Preparation method of layered cobalt manganese double-metal oxide as well as product thereof

A double metal oxide, cobalt manganese technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problem of irregular morphology of cobalt manganese oxide, catalytic Problems such as low activity and uneven size, to achieve the effects of excellent physical and chemical properties, large specific surface area, and uniform precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

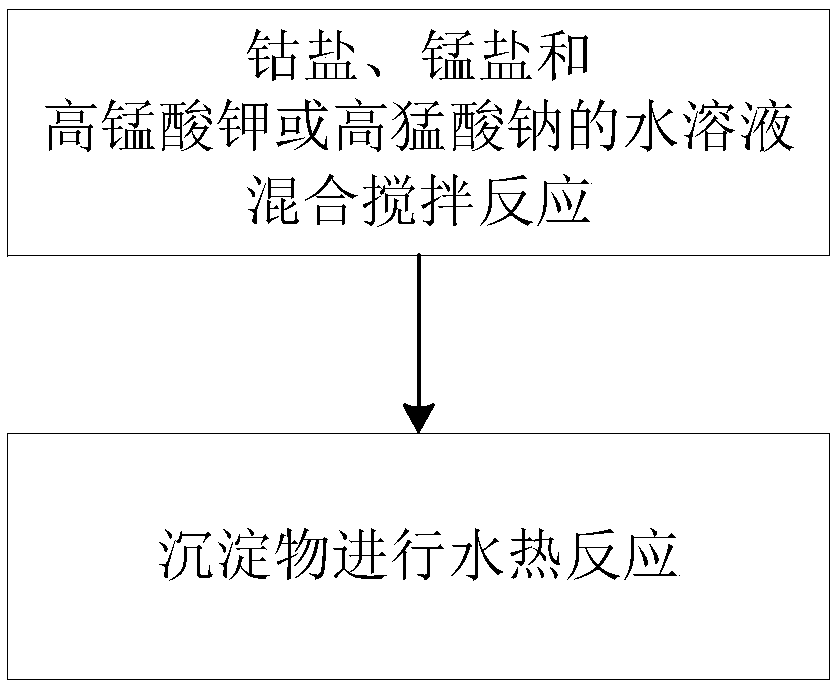

[0030] figure 1 It is a flow chart of the preparation method of the layered cobalt-manganese double metal oxide constructed according to the preferred embodiment of the present invention, such as figure 1Shown, a kind of preparation method of layered cobalt-manganese double metal oxide, comprises the following steps: prepare the precursor aqueous solution A+B of cobalt A and manganese B and mix uniformly; Mix a certain amount of potassium permanganate with alkali, prepare It is an aqueous potassium permanganate solution C with a pH value of 8.5-8.7; under the condition of 20-80°C, add the above-mentioned A+B solution dropwise into the C solution and stir vigorously for 2-4 hours, so that the C solution turns brown-black Precipitate, stop stirring and leave it to age for 2-10 hours, transfer the precipitate to the reactor for hydrothermal reaction, the hydrothermal reaction temperature is 100-160°C, and the hydrothermal reaction time is 12-48 hours. After the reaction, the obta...

Embodiment 1

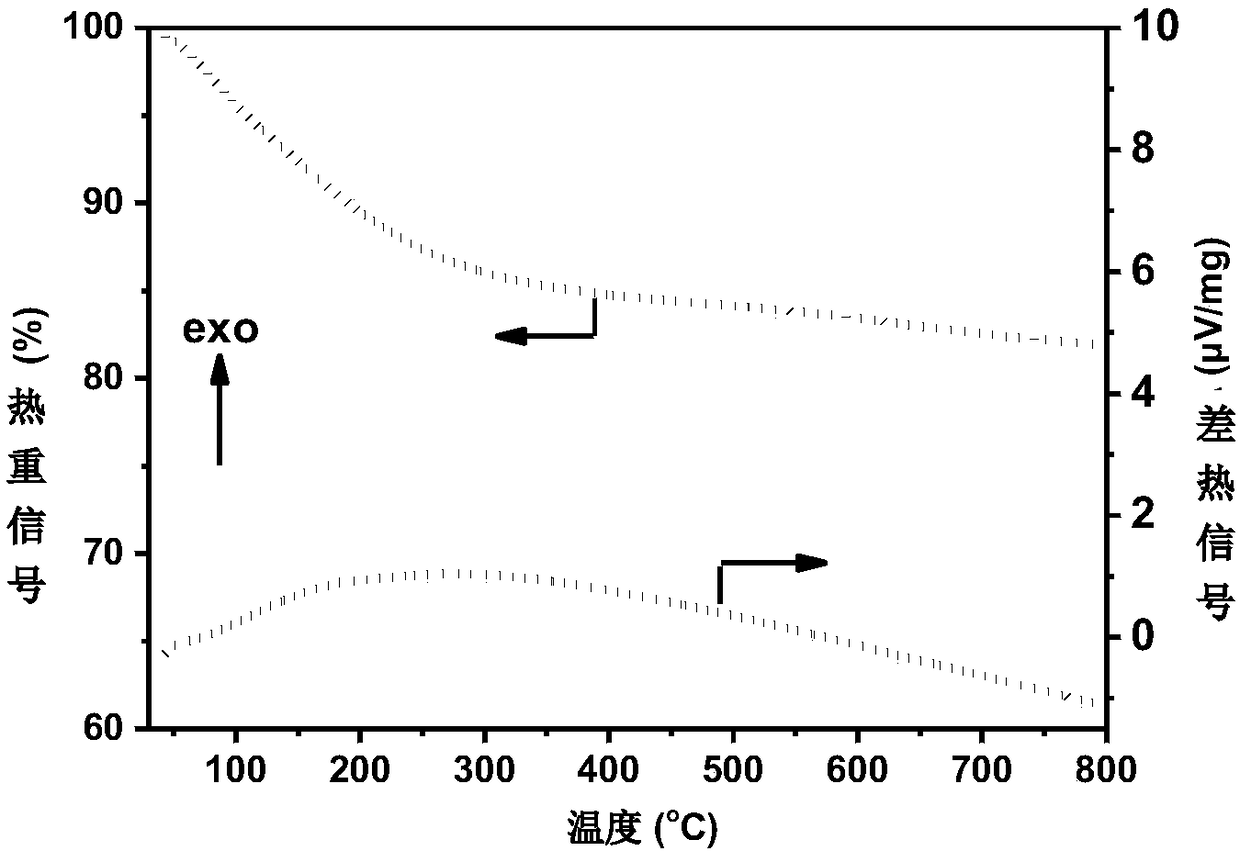

[0041] Measure 20 ml of deionized water into a beaker, then add 0.03 mol of cobalt nitrate and stir until completely dissolved. Measure 200 ml of deionized water into a blue-capped bottle, add 0.01 mol of potassium permanganate and stir until completely dissolved, adjust the pH of the reaction solution to 8.5 with NaOH, and place the blue-capped bottle in an 80-degree water bath. Afterwards, the cobalt nitrate aqueous solution was added dropwise to the potassium permanganate solution at a rate of 3 ml / min. After the dropwise addition, the solution was stirred at constant temperature for 2 hours, and the stirring was turned off for aging for 2 hours. The resulting precipitate was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal kettle and reacted at 100°C for 24 hours. After the reaction, a brown-black precipitate was obtained. After the precipitate was suction filtered, washed and dried, the atomic ratio of cobalt to manganese was 3:1, and the specif...

Embodiment 2

[0044] Measure 10 ml of deionized water into a beaker, then add 0.01 mole of cobalt nitrate and stir until completely dissolved. Measure 200 ml of deionized water into a blue-capped bottle, add 0.01 mol of potassium permanganate and stir until completely dissolved, adjust the pH of the reaction solution to 8.6 with NaOH, and place the blue-capped bottle in a 60-degree water bath. Afterwards, the cobalt nitrate aqueous solution was added dropwise to the potassium permanganate solution at a rate of 7 ml / min. After the dropwise addition was completed, the solution was stirred at a constant temperature for 3 hours, and the stirring was turned off for aging for 6 hours. The resulting precipitate was transferred to a polytetrafluoroethylene-lined stainless steel hydrothermal kettle and reacted at 120°C for 12 hours. After the reaction, a brown-black precipitate was obtained. After the precipitate was suction filtered, washed and dried, the atomic ratio of cobalt to manganese was 1:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com