Patents

Literature

288results about How to "Shorten assembly cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

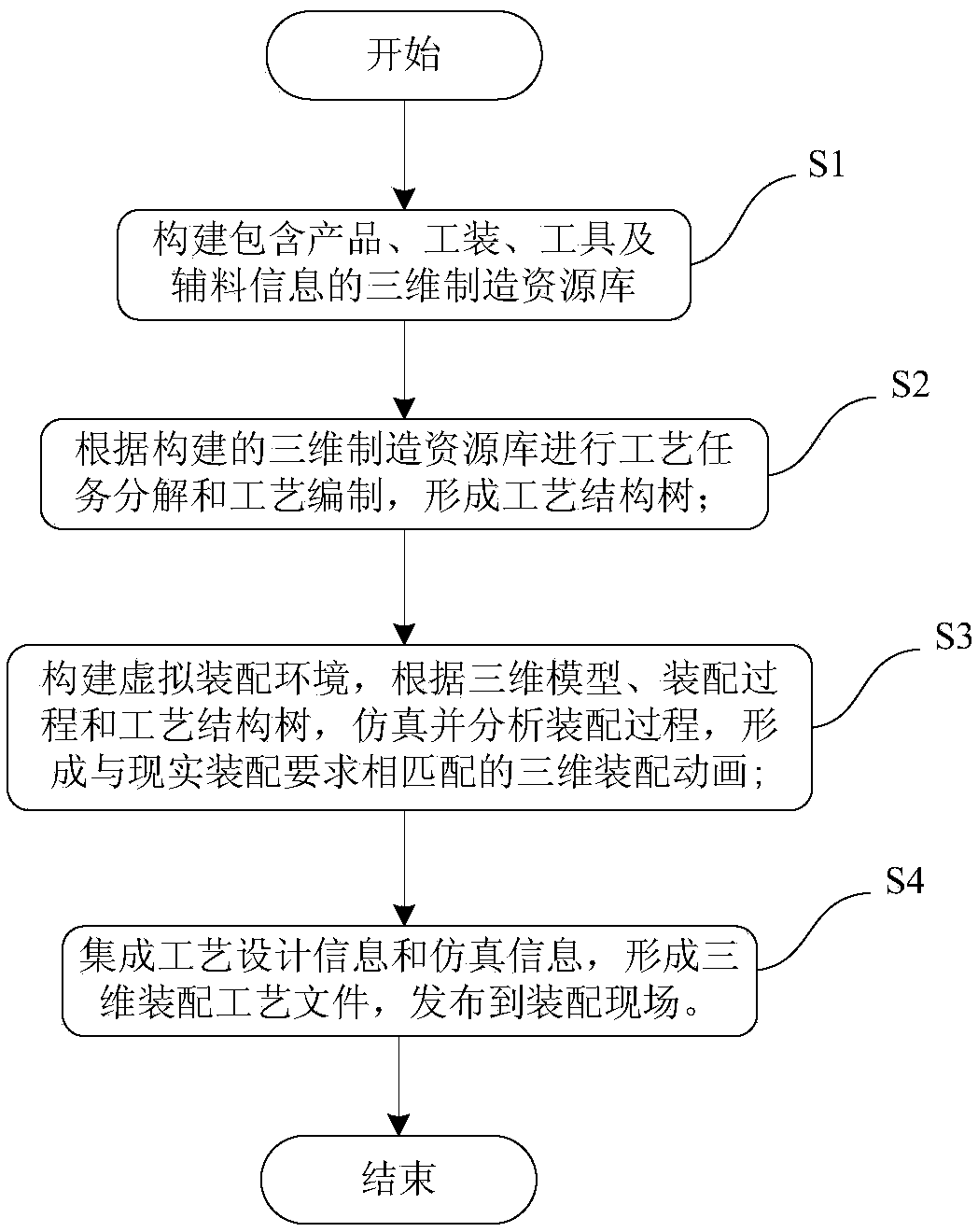

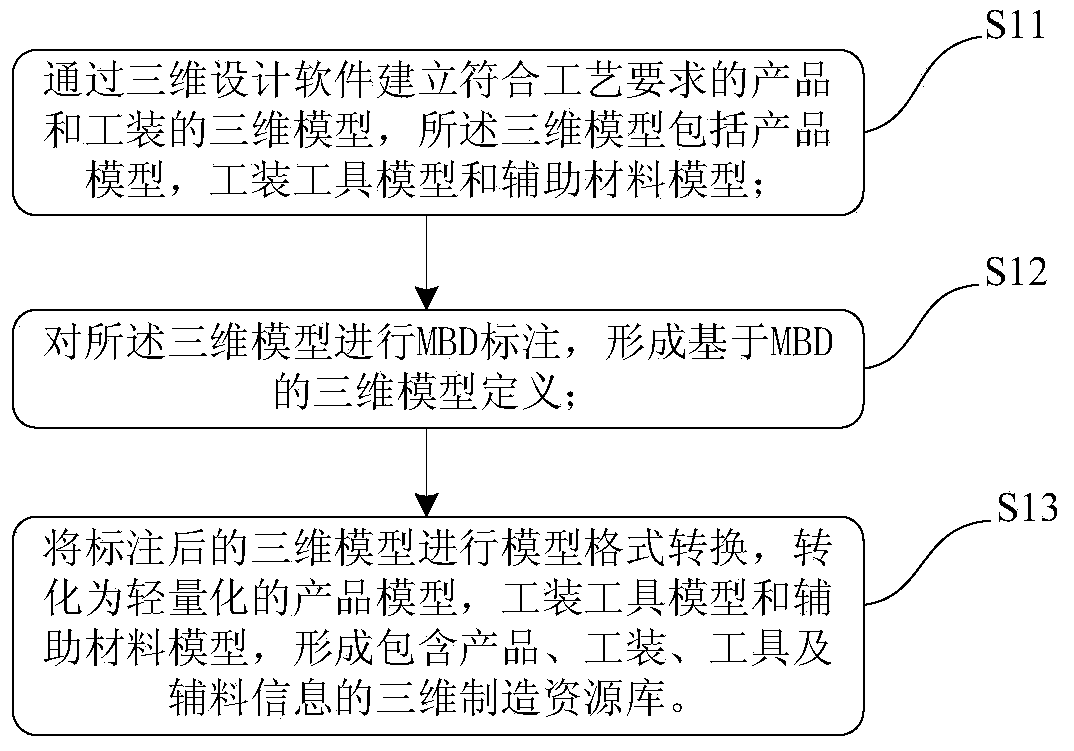

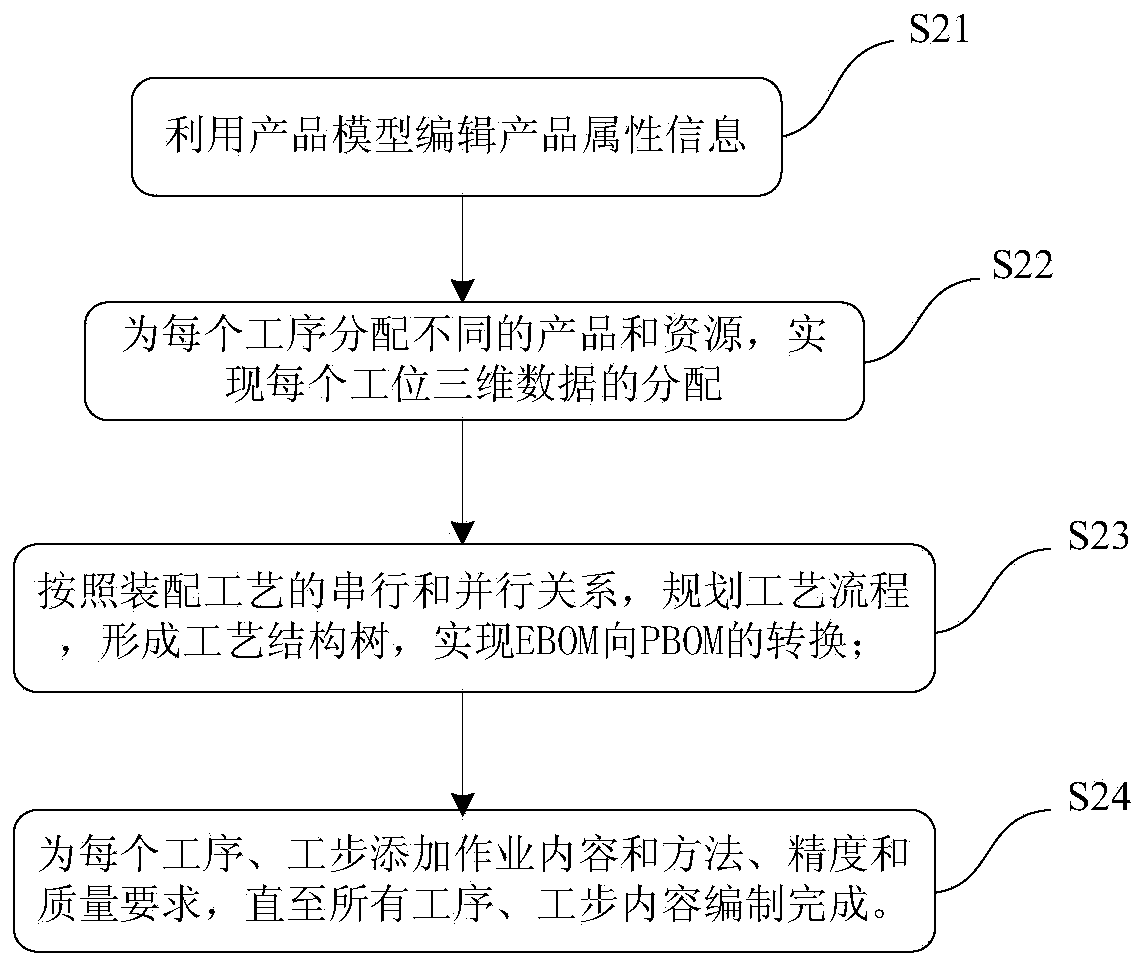

Three-dimensional assembly process generation method and system for aerospace product

InactiveCN103413004AAddressing the information gapAccurate visualizationAnimationSpecial data processing applicationsAnimationInformation gap

The invention provides a three-dimensional assembly process generation method and system for an aerospace product. The system comprises a three-dimensional manufacturing resource library building module, a three-dimensional assembly process design module, a three-dimensional assembly process simulation module and a three-dimensional assembly process release module, the three-dimensional manufacturing resource library building module is used for building a three-dimensional manufacturing resource library containing product, fixture, tool and auxiliary material information, the three-dimensional assembly process design module is used for decomposing process tasks and planning a process according to the built three-dimensional manufacturing resource library to form a process structure tree, the three-dimensional assembly process simulation module is used for building a virtual assembly environment and simulating and analyzing the assembly process according to a three-dimensional model, the assembly process and the process structure tree to form a three-dimensional assembly animation meeting actual assembly requirements, and the three-dimensional assembly process release module is used for integrating process design information and simulation information, forming a three-dimensional assembly process file and releasing the three-dimensional assembly process file to an assembly site. Accurate and visual three-dimensional visual means are provided for aerospace product assembly, so that the problem of information gaps among three-dimensional product design, three-dimensional process design and three-dimensional assembly site implementation in the prior art can be solved.

Owner:SHANGHAI JIAO TONG UNIV

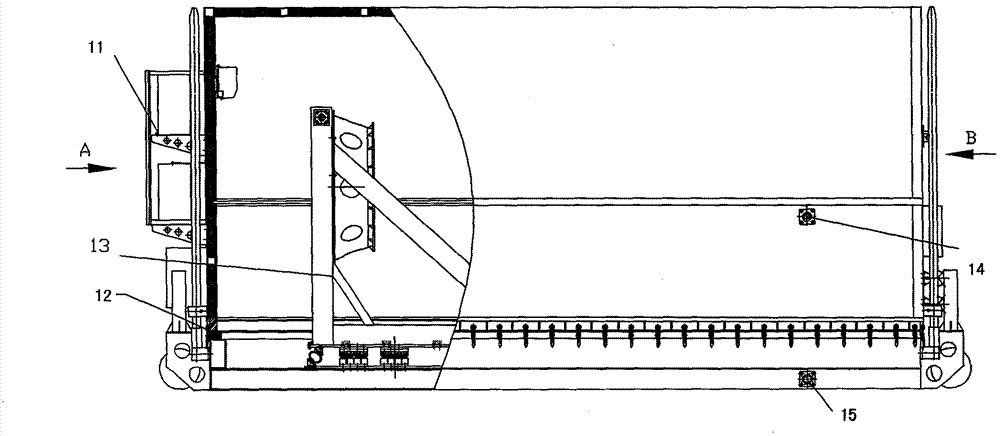

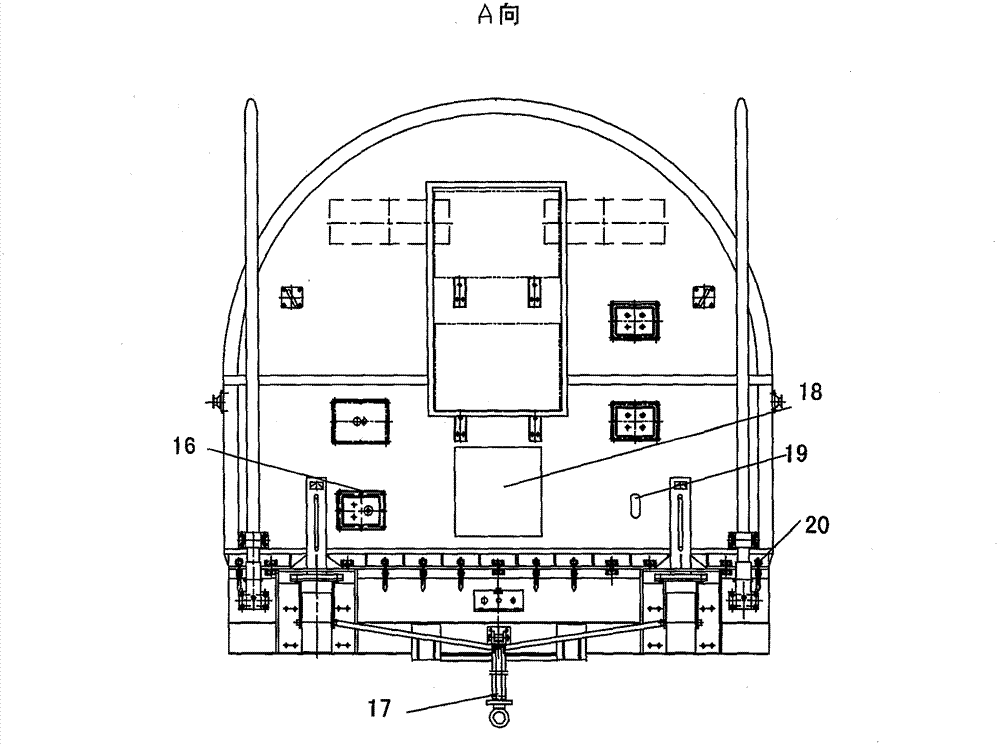

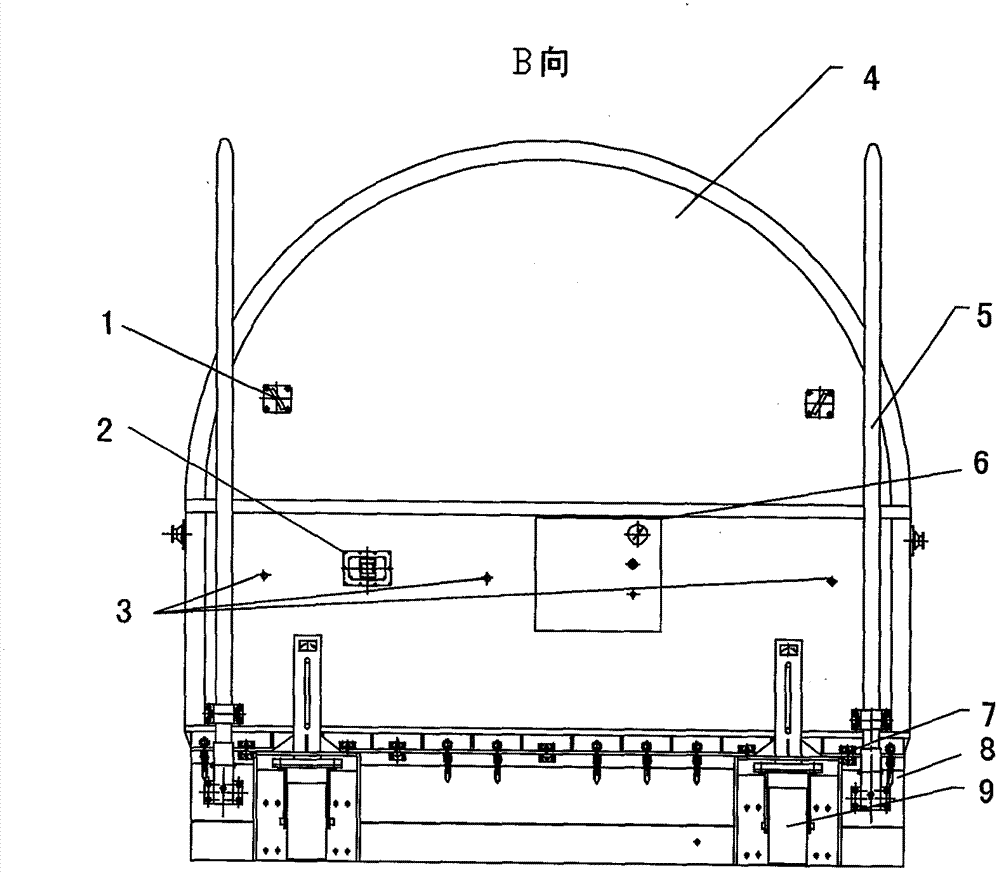

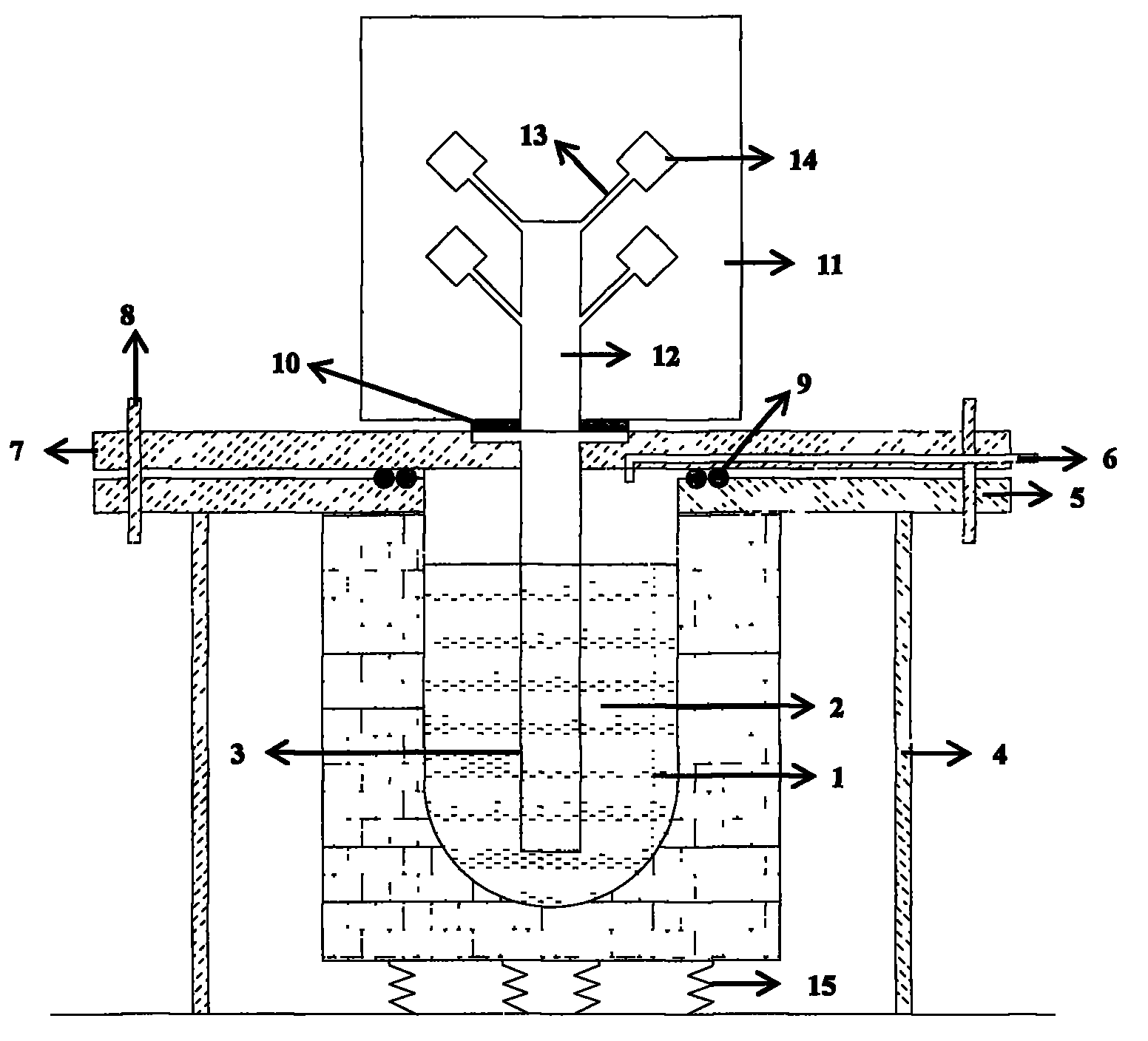

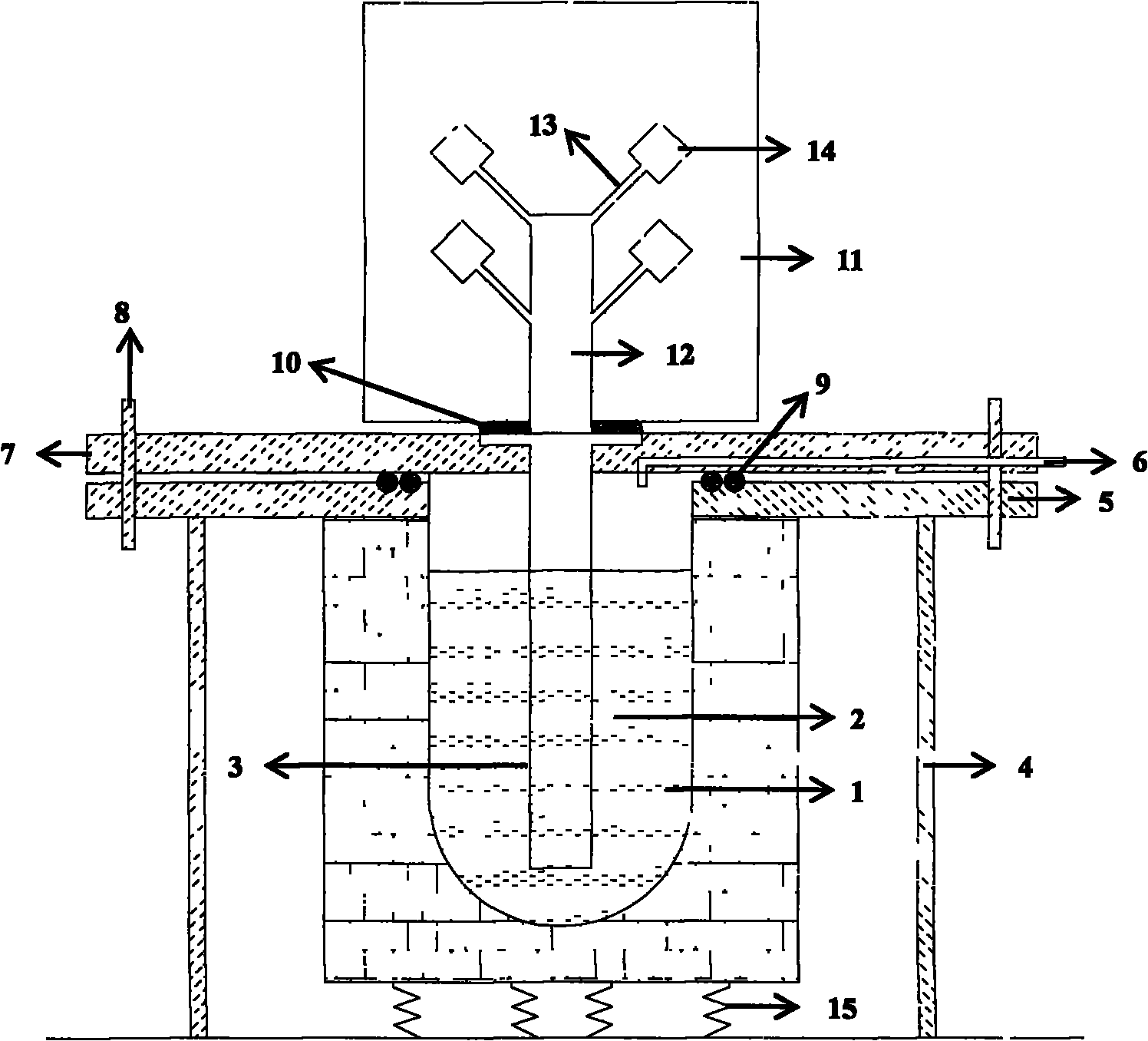

Universal transport packing case for remote sensing satellite

InactiveCN102774576AShorten assembly cyclePackaging vehiclesContainers for machinesData acquisitionEngineering

The invention discloses a universal transport packing case for a remote sensing satellite, which comprises a case cover and a case bottom, wherein an air conditioner, a temperature-humidity sensor, an inflatable / deflatable device capable of being automatically and / or manually inflated or deflated, hoisting points, transport fixing points and a data acquisition and control system are arranged on the case cover; a damping device is arranged on the inner side of the case bottom; an L-shaped bracket used during integrated satellite transport or a transport bracket used during subdivided transport, sensors comprising the temperature-humidity sensor and the like, and fans are arranged above the damping device; the data acquisition and control system is respectively and electrically telecommunicated with the temperature-humidity sensor, a pressure sensor, a vibration sensor, an impact sensor and the like, and is electrically telecommunicated with a remote control terminal so as to conveniently control the transport of the remote sensing satellite over a long distance in real time. The universal transport packing case for the remote sensing satellite can fulfill functions of highway transport, railway transport, system leakage detection and the like when different remote sensing satellites in integrated states or subdivided states are in various working conditions, the remote sensing satellites in the integrated states or the subdivided states can be highly reliably transported and the satellite development cycle is simultaneously shortened.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

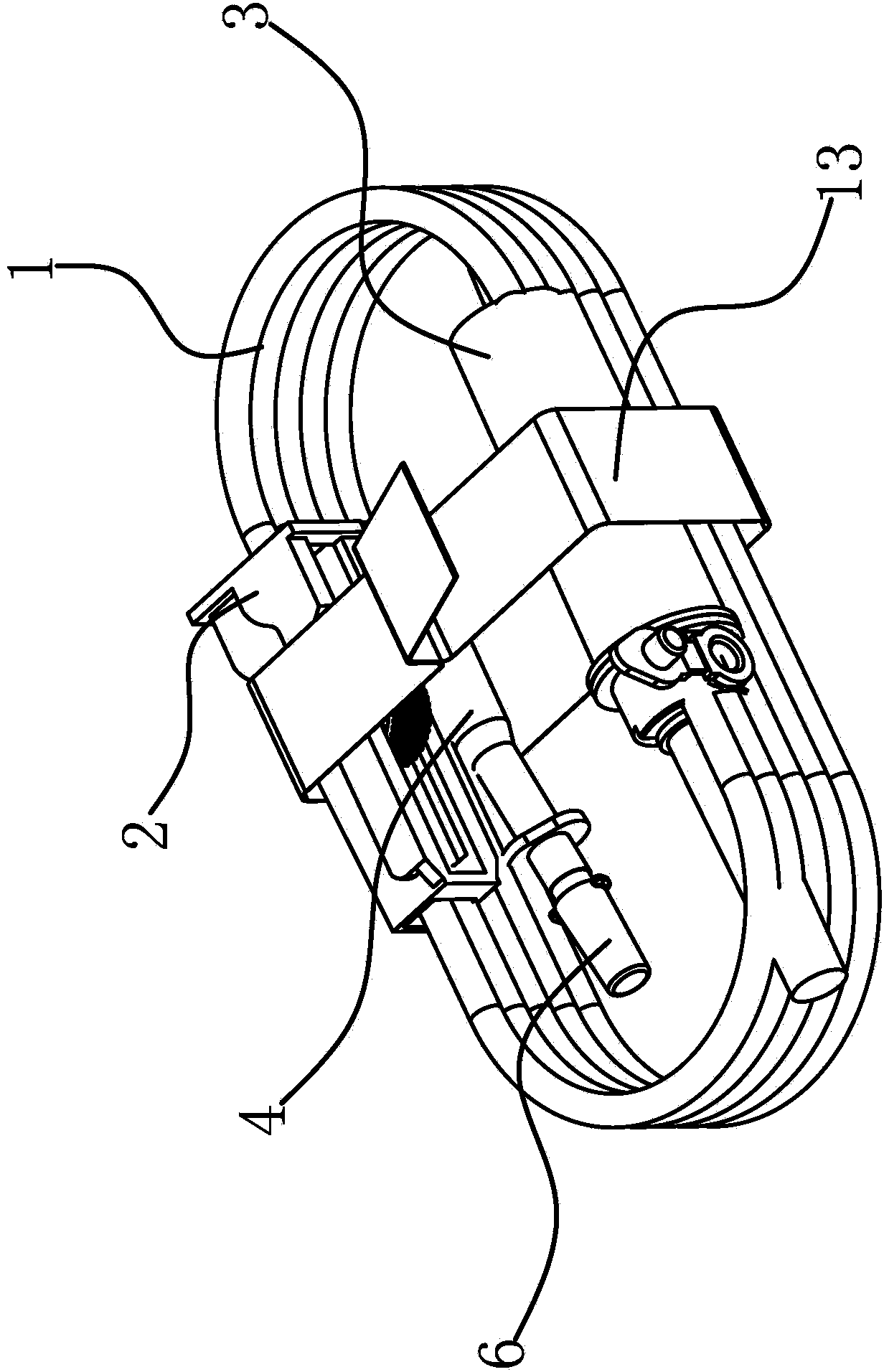

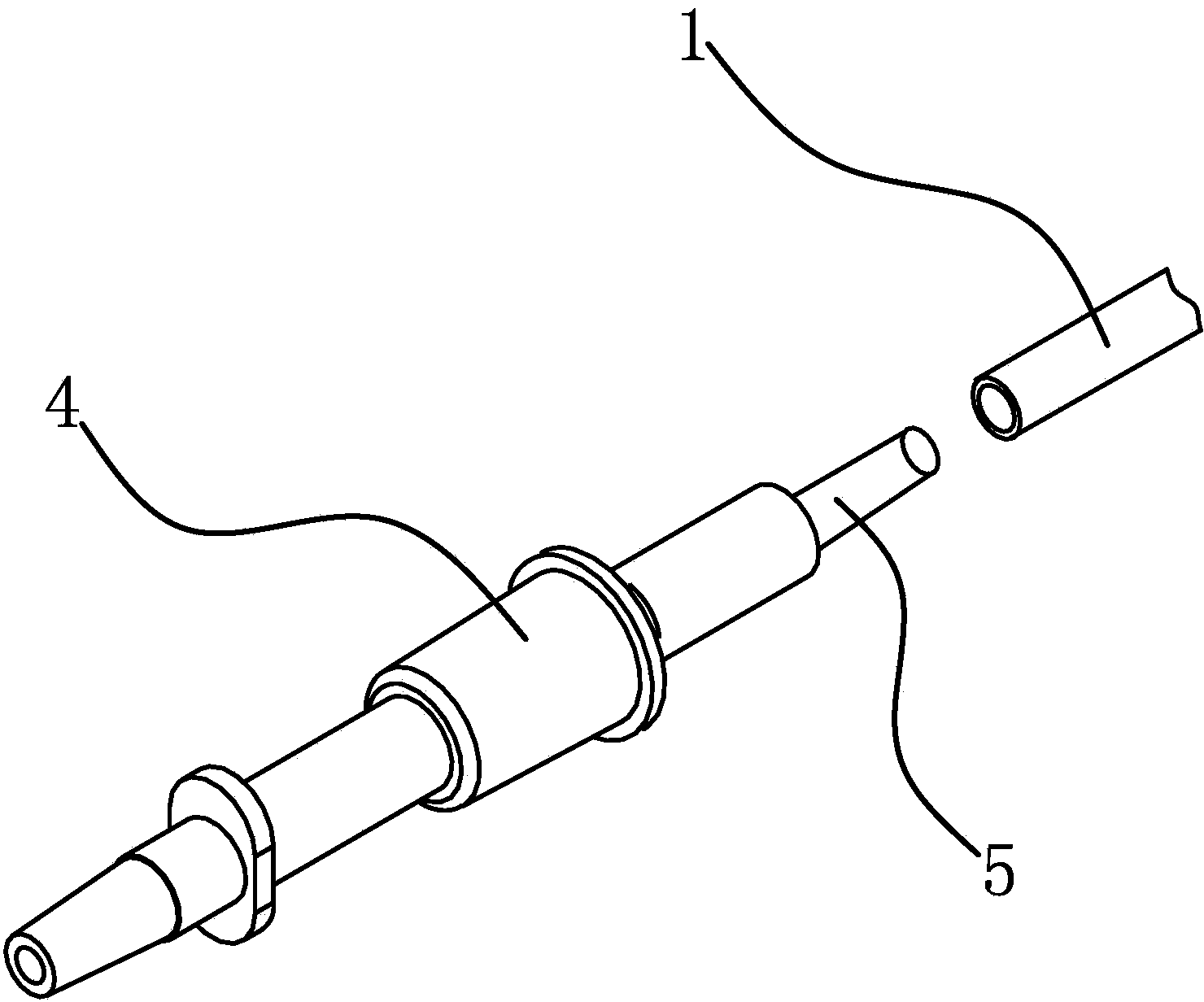

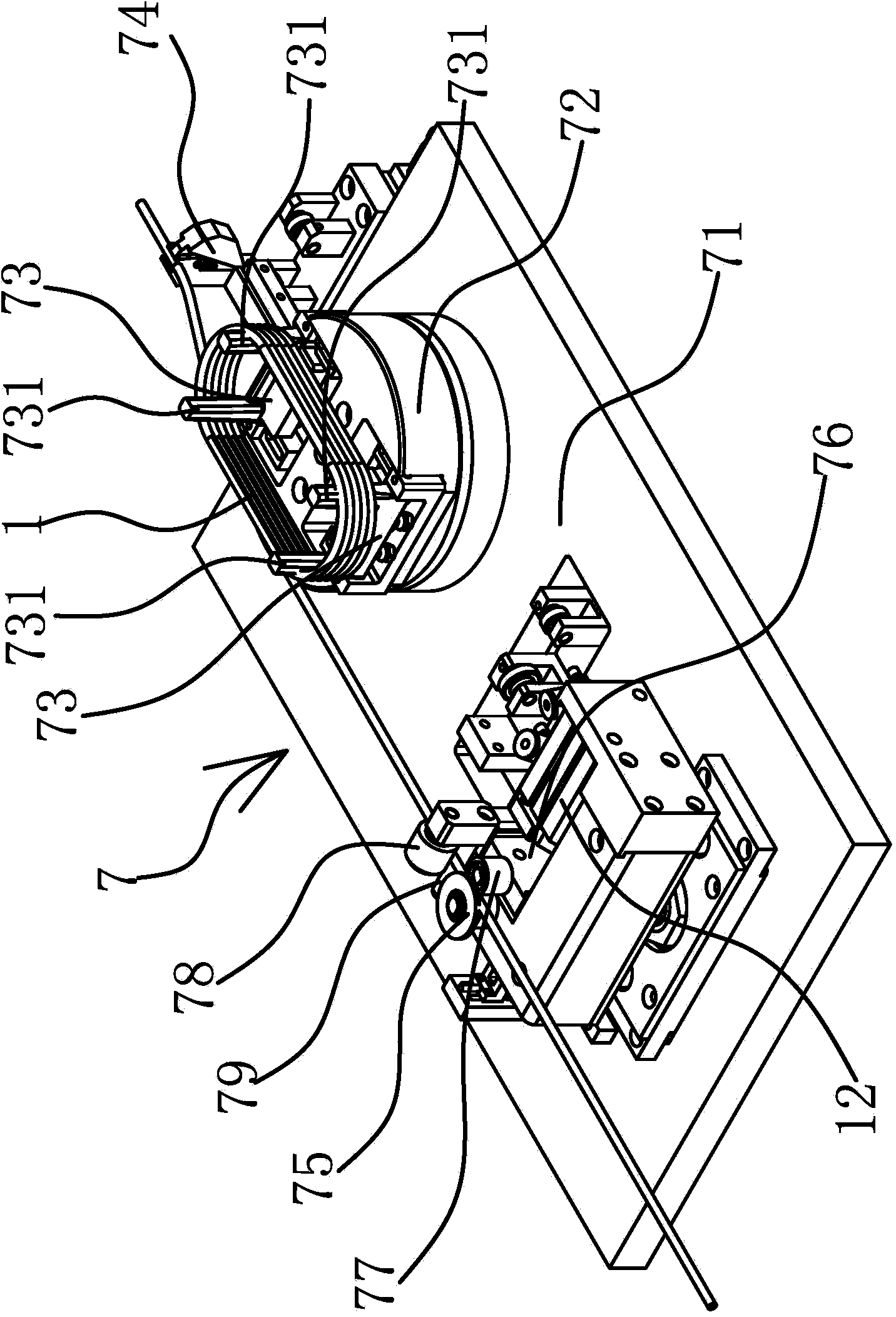

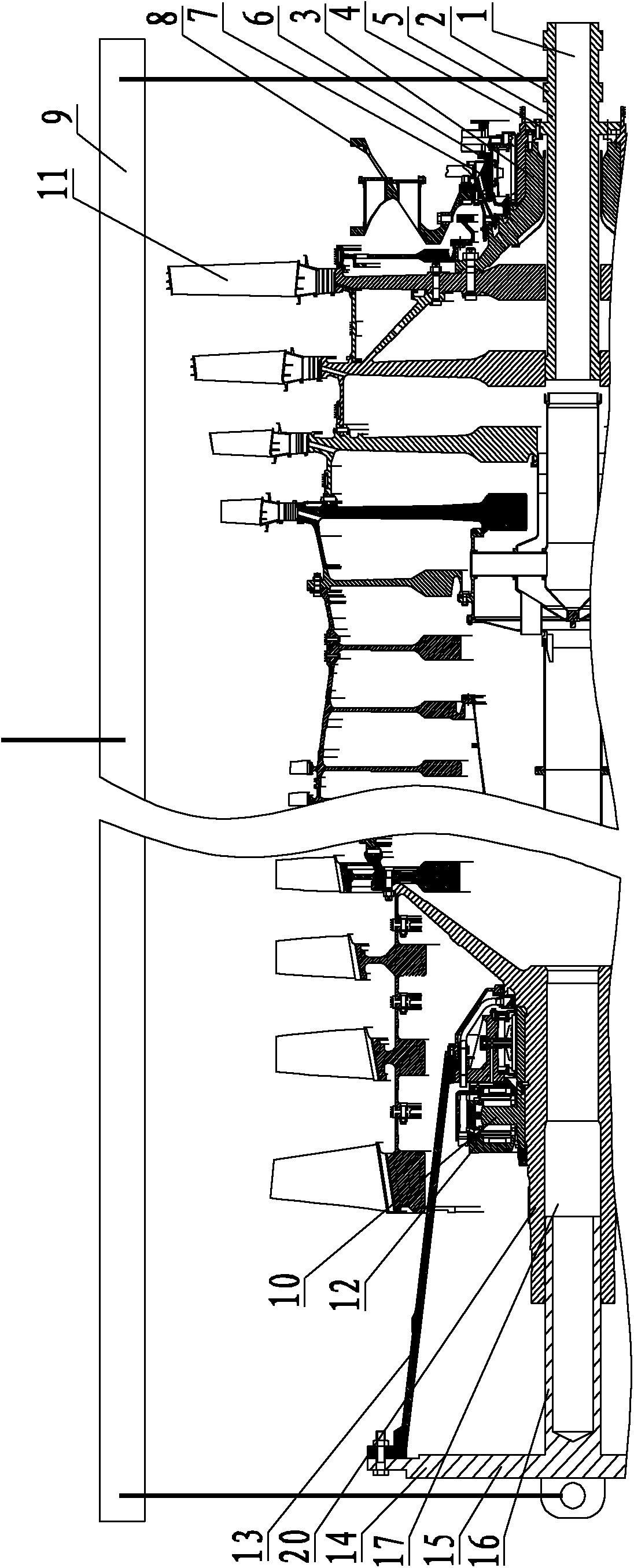

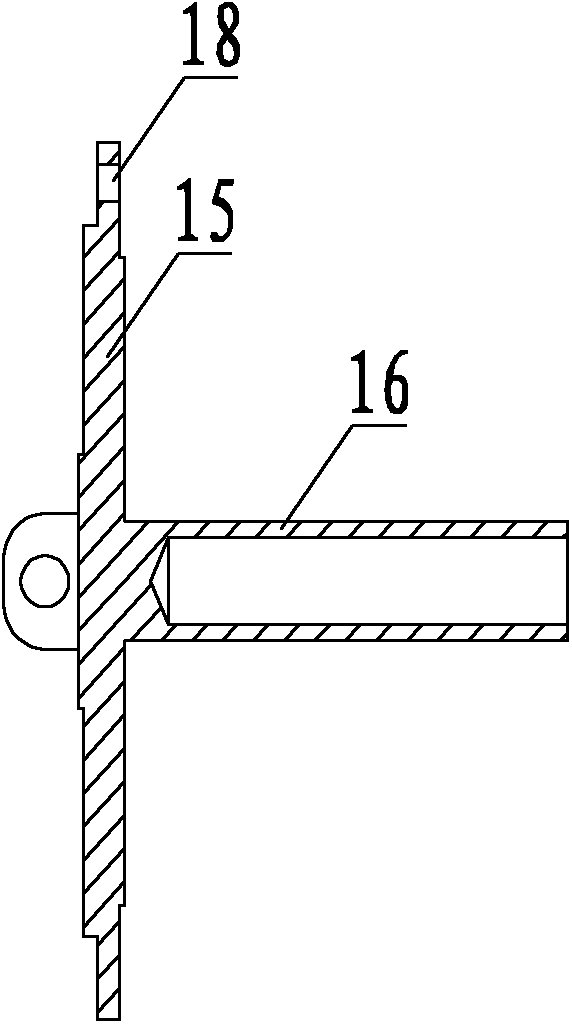

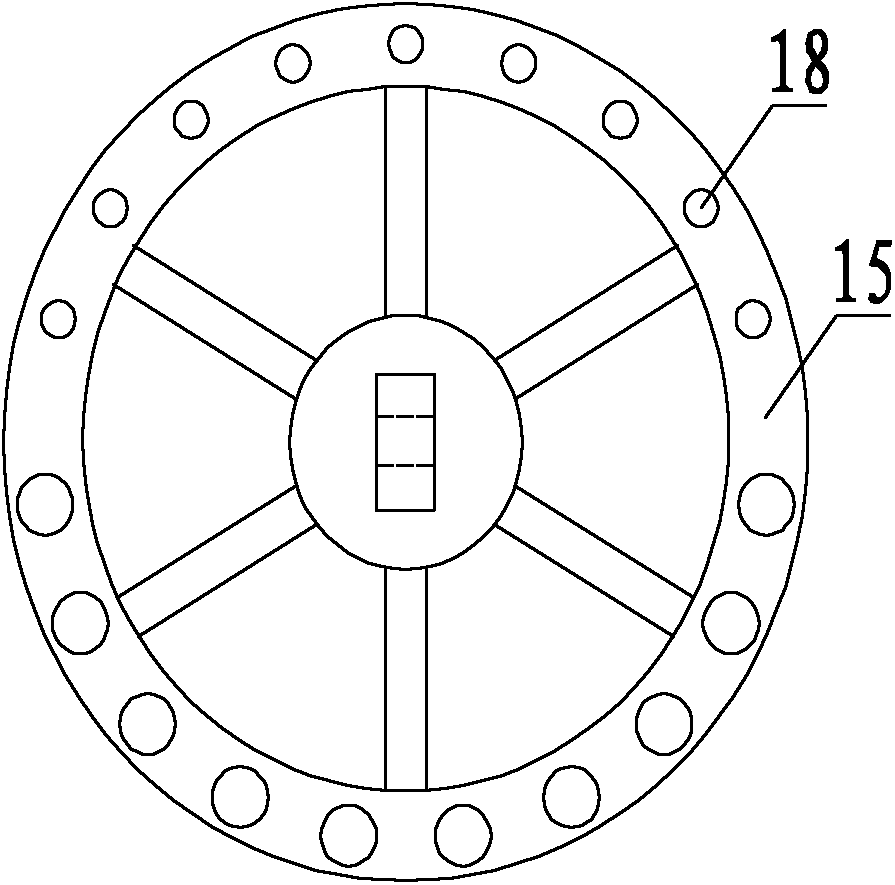

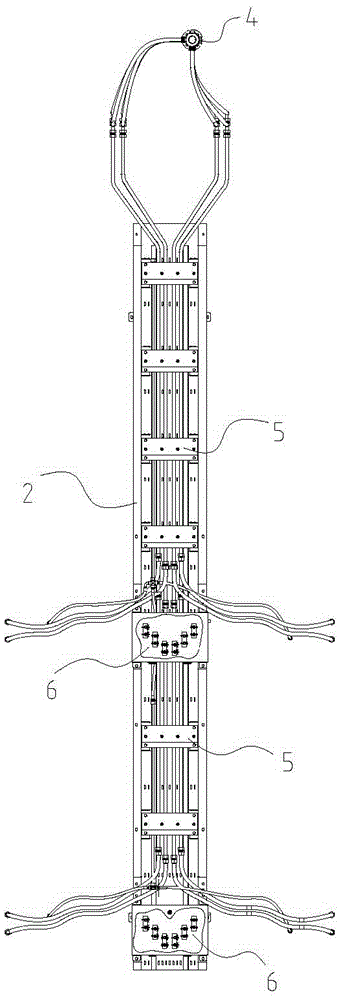

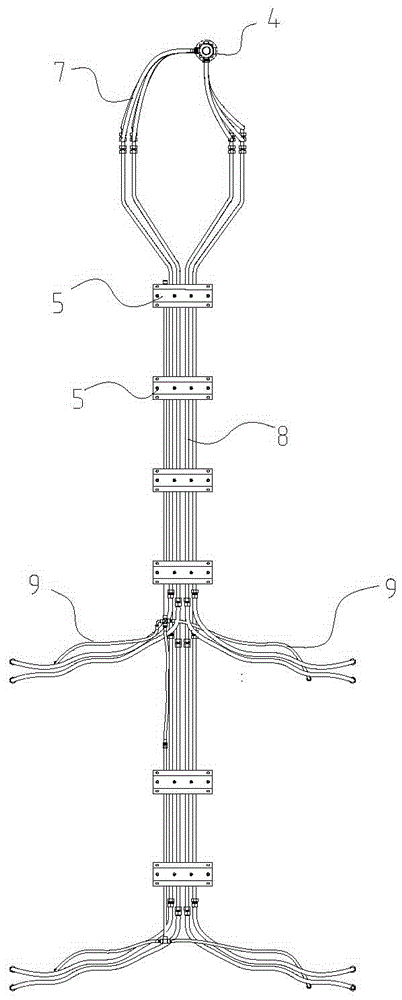

Automatic assembling process for infusion apparatus

The invention provides an automatic assembling process for infusion apparatus, and belongs to the technical field of medical instruments. The automatic assembling process for the infusion apparatus solves the problem that existing infusion apparatus is low in assembling efficiency. The process includes the following procedures, namely, a, medical catheter feeding, b, assembly of other components, c, finished product testing, and d, finished product discharging. According to the automatic assembling process, winding is carried out on medical catheter materials before assembling through a winding device, in addition, a medical catheter keeps in a winding state in the whole assembling process, therefore, the space occupied by the medical catheter is reduced, and feeding efficiency and assembling efficiency are improved. Due to the facts that the two end portions of the wound medical catheter are fixed in length, components on the left end portion and the right end portion of the medical catheter can be assembled at the same time, assembling efficiency is improved, and the assembling period of the infusion apparatus is shortened. In addition, the medical catheter is tied up through a band absorbing mechanism and a welding mechanism, and therefore the wound portion of the medical catheter will not disperse easily in the discharging and packaging process.

Owner:MAIDER MEDICAL IND EQUIP

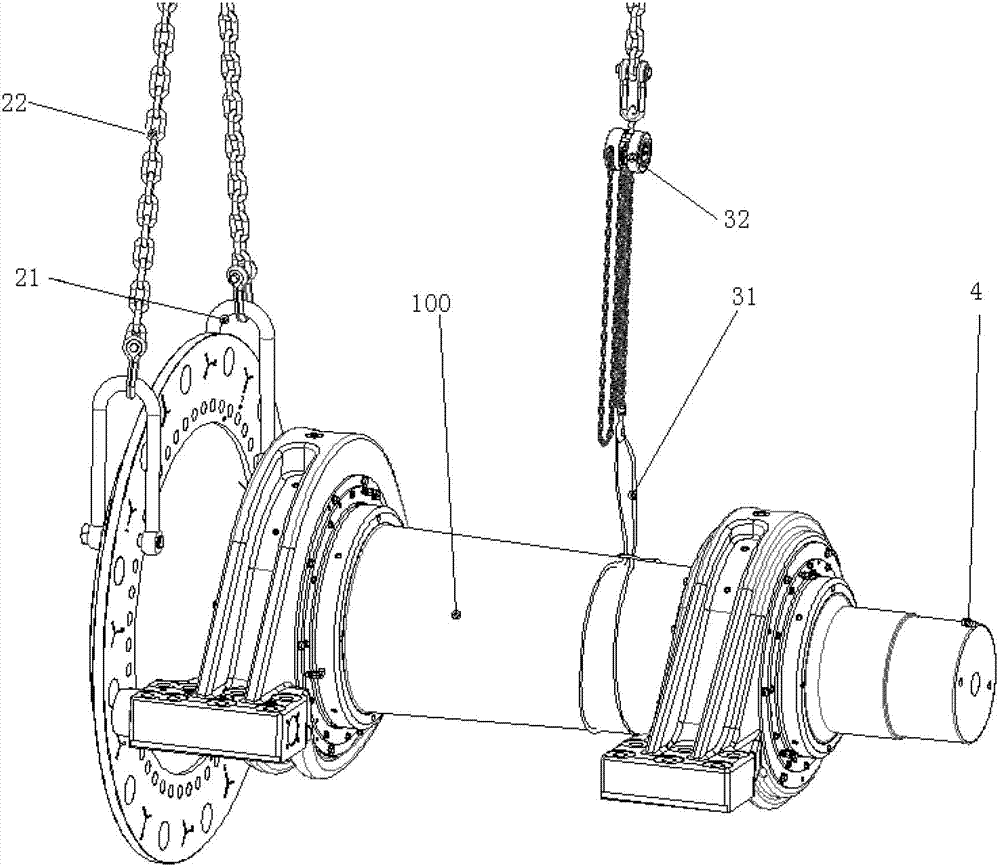

Heavy combustion engine assembling method for assembling rotor and front and rear supports in combining manner

ActiveCN102330605ASolve the problem of horizontal assemblyEasy to assembleGas turbine plantsJet propulsion plantsCombustionExternal combustion engine

The invention discloses a heavy combustion engine assembling method for assembling a rotor and a front and a rear supports in a combining manner, belonging to the technical field of combustion gas turbines. The heavy combustion engine comprises the steps of: vertically assembling a front bearing assembly and a front support cylinder into a front support, vertically assembling a rear bearing assembly and a rear support cylinder into a rear support; horizontally placing the rotor on a support base, horizontally arranging the front and the rear supports on the rotor, horizontally inserting a hollow shaft of a front hanging tool into a front shaft neck inner hole of the rotor; inserting a hollow shaft of a rear hanging tool into an rear shaft neck inner hole of the rotor of a combustion engine, vertically assembling an external stator assembly of the combustion engine, turning the external stator assembly to be in a horizontal state and then fixedly connecting with a combustion engine base, dismantling the upper half part of the external stator assembly; hoisting the front and the back of the rotor, hoisting the rotor with the front and the rear supports into the lower half part of the external stator assembly; fixedly connecting the front and the rear supports with the lower half part of the external stator assembly; and removing the front and the rear hanging tool and a rotor horizontal hanger, installing the upper half part of the external stator part, and horizontally assembling the rotor and the stator of the combustion engine.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

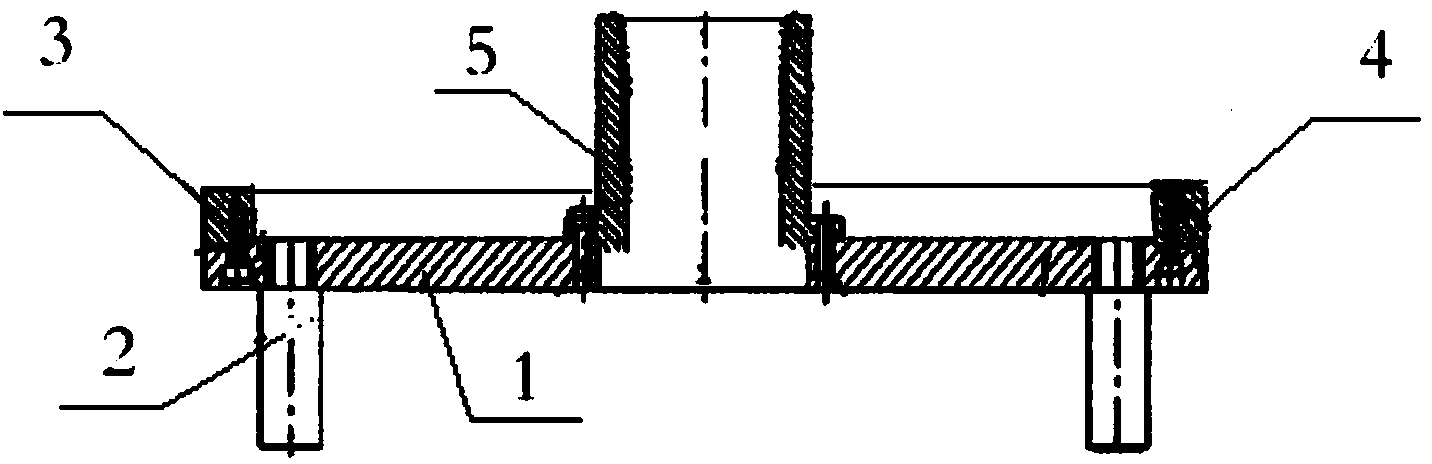

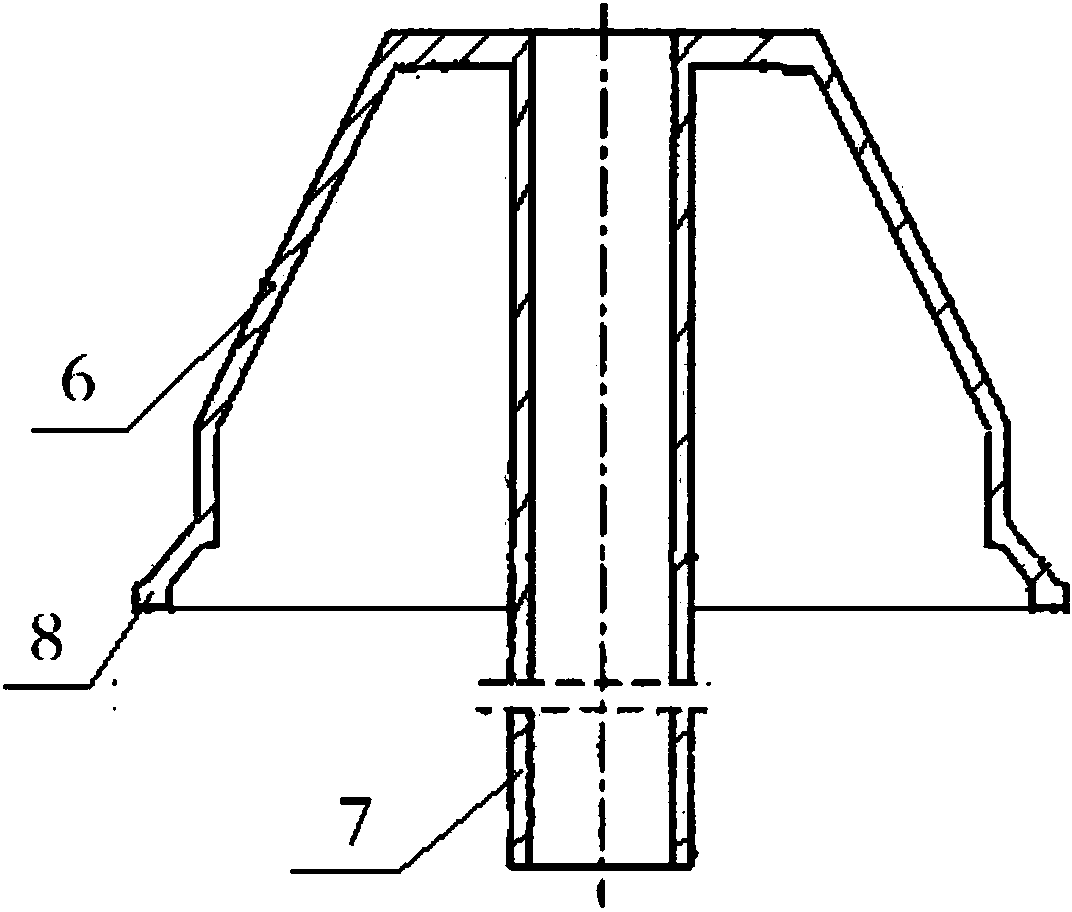

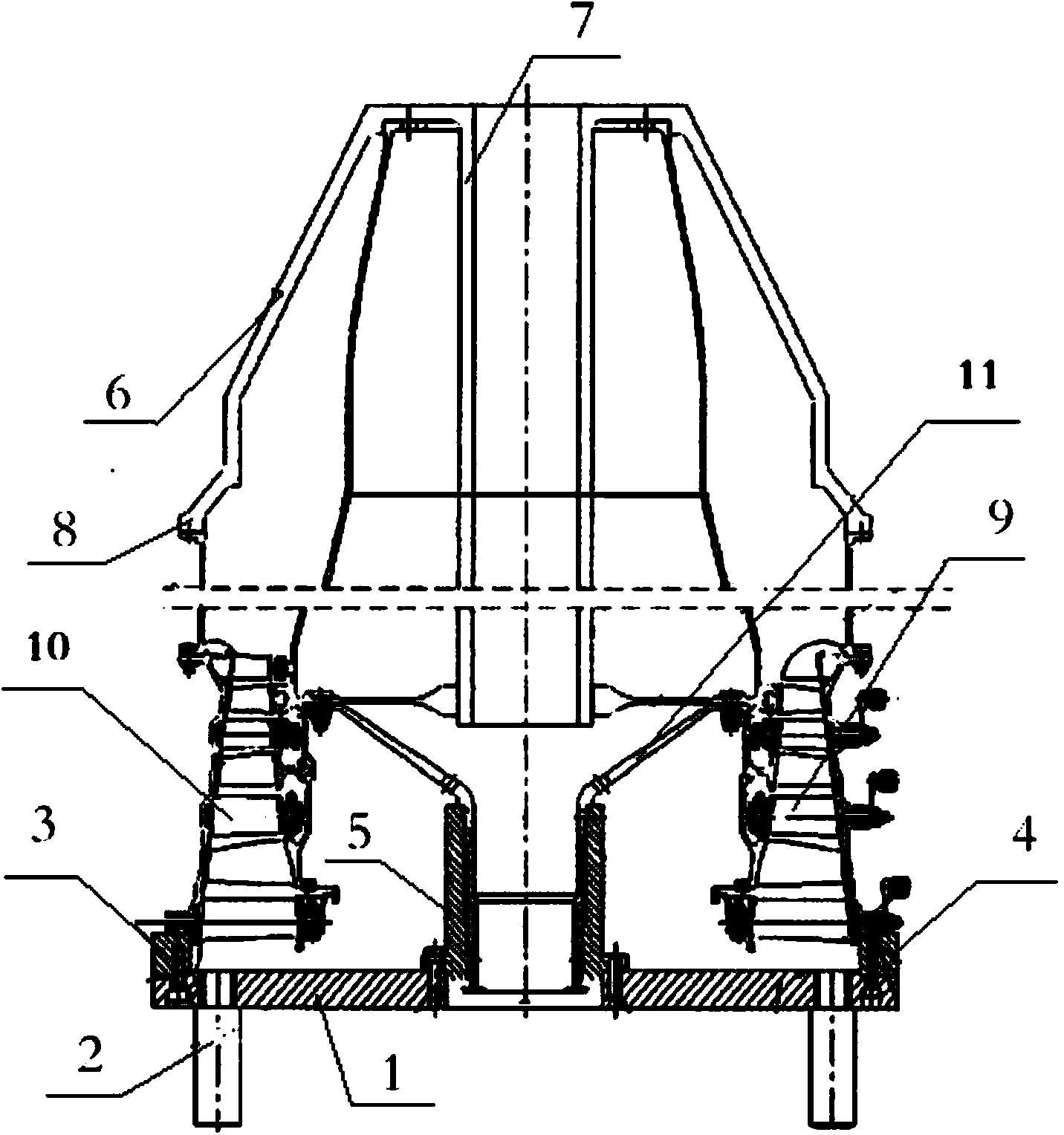

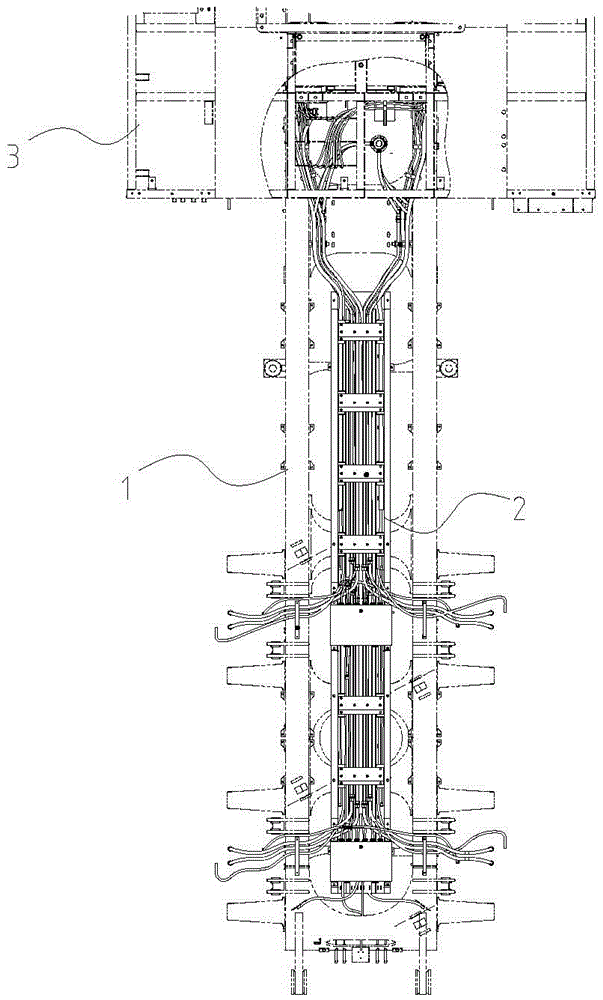

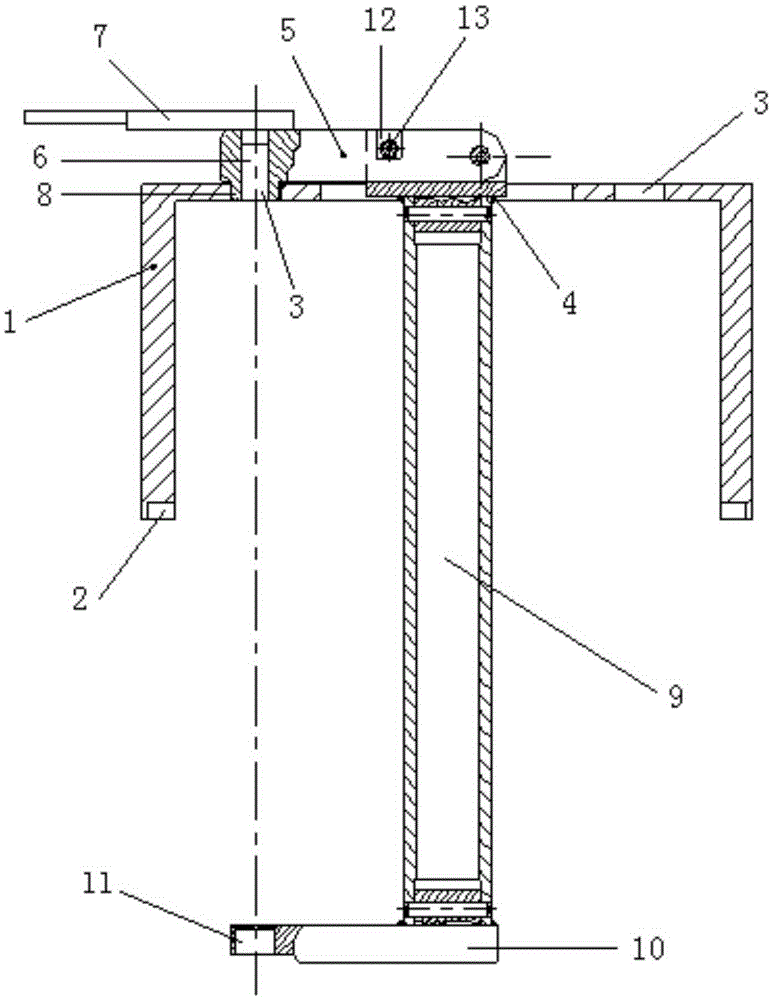

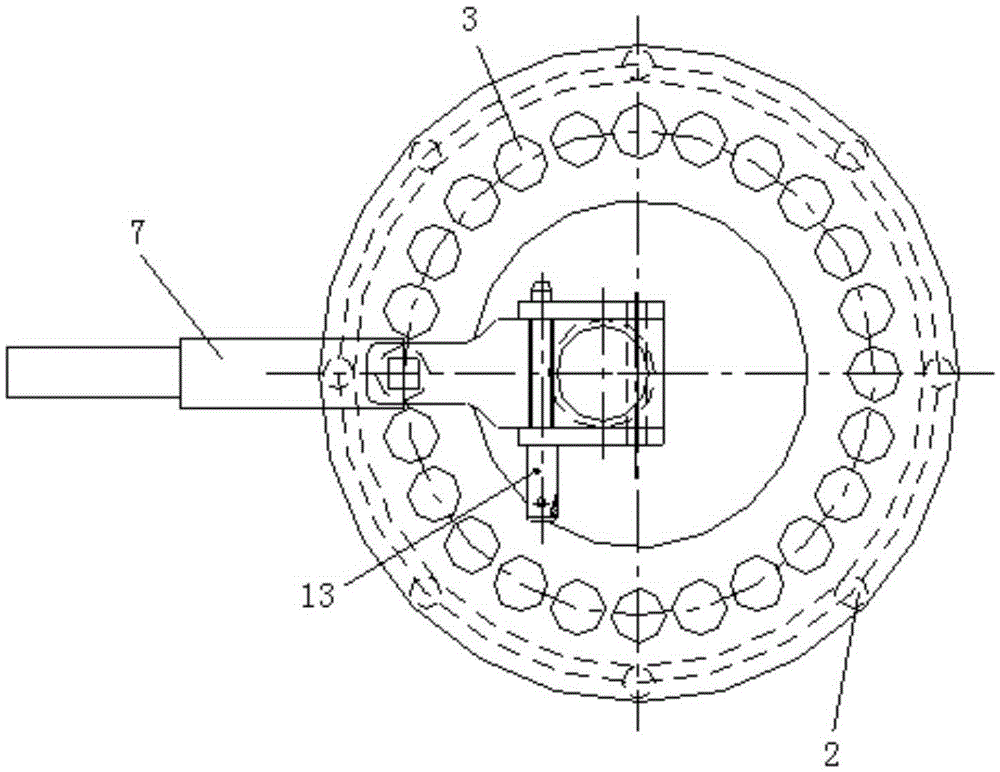

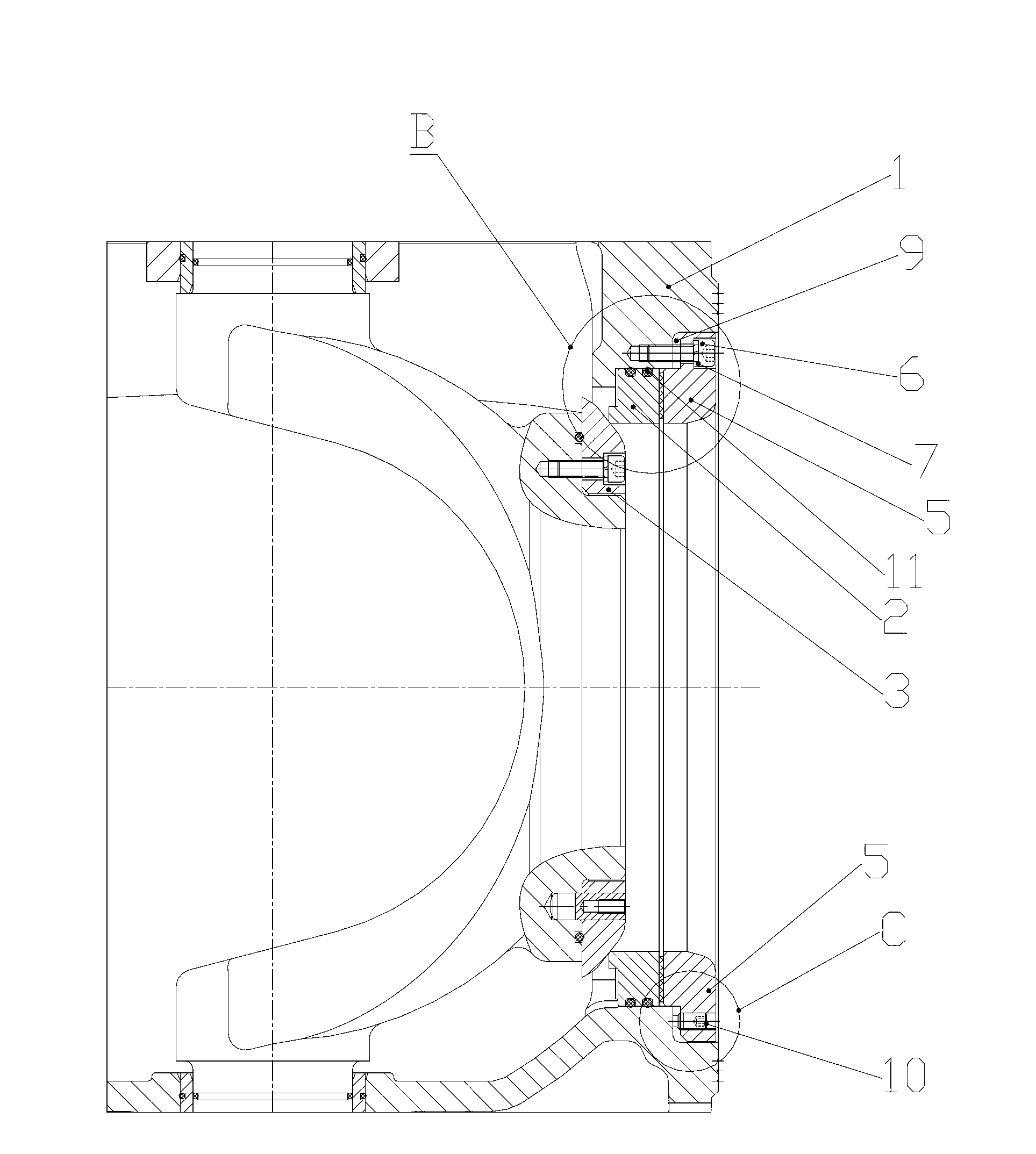

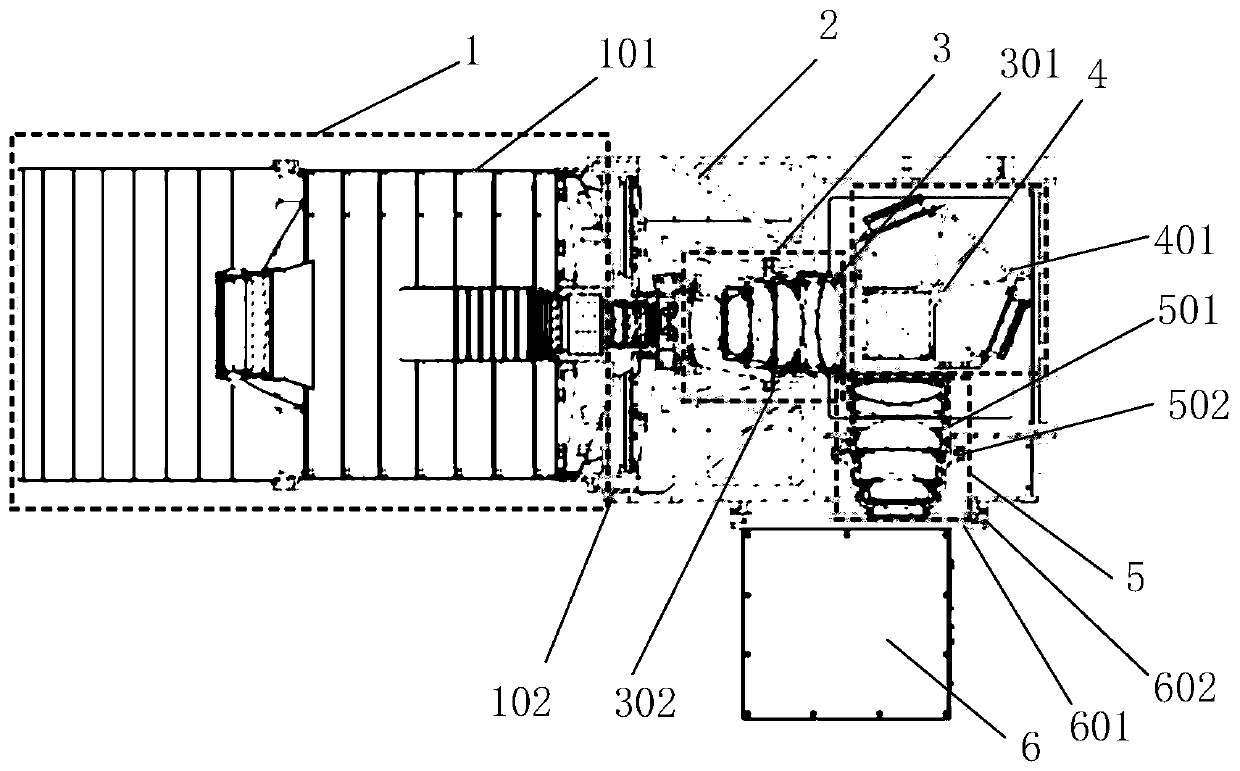

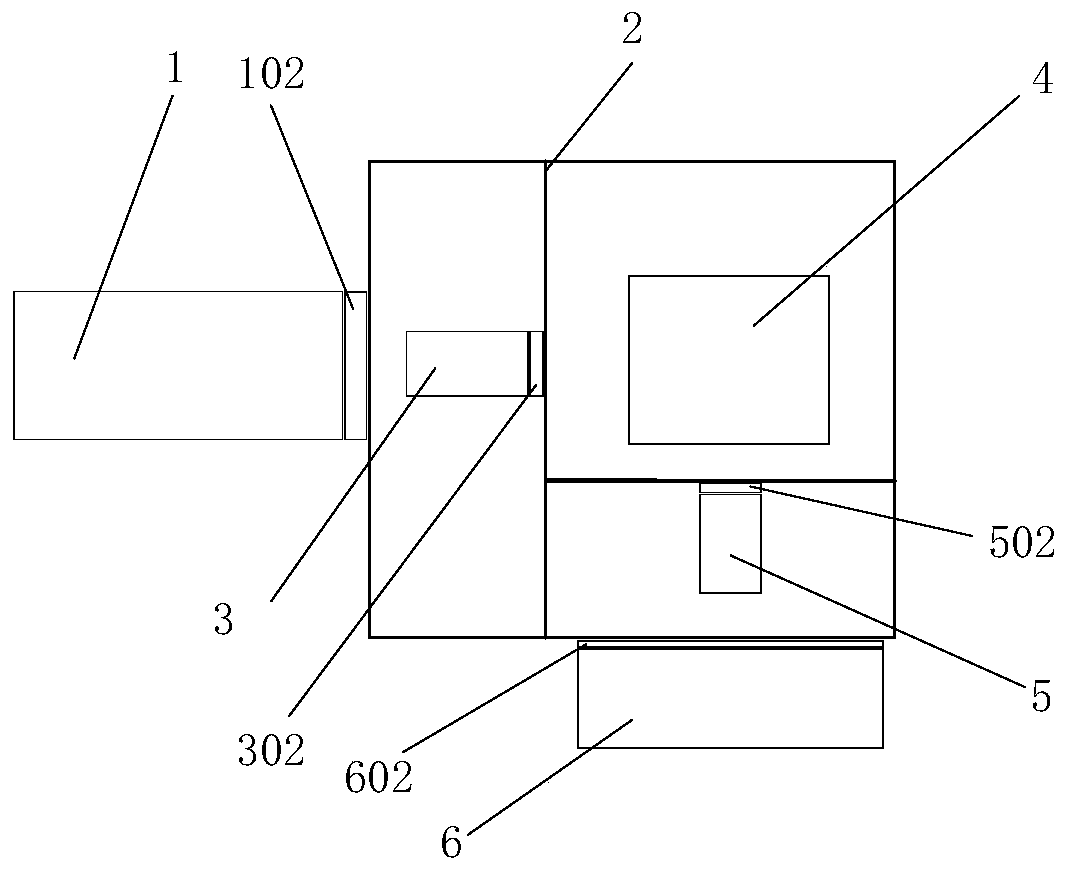

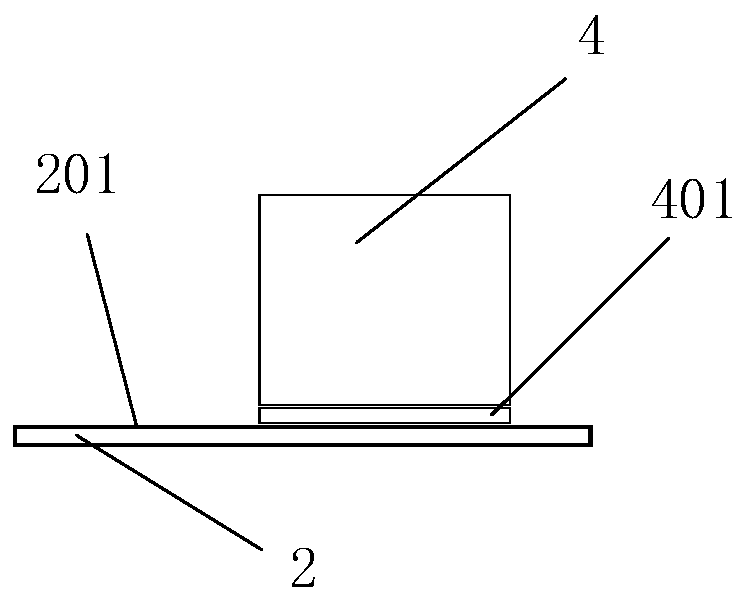

Axial-flow compressor unit body component assembling device and method

ActiveCN103586827AShorten assembly cycleReduce reassembly timesMetal-working hand toolsAxial compressorEngineering

The invention relates to an axial-flow compressor unit body component assembling device and method. According to the technical scheme, the axial-flow compressor unit body component assembling device comprises a base and a centering mechanism, wherein the base comprises a disc, supporting legs, a first positioning semiring, a second positioning semiring and a positioning sleeve, the supporting legs are arranged below the disc, and the first positioning semiring, the second positioning semiring and the positioning sleeve are arranged on the disc; the centering mechanism comprises a hollow shaft and a positioning cover, the hollow shaft is arranged in the center of the positioning cover, and the outer edge of the positioning cover is provided with a positioning edge. According to the technical scheme, conformity between axial clearance and radial clearance between a rotor and a stator of an axial-flow compressor and technical requirements can be check in advance, the axial-flow compressor is installed on an aircraft engine in the mode of an axial-flow compressor unit body component, the number of times for repeated assembly is reduced, and the assembly period of the aircraft engine is shortened.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for lifting whole steel structure to top of concrete cabin through slip form and low-altitude modular assembly

InactiveCN103510736AIncrease the construction work areaShorten assembly cycleBulk storage containerFalseworkEngineering

The invention discloses a method for lifting whole steel structure to the top of a concrete cabin through a slip form and low-altitude modular assembly. The method comprises the steps of assembling oblique beam units, assembling steel ring beams, assembling a slip form device, erecting a support ring beam scaffold platform, hoisting the steel ring beams, mounting the oblique steel beams, mounting a structure on a cabin top ring beam, hoisting the slip form system, and the like. As module units are assembled on the ground at the same time, the construction working area is increased, the assembling period is shortened, and the constriction duration is effectively shortened. Temperature and wind load influences when the unassembled large steel structure is assembled and measured at high altitude are reduced, the assembling precision is improved, and the engineering quality is ensured. As a great quantity of scaffolds are reduced duo to low-altitude assembling, and only a small quantity of simple scaffolds are needed to be erected, the mounting requirements can be met; meanwhile difficulty in high-altitude working, assembling and hoisting are reduced, and the security risk is effectively lowered.

Owner:成军

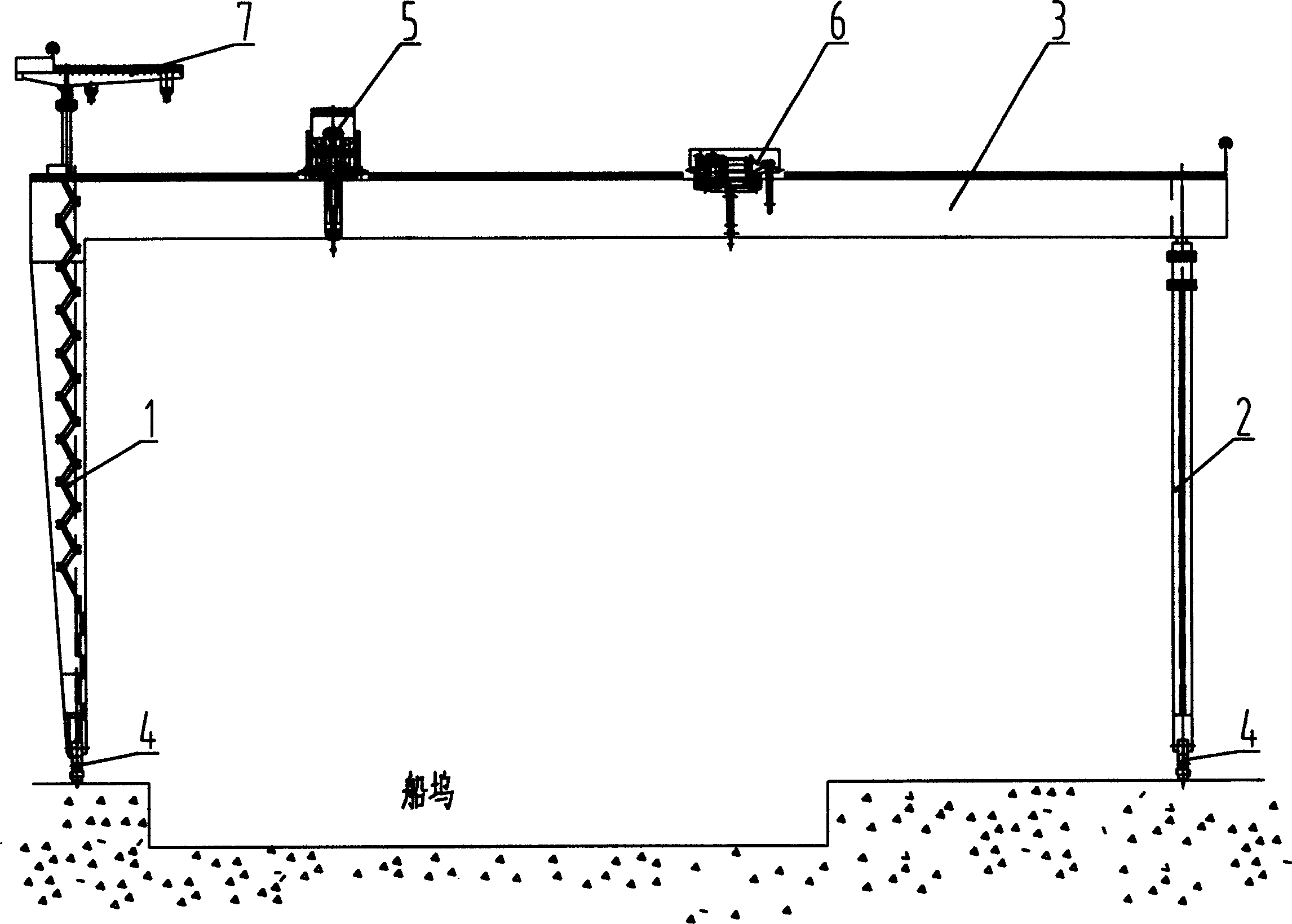

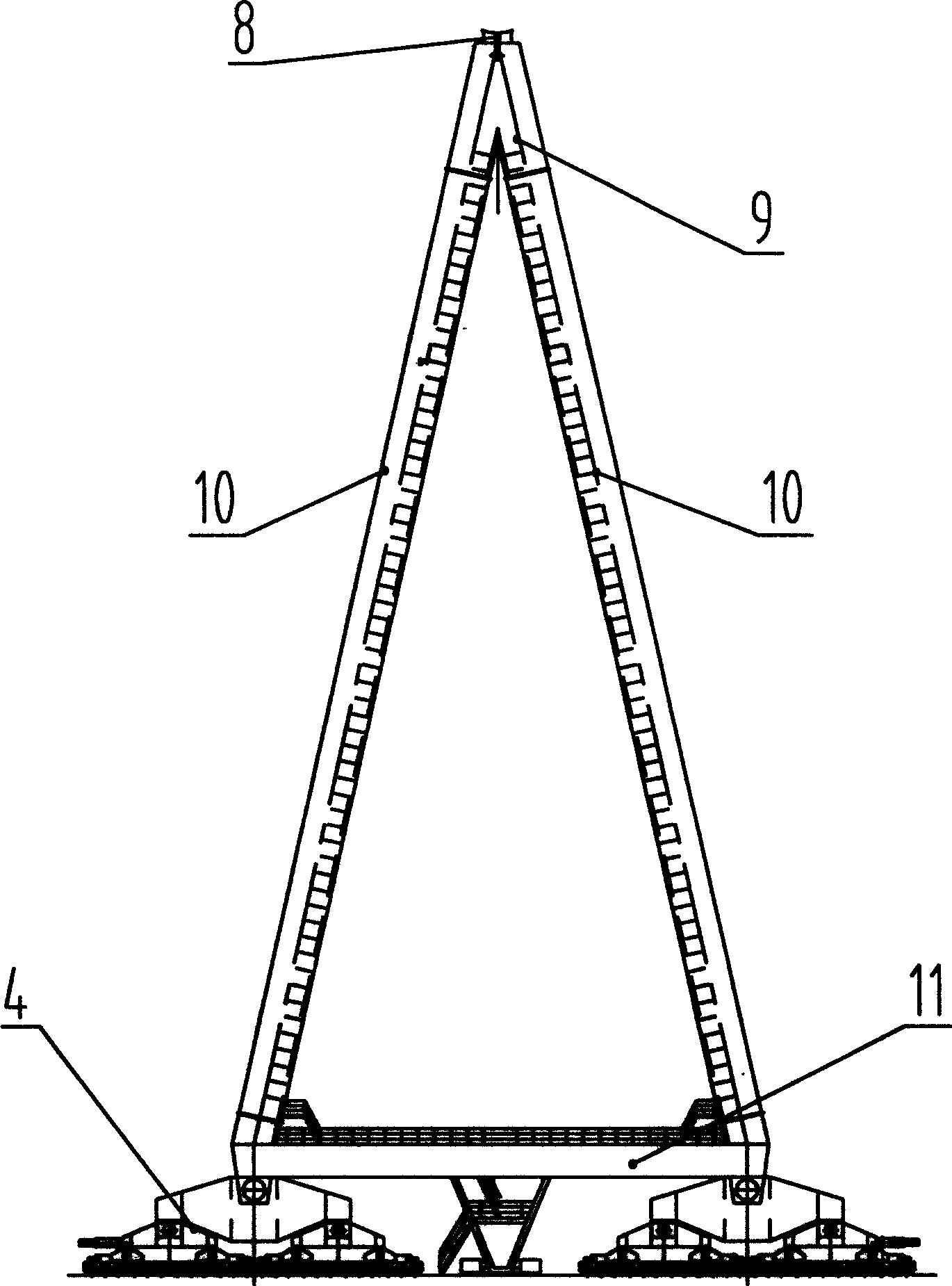

Method and apparatus for assembly of portal crane in shipbuilding

InactiveCN1463908ASolve the problem of insufficient bearing capacity of the structureEasy to useTrolley cranesButt jointEngineering

The assembling method and apparatus for ship-making portal crane features that the crossbeam rigid leg section and the flexible leg section with crossbeam raising system installed in the top are buttjointed to erected rigid leg and flexible leg; that the sections to be butt jointed are raised with the rigid leg and the flexible leg as support and hydraulic oil cylinder as raising sustained center; and that the butt joint seam is regulated by means of the hydraulic balance oil cylinder and balance twisted steel cable of the flexible hinge balance corbel system during the assembling. The saidassembling process has accurate regulation, convenient balance capacity configuration and easily controlled balance, and is stable and safe. The present invention is suitable for the assembling of large portal crane.

Owner:SHANGHAI PORT MACHINERY HEAVY IND +1

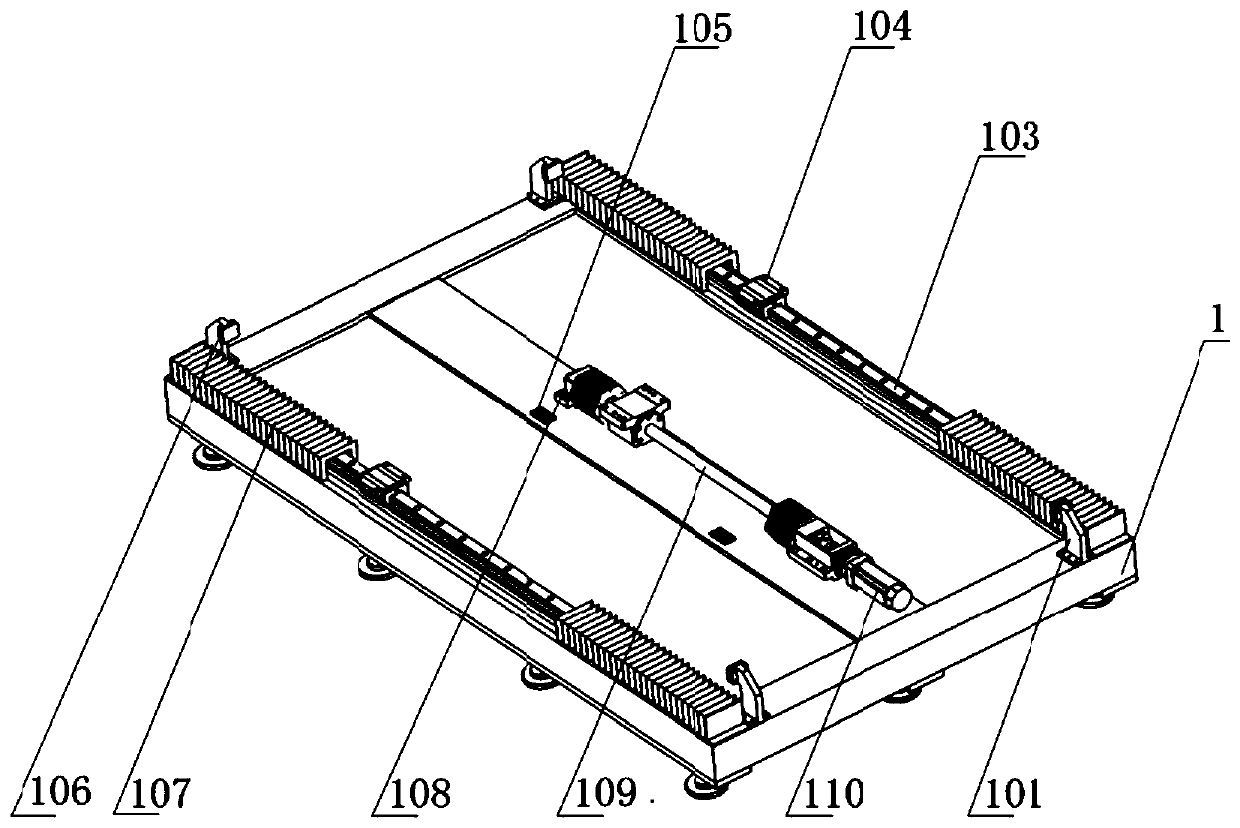

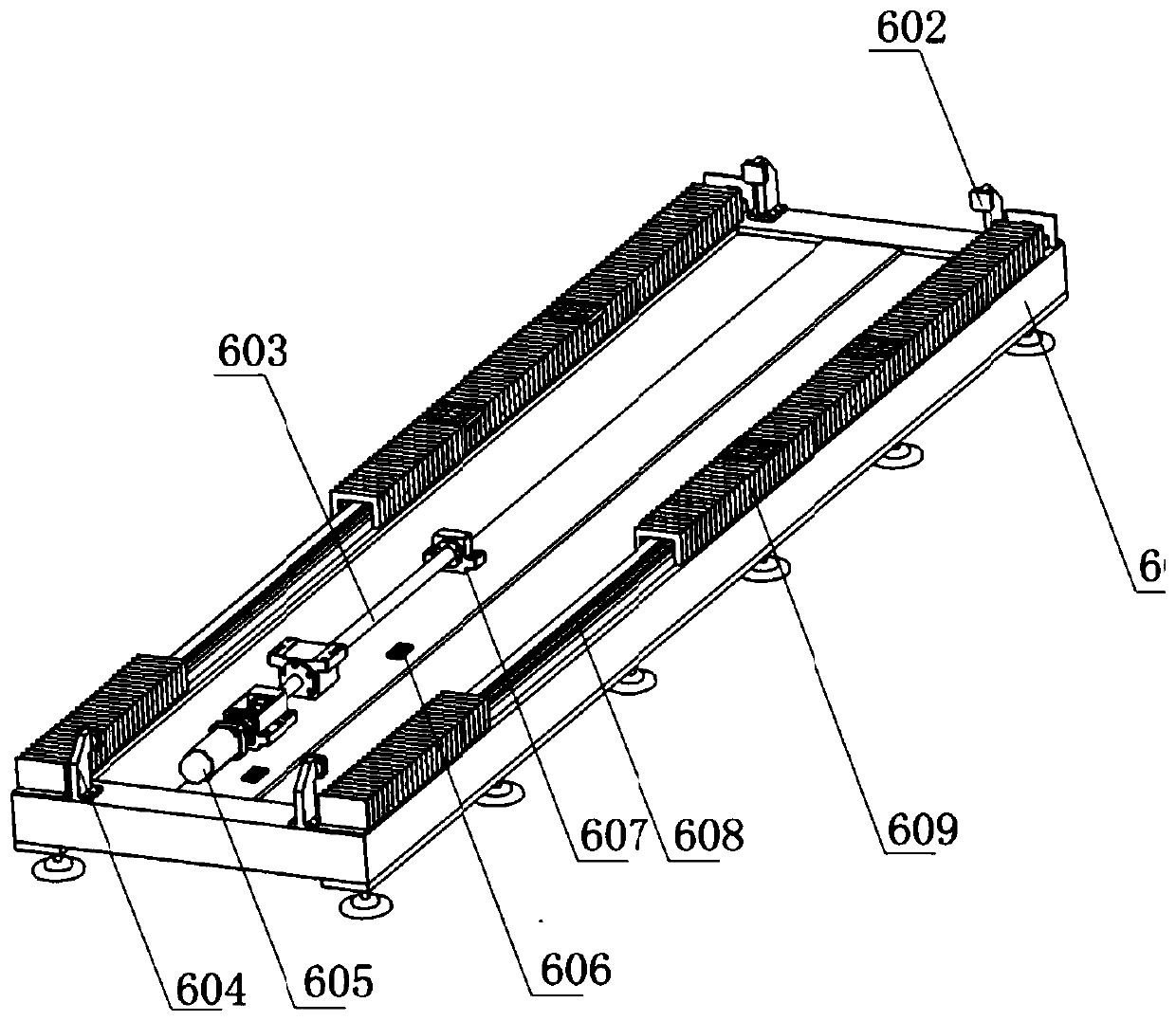

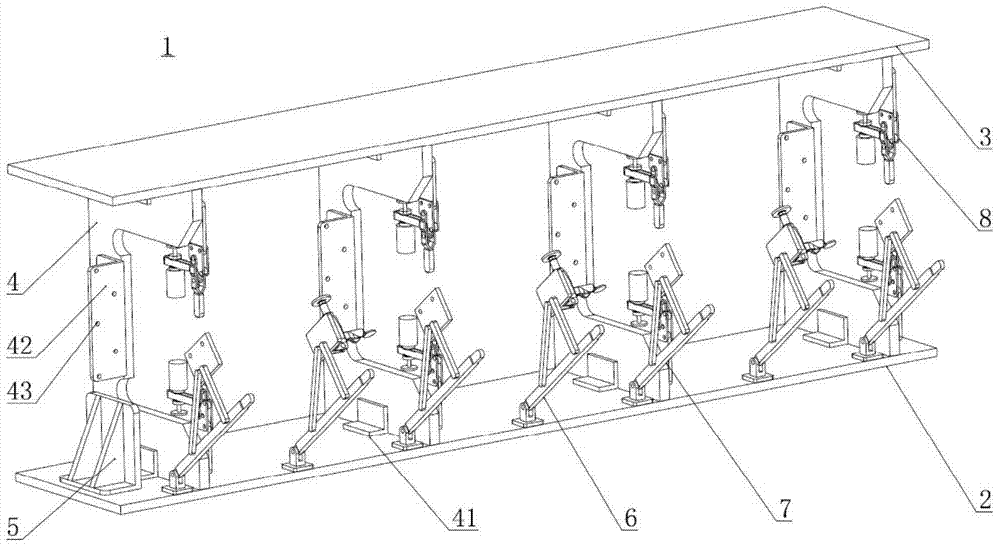

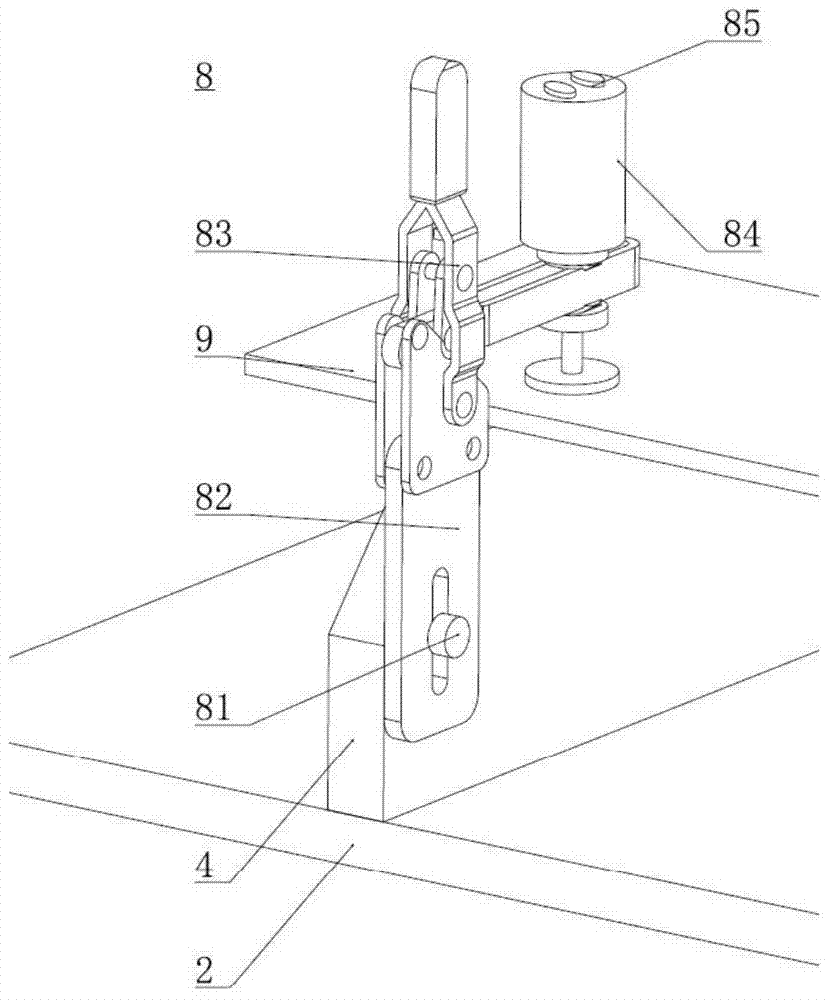

Flexible wallboard assembling tool

InactiveCN110920927AReduce the number of toolingShorten production preparation cycleAircraft assemblyAirplaneWall plate

The invention discloses a flexible wall plate assembling tool e, which belongs to the technical field of aircraft digital assembly. The tool comprises a base provided with a processing station, an assembly station and a drilling station, and an X-direction sliding table which is arranged on the base, slides between the processing station and the assembly station, is movably arranged on the base along the X direction, and is provided with a skin adsorption unit for fixing a skin; a Y-direction sliding table which slides between the assembly station and the drilling station; a base which is movably mounted on the base along the Y direction; wherein the Y-direction sliding table is provided with a wall plate frame positioning assembly for fixing the wall plate frame. The wallboard frame positioning assembly comprises a plurality of positioners which are oppositely arranged, each positioner comprises a fixing frame which is connected with the wallboard frame and has three-axis freedom degrees, an X-direction driving mechanism, a Y-direction driving mechanism and a Z-direction driving mechanism, and the X-direction driving mechanism, the Y-direction driving mechanism and the Z-directiondriving mechanism are used for driving the fixing frames and used for adjusting the position of the wallboard frame. Based on digital control technology, compared with a positioning mode of a traditional rigid tool, the digital positioning precision is greatly improved.

Owner:ZHEJIANG UNIV +1

Construction method of main beam of steel-concrete composite beam cable-stayed bridge

ActiveCN109972517ASolve the lifting installationSolve walkingBridge erection/assemblyCable stayedEngineering

The invention discloses a construction method of a main beam of a steel-concrete composite beam cable-stayed bridge. The construction method comprises the steps: a wall-attached crane is mounted on acable tower, and initial section steel beams are hoisted by the wall-attached crane and fixed; the wall-attached crane hoists a first deck crane onto the initial section steel beams, unit splicing section steel beams are hoisted by the first deck crane and fixed to the two ends of the initial section steel beams, the first deck crane moves forwards onto the unit splicing section steel beams at oneends of the initial section steel beams, and the wall-attached crane hoists a second deck crane onto the unit splicing section steel beams at the other ends of the initial section steel beams; and the first deck crane and the second deck crane move forwards to splice the steel beams extending towards bridge side-span sections and the steel beams extending towards bridge mid-span sections and close the steel beams on the side-span sections and the steel beams on the mid-span sections. The construction method has the advantages of being high in operability, safe, reliable, controllable in quality, economical, efficient, capable of saving energy and protecting the environment and the like.

Owner:CCCC SECOND HARBOR ENG +1

Transmission shaft set assembling technology

ActiveCN101380893AEliminate error accumulationGuarantee the quality of dynamic balanceControl devicesUniversal jointDynamic balance

The invention relates to an assembling process of a drive shaft assembly. The process comprises the following steps: the first step: the assembling of part A: an extruder and a working platform device are adopted to arrange a universal joint on a flange fork and a universal joint fork on the universal joint; the second step: the assembling of part B: an extruder and a working platform device are adopted to arrange a universal joint on a flange fork and a spline shaft fork and a spline hub sub-assembly or a sliding fork and a rear shaft head sub-assembly on the universal joint; the third step: an extruder and a universal clip extrudes and assembles components of part A, components of part B and a shaft tube into a drive shaft assembly; the fourth step: a welding machine and a universal clip are adopted for alignment and welding of the drive shaft assembly; and the fifth step: a dynamic balancer and a universal clip are adopted for the dynamic balance of the drive shaft assembly. Therefore, the invention can increase the assembling precision and product quality of the drive shaft assembly, eliminates the part processing error, improves the labor efficiency, shortens the production period and decreases the production cost and labor intensity.

Owner:XUCHANG YUANDONG DRIVE SHAFT

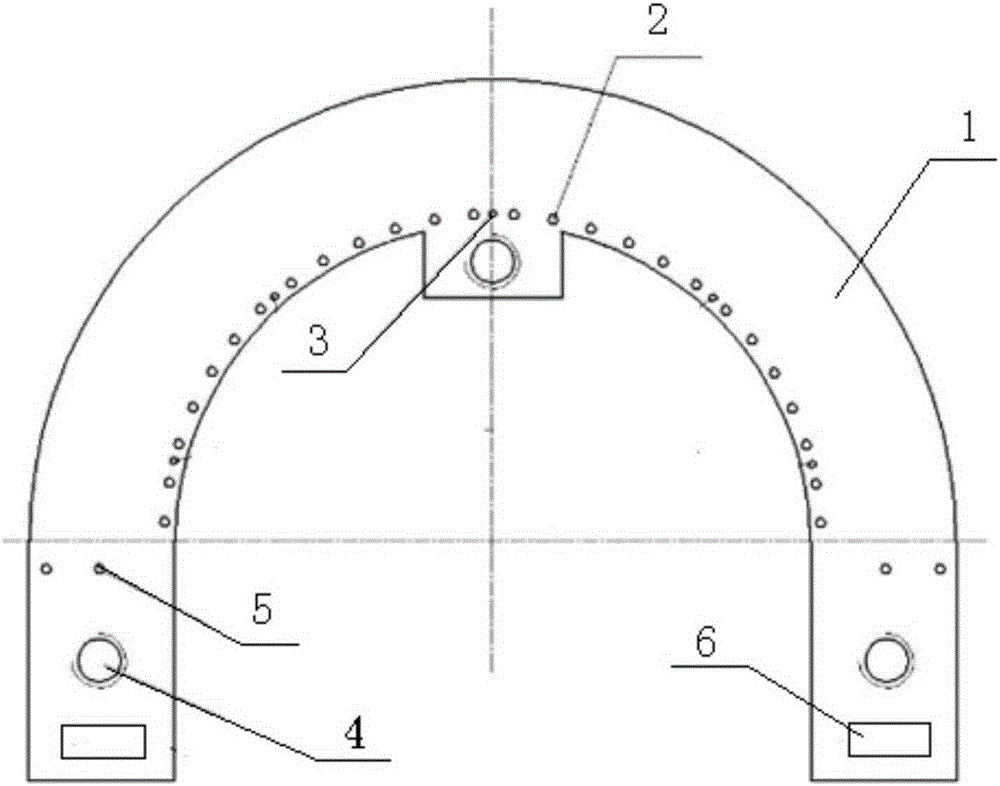

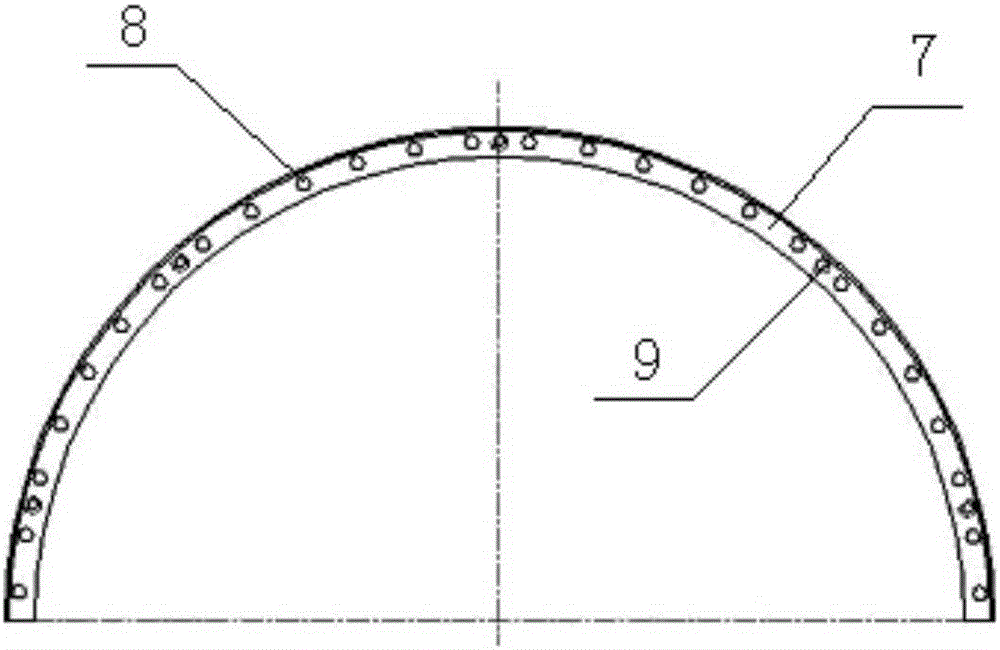

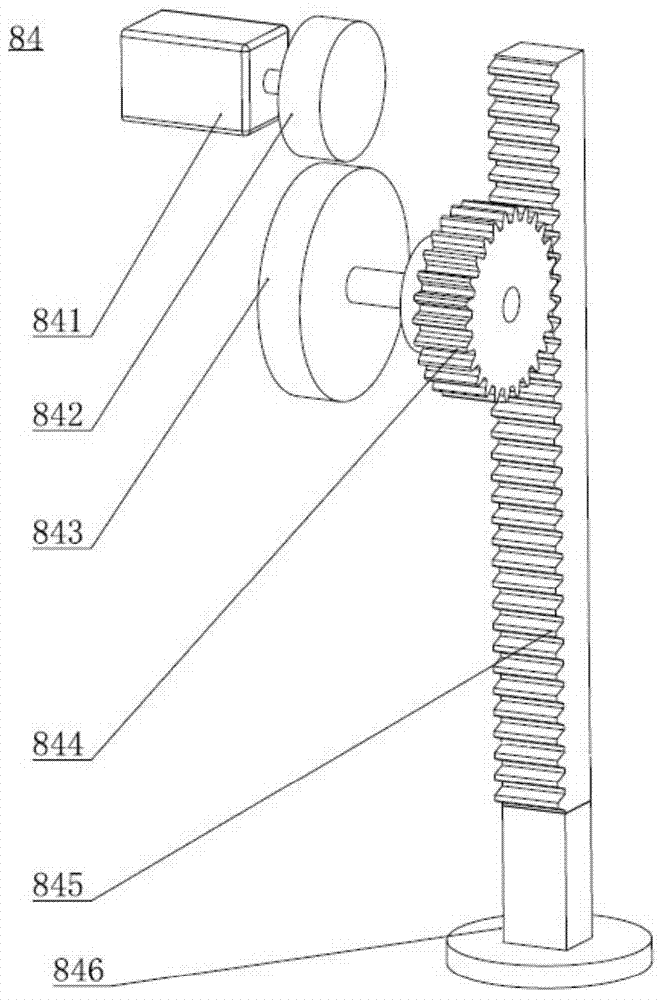

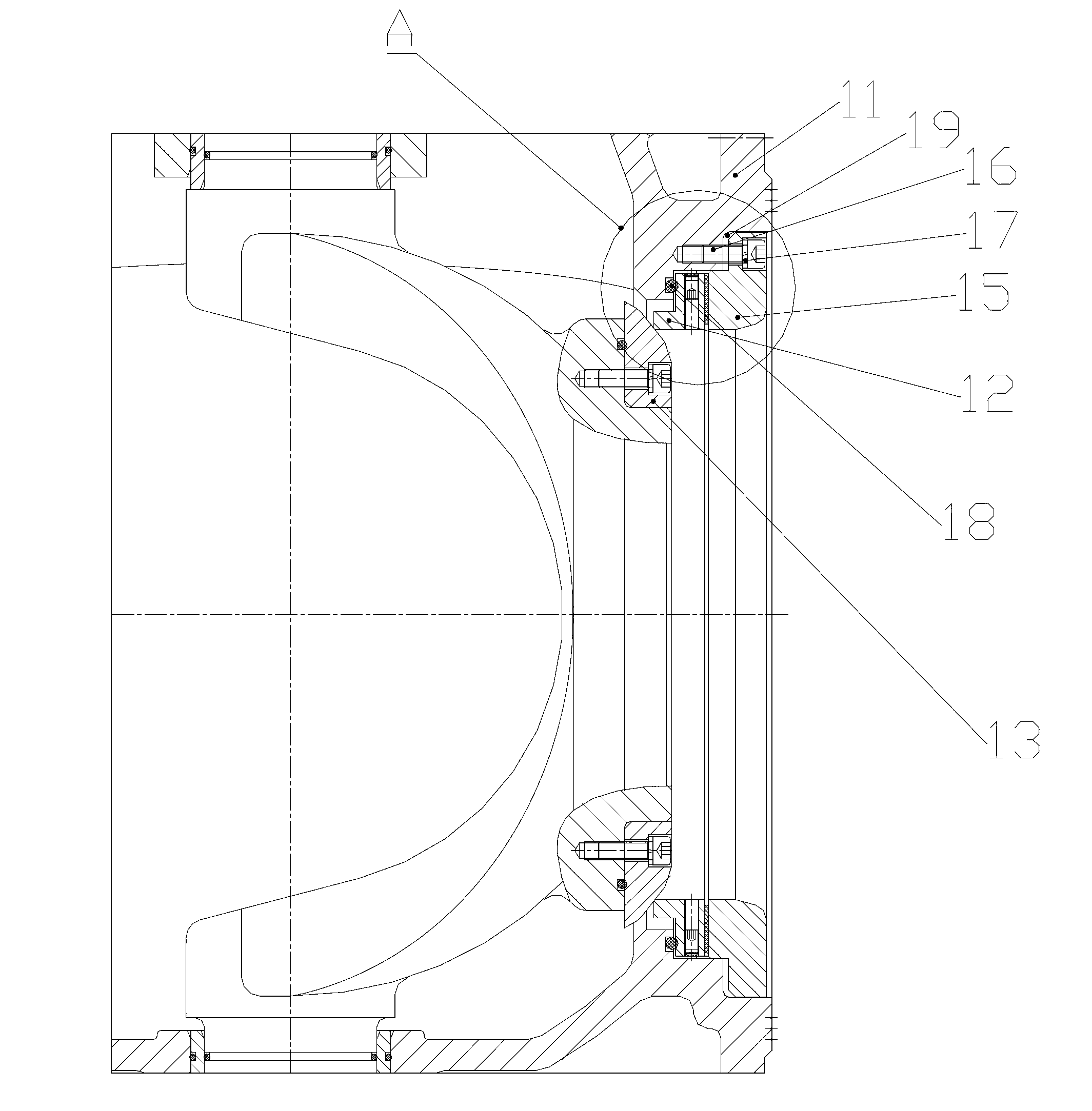

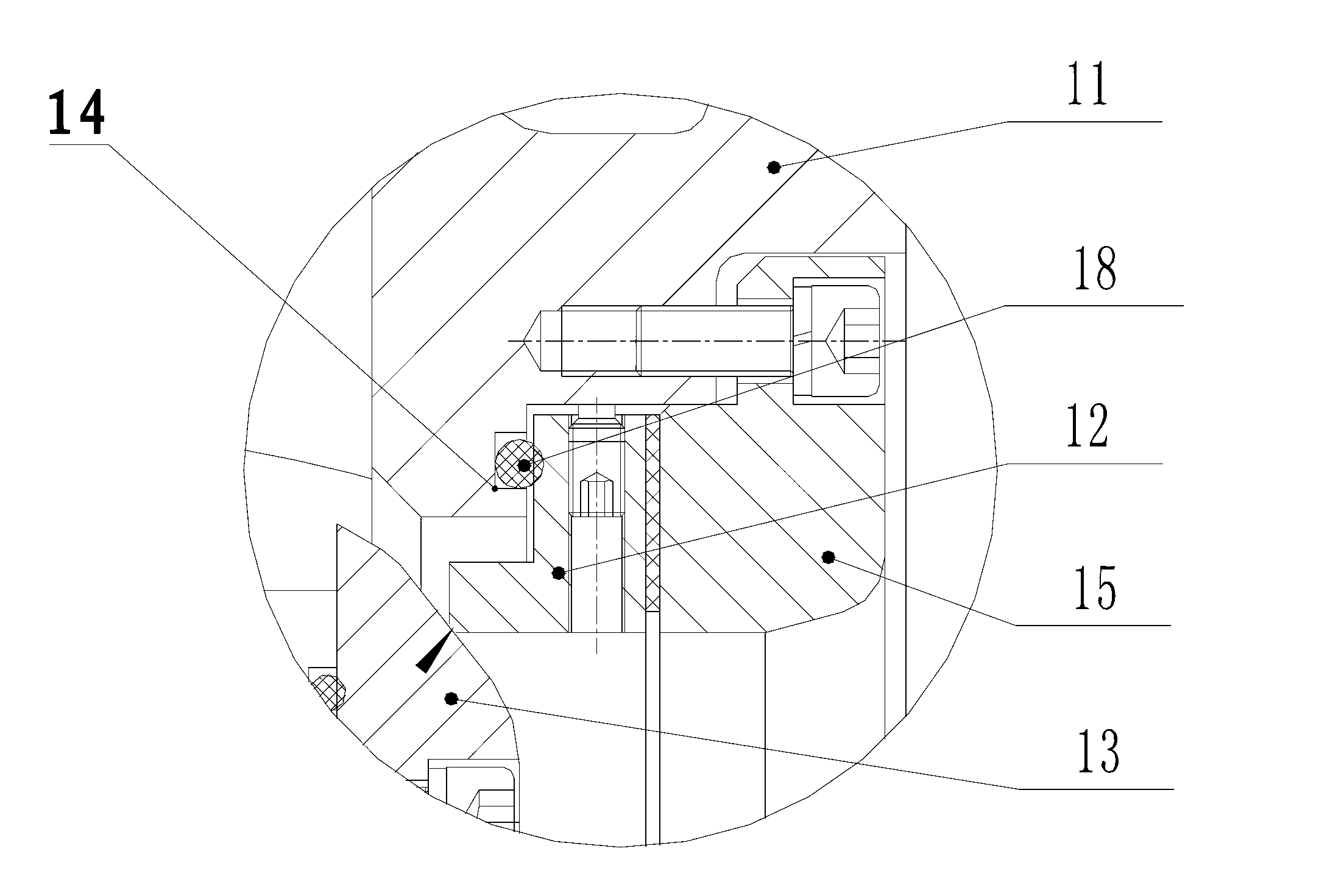

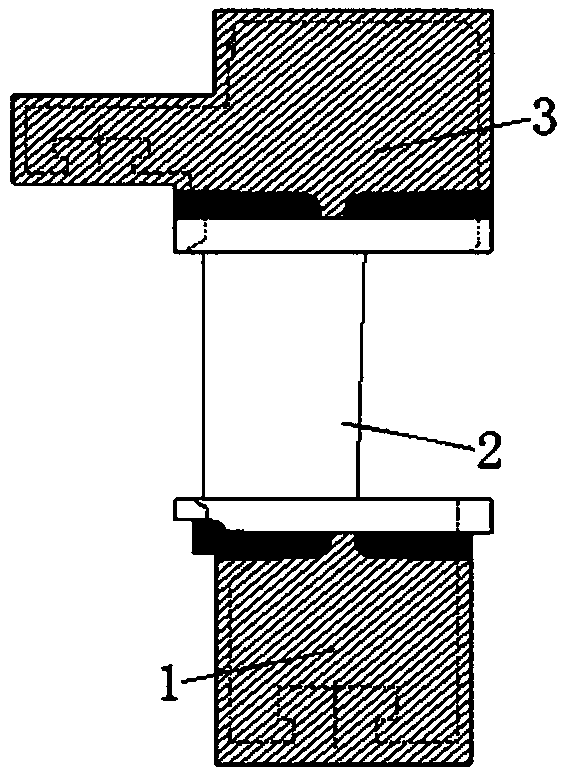

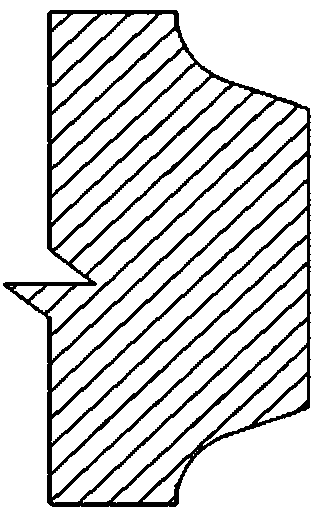

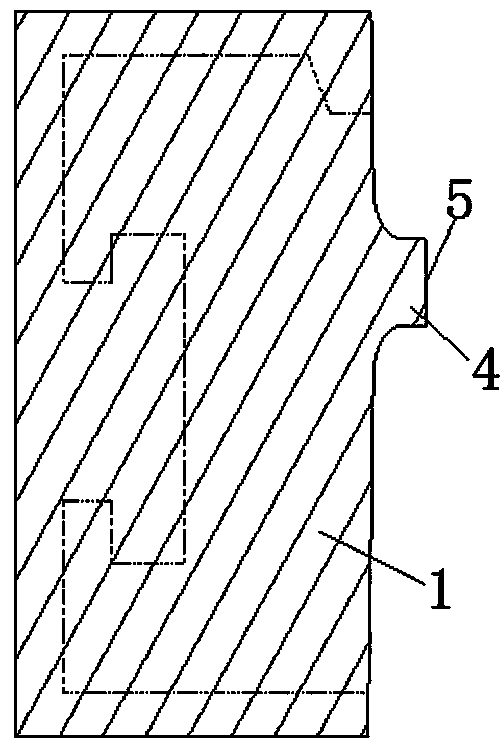

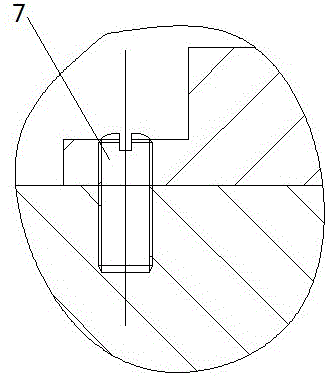

Packing-off piece installation device of turbine stator blades and use method of packing-off piece installation device

ActiveCN105298561AEasy to assembleShorten assembly cycleLeakage preventionStatorsStatorSoftware engineering

The invention relates to a device, in particular to a packing-off piece installation device of turbine stator blades and a use method of the packing-off piece installation device. According to the technical scheme, the packing-off piece installation device comprises an installation plate, an installation edge, first screws, balancing weights, limiting blocks, second screws, fixing bolts and nuts; the installation plate is a semicircular plate and is provided with two end plates and an auxiliary plate on the top of the arc; first installation holes are formed in the semicircular plate, the interval of the first installation holes is the same as the interval of end holes of the two turbine stator blades, and hoisting holes are formed in the end plates and the auxiliary plate; the balancing weights are fixedly arranged on the end plates, and the limiting blocks are arranged on the end plates through the second screws; the installation edge is in a semicircular shape and provided with second installation holes; the installation plate and the installation edge are connected together through the first screws, and the positions of the first installation holes correspond to the positions of the second installation holes; and the fixing bolts and the nuts are used for fixing the turbine stator blades. By means of the packing-off piece installation device, installation of packing-off pieces is achieved under the condition that positioning pins of the turbine stator blades are not decomposed.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

A six-wheel drive dumper assembling method

ActiveCN106080841AEasy maintenanceEasy to troubleshootElectric/fluid circuitVehiclesVehicle frameComputer module

The invention provides a six-wheel drive dumper assembling method comprising the steps of laying pipes and wires on a walking bench module in advance; laying wires for a rear axle in advance; laying pipes for the rear axle in advance; after the pre-laid pipes and wires for the rear axle are totally assembled off a vehicle, integrally hoisting and installing the part to a frame by using an overhead crane; hoisting and installing the walking bench module to the frame and electrically connecting the pre-laid wires of the walking bench module and the pre-laid wires of the rear axle. The method takes into account overall vehicle apparatus arrangement and the connectors of various system apparatuses and gives consideration to the factors such as optimal pipelines and circuits and convenient maintenance, and the design of the electrical circuits and pipelines of an overall vehicle is carried out in a modularized mode; in the modularized mode, the overall vehicle pipe and wire laying is divided into three major parts, which are the pre-laying of the pipes and wires of the rear axle, the pre-laying of the pipes and wires of the walking bench, and laying of pipes and wires on a vehicle; the pre-laying of the pipes and wires is carried out off the vehicle and the modules are hoisted and installed on the frame after completion, so that the assembling periods are reduced and troubleshooting is facilitated.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

Assembling tool of aircraft wing box C-shaped beam and detecting and correcting method of assembling tool

InactiveCN103586806AAvoid brittle damageShorten inspection cycleWork holdersMetal working apparatusC shapedAerospace engineering

The invention provides an assembling tool of an aircraft wing box C-shaped beam. The assembling tool comprises a rectangular base platform and a rectangular top platform which are the same in size and opposite in position. A vertical positioning device is disposed between the base platform and the top platform. A transverse positioning device and a vertical clamping and included angle correcting device using magnetic transmission are fixedly connected to the vertical. A longitudinal positioning device is disposed at the edge, close to the width, of the base platform. A transverse clamping device and a corner piece assembling device are disposed at the lateral edge in the length direction of the base platform. The invention further provides a detecting and correcting method of the assembling tool. The assembling tool and the detecting and correcting method have the advantages that cycle of quality inspection and assembling is shortened, cost is saved, and production efficiency and quality are improved; an overload protection function is provided, simple operation and practicality are achieved, and detection, correction and assembling can be completed fast.

Owner:SHANGHAI JIAO TONG UNIV

Sealing method used for low-pressure casting

The invention relates to a sealing method used between a low-pressure casting crucible and a workbench face and between the workbench face and a casting mould. In the sealing method, the middle part of the entire casting system comprising a crucible, a support plate and a sealed cover plate (the workbench face) generates downward tiny displacement by adding a plurality of strong springs at the bottom of the low-pressure casting crucible and utilizing the self mass of the casting mould or the mass of an additional casting mould to enable the strong springs to generate tiny compression deformation, the tiny displacement causes the support plate and the sealed cover plate to generate elastic deformation so as to generate an upward stress, and the stress can further press a sealing ring between the low-pressure casting crucible and the sealed cover plate and a sealing ring between the sealed cover plate and the casting mould so as to achieve a favorable sealing effect. The invention has low equipment requirement to low-pressure casting, easy realization, lower cost, simple operation and easy popularization.

Owner:NANTONG L S LIGHT METAL FORMING

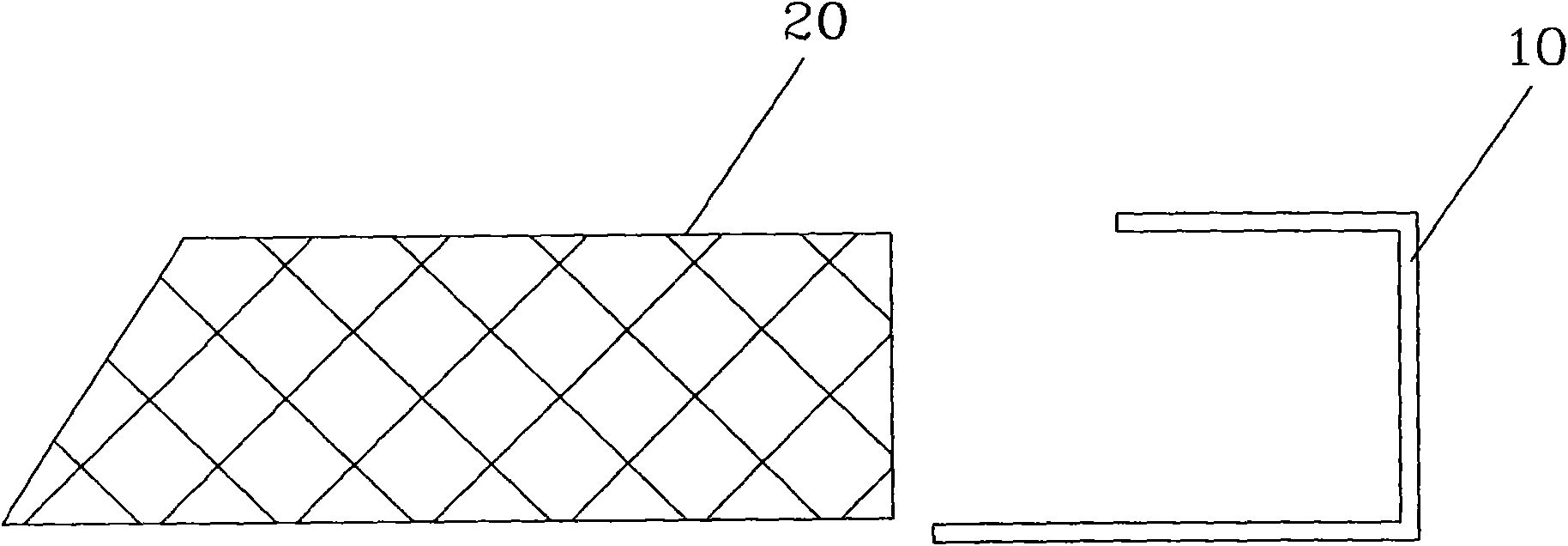

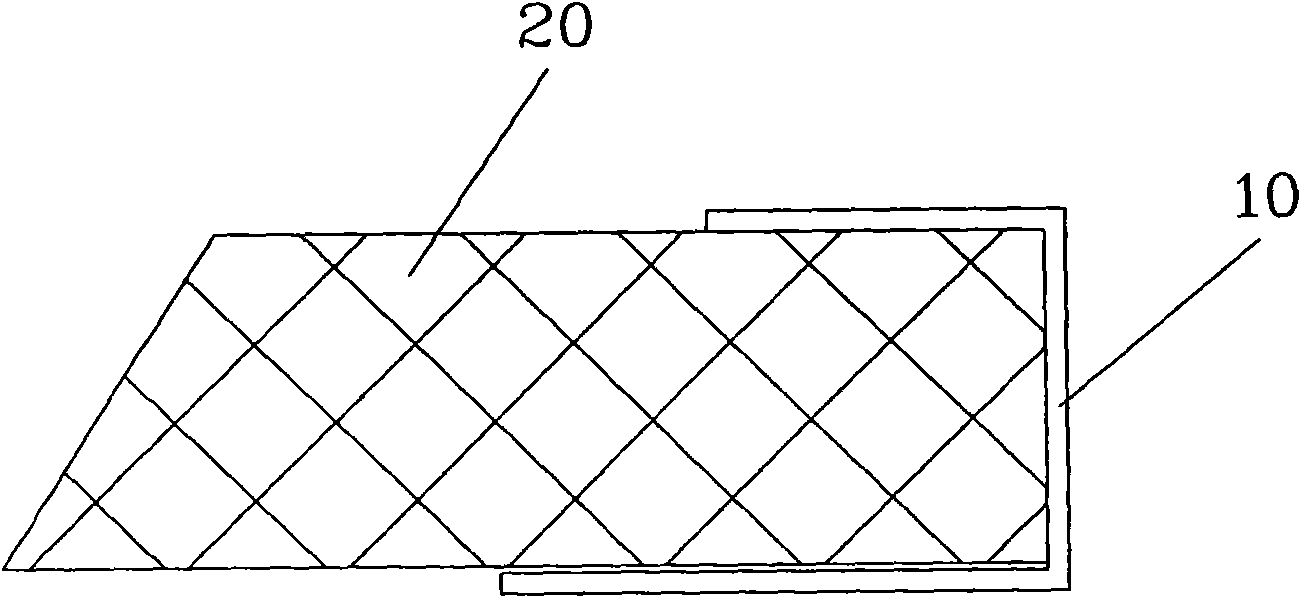

Refrigerated truck bed

ActiveCN102092334AReduce assembly man-hoursEasy to replaceRefrigerated goods vehicleLoading-carrying vehicle superstructuresRear quarterTruck

The invention provides a refrigerated truck bed. The refrigerated truck bed comprises a back frame, a side plate, an aluminium section and a back corner closure, wherein the aluminium section is shaped like a sheet and fixedly connected with the outside of the side plate, the end part of the aluminium section extends from the side plate, the extension part is provided with a side plate connection part which is integrated with the extension part; the section of the back frame is shaped like a right angle formed by a first right-angle side and a second right-angle side, the end part of the second right-angle side of the back frame extends to form a corner closure connection part, the end part of the first right-angle side of the back frame extends to form a back frame connection part, the back frame connection part is connected with the side plate connection part in a detachable manner; the back corner closure is shaped like a sheet, the both ends of the back corner closure are fixedly connected with the side plate and the corner closure connection part of the back frame; and the region embraced by the side plate, the aluminium section, the back frame and the back corner closure is filled with foaming bodies. By adopting the refrigerated truck bed, the total assembly time of the refrigerated truck bed can be greatly reduced, the assembly period can be shortened and the total assembly efficiency can be increased. In addition, when the refrigerated truck bed is used and the back frame or side plate is required to be displaced, the displacement is very convenient.

Owner:QINGDAO CIMC REEFER TRAILER

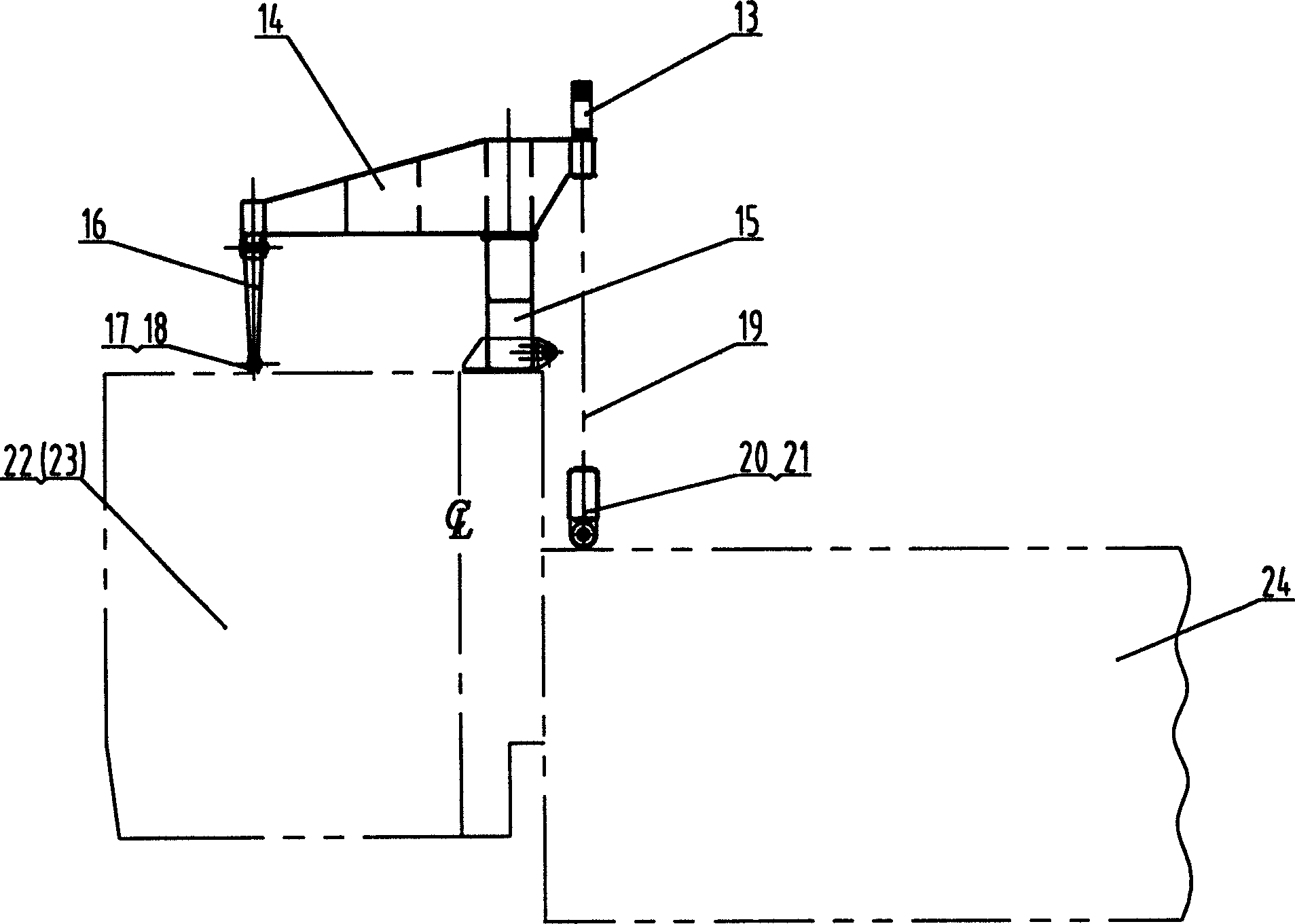

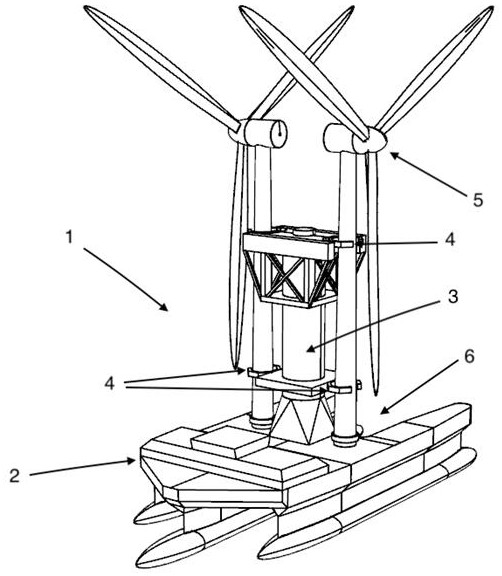

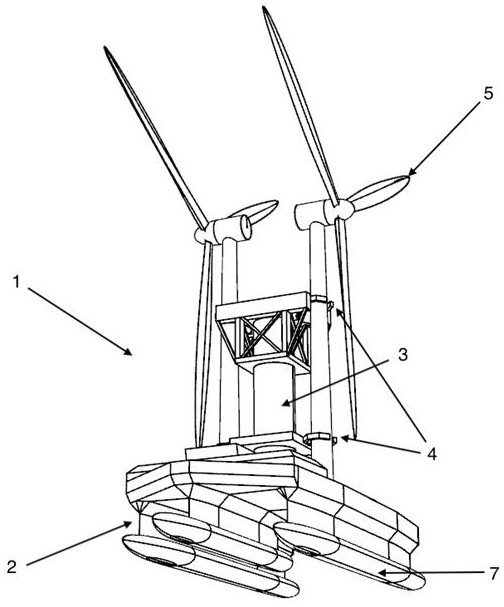

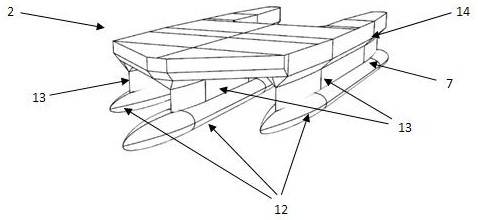

Offshore wind turbine integral transportation and installation ship and offshore wind turbine integral transportation and installation method

The invention discloses an offshore wind turbine integral transportation and installation ship which mainly comprises a multi-hull ship body and a fan transportation and installation tower, a motion compensation hoop is arranged on the fan transportation and installation tower; an opening for mounting a fan is formed in a deck at the middle rear part of the ship; the fan transportation and installation tower is a rotatable single-column mast type fan transportation and installation tower and is installed on the front edge of an opening in a triple-hulled vessel body main deck. The motion compensation hoop is arranged on the fan transportation and installation tower; in the installation process of the fan, six-freedom-degree motion compensation can be provided for the bottom of the fan, twofans of the fan transportation and installation tower shuttle back and forth between a wind power plant and a land wharf, overall transportation and offshore installation of the fan can be achieved,the transportation and installation process is rapid, efficient and safe, the development period of the wind power plant is shortened, and offshore operation cost is reduced; the integral transportation and installation ship for the offshore wind turbine can also be used for transportation and installation of a wind turbine foundation, disassembly of the offshore wind turbine and the like.

Owner:CHINA MERCHANTS MARINE & OFFSHORE RES INST CO LTD

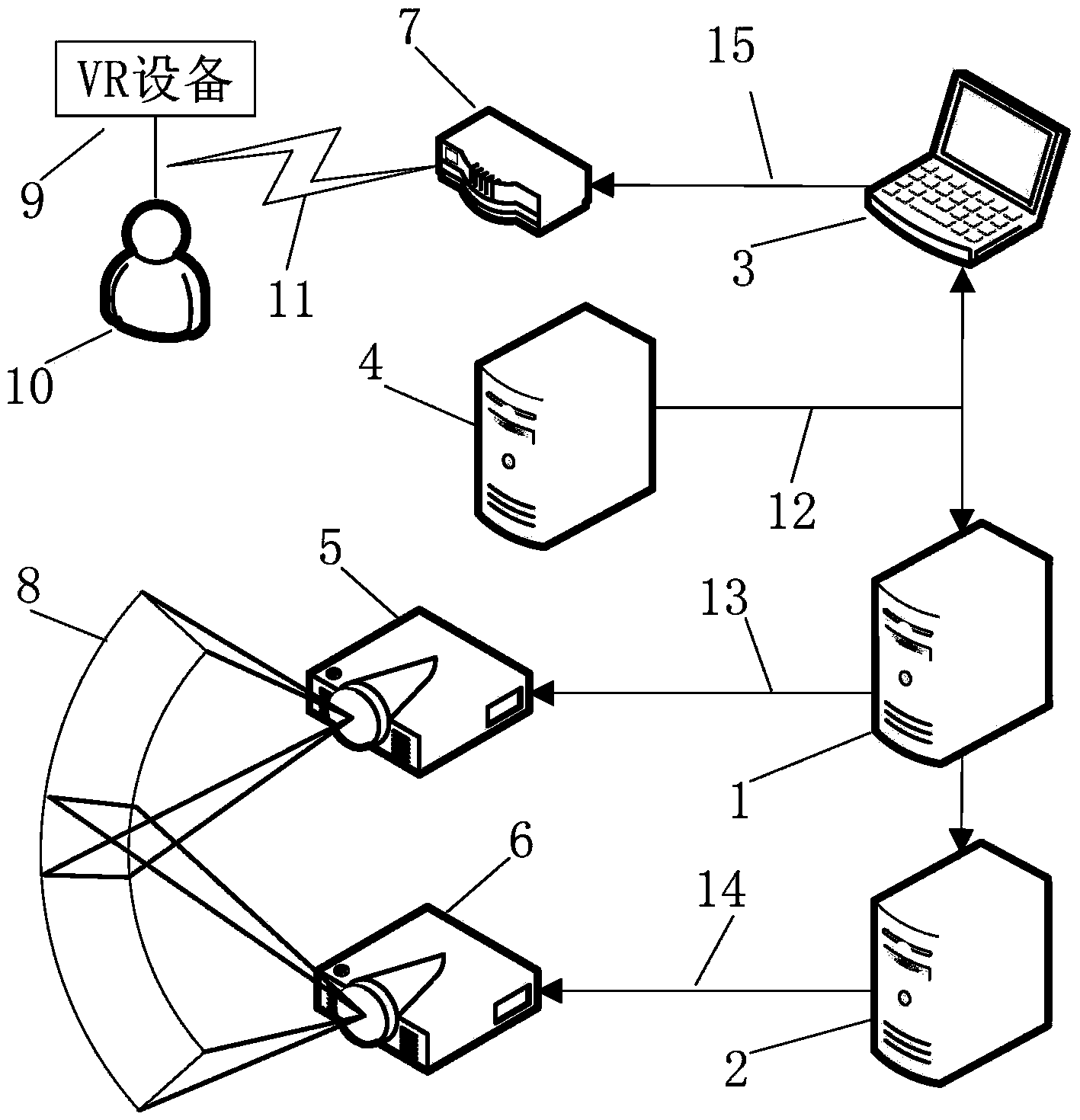

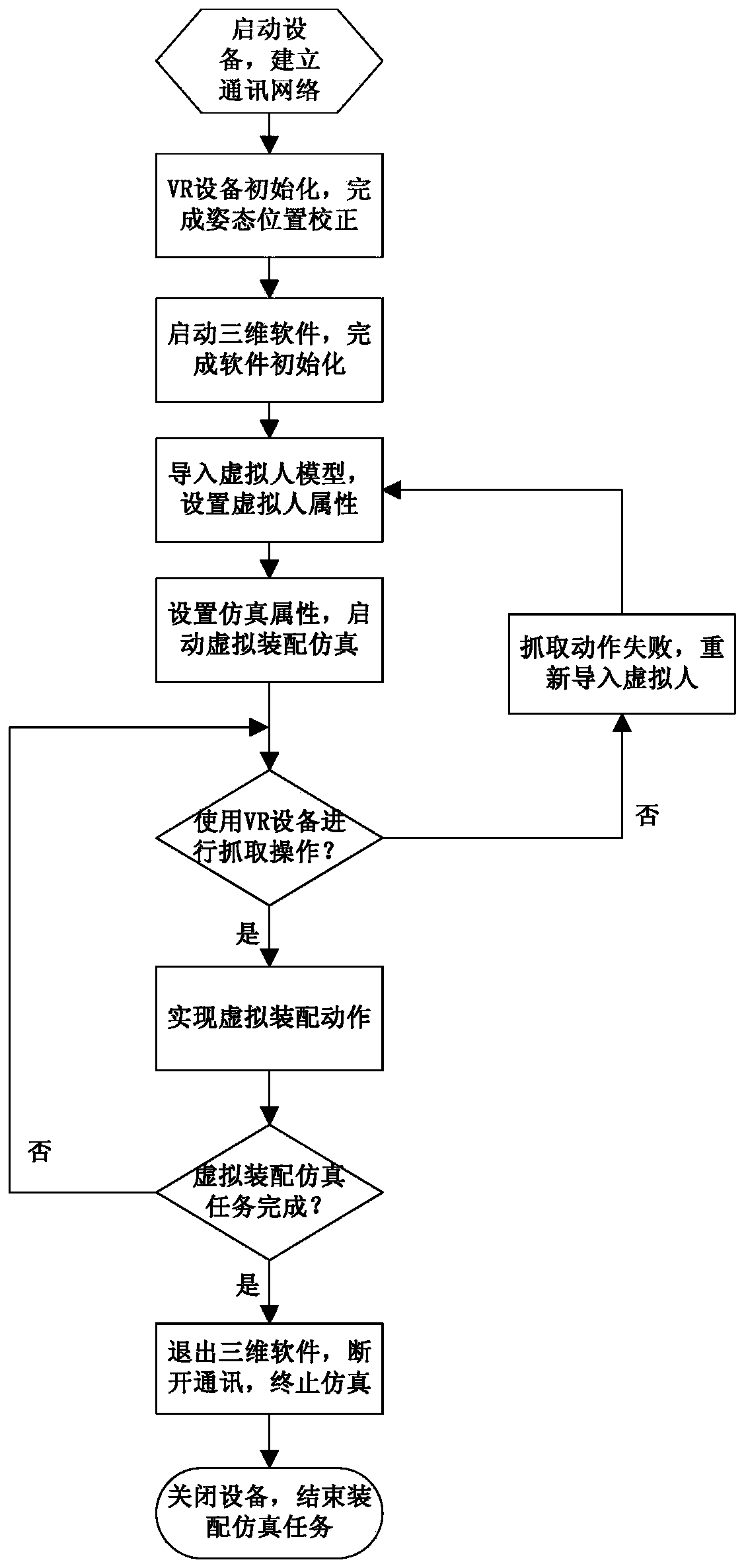

Plane pipeline assembly simulation method based on human motion capture system

ActiveCN103942385AImprove immersionIncrease authenticitySpecial data processing applicationsThree dimensional simulationProjection screen

The invention discloses a plane pipeline assembly simulation method based on a human motion capture system. The method comprises the seven steps that (1) devices in an assembly system are started, and related preparation work is finished; (2) the initialization process of the VR device is finished; (3) three-dimensional software is started on a main control computer, and initialization of the software is finished; (4) the VR device is used for operating a virtual human model to grab and release plane pipeline parts, and the step (3) is executed again if operation is not successfully executed; (5) if the operation is successful, the VR device is operated to grab and release the parts in the virtual assembly process by observing various view angles in a large projection screen, and a virtual assembly simulation task is finished; (6) if there are other tasks, it is required that related operation is executed after association between the corresponding VR device and the virtual human model is built; (7) after all the assembly simulation tasks are finished, the association between the VR device and the virtual human model is removed, communication between the main control computer and a controlled computer is cut off, the three-dimensional simulation software is quitted, and the assembly simulation task is ended.

Owner:BEIHANG UNIV

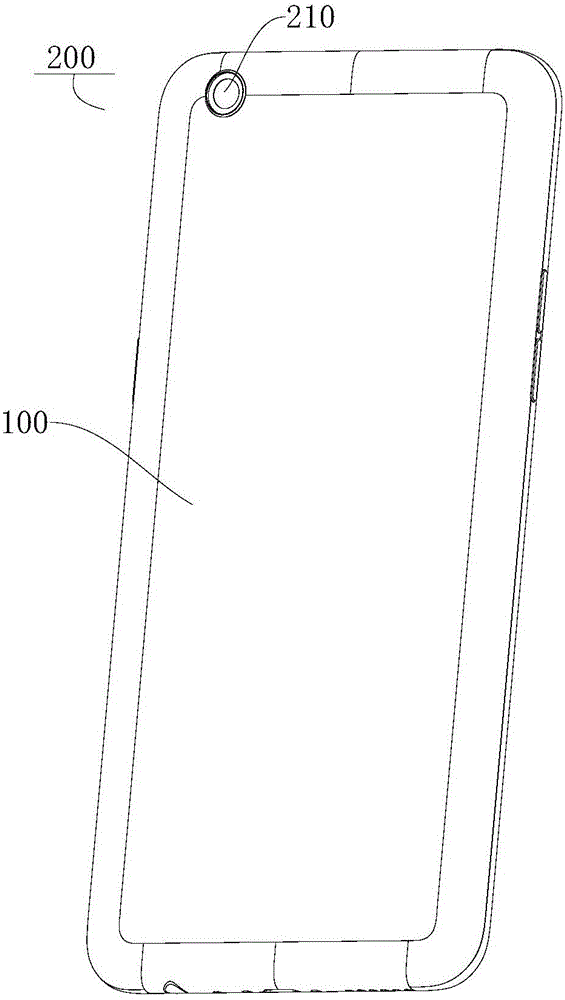

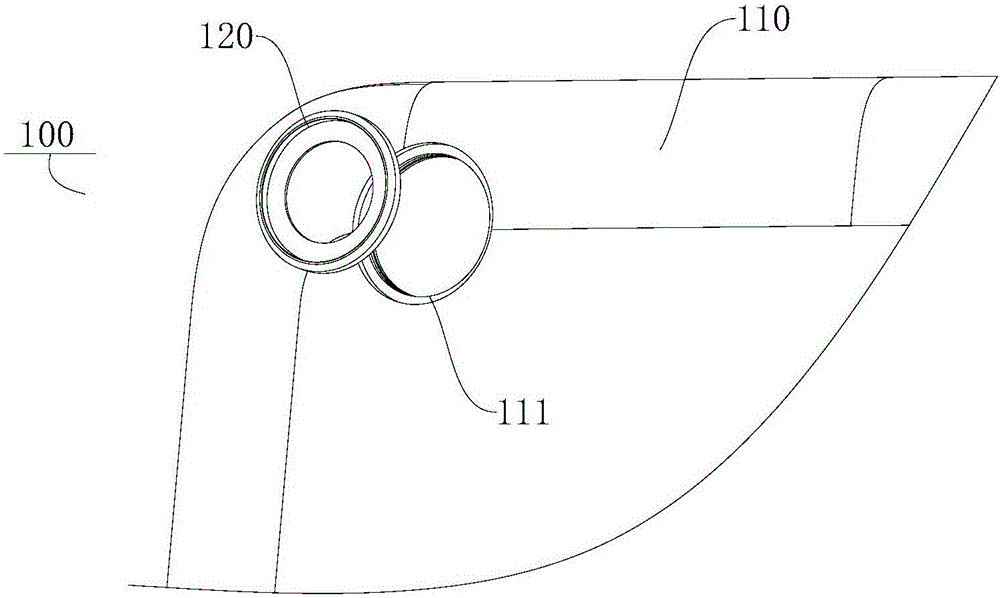

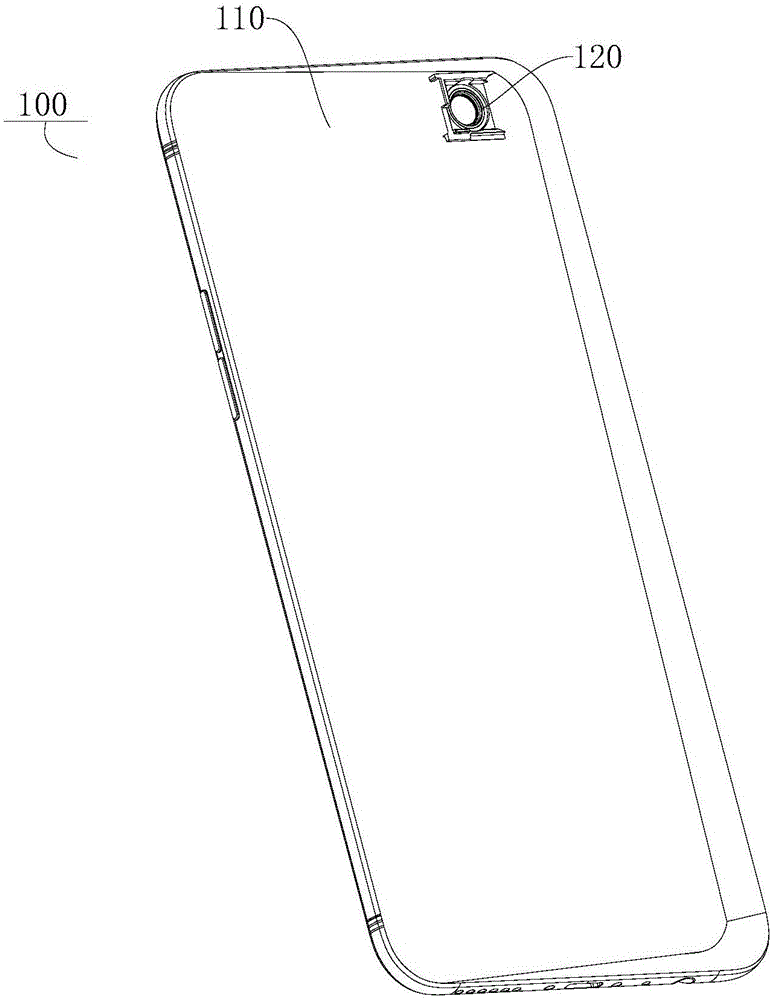

Terminal, and shell component and manufacturing method thereof

InactiveCN106790784ASave assembly spaceSimplify the assembly processTelephone set constructionsEngineering

The invention discloses a terminal, and a shell component and a manufacturing method thereof. The terminal is provided with a camera component; the shell component comprises a shell, an ornament ring, a connector and a conductive bonding layer; the ornament ring is arranged on the shell in a penetrating manner, and the camera component is embedded into the ornament ring; the connector is located inside the shell, and the connector is externally sleeved with the ornament ring and welded with the ornament ring; and the conductive bonding layer is sandwiched between the connector and the inner circumferential wall of the shell. According to the shell component of the terminal, the connector is externally sleeved with the ornament ring and welded with the ornament ring, the connector is bonded to the shell by using the conductive bonding layer, and the connector and the ornament ring can be firmly installed on the shell, so that the connecting strength between the shell and the ornament ring is improved, the assembly space for the ornament ring is saved, the assembly procedure for the ornament ring is simplified, the assembly period is shortened, and the production cost is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

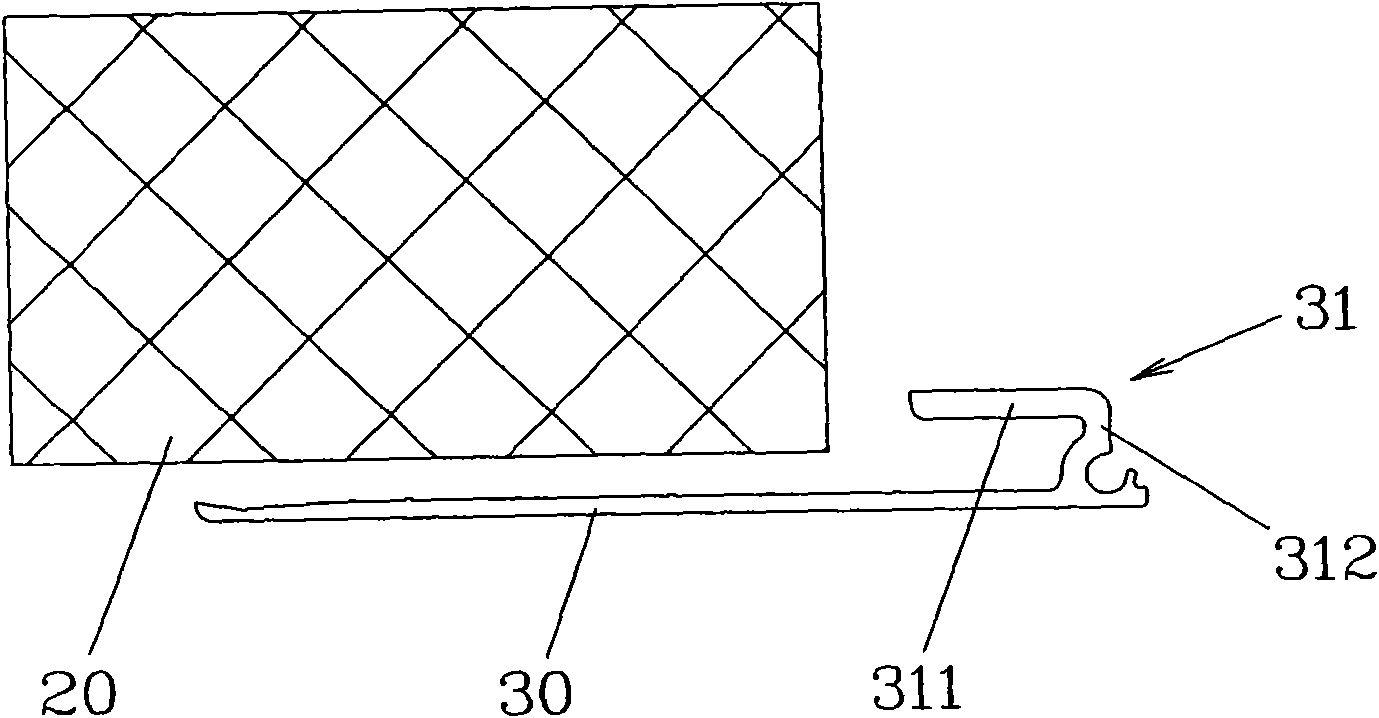

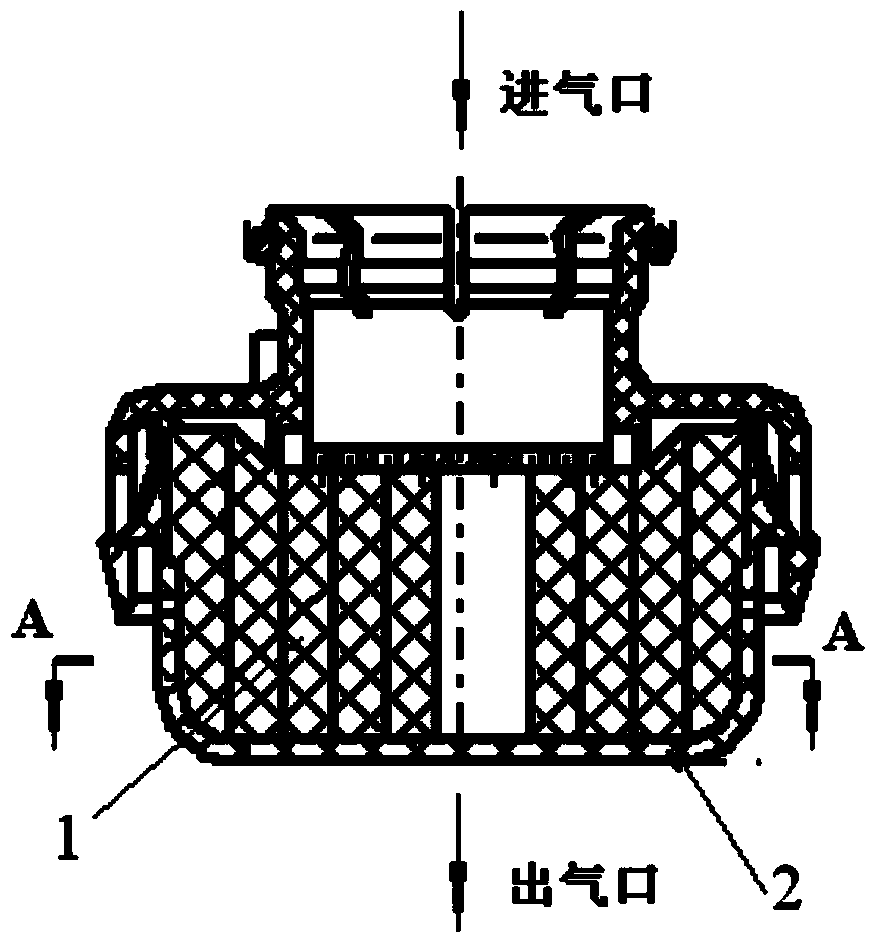

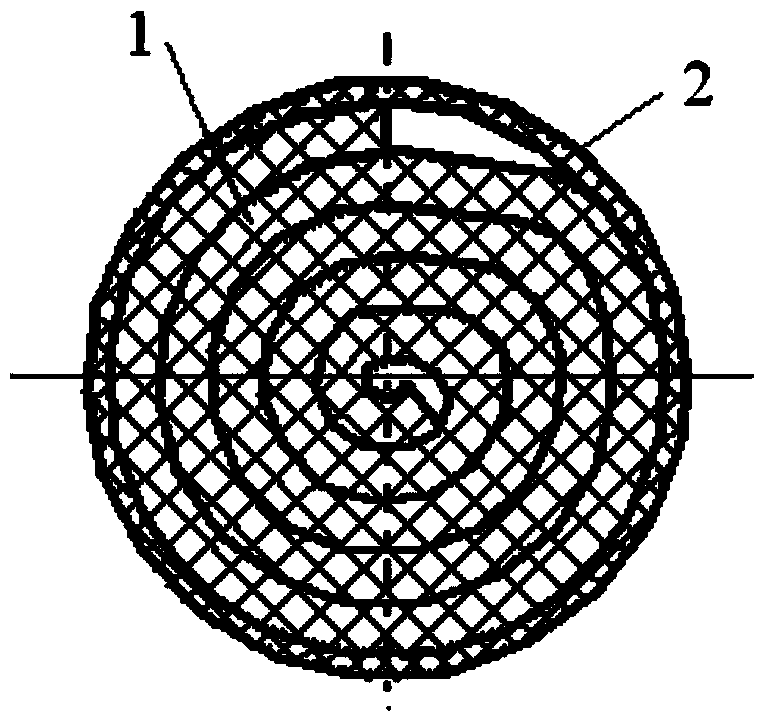

Commercial vehicle diesel engine brake system exhaust silencer

The invention discloses a commercial vehicle diesel engine brake system exhaust silencer which is applied to an air brake valve of a brake system. The exhaust silencer comprises an upper shell and a lower shell (2), an air inlet is formed in the upper shell, an air outlet is formed in the lower shell (2), and a filter screen (1) is wound in the lower shell (2) and made of coarse fibers. By the aid of the technical scheme, product structures are simplified, assembly cycle is shortened, productivity and performances of products are improved, moisture in air is sufficiently adsorbed, dust in the air is effectively resisted, and the service life of the air brake valve is prolonged.

Owner:WUHU SHENGLI TECH SHARES

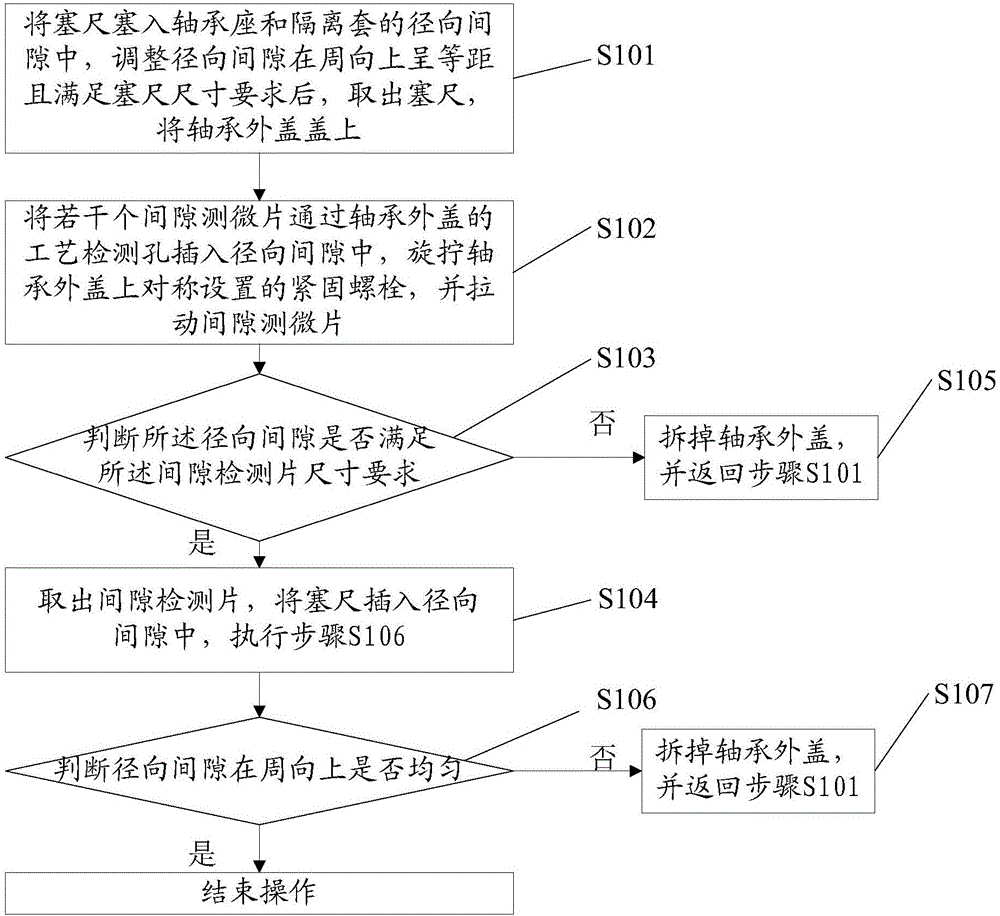

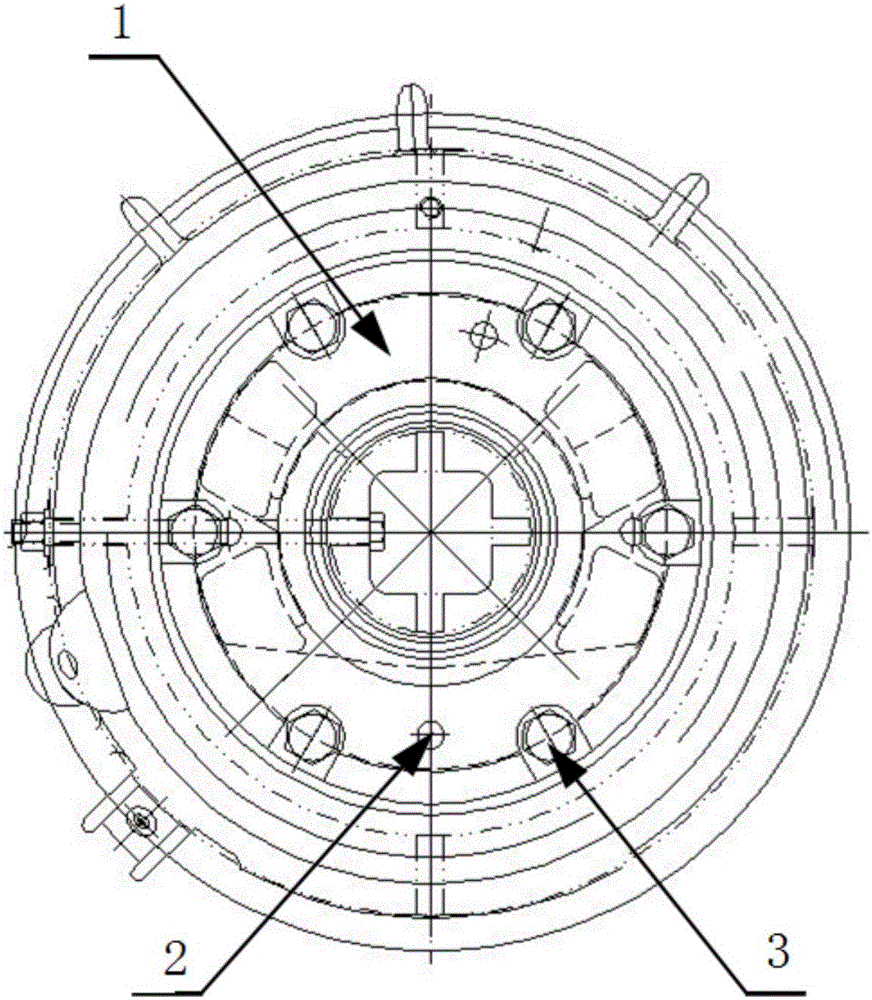

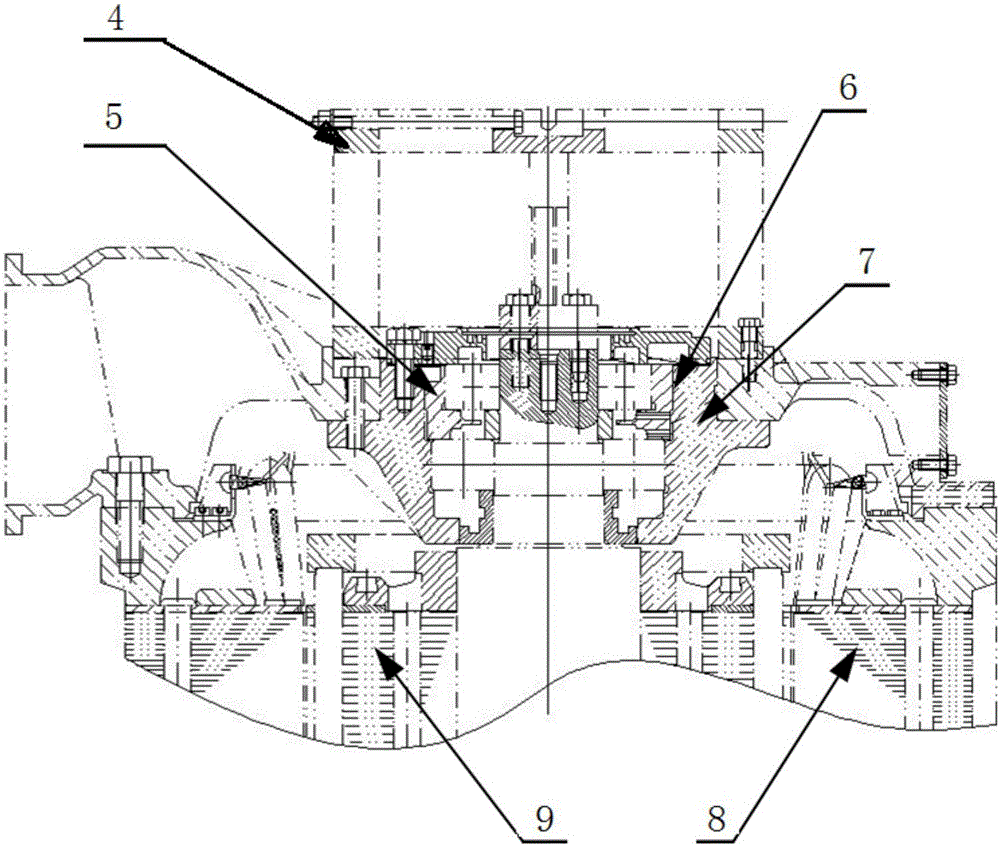

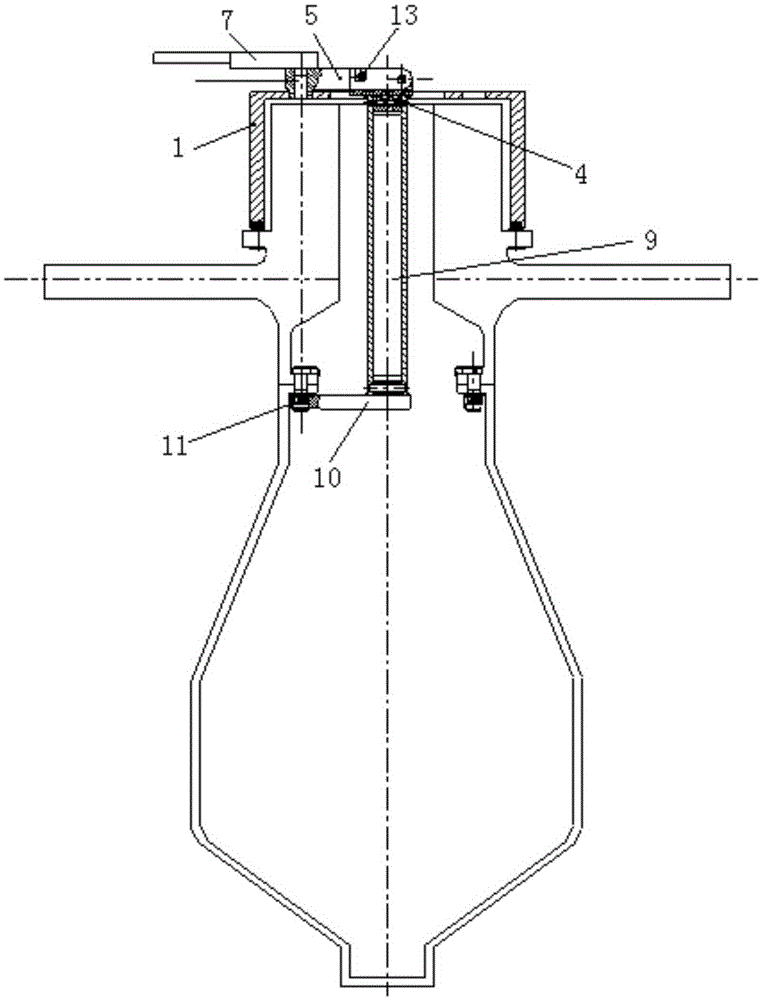

Motor bearing assembling clearance detecting method and device

ActiveCN104949601AAccurate radial clearanceImprove product qualityMechanical clearance measurementsEngineeringFeeler gauge

The invention discloses a motor bearing assembling clearance detecting method. The method comprises steps as follows: S101, a feeler gauge is inserted in radial clearance between a bearing block and an isolating sleeve, the feeler gauge is taken out and a bearing outer cover is put on a bearing after the radial clearance is equally spaced in the circumferential direction through adjustment and meets the size requirements of the feeler gauge; S102, a plurality of clearance detecting pieces are inserted into the radial clearance through process detection holes in the bearing outer cover, fastening bolts symmetrically arranged on the bearing outer cover are screwed tightly, and the clearance detecting pieces are pulled; S103, whether the radial clearance meets the size requirement of the clearance detecting pieces is judged, if yes, the step S104 is performed, and otherwise, the step S105 is performed; S104, the clearance detecting pieces are taken out, the feeler gauge is inserted into the radial clearance, and the step S106 is performed; S105, the bearing outer cover is taken down, and the step S101 is performed again; S106, whether the radial clearance is uniformly spaced in the circumferential direction is judged, if yes, operation ends, and otherwise, the step S107 is performed; S107, the bearing outer cover is taken down, and the step S101 is performed again. The invention further discloses a motor bearing assembling clearance detecting device. The stability of clearance adjustment of the bearing is improved.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Nut force limiting device and using method thereof

InactiveCN105291025AGuarantee the problem of tightening with high torque limitReduce labor intensitySpannersWrenchesEngineeringHigh torque

The invention relates to a nut force limiting device and a using method thereof. The device comprises an n-shaped support. Locking holes are formed in the lower ends of the n-shaped support so as to limit the n-shaped support. Locating holes and a first through hole are formed in the upper end of the n-shaped support to be used for being connected with a spanner assembly in an inserted mode. The spanner assembly is mounted on the n-shaped support and comprises an upper crossbeam. A second through hole is formed in one end of the upper crossbeam. A torque spanner is externally connected to the interior of the second through hole. The upper crossbeam is provided with a boss corresponding to the lower end of the second through hole. The boss is clamped in the corresponding locating hole. The upper crossbeam can rotate relative to the n-shaped support. The upper crossbeam is hinged to one end of a connecting rod, and the other end of the connecting rod penetrates through the first through hole to be fixedly connected with a lower crossbeam. A spanner head is arranged at the end of the lower crossbeam. Limiting units are correspondingly arranged on the upper crossbeam and the connecting rod. Manufacturing is simple, assembling is easy and convenient, implementation is easy, and high-torque force limiting tightening is guaranteed; labor intensity is relieved, the assembling period is shortened, and the working efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Eccentric half-ball valve

The invention discloses an eccentric half-ball valve, which comprises a valve body, wherein a valve seat and a valve crown which are matched with each other are arranged in the valve body; a pressure ring is arranged between the axial directions of the valve seat and the valve body through matching of a screw and an elastic gasket; axial gaps exist among the pressure ring, the valve seat and the valve body; the radial sealing cylindrical surface of the valve body or the valve seat is provided with at least one ring groove; a sealing ring is sleeved in the ring groove; the pressure ring is further provided with a plurality of fastening screws along the axial direction; and the end face of the top end of each fastening screw is pressed against the end face of the valve body. Compared with an original structure, the eccentric half-ball valve has the advantages that problems existing in the prior art can be solved without making any great change and increasing great cost, the technical requirements on assembly personnel can be lowered, the assembly period is shortened, the production efficiency is increased greatly, and maintenance is more convenient and rapid.

Owner:WUHAN DAYU VALVE

Steam turbine partition board assembly process

ActiveCN107717328AThere will be no problem of deformationAssembly technology is less difficultMetal working apparatusSteam turbine

The invention discloses a steam turbine partition board assembly process. A steam turbine partition board is mainly composed of a partition board body, a plurality of guide blades and a partition board outer ring. Each guide blade is mainly composed of an inner edge plate, a blade body and an outer edge plate. The partition board assembly process comprises the following technological steps of machining assembly surfaces of the edge plates of the guide blades to be smooth and free of welding groove structures; assembling the inner edge plates of the guide blades to the periphery of the partition board body in sequence to enable the guide blades to form a blade grid on the periphery of the partition board body, and assembling the partition board body and the blade grid an assembly combined body; conducting assembly treatment on the partition board outer ring and the assembly combined body; assembling the assembled partition board outer ring to the assembly combined body in a shrinkage assembly mode to enable the partition board outer ring to be located at the outer edge plates of the blade grid of the assembly combined body and obtaining the steam turbine partition board accordingly.The steam turbine partition board assembly process is little in assembly technical difficulty and has the characteristics of being short in assembly period, high in assembly efficiency, low in manufacturing cost, high in assembly precision and the like.

Owner:DONGFANG TURBINE CO LTD

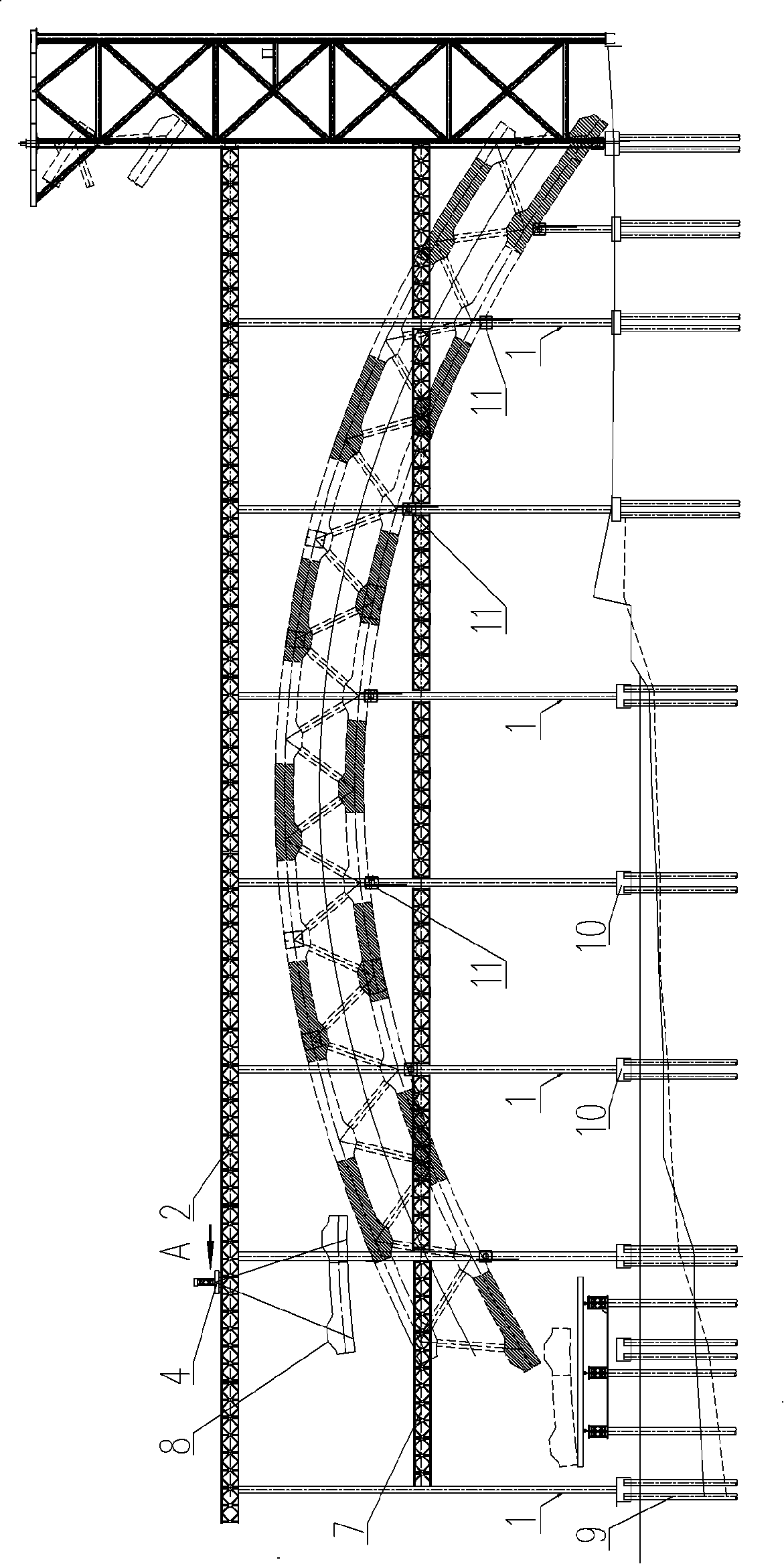

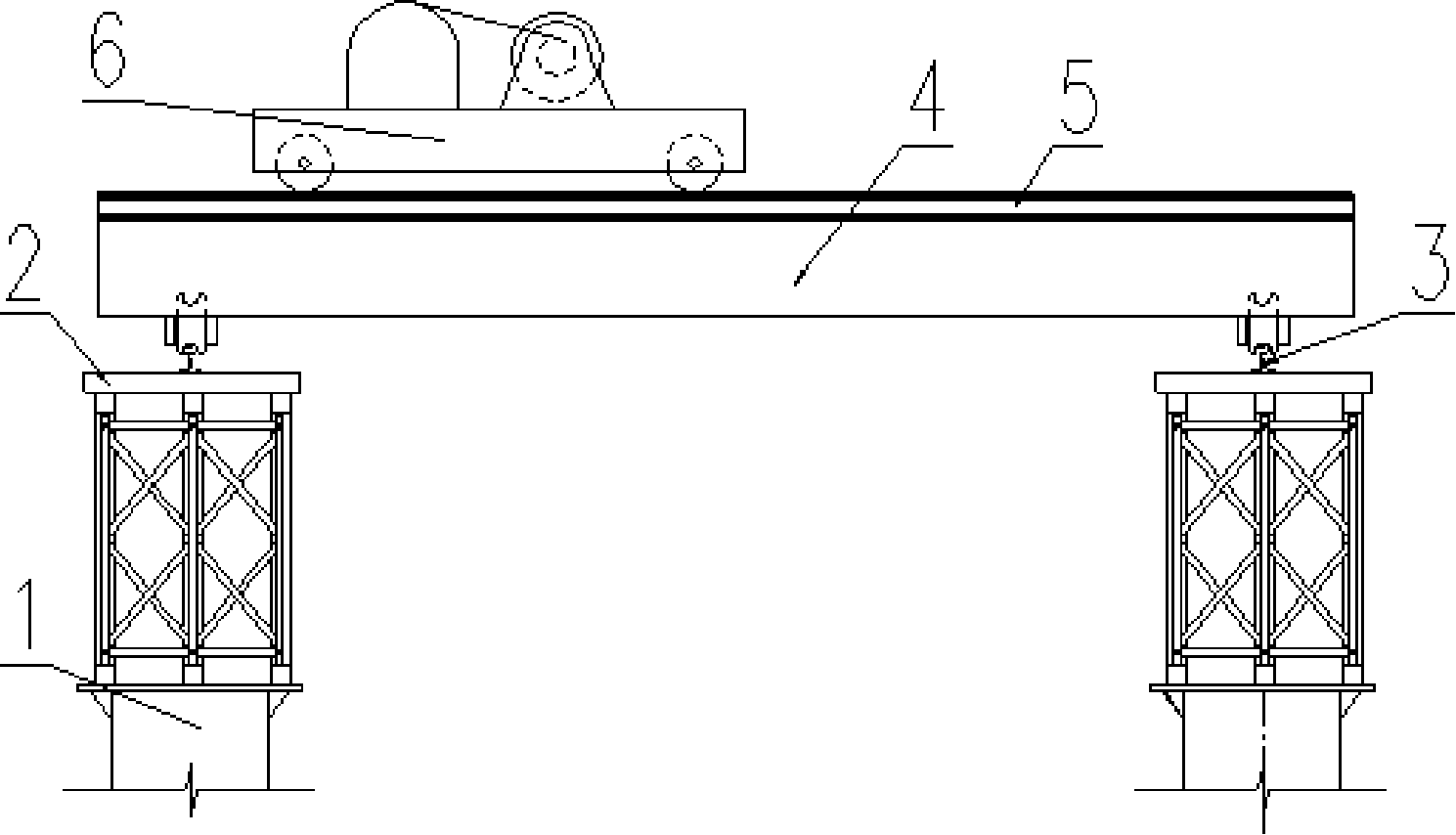

Bridge rib hoisting and supporting rack integral construction method and device

ActiveCN101177933AReduce investmentEasy to liftBridge erection/assemblySUSPENDING VEHICLEEngineering

The invention discloses an integration construction method for bridge arch-rib lifting and bracket supporting and a device thereof. The method is that: columns are arranged within the range of arch-rib assembling, and the column is provided with supporting corbels; each section of arch-rib is lifted and arranged on the corbels; lifting beams are positioned on the top part of the columns, and the lifting beam is provided with a longitudinal shift orbit; a crane is positioned on the longitudinal shift orbit, and the crane can move longitudinally on the lifting beam; the crane is also provided with a transversal shift orbit that are provided with a winch which can move transversally; therefore, the winch can move transversely or longitudinally within the arch-rib assembling scope and provide convenience for lifting arch-ribs to each assembling place. By integrating the brackets of lifting with that of supporting, the invention has the advantages of reducing the equipment used for lifting, flexible, simple operation and short operation period; and since floating crane and overhead crane are not used, investment of equipment and capital is shortened; the invention can be used for the arch-rib assembling and various bridge lifting construction fields.

Owner:GUIZHOU BRIDGE CONSTR GROUP

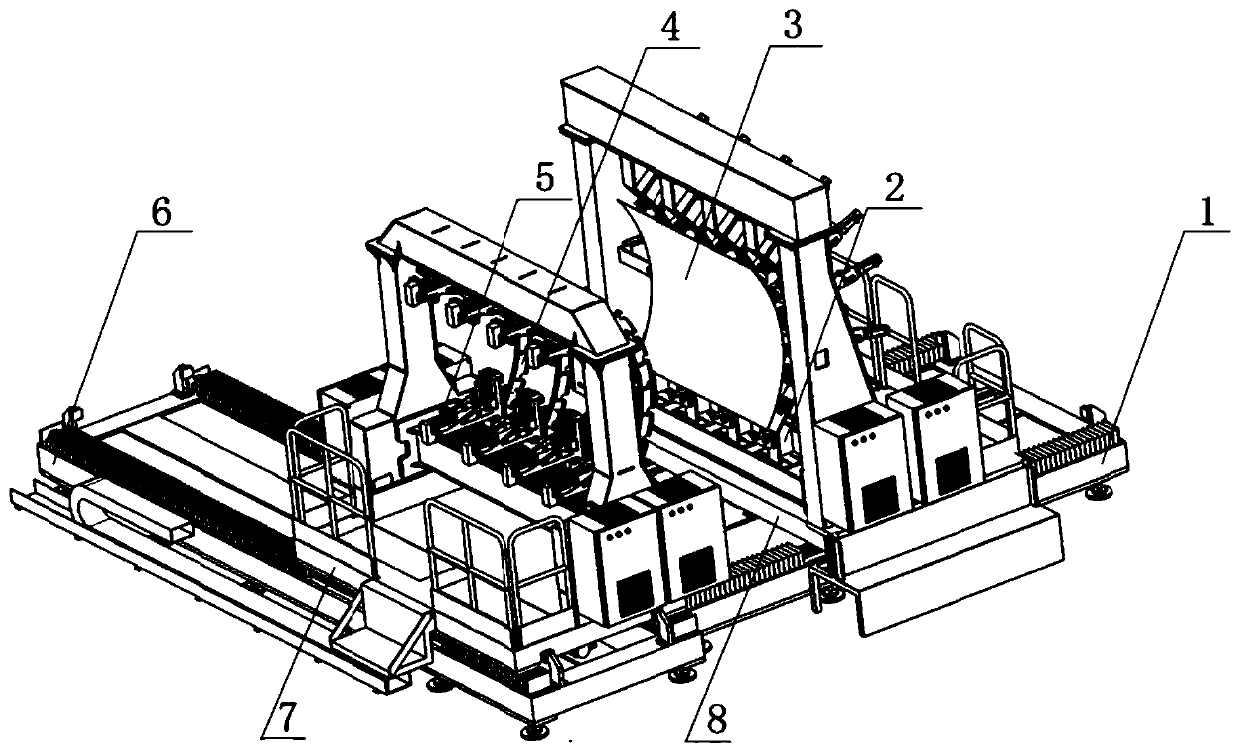

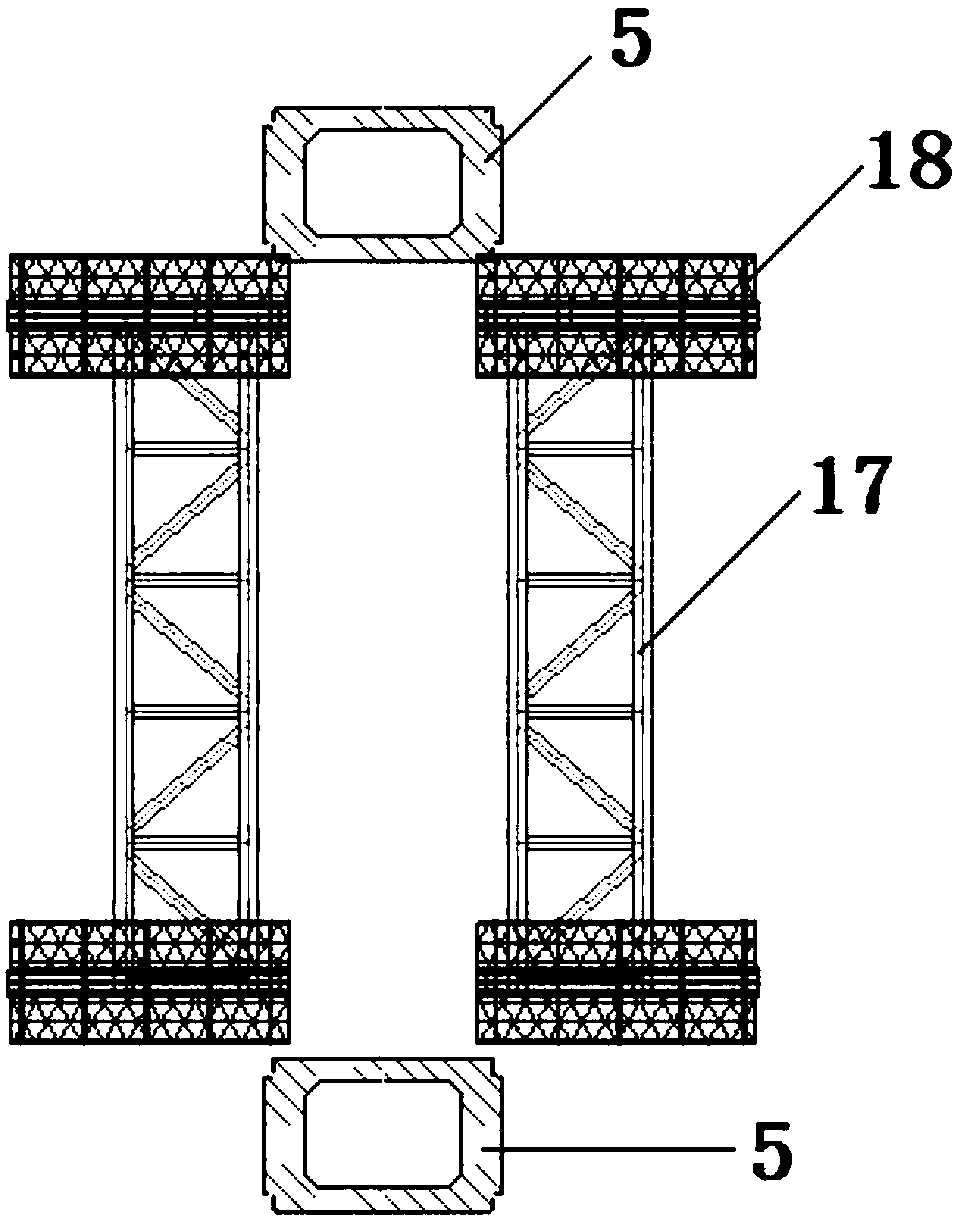

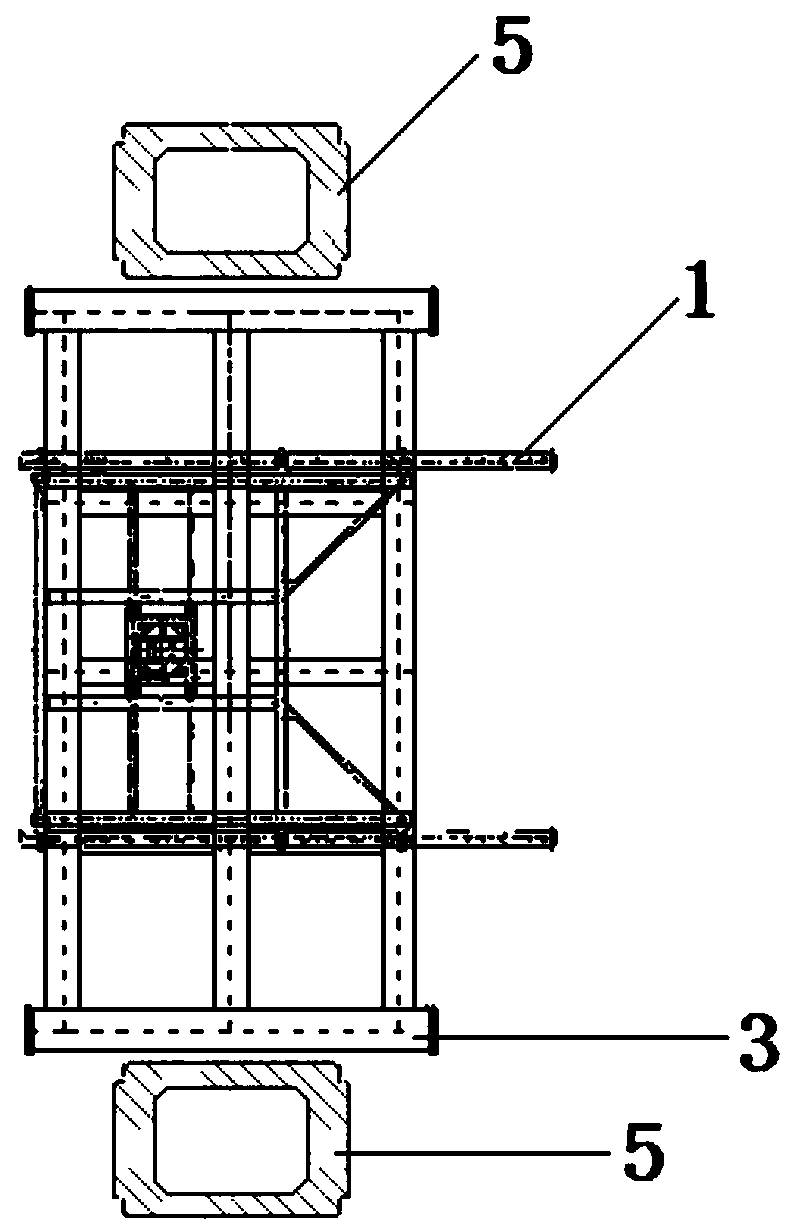

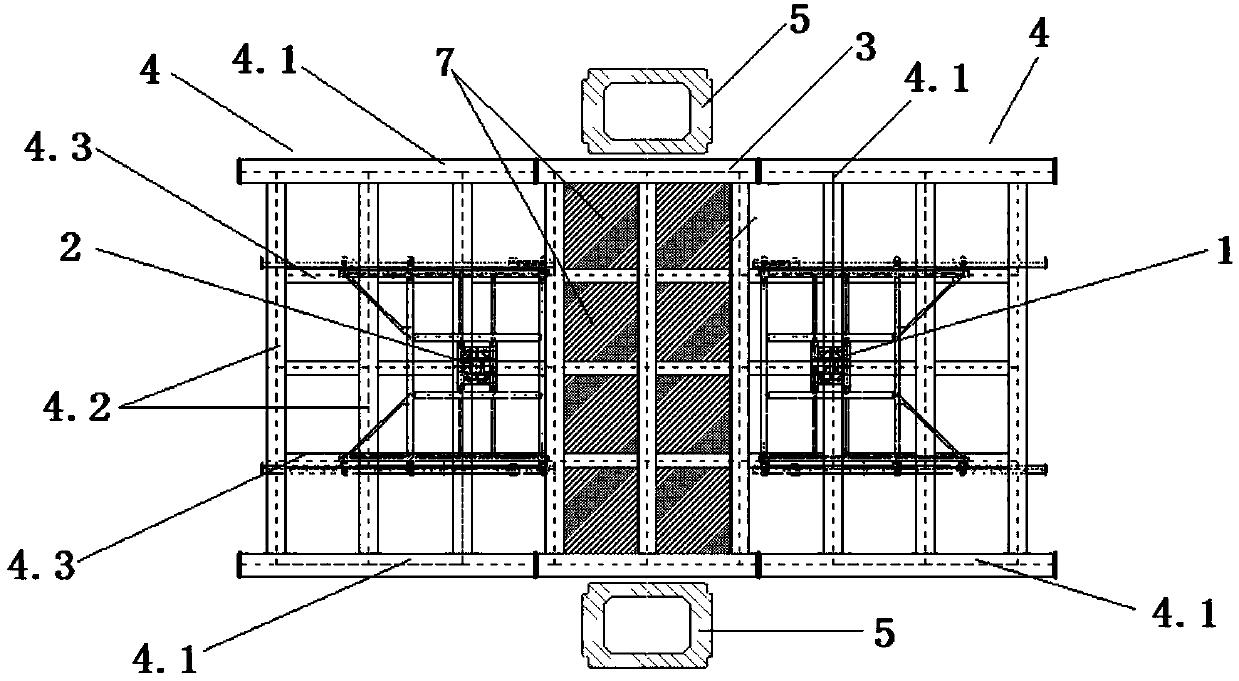

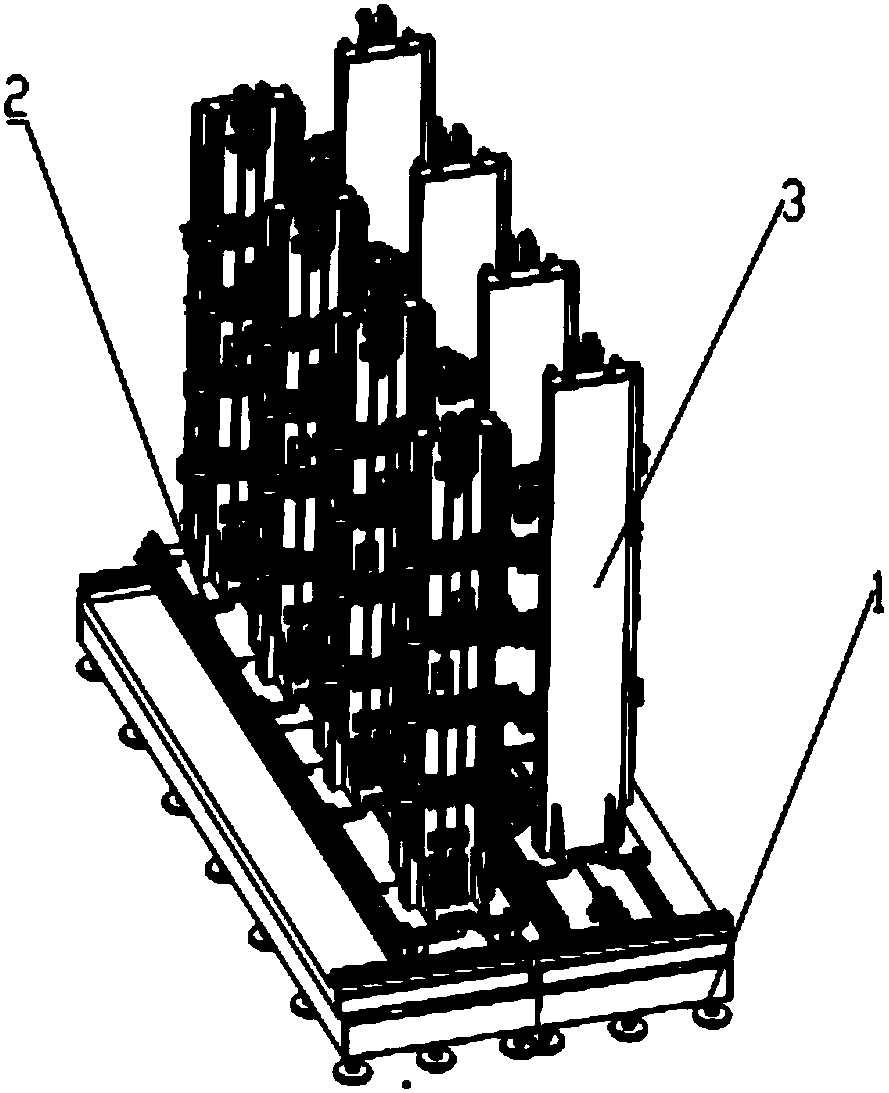

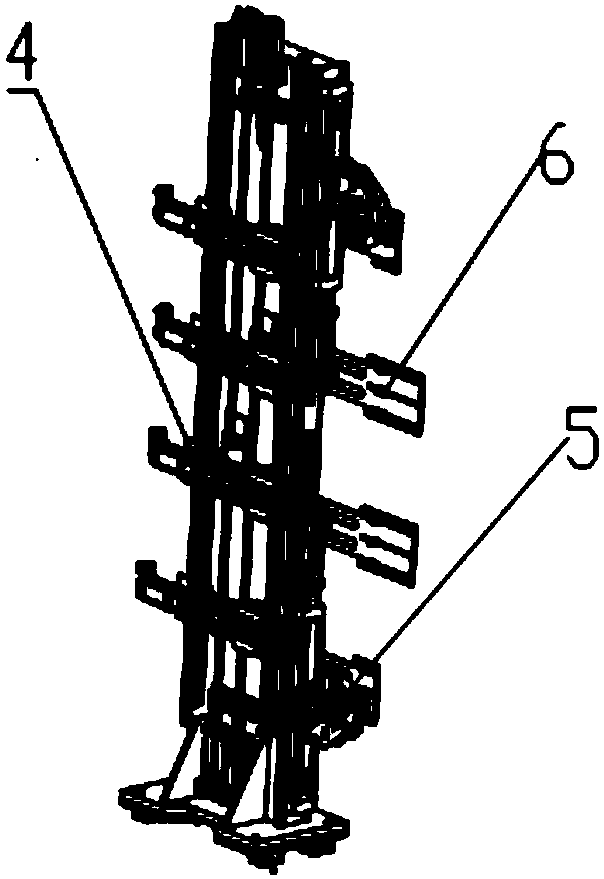

Reconfigurable aircraft panel assembly device

ActiveCN108082531AMeet assembly needsReduce work intensityWork holdersAircraft assemblyReconfigurabilityUltimate tensile strength

The invention discloses a reconfigurable aircraft panel assembly device which is suitable for positioning and mounting of skins and stringers in aircraft panel assembly. No extra auxiliary tool is needed in the positioning process, and the assembly demands of aircraft panels with different sizes and shapes are met. The reconfigurable aircraft panel assembly device is simple in structure, small inoccupied area and high in reconfigurable degree, achieves curved surface positioning point arrangement in assembly of the various different aircraft panels, and accordingly achieves efficient and high-quality assembly of the aircraft panels, the assembly period is greatly shortened, the cost is saved, the demand for personnel in the manufacturing process is reduced, and the work intensity of workers is relived. According to the reconfigurable aircraft panel assembly device, through outer shape adjusting, the positions of inner shape positioning clamping units and outer shape positioning clamping units of the panels can be changed, main positioning face positioning blocks of the positioning clamping units are replaced, the positioning assembly demands of the different aircraft panels are met, and the reconfigurability of the device is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

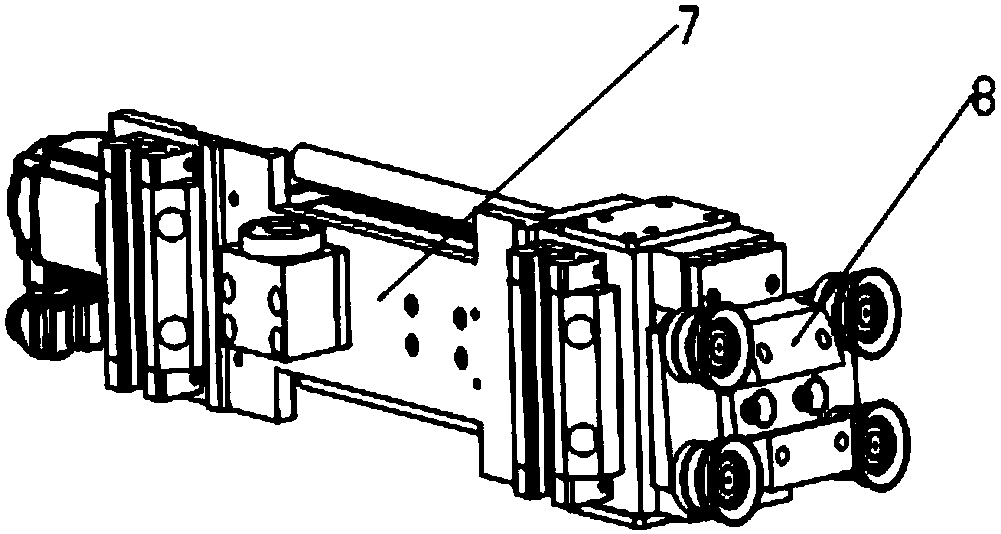

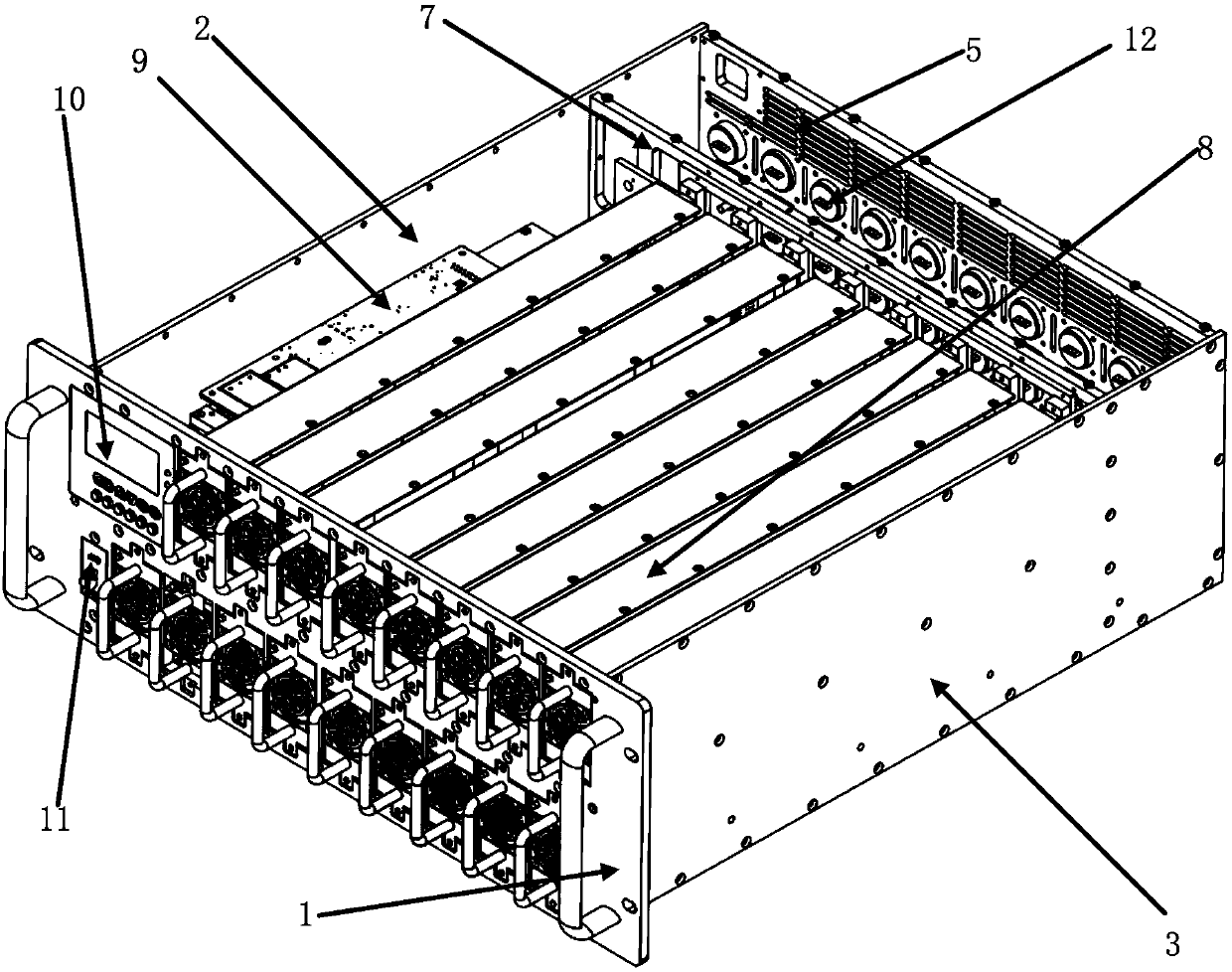

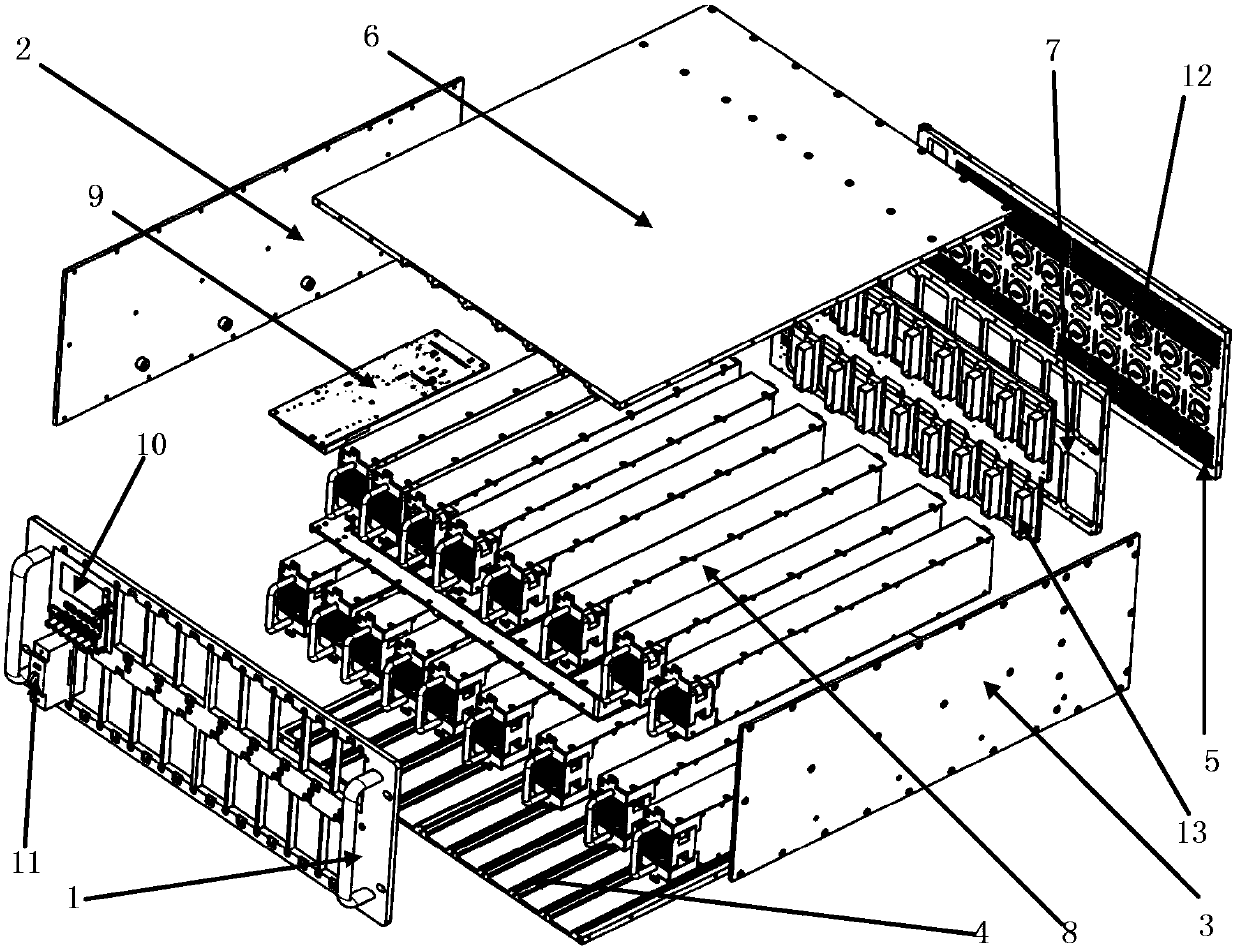

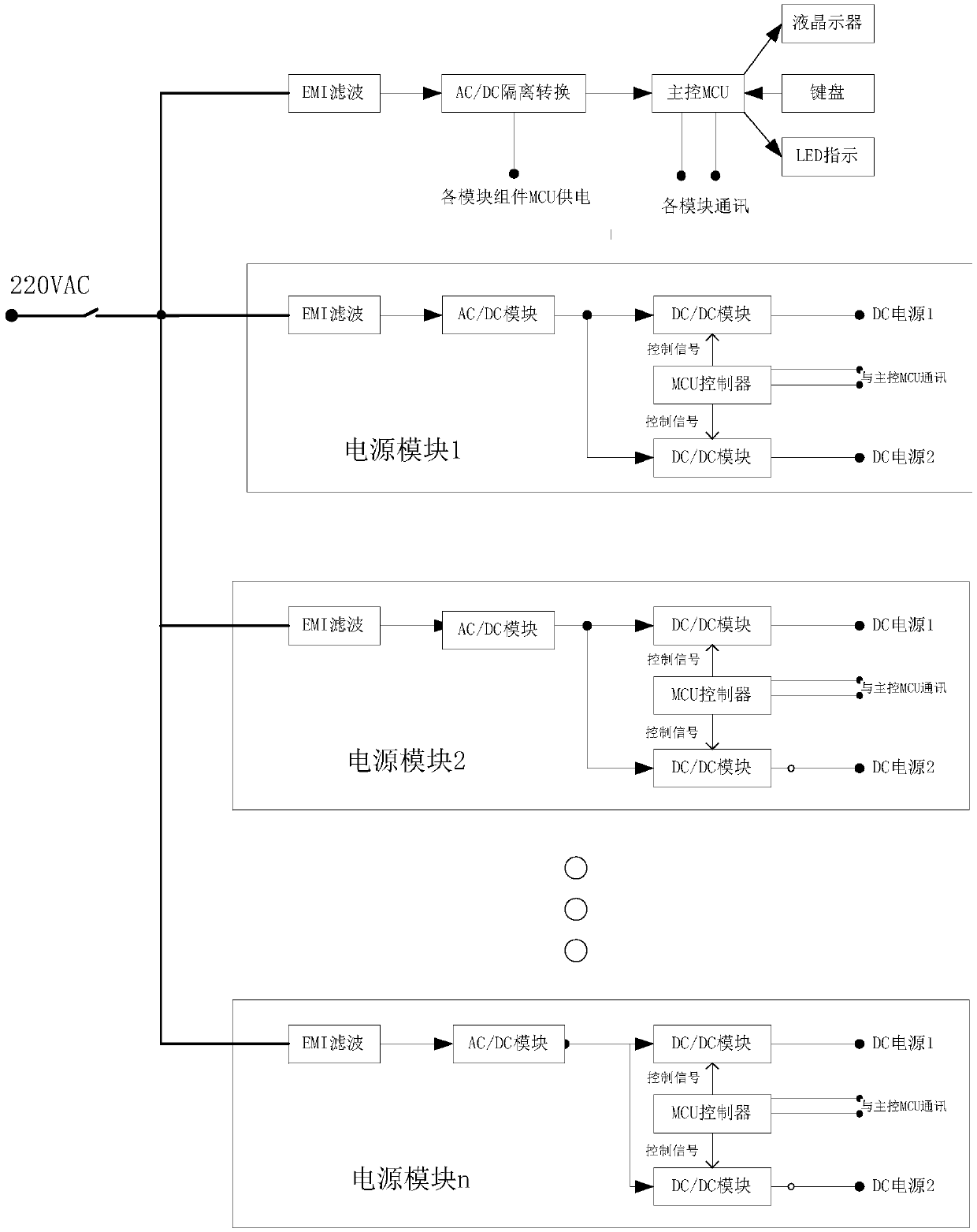

Phased array radar TR component power supply

PendingCN109633559AImprove reliabilityEasy to maintainWave based measurement systemsModifications using gaseous coolantsSurface plateMulti path

The invention discloses a phased array radar TR component power supply. The invention aims to provide the TR component power supply which is high in reliability, high in integration level, convenientto install, maintain as well as upgrade and expand; according to the technical scheme, power supply modules (8) with arch-shaped handles at the front ends are arranged in module channels of a power supply machine box bottom plate (4) side by side in a ranks mode through rectangular windows arranged in a linear array configuration mode through a power supply machine box front panel (1), the tail ends with connectors are inserted into module blind-plug connectors (13), the module blind-plug connectors (13) are connected to power input and output connectors (12) fixed on power supply machine boxrear panels (5) through connecting back plates (7), and are used for outputting a direct-current power supply; one end of a main control panel (9) is connected with a man-machine interaction panel (10) through a high-speed arranging cable, and the other end of the main control panel (9) is connected with the power supply modules (8) inserted in the module blind-plug connectors (13) through the connecting back plates (7), and reliable and stable conversion from one path of high-voltage alternating-current power supply to multi-path low-voltage direct-current power supply is completed.

Owner:10TH RES INST OF CETC

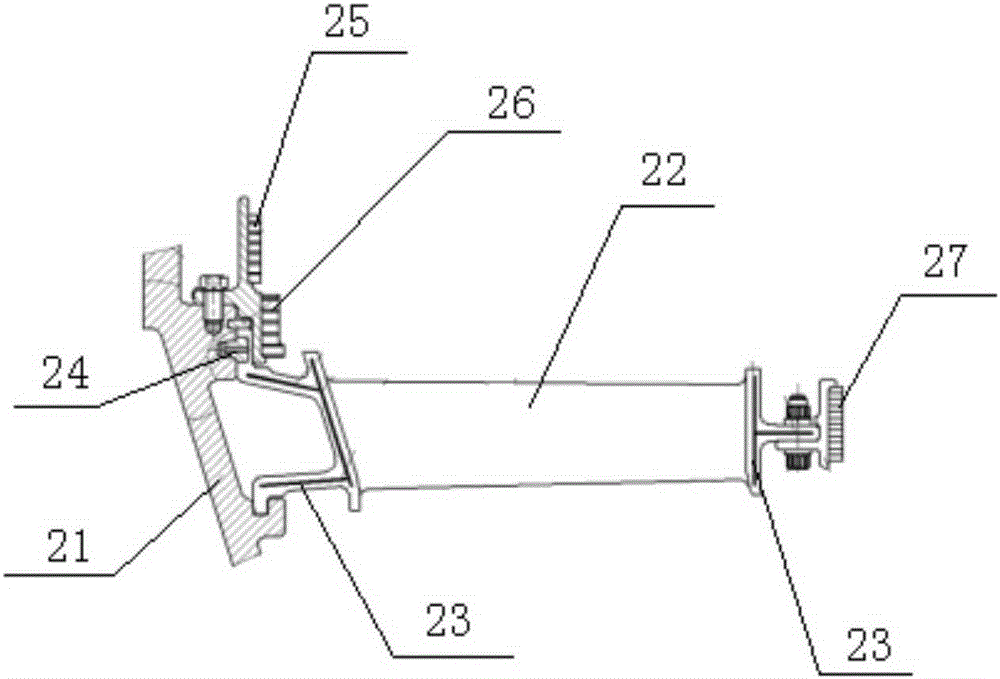

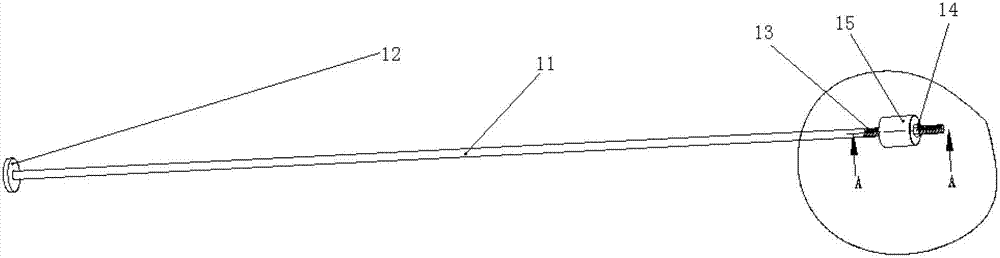

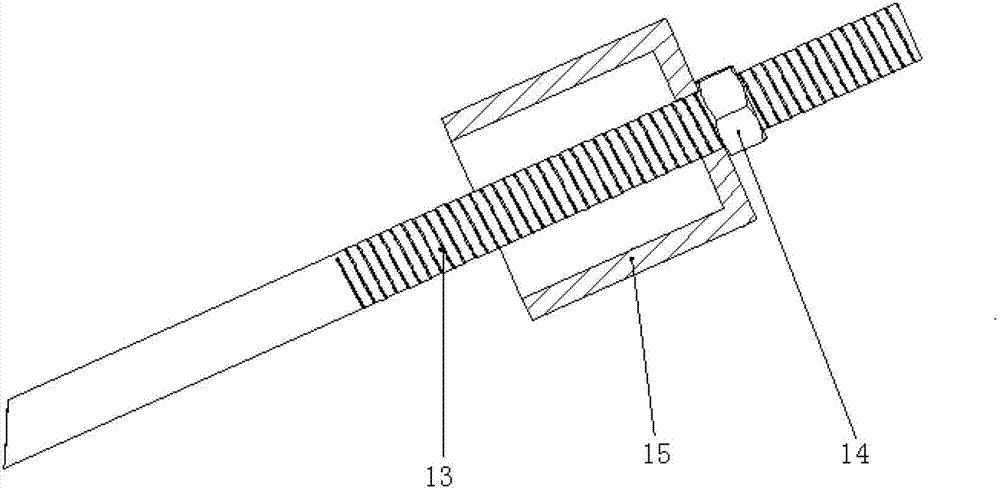

Tool and method for assembling transmission spindle and gearbox in wind turbine generator

InactiveCN103042378AGuaranteed assembly accuracyQuick assemblyMetal working apparatusEngineeringScrew thread

The invention discloses a tool for assembling a transmission spindle and a gearbox in a wind turbine generator. The tool comprises a primary positioning mechanism, and a pull rod mechanism. The primary positioning mechanism is used for lifting and moving the transmission spindle to keep the axis of the transmission spindle to be horizontally level to the axis of the gearbox, and slightly inserting the transmission spindle into a locking disk hole of the gearbox. The pull rod mechanism comprises a pull rod which can penetrate through a cable hole on the transmission spindle and a cable hole on a hollow shaft of the gearbox. One end of the pull rod is provided with a top ring which can overlap with the large end of the transmission spindle. The other end of the pull rod is in threaded structure on which a locknut is fitted. A protective hoop is sleeved on the pull rod inside the locknut and is used for contacting with the outer wall of the gearbox so as to locate the hollow shaft of the gearbox inside the protective hoop. The invention further discloses an assembly method of the assembly tool. By the use of the tool and method, fast assembly is achieved with guaranteed assembly precision and with no damage to the transmission spindle and the gearbox, and assembly efficiency is improved greatly.

Owner:国能联合动力技术(保定)有限公司

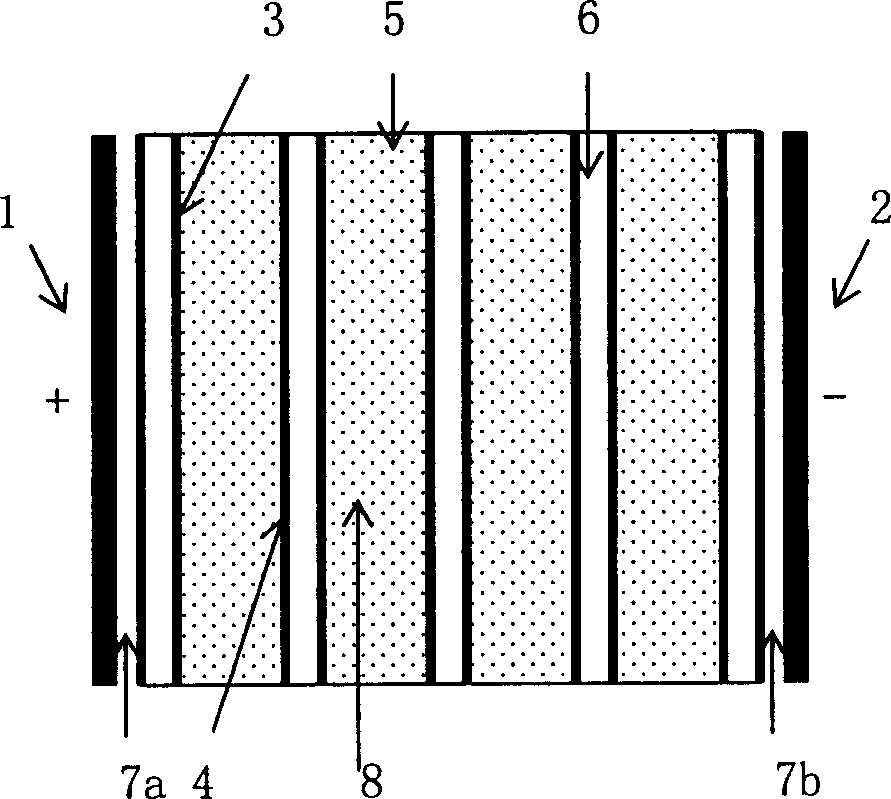

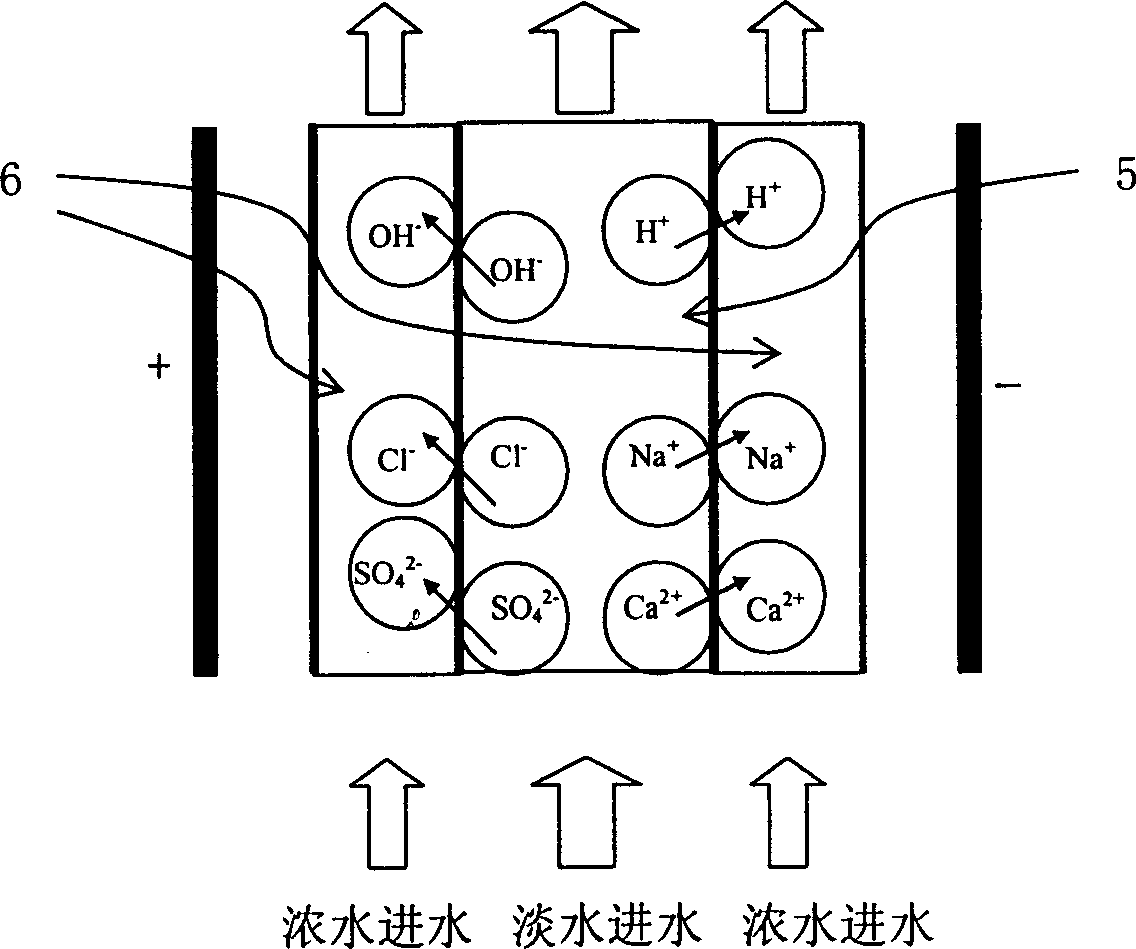

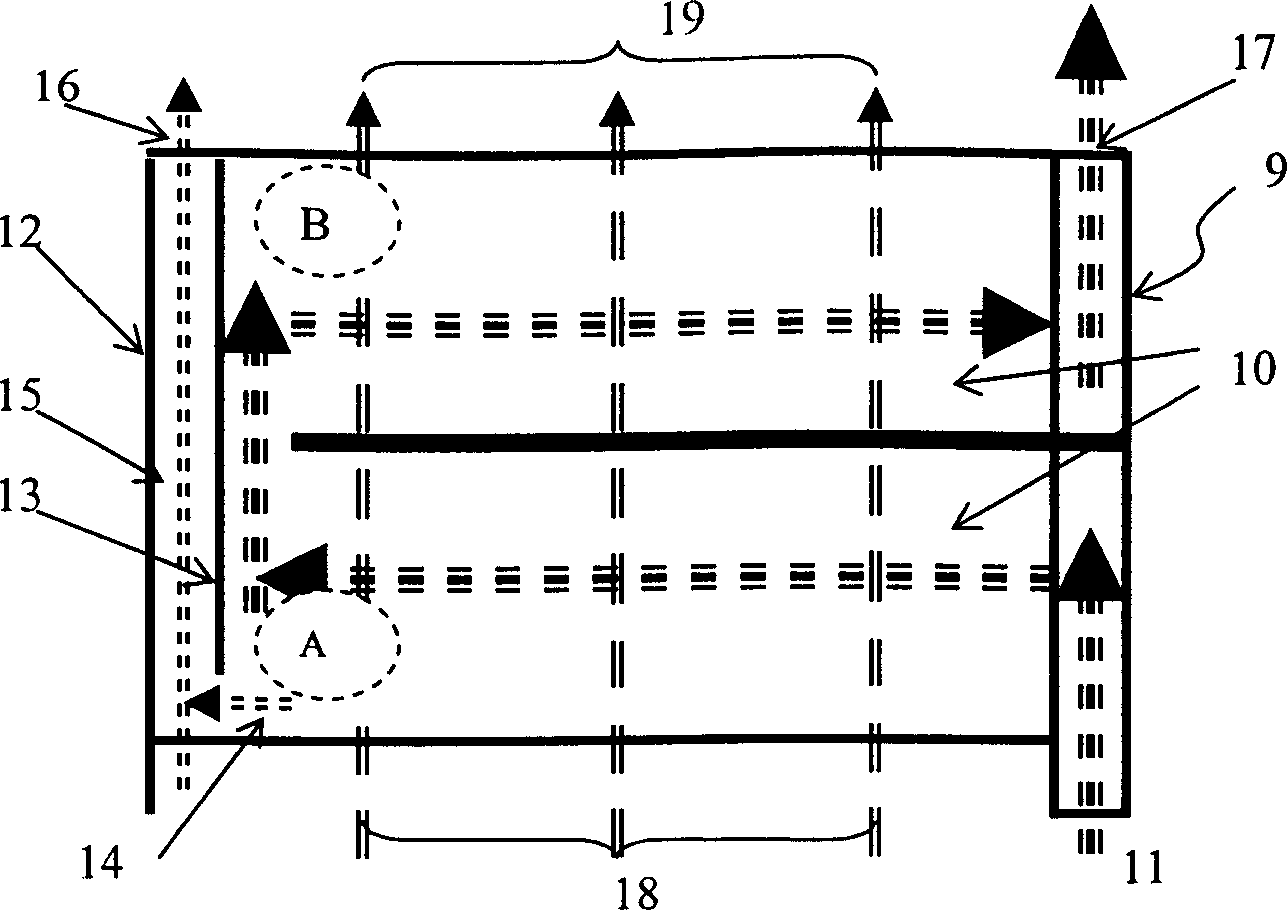

Continuous electrodeionization device

InactiveCN1864823ASimplify the assembly processShorten assembly cycleDispersed particle separationElectrodialysisElectricityWater flow

The invention discloses a plate-and-frame electric deionizing unit. One side of working zone of freah water room is equipped with a fresh water room opening (21) connected to it; said opening is used as filling port for filling or changing ion material, and is sealed by sealing baffle; the two relative sides in heavy concentration water room working zone paralleling to fresh water flowing direction are provided with water inlet (25) and outlet (26) for heavy concentration room respectively; said inlet and outlet extend along direction parallelling to fresh water flowing direction. It is convenient for said device to fill and change resin on the pot, and adjust the resin filling ratio; the sealing problem caused by resin particle is avoided; and the water flow direction of fresh water and heavy concentration water is in cross flow.

Owner:四川龙瑞源环境科技股份有限公司

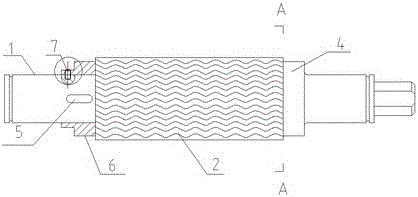

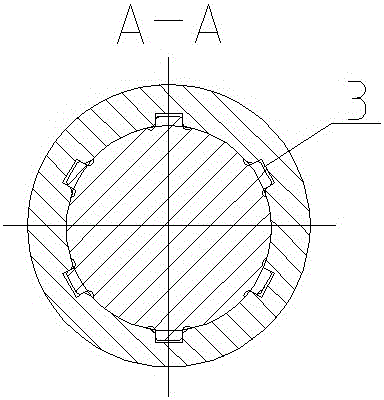

Combined type roller for rolling wave form corrugated composite boards

InactiveCN106734214ASolve deviationIncrease contact areaRollsMetal rolling arrangementsWave formComposite slab

The invention discloses a combined type roller for rolling wave form corrugated composite boards and belongs to the technical field of rollers. The combined type roller for rolling wave form corrugated composite board belts comprises a roller shaft, a roller shell, a spline, a flat key, a locking check ring and a screw. The combined type roller is structurally characterized in that an external spline is arranged on the roller shaft, an internal spline groove is formed in the roller shell, the roller shell is arranged on the roller shaft, the spline plays a role in positioning and is a rectangular spline, the outer surface of the roller shell is in a wave form corrugation shape, the metal composite board belts with wave form corrugation can be rapidly rolled, the contact area of a metallic matrix can be increased by using the wave form corrugation roller for making blanks, the combination strength of composite board interfaces can be enhanced, and the recombination rate of composite board interfaces can be increased; a step-shaped shaft shoulder is arranged at one end of the roller shaft and axially fixes the roller shell; and locking positioning, in the axial and radial directions of the roller shaft, of the other end of the roller shell is achieved through the cooperation of the flat key, the locking check ring and the screw. According to the combined type roller, the centring precision of the roller is high, the stability of centring is extremely high, axial roller shifting is prevented, the roller shell can be rapidly dismounted, and the assembling period of the combined type roller is shortened.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Alignment method of unfocused interference spectrometer

ActiveCN110470398AReduce the difficulty of ground installationHigh accuracy consistencyRadiation pyrometryInterferometric spectrometrySpace environmentEngineering

In order to solve the technical field of high ground alignment difficulty of an unfocused interference spectrometer, the invention provides an alignment method of an unfocused interference spectrometer. The method comprises the following steps of (1) designing and processing trimming pads between components; (2) performing single alignment on each component; (3) in ground air environment, performing integration alignment on each component and the corresponding trimming pads; (4) performing vacuum image surface presetting; (5) curing the assembly precision; and (6) verifying the performance. Byusing a block alignment and unified integration alignment method, the ground alignment difficulty of the unfocused interference spectrometer is greatly reduced; the precision consistency of the unfocused interference spectrometer in a space environment and a ground air environment is improved; meanwhile, the alignment period is shortened; after the alignment in the ground air environment is completed, a vacuum image surface presetting method and mechanics simulation tests are combined; and optical indexes of the unfocused interference spectrometer are enabled to meet the design requirements after the launching phase and orbit insertion.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com