Advanced nitrogen and phosphorus removal device and process control method thereof

A deep denitrification and nitrate nitrogen technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve complex pipeline layout, inability to fully utilize raw water carbon sources, Large energy consumption and other problems, to achieve the effect of simple control loop, improve the denitrification potential of the system, and save operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment describe the patent of the present invention in detail:

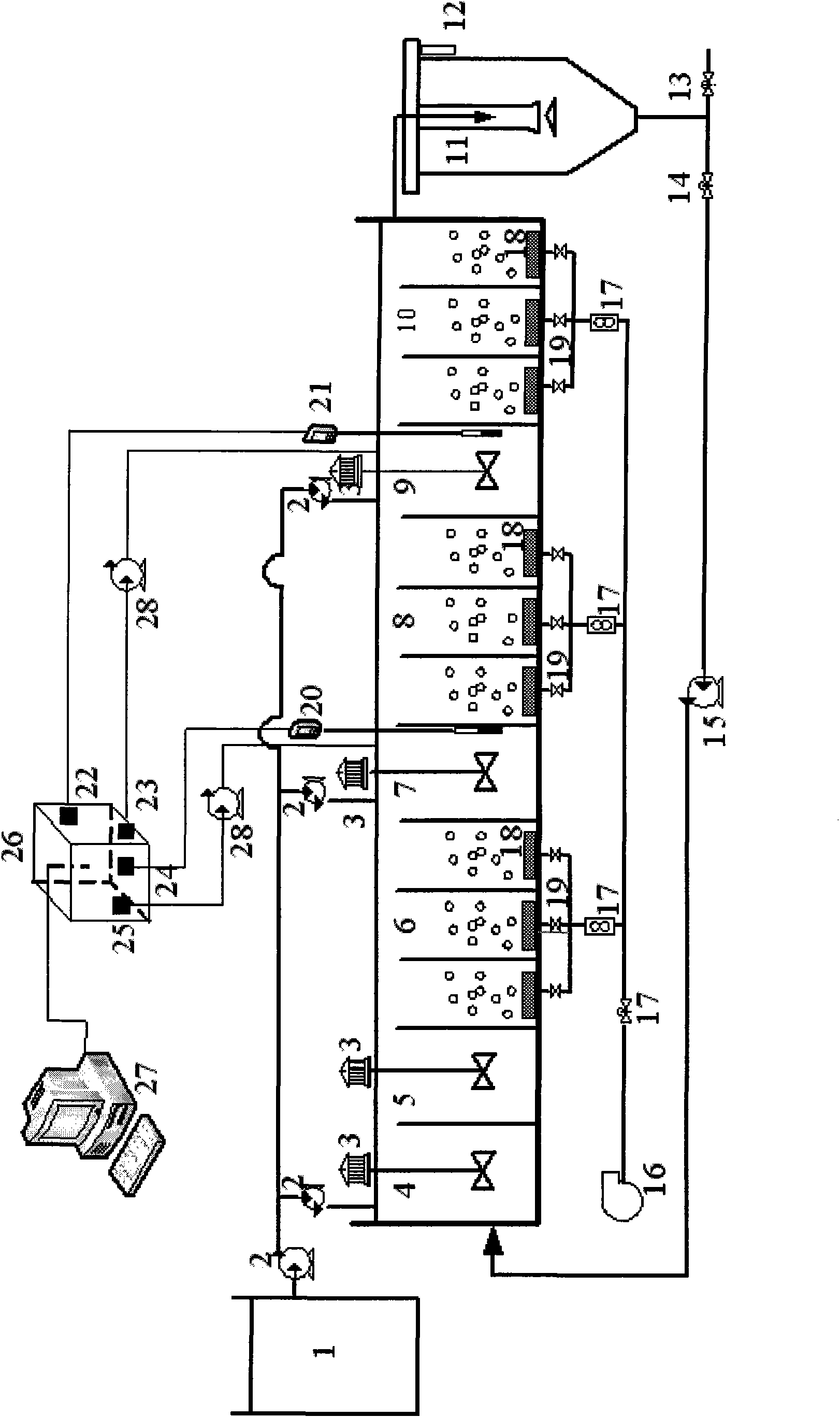

[0028] Such as figure 1 As shown, a deep denitrification and phosphorus removal device, wherein the sewage water tank 1 is connected with the main body bioreactor by the water inlet pipe, the main body bioreactor is connected with the sedimentation tank 11, and part of the sludge in the sedimentation tank 11 is returned to the In the first section of the bioreactor, the sewage water tank 1 has an effective volume of 200L. The test model selected for the test is a double-corridor rectangular reactor with an effective volume of 60L. It is divided into 13 compartments for operation: the first compartment is the second A section of anoxic reactor 4 (5L), the second compartment is anaerobic reactor 5 (5L), and the next three compartments are the first section of aerobic reactor 6 (15L), and then the second The first anoxic reactor 7 (5L), the second aerobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com