Patents

Literature

120results about How to "Prolong initial setting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement-based composite material used for 3D printing technology as well as preparation method and application thereof

ActiveCN104310918AEasy to get materialsLow costSolid waste managementHouse buildingConstruction 3D printing

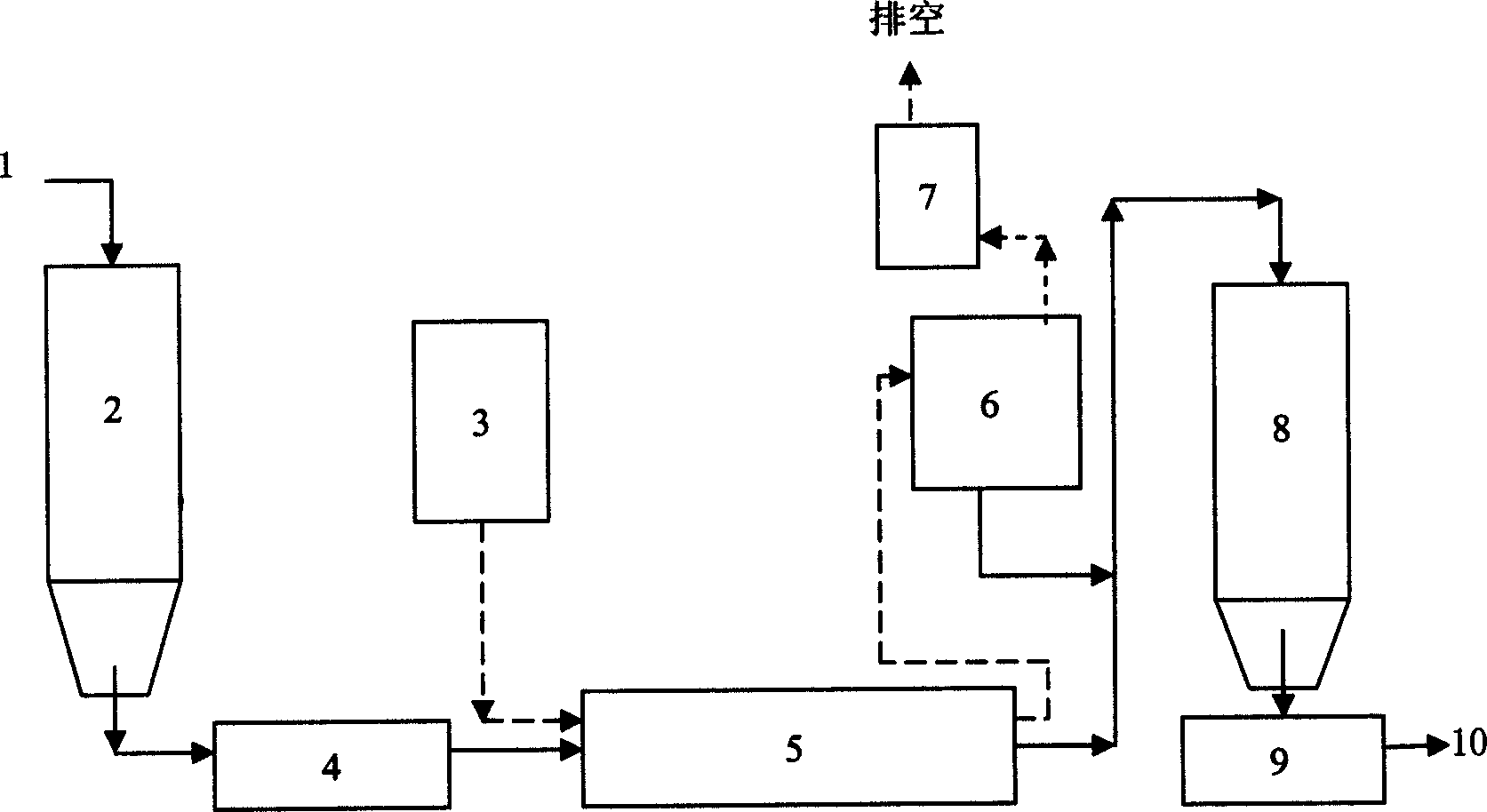

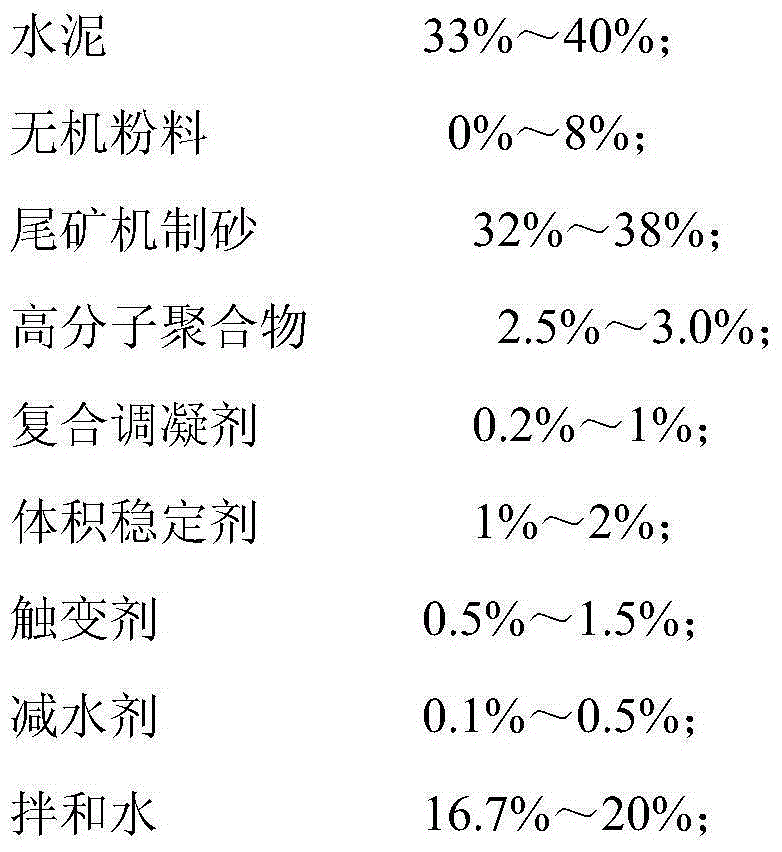

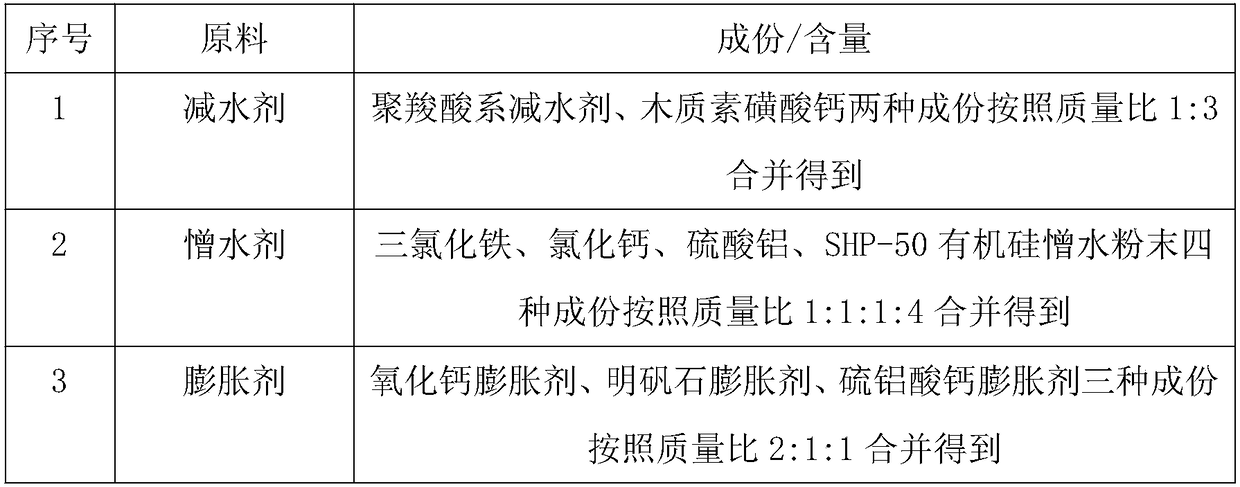

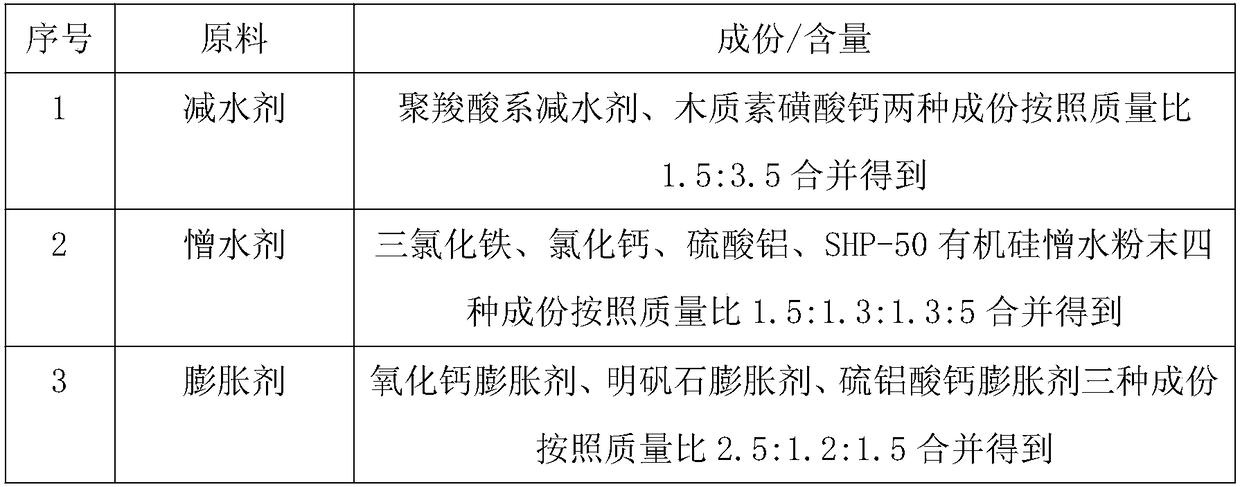

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Curing agent for filling iron tailings and preparation method thereof

The invention discloses a curing agent for filling iron tailings and a preparation method thereof and belongs to the technical field of mine safety. The curing agent comprise the following components in parts by mass: 0-70 parts of fly ash, 10-80 parts of superfine mineral slag powder, 0-70 parts of superfine steel slag powder, 0-20 parts of an alkaline activator, 0-20 parts of an sulfate activator, 0.1-1 part of a foam stabilizer and 2-5 parts of a microcapsule in which aluminum powder is used as a core material. The preparation method of the curing agent comprises the steps of firstly weighting fly ash, superfine mineral slag powder, superfine steel slag powder, alkaline activator, sulfate activator and foam stabilizer according to the blending ratio of the components of the curing agent, adding all the components in a stirrer, quickly stirring for 5-15 minutes, adding microcapsule in which aluminum powder is used as a core material and slowly stirring for 2-5 minutes to obtain the curing agent for filling iron tailings. The curing agent for filling iron tailings provided by the invention has strong curing capability and is simple and controllable in use and operation.

Owner:罗强

Phosphogypsum-base wall material for cast-in-place wall

The invention discloses a phosphogypsum-base wall material for a cast-in-place wall. The invention is characterized in that the material is prepared from the following raw materials in percentage by weight: 60-80% of beta-phosphogypsum, 10-20% of mineral admixture, 5-25% of cement, 0.25-0.5% of retarder, 0.05-0.15% of defoaming agent, 0.05-0.2% of thickener and 0.5-1% of water reducer. The raw materials are uniformly mixed to obtain the phosphogypsum-base cast-in-place wall material; and the material and water are mixed uniformly in a water / material ratio of 0.4-0.5 to obtain a slurry, and the slurry is cast in place and molded. The phosphogypsum-base wall material has the advantages of controllable setting time, low flowing loss rate, high utilization ratio of solid waste, low material cost and high strength, is convenient for construction, and can be widely used for frame-structure infilled internal walls of commercial and civil buildings.

Owner:WUHAN UNIV OF TECH

Shield synchronous grouting construction material

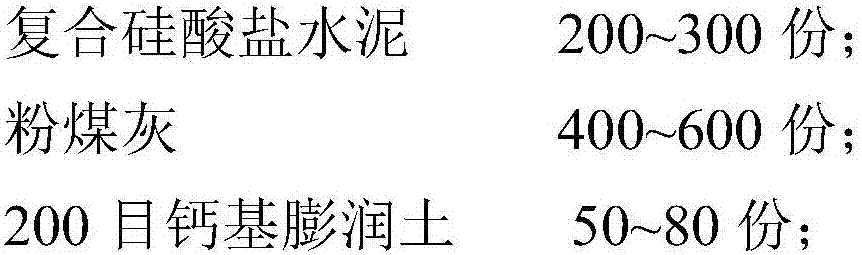

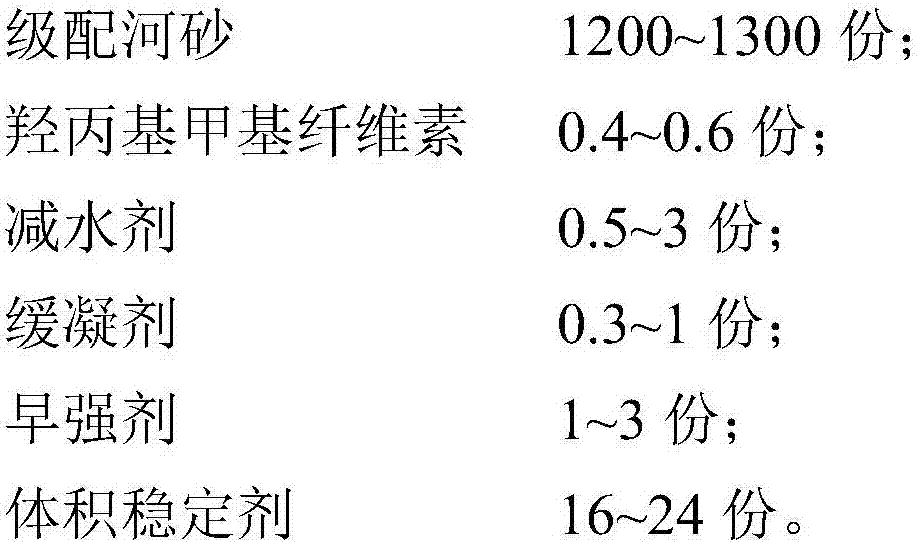

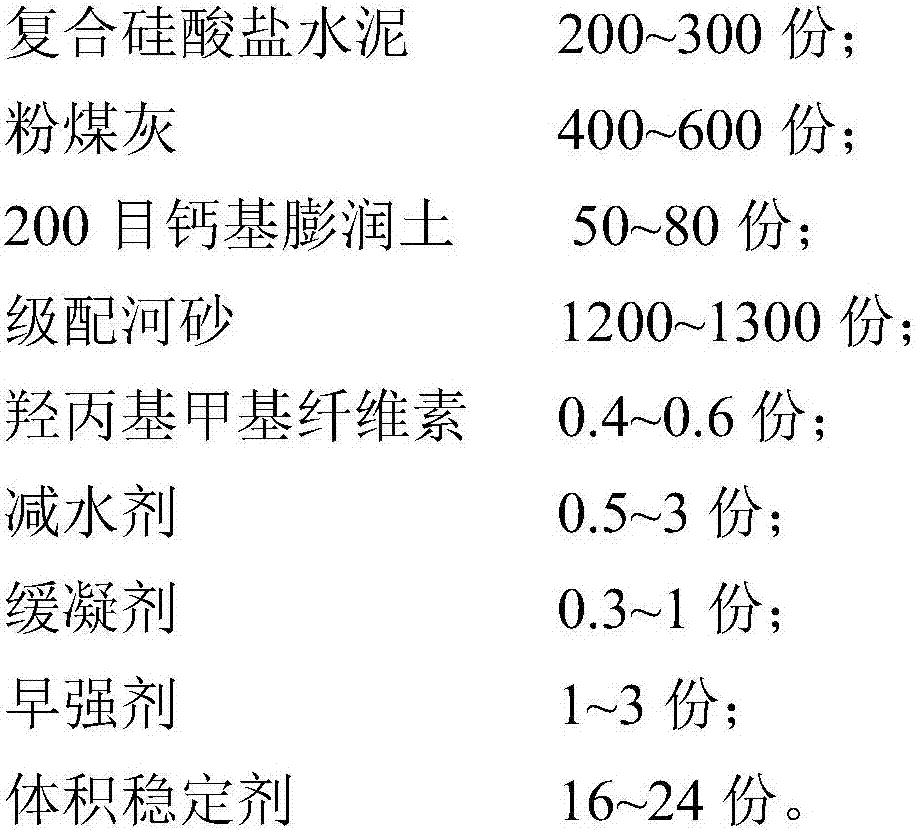

ActiveCN106946522AControl the compressive strengthControl bleeding rateSodium BentonitePortland cement

The invention discloses a shield synchronous grouting construction material including, by weight, 200-300 parts of composite Portland cement, 400-600 parts of fly ash, 50-80 parts of 200-mesh calcium based bentonite, 1200-1300 parts of grading river sand, 0.4-0.6 parts of hydroxypropylmethyl cellulose, 0.5-3 parts of a water reducer, 0.3-1 part of a retarder, 1-3 parts of an early strength agent and 16-24 parts of a volume stabilizing agent. Through reasonable adjustment of composition and content of the components, the compressive strength, bleeding ratio, setting time and flowability of the construction material are controlled, so that the construction material has long initial setting time, is quick in early strength development, is not liable to dissociation, has good volume stability, can effectively fill in gaps in buildings and prevent floatation and deformation of tunnel segments, has good flowability and anti-dispersing property, and is easy to transport and to store for a long period.

Owner:北京艺高世纪科技股份有限公司

Novel phosphorus and magnesium based cement grouting material and preparation method

The invention discloses a novel phosphorus and magnesium based cement grouting material and a preparation method and belongs to the field of technical application of grouting materials. The grouting material is prepared from the following raw materials in parts by weight: a component A: 30 to 90 parts of a compound magnesium compound, 0.5 to 5 parts of a compound retarder, 0.2 to 0.7 part of a water reducer, 0.2 to 1.5 parts of an acid-alkali buffering agent, 1 to 5 parts of a compound stabilizer and 0.5 to 1.5 parts of a compound surfactant; a component B: 20 to 50 parts of phosphate and 0.2to 2 parts of a de-foaming agent. The preparation method comprises the following steps: accurately weighing materials of the component A and the component B according to the ratio and uniformly stirring; mixing with water according to the weight ratio of 100 to (20 to 50) and stirring to form slurry; after uniformly mixing, pressing a mixture into gaps or cracks and curing. The novel phosphorus and magnesium based cement grouting material disclosed by the invention has the beneficial effects of controllable coagulation time, large adjustable range, high early age strength, high bonding strength, good permeability, simplicity and convenience for construction, greenness and environment protection and low cost, and meets the requirements on three properties including injectability, controllability and permeability resistance.

Owner:山东塔罗斯智能装备有限公司

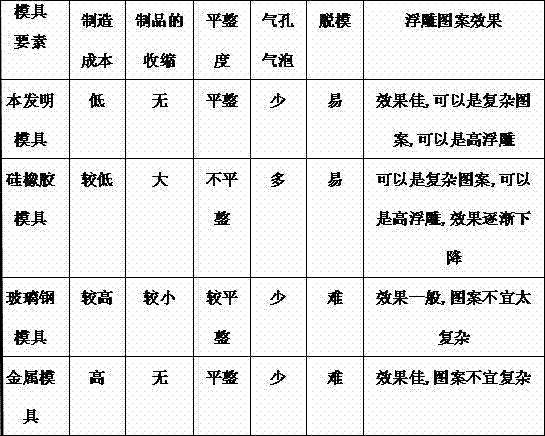

Production method of gypsum relief product

InactiveCN102343758AImprove surface strengthHigh strengthDecorative surface effectsOrnamental structuresFiberWeather resistance

The invention, belonging to the field of ornaments, relates to a method for producing a gypsum relief product, comprising the following steps: (1) preparing slurry, (2) making a die, (3) grouting, and (4) surface protection of the product. The step of preparing slurry comprises the following steps: 1, material preparation: high strength gesso a, redispersible polymer powder b, peach gum c, sodium tetraborate d, chopped fiber e, and water f; 2, preparation method: mixing f, b, c, d, and e with the weight ratio of f to b to c to d to e of 1000 to (40-50) to (3-5) to (2-3) to (15:20) to obtain a mixed emulsion g, and mixing a with g with the weight ratio of a to g of 1 to 1 to obtain slurry h. The gypsum relief product disclosed herein has the advantages of high surface hardness, scratch resistance, good toughness, impact resistance, strong weatherability, water resistance, and light weight.

Owner:义乌市项羽工艺品厂

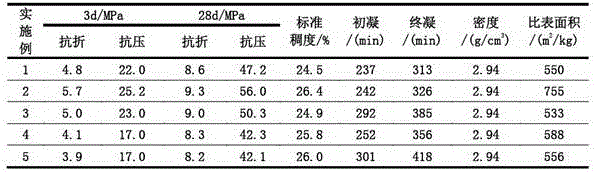

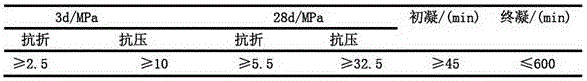

Anti-cracking reinforced ecological cement

InactiveCN101134645AProlong initial setting timeReduce early thermal cracksSolid waste managementGypsumFiber

The anticracking high strength ecological cement is produced with Portland clinker 35-80 wt%, fly ash 5-30 wt%, ferroalloy slag 1.0-30 wt%, boiler slag 5-40 wt%, gangue 10-40 wt%, grinding aid 0.1-2.0 wt%, gypsum 0.5-10 wt%, reinforcing fibrous inorganic mineral material 1-20 wt% and polymer fiber 0.01-10 wt%, and through grinding and mixing. Compared with available technology, the anticracking high strength ecological cement of the present invention has the advantages of low hydration heat, low shrinkage, low water demand, high early strength, etc.

Owner:JIANGXI GANFENG CEMENT

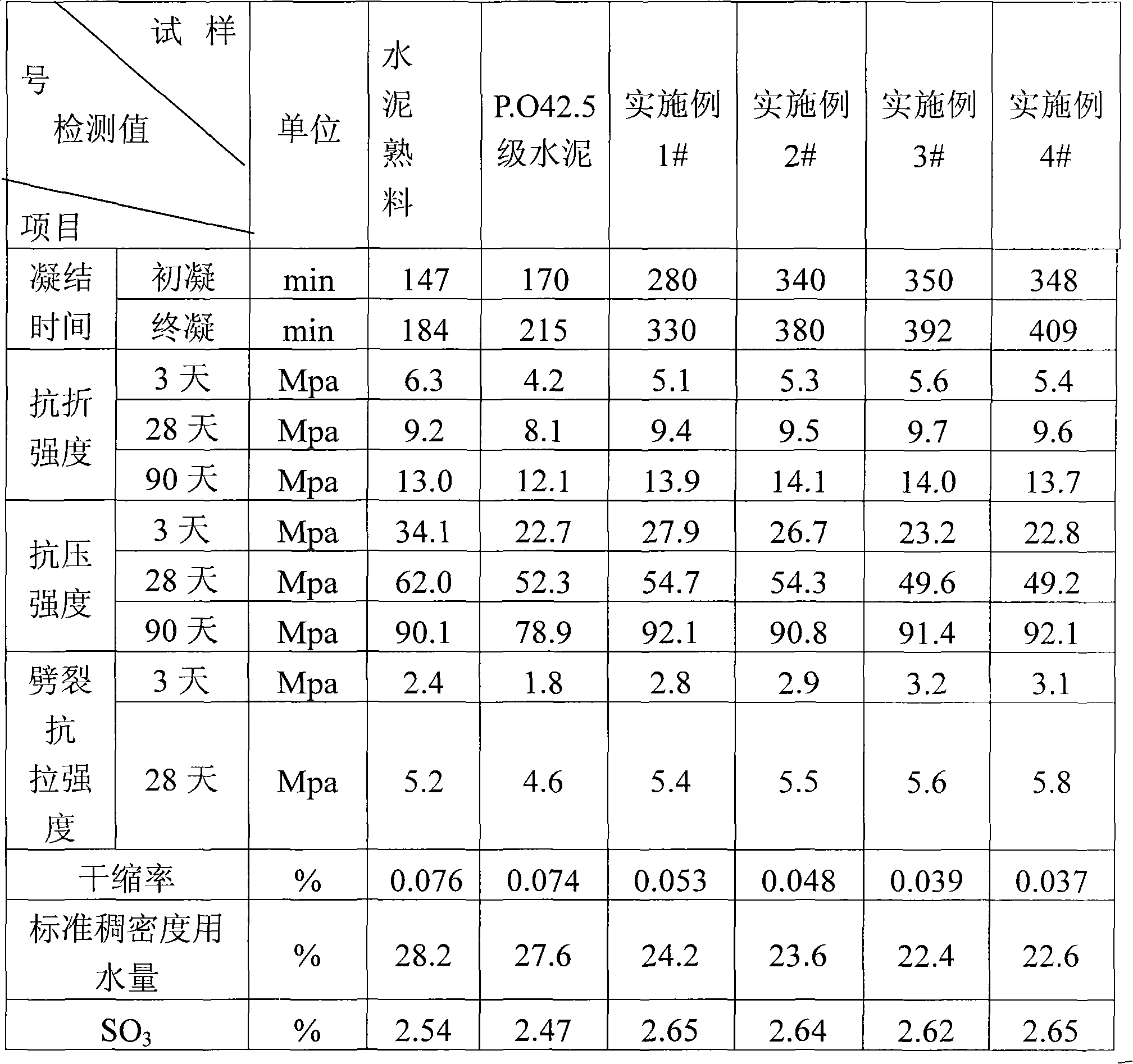

Retarded portland cement and preparation method thereof

InactiveCN105948544AProlong clotting timeIncrease late strengthCement productionSlagMaterials science

The invention relates to a retarded Portland cement and a preparation method thereof. The retarded Portland cement is prepared from the following components in percentage by weight: 52 to 58 percent of Portland cement clinkers, 22.2 to 25.5 percent of mixed slags, 14.8 to 17.5 percent of silica fume, and 5 percent of gypsum. The preparation method comprises the following steps of premixing a phosphorus slag, a vanadium-titanium bearing slag and a zinc slag according to the proportion to obtain a mixed slag a; mixing and grinding the mixed slag a, the Portland cement clinkers, the silica fume and the gypsum to prepare the retarded Portland cement. According to the retarded Portland cement provided by the invention, the usage amount of the Portland cement clinkers is reduced, so that the ingredient cost of producing the cement is effectively reduced, and the discharge of carbon dioxide is reduced; meanwhile, with the adding of the phosphorus slag and the silica fume, the problem that the long-term strength is reduced since the Portland cement clinkers are reduced is solved. The defects that the setting time is prolonged and the strength is reduced, or the strength is increased and the setting time is shorter due to the utilization of other materials in the prior art are overcome, and the obtained retarded Portland cement is remarkably prolonged in initial setting time and remarkably improved in long-term strength.

Owner:四川省宁南县白鹤滩水泥有限责任公司

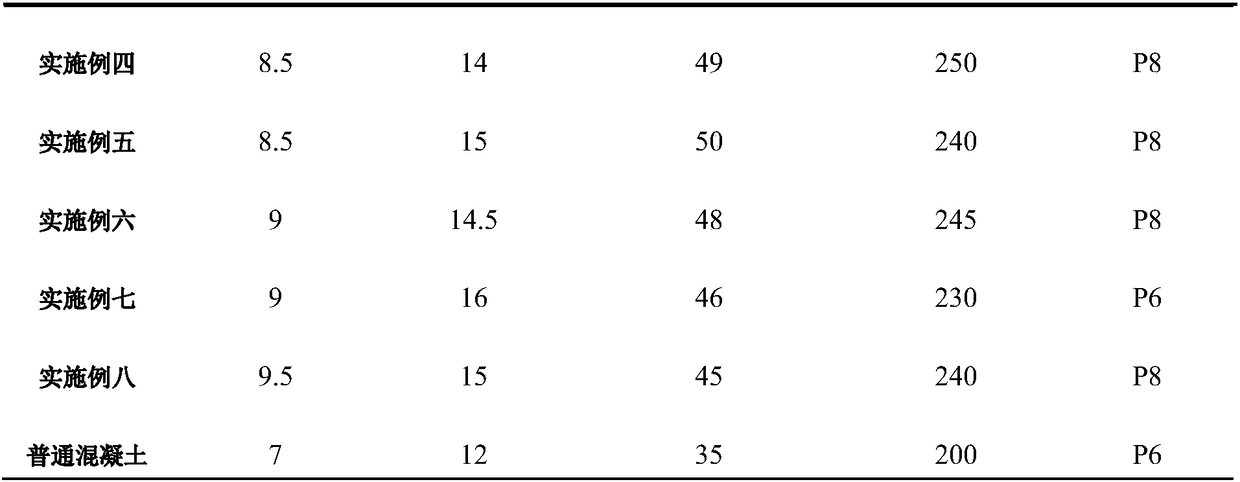

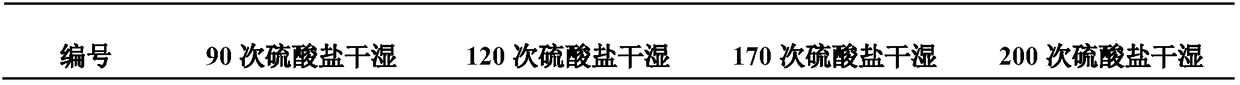

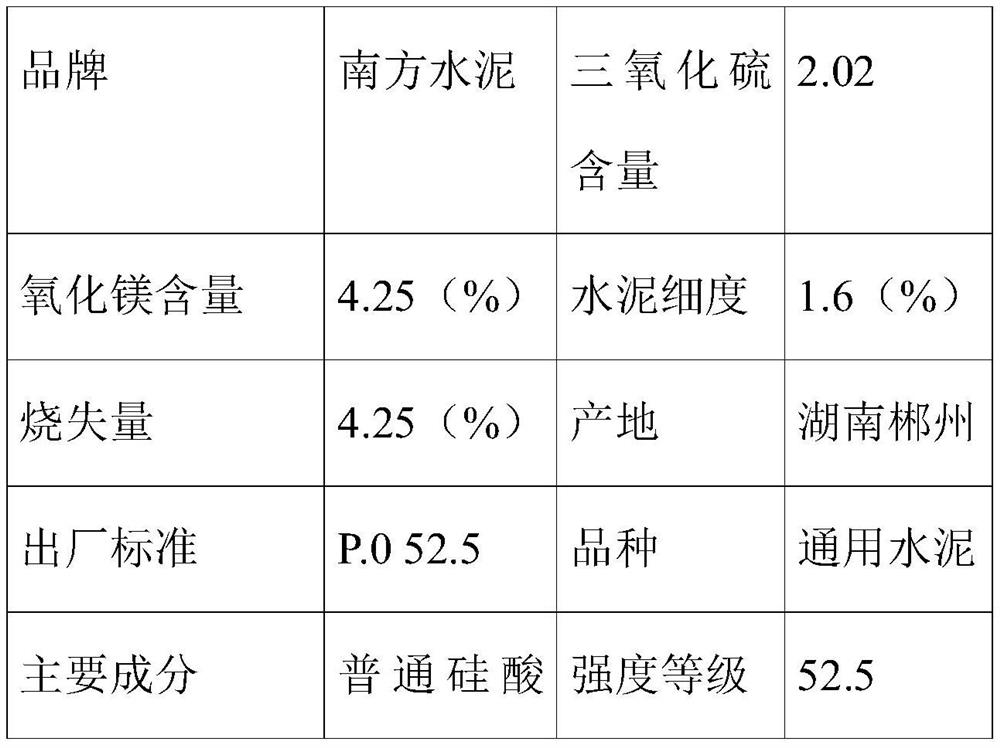

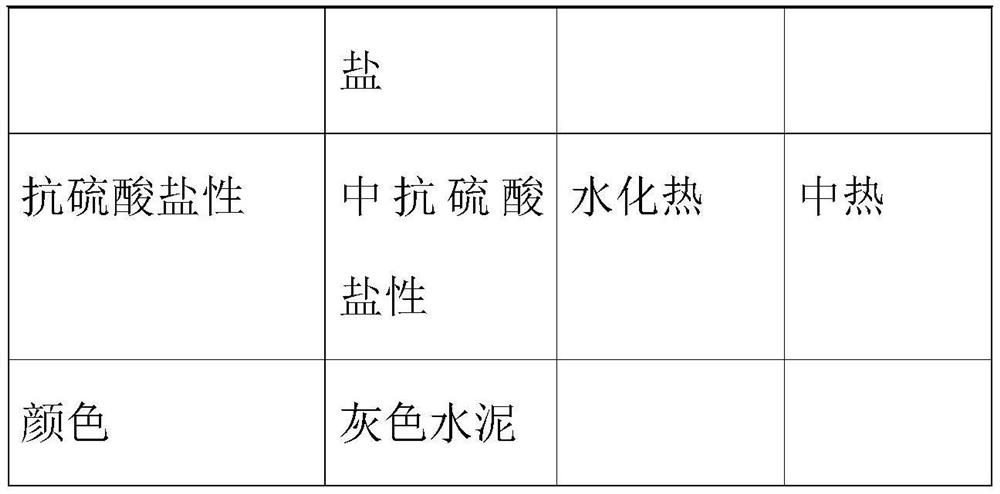

Sulfate-resistant concrete and preparation method thereof

The invention belongs to the technical field of concrete preparation, and provides a sulfate-resistant concrete. The sulfate-resistant concrete is characterized by being prepared from, by weight, 60-70 parts of sulfate-resistant cement, 30-40 parts of mineral admixture, 50-90 parts washed sand, 40-80 parts of machine-made sand, 110-160 parts of coarse aggregate, 4-6 parts of polypropylene fiber, 2-3 parts of carboxymethylcellulose, 70-90 parts of slurry forming water, 0.5-0.8 part of anhydrous ethanol, 2-3 parts of SBT-RMA concrete corrosion inhibitor and 1-2 parts of additive. The sulfate-resistant concrete solves the problems that the damage of corrosion to reinforced concrete is very serious, and sulfate-resistant concrete in the market is poor in anti-corrosion performance and short inservice life.

Owner:石家庄金隅混凝土有限公司

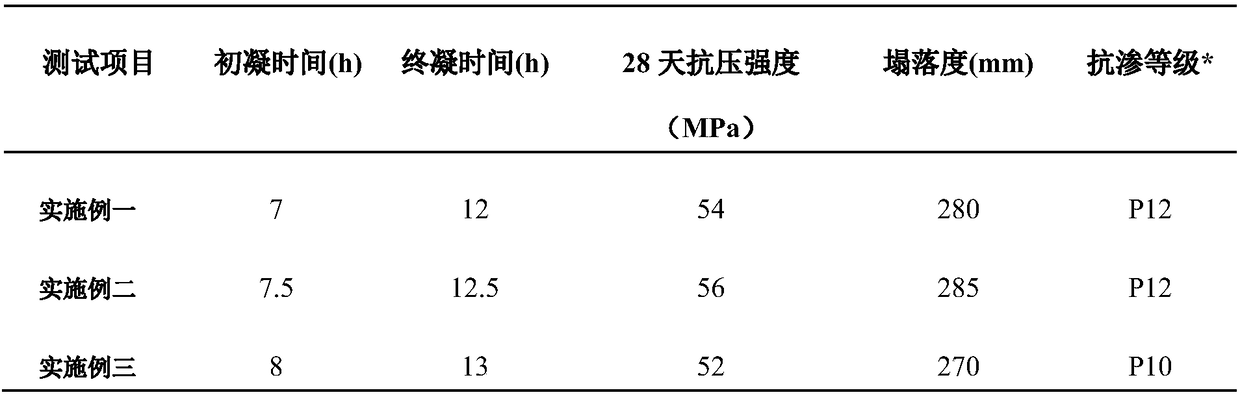

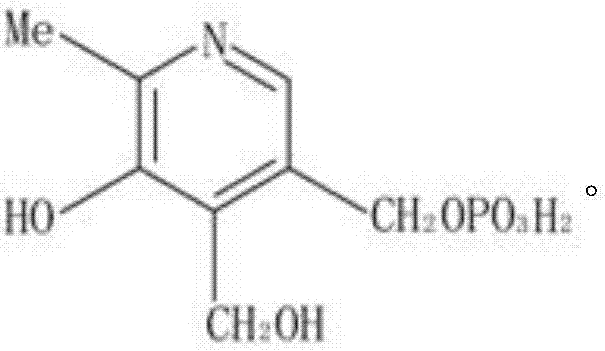

Delayed-coagulation high-toughness magnesium phosphate cement road rapid repair material

ActiveCN111056815AProlong initial setting timeInhibition formationMagnesium orthophosphateRepair material

The invention discloses a magnesium phosphate cement road rapid repair material which is prepared by compounding a phosphate-based powder material A, a magnesium oxide-based powder material B and a polymer emulsion C in proportion. By adopting a composite retarding technology, the operable time is effectively prolonged; the phosphorus slag powder is used as a mineral admixture, so that the hydration degree of the magnesium phosphate cement can be promoted while retarding; the multifunctional composite polymer emulsion is adopted, so that the toughness of the magnesium phosphate cement is improved while the waterproofness of the magnesium phosphate cement is improved; the obtained improved magnesium phosphate cement can show excellent operability, usability and stability, and the related preparation method is simple, low in cost and suitable for popularization and application.

Owner:广州市北二环交通科技有限公司

Method for preparing plaster evacuated mould

InactiveCN101531026AReduce water-cement ratioReduce solubilitySolid waste managementMixing operation control apparatusWater basedTime extension

This invention discloses a method for preparing plaster evacuated mould, including following steps: weighting and mixing the raw material based on that the mass ratio of plaster: inorganic filling material: glass fiber: high efficiency water reducing agent (mass ratio) is 80-90:10-20:3-4:0.5:2.5; weighting water based on the cement water ratio of o.45 to 0.65 by calculating with mass, then pouring the prepared raw materials into a stirring pot, at the same time, opening the stirrer, quickly stirring for 1 to 3 min with the rotating speed of 100 to 300 r / min; coating mineral oil at the four sides and the bottom of the module, then pouring the mixed ground paste into the mould, screeding the upper surface of the plaster evacuated mould, fetching out the concretionary plaster evacuated mould from the module, finally naturally drying the mould. The product prepared by this invention has short time for drying, enlarged delayed coagulation time and can improve the intensity and the hard wearing performance.

Owner:贵州金三利科技建材有限公司

High-early-strength low-expansibility filling material and filling method thereof

PendingCN108439910AWeak expansibilityImprove liquidityMaterial fill-upCeramicwareFoaming agentMaterials science

The invention discloses a high-early-strength low-expansibility filling material and a filling method thereof. The filling material comprises a matrix component and an admixture component; the matrixcomponent comprises an inert material, a cementing material and water; the admixture component comprises, by mass of the inert material, 3-10% of a foaming agent, 3-5% of a foam stabilizing agent and0.1-0.8% of a retarder. The high-early-strength low-expansibility filling material has advantages of high fluidity, long initial setting time, high early strength and low expansibility, the expansionrate is 20-50%, a high tight-filling ratio of 100% can be realized in application to mining filling, and effective support for roofs of goafs or roadways can be formed.

Owner:CHINA UNIV OF MINING & TECH

Well cementation material for medium and deep layer geothermal well, preparation method of well cementation material, and geothermal well

PendingCN110386780AHigh strengthProlong initial setting timeDrilling compositionSealing/packingSetting timeGraphite

The invention relates to the technical field of geothermal equipment, in particular to a well cementation material for a medium and deep layer geothermal well, a preparation method of the well cementation material, and the geothermal well. The well cementation material for the medium and deep layer geothermal well is prepared from water, cement, graphite powder, metal powder, a water reduction agent and a retarder which are in appropriate proportion. The well cementation material has good strength, thus the well cementation need can be met, meanwhile, the retarder is added in the well cementation material, thus the initial setting time of the well cementation material can be prolonged, and the construction requirements are met; flowability of the well cementation material can be optimizedthrough the water reduction agent, and thus liquidity is improved; and the strength, liquidity and initial setting time of the well cementation material meet the construction requirements, meanwhile,the heat conductivity coefficient of the well cementation material is 5-20 times that of the cement, and thus the utilization efficiency of geothermal energy can be effectively improved.

Owner:中国煤炭地质总局水文地质局

Anhydrous pebble backfill formation shield wall post-grouting material

InactiveCN106186993AAvoid churnProlong initial setting timeSolid waste managementSodium BentoniteEarth surface

The invention discloses an anhydrous pebble backfill formation shield wall post-grouting material which comprises, by weight, 10-16% of fly ash, 2-3.2% of lime, 0.5-4.5% of bentonite, 54-57% of stone chips and the balance of water added to 100%. Characteristics of an anhydrous pebble backfill formation are combined, specific raw materials and mixing proportion are adopted, needs on workability and fluidity of formation grouting liquid are met, cost is lowered greatly, loss of the grouting liquid is prevented, initial setting time of the grouting liquid is reduced, and ground surface settlement and duct piece dislocation are controlled effectively. The stone chips are adopted to replace river sand, so that local materials can be used and are convenient, quick and cheap in price, and economic cost is saved; lime is adopted to replace cement, so that setting time is shorter, and cost is lower.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Synchronous grouting slurry for shield driving construction of water-enriched sandy gravel stratum

The invention relates to synchronous grouting slurry for shield driving construction of a water-enriched sandy gravel stratum, which is used for synchronously grouting the stratum by using an earth pressure balance shield for the water-enriched sandy gravel stratum. The grouting slurry is prepared from the following components in percentage by weight: 8-8.8% of cement, 42-43% of river sands, 0.1-0.2% of polycarboxylate high performance water reducer, 4.5-4.7% of bentonite, 1.4-1.6% of yellow clay powder, 23-24% of coal ash and 19-20% of water. According to the slurry provided by the invention, by adding the polycarboxylate high performance water reducer, the use level of water in the equal flow condition is reduced, the use level of cement can be reduced under same strength by virtue of double effects of hydrophilicity and hydrophobicity of the polycarboxylate high performance water reducer, so that the initial setting time of the slurry is accelerated and the problem that the synchronous grouting slurry is separated within a short time is solved. The peaceability, the mobility and the set strength of the synchronous grouting slurry can be improved.

Owner:SOUTHWEST JIAOTONG UNIV +1

Concrete accelerator and preparation method thereof

The invention provides a concrete accelerator. The concrete accelerator is prepared from the following raw materials: aluminum sulfate, aluminum nitrate, phosphoric acid, ammonia water, a halloysite nanotube modified alkylol amine polymer grinding aid, a stabilizer, magnesium fluorosilicate, a tackifier and water. Various coagulation accelerating components are compounded, the coagulation time ofsprayed concrete can be further shortened, the comprehensive performance of cement is improved, a good coagulation accelerating effect is achieved on premixed concrete subjected to initial hydration,the coagulation time of the concrete can be obviously shortened, the early strength is improved, the stability, durability and safety of the concrete can be remarkably improved, and the cost is low. The concrete accelerator is particularly suitable for premixed concrete spraying construction of long-time and long-distance transportation.

Owner:海南佳益混凝土有限公司

Super-retarded concrete

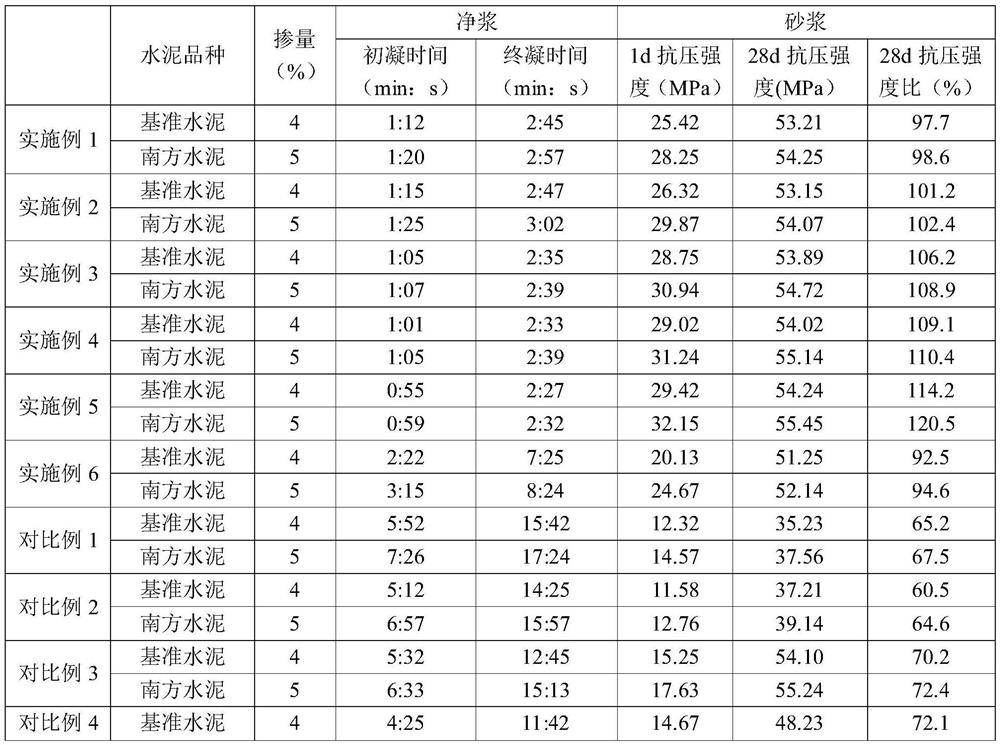

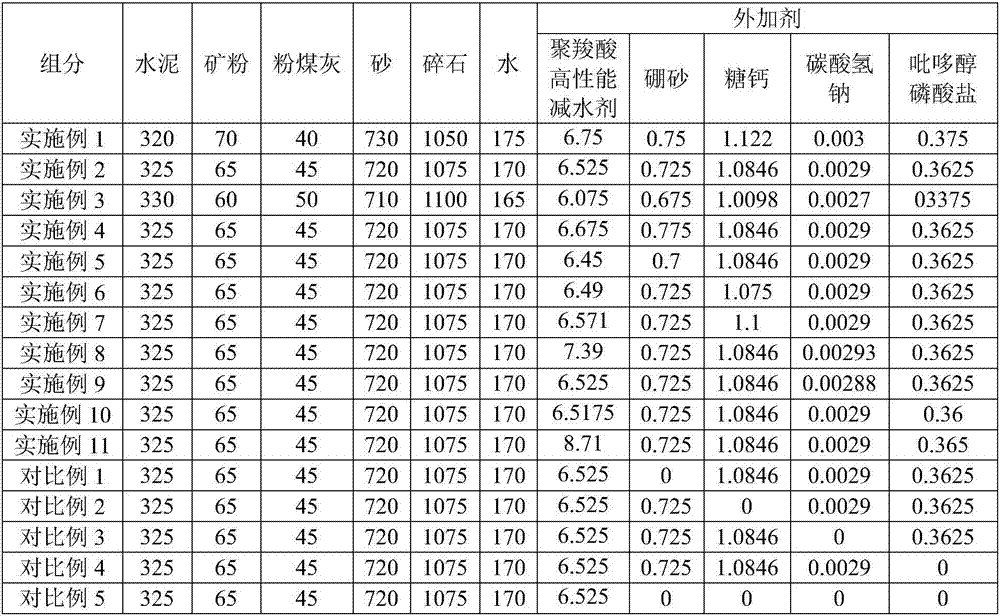

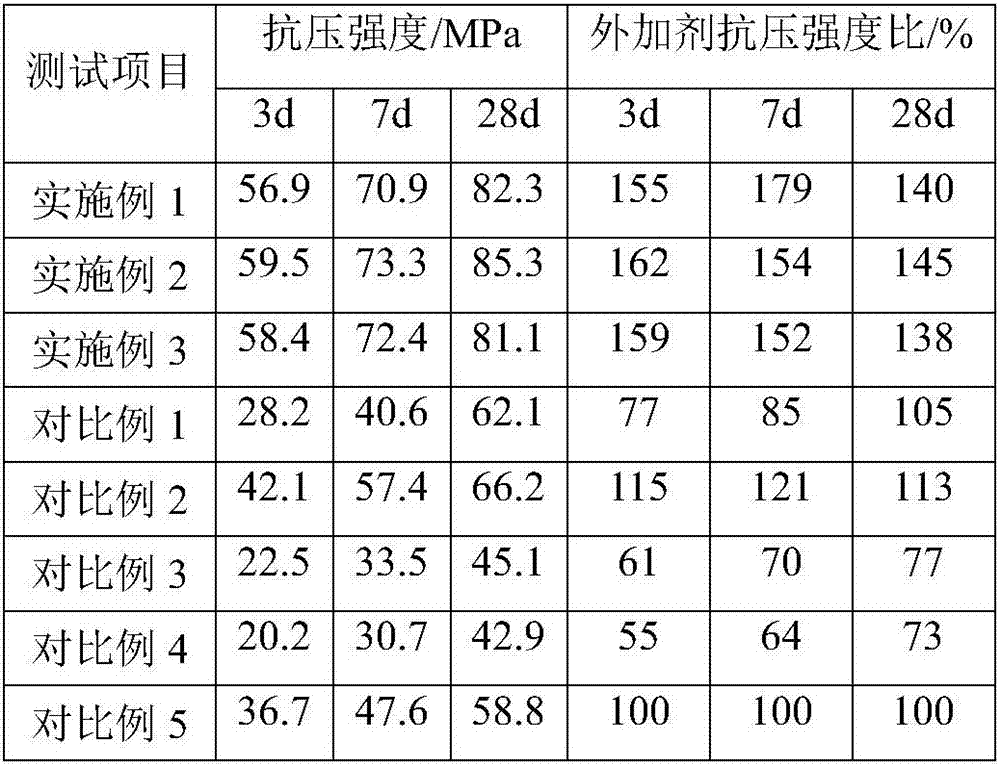

The invention relates to super-retarded concrete, which is characterized by comprising the following raw materials (by weight): 320-330 parts of cement, 60-70 parts of mineral powder, 40-50 parts of fly ash, 710-730 parts of sand, 1050-1100 parts of broken stone, 165-175 parts of water and 8.1-9 parts of an additive. The super-retarded concrete has long setting time and enough later strength.

Owner:天津金隅混凝土有限公司

Silicate plugging agent for oil-well water plugging and application method thereof

ActiveCN103571445AHigh water-cement ratioImprove pumping performanceDrilling compositionSealing/packingPhysical propertyMaterials science

The invention discloses a silicate plugging agent for oil-well water plugging and an application method thereof, wherein the silicate plugging agent comprises the following components by weight percentage: 8-12% of general purpose portland cement, 1-3% of silica fume, 0.3-0.7% of water glass, 0.01-0.03% of sodium lignin sulfonate and the balance of water. The application method of the silicate plugging agent for oil-well water plugging comprises the following steps: in the stirring process, orderly adding the water glass, the sodium lignin sulfonate and the silica fume in a stirring pot with water proportionally, and stirring evenly to obtain a mixed solution; next, adding the general purpose portland cement to the mixed solution while stirring to form the base solution of the silicate plugging agent; and pouring the base solution of the silicate plugging agent into formation fractures. The silicate plugging agent provided by the invention has the advantages of high water cement ratio, good pumping performance, long initial setting time, high after-final-setting strength, good water scouring resistance, all of which are similar to the own physical properties of the formation; the silicate plugging agent is capable of achieving the construction requirements of oil-well water plugging; and the properties of the silicate plugging agent are suitable for nonhomogeneous fractured reservoirs.

Owner:PETROCHINA CO LTD

Method for quickly preparing arc spraying mother plate substrate

The invention discloses a rapid preparation method for an arc-sprayed female die matrix. The female die matrix belongs to a magnesium oxychloride composite material, and contains 41.2 to 57.7 percent of light burned magnesia, 15.9 to 36.1 percent of industrial magnesium chloride, less than or equal to 2.0 percent of chopped carbon fiber, and the balance being water. During the use, raw materials are prepared into an uniform sizing agent, a prototype of a part to be sprayed is used to reclaim a female die made of magnesium oxychloride composite material, the female die is dried and finely machined, and finally hydrochloric acid is used to perform surface treatment on the female die to finish the rapid preparation of the sprayed female die. The sprayed female die produced by the method has low cost and high strength, is high temperature resistant, does not need high temperature baking during the production, can be machined, and is particularly suitable for middle-low melting point and high melting point electric arc spraying rapid molding technologies.

Owner:XI AN JIAOTONG UNIV +1

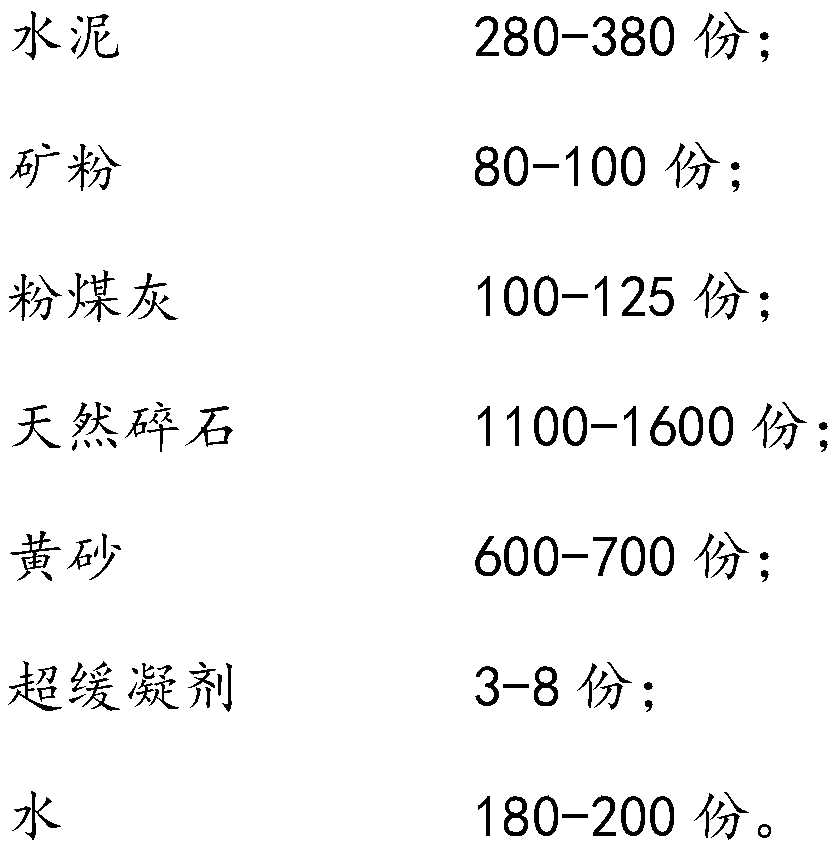

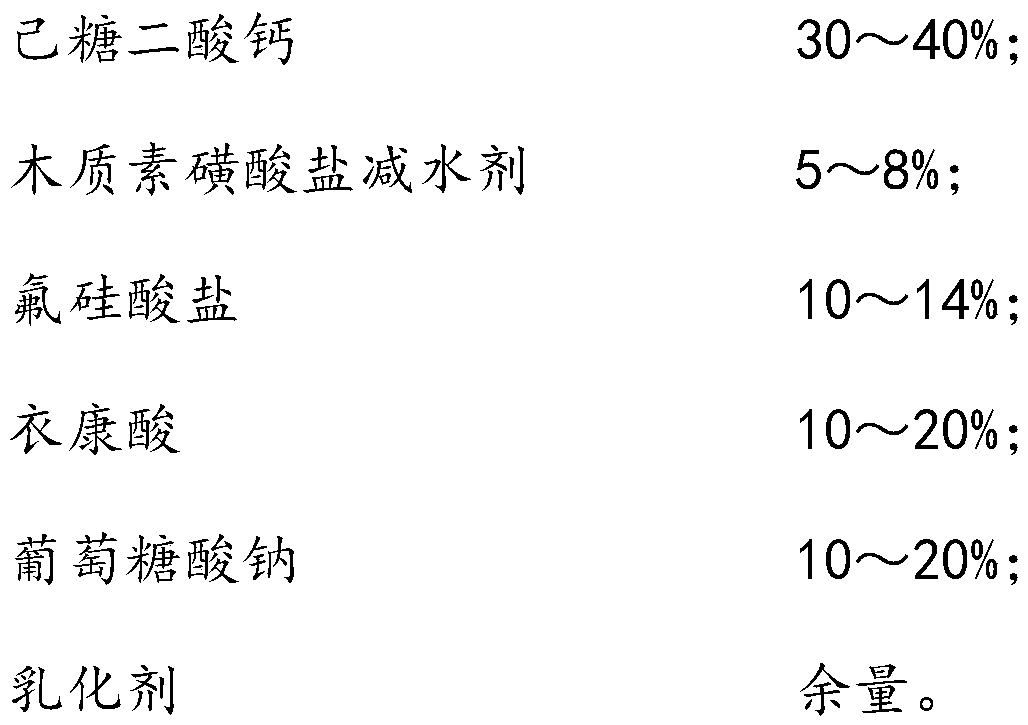

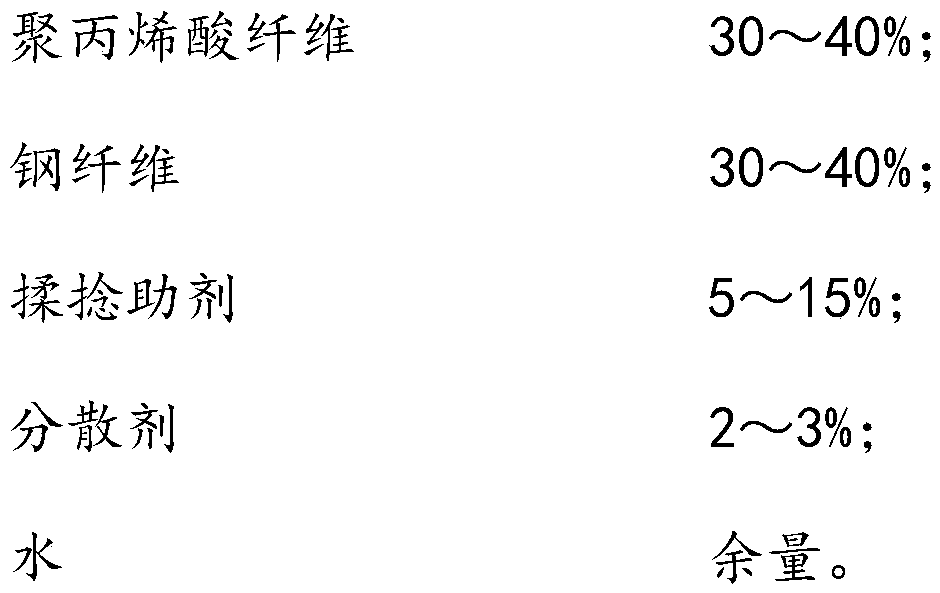

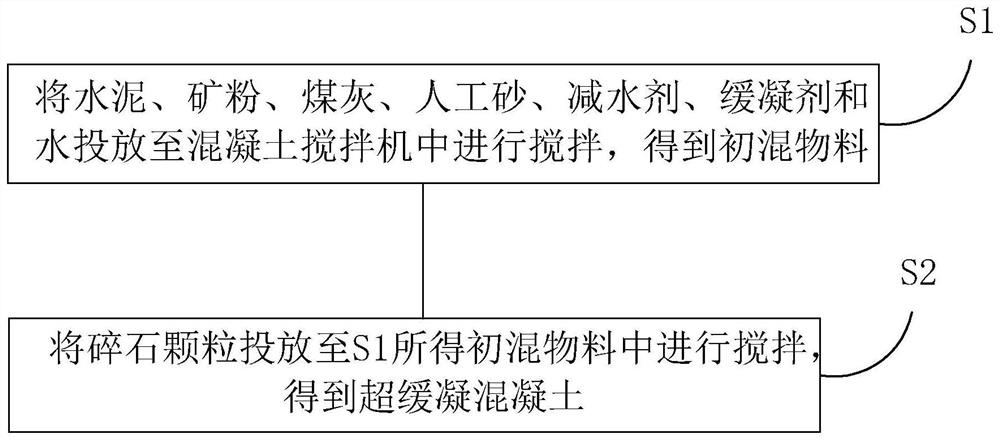

Super retarded concrete

The invention discloses super retarded concrete, and relates to the technical field of concrete, and the super retarded concrete comprises the following raw materials in parts by weight: 280-380 partsof cement, 80-100 parts of mineral powder, 100-125 parts of fly ash, 1100-1600 parts of natural macadam, 600-700 parts of yellow sand, 3-8 parts of an ultra-retarding agent and 180-200 parts of water. The preparation method has the advantages that the initial setting time of the concrete is prolonged, and the strength of the concrete is improved.

Owner:四川信敏绿色新建筑材料科技有限公司

Super-retarding concrete and preparation method thereof

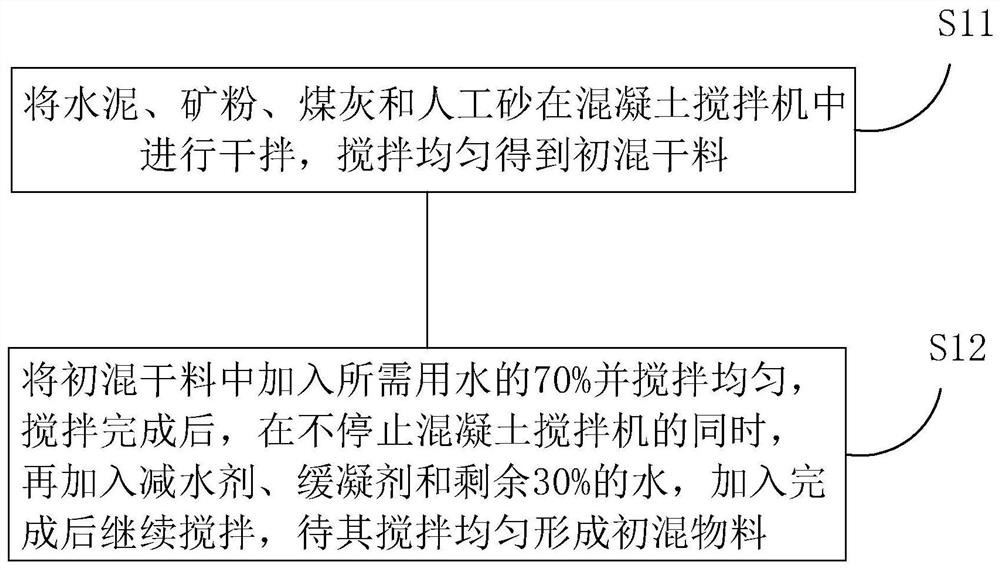

The invention relates to super-retarding concrete and a preparation method thereof, and relates to the technical field of concrete preparation. The concrete is prepared from the following components in parts by weight: 340 to 360 parts of a gel material, 700 to 900 parts of artificial sand, 900 to 1200 parts of broken stone, 7 to 8 parts of a water reducing agent, 8 to 10 parts of a retarder and 150 to 190 parts of water, wherein the gel material is formed by mixing cement, mineral powder and coal ash, the respective weight of the mineral powder and the coal ash in the gel material accounts for not less than 10% of the weight of the gel material, and the sum of the total weight of the mineral powder and the coal ash in the gel material accounts for 20-50% of the weight of the gel material.The retarder is prepared from sodium citrate, sodium gluconate, phosphogypsum, fly ash and carbide slag according to the weight ratio of (20-24): (16-18): (35-42): (16-20): 3. According to the invention, the concrete can be controlled not to be initially set within 48 hours, and the transportation is convenient.

Owner:湖北云海混凝土有限公司

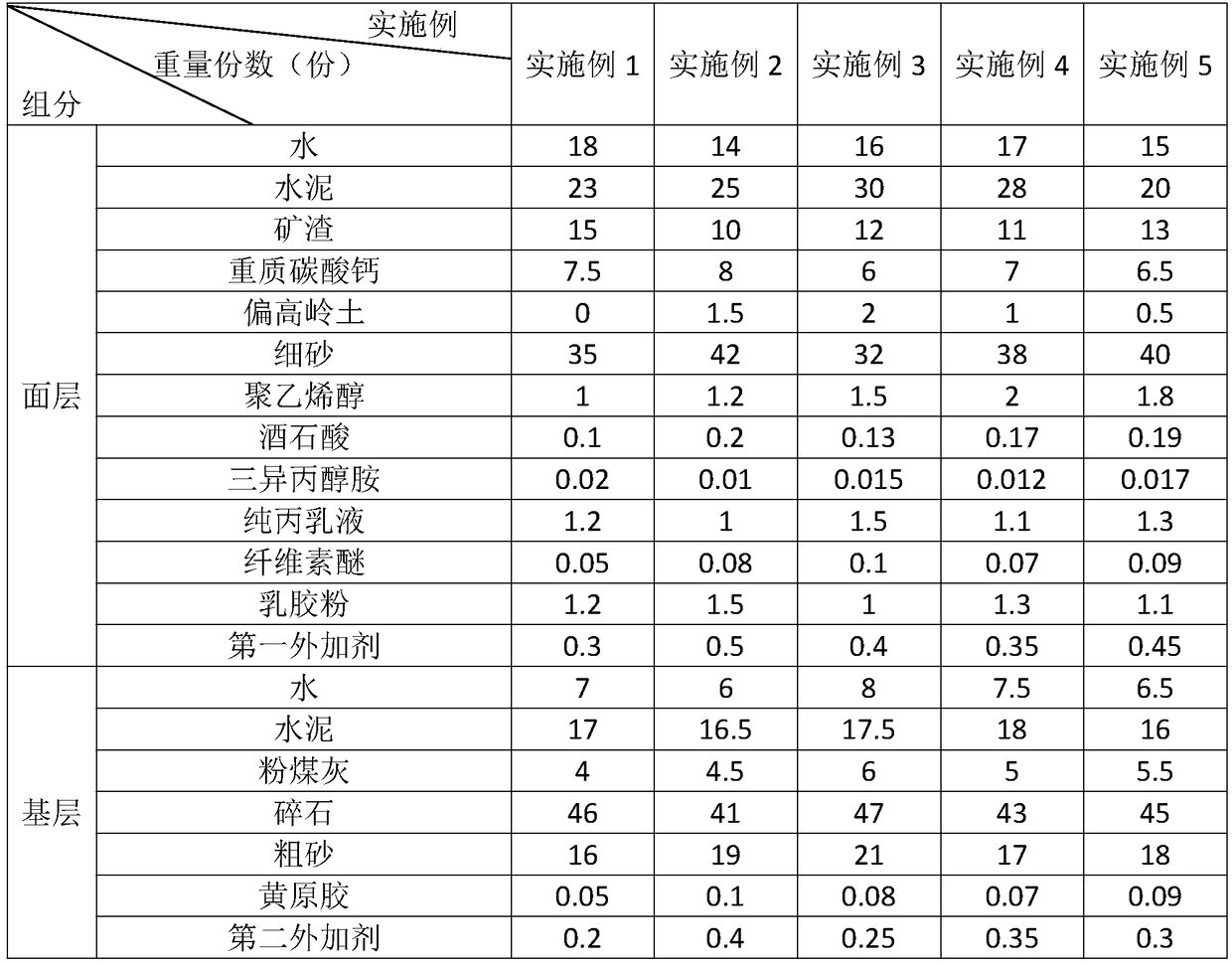

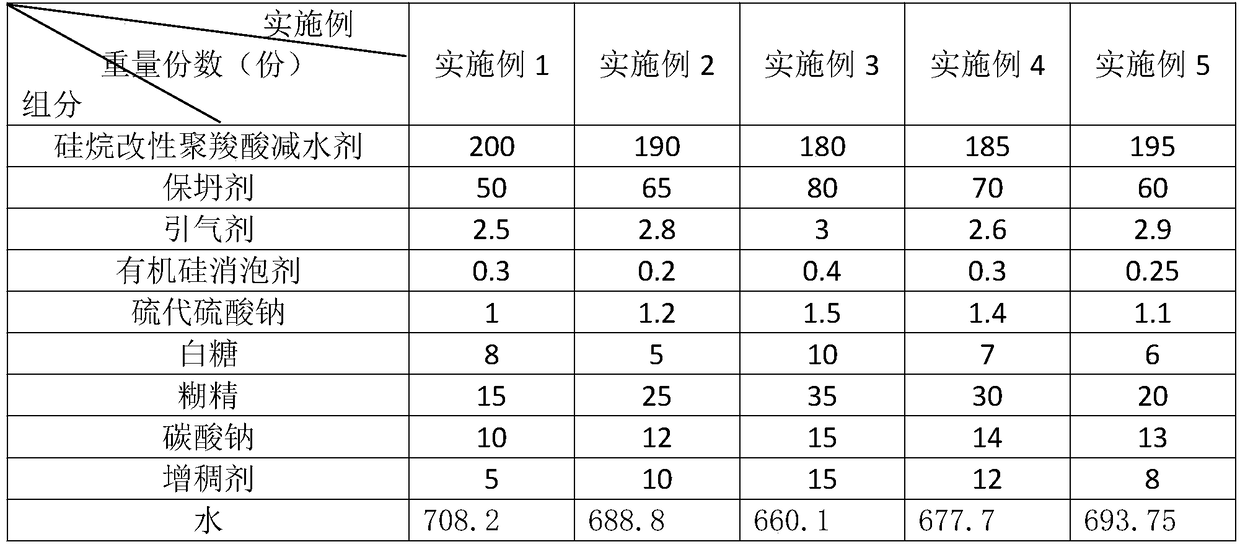

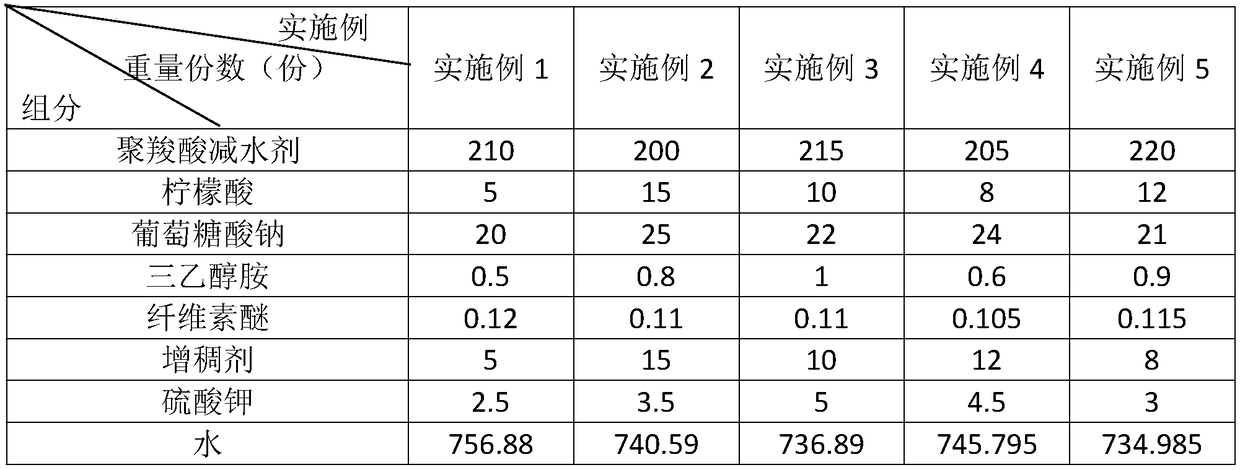

Road surface paving plate with waterproof surface layer and permeable base layer, and production technology thereof

ActiveCN108947389AImprove mobilityExtended use timeSingle unit pavingsPaving gutters/kerbsMetakaolinEmulsion

The invention discloses a road surface paving plate with a waterproof surface layer and a permeable base layer, and a production technology thereof. The road surface paving plate comprises a surface layer and a base layer, wherein the surface layer contains the following raw materials in parts by weight: 14-28 parts of water, 20-30 parts of cement, 10-15 parts of slag, 6-8 parts of coarse whiting,0-2 parts of metakaolin, 32-42 parts of fine sand, 1-2 parts of poval, 0.1-0.2 parts of tartaric acid, 0.01-0.02 parts of tri-isopropanolamine, 1-1.5 parts of pure acrylic emulsion, 0.05-0.1 parts ofcellulose ether, 1-1.5 parts of emulsion powder, 0.3-0.5 parts of first additive, 6-8 parts of water, 16-18 parts of cement, 4-6 parts of coal ash, 41-47 parts of macadam, 16-21 parts of coarse sand,0.05-0.1 parts of xanthan gum, and 0.2-0.4 parts of second additive. The road surface paving plate has the advantages of being excellent in waterproofness of the surface layer and permeability of thebase layer, and beneficial to smooth drainage after the road surface paving plate is arranged.

Owner:成都建工预筑科技有限公司

High efficient slow coagulating retarder for concrete and cement

InactiveCN1657478AReduce power consumptionProlong initial setting timeMaterials scienceCrystallization

Owner:申士富 +1

Cement-based composite material for 3D printing technology and its preparation method and use

ActiveCN104310918BEasy to get materialsLow costSolid waste managementComputer printingHouse building

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

High-temperature-resistant non-shrink early-strength grouting material and application thereof

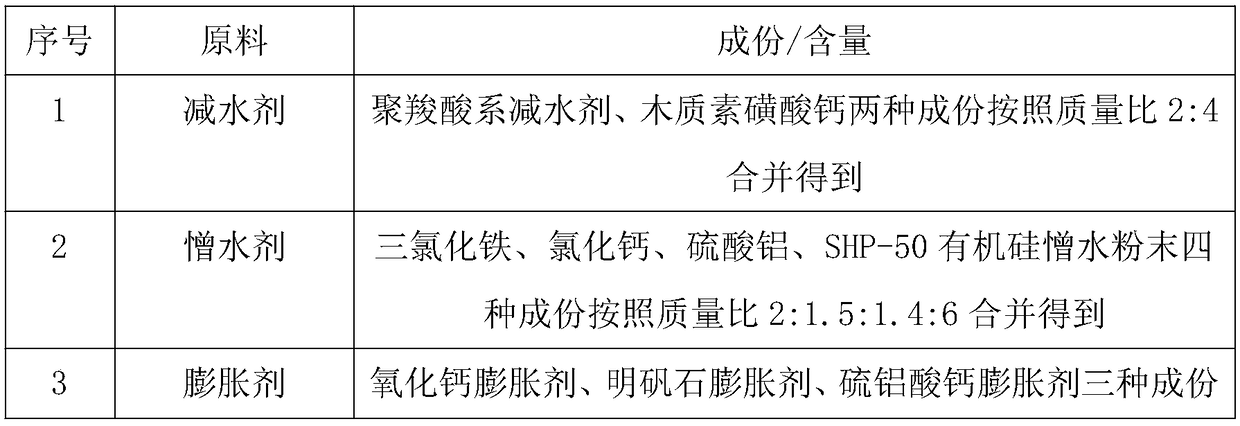

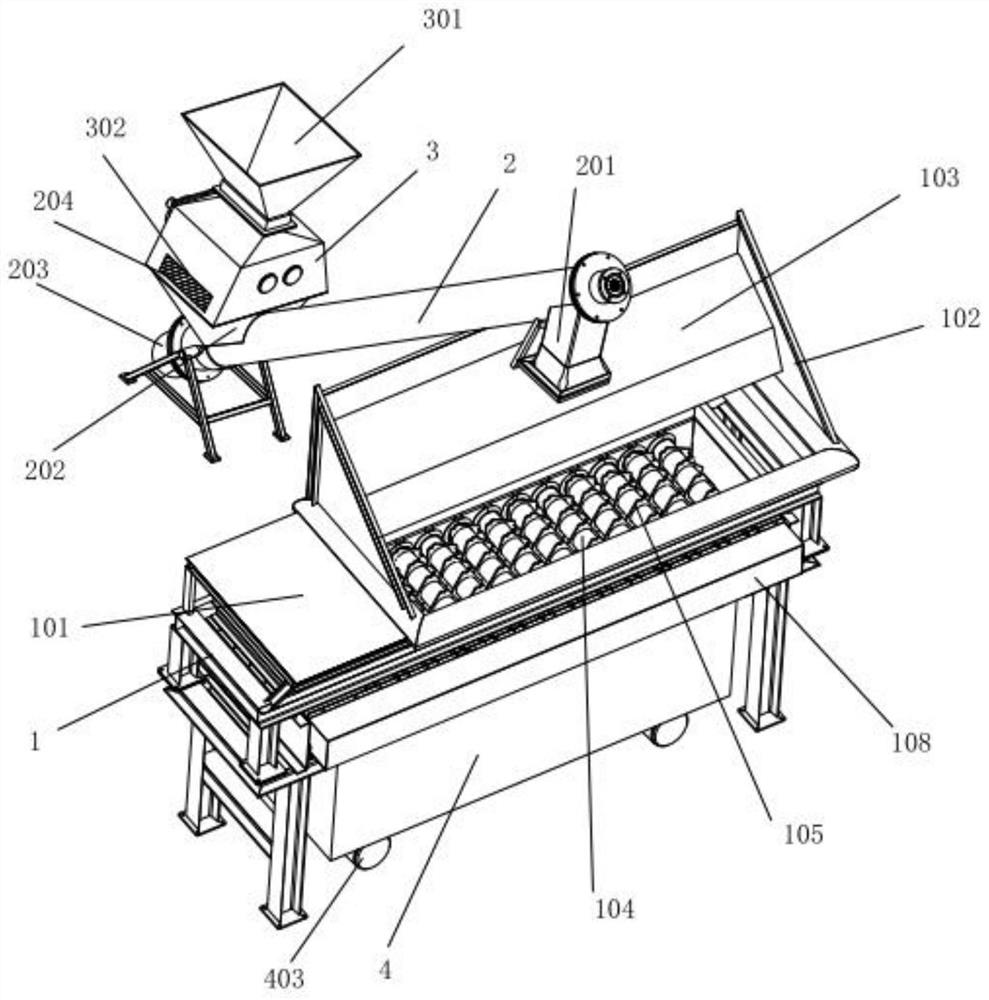

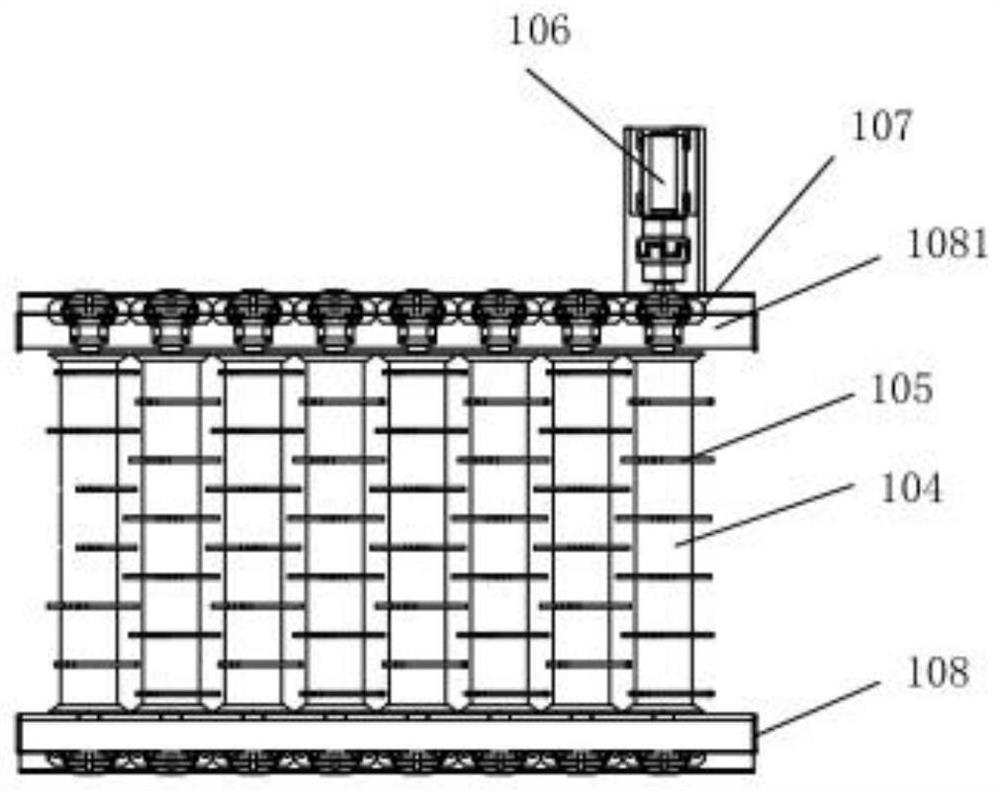

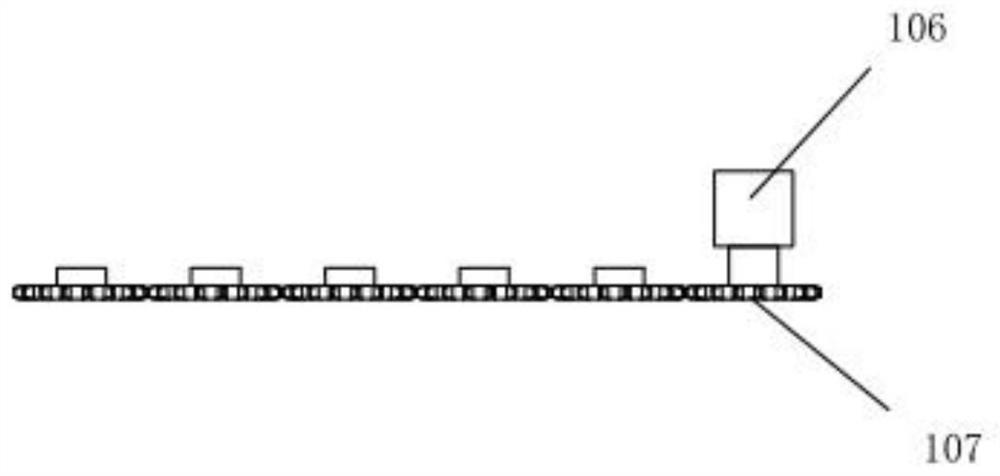

The invention discloses a high-temperature-resistant non-shrink early-strength grouting material and application thereof, and relates to the technical field of grouting materials. The high-temperature-resistant non-shrink early-strength grouting material comprises volcanic ash silicate cement 32.5R, perovskite flotation tailing, illite powder, shell powder, shale pottery sand, Swf-05 gelatin powder, water reducing agents, water repellents, expansive agents, rare-earth coupling agents and magnetized water. The high-temperature-resistant non-shrink early-strength grouting material and the application have the advantage that the high-temperature-resistant non-shrink early-strength grouting material is comprehensively obviously enhanced in the aspects of the physical properties, the frost resistance, the high-temperature resistance, the flowability, the mechanical strength and the like, is obviously progressed as compared with the prior art, and is good in applicability and long in servicelife.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Human body canal cast filler and preparation method thereof

InactiveCN102391617AEasy to prepareSimple and fast operationDead animal preservationEducational modelsHuman bodyPolymer science

The invention provides a human body canal cast filler and a preparation method of the human body canal cast filler; and the human body canal cast filler is good in physicochemical performance, strong in acid-base resistance, good in flexibility and stronger in support force. The human body canal cast filler is prepared by the components according to the volume ratio: 100ml of cyclodextrin (CYD)-128 type epoxy resin, 20-24ml of liquid-state nitrile rubber, 35-40ml of polypropylene glycol diglycidyl ether, 15ml of 2, 4, 6-tri-(dimethylamino methyl) phenol (DMP-30), 45ml of modified polyether amine epoxy resin curing agent ZY-1784 and 40-45ml of high-performance epoxy resin toughening modifier (RF-400). The human body canal cast filler is easy in preparation as well as simple and convenient in operation, can be completed by once injection without after-teeming, and can be immediately prepared when injection is not sufficient. The invention has the characteristics of being good in fluidity, low in injection resistance, full in molding, fin and attractive, low in contractibility rate, environment-friendly and the like.

Owner:黄海龙

Ready mixed dry mortar and preparation method thereof

InactiveCN102408209AFormula flexibleTechnical requirements to meet different needsCellulosePolymer science

The invention discloses a ready mixed dry mortar and a preparation method thereof. The ready mixed dry mortar is prepared by the following components in percentage by weight: 18-50% of cement, 48-80% of medium fine sand and 0.1-2% of cellulose ether high molecular polymer. The preparation method comprises the following steps of: A, drying the medium fine sand, screening to remove particles of more than 4.75mm and weighing for use; B, weighing the cellulose ether high molecular polymer and the cement, and uniformly stirring in advance for use; and C, adding the medium fine sand screened in the step A and the mixture of the cellulose ether high molecular polymer and the cement in the step B to a stirrer for uniformly stirring to obtain the product. The aim of the invention is to overcome the defects in the prior art and provide a high-quality ready mixed dry mortar containing high molecular polymer component. The other aim of the invention is to provide a method for preparing the ready mixed dry mortar.

Owner:中山建华墙体材料有限公司

Environment-friendly cement and preparation method thereof

PendingCN112174552AHigh strengthIncreased durabilitySievingScreeningKaolin clayToxic industrial waste

The invention discloses environment-friendly cement and a preparation method thereof. The environment-friendly cement is prepared from limestone, coal ash, fluorgypsum, kaolin, industrial waste residues, modified natural rubber, coal gangue, vanadium slag, a reinforcing agent, an anti-permeability agent and water, and the modified natural rubber, the limestone and the coal ash are added into the prepared cement for effective filling; the strength and durability of cement are improved, in addition, the kaolin can change the grain composition of the cement, improve the coarse grain content of the cement, enhance the skeleton effect and further improve the strength and durability of the cement, so that the cement has a wide application prospect, and meanwhile, the reinforcing agent is added in the cement preparation process; the reinforcing agent reduces the viscosity of the cement material and promotes the dispersion of the particles by adjusting the fluidity of the cement material and the surface electrical properties of the particles, so that the flowability of the cement material is improved, the initial setting time in the cement preparation process is remarkably prolonged, and the later compressive / flexural strength is also remarkably improved.

Owner:赵书成

Gypsum-based foam concrete and preparation method thereof

ActiveCN112679185ASmall and uniform pore sizeImprove water resistanceCeramicwareFoam concreteAluminate

The invention belongs to the technical field of building materials, and provides gypsum-based foam concrete and a preparation method of the gypsum-based foam concrete. The concrete comprises the following components in parts by weight: 50-65 parts of gypsum, 22-28 parts of Portland cement, 1-2 parts of sulphoaluminate cement, 1-2 parts of quick lime and / or slaked lime, 13-18 parts of fly ash, 4-8 parts of SiO2 aerogel, 0.2-0.4 part of graphene oxide, 0.2-0.4 part of a water reducing agent, 0.05-0.1 part of a waterproof agent and 0.09-0.2 part of a foaming agent. Each component can play a synergistic role in specific proportions, can significantly improve the water resistance of the gypsum-based foam concrete, and the water absorption rate of the gypsum-based foam concrete is obviously reduced.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

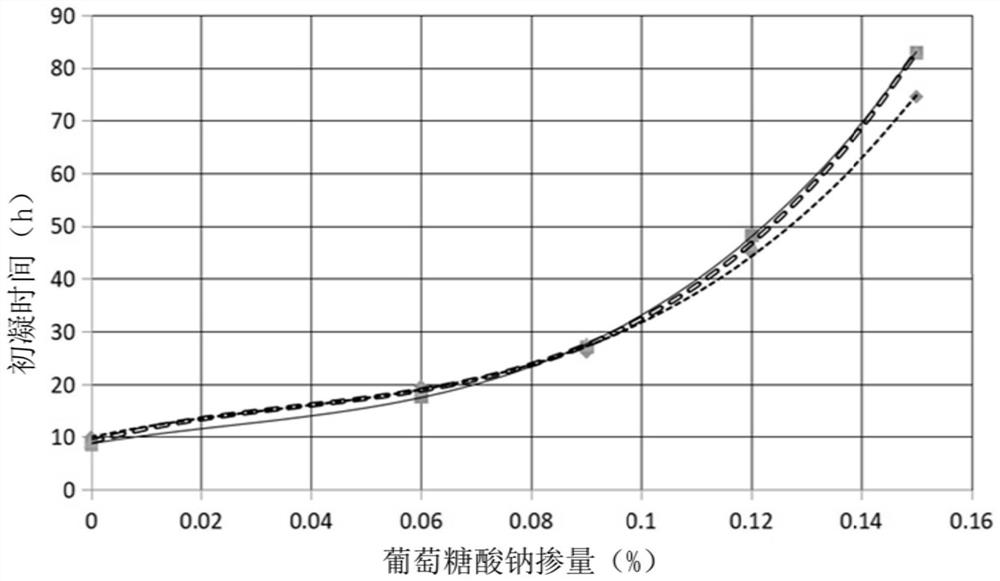

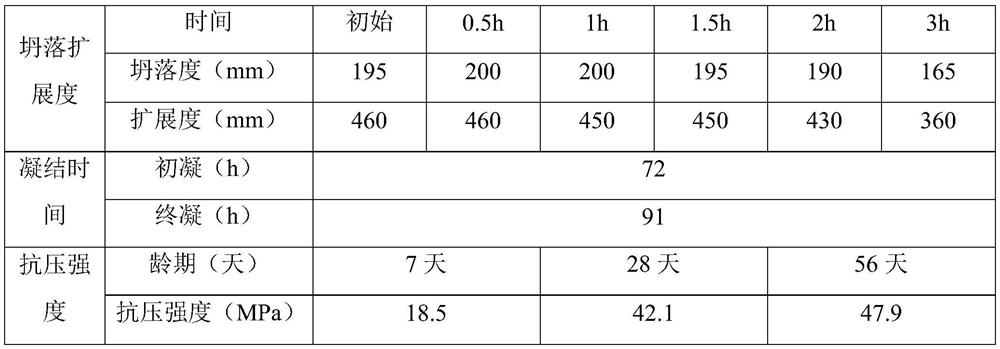

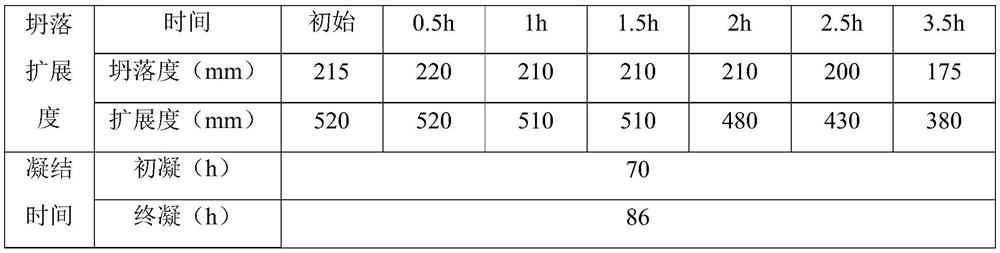

Composite retarding material and preparation method thereof

The invention relates to a composite retarding material. The composite retarding material comprises the following components in percentage by mass: 20-80% of a monosaccharide retarding material; 0-60%of a polysaccharide retarding material; 0-52% of an inorganic acid retarding material; and 0-14% of an organic acid retarding material. The composite retarding material disclosed by the invention isnot limited by a water-binder ratio and free of the influence of concrete admixture. After concrete is added, the initial setting time of the concrete can be controlled to be freely selected between 60h and 90h, the final setting time can be controlled between 70h and 100h, the phenomenon of concrete false setting caused by monosaccharide retarders is avoided, the situation that concrete slump loss is too fast due to polysaccharide retarders is avoided, the problem that inorganic acid retarders are short in setting time is solved, and later strength increase of concrete is not affected. The invention also relates to a preparation method of the composite retarding material. The preparation method comprises the step of uniformly mixing the monosaccharide retarding material, the polysaccharide retarding material, the inorganic acid retarding material and the organic acid retarding material according to a solid mass ratio to prepare powder.

Owner:THE 4TH ENG OF CHINA RAILWAY 5TH ENG GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com