Patents

Literature

572results about How to "Not easy to disperse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

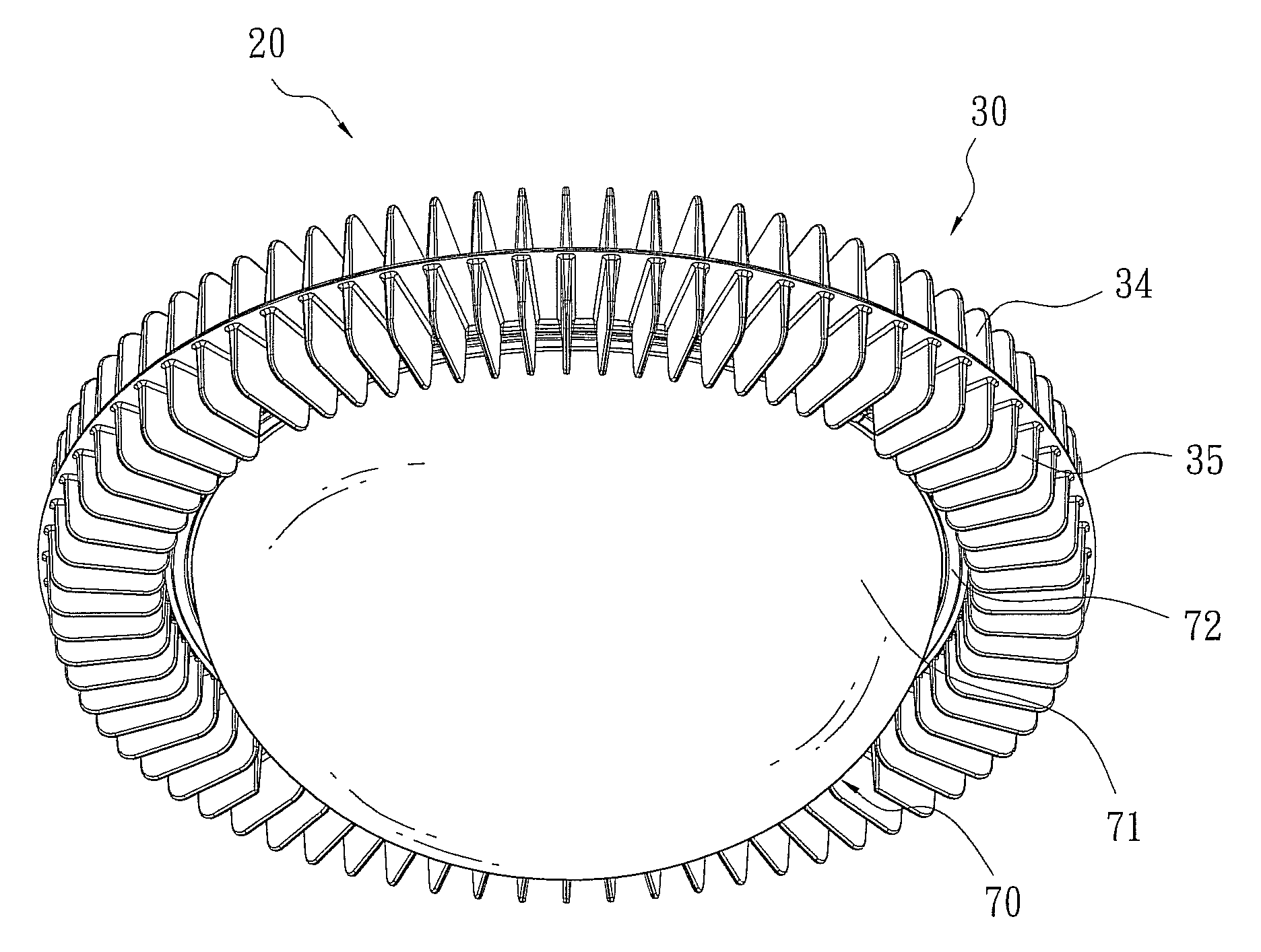

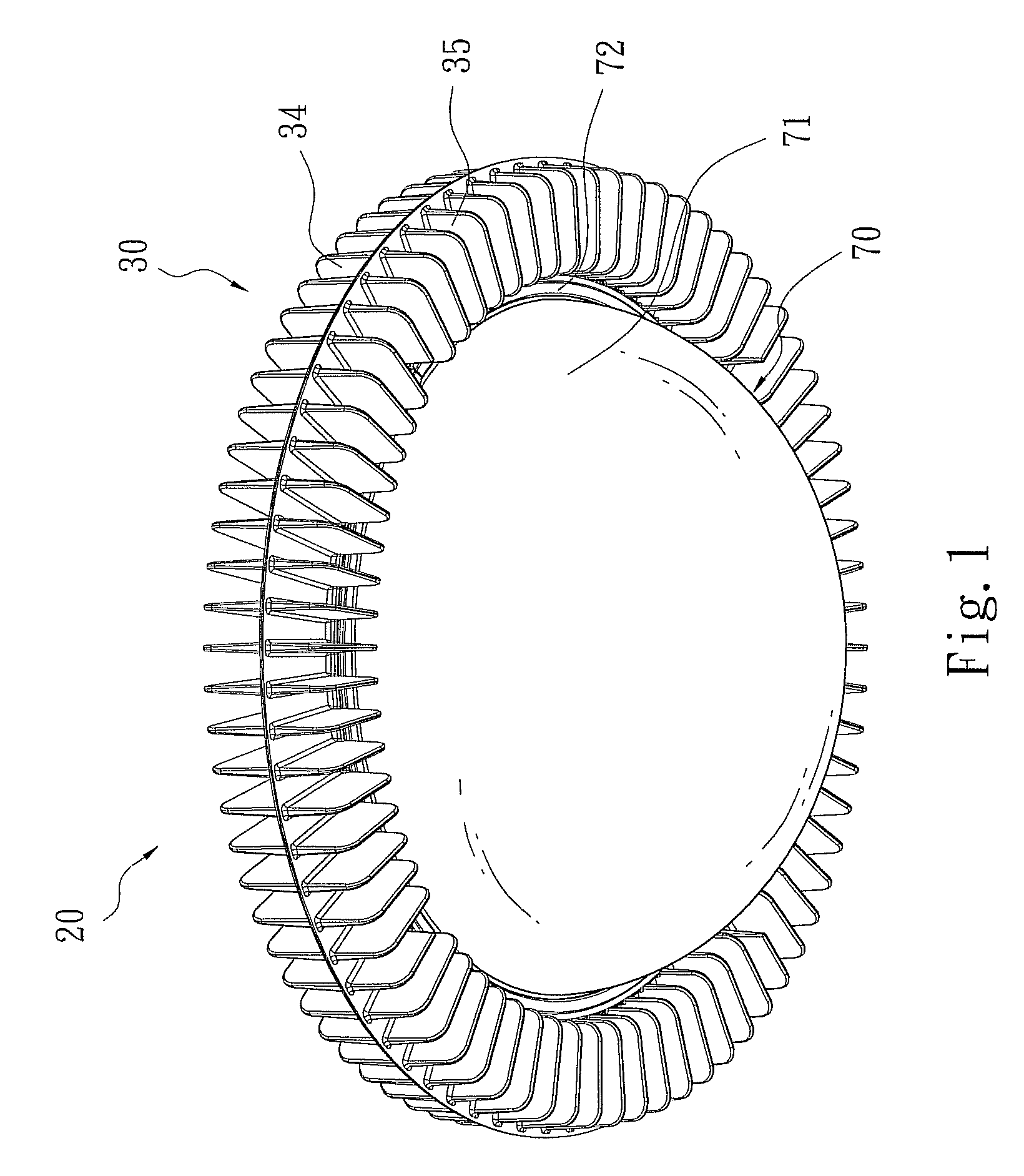

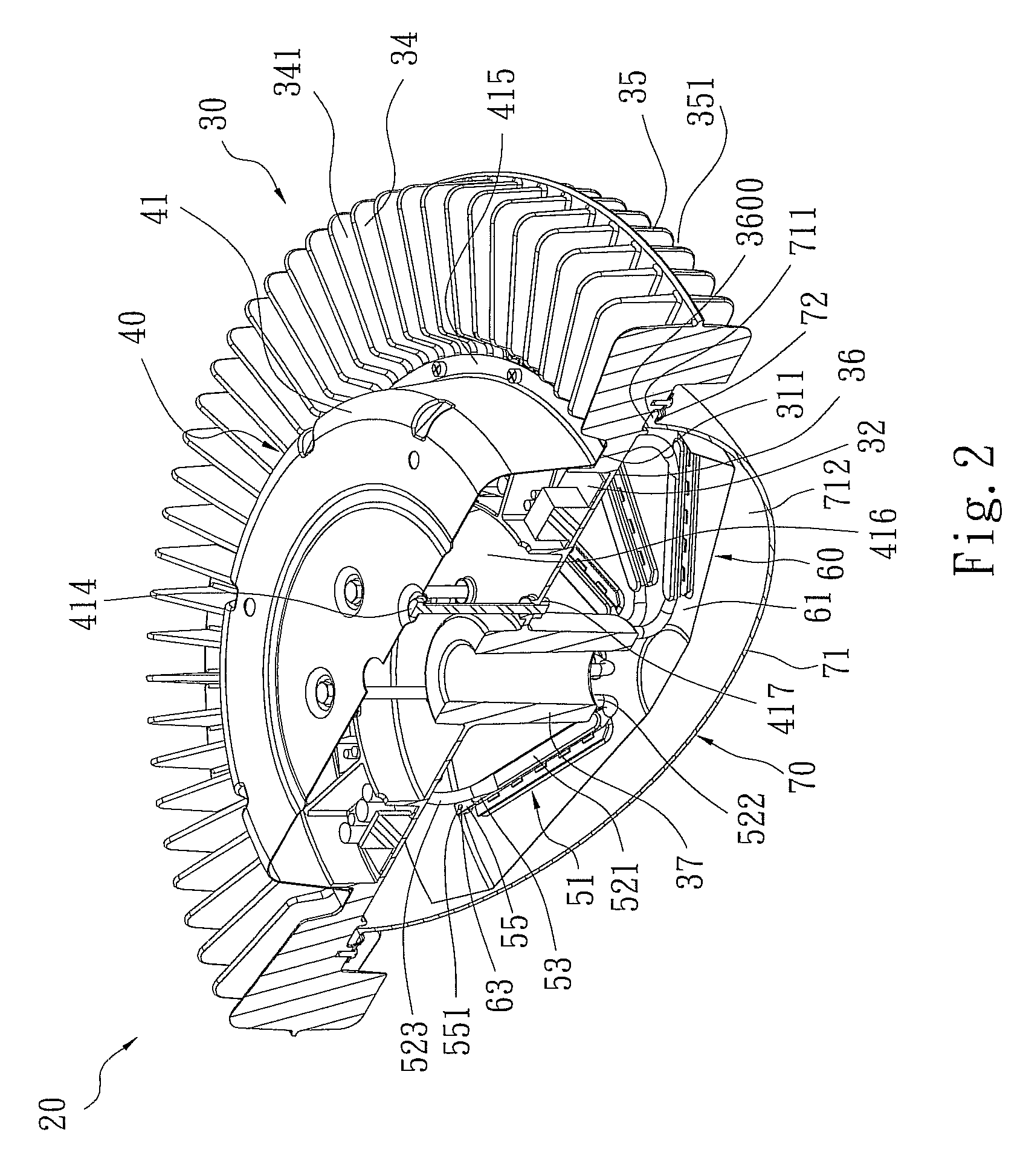

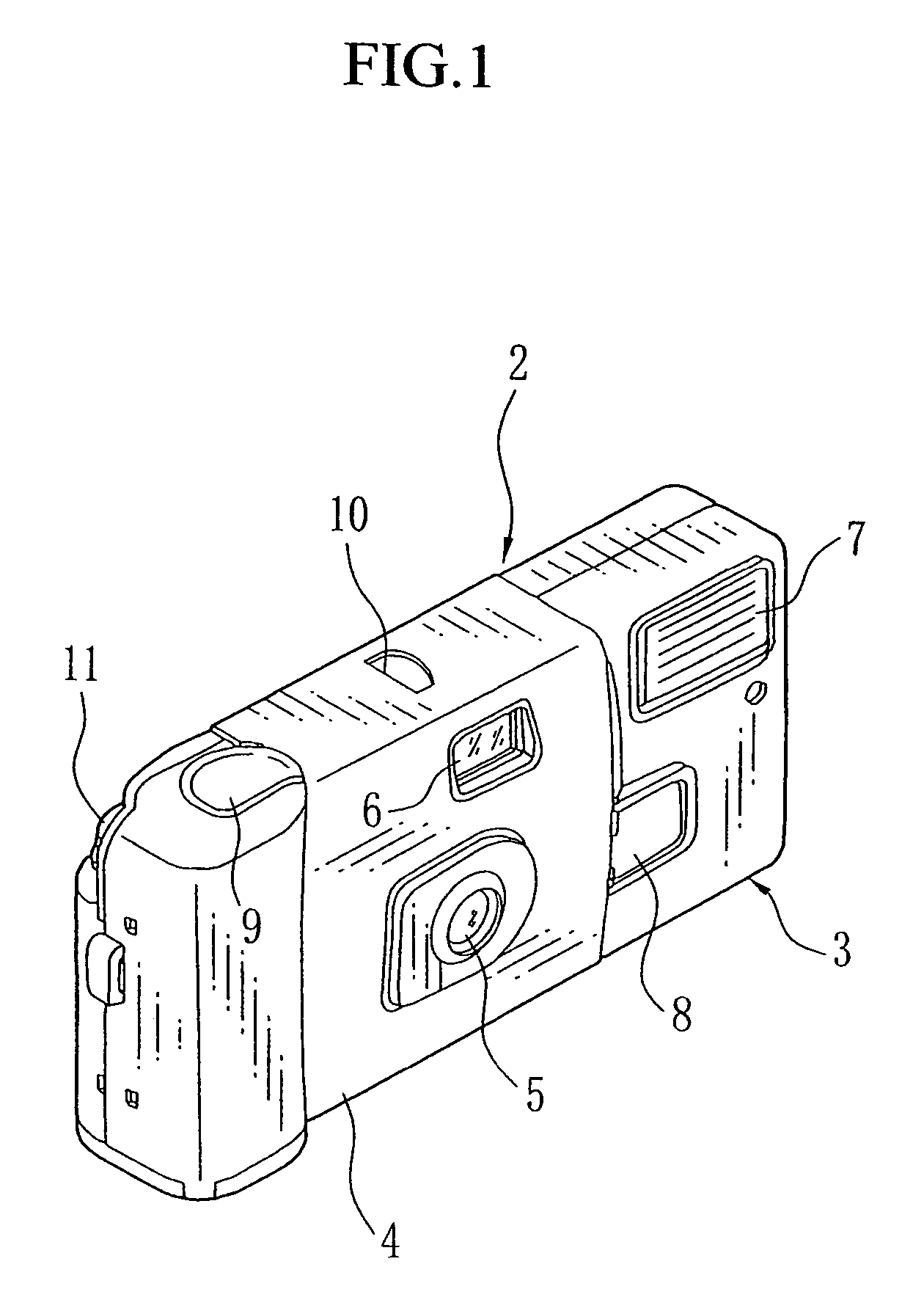

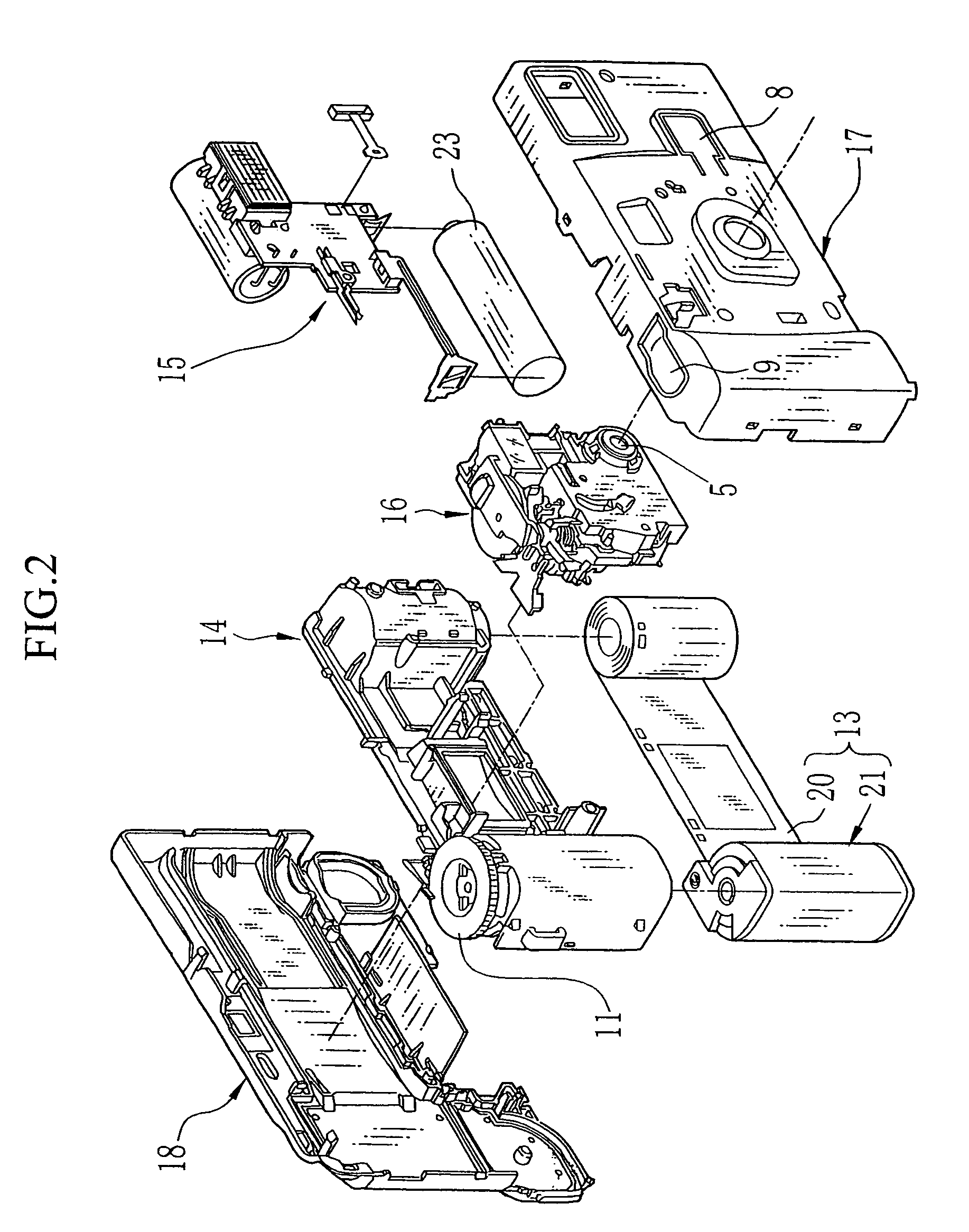

LED lamp

InactiveUS7611264B1Not easy to disperseEffective lightingMechanical apparatusLighting support devicesEngineeringLED lamp

A LED lamp includes a main body surrounded by a fin assembly on the periphery at an upper side and a lower side, a power supply holder located at the upper side and a plurality of LED lamp assemblies located at the lower side. The LED lamp assemblies are encased by a light converging plate which is further encased by a transparent lamp shade fastening to the lower side of the main body. The LED lamp thus formed may be fastened to a ceiling for indoor use through an upper cap of a fastening assembly, or an outdoor electric wire pole through a fastening tray. Each of the LED lamp assemblies has a heat transfer tube to transfer the generated heat to the main body for dispersing through the fin assembly. Thus desired heat dissipation can be accomplished.

Owner:LI HONG TECHNOLOGICAL

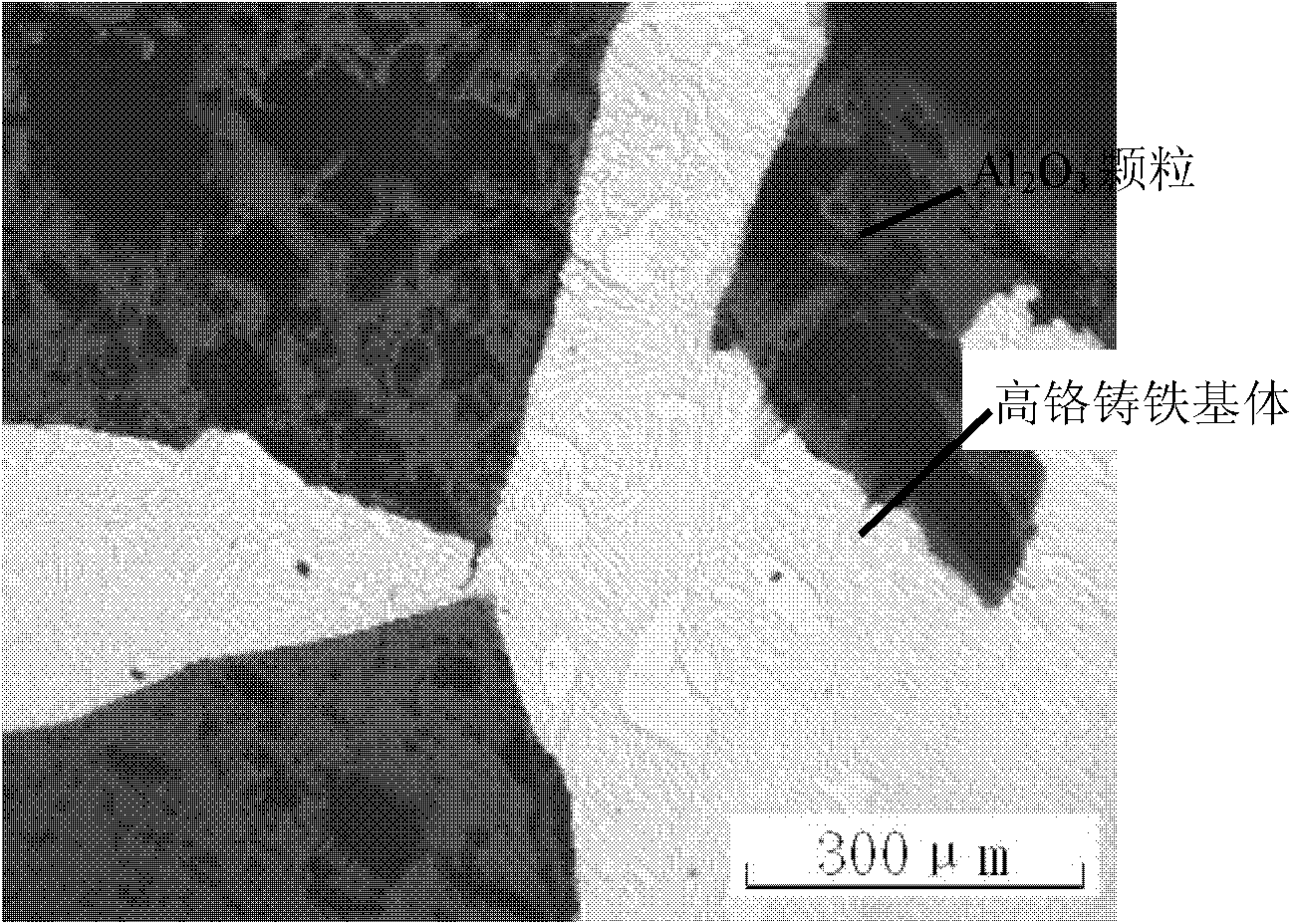

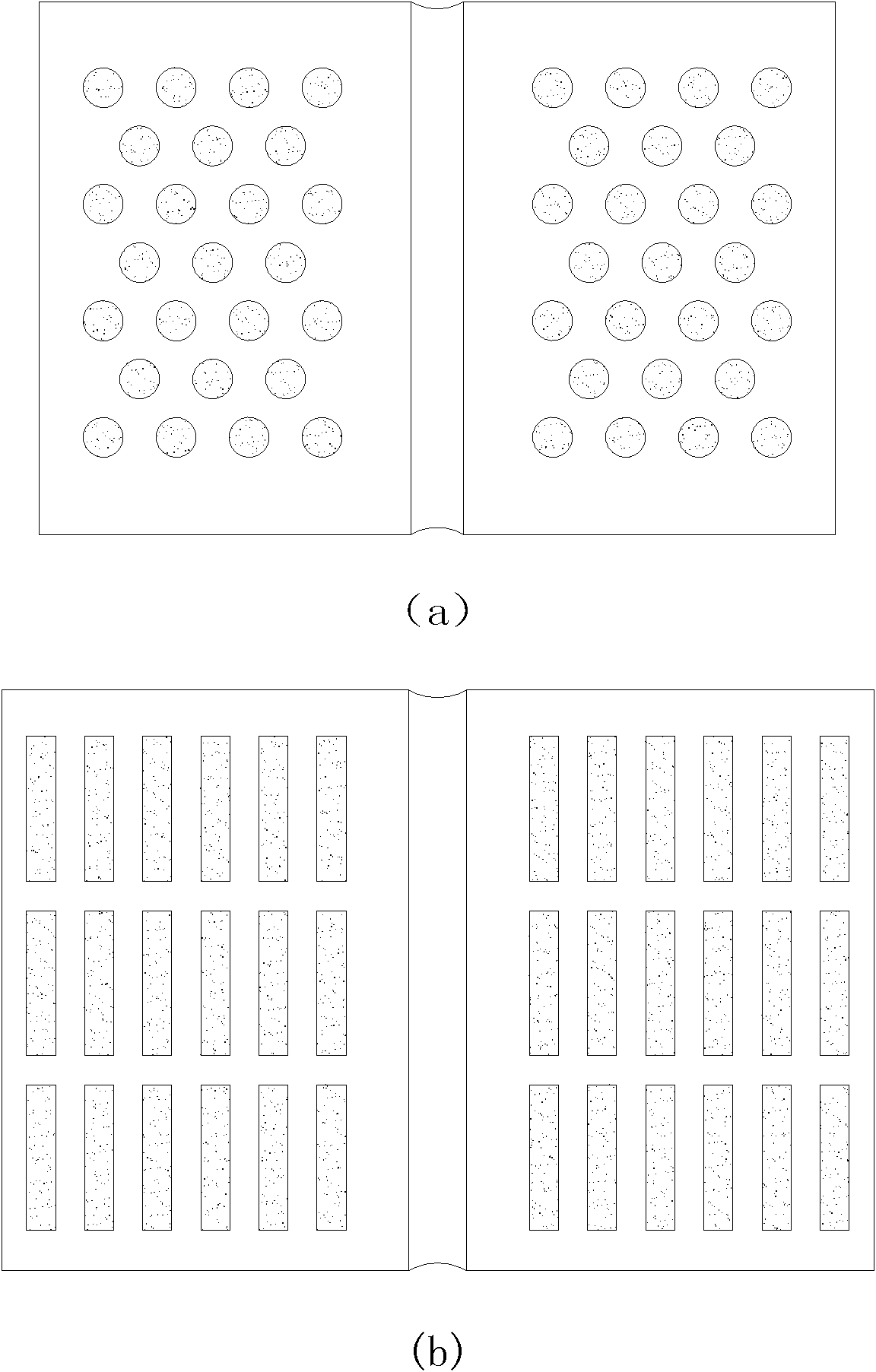

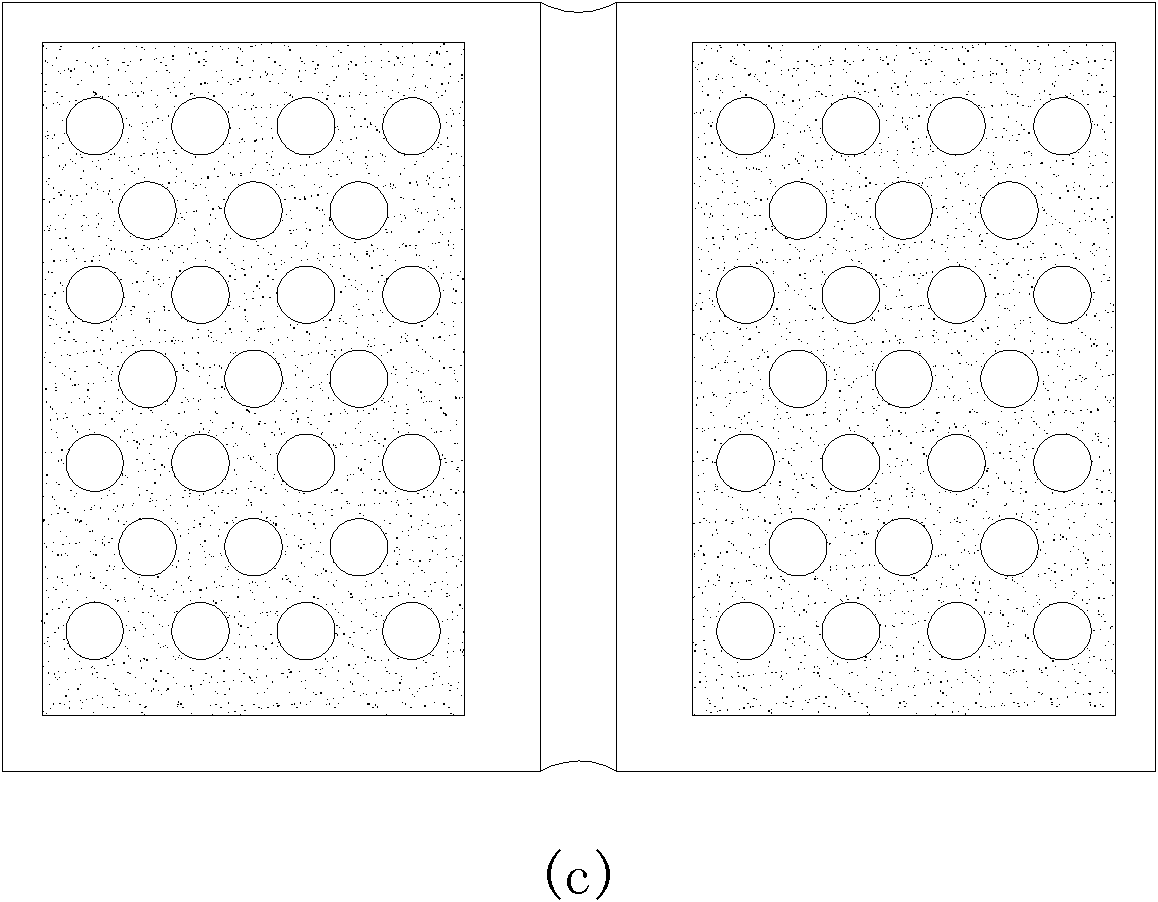

Ceramic particle reinforced composite wear-resistant part and preparation method thereof

InactiveCN101898238ASolve the problem of difficult penetrationImprove wear resistanceCeramic particleWear resistant

The invention relates to a ceramic particle reinforced composite wear-resistant part and a preparation method thereof. The method comprises the following steps: ceramic particles and metal powder are mixed evenly to fill in a special mould; then the mixture along with the mould is placed in a vacuum sintering furnace to sinter, wherein metal powder and ceramic particles are bound together to form a perform; after cooled, the mould is opened to take the perform out and place the perform on the side of the end face of a casting mold cavity; parent metal material is smelted by a medium-frequency induction furnace to form molten metal; during the casting, the molten metal is poured, metal powder in the perform is molten to form a cast-penetration path under the heat of molten metal, thus the molten metal can easily penetrate ceramic particles to form particle reinforced composite material in situ; and the surface layer of the obtained wear-resistant part consists of parent metal and composite material. The wear resistance of the composite material prepared by the method of the invention is ensured and the composite material has high impact resistance.

Owner:XI AN JIAOTONG UNIV +1

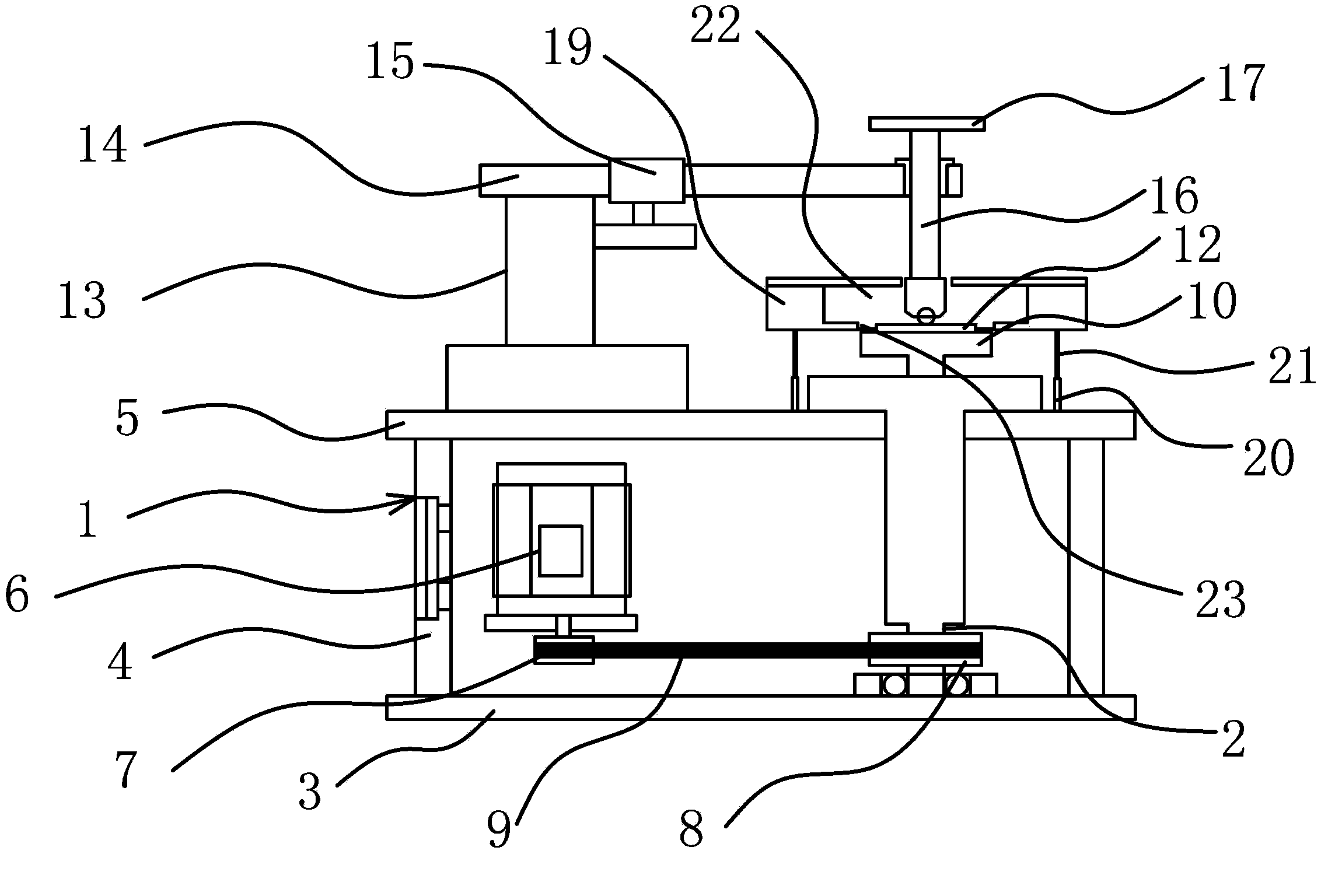

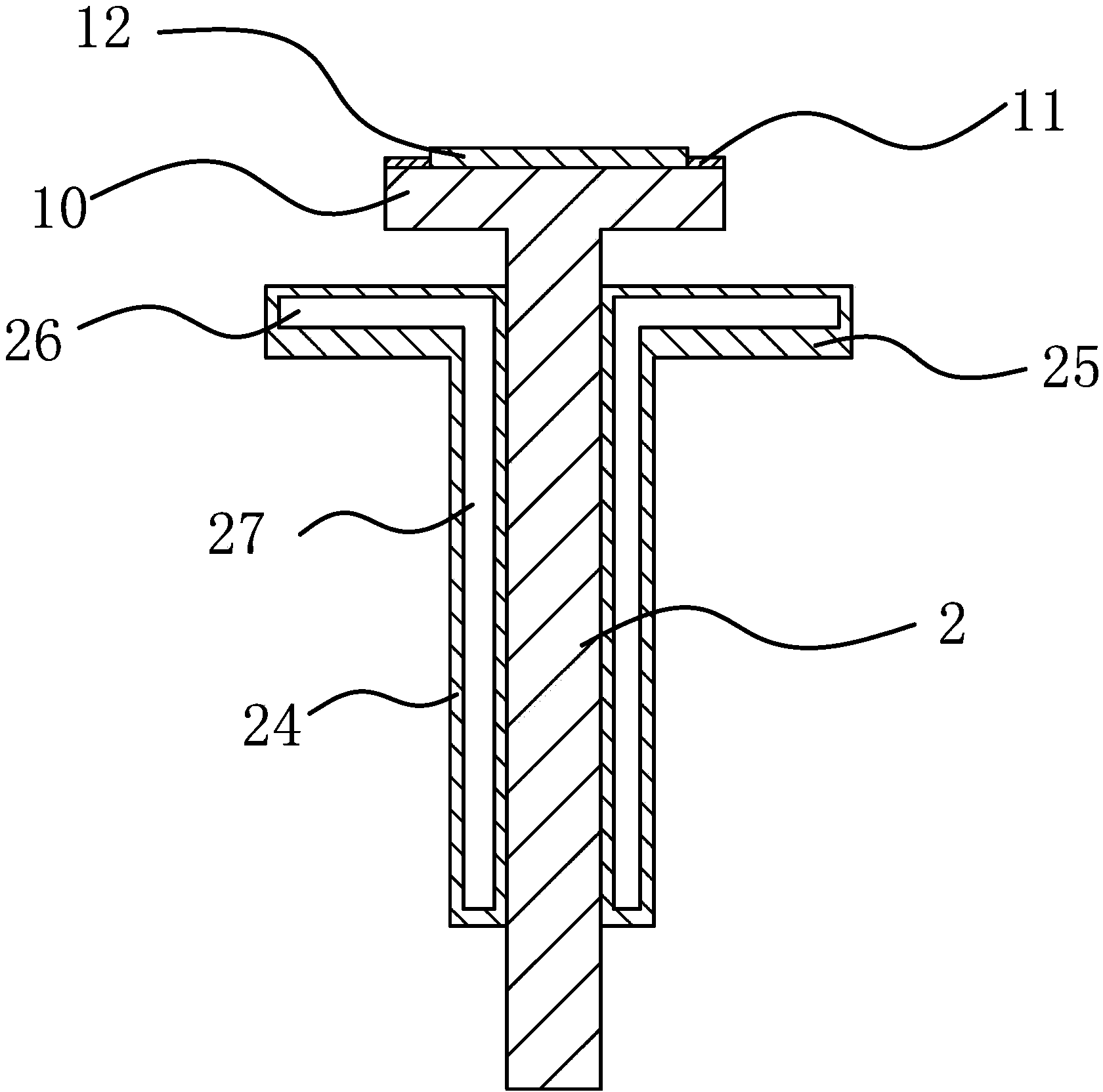

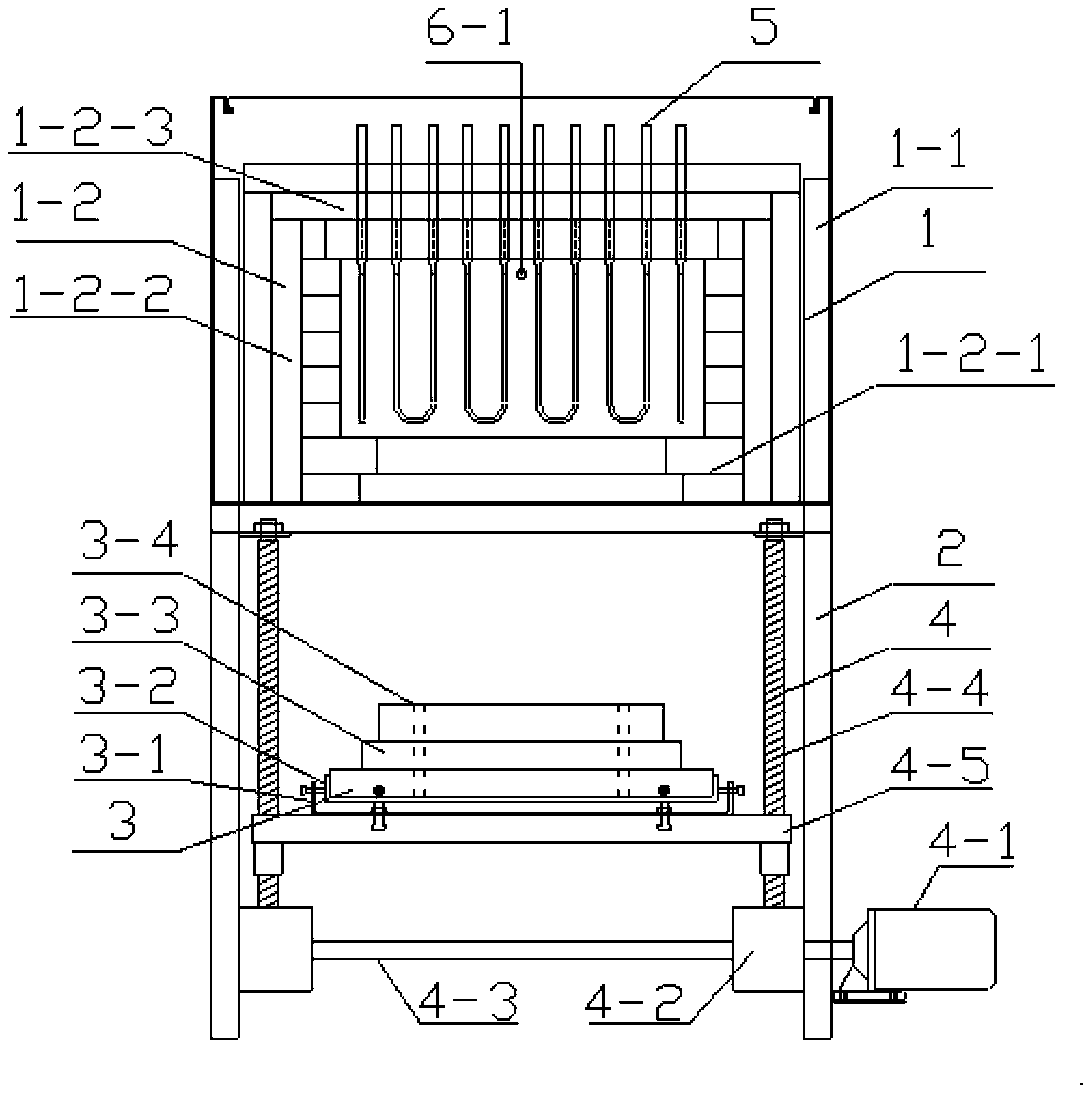

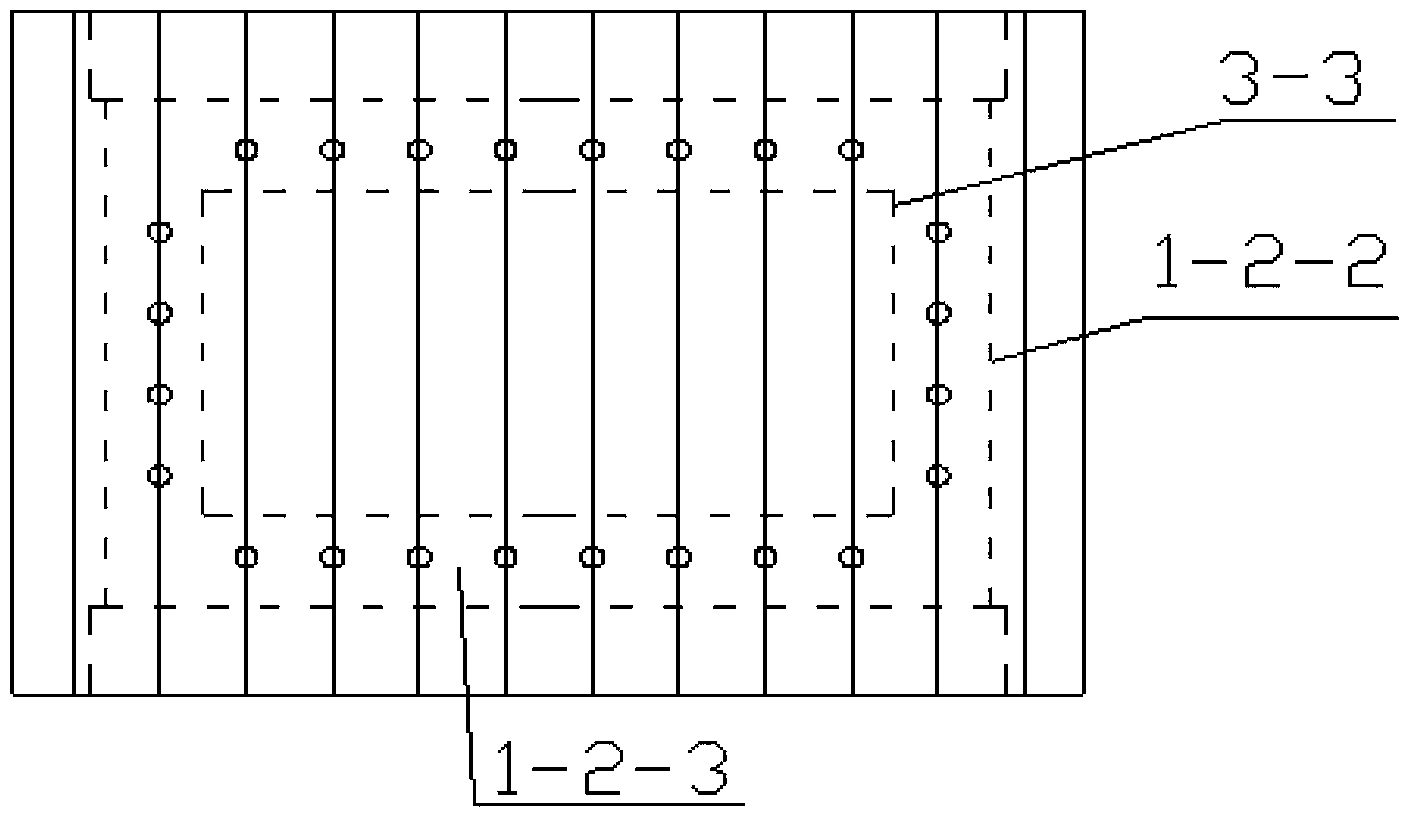

High temperature friction wear testing machine

InactiveCN103364296AAvoid stickingEasy to disperseInvestigating abrasion/wear resistanceWear testingThermal insulation

The invention provides a high temperature friction wear testing machine, belongs to the technical field of material wear tests, and solves the technical problems that the test precision of the testing machines in the prior art is low and the like. The high temperature friction wear testing machine comprises a frame. The frame is provided with a rotating shaft, and is also provided with a driving device. The top end of the rotating shaft is provided with a tray, the surface of the tray is coated with a thermal insulation layer, and a friction disk is fixed on the surface of the tray. The frame is provided with a bracket, and the bracket is provided with a beam. The beam is provided a force value sensor, and a loading rod is arranged at one end of the beam. A specimen holder is arranged at the bottom end of the loading rod. The high temperature friction wear testing machine comprises a high temperature furnace. The high temperature furnace is provided with a heating cavity, and the bottom end of the loading rod is inserted in the heating cavity. An opening is arranged at the bottom part of the heating cavity, the tray is located out of the opening, and the friction disk is located in the heating cavity. The high temperature friction wear testing machine has the advantages of high test precision and the like.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Sand modification method suitable for high-wind-erosion and high-water-erosion areas

The invention provides a sand modification method suitable for high-wind-erosion and high-water-erosion areas. The method includes: respectively drying various sludge rich in bacteria, various decayed straw, forest litter powder or forest soil rich in actinomycetes and fungi, organic flocculants at normal temperature, and mixing the same to obtain mixture, and storing; well mixing the mixture with local clay minerals, decomposed coal or humus soil, cross linking with water solution with cross-linking agent at normal temperature to form flocculent mixture, and crushing particles to form microorganism / microorganism cultivation medium cluster; mixing microorganism / microorganism cultivation medium cluster, plant straws, and soil with nitrogen-fixing bacteria, plowing with sand, and pouring 5-50 kilos of starch or molasses water solution to each mu of sand to activate microorganisms. The sand modified by the method is high in water retention, high in wind and water erosion resistance and low in cost.

Owner:QUANZHOU NORMAL UNIV

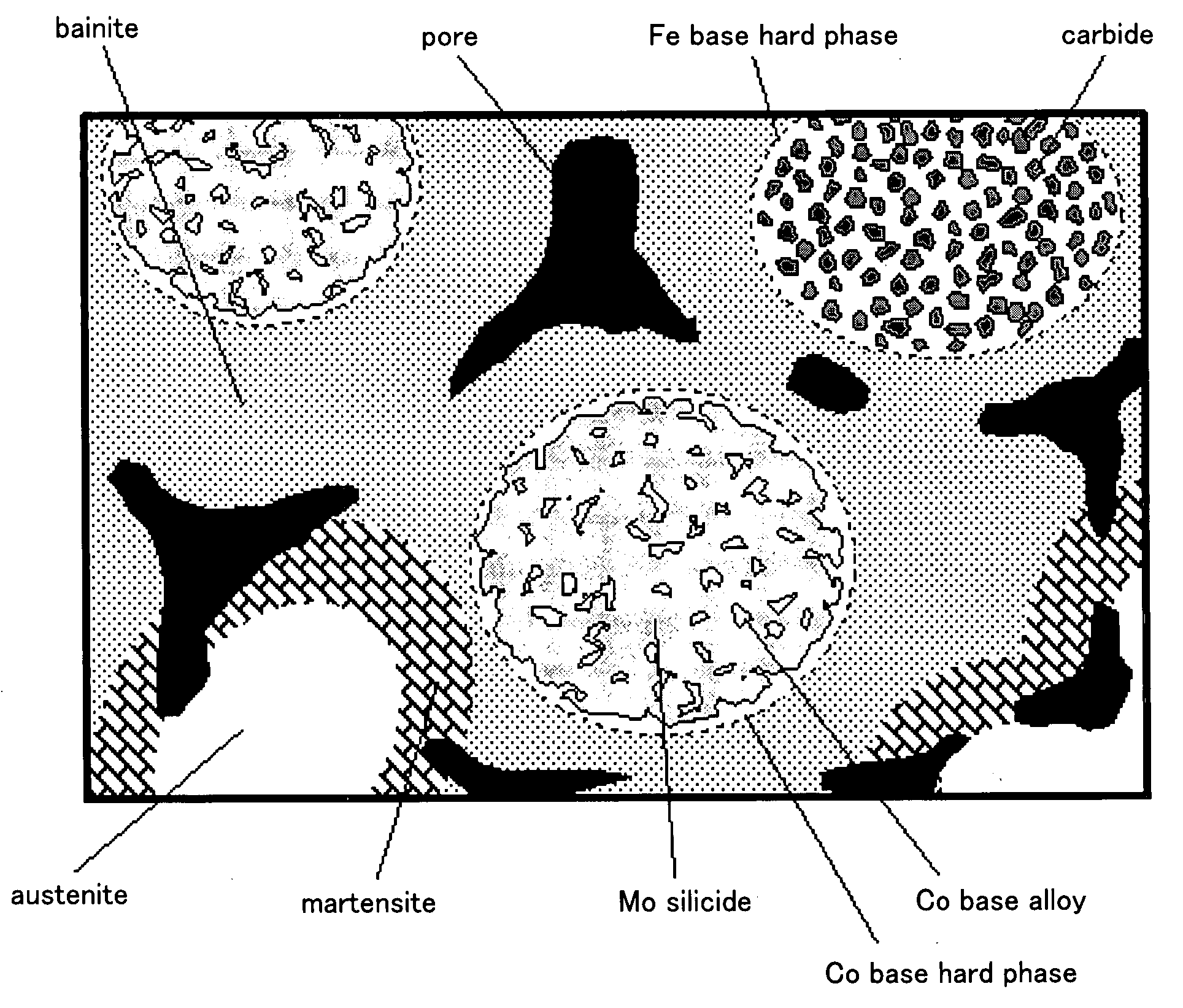

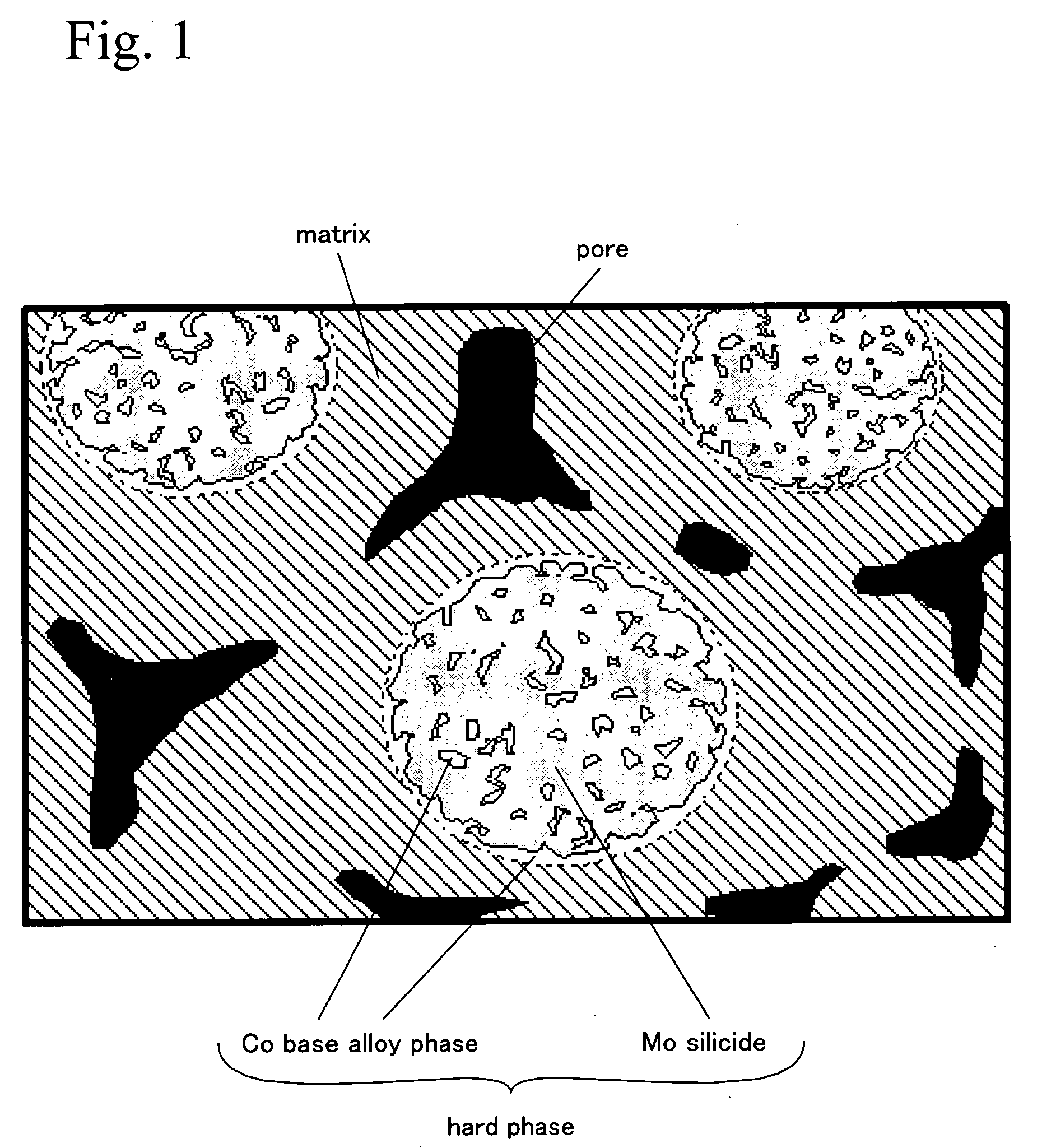

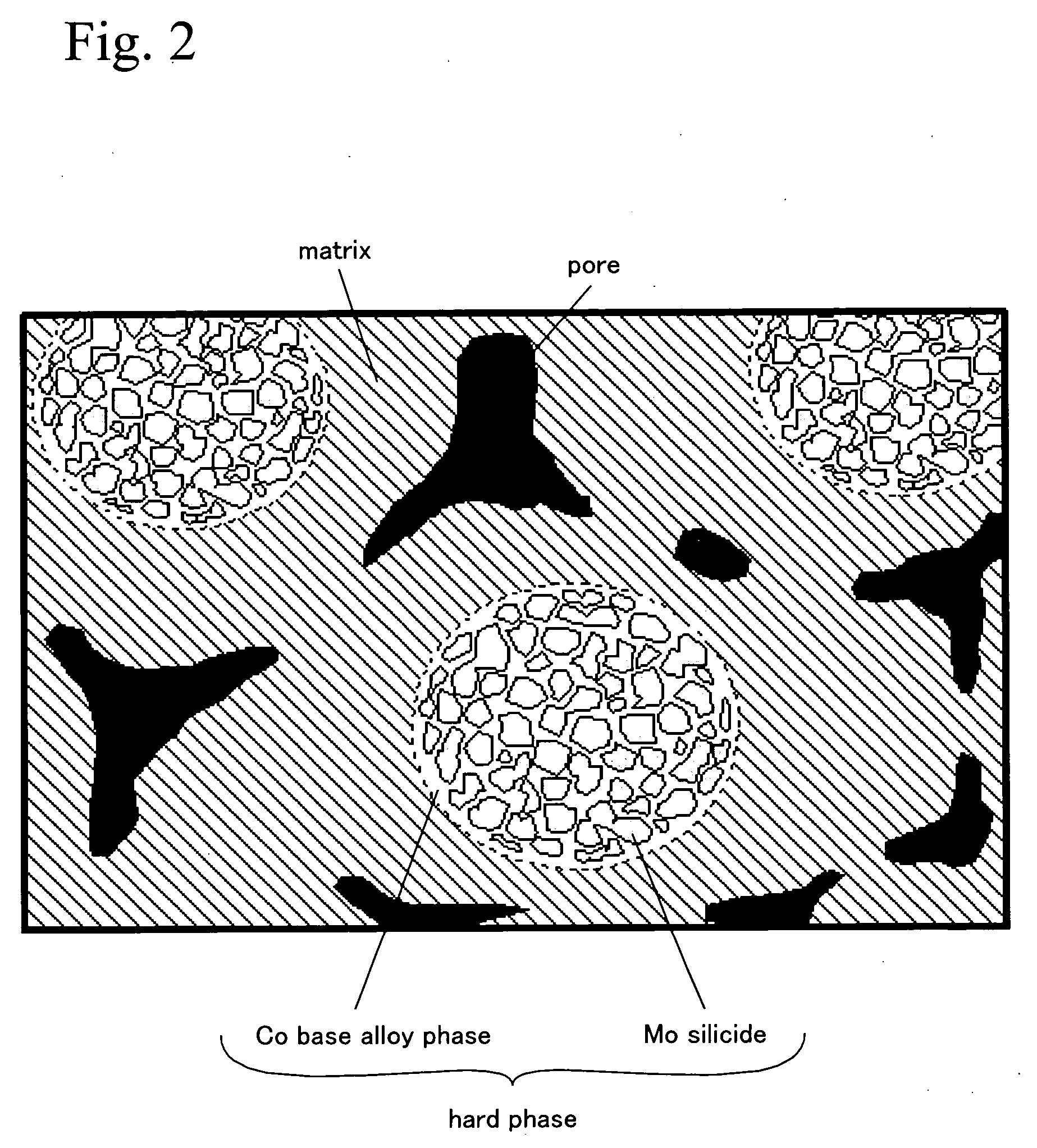

Alloy powder for forming hard phase and ferriferous mixed powder using the same, and manufacturing method for wear resistant sintered alloy and wear resistant sintered alloy

ActiveUS20050132842A1Good high temperature wear resistanceReduce pointsMachines/enginesLift valveWear resistantWear resistance

Alloy powder for forming a hard phase for a valve seat material having excellent high temperature wear resistance. The overall composition is consisted of Mo: 48 to 60 mass %, Cr: 3 to 12 mass % and Si: 1 to 5 mass %, and the balance of Co and inevitable impurities.

Owner:HITACHI POWDERED METALS COMPANY

Coenzyme Q10-containing fine particle with excellent dispersibility

InactiveUS20070053985A1Simple and easy mannerHandleability and transporting abilityBiocidePowder deliveryMicroparticleLotion

The present invention has an object to provide coenzyme Q10-containing particles, which can be easily and simply dispersed into water without any surfactants or other additives, and their production method. The present invention makes it easier to prepare an aqueous dispersion containing coenzyme Q10, which is hard to disperse in water, as fine particles by modifying coenzyme Q10 into a coenzyme Q10-containing fine particle comprising coenzyme Q10 covered with a biocompatible polymer. Therefore, compositions containing dispersed coenzyme Q10 in water, such as drinkable preparations, lotions, etc., can be produced in easy and simple manners.

Owner:KANEKA CORP

Preparation process of composite preform

The invention relates to a preparation process of a composite perform. The invention is characterized in that the preparation process comprises the following steps: taking alloy powder, using absolute ethyl alcohol to prepare ceramic particles which can infiltrate or not infiltrate an iron-based alloy and metal powder into mixture; filling the mixture into a specially designed graphite die; drying, and vacuum-sintering; and cooling, and then obtaining the composite perform the whole of which is in a porous structure. The process for preparing the composite perform of the invention dose not use any binder, dose not generate gases, is in favor of cast-penetration, is convenient for mass production, is simple in operation and has strong universality, and lays a foundation for preparing a particle enhanced iron-based skin layer composite workpiece by using a casting-penetrating method. The perform of the invention is placed at the end surface side of a cast form, then molten metal is poured, and the molten metal penetrates the perform to form the composite in situ, so that the selective local enhancement of a wear resistant component can be achieved, thereby significantly improving the wear resistance of the component and prolonging the service life of the component.

Owner:XI AN JIAOTONG UNIV +1

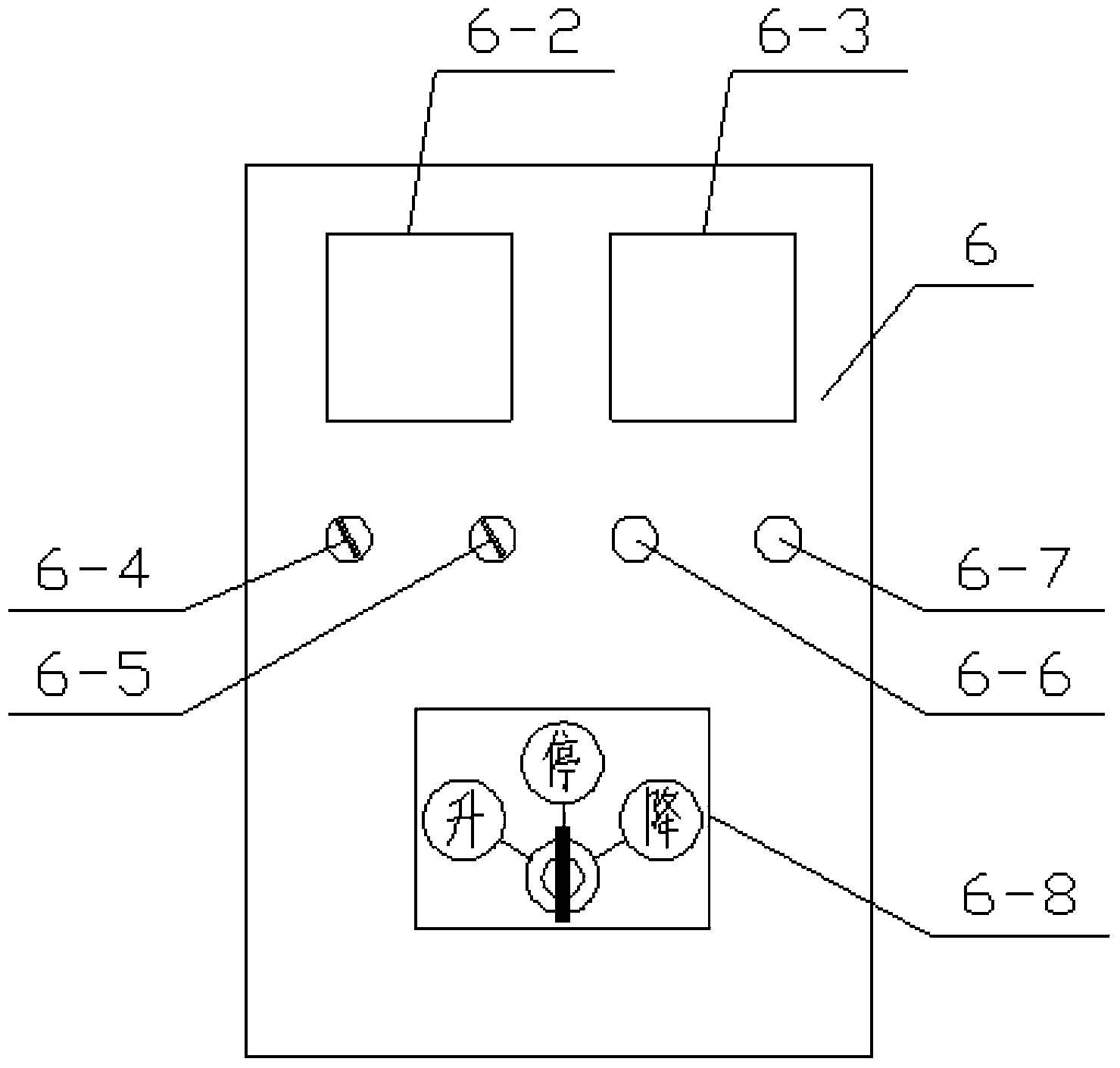

Efficient energy-saving high-temperature electric furnace with lifting furnace door and full-fiber hearth

ActiveCN103411427AImprove sealingGood heat insulationFurnace typesElectric heating for furnacesFiberEngineering

The invention discloses an efficient energy-saving high-temperature electric furnace with a lifting furnace door and a full-fiber hearth. Compared with a traditional electric furnace, the electric furnace has obvious innovation advantages in aspects such as structural design of a furnace body, selection of hearth materials and temperature control. The furnace door is arranged at the bottom of the electric furnace and controlled to rise and fall by a lead screw, calcined samples can be conveniently placed on the furnace door after the furnace door falls, loading capacity is high, the furnace door is excellent in tightness after the furnace door rises and is closed, and heat is not easily dissipated from a furnace mouth. By the aid of the multilayer graded temperature-resistant full-fiber hearth, heat insulation performance is excellent, heat storage capacity is low, the energy-saving effect of the electric furnace is quite remarkable, the temperature is rapidly raised and reduced, a furnace roof does not easily collapse by the aid of unique assembly structure design of the furnace roof, all sides of a heater are heated, temperature fields in the furnace are uniform, a temperature control system is advanced and simple and convenient to operate, running voltage, current, power, electricity consumption and the like are displayed in a centralized manner by the aid of a PID (proportion integration differentiation) intelligent temperature control instrument and an intelligent power display instrument, the electric furnace has an over-current alarm function, and heating elements are low in load, long in service life and convenient to replace.

Owner:JIANGSU HIGH TECHNO THERMAL EQUIP CO LTD

Shield tail seal grease of shield excavating machine

The invention discloses a shield tail seal grease of a shield excavating machine, which is used for passing through sand soil, rivers and lakes in the process of excavating construction of an underground project. The shield tail seal grease is combined by the following raw materials in parts by weight: 15-25 parts of plant oil, 15-25 parts of viscosity index modifying agents, 50-60 parts of stuffing, 5-10 parts of thickening agent, 0.8-1.2 parts of mildewproof agents, 0.5-1.0 part of wet dispersing agents and 2-6 parts of bamboo fibres. The seal grease has good seal performance and pumping ability and no pollution to the environment, can particularly play a favorable seal role in the sand soil or a deeper soil layer with more water content and solve the problem of easy slurry leakage or large dosage in the sand soil, which commonly exists in the grease in the current market.

Owner:SHANGHAI CIFU NEW BUILDING MATERIALS CO LTD

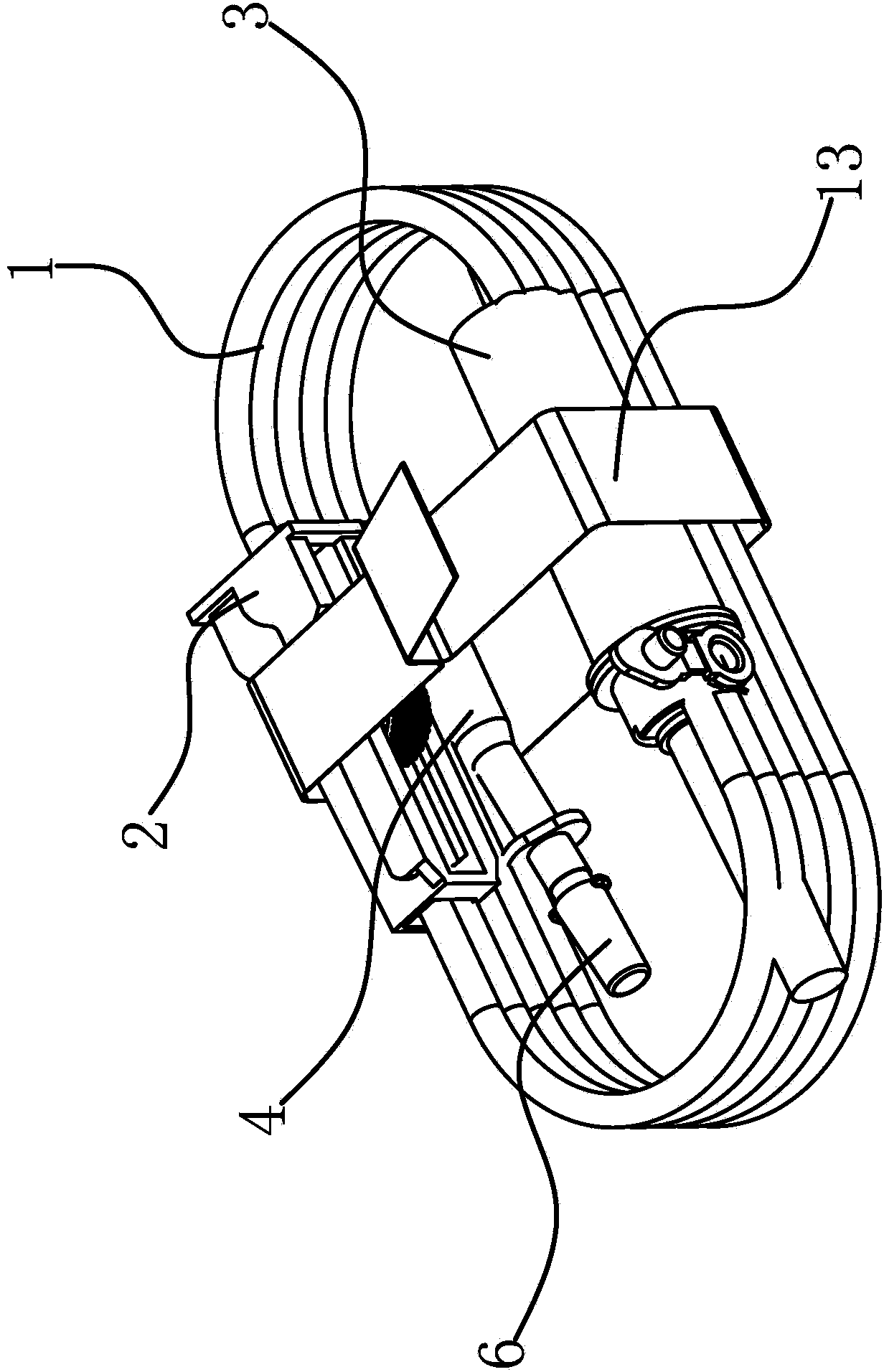

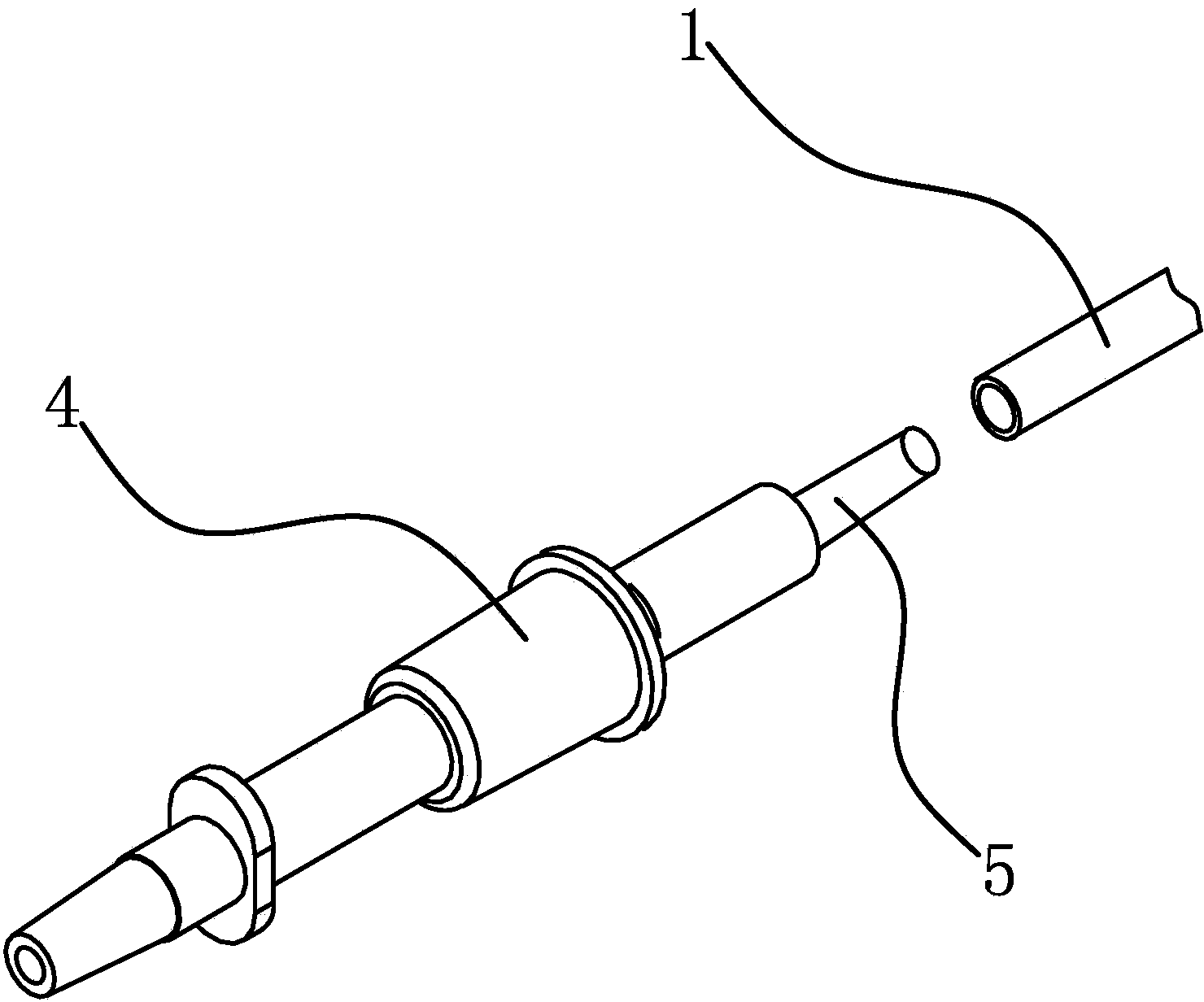

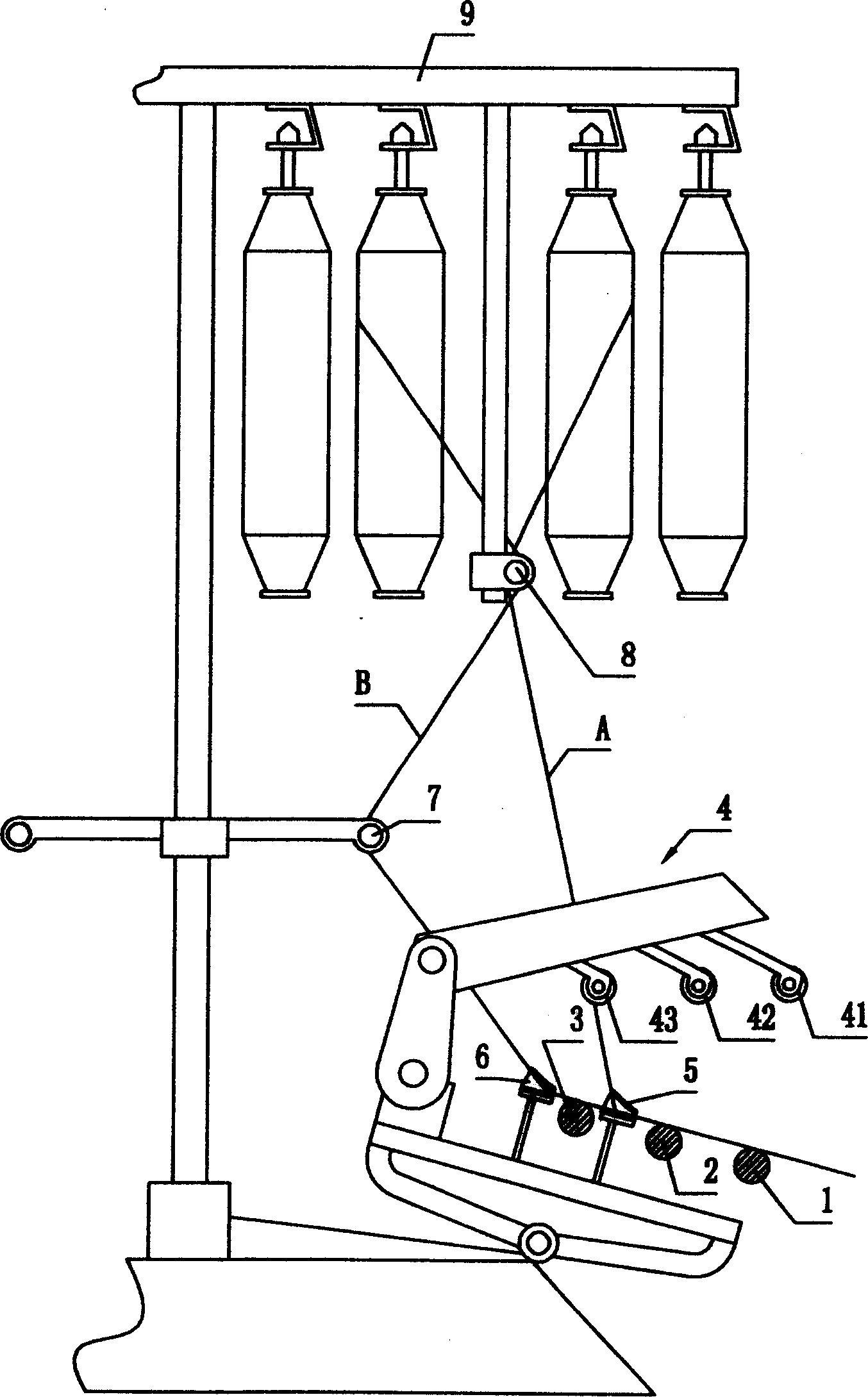

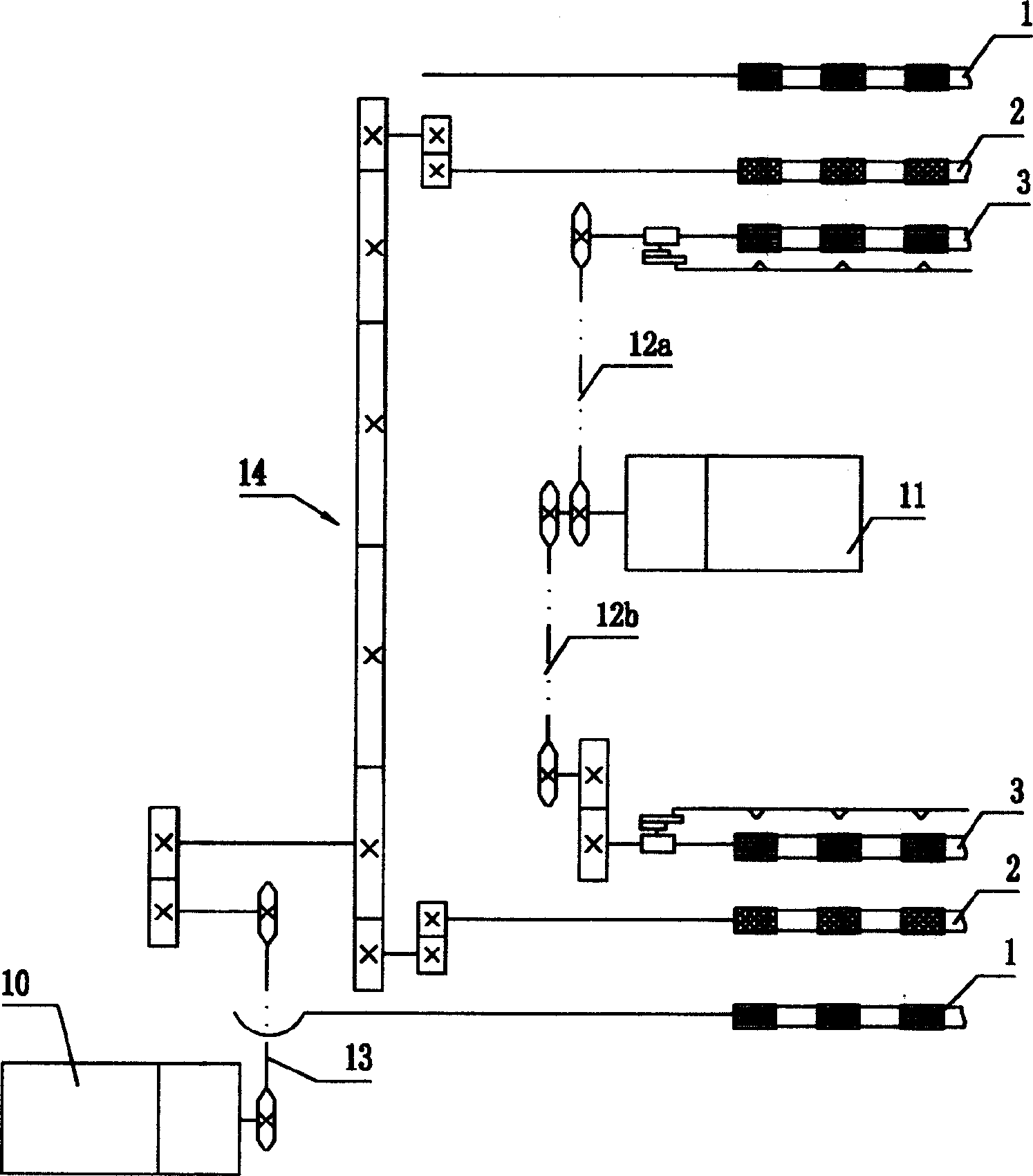

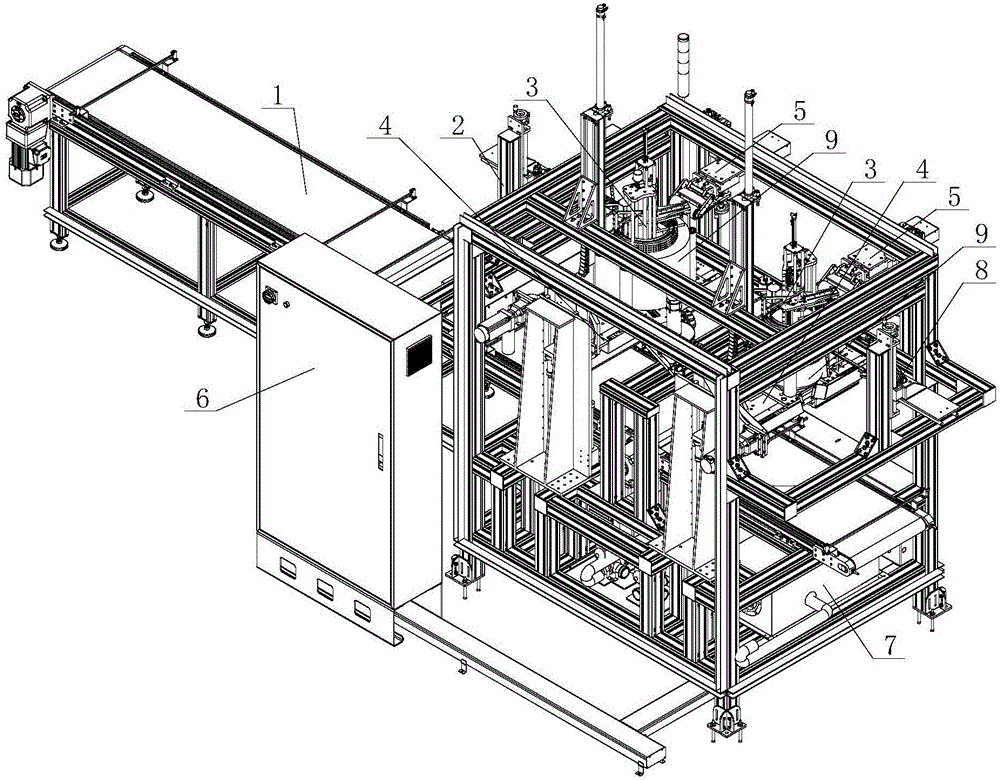

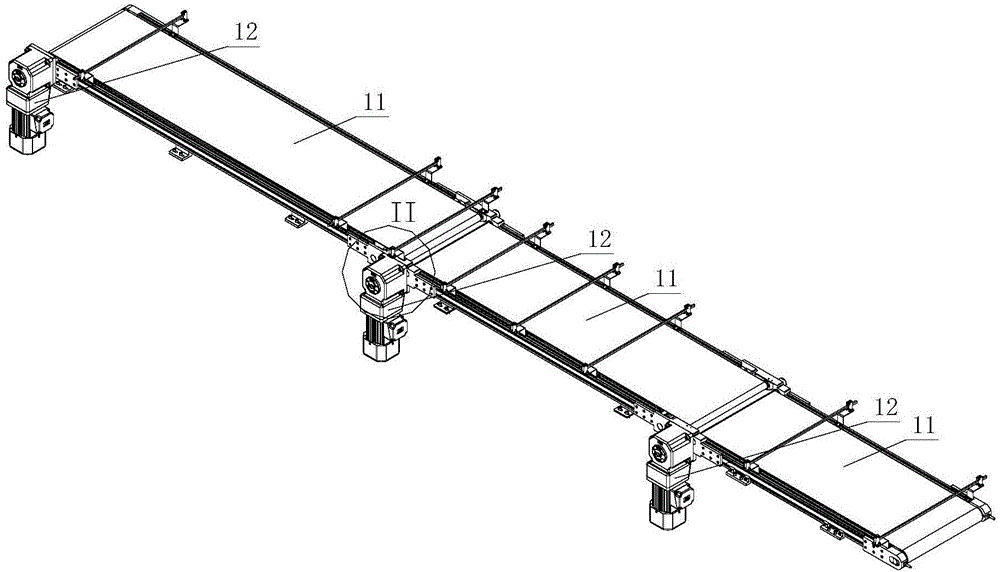

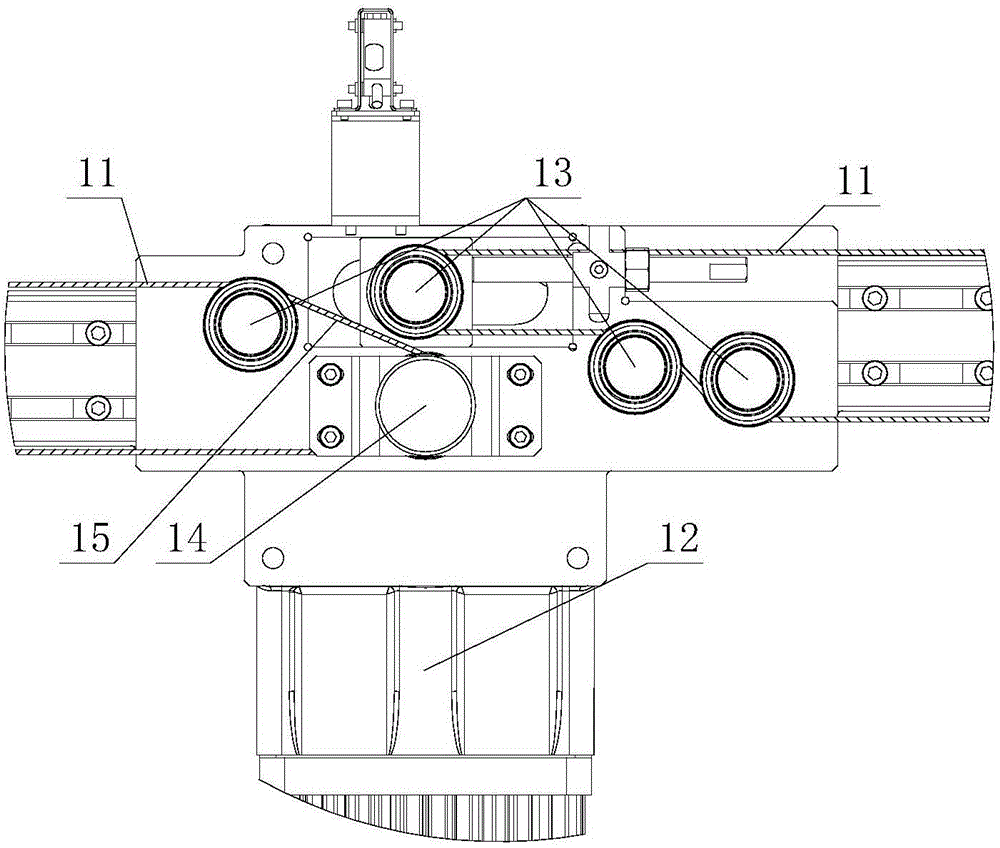

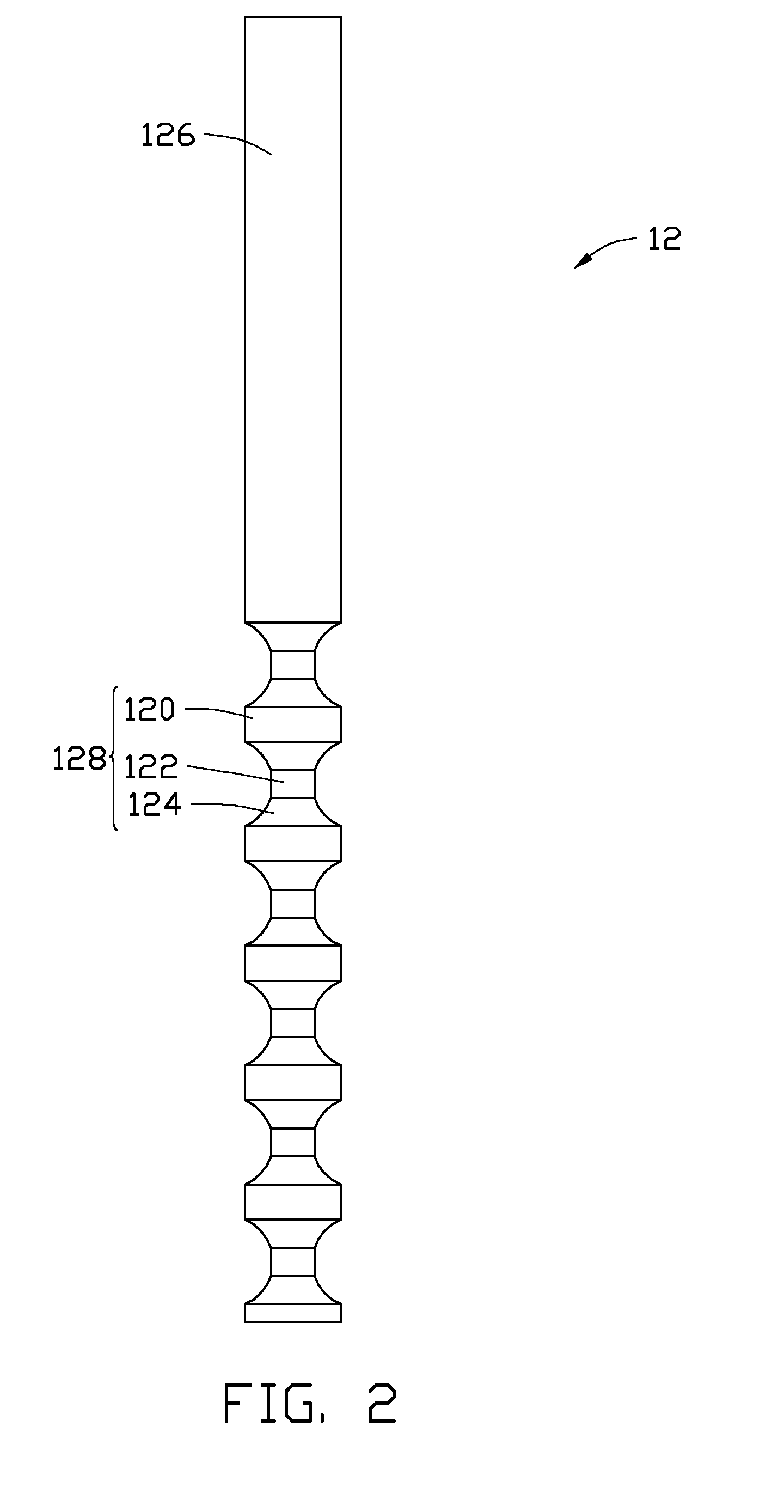

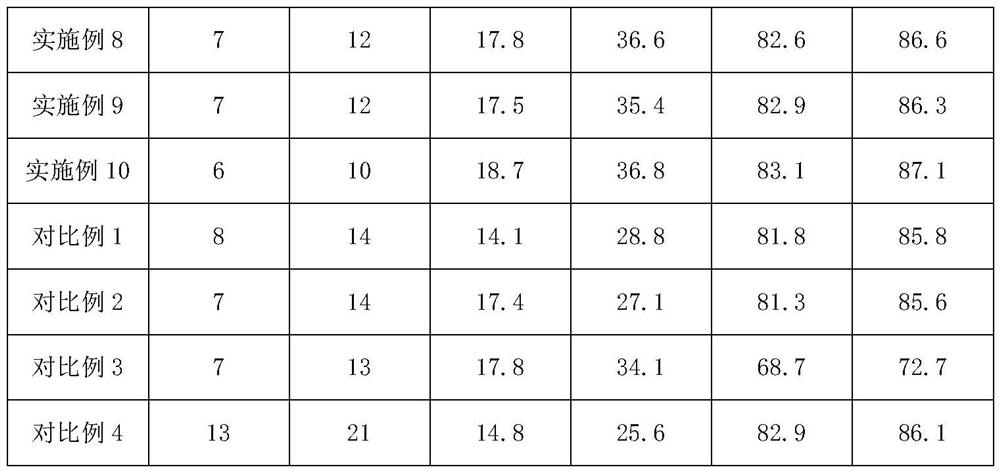

Automatic assembling process for infusion apparatus

The invention provides an automatic assembling process for infusion apparatus, and belongs to the technical field of medical instruments. The automatic assembling process for the infusion apparatus solves the problem that existing infusion apparatus is low in assembling efficiency. The process includes the following procedures, namely, a, medical catheter feeding, b, assembly of other components, c, finished product testing, and d, finished product discharging. According to the automatic assembling process, winding is carried out on medical catheter materials before assembling through a winding device, in addition, a medical catheter keeps in a winding state in the whole assembling process, therefore, the space occupied by the medical catheter is reduced, and feeding efficiency and assembling efficiency are improved. Due to the facts that the two end portions of the wound medical catheter are fixed in length, components on the left end portion and the right end portion of the medical catheter can be assembled at the same time, assembling efficiency is improved, and the assembling period of the infusion apparatus is shortened. In addition, the medical catheter is tied up through a band absorbing mechanism and a welding mechanism, and therefore the wound portion of the medical catheter will not disperse easily in the discharging and packaging process.

Owner:MAIDER MEDICAL IND EQUIP

Process for extracting and refining lavender oil

InactiveCN1693438ALow extraction and separation temperatureMild conditionsEssential-oils/perfumesWaxLavender oil

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Grinding tool and preparation method thereof

InactiveCN103481208AReduce the temperatureWork fasterAbrasion apparatusGrinding devicesMetallurgyCooling effect

The invention provides a grinding tool. The grinding tool comprises the main components of a grinding material, a filler, a binding agent, an antifoaming agent, a curing agent and a stabilizing agent, wherein the filler contains a compound which decomposes and absorbs heat at the temperature of 100 to 800 DEG C. The invention also provides a method for preparing the grinding tool. Compared with the prior art, the self-cooling effect of the grinding tool can be achieved; the work speed and the grinding performance of the grinding tool can be improved; the service life of the grinding tool is prolonged.

Owner:台山市兰宝磨具有限公司

Bombax cotton thermal shell fabric and its manufacturing method

The invention discloses a kapok warm face material. The fiber ingredients and the ratio are: natural kapok fiber 10-100%, cotton or other fiber 0-90%, urethane elastic fiber and other elastic fiber 0-50%. The invention also discloses the manufacture method including the following steps: selecting the fiber ingredients; spinning after mixing the raw material; weaving on the knitting great circle machine; dyeing and after processing. The advantage of the invention is good warm effect, soft tactility and comfort.

Owner:DONGHUA UNIV

Method for preparing orange peel tea

ActiveCN101248822AEasy to disperseEnjoy health benefitsPre-extraction tea treatmentFood preparationFood flavorHealth benefits

The invention discloses a method for preparing orange peel tea. The method comprises the following steps: firstly, an orange in good condition is chosen and a through hole is opened on the orange peel; secondly, the flesh in the orange is cleared away via the through hole to obtain a hollow cavity inside; thirdly, tea-leaves are filled into the orange hollow cavity through the through hole; fifthly, the orange with the filled tea-leaves is thoroughly dried; sixthly, the dried orange is packaged and finished. The method has the advantages that the orange and the tea-leaves can be completely combined and the tea-leaves are unlikely to loosen due to the filling of the tea-leaves inside the whole orange peel, and the tea-leaves are pervaded well with the flavor of the orange peel in making and storing, so that people can enjoy the health benefit of the orange peel in tea-tasting.

Owner:罗沛贤

Method for recycling used-up plastic products and washing process of crushed plastic and apparatus therefor

InactiveUS7231927B2Improve efficiencyImprove operationReversed direction vortexMouldsForeign matterFiltration

An object of the invention is to provide a method and an apparatus for recycling plastics which is improved with respect to operation efficiency, operation environment, lowering degradation of plastics, recycling cost and environment load including saving energy. The recycling is made as follows: coarse-crushing used-up plastic products, separating plastic materials from other foreign matters by air blow separation, fine-crushing the separated plastics, washing the fine-crushed plastics by the process using a circulation flow including a spiral flow in which interaction between crushed plastics helps themselves clean without washing agents, dewatering the washed plastics, drying them, removing metallic matters by using metal detector, then feeding them directly without pelletizing to an injection molding machine of which nozzle part is equipped with filter and flow-switching mechanism for cleaning the filter by backwash reverse filtration.

Owner:FUJIFILM CORP

Bunchy yarn, its spinning method and special spinning frame

The present invention discloses a kind of bunchy yarn and its spinning method and special spinning frame. The bunchy yarn includes connected nodes and sections, and the each of the nodes consists of twisted main yarn fiber and auxiliary yarn fiber. The special spinning frame has middle and later horn cotton collectors, and the front, middle and later rollers driven separately with the programmable controller controlled front, middle and later servo motors. The main yarn fiber is fed through the middle horn collector on front of the middle roller for single drafting; and the auxiliary yarn fiber is fed through the later horn collector on front of the later roller for twisting in the middle horn collector and double region drafting. The present invention makes it possible to produce bunchy yarn with less opening and different node and section colors.

Owner:潍坊四棉纺织有限公司

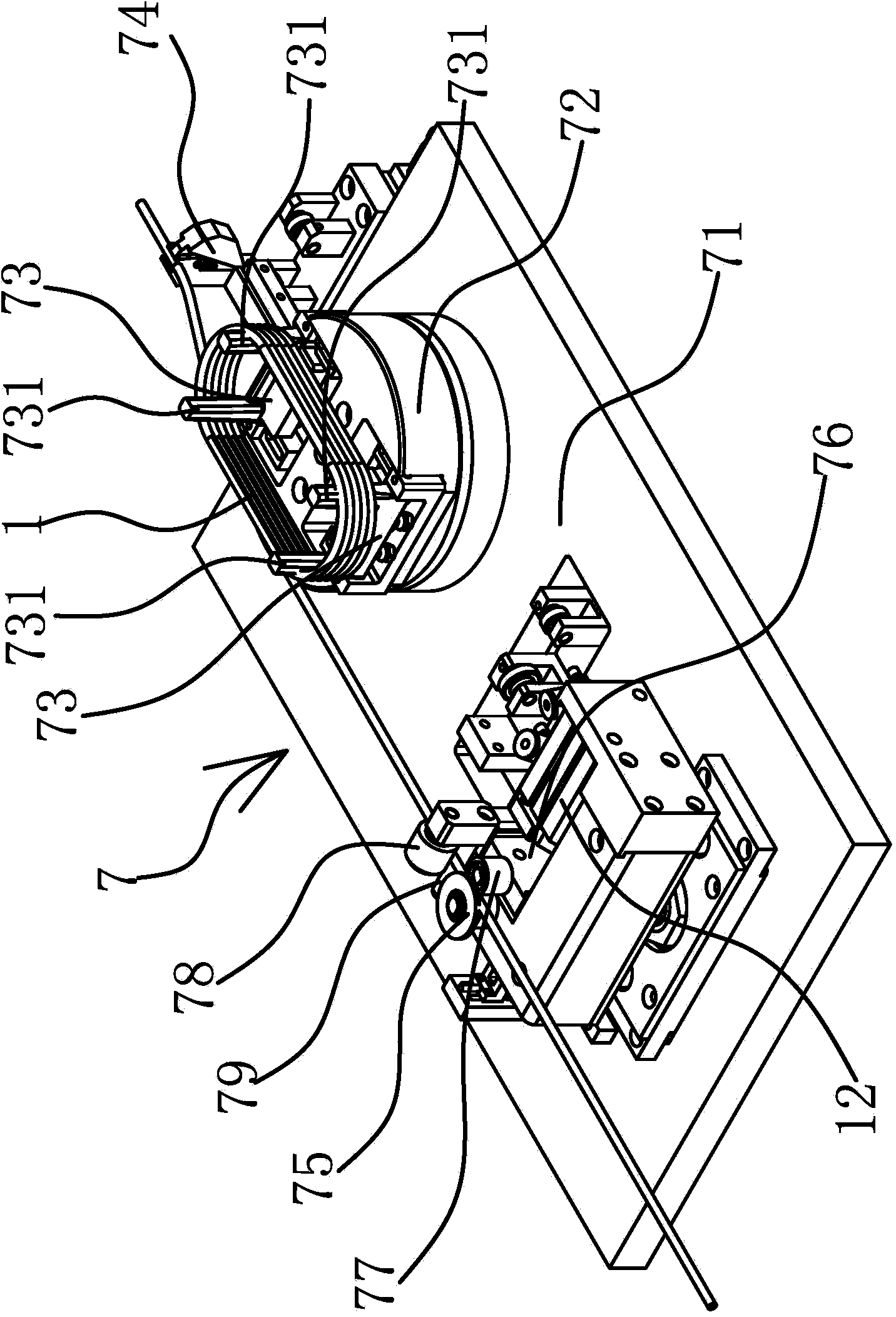

Film-coating method for glass fiber yarn cluster

ActiveCN106586060ATransport impactImprove coating efficiencyWrapper folding/bending apparatusWrapping with article rotationGlass fiberYarn

The invention discloses a film-coating method for a glass fiber yarn cluster, and belongs to the technical field of glass fiber production equipment. The invention aims to provide the film-coating method for the glass fiber yarn cluster, and the coating method is relatively good in coating effect and is high in film-coating efficiency. The film-coating method comprises the following steps: step I: conveying yarn clusters; step II: grabbing the yarn clusters; step III: pressing the yarn clusters; step IV: coating a film, wherein a coating film is pushed to a specific position through a film feeding device, a gas blowing tube of a film cutting mechanism of the film feeding device works to blow the coating film; and the coating is adhered on the yarn cluster in a sticky mode, and the coating film is pressed onto the yarn cluster through a film-pressing thin sheet of the film pressing device; a clamping rotating device drives the yarn cluster to rotate, the coating film is continuously guided out and is coated on the cluster yarn; and the film is cut off through a blade of a film cutting mechanism; step V: pushing a film, wherein the film pressing device moves upwards and the film pressing device works to level the coating film exceeding the upper end surface of the yarn cluster to the upper end surface of the yarn cluster; and step VI: outputting finished products. The film-coating method is a film-coating method suitable for coating a layer of film outside the glass fiber yarn cluster.

Owner:福德机器人(成都)有限责任公司

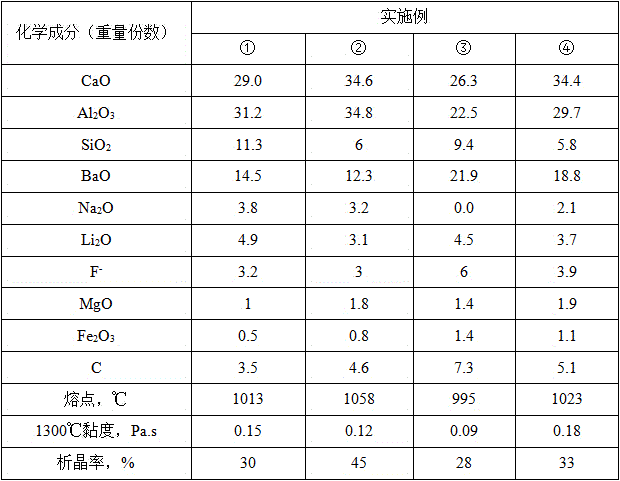

Crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of crystallizer covering slag

The invention provides a crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of the crystallizer covering slag. The covering slag is prepared from the following components in parts by weight: 20-38 parts of CaO, 20-35 parts of Al2O3, 5-18 parts of SiO2, 10-22 parts of BaO, 2-7 parts of Li2O, 5-12 parts of F<->, 1-4 parts of MgO, 2-8 parts of C and Fe2O3 which is less than or equal to 2 parts. According to the preparation method disclosed by the invention, wollastonite, limestone, quartz sand, fluorite, bauxite, barium carbonate, magnesia, soda, lithium carbonate and carbonaceous materials are used as raw materials, and the covering slag is prepared through the following steps of: calculating of consumption, melting, smashing, fine grinding, drying and granulation. The covering slag disclosed by the invention has the characteristics of being low in reactivity and good in property stability, the lubrication and the thermal transmission of casting blanks can be effectively coordinated and controlled, the smooth performing of the continuous casting process of the high-manganese high-aluminum steel can be guaranteed, high-manganese high-aluminum steel continuous casting blanks with excellent surface quality are cast, and multi-heat continuous casting can be realized.

Owner:CHONGQING UNIV

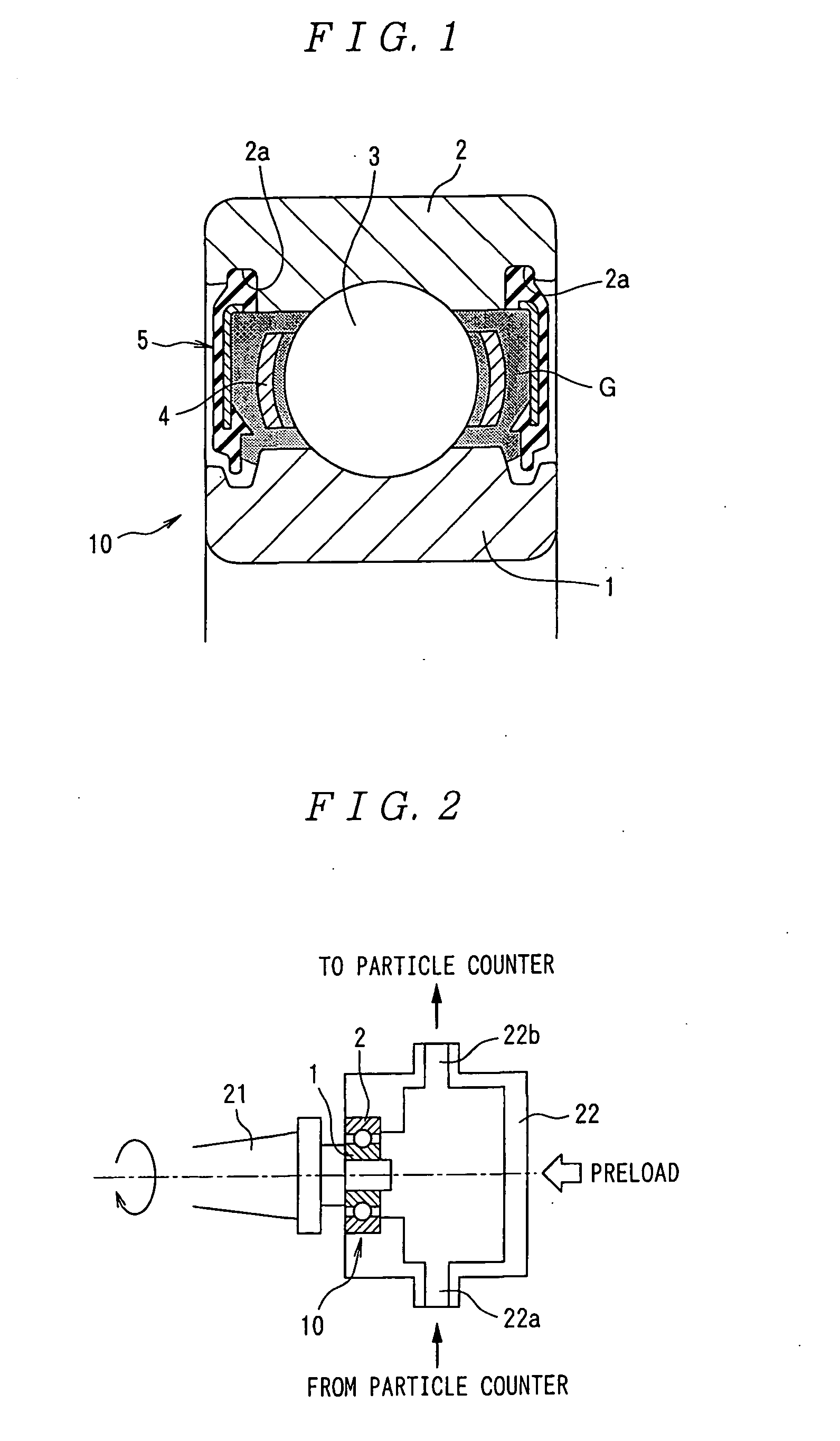

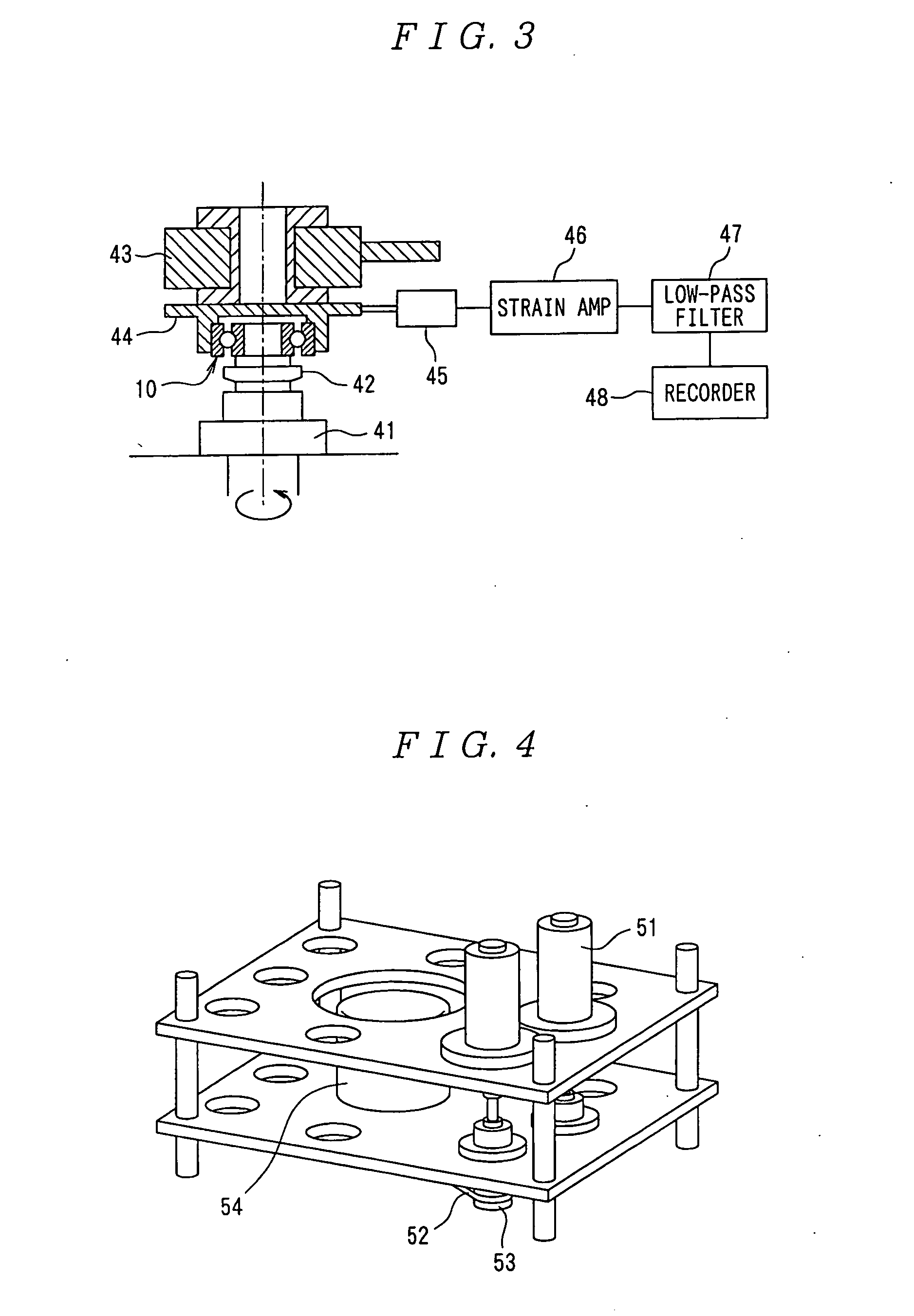

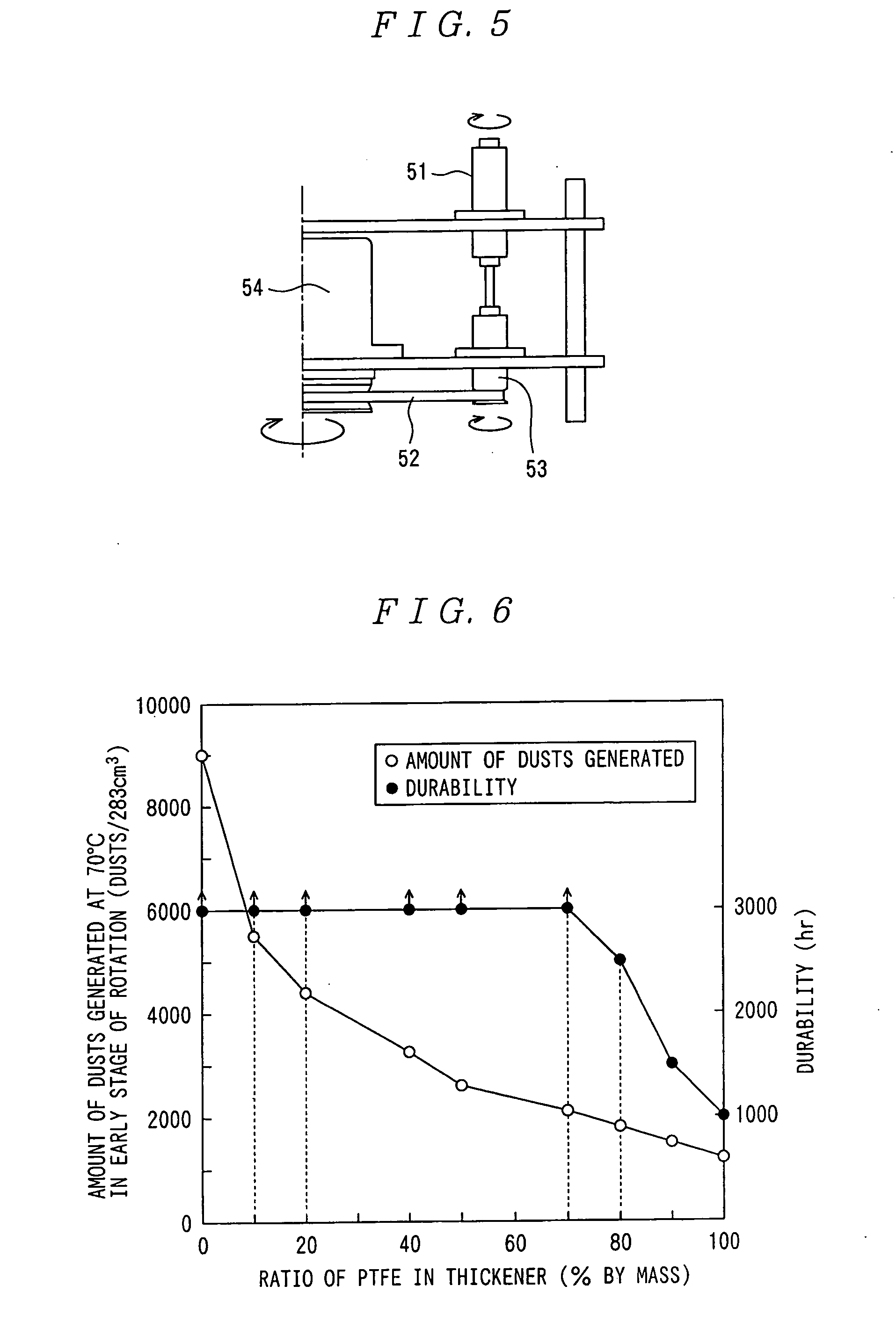

Grease composition and rolling apparatus

InactiveUS20050221999A1Hard to disperseExcellent high-temperature performanceThickenersAdditivesLoad carryingCarbon black

A grease composition is produced by mixing a thickener comprising a fluoro resin and a second thickener component (a metallic soap, a complex metallic soap, an N-substituted terephthalamic acid metal salt, organic bentonite or a calcium sulfonate complex) into a base oil. This grease composition is excellent in heat resistance, load carrying capacity, water resistance, rust protection, lubricating life and the like. A rolling apparatus filled with the above grease composition has excellent lubricating ability and is long-lived under high-temperature conditions. Moreover, a grease composition is produced by mixing a thickener comprising a fluoro resin and carbon black as a second thickener component into a base oil. This grease composition is excellent in heat resistance, water resistance, rust protection, lubricating life, electric conductivity and the like. A rolling apparatus filled with the above grease composition has excellent electric conductivity and is long-lived under high-temperature conditions.

Owner:NSK LTD

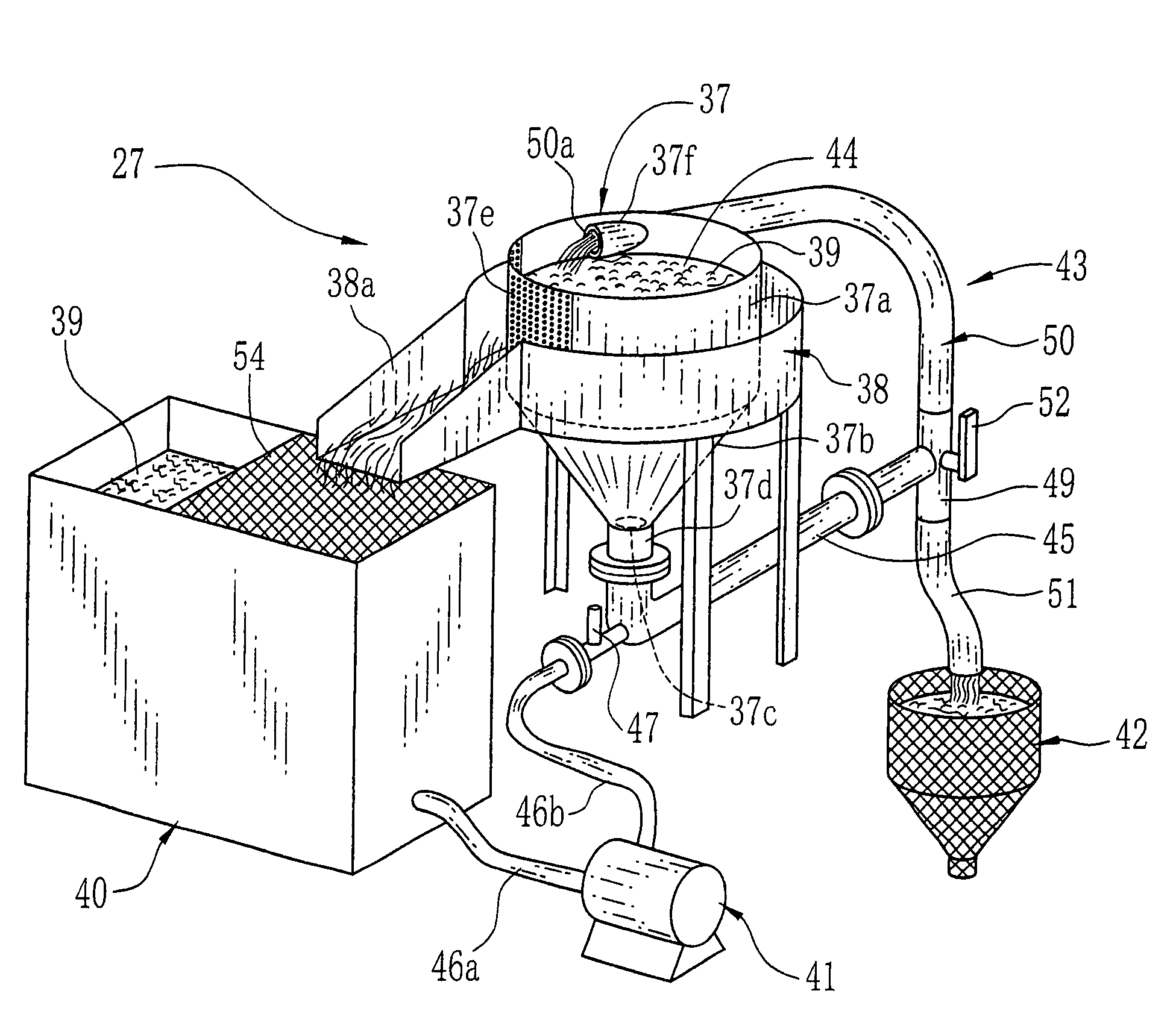

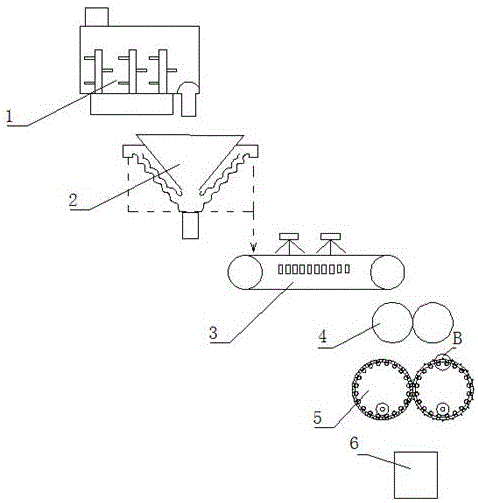

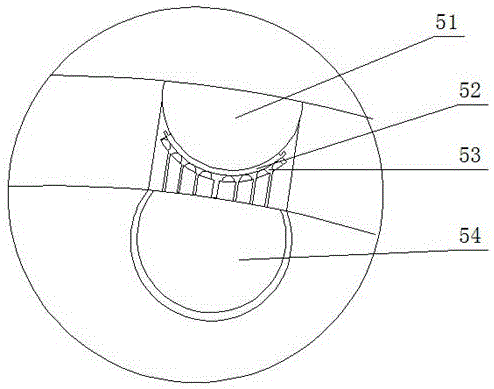

Biological manure recovery device

The invention relates to the field of manure recovery or treatment, in particular to a biological manure recovery device which comprises a crushing mechanism, a centrifugal mechanism, a drying mechanism, a pressing mechanism, a forming mechanism and a collecting mechanism. The centrifugal mechanism is used for centrifugal dewatering, dewatered materials are transferred to the centrifugal mechanism, the pressing mechanism comprises two matched extrusion rollers, the extrusion rollers are used for pressing the dried materials into strips and transferring the strip materials to the forming mechanism, the forming mechanism comprises two opposite forming rollers, the surface of each forming roller is provided with a die cavity, and the two forming rollers are mutually matched to extrude the materials. Manure is dried and solidified, so that the biological manure is recovered, pollution of the biological manure to rivers and water can be reduced, and manure recovery degradation speed is increased. The structure is convenient and simple, bio-fuels or feed can be rapidly manufactured, production can be facilitated, miniaturized manufacture can be realized, the biological manure recovery device is applicable to mini-plants or livestock farms, and cleanness and sanitation of workplaces can be ensured.

Owner:成都测迪森生物科技有限公司

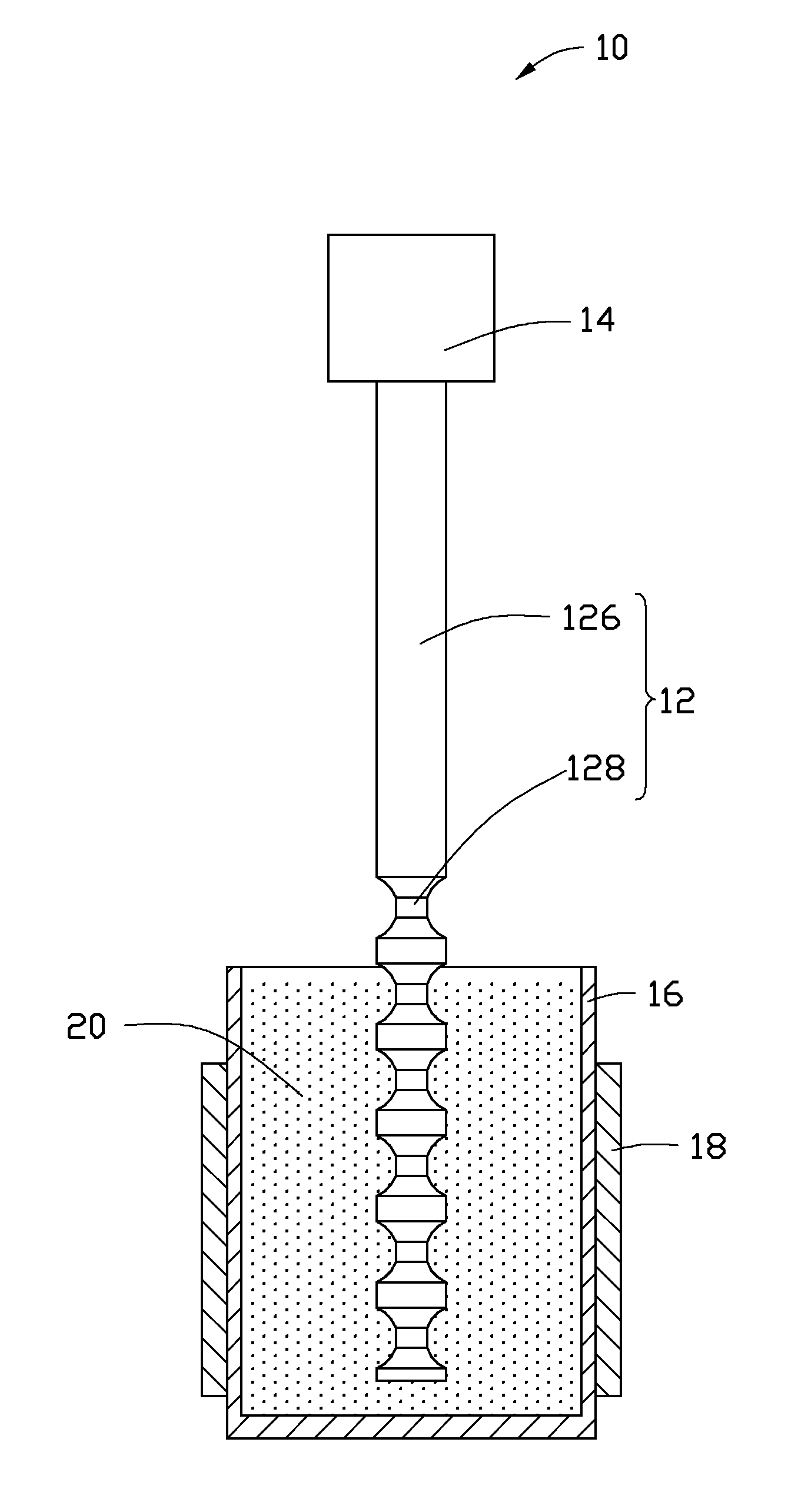

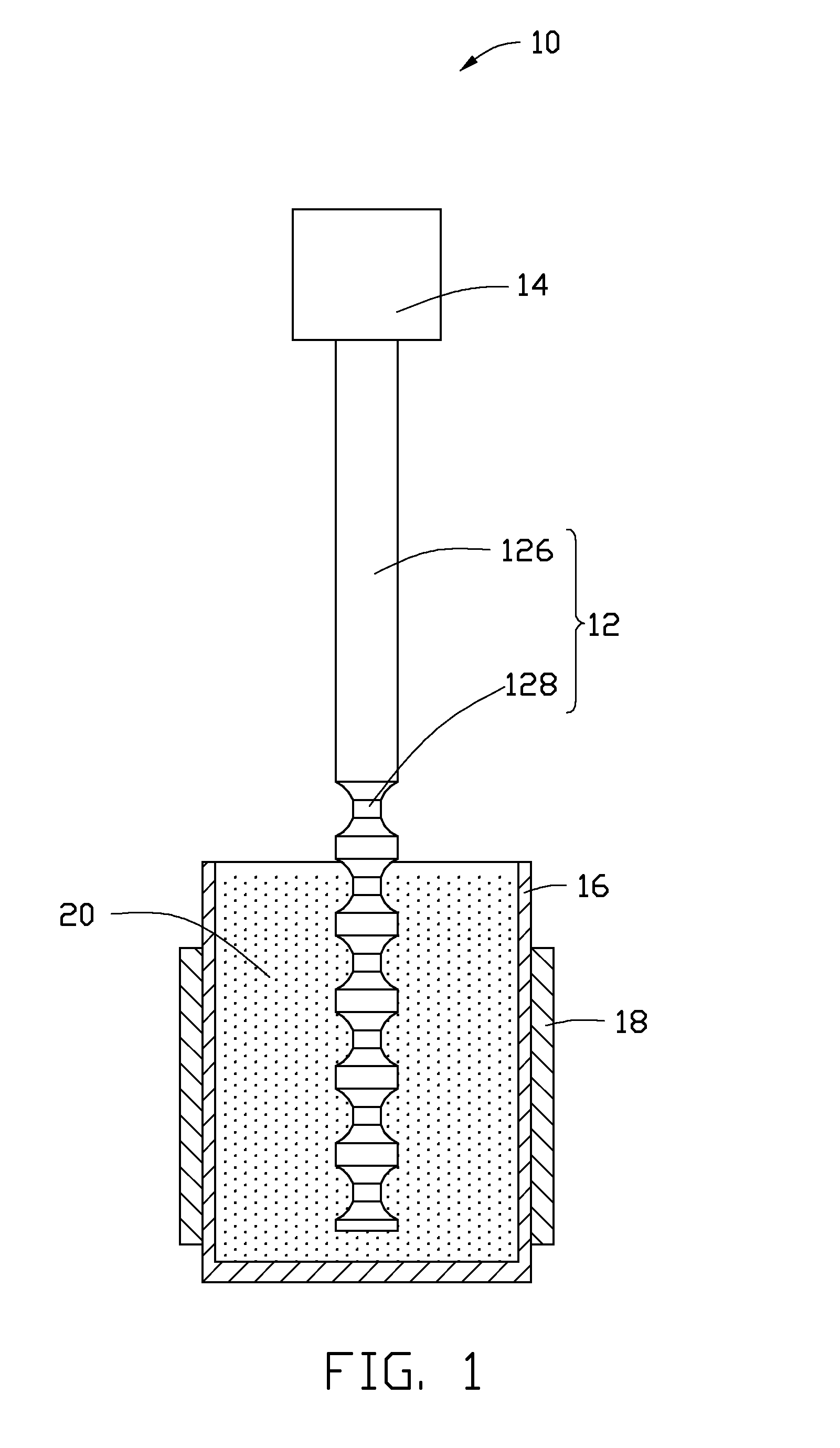

Method for making metal based nano-composite material

A method for making a metal based nano-composite material is disclosed. In the method, a semi-solid state metal based material is provided. The semi-solid state metal based material is stirred and nano sized reinforcements are added into the semi-solid state metal based material to obtain a semi-solid state mixture. The semi-solid state mixture is heated to a temperature above a liquidus temperature of the metal based material, to achieve a liquid metal-nano sized reinforcement mixture. The liquid metal-nano sized reinforcement mixture is ultrasonically processed at a temperature above the liquidus temperature by conducting ultrasonic vibrations to the liquid metal-nano sized reinforcement mixture along different directions at the same time.

Owner:TSINGHUA UNIV +1

Paddy rice tillering-promoting, lodging-resisting, and yield-increase-assisting multifunctional fertilizer and application method thereof

ActiveCN103360164AFormulation ScienceVersatileFertilising methodsFertilizer mixturesWater contentUniconazole

The invention relates to a paddy rice tillering-promoting, lodging-resisting, and yield-increase-assisting multifunctional fertilizer and an application method thereof. According to the invention, uniconazole, amine hexanoate, calcium chloride, magnesium sulfate, zinc sulfate, borax, EDTA-Fe, EDTA-Mn, EDTA-Cu, silicon fertilizer, and bentonite are crushed and sieved; the mixture is sufficiently mixed by stirring, and is uniformly delivered into a fertilizer granulator; preliminary granulation is carried out according to a round-disk granulation method; the granules are uniformly delivered into a multi-level granular fertilizer round polishing machine, and granulation is carried out again; drying is carried out, such that a water content is below 10%, such that formed granular fertilizer is obtained. Before paddy rice transplantation and before soil preparation before seeding, the fertilizer is uniformly mixed with a composite fertilizer or fine soil, and the mixture is used for application. After paddy rice transplantation, and during a reviving period, the fertilizer is uniformly mixed with a urea fertilizer, and the mixture is used for application. The fertilizer provided by the invention has the advantages of scientific formula, comprehensive functions, simple application, low residue in soil, and safety to succeeding crop. The granular fertilizer is convenient for packaging and transportation, and can be conveniently mixed with other fertilizers. The fertilizer has a substantial effect. With the fertilizer, paddy rice effective tillering can be increased by 2-5 pieces / group, yield can be increased by 10-20%, plant height is substantially reduced, and lodging resistance is improved.

Owner:武汉盛大神农生物工程有限公司

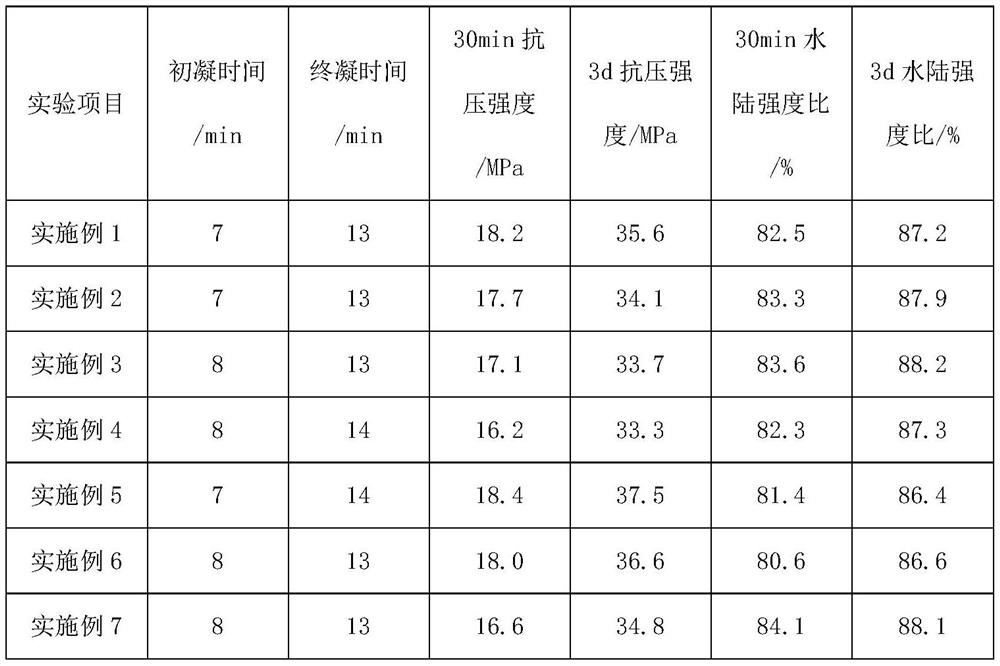

Quick-setting adjustable cement-based underwater anti-dispersion ultrafast-hardening grouting material as well as preparation method and application thereof

The invention provides a quick-setting adjustable cement-based underwater anti-dispersion ultrafast-hardening grouting material as well as a preparation method and application thereof. The quick-setting adjustable cement-based underwater anti-dispersion ultrafast-hardening grouting material comprises a component A and a component B, wherein the component A comprises 80-90% of a cementing material,3-10% of an active admixture, 3-7% of an expanding agent, 2-3% of a high-performance underwater anti-dispersion agent and 0.1-0.3% of a polycarboxylic acid high-performance water reducer; the component B comprises 80%-90% of a quick-hardening cementing material, 4%-10% of an active admixture, 3%-7% of an expanding agent, 2%-3% of a high-performance underwater anti-dispersing agent, 0.1%-0.3% of apolycarboxylic acid high-performance water reducing agent, 0.1%-0.2% of a retarder, 0.1%-0.2% of an early strength agent, 0.1%-0.15% of a thixotropic agent and 0.05%-0.1% of an interface impregnatingagent. The single liquid of the component A and the component B is long in working time, high in setting and hardening speed after being mixed, high in strength and good in underwater dispersion resistance, and the setting time can be adjusted by adjusting the ratio of the component A to the component B.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

High strength sapo-34 microsphere catalyst, method for preparing same, and method for preparing light olefins using same

ActiveUS20120203046A1Improve catalytic performanceImprove efficiencyCatalytic crackingMolecular sieve catalystsMicrosphereFluidized bed

The present invention relates to a high-strength silicoaluminophasphate-34 (SAPO-34) microsphere catalyst, a method for preparing the same, and a method for preparing light olefins by using the same, and when described in more detail, the present invention relates to a method for preparing a SAPO-34 microsphere catalyst, including: spray drying a mixed slurry including a matrix, a binder, an additive, and the like to a SAPO-34 slurry prepared by a hydrothermal synthesizing method using various organic templates such as tetraethylammonium hydroxide (TEAOH), and the like alone or in mixtures to prepare microspheres, and firing the microspheres, and to a SAPO-34 microsphere catalyst for a circulating-fluidized bed reactor, prepared by the preparation method. The SAPO-34 microsphere catalyst of the present invention has excellent reaction activity while having high strength, and thus is appropriate for use in a circulating-fluidized bed reactor requiring high strength of the catalyst. Further, the SAPO-34 microsphere catalyst has a long life-span and excellent conversion rate of C1 to C4 oxygen-including compounds (oxygenates), and thus is appropriate for use in the preparation of light olefins such as ethylene, propylene, butene, and the like.

Owner:KOREA RES INST OF CHEM TECH

Method for producing warp knitting coral velvet polyester filament yarn

InactiveCN101476188AAdjustable fine structureFine structure stabilityTextiles and paperHot boxEngineering

The invention provides a method for producing warp knitting coralon leather polyester filament. The processed POY protofilament is removed to false twist after being detected and balanced, the process flow is that: POY protofilament - a roller feeding in - a hot box for heating distortion - cooling - false twist - two rollers feeding in - two hot boxes for heating and forming - three rollers feeding out - oiling - DTY winding forming, a pre-network working procedure is added between the ROY protofilament and a roller feeding in. The method solves problem that coralon leather fabric processed by normal polyester has defects of no-soft hand touch, adhesive hair, down pile making, without coralon leather style, and can cover the prior art shortage.

Owner:JIANGSU HENGLI CHEM FIBER

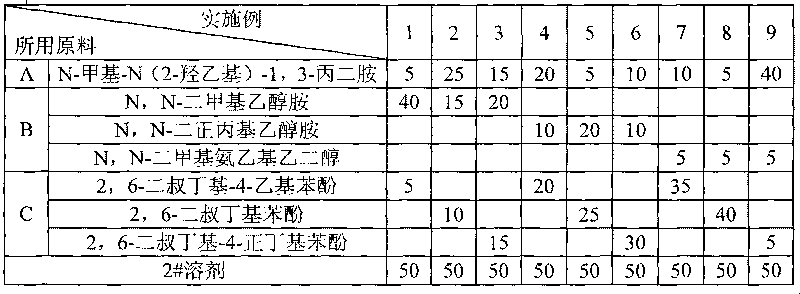

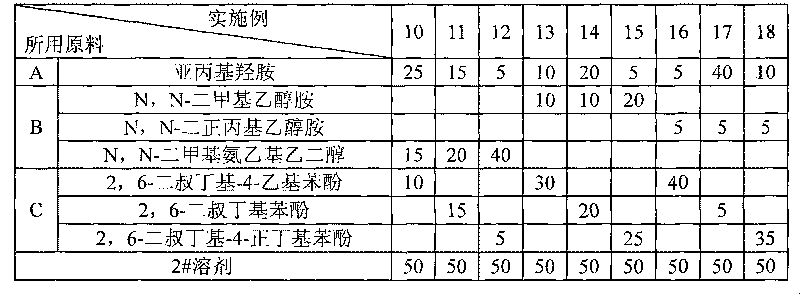

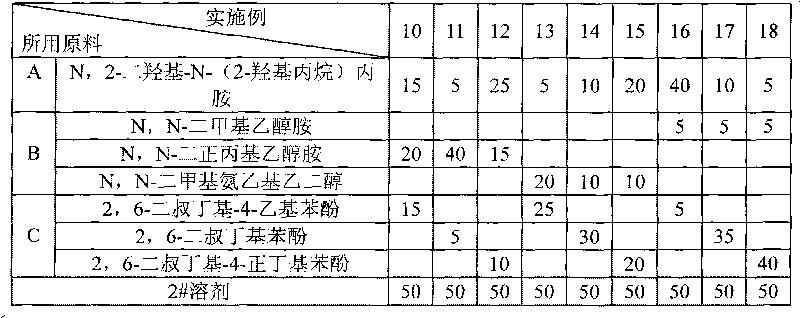

Efficient scale inhibitor of tail-gas compressor of styrene device and application method thereof

InactiveCN101700991AEasy to disperseNot easy to disperseHydrocarbonsHydrocarbon preparationGas compressorHydroxylamine Hydrochloride

The invention relates to an efficient scale inhibitor of a tail-gas compressor of a styrene device and an application method thereof, comprising hydroxylamine compounds, alcohol amine compounds and phenol compounds. The invention overcomes the disadvantages that the generation of polymer dirt in the tail-gas compressor can not be effectively inhibited by using an ethylbenzene physical spraying method, can thoroughly inhibit and suppress the radical polymerization of the styrene, alpha-methyl styrene, phenyl ethylene and the other activated alkenes in the styrene tail-gas compressor, and has the functions of metallic catalytic coke deposition suppression and detergency and dispersancy. The invention has the advantages of safety and environment protection, energy conservation and low energy consumption and simple use, has no influence on downstream processes, can effectively promote the operational cycle and working load of the styrene tail-gas compressor, reduce energy and material consumption of the styrene device, and can improve the economical and social effects of the whole styrene device.

Owner:北京斯伯乐科技发展有限公司

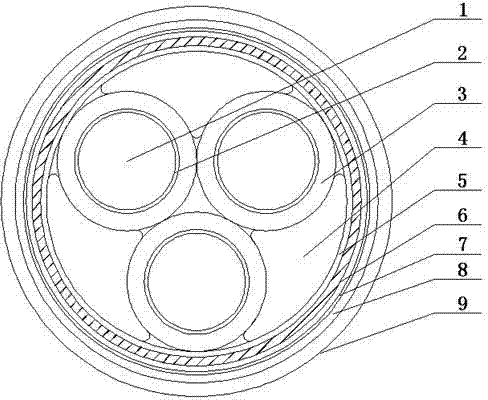

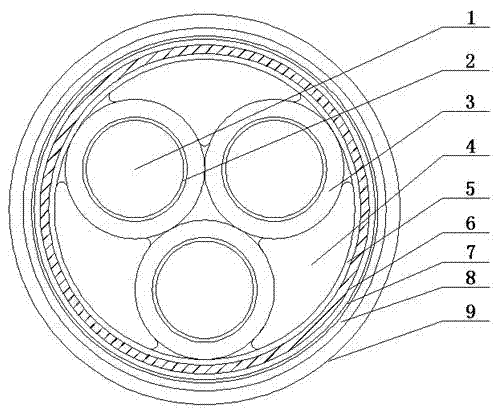

Heat-resistant shielded power cable for nuclear power stations

ActiveCN102332336ASmall expansion coefficientHigh dielectric strengthNon-insulated conductorsPower cables with screens/conductive layersAluminiumNuclear power plant

A heat-resistant shielded power cable for nuclear power stations comprises a combined cable core, three power cable cores are stranded to form the combined cable core, filler is arranged on the combined cable core, the periphery of the filler is sequentially wrapped by an isolating layer, a composite shielding layer, a flame-retardant tape, an oxygen barrier and an outer sheath, the filler is a low-smoke halogen-free flame-retardant polyolefin material, a polyester film is lapped to form the isolating layer, tinned copper wires are woven and lapped to form the inner layer of the composite shielding layer, an aluminium-plastic composite tape is overlapped to form the outer layer of the composite shielding layer, a glass fiber tape is lapped to form the flame-retardant tape, irradiation cross-linked low-smoke halogen-free flame-retardant polyethylene is extruded to form the wrapping oxygen barrier, and the outer sheath is made of ceramic fire-resistant silicon rubber; the three power cable cores respectively consist of a cable core conductor, an liner layer and an insulating layer which are arranged sequentially from the inside to the outside, wherein a synthetic mica tape is lappedto form the liner layer, and heat-resistant silicon rubber is extruded to form the insulating layer, and is then vulcanized. The heat-resistant shielded power cable has excellent heat resistance, shielding property and electric insulativity.

Owner:ZHONGGUAN CABLE CO LTD

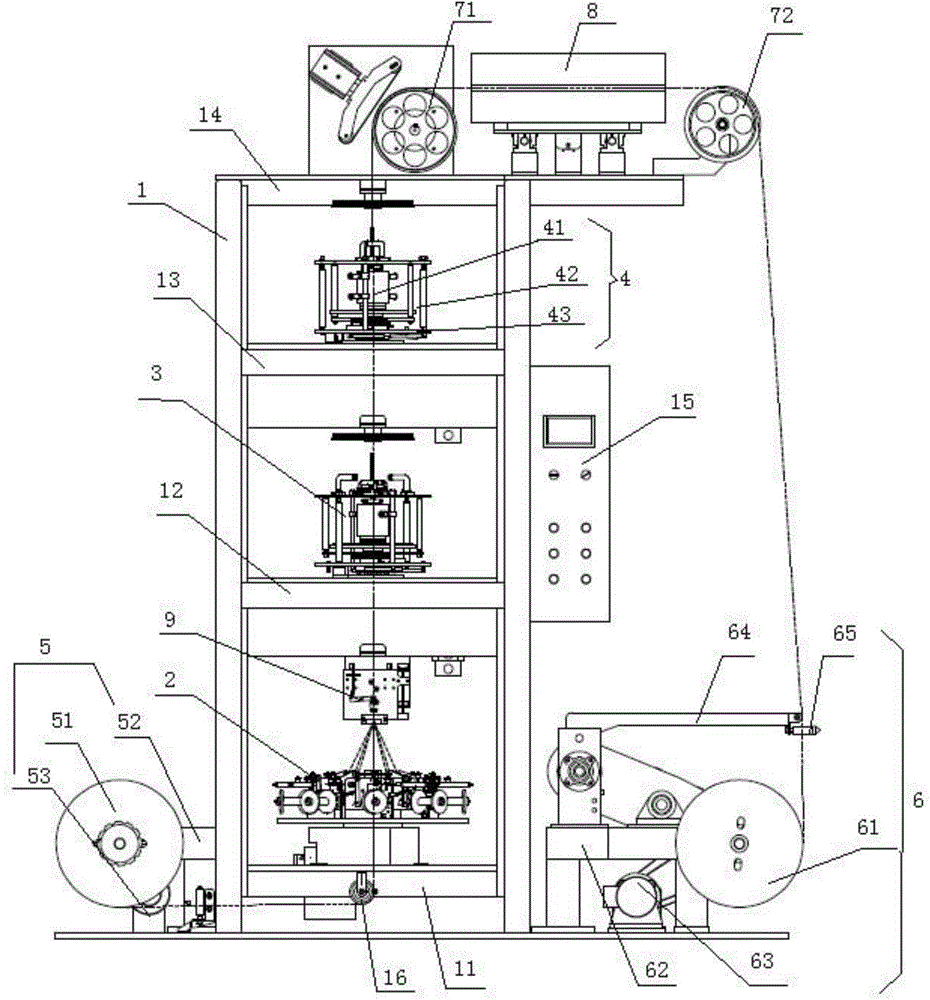

Dual-layer taping and winding machine

ActiveCN104658708ACompact structureSave spaceFilament handlingCable/conductor manufactureDrive motorElectric properties

The invention discloses a dual-layer taping and winding machine. The dual-layer taping and winding machine comprises a winding assembly and a servo motor driving the winding assembly to rotate, and further comprises a first taping assembly and a second taping assembly, wherein the winding assembly comprises a plurality of tension sets, a rotary plate and a main shaft; the tension sets are fixed on the rotary plate; the main shaft is used for supporting the rotary plate and is connected to an output shaft of the servo motor; each of the first taping assembly and the second taping assembly comprises a taping shaft, a motor driving the taping shaft to rotate, and a plurality of swing arms arranged at the periphery of the taping shaft; an inner hole allowing a cable to pass through is axially formed in the taping shaft; the swing arms are axially arranged on the taping shaft; the two swing arms are connected through a positioner; the swing arms are driven by the drive motor to adjust taping tension force through the positioner. The dual-layer winding machine is compact in structure, saves space, improves the production efficiency, and can guarantee electric properties of the cable.

Owner:东莞朝隆机械有限公司

Middle-modulus carbon fiber preparation method based on rapid spinning and high denier precursor

The invention discloses a middle-modulus carbon fiber preparation method based on rapid spinning and high denier precursor, and belongs to the field of high-performance carbon fiber preparation method. The middle-modulus carbon fiber preparation method comprises following steps: PAN precursor is delivered into a pre-oxidation furnace for pre-oxidation so as to obtain a pre-oxidized fiber body with a density ranging from 1.33 to 1.36g / cm<3>; the pre-oxidized fiber body is delivered into a low temperature carbonization furnace for low temperature carbonization so as to obtain a low temperature carbonized fiber body; the low temperature carbonized fiber body is delivered into a high temperature carbonization furnace for high temperature carbonization, and the carbon fiber with tensile strength ranging from 4500 to 5100MPa, tensile modulus ranging from 270 to 310GPa, and filament diameter ranging from 6 to 10<mu>m is obtained via carbonization. The middle-modulus carbon fiber preparation method is capable of realizing synchronous increasing of carbon fiber tensile modulus and strength, and solving key problems that the tensile strength of middle-modulus carbon fiber is reduced, and cost is high.

Owner:ZHONGFU SHENYING CARBON FIBER +1

Pellet feed for fish farming having excellent dissolution and digestion efficiency, and method for preparing same

ActiveCN102573515AImprove growth performanceNot easy to disperseClimate change adaptationAnimal feeding stuffFisheryDissolution

The present invention relates to a pellet feed for fish farming having excellent dissolution and digestion efficiency, and a method for preparing the same, and more specifically to a pellet feed for fish farming wherein the pellet feed is molded then coated with an enzyme, whereby the pellet feed disperses slowly in water over a certain time period, but quickly dissolves in a fish's stomach and has excellent digestion efficiency.

Owner:DAEBONG LS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com