Patents

Literature

494results about How to "Guaranteed crushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

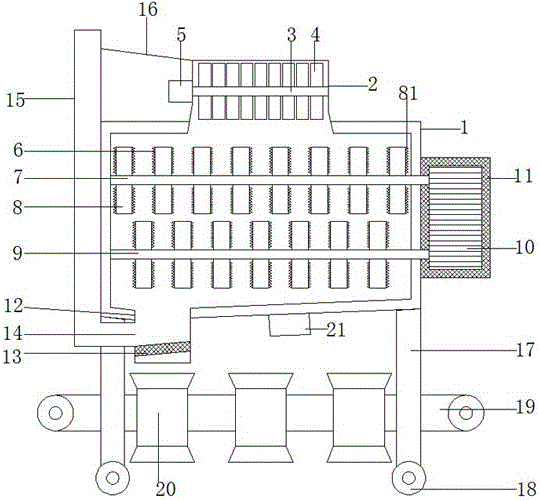

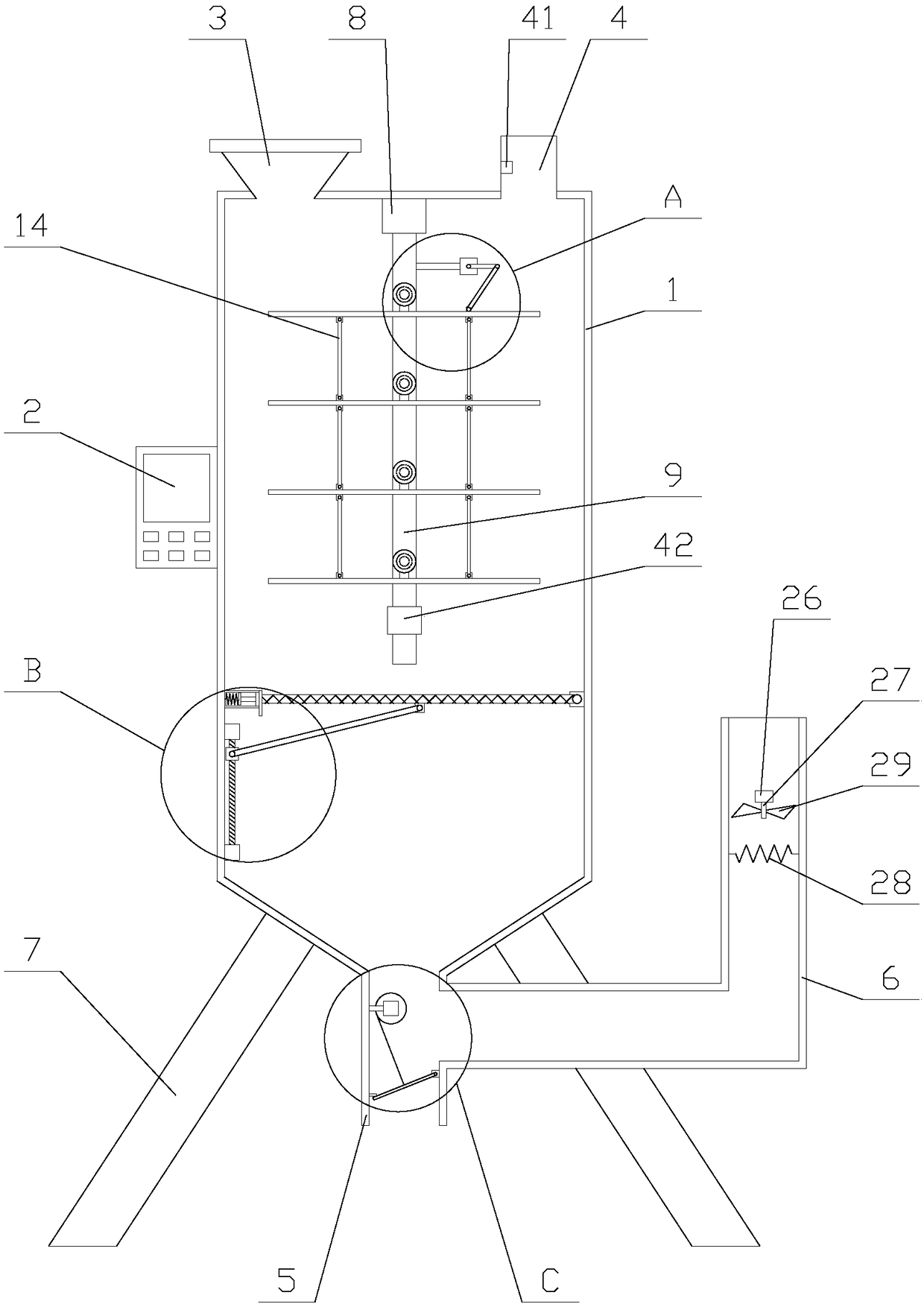

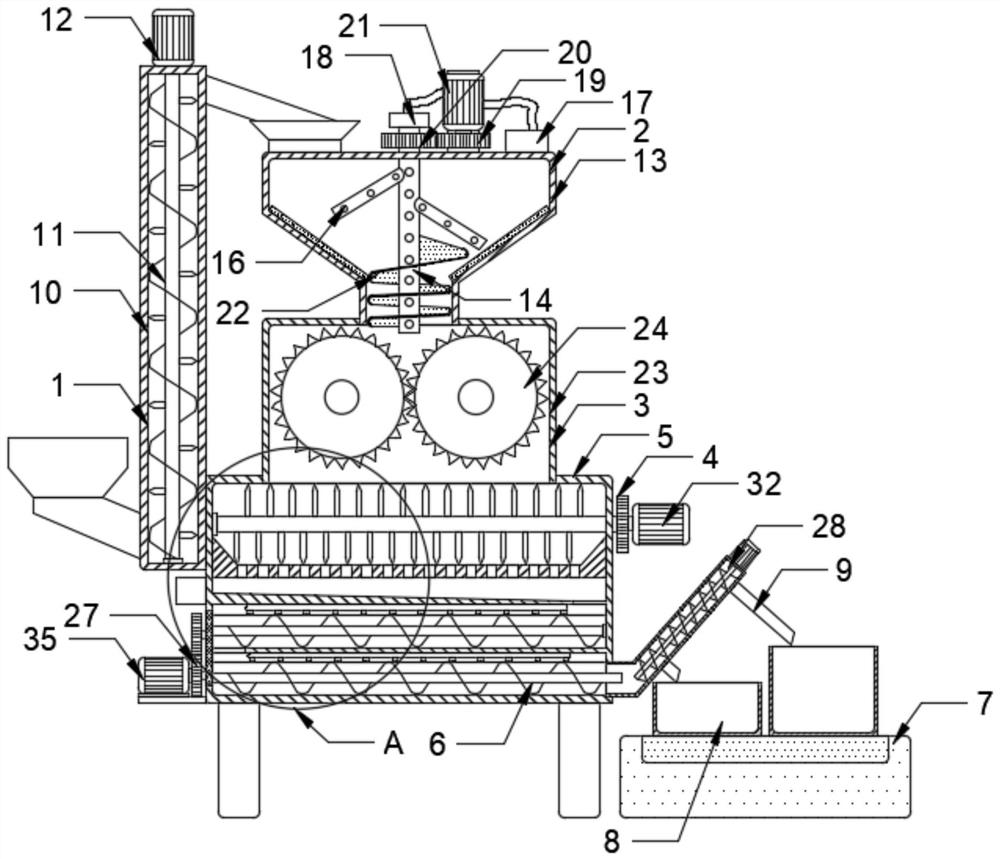

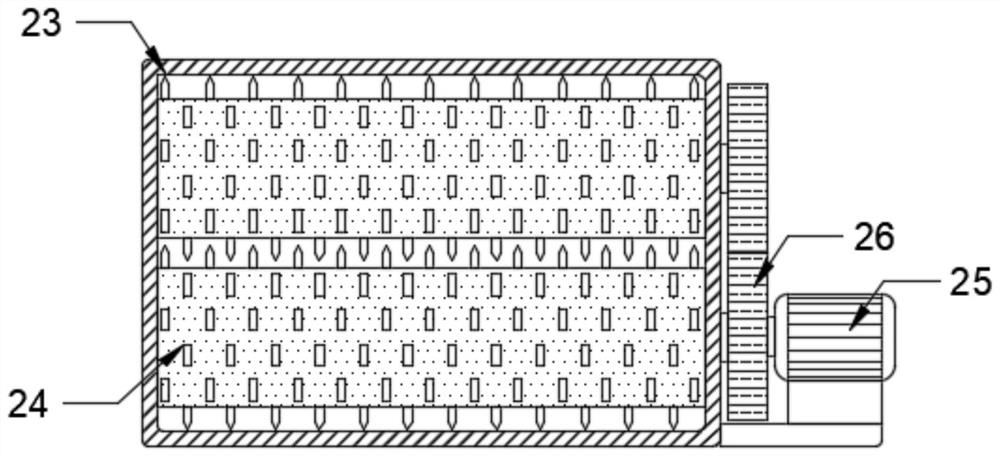

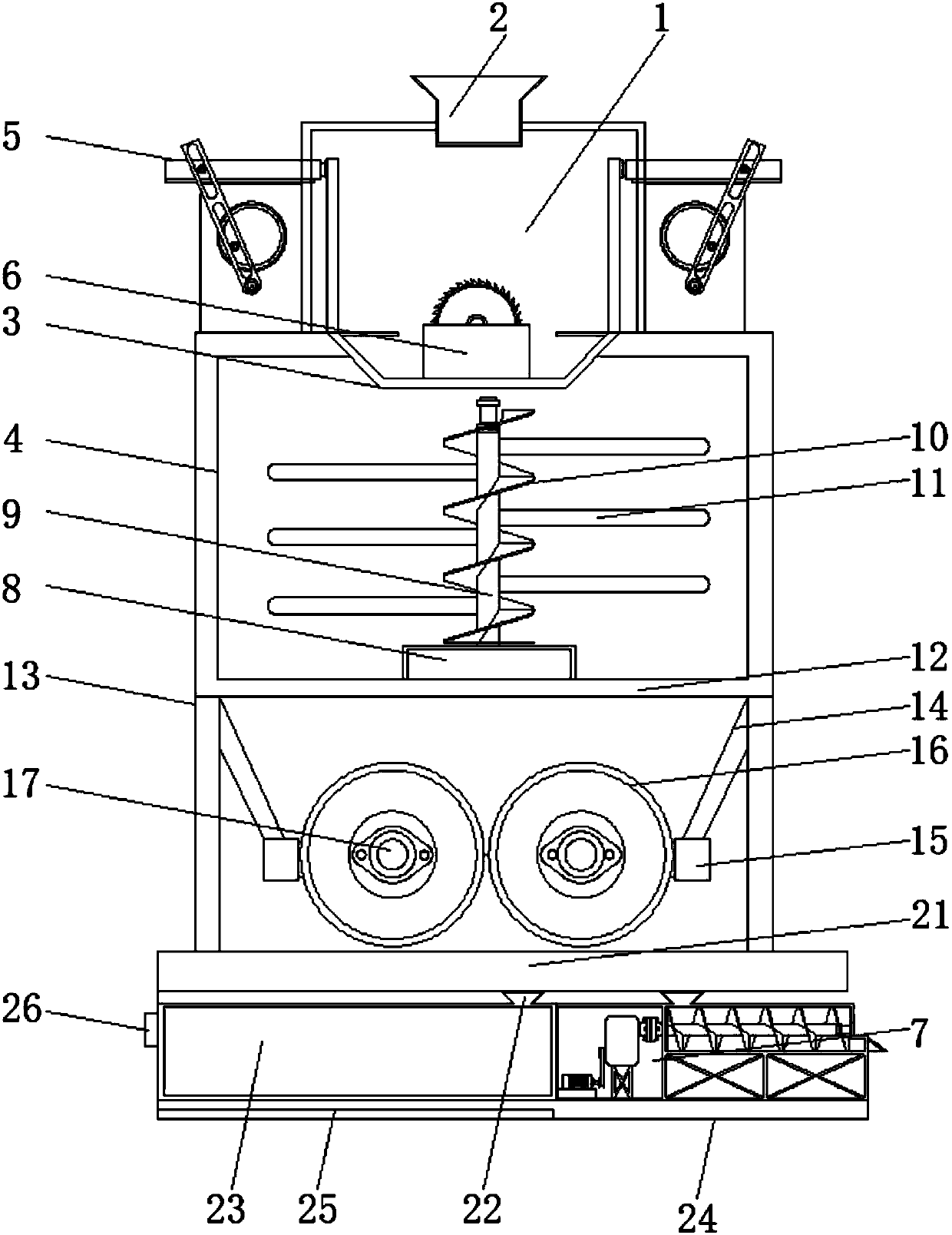

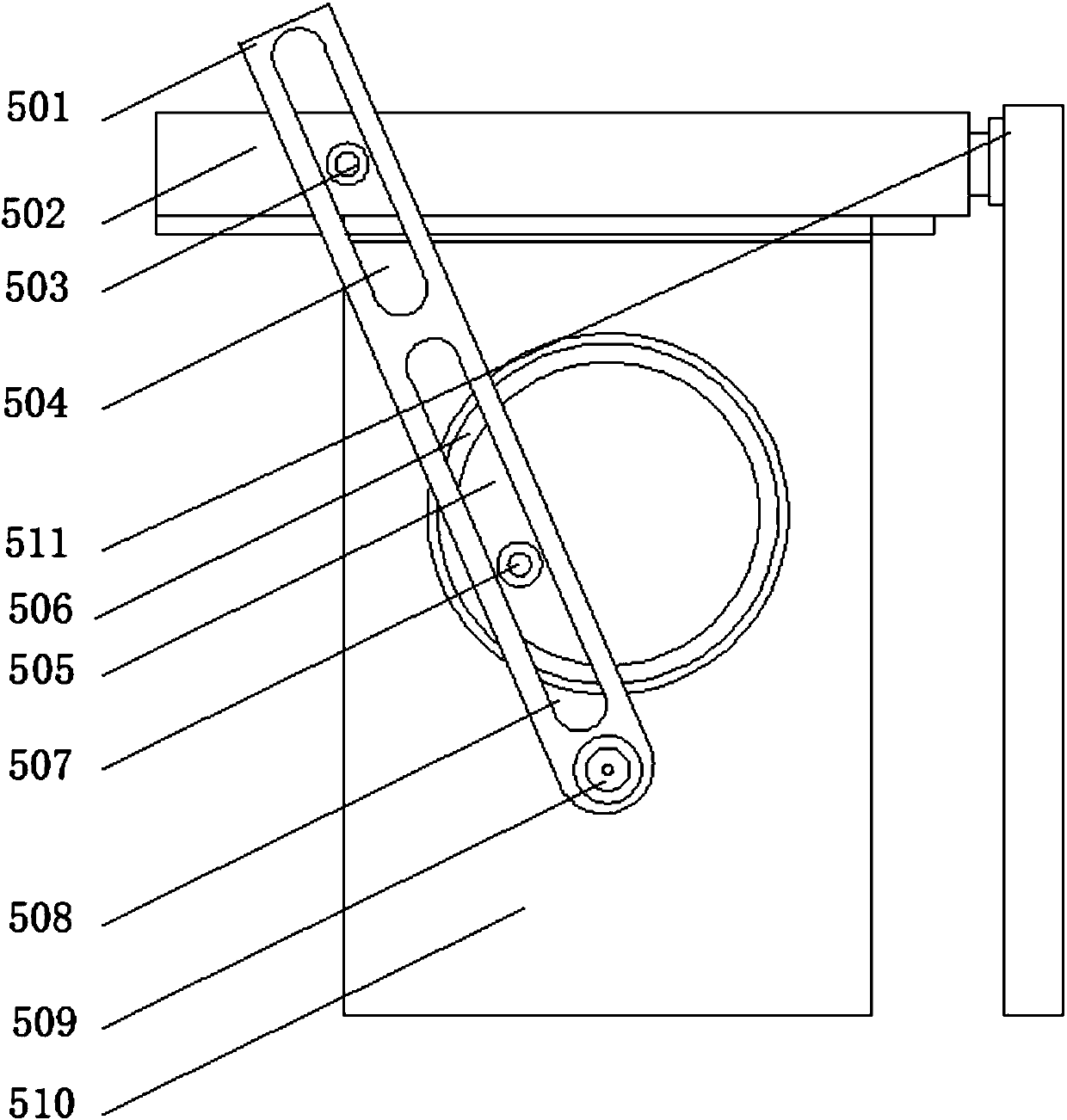

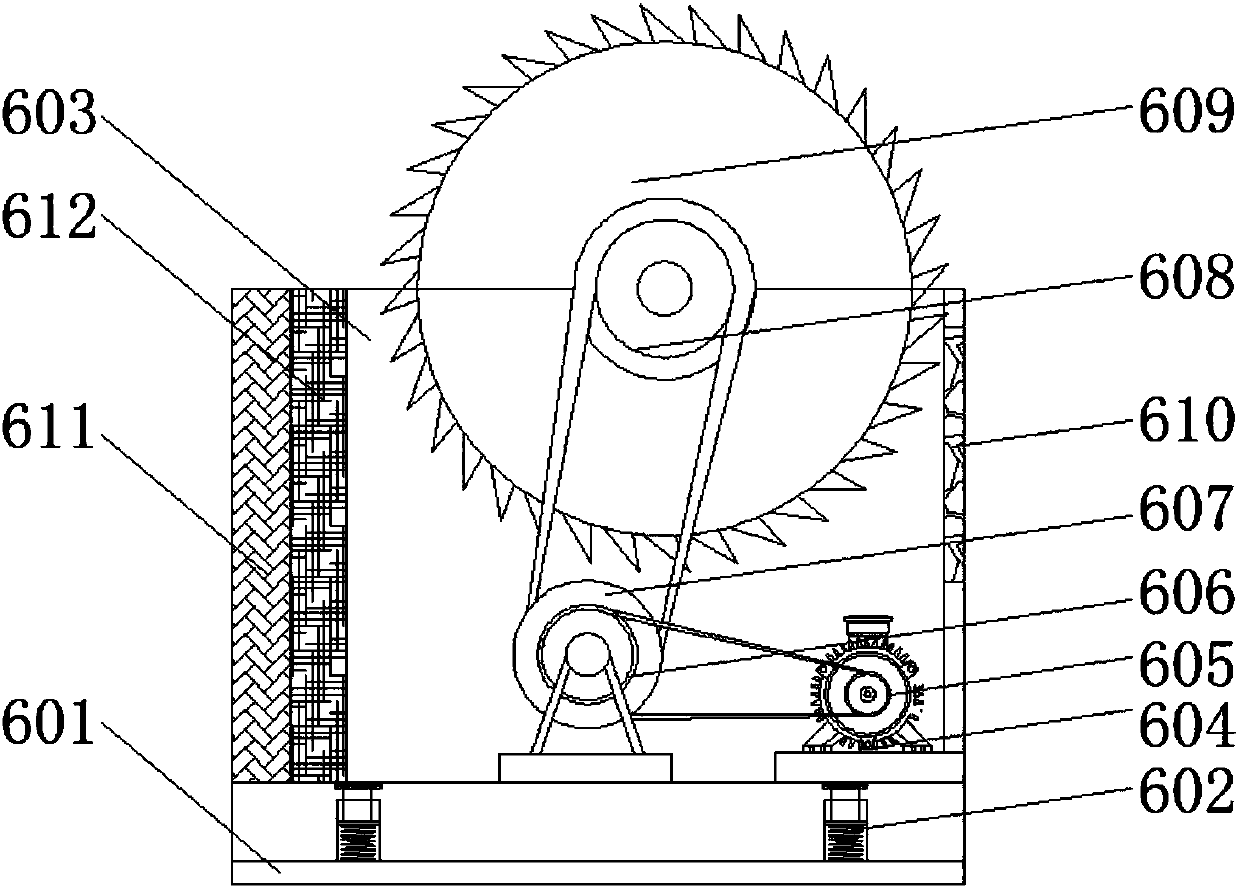

Efficient crushing device for traditional Chinese medicine production

InactiveCN107626418AImprove crushing effect and efficiencyImprove crushing effectSievingScreeningGrindChinese herbology

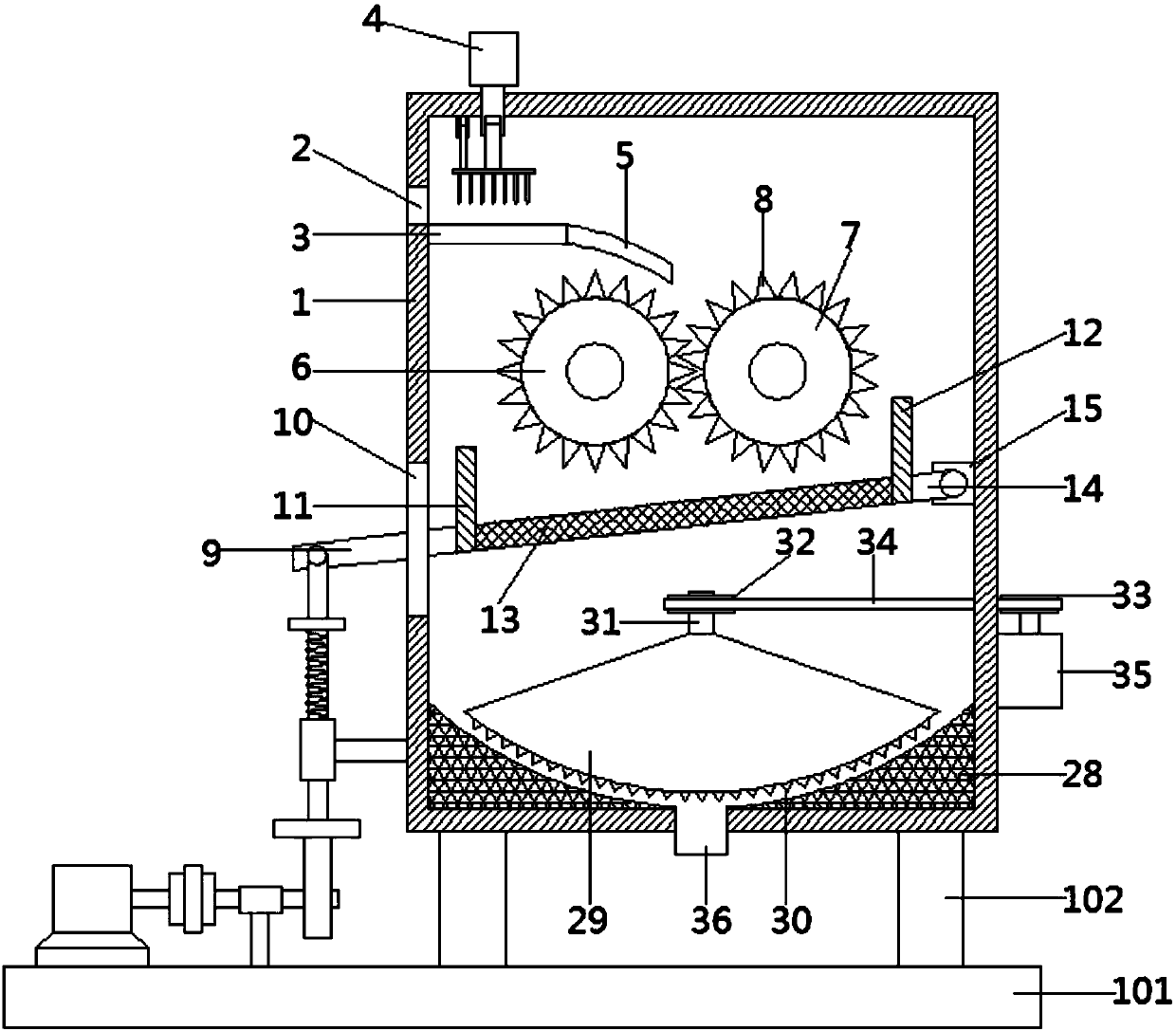

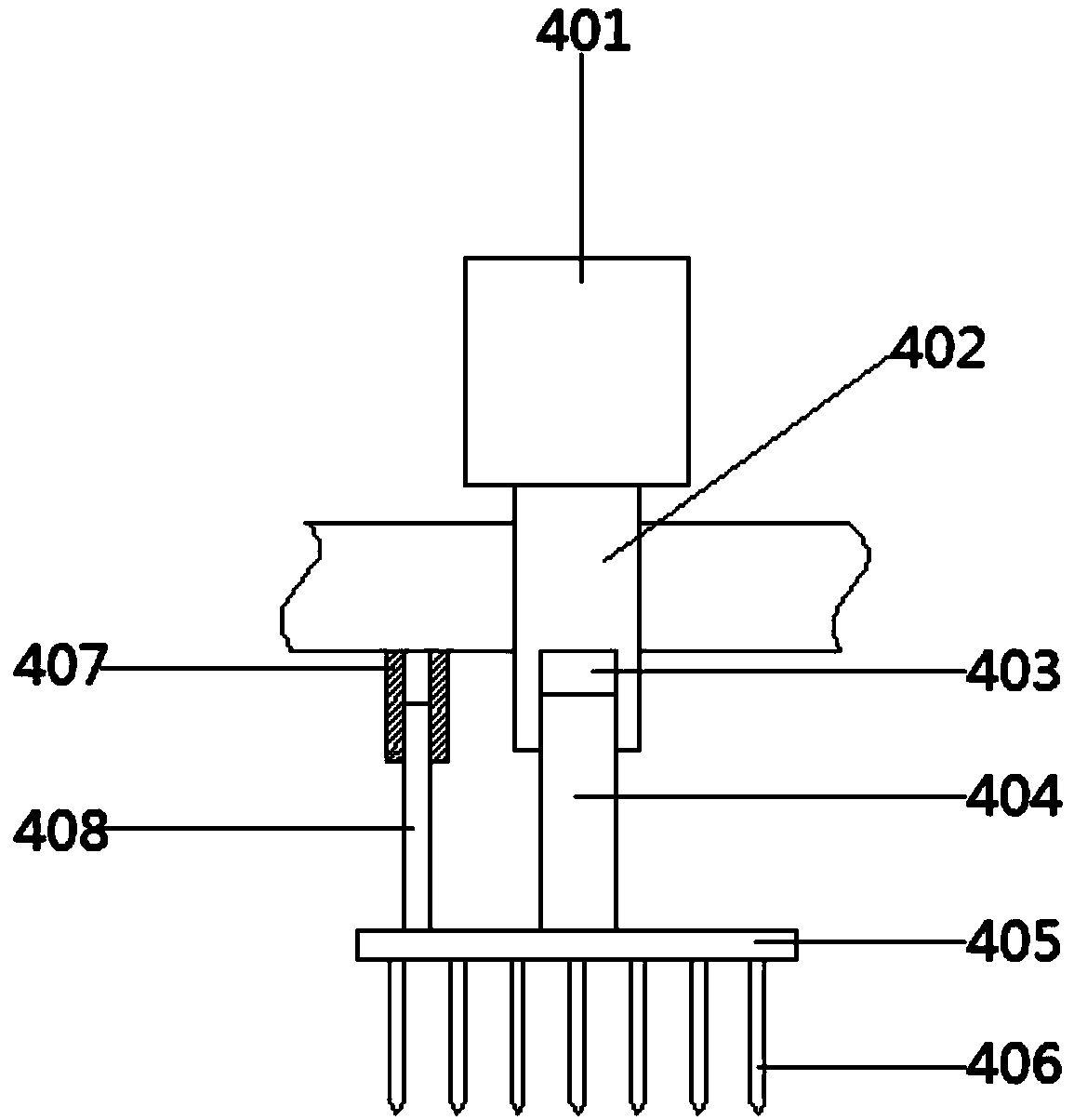

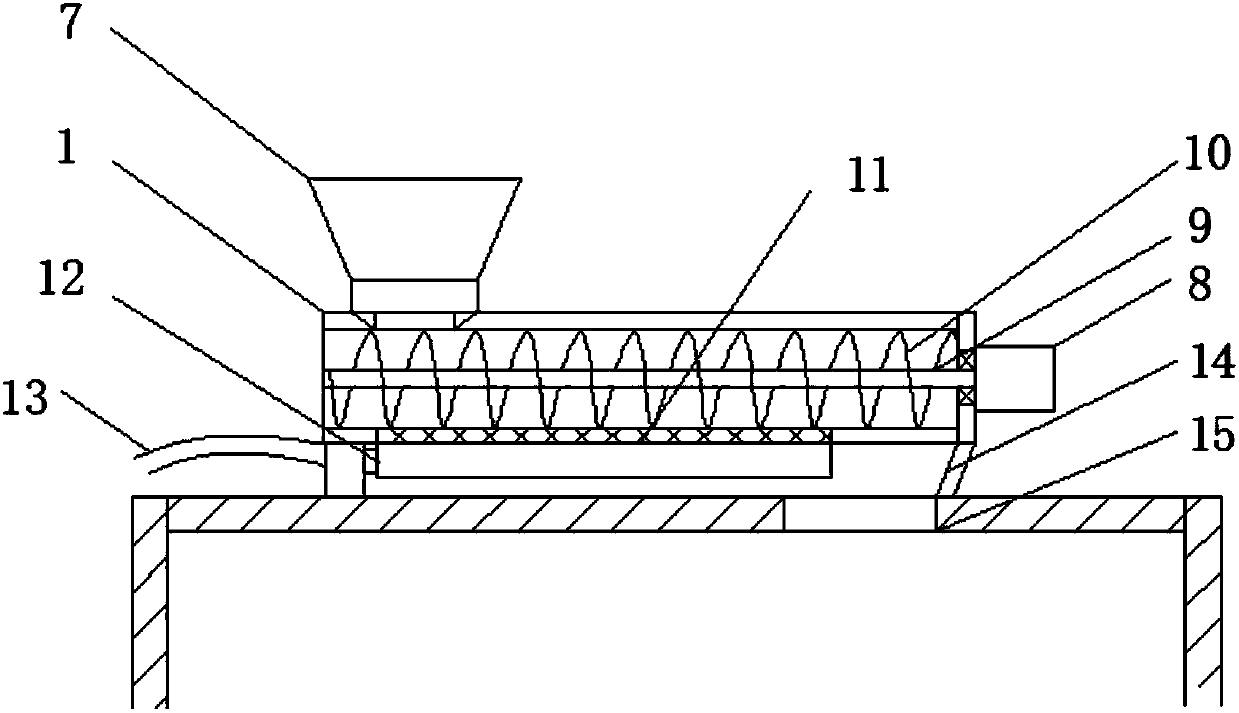

The invention discloses an efficient crushing device for traditional Chinese medicine production. The device comprises a body. A base is arranged in the bottom of the body; the periphery of the bottomof the body is fixed on the base through supporting legs; a feed inlet is formed in the top end of the left side wall of the body; a feeding supporting plate is horizontally arranged at the connection of the inner side of the body and the feed inlet; a pre-cutting device is arranged on one side of a supporting plate; the pre-cutting device comprises a first rotary shaft; the top end of the rotaryshaft penetrates through the body, and the top end of the first rotary shaft is fixedly connected to the output shaft of a first motor. The efficient crushing device for traditional Chinese medicineproduction disclosed by the invention separately pre-cuts the medicinal materials, crushes grinds and the same with crushing teeth through three crushing devices which are arranged up and down, so that the crushing effect of traditional Chinese medicinal materials is ensured, and the quality of the product traditional Chinese medicine is improved; the device fully and uniformly crushes, and is high in work efficiency; a filter screen is arranged to screen the traditional Chinese medicines; in addition, a jittering device is arranged to drive the filter screen to jitter up and down, so that thescreening efficiency is increased effectively.

Owner:单开禹

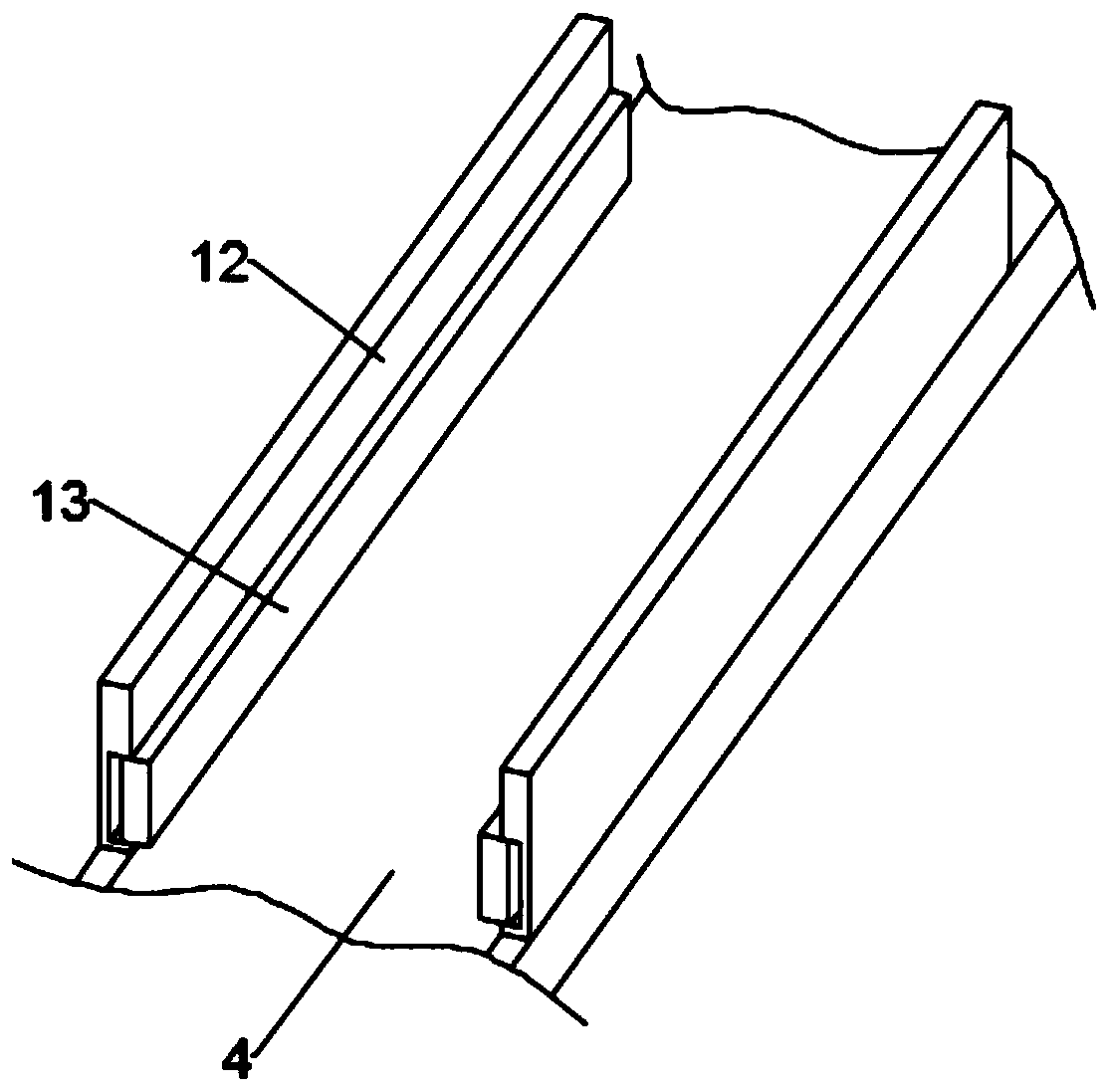

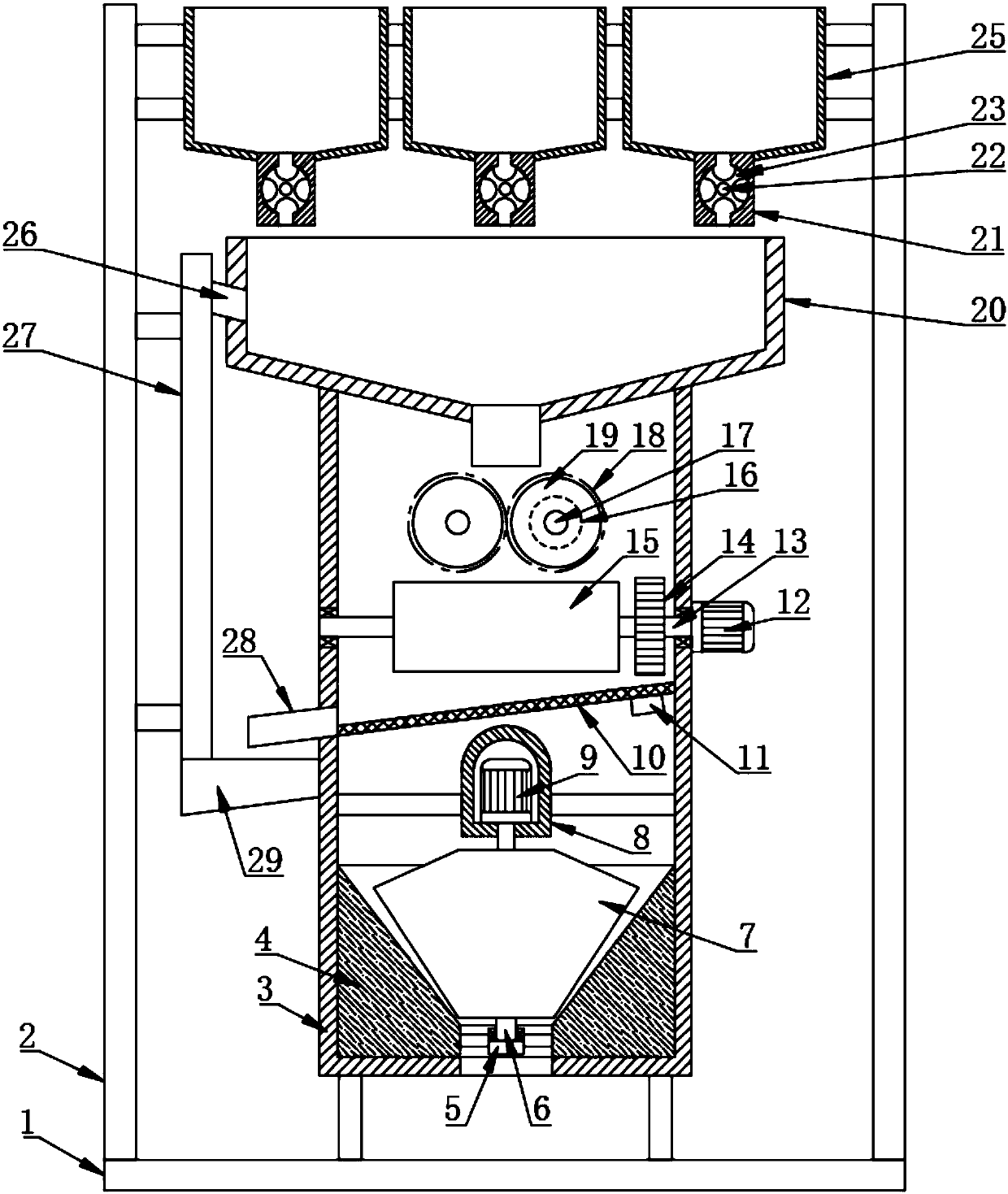

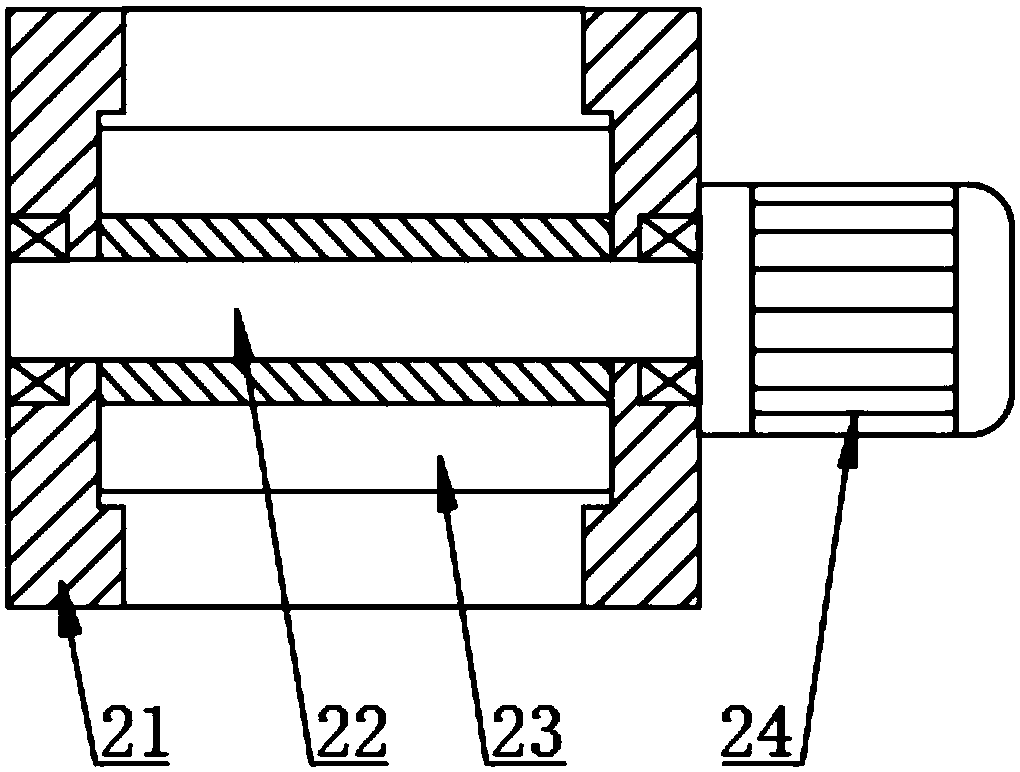

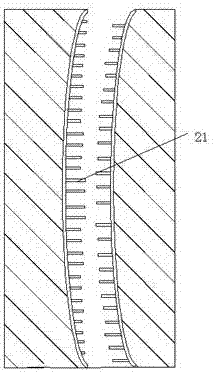

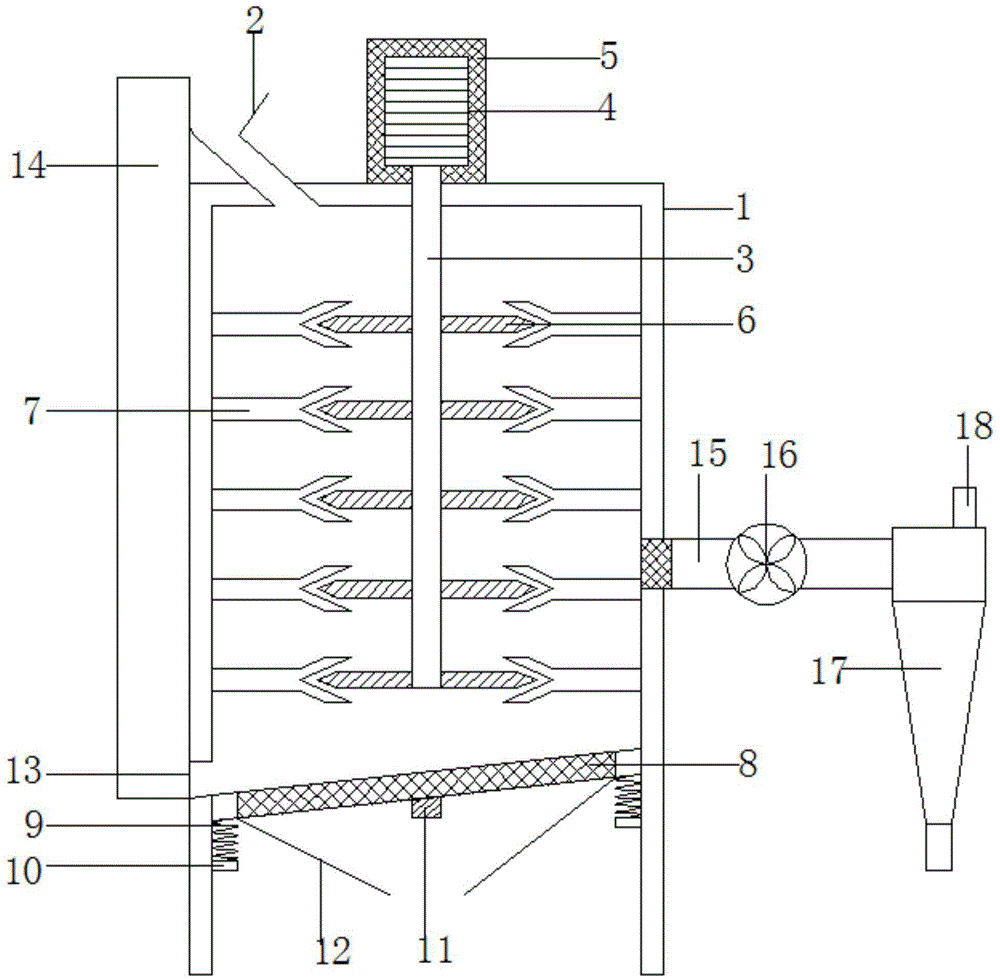

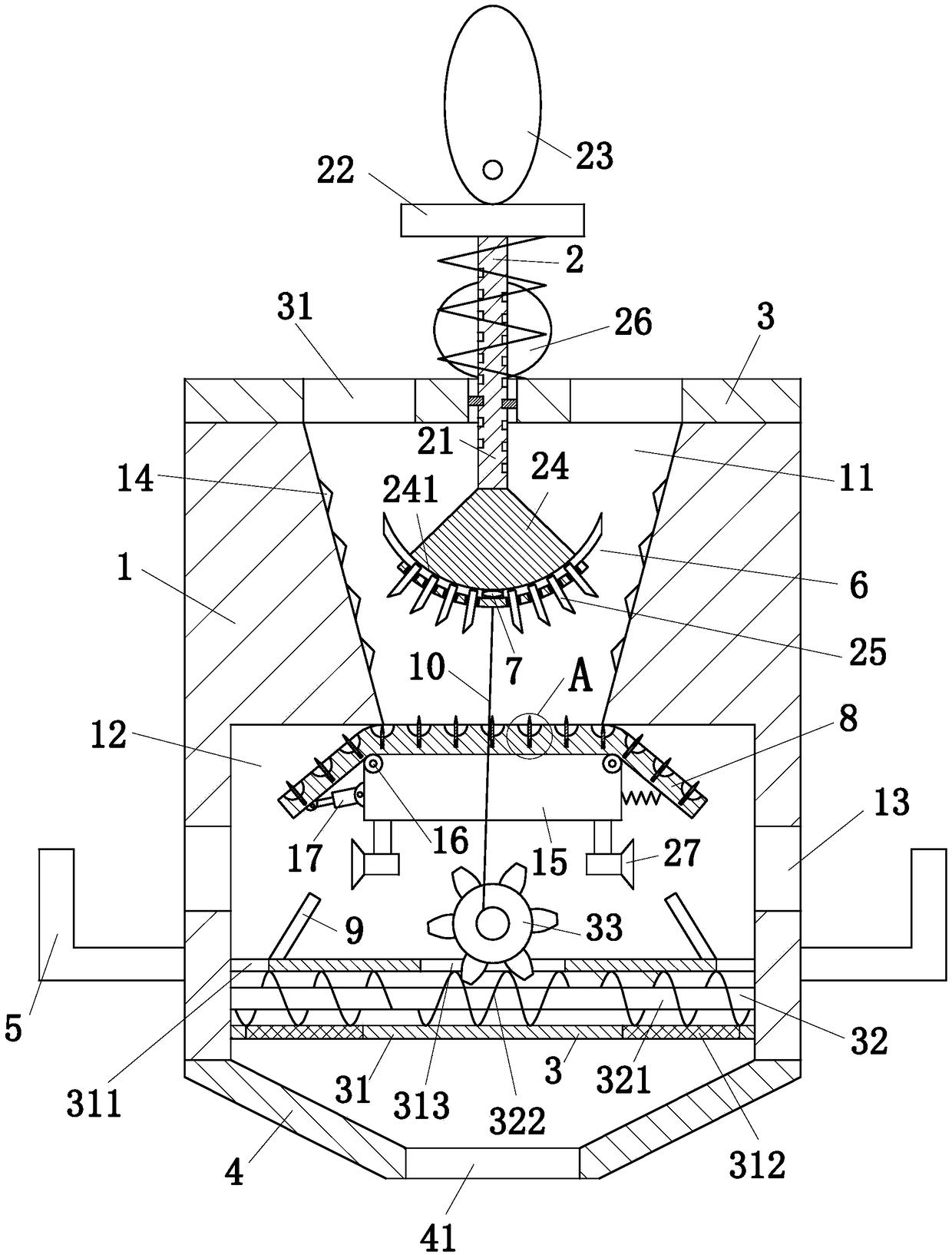

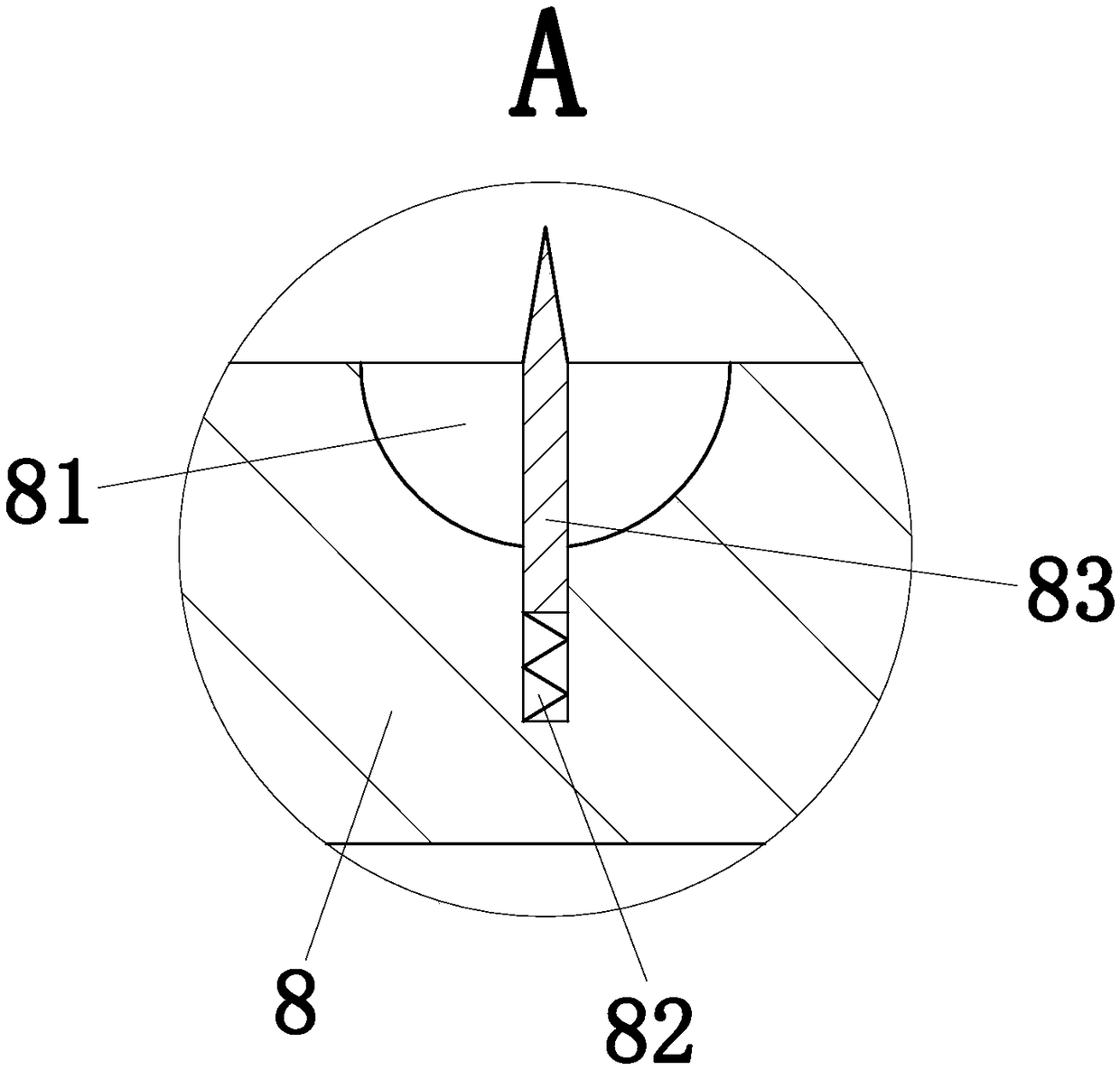

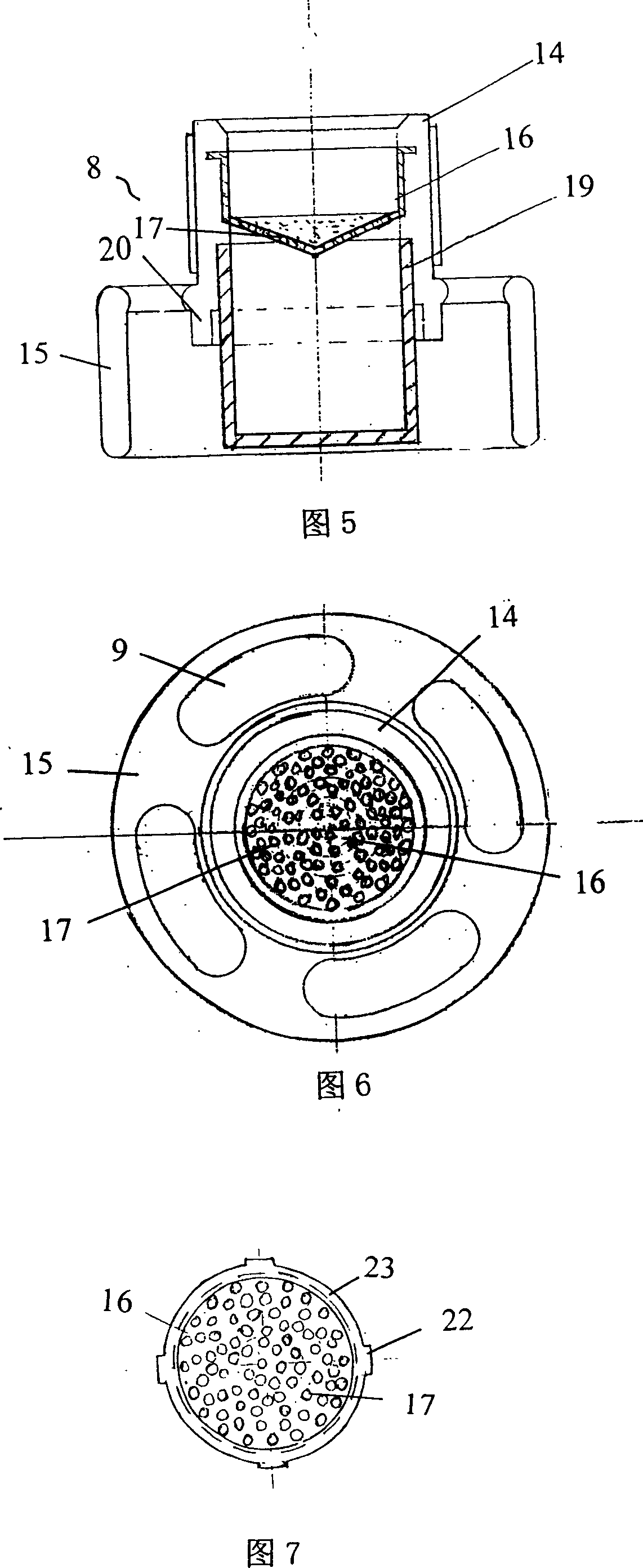

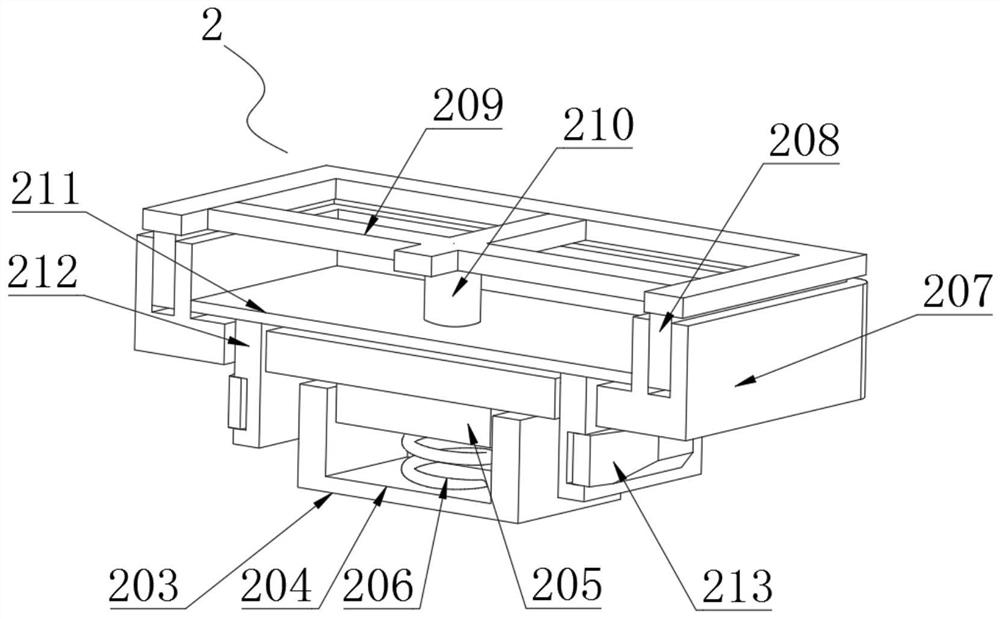

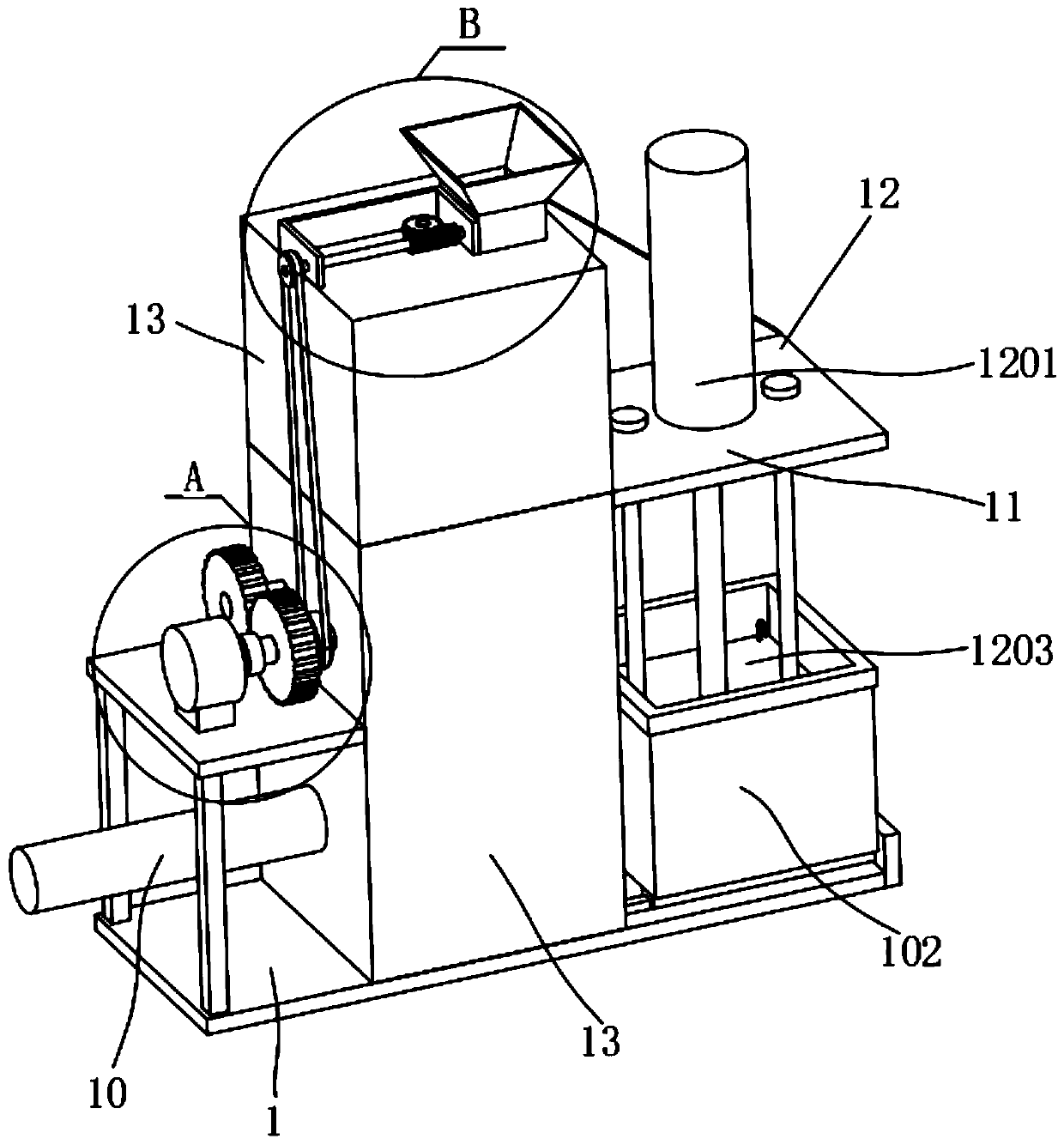

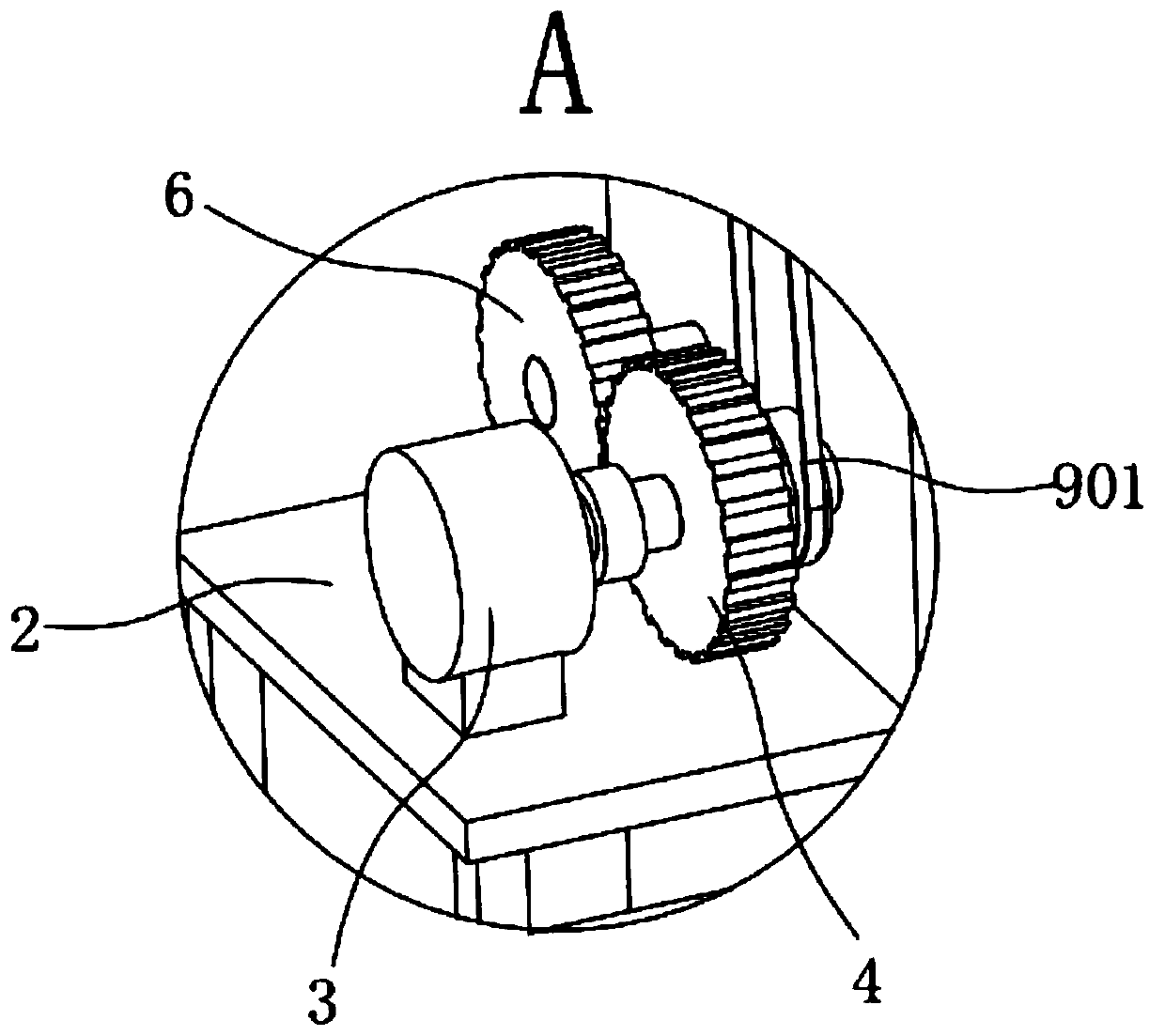

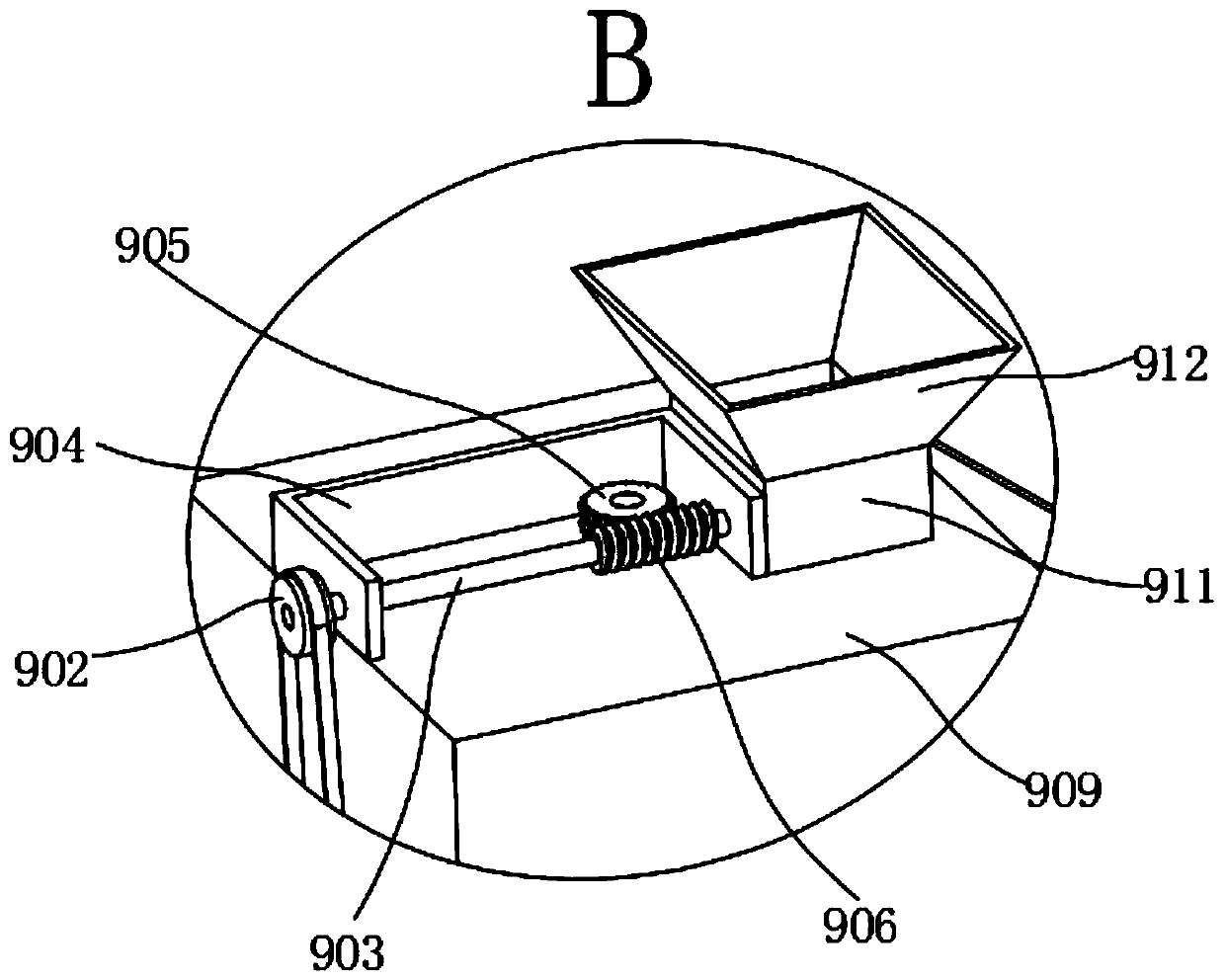

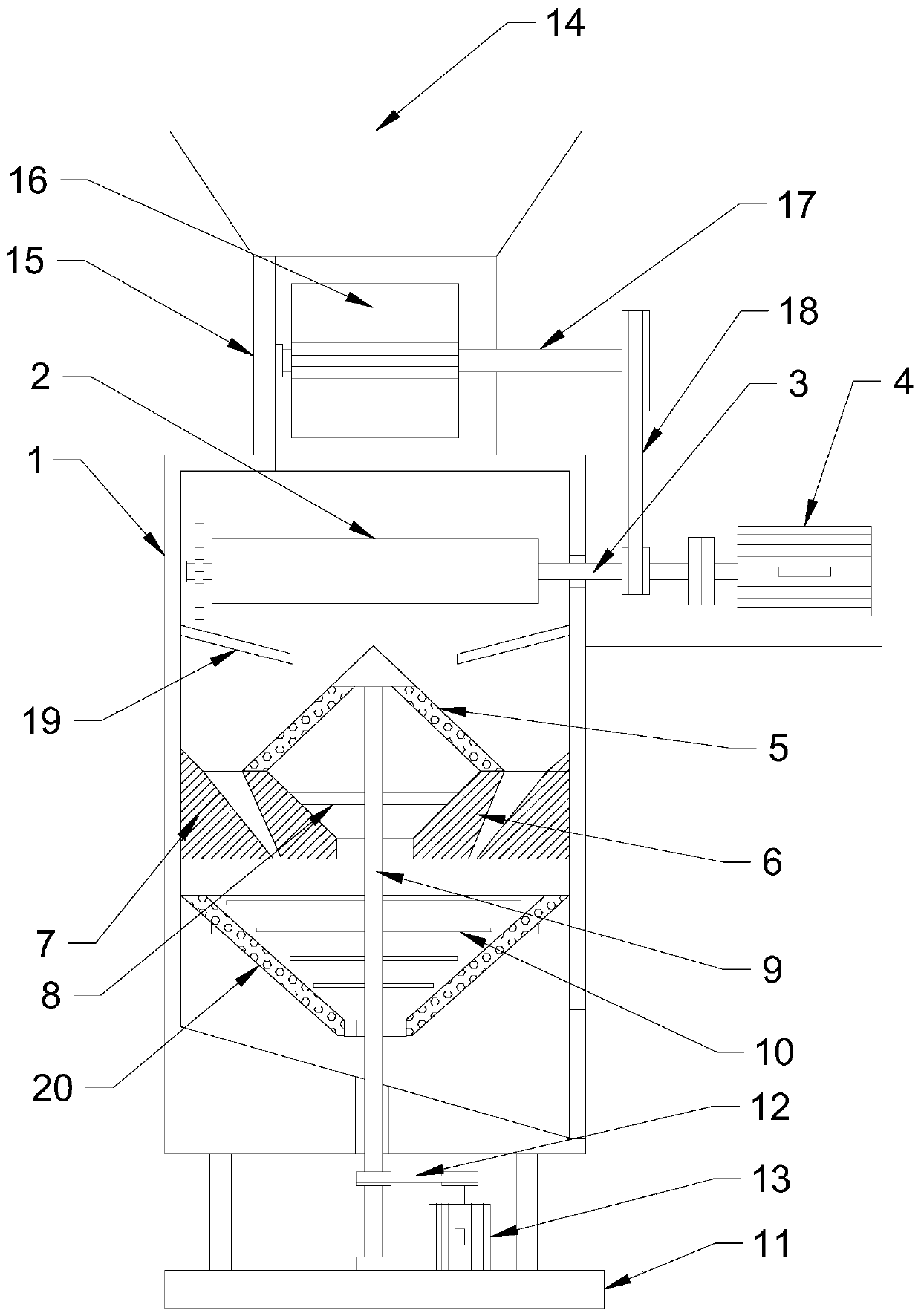

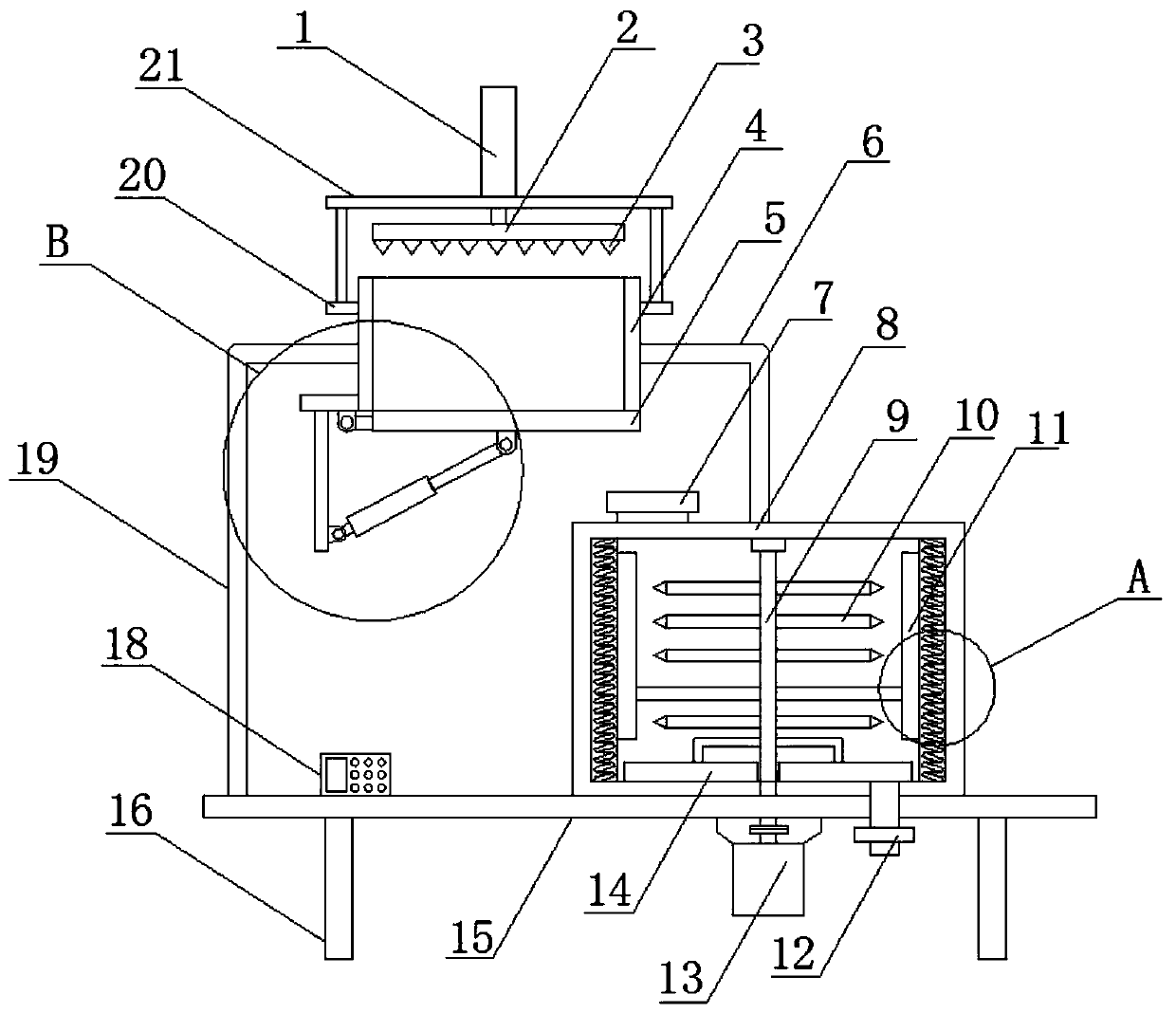

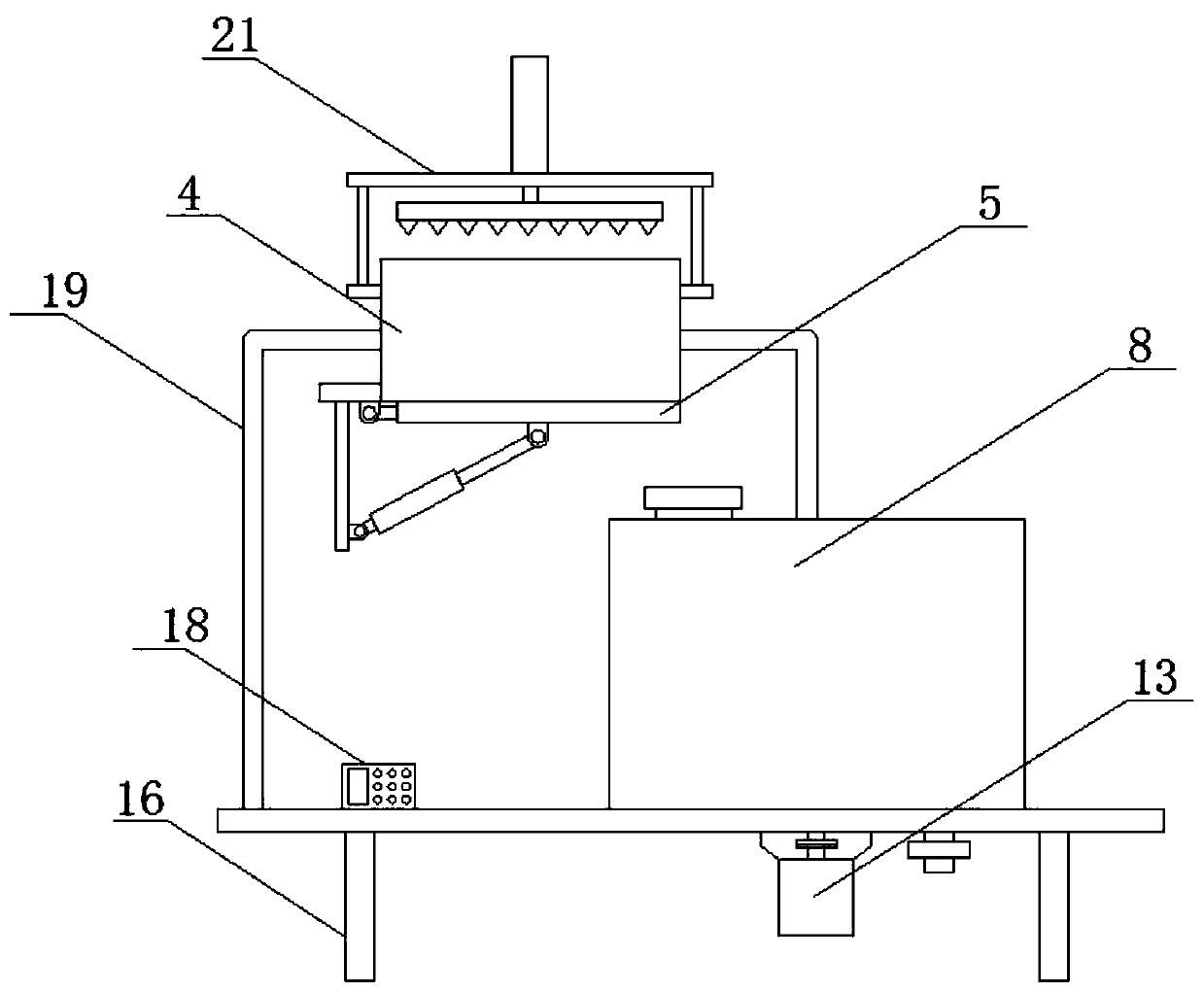

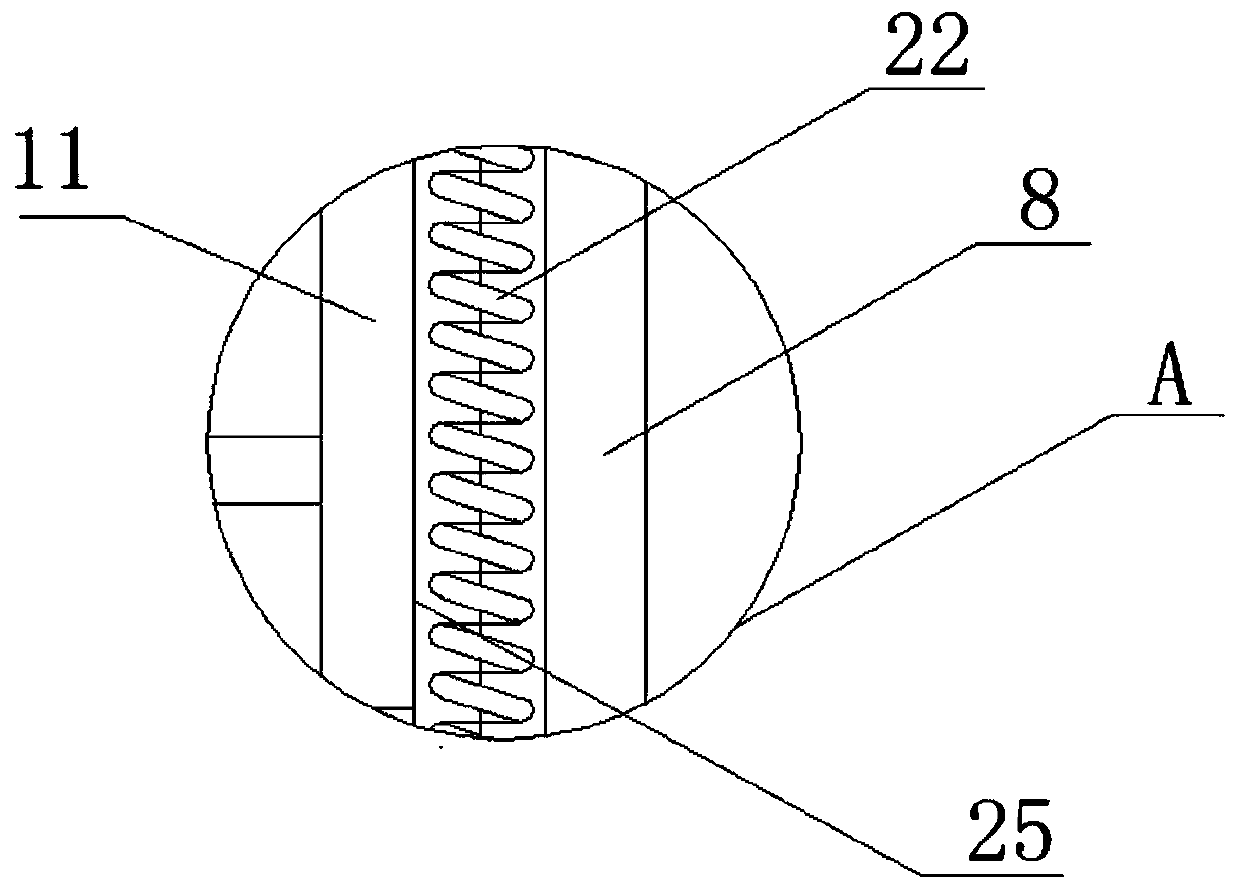

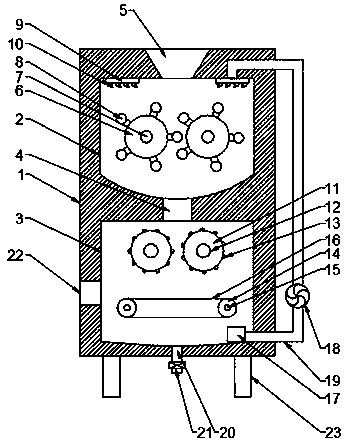

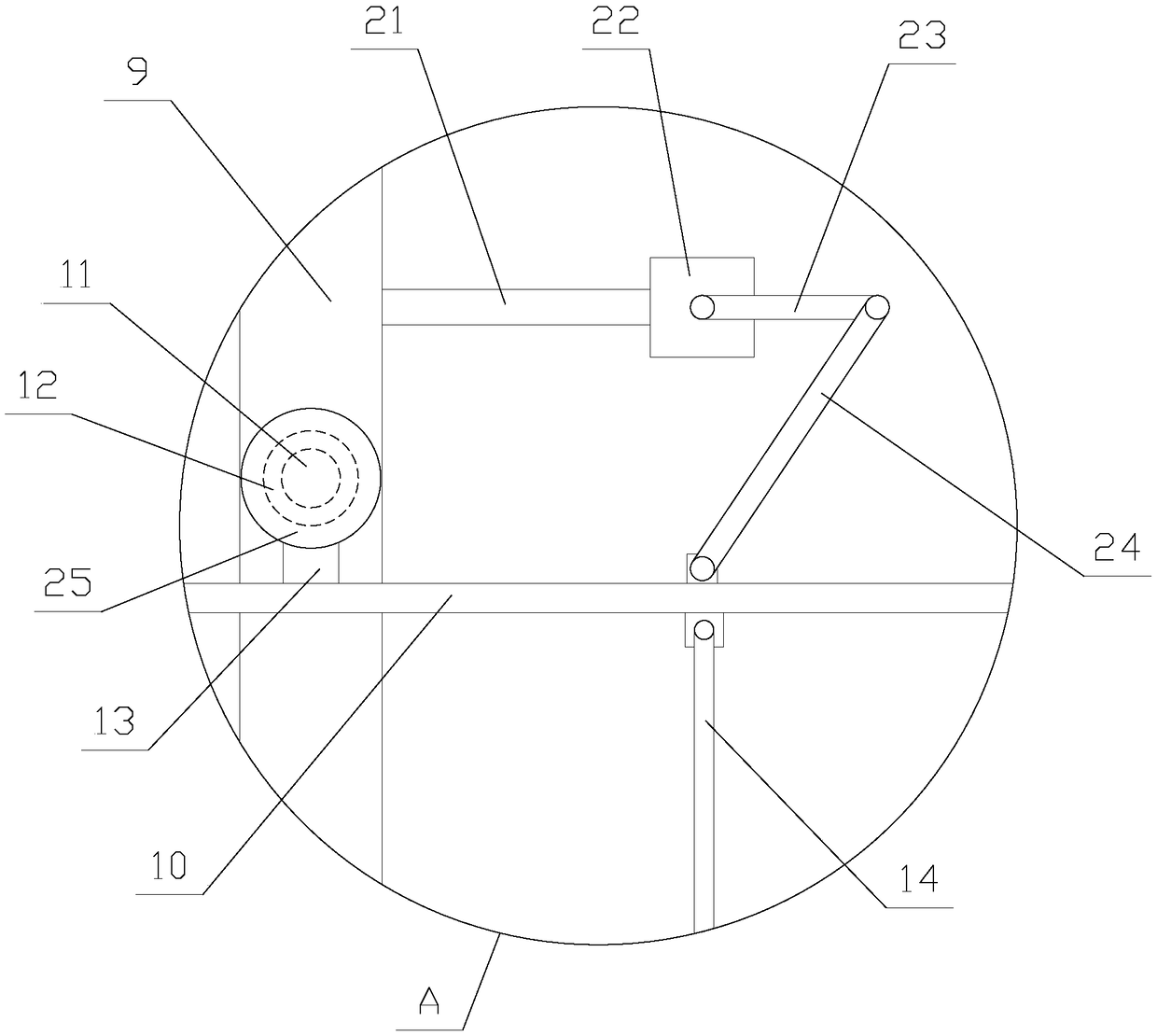

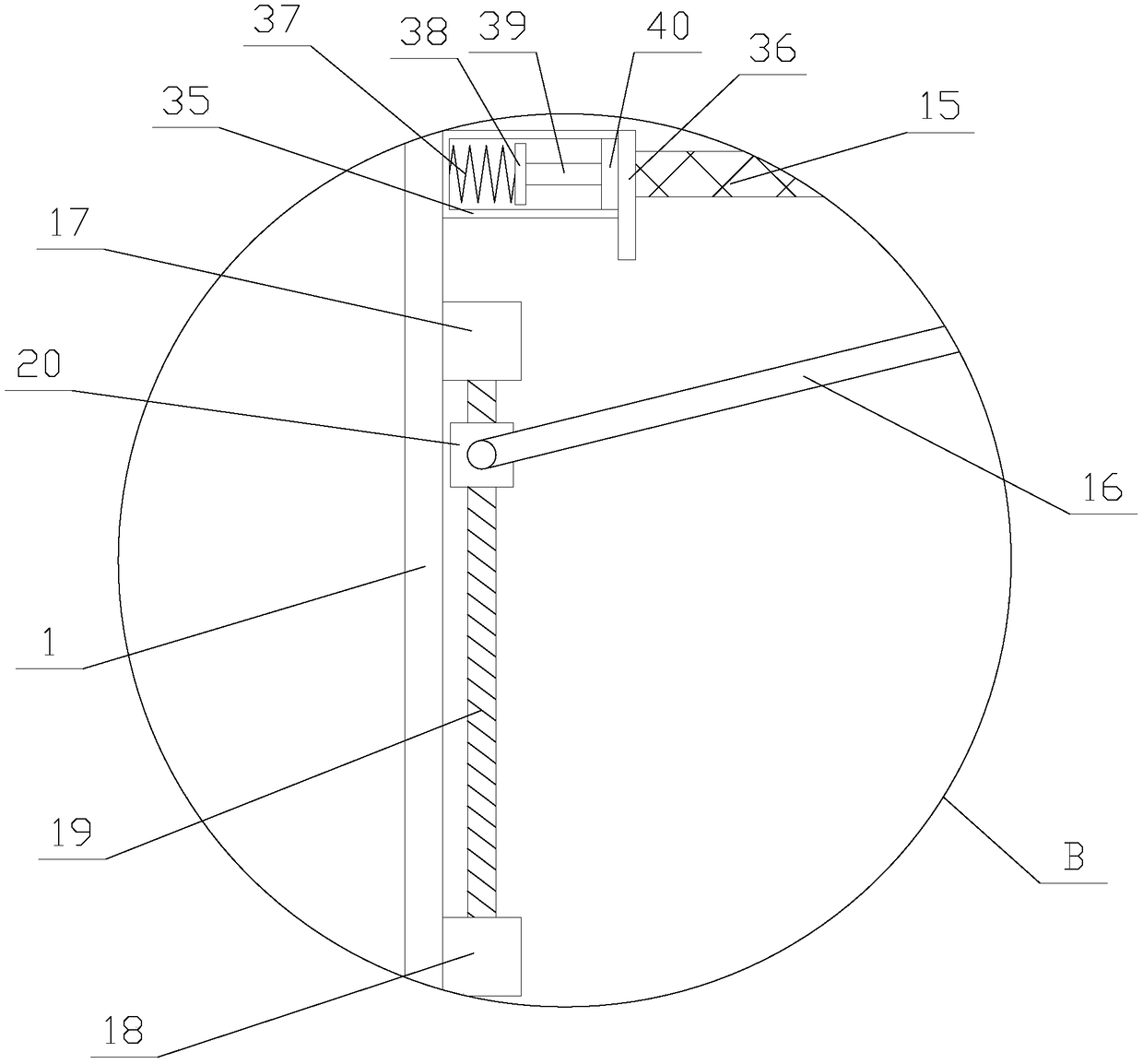

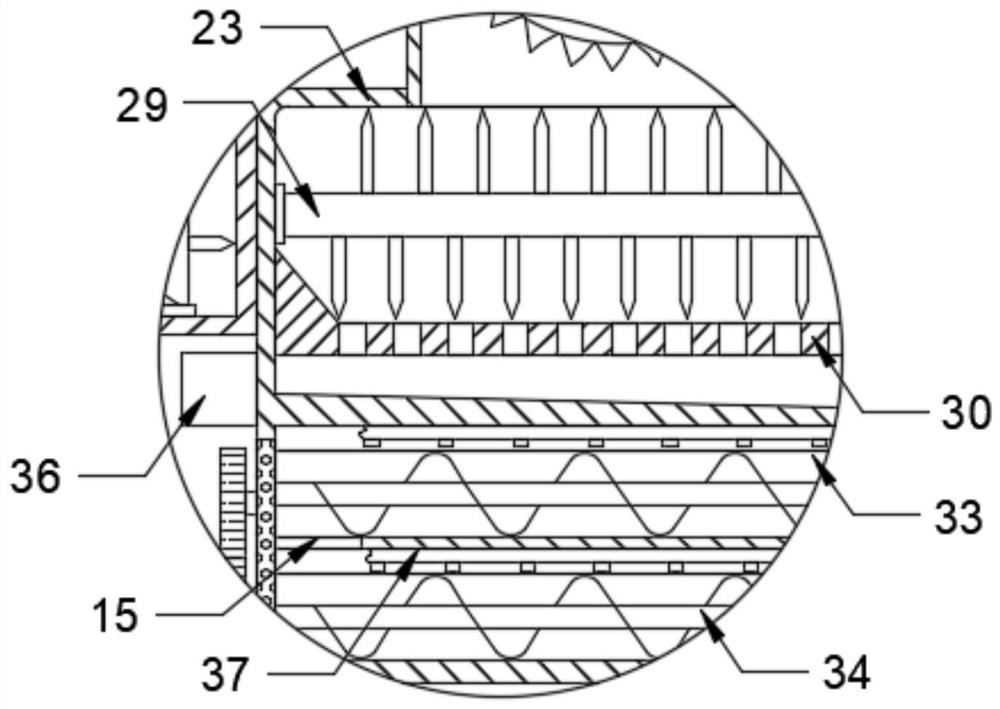

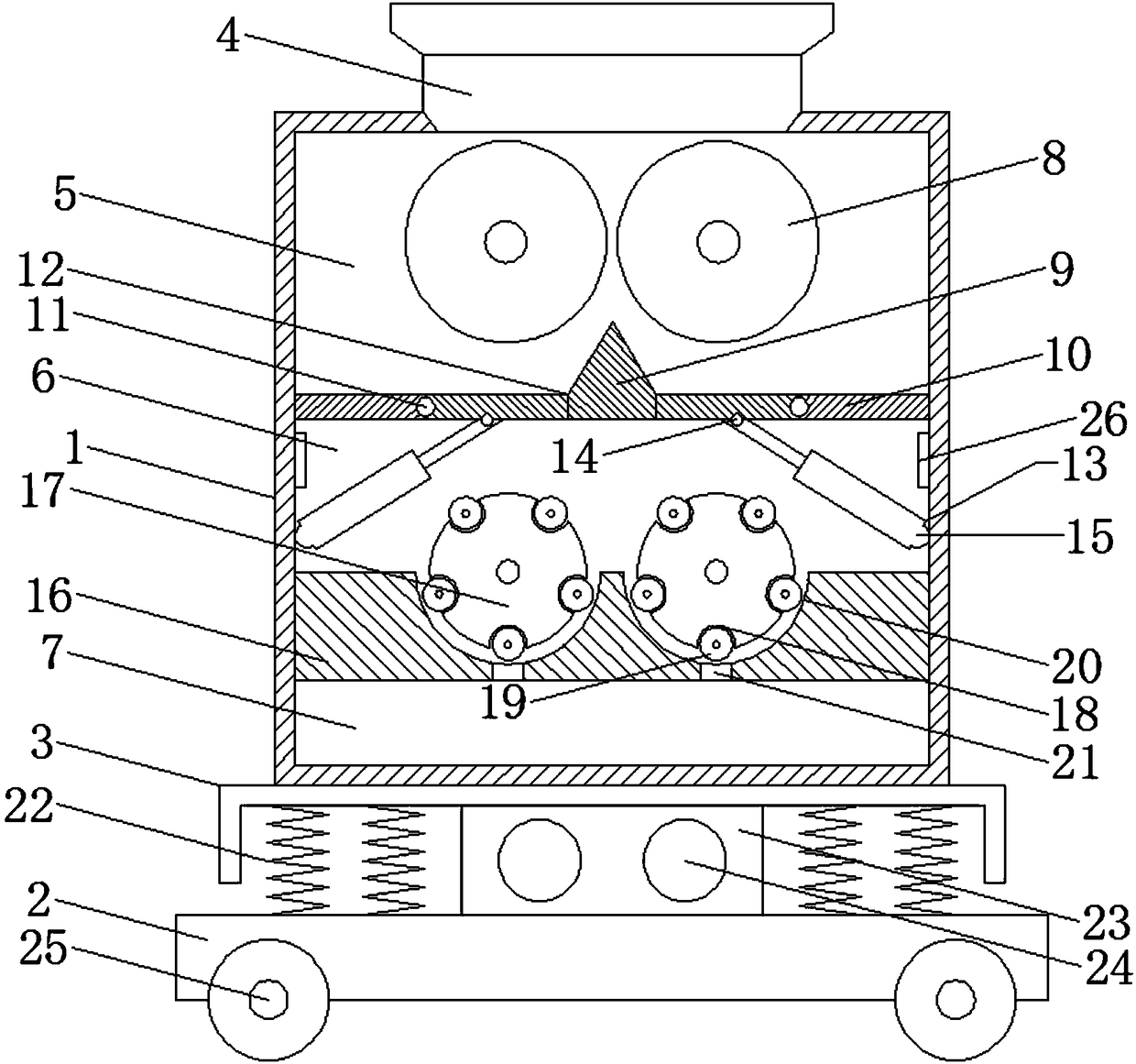

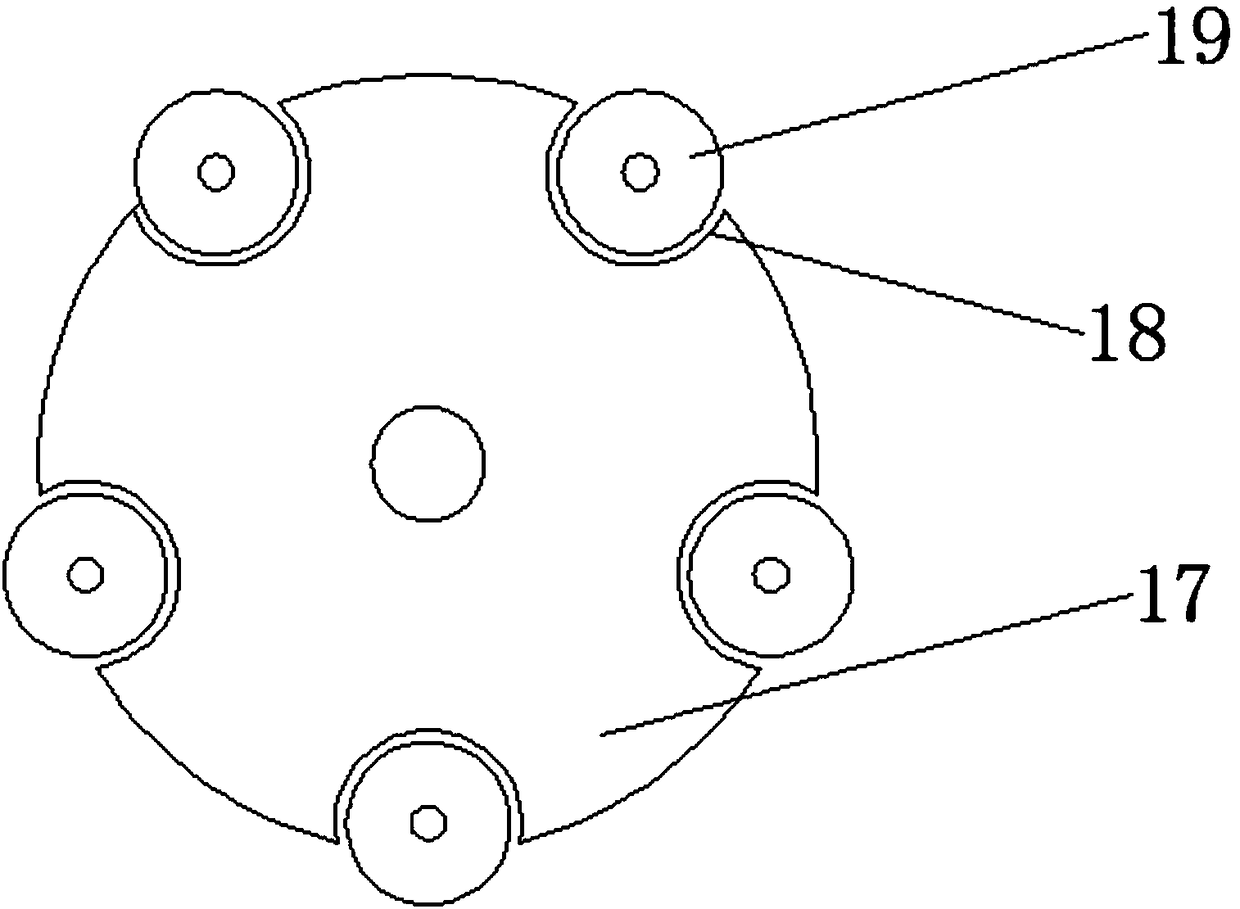

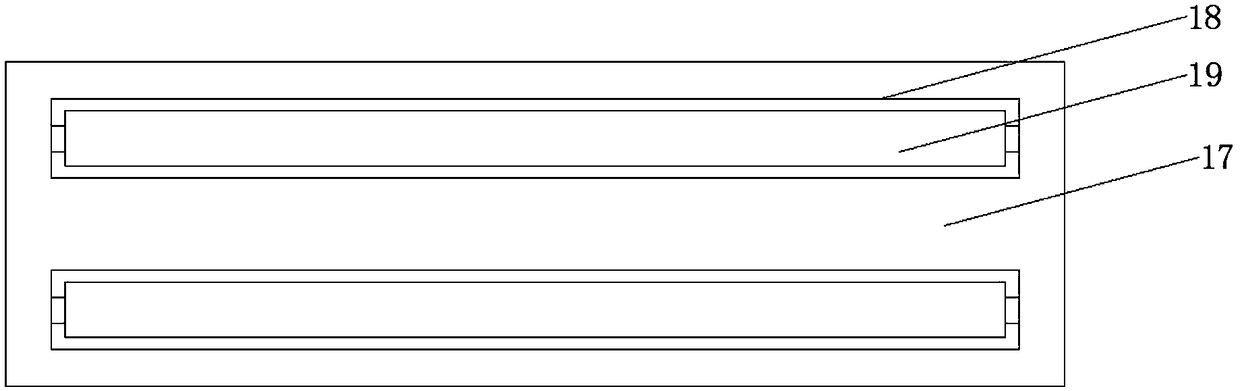

Traditional Chinese medicinal material three-level smashing device

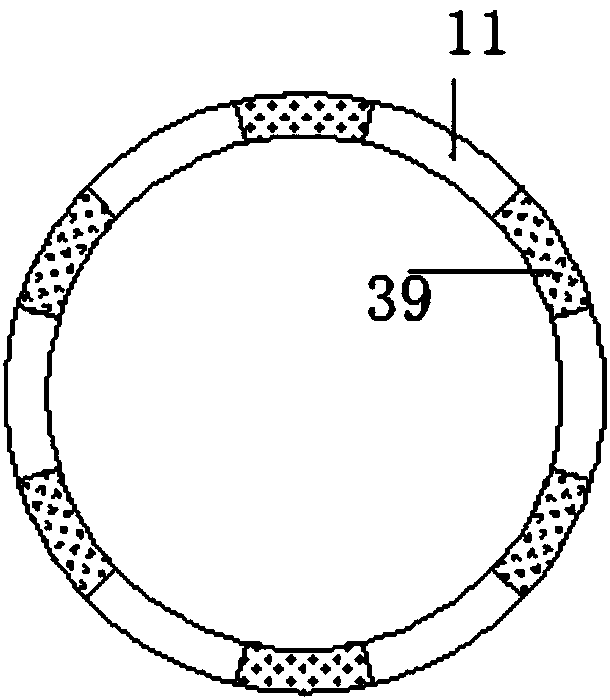

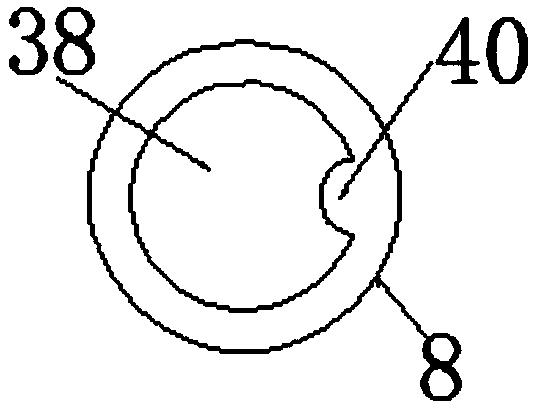

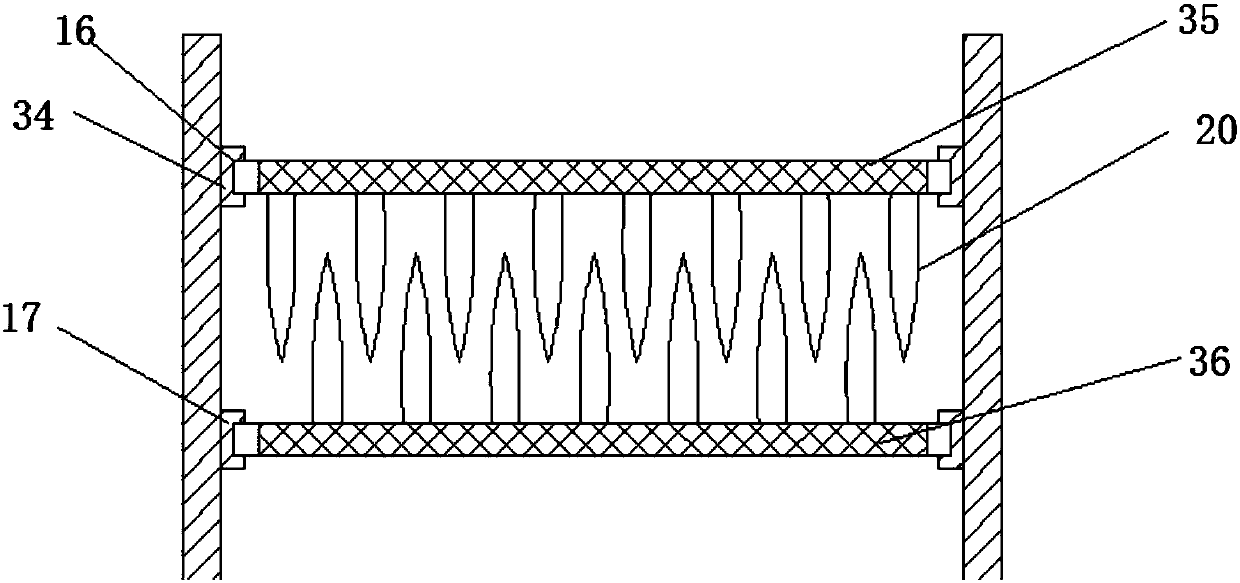

InactiveCN107552211AAchieve three-stage crushingGuaranteed crushing effectNon-rotating vibration suppressionGrain treatmentsThree levelMedicinal herbs

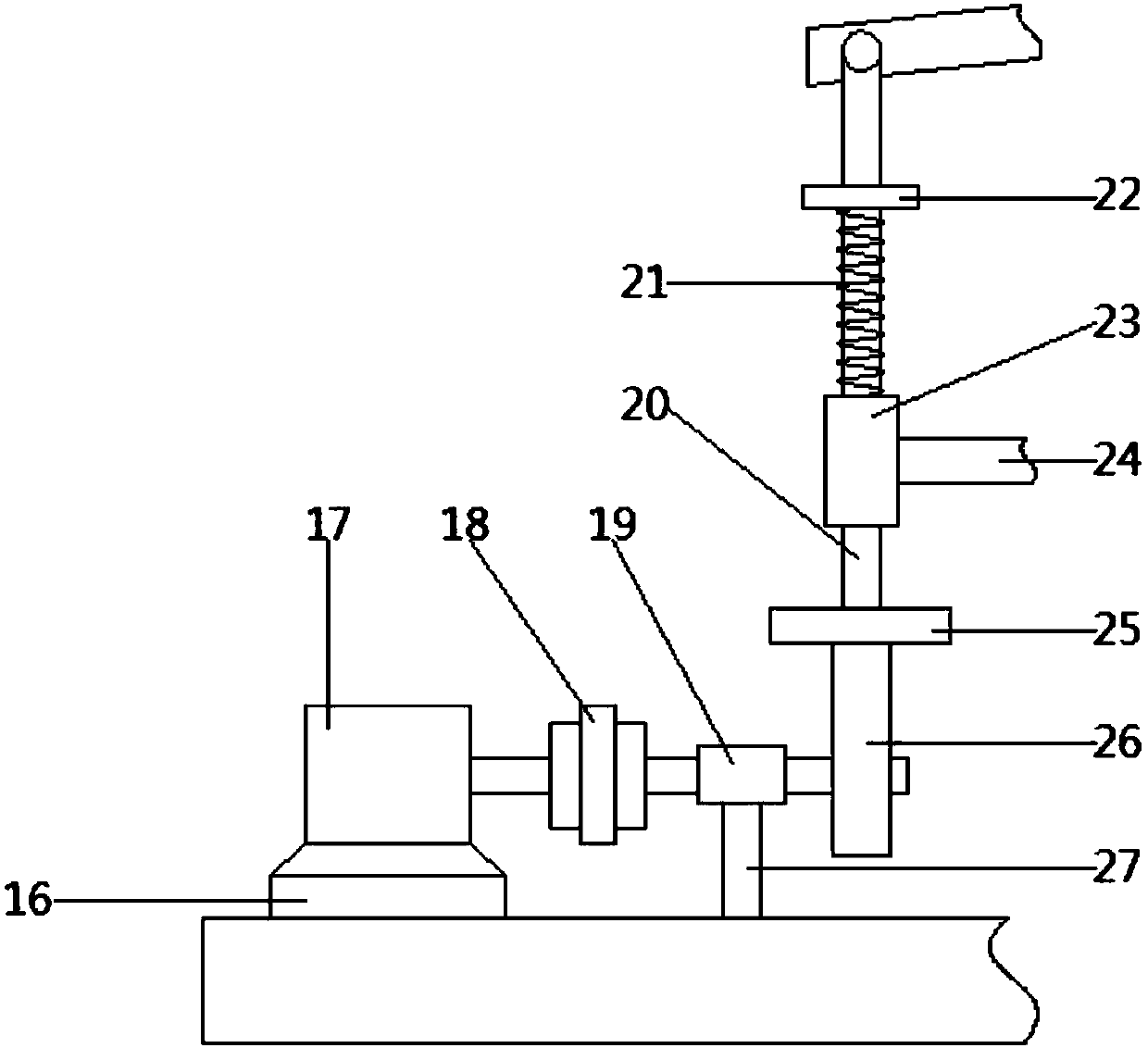

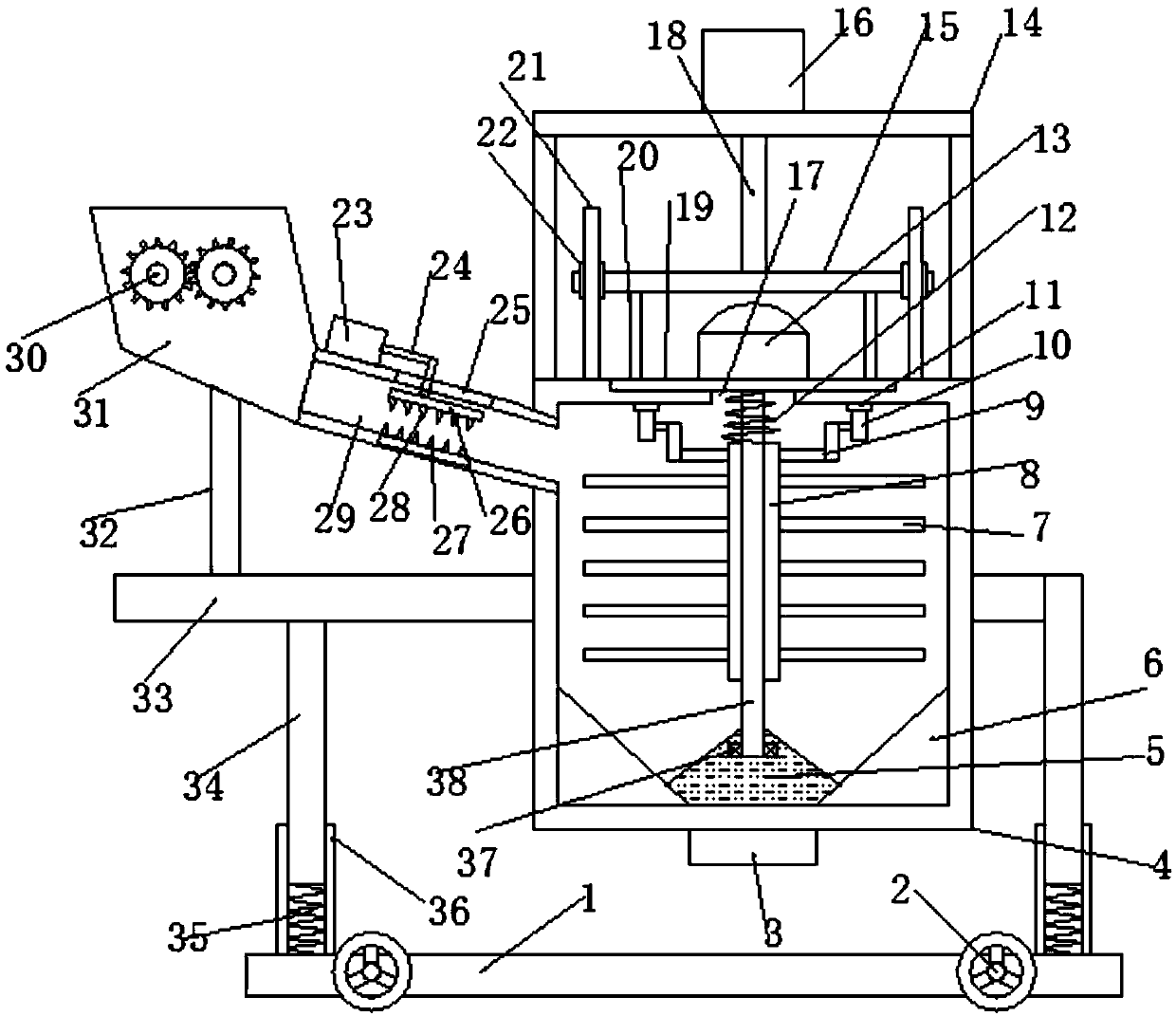

The invention discloses a three-stage crushing device for traditional Chinese medicinal materials, which includes a base and a crushing cylinder. Rollers are arranged on the left and right sides of the base to facilitate the device's transportation. A crushing cylinder is arranged above the base, and a side plate is fixed on the left side of the crushing cylinder. , the side plate and the right side of the support cylinder are provided with outriggers, and the lower end of the outriggers is slidingly provided with shock-absorbing sleeves. The shock-absorbing sleeve is connected and fixed. This shock-absorbing mechanism helps to improve the shock-absorbing effect of the device. The invention has a simple and reasonable structure, is easy to carry, has good shock resistance, and is convenient for discharging materials. It realizes three-stage crushing of materials, thereby ensuring In addition, in the final crushing process, the crushing knife 7 can be moved up and down, thereby increasing the crushing range of the crushing knife, which helps to improve the crushing effect, and has strong practicability.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

Construction waste treatment device for environmental protection

The invention relates to the technical field of environmental protection, and particularly discloses a construction waste treatment device for environmental protection. The construction waste treatment device comprises a baseplate, and the upper surface of the baseplate is provided with a conveyor mechanism, a crushing box and a dust collection box from left to right in sequence; the conveyor mechanism comprises a wet material conveyor belt and a dry material conveyor belt, and the wet material conveyor belt and the dry material conveyor belt are connected with a feeding conveyor belt separately; the feeding conveyor belt is connected with the crushing box, and the wet material conveyor belt penetrates through a drying box; a drying mechanism is arranged in the drying box; double crushingmechanisms are arranged in the crushing box, and screening mechanisms are arranged below the double crushing mechanisms; and the crushing box is connected with the dust collection box through a dust suction pipe. The construction waste treatment device is specially used for treatment of waste left in constructional engineering, especially solid waste, such as broken bricks and concrete, and the treated construction waste can be recycled; not only can the environment be protected, but also the resources can be saved; and the waste is avoided.

Owner:安徽砼筑新材料科技有限公司

Crushing device for recycled concrete production

ActiveCN110523505AEasy to crushReduce the probability of cloggingCleaning using liquidsGrain treatmentsEngineeringMachining

The invention discloses a crushing device for recycled concrete production. The device comprises a feeding box and a processing box, the bottom of the feeding box communicates with the left side at the top of the processing box, and a first crushing roller set is rotationally connected between the front side and the rear side of an inner cavity of the processing box through bearings. A conveying plate is rotationally connected to the top of the left side of the inner cavity of the processing box through a rotating block, and a transverse plate is fixedly connected to the position, located below the conveying plate, at the left side of the inner cavity of the processing box. The crushing device for recycled concrete production relates to the recycled concrete production technical field, after the preliminary crushing, the waste concrete is directly subjected to spray washing treatment, and the impurities are screened out, so that the treatment capacity of the device on the waste concrete can be reduced, the gaps on the surface of the waste concrete can be looser, the crushing is facilitated, and then the crushing treatment is conducted, and accordingly the crushing effect of the device on the waste concrete can be guaranteed, and the later-period reuse machining quality is guaranteed.

Owner:滁州高仁建设工程有限公司

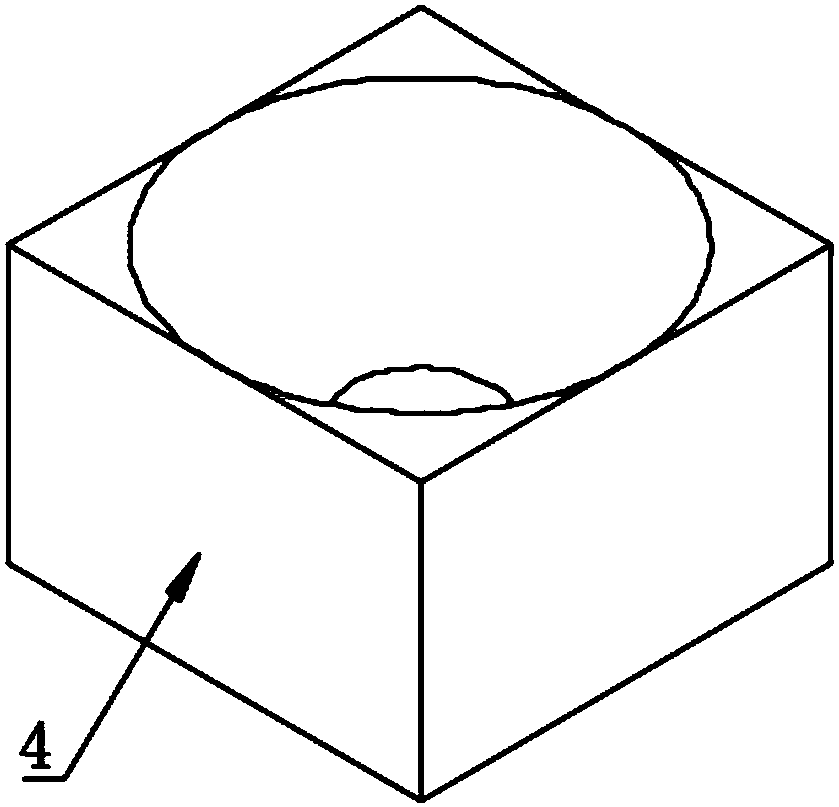

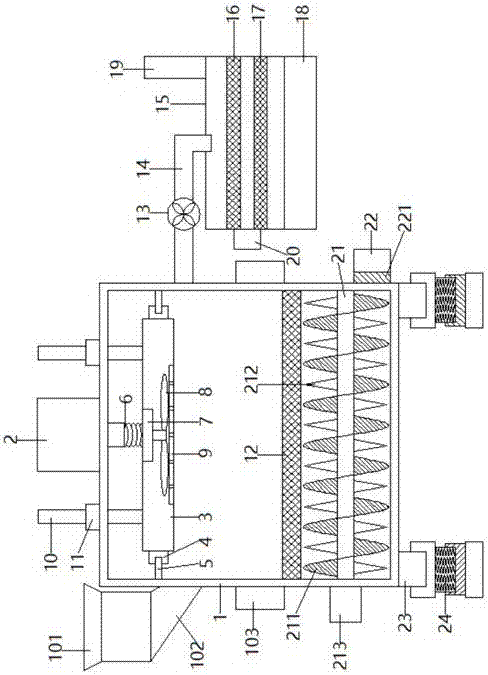

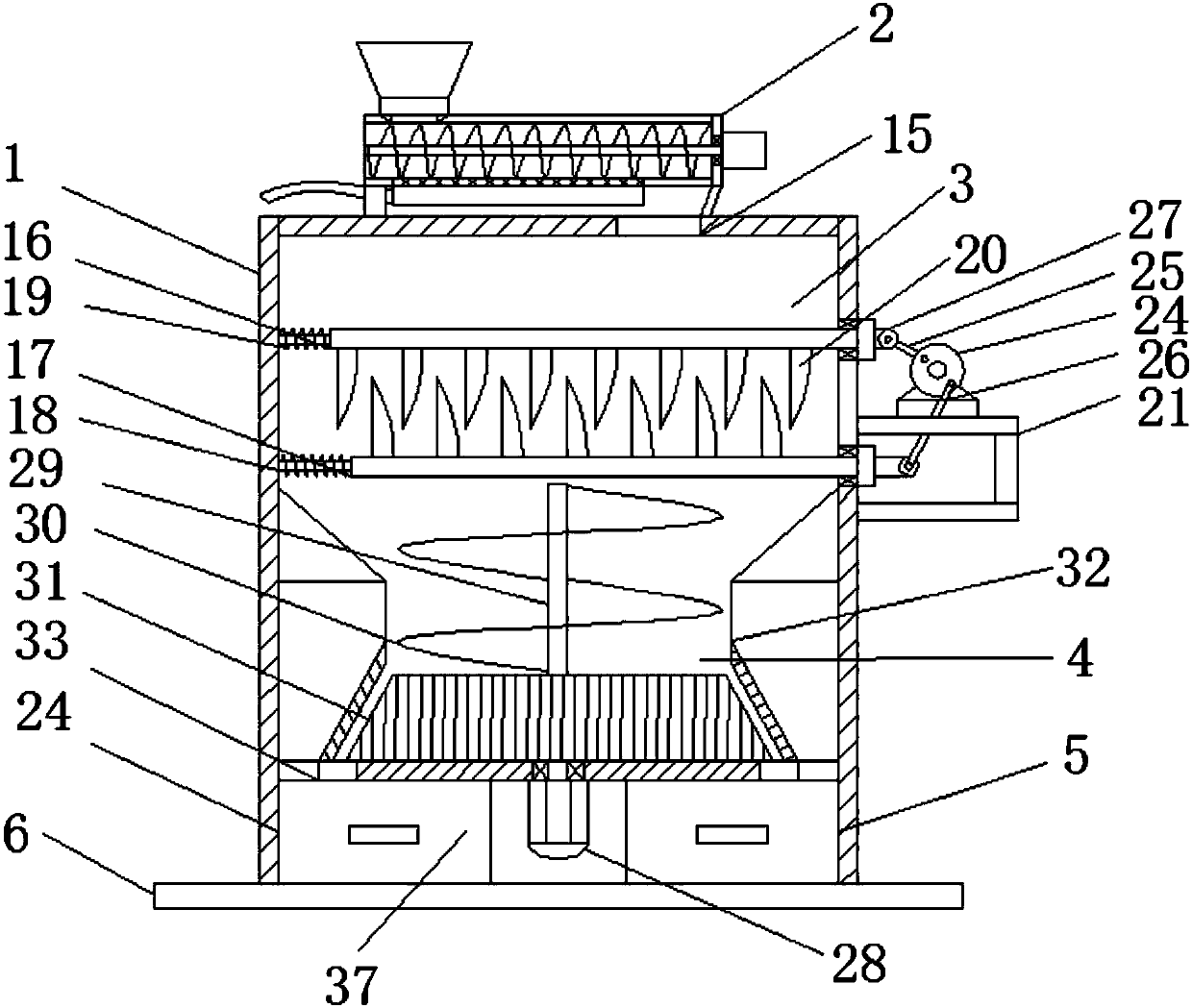

Multi-grain mixing-crushing-grinding device

InactiveCN107649235AGuaranteed crushing effectEasy to useGrain treatmentsEngineeringMechanical engineering

The invention discloses a multi-grain mixing-crushing-grinding device which comprises a base, wherein a working tank is fixedly arranged at the top of the base through a bracket I; a grinding seat isfixedly arranged at the inner bottom of the working tank; a mounted bearing is fixedly arranged in a cylindrical through hole in the bottom of the grinding seat through a bracket II; a first rotatingshaft is rotationally connected with the upper part of the mounted bearing; a grinding roller is mounted on the first rotating shaft; third rotating shafts are rotationally connected with the inner front and rear side walls of the working tank; second crushing rollers are mounted on the third rotating shafts; second rotating shafts are rotationally connected with the inner left and right side walls of the working tank; first crushing rollers are mounted on the second rotating shafts; supporting plates are fixedly arranged on the left and right sides of the top of the base through brackets III;storage tanks are fixedly arranged at the tops of the supporting plates through brackets IV; and discharging mechanisms are connected with the bottoms of the storage tanks. The multi-grain mixing-crushing-grinding device disclosed by the invention has the advantages that the grain mixing ratio can be controlled by controlling the rotating speed of each quantitative roller through a servo motor; grains can be squeezed and crushed by rotating the crushing rollers; the grinding and mixing operation can be performed by rotating the grinding rollers; and accordingly, the processing efficiency canbe improved.

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

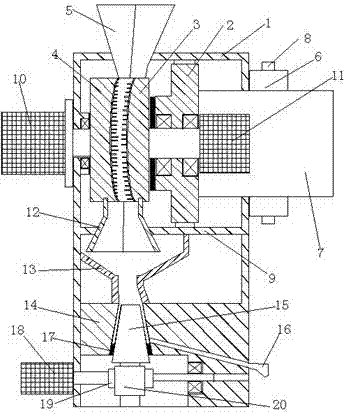

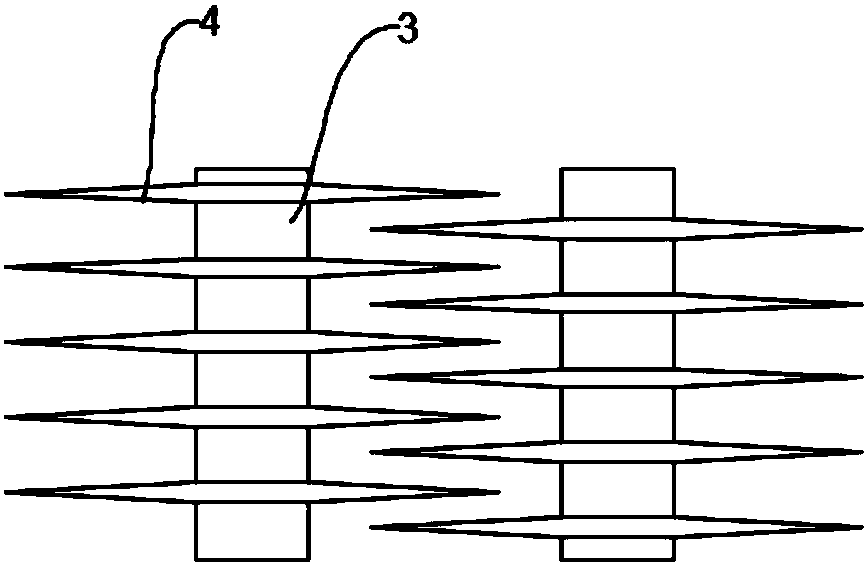

Multistage type traditional Chinese medicine smashing machine

InactiveCN107309057AGuaranteed crushing effectPracticalCocoaGrain treatmentsPulverizerChinese herbology

The invention discloses a multi-stage traditional Chinese medicine pulverizer. The invention adopts two stages of crushing. Firstly, a convex roller and a concave roller are used for primary crushing, and then a millstone is used to grind it to a required particle size. The method can make the Chinese medicine will not be subjected to excessive extrusion force every time it is crushed, so as to ensure that the molecular structure of the Chinese medicine is not damaged, and the efficacy of the Chinese medicine is guaranteed. In addition, the present invention is set as the center of the feeding port of the primary crushing component. The axial direction is perpendicular to the central rotation axis direction of the primary convex roller, and the central axis direction of the feed port of the secondary crushing assembly is parallel to the central axis of the secondary rotating grinding disc of the secondary crushing assembly, which can make the medicine from different Feeding at an angle ensures the crushing effect of the medicine. The distance between the first-stage crushing components of the present invention is adjustable, which can adapt to the crushing of different traditional Chinese medicines and has strong practicability.

Owner:王建梅

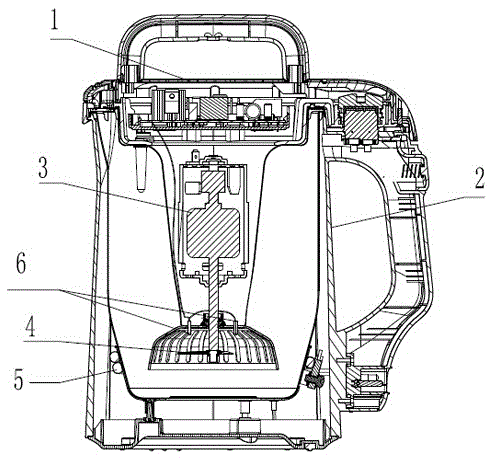

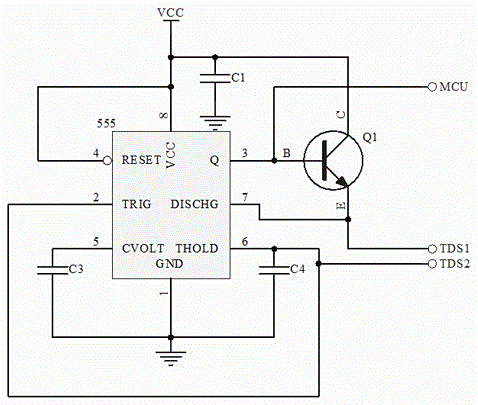

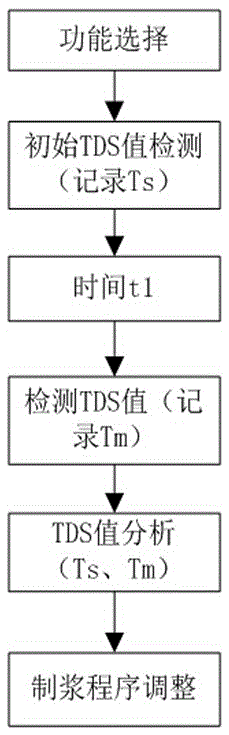

Intelligent identification method of material in soybean milk machine

ActiveCN106510492AEasy to detectReduce overflowBeverage vesselsMilk substitutesWater qualityPulp and paper industry

The invention relates to an intelligent identification method of a material in a soybean milk machine. The soybean milk machine includes a motor used for crushing the material, a heating device used for heating a liquid in a cup body and a main control chip used for controlling the motor and the heating device. The soybean milk machine is provided with a water quality detection device, the water quality detection device sends detected water quality data to the main control chip, and the pulping process of the soybean milk machine includes a turbid process. The main control chip is used for identifying the material in the cup body by analyzing water quality change of pulp in the cup body before and after the turbid process, and different pulping processes are executed according to different materials. By comparing the water quality change correspondingly, the corresponding type and amount of the material are identified out, the motor power, the motor working time and the like in the pulping process are adjusted according to preset conditions, and therefore the intelligent pulping effect is achieved. At the same time, the starting mode of the motor is adjusted according to different amounts of the material, the motor is protected, the service life of the motor is prolonged, and the noise in the pulping process is reduced.

Owner:JOYOUNG CO LTD

Efficient pulverizer for producing ceramics

The invention discloses an efficient pulverizer for producing ceramics. The efficient pulverizer comprises a pulverizer body, sharp edge movable blades and Y-shaped fixed blades. The upper segment of the left side of the pulverizer body is provided with a feeding pipe. The lower side of the feeding pipe is provided with an inclined pipe, and the upper side of the feeding pipe is in a hopper shape. A rotating shaft is vertically arranged on the axis in the pulverizer body. The top end of the rotating shaft stretches out of the pulverizer body and is connected with a rotating motor. The outer side of the rotating motor is provided with a sound attenuation cover. The outer wall of the rotating shaft is vertically and evenly provided with the sharp edge movable blades. The inner wall of the pulverizer body is provided with the Y-shaped fixed blades. According to the efficient pulverizer for producing the ceramics, the Y-shaped fixed blades and the sharp edge movable blades are vertically arranged and used for pulverizing materials, the pulverizing effect is good, the pulverizing efficiency is high, pulverized materials are thin and fine, the crushed materials are screened, the larger materials are pumped into the pulverizer through an elevator to be pulverized in a circulation mode, the pulverizing effect is guaranteed, dust generated in the pulverizing process is recycled by a cloth dedusting device, pollution is avoided, and raw materials are saved.

Owner:顾马飞

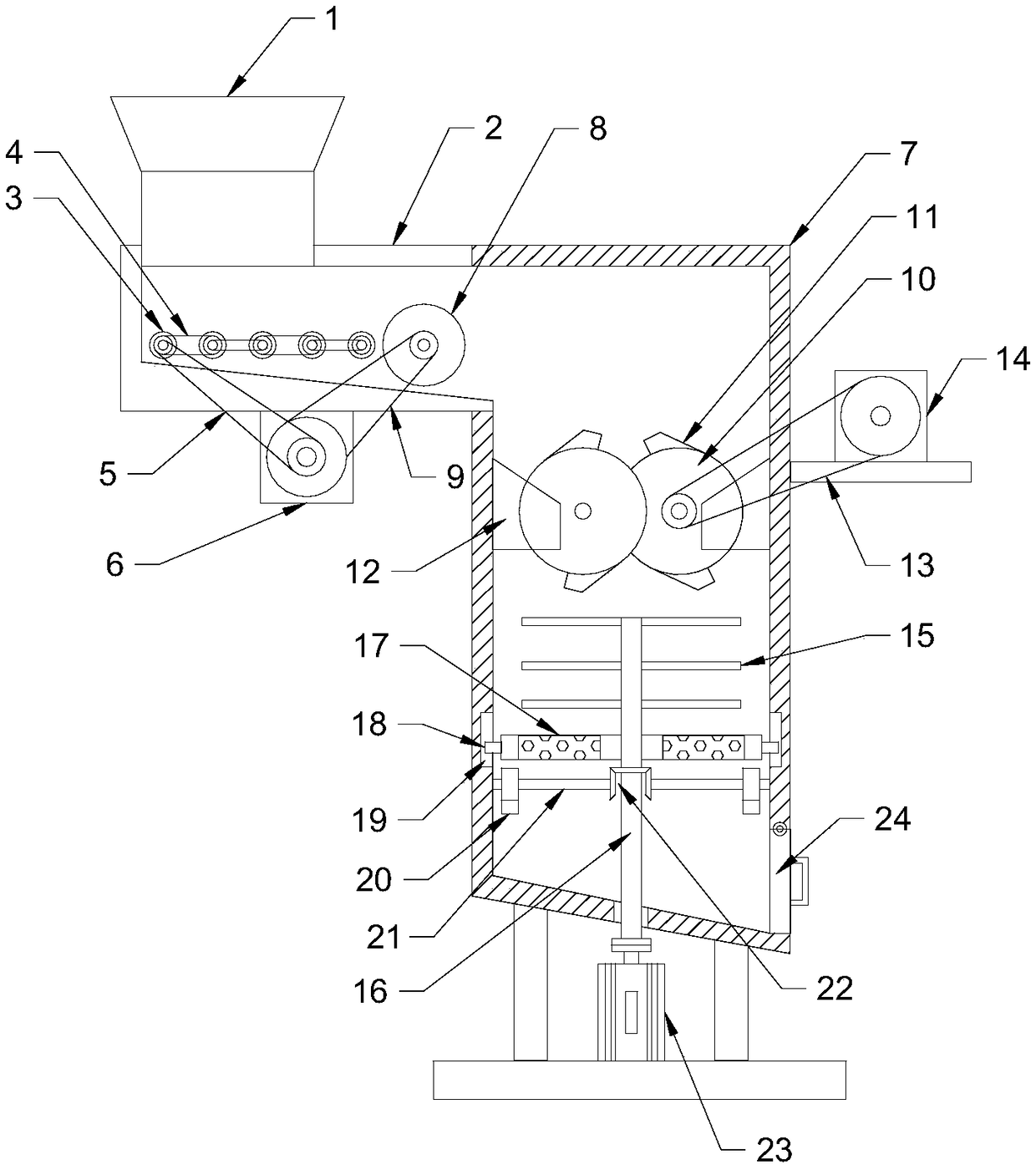

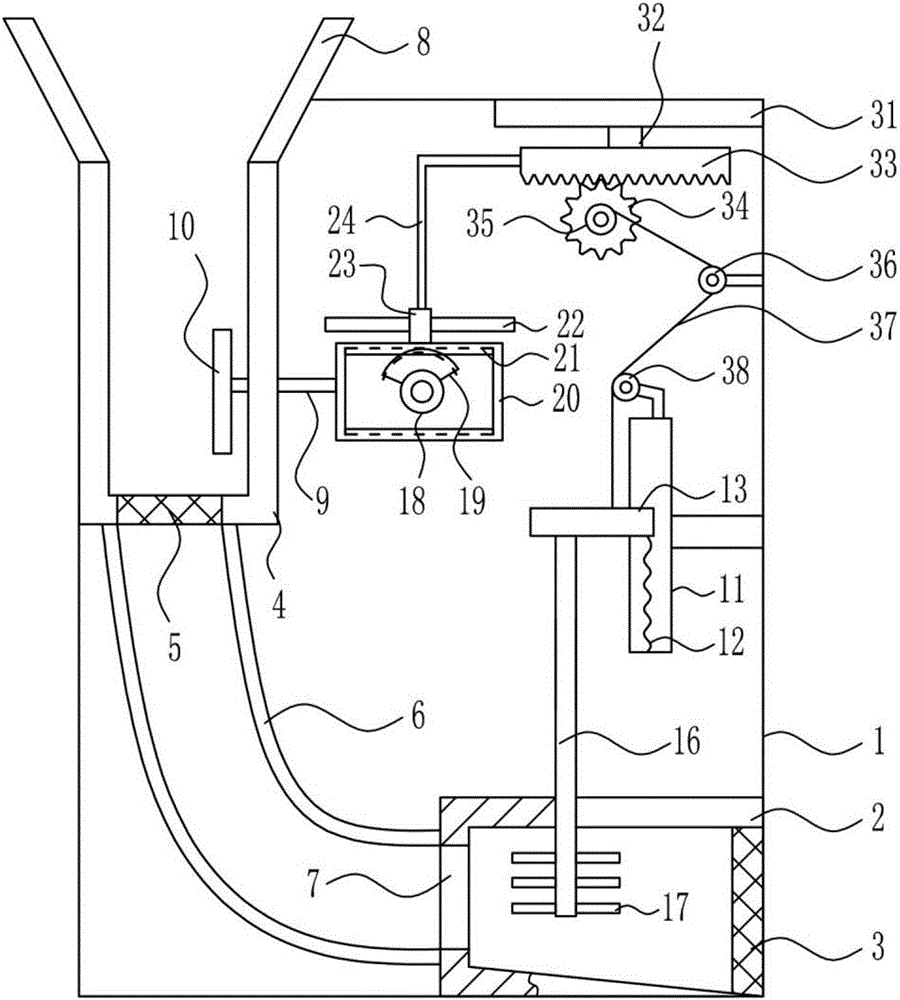

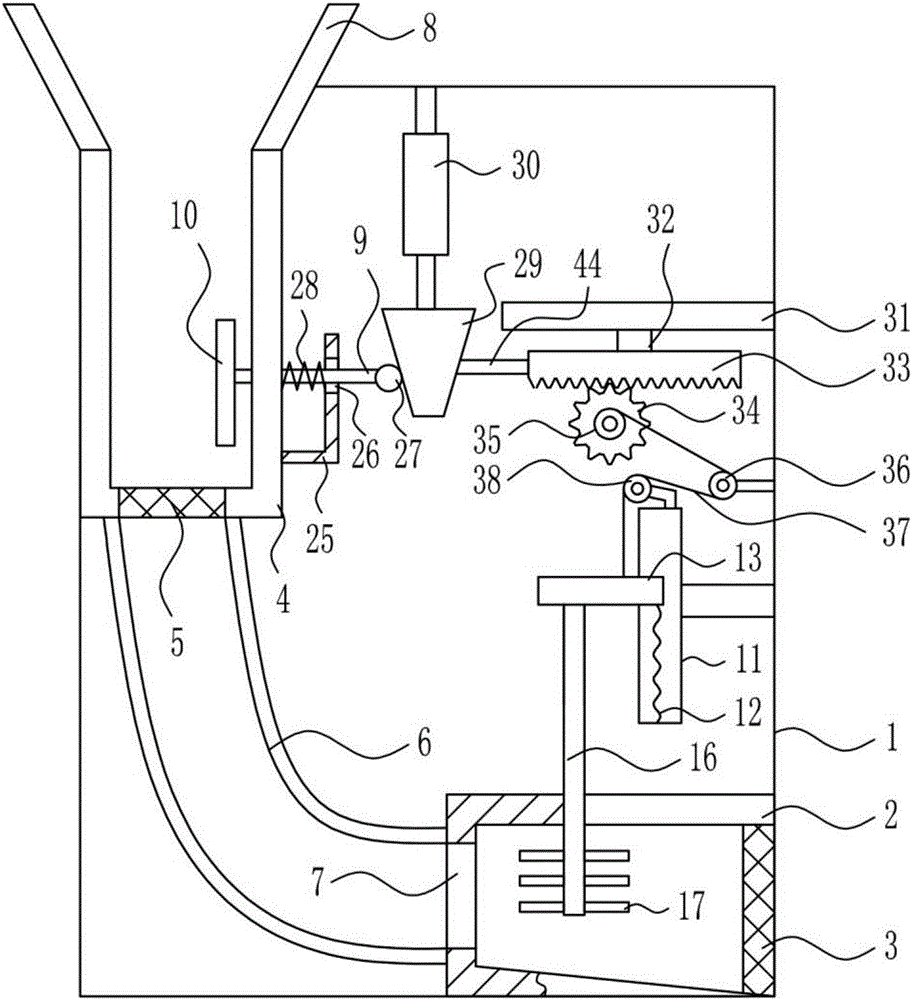

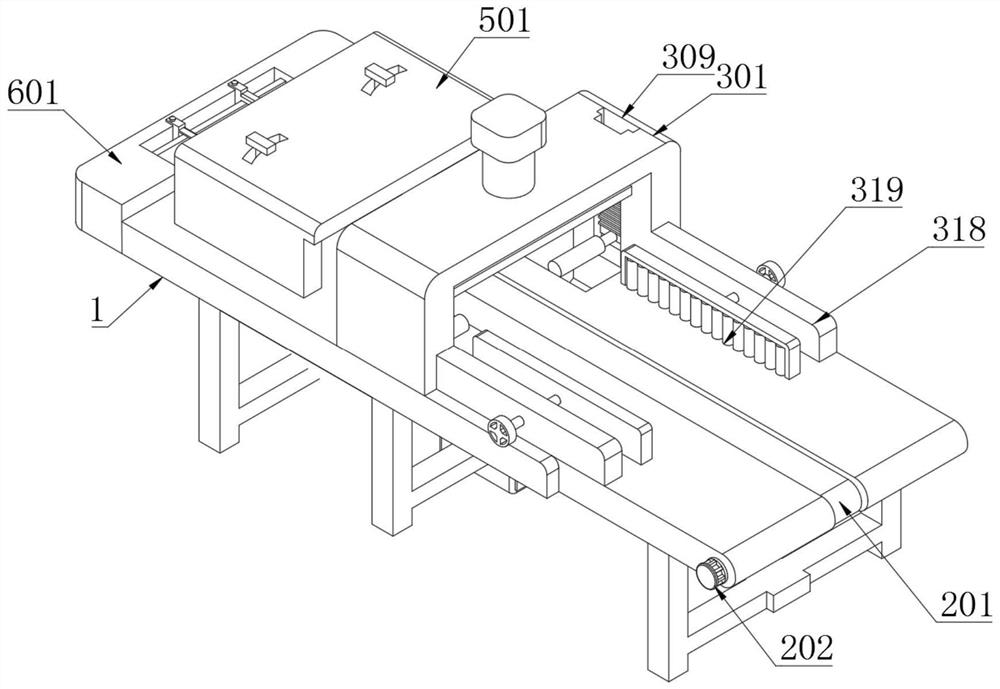

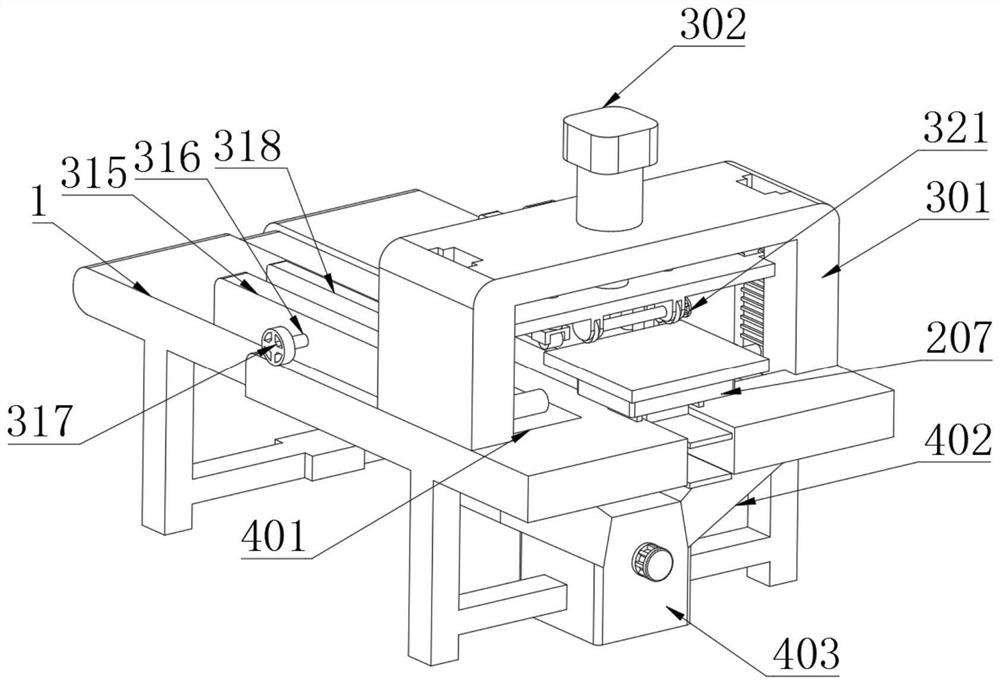

Construction waste treatment device

The invention discloses a construction waste treatment device. The construction waste treatment device comprises a feeding hopper, a material conveying box and a pulverizing box, wherein the lower part of the feeding hopper communicates with the material conveying box; material conveying rollers which are equidistantly distributed are arranged in the material conveying box; the right side of the material conveying box communicates with the pulverizing box; a cutting blade roller is arranged at a communicating part of the material conveying box and the pulverizing box; a squeezing roller groupis arranged in the pulverizing box; a pulverizing cutter is arranged below the squeezing roller group; a sieve plate is arranged below the pulverizing cutter; and a cam is abutted below the sieve plate. Construction waste blocks to be pulverized are cut by the cutting blade roller, and are separated, so that the follow-up crushing is facilitated, and the overall processing efficiency is improved;the sieve plate which vibrates up and down is arranged below the pulverizing cutter, is prevented from being blocked, and meanwhile causes the waste blocks which do not reach the pulverization particle sizes to be in contact with the pulverizing cutter again, and thus, the pulverizing effect is ensured; the rapid and efficient treatment of the waste blocks is realized by cutting, crushing and pulverizing three-stage mechanisms; and the follow-up transportation and recycling are facilitated.

Owner:重庆市安平建筑有限责任公司

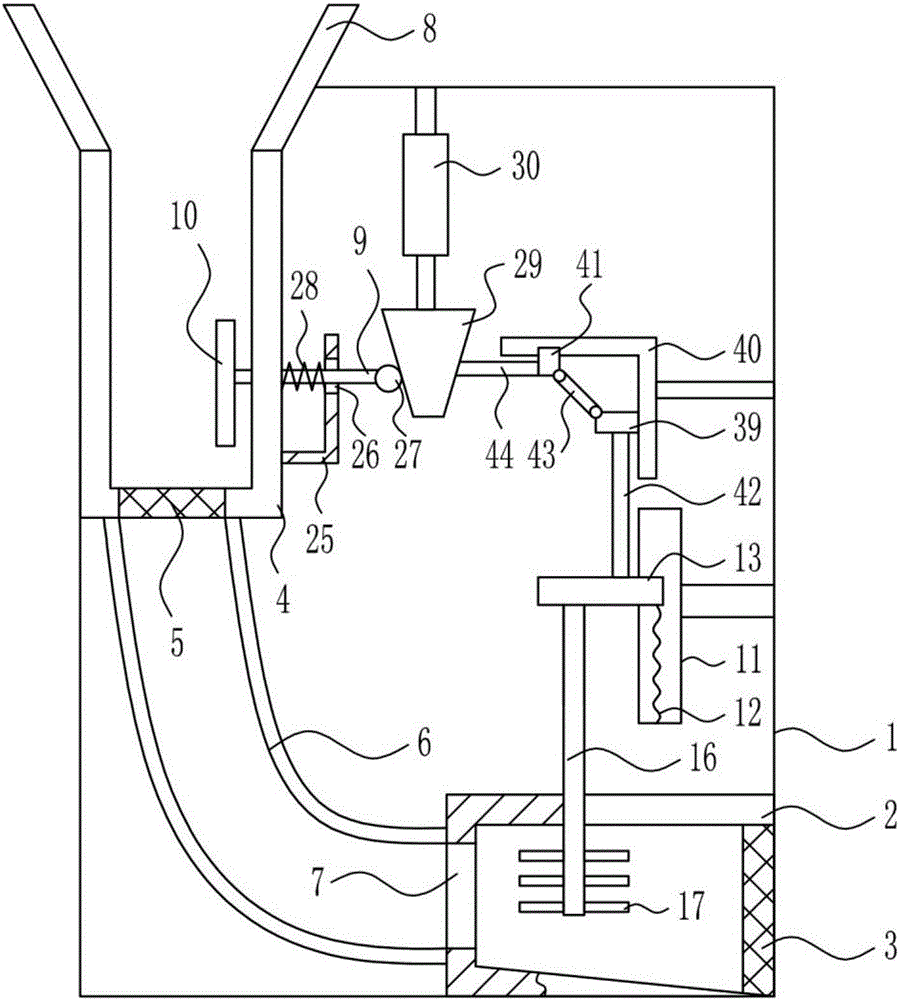

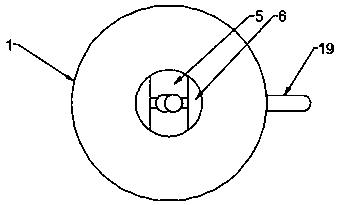

Waste lithium battery sorting and recycling equipment

ActiveCN108940428AImprove crushing effectImprove energy utilizationWaste accumulators reclaimingGrain treatmentsEngineeringMetal

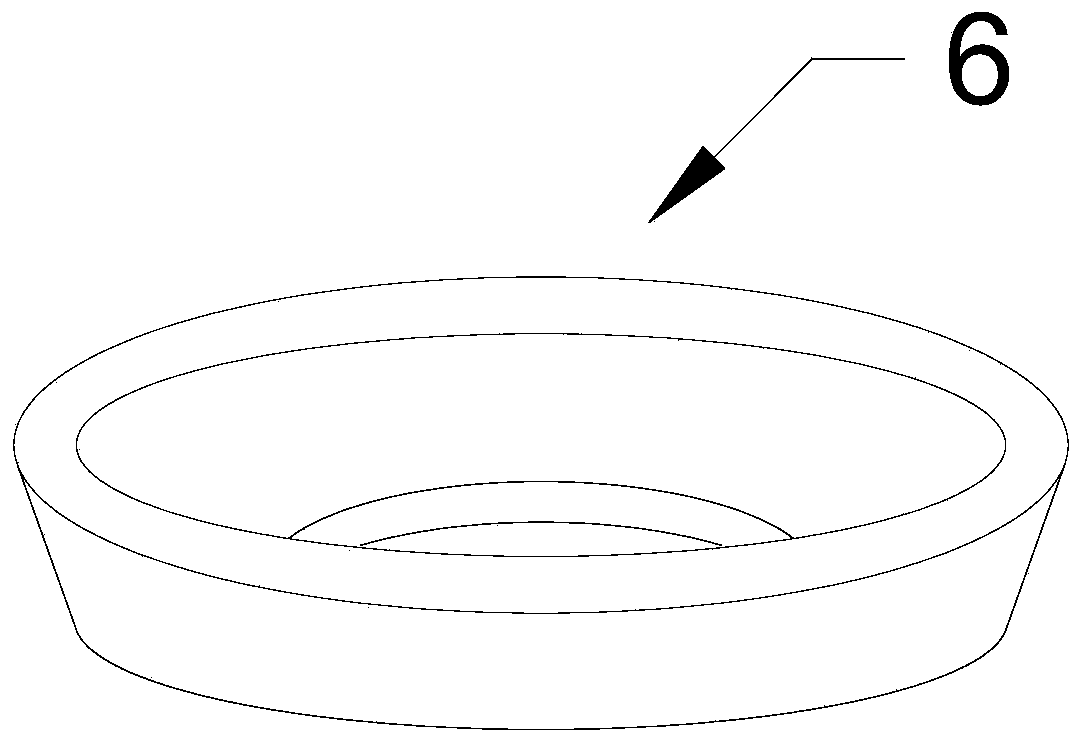

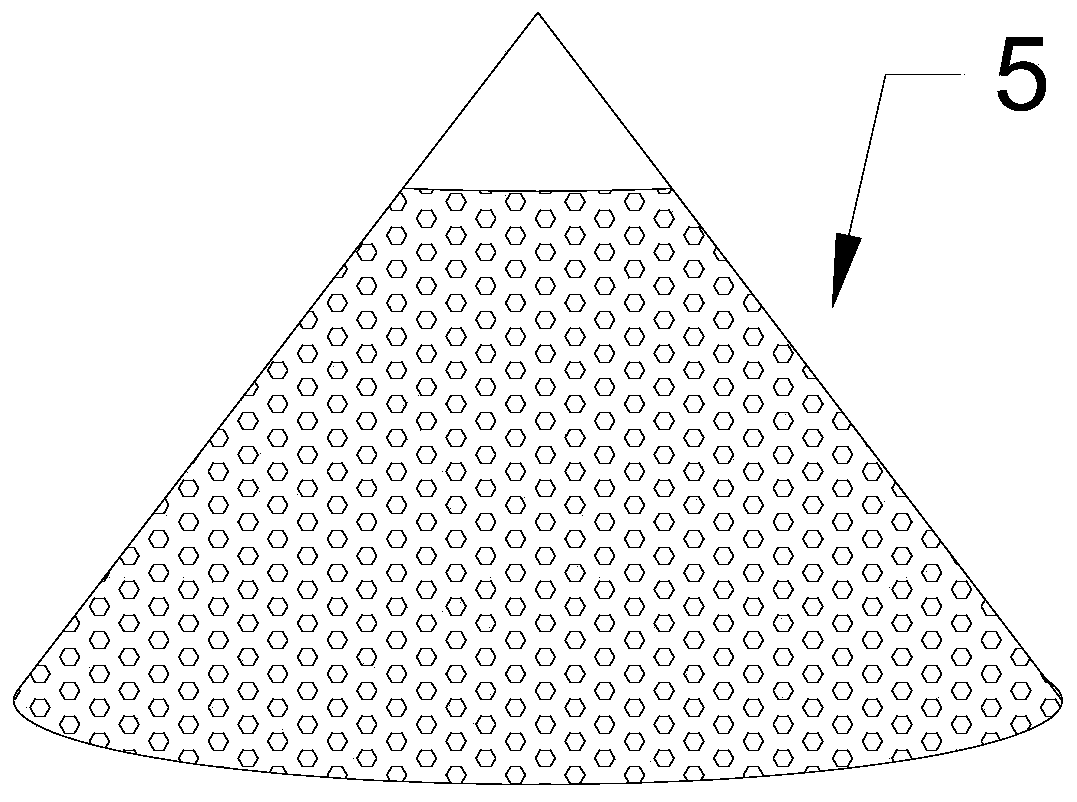

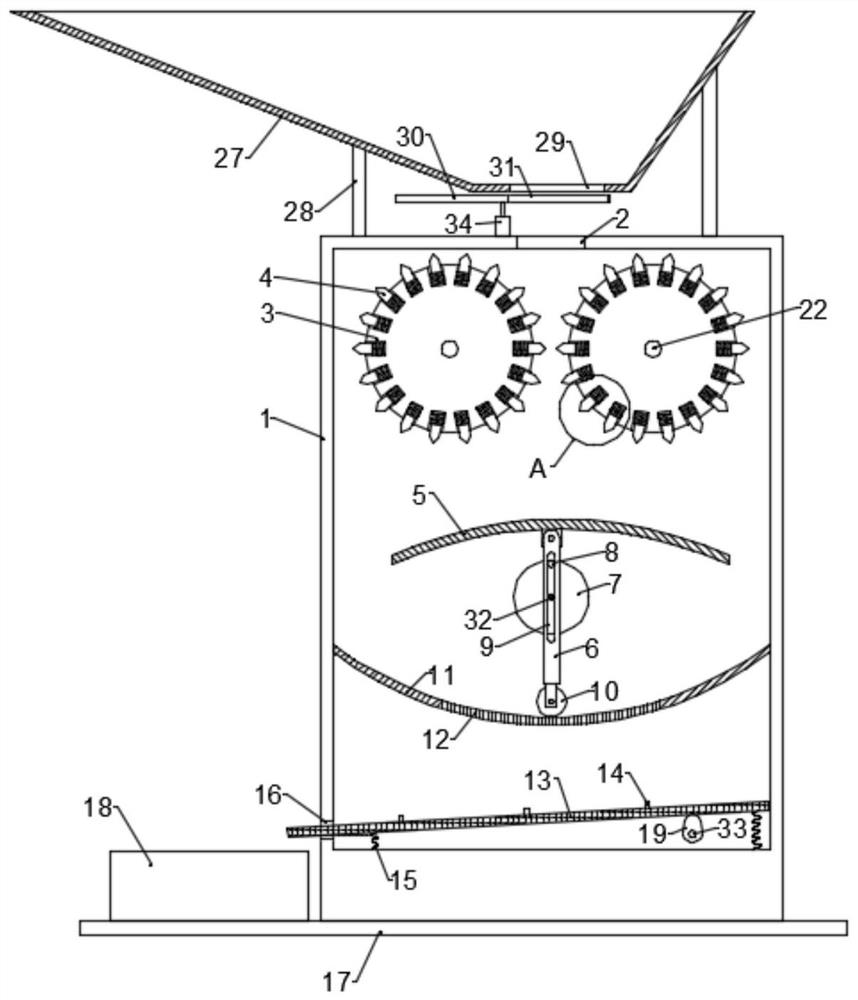

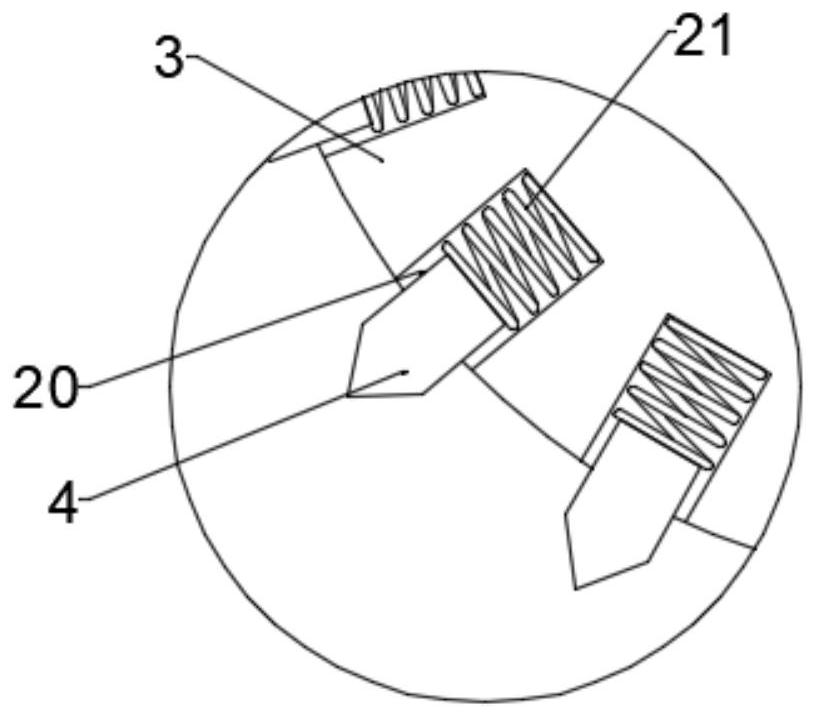

The invention belongs to the technical field of lithium battery recycling, and particularly relates to waste lithium battery sorting and recycling equipment. The waste lithium battery sorting and recycling equipment comprises a box, a first-level sorting unit and a second-level sorting unit. A circular-platform-shaped groove is formed in the middle position of the upper surface of the box. A rectangular groove is formed in the middle position of the lower surface of the box. A filter hole is formed in the part, between the circular-platform-shaped groove and the rectangular groove, of the box,and a cover plate is arranged above the box. The first-level sorting unit is located in the circular-platform-shaped groove of the box and used for conducting first-time pulverizing and screening onwaste lithium batteries, and plastic and metal composite materials are separated out. The second-level sorting unit is located in the rectangular groove in the lower portion of the box and used for pulverizing and screening the metal composite materials again, and positive and negative electrode materials and waste residues are separated out, wherein the metal composite materials are obtained after screening through the first-level sorting unit. The waste lithium battery sorting and recycling equipment achieves linkage between two levels of crushing, the crushing effect is good, and the energyutilization rate is high.

Owner:JIANGXI RUIDA NEW ENERGY TECH CO LTD

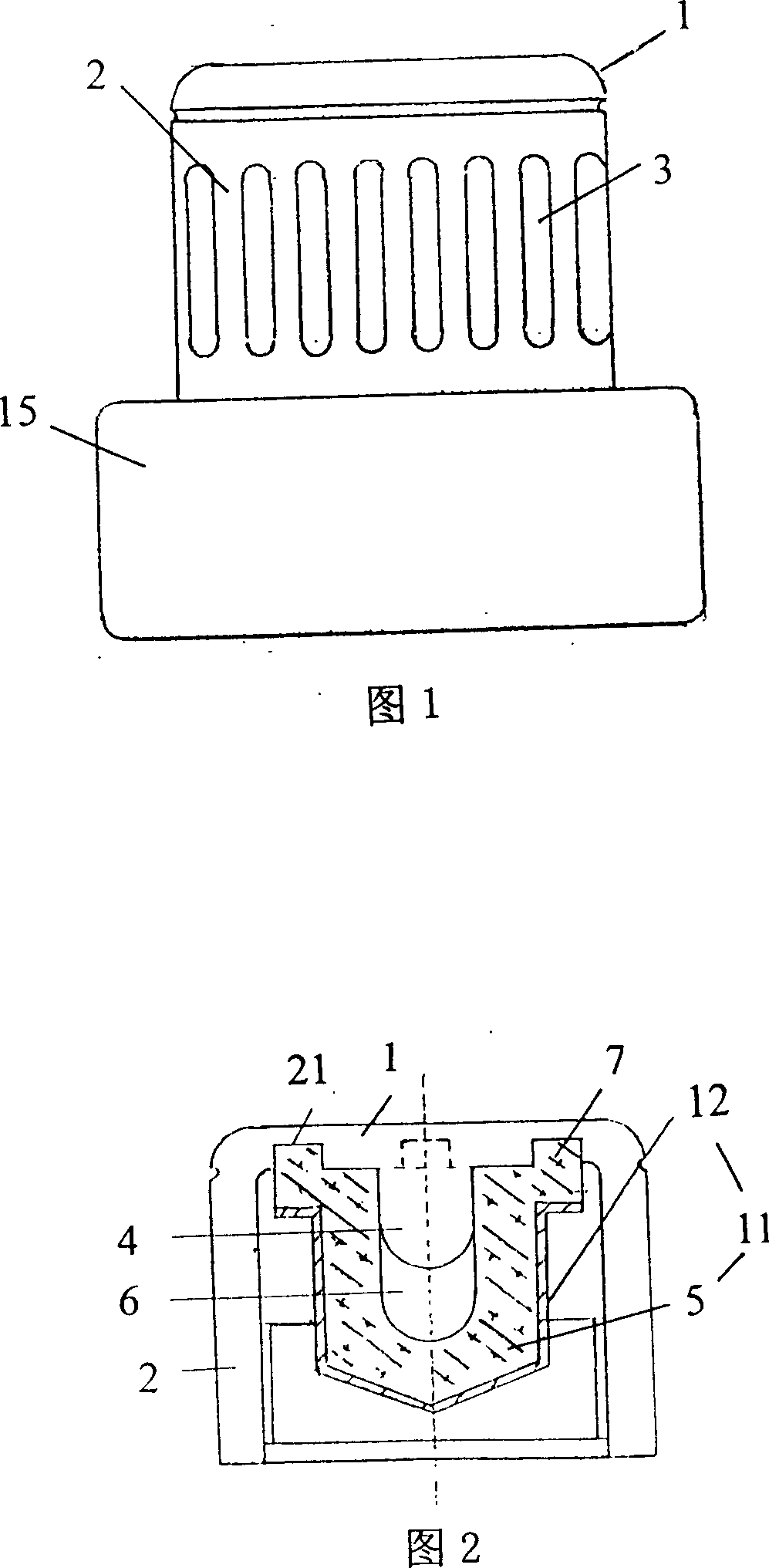

Device for grinding medical tablets

InactiveCN101002719APrevent the phenomenon of spinning grinding stickingEasy to carryPharmaceutical product form changeGrain treatmentsMedicineScrew thread

Owner:天津市公安医院

Material pulverizing device for construction site

InactiveCN106861880AGuaranteed to workAvoid cloggingDirt cleaningGrain treatmentsEngineeringRaw material

The invention discloses a material pulverizing device for a construction site. The material pulverizing device comprises a machine body. A feeding hopper is arranged on the left side of the machine body. A feeding port is formed in the left side wall of the machine body. The bottom end of the feeding hopper is connected with the feeding port through a discharging pipe. A downward pressing device is arranged at the upper end of the machine body. A downward pressing rod of the downward pressing device is provided a connecting spring. A pressing plate is arranged at the lower end of the connecting spring. Installing frames are arranged at the two ends of the pressing plate and provided with scrapers. According to the stone pulverizing device for the construction site and with a damping device, after stone enters the machine body, the stone is crushed and sufficiently pulverized, the pulverizing effect is guaranteed, and the situation of blockage of stone in the machine body can be avoided; dust generated in the pulverizing and discharging processes can be collected, the environment is protected, raw materials are saved, and automatic discharging can be achieved; and in addition, the damping effect is good, the work stability of the pulverizing device is improved, the service life is prolonged, and noise is lowered.

Owner:丽水市莲都区君正模具厂

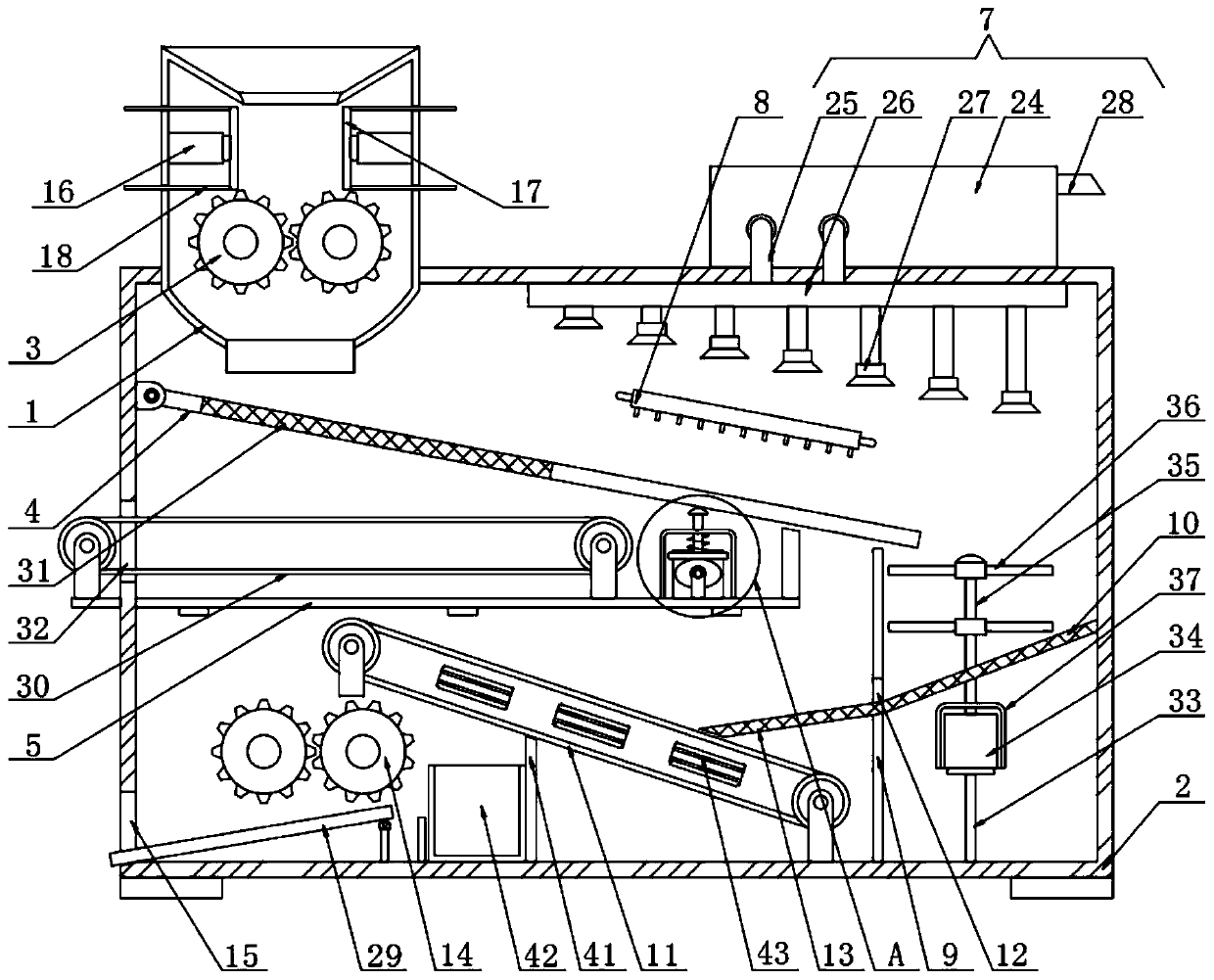

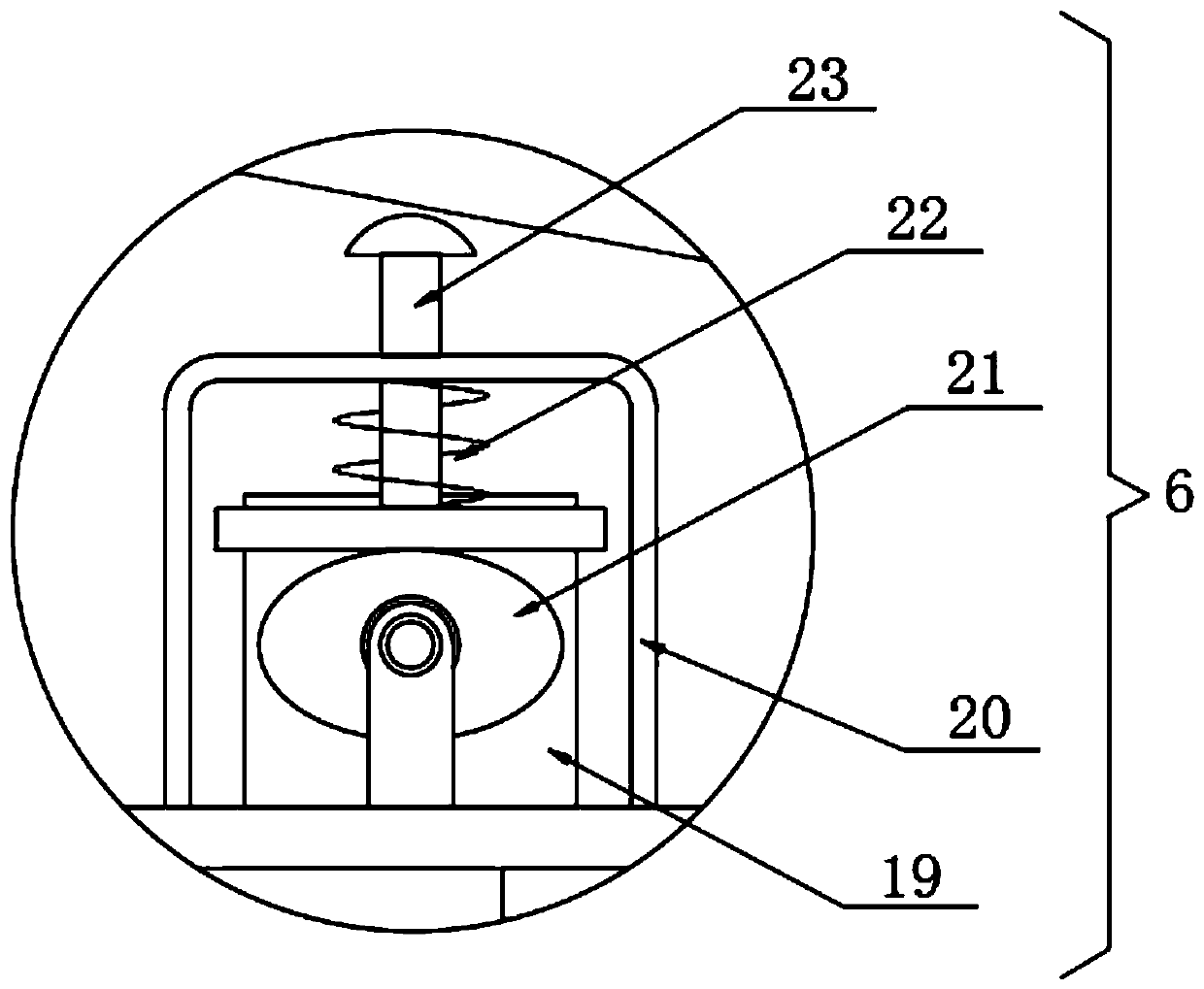

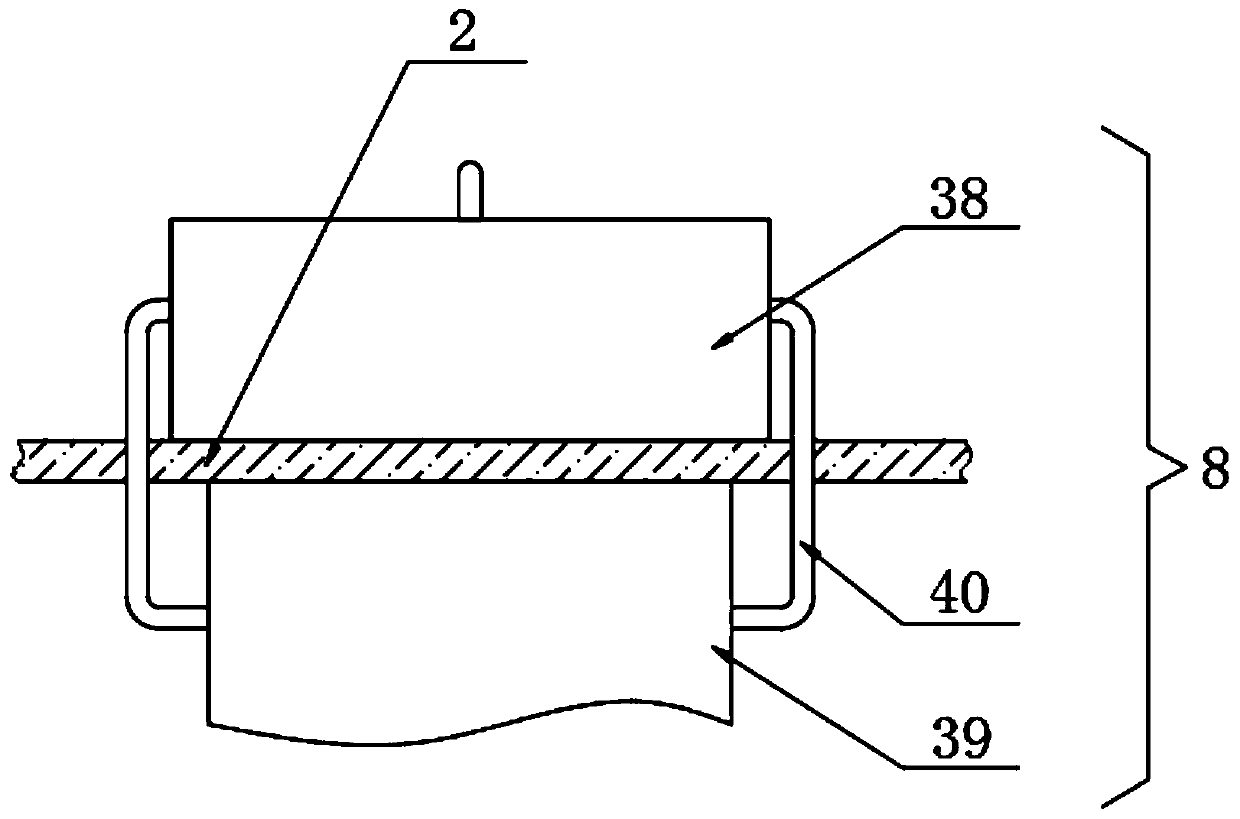

Automatic crushing device for frozen materials

InactiveCN106391181AImprove crushing effectGuaranteed crushing effectGrain treatmentsEngineeringMechanical engineering

Owner:GUANGDONG IND TECHN COLLEGE

High-efficiency crushing device for chemical production

InactiveCN106311422AAvoid cakingQuality assuranceMagnetic separationGrain treatmentsDischarge efficiencyIron removal

The invention discloses a high-efficiency crushing device for chemical production, comprising a crusher body, wherein a feeding hopper is arranged on the upper side of the crusher body; an iron removal rotation shaft is horizontally arranged on the lower side inside the feeding hopper; permanent magnets are arranged on the outer wall of the rotation shaft in longitudinal symmetry; a first crushing mechanism is horizontally arranged on the upper side inside the crusher body and a second crushing mechanism is horizontally arranged on the lower side of the first crushing mechanism. By the crushing device, iron can be removed from materials and the quality of materials is ensured; materials are fully crushed by two crushing mechanisms and crushing gears arranged in a staggered way, crushed materials are filtrated and materials without meeting the size are recurrently lifted to the crusher for being crushed by a lifter, the crushing effect is ensured, the crushing efficiency is increased, materials are discharged through vibration to prevent from stoppage and are discharged with driving of a conveyor belt and without manual operation, the discharging efficiency of materials is increased, and the crushing device is convenient and quick to operate.

Owner:GUANGXI UNIV

High-efficient grinding device for Chinese herbal medicine processing

The invention discloses a high-efficient grinding device for Chinese herbal medicine processing. The high-efficient grinding device for Chinese herbal medicine processing comprises a case, wherein thecase is divided into a primary processing cavity, a secondary processing cavity and a discharging cavity; a first drive plate and a second drive plate are arranged at an inner wall of the primary processing cavity; slide rods are arranged at the front sides and the rear sides of the first drive plate and the second drive plate; slide chutes are formed in the front side and the rear side of the primary processing cavity; the slide rods are arranged in the corresponding slide chutes; and cutting blades are arranged on a bottom plane of the first drive plate and an upper plane of the second drive plate. According to the high-efficient grinding device for Chinese herbal medicine processing provided by the invention, through a connecting rod mechanism, the cutting blades alternately cut medicines so as to horizontally and preliminarily grind the medicines, and spiral cutter blades grind and drive the medicines to stir up and down at the same time so as to regrind the medicines in a vertical direction.

Owner:博凯药业有限公司

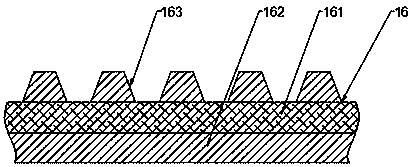

Flexible display screen and manufacturing method thereof

ActiveCN111882991AScientific and reasonable structureEasy to useEdge grinding machinesGrinding carriagesElectric machineryDrive motor

The invention discloses a flexible display screen and a manufacturing method thereof. The middle of the top end of a machine base is fixedly connected with a positioning cutting mechanism, the other side of the top end of the machine base is fixedly connected with a power conversion and grinding mechanism, and the middle of the machine base is rotationally connected with an adsorption fixing and moving mechanism; The adsorption fixing and moving mechanism comprises a conveying belt, a driving motor, a mounting base, an embedding groove, a movable plate, a supporting spring, a suction cup and arubber plate. The flexible display screen is scientific and reasonable in structure and safe and convenient to use, the adsorption fixing and moving mechanism is arranged, glass is adsorbed and fixedthrough the suction cups, the stability of the glass is improved, loss caused by falling of glass in moving machining process is avoided. The movable plug plate is driven to slide in the suction cupthrough cooperation of the rubber plate and the connecting rod in the glass adsorption process, and meanwhile the movable plug plate extrudes air pressure in the suction cup due to the fact that the movable plug plate is attached to the interior of the suction cup.

Owner:SHENZHEN RUGIN ELECTRONICS

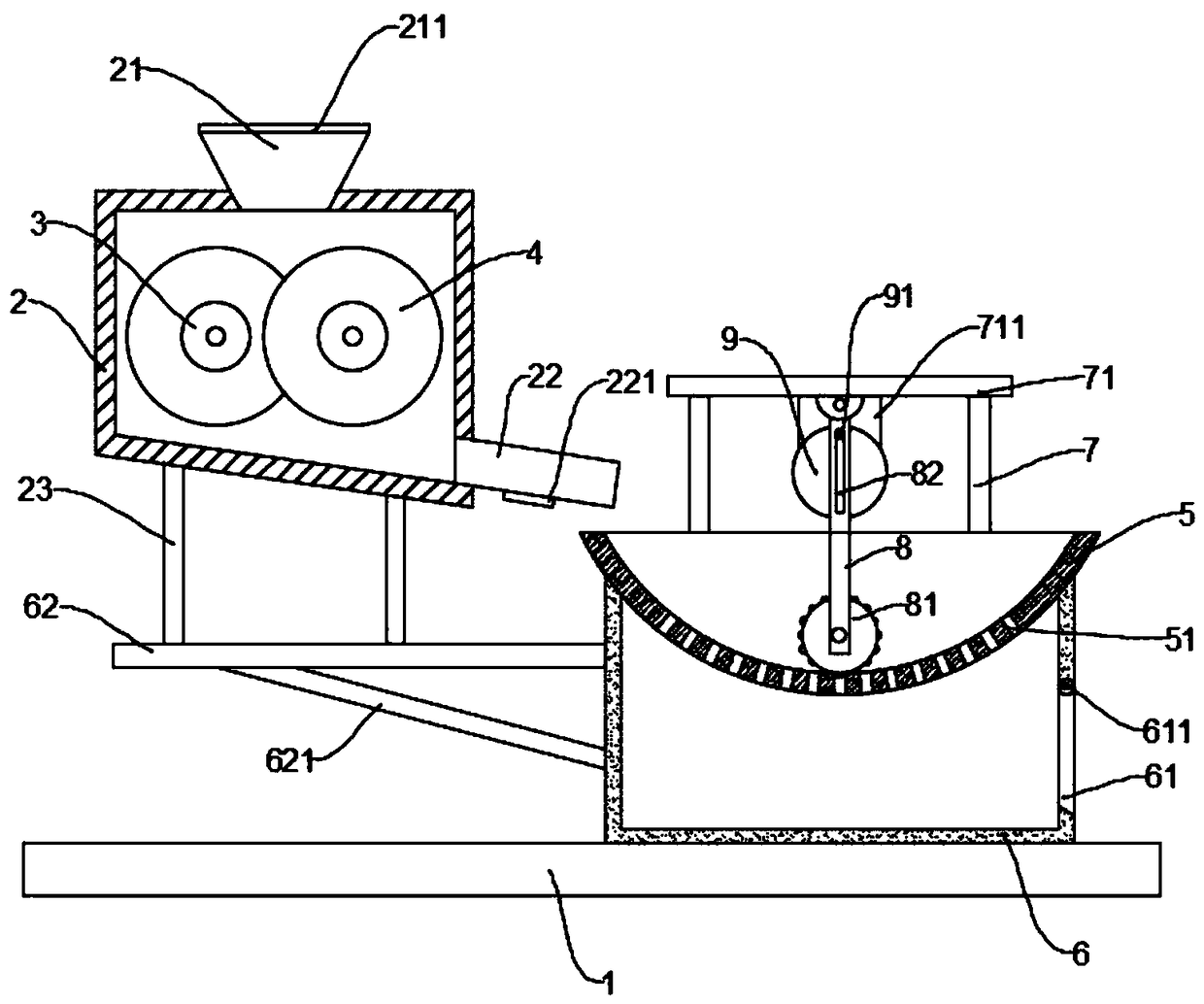

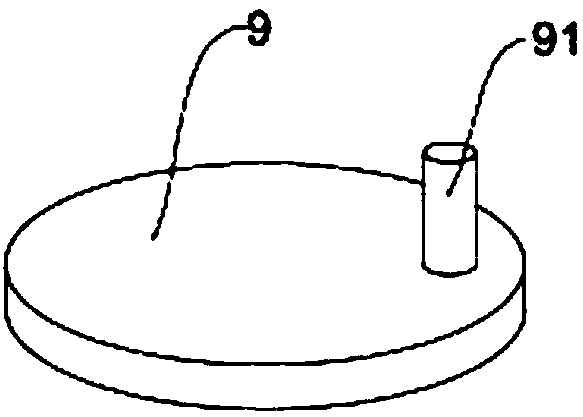

Garbage disposal device for improving disposal fragmentation degree

InactiveCN108201966AIncrease the degree of fragmentationEasy to handle workGrain treatmentsEngineeringMechanical engineering

The invention discloses a garbage disposal device for improving the disposal fragmentation degree. The device comprises a base, a smashing box and a receiving frame, wherein the smashing box and the receiving frame are arranged on the base from left to right. A grinding bowl is fixed to the top of the receiving frame. Garbage is smashed and then ground, so that the garbage fragmentation degree isgreatly improved, and convenience is brought to garbage disposal work. Annular blades on smashing rollers on the two sides are staggered, the gap between the annular blades on the two sides is gradually reduced from top to bottom, accordingly, gradual smashing for garbage is achieved, and the smashing effect is ensured. By means of cooperated use of a disc and swing, a grinding roller rolls back and forth on an inner cavity face of the grinding bowl for repeated grinding, and the grinding effect is ensured; and meanwhile due to the fact that the rotating radius of a swing rod is the same as the curvature radius of the bottom face of an inner cavity of the grinding bowl, the grinding roller is always kept to be in fit with the bottom face of the inner wall of the grinding bowl in the swingprocess, and therefore grinding uniformity is ensured.

Owner:SHENZHEN CHENGHONG ENTERPRISE MANAGEMENT CO LTD

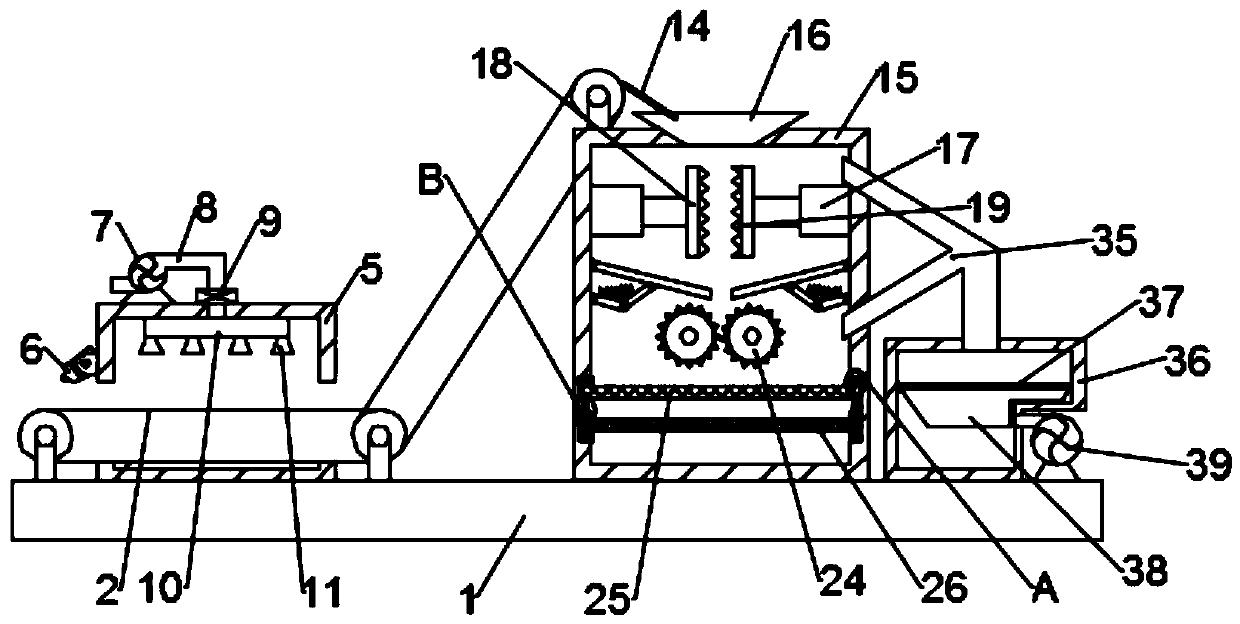

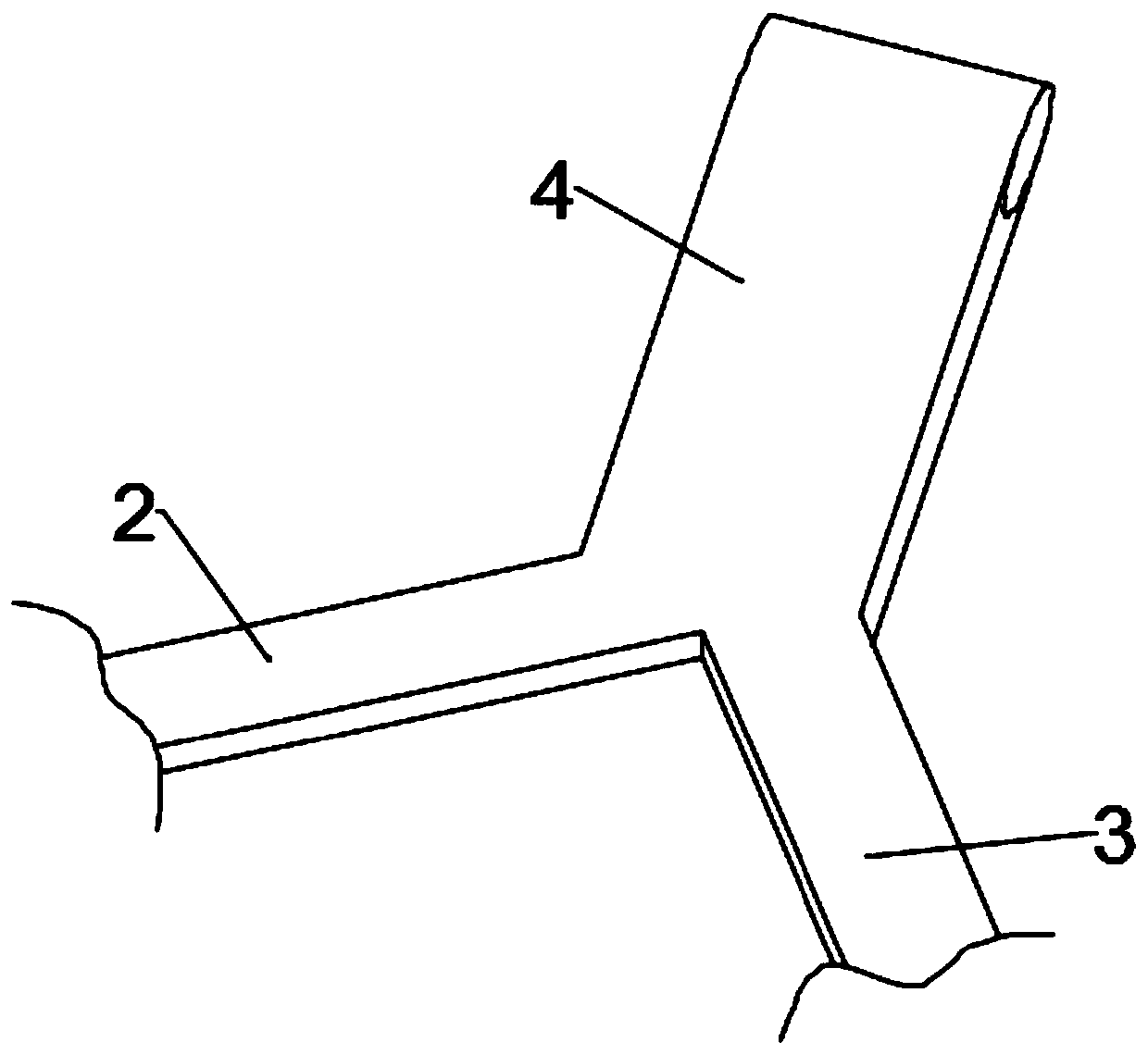

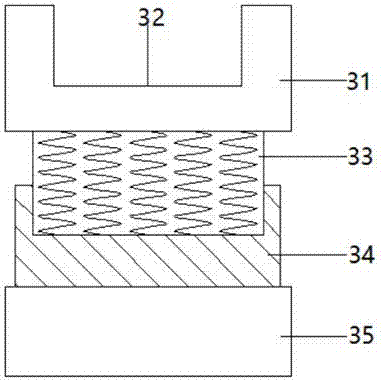

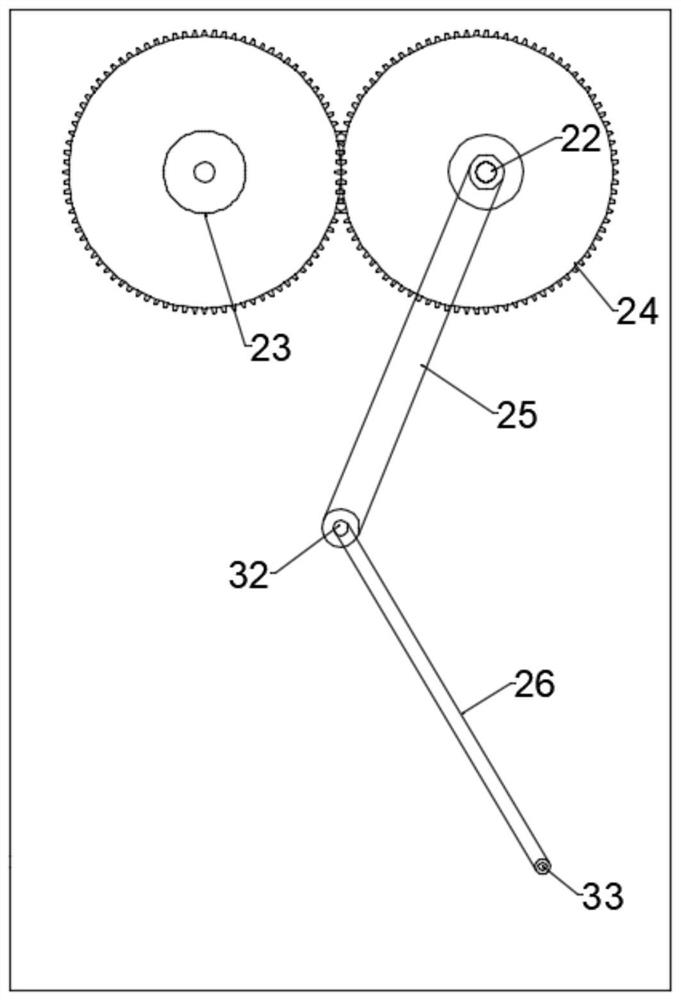

Crushing and packaging integrated machine for garbage treatment

InactiveCN110653241AReduce volumeReduce work intensitySolid waste disposalGrain treatmentsGear wheelRefuse Disposals

The invention discloses a crushing and packaging integrated machine for garbage treatment. The crushing and packaging integrated machine for garbage treatment comprises a first mounting plate, whereina crushing box is fixed on the first mounting plate; a second mounting plate is fixed on one side of the crushing box; a first servo motor is fixed on the second mounting plate; a first crushing roller is fixed on an output shaft of the first servo motor; the first crushing roller is in key connection with a first gear; the first gear is engaged with a second gear; the second gear is in key connection with an end of a second crushing roller; teeth are arranged on the outer cylindrical surfaces of the first crushing roller and the second crushing roller; a scattering mechanism is arranged at the upper end of the crushing box; a conveying mechanism is arranged at the lower end of the crushing box; a third mounting plate is fixed on one side of the upper end of the crushing box; and a pressing mechanism is arranged on the third mounting plate. Automatic scattering, crushing, compacting and packaging of garbage are realized on one piece of equipment, the cost is low and the working efficiency is high.

Owner:林冬

Crushing device for recycling construction waste

InactiveCN110152859AFor subsequent grindingImprove grinding efficiencyGrain treatmentsEngineeringConstruction waste

The invention discloses a crushing device for recycling construction waste. The crushing device comprises a crushing box and a crushing roller, an upper convex screen cover is arranged below the crushing roller, a grinding disc is fixedly connected to the lower end of the upper convex screen cover; a grinding disc matched with the grinding disc is arranged on the outer side of the grinding disc, alower convex screen cover is arranged below the grinding disc, and a crushing blade group is arranged in the lower convex screen cover. The upper convex screen cover and the grinding disc with the through holes are arranged, so that the crushed concrete blocks are screened and separated, the subsequent grinding is facilitated, the grinding efficiency is improved, by arranging the lower convex screen cover and the crushing blade set, the ground concrete particles are further crushed, meanwhile, the crushing effect is ensured through the lower convex screen cover.

Owner:孙哲西

Solid building waste crushing and recycling device

InactiveCN111921605AReduce the chance of jammingIncrease the degree of crushingSievingConstruction waste recoveryConstruction engineeringStructural engineering

The invention discloses a solid building waste crushing and recycling device. The solid building waste crushing and recycling device comprises a base and a main box body fixed to the base. A feeding port is formed in the shell wall of the top of the main box body, two symmetrically-arranged crushing rollers are arranged at the upper part of an inner cavity of the main box body, and the crushing rollers are rotationally connected with the main box body through first rotating shafts. Crushing teeth are evenly distributed on the crushing rollers, a gap between the two crushing rollers directly faces the feeding port, and a flow guide plate is fixed to the middle of the inner cavity of the main box body. An arc-shaped pressing plate is arranged below the flow guide plate in a spaced mode, anda material falling hole is formed in the pressing plate. A swing frame is rotationally connected to the center of the bottom of the flow guide plate, a pressing roller is installed at the bottom of the swing frame, and the rotating radius of the pressing roller is the same as the radius of the pressing plate. A strip-shaped hole is formed in the swing frame in the length direction of the swing frame, and a rotary disc is arranged on the rear side of the swing frame. The crushing degree of waste is improved, and the crushing effect can be effectively guaranteed when the pressing rollers crush the waste.

Owner:深圳市汇利德邦环保科技有限公司

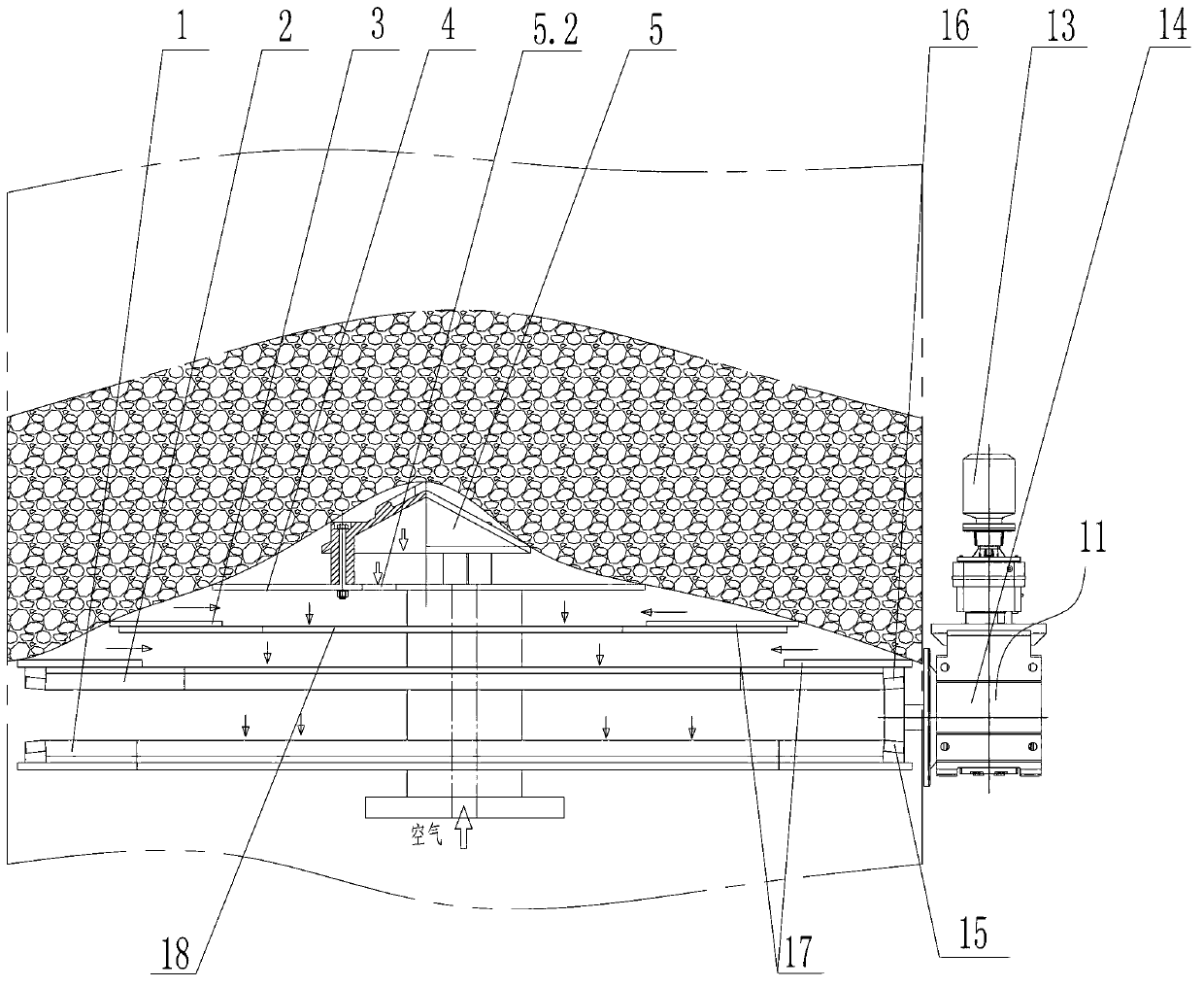

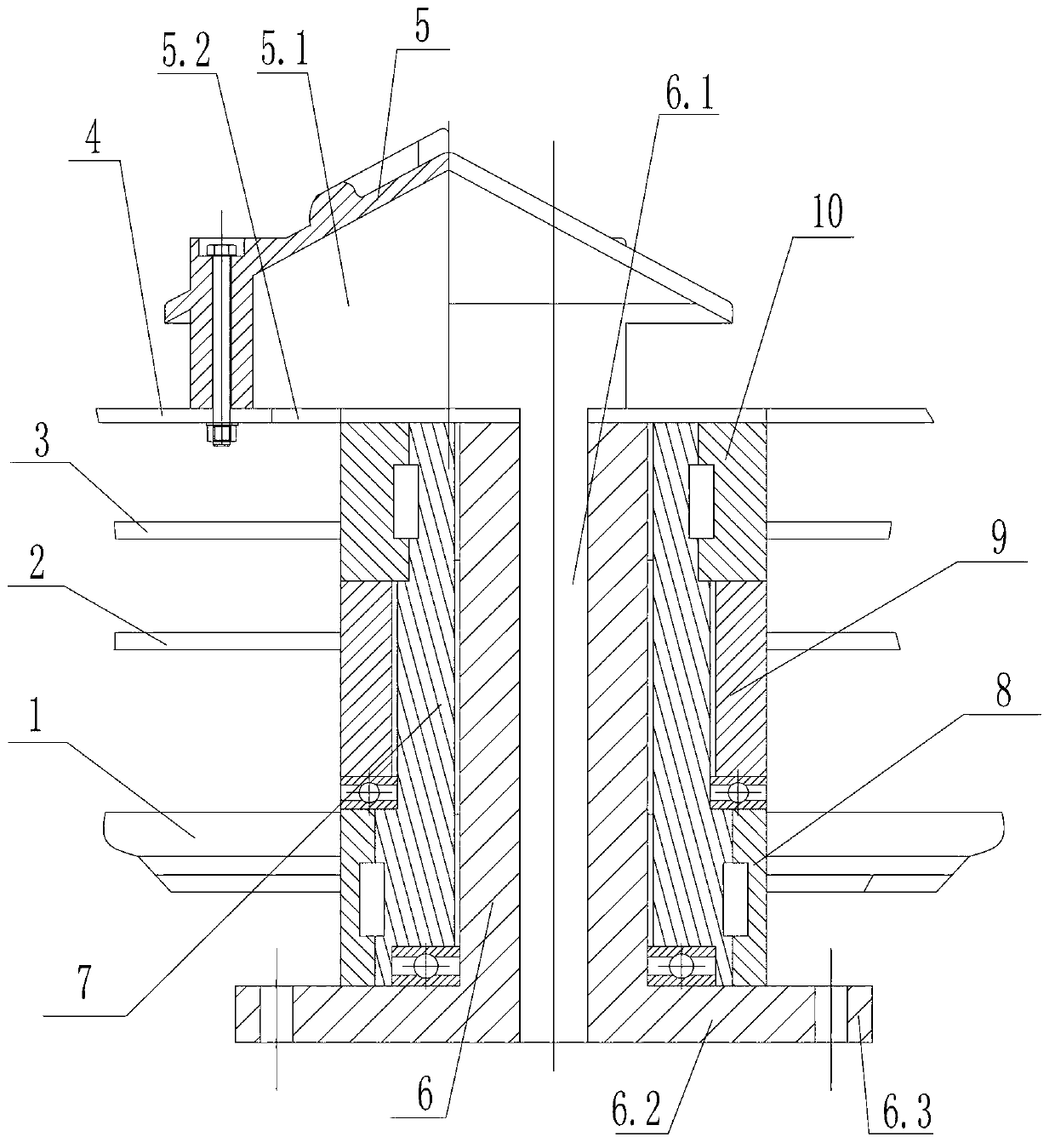

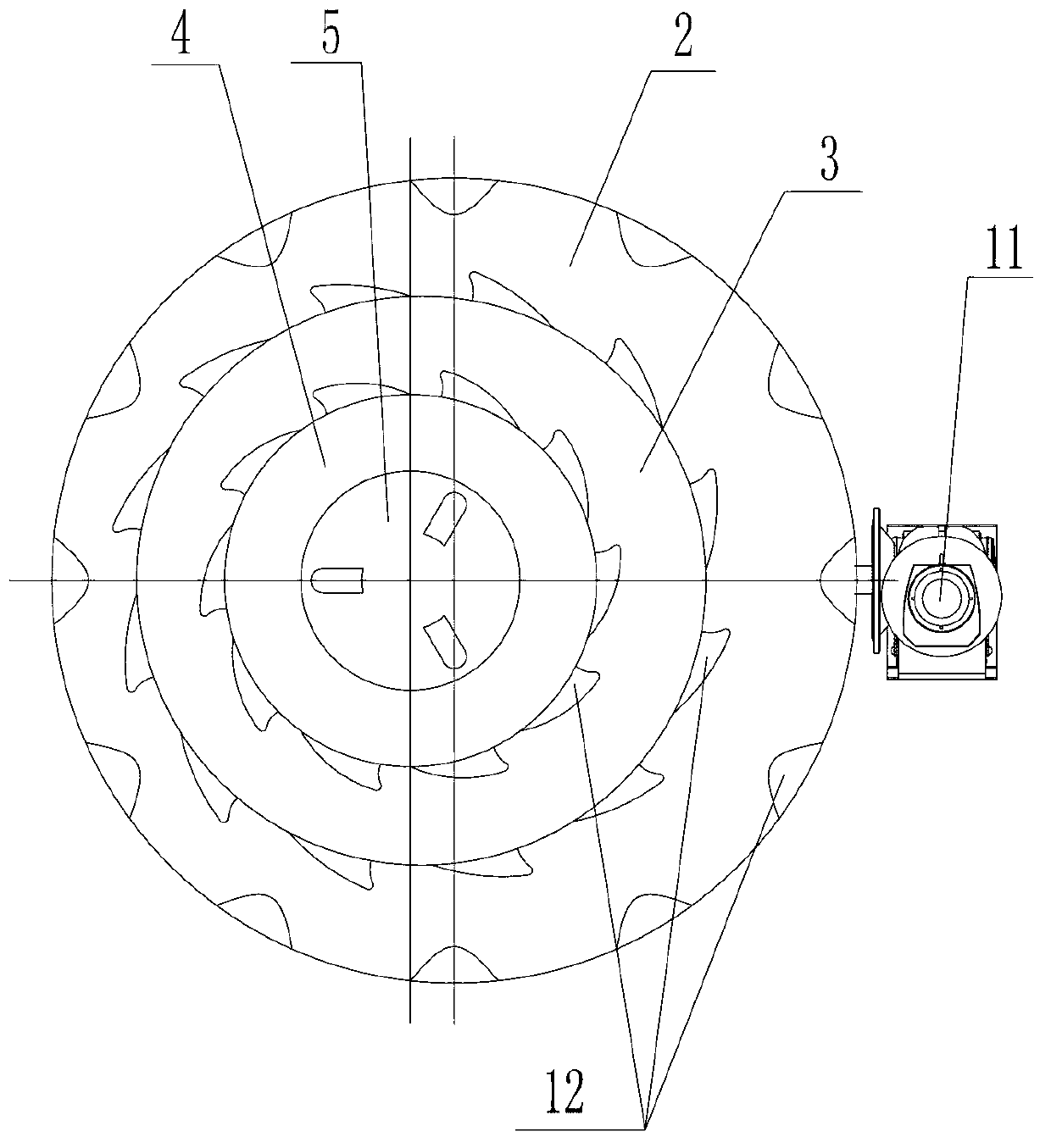

Rotary fire grate

The invention relates to a rotary fire grate which comprises a fixed shaft, a main shaft sleeve, a first forward driven fire grate, a second forward driven fire grate and a forward driving fire grate connected with a driving mechanism. The forward driving fire grate, the first forward driven fire grate and the second forward driven fire grate have slag removing holes. The forward driving fire grate, the first forward driven fire grate and the second forward driven fire grate are fixedly connected with the main shaft sleeve which is movably sleeved with the fixed shaft. The rotary fire grate further comprises a reverse driving fire grate. The forward driving fire grate, the reverse driving fire grate, the first forward driven fire grate and the second forward driven fire grate are arranged sequentially from bottom to top and distances are reserved between adjacent fire grates. The forward driving fire grate is connected with the driving mechanism, the reverse driving fire grate is movably sleeved with the main shaft sleeve, and the reverse driving fire grate has a slag removing hole. The rotary fire grate is good in slag breaking effect and smooth in slag discharge.

Owner:宁波泰来环保设备有限公司

Cultivation soil refining equipment used for garden potted cultivation

InactiveCN111036324AReasonable structureSimple designGrowth substratesCulture mediaAgricultural scienceElectric machine

The invention discloses cultivation soil thinning equipment used for garden potted cultivation. The equipment comprises a seal cover, a motor, a control switch, a scraping plate, a heating pipe, a push plate and a refining box. The seal cover is opened, cultivation soil can further enter the refining box, the control switch is used for starting the motor, the motor rotates to drive a smashing blade on a smashing rotating shaft to rotate to carry out smashing and refining on the cultivation soil in the refining box, the heating pipe is used for heating, heating drying of the cultivation soil inthe refining box can be further achieved, the phenomenon that due to the too large humidity, the cultivation soil is adhered, and smashing and refining effects are affected can be avoided, wet air generated by heating in the refining box is further discharged through a feeding opening of the refining box, after smashing and refining are finished, the scraping plate is driven by the smashing rotating shaft to scrap down the adhered cultivation soil on the inner side of a protection cover, the push plate is driven by the smashing rotating shaft to push the cultivation soil on the bottom of theinner side of the refining box, and the cultivation soil in the refining box is completely discharged out through a discharging pipe.

Owner:NINGBO CITY COLLEGE OF VOCATIONAL TECH

Medical glass bottle breaking and disinfecting apparatus

InactiveCN107744861AGuaranteed sterilityGuaranteed crushing effectGrain treatmentsChemicalsEngineeringBottle

The invention discloses a medical glass bottle breaking and disinfecting apparatus, which comprises a body, wherein a breaking cavity and a grinding cavity are arranged in the body, the top wall of the breaking cavity is connected to a material feeding hole in a penetrating manner, the left side and the right side of the top wall of the breaking cavity are symmetrically provided with a spraying device, breaking rollers are symmetrically arranged in the breaking cavity in a left-and-right manner, the breaking rollers are uniformly provided with a plurality of breaking balls, a grinding device and a transmission device are arranged in the grinding cavity, the grinding device comprises two grinding rollers, the transmission device comprises two rotation rollers and a transmission chain, the middle portion of one side wall of the grinding cavity is provided with a material outlet hole, the bottom portion of the grinding cavity is provided with a purifier, and the bottom end of the body isuniformly provided with a plurality of support legs. According to the present invention, by arranging the mutually-associated breaking cavity and grinding cavity, the medical glass bottle is broken bythe breaking balls in the breaking cavity, and then is grinded by the grinding rollers in the grinding cavity, such that the glass bottle is completely crushed, and the crushing effect is ensured; and the spraying devices continuously spray the disinfecting liquid to disinfect the broken glass bottle, such that the sterile broken glass residue can be ensured.

Owner:吴建锋

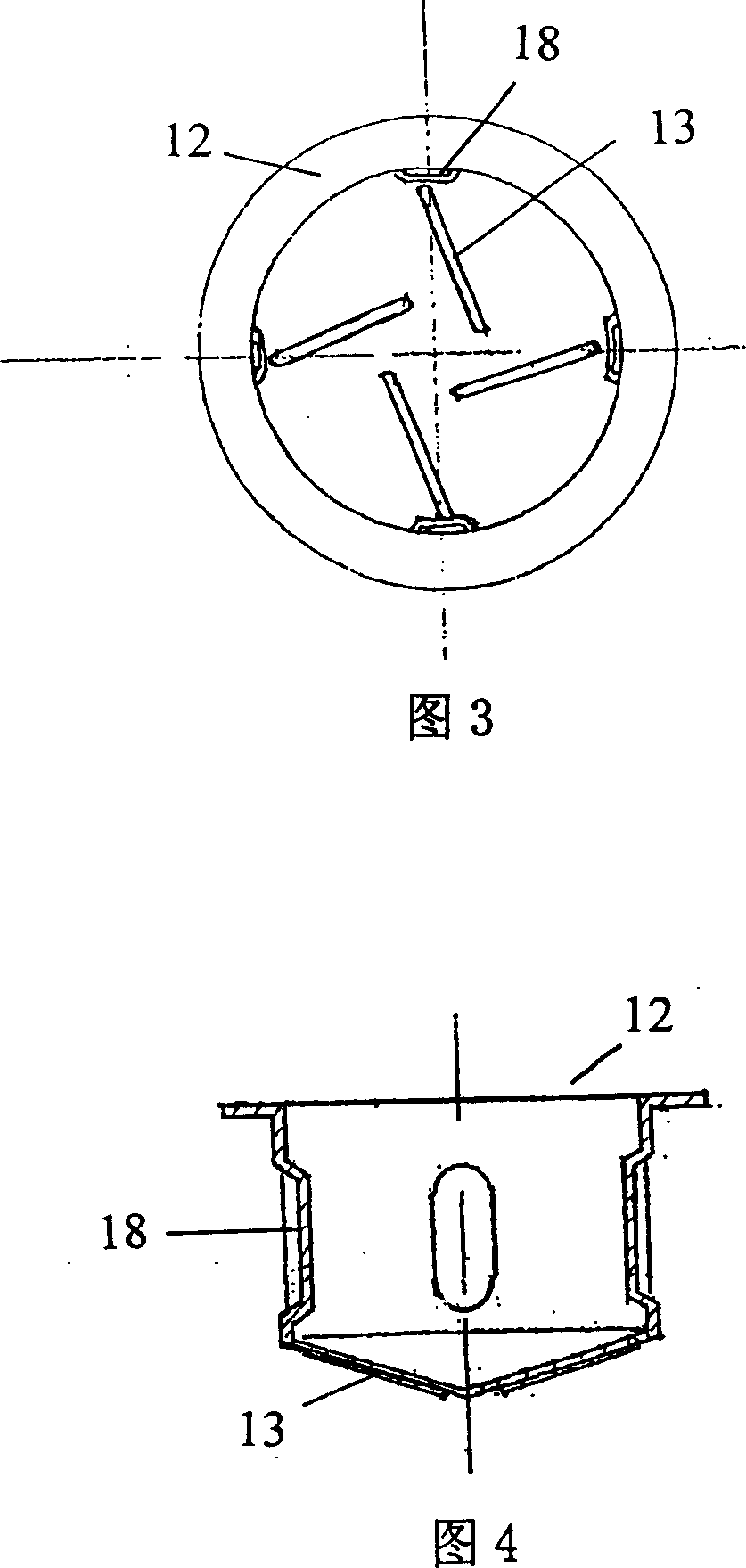

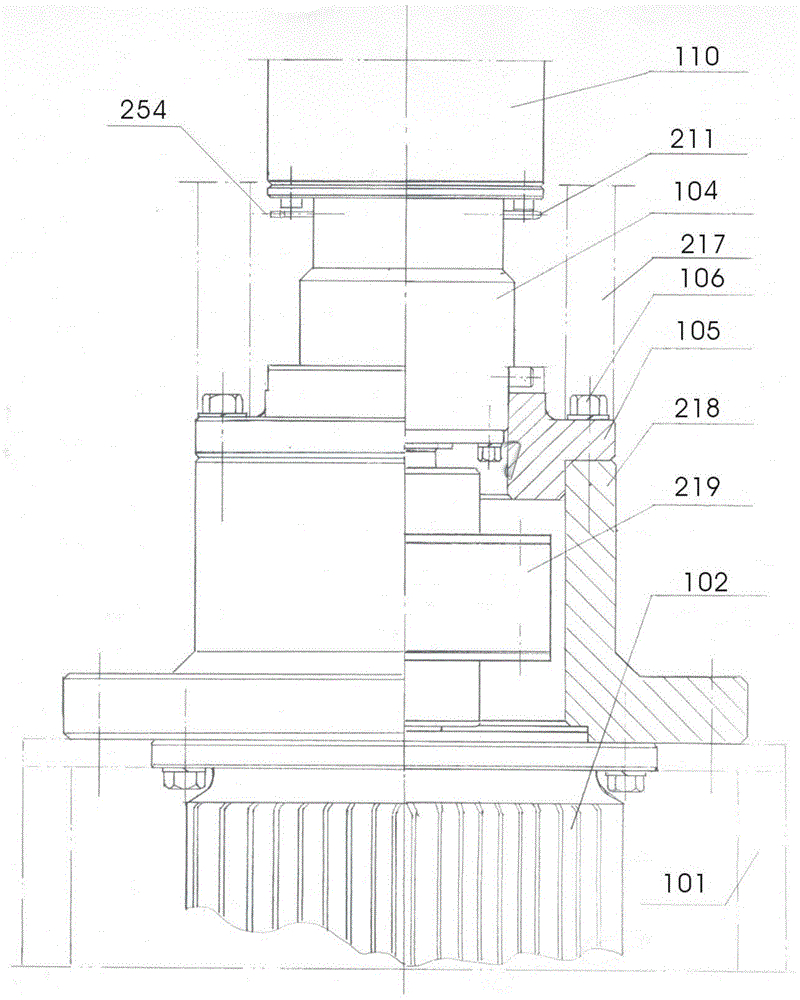

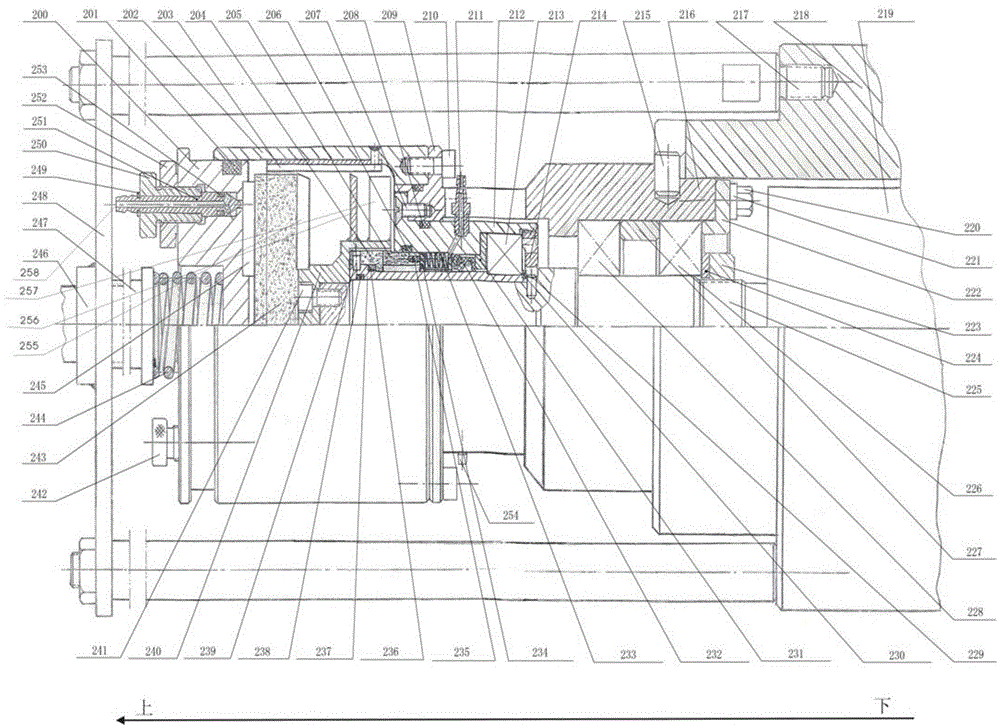

Shale gas content measurement device and method

ActiveCN104678076AReduce gas lossThe test results are accurateEarth material testingShale gasMeasurement device

The invention discloses a shale gas content measurement device and a shale gas content measurement method. The measurement device comprises a fixed base, a driving mechanism, a sealed sample crushing cylinder, a crushing combined tool and a seal cover, wherein the driving mechanism is connected to the fixed base; a cylinder body of the seal sample crushing cylinder is connected with the fixed base and is internally provided with a stirring shaft connected with the driving mechanism; the stirring shaft rotates under the driving of the driving mechanism; the crushing combined tool is connected to the stirring shaft of the sealed sample crushing cylinder and is matched for sample rough crushing and fine crushing; the seal cover is arranged at the opening of the seal sample crushing cylinder above the crushing combined tool and is connected with the sealed sample crushing cylinder in a sealed mode. The testing device cam seal, crush and degas the whole rock core or rock sample in an exploration field or a laboratory, so that the sample gas content can be obtained rapidly and accurately.

Owner:CHINA PETROLEUM & CHEM CORP +1

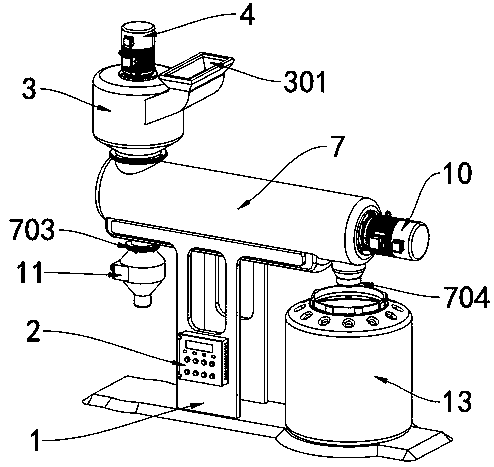

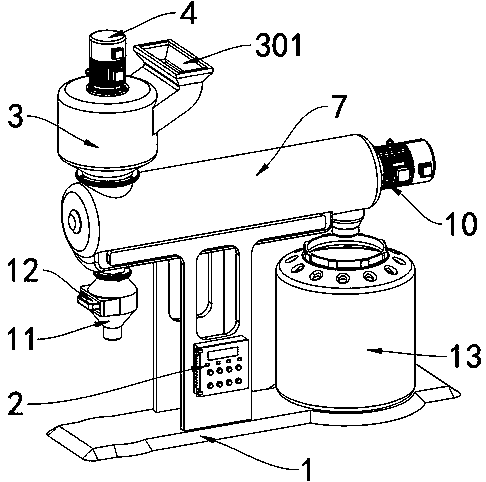

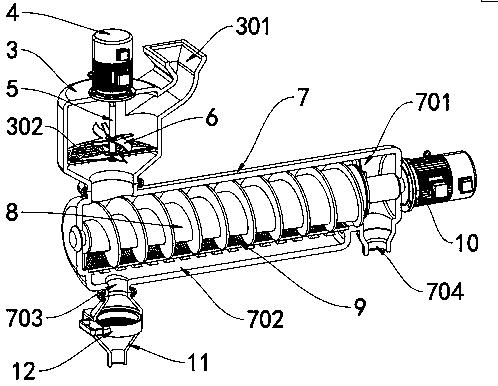

Food waste recycling processor

InactiveCN110918622AGuaranteed crushing effectGuaranteed cleanlinessSolid waste disposalTransportation and packagingElectric machineryRefuse Disposals

The invention provides a food waste recycling processor and relates to the technical field of food waste treatment. The processor comprises a crushing cylinder, an extrusion conveying cylinder and a garbage fermentation tank, wherein a control electric box is installed at a front end of a supporting frame and electrically connected with a smashing motor and a conveying motor through power lines, the crushing cylinder is installed at the top of a left end of the extrusion conveying cylinder through bolts, a feeding port is formed on the right side of the crushing cylinder, a crushing motor is installed on a top end face of the crushing cylinder, and the extrusion conveying cylinder is mounted at the top of the support frame. When the food waste falls into the extrusion conveying cylinder, the extrusion conveying cylinder rotates, the food waste is conveyed to a right end of the extrusion conveying cylinder through a rotating conical spiral conveying shaft, when the food waste is conveyed, the conical spiral conveying shaft extrudes the food waste, so the water contained in the food waste flows into a drainage cavity through a water filtering plate, the water content of the food waste is reduced, and the food waste is subjected to fermentation treatment.

Owner:宋洪涛

Method for extracting resveratrol from grape leaves

InactiveCN101913995AGood yieldGet rid of dependenceOrganic chemistryOrganic compound preparationSolventMacroporous resin

The invention provides a method for extracting resveratrol from grape leaves, comprising the steps of raw material pretreatment, extraction by using solvents and macroporous resin separation and purification. By using the grape leaves as raw materials, the invention provides a method for turning wastes into valuables for a grape industry, which can increase the incomes of peasants, reduce the agricultural production cost and also solve the conflict between the shortages of an increasingly reduced polydatin resource and the increase of a resveratrol demand. The method has simple operation without a precise instrument or automation equipment to avoid the dependence on the expensive raw materials and the precise instrument in an industrializing process, can be used for production in enterprises of rural areas with abundant grape resources and greatly reduce the production cost of the resveratrol; and liquid nitrogen as a freezing and crushing agent and alcohol as an extracting agent both have low toxicity and cheep prices, and a mature conventional technique for actual recovery can be utilized in the whole process, therefore, the environmental emission and the environmental pollution of extracted wastes are greatly reduced.

Owner:张波

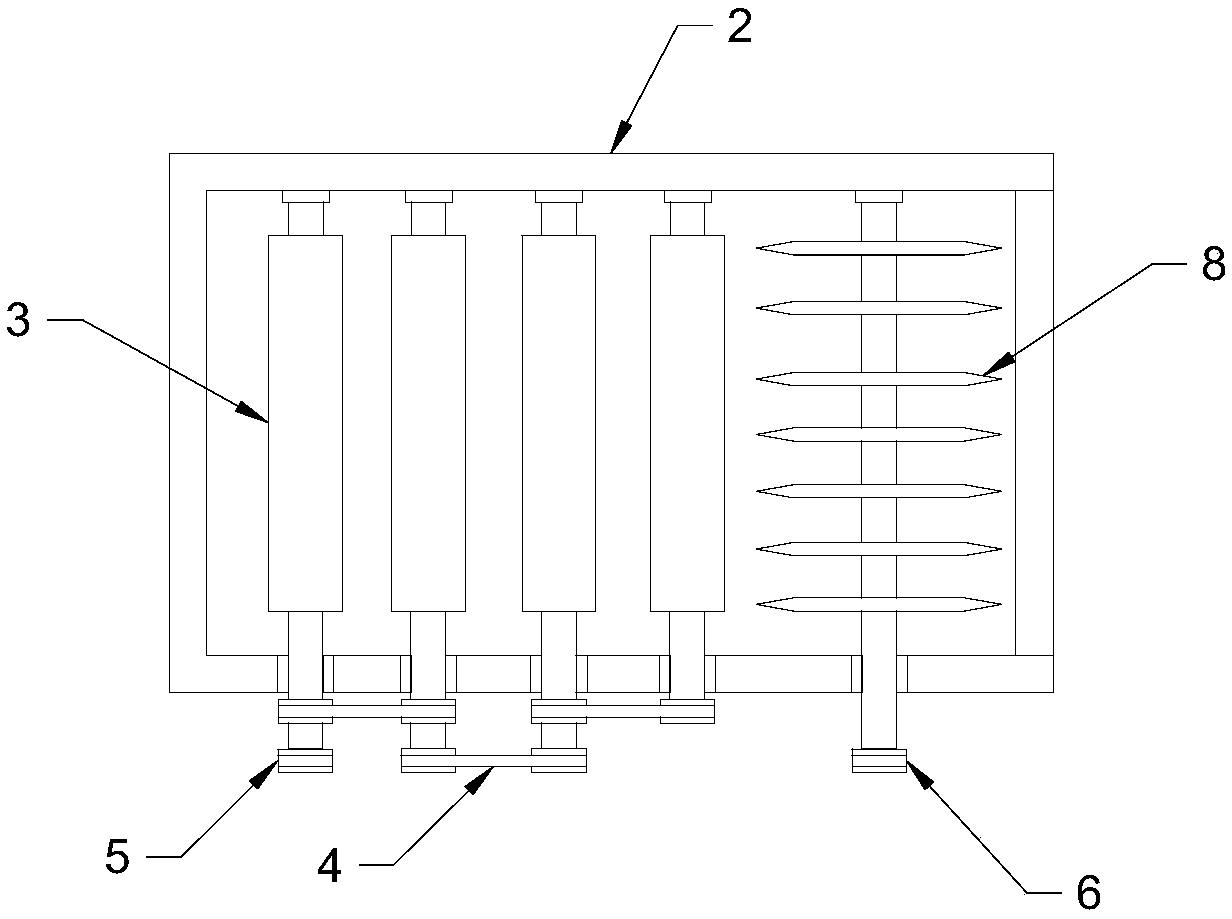

Anti-caking sand dryer

InactiveCN108731419AAvoid accumulationAvoid damageDrying gas arrangementsDrying machines with non-progressive movementsEngineering

The invention relates to an anti-caking sand dryer, comprising a drying barrel, a controller, a sand incoming tube, a sand outgoing tube, a hot air tube and a plurality of support legs. A dischargingmechanism is arranged in the sand outgoing tube. A crushing mechanism and a filtering mechanism are arranged in the drying barrel; the crushing mechanism includes a first motor, a spindle, a rocking component and a plurality of crushing components; the filtering mechanism includes a strainer, a sealing component, support rods and a driving component. The anti-caking sand dryer has the advantages that blades are rotated and rocked through the crushing mechanism during drying, sandstone is cut and crushed at different parts, and drying effect being affected by moist sand caking is avoided; in addition, after drying, the strainer in the filtering mechanism is rotated down, a discharge plate in the sand outgoing tube is rotated down, sand in the drying barrel slips from the bottom, accumulation of fine sand, passing through the strainer, in the drying barrel is avoided, sand damage and dryer damage are avoided, and the dryer has improved practicality.

Owner:永春福源建材科技有限公司

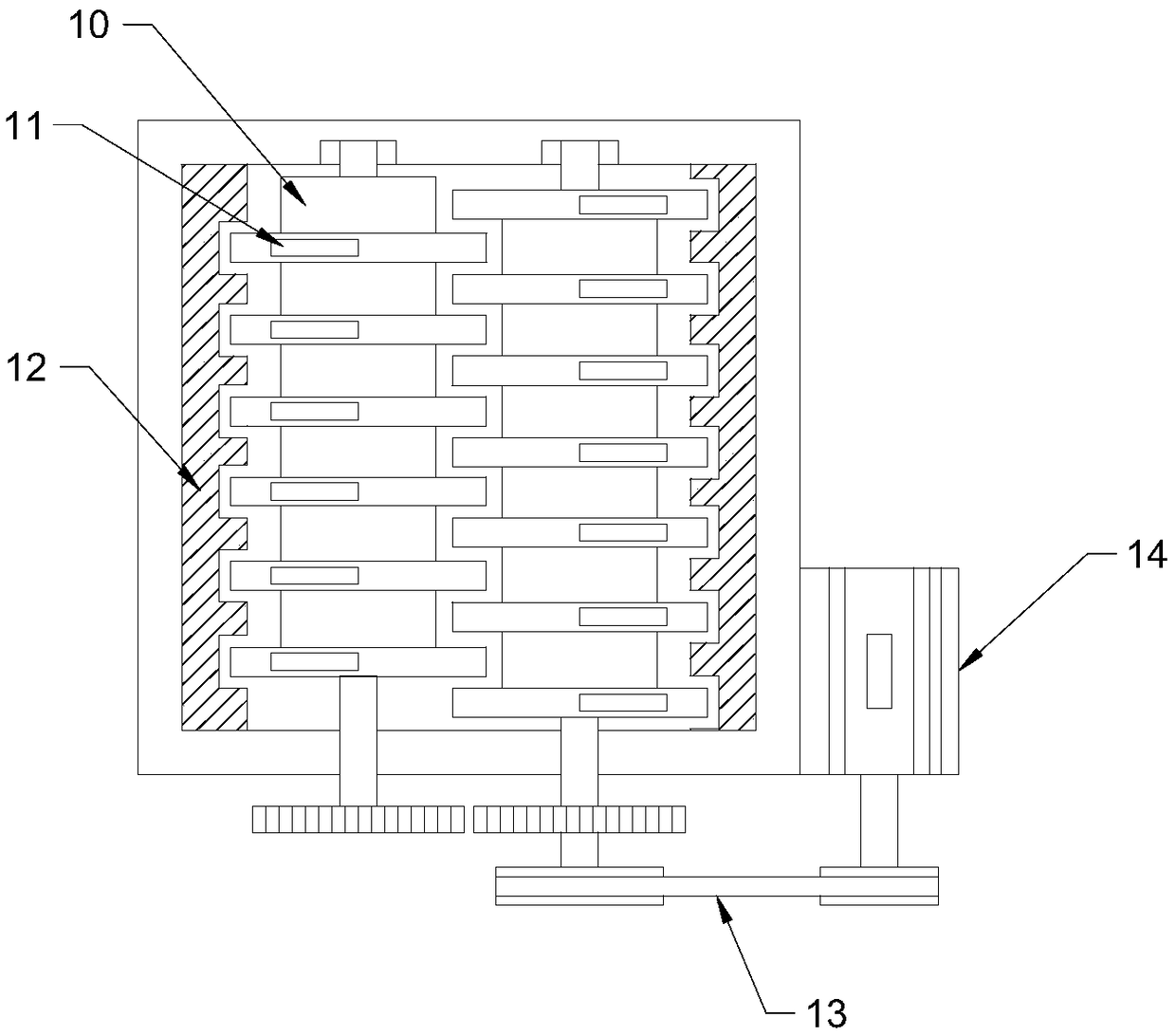

Pig feed grinding and drying integrated processing equipment

InactiveCN111889211ARealize the collectionRealize deliveryFeeding-stuffDrying gas arrangementsEngineeringProcess engineering

The invention discloses pig feed grinding and drying integrated processing equipment. The pig feed grinding and drying integrated processing equipment includes a feeding mechanism and a grinding mechanism. The feeding mechanism is arranged at the side edge of the fixed box, the grinding mechanism is arranged at the top of the fixed box, a material sending mechanism is arranged at the top of the grinding mechanism, a screw feeder is arranged at the lower end, away from the feeding mechanism, of the fixed box, a conveying mechanism is arranged at the position, located under the screw feeder, ofthe side edge of the fixed box, and two material collecting grooves are formed in the top of the conveying mechanism. According to the pig feed grinding and drying integrated processing equipment, thesuper strong grinding of materials is achieved through a crushing mechanism so as to ensure the grinding effect of materials, the complex process of secondary grinding caused by insufficient grindingof the materials is reduced, the strengthening drying of the materials is achieved through a drying mechanism, and the drying effect of the materials is ensured; and the overall structure is simple,grinding and drying can be integrated, moreover, the grinding and drying are relatively thorough, the complex process of subsequent processing is avoided, and the processing efficiency of pig feed isgreatly improved.

Owner:李超

Transportation integrated machine for chemical product pulverizing and garbage treatment

InactiveCN107597390AGuaranteed crushing effectGuaranteed sizeGrain treatmentsChemical productsEngineering

The invention discloses a transportation integrated machine for chemical product pulverizing and garbage treatment, and relates to the technical field of chemical products. The transportation integrated machine comprises a feeding box. Pushing devices are fixedly connected to the two sides of the outer wall of the feeding box. An opening and closing feeding port is fixedly connected to the middleposition of the top of the feeding box, and an opening and closing discharging port is fixedly connected to the bottom of the inner wall of the feeding box. The top of the opening and closing discharging port is fixedly connected with a primary pulverizing device. A second-level pulverizing box is fixedly connected to the bottom of the outer wall of the feeding box. The opening and closing discharging port penetrates the second-level pulverizing box and extends to the interior. The transportation integrated machine for chemical product pulverizing and garbage treatment achieves the purposes that multi-level pulverizing and automatic layering of the chemical products and rapid garbage treatment are achieved, the pulverizing effect and the needed size after pulverizing are guaranteed, the pulverizing efficiency, yield and quality are improved, the product discharging speed and the garbage treatment efficiency are guaranteed, and machine work cannot be delayed.

Owner:湖州城区天顺化工厂

Building waste smashing device with smashing rollers with extrusion rollers

InactiveCN108097360AReduce distanceFacilitate subsequent crushing and refinementNon-rotating vibration suppressionGrain treatmentsArchitectural engineeringExtrusion

The invention discloses a building waste smashing device with smashing rollers with extrusion rollers. The building waste smashing device comprises a shell, a base, a support plate and a feed hopper.A plurality of support springs and a damping block are fixedly connected between the support plate and the base. Two horizontally side-by-side pre-smashing rollers are arranged in a corresponding pre-smashing cavity under the feed hopper. The parts, corresponding to the lower portions of two movable plates, of a fixed seat are each provided with a downwards-concave smashing groove. The smashing rollers coaxial with the smashing grooves are arranged in the smashing grooves. A plurality of grooves which are concave toward the centers of the smashing rollers are evenly distributed on the side walls of the smashing rollers. The extrusion rollers of a cylindrical structure are installed in the grooves. According to the building waste smashing device, extrusion and smashing are conducted throughthe two pre-smashing rollers which go close to each other, and waste is pretreated. Building waste located between the smashing rollers and the smashing grooves are extruded by the extrusion rollerson the smashing rollers, the distance between the extrusion rollers and the smashing grooves is small, the smashing effect is ensured, the small effect of the smashed waste is ensured, and the numberof times of repeated smashing is reduced.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com