Patents

Literature

5687results about How to "Improve crushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

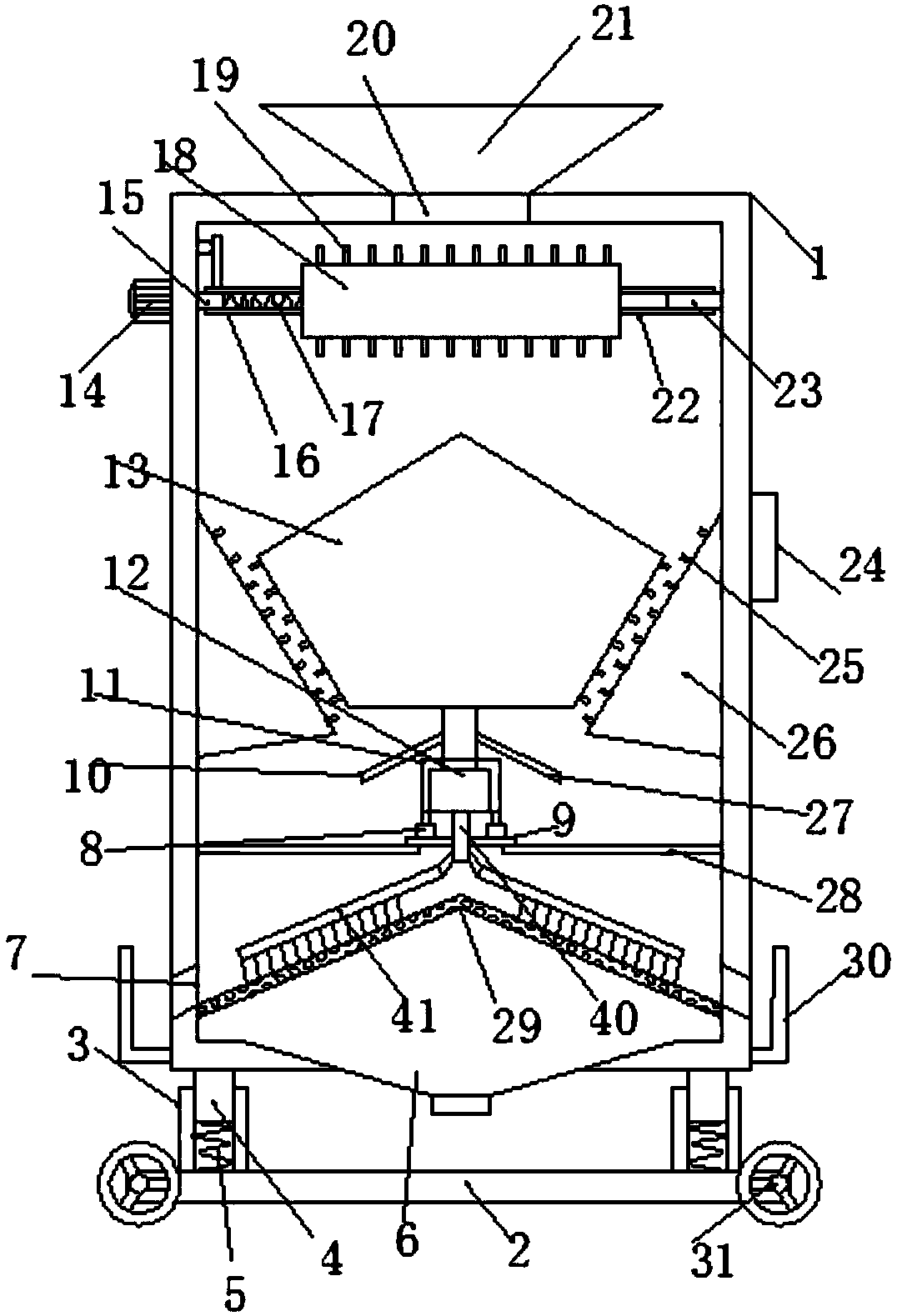

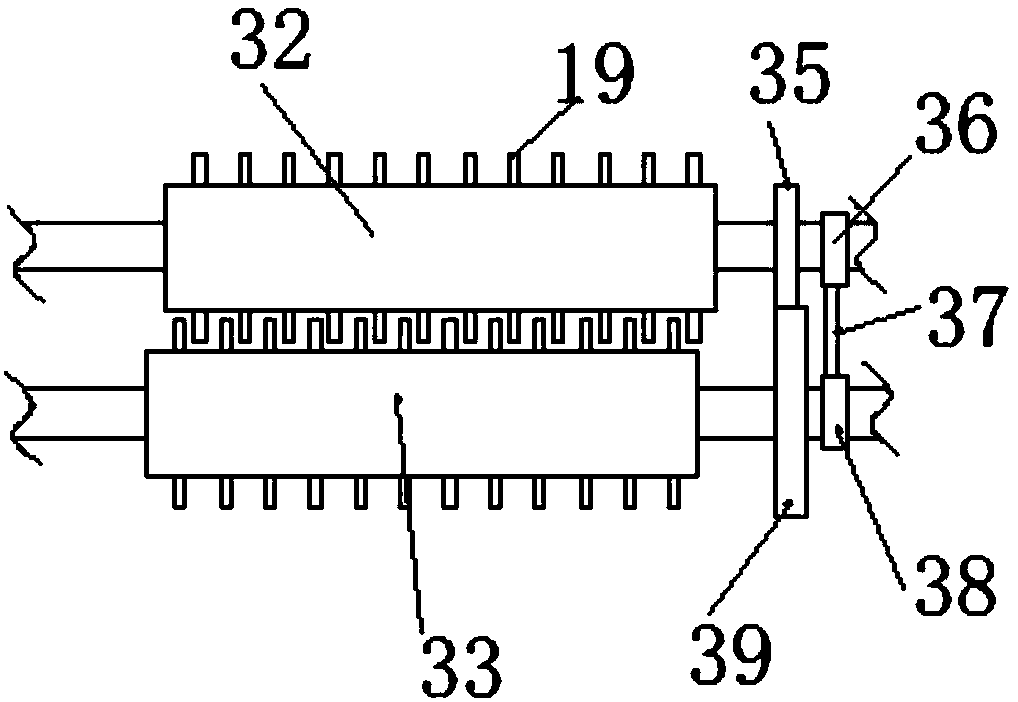

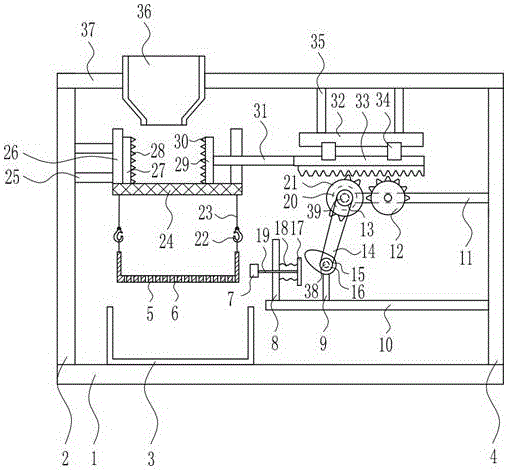

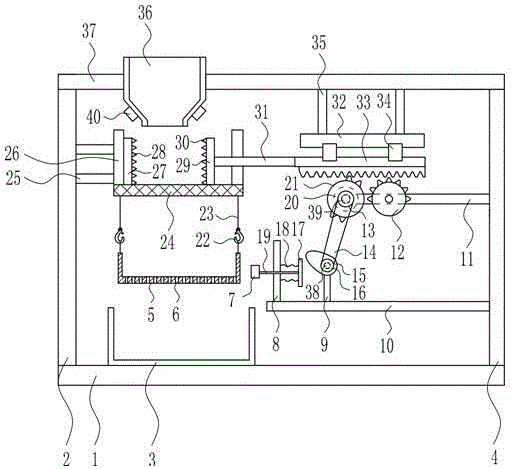

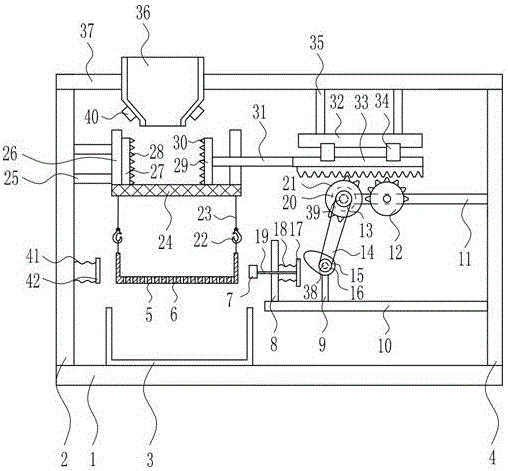

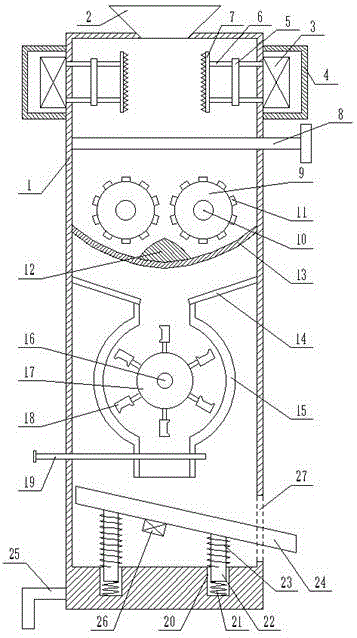

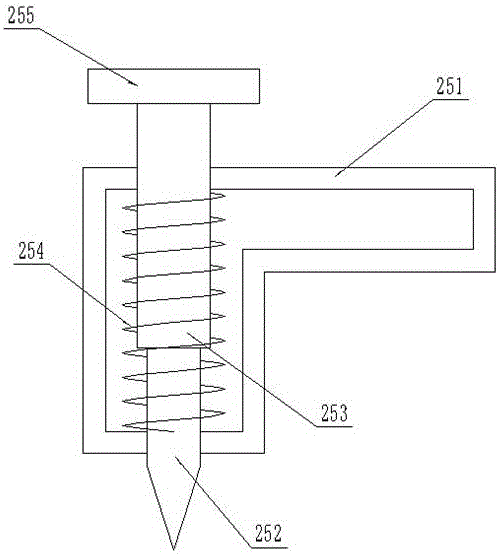

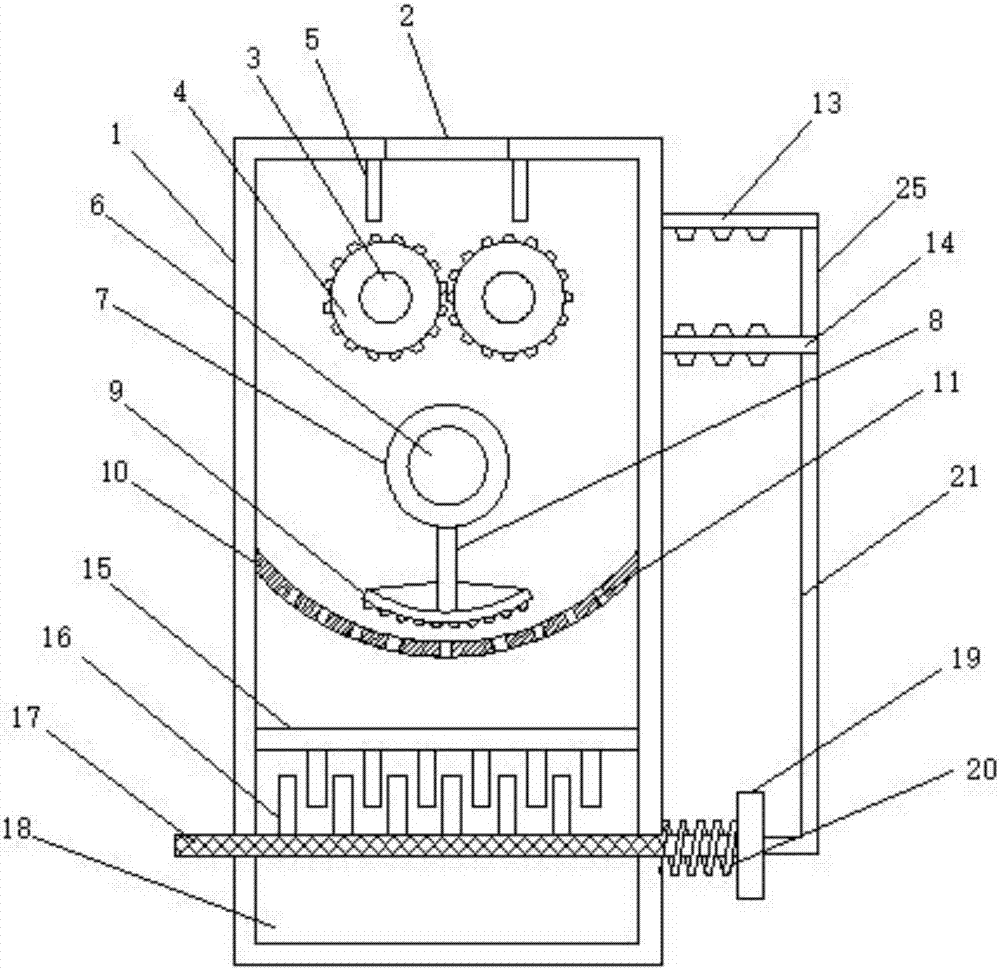

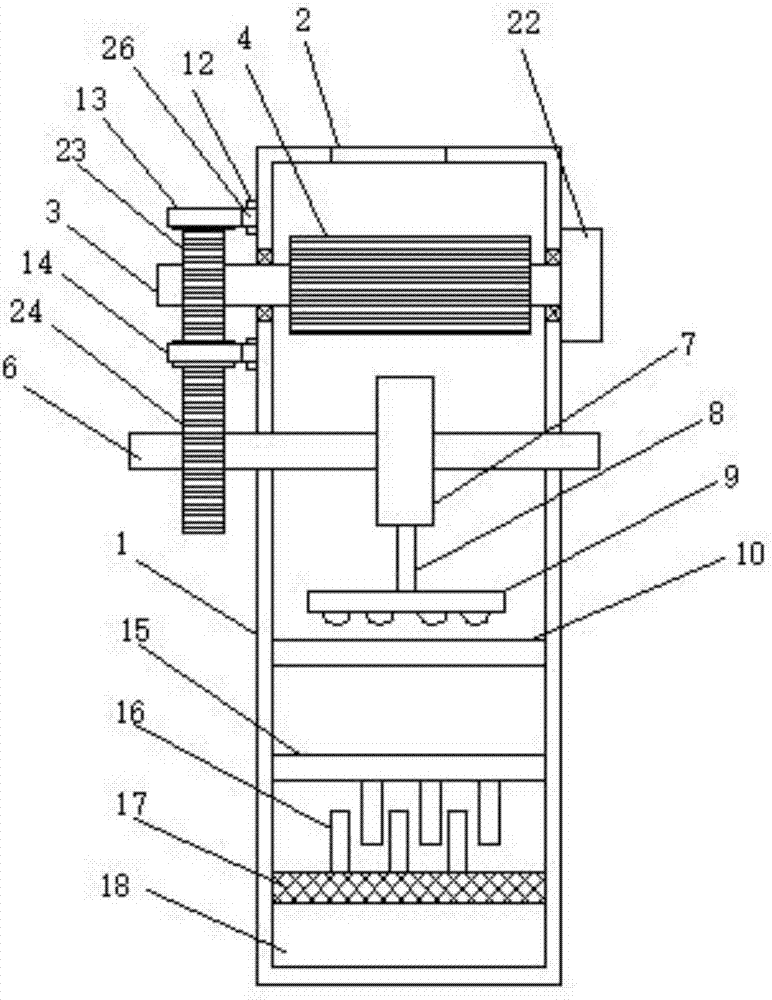

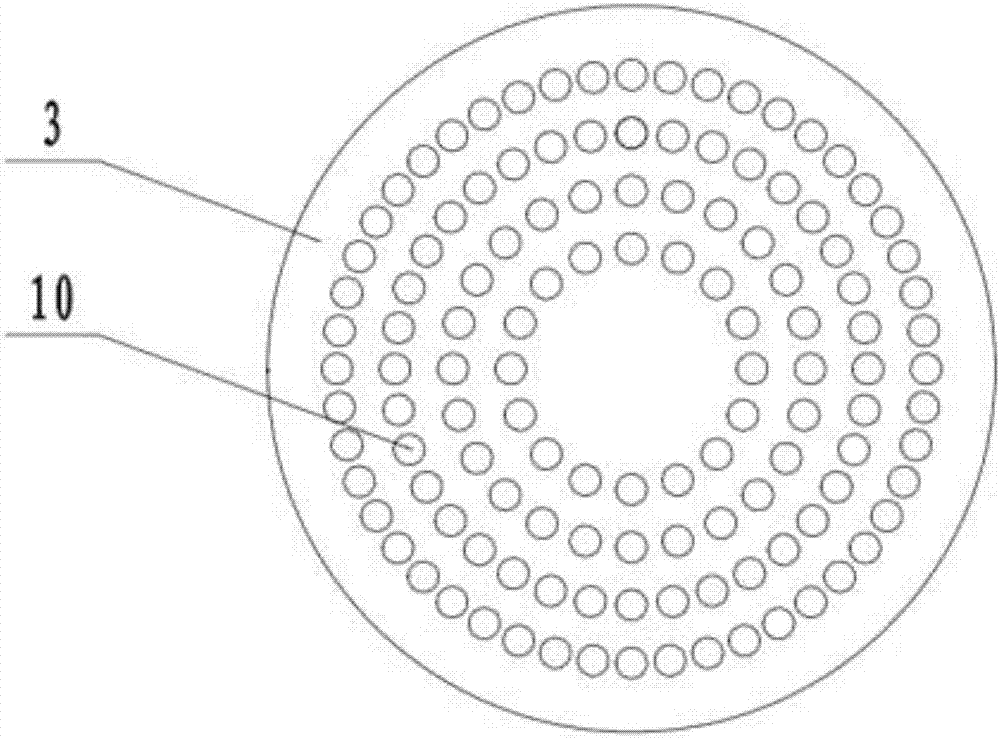

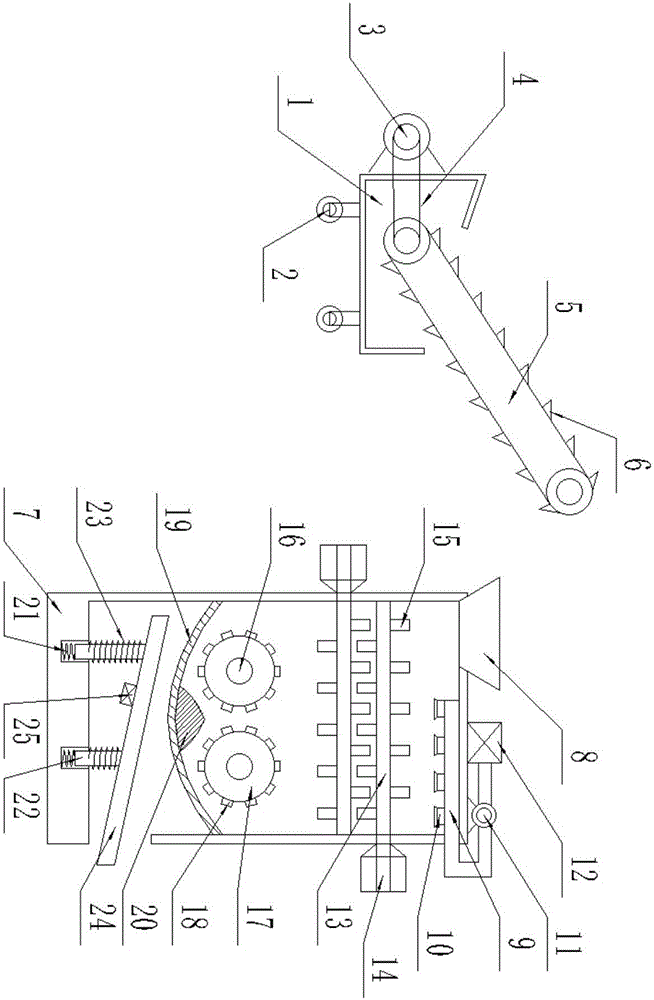

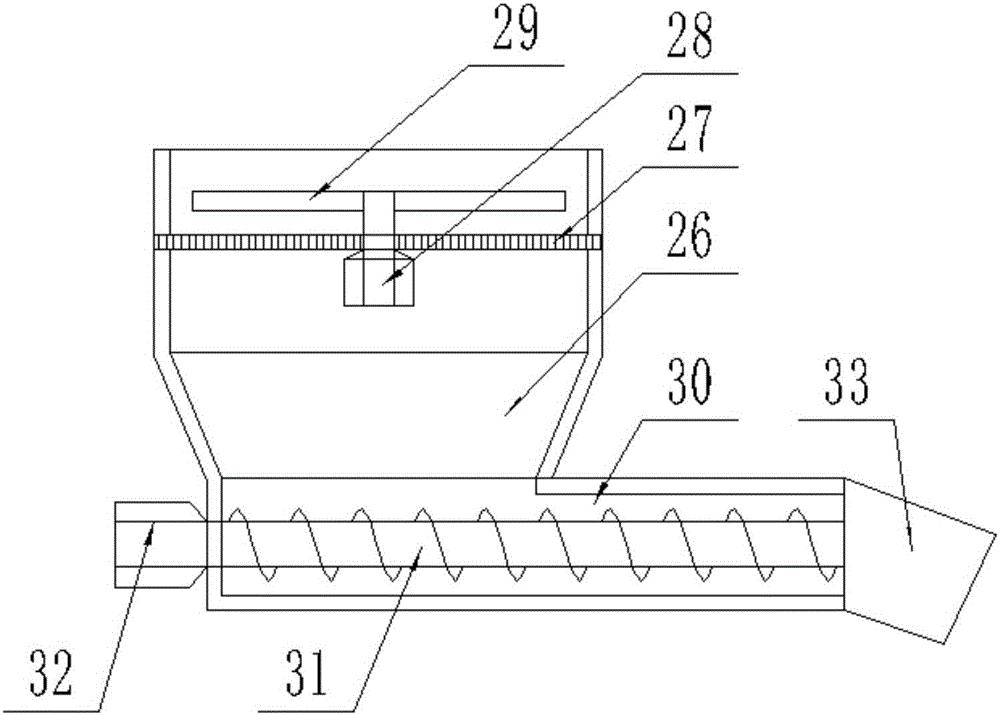

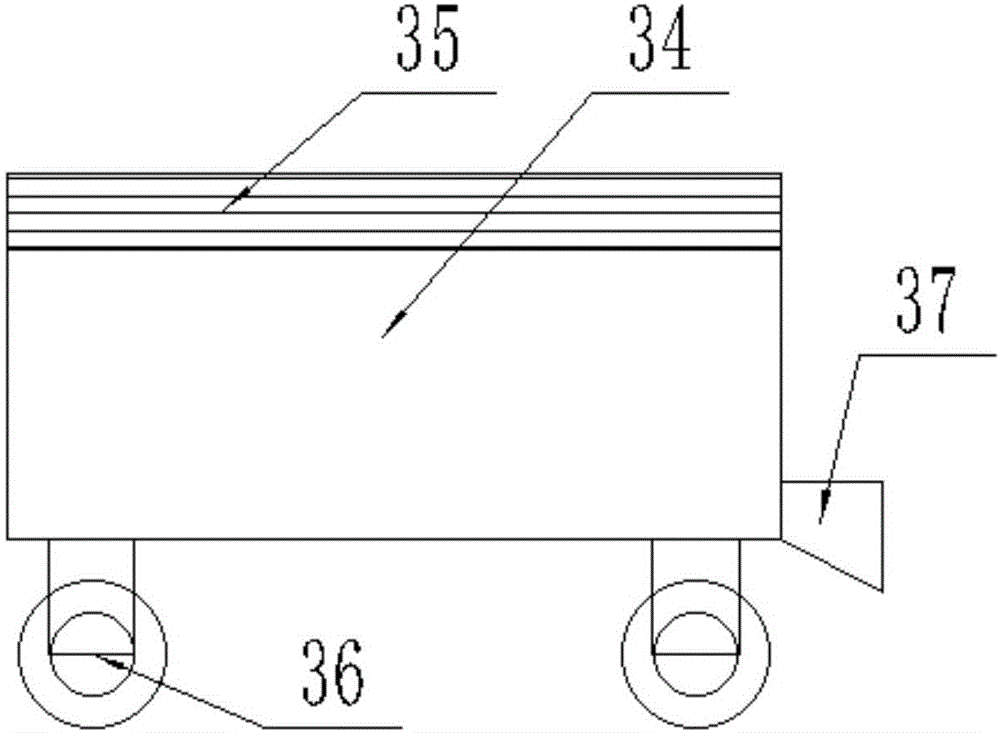

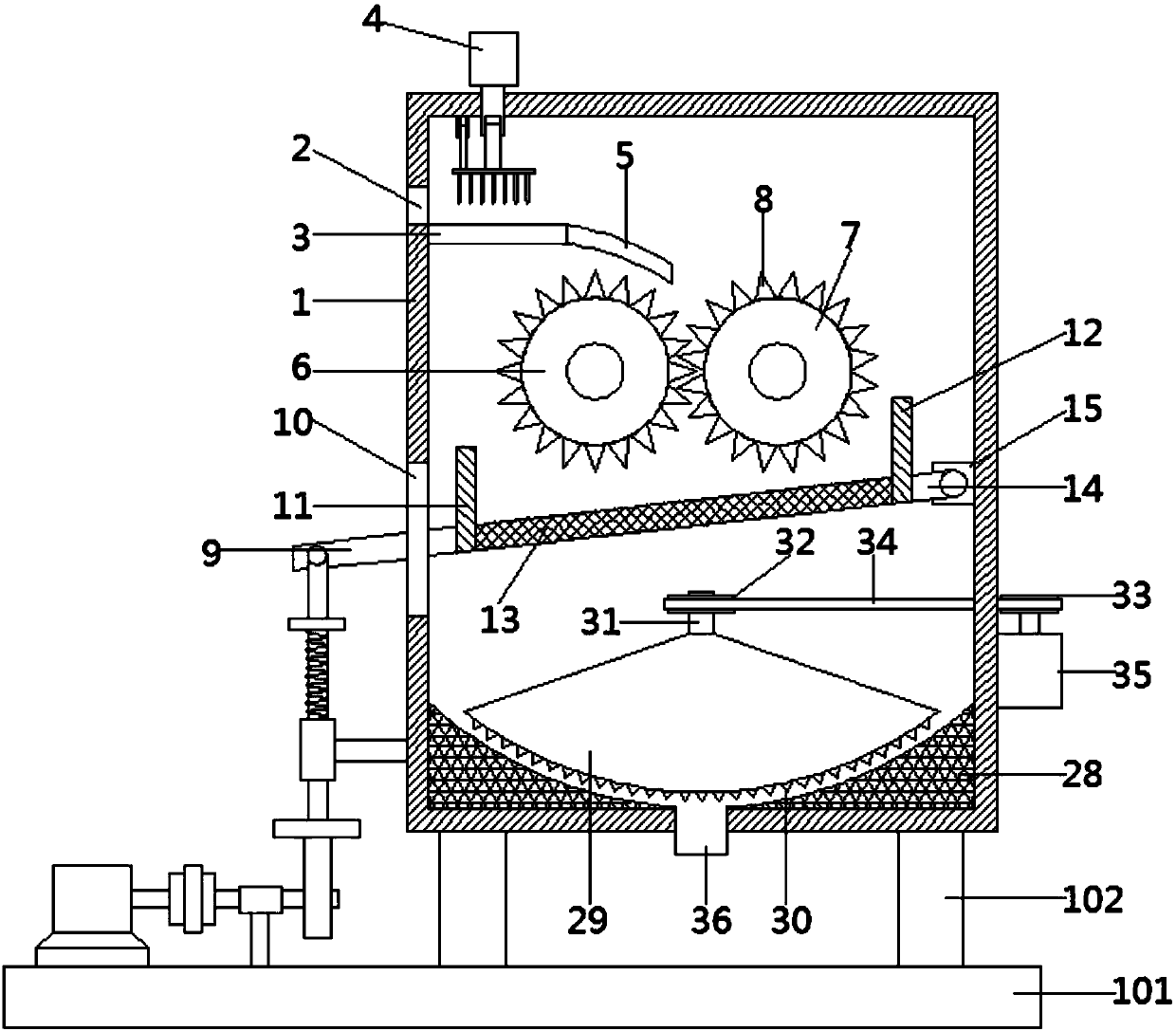

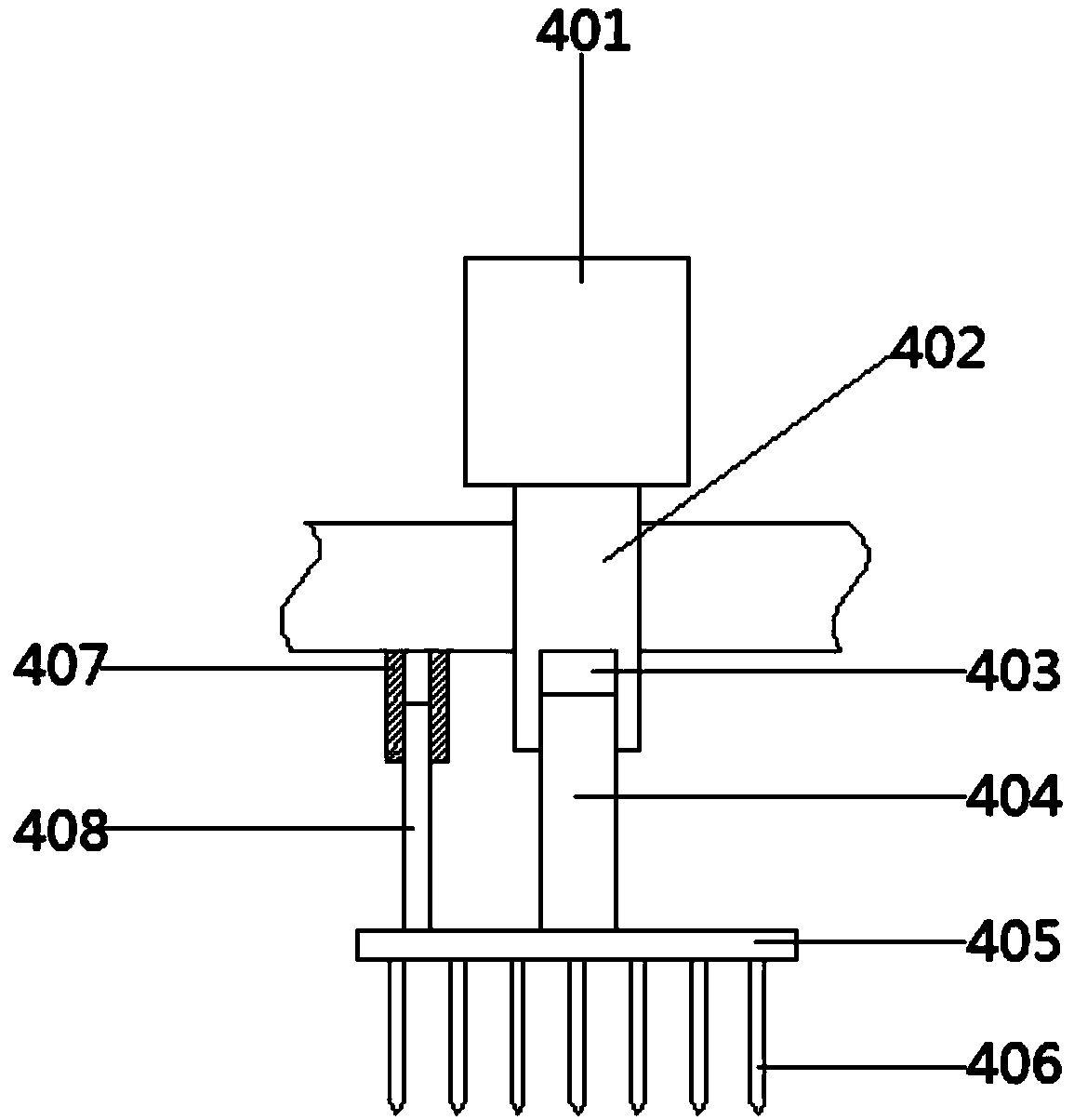

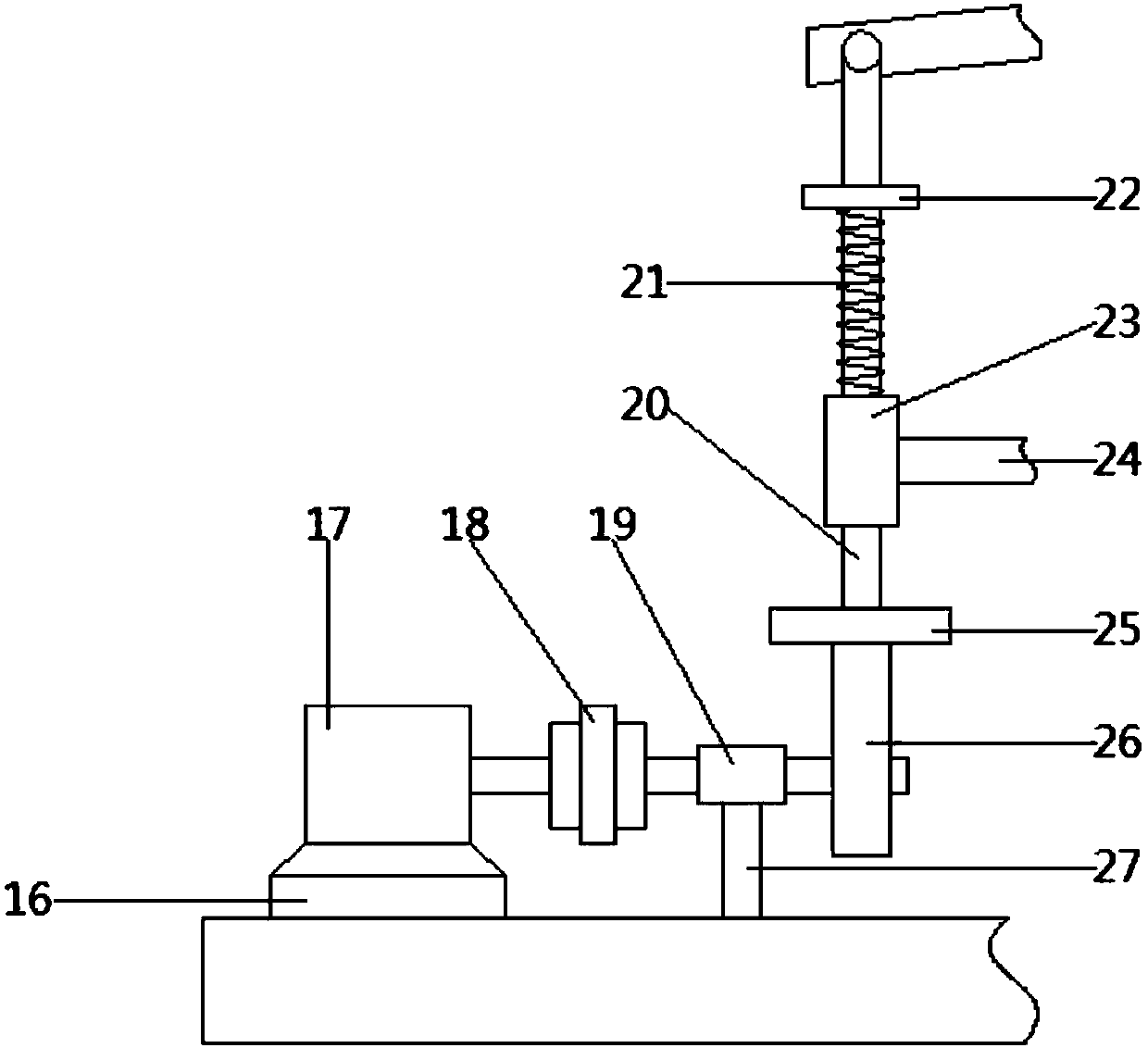

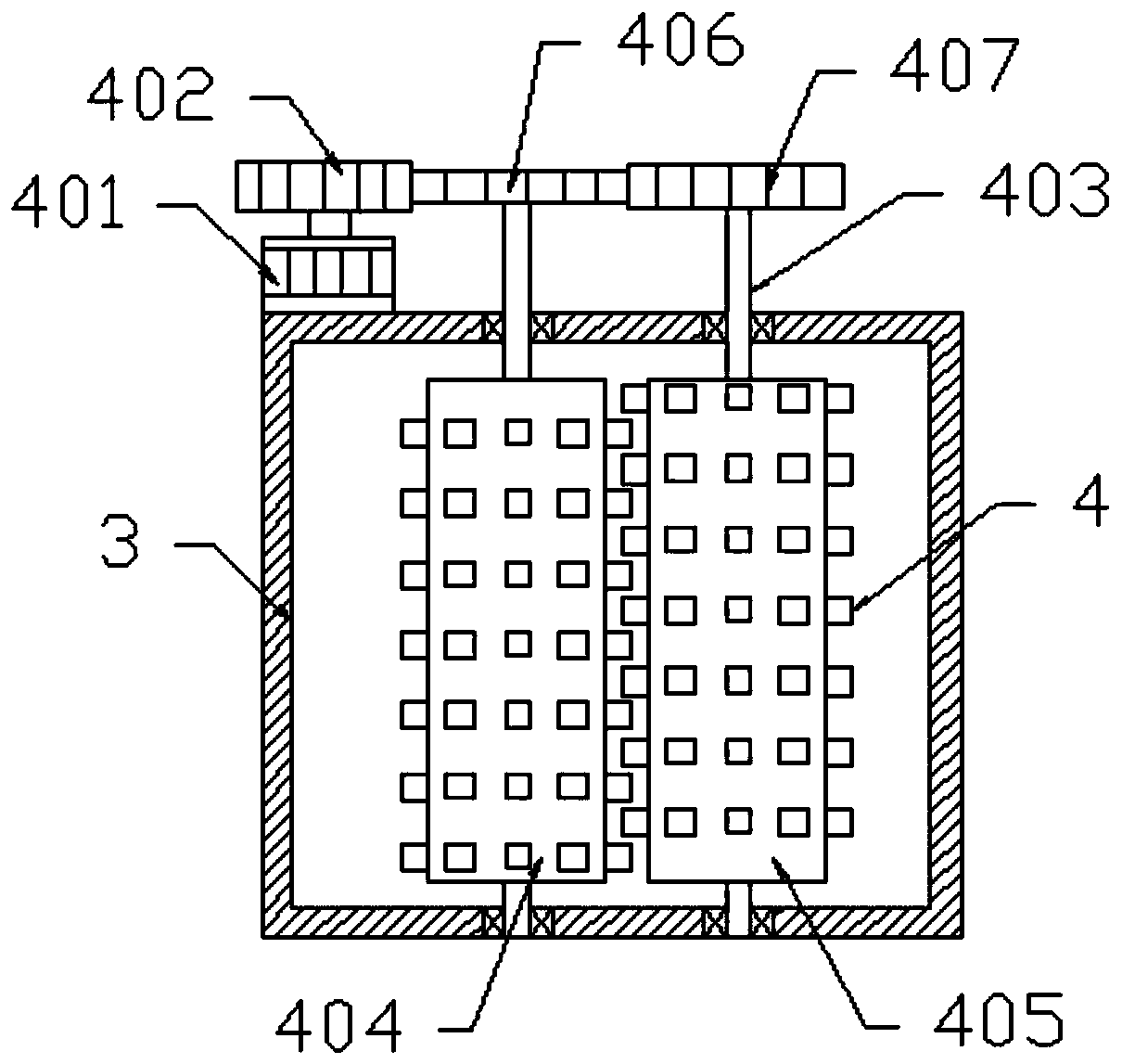

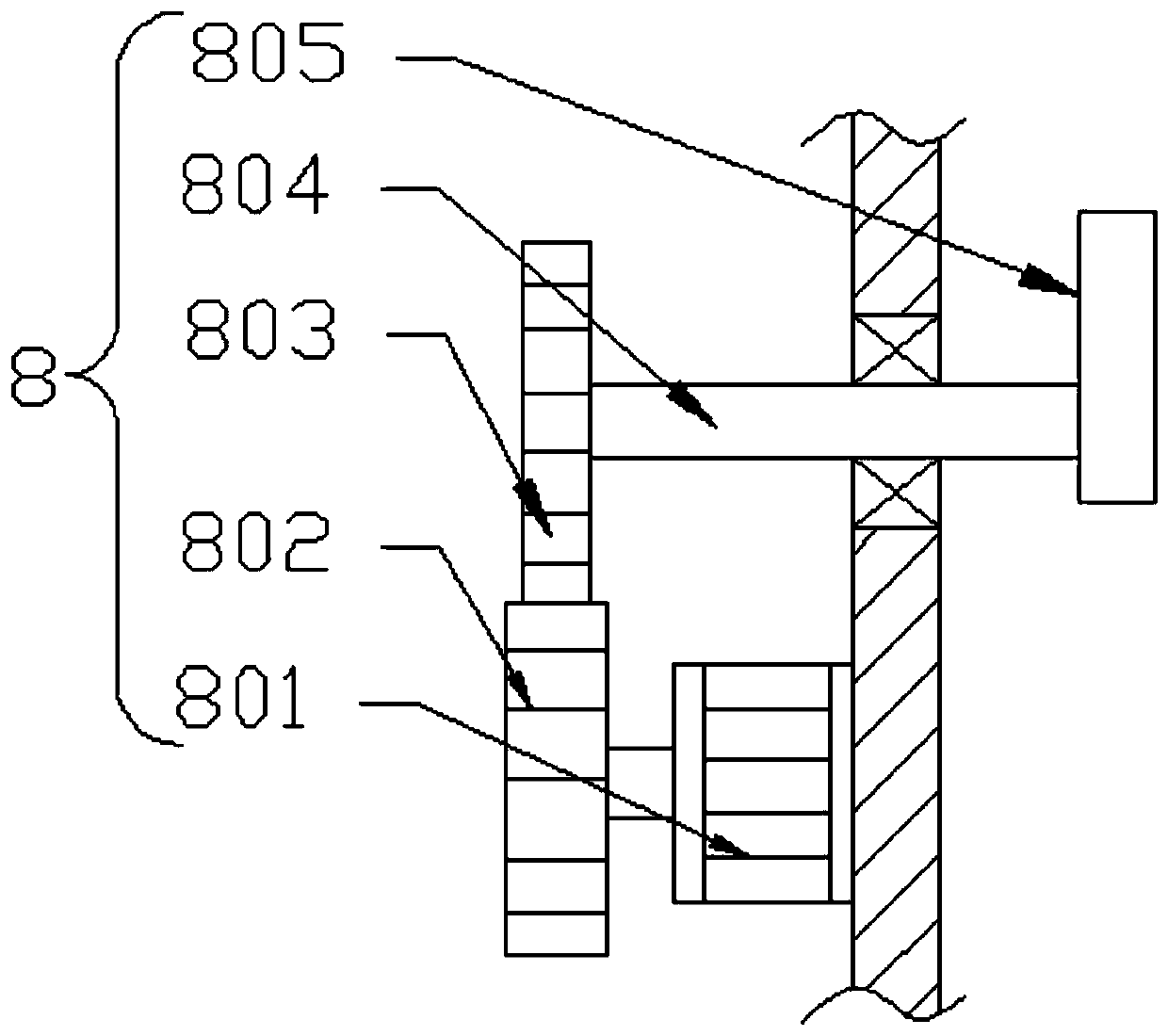

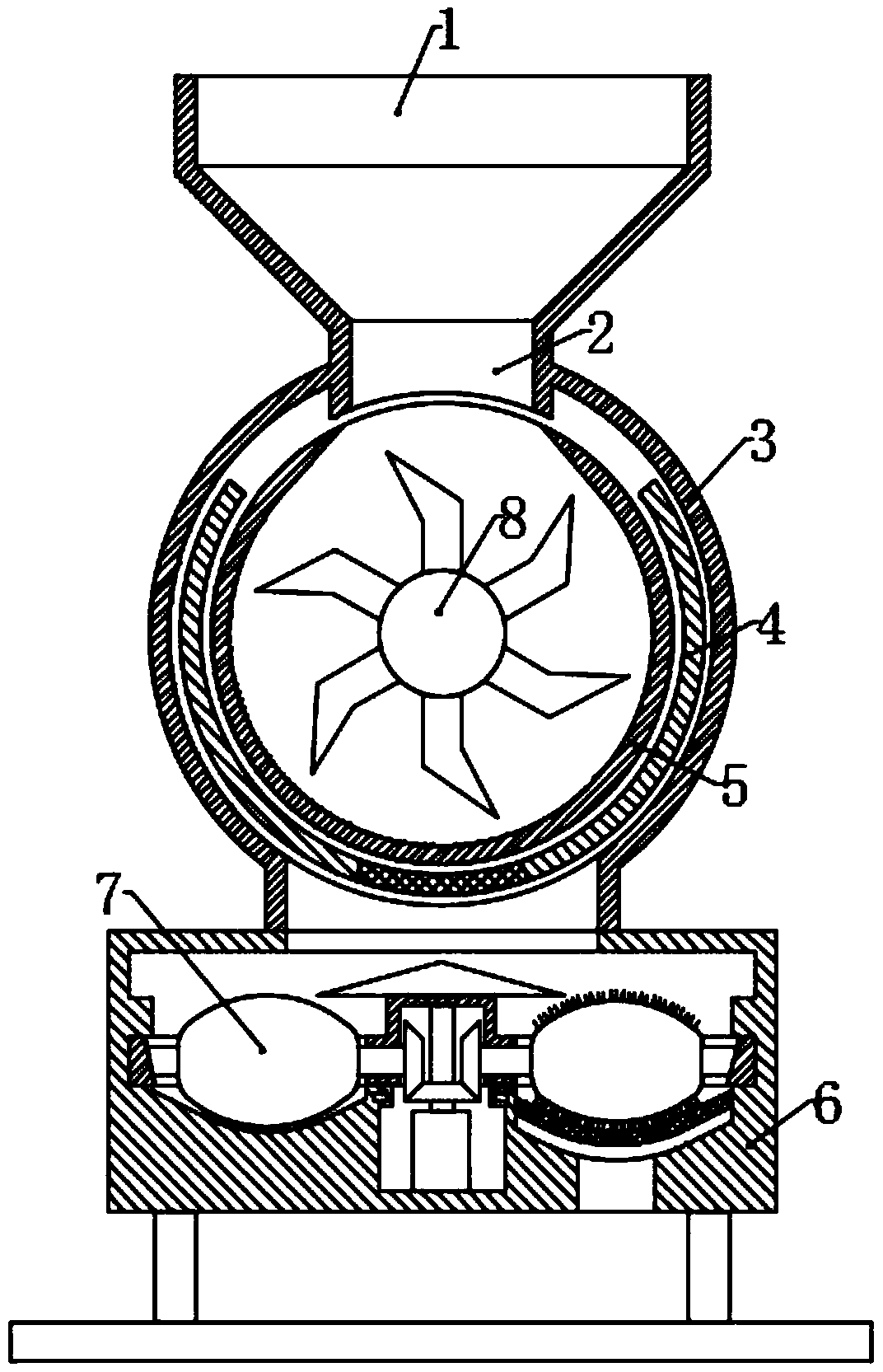

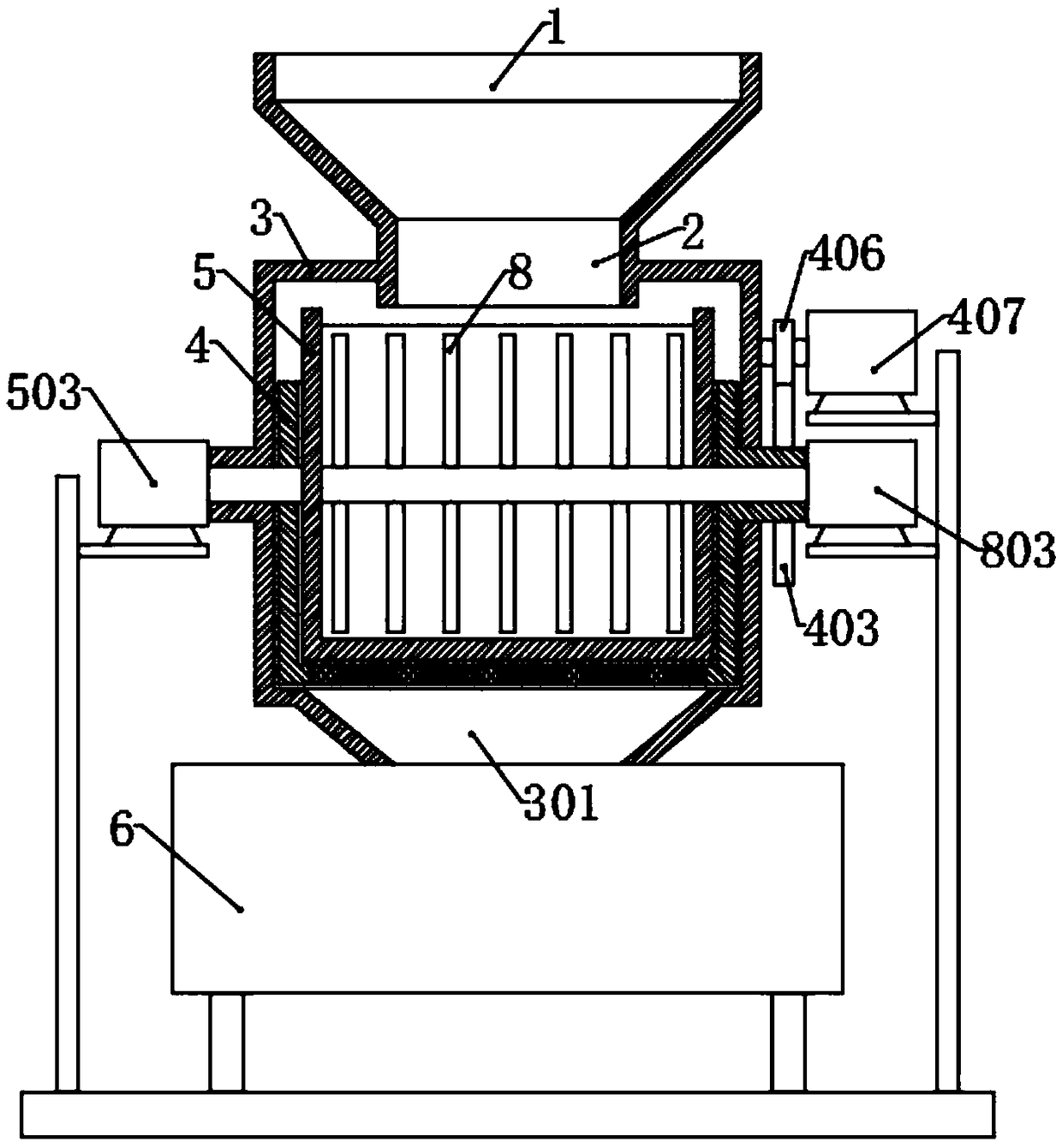

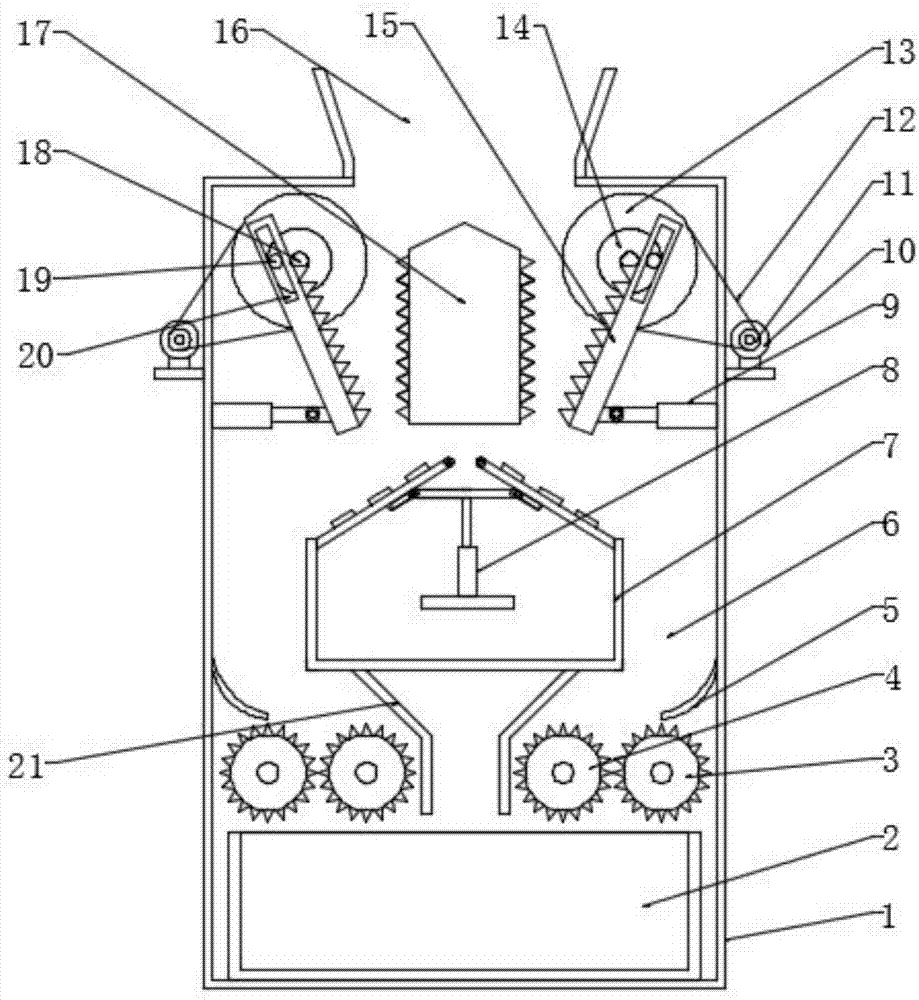

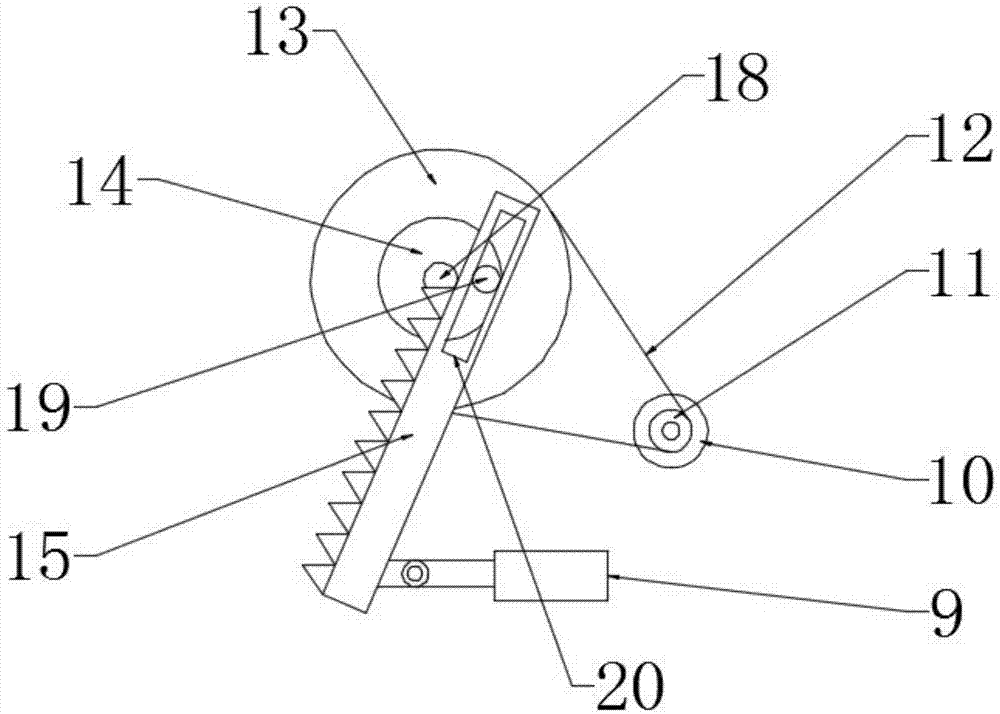

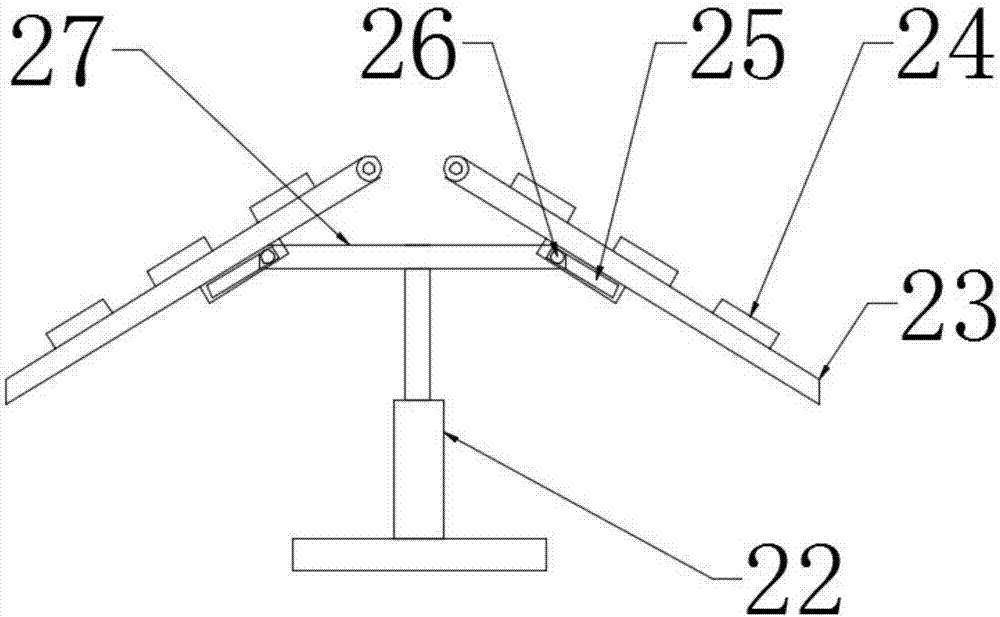

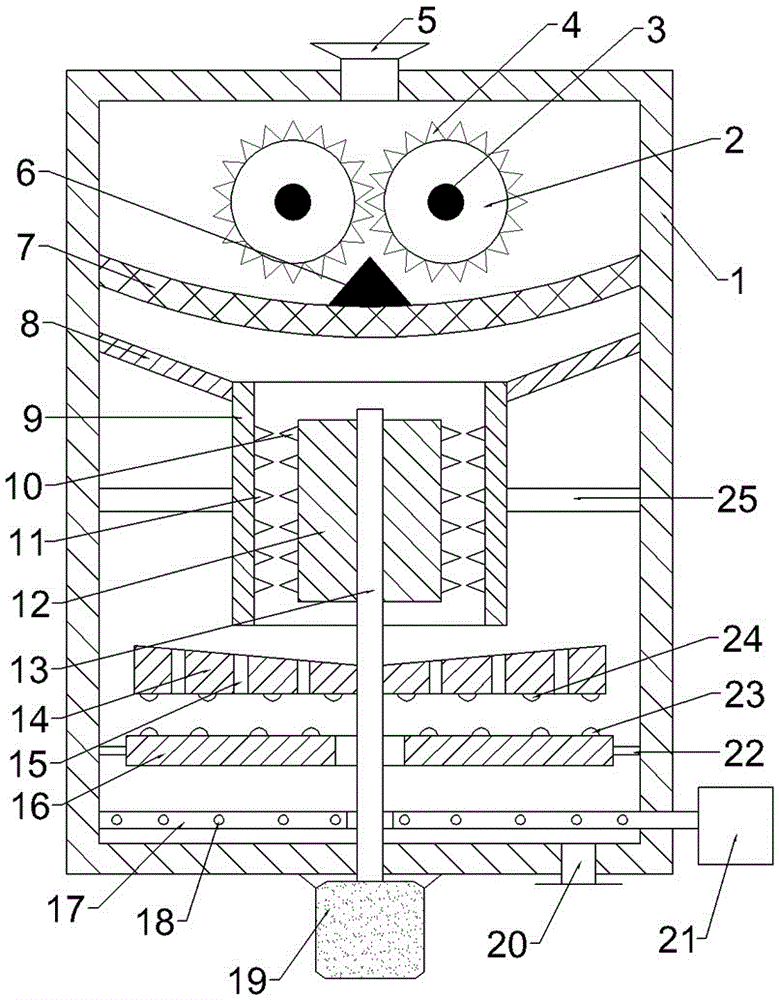

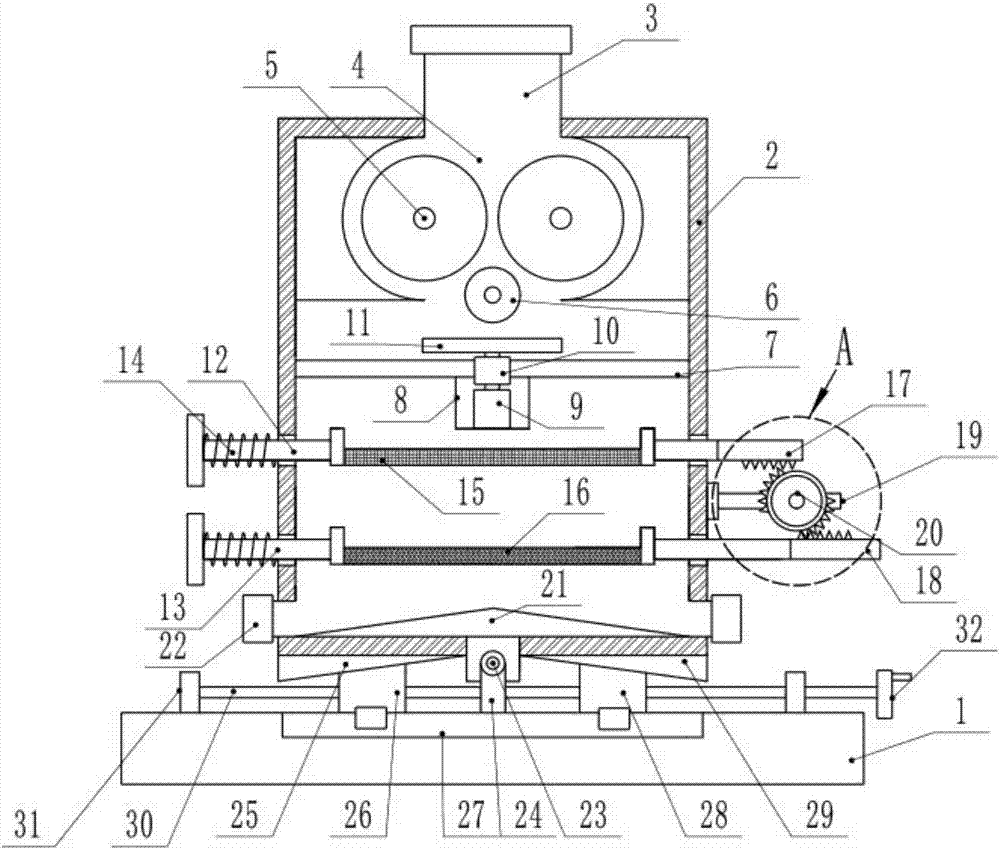

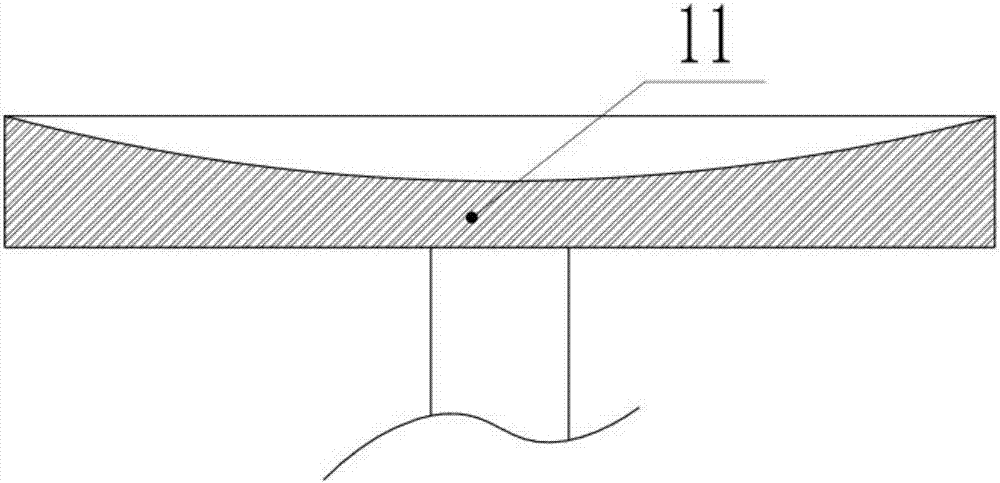

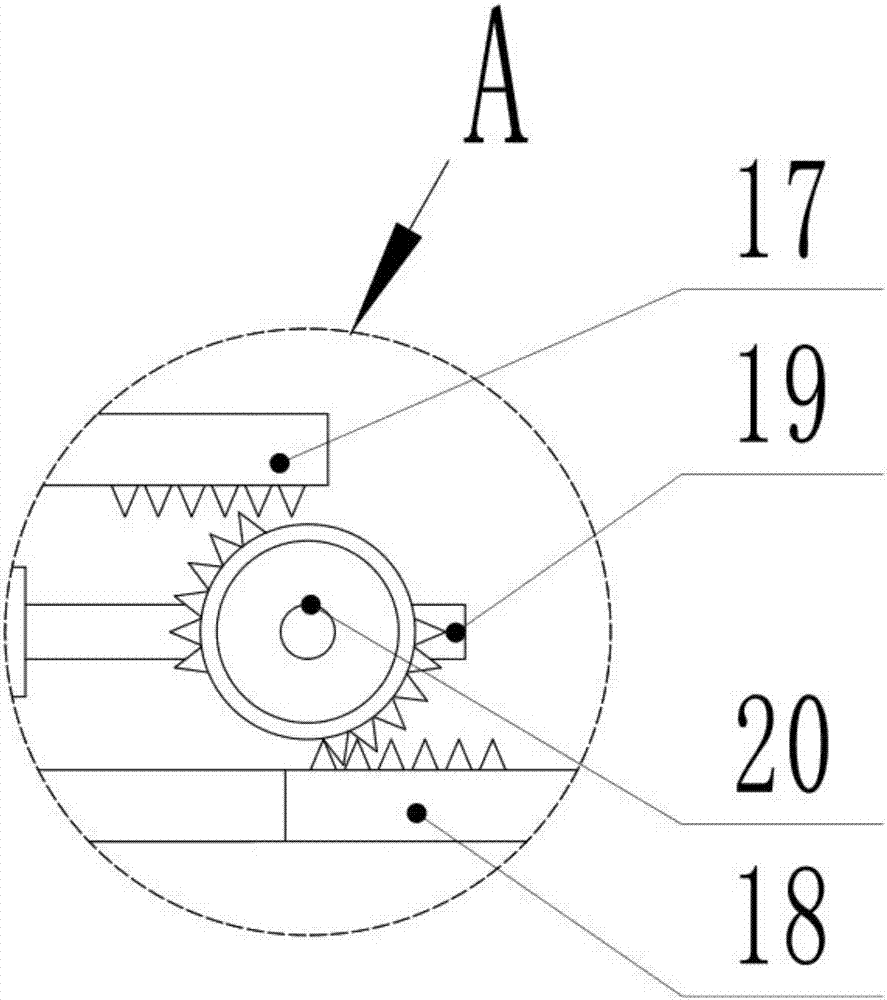

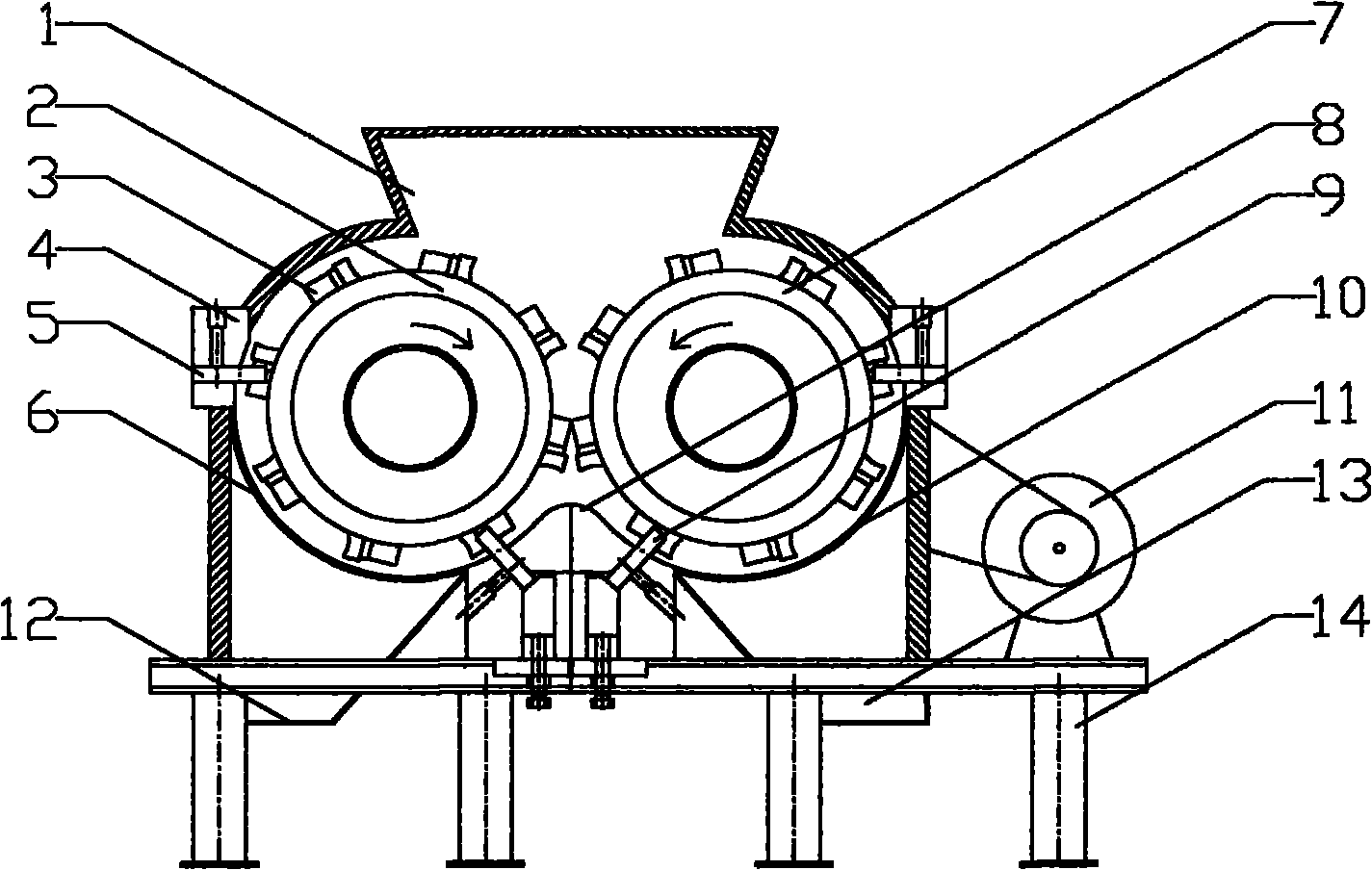

Grinding and sieving integrated traditional Chinese medicine processing device

InactiveCN108435357AImprove crushing effectEasy to processSievingScreeningEngineeringPulp and paper industry

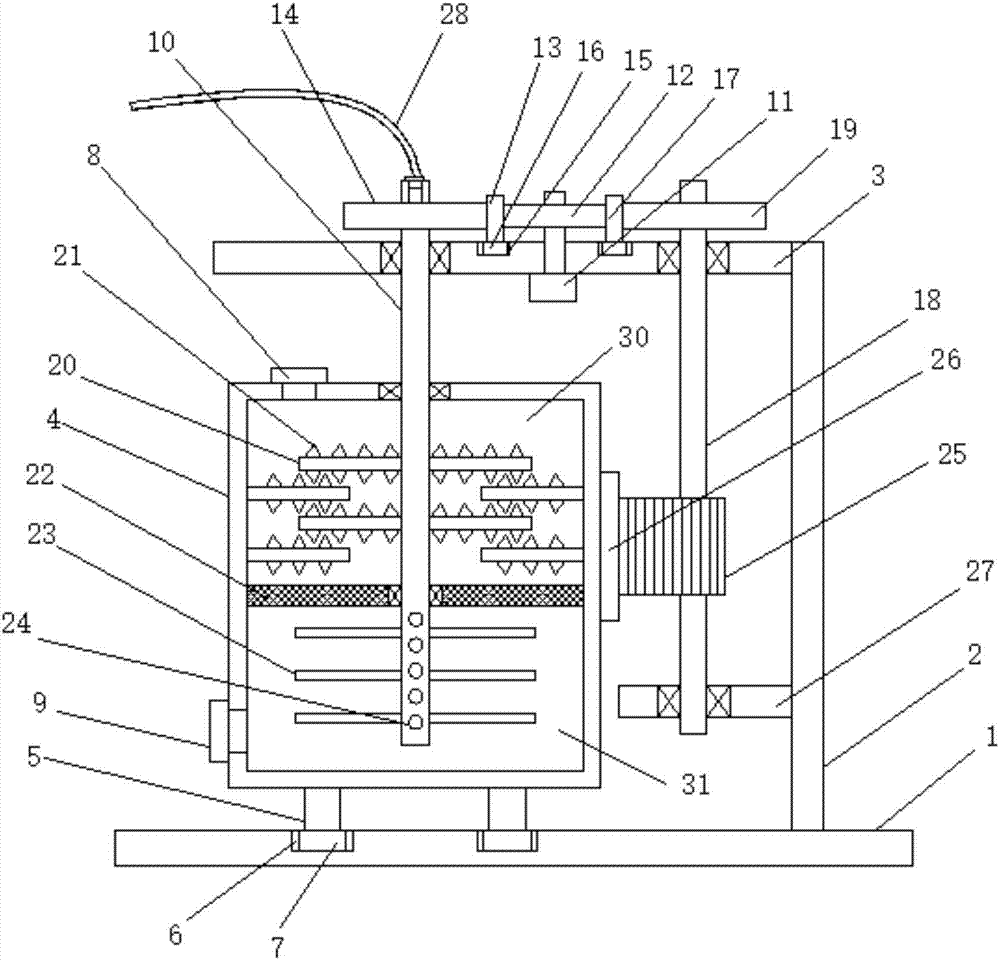

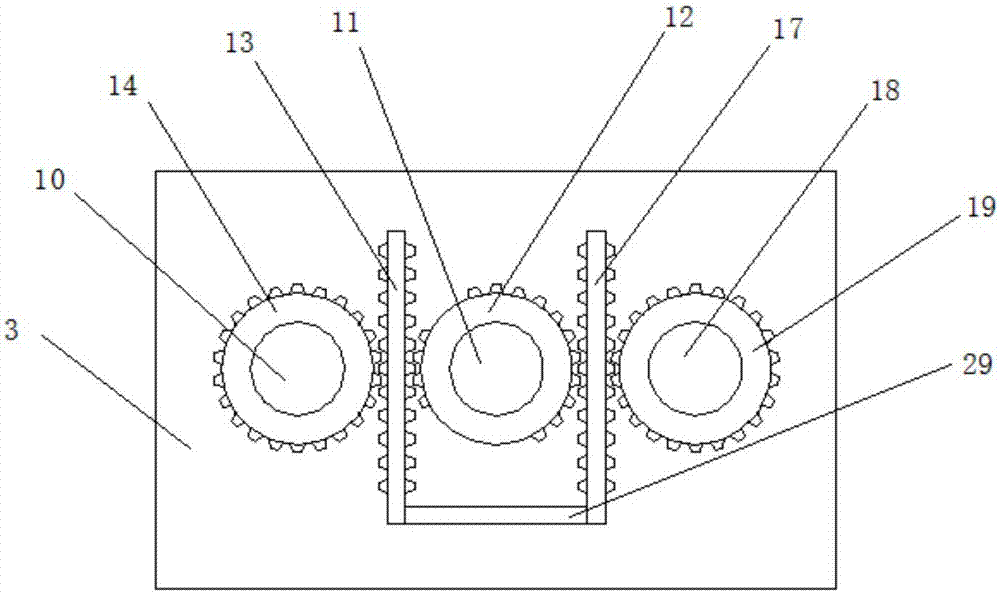

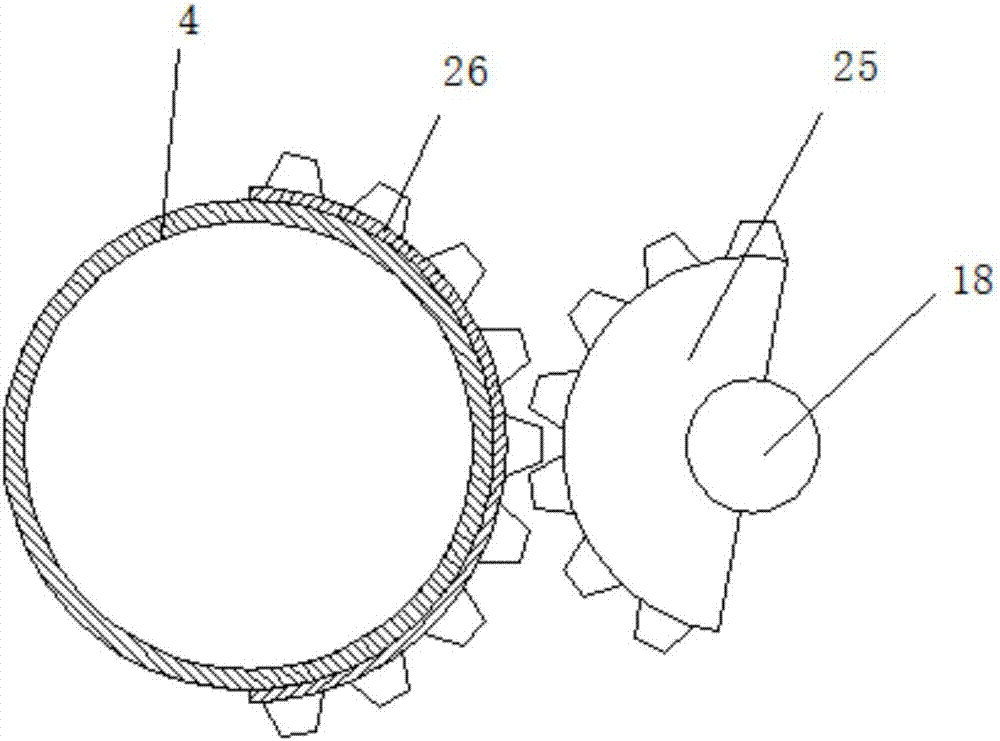

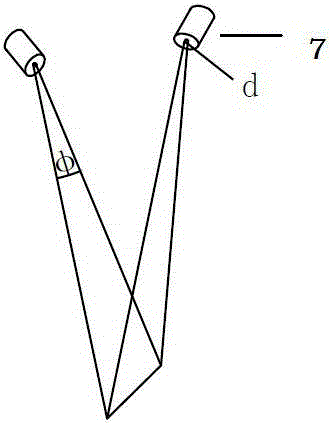

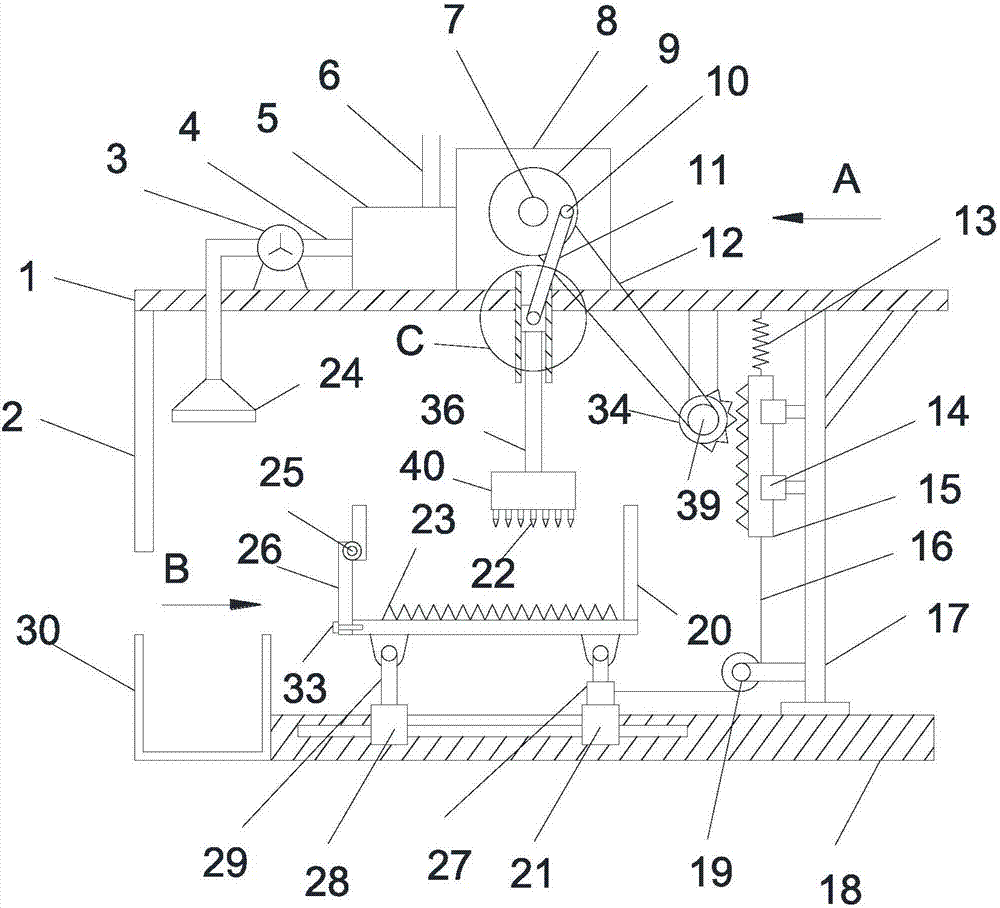

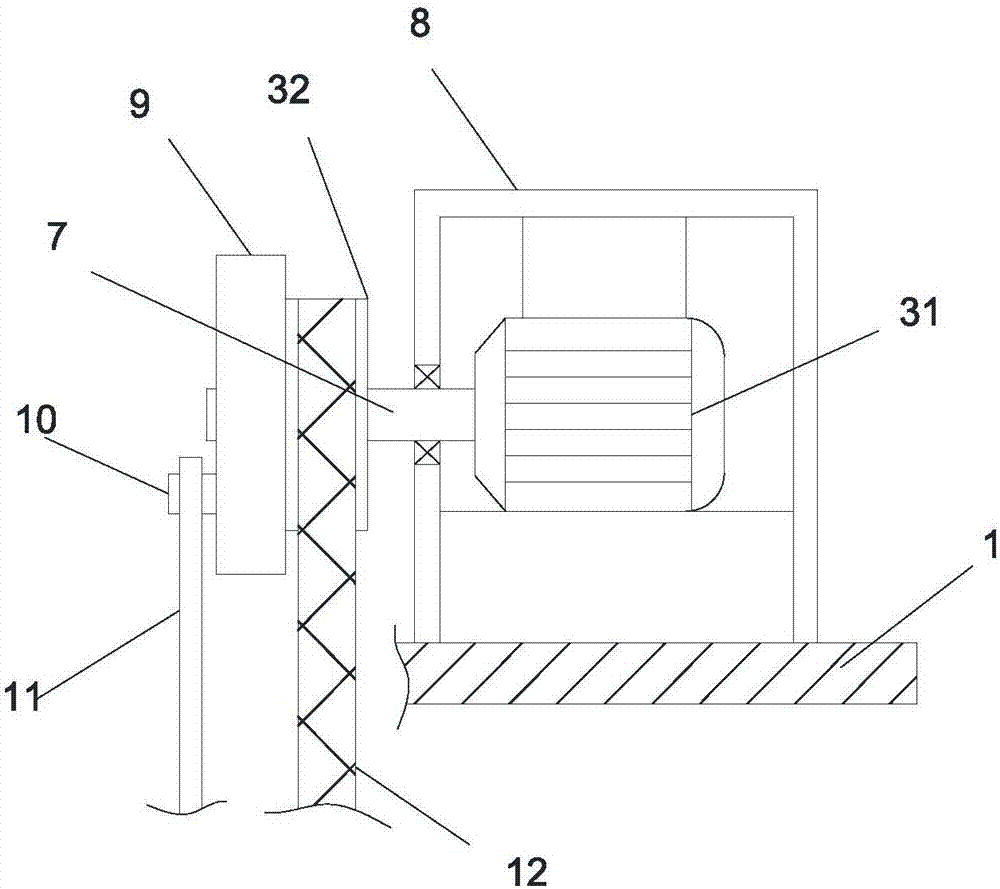

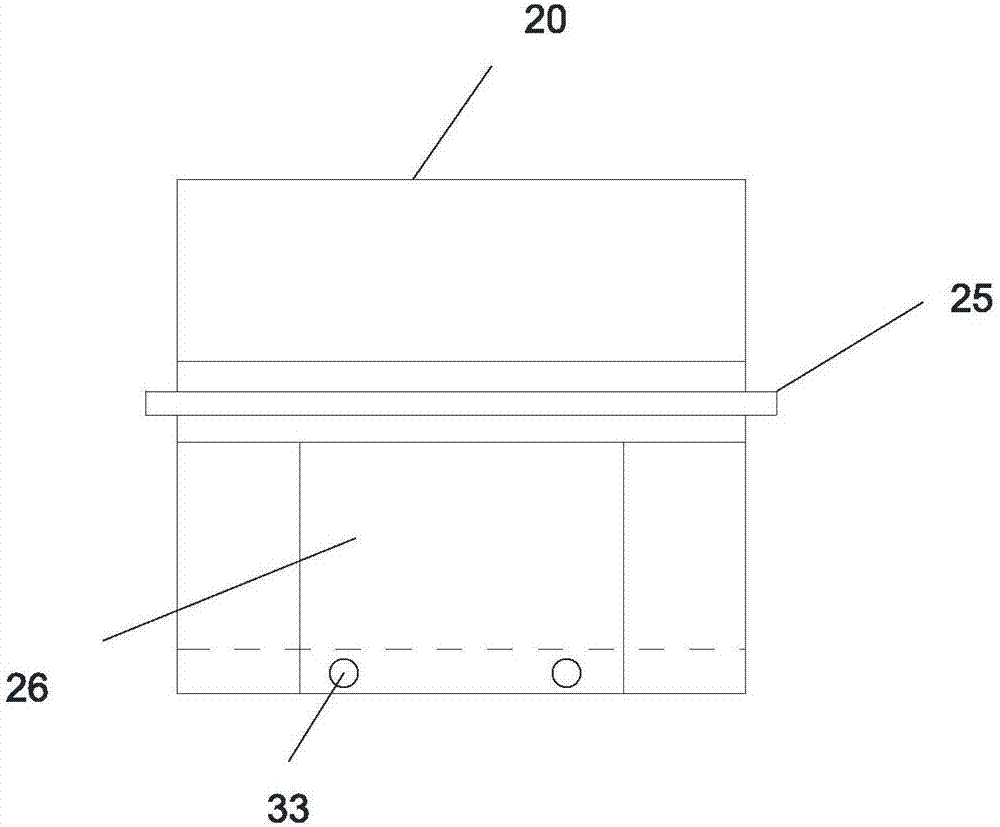

The invention discloses a grinding and sieving integrated traditional Chinese medicine processing device. The device comprises a processing box, wherein a base is arranged below the processing box; rollers through which the device can be conveniently carried are symmetrically arranged at the left side and the right side of the base; supporting legs are symmetrically arranged at two sides of the lower end of the processing box; supporting sleeves sleeve the lower ends of the supporting legs in a sliding manner, and the lower ends of the supporting sleeves are connected and fixed to the base; buffering springs for connecting and fixing the supporting sleeves and the supporting legs are arranged in the supporting sleeves, and the abovementioned buffering mechanism is capable of effectively improving the damping performance of the device; a feeding port is formed in the middle of the upper end of the processing box; and a crushing mechanism comprising a crushing roller is arranged below the feeding port. The device is simple and reasonable in structure, convenient to carry, and high in damping performance; the crushing mechanism shakes leftwards and rightwards to improve the material crushing effect; the grinding effect is adjustable, and thus particular materials with different particle size can be conveniently processed; the processed materials can be sieved, so that the processing quality is ensured; and the practicability is high.

Owner:安徽康和中药科技有限公司

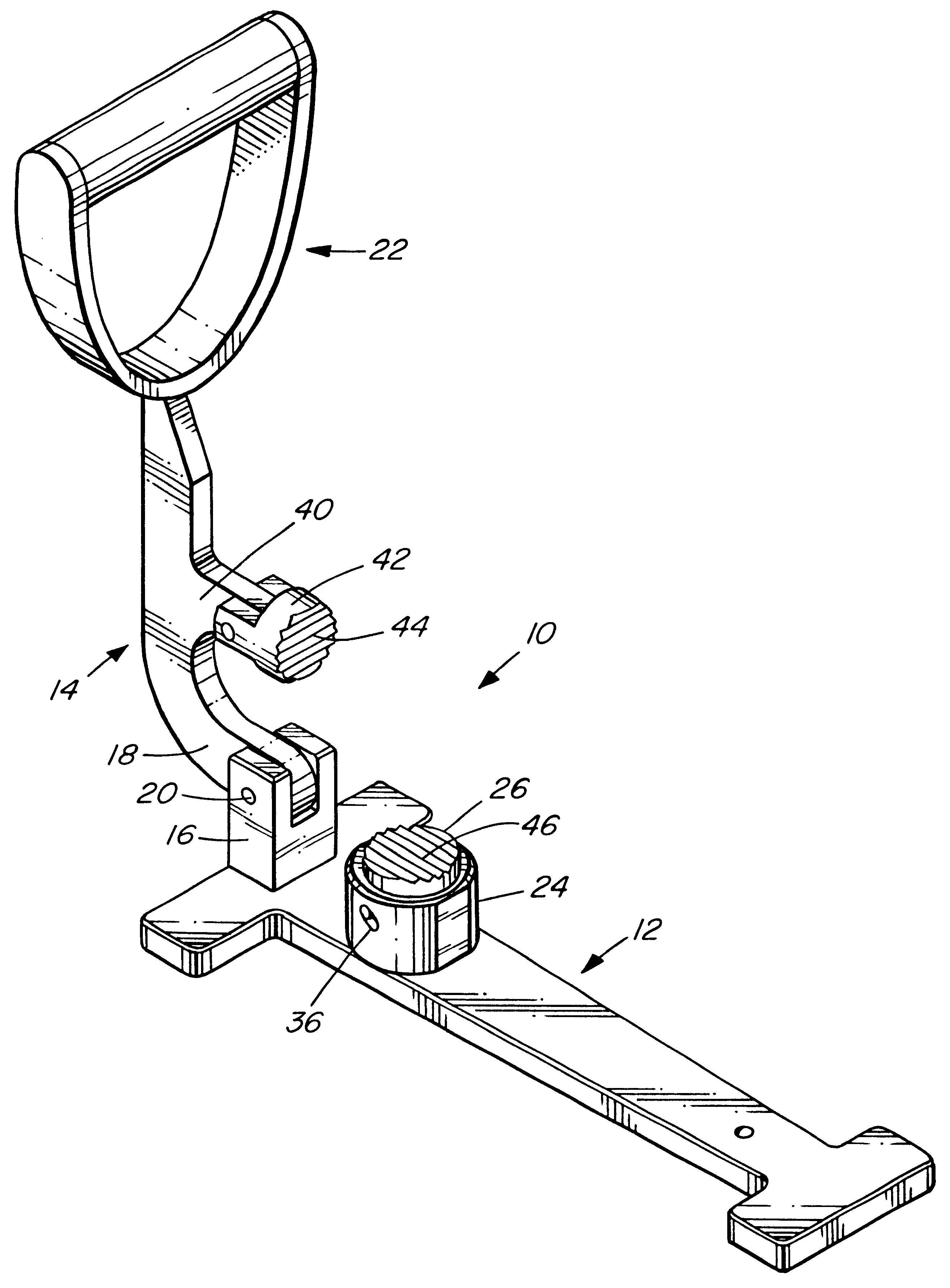

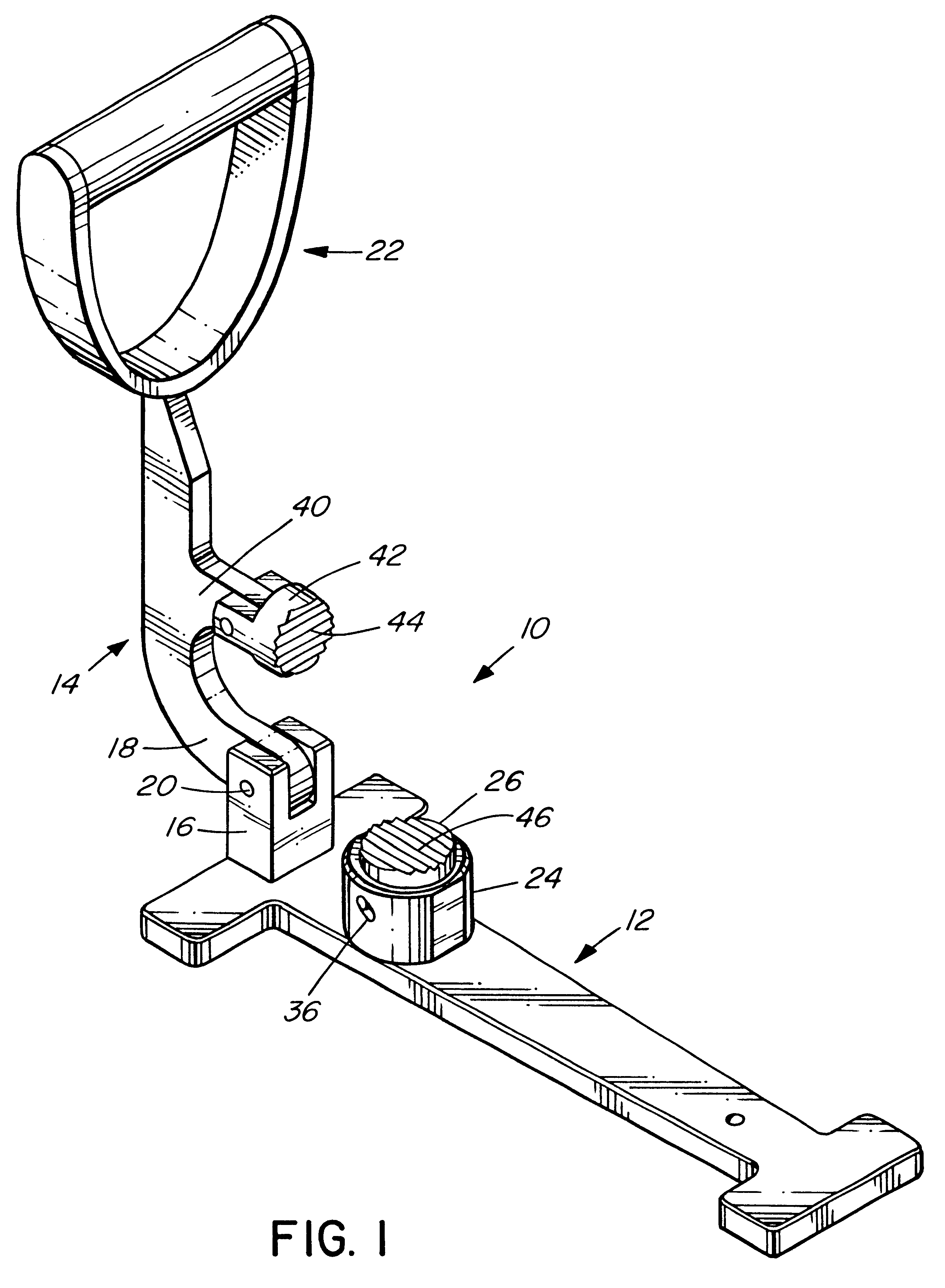

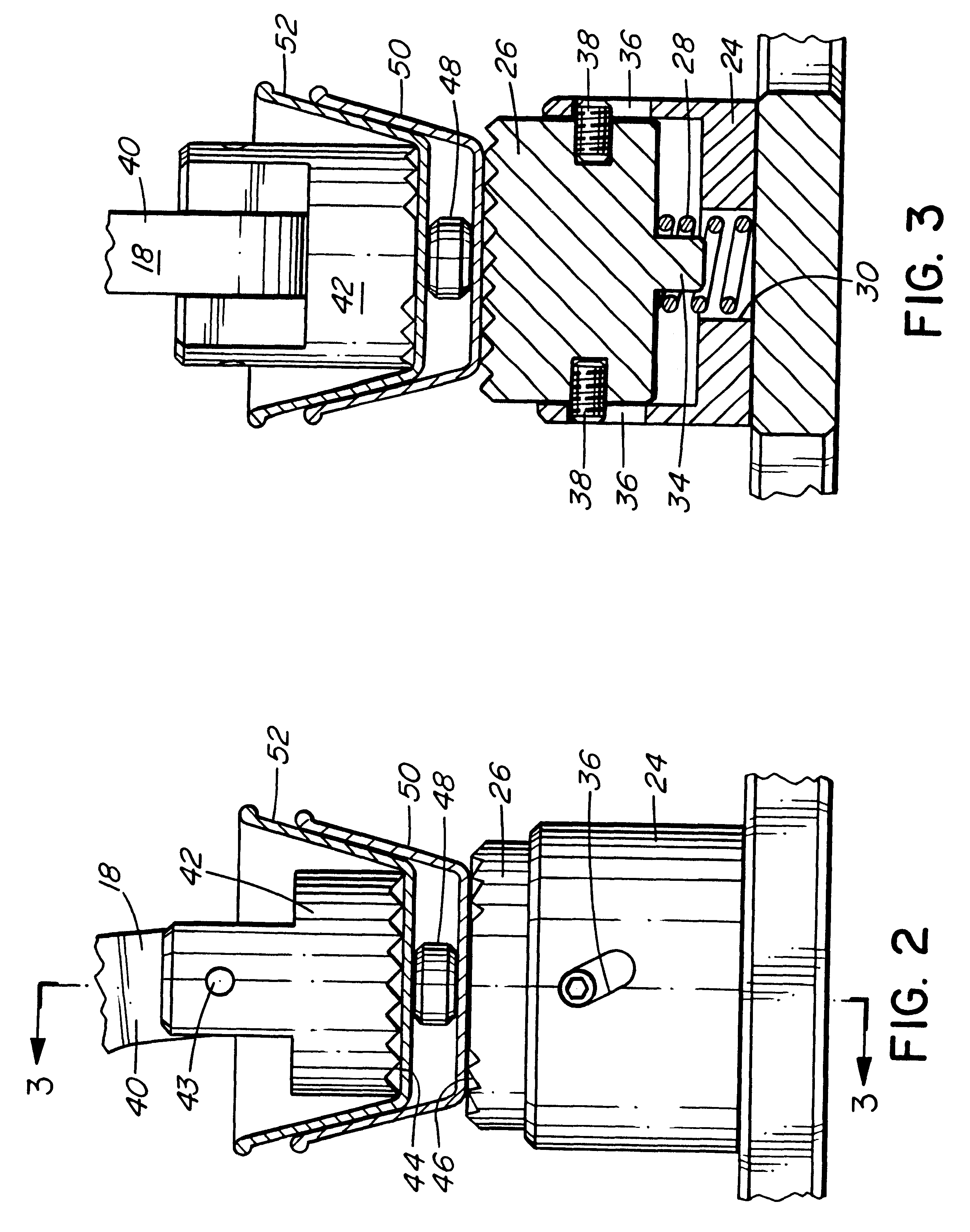

Pill crusher

A pill crusher has an arm extending over and along an elongate base, with a pivotal connection between the base and one end of the arm. An upwardly open cylindrical housing on the base has a longitudinal axis perpendicular to the base and a compression spring in the cylindrical housing between a cylindrical anvil member and the base. Interengaged guide formations on the housing and the anvil member at opposite sides of the housing are inclined so as to cause rotational movement of the anvil member relative to the cylindrical housing on displacement of the anvil member along the longitudinal axis against the action of the spring; and a cylindrical pressure member depending from the arm above the cylindrical housing. In use, the rotational movement of the anvil member causes a pill to be both crushed and also simultaneously ground between the pressure and anvil members, which have serrated opposed faces to improve the grinding.

Owner:KRUGER DENNIS

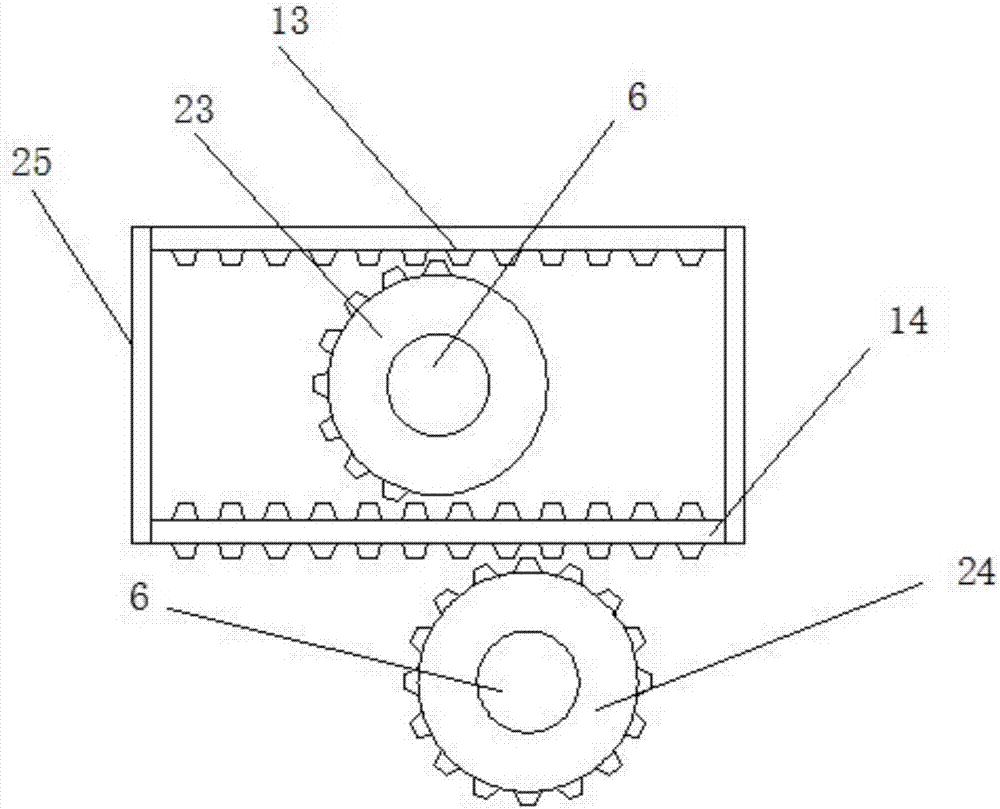

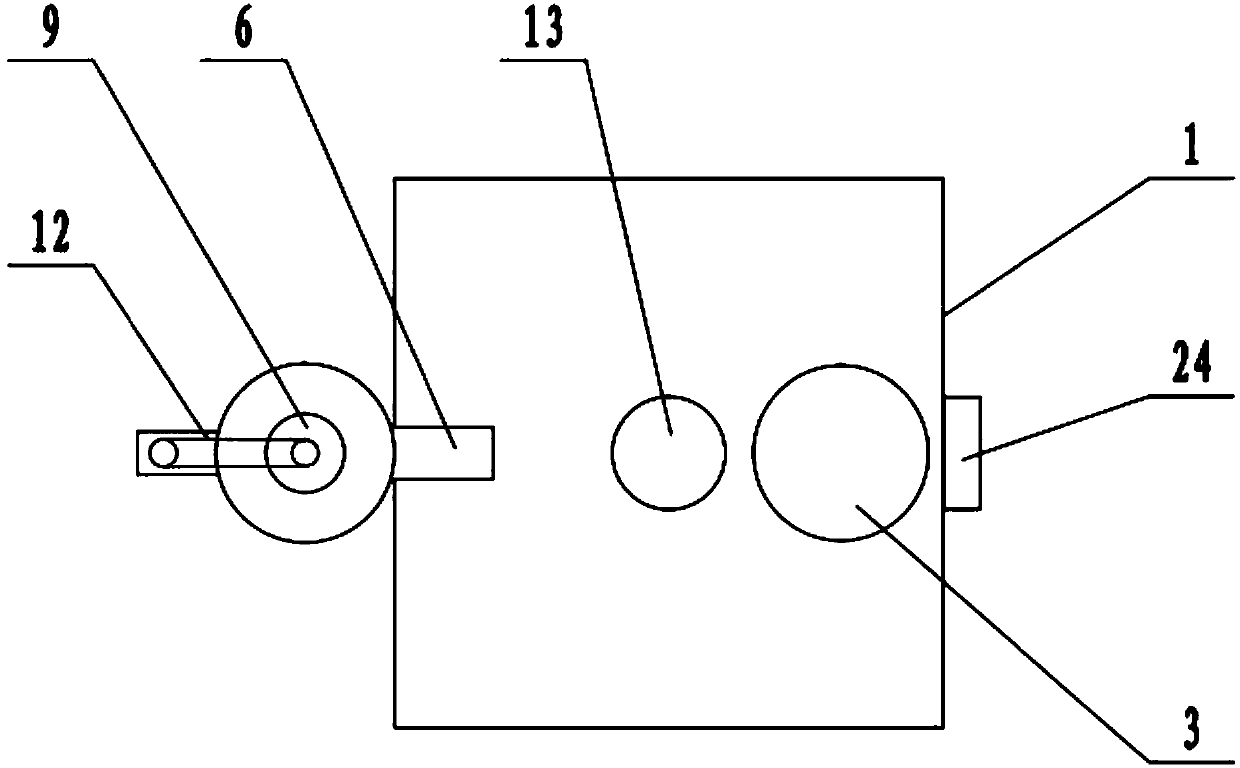

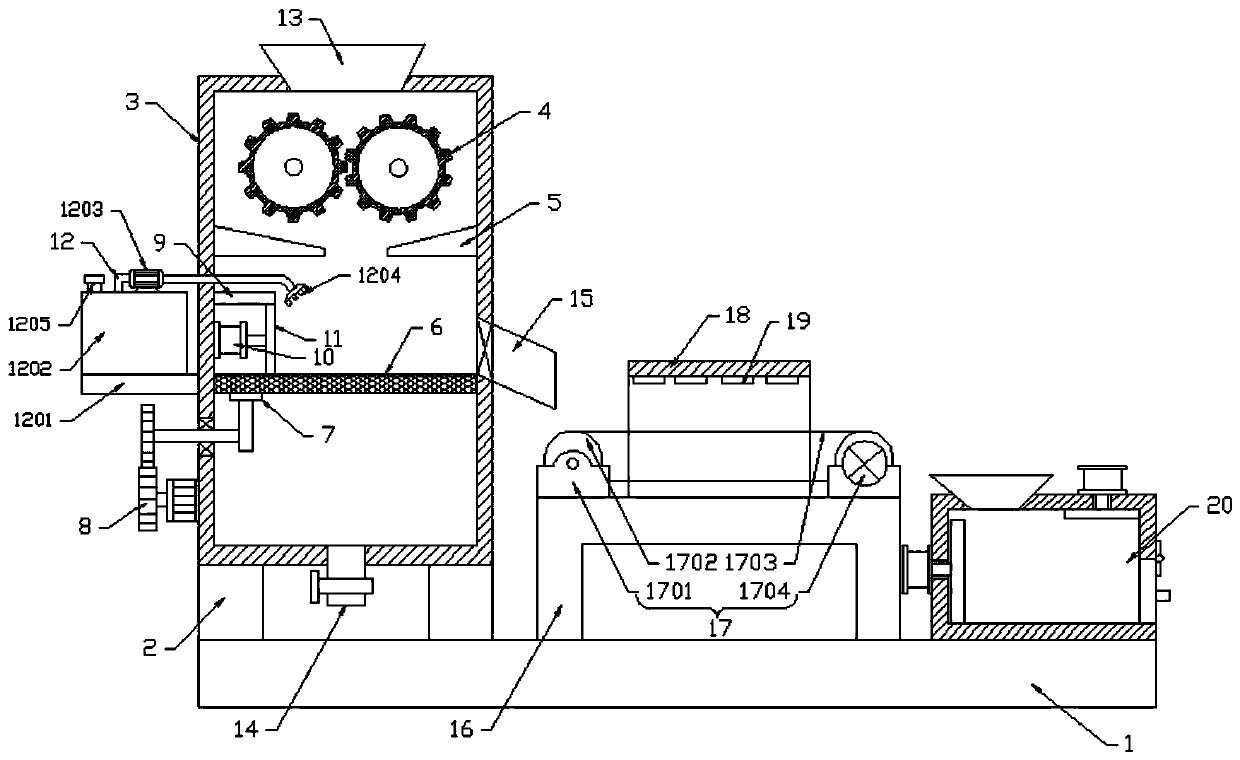

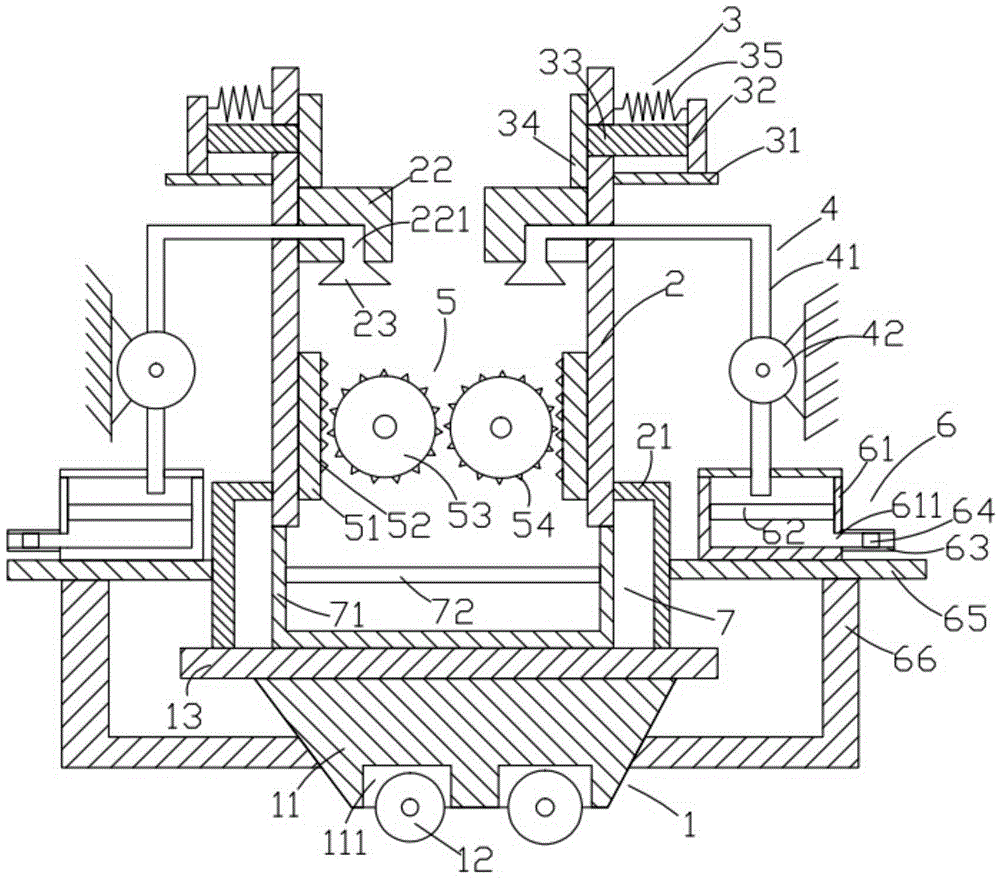

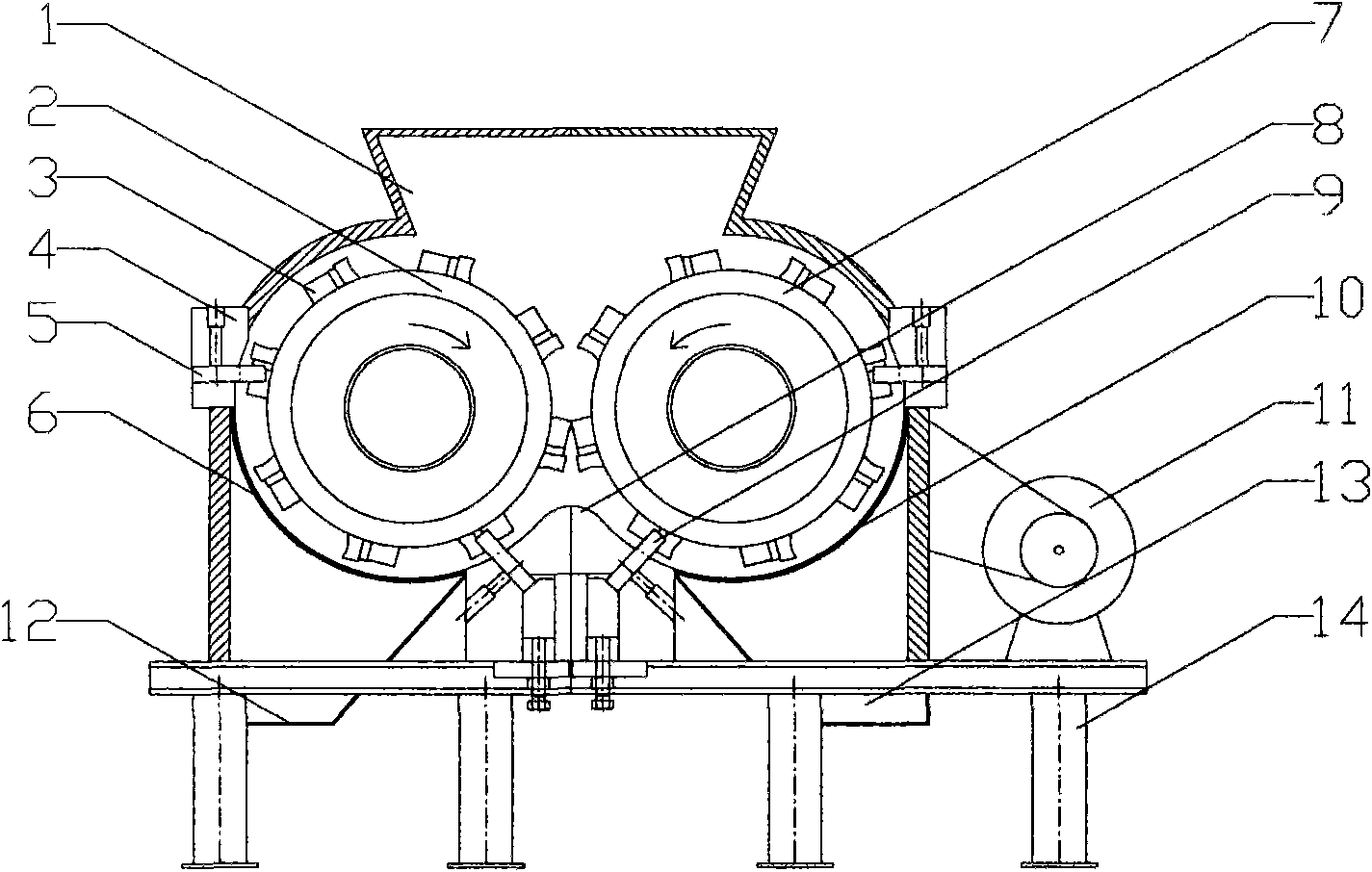

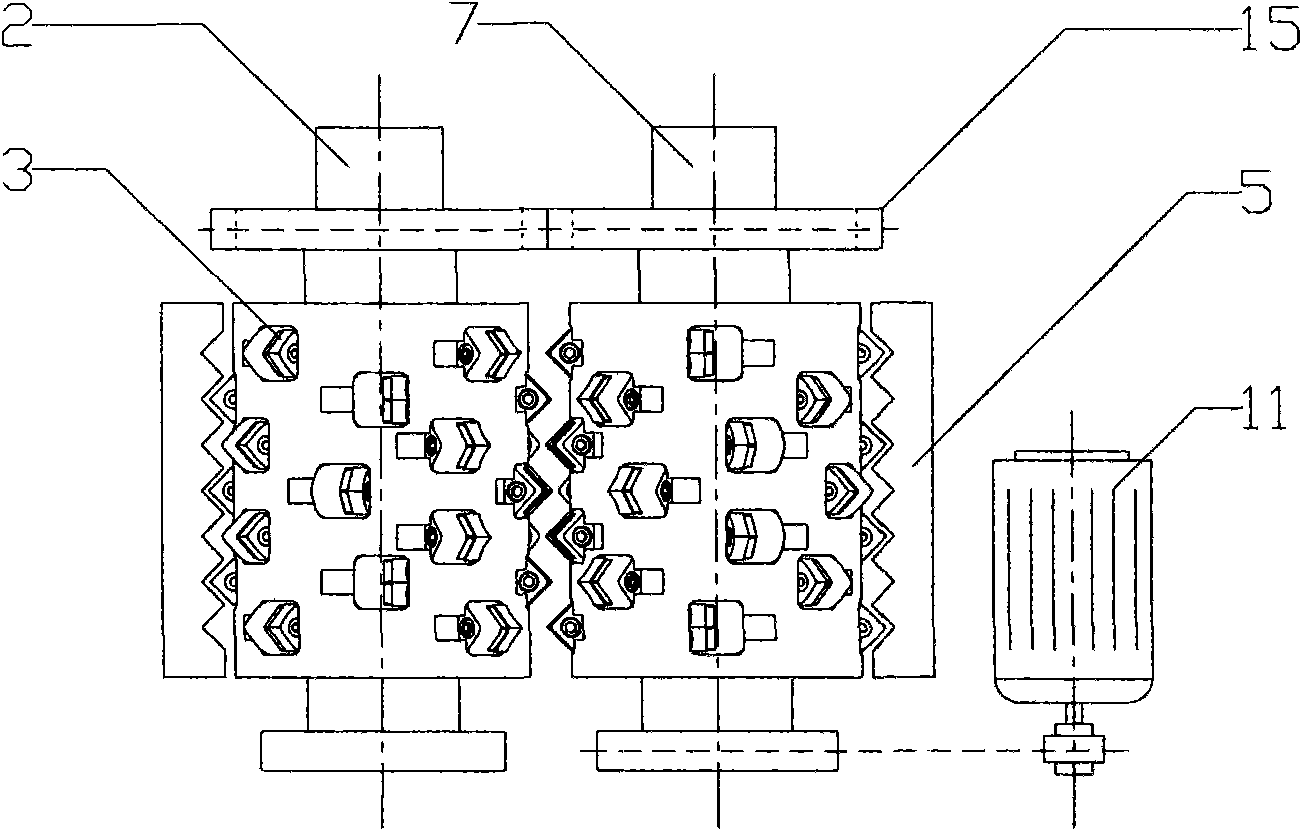

Gear type efficient crushing device for unformed fodder

The invention relates to a crushing device for unformed fodder, particularly to a gear type efficient crushing device for unformed fodder, and provides the low-cost, high-crushing speed and convenient-operation gear type efficient crushing device for unformed fodder which is aimed at solving the technical problem. The gear type efficient crushing device for unformed fodder provided to solve the technical problem comprises a bottom plate, a left rack, a collection frame, a right rack, a filter frame, a knock block, a first fixed rod, a bearing seat, a fixed plate, a second fixed rod, a first gear, a large belt pulley, and the like, wherein the left rack is welded on the left side of the top of the bottom plate; supporting rods are welded at the upper part of the right side of the left rack; a crushing frame is welded at the right ends of the supporting rods; and a net plate is welded at the bottom of the crushing frame. According to the gear type efficient crushing device, the effects of low cost, high crushing speed and convenient operation are achieved, the device always exerts an important function and has a good crushing effect, and the working efficiency is improved.

Owner:PHST CORP

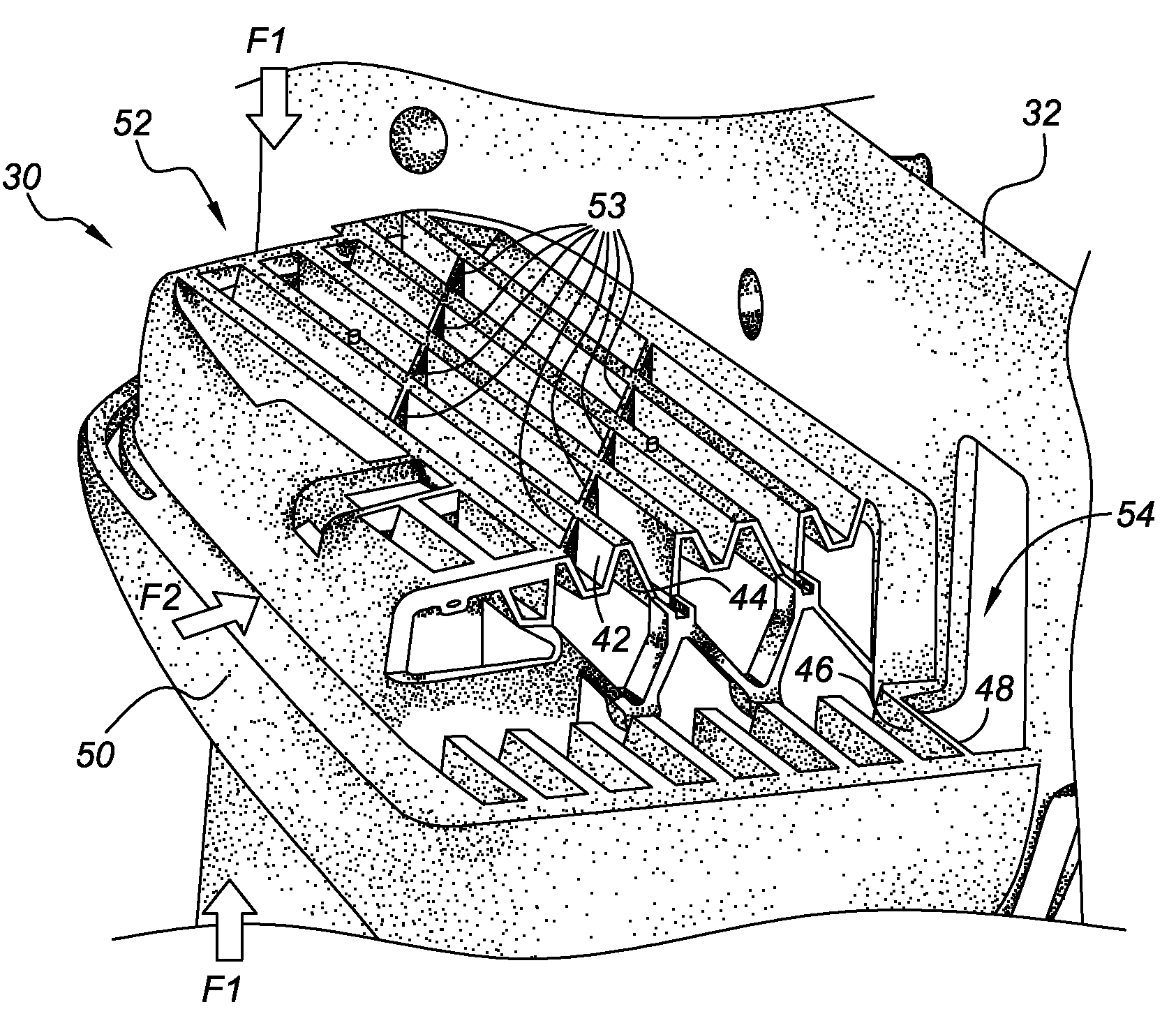

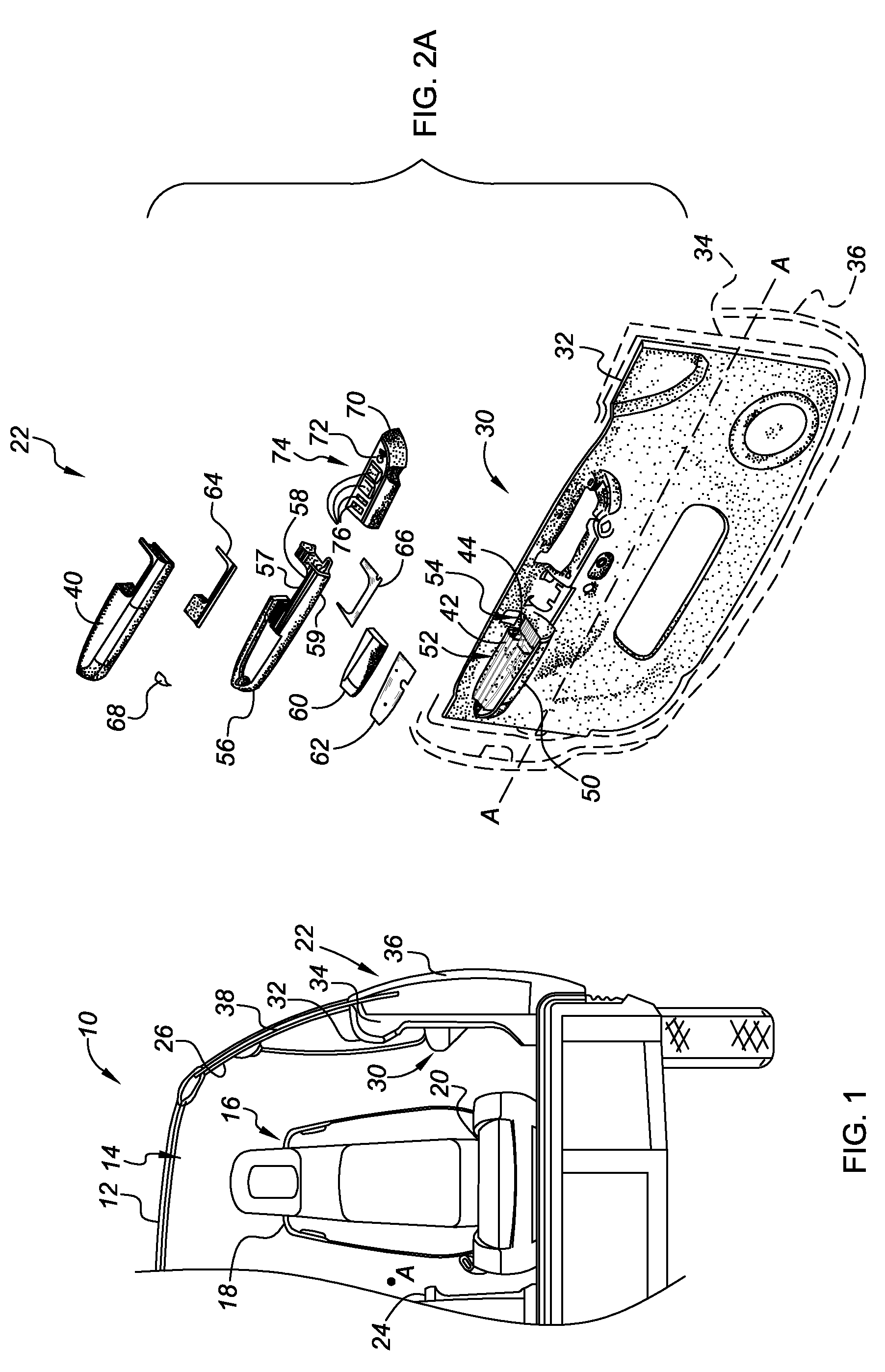

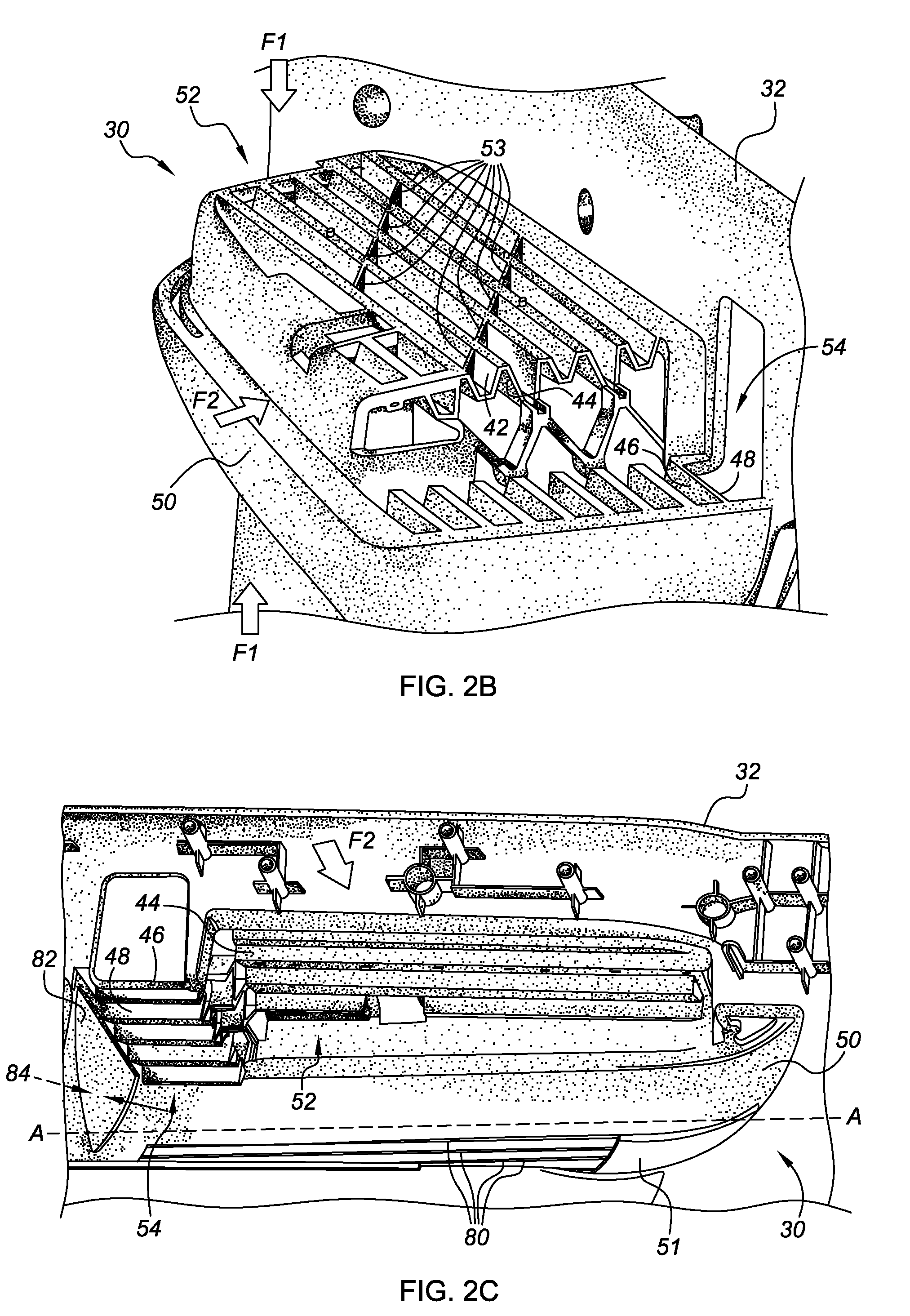

Crushable armrest assembly

InactiveUS7828388B2Improve crushing effectUniform energyPedestrian/occupant safety arrangementArm restsMobile vehicleEngineering

An armrest for use with a motorized vehicle is provided comprising first and second substantially opposing surfaces elongated longitudinally along the vehicle's interior surface and extending laterally inward therefrom. The armrest also includes a substantially vertical wall portion extending from the inner periphery of the first and second surfaces. The first and second surfaces define a plurality of channels oriented substantially parallel to one another and elongated longitudinally relative to the vehicle, in either a parallel or oblique fashion relative to a longitudinal axis of the vehicle. The plurality of channels is configured to sustain substantial vertical loading and controllably deform under a predetermined threshold lateral crush load. In addition, the plurality of channels preferably includes one or more partitions within each of the channels that are oriented relative to one another to thereby create a load path for lateral loads imparted to the armrest assembly.

Owner:GM GLOBAL TECH OPERATIONS LLC

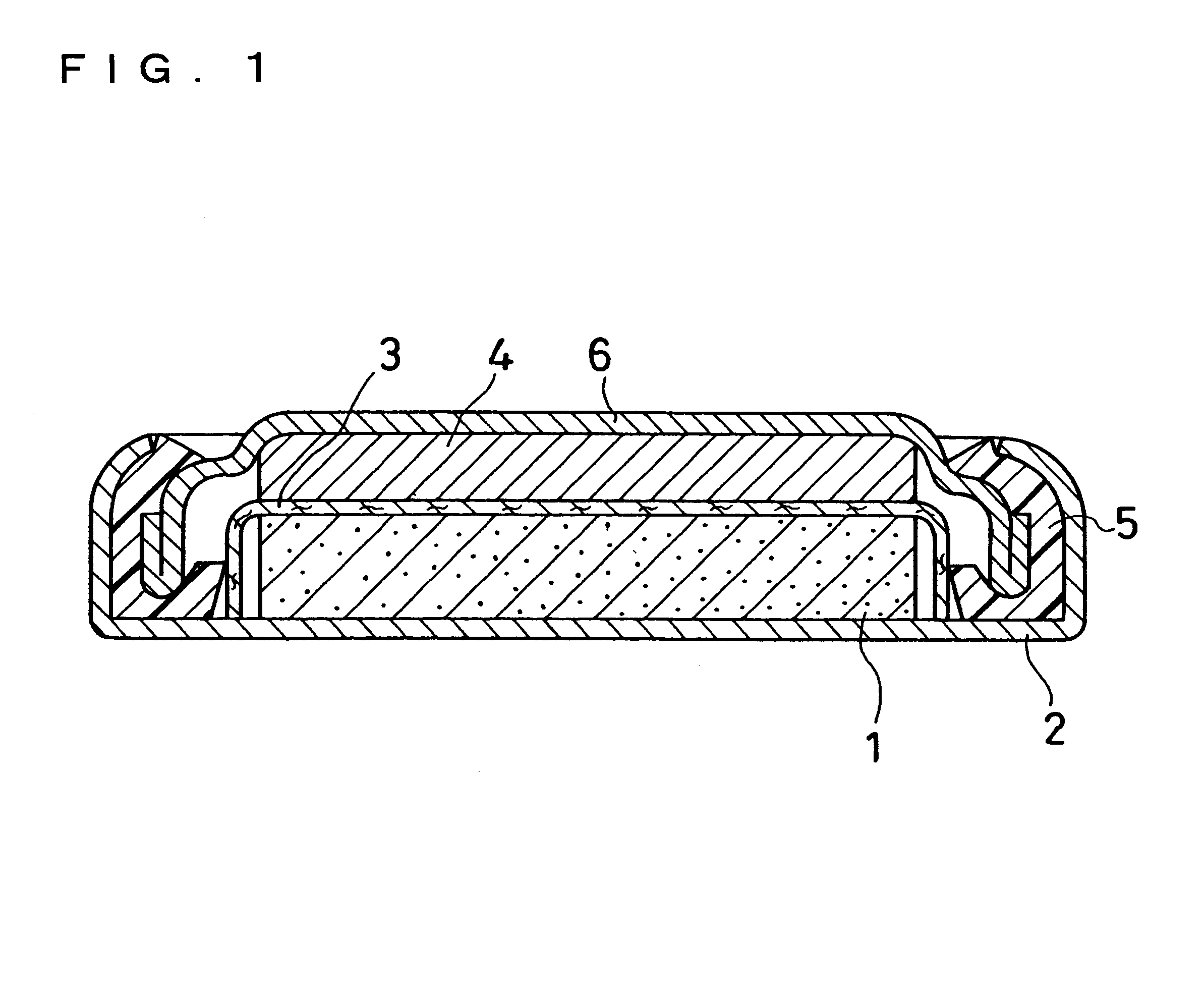

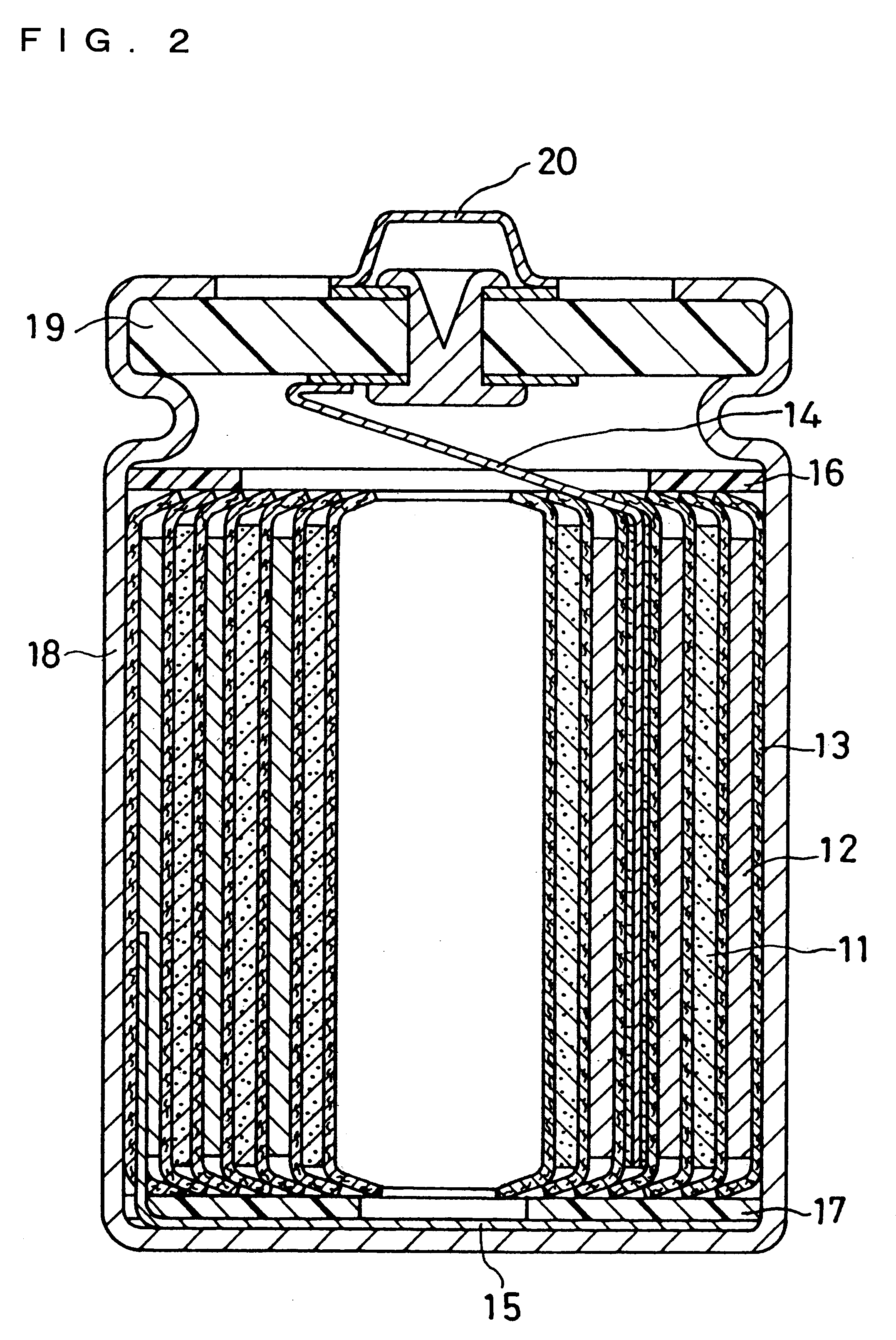

Non-aqueous electrolyte secondary battery

InactiveUS6265111B1Reduced activityImprove cycle lifeActive material electrodesNon-aqueous electrolyte accumulator electrodesAlloyMaterials science

A non-aqueous electrolyte secondary battery having an improved negative electrode is disclosed. The negative electrode comprises alloy particles having a composition represented by the formula:wherein M1 represents at least one element selected from the element group m1 consisting of Ti, Zr, V, Sr, Ba, Y, La, Cr, Mo, W, Mn, Co, Ir, Ni, Cu and Fe, M2 represents at least one element selected from the element group m2 consisting of Mg, Ca, Al, In, Si, Sn, Pb, Sb and Bi, M1 and M2 represent different elements each other, and wherein 0<=x<=10, 0.1<=a<=10, with the proviso that 2<=a<=10 when M1 is composed only of Fe, and having at least two phases which are different in composition each other.

Owner:PANASONIC CORP

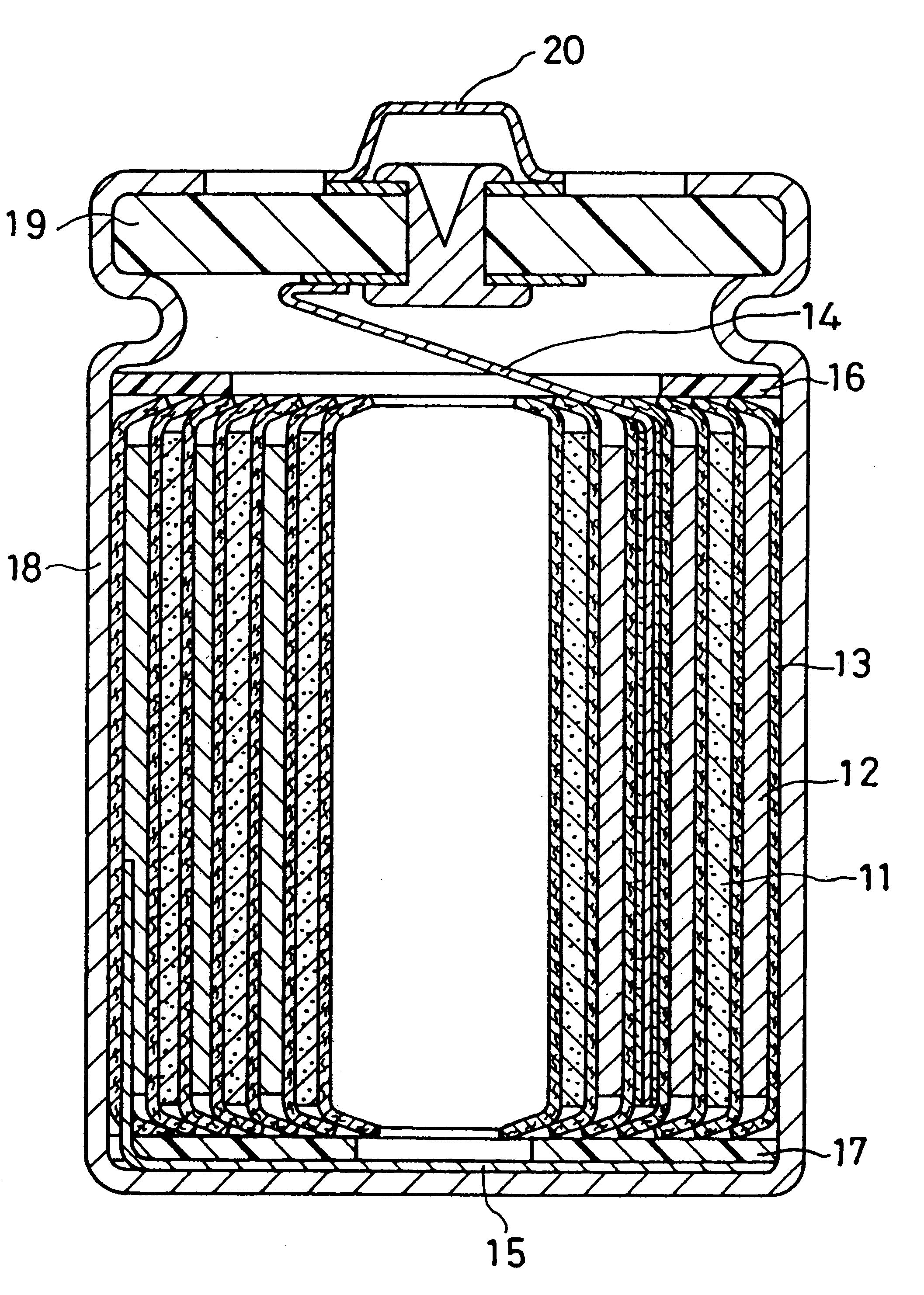

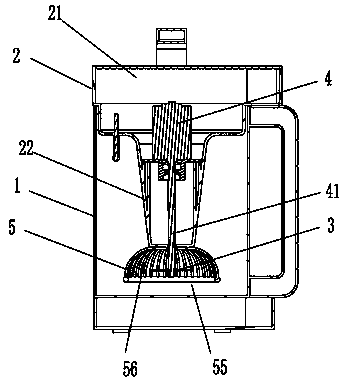

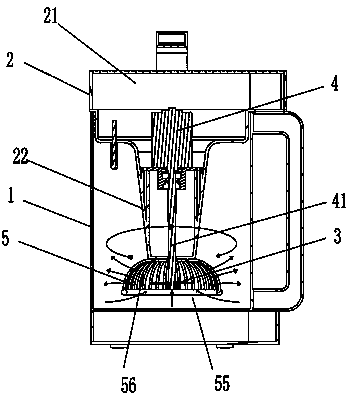

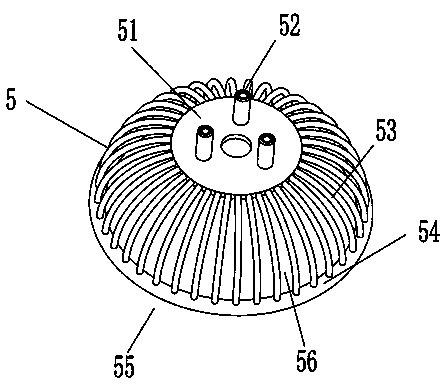

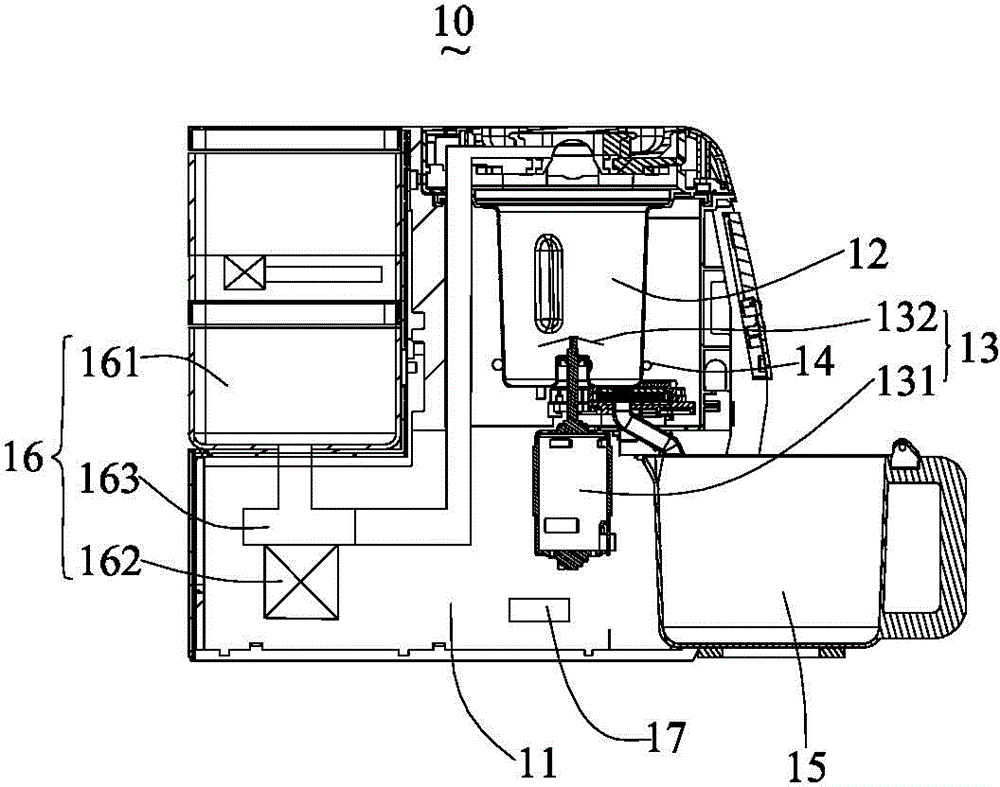

Soybean milk machine with small-space crushing cover

ActiveCN103654475AImproved material crushing effectEnsure consistencyBeverage vesselsEngineeringWater pumping

In order to solve the problems that the good material crushing effect and cleaning easiness of an existing soybean milk machine can not be achieved at the same time, and the uniformity of the crushing effect is difficult to guarantee, the invention provides a soybean milk machine with a small-space crushing cover. According to the soybean milk machine, the unsealed small-space crushing cover is arranged on the lower portion of a lower cover of a machine head, a cutter body is located inside the unsealed small-space crushing cover, the cutter body is provided with a water pumping part which enables water in a cup body to move towards the unsealed small-space crushing cover in the rotating process, the unsealed small-space crushing cover is provided with at least one bottom feed port and a plurality of discharge ports, and the maximal permission passing size of materials on the discharge ports is smaller than the original size of materials to be crushed. According to the soybean milk machine with the small-space crushing cover, material crushing is divided into the two phases of small-space concentrated crushing and cyclic crushing, the material crushing effect is made to be greatly improved, the uniformity of the crushing effect is guaranteed, meanwhile, the small-space crushing cover can be conveniently cleaned, and the problem that the good material crushing effect and cleaning easiness can not be achieved at the same time is solved.

Owner:JOYOUNG CO LTD

Mechanical multiple-stage building rubbish crushing device

InactiveCN106807475ASimple structureReduce manufacturing costSievingScreeningConstruction wasteMultiple stages

Owner:殷晓晴

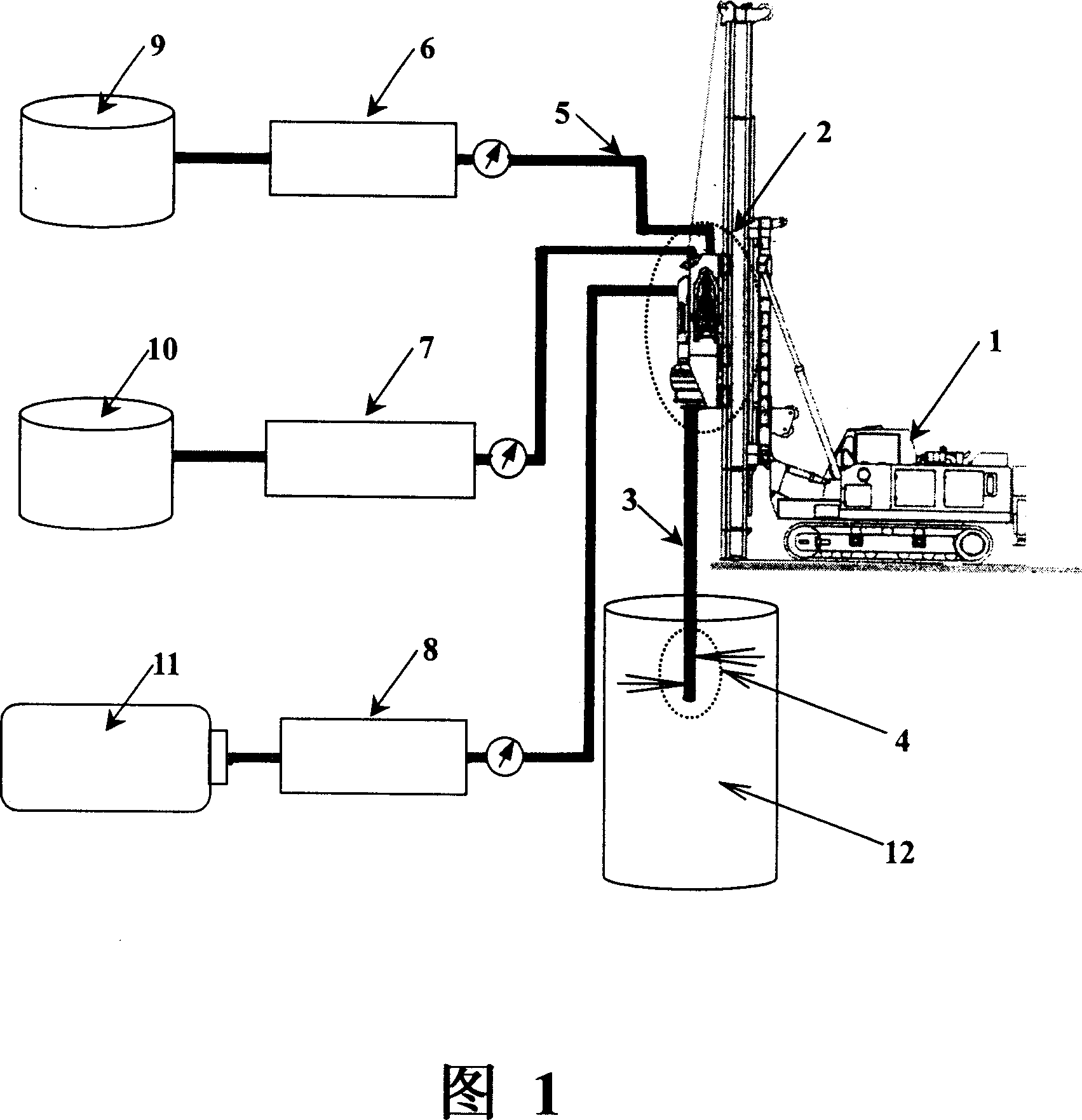

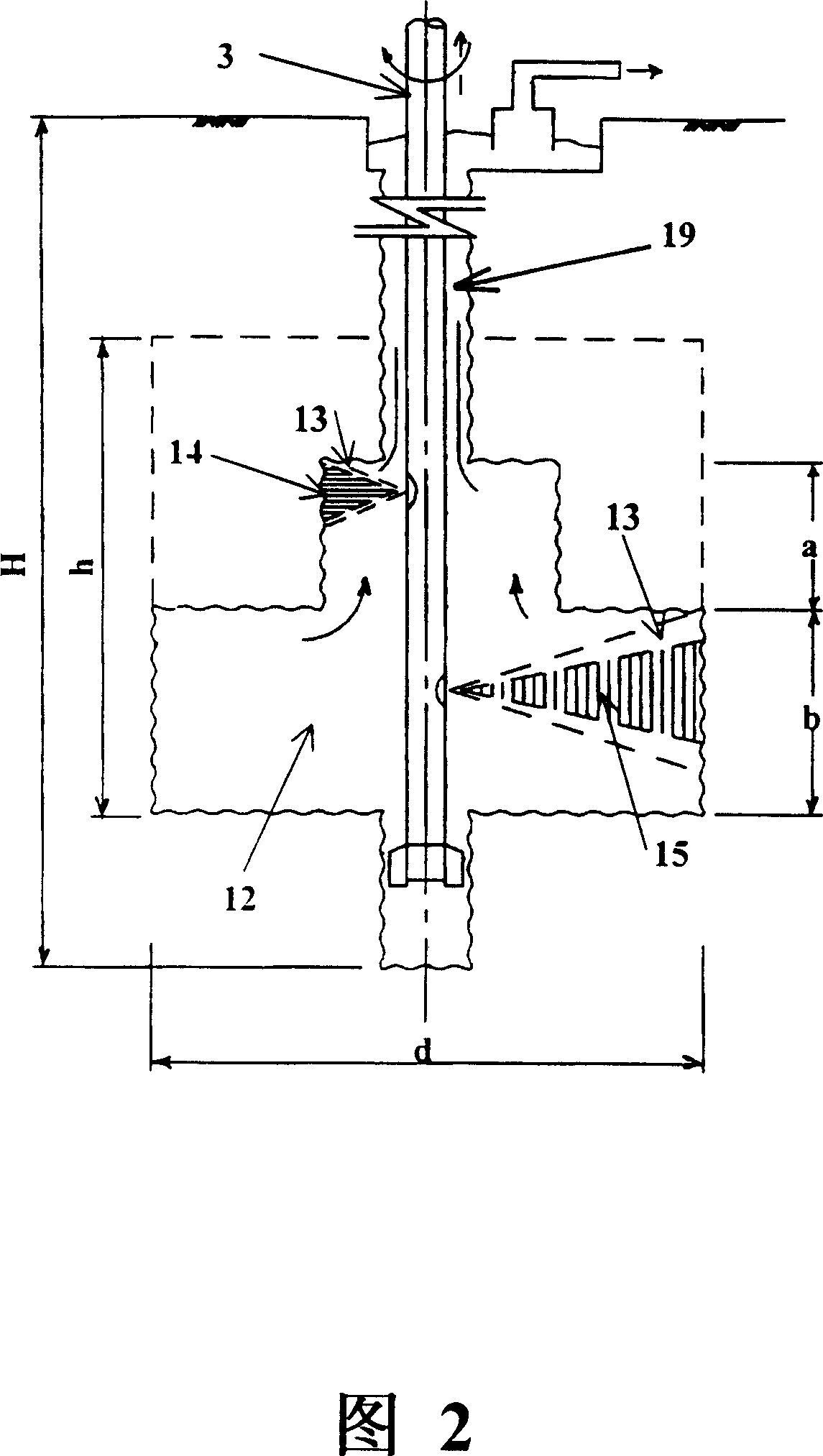

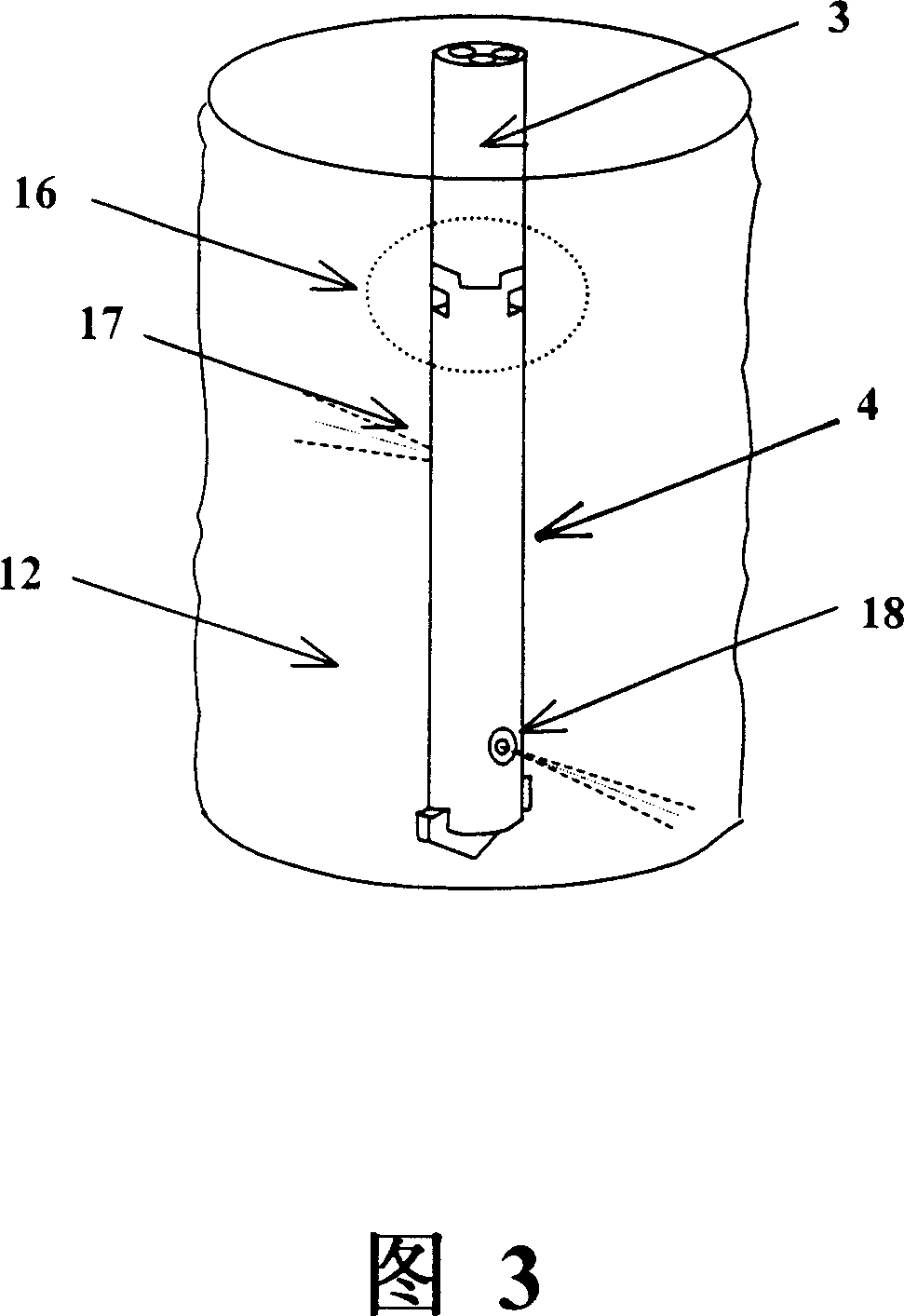

Three pipe double high pressure rotary jet sprouting reinforced construction method and its equipment

The triple pipe double high pressure rotary jetting sprouting method for reinforcing construction includes jetting high pressure water flow coating compressed air via the upper nozzle and jetting high pressure cement slurry coating compressed air via the lower nozzle separately to twice cut the soil before the cement slurry and the stirred soil mix to form foundation reinforcing pile. The rotary jetting apparatus for the construction has both high pressure water nozzle and high pressure cement slurry nozzle for the first soil cutting and the second soil cutting separately. The present invention can form high pressure jet with great energy and powerful soil breaking effect, and can form large and deep reinforcing pile.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

Preparation method of soybean milk

ActiveCN104798890AIncrease concentrationNot easy to agglomerateBeverage vesselsMilk substitutesWater vaporDry bean

The invention relates to a preparation method of soybean milk. The preparation method at least comprises the following stages: (a), flour preparation stage: providing a crushing container, a heating element for heating the crushing container and a crushing device, directly heating the crushing container through the heating element, so as to ensure that the temperature of the crushing container is increased to 70-90 DEG C, adding dried beans into the crushing container, crushing the dried beans into bean flour through the crushing device, and ensuring that lipase and beany flavor of the bean flour are removed in the crushing container at ambient temperature; (b), preparation and boiling stage: adding water to the bean flour, so as to prepare the bean flour into pulp, and heating and boiling the pulp till the pulp is well cooked. By adopting the air temperature inside the crushing device, crushing, lipase removal and beany flavor removal are performed at the same time, protein can keep invariant, beany flavor can be effectively removed, and crushing the beans into bean flour firstly can greatly enhance the crushing fineness, so that the soybean milk concentration can be effectively enhanced. In addition, water vapor can be evaporated during crushing of the beans in the high-temperature environment, the bean flour is not easy to agglomerate, and the crushing effect is good.

Owner:JOYOUNG CO LTD

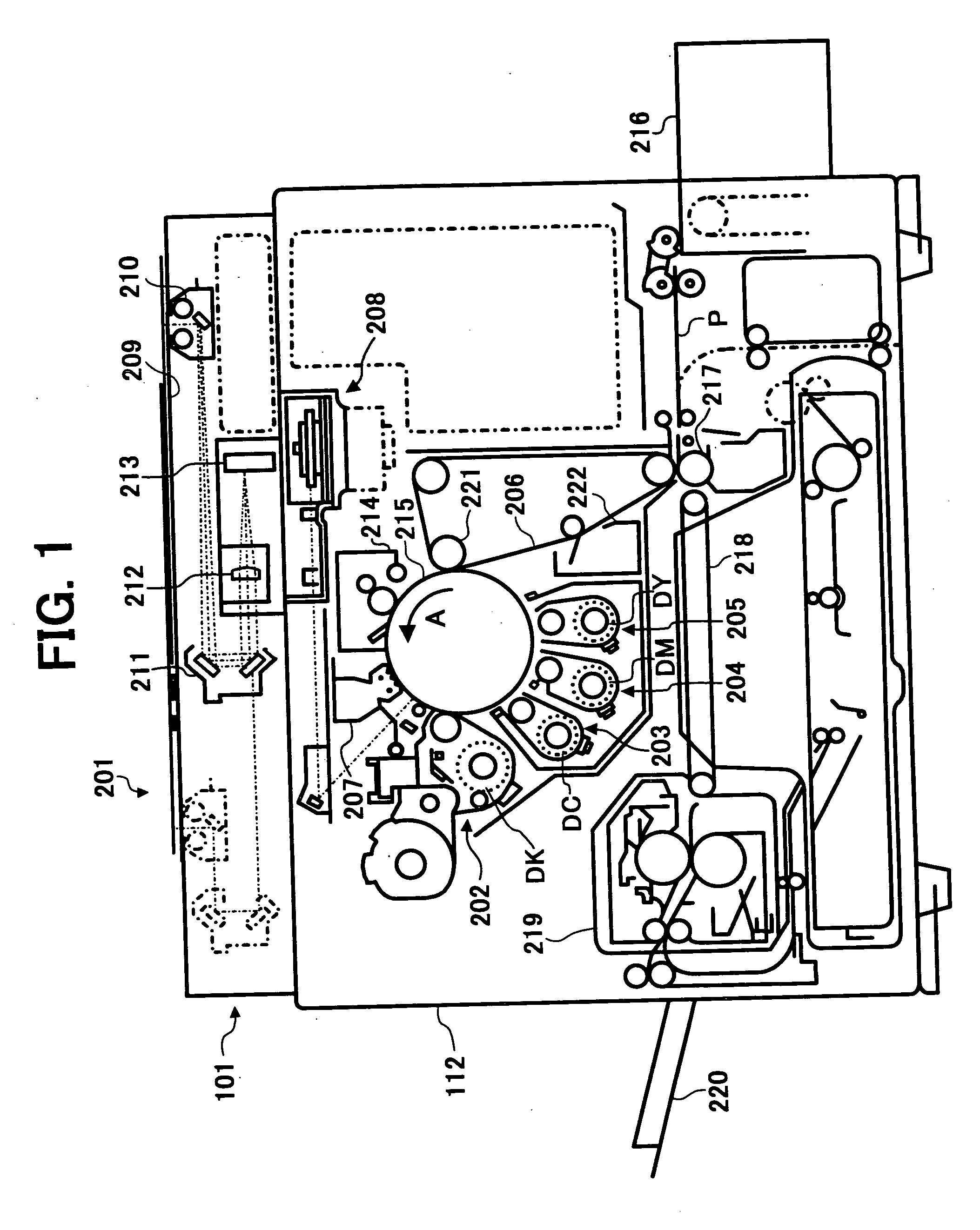

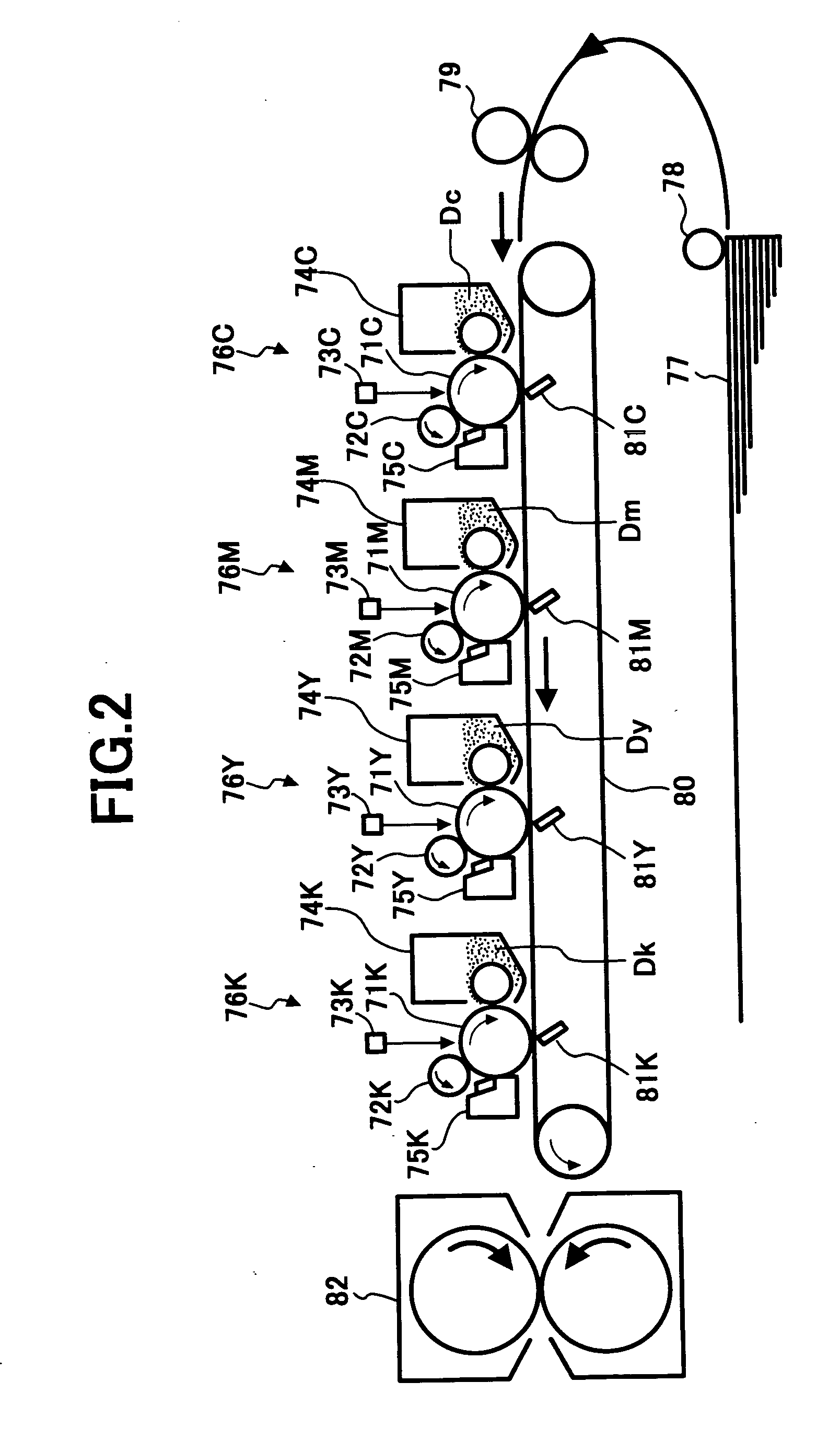

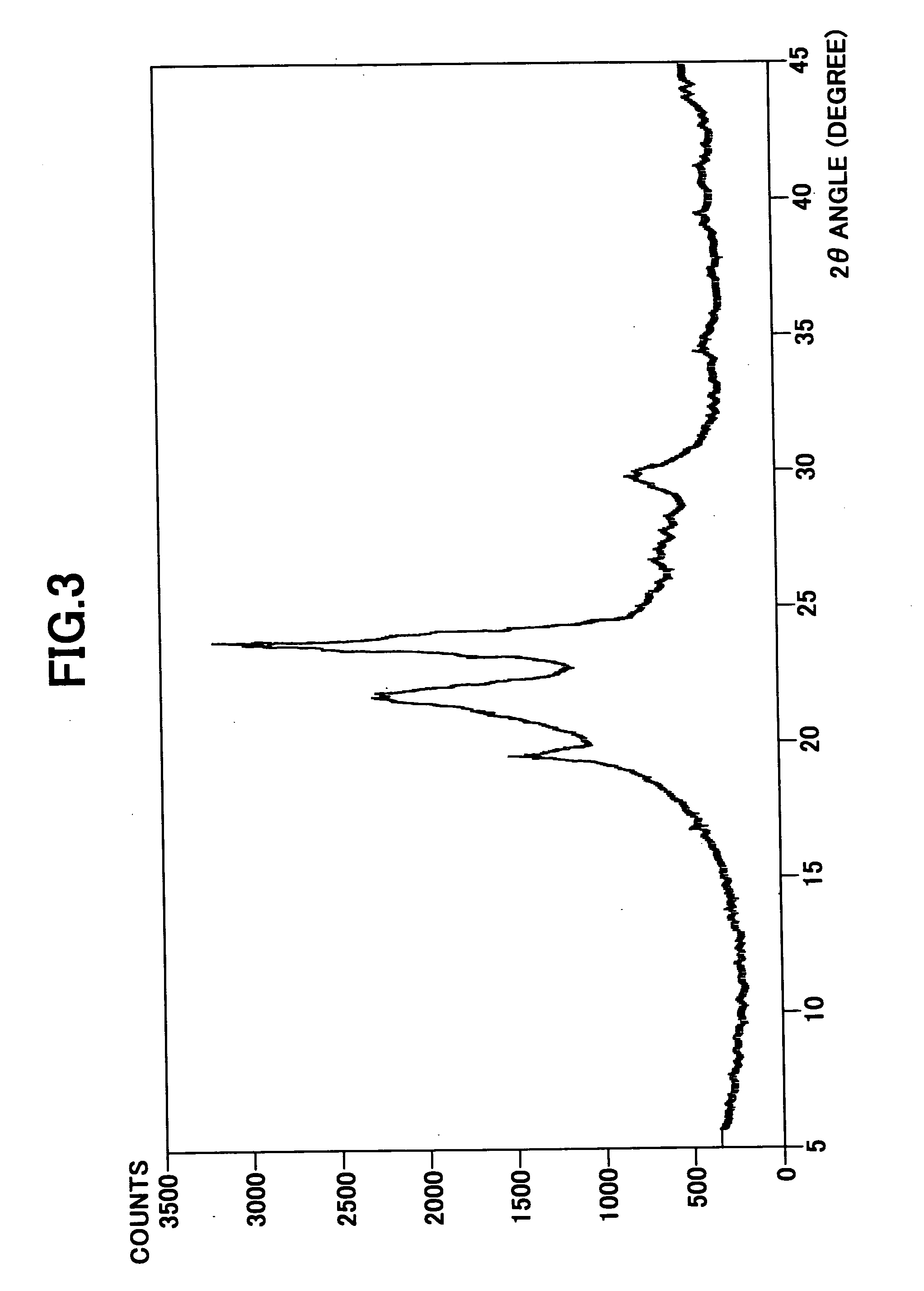

Color toner for developing electrostatic images, toner container containing the color toner, and image forming method and apparatus using the color toner

InactiveUS20050277046A1Low temperature fixabilityGood transferabilityDevelopersElectrographic processes using charge patternWaxImage formation

A color toner including toner particles including a colorant, a binder resin, and a wax; and an external additive including at least one of an inorganic particulate material and a particulate resin, wherein the binder resin includes a polyester resin (A) having a crystallinity and a formula (—O—CO—CR1═CR2—CO—O—(CH2)n—)m, wherein R1 and R2 independently represents a hydrocarbon, and n and m are repeating numbers; a resin (B); and a resin (C), wherein the resins (B) and (C) and the wax have an island-sea structure such that the resin (C) is present like islands in a sea of the resin (B) and the wax is substantially included in the resin (C). A toner container, an image forming method, an image forming apparatus and a process cartridge including the color toner are also provided.

Owner:SAWADA TOYOSHI +6

Sandstone smashing and grinding device for building engineering

The invention discloses a sandstone crushing and grinding device for construction engineering, which comprises a box body and a feeding port, the feeding port is arranged on the top wall of the box body, and two first horizontal shafts are arranged inside the box body , the inside of the box is also provided with a second horizontal shaft whose axis is parallel to the axis of the first horizontal shaft, one end of one of the first horizontal shafts is provided with a semi-circular gear, and an upper rack is arranged above the semi-circular gear, and the semi-circular gear A double-sided rack is arranged under the gear, a rotating gear is arranged at one end of the second horizontal axis, a swing rod is arranged on the rotating sleeve, a swing grinding disc is arranged at the lower end of the swing rod, and a side and the inner wall of the box are arranged under the swing grinding disc. connected to the fixed grinding disc, and the bottom of the box is also provided with a screen plate and a plurality of cross bars. The invention has the advantages of simple structure, high crushing efficiency, good crushing effect on sand and stone crushed three times, and can screen sand and stone grains at the same time, and has strong practicability.

Owner:宋衡星

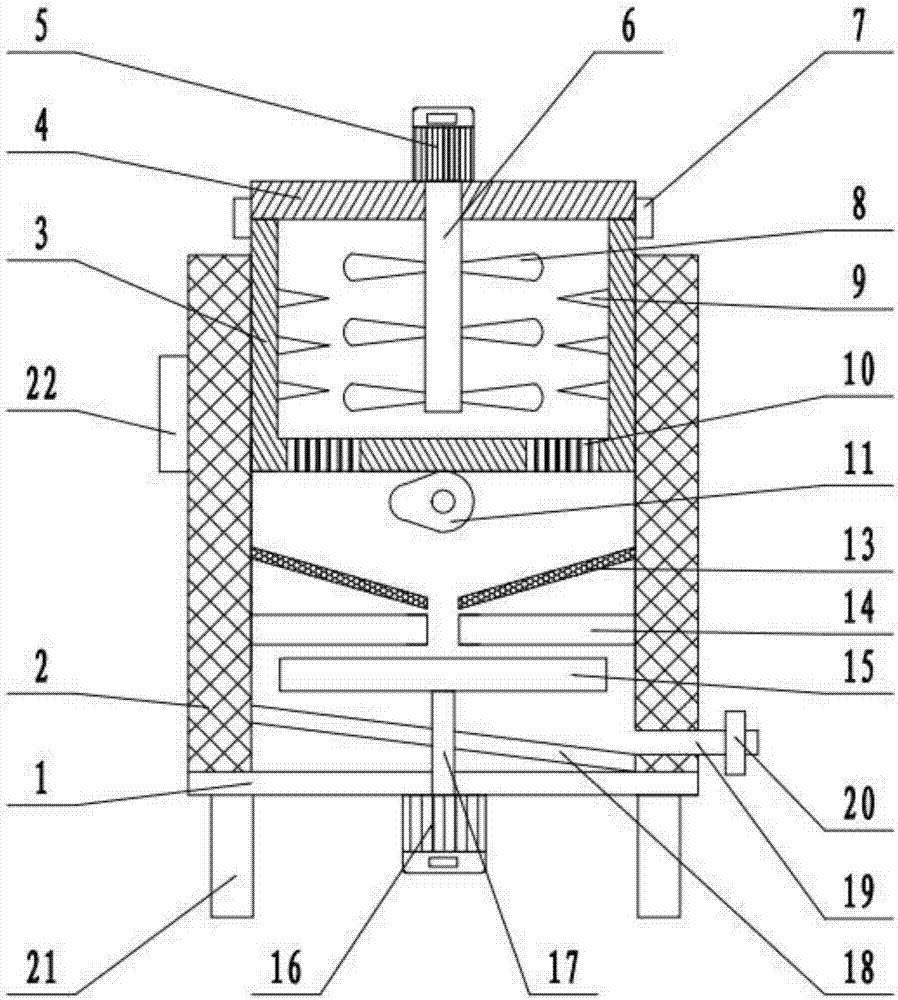

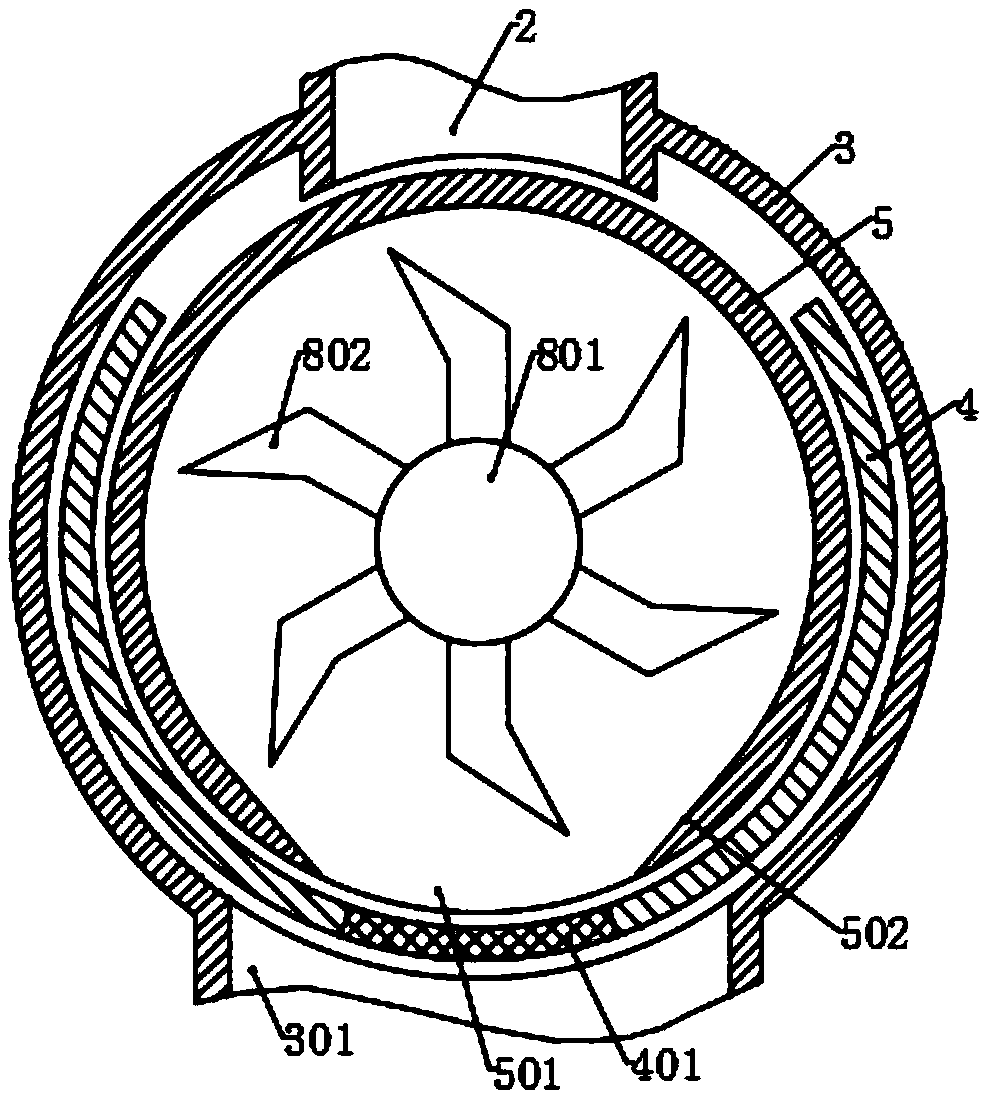

Self-circulation Chinese herbal medicine crushing and grinding integration device

InactiveCN107790244ACrushed fullyImprove crushing effectGrain treatmentsReciprocating motionElectric machinery

The invention discloses a self-circulation Chinese herbal medicine crushing and grinding integration device. The self-circulation Chinese herbal medicine crushing and grinding integration device comprises a shell, support legs, a feed port, a crushing motor, a crushing shaft, a crushing blade, a conical grinding hammer and a grinding motor; the left side wall of the shell is fixedly connected witha circulating cylinder; a screw rod is arranged in the circulating cylinder; the upper surface of the circulating cylinder is fixedly connected with a double-shaft motor; the upper surface of the shell is fixedly connected with the crushing motor; a shaft extension end of the crushing motor is fixedly connected with the crushing shaft; a screen plate is arranged below the crushing shaft; a grinding table is arranged below the screen plate; the conical grinding hammer is arranged in the grinding table; traditional Chinese medicines are crushed by using the crushing blade, and are stirred by using stirring blades during crushing, so that the traditional Chinese medicines are crushed more sufficiently; the crushed traditional Chinese medicines fall onto the screen plate, and the screen plateperforms a left-right reciprocating motion to improve the efficiency of the traditional Chinese medicine passing through the screen plate; and the conical grinding hammer and the grinding table are matched to crush the traditional Chinese medicines, and are opposite in rotating direction to improve the grinding efficiency.

Owner:李欢欢

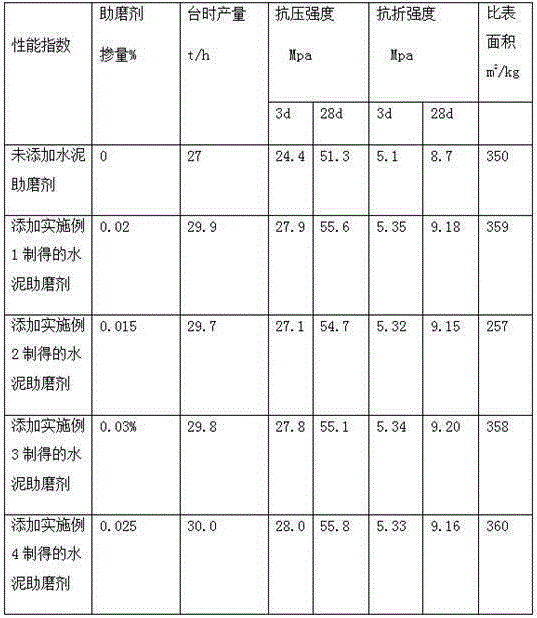

Cement grinding aid and preparation method thereof

The invention relates to a cement grinding aid, in particular to a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from, by weight, 13-18 parts of polymeric polylol, 8-12 parts of tri-isopropanolamine, 12-15 parts of polyol ether, 15-20 parts of ethanediol, 25-30 parts of triethanolamine, 15-18 parts of molasses, 13-15 parts of lignin, 0.03-0.06 part of sodium chloride, 0.5-1 part of silane coupling agents and 40-45 parts of water. By means of the obtained cement grinding aid, in the cement production process, the phenomena of clinker fine particle aggregation and ball pasting can be effectively improved, mobility of clinker particles is enhanced, thereby the pulverization effect of grinding media in a grinding machine for materials is enhanced, grinding efficiency can be improved by 15-20%, the cement machine-hour yield is increased, electricity consumption is greatly lowered, production cost is lowered, in addition, strength of cement at different ages can be remarkably improved, and flowability of the cement is improved.

Owner:内蒙古同佳技术发展有限公司

Vibration type material crushing and grinding integrated machine

The invention discloses a vibration type material crushing and grinding integrated machine which comprises a base, a sleeve, a tank, a tank cover and support legs. The vibration type material crushing and grinding integrated machine is characterized in that the lower end of the sleeve is fixedly connected with the base; the tank is mounted in the sleeve; the tank is in sliding connection with the inner wall of the sleeve; the upper surface of the tank cover is fixedly connected with a crushing motor; a shaft extending end of the crushing motor is fixedly connected with a rotary shaft; the rotary shaft is fixedly connected with crushing vanes; screening holes are formed in the bottom of the tank; a cam is arranged under the tank; a through hole is formed in the middle of a guide plate; the crushing motor drives the crushing vanes to rotate to crush materials; the crushing vanes are matched with crushing cutting blades on the inner wall of the tank, and the crushing efficiency is improved; the cam rotates to drive the tank to vibrate up and down along the inner wall of the sleeve, so that the crushing effect is further improved, and crushed materials can penetrate through the screening holes to fall off conveniently; and an upper grinding plate and a lower grinding plate are matched for use, and ridges on the surfaces of the crushed materials are ground off, so that the materials are ground into balls.

Owner:惠安县丽佳智能设备有限公司

Construction waste treatment device with dual functions of crushing and screening

InactiveCN106824485ASimple structureReduce manufacturing costSievingScreeningMotor driveDual function

The invention discloses a construction waste treatment device with dual functions of crushing and screening. The construction waste treatment device has the advantages of being reasonable and simple in structure, low in production cost, convenient to install, good in crushing effect, convenient to use and the like. Multiple crushing is conducted on construction waste by a multi-level crushing device, the crushing effect is good, and the size of the construction waste after the crushing can meet the requirements of recycling and reusing; when the construction waste treatment device is in use, the construction waste is put into a lifting box and carried to a crushing chamber through a material net on a synchronous belt, firstly the construction waste is crushed through crushing blades and ground through grinding teeth, when the construction waste becomes thin and small particles, the particles are filtered by a first filtering net, when the particles are relatively large, grinding continues to be carried out, filtered particles enter a screening chamber through an oblique plate, a screening motor drives a screening plate, and the particles are screened on a screening net, fall into a transport chamber, and finally go to a transport vehicle to be collected.

Owner:徐勇

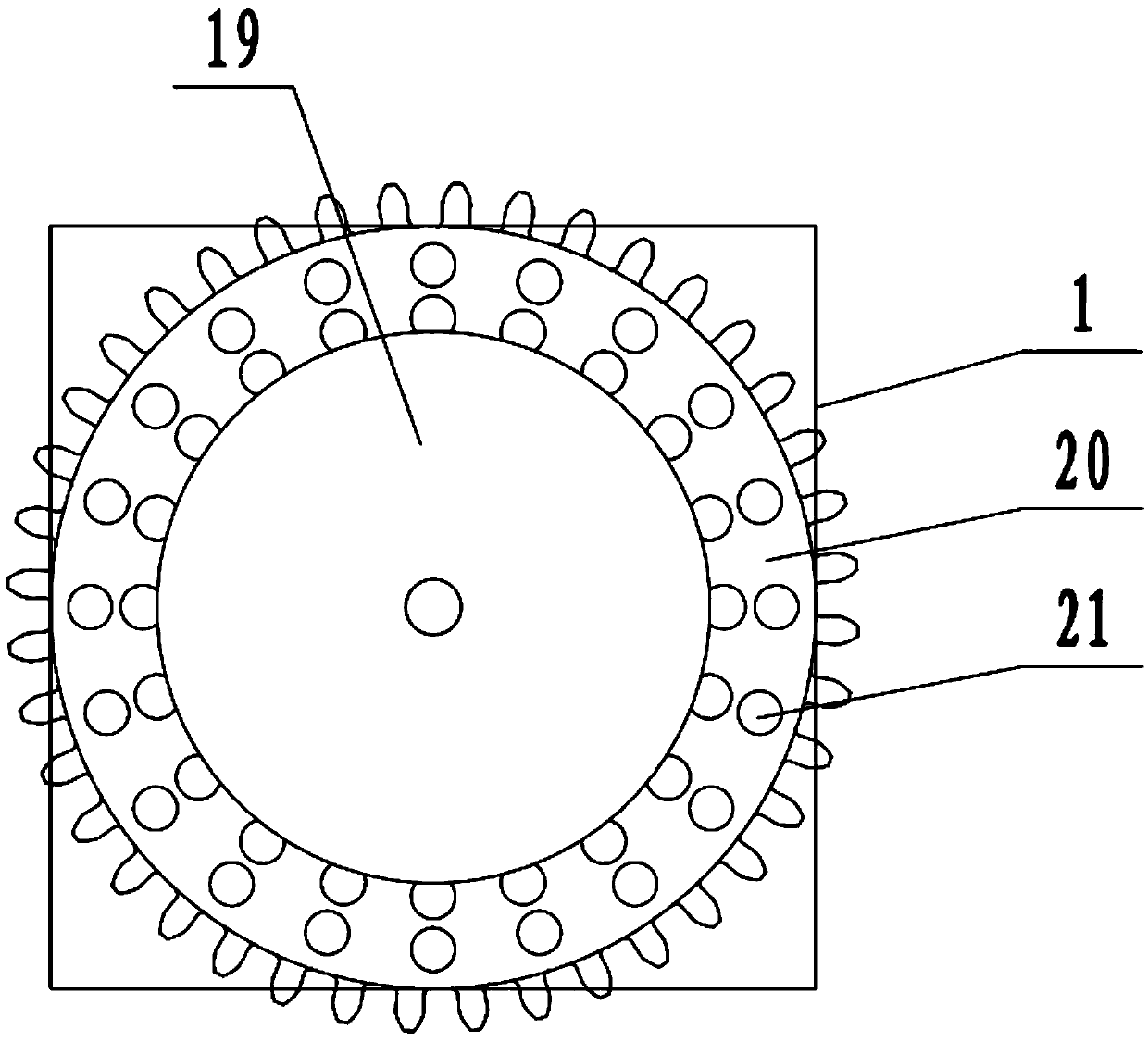

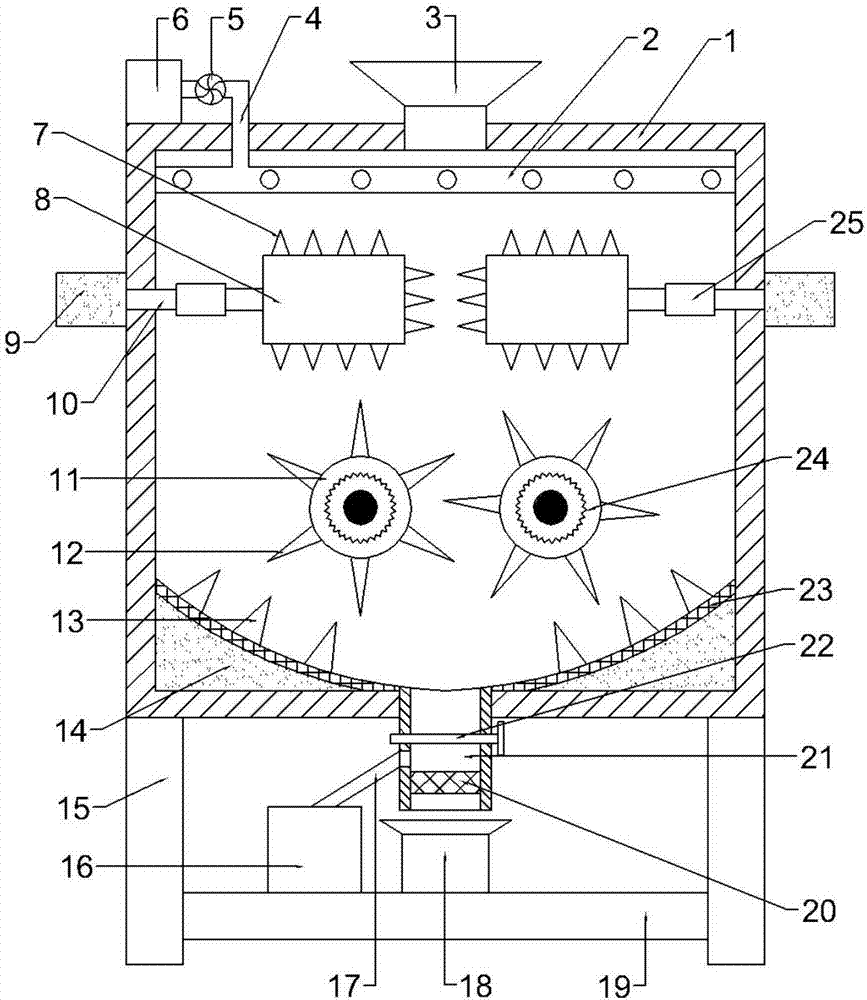

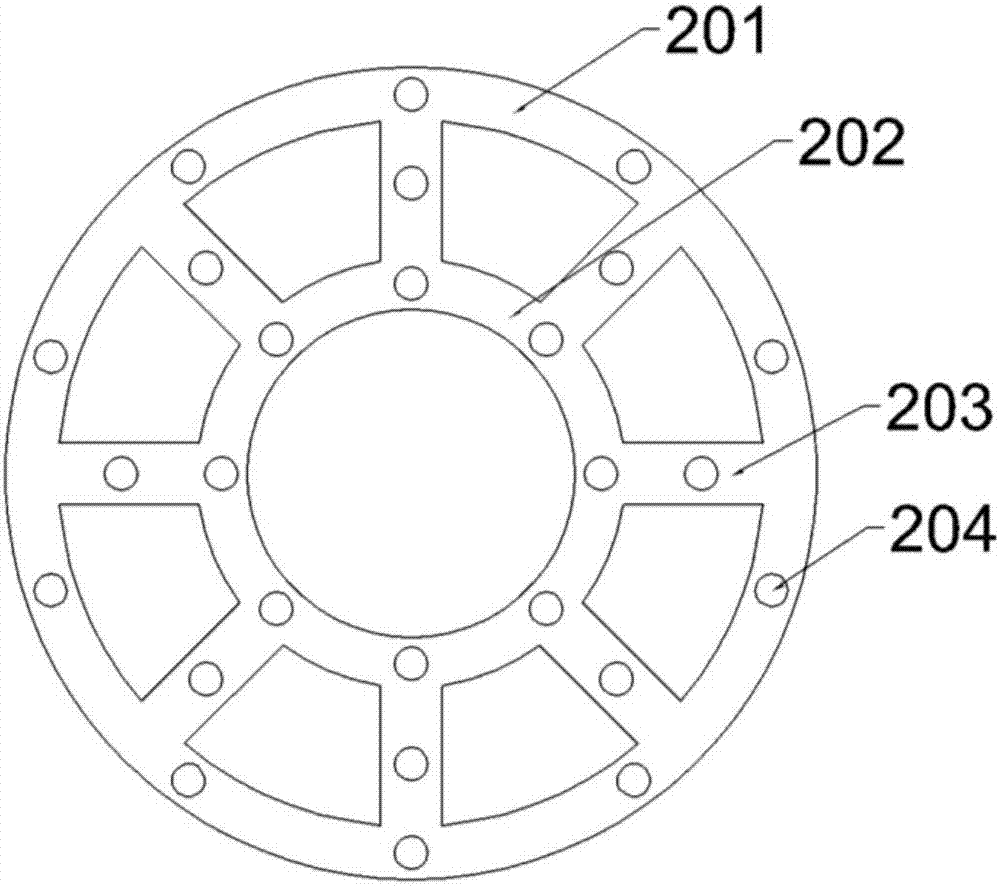

Efficient crushing device for traditional Chinese medicine production

InactiveCN107626418AImprove crushing effect and efficiencyImprove crushing effectSievingScreeningGrindChinese herbology

The invention discloses an efficient crushing device for traditional Chinese medicine production. The device comprises a body. A base is arranged in the bottom of the body; the periphery of the bottomof the body is fixed on the base through supporting legs; a feed inlet is formed in the top end of the left side wall of the body; a feeding supporting plate is horizontally arranged at the connection of the inner side of the body and the feed inlet; a pre-cutting device is arranged on one side of a supporting plate; the pre-cutting device comprises a first rotary shaft; the top end of the rotaryshaft penetrates through the body, and the top end of the first rotary shaft is fixedly connected to the output shaft of a first motor. The efficient crushing device for traditional Chinese medicineproduction disclosed by the invention separately pre-cuts the medicinal materials, crushes grinds and the same with crushing teeth through three crushing devices which are arranged up and down, so that the crushing effect of traditional Chinese medicinal materials is ensured, and the quality of the product traditional Chinese medicine is improved; the device fully and uniformly crushes, and is high in work efficiency; a filter screen is arranged to screen the traditional Chinese medicines; in addition, a jittering device is arranged to drive the filter screen to jitter up and down, so that thescreening efficiency is increased effectively.

Owner:单开禹

Environmentally-friendly medical waste treatment device

InactiveCN111530547AReasonable structural designImprove crushing effectMagnetic separationGrain treatmentsMedical wasteSpray nozzle

An environmentally-friendly medical waste treatment device comprises a base, a treatment box is arranged on the upper end of a pillar, a crushing mechanism is arranged on the upper side of the inner part of the treatment box, a filter screen is arranged on the inner part of the treatment box, a vibration mechanism is arranged at the lower end of the filter screen, a cleaning mechanism is connectedto the left side wall of the treatment box, a conveying mechanism is installed on the upper end of a frame, and a collection mechanism is arranged on the right side of the upper end of the base. Thedevice is reasonable in structure and design, wherein a first crushing roller and a second crushing roller rotate relatively through a counterclockwise first motor to crush medical wastes; the filterscreen realizes solid-liquid separation, and a second motor drives a cam to rotate to slightly vibrate the filter screen, so that the efficiency of the solid-liquid separation is improved; a water pump sprays disinfectant through a spray nozzle to the medical wastes for disinfection treatment; an electromagnet in a sieving room can adsorb and screen some metal needles or scissors in the wastes, sothat the waste of resources is avoided, the rest of the wastes finally enter a collection box for compression, the volume of the wastes is reduced, and the transportation is convenient.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Crushing and grinding device for production and processing of traditional Chinese medicinal materials

InactiveCN108940503AAvoid enteringImprove subsequent grinding efficiencyGrain treatmentsEngineeringMaterials processing

The invention discloses a crushing and grinding device for production and processing of traditional Chinese medicinal materials in the technical field of traditional Chinese medicinal material processing. The crushing and grinding device comprises a feeding hopper, a feeding pipe, a fixing case, a screening case, a crushing case and a grinding case. According to the crushing and grinding device, the traditional Chinese medicinal materials are put into the feeding hopper and then enter the crushing case along the feeding pipe, a crushing mechanism is used for crushing the traditional Chinese medicinal materials, and a feeding inlet of the crushing case conducting crushing rotates to face downwards; the traditional Chinese medicinal materials are screened through the screening case, and thenthe feeding inlet of the crushing case is rotated to face upwards; the traditional Chinese medicinal materials which do not penetrate through a first screening mesh return to the crushing case through the shovel face at the feeding inlet and are subjected to secondary crushing along with next batch of to-be-crushed medicinal materials, and the traditional Chinese medicinal materials enter the grinding case and are ground through a grinding mechanism; and meanwhile, completely ground medicine powder is fed into a powder outlet through a rotating brush, so that the situation that powder particles are too fine due to the fact that ground medicine powder is left in a grinding groove and ground repeatedly is avoided, and the grinding effect is good.

Owner:周意

Efficient crushing device for construction waste recovery

InactiveCN107350004AAdjustable sizeGood for subsequent crushingMagnetic separationGrain treatmentsHydraulic cylinderIron removal

The invention discloses an efficient crushing device for construction waste recovery. The efficient crushing device comprises a box body, and a preliminary breaking mechanism is fixedly arranged at the upper part of the inner chamber of the box body. The preliminary breaking mechanism comprises a fixed breaking plate, a movable breaking plate, a disc, a hydraulic cylinder and a motor. An iron removal mechanism is arranged under the preliminary breaking mechanism, and a first crushing roller and a second crushing roller are arranged under the iron removal mechanism. In the falling process of massive construction wastes, the preliminary breaking mechanism breaks the massive construction wastes step by step, so that metal in the wastes is exposed. Moreover, follow-up crushing is facilitated, and the crushing efficiency is improved. The size of broken particles of construction wastes can be adjusted, and the breaking degree can be adjusted. The construction wastes are subjected to second level of crushing through the first crushing roller and the second crushing roller, and the construction wastes are crushed more thoroughly. The crushing effect is good, and the crushing efficiency is high. The metal, such as steel bars in the construction wastes can be removed through the iron removal mechanism and are collected. The efficient crushing device has the advantages of simple structure and convenience in operation.

Owner:广西综改咨询服务有限公司

Swing-type concrete block crushing, mixing and stirring device

InactiveCN107336355AImprove processing efficiencyAffectMixing operation control apparatusPretreatment controlEngineeringDrive motor

The invention discloses a swing type concrete block crushing and mixing device, which comprises a bottom plate, a side plate, a top plate and a mixing drum. Double-sided rack and right double-sided rack, the mixing drum is provided with a rotating shaft coaxial with it, the top of the rotating shaft is provided with a left gear, the left gear meshes with the left double-sided rack, and the mixing drum A sieve plate is installed inside, and the sieve plate divides the mixing drum into a crushing chamber and a mixing chamber. A crushing rod is arranged on the shaft section of the rotating shaft in the crushing chamber and on the side wall of the crushing chamber, and a crushing rod is arranged on the crushing rod. The blade is provided with a mixing rod at the bottom of the rotating shaft in the mixing chamber. The invention has the advantages of simple structure, continuous crushing and mixing of concrete blocks, improved working efficiency, sufficient and uniform crushing and mixing, high mixing and crushing efficiency, simple operation and strong practicability.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

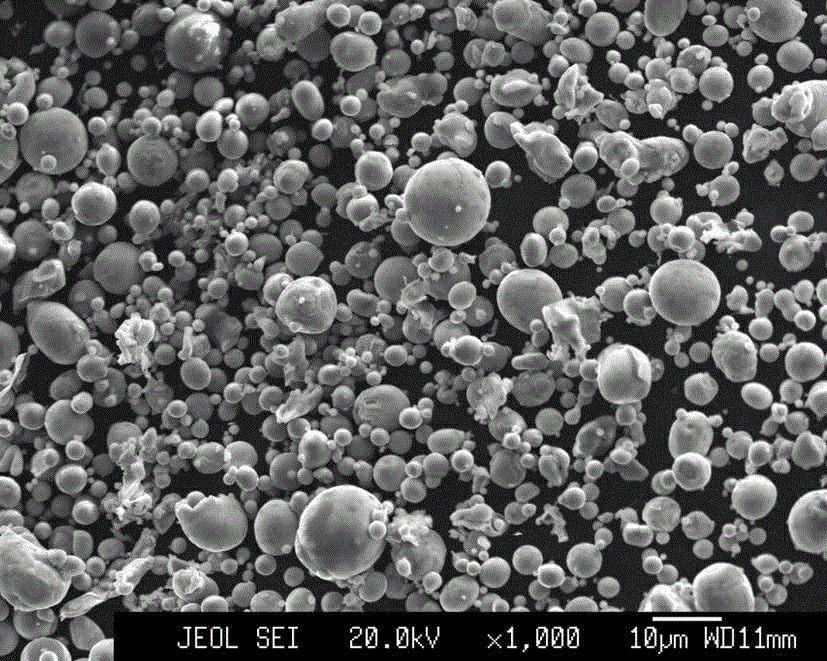

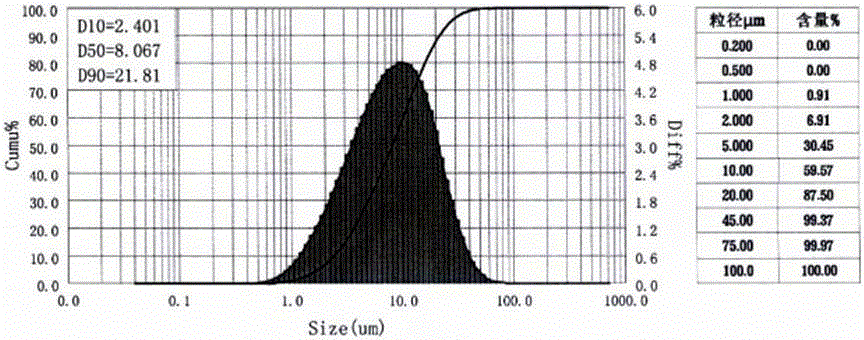

Atomizing method and device for preparing superfine near-spherical low-oxygen metal powder

InactiveCN105290412ASmall powder sizeThe amount of atomized water is reducedMetallurgyMetal injection molding

The invention discloses an atomizing method and device for preparing superfine near-spherical low-oxygen metal powder. The method includes the step that molten metal liquid flow is broken into liquid drops through high-pressure gas; the liquid drops are broken multiple times through high-pressure water to form finer liquid drops and contract to be in a near-spherical shape in an atomizing cylinder in the flying process; and finally, the liquid drops are solidified to be the superfine near-spherical low-oxygen metal powder. According to the device, compared with traditional gas atomization, the breaking function of high-pressure water is added, and powder is finer in size; due to the fact that the breaking effect of gas is added, the amount of atomizing water is greatly reduced, the contracting process of powder is prolonged, and the degree of sphericility is better than that in traditional water atomization; and in addition, the whole atomization process is conducted in inert protective gas, and therefore the oxygen content of powder is reduced. Furthermore, the technology is advanced and reliable, the technology device is simple, continuity is high, production cost is low, product performance is stable, and the atomizing method and device are suitable for industrial production and can be widely applied to the metal injection molding industry.

Owner:曾克里

Extraction method of microalga grease

InactiveCN103045352AImprove dissolution efficiencyHigh yieldFatty-oils/fats productionAlcoholOrganic solvent

The invention discloses an extraction method of microalga grease. The extraction method comprises the following steps of: (1) microalga cell collection: adjusting the pH value of a microalga culture solution to 11-12 at the later period of microalga cultivation, and collecting microalga cells in a centrifugal way; (2) microalga cell crushing: adding a C1-C6 short-chain alcohol solvent into microalga ooze obtained in the step (1), shaking and mixing the microalgae to be uniform, and then, carrying out cell breaking treatment on the microalgae; (3) grease extraction: adding one or more of organic solvents such as n-hexane and petroleum ether into a microalga cell breaking solution obtained in the step (2), and extracting the grease component in the cell breaking solution by using the organic solvents; and (4) solvent recovery: after the extraction reaction is ended, cooling the solvent to room temperature, standing for 10-30min, respectively extracting an organic solvent layer (oil phase) and a water layer (water phase), and recovering the organic solvents in the oil phase in a distillation way, and meanwhile, obtaining the microalga grease. The method has the advantages of simple operation process, short extraction time, low energy consumption, high microalga grease yield and the like and is suitable for directly extracting grease from alga ooze.

Owner:CHINA PETROLEUM & CHEM CORP +1

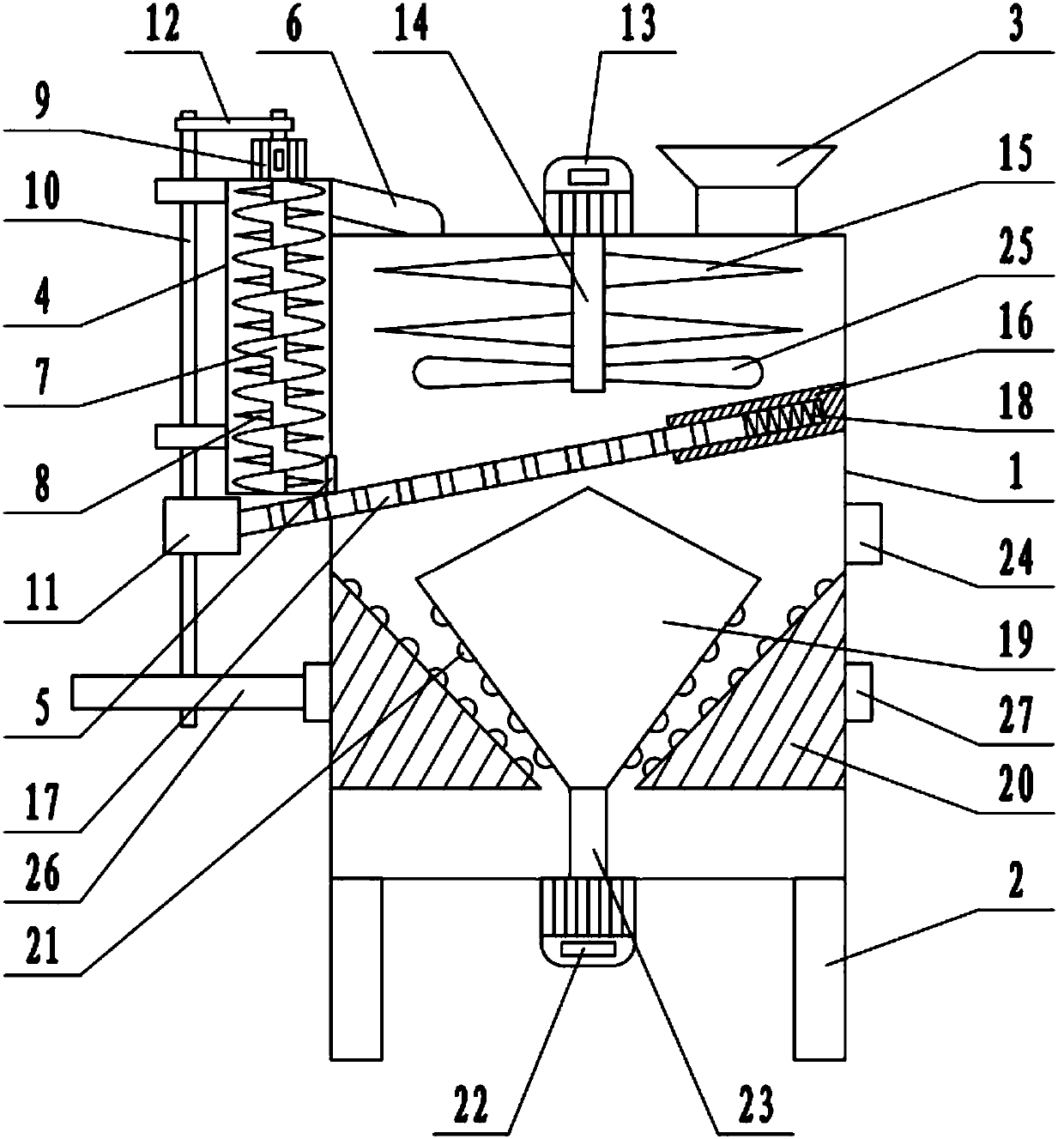

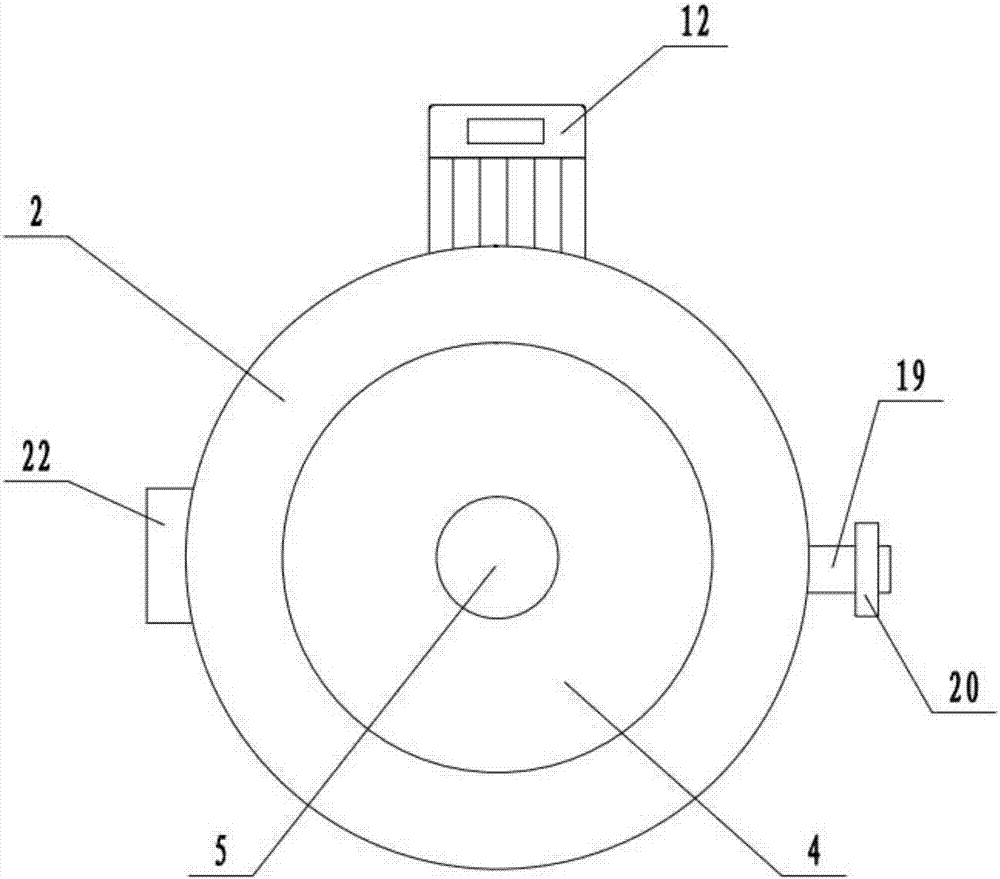

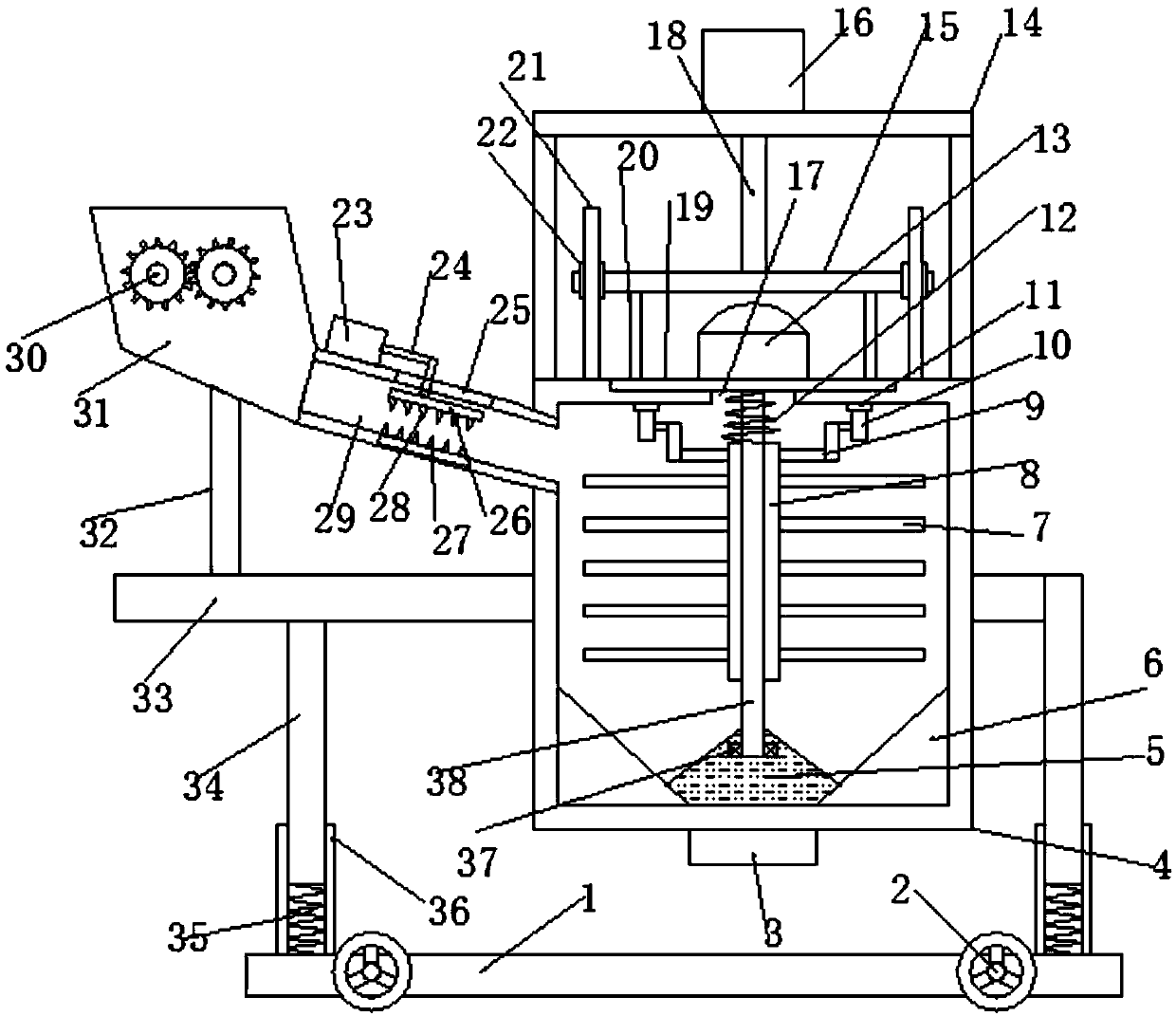

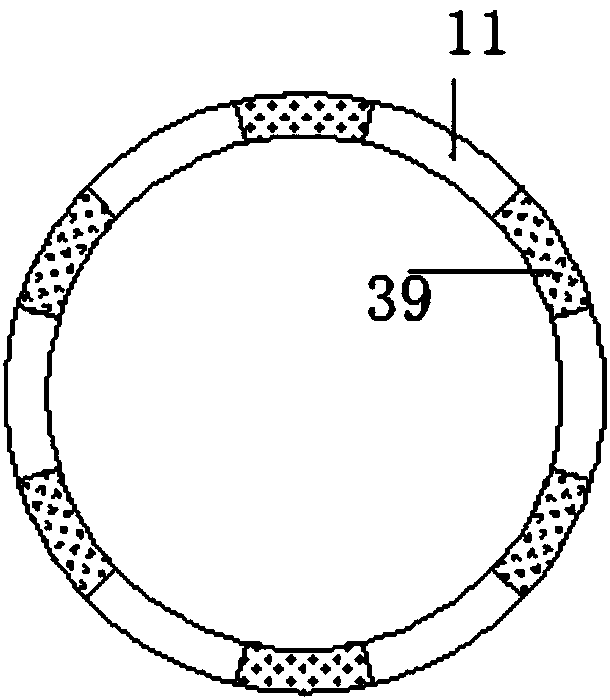

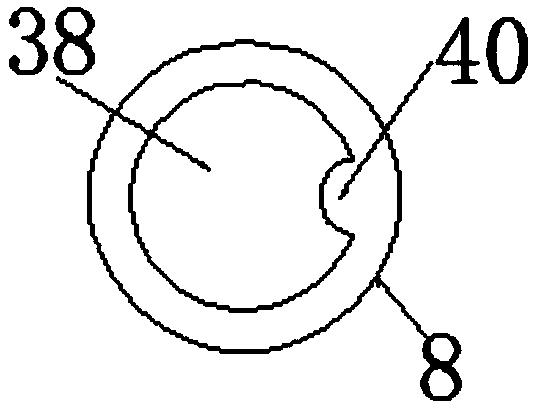

Traditional Chinese medicinal material three-level smashing device

InactiveCN107552211AAchieve three-stage crushingGuaranteed crushing effectNon-rotating vibration suppressionGrain treatmentsThree levelMedicinal herbs

The invention discloses a three-stage crushing device for traditional Chinese medicinal materials, which includes a base and a crushing cylinder. Rollers are arranged on the left and right sides of the base to facilitate the device's transportation. A crushing cylinder is arranged above the base, and a side plate is fixed on the left side of the crushing cylinder. , the side plate and the right side of the support cylinder are provided with outriggers, and the lower end of the outriggers is slidingly provided with shock-absorbing sleeves. The shock-absorbing sleeve is connected and fixed. This shock-absorbing mechanism helps to improve the shock-absorbing effect of the device. The invention has a simple and reasonable structure, is easy to carry, has good shock resistance, and is convenient for discharging materials. It realizes three-stage crushing of materials, thereby ensuring In addition, in the final crushing process, the crushing knife 7 can be moved up and down, thereby increasing the crushing range of the crushing knife, which helps to improve the crushing effect, and has strong practicability.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

Medical waste garbage treatment equipment with disinfection function

InactiveCN107138255APrevent diseaseGood crushing effectMedical waste disposalGrain treatmentsDisinfectantResistance wire

The invention discloses medical waste garbage treatment equipment with a disinfection function. The medical waste garbage treatment equipment comprises a housing, supporting legs arranged at the lower side of the housing and a placing plate arranged between the supporting legs, wherein a disinfectant distributing device is arranged on the top in the housing; the disinfectant distributing device communicates with a disinfectant box positioned above the housing through a liquid inlet tube; two rotary shafts are symmetrically arranged below the disinfectant distributing device; inner ends of the two rotary shafts are fixedly connected with electric pushing rods; rotary rollers are fixedly connected on free ends of the electric pushing rods; a plurality of pulverizing teeth are uniformly distributed on the surfaces of the rotary rollers; two pulverizing rollers are symmetrically arranged below the rotary rollers; a plurality of first pulverizing blades are uniformly distributed on the pulverizing rollers; a plurality of second pulverizing blades are arranged on the inner side wall of the housing and the inner bottom of the housing; and heating resistance wires are distributed in the pulverizing rollers. The medical waste garbage treatment equipment has the advantages of a reasonable structural design, simple and convenient operation, good pulverizing effect and the like, and has certain popularization and application value.

Owner:郑州永泰澳新商贸有限公司

Multifunctional biomass energy pulverizing equipment

InactiveCN106269165AImprove crushing efficiencyReasonable structural designCocoaGrain treatmentsEngineeringMechanical engineering

The invention provides multifunctional biomass energy pulverizing equipment. The equipment comprises a shell, wherein a feed hopper is arranged at the top of the shell; a pair of pulverizing rolls is arranged in the shell below the feed hopper and is supported by pulverizing roll shafts arranged in the centers; a plurality of pulverizing teeth are uniformly arranged on the pulverizing rolls; a screen is arranged below the pulverizing rolls and is shaped like a circular arc; a guide plate is arranged below the screen and is shaped like a hopper; a sleeve is arranged at an opening in the lower end of the guide plate; a rotating shaft is arranged in the sleeve; the lower end of the rotating shaft extends below the shell and is connected with a motor; a rotator is arranged on the rotating shaft in the sleeve and is shaped like a cylinder. The equipment has the beneficial effects that the materials are pulverized triply and the grain sizes of the materials are gradually reduced and meet the using requirements; the pulverizing efficiency is high; the equipment has the advantages of reasonable structural design, simplicity and convenience in operation, good pulverizing effects, and the like, and has certain popularization and application values.

Owner:王少平

Smashing and screening device for compound fertilizer production

InactiveCN107537621AUniform particlesEvenly distributedSievingScreeningPrimary screeningAgricultural engineering

The invention discloses a smashing and screening device for compound fertilizer production. The smashing and screening device for compound fertilizer production comprises a base, a smashing tank, a bearing, a primary screening tank, a secondary screening tank, a second drive motor and a special-shaped gear, wherein the smashing tank is fixedly installed on the base through screws; two sets of mainsmashing rollers are installed in a smashing cavity in a bilateral symmetry mode; auxiliary smashing rollers are further rotationally installed in the smashing cavity; a scattering disc is further fixedly connected to the upper end of an output shaft of a first drive motor; the second drive motor is further fixedly installed on the outer wall of the right side of the smashing tank; and the special-shaped gear is further installed on an output shaft of the second drive motor. According to the smashing and screening device for compound fertilizer production, the structure is novel, and fertilizer particles are more uniform in the smashing process; and through arrangement of the scattering disc, smashed fertilizer is evenly tossed out and then falls into the primary screening tank, so that the fertilizer on the primary screening tank is evenly distributed and prevented from being accumulated on a screen of the primary screening tank.

Owner:罗娟

Globefish skin active collagen and method for preparing peptide thereof

ActiveCN101182357ABroaden the field of useIncrease profitConnective tissue peptidesFermentationUltrafiltrationPepsin

The preparation methods of globefish skin active collagen and the peptide of the active collagen are that the globefish skin is cut into small pieces to be frozen, dried, crushed and put into sodium chloride solution to be stirred for 12 hours and then for centrifugation to discard supernatant and remove non-collagen proteins, deposition is put in to acetum, pepsin is added under 0 DEG C to 10 DEG C for enzymolysis and centrifugation, the supernatant is put through an ultrafiltration membrane, and the above part is frozen and dried to obtain the collagen. After the active collagen is prepared, the rest deposition is centrifugated until the pH value is between 2.0 to 7.0, papain is added into the deposition for the enzymolysis, the supernatant is centrifugated and respectively put through the ultrafiltration membrane after enzyme-denaturing to obtain the globefish skin collagen peptide of different molecular weight ranges, and the globefish skin collagen peptide are frozen and dried to obtain the light yellow or white powdery globefish skin collagen active peptide which has good antioxidation character and takes effects of eliminating free radical and reducing the senescence degree.

Owner:DALIAN POLYTECHNIC UNIVERSITY +1

Speed-adjustable dust collecting and crushing device used for crushing coal mines

InactiveCN104923340ASimple structureEasy to useDispersed particle filtrationDirt cleaningCoalExhaust pipe

A speed-adjustable dust collecting and crushing device used for crushing coal mines comprises a base unit, a frame, a collecting unit, two pushing units, dust collecting units, purifying units and crushing units. The base unit comprises a base, a rollers and a support plate, a first support, rectangular blocks and dust collecting buckets are arranged on the frame, each pushing unit comprises a first horizontal plate, a pushing plate, a pushing rod, a material pushing plate and a spring, each dust collecting unit comprises a dust collecting pipe and a fan, each crushing unit comprises a crushing plate, first crushing teeth, a crushing wheel and second crushing teeth, the collecting unit comprises a collecting box and a first filtering screen, each purifying unit comprises a purifying box, a second filtering screen, a second horizontal plate, a second support, an exhaust pipe and a sponge block, and a first through hole is arranged in the right surface of the purifying box. By the arrangement, dust generated from crushing can be recycled, fitness of workers is protected, and the device is small in size, low in cost and suitable for small enterprises and large-scale promotion and use.

Owner:孙亚光

Rock crushing device for municipal engineering construction

InactiveCN107309011APromote crushing and refinementImprove crushing effectDirt cleaningGrain treatmentsEnvironmentally friendlyCrusher

A stone crushing device for municipal engineering construction, comprising a bottom plate, the bottom plate is welded and fixed vertically with a support column, the support column is horizontally fixed with a top plate, the top of the support rod and the upper end of the telescopic hydraulic cylinder are hinged on the crushing The right end of the bottom of the basket; the inner bottom surface of the crushing basket is evenly provided with serrated tooth nails, and the end of the baffle away from the second hinge shaft is detachably connected with the crushing basket through locking screws; the end of the pull rope away from the straight rack is fixed on the telescopic hydraulic On the cylinder; the top plate is vertically provided with a limit slideway, the end of the connecting rod away from the runner is hinged on the limit slider, the lower end of the limit slider is fixed with a push-pull rod, and the bottom of the push-pull rod is fixed with an impact block. A purification box is installed, and there are several layers of adsorption layers in the purification box; the invention has ingenious structure, reasonable design, excellent stone crushing effect, convenient unloading, and the effect of dust suction and dust removal, which is more environmentally friendly and avoids dust pollution. .

Owner:石嘴山市塞企宝信息科技有限公司

High-efficiency combined type domestic garbage crusher

The invention relates to a high-efficiency combined type domestic garbage crusher, which belongs to the technical field of domestic garbage crushing and comprises a feed hole, a crushing system, a discharge system and a transmission system, wherein the crushing system comprises dual knife rolls, a moving knife group, a static knife group and a knife adjusting device; the discharge system comprises a left screen, a right screen and two discharge holes; and the transmission system comprises a motor and a synchronous gear group, and the synchronous gear group ensures the synchronous running of the dual knife rolls. The left knife roll and the right knife roll are arranged side by side in parallel, a certain gap is reserved between the two knife rolls, and the two knife rolls are connected by the synchronous gear group and run in opposite directions; and the knife rolls are provided with rotating moving knives, the bottoms of the knife rolls are provided with bottom blocks, the bottom blocks are provided with bottom static knives, and simultaneously a frame is provided with a side static knife. Firstly, domestic garbage is crushed in the gap between the two knife rolls, is crushed at the position of the bottom knives after being compressed, then passes through the left screen and the right screen and is respectively discharged from the left discharge hole and the right discharge hole; and the side static knife can crush the garbage with bigger size again. The invention has the advantages of large treatment capacity, high crushing efficiency and low energy consumption.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com