Patents

Literature

122 results about "Enrichment ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The enrichment ratio (ER), defined as the ratio of grade of a metal element in a deposit to the crustal abundance of the metal, is proposed for assessing mineral resources. According to the definition, the enrichment ratio of a polymetallic deposit is given as a sum of enrichment ratios of all metals.

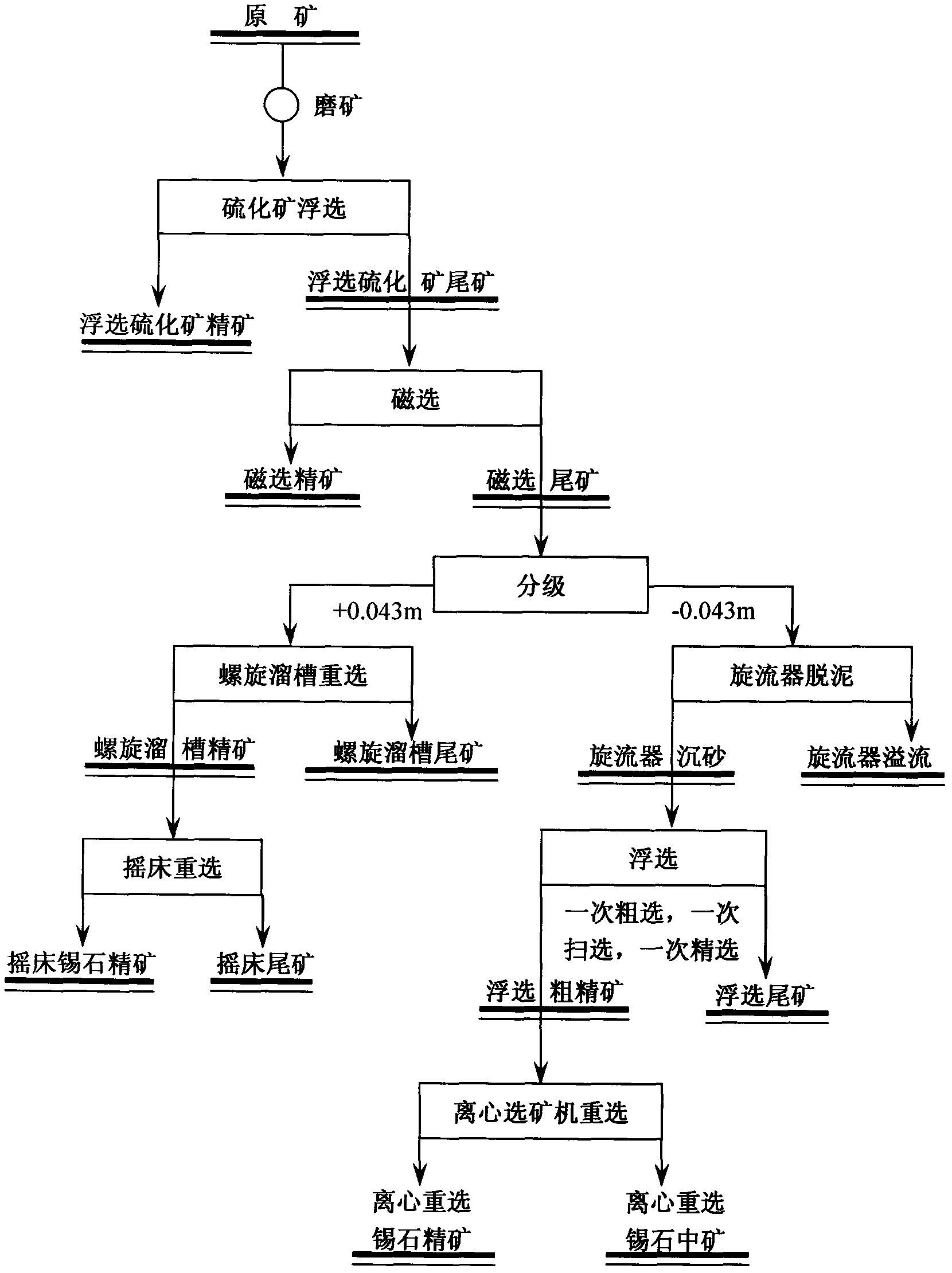

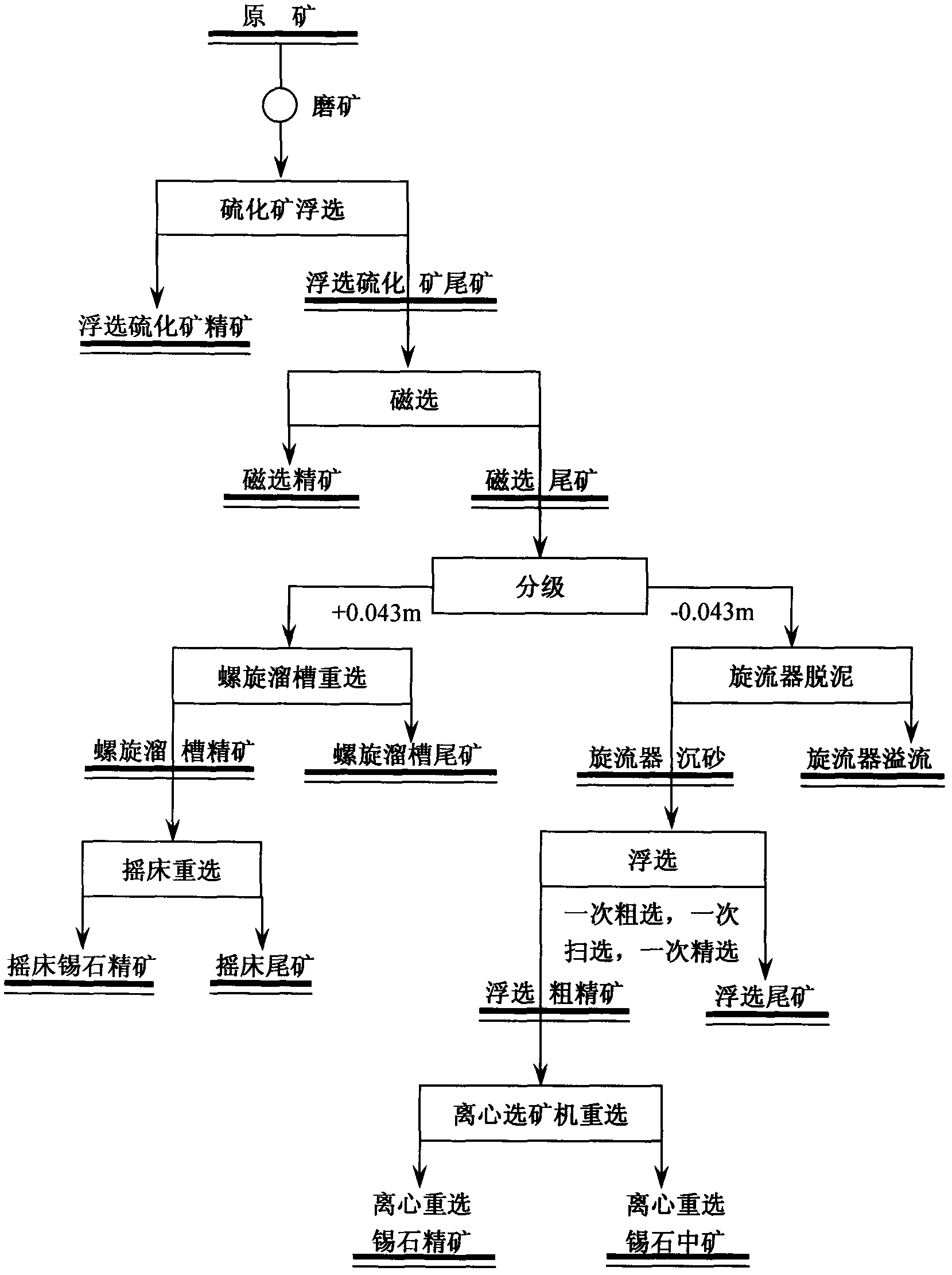

Method for separating fine cassiterite

The invention relates to a method for separating fine cassiterite, which is characterized by comprising the following steps of: grinding a raw ore, performing size mixing, and performing flotation on a sulfide ore; performing magnetic separation on tailings of the sulfide ore subjected to flotation, and grading the tailings subjected to magnetic separation into particles of +0.043mm and particlesof -0.043mm; performing gravity separation on the particles of +0.043mm by using a spiral chute and a shaker to obtain a shaker cassiterite concentrate; desliming the particles of -0.043mm by using acyclone to obtain cyclone settled sand; performing size mixing, primary flotation roughing, primary flotation scavenging and primary flotation cleaning on the cyclone settled sand to obtain a flotation coarse concentrate; performing gravity separation on the flotation coarse concentrate by using a centrifugal ore separator to obtain a centrifugal gravity separation cassiterite concentrate; and mixing the shaker cassiterite concentrate and the centrifugal gravity separation cassiterite concentrate to obtain a total cassiterite concentrate. Roughing is performed by the spiral chute, so that theprocessing capacity in a unit area is greatly improved, the occupied area is saved, and separation efficiency is high; and flotation roughing and gravity separation cleaning are combined, so that theconsumption of a flotation agent is low, cost is low, the ore separation enrichment ratio is 5 to 10, and the recovery rate of the cassiterite is high.

Owner:西乌珠穆沁旗银漫矿业有限责任公司

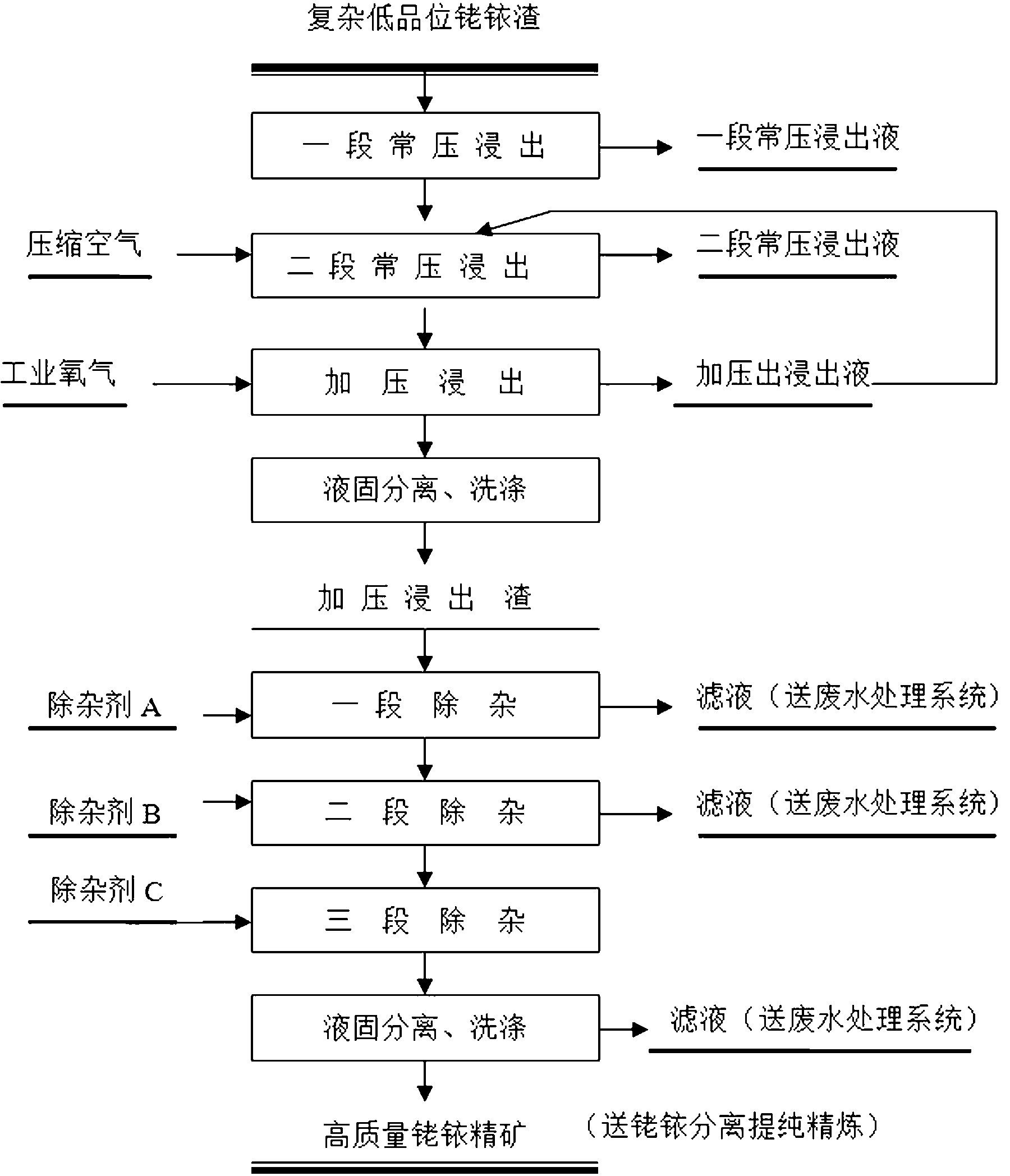

Method for efficiently enriching gold and platinum group metals from complex low-grade rhodium iridium residues

ActiveCN103320620AHigh recovery rateEliminate Scatter LossProcess efficiency improvementIridiumToxic material

The invention relates to a method for efficiently enriching gold and platinum group metals from complex low-grade rhodium iridium residues and belongs to the field of wet metallurgy of rare and precious metals. The method comprises the following steps that: primary normal pressure leaching, secondary normal pressure leaching and pressurization leaching are performed by using a low-concentration pure sulfuric acid solution, wherein an oxidizing agent is not introduced or added into the primary normal pressure leaching, air in the secondary normal pressure leaching serves as an oxidizing and leaching agent, industrial oxygen serves as an oxidizing and leaching agent in the pressurization leaching; the high-grade high-quality rhodium iridium concentrate is obtained by employing a three-step impurity removal process. The method is simple in process and environment-friendly, toxic waste gas, waste residues and the like are not generated in the process, a toxic agent is not used, the enrichment ratio and recovery rate of rare and precious metals such as rhodium and iridium are high, the grade of the precious metals in the enriched residue is 15 percent, the recovery rate of the precious metals is over 98 percent, and the method is conveniently linked with rhodium and iridium separating and refining.

Owner:JINCHUAN GROUP LIMITED

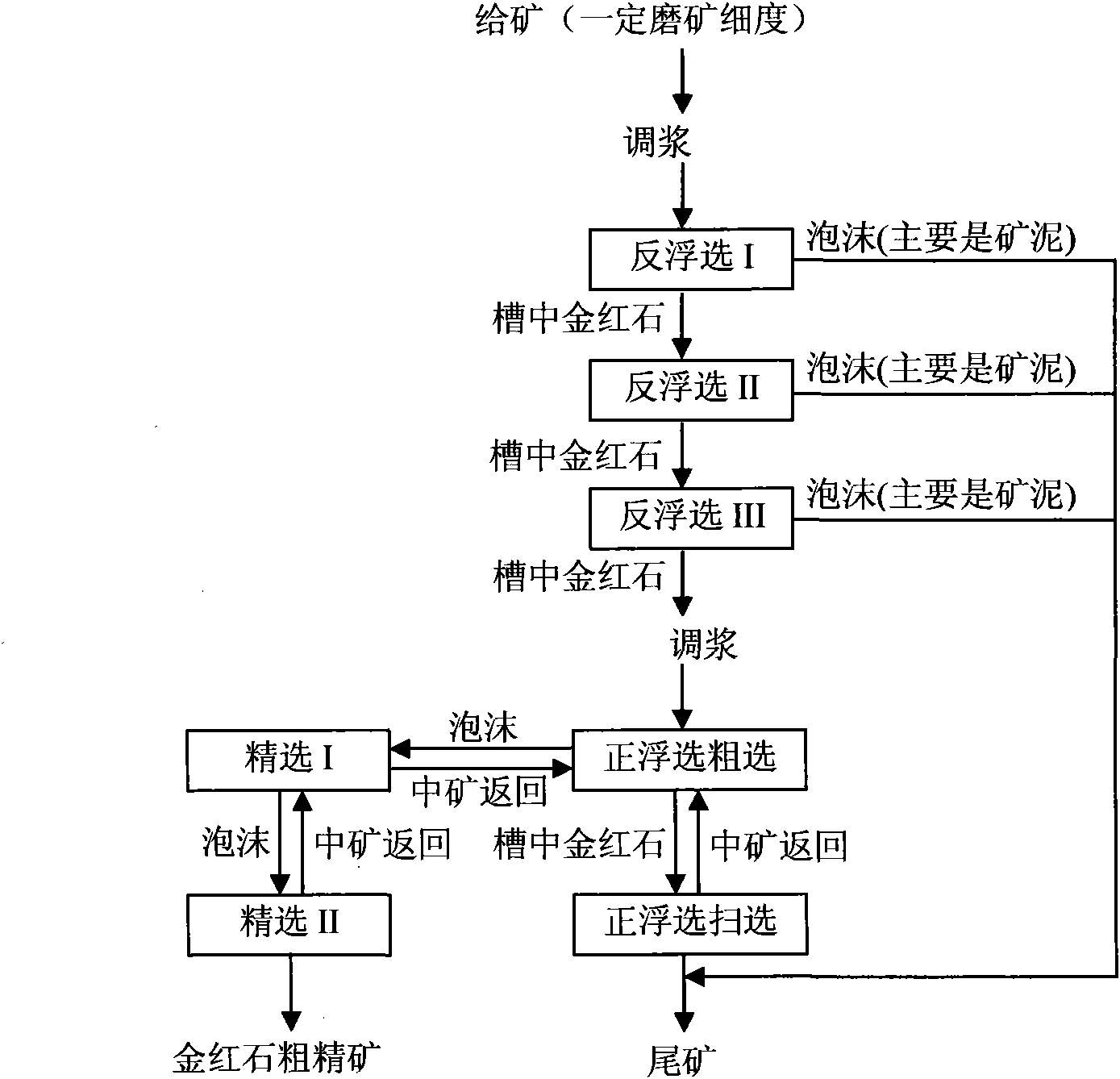

Method for roughing and tailings-discarding of fine rutile ore by multi-stage floatation

The invention provides a method for roughing and tailings-discarding of fine rutile ore by multi-stage floatation, relating to the technique for roughing and tailings-discarding of fine rutile ore by multi-stage floatation and belonging to the technical field of mineral processing engineering. The method of the invention comprises the following steps: firstly, conducting the reverse floatation of rutile by using sodium oleate as a collector according to the characteristics that aluminum sulfate can inhibit the rutile and activate silicate minerals in varying degrees, so as to effectively deslime in the process of reverse floatation; and then, conducting the forward floatation of rutile by using lead nitrate (or lead acetate) as an activator of rutile and using sodium alkyl hydroxamate and benzyl arsonic acid (or styryl phosphonic acid) as a combined collector according to the characteristic that gangue minerals can be inhibited on a combined basis under the synergistic action of sodium fluorosilicate, carboxymethylcellulose and the residual aluminum sulfate in the ore pulp, briefly, the method of the invention can realize the roughing and tailings-discarding of fine rutile by the multi-stage floatation comprising the following steps: firstly, conducting the reverse floatation by inhibiting the rutile; and then, conducting the forward floatation by activating the rutile. The method of the invention has the advantages that the enrichment ratio and recovery rate of rutile are high, the tailings of rutile ore can be discarded thoroughly and the mineral processing cost of rutile can be greatly reduced.

Owner:KUNMING UNIV OF SCI & TECH

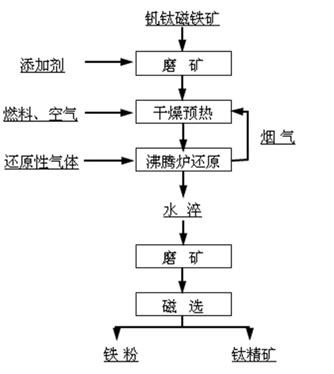

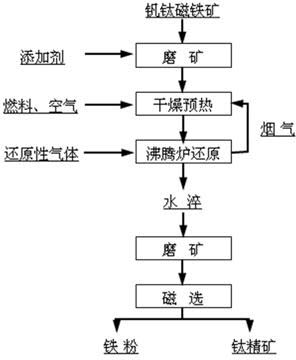

Method for processing vanadium titano-magnetite

ActiveCN102676796AAvoid askingAvoid ring formation in rotary kilnMagnetic separationMagnetiteQuenching

A method for processing vanadium titano-magnetite relates to a method for preparing iron powder and ilmenite concentrate from vanadium titano-magnetite through fluidized bed roasting and magnetic separation. The method is characterized by comprising the following steps in sequence: (1) crushing and grinding the raw ore of vanadium titano-magnetite; (2) drying and pre-heating the powdery material; (3) performing reducing roasting in a heat-ore fluidized bed furnace; (4) carrying out ball milling after calcining and water quenching; and (5) performing magnetic separation to obtain the iron powder and the ilmenite concentrate. The method provided by the invention employs two sections of furnace treatment: a drying preheating section and a reducing roasting section; and compared with a traditional method, the method is short in process flow and avoids briquetting, or pelletizing processing and roasting process sintering of the raw ore, and prevents the raw ore from being attached to the wall; the operation stability is enhanced, and simultaneously, metal enrichment ratio is increased; moreover, the select-out ratios of materials in the whole flow are as follows: the select-out ratio of concentrate iron is 90-96%, while the select-out ratio of vanadium is 55% and the select-out ratio of tailing titanium is 95%.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

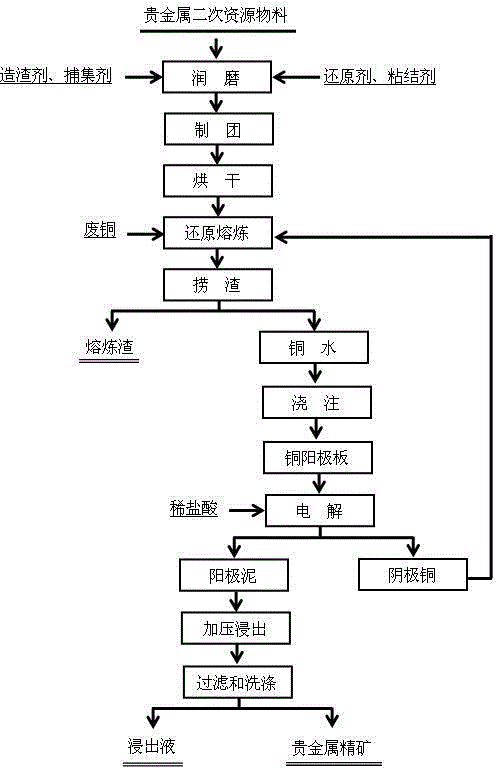

Efficient enrichment method for precious metal secondary resources

InactiveCN105886770AAdaptableSimple processProcess efficiency improvementElectrolysisEnrichment methods

The invention discloses an efficient enrichment method for precious metal secondary resources. The method comprises the steps that precious metal secondary resource materials, a copper collecting agent, a reducing agent, a slag forming constituent, a binding agent and water are subjected to full wet-grinding in a ball mill, and are mixed evenly and manufactured into pellets through a ball forming machine, and the pellets are dried to obtain composite pellets; after waste copper is molten in an intermediate-frequency furnace, the composite pellets are added into the intermediate-frequency furnace in batches and are subjected to mixing smelting for a period of time, smelting slag is fished out, and molten copper is poured into a casting mold to form a copper anode plate; cathode copper is obtained through an electrolysis method, precious metals enter anode mud, and electrolytic residual anodes return to conduct smelting and pouring on the anode plate and conduct electrolysis again; the anode mud is subjected to pressure acid leaching, filtering and washing to obtain precious metal concentrate, and accordingly precious metal enrichment is realized. By means of the method, the process is simple, the raw materials are high in adaptability, high efficiency and environmental friendliness are achieved, the enrichment ratio is high, cost is low, and industrialization is facilitated.

Owner:KUNMING METALLURGY COLLEGE

Technique for separating boron isotope with boron specific resin ion-exchange chromatography

ActiveCN101274217AEasy to separateHigh separation factorCation exchanger materialsOrganic anion exchangersIon exchangeIsotope

The invention provides a process for separating boron isotope with a boron special-effect resin ion exchange chromatography. The process adopts chelate-typed ion exchanging resin-boron special-effect resin, separates <10>B from boric acid solution, and uses hydrochloric acid or nitric acid as eluent to separate the boron isotope in the boric acid solution by the adsorption of the boric acid on resin columns and the washing of the eluent on the boric acid adsorbed on the resin. According to the process of the invention, the enrichment ratio of the <10>B can be enriched from natural 20 percent or so to 91 percent or so, with fast enrichment speed. The process of the invention is a simple and high-efficiency process which separates the boron isotope from the boric acid solution.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

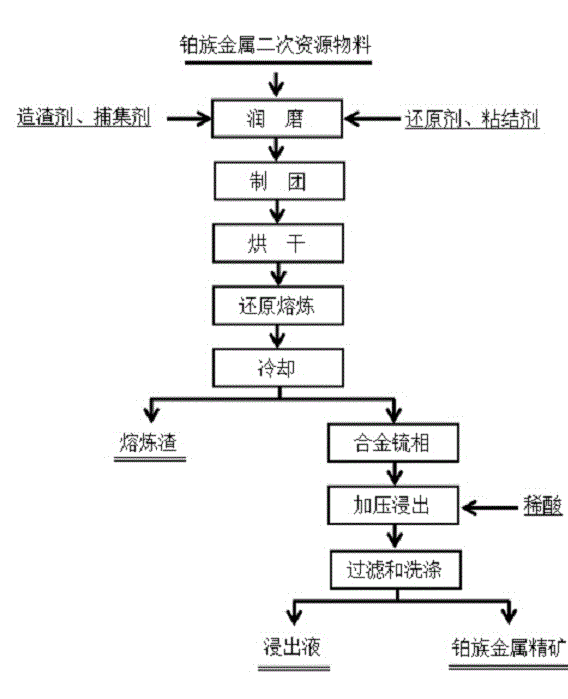

Method for enriching platinum group metal secondary resource with high efficiency

The invention discloses a method for enriching platinum group metal secondary resource with high efficiency. The technology comprises the following steps: a platinum group metal secondary resource material, a trapping agent, a reducing agent, a slagging agent, a binder and moisture are put in a bowl mill for wetting grinding, after the materials are uniformly mixed, a granulator is used for preparing the pellets, the pellets are dried to obtain the composite pellets; a graphite crucible is used for putting the composite pellets, the composite pellets are molten in a reduction furnace, after melting for a while, the composite pellets are dumped into the graphite crucible, then cooled, an upper layer is the melting slag, a lower layer is a platinum metal alloy sulfonium phase, the high efficiency trapping of the platinum group metal is realized; elements such as copper, iron, nickel and sulfur in the alloy phase can be leached by employing pressure acid leaching in a selective mode, after filtering and washing, the platinum group metal concentrate is obtained, and the high efficiency enrichment of the platinum group metal is realized. The method has the advantages of simple operation, high platinum yield, high enrichment ratio, environmental protection, low cost, low energy consumption, and good industrialization prospect.

Owner:KUNMING METALLURGY COLLEGE

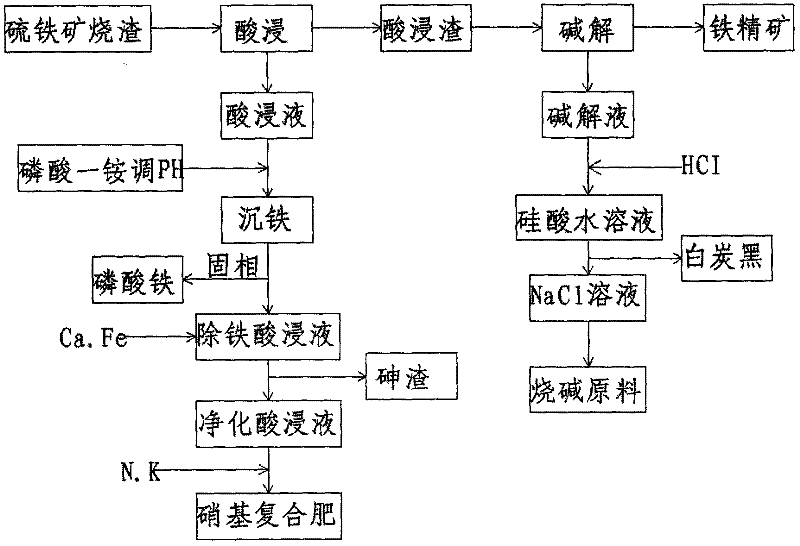

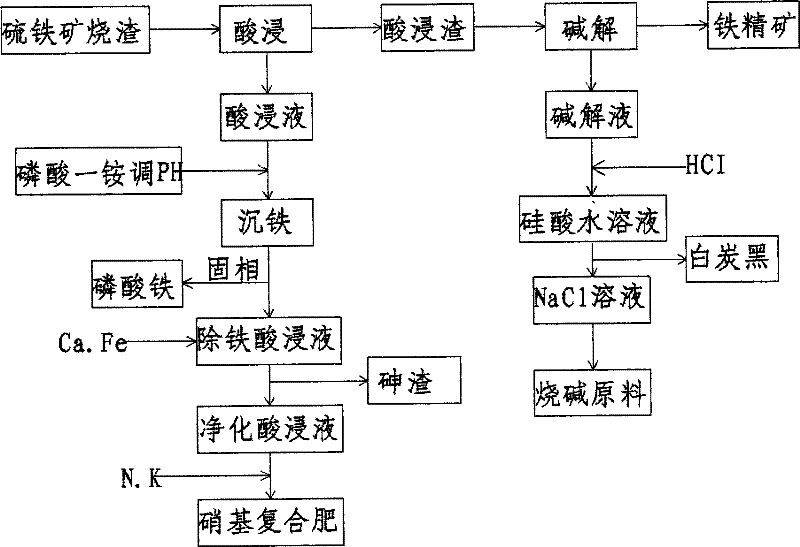

Method for treating pyrite cinder by combining acidic leaching with alkaline dissolving

ActiveCN102534187AEfficient enrichmentRealize cleaner productionProcess efficiency improvementNitro compoundResource utilization

The invention relates to a method for treating pyrite cinder by combining acidic leaching with alkaline dissolving. The method mainly comprises the following steps that: nitric acid is adopted to leach the pyrite cinder, so that alkaline oxide impurities containing sulfur and arsenic are desorbed, most of iron can still exist in a solid phase in the form of ferric oxide, and the iron is effectively enriched, wherein the iron enrichment ratio is more than 90%, the sulfur removal ratio is more than 98%, the arsenic removal ratio is more than 99%, the solid phase is acid-leached residue, and the liquid phase is acid-leached liquor; when the content of silicon dioxide is more than 15% and the total iron content can reach about 50% in the pyrite cinder, an alkaline dissolving treatment is needed, the alkaline-dissolved residue is iron ore concentrate, white carbon black is obtained after acidifying alkaline-dissolved liquor, and the liquid phase is a sodium chloride solution which can be used as a raw material of sodium hydroxide; the acid-leached liquor is added into ammonium dihydrogen phosphate to produce ferric phosphate which can be used as raw materials and ceramic raw materials of a lithium iron phosphate electromagnetic material; and purified acid-leached liquor is obtained after carrying out arsenic removal and can be applied to the production of nitro compound fertilizer. With the adoption of the method for treating the pyrite cinder by combining the acidic leaching with the alkaline dissolving, the pyrite cinder can be fully and comprehensively utilized, and thus, the resource utilization ratio is increased; and the energy-saving and emission-reduction effect is good, the method is beneficial to environment-friendliness, and the clean production in the acid making industry by using the pyrite cinder can be achieved.

Owner:师兆忠

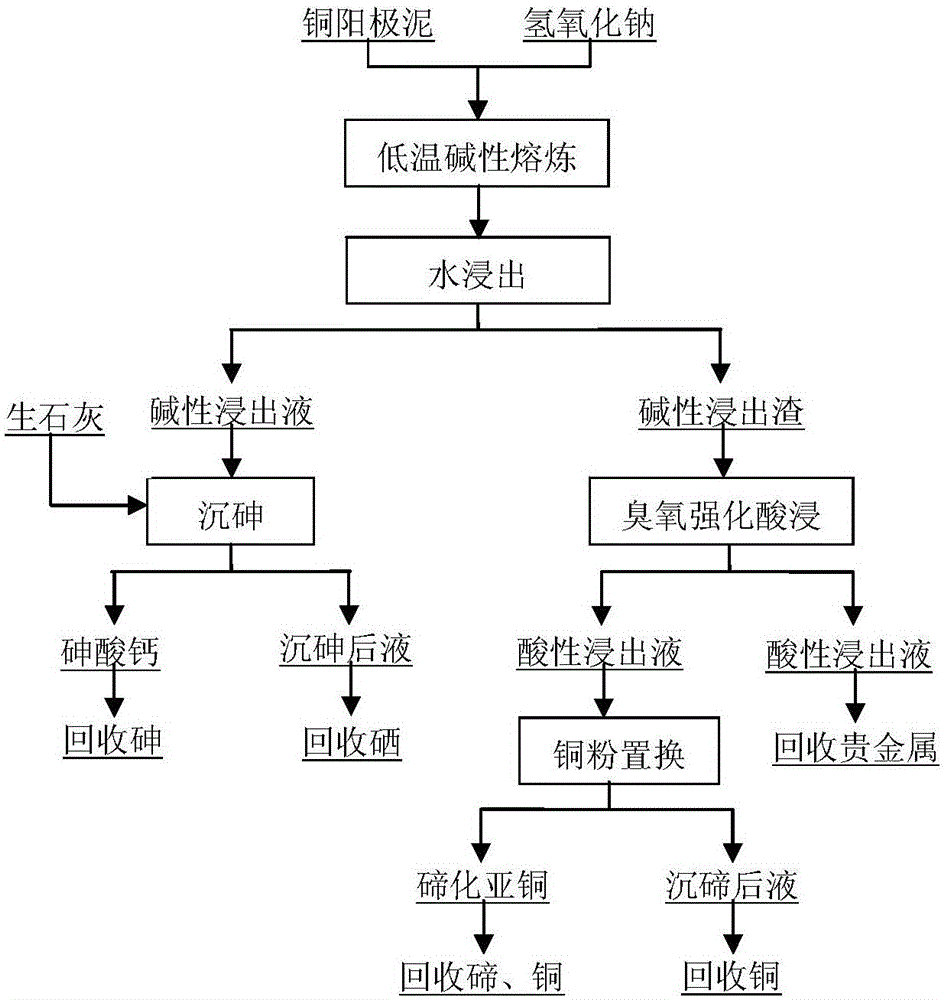

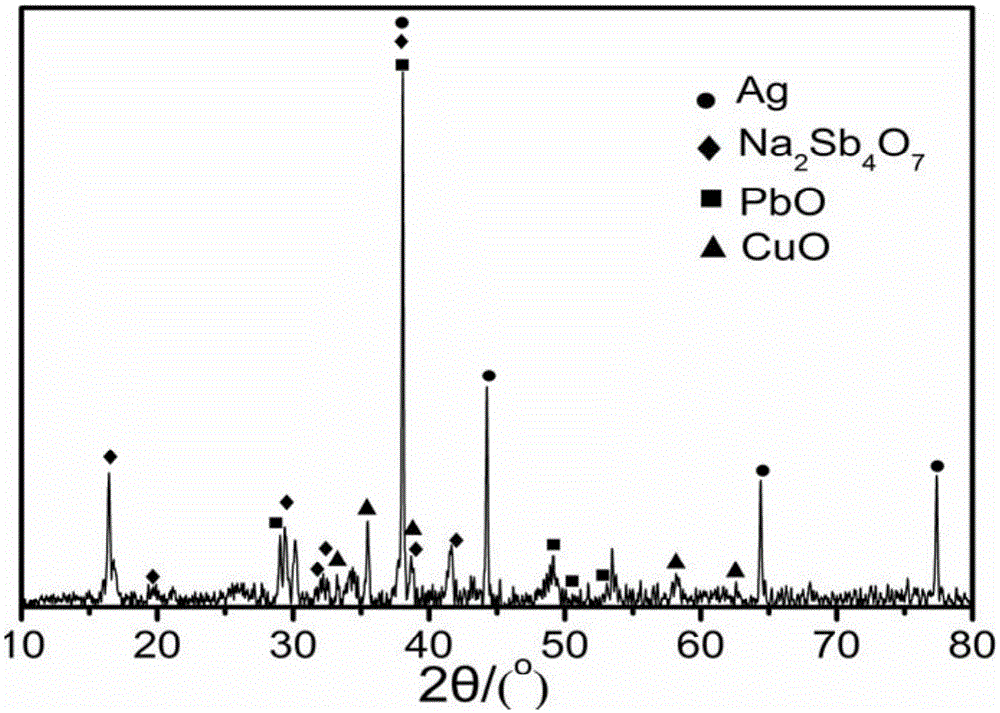

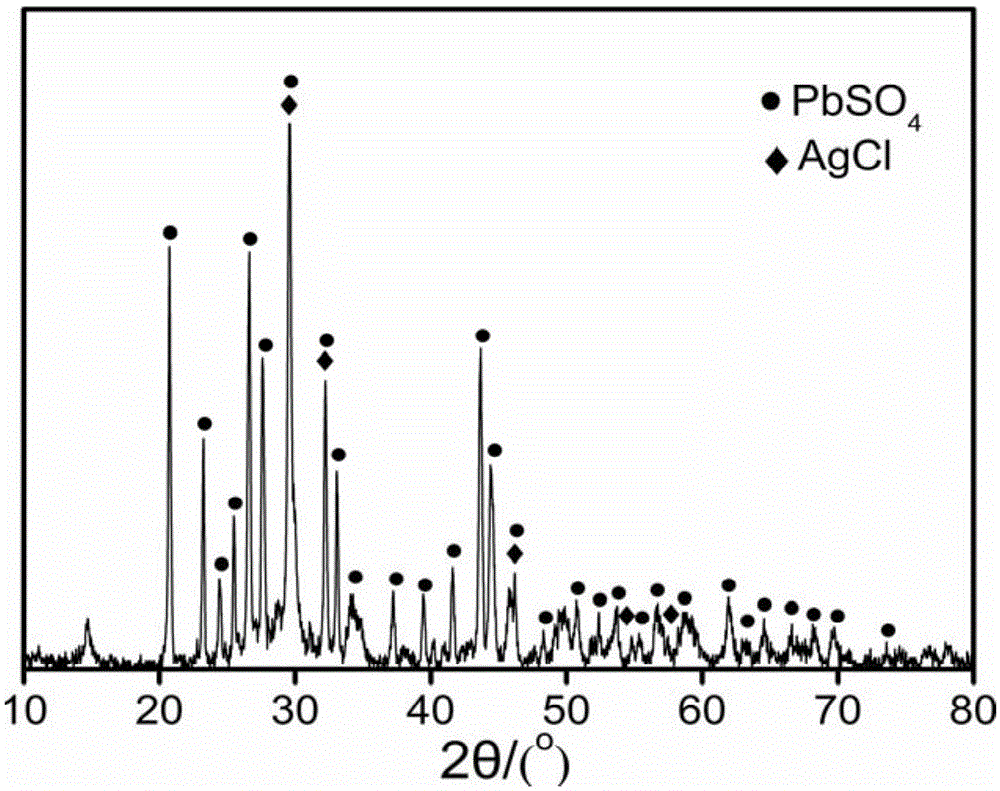

Method for separating and enriching valuable metals from copper anode mud

ActiveCN105112668AHigh removal rateHigh enrichment ratioProcess efficiency improvementMaterials scienceAntimony

The invention discloses a method for separating and enriching valuable metals from copper anode mud. The method comprises the following steps that (1) the copper anode mud and a smelting agent are mixed evenly and are smelted at the temperature of 350-700 DEG C, and a smelting product is obtained; (2) the smelting product is crushed and immersed in water, alkaline leaching residues and alkaline leaching liquid are obtained, and selenium and arsenic are recycled from the alkaline leaching liquid; (3) acid and sodium chloride are added into the alkaline leaching residues, ozone is introduced in the alkaline leaching residues for ozone strengthening acid leaching, and acid leaching residues and acid leaching liquid are obtained; and copper and tellurium are recycled from the acid leaching liquid, and lead, stibium and precious metals are recycled from the acid leaching residues. According to the process, the method has the advantages that the selenium and arsenic removal rate is high; the moving directions of the valuable metals are more reasonable and concentrated; the enrichment ratio of the precious metals is high; the direct recovery rate of all elements is high; the comprehensive recovery benefits are good; the problem that tellurium and arsenic in the copper anode mud are dispersed seriously in a traditional process is solved; operation is safe; the labor intensity is low; the treatment time is short; and the operation environment is good.

Owner:CENT SOUTH UNIV

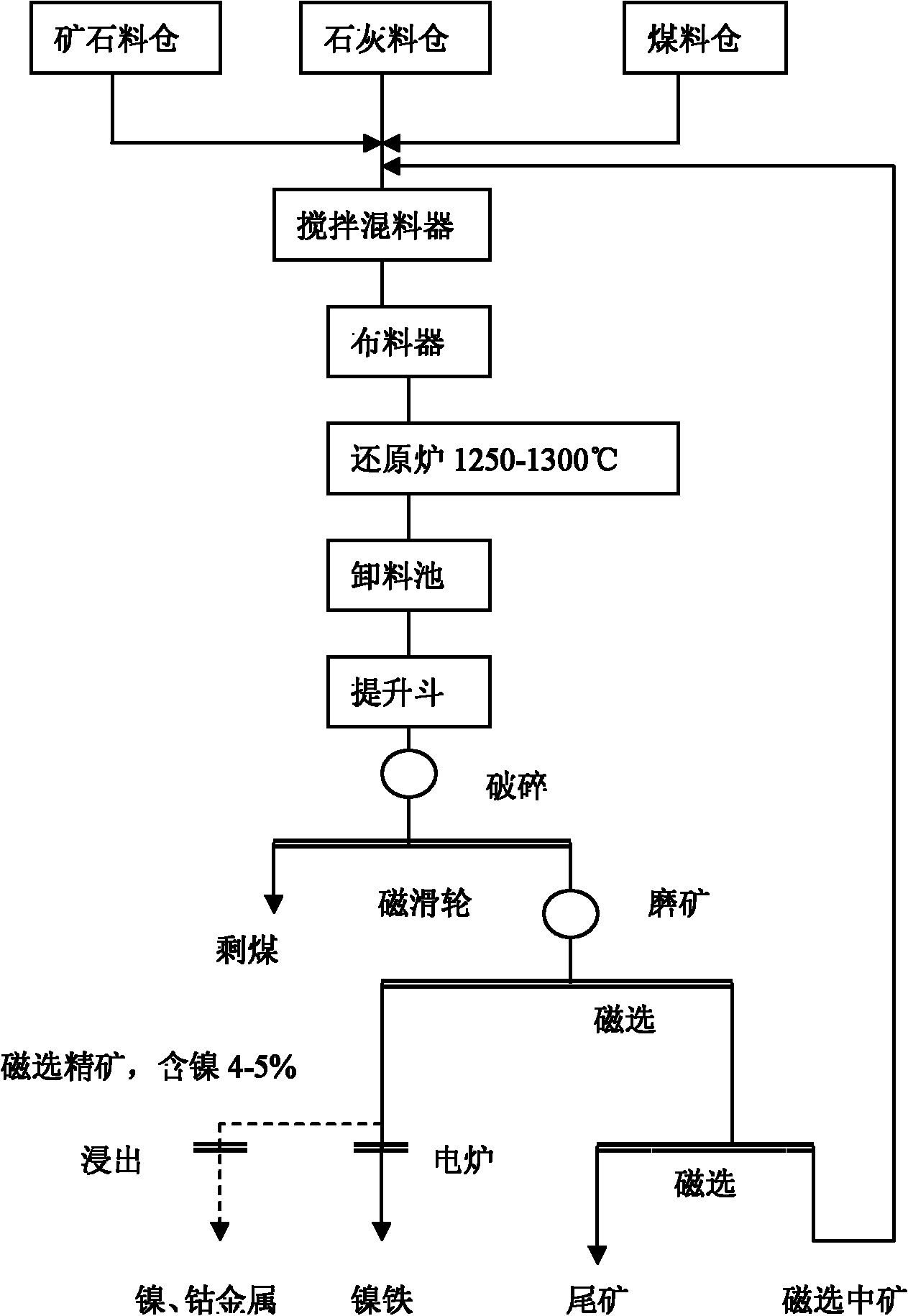

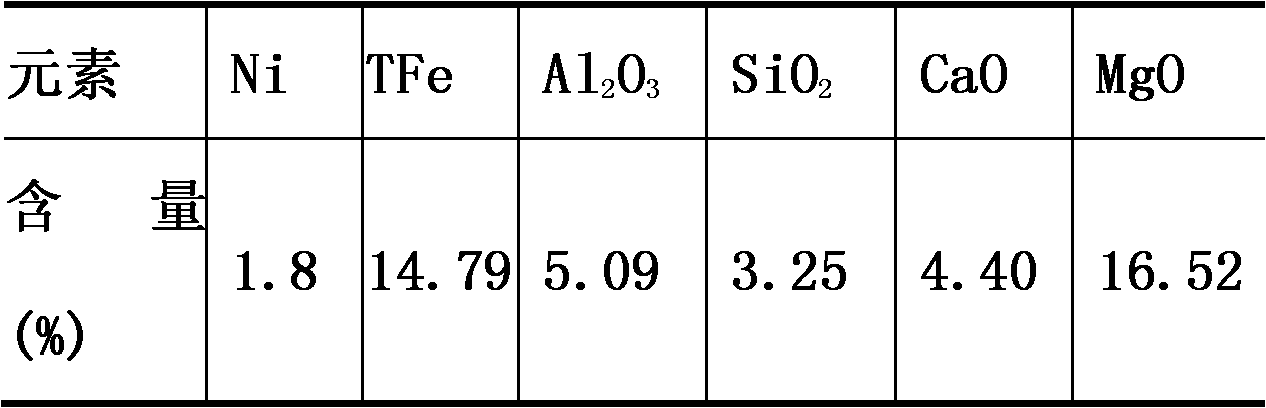

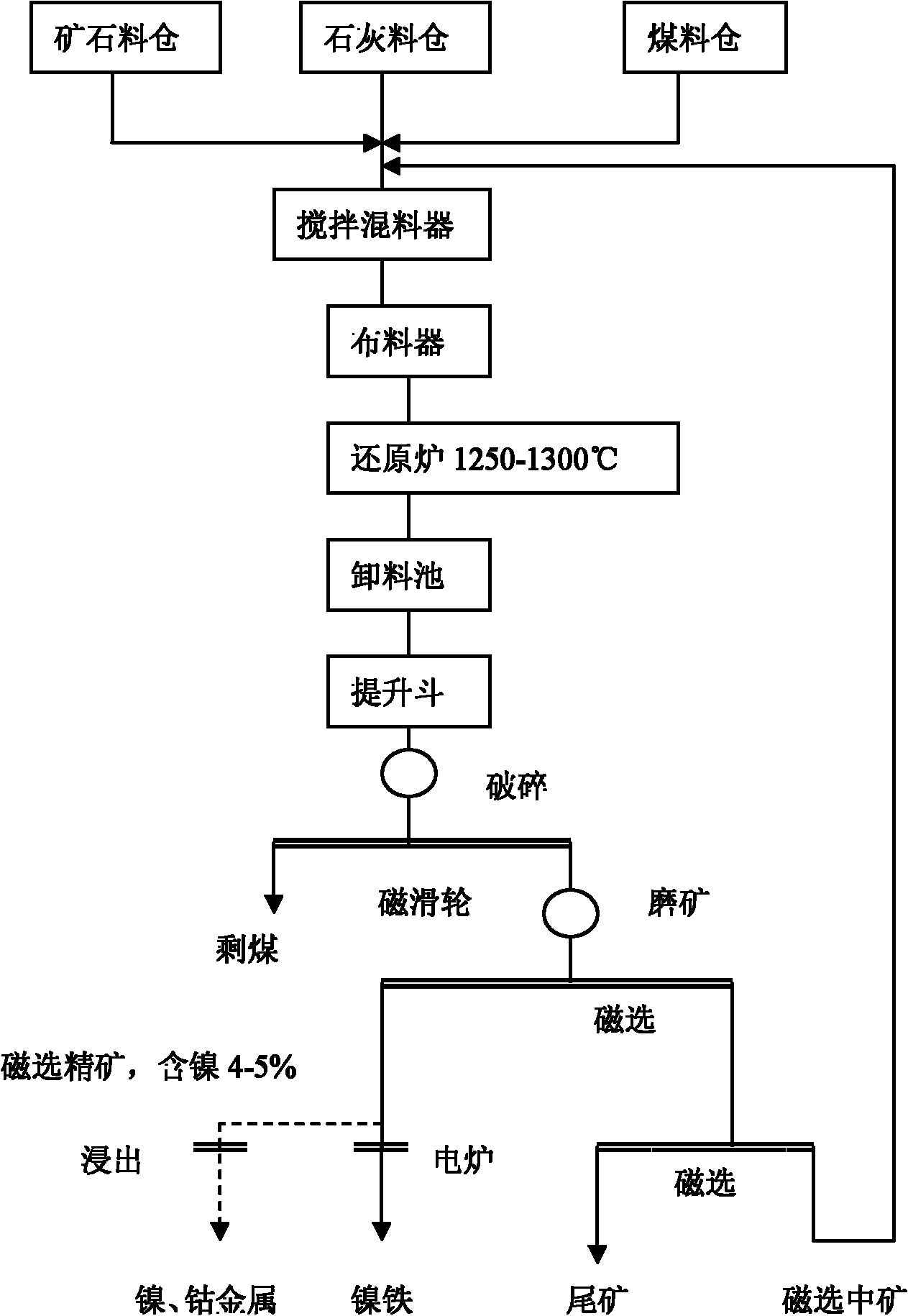

Method for gathering nickel and iron from laterite-nickel ores

The invention discloses a method for gathering nickel and iron from laterite-nickel ores. The method for gathering nickel and iron from laterite-nickel ores is characterized by comprising the following steps of 1, drying laterite-nickel ores, crushing the dried laterite-nickel ores into laterite-nickel ore powder having particle sizes of 2 to 10 millimeters, and crushing coal into coal powder having particle sizes of 2 to 10 millimeters, 2, uniformly mixing the laterite-nickel ore powder and the coal powder according to a weight part ratio of (5 to 50): 100, 3, putting the mixture into a reduction heating furnace, heating to a temperature of 1050 to 1400 DEG C, keeping for 30 to 90 minutes, and cooling, 4, grinding when the mixture is cooled to normal temperature, wherein grinded products have particle sizes less than 0.1 millimeters, 5, carrying out magnetic separation, removing tailings obtained by the magnetic separation, feeding back middlings obtained by the magnetic separation for re-reduction, controlling a grade of nickel in concentrates obtained by the magnetic separation in a range of 4 to 8% so that recovery rates of nickel and cobalt are greater than 90%, and feeding the concentrates as raw materials into an electric furnace nickel smelting system or carrying out wet leaching of the concentrates, and 6, carrying out comprehensive recovery of nickel and cobalt. The method for gathering nickel and iron from laterite-nickel ores can realize a laterite-nickel ore enrichment ratio of 4 to 8% in a non-bonded raw material state, remove a part of tailings, and improve a recovery rate through feeding back of middlings obtained by magnetic separation.

Owner:SHENYANG RES INST OF NONFERROUS METALS +1

Method for recovering germanium from germanium-containing materials

InactiveCN103952575AEfficient leachingImprove solubilityProcess efficiency improvementStrong acidsHydrometallurgy

The invention relates to a method for recovering germanium from germanium-containing materials, particularly relates to a method for recovering germanium from germanium-containing materials of non-ferrous smelting industry, and belongs to the technical field of hydrometallurgy. The method comprises the steps of leaching germanium-containing materials as raw materials of which the particle sizes are 100 meshes with inorganic strong acid as an leaching agent of which the concentration is 50-120g / L and an aid-leaching agent at 35-95 DEG C and filtering to obtain a germanium-containing leaching solution, adjusting the pH value of the germanium-containing leaching solution to be 6-9, stirring and carrying out liquid-solid separation to obtain germanium residues, and calcining the germanium residues at 350-500 DEG C to obtain a crude germanium dioxide product, wherein the aid-leaching agent is one of tartaric acid, water-soluble tartrate, citric acid, water-soluble citrate, oxalic acid and water-soluble oxalate. The method disclosed by the invention has the advantages of simple process, easiness in operation, high recovery ratio of germanium, large enrichment ratio, and convenience in industrial production and application.

Owner:CENT SOUTH UNIV

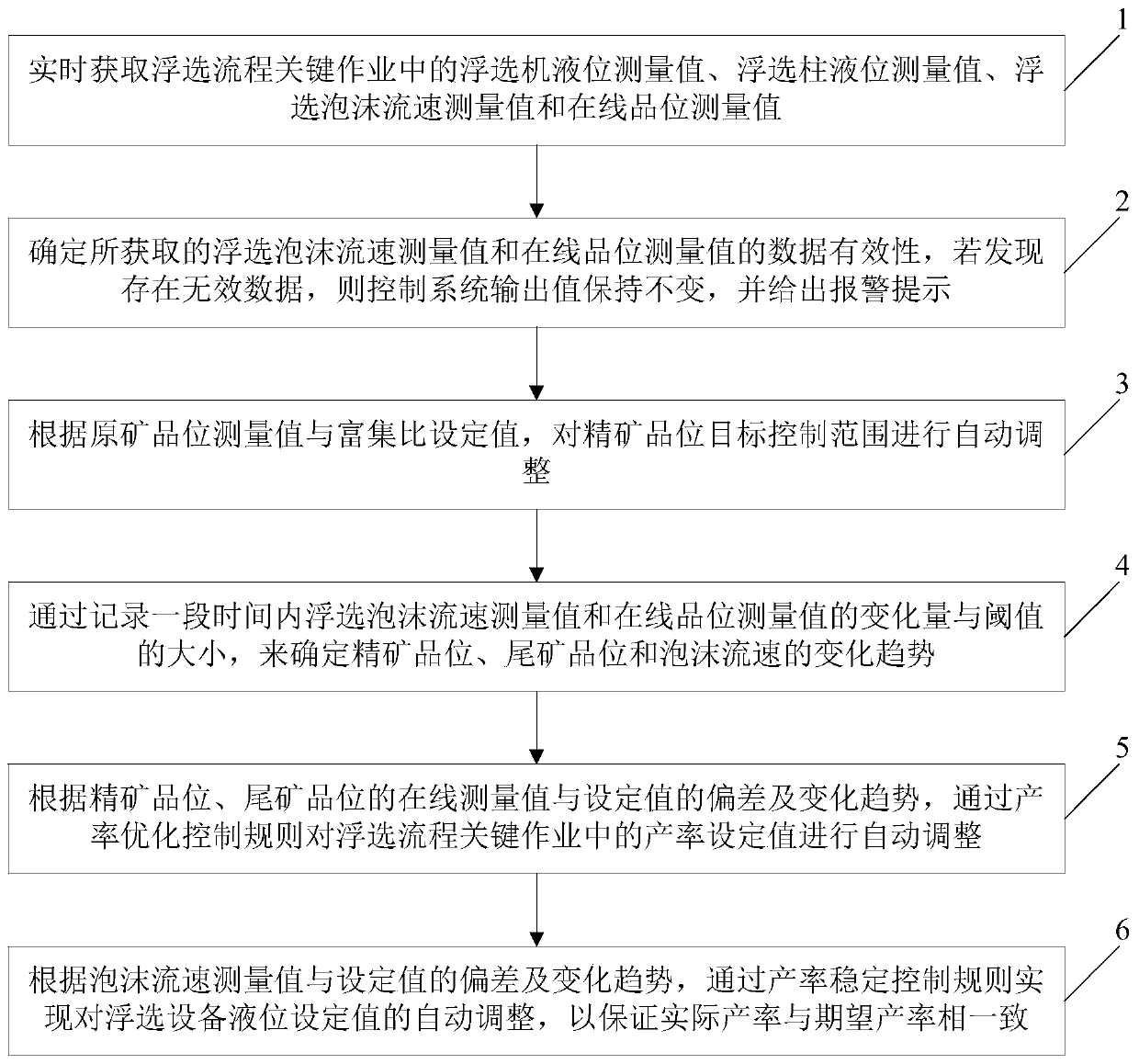

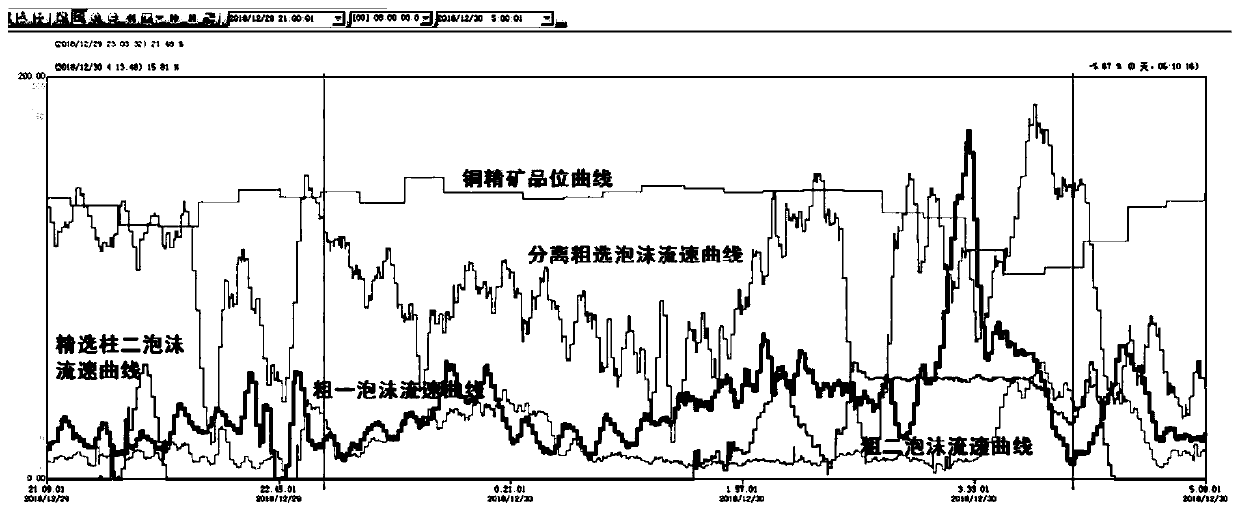

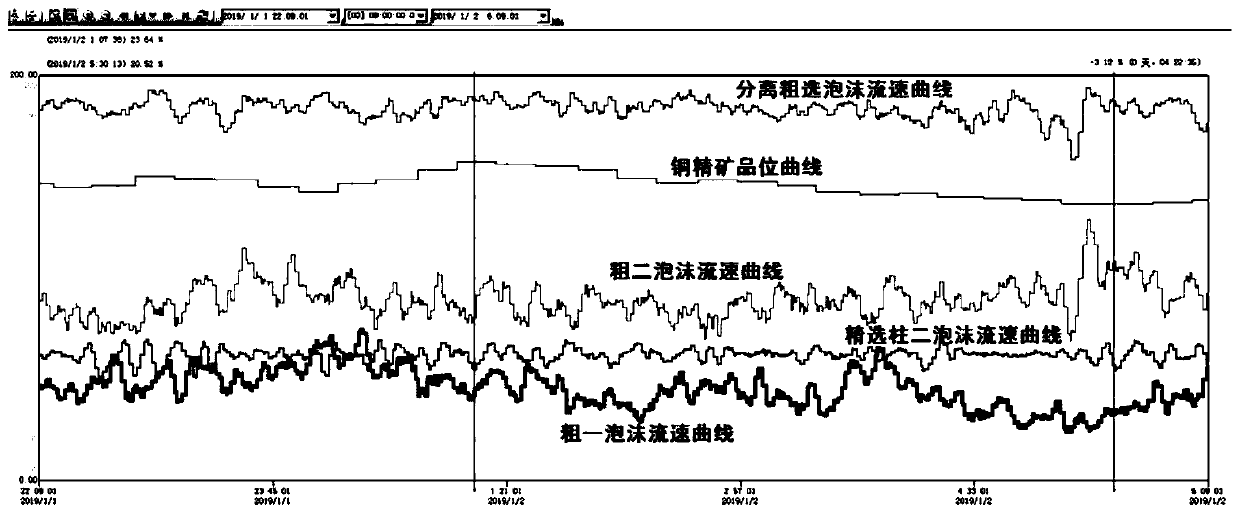

Flotation process yield optimization control method

ActiveCN110193428ALow recovery rateContinuous operationFlotationLiquid level measurementControl system

The invention discloses a flotation process yield optimization control method, which comprises: real-timely acquiring the flotation machine liquid level measurement value, the flotation column liquidlevel measurement value, the flotation foam flow rate measurement value and the online grade measurement value in flotation process key operation; determining the validity of the acquired data, and controlling the output value of the system at an unchanged state if the invalid data exists; according to a crude ore grade measurement value and an enrichment ratio set value, automatically adjusting aconcentrate grade target control range; determining the change trend of the concentrate grade, the tailing grade and the foam flow rate by recording the fluctuation and the threshold value of the flotation foam flow rate measurement value and the online grade measurement value for a certain time; and according to the deviation and the variation of the online measurement value and the set value, automatically adjusting the yield set value in the flotation process key operation through a yield optimization control rule. With the method of the present invention, the key operation yield set valuecan be correctly and timely optimized so as to effectively reduce the fluctuation of the concentrate grade and the recovery rate and ensure the continuous, efficient and stable operation of the flotation process.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

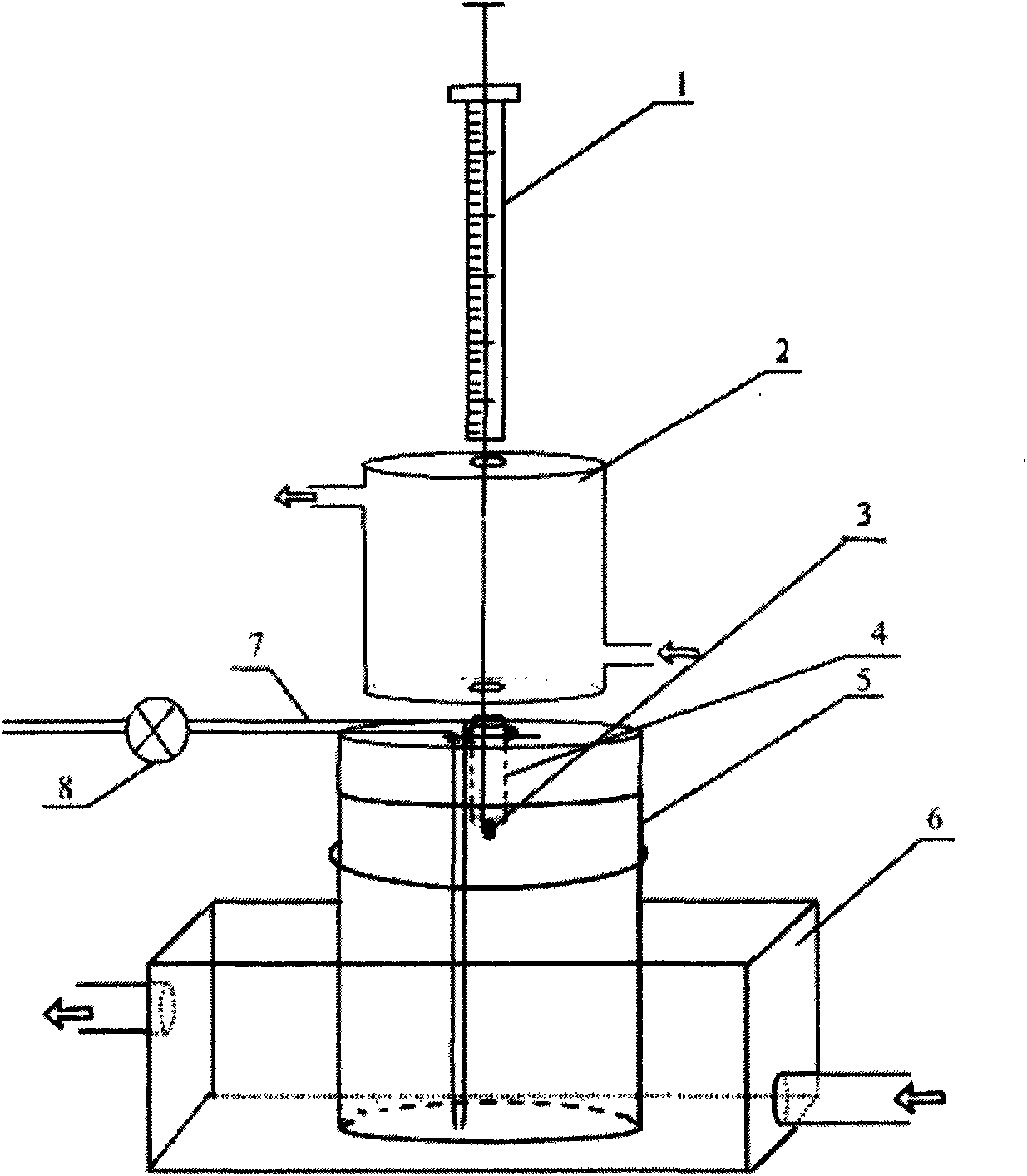

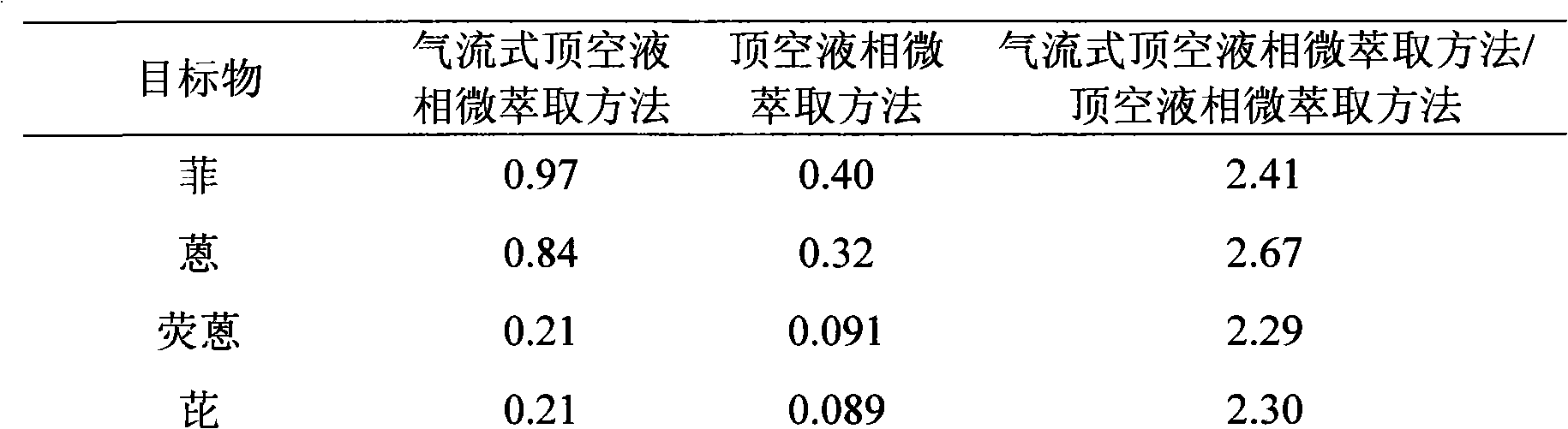

Airflow type headspace liquid-phase microextraction method

InactiveCN101632876AHigh enrichment rateGood enrichment rateComponent separationLiquid solutions solvent extractionGas phaseEvaporation

The invention discloses an airflow type headspace liquid-phase microextraction method. The airflow type headspace liquid-phase microextraction system is an open system, inert gas is introduced into the surface of the sample matrix through an inert gas inlet pipe so as to mix the inert gas with the object in the gaseous phase and also drive the object to move towards the extraction solvent continuously, when passing through the extraction solvent, the object is adsorbed by the extraction solvent, the inert gas flows out the extraction system, and the process is continuously repeated until the extraction ends. The introduction of the inert gas not only increases the rate of evaporation of the object from the sample matrix, but also increases the mass transfer velocity from the object to the extraction solvent, so as to increase the enrichment ratio of the object; as the airflow type headspace liquid-phase microextraction system is an open system, the gaseous phase volume is not limited, which is beneficial for enriching the low vapor-pressure object; and by prolonging the enrichment time, the gaseous phase volume in the enrichment system is enlarged so as to increase the enrichment ratio of the object. The invention has the advantages of the enrichment detection of the low vapor-pressure object.

Owner:YANBIAN UNIV

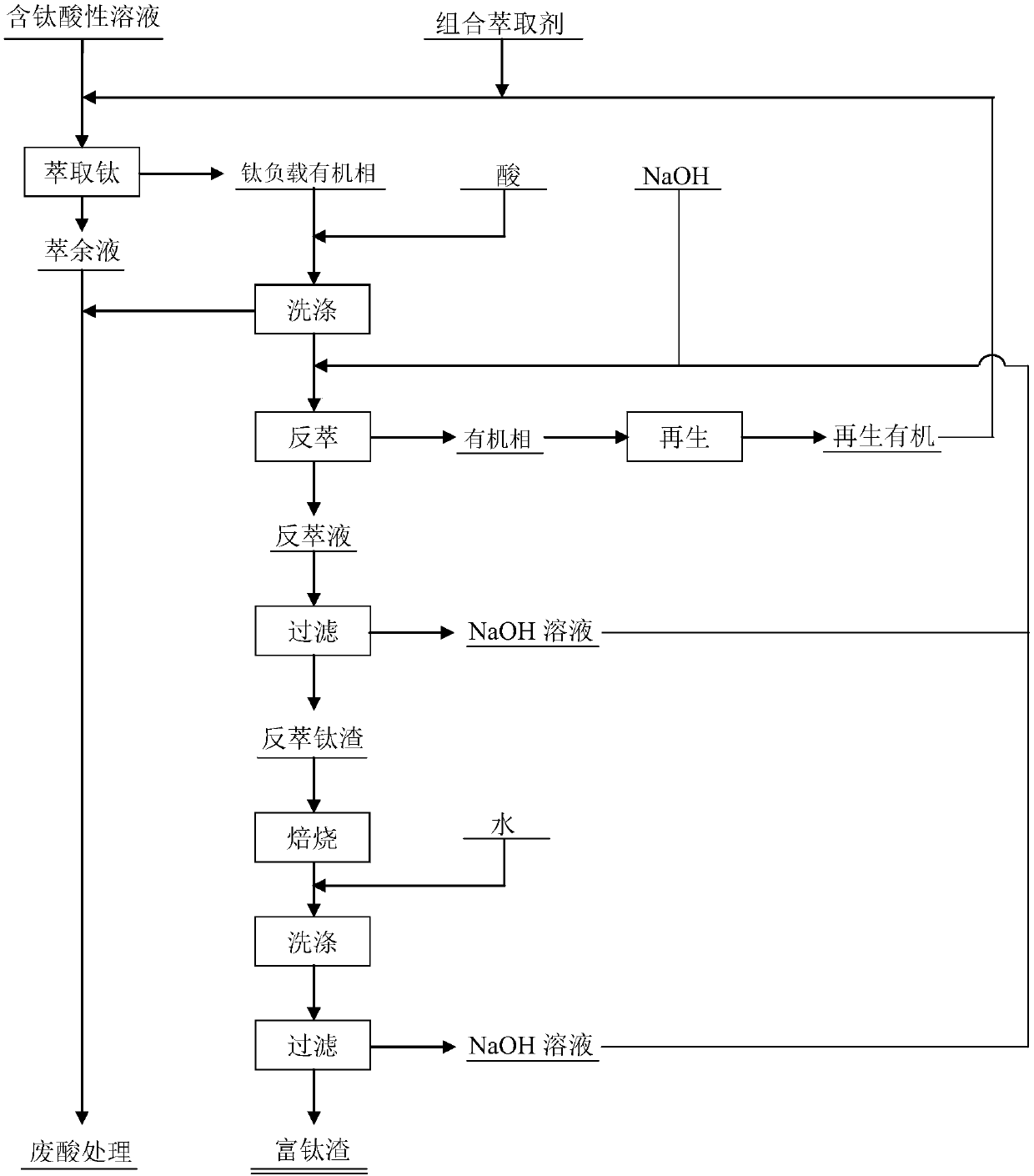

Method for extracting and recycling titanium from acid solution

ActiveCN108034841AEffective strippingResolve enrichmentProcess efficiency improvementImpurity ionsEnrichment ratio

The invention discloses a method for extracting and recycling titanium from an acid solution. Aiming at the acid solution with lower titanium concentration, organic phosphonate type extractants and amine type extractants are fully utilized and combined to generate a synergistic extraction effect, titanium can be selectively extracted and can be separated from impurity ions such as iron, aluminum and magnesium in the acid solution, an NaOH solution can be used for performing effective back extraction of titanium to obtain back extraction titanium slag, and performing calcination and water washing on the back extraction titanium slag to remove residual NaOH so as to obtain a titanium-rich material in which the content of TiO2 is 65-93%. The method disclosed by the invention solves the problems of selective separation and enrichment of titanium in the acid solution and the problem of difficult back extraction of titanium in other extraction processes, realizes the recycling of titanium with lower concentration in the acid solution, can enable low-concentration scandium contained in the solution to be together enriched into the titanium-rich material, and has the characteristics of simple technological process, high titanium enrichment ratio, thorough separation, low production cost, no pollution, comprehensive recycling of scandium and the like.

Owner:贵州鑫亚矿业有限公司 +1

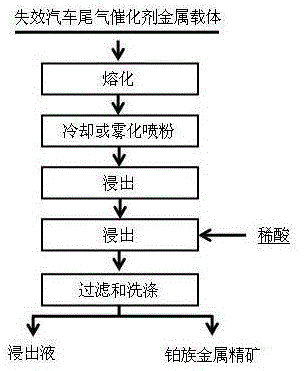

Method for enriching platinum group metal from invalid automobile exhaust catalyst metal carriers

InactiveCN106282568AEasy to operateHigh platinum yieldProcess efficiency improvementPt elementSmall particle

The invention discloses a method for enriching platinum group metal from invalid automobile exhaust catalyst metal carriers. The method includes the steps that the invalid automobile exhaust catalyst metal carriers are directly added into a high-temperature melting furnace to be melted, molten products are poured onto a water cooler to be quickly cooled or atomized to spray powder, through quick cooling on the water cooler, platinum group metal alloy is made to form brittle alloy which can be conveniently smashed into small particles, and through atomization and powder spraying, fine alloy containing platinum group metal is formed; and acid is added into the fine alloy containing platinum group metal to selectively leach base metal, and through filtering and washing, platinum group metal concentrate is obtained, so that efficient enrichment of the platinum group metal is achieved. According to the method, during high-temperature smelting, the metal carriers are used as a platinum group metal collector, no collector needs to be added, after melting, the platinum group metal enters alloy melt and then is subjected to cooling or atomization powder spraying subsequently, the fine-particle alloy is formed to facilitate selective leaching of the base metal, and therefore the whole process is simple in operation, high in platinum yield, high in enrichment ratio, environmentally friendly and low in cost, and the industrial application prospects are good.

Owner:KUNMING METALLURGY COLLEGE

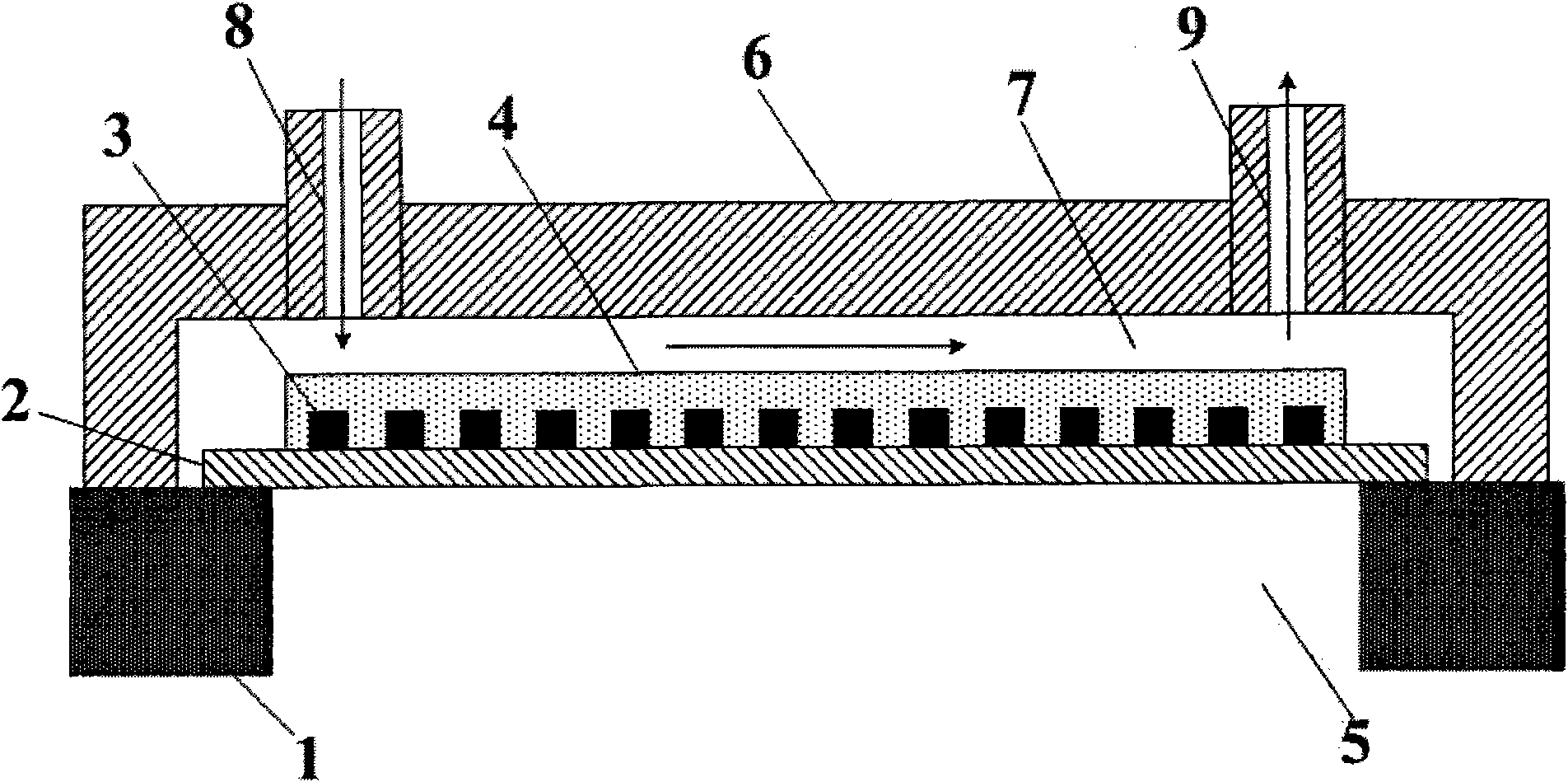

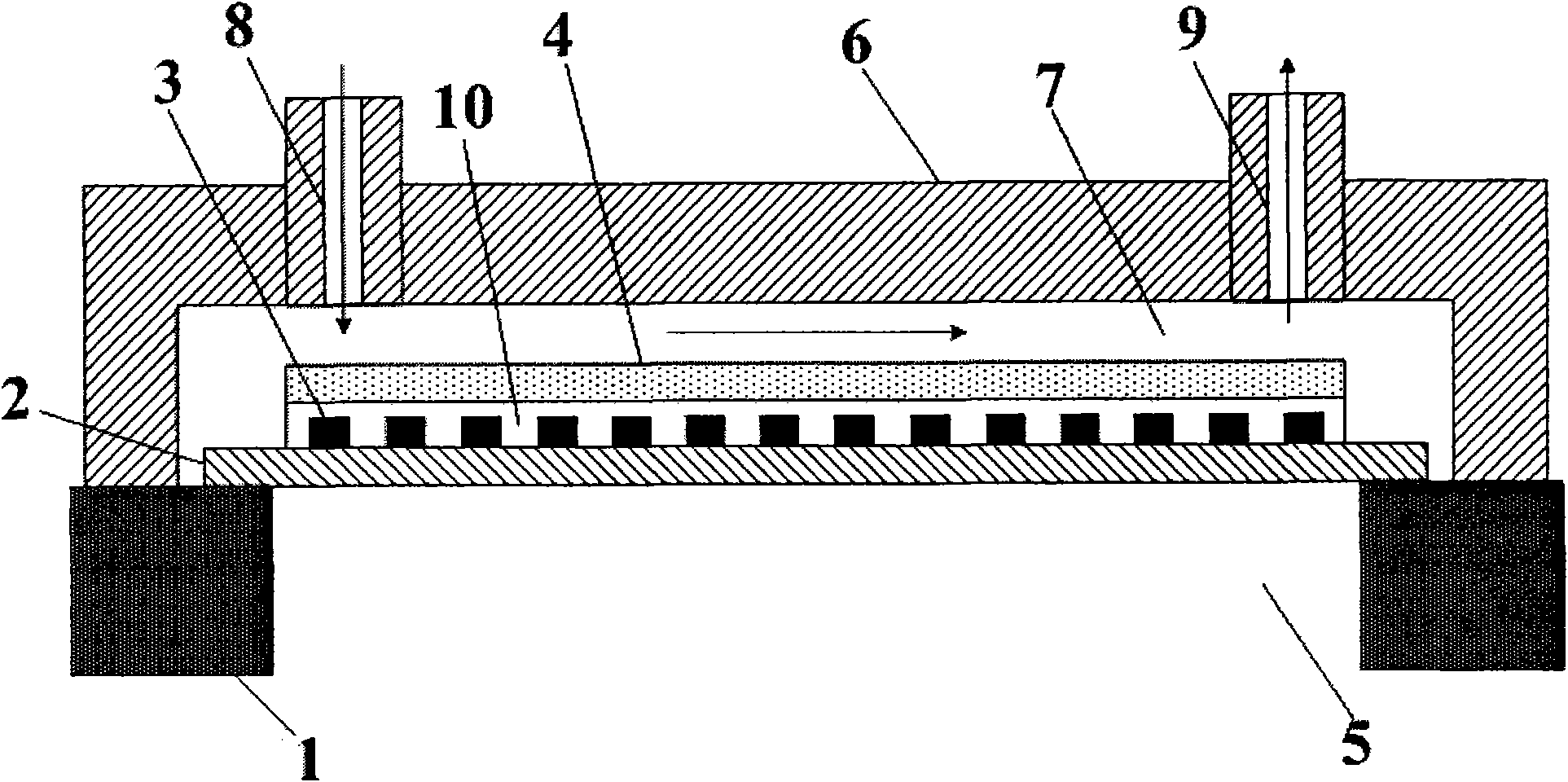

Membrane-type gas enrichment device based on polyimide film

The invention discloses a membrane-type gas enrichment device based on a polyimide film, comprising a silicon substrate, a top cap and an enrichment region arranged between the silicon substrate and the top cap; the enrichment region comprises a hanging membrane, a film heater and an adsorption film, the hanging membrane is arranged on the silicon substrate, the film heater and the adsorption film are arranged on the surface of the hanging membrane, the top cap is provided with an air inlet and an air outlet, an airflow passage is formed between the hanging membrane and the top cap; the invention is characterized in that the hanging membrane adopts the polyimide film which is not provided with a through hole, and airflow in the airflow passage flows along the surface thereof. Due to excellent tenacity of the polyimide film, the size of the polyimide film can be far greater than the size of the membrane of inorganic rigid materials such as SiN and SiO2, not only is the enrichment area greatly enlarged but also the effective contact between the airflow and the adsorption film is also given into consideration, thus improving the enrichment ratio.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

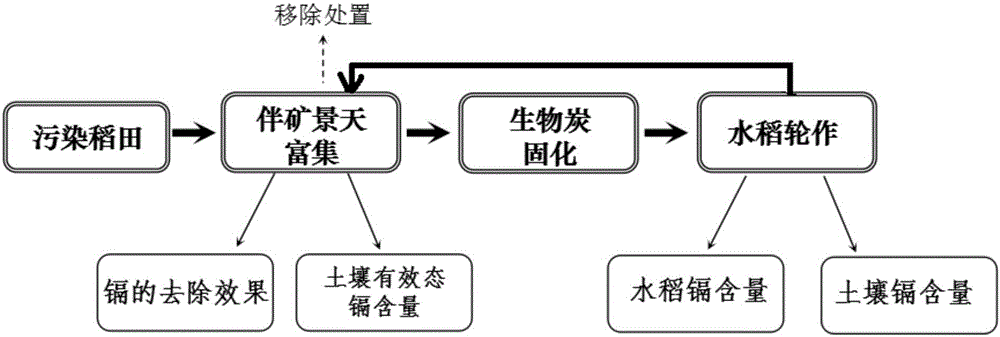

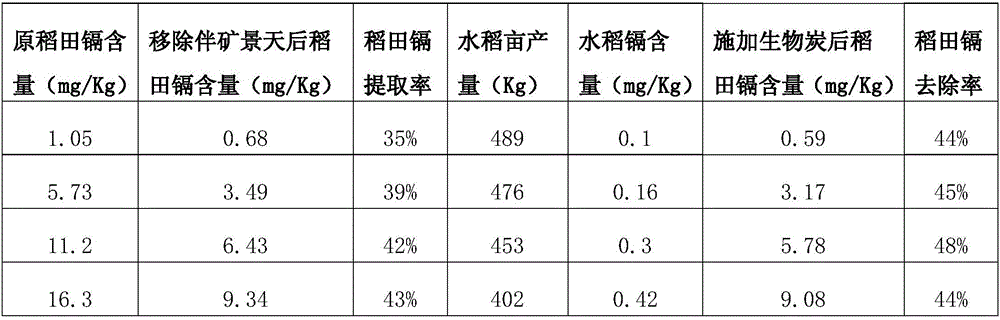

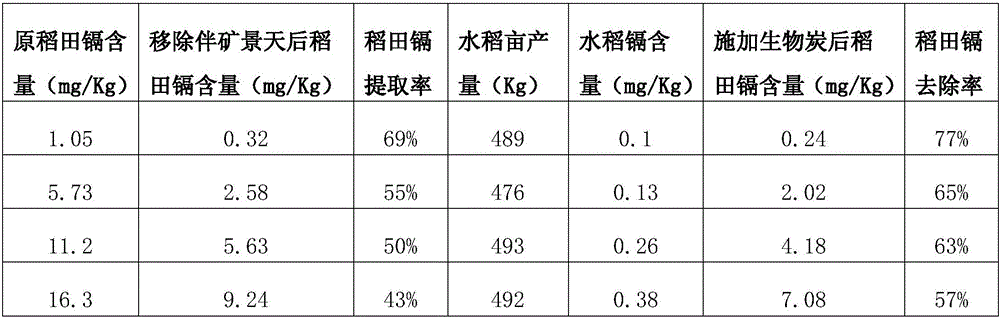

Restoration method for cadmium-contaminated rice field

InactiveCN106424130AHigh enrichment rateHigh removal rateContaminated soil reclamationRestoration methodRice grain

The invention belongs to the field of heavy-metal-contaminated soil restoration and discloses a restoration method for a cadmium-contaminated rice field. The restoration method comprises the steps of planting sedum plumbizincicola in the cadmium-contaminated rice field; after a certain growing period is reached, removing the sedum plumbizincicola, and then planting rice; when the rice reaches a certain growing period, applying biochar to the rice field; after the rice is harvested, detecting the content of cadmium in the rice field and the content of cadmium in rice grains; and if the content of cadmium is still high, repeating the above procedures to conduct circulatory planting till the content of cadmium is qualified. By means of the restoration method for the cadmium-contaminated rice field, the cadmium enrichment ratio of the sedum plumbizincicola is greatly increased, and through solidification of the biochar, the cadmium removal rate of the rice field is increased.

Owner:HUNAN UNIV OF SCI & ENG

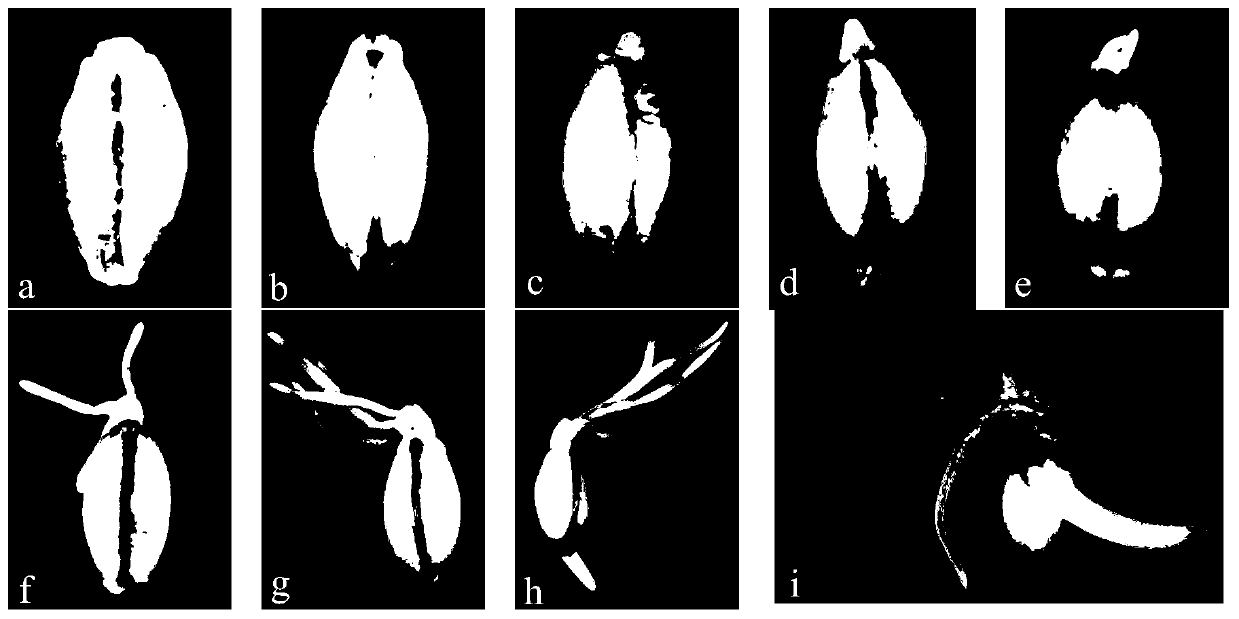

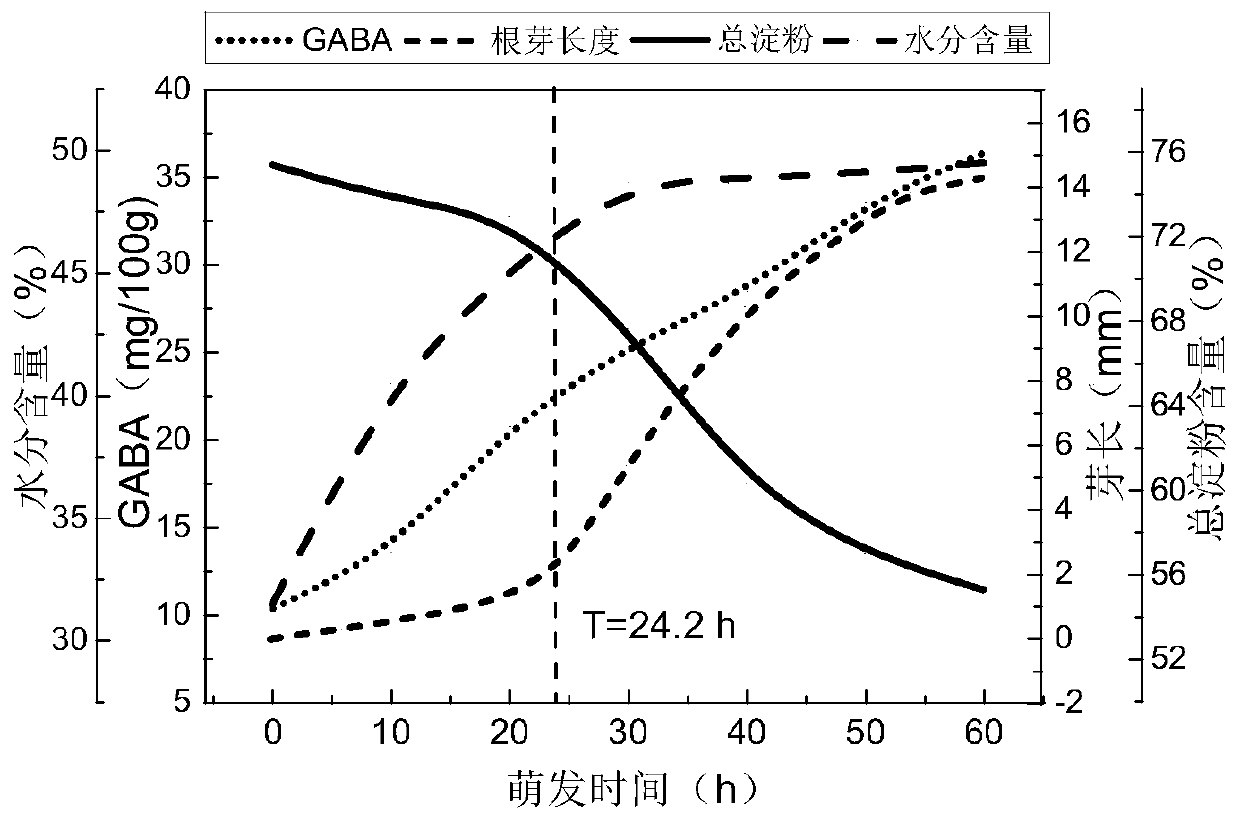

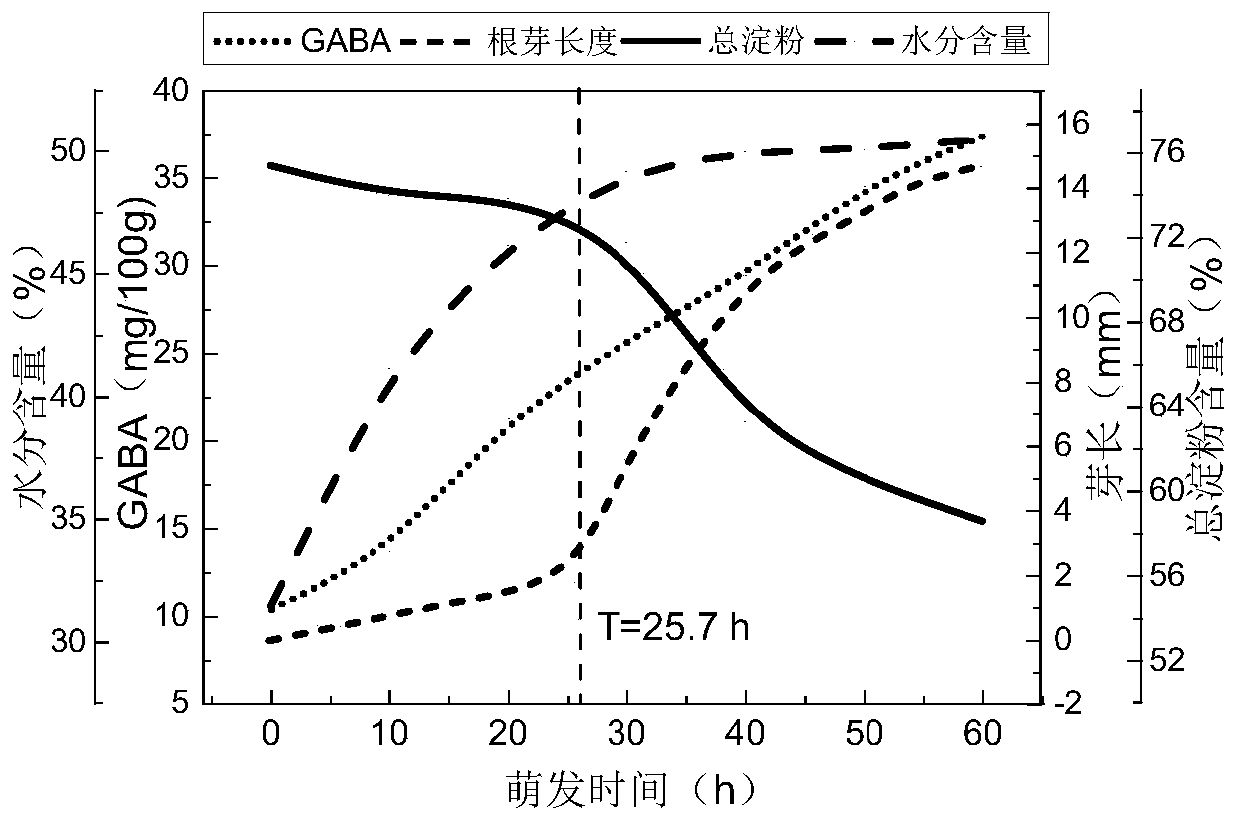

Production method for high yield ripened highland barley powder rich in gamma-aminobutyric acid

ActiveCN110089684AIncrease profitReduce lossesDough/pre-mixesFood thermal treatmentGamma-Aminobutyric acidSterile water

The invention discloses a production method for high yield ripened highland barley powder rich in gamma-aminobutyric acid. The method includes the following steps: placing highland barley seeds into agermination tank after pretreatment, and using sterile water to perform immersing for 3-4 h; pouring the sterile water in the germination tank, and performing germination culture for 24.0-26.8 h so that the seeds can be obtained; performing hot air baking and ripening treatment after the draining of the obtained highland barley seeds, and performing milling to obtain powder. The method studies the change rules of powder yield during the germination of the highland barley seeds, and selects appropriate germination conditions to perform follow-up ripening processing on the germination seeds; and the GABA enrichment ratio of the prepared highland barley ripened powder is 24-38%, and the powder yield is more than 80%, so that the loss of the powder during powder making can be greatly reduced,and the utilization rates of the seeds can be enhanced.

Owner:SOUTH CHINA UNIV OF TECH

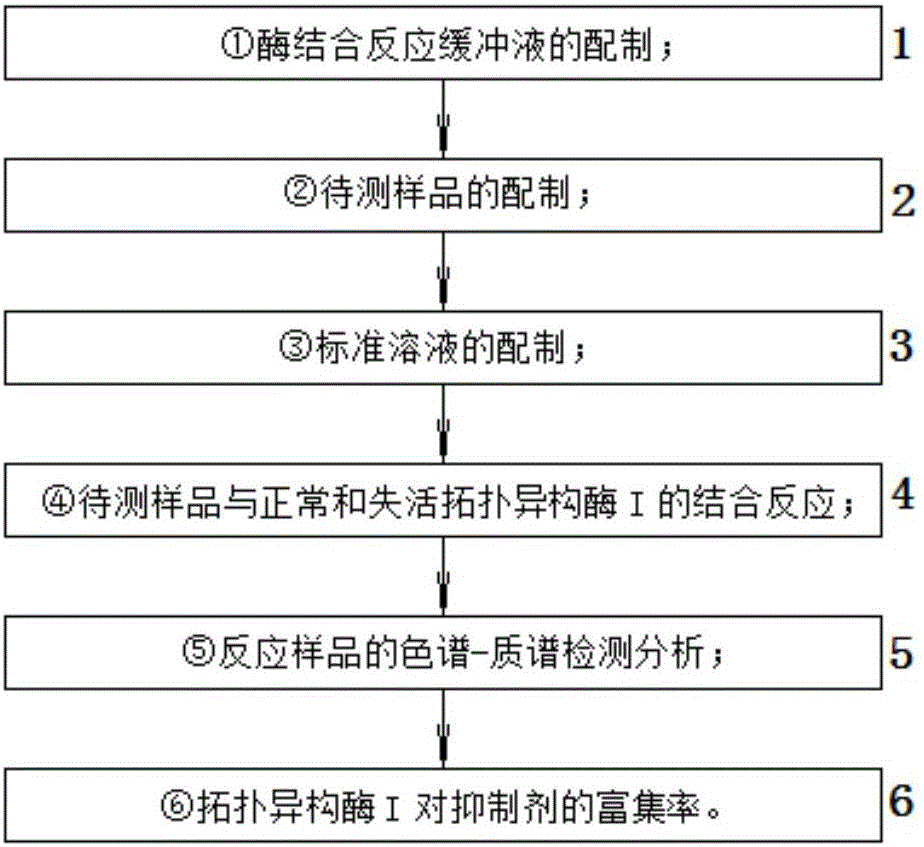

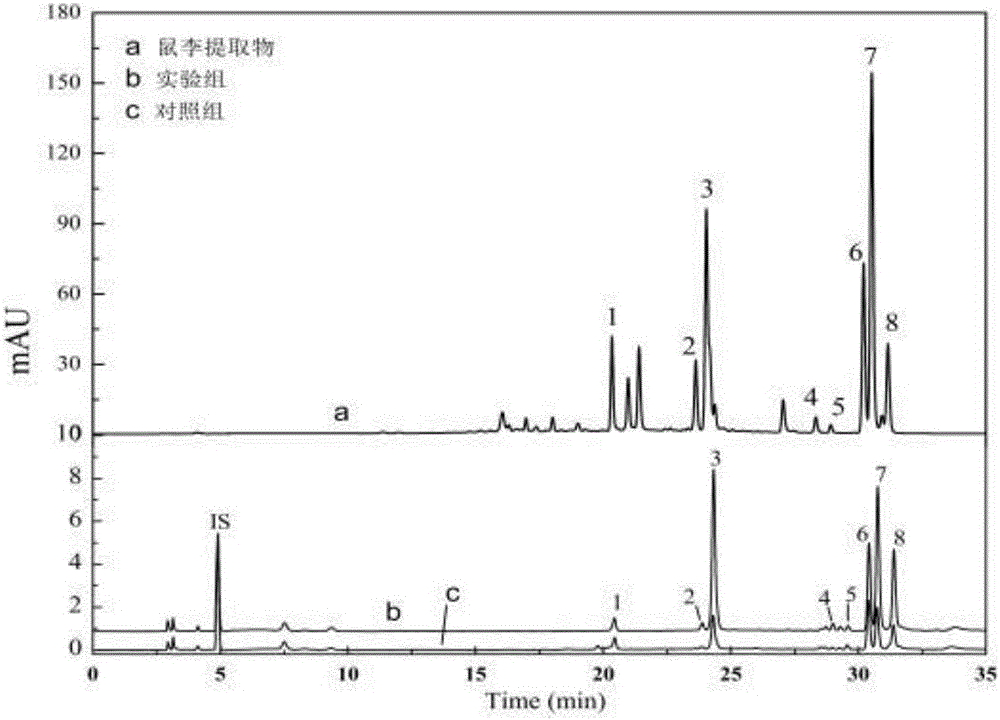

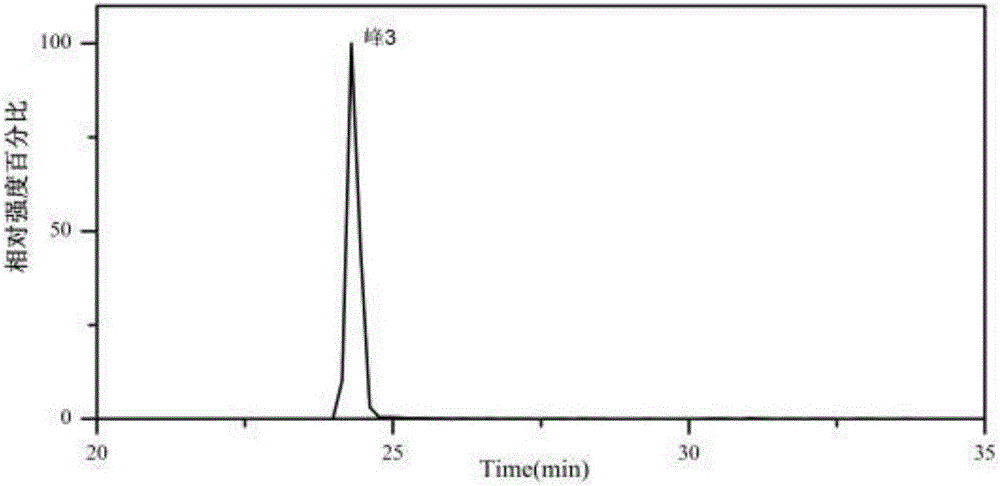

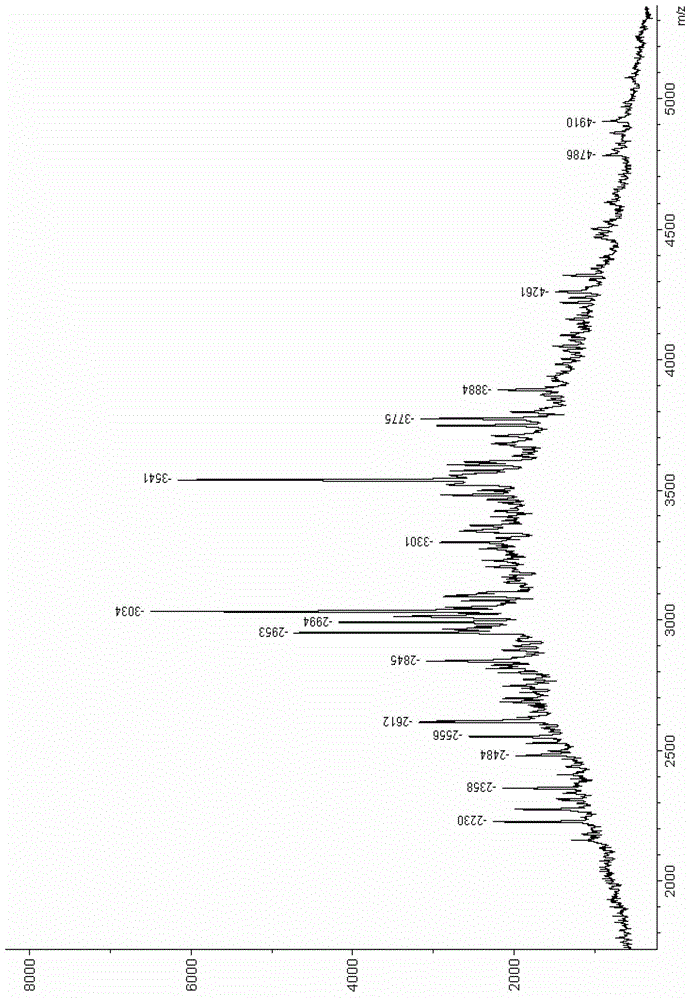

Method for fast screening topoisomerase I inhibitor from natural product

ActiveCN105717250AFast analysisStrong specificityComponent separationUltrafiltrationInformation quantity

The invention discloses a method for fast screening a topoisomerase I inhibitor from a natural product, and relates to the analysis field of natural products. The method comprises the following steps of: (1) preparation of an enzyme binding reaction buffer solution; (2) preparation of a to be detected sample; (3) preparation of a standard solution; (4) binding reaction of the to-be-detected sample and normal and inactive topoisomerase I; (5) chromatography-mass spectrometry detection analysis of reaction sample; and (6) enrichment ratio of the topoisomerase I to the inhibitor. The ultrafiltration membrane technology and the chromatography-mass spectrometry united technology united method are applied to the screening of the topoisomerase I inhibitor, the sample analysis speed is fast and the specificity is strong so as to conveniently recognize a medicine ligand combined with a biological target molecule; meanwhile, the sample analysis dosage is less, and the spectrogram information quantity is large so as to realize the fast screening of the lead compound, the method has great advantage on the aspect of researching mutual effect of medicine small molecule ligand and biological macromolecule receptor; the method is suitable for analyzing in-vitro enrichment ratio of the natural product extract or monomer compound to the topoisomerase I inhibitor.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

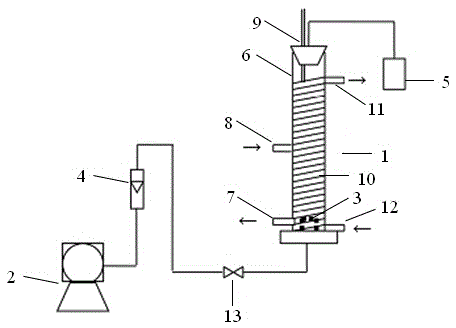

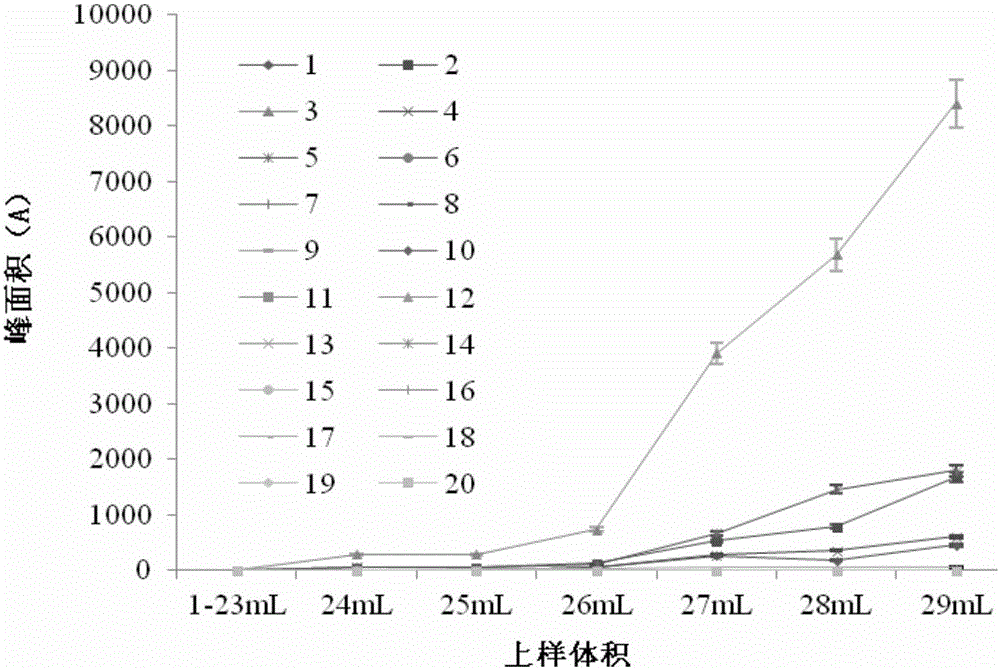

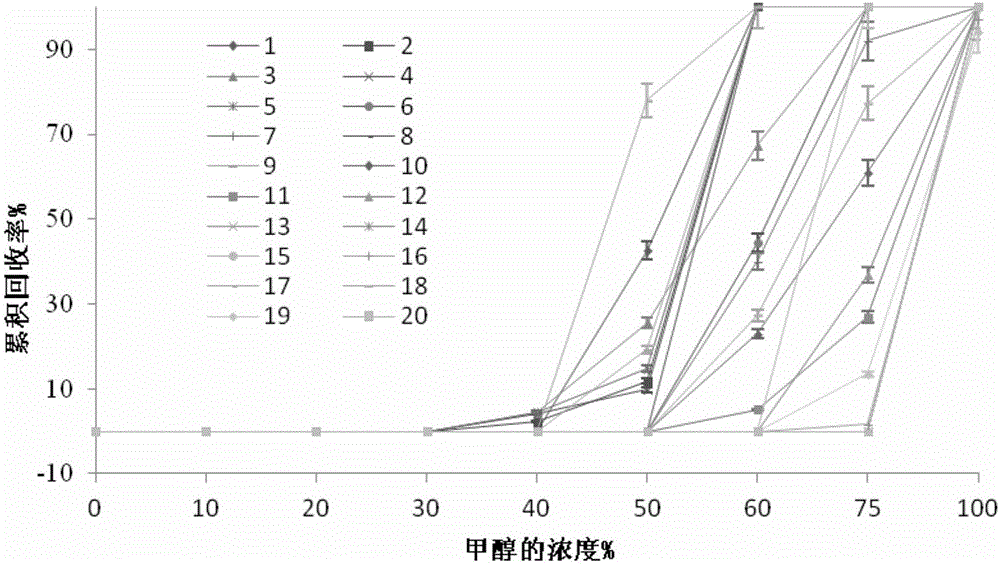

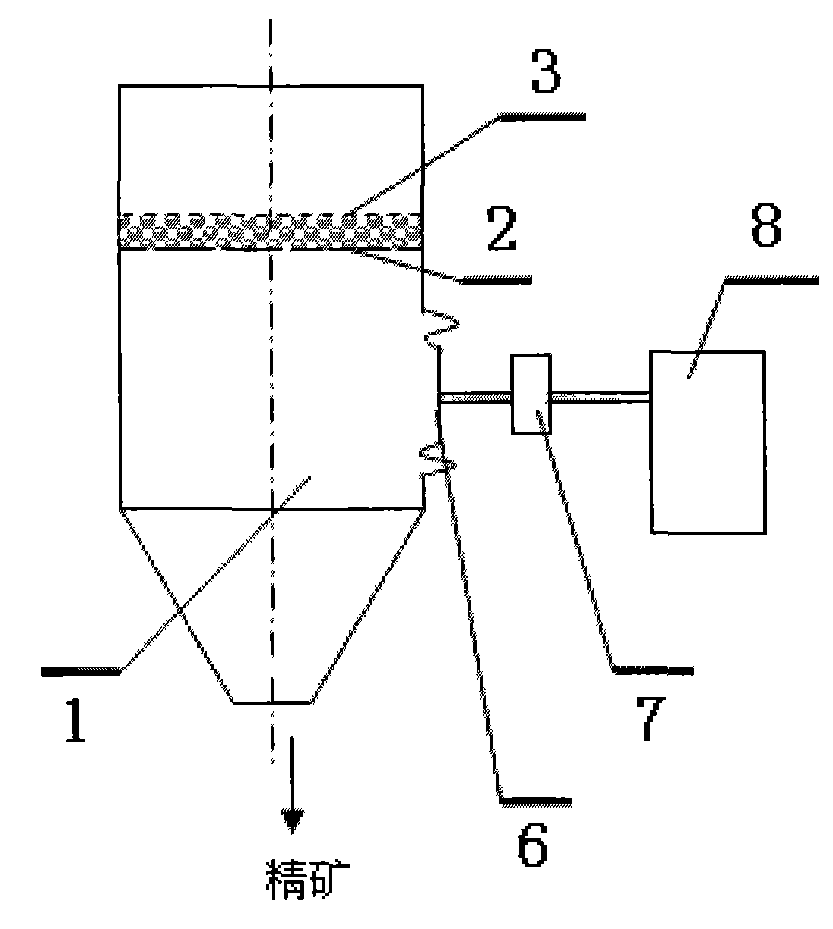

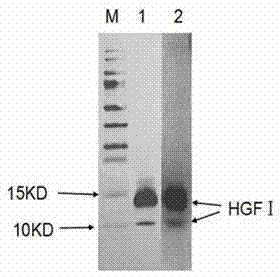

Preparation method for multistage separation extraction of earthworm active proteins and method

InactiveCN105273038AHigh enrichment ratioHigh recovery ratePeptide preparation methodsActive proteinEnrichment ratio

The invention discloses a preparation method for multistage separation extraction of earthworm active proteins and a method. The preparation device comprises a constant temperature foam separating column, an air pump, an air distributer, a rotor flowmeter and a foam collection device. The preparation method comprises the following steps: firstly, collection and detection of an earthworm protein homogenate material liquid is carried out; secondly, the earthworm protein homogenate material liquid is subjected to pretreatment; thirdly, first stage foam separation is carried out; fourthly, second-stage foam separation is carried out. A two-stage foam separation technology is established at a high temperature based on influences on earthworm active protein foam separating effects, and the two-stage foam separation technology can raise the enrichment ratio and can raise the recovery rate.

Owner:TIANJIN BAIMING SCI & TECH DEV CO LTD

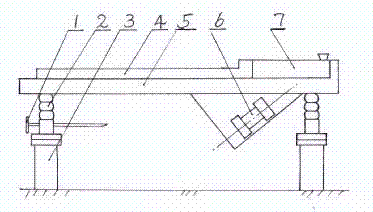

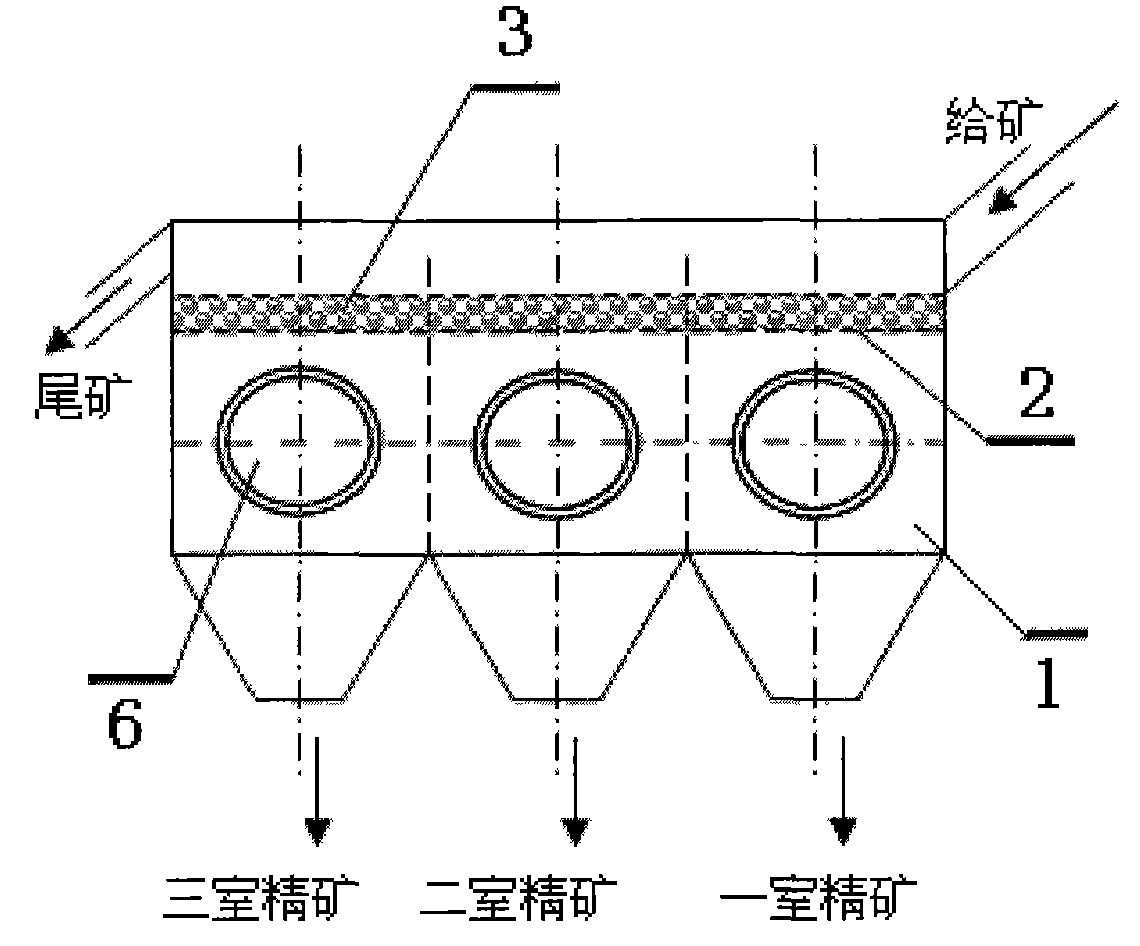

Frequency modulating linear motion transverse water current gravity ore dressing bed

InactiveCN102343302ALoose Layering AccelerationBand fastWet separationVertical vibrationLinear motion

The invention discloses a frequency modulating linear motion transverse water current gravity ore dressing bed, which comprises a sorting bed, a feeding groove, a flushing water groove and a rifle bar, wherein the sorting bed is supported by springs; the springs are arranged on machine bases; a vibration exciter is arranged on the abdomen of the sorting bed; the included angle between the vibrating direction of the vibration exciter and the be surface of the sorting bed is 0-80 degrees; the amplitude and frequency of the vibration exciter are adjusted by using a stepless speed change motor; four springs are arranged on four machine bases; the vibration exciter can be arranged on a frame of the multilayer sorting bed; the frame is supported on the springs or hung by the springs; and one vibration exciter is used for driving a plurality of sorting beds to vibrate simultaneously. Compared with the conventional swinging bed, the frequency modulating linear motion transverse water current gravity ore dressing bed has the advantage: the motion characteristics are improved. Apart from horizontal swinging force, buoyancy of transverse flushing water and flushing force, vertical vibration force is applied to mineral particles, mineral particle groups move on the bed surface like the jump of a frog, and the loosening and layering of the mineral particles are accelerated remarkably, so that zoning of light and heavy minerals is accelerated, and the treating capability and enrichment ratio of equipment are increased.

Owner:金国栋

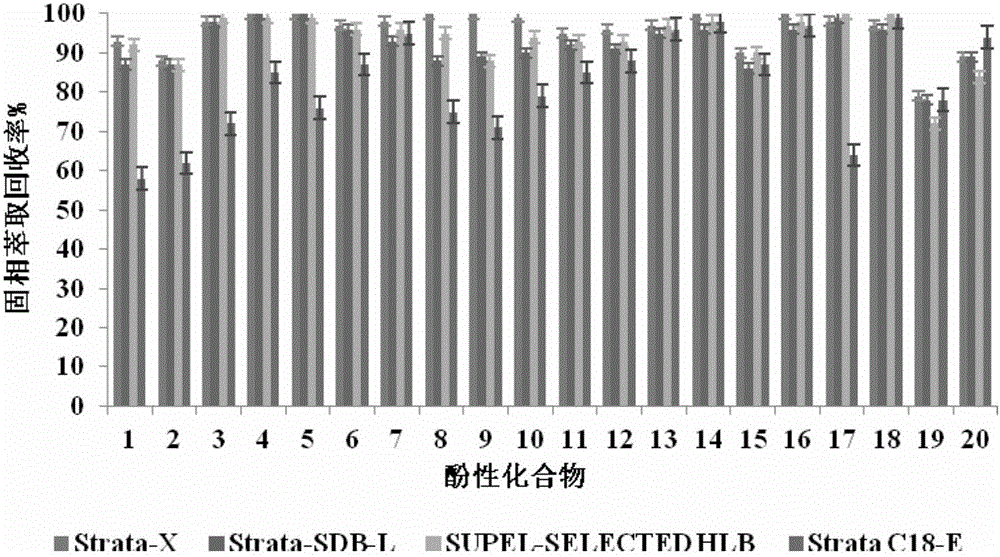

Method for measuring phenolic compounds in immature bitter oranges or fructus aurantii through SPE-HPLC

InactiveCN105806978AReduce consumptionLess solvent consumptionComponent separationAlcoholSolid phase extraction

The invention relates to a method for measuring phenolic compounds in immature bitter oranges or fructus aurantii through SPE-HPLC.The method specifically comprises the steps that powder of the immature bitter oranges or powder of fructus aurantii is taken, accurately weighed and placed into a conical flask with a cover, methyl alcohol is precisely added, ultrasonic extraction, cooling, well shaking and filtering are conducted, filtrate is precisely measured, pressure is reduced, the filtrate is recovered and dried, the product is dissolved with water, the mixture flows through a solid-phase extraction column which is balanced through methyl alcohol and water in advance, then, leaching with methyl alcohol, eluting with pure methyl alcohol, volume metering for the part eluted with pure methyl alcohol and filtering with a millipore filter membrane are sequentially conducted, and testing liquid is obtained; the phenolic compounds are measured.Compared with the prior art, the method has the advantage that as SPE is adopted for pretreating the sample, the effect of impurities on measuring is reduced; solid-phase extraction has the advantages that operation is easy and convenient, the enrichment ratio is high, less solvent is consumed, cost is low, and extraction and separation are integrated.In addition, chromatographic conditions established through the method have good resolution for the phenolic compounds to be measured, and analysis conditions are appropriate.

Owner:BEIJING UNIV OF CHINESE MEDICINE

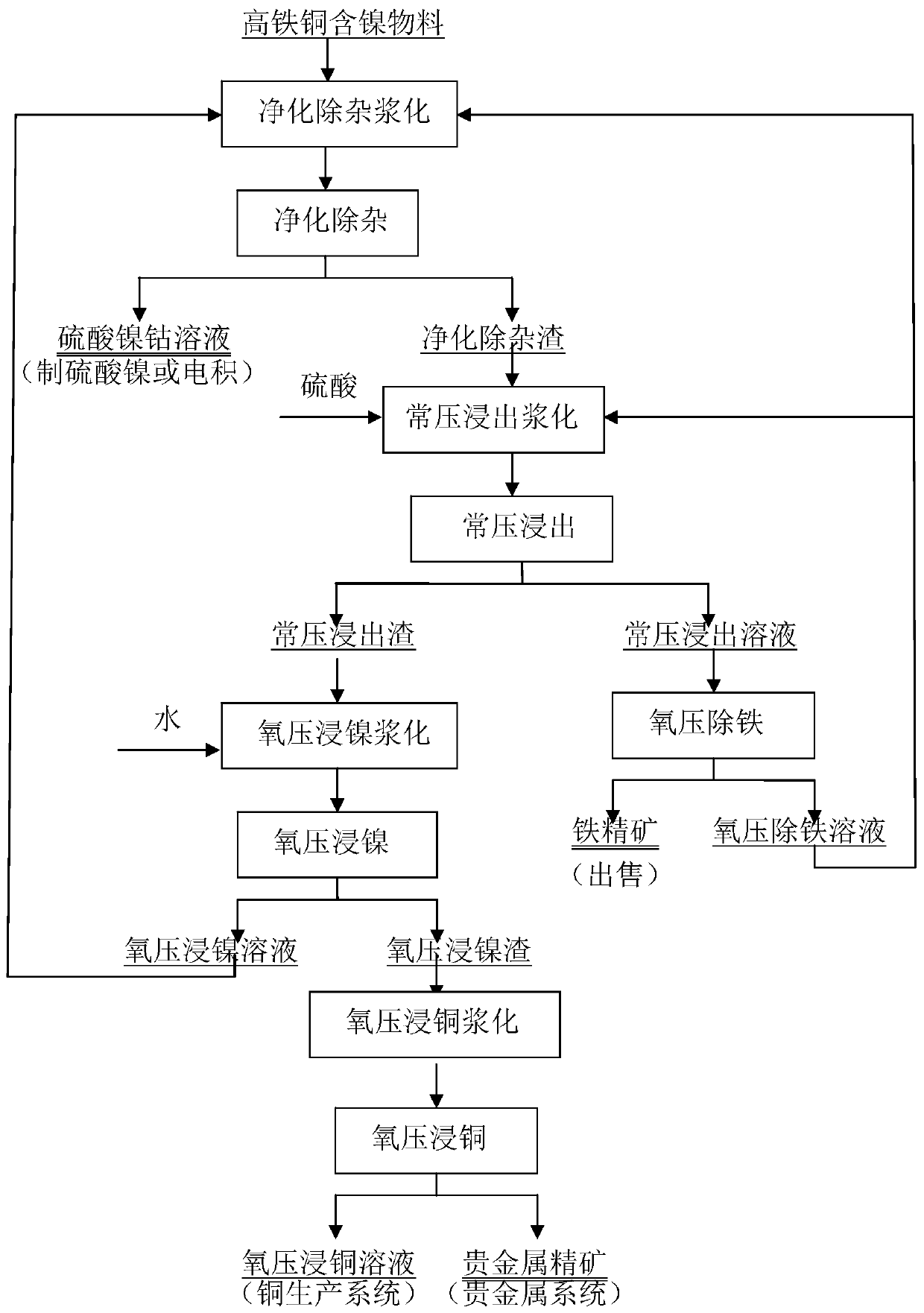

Selective oxygen pressure leaching method for the enrichment of precious metals from high-iron, high-copper and nickel-containing materials

ActiveCN110241310AImprove direct yieldHigh enrichment ratioProcess efficiency improvementAlloyNickel sulfide

The invention belongs to the technical field of nonferrous metallurgy, and particularly relates to a selective oxygen pressure leaching method for the enrichment of precious metals from high-iron, high-copper and nickel-containing materials. The method comprises the following steps of purification and impurity removal, normal-pressure leaching, oxygen-pressure deironing, oxygen-pressure nickel immersion and oxygen-pressure copper immersion. The method is short in technological process and high in direct yield, and can be used for selectively leaching nickel, cobalt, copper and iron and respectively realizing open circuit; and the method is wide in raw material adaptability, suitable for treating various high-iron high-copper nickel-containing materials such as intermediate product low-nickel matte generated in the conventional nickel sulfide ore smelting process, primary alloys, fine grain alloys, cobalt-rich low-nickel matte and cobalt-rich matte, and is remarkable in benefit. The nickel sulfate cobalt sulfate solution obtained by adopting the method is high in the product quality, and the requirements of multi-variety production can be met at the same time; the noble metal can be totally enriched in the oxygen pressure leaching copper slag and can be used as a noble metal concentrate, the direct yield and the enrichment ratio are high, and iron is directly used in a product form; and copper is leached to obtain a copper sulfate solution, and crystallized copper sulfate or electrodeposition copper can be produced.

Owner:SHENZHEN KUNPENG METALLURGY ENG TECH LTD

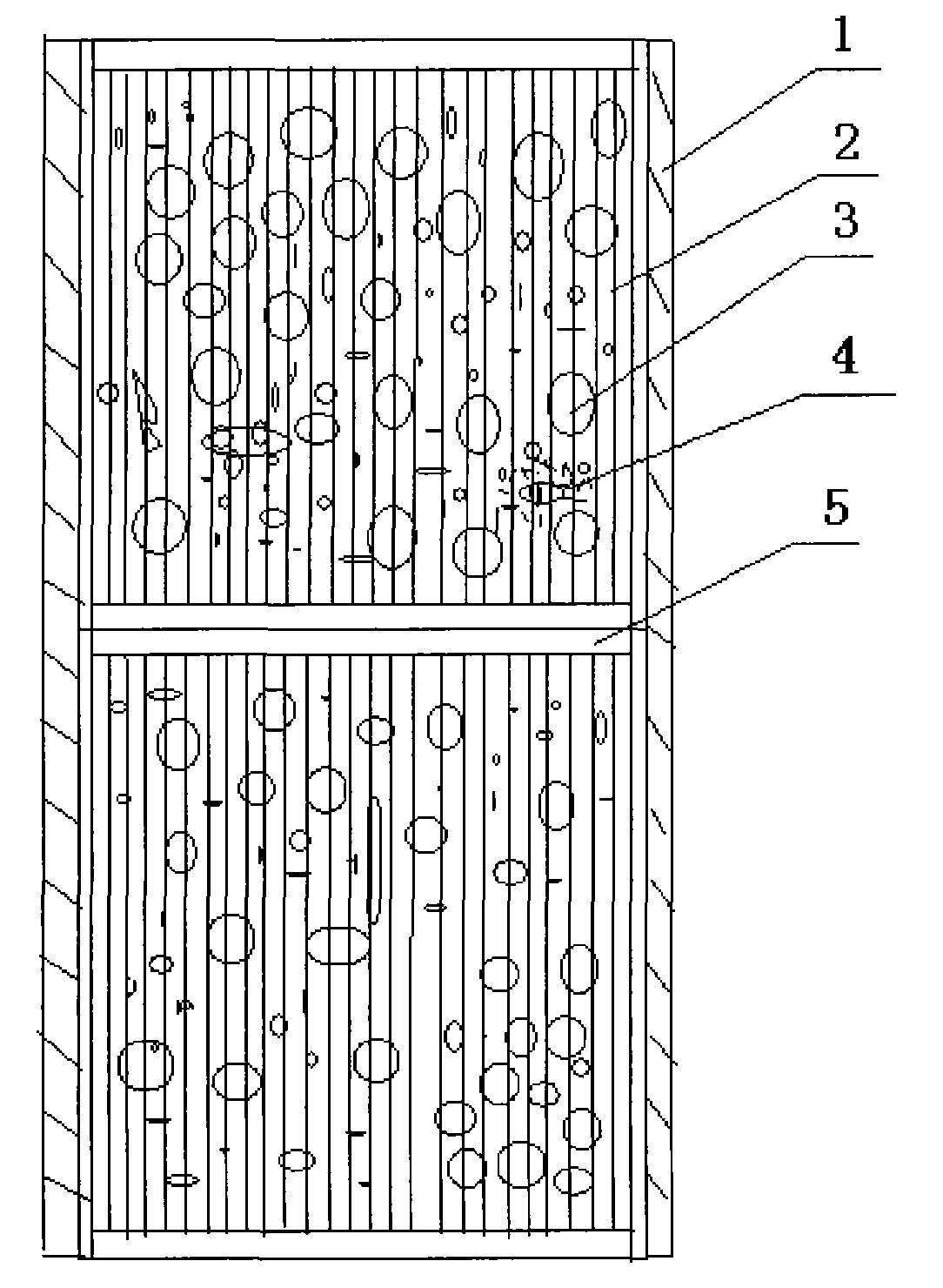

Artificial bed stone and gravity separation method for complex ores

ActiveCN101767052AImprove anti-wear performanceImproves breakage resistanceWet separationMolten stateAdhesive

The invention relates to an artificial bed stone and a gravity separation method for complex ores. The method comprises the following steps: adding a selected ferric oxide material or an iron mixed material into adhesive and coal, mechanically molding the mixture to form circular balls, then burning the circular balls at the high temperature of between 1,150 and 1,500 DEG C in a common smelting furnace to make the circular balls in a molten state, pouring the molten circular balls into a spherical die, and cooling the circular balls to obtain the artificial bed stone with good abrasion resistance and breakage resistance and high hardness. The artificial bed stone is manufactured into the bed stone for a spherical jigging machine with specific gravity and specification and is applied to all jigging machines according to different proportion combinations of various specification so as to overcome the defects of conventional bed stones; the enrichment ratio of ore concentrate is high (2.5 times), the grade of tailings is low (the tin content of the tailings is less than 0.1 percent), the abandon rate is high (more than or equal to 30 percent), the separation efficiency is high (more than or equal to 92 percent), and each equipment has a handling capacity of 5 to 8 tons of ores per hour; and the artificial bed stone is an ideal separation medium for the jigging machine and can greatly improve the economic indicator of ore dressing technology and the economic benefit of all flows.

Owner:广西华锡矿业有限公司铜坑矿业分公司

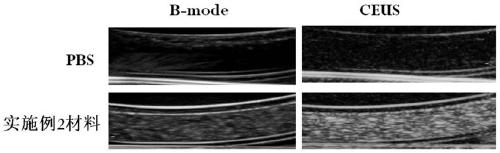

Nano metal organic framework cavitation material, synthetic method and application

ActiveCN110124034AImprove stabilityReduce usageEchographic/ultrasound-imaging preparationsAntineoplastic agentsUltrasonic cavitationSynthesis methods

The invention discloses a nano metal organic framework cavitation material, a synthetic method and an application, and belongs to the field of ultrasonic cavitation materials. The material is capableof using a nano metal organic framework as a carrier, and using a cavitation agent active component as a carrying object. The preparation method for the material comprises the following steps: 1) enabling a metal source and an organic ligand to be dissolved in a solvent, to obtain metal source mother liquor and organic ligand mother liquor; 2) mixing the metal source mother liquor and the organicligand mother liquor obtained in the step 1) in proportion, performing a heating reaction, centrifugally-separating, and drying, to obtain a dry product; and 3) enabling the obtained dry product and the cavitation agent active component to be dispersed in the solvent, after stirring, centrifugally-separating, and drying. Compared with lipid bubbles used in the prior art, the nano metal organic framework cavitation material is capable of remarkably improving stability, prolonging in-vivo circulating time, improving an enrichment ratio of the material in a tumor site, and improving the curativeeffect of tumor therapy.

Owner:ZHEJIANG UNIV

Method for separating whey protein from whey wastewater by foam separation method

ActiveCN108640342AEfficient recyclingHigh recovery rateWater/sewage treatment by centrifugal separationPeptide preparation methodsWhey proteinWastewater

The invention provides a method for separating whey protein from whey wastewater by a foam separation method. According to the method, by the study of multiple key factors, such as the whey protein concentration, gas velocity, temperature and pH, affecting the foam separation of yak whey protein, based on single-factor experiments, a process is optimized through a response surface method, and an optimal technological condition combination is obtained and comprises that the concentration of the whey protein is 100-160 [mu]g / mL, the gas velocity is 250-350 mL / min, the temperature is 40-50 DEG C,and the pH value is 3.5-4.5. Through verification tests, the recovery rate is 75-90% and the enrichment ratio is 8-10. The method is suitable for life characteristics of scattered nomads in Qinghai-Tibet Plateau, can effectively recover the whey protein from yak whey wastewater, also overcomes the difficulties that other technologies difficultly efficiently separate and enrich whey protein from low-concentration whey wastewater, and reduces the recovery cost of the whey protein.

Owner:QINGHAI NORMAL UNIV

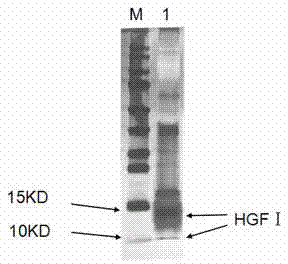

Foam distillation purification method

ActiveCN104117220ALow costReduce pollutionDistillation regulation/controlFractional distillationPurification methodsDistillation

A foam separation method for extraction and concentration of a surface active substance is different from traditional. The invention provides the foam rectification purification method which can extract, concentrate, rectify and purify the surface active substance. The method can be roughly divided into 7 steps: 1, estimating the contents of an objective component and an objective impurity in a material liquid; 2, determining the pH and the temperature T allowing the objective component to have highest surface activity in a tolerance range of the objective component; 3, determining the highest collect height beta and the corresponding apparent gas velocity Q; 4, determining the lowest collect height alpha; 5, determining the objective component enrichment ratio and recovery rate changed along with the height and between the height alpha and the height beta; 6, according to the data obtained in the steps 1-5 and according to purity requirements of a product, designing a purification strategy, trying to purify the material liquid, and carrying out fine adjustment on the purification strategy according to the detection result; and 7, producing according to all the production conditions determined in the steps 1-6. After purification by the method, a concentrated solution of the object component can be acquired, and the product with required purity is obtained.

Owner:NANKAI UNIV

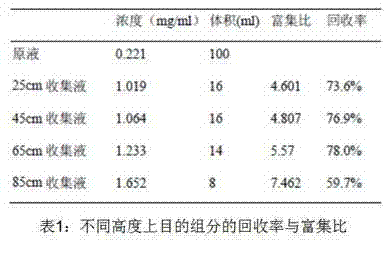

Flotation method for high-content slip manganese rock type low-grade nickel ores

InactiveCN102716805ASuppress interferenceHigh recovery rateFlotationCarboxymethyl celluloseFoaming agent

The invention discloses a flotation method for high-content slip manganese rock type low-grade nickel ores. The flotation method includes that raw ores are ground after being crushed, the fineness of 84-86% of ground products reaches -200 meshes, and the concentration of pulp ranges from 30% to 33%; the pulp is stirred while flotation combined reagent is added into the pulp; the flotation combined reagent comprises carboxymethyl cellulose salt, hexametaphosphate, a flotation regulator, a collector, an activator and a foaming agent; the pulp added with the combined reagent is fed into a flotation machine to be in closed cycle flotation, and flotation foams carrying the nickel ores are separated; and enriched nickel concentrations are obtained after combined reagents are added into the flotation foams to be in flotation by multiple times. Service effect show that by the aid of secondary flotation, tertiary scavenging and primary concentration technological flows, raw nickel ores with the grade ranging from 0.40% to 0.60% is in flotation by the flotation combined reagents to obtain the nickel concentrates with the grade ranging from 5.0% to 6.0%, nickel recovery rate ranges from 75% to 80%, accordingly, the high-content slip manganese rock type low-grade nickel ores are efficiently recovered in a flotation manner, the enrichment ratio of the concentrates is higher than 10, the technological processes are simple, and the flotation recovery rate is high.

Owner:陕西煎茶岭镍业有限公司

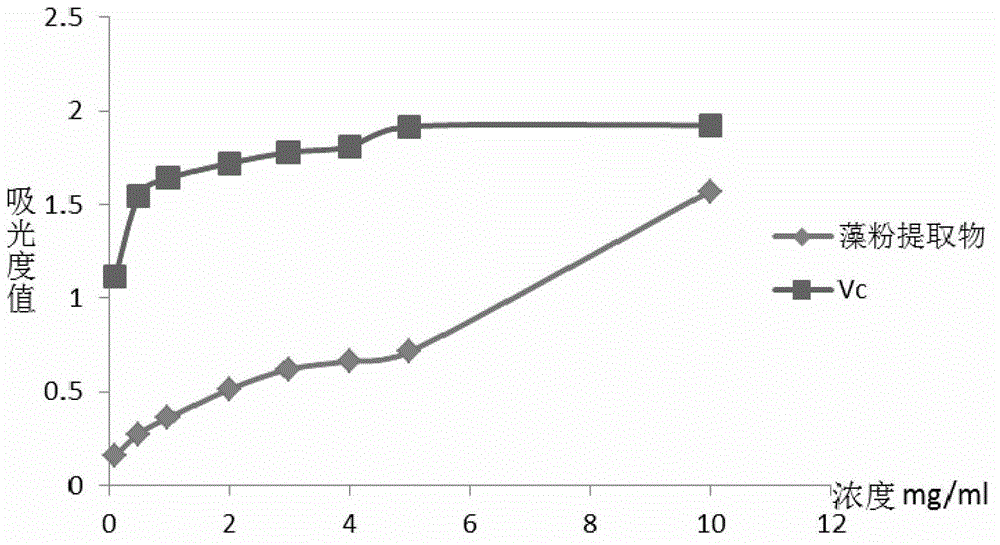

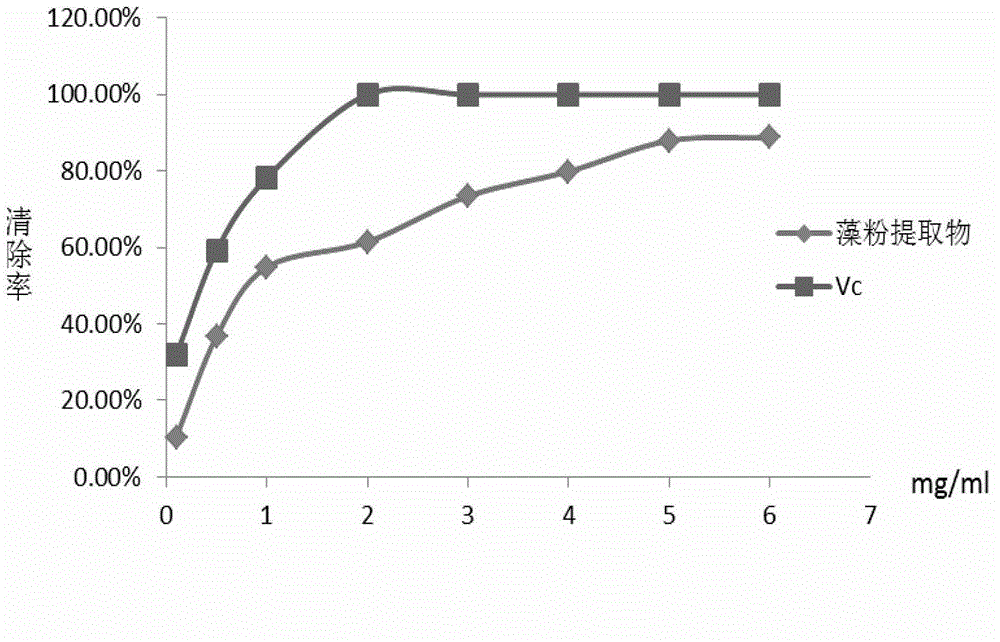

Method for extracting small-molecule peptides of spirulina

InactiveCN102875640AAntioxidantSimple processPeptide preparation methodsFood preparationHydrogenLiquid ratio

The invention provides a method for extracting small-molecule peptides of spirulina. The method includes: preprocessing the spirulina, adjusting the feed-liquid ratio to be 0.5-8g / L and the pH (potential of hydrogen) value to be 5-10, and performing foam separation of the spirulina after sufficient mixing so as to obtain foam extracting solution, namely small-molecule bioactive peptides with the molecular weight of 5000Da. The dissolution rate of spirulina protein obtained by the method can reach 12.6%, enrichment ratio can reach 4.4, and the highest recovery rate can reach 98%. Compared with a traditional method, the method for extracting the small-molecule active peptides is quite simple in process and does not need expensive equipment and apparatuses, extracting procedures are greatly simplified, extracting cost is greatly saved, and economic benefits are remarkable.

Owner:BEIJING FORESTRY UNIVERSITY

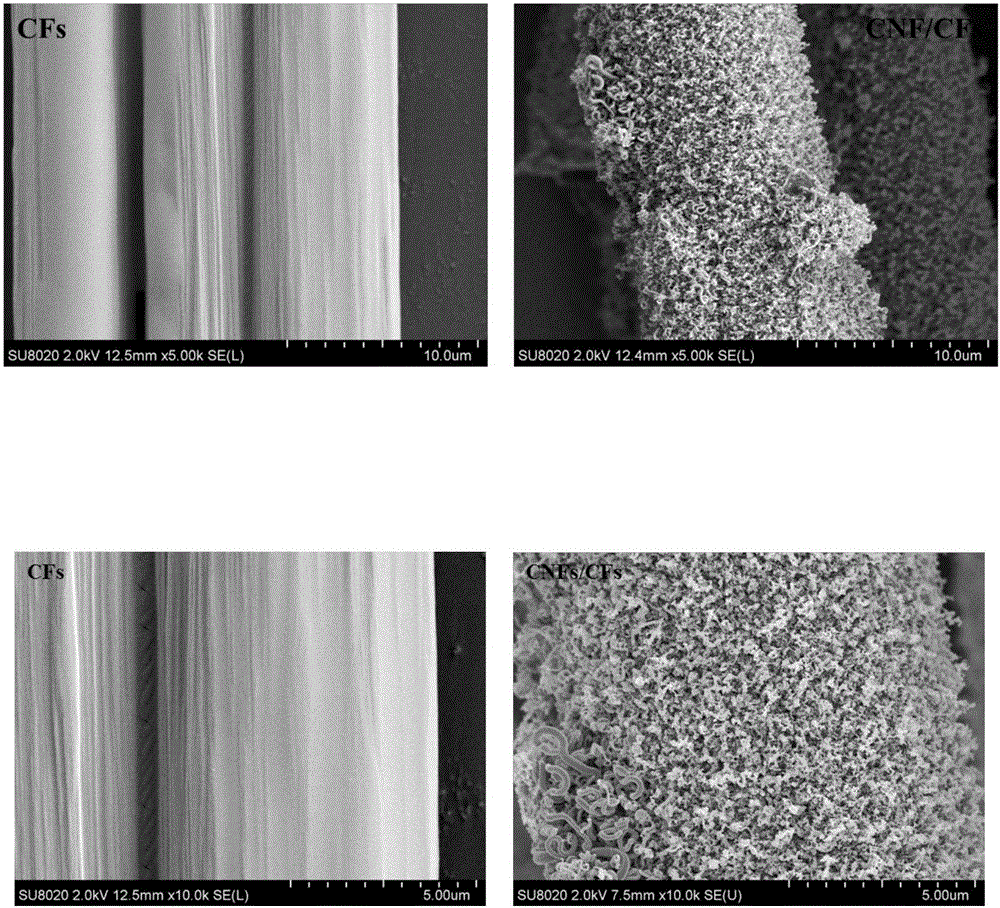

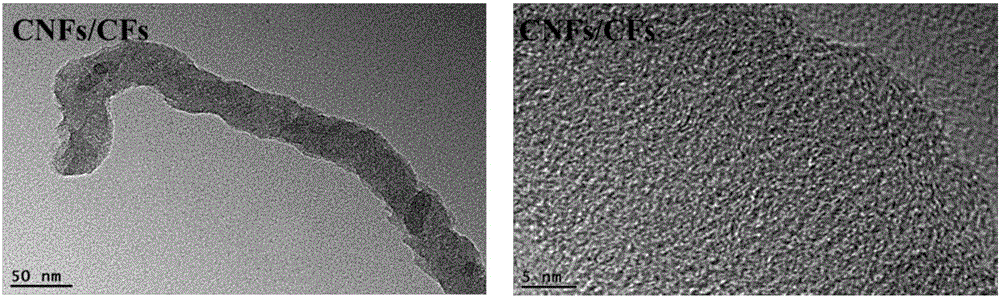

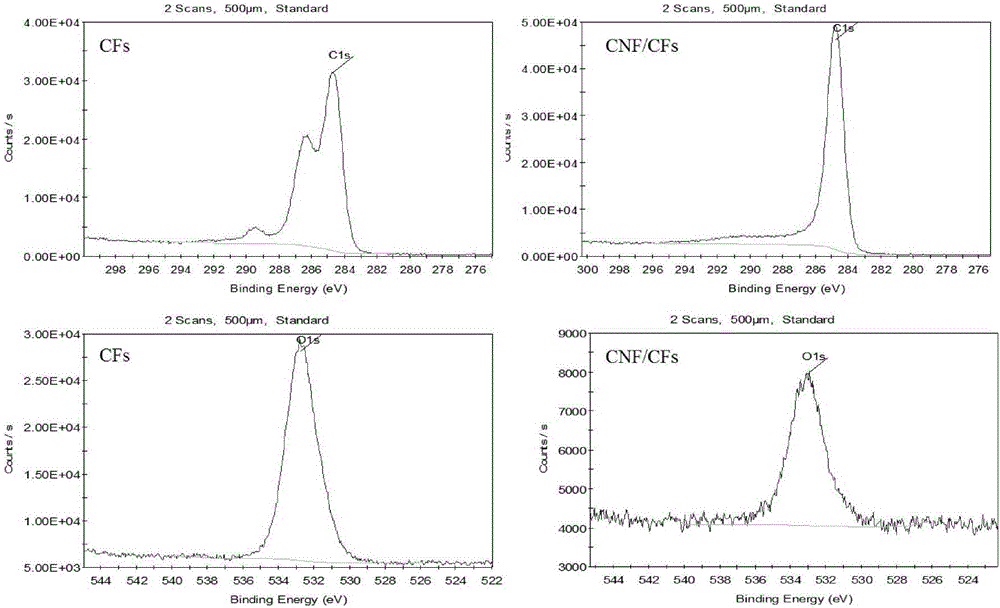

Method and device for preparing carbon nano-fiber/carbon fiber solid-phase micro-extraction coatings

ActiveCN106353439AIncrease the active siteHigh enrichment rateComponent separationFiberPlant hormone

The invention discloses a carbon nano-fiber / carbon fiber solid-phase micro-extraction material, a method for preparing the same and a method and a device for manufacturing carbon nano-fiber / carbon fiber solid-phase micro-extraction devices. The carbon nano-fiber / carbon fiber solid-phase micro-extraction material, the methods and the device have the advantages that carbon nano-fibers / carbon fibers can be prepared, and chromatographic analysis processes are provided for detecting plant hormones by means of infusion and micro-enrichment in real time; the carbon nano-fibers are modified on the carbon fibers, so that spatial stereoscopic three-dimensional structures can be formed, active sites can be effectively increased, the enrichment ratios can be increased, and the difficult problem of difficulty in detecting plant hormones in real time due to the low concentration of the plant hormones can be solved.

Owner:YANBIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com