Grease composition and rolling apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example a13

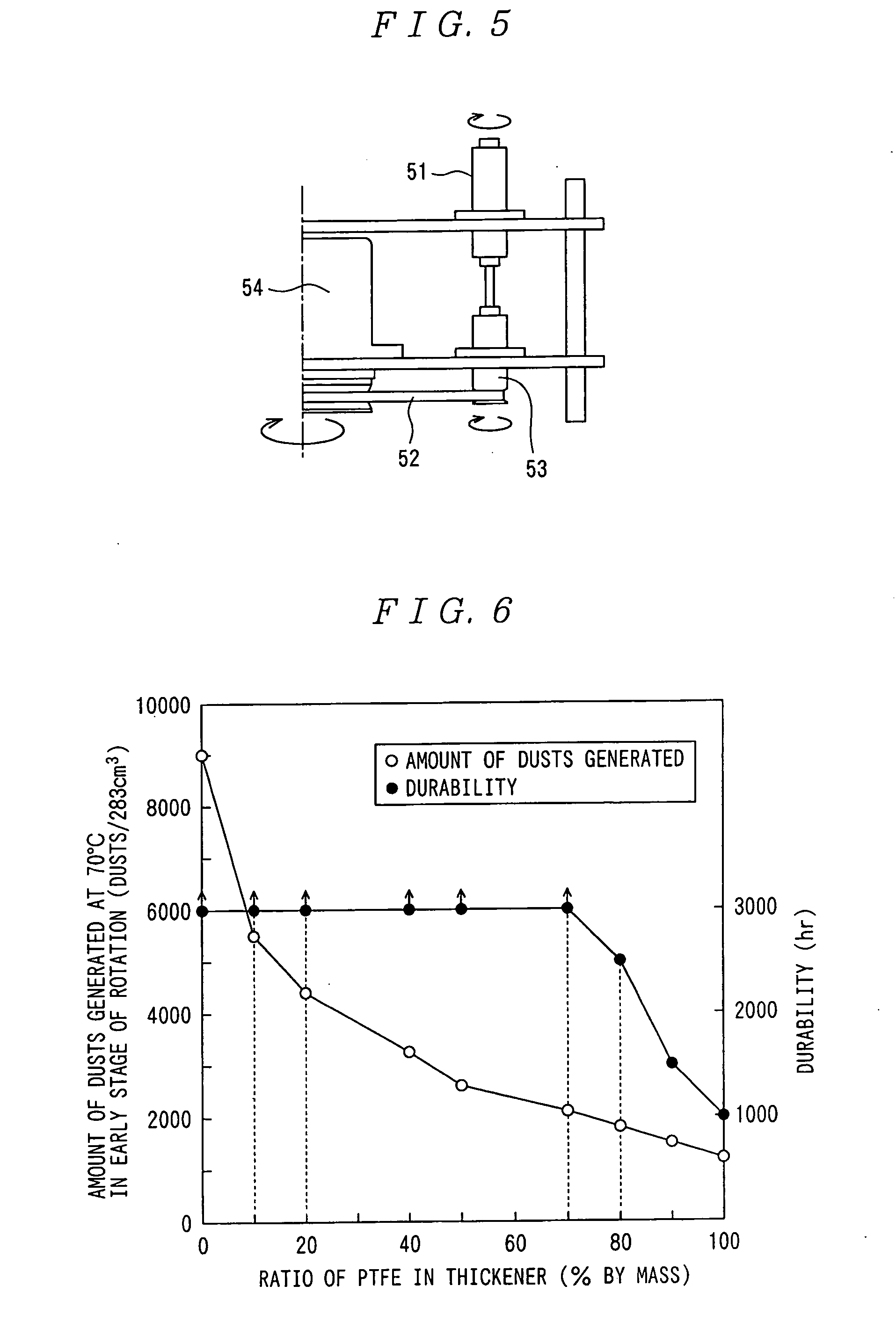

[0236] excellent in the amount of dusts generated, acoustic performance and torque value in the initial rotation stage. However, since the amount of the mineral oil and the synthetic oil in the base oil was smaller than the case of the perfluoropolyether oil, it was somewhat poor in durability.

[0237] Example A14 had a small amount of dusts generated and good acoustic performance in the initial rotation stage, but since the worked penetration was small, the torque value in the initial rotation stage was unsatisfactory.

[0238] Example A15 had good acoustic performance, torque value in the initial rotation stage and durability, but since the worked penetration was large, it generated a large amount of dusts in the initial rotation stage both at an ordinary temperature and at a high temperature, and further, the amount of dusts significantly increased when rotated at a high temperature for a long time in comparison with the grease compositions in Examples A1 to A12.

[0239] Next, the rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com