Road surface paving plate with waterproof surface layer and permeable base layer, and production technology thereof

A permeable base layer and pavement board technology, which is applied in the direction of roads, roads, and pavement details, etc., can solve the problems of poor connection effect and difficulty in draining water from the permeable base layer, so as to improve fluidity, increase strength, and long-term use the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

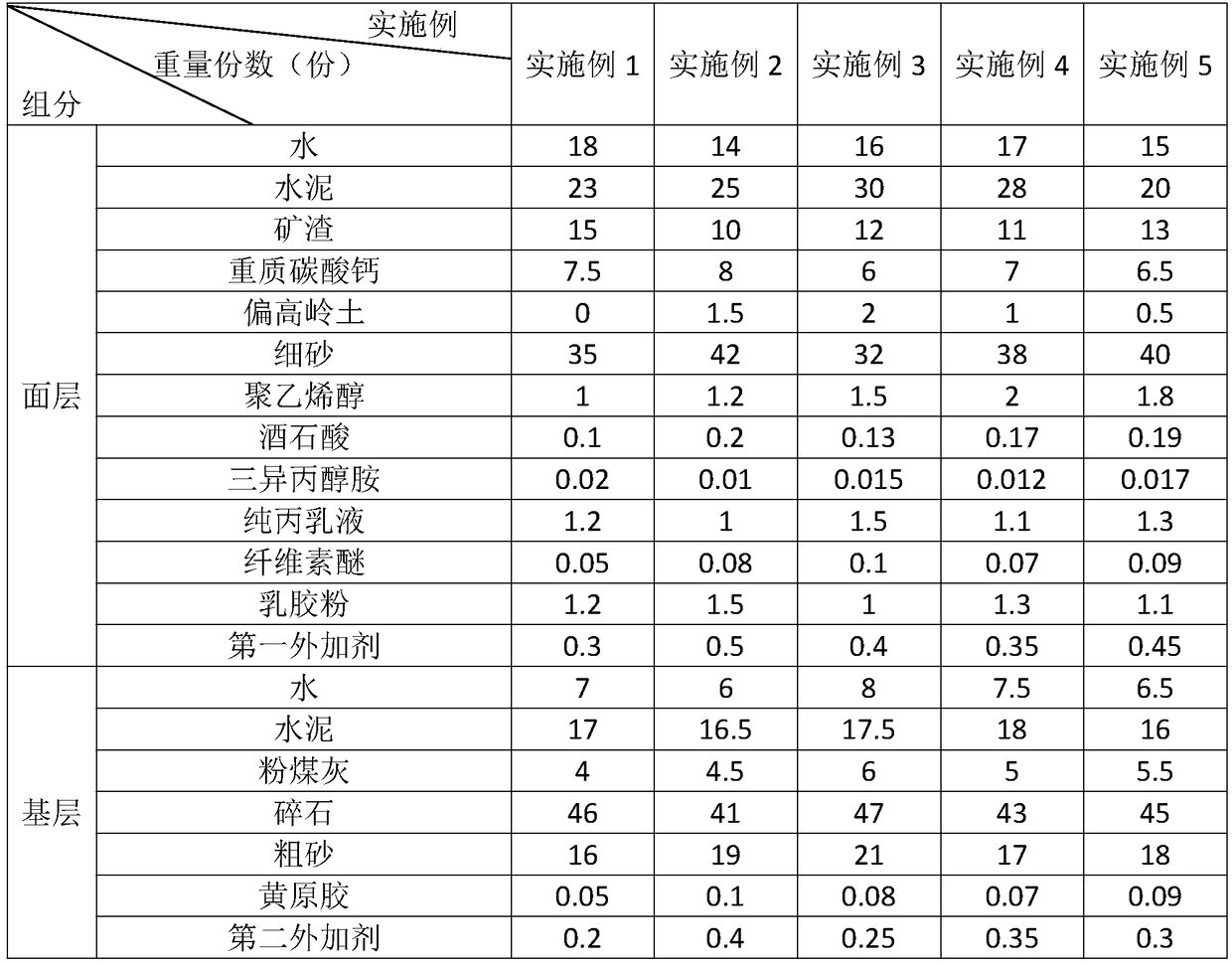

[0086] Embodiment 1: A pavement pavement board with an impermeable surface layer and a water-permeable base layer, including a base layer and a surface layer, wherein the components included in the base layer and the surface layer and their corresponding parts by weight are shown in Table 1. The components included in the first admixture and the second admixture and their corresponding parts by weight are shown in Table 2 and Table 3 respectively, and the pavement paving board is prepared through the following steps:

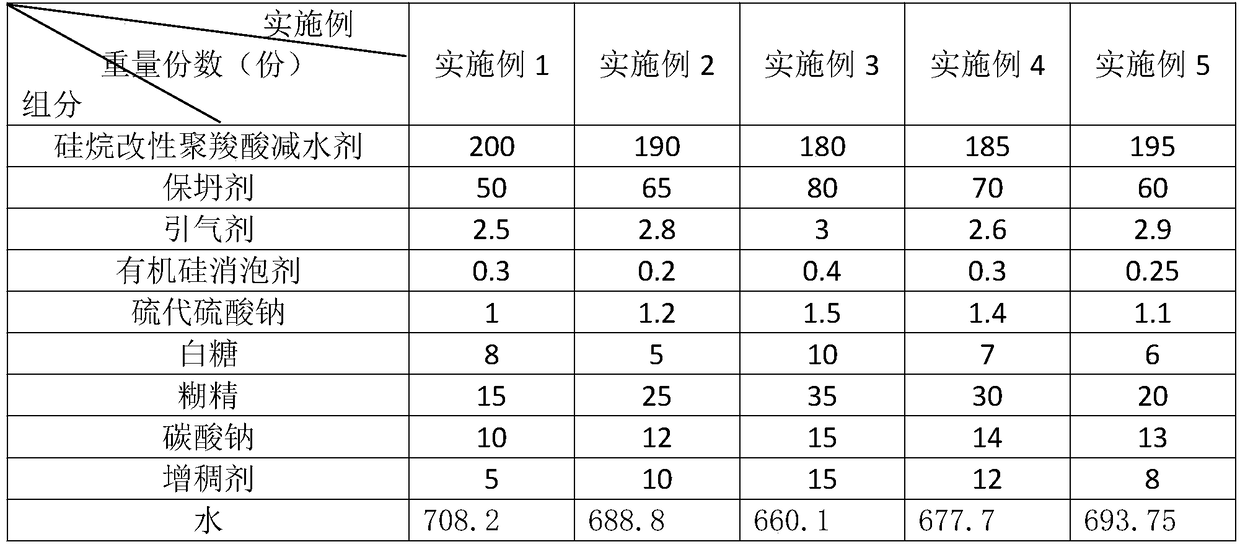

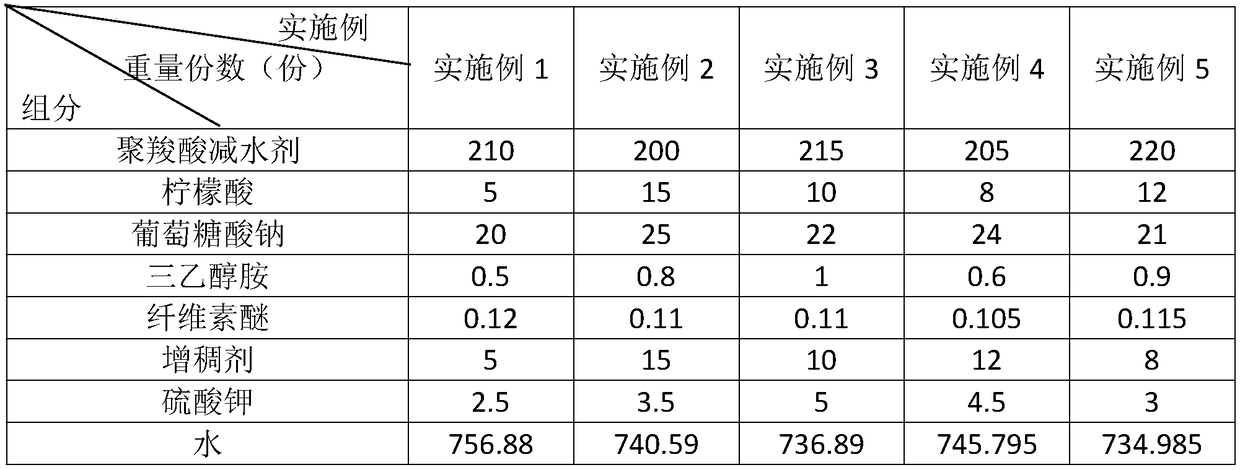

[0087] S1, the silane modified polycarboxylate water reducer, slump retaining agent, air-entraining agent, silicone defoamer, sodium thiosulfate, white sugar, dextrin, cellulose ether, sodium carbonate, water Mix with each other, then add a thickener, fully mix to obtain the first admixture; mix the corresponding parts by weight of polycarboxylate superplasticizer, citric acid, sodium gluconate, triethanolamine, cellulose ether, potassium sulfate, and water with ...

Embodiment 2-5

[0092] Embodiment 2-5: A pavement pavement board with an impermeable surface layer and a water-permeable base layer. The difference from Example 1 is that the components included in the base layer and the surface layer and their corresponding parts by weight are shown in Table 1. , the components included in the first admixture and the second admixture and their corresponding parts by weight are shown in Table 2 and Table 3, respectively.

[0093] Components included in the base layer and the surface layer and their corresponding parts by weight in the embodiment 1-5 of table 1

[0094]

[0095] Components included in the first admixture and their corresponding parts by weight in the embodiment 1-5 of table 2

[0096]

[0097] Components included in the second admixture and their corresponding parts by weight in the embodiment 1-5 of table 3

[0098]

Embodiment 6

[0099] Embodiment 6: A pavement paving board with an impermeable surface layer and a water-permeable base layer. The difference from Embodiment 1 is that the air-entraining agent is a saponin-based composite air-entraining agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com