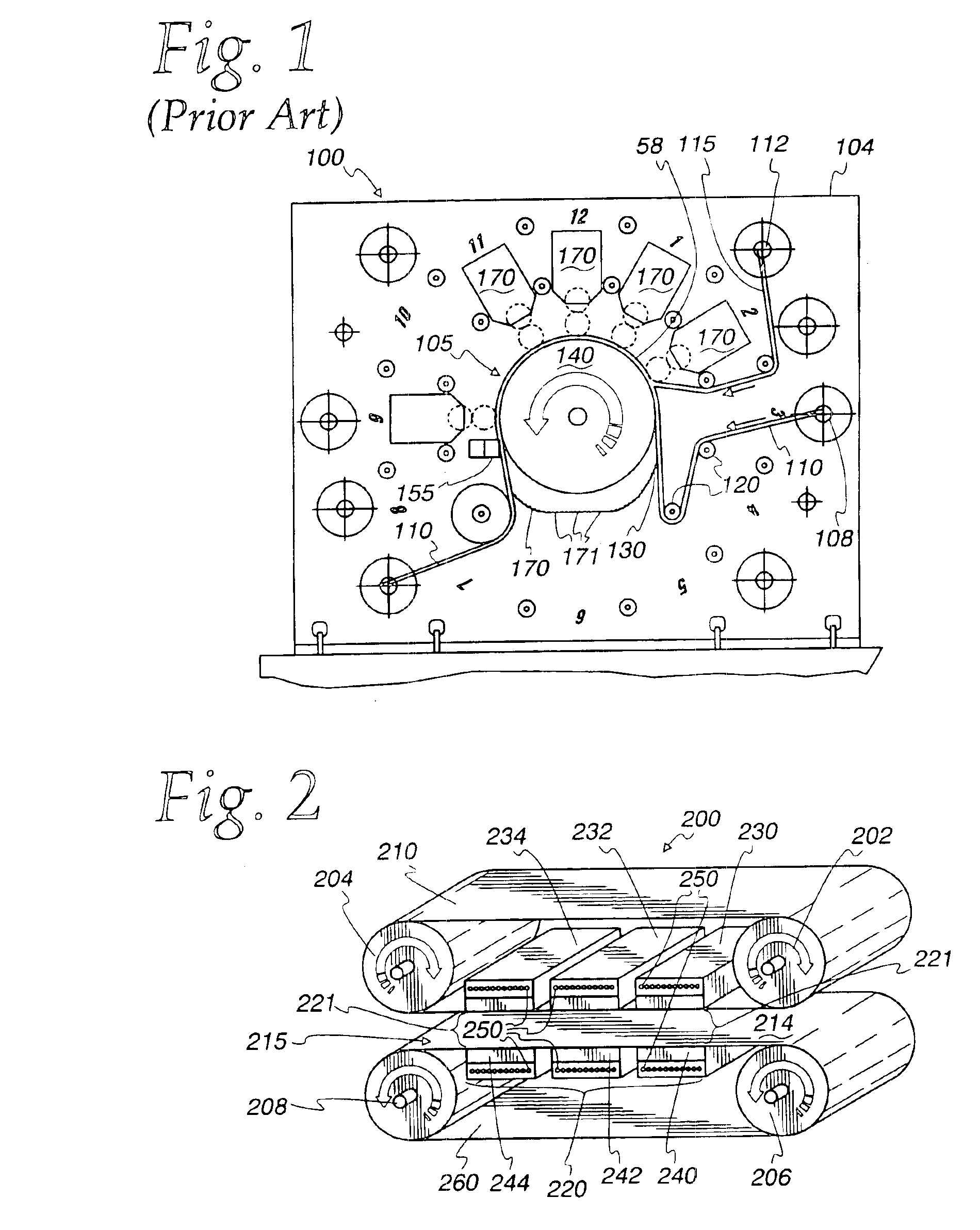

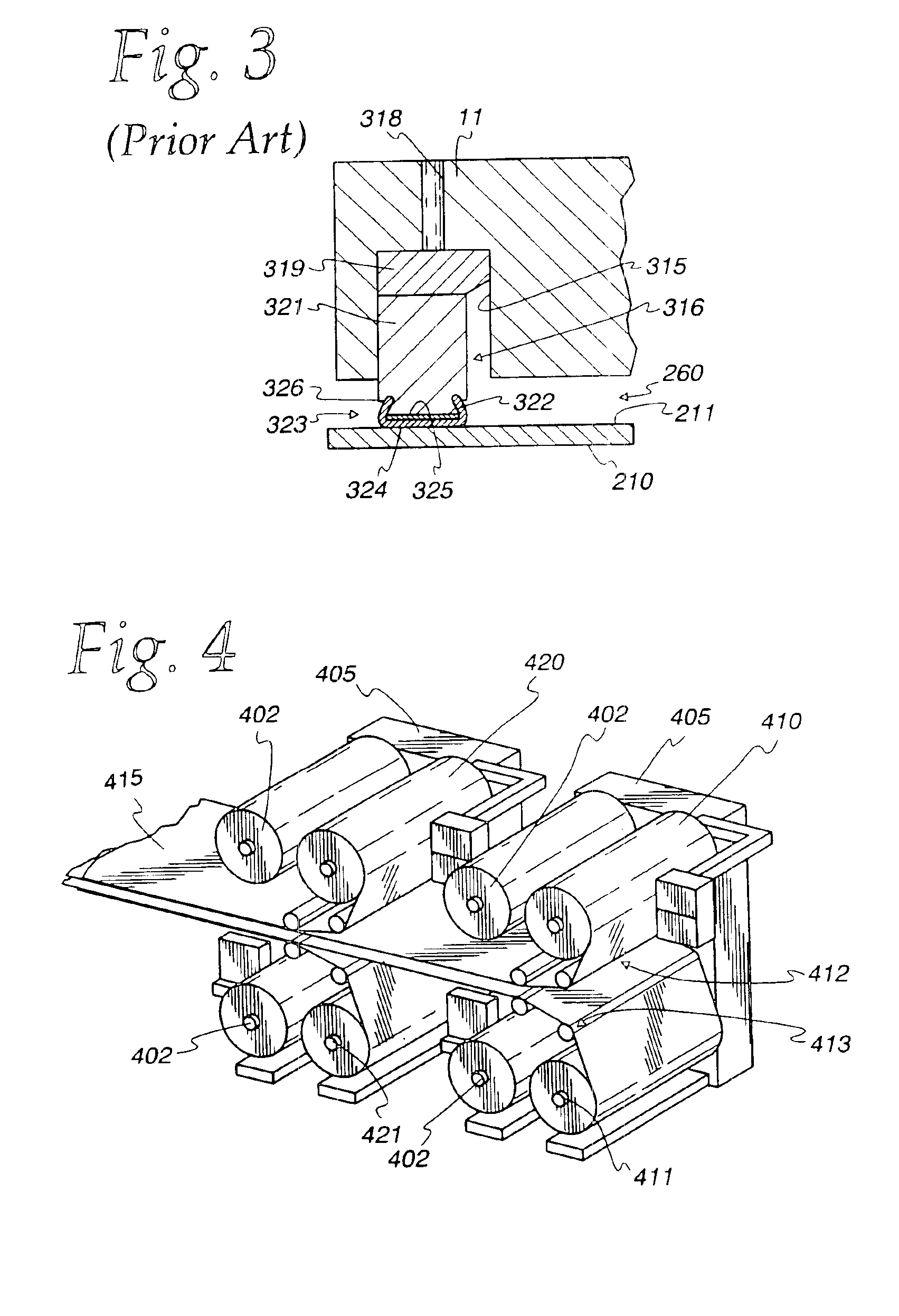

Process and apparatus for embossing precise microstructures and embossing tool for making same

InactiveUS6908295B2Maintain pressureReduce frictionConfectionerySolid-state devicesEngineeringPlastic property

A process and apparatus for embossing thermoplastic products having precise microstructured surfaces including using a continuous press having upper and lower belts with the embossing pattern(s); feeding thermoplastic material through the press where heat and pressure are applied to form the embossed pressure microstructure, and cooling the embossed material, all while maintaining pressure. A continuous embossing tool is provided by welding segments together, the welds including interface material at the weld joint which is of a different material than the segment material to increase the tensile strength.

Owner:AVERY DENNISON CORP

Decorative interior sound absorbing panel

A multi-layered fiber reinforced thermoplastic sound absorbing panel includes a porous fiber reinforced thermoplastic core layer having a first surface and a second surface, and includes a thermoplastic material and from about 20 weight percent to about 80 weight percent fibers, a tie layer covering the second surface of the core layer and including a thermoplastic material, and a barrier layer covering the tie layer. The barrier layer includes a thermoplastic material having a melting temperature higher than the melting temperature of the core layer thermoplastic material. The tie layer bonds the barrier layer to the core layer. The panel also includes a non-woven layer including a fabric bonded to the barrier layer. The non-woven layer forms an outer surface of the panel.

Owner:HANWA AZDEL INC

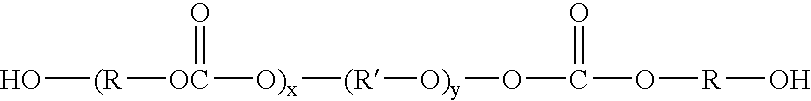

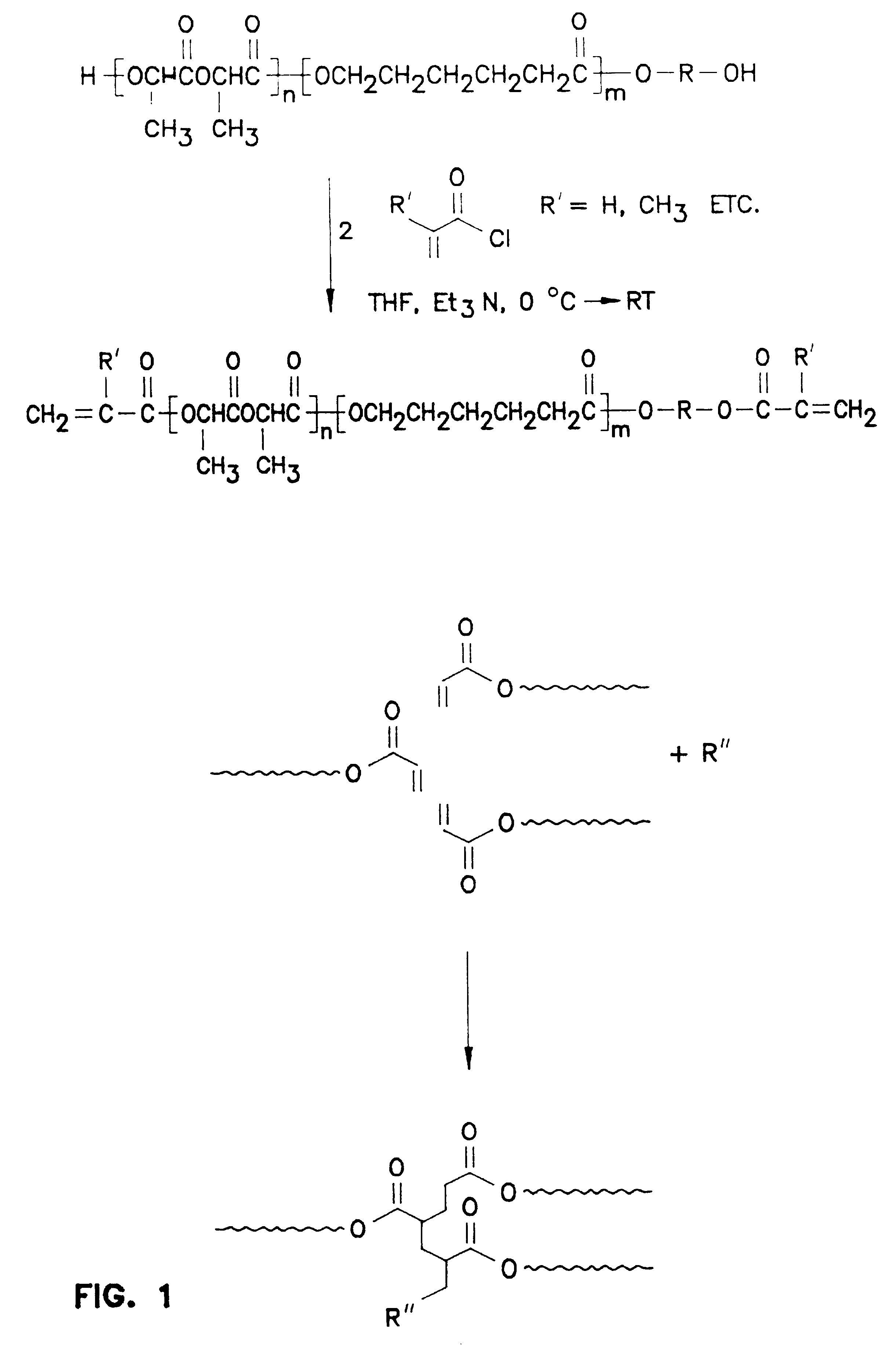

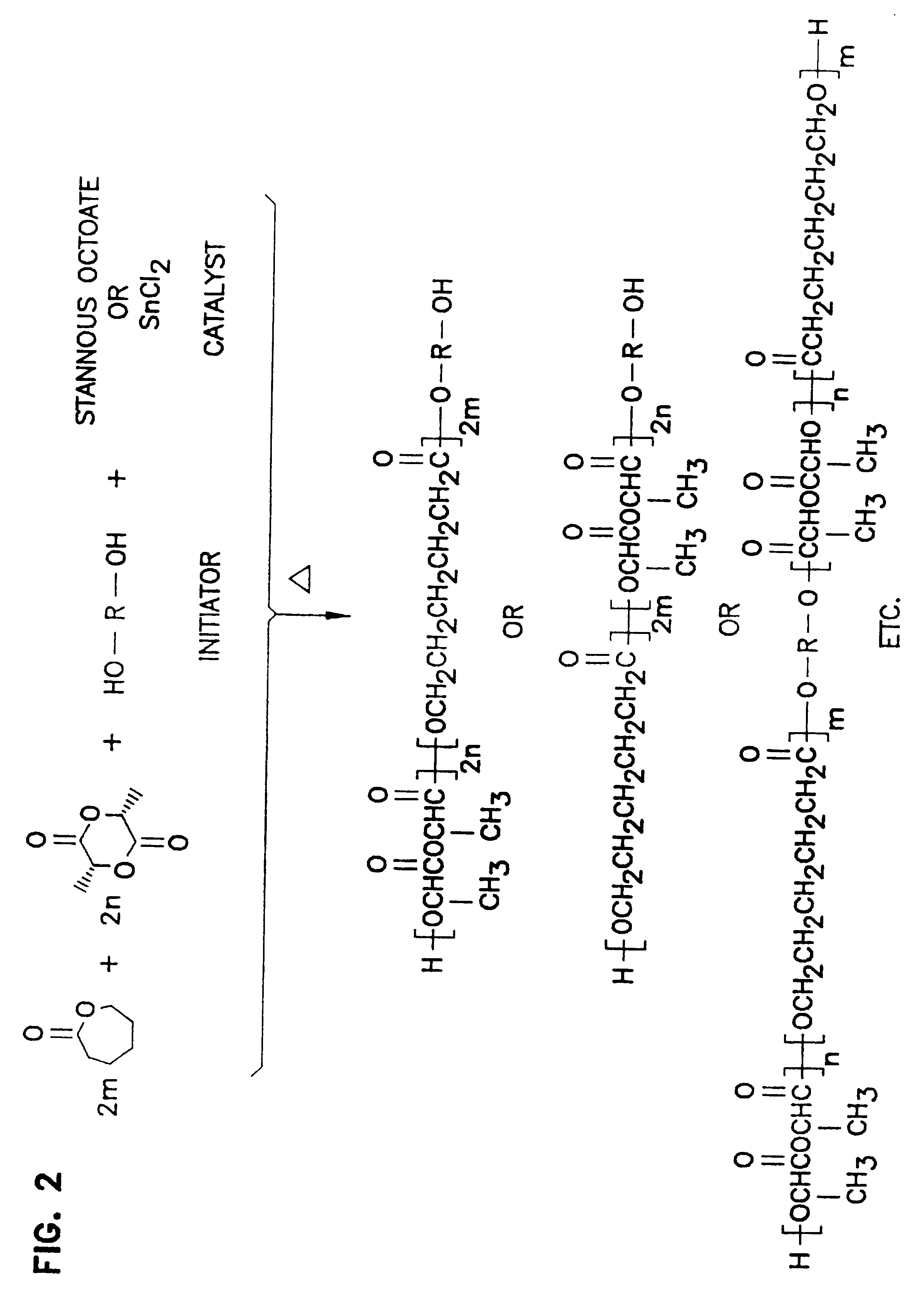

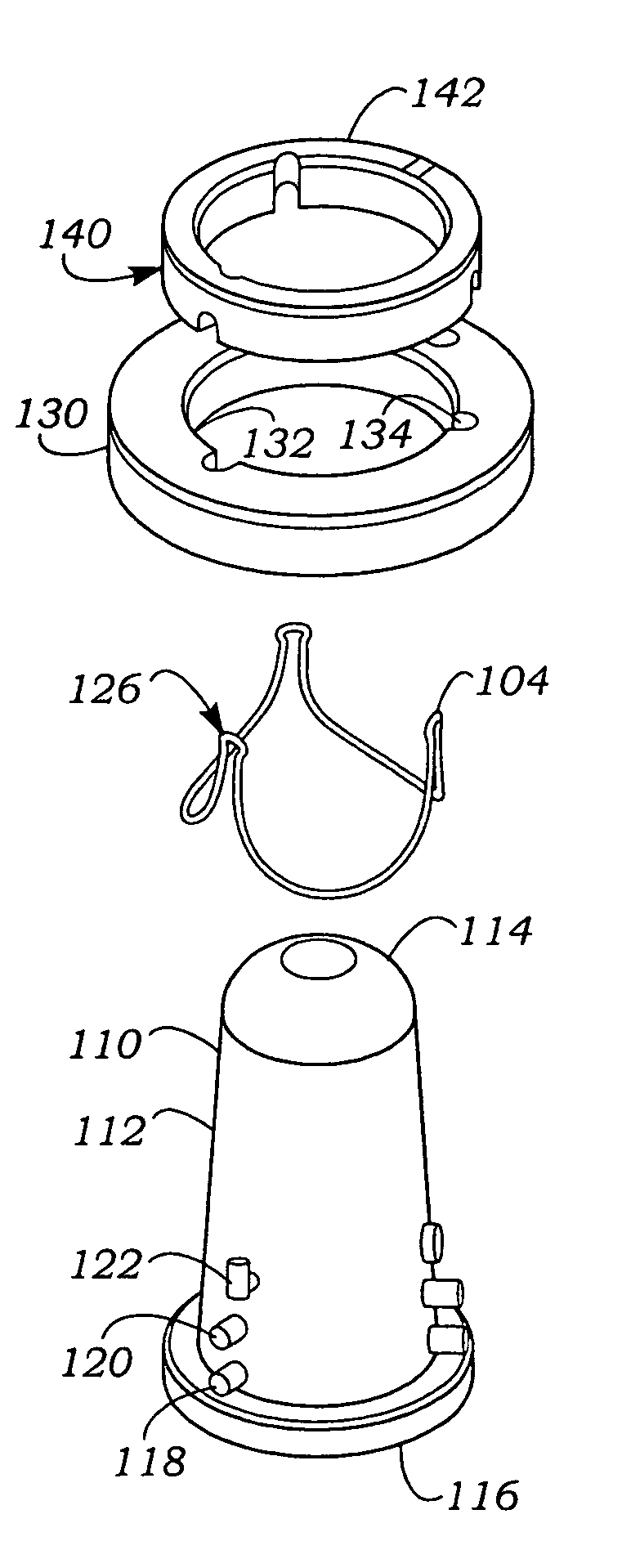

Biodegradable in-situ forming implants and methods of producing the same

A biodegradable polymer is provided for use in providing syringeable, in-situ forming, solid biodegradable implants for animals. The polymer is placed into the animal in liquid form and cures to form the implant in-situ. A thermoplastic system to form said implant comprises the steps of dissolving a non-reactive polymer in biocompatible solvent to form a liquid, placing the liquid within the animal, and allowing the solvent to dissipate to produce the implant. An alternative, thermosetting system comprises mixing together effective amounts of a liquid acrylic ester terminated, biodegradable prepolymer and a curing agent, placing the liquid mixture within an animal and allowing the prepolymer to cure to form the implant. Both systems provide a syringeable, solid biodegradable delivery system by the addition of an effective level of biologically active agent to the liquid before injection into the body.

Owner:ATRIX LAB

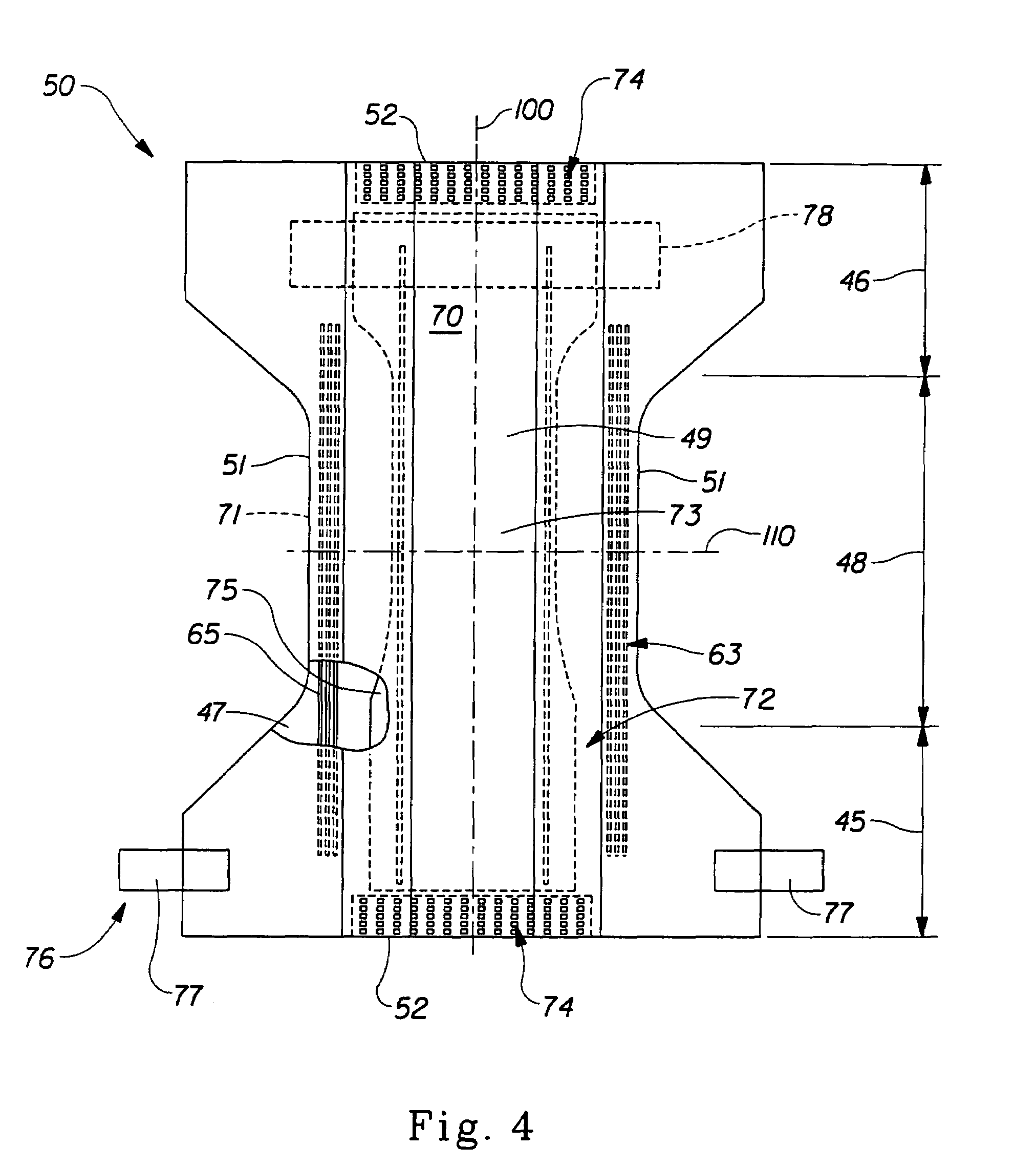

Disposable absorbent articles with components having both plastic and elastic properties

InactiveUS20050215963A1Efficient use ofEnhanced leak protectionBaby linensWoven fabricsEngineeringSizing

Absorbent articles having a liquid permeable topsheet, a liquid impermeable backsheet, and an absorbent core disposed between said topsheet and said backsheet are disclosed. The absorbent articles include a plasto-elastic material joined to or disposed on at least one of component of the absorbent article to impart sizing or shaping capabilities to the article. The plasto-elastic material has substantially plastic properties when said absorbent article is subjected to an initial strain cycle, for example, when the article is placed on a wearer, and has substantially elastic properties when subjected to a second strain cycle such as when the article is subsequently adjusted to conform to the size of the wearer. The absorbent article can be in the form of diapers, pull-on diapers, training pants, sanitary napkins, wipes, bibs, incontinence briefs or inserts.

Owner:THE PROCTER & GAMBLE COMPANY

Hybrid glass-sealed electrical connectors

An electrical connector adapted for mounting to an electrical apparatus used in either high pressure or high temperature, or both high temperature and high pressure, applications. A metal body is provided for mounting to the electrical apparatus with at least one conductor for carrying electricity to or from the electrical apparatus extending therethrough and a thermoplastic jacket is applied over the conductors to the end of the metal body that is subjected to either high pressure or high temperature, or both high temperature and high pressure, for sealing around the conductor. An insulative material is interposed between the metal body and the conductor for sealing around the conductor. In addition to providing two independent internal and two independent external seals, the glass-to-metal seal limits cold-flow (creep) of thermoplastic along the pin and through the metal body. This feature effectively eliminates the catastrophic hydraulic failures possible with prior connectors utilizing a pin, metal body, and high temperature thermoplastic. Because of the redundant internal and external seals, the connector provides undistorted electrical performance in the most hostile environments of temperature and pressure.

Owner:RING JOHN H +1

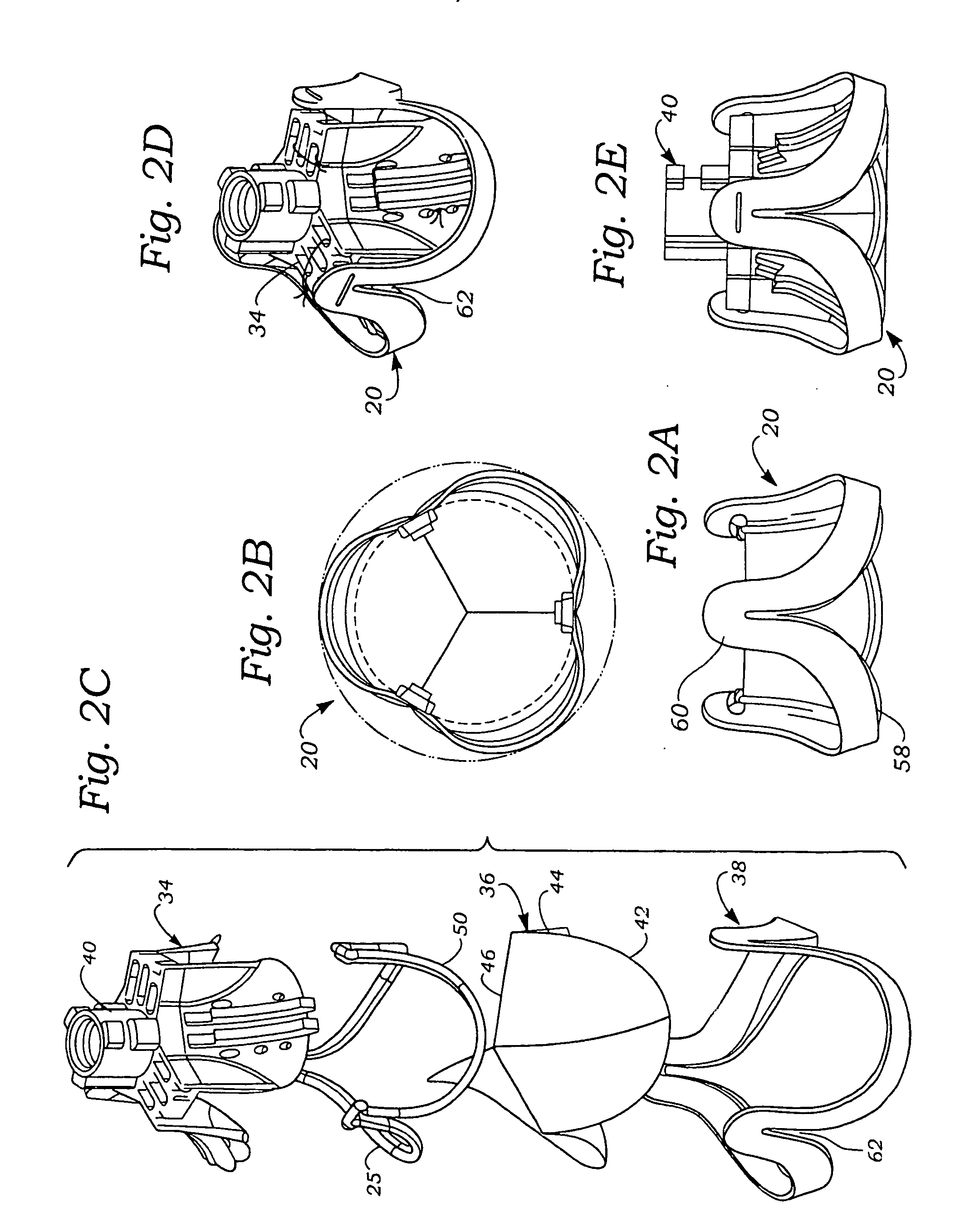

Method of manufacture of a heart valve support frame

InactiveUS20050150775A1Eliminate unevennessIncrease flexibilityElectrolysis componentsFrom normal temperature solutionsEngineeringReady to use

Methods for forming a support frame for flexible leaflet heart valves from a starting blank include converting a two-dimensional starting blank into the three-dimensional support frame. The material may be superelastic, such as NITINOL, and the method may include bending the 2-D blank into the 3-D form and shape setting it. A merely elastic material such as ELGILOY may be used and plastically deformed in stages, possibly accompanied by annealing, to obtain the 3-D shape. Alternatively, a tubular blank could be formed to define a non-tubular shape, typically conical. A method for calculating the precise 2-D blank shape is also disclosed. A mandrel assembly includes a mandrel and ring elements for pressing the blank against the external surface of the mandrel prior to shape setting.

Owner:EDWARDS LIFESCIENCES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com