Preparation method for hydrogenation catalyst

A hydrogenation catalyst, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Activity and stability need to be further improved to achieve the effect of easy reduction and improved comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

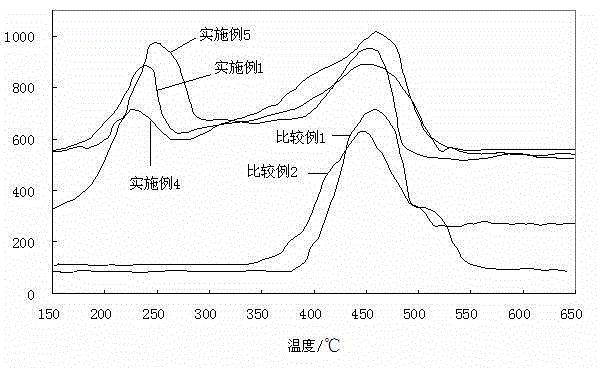

Image

Examples

Embodiment 1

[0030] (1) Get 242.5g of nickel chloride hexahydrate and 14.9g of lanthanum nitrate hexahydrate to prepare a mixed solution, so that the concentration of the two salts in this solution is 0.7mol / L. After the two salts are completely dissolved, add pseudo-both aluminum stone (containing Al 2 o 3 70% (mass fraction)) 288.1g, made into slurry I, heated to 75°C for use;

[0031] (2) Take 114.1g nickel chloride hexahydrate and prepare 2000mL solution II, heat to 75°C, and set aside;

[0032] (3) At 75°C, add 500mL of bottom water to the reaction tank, co-precipitate the slurry I and the precipitating agent sodium carbonate (concentration: 1.0mol / L), and keep the pH value of the precipitation system at 7.8. After continuing to stir at constant temperature for 30 minutes, filter;

[0033] (4) Add the obtained filter cake to solution II, stir, keep the system temperature at 80°C, and add ammonium carbonate solution (concentration: 0.5 mol / L) dropwise to the slurry, and stop the dro...

Embodiment 2

[0037] Other conditions are the same as in Example 1, except that the precipitating agent of the co-precipitation reaction is changed to sodium hydroxide solution, and the concentration is changed to 1.2 mol / L, and hydrogenation catalyst A3 is prepared, and its properties are shown in Table 1.

Embodiment 3

[0039] Other conditions were the same as in Example 1, except that the carrier pseudo-boehmite was changed to silica (powder greater than 150 mesh), and hydrogenation catalyst A3 was prepared, and its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com