Patents

Literature

985results about How to "Absorb evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

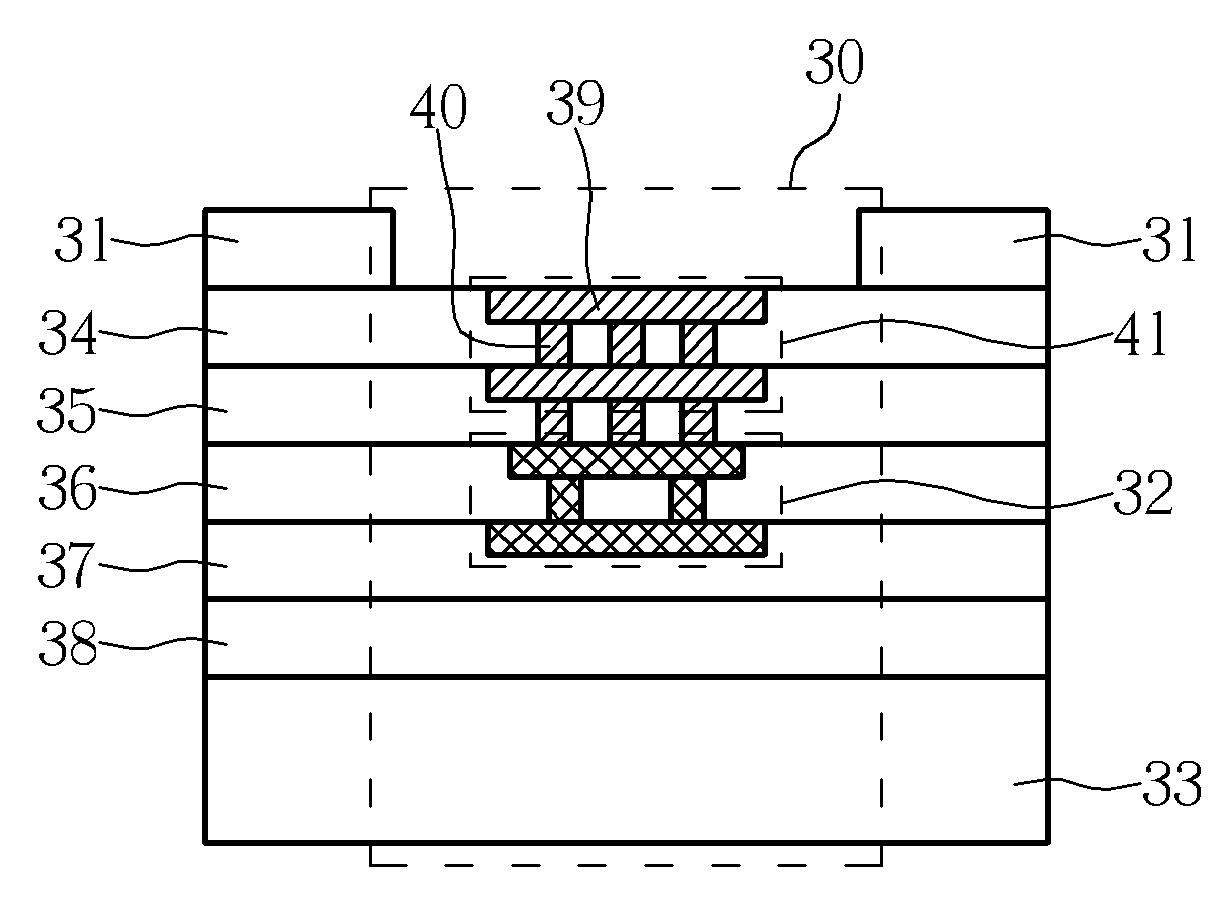

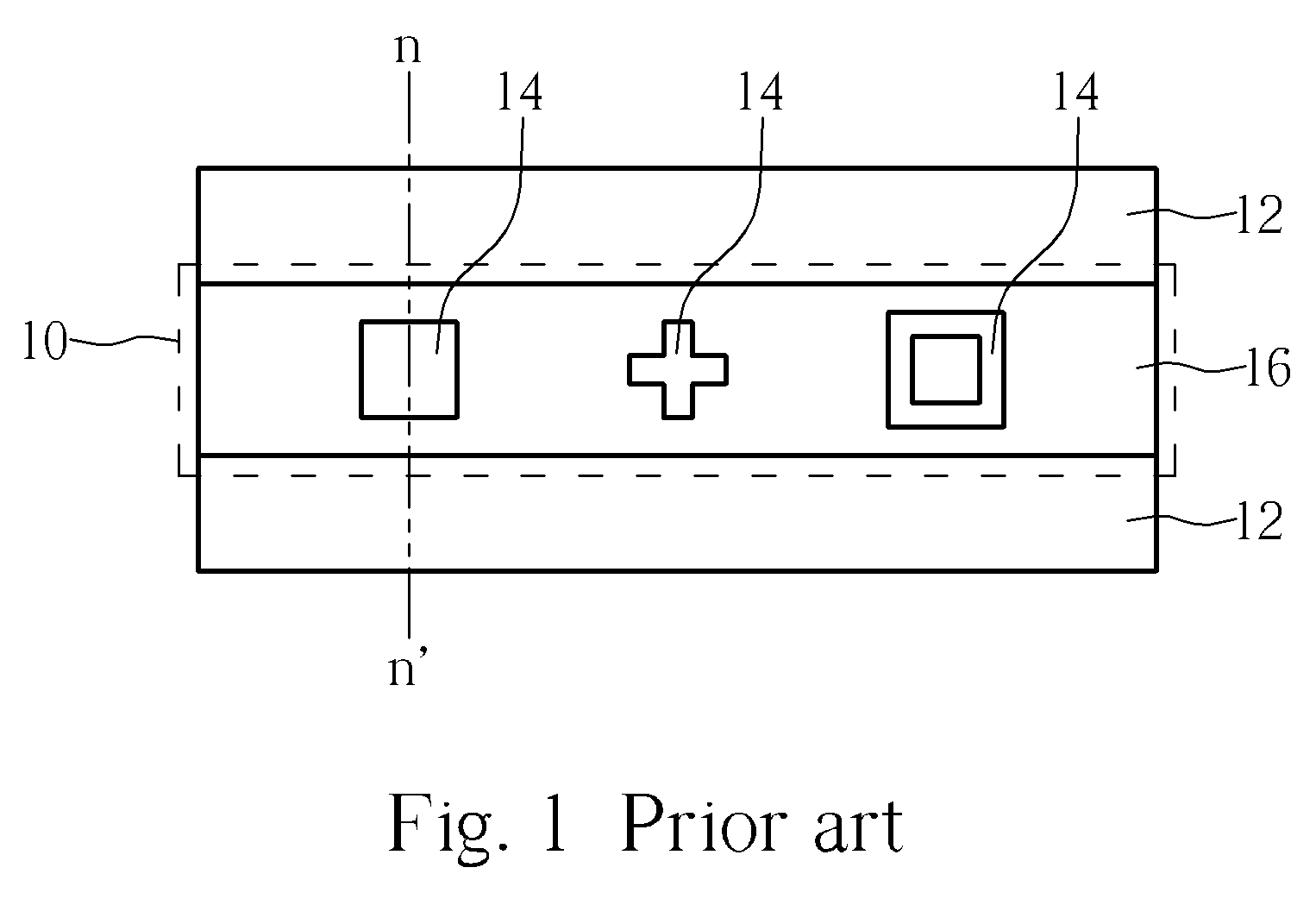

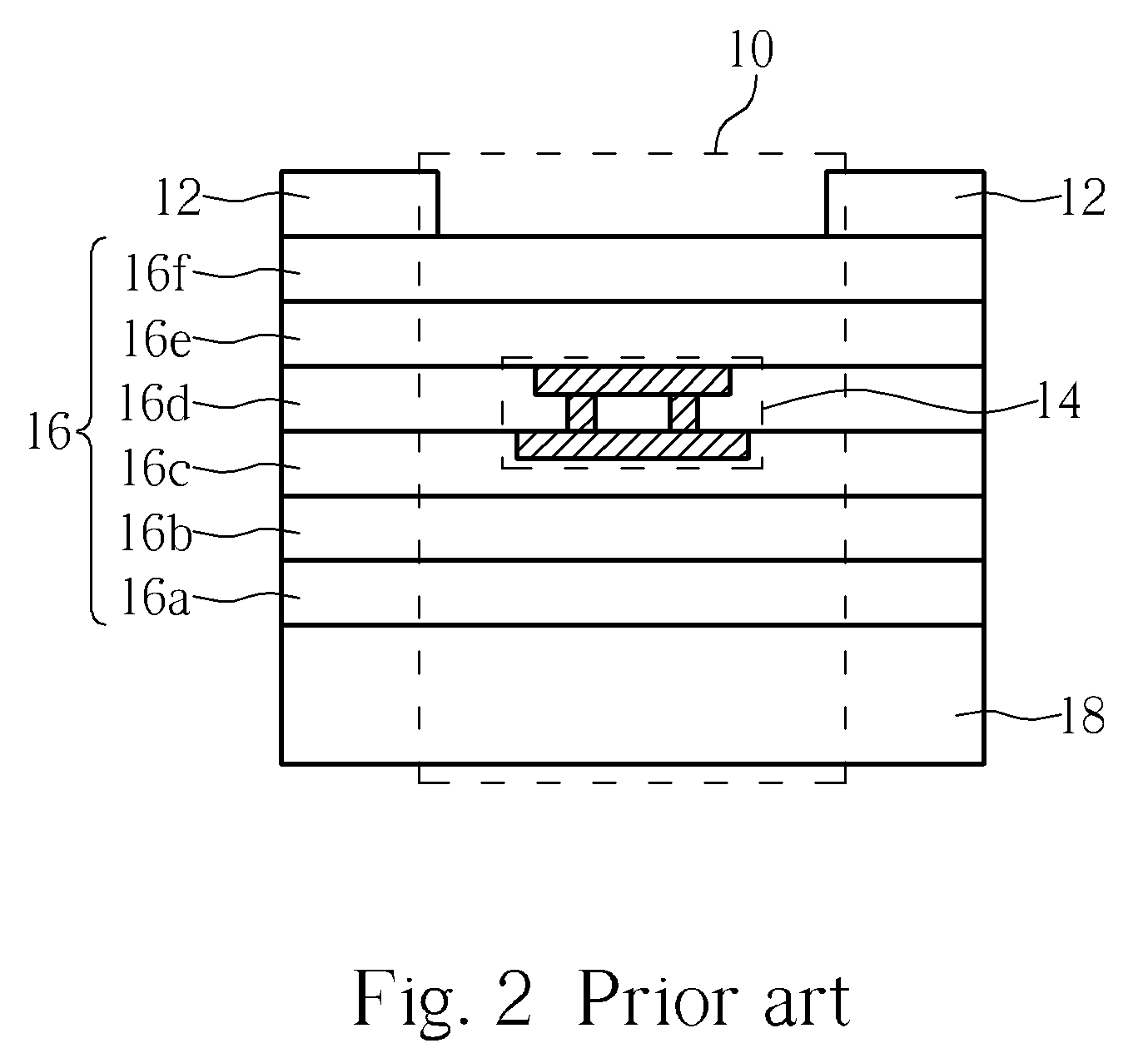

Scribe line structure

InactiveUS20060022195A1Avoid crackingIncrease productionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMetallic materialsDielectric layer

The present invention provides a scribe line structure, which includes a substrate, a plurality of dielectric layers of low dielectric constant materials formed on the substrate, at least a process monitor pattern made of materials of metal formed between the dielectric layers, and a dummy metal structure connected to the process monitor pattern. The dummy metal structure includes a plurality of dummy metal layers and a plurality of dummy vias. The dummy metal structure is formed on the surface of the substrate and is exposed in the region of the scribe line, thus facilitating heat dissipation and energy release from the scribe line structure.

Owner:UNITED MICROELECTRONICS CORP

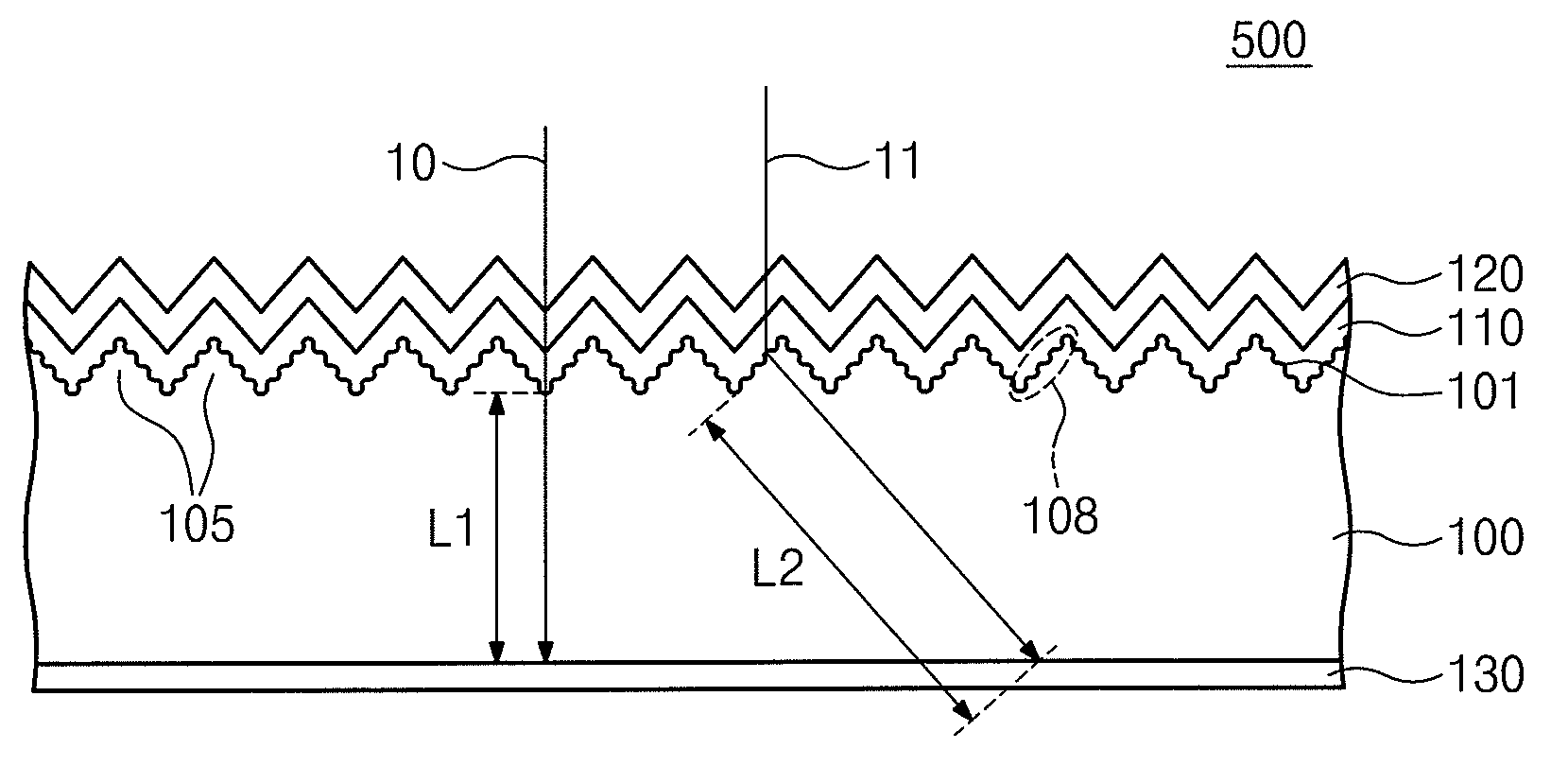

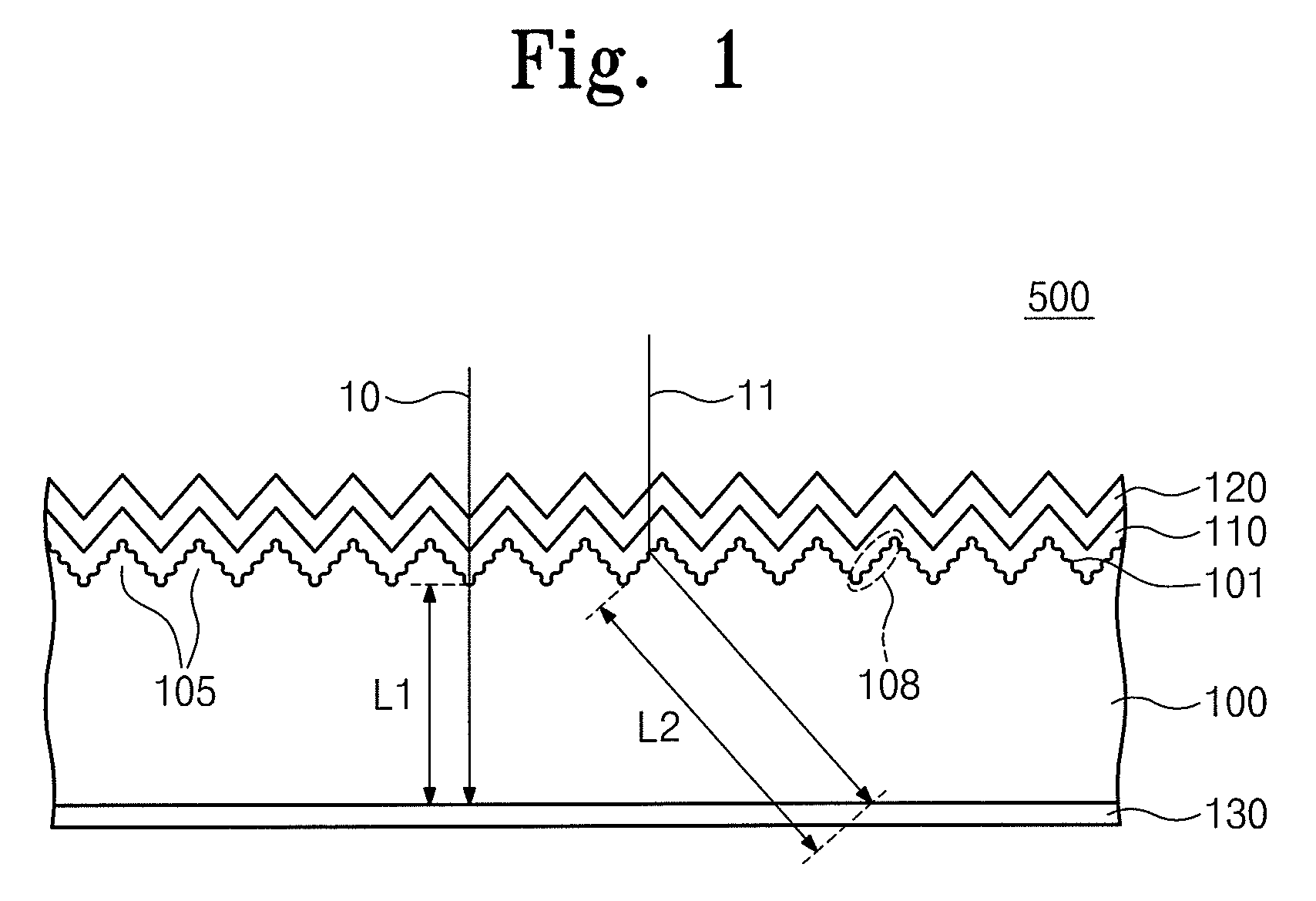

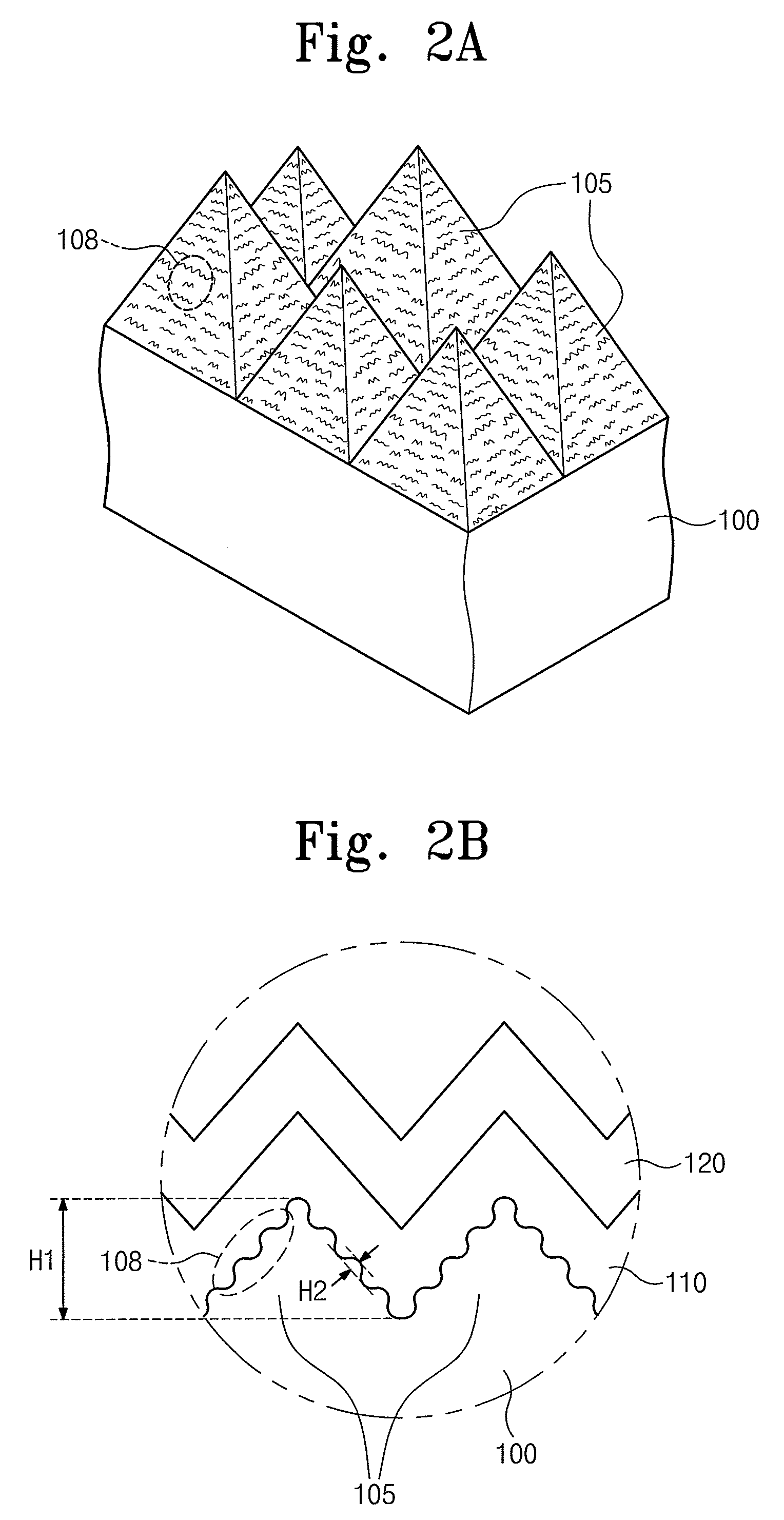

Photovoltaic device and method of manufacturing the same

InactiveUS20100024871A1Speed up the conversion processImprove photoelectric conversion efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationCrystalline siliconSemiconductor

A method of manufacturing a photovoltaic device includes preparing a semiconductor substrate having a light incidence surface receiving light and including single crystalline silicon, wet-etching the light incidence surface to form a plurality of first protrusions on the light incidence surface, dry etching a plurality of surfaces of the first protrusions to form a plurality of second protrusions on the plurality of surfaces of the first protrusions, and forming a semiconductor layer on the light incidence surface. The method further includes forming a first electrode on the semiconductor layer and forming a second electrode on a rear surface of the semiconductor substrate facing the light incidence surface.

Owner:SAMSUNG DISPLAY CO LTD +1

Preparation method for edible fungus flavor food

The invention discloses a preparation method for an edible fungus flavor food. The edible fungus can be any one from edible agaricus bisporus, straw mushrooms, oyster mushrooms, shii-take, needle mushrooms, pleurotus nebrodensis, pleurotus eryngii, agrocybe aegerita, hypsizigus marmoreus, agaricus pratensis schaeff, spring mushrooms, stropharia rugoso-annulata, sparassis crispa, macrolepiota procera, tremellodon gelatinosum, black trumpet mushrooms, hericium erinaceus, pholiota nameko, lepista personata, mitake mushrooms, lactarius hatsudake, golden oyster mushrooms, pholiota adiposa, cantharellus cibarius, termitomyces albuminosus, tricholoma giganteum, pleurotus citrinopileatus, calocybe gambosa, truffle, amillariella mellea, fungus suillus, beef-steak fungus, lactarius deliciosus, tricholoma matsutake, agaricus bitorquis, pleurotus pulmonarius, toadstool and russula vinosa, and after treatment, the edible fungus is steeped into a steeping liquor prepared from red wine vinasse, high quality dry red wine and a flavouring agent in a vacuum and normal temperature and normal pressure combined condition, so as to obtain the flavor food; the edible fungus flavor food for leisure is prepared through oil-bath dewatering; a flavor food flavor puffed food is obtained through a swelling process, so as to meet consumers' hobbies and requirements.

Owner:徐州绿之野生物食品有限公司

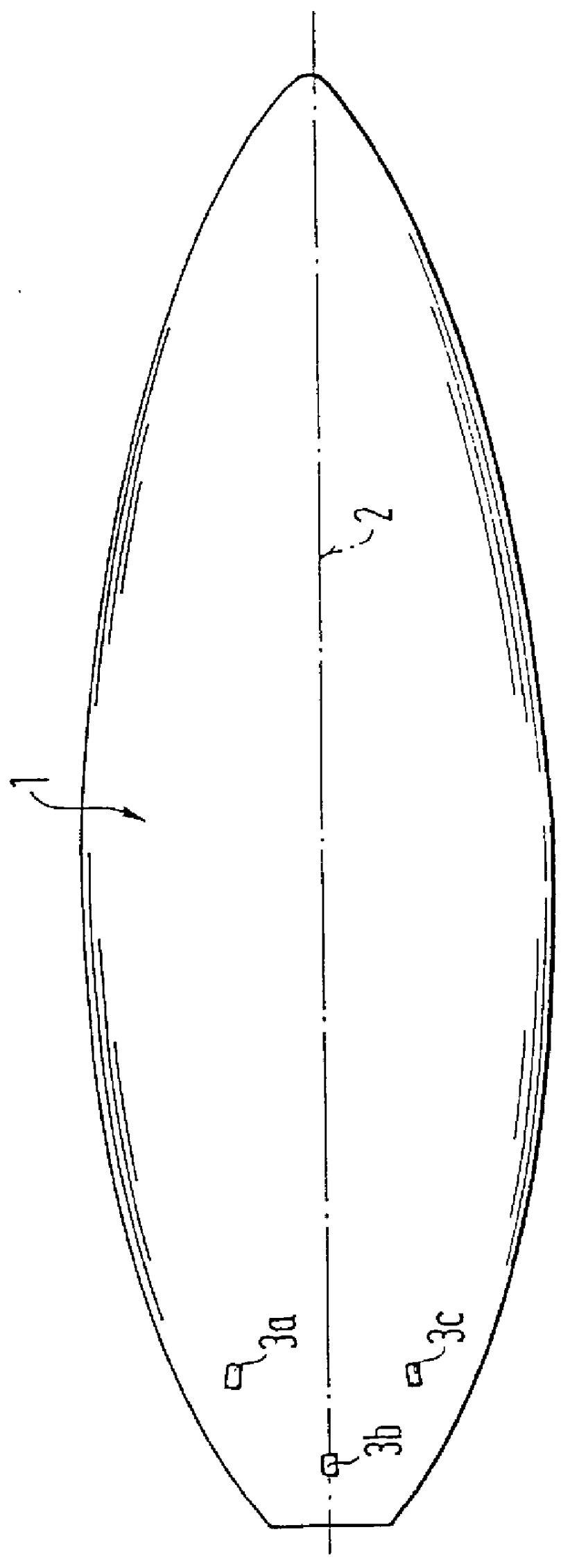

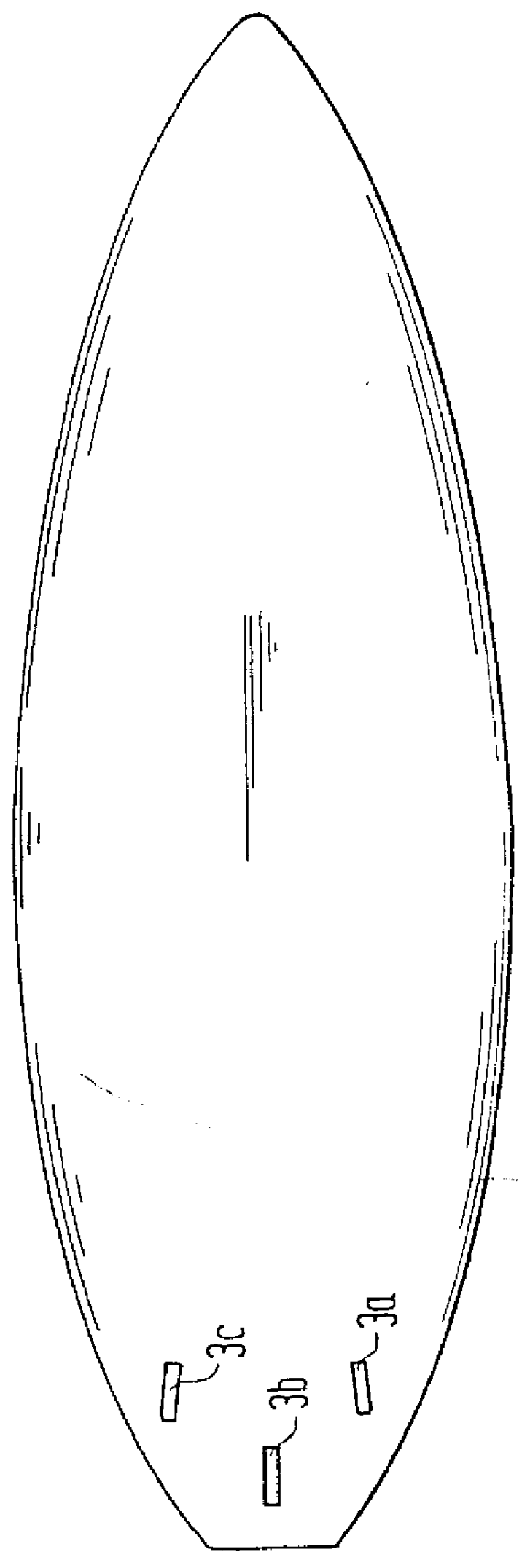

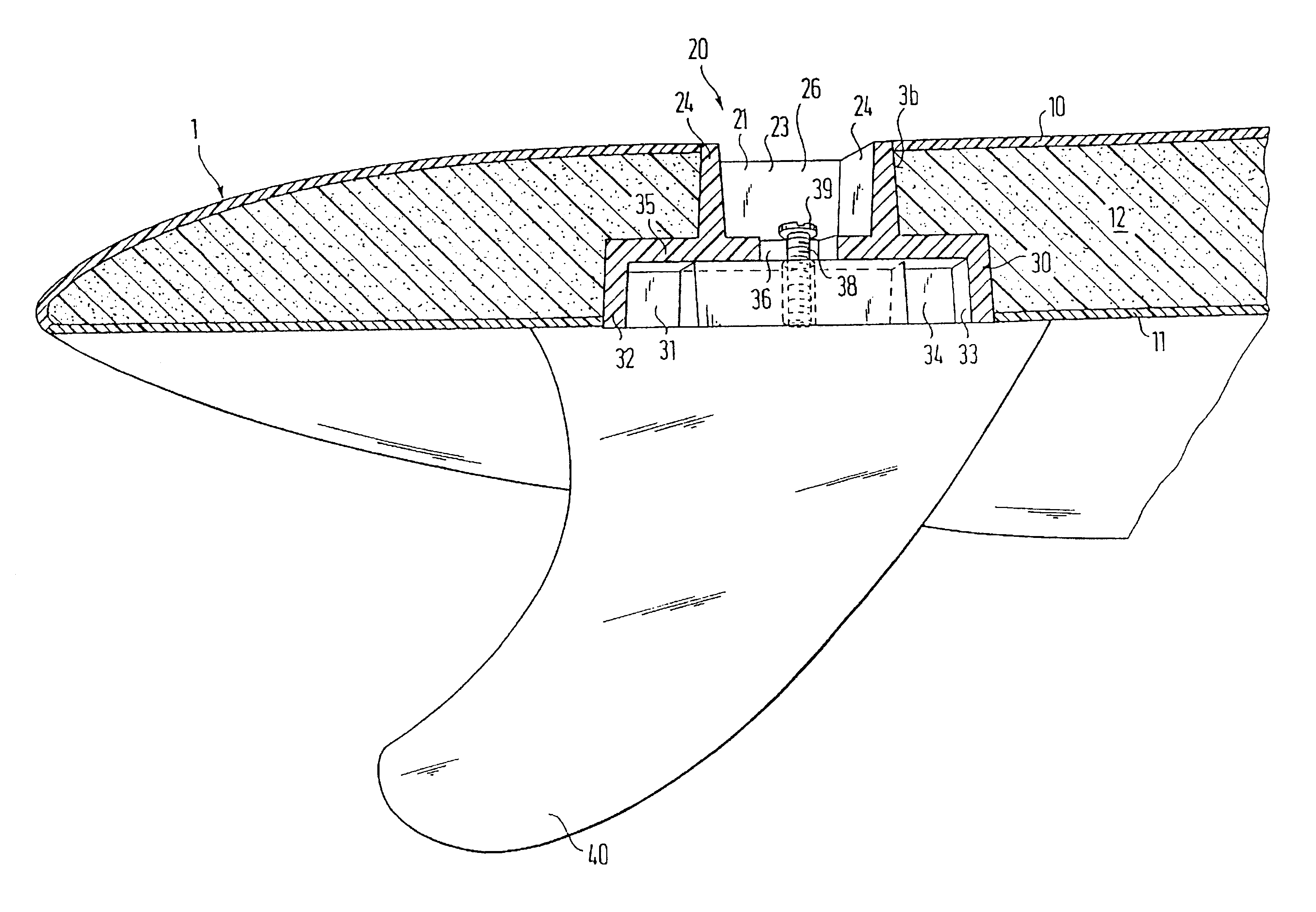

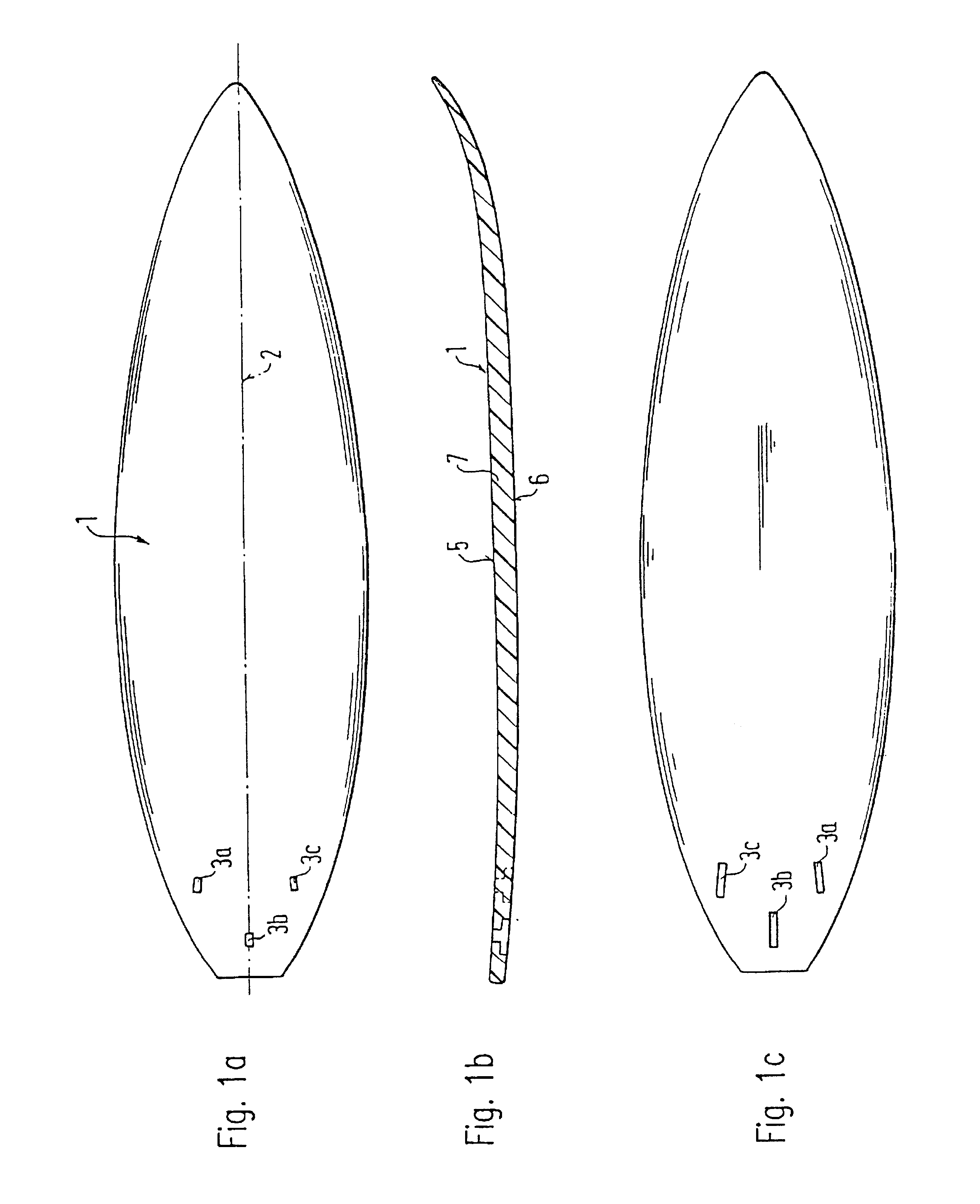

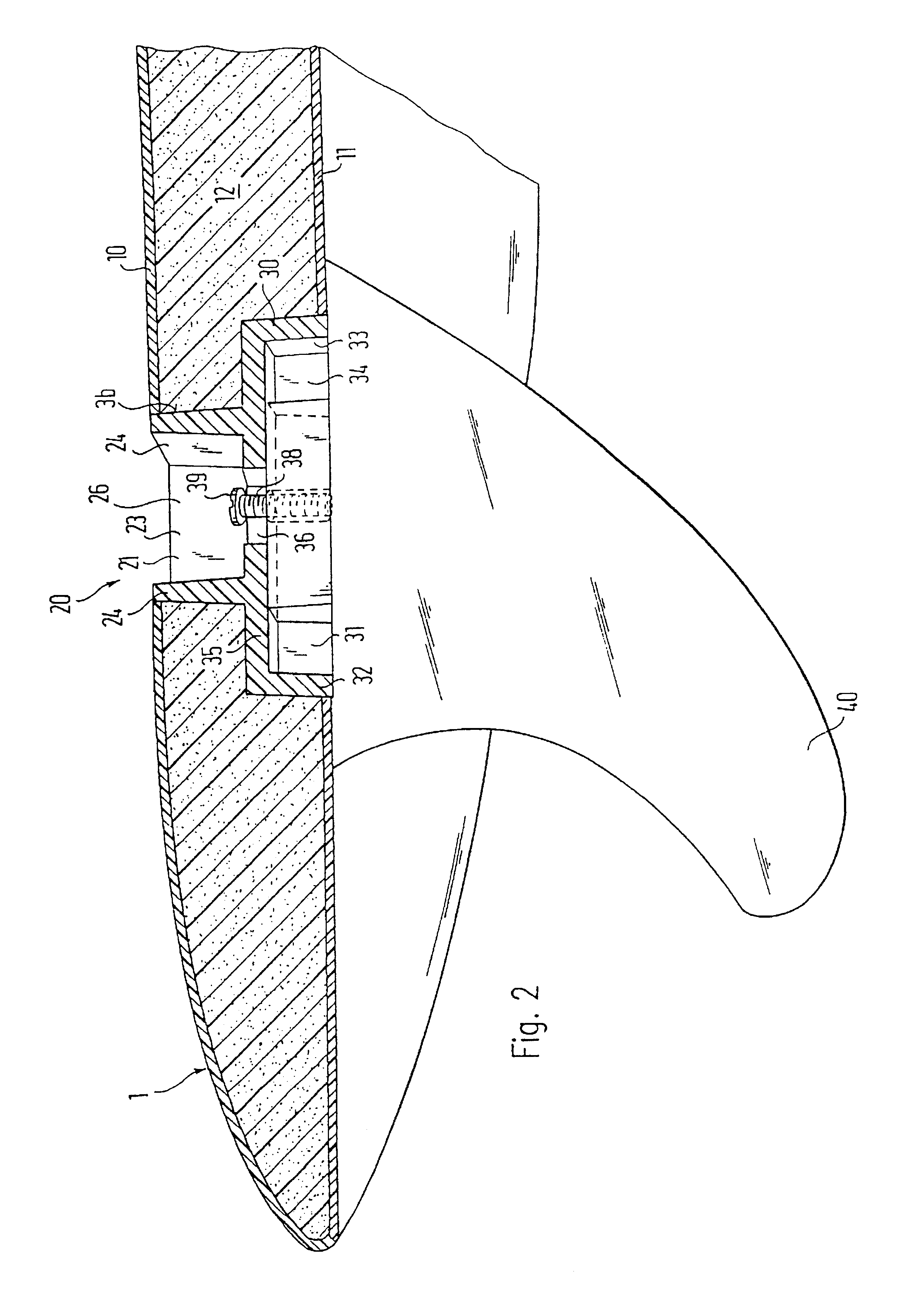

Surf- or sail-board and method of producing the same

Owner:RAPP PETER

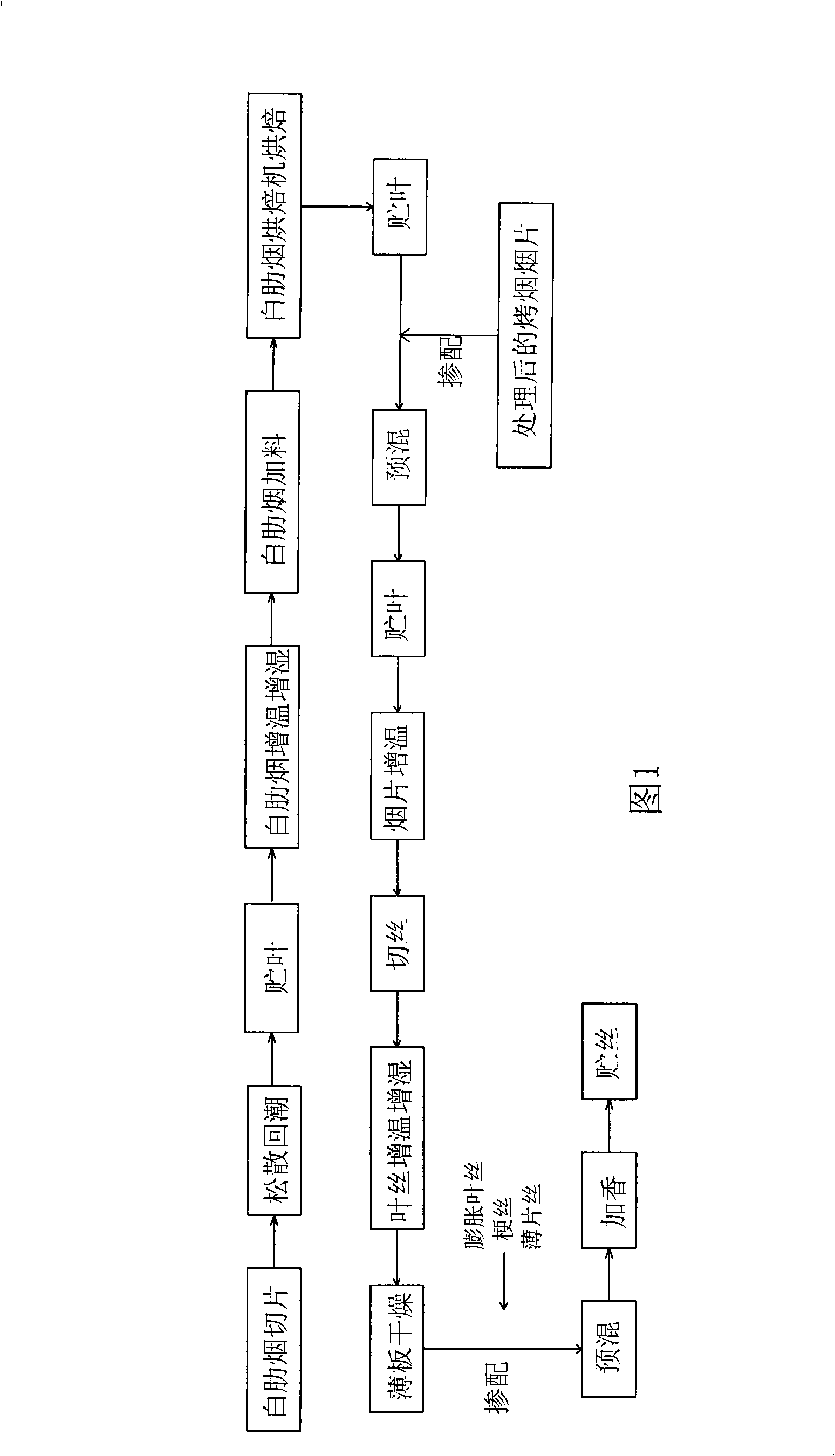

Process technique for burley tobacco in blend type cigarette

The invention discloses a burley tobacco processing and treating technic in a blended type cigarette. The technic performs a burley tobacco leaf blade making workshop section, a burley tobacco making leaf shred workshop section, and a leaf shred mixing workshop section. The burley tobacco processing and treating technic is used for processing and treating a burley tobacco which is used as an individual formula module in the blended type cigarette, and is impenetrated in the whole process from leaf blade making to leaf shred marking; aiming at the treatment of the material of the burley tobacco, for example, the feed liquid of the burley tobacco is applied by steps and proportion; the baking and the drying of the burley tobacco are performed after cutting shred; the existing burley tobacco baking mode is substituted, a burley tobacco leaf shred baking and drying process mode is adopted, the water ratio and the temperature of the exported leaf shred is fed back and controlled; the processing route of the existing burley tobacco processing technic is changed, a processing technic for shred mixing is adopted. The burley tobacco processing and treating technic can adopt different processing parameters and routes according to the needs of products and different qualities and characters of different burley tobacco raw materials, thus the aesthetic quality of the blended type cigarette is improved, the process flow is simpler, and the processing method is more flexible.

Owner:XIAMEN TOBACCO IND

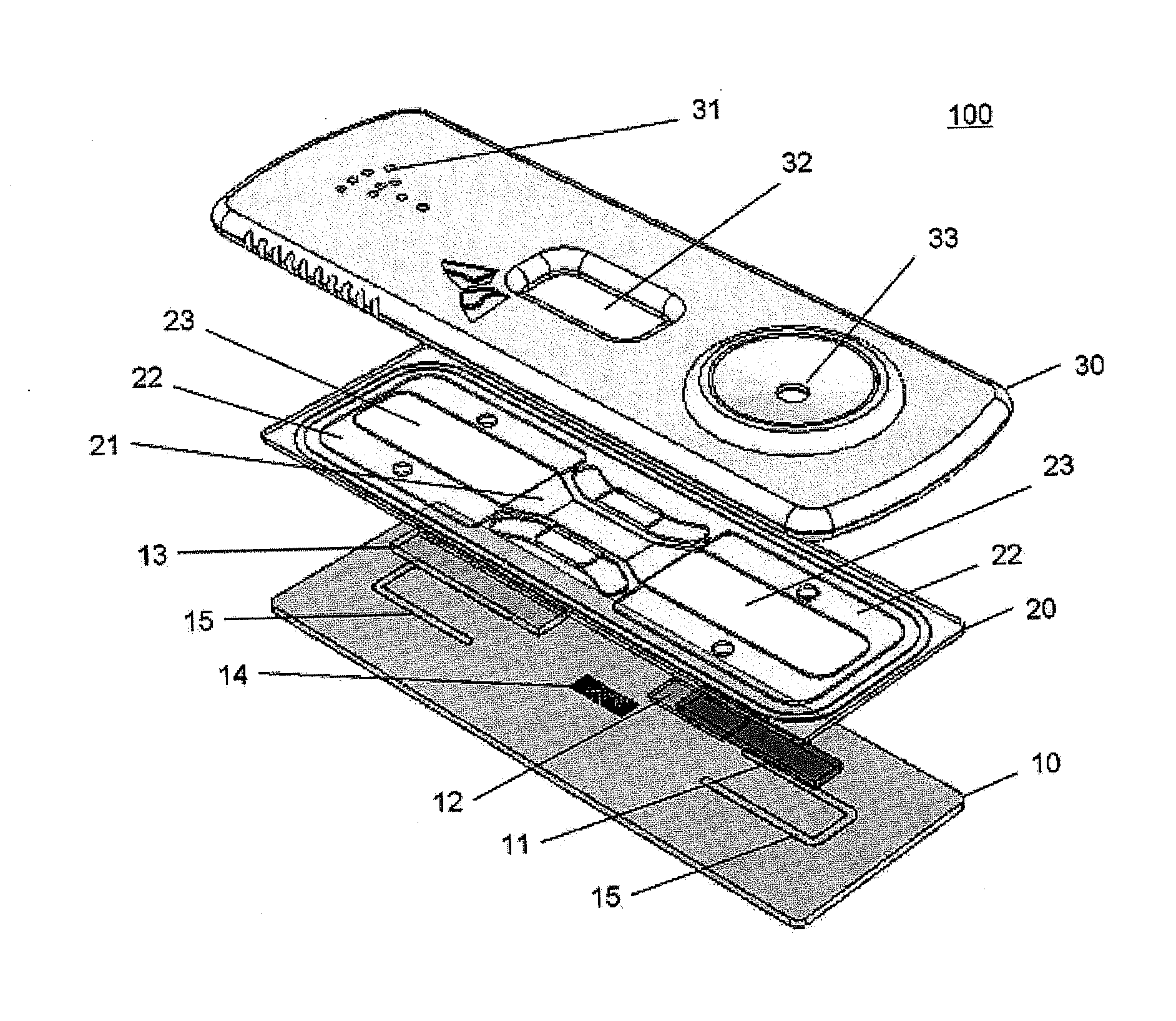

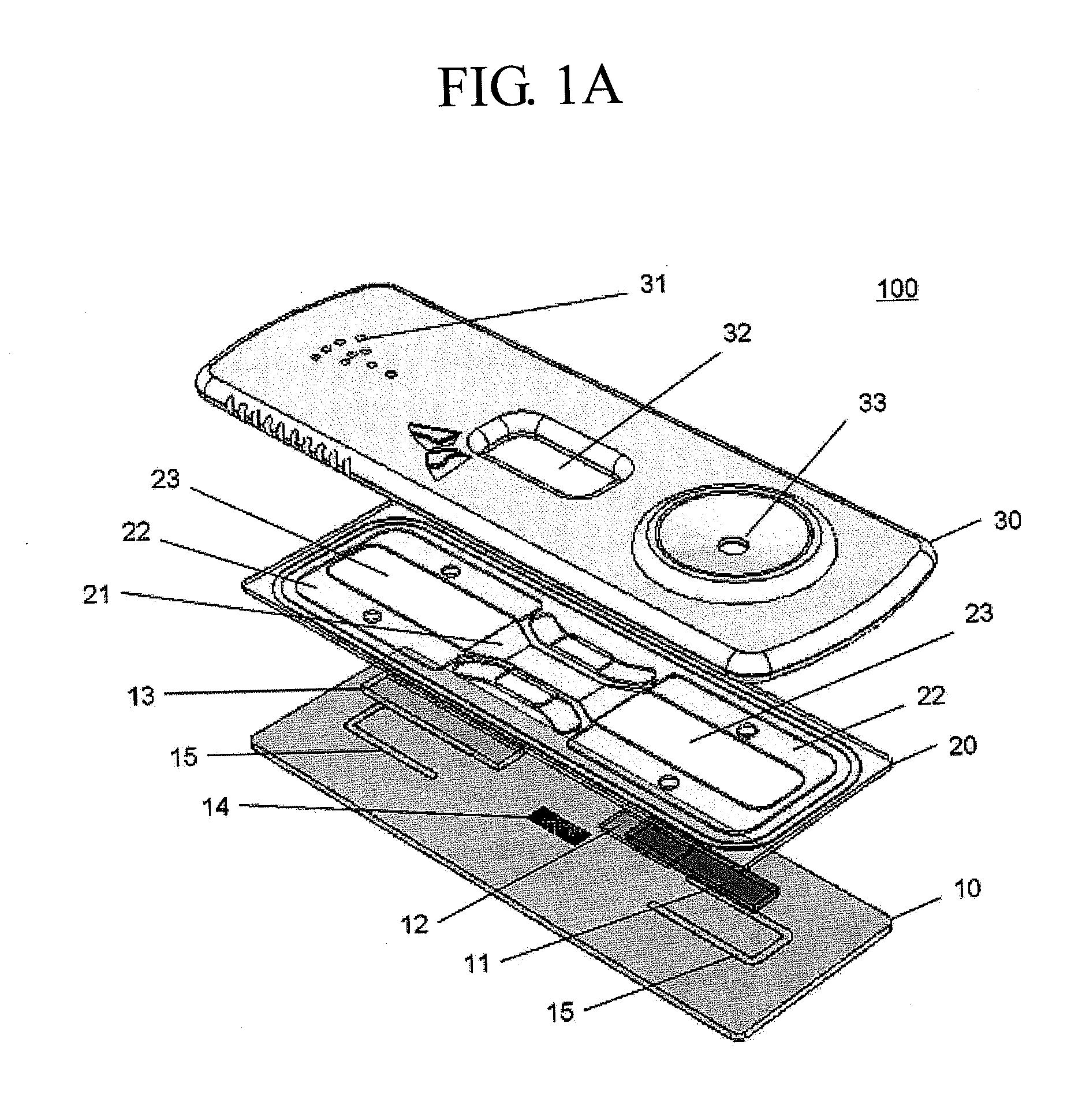

Micro-nano fluidic biochip for assaying biological sample

InactiveUS20110027873A1High sample absorption capacityAnalyze and diagnose small amount of sampleBioreactor/fermenter combinationsBiological substance pretreatmentsMicro nanoEngineering

Disclosed is a micro-nano fluidic biochip for assaying a biological sample comprising a first substrate, a second substrate and a third substrate which are sequentially stacked from bottom to top, wherein an upper channel assembly disposed on the second substrate is coupled with the lower channel assembly provided on the first substrate, to form a microfluidic channel, and the microfluidic channel has nano interstices formed at both sides thereof, the nano interstices having a height less than that of the center of the channel.

Owner:INCYTO

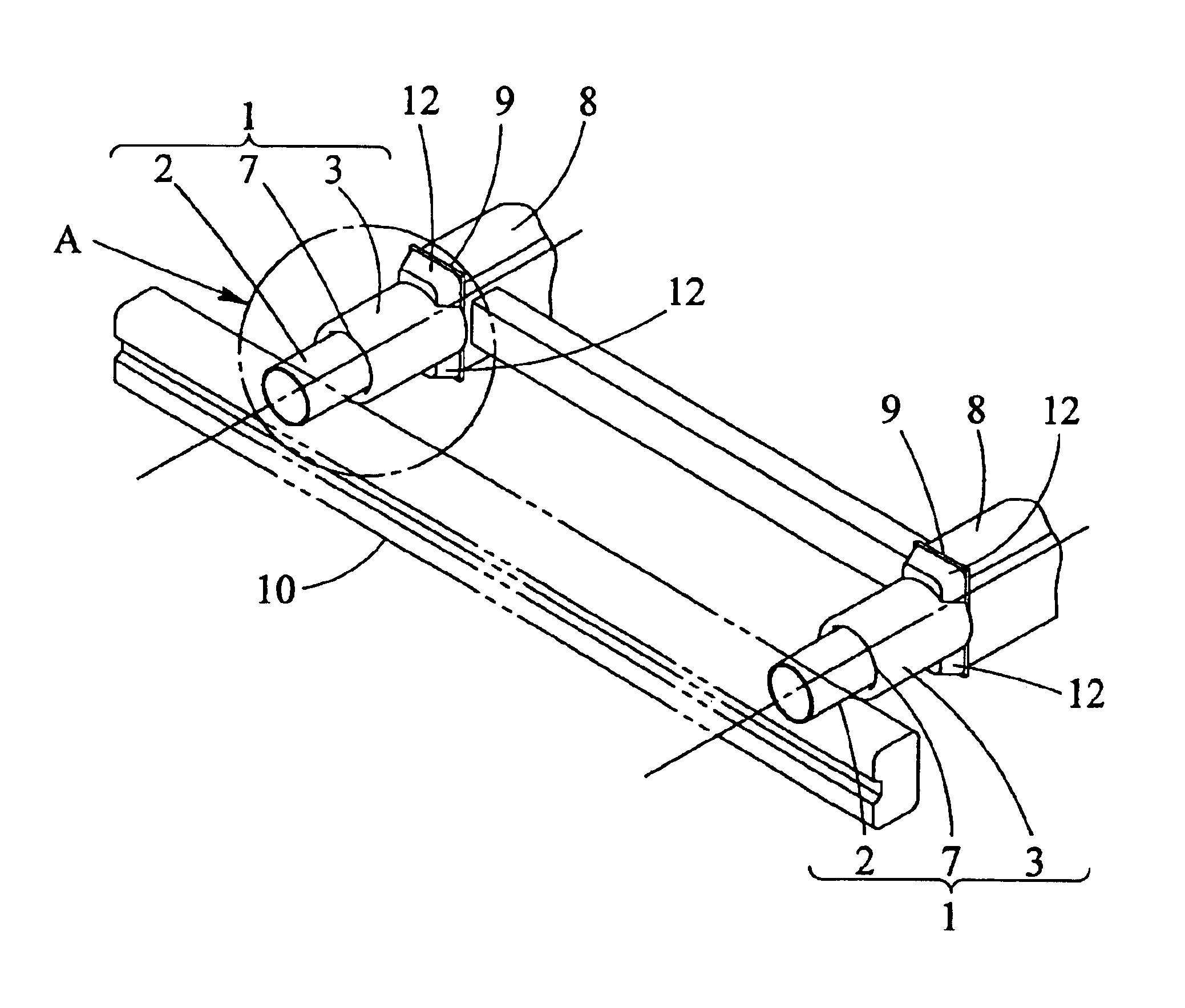

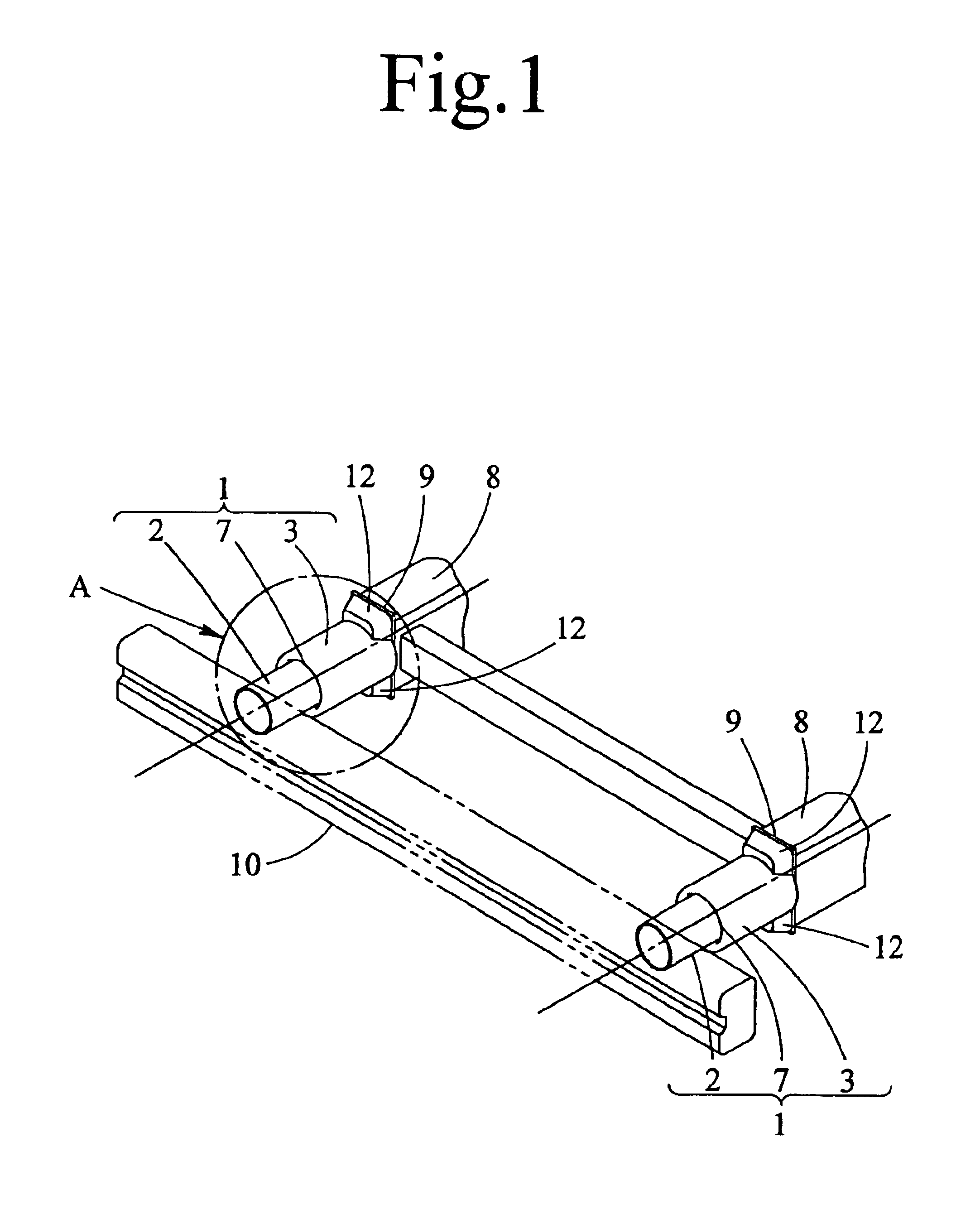

Shock absorber

InactiveUS6908129B2Improve performancePrevention of collapse and deformationBumpersEngineeringDiagonal

A shock absorber capable of preventing the collapse or deformation of a vehicle body member when a local load applied to a bumper, without being influenced by the arrangement and construction of the vehicle body member. The shock absorber comprises a multi-diameter stepped tube having different diameter tube portions integrally formed by partially reducing or partially enlarging a straight tube that can be plastically deformed through a stepped portion connecting those tube portions under installation of which a smaller-diameter tube portion connecting to the bumper and of which a larger-diameter tube portion connecting to the side member, a mounting part having a quadrilateral shape with a diagonal length of which is longer than the diameter of the larger-diameter tube portion and positioned at a front end of the side member, and load transmission members fixed between an outer side surface of the larger-diameter tube portion and the mounting part.

Owner:ASTEER

Paper and coating medium for multifunctional printing

ActiveUS20090131570A1High porosityAbsorb evenlyPigmenting treatmentNon-fibrous pulp additionPolymer scienceButadiene-styrene rubber

A paper coating includes a combination of a primary pigment and a secondary pigment. The primary pigment includes anionic particles having a particle size distribution where at least 96% of the particles by weight have a particle size less than 2 microns. The secondary pigment is a cationic, grit-free pigment having an average particle size of 3 microns or less. The coating also includes up to 17 weight % of a hydrophilic styrene-butadiene latex based on the weight of the dry pigments and a co-binder. Another embodiment of this invention is a coated base sheet that includes a base sheet to which the above coating has been applied.

Owner:VERSO MINNESOTA WISCONSIN LLC

Aqueous culture method of anoectochilus

InactiveCN102100171AAbsorb evenlyAdequately meet nutritional needsCultivating equipmentsSoilless cultivationBiotechnologyCalcium nitrate tetrahydrate

The invention relates to an aqueous culture method of anoectochilus. In the method, anoectochilus germchits are cleaned and sterilized, transplanted in a culture dish and cultured in a culture groove filled with an aqueous culture solution; each 10L of aqueous culture solution contains the following components: 650 to 800mg of calcium nitrate tetrahydrate, 50 to 60mg of ammonium nitrate, 280 to 350mg of potassium nitrate, 100 to 130mg of potassium dihydrogen phosphate, 350 to 380mg of magnesium sulfate, 0.5 to 0.8mg of potassium iodide, 2 to 5mg of manganese sulfate, 0.2 to 0.3mg of sodium molybdate, 0.1 to 0.2mg of cobalt chloride, 2 to 4mg of boric acid, 0.5 to 1mg of zinc sulfate, 0.3 to 0.5mg of copper sulfate and 3 to 5ml of iron salt solution, wherein the iron salt solution is prepared by mixing water, green vitriol and ethylenediamine tetraacetic acid disodium. The method has the advantages of lowering production cost, simplifying production process, improving the growth of anoectochilus plants and improving the survival rate of anoectochilus plants.

Owner:福建永安天奇健金线莲生态实业有限公司

Multifunctional synergistic nitrogen fertilizer and preparation method thereof

InactiveCN102515968APromote growthThe synergistic function is significantly stableAgriculture gas emission reductionFertilizer mixturesAmmonium sulfateChemistry

The invention relates to a multifunctional synergistic nitrogen fertilizer and a preparation method thereof, and is applied in the field of agriculture and forestry production. The product comprises medium trace elements, a plant nutrition conditioner and a nitrogen fertilizer synergist. The product is rich in the medium trace elements, such as calcium, magnesium, sulfur, boron, manganese, zinc and the like, required by crop growth and guarantees full absorption of crop nutrition. The plant nutrition conditioner and the nitrogen fertilizer synergist can effectively promote plants to absorb nutrient elements and improve the utilization ratio of the nitrogen fertilizer. The multifunctional synergistic nitrogen fertilizer is prepared by the following steps: mixing urea, ammonium sulfate, ammonium chloride, bentonite, zinc sulfate, manganese sulfate, calcium chloride, magnesium sulfate, disodium octoborate tetrahydrate and the like according to a certain scientific ratio; adding a certain dose of plant nutrition conditioner and the nitrogen fertilizer synergist; mixing completely; and pelletizing. The multifunctional synergistic nitrogen fertilizer can prolong the useful life of the nitrogen fertilizer by 90 to 120 days, increases the utilization ratio of the nitrogen fertilizer by over 30 percent, increases yield by 15 to 20 percent, and enhances resistance, such as drought resistance, cold resistance, disease resistance and the like, of crops.

Owner:GUANGXI NEW ORIENTATION CHEM IND

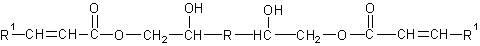

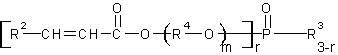

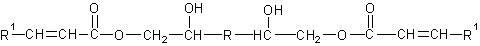

Ultraviolet (UV) light-curable polyurethane acrylic resin composite

ActiveCN102161862AAbsorb evenlyImprove adhesionPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention discloses a UV light-curable polyurethane acrylic resin composite, which comprises the following components: polyurethane acrylic resin, epoxy acrylate, acrylic phosphate, an active diluent and a photoinitiator. The composite also may comprise a filler and an assistant. When the composite disclosed by the invention is used, the adhesive force of UV paint for metal substrates can be improved, the uniform absorption of UV paint can be guaranteed, the fullness of finish can be increased, a paint system can produce the best effect and has high adhesive force for various metal veneers, the paint film at a production position has high toughness and continuity and good rubbing property, and the paint is applicable to rolling painting and spray painting construction.

Owner:SHANGHAI CHANGRUNFA PAINT

Preparation method of preserved rice noodles

InactiveCN102178179ASolve the problem of resurrectionSolve cohesionFood preparationWater bathsFiltration

The invention relates to a preparation method of preserved rice noodles. The preparation method includes the steps of rice machining and sand filtration, smashing, humidity adjustment, extrusion for gelatinization, extrusion for emerging of silk noodles, cutting off, checking and packaging. The preparation method is characterized by taking the rice noodles before extrusion for emerging of silk noodle and drying as materials, wherein the water content of the rice noodles at the moment is 25wt%-30wt% and the temperature is 40-60 DEG C; cutting the rice noodles to 17-19cm; soaking the rice noodles for 60-100min in Didazuril bactericide solution with concentration of 50%-60% and temperature of 35-45 DEG C, wherein the ratio of material to liquid is 1wt%:5wt%; conducting vacuum packaging, wherein the vacuum degree is 0.09MPa-0.092Mpa; thermally sterilizing the rice noodles for 0.5h-1h in a water bath maintained at the temperature of 90-95 DEG C; cooling packaging bags with circulating cold water so as to fast reduce the temperature in the center of the packaged material to 30-35 5 DEG C; blowing the water at the outer surfaces of the packaging bags to dry; checking whether the packaging bags bulge and break and conducing metal detection; putting the rice noodles together with auxiliary materials such as matched sauce bags in a packaging box; and sealing the packaging box, thus obtaining a finished product. For the preserved rice noodles produced according to the preparation method, the water content is higher than 60% and the quality guarantee period is longer than 6 months; the infusing and dispersing performance is good; caking does not happen and undesirable odor does not emerge; the dissolving starch rate of the rice noodles is low; after culture for 1 month at the temperature of 37 DEG C, the rice noodles achieve 1426g of hardness, 26.14gs of crisp performance, 512 of viscosity, 0.513s of viscoelasticity.

Owner:江西华达昌食品有限公司

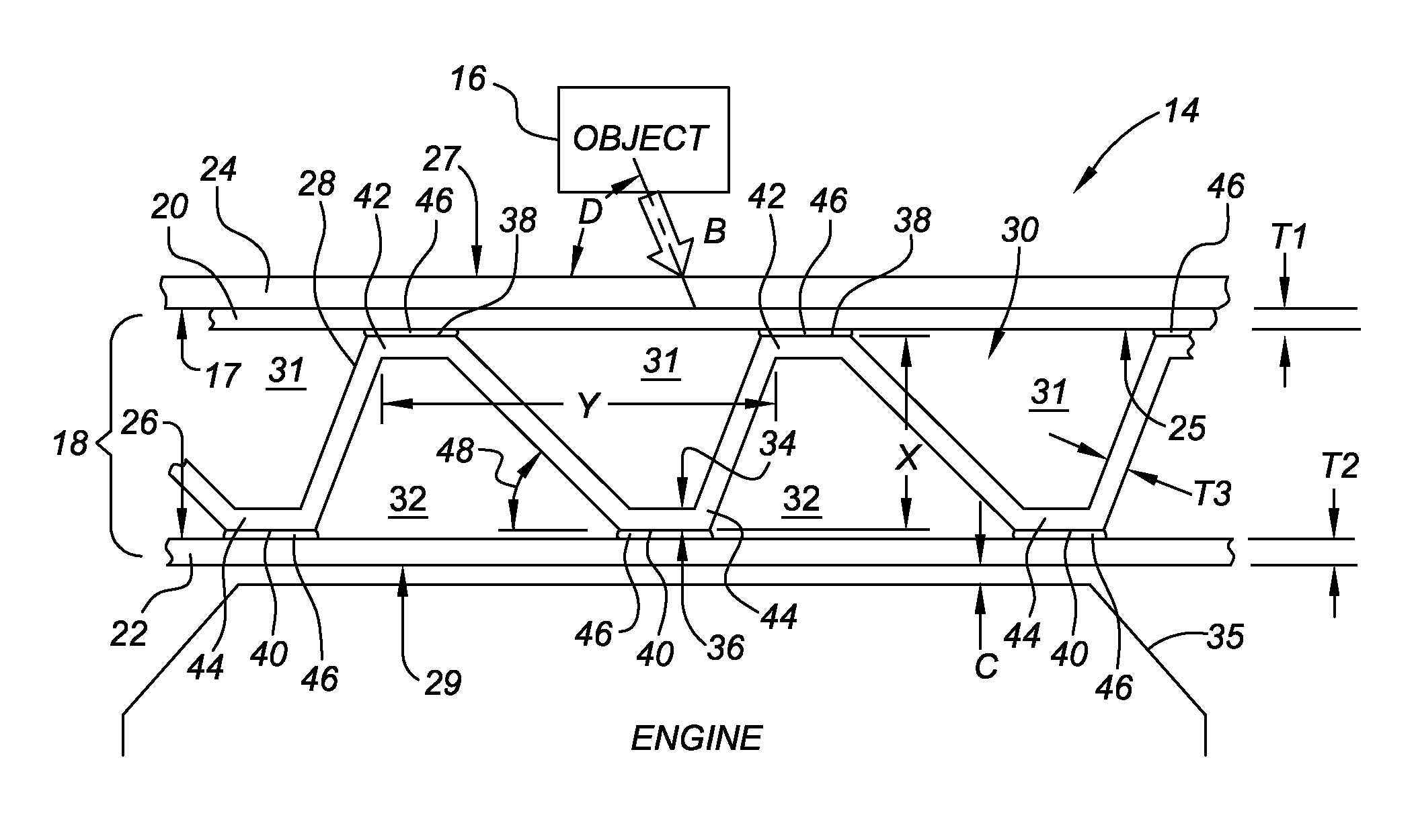

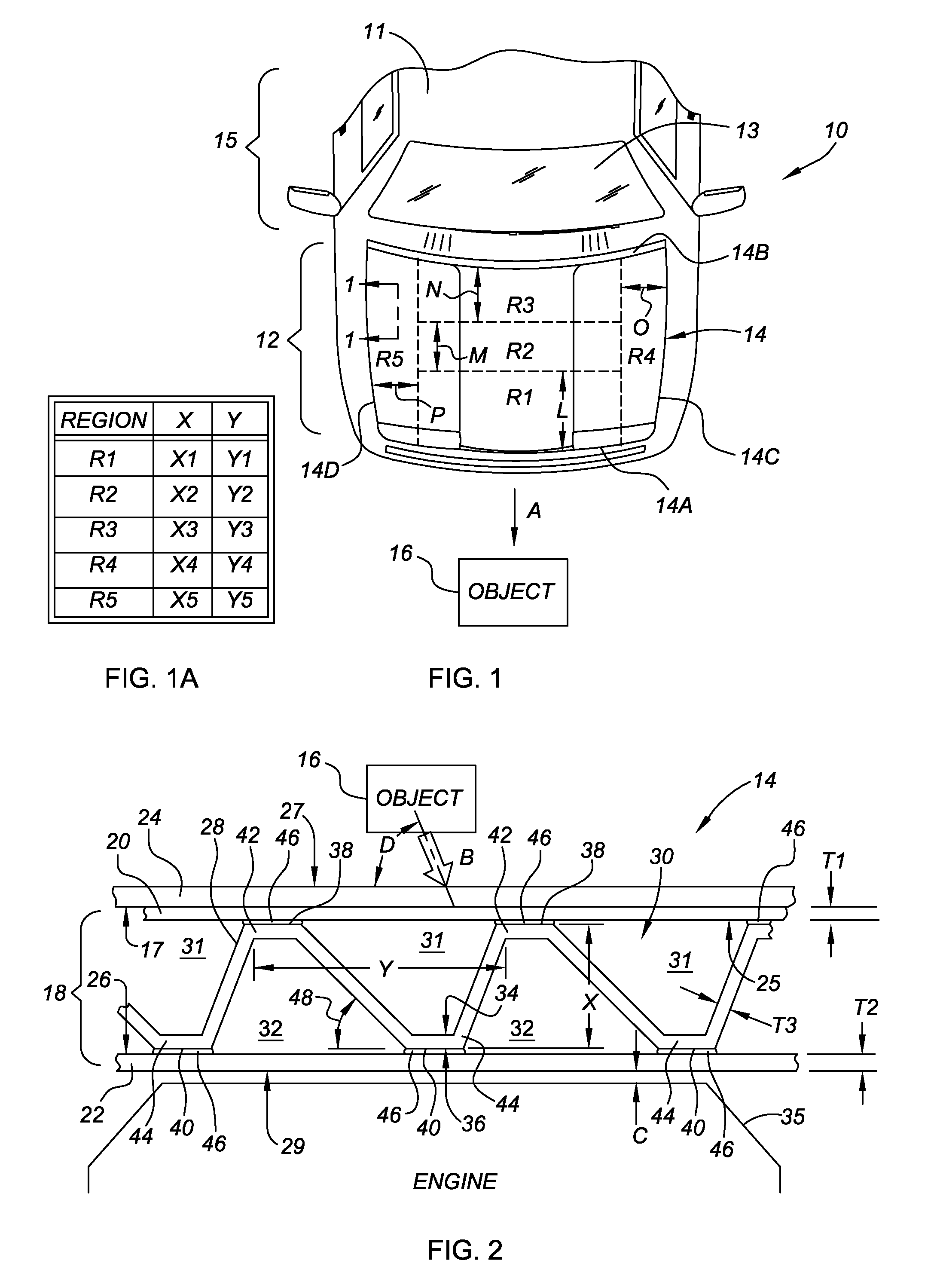

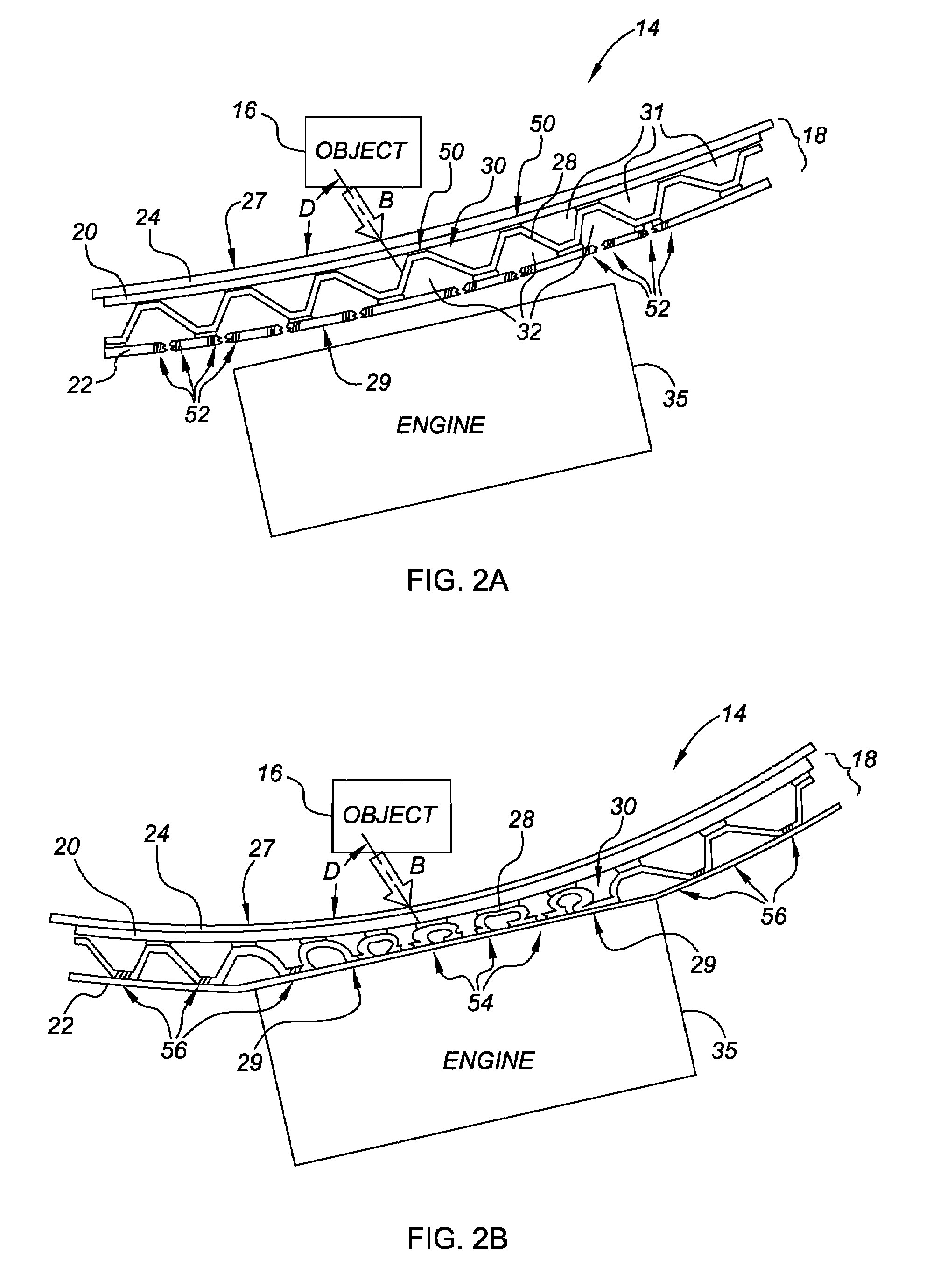

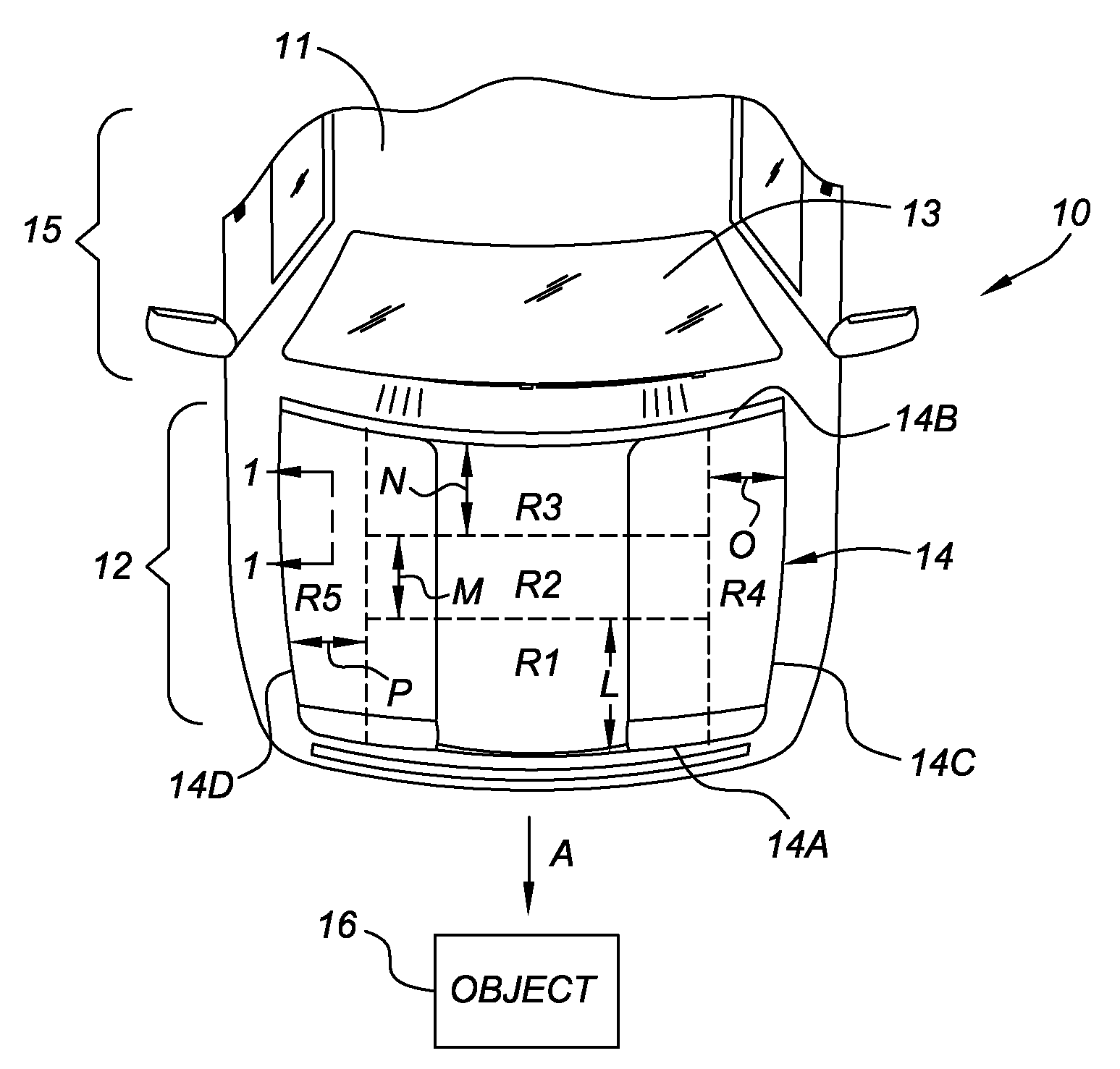

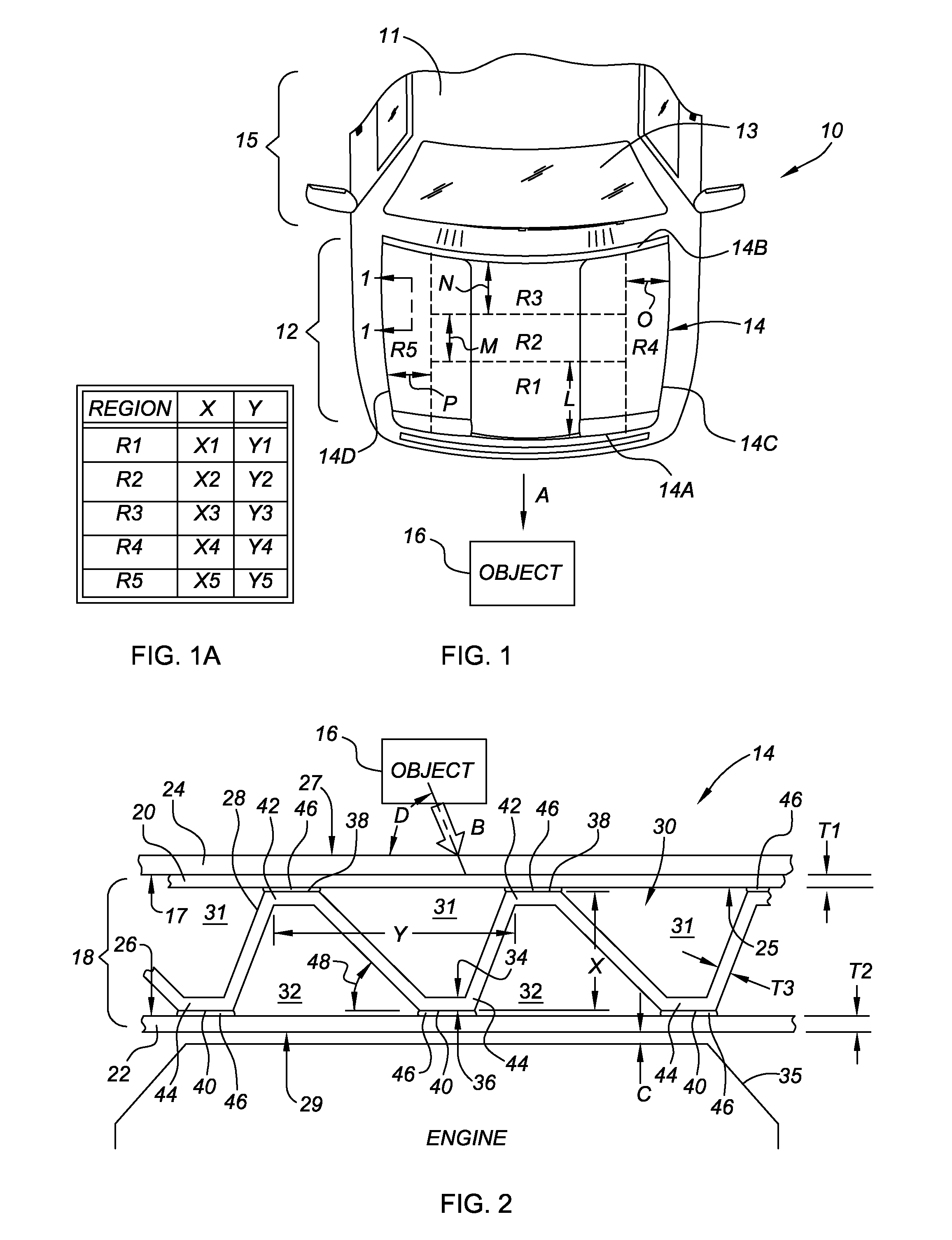

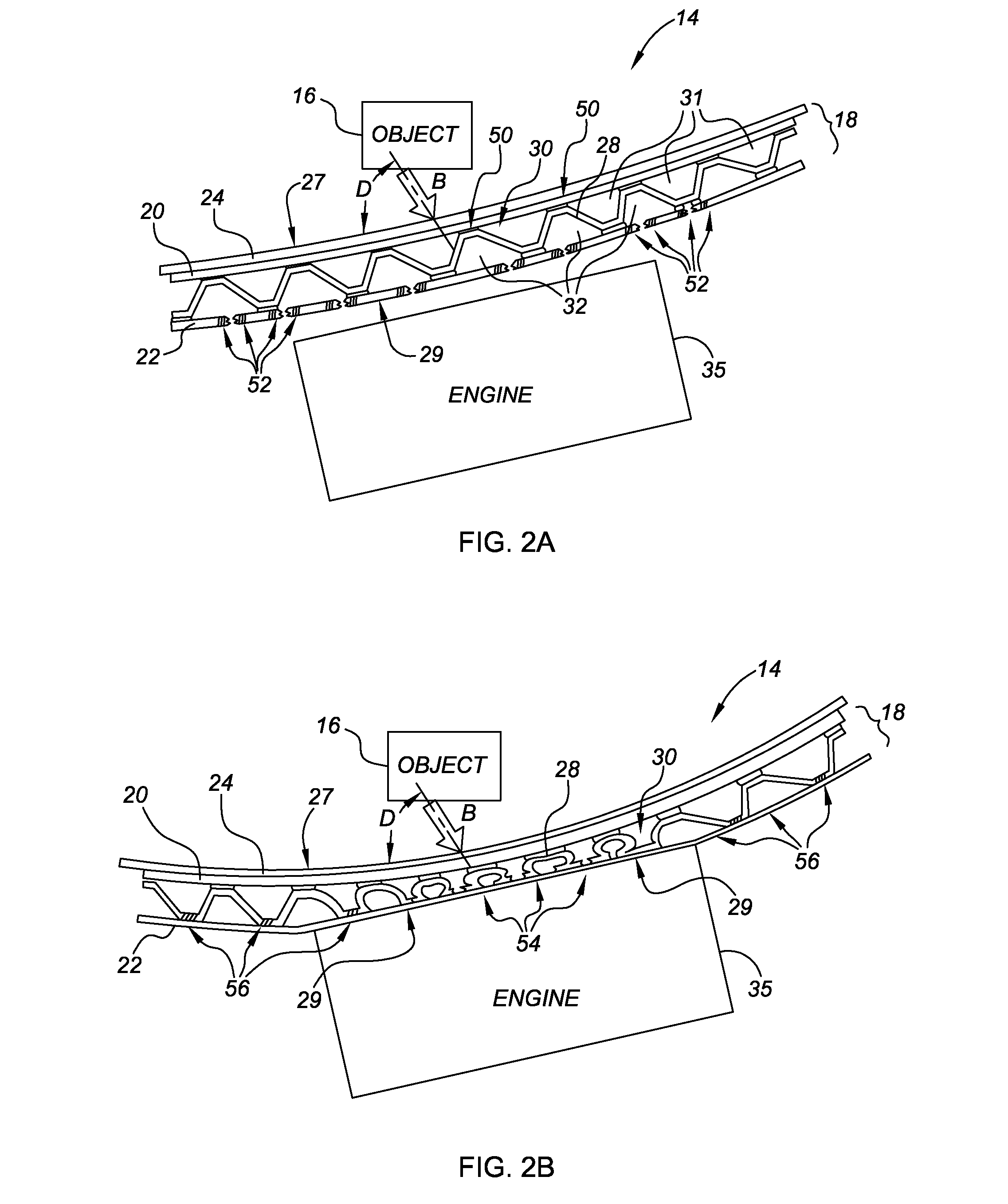

Energy absorbing vehicle hood assembly with asymmetric sandwich inner structure

ActiveUS7690720B2Improved and uniform crush characteristicAbility to absorb and attenuateVehicle seatsPedestrian/occupant safety arrangementUltrasound attenuationEnergy absorption

An energy-absorbing hood assembly for a vehicle includes upper, lower, and middle panels. The upper and lower panels respectively include first and second interface surfaces. The upper panel is preferably secured to an inner surface of an outer panel. The middle panel has opposing first and second surfaces defining an asymmetric waveform profile, preferably having a polygonal geometry. The middle panel member is secured to the first and second interface surfaces at preselected locations along the upper and lower surfaces, thereby defining a plurality of laterally oriented asymmetric channels. The asymmetric waveform profile is configured with distinct amplitudes and wavelengths along different regions of the hood assembly, each configured to provide different predetermined levels of absorption and attenuation of kinetic energy imparted to the hood assembly by objects upon impact therebetween. Ideally, the lower and middle panels are respectively configured to controllably fail at first and second predetermined crush loads.

Owner:GM GLOBAL TECH OPERATIONS LLC

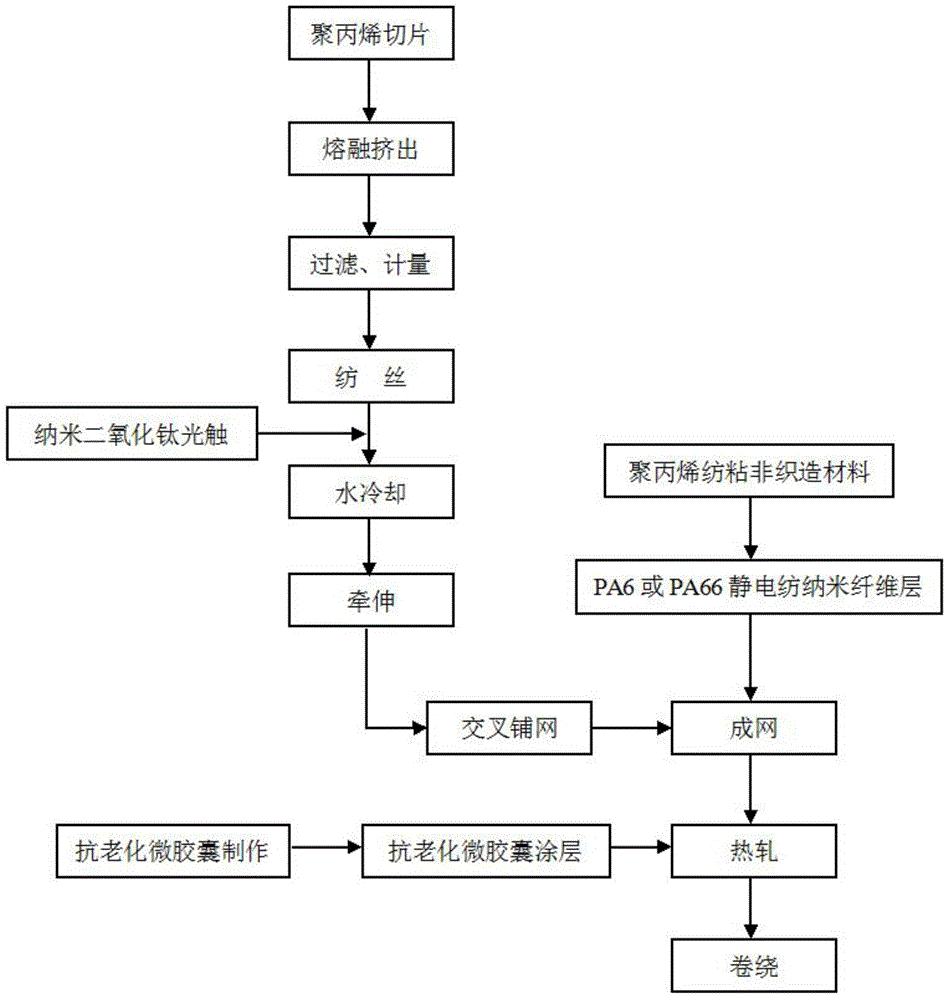

Composite nonwoven material and preparation method thereof

ActiveCN104553174AEvenly dispersedUniform and effective dispersionSynthetic resin layered productsLaminationFiberPorosity

The invention discloses a composite nonwoven material and a preparation method thereof. The composite nonwoven material disclosed by the invention comprises at least two PP spun-bonded nonwoven material layers and a PA6 or PA66 electrostatic spinning nanofiber material layer sandwiched between the two PP spun-bonded nonwoven material layers, wherein an ultraviolet light absorber and an antibacterial agent are uniformly absorbed to the surface of the composite nonwoven material; and in the two PP spun-bonded nonwoven material layers between which the PA6 or PA66 electrostatic spinning nanofiber material layer is sandwiched, the surface of at least one PP spun-bonded nonwoven material layer is coated with a nanometer titania photocatalytic coating. The composite nonwoven material disclosed by the invention is high in strength and low in fiber fineness and has the advantages of high porosity, high specific surface area, excellent barrier property, excellent gas permeability, aging resistance and antibacterial property. Compared with a blended nonwoven material, the composite nonwoven material disclosed by the invention has the advantages that the production and quality defects caused by the reason that the additives are non-uniformly mixed or separated out are overcome; and moreover, the preparation method is simple, and only general nonwoven material production equipment needs to be adopted.

Owner:东营俊富净化科技有限公司

Novel liquid injection and activation process for lithium ion batteries

InactiveCN102315417ASpeed up entrySmooth entrySecondary cells charging/dischargingCell component detailsElectrical batteryPre-charge

The invention relates to a novel liquid injection, infiltration and pre-charging process for lithium ion batteries. The process comprises the following steps: (S1) carrying out vacuum operation on a lithium ion battery before liquid injection, injecting a predetermined amount of electrolyte, and filling a proper amount of film forming additive gas into the battery after injection of electrolyte is finished; (S2) employing the manner of cyclical fluctuation negative pressure infiltration, wherein, fluctuation of negative pressure is expressed with a waveform function instead of a simple first grade linear function; (S3) carrying out formation under the conditions of changing negative pressure and changing temperature, wherein, the negative pressure and temperature both increase gradiently with time, a charging current is not constant and varies in a manner of small gradient increase. The invention enables a predetermined amount of electrolyte to be rapidly absorbed by anode and cathode materials and diaphragms of the battery, and absorption time is short while full absorption is realized, thereby improving the utilization rate of the electrolyte and shortening time for liquid injection; addition of a proper amount of film forming additive gas is beneficial for the formation of SEI membranes and enables inreversible capacity loss of the battery in initial charge to be reduced; the method of pre-charging brought forward in the invention enables uniform and stable SEI membranes to form on the surface of electrodes, thereby improving safety performance and electrochemical performance of lithium ion batteries; the process is simple and is easy to control, investment cost for equipment used in the process is low, and the process is easy to realize.

Owner:HUNAN UNIV

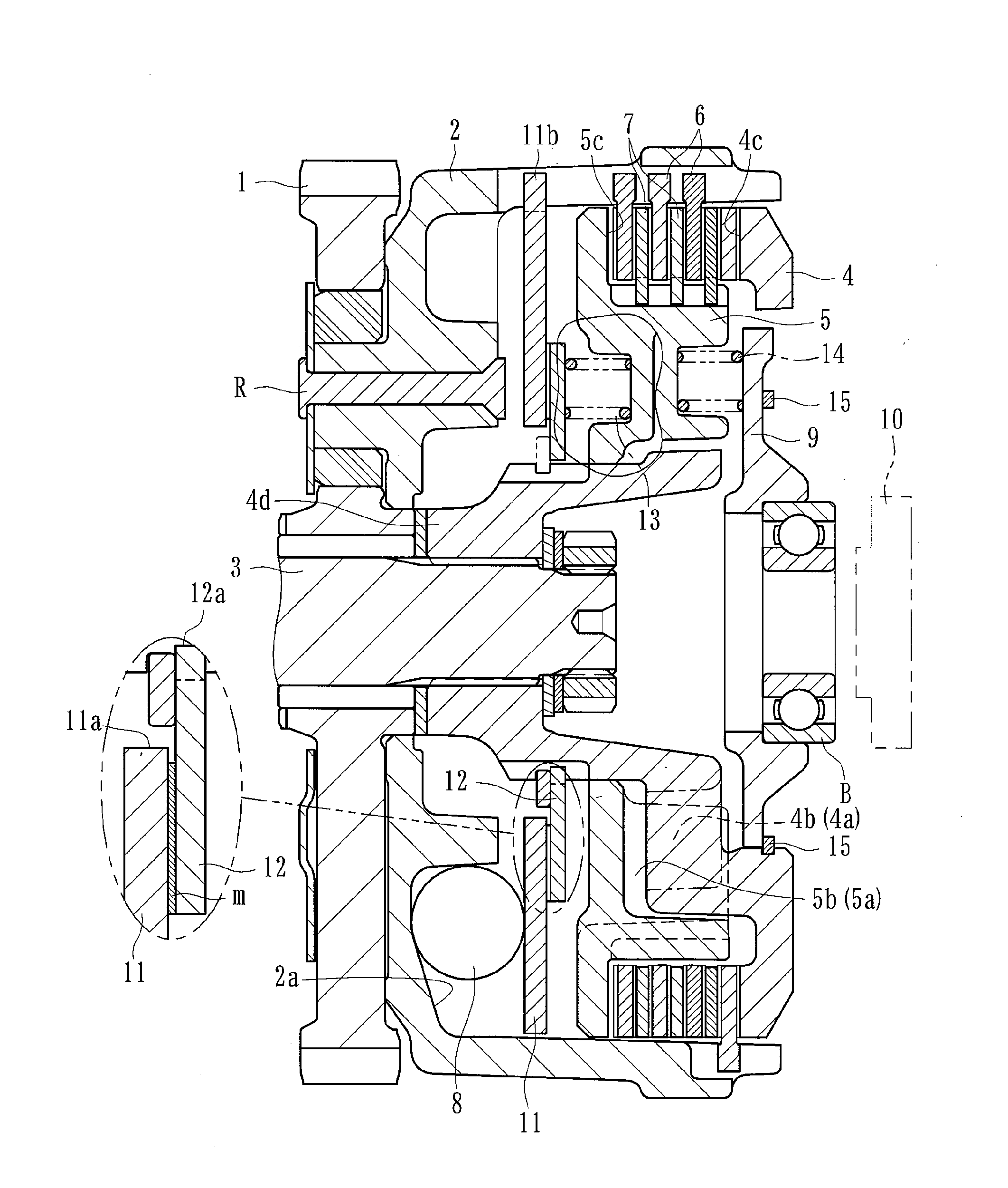

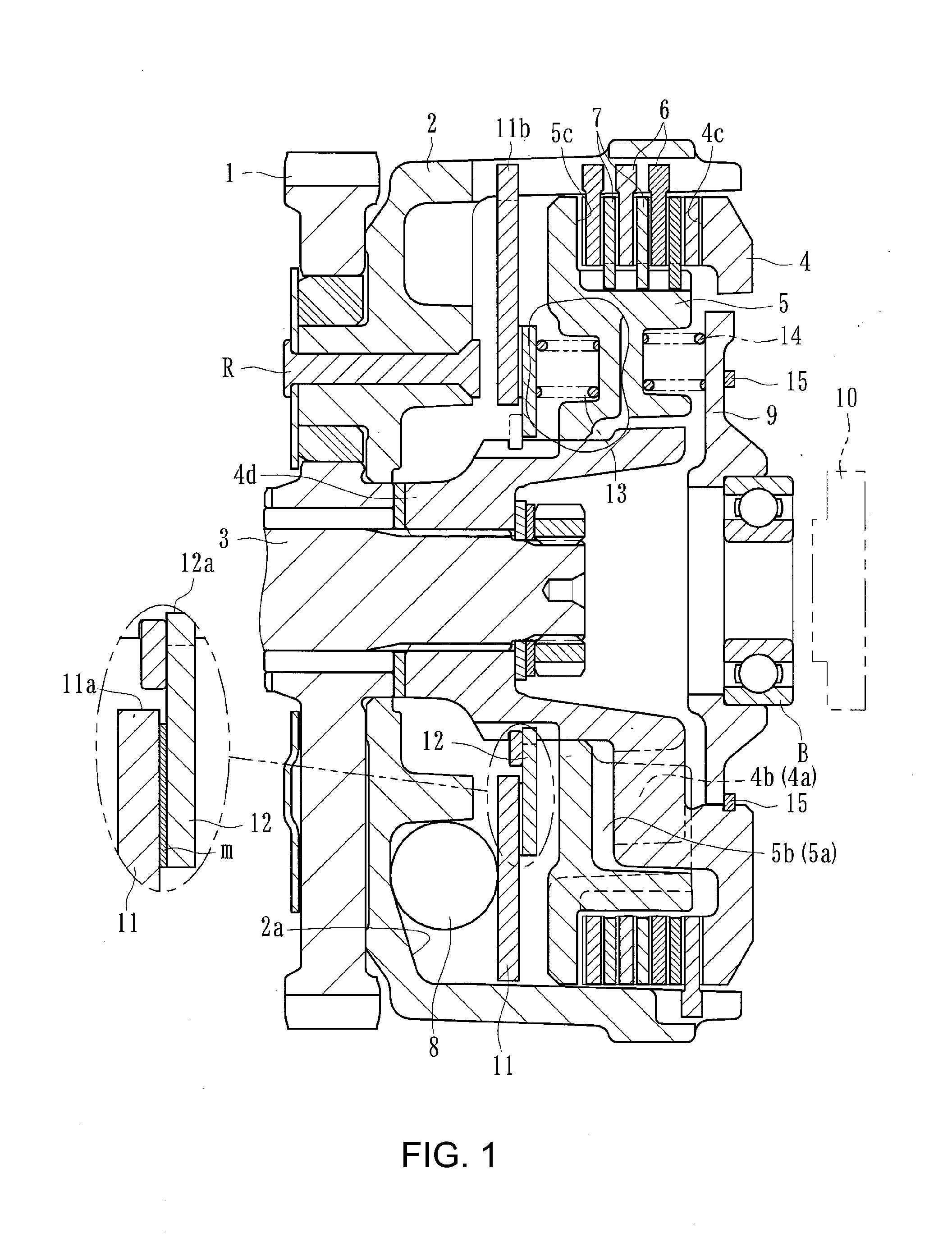

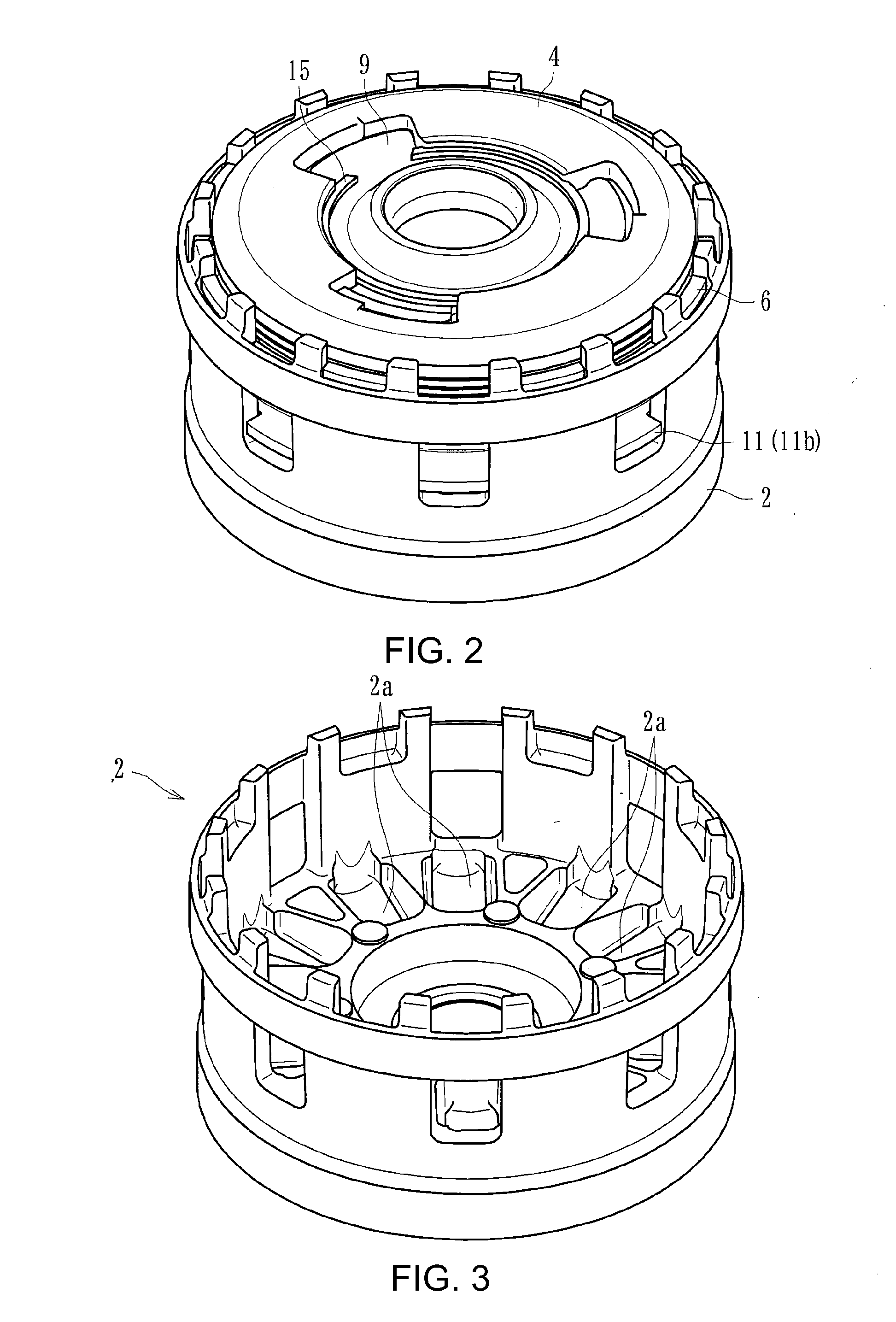

Power transmitting apparatus

InactiveUS20150337910A1Simple structureReduce riskFriction clutchesAutomatic clutchesContact forceEngineering

A power transmitting apparatus for transmitting or cutting-off the rotational driving power inputted to an input member to or from an output member by press-contacting or releasing the press-contacting force between driving-side clutch discs and driven-side clutch discs, wherein the power transmitting apparatus comprises interlocking members (e.g., a first member and second member) interlocking with the motion of the weight members from their radially inward positions to radially outward positions and movable toward a direction approaching to the pressure member; and elastic members interposed between the interlocking members and the pressure member and able to move the pressure member toward a direction for press-contacting the driving-side clutch discs and the driven-side clutch discs by urging the pressure member according to the movement of the interlocking members and also able to absorb the urging force of the pressure member applied to interlocking members when the actuating member is operated.

Owner:FCC KK

Energy Absorbing Vehicle Hood Assembly with Asymmetric Sandwich Inner Structure

ActiveUS20090195020A1Improve crushing effectUniform kinetic energy absorptionVehicle seatsPedestrian/occupant safety arrangementUltrasound attenuationEnergy absorption

An energy-absorbing hood assembly for a vehicle includes upper, lower, and middle panels. The upper and lower panels respectively include first and second interface surfaces. The upper panel is preferably secured to an inner surface of an outer panel. The middle panel has opposing first and second surfaces defining an asymmetric waveform profile, preferably having a polygonal geometry. The middle panel member is secured to the first and second interface surfaces at preselected locations along the upper and lower surfaces, thereby defining a plurality of laterally oriented asymmetric channels. The asymmetric waveform profile is configured with distinct amplitudes and wavelengths along different regions of the hood assembly, each configured to provide different predetermined levels of absorption and attenuation of kinetic energy imparted to the hood assembly by objects upon impact therebetween. Ideally, the lower and middle panels are respectively configured to controllably fail at first and second predetermined crush loads.

Owner:GM GLOBAL TECH OPERATIONS LLC

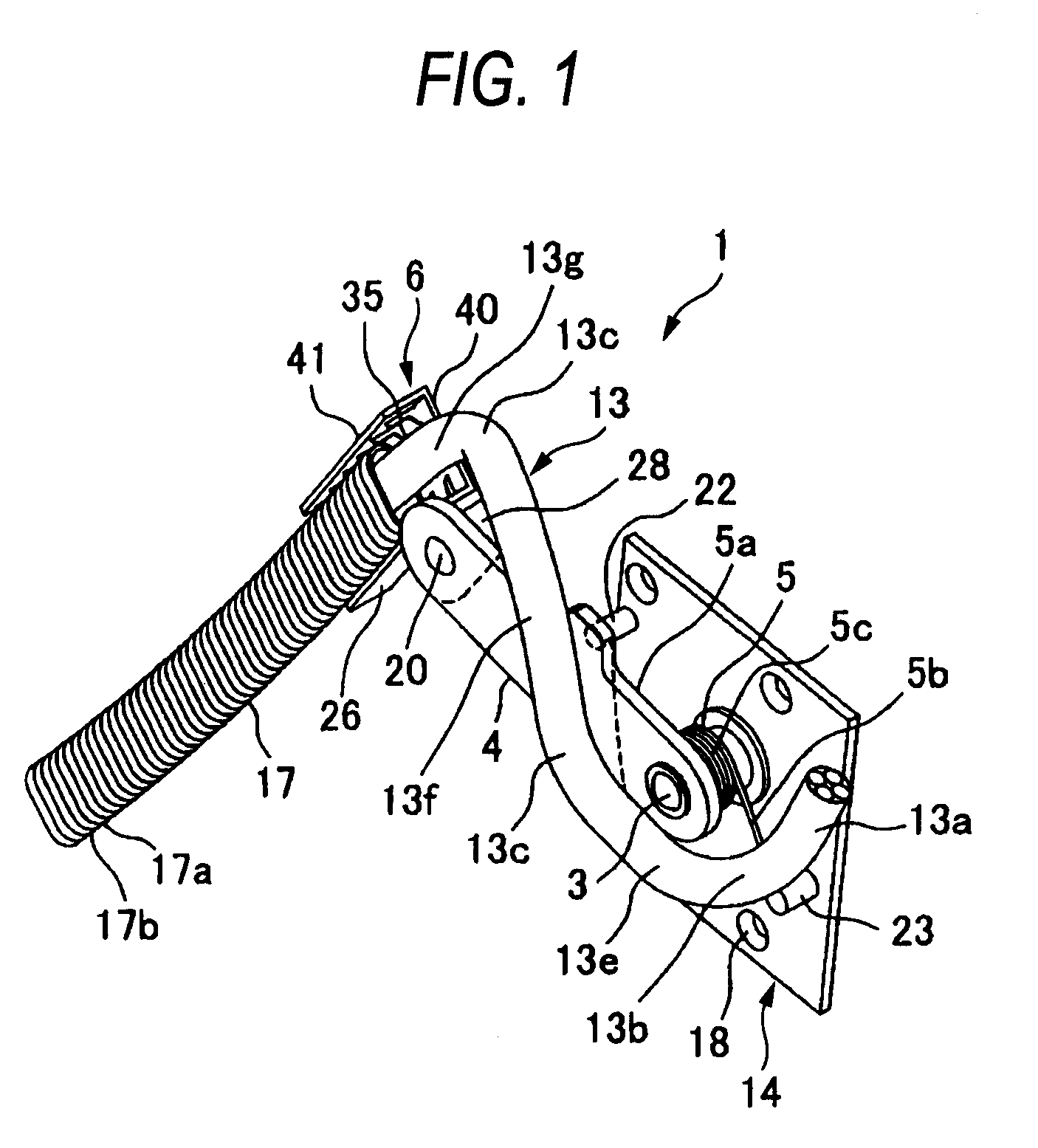

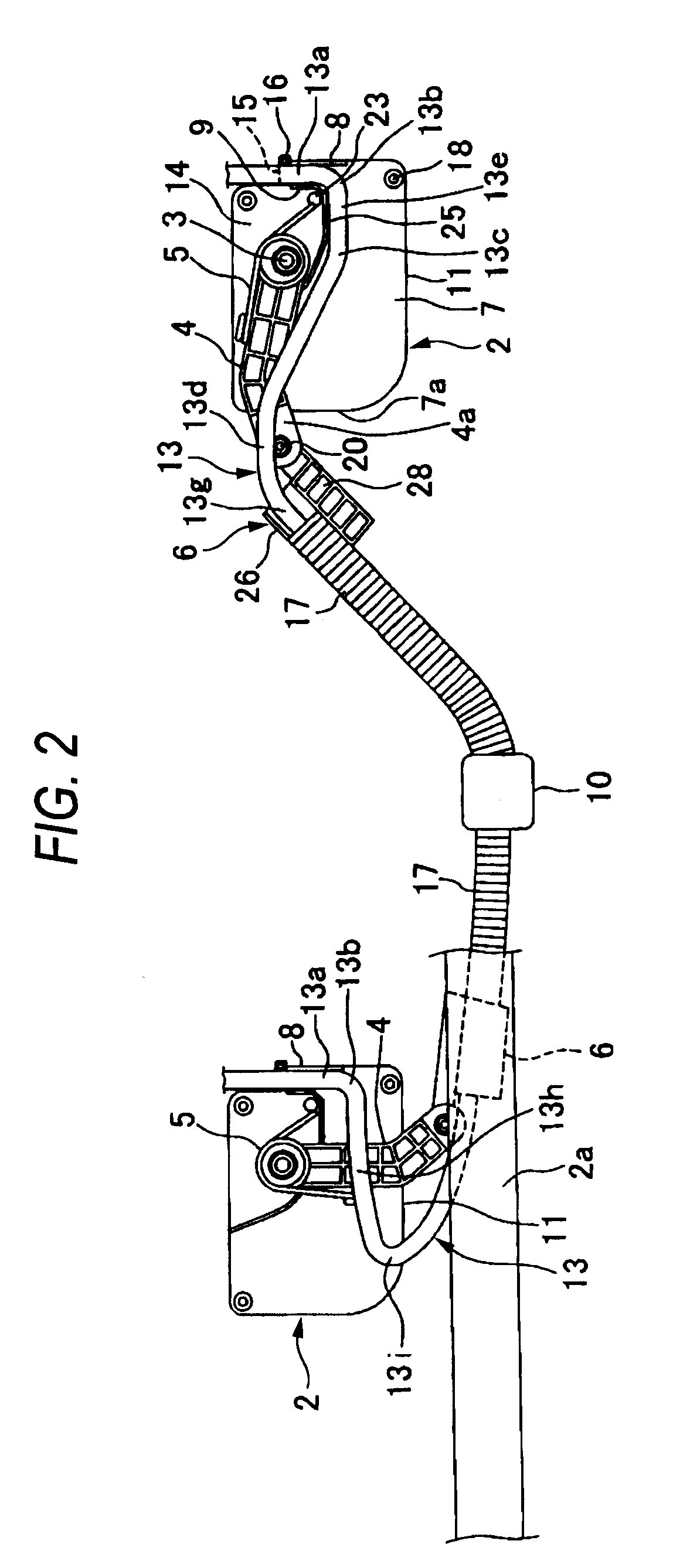

Feeding structure for sliding structural body

ActiveUS20090095858A1Reduce extra spaceMade thinnerSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

Owner:YAZAKI CORP +1

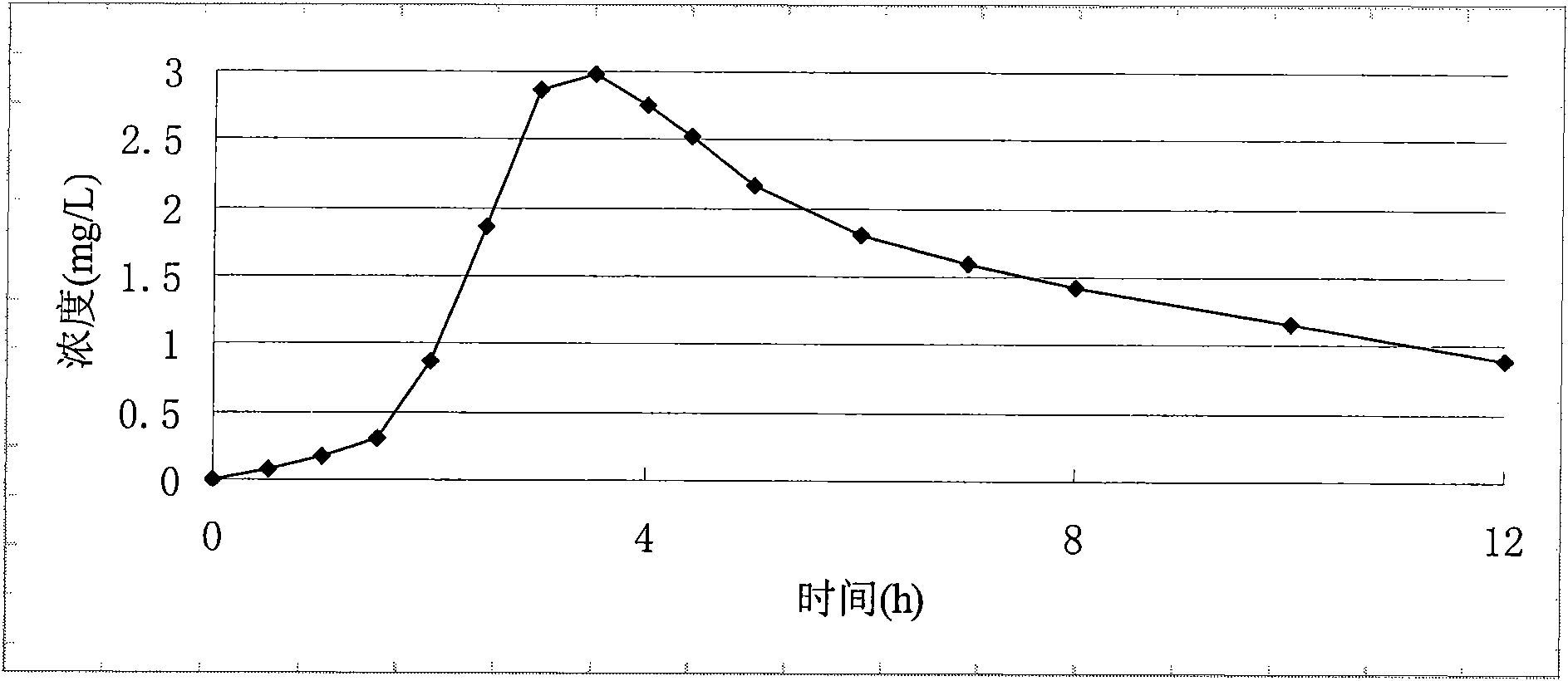

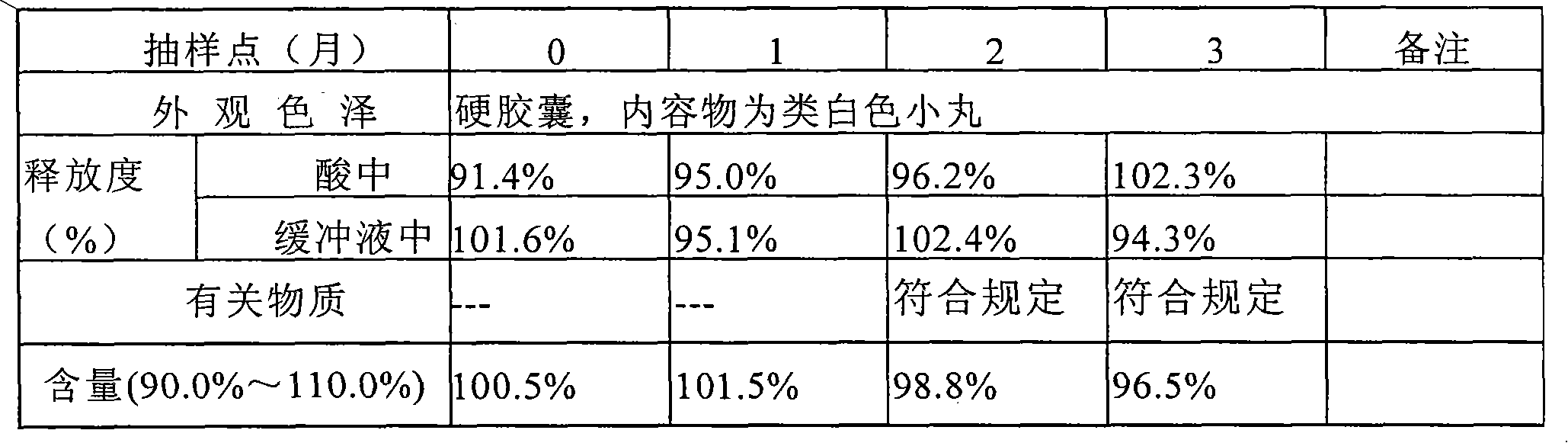

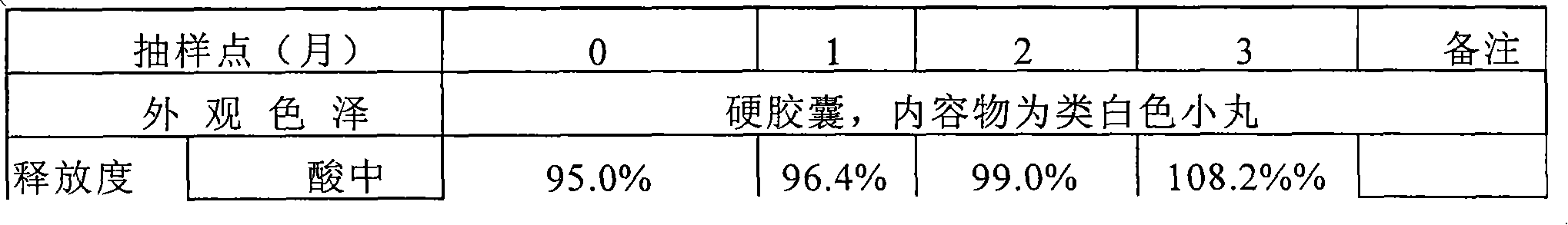

Pantoprazole sodium enteric-coated pellet

ActiveCN101596165AImprove stabilityAbsorb evenlyOrganic active ingredientsDigestive systemBioavailabilityPantoprazole Sodium

The invention discloses a pantoprazole sodium enteric-coated pellet which contains the following components in percentage by weight from inside to outside: 20-60 percent of blank core pellet, 4-38 percent of medicinal layer containing pantoprazole sodium and one or more medicinal excipients, 2-15 percent of isolated layer and 15-26 percent of enteric-coated layer. The invention also discloses a preparation method and an application of the enteric-coated pantoprazole sodium pellet. The pantoprazole sodium enteric-coated capsule has the advantages of better stability, uniform absorption, smaller difference of bioavailability among individuals, and the like.

Owner:Yung Shin Pharm Ind (Kunshan) Co Ltd

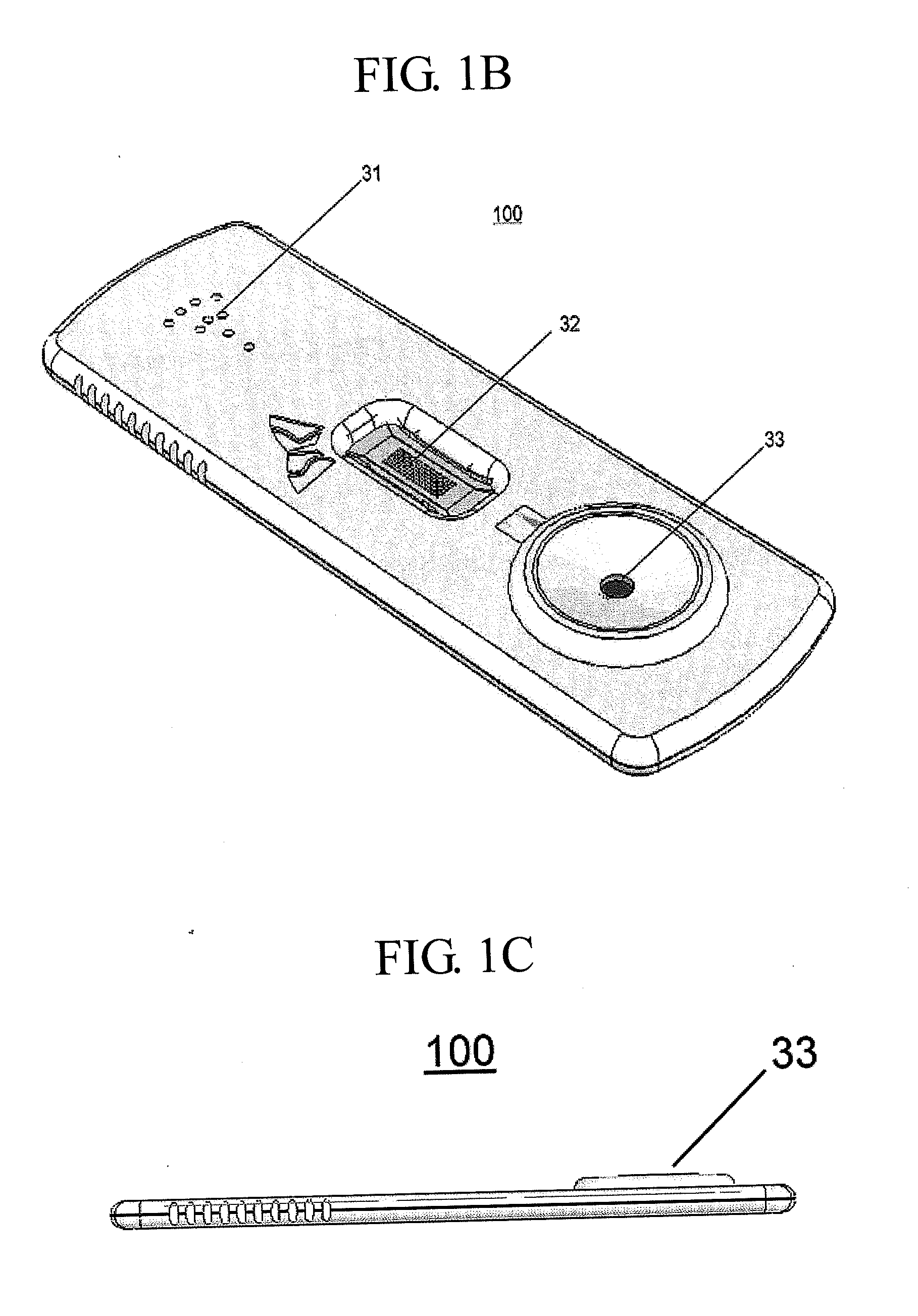

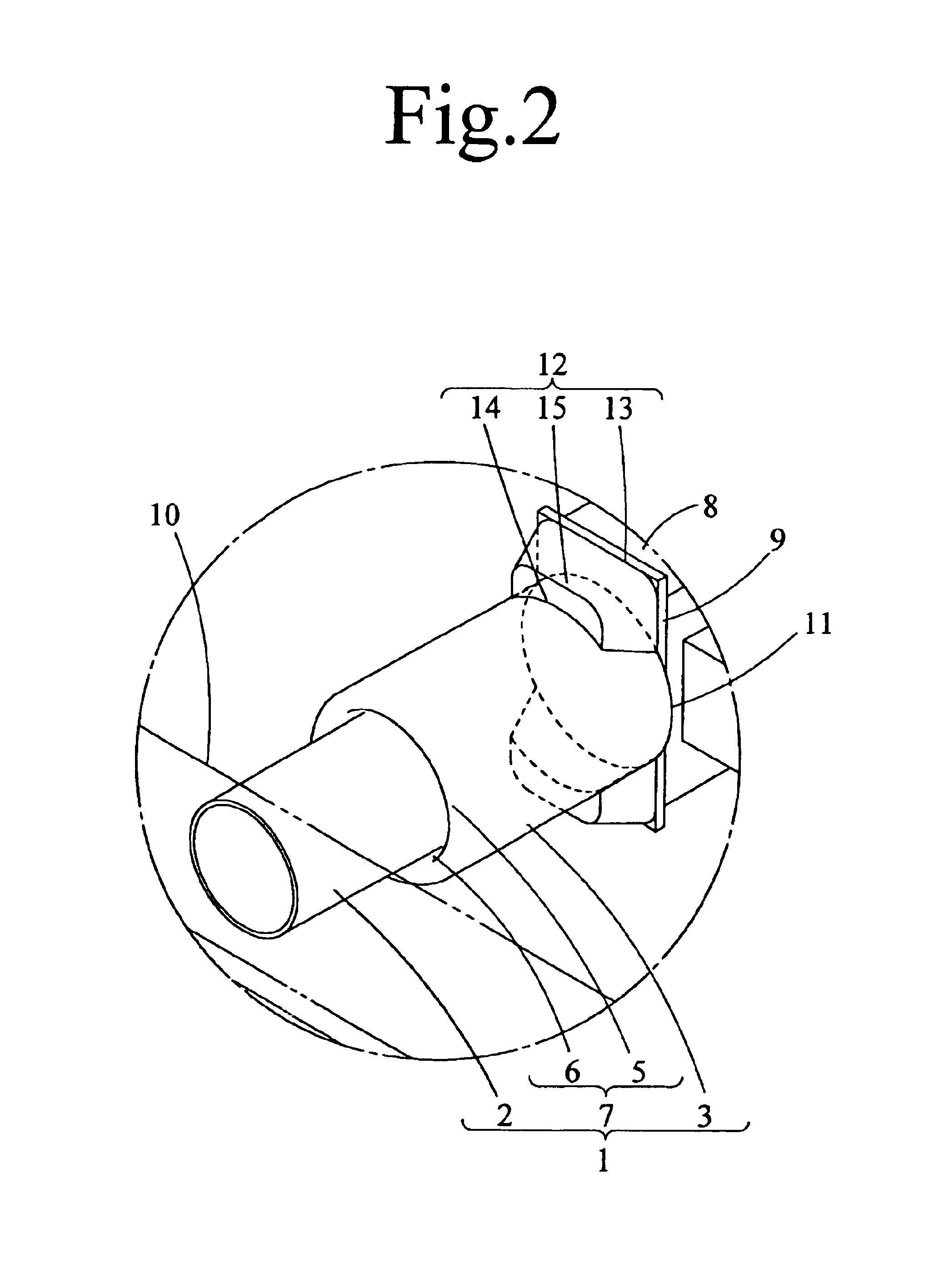

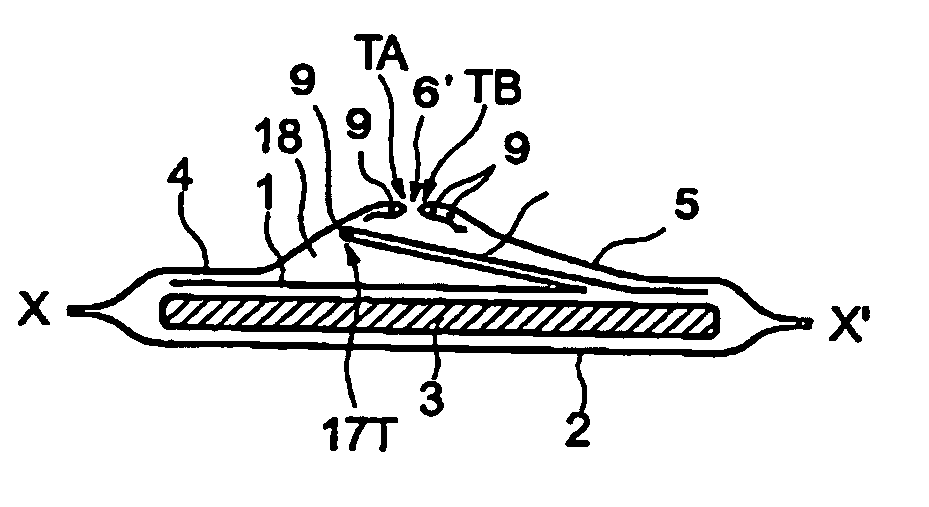

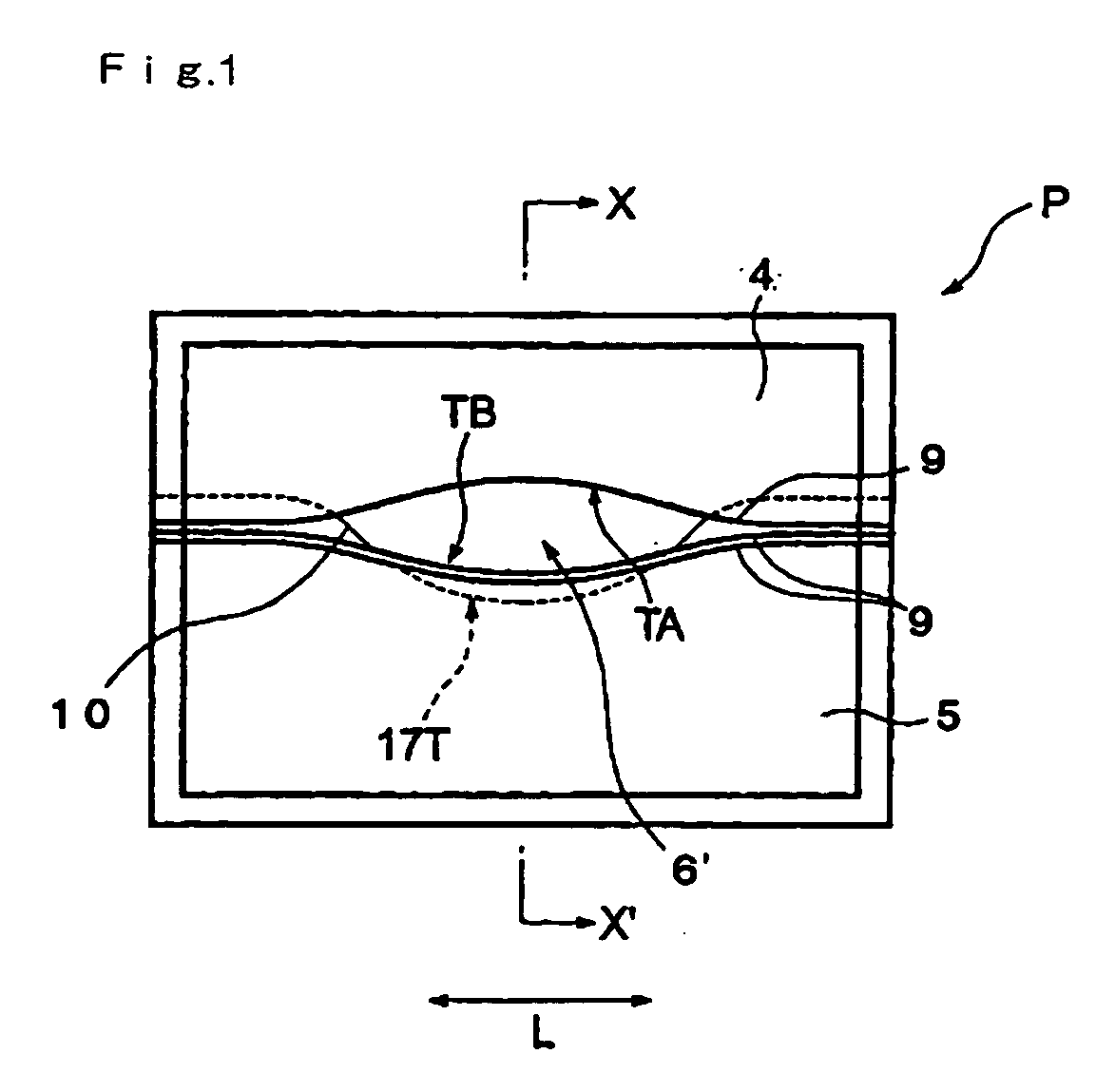

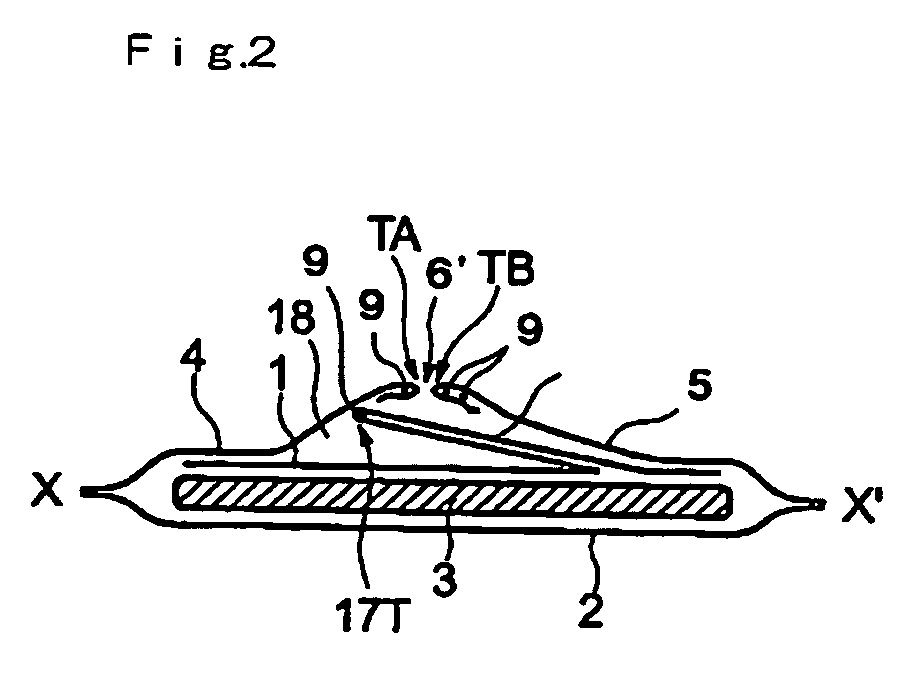

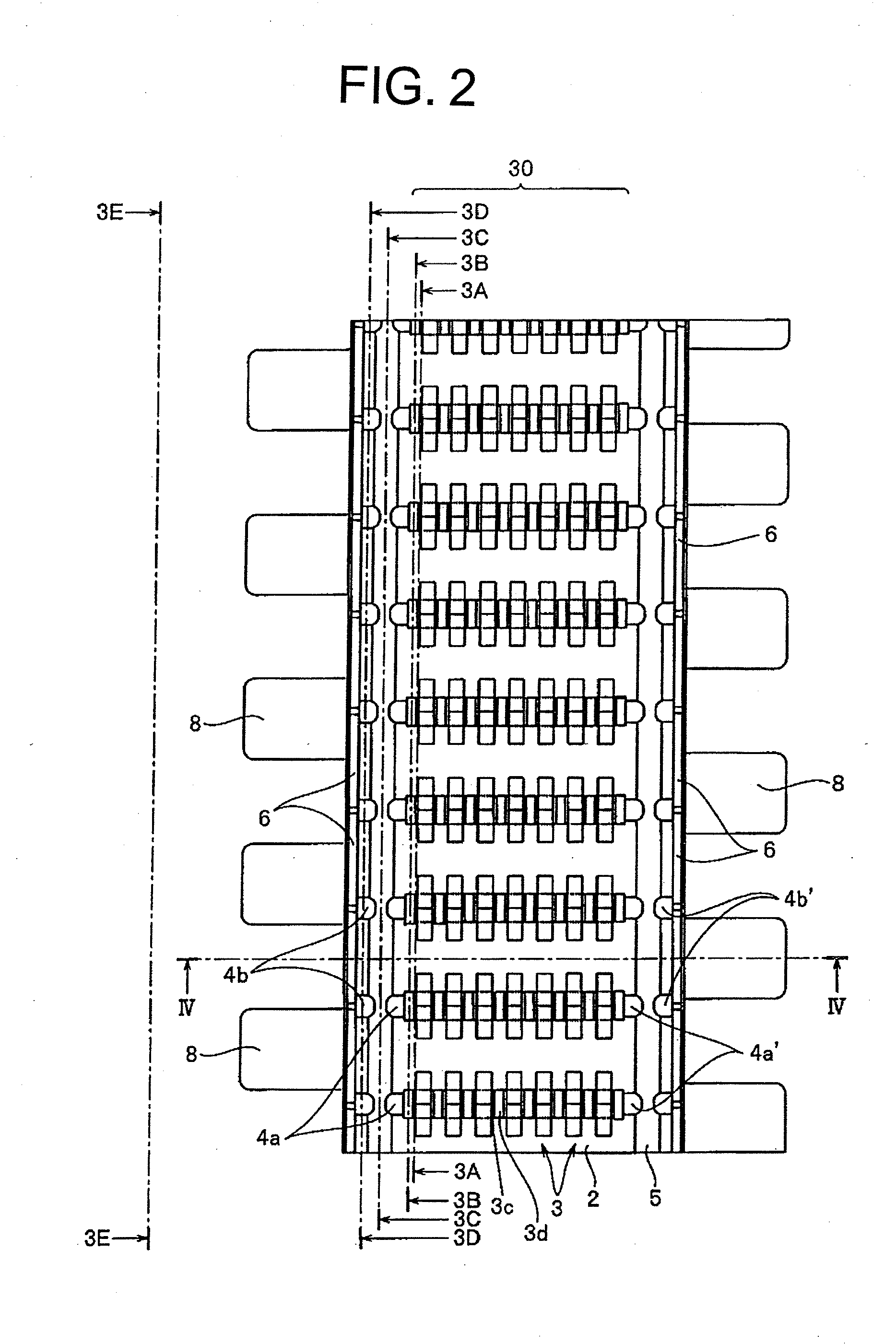

Absorbing pad for male

InactiveUS20060282055A1Prevent leakageAbsorb evenlySanitary towelsBaby linensAbsorbent PadsMechanical engineering

This invention provides a leakage-free absorbent pad for men. The absorbent pad for men of this invention includes a liquid permeable top sheet 1, a back sheet 2, an absorbent member 3 arranged between the both sheets, and a pair of liquid impermeable gather sheets facing each other on the top sheet 1, wherein a liquid permeable auxiliary sheet 10 is provided to extend from a side of one gather sheet 5 toward the other gather sheet 4 between the top sheet 1 and the gather sheets 4 and 5, and an opening 6 for inserting male genitals is formed by the auxiliary sheet and the other gather sheet 4.

Owner:DAIO PAPER CORP

Preparation method and application method of tomato special fertilizer

ActiveCN101693638AImprove stress resistanceIncrease productionAlkali orthophosphate fertiliserClimate change adaptationSodium BentoniteAdditive ingredient

The invention relates to a preparation method and an application method of a tomato special fertilizer, wherein the preparation method comprises the following steps: preparing an I-type fertilizer by taking the following ingredients in parts by weight: 20-30 parts of urea, 20-30 parts ammonium phosphate, 15-20 parts of potassium sulphate, 1-3 parts of humic acid, 1-3 parts of rubbish and excrement, 1-5 parts of synergist, 0.1-1 part of ferrous sulphate, 0.1-0.8 part of zinc sulfate, 0.1-0.6 part of manganese sulphate, 0.1-0.6 part of borax, 0.1-0.4 part of copper sulfate, 2-7 parts of plaster and 3-13 parts of bentonite; preparing an II-type fertilizer by taking the following ingredients in parts by weight: 20-30 parts of urea, 5-10 parts ammonium phosphate, 35-45 parts of potassium sulphate, 1-3 parts of humic acid, 1-5 parts of rubbish and excrement, 2-5 parts of synergist, 0.1-1 part of ferrous sulphate, 0.1-0.8 part of zinc sulfate, 0.1-0.6 part of manganese sulphate, 0.1-0.6 part of borax, 0.1-0.4 part of copper sulfate, 2-7 parts of plaster and 3-13 parts of bentonite; evenly blending, spraying, pelleting, adding 1-6 parts of diluted polyaspartic acid, drying at lower temperature and detecting to be qualified to obtain the special fertilizer. The application method of the special fertilizer comprises the following steps: applying an organic fertilizer and the II-type fertilizer before spring sowing; applying the II-type fertilizer at the flowering and fruiting periods, and applying the II-type fertilizer in the young fruit development period; and the .production yield can be increased by 16-18 percent.

Owner:新疆满疆红农资化肥科技有限公司

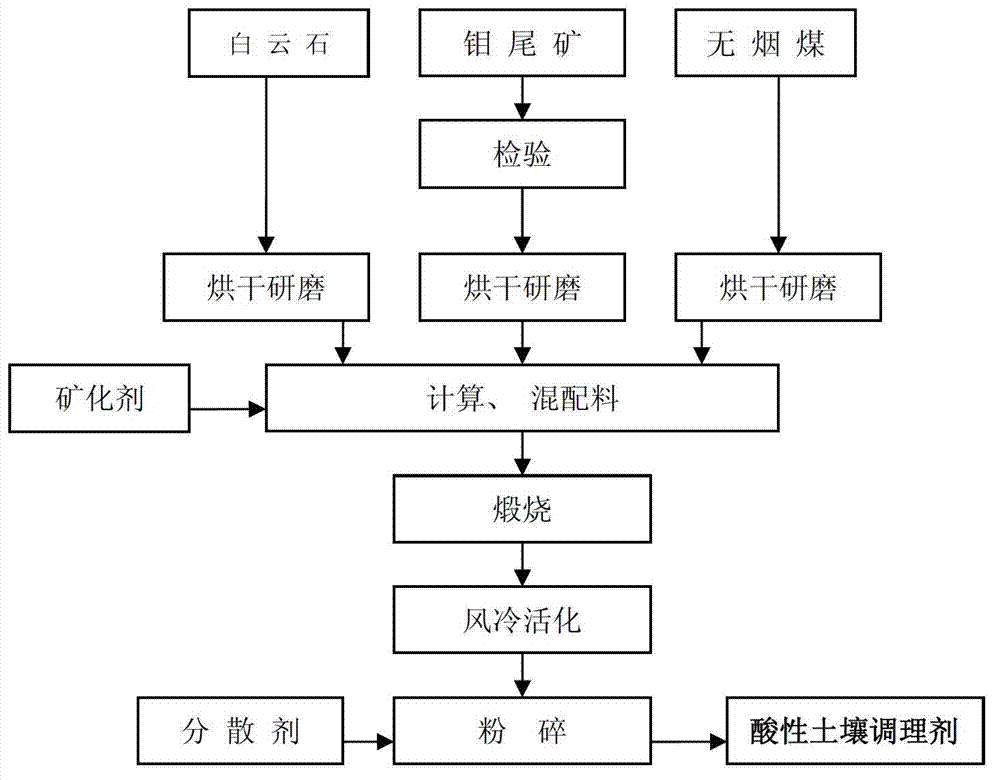

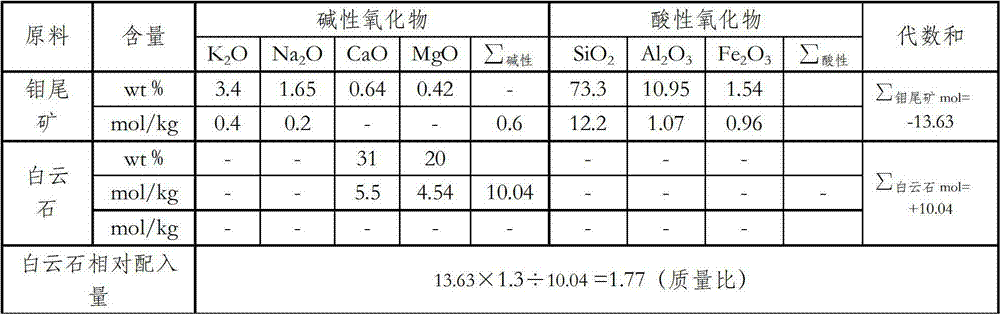

Molybdenum tailings acid soil conditioner and production process thereof

ActiveCN102826926AAchieve reductionEfficient improvementFertilizer mixturesAnthraciteSoil conditioner

The invention discloses a molybdenum tailings acid soil conditioner and a production process for the molybdenum tailings acid soil conditioner. The molybdenum tailings acid soil conditioner comprises clinkers and dispersing agents, the clinkers use molybdenum tailings, dolomites and anthracite to serve as raw materials, activated clinkers are obtained through inspection, grinding, material mixing, burning at the temperature of 1150-1350 DEG C and activating, and then the dispersing agents are added to be smashed to be the acid soil conditioner. The molybdenum tailings acid soil conditioner can efficiently, stably and enduringly improve acid soil, simultaneously provides microelement mineral nutrition for weak acid soil, and has advantages of low energy consumption, low cost and low price and the like, wherein the microelement mineral nutrition can be absorbed by crops in balance and are not easy to run off. The production process for the molybdenum tailings acid soil conditioner can sufficiently use valuable resources in molybdenum tailings, achieves decrement discharge of the tailings, lowers environment stress and reduces potential safety hazards.

Owner:广东万山环境科技有限公司

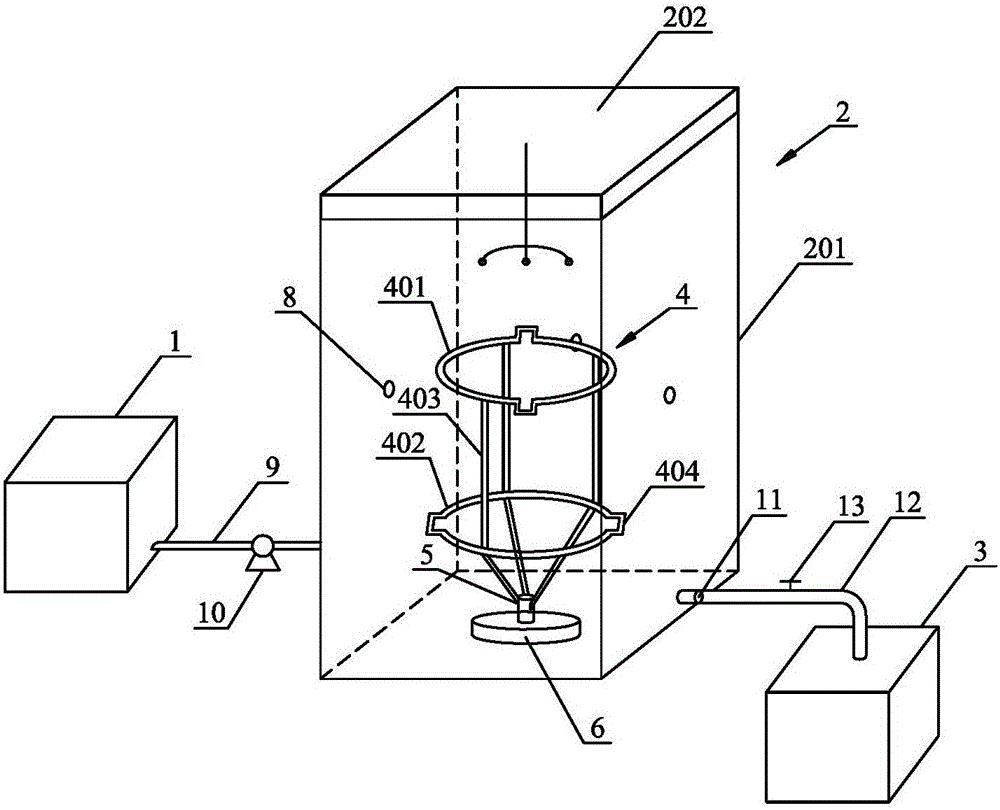

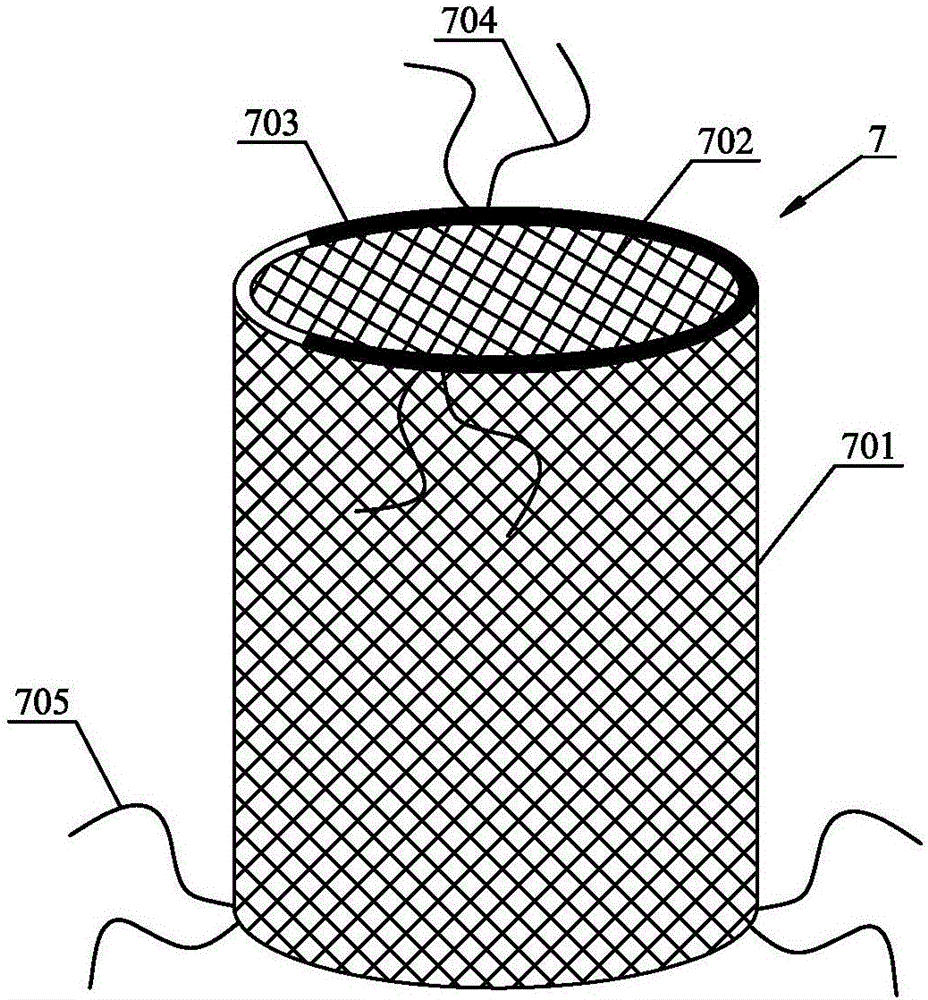

Method for culturing pleurotus geesteranus uniformly rich in selenium by using mixed selenium source

InactiveCN102150555ADifferent releaseAchieve stabilityHorticultureFertilizer mixturesYeastSodium selenate

The invention discloses a method for culturing pleurotus geesteranus uniformly rich in selenium by using a mixed selenium source. The method is characterized by comprising steps of: mixing selenium-enriched culture material additive in an amount which is 1 to 10 percent of the total weight of a dry culture material in the dry culture material, and culturing according to the common culture method to obtain the pleurotus geesteranus uniformly rich in selenium, wherein the selenium-enriched culture material additive has the total selenium content of 5 to 300mg / kg; the particles with the particle size of 0.005 to 5.0mm in the selenium-enriched culture material additive are in multi-particle-size regional distribution, and particles with the particle size of 1.0 to 5.0mm at least account for 10 percent of the total weight of the additive; particles with the particle size of 0.005 to 0.1mm at least account for 40 percent of the total weight of the additive; the mixed selenium source is a mixture of an organic selenium source and an inorganic selenium source; the inorganic selenium source is one or a combination of two of sodium selenate and sodium selenite; and the organic selenium source is selenious yeast. The pleurotus geesteranus prepared by the method has high utilization rate and stable selenium content in different batches; in addition, by the method, selenium pollution is avoided, and the method is easy to operate and easy to promote.

Owner:SUZHOU SETEK

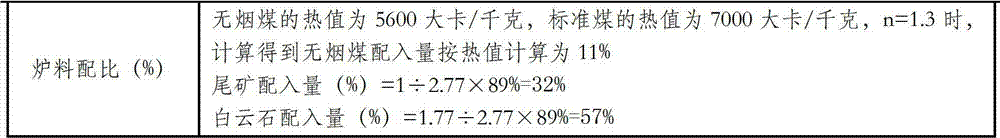

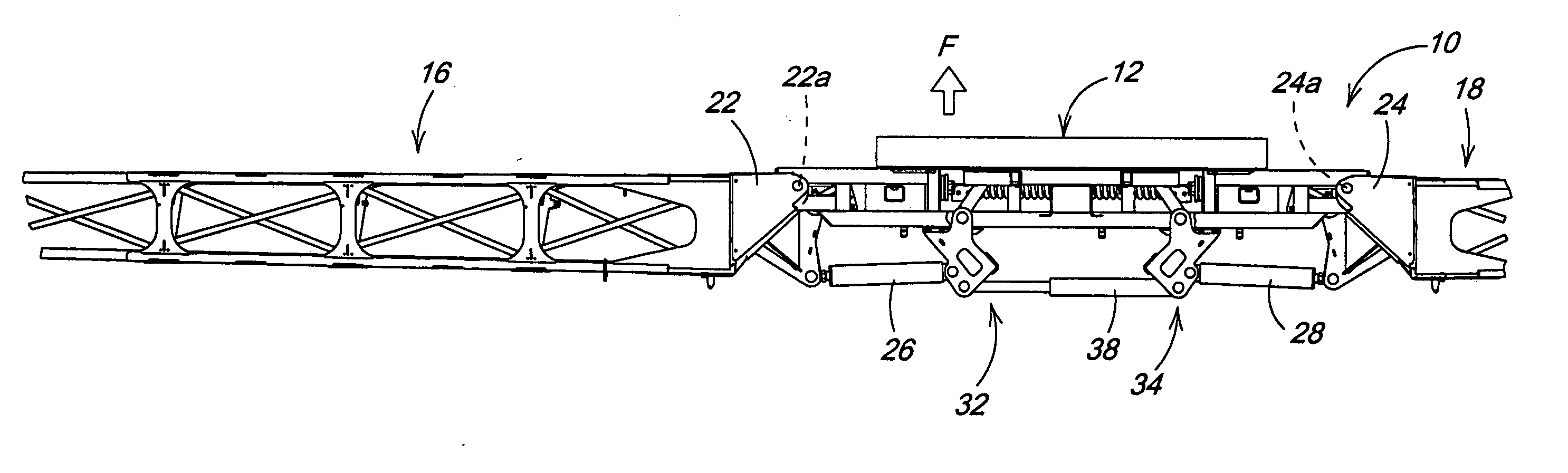

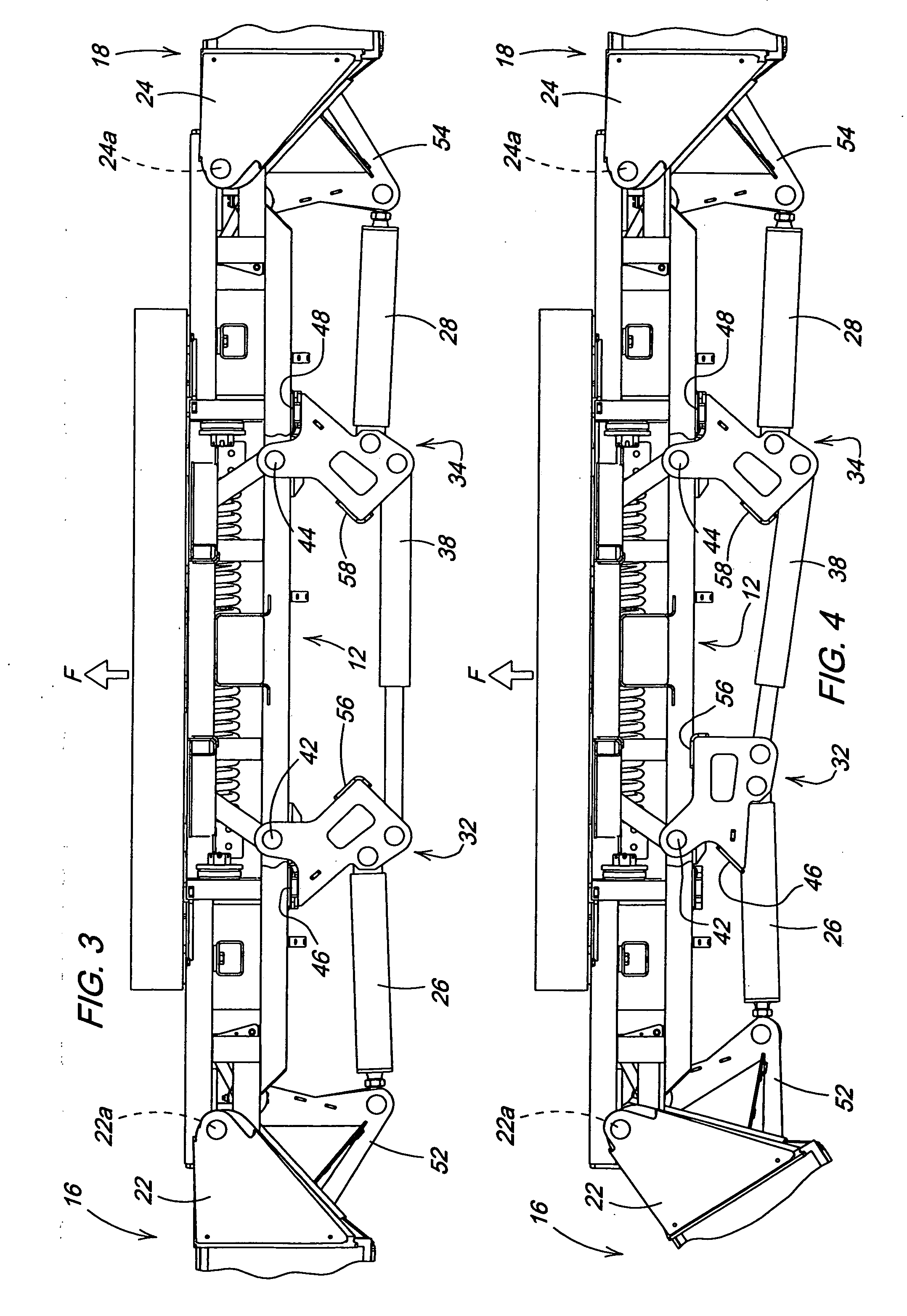

Boom breakaway system

ActiveUS20050184175A1Control loadReduce and eliminate structural damageMovable spraying apparatusInsect catchers and killersHydraulic cylinderPressure curve

Foldable boom inner wings are attached to a boom center frame through a rocker attached to a breakaway hydraulic cylinder pressurized to full stroke and connected to an accumulator. When a wing impacts an object, the impact load is transmitted through the fold cylinder and rocker into the breakaway cylinder. As the breakaway cylinder retracts to allow the wing to pivot, pressure builds in the system in three stages. First pressure builds along an accumulator pressure curve until a relief valve in the hydraulic system actives to initiate the second stage wherein oil is dumped through the relief valve. Thereafter, pressure is again allowed to build along the same accumulator curve to absorb impact hydraulically before the cylinder reaches full stroke. The staged pressure buildup prevents boom momentum from gaining and loads from increasing above the strength of the overall structure.

Owner:DEERE & CO

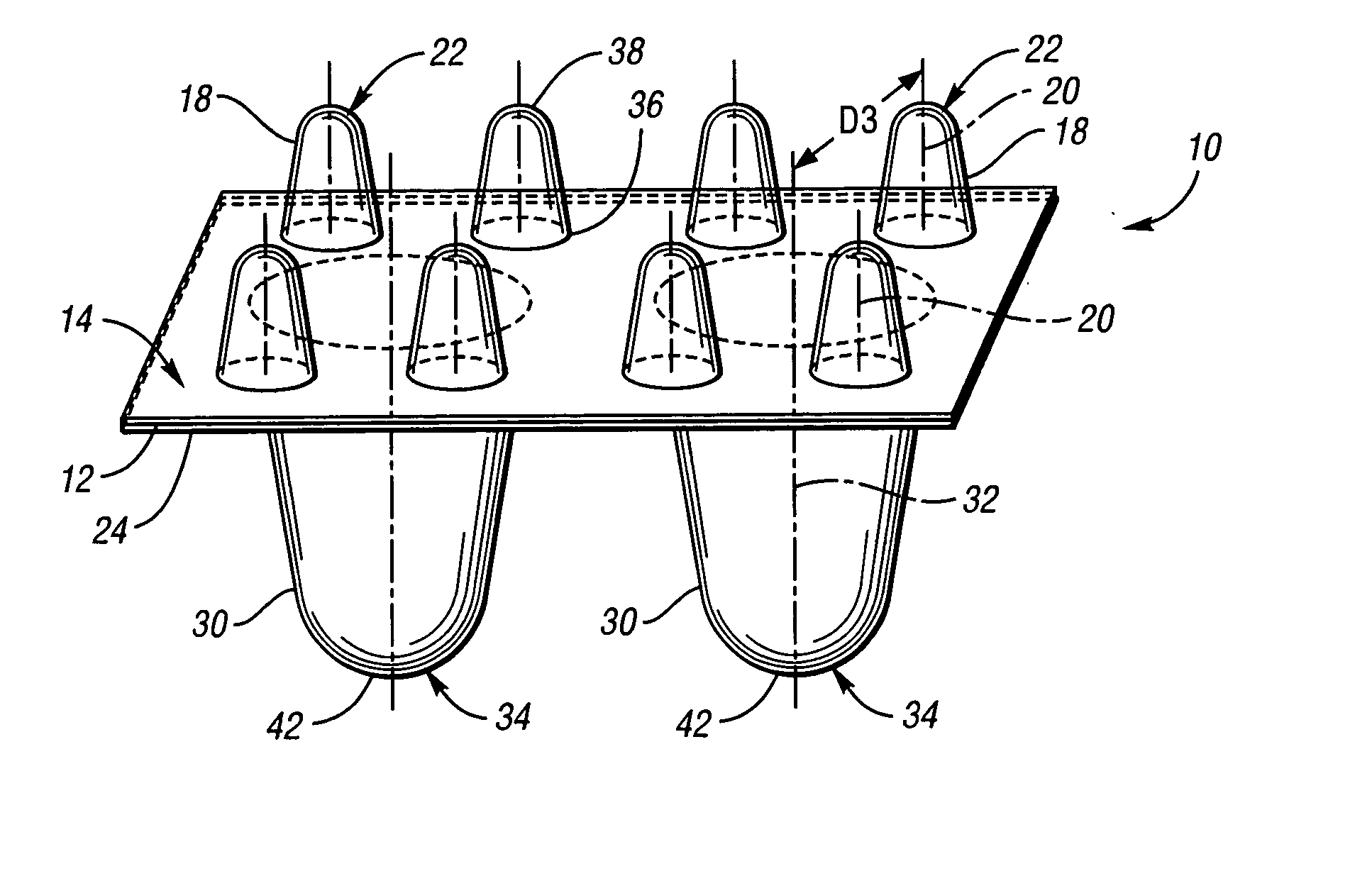

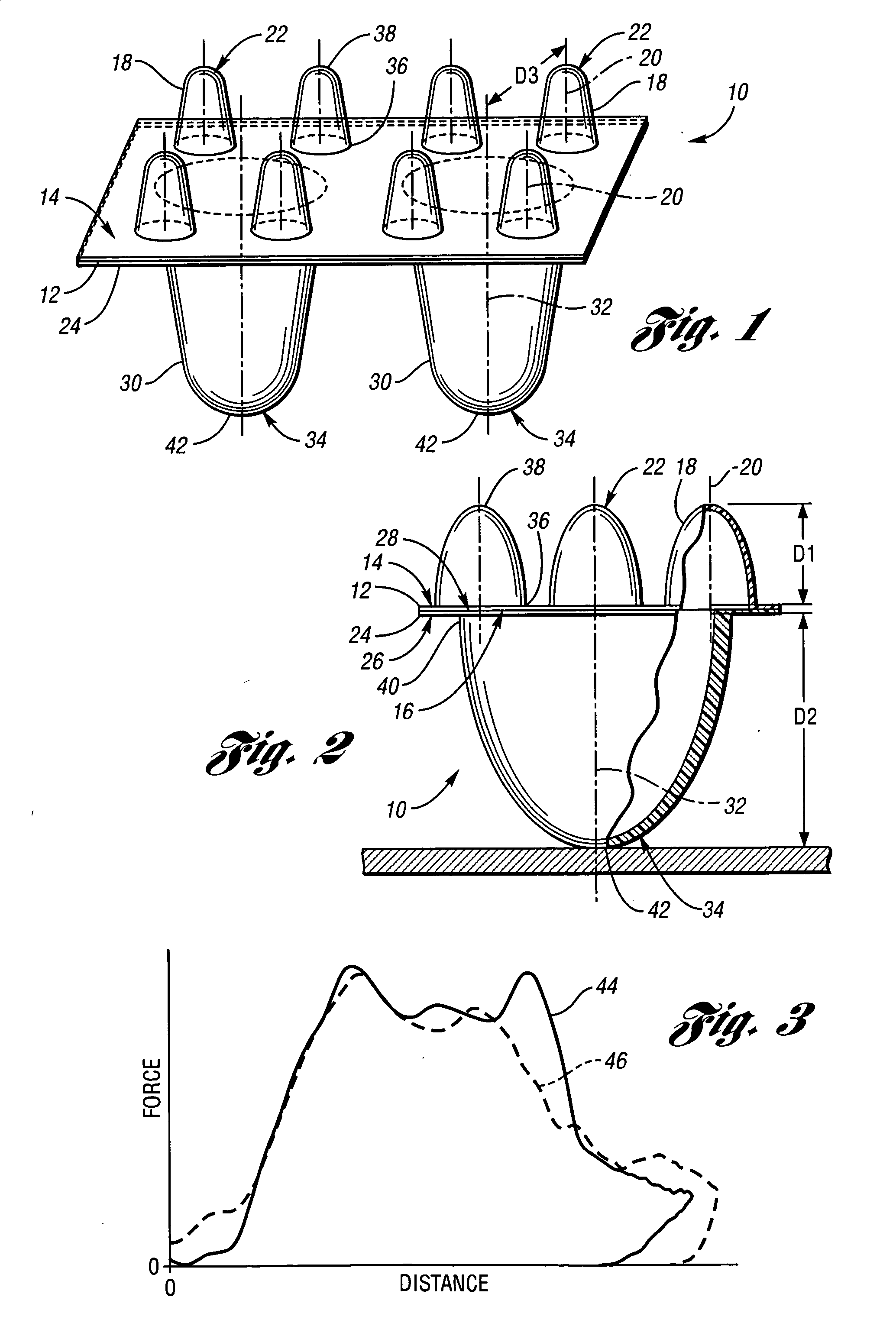

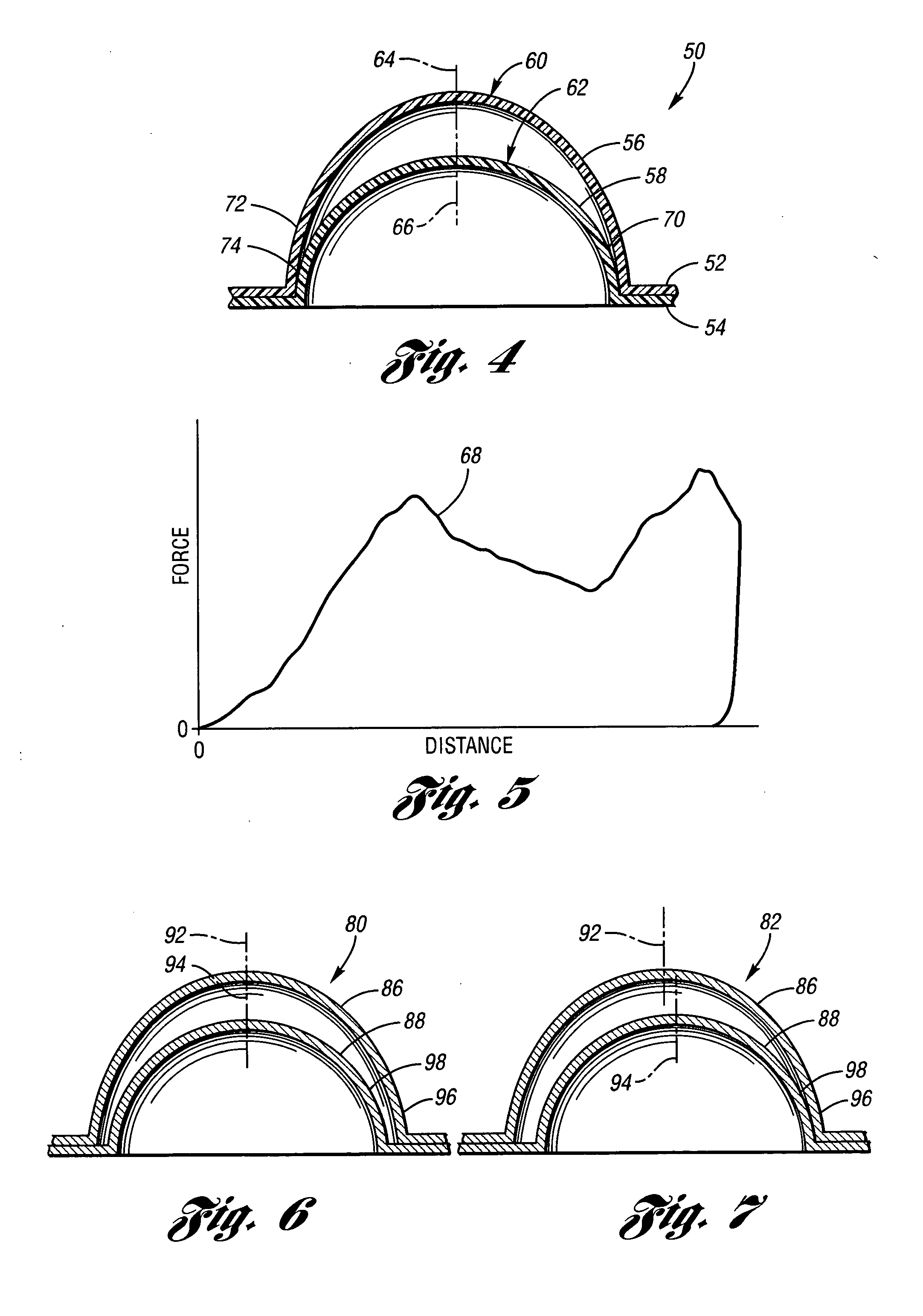

Energy-absorbing padding with staged elements

InactiveUS20050230205A1Improved occupant protectionHigh stiffnessVehicle arrangementsPedestrian/occupant safety arrangementEnergy absorptionEngineering

An energy-absorbing padding includes multiple stacked base layers, each of which includes a plurality of projecting, hollow, hemispherical or dome-shaped impact-absorbing elements defining respective convex impact surfaces. The elements of a first base layer, which either project in a direction opposite those of at least one other base layer or project in the same direction in a nested relationship, provide a staged response characteristic in which the first elements of a first base layer accommodate initial and off-axis occupant impacts, while the elements of the at least one other layers provide additional stiffness and energy absorption capability subsequent to at least a partial collapse of the first elements. The wall thickness of the elements may advantageously vary, for example, as a function of distance from the base layer, while a plurality of strengthening ribs may advantageously further serve to enhance the energy absorption capacity of the elements.

Owner:VISTEON GLOBAL TECH INC

Surf- or sail-board and method of producing the same

Owner:RAPP PETER

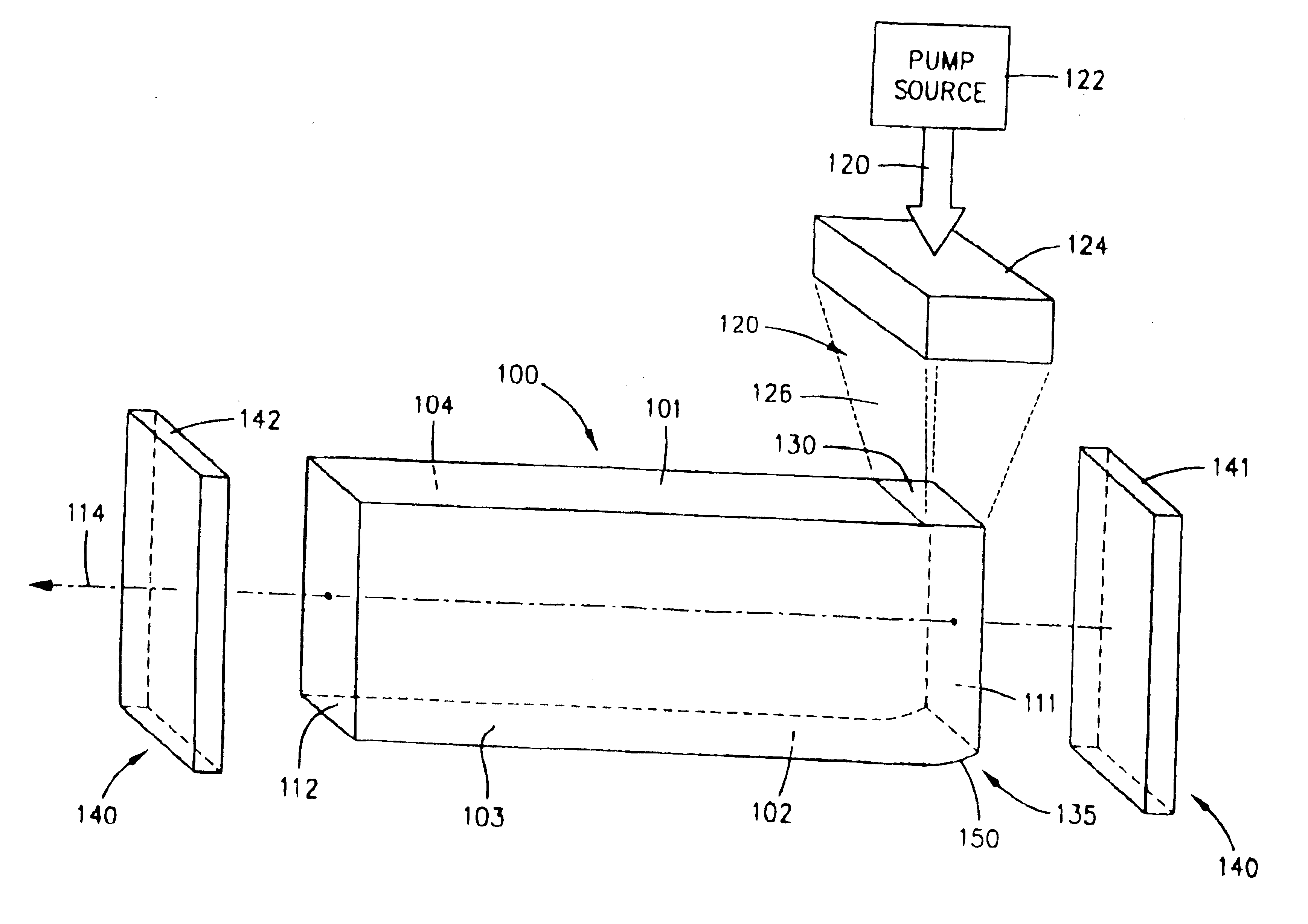

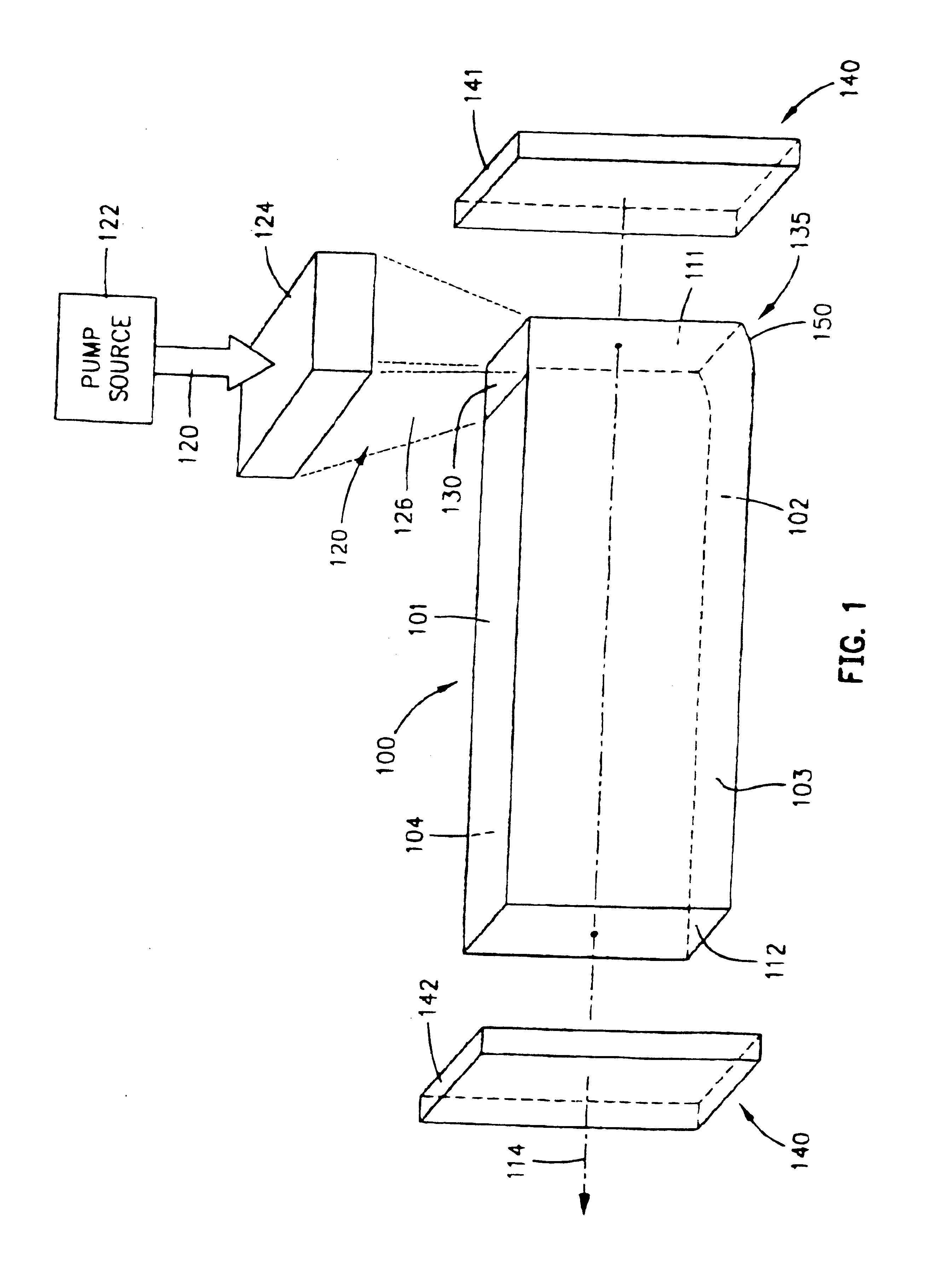

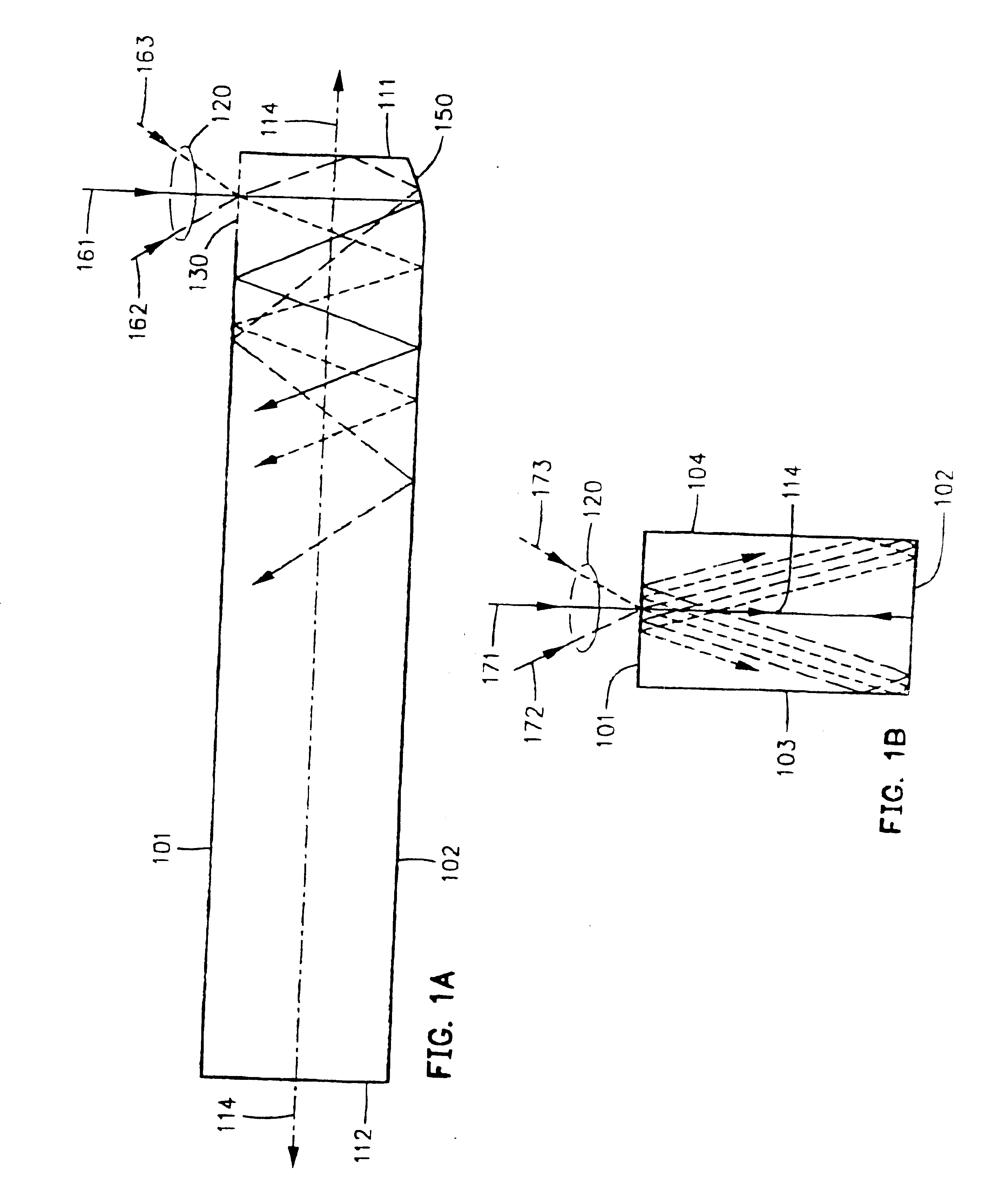

Laser with gain medium configured to provide an integrated optical pump cavity

InactiveUS20020057725A1Reduce lossEfficient extractionOptical resonator shape and constructionActive medium shape and constructionDopantOptical pumping

An optically-pumped laser having a gain medium configured to provide a low loss, three-dimensional integrated optical pump cavity that substantially confines optical pump radiation within the lasing volume, which is particularly useful for efficiently pumping solid state gain media that has low pump dopant concentration. The integrated pump cavity includes a plurality of boundaries contiguous with the gain medium. An optical pump source such as a laser diode array supplies optical pump radiation that is input into the gain medium through one or more pump cavity windows with a propagation direction transverse to a laser axis defined through the gain medium. In some embodiments, an optical surface is situated opposite the window to approximately recollimate the input pump radiation. The optical pump cavity may be designed to concentrate the optical pump radiation and approximately uniformly pump the entire volume of the lasing medium. In one such embodiment, the pump cavity includes opposing converging surfaces that concentrate the optical pump radiation as it projects along the laser axis. Embodiments are disclosed in which a solid state gain medium has coatings that operate to suppress amplified spontaneous emission ("ASE"). Some embodiments also include heat sinks that directly contact the transverse boundaries and control the temperature distribution within the gain medium in a predetermined manner.

Owner:RAYTHEON CO

Plant cultivation method

ActiveCN107173223AReduce workloadImprove protectionPhotovoltaic supportsElectric circuit arrangementsSolar power systemLighting system

The invention discloses a plant cultivation method which includes the step: cultivating tissue culture seedlings acquired by tissue culture in an energy-saving greenhouse or energy-saving planting greenhouse. A tissue culture process includes the steps: collection of explants; cleaning; disinfection; inoculation of the explants; subculture; rooting culture; transplant. The energy-saving greenhouse or energy-saving planting greenhouse comprises a solar power system, a spray irrigation system and a lighting system. According to the method, horticultural facilities applied in plant cultivation process are uniformly improved and comprise the solar power system, the lighting system, the spray irrigation system, a cleaning and disinfection device, a culture medium filling device and the like, wherein the cleaning and disinfection device and the culture medium filling device are used for the tissue culture process, the whole plant cultivation process is more complete by the aid of a series of improvements and combinations, working efficiency is improved, and each improvement is quite important.

Owner:杭州树联生态工程有限公司

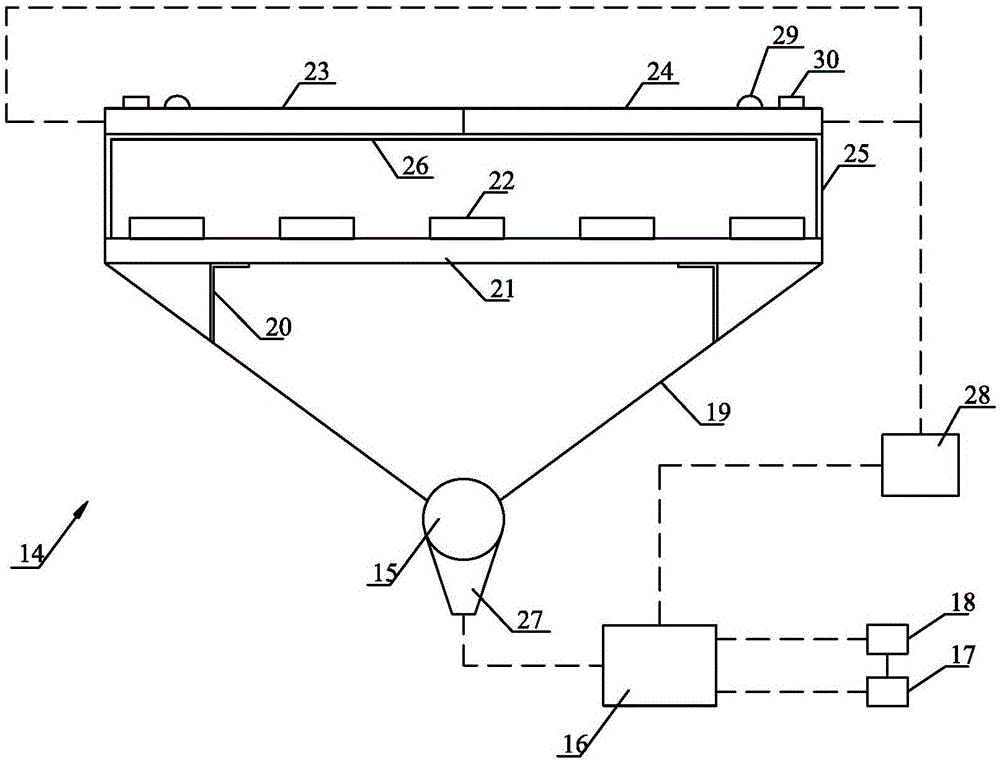

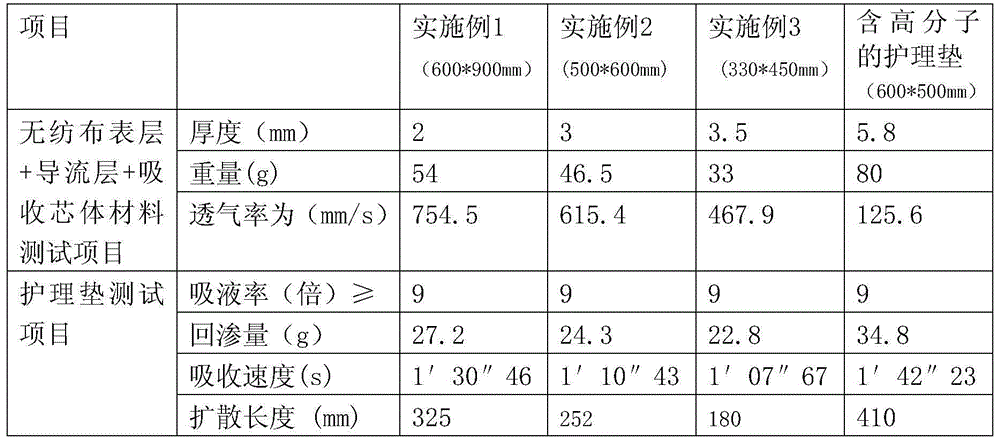

Portable nursing pad containing polylactic acid fiber and preparation method thereof

ActiveCN104002527ANot easy to lose powderEasy to operateSynthetic resin layered productsLaminationPolylactic acidMaterial resources

The invention discloses a portable nursing pad containing a polylactic acid fiber and a preparation method thereof. A conventional nursing pad has a relatively long processing flow, and the long production process wastes a lot of manpower, material resources and financial resources. The nursing pad is composed of an upper-layer assembly body and an impermeable bottom layer, wherein the upper-layer assembly body is composed of a surface layer composed of a polylactic acid fiber net, a flow-guiding moisture-absorption layer composed of a water-repellency bicomponent fiber and a superabsorbent fiber net, and an absorption layer composed of a hydrophilic bicomponent fiber and a superabsorbent fiber net, and the three layers are subjected to hot melt compounding to form a whole; the upper layer and the impermeable bottom layer are subjected to hot melt adhesive compounding to form a whole. The prepared nursing pad has the characteristics of short process flow, good molding, bacteriostasis, deodorness, gas permeation and dryness, does not produce lumps and allows powder not to fall off in a use process, and is an ideal material for preparing disposable medical treatment health supplies.

Owner:HANGZHOU COCO HEALTHCARE PRODS

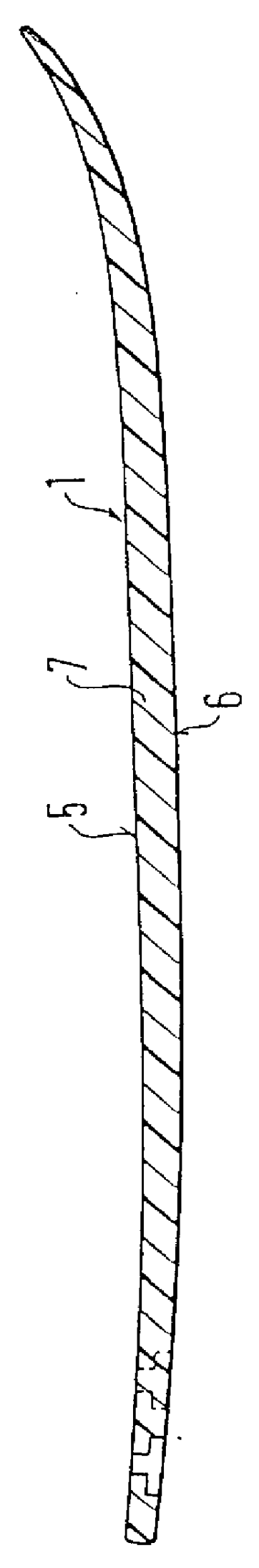

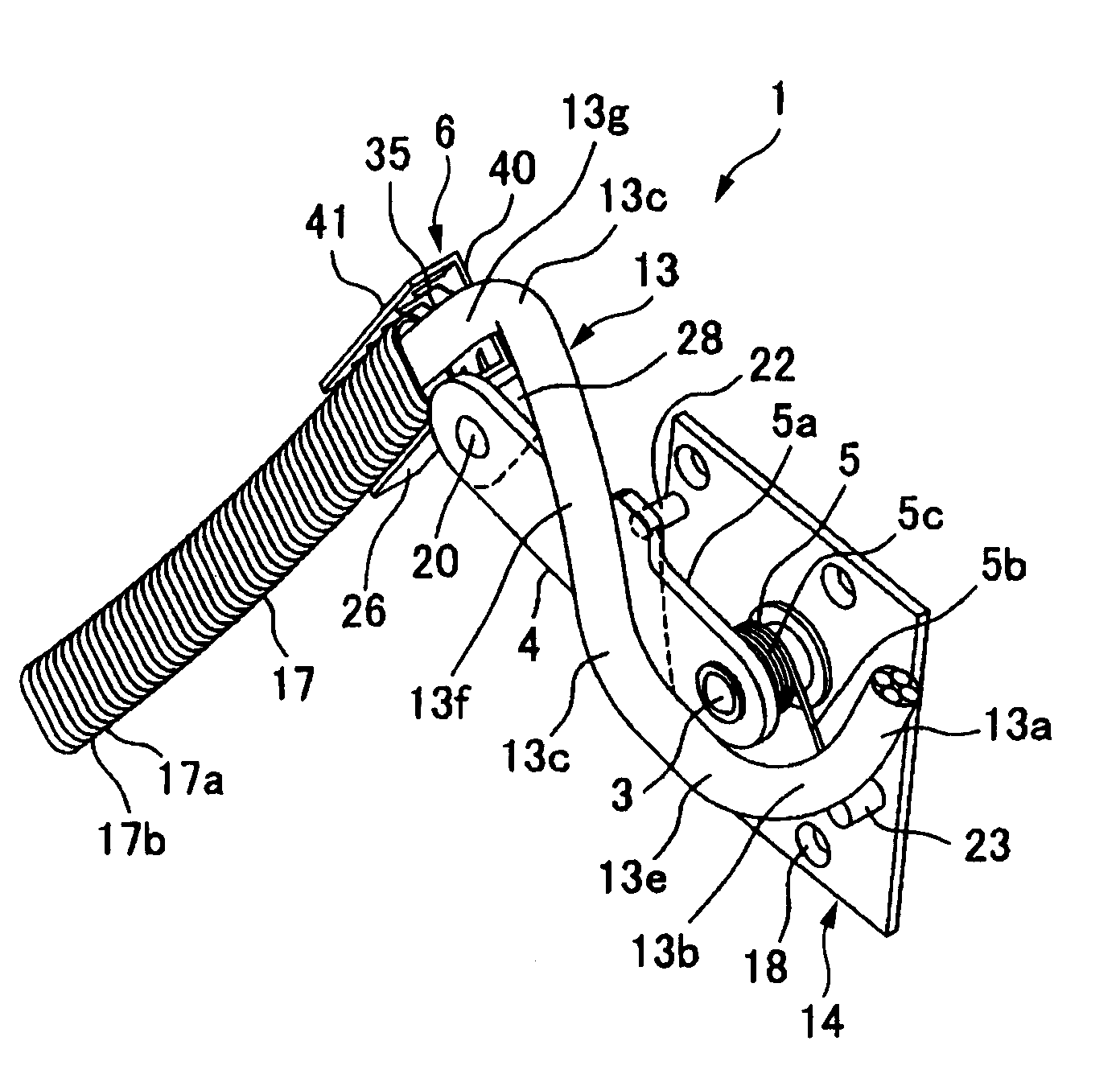

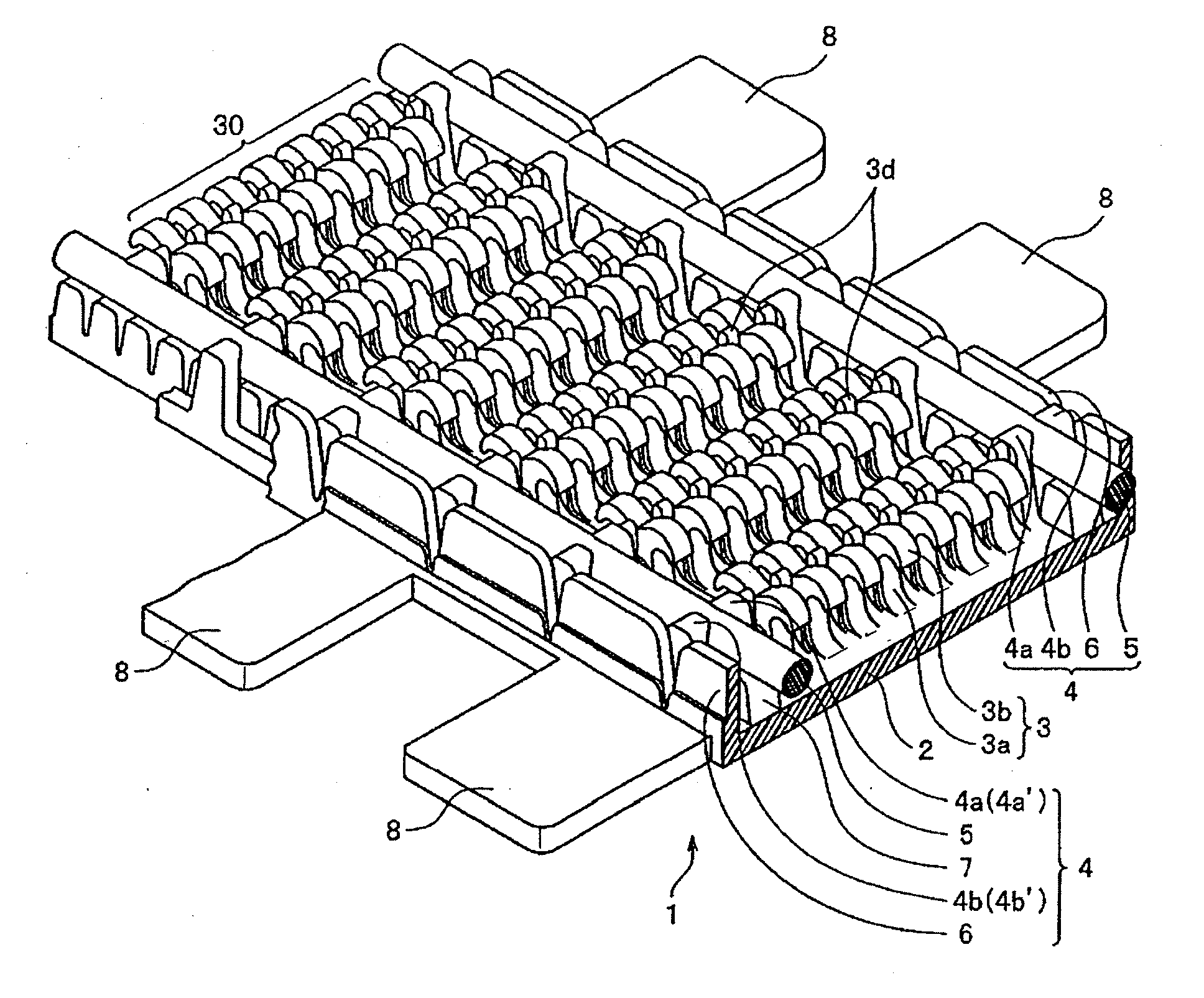

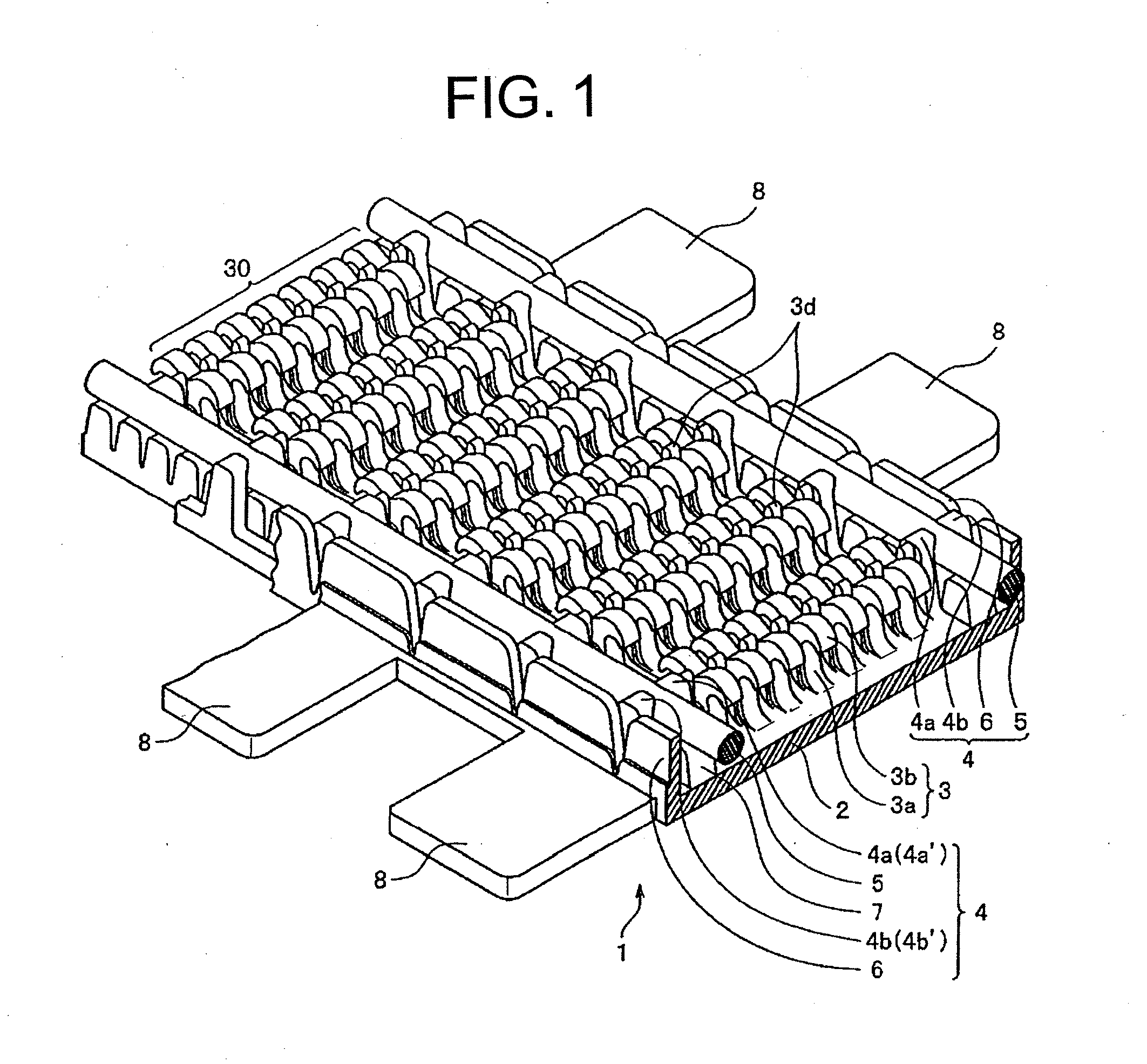

Molded Male Surface Fastener

A molded male surface fastener (1) comprises resin invasion preventing walls (4), which prevent an invasion of a molding foamable resin material of a cushion body, on right and left edge portions along a longitudinal direction of a surface of a flat base member (2) made of a thermoplastic resin, a plurality of engaging elements (3) provided between left and right resin invasion preventing walls (4), and a linear sealing body (5) that is continuously disposed in the longitudinal direction of the base member (2) along a peripheral portion of a top portion of each resin invasion preventing wall (4). When an engaging element forming surface of the surface fastener (1) is placed on a concavo-convex surface of foaming body molding cavities of a foaming mold (100), if the mold has the same magnetic force as that in the related art, the linear sealing body (5) is well adhered along the concavo-convex surface. Therefore, sealing performance between the mold and the resin invasion preventing walls (4) can be greatly improved. As a result, even when foam molding is performed, a foamable resin material (200) is not invaded into an engaging element forming region, and the molded male surface fastener (1) can be accurately molded and integrated at a predetermined position of a foaming body.

Owner:YKK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com