Patents

Literature

342results about How to "Uniform precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing high density spherical nickel-cobalt lithium manganate as anode material of lithium ion cell

InactiveCN1622371AWell mixedImprove performanceElectrode manufacturing processesLithium compoundsNickel saltManganate

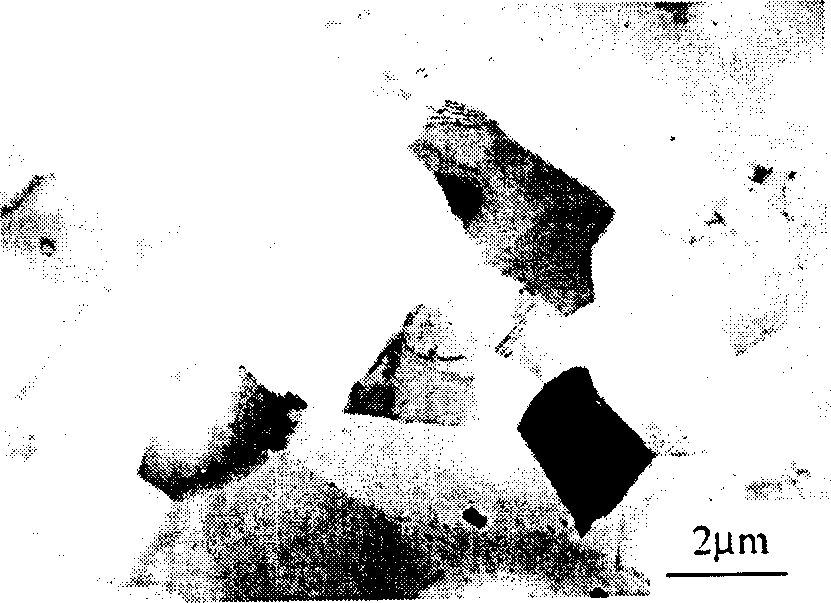

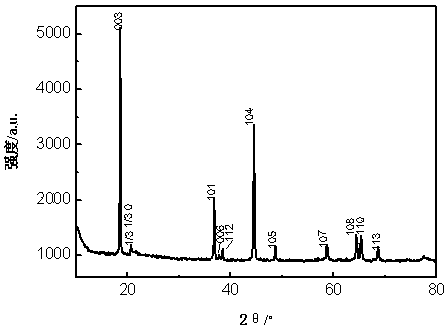

The present invention relates to energy source material technology, and is preparation process of high density spherical lithium nickel-cobalt-manganate as positive electrode material for lithium ion cell. The preparation process includes the reaction of nickel salt, cobalt salt, manganese salt, ammonium hydroxide and ammonian in water solution to synthesize spherical or spheroid precursor Ni1 / 3Co1 / 3Mn1 / 3 (OTHER)2, washing, drying and mixing with lithium carbonate; and high temperature treatment in the air at 750-950 deg.c for 8-48 hr to obtain spherical lithium nickel-cobalt-manganate. The spherical lithium nickel-cobalt-manganate has great bulk density reaching 2.25-2.50 g / cu cm after vibration densifying, average grain size of 3-7 microns, and reversible specific capacity up to 172-185 mA.hr / g.

Owner:TSINGHUA UNIV

Dandelion health-care tea and preparing process thereof

The invention discloses a dandelion health care tea which consists of the following components and mass percentage of the components is: dandelion leaves: 50 to 70 percent; dandelion rootlets: 25 to 35 percent; ganoderma lucidum rootlets: 2 to 8 percent; and wild chrysanthemum: 2 to 8 percent. The invention also discloses a preparation method of the health care tea which comprises the following steps: first cleaning the dandelion, and cutting the leaves and the root off by a knife, dipping the leaves in warm water for 3 minutes and drying after cutting the leaves into lumps of 1 square centimeter; cutting the root into threads by a blanket machine and drying; cutting the ganoderma lucidum into threads by the blanket machine and drying, and drying the wild chrysanthemum directly, then the health care tea is obtained by mixing and sterilizing the raw materials according to the mass percentage. The health care tea of the invention can effectively prevent and treat hyperplasia of mammary glands at the same time when satisfying the needs of drinking tea. After drinking the health care tea, the occurrence of mammary gland diseases such as hyperplasia of mammary glands of the female can be prevented; the female who suffer from the mammary gland diseases such as hyperplasia of mammary glands can also have good treatment effect after drinking the health care tea without side effects, risk of operation or scar.

Owner:钟伟珍

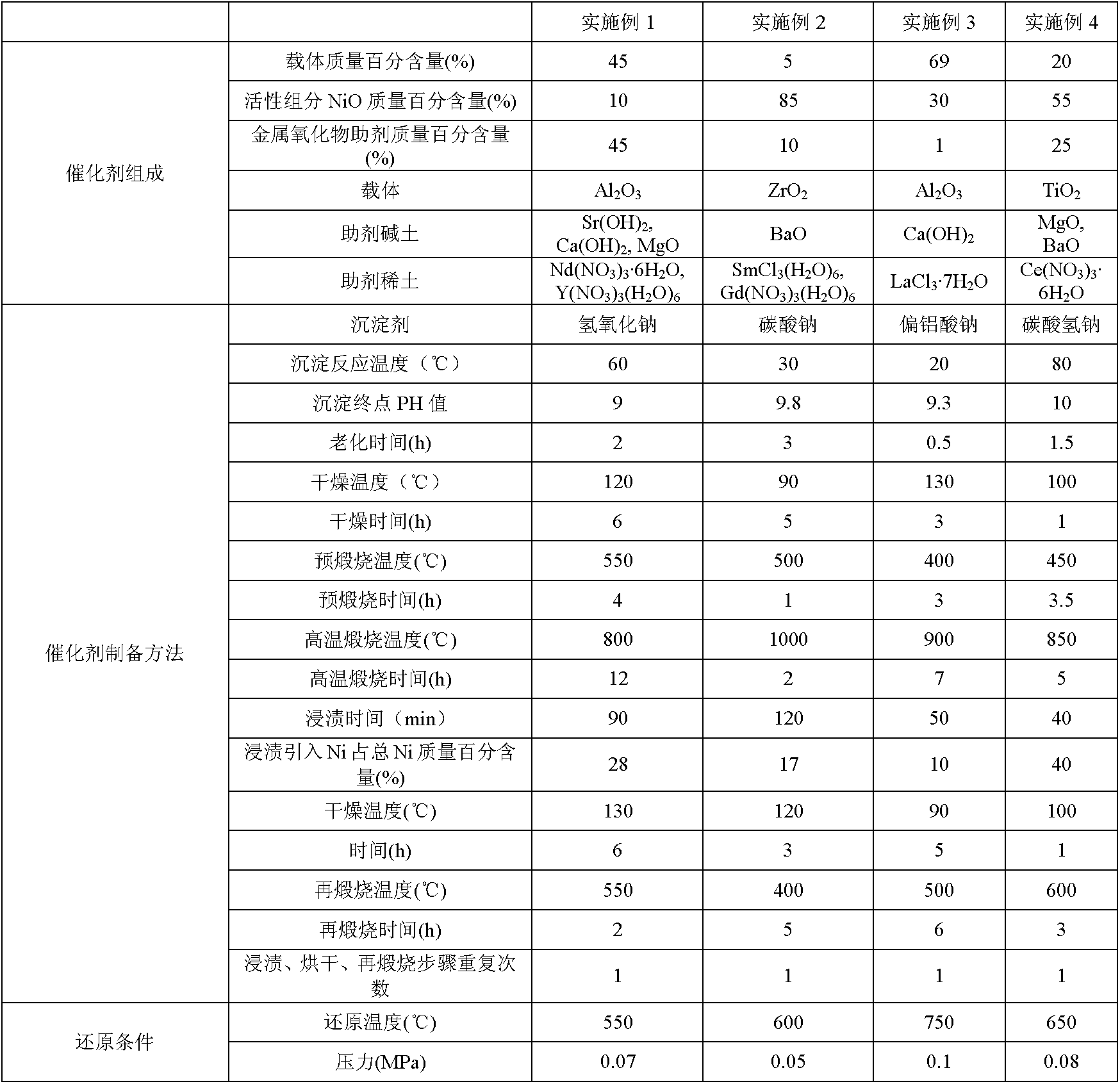

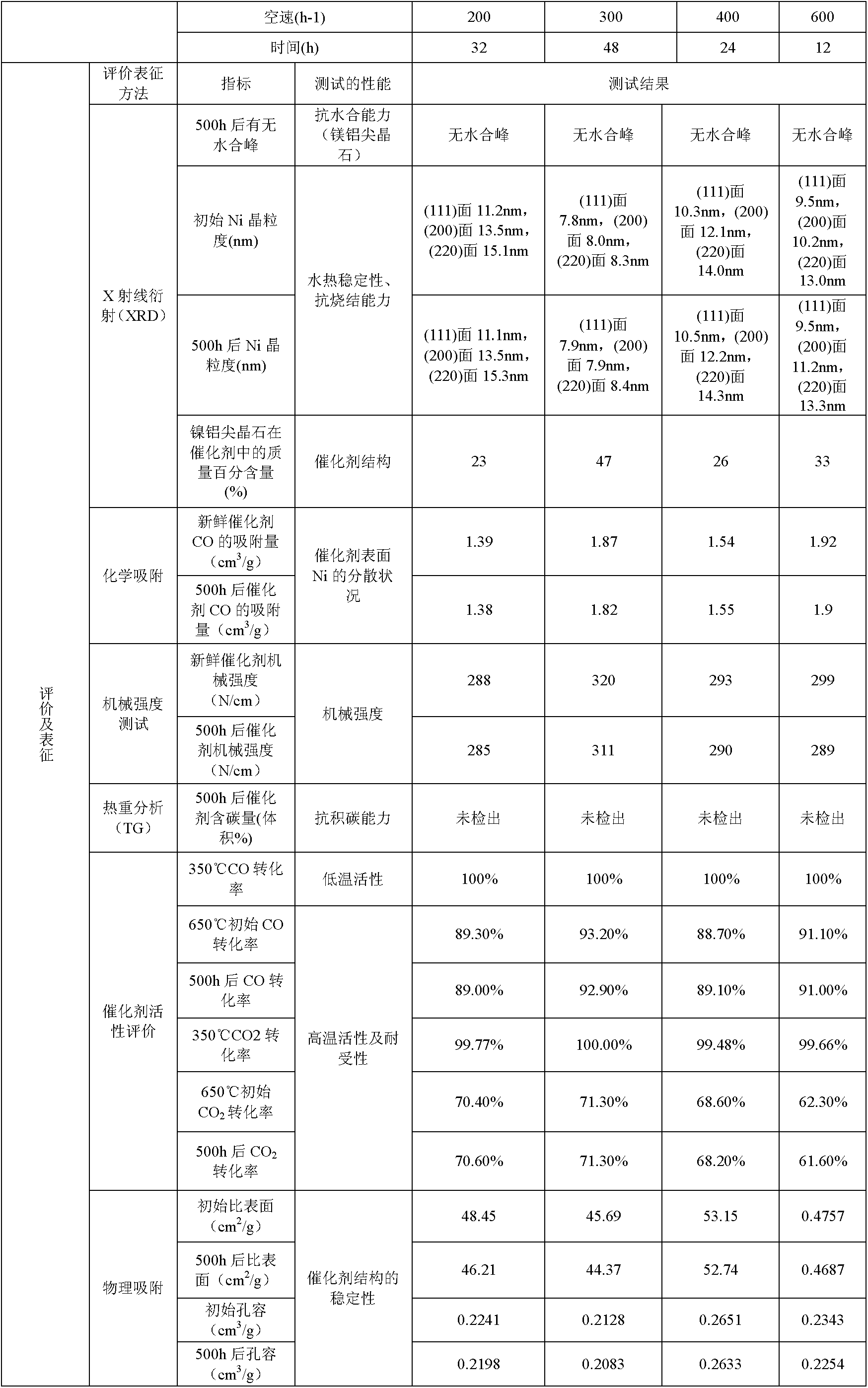

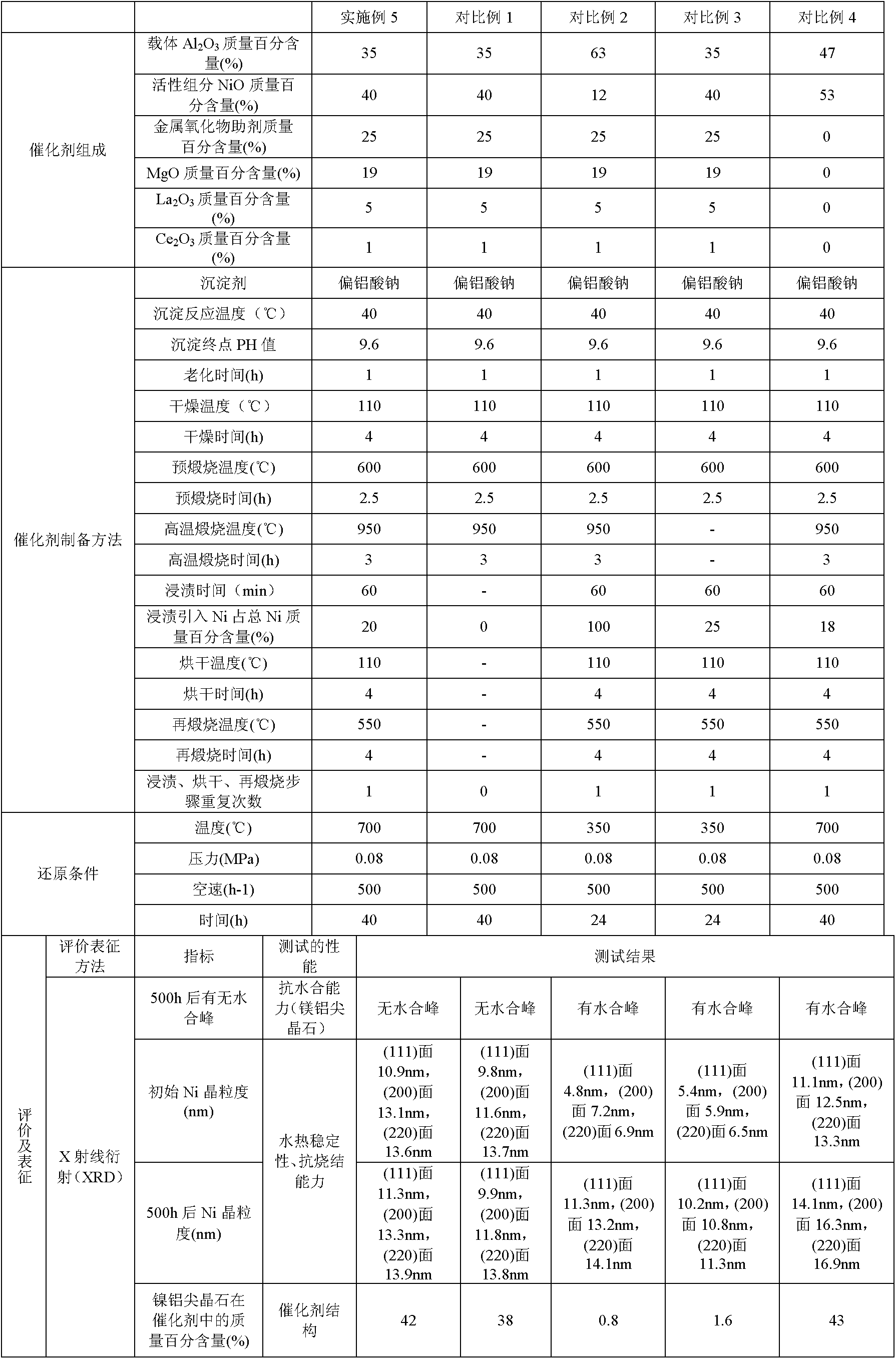

Preparation method of wide-temperature methanation catalyst

ActiveCN103055876AActiveStrong anti-sintering abilityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsCoalAdjuvant

The invention provides a preparation method of a wide-temperature methanation catalyst. The wide-temperature methanation catalyst comprises the following components in percentage by mass: 5-75% of a carrier, 10-90% of NiO as an active constituent and 1-50% of a metal oxide adjuvant. In the preparation method, the wide-temperature methanation catalyst is obtained in a way of combining a precipitation process and an impregnation method. The obtained catalyst has good methanation activity in a wide-temperate range of 260-800 DEG C, stable performance, long service life and strong practicality, so that the catalyst is suitable for the application in a diversified coal methane industry.

Owner:XINDI ENERGY ENG TECH

Catalyzer for industrial production of 1,6-hexamethylene glycol and method of preparing the same

InactiveCN101138726AGood thermal stability and dispersibilityUniform precipitationOrganic compound preparationHydroxy compound preparationCopper nitrateZinc nitrate hexahydrate

A catalyst used for industrial production of 1, 6-hexanediol and a preparation method for the catalyst and relate to a catalyst used for hydrogenated production of 1, 6-hexanediol with 1, 6 dimethylene adipate, and a preparation method for the catalyst. The catalyst basically comprises copper oxide, zinc oxide and aluminum oxide. The copper oxide takes up 25 to 60 percent of the total catalyst weight, the zinc oxide takes up 25 to 60 percent of the total catalyst weight, and the aluminum oxide takes up 10 to 30 percent. The preparation method comprises preparation of a copper nitrate and zinc nitrate mixed solution, preparation of a aluminum hydroxide suspension, deposition, filtering, washing, drying, granule making, calcination, mixing with an extender, tablet pressing and molding. Thus, the catalyst used for industrial production of 1, 6-hexanediol is produced, and make the conversion rate of the raw material of 1, 6 dimethylene adipate larger than 99 percent and the hexanediol selectivity larger than 96 percent.

Owner:PETROCHINA CO LTD

Nickel-base spraying smelting alloy powder and its preparation process

InactiveCN1623720AStrong precipitation strengthening abilityImprove wear resistanceWelding/cutting media/materialsSoldering mediaAlloyImpurity

A Ni-based alloy powder for processing or reparing the surface of iron and steel workpiece by spray and melting it contains C (0.4-1.2%), Si (3.5-5.0), B(2.5-4.5), Cr (13.0-20.0), Fe (0-17), V (0.5-1.8), Al (0.5-4.0), Ni and one of Nb, Ti, W, Mo and Cu. Its advantage is high antiwear property.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Purifying method for ultra-pure aluminum

The invention relates to a purifying method for ultra-pure aluminum. The purifying method specifically comprises the following steps: injecting molten aluminum with purity being 4N6 into a cast iron crucible, and heating the molten aluminum by a heating wire on the outer wall of the cast iron crucible for preserving the temperature of the molten aluminum to be 680-700 DEG C; stretching seed crystals above the cast iron crucible into a position 2-3cm under the liquid level of the molten aluminum, and introducing cooling gas to the other ends of the seed crystals to cool and crystallize the molten aluminum; spirally rotating the seed crystals in the cast iron crucible, thereby enabling the molten aluminum to carry out rotary motion in the cast iron crucible; and after the crystallizing is ended, quickly pulling out the seed crystals with crystallized ingots, and finally enabling the crystal seeds and the formed crystallized ingots to be in shape of inverted mushroom. The purifying method has the advantages of greatly reducing the purifying cost, and greatly improving the purifying efficiency and the purifying purity, and is suitable for industrial production.

Owner:NANTONG TADE ELECTRONICS MATERIAL TECH

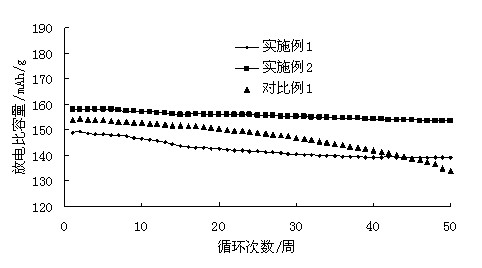

Lithium ion battery anode material and manufacturing method thereof

InactiveCN102637877AUniform particle sizeHas a layered crystal structureCell electrodesPhosphateManganese

The invention discloses a lithium ion battery anode material and a manufacturing method of the lithium ion battery anode material. The anode material is cobalt nickel oxide manganese with a layer structure and has the chemical composition of LiNil-x-yCoxMnyO2, wherein x is equal to and larger than 0.15 and is equal to and less than 0.3, and y is equal to and larger than 0.2 and is equal to and less than 0.4. The manufacturing method provided by the invention has the following steps: the cobalt nickel oxide manganese powder is manufactured through a coprecipitation method, metal phosphate is adopted as a cladding material with the cladding quantity as 0.5-1.5% of the anode material; and the cobalt nickel oxide manganese is externally cladded by zinc phosphate through fluidization. The cladded battery material after modification with the manufacturing method has high special capacity and has good cycling stability at high temperature.

Owner:KUNMING UNIV OF SCI & TECH

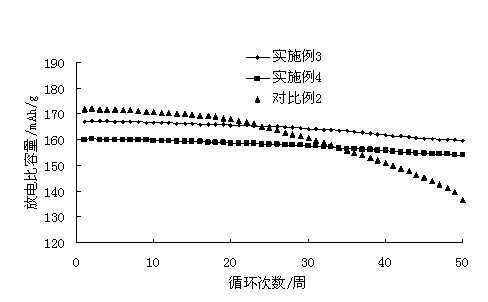

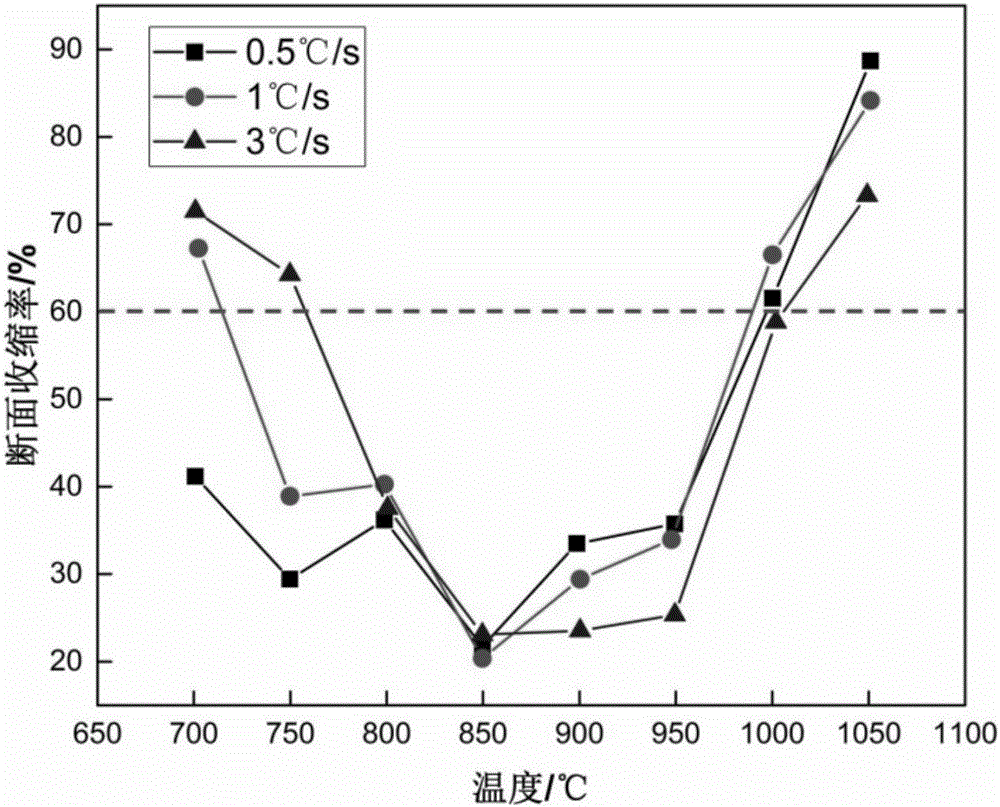

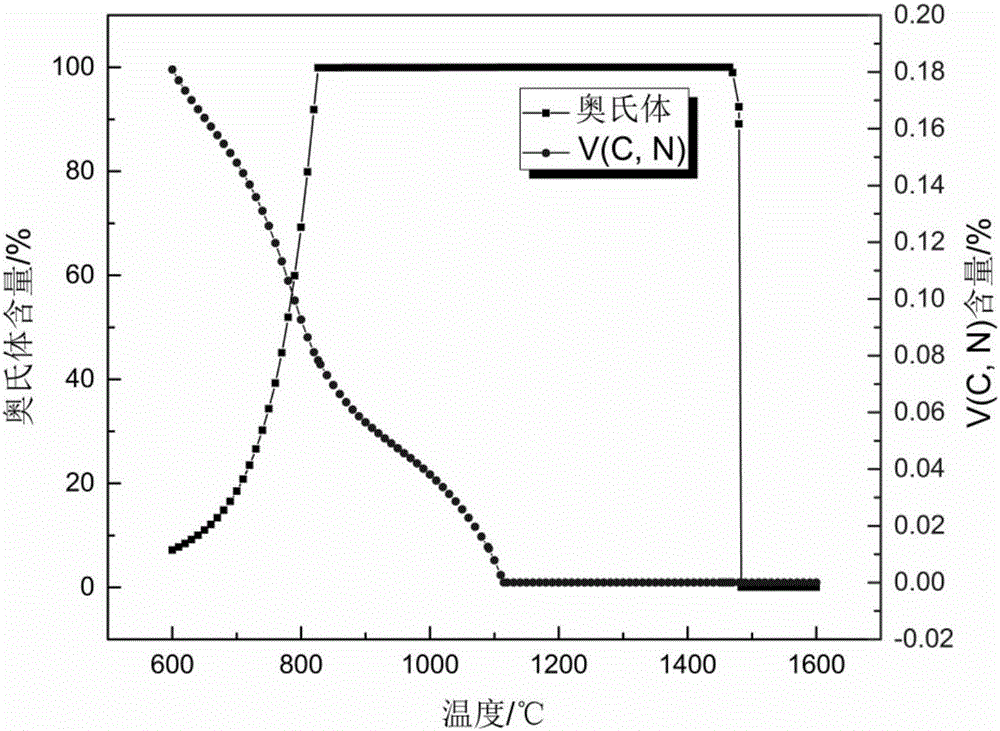

Microalloyed steel continuous casting cooling control method based on steel grade solidification characteristic and evolution of microstructures

The invention relates to a microalloyed steel continuous casting cooling control method based on the steel grade solidification characteristic and evolution of microstructures. The critical technical contents of the microalloyed steel continuous casting cooling control method comprise steel grade solidification characteristic experimental analysis, continuous cast blank solidification structure numerical simulation, continuous casting cooling process water amount regulation and control and the like. Change rules of the thermoplasticity and a third brittle temperature range of a target steel grade at different cooling rates are determined through experiments at first, then the influences of the cooling rates on austenite / ferrite transformation and the microalloy element second-phase particle precipitation law are comprehensively analyzed with te combination with the experiments, and finally, the microalloyed steel square blank continuous casting cooling precise control strategy of "low superheat pouring, low cooling of a third secondary cooling zone and high cooling of a fourth secondary cooling zone" is provided, relevant regulation and control schemes, that is, the superheating temperature is 23 DEG C (the original value is 37 DEG C), the water amount of the third secondary cooling zone is 2.6 L / min (the original value is 51.5 L / min), and the water amount of the fourth secondary cooling zone is 165.6 L / min (the original value is 18.4 L / min) are made a new continuous casting secondary cooling regulation and control mechanism based on the microalloyed steel characteristic is built, a cast blank solidification structure is optimized, and the strength of a surface microstructure of the solidification structure is improved.

Owner:UNIV OF SCI & TECH BEIJING

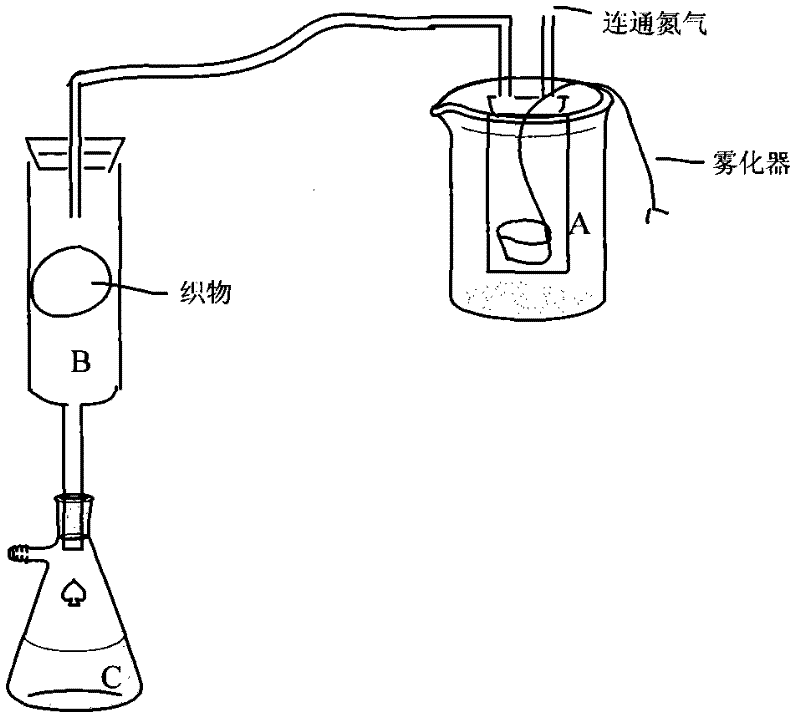

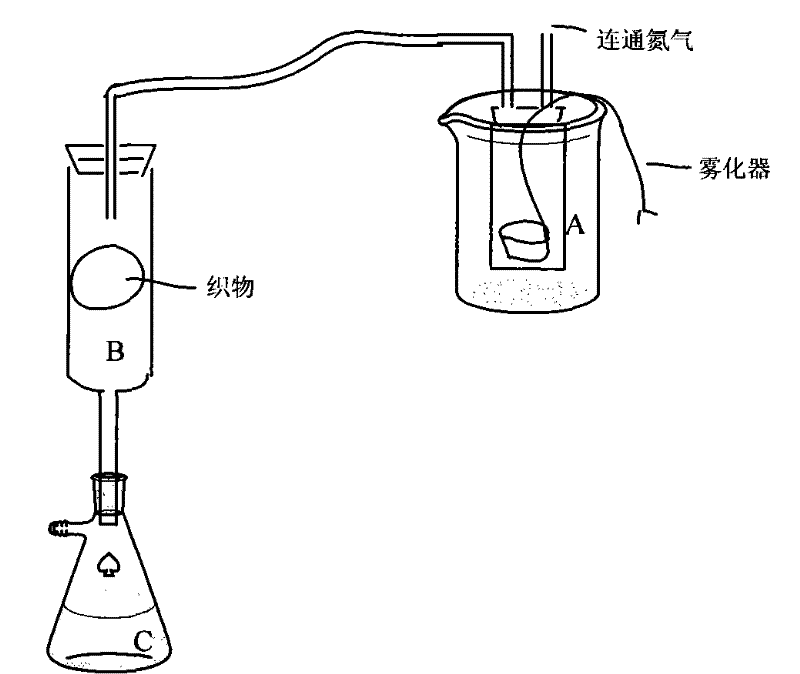

Preparation method of composite conductive fabric with spray polymerization

InactiveCN102312376AImprove conductivityStable conductivityVegetal fibresAnimal fibresSolventChemistry

The invention which relates to a preparation method of a composite conductive fabric with spray polymerization belongs to the technical field of textiles. An atomization mode is adopted in the invention to atomize a monomer solution into particles, and an in situ polymerization reaction is initiated on a monomer under the effect of an oxidant deposited in the fabric to prepare the composite conductive fabric. The preparation method of the invention which has the advantages of easy controlled condition, simple operation, low raw material cost, and less energy consumption is suitable for the large scale and industrial production. Compared with routine products prepared with a liquid-phase oxidation method, the adhesion between a conducting layer and a fabric matrix of the composite conductive fabric prepared in the invention is substantially improved, the conducting layer is more compacted, and protrude wear resistances and solvent resistances are possessed; the surface resistor of the preparative composite conductive fabric is 10-10<5>omega / cm<2>, the conductivity is good, the electromagnetic shielding property and the flexibility of a product (the composite conductive fabric) are good, and the surface resistor of the product in the invention is sensitive to the change of pressure, elasticity and the like, so the product can be widely applied to the sensor field, the antistaticfield, the anti-electromagnetic shielding field and the like.

Owner:WUHAN TEXTILE UNIV

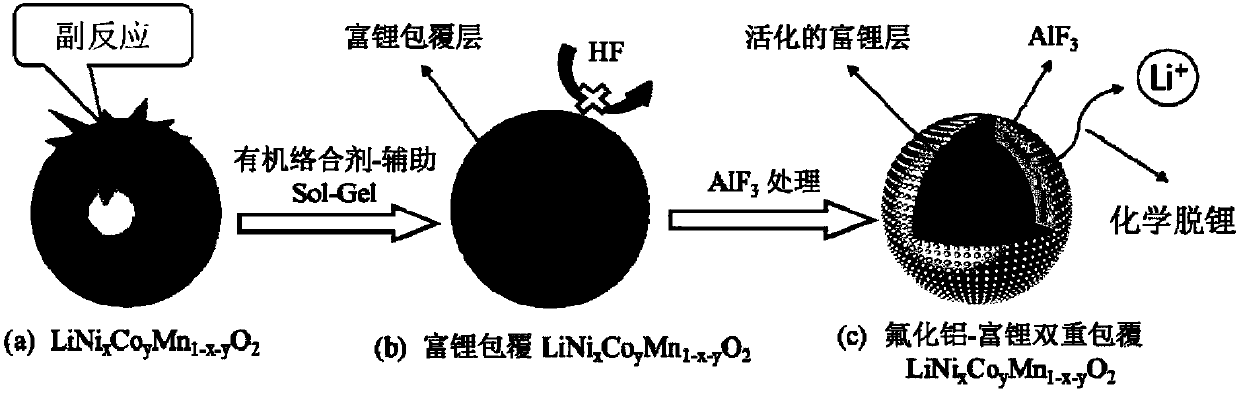

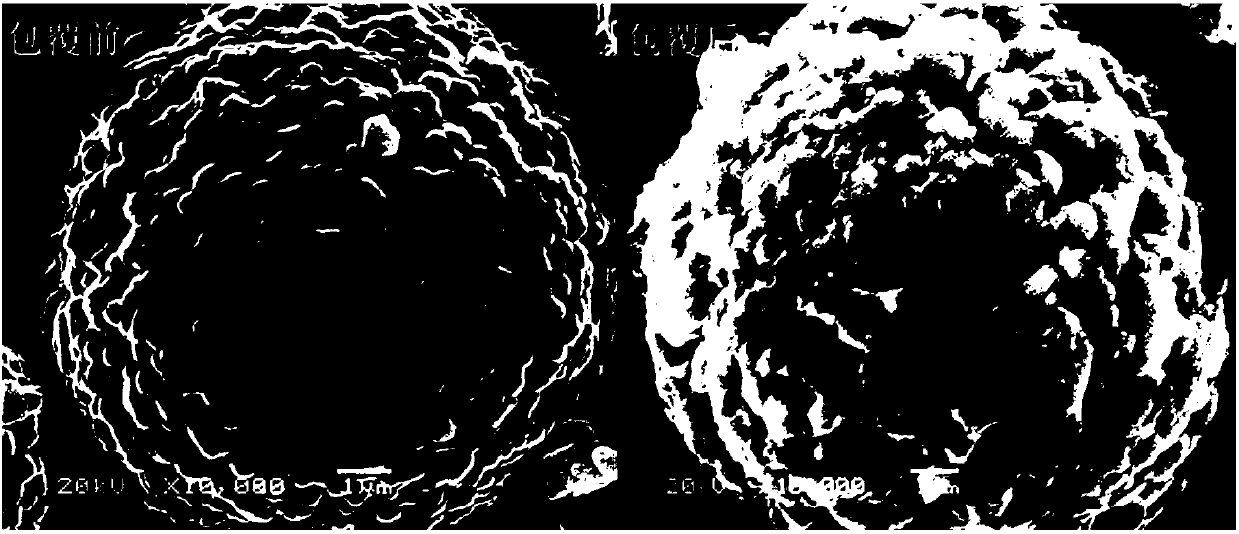

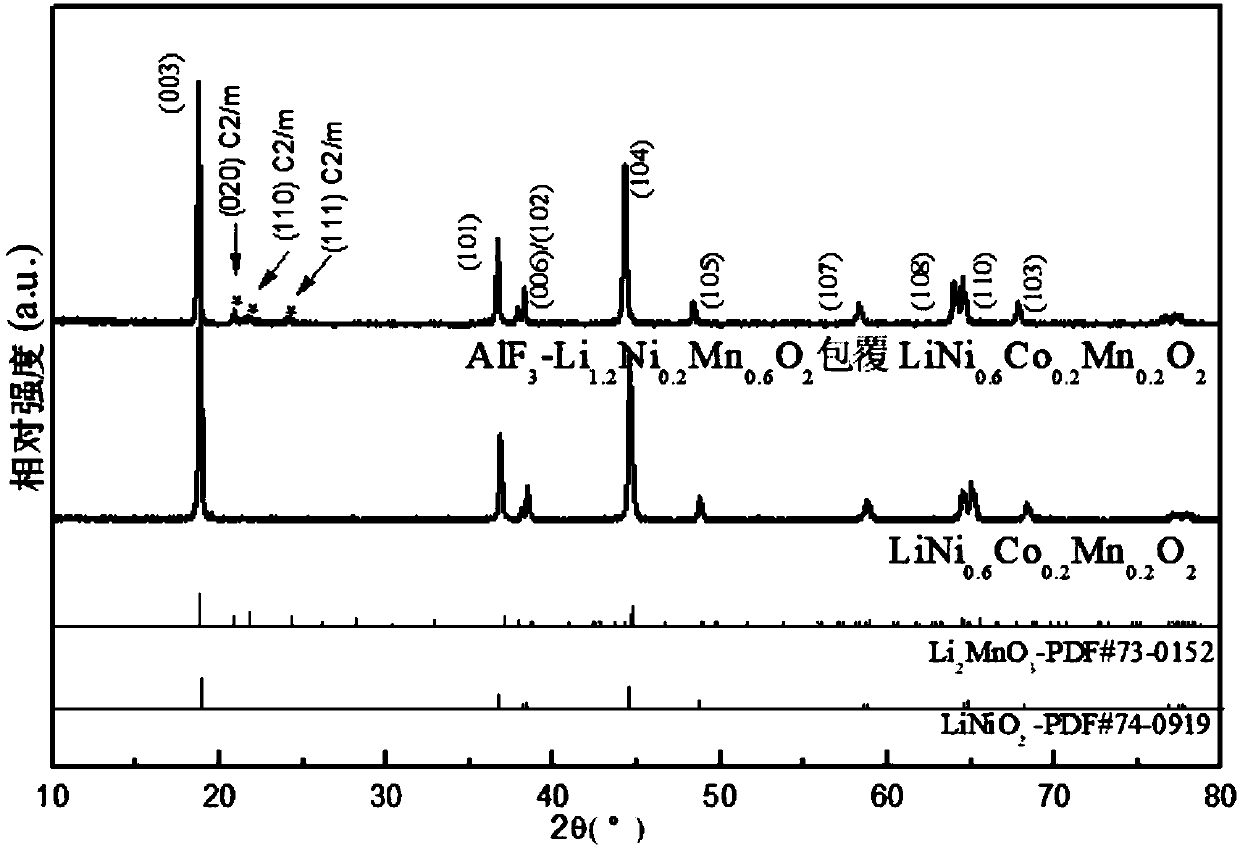

Lithium ion battery ternary material with double-coated surface and preparation method thereof

InactiveCN107768642AHigh Capacity FeaturesImprove protectionCell electrodesSecondary cellsManganeseCobalt

The invention discloses a lithium ion battery ternary material with a double-coated surface. The lithium ion battery ternary material with the double-coated surface comprises a nickel-cobalt-manganeseternary material, wherein a lithium-rich layered oxide coating layer is covered on a surface of the nickel-cobalt-manganese ternary material; an aluminum fluoride coating layer is covered on a surface of the lithium-rich layered oxide coating layer; the lithium ion battery ternary material with the double-coated surface is not easy to fall off, and has good chemical stability and high capacity. The invention also discloses a preparation method of the lithium ion battery ternary material. The method comprises the steps of firstly adopting an organic complexing agent-auxiliary sol-gel method for covering lithium-rich layered oxide on the surface of the ternary material so as to form the lithium-rich coating layer; then using a liquid phase method for coating aluminum fluoride on the surfaceof the lithium-rich layered oxide coating layer, and obtaining the double-coated lithium ion battery ternary material. The preparation method is simple in process, high in operation feasibility, andhigh in element utilization rate.

Owner:CENT SOUTH UNIV

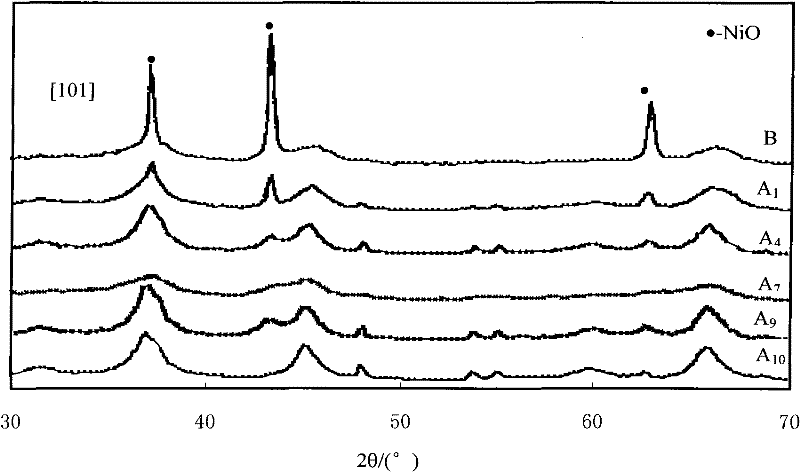

Method for preparing nickel-based catalyst precursor

ActiveCN102451689AUniform precipitationEvenly dispersedCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPetroleum resinSilicon oxide

The invention discloses a method for preparing a nickel-based catalyst precursor. The method comprises the following steps of: preparing slurry from aluminum oxide and / or silicon oxide serving as a carrier, an active metal ingredient and an aid ingredient; and adding the slurry and a precipitating agent into a reaction kettle in a cocurrent flow mode. By the method, the active ingredient is uniformly precipitated and highly and uniformly dispersed on the carrier; meanwhile, precipitation is performed in the cocurrent flow mode, and a precipitation environment in the precipitation process is uniform, so that precipitates have the same shape and grain size. A catalyst prepared from the nickel-based catalyst precursor prepared by the method can be used in the process of hydrodecolorizing C5 petroleum resin, C9 petroleum resin and C5 and C9 blended petroleum resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

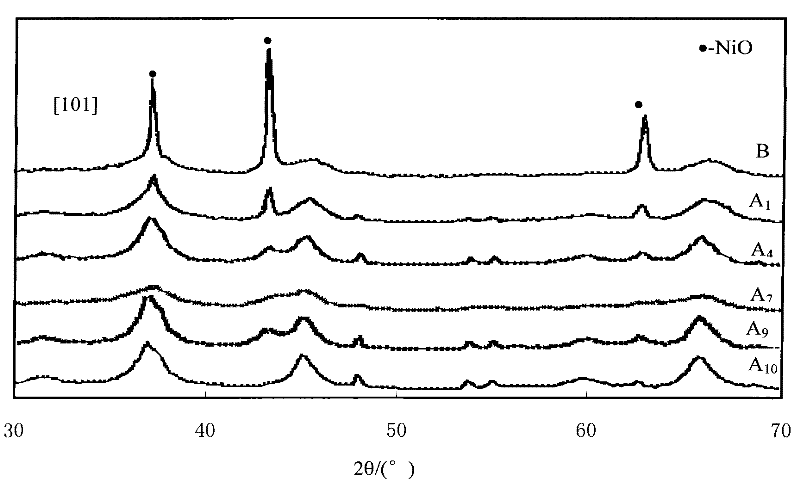

Preparation method for hydrogenation catalyst

ActiveCN104588024AUniform precipitationUniform adsorptionMetal/metal-oxides/metal-hydroxide catalystsNickel catalystPtru catalyst

The invention discloses a preparation method for a hydrogenation catalyst. The catalyst is a nickel catalyst. The preparation method for the hydrogenation catalyst comprises the following step: preparing slurry from a part of active metal nickel, an auxiliary agent and a carrier and subjecting the slurry and a precipitating agent to parallel-flow precipitation; then adding a filter cake obtained after filtration into a solution prepared from rest active metal nickel and dropwise adding an alkaline solution; successively carrying out aging, washing and drying; and carrying out molding, drying and roasting so as to prepare the hydrogenation catalyst. The catalyst prepared by using the method is particularly applicable to hydro-decolorization of C5 petroleum resin, C9 petroleum resin and blended C5 and C9 petroleum resin and has the advantages of good activity, high selectivity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for graphene rare earth aluminum alloy high-conductive material

ActiveCN107099708AReduce the degree of reunionLow densityConductive materialMetal/alloy conductorsRare earthConductive materials

The invention discloses a preparation method for a graphene rare earth aluminum alloy high-conductive material. The method comprises the following steps: adding aluminum scrap, silicon calcium alloy, copper aluminum alloy, zinc aluminum alloy, magnesium ingot, rare earth aluminum alloy and graphene into a smelting furnace for smelting; performing ladle analysis, thereby acquiring an aluminum alloy solution; casting and rolling the aluminum alloy solution, thereby acquiring aluminum alloy; performing homogenization treatment on the aluminum alloy; performing ageing treatment, thereby acquiring the graphene rare earth aluminum alloy high-conductive material. According to the preparation method for the graphene rare earth aluminum alloy high-conductive material, provided by the invention, the technical parameters are reasonably set, the graphene structure is optimized and the overall performance of the aluminum alloy is effectively improved, so that the acquired graphene rare earth aluminum alloy high-conductive material has excellent electric conductivity, heat resistance, arc altitude resistance and mechanical properties.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

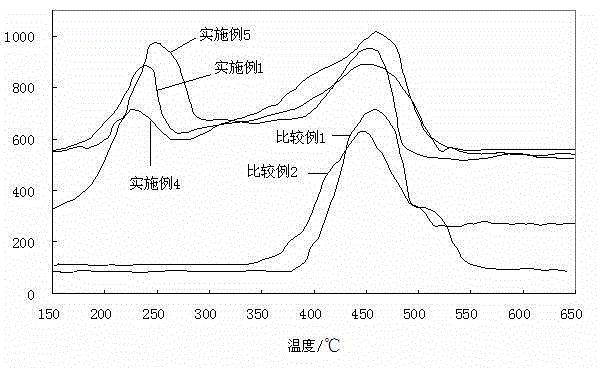

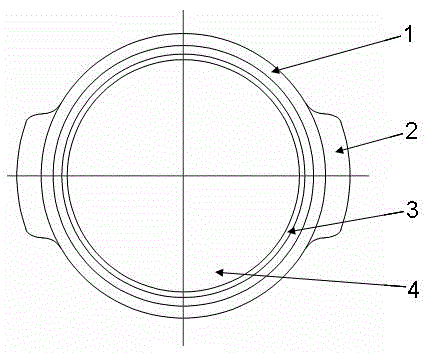

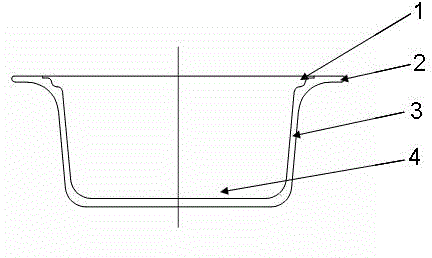

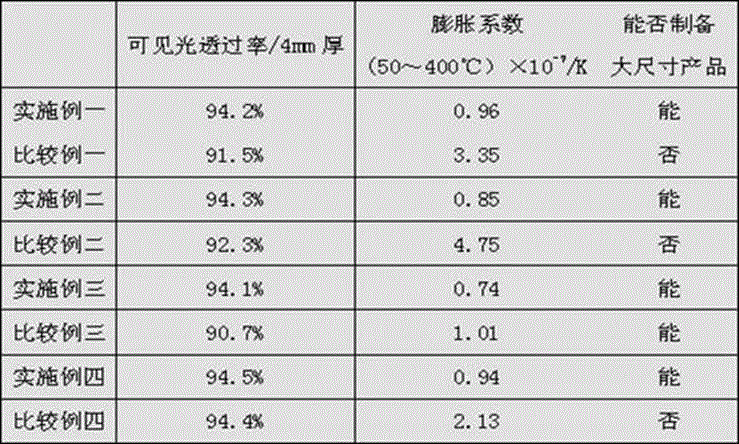

Ultralow-expansion-coefficient high-transparency microcrystalline glass and preparation method thereof

The invention discloses an ultralow-expansion-coefficient high-transparency microcrystalline glass which comprises the following components in percentage by weight: 65-69% of SiO2, 19-20% of Al2O3, 3.1-4.2% of Li2O, 3-4.5% of B2O3, 0.1-0.4% of Na2O, 0.1-0.4% of K2O, 0.3-0.5% of MgO, 0.6-1.4% of BaO, 0.6-1.4% of ZnO, 1.0-1.7% of TiO2, 1.0-1.3% of ZrO2, 0.4-0.8% of P2O5, 0.3-0.8% of F and 0.02-0.3% of CeO2. The preparation method comprises the following steps: melting glass raw materials, cooling, molding, annealing, crystallizing, and carrying out after treatment to obtain the microcrystalline glass finished product. The microcrystalline glass has the advantages of high transparency and ultralow expansion coefficient, and can be used for manufacturing large-size or complex-structure products.

Owner:虎石新材料(宜兴)有限公司

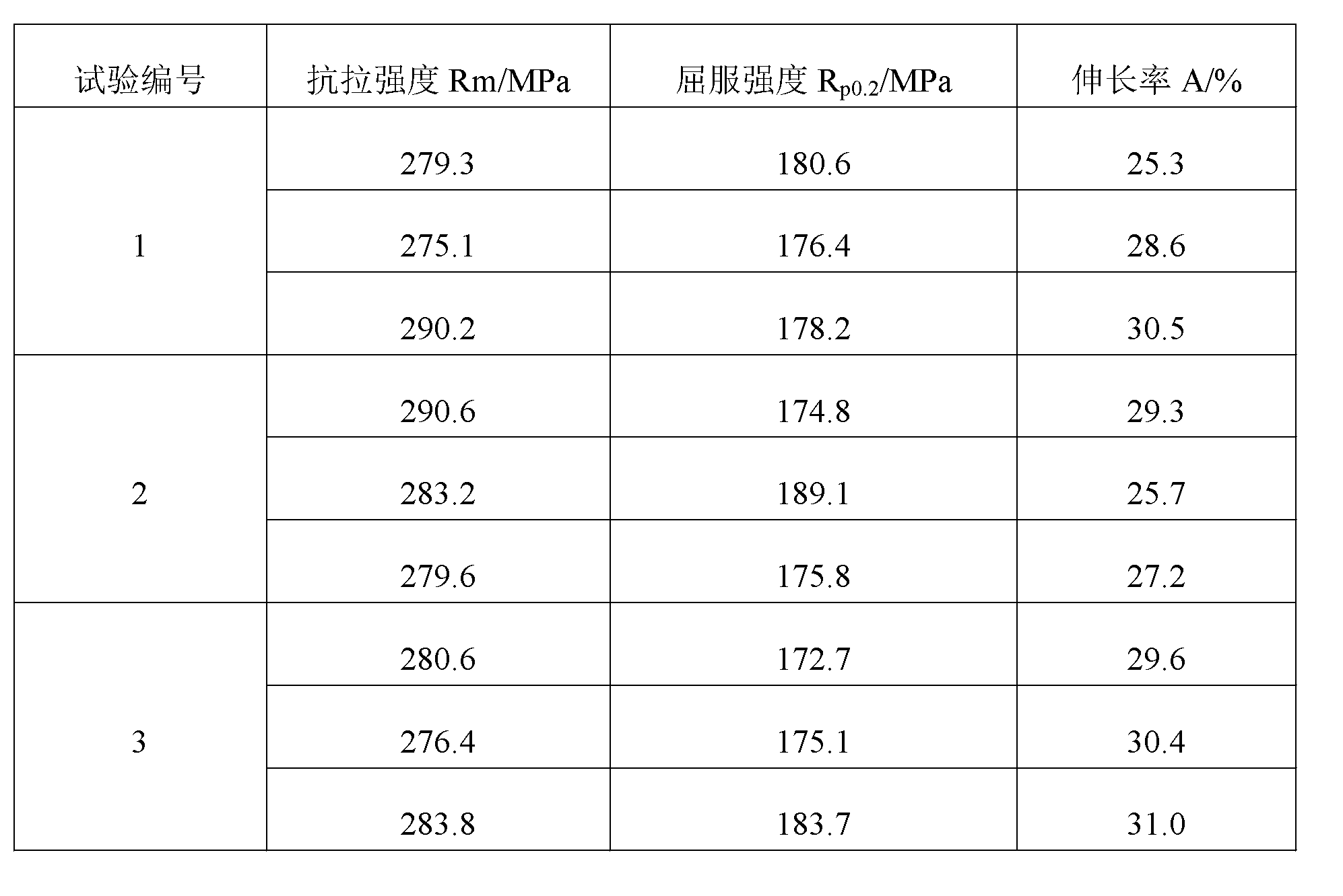

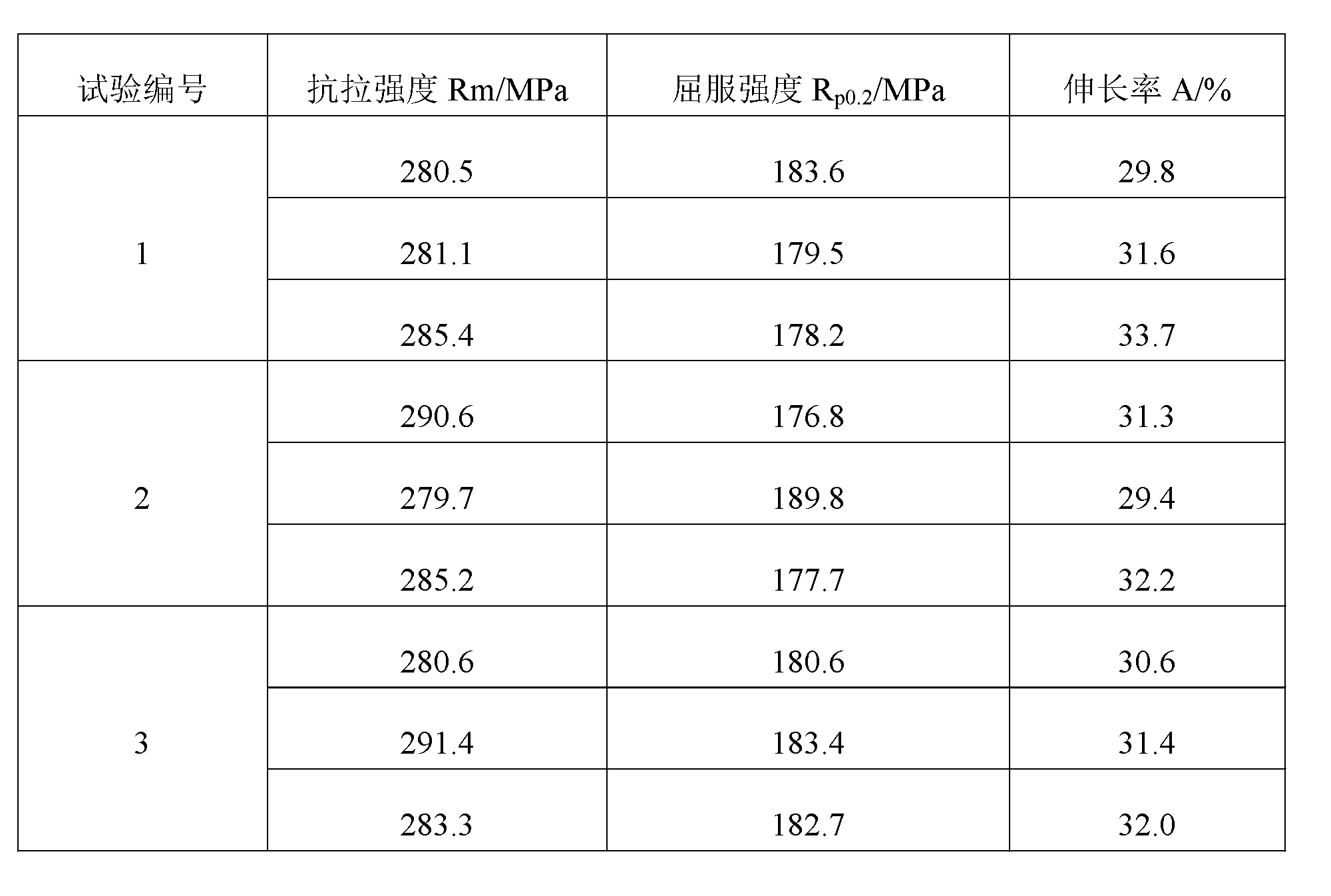

Two-stage forced solution treatment method for high strength deformed aluminum alloy

This invention discloses a double-stage forced solutionizing method for manufacturing a high-strength flexible alumina alloy. The method comprises the steps of: (1) performing a first stage solutionizing method at 430-460 deg.C for 1-3 h; and (2) performing a second stage solutionizing method at 460-500 deg.C for 1-3 h. The method can ensure the remelting of the precipitated phase during performing and hot-pressing processes, while recystallization and crystal grain growth can be avoided. Therefore, the precipitated phase can be uniform and fine during the subsequent aging treatment. The alumina alloy manufactured by this method has improved ultimate tensile strength and yield strength (by 3-10%), elongation percentage (by 1-5%), fracture ductility, fatigue resistance and stress corrosion resistance.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Preparation method of cathode material of lithium-rich ternary compound lithium ion battery

InactiveCN103956477AUniform precipitationSimple processCell electrodesSecondary cellsWater bathsNickel salt

The invention discloses a preparation method of a cathode material of a lithium-rich ternary compound lithium ion battery. The molecular formula of the cathode material is Li1.2Ni0.13Co0.13Mn0.54O2. The preparation method comprises the steps of firstly, stirring an organic precipitant in constant temperature water bath to dissolve the organic precipitant in an organic solvent to obtain a solution I; after that, ultrasonically dissolving soluble cobalt salt, nickel salt, manganese salt and lithium salt in deionized water to obtain a solution II; then, dropwise adding the solution II into the solution I at constant speed, and carrying out a reaction at the temperature of 40-80 DEG C for 2h-4h; drying at 100-120 DEG C; and heating the obtained solid powder in a high temperature tube furnace system by stages, calcining, and cooling the product to room temperature along with the furnace to obtain the lithium-rich ternary compound lithium ion battery cathode material which is good in electrochemical performance and uniform in particles, and has a spherical or ellipsoidal morphology feature. The preparation technology is simple and suitable for industrial scale production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

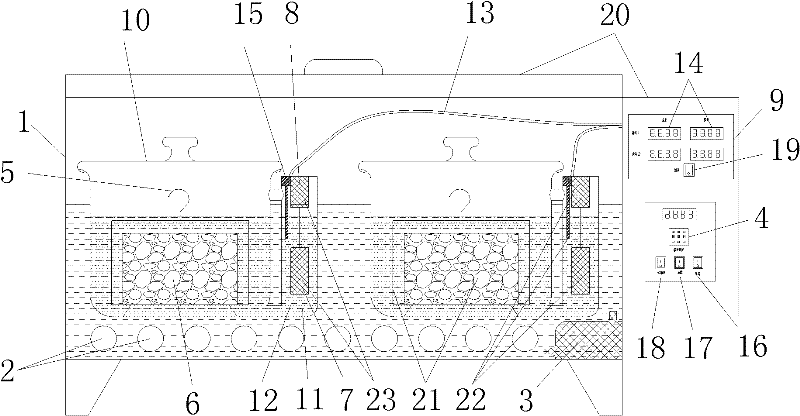

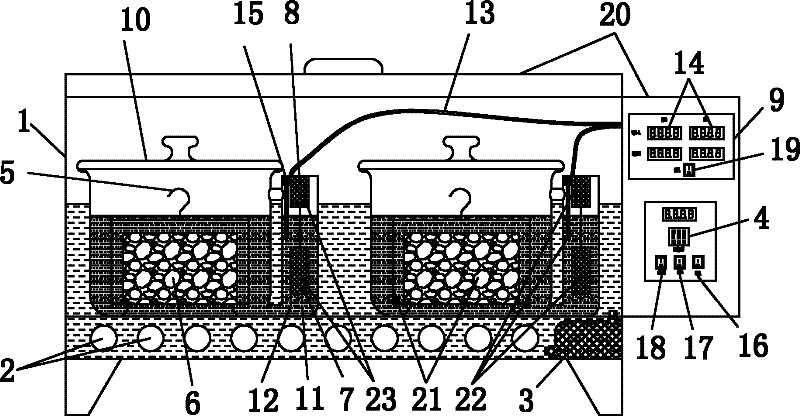

Device for evaluating longer-term snow-melting property of salinization matter for automatically melting snows on road surface

InactiveCN102175568APrecise measurement of precipitationAccurate measurement rateMaterial analysis by measuring buoyant forcesWater bathsSnow melting

The invention discloses a device for evaluating longer-term snow-melting property of a salinization matter for automatically melting the snows on the road surface and relates to the technique of road surface tests. The device comprises a constant temperature water bath box and a soaking unit and a testing unit which are arranged in the constant temperature water bath box, wherein the soaking unitcomprises a test bracket; a test piece is arranged in the test bracket; the testing unit comprises a temperature measuring device and a density measuring device; and the soaking unit and the testing unit are mutually communicated and are together placed in a closed container. The device provided by the invention can be applied to a test for simulating the longer-term snow-melting effect of the salinization matter for automatically melting the snows on the road surface and can be used for evaluating the longer-term snow-melting property of the salinization matter for automatically melting the snows on the road surface.

Owner:CHANGAN UNIV

Purification method of ultra-pure aluminum

The invention relates to a purification method of ultra-pure aluminum, comprising the following steps: cleaning and drying raw refined aluminum, wherein the purity of the selected refined aluminum is at least 4N6, Mg is less than 6ppm, Ti is less than 0.2ppm and Zr is less than 0.2ppm; loading the selected raw refined aluminum into a purification furnace, sealing and vacuumizing the furnace, and heating to 680-750 DEG C by using a gas furnace to melt the solid raw refined aluminum to form liquid; moving the purification furnace heated to 680-750 DEG C to a crystal growing furnace which is kept at 660 DEG C inside by a crystal growing furnace heater, rotating the aluminum liquid of the purification furnace in the crystal growing furnace heater, and enabling the aluminum liquid inside the purification furnace to self-keep the crystallization speed at 5-10 cm / h by controlling the heat dissipating capacity of the crystal growing furnace and finishing the crystallization after 4-6 hours; cooling the crystallized purification furnace, taking out a crystallization ingot, removing 25-35 percent relative to the mass of the crystallization from the tail part of the crystallization ingot and obtaining a first purified aluminum ingot; placing the first purified aluminum ingot into the purification furnace again, and repeating purification until the aluminum ingot reaching the required precision is obtained.

Owner:CHANGSHA ZHONGDA TIMES ELECTRONICS TECH DEV

A scandium-containing cast aluminum-lithium alloy and a preparation method thereof

A novel scandium-containing cast aluminum-lithium alloy is disclosed. The alloy includes, by weight, 1.6-1.99% of Li, 0.9-1.9% of Cu, 0.2-0.7% of Mg, 0.1-0.25% of Zr, 0.05-0.35% of Sc, and impurity elements which are Fe, Si, Na, K and P, with the balance being Al, with the Fe content being less than 0.15% and the total content of the impurity elements being less than 0.25%. During preparation, Al-Cu and Al-Zr master alloys, pure aluminum, pure Mg and pure Li are smelted to obtain an aluminum alloy; then three stages of solid solution heat treatment are performed including solid solution heat treatment at 440-460 DEG C for 32 h, solid solution heat treatment at 510-520 DEG C for 24-32 h and solid solution heat treatment at 530-540 DEG C for 1-6 h; and after water quenching, artificial ageing treatment at 150-190 DEG C is performed for 16-48 h to obtain the novel scandium-containing cast aluminum-lithium alloy. The obtained novel scandium-containing cast aluminum-lithium alloy has a uniform microscopic structure, stable performance, density lower than density of traditional aluminum alloys, higher elastic modulus and rigidity, and other mechanical properties, and is low in cost. Theultimate tensile strength of the novel scandium-containing cast aluminum-lithium alloy can be 450-490 MPa and the specific elongation is 4.5-7.0%.

Owner:SHANGHAI JIAO TONG UNIV

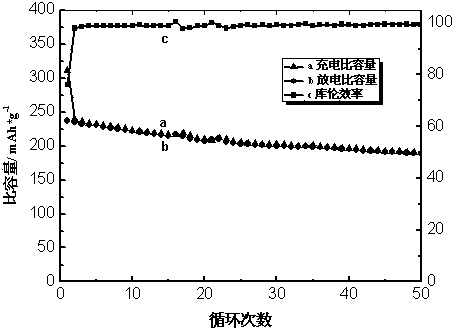

Lithium titanate composite material and preparation method thereof

InactiveCN101759227AThe first discharge specific capacity is highImprove rate discharge performanceMaterial nanotechnologyAlkali titanatesElectrochemistryImpurity

Owner:BYD CO LTD

Automatic acid mixing apparatus and method thereof, and automatic pipeline iodic acid apparatus and method thereof

ActiveCN102351945AUniform precipitationRapid precipitationPeptide preparation methodsOther dairy technologyHigh concentrationAutomatic control

An objective of the invention is to provide an automatic acid mixing apparatus and a method thereof, and an automatic pipeline iodic acid apparatus and a method thereof. Therefore, problems of nonuniform mixing and over high local acidity are solved, wherein the problems exist in a current on-line souring system. The automatic pipeline iodic acid apparatus comprises a material pipeline, a material variable frequency pump, an acid pipeline, a diluted acid variable frequency pump, a Venturi tube and a mixer; an entrance section of the Venturi tube is connected with a premixer; an acid jetting pipeline is arranged in the premixer; and a tail portion of the mixer is connected with an iodic acid pH monitor, which is connected with an automatic control module. according to the invention, the automatic pipeline iodic acid apparatus is utilized to enable automatic iodic acid to be realized; a diluted acid that is configured by the automatic iodic acid apparatus enters the automatic acid mixing apparatus to carry out automatic acid mixing. Besides, materials can be mixed fully, rapidly and high efficiently; occurrences of unstable acid concentration and a local peracid phenomenon during the iodic acid processing can be effectively avoided; and denaturation of active materials with acid nonresistant performance on the condition of acid with high concentration can be reduced.

Owner:甘肃华羚乳品股份有限公司

Rare earth magnesium-lithium alloy sheet and preparation method thereof

The invention discloses a rare earth magnesium-lithium alloy sheet and a preparation method thereof, belonging to the field of metal processing. The rare earth magnesium-lithium alloy sheet is characterized by comprising the following components in percentage by weight: 11-15% of Li, 0.5-2% of Y, 0.5-2% of Gd, 0.1-1% of Sc, 7-9% of Al and the balance of magnesium. The preparation method comprises the following steps of: melting magnesium and intermediate alloy by using an industrial medium-frequency or line-frequency induction melting furnace, adjusting the furnace temperature for heat preservation treatment, sampling from the furnace and carrying out rapid on-the-spot sample analysis after the heat preservation time is reached, and detecting whether the components are qualified; and hot rolling and cold rolling a pouring and rolling sheet, carrying out T6 treatment, then, making a mechanical sample, and measuring the mechanical property. By using the rare earth magnesium-lithium alloy sheet and the preparation method thereof, the strength of magnesium-lithium alloy is ensured, the plastic deformation capability of the magnesium-lithium alloy is also greatly enhanced, the production difficulty of the deformed magnesium-lithium alloy sheet is lowered, and the production efficiency is increased. The alloy smelting process is simple, convenient and reliable, convenient to operate and free of special processing process and alloy adding methods. A cast ingot is fine and uniform in tissue, free of meshy and thick sheet-like Mg17Al12 phase and uniform in precipitated phase. The rolling process is simple, convenient, reliable and feasible, and the sheet has favorable comprehensive mechanical property.

Owner:INNER MONGOLIA 52 SPECIAL MATERIAL ENG TECH RES CENT

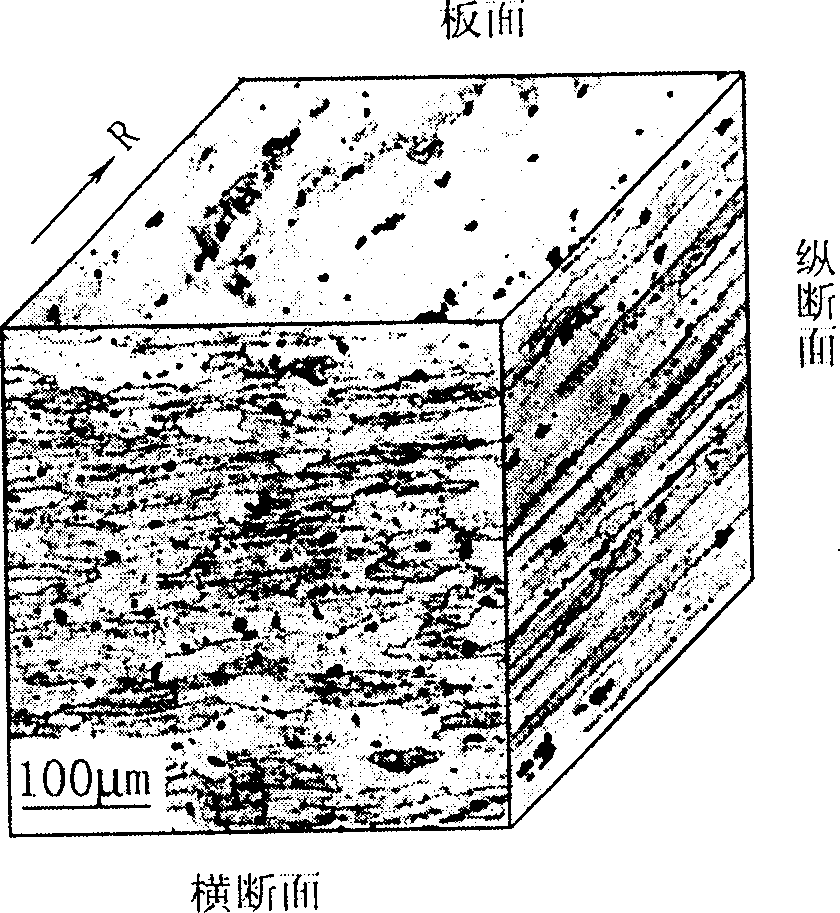

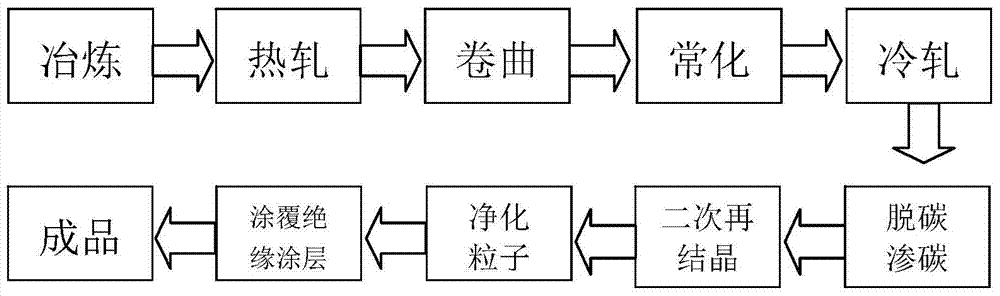

Thin-gauge, ultra-low iron loss, low-noise and high-magnetic induction oriented silicon steel sheet and production method thereof

The invention discloses a production technology of a thin-gauge, ultra-low iron loss, low-noise and high-magnetic induction oriented silicon steel sheet. The oriented silicon steel sheet comprises the following components in percentage by weight: 0.003-0.05 percent of C, 4.1-9 percent of Si, 0.05-0.5 percent of Mn, 0.02-0.06 percent of Al, 0.01-1 percent of Sn, 0.05-0.1 percent of Mo, 0.2-1 percent of Cu, 0.003-0.02 percent of N, 0.002-0.06 percent of P, 0.001-0.008 percent of S and the balance of iron and other inevitable impurities. The high-magnetic induction oriented silicon steel sheet which is produced through hot rolling, cold rolling and annealing processes and the like has the superior performances such as ultra-low iron loss, high flux density, low magnetostriction coefficient and small thickness, has the advantages of simple process, stable texture and capabilities of greatly saving the materials and saving the resources while guaranteeing that the capacity of a transformer is unchanged, and is the best candidate material for manufacturing high-grade power transmission and distribution transformer cores at present.

Owner:STATE GRID CORP OF CHINA +2

Method for producing 4N5 pure indium by electrolyzing high impurity crude indium once

InactiveCN101892495AEasy and precise controlEasy to controlPhotography auxillary processesElectrolysis componentsIndiumElectrolysis

A method for producing 4N5 pure indium by electrolyzing high impurity crude indium once comprises the steps of preparing crude indium anode, preparing starting sheet cathode and conductive bands, preparing electrolyte according to the process requirement and carrying out electrolysis. An electrolytic bath below the crude indium anode is used for electrolysis. The starting sheet cathode is arranged in the electrolytic bath. The distance between different sheets is 25-30mm. The electrolyte is placed into the electrolytic bath and contains 60-80g / l of indium, NaCl with a concentration of 40-60g / l and gelatin with a concentration of 0.2-0.3g / l and has pH value of 2-2.5. The electrolysis temperature is 20-30 DEG C, the current density is 15-25A / m2 and the bath voltage is 0.12-0.18V. The method can realize producing 4N5 pure indium with purity of 99.995% by electrolyzing high impurity crude indium once. In the invention, the starting sheet manufactured by the 4N5 pure indium is used as the cathode, the electrolytic current is stable, precipitation is uniform and the bath voltage is easier to control precisely. Besides, the 4N5 pure indium is produced by electrolyzing once, thus reducing the intermediate links, avoiding production pollution, greatly improving the quality of the pure indium products and lowering the production cost.

Owner:HULUDAO ZINC IND CO LTD

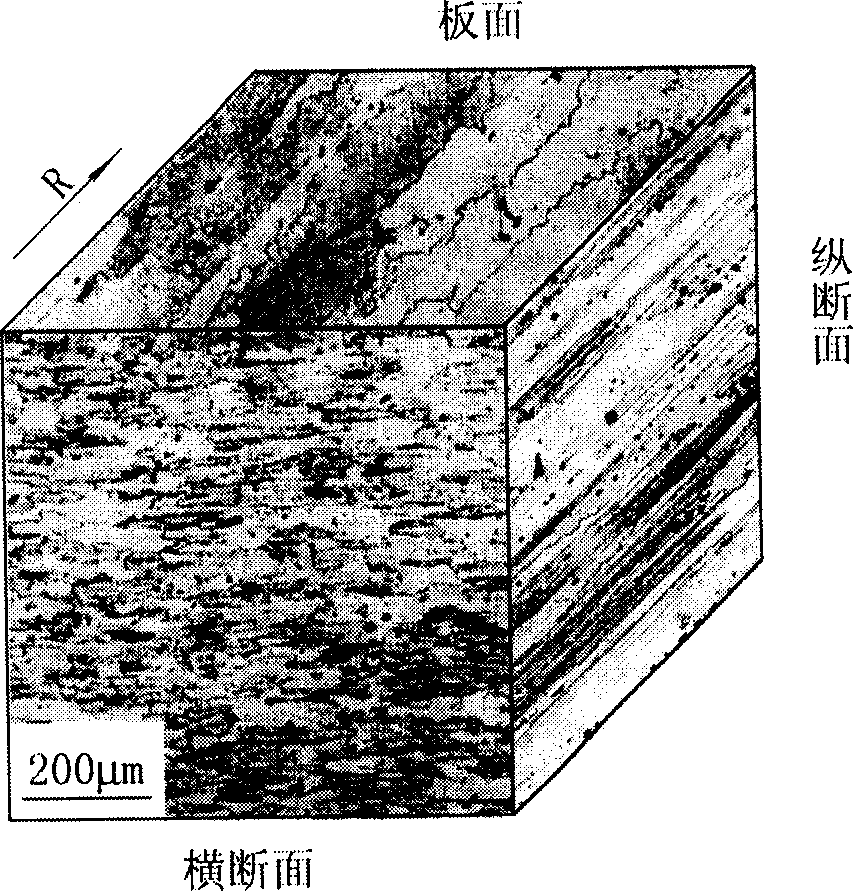

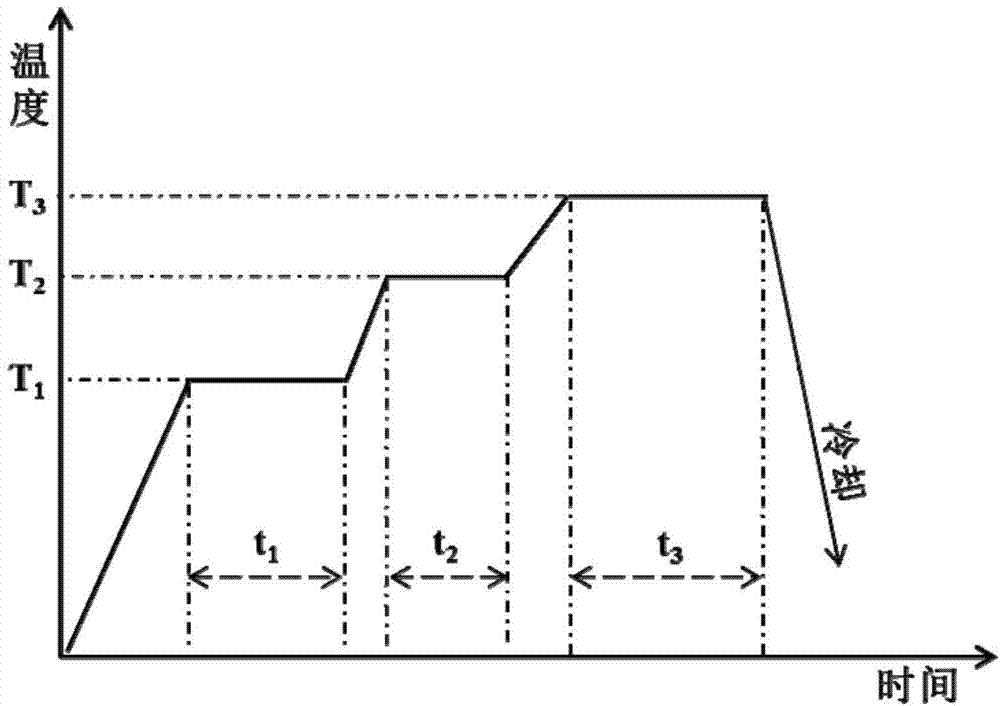

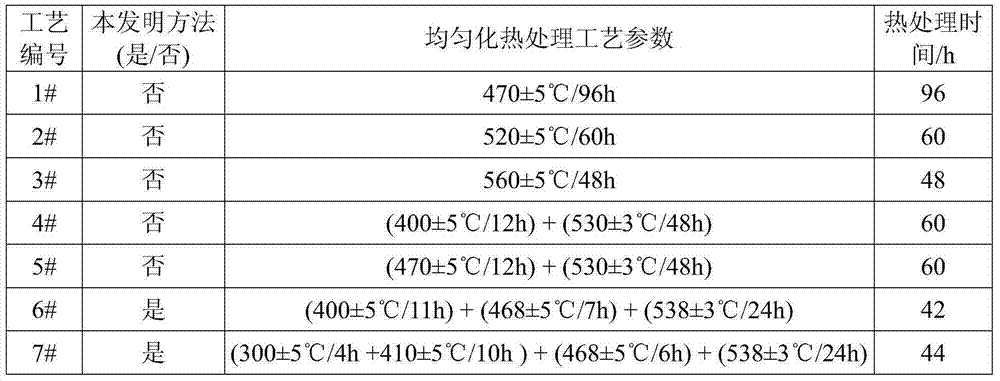

Multi-stage homogenization heat treatment method for Zn-containing 6XXX series aluminum alloy

The invention relates to a multi-stage homogenization heat treatment method for a Zn-containing 6XXX series aluminum alloy, wherein a Zn-containing 6XXX series aluminum alloy casting ingot is placed into a heat treatment heating furnace and the following steps are sequentially performed: (1) carrying out a first-stage homogenization heat treatment, wherein heating is performed to a temperature T1 from a room temperature, a thermal insulation treatment is performed, the thermal insulation time is t1, T1 is more than or equal to 250 DEG C and is less than or equal to 440 DEG C, and t1 is more than or equal to 1 h and is less than or equal to 24 h, (2) carrying out a second-stage homogenization heat treatment, wherein heating is performed to a temperature T2 from the temperature T1, a thermal insulation treatment is performed, the thermal insulation time is t2, T2 is more than or equal to 450 DEG C and is less than or equal to 490 DEG C, and t2 is more than or equal to 1 h and is less than or equal to 24 h, (3) carrying out a third-stage homogenization heat treatment, wherein heating is performed to a temperature T3 from the temperature T2, a thermal insulation treatment is performed, the thermal insulation time is t3, T3 is more than or equal to 510 DEG C and is less than or equal to 580 DEG C, and t3 is more than or equal to 6 h and is less than or equal to 60 h, and (4) cooling to a room temperature from the temperature T3. According to the present invention, through the synergism of the three-stage treatment, the technical defects of the structure of the existing method can be effectively improved, such that the alloy can achieve the good microstructure and the excellent comprehensive performance matching.

Owner:GRIMAT ENG INST CO LTD

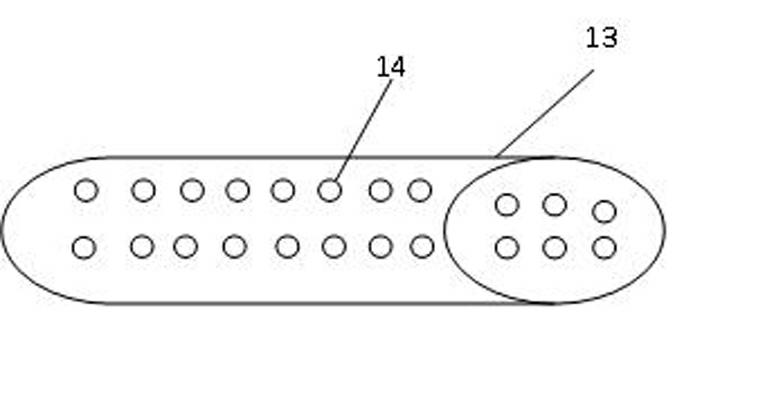

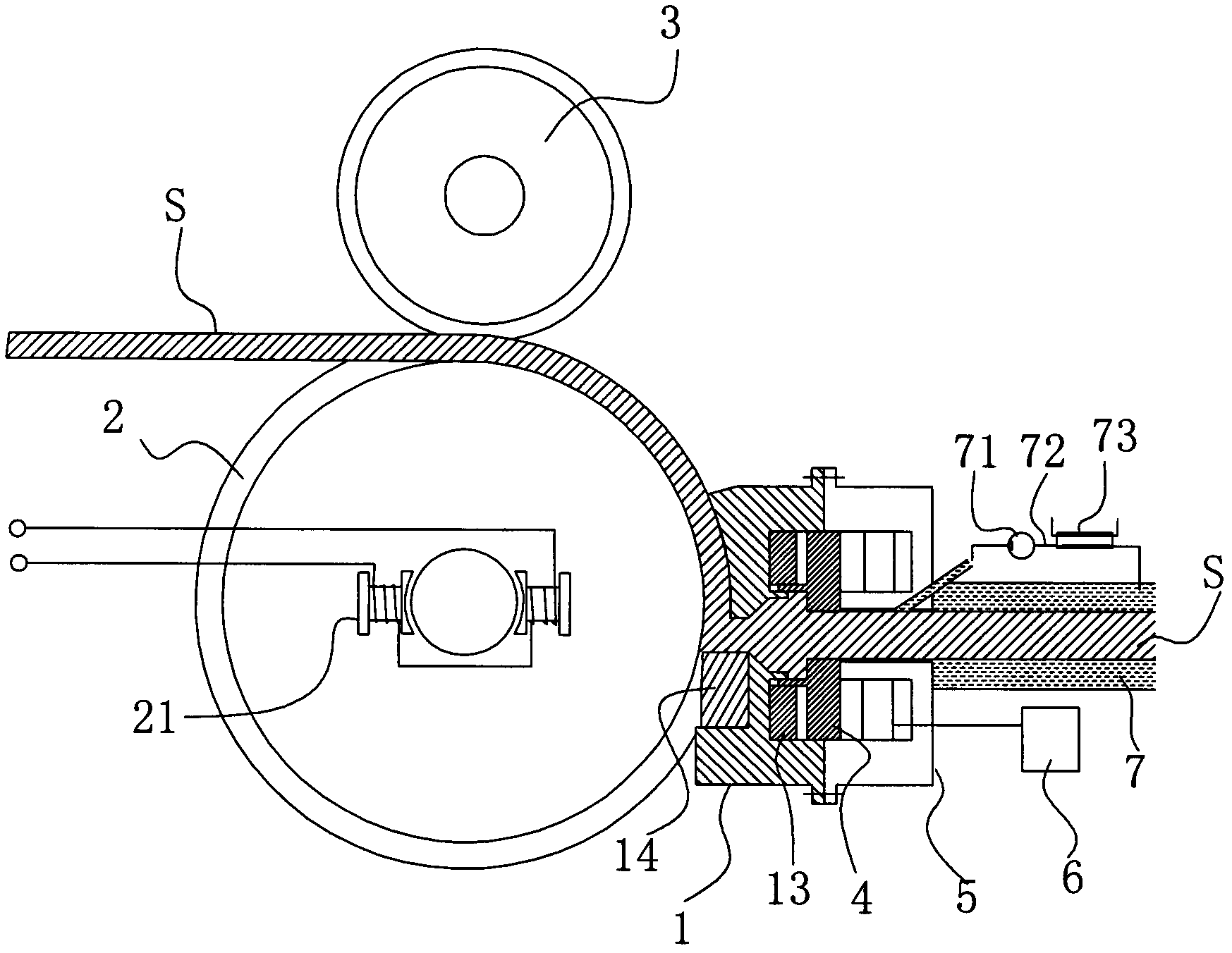

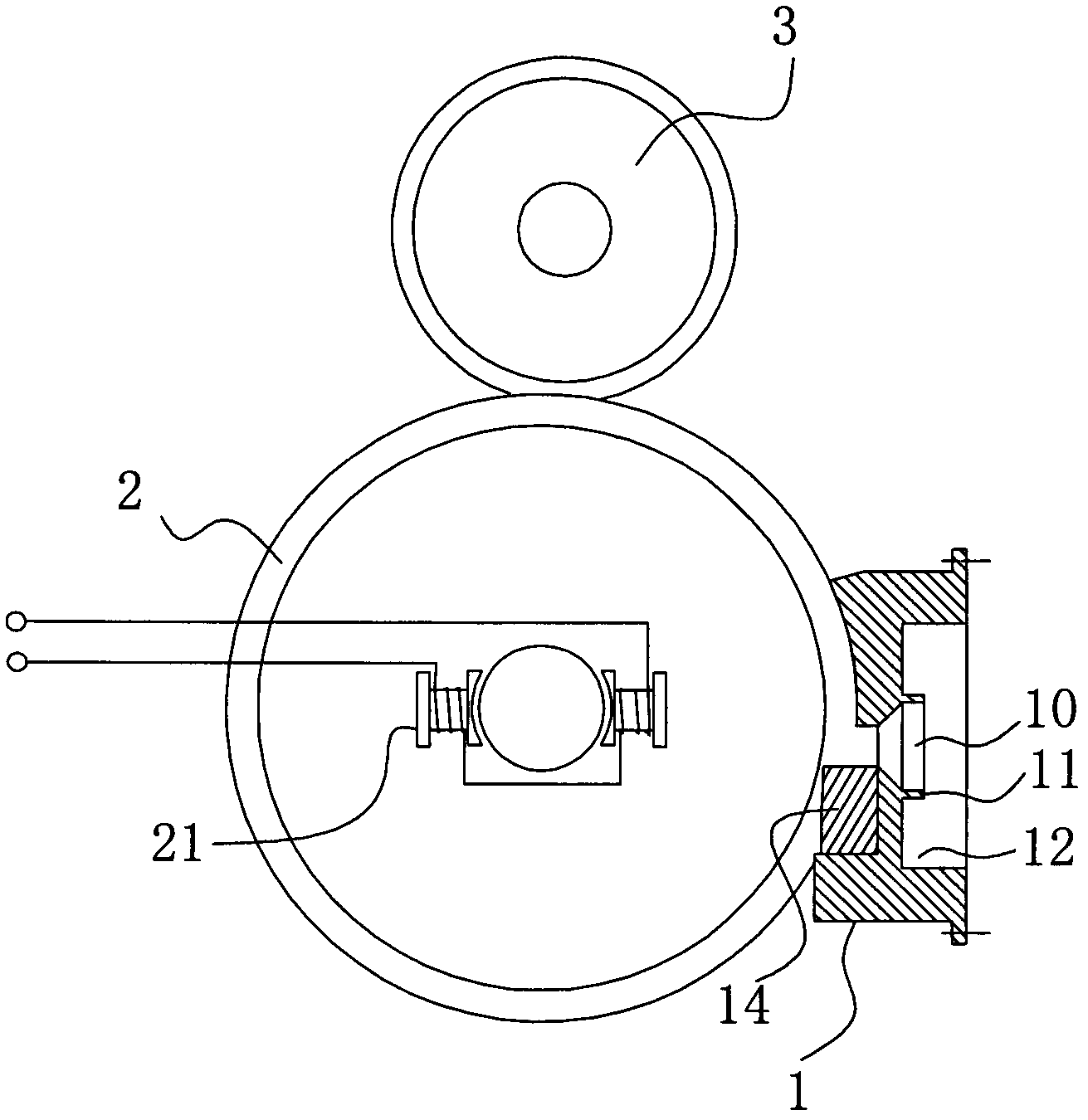

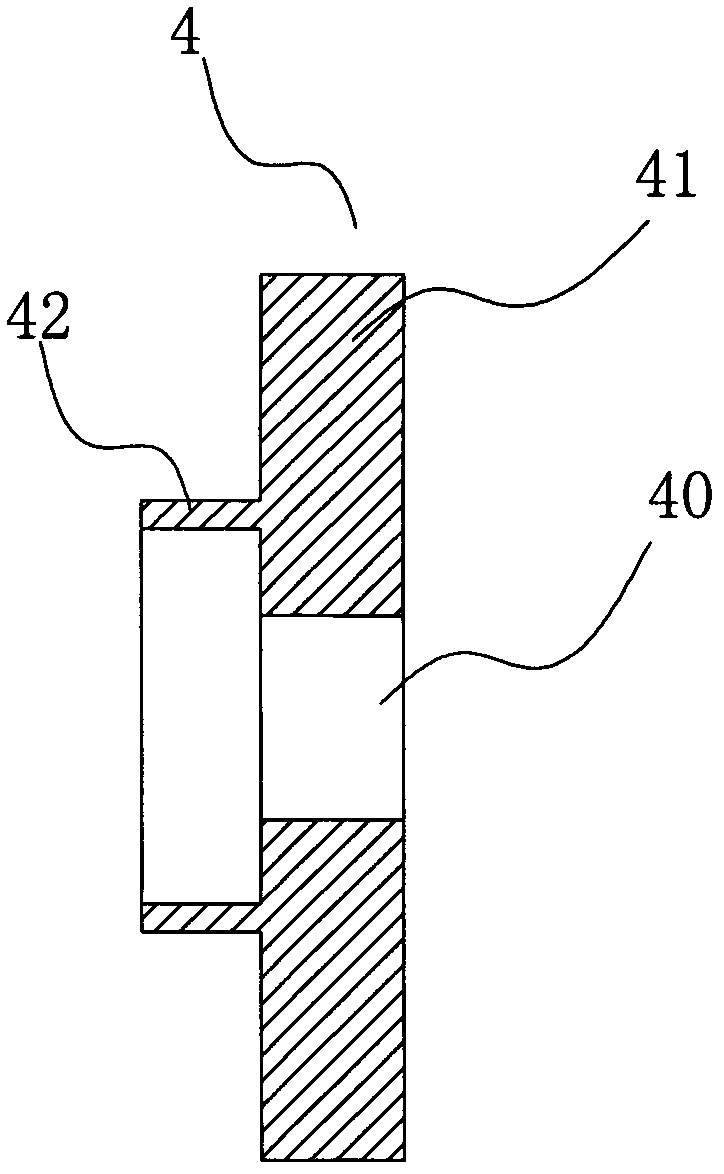

Microcrystal extrusion equipment and production method thereof

ActiveCN102294377ASmall particlesUniform particlesExtrusion diesExtrusion control devicesEngineeringMethods of production

The invention discloses microcrystalline extrusion equipment and a microcrystalline extrusion production method. The microcrystalline extrusion equipment comprises a machine base, an extrusion wheel and a compaction wheel which are arranged on the machine base, and a power source, wherein an extrusion mould cavity is formed in the machine base; a movable mould which is butted with the extrusion mould cavity and a power mechanism for driving the movable mould are arranged on the machine base; the power mechanism is arranged at the extrusion end of the movable mould, and is provided with a fixed end which is coupled with the machine base and a movable end which is pressed against the outer side of the movable mould; and the power source is coupled with the power mechanism. By the microcrystalline extrusion equipment and the microcrystalline extrusion production method, process parameters in the extruding process can be detected in real time and adjusted in time, so that a metal material is under ideal extrusion pressure and at an ideal extrusion temperature all the time in the extruding process, and the high uniformity of the material performance of the extruded metal material can be ensured. The microcrystalline extrusion equipment has a rational and simple structure and is convenient to operate and maintain, the influence of man-made factors on product quality can be reduced, and the product quality can be improved.

Owner:佛山市承安集团股份有限公司

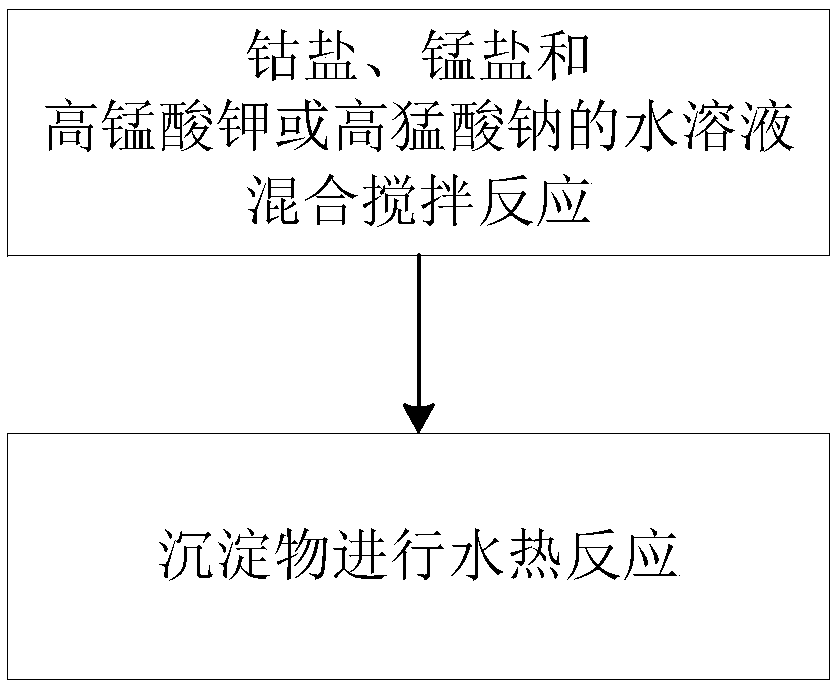

Preparation method of layered cobalt manganese double-metal oxide as well as product thereof

InactiveCN108380221AUniform precipitationUnique layered structureCatalyst activation/preparationManganese oxides/hydroxidesFiltrationManganese oxide

The invention belongs to the technical field of preparation of cobalt manganese oxide and discloses a preparation method of layered cobalt manganese double-metal oxide as well as a product thereof. The preparation method comprises the following steps: (a) mixing water-soluble cobalt salt containing divalent cobalt and water-soluble manganese salt containing divalent manganese uniformly to form a precursor aqueous solution, adding the precursor aqueous solution into an alkaline aqueous solution of potassium permanganate or sodium permanganate, and mixing, stirring and reacting to generate precipitate; and (b) filtering out the precipitate, performing hydrothermal reaction, performing suction filtration and washing on the product after reaction, removing the residual solvent and drying to obtain the needed layered cobalt manganese double-metal oxide. By the preparation method, the obtained layered cobalt manganese double-metal oxide has uniform shape, enables cobalt and manganese elements to be precipitated uniformly and highly, has large specific surface area and has excellent methylbenzene catalytic combustion cavity; furthermore, the preparation method is simple, simple in requirement on equipment, low in raw material price, low in preparation energy consumption, high in repeatability and suitable for popularization and application.

Owner:HUAZHONG UNIV OF SCI & TECH +1

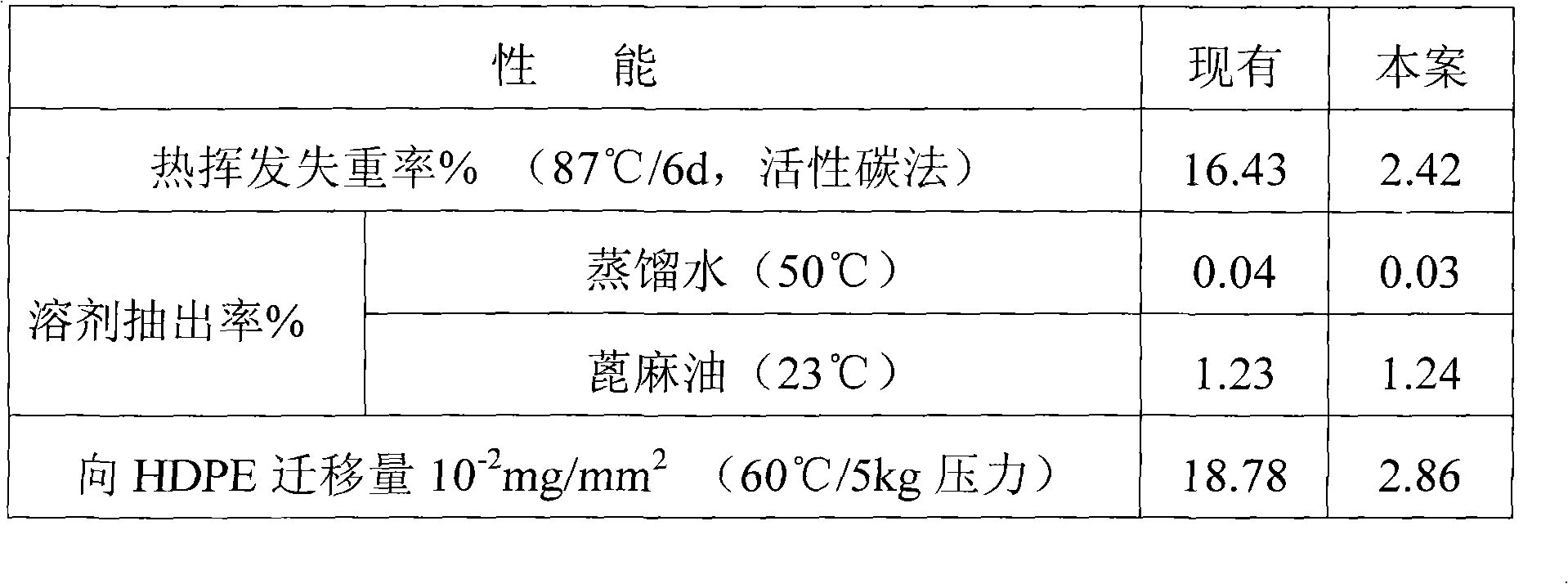

Preparation of polychloroethylene film for jet drawing

InactiveCN101298508AImprove precipitation effectDoes not affect the inkjet effectFlat articlesCoatingsEpoxyProduction line

A preparation method of polyvinyl chloride film for spray painting relates to a preparation method of a polyvinyl chloride film. The method resolves problems of complex technology, high cost, and low plasticizing efficiency of plasticizer and poor spray painting effect of polyvinyl chloride film for spray painting of polyvinyl chloride film precipitated from low plasticizer of existing preparation. The method is that: 1. Inorganic nano-particles and epoxy soybean oil are mixed to gain a mixture; 2. Polyvinyl chloride resin, triethyl trimellitate (2-ethyl), antioxidant, titanium pigment and ultraviolet absorber are added into the mixture to gain mixing materials; 3. The mixing materials are filled into a PVC calendaring production line to produce polyvinyl chloride film, namely, the polyvinyl chloride film for spray painting. The invention is characterized by simple technology, low cost, high plasticizing efficiency and good effect of spray painting.

Owner:HARBIN INST OF TECH

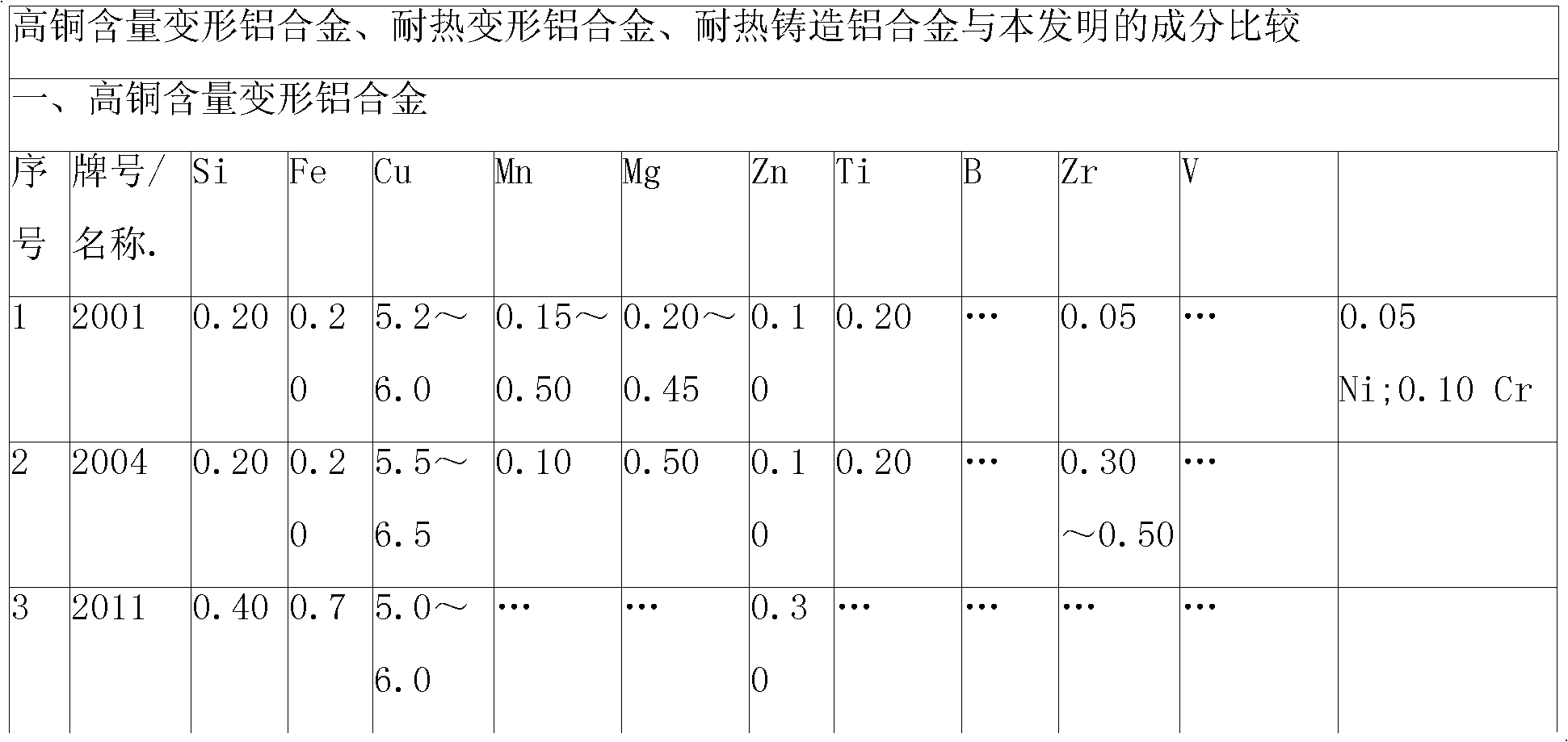

Li-W-RE high-strength heat resistant aluminum alloy material modified with C and preparation method thereof

The invention discloses a Li-W-RE high-strength heat resistant aluminum alloy material modified with C. The alloy comprises the following components by weight percent: 1.0 to 10.0 percent of Cu, 0.05 to 1.5 percent of Mn, 0.01 to 0.5 percent of Cd, 0.01 to 0.5 percent of Ti, 0.0001 to 0.15 percent of C, 0.01 to 1.0 percent of Zr, 0.1 to 3.0 percent of Li, 0.01 to 1.0 percent of W, and 0.05 to 5 percent of rare earth element and the rest is Al. Through optimally choosing alloy host element Cu, Mn and RE prescription, the invention reduces alloy quasi-solid phase temperature range and solves the problems of large hot tear tend and low product high temperature strength in the casting process, guided by high quality melt, solid solution and phase diagram theory and taking a C element as modificator. The low cost multiple microalloyed element prescription is optimally choosen. Finally, a high-strength heat resistant aluminum alloy material is developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

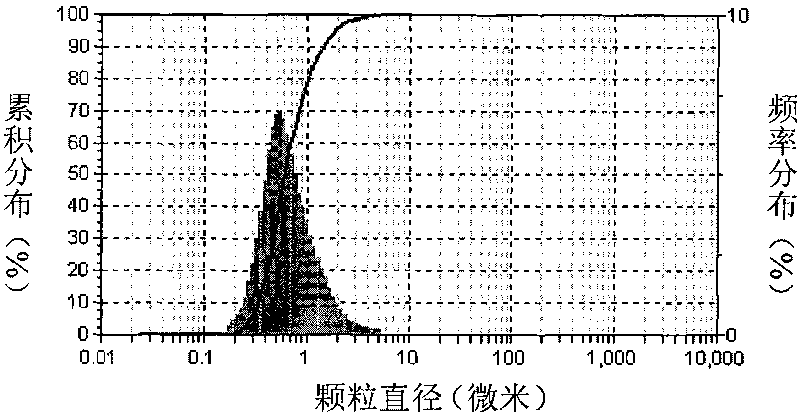

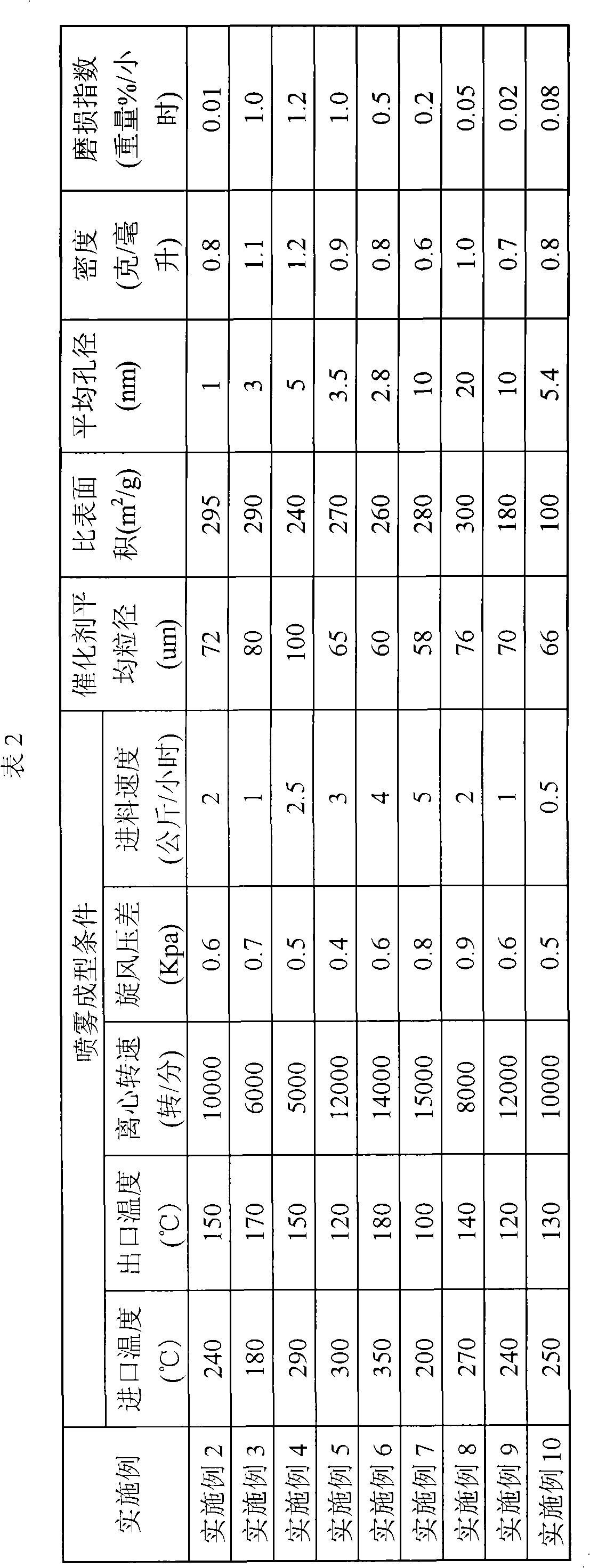

Preparation method of fluid catalyst

ActiveCN102371168AHigh activityEvenly dispersedMolecular sieve catalystsCatalyst activation/preparationMolecular sieveCatalytic pyrolysis

The invention relates to a preparation method of a fluid catalyst, and mainly solves the problem of low wear resistance of fluid catalysts in existing technologies. The method comprises the following steps of: (a) mixing a molecular sieve, a binder, a matrix material, a pore-expanding agent, a dispersing agent and a liquid medium uniformly so as to form a suspension; (b) controlling the particle size of materials in the suspension ranging from 0.1 to 5 micrometers; (c) conducting spray drying to the suspension so as to form a microsphere catalyst; (d) roasting the microsphere catalyst, thus obtaining a finished catalyst. The technical method provided in the invention well solves the above problem, and can be used in the reaction process of carbon olefin production through light oil catalytic pyrolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com