Preparation of polychloroethylene film for jet drawing

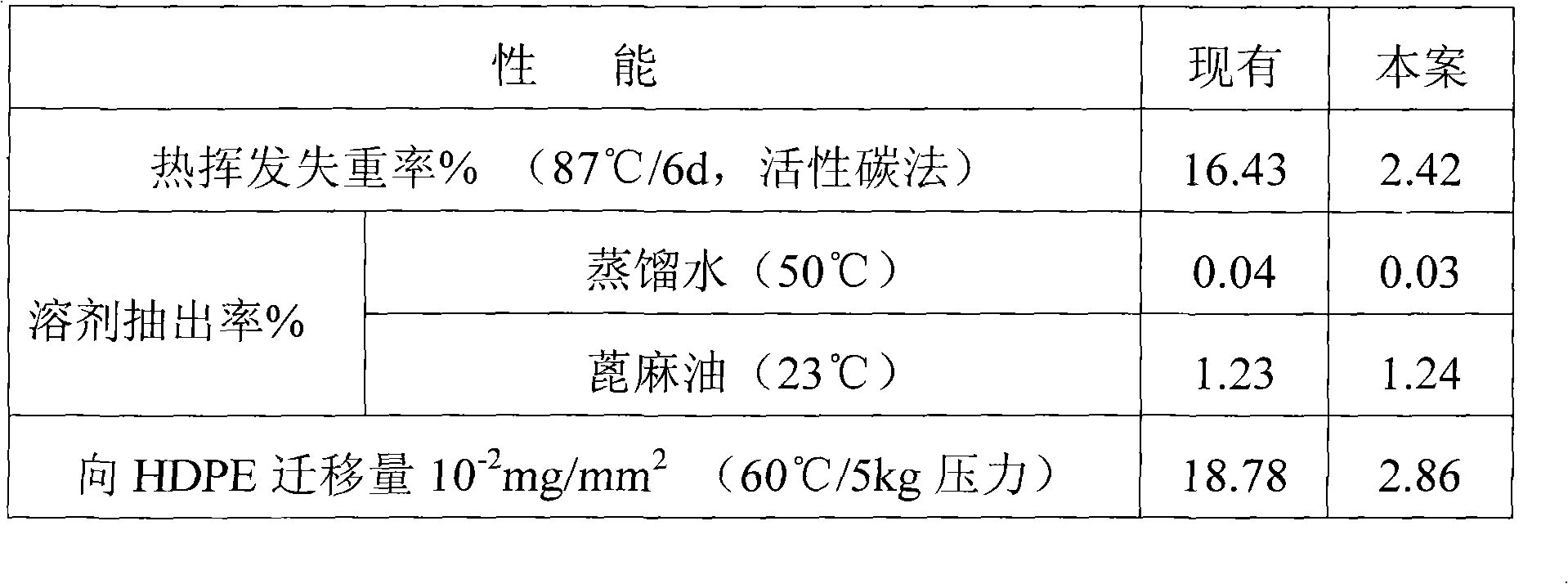

A polyvinyl chloride film and inkjet technology, applied in applications, household appliances, flat products, etc., can solve the problem of poor inkjet printing effect of polyvinyl chloride film for inkjet, complicated polyvinyl chloride film process, and low plasticizer plasticizing efficiency. problems, to achieve the effects of weight loss by volatilization, excellent resistance to solvent precipitation, bright colors, and high plasticizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0007] The specific embodiment one: the preparation method of the polyvinyl chloride film used for inkjet painting in this embodiment is realized according to the following steps: one, 5 to 30 parts of nano-inorganic particles and 3 to 20 parts of epoxy soybean oil are packed into the mixer, and Mix at a speed of 500-1000r / min for 5-60 minutes to obtain a mixture; 2. Mix 100 parts of polyvinyl chloride resin, 30-80 parts of tris(2-ethyl)hexyl trimellitate, 0.1-5 parts of Antioxidant, 0.1-30 parts of titanium dioxide and 0.1-5 parts of ultraviolet absorber are added to the mixture, and mixed at a speed of 500-1000r / min for 10-60 minutes to obtain a mixture; 3. Put the mixture into PVC The calendering production line is used to make a polyvinyl chloride film, which is a polyvinyl chloride film for inkjet painting; wherein the nano-inorganic particles in step 1 are nano-calcium carbonate or nano-silicon dioxide.

[0008] Both antioxidants and ultraviolet absorbers currently used ...

specific Embodiment approach 2

[0009] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 15 parts of nano-inorganic particles and 5 parts of epoxidized soybean oil are put into the mixer, and mixed at a speed of 800 r / min for 20 min. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0010] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step two, 100 parts of polyvinyl chloride resin, 50 parts of tris(2-ethyl)hexyl trimellitate, 1 part of antioxidant Agent, 5 parts of titanium dioxide and 1 part of ultraviolet absorber were added to the mixture, and mixed at a speed of 800r / min for 30min. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com