Patents

Literature

1034results about How to "Reduce overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

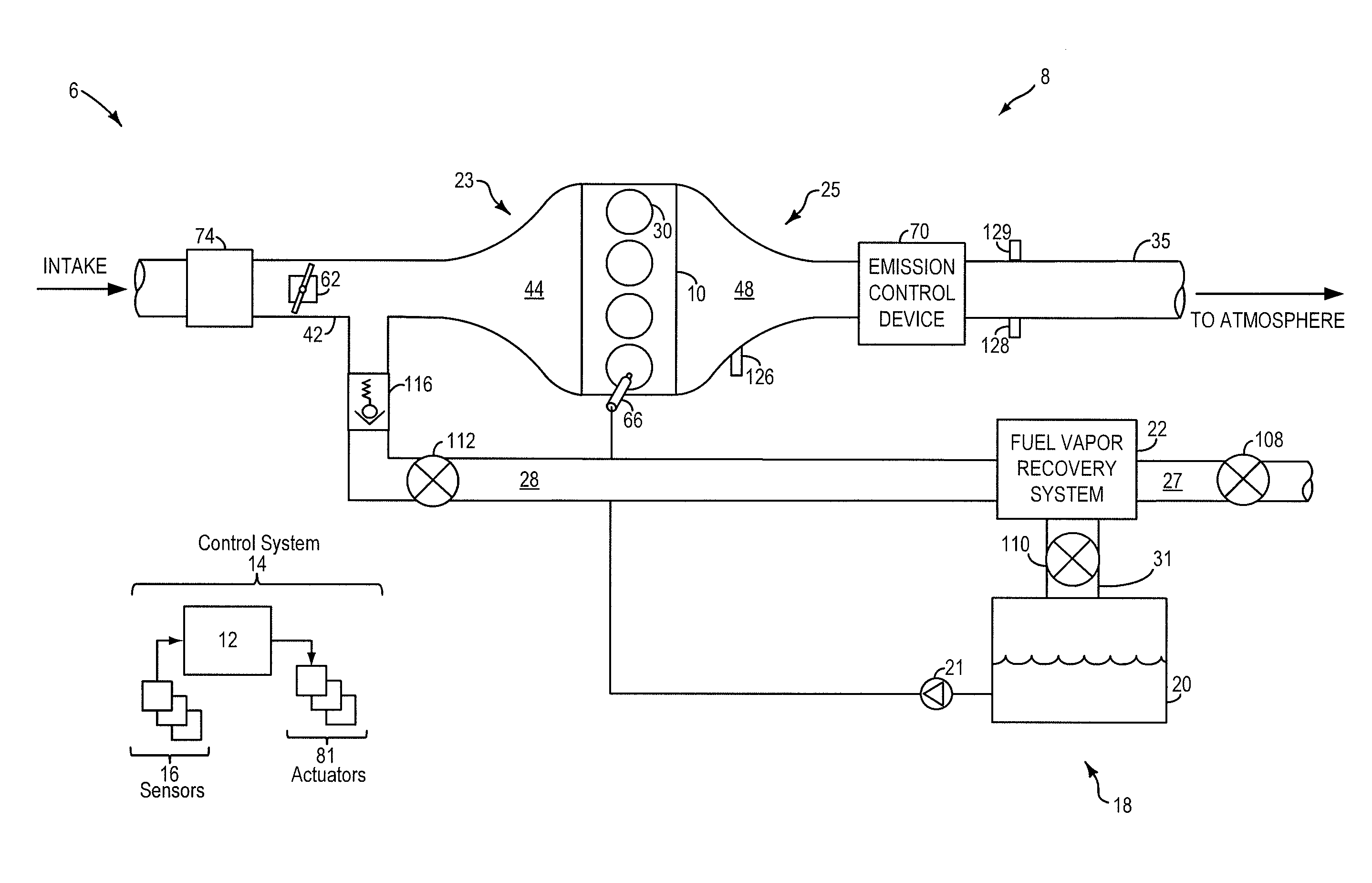

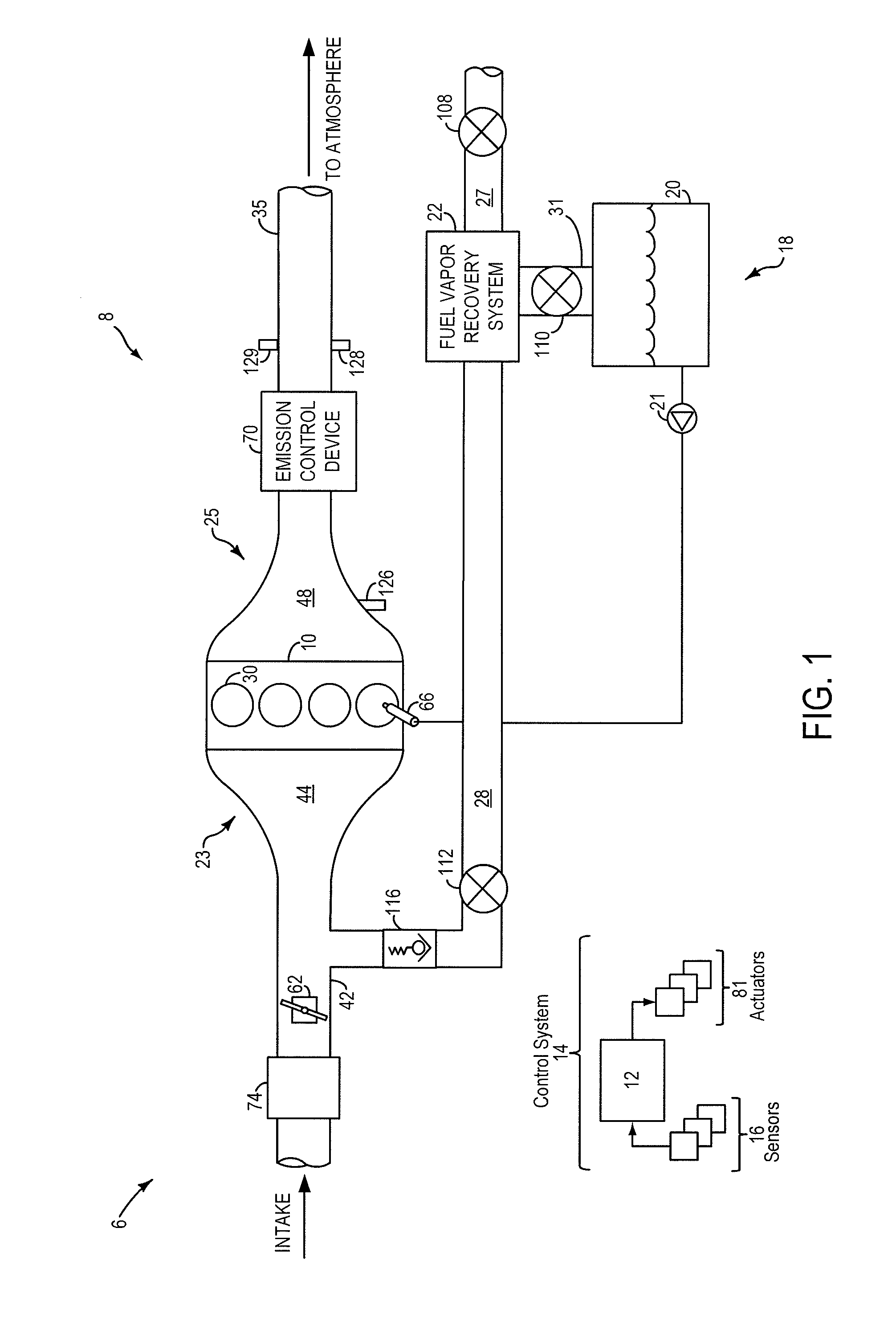

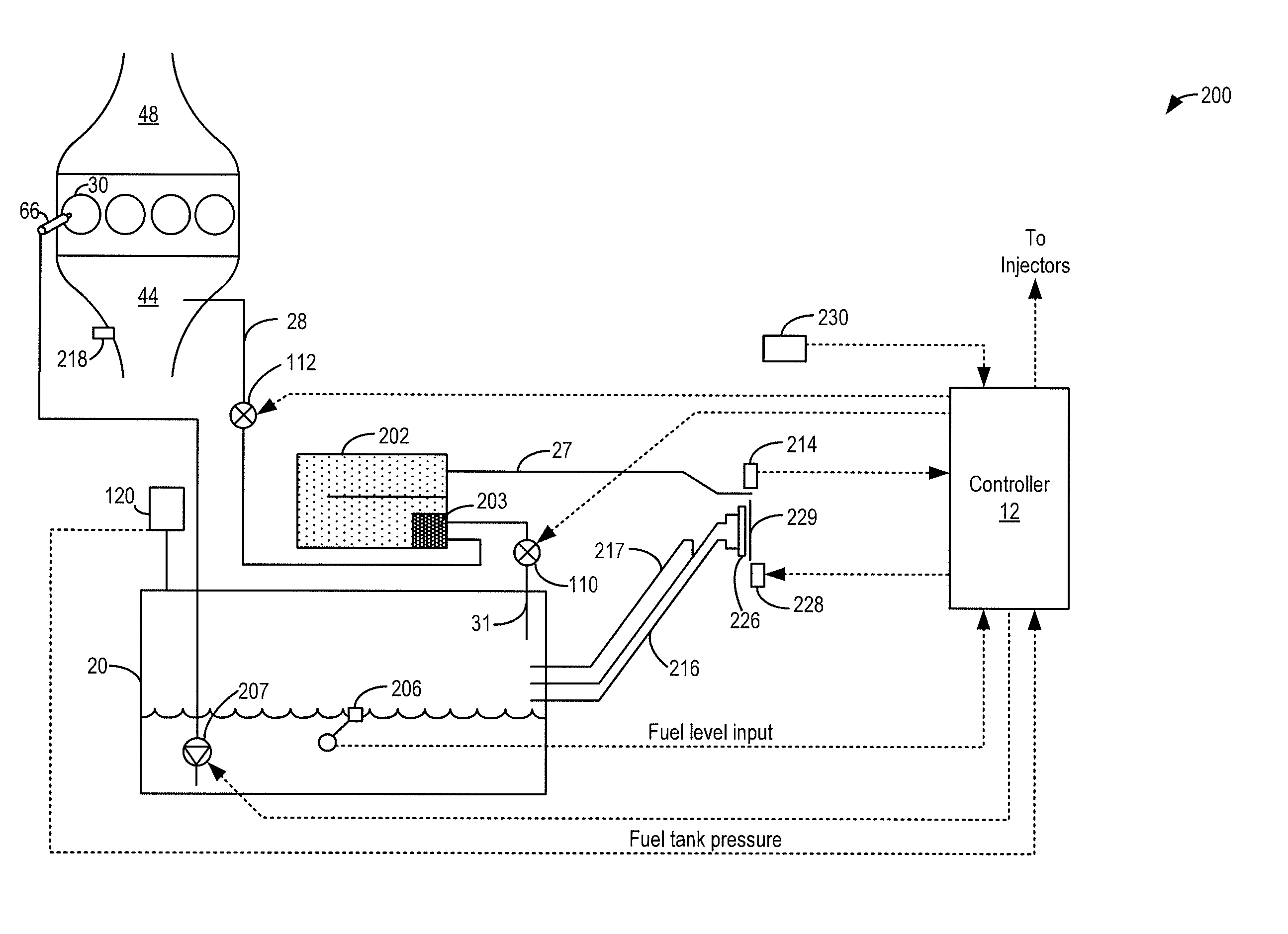

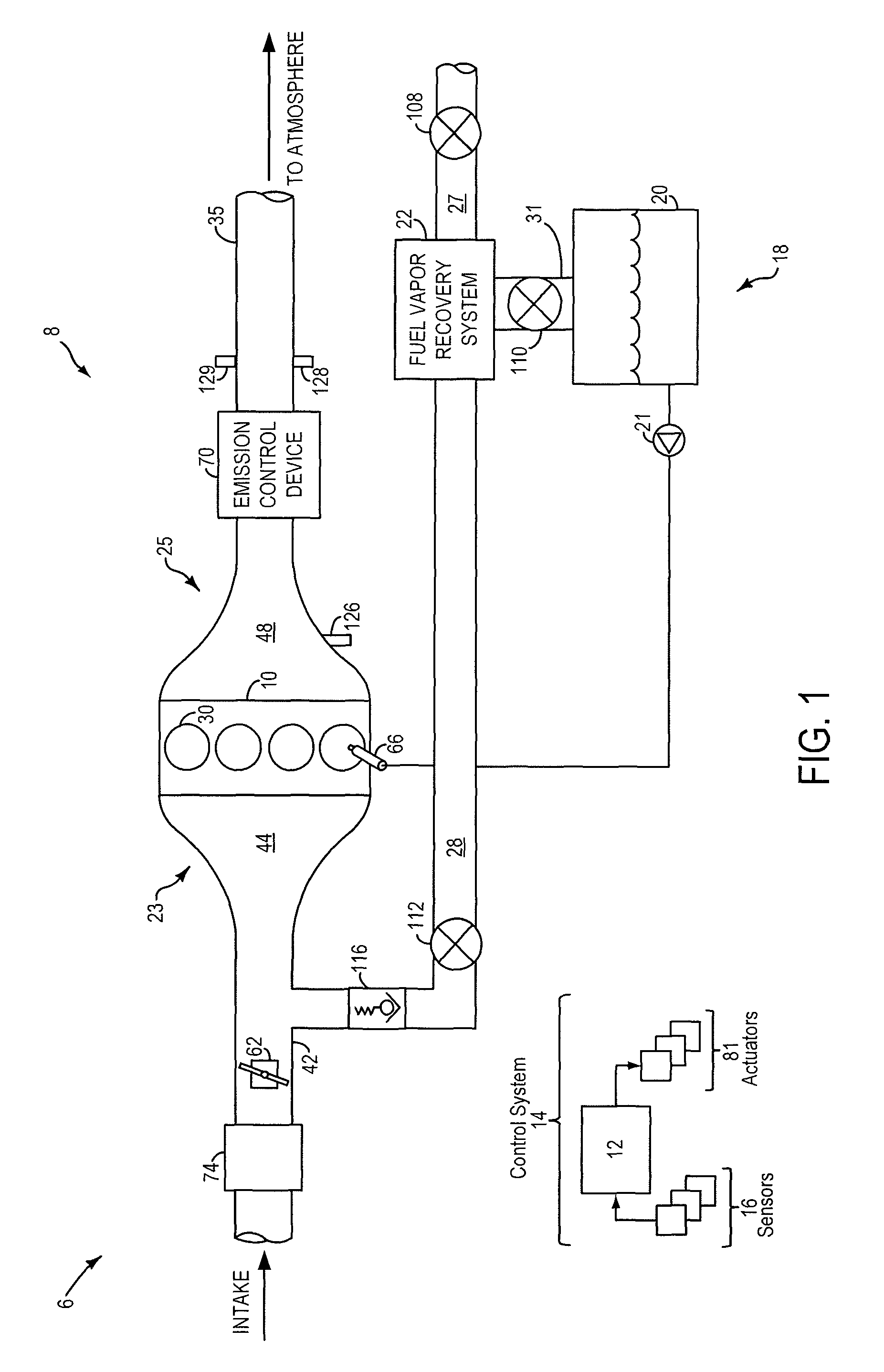

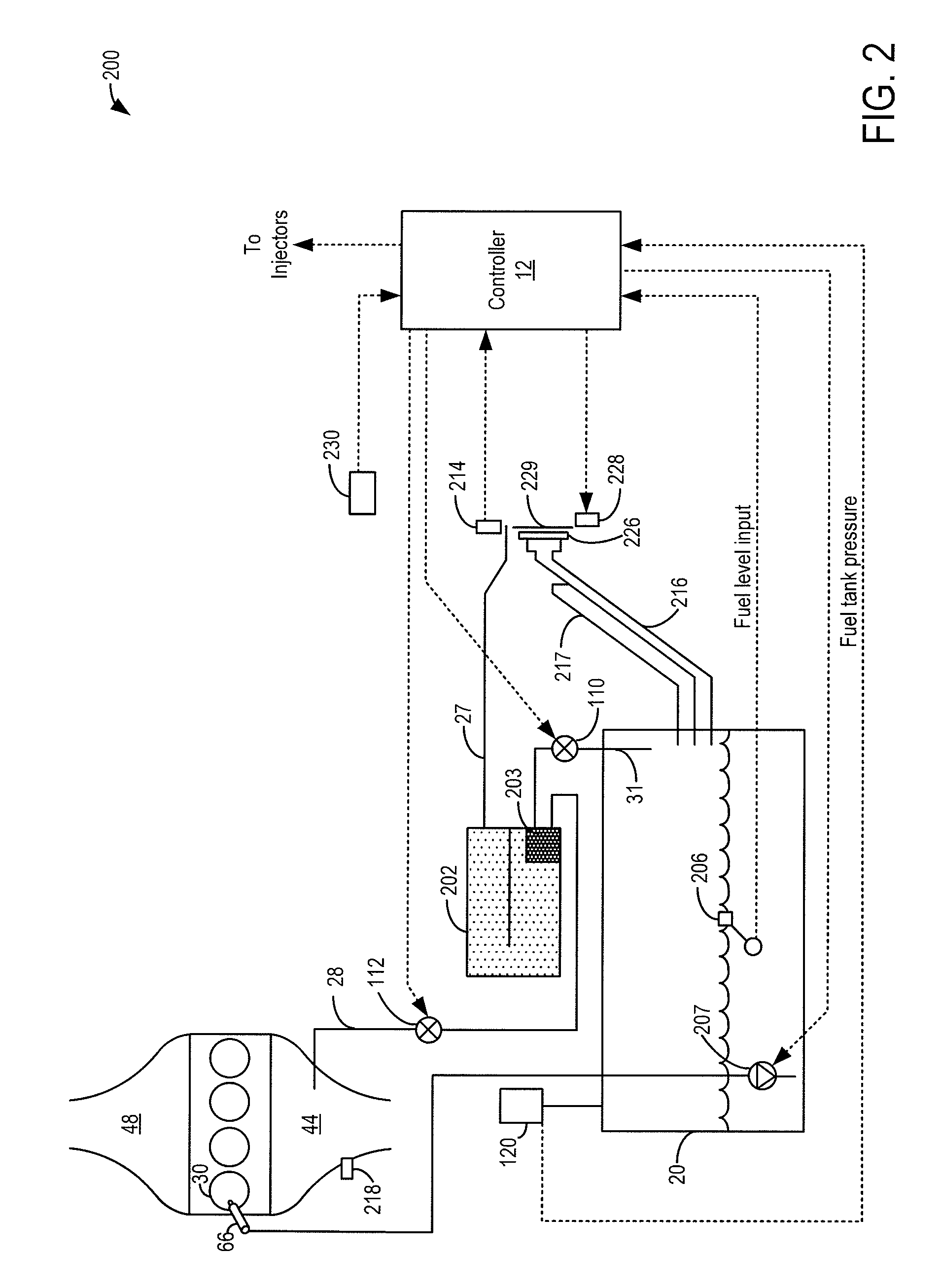

Method and System for Fuel Vapor Control

ActiveUS20110265768A1Shorten operation timeEnable fuel economyNon-fuel substance addition to fuelMachines/enginesIsolation valveEngineering

Methods and systems are provided for operating a fuel vapor recovery system having a fuel tank isolation valve coupled between a fuel tank and a canister. Fuel vapors are purged from the fuel tank to a canister buffer over a plurality of purge pulses. The pulses are adjusted based on the buffer capacity, a purge flow rate, and a fuel tank pressure to improve control of canister loading and reduce air-to-fuel ratio disturbances.

Owner:FORD GLOBAL TECH LLC

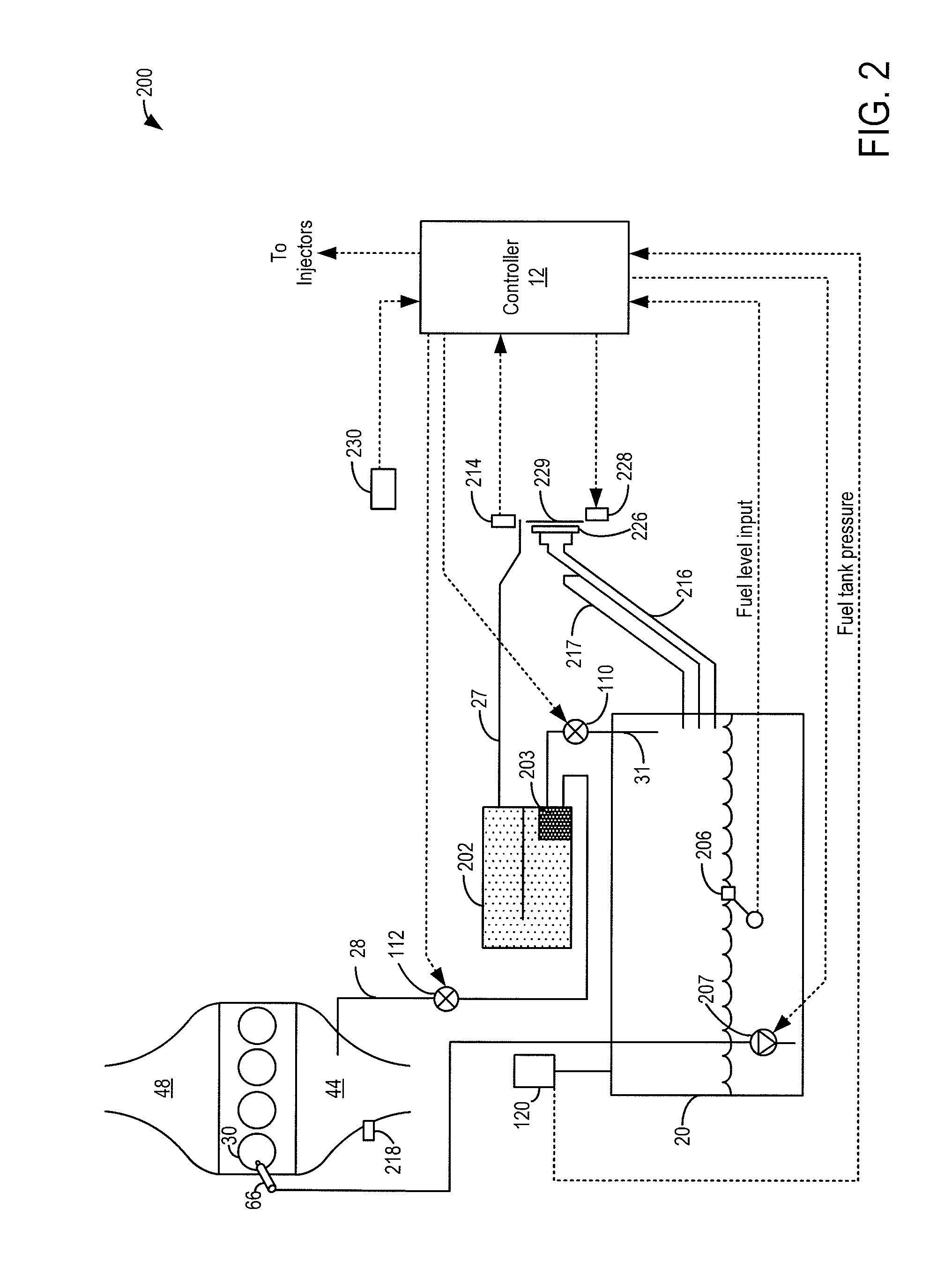

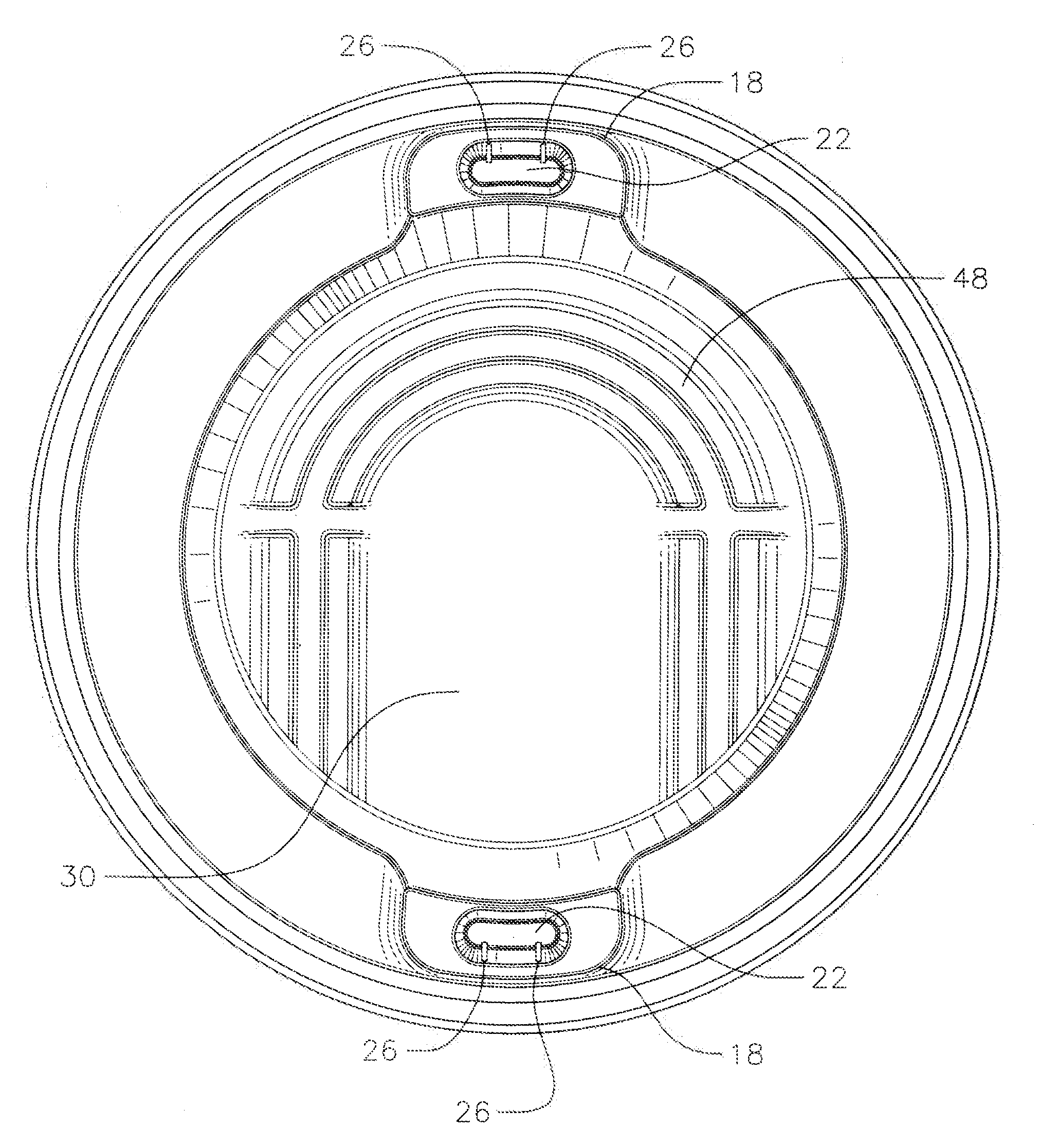

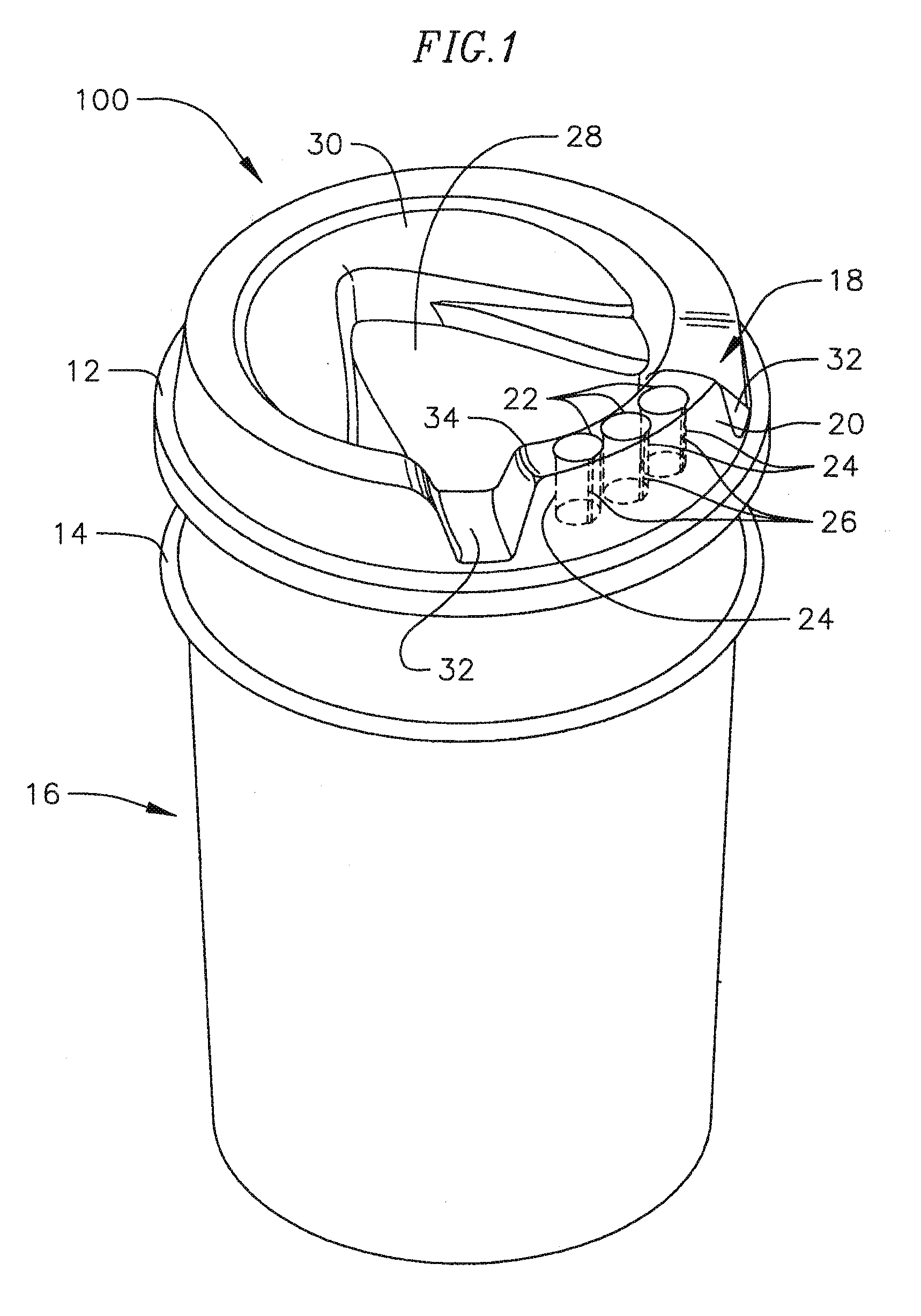

Coffee cup lid

InactiveUS20090294460A1Improve comfortReduce spillLidsDrinking vesselsMechanical engineeringEngineering

Owner:COMERICA BANK

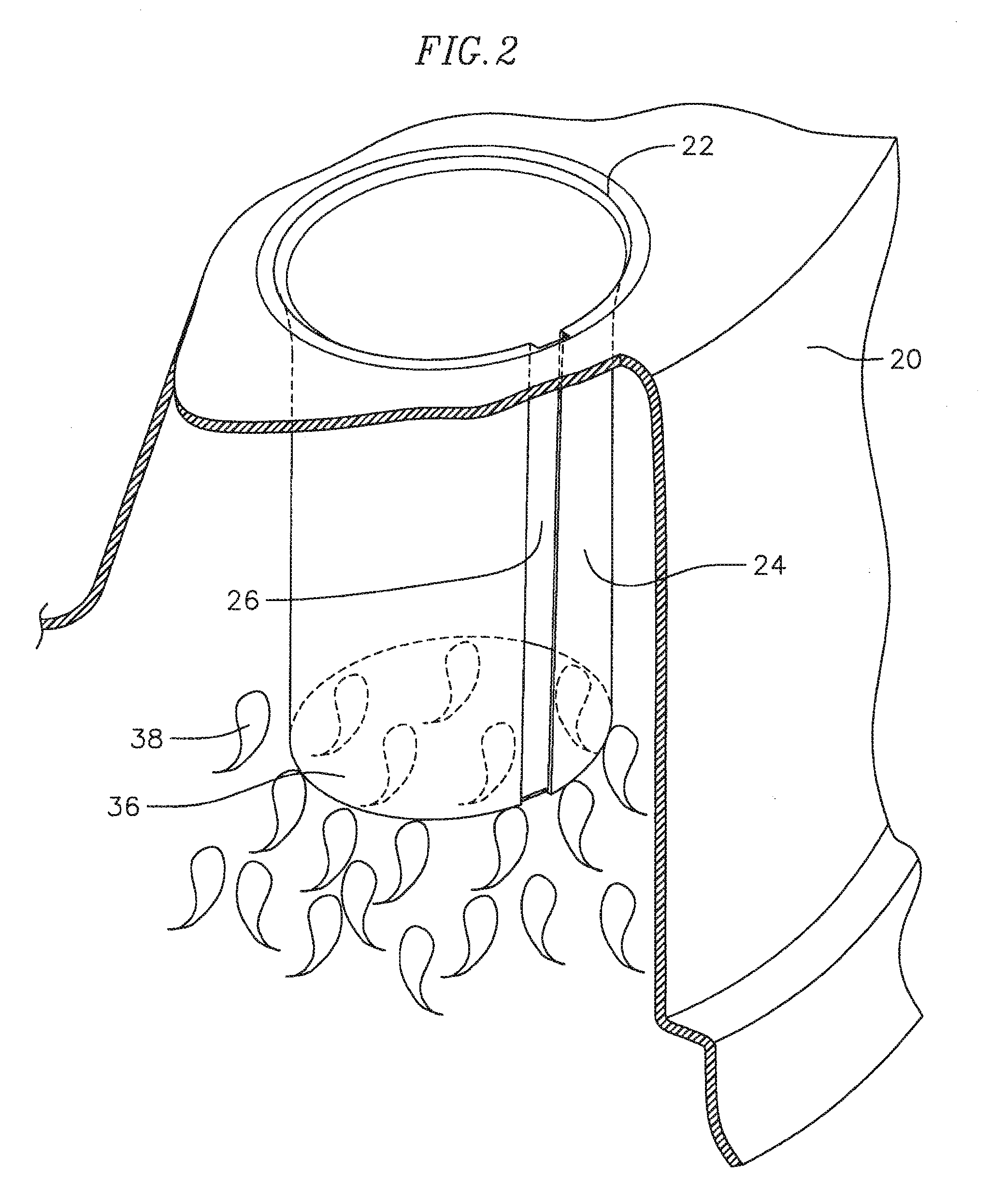

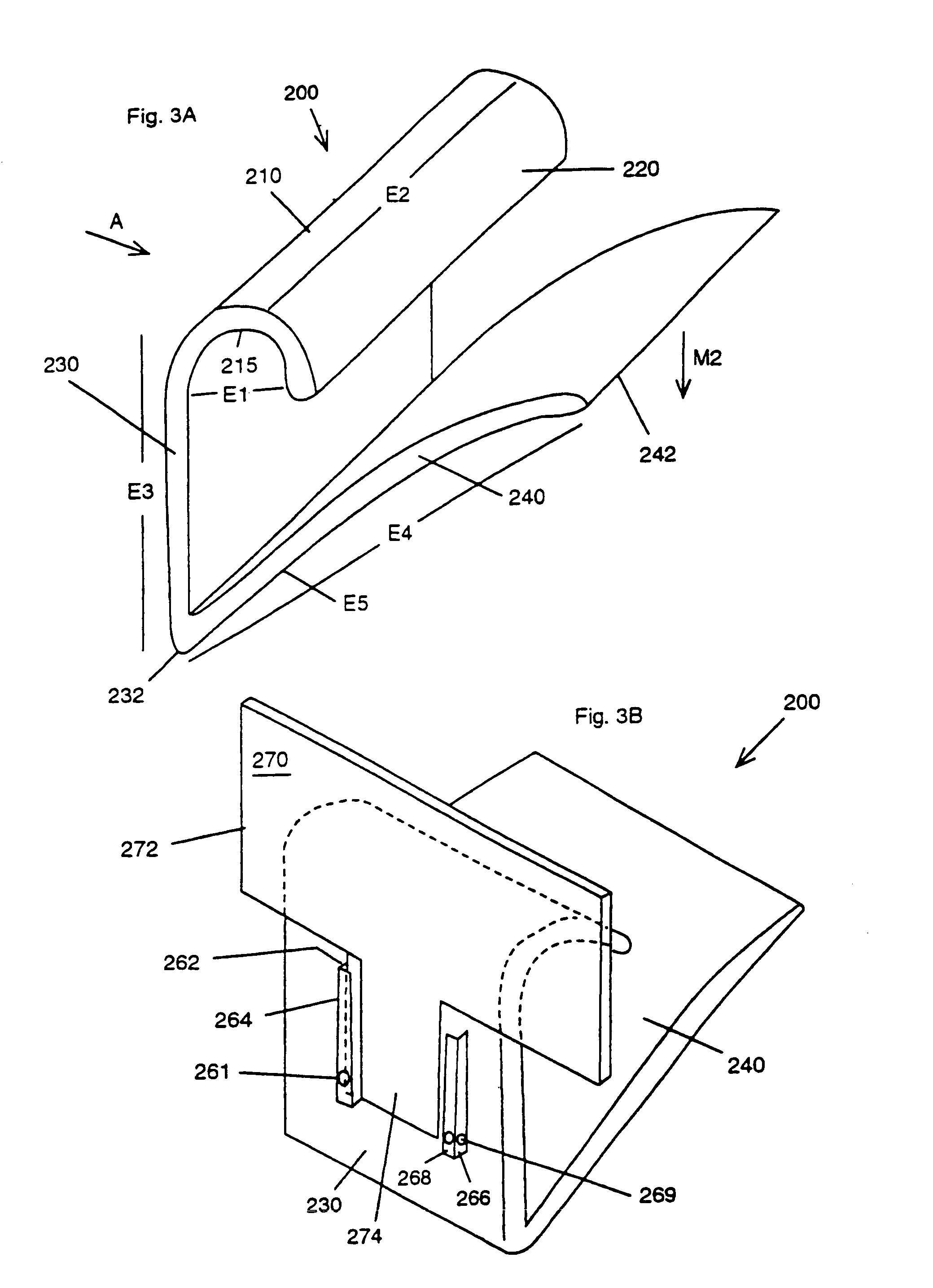

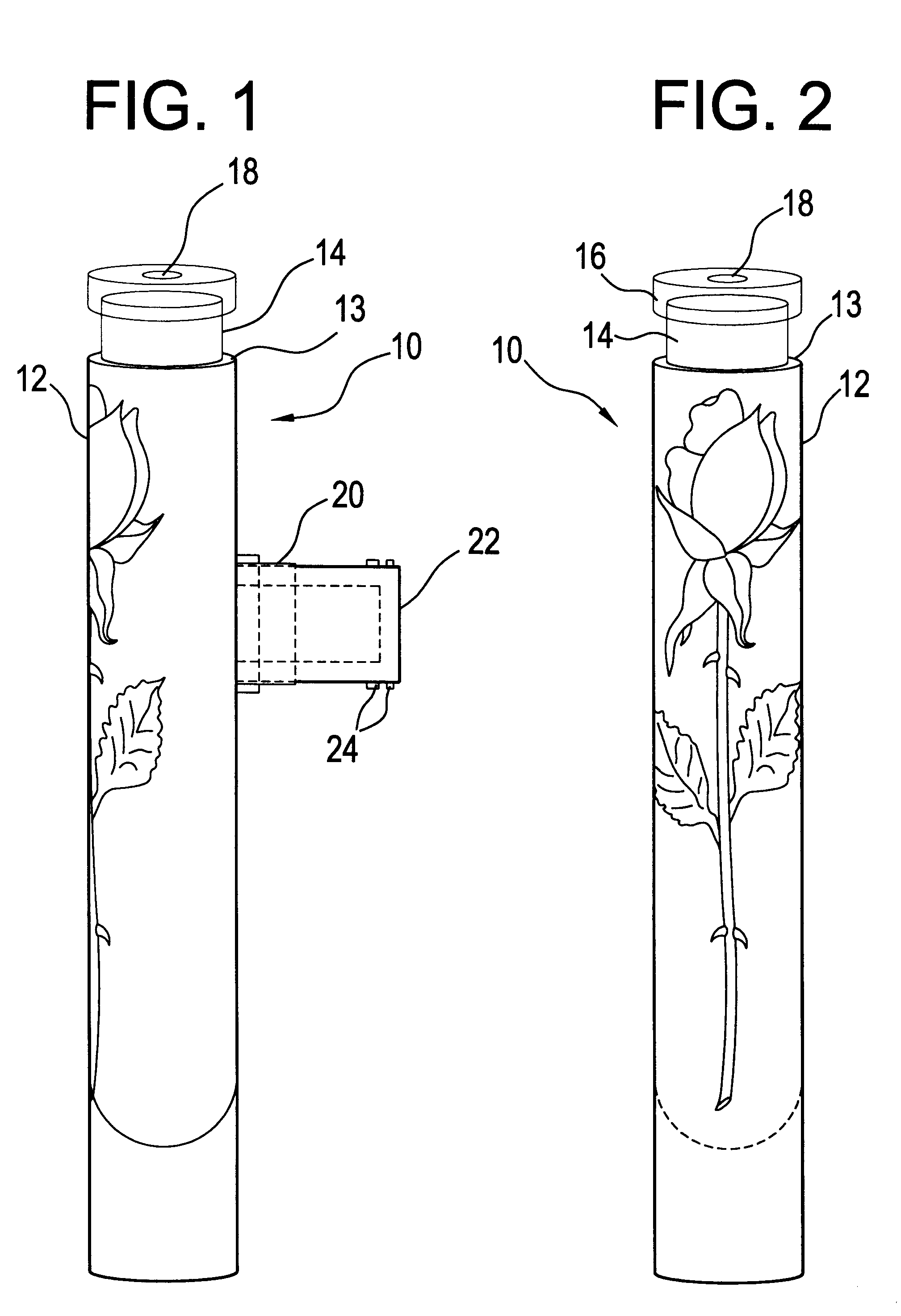

Systems and devices for delivering volatile materials

InactiveUS20050211790A1Facilitate cognitionReduce overflowTobacco devicesGaseous substancesProcess engineeringEnvironmental engineering

A non-energized volatile material delivery system for emitting or releasing volatile materials to the atmosphere is provided. More specifically, delivery systems for delivering one or more volatile materials using a non-aerosol, non-energized volatile material delivery system via an evaporative surface device, without a source of heat, gas, or electrical current, are also provided.

Owner:THE PROCTER & GAMBLE COMPANY

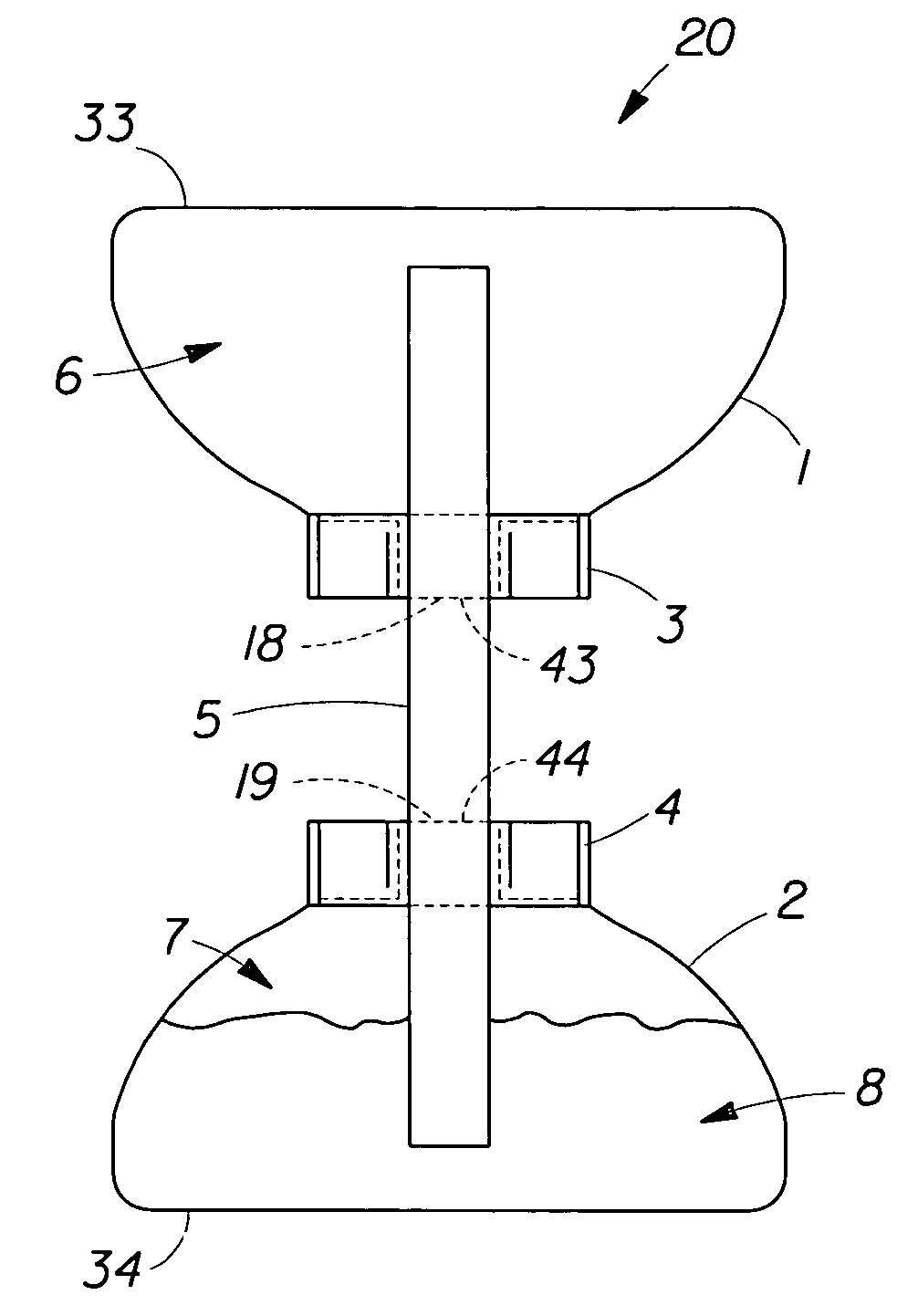

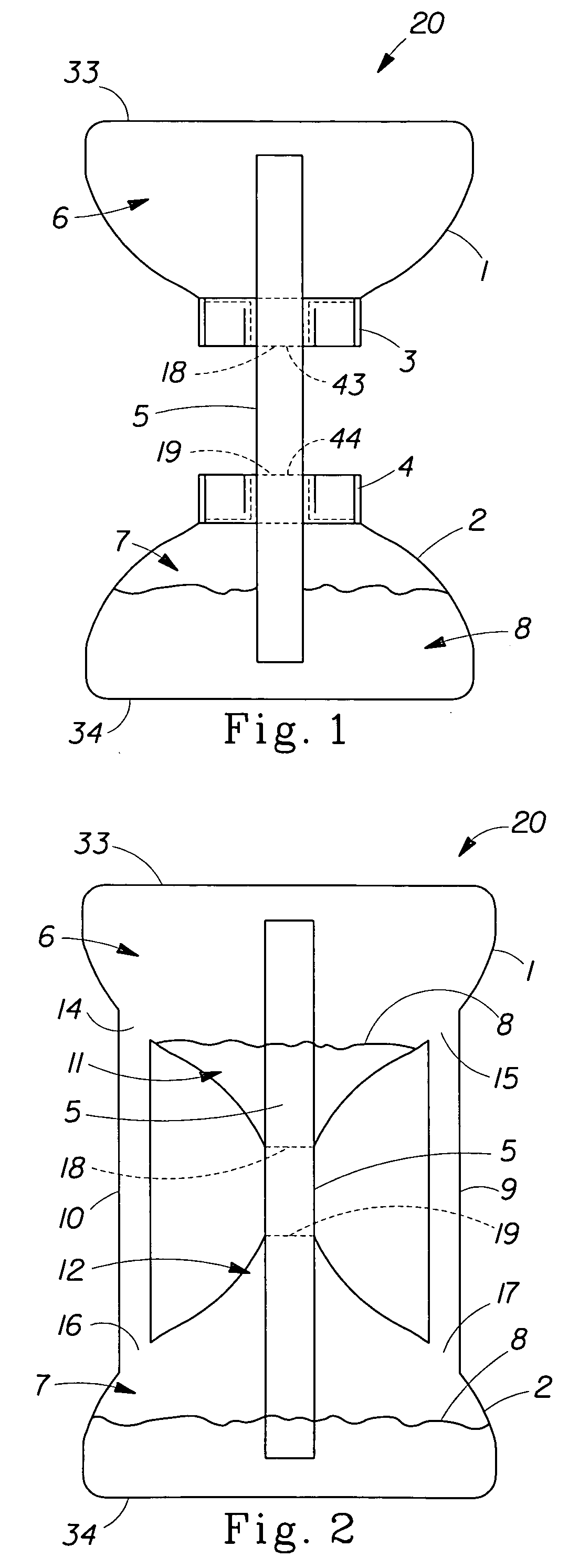

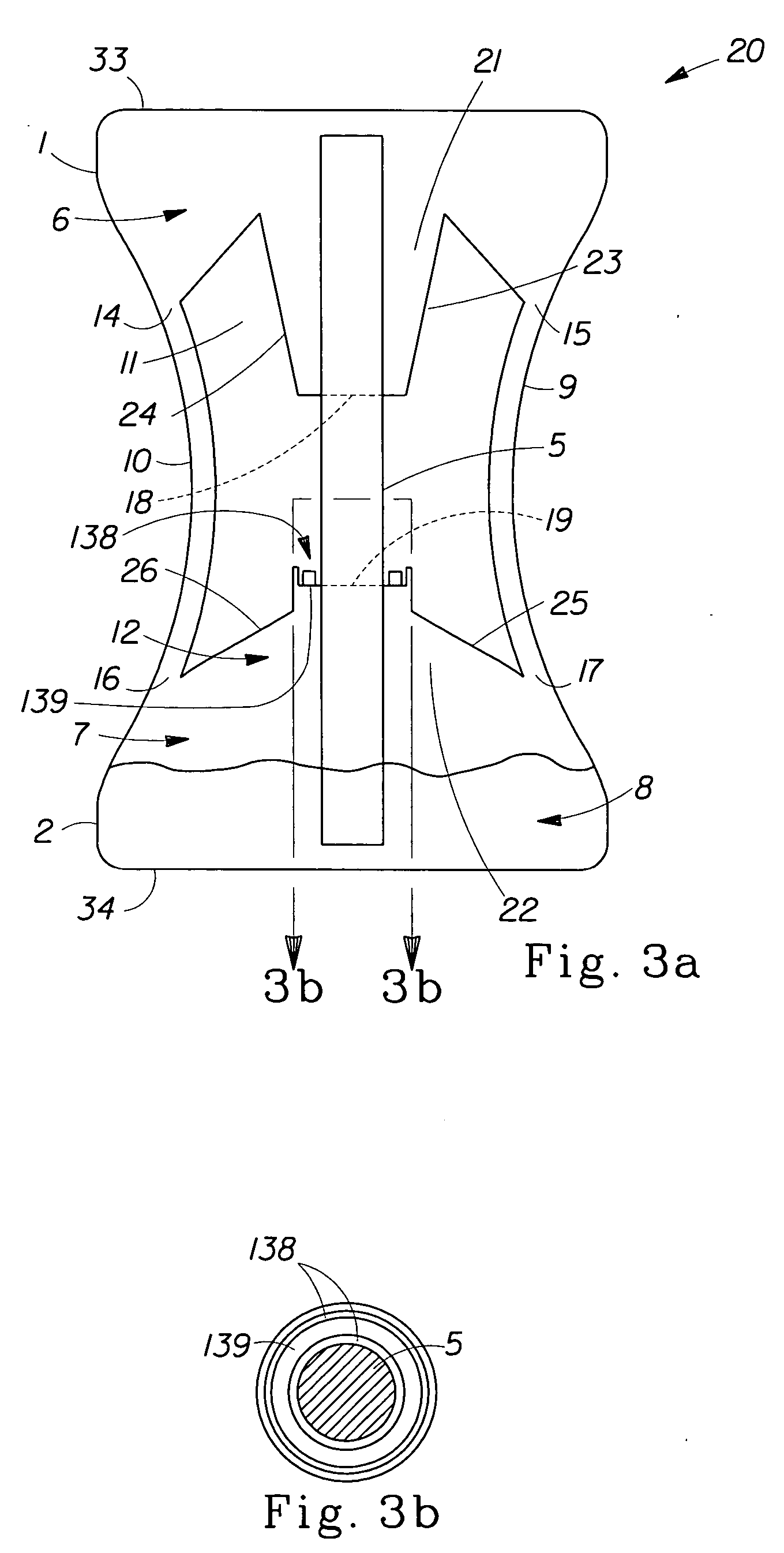

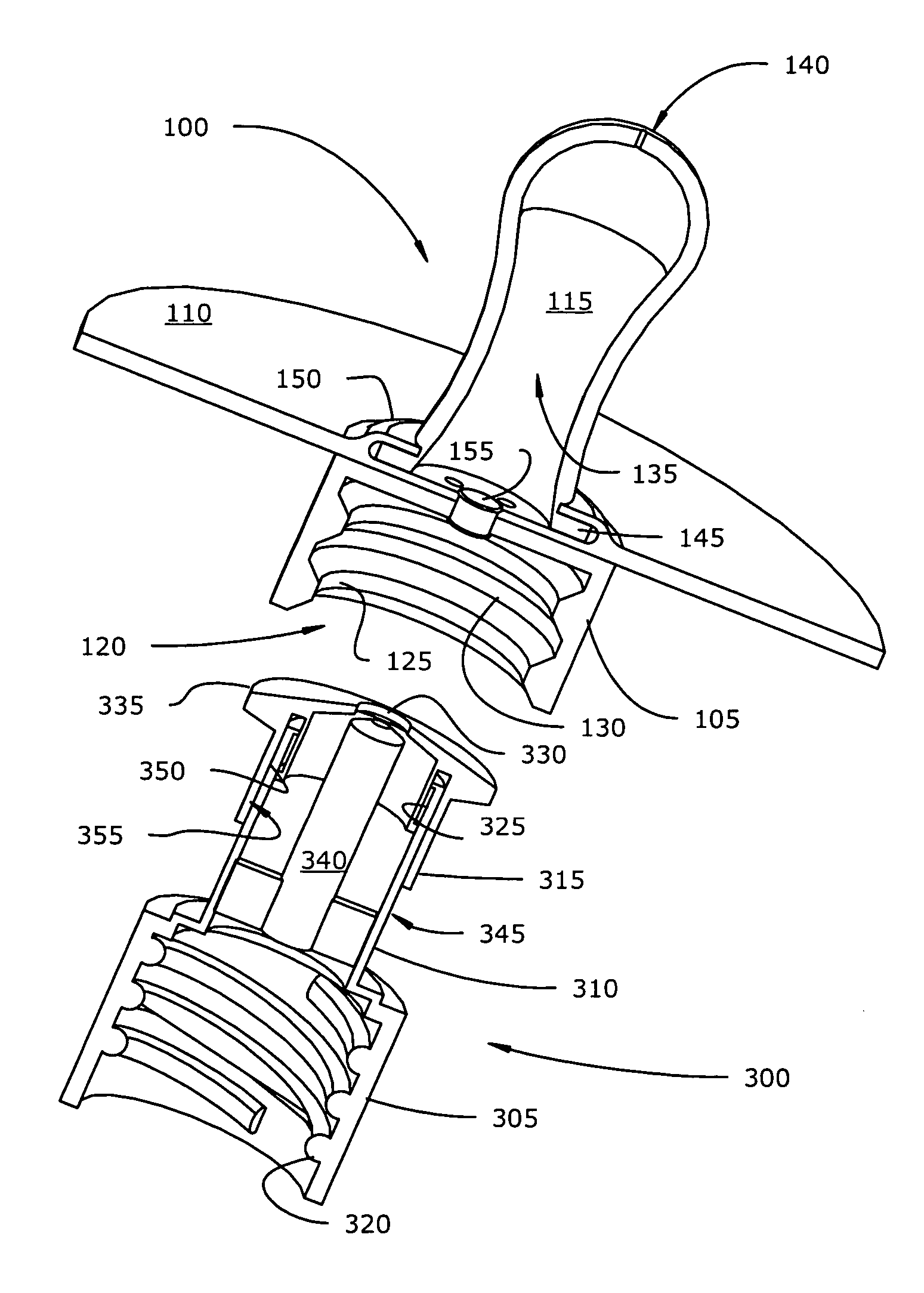

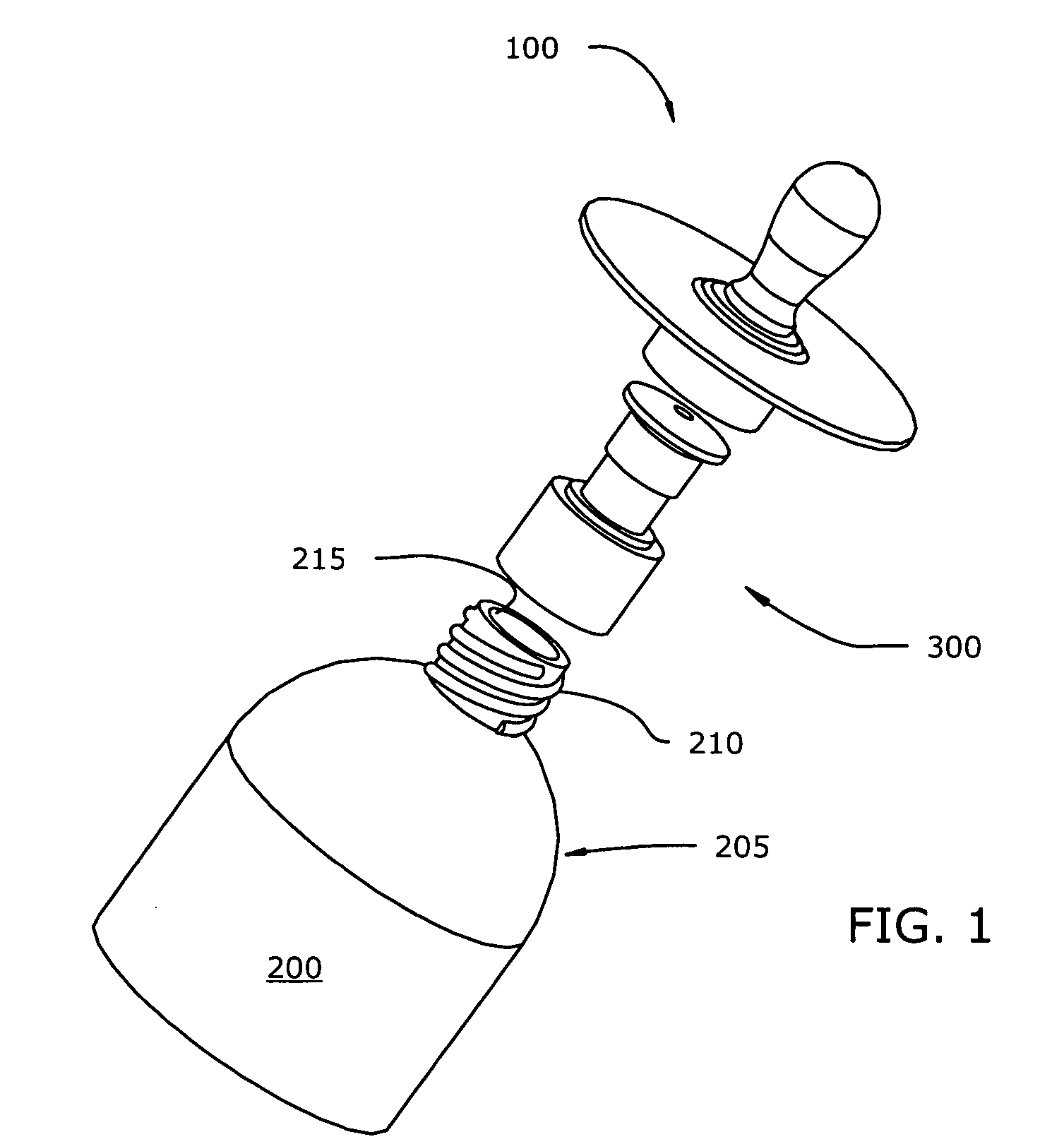

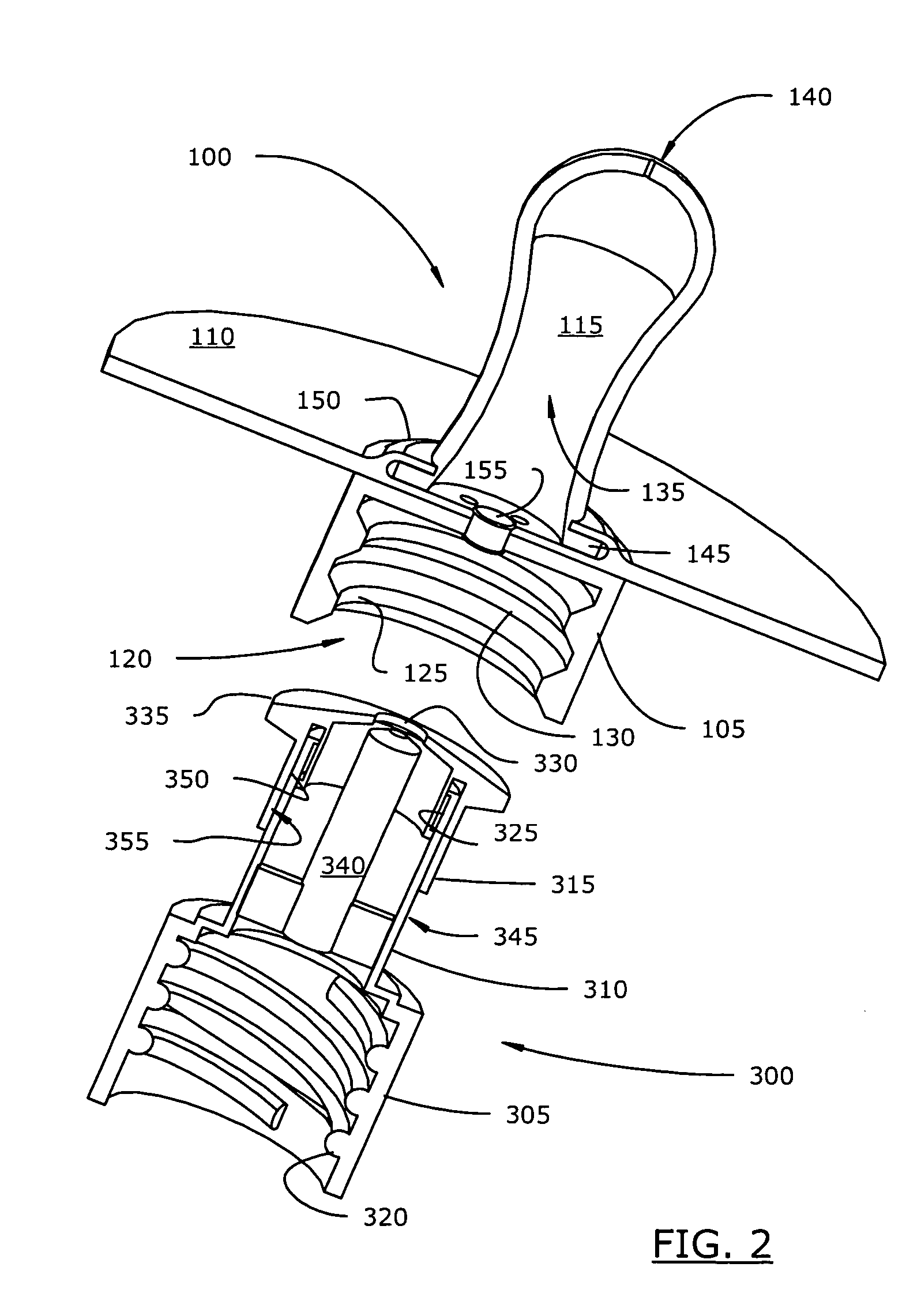

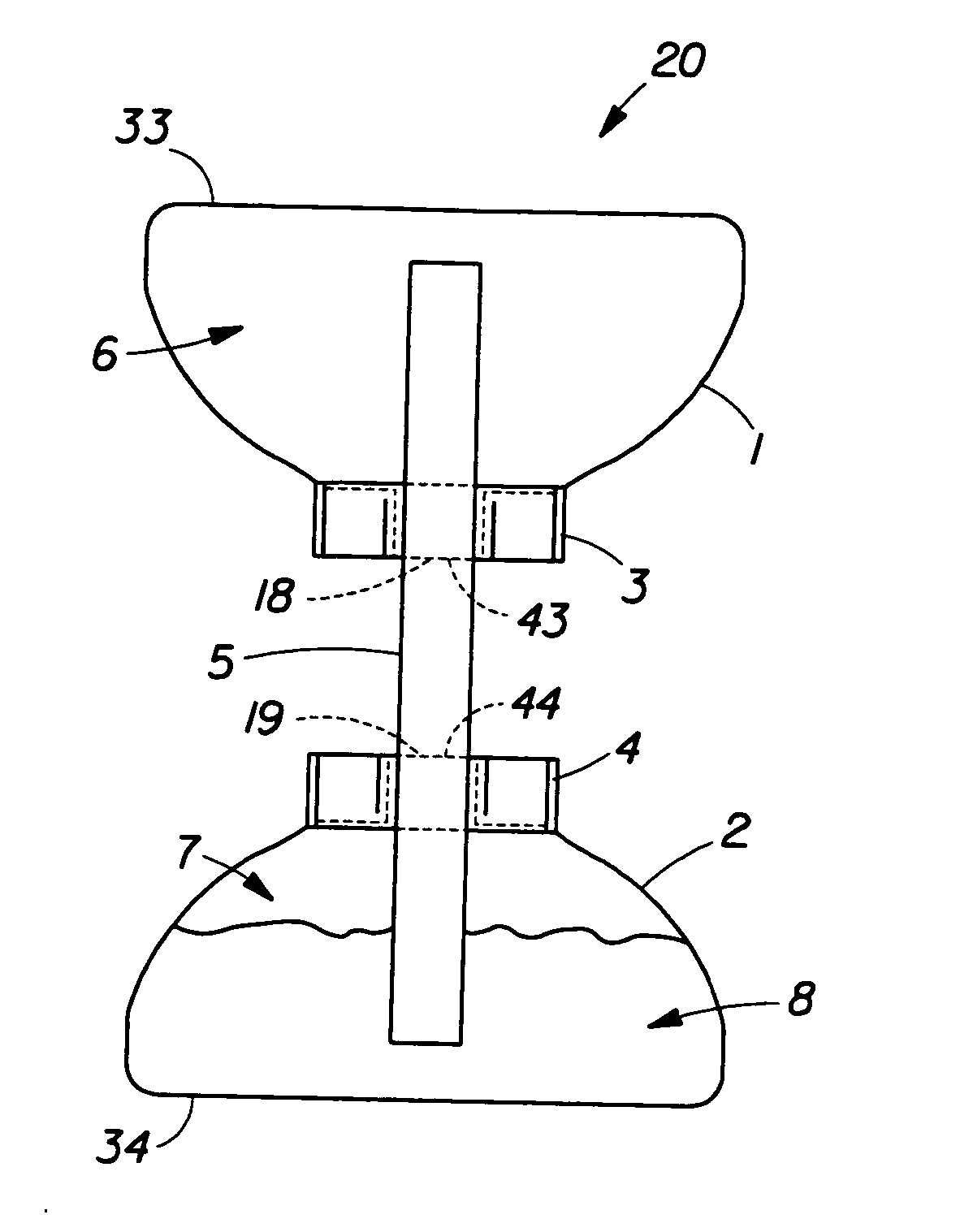

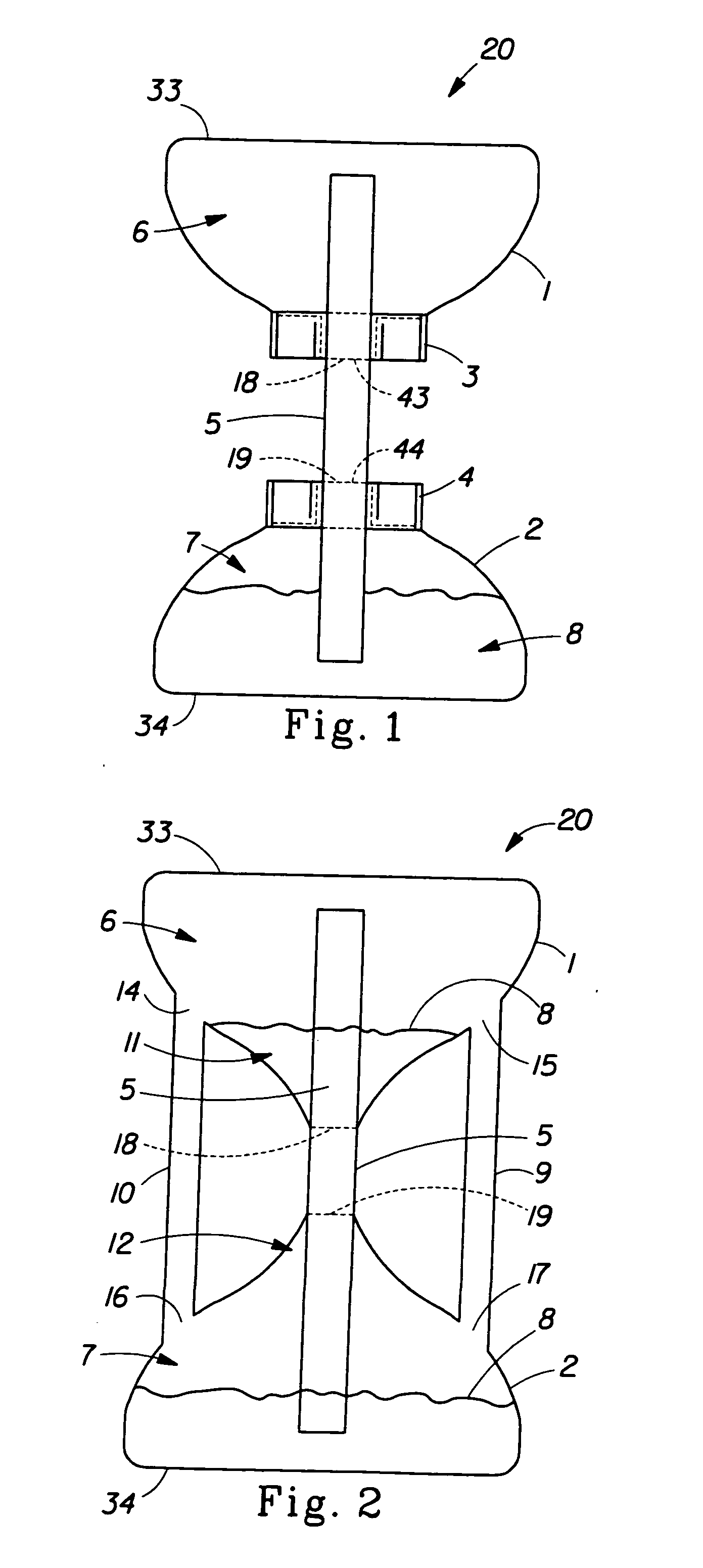

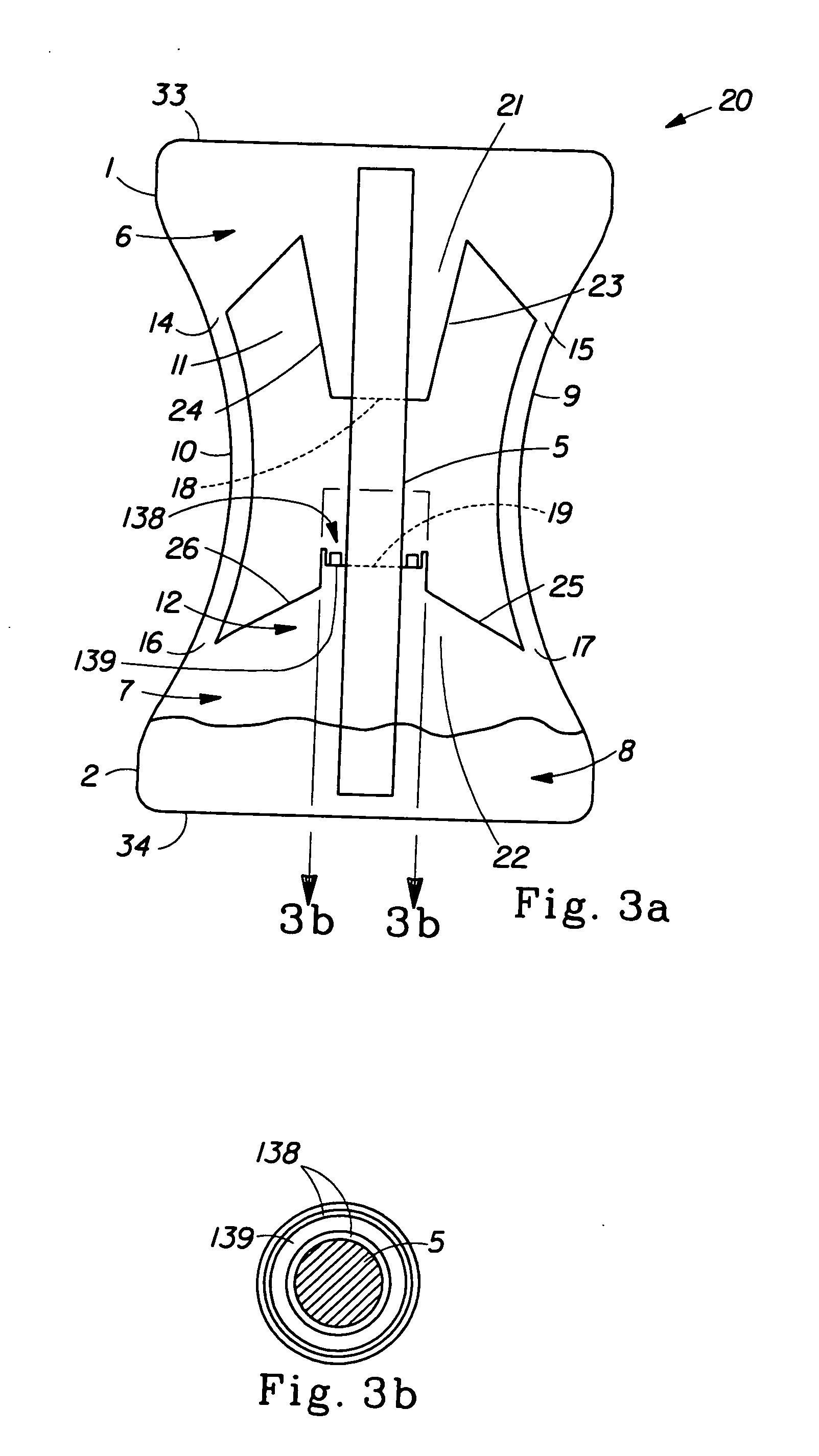

Infant care apparatus

InactiveUS7032764B2Inexpensive and safeThe process is simple and easy to understandFeeding-bottlesTeatsVALVE PORTInfant Care

An infant care apparatus including a nipple having a nipple passage for drawing fluid therethrough. A fitting is adapted to secure the infant care apparatus on a closure adapted to regulate flow between the infant care apparatus and a container. A valve is adapted to regulate flow between the nipple passage and the closure.

Owner:TRIO CHILD

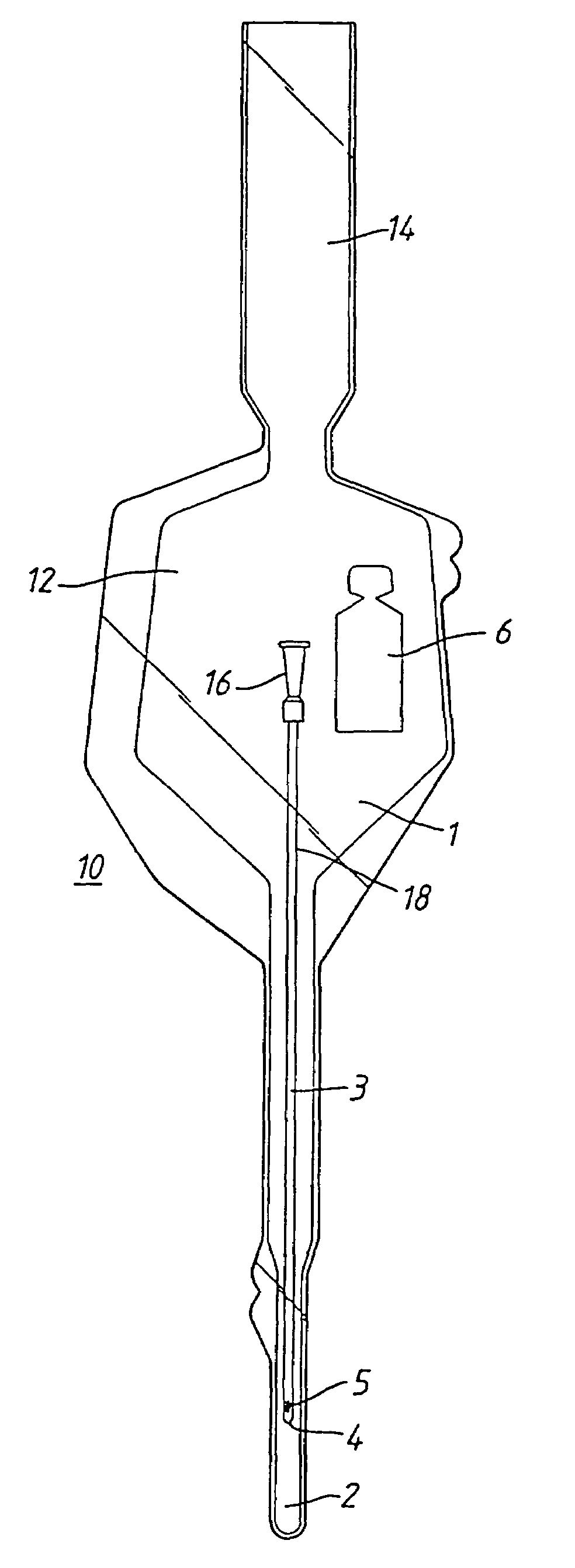

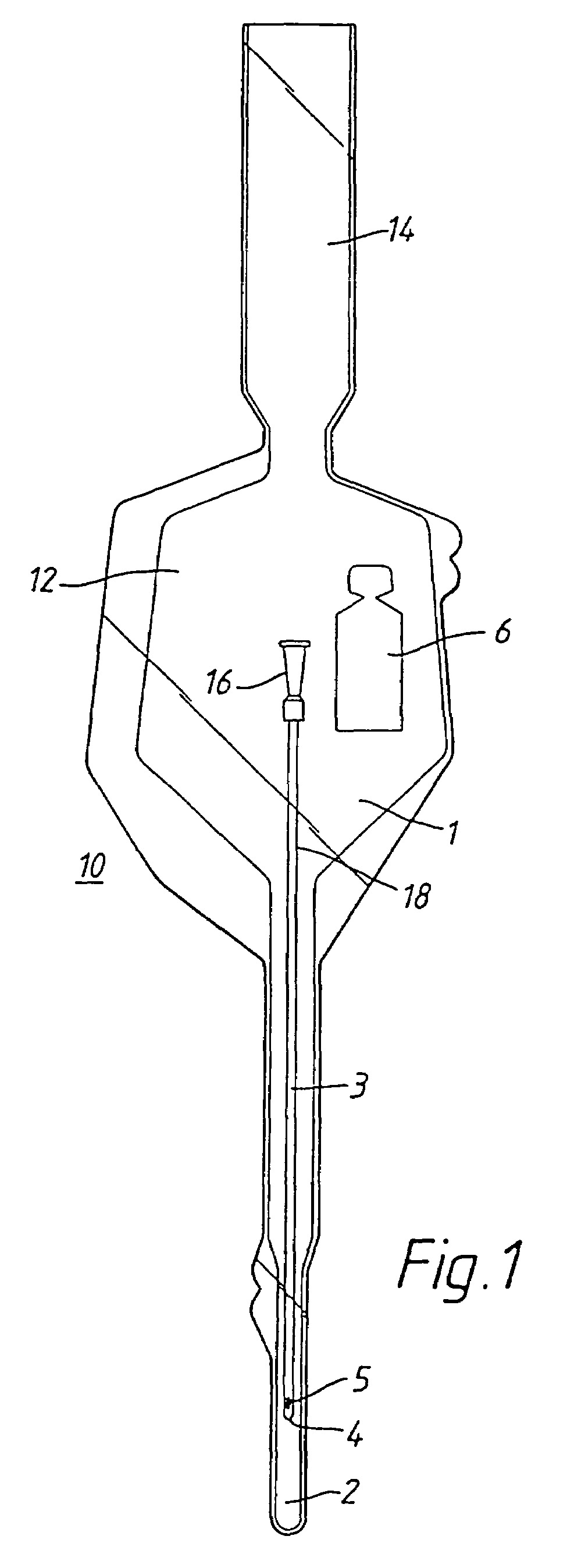

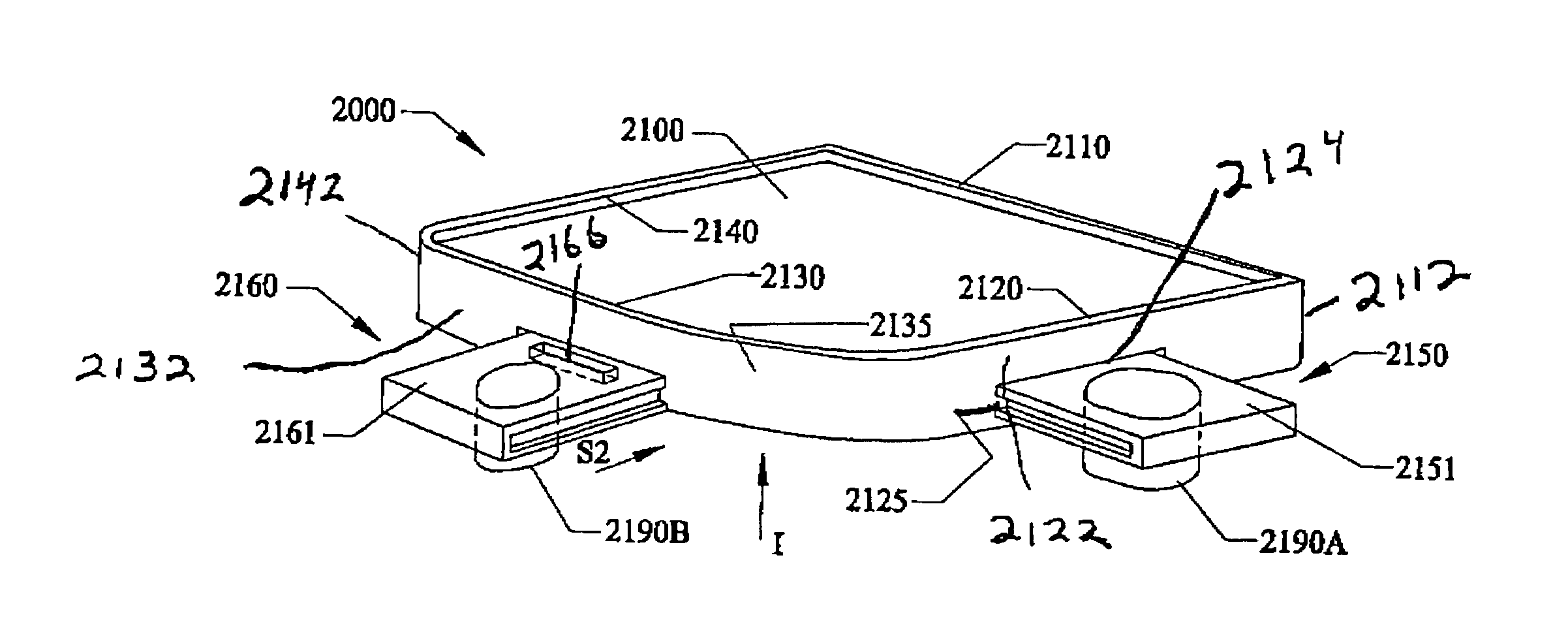

Hydrophilic urinary catheter having a water-containing sachet

A wetting apparatus (110) for wetting a hydrophilic urinary catheter (103) comprises a wetting receptacle (101) which defines a wetting fluid receiving area (102) for receiving the hydrophilic urinary catheter and a hydrophilic urinary catheter wetting fluid container (106) having a discharge outlet (126) movable from a closed position to an open position on application of a predetermined condition thereto to enable the wetting fluid to be discharged from the wetting fluid container. The wetting fluid container provided can be positioned in the wetting receptacle in an operational position in which at least the discharge outlet of the wetting fluid container is disposed within the bounds of the wetting receptacle, the wetting receptacle being so constructed and the wetting fluid container being so disposed relative to the wetting receptacle when in the operational position that application of the predetermined condition to the discharge outlet of the wetting fluid container when in the operational position enables the wetting fluid to be discharged into the wetting fluid receiving area for wetting of the hydrophilic urinary catheter.

Owner:ASTRAZENECA AB

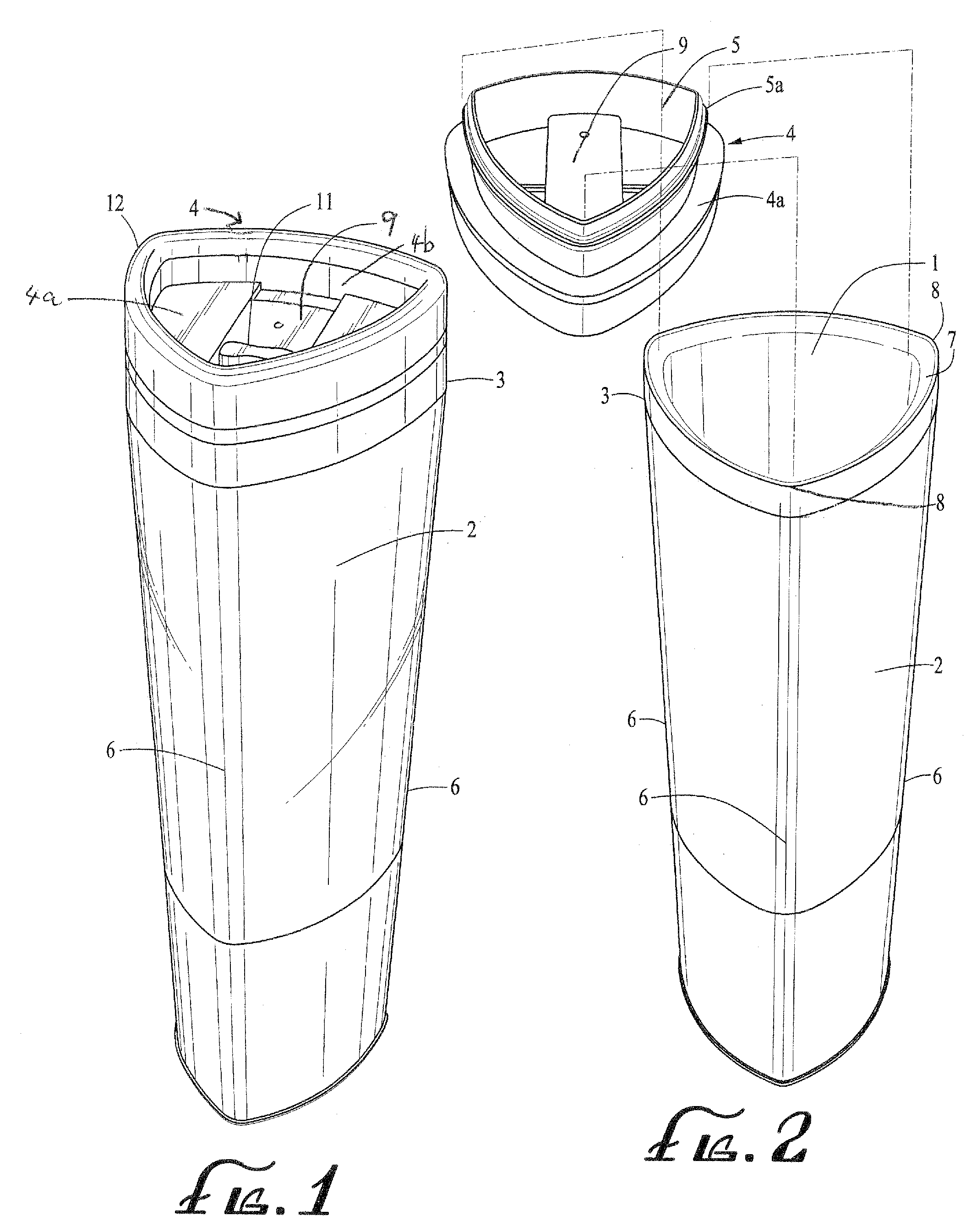

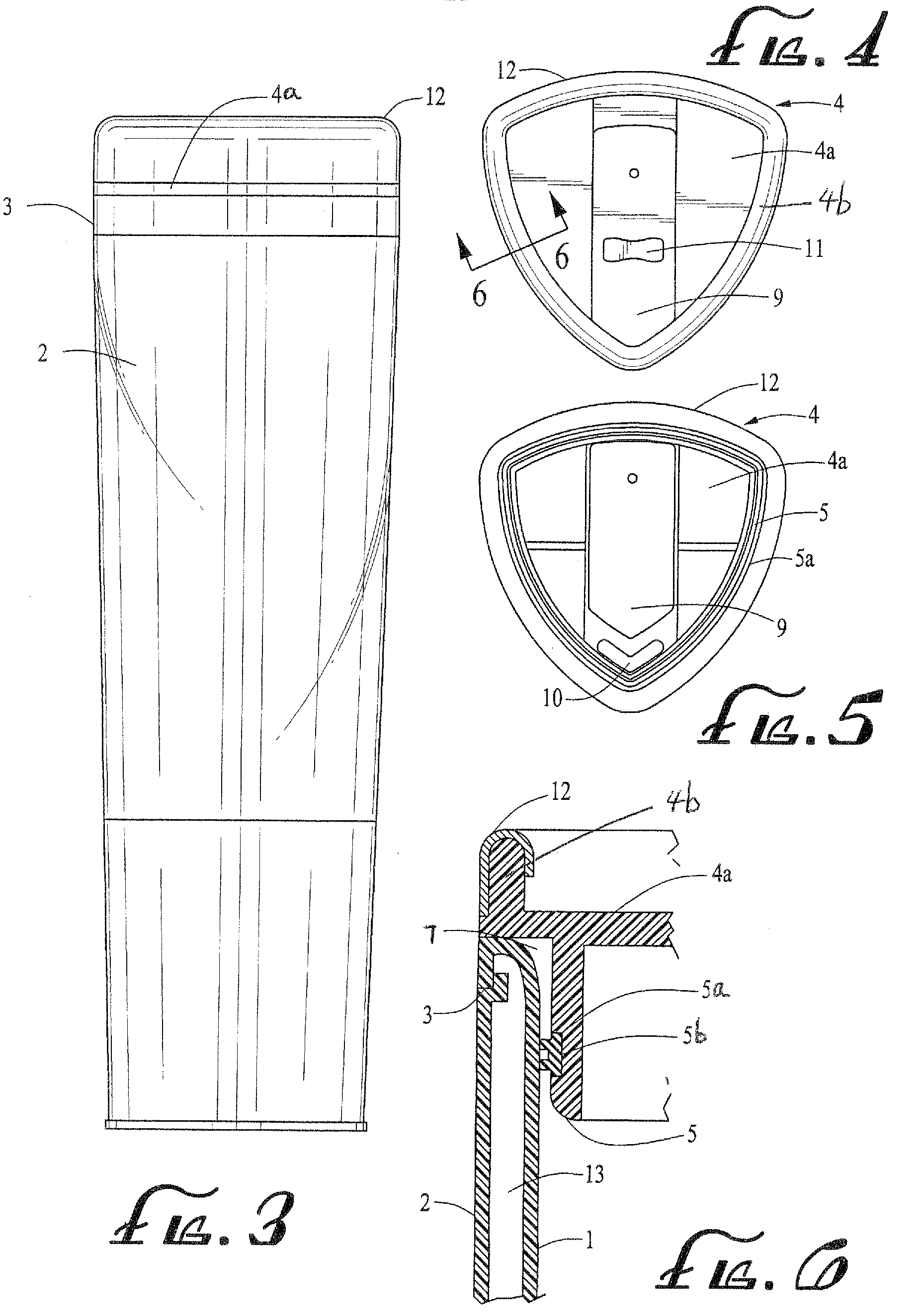

Triangular mug and advertising means

InactiveUS7455191B2Accurate and controlled fashionEasy flow controlDomestic cooling apparatusClosuresTriangular mouthMechanical engineering

Owner:SUN COAST MERCHANDISE

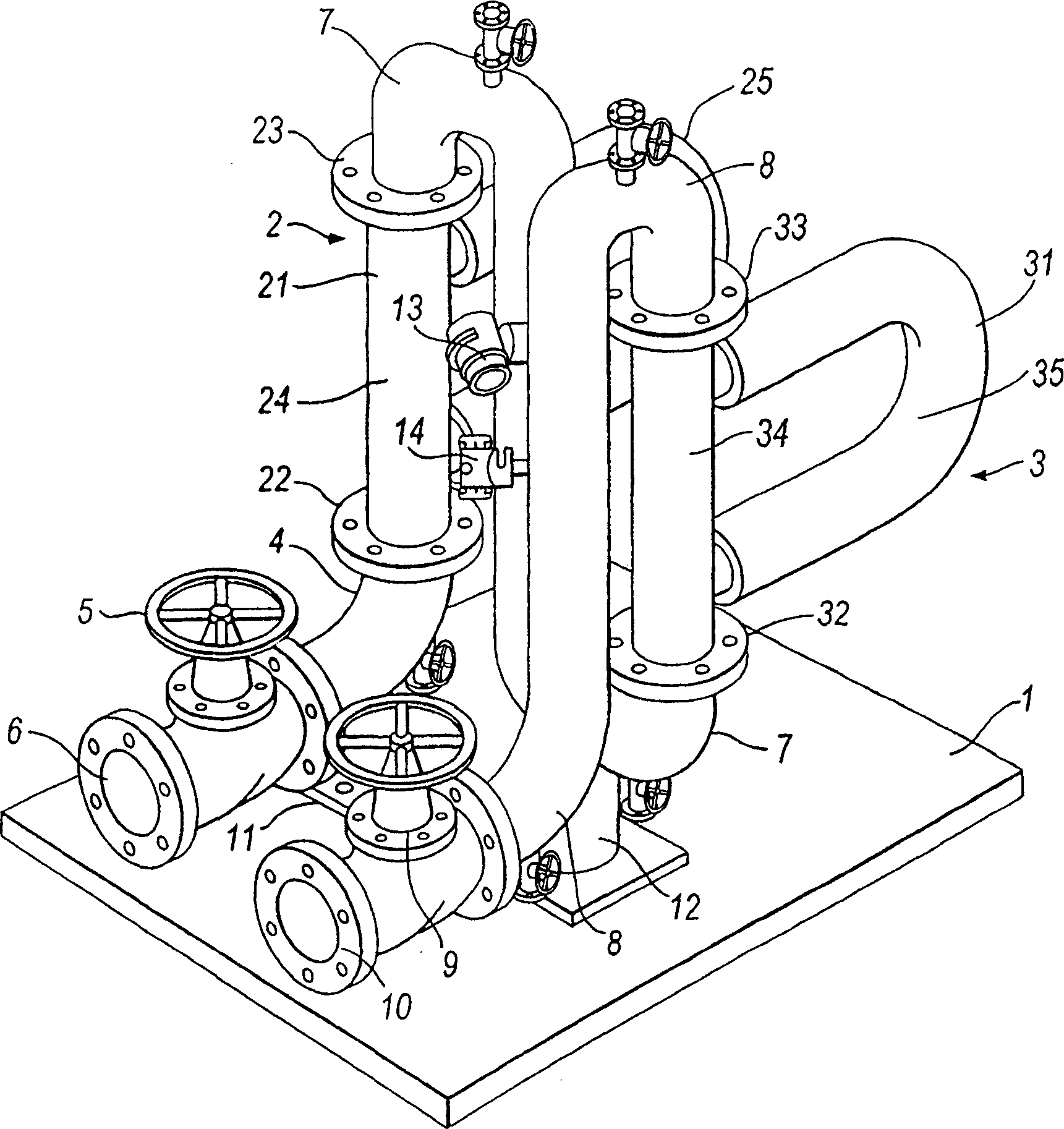

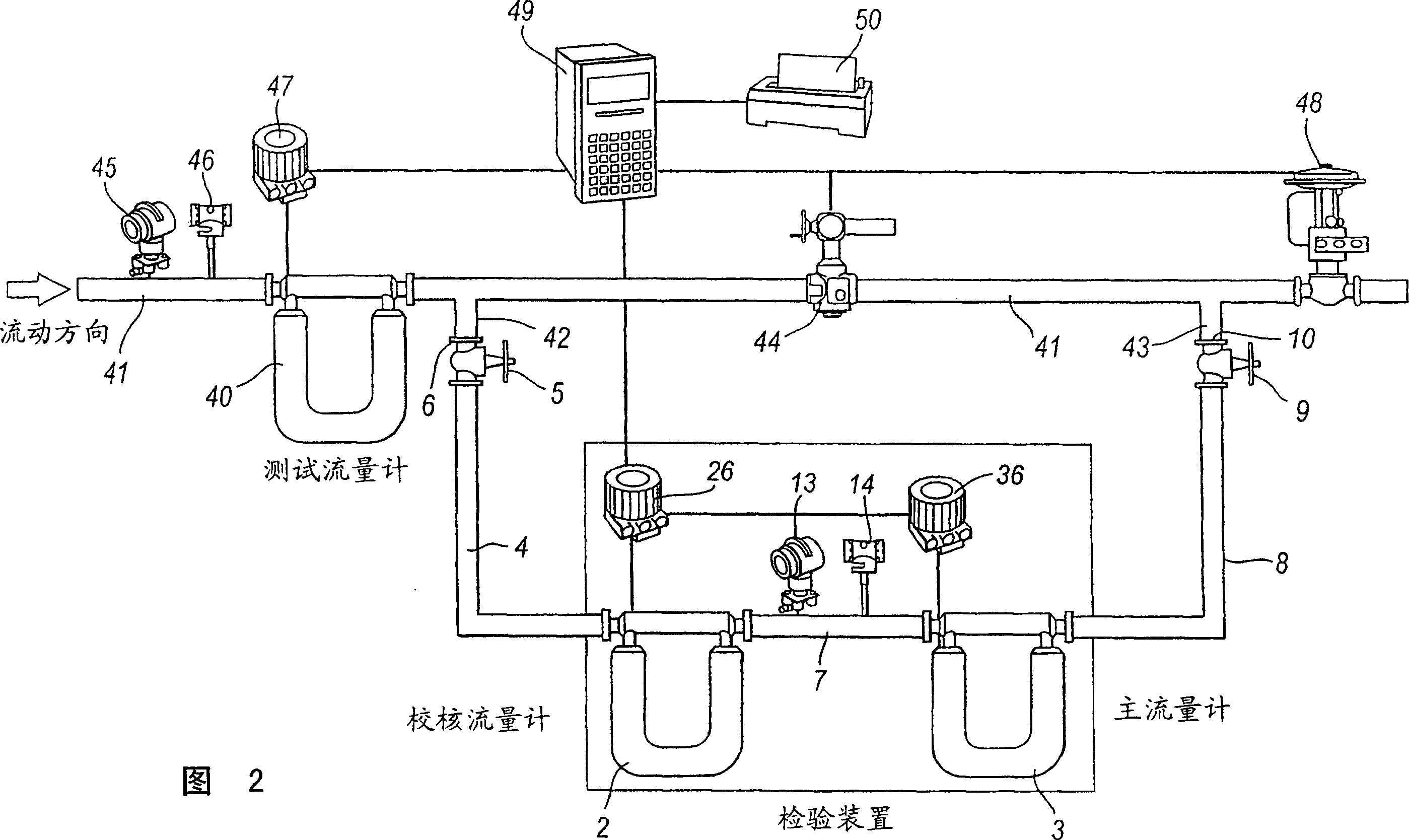

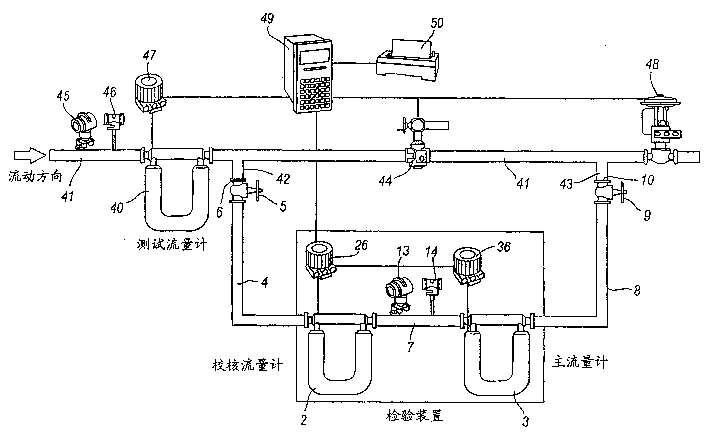

Flowmeter providing device and method

InactiveCN1513110AReduce overflowReduce lossVolume meteringTesting/calibration for volume flowLine tubingEngineering

A flowmeter proving device and method for use in proving a flowmeter in situ under operating conditions comprises a pair of standard Coriolis based mass flowmeters (2, 3) which are connected together in series by a conduit (7) connecting the fluid outlet (23) of the first flowmeter (2) to the fluid inlet (32) of the second flowmeter (3). A valved fluid supply conduit (4) is connected to the fluid inlet (22) of the first flowmeter (2), and a valved fluid return conduit (8) is connected to the fluid outlet (33) of the second flowmeter (3). These supply and return conduits (4 and 8) enable the device to be connected to a fluid flow line containing a flowmeter which is to be proved such that fluid flowing in the flow line will flow in series through the flowmeter to be proved and the two flowmeters (2 and 3) of the proving device. The device includes control means which is operative to use the second flowmeter (3) as a master meter to check the accuracy of the flowmeter to be proved, and the first flowmeter (2) as a check meter for the master meter (3).

Owner:MICRO MOTION INC

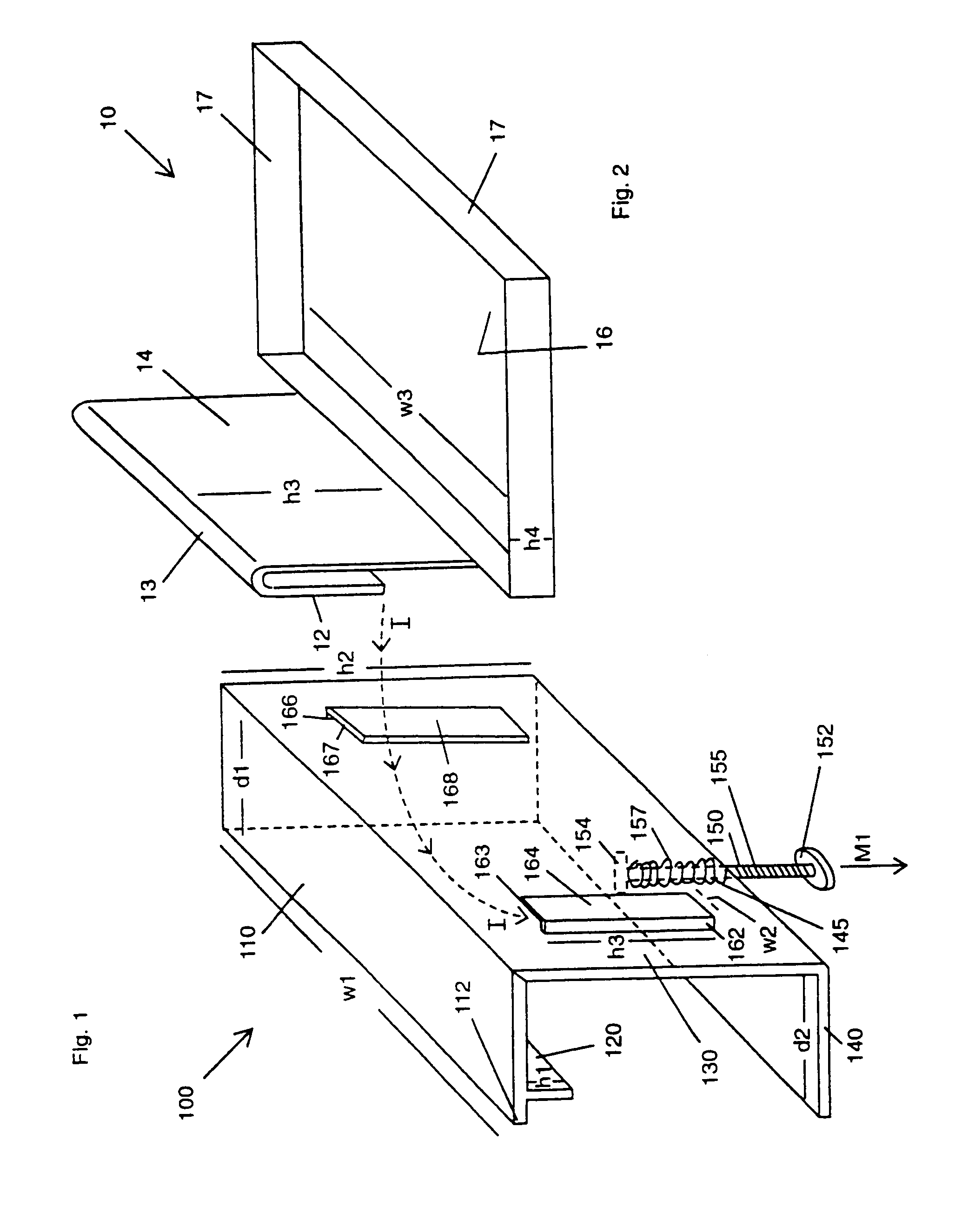

Highchair helper improvements

Detachable bottle and food holding subtrays, clips and support attachments for juvenile chairs such as highchairs, strollers, booster chairs, car seats and activity chairs. The clips can be a snapable C-shape, use a screwable post or a spring biased post for attachment to an existing tray. Removable lids and removable bottle sizing rings can be used. Pre-attached clips can be pre-molded directly to the existing tray. Alternatively, clips can be attached by hook and loop fasteners or peel and stick tape. A drawer type subtray can slide in and out from the existing tray. Alternatively, a pivoting arm can be folded out from the existing tray. The clips, supports, drawers and arms can be used to support and / or hold items such as food out of reach of sitting children, and / or can keep items such as mirrors and toys at selected locations within reach of the sitting child.

Owner:RESPONSIBLE ME

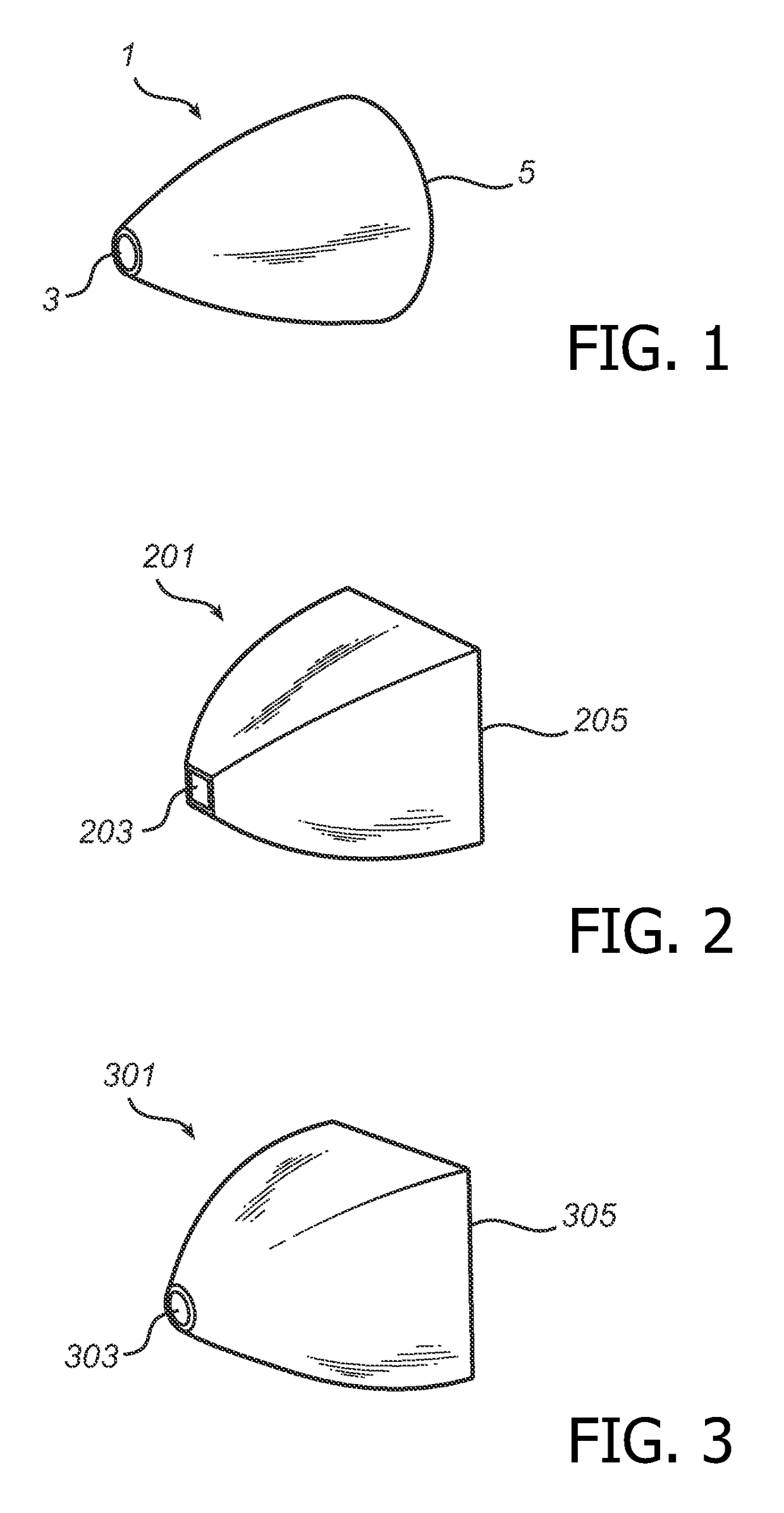

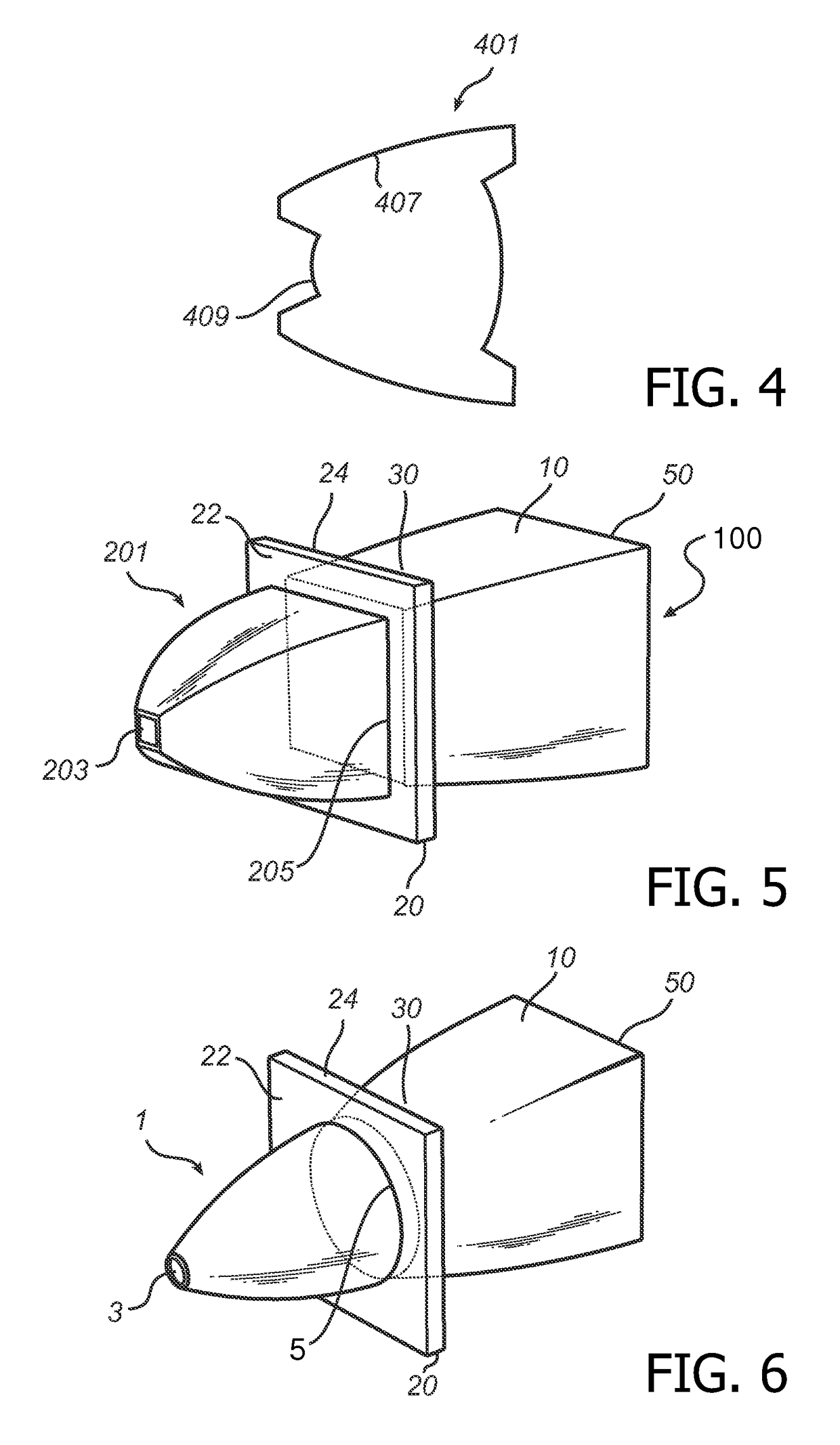

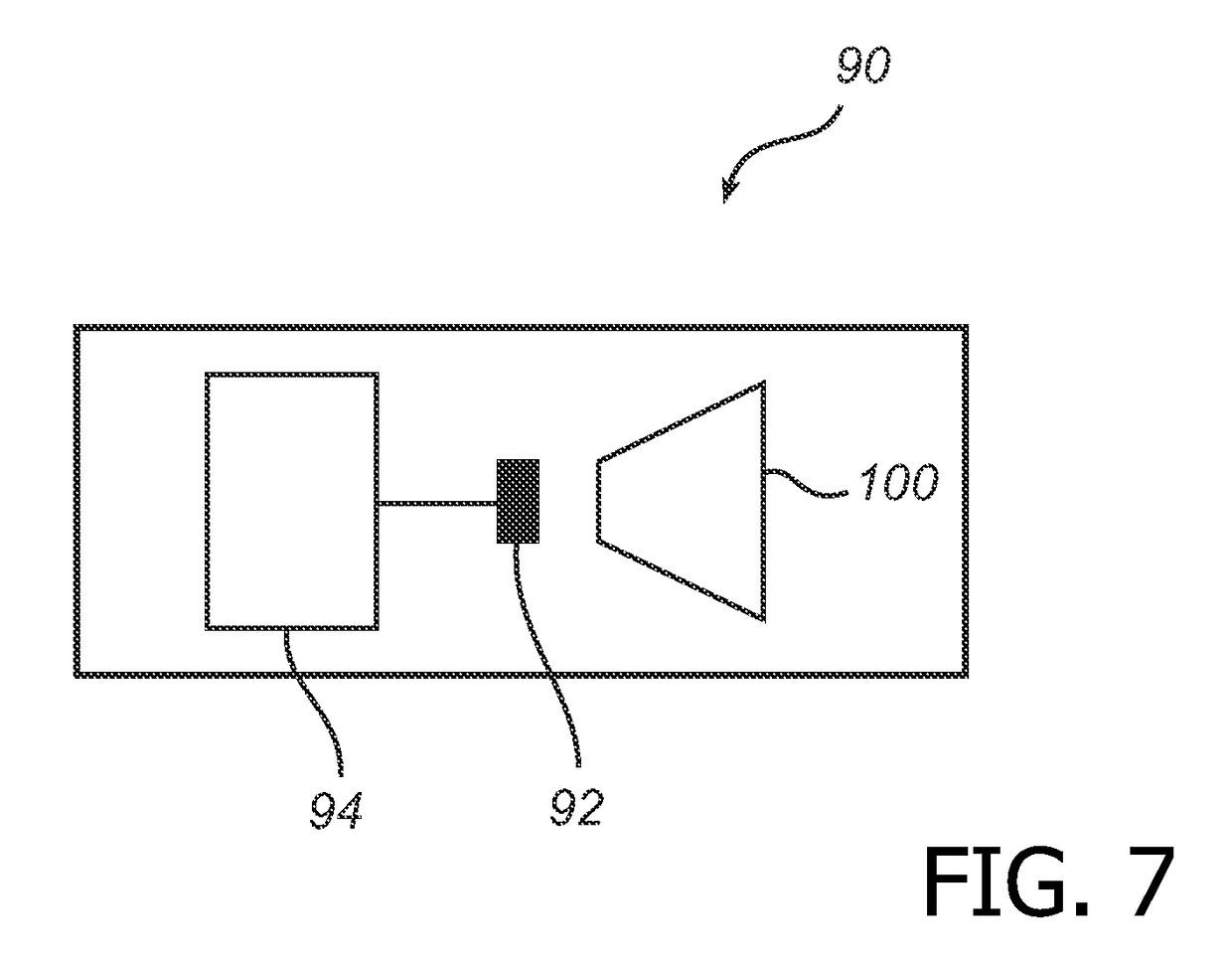

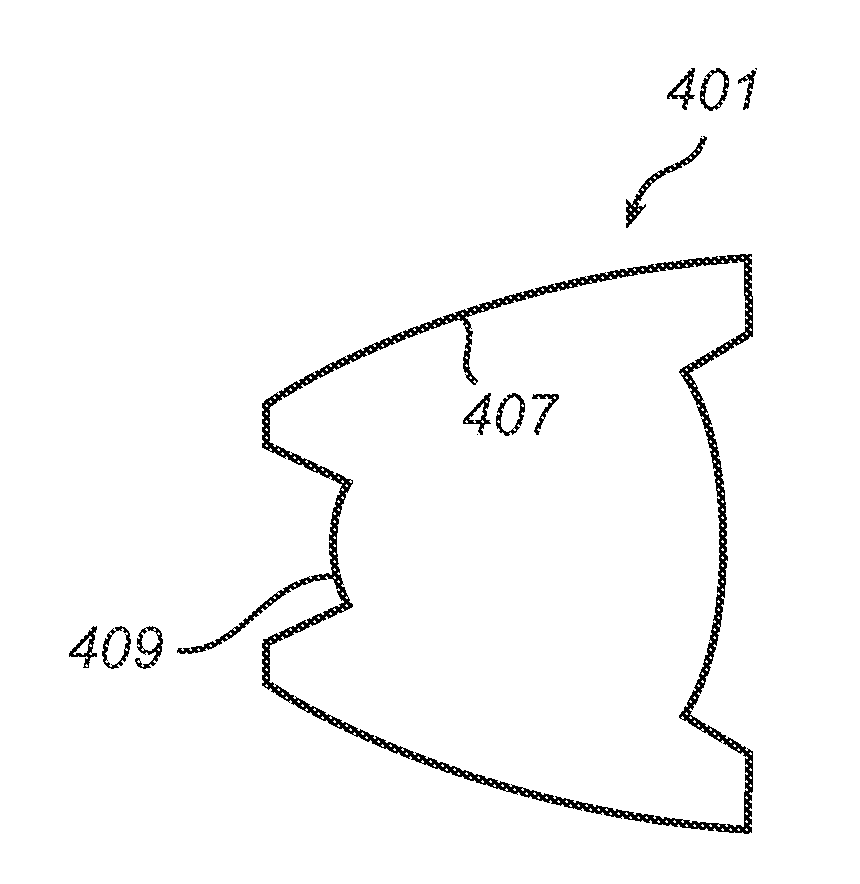

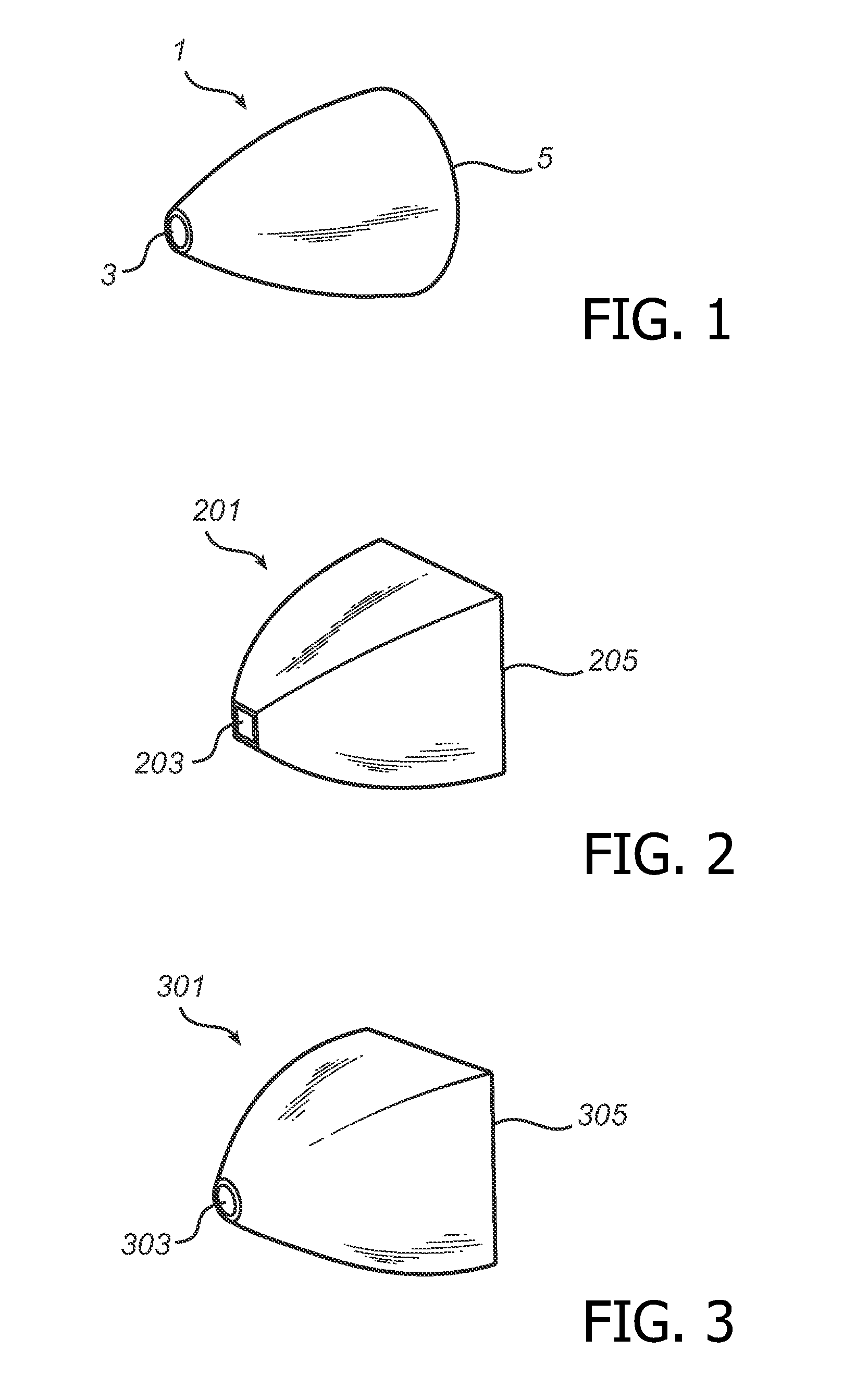

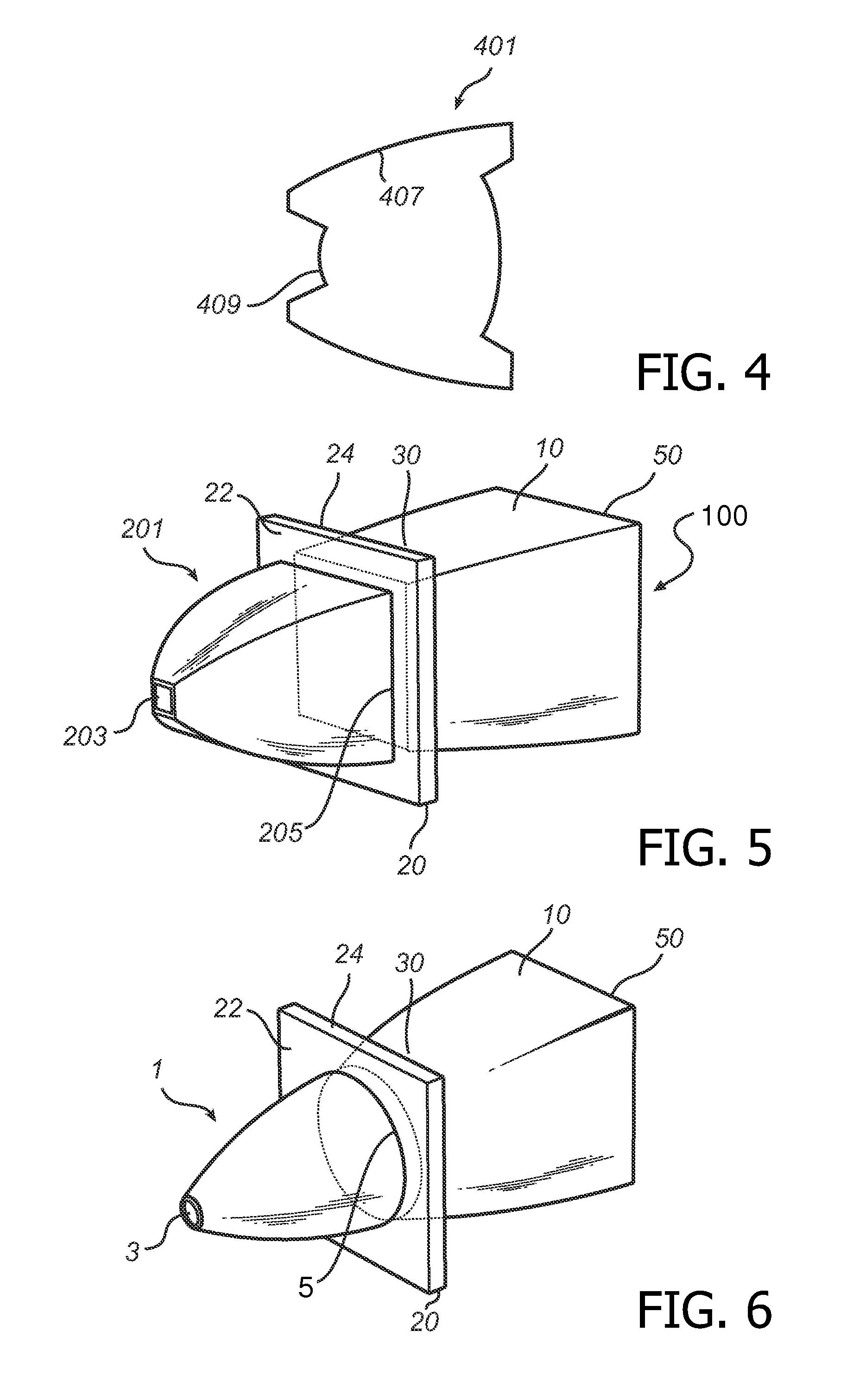

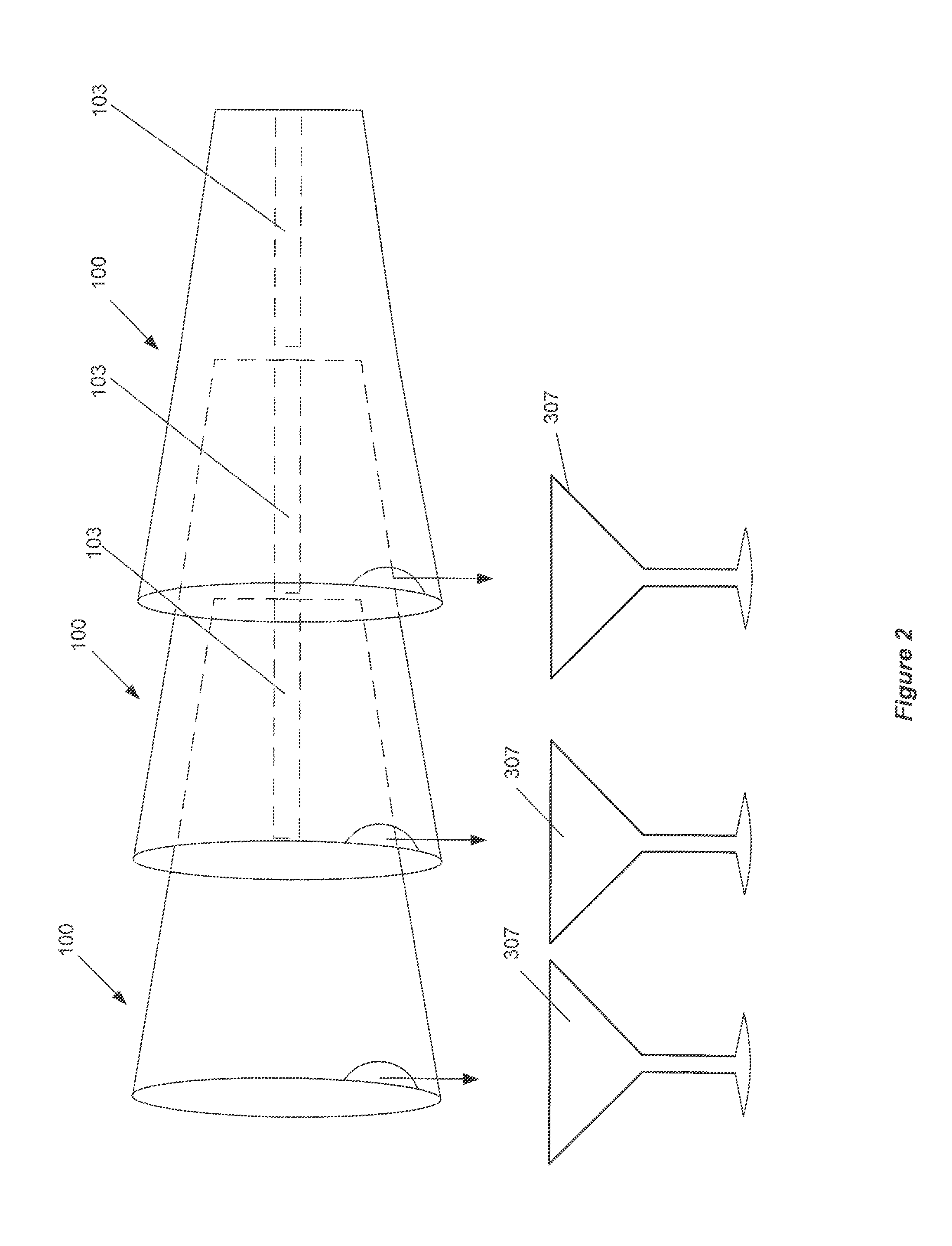

Collimating module and device for zero overfill illumination applications with beam width control

Owner:SIGNIFY HLDG BV

Systems and devices for delivering volatile materials

InactiveUS20060097066A1Facilitate cognitionReduce overflowTobacco devicesGaseous substancesBiomedical engineeringDelivery system

A non-energized volatile material delivery system for emitting or releasing volatile materials to the atmosphere is provided. More specifically, delivery systems for delivering one or more volatile materials using a non-aerosol, non-energized volatile material delivery system via an evaporative surface device, without a source of heat, gas, or electrical current, are also provided.

Owner:THE PROCTER & GAMBLE COMPANY

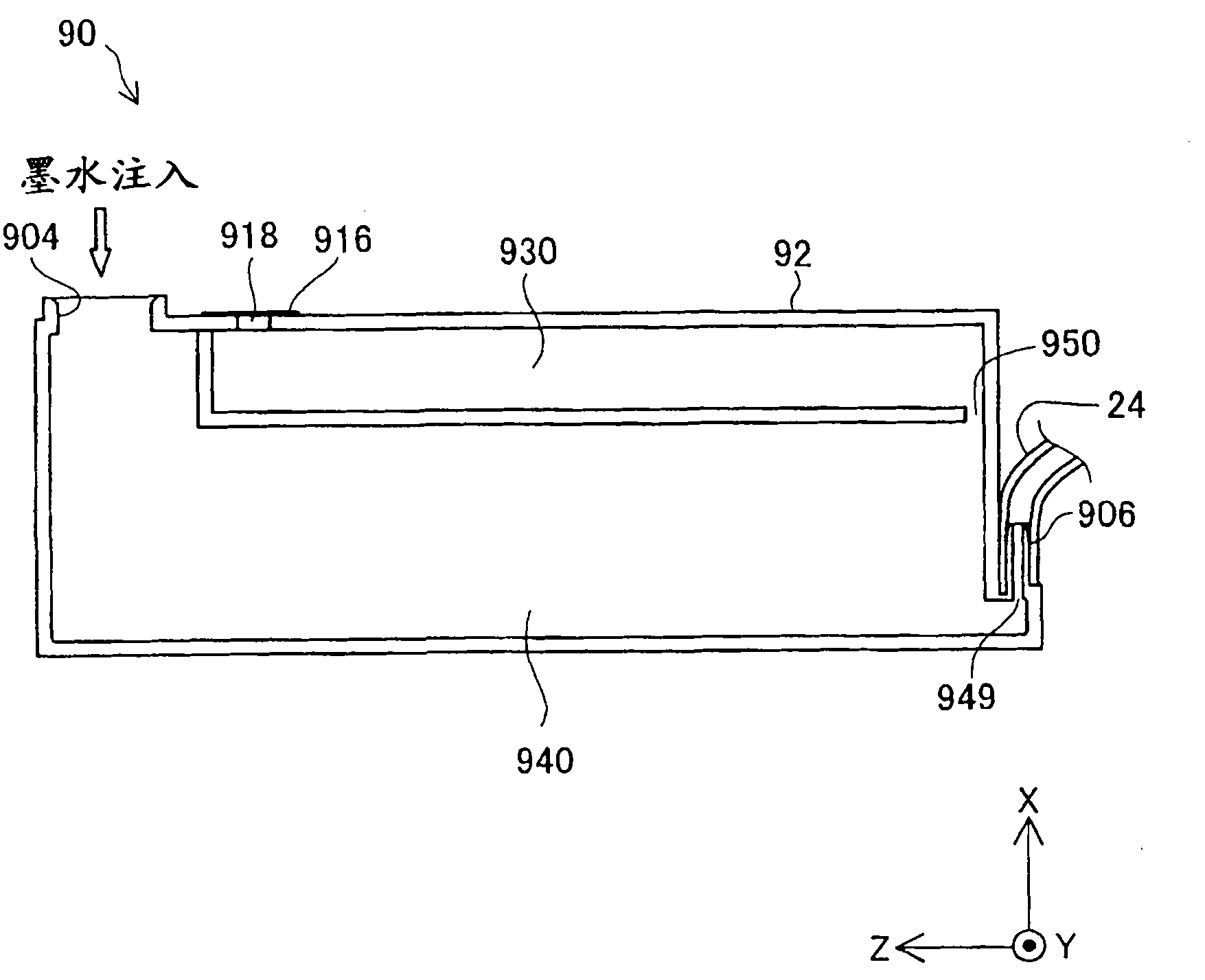

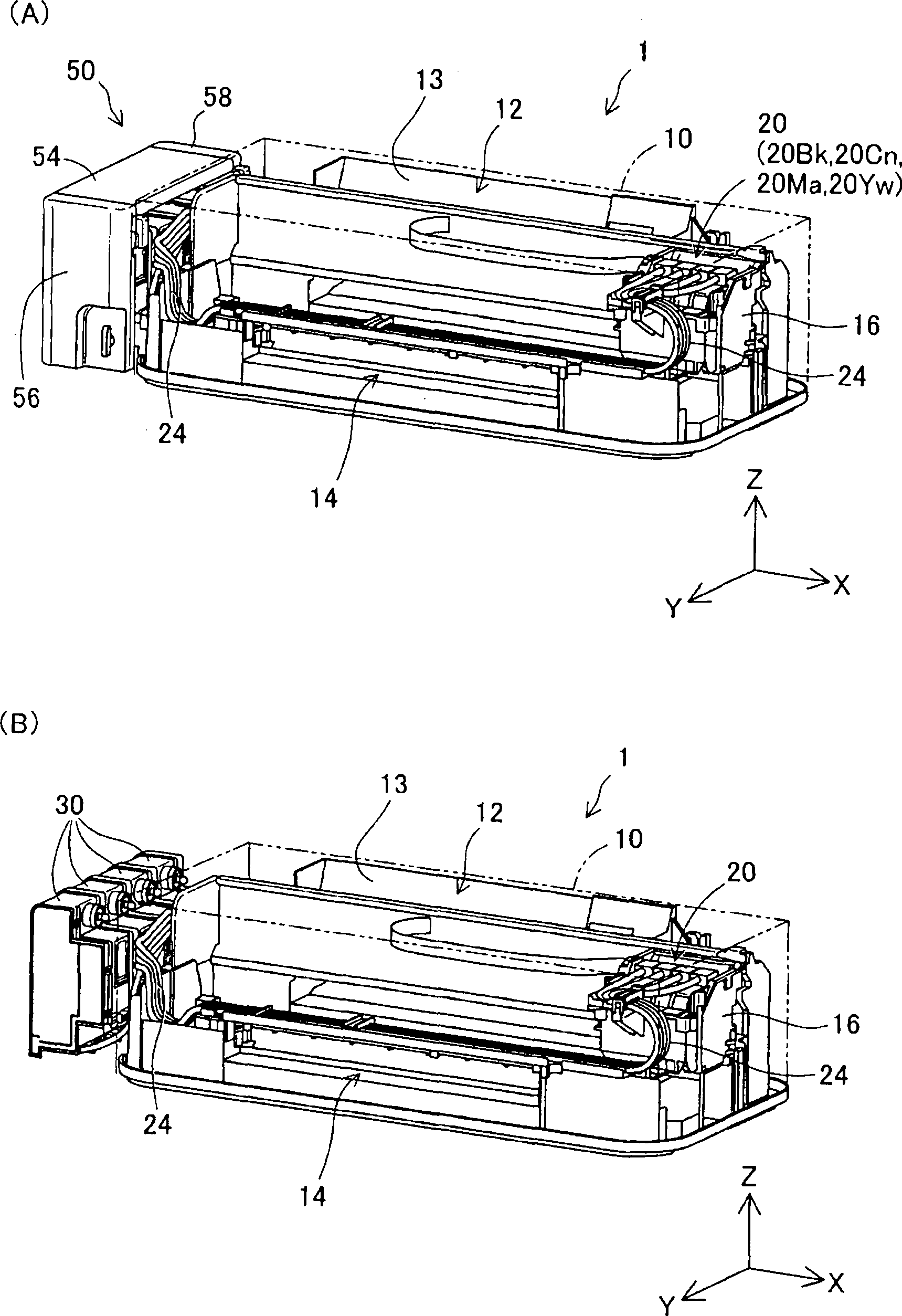

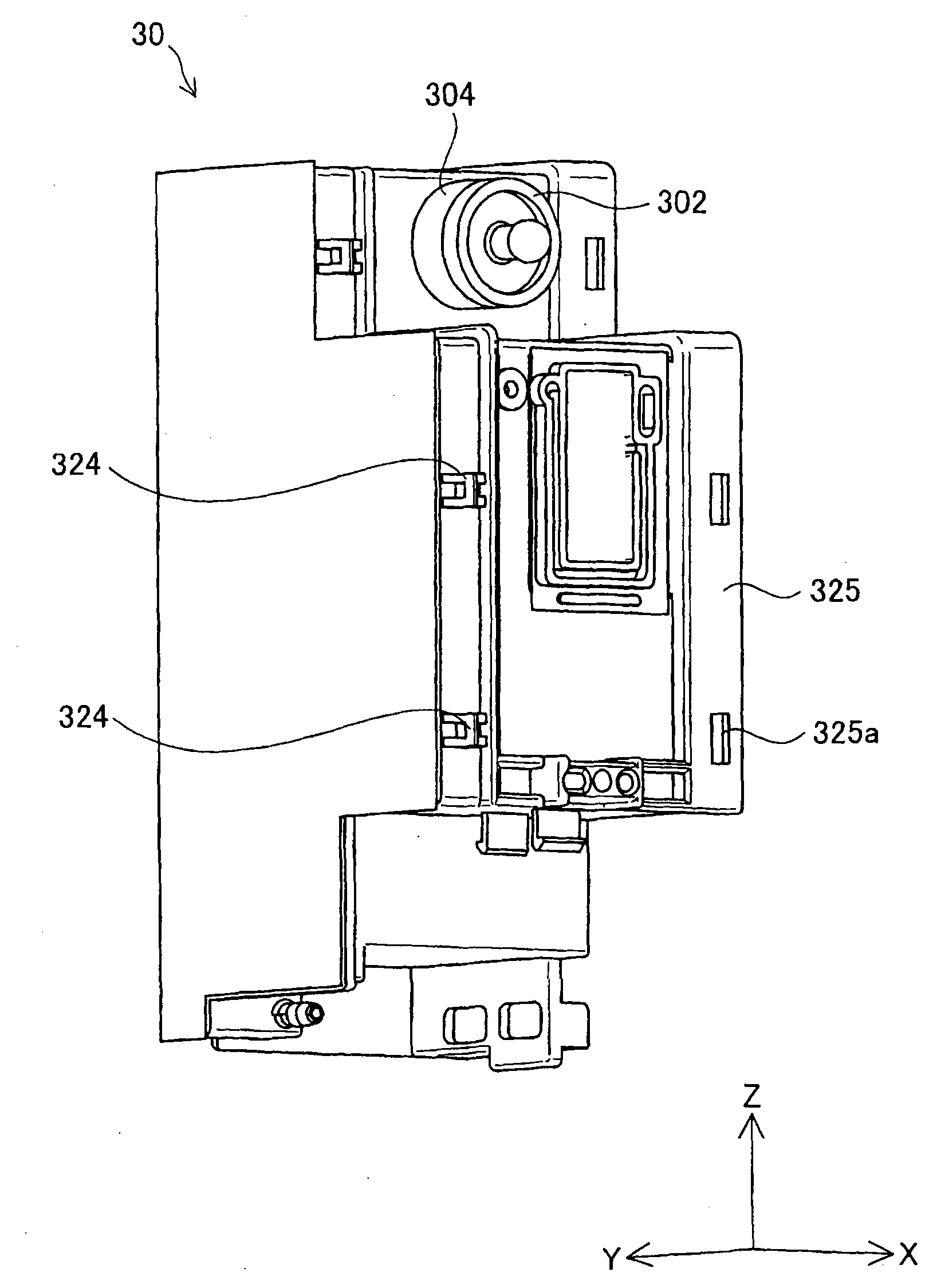

Liquid container and liquid ejection system

ActiveCN102336061AReduce overflowReduces the possibility of spilled liquidPrintingLiquid jetEngineering

The invention provides a liquid container and a liquid ejection system. A technology is provided, in the liquid container respectively provided with a liquid injection port and an atmospheric vent, possibility of liquid spill from the atmospheric vent when the liquid is injected from the liquid injection port to the liquid container can be reduced. Disclosed is a liquid container for supplying a liquid to a liquid ejection device, said liquid container being provided with: a liquid storage chamber for storing the liquid; an air storage chamber which communicates with the liquid storage chamber, and which is for introducing external air into the liquid storage chamber as the liquid in the liquid storage chamber is consumed; an atmospheric vent which introduces external air into the air storage chamber; and a liquid injection port which is for injecting the liquid into the liquid storage chamber, and which is disposed at a lower position than the atmospheric vent when the liquid container is in an injection position when the liquid is to be injected into the liquid storage chamber.

Owner:SEIKO EPSON CORP

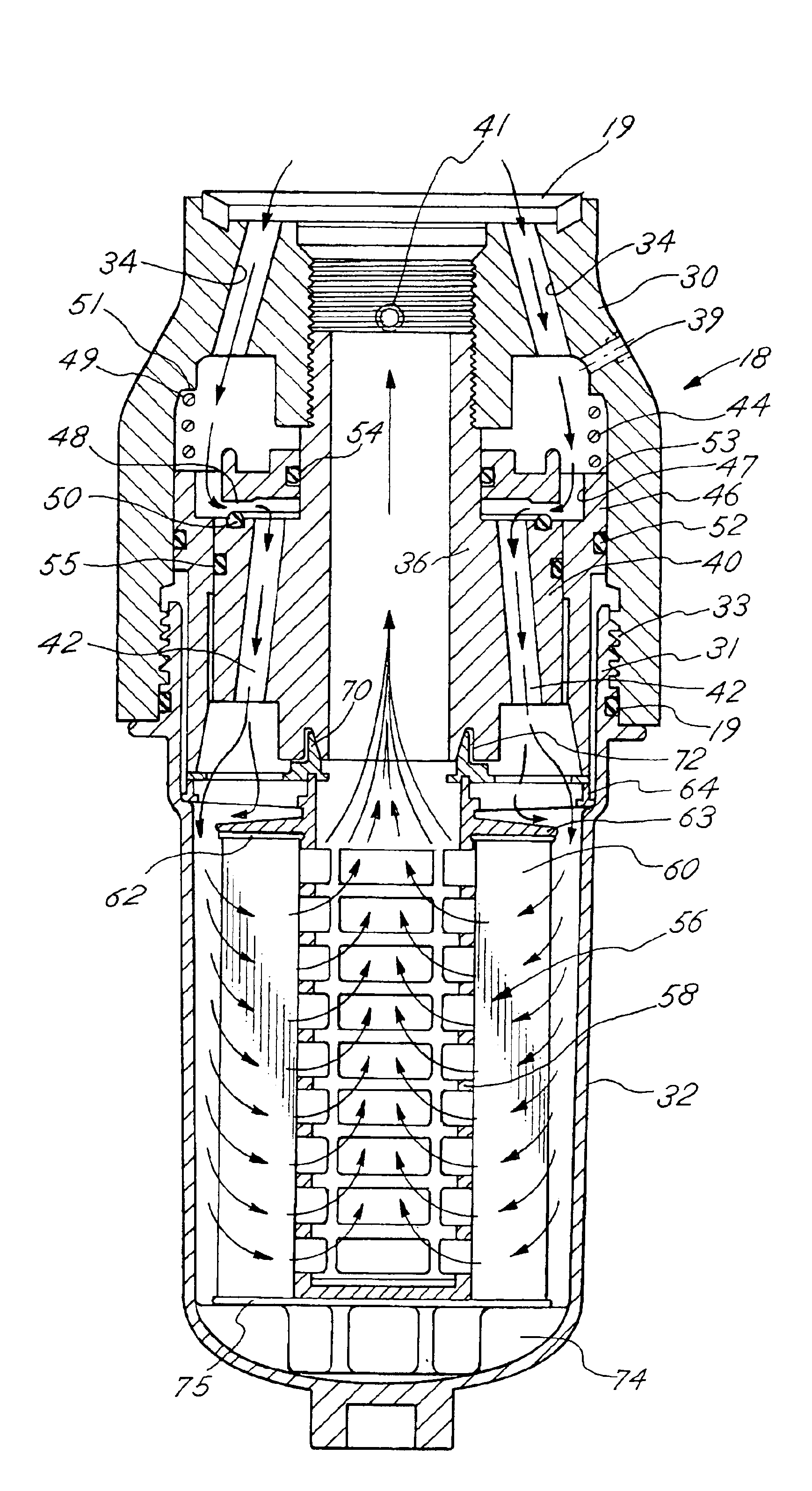

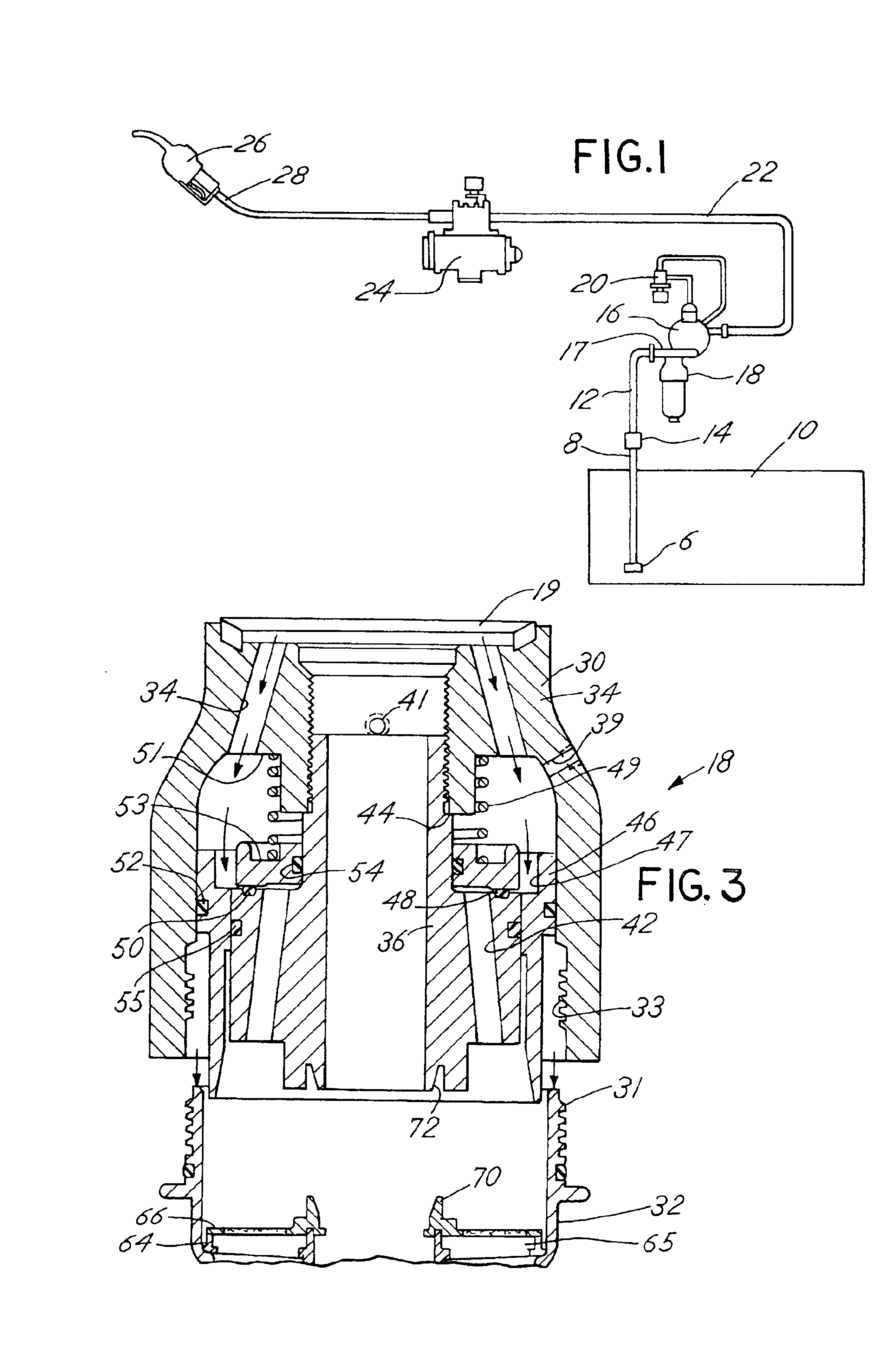

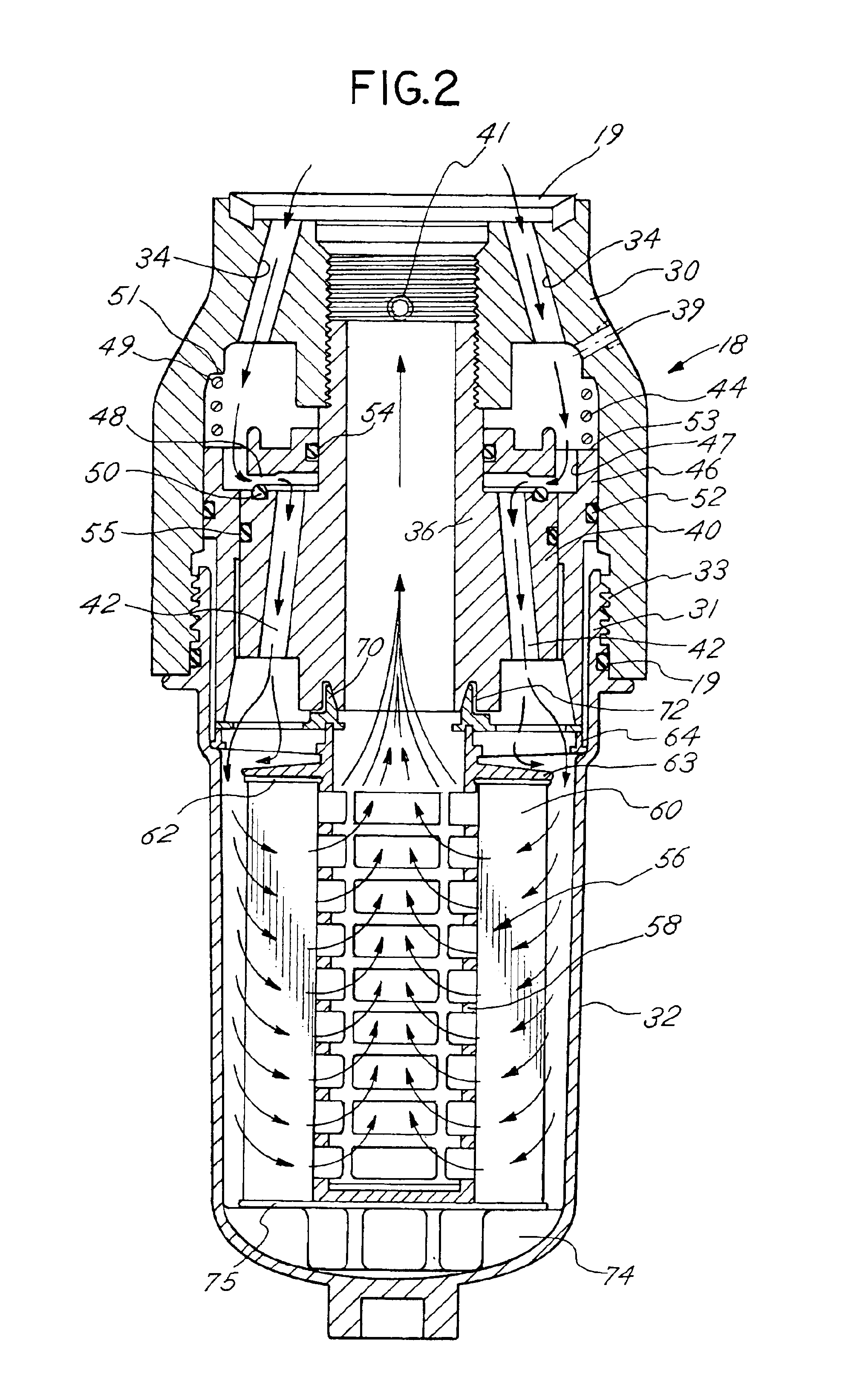

Fuel dispenser filter with removable filter media

InactiveUS6926827B2Reduce hazardous wasteReduce overflowIon-exchanger regenerationWater/sewage treatmentFuel distributionFilter media

A fuel dispenser filter for filtering fuel is adapted to be connected to a support in a fuel distribution system. The filter comprises a housing including an adaptor constructed and arranged to be secured to the support and a bowl operatively connected to the adaptor. A stud / spacer is secured in the adaptor. The stud / spacer defines a centrally disposed outlet flow passage and outwardly disposed inlet flow passages. A sleeve member is movably supported in the adaptor between the stud / spacer and the adaptor. The sleeve member is constructed and arranged to open and close the fuel flow through the inlet flow passages. A filter assembly including filter media is provided in the bowl for filtering the fuel passing through the filter. When the bowl is firmly engaged with the adaptor, the sleeve member is moved to open position to permit the flow of fuel through the filter and when the bowl is removed from the adaptor, the sleeve member is moved to a closed position to stop the flow of fuel. A spring is provided to bias the sleeve member to the closed position when the bowl is removed from the adaptor. Various seals are provided within the filter to confine fuel flow to the desired flow paths.

Owner:CHAMPION LAB

Method and system for fuel vapor control

ActiveUS8434461B2Shorten operation timeEnable fuel economyNon-fuel substance addition to fuelMachines/enginesIsolation valveFuel vapor

Methods and systems are provided for operating a fuel vapor recovery system having a fuel tank isolation valve coupled between a fuel tank and a canister. Fuel vapors are purged from the fuel tank to a canister buffer over a plurality of purge pulses. The pulses are adjusted based on the buffer capacity, a purge flow rate, and a fuel tank pressure to improve control of canister loading and reduce air-to-fuel ratio disturbances.

Owner:FORD GLOBAL TECH LLC

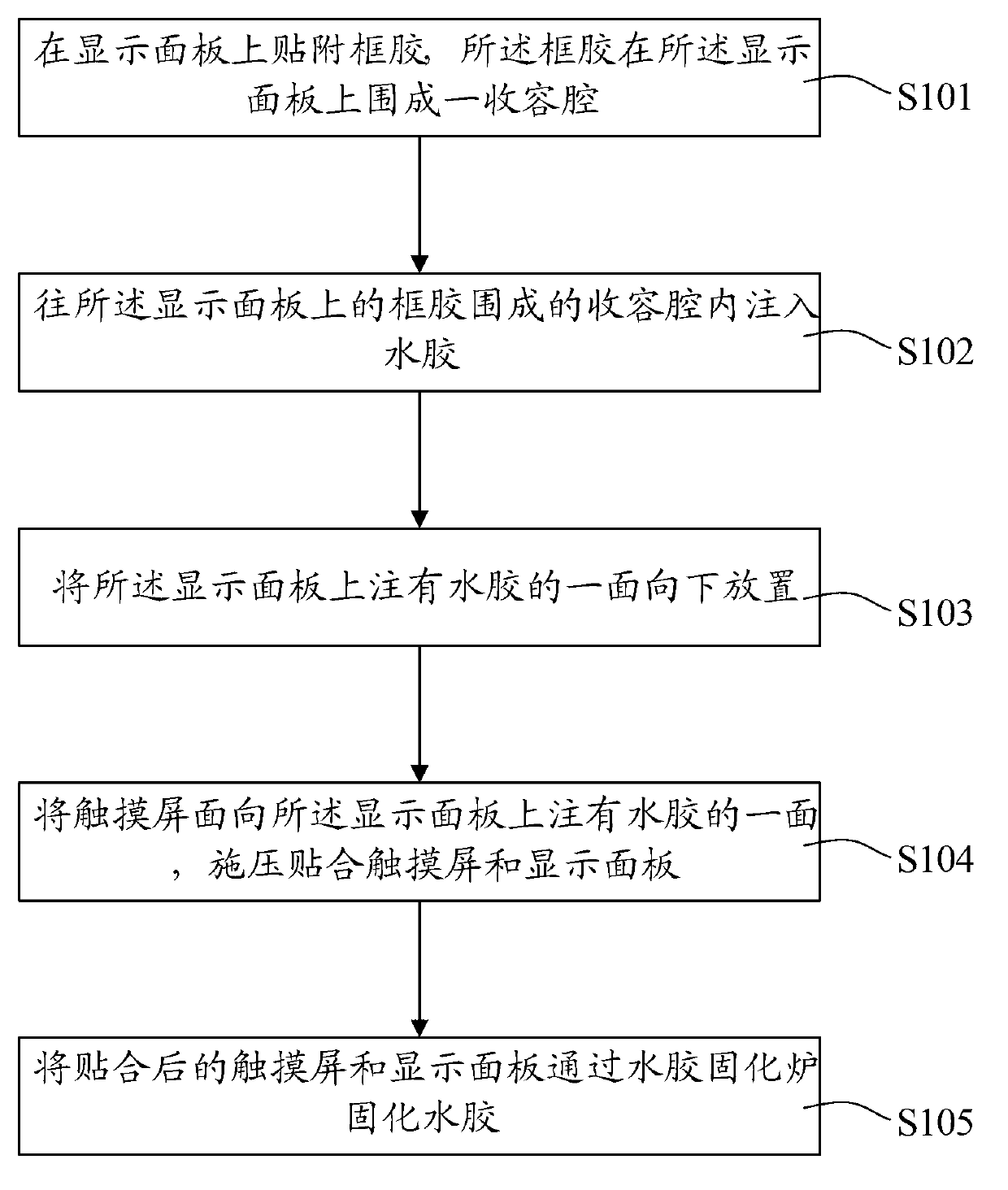

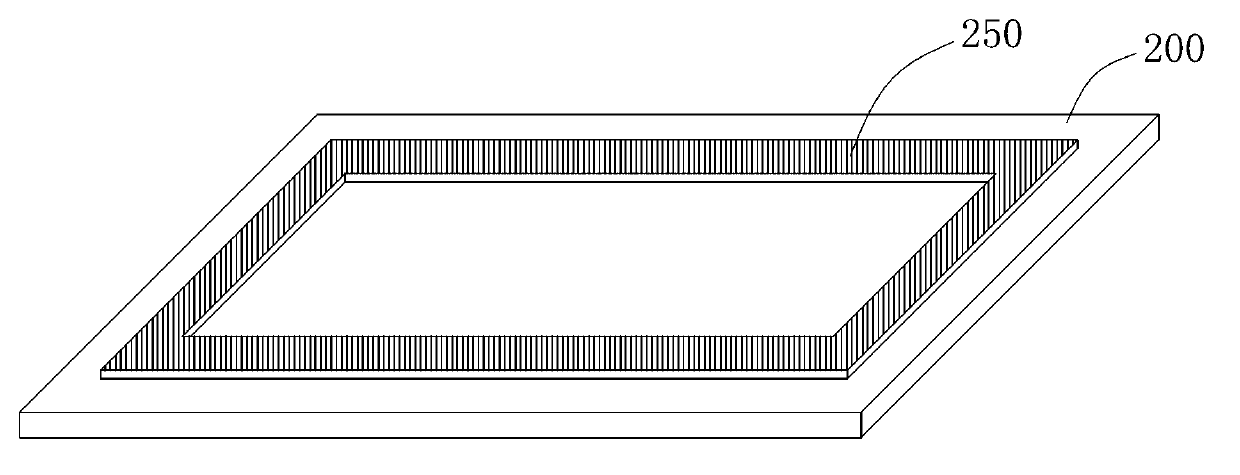

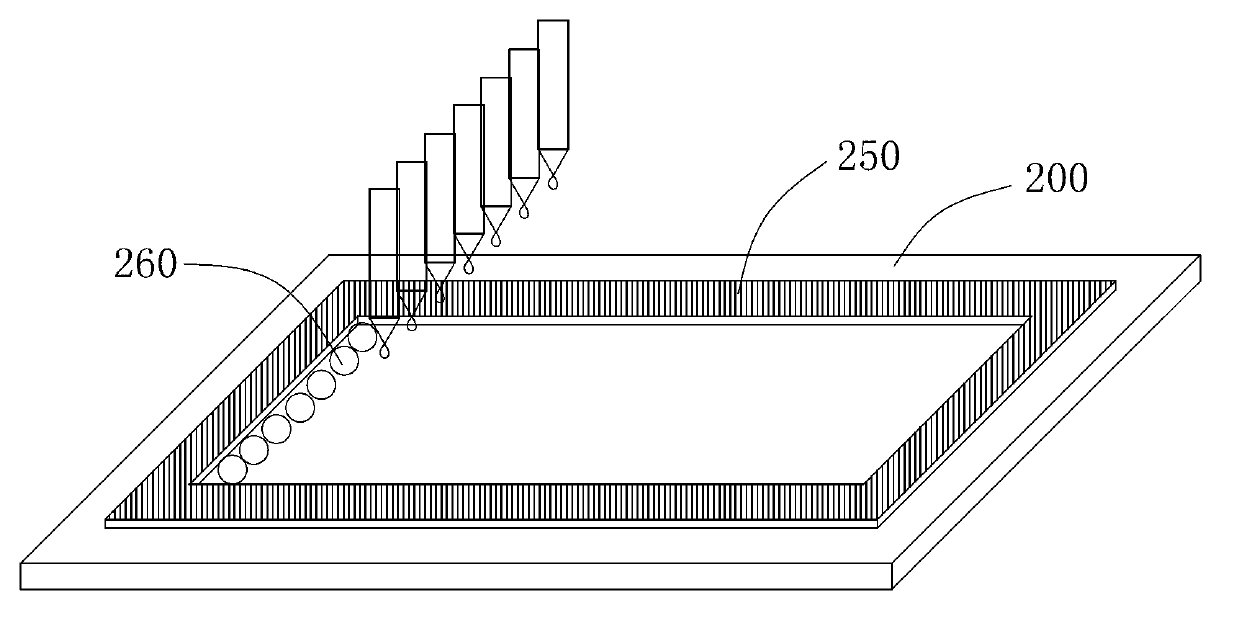

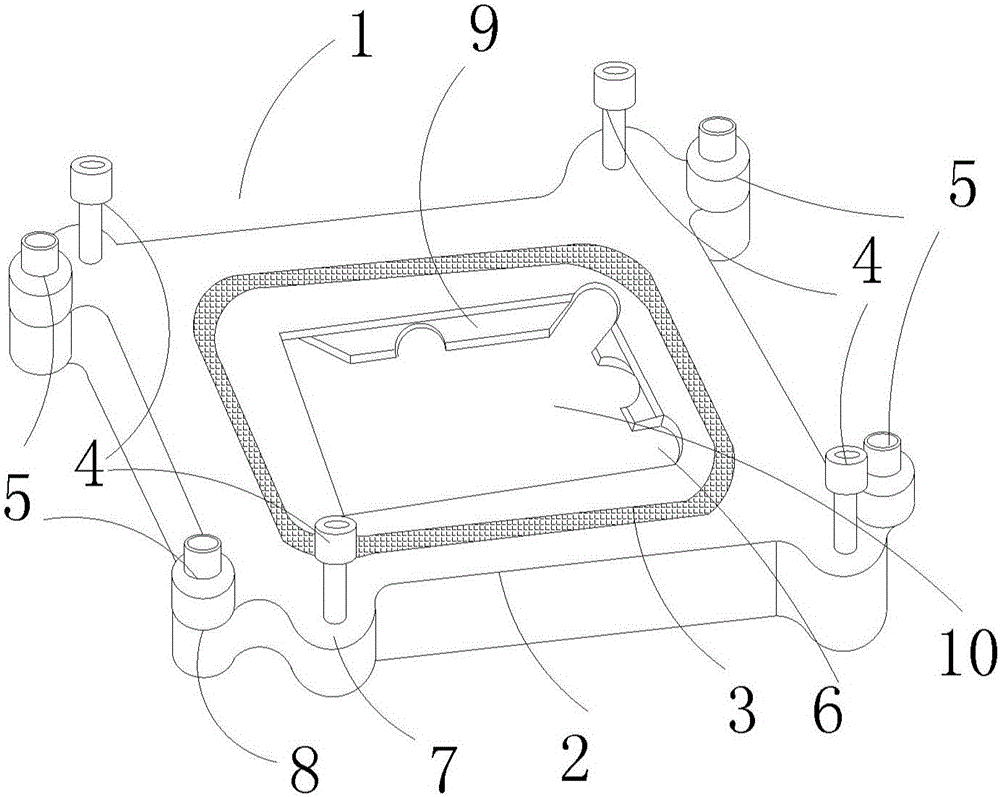

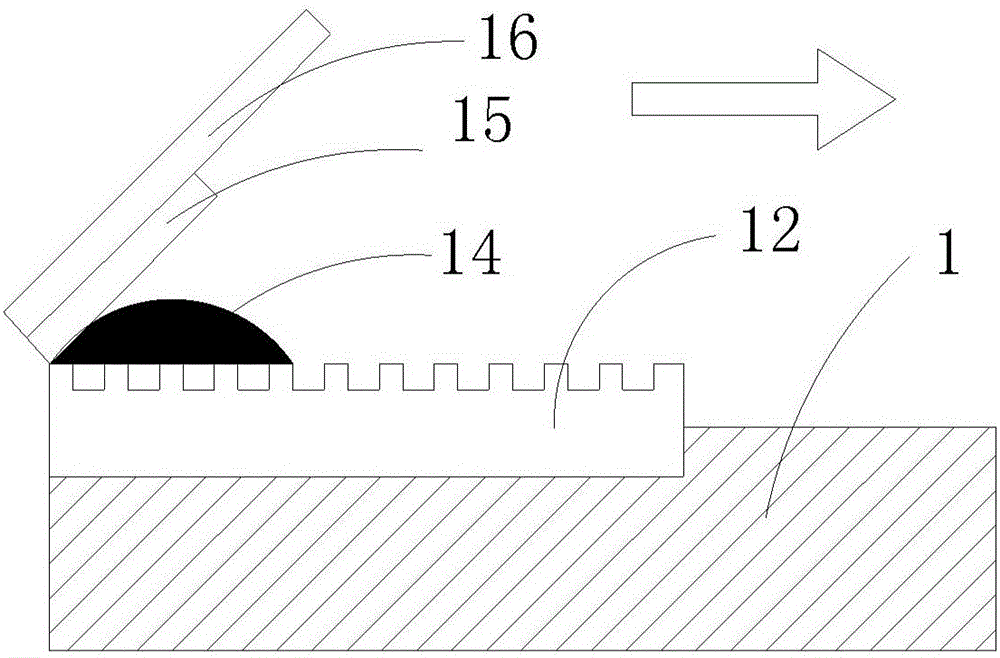

Method for adhering touch screen and display panel

The invention provides a method for adhering a touch screen and a display panel. The method comprises the following steps of adhering a frame sealant on the display panel, wherein the sealant a containing cavity is defined on the display panel by the sealant; pouring glue inside the containing cavity defined on the display panel by the sealant; and pressing the touch screen towards one surface of the display panel, which is poured with the glue, so as to press and adhere the touch screen and the display panel. According to the method, the touch screen and the display panel can be exchanged. According to the method provided by the invention, the interval thickness after the touch screen and the display panel are adhered is limited by the thickness of the frame sealant, so that the adhering thickness for each time is uniform. Furthermore, an operator can conveniently control the pouring amount of the glue through the limitation of the frame sealant, so that the pouring amount of the glue can be controlled well; the overflowing glue after an adhering process can be greatly reduced; and the workload caused by wiping the overflowing glue can be greatly reduced.

Owner:TCL DISPLAY TECH HUIZHOU

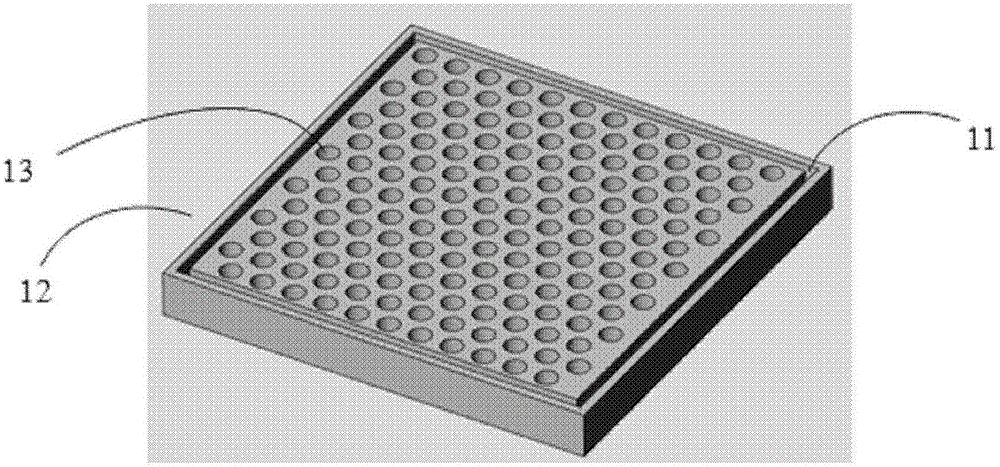

Digital PCR (polymerase chain reaction) chip with silicon substrate arrays and micro-reaction pools and method for manufacturing digital PCR chip

ActiveCN105039153AFast heat transferShorten Thermal Cycle TimeBioreactor/fermenter combinationsBiological substance pretreatmentsSilicon chipPhotoresist

The invention belongs to the technical field of PCR (polymerase chain reaction), and particularly relates to a digital PCR chip with silicon substrate arrays and micro-reaction pools and a method for manufacturing the digital PCR chip. The digital PCR chip mainly comprises an upper cover and a chip. Micro-pores which are arrayed to form honeycombs are formed in the chip, and the upper cover is fixed onto a chip groove. The method includes particular steps of selecting a silicon chip with a single polished surface; cleaning the silicon chip; coating a layer of uniform photoresist on the polished surface of the silicon chip in a spinning manner; forming circular graphic arrays by means of exposure; etching silicon by the aid of a dry process in masks, namely, the circular graphic arrays to form micro-pore structures; removing the photoresist and scribing the chip to completely manufacture the digital PCR chip.

Owner:宁波胤瑞生物医学仪器有限责任公司

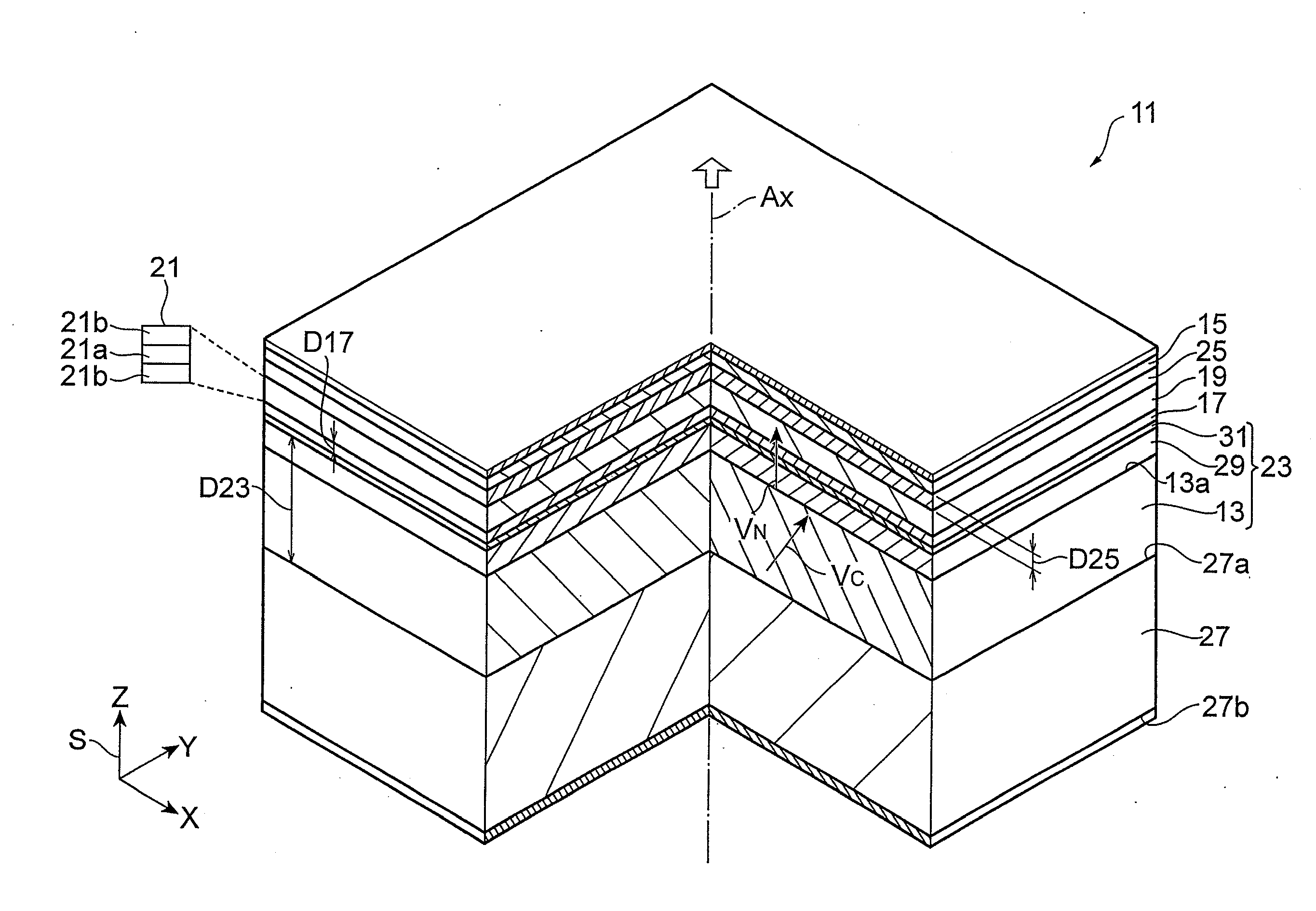

Group iii nitride semiconductor light-emitting device and epitaxial wafer

InactiveUS20100008393A1Improve crystal qualityRelieve pressureLaser detailsSemiconductor lasersElectron holeGallium nitride

The group II nitride semiconductor light-emitting device includes: a gallium nitride based semiconductor region of n-type; a p-type gallium nitride based semiconductor region; a hole-blocking layer; and an active layer. The gallium nitride based semiconductor region of n-type has a primary surface, and the primary surface extends on a predetermined plane. The c-axis of the gallium nitride based semiconductor region tilts from a normal line of the predetermined plane. The hole-blocking layer comprises a first gallium nitride based semiconductor. The band gap of the hole-blocking layer is greater than the band gap of the gallium nitride based semiconductor region, and the thickness of the hole-blocking layer is less than the thickness of the gallium nitride based semiconductor region. The active layer comprises a gallium nitride semiconductor. The active layer is provided between the p-type gallium nitride based semiconductor region and the hole-blocking layer. The hole-blocking layer and the active layer is provided between the primary surface of the gallium nitride based semiconductor region and the p-type gallium nitride based semiconductor region. The band gap of the hole-blocking layer is greater than a maximum band gap of the active layer.

Owner:SUMITOMO ELECTRIC IND LTD

Collimating module and device for zero overfill illumination applications with beam width control

InactiveUS20100188753A1Reducing overfill lightReduce lightDiffusing elementsCondensersLight beamOptoelectronics

A collimating module is presented. The collimating module comprises a rounded light entry side and a rectangular light exit side. A collimating device is also presented, and a method for providing collimated light. The collimating device comprises a first collimator having a light entry side and a light exit side, a scattering component having a light entry surface arranged adjacent to said light exit side, and a light exit surface. The collimating device further comprises a collimating module having a light entry side arranged adjacent to said light exit surface.

Owner:SIGNIFY HLDG BV

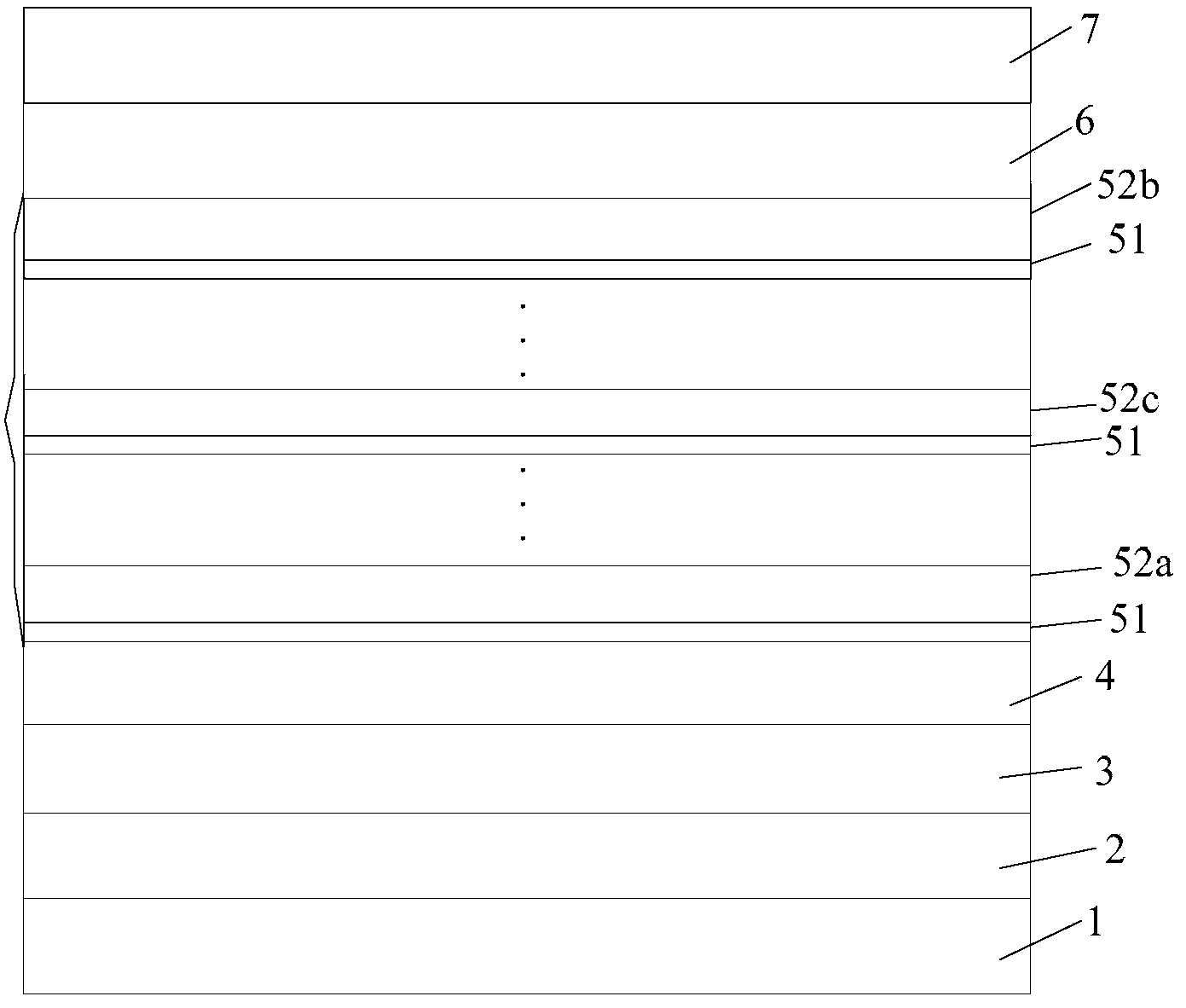

Light-emitting diode epitaxial wafer and manufacture method thereof

ActiveCN103681985ARaise the barrier heightImprove injection efficiencySemiconductor devicesQuantum efficiencyNon doped

The invention discloses a light-emitting diode epitaxial wafer and a manufacture method thereof and belongs to the field of semiconductor technology. The epitaxial wafer comprises a substrate, a low-temperature buffer layer grown on the substrate, a non-doped gallium nitride layer, a type-N gallium nitride layer, a multiple-quantum well layer and a type-P gallium nitride layer. At least one quantum barrier from one side of the type-N gallium nitride layer is grown by AlxGa1-xN; 0<x<0.3. At least one quantum barrier layer from one side of the type-P gallium nitride layer is grown by InzGa1-zN; 0<z<0.15. The type-P gallium nitride layer is directly grown on the multiple-quantum well layer. The quantum barrier layers close to the type-N gallium nitride layer are provided with high potential barrier, the quantum barrier layers close to the type-P gallium nitride layer are provided with low potential barrier, electron overflow is reduced, hole injection efficiency is improved, more electrons and holes are composited in the quantum well layer, and internal quantum efficiency of the light-emitting diode is improved accordingly.

Owner:HC SEMITEK SUZHOU

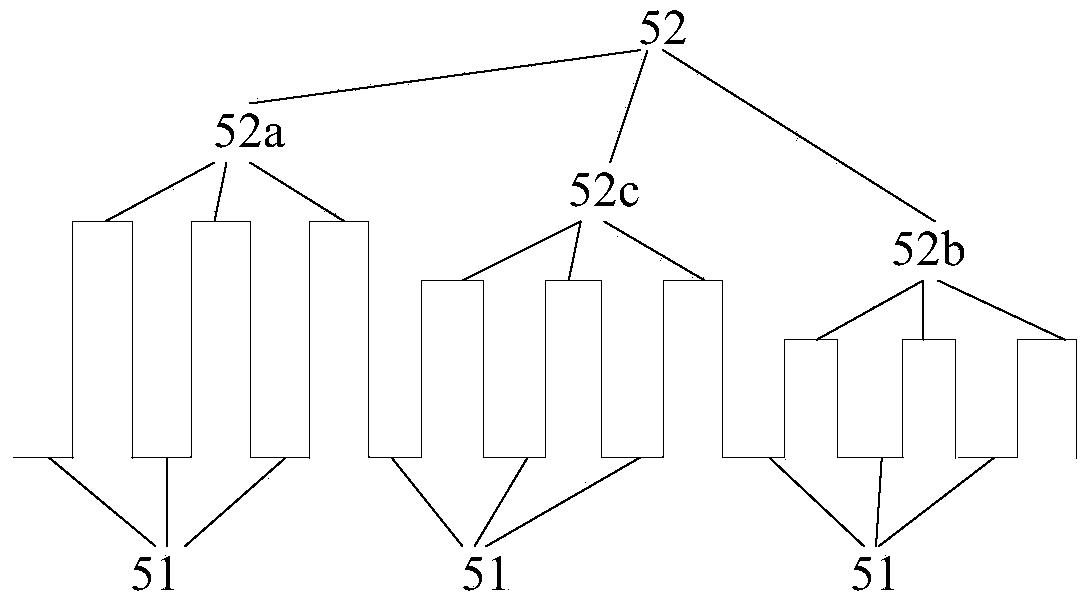

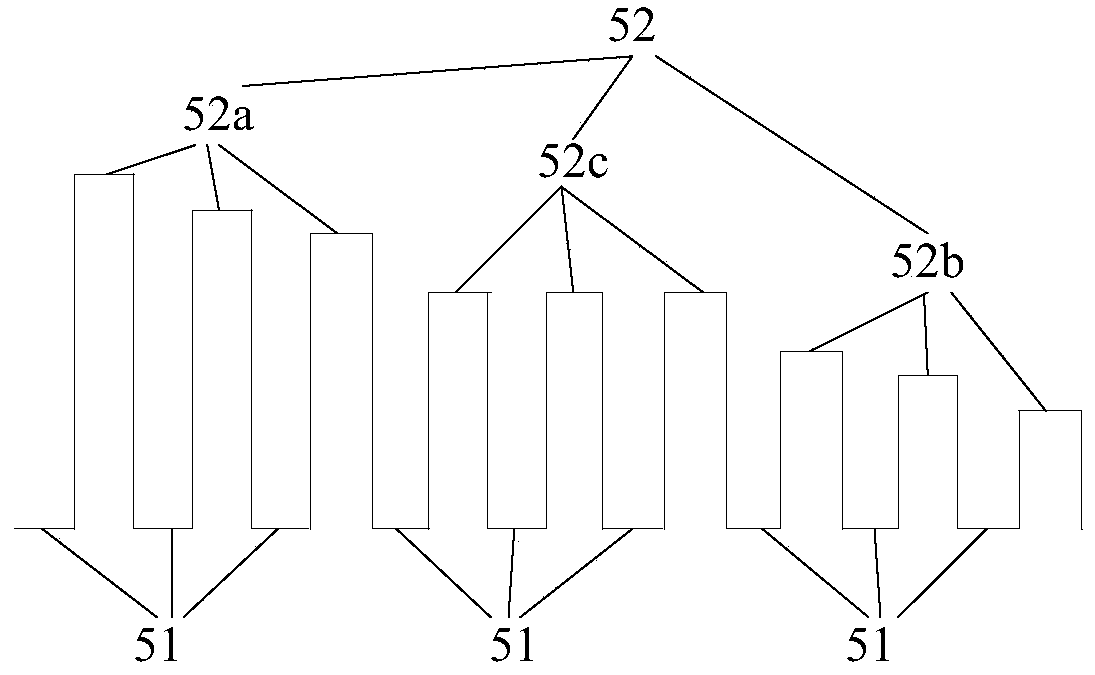

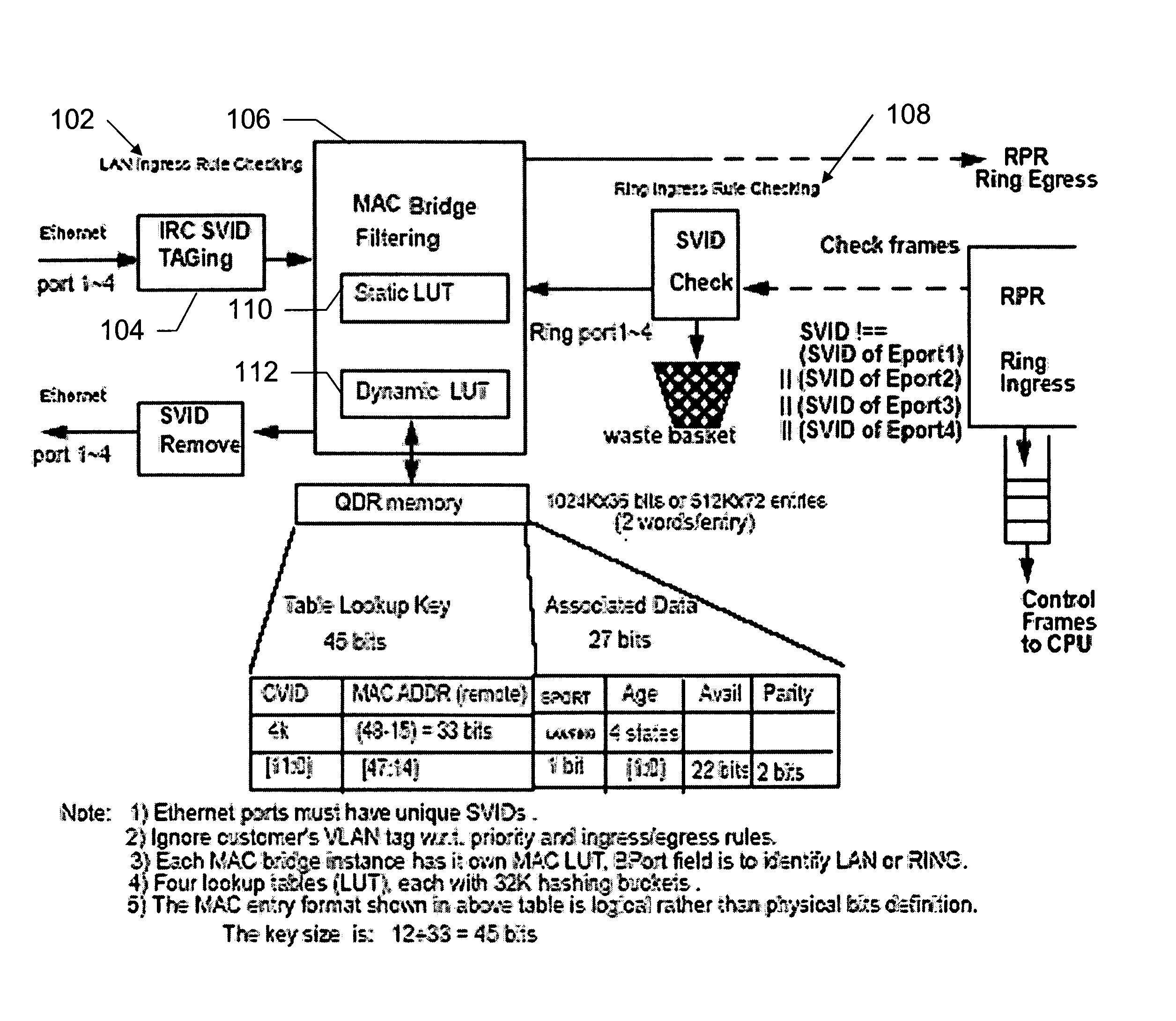

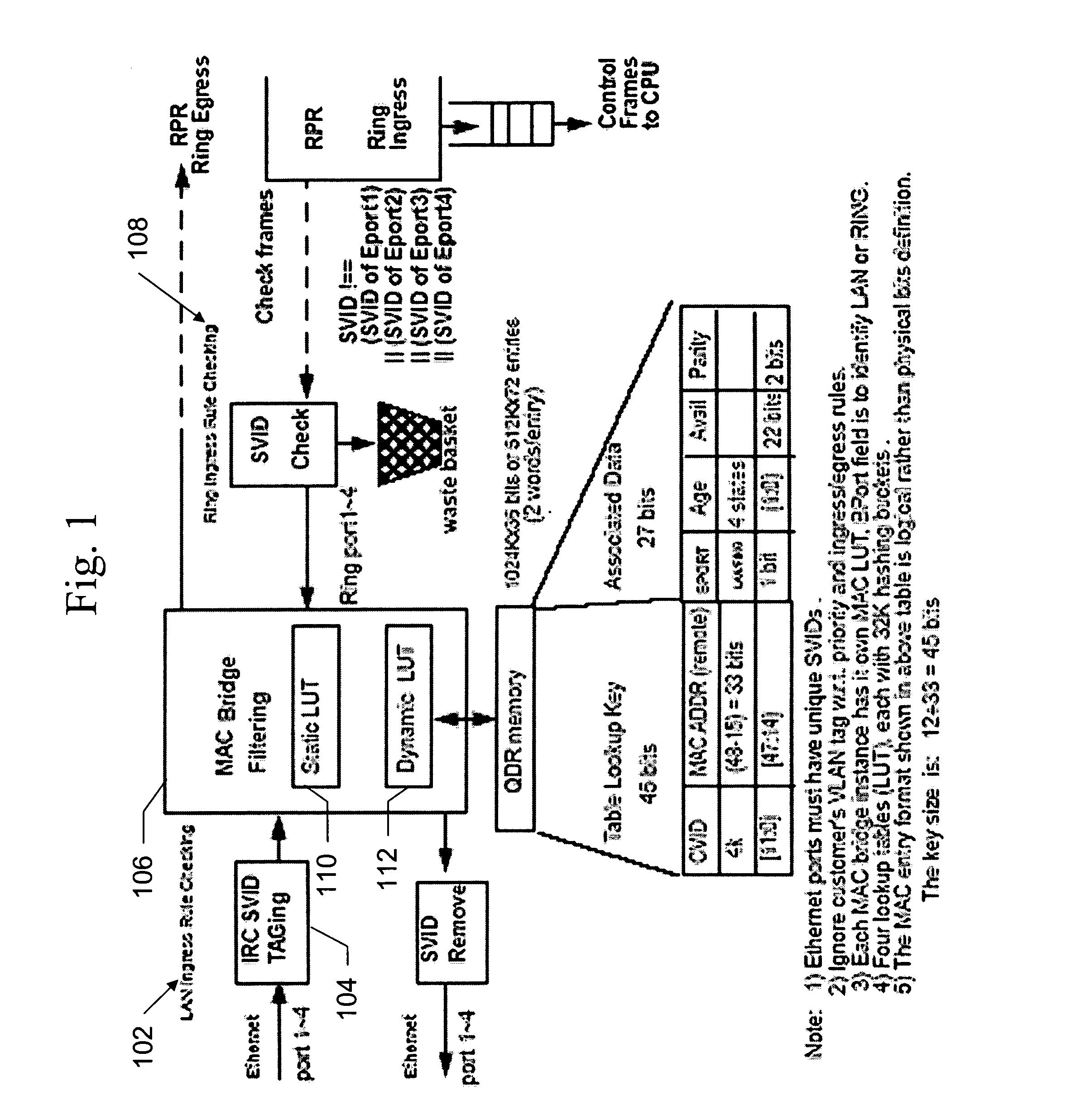

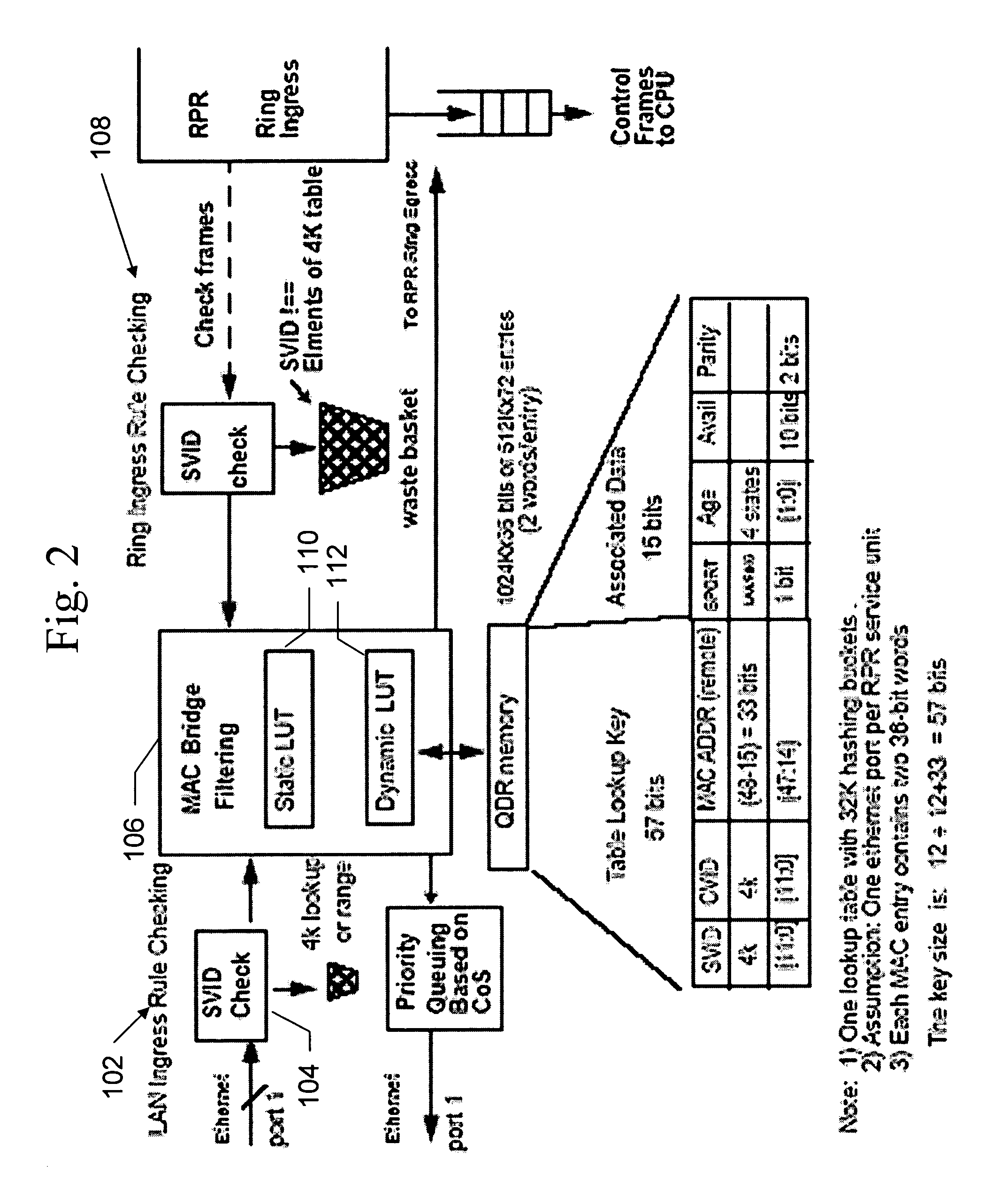

Using CRC-15 as hash function for MAC bridge filter design

InactiveUS20070071015A1Reduce overflowReduce equipment costsData switching by path configurationComputer hardwareHash function

A hash function for a MAC bridge filter that improves bridge performance by reducing overflow of the MAC bridge database and which reduces cost of the device by using relatively few hardware resources. A CRC hash function is used to randomize the search string in the MAC bridge filter so that a consistent bridge performance is achieved regardless of where the bridge is used. Using the CRC as a hash function also results in efficient hardware implementation. In addition, the present invention may be generalized to use a CRC-M as hash function for any bridge filter design.

Owner:FUJITSU LTD

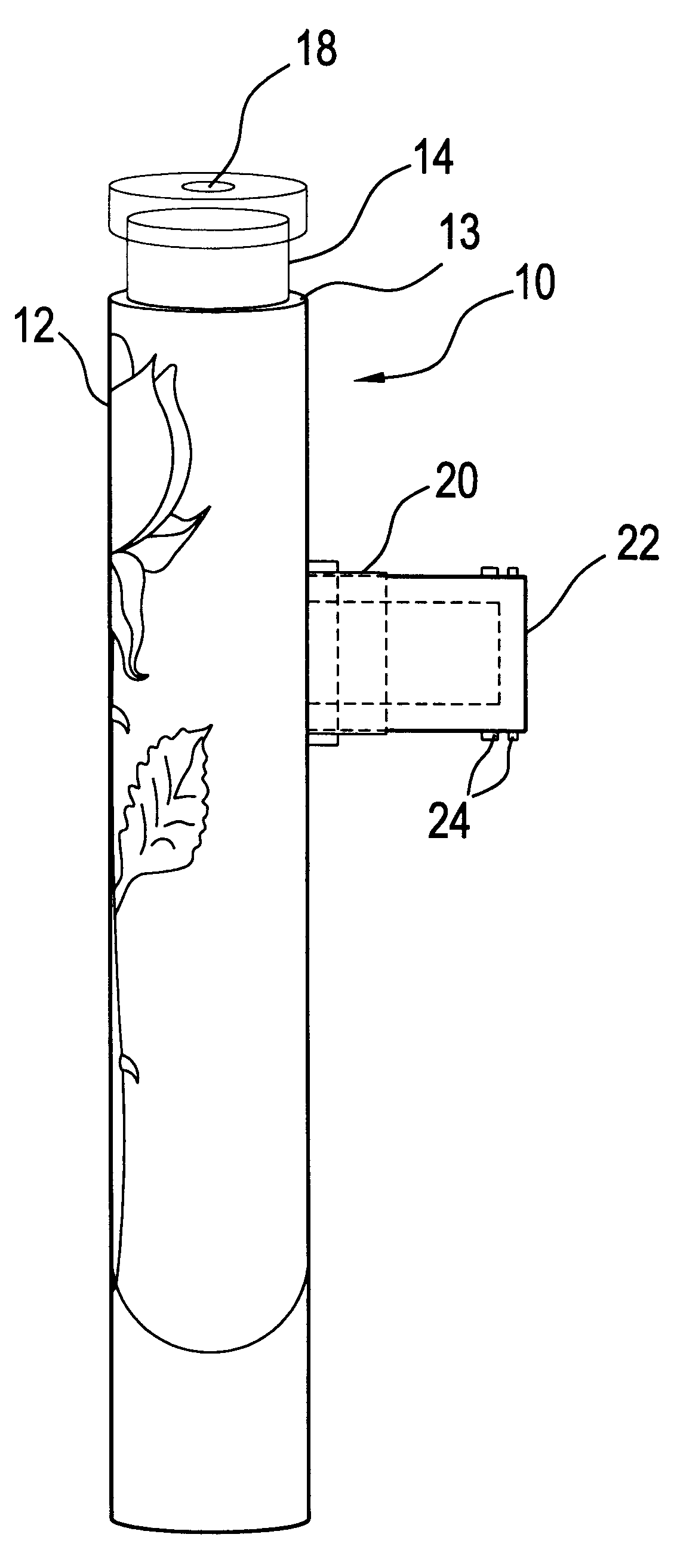

Support structure for attachment to automotive cigarette lighter receptacle

InactiveUS6202345B1Preventing inadvertent spillageReduce openingPassenger spaceSeed and root treatmentDashboardTest tube

A holding device which can be attached to a standard cigarette lighter receptacle which is located in the dashboard of an automobile.The holding device comprises: 1) a support member which is inserted into the cigarette lighter receptacle; and 2) an elongated holding member which can accept an object such as a cigar for storage; or a test-tube shaped container which is capable of holding water and one flower or a small floral arrangement.The elongated holding member can have various artistic designs on its outer wall surface which will add to the pleasing aesthetics of the holder in an automobile.

Owner:WOKAL GARY

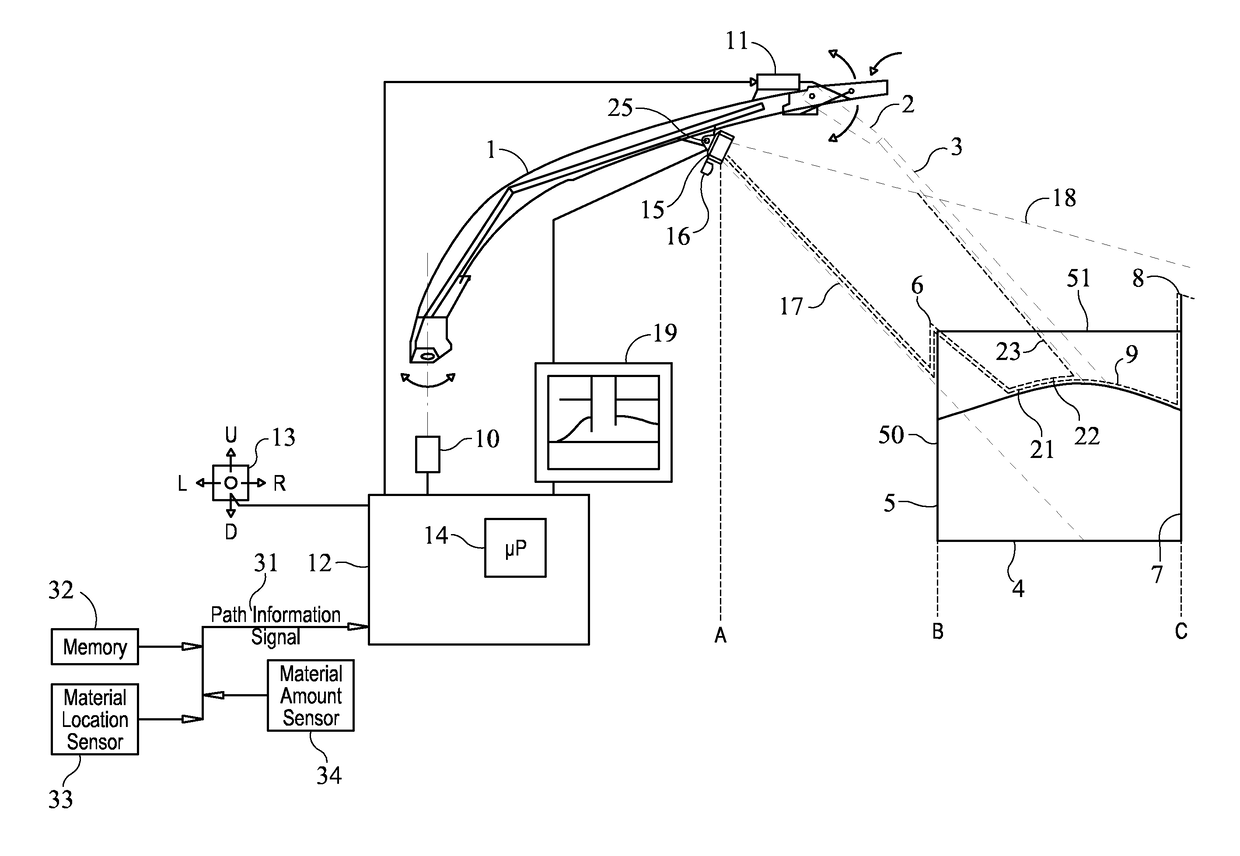

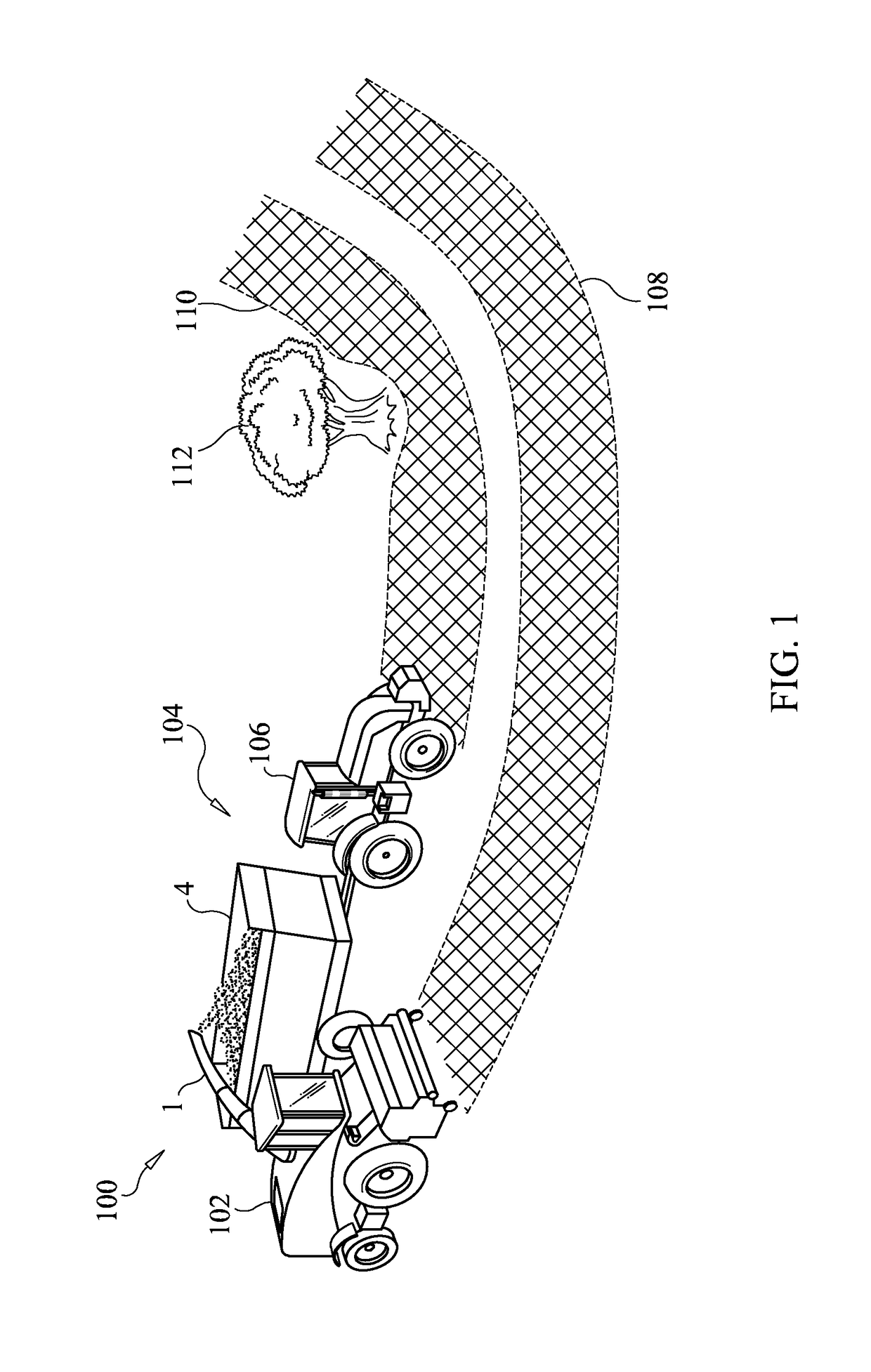

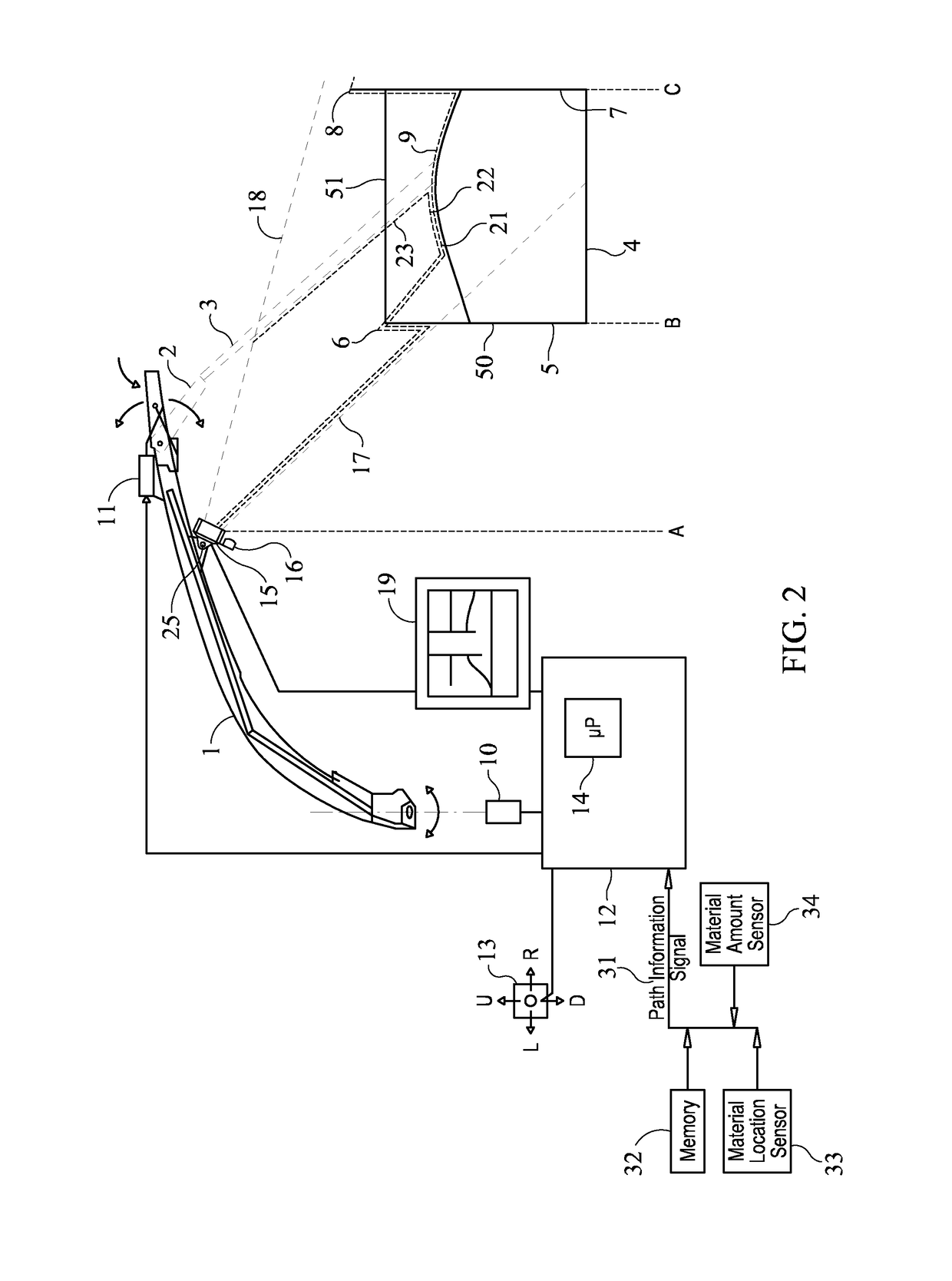

Unloading systems

Owner:BLUE LEAF I P INC

Phosphogypsum-base wall material for cast-in-place wall

The invention discloses a phosphogypsum-base wall material for a cast-in-place wall. The invention is characterized in that the material is prepared from the following raw materials in percentage by weight: 60-80% of beta-phosphogypsum, 10-20% of mineral admixture, 5-25% of cement, 0.25-0.5% of retarder, 0.05-0.15% of defoaming agent, 0.05-0.2% of thickener and 0.5-1% of water reducer. The raw materials are uniformly mixed to obtain the phosphogypsum-base cast-in-place wall material; and the material and water are mixed uniformly in a water / material ratio of 0.4-0.5 to obtain a slurry, and the slurry is cast in place and molded. The phosphogypsum-base wall material has the advantages of controllable setting time, low flowing loss rate, high utilization ratio of solid waste, low material cost and high strength, is convenient for construction, and can be widely used for frame-structure infilled internal walls of commercial and civil buildings.

Owner:WUHAN UNIV OF TECH

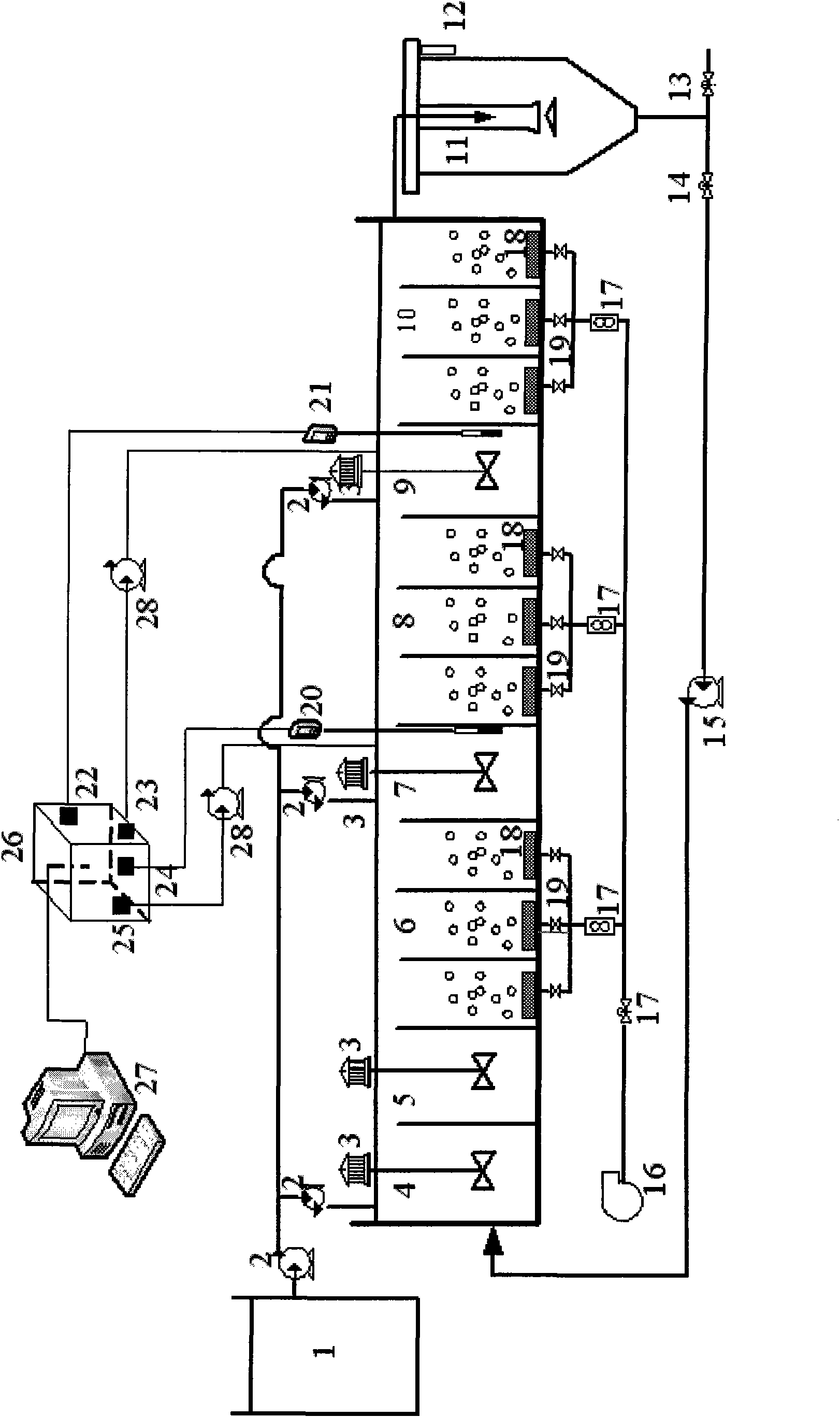

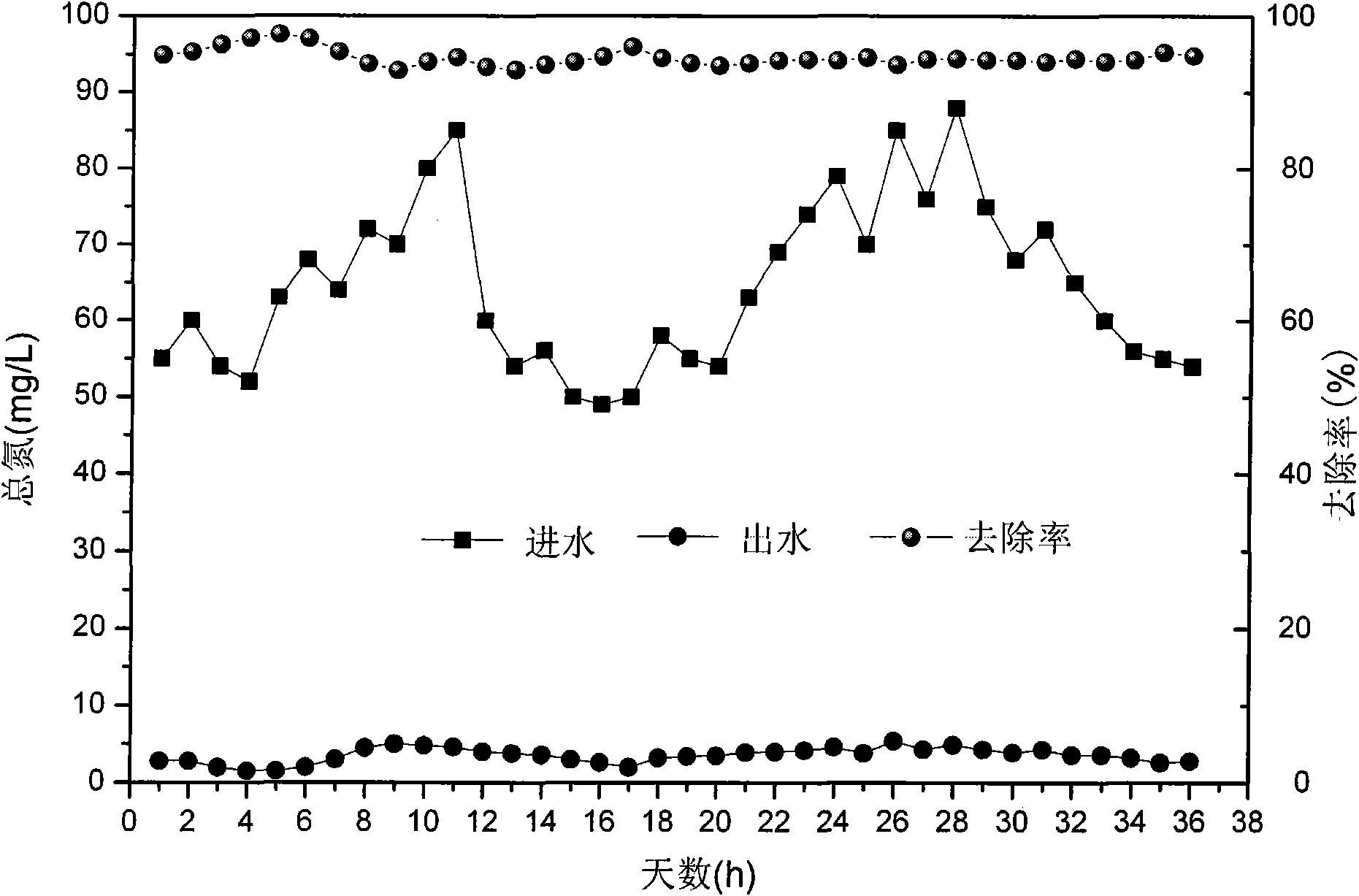

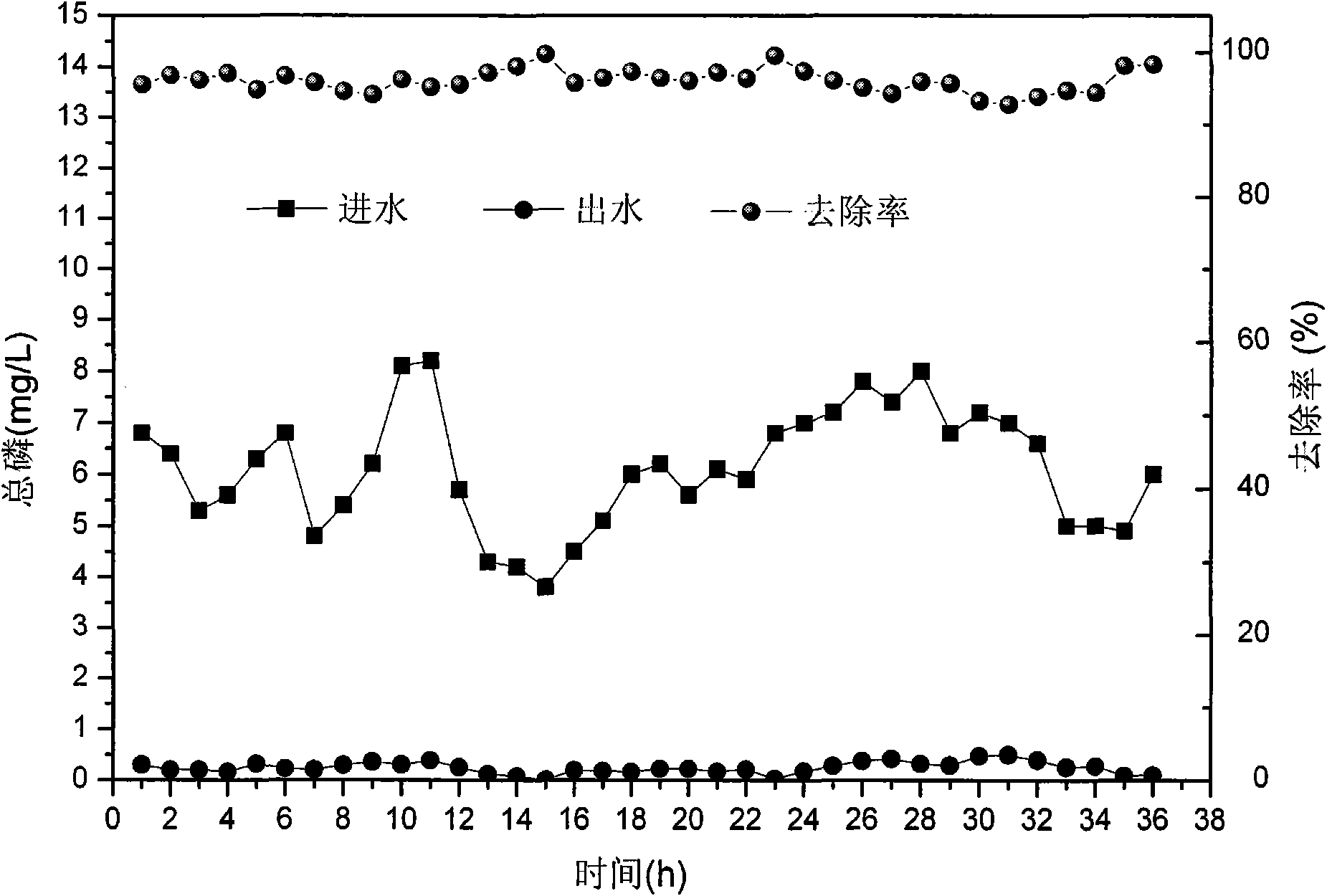

Advanced nitrogen and phosphorus removal device and process control method thereof

ActiveCN101570383ARealize denitrification and dephosphorizationBreaking through the bottleneck that is difficult to improve the efficiency of nitrogen and phosphorus removalTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentLine sensorWater quality

The invention relates to an advanced nitrogen and phosphorus removal device and a process control method thereof, belonging to the technical field of biological sewage treatment by using a biochemical method. Aiming at the defects that the existing A / O step feed technology can not synchronously have advanced biological phosphorus removal, reverse A / O technology is high in energy consumption and complicated in operation and the like, the invention combines the reverse A / O technology and the step feed technology, nitrification liquid internal reflux does not needed to be set, a first section is provided with an anaerobic reactor, anoxic reactors at a second section and a third section are respectively installed on an ORP on-line sensor and a nitrate on-line sensor, and data obtained by collecting ORP and nitrate in an on-line way can be taken as input of a process controller, is output by fuzzification treatment and can act on opening and closing a frequency converter of an actuating mechanism and an external carbon source dosing metering pump so as to save the external carbon dosage. The invention can greatly improve the denitrification effect of the step feed technology, utilizes carbon source of raw water to the utmost extent, realizes synchronous nitrogen and phosphorus removal, and has the advantages of simple control structure and stable quality of yielding water.

Owner:BEIJING UNIV OF TECH

Acne removing and antiallergic cream and preparation method thereof

InactiveCN103565714ANo drug resistanceAnti-acidificationCosmetic preparationsToilet preparationsPolyethylene glycolGlycerol

The invention discloses an acne removing and antiallergic cream which is prepared by mixing stearyl alcohol polyether-2, stearyl alcohol polyether-20, glycerin stearate, PEG (Polyethylene Glycol)-100 stearate, stearic acid, cetearyl alcohol, aloe oil, polydimethyl siloxane, isopropyl myristate, propyl p-hydroxybenzoate, methyl p-hydroxybenzene, tocopherol, azone, bisabolol, glycerol, xanthan gum, EDTA (Ethylene Diamine Tetraacetic Acid)-2Na, propylene glycol, ethanol, menthol, salicylic acid, a golden cypress extractive, a scutellaria baicalensis extractive, an India chinaberry leaf extractive, a spiraea ulmaria extractive, a bee milk extractive, an aloe leaf extractive, tea tree oil and sodium hydroxide. The acne removing and antiallergic cream disclosed by the invention can be used for removing acnes, promoting the facial blood circulation and skin cell regeneration, improving the skin tolerance and reducing or eliminating the allergic reaction of the skin; the allergic tolerance of the skin is improved, so that the cream is safe and effective; no any spices are added, so that allergens are greatly reduced.

Owner:SHENZHEN GUAFEN BIOTECH

Method for preparing cryolite by alkaline leachate of cathode carbon block of aluminum electrolytic cell

The invention relates to a method for preparing cryolite by alkaline leachate of a cathode carbon block of an aluminum electrolytic cell, and belongs to a leachate preparation method. The method comprises the steps of grinding the cathode carbon block of the aluminum electrolytic cell to a certain particle size, mixing the ground cathode carbon block with alkaline liquid, carrying out size mixing, carrying out stirring leaching at a heating temperature of 20-90 DEG C, filtering to obtain first filtrate and a first filter residue, adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate, controlling the introducing velocity of CO2-rich gas to generate precipitates while heating and stirring, after the reaction is finished, filtering to obtain second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C, so as to obtain a cryolite product. According to the method, acidy leaching is replaced with alkaline leaching, so that the equipment requirements in the production process are reduced, processing processes such as flotation are omitted, an absorption process of hydrogen fluoride is omitted, and the processing process is simplified; a high-temperature processing process is saved, so that the energy consumption is reduced; and by adding crystal seeds, high-quality cryolite with the uniform particle size is generated when airflow rate is controlled. The method has the beneficial effects that the process is simple, a closed loop is utilized, the resource utilization rate is high, and the secondary pollution is avoided.

Owner:CENT SOUTH UNIV

Method for producing cryolites by using aluminum electrolytic cell cathode carbon block alkaline leaching solution

The invention relates to a method for preparing cryolites by using an aluminum electrolytic cell cathode carbon block alkaline leaching solution, and belongs to preparation methods of the cryolites. The method comprises the following steps: grinding aluminum electrolytic cell cathode carbon blocks finely to a certain particle size, performing slurry mixing with alkali liquor, and performing agitation leaching at a heating temperature of 20-90 DEG C; then performing filtration to obtain a first filtrate and a first filter residue; adding sodium fluoride and a small amount of Na3AlF6 solids into the first filtrate; then controlling the speed of introducing NH3-rich gas or adding NH4F to generate a deposit under the action of heating agitation; and after reaction, performing filtration to obtain a second filtrate and a second filter residue, and drying the second filter residue at 100-150 DEG C to obtain a cryolite product. According to the method provided by the invention, by replacing acid leaching with alkali leaching, the requirement of a production process on equipment is reduced, treatment processes including floatation are reduced, an absorption process of hydrogen fluoride is reduced, and the treatment process is simplified; a high-temperature treatment process is not used, so that the energy consumption is reduced; and by adding a crystal seed, high-quality cryolites with uniform particle sizes are generated under the condition that the airflow rate is controlled. The method provided by the invention is simple in process, achieves closed cycle, is high in resource utilization rate and avoids secondary pollution.

Owner:CENT SOUTH UNIV

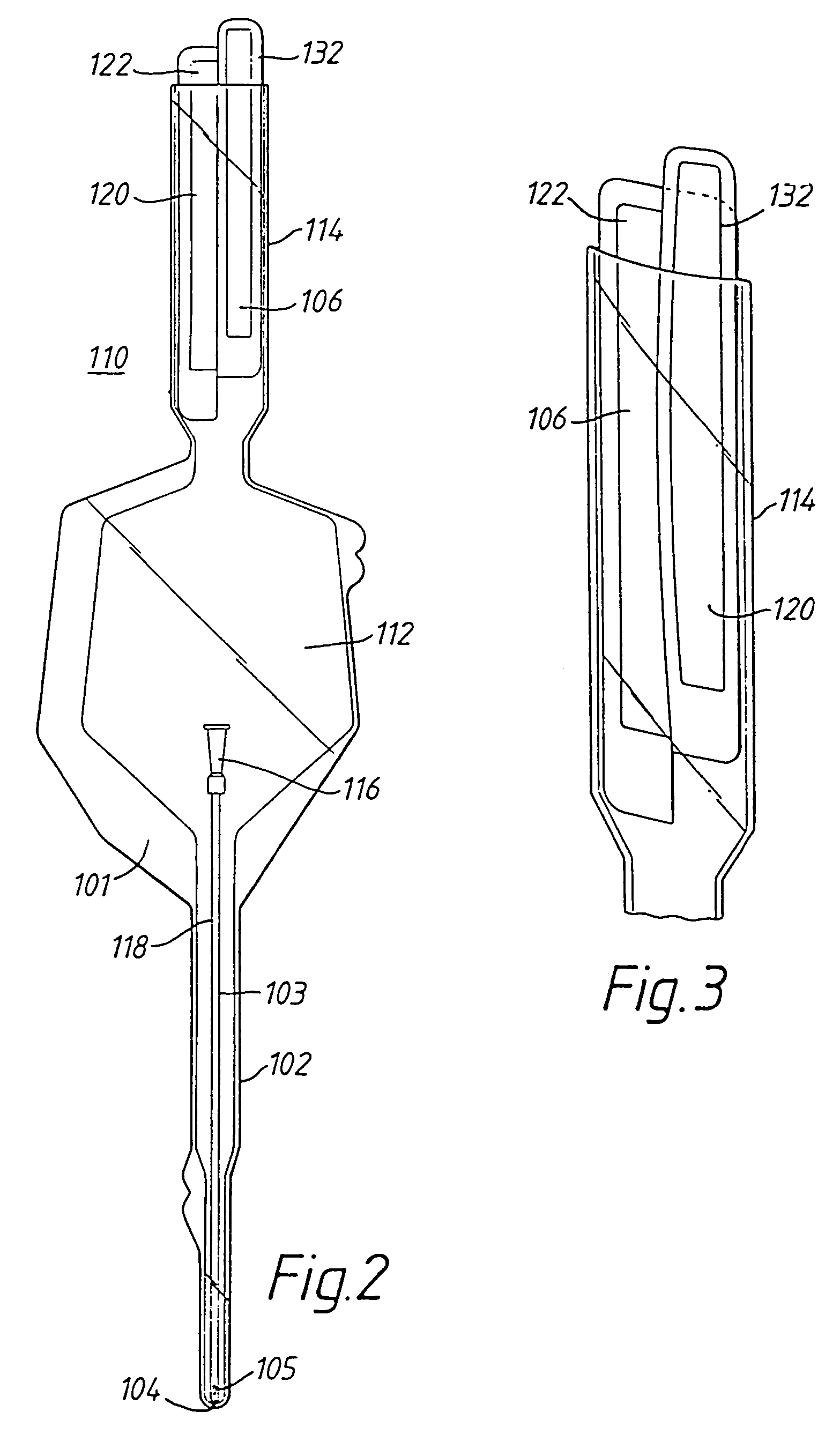

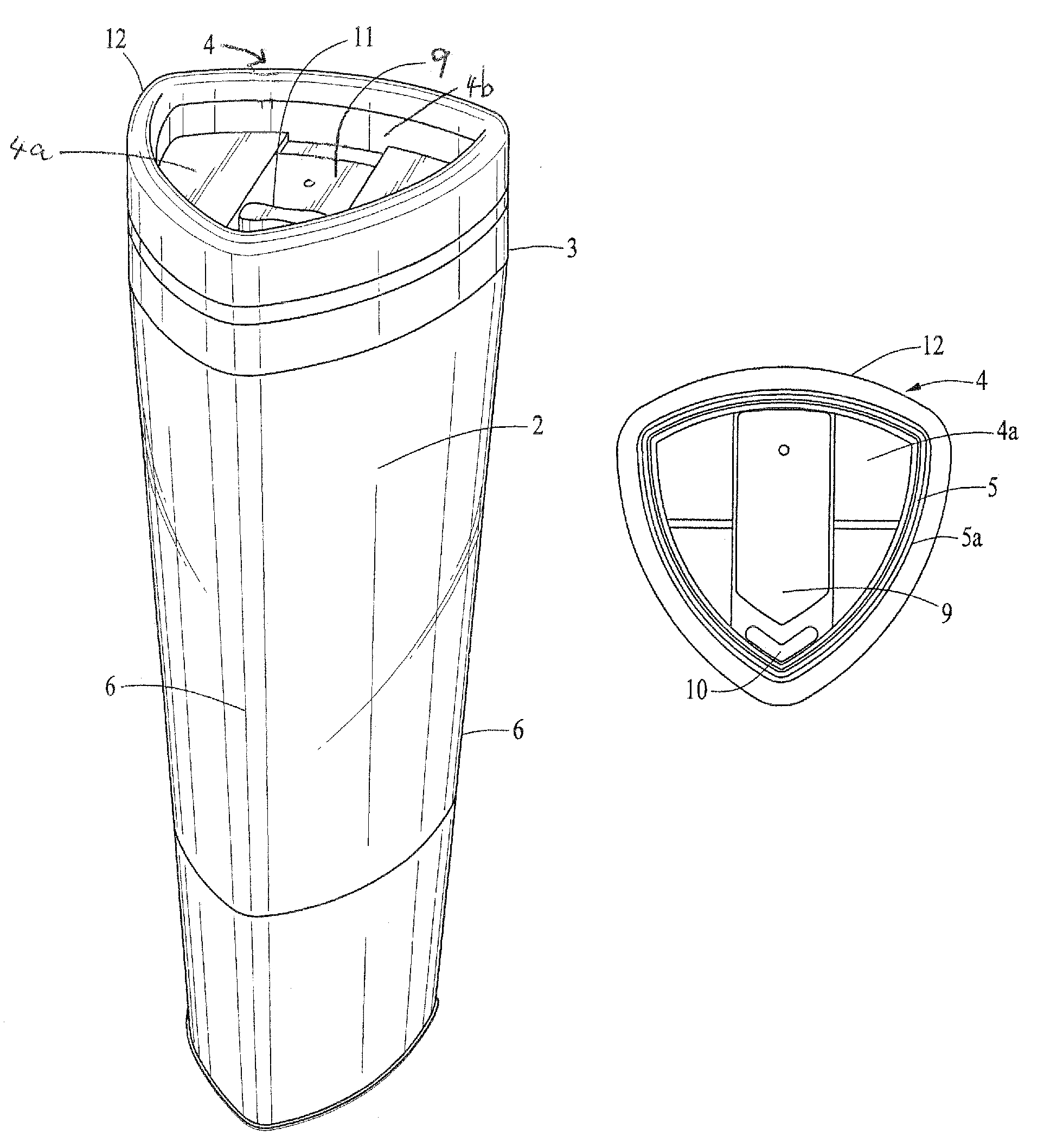

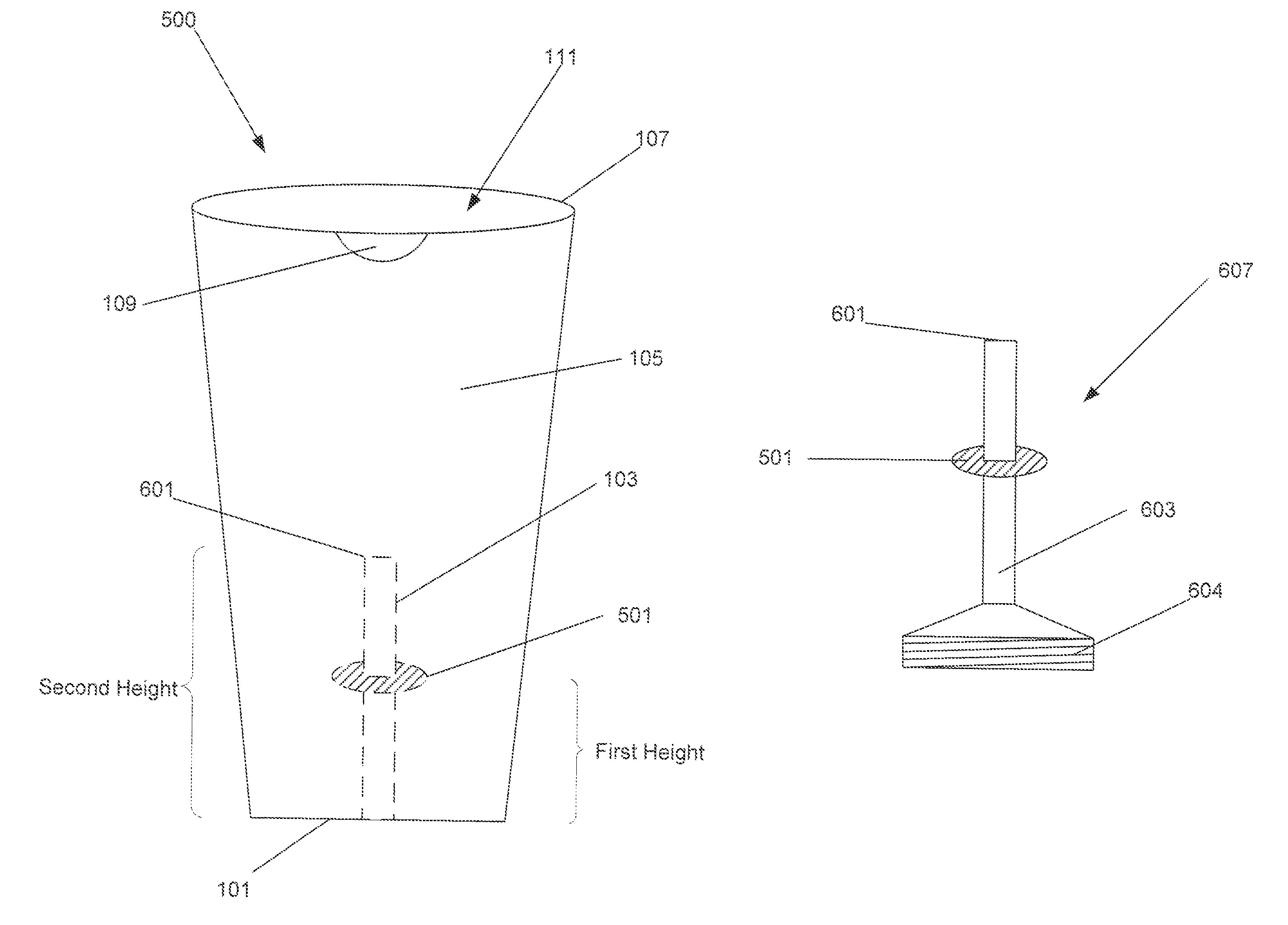

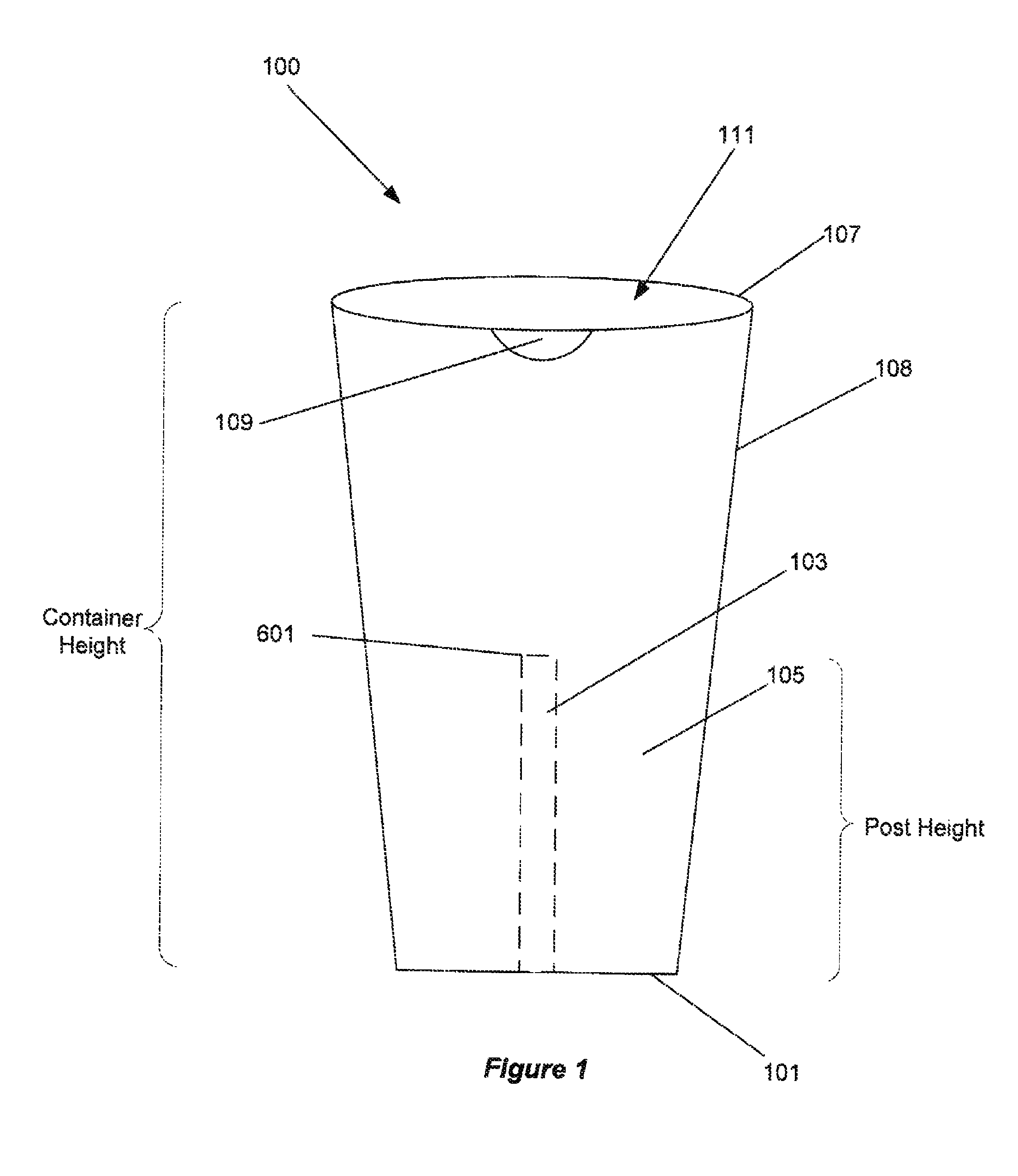

Precision pour drink shaker

ActiveUS8225956B1Reduce overflowShaking/oscillating/vibrating mixersOther accessoriesEngineeringBiomedical engineering

A precision pour drink shaker is disclosed herein. The precision pour drink shaker includes a first means for containing one or more liquids, and a second means for measuring an amount of matter placed into the first means. In one aspect, the first means may include a shaker and the second means may include a post extending from the first means, for example, from an interior surface of a base of the first means.

Owner:A&M INNOVATIVE PROD

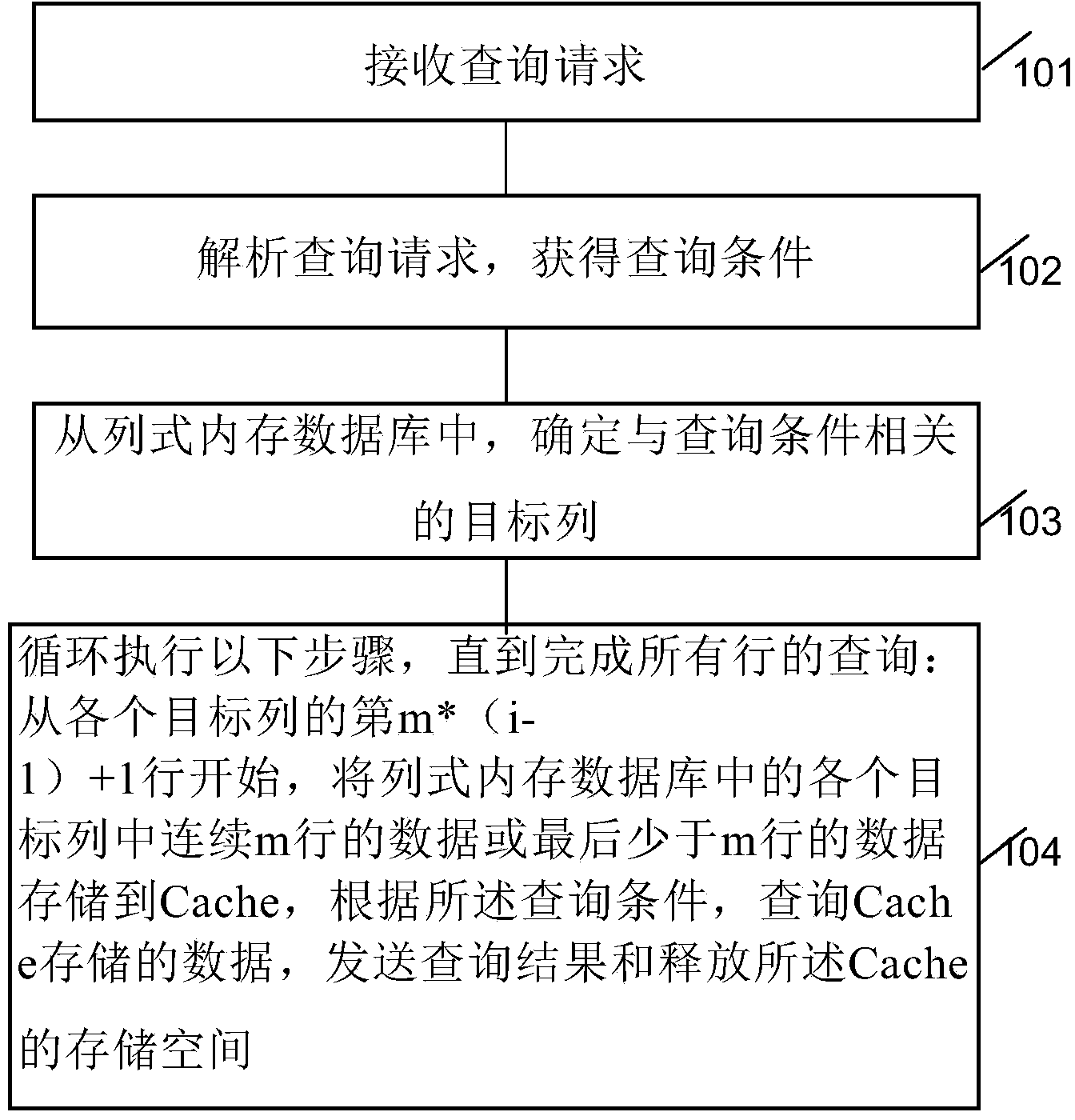

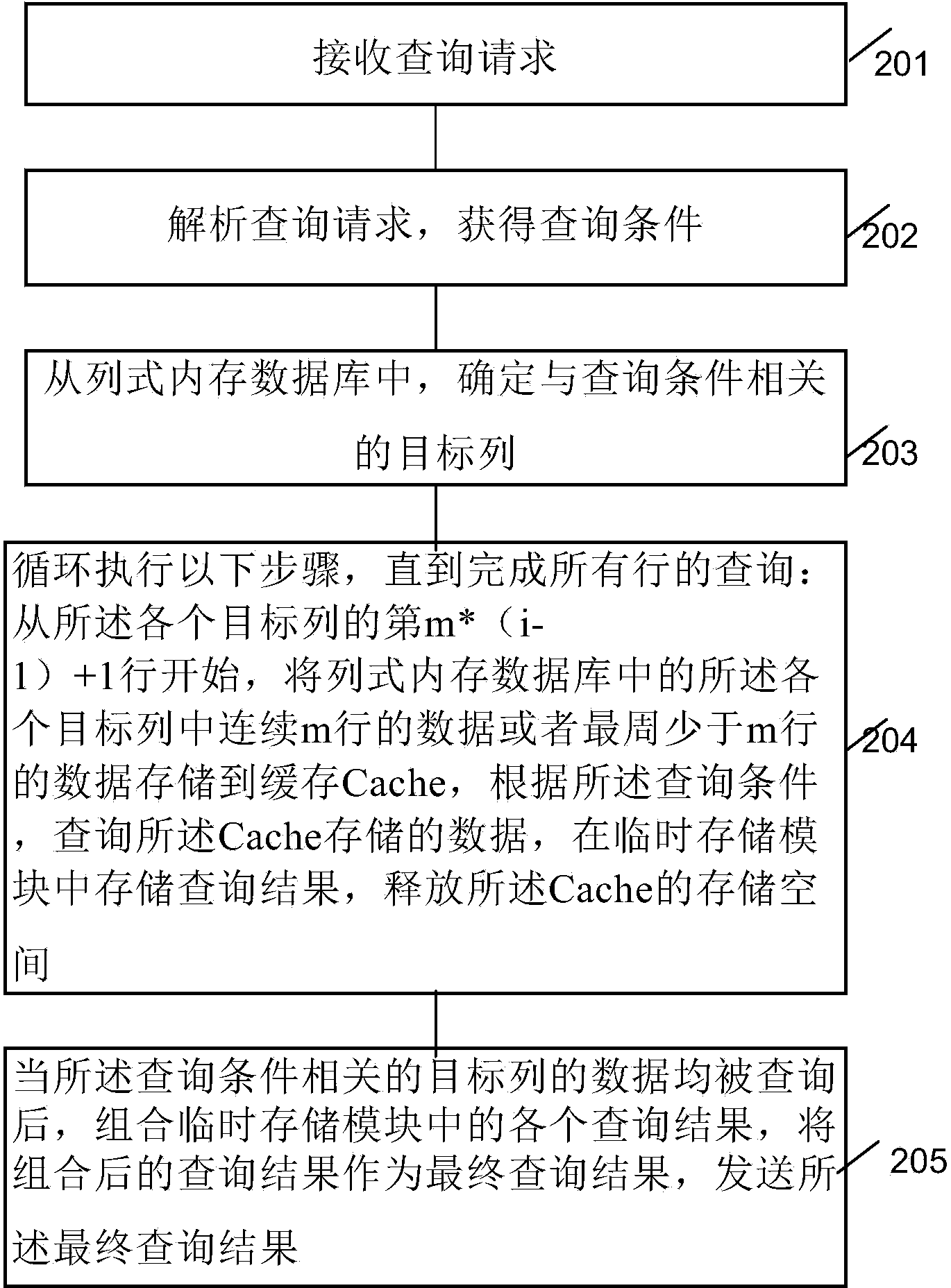

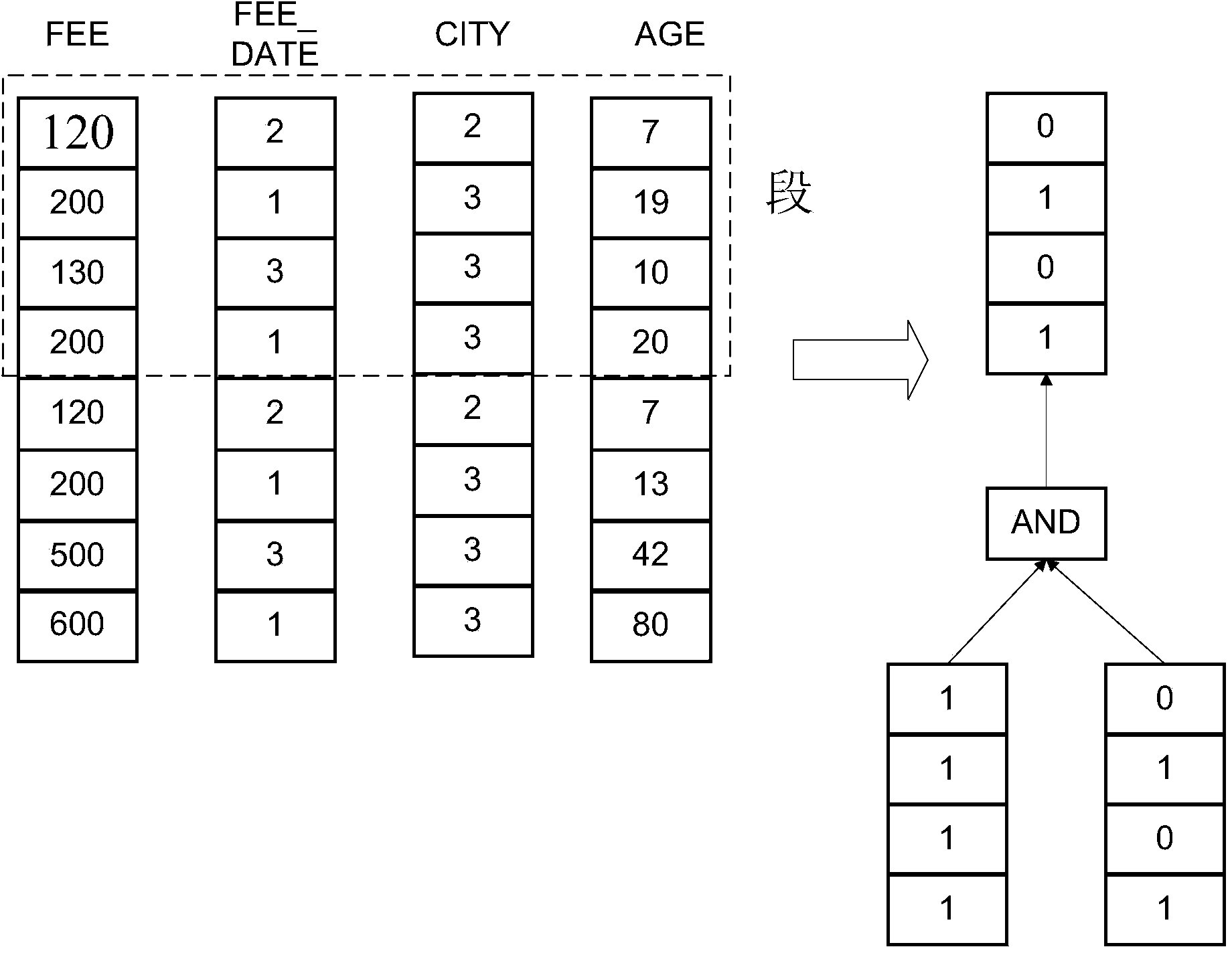

Database query method and server

InactiveCN103970870AReduce overflowReduce latencySpecial data processing applicationsDatabase queryIn-memory database

The embodiment of the invention provides a method for querying a column type internal memory database. The method comprises the steps of receiving a query request, analyzing the query request, acquiring a query condition, determining a target column related to the query condition from the column type internal memory database, executing the following steps in a cycled mode until query of all rows is achieved, storing data queried in the continuous m rows in all the target columns or the data less than m rows at last into a Cache from the column type internal memory database starting from the [m*(i-1)+1]th row of each target column, querying the data stored in the Cache according to the query condition, sending sectionalized query results, and releasing the storage space of the Cache, wherein the m is a natural constant, and the i is a variable and represents the cycled executing frequency. The method is used, so that data flooding in the query process is lowered, and time delay of data query is reduced.

Owner:HUAWEI TECH CO LTD

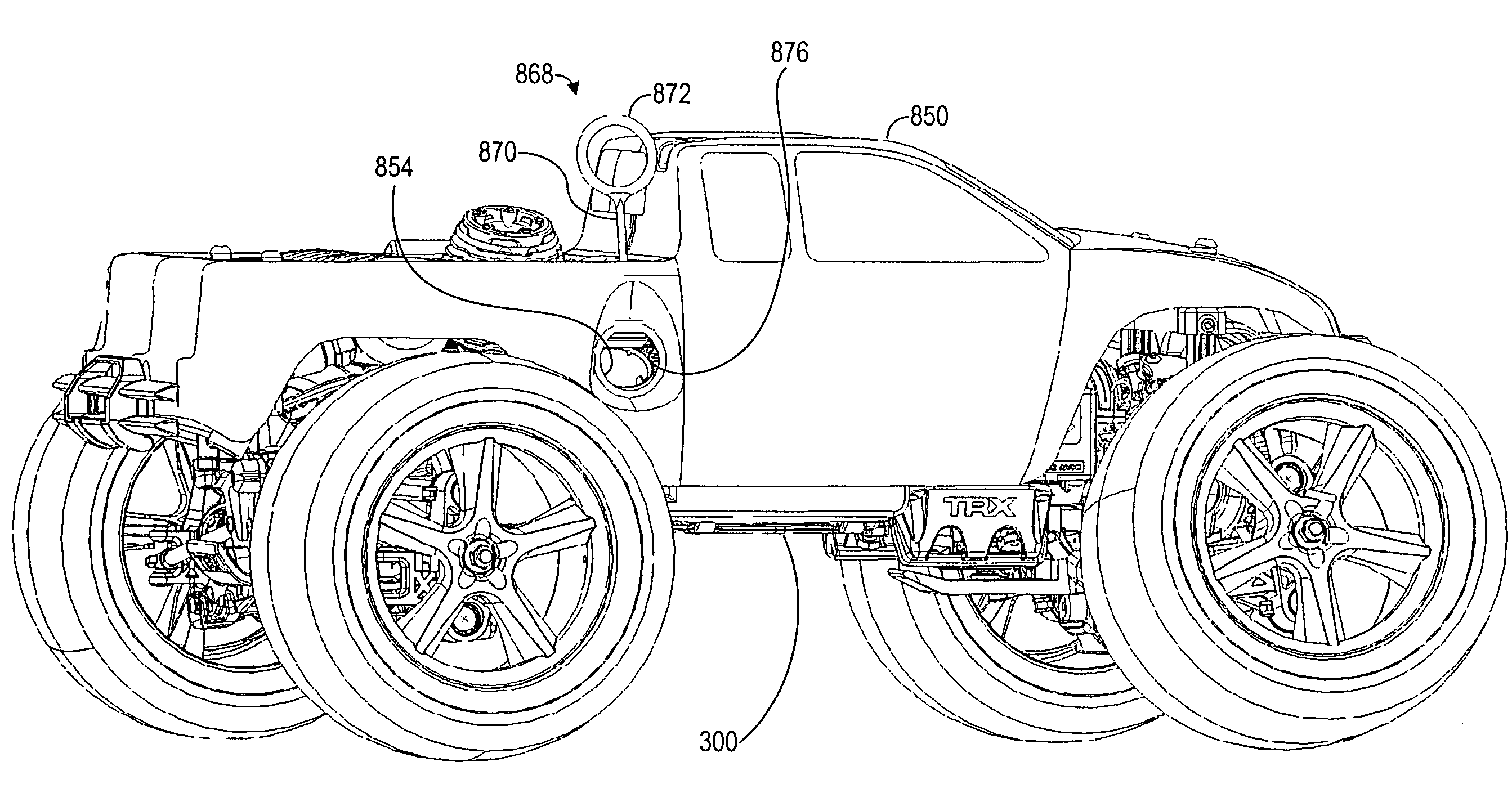

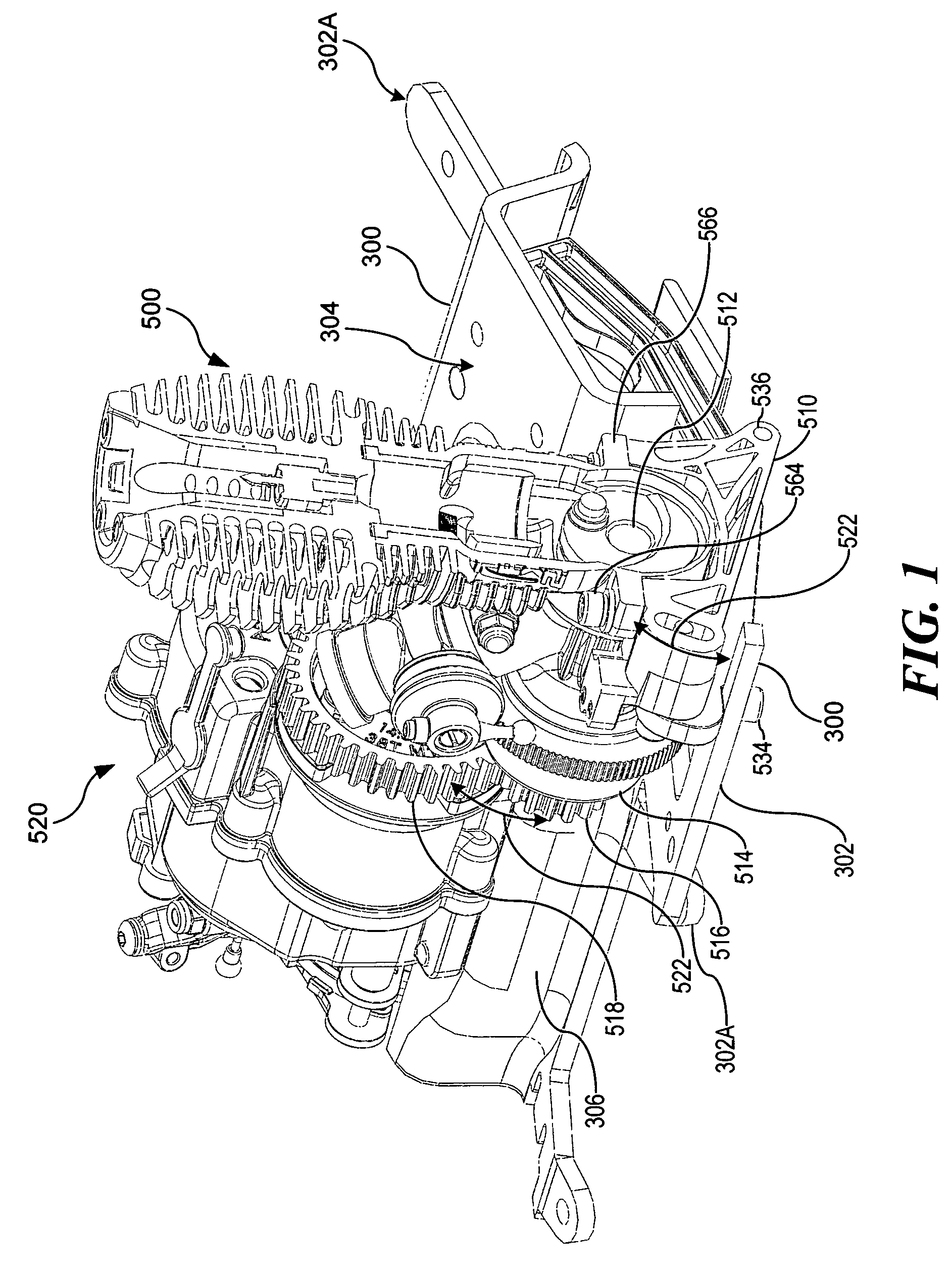

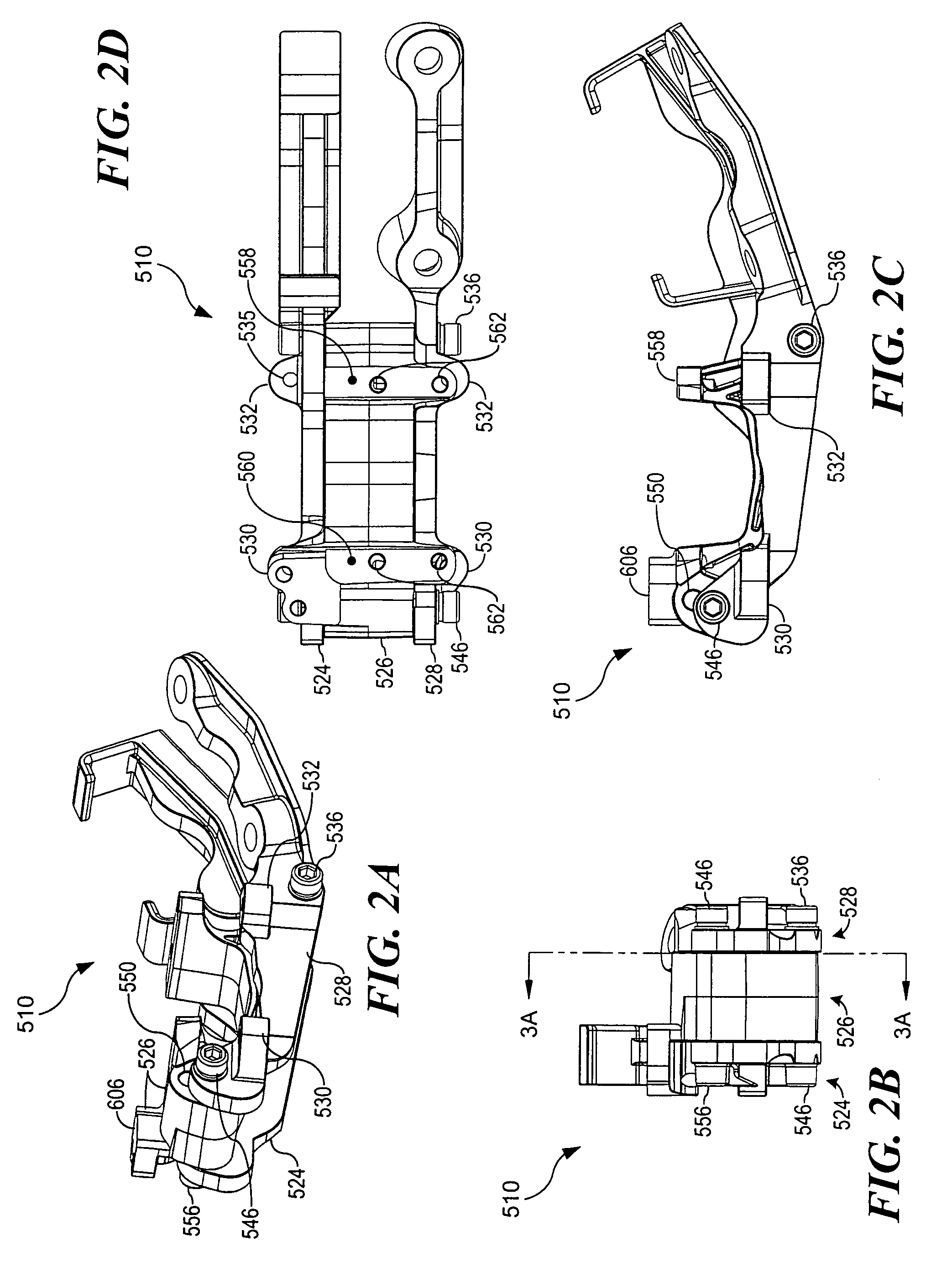

Fuel filler cap for a model vehicle

A model vehicle fuel filler system is provided, comprising a fuel tank secured to a vehicle chassis, a fuel tank opening extending from the fuel tank, the opening having a rim tipped toward a lateral side of the vehicle chassis, thereby allowing a fuel filler bottle opening to be withdrawn away from the tank opening with less spillage.

Owner:TRAXXAS

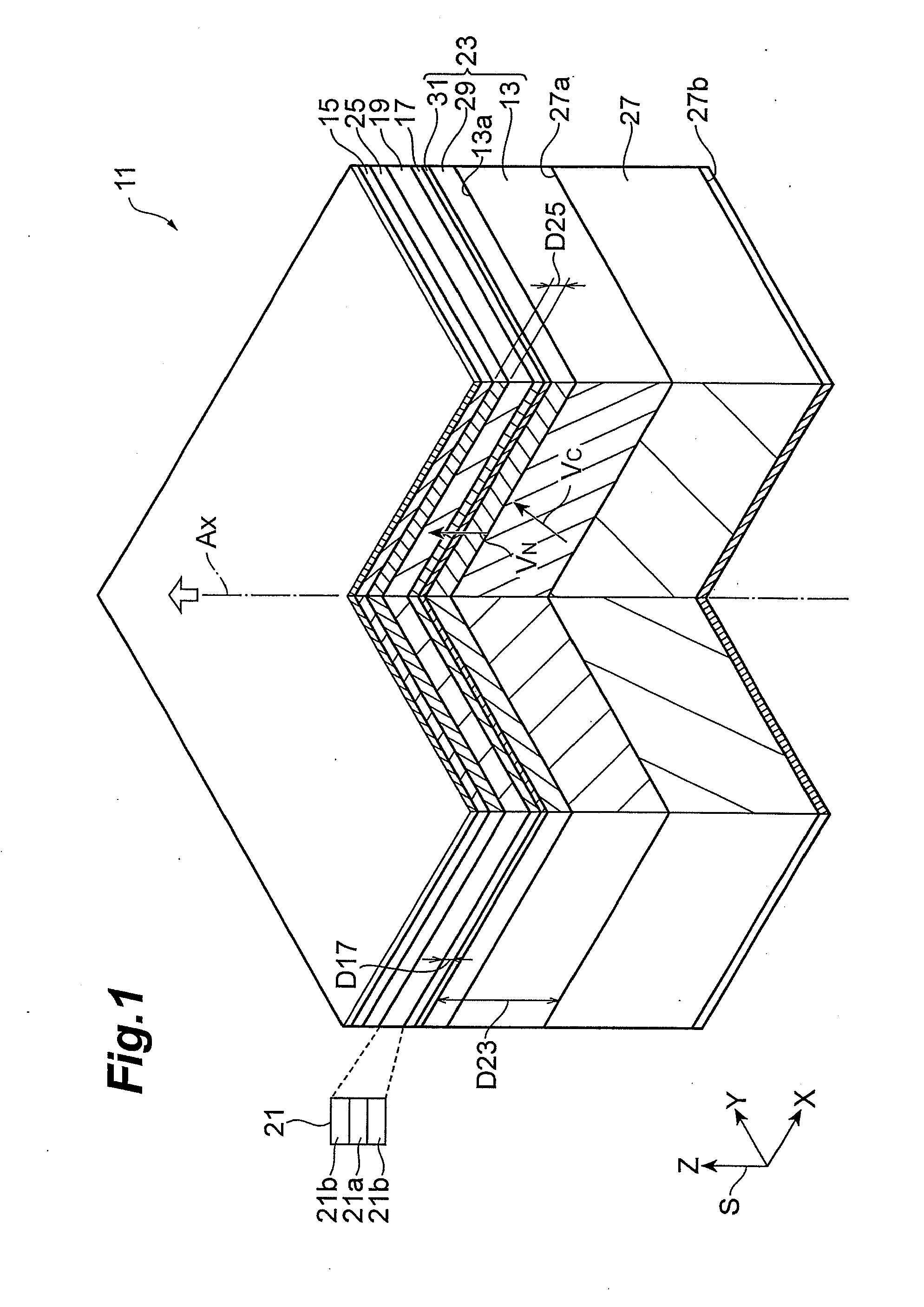

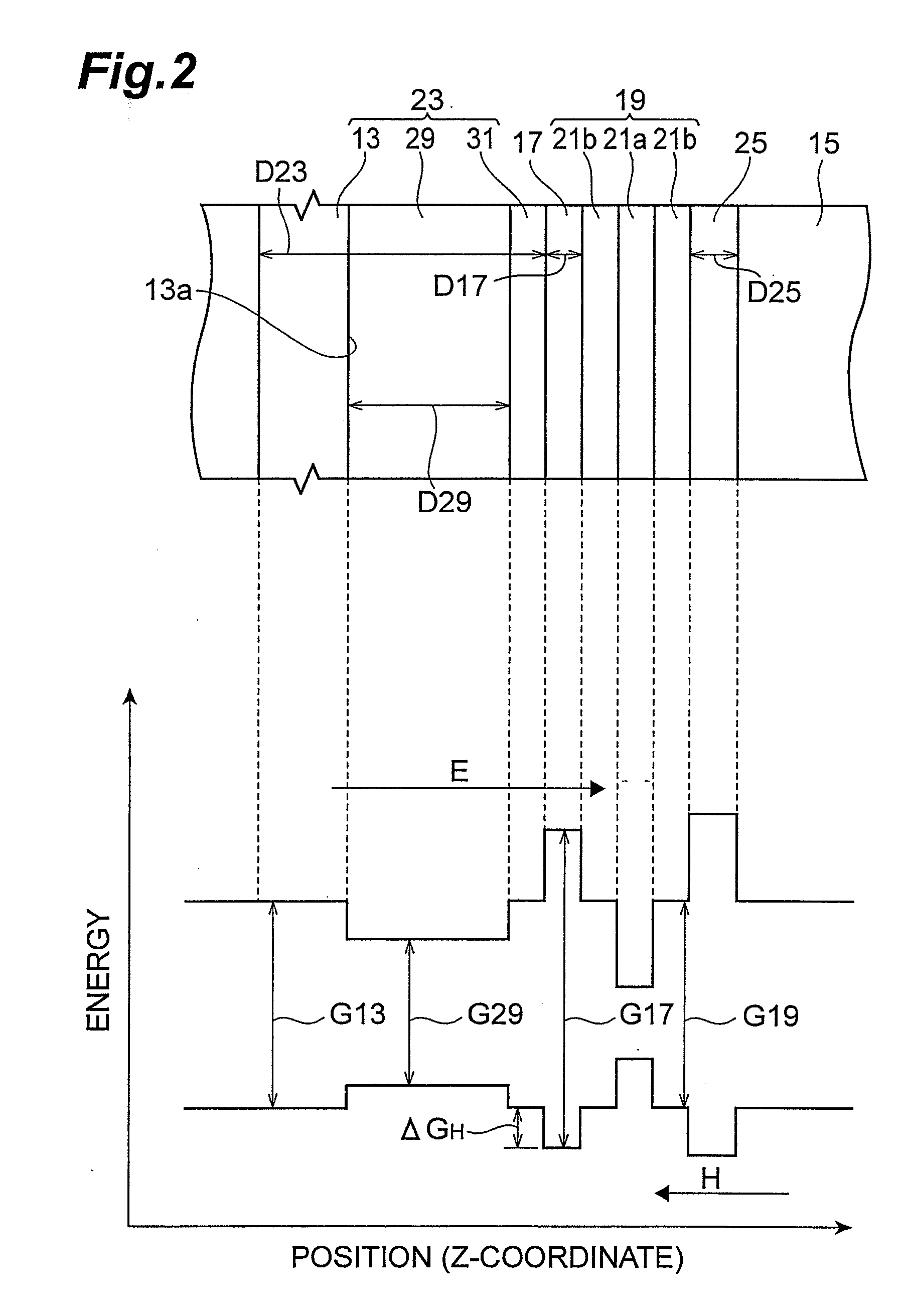

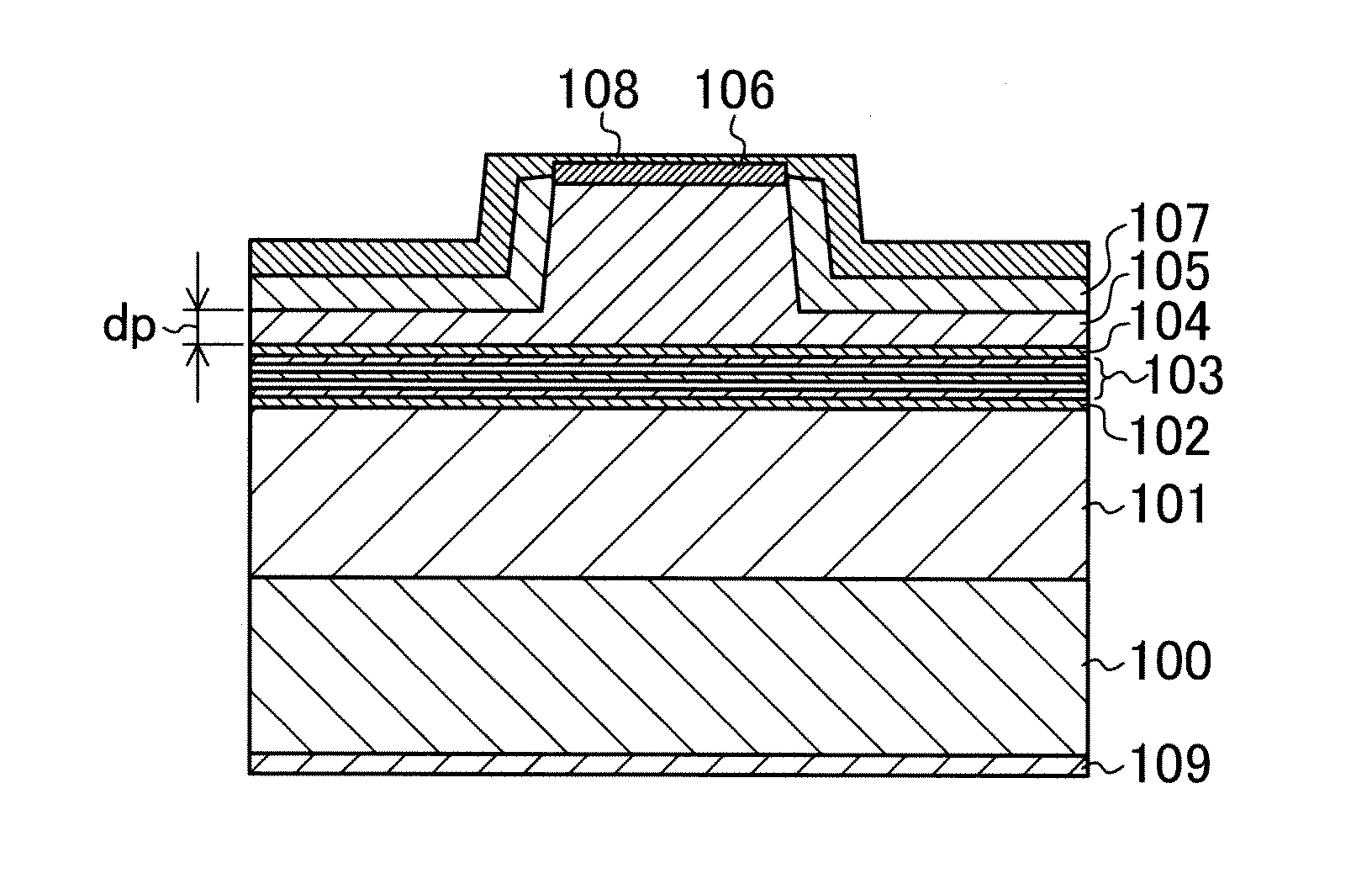

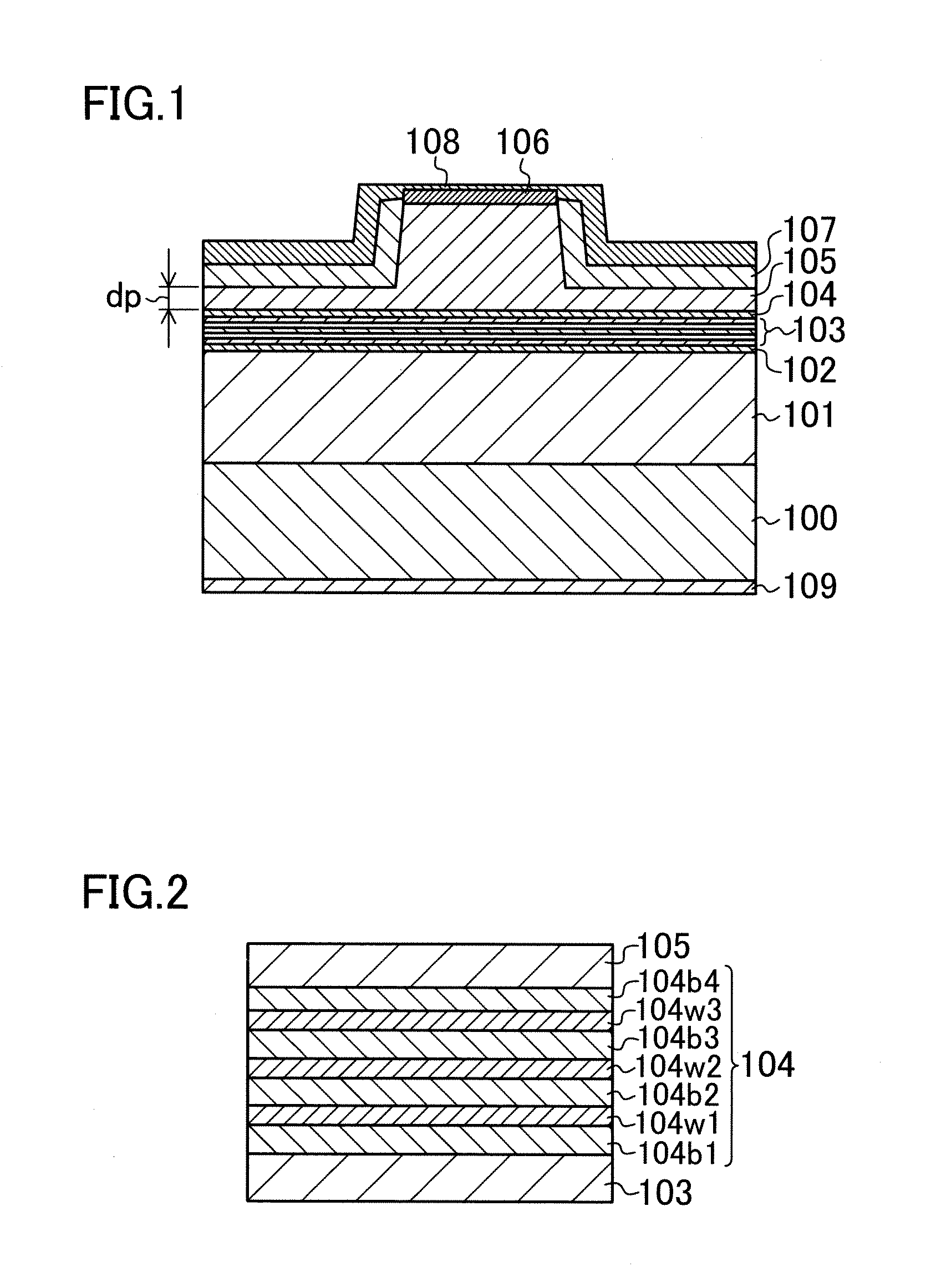

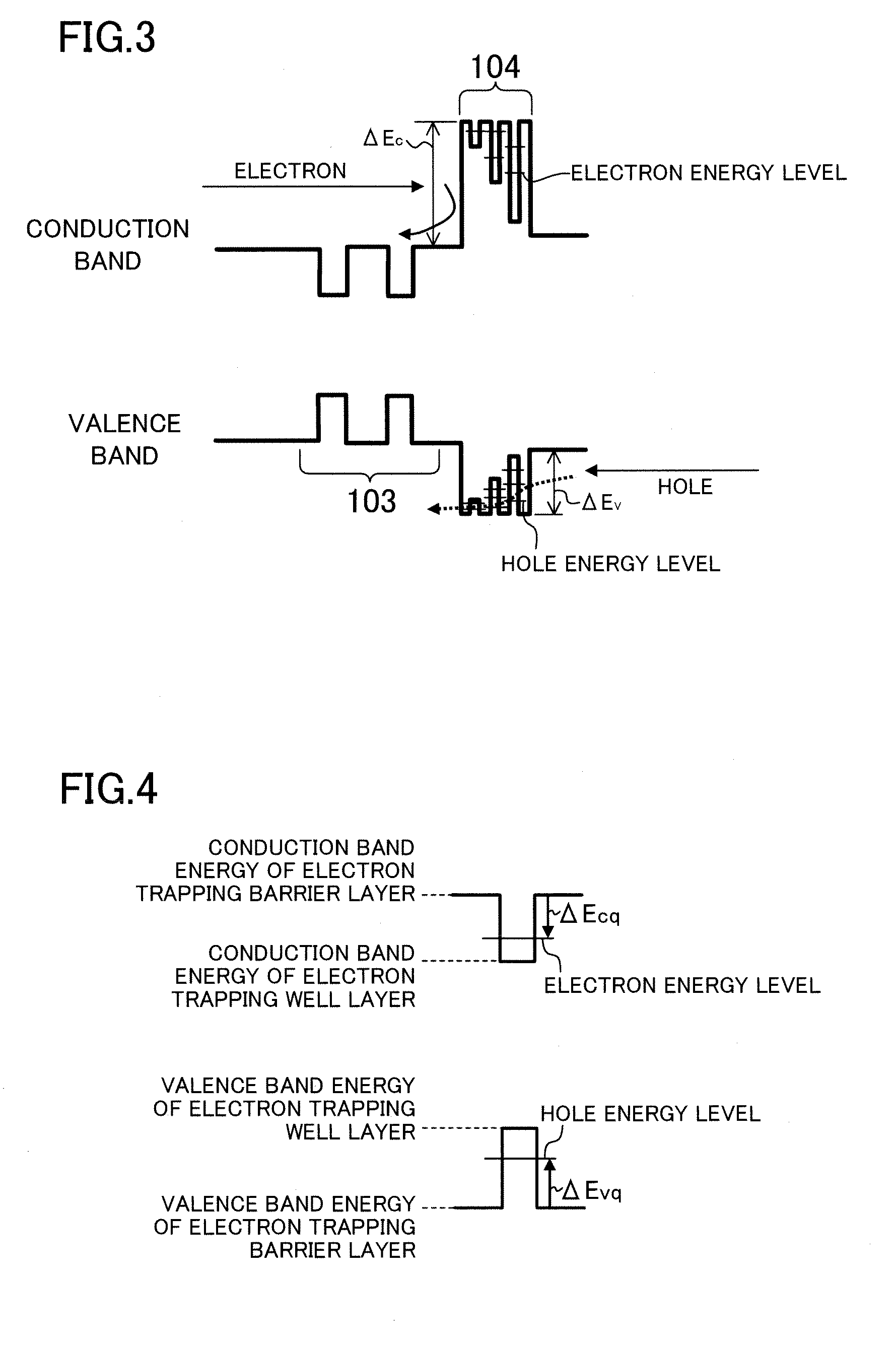

Semiconductor light emitting device

InactiveUS20110272667A1Reduce overflowOverflow of the electrons can be reducedOptical wave guidanceNanoopticsQuantum wellElectron capture

A semiconductor light emitting device includes: a first cladding layer made of a first conductivity type group III nitride semiconductor; an active layer formed on the first cladding layer; a quantum well electron barrier layer which is formed on the active layer, and includes electron trapping barrier layers made of AlxbGaybIn1-xb-ybN (0≦xb<1, 0<yb≦1, 0≦1-xb-yb<1), and two or more electron trapping well layers made of AlxwGaywIn1-xw-ywN (0≦xw<1, 0<yw≦1, 0≦1-xw-yw<1); and a second cladding layer which is formed on the quantum well electron barrier layer, and is made of a second conductive type group III nitride semiconductor. Each of the electron trapping well layers is formed between the electron trapping barrier layers, and band gap energies of the electron trapping well layers increase with decreasing distance from the active layer.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com