Patents

Literature

329 results about "Composite pellet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer wood composite

InactiveUS6015612AHigh modulusHigh compressive strengthWood working apparatusRecord information storageFiberThermoplastic

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

Advanced compatible polymer wood fiber composite

InactiveUS6210792B1Improve compatibilityGood material compatibilitySynthetic resin layered productsCellulosic plastic layered productsThermoplasticFiber

The invention relates to a composition comprising a thermoplastic polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer, the fiber or both can be modified to increase compatibility. The wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

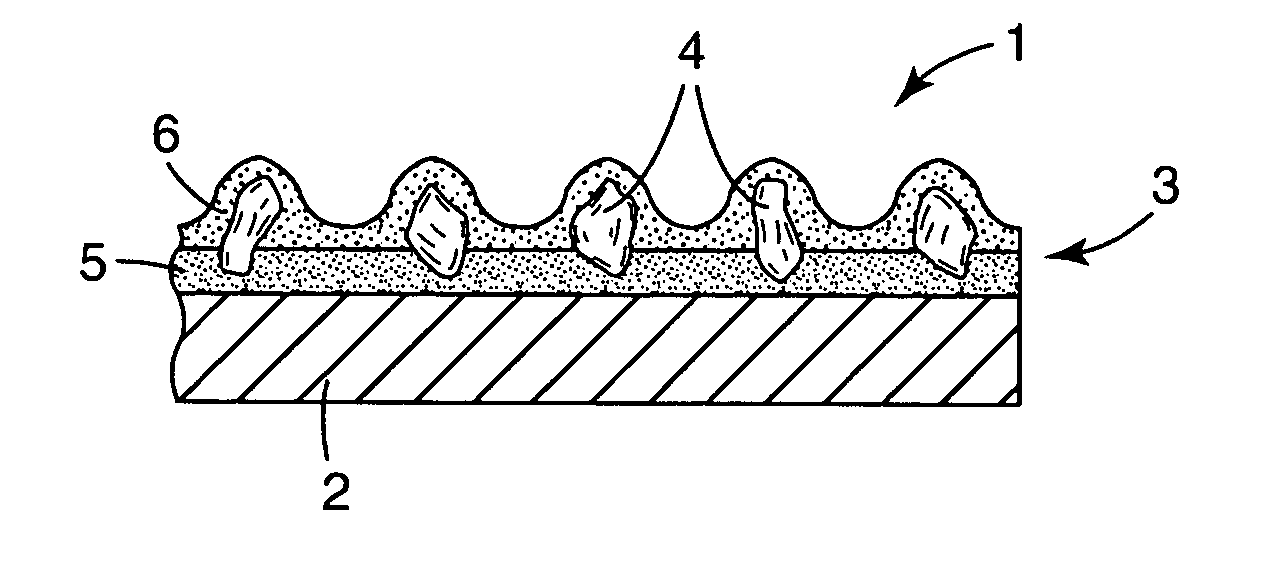

Composite particle comprising an abrasive grit

InactiveUS20070020457A1Delay premature failureProlong lifePigmenting treatmentOther chemical processesAbrasiveComposite pellet

Owner:3M INNOVATIVE PROPERTIES CO

Sintered spherical pellets

Sintered, spherical composite pellets or particles comprising alumina fines, at least one of clay and bauxite and optionally a sintering aid, are described, along with a process for their manufacture. The use of such pellets in hydraulic fracturing of subterranean formations and in grinding is also described.

Owner:CARBO CERAMICS

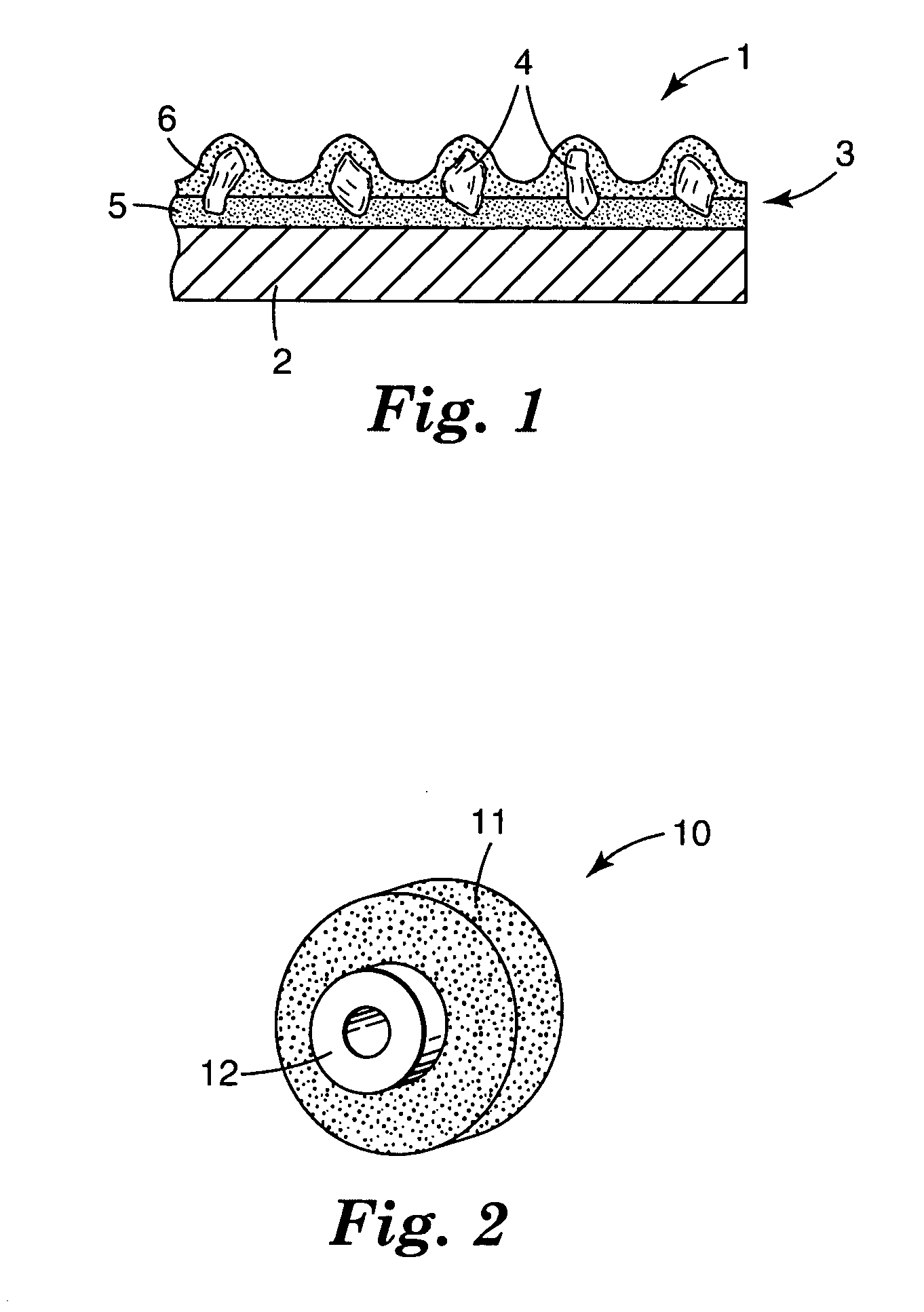

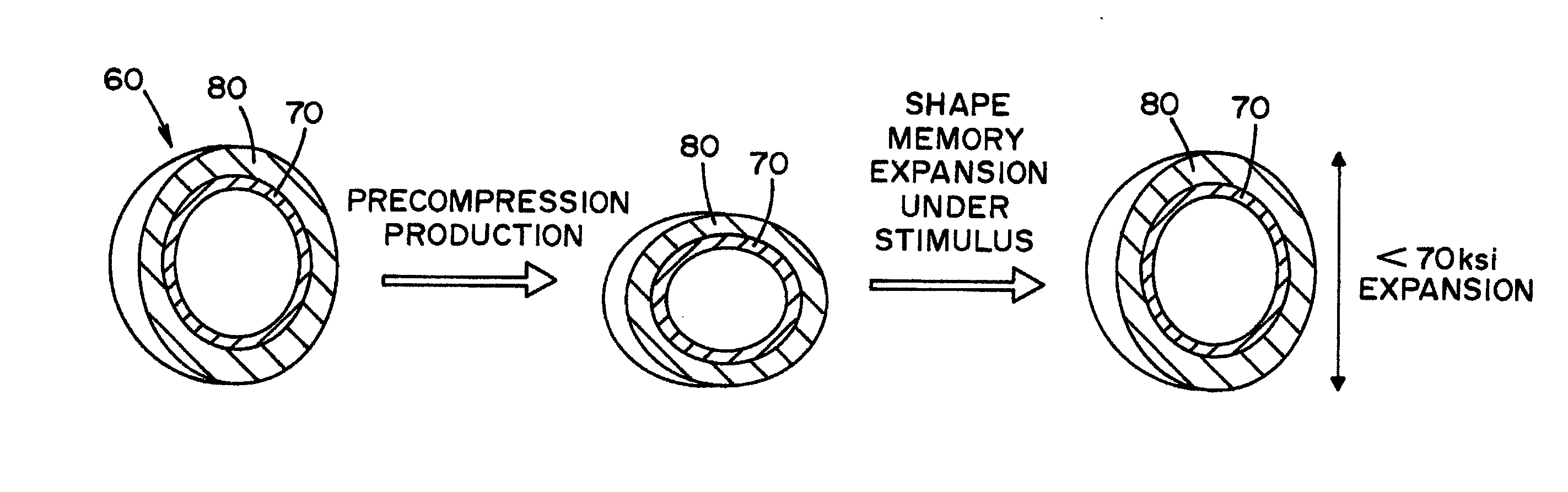

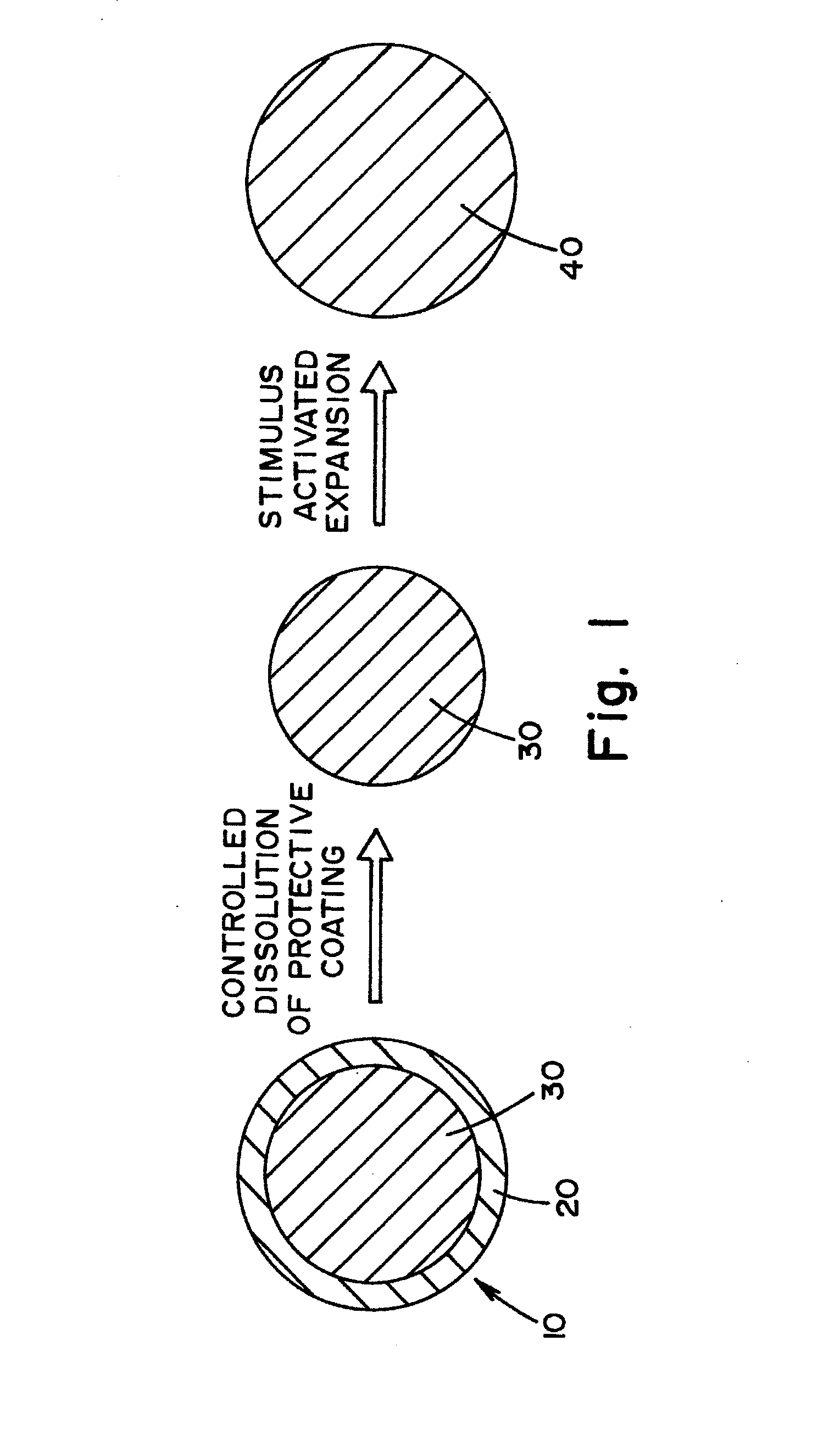

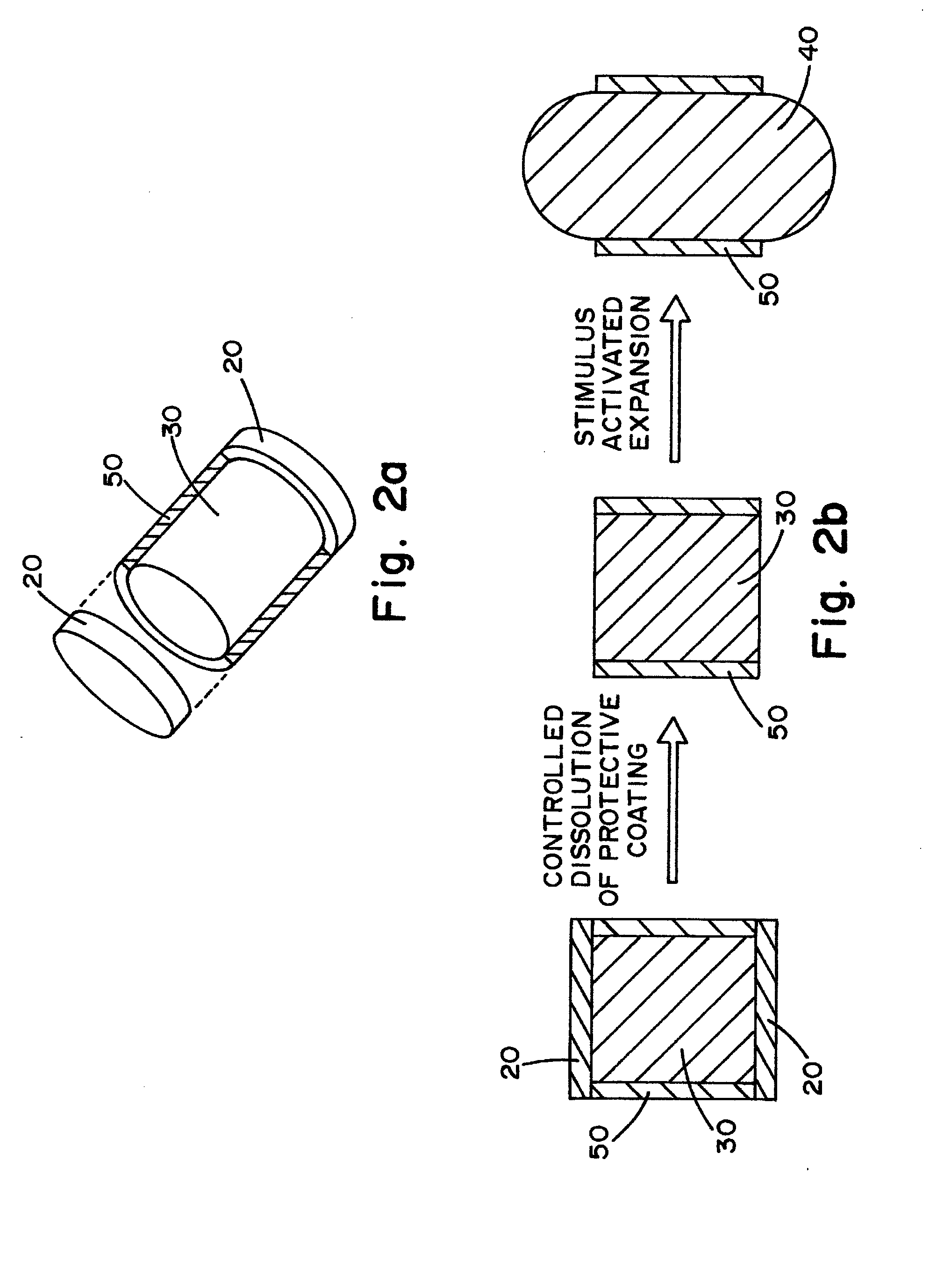

Structural Expandable Materials

ActiveUS20160137912A1Control expansionReduce the amount of waterFluid removalFlushingMaterials scienceChemical change

A composite particle that incorporates a material and is designed to undergo a reaction and / or mechanical or chemical change with the environment to increase in volume. The composite particle can be combined with a constraining matrix to create an expandable particle upon reaction. These particles can be used in stimulating wells, including oil and gas reservoirs.

Owner:POWDERMET

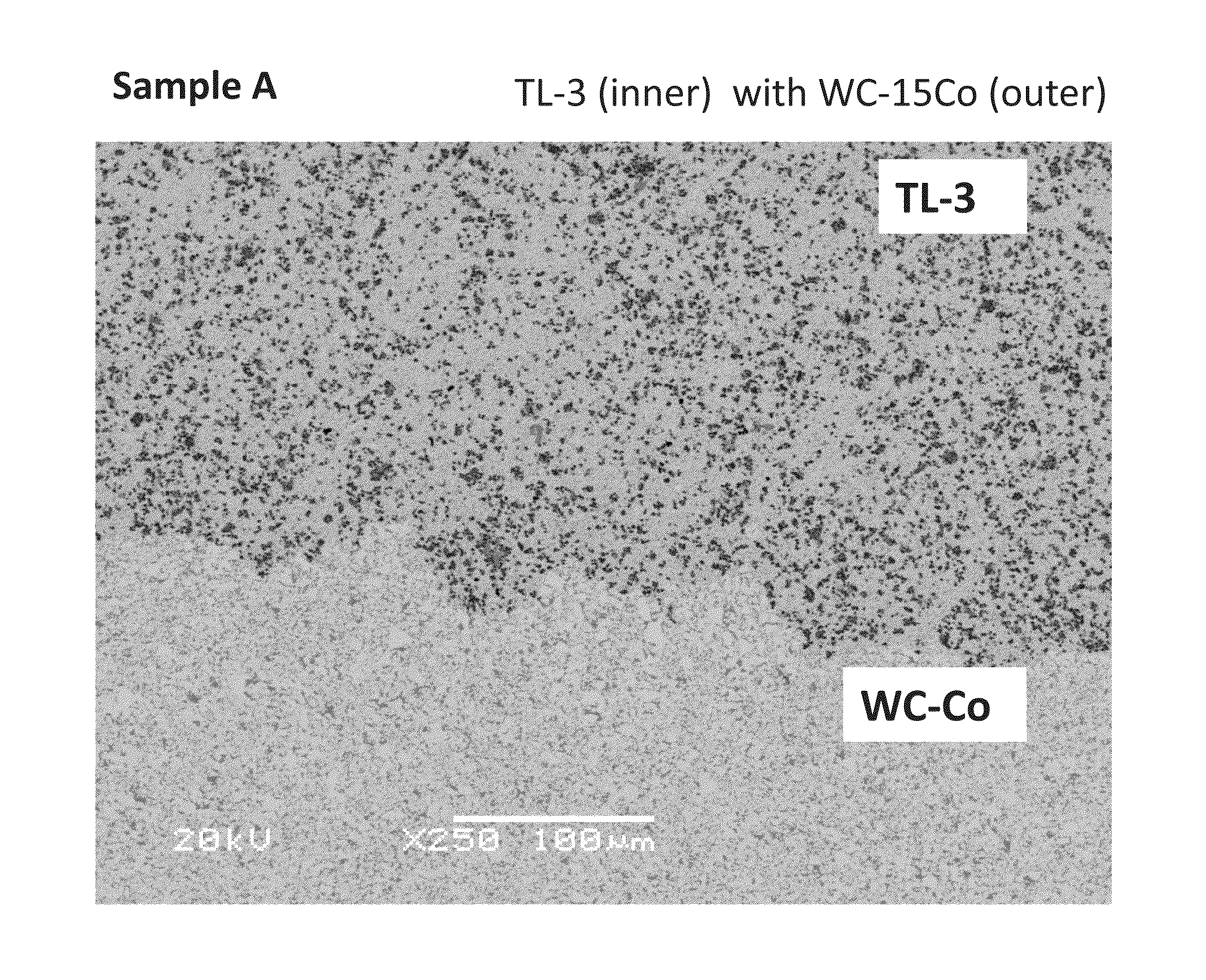

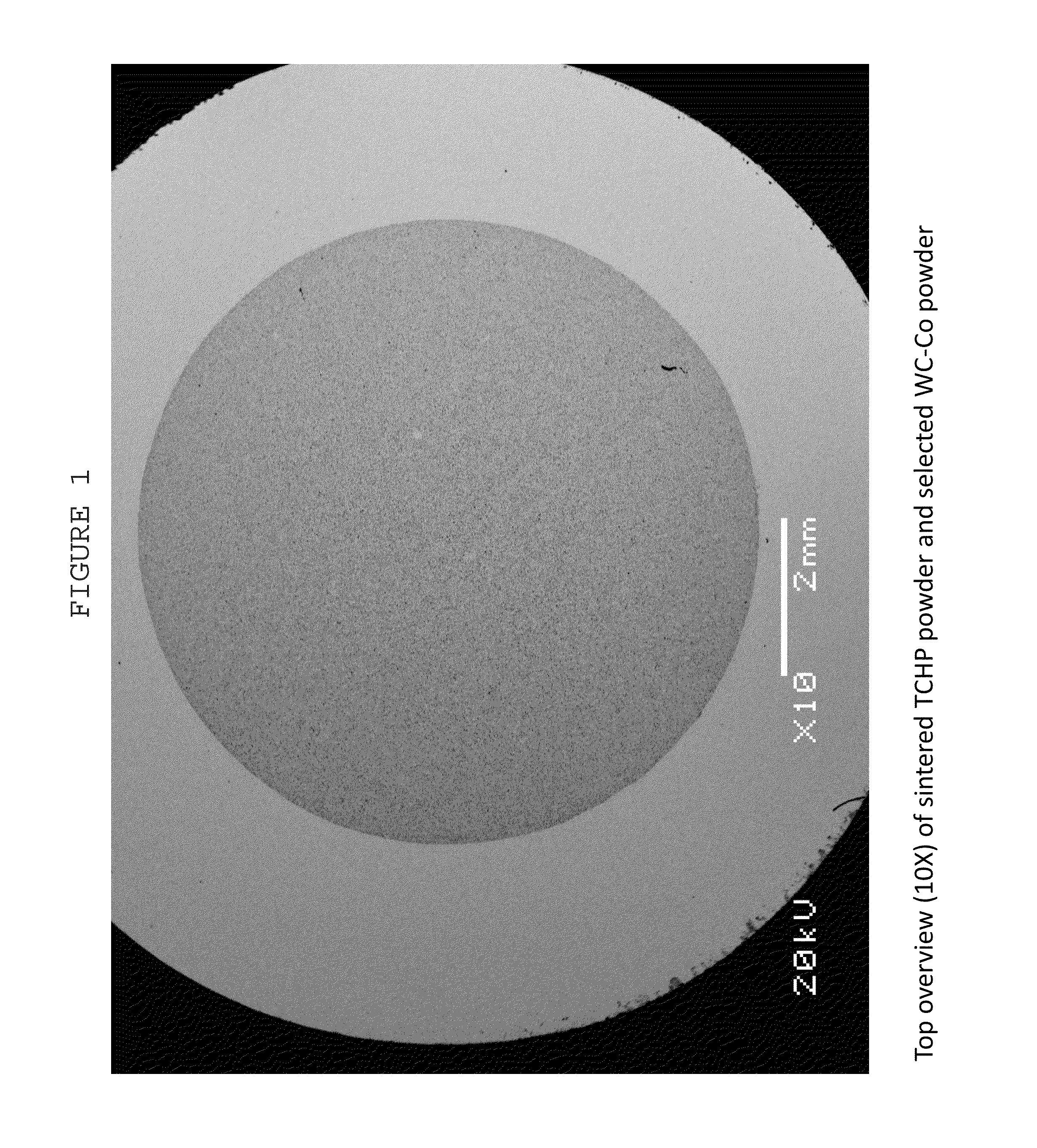

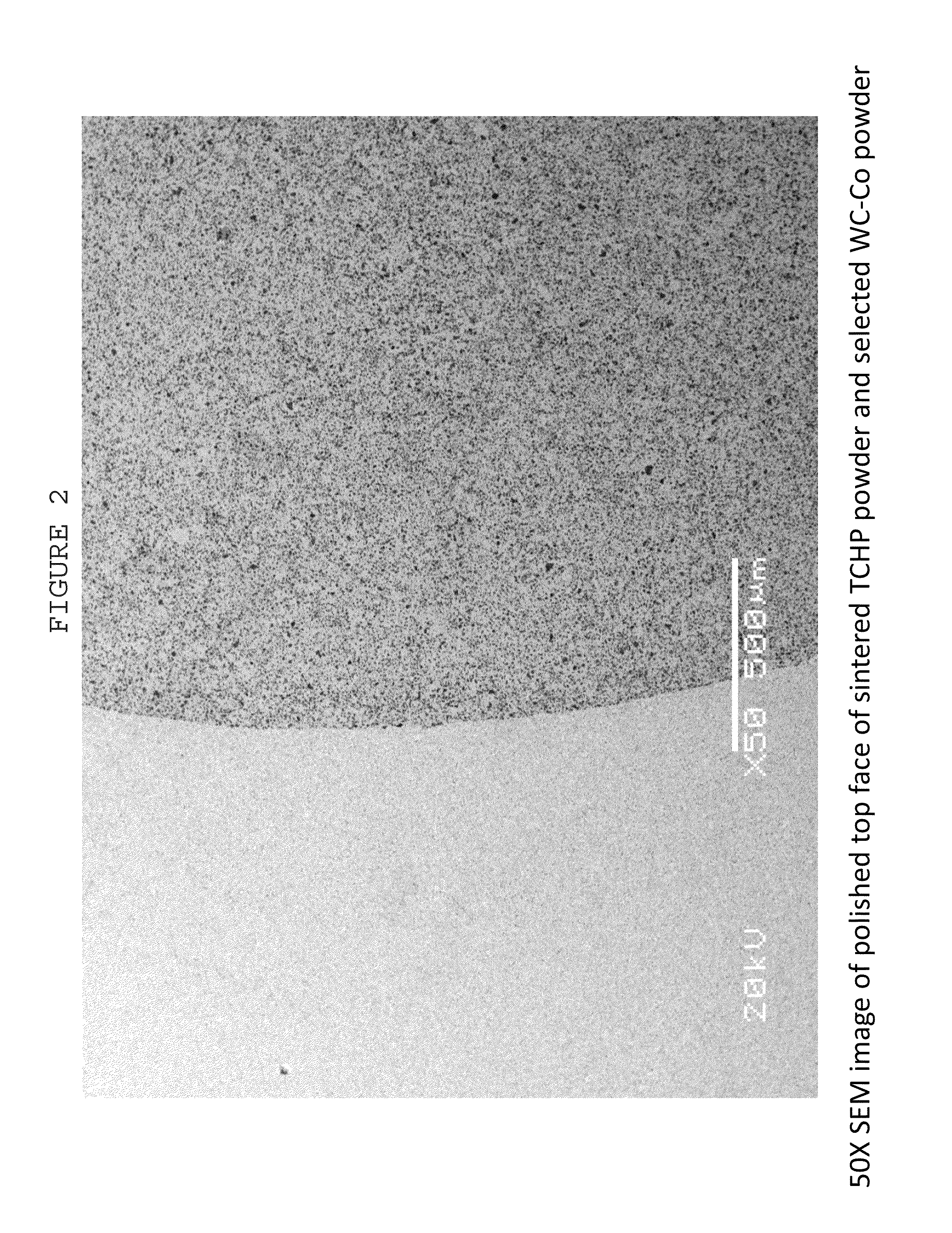

Methods of forming a metallic or ceramic article having a novel composition of functionally graded material and articles containing the same

ActiveUS20140087210A1Improve fracture toughnessLow costAdditive manufacturing apparatusLayered productsCarbideFunctionally graded material

There is disclosed a method of making a metallic or ceramic component, such as a cutting or forming tool, from at least two distinct powder precursors. In one embodiment, the method comprising forming a first mixture comprised of a plurality of coated particles, such as Tough-Coated Hard Powder (TCHP) composite particles created by encapsulating extremely hard core particles with very tough binder and structural materials, and at least one support powder, such as a carbide, typically WC—Co. The mixture is formed into a green body and sintered to form a functionally graded or multicomponent article. Non-limiting examples of the articles made from the disclosed methods are also disclosed and include drills, mills, cutting tools, forming tools, wires dies and mechanical components.

Owner:ETERNALOY HLDG GMBH

Sintered spherical pellets useful for gas and oil well proppants

Sintered, spherical composite pellets having high strength and low density, are described, along with processes for their manufacture. One method includes forming a green pellet from a mixture of clay, bauxite or a clay-bauxite mixture with a sacrificial phase such that upon sintering of the pellet, the sacrificial phase is removed from the pellet. The use of such sintered pellets in hydraulic fracturing of subterranean formations is also described.

Owner:CARBO CERAMICS

Composite particle animal litter and method thereof

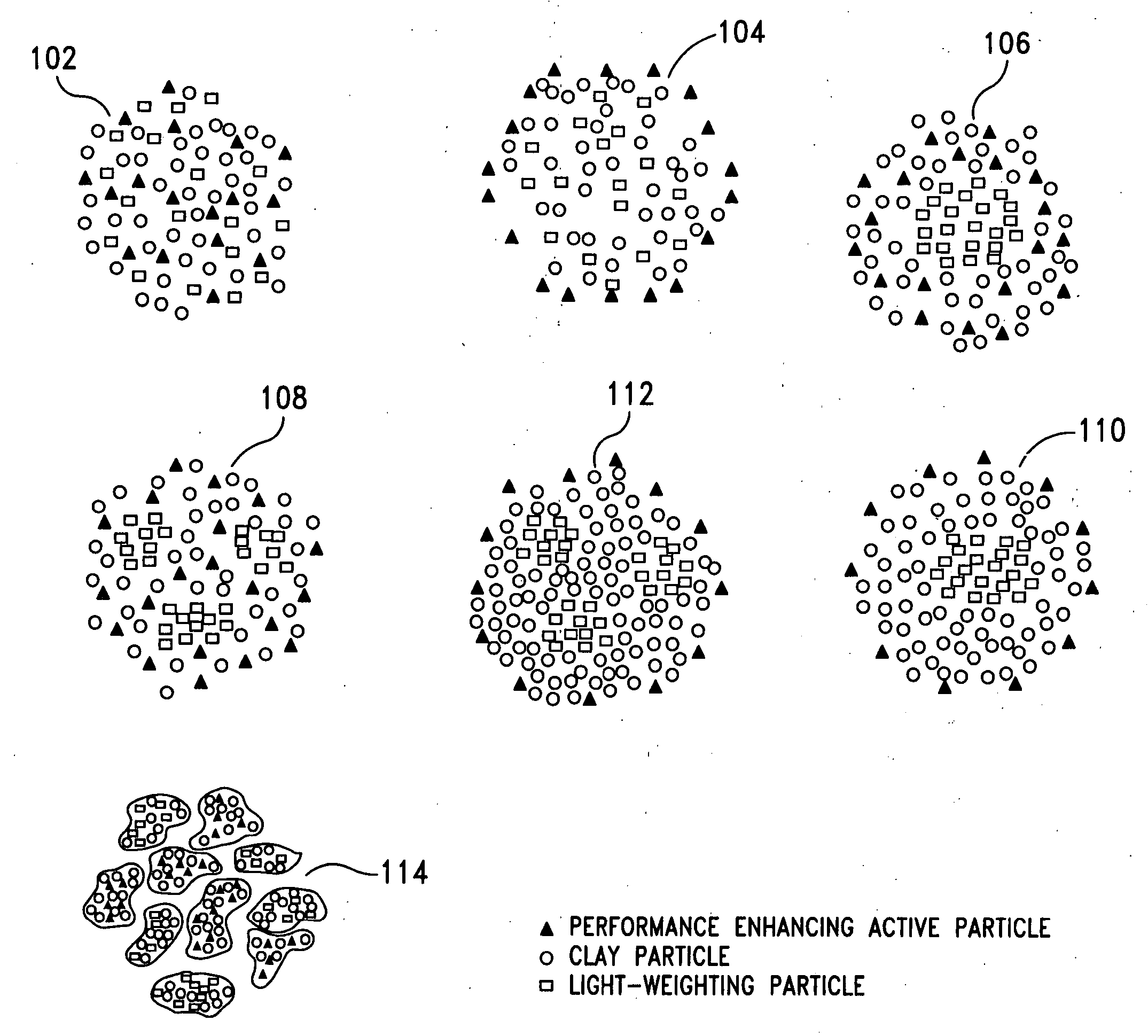

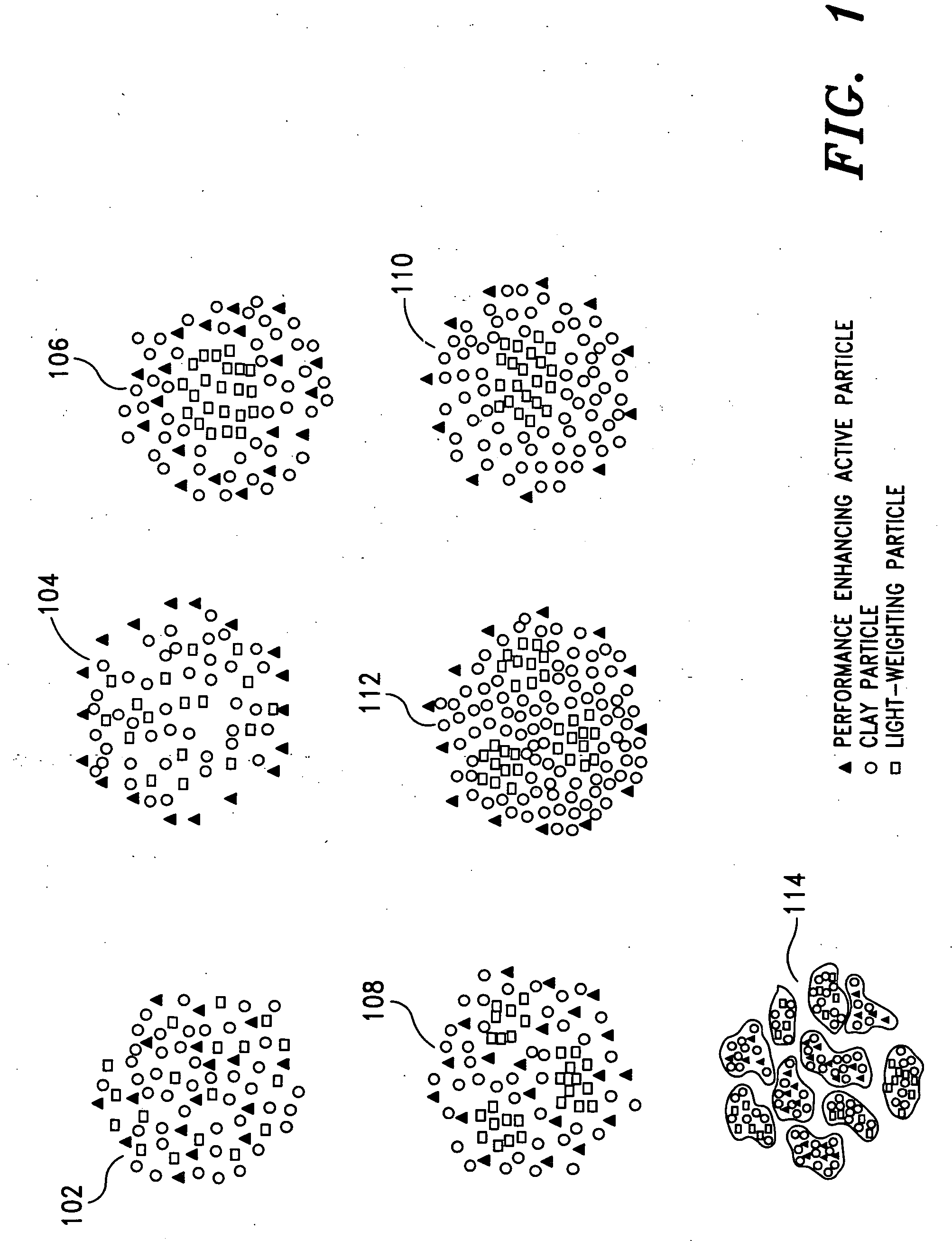

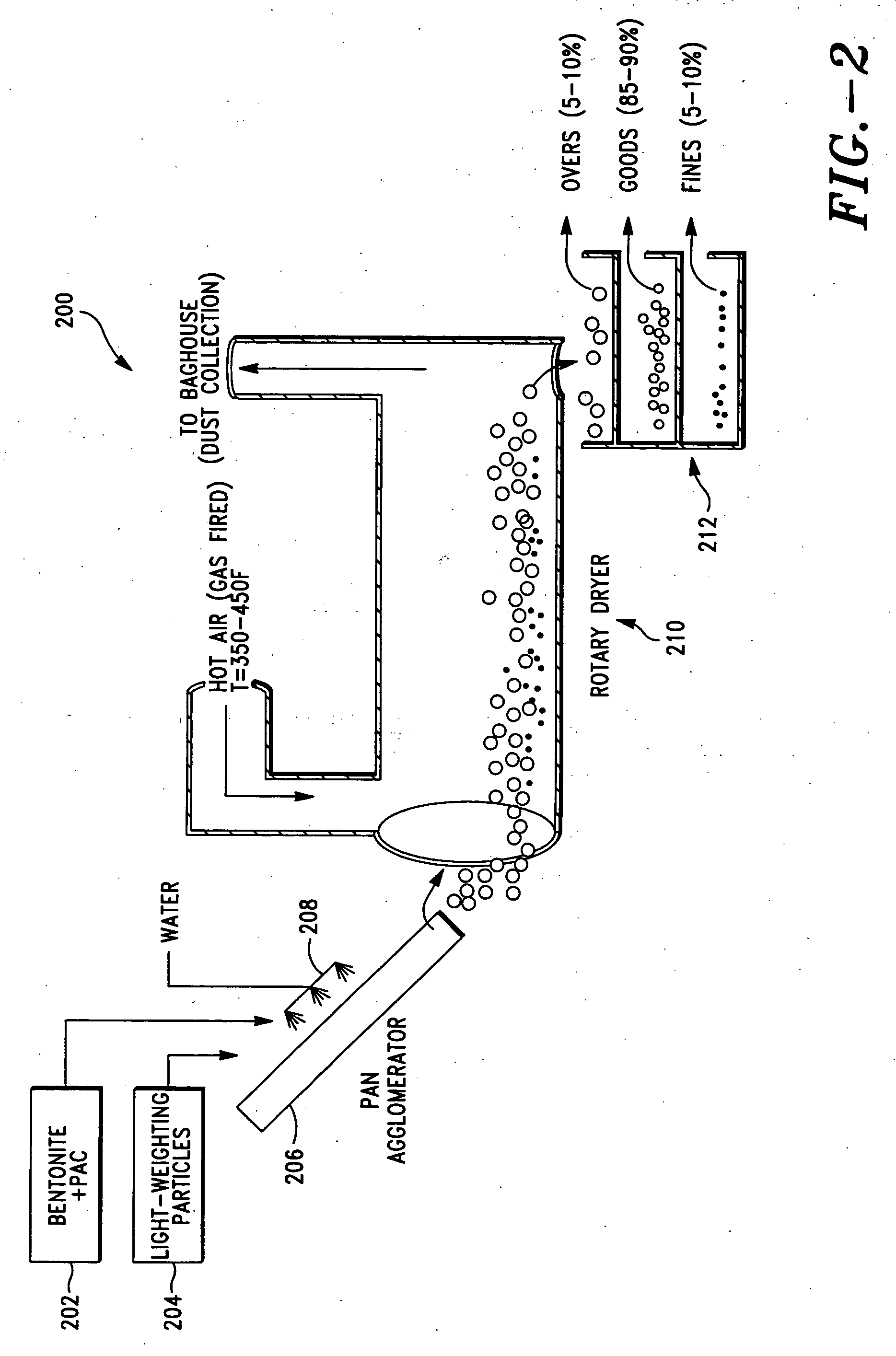

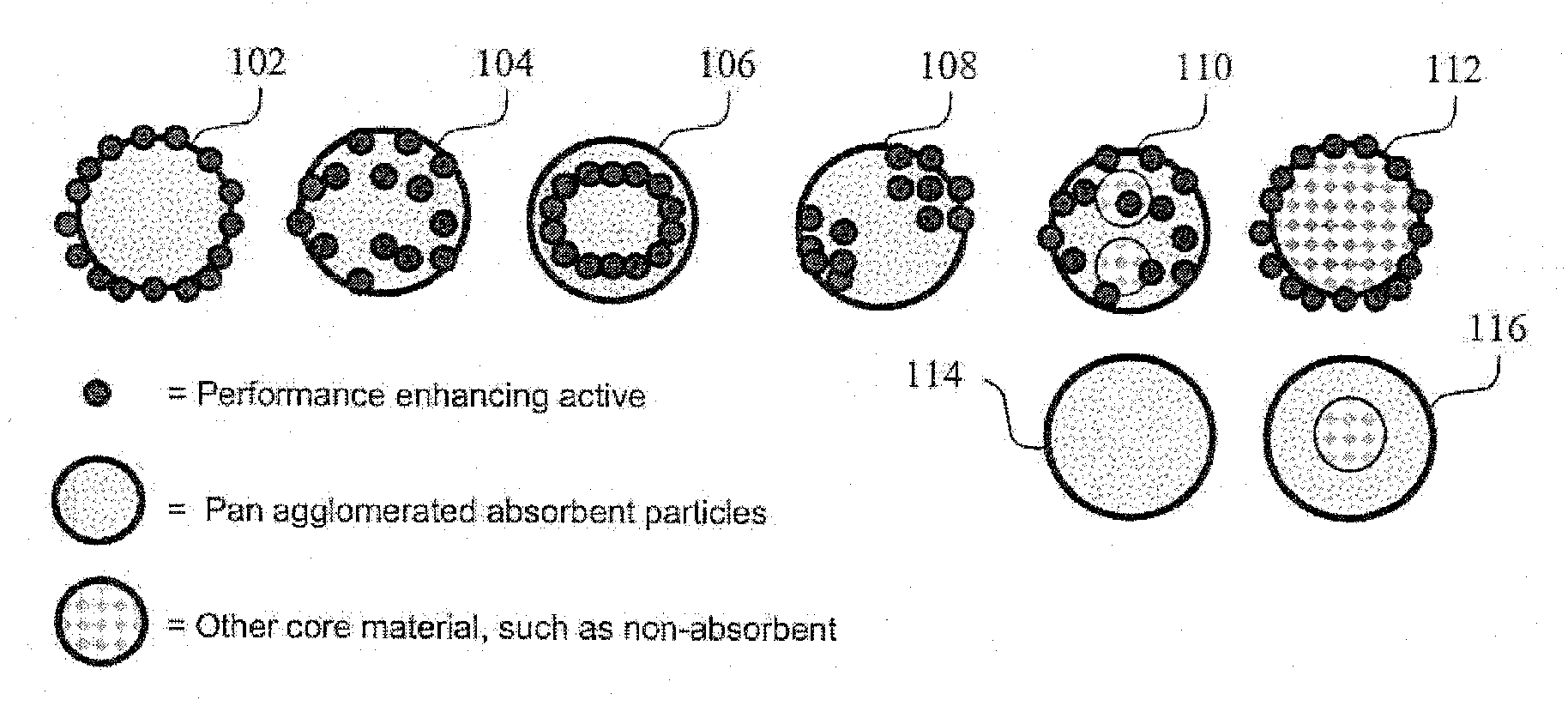

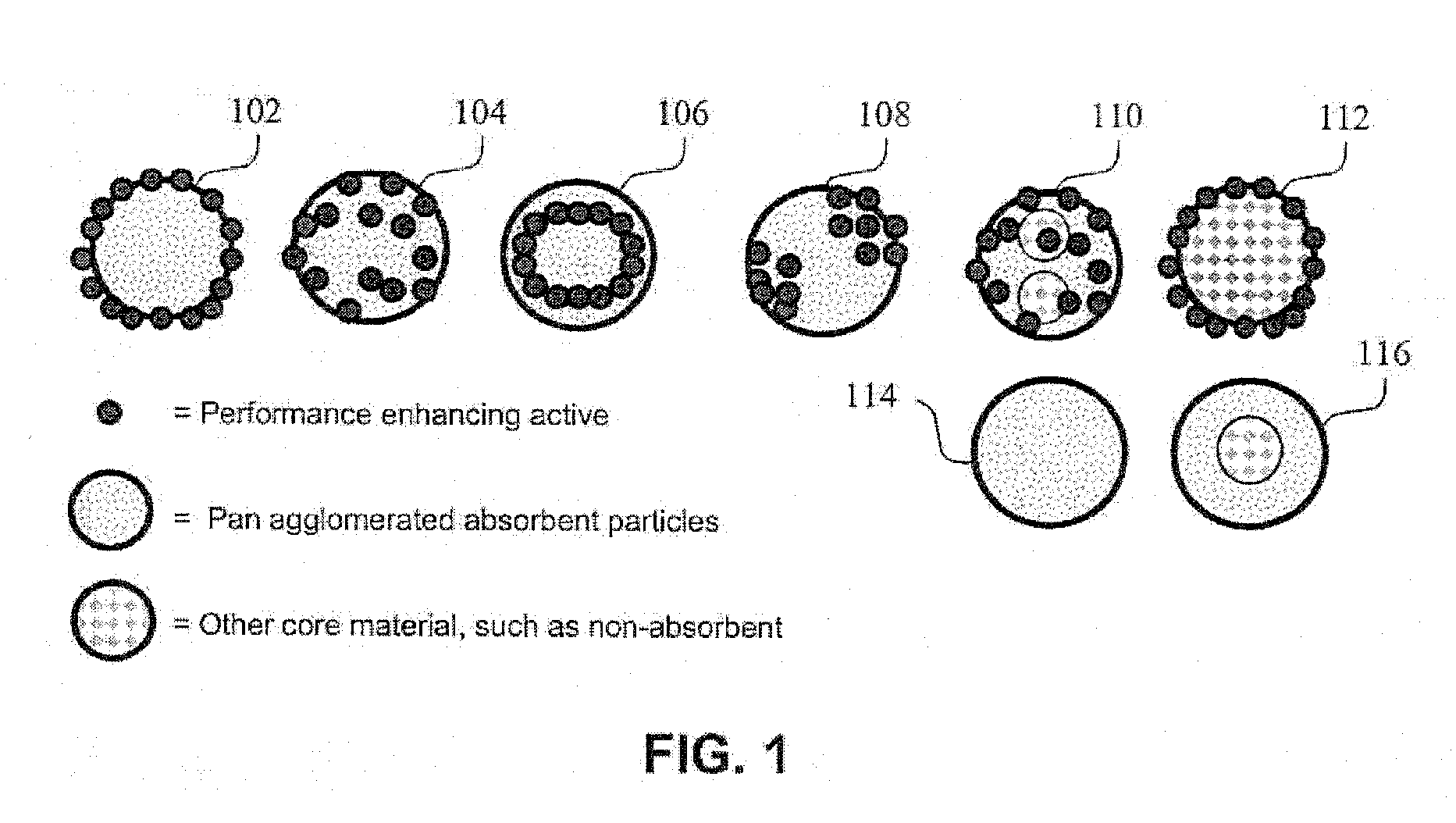

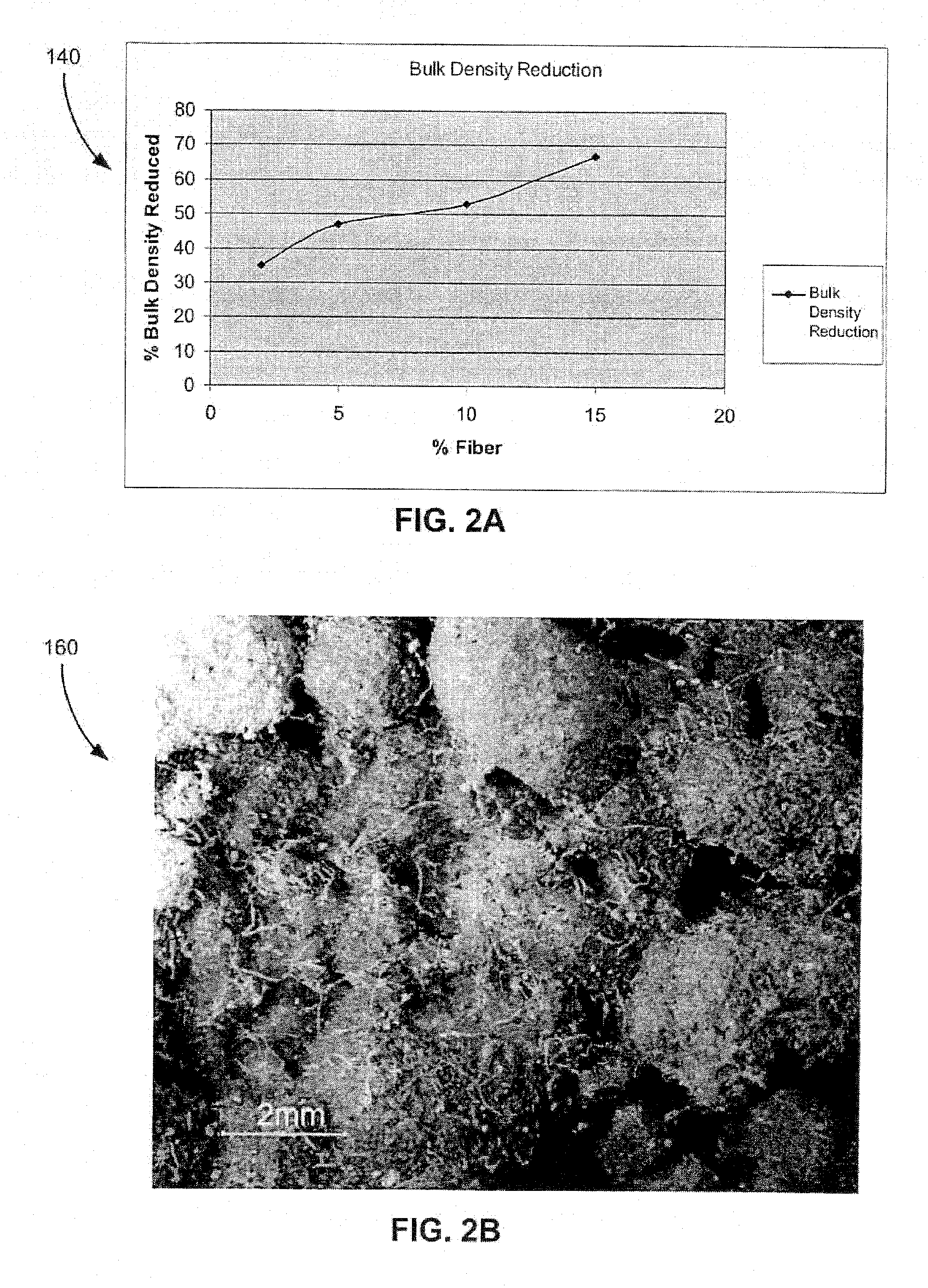

Composites and methods for making the same. A mixture of clay material and a light-weighting material is formed into a composite particle. An optional performance-enhancing active is coupled to the composite particle material before, during, or after the particle-forming process, homogeneously and / or in layers. Preferred methods for creating the composites include a pan agglomeration process, a high shear agglomeration process, a low shear agglomeration process, a high pressure agglomeration process, a low pressure agglomeration process, a rotary drum agglomeration process, a mix muller process, a roll press compaction process, a pin mixer process, a batch tumble blending mixer process, an extrusion process, and a fluid bed process.

Owner:THE CLOROX CO

Dry Bed Agglomeration Process and Product Formed Thereby

A method for creating a particle from a powder according to one embodiment includes applying a droplet of a liquid to a bed of powder, wherein a particle is formed at about a point of contact of the droplet with the bed. A composite particle according to one embodiment includes a liquid-absorbing material and a liquid-induced binding agent substantially homogeneously dispersed in the particle. A composite particle according to yet another embodiment includes a liquid-absorbing material and a byproduct of a liquid-induced gas forming agent substantially homogeneously dispersed in the particle. A composite particle suitable for use as an animal litter according to an embodiment includes a liquid-absorbing material, where the particle has at least one of the following properties: hollow, cupped, and generally bagel shaped. A composite particle in yet another embodiment includes a material formed in a shape substantially defined by a droplet of liquid.

Owner:THE CLOROX CO

Advanced polymer wood composite

InactiveUS20020106498A1High modulusHigh modulus of elasticityFibreboardWood working apparatusThermoplasticPolymer science

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprise, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of an elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

High strength particles and methods of their use in subterranean operations

The present invention relates to composite particulates comprising a base material and a nanoparticle material. One embodiment of the present invention provides a method of using a sintered composite particulate in a subterranean application comprising providing a slurry comprising a sintered composite particulate comprising a base material and at least one nanoparticle material; and placing the slurry into a well bore penetrating a subterranean formation. Another embodiment of the present invention provides sintered composite particulates useful in completing and stimulating wells comprising a base material and nanoparticle material wherein the composite particulate comprises from about 0.1% to about 30% nanoparticle material by weight of the composite particulate and wherein the composite particulates are sintered

Owner:HALLIBURTON ENERGY SERVICES INC

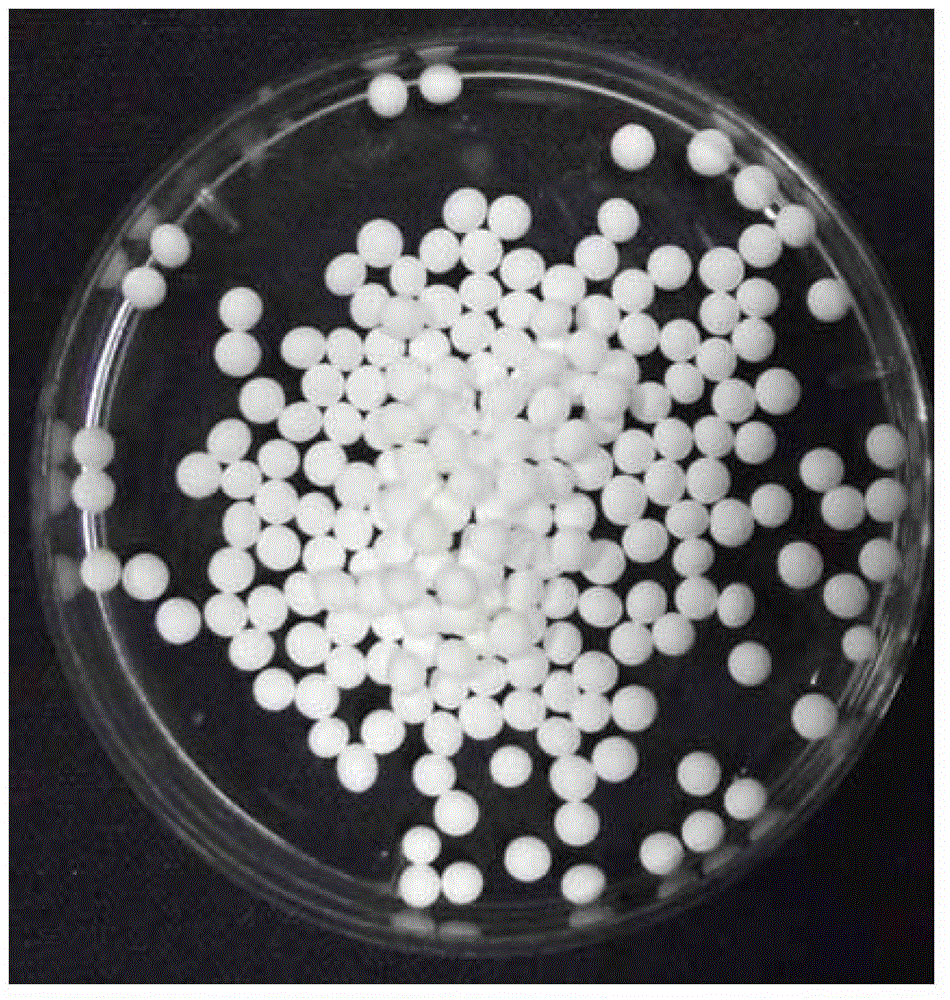

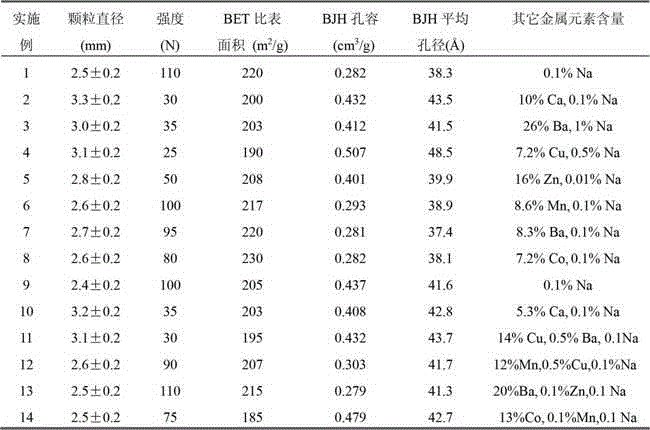

Method for preparing spherical alumina particles by alginic acid auxiliary forming method

ActiveCN102718241AReduce energy consumptionNo pollution in the processAluminium oxide/hydroxide preparationIonComposite pellet

The invention discloses a method for preparing spherical alumina particles by an alginic acid auxiliary forming method. The method includes the following steps of firstly, taking pseudo-boehmite, adding water for dispensing, and then adding a sodium alginate aqueous solution to stir to form a sodium-alginate-pseudo-boehmite suspension; secondly, dropping the sodium-alginate-pseudo-boehmite suspension into an aqueous solution of aluminum, calcium, barium, copper, zinc, manganese or cobalt metal ion, and forming alginic-acid-pseudo-boehmite rubber composite pellets in a gel mode; and thirdly, subjecting the alginic-acid-pseudo-boehmite rubber composite pellets to a washing by water, a drying and a calcination to obtain the spherical alumina particles. According to the method for preparing the spherical alumina particles, the forming of the particles is performed in mild aqueous phase, the energy consumption is low, the pollution is absent during a preparation process, the production efficiency is high, the specific surface area, the pore volume, the pore diameter and the metallic oxide content of the spherical alumina can be conveniently adjusted, the preparation process is simple, the operation is convenient, and the industrial production is easy to achieve.

Owner:TIANJIN UNIV

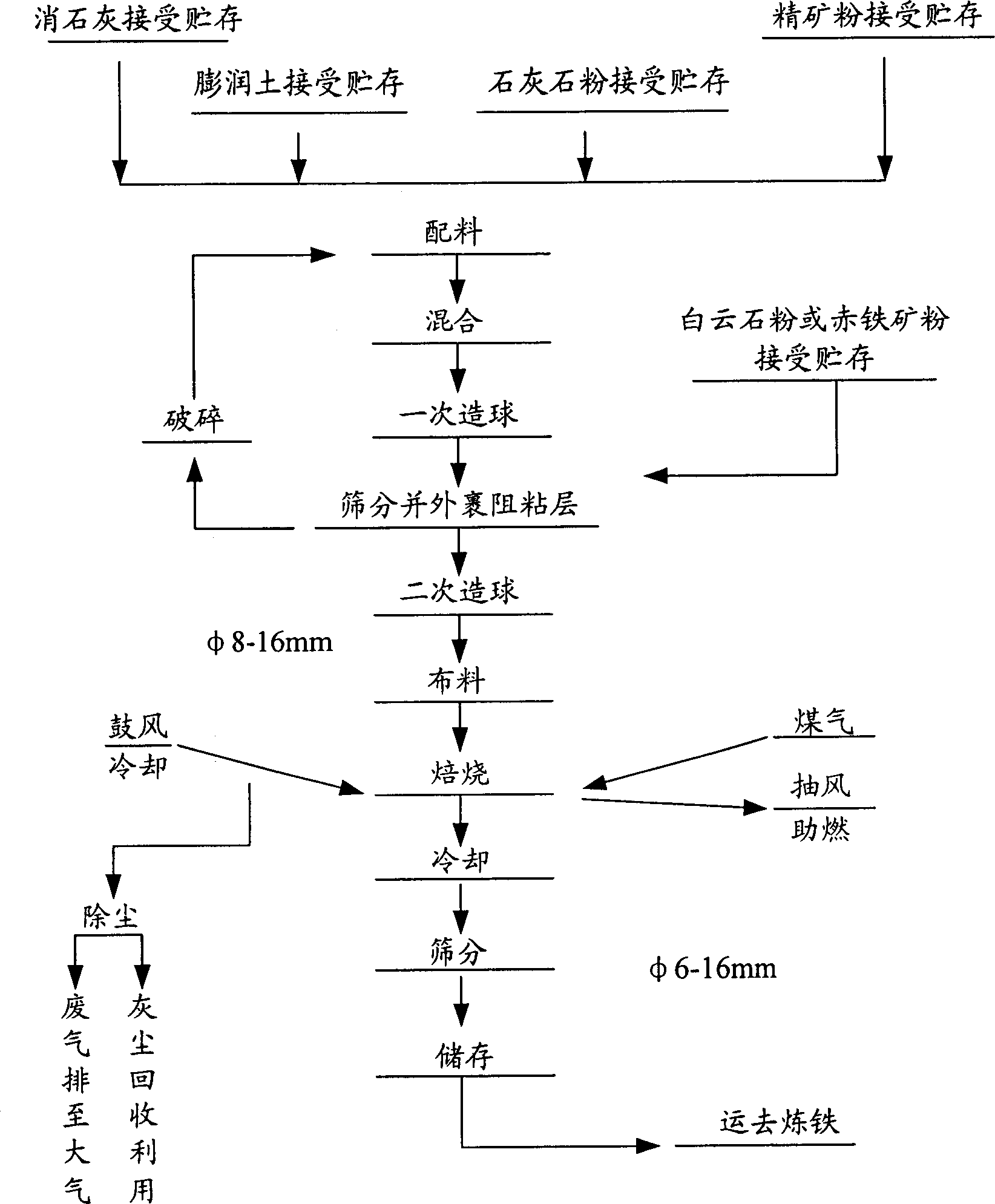

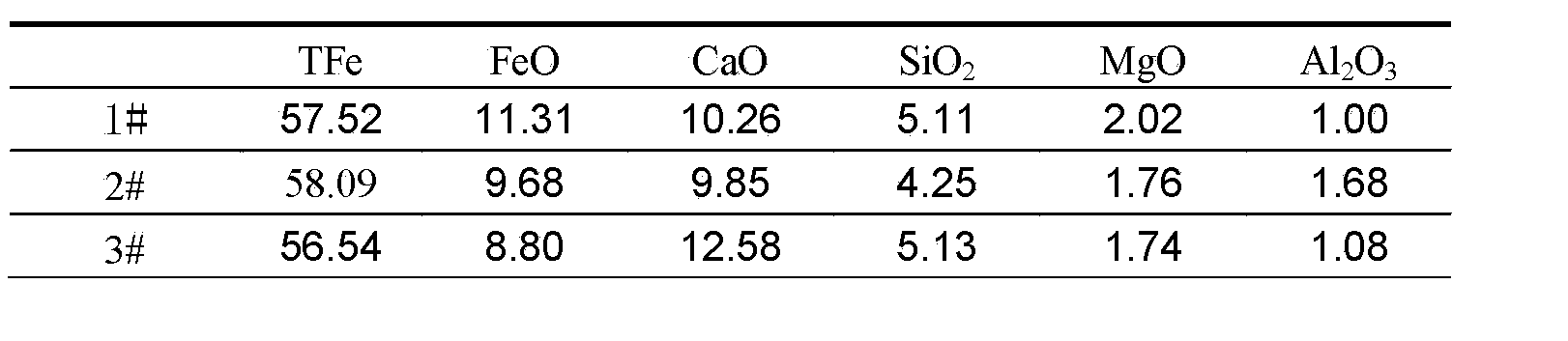

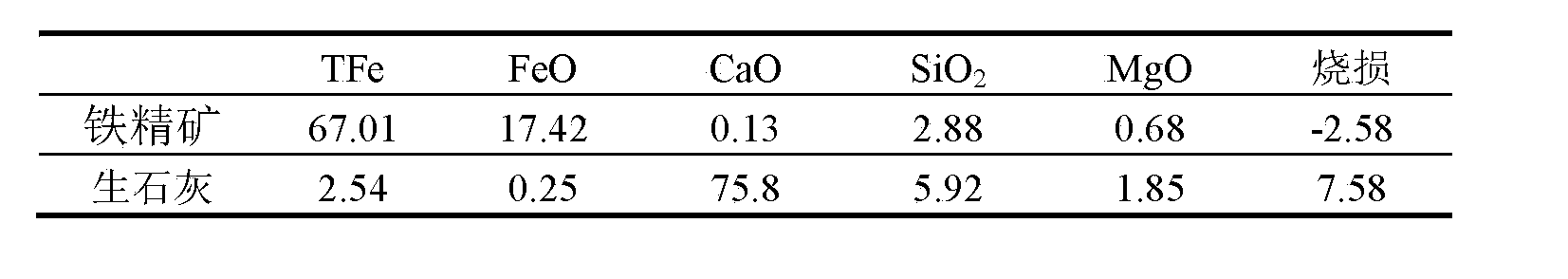

Method for making fluxed iron ore powder composite pellet

The preparation method for a solvent-type iron ore composite aggregate comprises: ensuring the proper CaO and 2-4% MgO with weight o.5-2.0 in the first process; then coming the secondary time, wrapping one block layer evenly of CaCo3 powder, dolomite powder, hematite dried powder or acidic iron concentrate ore; then, baking as the acidic aggregate baking temperature and means to ensure the ore not bond. This invention overcomes bonding problem with low cost and little pollution, and improves blast furnace yield even meets the pH balance or desulfurization request.

Owner:许贵宾

Waste paper treatment process

According to the present invention there is provided a method of treating reject from a plant for de-inking waste paper which reject comprises in an aqueous medium a mixture of suspended solids comprising at least ink particles, inorganic particles and fibers, which method includes the steps of (i) chemically treating an aqueous suspension comprising said reject by adding to the aqueous suspension a source of alkaline earth metal ions and a source of carbonate ions to react with the alkaline earth metal ions to form therein a composite particulate material comprising a substantially white insoluble alkaline earth metal carbonate compound precipitated by the said reaction which compound bonds to and entrains material comprising ink particles, inorganic particles and fibers contained in said reject, whereby the darkness of the reject is reduced by formation of the precipitate of the carbonate compound; and (ii) recovering the composite particulate material and delivering the composite particulate material for re-use as a pigment in a process for making or coating cellulosic sheet material.

Owner:IMERYS MINERALS

Preparation of polystyrene/expanded graphite composite foaming material

InactiveCN101891852APhysical and mechanical properties do not deteriorateImprove physical and mechanical propertiesCompression moldingFoaming agent

Owner:SHANGHAI BOTAO ENVIRONMENT PROTECTION SCI & TECH +1

Wood composite alloy composition having a compatibilizer that improves the ability to process and compress cellulosic fiber

A crystalline polyamide 6 in a compounding extrusion process to make wood flour-polyolefin composite. The wood plastic composite pellet and can be post-blended with reinforced polyolefin pellets in an injection molding step to produce hybrid fibrous composites. The resulting compatibilization in the hybrid fibrous composites gives molded parts having enhanced mechanical properties at greatly reduced temperatures. There is wide variety of molded parts that can be made by varying the blend ratio of the wood plastic compounded product with or without and glass fiber reinforced pellets in the injection molding step.

Owner:INNOVATIVE PLASTICS & MOLDING +1

Advanced polymer wood composite

InactiveUS20040126568A1High modulusHigh compressive strengthFibreboardWood working apparatusThermoplasticFiber

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm<3>. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

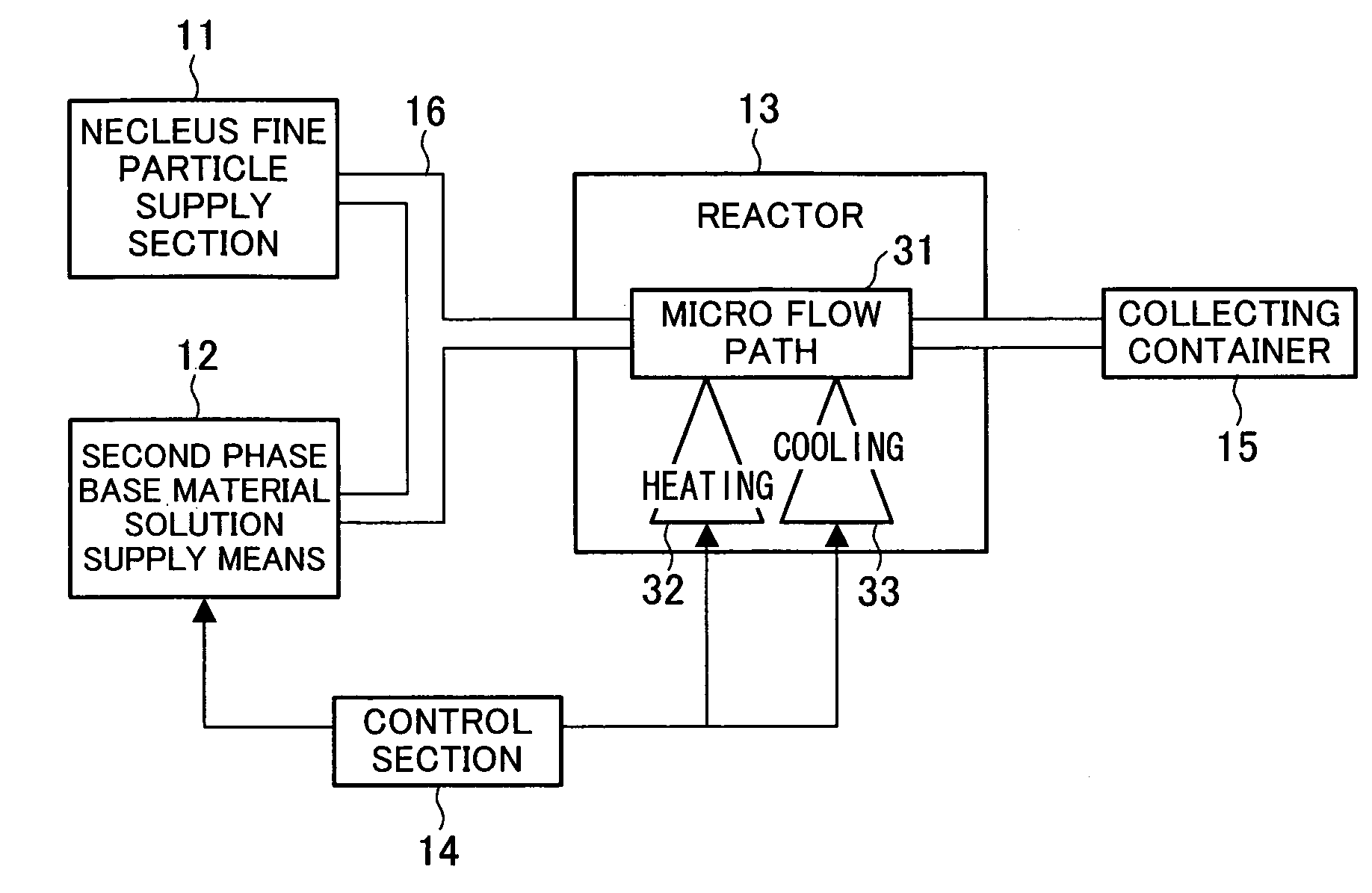

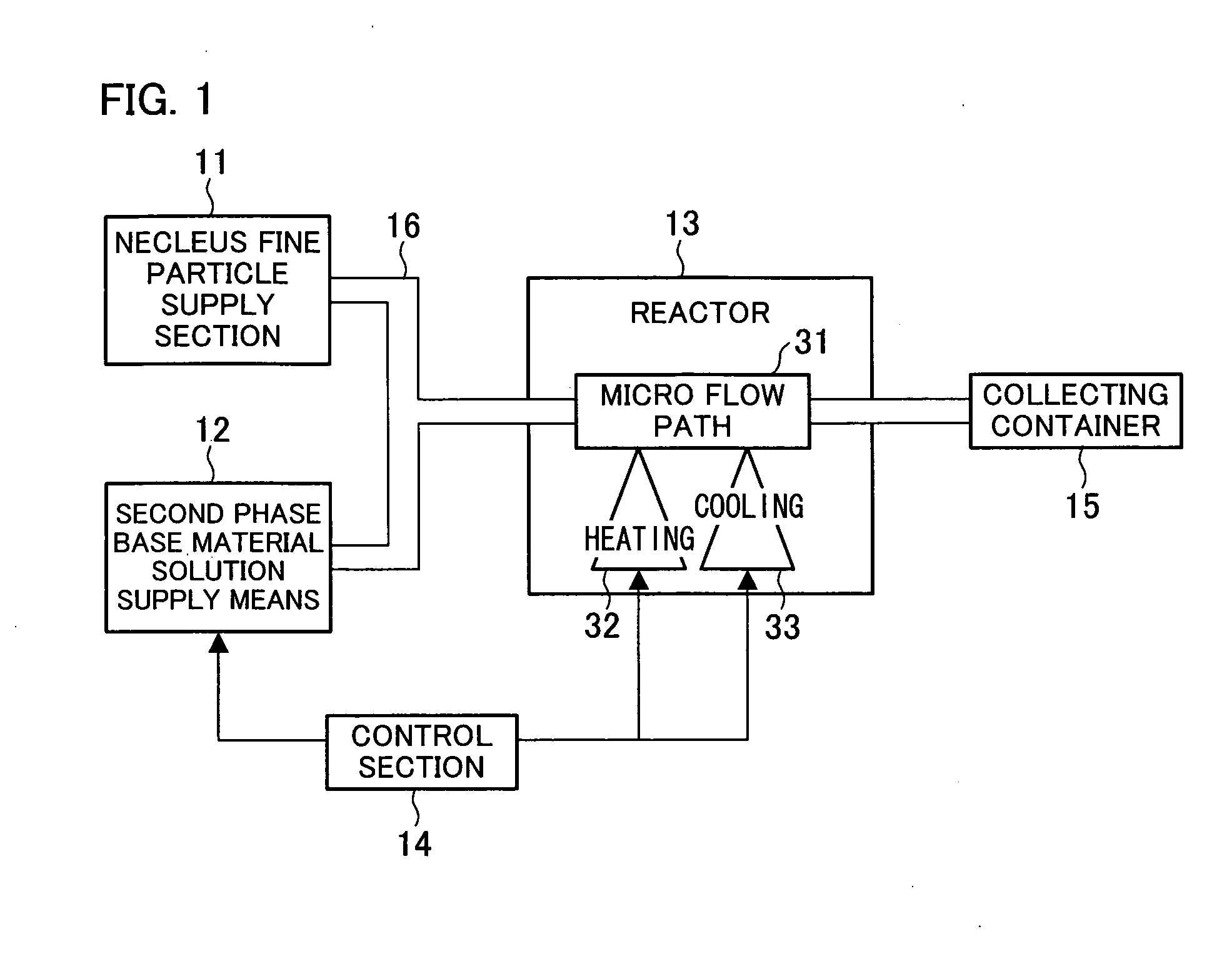

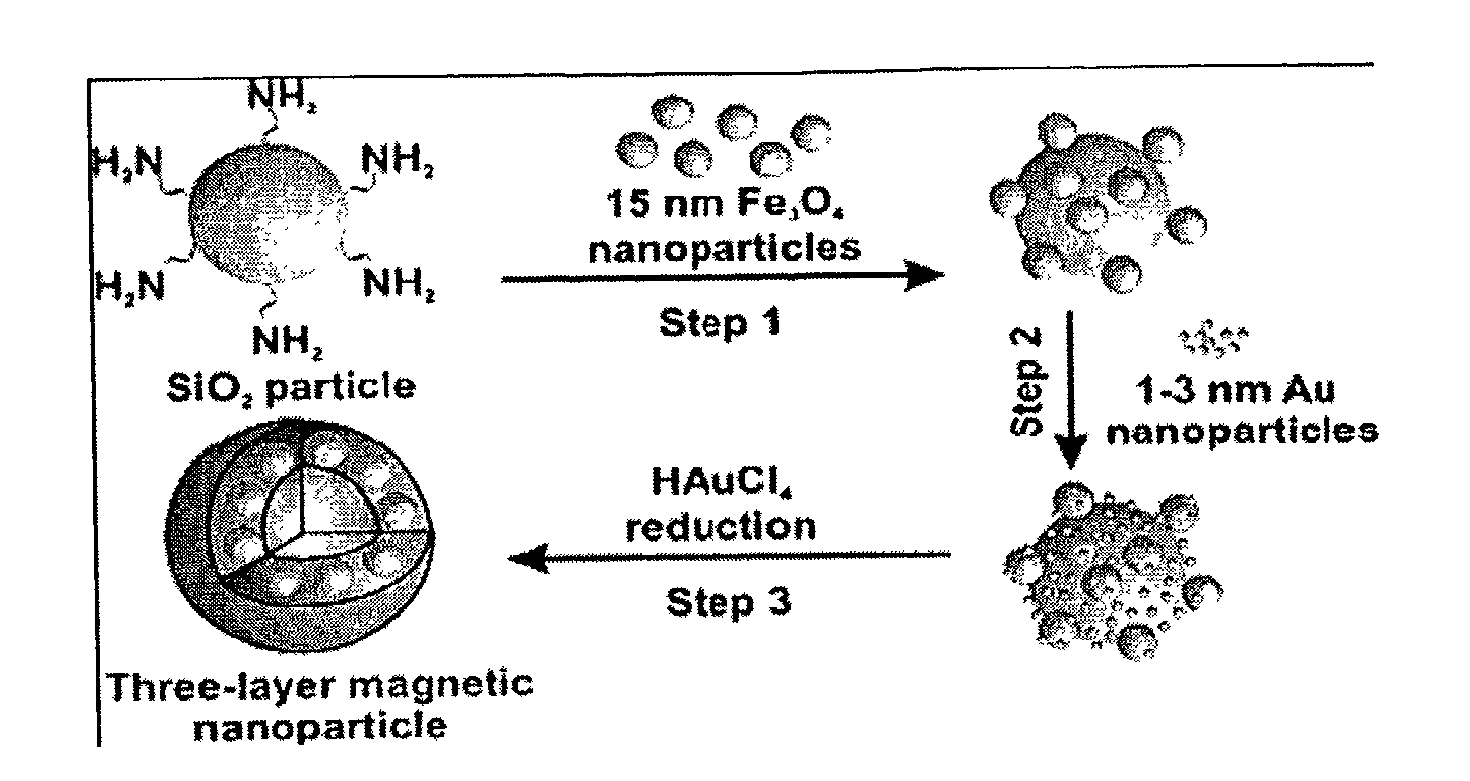

Method for manufacturing fine composite particles, apparatus for manufacturing fine composite particles, and fine composite particles

ActiveUS20070128350A1Easy to controlContinuous productionPigmenting treatmentMaterial nanotechnologyMicroparticleCore Particle

In the present invention, the fine particle composite process is carried out with the step of reacting fine core particles and a raw material for coating layer by mixing them and continuously supplying a resulting mixture into a micro flow path. The micro flow path is specified to 1-4000 in Reynolds number. With this arrangement, the present invention ensures, in a technology using a reactor having a micro flow path, accurate control of reaction condition, uniformity of coating amount distribution, easy layer formation, and successive production of fine composite particles.

Owner:NAT INST OF ADVANCED IND SCI & TECH

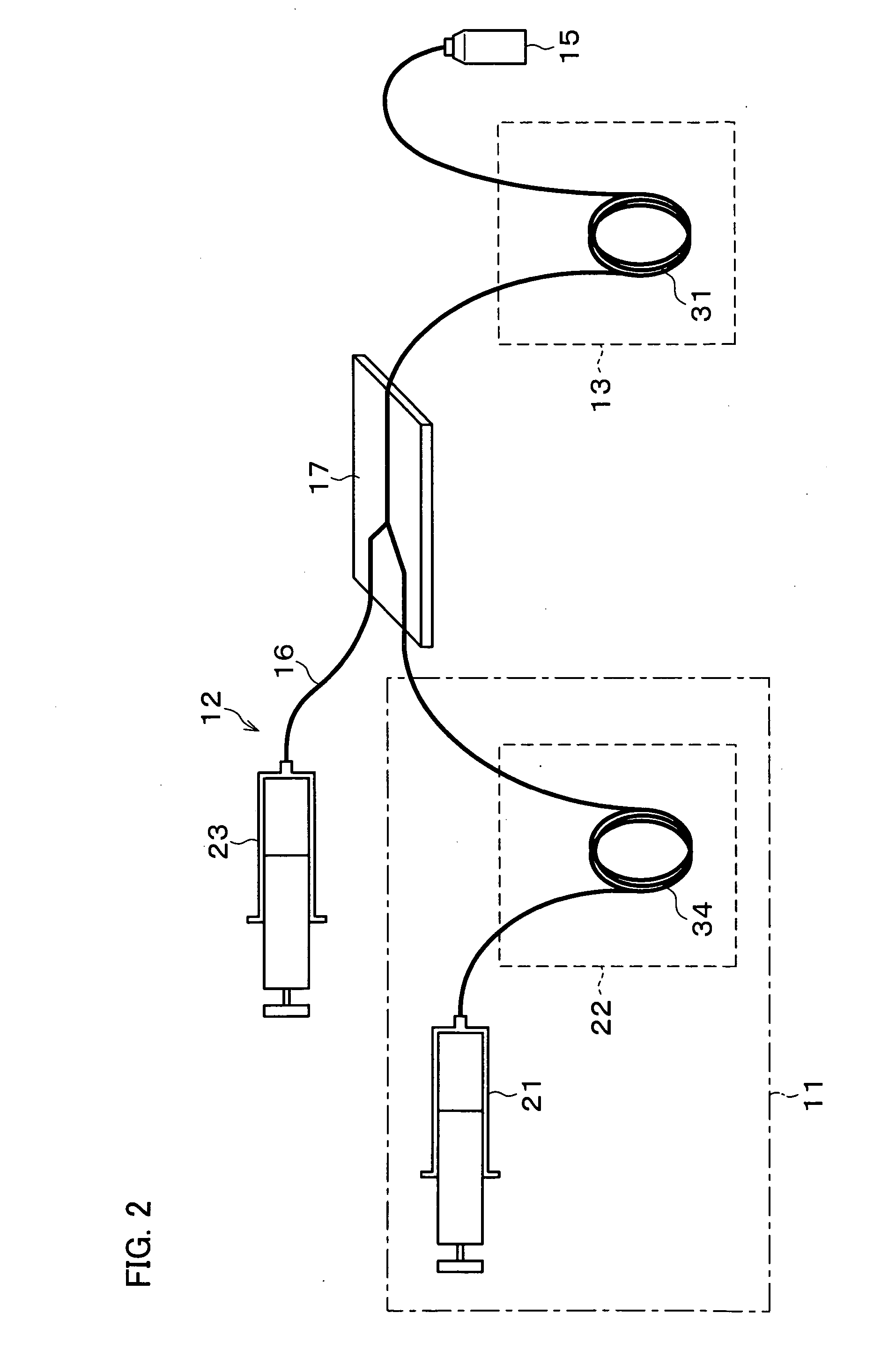

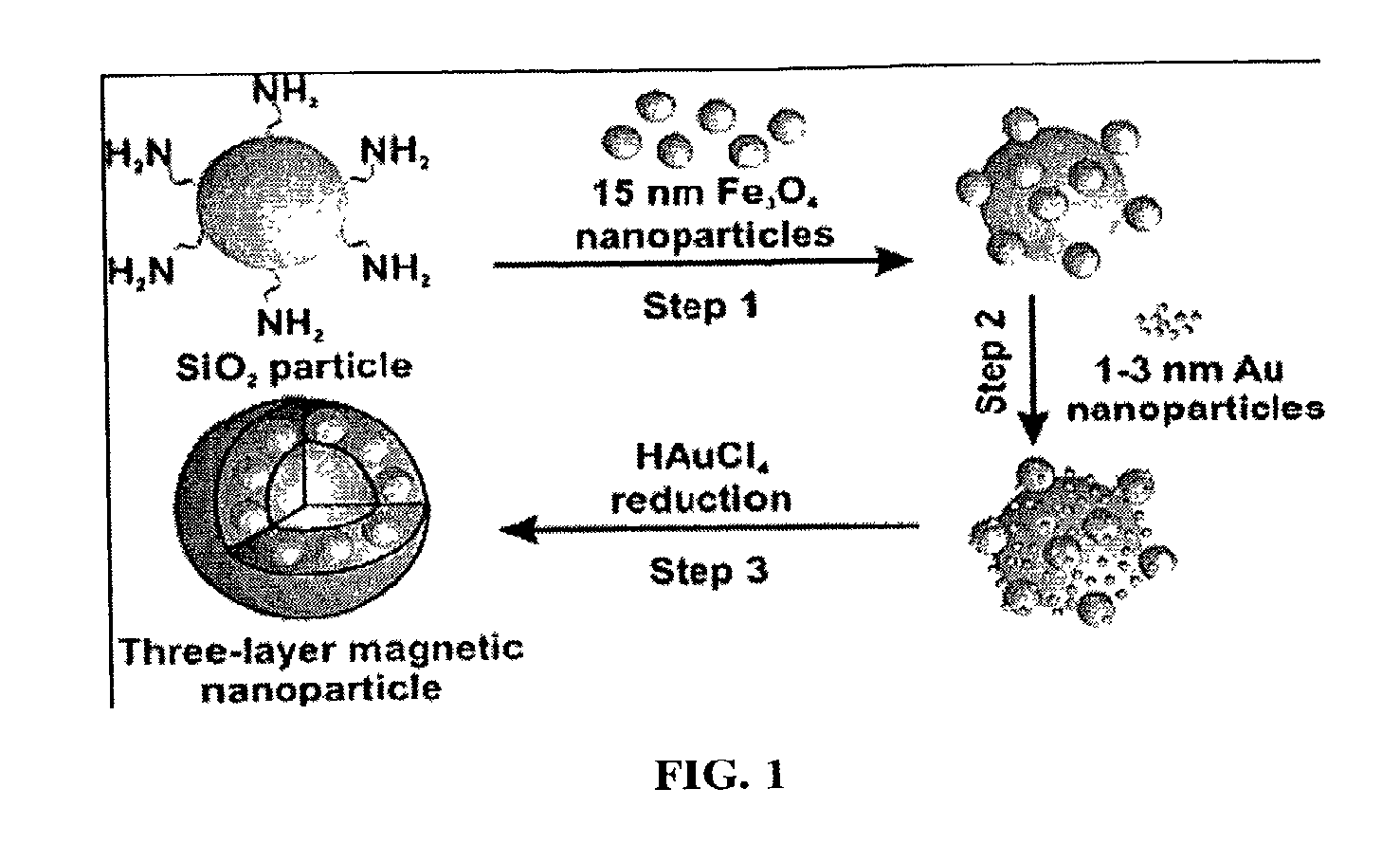

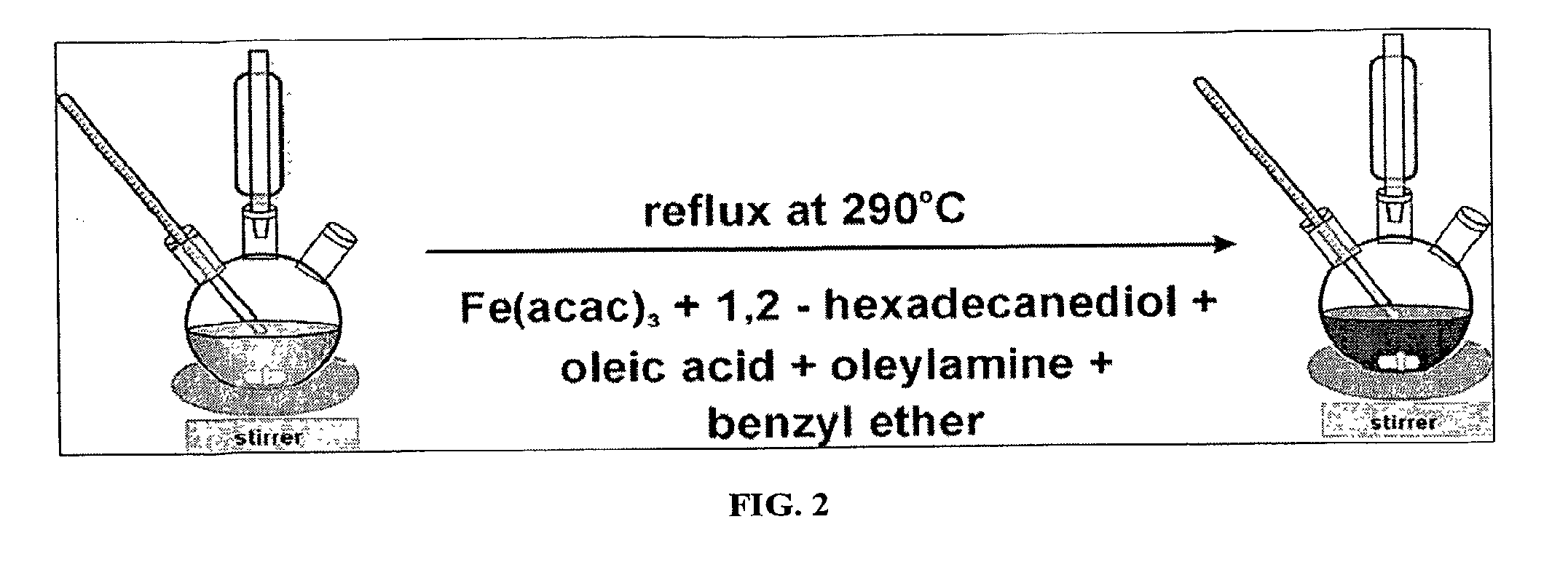

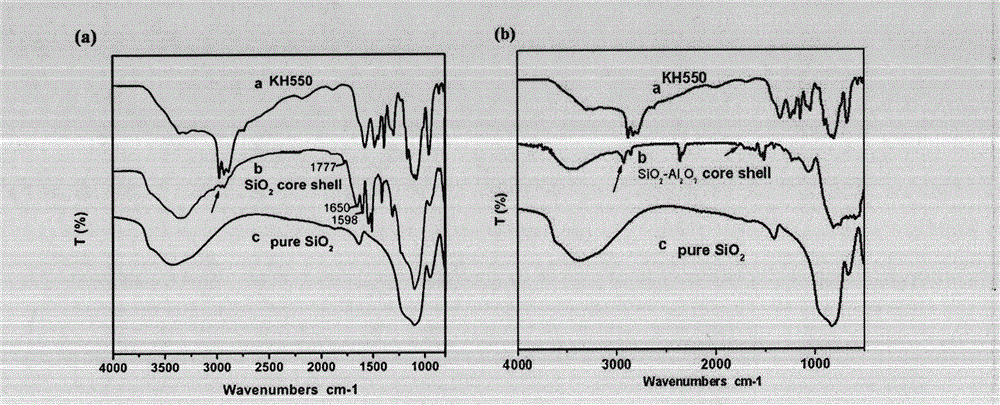

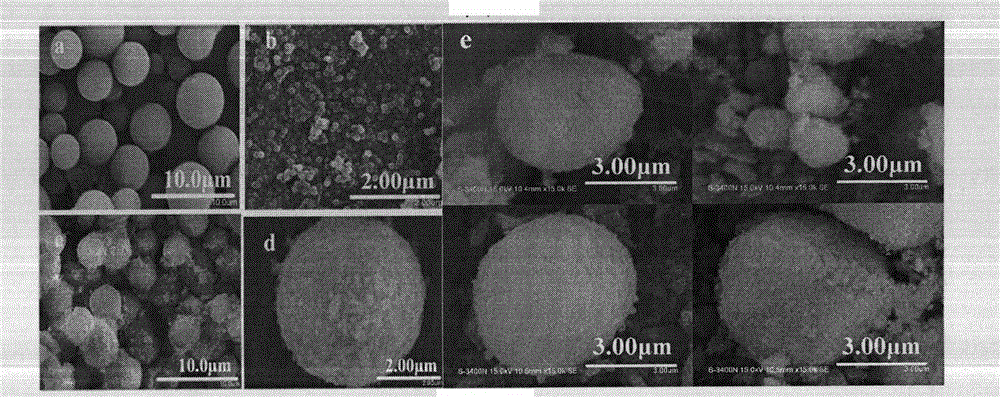

Composite particles

Composite particles and methods of synthesizing a composite particle are disclosed, in particular, methods of synthesizing a composite particle comprising a dielectric component, a magnetic component, and a gold shell are disclosed. Further disclosed herein are methods of detecting a target compound using the composite particles of the present invention. Also disclosed are photonic crystals that can be manipulated with an external magnetic field comprising the composite particles of the present invention.

Owner:NORTHWESTERN UNIV

Method for preparing lyophobic heat conduction material with micro-nano core-shell structure

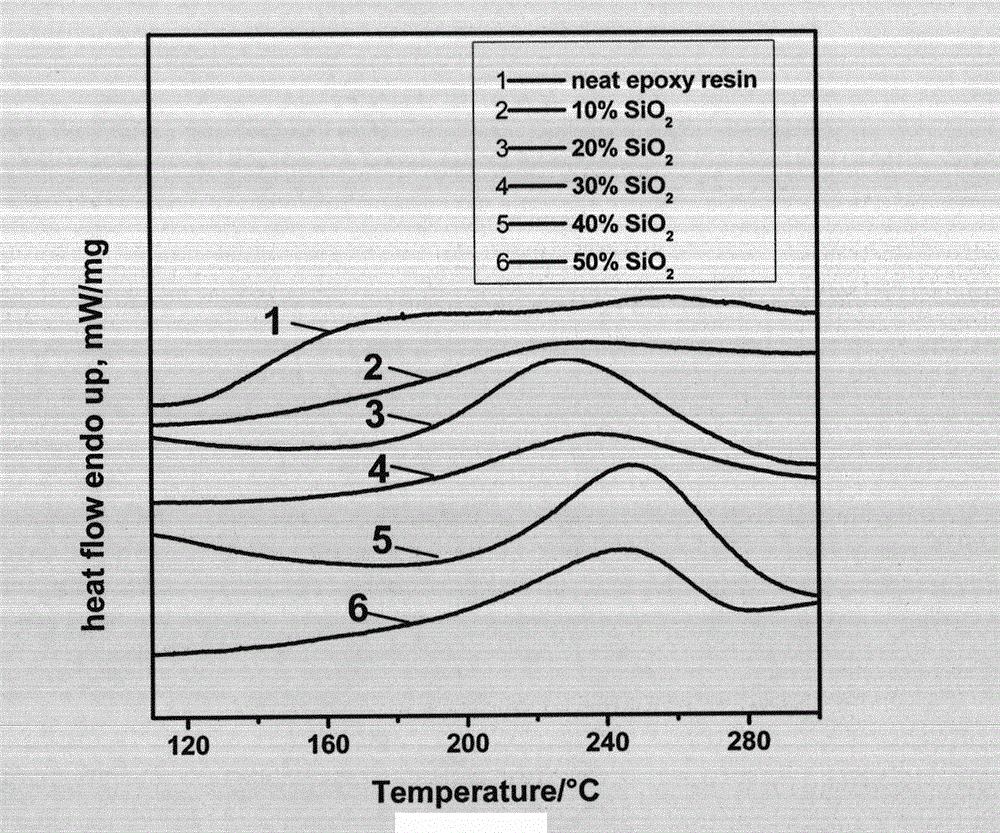

ActiveCN103146197AReduce the amount requiredHigh thermal conductivitySilicaOther chemical processesMicro nanoEpoxy

The invention discloses a method for preparing a lyophobic heat conduction material with a micro-nano core-shell structure. The method comprises the following steps of: preparing micro-nano particles with different particle sizes by adopting a colloidal sol method at first; utilizing organic matters containing special functional groups to wrap the nano particles on microparticles because nano particle surfaces comprise hydroxyls, and thus obtaining composite particles with core-shell structures; and filling the composite particles into epoxy resin or organic silicon resin so as to prepare a packaging material with high thermal conductivity, super hydrophobicity, good heat resistance and thermal mechanical performance. Compared with a conventional particle filling packaging material or thermal interface material, the material has more excellent performances.

Owner:东莞市维赛实业有限公司

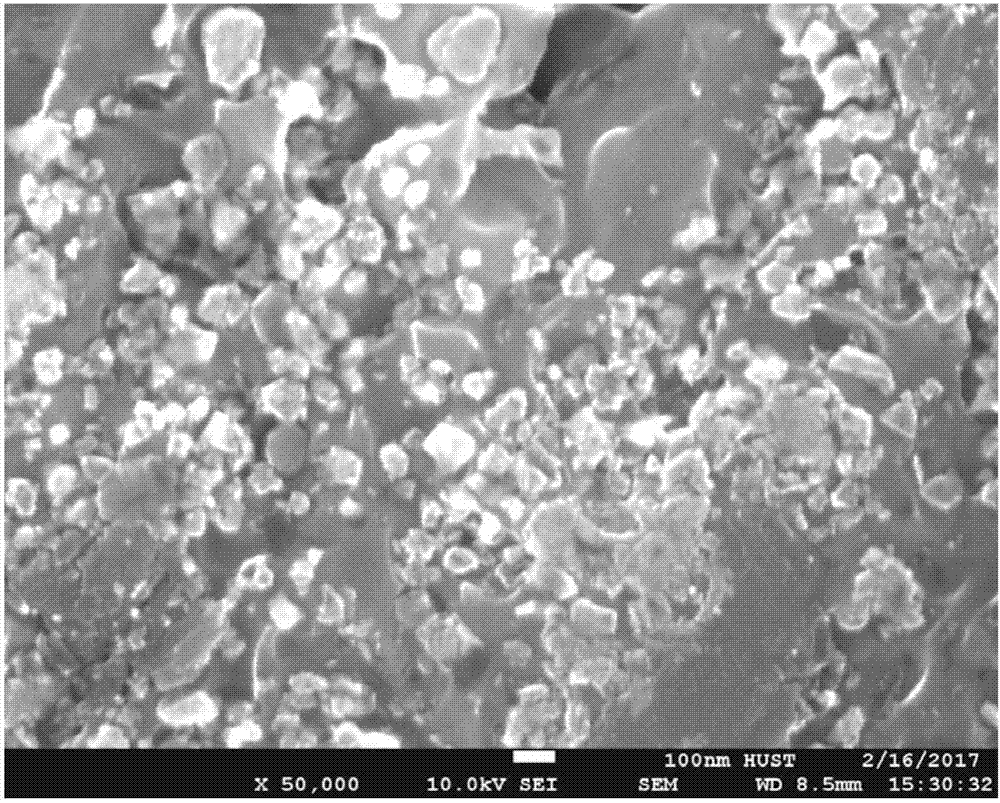

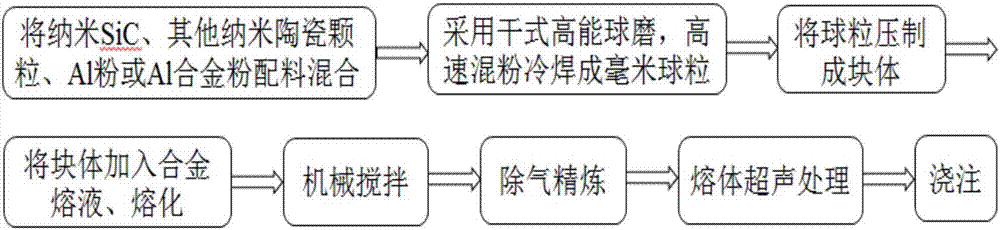

Hybrid strengthened aluminum matrix composite and preparation method thereof

The invention discloses a hybrid strengthened aluminum matrix composite and a preparation method of the hybrid strengthened aluminum matrix composite and belongs to the field of casting metal matrix composites. The matrix of the material is aluminum or an aluminum alloy, and nano-sized SiC particles and other nanoparticles are used as the strengthening phase. The invention further provides the method for preparing the hybrid strengthened aluminum matrix composite. The method comprises the following steps that firstly, under vacuum or argon protection, nano-sized SiC powder, one or more of other nanoparticles and micro-sized aluminum or aluminum alloy powder are mixed, and millimeter-sized composite particles are prepared; and then the millimeter-sized composite particles are pressed into a prefabricated intermediate alloy block, then the intermediate alloy block is added to aluminum or aluminum alloy melt, through refining and degassing processing, scum and oxide inclusions are stripped off, mechanical mixing and ultrasonic vibration are applied, the nano-sized ceramic particles are promoted to be uniformly dispersed in the metal melt, and the nano-sized ceramic particle hybrid strengthened aluminum matrix composite is prepared. According to the hybrid strengthened aluminum matrix composite and the preparation method, the multi-phase hybrid strengthened supplementary effect and advantage are fully played, and all the performances of the metal matrix composite is improved remarkably.

Owner:HUAZHONG UNIV OF SCI & TECH

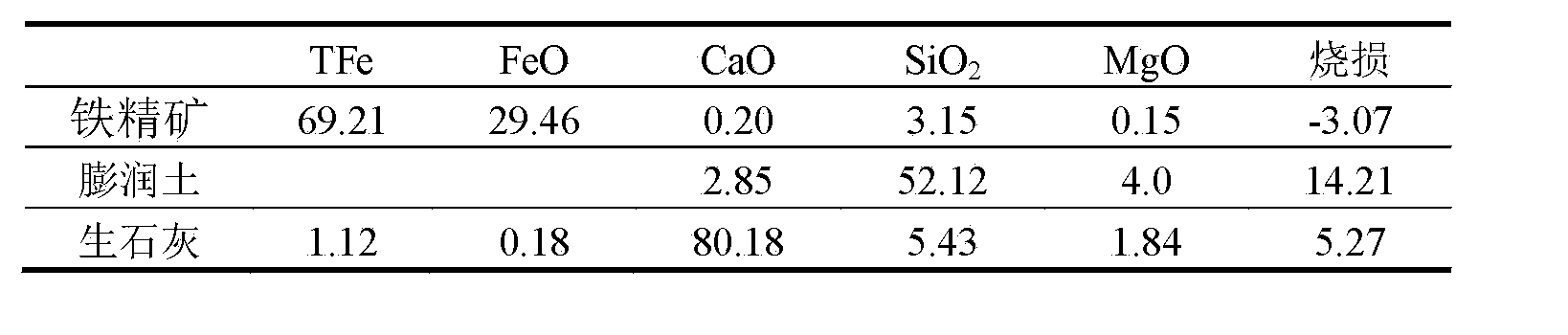

Producing method of fluxed composite pellet

A producing method of a fluxed composite pellet is disclosed. The method includes: (1) mixing a iron material, a flux, and an adhesive to obtain a material mixture with the iron material being high-iron low-silicon iron ore powder, the flux being quicklime powder and the adhesive being bentonite, water glass or sodium humate, etc., adjusting the content of the quicklime powder to make the alkalinity of the material mixture to be 0.6-1.0, adding water into the material mixture to wet the material mixture and uniformly mixing; and (2) wetting high-alkalinity sintering return mine, subjecting the material mixture in the step (1) to primary pelletizing in a disk pelletizer to produce raw pellets by adopting the return mine as a pelletizing core, and calcinating according to fluxed composite pellet calcinating rules to obtain the fluxed composite pellet finished product with double alkalinity for one pellet. The composite pellet having advantages of high-alkalinity sintering ore and advantages of pellets is produced. The metallurgical performance of pellets is enhanced. A novel utilization route of the sintering return mine is provided.

Owner:ANGANG STEEL CO LTD

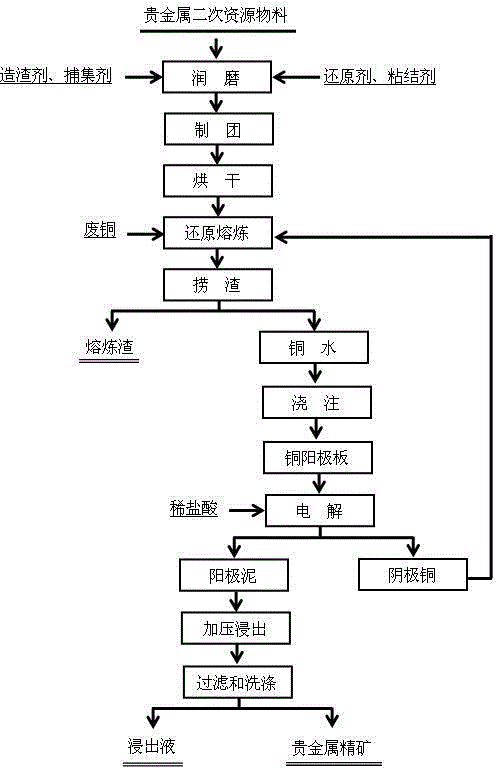

Efficient enrichment method for precious metal secondary resources

InactiveCN105886770AAdaptableSimple processProcess efficiency improvementElectrolysisEnrichment methods

The invention discloses an efficient enrichment method for precious metal secondary resources. The method comprises the steps that precious metal secondary resource materials, a copper collecting agent, a reducing agent, a slag forming constituent, a binding agent and water are subjected to full wet-grinding in a ball mill, and are mixed evenly and manufactured into pellets through a ball forming machine, and the pellets are dried to obtain composite pellets; after waste copper is molten in an intermediate-frequency furnace, the composite pellets are added into the intermediate-frequency furnace in batches and are subjected to mixing smelting for a period of time, smelting slag is fished out, and molten copper is poured into a casting mold to form a copper anode plate; cathode copper is obtained through an electrolysis method, precious metals enter anode mud, and electrolytic residual anodes return to conduct smelting and pouring on the anode plate and conduct electrolysis again; the anode mud is subjected to pressure acid leaching, filtering and washing to obtain precious metal concentrate, and accordingly precious metal enrichment is realized. By means of the method, the process is simple, the raw materials are high in adaptability, high efficiency and environmental friendliness are achieved, the enrichment ratio is high, cost is low, and industrialization is facilitated.

Owner:KUNMING METALLURGY COLLEGE

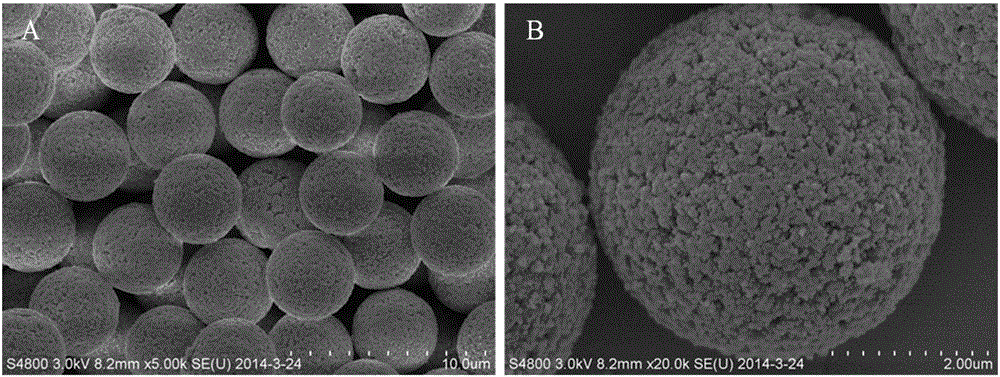

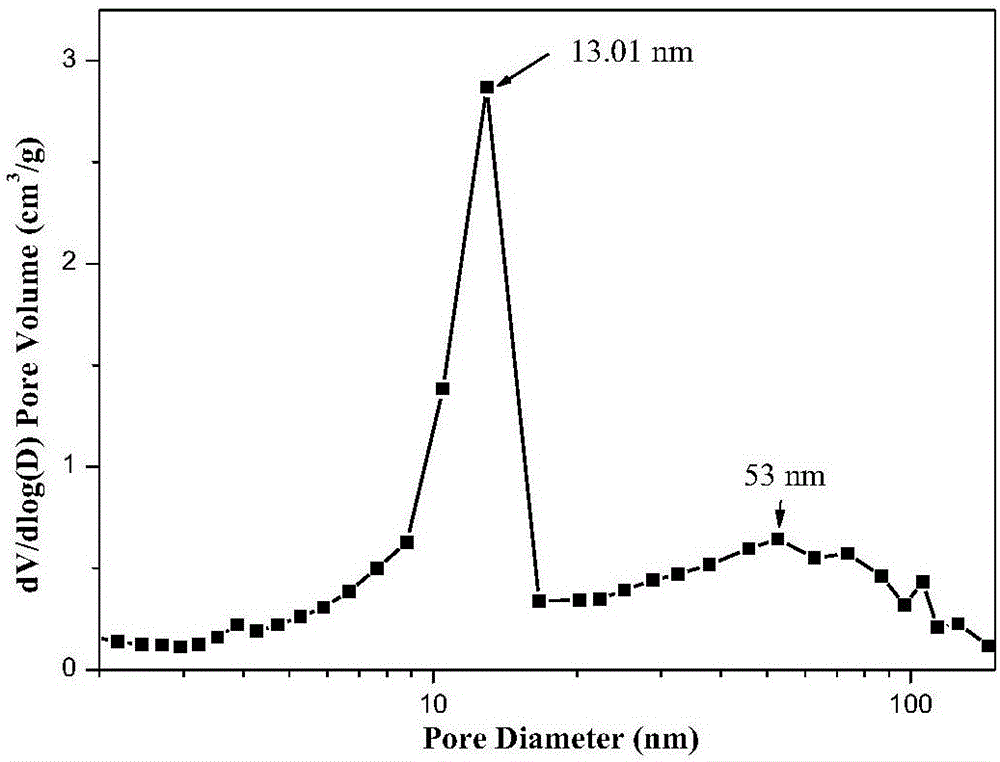

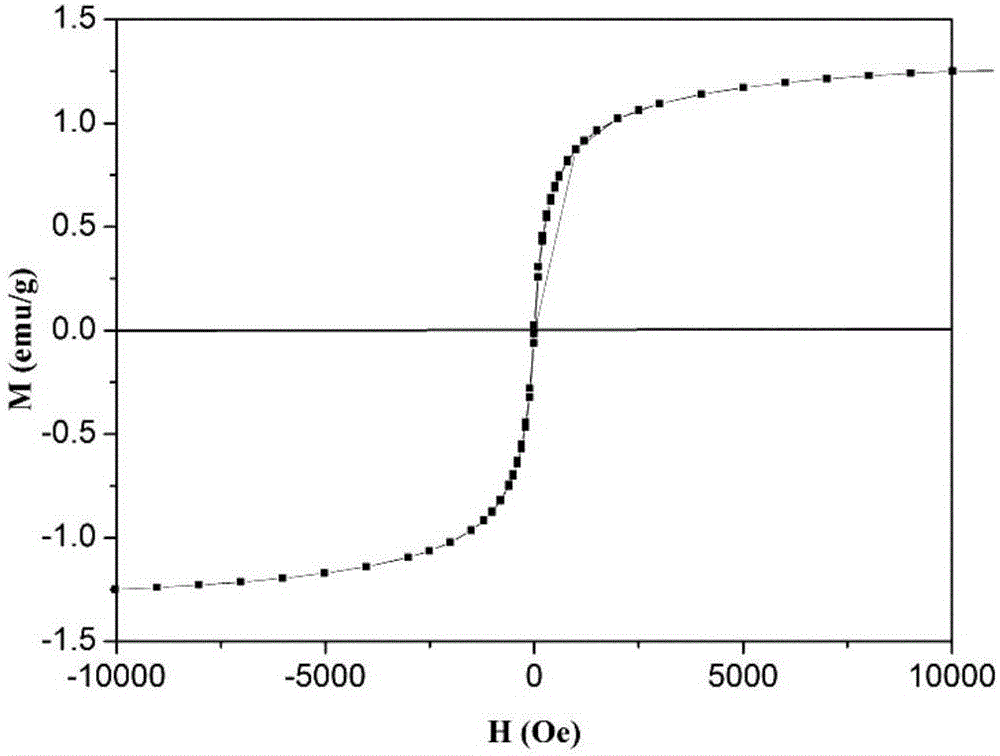

Monodisperse magnetic porous silicon dioxide pellet and preparing method thereof

InactiveCN106710773AMagnetically stableControllable particle sizeSilicaInorganic material magnetismMicrosphereMagnetite Nanoparticles

The invention discloses a monodisperse magnetic porous silicon dioxide pellet and a preparing method thereof. The preparing method of the monodisperse porous silicon dioxide pellet comprises the steps of utilizing a monodisperse magnetic porous macromolecule pellet as a template, generating in situ a magnetic Fe3O4 particle and sol-gelation of a silicon source and using a Fe3O4 particle to oxidize gamma-Fe2O3, forming a magnetic macromolecule-silicon dioxide composite pellet, and then removing the macromolecule template after calcination to obtain the monodisperse magnetic porous silicon dioxide pellet. The preparing method of the monodisperse magnetic porous silicon dioxide pellet is simple in process and easy to operate, and the prepared monodisperse magnetic porous silicon dioxide pellet has the advantages of being homogenous in particle size, controllable in particle diameter and pore diameter, connective in pore, simple in method of introducing magnetic nanoparticles, stable in magnetism and the like.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

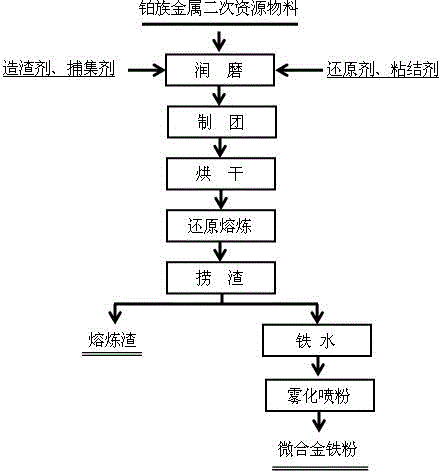

Method for efficiently collecting platinum group metals through mixing reduction smelting of iron powder and iron ores

InactiveCN105886771AAdaptableThis method is simpleProcess efficiency improvementWet grindingComposite pellet

The invention discloses a method for efficiently collecting platinum group metals through mixing reduction smelting of iron powder and iron ores. The method comprises the steps that platinum group metal secondary resource materials, an iron collecting agent, a reducing agent, a slag forming constituent, a binding agent and water are subjected to full wet-grinding in a ball mill and are mixed evenly and manufactured into pellets through a ball forming machine, and the pellets are dried to obtain composite pellets; the composite pellets are added into an electric induction furnace in batches and are subjected to mixing smelting for a period of time, smelting slag is fished out, and molten iron is poured into a powder spraying device and subjected to atomization and powder spraying to form fine-grained microalloy iron powder. From the raw materials to the microalloy iron powder, the platinum group metals are efficiently collected. The method is simple in process, the raw materials are high in adaptability, high efficiency and environment friendliness are realized, the enrichment ratio is high, cost is low, and industrialization is facilitated.

Owner:KUNMING METALLURGY COLLEGE

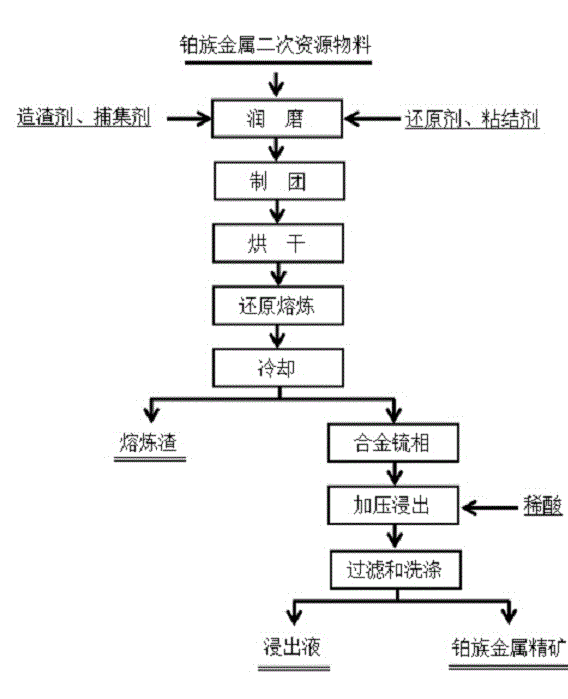

Method for enriching platinum group metal secondary resource with high efficiency

The invention discloses a method for enriching platinum group metal secondary resource with high efficiency. The technology comprises the following steps: a platinum group metal secondary resource material, a trapping agent, a reducing agent, a slagging agent, a binder and moisture are put in a bowl mill for wetting grinding, after the materials are uniformly mixed, a granulator is used for preparing the pellets, the pellets are dried to obtain the composite pellets; a graphite crucible is used for putting the composite pellets, the composite pellets are molten in a reduction furnace, after melting for a while, the composite pellets are dumped into the graphite crucible, then cooled, an upper layer is the melting slag, a lower layer is a platinum metal alloy sulfonium phase, the high efficiency trapping of the platinum group metal is realized; elements such as copper, iron, nickel and sulfur in the alloy phase can be leached by employing pressure acid leaching in a selective mode, after filtering and washing, the platinum group metal concentrate is obtained, and the high efficiency enrichment of the platinum group metal is realized. The method has the advantages of simple operation, high platinum yield, high enrichment ratio, environmental protection, low cost, low energy consumption, and good industrialization prospect.

Owner:KUNMING METALLURGY COLLEGE

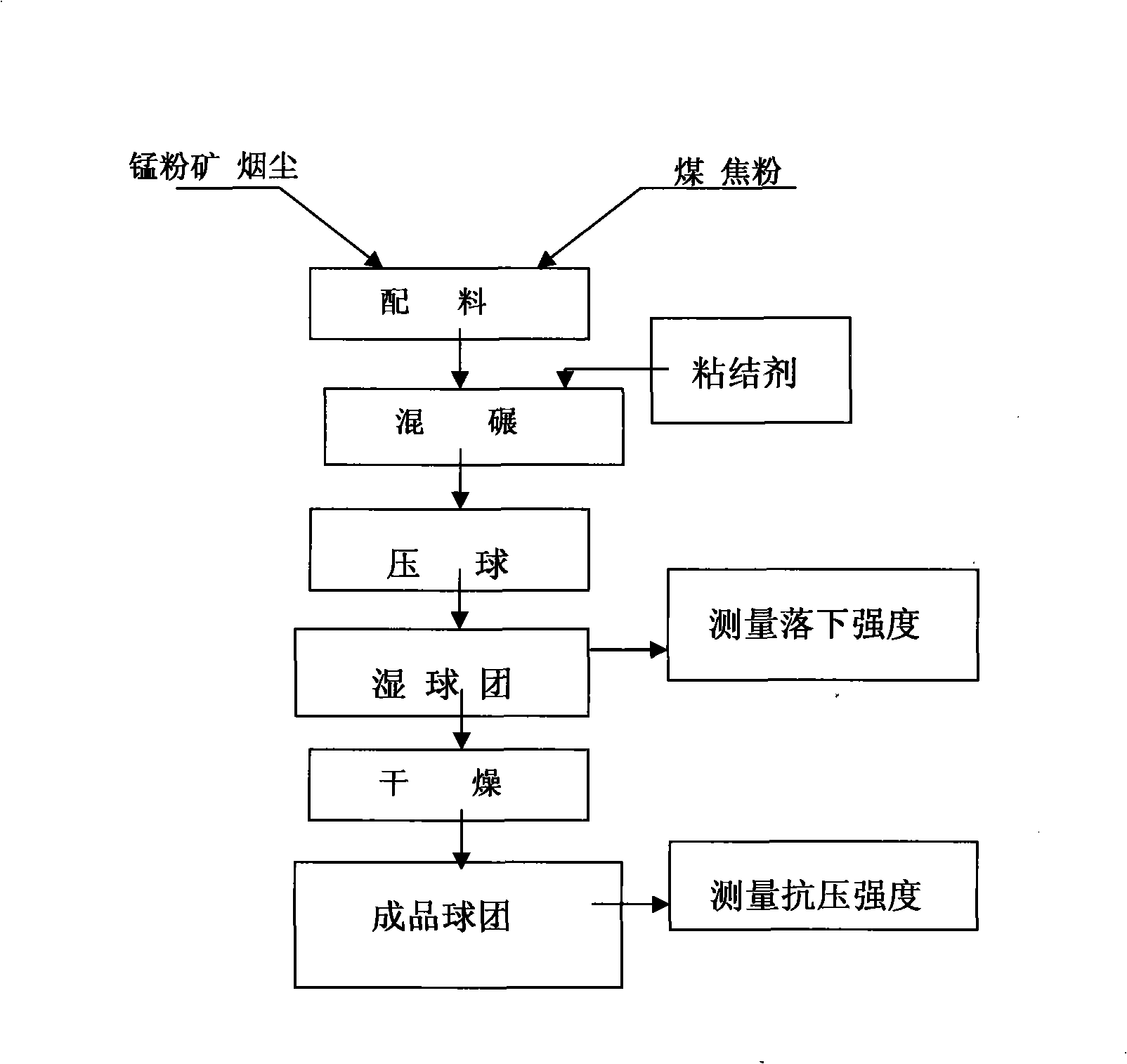

Preparation of carbonaceous composite pellet containing manganese

The invention discloses a preparation method of a composite pellet, which includes the working procedures of preparing materials, measuring, mulling, pressing and drying. Compared with the prior art, the preparation method is simple to be operated and has the advantages that: (1) the composite conception is broad; the pellet not only has a manganese material, but also has a reducer needed by smelting and takes coal for replacing tar and reducing the production cost; the material containing manganese not only includes the powder of a manganese ore (molybdenum concentrate, imported fine ore, slag rich in manganese, sintering fine ore and baking fine ore), but also includes manganese soot and improves the operating factor of resources; (2) the materials adopted by the composite pellet are broad in granularity; the granularity of the manganese ore (molybdenum concentrate, slag rich in manganese, sintering fine ore and baking fine ore) is between 0 and -3mm, the granularity of the coal is between 0 and -5mm, and the production technique is simplified; (3) drying is carried out under lower temperature, thus saving energy resources; and (4) a dry power sintering agent is used and the operation is simple and convenient. The composite pellet is applied to smelting manganese series iron alloys by electric furnaces and the smelting effect of the electric furnaces is good.

Owner:云南文山斗南锰业股份有限公司 +1

Sintered spherical pellets useful for gas and oil well proppants

Sintered, spherical composite pellets having high strength and low density, are described, along with processes for their manufacture. One method includes forming a green pellet from a mixture of clay, bauxite or a clay-bauxite mixture with a sacrificial phase such that upon sintering of the pellet, the sacrificial phase is removed from the pellet. The use of such sintered pellets in hydraulic fracturing of subterranean formations is also described.

Owner:CARBO CERAMICS

Cold press composite pellet binder

The invention relates to a novel caking agent for preparing a pellet used for smelting by using a cold pressing method, in particular to a caking agent which needs to be added when using the cold pressing method to prepare a composite pellet comprising manganese powder. The invention is characterized in that the caking agent is formed by mixing the following two matters: (1) cornstarch and potato starch are used as the main materials, potassium permanganate and sodium hydroxide are added and mixed; and (2) solid sodium silicate is used as a main component, aluminum potassium sulfate and sodium fluosilicate are added. The first types of matters mainly obtain the wet pellet intensity and meet the intensity demand of the strap transmission on the pellet between a pellet press and a drying kiln. The second types of matters mainly obtain the dry pellet intensity, meet the intensity demand of transmission and autoimmunization pellet matching on the pellet and maintain the pellet to not crack at high temperature. Compared with the traditional sintering technique, the cold-pressing composite pellet caking agent saves the energies and reduces pollution. The technique can also be applied to produce carbon pellets, realizes using coal for replacing coke, reduces the cost of the reducer and promotes the comprehensive utilization of the resources.

Owner:云南文山斗南锰业股份有限公司 +2

Sintered spherical pellets

Sintered, spherical composite pellets or particles comprising alumina fines, at least one of clay and bauxite and optionally a sintering aid, are described, along with a process for their manufacture. The use of such pellets in hydraulic fracturing of subterranean formations and in grinding is also described.

Owner:CARBO CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com