Airflow type headspace liquid-phase microextraction method

An air-flow, extraction technology, applied in liquid solution solvent extraction, measurement devices, instruments, etc., can solve problems such as unfavorable enrichment of low-vapor pressure target substances, increase in gas phase volume, and increase in absolute content of target substances in gas phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

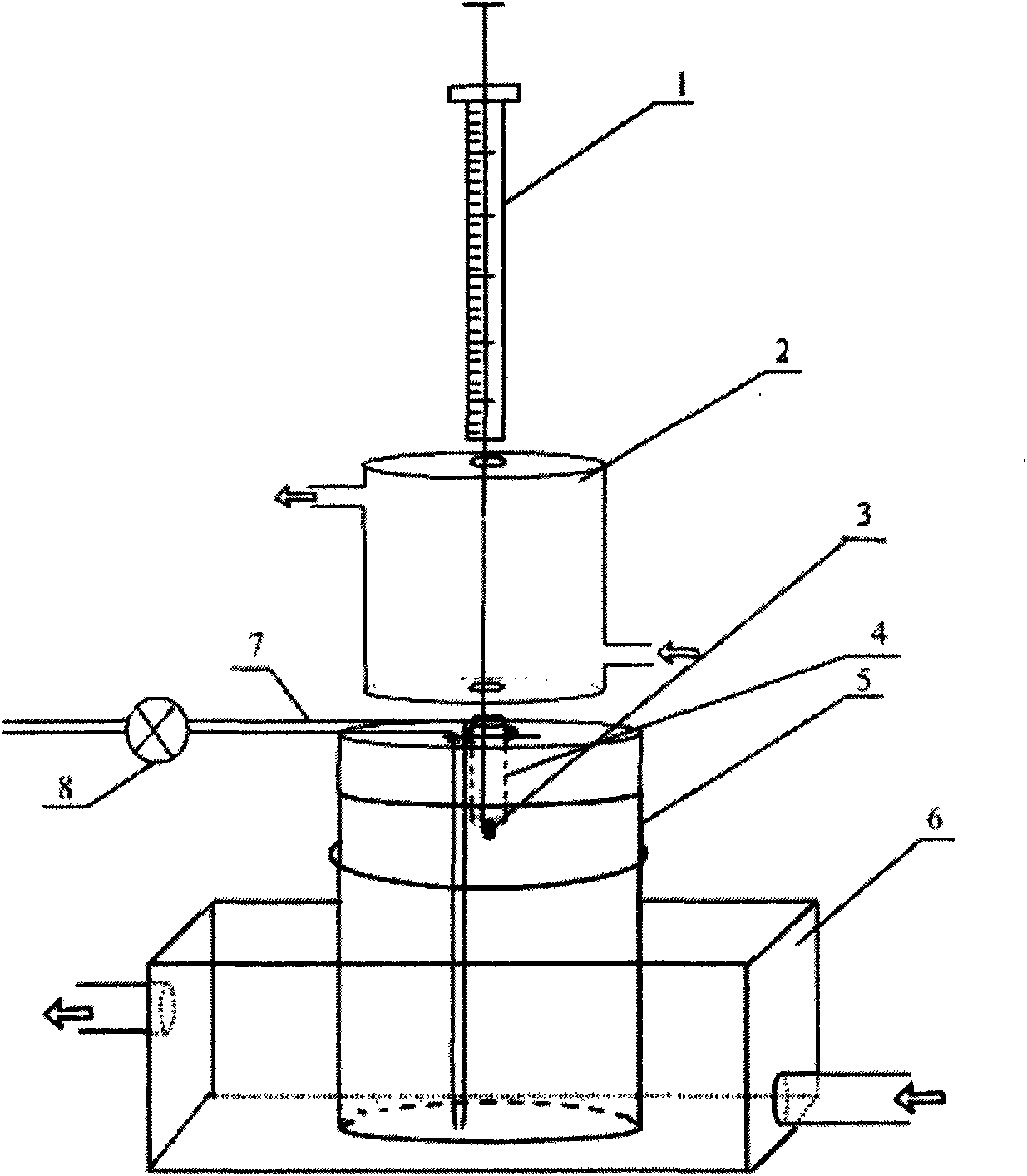

[0012] refer to figure 1 , the specific experimental process is as follows: ① the standard sample or the actual sample is put into the sample bottle 5, ② the inert gas enters the tube 7 and is placed on the upper part of the sample through the PTFE cover matched with the sample bottle 5, and the inert gas enters the tube 7 There is a mass flow controller 8 on it, 3. the sample bottle 5 is put into the heating device 6, a condensation device 2 is installed above the sample bottle 5, and 4. a special equipment for washing a chromatographic injection needle invented by this laboratory is used-- The patent number is 200820071370.4" to clean the chromatographic injection needle 1. The cleaning solvent is determined by the properties of the target. After that, it is washed at least five times with the extraction solvent. Finally, a certain volume of the extraction solvent 3 is taken. Insert the gas outlet tube 4 into the sample bottle 5, and fix the needle tip to a proper position. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com