Patents

Literature

1280results about How to "Avoid bruises" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

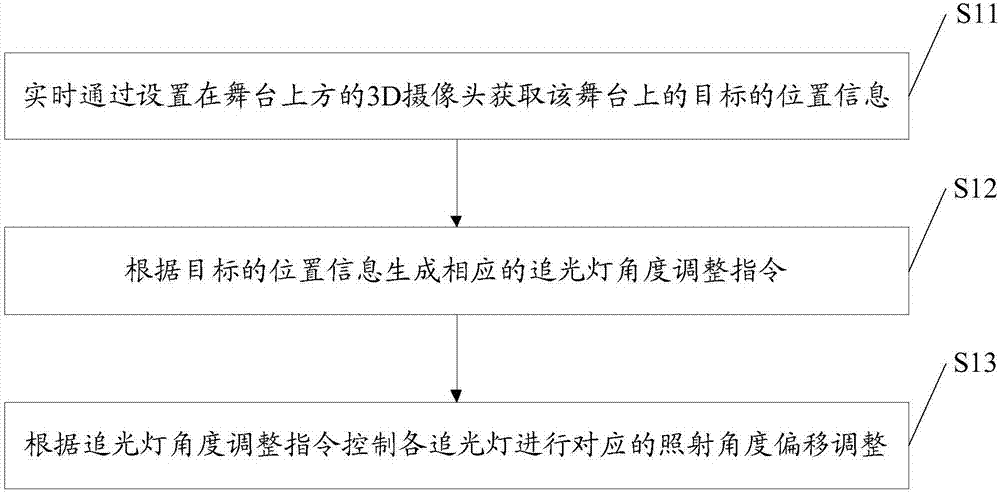

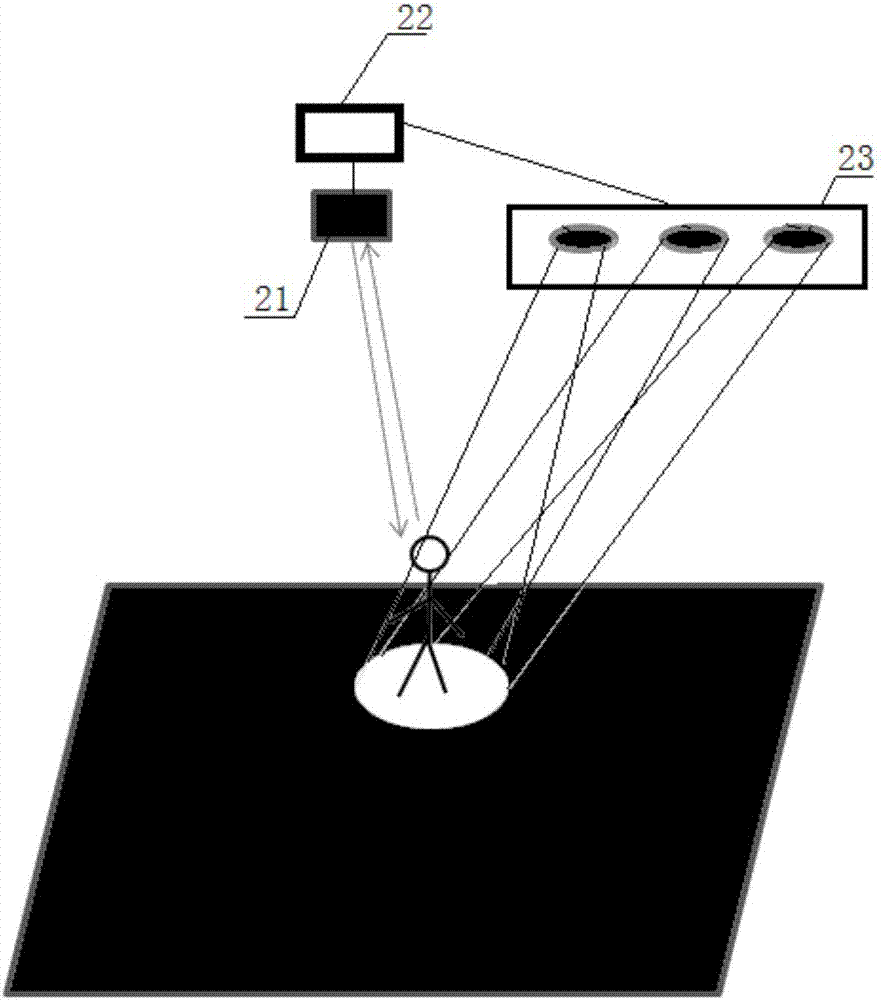

Automatic lamp light following method and system for stage

The invention discloses an automatic lamp light following method and system for a stage. The method comprises the steps of obtaining the position information of a target on the stage in real time through a 3D camera above the stage, generating a corresponding follow spotlight angle adjusting command according to the position information of the target, and controlling follow spotlights to be subjected to corresponding irradiating angle offset adjustment according to the follow spotlight angle adjusting command. The position of the target on the stage is detected by the 3D camera, so that the angles of the follow spotlights of the stage are adjusted automatically to achieve automatic following of the stage lamp light, automation is achieved, manual control over the follow spotlights is not needed, the follow spotlights can be arranged at the positions above the stage or far higher than audiences accordingly and are prevented from injuring the audiences or workers in the running process,and the follow spotlights can also be used for directly irradiating the target so that the situation that a reflection mirror is used for reflecting light and consequently light beam losses are causedcan be avoided.

Owner:TRULY OPTO ELECTRONICS

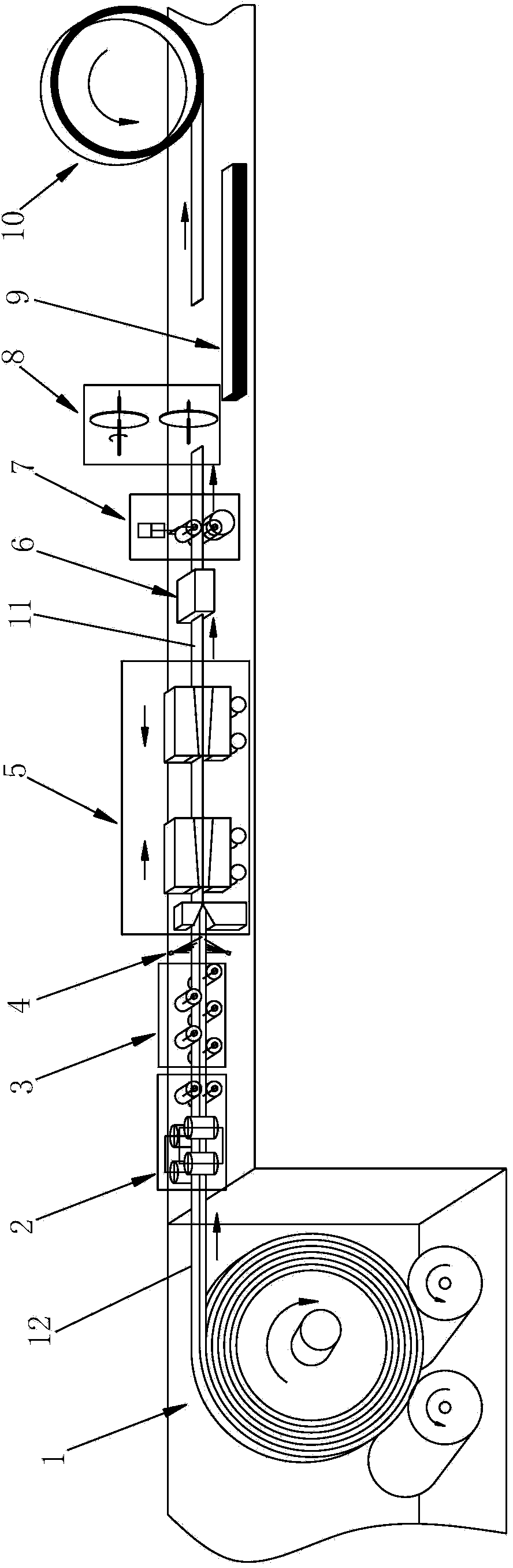

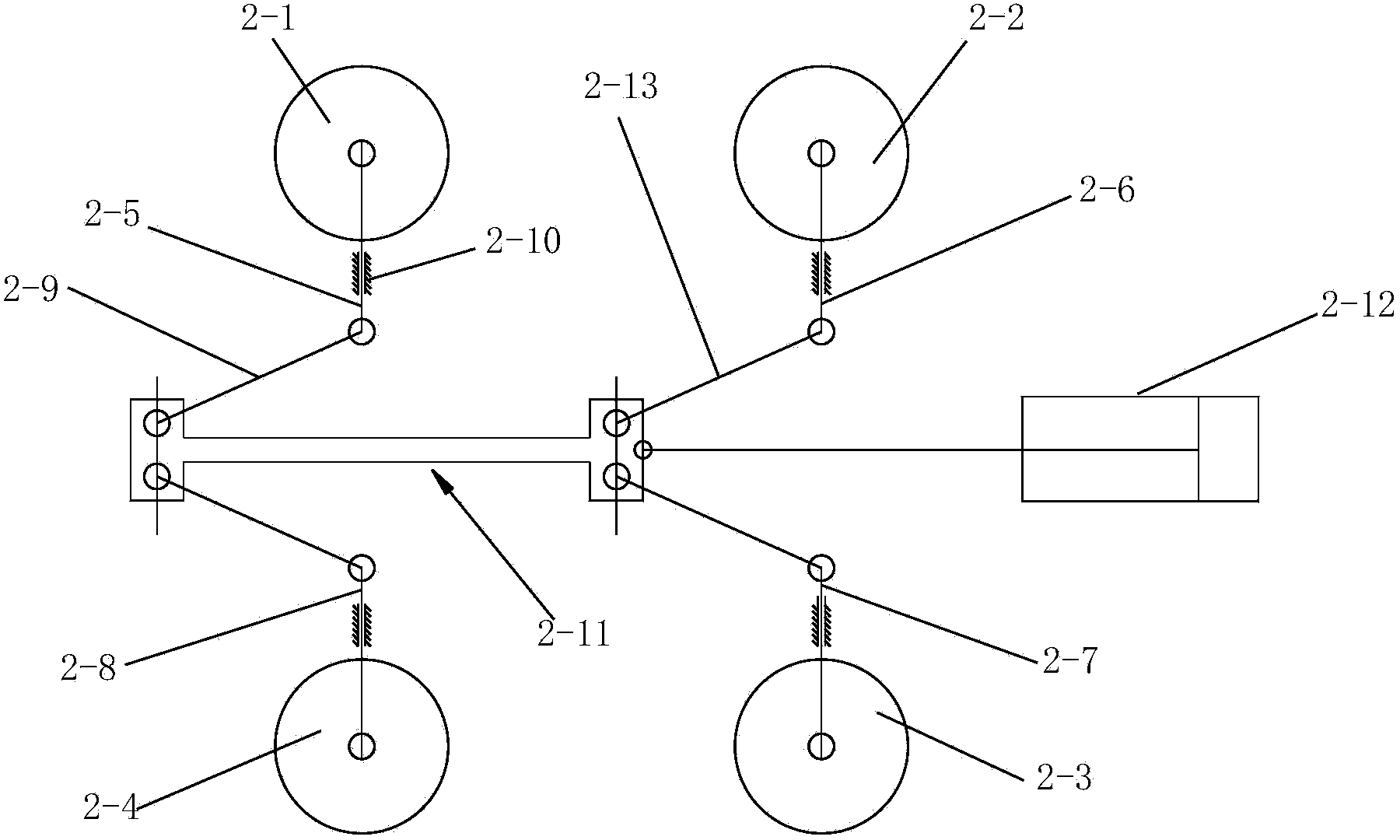

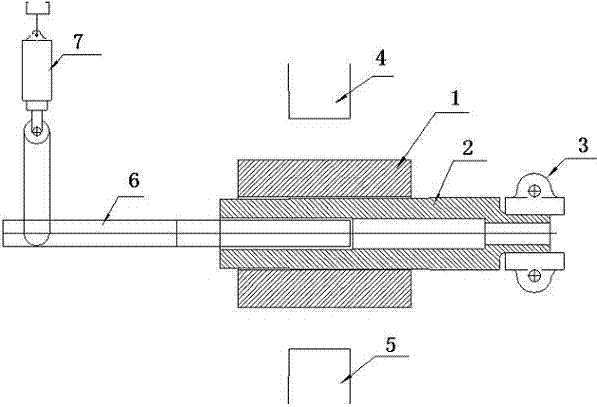

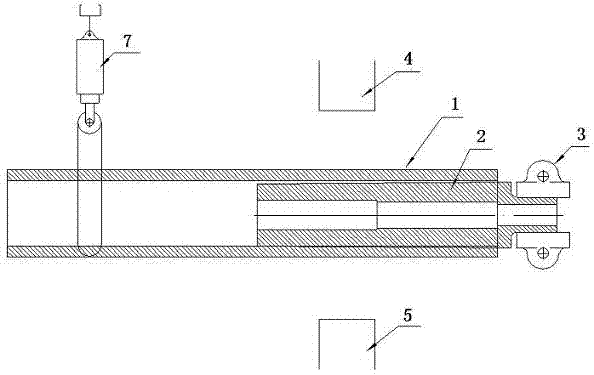

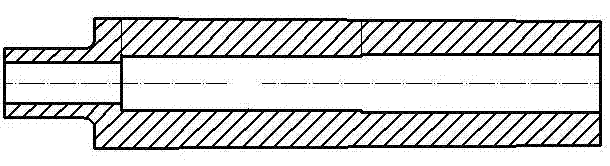

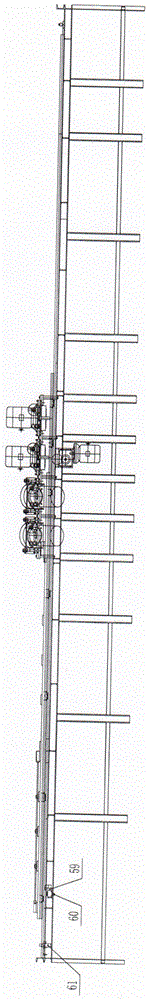

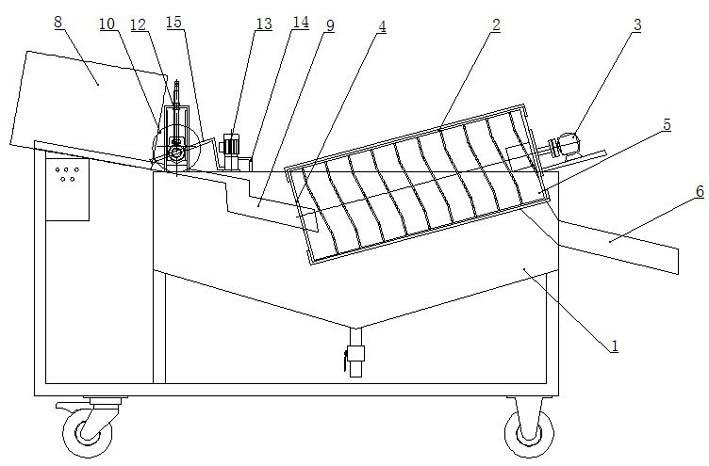

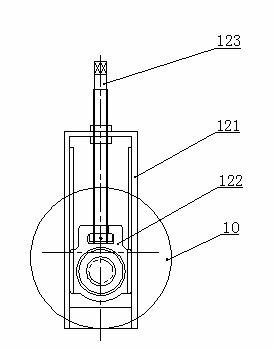

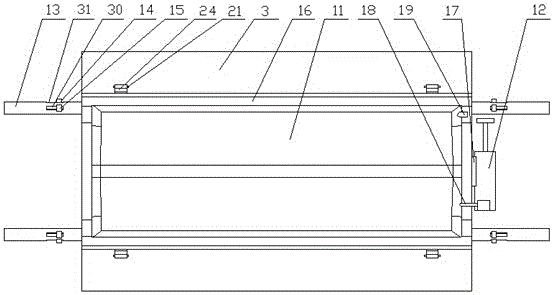

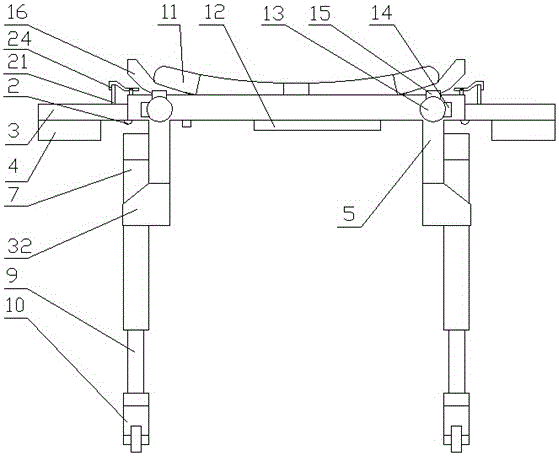

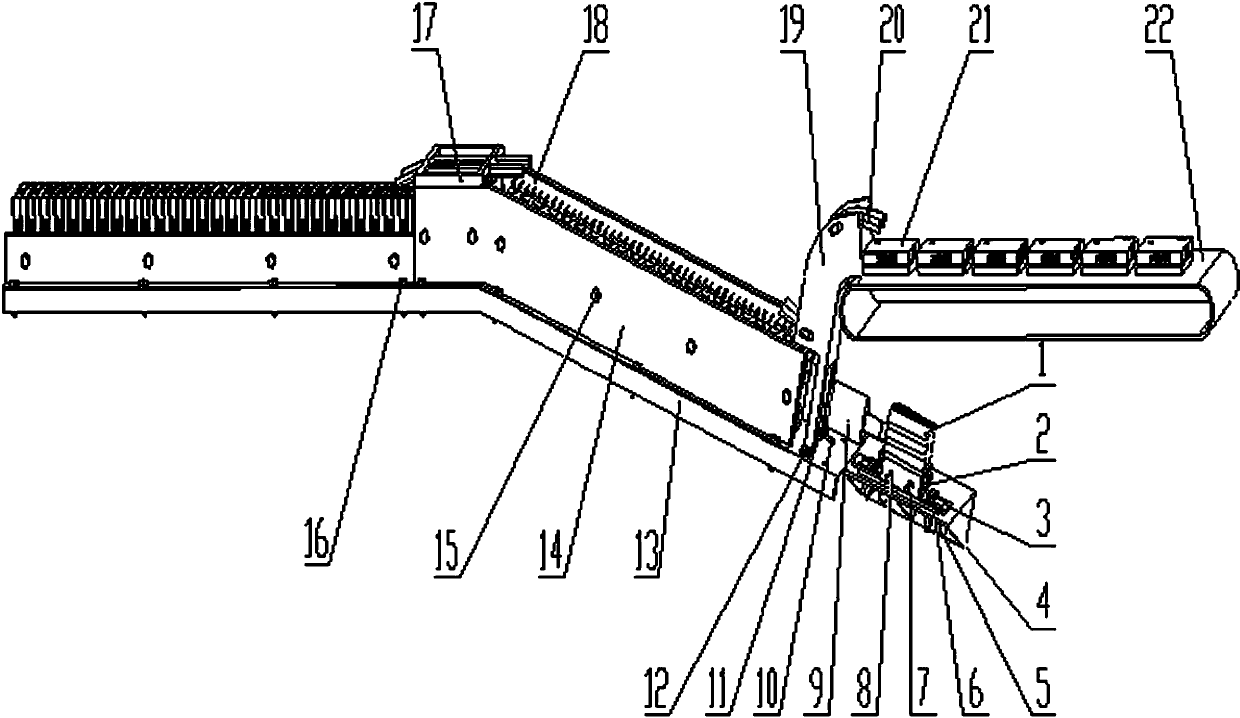

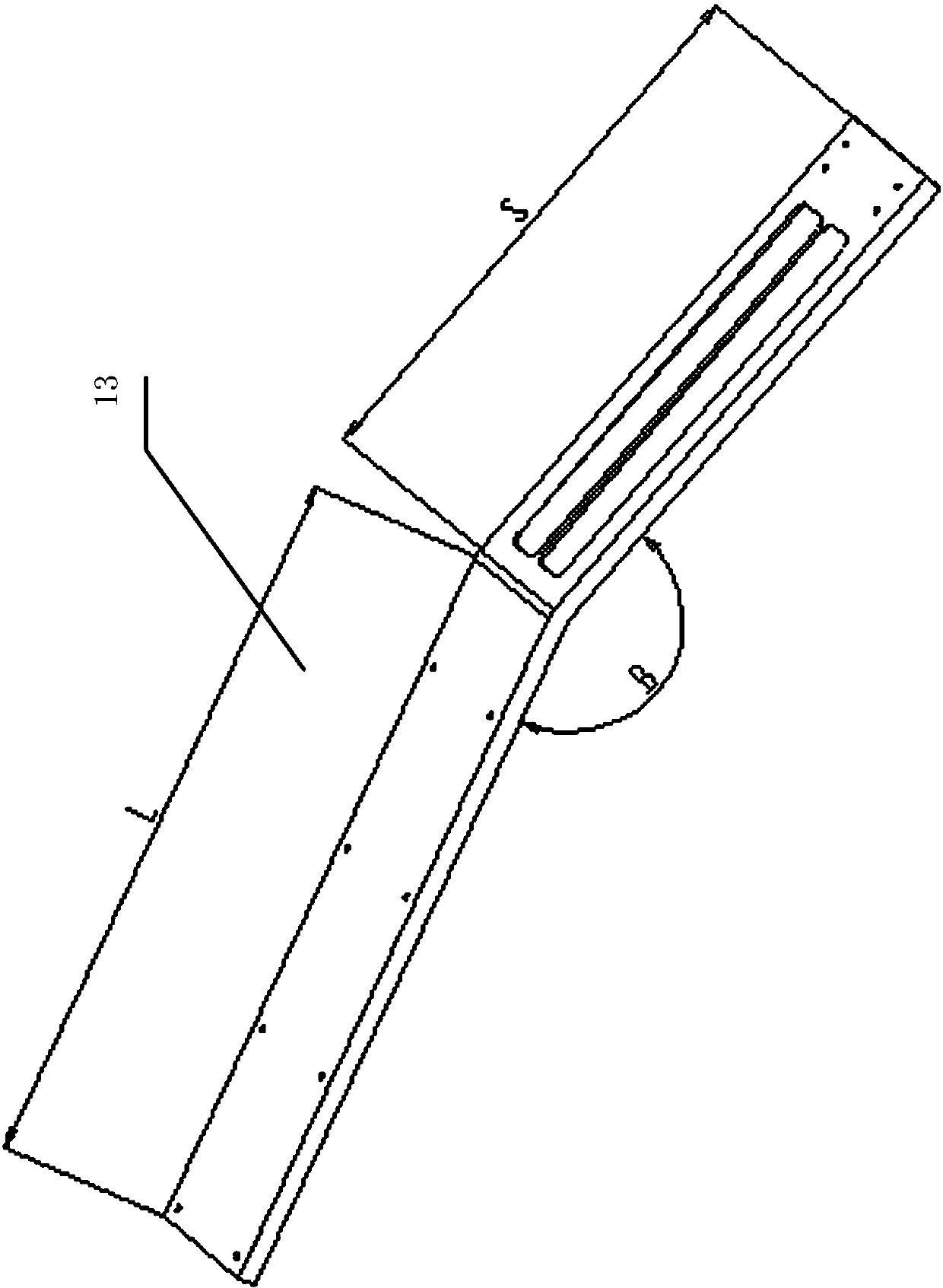

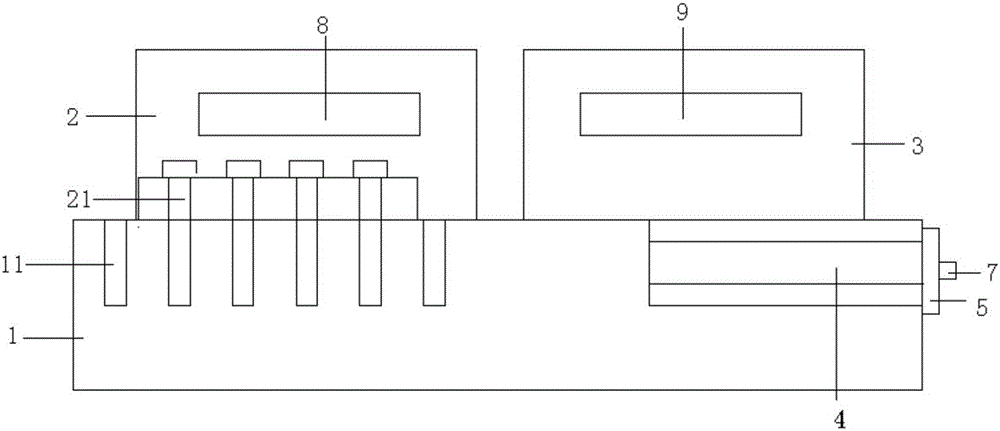

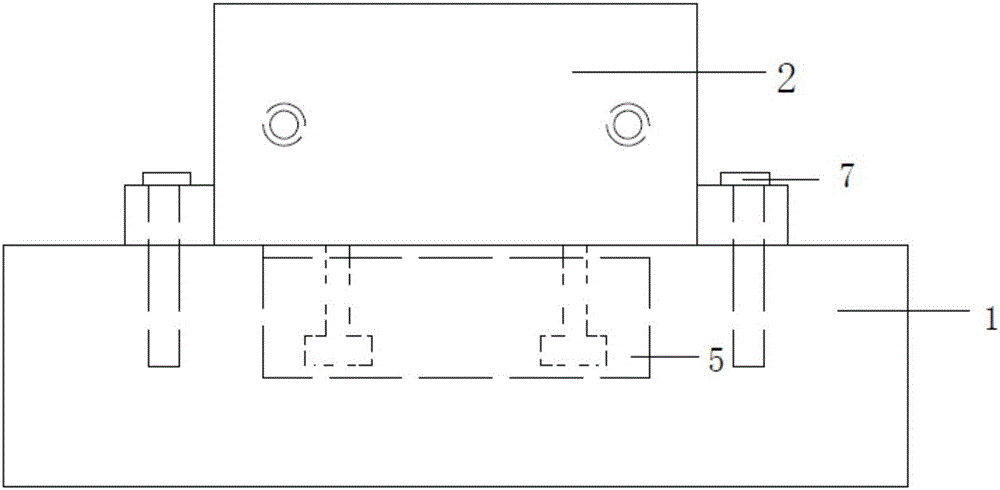

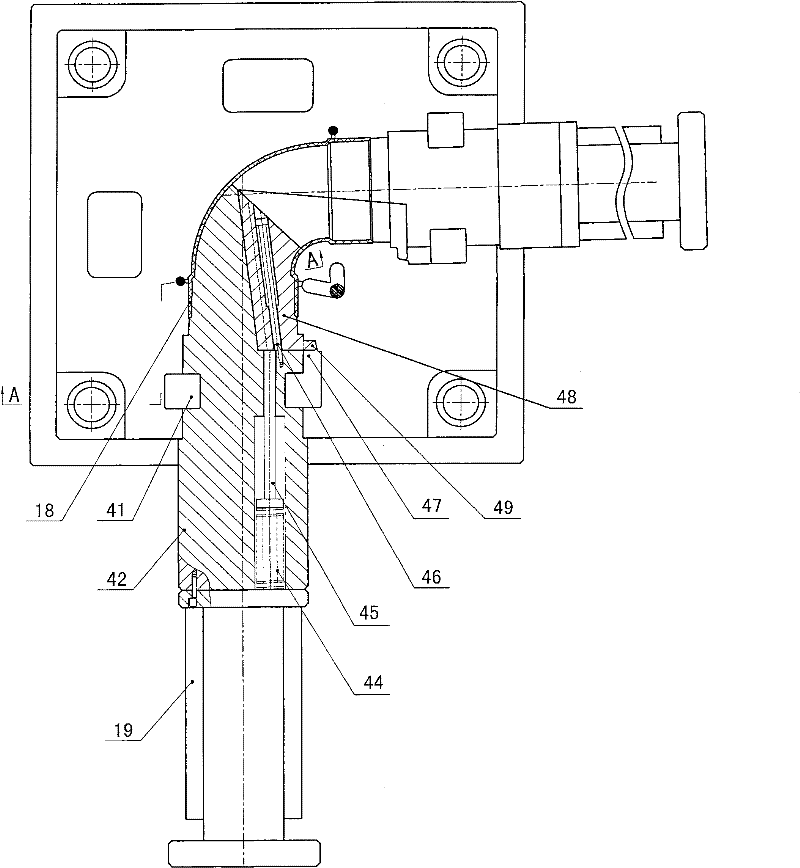

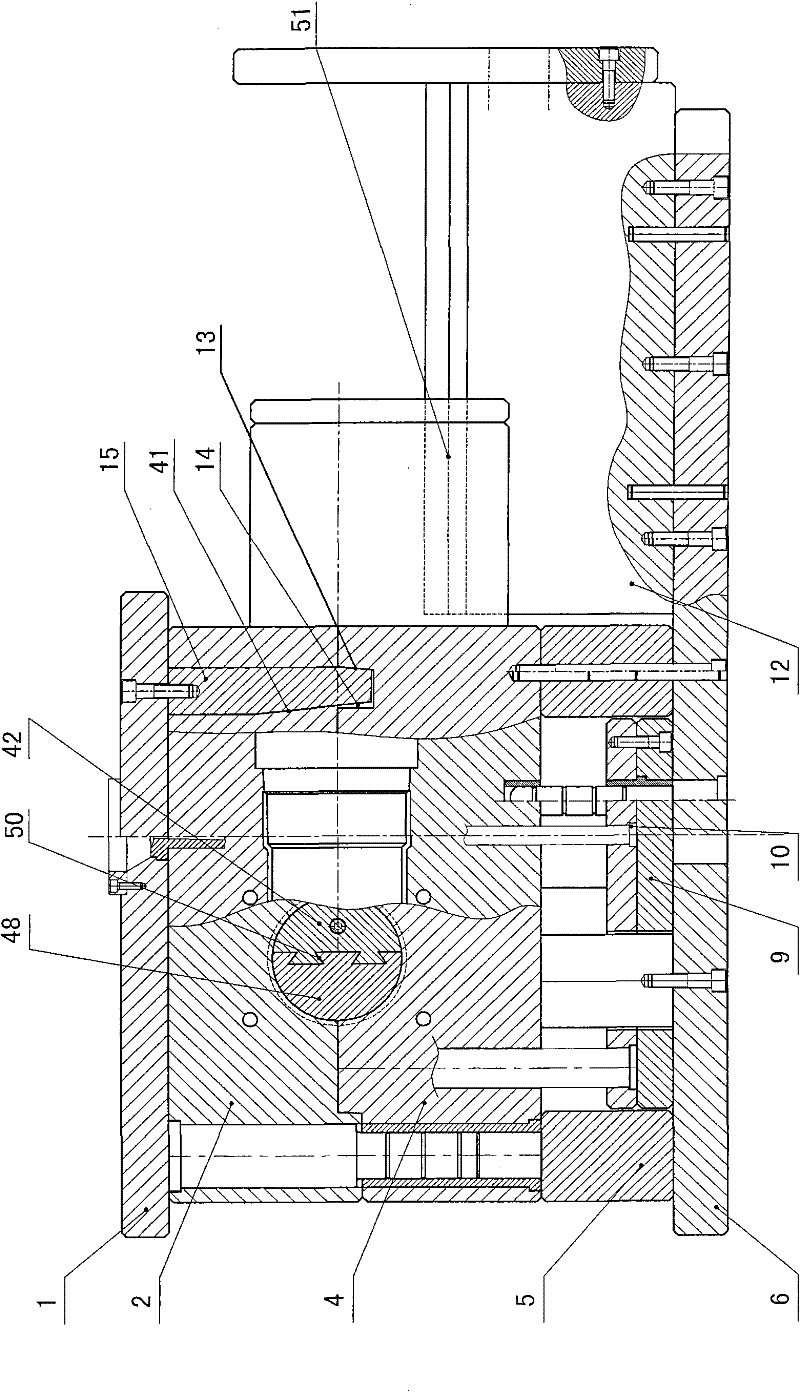

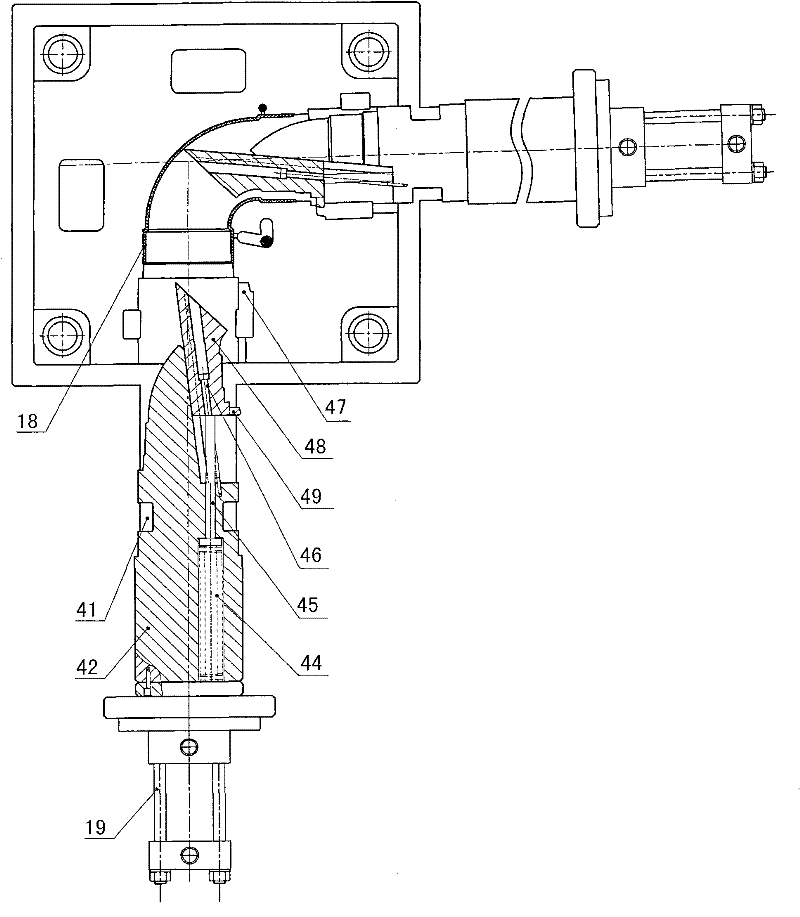

Continuous drawing production line and production method of strip product

ActiveCN103447347ASimple structureNovel and reasonable designMetal sawing devicesMetal sawing accessoriesProduction lineManufacturing engineering

The invention discloses a continuous drawing production line of a strip product. The continuous drawing production line comprises an uncoiler, a straightener, a continuous drawing machine, a length measuring device and a cuttolength saw, as well as a stacking device for stacking the sawn product or a rolling machine for rolling up the sawn product, wherein the uncoiler, the straightener, the continuous drawing machine, the length measuring device and the cuttolength saw as well as the stacking device or the rolling machine are arranged in sequence. The continuous drawing production line provided by the invention has the advantages that the floor space is reduced, the damage and transformation of the products are avoided in hoisting, and the yield is improved. The invention also discloses a production method of the continuous drawing production line of the strip product. The production method comprises the steps of unfolding a pony roll blank to a straight line state, straightening the blank which is unfolded to the straight line state, carrying out continuous drawing processing on the straightened blank to form the product, measuring the length of the product according to the preinstalling length, sawing the product according to the preinstalling length, and stacking the sawn product or rolling up the sawn product. The production method of the continuous drawing production line provided by the invention has the advantages that the production efficiency and the yield are improved.

Owner:XIAN METALWK HYDRAUMATIC MACHINERY

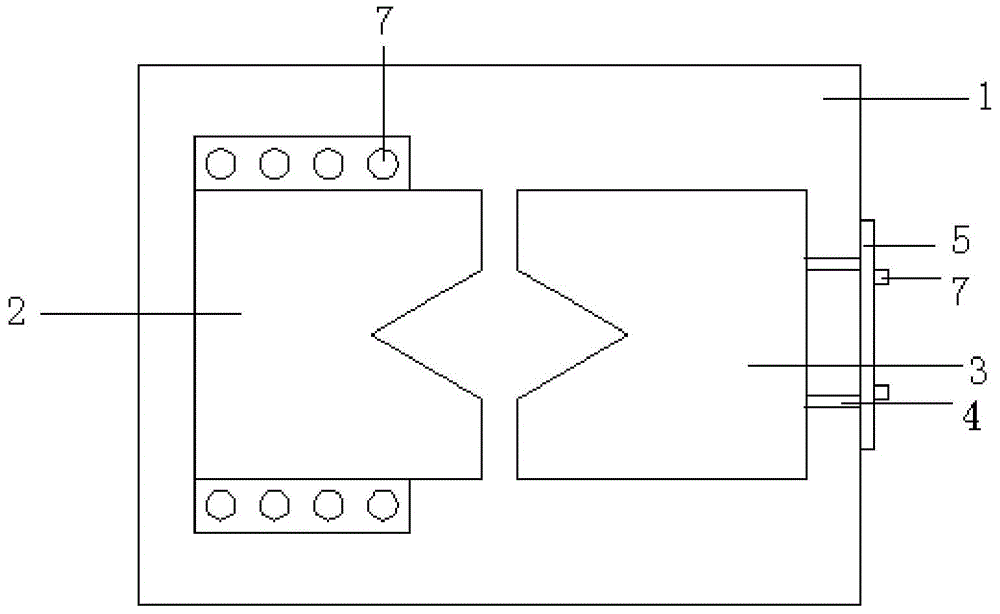

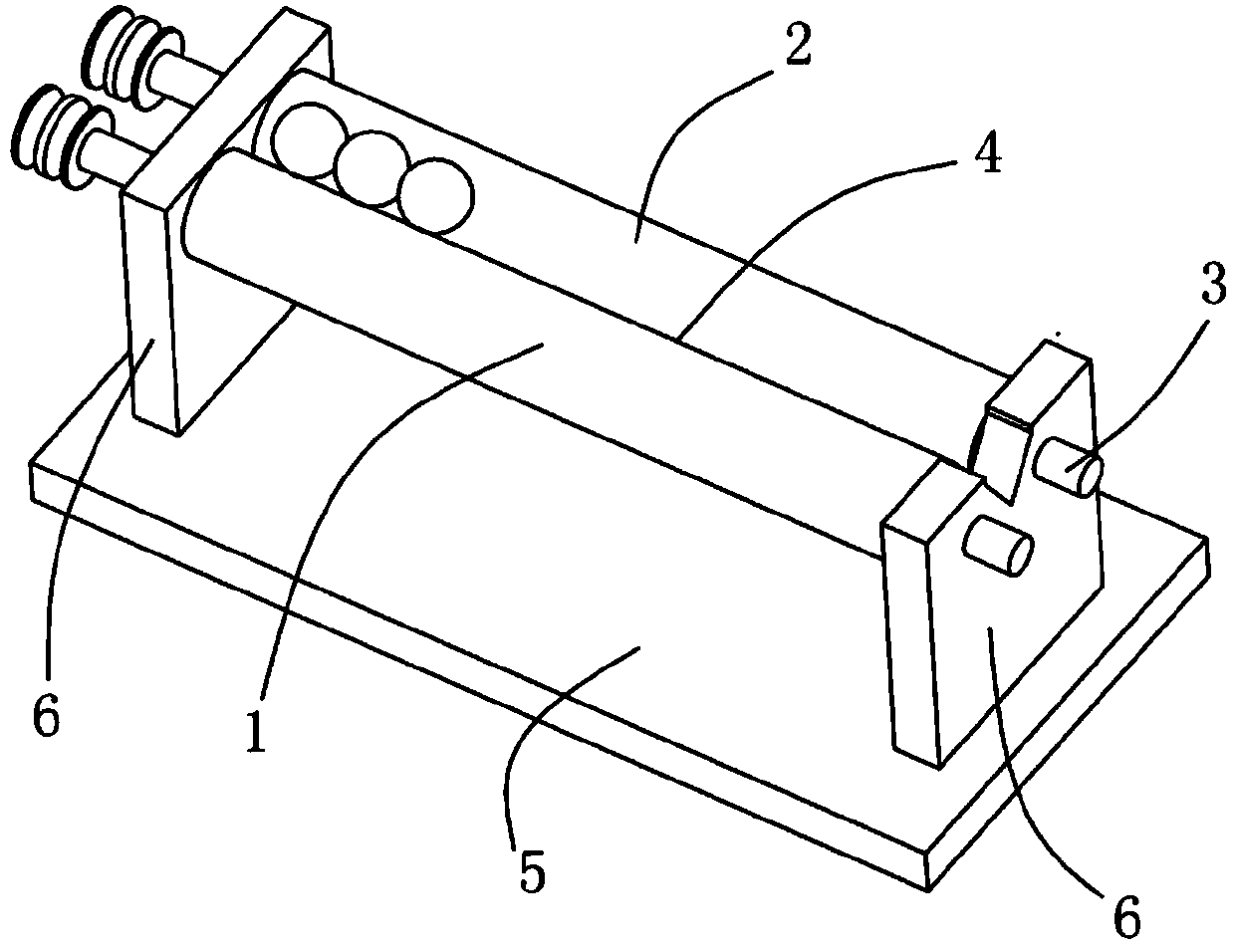

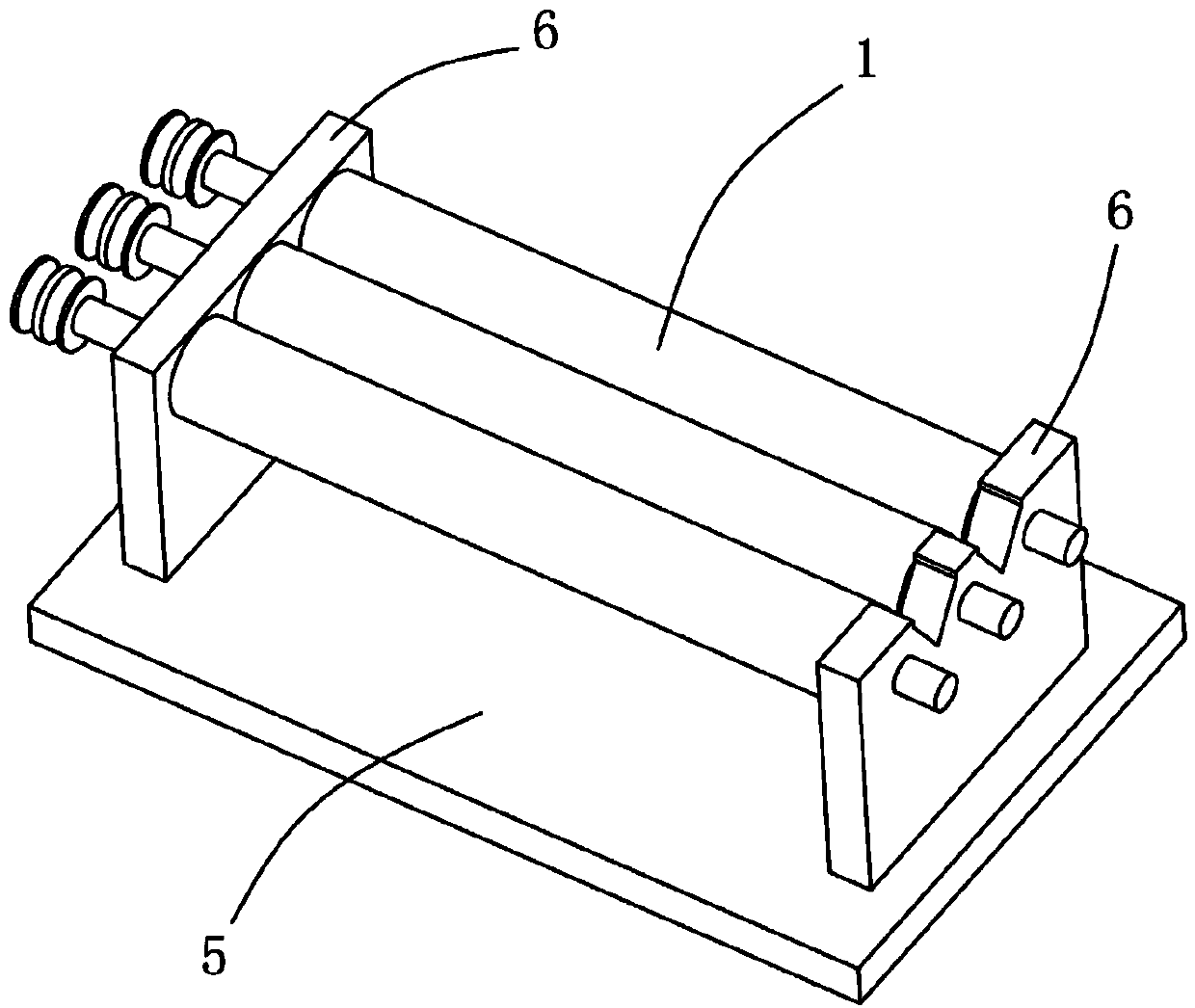

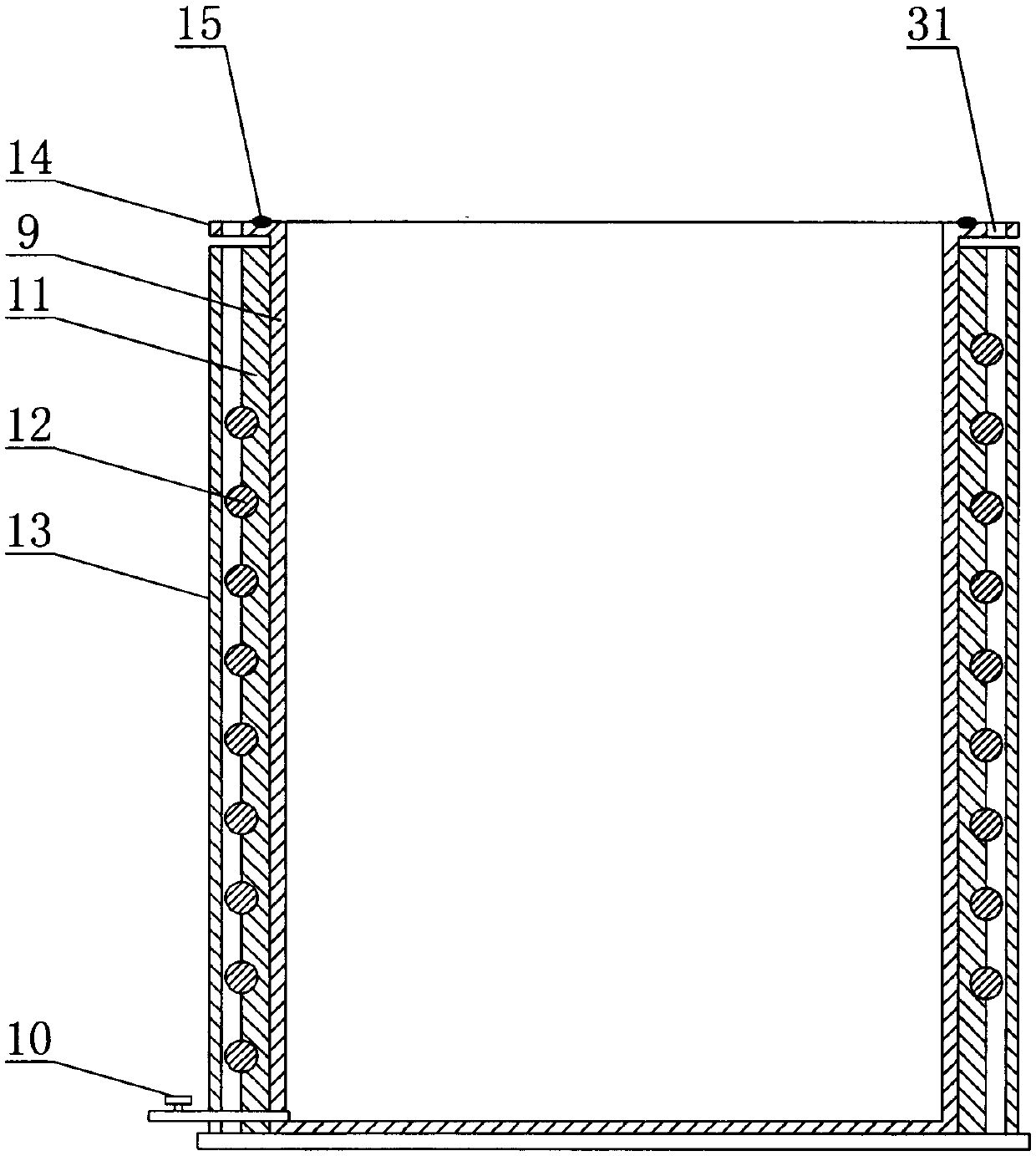

Electromagnetic clamp

ActiveCN103909437AAchieve clampingSuitable for fixingPositioning apparatusMetal-working holdersElectricityEngineering

The invention discloses an electromagnetic clamp. The electromagnetic clamp comprises a base seat, wherein a left clamping portion and a right clamping portion which are connected together in separable mode are oppositely arranged on the base seat, a containing space which contains a work piece is formed after the left clamping portion and the right clamping portion are connected together, the left clamping portion is connected with the base seat in detachable mode, the right clamping portion is connected with the base seat in sliding mode, the left clamping portion and the right clamping portion are both provided with cavities, controllers are arranged in the cavities, a first electromagnet is arranged in the cavity of the left clamping portion, a second electromagnet is arranged in the cavity of the right clamping portion, winding directions of coils of the first electromagnet and the second electromagnet are opposite, the first electromagnet and the second electromagnet are both connected with the controllers, and the controllers are electrically connected with a power source. The electromagnetic clamp can be used in individual product production and large batch production, avoids repeated actions of drawing lines and aligning, improves production efficiency, and guarantees quality of the work piece.

Owner:浙江西塘实业有限公司

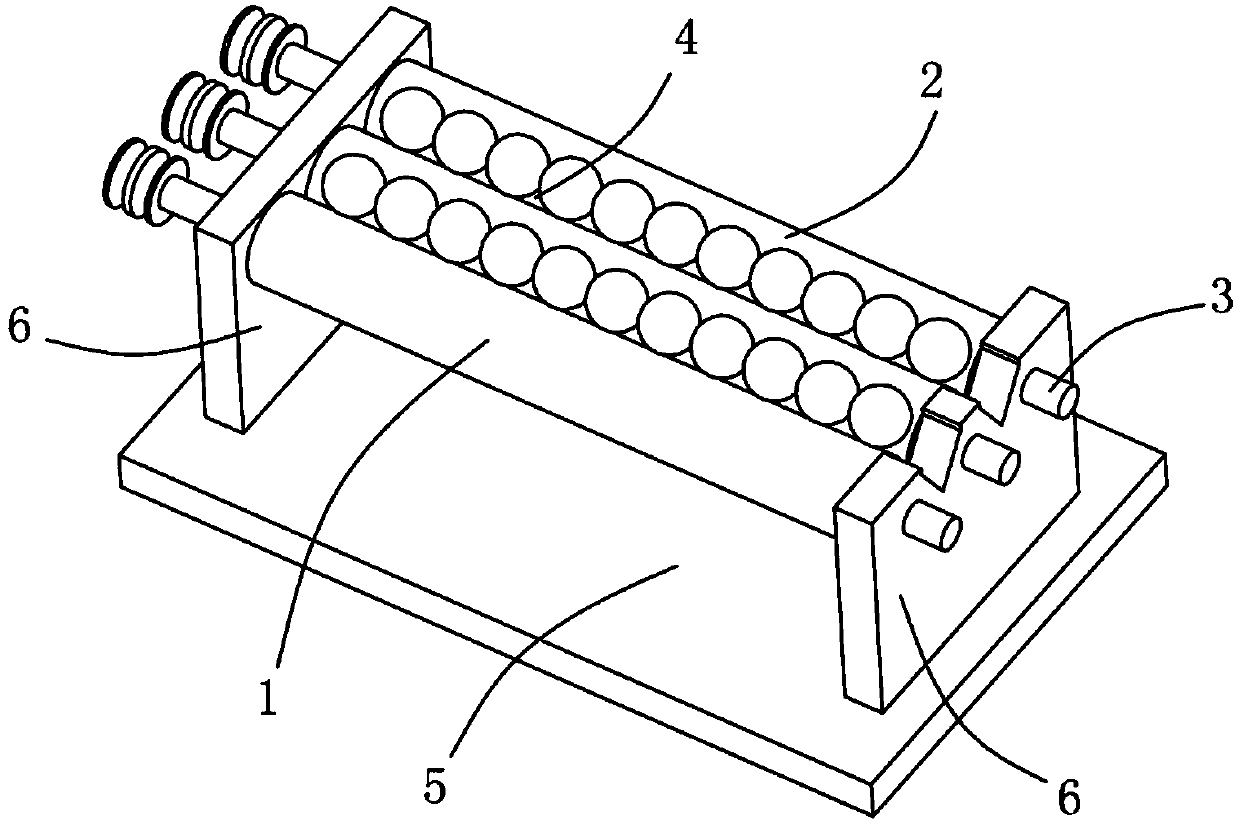

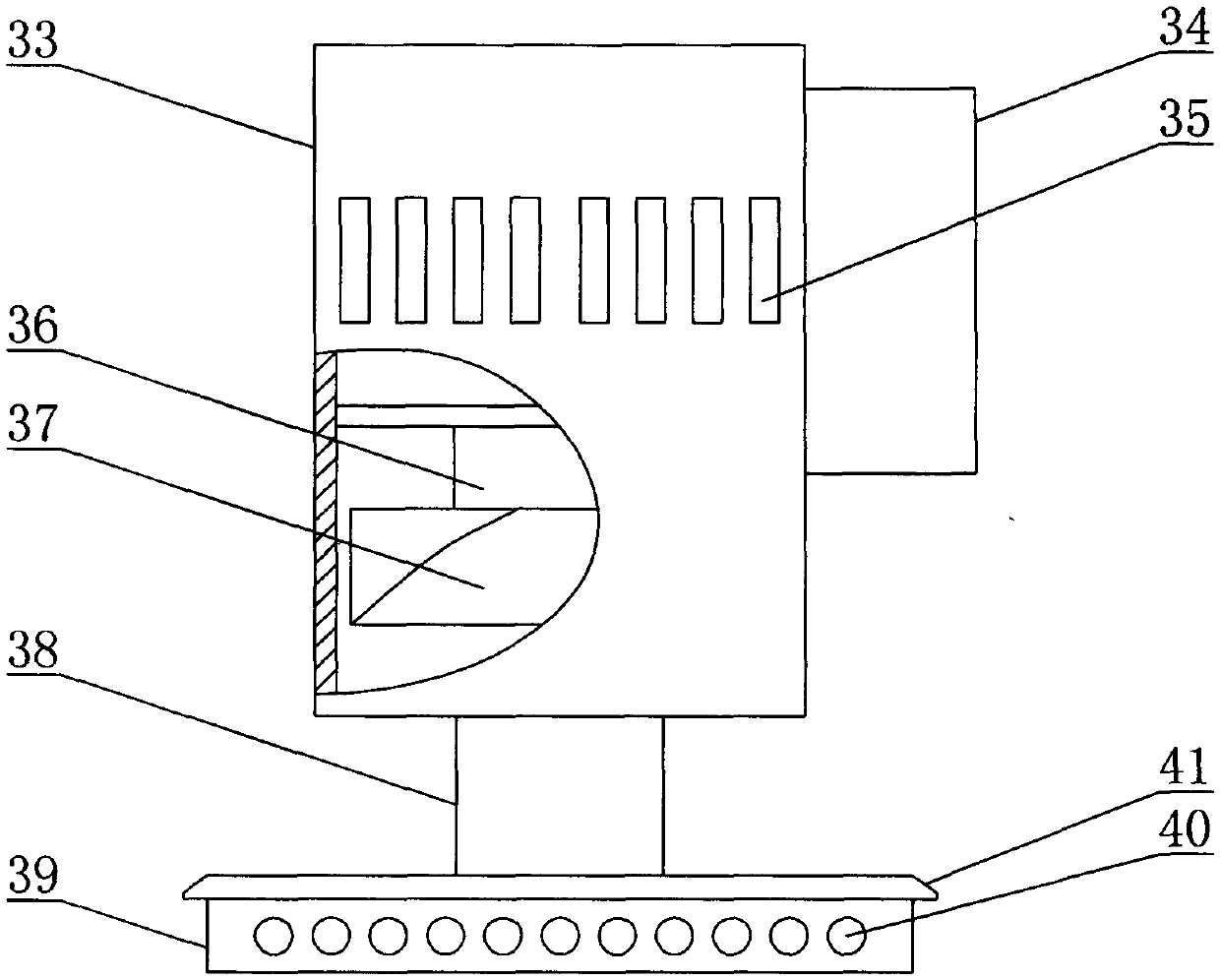

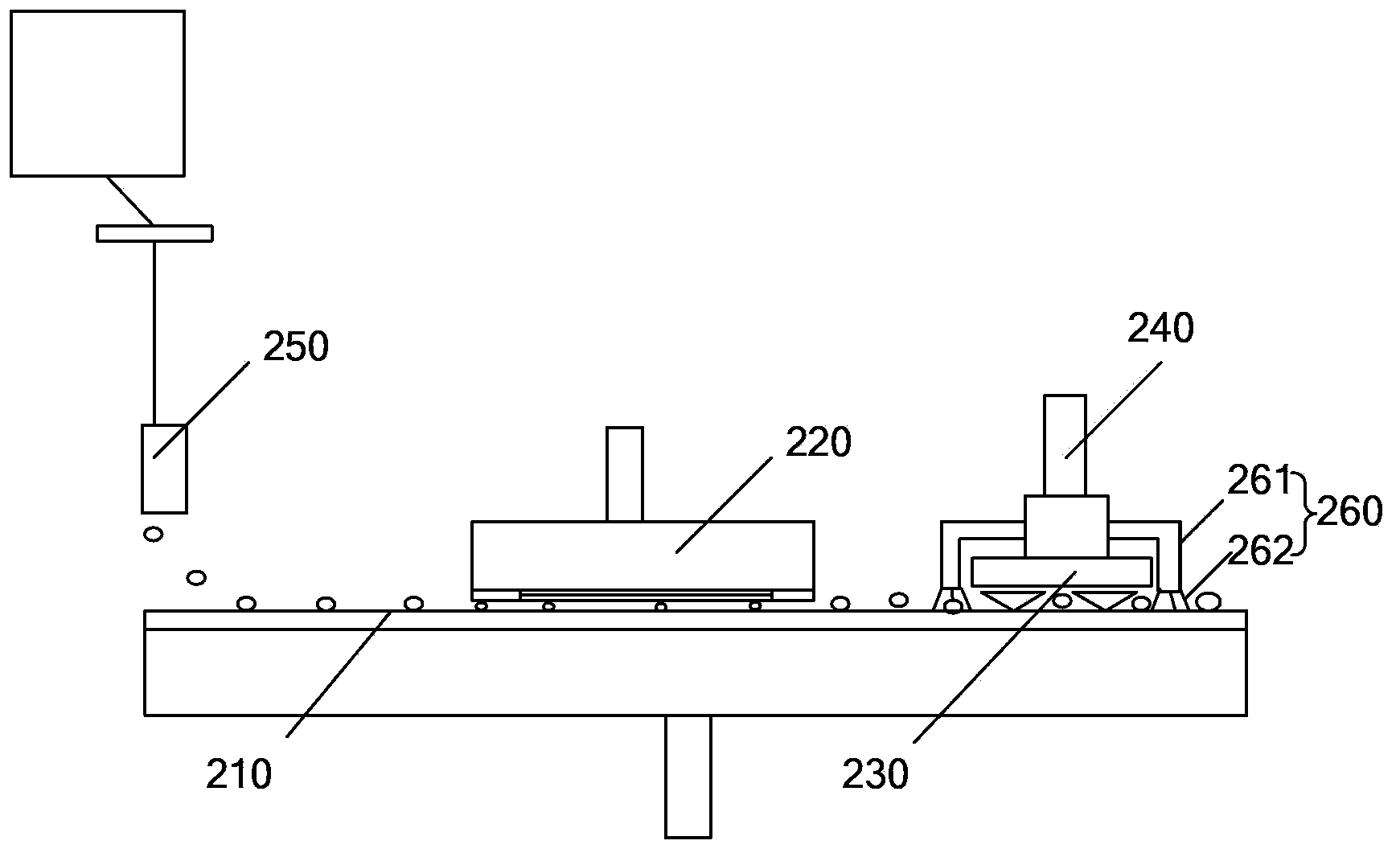

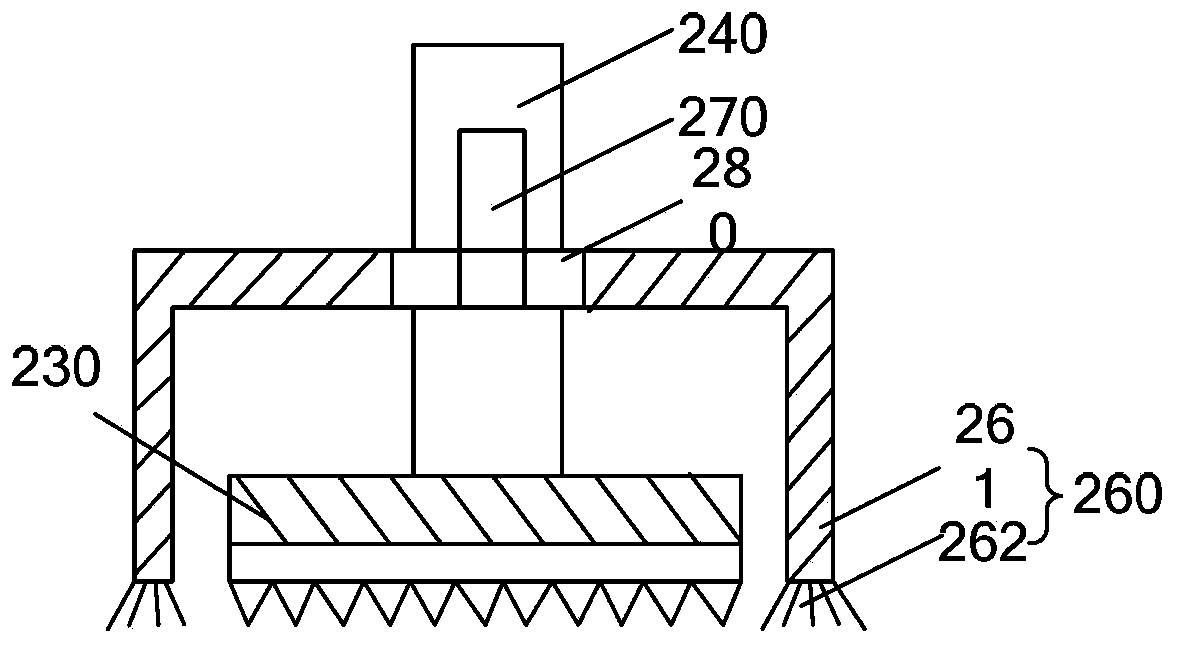

Steel ball surface defect detection sorting equipment

ActiveCN104190634AImprove fullyHigh false positive rateOptically investigating flaws/contaminationCleaning using toolsMetallurgySurface cleaning

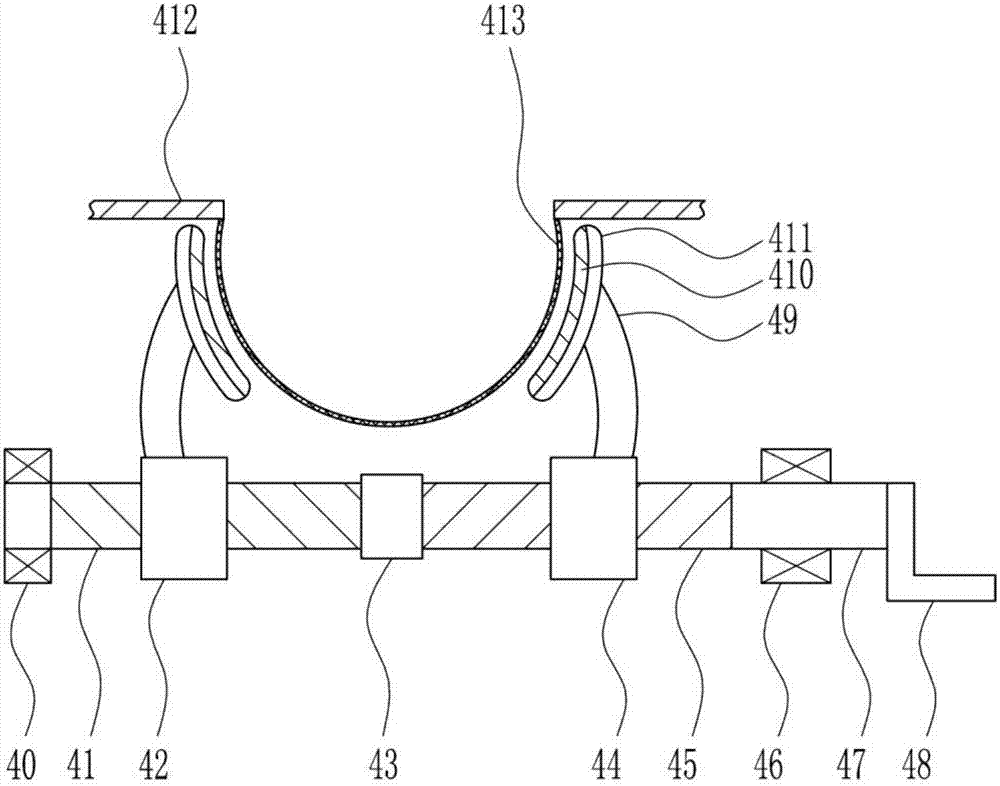

The invention discloses steel ball surface defect detection sorting equipment. The steel ball surface defect detection sorting equipment comprises a steel ball size screening device, a steel ball surface cleaning device, a steel ball surface unfolding device, a camera, a sorting device and a control module, wherein the steel ball size screening device comprises two parallel rolling shafts; the steel ball surface cleaning device comprises a trapezoid rotary table and a rotary sleeve covering the rotary table; the steel ball surface unfolding device comprises at least two rolling bars, wherein a containing groove is formed between two adjacent rolling bars, and at least one rotatable rolling bar in the two adjacent rolling bars can be used for driving steel balls to roll in the containing groove in synchronism with the rolling bars. The equipment disclosed by the invention can screen out the out-of-size steel balls and can clean the surfaces of the steel balls so as to prevent the false detection caused by blots on the surfaces of the steel balls; in combination with the specific steel ball surface unfolding device, the steel ball surface defect detection storing equipment can rapidly and accurately sort the steel ball sizes and the steel ball surface defects, and the steel ball sorting efficiency is greatly promoted.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

Chemical material mixing device

InactiveCN105536613AReduce manufacturing costIncrease productivityRotary stirring mixersTransportation and packagingElectromagnetic inductionEngineering

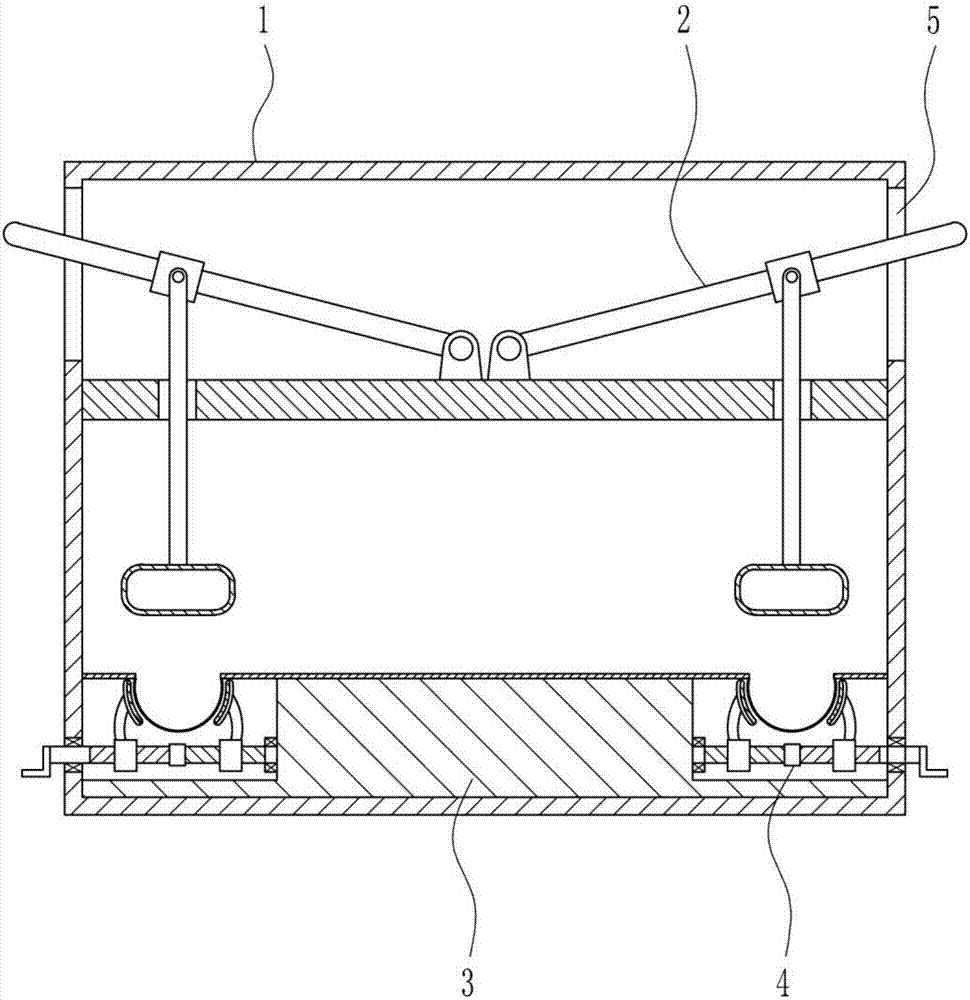

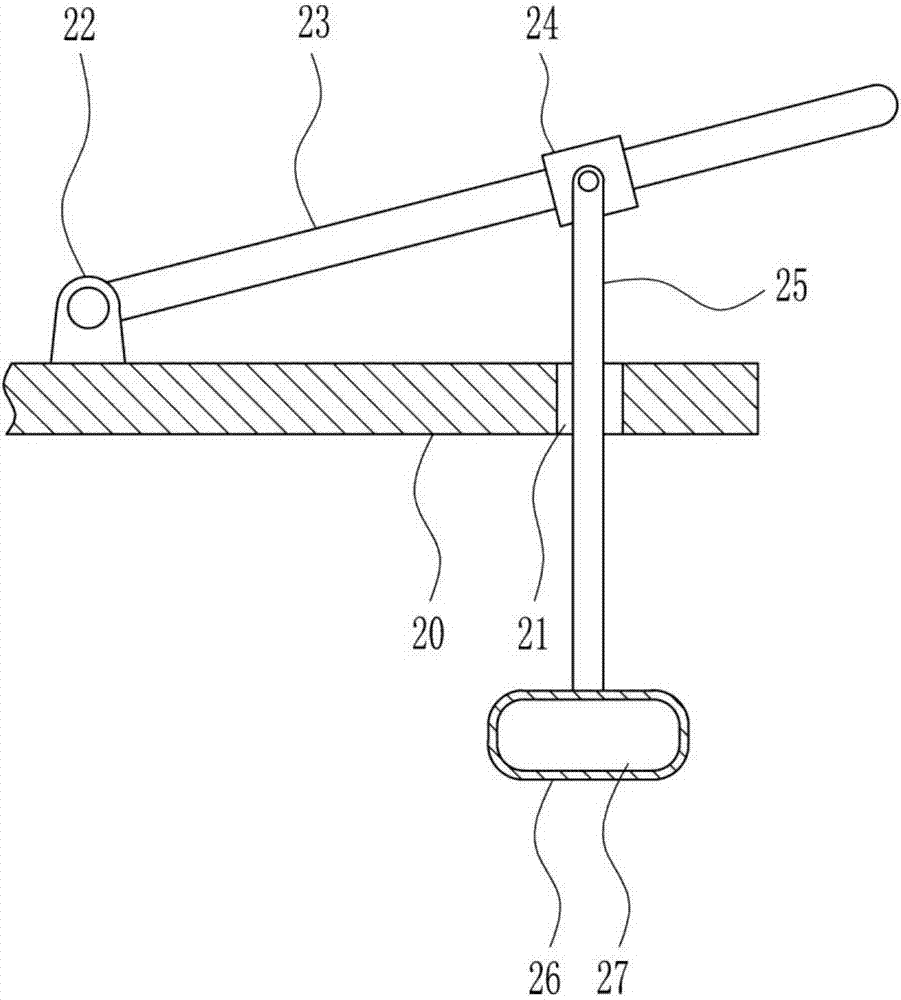

The invention discloses a chemical material mixing device and mainly relates to the technical field of chemical material mixing. The device comprises a machine frame, wherein a first guide rail is horizontally arranged on the lower portion of the machine frame, a first sliding block is arranged on the first guide rail, a first nut is arranged on the first sliding block, and a first lead screw is arranged in the first nut; a connecting plate is arranged on the first sliding block, a mixing cylinder is arranged on the connecting plate, a heat insulation cotton layer is arranged on the side wall of the mixing cylinder, and an electromagnetic induction heating coil is arranged on the heat insulation cotton layer; a movable supporting frame is horizontally arranged above the mixing cylinder, a cover is arranged on the movable supporting frame, a rotary shaft is arranged in the middle of the cover, a stirring paddle is arranged on the rotary shaft, and a cleaning device is arranged on the movable supporting frame. The device has the advantages that materials can be dried while being mixed, so that production cost is reduced and production efficiency is improved; materials left in the mixing cylinder can be cleared automatically, so that the labor intensity of workers is relieved.

Owner:HENAN INST OF SCI & TECH

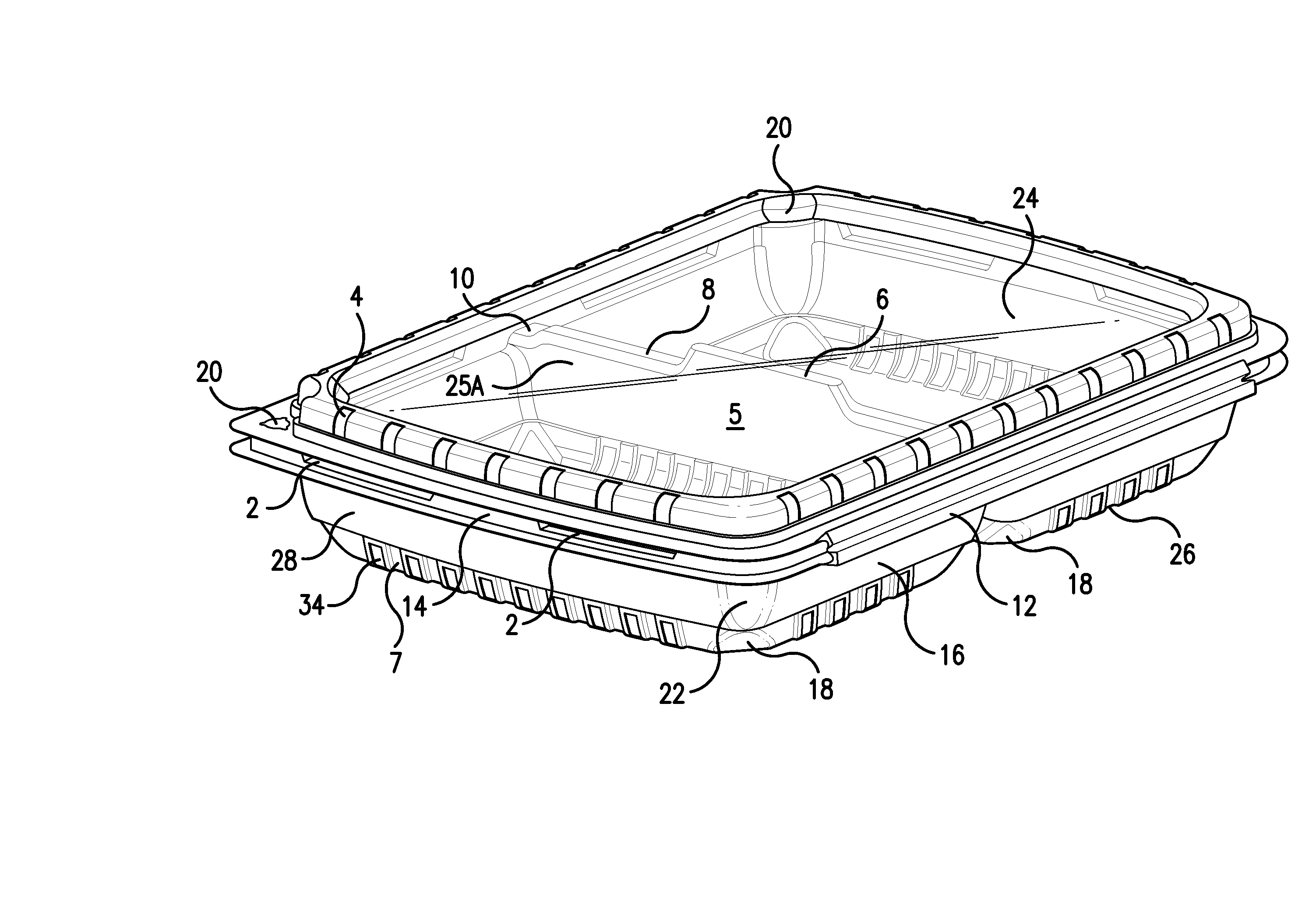

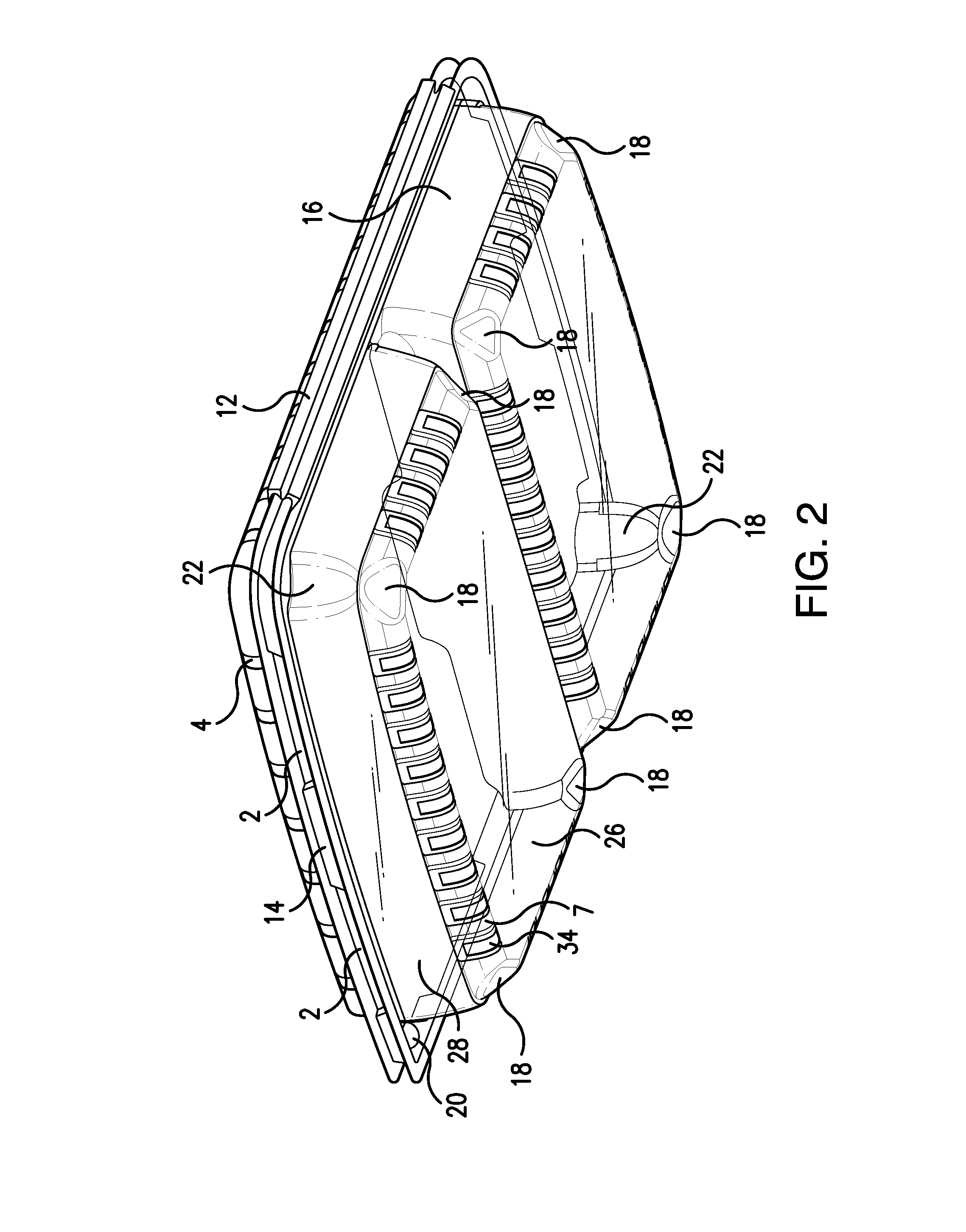

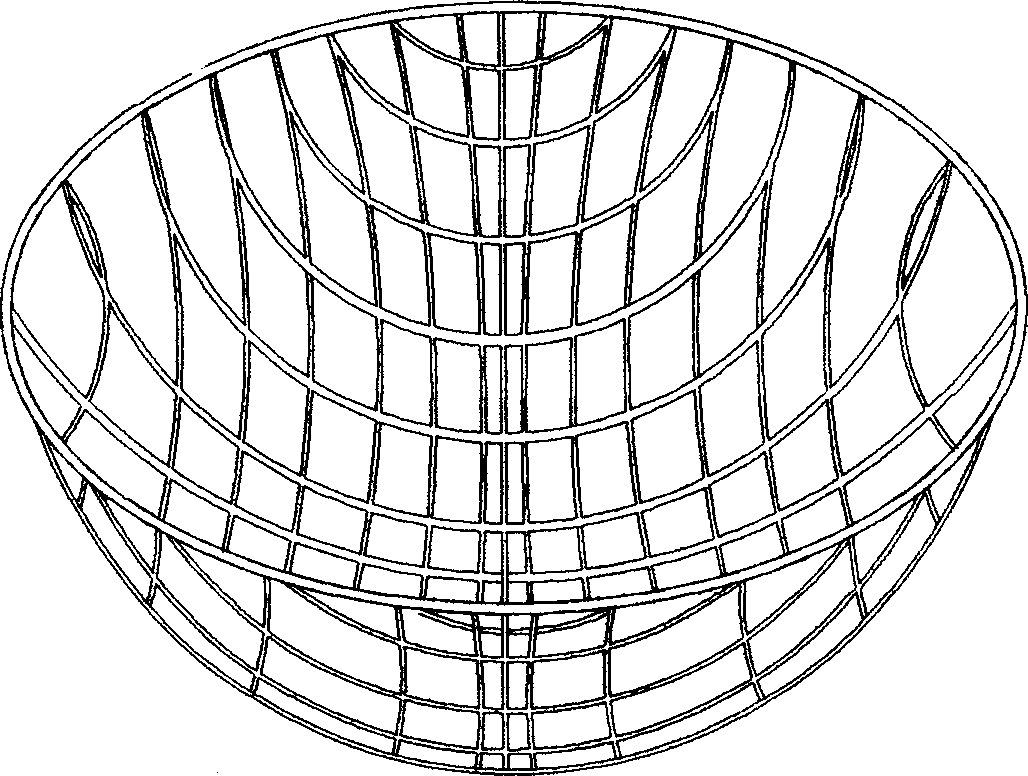

Clamshell raspberry container

InactiveUS20150307257A1Easy to fillAvoid bruisesVenting meansInternal framesTorsional rigidityEngineering

A container that includes a tray having a base bottom portion and one or more sidewalls having a volume for holding a product; a lid that is attachable to the tray to protect the product in the tray when attached thereto; and a divider for providing a plurality of compartments with a predetermined volume in the tray, the divider configured, dimensioned and positioned to provide support to the lid, air flow between the compartments and torsional rigidity to the tray. The most preferred container of the invention is a rectangular clamshell container as described herein that includes a spine which is pivotally hinged to the base bottom portion via the lid. This preferred container also includes a plurality of snap locking members for attaching the lid to the tray for retaining contents therein.

Owner:DRISCOLLS INC

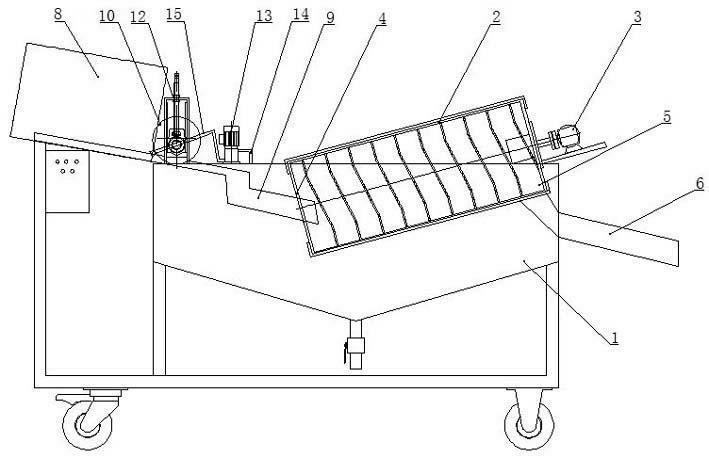

Conveying, turning and unloading device used for fruit grading

InactiveCN101658843ARealize the collection of optoelectronicsRealize the weighing functionSortingConveyor partsMechanical engineeringEnergy conservation

Owner:HANGZHOU XINGDI GROUP

Method for forging super-long hollow part from short core rod through free forging press

ActiveCN102357625ASolve the clamping torque problemIncrease tonnageMetal-working apparatusPunchingTempering

The invention belongs to the technical field of forging and in particular relates to a method for forging a super-long hollow part through an oil pressing and forging machine. The method comprises the steps of heating a steel ingot, cutting and blanking through an oil press, upsetting, punching, chambering, drawing a core shaft, forging to form a finished product, annealing, roughly processing, tempering and finely processing to form the finished product. On the premise of not increasing equipment, the clamping moment problem of a free forging oil press and an operation machine can be solved by using a specific tooling and a unique forging method. According to the method disclosed by the invention, the tonnage for the free forging press to forge the steel ingot can be greatly increased; by using the method, a pipe casting die blank beyond the clamping moment of the free forging press can be successively forged; furthermore, the free forging operation machine cannot operate in overloading the forging process; and the forging capability of the equipment is greatly increased.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

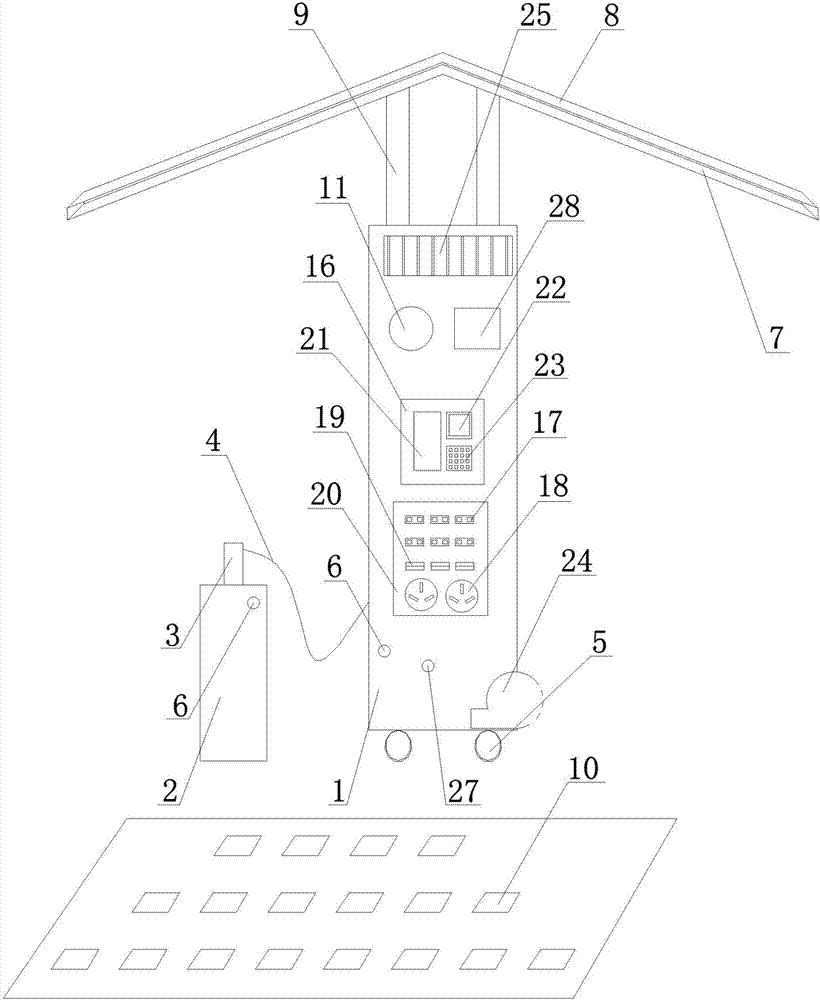

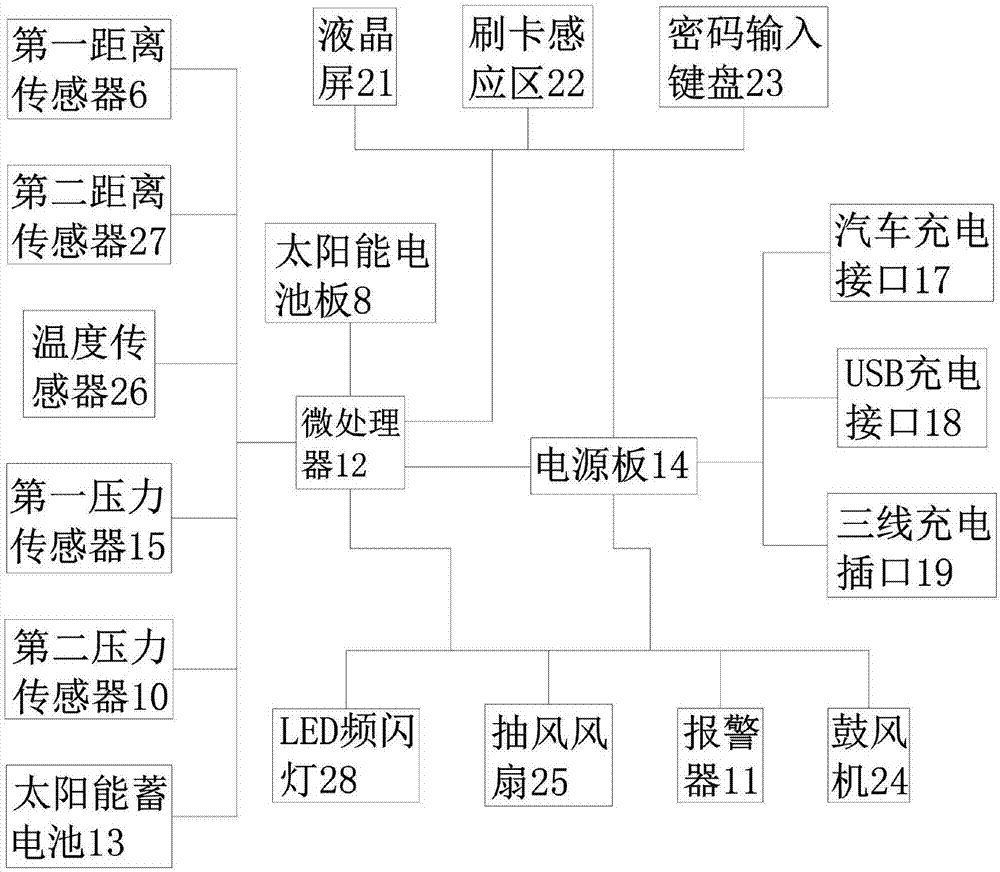

Multifunctional integral convenient charge pile

InactiveCN107020974ASimple structureScientific and reasonable designCharging stationsMobile unit charging stationsElectricityEngineering

The invention discloses a multifunctional integral convenient charge pile, and aims to solve the problems, in the prior art, that the energy is wasted and potential safety hazard can be caused as a charge pile is fixed and is convenient to use. The multifunctional integral convenient charge pile comprises a charge pile body with a microprocessor, a fixing pile, a rotating column, universal wheels, a chain lock, a first distance sensor, a sunshade plate, a solar battery panel, a solar storage battery, a power supply plate, an alarm, a first pressure sensor, an operation and control interface, a charge plate and a heat radiation system, wherein the heat radiation system comprises an air blower, an exhaust fan and a temperature sensor; the power supply plate is electrically connected with the alarm, the operation and control interface, the charge plate, the air blower and the exhaust fan. The multifunctional integral convenient charge pile is simple in structure, scientific and reasonable in design, convenient to use, energy-saving and environmental-friendly and capable of effectively eliminating potential safety hazard and preventing thefts.

Owner:CHENGDU UNIV OF INFORMATION TECH

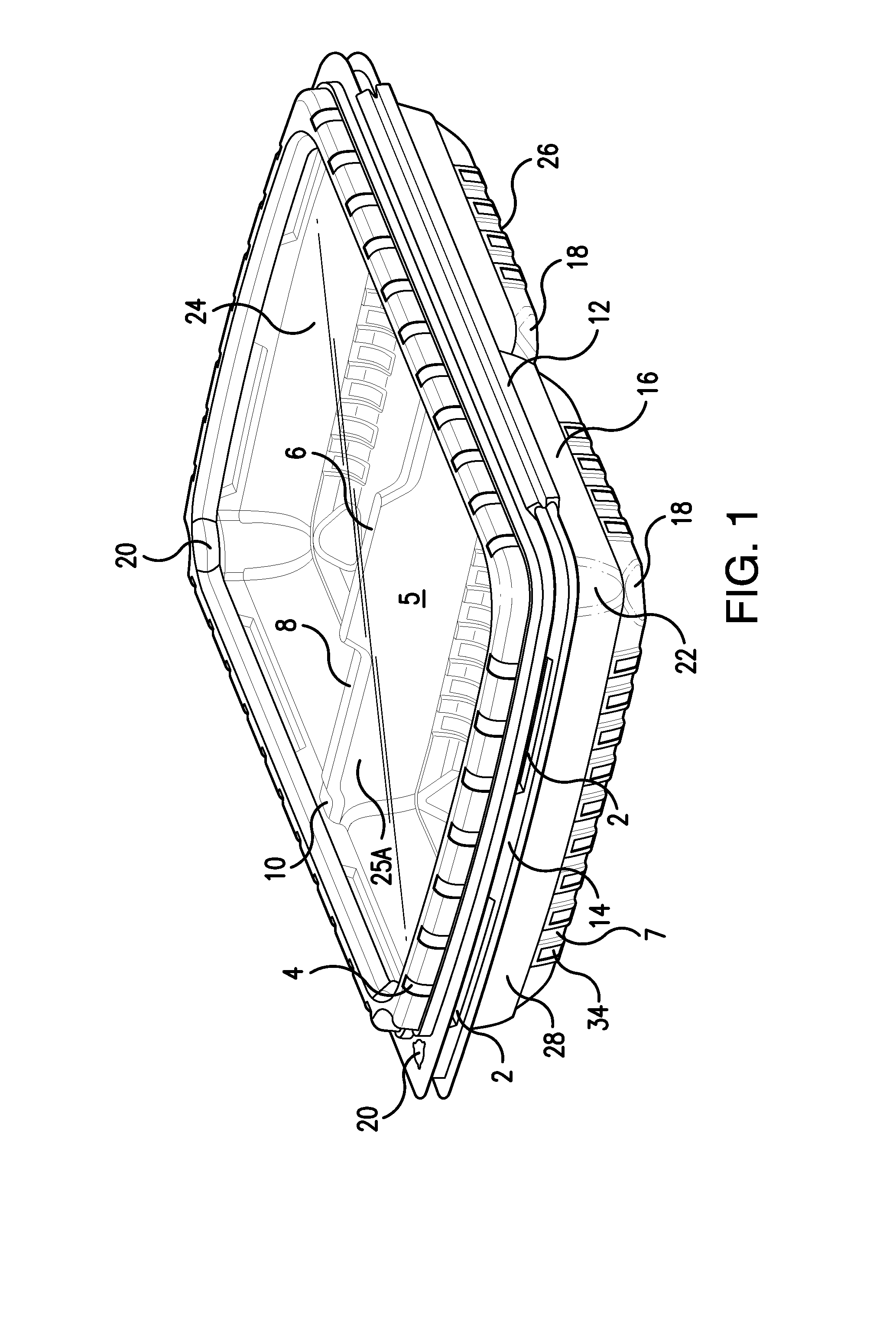

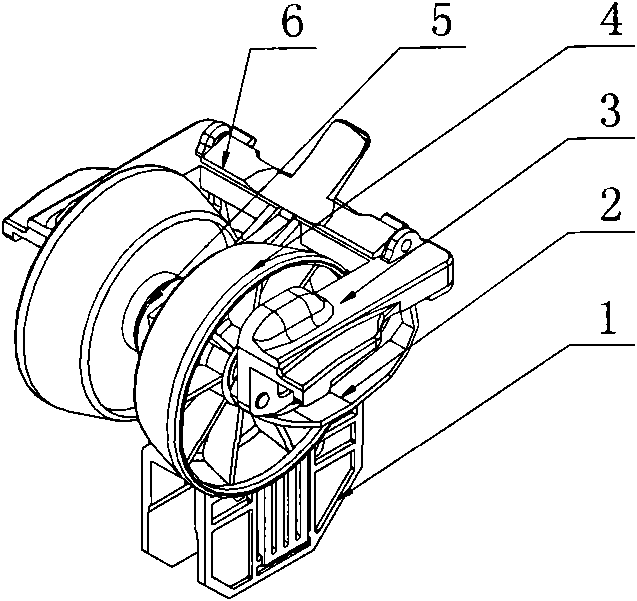

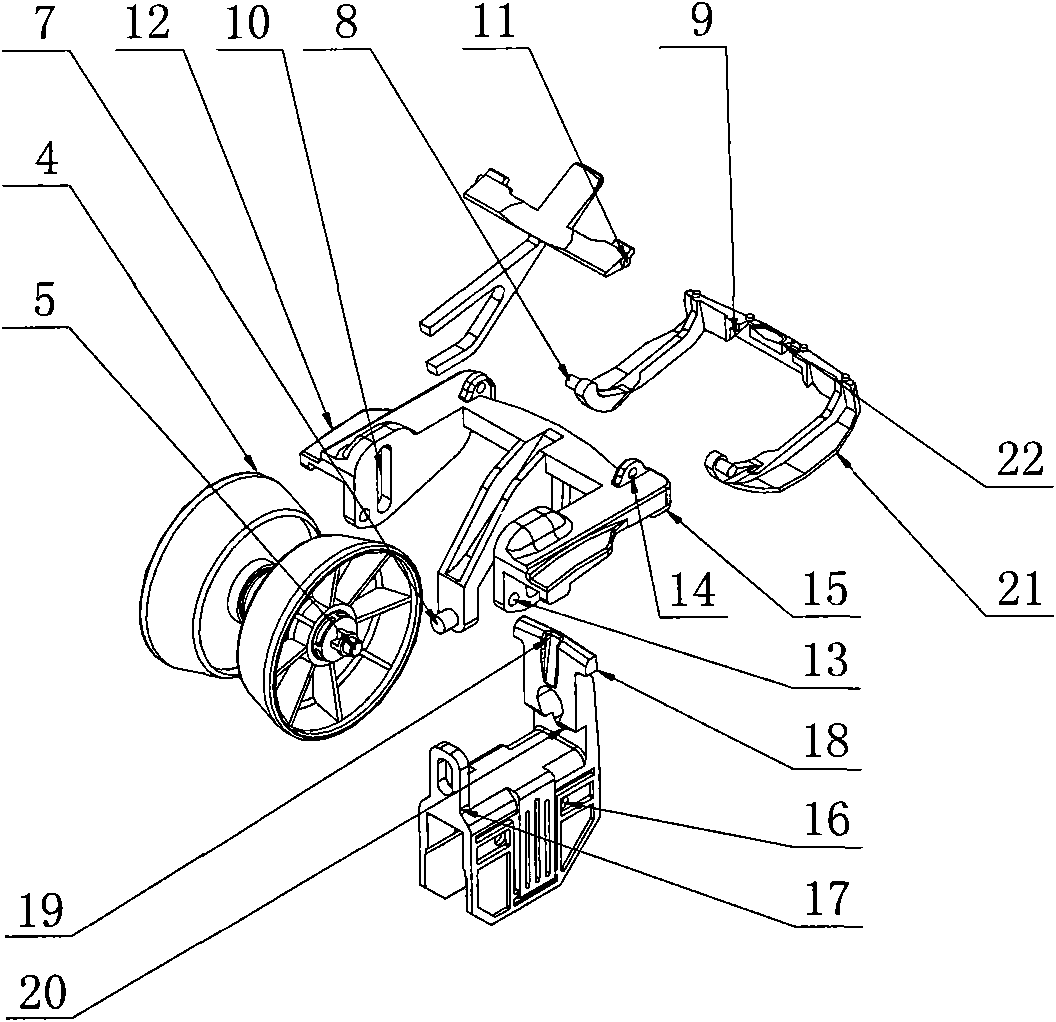

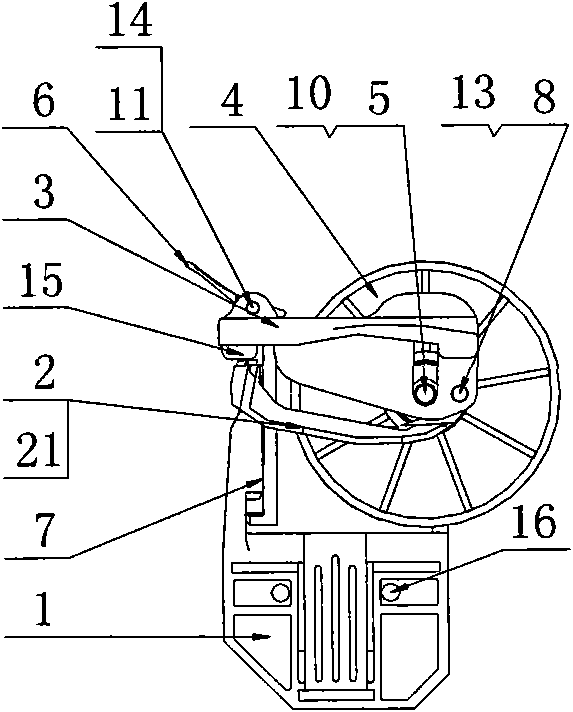

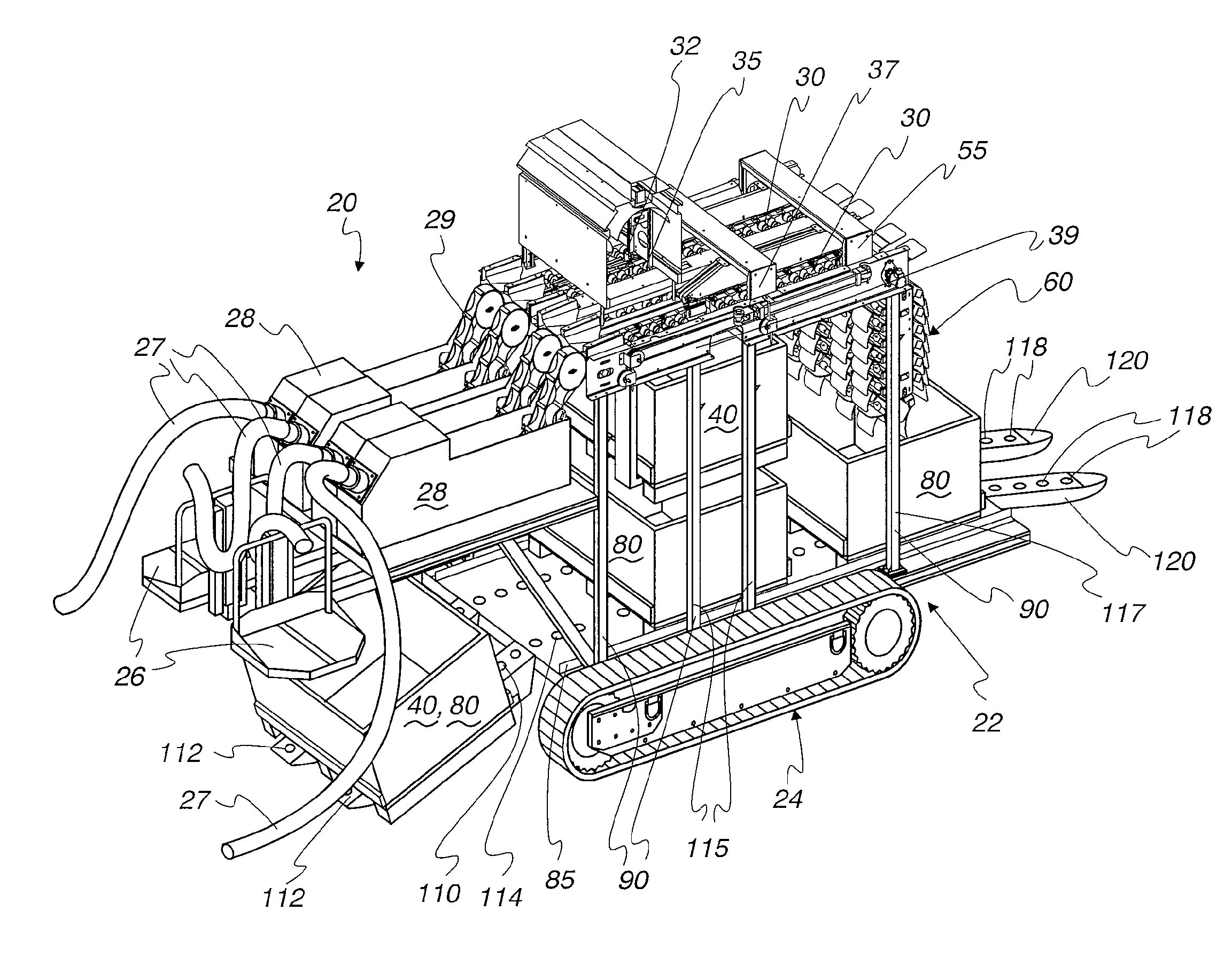

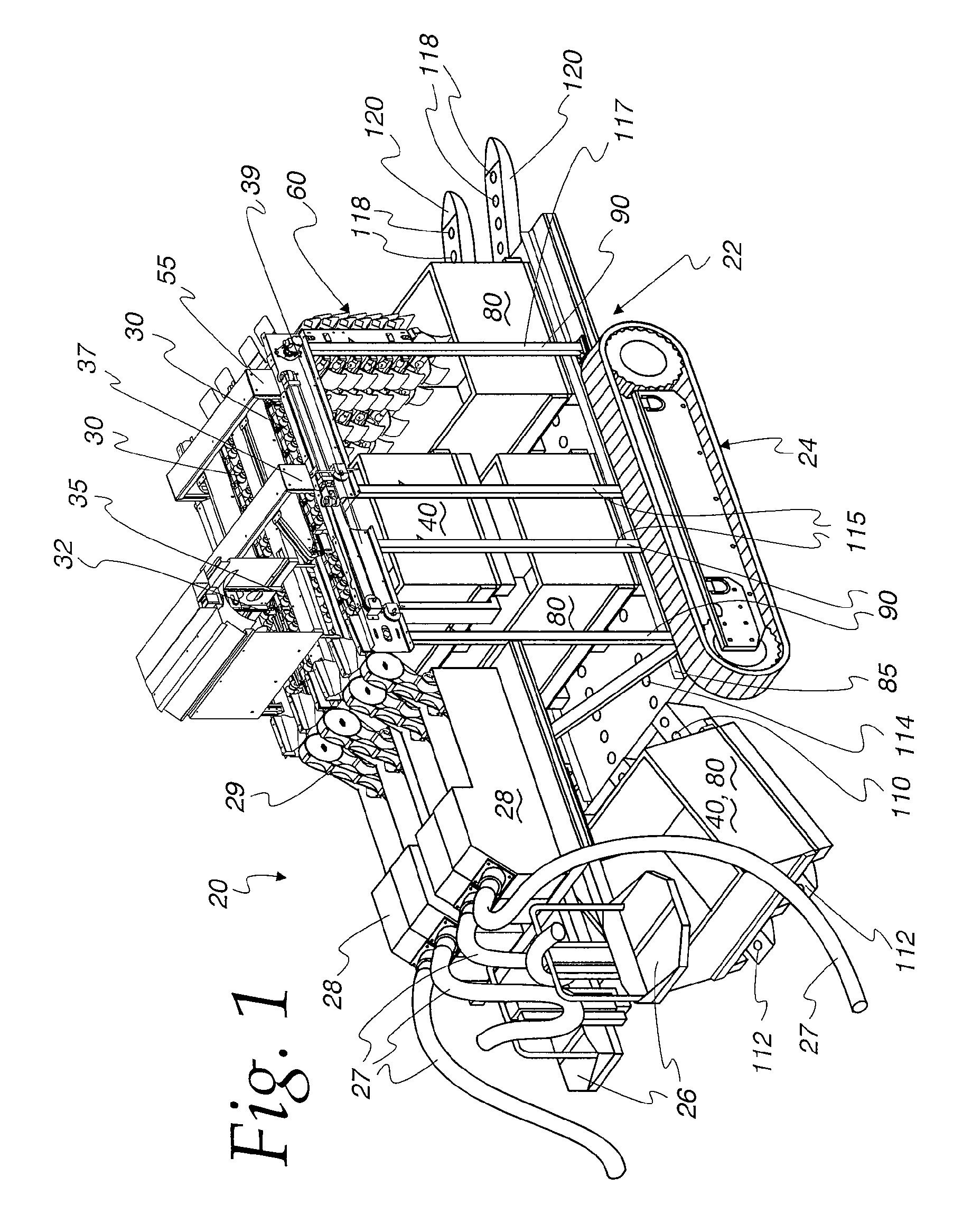

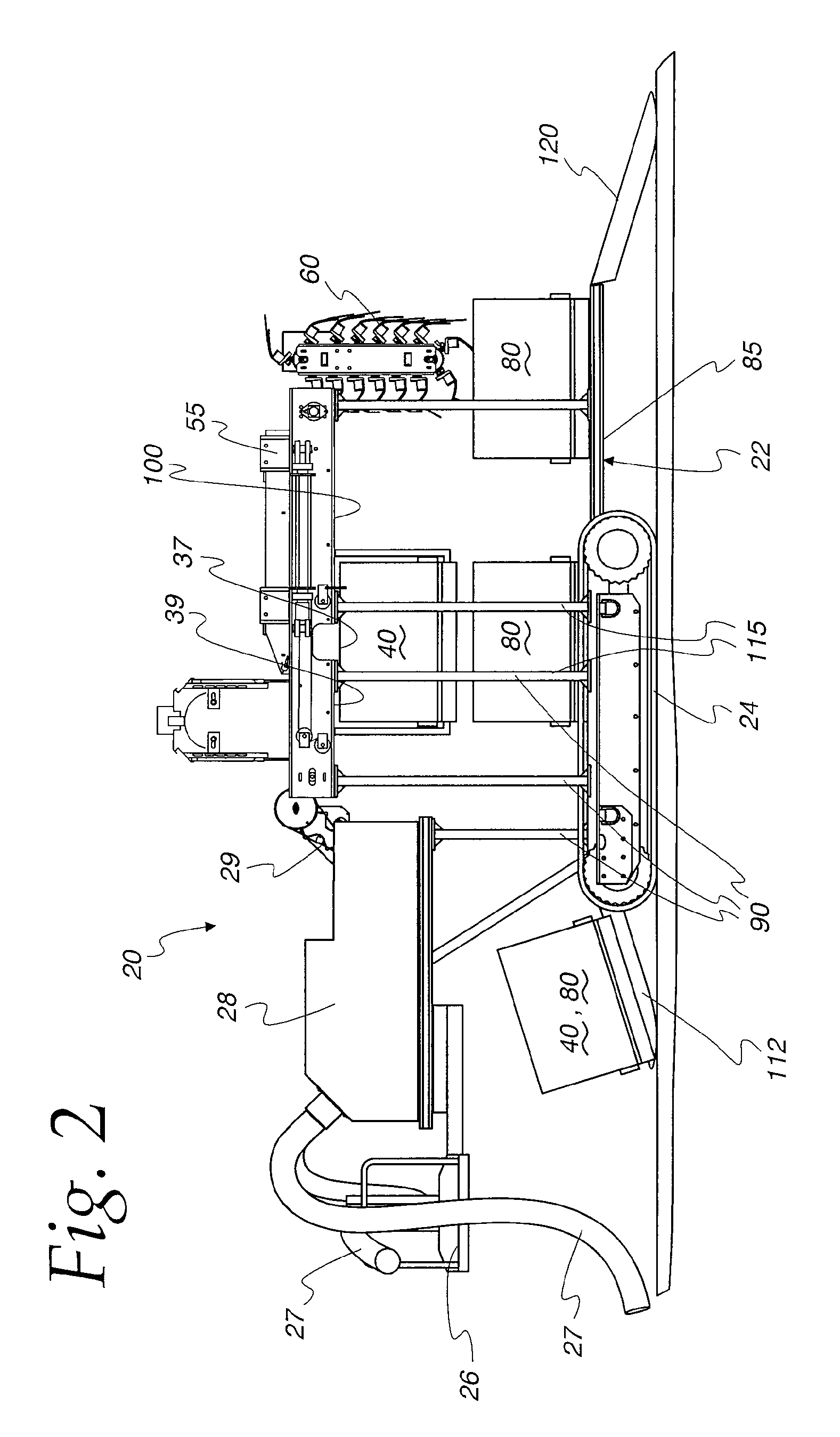

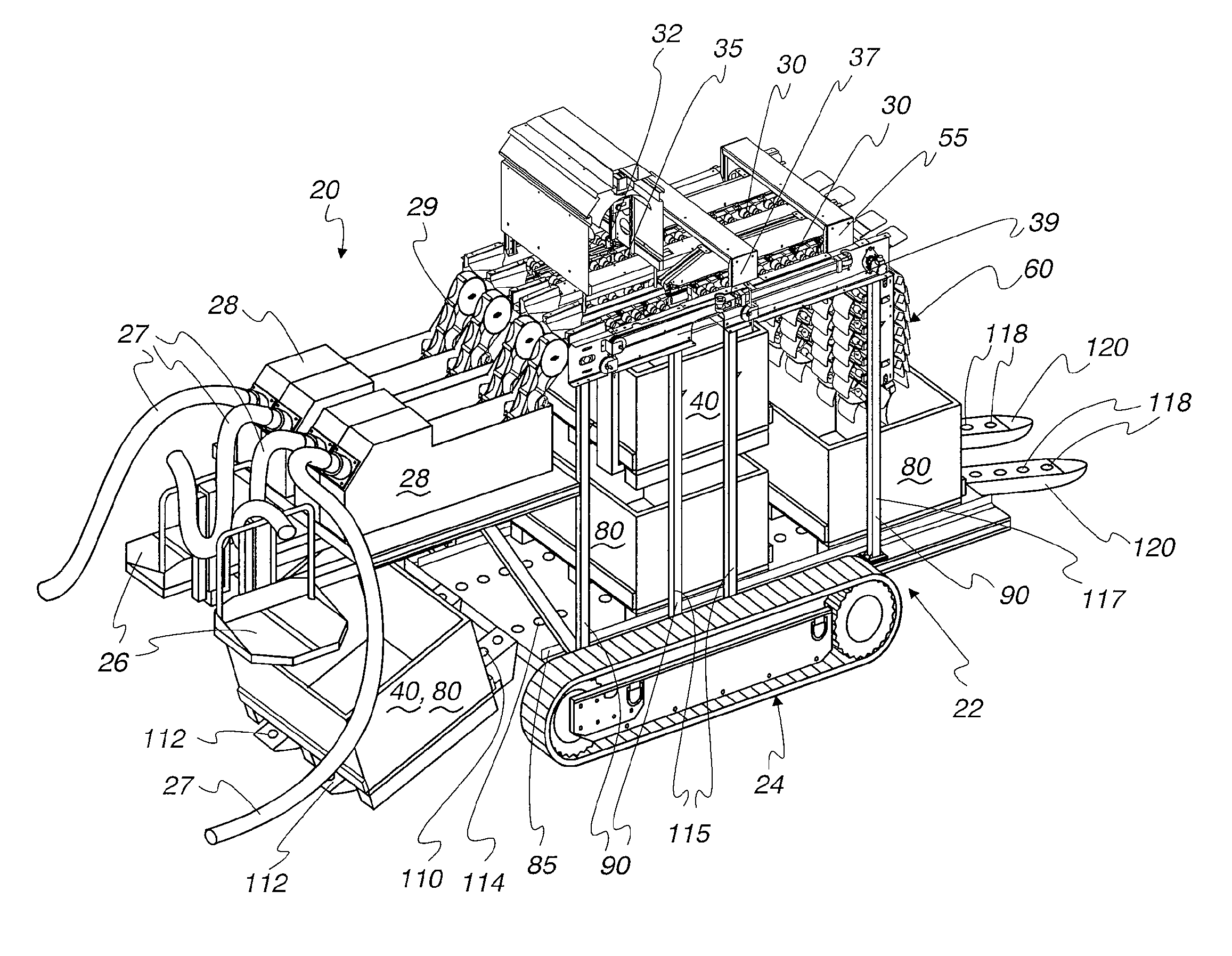

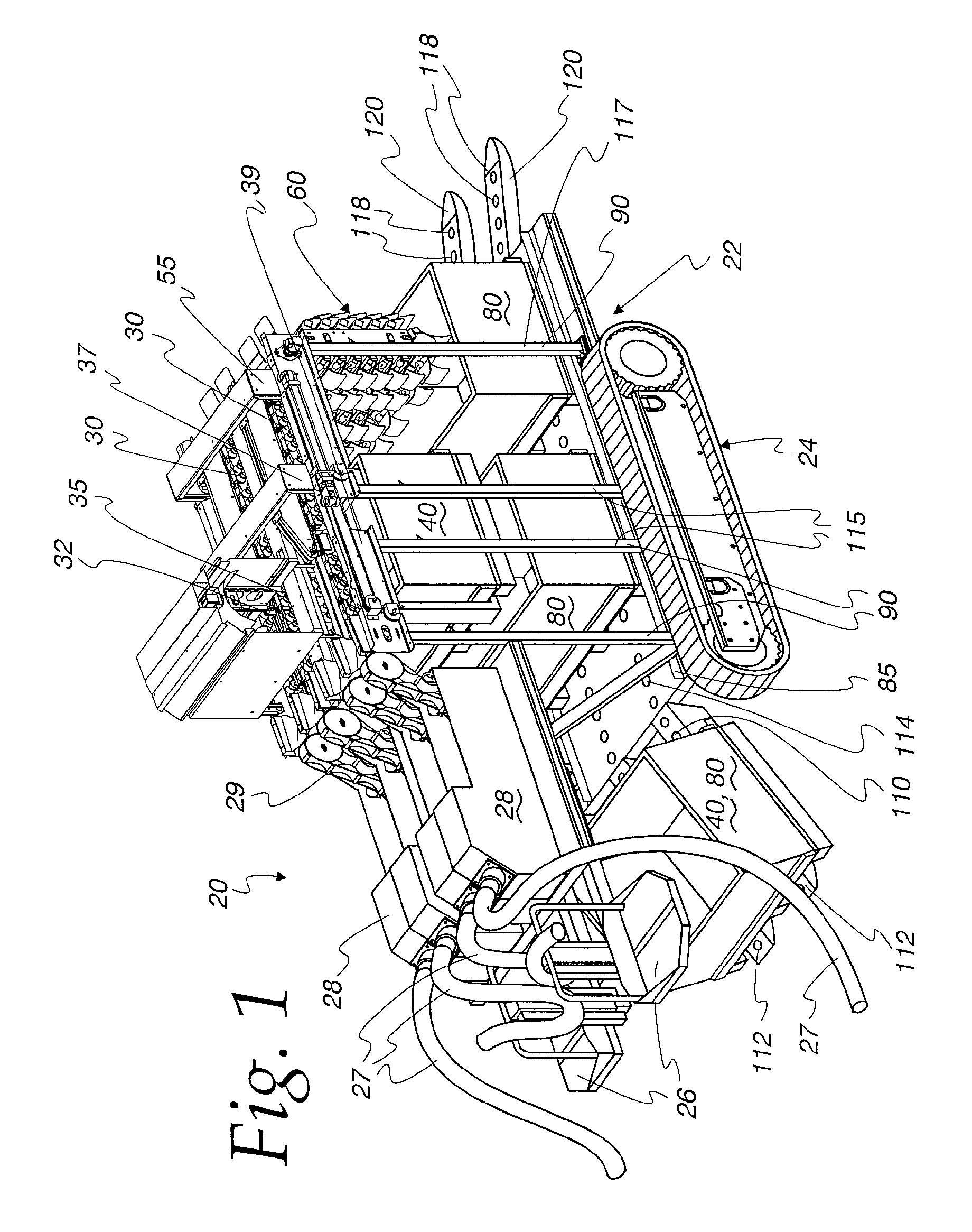

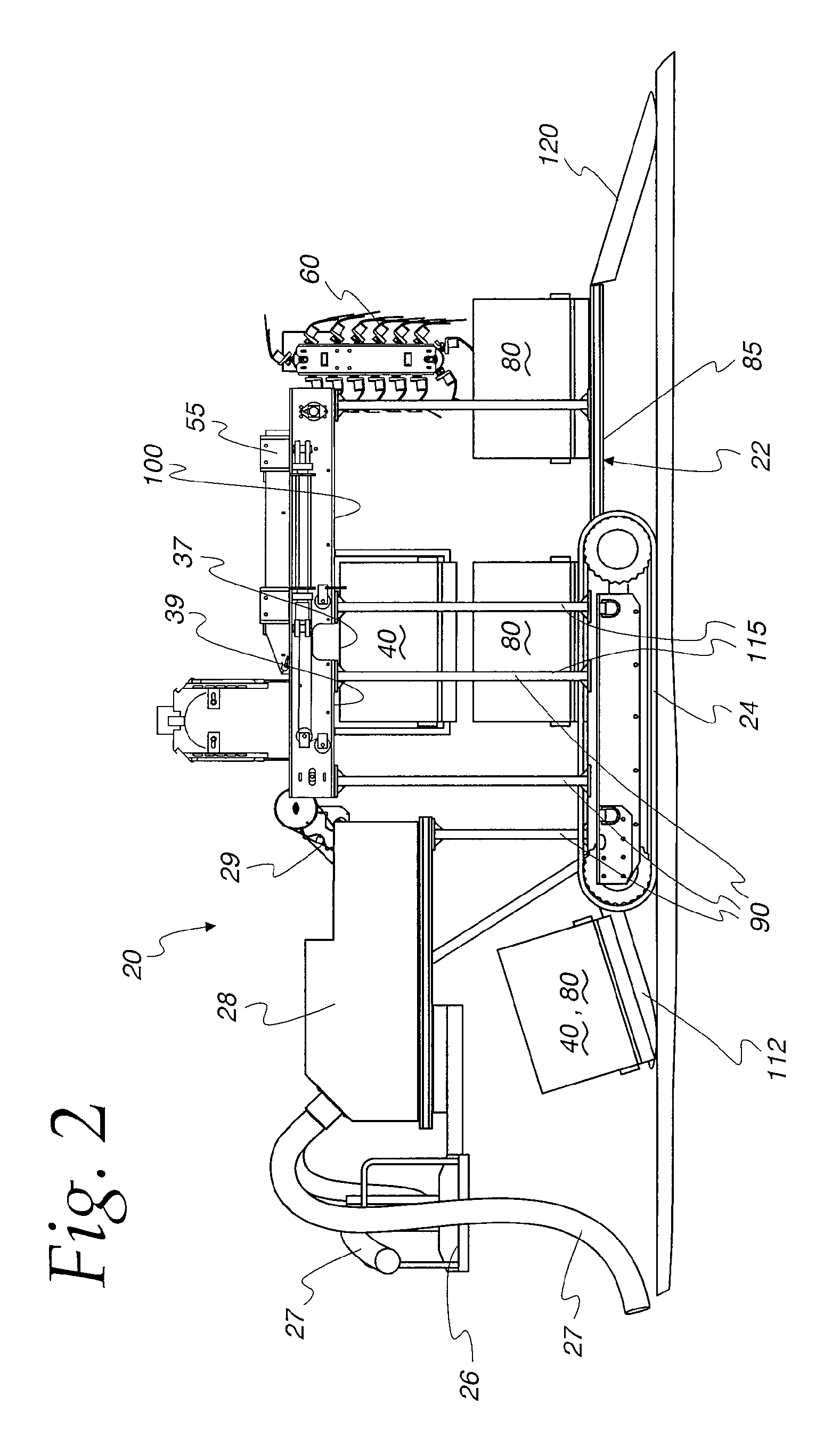

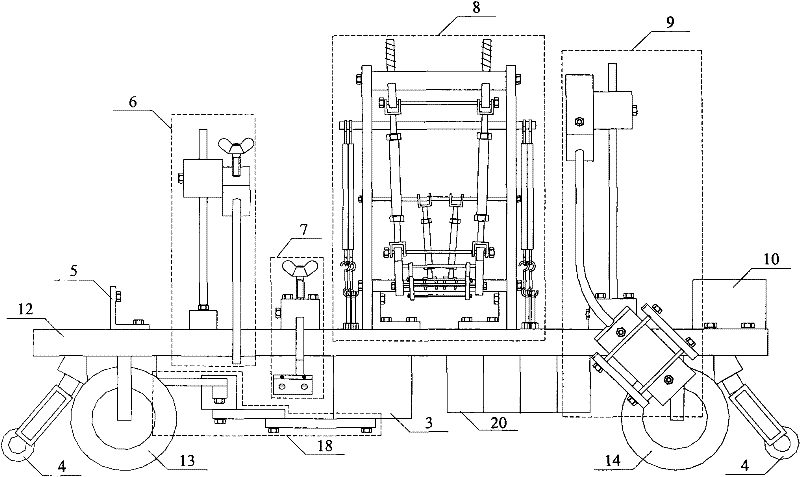

Mobile system for improving the picking and preliminary processing of apples, citrus, stone fruit and like objects

ActiveUS20100037583A1Improve productivityAvoid bruisesConveyorsLoading/unloading vehicle arrangmentEngineeringPneumatic tube

A mobile system for improving the picking and preliminary processing of apples, citrus, stone fruit and the like is disclosed and claimed. The system comprises a mobile chassis upon which can be mounted picking stations, pneumatic tube transport subsystems, receiving and conveying subsystems, object scanning subsystems, cull diverter subsystems, labeling subsystems, and subsystems for relatively gently placing the objects in a predetermined location in a receiving bin. The system can also include a subsystem for gently placing diverted objects in a receiving bin.

Owner:PICKER TECH

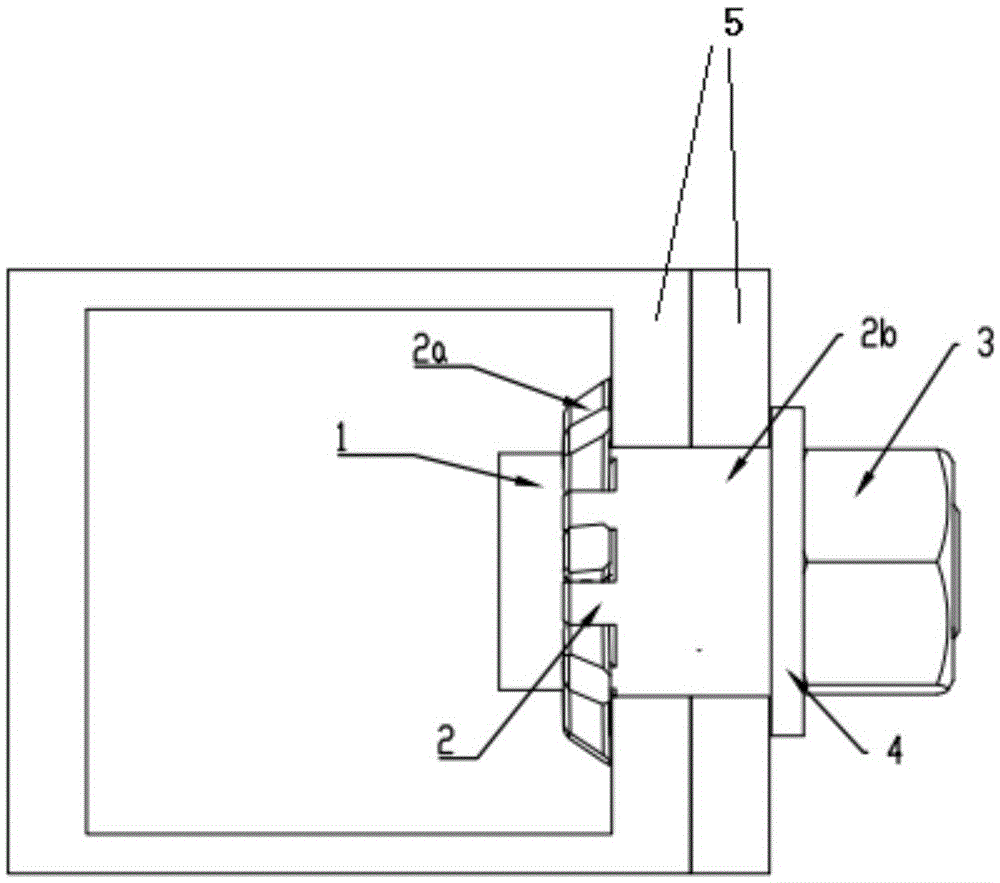

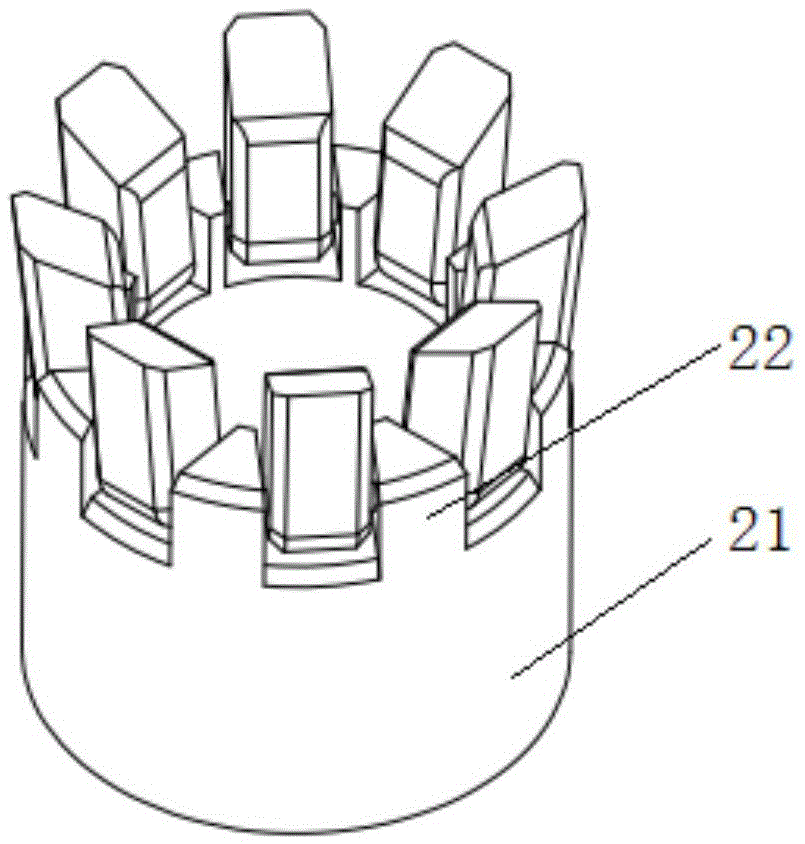

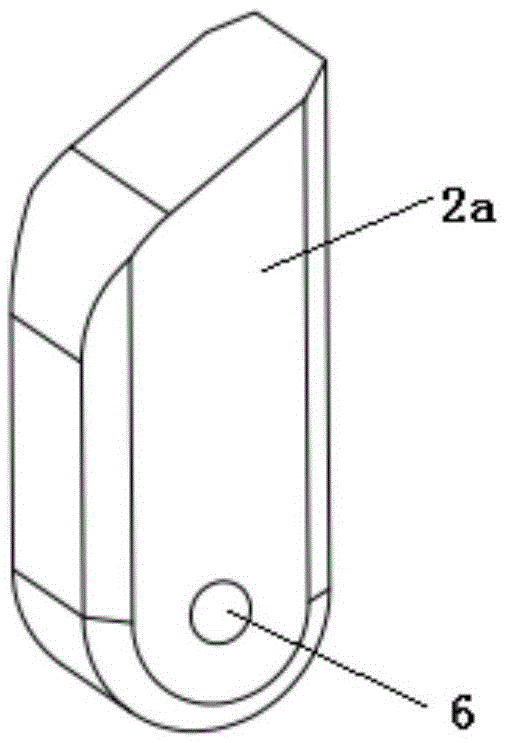

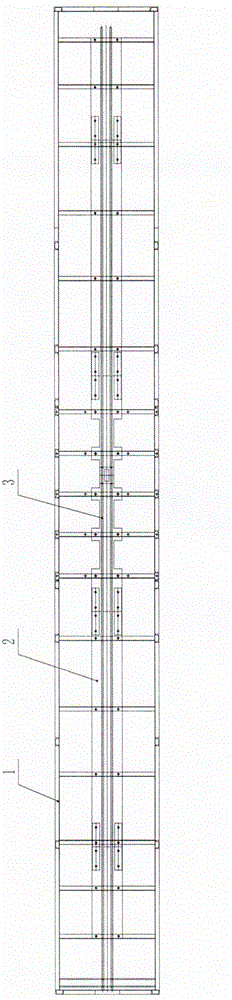

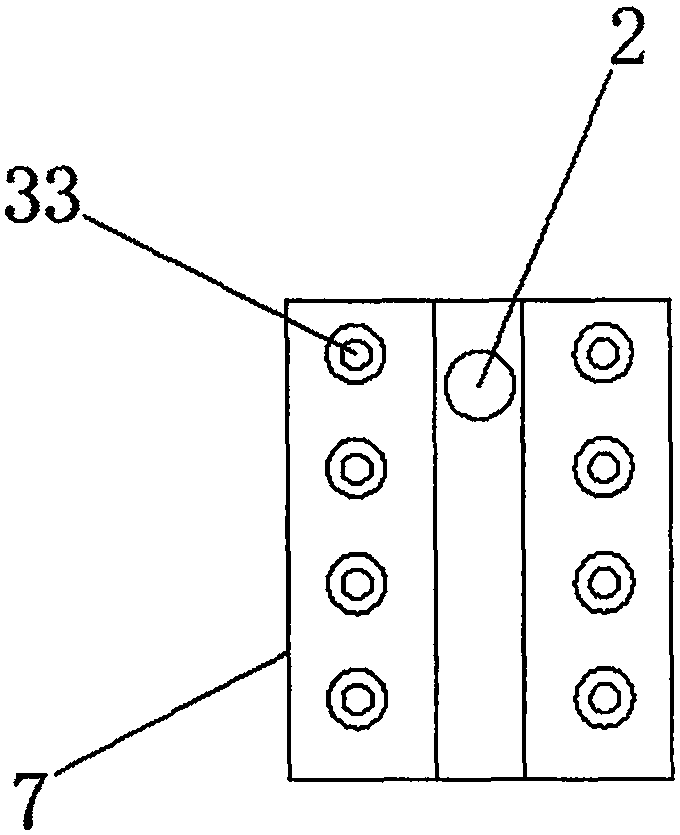

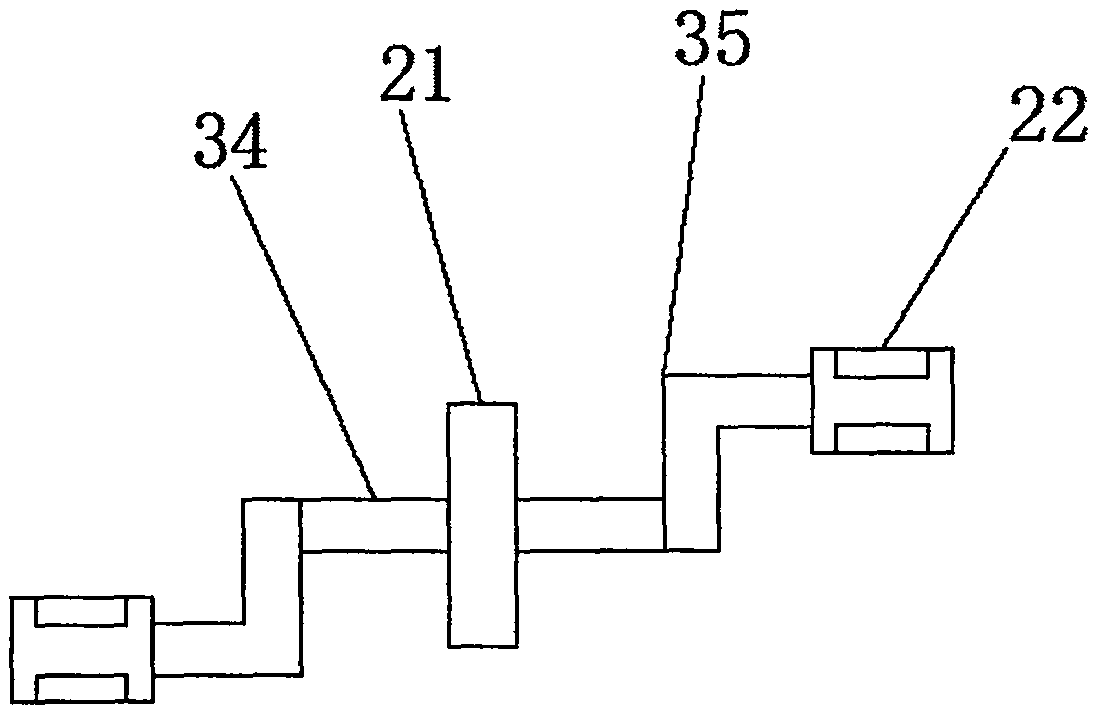

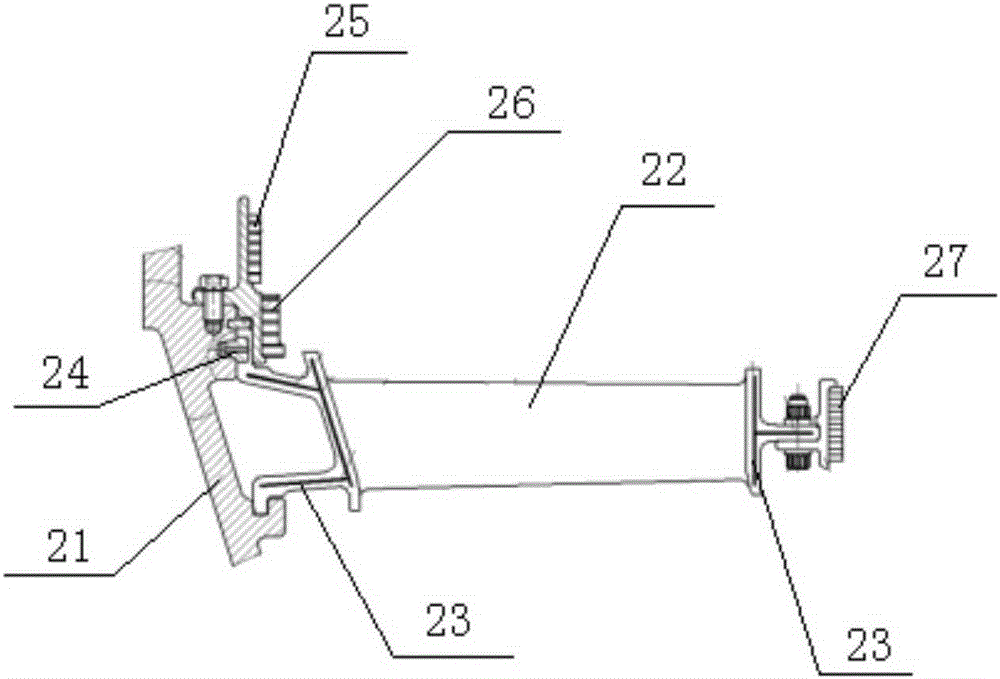

Whole overturning single-edge bolt fastening piece

The invention relates to a whole overturning single-edge bolt fastening piece for performing single-edge fastening installation for a connecting plate piece (5). The whole overturning single-edge bolt fastening piece is characterized by comprising a bolt (1), a sleeve component (2), a nut (3) and a whole washer (4); the sleeve component (2) includes multiple split washers (2a) and a sleeve (2b); inclined surfaces are respectively arranged at the head parts of all the split washers (2a); and the root parts of all the split washers (2a) are respectively connected with the sleeve (2b) to form a rotating friction pair. Compared with the prior art, the designed combination of the split washers and the sleeve with a special form is installed together, and can bear greater force, so that the mechanical performance is enhanced; and the bolt connecting and fastening operation can be finished by only needing one-side operation, so that the bolt installation under several special working conditions is finished.

Owner:TONGJI UNIV

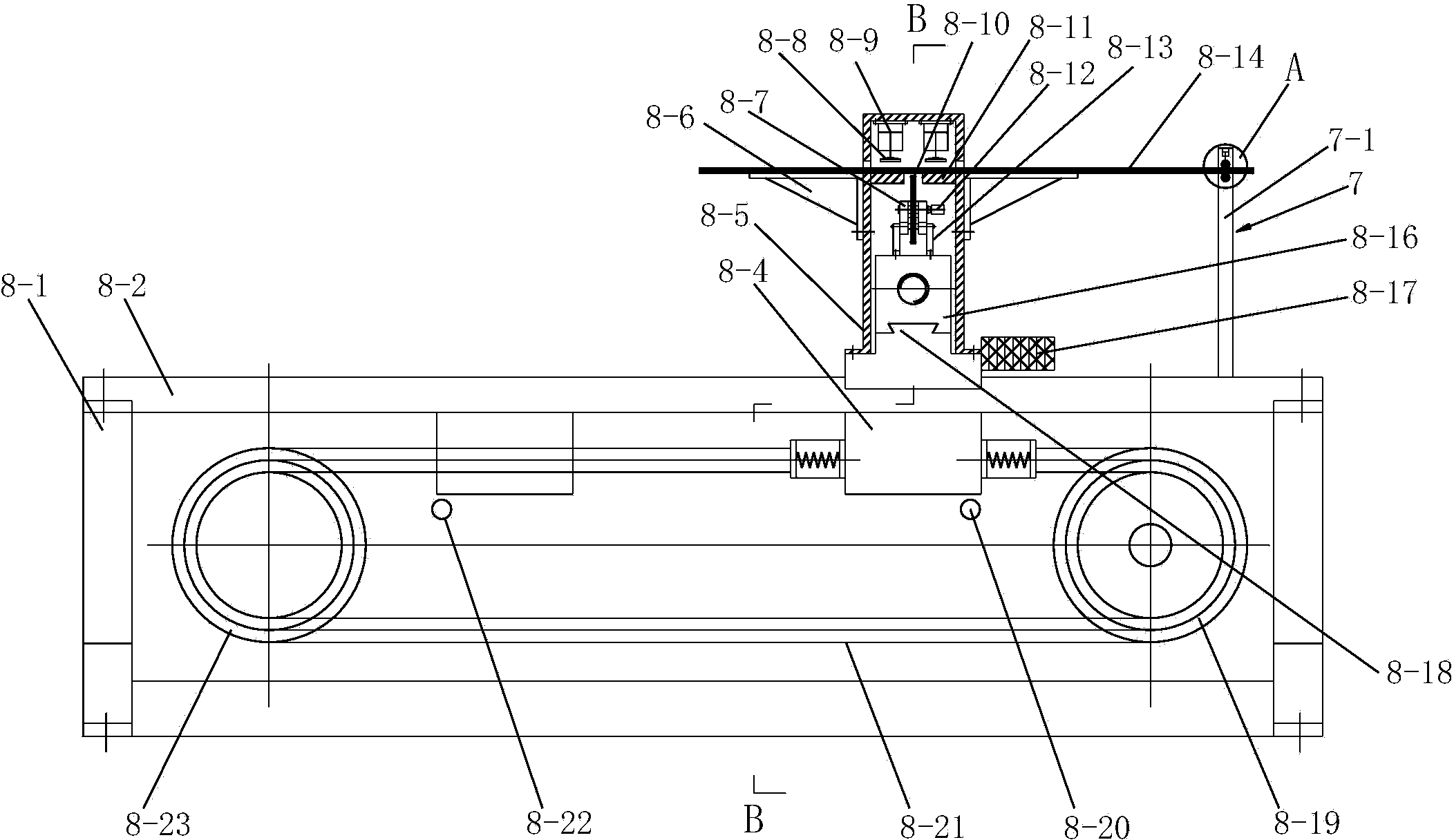

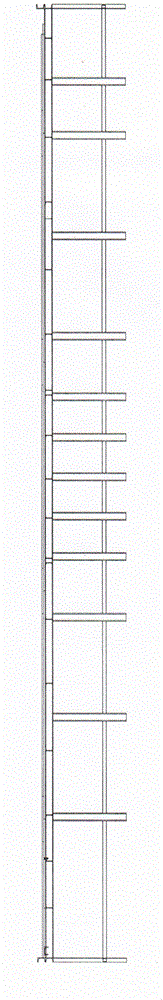

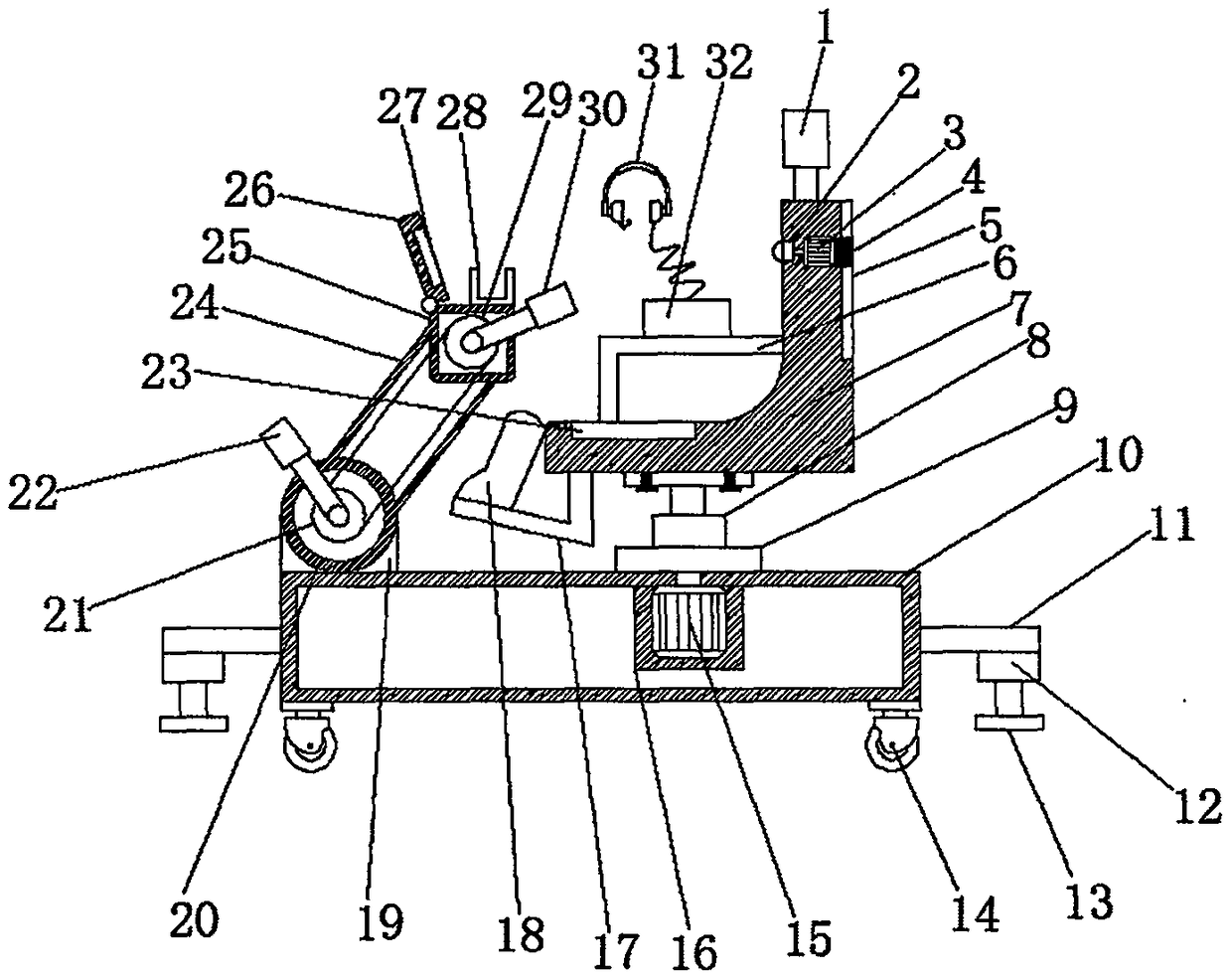

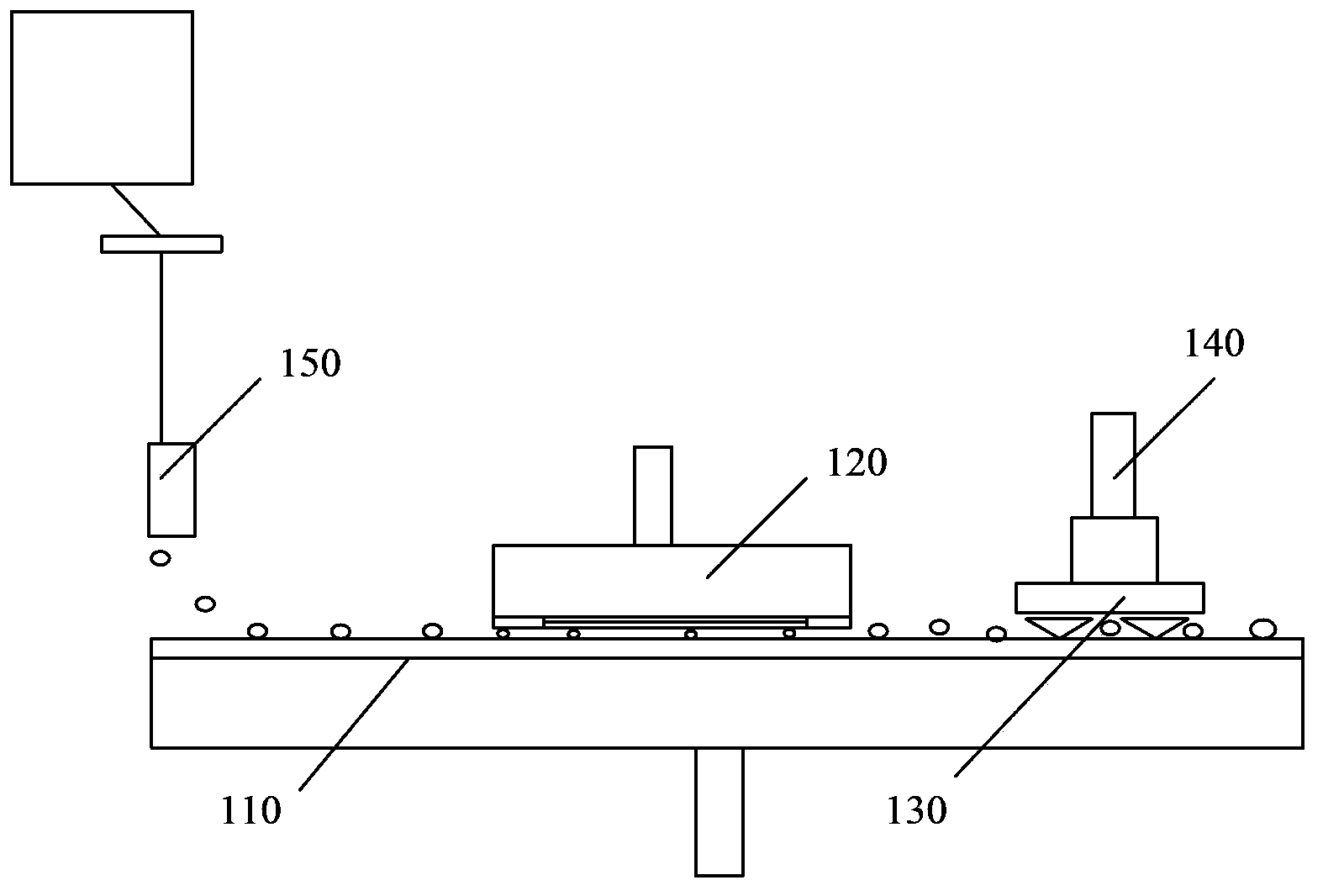

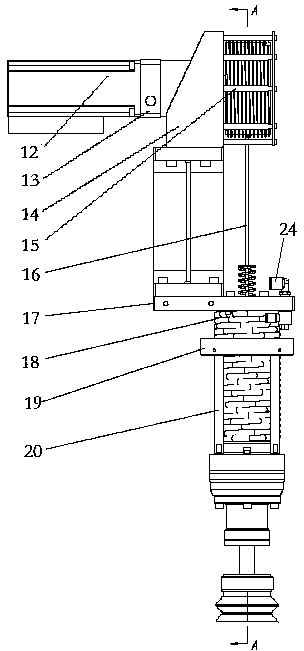

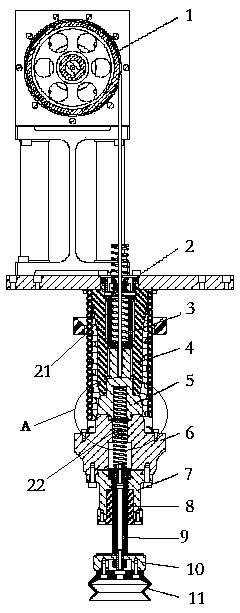

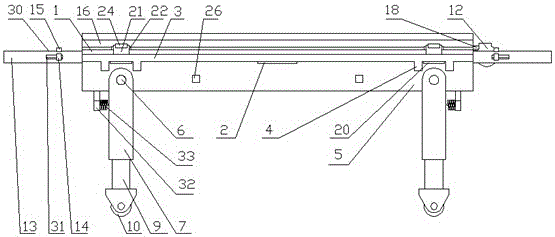

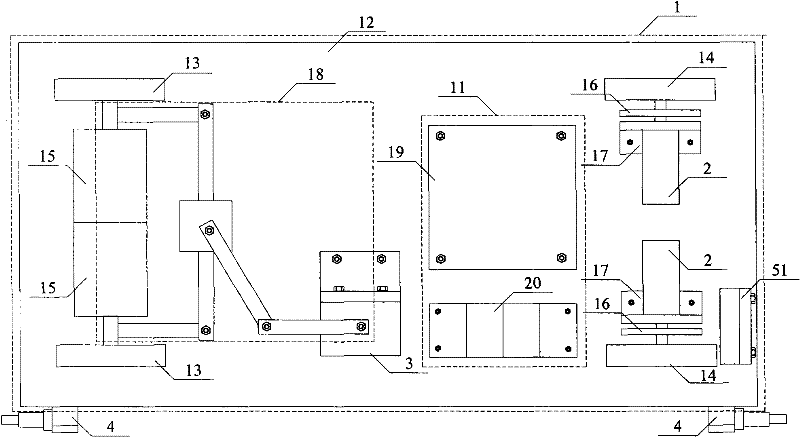

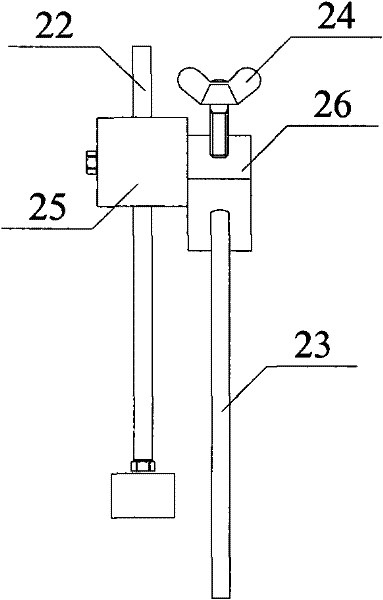

Wire drawing machine and wire drawing technology for automobile stepping bar surface wire drawing treatment

ActiveCN105127852ASmooth and reliable reciprocating motionEasy to replaceGrinding work supportsPlane surface grinding machinesOptical axisEngineering

The invention belongs to the technical field of wire drawing machines, particularly relates to a wire drawing machine and wire drawing technology for automobile stepping bar surface wire drawing treatment, and mainly solves the problems that the conventional wire drawing machine is unstable in wire drawing effect and low in efficiency and the wire drawing quality is not guaranteed. The wire drawing machine for automobile stepping bar surface wire drawing treatment comprise a workbench, a tool clamping mechanism, a feeding transmission mechanism, a wire drawing mechanism, a limiting mechanism, a circuit control part and a gas circuit control part, wherein the tool clamping mechanism comprises a clamping air cylinder, an optical axis ejector rod, three linear bearings, a front clamping block, a plurality of rod body fixing plates, a T-shaped sliding groove, a plurality of T-shaped sliding blocks and a back clamping block; the wire drawing mechanism comprises a lateral wire drawing part and a chamfer wire drawing part; the lateral wire drawing part comprises two working stations; two lateral wire drawing mechanisms are symmetrically mounted on each working station; the chamfer wire drawing part also comprises two working stations; two chamfer wire drawing mechanisms are symmetrically mounted on each working station.

Owner:SHANXI KAMEITE IND MACHINERY CO LTD

Rehabilitation leg training device for neurology department

InactiveCN108078738AEasy to get on and offAvoid bruisesPneumatic massageChiropractic devicesHydraulic cylinderPhysical medicine and rehabilitation

The invention belongs to the technical field of medical apparatus and instruments, particularly relates to a rehabilitation leg training device for neurology department, and aims to solve the problemsthat an existing rehabilitation leg training device is simple in structural design, single in function, poor in training effect and incapable of providing good treatment experience for patients. According to the technical scheme, the rehabilitation leg training device comprises a hollow base and is characterized in that universal wheels are fixed at the four corners of the bottom outer wall of the base through screws, a motor box is fixed to the top inner wall of the base through screws, a rotating motor is connected to the bottom inner wall of the motor box through screws, a rotary disc sleeves the output shaft of the rotating motor, and a first hydraulic cylinder is fixed to the top outer wall of the rotary disc through screws. The rehabilitation leg training device has the advantages that the patients are prevented from being injured, training comfortableness is increased, the device is powerful in function, patient training experience is improved, the use requirements of the patients are satisfied, device stability is increased, and the device is high in safety performance, capable of intensifying the training effect and capable of helping the fast rehabilitation of the legs of the patients.

Owner:赵加芳

Method for arranging grinding pad, grinding pad arranging device and grinder table

ActiveCN103522188AAvoid bruisesAvoid pollutionLapping machinesAbrasive surface conditioning devicesDrive shaftEngineering

The invention discloses a method for arranging a grinding pad. When wafers are ground, a grinding disc is pressed downwards to arrange the grinding pad. After one wafer is ground and before the next wafer is ground, the grinding disc stays on the grinding pad in the mode of zero-pressure. The invention further discloses a grinding pad arranging device applied to the method for arranging the grinding pad. The grinding pad arranging device comprises the grinding disc and a driving shaft. The driving shaft drives the grinding disc to rotate. The invention further discloses a grinder table which comprises the grinding pad and further comprises the grinding pad arranging device. The grinding pad arranging device is arranged on the grinding pad. The grinding disc can stay on the grinding pad in the whole process that the wafers are ground in batches all the time and the grinding disc does not need to return to a cleaning zone, so that repeated upward movement and downward movement of the grinding disc are avoided. On one hand, the wafers are prevented from being bumped by the grinding disc and on the other hand, the wafers are prevented from being polluted by particulate matters due to friction of the grinding disc and other parts.

Owner:SEMICON TECH INNOVATION CENT(BEIJING) CORP

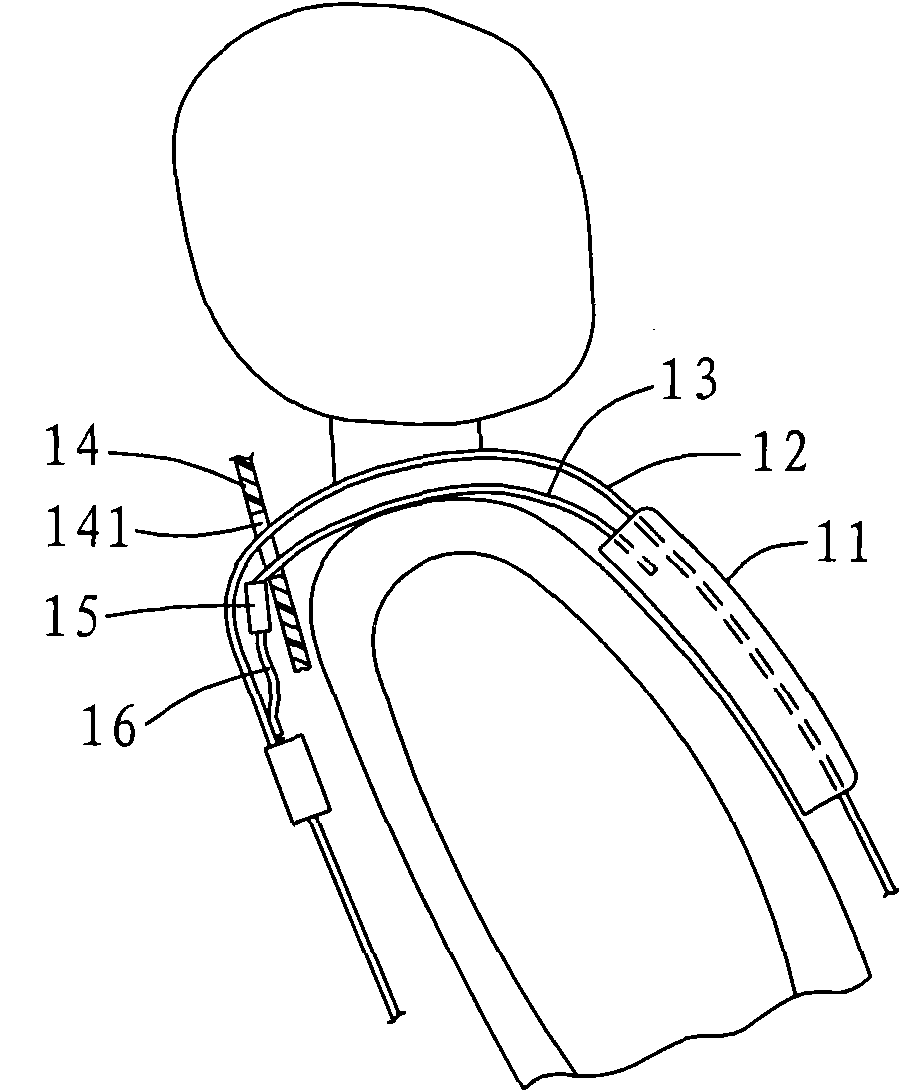

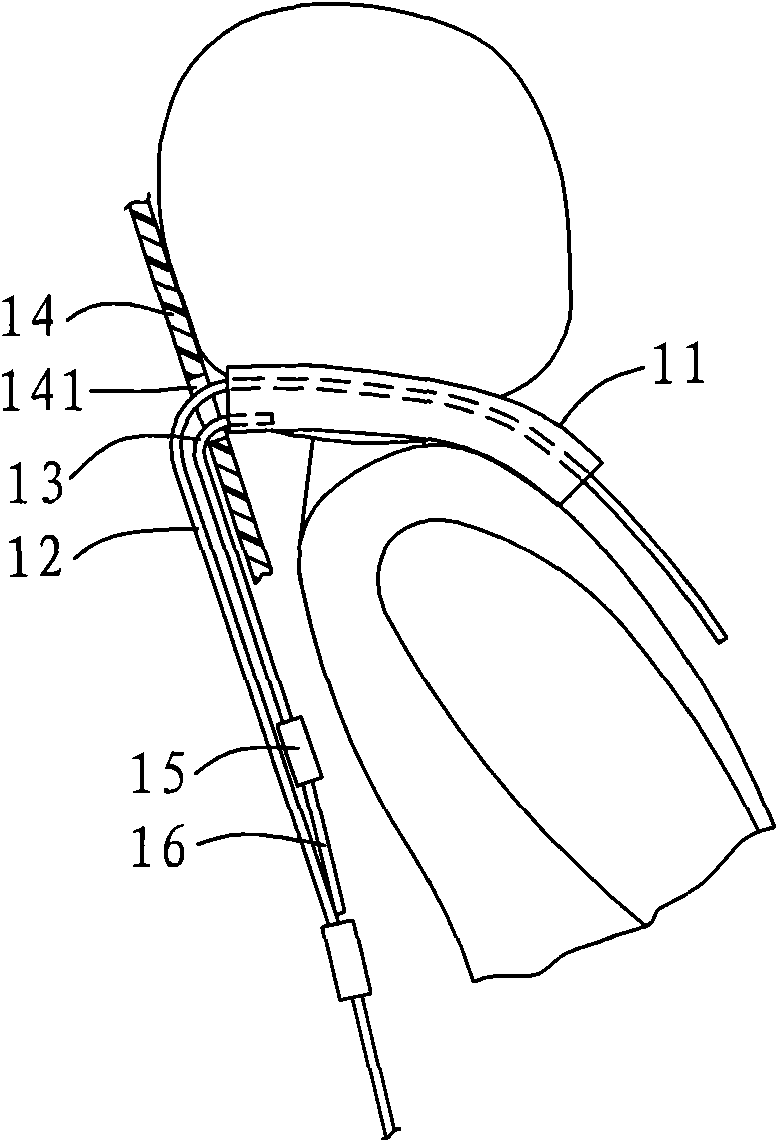

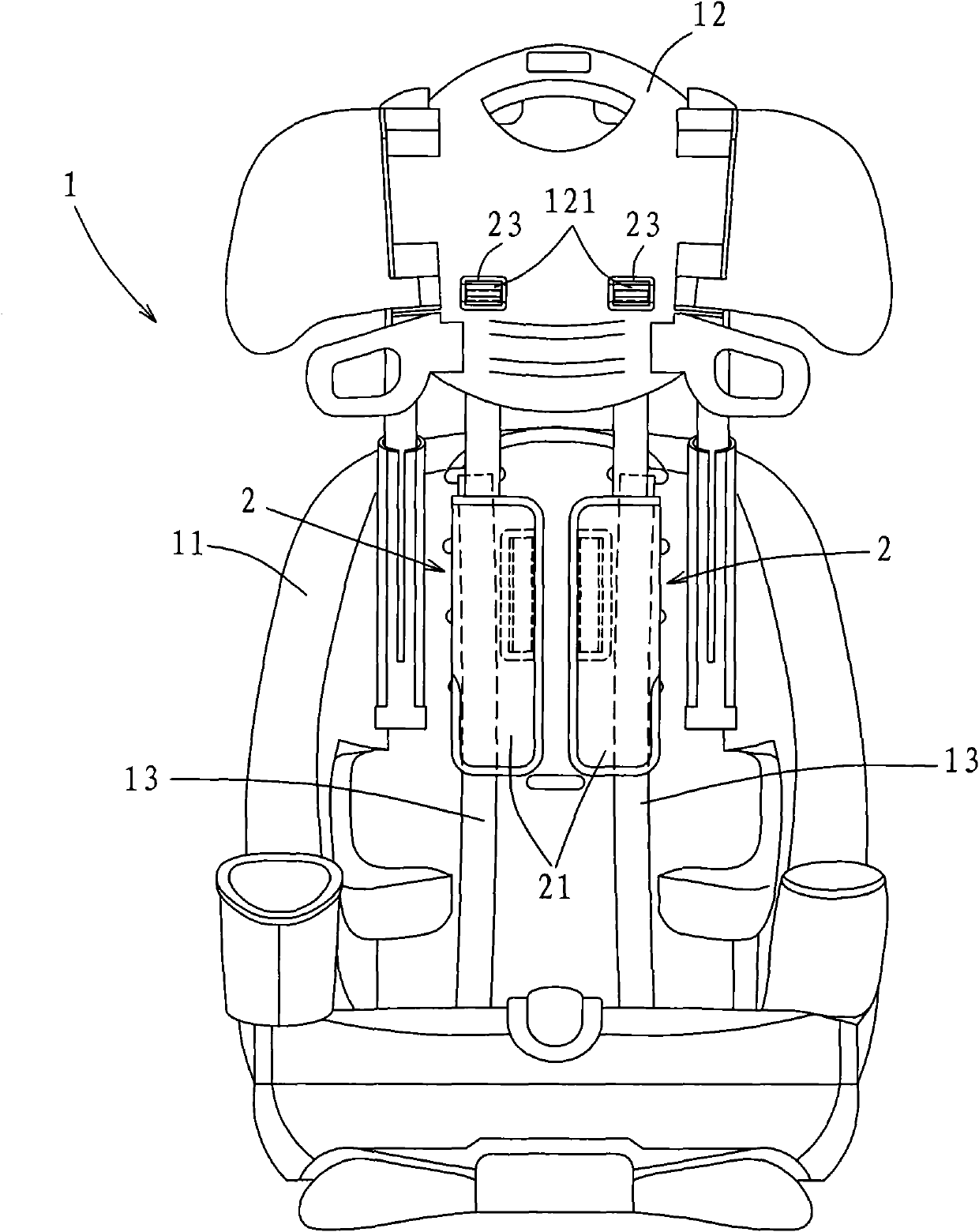

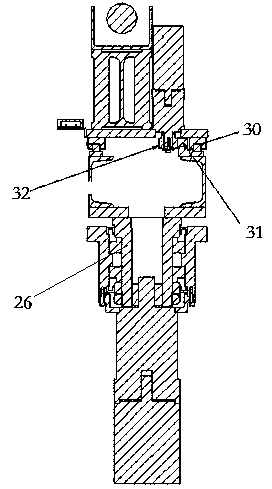

Children automobile seat and combination of headrest and shoulder belt pads of children automobile seat

Owner:WONDERLAND NURSERYGOODS CO LTD

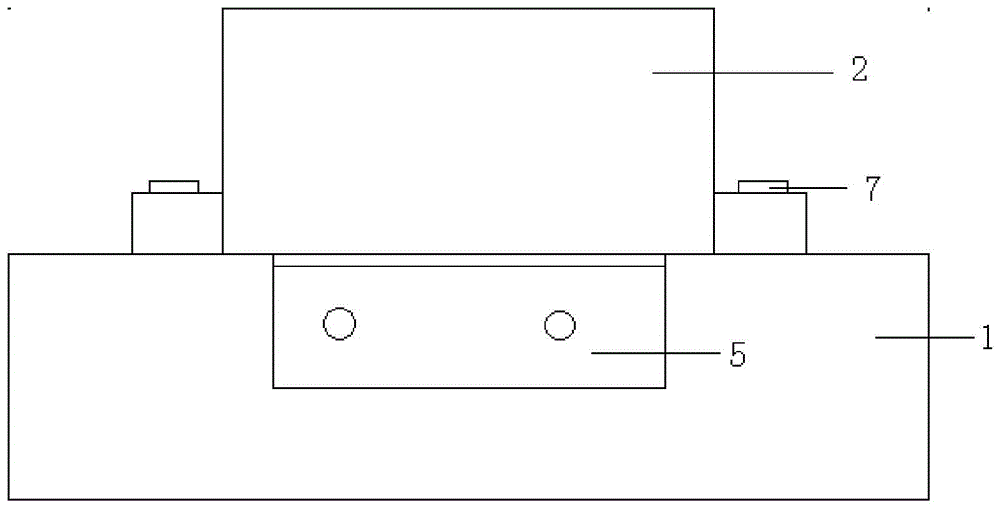

Movable sucking disk hoisting device

ActiveCN103964292APrevent disengagementAvoid bruisesWinding mechanismsLoad-engaging elementsEngineeringConductor Coil

The invention discloses a movable sucking disk hoisting device. The movable sucking disk hoisting device comprises a support frame, wherein a rotating mechanism, a sliding mechanism and a sucking disk hoisting device are arranged on the support frame; the sucking disk hoisting device comprises a sucking disk and a mounting seat connected with the sliding mechanism; a winding drum which a steel wire rope winds is arranged on the mounting seat and is controlled to rotate by a first servo motor; the steel wire rope is connected with the sucking disk; the sucking disk is controlled to generate vacuum by a vacuum generator. According to the sucking disk hoisting device, a workpiece can be prevented from being damaged during a placement process; the workpiece taking and placing position precision is high; the sucking disk hoisting device is not influenced by an external force, is wide in movable range, and can rotate and move linearly.

Owner:深圳集美家投资发展有限公司

Immersed car hub steel ball cleaning system

The invention relates to an immersed car hub steel ball cleaning system which mainly comprises an automatic cleaning device and a ball feeding mechanism arranged at the front end of the automatic cleaning device. The automatic cleaning device comprises a cleaning box used for storing a cleaning liquid; a nylon roller is arranged in the cleaning box; the front end of the roller tilts downwards; a spiral groove is arranged on the inner wall of the roller; through holes are distributed on the roller surface; the ball feeding mechanism comprises a ball storage box; a ball feeding channel is mounted at a ball outlet of the ball storage box; and a ball feeding brush is mounted on the ball feeding channel. When the roller rotates, the steel ball moves forwards along the spiral groove and sufficiently contacts with kerosene for cleaning in the forward-moving process. In the cleaning process, as the steel ball is immersed in the kerosene, an oil film protection layer is formed by the kerosene on the surface of the steel ball, and a good anti-impact effect is realized on the surface of the steel ball. The steel balls enter the roller through the ball feeding brush in turn and are not accumulated at the front section of the roller for sure, thereby improving the cleaning effect; and meanwhile, the friction frequency among the steel balls is lowered, and surface scratch is reduced.

Owner:JIANGSU LIXING GENERAL STEEL BALL

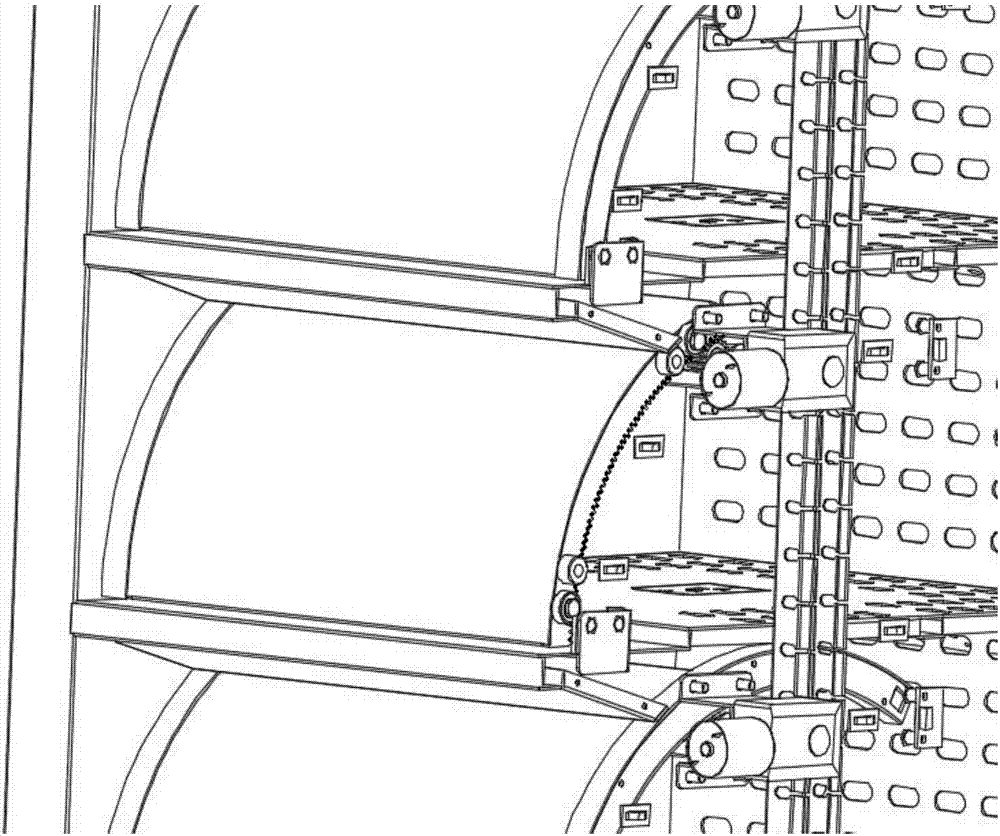

Door opening link gear of automatic vending machine

ActiveCN107301731AMany layersAvoid burnsCoin-freed apparatus detailsPower-operated mechanismEconomic benefitsEngineering

The invention discloses a door opening link gear of an automatic vending machine, which comprises a storage cabin, a moveable drawer, a cabin door, a link gear and front and back driving devices; the storage cabin is used as a cargo storage space, and the inner part is provided with the moveable drawer; the moveable drawer can moveably arranged at the bottom part of the storage cabin forwards and backwards, and cargo can be placed in the inner part; the cabin door is arranged at a cabin opening of the storage cabin to open and close the cabin opening; the link gear is connected with the front and back driving devices, the cabin door and the moveable drawer; the moveable drawer is extended out and contracted through opening and closing the cabin door; the and front and back driving devices can drive the cabin door to open and close and the moveable drawer to stretch through the link gear. After applying the technical scheme, the cargo capacity of the automatic vending machine is more, the use is more convenient, and the use safety is higher; the cargo storage risk is higher; the door opening link gear is energy-saving and environment-friendly, longer in service life, more reasonable in structural design, lower in manufacturing, using and maintaining costs, and better in economic benefit.

Owner:XIAMEN WHOLLER TECH

Healthcare massage device for neurology department

InactiveCN107496148AReduce the burden onPress comfortablySuction-kneading massageNeurology departmentMassage

The invention relates to a healthcare massage device, in particular to the healthcare massage device for the neurology department, and aims at achieving the technical purpose of providing the healthcare massage device for the neurology department. To achieve the technical purpose, the healthcare massage device comprises a frame and the like; first openings are formed in the upper sides of the left wall and the right wall of the frame, a press mechanism is arranged between the two walls of the frame, the left end and the right end of the press mechanism penetrate through the first openings, and a supporting plate is arranged at the bottom in the frame and is provided with a tightening mechanism. The healthcare massage device for the neurology department has the advantages that the work intensity of medical personnel can be lowered, and the rehabilitation of a patient can be promoted; after the legs of the patient are placed, the device can automatically massage the legs of the patient simply by starting a motor, and in this way, a large amount of time and energy of the medical personnel can be saved.

Owner:王利兵

Stretcher for spine surgery

The invention discloses a stretcher for spine surgery. The stretcher comprises a device main frame, wherein both sides of the device main frame are hinged with side frames by virtue of hinges; a group of limiting plates are arranged at the lower sides of the side frames; a group of mounting frames are arranged at the lower side of the device main frame; a group of rotating shafts are arranged on the mounting frames; the rotating shafts are matched with rotary square sleeves in rotary mode; the rotary square sleeves are connected to supporting legs by virtue of supporting springs; universal wheels are arranged at the lower ends of the supporting legs; an air cushion is arranged at the upper side of the device main frame; an inflator, which is matched with the air cushion, is arranged at one end of the device main body; a group of handles are arranged at each of two ends of the device main frame; and clamping block sliding buttons and pull arm sliding buttons are arranged on the handles in a sliding mode. The stretcher for the spine surgery is convenient to operate, and the stretcher, when used, can relieve burden of medical personnel, so that the medical personnel can carry a patient with lower physical power consumed; meanwhile, the patient can be protected well; and the stretcher can effectively prevent the body of the patient from getting displaced, so that the occurrence of secondary injury can be prevented.

Owner:LUOYANG ORTHOPEDIC TRAUMATOLOGICAL HOSPITAL

Automatic overturning and transmitting device for cigarette packet

The invention relates to an automatic overturning and transmitting device for a cigarette packet, and belongs to the technical field of cigarette packing. The automatic overturning and transmitting device for the cigarette packet is installed at the tail end of a conveyer belt on a C90 packer after packet oil seal packing processes are completed, and is used for 90-degree turnover of a 'YuXi Manor' packet with 16 cigarettes to achieve close attachment of the obverse side and the reverse side of the surface of the brand of the 'YuXi Manor'. The automatic overturning and transmitting device mainly comprises a slide way, a conveying tank, a cylinder, a push rod, a photoelectric tube and the like. The cylinder and the push rod are installed on the base of the C90 packer, the upper portion of the slide way is linked with the tail end of the conveyor belt of the C90 packer, the lower portion of the slide way is linked with the conveying tank, and the photoelectric tube is installed on the side face of the bottom of the slide way. Whenever the photoelectric tube detects that the cigarette packet sliding downwards to a proper position, trigger signals enable a C90 controller to start a solenoid valve to activate the cylinder and bounce the push rod out, the cigarette packet is pushed into the conveying tank, turnover and rank ordering in the conveying tank of the cigarette packet are completed, stacking is facilitated, the cigarette packet can be loaded to a carton conveniently and manually, and packing quality and efficiency are improved. The automatic overturning and transmitting device has the advantages of being simple in structure and convenient to debug, achieving automatic overturning of the packet and smooth transmitting, and the like.

Owner:HONGTA TOBACCO GRP

Mobile system for improving the picking and preliminary processing of apples, citrus, stone fruit and like objects

ActiveUS7882686B2Improve productivityAvoid bruisesConveyorsLoading/unloading vehicle arrangmentEngineeringPneumatic tube

A mobile system for improving the picking and preliminary processing of apples, citrus, stone fruit and the like is disclosed and claimed. The system comprises a mobile chassis upon which can be mounted picking stations, pneumatic tube transport subsystems, receiving and conveying subsystems, object scanning subsystems, cull diverter subsystems, labeling subsystems, and subsystems for relatively gently placing the objects in a predetermined location in a receiving bin. The system can also include a subsystem for gently placing diverted objects in a receiving bin.

Owner:PICKER TECH

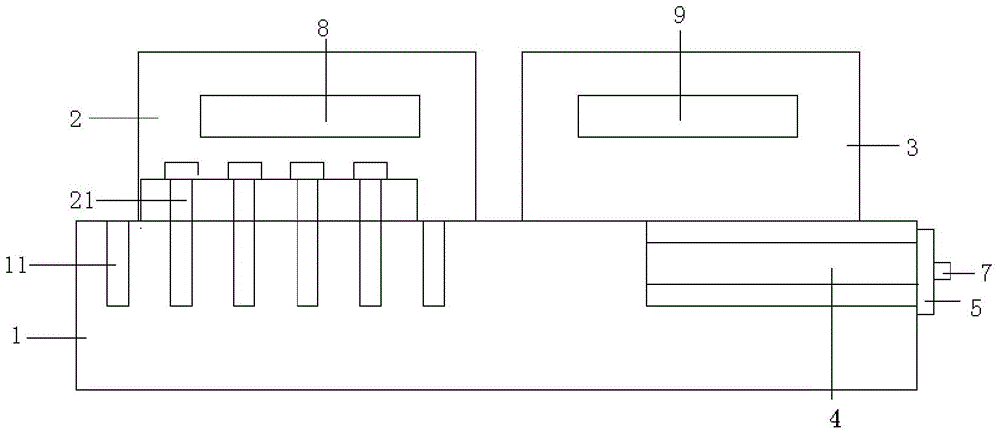

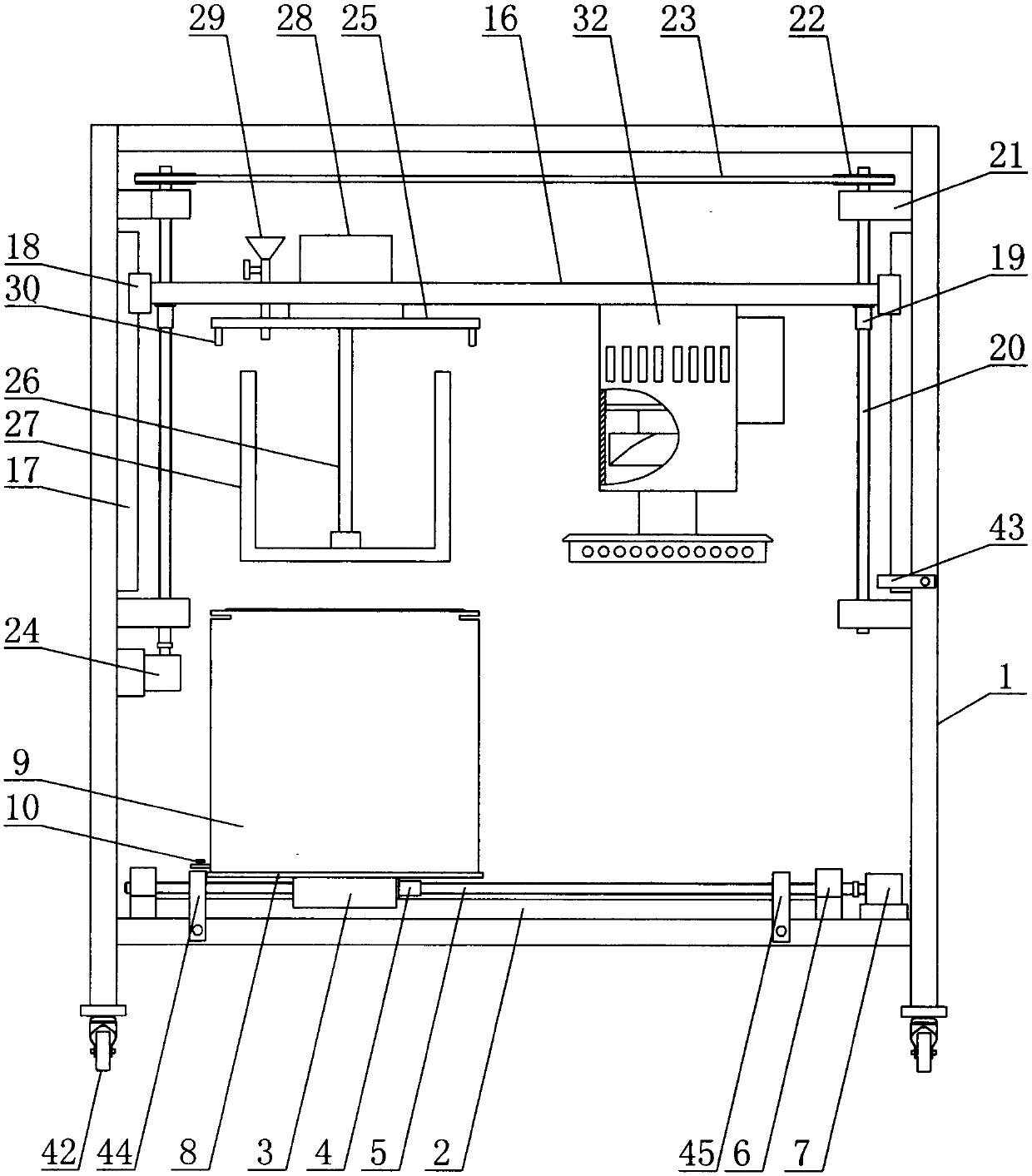

Automatic magnetic particle testing unit for toe cracks at inner wall of straight welded pipe

InactiveCN102346151ARapid Batch DetectionAutomatic detection speed adjustableOptically investigating flaws/contaminationMaterial magnetic variablesDrive wheelTransformer

The invention relates to a testing unit for a straight welded pipe, in particular to an automatic magnetic particle testing unit for toe cracks at inner wall of the straight welded pipe, comprising a car body consisting of a sweep template, a driving wheel, a stop block, a supporting plate, universal wheels and a guide bar which are connected with each other coaxially, and a rotary bearing, a driving motor, a control part, a steering engine, a position switch arranged on the two ends of one end of the car body, and a transformer bearing, a camera bearing, a sprayer bearing, a crossed yoke, an ultraviolet lamp bearing, and a water pump water tank bearing which are successively arranged on the top of the sweep template from left to right, wherein, the upper end of the stop block is fixedly connected with the two sides of the rear end of the sweep template bottom in parallel, the output end of the steering engine is fixedly connected with the universal wheels through the guide bar, the upper end of the rotary bearing is fixedly connected with the two sides of the rear end of the sweep template bottom in parallel, the lower end of the rotary bearing is fixedly connected with one end of the supporting plate, the other end of the supporting plate is fixed connected with the sweep template bottom, and output shaft of the driving motor is respectively connected with the two driving wheels fixedly. The invention can completely takes the place of manual work to carry out automatic magnetic particle testing, and has the advantages of compact structure and convenient operation.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

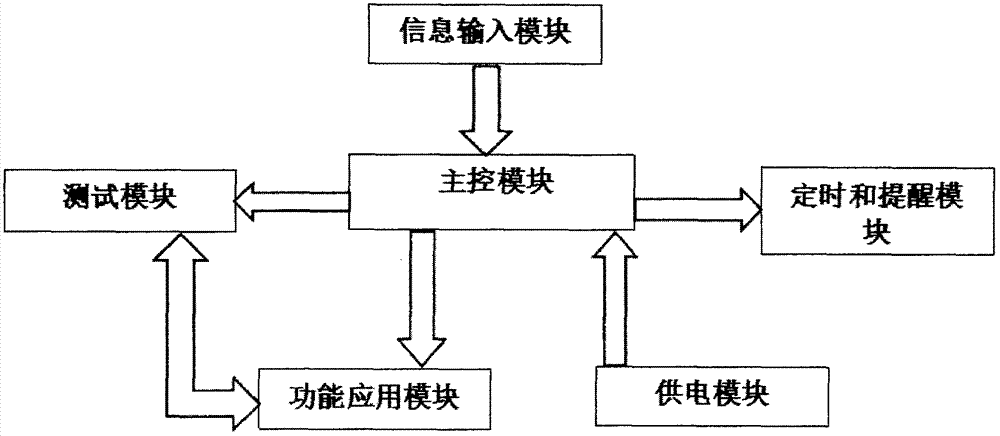

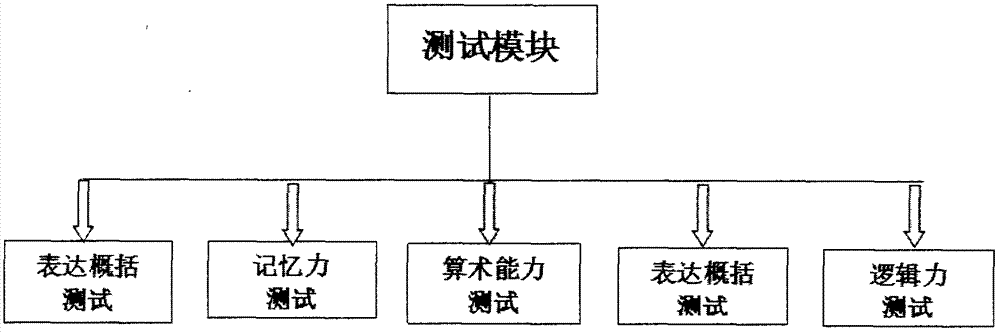

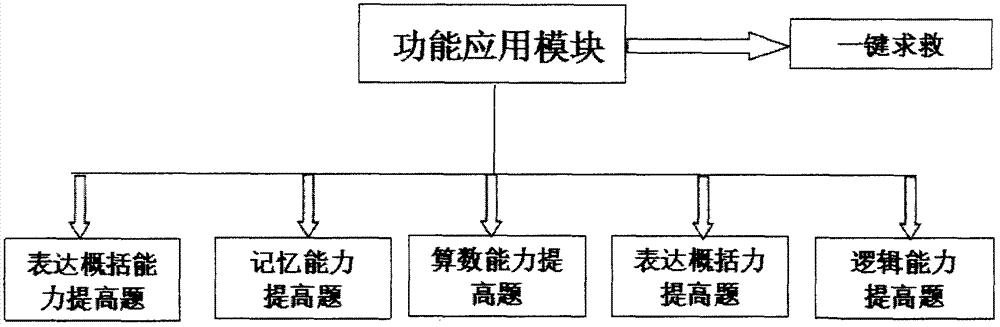

Robot for preventing senile dementia mainly based on mental stimulation

InactiveCN107186722AImprove computing powerImprove generalizationManipulatorMental functionsOlder people

The invention relates to the field of robots, and discloses a robot for preventing senile dementia mainly based on mental stimulation. The robot mainly comprises an information input module, a testing module, a main control module, a function application module, a timing and reminding module, an interaction module, and a shape designing and moving module. The information input module is mainly used for inputting basic information of old people; the testing module tests mental functions of the old people; the main control module can store information and process the information; the function application module can realize various manners of the mental stimulation; the timing and reminding module can finish functions of medicine taking, exercising and position reminding; the interaction module can realize function interaction with the old people; and for the shape designing and moving module, a tumbler base and idler wheels capable of realizing differential steering ensure safety and movability. A power supply module provides energy required by the system, and the robot realizes the function of preventing the senile dementia from the metal stimulation.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

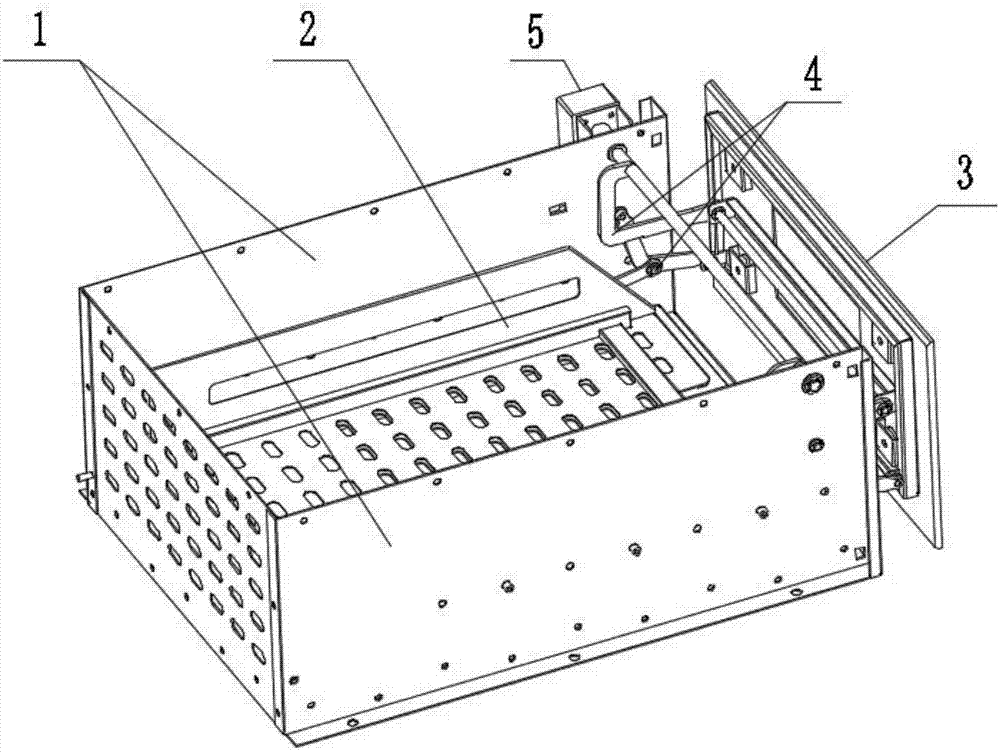

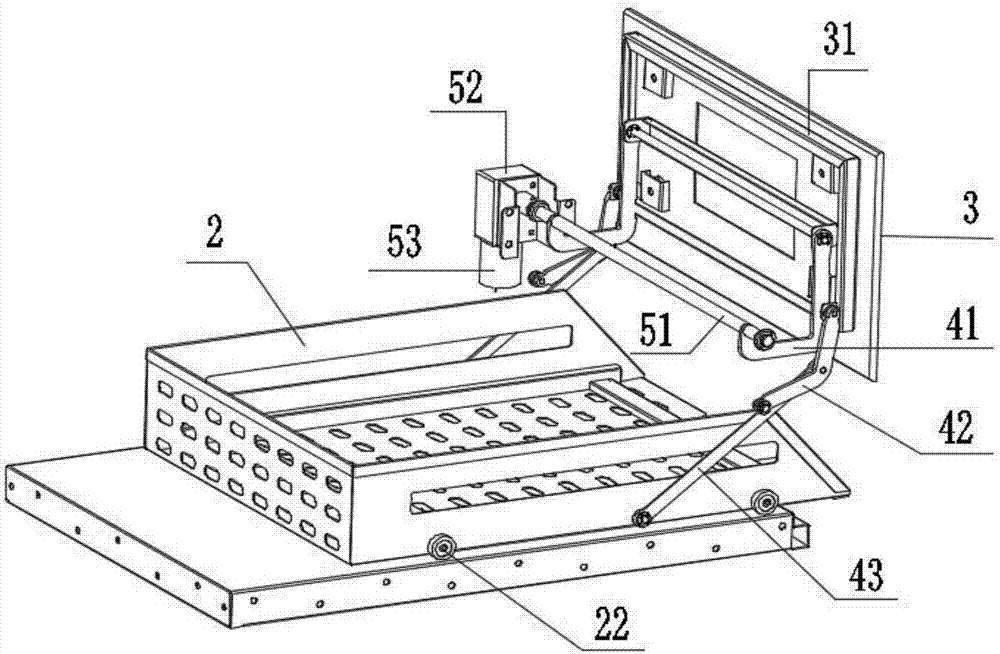

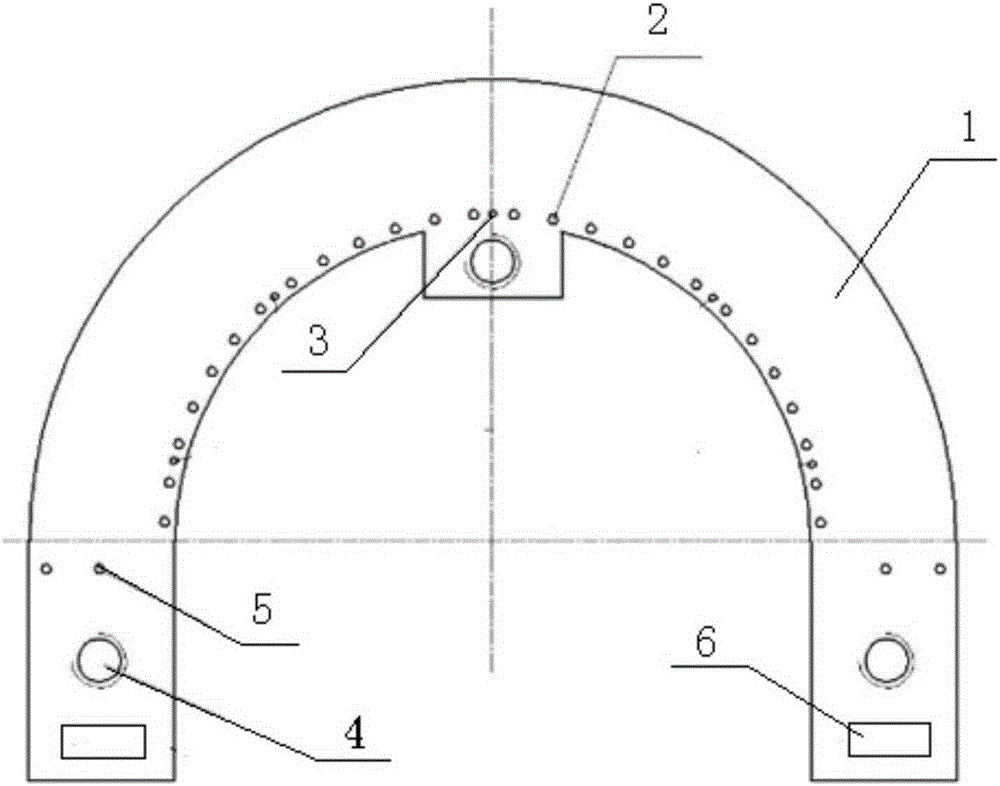

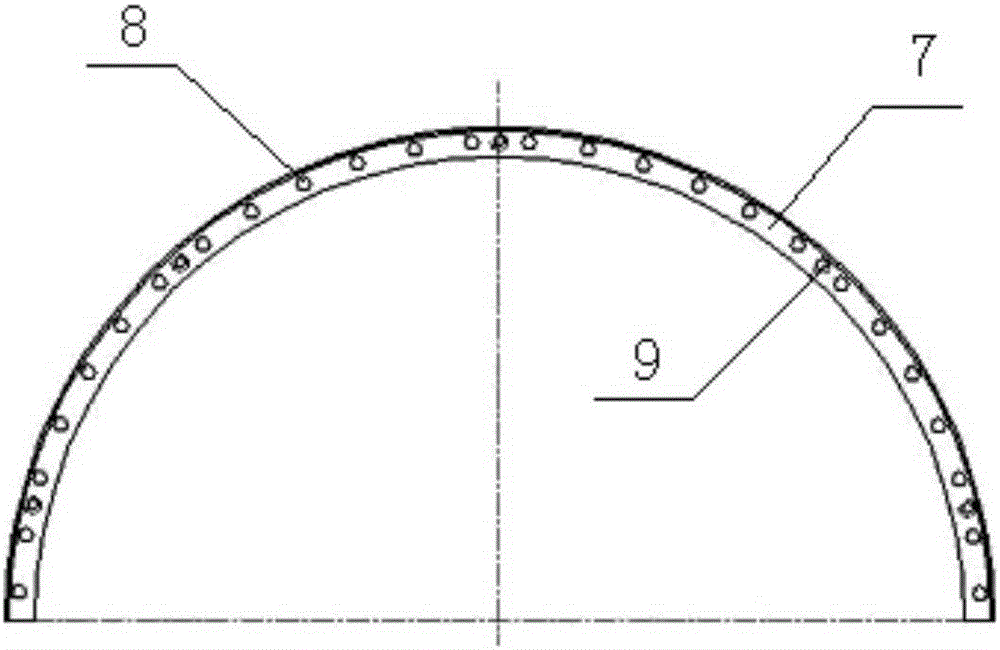

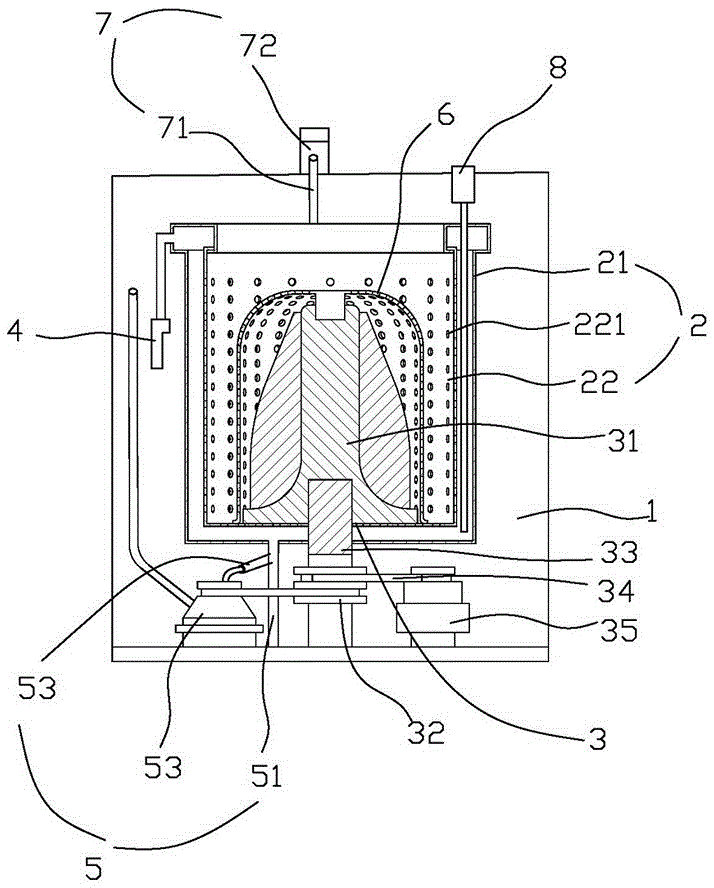

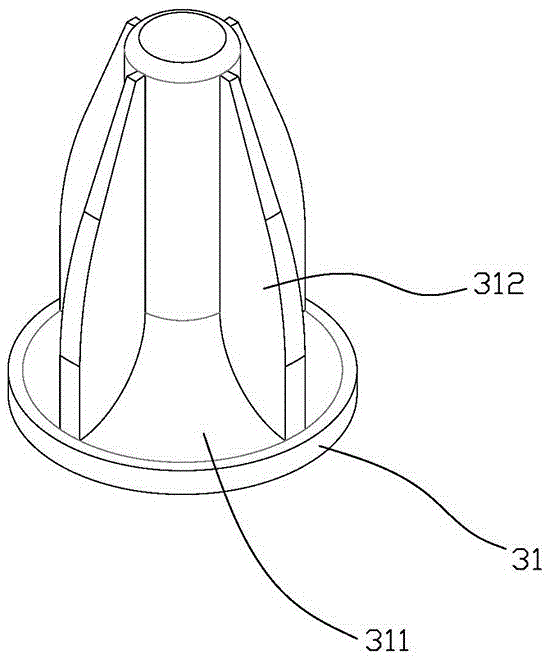

Packing-off piece installation device of turbine stator blades and use method of packing-off piece installation device

ActiveCN105298561AEasy to assembleShorten assembly cycleLeakage preventionStatorsStatorSoftware engineering

The invention relates to a device, in particular to a packing-off piece installation device of turbine stator blades and a use method of the packing-off piece installation device. According to the technical scheme, the packing-off piece installation device comprises an installation plate, an installation edge, first screws, balancing weights, limiting blocks, second screws, fixing bolts and nuts; the installation plate is a semicircular plate and is provided with two end plates and an auxiliary plate on the top of the arc; first installation holes are formed in the semicircular plate, the interval of the first installation holes is the same as the interval of end holes of the two turbine stator blades, and hoisting holes are formed in the end plates and the auxiliary plate; the balancing weights are fixedly arranged on the end plates, and the limiting blocks are arranged on the end plates through the second screws; the installation edge is in a semicircular shape and provided with second installation holes; the installation plate and the installation edge are connected together through the first screws, and the positions of the first installation holes correspond to the positions of the second installation holes; and the fixing bolts and the nuts are used for fixing the turbine stator blades. By means of the packing-off piece installation device, installation of packing-off pieces is achieved under the condition that positioning pins of the turbine stator blades are not decomposed.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

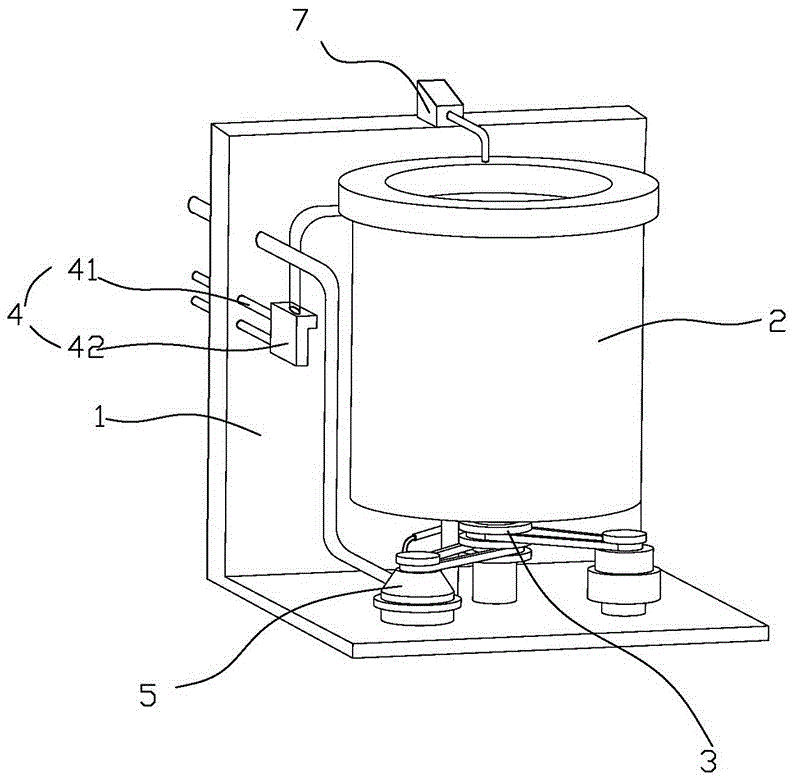

Grape cleaning equipment

InactiveCN105876830AFully automatedImprove cleanlinessFood treatmentBiochemical engineeringCleansing Agents

The invention relates to fruit cleaning equipment, in particular to grape cleaning equipment. The grape cleaning equipment comprises a rack, a cleaning bucket assembly arranged on the rack, a stirring assembly arranged inside the cleaning bucket assembly, a water inlet assembly connected to the cleaning bucket assembly and a drainage assembly. By means of the grape cleaning equipment, automation of grape cleaning is achieved, cleanliness of cleaned grapes is guaranteed, and cleaning efficiency is improved; a cleaning agent or flour or detergent is used, it is more helpful to remove dirt, and cleanliness of the grapes is improved; through design of a water containing bucket and a cleaning bucket, dirt is isolated from the grapes, cleanliness of the grapes is greatly improved, the grapes are prevented from being bruised or damaged in the cleaning process, and cleaning quality and cleaning efficiency are improved.

Owner:广德县富农葡萄专业合作社

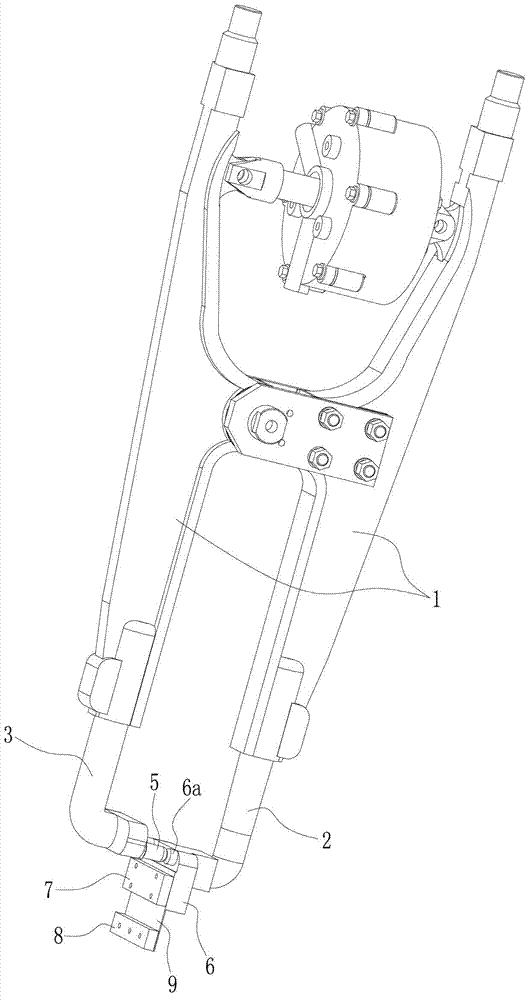

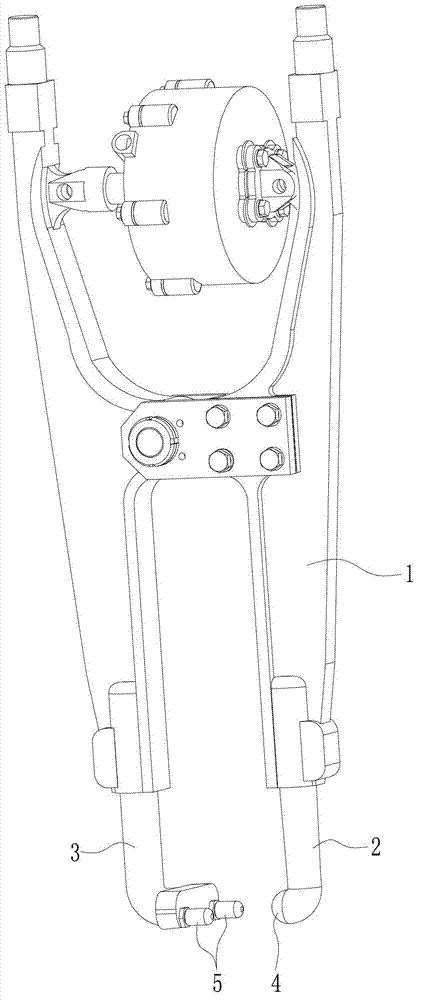

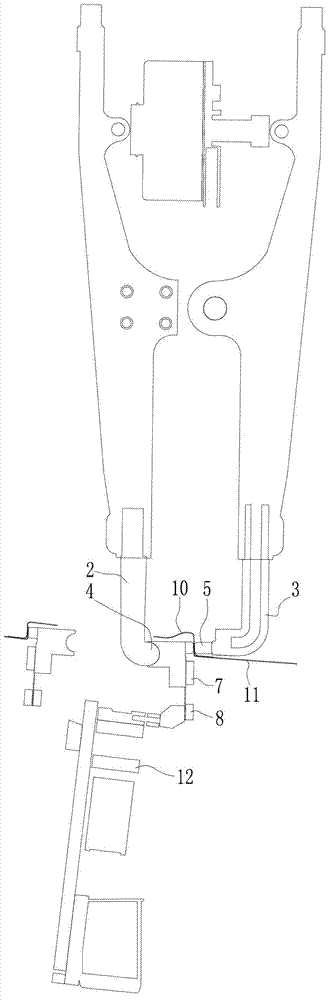

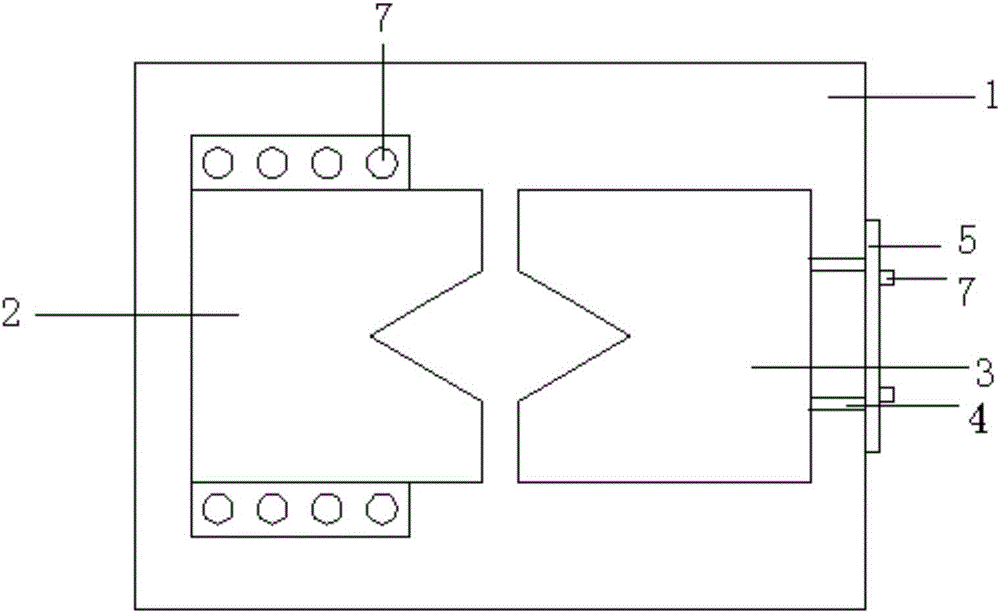

Double-head separate resistance spot welding tongs

InactiveCN102962571AReduce the time to flip the gunEasy to installResistance electrode holdersBiochemical engineeringSpot welding

The invention discloses a pair of double-head separate resistance spot welding tongs. A first electrode arm (2) is mounted at the lower end of an electrode rod (1); a second electrode arm (3) is mounted at the lower end of another electrode rod (1); a round-head electrode (4) is fixed on the inner side of the lower end of the first electrode arm (2); two cylinder electrodes (5) are fixed side by side on the inner side of the lower end of the second electrode arm (3); distances from the round-head electrode (4) to the two cylinder electrodes (5) are equal; and a copper cushion block (6) is arranged among the round-head electrode (4) and the two cylinder electrode (5). The pair of welding tongs can be used for welding similar workpieces such as filler caps, is free from interference with the workpieces, can effectively prevent damaging the workpieces in the welding and clinching process, is simple to operate, and can weld two points simultaneously, the welding quality is guaranteed, the turning time of the pair of welding tongs is reduced, and the welding efficiency is improved greatly.

Owner:力帆科技(集团)股份有限公司

Electromagnetic fixture

ActiveCN103909437BAchieve clampingSuitable for fixingPositioning apparatusMetal-working holdersElectricityEngineering

Owner:浙江西塘实业有限公司

Secondary slide block core pulling mechanism for plastic mould

Owner:YONGGAO CO LTD

Fiber reinforced resin base composite material manhole cover

InactiveCN1648356AHigh compressive strengthImprove toughnessArtificial islandsUnderwater structuresPolyester resinResin-Based Composite

The present invention relates to manhole cover of composite thermoset resin base material, and especially a kind of manhole well of pre-soaked FRP rib and polyester cemented quartz mortar. The manhole cover has reinforcing ribs of pre-soaked FRP, and its material includes polyester resin 10-30 wt%, pre-soaked FRP ribs 1-8 wt%, aggregate 40-75 wt%, stuffing 5-30 wt%, and nanometer material 1-8 wt%. The manhole cover has high compression strength, high toughness, high impact strength and less damage and cracking, is anticorrosive and noise-less, and may be colorized.

Owner:廖国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com