Dedicated recycled concrete additive

A technology of recycled concrete and admixtures, applied in the field of concrete admixtures, can solve problems such as inconvenient use, achieve the effects of reducing slump loss, reducing bleeding at the bottom, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

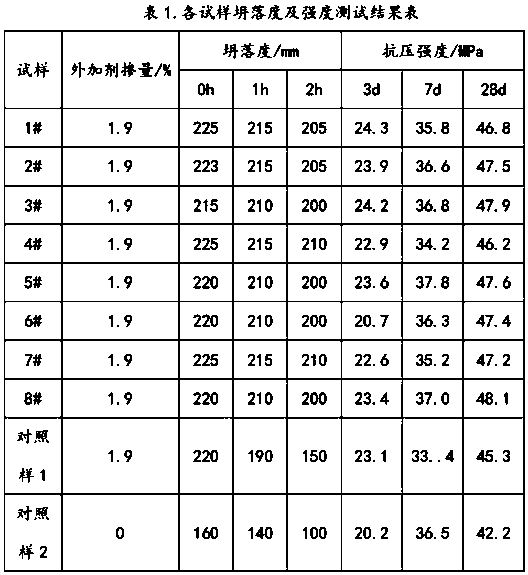

Examples

Embodiment 1

[0030] A special admixture for recycled concrete, each component is calculated by mass percentage:

[0031] Polycarboxylic acid water reducer 7%, slump retention agent 16%, polyvinyl alcohol 0.3%, sodium sulfate 4%, sodium gluconate 3%, white sugar 0.5%, hydroxypropyl cellulose 0.05%, polyacrylamide 1.5% , Hydrophilic resin 1.5%, the balance is water.

[0032] The hydrophilic resin is a mixture of polyethylene oxide, water-based polyurethane and polyglycidyl ether, with a mass ratio of 1:0.5:0.02.

Embodiment 2

[0034] A special admixture for recycled concrete, each component is calculated by mass percentage:

[0035] Polycarboxylic acid water reducer 8%, slump retention agent 17%, polyvinyl alcohol 0.3%, sodium sulfate 4%, sodium gluconate 3.2%, white sugar 0.5%, hydroxypropyl cellulose 0.07%, polyacrylic acid 1.4%, The hydrophilic resin is 1.8%, and the balance is water.

[0036] The hydrophilic resin is a mixture of polyethylene oxide, water-based polyurethane, polyglycidyl ether and dibutyl sebacate ethanol solution, and its mass ratio is 1:0.5:0.02:0.01.

Embodiment 3

[0038] A special admixture for recycled concrete, each component is calculated by mass percentage:

[0039] Polycarboxylic acid water reducer 9%, slump retention agent 18%, polyvinyl alcohol 0.3%, sodium sulfate 4%, sodium gluconate 3.5%, sugar 0.5%, hydroxypropyl cellulose 0.1%, polyacrylamide 2.0% , Hydrophilic resin 2.5%, the balance is water.

[0040] The hydrophilic resin is a mixture of polyethylene oxide, water-based polyurethane and polyglycidyl ether, with a mass ratio of 1:0.5:0.02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com