Patents

Literature

133results about How to "Extend the usable time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

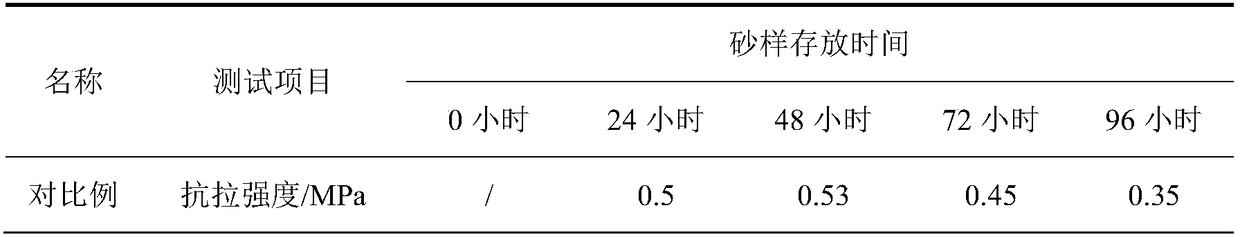

Formula of water glass modifying additive and production process and using method thereof

InactiveCN101885035AImprove adhesionImprove sand performanceFoundry mouldsFoundry coresEmulsionMetallurgy

The invention relates to a water glass modifying additive for casting and a production process and a using method thereof. The modifying additive consists of the following components in percentage by mass: 40 to 65 percent of styrene-acrylate emulsion, 0 to 10 percent of urea resin, 0.1 to 0.5 percent of quaternary ammonium salt and 25 to 55 percent of water. Used water glass sand is subjected to dry reclamation, the residual Na2O content of the used sand is controlled in a certain range and the water galls with ultra-low modulus is matched with the modifying additive so that the available time for preparing molding sand by mixing all or partial reclaimed sand can be prolonged and the molding sand has good process performance; and the reclamation rate of the used water glass sand can reach over 85 percent. The water glass modifying additive is directly added into the water glass at normal temperature and stirred uniformly without a fussy heating-cooling process so as to facilitate the operation on a molding site.

Owner:深圳市景鼎现代科技有限公司

Moisture cured reaction type polyurethane hot melt adhesive and preparation technique thereof

InactiveCN106433540AImprove regularityExtend the usable timePolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolyesterPolyol

The invention relates to a moisture cured reaction type polyurethane hot melt adhesive and a preparation technique thereof. The moisture cured reaction type polyurethane hot melt adhesive mainly contains polyester polyol, polyether polyol, thermoplastic polymer resin, isocyanate MDI, tackifying resin, padding, catalyst and coupling reagent. The components can have a polymerization reaction under a specific technical condition, so as to generate the moisture cured reaction type polyurethane hot melt adhesive with excellent performance. The moisture cured reaction type polyurethane hot melt adhesive is characterized in that the components by weight percent are as follows: 25%-35% of polyester polyol, 25%-35% of polyether polyol, 25%-35% of thermoplastic polymer resin, 10%-20% of isocyanate MDI, 1%-3% of tackifying resin, 1%-5% of padding, 0.5%-1% of catalyst and 0-3% of coupling reagent. Compared with the same formula under different reaction technical conditions, the moisture cured reaction type polyurethane hot melt adhesive generated under the technical condition provided by the invention has the advantages of tiny difference between different batches, performance stability, strong adhesive force and excellent viscosity stability in a gluing process.

Owner:苏州孚霖工业品科技有限公司

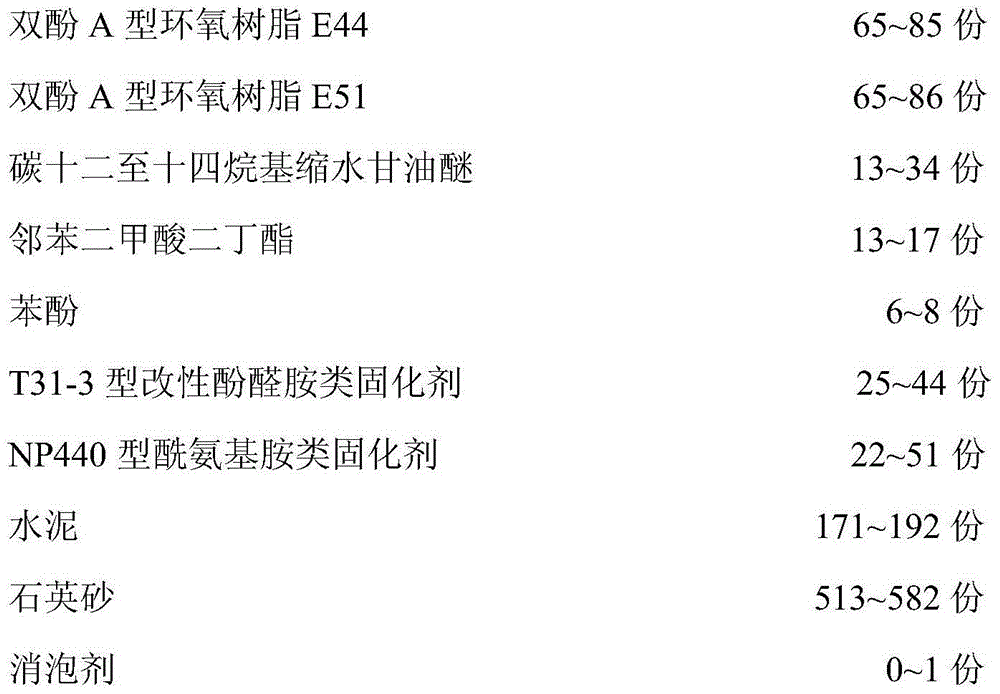

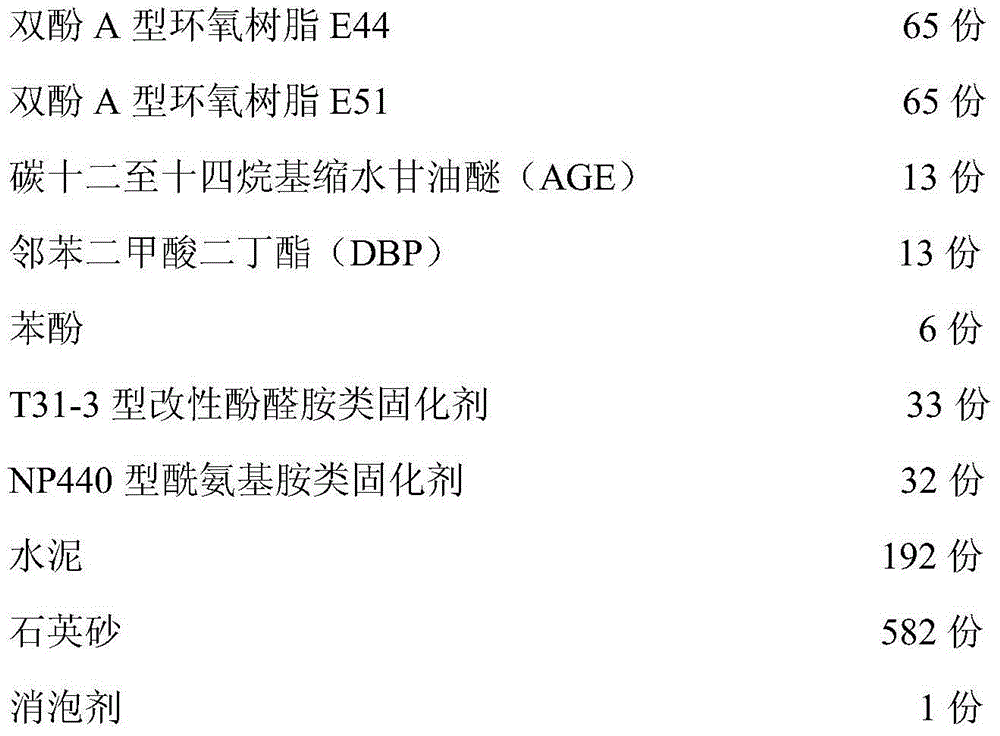

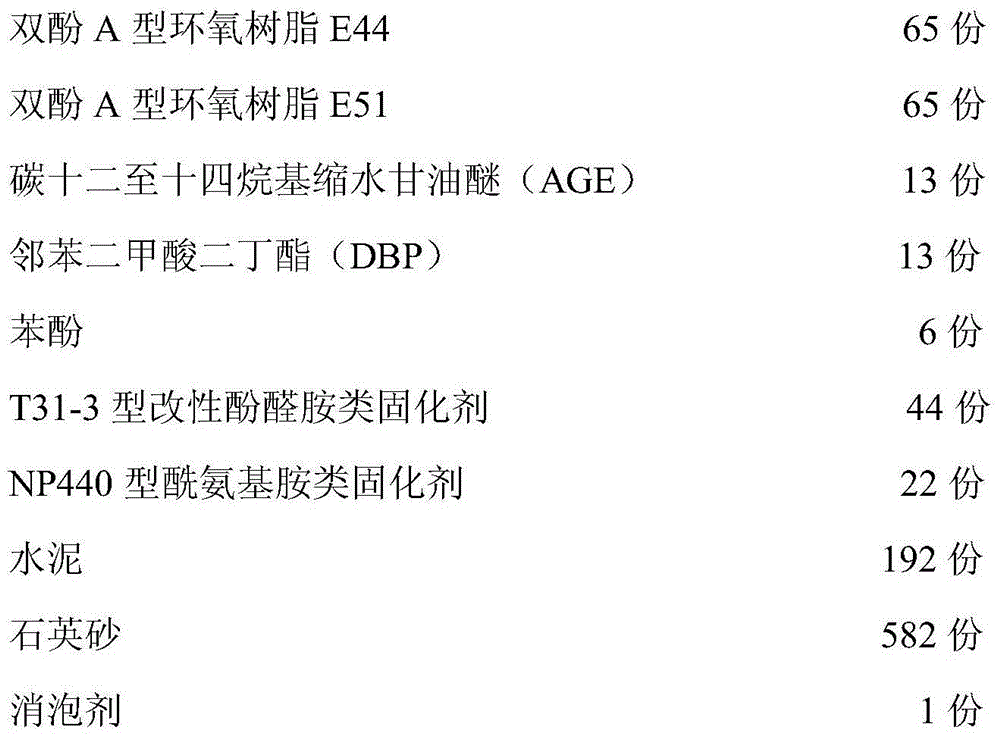

Epoxy mortar used for repairing sea oil gas pipeline and preparation method thereof

The invention discloses an epoxy mortar used for repairing sea oil gas pipeline and a preparation method thereof, which belongs to the technical field of polymer mortar application. The epoxy mortar is composed of a component A, a component B and a component C, the component A is prepared by bisphenol A epoxy resin E44, E51 and a certain amount of auxiliary agent, the component B is prepared by mixing a T31-3 type modified phenolic amine curing agent and a NP440 amidoamines curing agent according to a certain proportion, and the component C is an aggregate by mixing cement and quartz sand according to a certain proportion. The preparation method comprises the following steps: heating the component A to the temperature of 30-50 DEG C, stirring to homogeneous phase, then mixing the component A and the component B according to a certain proportion, uniformly mixing, adding the component C according to a certain proportion, and uniformly blending to obtain the epoxy mortar. The preparation method has simple technology, the epoxy mortar has strong cohesiveness, the epoxy mortar through solidification has excellent anti-compression, anti-punching and anti-seawater corrosion performances, and the epoxy mortar can be used for repairing and reinforcing a concrete coating on the sea oil gas pipeline and a thin layer of an underwater concrete structure.

Owner:TIANJIN UNIV OF SCI & TECH +1

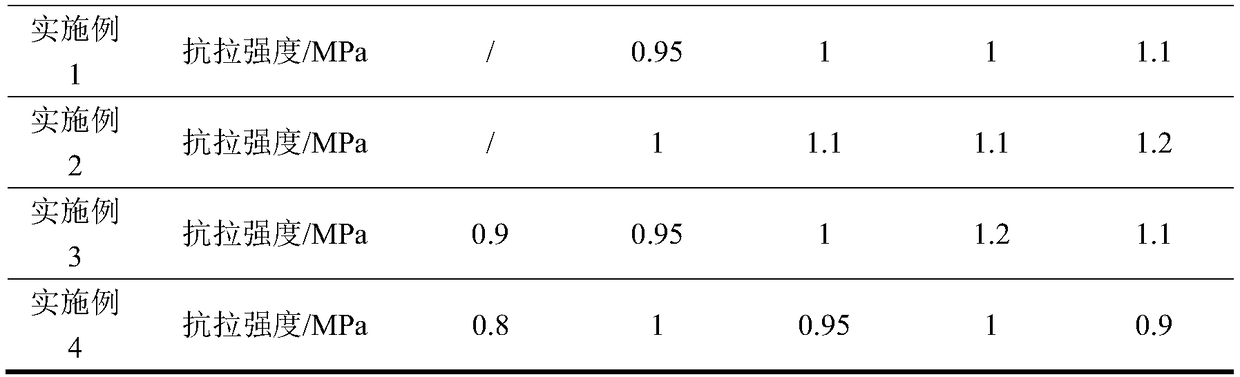

Inorganic binder, preparation method and application thereof

InactiveCN103111581AExtend the usable timeExtended use timeFoundry mouldsFoundry coresO-Phosphoric AcidAluminium hydroxide

The invention discloses a casting inorganic binder suitable for curing by hot air, a preparation method and application thereof, wherein the binder contains 30-40 parts of 200-400-mesh aluminium hydroxide, 140-180 parts of 80-90% phosphoric acid, 6-12 parts of 200-400-mesh boric acid, 10-20 parts of 200-400-mesh magnesium carbonate, 5-10 parts of 200-400-mesh zinc oxide, and 150-280 parts of water. The binder disclosed by the invention is cured by hot air; dust pollution of adding a powder curing agent when the sand is mixed is avoided; core sand can be used for a long period of time; no substance with poison or pungent odor is discharged in the whole process; the poured cast oil sand is easily cleaned; and the workload of a worker is reduced.

Owner:HUBEI UNIV OF TECH

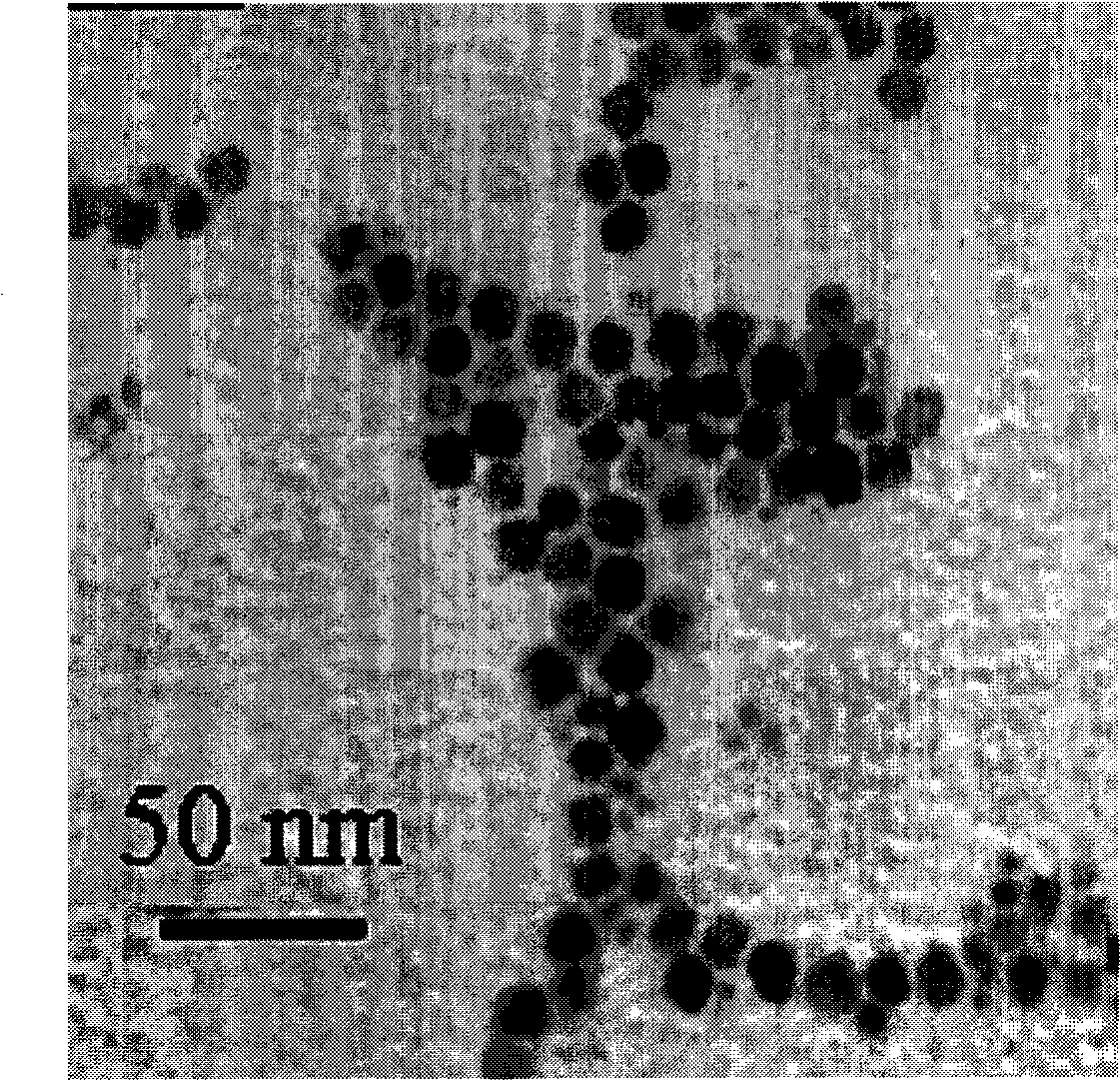

Liposome calcium sulphate composite nano artificial bone, preparation method and use thereof

ActiveCN101507840AImprove mechanical strengthExtend the usable timeProsthesisLiposomeBiocompatibility Testing

The invention relates to a liposome calcium sulfate composite nanometer artificial boneware, as well as a preparation method and application thereof. The preparation method comprises the steps of well mixing liposome (1 to 40 percent), calcium sulfate powder (40 to 80 percent) and diluent (10 to 50 percent), curing the materials and then preparing a bone graft substitute containing nanometer liposome. The liposome can carry medicine and can modify surface, has two forms, namely solution and powder, and comprises traditional micromolecule liposome and macromolecule liposome having macromolecule characteristics. The invention can provide an artificial bone material which has nanometer reinforcing effects, function of sustaining and controlling medicine release, controllable degradation time, good biocompatibility and mechanical strength, can induce bone growth in vivo, and is beneficial to the healing of defective areas of bones.

Owner:SHANGHAI INST OF ONCOLOGY

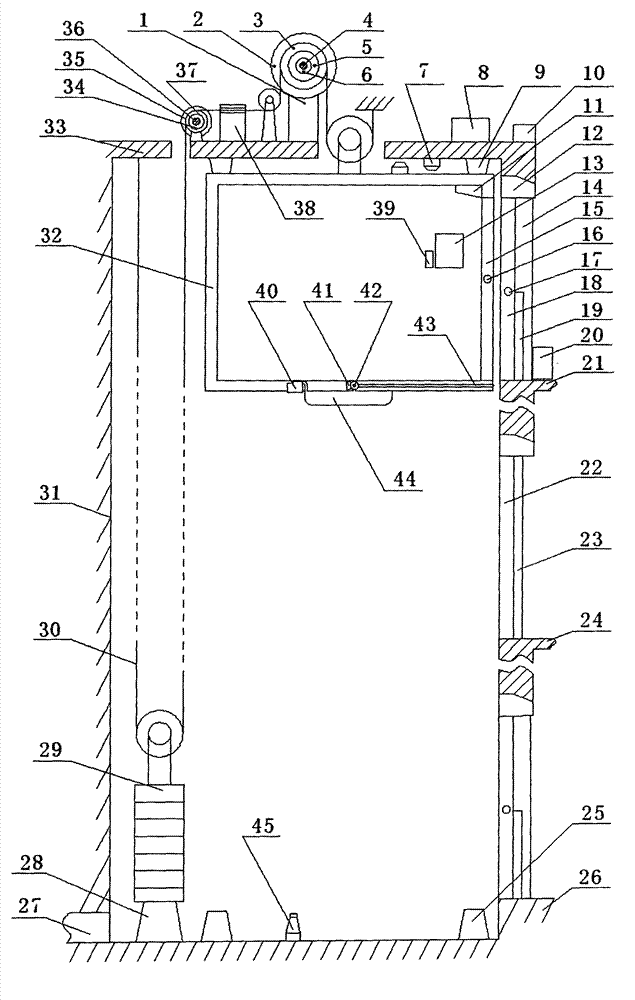

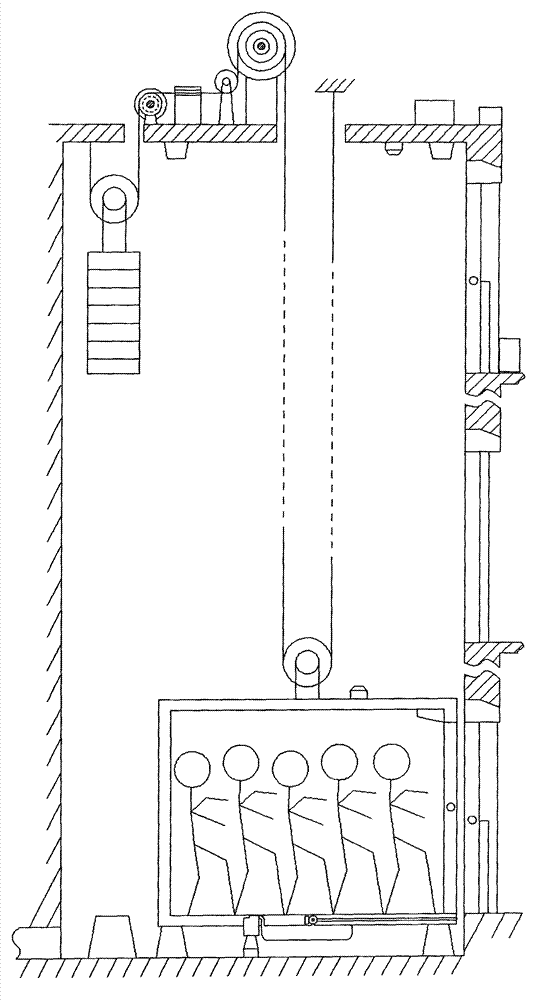

Elevator with auto-operation life-saving function under flame outage

ActiveCN102862892ASmooth evacuationImprove the operating environmentElevatorsEngineeringDependability

The invention relates to an elevator, and discloses an elevator capable of meeting an emergency and automatically reciprocally operating, transmitting a person at a set floor to a ground floor or a safe floor safely, and transmitting a firefighter to the set floor so as to carry out sequential life-saving work under a condition of flame outage. The elevator mainly comprises a counterweight and a carriage buffer device which are arranged at the bottom of an elevator shaft, and a special water supply joint, wherein a channel port is provided with a special fireproof elevator door and a fire screen release device; the end of a drag axle at the top of the elevator shaft is connected with a clutch, and the other end of the clutch is connected with a damping device; and a carriage in the elevator shaft is provided with an emergency water spray cooling device. According to the invention, the elevator is automatically operated under the condition of sudden outage of flame of a building, a life-saving way of a trapped person is increased, the uploading layout efficiency of a rescue worker is improved, and the elevator has the advantages of high operation automation degree and reliability, high rescue efficiency, and the like.

Owner:上海熠优电梯安全科技有限公司

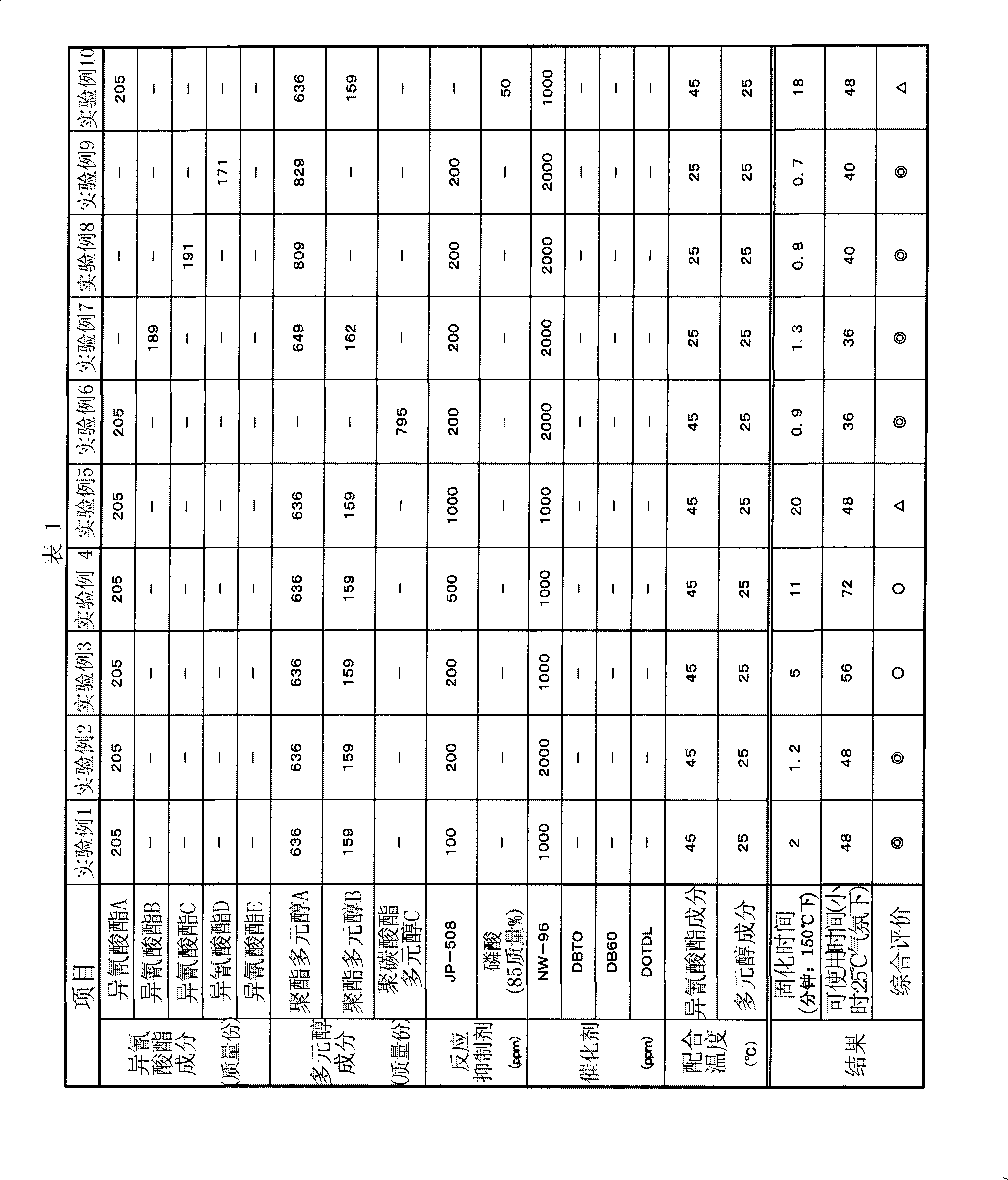

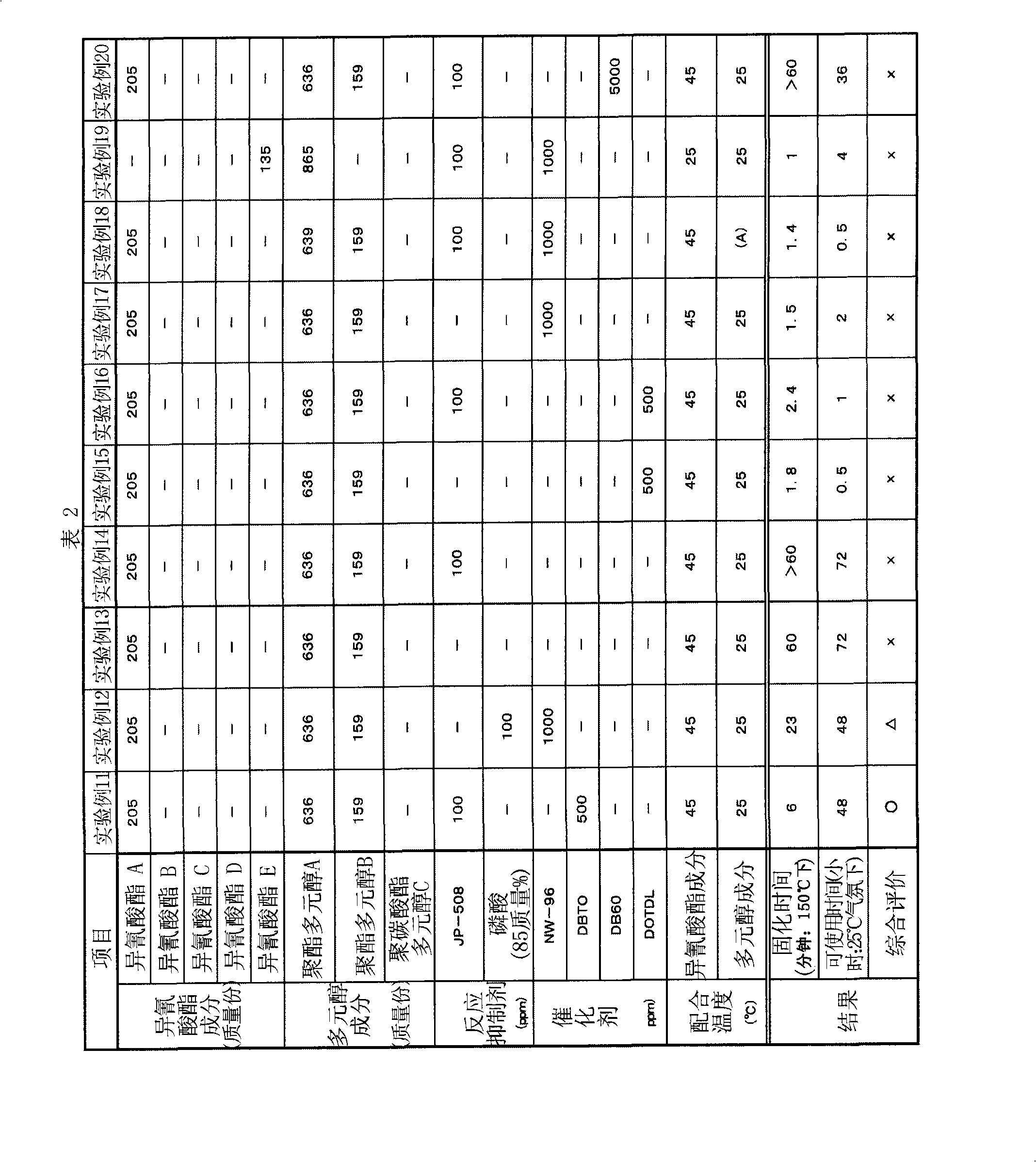

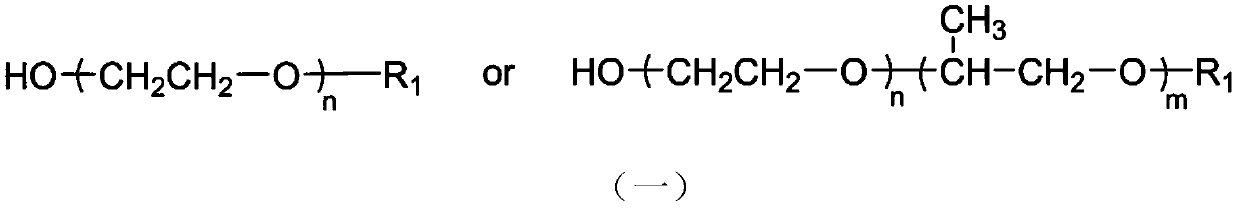

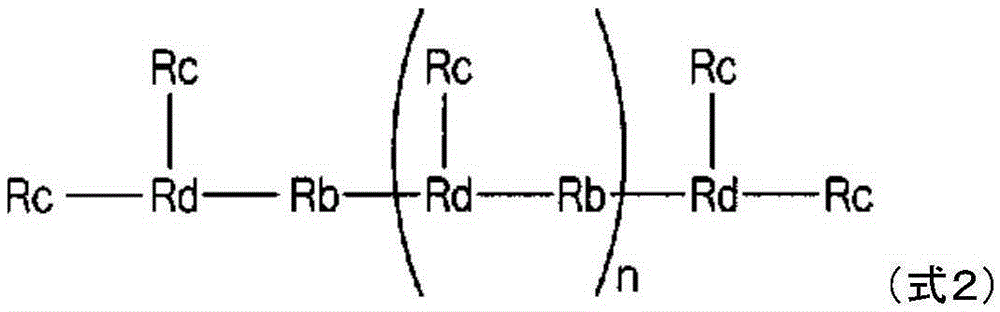

Method for preparing polyurethanes forming composition, polyatomic alcohol composition, and polyurethane resin

The present invention provides a method for preparing a polyurethanes forming composition, a polyatomic alcohol composition, and a polyurethane resin, capable of prolonging the usage time at a normal temperature and having excellent solidifying character. The polyurethanes forming composition of the invention cooperates and modulates the following components: an isocyanate component, containing at least one of fatty group and alicyclic isocyanate, and their derivant and modified substance, or their mixture; a liquid state polyatomic alcohol component at a normal temperature; a reaction restraining agent; and a normal temperature solid state organic metal series catalyst existed in the composition in a solid state.

Owner:NIPPON POLYURETHANE IND CO LTD

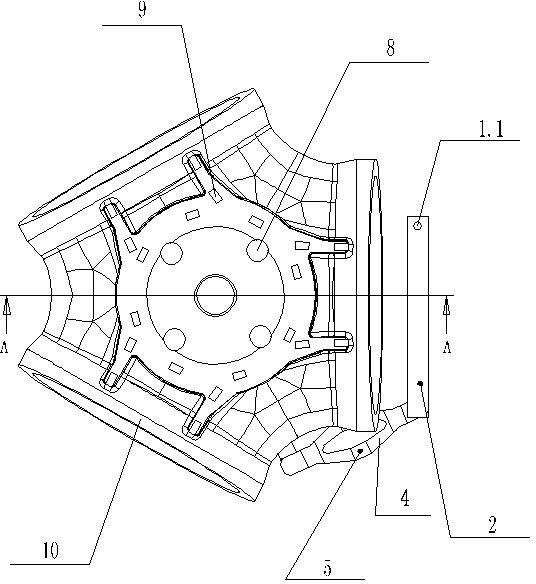

Chill-free processing method of wind-driven generator hub

The invention discloses a chill-free processing method of a wind-driven generator hub, and the method comprises the following steps: manufacture of a mould, manufacture of a sand mould and moulding by casting, wherein in the manufacture of the sand mould, a completely opened bottom gating system is utilized; an ingate is designed to be disc-shaped; a downgate on an upper sprue is a quantitative ladle stopper sprue gate; the ratio of the components is F(straight):F(transverse):F(internal)=1:(1.5-2):(25-28); a rectangular vent hole is arranged at the highest point at the top face of a casting; the total section area of the rectangular vent hole is greater than that of the ingate; a casting head is arranged on the top face of the casting; the height of the single casting head is greater than 400 mm; no chills are discharged during the manufacture procedure; in the moulding by casting, the casting speed of melted iron entering into a casting cavity is controlled within 0.5-1.0 m / s; the casting time is controlled within 150-210 seconds; and the casting temperature is between 1300 and 1310 DEG C. The chill-free processing method of the wind-driven generator hub disclosed by the invention has the advantages that the method adapts to the large scale production of low-temperature ductile iron castings for large wind-driven generator with quite high requirements, the process is simple, and the production cost is low.

Owner:宁波日星铸业有限公司

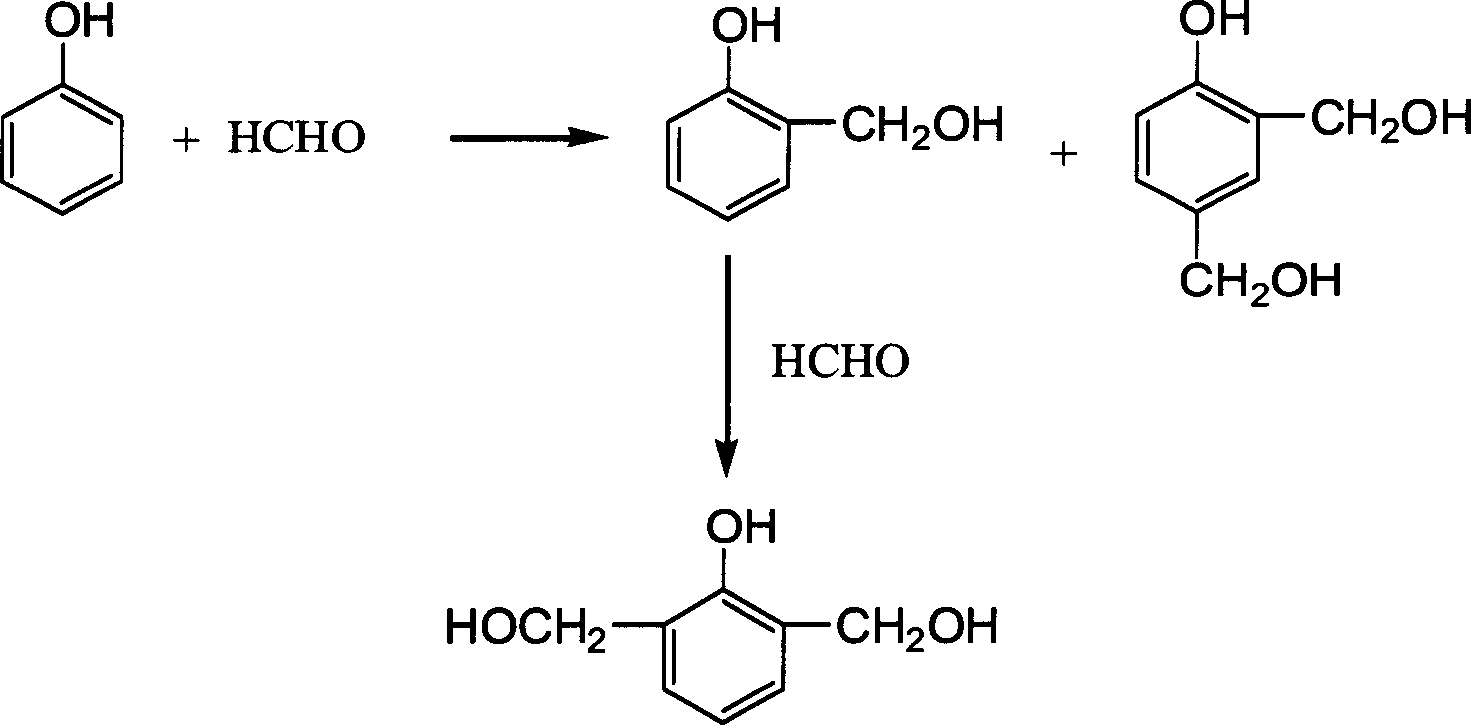

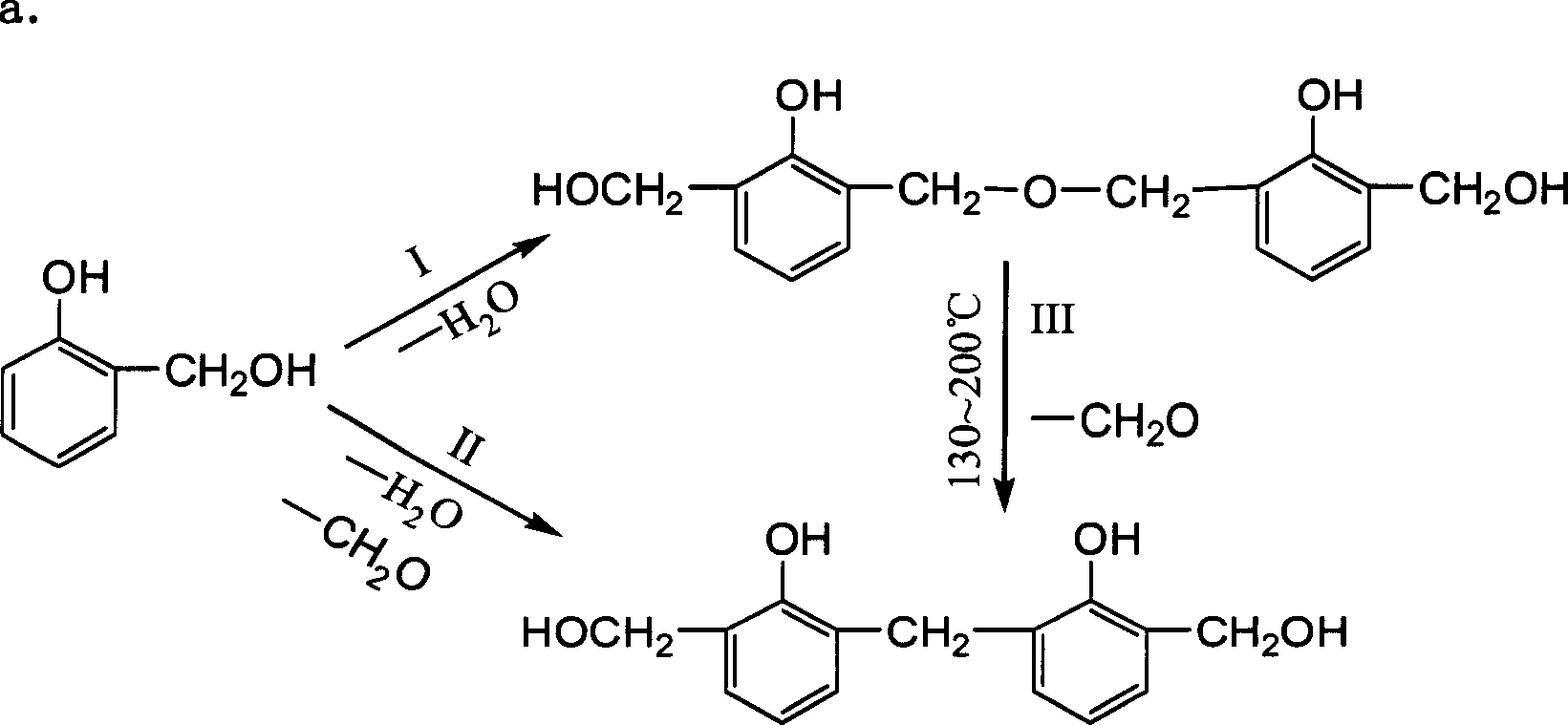

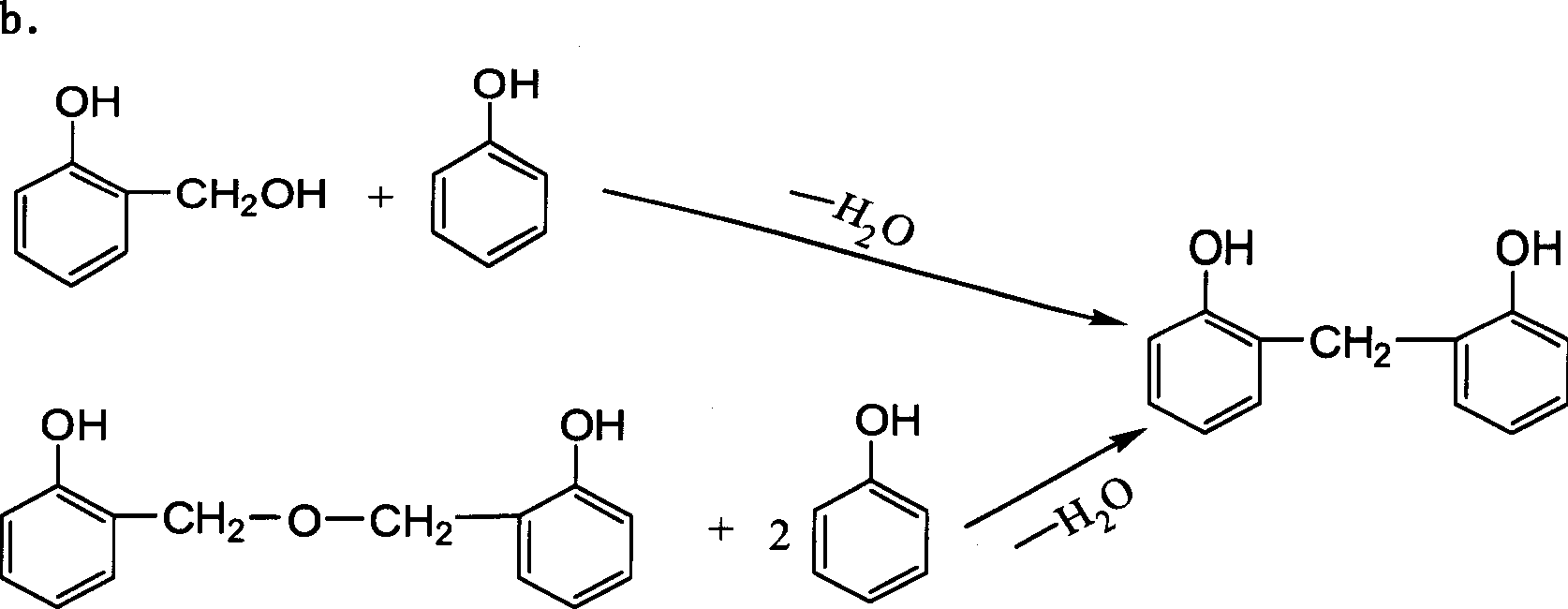

Characteristic aldehyde-less cold core box resin

InactiveCN1824427AGood for healthProtect your healthFoundry mouldsFoundry coresChemical reactionAromatic solvent

The present invention discloses a characteristic aldehydeless cold core box resin. It includes two components of A and B. The component A is synthesized by using formaldehyde, benzophenol, modified animal fat and aromatic solvent as main raw material through chemical reaction, and the component B is made up by using polymeric isocyanate and modified animal fat as main raw material. Said invention can greatly raise the strength of sand core and sand mould.

Owner:SUZHOU XINGYE MATERIALS TECH

Polyaspartic ester urea adhesive and construction technology thereof

ActiveCN107522845AGood physical propertiesGood weather resistancePolyurea/polyurethane coatingsPolyurethane adhesiveEquivalence ratio

The invention discloses a polyaspartic ester urea adhesive and a construction technology thereof. The adhesive comprises a main agent and a curing agent in an equivalence ratio being 1:(0.9-1.1), and the main agent is prepared from 80-90 parts by weight of polyaspartic ester resin, 2-5 parts by weight of an oxazolidine absorbent, 8-12 parts by weight of a molecular sieve, 0.1-0.5 parts by weight of a defoaming agent and 0.1-0.5 parts by weight of a base material wetting agent. The adhesive contains no toxic substances such as free TDI (toluene diisocyanate) and the like, contains no organic solvents, phthalate plasticizers and heavy metal, belongs to a solvent-free system, is environmentally friendly, non-toxic and harmless, further has good physical performance and is good in weather fastness, high in tensile strength and elongation at break, good in rebound resilience and not prone to discoloration, construction is easy, operability and physical performance of the adhesive are equivalent to those of a conventional polyurethane adhesive, and excellent environment-friendly safety and physical characteristics are integrated. The technological process of preparation is simple, conditions are mild, construction performance is good, coating is easy, and therefore, the adhesive is suitable for industrial batch production.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

Full-automatic kitchen waste recycling equipment and method

The invention discloses full-automatic kitchen waste recycling equipment and full-automatic kitchen waste recycling method. The full-automatic kitchen waste recycling equipment comprises a grinding main machine, a solid-liquid separator, a biochemical treatment bin, an oil-water separator and a full-automatic soap powder machine, wherein the grinding main machine, the solid-liquid separator, the oil-water separator and the full-automatic soap powder machine are sequentially connected through pipes; the biochemical treatment bin is connected to the solid-liquid separator; an electromagnetic water stop valve is arranged on each of the pipes between the grinding main machine and the solid-liquid separator and between the solid-liquid separator and the oil-water separator. Compared with the prior art, the full-automatic kitchen waste recycling equipment and the full-automatic kitchen waste recycling method have the advantages as follows: kitchen waste can be quickly disposed on site, so that on one hand, the kitchen waste is converted into biofeed or a fertilizer with considerable economic value, and on the other hand, washing soap powder is produced; meanwhile, wastewater obtained after washing is rich in soap powder can further help to discompose oil stains on the pipe wall of a sewage pipe to a certain extent, so that the trend of shrinkage of the pipe diameter due to oil accumulation on the pipe wall is delayed and the service life of the sewage pipe is prolonged.

Owner:广州蒙太奇电器有限公司

Rapidly-dried water-dispersible isocyanate curing agent composition and preparation method thereof

The invention belongs to the technical field of isocyanate curing agents, and discloses a rapidly-dried water-dispersible isocyanate curing agent composition and a preparation method thereof. The rapidly-dried water-dispersible isocyanate curing agent composition disclosed by the invention comprises the following two parts: 50-95 parts by mass of a hydrophilically modified aliphatic polyisocyanatepart and 5-50 parts by mass of a non-hydrophilically modified aromatic polyisocyanate part. After emulsification in a water system, the non-hydrophilically modified aromatic polyisocyanate is partially wrapped by the hydrophilically modified aliphatic polyisocyanate, so that long usable time can be kept in a water phase. After water of coating construction is volatilized, the drying speed is greatly improved, and a long usable time is achieved while rapid drying is realized. The problem that an application is limited due to the fact that hydrophilically modified aliphatic polyisocyanate is fast in drying speed but very short in usable time and hydrophilically modified aliphatic polyisocyanate is slow in curing speed is solved.

Owner:GUANGZHOU GUANZHI NEW MATERIAL TECH

Liquid curing agent for phosphate bonding agent and application thereof

ActiveCN109454200AWith initial strengthHigh strengthFoundry mouldsFoundry coresPhosphateCalcium Binder

The invention discloses a liquid curing agent for a phosphate bonding agent and application thereof. The curing agent comprises two components, wherein 45.16%-55.17% of silane coupling agent serves asthe component I; 44.83%-54.84% of the component II comprising water and citric acid, and the component II, the citric acid accounts for 9.68%-17.24%, and the water accounts for 27.59%-45.16%. The liquid curing agent disclosed by the invention is wide in ram material source, low in cost and simple in preparation and application process. The liquid curing agent is long in using time when used for self-hardening sand production and short in demolding time and is used for bowing hardening of cold core boxes. The adopted compressed air is low in cost, environment-friendly and free of pollution.

Owner:HUBEI UNIV OF TECH

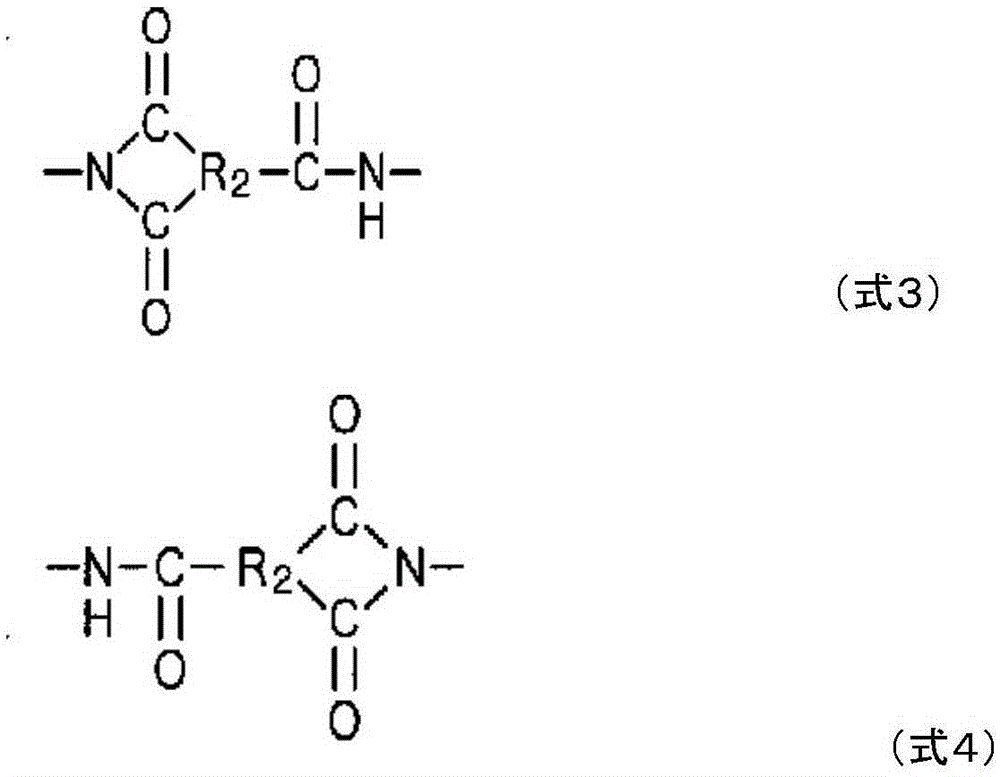

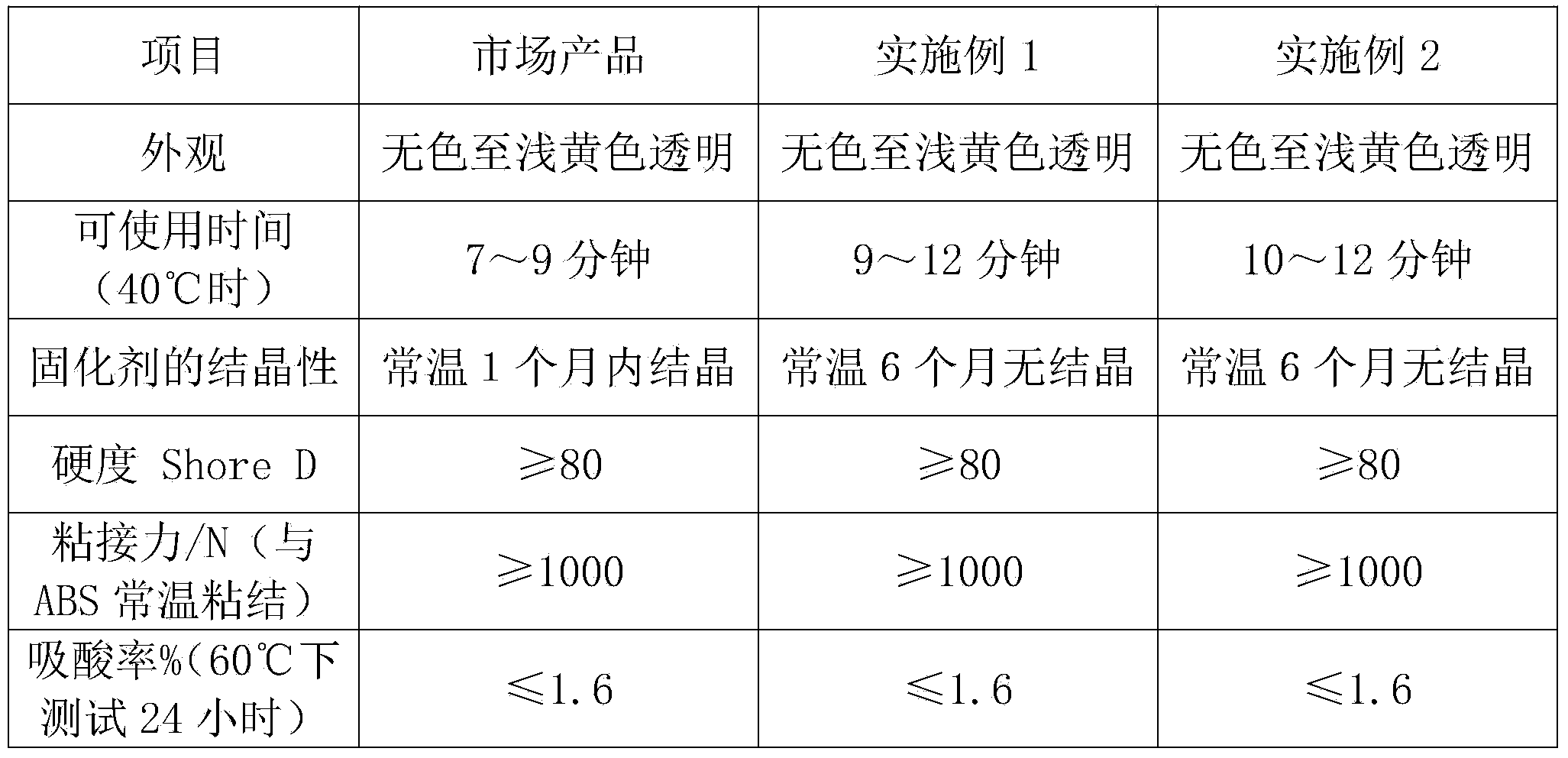

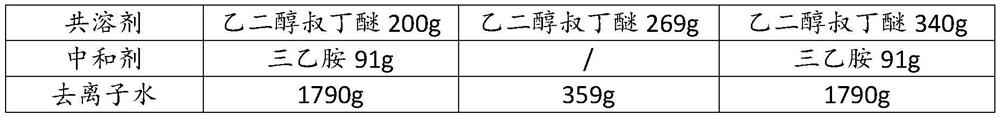

Storage battery sealing gum and preparation method of storage battery sealing gum

ActiveCN103468192AHigh crystallinityExtend the usable timeNon-macromolecular adhesive additivesEpoxy resin adhesivesEngineeringCrystallinity

The invention relates to storage battery sealing gum and a preparation method of the storage battery sealing gum. The storage battery sealing gum is prepared from the following components: (1) a resin part and (2) a curing agent part in ratio of 100:(20-40), wherein the resin part comprises 80-95 parts of bisphenol A epoxy resin, 5-15 parts of an activated thinner and 0-3 parts of a defoaming agent, and the curing agent part comprises 40-60 parts of aliphatic series polyamine, 10-30 parts of alicyclic amine, and 20-40 parts of an activated thinner. The preparation method comprises the following steps: (1) uniformly mixing the raw materials of the resin part; (2) uniformly mixing the alicyclic amine and 60-80% of aliphatic series polyamine of the curing agent part, dropping in 50-70% of activated thinner of the curing agent part while stirring, heating, adding the remaining aliphatic series polyamine, dropping in the remaining activated thinner and heating; and (3) uniformly mixing the products in the step (1) and the step (2). The usable time of the sealing gum is prolonged and the crystallinity of the curing agent is improved by proper proportion of raw materials and improved production process of the curing agent.

Owner:GUANGZHOU POCHELY NEW MATERIAL TECH CO LTD

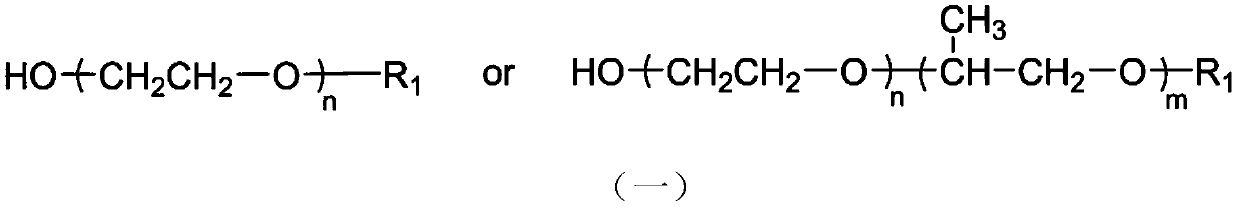

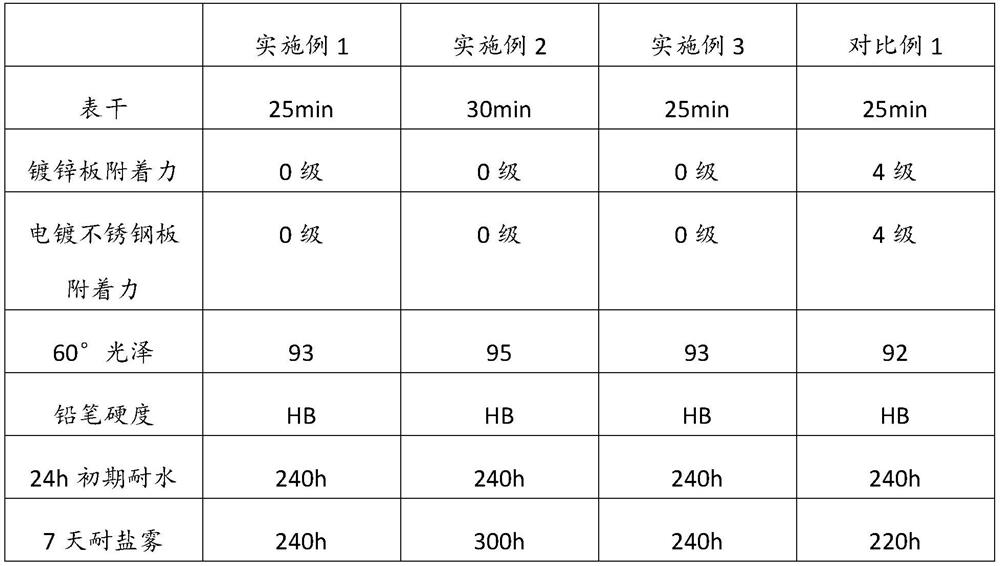

Water-based single-component modified epoxy resin as well as preparation method and application thereof

The invention provides water-based single-component modified epoxy resin as well as a preparation method and application thereof. The water-based single-component modified epoxy resin comprises the preparation raw materials: epoxy resin, a modifier, an adhesion promoter, a catalyst, an initiator, a hydrophilic monomer, a cosolvent and a neutralizer, wherein the epoxy resin comprises at least one of E20, E44, E51, E54, F51 and E12. The water-based single-component modified epoxy resin is convenient to use, long in service life, quick to dry, high in gloss, good in salt mist resistance, particularly good in adhesive force to substrates difficult to adhere, such as galvanized plates and aluminum plates, wide in universality and environmentally friendly. The invention also provides a coating composition containing the water-based single-component modified epoxy resin and a coating product.

Owner:JIANGMEN PAINT FACTORY

Controllable cured calcium sulfate bone-cementing agent and its preparation method

The related preparation method for a controllable solidifying CaSO4 bone adhesive comprises: mixing 40-80wt% dehydrated CaSO4 and 1-20wt% adjuvant to age for 1-48h, mixing material and 10-50wt% solidifying solution for 2-5min, and hydrating to obtain the slurry. This invention has well performance for medical purpose.

Owner:TIANJIN UNIV

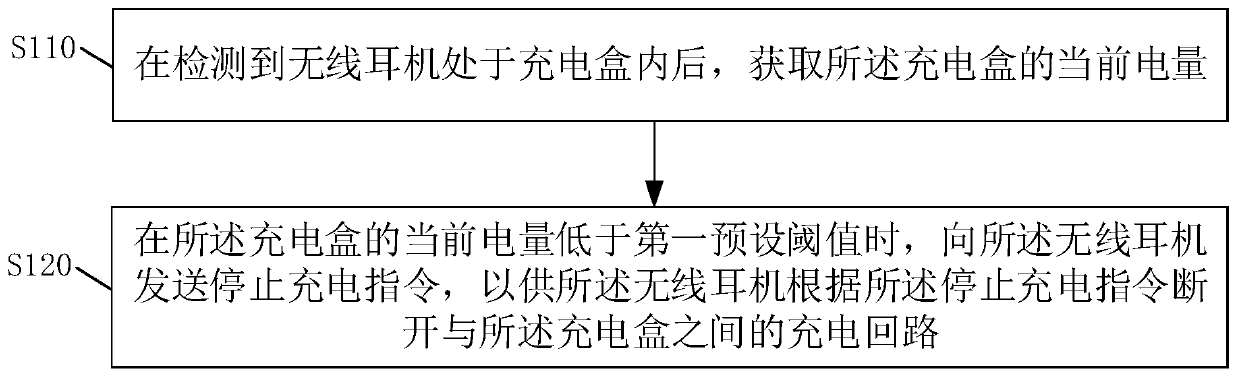

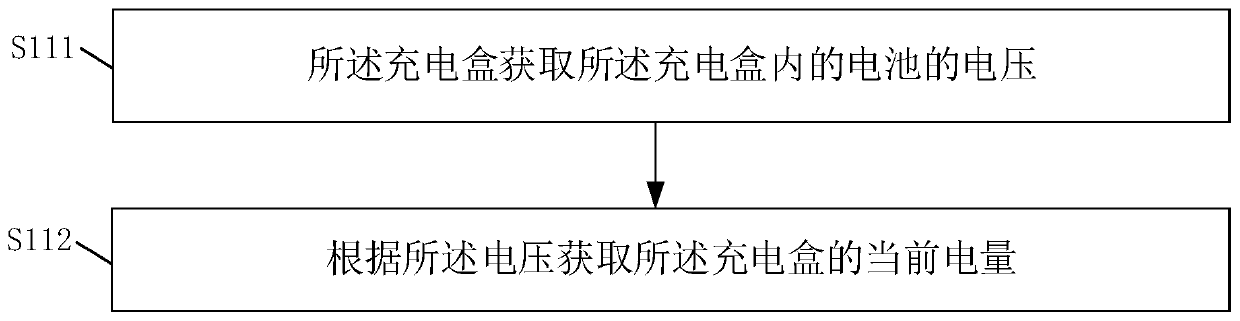

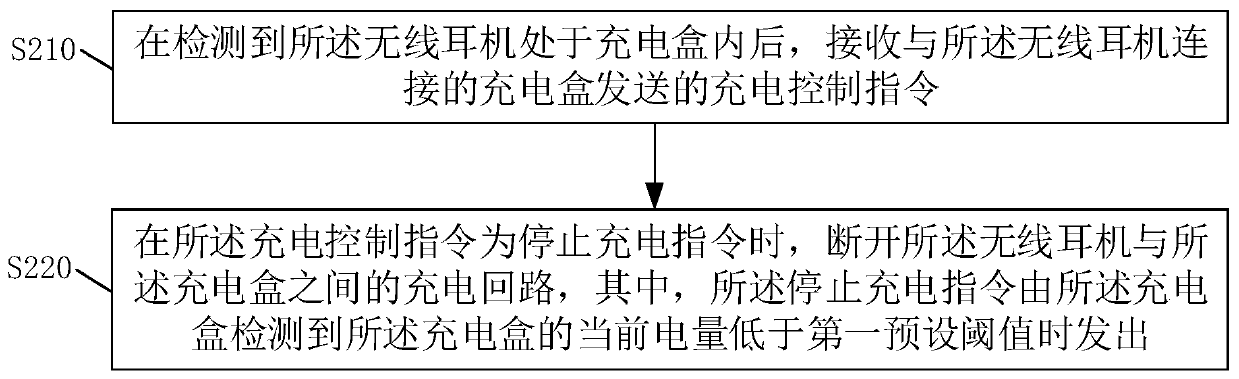

Wireless earphone, charging method thereof, charging box and readable storage medium

PendingCN111049230AExtend standby timeExtend the usable timeBatteries circuit arrangementsElectric powerCurrent electricTerminal equipment

The invention discloses a wireless earphone, a charging method thereof, a charging box and a readable storage medium. The charging method applied to the charging box comprises the following steps that: the current electric quantity of the charging box is obtained after it is detected that a wireless earphone is located in the charging box; when the current electric quantity of the charging box islower than a first preset threshold value, a charging stopping instruction is sent to the wireless earphone, so that the wireless earphone disconnects a charging loop from the charging box according to the charging stopping instruction. Therefore, the charging box cannot continuously charge the wireless earphone, the standby time of the charging box is prolonged, and the charging box can be continuously matched with the wireless earphone; related functions between the wireless earphone and terminal equipment such as a mobile phone are achieved, for example, pairing connection between the wireless earphone and the terminal equipment is achieved, and the available time of the wireless earphone can be prolonged.

Owner:GEER TECH CO LTD

Method for producing casting cold-box resin

The invention relates to a method for producing resin, and particularly relates to a method for producing casting cold-box resin. The method comprises the following steps: adding dissolved industrial phenol to a reaction kettle; starting an agitator; adding solid paraformaldehyde, a regulator and 0.08-0.12% of metal ion catalyst; opening a steam valve, slowly heating up, and heating up to 105 DEG C within 40-50 minutes; keeping constant temperature at 105-108 DEG C for 30 minutes; heating up to 112 DEG C within 10-20 minutes, and keeping constant temperature at 112-115 DEG C for 50 minutes; continuing to heat up and dewatering under normal pressure after heat preservation is finished; timing constant temperature when the temperature inside the kettle ascends to 120 DEG C, and keeping constant temperature at 120-123 DEG C for 30 minutes; after constant temperature is finished, vacuumizing and continuing to dewater; stopping dewatering when the total dewatering amount achieves 60% of formaldehyde amount; adding a polar dibasic acid ester, nonpolar high-boiling point solvent oil and a modifier; agitating for 60 minutes; adding an enhancer when cooling to below 40 DEG C; evenly agitating, detecting and packaging. The casting cold-box resin which is low in viscosity, and high in casting sand strength, can be used for a long period of time, and meets core-making production in batches is provided by the invention.

Owner:共享新材料(山东)有限公司

Tung oil modified triethylamine cold-box resin component I and production method thereof

InactiveCN107083015AImprove technical indicatorsImprove moisture resistanceFoundry mouldsFoundry coresAromatic solventsParaformaldehyde

In allusion to problems existing in the prior art, the invention provides a production method of a tung oil modified triethylamine cold-box resin component I. The production method of the tung oil modified triethylamine cold-box resin component I includes the following raw materials (by weight): 25-40% of phenol, 2-8% of tung oil, 0.01-0.04% of a catalyst 1, 11-19% of paraformaldehyde, 0.04-0.1% of a catalyst 2, 1-2% of a regulator, 12-24% of dibasic acid ester, 14-25% of high-boiling-point aromatic solvent oil, 2.5-5% of a high-boiling-point plasticizer, 2-6% of ethyl silicate and 0.5-1% of a reinforcing agent. According to the invention, tung oil and phenol are subjected to a cationic alkylation reaction under an acidic condition, and then modified phenol and formaldehyde react to generate tung oil modified phenolic resin. Then, the triethylamine cold-box resin component I which has high molding-sand strength, good high-temperature property and good wet resistance, has long service time and excellent environment protection property and can satisfy batch core production is obtained.

Owner:GANSU KOCEL CHEM

Elastic phenylethylene-ester acrylate water-proof emulsion and preparation method thereof

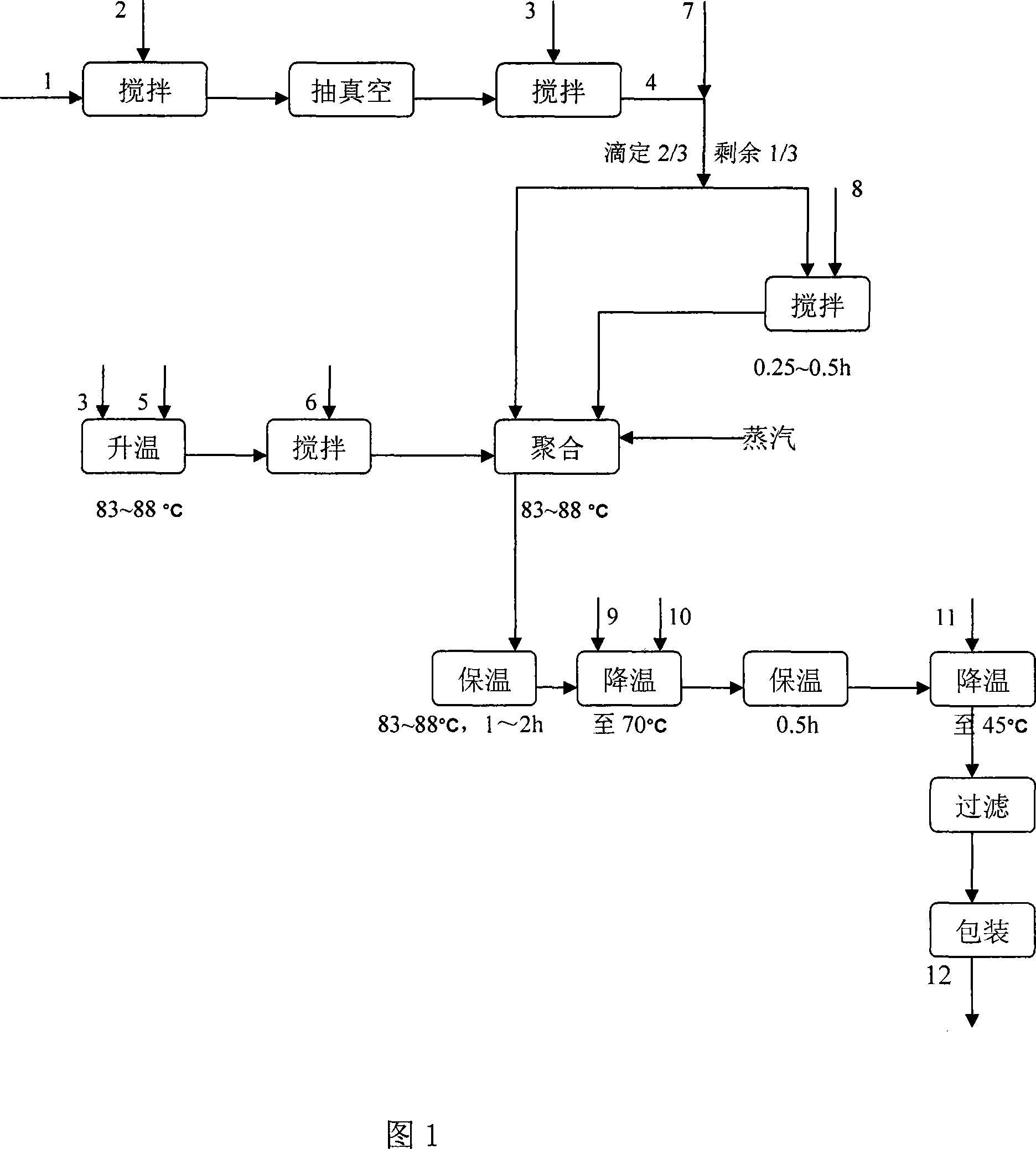

This invention relates to elasticity styrene - acrylate waterproof latices and its preparation method. It is polymerized by nine kind component and seed emulsion. The preparation method includes as follows steps: whip, vacuumize, whip, polymerization, thermal insulation, cooling, thermal insulation, cooling, filter, casing. This invention has low cost, stable color phase, moderate consistency, good acid and alkaline protection, and lower vitrification point. It can effectively eliminate liberation monomer, avoid enviroment pollution. This invention especially fit for cement group polymer waterproof, waterproofing work as well as impervious seal stuff.

Owner:陈毅曦

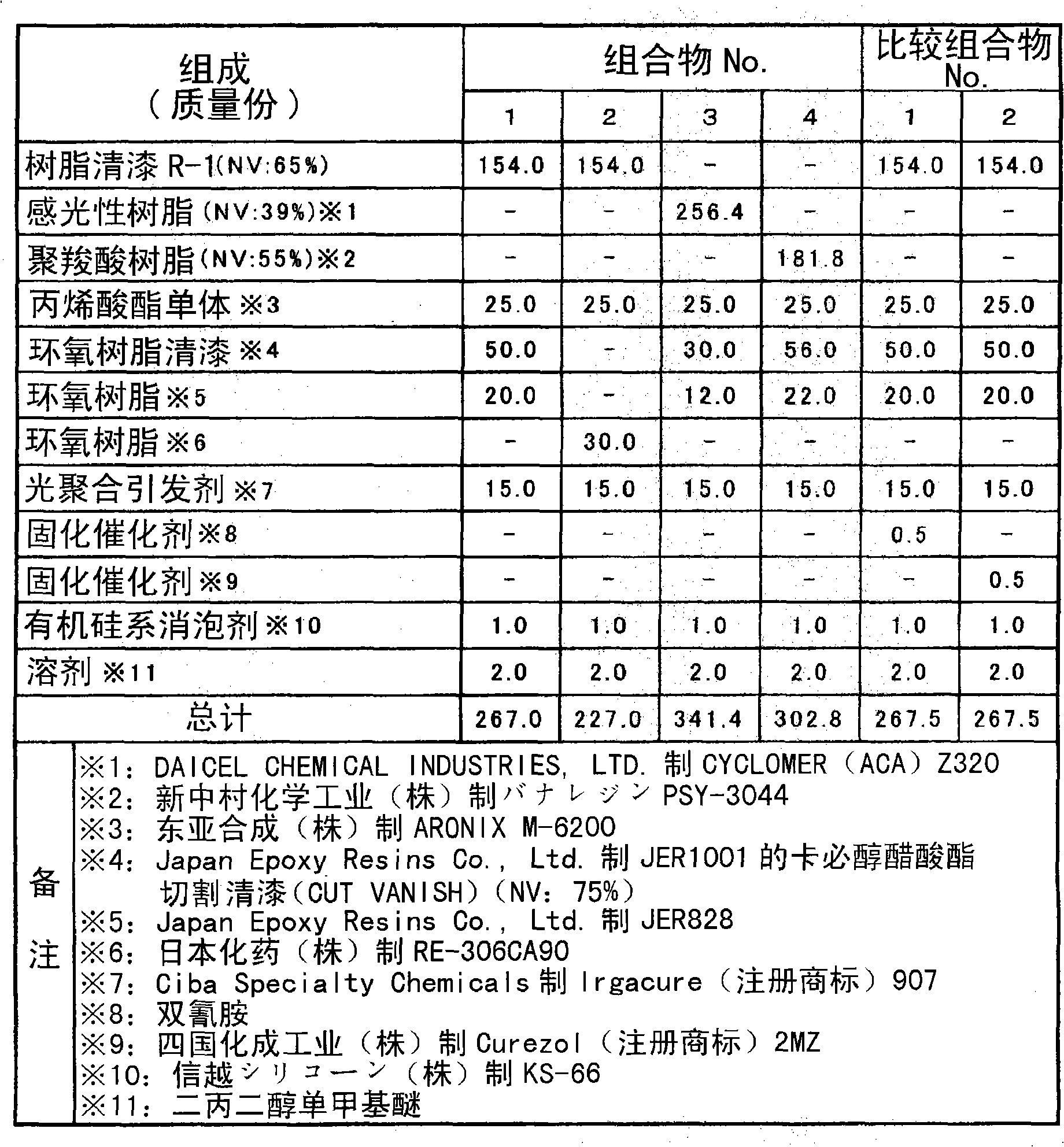

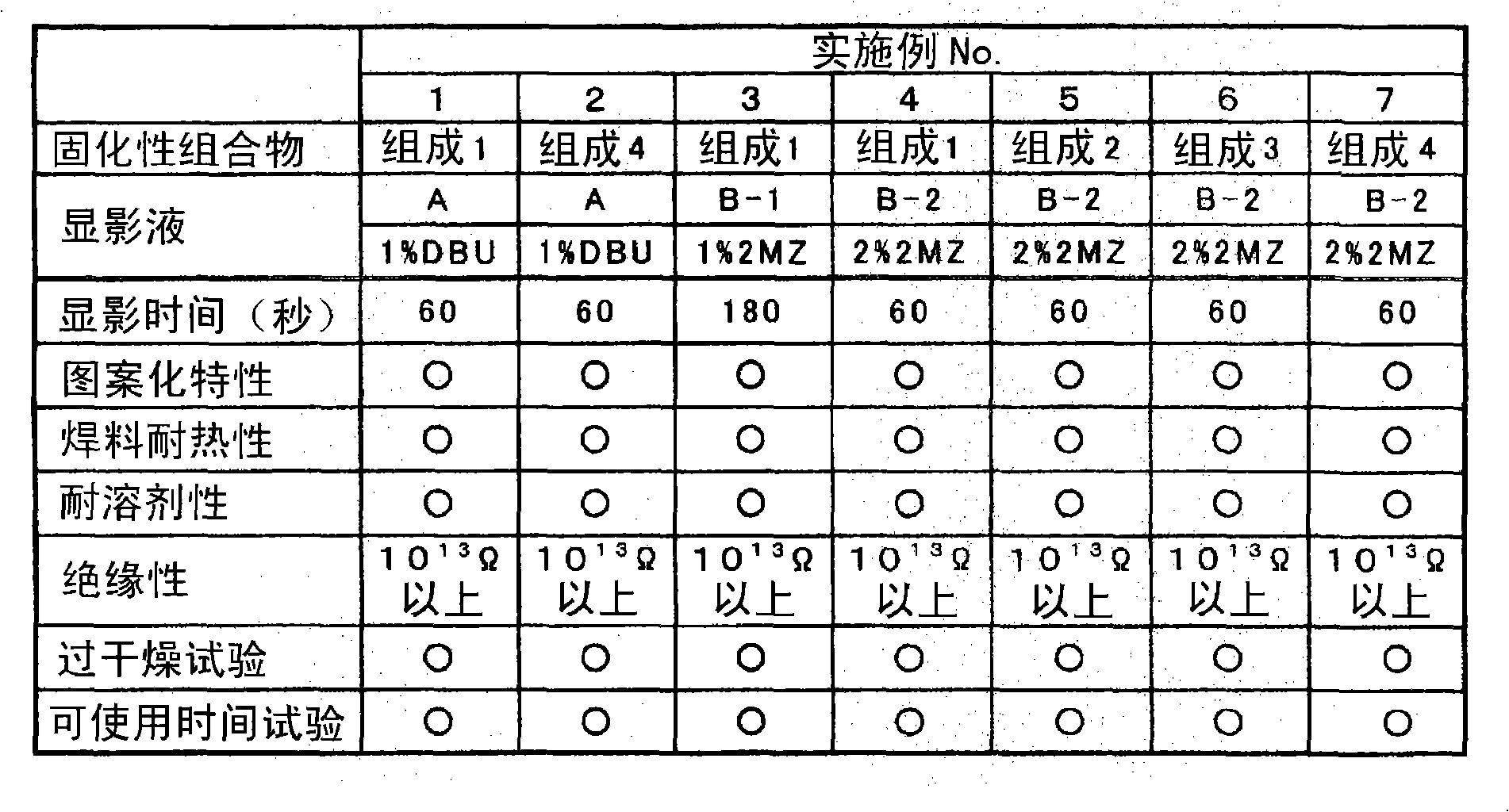

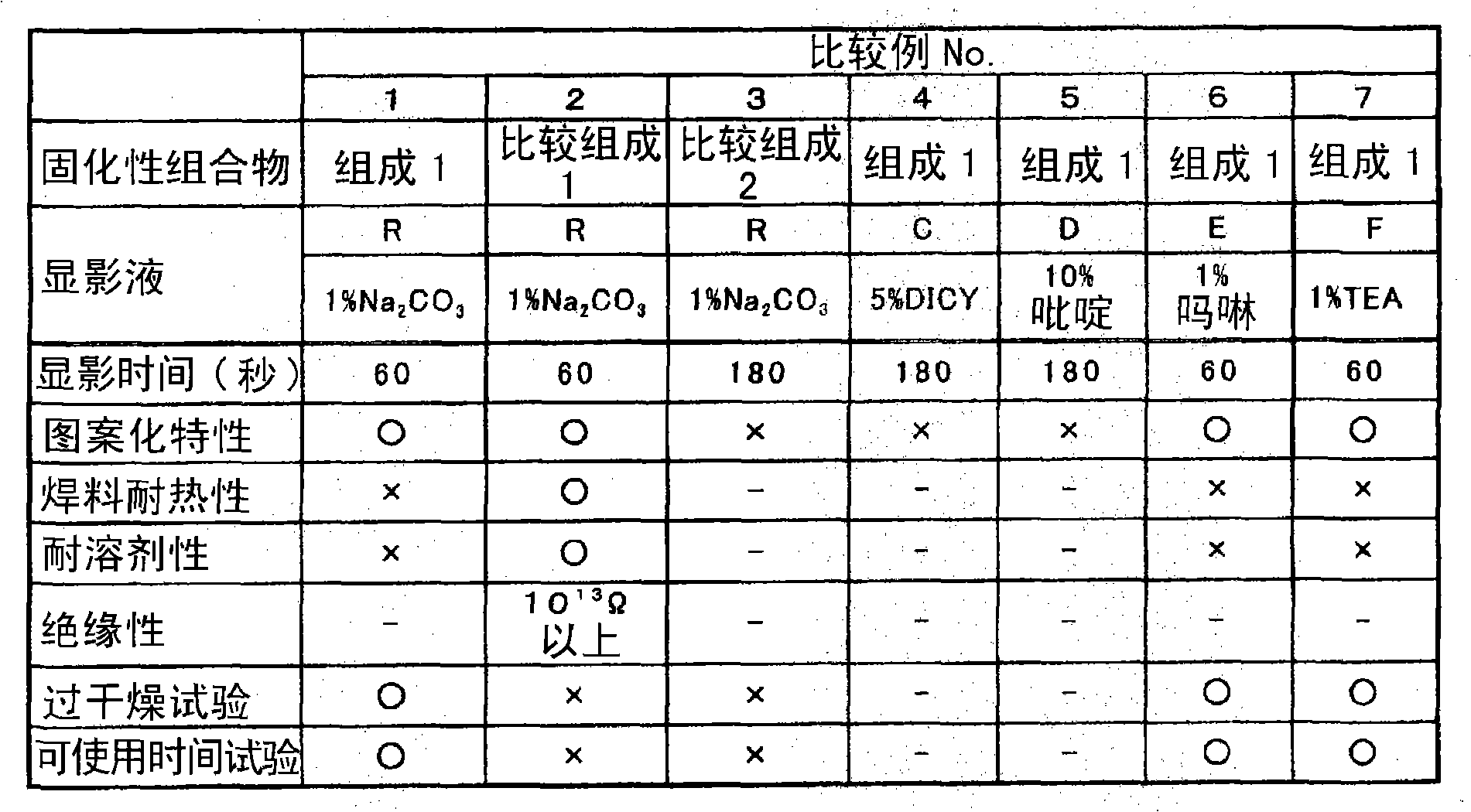

Composition for forming cured film pattern, and method for producing cured film pattern by using the same

ActiveCN101611353AGood storage stabilityExtend the usable timeSemiconductor/solid-state device manufacturingPrinted circuit manufactureNitrogenAqueous solution

A composition for forming a cured film pattern comprises a combination of: an alkaline developable photocurable and thermosetting composition containing no thermal curing catalyst; and a developing solution comprising an aqueous solution of a basic curing catalyst of a nitrogen-containing heterocyclic compound for promoting a thermosetting reaction so that it has a long pot-life (useful life) after mixing of a main agent and a hardener or has excellent storage stability as a one-package composition. Preferably, the basic curing catalyst is a heterocyclic compound having an amidine structure. A film of the photocurable and thermosetting composition is selectively exposed to an actinic energy ray and then developed with the developing solution to remove an unexposed area of the film. At this time, the basic curing catalyst penetrates into the photocured film to effect doping. As a result, the film becomes excellent in thermosetting properties besides the patterning properties by development.

Owner:TAIYO HLDG CO LTD

Hydroxyl acrylic resin aqueous dispersion and preparation method thereof

ActiveCN112538134AAvoid the disadvantage of being prone to side reactions with waterNo bubble film thickness is goodPolyurea/polyurethane coatingsHydrophilic monomerPolymer science

The invention belongs to the technical field of water-based resin, and discloses a hydroxyl acrylic resin aqueous dispersion and a preparation method thereof. The hydroxyl acrylic resin aqueous dispersion comprises the following preparation raw materials: a hydroxyl-containing unsaturated monomer A1, a hydrophobic unsaturated monomer B1, a hydroxyl-containing unsaturated monomer A2, a hydrophobicunsaturated monomer B2, an unsaturated monomer C containing an HDI trimer structure, and a hydrophilic monomer D containing carboxylic acid or sulfonic acid. The hydroxyl acrylic resin aqueous dispersion prepared from the unsaturated monomer C containing the HDI trimer structure can be compounded with a solvent type isocyanate curing agent with low price, so that the high-gloss water-based two-component polyurethane coating is obtained. The water-based two-component polyurethane coating has excellent bubble-free film thickness, can be used for a long time and has water resistance.

Owner:GUANGZHOU GUANZHI NEW MATERIAL TECH

Dedicated recycled concrete additive

The invention discloses a dedicated recycled concrete additive, relates to the field of concrete additive and aims at solving the problems that additives in the prior art is inconvenient to use and isnot favorable for environmental friendliness. The dedicated recycled concrete additive is characterized by being prepared from the following ingredients in mass percent: 7% to 9% of a water reducingagent, 16% to 18% of a slump loss resisting agent, 0.3% of polyvinyl alcohol, 4% of an early strength agent, 3.5% to 4.0% of a retarder, 0.05% to 0.1% of cellulose ether, 1% to 2% of a thickening agent, 1.5% to 2.5% of hydrophilic resin and the balance of water. The dedicated recycled concrete additive disclosed by the invention has the advantages of having no toxin, having environmental friendliness, effectively improving concrete workability and reducing concrete slump loss.

Owner:成都建工预筑科技有限公司

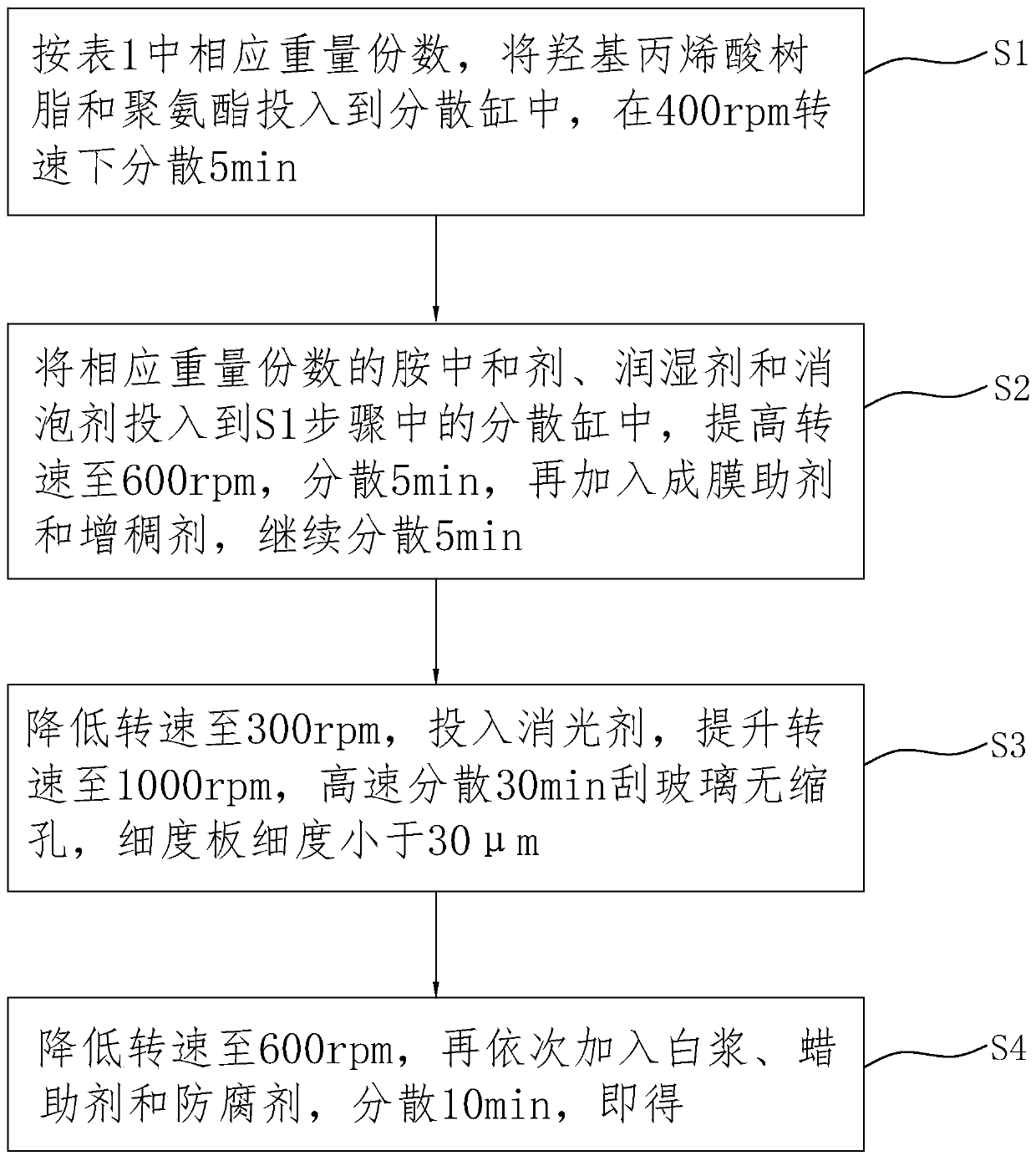

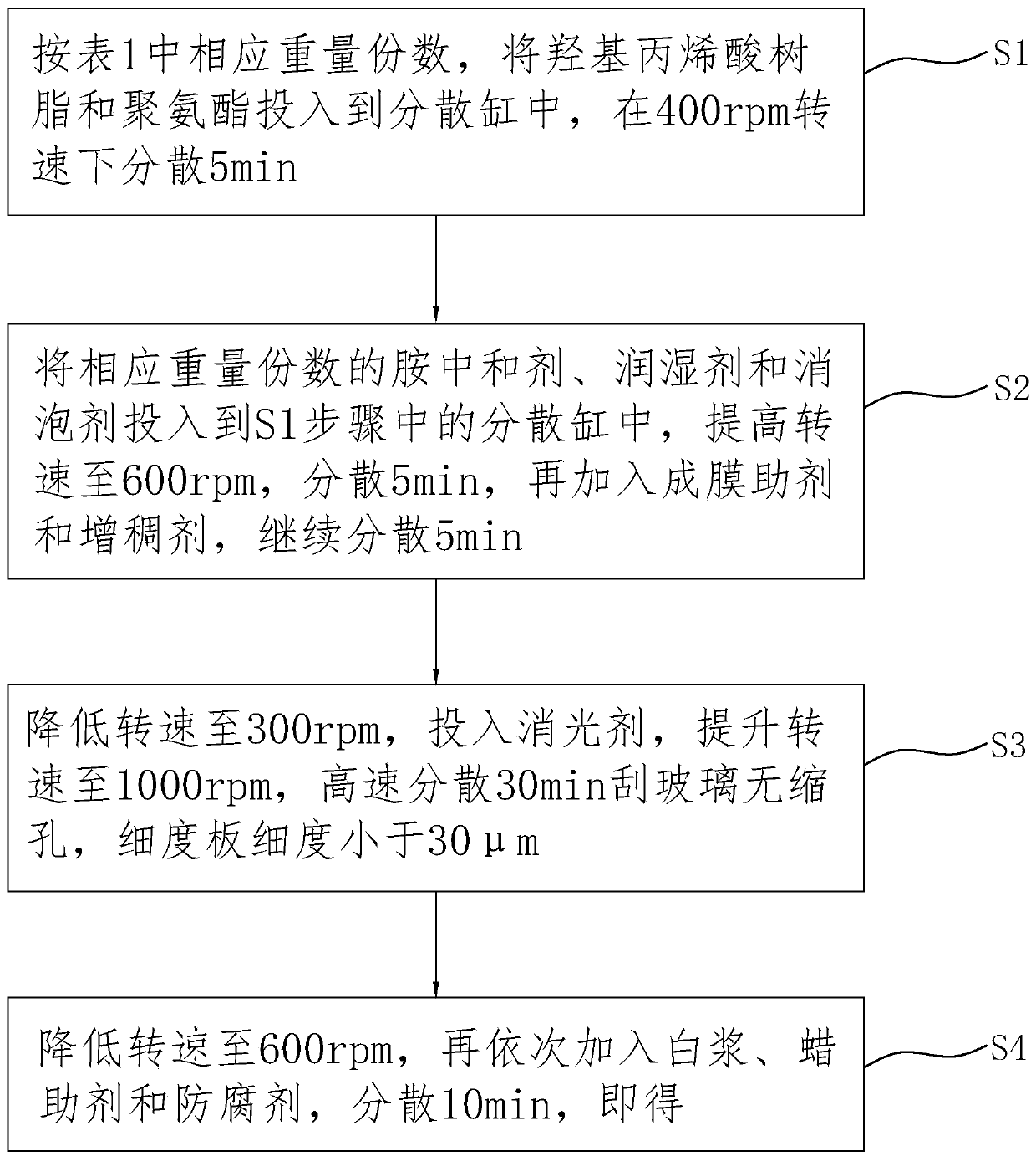

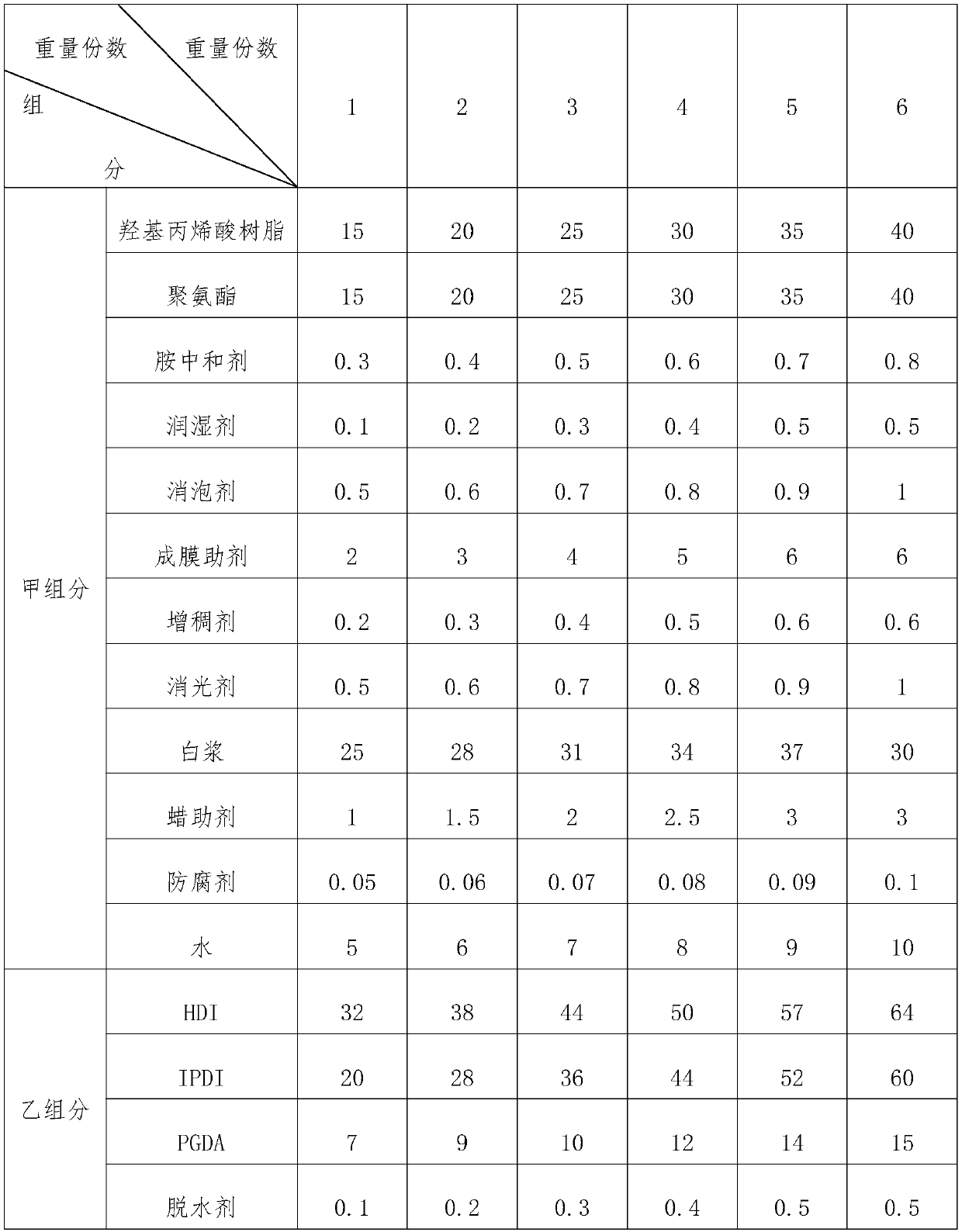

Water-based two-component matte white finish paint and preparation method thereof

InactiveCN111171696AExtend the usable timeLow usable timePolyurea/polyurethane coatingsFoaming agentAcrylic resin

The invention discloses water-based two-component matte white finish paint and a preparation method thereof, and relates to the technical field of water-based paint. The technical key points are as follows: the water-based two-component matte white finish paint comprises a component A and a component B. The component A comprises the following components in parts by weight: 15-40 parts of hydroxy acrylic resin; 15-40 parts of polyurethane; 0.3-0.8 parts of an amine neutralizer; 0.1-0.5 parts of a wetting agent; 0.5-1 parts of a de-foaming agent; 2-6 parts of a coalescing agent; 0.2-0.6 parts ofa thickening agent; 0.5-1 parts of a delustering agent; 25-30 parts of white pulp; 1-3 parts of a wax additive; 0.05-0.1 parts of a preservative; 5-10 parts of water; the component B is prepared fromthe following components in parts by weight: 32-64 parts of HDI; 20-60 parts of IPDI; 7-15 parts of PGDA; and 0.1-0.5 parts of a dehydrating agent. The water-based two-component matte white finish paint prepared by adopting the formula has the advantages of the long service life and recyclability.

Owner:SHANGHAI CHANGRUNFA PAINT

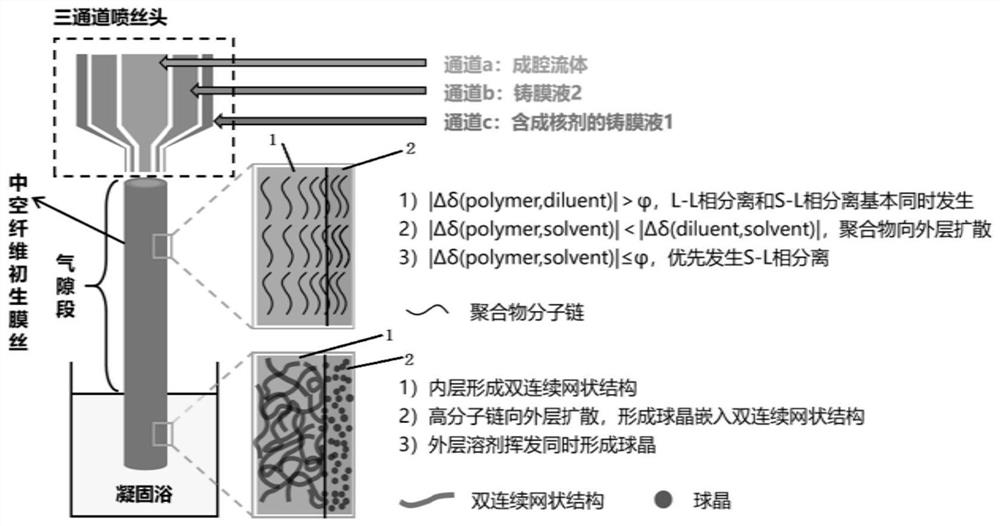

Super-hydrophobic polyolefin hollow fiber membrane for oxygenated membrane and preparation method of super-hydrophobic polyolefin hollow fiber membrane

ActiveCN112535956AReduce usagePrecise control of membrane structureSemi-permeable membranesSustainable biological treatmentPolymer sciencePolyolefin

The invention relates to the technical field of polymer films, in particular to a super-hydrophobic polyolefin hollow fiber membrane for an oxygenation membrane and a preparation method of the super-hydrophobic polyolefin hollow fiber membrane. Polyolefin is used as a raw material, a three-channel spinning nozzle is used, and the material is prepared through a thermally induced phase separation method. A membrane casting solution formed by a polyolefin solvent is a solution system with the highest critical dissolving temperature, polyolefin can be dissolved in the corresponding solvent when the temperature is higher than the highest critical dissolving temperature, and liquid-liquid phase separation occurs when the temperature is lower than the highest critical dissolving temperature. Thepore diameters of the inner surface and the main body structure of the prepared hollow fiber membrane are uniform, and the hollow fiber membrane is of a spongy bicontinuous network structure; the outer layer is composed of spherical crystals which have a certain thickness and are closely arranged; and a composite structure with a spherical crystal structure embedded into a bicontinuous reticular structure is formed close to the outer layer, namely the junction of the outer layer and the membrane main body structure. The hollow fiber membrane prepared by the invention has high gas transmissionproperty, blood compatibility and plasma leakage resistance, can be directly used for extracorporeal membrane pulmonary oxygenation, and can reduce the use of a blood compatibility coating.

Owner:上海翊科聚合物科技有限公司

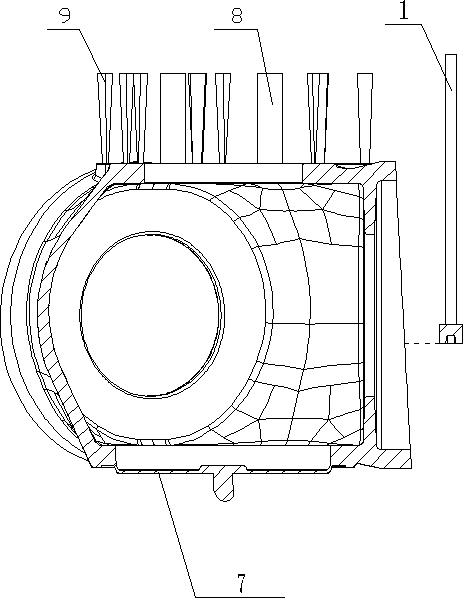

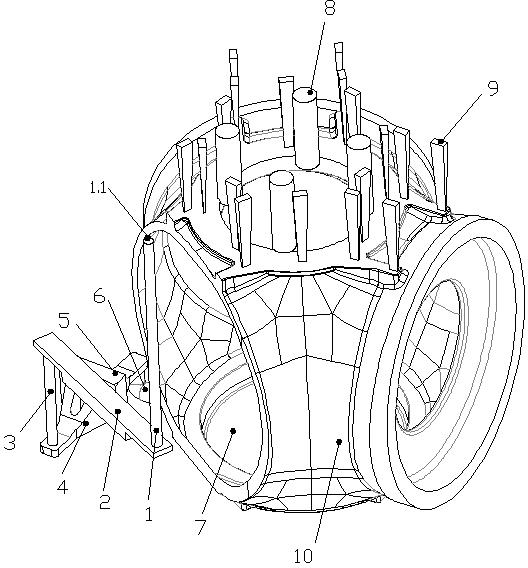

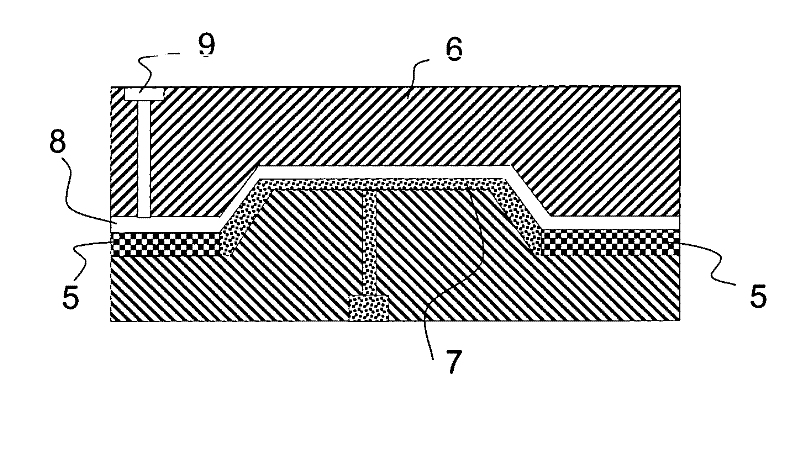

Mold and method for making multilayer plastic molded parts

ActiveCN102292198AExtend the usable timeGood typing performanceCoatingsEngineeringMechanical engineering

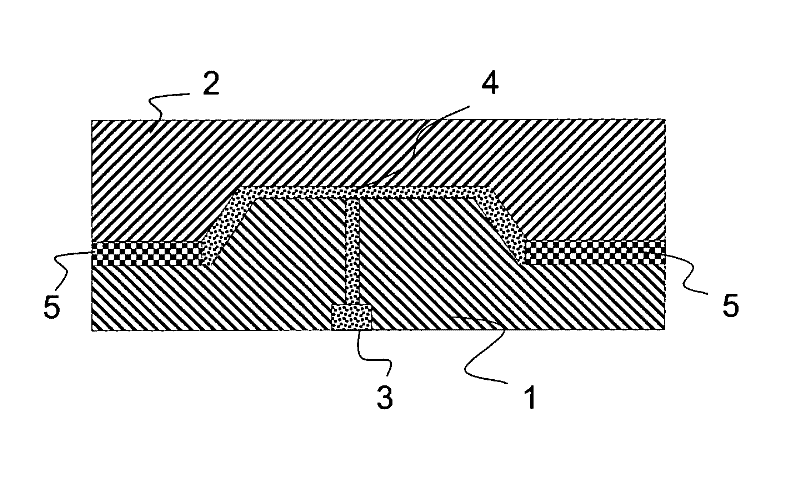

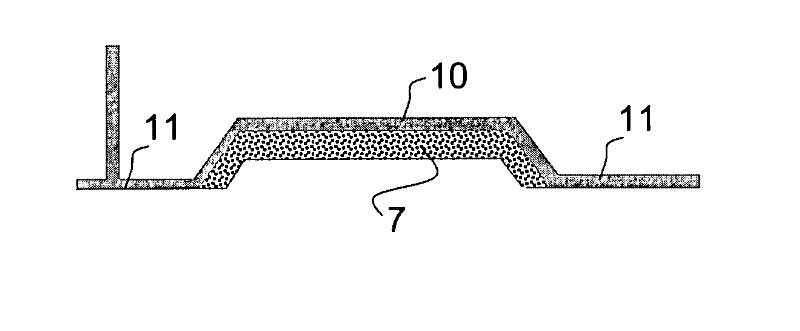

The invention relates to a mould for producing multi-layer shaped parts of plastic comprising at least two mould halves (1, 2, 6) and a cavity (4), in which the plastic is held, a gating system (9) with a runner and an exchangeable separating mould insert (5), as well as a method for producing the multi-layer shaped parts of plastic.

Owner:COVESTRO DEUTSCHLAND AG

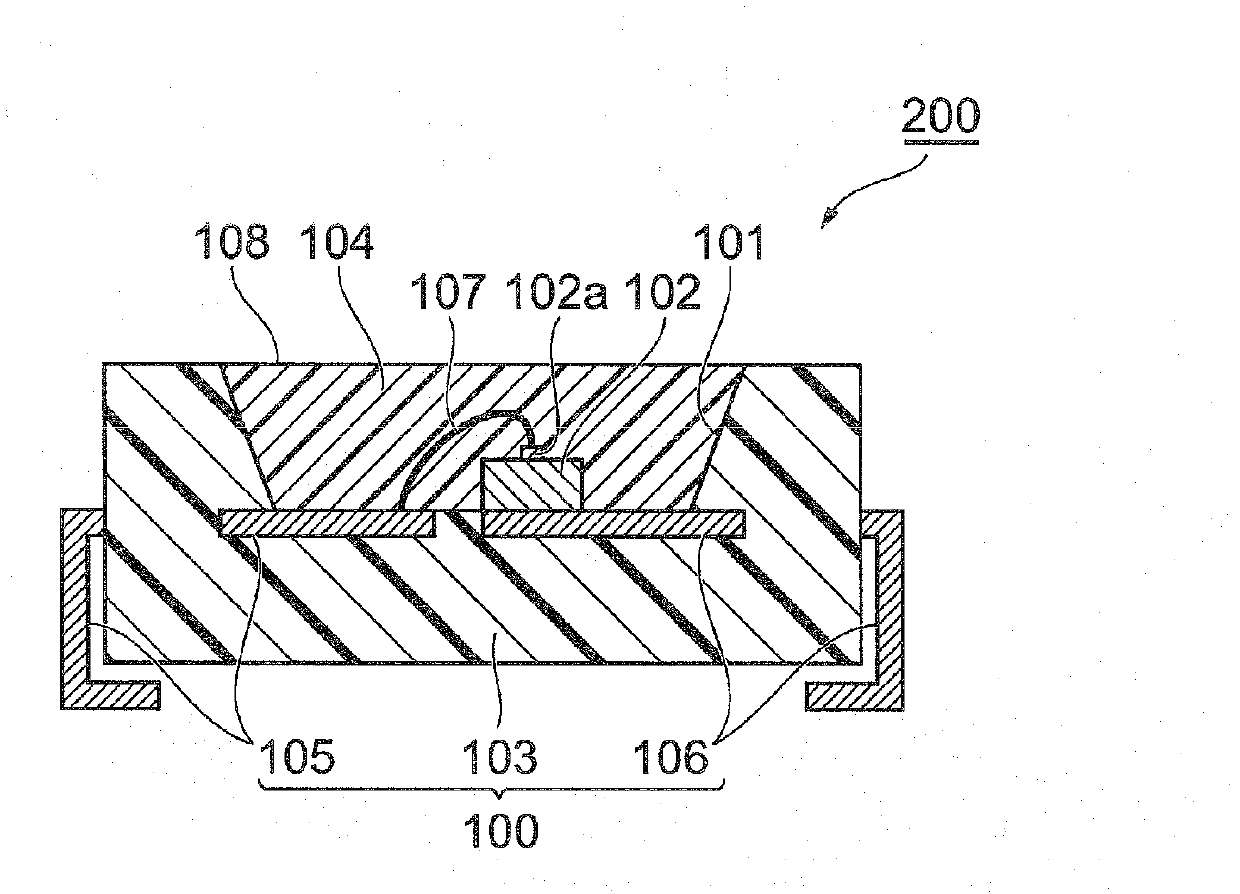

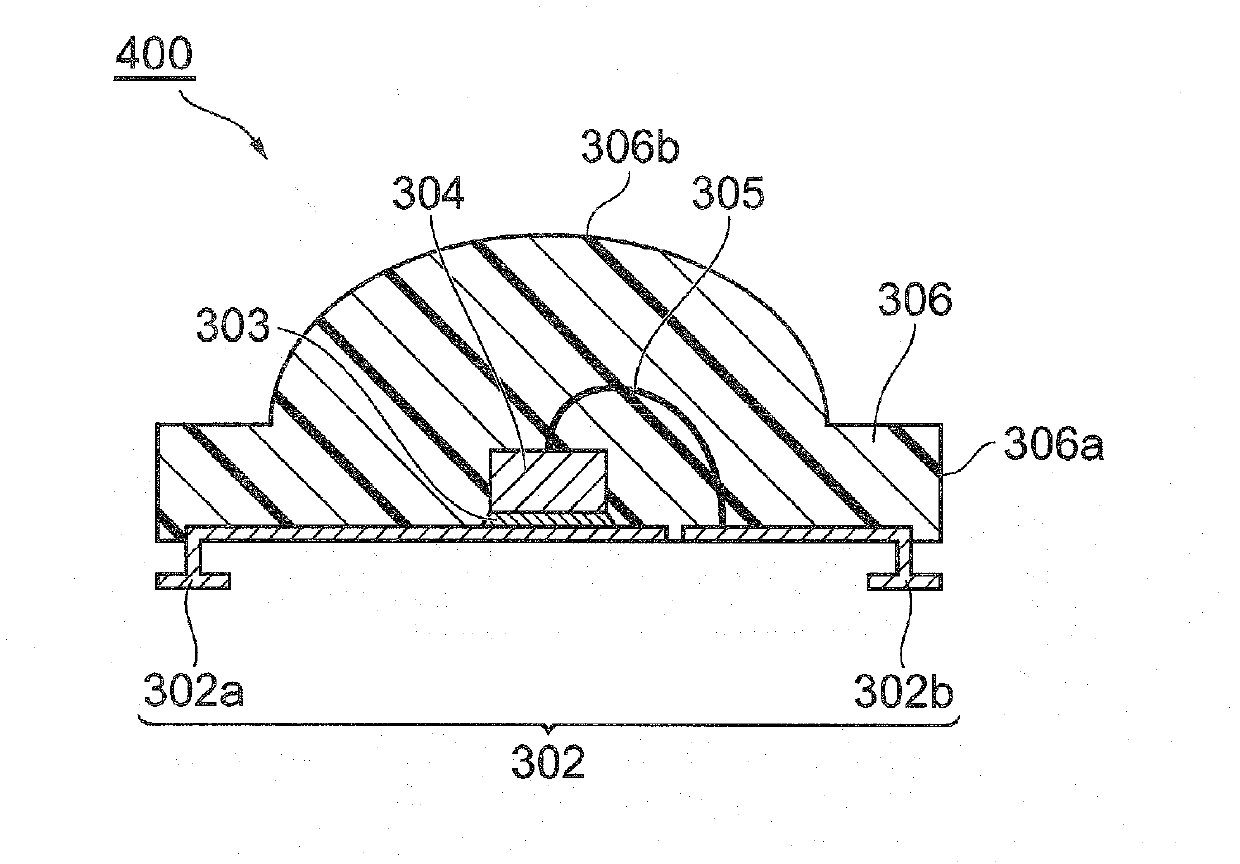

Urethane resin composition, cured object, and photosemiconductor device using cured object

InactiveCN102549038AHigh transparencyExcellent curing accelerationSemiconductor/solid-state device detailsSolid-state devicesPolyolSemiconductor

Owner:RESONAC CORPORATION

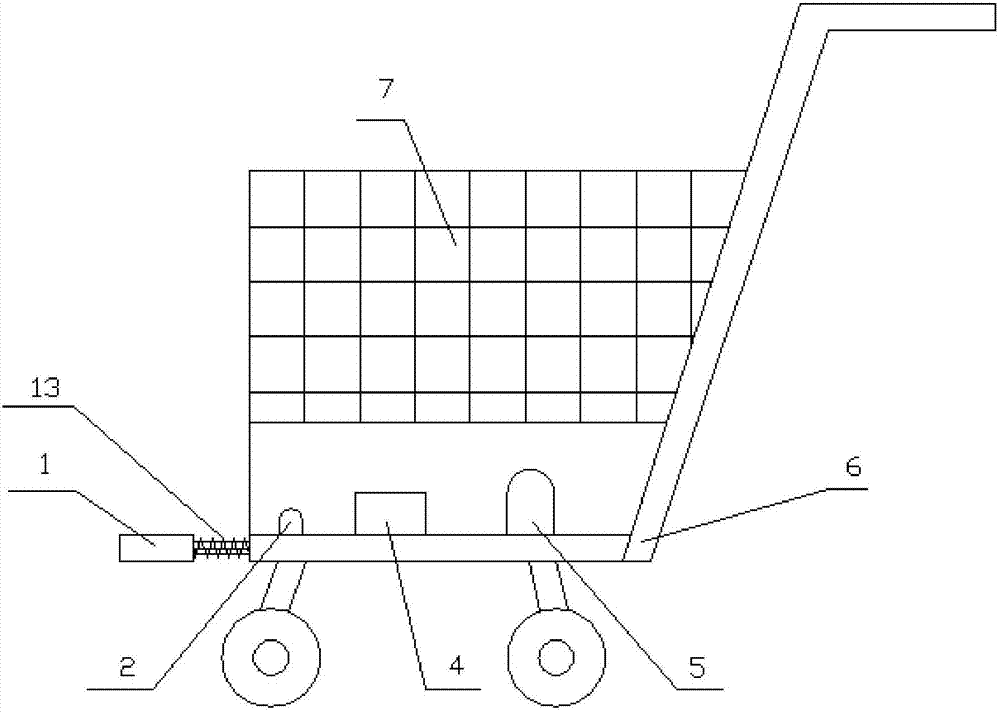

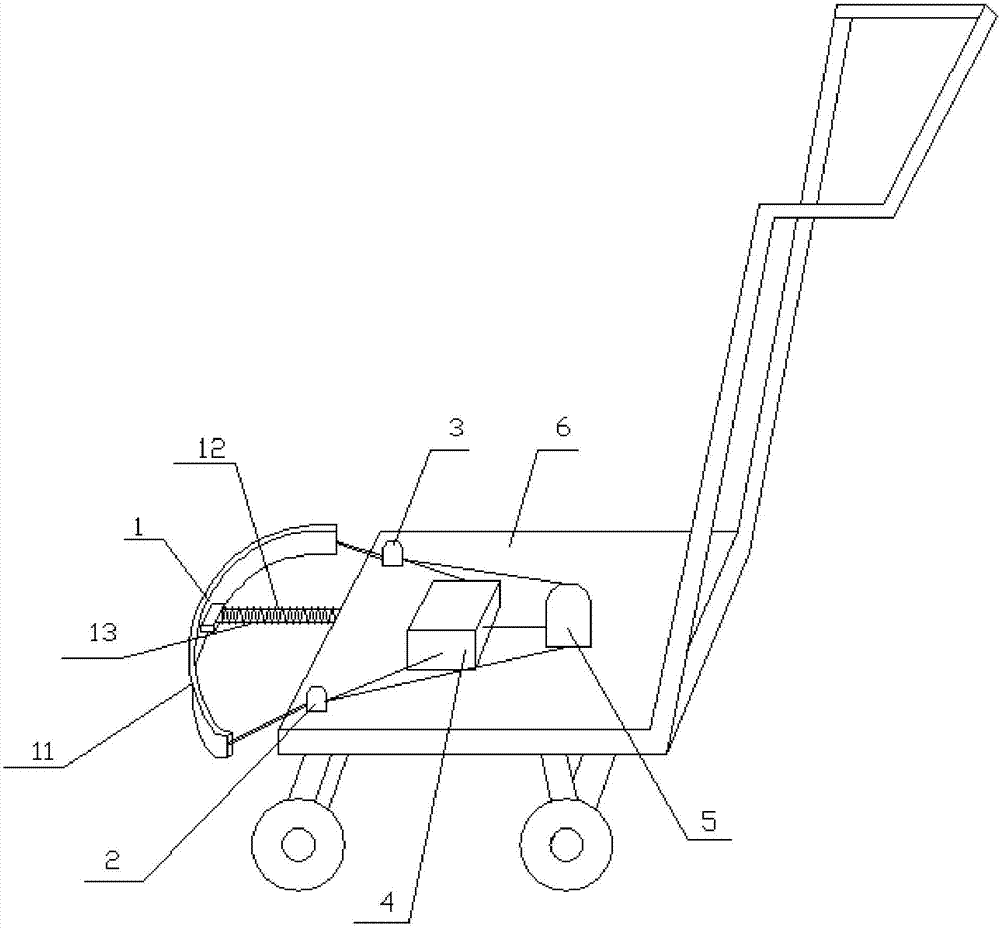

Anti-collision alarming device of shopping trolley

InactiveCN106981168AImprove securityAvoid bruisesAlarmsHand carts with multiple axesElectricityVehicle frame

An anti-collision alarm device for a shopping cart according to the present invention comprises a vehicle frame, an anti-collision module, a power supply module and an alarm module are arranged on the vehicle frame, the anti-collision module includes an arc-shaped anti-collision plate, and the anti-collision plate Located at the front end of the shopping cart, an anti-collision spring is clamped between the anti-collision plate and the shopping cart; the alarm module includes a first induction switch, a second induction switch and an alarm; the anti-collision plate A first connecting rod is provided between one end and the first induction switch, a second connecting rod is provided between the other end of the anti-collision plate and the second induction switch, and the first induction switch and the The second induction switch is electrically connected to the alarm respectively; its anti-collision module is retractable, and when it hits a person or an object, the anti-collision module retracts to reduce the impact force, prevent collision accidents, and alarm The module will emit an alarm sound to remind the pusher and the hit person to pay attention to avoiding.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

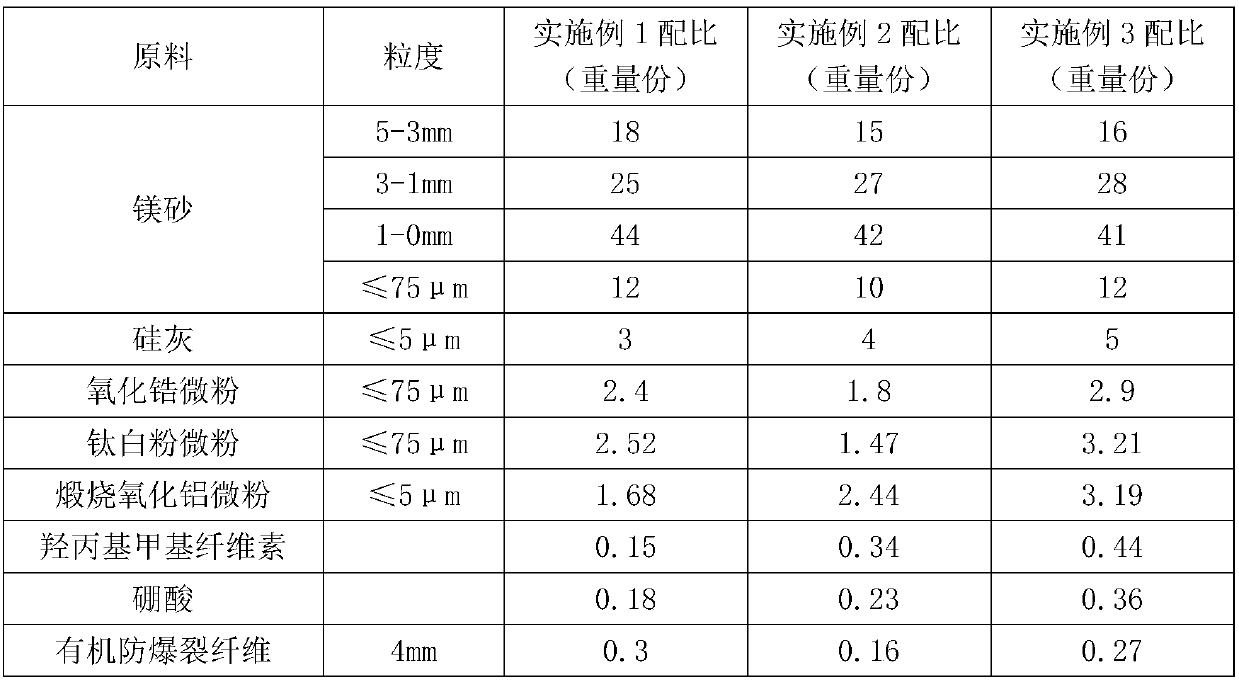

Magnesia material for repairing converter lining, and preparation method and using method thereof

InactiveCN109678470AImprove high temperature performanceNo pollution in the processManufacturing convertersFiberPollution

The invention relates to a magnesia material for repairing a converter lining, and a preparation method and a using method thereof. According to the magnesia material, magnesia is taken as a main rawmaterial, silica fume is taken as a binding agent, at least one magnesium oxide micro powder, calcined alumina micro powder, silicon carbide micro powder, zirconium oxide micro powder and titanium dioxide micro powder is taken as an additive, at least one of hydroxypropyl methyl cellulose and carboxymethylcellulose is taken as a bleeding prevention agent, at least one of boric acid, citric acid, tartaric acid and oxalic acid is taken as a retarder, at least one of metal aluminum powder and organic anti-explosion fiber is taken as an anti-burst agent, water is taken as a medium, and the magnesia material is prepared after uniform mixing. The magnesia material is an environmentally-friendly magnesia material which is rapid in sintering and long in service life, and has the advantages of environmental protection, no pollution, high mobility, short sintering time and the like.

Owner:辽宁利尔镁质合成材料股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com